Microbial preparation for improvement of freshwater aquaculture water body

A technology for microbial preparation and water improvement, which is applied in the fields of microorganism-based methods, microorganisms, biological water/sewage treatment, etc. The effect of reducing and increasing the amount of dissolved oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

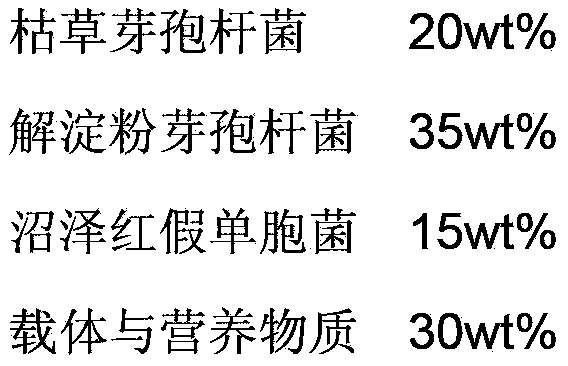

[0052] Raw material composition:

[0053]

[0054] Preparation:

[0055] step 1:

[0056] Bacillus subtilis and Bacillus amyloliquefaciens were respectively inoculated in the first culture medium under aseptic conditions, 30 DEG C-35 DEG C, single bacterial species was cultivated for 48 hours, obtained Bacillus subtilis and Bacillus amyloliquefaciens seed culture solution, which The number of live bacteria is greater than 5.0×10 9 cfu / ml. Among them, the first medium is composed of molasses 1-1.2wt%, peptone 0.4-0.6wt%, yeast extract 1-1.2wt%, calcium chloride 0.1-0.15wt%, sodium chloride 0.2-0.25wt%, iron sulfate 30 -35wt%, magnesium sulfate 0.02-0.03wt%, growth factor solution 1-1.2wt% (including vitamin H2-2.3wt%, vitamin B12-15wt% aqueous solution) and the rest of water, the pH value is 6.5-6.8 .

[0057] Inoculate Rhodopseudomonas palustris in the second culture medium under aseptic conditions, under the conditions of 4500-10000lx light intensity and 29°C-33°C tem...

Embodiment 2

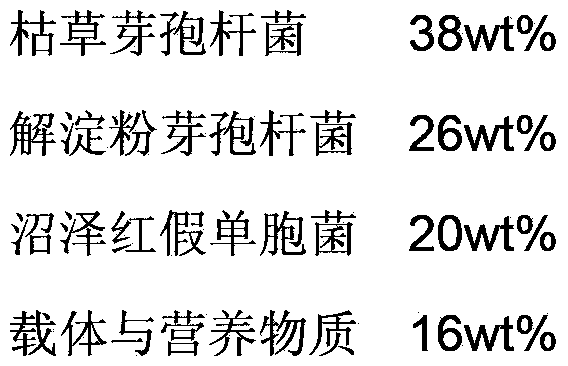

[0068] Raw material composition:

[0069]

[0070] Preparation:

[0071] step 1:

[0072] According to the method described in Example 1, the seed culture liquid of Bacillus subtilis, the seed culture liquid of Bacillus amyloliquefaciens and the seed culture liquid of Rhodopseudomonas palustris were provided.

[0073] Step 2,

[0074] According to the method described in Example 1, a high-concentration concentrated bacterial solution was obtained as a mother solution.

[0075] Step 3,

[0076] Move the concentrated bacterial liquid into the matrix composed of zeolite powder + calcium carbonate for feed + cornstarch + molasses and mix. The mixed fluid is granulated on a swing machine, and then boiled and dried. The mass percentage of moisture after drying is 5-7%.

[0077] Wherein, based on the total weight of the matrix (carrier and nutrients), the matrix is composed of 75wt% zeolite powder, 10wt% calcium carbonate, 8wt% cornstarch, and 7wt% molasses.

[0078] Step 4...

Embodiment 3

[0081] Raw material composition:

[0082]

[0083]

[0084] Preparation:

[0085] step 1:

[0086] According to the method described in Example 1, the seed culture liquid of Bacillus subtilis, the seed culture liquid of Bacillus amyloliquefaciens and the seed culture liquid of Rhodopseudomonas palustris were provided.

[0087] Step 2,

[0088] According to the method described in Example 1, a high-concentration concentrated bacterial solution was obtained as a mother solution.

[0089] Step 3,

[0090] Move the concentrated bacterial liquid into the matrix composed of zeolite powder + calcium carbonate for feed + cornstarch + molasses and mix. The mixed fluid is granulated on a swing machine, and then boiled and dried. The mass percentage of moisture after drying is 5-7%.

[0091] Wherein, based on the total weight of the matrix (carrier and nutrients), the matrix is composed of 65wt% zeolite powder, 15wt% calcium carbonate, 5wt% cornstarch and 5wt% molasses.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com