Patents

Literature

235results about "Mercerising" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

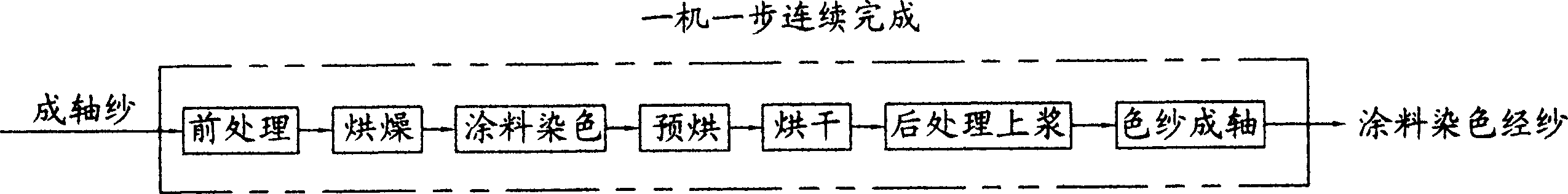

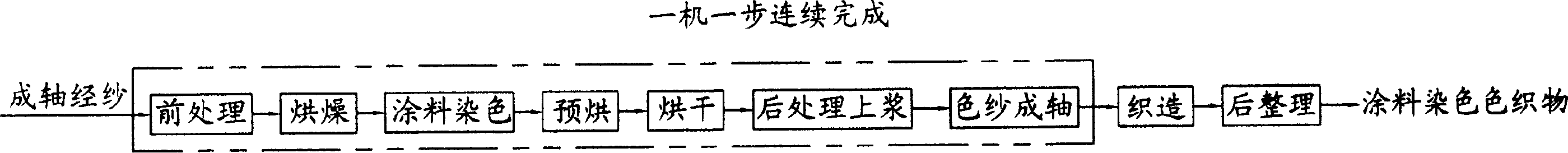

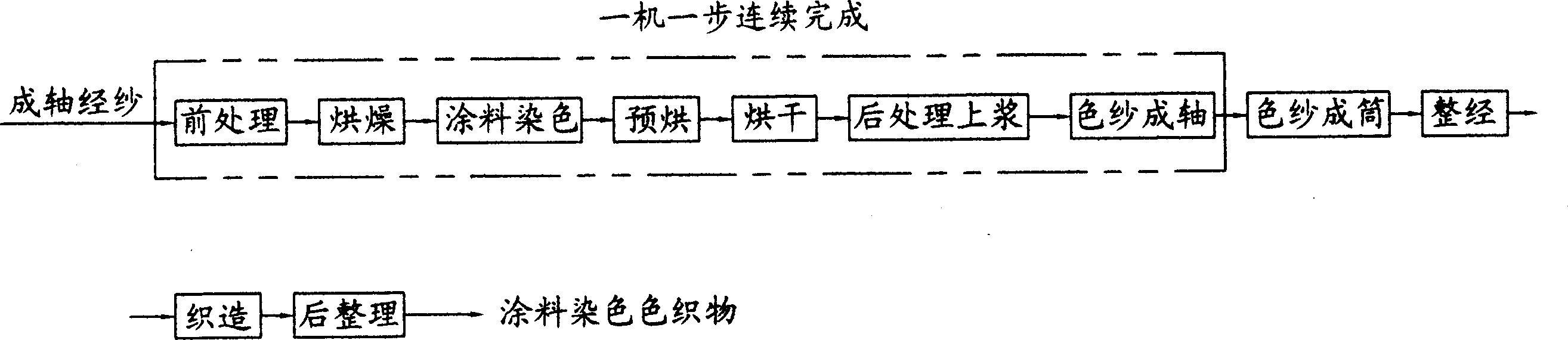

Pigment dyed colored cloth production method

InactiveCN1884659AQuality improvementGood processing depthSucessive textile treatmentsSingeingSewageEnergy consumption

The invention discloses a manufacturing method of paint dyeing weaver with oxford textile, chambray and denim, which comprises the following steps: predisposing warp; drying; dyeing; predrying; drying; after-treating; shafting warp; weaving; dressing; finishing one step by one machine continually. The invention satisfies large batch and scale manufacturing request, which is fit for producing original paint dyeing and other pain dyeing weaver product.

Owner:常州市森容纺织品有限公司

Method for dyeing and finishing pure-cotton high-count high-density fabric

ActiveCN101532230AReduce trafficEmission reductionTextile storage in superimposed formSingeingHigh densityMoisture absorption

The invention discloses a method for dyeing and finishing pure-cotton high-count high-density fabric, which includes steps of singeing, cold dome, desizing and boiling-off, bleaching, mercerization, dyeing, moisture absorption and breath, no-iron sorting, tentering, pre-shrinking and packaging. The fabric dyed and finished by the present invention has advantages of high rebound, moisture absorption and breath, crease-resistance and soft feel.

Owner:SUNTEX

Process for making anti-infrared multifunctional camouflaged color cloth

InactiveCN101397708AShort production processHue once goodFibre treatmentSingeingFiberTextile printer

The invention relates to a textile printing and dyeing technique, in particular to a manufacturing technique of an infrared ray resistant multi-functional camouflage fabric. The technique flow is as follows: original cloth seaming, singeing, old rolling, 180 pre-treatment, shaping, mercerizing, ground dyeing, pattern printing, baking, aging, stentering of post treatment, examination and acceptance; wherein, the ground dyeing flow is as follows: padding liquor, two groups of infrared rays and drying; a formula adopted in the ground dyeing flow comprises 2g / l to 10g / l of dispersion dyes, 5g / l to 15g / l of vat dyes and 0.01g / l to 1.0g / l of infrared ray resistant regulators; the formula of pattern printing is as follows: 2kg to 15.7kg of dispersion material, 2. kg / l to 10.5kg / l of vat material and 0.01kg to 2.5kg of infrared ray resistant regulators; post treatment has the function compatibility of multiple functions which are water proofing, oil repellence, ventilation, crease resistance and static resistance. The technique has the advantages of having short production procedure, color phase with good uniformity, stable infrared reflectivity, low cost, multiple functions, mainly using environment friendly dyes and being suitable for infrared ray resistant camouflage fabric products with different fibers and different specifications.

Owner:XIANYANG JIHUA NEW 30 DYEING & PRINTING

Processing method for low-elastic non-ironing knitted face fabric

InactiveCN101200852AShrunkGood color retentionWeft knittingBiochemical fibre treatmentAmmoniaComputer science

The present invention discloses a processing method of a low-elasticity, wrinkle-free knitted fabric, which includes steps: greige cloth weaving, boiling and bleaching, bio-enzyme washing, dyeing, softening, dehydration, scutching, drying, shaping and preshrinking. The present invention is characterized in that the processing steps of pre-relaxation and ammonia mercerization are added before boiling and bleaching, so that the whole processing steps are changed as greige cloth weaving, pre-relaxation, ammonia mercerization, boiling and bleaching, bio-enzyme washing, dyeing, softening, dehydration, scutching, drying, shaping and preshrinking; the pre-relaxation processing is to add refining agent of 0.5 to 1.5g / L, the processing temperature is between 90 and 130 DEG C, and the processing period is twenty to sixty minutes; in the step of ammonia mercerization, the pre-relaxed fabric receives the processing of ammonia mercerization in an ammonia mercerizing machine at the speed of 15 to 50m / min. The present invention ensures that the cotton and the blended elastic knitted fabric can have soft, smooth handfeel and high washing resistance and shape-keeping property.

Owner:浙江盛泰服装集团股份有限公司

Woven monofilament and production method

InactiveCN101440542AWith ultra-thinSoft and breathableSingeingHeating/cooling textile fabricsYarnEngineering

The invention discloses a monofilament fabric and a method for producing the same, wherein warp yarn forming the fabric is a monofilament. The method comprises the following steps: a preparing process before weaving, weaving, dyeing and finishing processes, wherein the preparing process comprises warping, rebeaming, drafting and healding processes; and the dyeing and finishing process comprises gray cloth forming, refining, intermediate forming, decrement, dyeing, functional resin finishing, and finishing forming. The fabric has the characteristics of lightness, ultra-thinness, softness, air permeability and the like, and is applicable to various styles of fashionable clothes.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Antifouling, water-proof and non-ironing post finishing method for woven plus material

ActiveCN101122082AEasy to decontaminateImprove waterproof performanceSucessive textile treatmentsSingeingEngineeringStain

A stain proof, water proof and non-iron post-management method for textile fabrics relates to a post-management technology for textile fabrics, in particular to a stain proof, water proof and non-iron post-management processing technology. The method includes singeing, desizing, mercerizing, first setting, batching, neutralizing and water washing, second setting, baking and shrinking. The one-stop textile special post-management processing technology of ''Moist-cure+ stain easily removable+ refreshing+ three proofs'' can provide the cotton fabrics surface material with stain easily removable, refreshing, water proof, oil proof, stain proof and iron free functions at the same time, which greatly improves the service performance of the surface material, and better meets the demand of the consumers.

