Color fixing anti-ultraviolet one bath process processing method for dacron-cotton dispersive/active dye

A technology of reactive dyes and processing methods, applied in the field of textile fabric dyeing and finishing, can solve problems such as poor color fastness, and achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

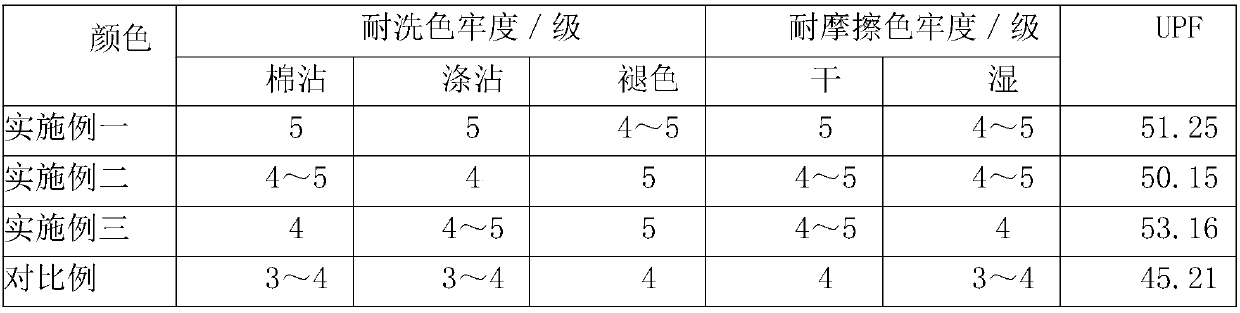

Examples

Embodiment 1

[0039] A kind of polyester-cotton disperse / reactive dye fixation and anti-ultraviolet one-bath processing method involved in the present embodiment comprises the following steps: selecting fabric, singeing, desizing, scouring, bleaching, mercerizing, presetting, dyeing and Anti-ultraviolet one-bath finishing, soaping, color fixing, and setting.

[0040] In the step S1 of selecting the fabric, the cotton content in the selected polyester-cotton fabric is 35-60%. Both the warp and weft of the selected fabrics use polyester-cotton blended yarns, specifically polyester-cotton 65 / 35, and the fineness of the polyester-cotton blended yarns used is 32.

[0041] In step S2 singeing, adopt the method of singeing the front and back sides of the natural gas singeing machine to carry out singeing treatment to the selected fabric, the flow rate of natural gas during singeing is 1 cubic meter per hour, and the vehicle speed is 120 meters per minute; The distance from the weaving is 10mm, ke...

Embodiment 2

[0051] A kind of polyester-cotton disperse / reactive dye fixation and anti-ultraviolet one-bath processing method involved in the present embodiment comprises the following steps: selecting fabric, singeing, desizing, scouring, bleaching, mercerizing, presetting, dyeing and Anti-ultraviolet one-bath finishing, soaping, color fixing, and setting.

[0052] In the step S1 of selecting the fabric, the cotton content in the selected polyester-cotton fabric is 35-60%. Both the warp and weft of the selected fabrics use polyester-cotton blended yarns, specifically polyester-cotton 55 / 45, and the fineness of the polyester-cotton blended yarns used is 40 counts.

[0053] In step S2 singeing, adopt the method of singeing the front and back sides of the natural gas singeing machine to carry out singeing treatment to the selected fabric, the flow rate of natural gas during singeing is 1 cubic meter per hour, and the vehicle speed is 110 meters per minute; The distance from the weaving is 9...

Embodiment 3

[0063] A kind of polyester-cotton disperse / reactive dye fixation and anti-ultraviolet one-bath processing method involved in the present embodiment comprises the following steps: selecting fabric, singeing, desizing, scouring, bleaching, mercerizing, presetting, dyeing and Anti-ultraviolet one-bath finishing, soaping, color fixing, and setting.

[0064] In the step S1 of selecting the fabric, the cotton content in the selected polyester-cotton fabric is 35-60%. Both the warp and weft of the selected fabrics use polyester-cotton blended yarns, specifically polyester-cotton 40 / 60, and the fineness of the polyester-cotton blended yarns used is 45 counts.

[0065] In step S2 singeing, adopt the method of singeing the front and back sides of the natural gas singeing machine to carry out singeing treatment to the selected fabric, the flow rate of natural gas during singeing is 0.8 cubic meters per hour, and the vehicle speed is 100 meters per minute; The distance from the weaving i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com