Patents

Literature

138results about How to "Reduce BOD" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

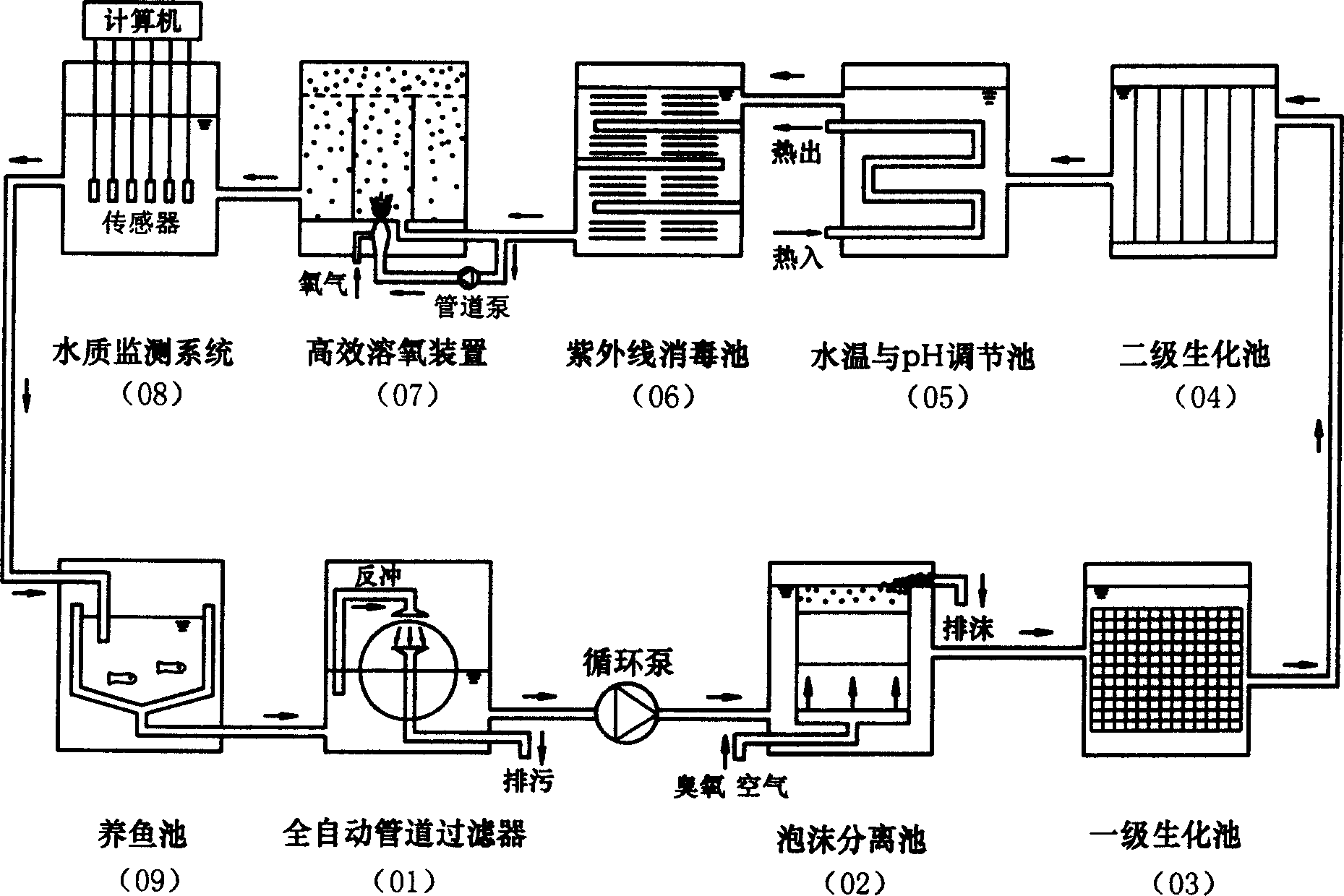

Water treatment method of circulating water fish culture in factory style

InactiveCN1545865AReduce BODReduce CODClimate change adaptationPisciculture and aquariaHuman wasteWater quality

The invention discloses a seawater factory-style circulating water fish farming treatment method which comprises, removing the residual bait and excrement from the seawater flowing out of the fish pond through full-automatic conduit pipe filter apparatus, entering foam separate tank from the circulating pump to remove part of the suspended matter and protein, then removing ammonia nitrogen through biological cleaning tank, adjusting water temperature and pH, disinfecting through ultraviolet rays, oxygenation, charging the detected water into the fish pond again, thus completing a circulation.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

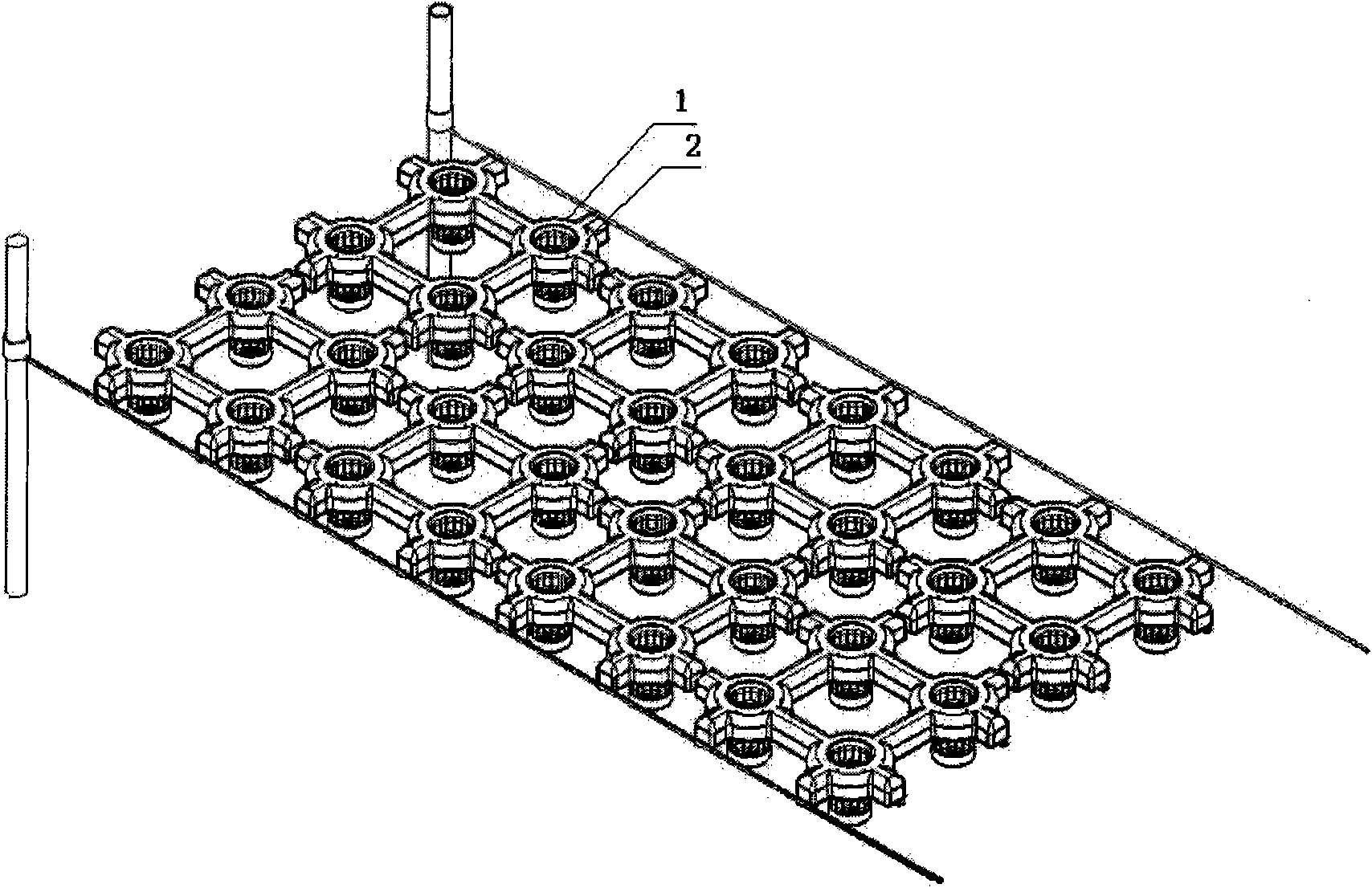

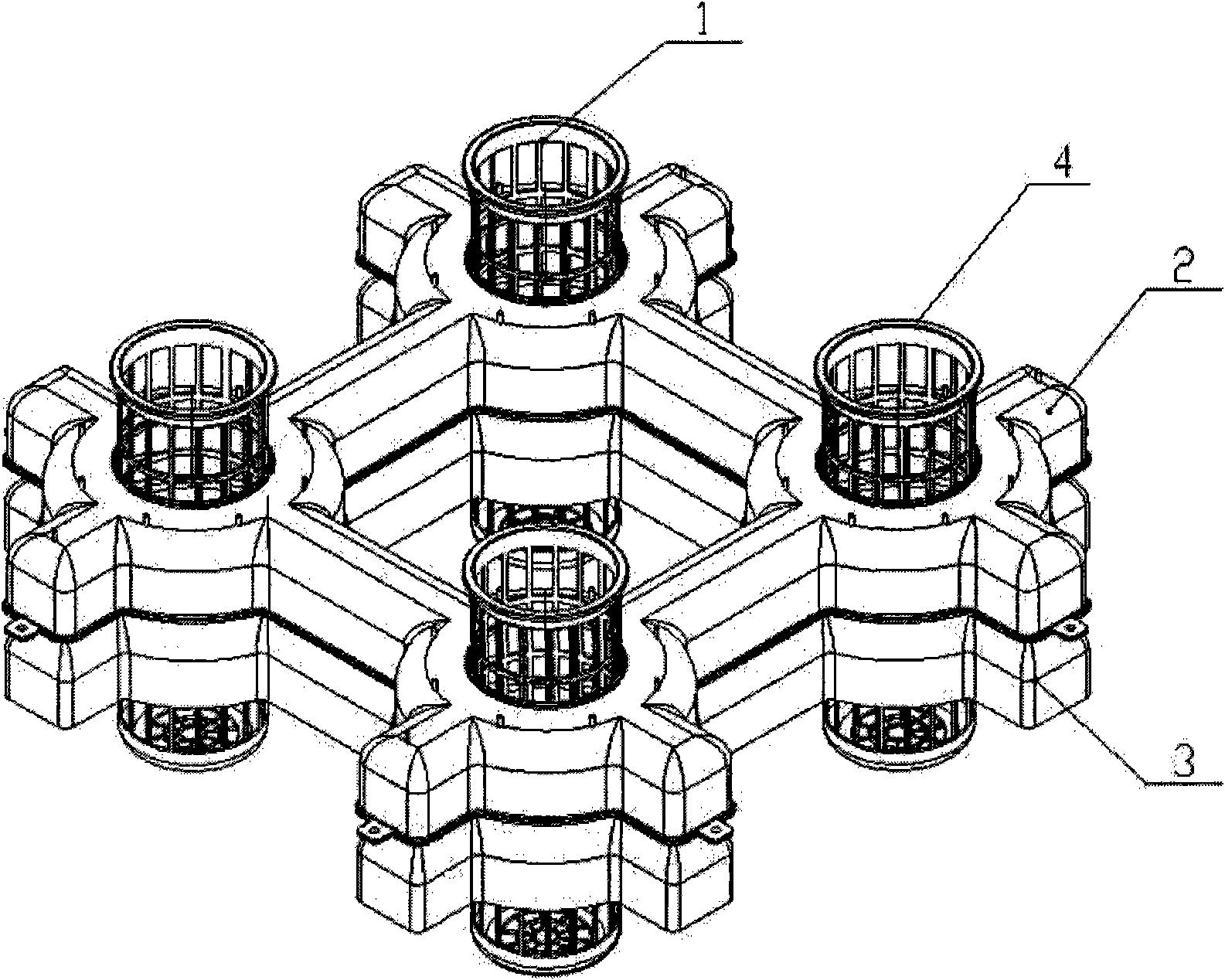

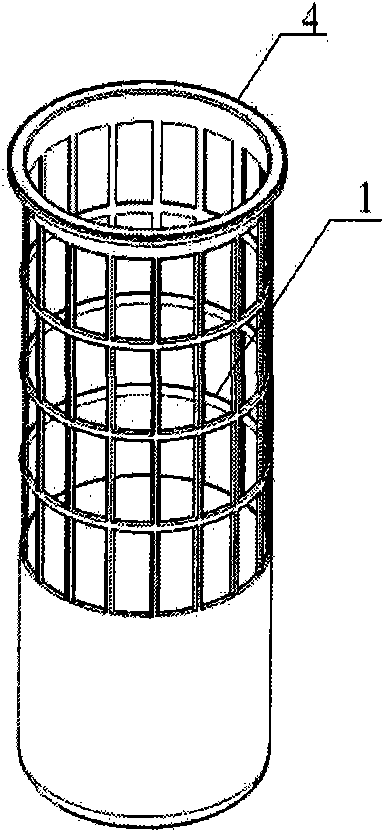

Combined ecological floating bed for water planting plants and flowers

InactiveCN101874469AReduce CODReduce BODAgriculture gas emission reductionCultivating equipmentsFlower gardenNitrogen

The invention relates to a combined ecological floating bed for water planting plants and flowers, which is characterized by comprising one or more ecological floating bed units which are combined, interconnected and fixed to form the combined ecological floating bed for the water planting plants and flowers with various patterns; the ecological floating bed unit comprises a planting basket, a floating bed framework and a foam piece, wherein the planting basket is placed in a planting basket placing port of the floating bed framework; the foam piece is sleeved in a cavity of the floating bed framework; and a plurality of ecological floating bed units are connected to form a large-area water planing plant-flower garden or a fixed green ecological floating island. The ecological floating bed has the advantages of unique structure, convenient manufacture and low cost, can effectively reduce the content of phosphorus and nitrogen-like eutrophic salts polluting the water and COD and BOD, promote the water quality from VI class to III class and beautify the environment, and can be widely applied to the water surfaces of extensive polluted rivers and lakes.

Owner:常州华钛化学有限公司 +1

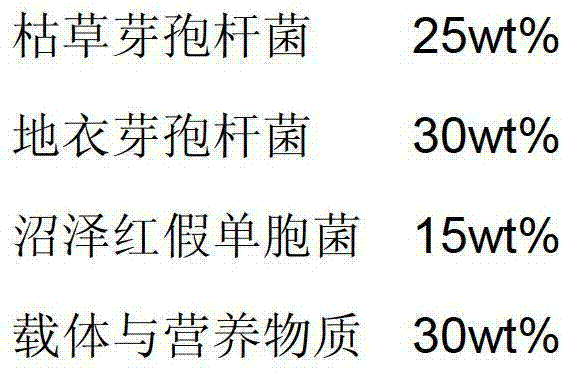

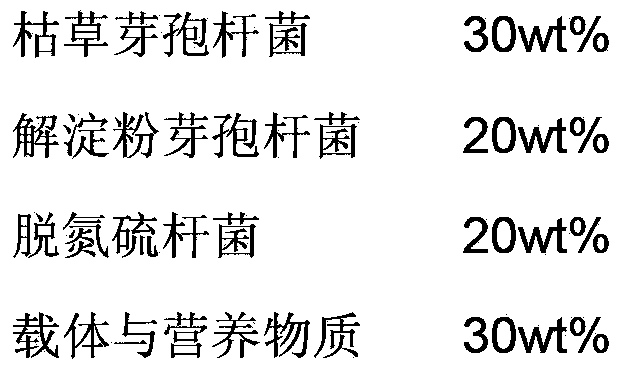

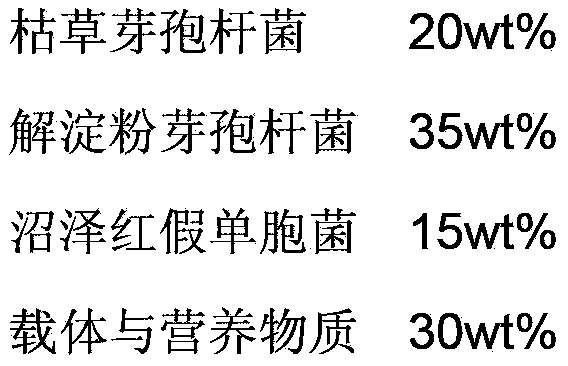

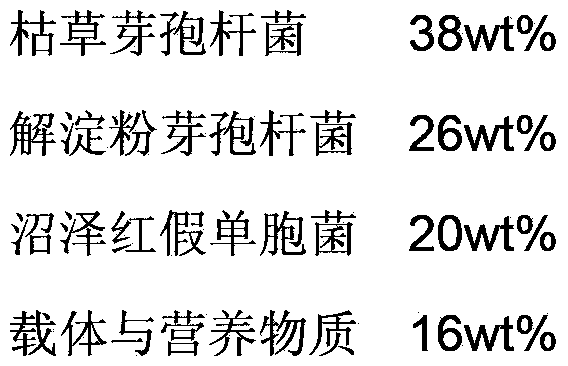

Microbial preparation for improving freshwater aquaculture water body and preparation method thereof

InactiveCN103395890AReduce BODReduce ammonia nitrogen contentBacteriaMicroorganism based processesBacillus licheniformisFresh water organism

The invention provides a microbial preparation for improving freshwater aquaculture water body. The microbial preparation comprises the following raw materials by weight percentage: 25-30 wt% of bacillus subtilis, 25-30 wt% of bacillus licheniformis and 15-20 wt% of rhodopseudomonas palustris. The invention also provides a method for preparing the microbial preparation, which comprises the following steps of: sequentially inoculating the seed culture liquids of the bacillus subtilis, the bacillus licheniformis and the rhodopseudomonas palustris into a culture medium, fermenting to obtain a bacteria liquid, and mixing the obtained bacteria liquid with a carrier and nutrient substances to obtain the microbial preparation. The microbial preparation provided by the invention can significantly improve the water quality of the aquaculture water body and can also improve the meat quality of bred animals.