Owner:JIANGSU LIANFA TEXTILE

Water-soluble hot melt lining cloth and production method thereof

ActiveCN101353843AEasy to operateGood water solubilityFibre treatmentLiquid/gas/vapor removalInterliningMetallurgy

The invention discloses a water-soluble fusible interlining which is characterized in that longitudinal shrinkage and latitudinal shrinkage of the cotton interlining are less than or equal to one percent respectively and the formaldehyde emission is less than or equal to 50mg / kg. After the interlining is joined with a fabric by ironing, the interlining is treated in the water at the temperature of 35 DEG C for 15 seconds and separated with the fabric. The water-soluble fusible interlining has good water-soluble performance, low longitudinal shrinkage and latitudinal shrinkage, good environmental protection performance and easy operation of the production method.

Owner:曹平

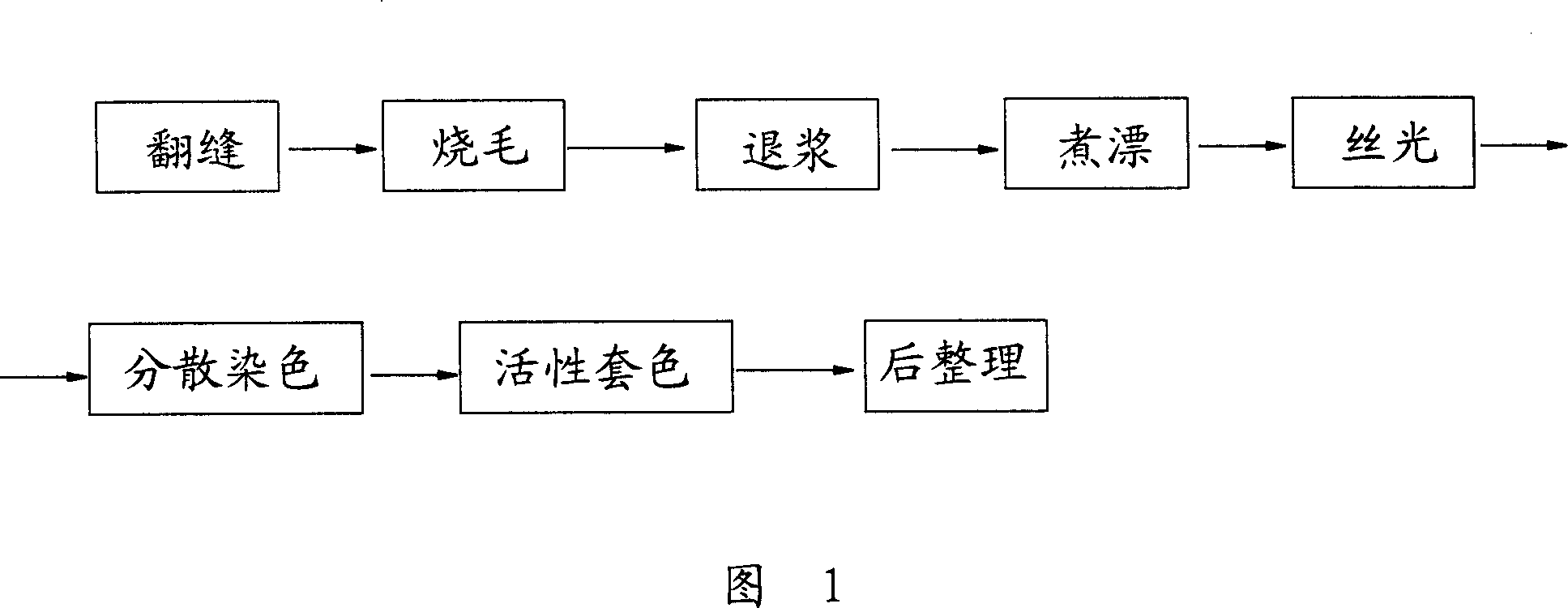

Dyeing technique for polylactic acid fabric/cotton blended shuttle weaving

InactiveCN101082154AHigh color fastnessBright colorMercerisingDyeing processDisperse dyeTextile dyeing

The process of dyeing woven polylactic acid fiber / cotton blended fabric belongs to the field of textile dyeing technology. The process of dyeing woven polylactic acid fiber / cotton blended fabric has China produced disperse dye and assistant adopted and improved steps of desizing, boiling and rinsing, mercerizing and dyeing. The dyed product has bright colors, proper shade and high color fastness. The present invention is suitable for industrial production.

Owner:SHANDONG UNIV OF TECH

Ultra-low shrinkage rate purified cotton lining cloth and production method thereof

The invention discloses a purified cotton interlining with an ultra-low shrinkage, and a production method thereof. Longitudinal shrinkage and latitudinal shrinkage of the cotton interlining are less than or equal to 0.8 percent respectively and the formaldehyde emission is less than or equal to 50mg / kg. The production method thereof sequentially comprises the steps of sewing, singeing, bleaching, mercerizing, re-bleaching, drying, dyeing, post-processing, shrink-proof finishing and powder point coating. The cotton interlining the invention has low longitudinal shrinkage and latitudinal shrinkage, good environmental protection performance and easy operation of the production method.

Owner:曹平

Ordering method for pure cotton fabric weftwise elasticity

The invention provides a method for conditioning latitudinal elastic force of pure cotton fabric, in particular to a method for processing a pure cotton elastic weft fabric without adding elastic fibers such as spandex, which sequentially comprises the following steps of: weaving grey fabrics, singeing and desizing, mercerizing with caustic soda, stentering and setting and pre-shrinking. The method is characterized in that a pure cotton yarn or a wrapped yarn including pure cotton and water-soluble polyvinyl alcohol fiber are adopted in the weft in the grey fabric weaving procedure; the mercerizing procedure adopts 20 to 30% caustic soda solution; a fabric expanding device is adopted for keeping 80 to 100% the breadth of the fabric after the singeing and desizing procedure; and the fabric expanding device is adopted in the stentering and setting procedure to keep the 100 to 102% the breadth of the fabric after the mercerizing procedure, thereby ensuring the elasticity of the fabric. The process fabric has soft handle, good moisture absorption and permeability, and good elasticity within 15 to 25%. Clothes made from the fabrics are comfortable and natural, and can maintain good flat state and elasticity after washing and drying.

Owner:LUTAI TEXTILE

Processing method for cotton/hemp blended knitted fabric

InactiveCN101200845AEliminate internal stressReduce heavy metal contentWeft knittingBiochemical fibre treatmentYarnBoiling process

The invention discloses a processing method of cotton / ramie blended knitting fabric which adopts processing equipment of a cotton mill and adds yarn boiling and demineralizing processes before a weaving process. The whole technological process is from yarn boiling, demineralizing, weaving, mercerizing, bleaching and boiling, biological enzyme washing, and dyeing, softening, dehydration, width opening, drying and setting to preshrinking. The yarn boiling temperature in the yarn boiling process is 80 to 130 DEG C and the time is 10-30m. The demineralizing temperature in the demineralizing process is 30 to 90 DEG C and the time is 10-30m. In the demineralizing treatment, acid demineralizing agent and refining agent are used to remove heavy metal ions in cotton / ramie blended yarn. The invention has the advantages of ensuring the neat surface of the knitting fabric, comfort handle, light shrinkage and distortion and good durability with the added yarn boiling and demineralizing processes, eliminating the internal stress of the cotton / ramie blended yarn through the yarn boiling process, improving the toughness and the weaving efficiency of the knitting fabric, improving the insurance coefficient of the boiling and bleaching process through the demineralizing process and providing a guarantee for the strength of the knitting fabric.

