Patents

Literature

90results about How to "Good resistance to hard water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Foaming agent for hydrophobic foam concrete and preparation method of foaming agent

The invention belongs to the technical field of building materials and particularly relates to a foaming agent for hydrophobic foam concrete and a preparation method of the foaming agent. The foaming agent for the hydrophobic foam concrete is prepared from the following raw materials in parts by weight: 200-260 parts of a frother, 20-30 parts of a foam stabilizer, 1-2.5 parts of a thickener, 210-300 parts of an enhancer, 15-20 parts of a diluent, 1.5-2.5 parts of a preservative and 420-480 parts of water. The foaming agent for the hydrophobic foam concrete is good in stability of generated foams, good in foaming effect, high in closed pore ratio of generated foamed concrete, good in hydrophobicity and high in compressive strength.

Owner:河南华泰新材科技股份有限公司

Foaming agent for shield

The invention discloses a foaming agent for a shield. The foaming agent contains the components in percentage by weight: 1.0-10.0% of alpha-olefin sulfonate (AOS), 1.0-8.0% of sodium fatty alcohol -polyoxyethyleneether sulfate (AES), 1.0-6.0% of ammonium lauryl sulfate (K12 ammonium), 1.0-6.0% of cocoanut fatty acid diethanolamide (6501), 1.0-5.0% of dodecyl dimethyl betaine (BS-12), 0.005-0.1% of fluorocarbon surfactant (FS), 0.2-5.0% of sodium nitrilo triacetate (A92R), 0.2-5.0% of ethylene diamine tetraacetic acid disodium salt (EDTA) and the balance of water. The foaming agent for the shield provided by the invention realizes high multiple foaming rate, long foam stabilizing time, nontoxicity and innocuity and is an environment friendly biodegradable product which does not contain phosphorus.

Owner:GUANGZHOU TAISHENG BIOTECH

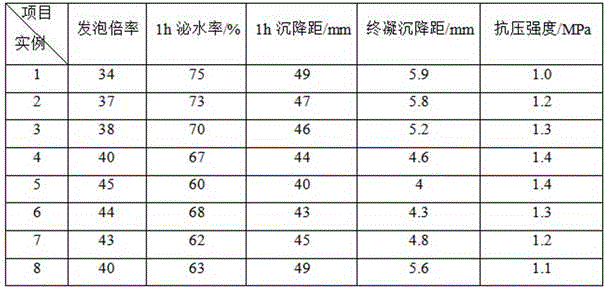

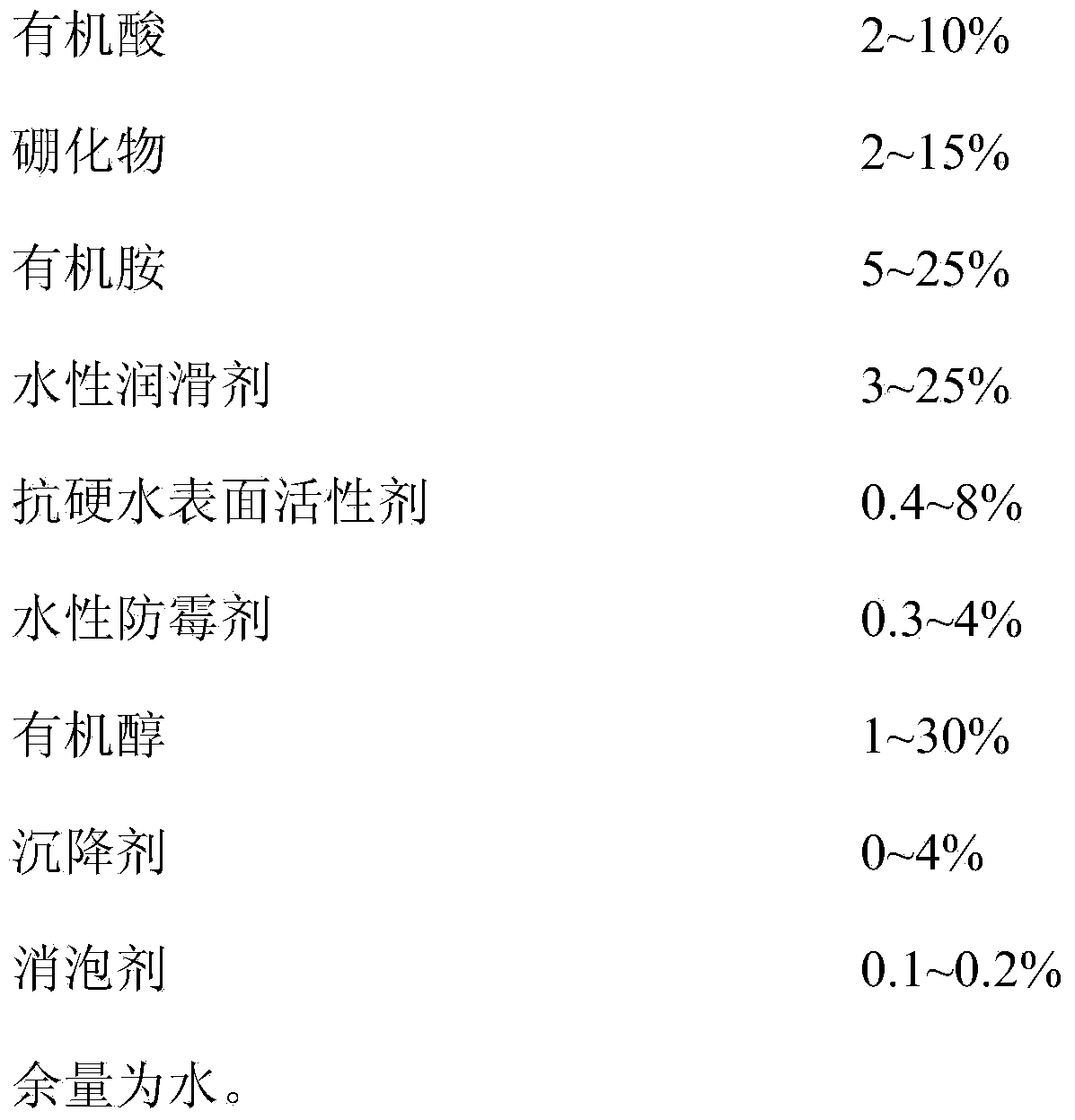

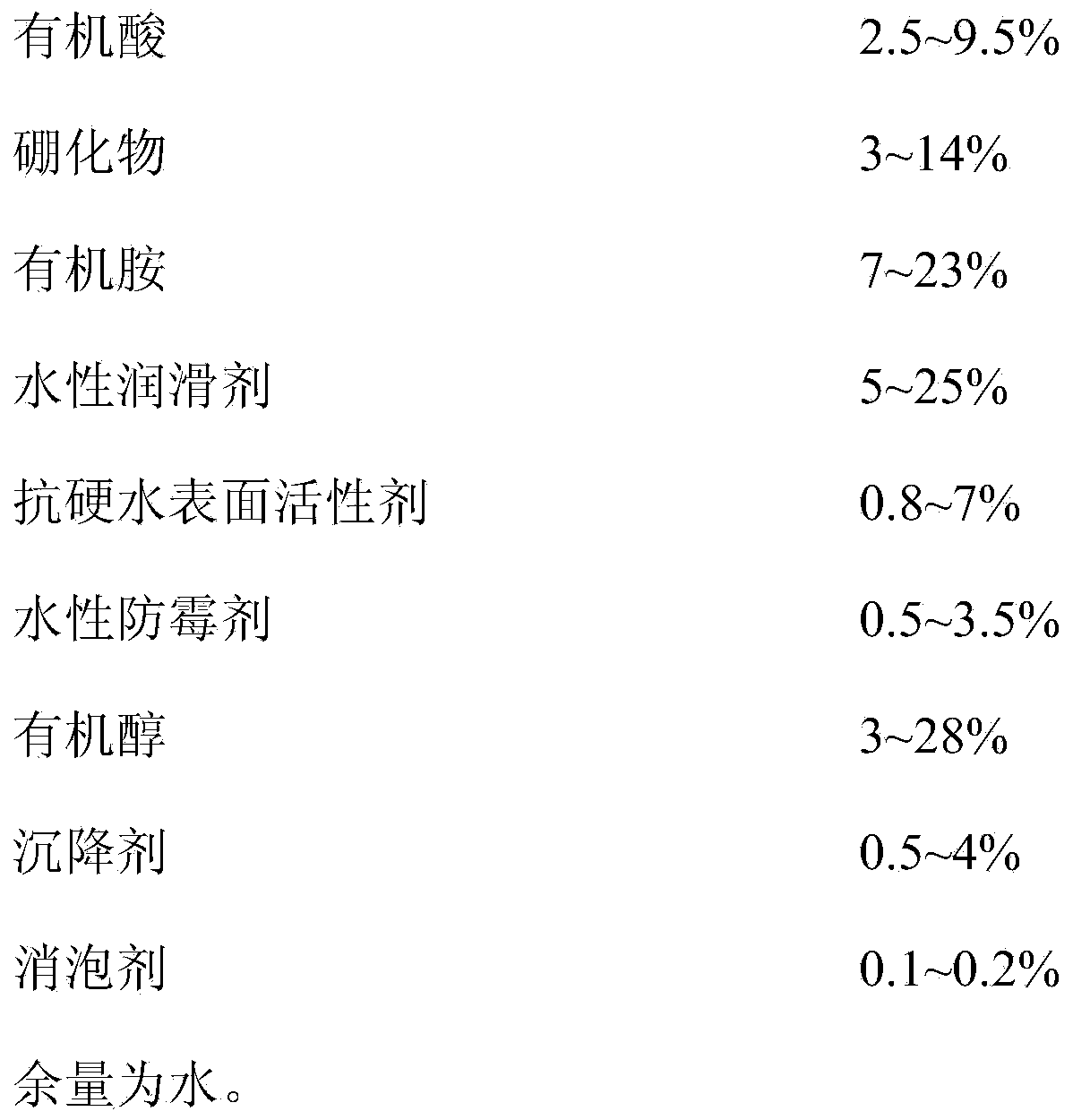

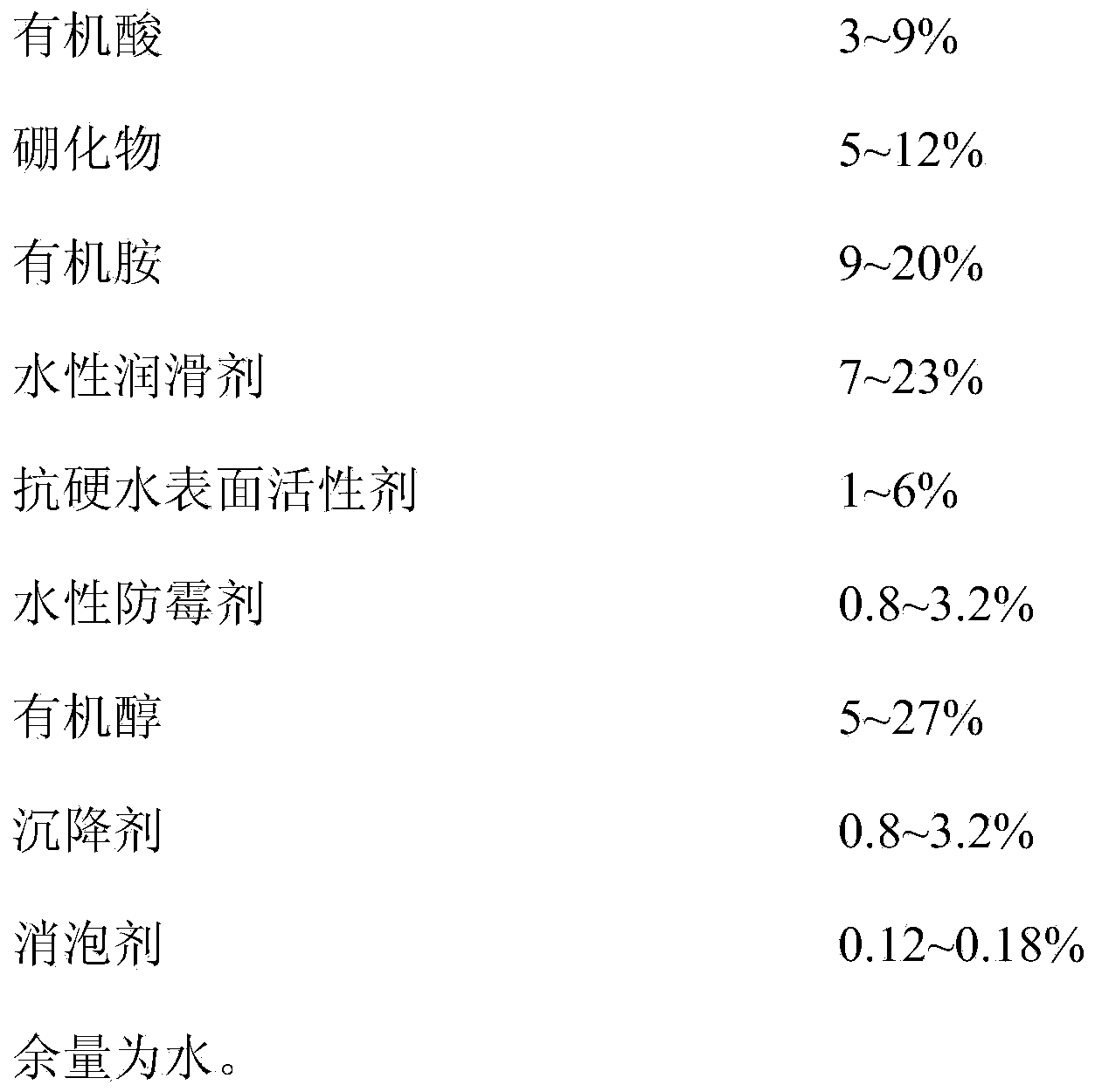

Full-synthetic glass grinding fluid

ActiveCN103525533AImprove general performanceGuaranteed service lifeLubricant compositionWater basedBoride

The invention discloses an environment-friendly glass grinding fluid, which is efficient, and long in service. The full-synthetic glass grinding fluid is prepared from an organic acid, a boride, an organic amine, a water-based lubricant, a hard water-resisting surfactant, a water-based mould inhibitor, an organic alcohol, a settling agent, a defoaming agent and water in a mixing manner. The glass grinding fluid disclosed by the invention has excellent cooling property, anti-rotting ability and lubricating abrasion resistance, and outstanding hard water resistance, can be recycled for a long period of time, can ensure the working accuracy and the service life of a tool, and has excellent cleaning performance; the blocking phenomenon of a grinding wheel can be effectively prevented; the product is good in settleability; processing is facilitated; the product is free of poison, environment-friendly, free of pollution, small in smell, good in working performance, good in compatibility with a paint of equipment, low in pH value, free of bad effects on skin and the like; the phenomenon that the paint of the equipment peels off is not generated. The grinding fluid disclosed by the invention is simple in reparation method, low in cost, excellent in performance, and good in market prospect at present.