Owner:SHANGHAI CHUANGBO ECOLOGICAL ENG

Oil-containing wastewater treatment agent and preparation method thereof

ActiveCN103864177AReduce CODReduce BODFatty/oily/floating substances removal devicesLiquid separationTherapeutic effectPollution

The invention belongs to the technical field of sewage treatment agents, and in particular relates to an oil-containing wastewater treatment agent and a preparation method thereof. The oil-containing wastewater treatment agent disclosed by the invention comprises the following raw materials in parts by weight: 35-45 parts of polyacrylamide, 15-25 parts of polymeric aluminium, 12-18 parts of expanded graphite, 15-20 parts of zeolite mineral, 20-30 parts of hydrolyzed tannin, 3-5 parts of organic acid, 5-10 parts of TiO2, and 3-5 parts of chitosan-graphene composite material. The oil-containing wastewater treatment agent disclosed by the invention has the advantages of being good in treatment effect, low in production cost, high in purity, free from toxicity, influence to operators and secondary pollution after treatment; the preparation method is simple and easy for popularization.

Owner:广州小众环保科技有限公司

Probiotic bacterium compound formulation preparation method

ActiveCN1544356AReduce BODReduce CODMicroorganism preservationBiological water/sewage treatmentLactic acid bacteriumSewage

A process for preparing healthy composite bacteria, characterized in that photosynthetic bacteria, saccharomycete, pachydermatis and lactic acid bacteria are used as basic bacterial, and the process comprises the steps of, planting these bacterial into organic sewage environment whose COD concentration is greater than 400 for adaptation acclimation, screening dominant production bacterial strain adaptive to high COD and BOD environment, subjecting saccharomycete and photosynthetic bacteria to composite culture, subjecting culturing liquid and pachydermatis to composite culture, and subjecting composite culturing liquid and lactic acid bacteria to composite culture, repeating the above steps to screen and confirm production bacterial strain adaptive to composite environment, on the basis of which a three-step method for fermentation manufacturing technique and culture medium formula can be determined.

Owner:HESHAN SEWETE BIOLOGICAL PROD +1

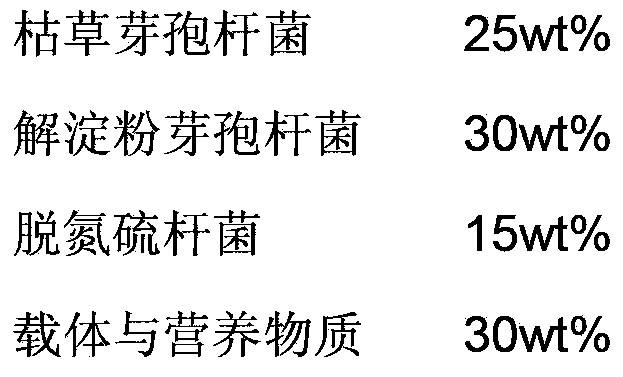

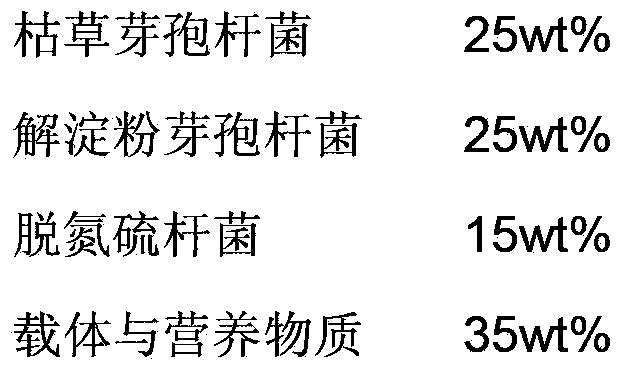

Compound microorganism preparation used for aquiculture water body improvement and preparation method of compound microorganism preparation

ActiveCN103352018AReduce BODIncrease dissolved oxygenBacteriaMicroorganism based processesCulture fluidBacillus amyloliquefaciens

The invention provides a compound microorganism preparation used for freshwater aquiculture water body improvement, which comprises the raw materials by weight percentage: 25-30wt% of bacillus subtilis, 25-30wt% of bacillus amyloliquefaciens and 15-20wt% of thiobacillus denitrificans. The invention further provides a preparation method of the microorganism preparation, which comprises the steps that bacillus subtilis, bacillus amyloliquefaciens and thiobacillus denitrificans seed culture fluids are sequentially inoculated into a culture medium and fermented; an obtained bacterium fluid is mixed with a carrier and a nutritional substance; and the microorganism preparation is obtained. The microorganism preparation can obviously improve the water quality of an aquiculture water body, and can improve the meat quality of an aquiculture animal.

Owner:SHANGHAI CHUANGBO ECOLOGICAL ENG

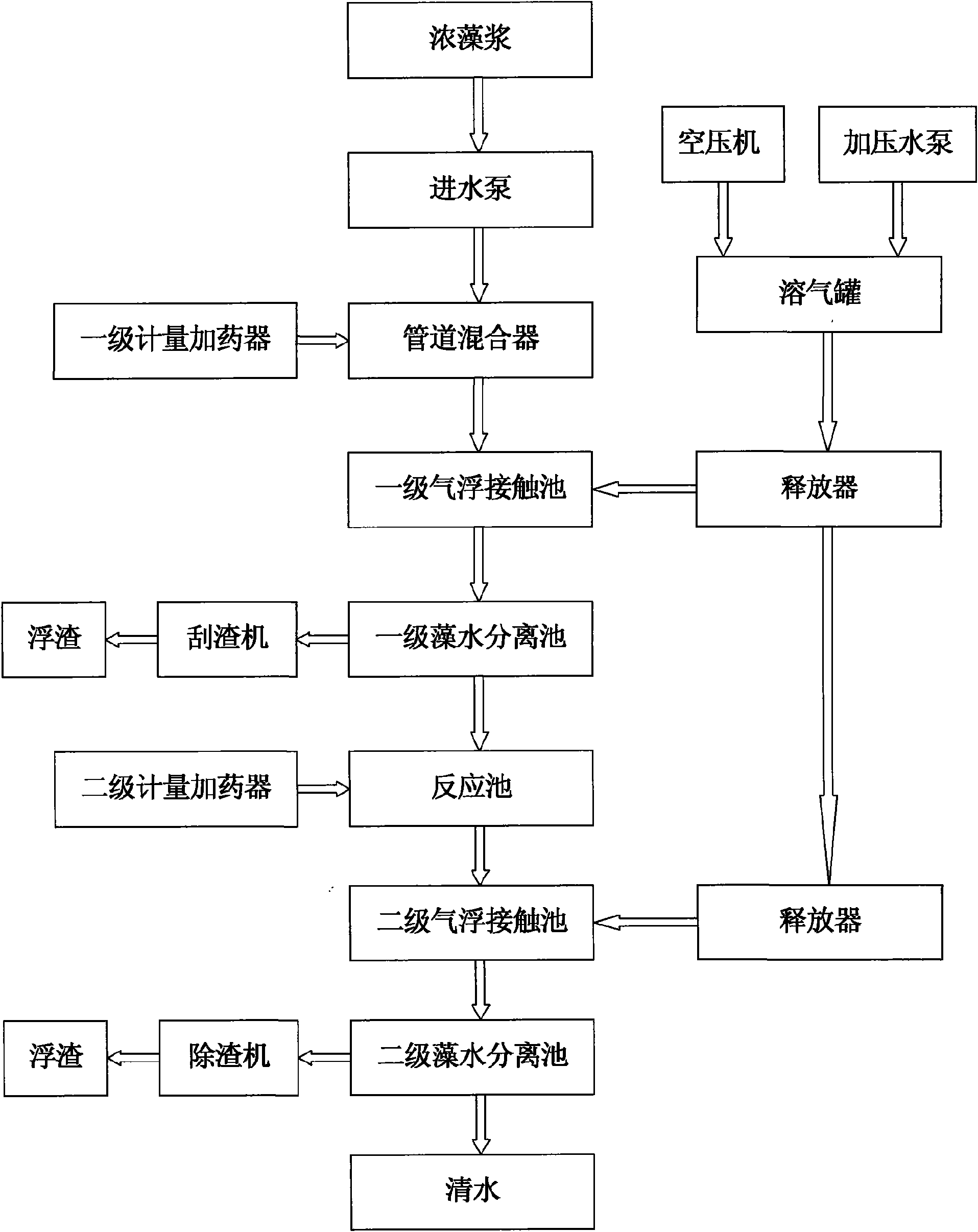

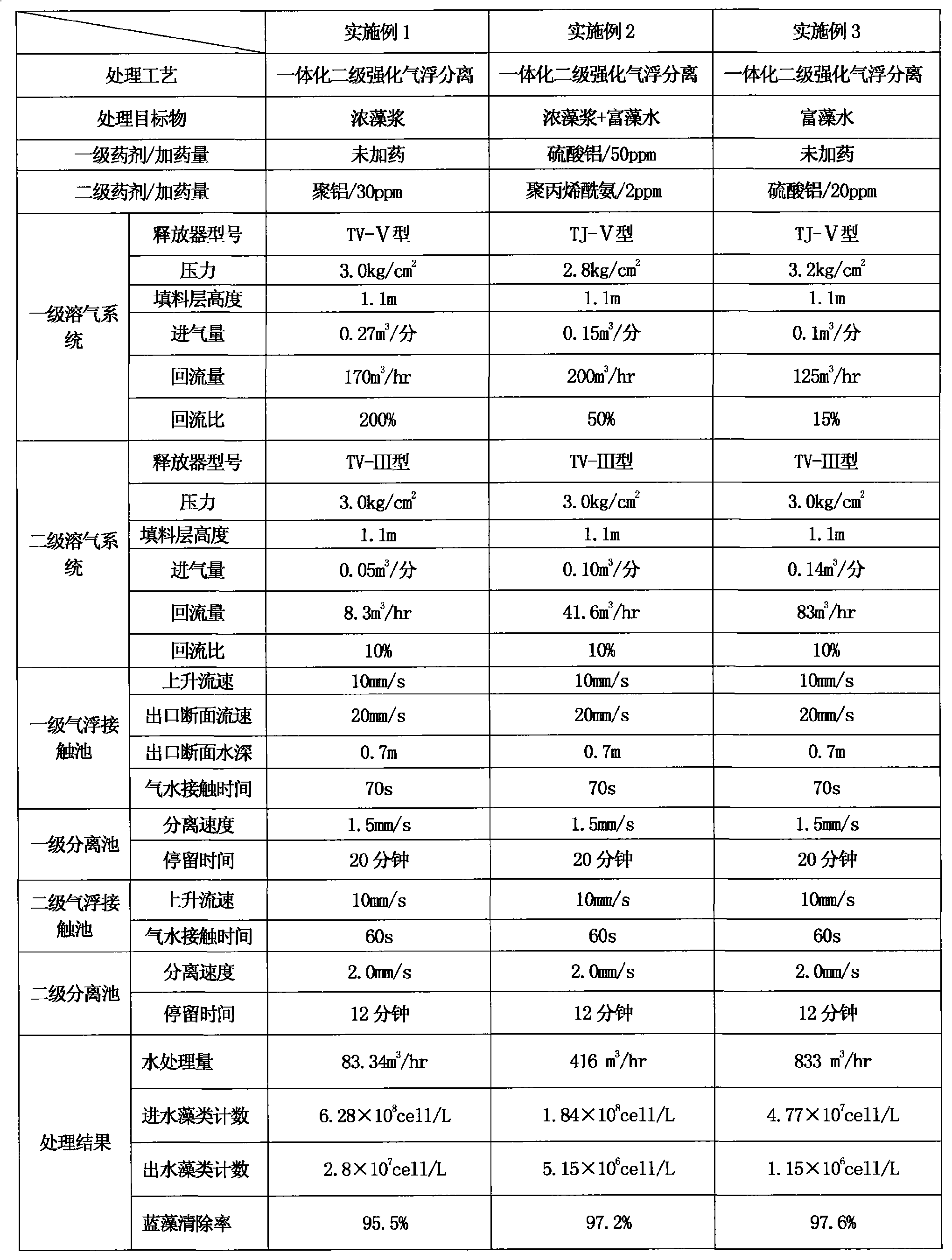

Technique and device for integrated two-stage strengthened air-flotation separation of dense algae slurry

ActiveCN101602551ARealize solid-liquid separationReduce total nitrogenMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationMicro bubbleHigh density

The invention relates to a technique for integrated two-stage strengthened air-flotation separation of dense algae slurry. The technique comprises that: collected dense algae slurry first enters a first-stage air-flotation tank where algae and high-density micro-bubbles have contact with and adhere to each other so as to separate algae and water and remove about 50 to 80 percent of algae, and then water enters a second-stage strengthening air-flotation tank, is added with an appropriate amount of flocculant, and then is subjected to air-flotation treatment again so as to remove the remaining algae and other suspended substances in the water. The invention not only applies to the disposal of dense algae slurry, but also can be used to treat algae-rich water low in algae content. The invention has the advantages of effectively removing blue-green algae in water, transferring nitrogen, phosphorus and other nutrient loads in water, purifying water, preventing the explosion of blue-green algae and providing an effective method and a device for controlling the pollution of lakes and reservoirs.

Owner:WUXI DELINHAI ENVIRONMENTAL PROTECTION TECH CO LTD

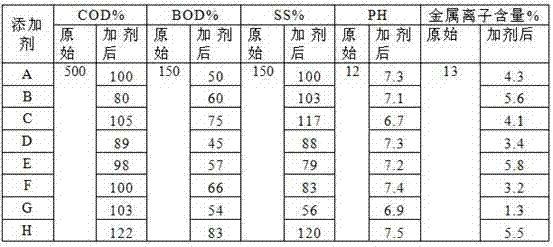

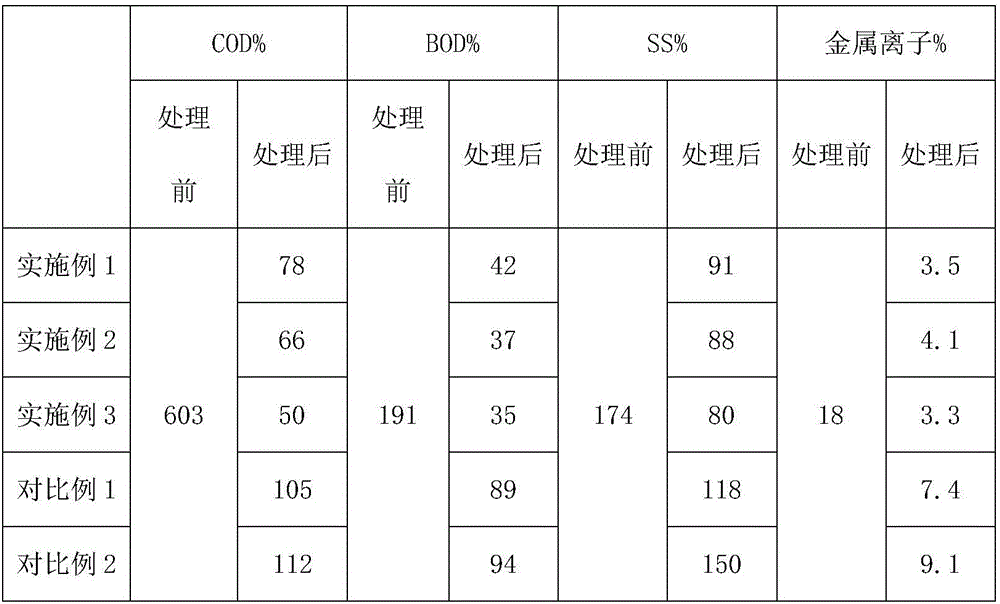

Treating agent applied to papermaking sewage

ActiveCN102951715AReduce CODReduce BODWater/sewage treatment by ion-exchangeWater/sewage treatment by neutralisationSorbentSewage

The invention belongs to the technical field of a sewage treating agent and especially relates to a treating agent applied to papermaking sewage. The treating agent applied to the papermaking sewage comprises the following components by weight part: 40-55 parts of flocculating agents, 15-25 parts of chelating agents, 10-15 parts of adsorbents and 5-35 parts of PH(Potential of Hydrogen) regulators. The treating agent can enable the physicochemical indexes of the papermaking sewage to meet the GB18918-2002 standard, the contents of COD (Chemical Oxygen Demand), BOD (Biochemical Oxygen Demand), SS (Suspended Solids) and metal ions are effectively reduced and the PH is approximately neutral and meets a emission standard.