Owner:宁波雅戈尔日中纺织印染有限公司

Dyeing and finishing process of polyolefin elastic fiber fabric coated by polyester cotton filling yarn

InactiveCN101392444AImprove breathabilityGood hygroscopicityBiochemical fibre treatmentSingeingFiberPolyester

The invention provides a dyeing and finishing technology for using polyester cotton warp and weft yarn to warp a polyolefin elastic fiber fabric, and belongs to a processing technology of an elastic fabric. The technology sequentially includes the following steps: turning and sewing of the cloth, shrinking, singeing, desizing, mercerizing, setting, dyeing, after finishing and pre-shrinkage. The dyeing and finishing technology decreases the density of the warp and weft direction during the preliminary treatment before the dyeing of the fabric, and leads the cloth easier to retract, and the width is sufficiently shrunk after the shrinkage, desizing and mercerization process, thus obtaining the cloth has good elastic effect and soft feeling. Compared with the prior art, the fabric has good tensile recovery property, stable and lower washing shrinkage and high temperature resistance, strong acid resistance and strong alkaline resistance, which is favorable for various professional finishing; therefore, the soft dacron-cotton warp and weft elastic fabric with high elasticity, good air permeability and strong moisture absorption property can be obtained.

Owner:HUAFANG

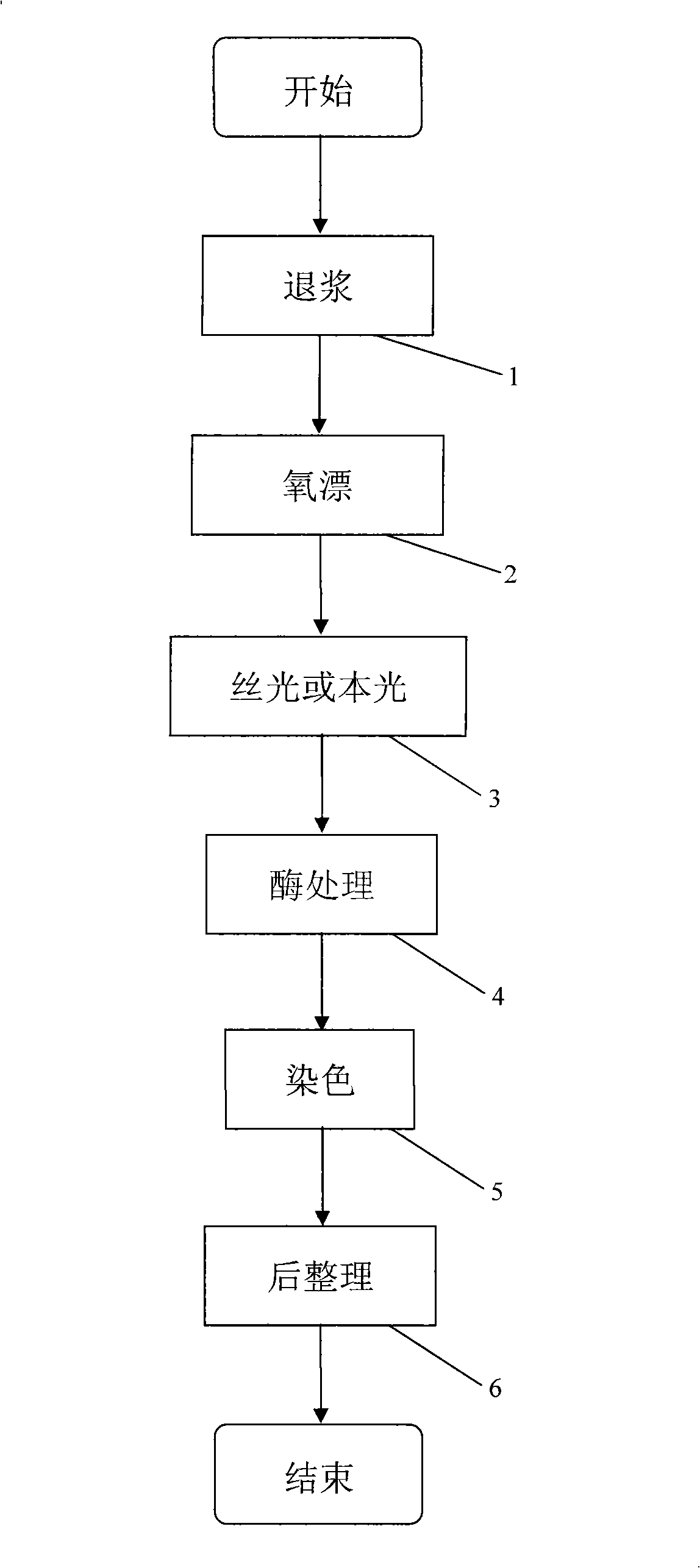

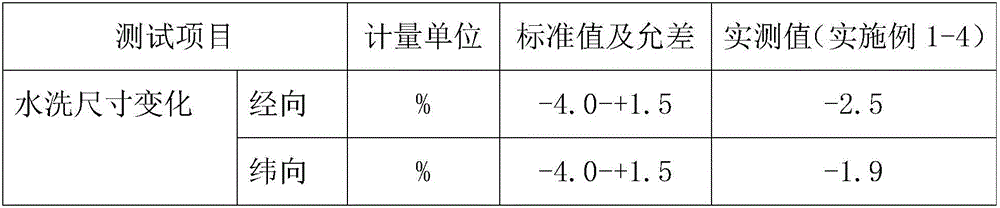

All-cotton fabric imitated tencel treating process

InactiveCN101338502AImprove applicabilitySimple processBiochemical fibre treatmentLiquid/gas/vapor removalFiberHigh density

The present invention discloses a cotton fabric tencel-like treatment process, which sequentially comprises the procedures as follows: desizing, oxide bleaching, mercerizing, enzyme treatment, dyeing, after-classification and other procedures. The present invention carries out the tencel-like treatment for cotton fabrics and increases the adaptability of cotton fabrics, so that the high-count and high-density poplin fabrics feels smooth and wears comfortable and permeable after the treatment. The tencel-like treatment for cotton fabrics is simple and the cost is low. In addition, the raw material for cotton fabrics is easily obtained and the tencel-like treatment increases the added value of the product. Through the tencel-like treatment, the price of the cotton fabrics is low and thus ordinary people can enjoy soft hand feeling, elegance, comfort and permeability of the tencel fiber.

Owner:浙江誉华集团湖州印染有限公司

Heavy-twisted stranded elastic pure-cotton jacquard shell fabric and processing process thereof

InactiveCN102560812AGood moisture absorption and air permeabilityHigh resilienceFabric breaking/softeningSingeingEngineeringMoisture absorption

The invention discloses a heavy-twisted stranded elastic pure-cotton jacquard shell fabric, which comprises warps and wefts according to the proportion of 1:1, wherein the warps are JC5.8texX2 high-count stranded heavy-twister yarns, and the wefts are JC / S5.8tex / 5.8tex / 30D(denier) core spun yarns and JC5.8texX2. The fabric weaving structure is the small plain-weave jacquard structure. Special treatment methods are utilized in the steps of slashing, weaving, dyeing and finishing. The heavy-twisted stranded elastic pure-cotton jacquard shell fabric has the characteristics of fine moisture absorption and air permeability of pure cotton while having high elasticity, luster and smoothness, stiffness and high suspension effect, and is applicable to spring and summer clothing due to natural crinkling effect and cambric styles thereof. Besides, the heavy-twisted stranded elastic pure-cotton jacquard shell fabric which is popularized is development from single-yarn heavy twist to heavy strand twist and is the extension from singular plain weaves to jacquard varieties. By the special treatment method utilized in the processing process, quality and grade of the heavy-twisted stranded elastic pure-cotton jacquard shell fabric are improved evidently, and the breakthrough in research and development and process of the heavy-twisted stranded elastic pure-cotton jacquard shell fabric provides reference for development of high-end and individual spinning fabric and guidance for expanding the market.

