Patents

Literature

38results about How to "Easy to process on site" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

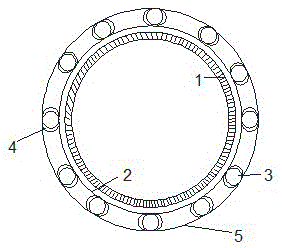

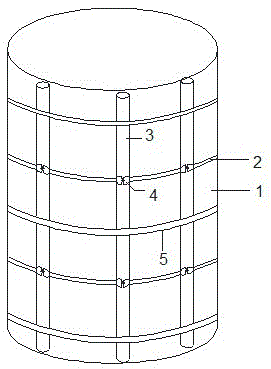

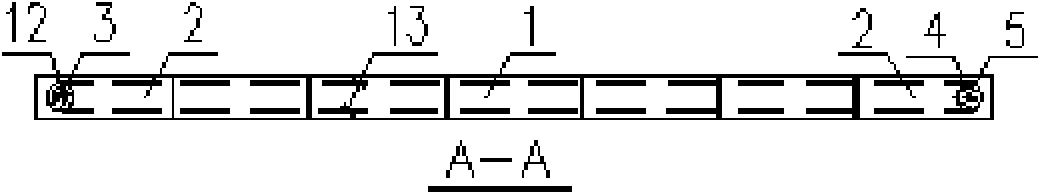

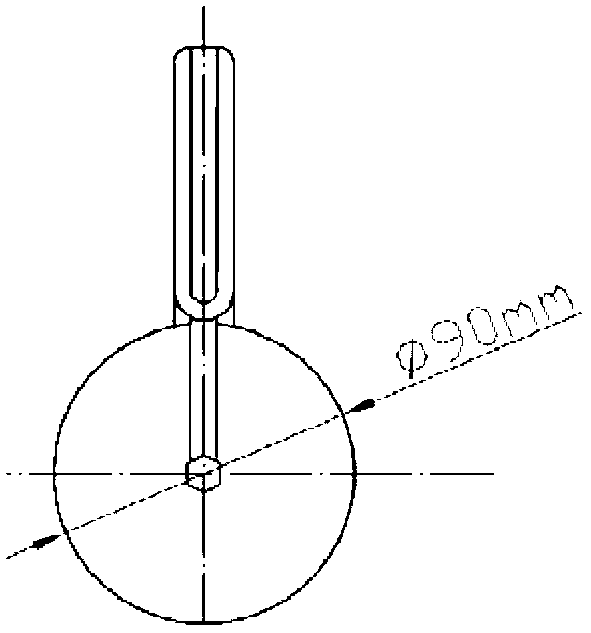

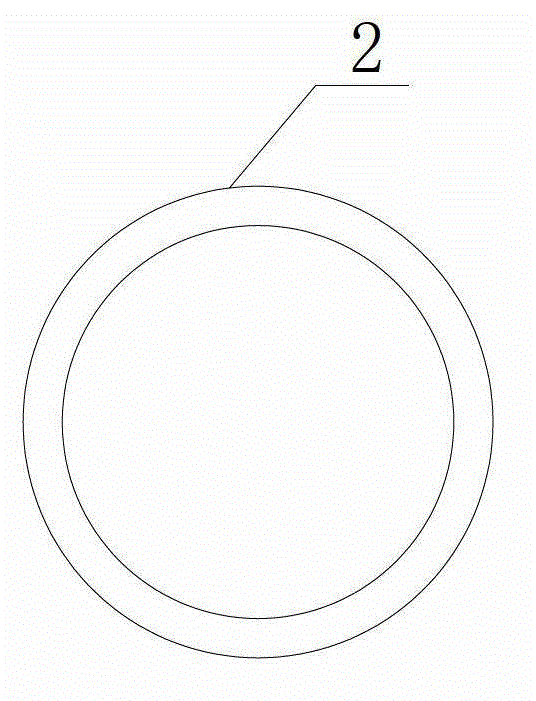

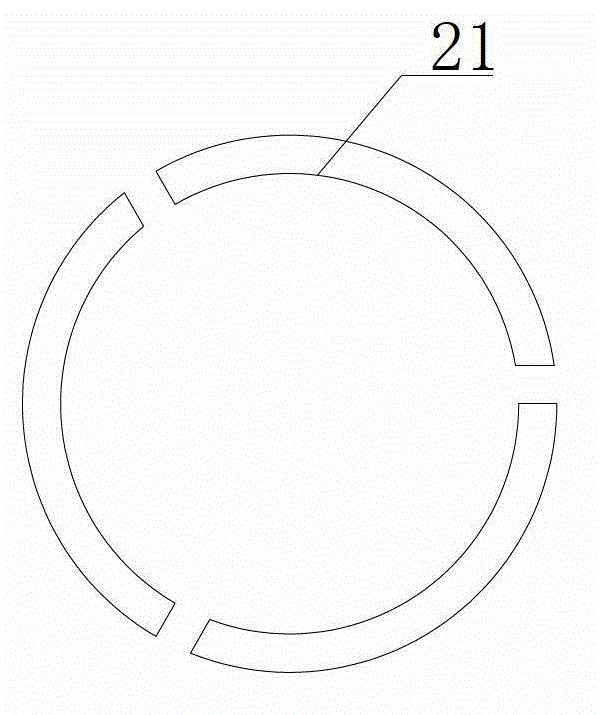

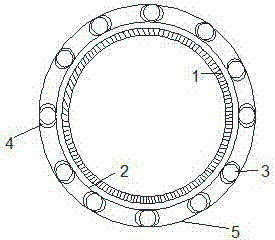

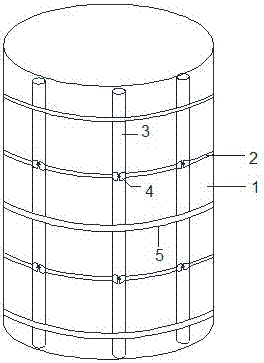

Simple supporting method for cylindrical concrete formwork

ActiveCN105569331AEasy to processImprove turnover rateForms/shuttering/falseworksMaterials scienceSteel tube

The invention discloses a simple supporting method for a cylindrical concrete formwork, and belongs to the technical field of building concrete formworks. An inner flat iron hoop, supporting steel tubes and an outer flat iron hoop are involved in the method. The method is characterized in that a bamboo wood formwork is further involved in the method and is of a cylindrical structure formed by splicing two or more composite bamboo glue formworks; the inner flat iron hoop is fixedly installed on the periphery of the bamboo wood formwork, and the supporting steel tubes are fixed to the inner flat iron hoop through steel tube fasteners and are sleeved with the outer flat iron hoop. The cylindrical concrete formwork is compact in structure, easy to machine, not prone to deformation, light in weight and low in cost, the surface of poured concrete is smooth, and dimension errors are small; the supporting components are high in circulation rate, convenient to assemble and disassemble and high in working efficiency; no complex outer supporting structure is needed, and the cylindrical concrete formwork is suitable for narrow sites and is convenient to maintain and clean after being dismantled.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