Owner:临沂星火知识产权服务有限公司

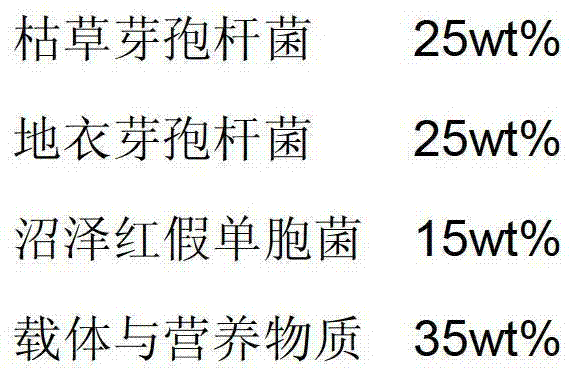

Microbial preparation for improvement of freshwater aquaculture water body

InactiveCN104045164AReduce BODIncrease dissolved oxygenBacteriaMicroorganism based processesNutrientBacillus amyloliquefaciens

The invention provides a microbial preparation for improvement of a freshwater aquaculture water body. Raw materials of the microbial preparation comprise, by weight, 15-40% of bacillus subtilis, 15-40% of bacillus amyloliquefaciens and 10-20% of rhodopseudomonas palustris. The invention also provides a method for preparing the above microbial preparation, comprising the following steps: successively inoculating bacillus subtilis, bacillus amyloliquefaciens and rhodopseudomonas palustris to a medium, fermenting and mixing a fermented liquid obtained with a carrier and nutrients so as to obtain the microbial preparation. By the use of the microbial preparation provided by the invention, water quality of an aquaculture water body can obviously be improved, and meat quality of farmed animals also can be raised.

Owner:SHANGHAI WEIMING BIOTECH

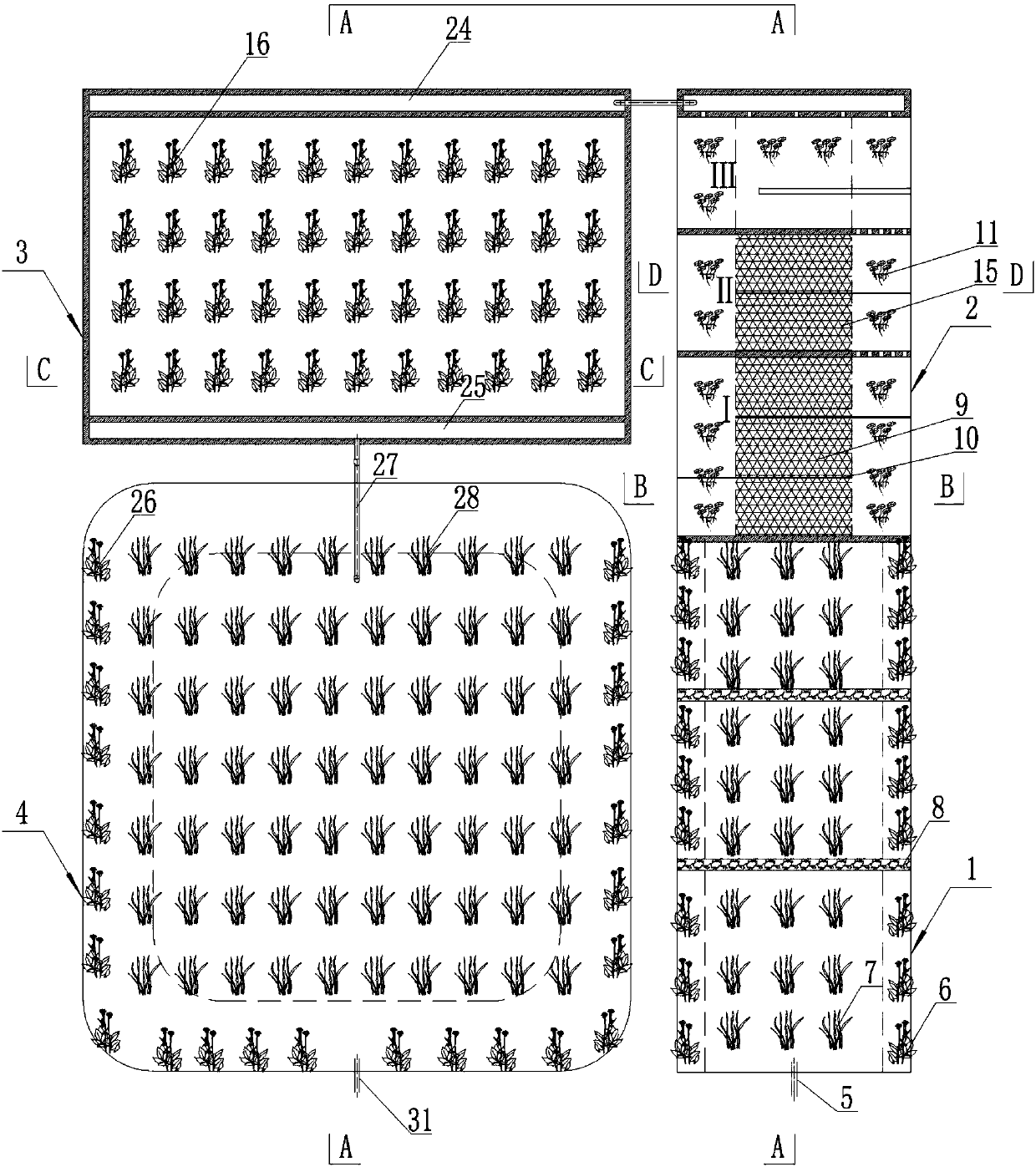

Artificial wetland treatment system for tail water of sewage treatment plant

PendingCN107720973AAchieve final purificationReduce oxygen consumptionWater treatment compoundsTreatment involving sedimentationEmergent plantAquatic animal

The invention provides an artificial wetland treatment system for tail water of a sewage treatment plant. The artificial wetland treatment system at least comprises a shallow water multi-stage water falling channel, an artificial combination unit wetland, an underflow wetland and a biological stabilizing pond; the shallow water multi-stage water falling channel comprises a water channel and a multi-stage water falling dam; the artificial combination unit wetland comprises an aerobic nitrification area, an anoxic denitrification area and a settling area; the underflow wetland comprises a waterinlet channel, a microbial reaction area, wetland plants and a water outlet channel; the biological stabilizing pond is provided with an aquatic plant system and an aquatic animal system; sewage sequentially passes through the shallow water multi-stage water falling channel, the artificial combination unit wetland, the underflow wetland and the biological stabilizing pond sequentially; dwarf vallisneria longipedunculata and emergent aquatic plants are planted in the shallow water multi-stage water falling channel; a plurality of microbial growth based units are arranged in the aerobic nitrification area and the anoxic denitrification area of the artificial combination unit wetland at intervals; and the microbial reaction area of the underflow wetland consists of limestone, volcanic and gravel from top to bottom, and the grain size is from small to big.

Owner:SHANGHAI HEYUAN ENVIRONMENTAL PROTECTION GRP

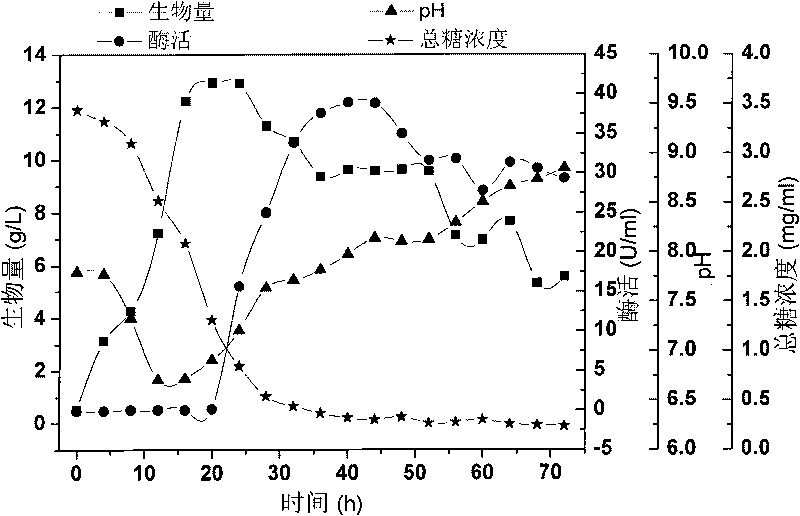

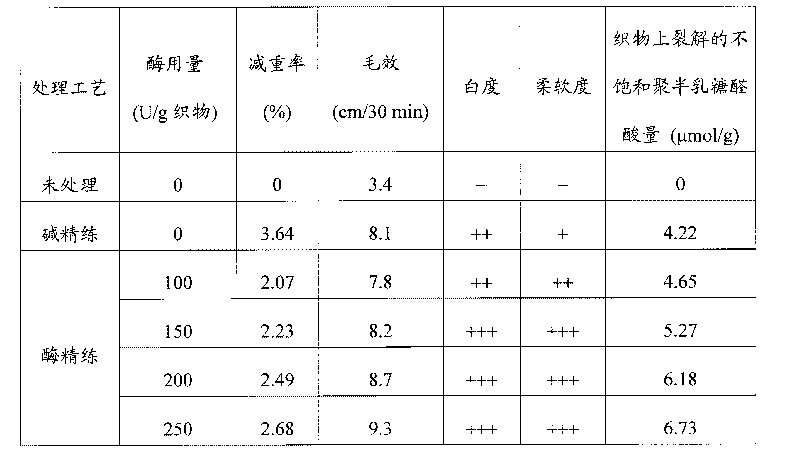

Compound enzyme preparation for textile fabrics and applications thereof

ActiveCN101713150AReduce processing costsReduce salt contentBacteriaBiochemical fibre treatmentPectinaseSolvent

The invention provides a high-efficiency compound enzyme preparation used for a pretreatment process of textile fabrics, particularly cotton fabrics, and application thereof. The compound enzyme preparation mainly comprises the following components by final concentration: 50 to 100g / L of polysiloxane, 50 to 100g / L of fatty alcohol-polyoxyethylene ether, 80 to 150g / L of Tween 20 to 80 series, 80 to 150g / L of Span 20 to 80 series, 30 to 80g / L of sorbitol, 3 to 10g / L of calcium chloride, 5 to 15g / L of sodium benzoate, 800 to 1,000U / mL of alkaline pectinase, 1,000 to 1,200U / nL of cellulase, and water serving as a solvent. The compound enzyme preparation is applied to the pretreatment of the textile fabrics to replace the conventional alkali boiling off process, can effectively reduce production cost, reduce labor intensity and enable the quality of the product to be obviously improved, can also reduce the salt content and BOD, COD and the like in the water discharged into the environment and obviously reduce the pollution to the environment, and is a green process route which accords with the sustainable development.

Owner:ZHEJIANG UNIV OF TECH

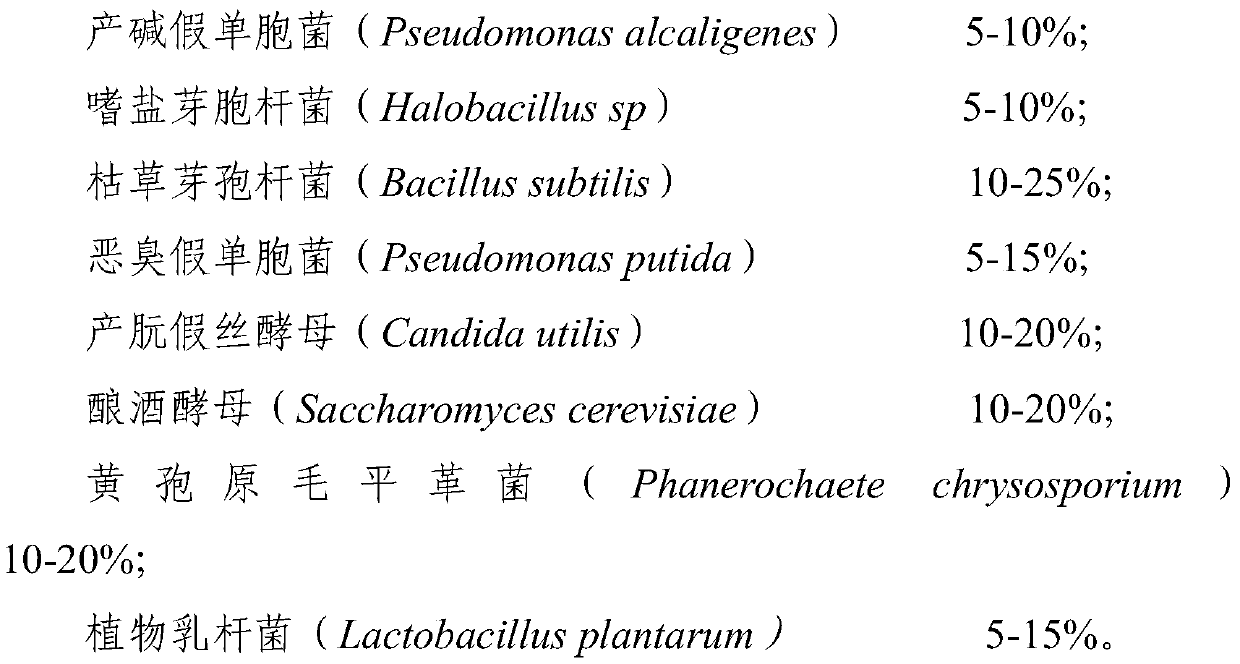

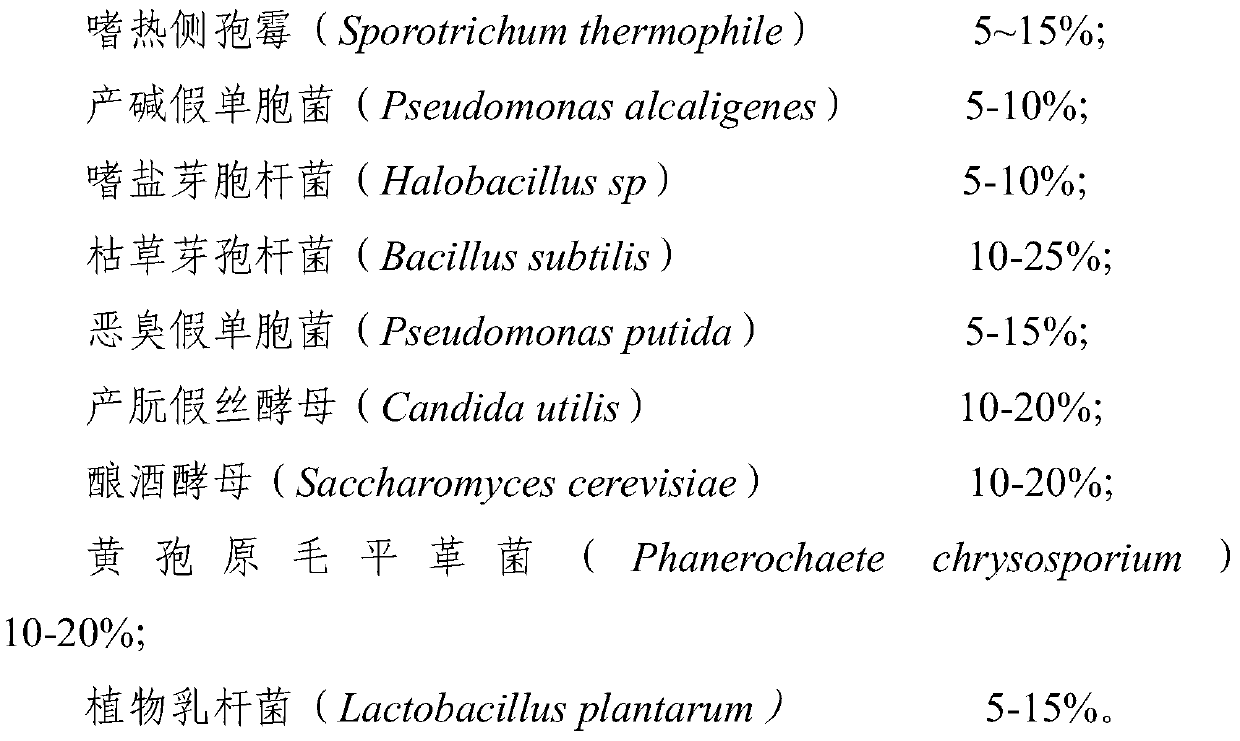

Complex microbial agent for stabilizing treatment of stock garbage in cities and towns as well as preparation method and application of complex microbial agent