Owner:TIANJIN TIANFANG INVESTMENT HLDG

Cold dyeing process for cellulose fiber fabric

InactiveCN101864648AReduce usageEasy to handleTextile storage in superimposed formSingeingSmall sampleCellulose fiber

The invention provides a cold dyeing process for a cellulose fiber fabric. The process comprises the following steps of: a, pre-treating a fiber fabric; b, preparing mixed alkali liquid and dye solution respectively; b, pumping the mixed alkali liquid and the dye solution into a chassis by using a proportioning pump to perform mixing so as to obtain dye solution; d, soaking the fiber fabric into the chassis to pad the dye solution; e, curling the padded fiber fabric; f, heaping and color-fixing the curled fiber fabric; and g, after heaping, finishing dyeing by washing, soaping, washing, drying, tentering and finishing. The cold dyeing process has the advantages that: dyeing can be finished at normal temperature without a vapor-solid process; washing and post finishing can be performed, and the energy consumption is low; and the dye solution contains a little chemical auxiliary agent, and is favorable for sewage treatment. Compared with long rolling and dyeing, the cold dyeing process has greater advantages that the dyeing production is performed by adjusting directly based on a small sample formula without trying a large sample, the one-time success rate is high, and the sample cost is reduced.

Owner:HUAFANG

Single-face dyeing method for woven fabric

InactiveCN101200858AReduce dosageEasy emissionsSingeingHeating/cooling textile fabricsTextile printerEngineering

A single-side dyeing method of woven fabrics belongs to the novel technical field of textile printing and dyeing. The single-side dyeing method of woven fabrics includes three steps; firstly, pure cotton, tencel and an elastic woven fabric are preprocessed, including the turnover sewing of greige cloth, singeing, desizing, boiling-off, bleaching, mercerization, etc., secondly, the full-width single-side dying of the woven fabric is to coat color sizing A on the woven fabric by a coating machine, and then high-temperature hot-air stentering, oxygenation, soaping, water washing, drying and cropping are carried out; finally, color sizing B is coated on the woven fabric by the coating machine, and high-temperature hot-air stentering and cropping are carried out. The technology realizes the fashion of the fabrics of jeans, leisure clothes and children dresses and has obvious ecological function; the technology also resolves the technical problem that a coating-shaping combination machine can carry out the single-side dyeing of fabrics by using sulfide colours, paints, etc., meanwhile, compared with the conventional techniques of vat dye, reactive dye, etc., the technology saves water, gas and electricity and reduces the discharge of a great deal of dyeing sewage. The side of the single-side dyed fabric, which touches the skin of the body, does not contain dyestuff and auxiliaries, thus having the characteristics of ecological and environmental protection.

Owner:SHANXI CAIJIA PRINTING & DYEING

High grade three-mercerization pure cotton fabric

The invention relates to high grade three-mercerized purified cotton face fabric. The face fabric is fabric knitted used mercerized cotton yarn as raw material. Then it is processed mercerized cotton, two times calender finish, and resin finishing. The invention is optimization product of purified cotton double- mercerized cloth, and has better smooth finish, surface lines, feel, and color matching of main body and auxiliary materials. The fabric surface gloss will not disappear after many times family washing.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

High-grad mercerized rapid-drying cotton-terylene fabric

InactiveCN1776057AImprove moisture absorption and quick drying effectImprove parallel straightnessWeft knittingBiochemical fibre treatmentYarnPolyester

A mercerizing quick drying cotton-polyester face fabric, which is a single side fabric with double layer structure adopting compact cotton yarn as face yarn and ultrafine polyester as base yarn through process of mercerizing, biological enzyme, resin and moisture absorption quick drying finishing. Said face fabric can be used in making both sports dress and office dress.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Grey cloth cold batch mercerizing process method for cotton and cotton blended fabric

ActiveCN101858020AAvoid spendingReduce consumptionTextile storage in wounded formSingeingWastewaterEngineering

The invention provides a grey cloth cold batch mercerizing process method for cotton and cotton blended fabric, which belongs to a dyeing and finishing pretreatment process for cotton and cotton blended fabric. The process method comprises processes of singeing, alkali padding, rolling, reverse rolling and heaping, washing, oxygen bleaching, weft finishing and tentering; in the alkali padding process, alkali liquor is padded by using a padding liquor roller, the NaOH content of the alkali liquor in an alkali liquor tank is 160 to 180 grams per liter, the balance is water, and the alkali liquor in the alkali liquor tank is circulated by using a circulating pump; in the washing process, counter current washing is performed in a de-sizing machine by using 90 to 95 DEG C hot water, the speed is 48 to 52 meters per minute, and the cloth falls with tide; and in the oxygen bleaching process, the speed is 45 minutes per minute, the temperature in a track-type steam box is between 96 and 99 DEG C, and the heaping is performed for 45 minutes. The mercerizing process method combines the mercerizing process and the de-sizing process into a one-step process so as to shorten the process flow, reduce the steam consumption, relatively reduce the consumed caustic soda quantity and save the wastewater treatment expense.

Owner:YUYUE HOME TEXTILE

Method for finishing cotton-nylon elastic woven fabrics

InactiveCN101845735AImprove color vibrancyWrinkle freeTextile storage in superimposed formFibre treatmentEngineeringAmmonia

The invention provides a method for finishing cotton-nylon elastic woven fabrics, and the process flow comprises singeing, desizing, mercerizing, dry setting and preshrinking, which is characterized in that a step of cold batching yarding is added between the steps of singeing and desizing, and the steps of liquefying ammonia and pre-tendering are added between the steps of mercerizing and dry setting, therefore the whole process flow is as follows: singeing, cold batching yarding, desizing, mercerizing, liquefying ammonia, pre-tendering, dry forming and preshrinking. The invention has scientific and easily-operated process, compared with conventional cotton-nylon elastic woven fabrics, the cotton-nylon elastic woven fabrics obtained by the invention has better gloss, greatly improved fabric color brightness, no fold and turned edge on surface fabric, uniform fabric width, good tendering and setting effects, favorable elasticity up to 20-30% and the first-rate product rate above 99%, can further perfect the stability of product quality and satisfies high quality requirement on top grade fabrics.

Owner:LUTAI TEXTILE

Dyeing and finishing method for cotton-Dacron blended fabric

The invention discloses a dyeing and finishing method for a cotton-Dacron blended fabric. The method is characterized by comprising the following steps: (S1) carrying out pretreatment, (S2) carrying out dyeing, (S3) carrying out softening and non-shrink, and (S4) sizing, wherein the pretreatment step comprises the steps of sequentially carrying out cold composting, oxygen bleaching and mercerization, and the dyeing step adopts a disperse dye and reactive dye dispersed bath-method for dyeing. In addition, according to the dyeing and finishing method for the cotton-Dacron blended fabric, disclosed by the invention, the method is simple, energy-saving and low-consumption, the dyeing is uniform, the color fastness is high, the color and luster are plump, and the hand feeling is soft.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

