Patents

Literature

57results about How to "Lower dynamic viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Viscosity reducing composition and method for reducing viscosity of viscous oil

ActiveCN104164225ALower dynamic viscosityTo achieve the purpose of reducing viscosityFluid removalDrilling compositionPhenolViscous oil

The invention discloses a viscosity reducing composition, which comprises (a) phenolic compounds and (b) thin oil; wherein the phenolic compounds can be alkyl phenol and / or alkyl naphthol, the alkyl chain comprises 6 to 16 carbon atoms, and the weight ratio of the phenolic compound to the thin oil is 1:1-300. The invention further provides a method for reducing the viscosity of viscous oil, and comprises a step of contacting the provided viscosity reducing composition with viscous oil. The provided method can effectively reduce the dynamic viscosity of viscous oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

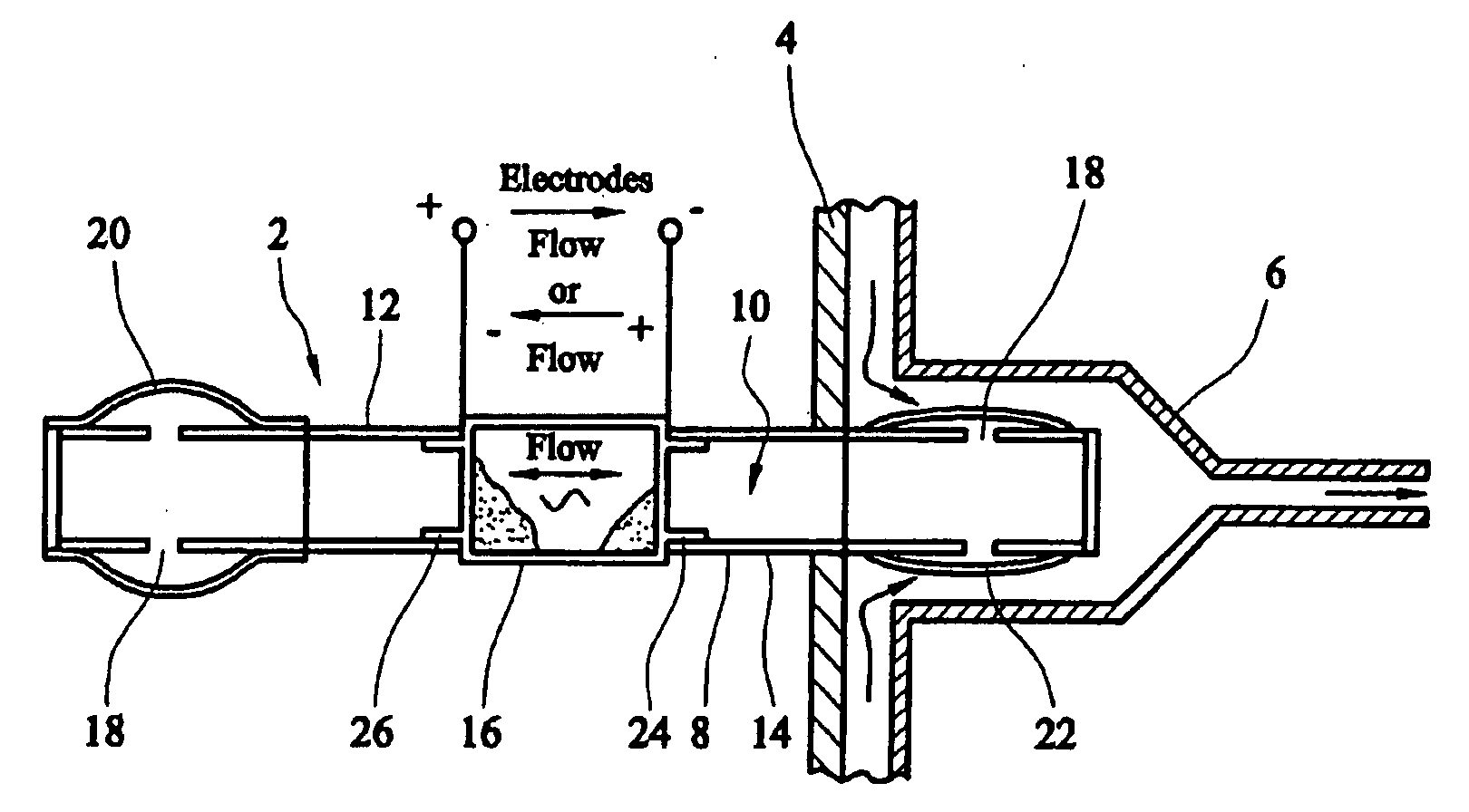

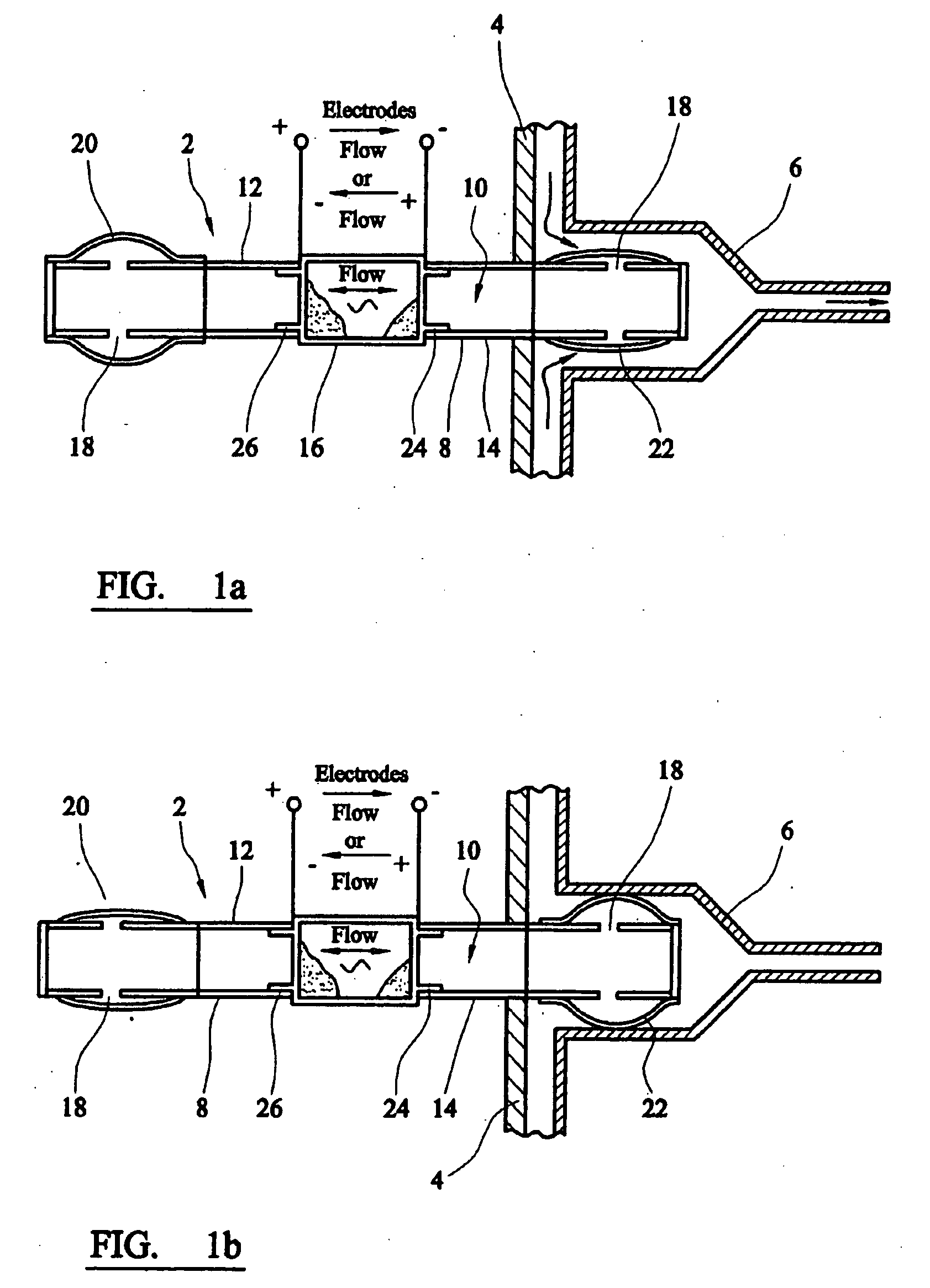

Valve for controlling flow of a fluid

InactiveUS20080029393A1Lower dynamic viscosityHigh zeta potentialSludge treatmentEngine diaphragmsControl flowElectricity

A valve for controlling flow of a primary fluid in a primary flow channel comprises a valve fluid channel, and a membrane of a porous dielectric material located in the channel so as to divide the channel into an inlet part and an outlet part and so that valve fluid flowing between the inlet and outlet parts flows through the said membrane. First and second electrodes are located for electrical communication with valve fluid in the inlet and outlet parts respectively of the valve fluid channel for application of an electric potential across the membrane in order to promote electro-osmotic flow of valve fluid through the membrane. A valve member can be displaced between open and closed positions as a result of valve fluid moving in the valve fluid channel through the membrane, into or out of the outlet part of the valve fluid channel, in which the valve member causes a reduction in the capacity for flow of the primary fluid in the primary flow channel when it is in the closed position compared with when it is in the open position.

Owner:BETA MICROPUMP PARTNERS

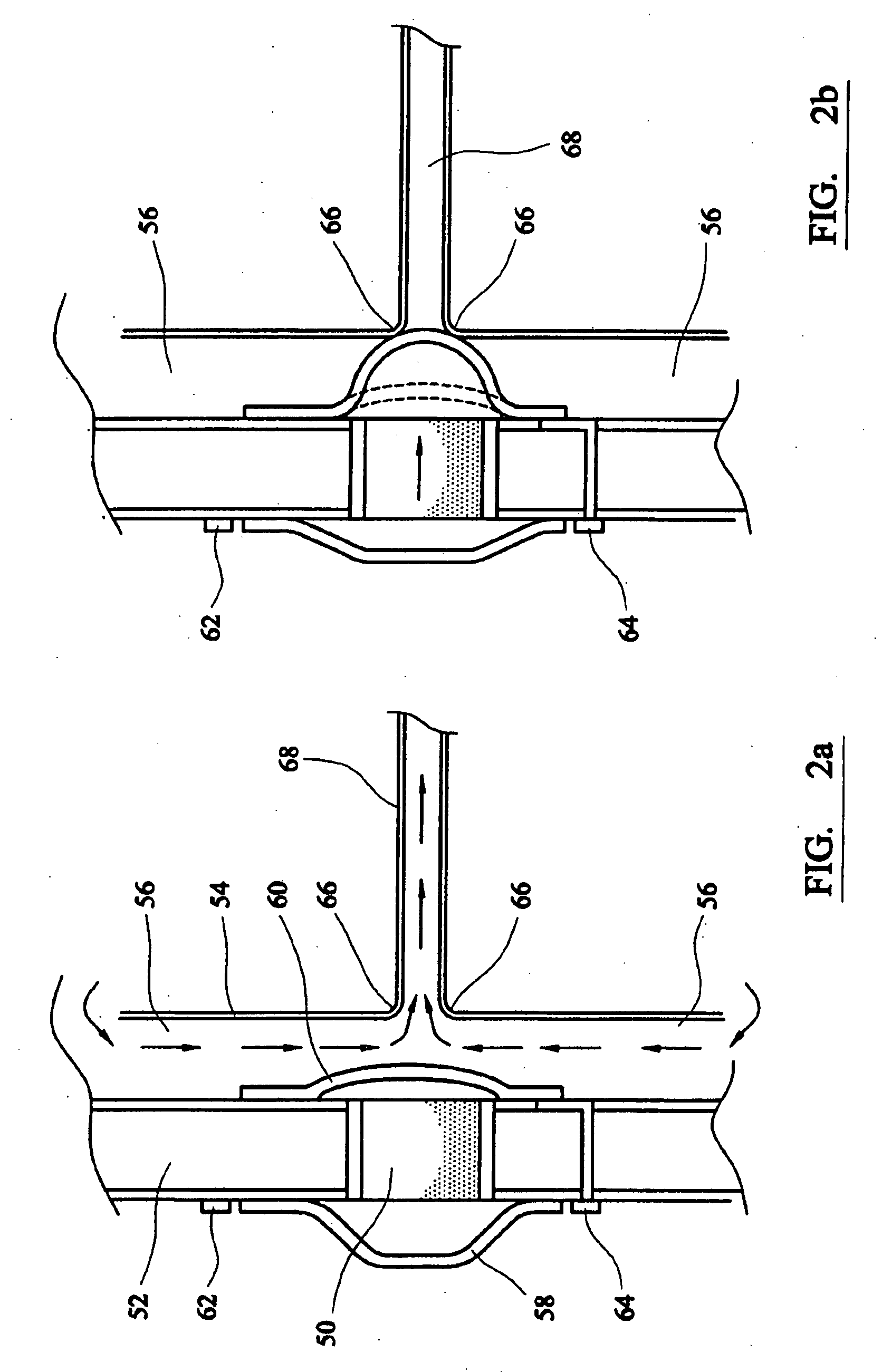

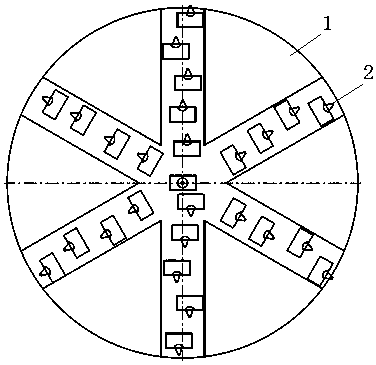

Heading machine using supercritical carbon dioxide jet flow to break rock

InactiveCN109899081AGuaranteed reliabilityImprove diffusivityMining devicesTunnelsSpray nozzleEngineering

The invention discloses a heading machine using a supercritical carbon dioxide jet flow to break a rock. The technical problems that a disc cutter of the existing heading machine is easy to damage anomaly, low in heading efficiency, and high in cost are solved. The heading machine includes a cutter head system, a supercritical carbon dioxide jet nozzle is arranged on the cutter head system, the supercritical carbon dioxide jet nozzle is connected with a supercritical carbon dioxide generating device through a high-pressure pipeline, and the supercritical carbon dioxide jet nozzle is connectedwith the supercritical carbon dioxide generating device through a high-pressure pump station. The supercritical carbon dioxide generating device can generate supercritical carbon dioxide, the supercritical carbon dioxide can be transported to the supercritical carbon dioxide jet nozzle by the high-pressure pump station, the supercritical carbon dioxide can be jetted at a higher speed by the supercritical carbon dioxide jet nozzle to form a jet flow beam with high concentrated energy, and the jet flow beam is provided with the high destructive effect and can broke the rock to realize heading. According to the heading machine using the supercritical carbon dioxide jet flow to break the rock, the rock breaking efficiency is high, the cost is low, and a rock breaking medium is green and environmental protection.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Lubricating Oil Composition For Automoblie Engine Lubrication.

InactiveUS20130237465A1Lower viscosityImprove fuel efficiencyAdditivesFoam dispersion/preventionLubricationAntioxidant

Provided is a lubricating oil composition that is highly fuel-efficient and has high wear resistance and is particularly suited for lubrication of a motorcycle four-cycle gasoline engine or a diesel engine vehicle having an exhaust gas after-treatment device. The lubricating oil composition, which is a lubricating oil composition having an SAE viscosity grade of 5W20, comprises a base oil and predetermined amounts of additive components comprising of a nitrogen-containing ash-free dispersant, an alkali earth metal-containing detergent, a phosphorus-containing anti-wear agent, an antioxidant, and a viscosity index-improving agent, wherein the viscosity index is within a range of 140 to 230, the high-shear viscosity at 150° C. is 2.9 mPa·s or higher, and the NOACK evaporation loss is 13% or less.

Owner:CHEVRON JAPAN

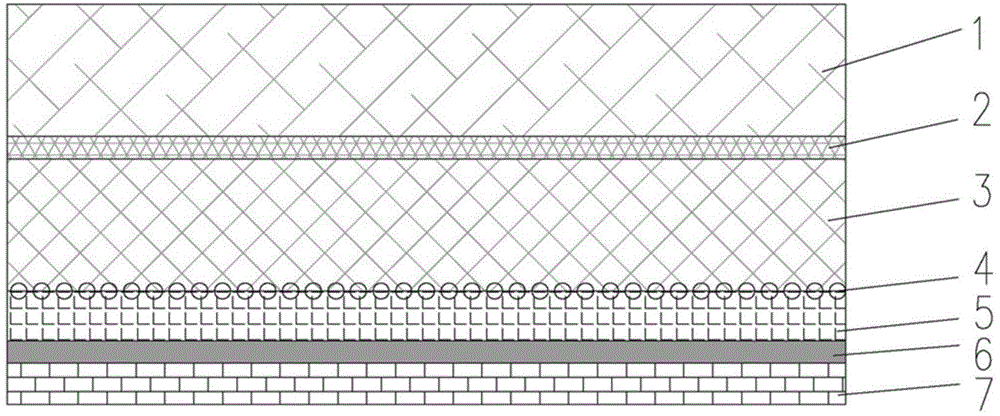

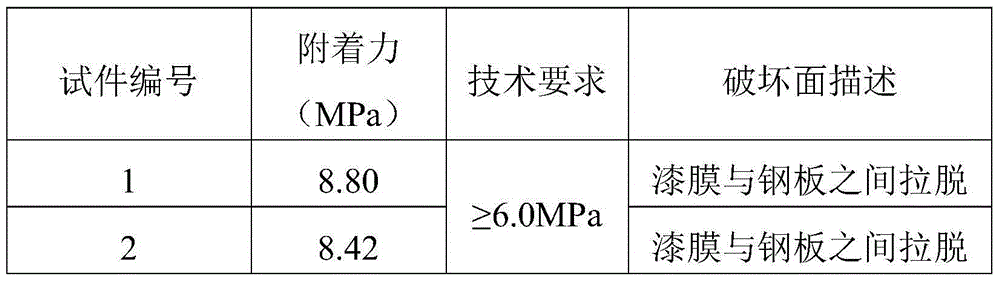

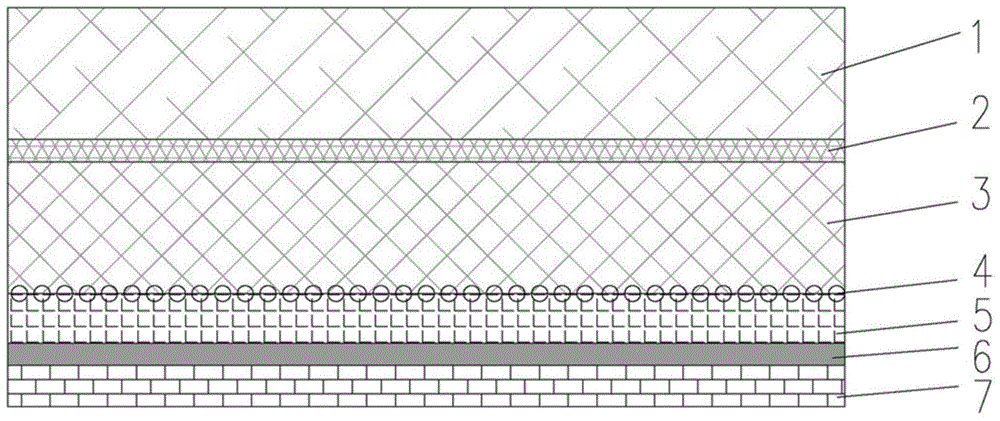

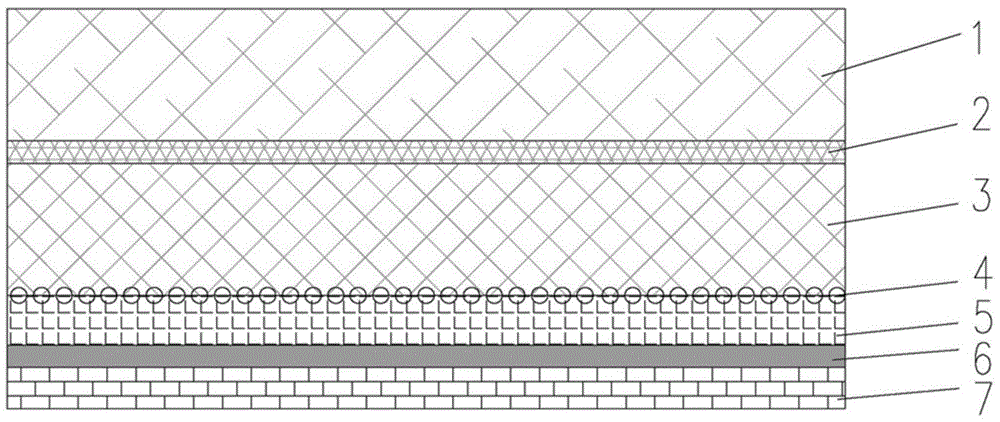

Bridge deck pavement method for orthotropic steel bridge

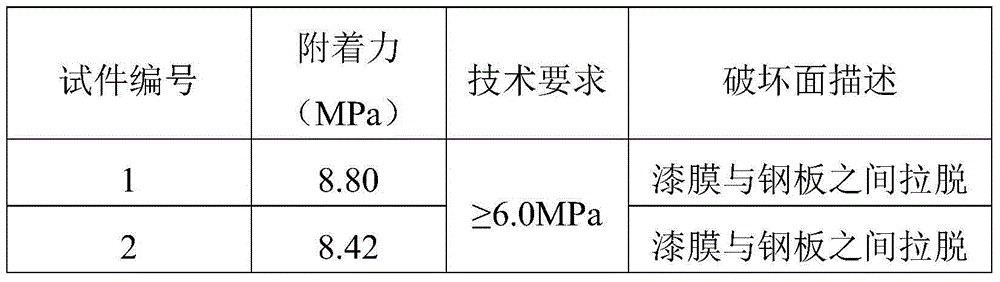

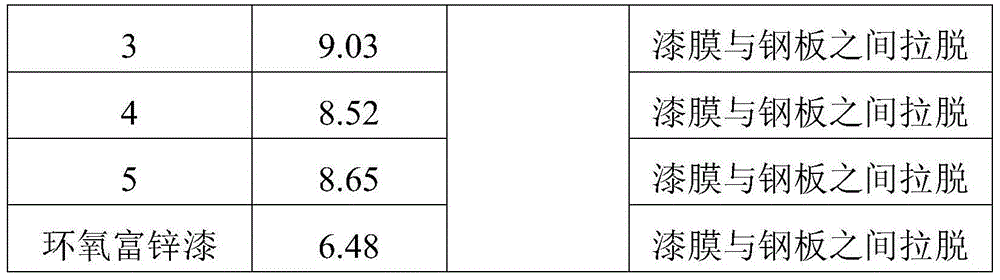

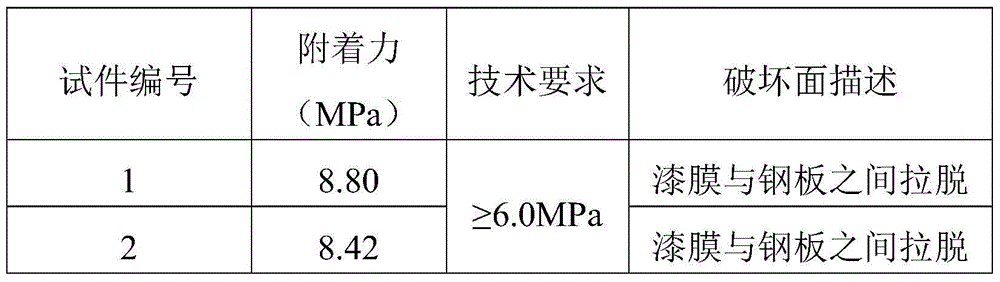

ActiveCN104652270AImprove pull strengthGood deformabilityIn situ pavingsBridge structural detailsEpoxyFull life cycle

