Process for pretreating pure cotton fabric

A pure cotton fabric and pre-treatment technology, applied in the processing of textile materials, continuous processing of textile materials, fiber processing, etc. Enhanced ability, fluffy and soft hand feel, and uniform hair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Fabric selection in this example: 36.9tex+36.9rex / 59tex+59tex 425 threads / 10cm×205 threads / 10cm 160cm pure cotton canvas, using enzyme stacking process, the main process is seam turning→shaking code→enzyme stacking→mercerizing, in which turning The sewing process refers to unpacking and sewing, so that the cloth to be dyed is continuously put on the car; then it is shaken, and then the enzyme stacking process, scouring enzyme 9g.L -1 , Triple A additive 4g.L -1 , the temperature is 55°C, the excess rolling rate is 100%, coiled and stacked for 20 hours. The last is the mercerizing process.

Embodiment 2

[0011] Fabric selection in this example: 36.9tex+36.9rex / 59tex+59tex 425 pieces / 10cm×205 pieces / 10cm 160cm pure cotton canvas, using enzyme stacking + alkaline oxygen cooking and bleaching process, the main process is seam turning→shaking code→enzyme stacking →scouring→bleaching→mercerizing, in which 9g.L of scouring enzyme is used in the enzyme stacking process -1 , Triple A additive 4g.L -1 , the temperature is 55°C, the excess rolling rate is 100%, coiled and stacked for 20 hours. NaOH 18~20g.L is used in the scouring process -1 , Triple A additive 6g.L -1 , the rolling rate is 100%, steamed at 100°C for 45 minutes, and washed with water at 90°C. Then carry out the bleaching process, using H 2 o 2 6~7g.L -1 , Triple A additive 3g.L -1 , the rolling ratio is 90%, steamed at 100°C for 40min, and washed with water at 90°C.

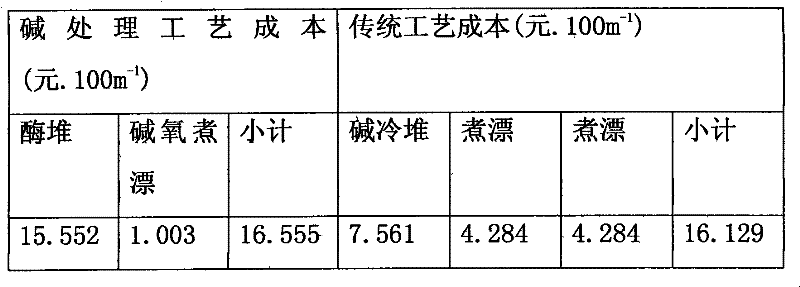

[0012] See Table 1 for the effects after the treatment of the above two embodiments.

[0013] Known from Table 1, the pure enzyme pile process tr...

Embodiment 3

[0015] The traditional process adopts alkali stacking + boiling and bleaching process, including seam turning→shaking→alkali stacking→scouring→bleaching→mercerizing, in which the alkali stacking uses NaOH 42±2g.L -1 , scouring agent 10g.L -1 , stabilizer 10g.L -1 , H 2 o 2 18~20g.L -1 , liquid rolling at room temperature, the rolling rate is 100%, coiling and stacking for 24 hours. NaOH28~30g.L is used in the scouring process -1 , scouring agent 6g.L -1 , the rolling ratio is 90%, steamed at 100°C for 60min, and washed with water at 90°C. Bleaching with H 2 o 2 1.6~1.8g.L -1 , scouring agent 2g.L -1 , stabilizer 3g.L -1 , the rolling ratio is 90%, steamed at 100°C for 40min, and washed with water at 90°C.

[0016] By comparing the semi-finished product test indicators of the above three embodiments, the structure is shown in Table 2. From Table 2, it is known that the enzyme reactor process has higher desizing rate and gross effect and less weight loss than the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com