Owner:东莞太平洋博高润滑油有限公司

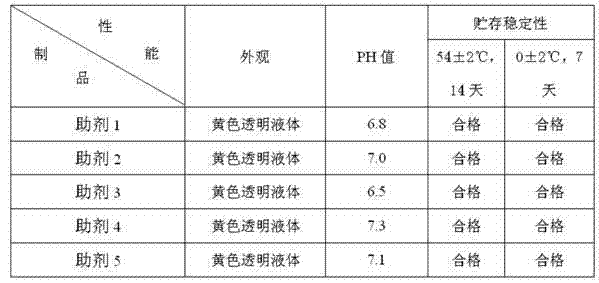

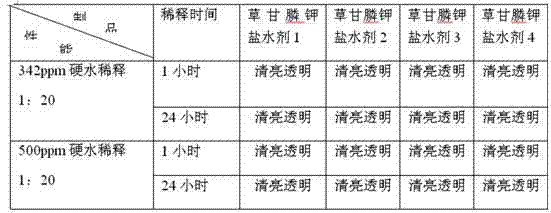

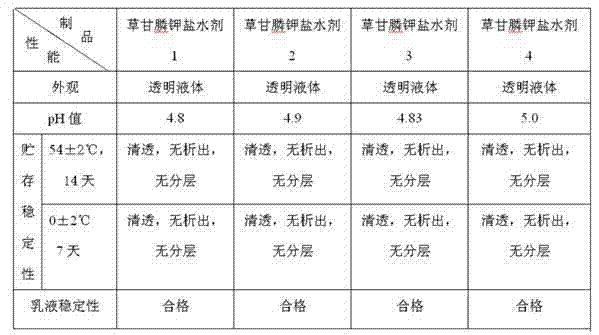

Special adjuvant of glyphosate potassium salt aqueous solution and salt aqueous solution using same

The invention relates to a special adjuvant of glyphosate potassium salt aqueous solution. The special adjuvant comprises (by weight percentage) alkyl polyglycoside (APG) 10-80, fatty alcohol polyoxyethylene ether 0-20, betaine 0-40, tallow amine polyoxyethylene ether 0-20, and the balance of water. The contents of fatty alcohol polyoxyethylene ether, betaine and tallow amine polyoxyethylene ether are not simultaneously zero. The adjuvant adopts environment friendly surfactant such as APG and betaine, is safe, green and bio-degradable, and reduces environment pollution of pesticide. When the adjuvant is used for the glyphosate potassium salt aqueous solution, the adjuvant has good synergic effect to product. With the adoption of the adjuvant, the glyphosate potassium salt aqueous solution has the advantages of simple process, low cost, good hard water resistance, good compatibility with other pesticides, and no layering or condensation phenomenon.

Owner:南京太化化工有限公司

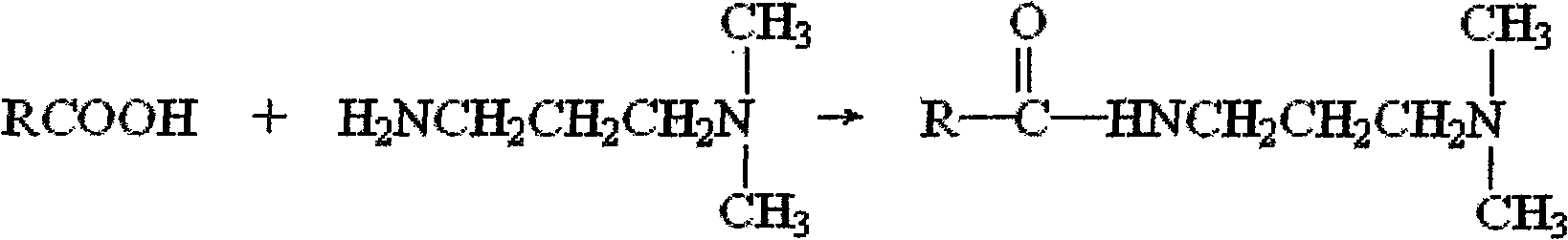

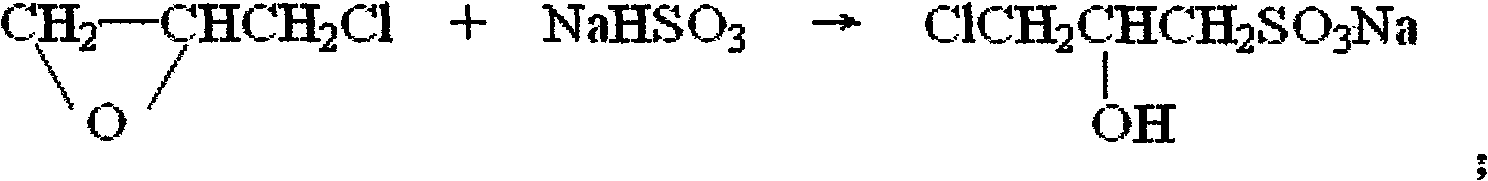

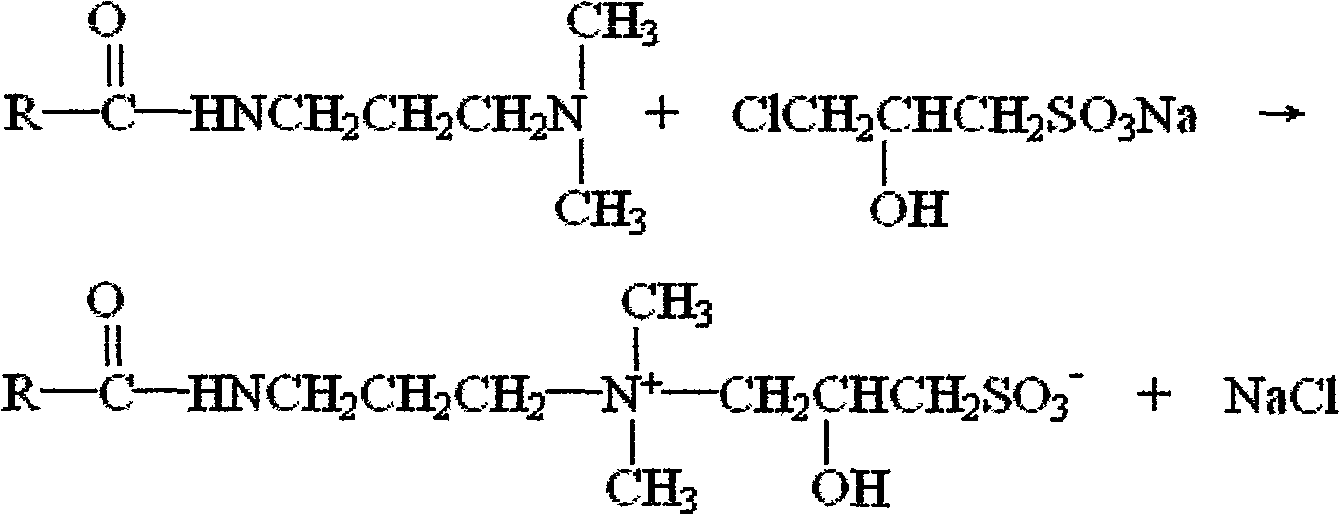

Synthesis method of cocoamidopropyl-2-hydroxyl-3-sulfopropyl betaine

InactiveCN101654421ALess irritatingGood resistance to hard waterSulfonic acid preparationEpoxyBetaine

The invention discloses a synthesis method of cocoamidopropyl-2-hydroxyl-3-sulfopropyl betaine, which adopts coconut oil fatty acid, N,N-dimethyl propane diamine, epoxy chloropropane and sodium bisulfite anhydrous as raw materials. The synthesis method comprises the following specific steps of carrying out amidation reaction on coconut oil fatty acid and N,N-dimethyl propane diamine to generate intermediate cocoamide; then carrying out addition reaction on epoxy chloropropane and sodium bisulfite anhydrous to generate intermediate sodium propylsulfonate; and finally carrying out quaternizationreaction on the produced intermediate cocoamide and the intermediate sodium propylsulfonate under the existence of a catalyst so as to generate the target product, namely, the cocoamidopropyl-2-hydroxyl-3-sulfopropyl betaine. The product of the synthesis method has good hard water resistance, conditioning and antistatic property, is stable in the wide range of pH value, is not influenced in acid-base medium, is stable in an electrolyte system and is degradable and non-toxic.

