Cotton fabric scouring and bleaching processes by using heavy metal ions and polyphosphates as catalyst

A technology of heavy metal ions and polyphosphate, which is applied in the field of scouring and bleaching of cotton fabrics, can solve the problems of difficult catalyst synthesis, poor product stability, and low output rate, and achieve the effects of product stability, whiteness improvement, and high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Catalyst preparation:

[0040] Catalyst A:

[0041] CuSO 4 ·5H 2 O 0.78 g

[0042] Chelating agent 30.00g

[0043] High Concentration Scouring Agent DM-1361 15.00g

[0044] NaOH 0.25g

[0045] Add deionized water to make up to 100 g.

[0046] Fabric: 18.3tex combed cotton double-sided knitted fabric (gram weight 180g / m 2 , Guangzhou Meiming Textile Co., Ltd. weaving)

[0047] Practicing and bleaching process:

[0048] Catalyst A 2.0g / L

[0049] NaOH 2.0g / L

[0050] 30%H 2 o 2 5.0-7.0g / L

[0051] The bath ratio is 1:10, the temperature is raised to 80°C at 2°C / min, the temperature is kept for 45 minutes, the liquid is drained, and the water is washed at 80°C for 10 minutes.

[0052] Wash in cold water, spin, and line dry.

Embodiment 2

[0054] Catalyst preparation:

[0055] Catalyst B:

[0056] CuSO 4 ·5H 2 O 1.56 g

[0057] Chelating agent 60.00g

[0058] NaOH 16.00g

[0059] Add deionized water to make up to 100 g.

[0060] Fabric: 18.3tex combed cotton double-sided knitted fabric (gram weight 180g / m 2, Guangzhou Meiming Textile Co., Ltd. weaving)

[0061] Practicing and bleaching process:

[0062] High concentration scouring agent 0.3g / L

[0063] Catalyst B 1.0g / L

[0064] NaOH 2.0g / L

[0065] 30%H 2 o 2 5.0-7.0g / L

[0066] The bath ratio is 1:10, the temperature is raised to 80°C at 2°C / min, the temperature is kept for 45min, the liquid is drained, the water is washed at 80°C for 10 minutes, washed in cold water, dehydrated, and dried in the air.

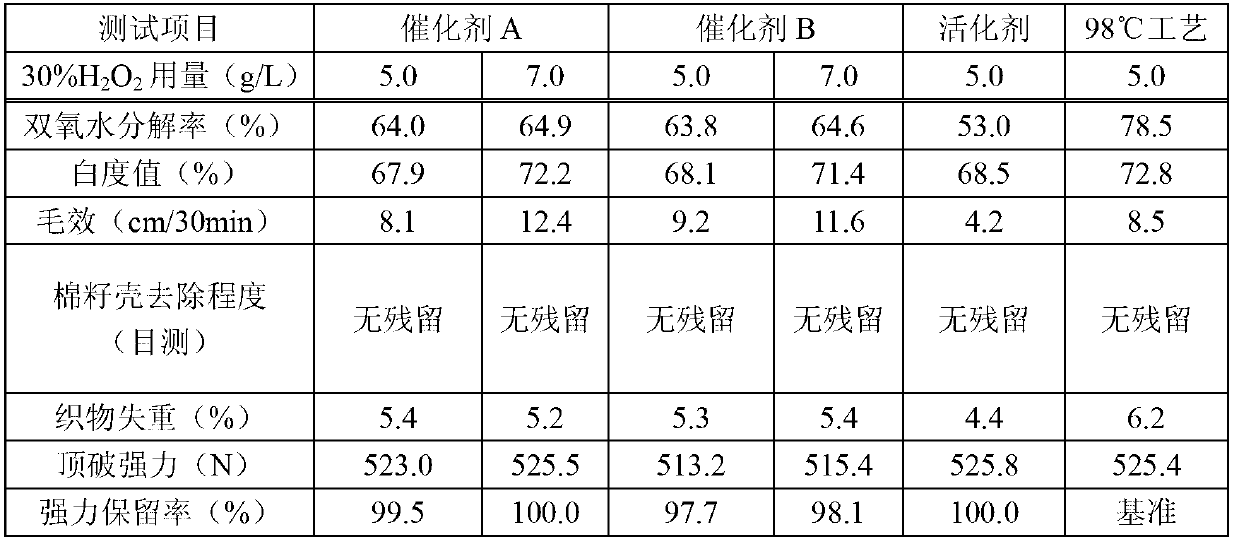

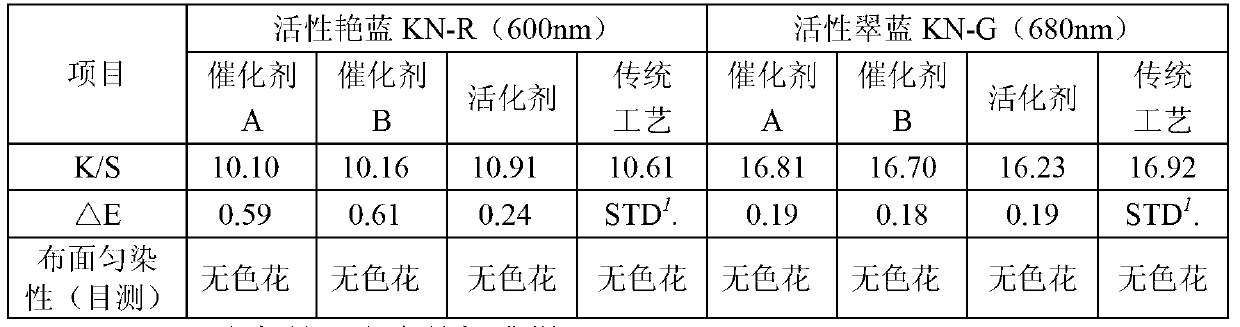

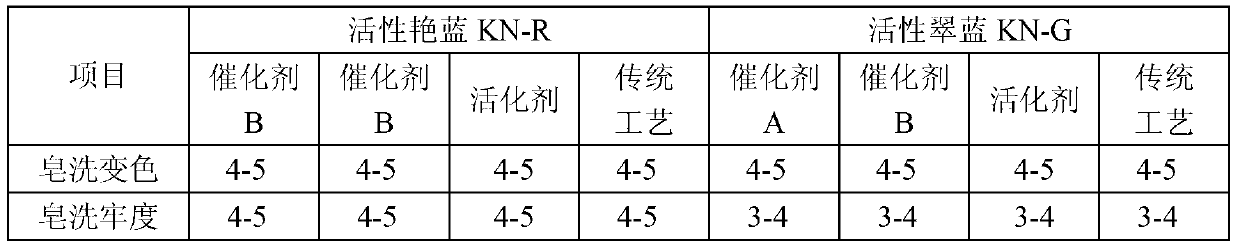

[0067] Comparative embodiment and effect:

[0068] Below by the comparative experiment of the present invention and high-temperature scouring and bleaching, activator scouring and bleaching process, and the effect after dyeing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com