A bridge deck pavement method for orthotropic steel bridges

An orthotropic, bridge deck paving technology, applied in the direction of on-site coagulation pavement, bridges, bridge parts, etc., can solve the problem that the pavement structure cannot well meet the high temperature stability, low temperature deformation ability and fatigue resistance Cracking requirements, high temperature resistance of waterproof bonding system, difficult construction of bridge deck pavement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

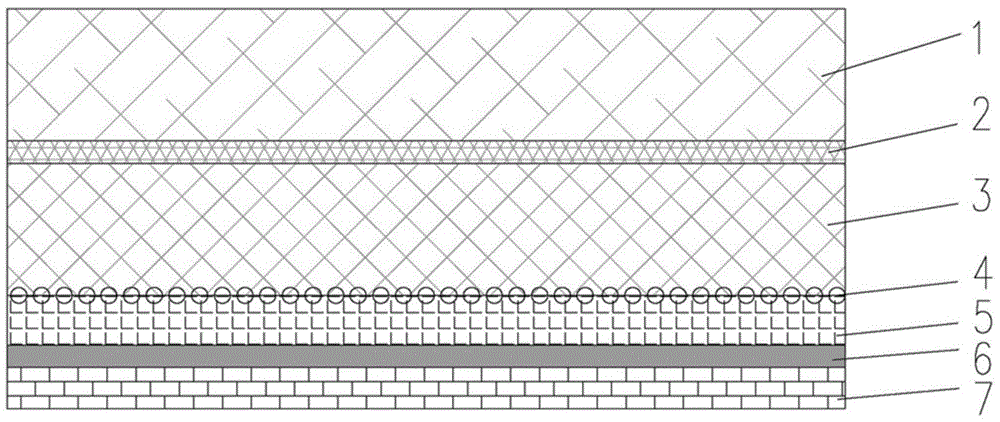

[0055] A pavement method for a deck pavement structure of an orthotropic steel bridge, comprising the steps of:

[0056] (1) Sandblasting and derusting the steel bridge deck to make the cleanliness reach Sa2.5 level and the roughness is 70μm; according to 0.3kg / m 2 The amount of mica-containing epoxy resin used is artificially brushed and rolled to coat a mica-containing epoxy anti-corrosion layer;

[0057] (2) After 24 hours of mica-containing epoxy anti-corrosion coating curing, according to 2.5kg / m 2 The amount of solvent-free epoxy resin is used to scrape a solvent-free epoxy resin waterproof layer;

[0058] (3) Within 30 minutes of completing the solvent-free epoxy resin waterproof layer, according to 0.8kg / m 2 Sprinkle the hot-melt particles with a certain amount, so that half of them are trapped in the solvent-free epoxy resin waterproof layer to form a hot-melt particle bonding layer;

[0059] (4) After 48 hours of curing of the solvent-free epoxy resin waterproof l...

Embodiment 2

[0064] A pavement method for a deck pavement structure of an orthotropic steel bridge, comprising the steps of:

[0065] (1) Sandblasting and derusting the steel bridge deck to make the cleanliness reach Sa2.5 level and the roughness is 80μm; according to 0.3kg / m 2 The amount of mica-containing epoxy resin used is artificially brushed and rolled to coat a mica-containing epoxy anti-corrosion layer;

[0066] (2) After 24 hours of mica-containing epoxy anti-corrosion layer curing, according to 3.0kg / m 2 The amount of solvent-free epoxy resin is used to scrape a solvent-free epoxy resin waterproof layer;

[0067] (3) Within 30 minutes of completing the solvent-free epoxy resin waterproof layer, according to 0.8kg / m 2 Sprinkle the hot-melt particles with a certain amount, so that half of them are trapped in the solvent-free epoxy resin waterproof layer to form a hot-melt particle bonding layer;

[0068] (4) After 48 hours of curing of the solvent-free epoxy resin waterproof lay...

Embodiment 3

[0073] A pavement method for a deck pavement structure of an orthotropic steel bridge, comprising the steps of:

[0074] (1) Sandblasting and derusting the steel bridge deck to make the cleanliness reach Sa2.5 level and the roughness is 80μm; according to 0.4kg / m 2 The amount of mica-containing epoxy resin used is artificially brushed and rolled to coat a mica-containing epoxy anti-corrosion layer;

[0075] (2) After 24 hours of mica-containing epoxy anti-corrosion layer curing, according to 3.0kg / m 2 The amount of solvent-free epoxy resin is used to scrape a solvent-free epoxy resin waterproof layer;

[0076] (3) Within 30 minutes of completing the solvent-free epoxy resin waterproof layer, according to 1.0kg / m 2 Sprinkle the hot-melt particles with a certain amount, so that half of them are trapped in the solvent-free epoxy resin waterproof layer to form a hot-melt particle bonding layer;

[0077] (4) After 48 hours of curing of the solvent-free epoxy resin waterproof lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com