Aqueous silane treatment agent for improving metal surface protection performance

A silane treatment agent and protective performance technology, applied in the direction of metal material coating process, can solve the problems of increased cost, poor water solubility, high price, etc., to reduce biochemical oxygen consumption BOD, improve corrosion resistance, and improve corrosion resistance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

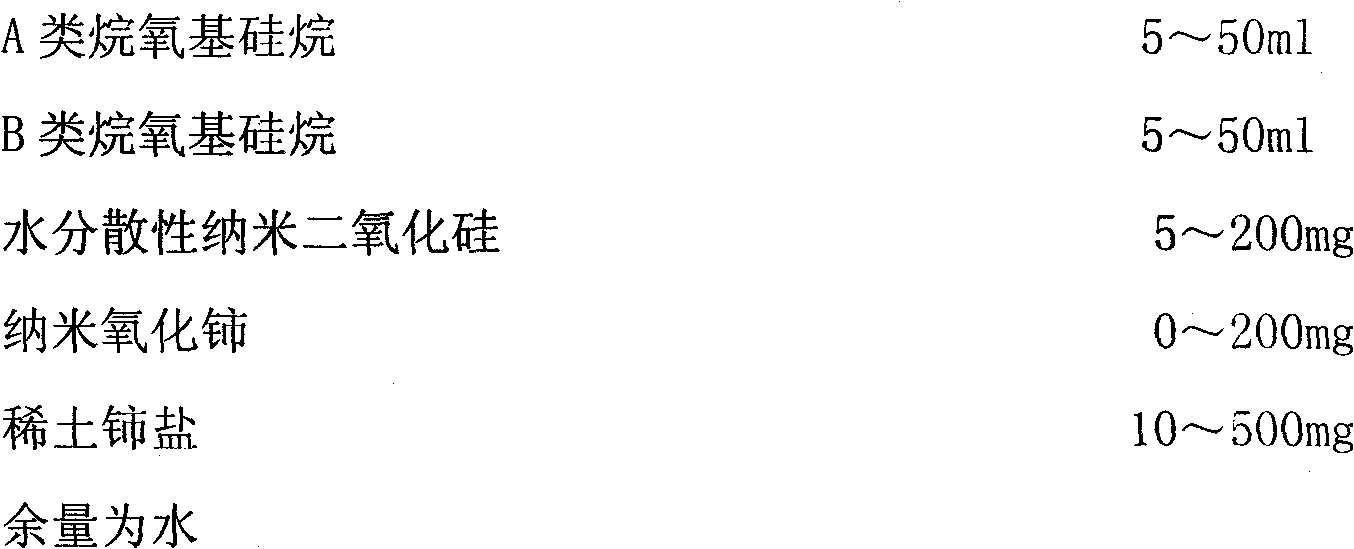

[0028] A kind of component and mass percent thereof of the aqueous silane treatment agent that improves metal surface protection performance are as follows:

[0029]

[0030]

[0031] Wherein: the volume ratio of the vinyltriacetoxysilane:bis-(trimethoxysilylpropyl)amine is 1:5.

Embodiment 2

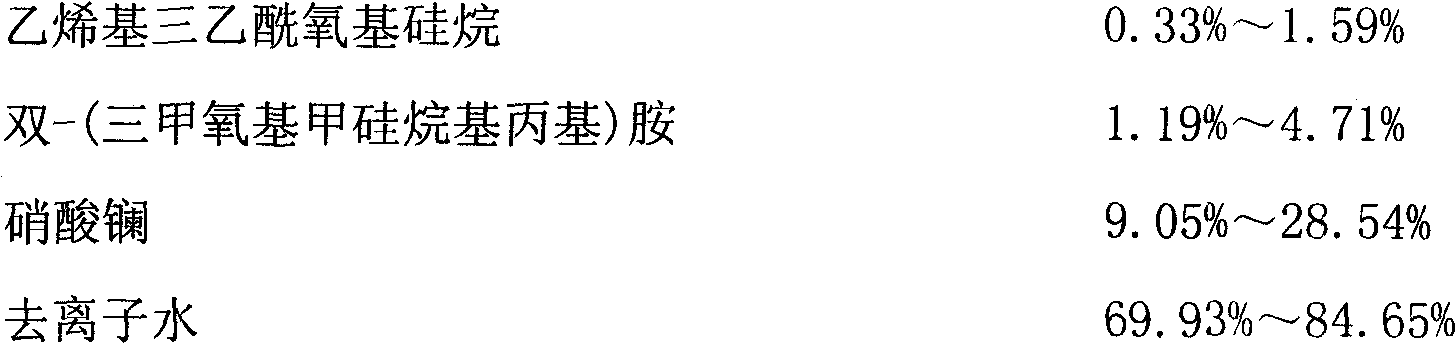

[0033] A kind of component and mass percent thereof of the aqueous silane treatment agent that improves metal surface protection performance are as follows:

[0034]

[0035] Wherein: the volume ratio of said vinyltriacetoxysilane:bis-(trimethoxysilylpropyl)amine is 1:4.

Embodiment 3

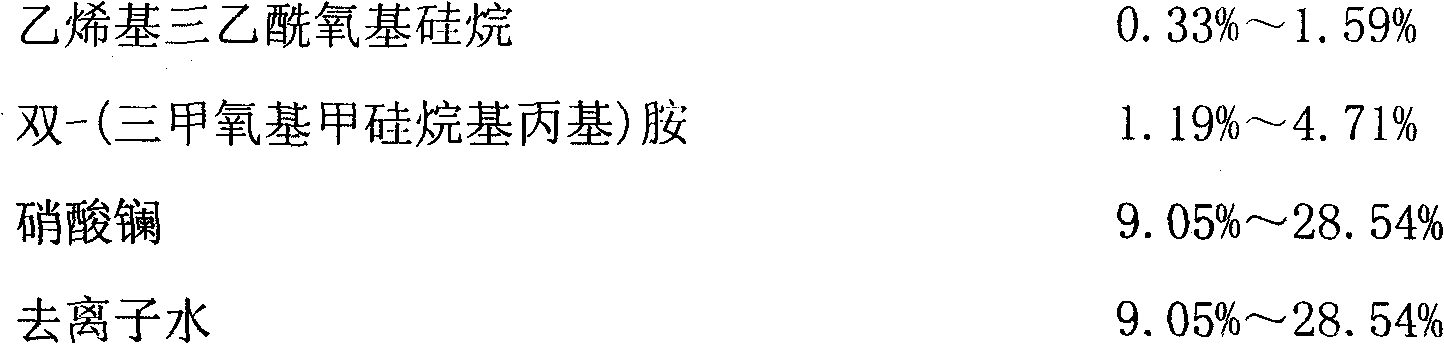

[0037] A kind of component and mass percent thereof of the aqueous silane treatment agent that improves metal surface protection performance are as follows:

[0038]

[0039] Wherein: the volume ratio of the vinyltriacetoxysilane:bis-(trimethoxysilylpropyl)amine is 1:3.33.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com