Patents

Literature

125results about How to "Improve gross effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Scouring and bleaching agent combination and application thereof

InactiveCN101929064AReduce fiber damageAvoid Hole DefectsFibre treatmentBleaching apparatusWater savingAgent Combination

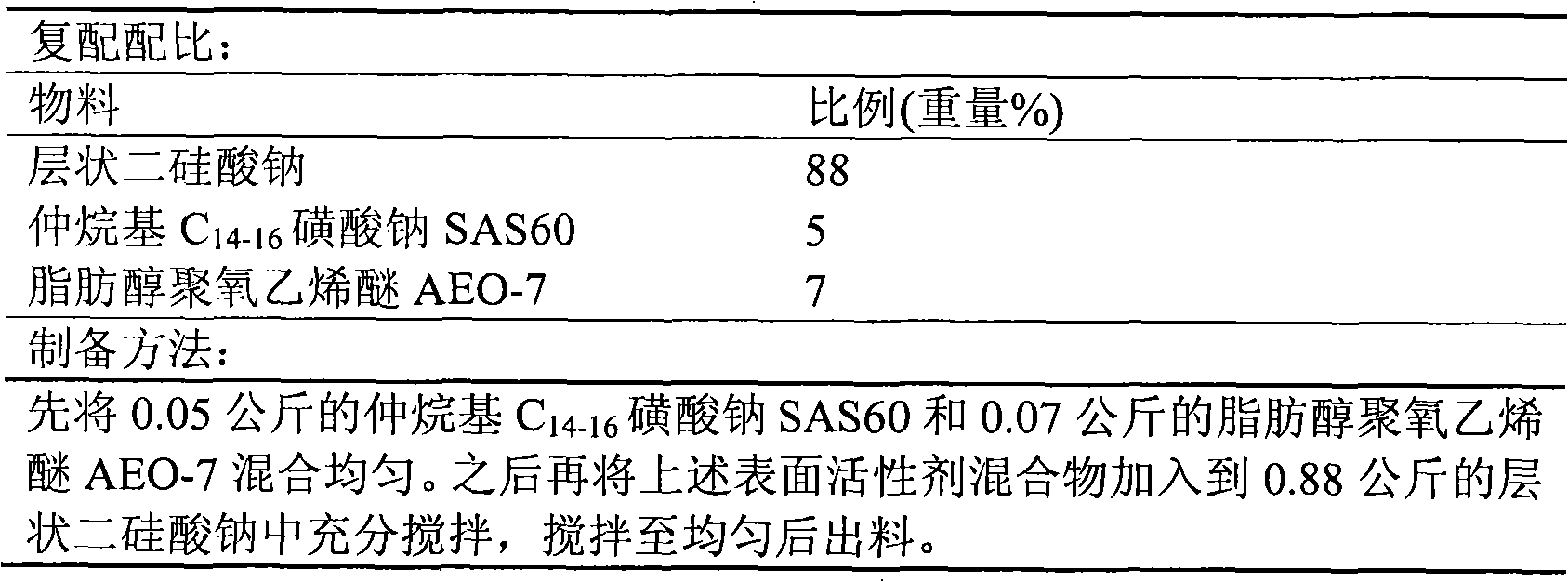

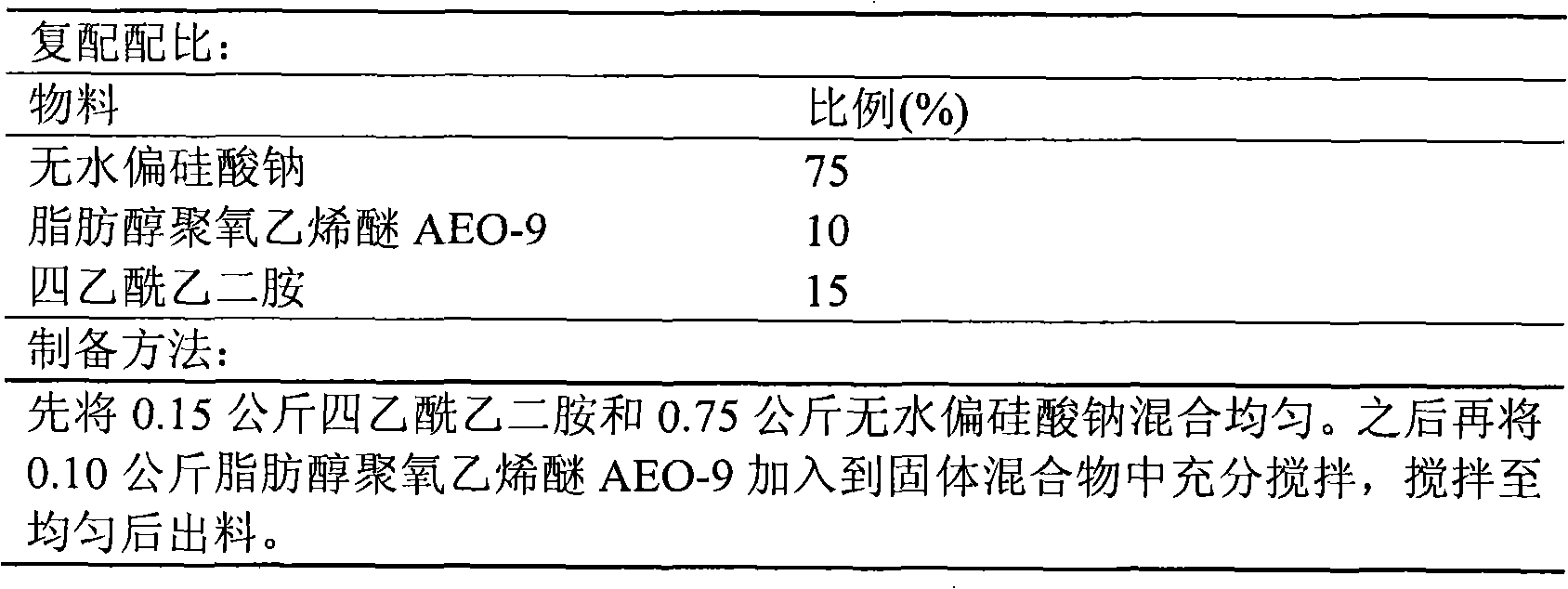

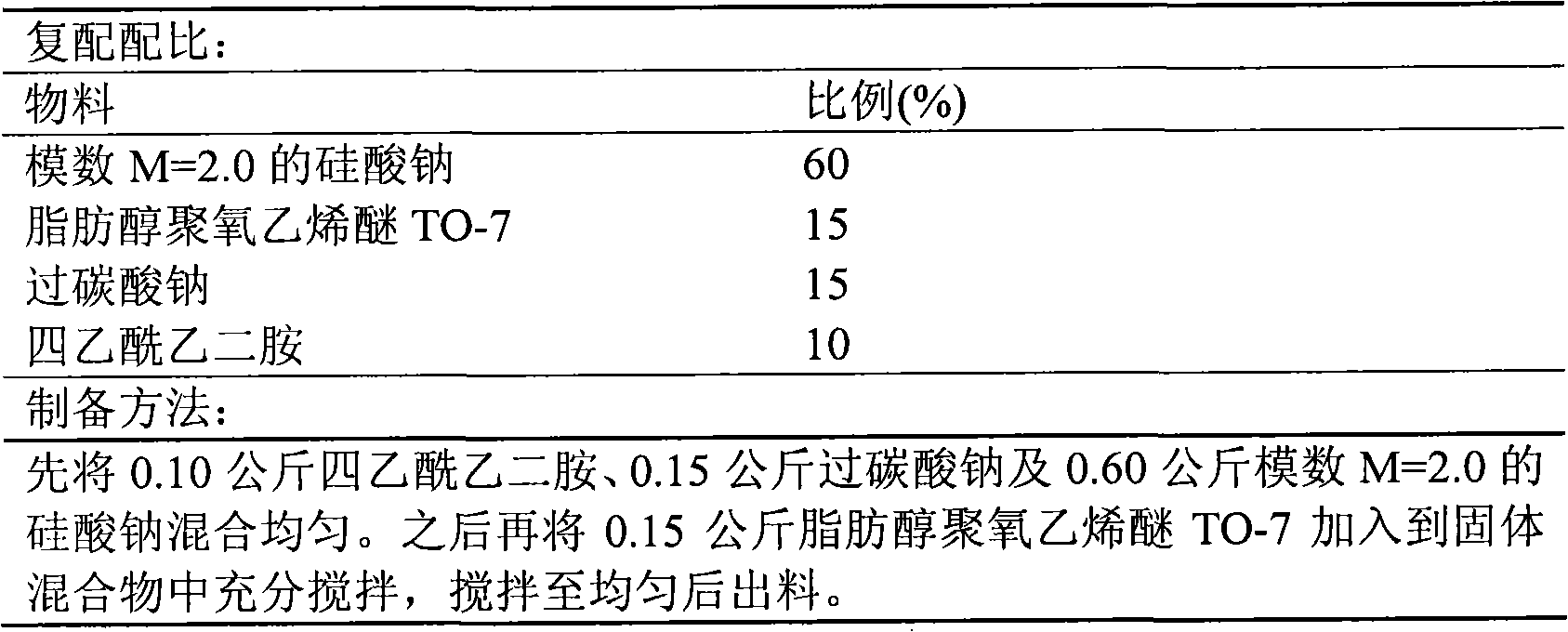

The invention discloses a scouring and bleaching agent combination used as an assistant for the pretreatment of cotton and blended fabrics and application thereof. Based on the total weight of the combination, the scouring and bleaching agent combination comprises the following components in percentage by weight: 40-95% of adsorptive abstergent, 5-20% of surfactant, 0-25% of water soluble alkali, 0-25% of scouring and bleaching synergist and 0-20% of chelate dispersant. When being used with oxydol, the scouring and bleaching agent can achieve a favorable effect of combining the refining procedure and the bleaching procedure. Compared with the traditional process, the treated fabric has better quality. The whole process achieves the advantages of continuous operation, low alkali discharge, water saving, energy saving, time saving and labor saving, thereby improving the production efficiency.