The invention discloses a bridge deck pavement method for an orthotropic steel bridge. The pavement method comprises the following steps: (1) performing sand-blasting and de-rusting treatment on a steel bridge panel, and coating a mica-containing epoxy anti-corrosion layer; (2) coating a solvent-free epoxy resin water-proof layer; (3) spreading a hot melt particle bonding layer which is partially sunken into the solvent-free epoxy resin water-proof layer, wherein the hot melt particles are high-polymer particles of which the softening point is greater than 150 DEG C; (4) paving a fine-particle asphalt mixture to form a high-elasticity modified asphalt pavement lower layer; (5) spreading a modified emulsified asphalt bonding layer; (6) paving a fine-particle or medium-particle asphalt mixture to form a high-elasticity modified asphalt pavement upper layer. By adopting the pavement method, the construction difficulty is lowered greatly, later maintenance is easy, the universality is high, a pavement lower structure is durable and long in service life, only the surface needs to be maintained in daily use, overall repeated maintenance is avoided, and the investment in a full life cycle is lowered.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

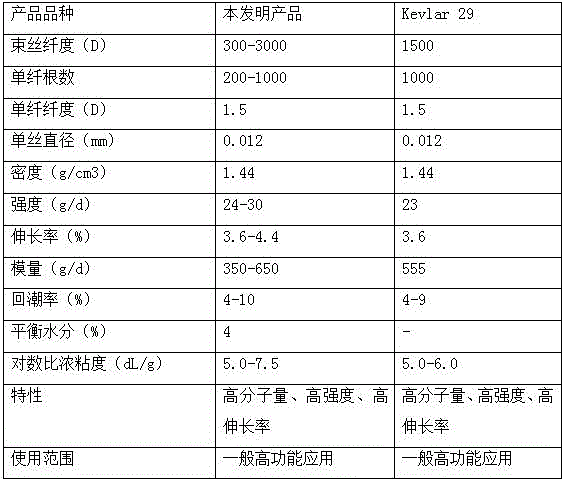

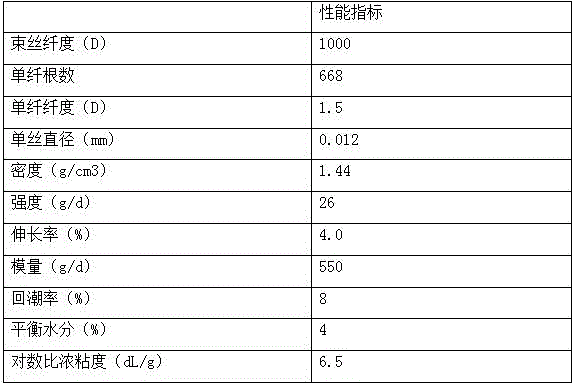

Preparation method of poly (p-phenylene terephthalamide) (PPTA) fiber with high elongation at break

InactiveCN106591996AImprove impact resistanceImprove fatigue resistanceSpinning solution de-aeratingSpinnerette packsFiberPolymer science

The invention relates to a preparation method of poly (p-phenylene terephthalamide) (PPTA) fiber with high elongation at break, and belongs to the technical field of artificial fiber. The preparation method is characterized by after preparing a spinning solution by taking a PPTA polymer of which the logarithmic viscosity is 4.5 to 7.5 dl / g as a raw material and concentrated sulfuric acid of which the concentration is 96 to 100 percent as a solution, forming as-spun filaments through a spinneret plate by adopting a dry-jet wet-spinning technology, then entering a coagulating bath to realize coagulation forming, and winding fiber after coagulation forming into a product after washing, neutralizing, drying and oiling the fiber, wherein the filament tension is controlled to be 0.5g / d or lower during the processes of washing, neutralizing, drying, oiling and winding. The PPTA fiber with the high elongation at break has good impact resistance and good fatigue resistance, and is relatively suitable for the field of rubber composite materials and bulletproof composite materials.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

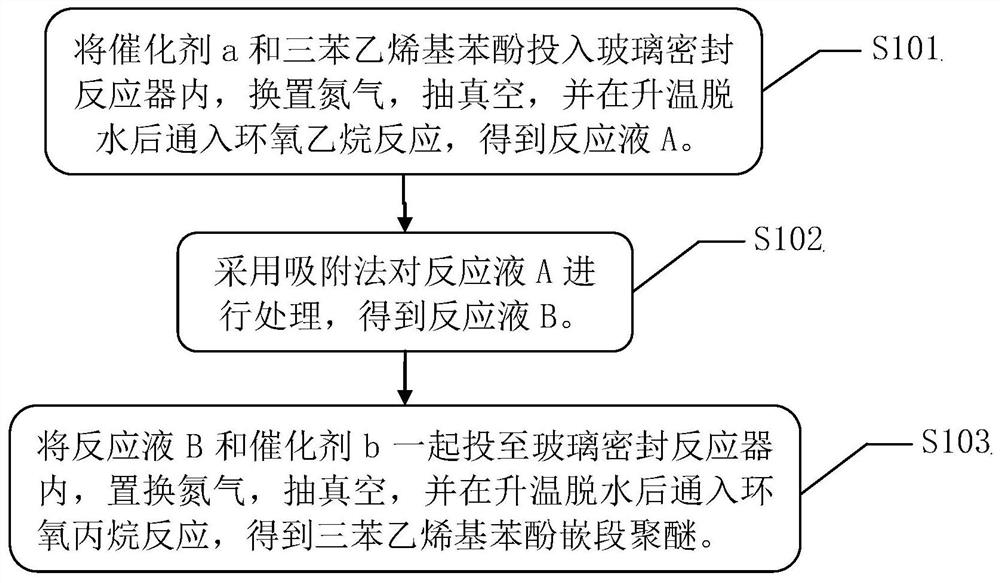

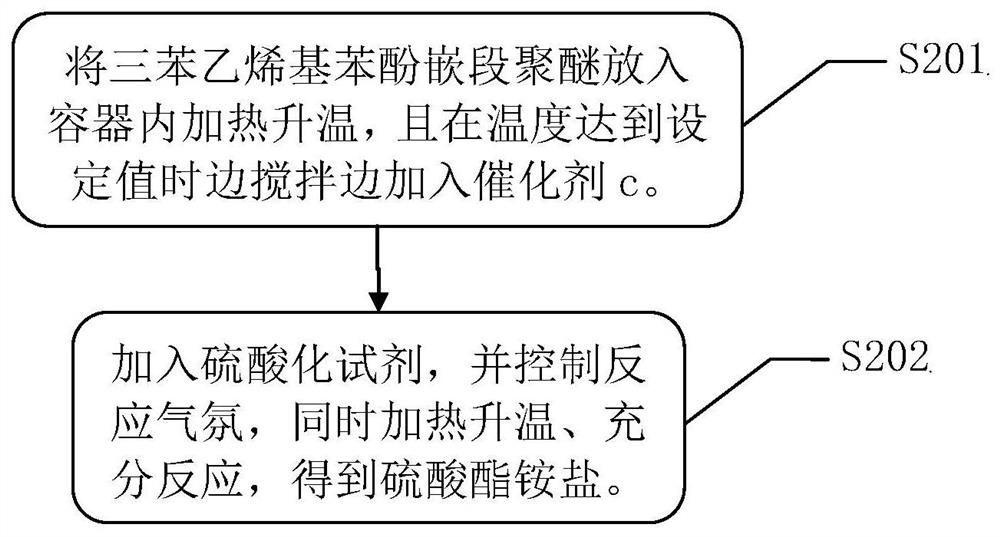

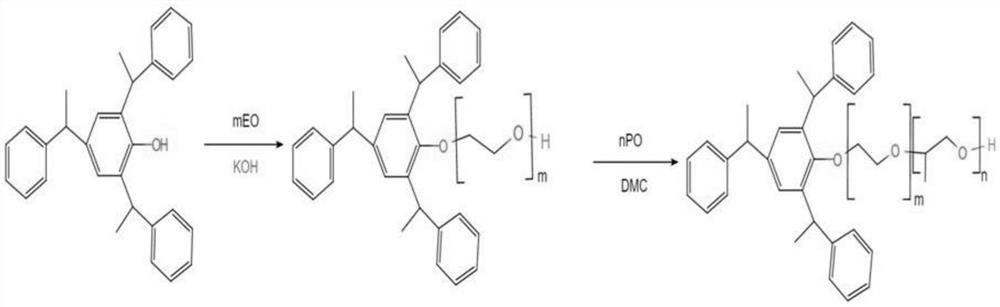

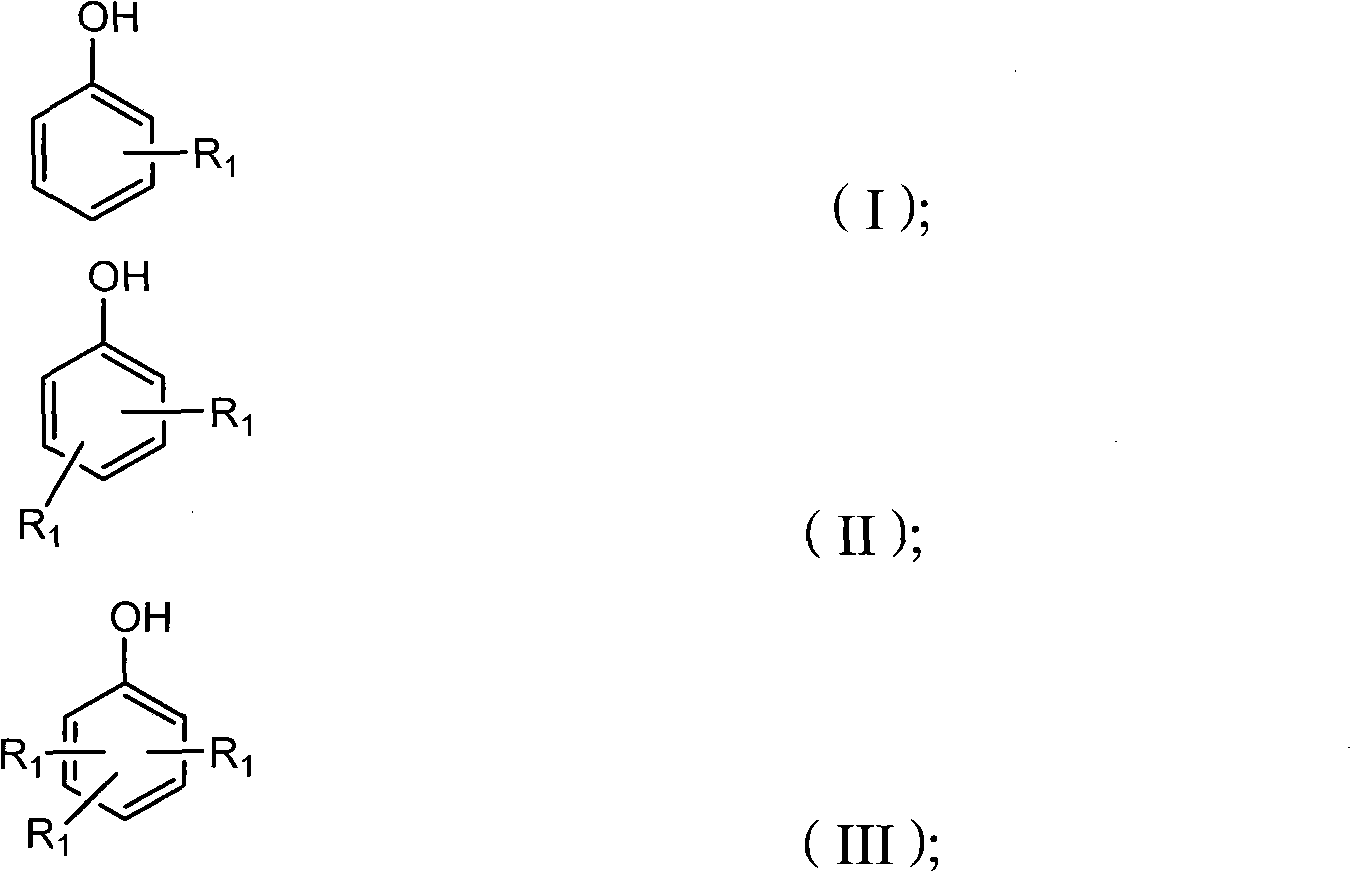

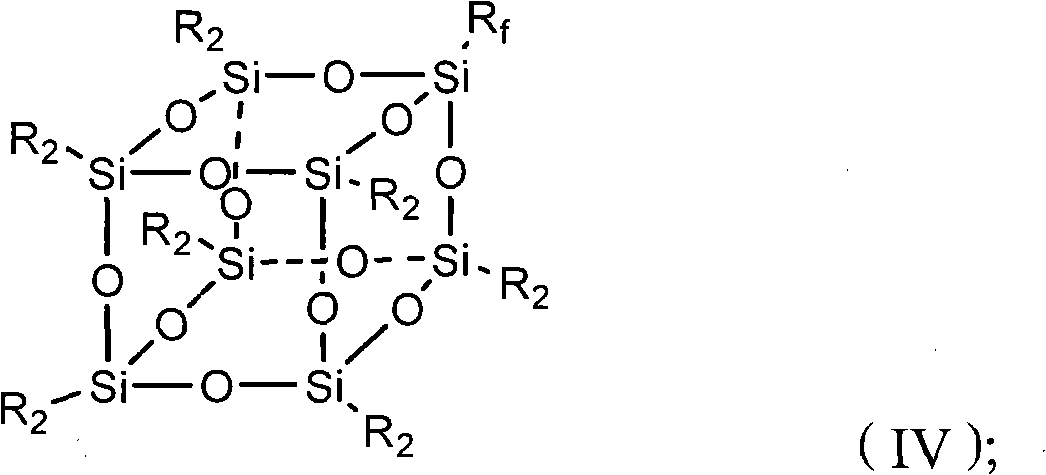

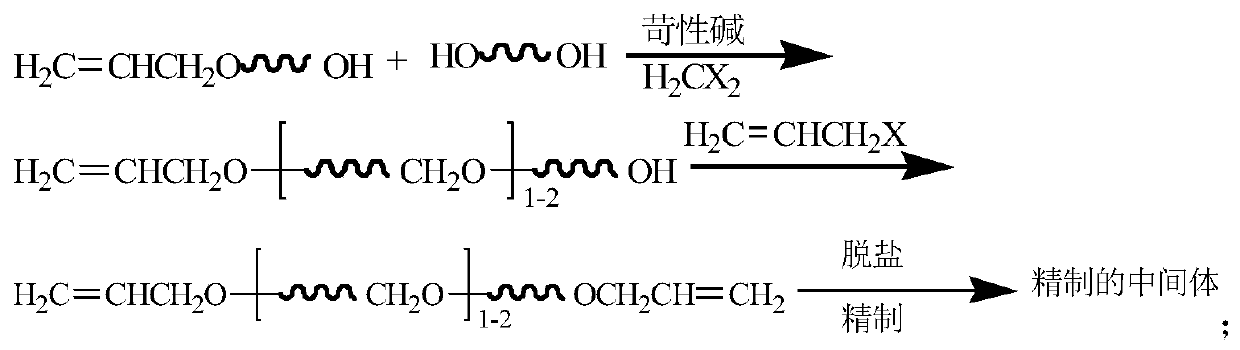

Tristyrylphenol block polyether, sulfate ammonium salt and preparation method thereof

PendingCN113214466ANarrow molecular weight distributionLow raw material residueEster sulfateSulfuric acid

TThe invention relates to tristyrylphenol block polyether, sulfate ammonium salt and a preparation method thereof. The tristyrylphenol block polyether is prepared from tristyrylphenol, ethylene oxide, propylene oxide, a catalyst a and a catalyst b, and the structural formula of the tristyrylphenol block polyether is as follows: m is 10-30, and n is 25-35. According to the present invention, the prepared sulfate ammonium salt has characteristics of narrow molecular weight distribution, low raw material residue and wide application range, and the prepared sulfate ammonium salt has characteristics of low dynamic viscosity, high active matter content, light product color and close-to-neutral pH value, can well meet the requirements of high-end users and use under harsh conditions, and further has effects of permeation, wetting, dispersion and the like.