Owner:ZHEJIANG HECHENG CHEM

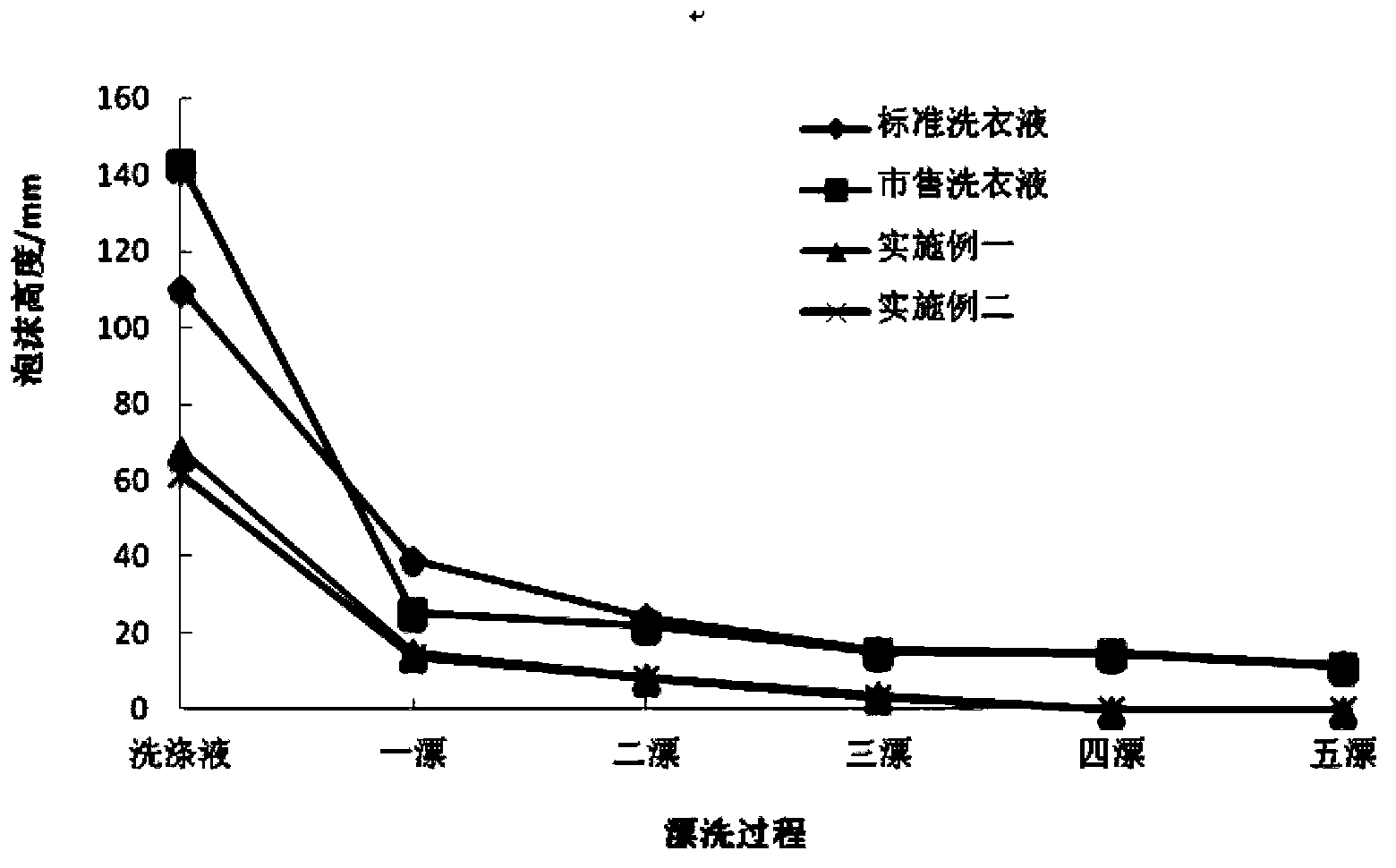

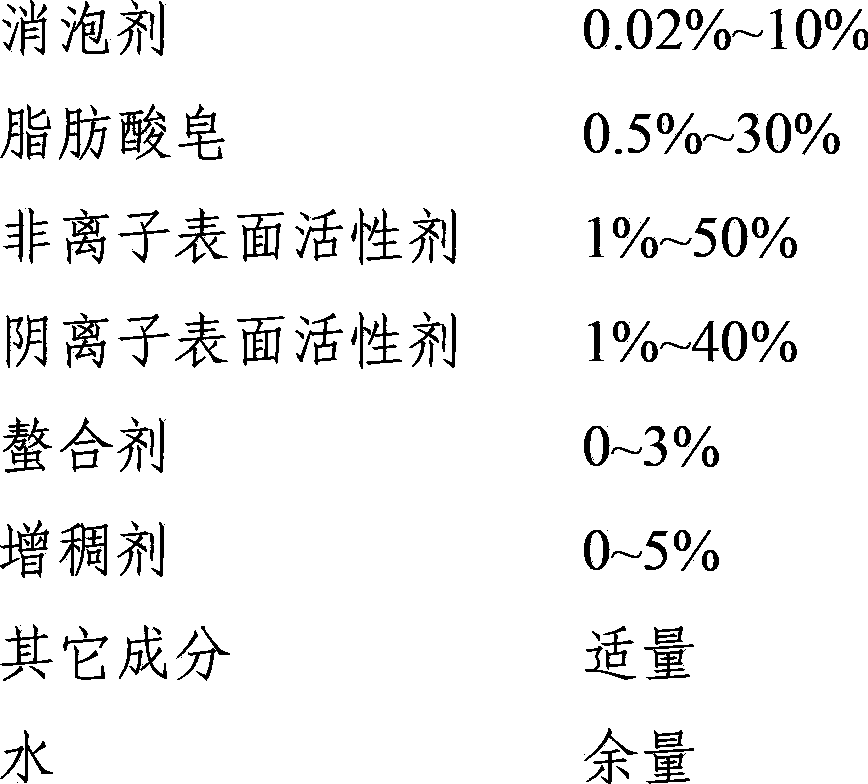

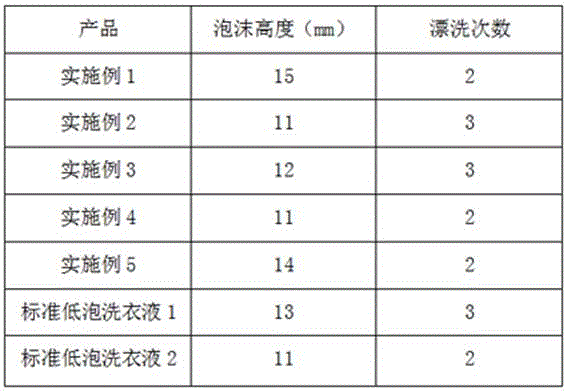

Low-foam laundry detergent composite facilitating rinsing

ActiveCN103013723BLow foam and easy to rinseDon't worry about the annoying problem of overflowSurface-active non-soap compounds and soap mixture detergentsWater savingFatty acid

Owner:纳爱斯丽水日化有限公司

Environment-friendly concentrated solution for hydraulic support

ActiveCN103266004AGood resistance to hard waterStorage stability and biodegradabilityLubricant compositionAntifoam agentCorrosion resistant

The invention relates to an environment-friendly concentrated solution for a hydraulic support. The environment-friendly concentrated solution comprises the following components in percentage by mass: 12%-25% of composite lubricant, 0.005%-0.015% of antifoam agent, 0.005%-0.02% of foam inhibitor, 1.0%-7.0% of water treatment agent, 8%-15% of composite rust protection corrosive, 12%-25% of compound emulsifier and the balance of deionized water. The environment-friendly concentrated solution for the hydraulic support has good freezing and thawing property, good hard water resistance, stable storage property and biodegradability, and good rust protection and corrosion resistant performances, and can be used for preventing a working solution from corroding equipment, thereby prolonging the service life of relative equipment and improving the safety. The environment-friendly concentrated solution has good lubricating property and airtightness and material compatibility, the abrasion and leakage of a support hydraulic moving part in a use process are effectively reduced, the cost for maintenance and use is lowered, and the requirement of the hydraulic support working in a harsh work condition can be met.

