FFU (Fiber Reinforce-Foamed-Urethane) composite sleeper

A technology for sleepers and synthetic resins is applied in the field of new materials for railway sleeper systems, which can solve the problems of insufficient uniformity of elasticity, strength and durability of wooden sleepers, increase the dynamic action of wheels and rails, and high maintenance costs, so as to protect forests and reduce exhaust gas. material, the effect of high connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

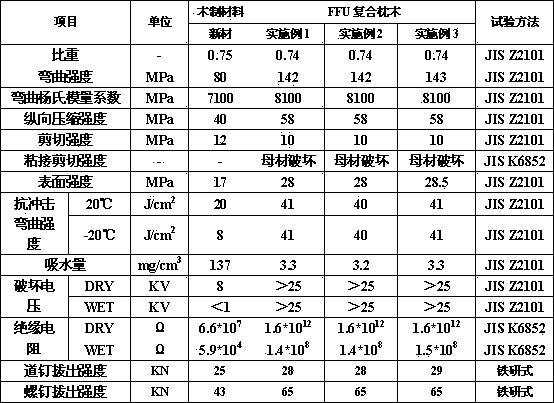

Embodiment 1

[0030] Long glass fiber 14%

[0031] Rigid urethane resin foam 85%

[0032] Melamine colorant 0.25%

[0033] Release agent 0.25%

[0034] Coupling agent 0.25%

[0035] Foaming agent 0.25%

Embodiment 2

[0037] Long glass fiber 16%

[0038] Rigid urethane resin foam 82%

[0039] Melamine colorant 1%

[0040] Release agent 0.2%

[0041] Coupling agent 0.3%

[0042] Foaming agent 0.5%

Embodiment 3

[0044] Long glass fiber 18.5%

[0045] Rigid urethane resin foam 80%

[0046] Melamine colorant 0.3%

[0047] Release agent 0.3%

[0048] Coupling agent 0.4%

[0049] Foaming agent 0.5%

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com