Owner:ZHEJIANG HUANGMA TECH +3

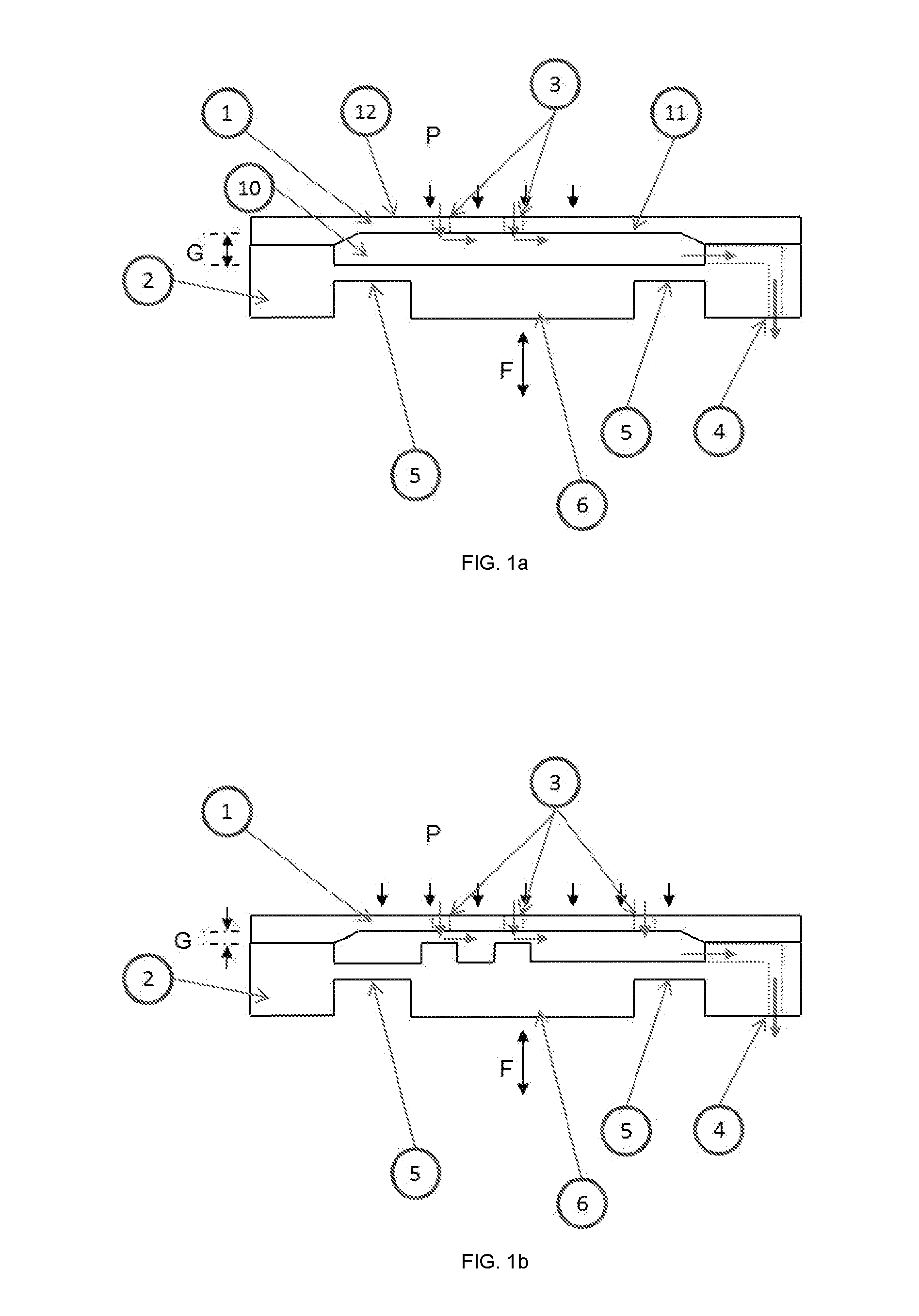

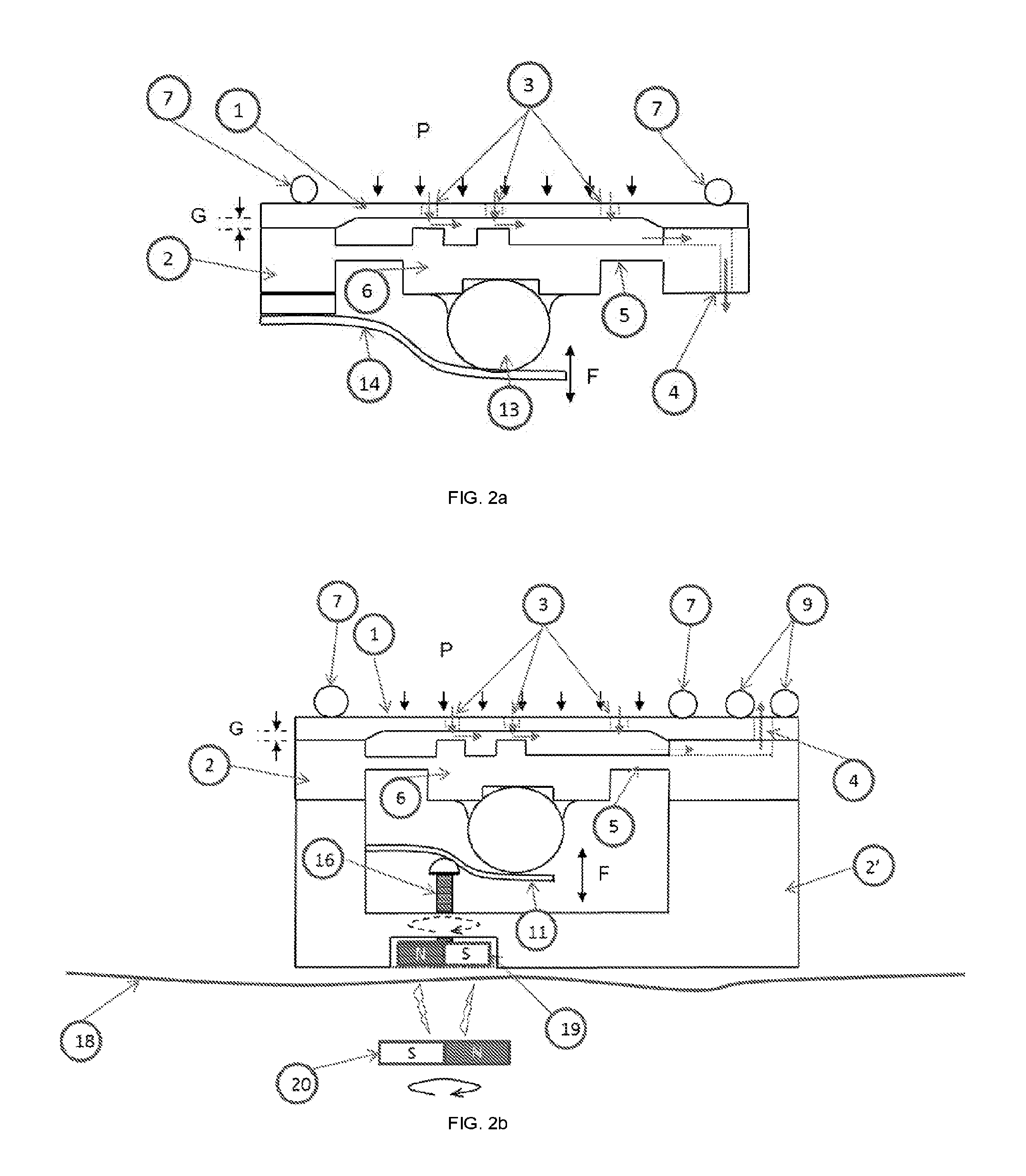

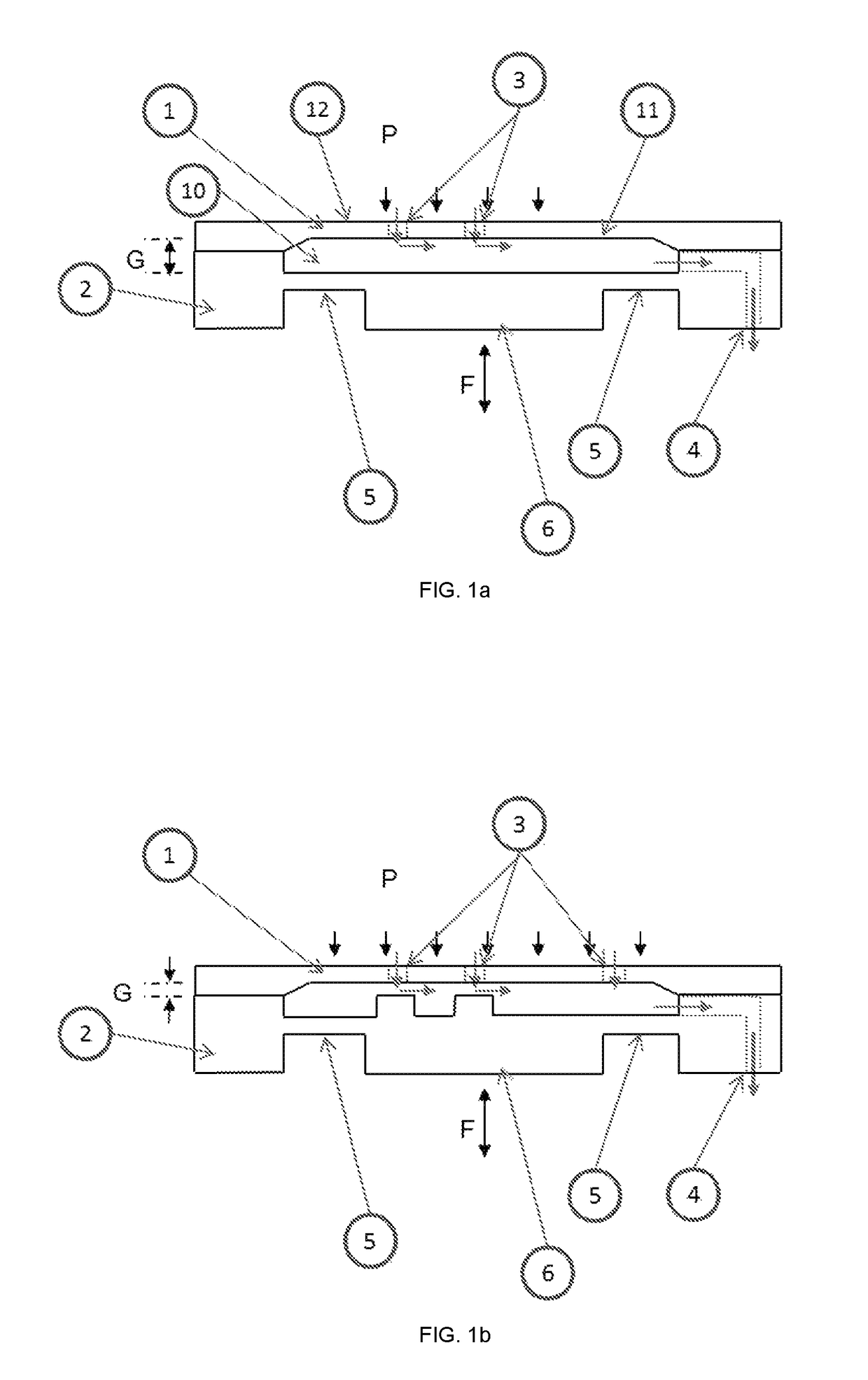

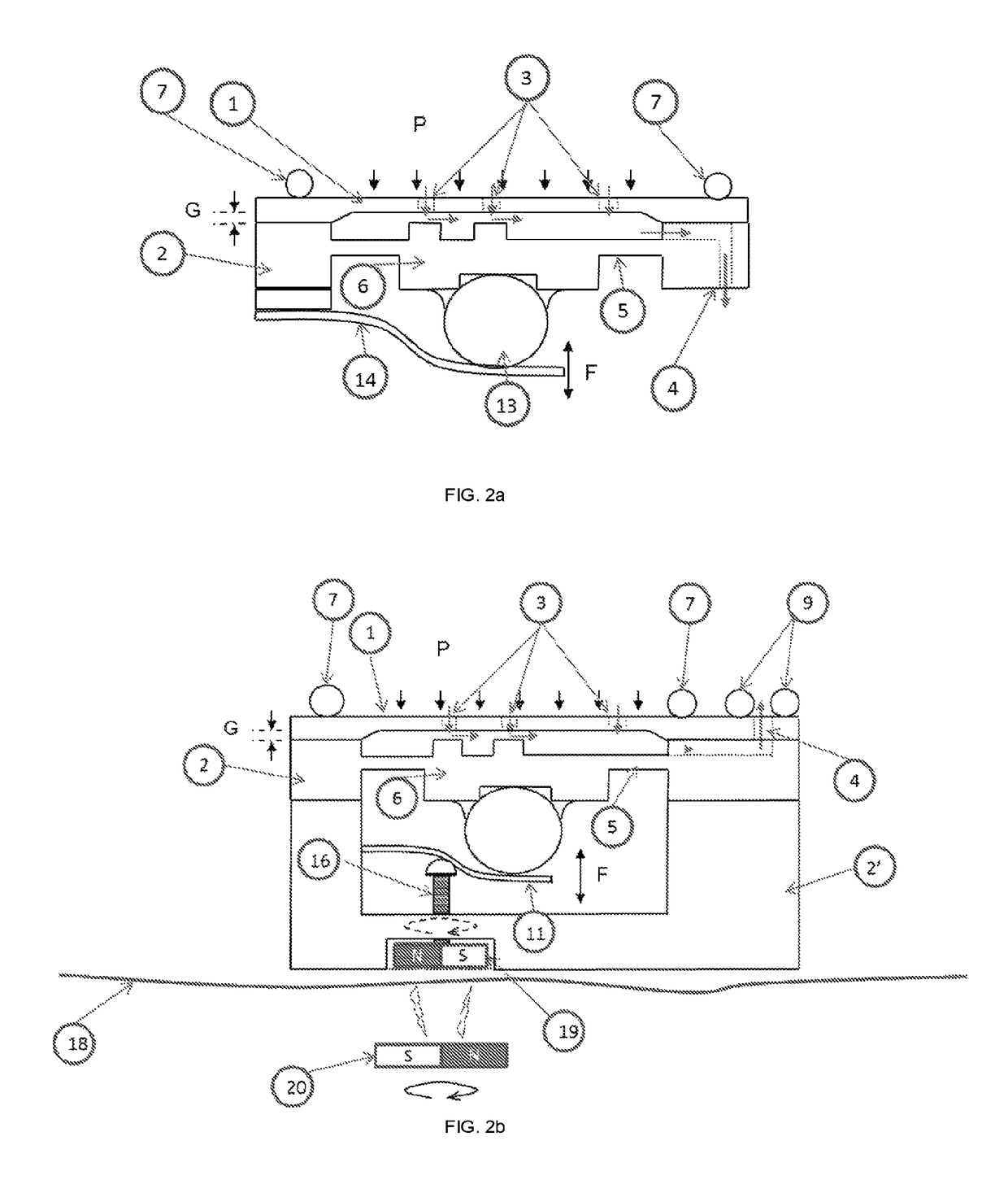

Adjustable passive flow regulator

InactiveUS20150346732A1Increase fluid resistanceAvoid flowWound drainsCheck valvesHydrocephalusPain management

An adjustable passive flow regulator may be used in the field of drug delivery (liquid or gaseous, e.g. for pain management) or for draining cerebrospinal fluid (CSF) for hydrocephalus patient.

Owner:DEBIOTECH SA

Metalworking fluid base oil

InactiveUS20130116460A1Low kinetic viscosityExcellent wettabilityOrganic chemistryBase-materialsOxideCarbon atom

A water-insoluble cutting fluid base oil or grinding fluid base oil for metalworking includes a fatty acid polyoxyalkylene alkyl ether represented by the following formula (I-A), wherein a hydroxyl value of the fatty acid polyoxyalkylene alkyl ether is less than or equal to 2.0 mgKOH / g.R1—CO—(OA)n-OR3 (I-A)(In the formula (I-A), R1 represents a linear or branched, saturated or unsaturated monovalent hydrocarbon group having 15 to 21 carbon atoms and R3 represents a linear, branched, or cyclic monovalent hydrocarbon group having 1 to 8 carbon atoms. In addition, A represents an alkylene group having 2 to 4 carbon atoms, OA represents alkylene oxide, and n represents 1 to 6 which is an average mole number of added alkylene oxide (AO).)

Owner:LION SPECIALTY CHEM

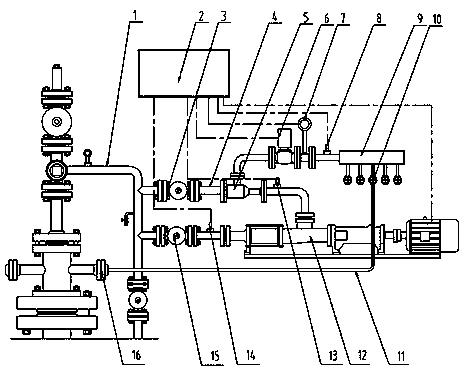

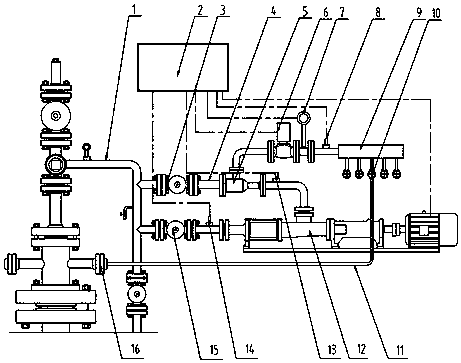

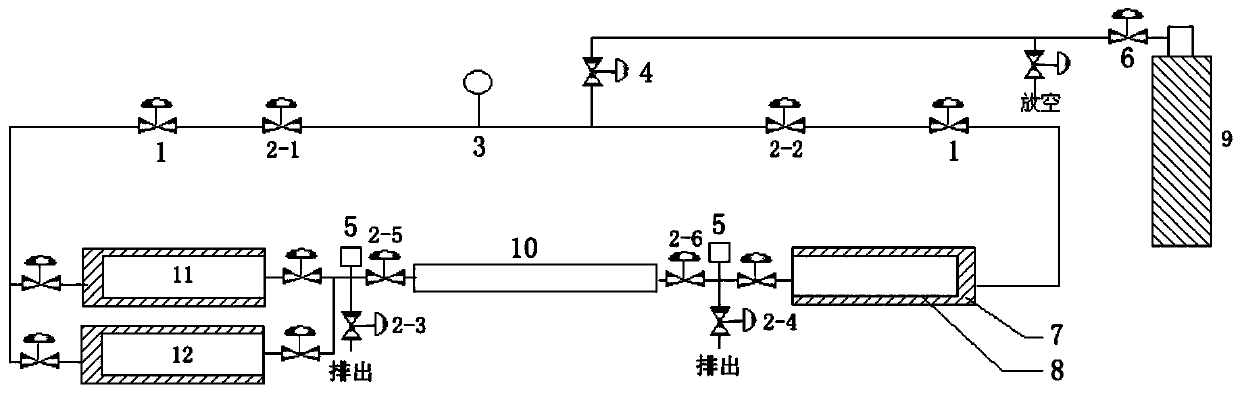

Ejection pressurizing type sleeve gas recovery device

The invention provides an ejection pressurizing type sleeve gas recovery device which is used for recovering sleeve gas in a wellhead of an oil field. The ejection pressurizing type sleeve gas recovery device comprises an ejector, a gas-liquid mixing and conveying pump, a liquid inlet valve, a liquid outlet valve, gas inlet valves, a gas storage tank, a gas pressure sensor, a gas flow meter, an electric valve, a control unit and the like, and is integrally manufactured into a skid-mounted block. A liquid inlet opening of the ejector is connected with the upstream part of an oil outlet pipeline of an oil well, and a liquid outlet opening of the ejector is connected with an inlet of the gas-liquid mixing and conveying pump. When the ejection pressurizing type sleeve gas recovery device works normally, the liquid inlet valve and the liquid outlet valve are both opened; when the pressure of the sleeve gas reaches a certain value, the gas pressure sensor transmits a signal to the control unit, the control unit sends an instruction to start the gas-liquid mixing and conveying pump, and the electric valve is opened in a delayed mode; liquid which flows at a high speed in the ejector sucks in the sleeve gas, the liquid and the sleeve gas are mixed to enter the liquid-gas mixing and conveying pump to be pressurized, and then are conveyed into the oil outlet pipeline of the oil well, the sleeve gas can be recovered, and the situation that waste of energy sources and air pollution are caused by combustion or emptying of the sleeve gas is avoided.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Bridge deck pavement structure for orthotropic steel bridge

ActiveCN104652269AImprove pull strengthGood deformabilityIn situ pavingsBridge structural detailsEpoxySolvent free

The invention discloses a bridge deck pavement structure for an orthotropic steel bridge. The pavement structure comprises a mica-containing epoxy anti-corrosion layer, a solvent-free epoxy resin water-proof layer, a hot melt particle bonding layer, a high-elasticity modified asphalt pavement lower layer, a modified emulsified asphalt bonding layer and a high-elasticity modified asphalt pavement upper layer from bottom to top, wherein the total pavement thickness is 6-8 centimeters; the hot melt particles are high-polymer particles of which the softening point is greater than 150 DEG C; the high-elasticity modified asphalt is modified asphalt of which the elastic recovery is over 95 percent at 25 DEG C; the pavement lower layer is formed by paving a fine-particle asphalt mixture prepared by mixing the high-elasticity modified asphalt with a mineral mixture; the pavement upper layer is formed by paving a fine-particle or medium-particle asphalt mixture prepared by mixing the high-elasticity modified asphalt with the mineral mixture. By adopting the pavement structure, the water-proof layer and the asphalt pavement layer are combined integrally through the hot melt particle bonding layer, so that the shearing strength and durability of the pavement structure are ensured.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

