Paper mill sewage treatment agent

A sewage treatment agent and technology of paper mills, applied in water/sewage treatment, water/sludge/sewage treatment, process wastewater treatment, etc., can solve the problems of poor control effect of biodegradation, waste of resources, pollution of water resources, etc. , to achieve high sewage treatment efficiency, avoid waste of resources, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

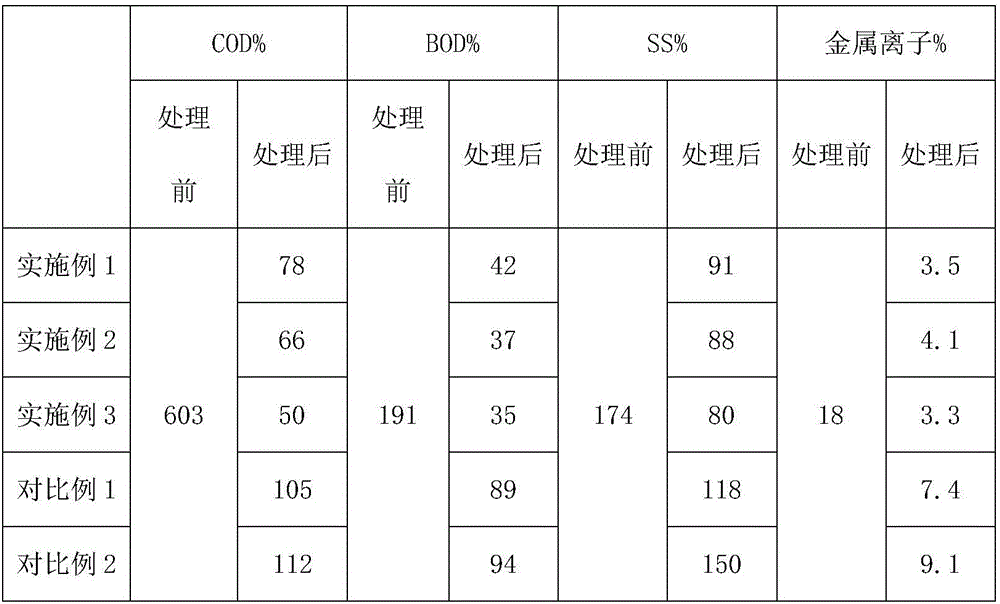

Examples

Embodiment 1

[0020] A paper mill sewage treatment agent, comprising the following raw materials in parts by weight: 40 parts of modified bagasse powder, 11 parts of polyacrylamide, 3 parts of ethyl maltol, 3 parts of green algae powder, 8 parts of humic acid, soybean meal 13 parts of powder, 11 parts of lotus leaf ash, 7 parts of ferric chloride, 15 parts of kaolin, 98 parts of water, 2 parts of salicylic acid, 1 part of potassium dihydrogen phosphate; the preparation of the modified bagasse powder: bagasse After drying 35 parts, put them into a pulverizer and grind them, sieve through 120 meshes to obtain bagasse powder, mix the bagasse powder with 4 parts of sodium carbonate and 3.5 parts of barium chloride evenly, and calcinate at 810°C for 1.5h , cooled to room temperature and ground into powder to obtain modified bagasse powder.

[0021] A preparation method of a paper mill sewage treatment agent, the specific steps are:

[0022] (1) Take each raw material according to the above form...

Embodiment 2

[0027] A paper mill sewage treatment agent, comprising the following raw materials in parts by weight: 65 parts of modified bagasse powder, 16 parts of polyacrylamide, 7 parts of ethyl maltol, 8 parts of green algae powder, 13 parts of humic acid, soybean meal 18 parts of powder, 14 parts of lotus leaf ash, 10 parts of ferric chloride, 23 parts of kaolin, 125 parts of water, 5 parts of salicylic acid, 3 parts of potassium dihydrogen phosphate; the preparation of the modified bagasse powder: bagasse After drying 45 parts, put them into a pulverizer to pulverize, sieve through a 150-mesh bagasse powder, mix the bagasse powder with 9 parts of sodium carbonate and 6 parts of barium chloride, and then calcinate at 950°C for 3 hours. After cooling to room temperature, it is ground into powder to obtain modified bagasse powder.

[0028] A preparation method of a paper mill sewage treatment agent, the specific steps are:

[0029] (1) Take each raw material according to the above form...

Embodiment 3

[0034] A paper mill sewage treatment agent, comprising the following raw materials in parts by weight: 55 parts of modified bagasse powder, 14 parts of polyacrylamide, 6 parts of ethyl maltol, 6.5 parts of green algae powder, 11 parts of humic acid, soybean meal 15.3 parts of powder, 12 parts of lotus leaf ash, 8.3 parts of ferric chloride, 18 parts of kaolin, 112 parts of water, 3 parts of salicylic acid, 2 parts of potassium dihydrogen phosphate; the preparation of the modified bagasse powder: bagasse After drying 36 parts, put them into a pulverizer and crush them, sieve through 130 meshes to obtain bagasse powder, mix the bagasse powder with 7 parts of sodium carbonate and 4.8 parts of barium chloride, and then calcinate at 864°C for 2.2 hours , cooled to room temperature and ground into powder to obtain modified bagasse powder.

[0035] A preparation method of a paper mill sewage treatment agent, the specific steps are:

[0036] (1) Take each raw material according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com