Biological enzyme pretreatment method for textiles

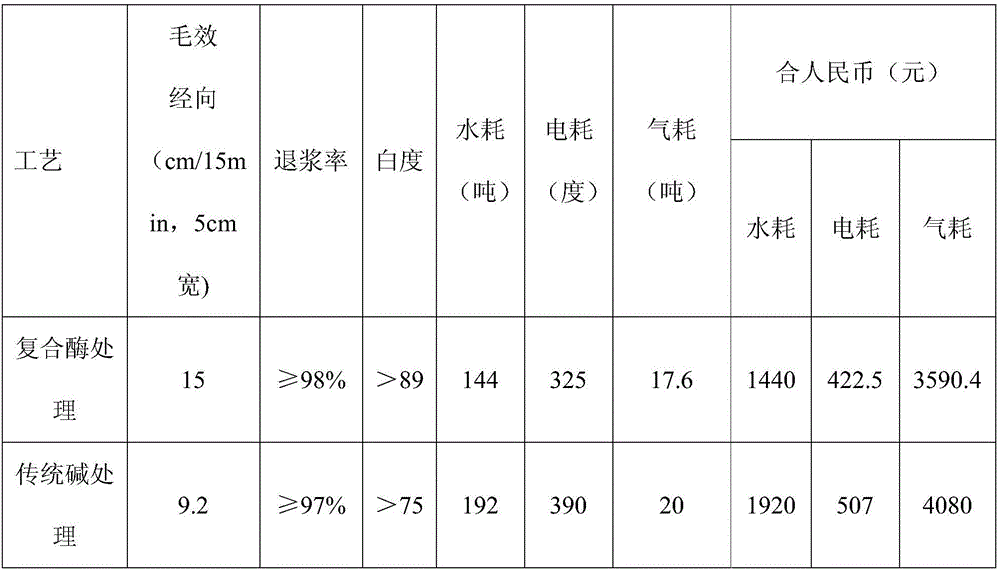

A technology of textiles and biological enzymes, which is applied in the fields of enzyme/microbial biochemical treatment, biochemical fiber treatment, textiles and papermaking, etc. It can solve the problems of high energy consumption, high water consumption, environmental pollution, etc., and achieve low equipment requirements and reduce processing Process, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] In this embodiment, textiles are subjected to enzymatic cold-heap treatment by the following method, which specifically includes the following steps:

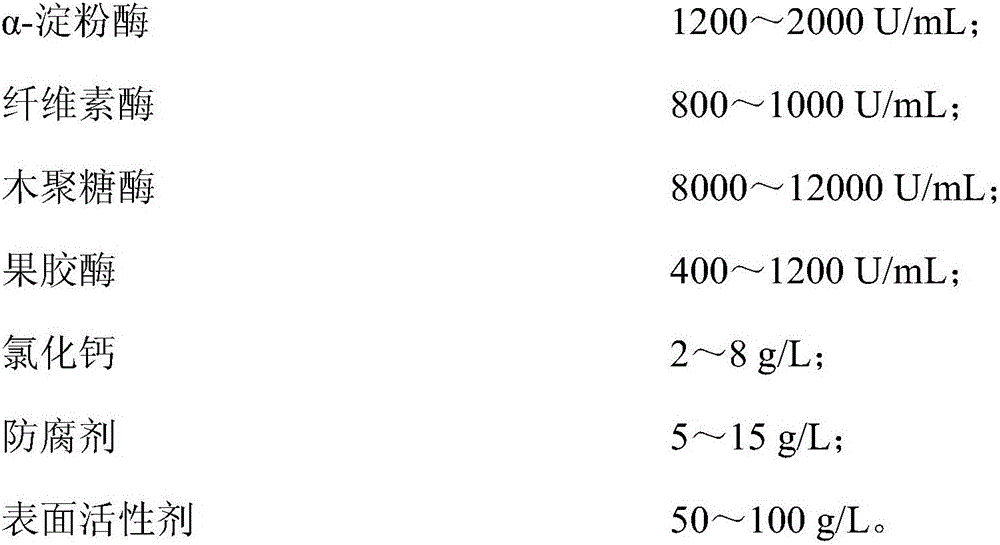

[0056] (1) Padding biological compound enzyme liquid: pad cotton gray cloth (specification 20×16) in the biological compound enzyme liquid at 40°C, one dipping and one rolling, the liquid retention rate is 100%; Biological compound enzyme solution includes the following components: 1200U / mL α-amylase, 900U / mL cellulase, 10000U / mL xylanase, 800U / mL pectinase, 2g / L calcium chloride, 10g / L preservative agent and 80g / L surfactant, pH6.0~7.0;