Owner:营口福斯油品有限公司

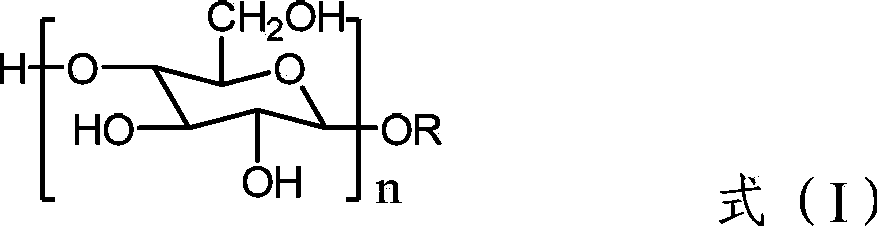

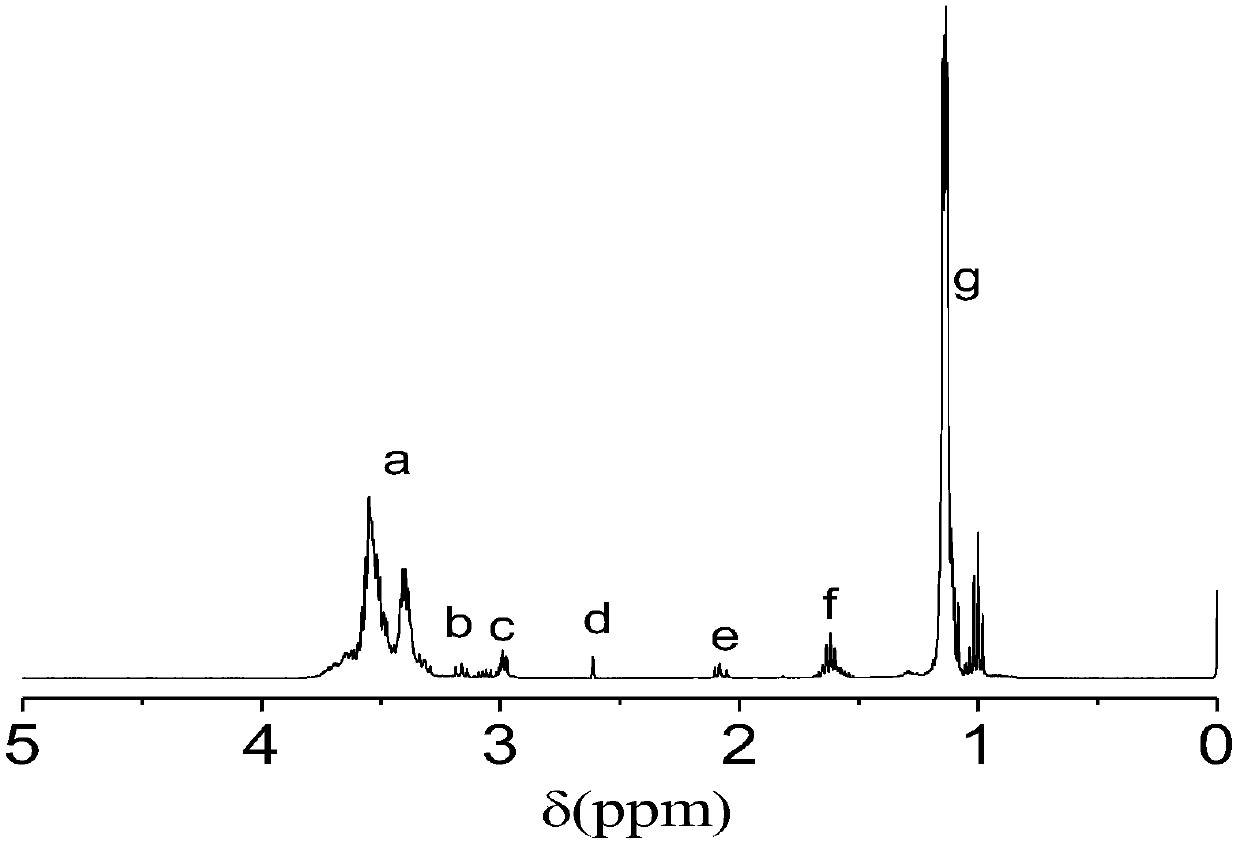

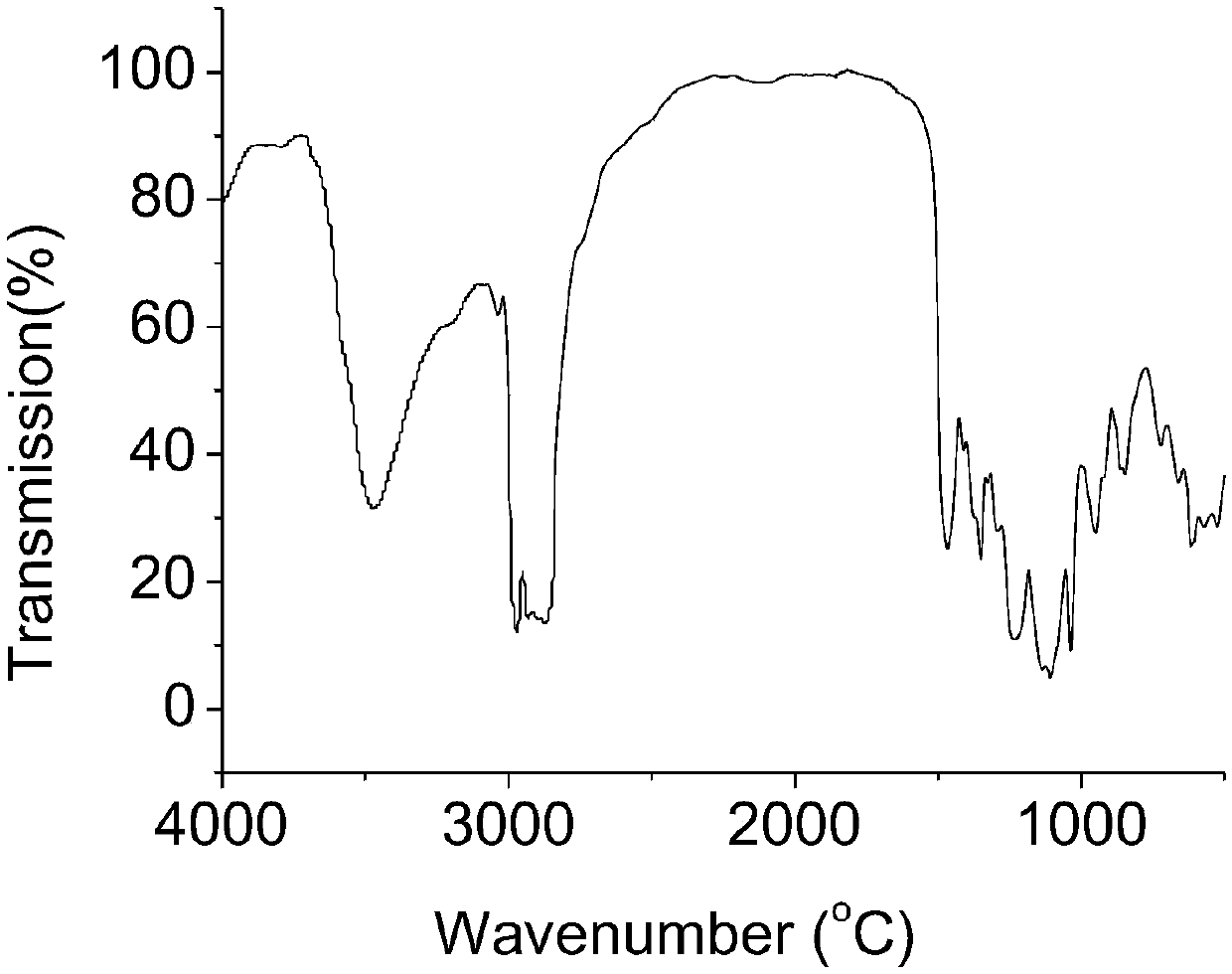

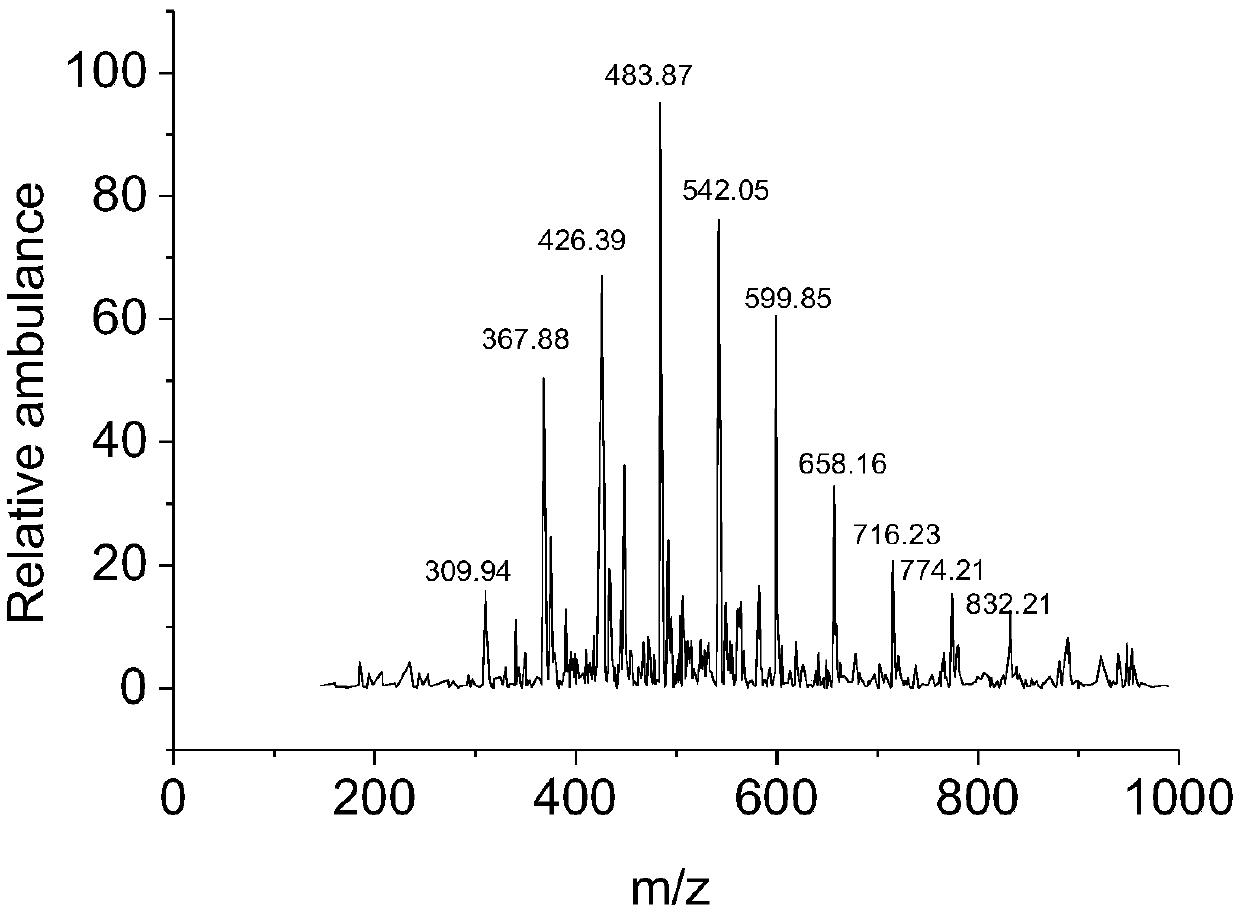

Fluorine-containing polyether hydrophilic modifier, preparation method and water-dispersible polyisocyanates curing agent

ActiveCN109575270AOvercome the shortcoming of short pot lifeLong application periodWater dispersibleBenzoyl chloride

The invention relates to the field of double-component waterborne resin, and relates to a fluorine-containing polyether hydrophilic modifier, a preparation method and a water-dispersible polyisocyanates curing agent. The structural formula of the fluorine-containing polyether hydrophilic modifier is as shown in specification. The preparation method of the fluorine-containing polyether hydrophilicmodifier comprises the following steps: synthesizing tertiary amino polyether monool, then synthesizing amphoteric polyether monool, and finally synthesizing amphoteric polyether monool with a zwitterionic group. Preparation of the water-dispersible polyisocyanates curing agent comprises the steps of reacting polyisocyanates and the fluorine-containing polyether hydrophilic modifier with the zwitterionic group in the presence of a catalyst for 2.5-3 h, then adding benzoyl chloride, and then stopping reaction. The shortcoming that the water-dispersible polyisocyanates curing agent in the priorart is short in pot life is overcome, and therefore, a purpose of prolonging the pot life of the water-dispersible polyisocyanates curing agent is achieved.

Owner:WUYI UNIV

Low-alkaline scouring agent for continuous rope scouring of cotton fabrics

ActiveCN105525509AImprove gross effectHigh desizing rateVegetal fibresFatty acid methyl esterDefoaming Agents

The invention discloses a low-alkaline scouring agent for continuous rope scouring of cotton fabrics. The low-alkaline scouring agent comprises, in percentage by weight, 5%-15% of fatty acid methyl ester polyoxyethylene ether, 5%-15% of isomerized alcohol ether sulphate, 5%-15% of alkyl ethoxy polyglycosides, 15%-25% of isomerized alcohol polyoxyethylene ether, 0.5%-2% of a polyether modified organic silicon defoaming agent and 28%-69.5% of water. A preparation method of the low-alkaline scouring agent comprises steps as follows: (1), isomerized alcohol ether sulphate and water are mixed uniformly, and a proper amount of sodium hydroxide is added until the pH value is adjusted to range from 6 to 7; (2), alkyl ethoxy polyglycosides and fatty acid methyl ester polyoxyethylene ether are added to a mixed solution in the step (1), and the mixture is stirred and mixed uniformly; (3), the solution mixed in the step (2) is heated to 50-60 DEG C, isomerized alcohol polyoxyethylene ether is slowly poured into the solution, and the mixture is stirred and mixed uniformly. The low-alkaline scouring agent is especially suitable for continuous rope pre-processing of pure cotton fabrics, has the advantages of high desizing level, high capillary effect and low foam and can reduce the consumption of caustic soda in the scouring process and reduce pollution of caustic soda to the environment.

Owner:SHANDONG HUANGHE DELTA INST OF TEXTILE SCI & TECH RES INST

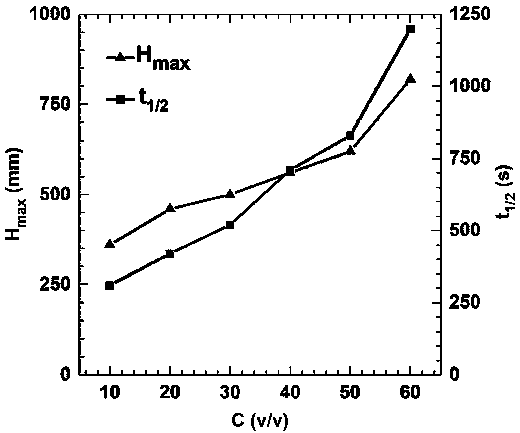

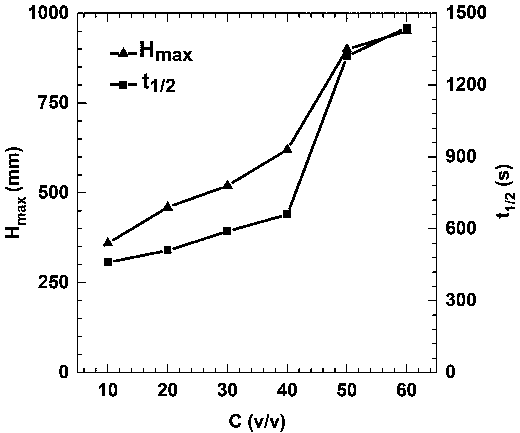

Foam drainage agent with resistance to high-content gas condensate and resistance to high mineralization and preparation method of foam drainage agent

ActiveCN110819327AGood foam stabilityImprove liquid carrying capacityDrilling compositionActive agentFluorocarbon

The invention discloses a foam drainage agent with resistance to high-content gas condensate and resistance to high mineralization and a preparation method of the foam drainage agent, and belongs to the technical field of materials for gas well mining in oil-gas fields. The foam drainage agent includes the following raw material components: in percent by mass, 20-35% of a zwitterionic surfactant,1-5% of a fluorocarbon surfactant, 1-5% of an anionic surfactant, 1-5% of cocinic acid monoethanolamide and the balance water. The preparation method comprises the steps: performing weighing, stirring, mixing and heating, and performing dissolution so as to obtain the foam drainage agent finished product. Through arrangement of the specific raw materials and the ratios, good resistance to high-content gas condensate and resistance to high mineralization are achieved, and it is ensured that the foam drainage agent can have excellent capacity of foam generation, foam stabilization and liquid carrying under the conditions of high-content gas condensate and high mineralization; and meanwhile, the foam drainage agent has a wide range of raw material sources, low price, a simple production technology, low requirements of equipment and environments and large-scale production.