Owner:SHANGHAI ARGUS NEW MATERIAL CO LTD

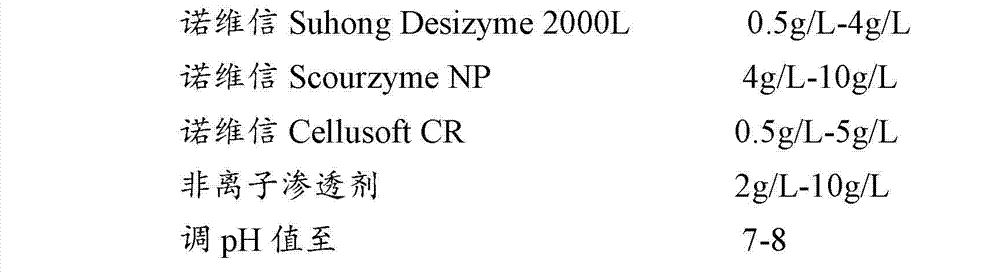

Heavy pure cotton fabric cold padding and stacking pretreatment method

ActiveCN103088645AExcellent desizingExcellent and refinedPhysical treatmentBiochemical fibre treatmentPretreatment methodTherapeutic effect

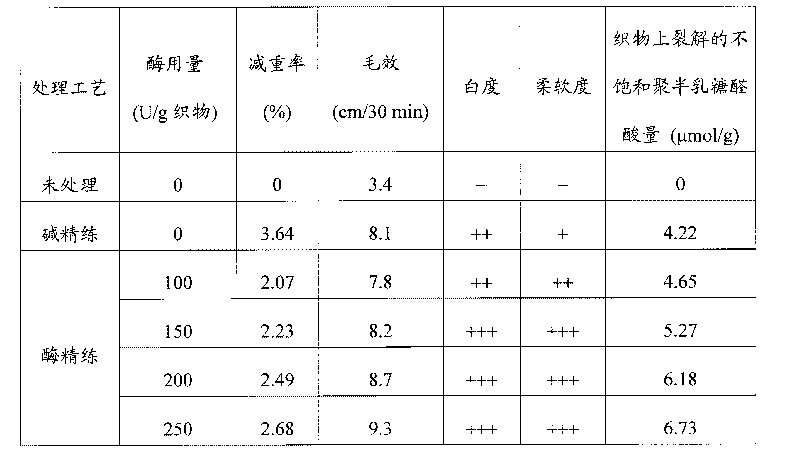

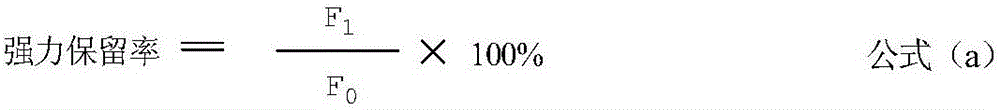

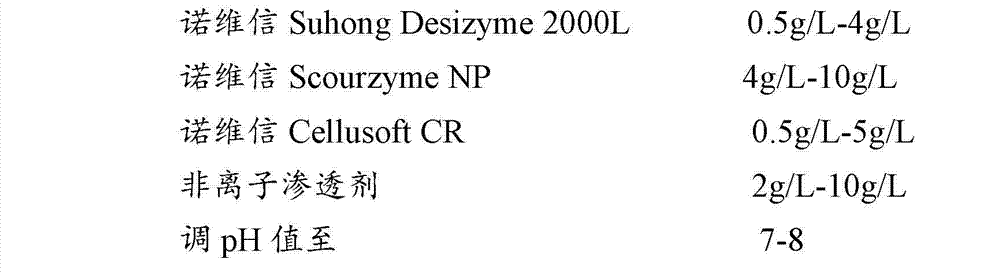

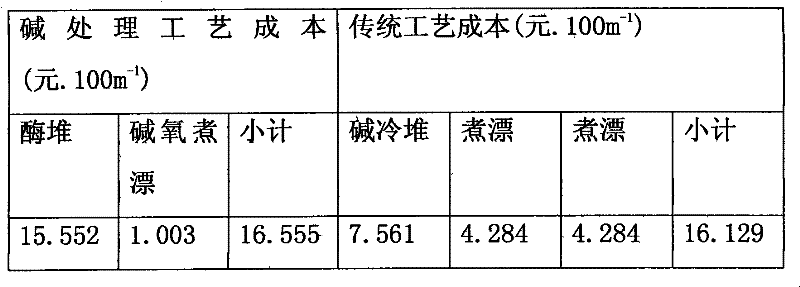

The invention discloses a heavy pure cotton fabric enzyme padding and stacking pretreatment process after normal pressure plasma treatment, and belongs to the technical field of dyeing and finishing pretreatment. The technological process comprises the following steps of: carrying out the normal pressure plasma treatment on the singed heavy pure cotton grey fabric; carrying out refining enzyme liquid padding on the fabric; then stacking at room temperature; then carrying out oxygen bleaching and low alkali mercerization; and finally sufficiently rinsing to complete the pretreatment process of the heavy pure cotton fabric. According to the method, the process has the characteristics of being good in treatment effect, little in fabrics strength damage, high in quality, soft in hand feeling, high in capillary effect and good in glossiness; the method provides a condition of high color yield for the subsequent dyeing and printing processing; the process operation is simple and high in controllability; the treated waste water, the pH value and the energy consumption of the process are far lower than the treated waste water, the pH value and the energy consumption of the traditional strong base scouring process; and the process is a clean production process meeting the environmental protection requirement, so that the sewage treatment burdens of enterprises are greatly reduced, the process is very high in social benefit and market prospect, and the process conditions are optimized.

Owner:浙江肯特科技股份有限公司

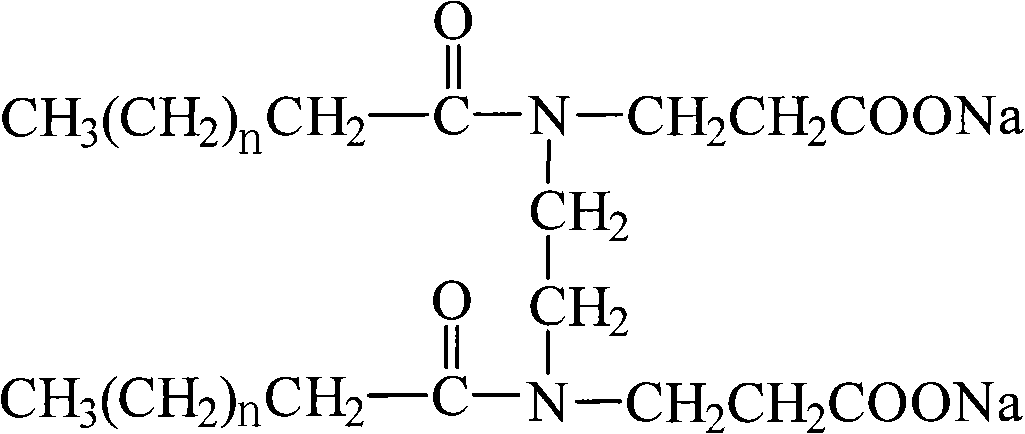

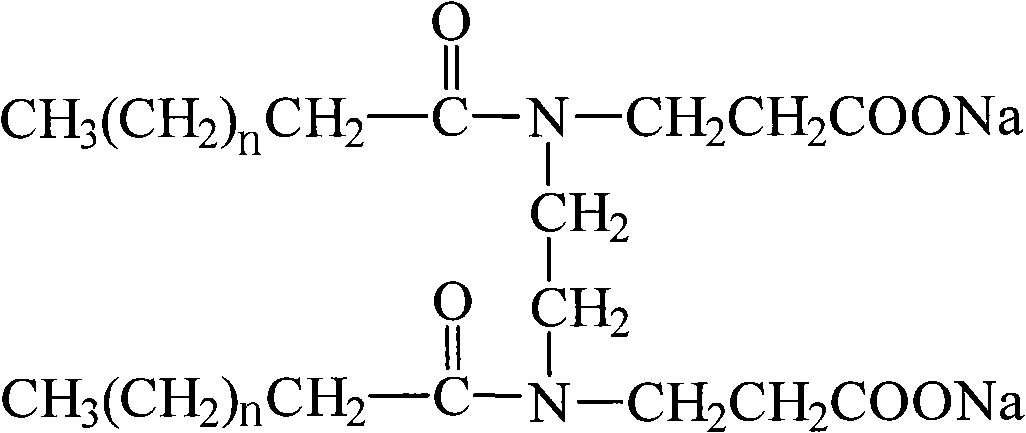

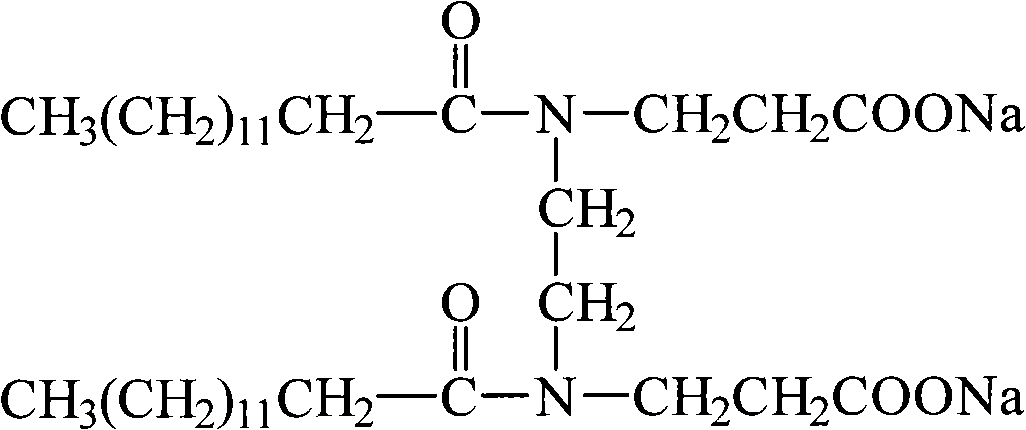

Silk broadcloth scouring agent

The invention relates to a finish process technology for textile, especially a scouring agent for real silk scouring and processing. According to the quality percentage, the ingredients scouring agent is 5-20% double-surfactant N,N'-dialkylamide and carboxylate sodium, 5-20% surfactant alkyl polyoxyethylene ether carboxylate, 2-10% maleic acid / acrylic acid copolymer, 2-10% fibroin protective agent, 1-10% inorganic salts, and water for the rest. The scouring agent take the double-surfactant as the essential component, so the surface activity and the solubility of the scouring agent are improved greatly, and the moistening and the scrubbing effect are strengthened; taking the alkyl polyoxyethylene ether carboxylate surfactant as a complex surfactant, the scouring agent has good emulsification and lime soap dispersing capacity, so as to enhances the scouring effect. At the same time, because amide bond exists in the molecular structure, the scouring agent has good hard water-resistant capacity and lime soap dispersing capacity, and has the advantages of improving the smooth feeling of the scoured textile, and enhancing the capillary effect.