[0057] (2) Cold pile at 40°C for 6h;

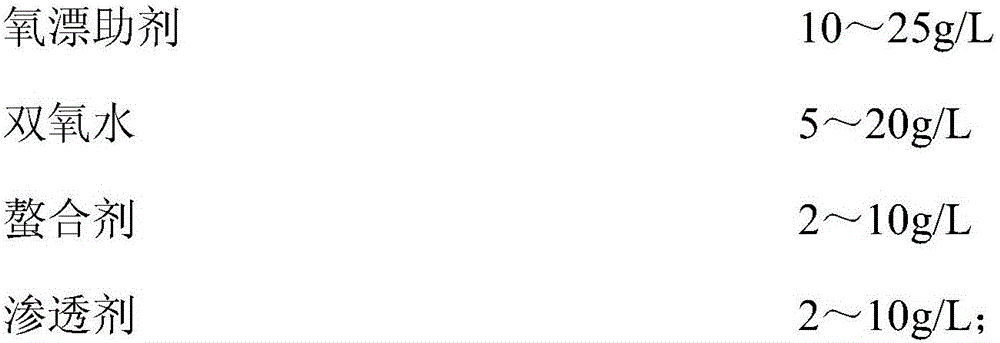

[0058] (3) Wash 2 times with hot water at a temperature of 70° C., wash 1 time with cold water (i.e. normal temperature water), and then use oxygen bleaching liquid for oxygen bleaching. The oxygen bleaching liquid includes the following components: 10g / L oxygen bleaching aid, 15g / L hydrogen peroxide, 8g / L chelating agent and 2g / L penetrating ag...

Embodiment 2

[0061] In this embodiment, textiles are subjected to enzymatic cold-heap treatment by the following method, which specifically includes the following steps:

[0062] (1) Padding biological compound enzyme liquid: pad cotton gray cloth (specification 20×16) in the biological compound enzyme liquid at 20°C, one dipping and one rolling, the liquid retention rate is 80%; Biological compound enzyme solution includes the following components: 2000U / mL α-amylase, 800U / mL cellulase, 9000U / mL xylanase, 400U / mL pectinase, 8g / L calcium chloride, 15g / L preservative agent and 100g / L surfactant, pH6.0~7.0;

[0063] (2) Cold pile at 20°C for 12h;

[0064] (3) Wash 4 lanes with hot water at a temperature of 80° C., wash 1 lane with cold water, and then use oxygen bleaching liquid for oxygen bleaching. The oxygen bleaching liquid includes the following components: 20g / L oxygen bleaching aid, 5g / L hydrogen peroxide, 10g / L chelating agent and 5g / L penetrating agent, the liquid carrying rate is...

Embodiment 3

[0067] In this embodiment, textiles are subjected to enzymatic cold-heap treatment by the following method, which specifically includes the following steps:

[0068] (1) Padding biological compound enzyme liquid: pad cotton gray cloth (specification 20×16) in the biological compound enzyme liquid at 60°C, one dipping and one rolling, the liquid retention rate is 90%; Biological compound enzyme solution includes the following components: 1500U / mL α-amylase, 1000U / mL cellulase, 12000U / mL xylanase, 1000U / mL pectinase, 5g / L calcium chloride, 5g / L preservative agent and 50g / L surfactant, pH6.0~7.0;

[0069] (2) Cold pile at 30°C for 8h;

[0070] (3) Wash 3 times with hot water at a temperature of 80° C., wash 1 way with cold water, and then use oxygen bleaching liquid for oxygen bleaching. The oxygen bleaching liquid includes the following components: 25g / L oxygen bleaching aid, 10g / L hydrogen peroxide, 2g / L chelating agent and 10g / L penetrating agent, the liquid carrying rate is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gross effect | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com