Owner:CHINA PETROLEUM & CHEM CORP +1

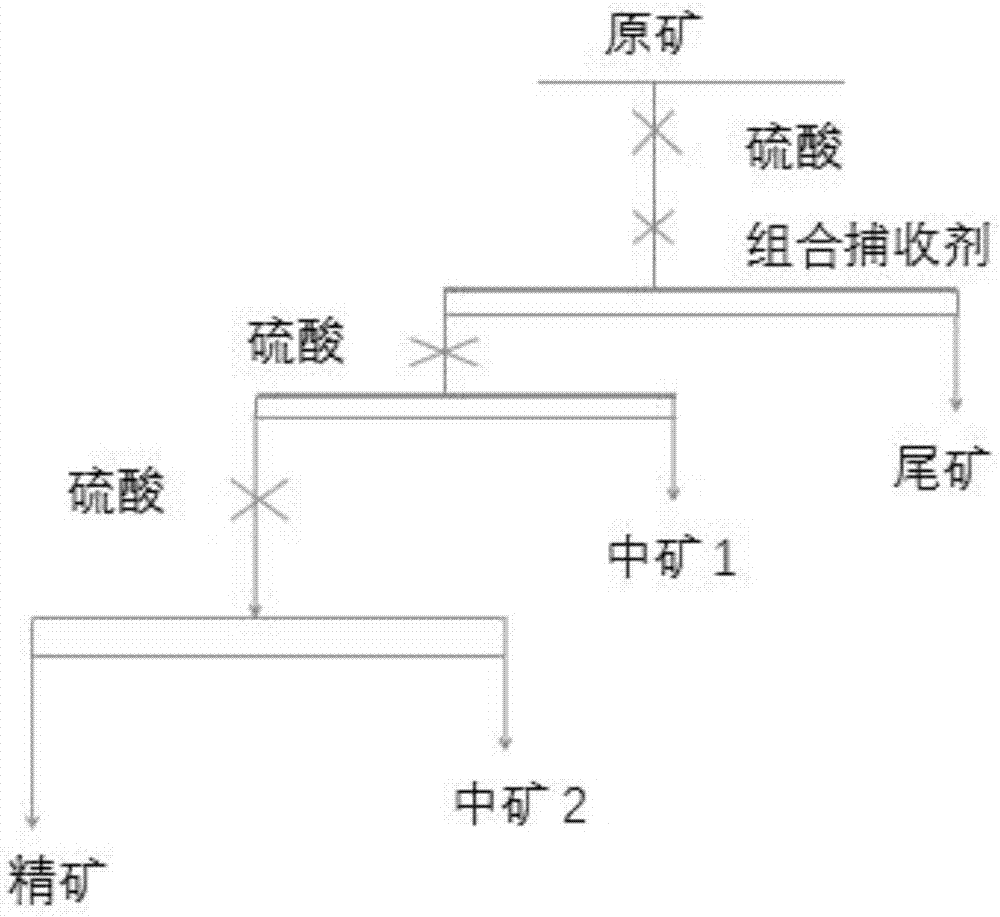

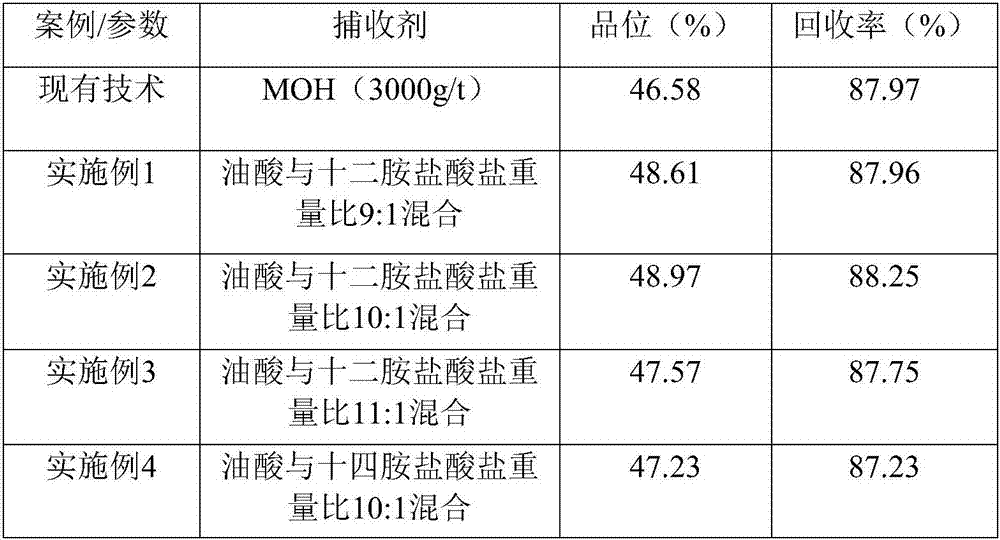

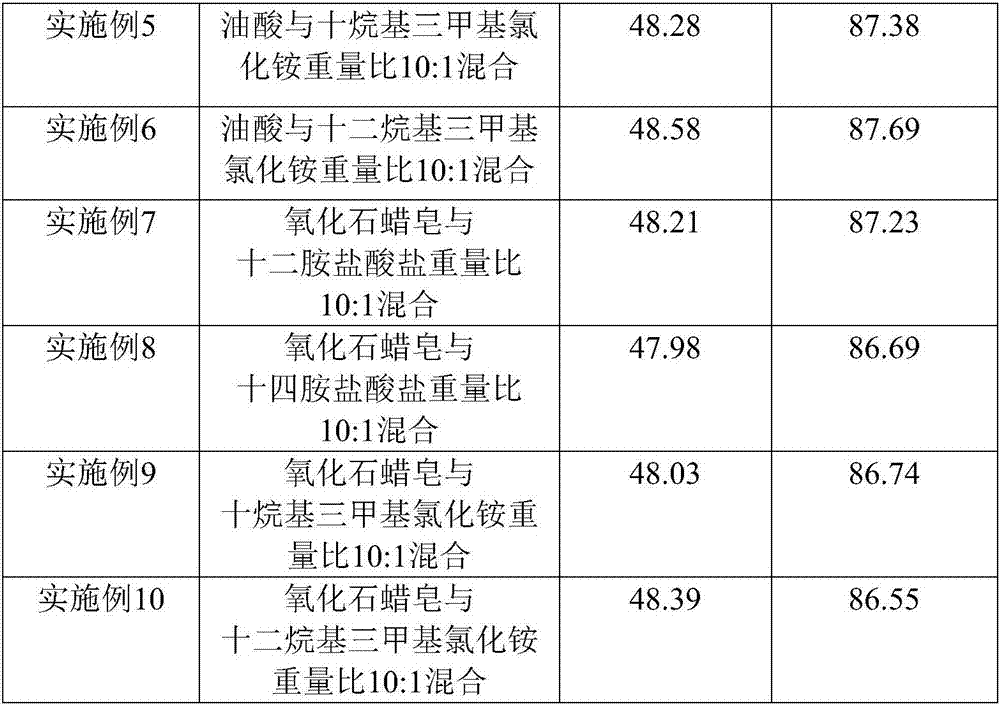

Combined collecting agent used for conducting flotation on pyroxene peridotite type ilmenite, preparation method and application

The invention provides a combined collecting agent used for conducting flotation on pyroxene peridotite type ilmenite. The combined collecting agent is composed of a component A, a component B and water. The component A is oleic acid or oxidized paraffin soap. The component B is primary amine hydrochloride or quaternary ammonium salt. The weight ratio of the component A to the component B ranges from 9:1 to 12:1. The weight ratio of the sum of the weight of the component A and the weight of the component B to the weight of the water is 1:(4-19). The raw ore grade of the pyroxene peridotite type ilmenite is not higher than 18%. The invention further provides a preparation method and application of the combined collecting agent. The flotation index achieved through the combined collecting agent is good, the number of required concentration times is small, and the quantity of the agent which is used is small; and meanwhile the requirement of the collecting agent for flotation conditions is loose, and the combined collecting agent has good hard water resistance.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Diester-type semisynthetic cutting fluid with high lubrication and high hard water resistance and preparation method thereof

InactiveCN105647633AExcellent extreme pressure lubricityGood resistance to hard waterLubricant compositionHard waterSurface-active agents

The invention discloses a diester-type semisynthetic cutting fluid with high lubrication and high hard water resistance. The cutting fluid comprises, by weight, 30-40% of synthetic ester, 3%-5% of a surface active agent, 12%-20% of an antirust, 2%-5% of a solubilizer, 1%-5% of a corrosion inhibitor, 0.2%-0.5% of an aluminum corrosion inhibitor, 0.5%-1% of a defoaming agent, 2%-5% of a bactericidal agent and the balance of water. The invention also provides a preparation method of the semisynthetic cutting fluid. The method is as below: adding the surface active agent, antirust agent, corrosion inhibitor, solubilizer, aluminum corrosion inhibitor, defoaming agent, bactericidal agent and water in the synthetic diester in order, and mixing evenly to obtain the diester-type semisynthetic cutting fluid with high lubrication and high hard water resistance. The diester-type semisynthetic cutting fluid with high lubrication and high hard water resistance has superior performances in lubrication, hard water resistance, aluminum corrosion inhibition, corrosion resistance, rust proof and defoaming.

Owner:SHANGHAI INST OF TECH

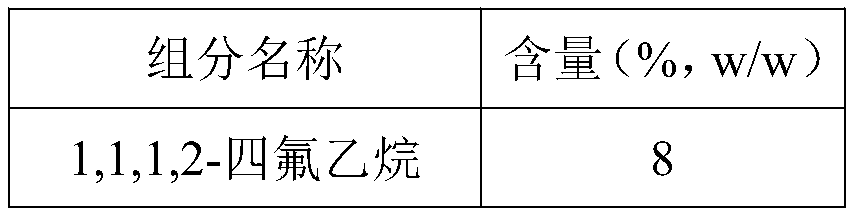

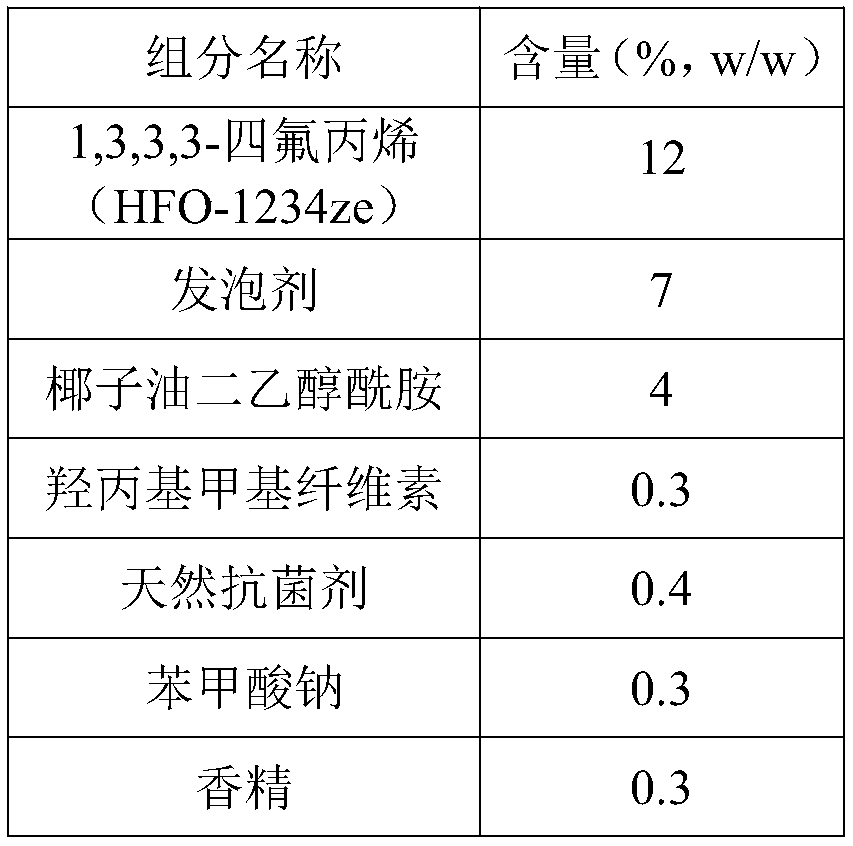

Effective toilet-cleaning foam aerosol and preparation method thereof

ActiveCN109666545ATime stableEasy to rinseNon-ionic surface-active compoundsAnionic surface-active compoundsWater savingFoaming agent

The invention belongs to the technical field of preparation products for daily appliances, and particularly relates to an effective toilet-cleaning foam aerosol and a preparation method thereof. The foam aerosol comprises, by weight, 8-18% of a propellant, 5-10% of a foaming agent, 2-8% of a deodorizing agent, 0.1-0.6% of a thickener, 0.3-0.6% of natural bio-antimicrobial agents, 0.2-0.4% of preservatives, 0.2-0.4% of essences, and 62-84.2% of deionized water. The effective toilet-cleaning foam aerosol has the advantages of effectively removing and isolating foul smell, having fine and rich foams, keeping stable for a long time, resisting to water splashing, cleaning toilets with toilet paper saved, being environmental friendly and water saving and the like.

Owner:ZHONGSHAN TIANTU FINE CHEM CO LTD

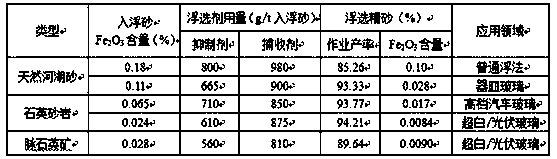

Preparation method of neutral flotation agent for purifying quartz minerals

The invention relates to a preparation method of a neutral flotation agent for purifying quartz minerals. The preparation method comprises the following steps of mixing raw materials, namely amines, an organic halogenated acid or a halogenated acid salt according to the molar ratio greater than or equal to 1, putting the mixture into a reaction kettle so as to prepare a crude flotation agent through reaction, and adjusting the pH value to obtain the neutral flotation agent. The preparation method of the neutral flotation agent for purifying the quartz minerals has the advantages that the prepared flotation agent has the functions of collecting and foaming, and is relatively low in kinematic viscosity, relatively good in hard water resistance and relatively low in freezing point; and directflotation of quartz sand can be realized without acids under the neutral conditions, so that the investment cost and the maintenance cost of ore dressing corrosion-resistant equipment are reduced, and the wastewater treatment cost of an ore dressing plant is reduced; the prepared floatation agent is used in coordination with an inhibitor, so that effective separation of the quartz sand from ironoxide disseminated type quartz sand and iron-containing aluminosilicate minerals is realized, and flotation and purification of the quartz minerals are realized; and the quartz fine sand can meet therequirements of glass, ceramic, plates and chemical industries for high-quality quartz raw materials.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD

Chinese torreya essential oil soap

InactiveCN106883959AMild ingredientsRich and fine foamSurface-active detergent compositionsSurface-active non-soap compounds and soap mixture detergentsChemistryWool

The invention discloses Chinese torreya essential oil soap. The soap contains the following components in percentage by weight: 7 to 10% of water, 13 to 18% of sorbitol, 8 to 10% of propylene glycol, 15 to 18% of stearic acid, 8 to 12% of lauric acid, 3 to 6% of glycerinum, 6 to 8% of AES, 20 to 25% of saccharose, 0.6 to 1.5% of wool fat, 0.2 to 0.5% of sodium hydroxide, 1 to 3% of alkyl glycoside, 1 to 2% of potassium cocoyl glycinate, 1 to 2% of Chinese torreya essential oil, 0.4 to 0.7% of daily chemical fragrance compound and 0.3 to 0.6% of a Curasao Aloe extract. The Chinese torreya essential oil soap can solve the detects in the prior art, and is a good skin care product capable of moistening skin, delaying senescence and promoting cell metabolism when used at home or during travel.

Owner:浙江如美日化有限公司

Antibacterial low-foam laundry detergent and preparation method thereof

InactiveCN106244352ANo side effectsLong-lasting bactericidal and antibacterial effectNon-ionic surface-active compoundsDetergent mixture composition preparationCitrate sodiumChemistry

The invention belongs to the field of hygienic products and particularly relates to an antibacterial low-foam laundry detergent and a preparation method thereof. The antibacterial low-foam laundry detergent is prepared from, by weight, 10-30 parts of sodium dodecyl benzene sulfonate, 10-30 parts of coconutt diethanol amide, 15-35 parts of octadecyl dimethyl betaine, 30-50 parts of tea saponin, 10-25 parts of sodium citrate, 20-40 parts of a bacteriostat, 1-15 parts of rose essential oil and 70-90 parts of deionized water. The antibacterial low-foam laundry detergent is reasonable in formulation, excellent in antibacterial effect, high in detergency, low in foam and easy to rinse, integrates functions of sterilization and cleaning and has excellent bactericidal and antibacterial efficacies and energy saving and environment friendly effects.