Owner:SUZHOU UNIV

Highly-effective refine agent and production method thereof

The invention provides a high-efficient scouring agent and a production method thereof, pertaining to a treatment agent used for fabric printing and dyeing and the production method thereof. The invention is mixed by the mixture ratio of hydrolyzed fatty alcohol ether phosphate ester, fatty alcohol ether and synergic agent which are dydrolyzed. The scouring agent can effectively erase impurities such as fruit wax, husks, floating material, etc when the scouring agent are used for preprinting treatment of cotton and fabric. After being treated, the textile has face-finished, rather high fur effect and whiteness, facilitates coloration and printing of textile, alkali resistant (200g / L NaOH), high temperature resistant, hard water resistant, and has high-speed filtration ability and good separating ability to fiber. The preparation technology not only can be used for a successive padding method, but also be used for a cold pad dyeing method, a one-step process of decoloring, boil out and bleaching method, etc. The scouring agent is alkylphenol ethoxylates free, and conforms to the environmental protective requirement.

Owner:YUYUE HOME TEXTILE

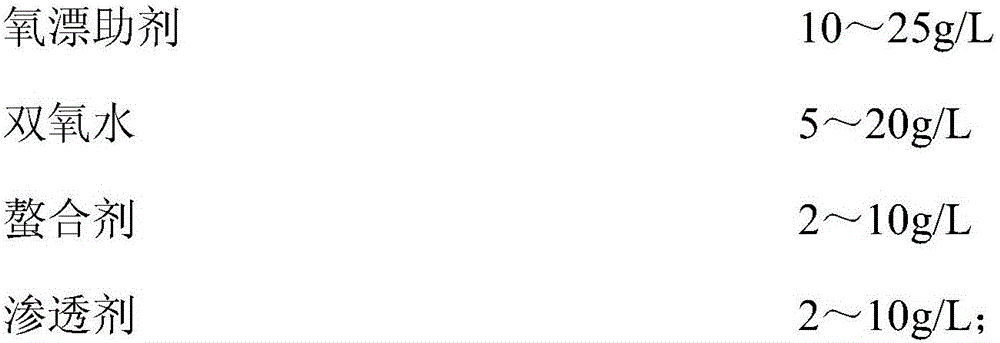

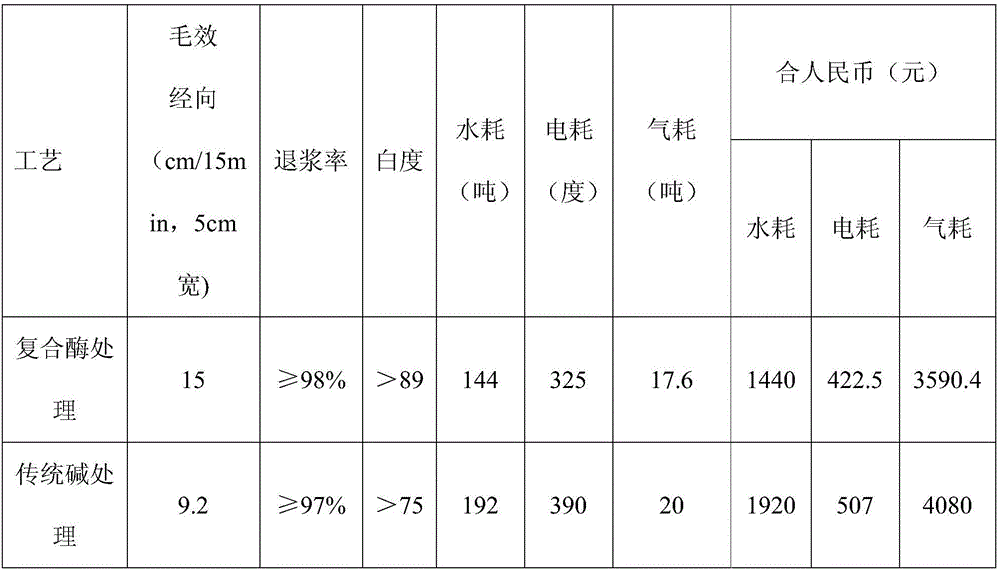

Biological enzyme pretreatment method for textiles

ActiveCN105970632AImprove qualityAvoid damageDry-cleaning apparatus for textilesBleaching apparatusPretreatment methodWastewater

The invention provides a biological enzyme pretreatment method for textiles. The biological enzyme pretreatment method comprises the following steps: padding a textile in a biological compound enzyme liquid at 20 to 70 DEG C till the liquid content is 80 to 100%; carrying out cold batching at 20 to 40 DEG C for 6 to 12 hours, or carrying out steaming with 50 to 70 DEG C saturated steam for 0.5 to 1 hour; washing with 70 to 80 DEG C hot water for 2 to 4 times; carrying out oxygen bleaching with an oxygen bleaching liquid till the liquid content is 80 to 100%; carrying out steaming with 100 DEG C saturated steam for 10 to 30 minutes; washing with 70 to 80 DEG C hot water for 2 to 4 times again; drying. The biological enzyme pretreatment method has the advantages that treatment before desizing and refining is realized with the biological compound enzyme in one step; a bleaching auxiliary agent replaces caustic soda in the oxygen bleaching step, so that the neutralizing step of the conventional alkali wastewater treatment process is eliminated, energy and water are saved, and pollution and cost are reduced; meanwhile, the quality of a textile treated according to the biological enzyme pretreatment method is higher than that of a textile treated according to the conventional process, the desizing rate of the textile subjected to enzymatic treatment is equal to or higher than 98%; the capillary effect is equal to or higher than 10cm / 15min (radial); the whiteness is equal to or higher than 89.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

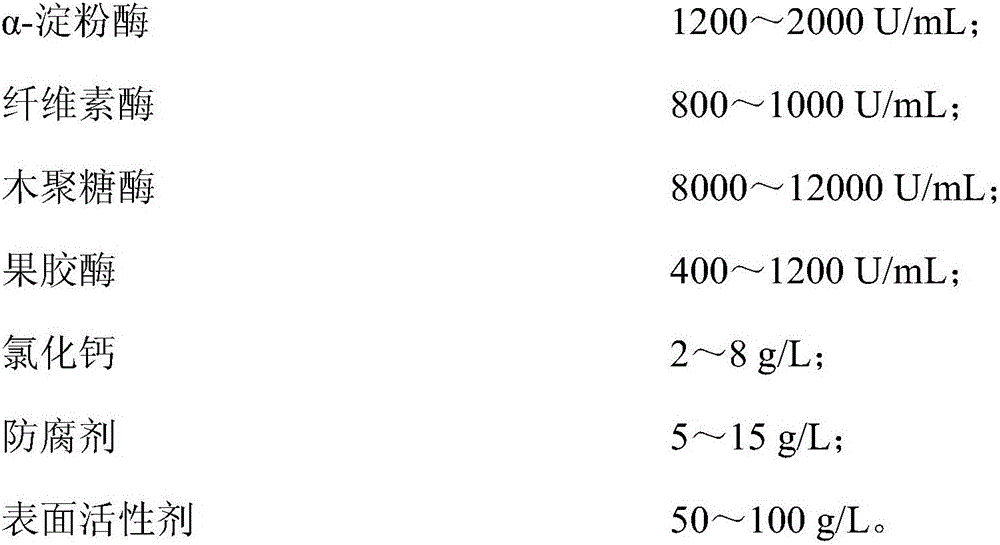

Compound enzyme preparation for textile fabrics and applications thereof

ActiveCN101713150AReduce processing costsReduce salt contentBacteriaBiochemical fibre treatmentPectinaseSolvent

The invention provides a high-efficiency compound enzyme preparation used for a pretreatment process of textile fabrics, particularly cotton fabrics, and application thereof. The compound enzyme preparation mainly comprises the following components by final concentration: 50 to 100g / L of polysiloxane, 50 to 100g / L of fatty alcohol-polyoxyethylene ether, 80 to 150g / L of Tween 20 to 80 series, 80 to 150g / L of Span 20 to 80 series, 30 to 80g / L of sorbitol, 3 to 10g / L of calcium chloride, 5 to 15g / L of sodium benzoate, 800 to 1,000U / mL of alkaline pectinase, 1,000 to 1,200U / nL of cellulase, and water serving as a solvent. The compound enzyme preparation is applied to the pretreatment of the textile fabrics to replace the conventional alkali boiling off process, can effectively reduce production cost, reduce labor intensity and enable the quality of the product to be obviously improved, can also reduce the salt content and BOD, COD and the like in the water discharged into the environment and obviously reduce the pollution to the environment, and is a green process route which accords with the sustainable development.

Owner:ZHEJIANG UNIV OF TECH

Method for producing polyester cotton blended spinning latitudinal elastic fabric

InactiveCN101392425AHigh weft stretchEasy to retractFibre treatmentSingeingPolyurethane elastomerPolyester

This invention provides a production method of stretch-yarnless cotton-polyester blended latitudinal stretch fabric. The production method successively comprises the working procedures as follows: manufacture of grey cloth, sewing of the lining side of the grey cloth, singeing of the grey cloth, desizing, sizing, coloration, preshrinking and trimming inspection. After the desizing procedure and before the sizing procedure, a slack mercerizing procedure is conducted; after the coloration procedure and before the preshrinking procedure, a slack cloth-ironing procedure is conducted. By using the trimming method, before the singeing and desizing procedures, the pick count of the cotton-polyester blended fabric is small, thereby being prone to be back-shrunk. Trough the sizing procedure, the width can be shrunk and the capillary effect is increased, then through the slack mercerizing procedure, by slackly piling in a J-shaped box and mercerizing in the condition free from latitudinal tension, the width can be sufficiently shrunk and get an excellent stretch effect. In the procedure of slack cloth-ironing, polyurethane elastomer is added to the cotton-polyester blended fabric under the condition free from latitudinal tension, and through sanforizing cotton-polyester blended fabric gets higher longitudinal elasticity.