ActiveCN109852557APromote degradationAltered ion valence diseaseFungiBacteriaMicrobial agentPseudomonas putida

The invention provides a complex microbial agent for stabilizing treatment of stock garbage in cities and towns as well as a preparation method and an application of the complex microbial agent. The complex microbial agent contains sporotrichum thermophile, pseudomonas alcaligenes, halobacillus sp, bacillus subtilis, pseudomonas putida, candida utilis, saccharomyces cerevisiae, phanerochaete chrysosporium and lactobacillus plantarum. Growth metabolism, degradability and activity of all microbial strains in the complex microbial agent can effectively complement and cooperate with one another, the microbial strains can grow and propagate quickly in a landfill system to promote the temperature of a garbage treatment environment to increase quickly, meanwhile, organic matter, BDM and toxic andharmful substances in a landfill can be quickly and efficiently degraded, the stabilizing time of the garbage landfill is greatly shortened, stable harmless treatment of landfill is promoted, and thecomplex microbial agent can be applied to aerobic stabilizing treatment of garbage in cities and towns in practice.

Owner:BEIJING GUOHUAN TSINGHUA ENVIRONMENT ENG DESIGN & RES INST CO LTD BEIJING CHINA

Waste alkali solution recovery method

InactiveCN102616968AGuaranteed continuityAlleviate Difficult Filtration ProblemsMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationSpinningWastewater

The invention discloses a waste alkali solution recovery method, which is mainly applicable to recovery of waste alkali solution generated during dipping and pressing of pulp in viscose fiber production, and is also applicable to recovery of alkali solution generated during papermaking, pulping, dying, spinning and the like in textile industries. Through procedures of two-stage coagulation, two-stage precipitation and filtration, oxidization, adsorption and the like, the waste alkali solution recovery method ensures continuity of production, reduces filtration difficulties, reduces energy consumption, and enables the production to be more stable. After the alkali solution is treated by the method, the content of impurities in the alkali solution is less, and the chromaticity of the alkali solution is low, thereby realizing the aim of recycling waste alkali. According to the method, equipment investment and energy consumption are low, and operation expense is low; and the method has the characteristics of environmental friendliness, safety and high production efficiency, has remarkable benefits, and can reduce the pollution of the waste alkali on environment.

Owner:YIBIN GRACE +2

Printing and dyeing wastewater treatment process

InactiveCN103771662AReduce CODReduce BODMultistage water/sewage treatmentPrecipitationNational standard

The invention relates to a printing and dyeing wastewater treatment process. The process comprises the following steps: sequentially feeding wastewater into a regulating pond, a coagulative precipitation pond, a hydrolysis pond, a contact oxidation pond and a decolorization treatment pond so as to obtain effluent, namely, regulating the pH (Power of Hydrogen) of the wastewater in the regulating pond to reach 6 to 8 and remaining for 12 to 24 hours; then feeding the wastewater into the coagulative precipitation pond and precipitating for 3 to 5 hours by adding a flocculating agent; feeding the wastewater into the hydrolysis pond and performing acidification hydrolysis for 2 to 5 hours; feeding the wastewater into the contact oxidation pond and performing contact oxidation for 3 to 5 hours; and feeding the wastewater into the decolorization treatment pond and performing decolorization treatment for 1 to 2 hours, thereby obtaining the effluent. A decoloring agent is added into the decolorization treatment pond. After the effluent is precipitated once, the removal rate of COD (Chemical Oxygen Demand) can reach more than 70%; the removal rate of BOD (Biochemical Oxygen Demand) can reach 40% or so. The effluent is acidified and oxidated after entering the hydrolysis pond and the contact oxidation pond; finally, the step of the decolorization treatment to the effluent is added. The effluent after being treated in the decolorization treatment pond can reach the national standard, and can be directly discharged. According to the process, multiple precipitations are not required, i.e., the few steps are needed, so that the cost is greatly saved while the efficiency is improved.

Owner:NANTONG HUAXIN ENVIRONMENTAL ENG EQUIP

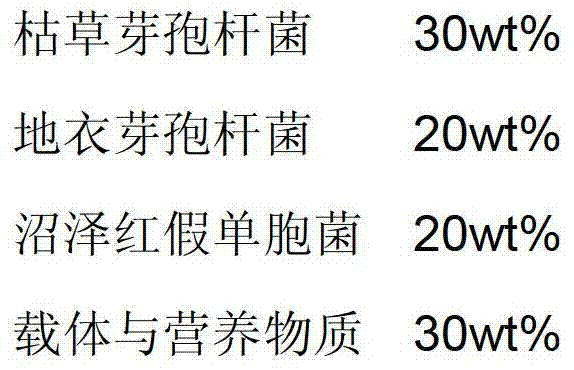

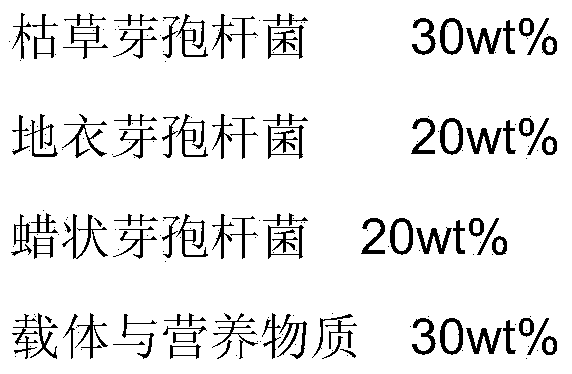

Composite microbial preparation for culture water body improvement

InactiveCN103667139AReduce BODReduce ammonia nitrogen contentBacteriaMicroorganism based processesBacillus licheniformisWater quality

The invention provides a microbial preparation for culture water body improvement, which is prepared from the following raw materials in percentage by weight: 25-30 wt% of Bacillus subtilis, 25-30 wt% of Bacillus licheniformis and 15-20 wt% of Thiobacillus denitrificans. The invention also provides a method for preparing the microbial preparation, which comprises the following steps: sequentially inoculating the Bacillus subtilis, Bacillus licheniformis and Thiobacillus denitrificans seed culture solutions into a culture medium, fermenting to obtain a bacterial solution, and mixing the microbial solution with a carrier and nutrient substances to obtain the microbial preparation. The microbial preparation provided by the invention can obviously improve the quality of the culture water body and enhance the flesh texture of the cultured animals.

Owner:陈汇梁

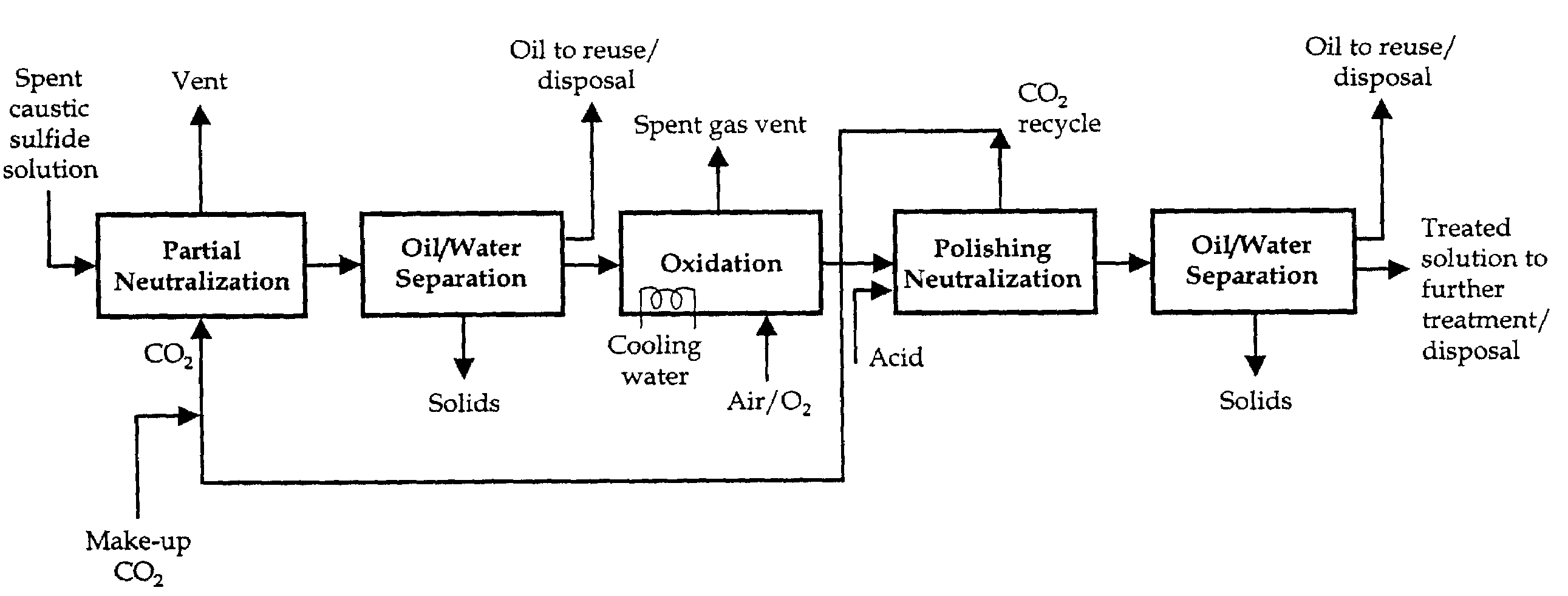

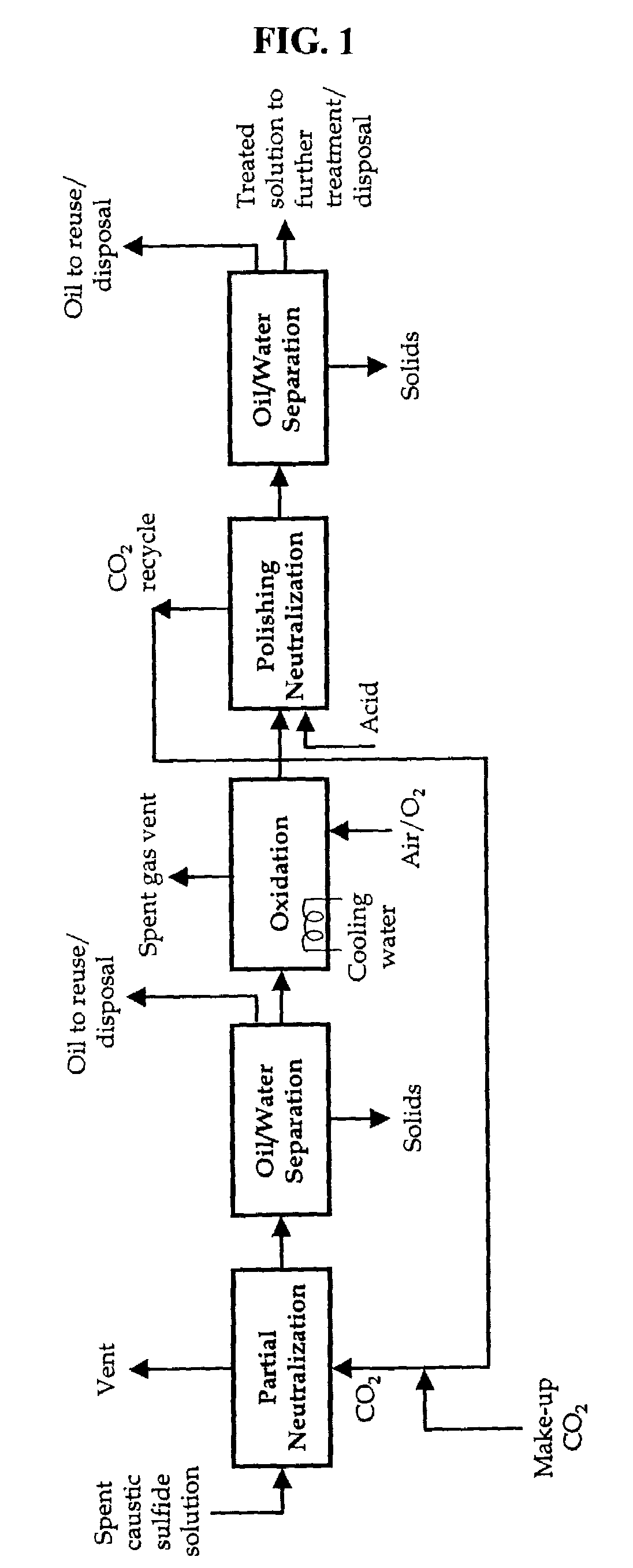

Caustic solution treatment process

InactiveUS7005076B2Not be lowerLow bod and codWater treatment parameter controlWaste water treatment from gaseous effluentsChemistrySulfide

A method for treating a spent caustic solution having a pH greater than about 10.5 includes the steps of (a) lowering the pH of the caustic solution into the range of between about 10 to 10.5 to produce a pH-modified caustic solution; (b) oxidizing the pH-modified caustic solution until the solution to produce a non-sulfide reactive oxidized solution; and (c) lowering the pH of the oxidized solution to a pH less than 9.

Owner:TRC ENVIRONMENTAL CORP

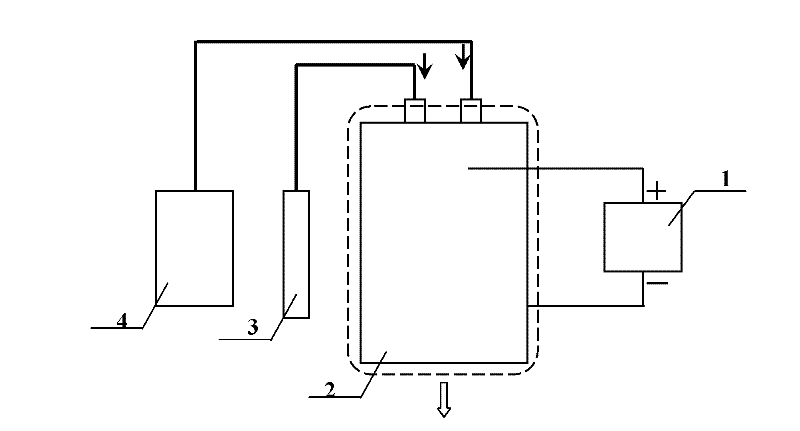

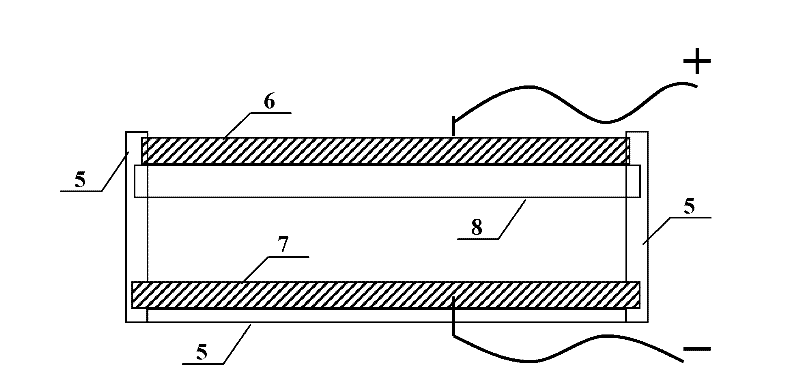

Device for treating rubbish leachate with atmosphere plasma

InactiveCN102372342AReduce BODReduce CODWater/sewage treatment by electrochemical methodsPlasma generatorSewage

The invention provides a device for treating rubbish leachate with atmosphere plasma and relates to a rubbish treatment device. The device comprises a direct-current pulse power supply, a plasma generator, a sewage source and an air source, wherein the plasma generator is provided with an insulated cavity, a positive plate, a negative plate and an insulated pate; one side of the insulated cavity is provided with an air inlet and a water inlet, and the other side of the insulated cavity is provided with a water outlet and an air outlet; the positive plate is located on the insulated plate, thenegative plate is arranged under the insulated cavity and inserted from the negative plate fixing slot arranged below the insulated cavity, and the positive plate and the negative plate are respectively connected with the positive electrode and the negative electrode of the direct-current pulse power supply; the insulated plate is inserted from the insulated plate fixing slot in the middle of theinsulated cavity; and the air source is connected with the air inlet of the insulated cavity, and the sewage source is connected with the water inlet of the insulated cavity. By the device provided by the invention, the treatment of large-area sewage in the flowing process can be realized; and the device has the effects of high degradation speed, high degradation efficiency and the like, has simple structure, is easy to operate, and is easily popularized in the field of rubbish leachate degradation.

