Low-alkaline scouring agent for continuous rope scouring of cotton fabrics

A scouring agent and cotton fabric technology, applied in plant fibers, textiles, papermaking, fiber treatment, etc., can solve the problems of affecting washing effect, reducing washing efficiency, increasing water consumption, etc., and achieve excellent emulsifying power, low alkali consumption, Good hard water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

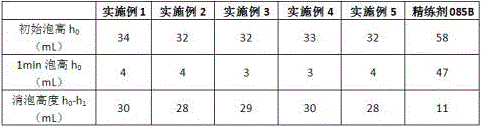

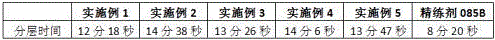

Examples

Embodiment 1

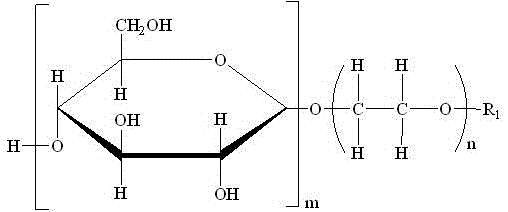

[0022] A low-alkali scouring agent for rope-like continuous scouring of cotton fabrics, its components and weight percentages are as follows: fatty acid methyl ester polyoxyethylene ether 6%, isomeric alcohol ether sulfate 14%, alcohol ether glycoside 5% %, isomer alcohol polyoxyethylene ether 24%, silicone defoamer 1%, water 50%.

Embodiment 2

[0024] A low-alkali scouring agent for rope-like continuous scouring of cotton fabrics. Its components and weight percentages are as follows: fatty acid methyl ester polyoxyethylene ether 8%, isomeric alcohol ether sulfate 12%, alcohol ether glycoside 7% %, isomer alcohol polyoxyethylene ether 22%, silicone defoamer 1%, water 50%.

Embodiment 3

[0026] A low-alkali scouring agent for rope-like continuous scouring of cotton fabrics, its components and weight percentages are as follows: fatty acid methyl ester polyoxyethylene ether 10%, isomeric alcohol ether sulfate 10%, alcohol ether glycoside 9 %, isomerized alcohol polyoxyethylene ether 20%, silicone defoamer 1%, water 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| alkali resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com