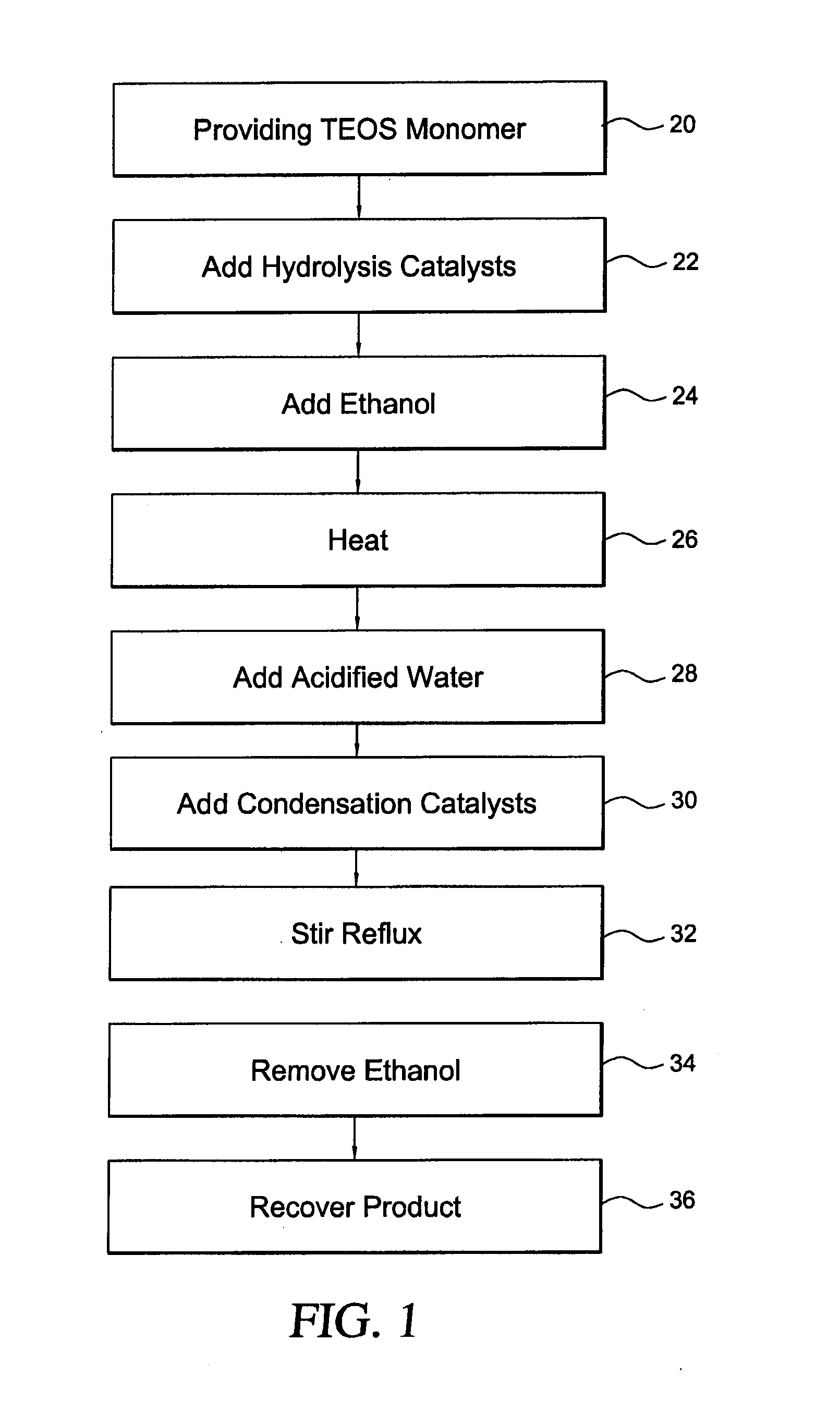

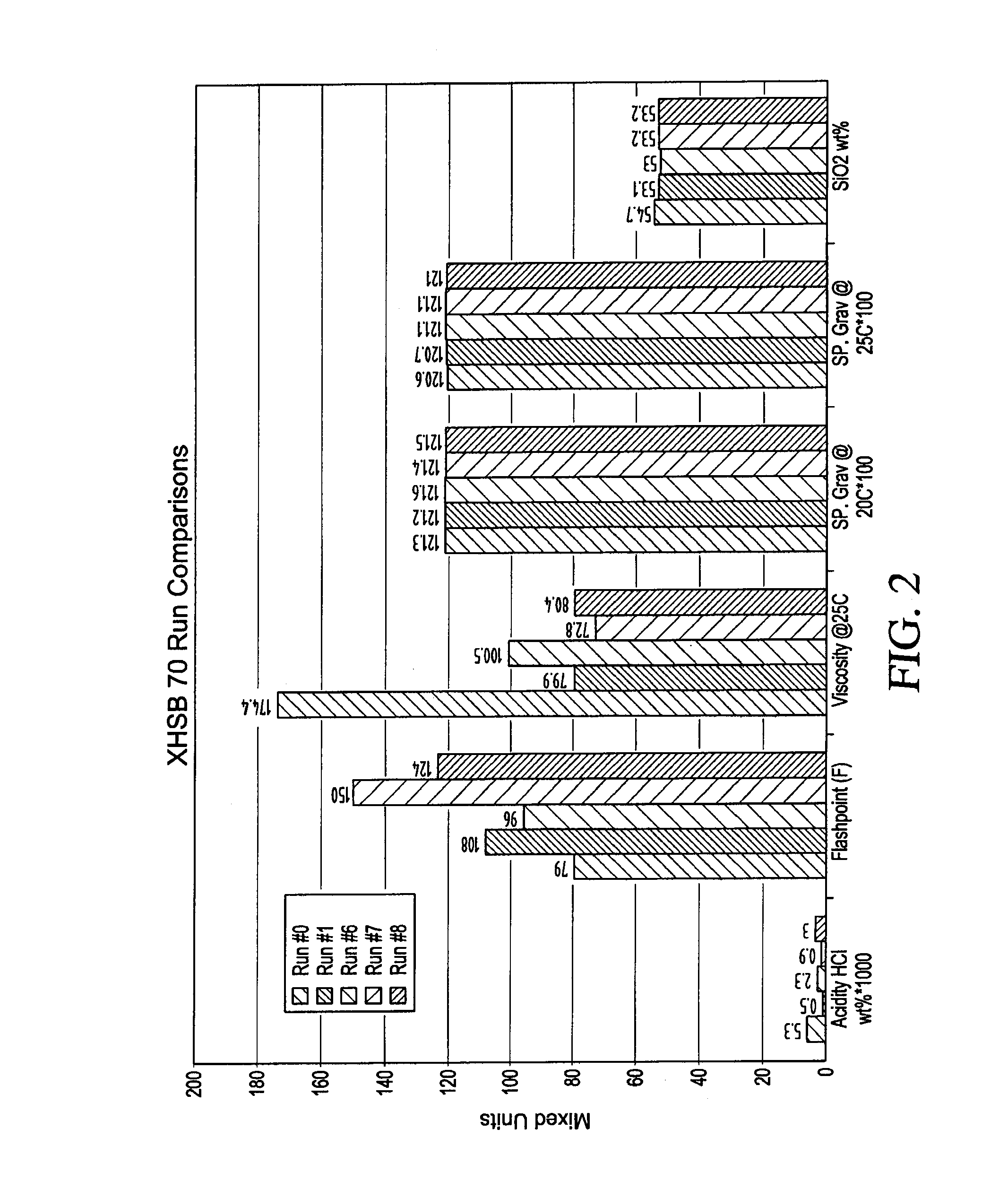

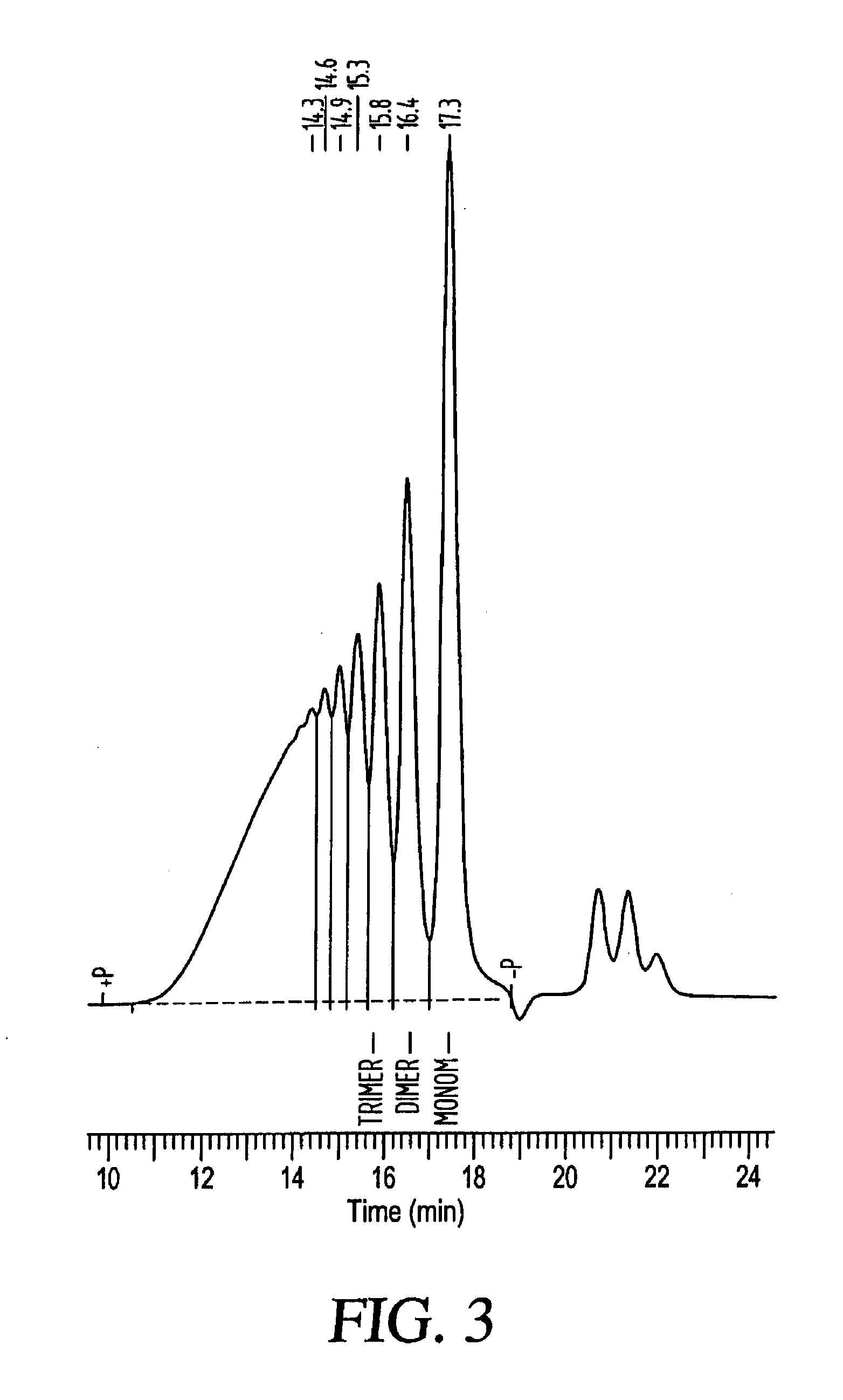

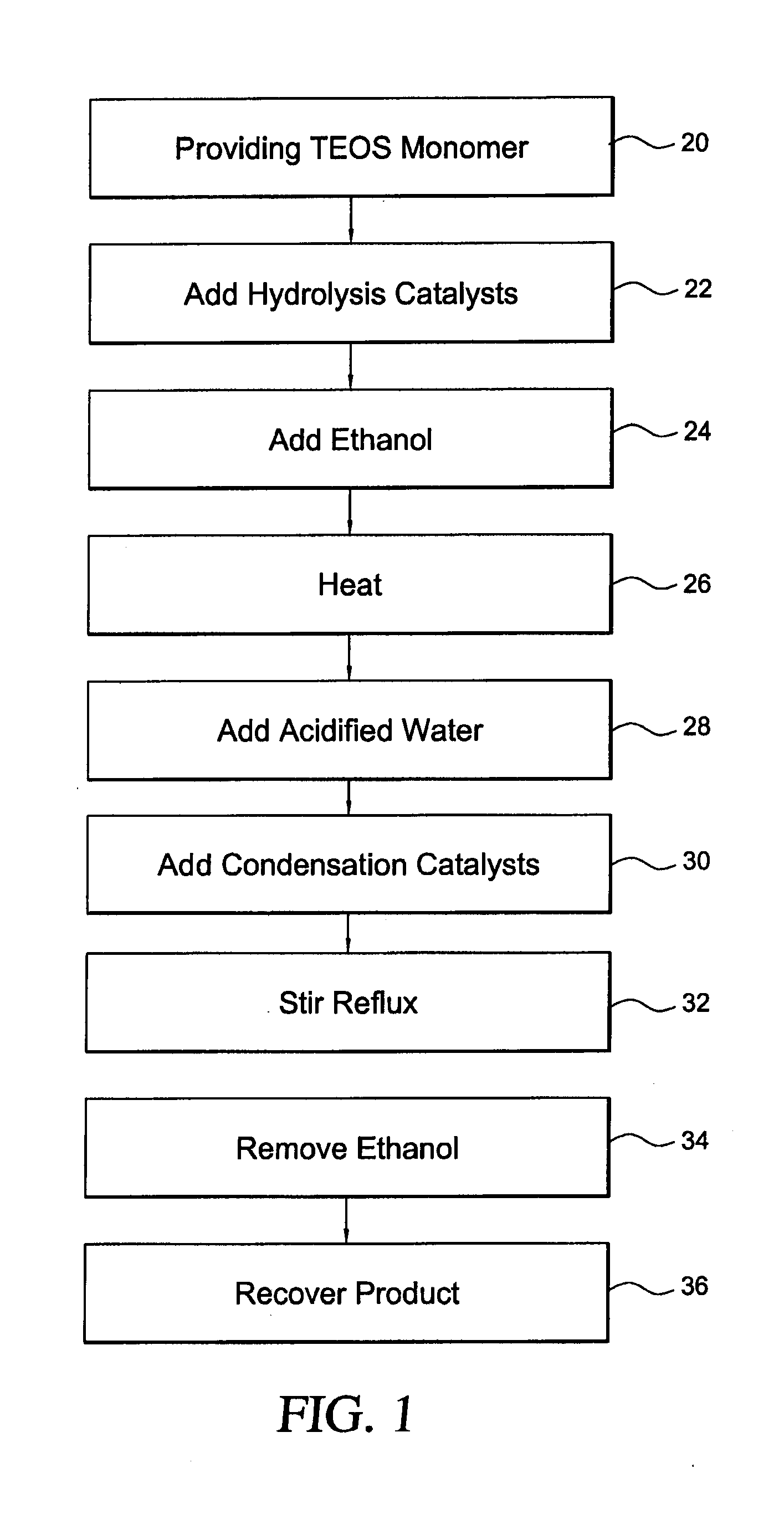

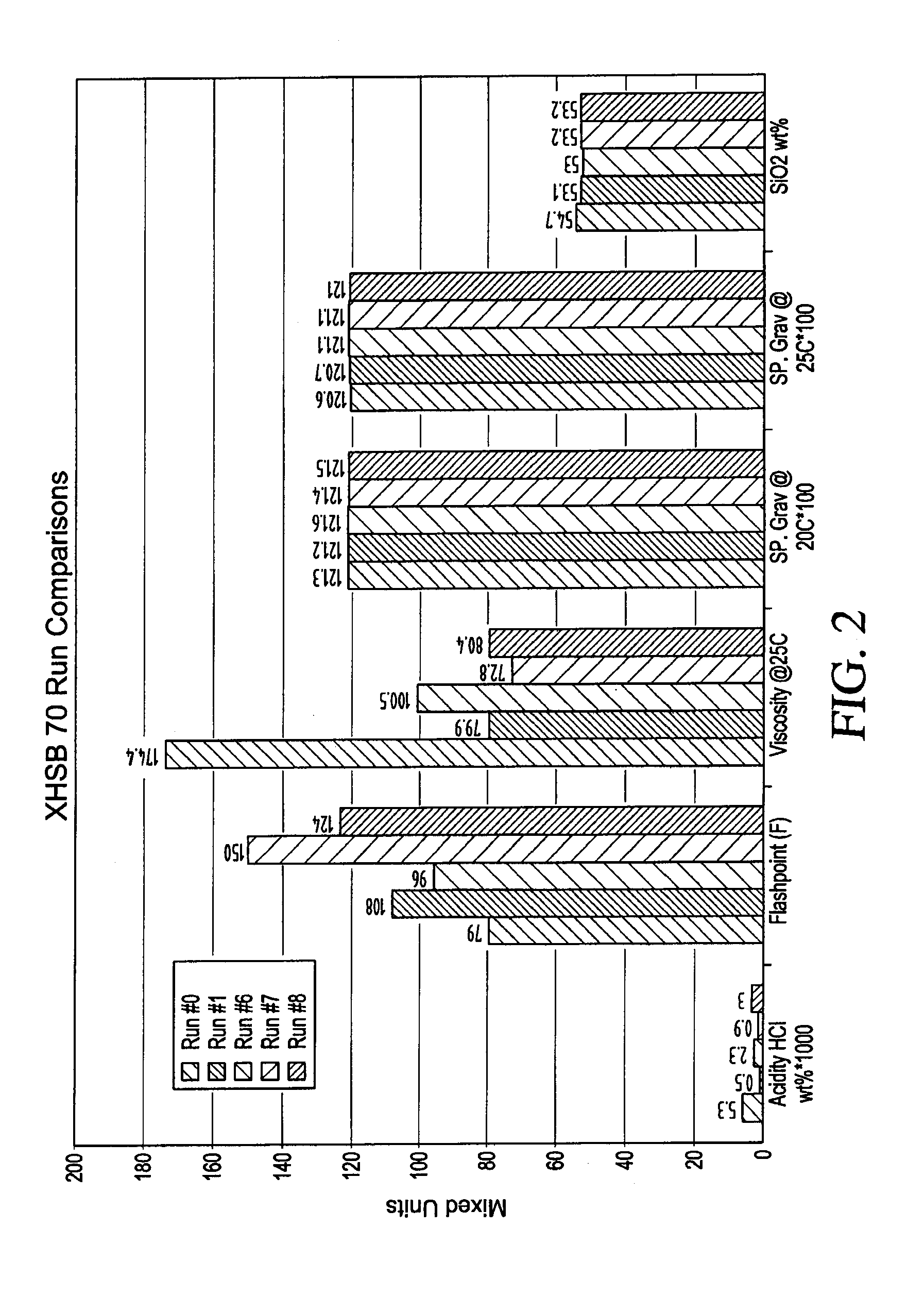

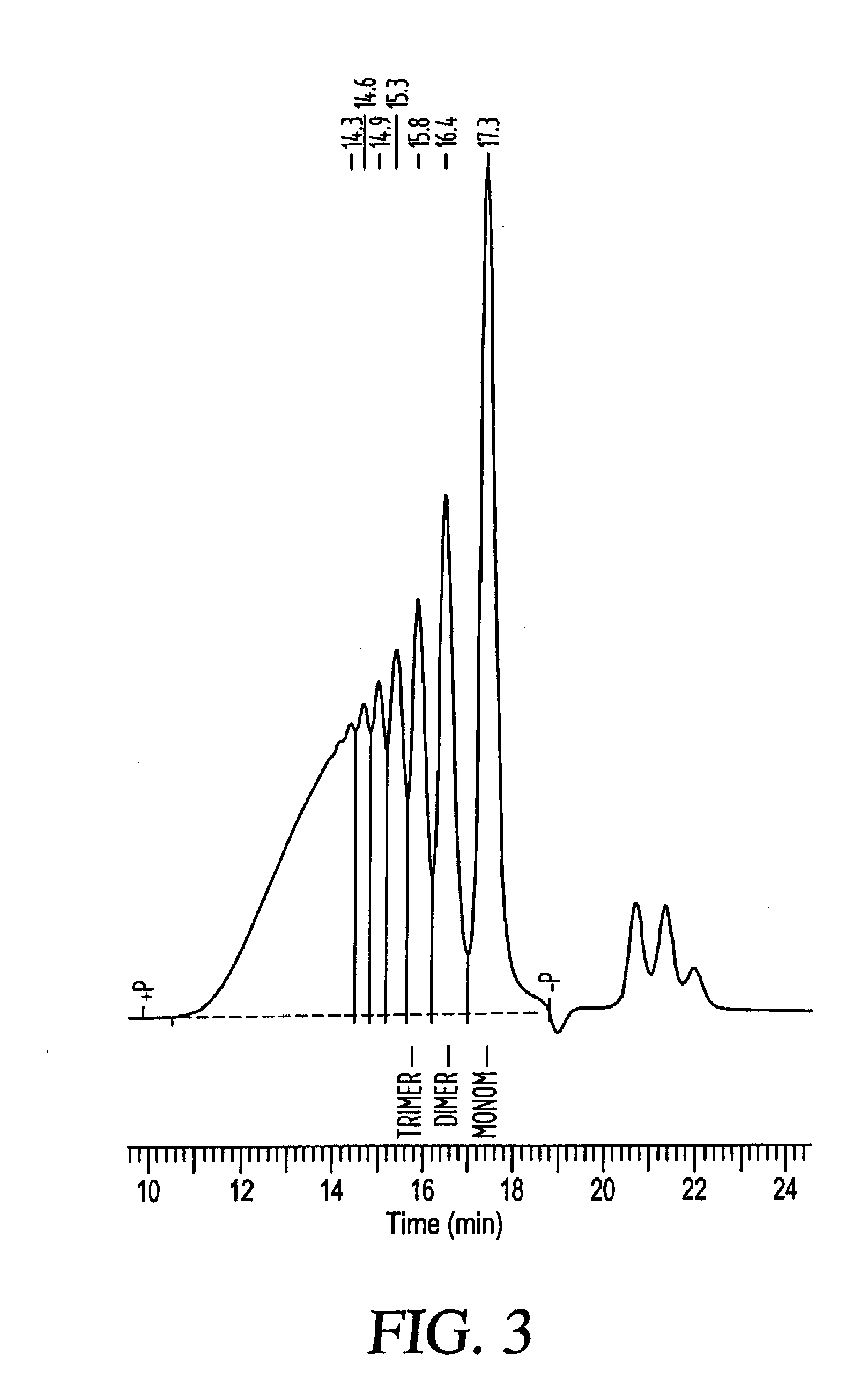

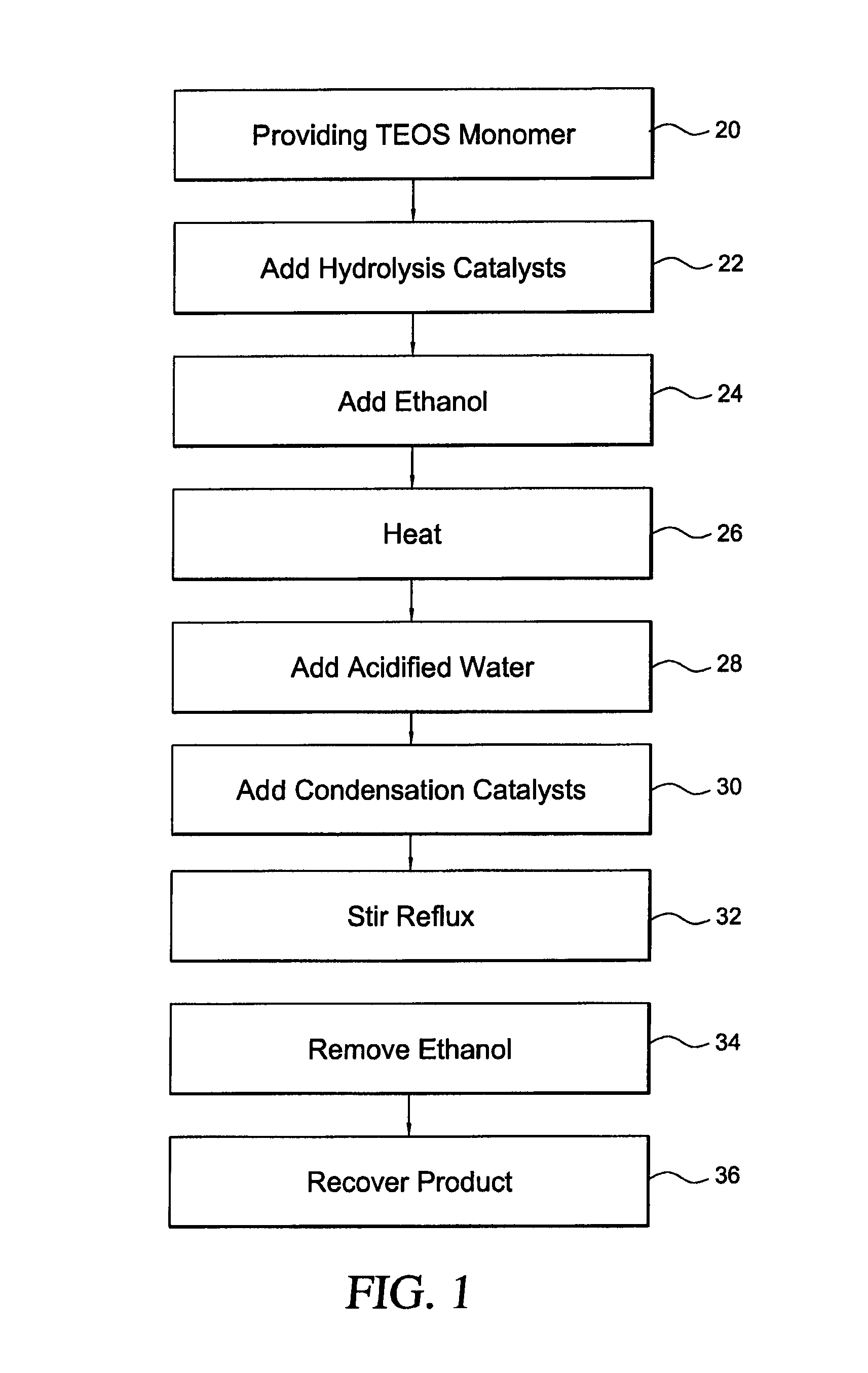

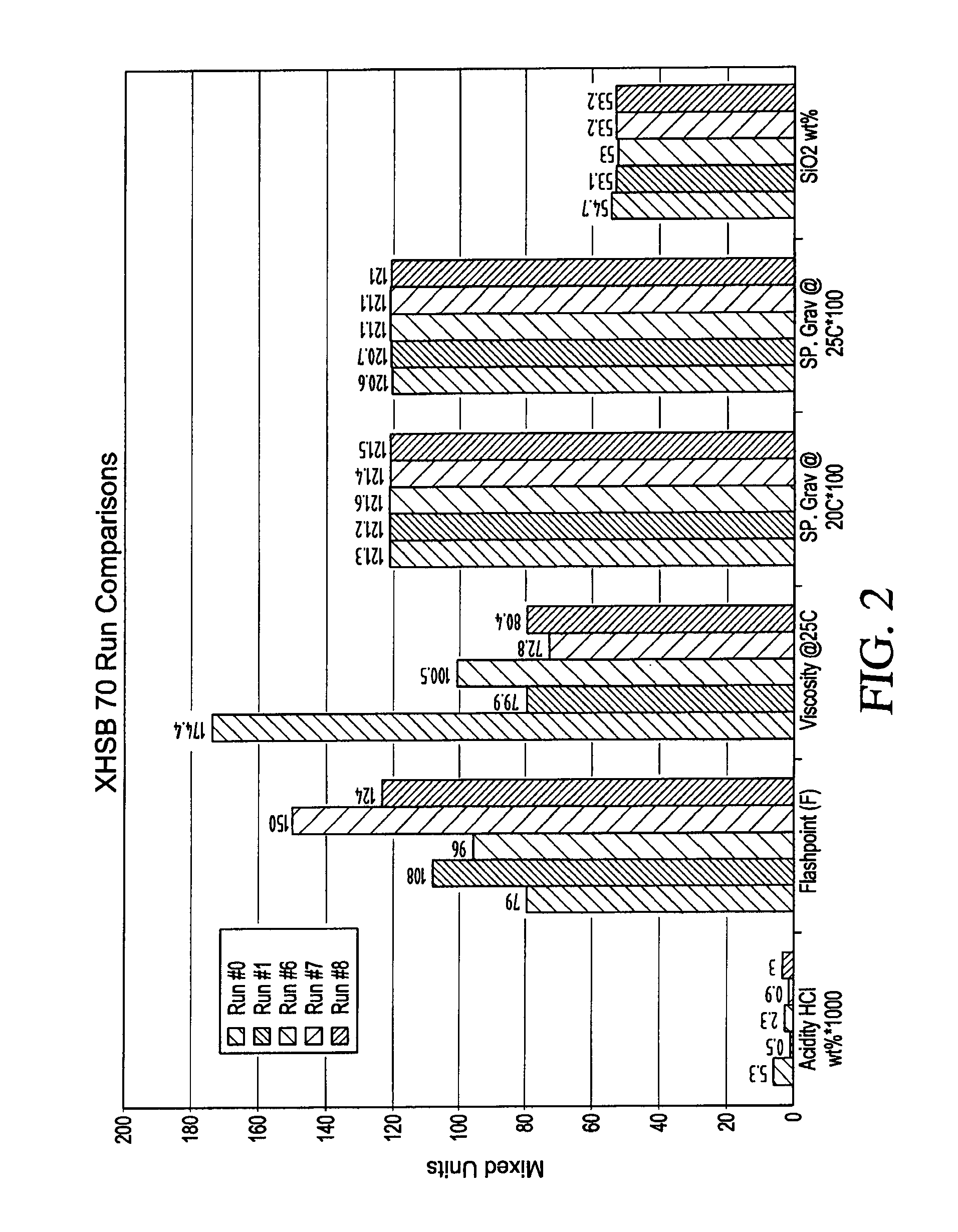

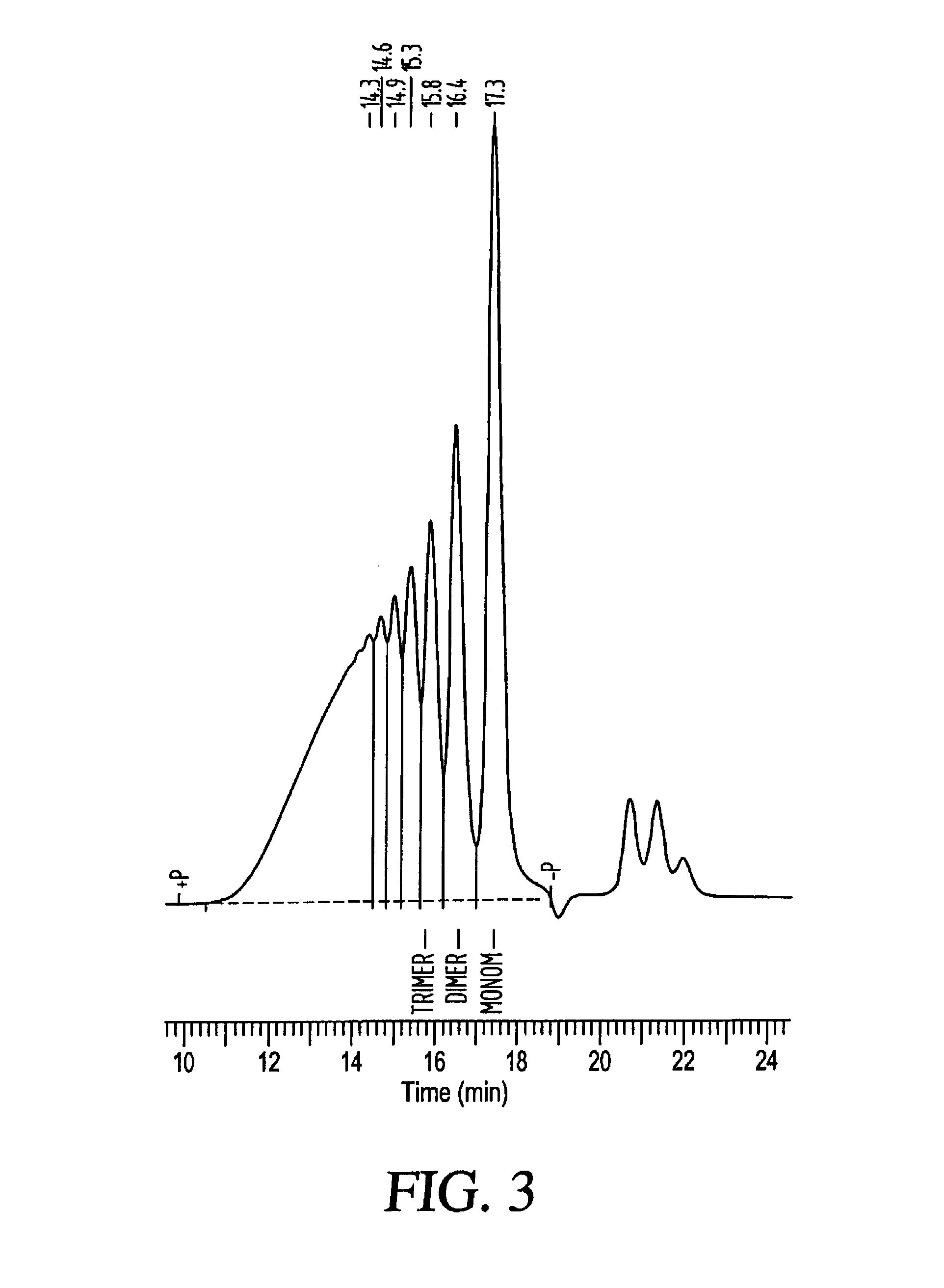

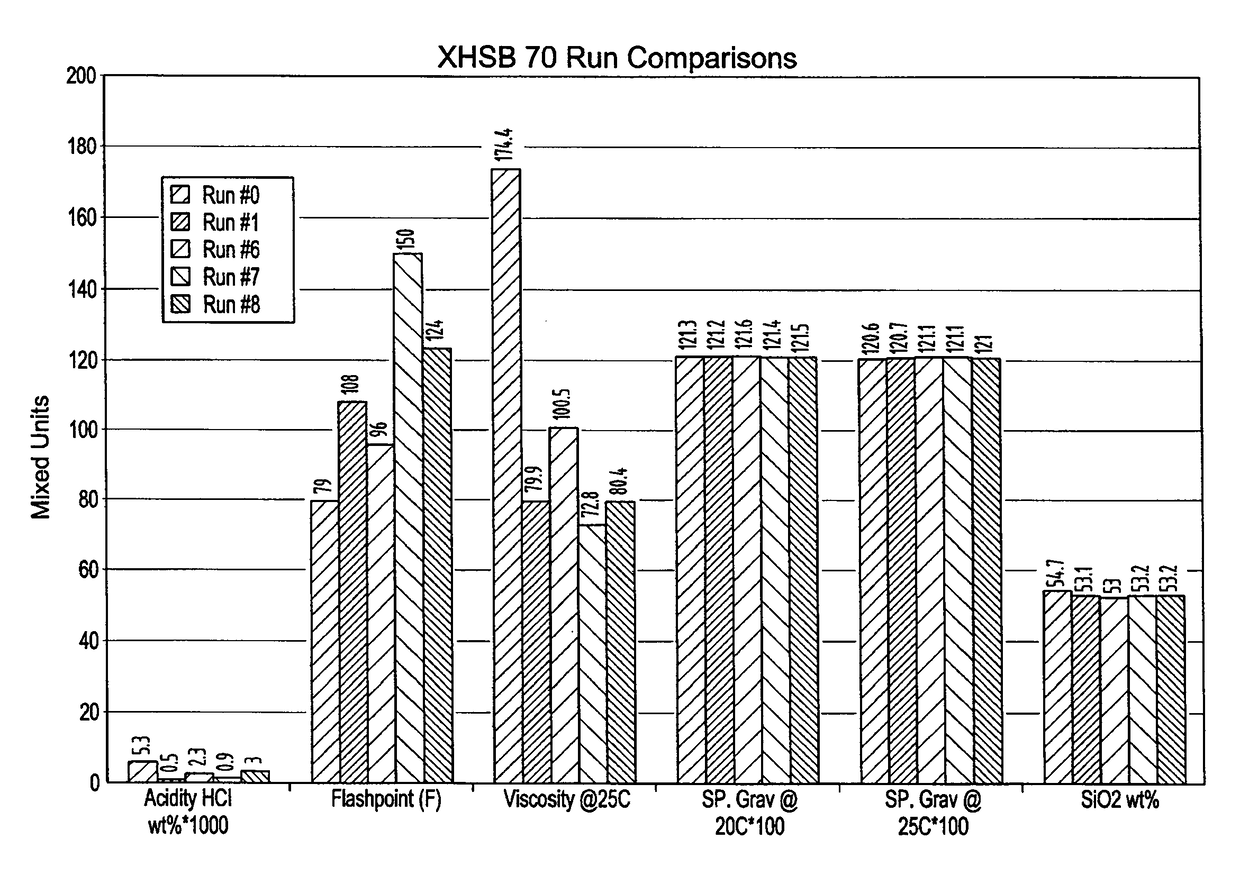

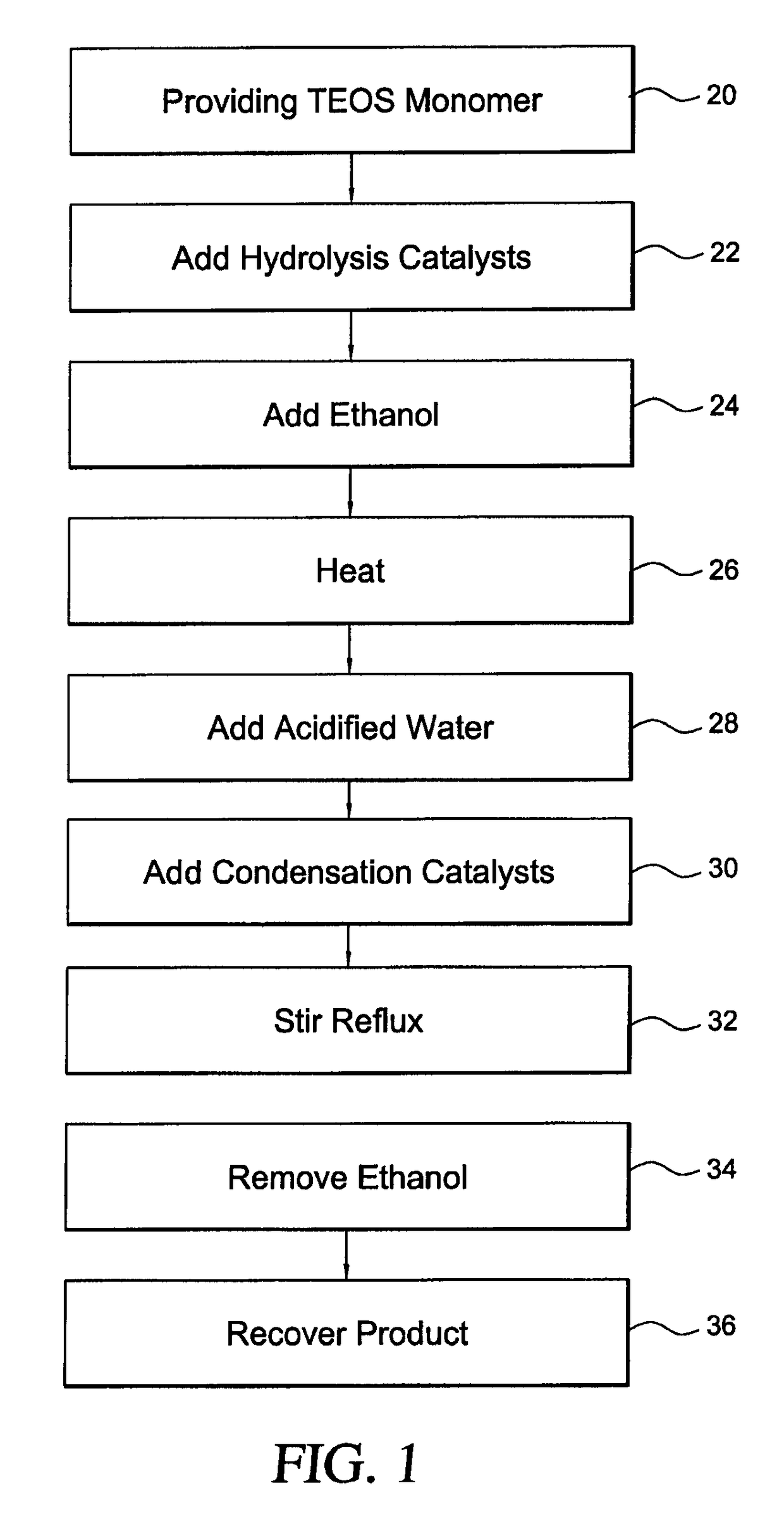

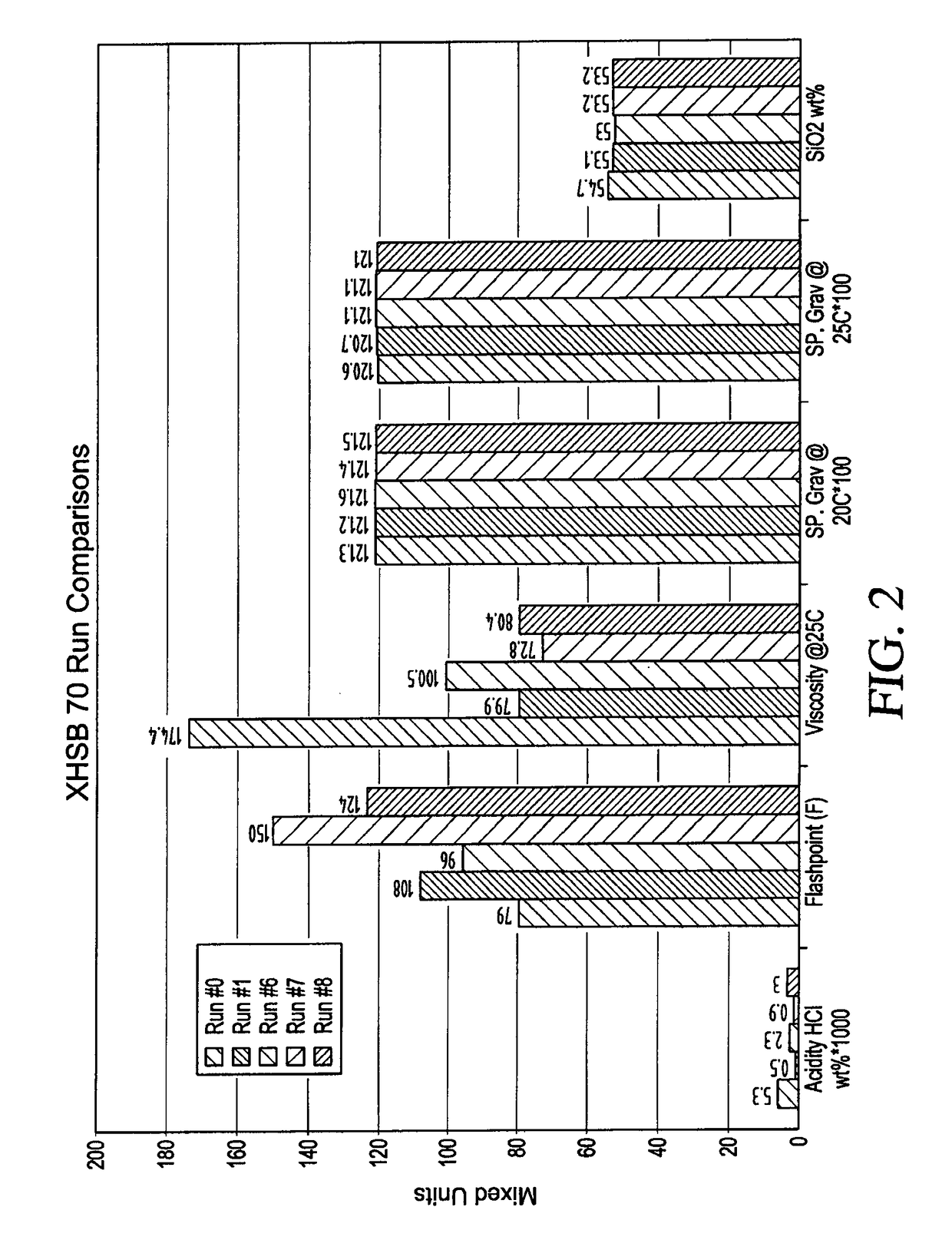

Stable Ethylsilicate Polymers

An stable ethylsilicate polymer having a dynamic viscosity of 10 centipoises (cps) to 1,000 cps at 25° C. and 50 wt % to 60 wt % silica (SiO2). The stable ethylsilicate polymer includes not greater than 1 wt % of TEOS monomer. The process of forming the ethylsilicate polymer includes a two step addition of catalysts. A hydrolysis catalyst is added initially, for example hydrochloric acid, and a second catalyst is added subsequently, such as phosphonitrilic chloride trimer. The ethylsilicate polymer is used to form MQ resins.

Owner:SILBOND CORP

MQ Resins From Stable Ethylsilicate Polymer Polymers

InactiveUS20110184142A1Lower dynamic viscosityHigh viscositySilicon organic compoundsPolymer scienceChloride

An MQ resin including at least 30% SiO2, preferably at least 50 wt % SiO2, and having dynamic viscosity of 50 centipoises (cps) to 750 cps at 25° C. is produced from a stable ethylsilicate polymer. The ethylsilicate polymer includes not greater than 1 wt % of TEOS monomer. The ethylsilicate polymer is produced by a two step addition of catalysts wherein a hydrolysis catalyst, for example, hydrochloric acid is added initially and a second catalyst, such as phosphonitrilic chloride trimer, is added subsequently.

Owner:SILBOND CORP

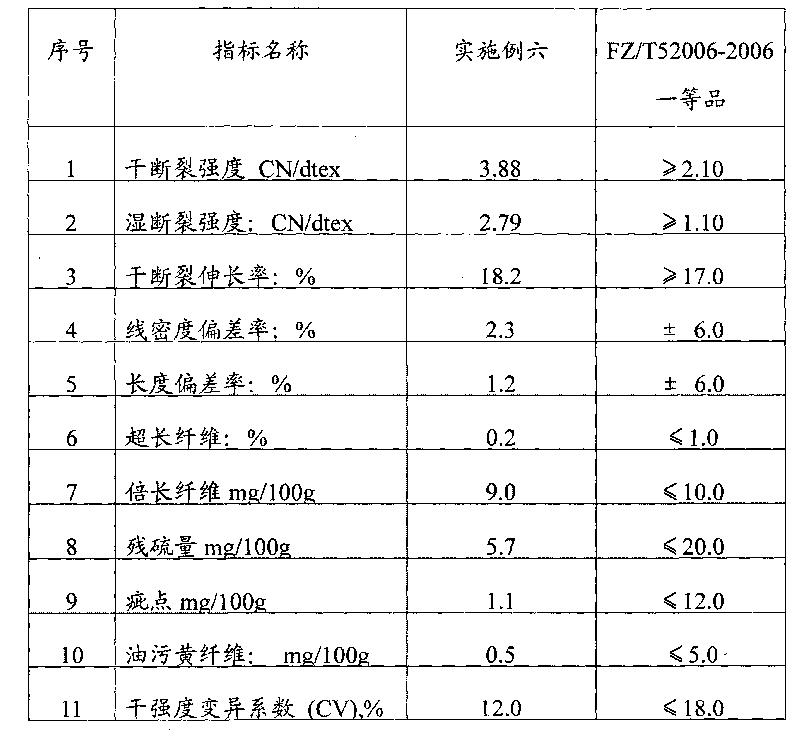

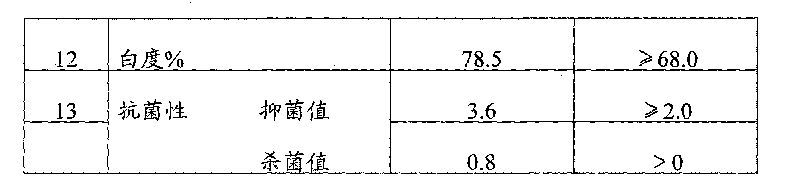

Production method of high-strength bamboo pulp viscose glue short fiber

ActiveCN101736409ANot easy to fadeSilky feelArtificial filaments from viscoseWet spinning methodsBreaking strengthWear resistance

The invention discloses a production method of high-strength bamboo pulp viscose glue short fiber, which adopts the steps of dipping, squeezing, smashing, maturing, yellowing, spinning, drawing, refining, drying and the like to prepare high-strength bamboo pulp viscose glue short fiber. The high-strength bamboo pulp viscose glue short fiber prepared with the method has dry breaking strength of 3.2-3.4 CN / dtex and wet breaking strength of 2.0-2.3 CN / dtex, is firm and has strong spinnability; fabrics and clothes manufactured by the fiber have favourable toughness and high abrasive resistance; other indexes are all superior to the first-rate product index of FZ / T 52006-2006. The fiber manufactured with the method is ideal material for high-rank clothes and household textiles.

Owner:上海中纺物产发展有限公司

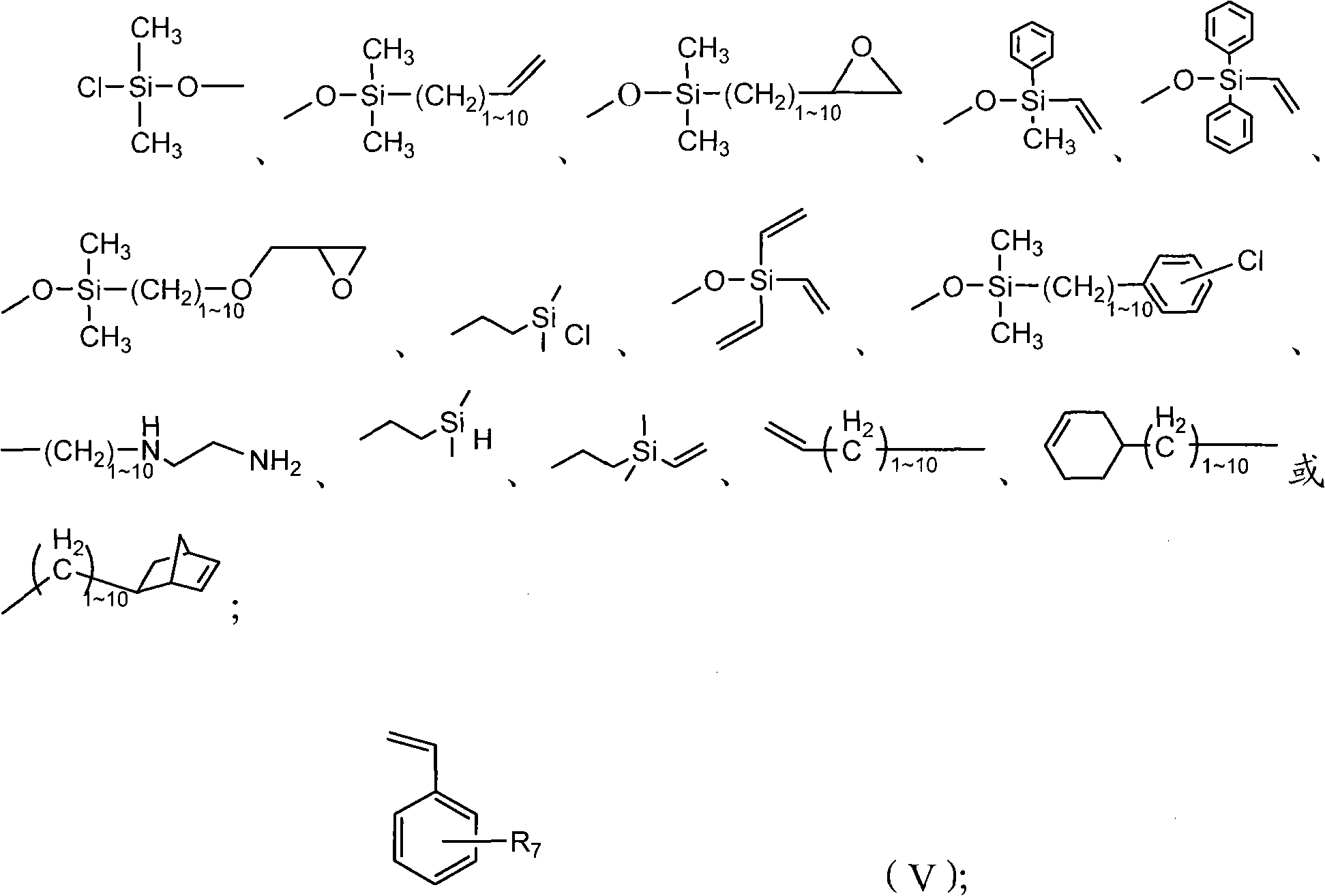

Nanometer silicon-containing ultraviolet thick film positive photoresist and film forming resin thereof

