Preprocessing method of fabric printing and dyeing

A kind of fabric, medium technology, applied in the field of pretreatment of fabric printing and dyeing, can solve the problems of low gross efficiency, unfavorable, waste of energy and water purification resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

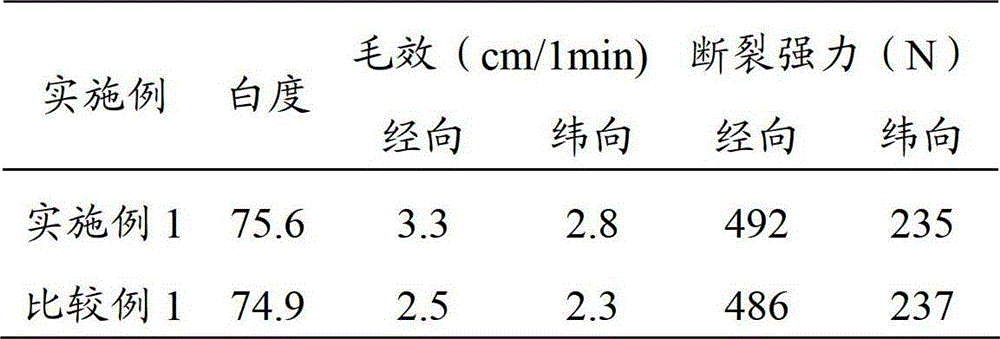

Embodiment 1

[0039] The specification is 40*40 133*72 63 " full cotton carding is turned over and seamed, then the fabric obtained is placed in the singeing treatment machine and singed. The parameters of the singeing treatment are: 100±2m / min; wind pressure is 13±1mbar; the burner is permeable (one positive and one reverse); gas pressure is 0.11±0.01Mpa; drying steam pressure is 0.10±0.05Mpa; fire extinguishing steam box pressure is 0.02±0.01 Mpa; the padding pressure is 0.3±0.05Mpa; the tension frame pressure is 0.4±0.1Mpa, so that the singeing level of the obtained fabric is grade 4 and above;

[0040] Place the obtained fabric after singeing treatment in a textile fabric plasma treatment machine model SZW-1800 for plasma treatment. The input voltage of the plasma treatment machine is set to 350V~400V, the current is set to 75A~85A, and the power is 25KW ~30KW, the frequency of the obtained plasma is 20000 Hz ~ 25000 Hz, and the vehicle speed is 30±2m / min;

[0041] The obtained plasma-...

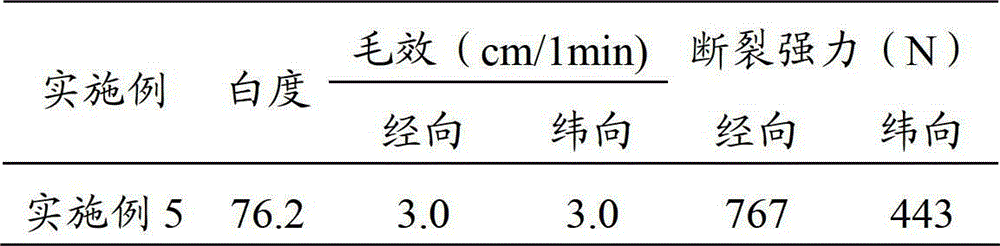

Embodiment 2

[0053] The specification is 40*40 133*72 63 " full cotton carding is turned over and seamed, then the fabric obtained is placed in the singeing treatment machine and singed. The parameters of the singeing treatment are: 100±2m / min; wind pressure is 13±1mbar; the burner is permeable (one positive and one reverse); gas pressure is 0.11±0.01Mpa; drying steam pressure is 0.10±0.05Mpa; fire extinguishing steam box pressure is 0.02±0.01 Mpa; the padding pressure is 0.3±0.05Mpa; the tension frame pressure is 0.4±0.1Mpa, so that the singeing level of the obtained fabric is grade 4 and above;

[0054] Place the obtained fabric after singeing treatment in a textile fabric plasma treatment machine model SZW-1800 for plasma treatment. The input voltage of the plasma treatment machine is set to 350V~400V, the current is set to 75A~85A, and the power is 25KW ~30KW, the frequency of the obtained plasma is 20000 Hz ~ 25000 Hz, and the vehicle speed is 30±2m / min;

[0055] The obtained plasma-...

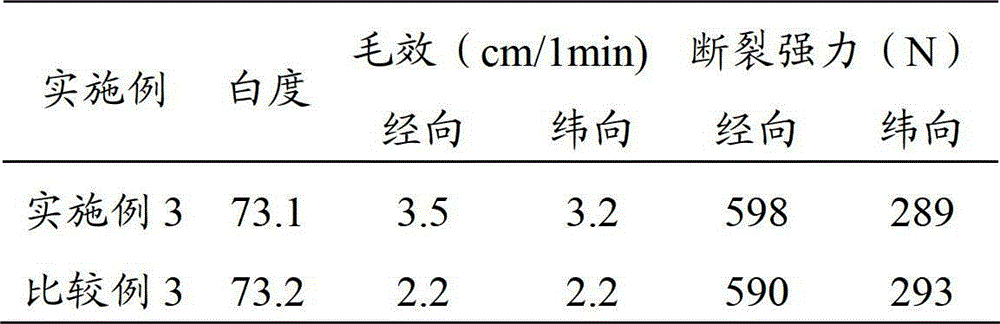

Embodiment 3

[0064] The specification is 40 * 40 110 * 90 63 " full cotton carding is turned over and stitched, then the fabric obtained is placed in the singeing treatment machine and singed. The parameters of the singeing process are: speed The air pressure is 95±2m / min; the wind pressure is 13±1mbar; the burner is permeable (one positive and one reverse); the gas pressure is 0.11±0.01Mpa; the drying steam pressure is 0.10±0.05Mpa; the pressure of the fire extinguishing steam box is 0.02± 0.01Mpa; paddle pressure is 0.3±0.05Mpa; tension frame pressure is 0.4±0.1Mpa, so that the singeing level of the obtained fabric is 4 or above;

[0065] Place the obtained fabric after singeing treatment in a textile fabric plasma treatment machine model SZW-1800 for plasma treatment. The input voltage of the plasma treatment machine is set to 350V~400V, the current is set to 75A~85A, and the power is 25KW ~30KW, the frequency of the obtained plasma is 20000 Hz ~ 25000 Hz, and the vehicle speed is 30±2m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com