Owner:XIAMEN UNIV

Method for producing saccharomycete and organic fertilizer mother solution by utilizing papermaking black liquor

InactiveCN104232494AReduce BODRealize resource utilizationFungiClimate change adaptationSingle-cell proteinBiology

The invention discloses a method for producing a saccharomycete and an organic fertilizer mother solution by utilizing papermaking black liquor. The method is characterized by comprising the following steps of carrying out aeration pretreatment on papermaking digesting black liquor, and then regulating a pH value to 4-7; culturing candida utilis to obtain fermenting strain liquid; carrying out second-stage strain culture on the saccharomycete by utilizing diluted digesting black liquor and nutrient substances; adding a second-stage seed to the pretreated papermaking black liquor for fermentation; and after the fermentation is completed, filtering to obtain the saccharomycete; filtering a supernatant, and carrying out spraying granulation or concentration compounding to obtain an organic fertilizer. The method disclosed by the invention extends the treatment modes of the papermaking black liquor, effectively reduces the BOD (Biochemical Oxygen Demand) of black liquor, effectively realizes the recycling of the papermaking black liquor, reduces the sewage treatment cost and is simple in process and high in practicability. The saccharomycete can be used for producing ribonucleic acid and single-cell protein, and the organic fertilizer can increase the crop yield and enhance the stress resistance of crops because of rich fulvic acid and is an environmental-friendly fertilizer suitable for modern agriculture.

Owner:JIAHE BIOTECH

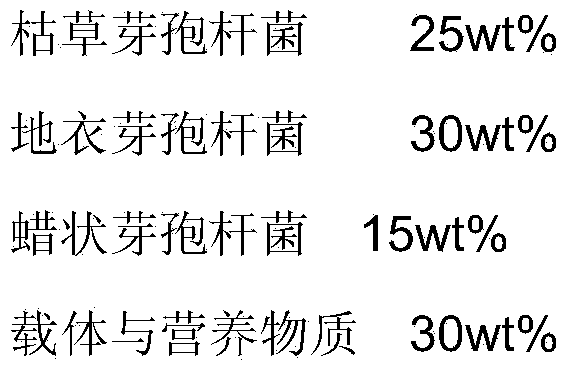

Composite microbial preparation for seaculture water body improvement

InactiveCN103667138AReduce BODReduce ammonia nitrogen contentBacteriaSeawater treatmentBacillus licheniformisWater quality

The invention provides a microbial preparation for seaculture water body improvement, which is prepared from the following raw materials in percentage by weight: 25-30 wt% of Bacillus subtilis, 25-30 wt% of Bacillus licheniformis and 15-20 wt% of Bacillus cereus. The invention also provides a method for preparing the microbial preparation, which comprises the following steps: sequentially inoculating the Bacillus subtilis, Bacillus licheniformis and Rhodopseudomonas palustris seed culture solutions into a culture medium, fermenting to obtain a bacterial solution, and mixing the microbial solution with a carrier and nutrient substances to obtain the microbial preparation. The microbial preparation provided by the invention can obviously improve the quality of the culture water body and enhance the flesh texture of the cultured animals.

Owner:陈汇梁

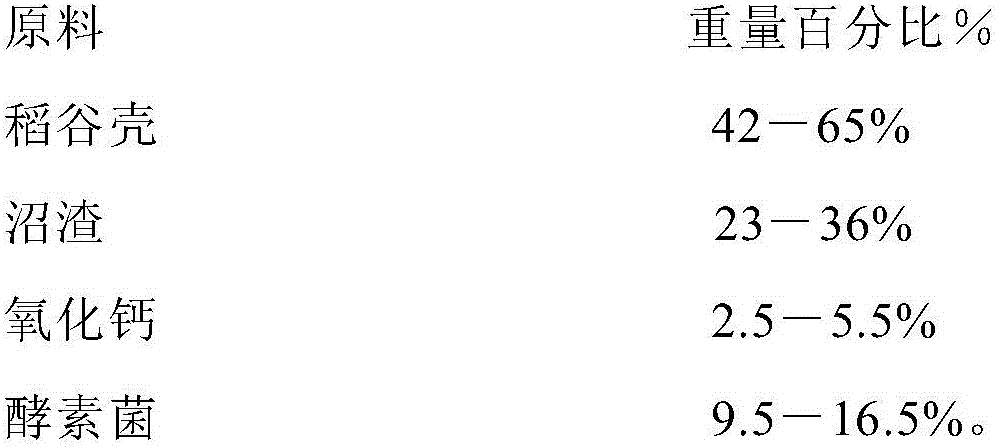

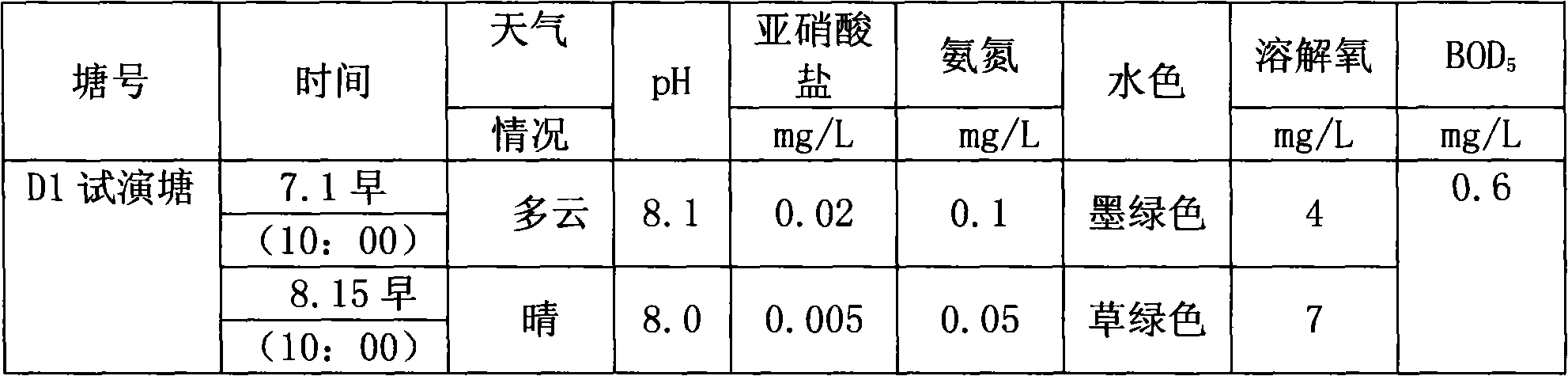

Microbial agent for live pig breeding wastewater treatment as well as preparation method and application of microbial agent

The invention discloses a microbial agent for live pig breeding wastewater treatment as well as a preparation method and application of the microbial agent. The microbial agent comprises rice husks, biogas residues, calcium oxide and enzyme microorganisms in a certain ratio. The microbial agent comprises the following steps: (1) putting the biogas residues into a pressure cooker, and cooking; (2) uniformly mixing the rice husks and the enzyme microorganisms, and naturally heaping up for fermenting; (3) adding products obtained in the former steps into the calcium oxide, uniformly mixing and performing secondary fermentation to prepare the special microbial agent for the live pig breeding wastewater treatment. The microbial agent is applied to the live pig breeding wastewater treatment. The preparation method is feasible, and easy and convenient to operate; the rice husks after the secondary fermentation contain polysaccharide, crude fat, crude protein and other nutritional substances, can provide necessary nutritional components for microbes, have relatively strong synchronous decarbonizing and denitrogenating effects, and have strong anti-interference capability; according to the preparation method, the problems that in the prior art, certain organic matters, phosphorus, nitrogen and other soluble pollutants cannot be effectively removed and the like are solved, and the first-level B standard of the national urban sewage discharge standard is reached.