ActiveCN101979435AImprove adhesionGood flexibilityPhotomechanical apparatusSolventPhotosensitizing compounds

The invention relates to ultraviolet thick film photoresist, which is mainly prepared from 10 to 35 parts of phenolic resin, 1 to 10 parts of nanometer silicon-containing copolymer film forming resin, 5 to 20 parts of diazo naphthoquinone light-sensitive compound, 30 to 85 parts of solvent and a small number of other additives such as n-butylamine and surfactants which serve as raw materials by blending the raw materials and filtering through 5 micrometers, 1 micrometer and 0.2 micrometer filters. The nanometer silicon-containing alkaline soluble copolymer film forming resin is added into the film forming resin to increase the adhesivity, flexibility, side-wall verticality and mechanical properties of a film-forming agent and fulfill the aims of preventing adhesive films from cracking and patterns from deforming and even dropping in a salient point process, three-dimensional (3D) combined encapsulation and the manufacturing of micro-electromechanical systems (MEMS).

Owner:昆山西迪光电材料有限公司

Adjustable passive flow regulator

InactiveUS9971358B2Easy to manageReduce sensitivityValve arrangementsWound drainsHydrocephalusPain management

An adjustable passive flow regulator may be used in the field of drug delivery (liquid or gaseous, e.g. for pain management) or for draining cerebrospinal fluid (CSF) for hydrocephalus patient.

Owner:DEBIOTECH SA

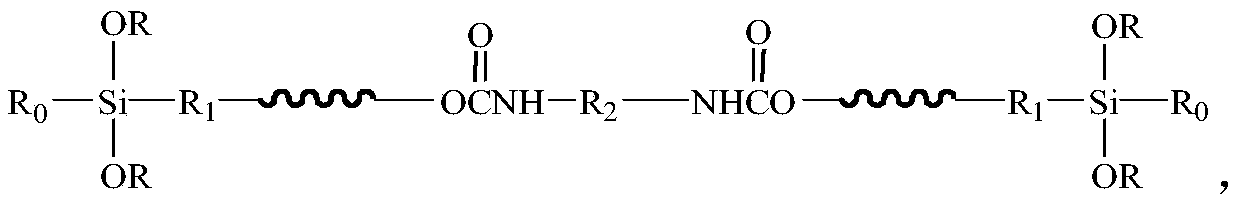

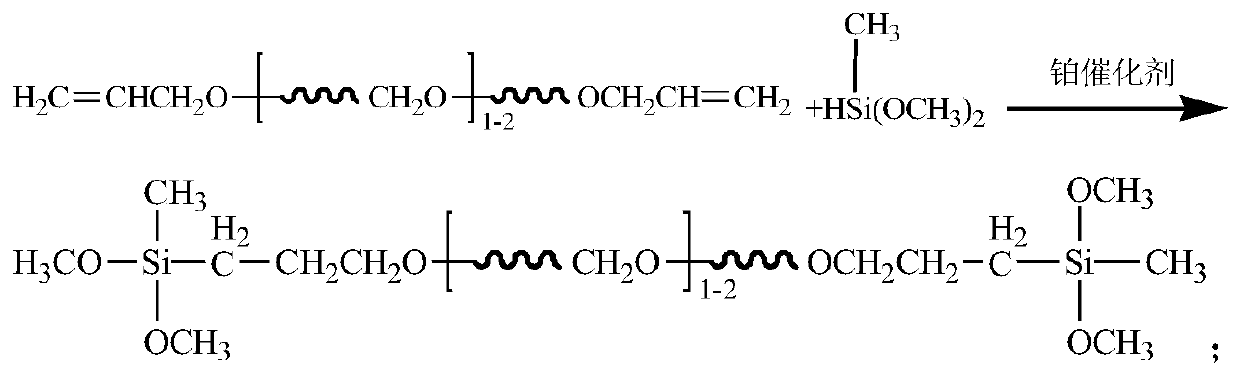

Silane-terminated resin for sealant and preparation method thereof

ActiveCN111393611AShorten the supply chainLow costPolyureas/polyurethane adhesivesPolymer scienceSilanes

The invention provides a silane-terminated resin for a sealant. The structural formula of the silane-terminated resin is shown as the specification, wherein R is straight-chain or branched-chain C1-C10 alkyl; R0 is straight-chain or branched-chain C1-C10 alkyl or branched-chain C1-C10 alkoxy; R1 is straight-chain or branched-chain C1-C10 alkyl; and R2 is a diisocyanate group. The invention also discloses a preparation method of the resin, and the method comprises the following steps: using hydroxyl alkoxy silane as the raw material, adding a first catalyst, carrying out nitrogen placement, then performing heating, introducing an epoxy compound to carry out pre-reaction, initiating the reaction, then continuously introducing an epoxy compound for reaction, thereby obtaining a monosiloxane group terminated polyether intermediate; adding a second catalyst and diisocyanate into the intermediate, and performing heat preservation to further carry out reaction, thus obtaining the silane-terminated resin for a sealant. According to the method, the reaction path is shortened, so that side reactions are reduced, the utilization rate of raw materials is increased, three wastes are not generated in the preparation process, the preparation process is simple and environment-friendly, and the prepared resin is low in dynamic viscosity.