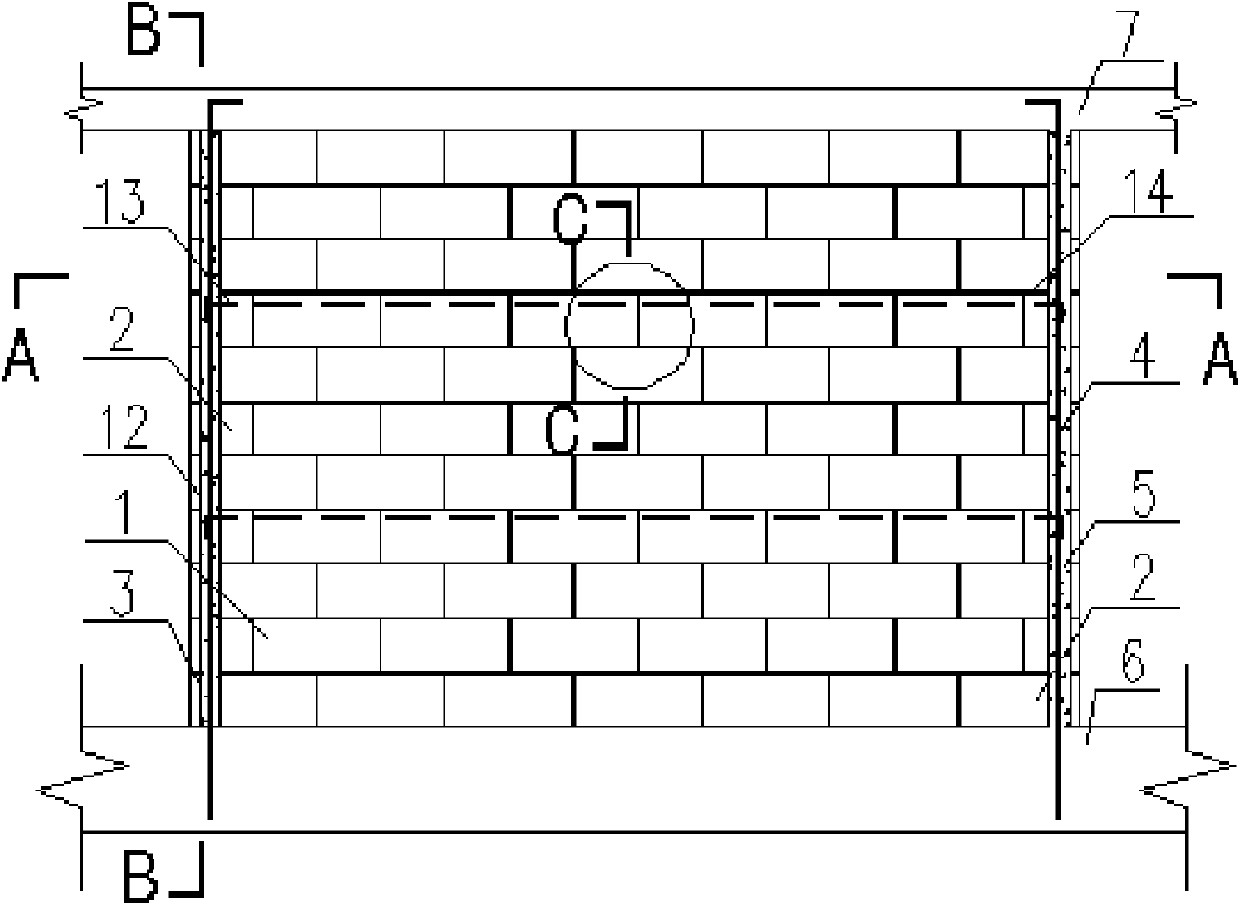

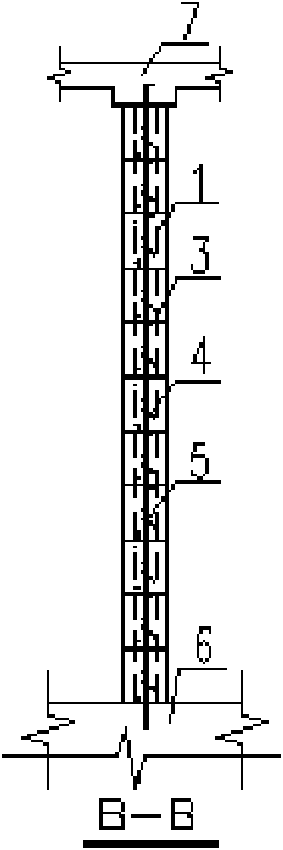

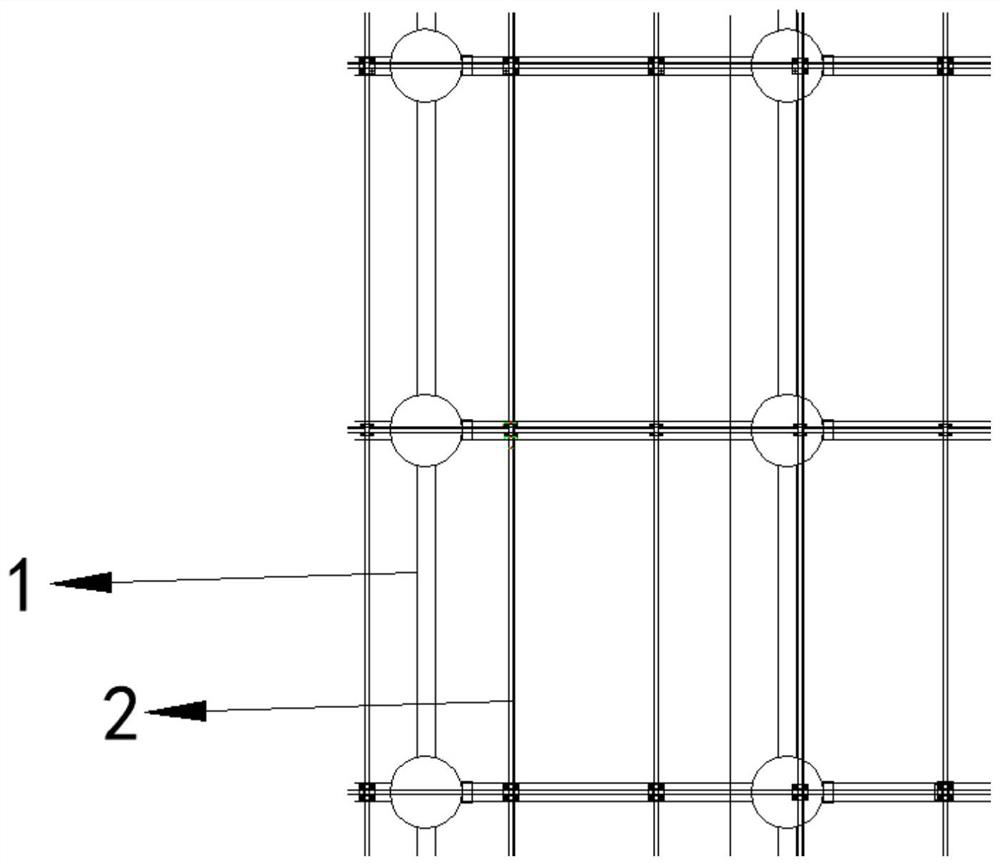

Aerated concrete block masonry composite wall reinforced with embedded reinforcements and borehole core columns

InactiveCN102168460ARealize the insulation effectAchieve load bearingWallsBuilding material handlingRebarLoad-bearing wall

The invention discloses an aerated concrete block masonry composite wall reinforced with embedded reinforcements and borehole core columns, which belongs to the field of masonry structure and is mainly applied to the building structure engineering. The aerated concrete block masonry composite wall comprises block masonry composed of aerated concrete blocks and dedicated mortar, wall core columns vertically arranged in the block masonry and embedded reinforcements horizontally arranged in the block masonry; horizontal steel bars are generally arranged in block hollow grooves arranged along the length direction of a wall body, and the horizontal steel bars and mortar filled in horizontal mortar joints during the wall building form the embedded reinforcements; vertically through holes are drilled on the block masonry, and core column steel bars are vertically arranged in the holes; and the core column steel bars and core column concrete made of concrete poured after the wall building form wall core columns. The aerated concrete block masonry composite wall disclosed by the invention has relatively good popularization and application prospect in the load-bearing walls of multi-layer masonry structures in seismic areas and even non-load-bearing walls taking aerated concrete block masonries as filler walls in various structure systems.