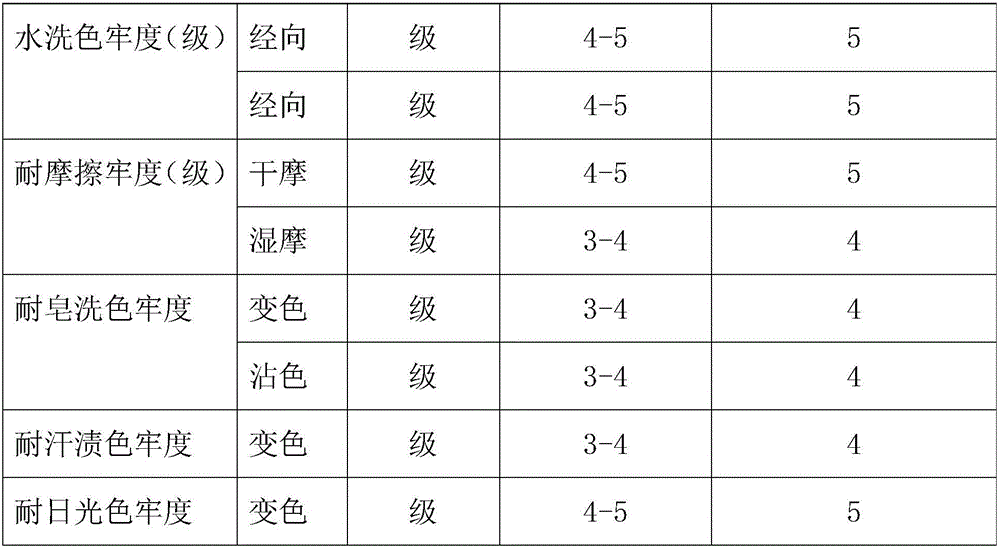

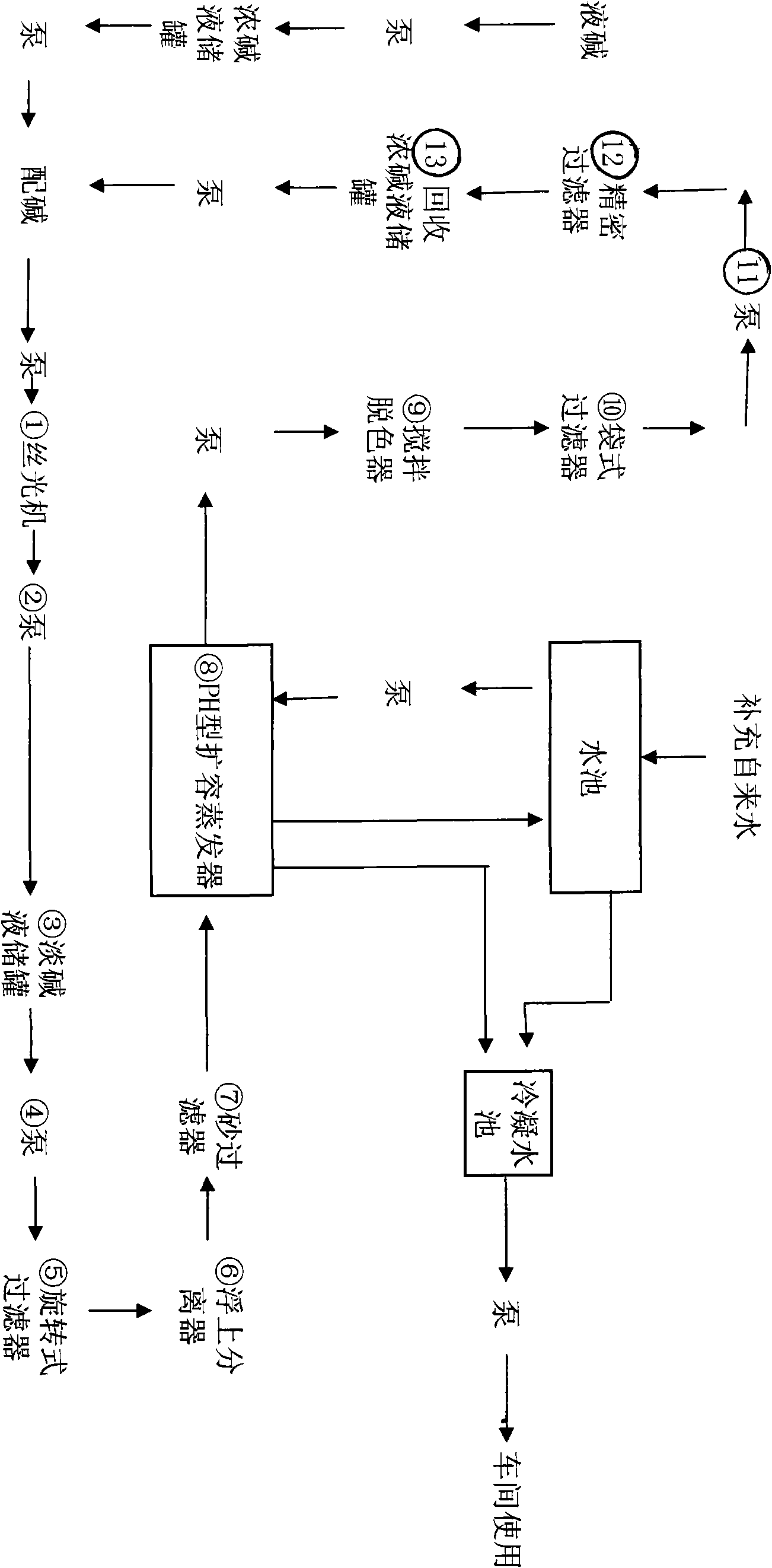

Alkali recovery device of jean mercerizing process weak alkali liquor

InactiveCN101585618ALow impurity contentReduce chromaTextile treatment machine partsMercerisingWater useProcess engineering

The invention discloses an alkali recovery device of jean mercerizing process weak alkali liquor, includes a process weak alkali liquor tank (3), a weak alkali liquor transfer pump (4), a rotary filter (5), a floating separator (6), a sand filter (7), a flash evaporator (8), a stirring decloring device (9), a bag-type filter (10), a precision filter (12) and strong alkali liquor recovery tank (13) arranged in sequence. The invention is provided with characteristics of reasonable structure, compact device distribution, high steam-water ratio, small steam consmption; small impurity content in processed alkali solution, low chroma, and the recovered alkali can be used repeatly and directly; water used are all recycling used without discharge with safe environmental protection and high production efficiency.