Owner:HUAFANG

After-finishing process of shrink-proof, anti-wrinkling, moisture absorption and quick-drying shirt collar support

The invention discloses an after-finishing process of a shrink-proof, anti-wrinkling, moisture absorption and quick-drying shirt collar support. The process comprises the following steps of: preparing a 30-40 g / l modifier of polyethylene siloxane serving as a quick-drying hygroscopic agent of an after-finishing agent, resin of a certain concentration and a Cat.D catalyst into a padding liquid of which the pH value is 4.5; and putting a fabric to be finished into the padding liquid, and performing pre-baking and baking steps when the padding rate is 80 percent. In the padding finishing liquid, the modifier of the polyethylene siloxane plays a role in absorbing moisture and drying quickly and is suitable for moisture absorption and quick-drying finishing of cotton, terylene and a blended fabric thereof, and the fabric is endowed with extremely good soft handfeel. The modifier of the polyethylene siloxane can be used separately with a padding method, and can be used together with initial condensation bodies such as a shrink-proof and anti-wrinkling agent, stiff resin and the like, so that the swelling ratio of a fiber pore canal is lowered, and better moisture absorption and quick-drying effects are achieved.

Owner:南通海盟实业股份有限公司

Method for printing flocked fabric

The invention provides a method for printing a flocked fabric, which comprises the steps of: using a treatment fluid to perform printing pre-treatment on polyamide villi flocked fabric, wherein the treatment fluid contains a refining agent, and the refining agent comprises 75 to 90 weight percent of hydrolyzed fatty alcohol ether phosphate ester, 5 to 15 weight percent of fatty alcohol ether, and 3 to 10 weight percent of synergistic agent; using color paste to print the polyamide villi flocked fabric after pre-dyeing treatment, wherein the color paste comprises 60 to 80 weight percent of printing paste, 2 to 5 weight percent of weak acid printing dye, 2 to 3 weight percent of citric acid and the balance of water; and performing steaming fixation on the printed polyamide villi flocked fabric, and then scrubbing and drying the polyamide villi flocked fabric. The method is adopted to print the polyamide villi flocked fabric to ensure that the printing color paste has good permeability on polyamide fiber to reduce the defects in printing patterns, so that the printed polyamide villi flocked fabric has clear printing patterns and also has higher color fastness at the same time to improve the quality of printed articles.

Owner:YUYUE HOME TEXTILE

Bamboo fiber dyeing technology

InactiveCN104420362AImprove gross effectAvoid stainsDry-cleaning apparatus for textilesDyeing processFiberSodium sulfate

The invention discloses a bamboo fiber dyeing technology, which comprises the following flows: pretreatment, dyeing, hot water washing, cold water washing, soaping and water washing. The capillary effect of the bamboo fiber can be improved through the pretreatment, the oil removal is prepared for dyeing, the dyeing problem due to manual operation can be effectively avoided by linear addition of anhydrous sodium sulfate and sodium carbonate, the operation is simple, and the dyeing is convenient.

Owner:QINGDAO SINGAO TEX NEW TECH COMPOSITE MATERIAL

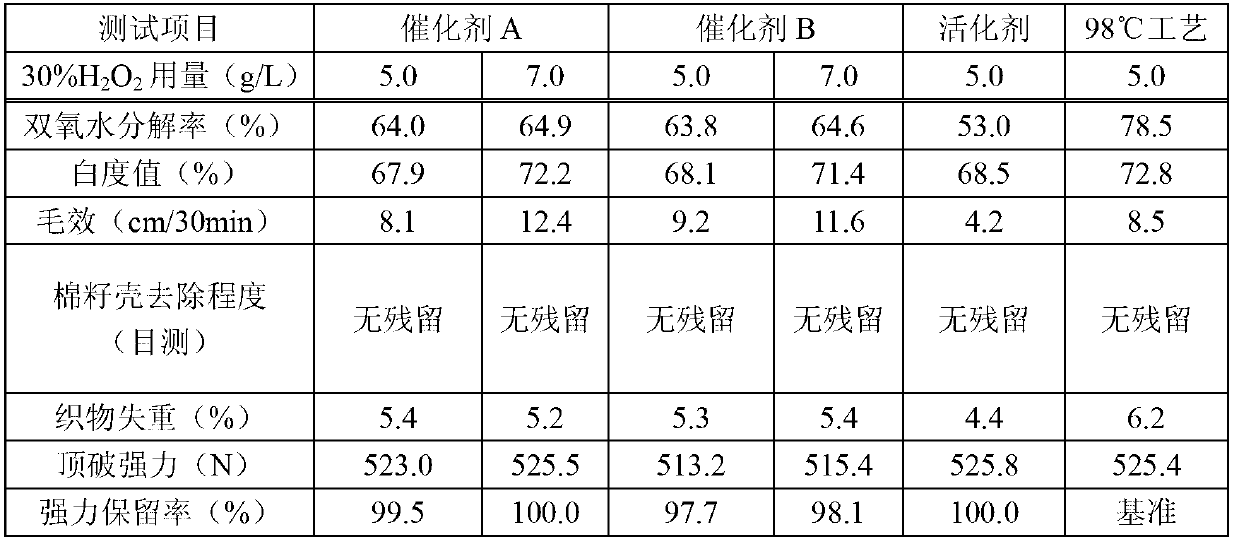

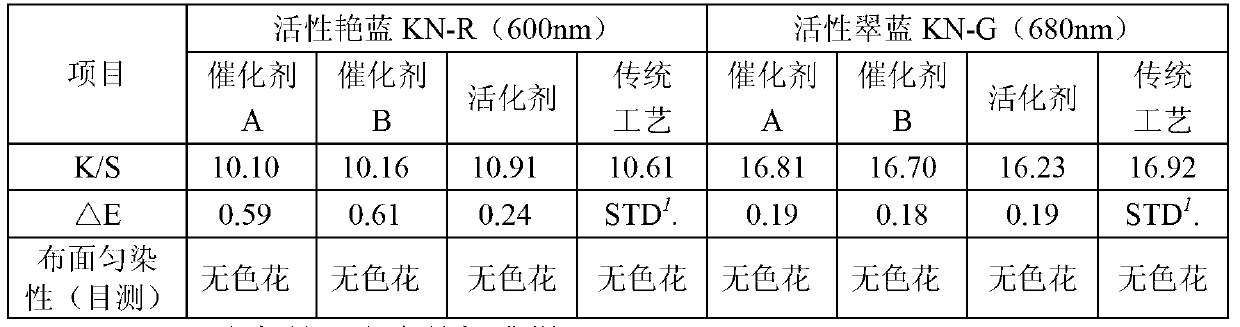

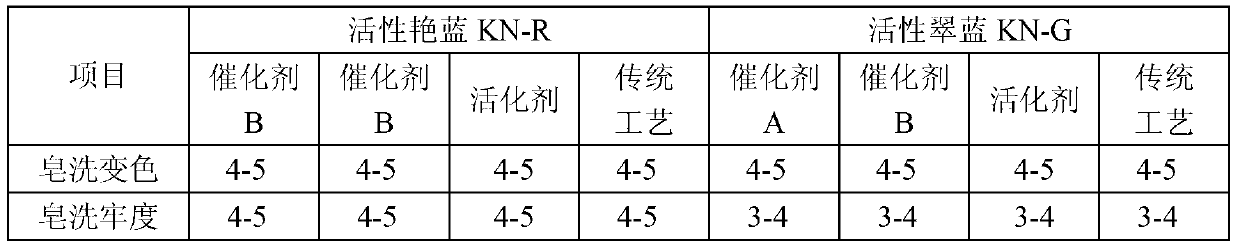

Cotton fabric scouring and bleaching processes by using heavy metal ions and polyphosphates as catalyst

ActiveCN103276583APromote decompositionHigh whitenessBleaching apparatusDecompositionPhosphoric acid

The invention provides a catalyst for cotton fabric scouring and bleaching processes and the scouring and bleaching processes, and particularly provides cotton fabric scouring and bleaching processes by using heavy metal ions and polyphosphates as a catalyst. The catalyst for H2O2 low-temperature scouring and bleaching is prepared by mixing Cu<2+> and a chelating agent (polyphosphate compounds) in a certain ratio, at a low temperature, a metal complex formed by Cu<2+> and the polyphosphate compounds can effectively promote decomposition of H2O2, so that the whiteness can be substantially improved, and further the capillary effect can also be considerably improved. The complex can be used as the catalyst and is used for the cotton fabric low-temperature scouring and bleaching processes, and can exert application effects that low-temperature scouring and bleaching processes by using activators and traditional high-temperature processes have. At the same time, the catalyst has the characteristics of simple preparation, stable products, efficient performance and the like.

Owner:DYMATIC CHEM +1

Method for processing yarn-dyed four-side stretch fabric garment

ActiveCN109097974AClear organizationImprove cohesionLiquid/gas/vapor removalBiochemical treatment with enzymes/microorganismsYarnEngineering

The invention discloses a method for processing a yarn-dyed four-side stretch fabric garment. The method comprises the following steps: (a) alkali soaking; (b) biological enzyme polishing; (c) dyeing;(d) air drying; (e) sizing; (f) weaving; (g) desizing; (h) scouring and bleaching; (i) padding; (j) drying; (k) finishing; and (l) pre-shrinking. The method is simple in process, saves energy and reduces consumption and is easy to control, and an obtained fabric is soft and comfortable in touch and has a fine and soft gloss, good non-ironing property, anti-wrinkle performance and anti-pilling performance and dimensional stability.

Owner:盛泰智造集团股份有限公司

After-finishing process of shrink-proof, anti-wrinkling, moisture absorption and quick-drying shirt collar support

The invention discloses an after-finishing process of a shrink-proof, anti-wrinkling, moisture absorption and quick-drying shirt collar support. The process comprises the following steps of: preparing a 30-40 g / l modifier of polyethylene siloxane serving as a quick-drying hygroscopic agent of an after-finishing agent, resin of a certain concentration and a Cat.D catalyst into a padding liquid of which the pH value is 4.5; and putting a fabric to be finished into the padding liquid, and performing pre-baking and baking steps when the padding rate is 80 percent. In the padding finishing liquid, the modifier of the polyethylene siloxane plays a role in absorbing moisture and drying quickly and is suitable for moisture absorption and quick-drying finishing of cotton, terylene and a blended fabric thereof, and the fabric is endowed with extremely good soft handfeel. The modifier of the polyethylene siloxane can be used separately with a padding method, and can be used together with initial condensation bodies such as a shrink-proof and anti-wrinkling agent, stiff resin and the like, so that the swelling ratio of a fiber pore canal is lowered, and better moisture absorption and quick-drying effects are achieved.

