Liquid laundry detergent and preparation method thereof

A technology of laundry detergent and soap base, which is applied in chemical instruments and methods, detergent compositions, soap detergent compositions, etc., can solve the problems of poor detergency of laundry detergents, etc., achieve good foaming, save water resources, etc. , good emulsification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

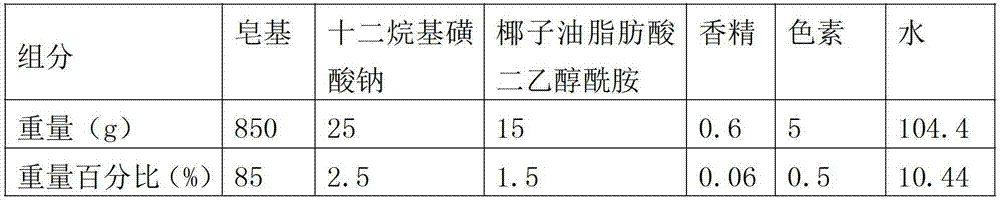

[0033] The components of laundry detergent and the percentage by weight of each component are: (total weight: 1kg)

[0034]

[0035] Among them, the composition of the soap base and the weight percentage of each component are: (total weight: 1Kg)

[0036] components

alkali

Absolute ethanol

water

Weight (g)

200

140

290

370

Weight percentage (%)

20

14

29

37

[0037] Wherein, the oil can be animal oil or vegetable oil; the alkali can be commonly used alkalis such as sodium hydroxide, potassium hydroxide, and sodium carbonate. Soap base also can be the soap base of prior art in the market.

[0038] The preparation method of laundry detergent is:

[0039] a, the components of the above-mentioned laundry detergent are mixed in the above ratio;

[0040] b. Stir and heat to 80°C, wherein the stirring speed is 260r / min;

[0041] c. After cooling, the finished laundry detergent is obtained.

[...

Embodiment 2

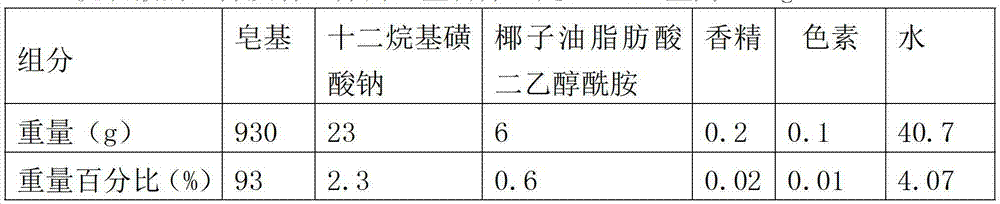

[0047] The components of laundry detergent and the percentage by weight of each component are: (total weight: 1kg)

[0048]

[0049] Among them, the composition of the soap base and the weight percentage of each component are: (total weight: 1Kg)

[0050] components

alkali

Absolute ethanol

water

Weight (g)

210

120

260

410

Weight percentage (%)

21

12

26

41

[0051] Wherein, the grease is the product of waste edible oil purification treatment; the alkali can be common alkali such as sodium hydroxide, potassium hydroxide, sodium carbonate.

[0052] The preparation method of laundry detergent is:

[0053] a, the components of the above-mentioned laundry detergent are mixed in the above ratio;

[0054] b. Stir and heat to 85°C, wherein the stirring speed is 310r / min;

[0055] c. After cooling, the finished laundry detergent is obtained.

[0056] Wherein, the preparation method of soap base ...

Embodiment 3

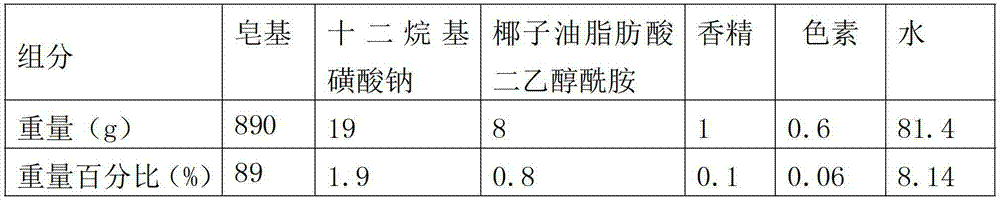

[0063] The components of laundry detergent and the percentage by weight of each component are: (total weight: 1kg)

[0064]

[0065] Among them, the composition of the soap base and the weight percentage of each component are: (total weight: 1Kg)

[0066] components

grease

alkali

Absolute ethanol

water

Weight (g)

230

100

300

370

Weight percentage (%)

23

10

30

37

[0067] Wherein, the grease is the product of waste edible oil purification treatment; the alkali can be common alkali such as sodium hydroxide, potassium hydroxide, sodium carbonate.

[0068] The preparation method of laundry detergent is:

[0069] a, the components of the above-mentioned laundry detergent are mixed in the above ratio;

[0070] b. Stir and heat to 84°C, wherein the stirring speed is 295r / min;

[0071] c. After cooling, the finished laundry detergent is obtained.

[0072] Wherein, the preparation method of soap base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com