Owner:俞国兴

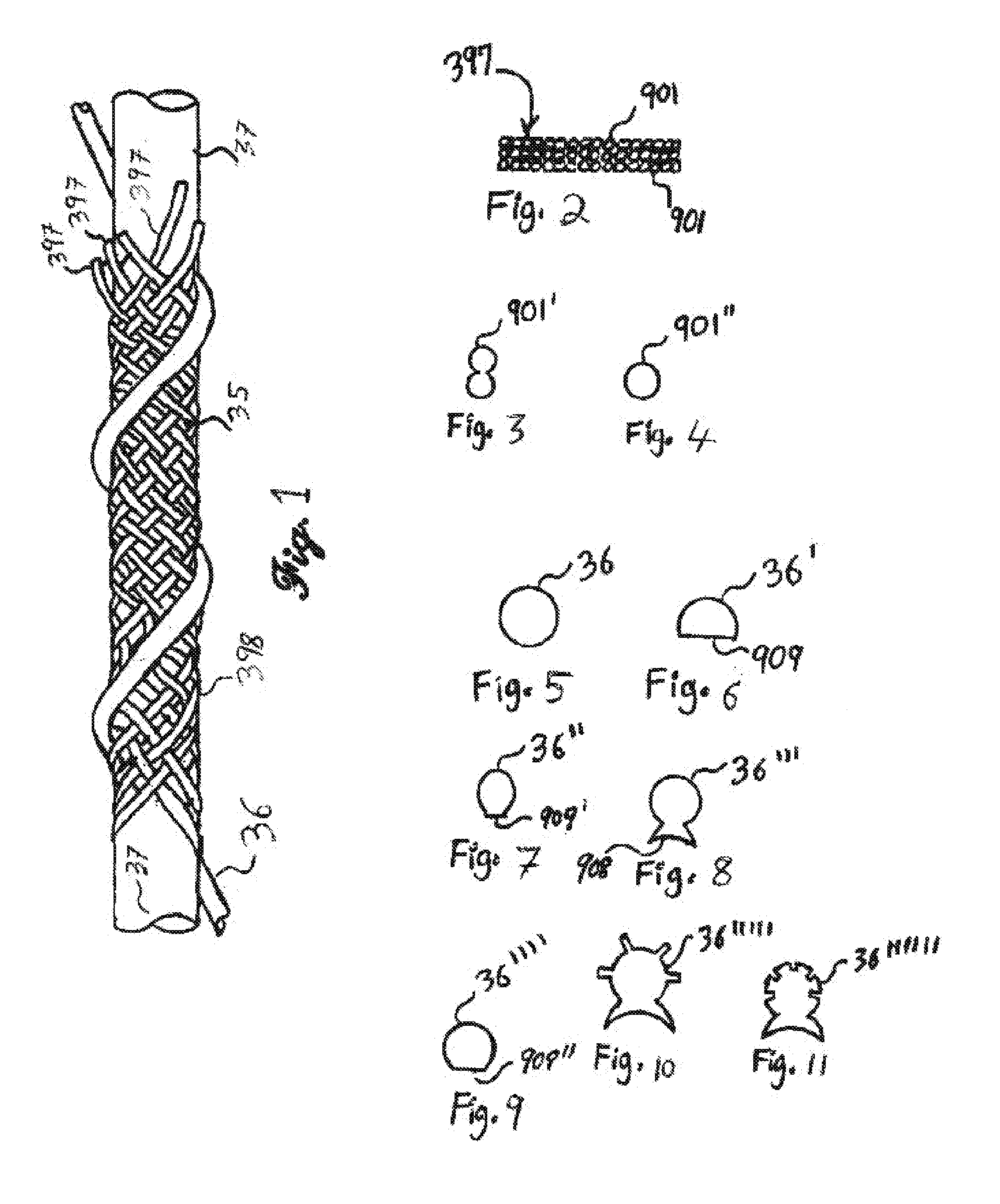

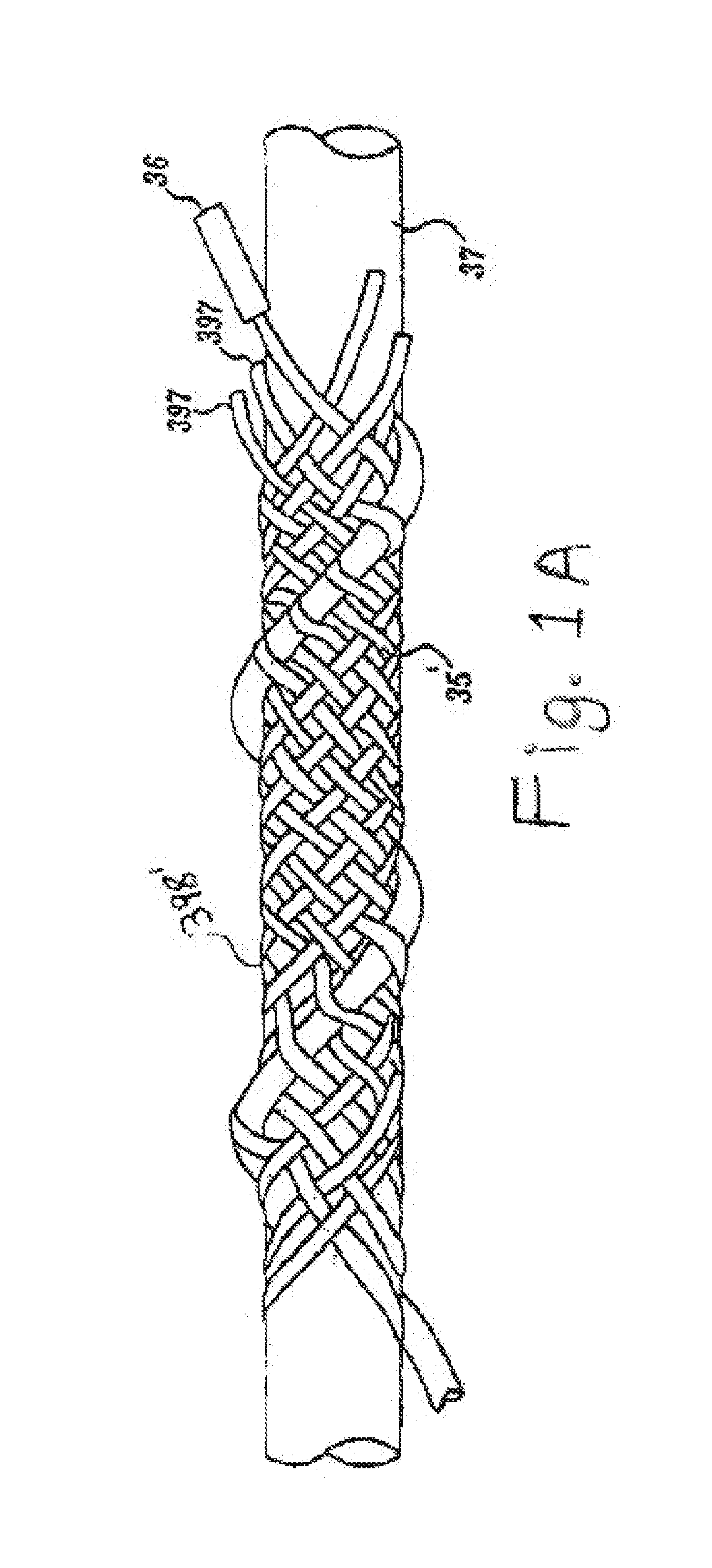

Lower drag helix rope for pelagic trawls and methods

InactiveUS20120118131A1High strengthAgriculture tools and machinesFishing netsEngineeringSeismic line

A method for forming a helix rope for a trawl comprising the steps of: a) situating upon a portion of a rope a bead of a substance being selected from a group consisting of: (i) a liquid substance; and (ii) a semi-liquid substance. A helix rope (35) for forming portions of a pelagic trawl, the helix rope comprising a braided sheath (398) formed of greater than sixteen strands (397), whereby drag is reduced. A method for forming a high strength synthetic rope useful for towing warps, trawler warps, yachting ropes, mooring lines, anchoring lines, oil derrick anchoring lines, seismic lines, paravane lines, and any other uses for rope, cable or chain.

Owner:HAMPIDJAN

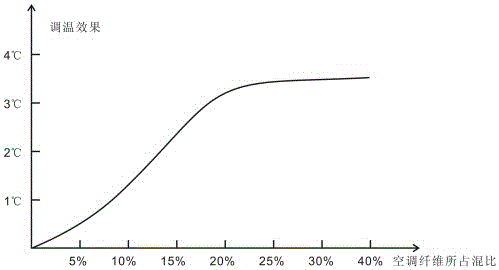

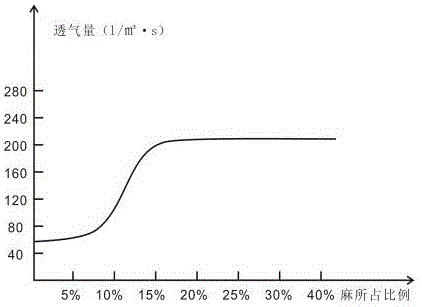

Ramie fiber, air conditioning fiber, tencel fiber and polyester fiber blended thermoregulation fabric and manufacturing method thereof

ActiveCN106222840ARetain functionalityImprove antibacterial propertiesSingeingProtective fabricsYarnPolyester

The invention discloses ramie fiber, air conditioning fiber, tencel fiber and polyester fiber blended thermoregulation fabric which comprises blended yarns formed by blending ramie fiber, air conditioning fiber, tencel fiber and polyester fiber. The blended yarns are connected by means of tatting. Excellent wearability of each fiber is retained and given into play, even wearability like thermoregulation effect, wool-like effect, breathability, hygroscopicity and tearing and marking performance is better improved when compared with single-fiber fabric, functional advantages of the ramie fiber are retained, and the blended thermoregulation fabric has good antibacterial function, uvioresistant performance and antistatic performance. The invention further discloses a manufacturing method of the blended thermoregulation fiber. Hand feel and wool-like effect of the fabric are improved.

Owner:湖南华升服饰股份有限公司

Production process of cotton leno yarn dyed fabric

The invention discloses a production process of a cotton leno yarn-dyed fabric with good comfort and air permeability, soft feeling, and excellent water absorbability and wet permeability. The production process comprises the following steps: cotton yarn bleaching - dyeing - warping - sizing - weaving - grey cloth reconditioning - singeing -desizing - mercerizing - forming -pre-shrinking. The production process is characterized in that: in the weaving process: (1) pressurization and letoff are performed on a hollow part by a small shaft; (2) a doup release device is adopted to ensure the tension of the small shaft part to be the same as that of the upper yarn and the lower yarn of ground weave when doup warps fully open, and the warp end release amount is controlled at 2.5-3cm; (3) doup yarns are 0.5-1.0cm higher than ground harnesses at heald level time; and (4) a wefting mode is a large wefting travel mode with the inserting angle being 60-65 degrees and withdrawing angle being 310-315 degrees. In the singeing process, the direction of burner flame is changed into tangential singeing; and a mid-high alkali concentration singeing method and a three-step expanding adjustment method are adopted in the mercerizing and forming processes.