Owner:ZHEJIANG HUANGMA TECH +3

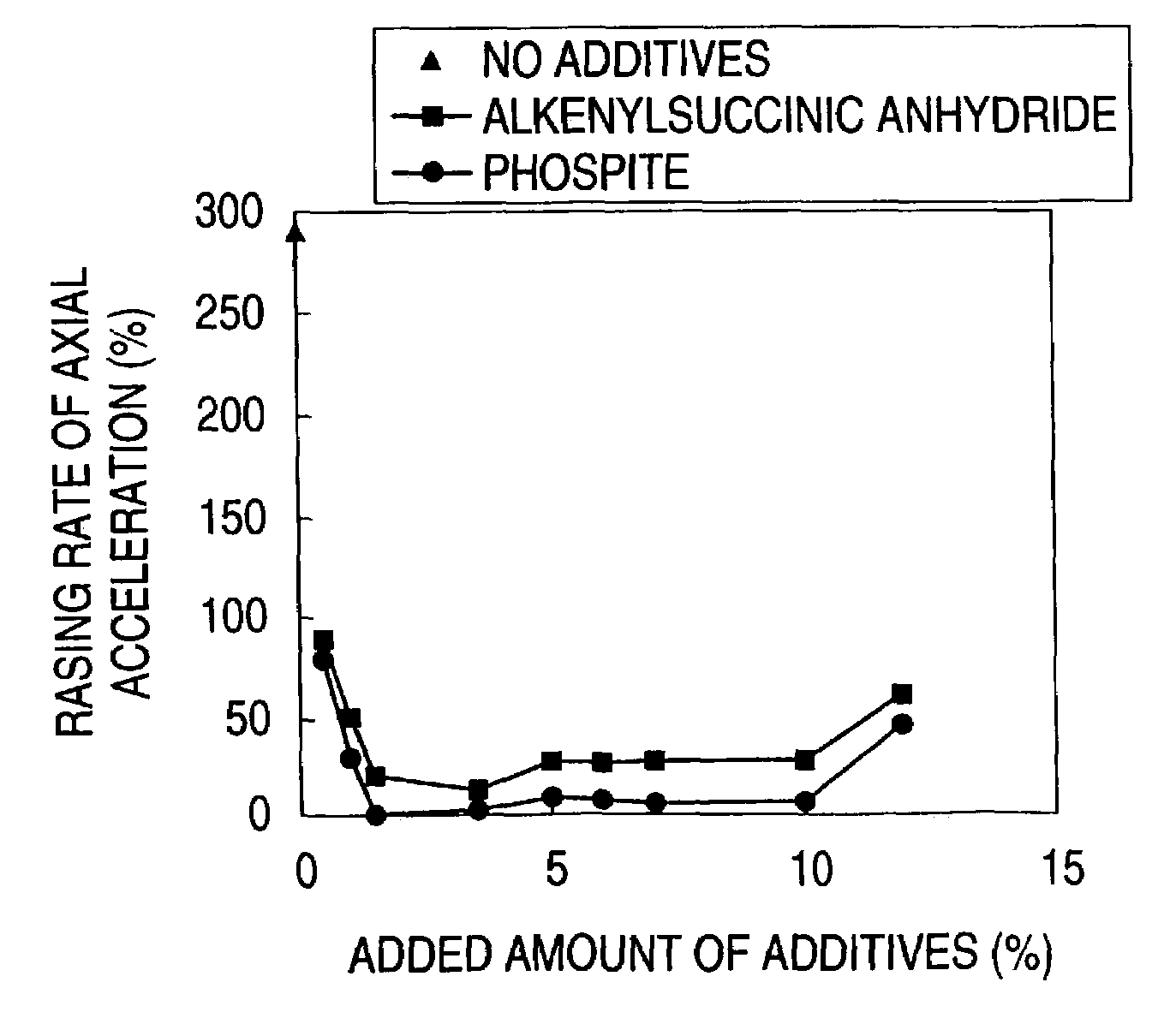

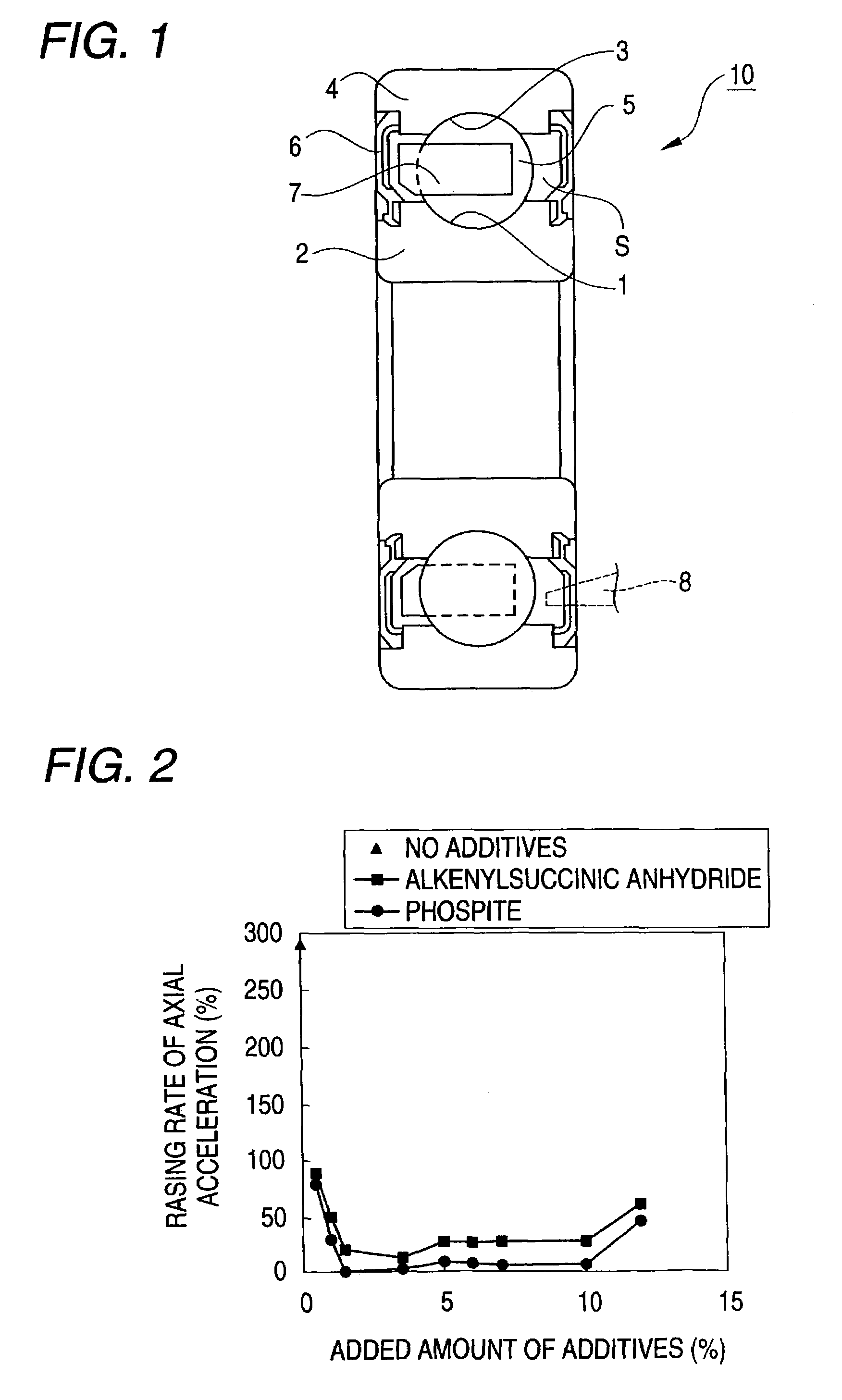

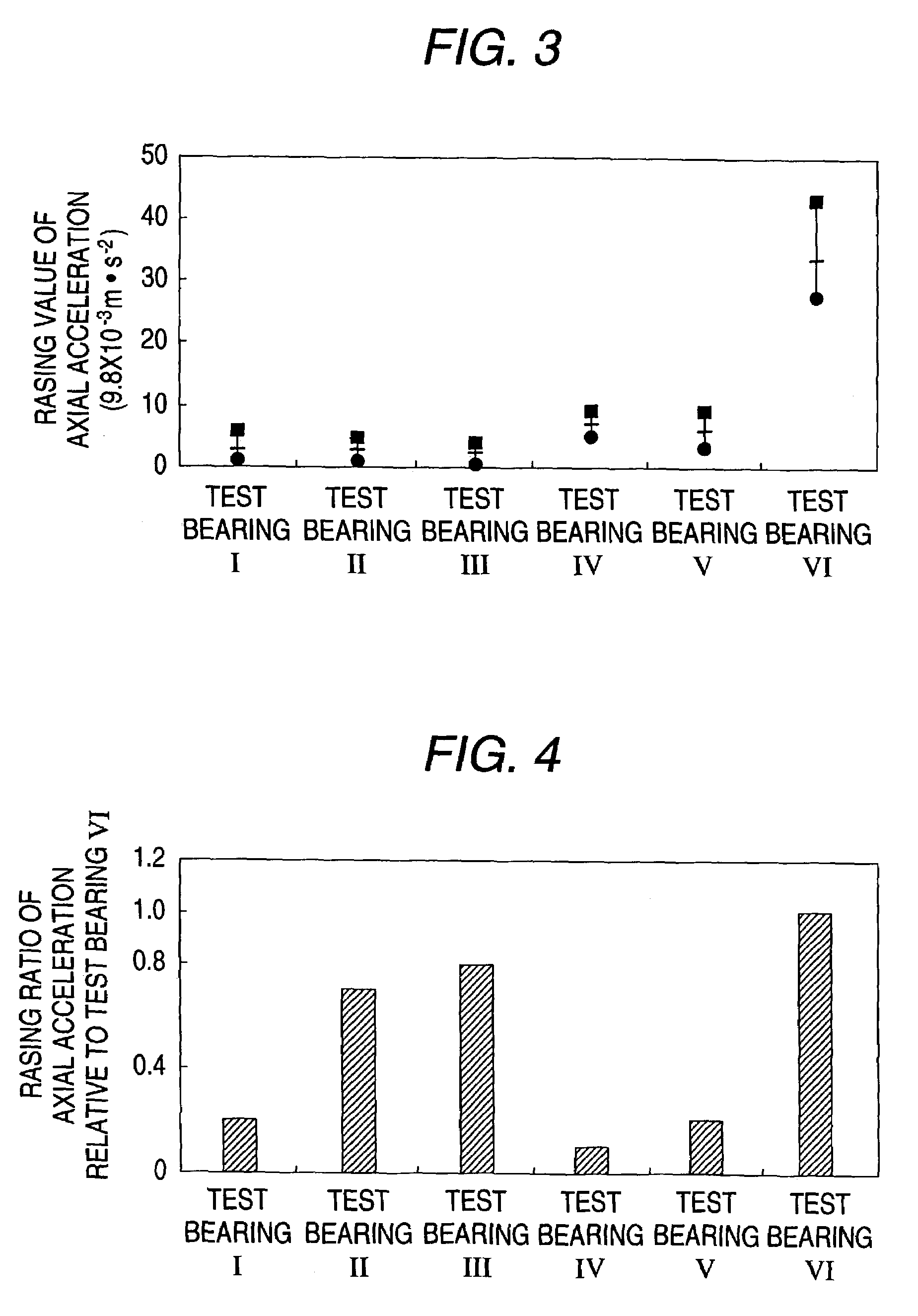

Rolling Bearing

InactiveUS7234872B2Improve resistanceReduces dynamic viscosityShaftsBall bearingsAcid derivativeEngineering

A rolling bearing includes a plurality of rolling elements movably retained at almost the same interval between an inner ring and an outer ring with a cage made of synthetic resin provided interposed therebetween. The rolling bearing further includes, an oil film made of a lubricant, and a grease containing a synthetic oil as a base oil enclosed therein. The lubricant contains at least one additive selected from the group consisting of organic aliphatic acid, organic aliphatic acid derivative and organic phosphorus compound incorporated in a synthetic oil in a proportion of from 0.5 to 10% by weight formed on the surface of the raceways of the inner and outer rings and the surface of the rolling elements, and a grease containing a synthetic oil as a base oil enclosed therein.

Owner:NSK LTD

MQ resins from stable ethylsilicate polymers

InactiveUS8829144B2Lower dynamic viscosityHigh viscositySilicon organic compoundsPolymer scienceChloride

An MQ resin including at least 30% SiO2, preferably at least 50 wt % SiO2, and having dynamic viscosity of 50 centipoises (cps) to 750 cps at 25° C. is produced from a stable ethylsilicate polymer. The ethylsilicate polymer includes not greater than 1 wt % of TEOS monomer. The ethylsilicate polymer is produced by a two step addition of catalysts wherein a hydrolysis catalyst, for example, hydrochloric acid is added initially and a second catalyst, such as phosphonitrilic chloride trimer, is added subsequently.

Owner:SILBOND CORP

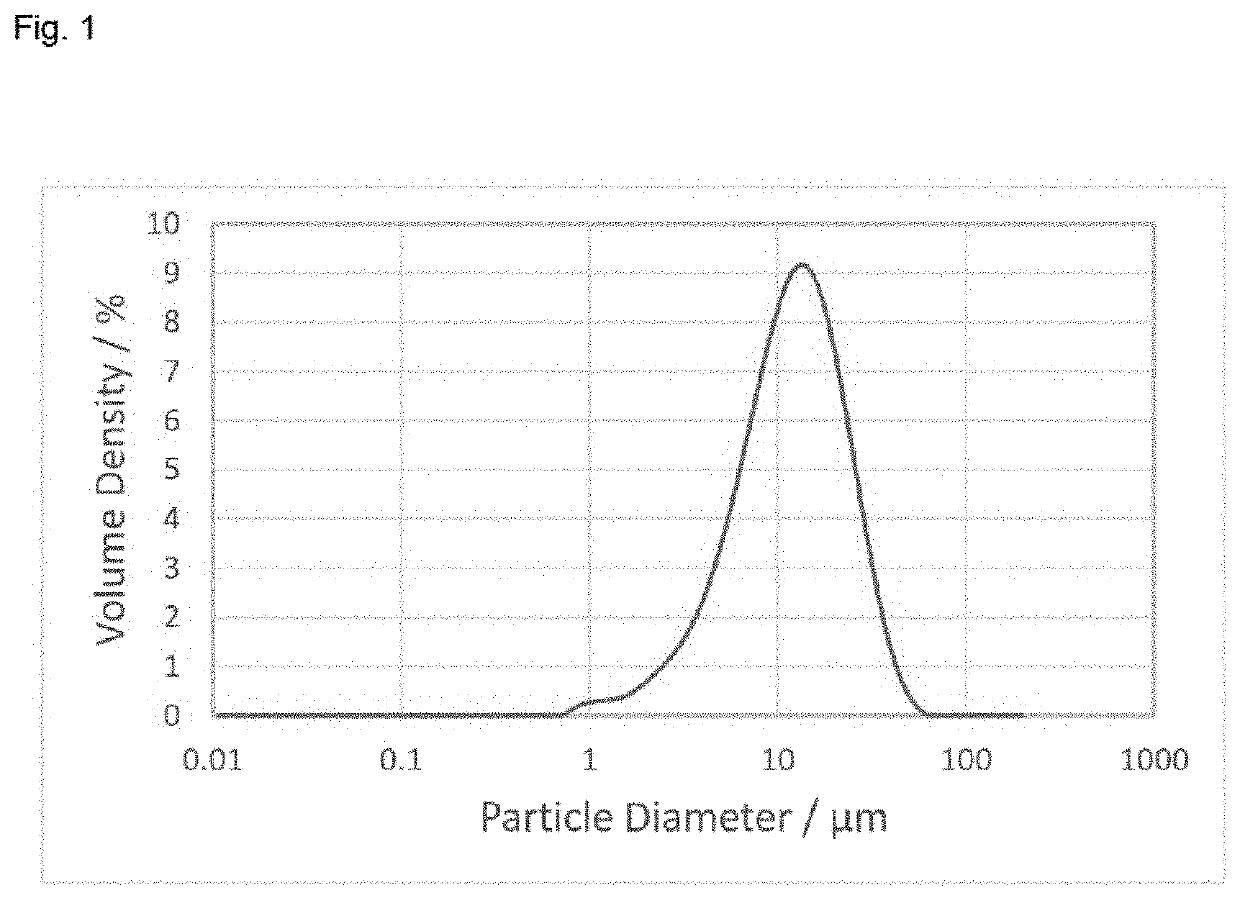

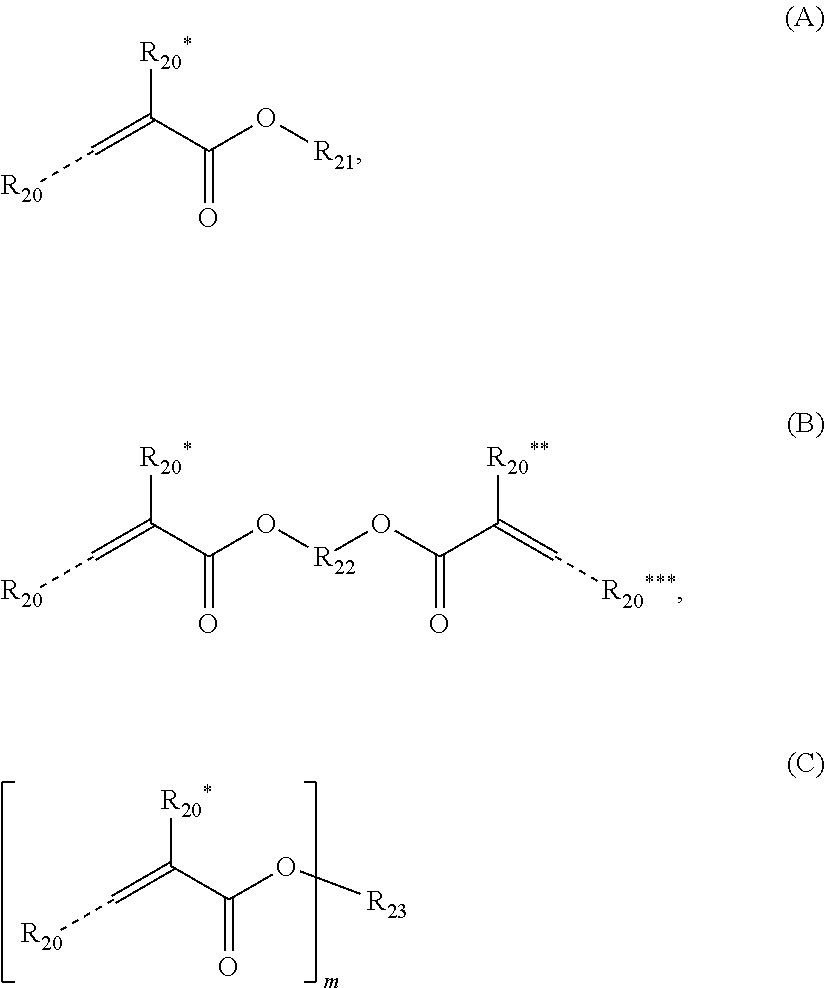

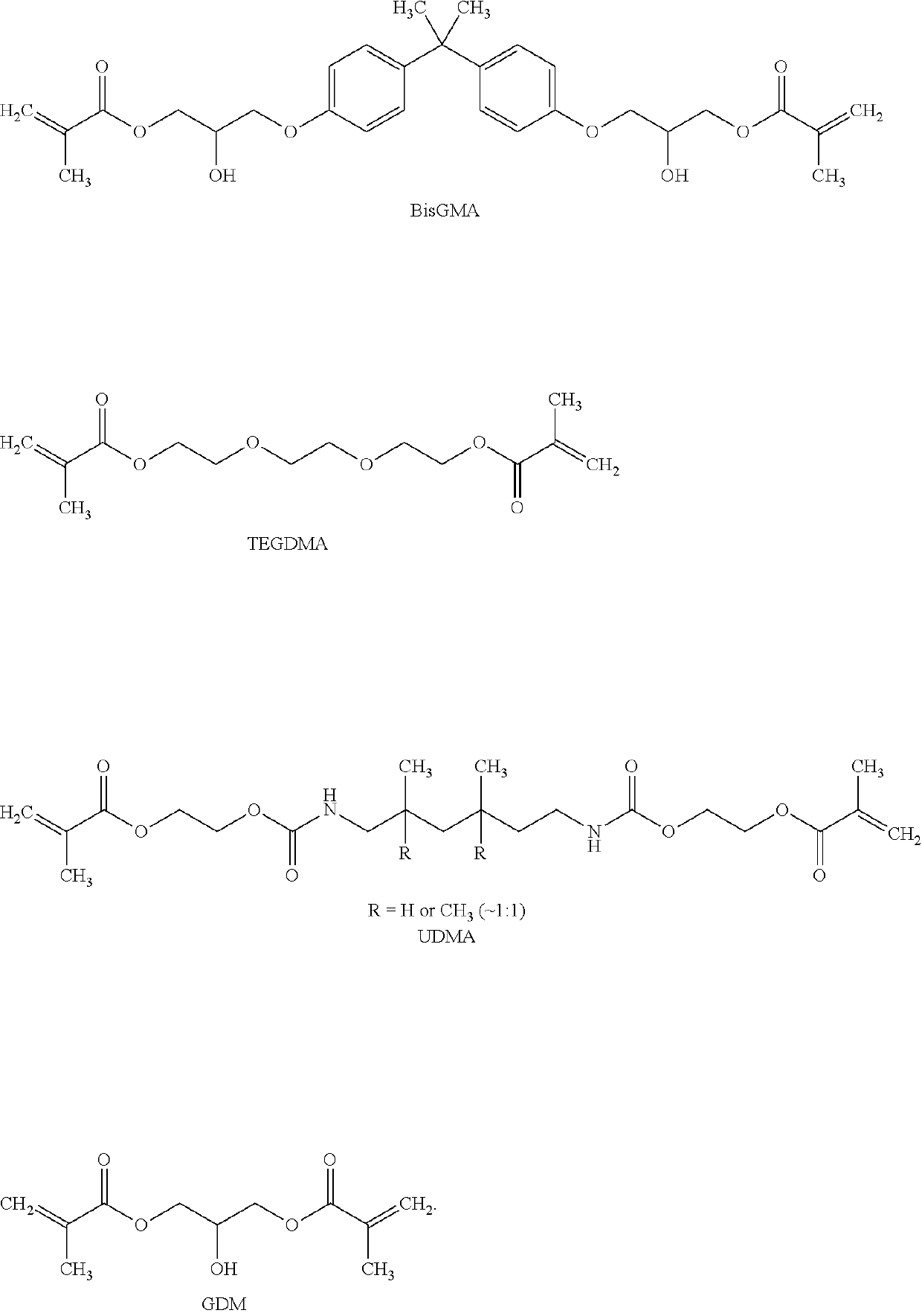

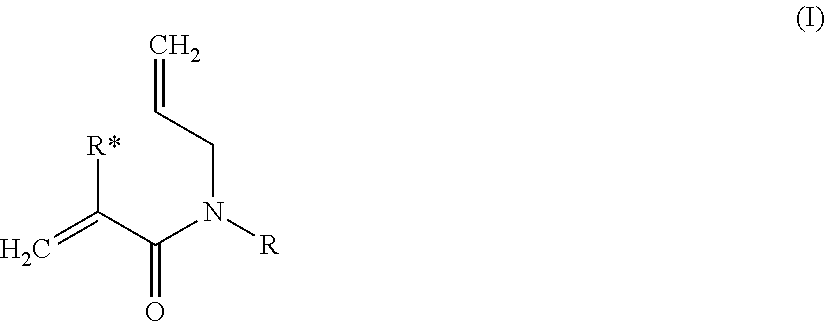

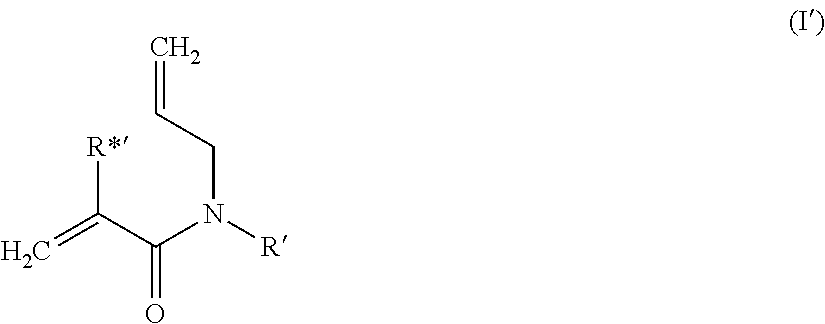

Additive manufacturing process

PendingUS20220031576A1Low viscosityImprove mechanical propertiesImpression capsManufacturing enclosuresOrganic chemistryAdditive layer manufacturing

An additive manufacturing process comprising:(a) providing a curable composition comprising:(i) a filler comprising glassflakes having a diameter D3,99 as determined by light scattering in the range of from 5 to 150 μm; and(ii) one or more curable compounds;(b) controlling an apparatus to form an object by using the curable composition, whereby the curable composition passes a discharge orifice having a minimum diameter Φmin,wherein the ratio of the minimum diameter of the discharge orifice to the diameter D3,99 of the glassflakes (Φmin / D3,99) is in the range of 2 to less than 10; and wherein the median diameter D3,50 of the glassflakes is larger than the thickness of the glassflakes.