Owner:INST OF AQUATIC LIFE ACAD SINICA +1

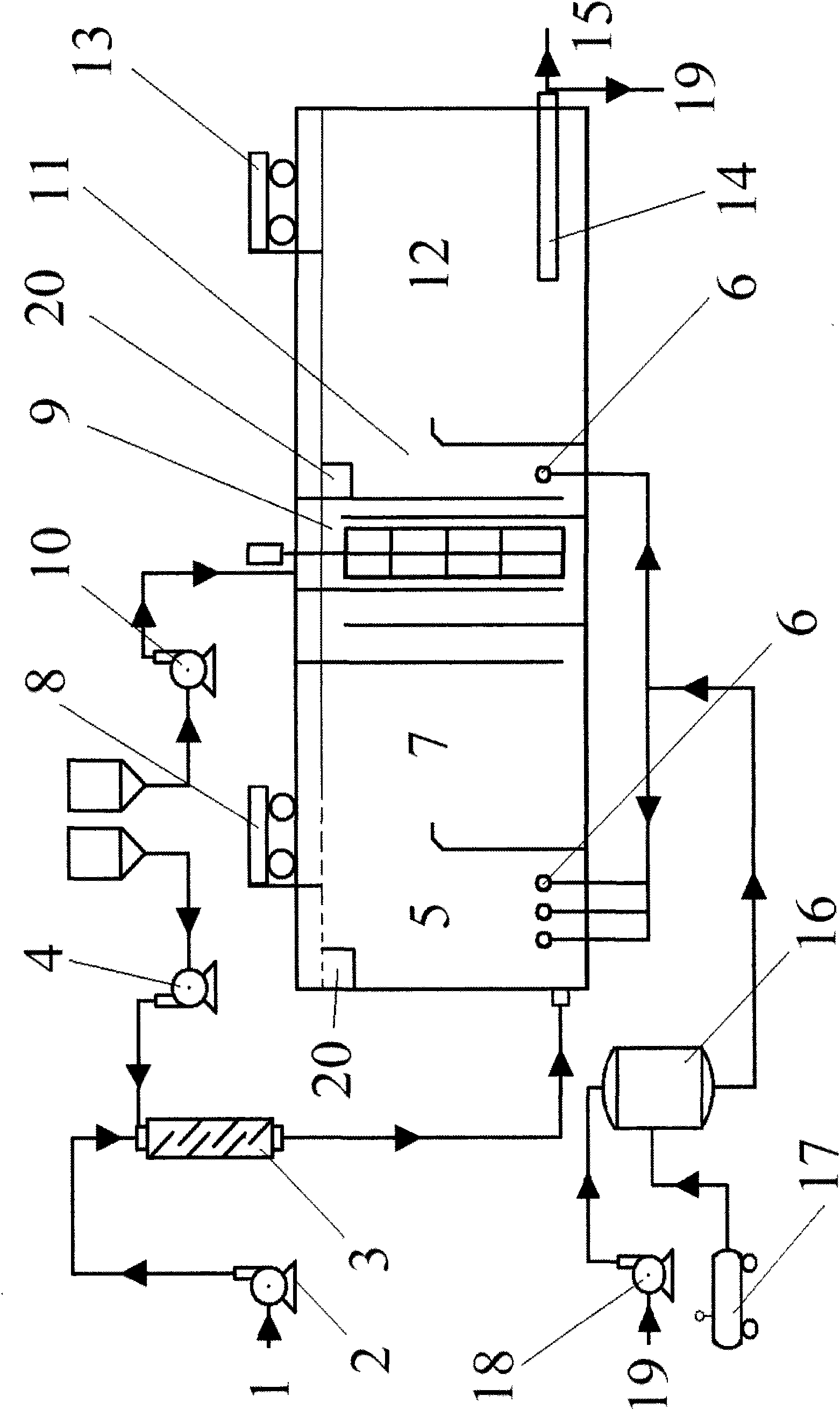

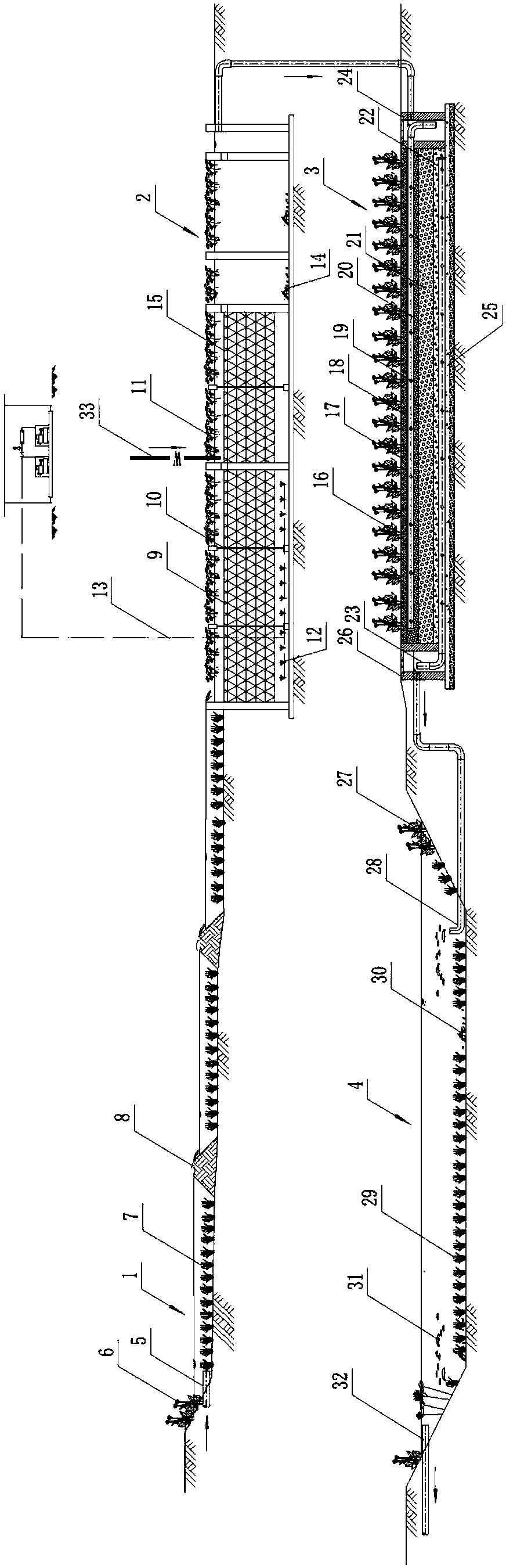

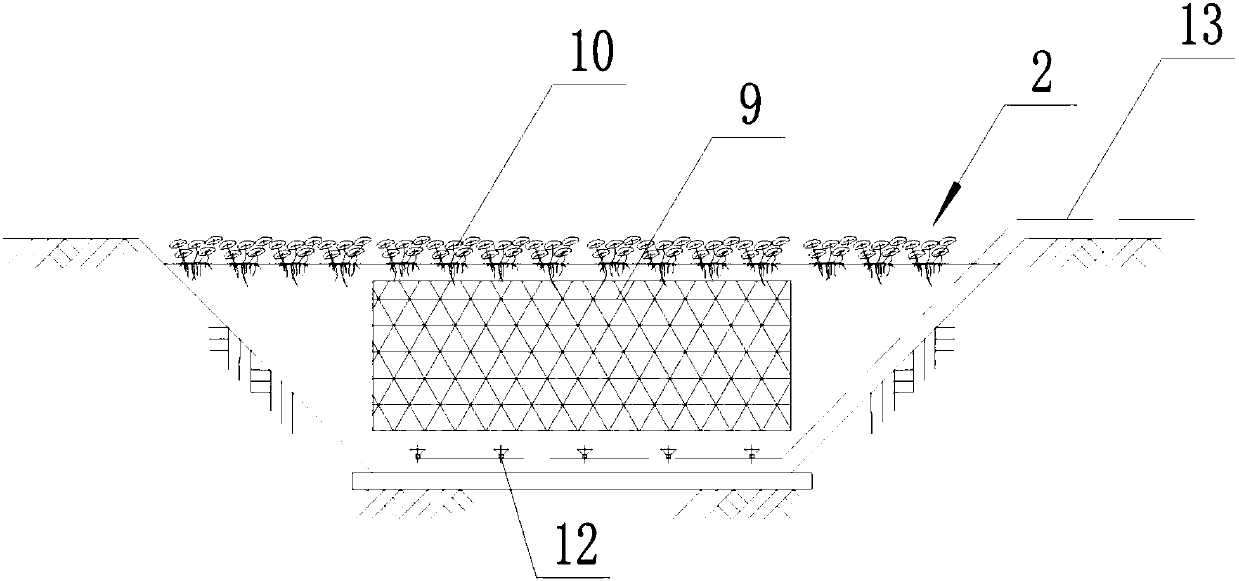

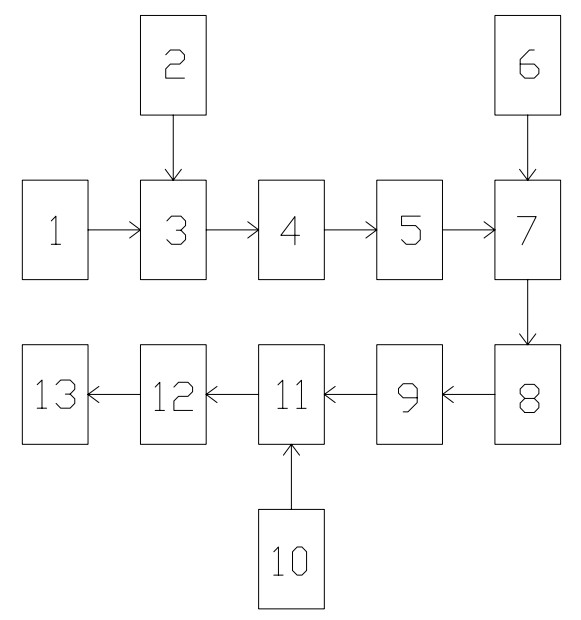

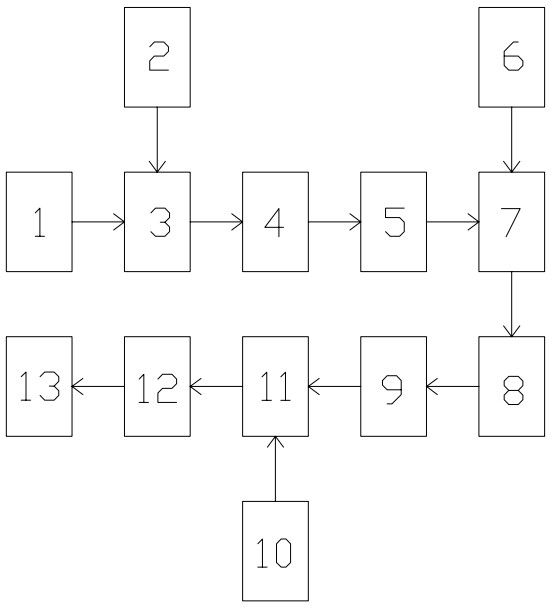

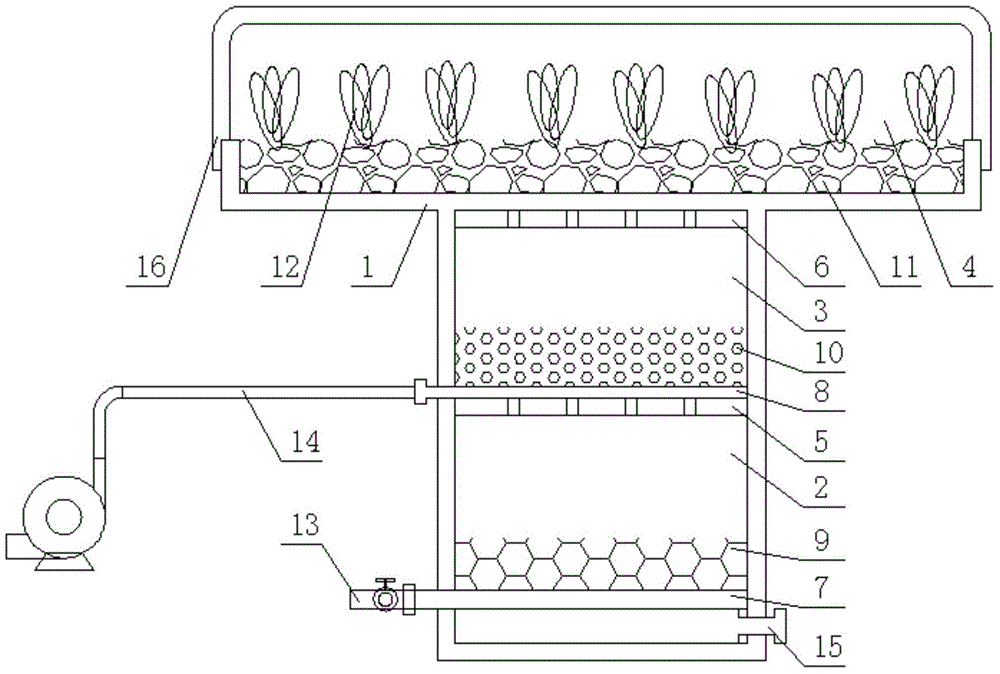

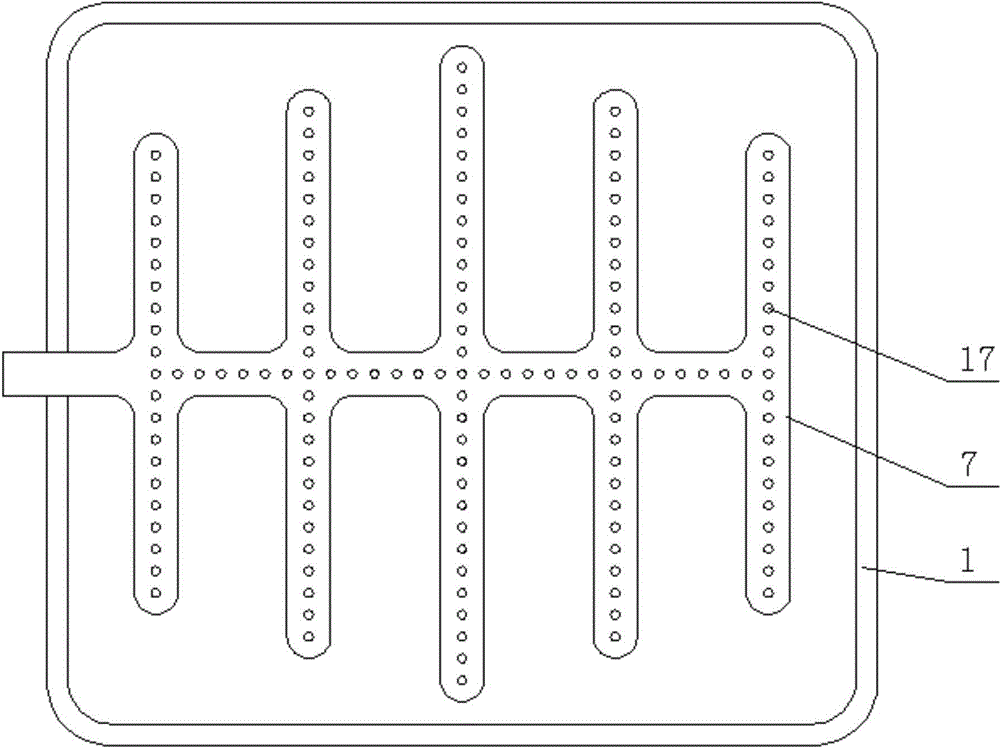

Distributed domestic sewage integrated treatment device and treatment method

ActiveCN104150596AReduce nitrogen and phosphorus contentReduce CODTreatment with aerobic and anaerobic processesTherapeutic effectOxygen

The invention relates to the field of sewage treatment and discloses a distributed domestic sewage integrated treatment device and treatment method. The distributed domestic sewage integrated treatment device comprises a water inlet pipe (13), an aeration device (14) and a housing (1), wherein the interior of the housing (1) is divided into an anaerobic reaction chamber (2), an aerobic reaction chamber (3) and an artificial wetland chamber (4) by a first porous partition plate (5) and a second porous partition plate (6), a perforated water distribution pipe (7) is arranged in the anaerobic reaction chamber (2), the water inlet pipe (13) is connected with the perforated water distribution pipe (7) and the anaerobic reaction chamber (2) is filled by an anaerobic filler (9); an aeration pipe (8) is arranged in the aerobic reaction chamber (3), the aeration pipe (8) is connected with the aeration device (14) and the aerobic reaction chamber (3) is filled by a foam block (10); the artificial wetland chamber (4) is filled by a planting matrix (11)and aquatic plants (12) are planted on the planting matrix (11). The distributed domestic sewage integrated treatment device disclosed by the invention has the advantages of compact structure, low equipment and operation cost and obvious treatment effects.

Owner:温州创源环境科技有限公司

Method for preparing culture environment purifying agent by spore fermentation waste liquid