Owner:张家港市金陵纺织有限公司

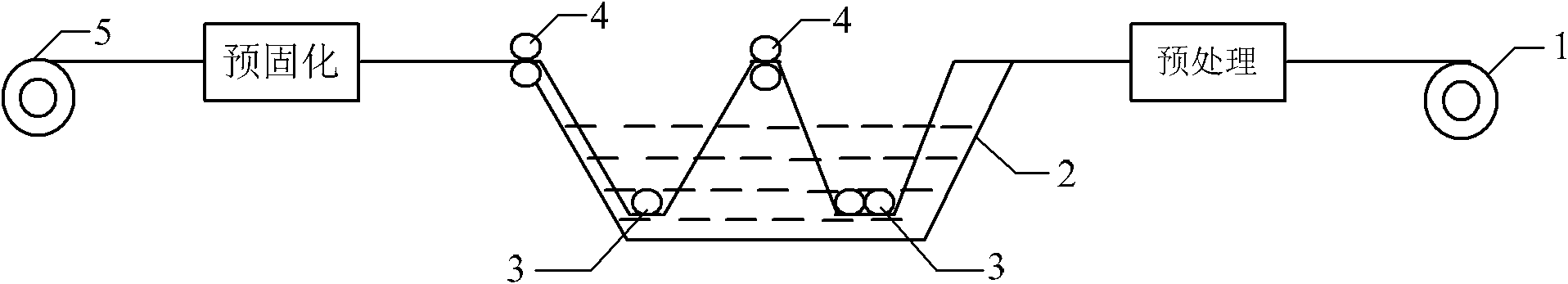

Method for enhancing permeability of prepregs

InactiveCN102002836AImprove permeabilityLiquid/gas/vapor removal by squeezing rollersMercerisingInternal temperatureChemistry

The invention relates to a method for enhancing the permeability of prepregs, relating to a method for enhancing the permeability of the prepregs and solving the problems of poorer permeability of the prepregs processed by the traditional method. The method comprises the following steps of: preprocessing reinforcing materials to be processed, then delivering into a gum dipping tank, and carrying out gum dipping on the preprocessed reinforcing materials by adopting two dandy rolls in a gum solution inside the gum dipping tank; then carrying out gum extrusion above the gum surface of the gum dipping tank by adopting a gum extruding roll; then carrying out the gum dipping again in the gum solution inside the gum dipping tank by adopting one dandy roll, carrying out the gum extrusion again, and then delivering into a curing oven with the internal temperature of 100-120 DEG C for precuring so as to obtain the prepregs. The invention is suitable for the dipping of glass cloths or carbon cloths.