Owner:DENTSPLY SIRONA INC

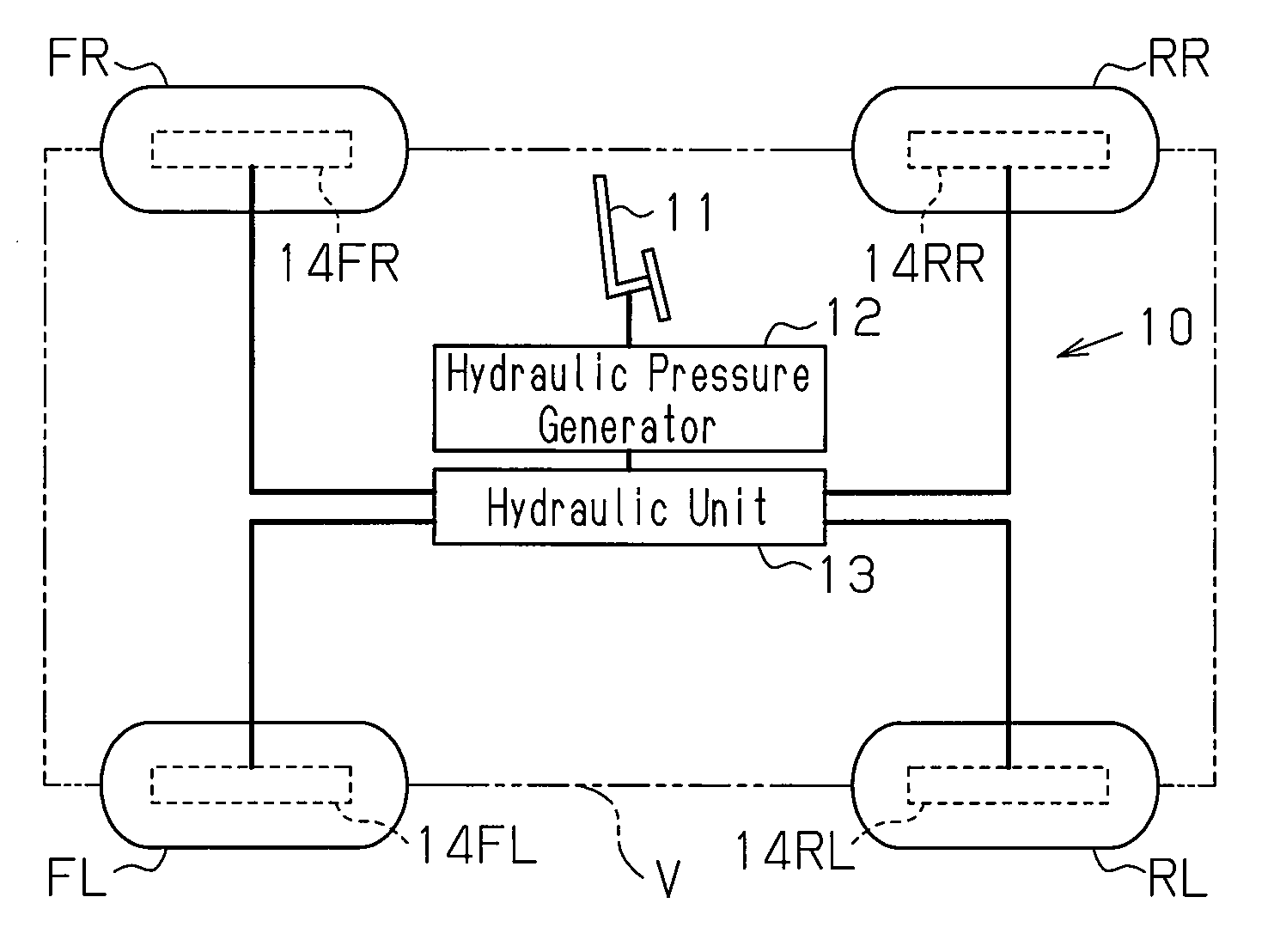

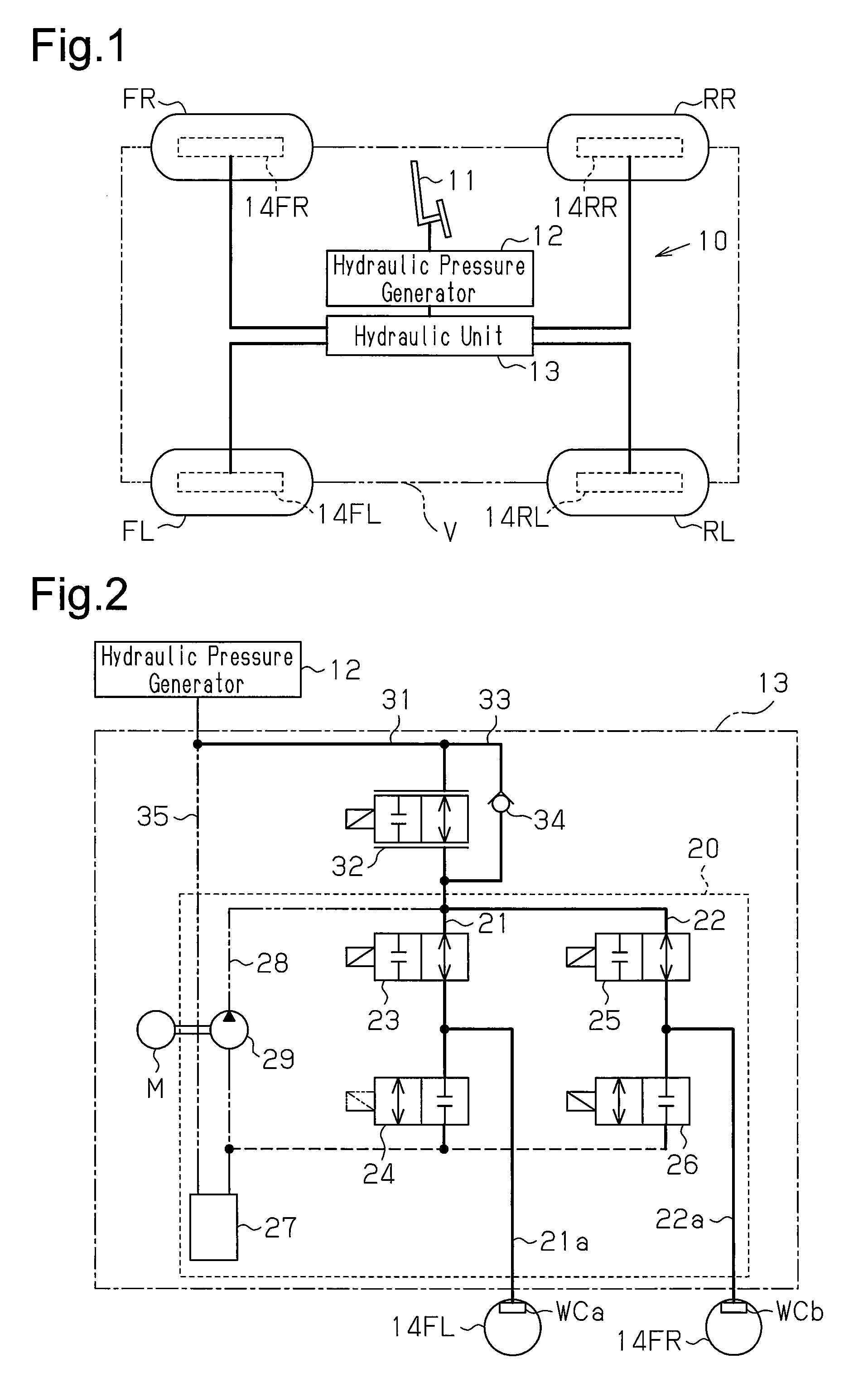

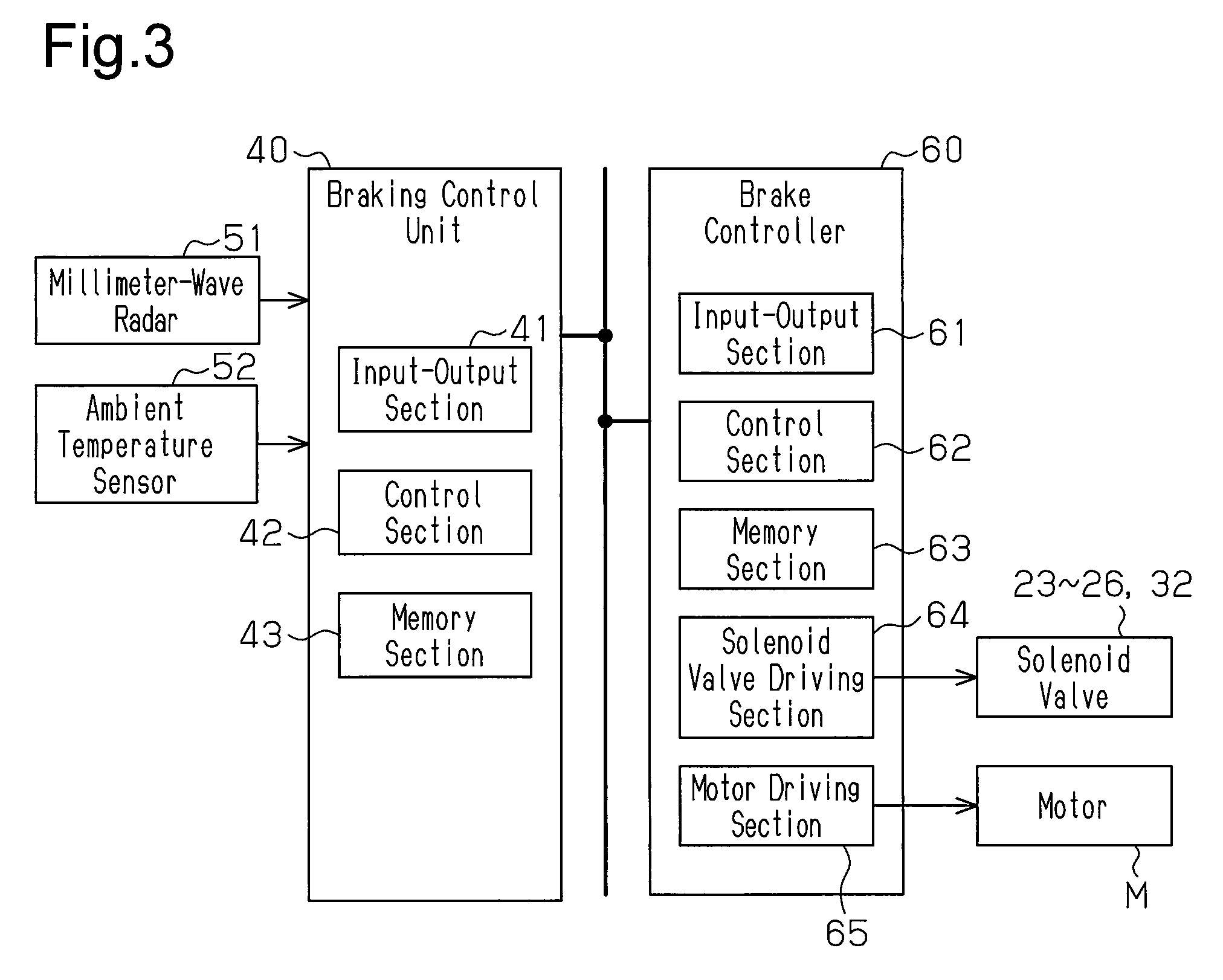

Automatic braking control device

ActiveUS9321438B2Improve accuracyImprove reliabilityBraking action transmissionAutomatic initiationsStart timeAutomatic braking

An automatic braking control device includes a temperature obtaining section for obtaining an index value of a temperature of brake fluid, a collision prediction time calculation section for calculating collision prediction time of a vehicle with an object, a collision determination section for determining whether the collision prediction time is less than or equal to a threshold, and a pressure control section for controlling a start timing of pressurization of the brake fluid when the collision prediction time is less than or equal to the threshold. The pressure control section sets the start timing to a first timing when the index value is a first temperature and to a second timing when the index value is a second temperature higher than the first temperature. Time from determination of the collision determination section to the first timing is shorter than time from the determination to the second timing.

Owner:HINO MOTORS LTD

Heat treatment oil composition

ActiveUS20180023022A1Reduce materialLower dynamic viscosityAdditivesBase-materialsPetroleum resinMedicine

A heat treatment oil composition is provided that suppresses the decrease of luster in a heat treatment of a metal material, and is capable of suppressing the increase of the number of second (characteristic number of second) until reaching the temperature where the vapor blanket stage ends with the lapse of time and the decrease of the kinetic viscosity with the lapse of time. The heat treatment oil composition contains (A) a base oil and (B) a vapor blanket breaking agent selected from one or more of a petroleum resin, a terpene resin, rosin, and derivatives thereof.

Owner:IDEMITSU KOSAN CO LTD

A bridge deck pavement method for orthotropic steel bridges

ActiveCN104652270BImprove pull strengthGood deformabilityIn situ pavingsBridge structural detailsEpoxySolvent free