Owner:南通海盟实业股份有限公司

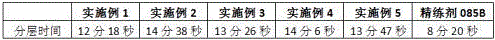

Low-alkaline scouring agent for continuous rope scouring of cotton fabrics

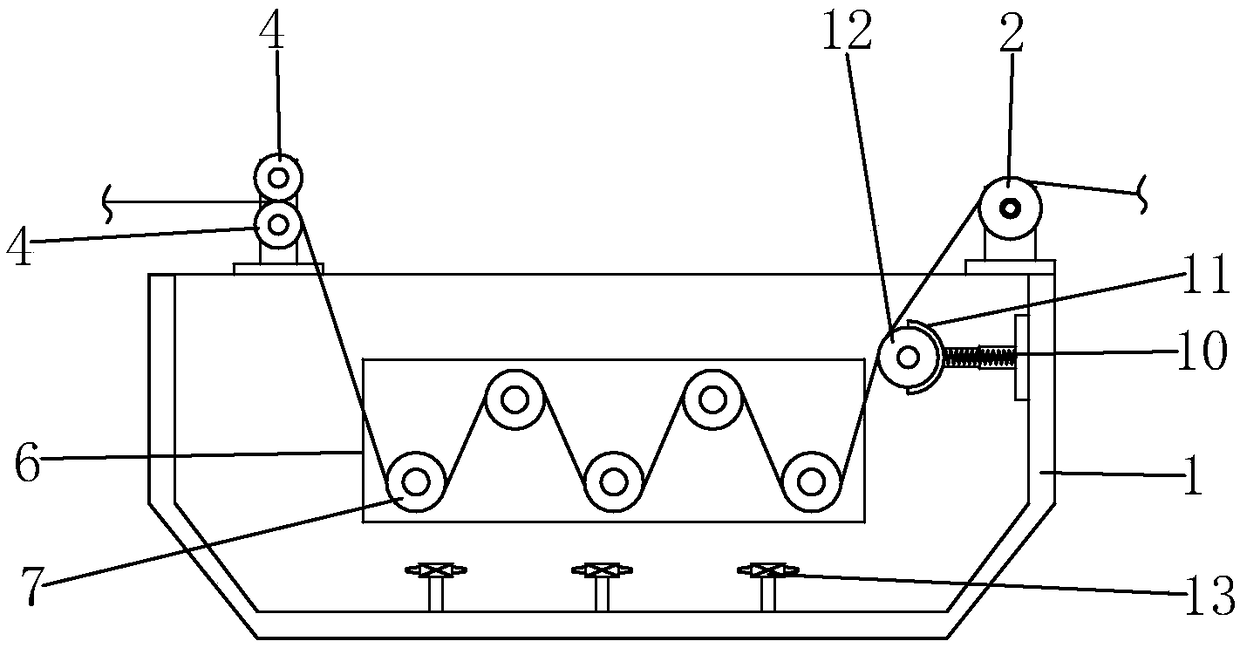

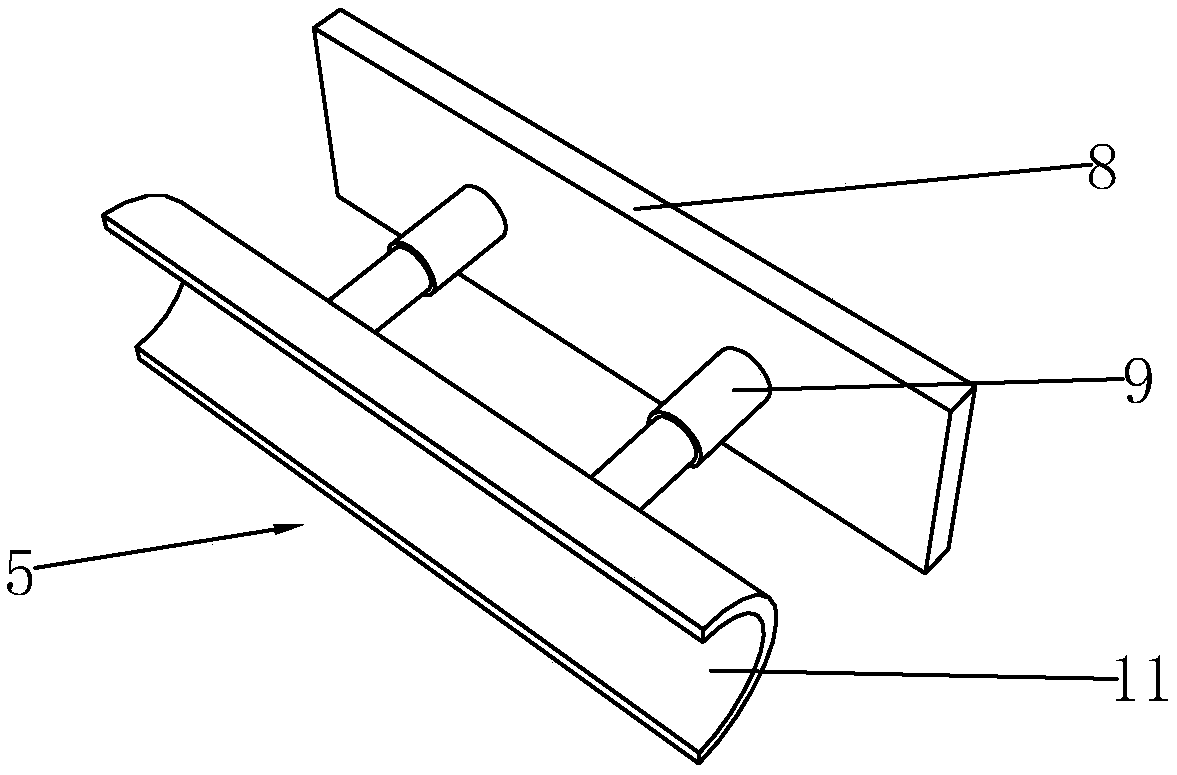

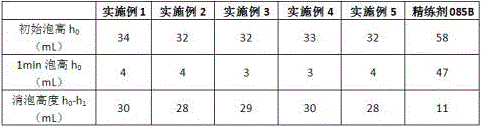

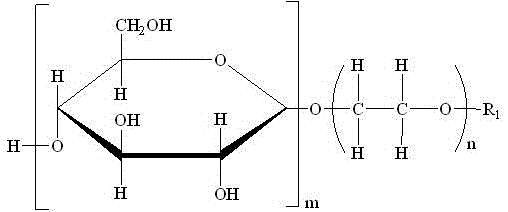

ActiveCN105525509AImprove gross effectHigh desizing rateVegetal fibresFatty acid methyl esterDefoaming Agents

The invention discloses a low-alkaline scouring agent for continuous rope scouring of cotton fabrics. The low-alkaline scouring agent comprises, in percentage by weight, 5%-15% of fatty acid methyl ester polyoxyethylene ether, 5%-15% of isomerized alcohol ether sulphate, 5%-15% of alkyl ethoxy polyglycosides, 15%-25% of isomerized alcohol polyoxyethylene ether, 0.5%-2% of a polyether modified organic silicon defoaming agent and 28%-69.5% of water. A preparation method of the low-alkaline scouring agent comprises steps as follows: (1), isomerized alcohol ether sulphate and water are mixed uniformly, and a proper amount of sodium hydroxide is added until the pH value is adjusted to range from 6 to 7; (2), alkyl ethoxy polyglycosides and fatty acid methyl ester polyoxyethylene ether are added to a mixed solution in the step (1), and the mixture is stirred and mixed uniformly; (3), the solution mixed in the step (2) is heated to 50-60 DEG C, isomerized alcohol polyoxyethylene ether is slowly poured into the solution, and the mixture is stirred and mixed uniformly. The low-alkaline scouring agent is especially suitable for continuous rope pre-processing of pure cotton fabrics, has the advantages of high desizing level, high capillary effect and low foam and can reduce the consumption of caustic soda in the scouring process and reduce pollution of caustic soda to the environment.

Owner:SHANDONG HUANGHE DELTA INST OF TEXTILE SCI & TECH RES INST

Manufacture method of mixed yarn towel

ActiveCN103088523AAppearance plump and thickFeel comfortableDry-cleaning apparatus for textilesWoven fabricsYarnBiochemical engineering

The invention discloses a manufacture method of a mixed yarn towel. The manufacture method of the mixed yarn towel is characterized in that raw materials of the towel is mixed yarn, the mixed yarn is formed by blending of China hemp fiber and cotton fiber, and the weight ratio of the China hemp fiber to the cotton fiber is 20-30: 70-80. The mixed yarn towel generated by means of the manufacture method is fluffy, full in appearance, thick, comfortable in hand feel, and good in moisture absorption performance. By means of added auxiliaries, impurities such as size, pectin substances, waxiness, a certain hemicellulose materials which are on the fabric are effectively eliminated, a capillary effect is improved and hand feel and product quality are further improved.

Owner:安徽星星服装股份有限公司

Five-in-one low-temperature quickly-smelting agent

InactiveCN101418514AGood whitenessImprove gross effectFibre treatmentDry-cleaning apparatus for textilesSodium silicateAlkyl phosphate

The invention discloses a five-into-one low temperature rapid scouring agent, which belongs to the technical field of fabric dyeing and finishing. The rapid scouring agent is characterized in that the rapid scouring agent is prepared by the following raw materials in weight portion: 18 to 20 portions of alkyl phosphate, 10 to 18 portions of alkyl polyether phosphate ester, 8 to 19 portions of alkyl polyethenoxy ether, 15 to 16 portions of calcined soda, and 40 to 45 portions of sodium silicate. The product is used for the desizing, the scouring and the bleaching of cellulose fiber, has excellent osmosis, dispersivity, hydrogen peroxide stability and scouring effect, replaces the prior osmotic agent, dispersion chelator, hydrogen peroxide stabilizer, caustic soda and scouring agent, is time-saving and labor-saving, and has good scouring effect and high whiteness.