Owner:BEIJING UNIV OF TECH

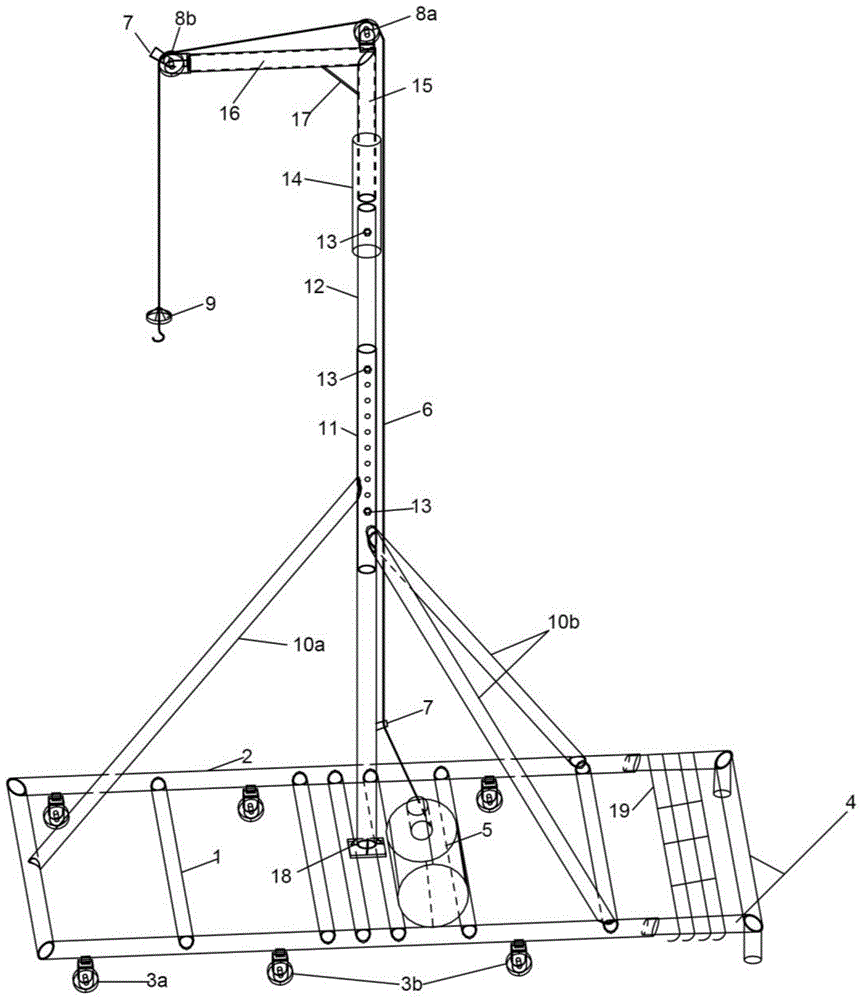