Owner:李金新

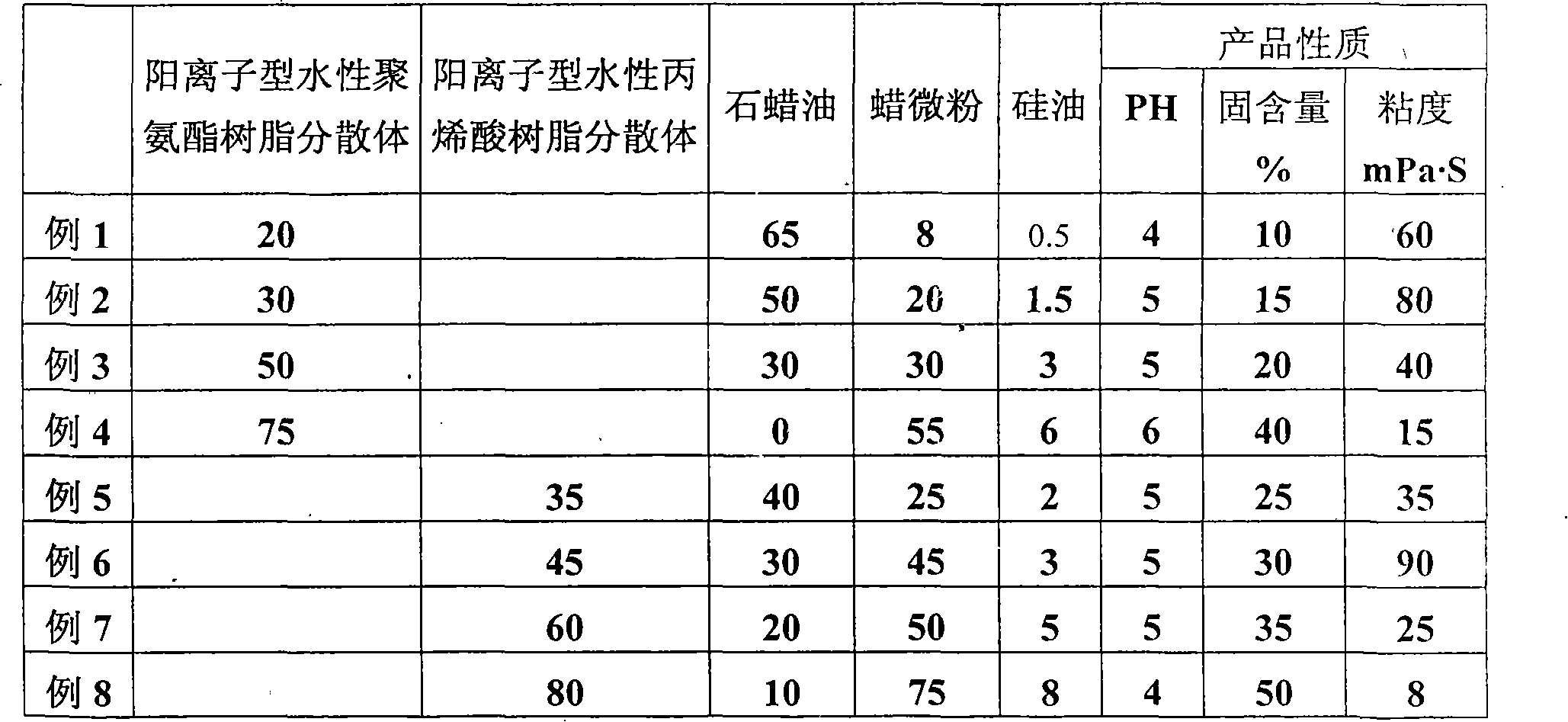

Non-powder treating agent for gloves made of latex

The invention relates to a powder-free treatment agent used for latex gloves, which pertains to the field of chemical products. The invention mainly resolves the coating raw materials used in the latex glove coating process. The invention replaces the treatment agent of anionic water-base resin system in the prior art with the treatment agent of cationic water-base resin system. The cationic water-base resin prefers 10 to 90 parts of cationic water-base polyurethane resin and cationic water-base acrylic resin, 0 to 70 parts of paraffin oil, 1 to 80 parts of wax powder and 0.1 to 10 parts of silicone oil which are mixed for uniform and complete stirring. The powder-free treatment agent has the advantages of good coating quality for the latex gloves, strong binding between the coating and the latex glove surface, uneasy to flake off as well as excellent smoothness property and anti-blocking property. The invention also has high weather resistance for polyvalent metal cations as well as hard-water resistance. When being applied in coating process, the emulsion of the invention is not easy to break and gelatinize to produce sediment, thus greatly improving coating quality and production efficiency, saving raw materials and reducing cost.

Owner:濮阳林氏化学新材料股份有限公司

Enzyme-added whitening laundry detergent and preparation method thereof

InactiveCN102827711AReduce manufacturing costGood resistance to hard waterSurface-active non-soap compounds and soap mixture detergentsPolyesterActive agent

The invention provides enzyme-added whitening laundry detergent and a preparation method thereof. The enzyme-added whitening laundry detergent consists of the following components in parts by weight: 5-10 parts of enzyme preparation, 2-6 parts of polyester color factor, 5-10 parts of surfactant, 1-6 parts of water-softening agent, 5-8 parts of builder, 0.1-0.2 part of dispersing agent, 0.1-0.5 part of brightening agent, 0.1-1 part of high-quality essence and 50-80 parts of deionized water. The laundry detergent disclosed by the invention has the advantages of low production cost, wide application range and no toxin and odor in the production process. Because the product does not contain phosphorus, the environment is not affected. The product is neutral, does not hurt hands and has a strong dirt-removing power. In addition, the enzyme-added whitening laundry detergent has the advantages of good hard water resistance and obvious whitening effect, is convenient to manufacture, can be widely used and can be used for continuously replacing the traditional laundry detergent.

Owner:SUZHOU GULI BIOTECH

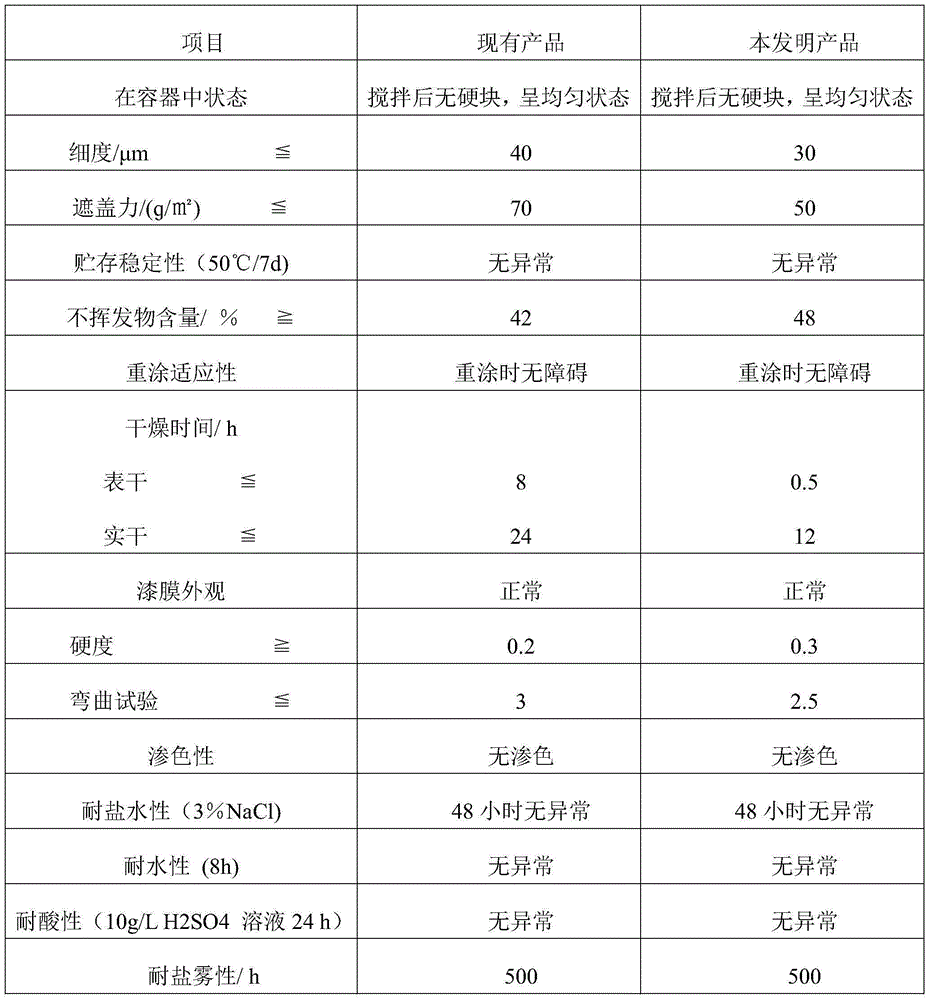

Aqueous anti-rusting paint and preparation method therefor

ActiveCN105219239AUnparalleled environmental friendlinessGood resistance to salt sprayAnti-corrosive paintsPolyester coatingsSolubilityLacquer

An aqueous anti-rusting paint and a preparation method therefor. The paint is characterized in that: the raw materials in a formula in parts by mass are as follow: 600-700 parts of an acrylate modified alkyd resin emulsion, 100-120 parts of deionized water, 90-110 parts of pigments and fillers, 5-10 parts of a rheological agent, 5-10 parts of a dispersant, 1-5 parts of a defoamer, 1-3 parts of a bactericide, 70-90 parts of film forming auxiliaries, 15-25 parts of a co-solvent, 3-8 parts of a flash-rust agent, 5-10 parts of a multi-functional agent and 4-10 parts of a thickener solution. The process steps comprises: dispersing, milling, paint mixing, thickening, filtering and packaging. According to the present invention, water is used as a dispersion medium, multiple anti-rusting mechanism of physical, chemical and the like are used to prepare and produce the anti-rusting industrial paint. The paint combines an undercoat and a finishing coat and is constructed at one-time, so that the mode that the undercoat and the finishing coat of the conventional paint are constructed separately is broken. The paint is unequalled in environmental protection performance, good in salt-spray resistance and weather resistance and strong in anti-rusting function, and is an excellent product of a new generation that can replace the traditional anti-rusting paint. The paint has water solubility and non-flammable property, and is safe in use, and the paint is good in water resistance and good in thermal stability, and has a good anti-rusting function even in a high-temperature state.

Owner:LIAOYANG YIBANG NEW BUILDING MATERIALS GRP CO LTD

Acidic cleaning agent and application thereof in cleaning of cooling fins of air conditioners of railway bullet trains

The invention discloses an acidic cleaning agent and application thereof in cleaning of cooling fins of air conditioners of railway bullet trains. The acidic cleaning agent comprises the following components in percentage by mass: 1.0-5.0% of cleaning components, 1.0-3.0% of corrosion and scale inhibition components, 0.2-2.0% of surface active components, 0.5-1.0% of an auxiliary agent and the balance water; the cleaning components include inorganic acid and organic acid; the corrosion and scale inhibition components include aniline, urotropine and a dicarboxylation imidazoline derivative; the surface active components include cationic alkyl glycoside, lauryl polyoxyethylene ether sodium sulfate and polyol phosphate; and the auxiliary agent is a dispersing agent which is polyanionic cellulose sodium. The acid cleaning agent provided by the invention has the advantages of high efficiency, easiness in rinsing, low residue, high stability and the like when being used for cleaning the cooling fins of the air conditioners of the railway bullet trains.

Owner:TAISHAN UNIV

Washing powder with bactericidal effect

InactiveCN104232330AEfficient bactericidal effectImprove the bactericidal effectInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsEster sulfonateSodium silicate

The invention belongs to the field of washing products and provides washing powder with a bactericidal effect. The washing powder comprises the following components: antibacterial zeolite, C14-C18 methyl ester sulfonate, sodium dodecyl benzene sulfonate, sodium silicate, anhydrous sodium sulphate, and an assistant, wherein the antibacterial zeolite is 4A zeolite loaded with nano TiO2. The antibacterial zeolite with the bacterial effect is added to the washing powder, so that the washing powder has a high-efficient sterilization effect, and has the characteristics of being strong in soil removability, non-toxic, and low in price.