Owner:SHANDONG JINLU CHEM

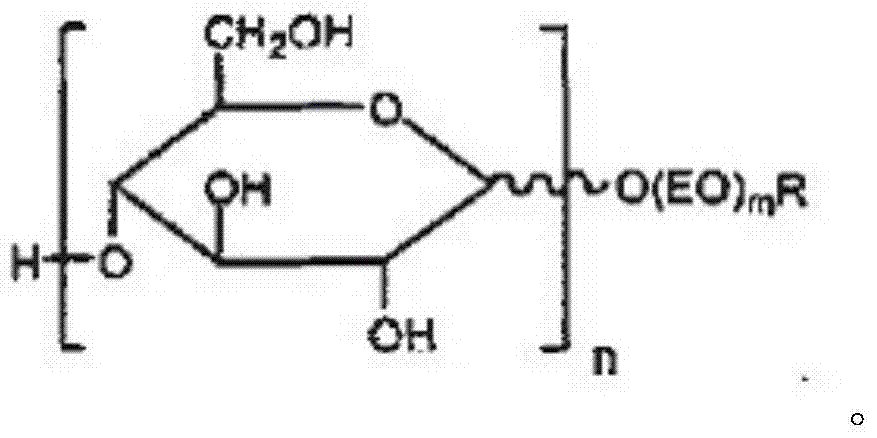

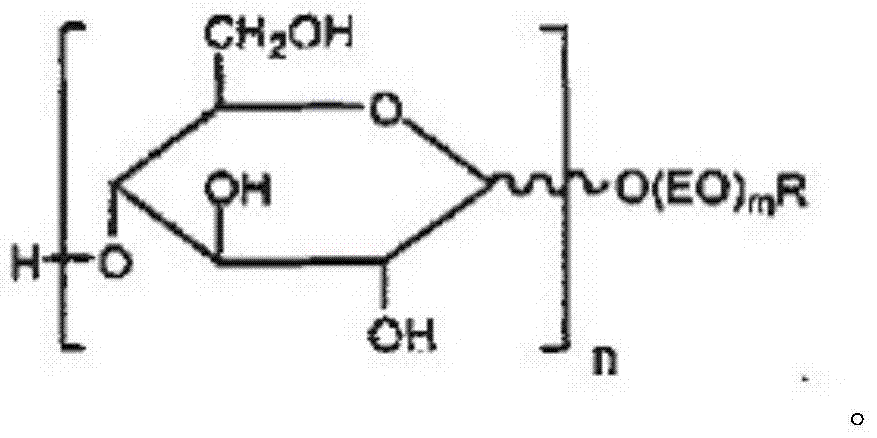

Application of environment-friendly scouring agent

The invention belongs to the technical field of textile assistants, and particularly relates to application of an environment-friendly scouring agent. The scouring agent is composed of the following components in parts by weight: 2-50 parts of alcohol ether glucoside, 2-50 parts of alkyl glycoside and 20-60 parts of water. When in use, the scouring agent can be prepared into a 0.1-5g / L water solution. The raw materials have fewer varieties and are biodegradable nonionic surfactants, and have the advantages of high permeability, high hair effect and the like after combination; and the scouring agent can effectively reinforce cleaning and enhance the hair effect in the textile pretreatment technique, and is superior to like products in a cold dome technique and scouring technique.

Owner:ANYANG BOAO BIOLOGICAL NEW SYNTHESIS

Preprocessing method of fabric printing and dyeing

InactiveCN102912617AImprove gross effectImprove hydrophilicityPhysical treatmentDry-cleaning apparatus for textilesIonPlasma processing

The invention provides a preprocessing method of fabric printing and dyeing. The preprocessing method comprises the following steps: a) performing plasma processing on the fabrics to be processed; b) desizing the fabrics obtained in the step a); c) bleaching the fabrics obtained in the step b), and finishing preprocessing of the fabrics. The method provided by the invention comprises the following steps: performing plasma processing on the fabrics to be processed, and then desizing and bleaching the obtained fabrics in turn to finish the preprocessing of the fabrics. According to the preprocessing method, in the process of performing plasma processing for the fabrics, the macromolecular chains of the surface layers of the fibers are broken after the fabrics are subjected to plasma processing and the fibers are in the rough state with uneven appearances, so that the conditions are created for further modifying the materials; or the ions and free groups are generated on the surfaces of the fabrics so as to improve hydrophily and permeability on the surfaces of the fibers, so that the capillary effect of the fabrics is improved. The preprocessing method of fabric printing and dyeing provided by the invention has better effects on saving energy and reducing emission as well.

Owner:YUYUE HOME TEXTILE

Production process of pure linen cheese

InactiveCN109295735AFeel goodReduce degradation rateBiochemical treatment with enzymes/microorganismsVegetal fibresYarnPectinase

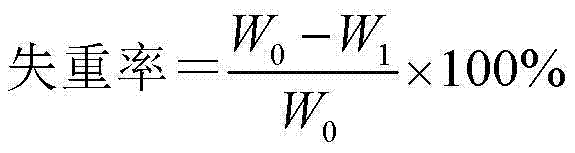

The invention relates to a production process of pure linen cheese. Pure linen cheese which has undergone chlorite bleaching is then subjected to oxygen bleaching, dyeing, softening and yarn drying processes. The invention is characterized in that pure linen cheese is subjected to bio-enzyme scouring treatment before oxygen bleaching, and a mixed solution for the bio-enzyme scouring is mainly composed of pectinase, scouring agent and chelating agent; the heating rate of a rinsing liquid used in the oxygen bleaching is 1-1.5 DEG C / min; during the softening process, a hydrophilic softener is adopted; and the moisture content of the cheese obtained after the yarn drying is 6-8%. By the process, hydrophilicity of the fiber can be enhanced and hand feeling of the yarn can be improved, strengthreduction rate of the yarn is reduced, rewinding is promoted for the linen yarn, capillary effect of the yarn is improved, and the soft hand feeling is beneficial to subsequent weaving.

Owner:JIANGSU LIANFA TEXTILE

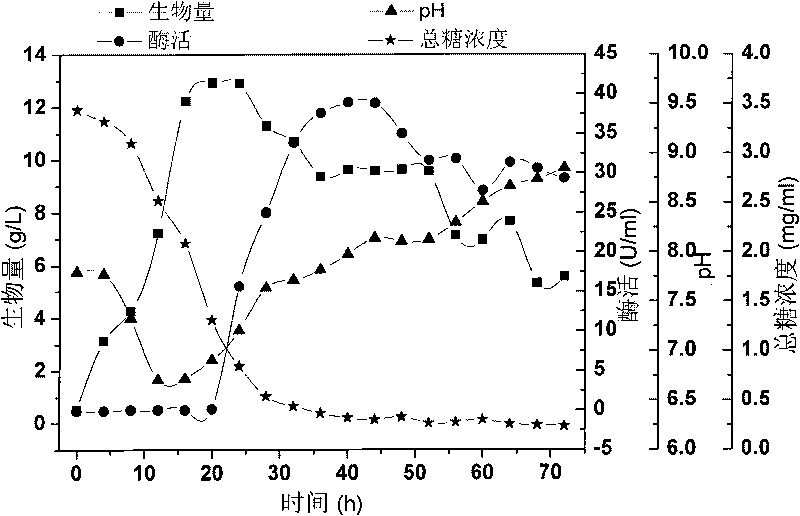

Cleaning production auxiliaries for pretreatment

The invention provides a pre-treating clean production additive with the characteristics of high efficiency and short flow. The characteristic additive components includes: enzyme 90%, pure water 1%, hydrogen peroxide decomposer 3%, NaCl 5%, and other additives. The invention is mainly used in the fabric working procedures of polishing and desizing. The smooth and soft fabric effect can be achieved through the enzyme hydrolyzing fabric in order to enable the fabric fluff to be divorced from the fabric surface, and meanwhile the slurry on the grey clothes can be removed through desizing reaction in order to guarantee the qualities of printing and dyeing products. The dosages of water, electricity, and gas are saved, and the cost for processing waste water is reduced.

