Impact-resistant wear-resistant environment-friendly pavement and construction method

An environmentally friendly and impact-resistant technology, applied in the airport field, can solve the problems of high cost and poor aging resistance, and achieve the effect of low cost, high bearing capacity and stable temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

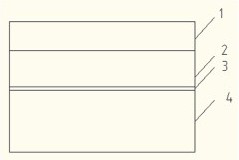

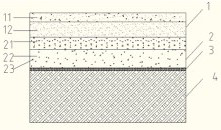

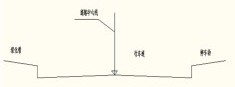

[0033] An impact-resistant and wear-resistant environment-friendly road surface, comprising a surface layer (1), a base layer (2), a soil cloth layer (3) and a roadbed (4), characterized in that: the surface layer (1) is provided with a wear-resistant layer (11) and gravel-grade steel slag layer (12), the wear-resistant layer (11) is ultra-high performance concrete mixed with glass powder and rice husk ash, and the inside of the gravel-grade steel slag layer (12) is made of gravel-grade steel scrap slag, epoxy resin, asphalt and other materials, the base (2) is provided with a high modulus epoxy asphalt steel slag layer (21) and a building recycling layer (22), and the building recycling layer (22) is set There is a stone chip filling body (23), and the earth cloth layer (3) is located under the building recycling layer (22) and above the road foundation (4), and the connection is firm, and the structure is as follows: figure 1 and figure 2 as shown, image 3 A standard cro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com