Process for dyeing check for cross-stitch

A plaid and cross-stitch technology, applied in the dyeing process of plaid, can solve the problems of unfavorable product promotion, high production cost, long process flow, etc., and achieve the effects of stable product quality, high equipment utilization rate, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: a kind of dyeing process of the plaid cloth that is used for cross-stitching, comprises following technological process: turn over cloth---sew head---singeing---mercerizing---enzyme oxygen one bath---back bleaching and whitening, dyeing--- —Whole weft sizing——Finished product inspection.

[0021] Fabric turning, seaming, singeing, and finished product inspection processes are handled using traditional techniques or standards;

[0022] In the mercerizing process, the concentration of mercerizing alkali is 256g / L, and the mercerizing penetrant is 2g / L. The mercerizing penetrating agent is commercially available, such as M-1039 produced by Hangzhou Meigao Huayi Chemical Co., Ltd., and the door width is used to wet the cloth. The width of the falling cloth is 136cm ~ 142cm, and the cloth surface can be slightly alkali;

[0023] Enzyme oxygen first bath: Use scouring enzymes and hydrogen peroxide, steam in a steamer at 95°C to 100°C for 60 minutes, then wash w...

Embodiment 2

[0027] Embodiment 2: technical process with reference to embodiment 1, its difference is:

[0028] In the mercerizing process, the concentration of mercerizing base is 200g / L, and the concentration of mercerizing penetrant is 2g / L;

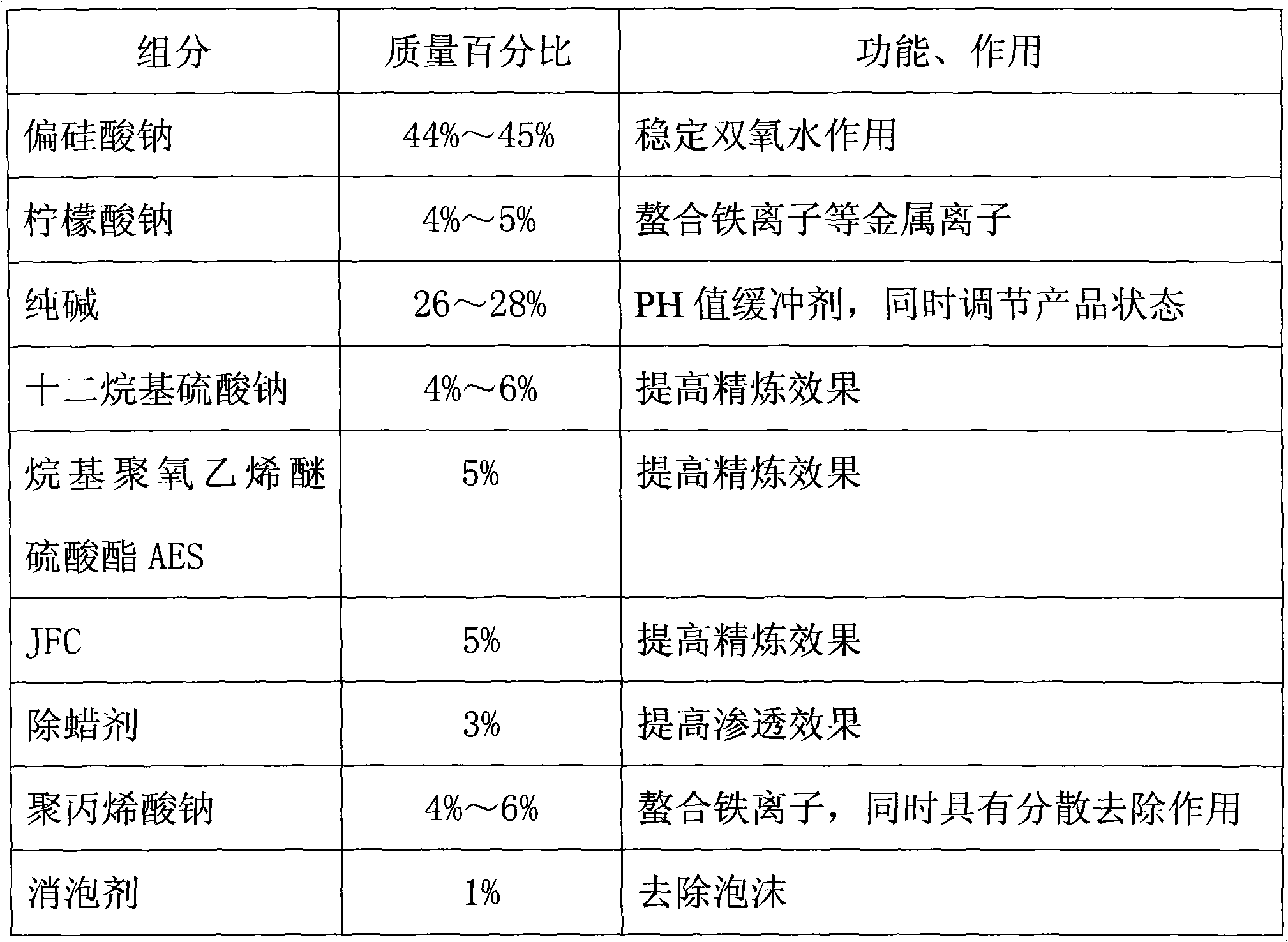

[0029] Enzyme oxygen bath: hydrogen peroxide is 15g / L, scouring enzyme is 30g / L, the mass percentage of each component of this scouring enzyme is: sodium metasilicate 44%, sodium citrate 4%, soda ash 28%, dodecane 6% sodium base sulfate, 5% alkyl polyoxyethylene ether sulfate AES, 5% JFC, 3% wax remover, 4% sodium polyacrylate, 1% defoamer; and add refined penetrant to 3g / L .

[0030] Whole weft sizing: the sizing formula is 40g / L of size, 0.5g / L of soft film, and 1g / L of wax film;

[0031] Other processes are the same as in Example 1.

Embodiment 3

[0032] Embodiment 3: technical process with reference to embodiment 1, its difference is:

[0033] In the mercerizing process, the concentration of mercerizing alkali is 280g / L;

[0034] Enzyme oxygen bath: hydrogen peroxide is 18g / L, scouring enzyme is 36g / L, the mass percentage of each component of this scouring enzyme is: sodium metasilicate 44%, sodium citrate 5%, soda ash 27%, dodecane 5% sodium base sulfate, 5% alkyl polyoxyethylene ether sulfate AES, 5% JFC, 3% wax remover, 5% sodium polyacrylate, 1% defoamer; and add scouring penetrant to 4g / L.

[0035] Whole weft sizing: the sizing formula is 48g / L of size, 0.5g / L of soft film, and 1g / L of wax film;

[0036] Other processes are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com