Owner:天津市天亨洗涤剂有限公司

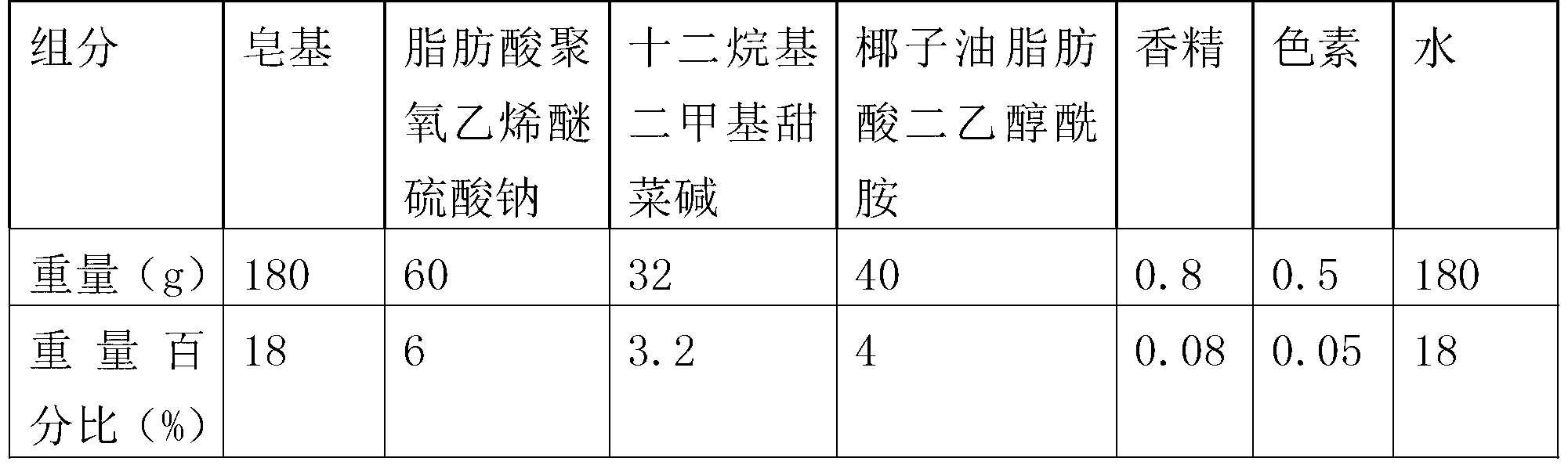

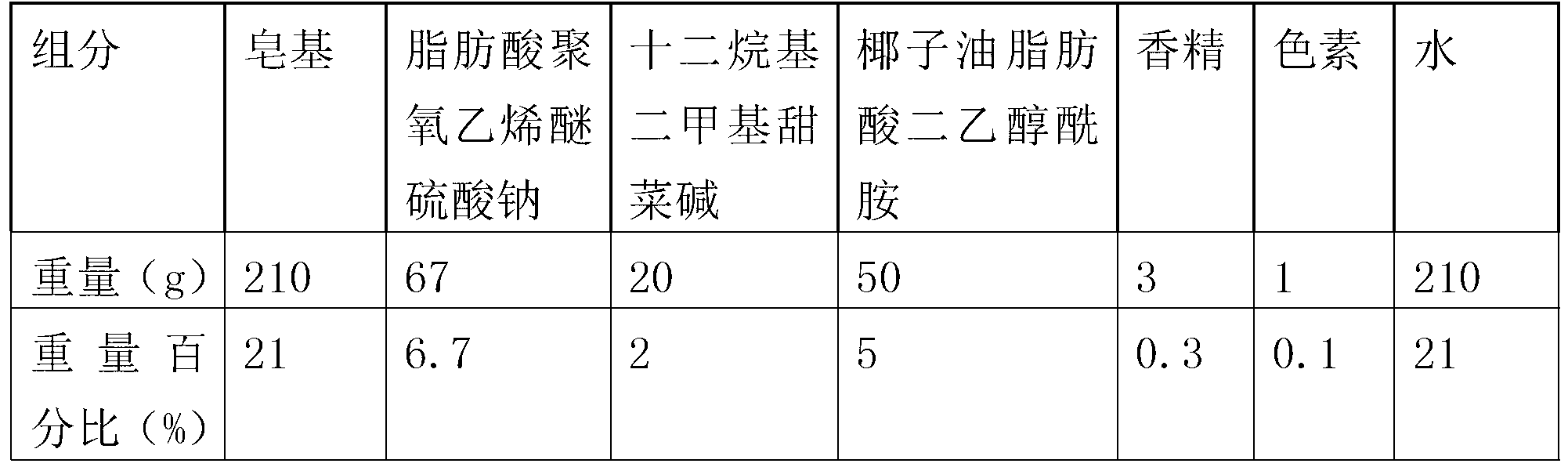

Liquid soap and preparation method thereof

The invention discloses liquid soap. The liquid soap is prepared from the following components by weight percent: 16-25% of soap base, 3-8% of sodium alcohol ether sulphate, 2-5% of dodecyldimethyl betaine, 2-5% of coconutt diethanol amide, 0.01-0.5% of essence, 0.01-0.5% of pigment, and the balance of water. The preparation method of the liquid soap comprises the following steps of a. mixing the components of the liquid soap according to proportion; b. stirring and heating to 80-85 DEG C; and c. cooling down to obtain the liquid soap product. According to the liquid soap and the preparation method of the liquid soap disclosed by the invention, the obtained liquid soap is strong in cleaning degree and tender in performances.

Owner:武汉创新环保工程有限公司

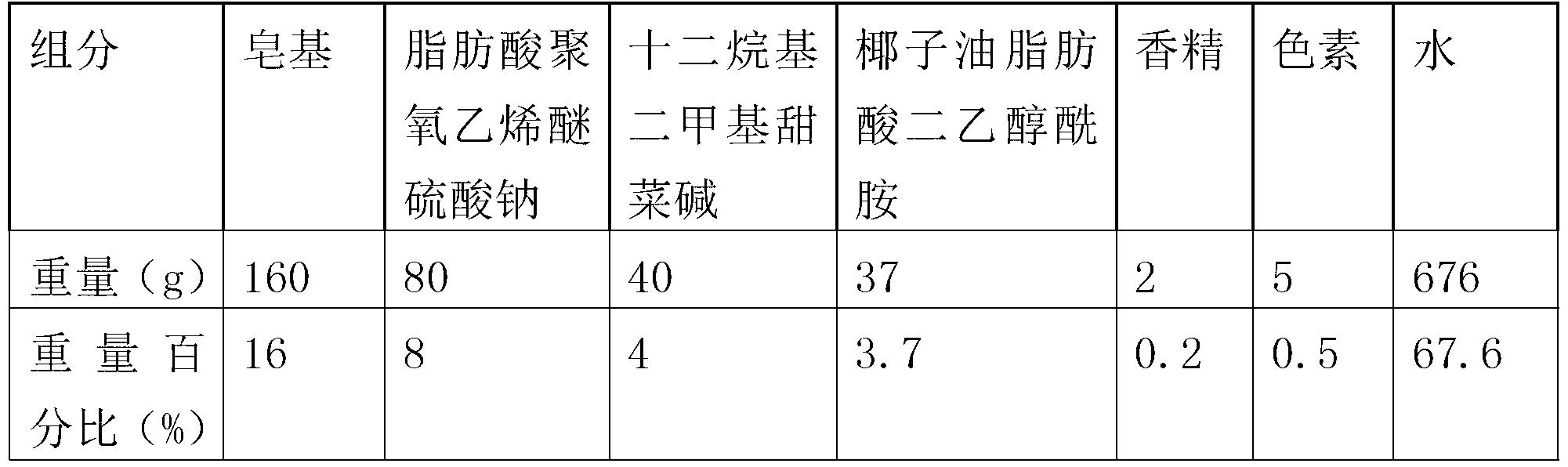

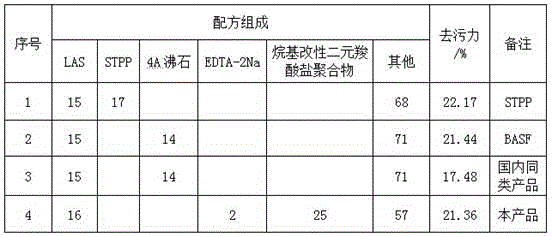

Phosphate-free detergent and production method thereof

InactiveCN105602746AGood resistance to hard waterDissolve fastInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsIonSodium silicate

The invention discloses a formula of phosphate-free detergent. The phosphate-free detergent is prepared from 150-170 parts of sodium dodecyl benzene sulfonate, 185-220 parts of light sodium carbonate, 95-115 parts of anhydrous sodium metasilicate, 32-46 parts of acrylic acid-maleic acid copolymer sodium salt, 15-28 parts of disodium ethylenediamine tetraacetate, 230-270 parts of alkyl modified dicarboxylate polymers, 1-3 parts of a fluorescent whitening agent, 145-170 parts of anhydrous sodium sulphate, 20-40 parts of fatty alcohol-polyoxyethylene ether AEO-3, 30-50 parts of fatty alcohol-polyoxyethylene ether AEO-9 and 1-2 parts of lemon essence. The phosphate-free detergent of the formula can effectively overcome the defect of a phosphate-substituted additive of existing phosphate-free detergent, and chelate most calcium, magnesium and iron ions in water, the effect is far better than that of a current 4A zeolite system, and the phosphate-free detergent has the advantages of being good in hard water resistance, capable of being dissolved fast, high in detergency, mild, free of stimulation and the like; moreover, the price of the phosphate-substituted additive in the phosphate-free detergent of the formula is lower than that of the 4A zeolite system, the phosphate-substituted additive is convenient to use and popularize on a large scale, and is the new direction of detergent phosphate-free additives in the future.

Owner:CHIZHOU HANNUOWEI ELECTROMECHANICAL DEVICE TECH CO LTD

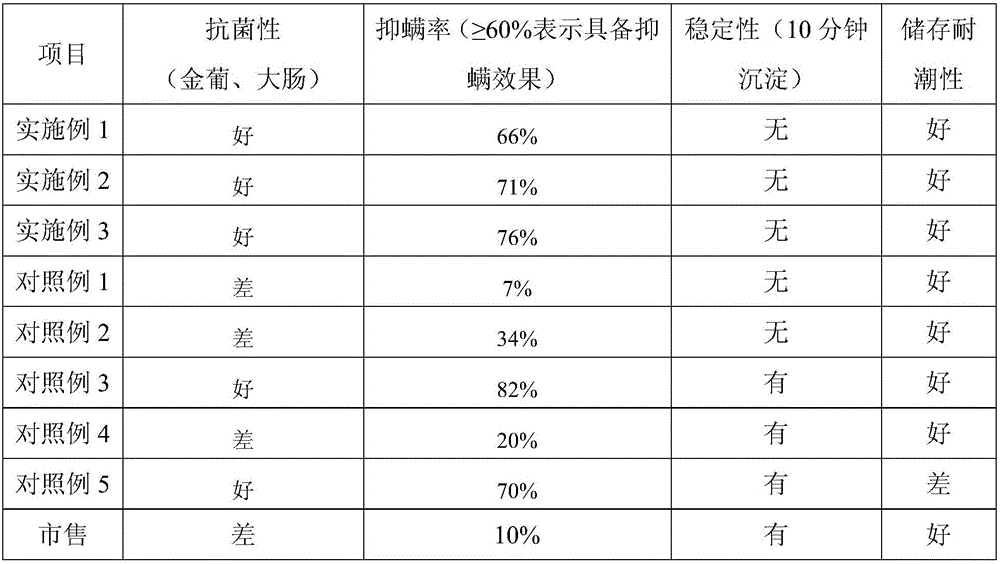

Antibacterial anti-mite laundry tablet and preparation method thereof

ActiveCN106811329ASewage non-toxicPromote degradationOrganic detergent compounding agentsSurface-active detergent compositionsPreservativeLaundry

The invention provides an antibacterial anti-mite laundry tablet and a preparation method thereof. The laundry tablet is prepared from a nonionic surfactant, an anionic surfactant, deionized water, anhydrous ethanol, a disintegrant, glutinous rice pulp, antibacterial anti-mite microcapsules, a crosslinking agent, protease, acids, essences, a colorant and a preservative. The preparation method comprises the following steps: adding the crosslinking agent, colorant, acids, essences and preservative into the deionized water, adding the nonionic surfactant-anionic surfactant-protease mixture, emulsifying, adding the glutinous rice pulp and disintegrant, adding the antibacterial anti-mite microcapsule dispersion solution to obtain a mixture, and drying and forming to obtain the laundry tablet. By adding the pure natural essential oil microcapsules with antibacterial anti-mite effects into the product, the product can be adsorbed to clothes after washing, and can slowly release the antibacterial anti-mite effects in the use process.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

Green and environment-friendly aqueous film-forming foam fire extinguishing agent

InactiveCN111420340AGood stabilityGood compatibilityFire extinguisherEthyleneglycol monobutyl etherActive agent

The invention discloses a green and environment-friendly aqueous film-forming foam fire extinguishing agent which is composed of the following raw materials in parts by mass: 1 to 3 parts of a polysiloxane surfactant, 5 to 8 parts of C9-11 alkanol polyether, 3 to 4 parts of 2-methyl-2,4-pentanediol, 0.5 to 1.2 parts of a composite film forming agent, 1 to 3 parts of polyoxyethylene, 20 to 30 partsof a polymer micro-cell capsule agent, 2.5 to 4.5 parts of diethylene glycol monobutyl ether, and 46.5 to 61 parts of deionized water. Beneficial effects are that: the method is suitable for large-scale production; the preparation method comprises the following steps: compounding a polysiloxane surfactant and C9-11 alkanol polyether; the traditional fluorocarbon surfactant is replaced; the fluorocarbon surfactant has excellent stability, good compatibility, no irritation to skin, good biodegradability and excellent decontamination, emulsification and hard water resistance under acidic and alkaline conditions, solves the problem that the fluorocarbon surfactant is difficult to degrade, reduces pollution to the natural environment and prevents indirect harm to human beings.

