Compound enzyme preparation for textile fabrics and applications thereof

A composite enzyme preparation and textile technology, which is applied in the field of high-efficiency composite enzyme preparations, can solve the problems of inability to adapt to the development trend of green textiles, the influence of fabric color and luster, high water consumption and energy consumption, etc., and achieve product quality improvement, softness and drape. Good temperature and water saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Using Paenibacillus pabuli WZ008 as the starting strain, the strain was screened by the inventors from rotten apple skins and has been preserved in the China Center for Type Culture Collection with the preservation number CCTCC No: M 207183 .

[0037] Alkaline pectinase and cellulase were produced by liquid submerged fermentation. The final concentration of the fermentation medium is composed of: pectin 6g / L, bran 4g / L, yeast extract 5g / L, peptone 1.5g / L, CaCO 3 5g / L, (NH 4 ) 2 SO 4 20g / L, NaCl 0.3g / L, KH 2 PO 4 0.5g / L, K 2 HPO 4 2g / L, MgSO 4 ·7H 2 O 2g / L, FeSO 4 0.01g / L, pH 8.5~9.0, solvent is water.

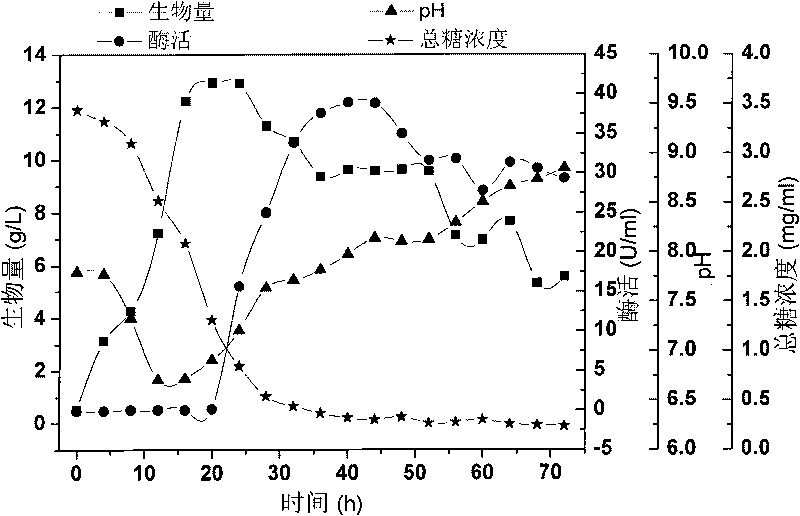

[0038] The fermentation conditions are: in a 15L self-controlled mechanical agitation fermenter, transfer the prepared seed solution into a 9L fermentation medium with an inoculation amount of 10% (v / v), so that the liquid filling volume is 10L, and the tank pressure is controlled to 0.03Mpa , the air pressure is 0.12Mpa, the air flow rate is 25NL / min, th...

Embodiment 2

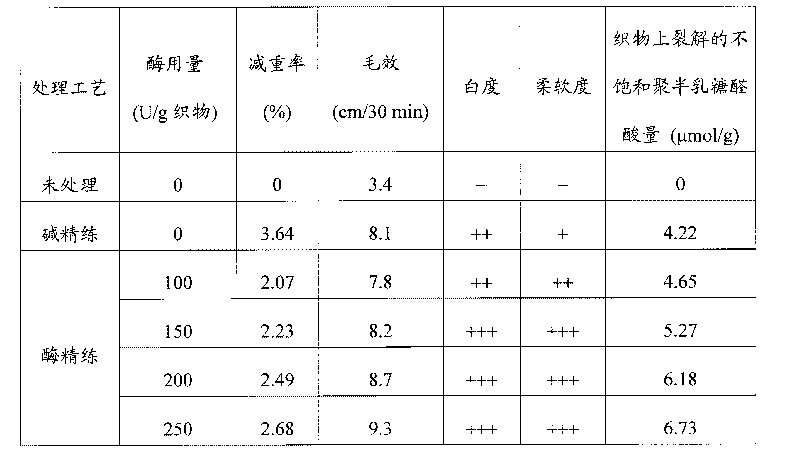

[0040] Cotton cloth was treated with alkali scouring process and enzyme scouring process respectively.

[0041] Alkali scouring process: boiling water pretreatment for 30 minutes→alkali scouring→hot water washing→cold water washing→drying (105°C, 1h).

[0042] Wherein the alkali refining treatment conditions: NaOH 40% (o.w.f, NaOH mass accounts for fabric mass percentage), soap 2g / L, temperature 100 ℃, bath ratio 1: 15 (cotton cloth and treatment liquid mass ratio), treatment time 150min.

[0043] Enzyme scouring process: boiling water pretreatment for 30 minutes→enzyme scouring→hot water washing→cold water washing→drying (105°C, 1h).

[0044] Among them, enzyme refining treatment conditions: compound enzyme 100-250U / g fabric (calculated as alkaline pectinase), temperature 55°C, pH 9.6, bath ratio 1:15 (mass ratio of cotton cloth to treatment solution), treatment time 150min.

[0045] Compound enzyme preparation method: dissolve the spray-dried biological enzyme solid powder in...

Embodiment 3

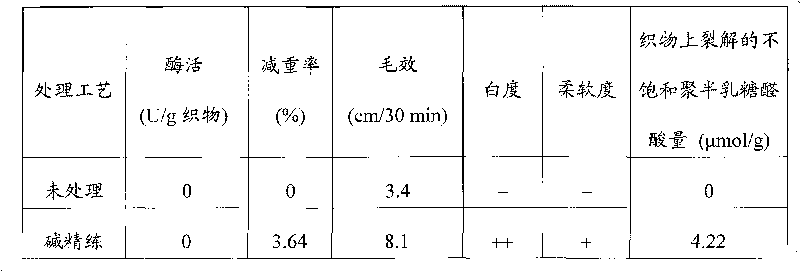

[0050] Cotton cloth was treated with alkali scouring process and enzyme scouring process respectively.

[0051] Alkali scouring process: boiling water pretreatment for 30 minutes→alkali scouring→hot water washing→cold water washing→drying (105°C, 1h).

[0052] The alkali refining treatment conditions: NaOH 40% (o.w.f), soap 2g / L, temperature 100°C, bath ratio 1:15, treatment time 150min.

[0053] Enzyme scouring process: boiling water pretreatment for 30 minutes→enzyme scouring→hot water washing→cold water washing→drying (105°C, 1h).

[0054] Wherein the enzyme refining treatment conditions: compound enzyme 100-250U / g fabric (calculated by alkaline pectinase), temperature 55°C, pH 9.6, bath ratio 1:15, treatment time 150min.

[0055] Compound enzyme preparation method: dissolve the spray-dried biological enzyme solid powder in the following system: polysiloxane 100g / L, fatty alcohol polyoxyethylene ether 80g / L, Tween-80 120g / L, Span-20 120g / L, sorbitol 50g / L, calcium chlori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com