Owner:SUZHOU HUACHOU TECH

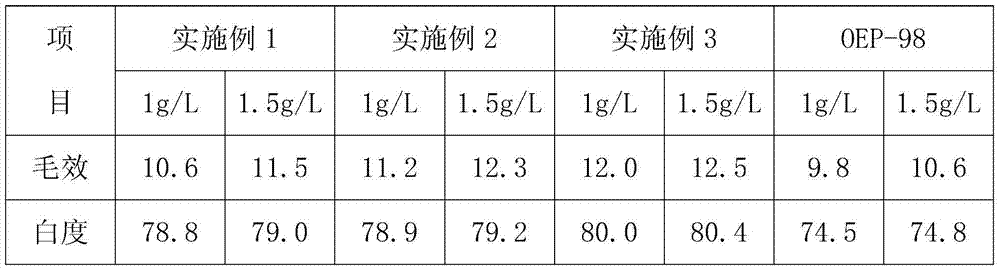

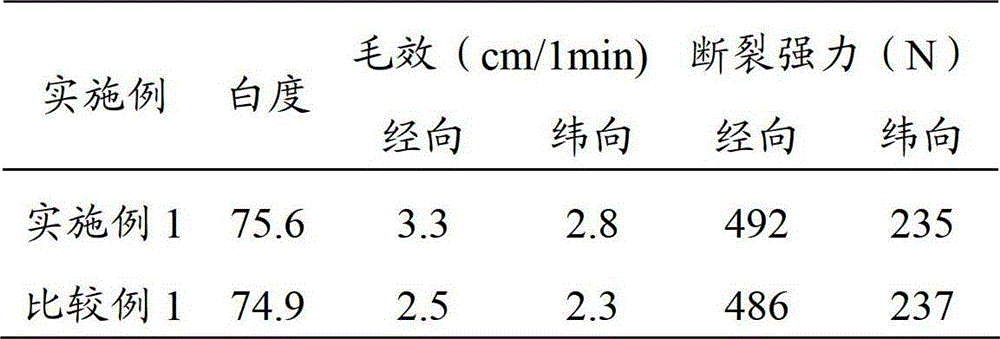

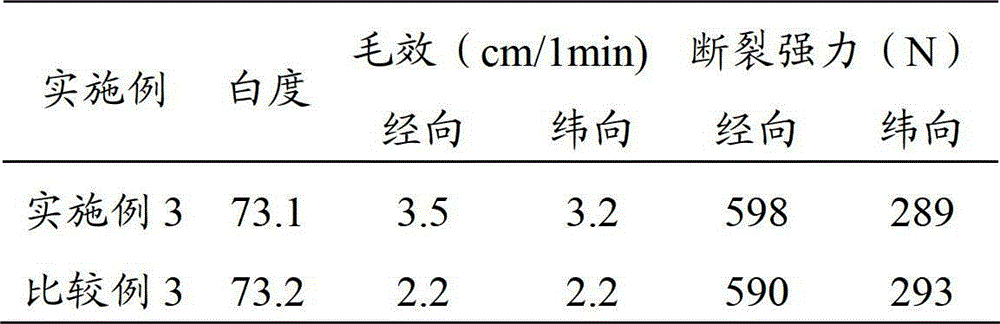

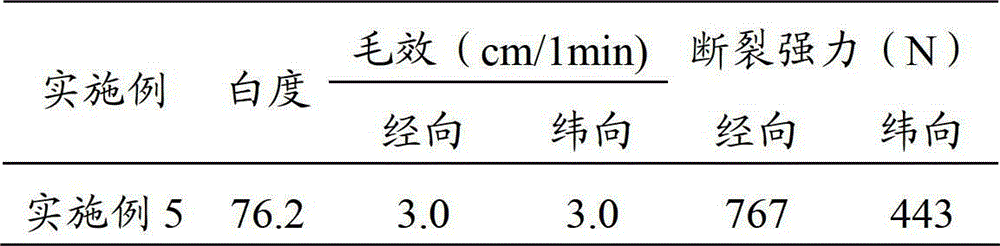

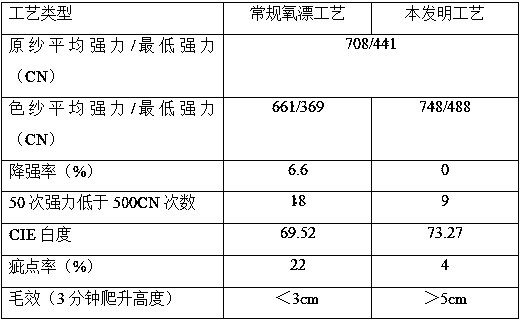

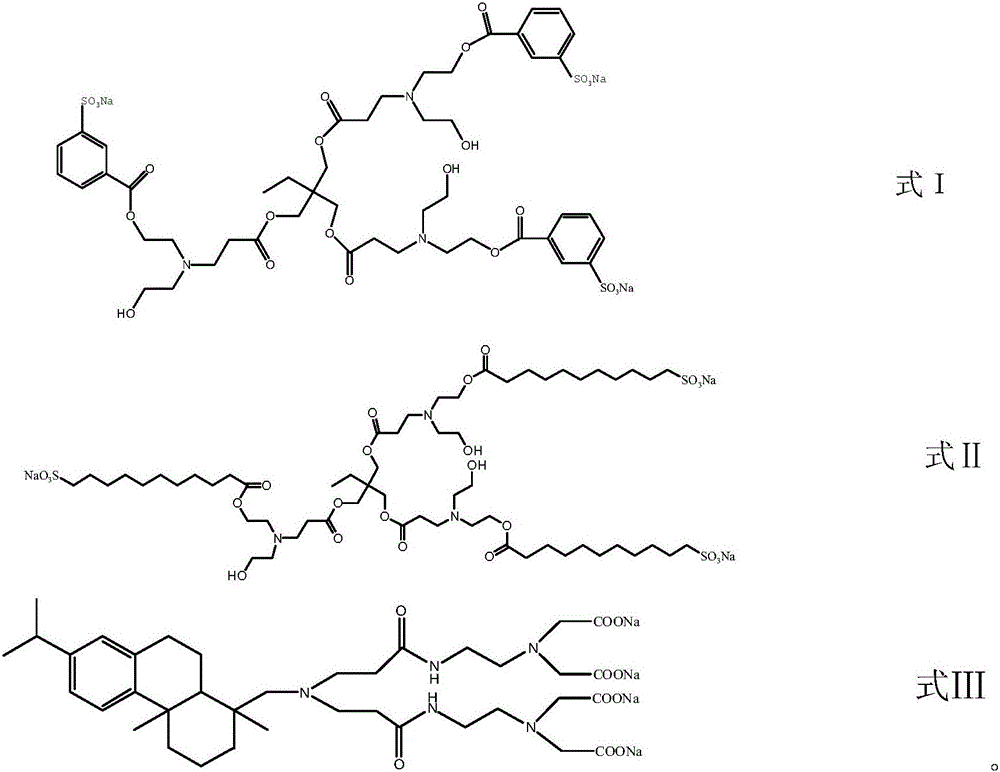

Continuous oxygen bleaching refining agent and preparation method thereof

The invention relates to a continuous oxygen bleaching refining agent and a preparation method thereof. The continuous oxygen bleaching refining agent comprises a rare-earth catalyst, a hydrogen peroxide stabilizer, biodegradable surfactant, Gemini surfactant, hyperbranched surfactant and water. Compared with a conventional refining agent, the continuous oxygen bleaching refining agent has the advantages that the continuous oxygen bleaching refining agent is efficient and environmental friendly and wide in process applicability, the NaOH use amount is lowered by about 40%, the COD value of discharged wastewater is lowered by more than 40%, and the whiteness, capillary effect and breaking strength of fabric treated by the continuous oxygen bleaching refining agent are evidently better.

Owner:SHANGHAI ARGUS NEW MATERIAL CO LTD

Heavy pure cotton fabric corona discharge plasma and enzyme cold padding and stacking pretreatment method

ActiveCN103088625AExcellent desizingExcellent and refinedBiochemical fibre treatmentUltrasonic/sonic fibre treatmentPretreatment methodCorona discharge

The invention discloses a heavy pure cotton fabric enzyme padding and stacking pretreatment process after corona discharge plasma treatment, and belongs to the technical field of dyeing and finishing pretreatment. The technological process comprises the following steps of: carrying out the corona discharge plasma treatment for the singed heavy pure cotton grey fabric; carrying out complex enzyme liquid padding for the fabric; then stacking at room temperature; then carrying out oxygen bleaching and low alkali mercerization; and finally sufficiently rinsing to complete the pretreatment process of the heavy pure cotton fabric. According to the method, the process has the characteristics of being good in treatment effect, little in fabrics strength damage, high in quality, soft in hand feeling, high in capillary effect and good in glossiness; the method provides a condition of high color yield for the subsequent dyeing and printing processing; the process operation is simple and high in controllability; and the treated waste water, the pH value and the energy consumption of the process are far lower than the treated waste water, the pH value and the energy consumption of the traditional strong base scouring process, the energy is saved and the emission is reduced, the production cost is reduced; and the process is a clean production process meeting the environmental protection requirement, so that the process is very high in social benefit and market prospect, and the process conditions are optimized.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

Afterfinish process of stiff, moisture-absorption and quick-drying shirt collar lining

InactiveCN102505483AIncreasing concentration gradientImprove antistatic performanceFibre treatmentFiberResist

The invention discloses an afterfinish process of stiff, moisture-absorption and quick-drying shirt collar lining. A certain amount of modifier of polyethylene siloxane is selected to serve as quick-drying moisture absorber of finishing agent and is mixed with resin and Cat / M catalyst prepare a padding liquor, of which the PH value is 4.5; then fabric to be finished is put into the padding liquor; and when the padding rate reaches 80 percent, the only thing to do is to perform two steps (namely predrying and baking). The substance mainly having moisture-absorption and quick-drying effects in the padding finishing liquor is the modifier of the polyethylene siloxane, which is applicable to the moisture-absorption and quick-drying finishing of cotton, terylen and the blending intertexture thereof, and gives the fabric magnificent soft feel. The modifier of the polyethylene siloxane adopts a padding method and can be used independently, can also be used with first minification bodies, such as shrink-resist and crease-resist finishing agent, stiff resin and the like, reduces the swelling ratio of fiber hole canals, and obtains better moisture-absorption and quick-drying effects.

Owner:如皋市五山漂染有限责任公司

Pretreatment method for pineapple fibers

The invention discloses a pretreatment method for pineapple fibers. The pretreatment method is characterized by comprising the following steps of: (1) injecting water, namely adding water into a container with pineapple fiber yarns; (2) adding auxiliaries, namely sequentially adding composite tea saponin powder and composite tea saponin dispersion liquid into the container; (3) boiling, namely heating the mixed liquid to 100 DEG C, and boiling for a period of time; (4) performing thermal washing, namely washing the pineapple fiber yarns by water with the temperature of 85-90 DEG C; (5) performing cold washing, namely washing the pineapple fiber yarns by cold water; and (6) drying, namely drying the pineapple fiber yarns. The pretreatment has the beneficial effects that the composite tea saponin is added into the pineapple fiber yarns and is boiled for a period of time, so that various indexes such as the whiteness, the rough efficiency and the strength of the pretreated pineapple fiber yarns can be improved.

Owner:TONGLING XIAFEI NEW MATERIAL

Production method of fiberglass gridding cloth

InactiveCN103541167ADrop high temperature damageLittle strengthSingeingMercerisingPolymer scienceEngineering

The invention relates to a production method of textiles and in particular relates to a production method of fiberglass gridding cloth. The production method of the fiberglass gridding cloth sequentially comprises the following steps: turning cloth, cutting weft yarns, sewing, singeing, desizing, scouring and bleaching, mercerizing, dyeing, weft processing and tentering, wherein the weft yarn cutting process comprises the step that a shell fabric is cut according to weft yarns; the sewing comprises the step that weft yarns are sewn in parallel between machines and between shell fabrics; the desizing, scouring and bleaching step comprises the sub-steps of desizing, scouring and oxygen bleaching, a scouring and bleaching combined production line is adopted, and after six-lattice countercurrent unfolding washing is adopted, a textile is rolled to control the moisture content to be 45%-55%, and then is subjected to steaming and bleaching by direct padding with a bleaching solution; the moisture content of the textile in mercerizing is controlled to be 25%-35%, and semi-wet mercerizing is carried out in a mercerizing solution containing sodium hydroxide with the concentration of 265-300 g / L and sodium alkyl alcohol sulphate with the concentration of 5-8 g / L; tentering is carried out at a processing speed of 45-50 m / min; an aftertreatment liquid contains an antistatic agent SN, and the concentration of the antistatic agent SN in the aftertreatment liquid is 0.5-2 g / L. The production method of the fiberglass gridding cloth has the advantages that the whole process is improved, weft displacement of wefts of the fiberglass gridding cloth is reduced and even not produced, and Chinese standard requirements can be completely met.