Owner:LUOYANG LANGCHAO FIRE SCI & TECH

Hydrangea and peony non-phosphorus fragrant detergent

InactiveCN101864345AGood resistance to hard waterStrong decontamination abilityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsChemistrySurface-active agents

The invention discloses hydrangea and peony non-phosphorus fragrant detergent, which comprises the following component in percent by weight: 9-11% of sodium percarbonate, 8-16% of sodium dodecyl benzene sulfonate, 5-7% of sodium sulfate, 9-13% of zeolite MAP, 7-9% of anionic surface active agent, 2-6% of carboxymethylcellulose, 11-15% of sodium disilicate, 2-4% of protease, 5-7% of extruded powder, 1-3% of hydrangea alcohol, 1-3% of peony alcohol, 0.5-1% of hydrangea essence, 0.5-1% of peony essence, 0.5-1% of semen cassiae essence, 0.5-1% of perilla essence and 19-21% of water. According to the proportion, the nine raw materials are taken to be fully combined together and then be poured into a sizing agent blender, stirring is carried out after 19-21% of water is added, the sizing agent is transferred into a sprayer to be dried into hollow granules, hydrangea alcohol, peony alcohol, hydrangea essence, peony essence, semen cassiae essence and perilla essence are then added, and then the mixture only needs to be transferred to a product molding and packaging machine unit to be packaged into a product.

Owner:王来军

Special cleaning agent for kitchen appliances

InactiveCN109468176AExcellent decontaminationGood emulsifying effectInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPhytic acidLinear alkylbenzene

The invention discloses a special cleaning agent for kitchen appliances. The cleaning agent is prepared from the following raw materials in percentage by weight: 50-60 parts of deionized water, 8-10 parts of an antirust corrosion inhibitor, 3-5 parts of phytic acid, 8-10 parts of a surfactant, 3-5 parts of a builder, 1-2.5 parts of a preservative, 2-5 parts of a bactericide, 2-5 parts of a pH adjuster, 1-2.5 parts of aromatic, 1-2.5 parts of citrate, 3-5 parts of an anti-foaming agent and 5-10 parts of a thickener. Added linear sodium alkyl benzene sulfonate has good detergency and emulsifyingpower, good hard water resistance and foaming power and excellent biodegradability and is a green surfactant; sodium fatty alcohol polyoxyethylene ether sulfate is an anionic surfactant, is easily soluble in water, has excellent detergency, emulsification, foaming performance and hard water resistance, cannot damage skin due to mild washing property, and has strong detergency; the added antirustcorrosion inhibitor is used for cleaning the metal surface, is corrosion-free and damage-free to metal, enables the cleaned metal surface to be clean and bright and has certain corrosion inhibition and antirust effects.

Owner:河南绿澳化工科技有限公司

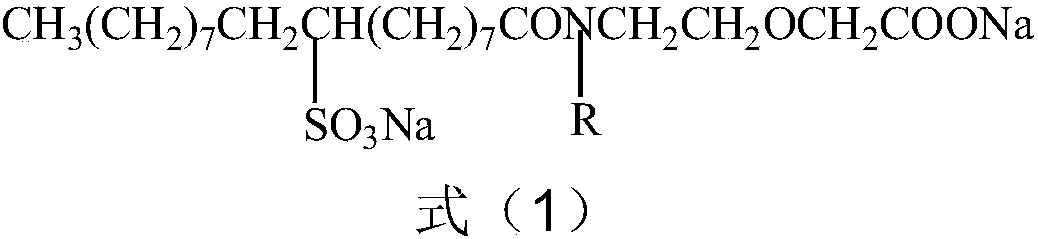

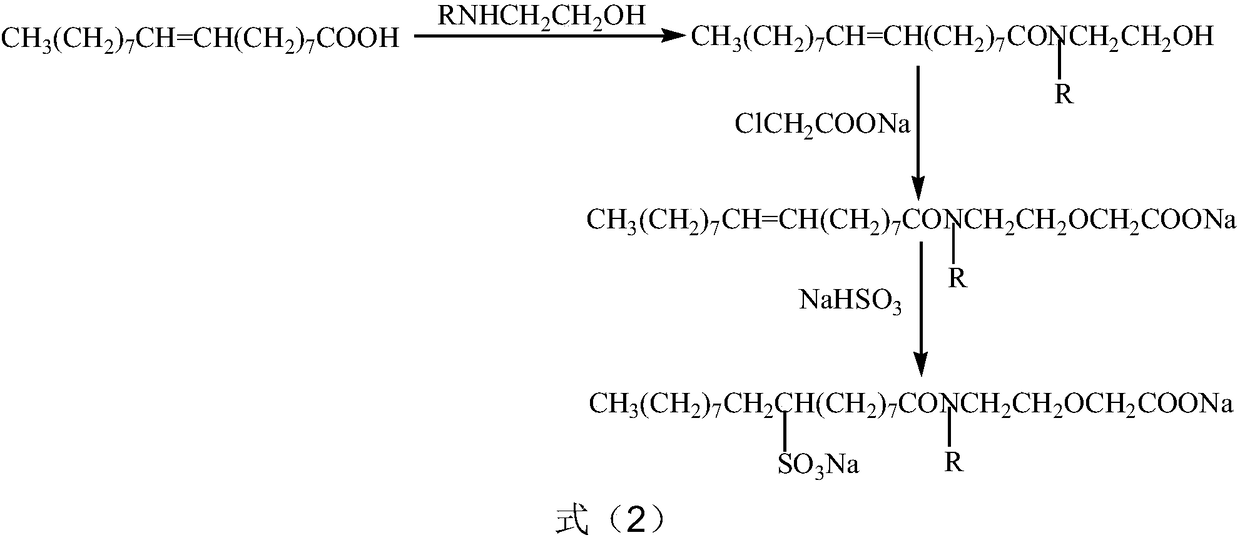

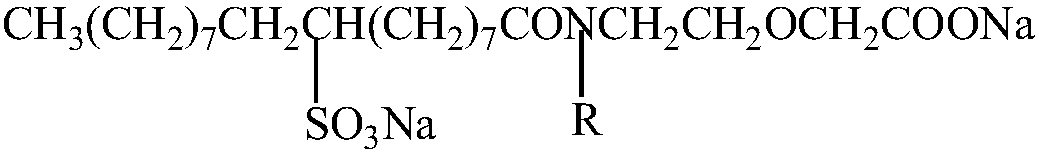

Dianionic surfactant containing acylamino and synthesis method thereof

ActiveCN109111379AThe synthesis process is simpleEasy to operateOrganic compound preparationTransportation and packagingSodium chloroacetateSynthesis methods

The invention discloses a dianionic surfactant containing acylamino and a synthesis method thereof. The synthesis method comprises the following steps: adding oleic acid, N-alkyl ethanolamine and a catalyst into a reaction kettle, thereby obtaining an intermediate A; adding the intermediate A into a reaction kettle, slowly dropwise adding 50% of a sodium hydroxide solution, dropwise adding a sodium chloroacetate solution into the reaction kettle, thereby obtaining an intermediate B; and adding the intermediate B and sodium hydrogen sulphite into the reaction kettle, thereby obtaining the dianionic surfactant containing acylamino. The synthesis process is simple, and is convenient to operate; the synthesized dianionic surfactant has good wetting, foaming and dirt-removing properties, good biological degradability, good hard water resistance and the like.

Owner:GUANGDONG YESER IND CO LTD

Laundry piece with good dissolving performance and preparation method of laundry piece

ActiveCN106753866ASewage non-toxicPromote degradationNon-ionic surface-active compoundsDetergent dyesChemical compositionAdhesive

The invention provides a laundry piece with good dissolving performance and a preparation method of the laundry piece. The laundry piece is prepared from the following raw materials: a non-ionic surfactant, an anionic surfactant, de-ionized water, a disintegrating agent, glutinous rice pulp, a protein enzyme, an acid agent, essence, a coloring agent and a preservative. The preparation method comprises the following steps: adding the coloring agent, the acid agent, the essence and the preservative into the de-ionized water; adding a mixture of the non-ionic surfactant, the anionic surfactant and the protein enzyme; after emulsifying, adding the glutinous rice pulp and the disintegrating agent; drying and forming an obtained mixed material to obtain the laundry piece. According to the laundry piece provided by the invention, the raw materials are uniformly mixed with the raw materials including the disintegrating agent, the surfactants and the like, so that the aim of good dissolving effect is realized; green pure-natural substances are used for replacing existing film forming agent and adhesive, which are made of chemical components.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

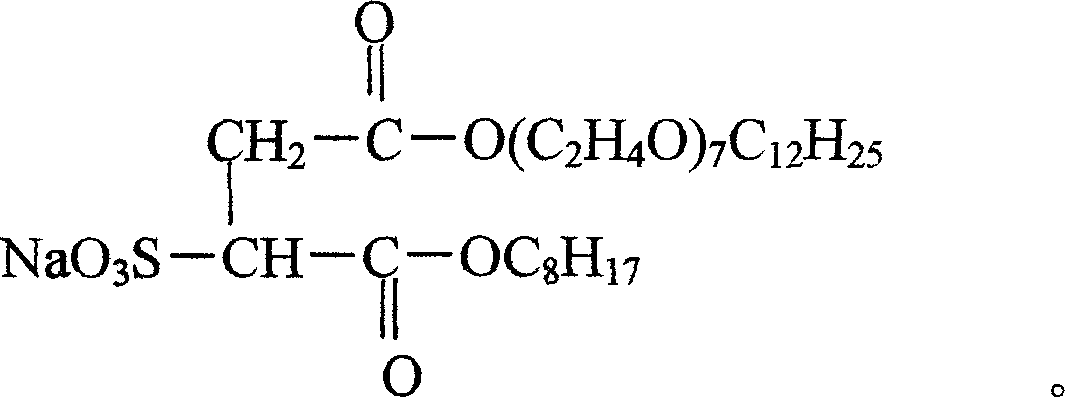

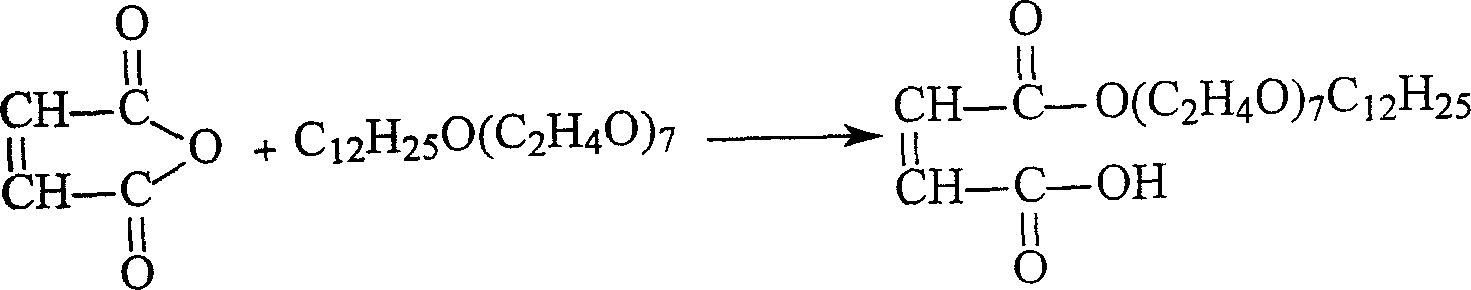

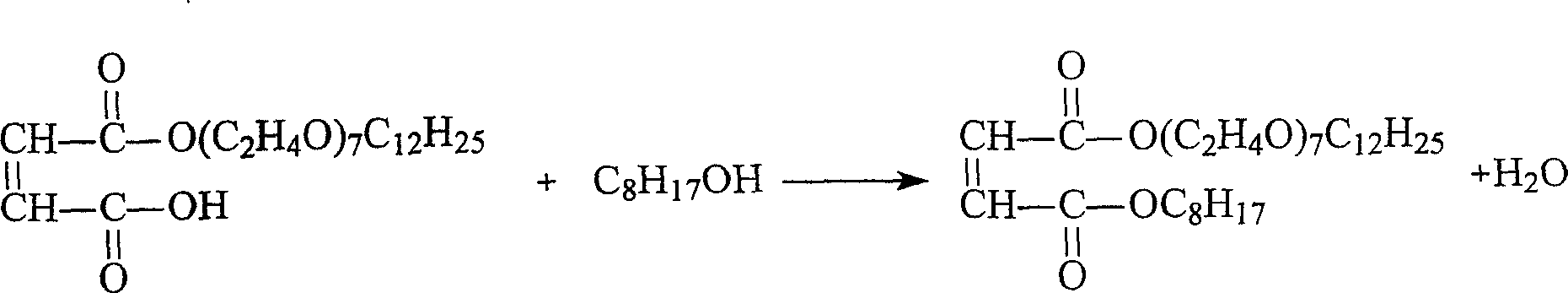

Sodium lauryl polyoxyethylene (7) octyl sulfosuccinate and its preparing process

InactiveCN101015779AReduce consumptionIncrease profitTransportation and packagingMixingEtherSodium bisulfite

The invention discloses a lauryl alcohol polyvinyl ether (7) octyl sulfo succinic mixed diester sodium and relative preparation, comprising that processing monoester reaction between maleic anhydride and lauryl alcohol polyvinyl ether (7), and processing diester reaction between the reaction product of monoester reaction and octanol, and processing conjugate addition reaction between the reaction product of diester reaction and sodium bisulfite to obtain final product. The invention has high-quality property and simple process.

Owner:NANTONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com