Owner:HARBIN INST OF TECH

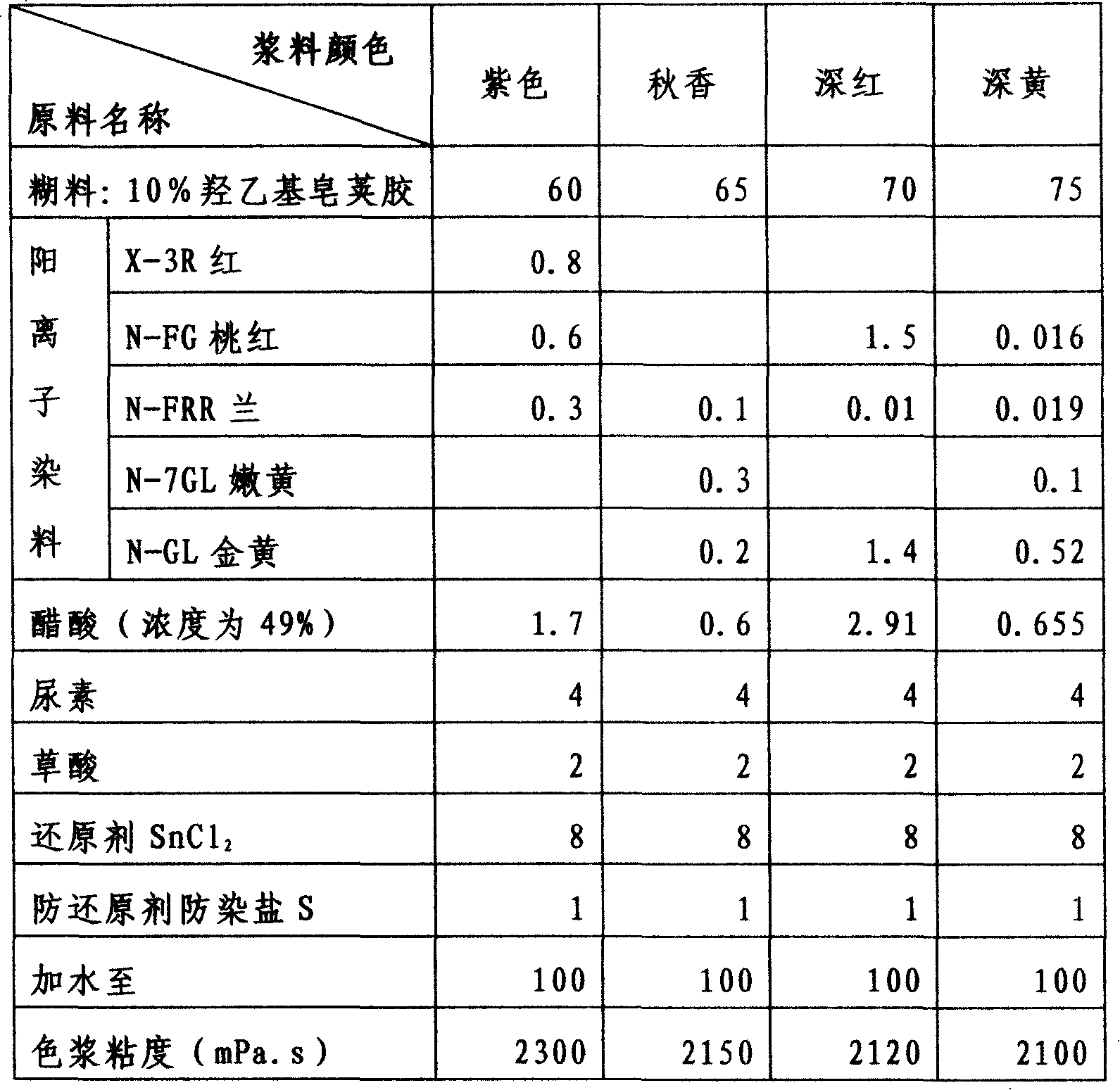

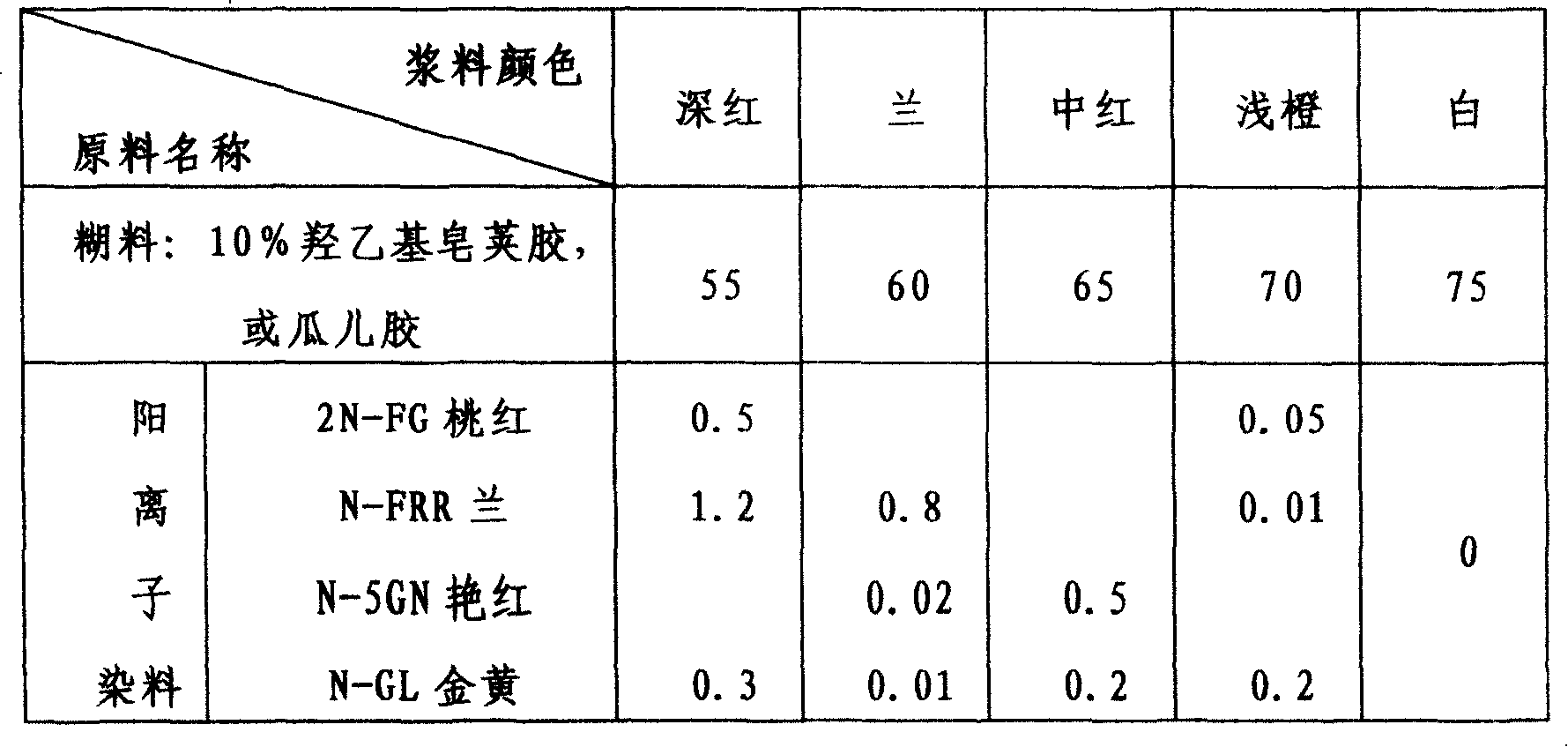

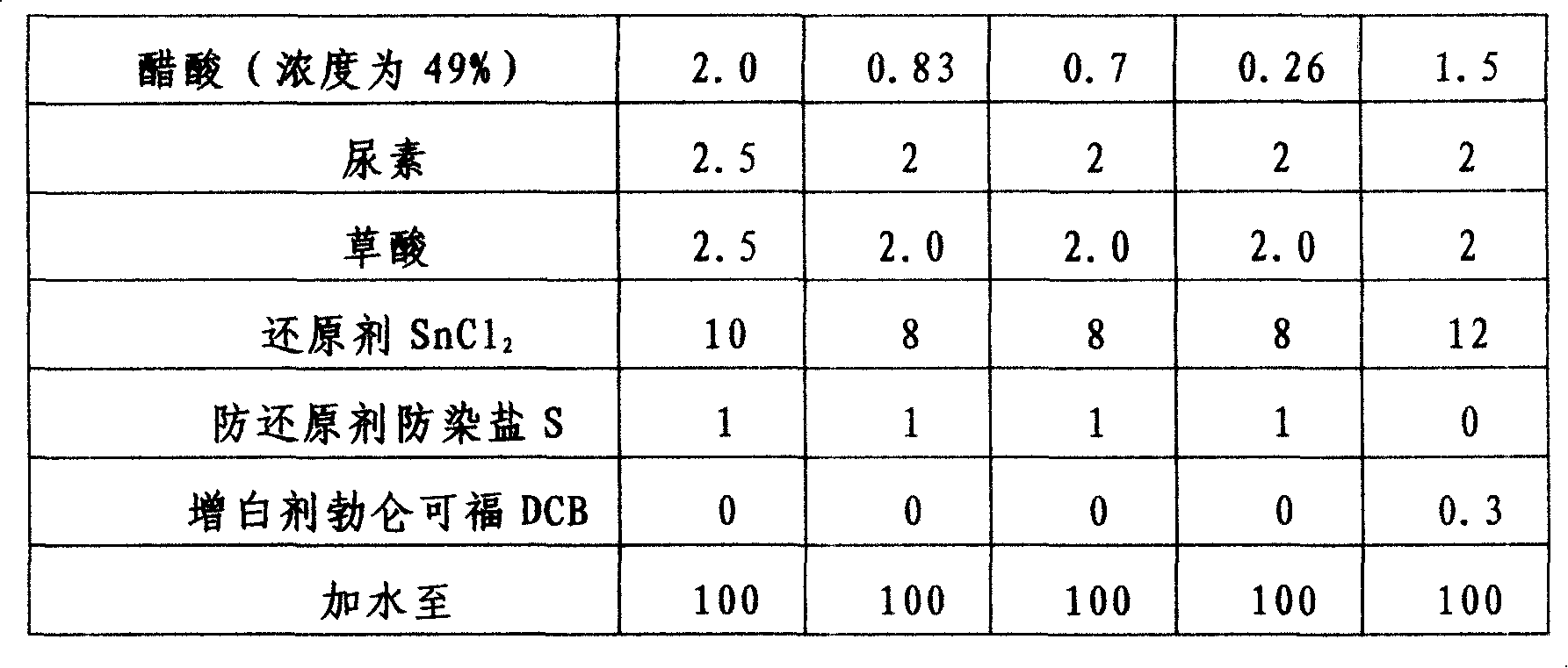

Engraving printing technique for polyacrylonitrile knitted fabric

The invention relates to an embossing printing technique for polyacrylonitrile knitted fabrics. The flow of the invention is that: firstly, cationic dyes are adopted for dyeing background color of the fabrics; secondly, acid resistant and reducing agent resistant pastes and reducing agent resistant cationic dyes are adopted for preparing color pastes which are then used for embossing and printing the fabrics; thirdly, evaporation and color development are performed; fourthly, water scrubbing is performed; fifthly, after-finishing is performed, wherein, compositions of the color pastes by weight percent are that: acid resistant and SnCl2 resistant pastes of 55 to 75 percent; SnCl2 resistant cationic dyes are added into mixture according to depth of color lights; acetic acids with a concentration of 49 percent is the same with the cationic dyes; urea of 2 to 5 percent; oxalic acids of 2.0 to 2.5 percent; reducing agents SnCl2 of 6 to 10 percent; anti-reducing agents of 0.5 to 10 percent; water is added into the mixture to 100 percent. The invention has the advantages that: by adoption of the printing technique and the printing pastes, the polyacrylonitrile embossing printing knitted fabrics with high quality and bright colors can be obtained on the production line.

Owner:上海和晓印花有限公司

Process for dyeing check for cross-stitch

InactiveCN101899754AWhiteness stabilityStable capillary effectMercerisingBleaching apparatusEngineeringEnzyme

The invention relates to a process for dyeing a check for cross-stitch, which comprises the steps of: turning cloth, sewing tips, singeing, mercerizing, performing enzyme-peroxide one-bath, bleaching and dyeing, straightening weft and sizing, inspecting finished products and the like. By adopting the process of first mercerizing and then enzyme-peroxide one-bath, the products have stable quality and the comprehensive first-rate product ratio of over 99 percent. The yarn counts of the cotton check for cross-stitch are thicker, the warp yarns are not sized, desizing is not adopted in the pretreatment, impurities and pigments in the fabric are subjected to oxygenolysis under the action of scouring enzyme and hydrogen peroxide, particularly the selection and formula of the scouring enzyme are greatly broken through, and the impurities and the pigments are removed through even washing, so that the fabric has stable whiteness and capillary effect.

Owner:ZHEJIANG FURUN DYEING & PRINTING

Method for manufacturing moisture-absorption and perspiration finish fabric

The invention discloses a method for manufacturing a moisture-absorption and perspiration finish fabric. The method comprises the following steps: A, selecting a fabric; B, scouring and bleaching the fabric; C, mercerizing the fabric; D, dyeing the fabric; E, softly finishing the fabric; F, inspecting the fabric; G, carrying out moisture-absorption and perspiration treatment on the fabric; and H, baking and shaping the fabric. The method can be applied to cotton, hemp, wool, silk and other natural fiber fabrics or regenerated fiber fabrics; and the manufactured finish fabric has effects of duration, wash resistance, moisture absorption and perspiration, can greatly improve the grade and quality of clothes, and can replace dacron fabrics to a great extent.

Owner:何汉沛

Color fixing anti-ultraviolet one bath process processing method for dacron-cotton dispersive/active dye

InactiveCN109680524AWith plasticizing and expanding propertiesReduce the impactSingeingHeating/cooling textile fabricsBENZYL ALCOHOL/WATERSOAP

The invention discloses a color fixing anti-ultraviolet one bath process processing method for a dacron-cotton dispersive / active dye. The method comprises the following steps: selecting a shell fabric; singeing; desizing; boiling off; bleaching; mercerizing; pre-setting; dyeing and anti-ultraviolet one bath process finishing; soap washing and color fixing; and setting. According to the color fixing anti-ultraviolet one bath process processing method for the dacron-cotton dispersive / active dye, a cold dome method is used for desizing and bleaching, so that influence of temperature to the shellfabric can be reduced. Benzyl alcohol is used as a low-temperature dyeing carrier, so that the dye has plasticizing and expanding performance to dacron. A neutral color fixing active dye is dyed favorably at a certain amount. By adopting a reasonable process, a dacron-cotton fabric one bath low-temperature dyeing process can be achieved by adopting a reasonable process, and the dyefastness can achieve the service performance.

Owner:桐乡市金达染整科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com