Owner:上海亘卓生物工程有限公司

Colored wastewater discoloration method

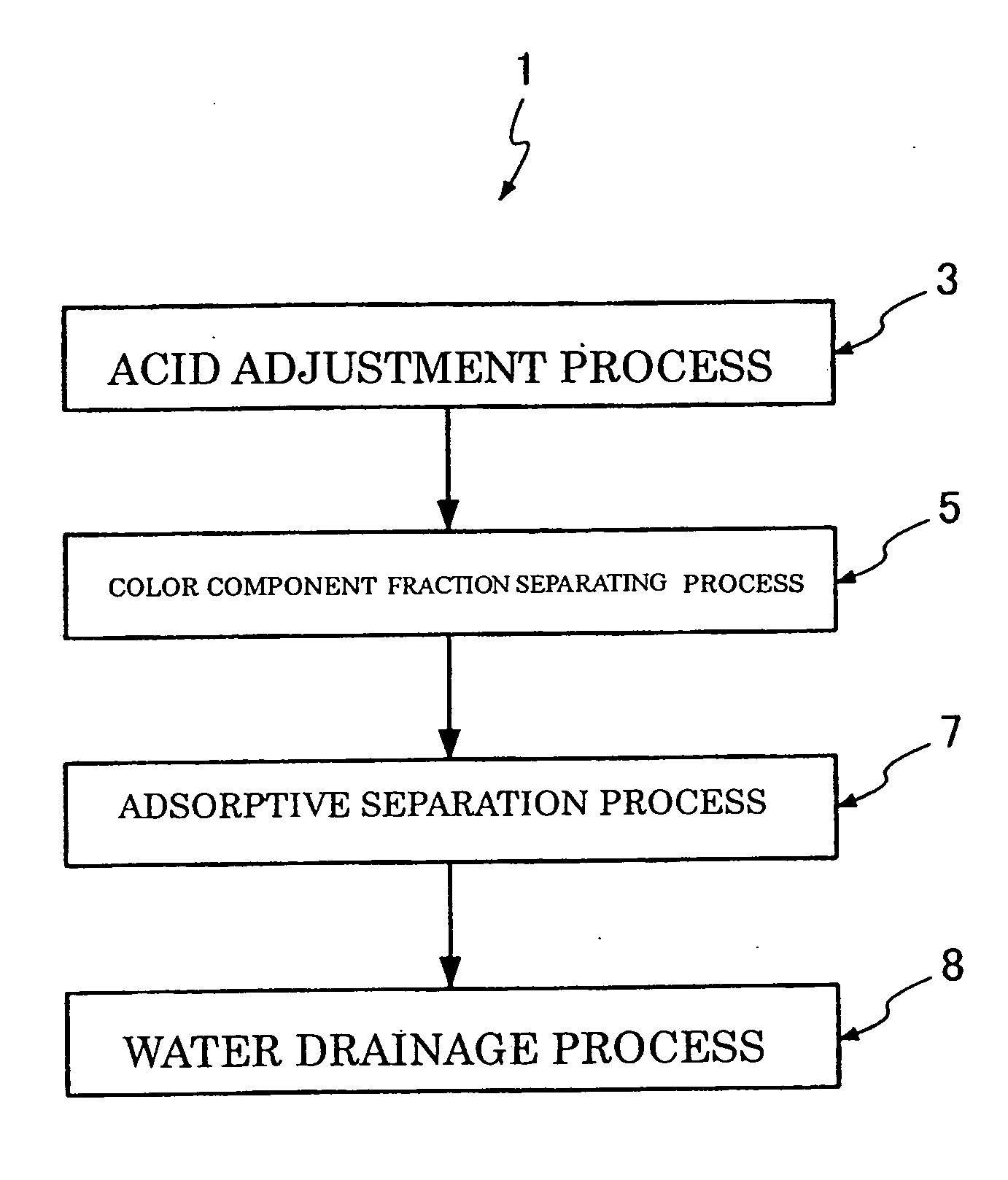

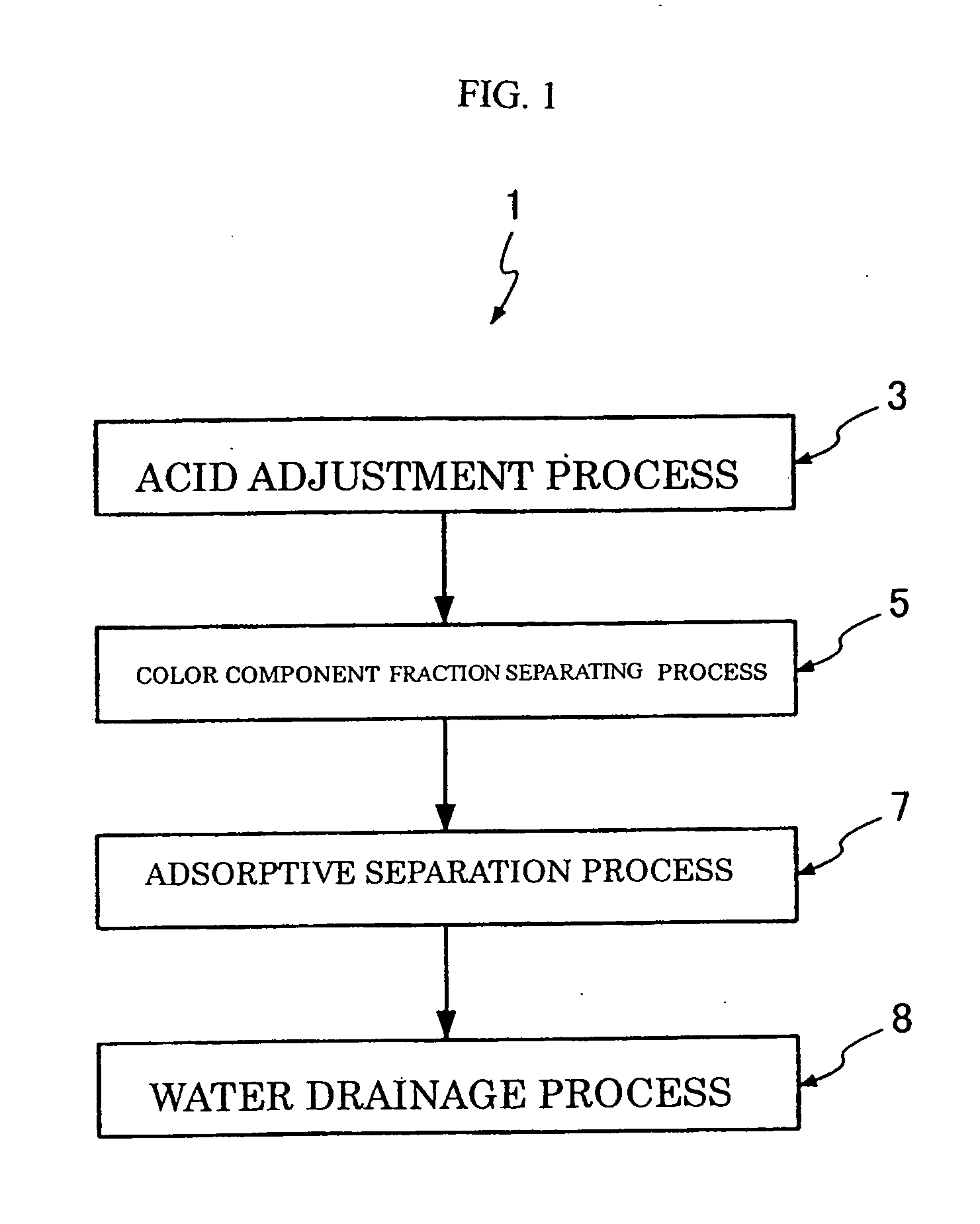

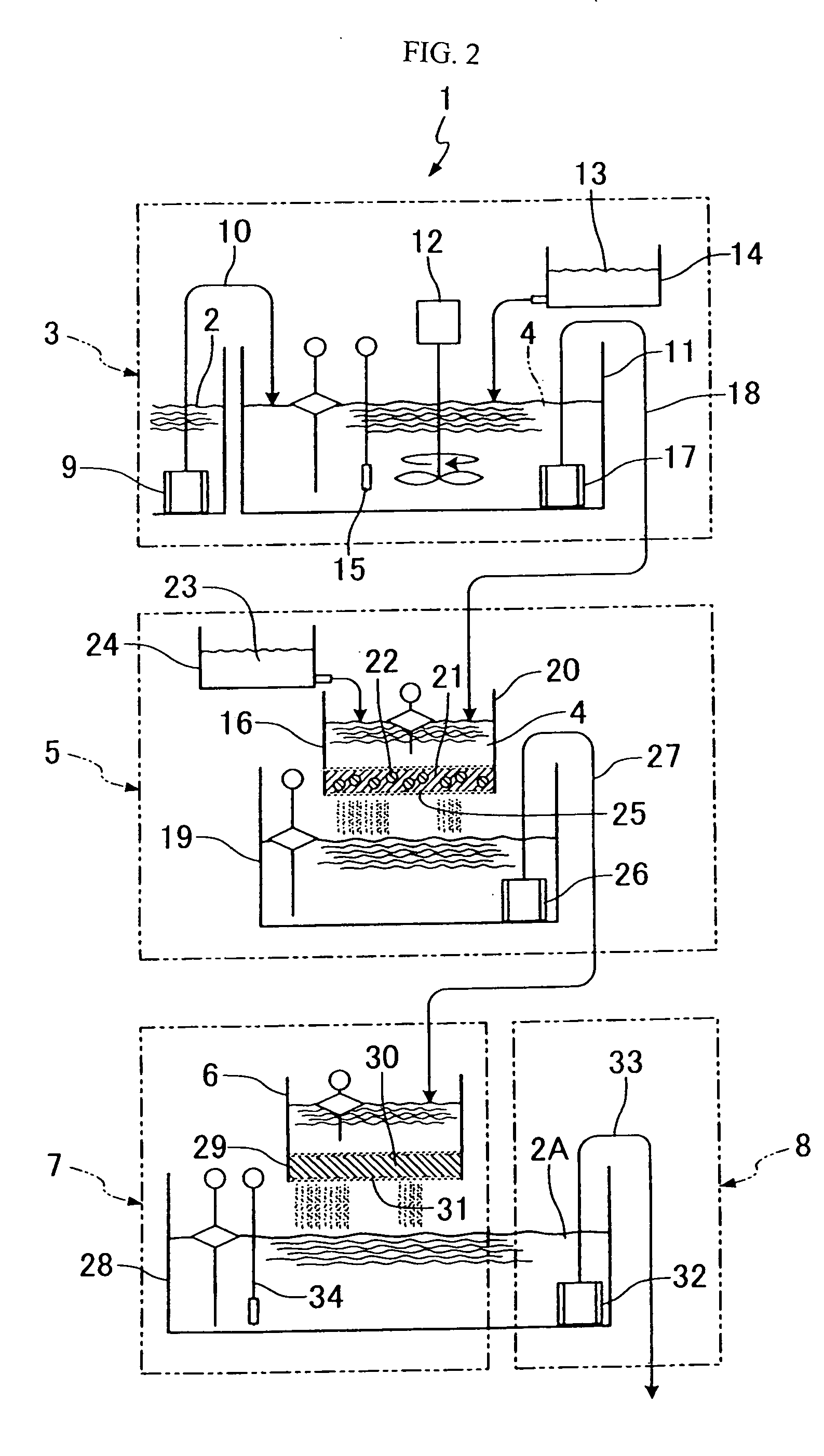

InactiveUS20090032459A1Effective treatmentReduce BODWater treatment parameter controlIon-exchanger regenerationWastewaterFilter material

Colored wastewater from industries, agriculture and the like is discolored by adjusting pH of the wastewater and filtering the wastewater through a mixture of acid-treated sawdust produced from sawdust which has been disposed of after being used for fungi production and charcoal thereby to remove a color component fraction from the wastewater and through a filter material, for example acid-treated rice husk charcoal, in which autochthonous microorganisms are embedded thereby to absorb color components remaining in the wastewater.

Owner:TANABE SEISUKE

Disinfection powder for sewage, and preparation method and application method thereof

InactiveCN107094794AReduce CODReduce BODBiocideSpecific water treatment objectivesSodium bicarbonateMonoglyceride

The invention provides a sewage disinfector, and a preparation method and application method thereof. The sewage disinfector comprises, by mass, 40 to 60% of potassium monopersulfate, 0 to 5% of calcium peroxide, 4 to 15% of magnesium sulfate, 6 to 12% of iron chloride, 5 to 15% of sodium bicarbonate, 0 to 7% of nanometer titanium dioxide, 0 to 10% of chitosan, 0 to 12% of starch xanthate, 3 to 8% of fatty acid monoglyceride, 4 to 20% of a weak acid component and 1 to 15% of a stabilizing agent. After dissolving of the sewage disinfector provided by the invention, a plurality of high-activity free radicals are continuously produced and exert combined disinfection effect, so the sewage disinfector has the advantages of a wide disinfection spectrum, good disinfection effect, high efficiency and safety; through combined usage of three flocculating agents consisting of iron chloride, chitosan and starch xanthate, the sewage disinfector can remove metal ions, radioactive substances and organic matters in water and effectively decrease CODs and BODs in a water body; and nanometer titanium dioxide can kill a plurality of bacteria and fungi in water in long duration and is free of toxicity and harm. When the sewage disinfector is applied to treatment of sewage, procedures like grating filtering, fermentation, precipitation and flotation are not necessarily needed, so the sewage disinfector is convenient to use.

Owner:江苏苏沃尚新材料科技有限公司

Paper mill sewage treatment agent

ActiveCN106745412ARaw materials are easy to getEasy to prepareWater/sewage treatmentWaste water treatment from plant processingSalicylic acidEmission standard

The invention discloses a paper mill sewage treatment agent. The paper mill sewage treatment agent is prepared from the following raw materials in parts by weight: 40 to 65 parts of modified bagasse powder, 11 to 16 parts of polyacrylamide, 3 to 7 parts of ethyl maltol, 3 to 8 parts of chlorella powder, 8 to 13 parts of humic acid, 13 to 18 parts of soya bean meal, 11 to 14 parts of lotus leaf ash, 7 to 10 parts of ferric chloride, 15 to 23 parts of kaolin, 98 to 125 parts of water, 2 to 5 parts of salicylic acid and 1 to 3 parts of monopotassium phosphate. By adopting the paper mill sewage treatment agent, COD (Chemical Oxygen Demand), BOD (Biochemical Oxygen Demand), SS (Stainless Steel) and metal ion content of sewage can be lowered effectively, and the emission standard can be reached; the paper mill sewage is treated with the modified bagasse, so that waste is turned into treasure, and resource waste is avoided; the paper mill sewage treatment agent has the advantages of simple preparation method, adoption of readily available raw materials, relatively low production cost and high sewage treatment efficiency.

Owner:SHANGHAI TIANLIN WATER TREATMENT EQUIP MAINTENANCE

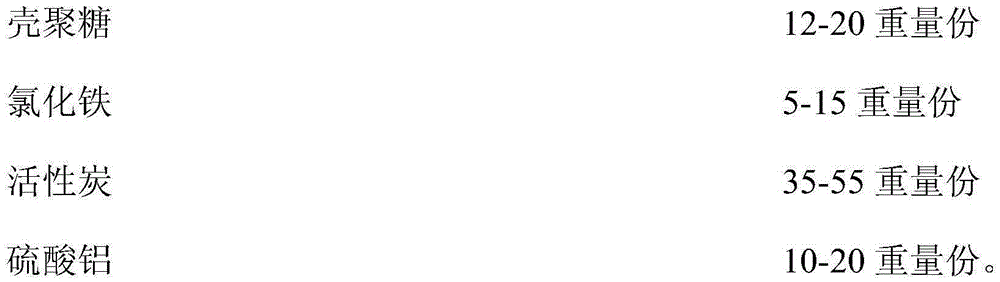

Wastewater treatment agent and application of wastewater treatment agent

InactiveCN105253972AImprove adsorption capacityEfficient functionWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by flocculation/precipitationMedicineTurbidity

The invention provides a wastewater treatment agent and application of the wastewater treatment agent. The wastewater treatment agent mainly is prepared from the following ingredients in parts by weight: 12 to 20 parts by weight of chitosan, 5 to 15 parts by weight of ferric chloride, 35 to 55 parts by weight of active carbon and 10 to 20 parts by weight of aluminum sulfate. The wastewater treatment agent has the advantages that when the wastewater treatment agent is applied to wastewater treatment, and the adding quantity is 200mg / L, the wastewater turbidity removal rate can reach more than 95 percent; the total phosphorus removal rate can reach more than 90 percent; the COD removal rate can reach more than 33 percent; the BOD removal rate can reach more than 78 percent; in addition, the raw material resources of the wastewater treatment agent are rich; the cost is low; a better market application prospect is realized.

Owner:WUXI JIABANG ELECTRIC POWER PIPE FACTORY

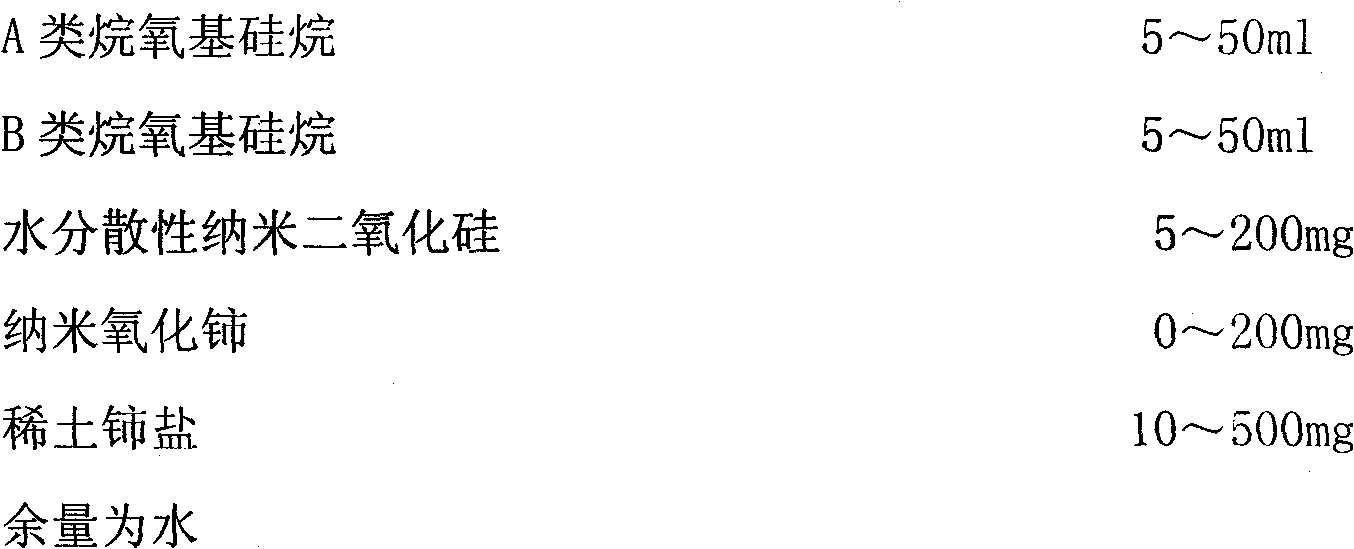

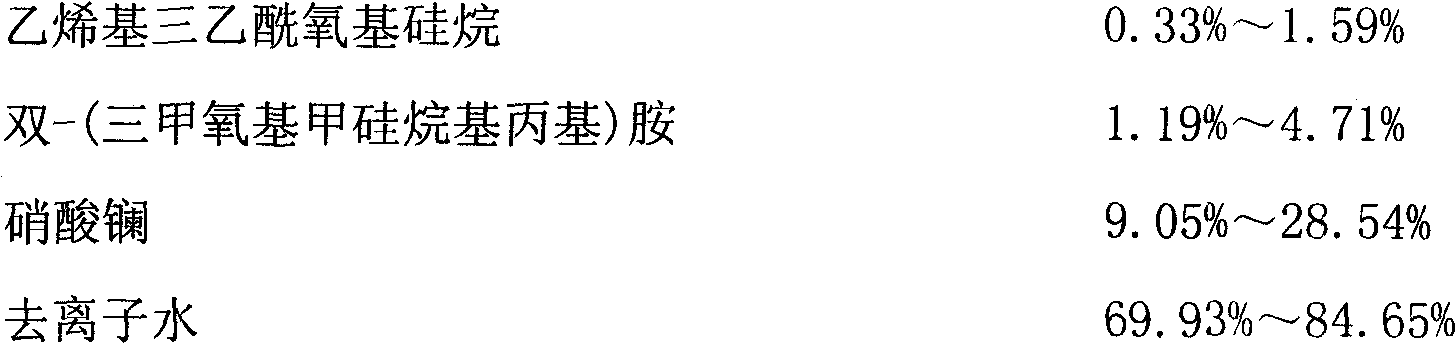

Aqueous silane treatment agent for improving metal surface protection performance

InactiveCN102304704AGood corrosion resistanceLow priceMetallic material coating processesIonCorrosion resistant

The invention discloses an aqueous silane treatment agent for improving metal surface protection performance, and relates to a silane treatment agent for the metal surface pretreatment. The aqueous silane treatment agent provided by the present invention comprises vinyltriacetoxysilane, bis-(trimethoxysilylpropyl)amine, lanthanum nitrate and deionized water. The aqueous silane treatment agent provided by the present invention has characteristics of high corrosion resistance, high storage stability, high adhesion, low cost, easy popularization and application, and the like. The aqueous silane treatment agent can be widely applicable for the metal surface pretreatment, and is the ideal treatment agent for improving the metal surface protection performance.