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

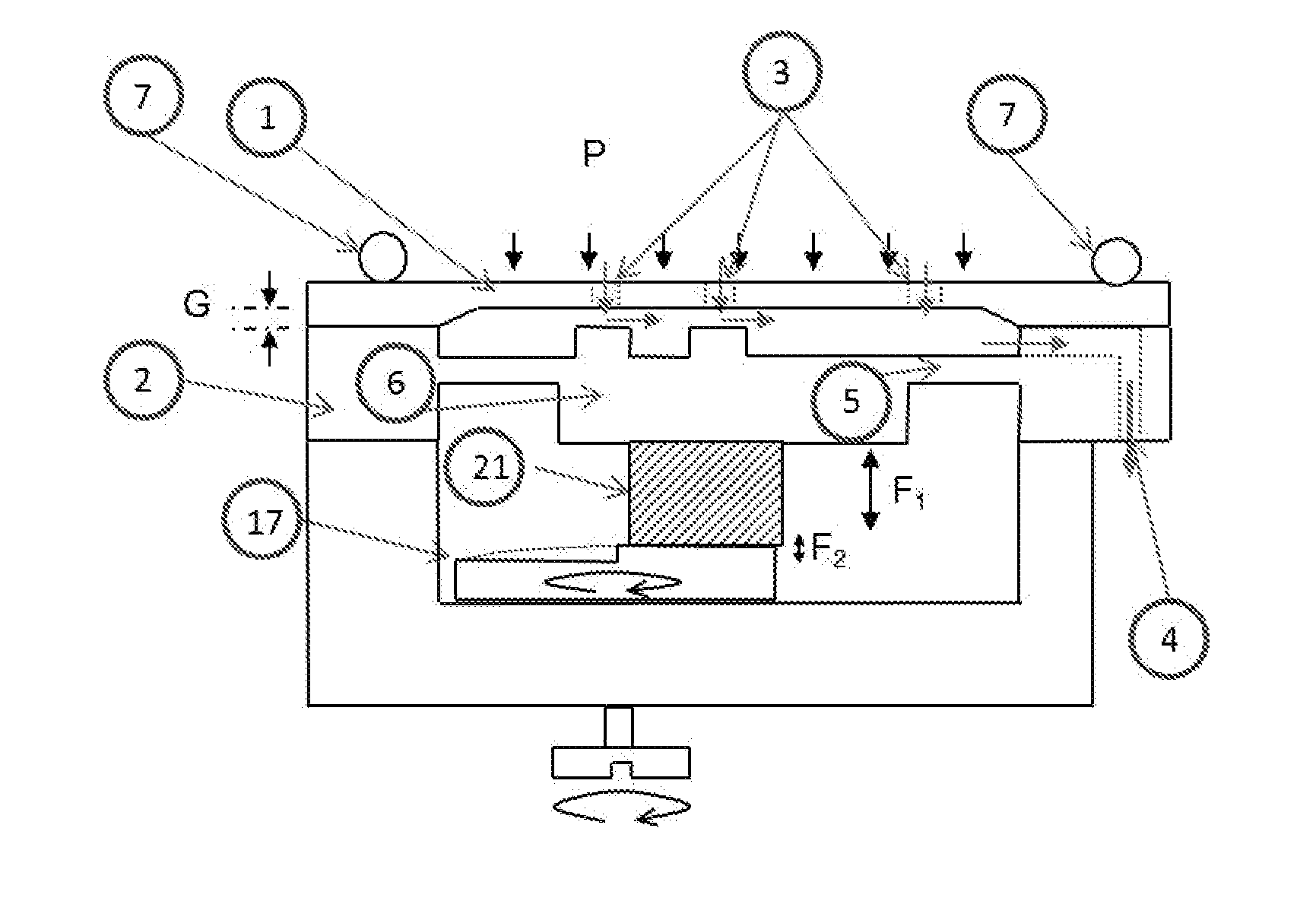

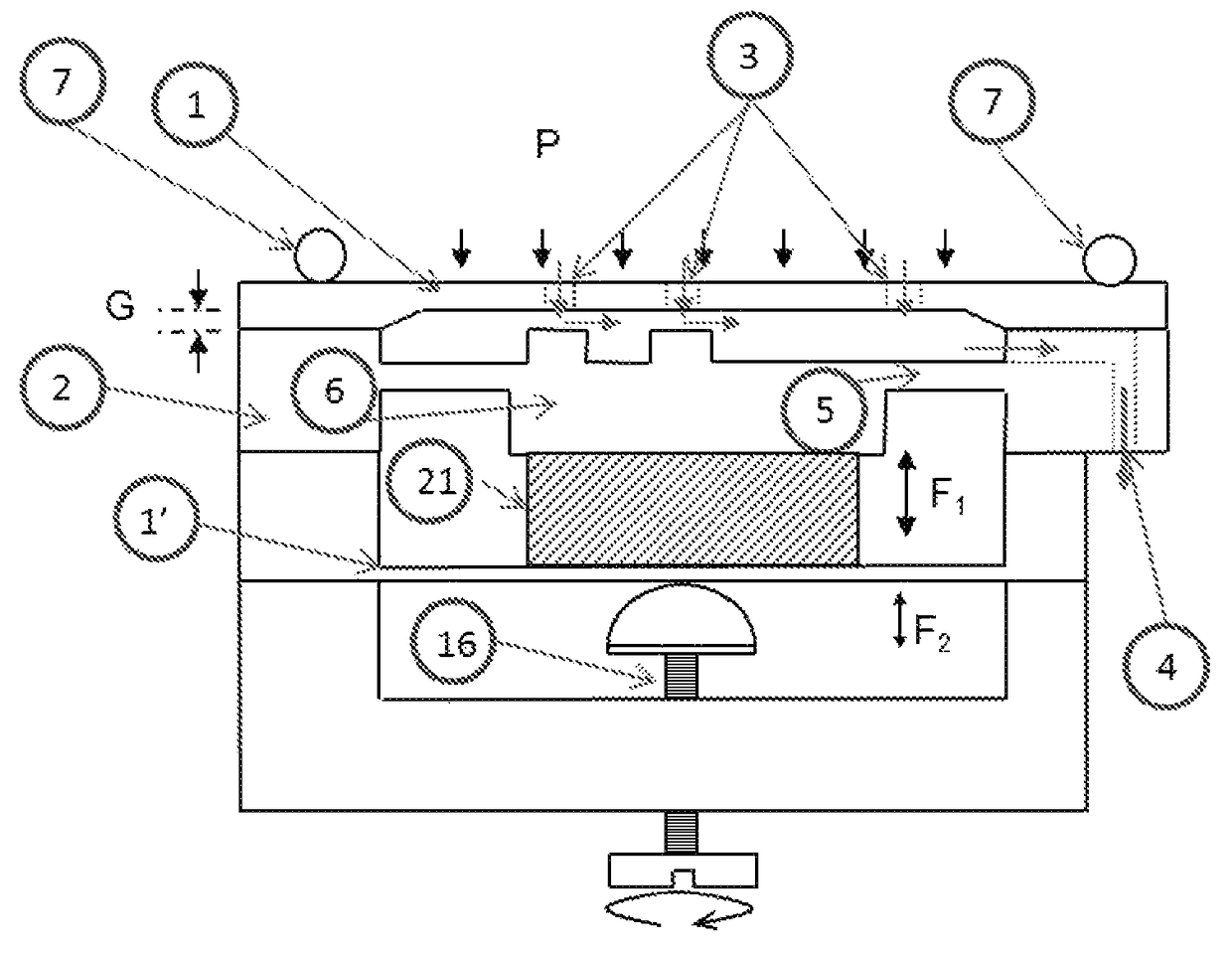

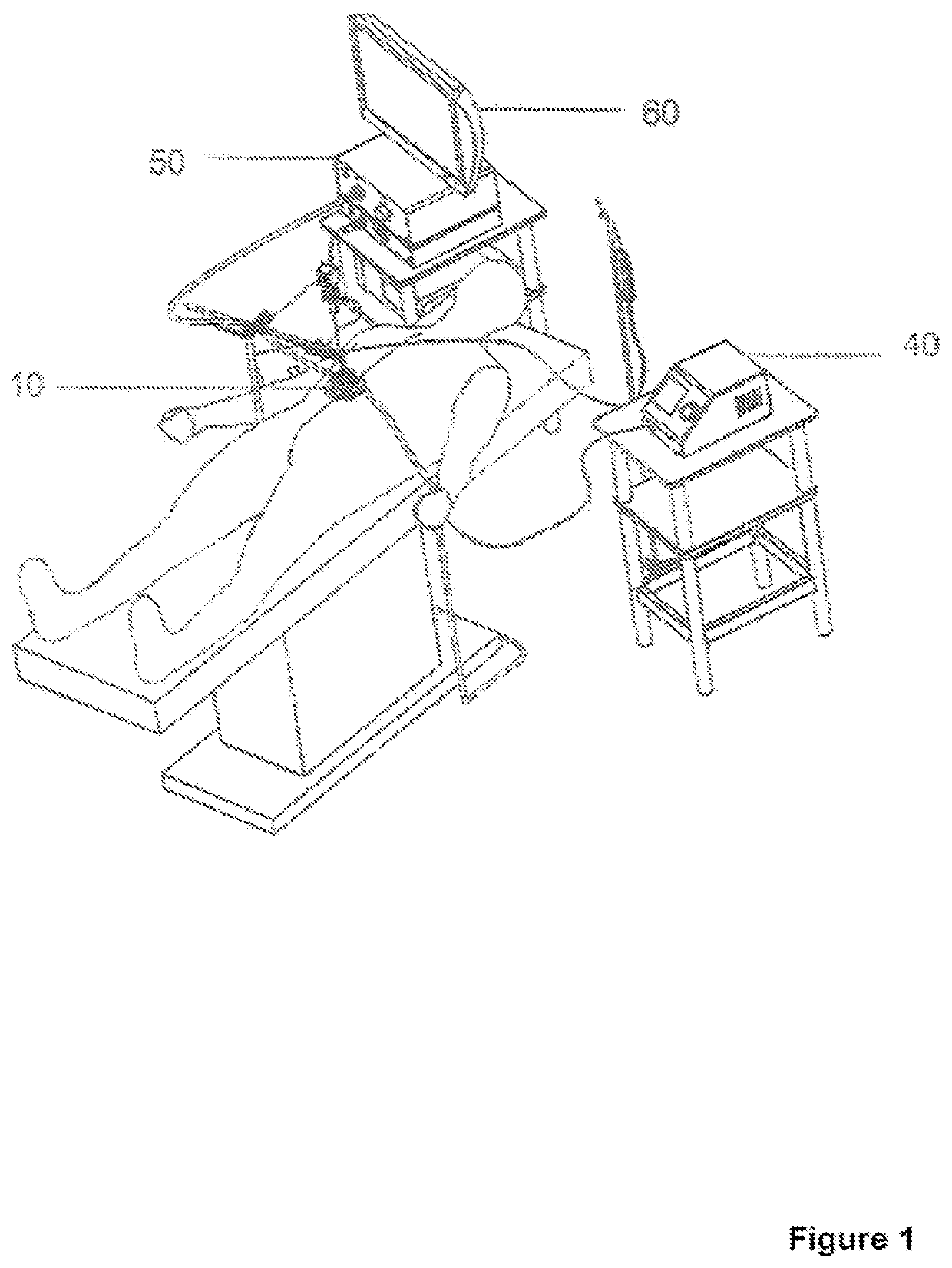

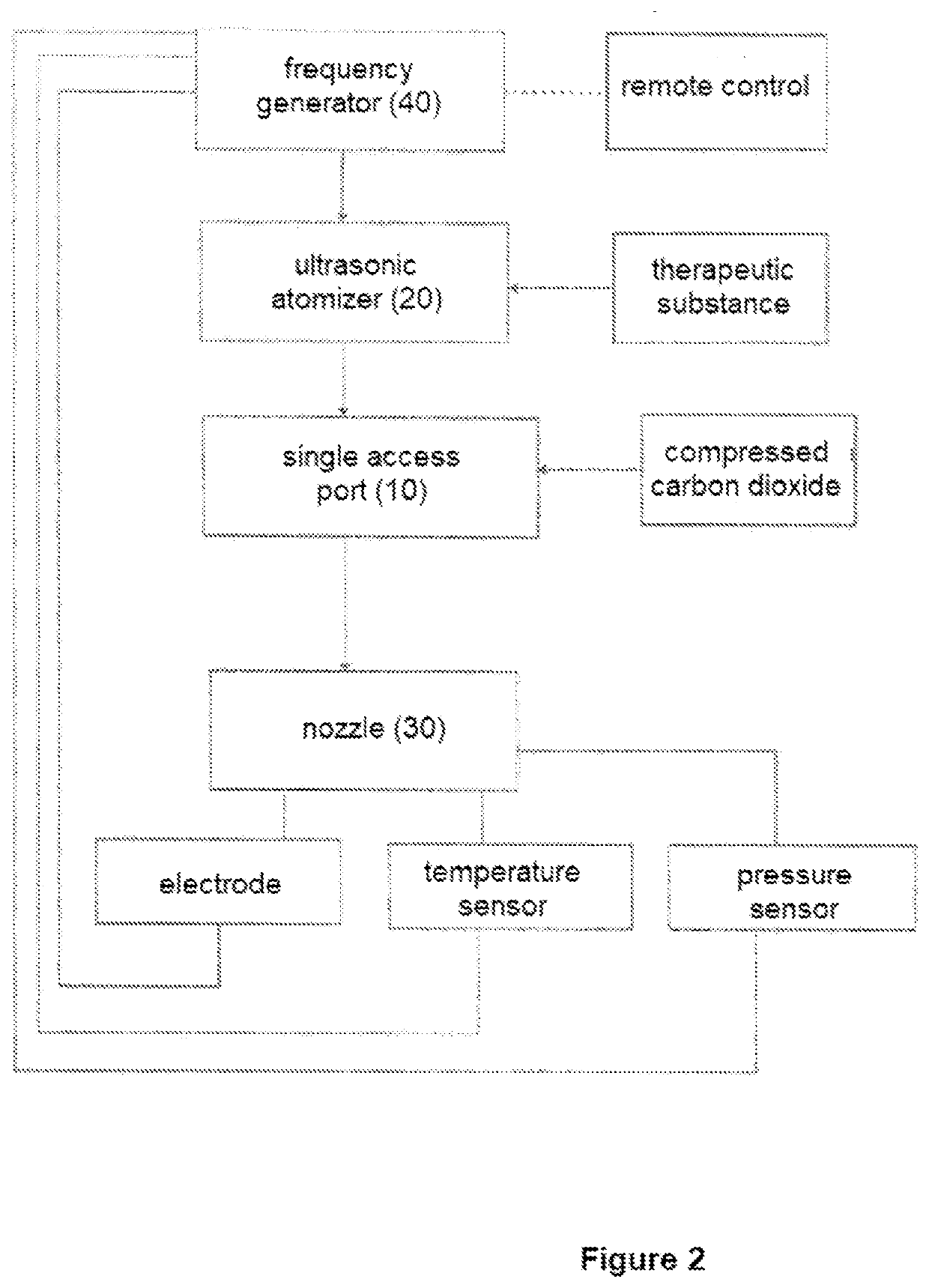

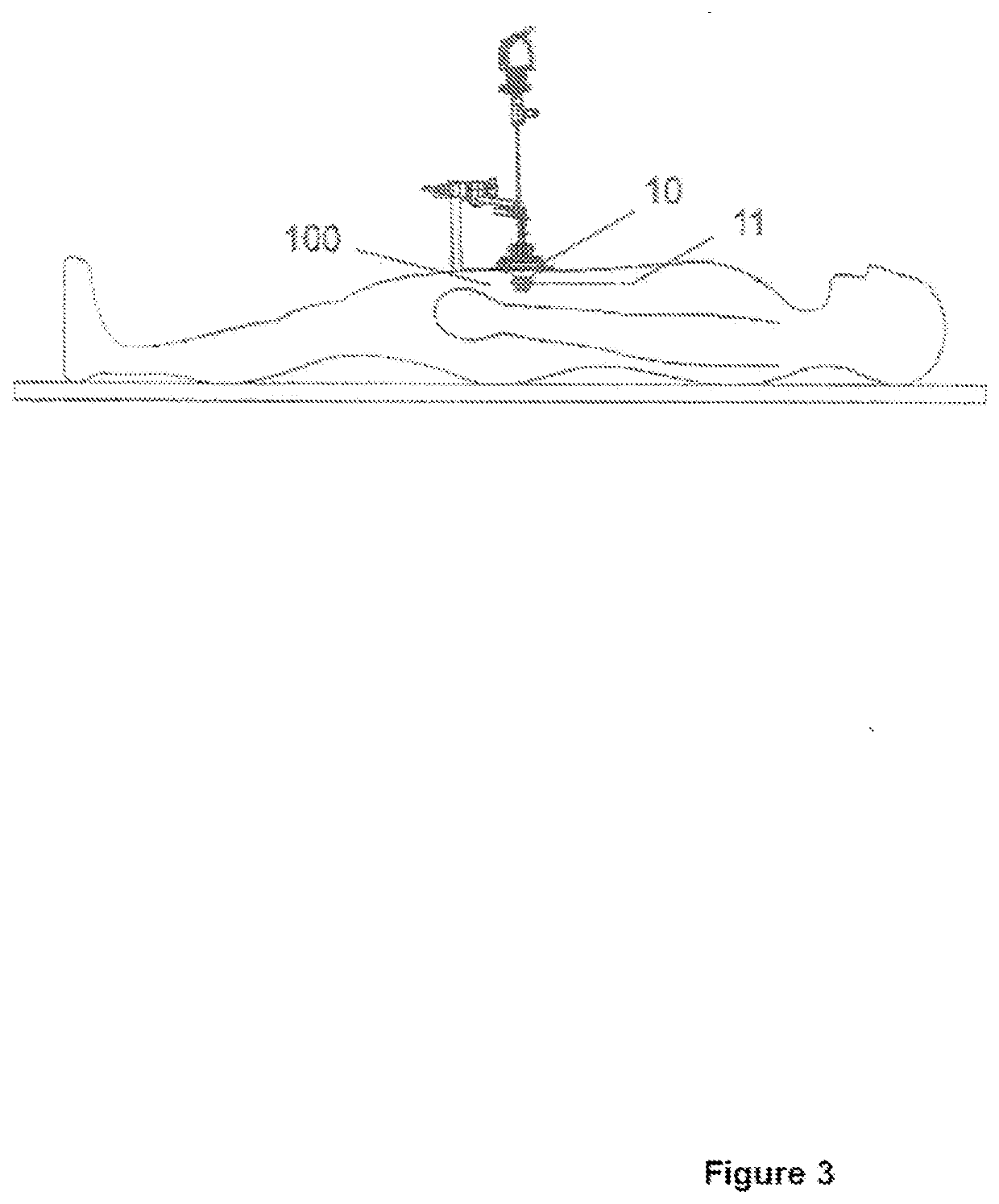

Ultrasonic aerosolization platform for the application of therapeutic substances to body cavities

PendingUS20220152320A1Lower dynamic viscosityLow densitySurgical needlesMedical devicesAtomizer nozzleUltrasonic atomizer

The present invention relates to an ultrasonic aerosolization platform that has a single access port (10) provided with a trocar (11) inserted into the surgical cavity through a single incision and provided with at least one internal channel (101) in which is positioned an ultrasonic aerosolizer (20) provided with a head (21) that houses a power piezoelectric transducer (214) and a resonating rod (22) that extends orthogonally from the head (21), provided with an internal channel (221) in communication with the internal channel (212) of the head (21) and a free end (222) with an atomization nozzle (30) with orifices (31); a high-frequency ultrasound generator (40) that provides an electrical signal to the power piezoelectric transducer (214), which converts said electrical signal into mechanical oscillations transmitted to the resonating rod (22) in the form of mechanical standing waves; and a processing unit (50) provided with an interface (60) for adjusting the excitation frequency of the transducer (214), adjusting the flow of the therapeutic substance, and adjusting the operating and actuation time of the electrode (not shown) arranged in the resonating rod (22).

Owner:BHIO SUPPLY IND E COMERCIO DE EQUIPAMENTOS MEDICOS +1

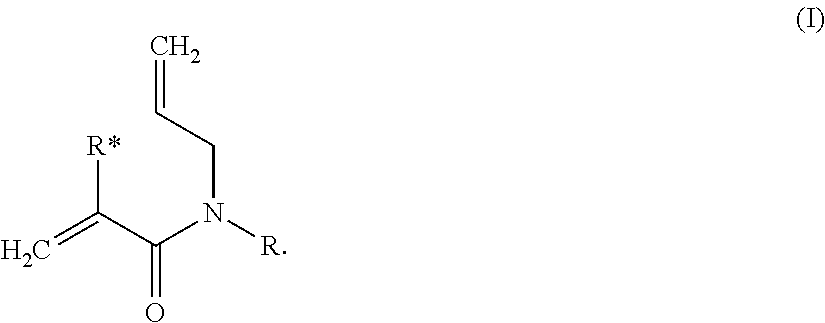

Dental composition

ActiveUS11116702B2Lower dynamic viscosityImprove responseImpression capsOrganic chemistryMeth-Heteroatom

Owner:DENTSPLY SIRONA INC

Injection pressurized casing gas recovery device

The invention provides an injection pressurized casing gas recovery device, which is used for recovering the casing gas in the wellhead of an oil field. The device includes: ejector, gas-liquid mixed pump, liquid inlet valve, liquid outlet valve, inlet valve, gas storage tank, gas pressure sensor, gas flow meter, electric valve, control unit, etc., and is made into a skid-mounted piece. The liquid inlet of the ejector is connected with the upstream of the oil well oil outlet pipeline, and the liquid outlet is connected with the inlet of the gas-liquid mixed transport pump. When working normally, both the liquid inlet valve and the liquid outlet valve are opened. When the pressure of the casing gas reaches a certain value, the gas pressure sensor sends a signal to the control unit, and the control unit sends an instruction to start the mixed pump and open the electric valve after a delay; The high-speed flowing liquid in the introducer attracts the casing gas, and after mixing, it enters the mixed transport pump for pressurization, and then enters the oil well outlet pipeline to realize the recovery of the casing gas and avoid the damage caused by burning or venting the casing gas. Energy waste and air pollution.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Stable ethylsilicate polymers

An stable ethylsilicate polymer having a dynamic viscosity of 10 centipoises (cps) to 1,000 cps at 25° C. and 50 wt % to 60 wt % silica (SiO2). The stable ethylsilicate polymer includes not greater than 1 wt % of TEOS monomer. The process of forming the ethylsilicate polymer includes a two step addition of catalysts. A hydrolysis catalyst is added initially, for example hydrochloric acid, and a second catalyst is added subsequently, such as phosphonitrilic chloride trimer. The ethylsilicate polymer is used to form MQ resins.

Owner:SILBOND CORP

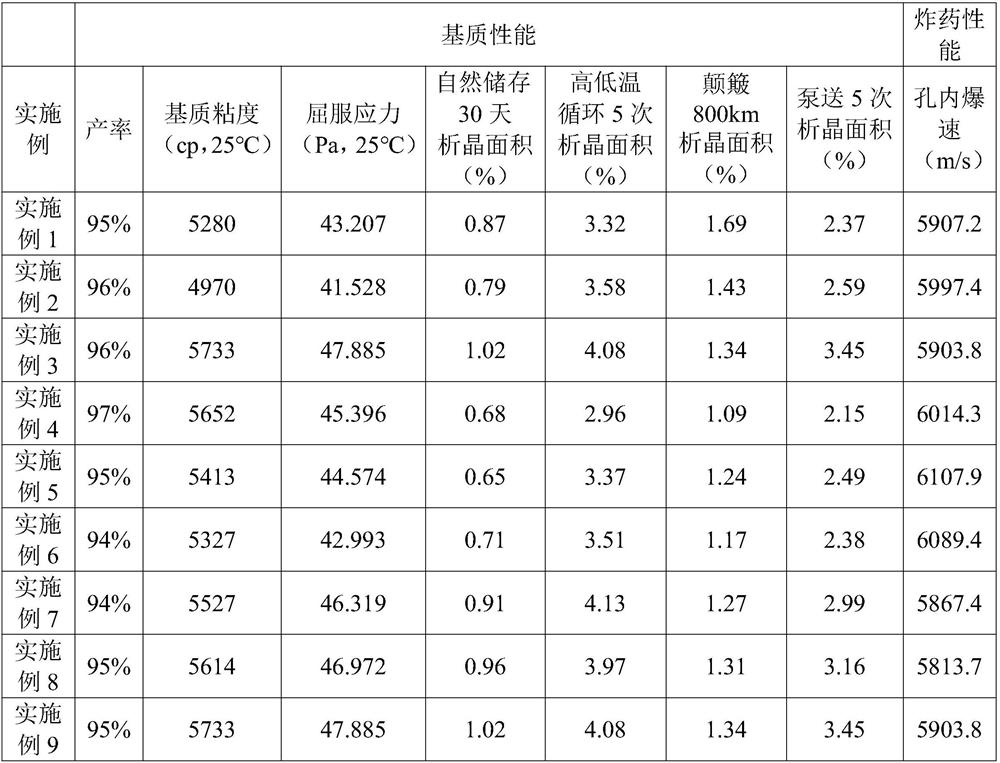

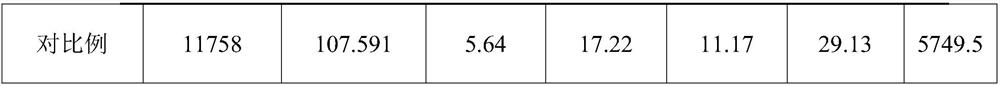

Emulsifier for remote distribution of emulsion matrix and preparation method and application thereof

ActiveCN113493532AGood storage stabilityGood anti-turbulence and pumping performanceNon-explosive/non-thermic compositionsPolyolefinEmulsion

The invention discloses an emulsifier for remote distribution of an emulsion matrix and a preparation method and application thereof, the emulsifier comprises polyolefin carboxylic acid anhydride, alcohol or polyoxyethylene alkyl ether, dihydrazide and diluent oil, the molar ratio of the polyolefin carboxylic acid anhydride to the alcohol or polyoxyethylene alkyl ether to the dihydrazide is 1.0: (0.5-1.2): (0.5-1.2), and the mass of the diluent oil is 0.3-1 time that of the polyolefin carboxylic acid anhydride; the preparation method comprises the following steps: S1, adding polyolefin carboxylic acid anhydride into a reaction kettle; s2, introducing protective gas into the reaction kettle; s3, adding alcohol or polyoxyethylene alkyl ether into the reaction kettle, adding diluent oil, heating to 100-120 DEG C, and keeping the temperature for 2-3 hours; s4, adding dihydrazide under a protective gas, increasing the temperature to 160-180 DEG C, and performing heat preservation and stirring for 4-6 h; and s5, filtering while the mixture is hot to obtain filtrate which is an emulsifier finished product; and the emulsion matrix prepared from the prepared emulsifier is good in fluidity, stable in storage, excellent in bumping resistance and pumping resistance, and suitable for remote distribution of the emulsion matrix.

Owner:CHINA GEZHOUBA GRP YIPULI CO LTD

Lubricating oil composition for automobile engine lubrication

InactiveUS20150175929A1Improve efficiencyImprove wear resistanceLiquid carbonaceous fuelsAdditivesAlkaline earth metalAntioxidant

Provided is a lubricating oil composition that is highly fuel-efficient and has high wear resistance and is particularly suited for lubrication of a motorcycle four-cycle gasoline engine or a diesel engine vehicle having an exhaust gas after-treatment device. The lubricating oil composition, which is a lubricating oil composition having an SAE viscosity grade of 5W20, comprises a base oil and predetermined amounts of additive components comprising of a nitrogen-containing ash-free dispersant, an alkali earth metal-containing detergent, a phosphorus-containing anti-wear agent, an antioxidant, and a viscosity index-improving agent, wherein the viscosity index is within a range of 140 to 230, the high-shear viscosity at 150° C. is 2.9 mPa·s or higher, and the NOACK evaporation loss is 13% or less.

Owner:CHEVRON JAPAN

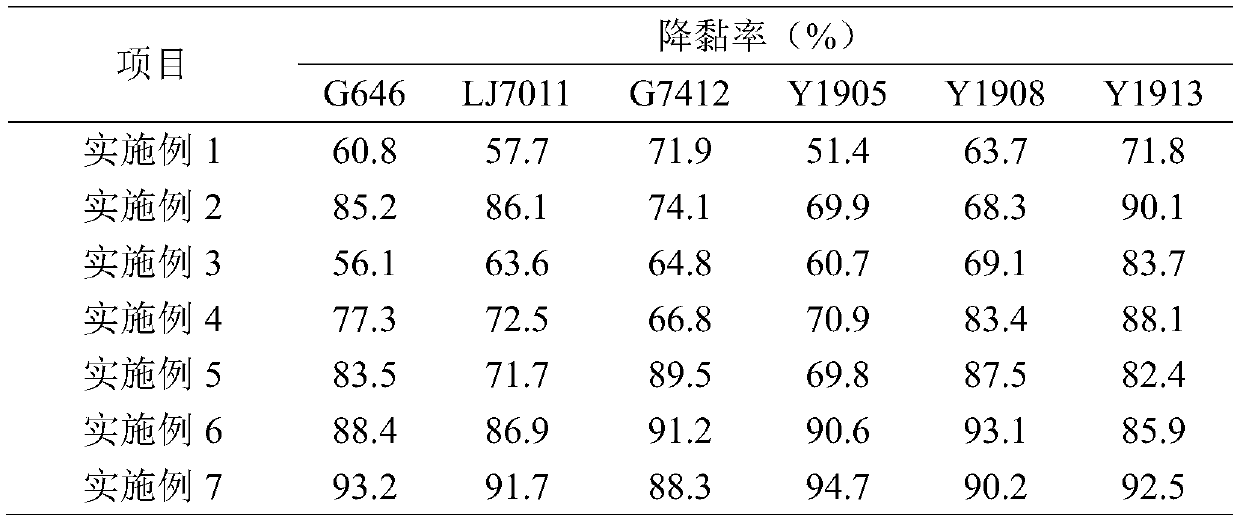

Viscosity-reducing and drainage-aiding composition for heavy oil, viscosity-reducing and drainage-aiding agent, preparation method and application

ActiveCN106967404BLower dynamic viscosityImprove wettabilityFluid removalDrilling compositionSulfonateRock core

The invention discloses a viscosity-reducing and cleanup composition for thickened oil, and a viscosity-reducing and cleanup additive and a preparation method and application thereof, belonging to the technical field of oil exploitation. The viscosity-reducing and cleanup composition comprises, by mass, 0.1 to 2 parts of a fluorocarbon surfactant, 0.5 to 1 part of a hydrocarbon surfactant, 0.25 to 1 part of an auxiliary agent and 0.05 to 0.3 part of the cleanup additive, wherein the fluorocarbon surfactant is one or more selected from a group consisting of FC-01, FC-02, FC-04-1, FC-06, FC-08 and FC-11; the hydrocarbon surfactant is one or more selected from a group consisting of sodium alpha-olefin sulfonate, SYHSY, SDBS and YN; and the cleanup additive is one or more selected from a group consisting of F370, F633 and SH6. The viscosity-reducing and cleanup composition has low surface and interfacial tension, can effectively reduce the dynamic viscosity of thickened oil, improves surface wettability of a rock core and enhances water recovery rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com