Owner:ZHEJIANG DAGANG PRINTING & DYEING

Process for pretreating pure cotton fabric

ActiveCN101603258BSo as not to damageFluffy and softSucessive textile treatmentsBiochemical fibre treatmentCelluloseChemistry

The present invention discloses a process for pretreating pure cotton fabric. The process comprises the following steps of inverse sewing, size shaking, enzyme piling, scouring, bleaching and silken processing, wherein in the enzyme piling step, the 9g.L<-1> scouring enzyme and a 4g.L<-1> AAA auxiliary agent are used, the temperature is 55 DEG C, the rolling-piling time is 20h, and the pick-up is 100 percent; and in the scouring step, 18 to 20g.L<-1> NaOH, and 6g.L<-1> AAA auxiliary agent are used, the pick-up is 100 percent, the pure cotton fabric is steamed at a temperature of 100 DEG C for 45min, and then water-washed at a temperature of 90 DEG C. The process has the characteristics of no damage of cellulose components of plants, good handfeel and environmental protection.

Owner:ZHEJIANG HAIHONG DYEING PRINTING

Environment-friendly scouring agent

The invention belongs to the technical field of textile assistants, and particularly relates to an environment-friendly scouring agent. The scouring agent is composed of the following components in parts by weight: 2-50 parts of alcohol ether glucoside, 2-50 parts of alkyl glycoside and 20-60 parts of water. The raw materials have fewer varieties and are biodegradable nonionic surfactants, and have the advantages of high permeability, high hair effect and the like after combination; and the scouring agent can effectively reinforce cleaning and enhance the hair effect in the textile pretreatment technique, and is superior to like products in a cold dome technique and scouring technique.

Owner:ANYANG BOAO BIOLOGICAL NEW SYNTHESIS

Processing method for improving hair effect and water absorption of fabric after resin finishing

InactiveCN111851076AImprove gross effectWrinkle resistant fibresGrip property fibresTextile printerFiber

The invention belongs to the technical field of textile printing and dyeing, and particularly relates to a processing method for improving the hair efficiency and water absorption of fabrics after resin finishing. The method comprises the steps of singeing, desizing, oxygen bleaching, mercerizing, dyeing, liquid ammonia, non-ironing, baking, washing, softening, and pre-shrinking of a pure cotton fabric are carried out in sequence, and the non-ironing process conditions comprise: non-iron resin CR-E: 80-130g / L, a resin catalyst CT-C: 24-39g / L, a fiber protection agent: 10-30g / L, a resin synergist: 10-30g / L, a penetrant MRZ: 1.3g / L, a super hydrophilic auxiliary agent: 10-20g / L, wherein the materials are mixed; and material liquid is added to a padding tank for padding the pure cotton fabric, wherein the nip rate is 65 to 70%, twice padding and twice rolling are carried out, wherein the tank liquid level is 60%, the drying room temperature is 100 to 110 DEG C, and the vehicle speed is 60-70m / min. The fabric finished by the method has a 5min hair effect of more than 2.0 inches, water absorption of less than 10 seconds, and a non-ironing property of more than the 3.2 level.

Owner:鲁丰织染有限公司

Scouring and bleaching liquid for bamboo and cotton blended fabric and scouring and bleaching method

The invention discloses scouring and bleaching liquid for bamboo and cotton blended fabric. The scouring and bleaching liquid is prepared by scouring agents, 100% hydrogen peroxide, stabilizers, softening agents, anti-wrinkle agents and sodium hydroxide, wherein the concentration of the scouring agents is 1-2 g / L, the concentration of the 100% hydrogen peroxide is 2-4 g / L, the concentration of the stabilizers is 0.5-1 g / L, the concentration of the softening agents is 1-2 g / L, the concentration of the anti-wrinkle agents is 1-1.5 g / L, and the concentration of the sodium hydroxide is 2-3 g / L. The invention further discloses a scouring and bleaching method using the scouring and bleaching liquid. Through improving an existing scouring and bleaching method and the formula of the scouring and bleaching liquid, the whiteness and capillary effect of fibers used for blending are greatly improved, the strength damage of the fibers is reduced, the finally-produced fabric is flat in surface, even in color and luster, high in dye color fastness, free of staining and excellent in appearance, and all the properties are capable of meeting requirements.

Owner:TAICANG GUOFENG TEXTILE PRINTING & DYEING

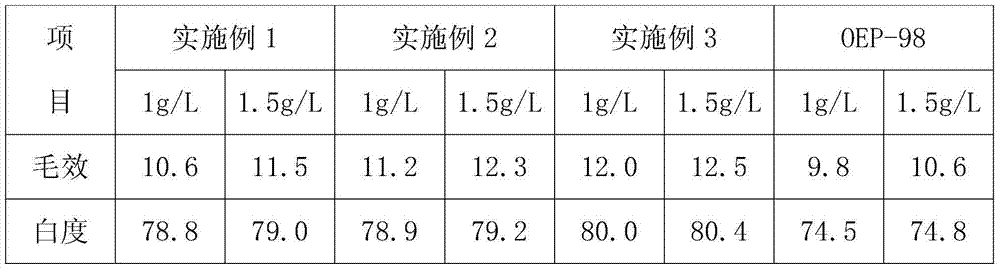

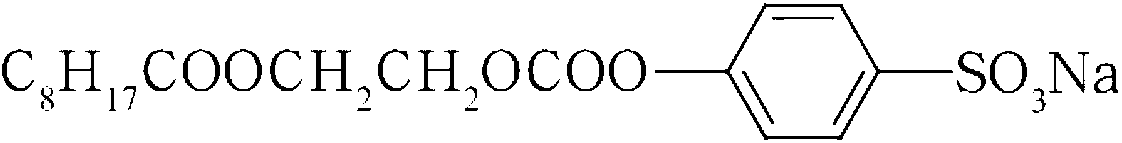

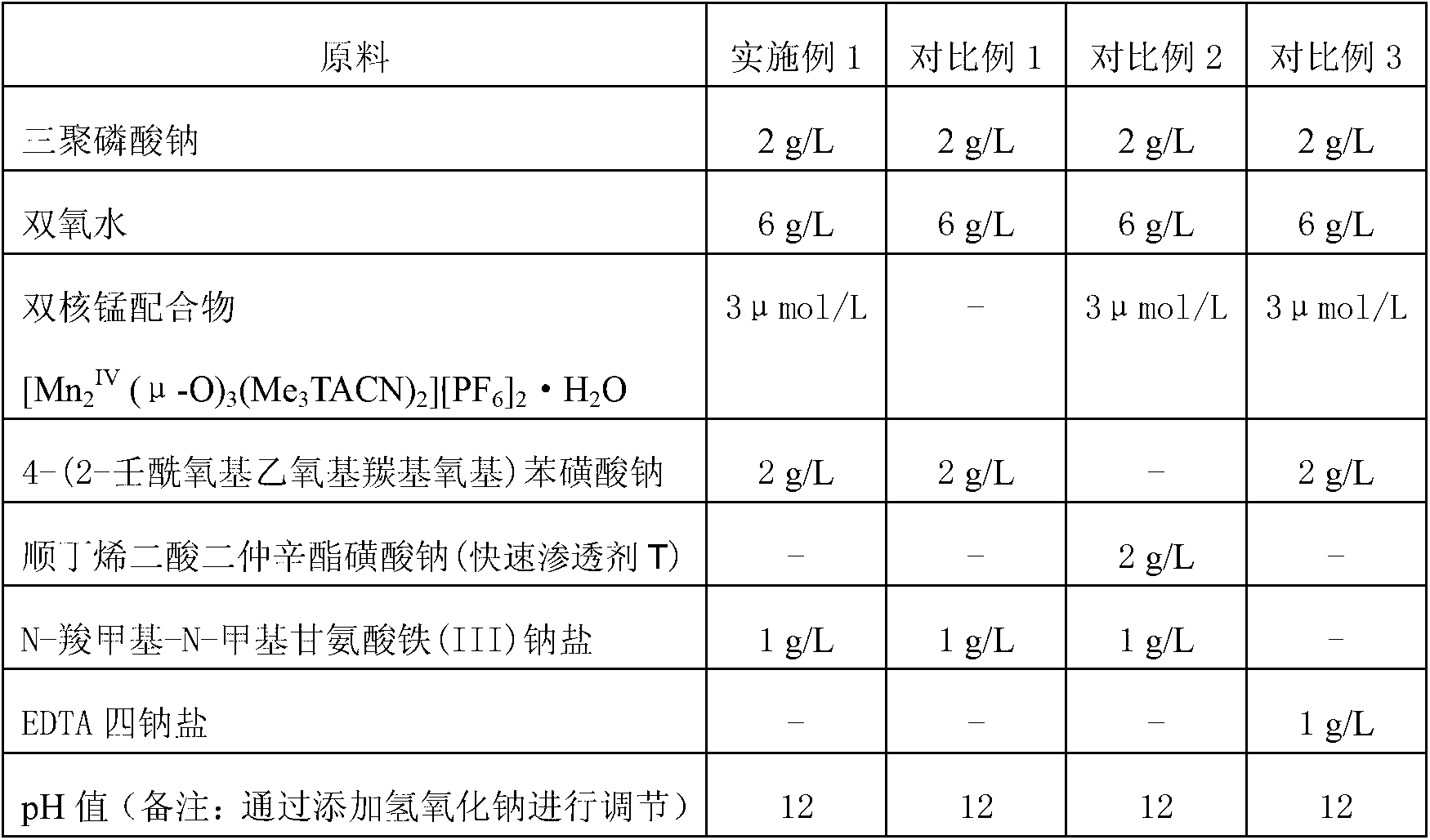

Desizing liquid and desizing method for dacron fabric

InactiveCN103173982AImprove gross effectImprove mechanical propertiesDry-cleaning apparatus for textilesDyeingCoordination complex

The invention discloses a desizing liquid and a desizing method for dacron fabric. The desizing liquid has the pH value between 11 and 12 and comprises the following components: 1 to 3g / L of sodium tripolyphosphate, 4 to 8g / L of hydrogen peroxide, 2 to 4mumol / L of binuclear manganese complexes, 1 to 3g / L of 4-(2-nonanoyl acyloxy ethyoxyl carbonyl oxygroup) sodium benzene sulfonate, 0.5 to 1.5g / L of N-carboxymethyl-N-methyl ferric glycine (III) sodium salt and proper amount of sodium hydroxide. When the desizing liquid is utilized for performing desizing treatment on the dacron fabric, the desizing rate is high as well as the obtained fabric is high in capillary effect and mechanical property, so that the implementation of the subsequent dyeing and printing process is facilitated and the subsequent dyeing and printing quality is guaranteed. In addition, the sizing slurry is removed effectively, so that the fabric handfeeling is improved.

Owner:中山市铨泽化纤材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com