Owner:CHONGQING UNIV

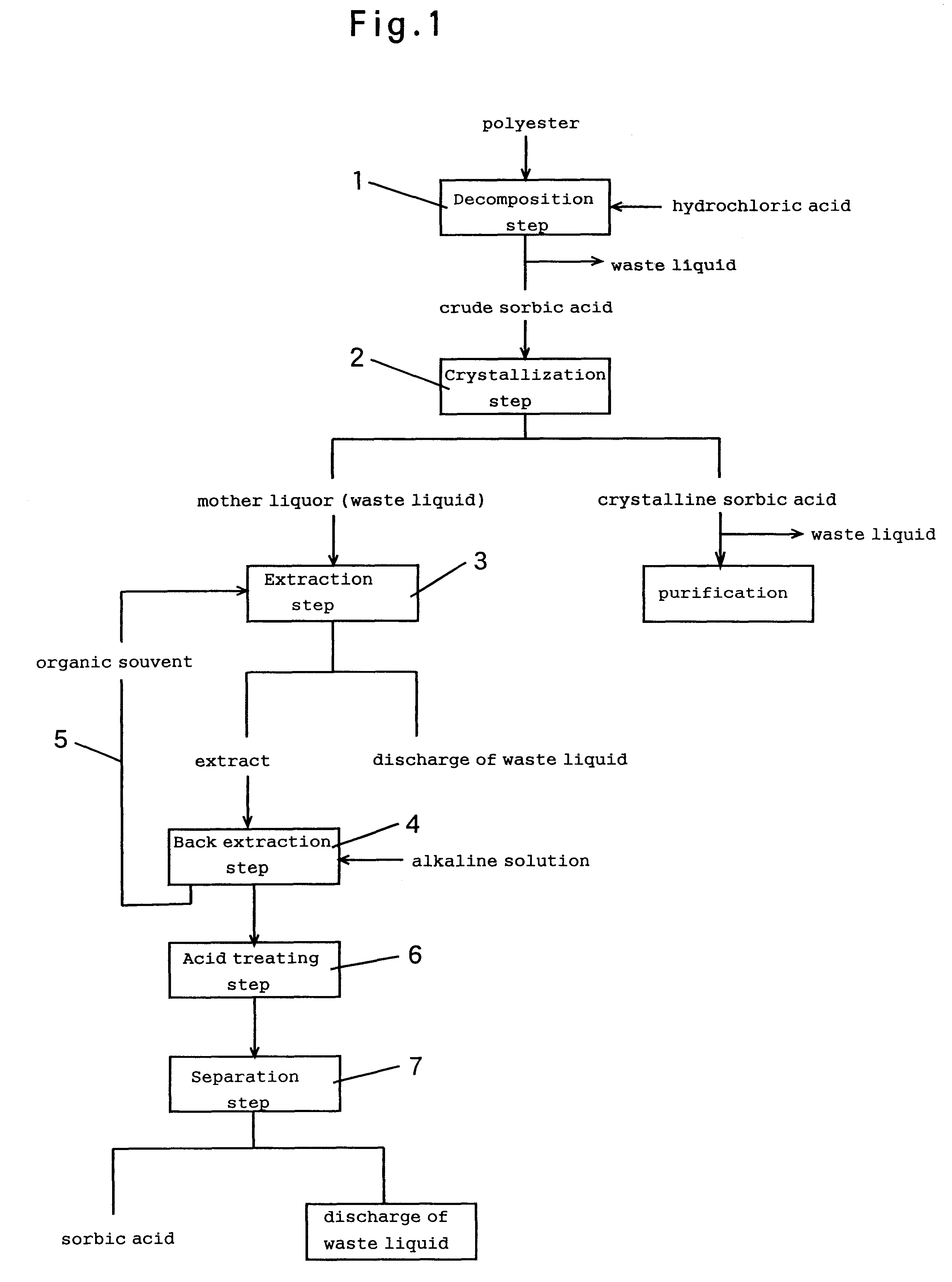

Apparatus and method for recovering sorbic acid

InactiveUS6455733B1Easy extractionReduce wasteCarboxylic compound separation/purificationSolubilityOrganic solvent

Crude sorbic acid produced in a decomposition step 1 is subjected to a crystallization step 2 to precipitate crystalline sorbic acid, and the crystalline sorbic acid is separated from a mother liquor (filtrate). The mother liquor was subjected to an extraction step 3 in which a specific extractant is employed, and an extract (organic phase) is subjected to a back extraction step 4 and treated with an alkaline solution to extract the sorbic acid into an aqueous phase in the form of a salt. The aqueous phase is neutralized in a neutralization step 6 and the produced sorbic acid is recovered in a separation step 7. As the extractant, use can be made of an organic solvent which is separable from water and has a solubility in water of not more than 1% by weight and in which not less than 0.5% by weight of sorbic acid is dissolvable (e.g., aliphatic C6-20 alcohols, ketones, esters, aromatic ethers). According to the above process, sorbic acid can be recovered from a filtrate (mother liquor) produced in a sorbic acid production process with high recovering efficiency and therefore results in a consequent and effective reduction in the BOD of the waste liquid.

Owner:DAICEL CHEM IND LTD

Domestic sewage treatment agent and preparation method thereof

ActiveCN107758823AGood flocculation effectFast hydrolysisWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionPorous carbonTherapeutic effect

The invention discloses a domestic sewage treatment agent and a preparation method of the domestic sewage treatment agent. The domestic sewage treatment agent comprises the following raw materials inparts by weight: 12-15 parts of polyferric chloride, 20-30 parts of meerschaum, 5-10 parts of modified silkworm excrement based porous carbon material, 10-15 parts of sodium hydroxide, 12-15 parts ofpolyacrylamide, 10-15 parts of sodium carbonate and 1-5 parts of bio-based porous composite material. According to the treatment agent, two novel biological carbon materials are added, so that the adsorption purification capacity of the sewage treatment agent is improved; the treatment agent can effectively treat domestic sewage of residents under matching of the other raw materials, and is good in treatment effect, lower in cost and stable in performance; and treated pollution reaches a national sewage discharge standard.

Owner:SHANGHAI ZHONGHAILONG NEW ENERGY

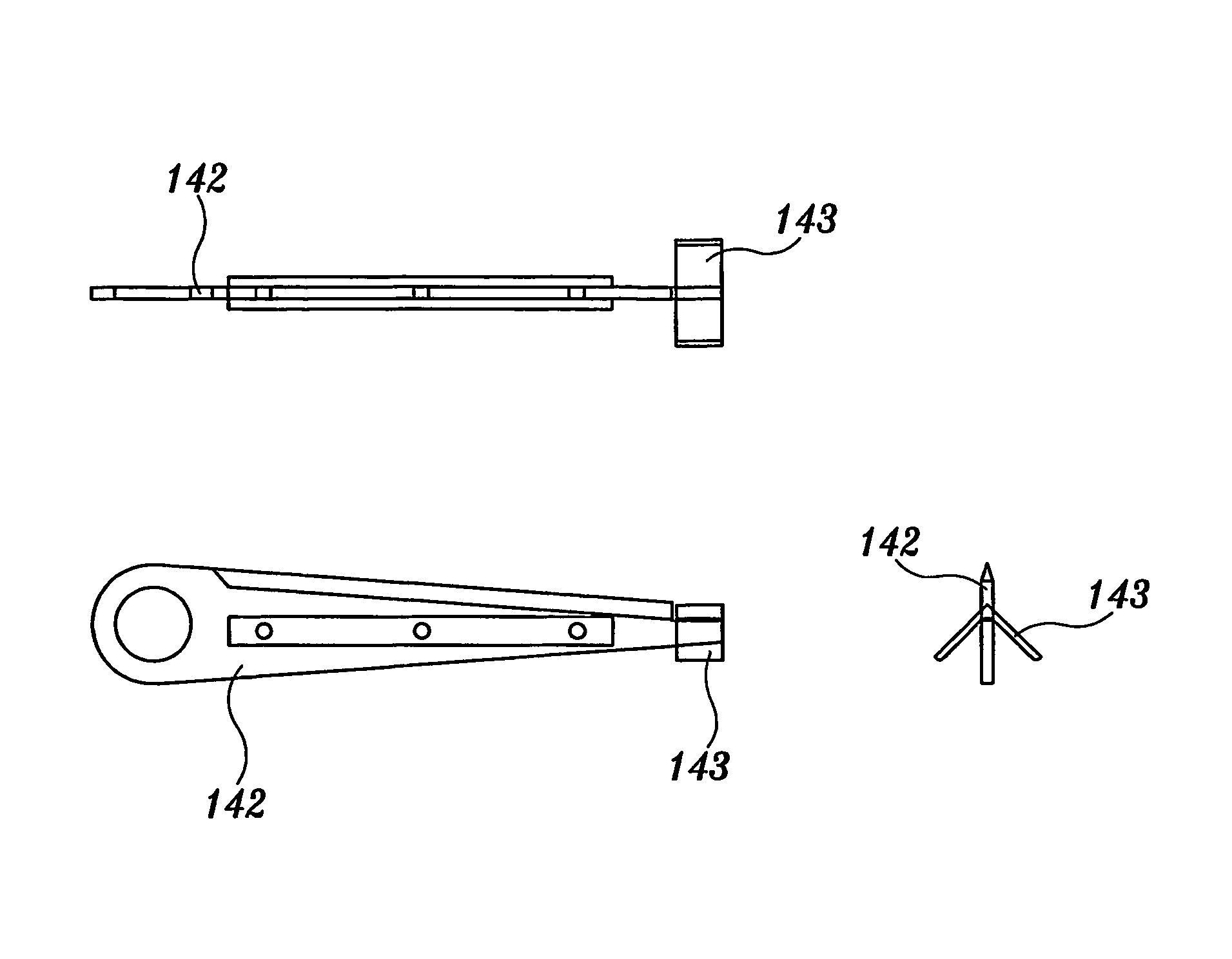

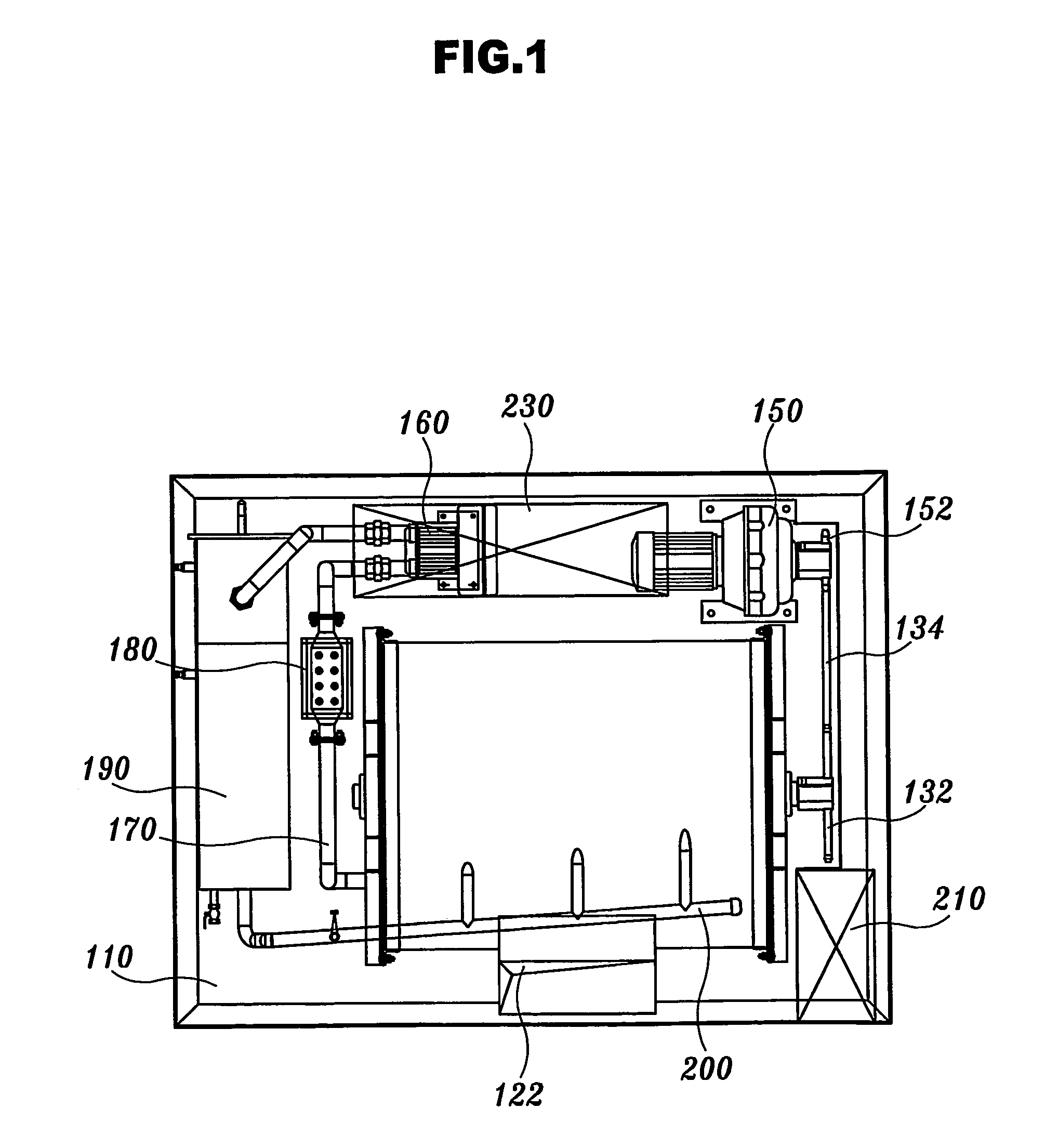

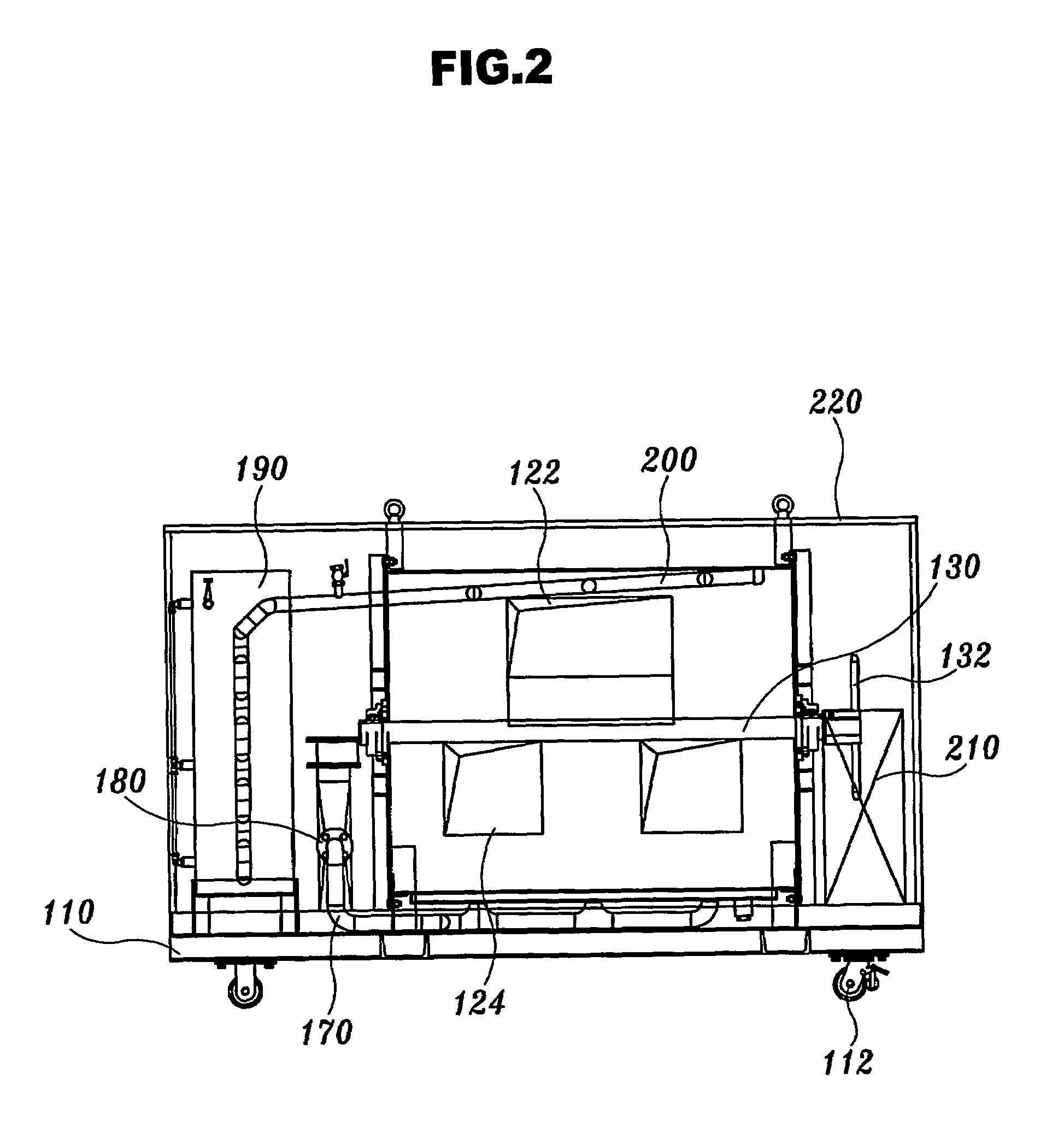

Decomposition device of organic waste and automatic cleaning system thereof

ActiveUS7604986B2Overcome problemsEffectively preventing a bad smellBioreactor/fermenter combinationsBio-organic fraction processingDecompositionDrive motor

An organic waste decomposition device comprises a base frame (110), a cylindrical shell casing (120), a shaft (130) which is rotatably installed in the shell casing, a plurality of arm blades (140) which Are engaged to the shaft, a driving motor (150) adapted to provide a rotational force to the shaft, a ring blower (160) which is adapted to supply air into the interior of the shell casing, an air pipe (170) which is adapted to connect the ring blower and a lower portion of the shell casing, a pre-heater (180) which is adapted to pre-heat the air supplied into the interior of the shell casing, a condenser (190) which liquidefies the discharged vapor, a steam pipe (200) which connects an upper portion of the shell casing and the condenser, and a control box (210).

Owner:KOH JOYCE TAEYA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com