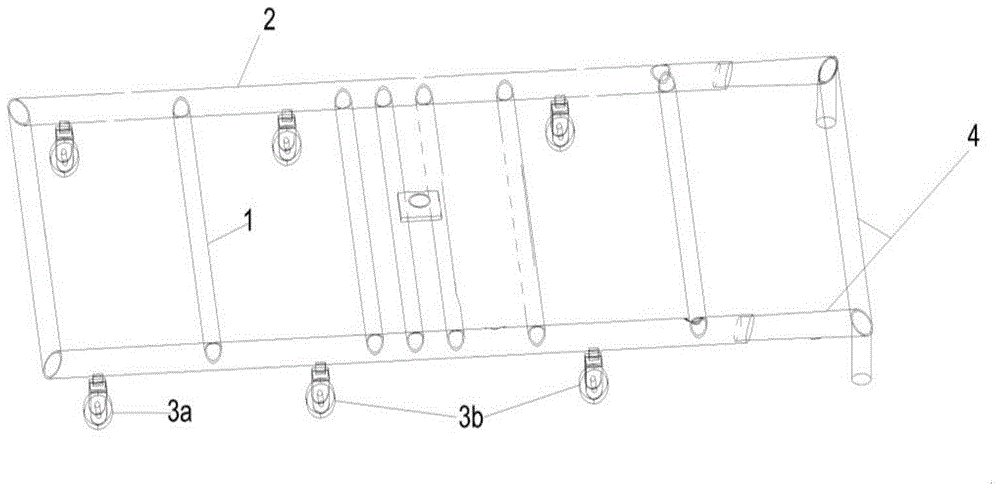

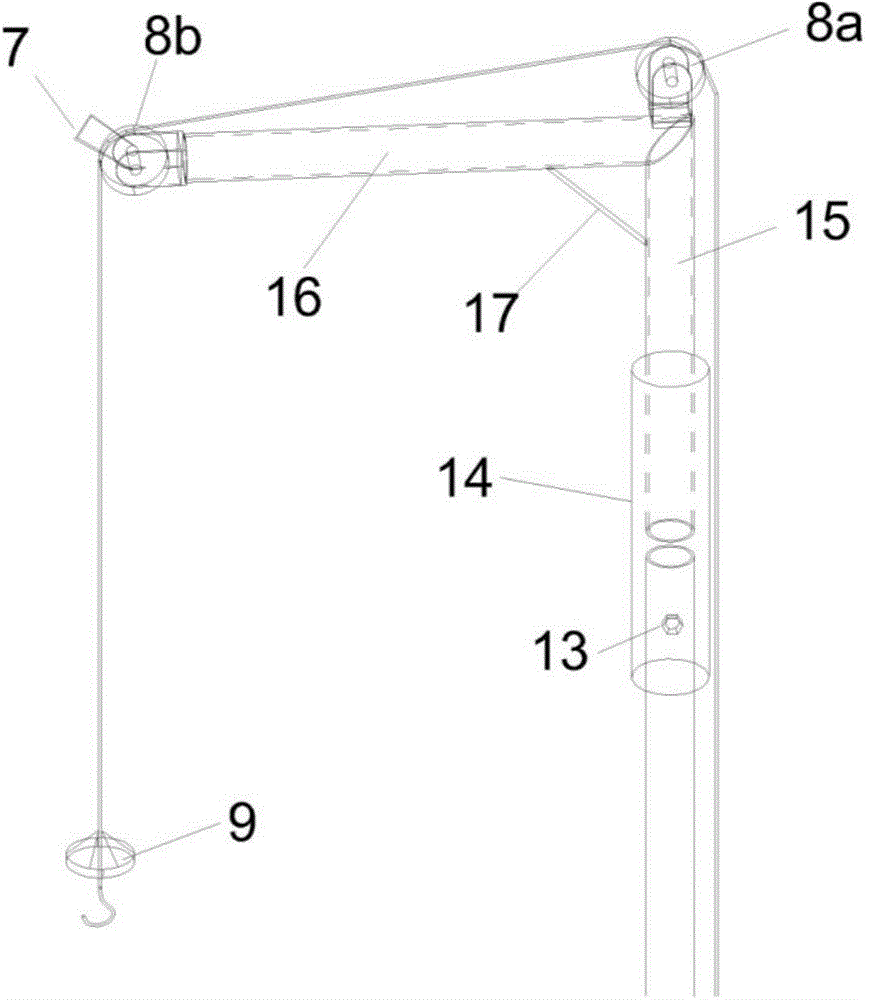

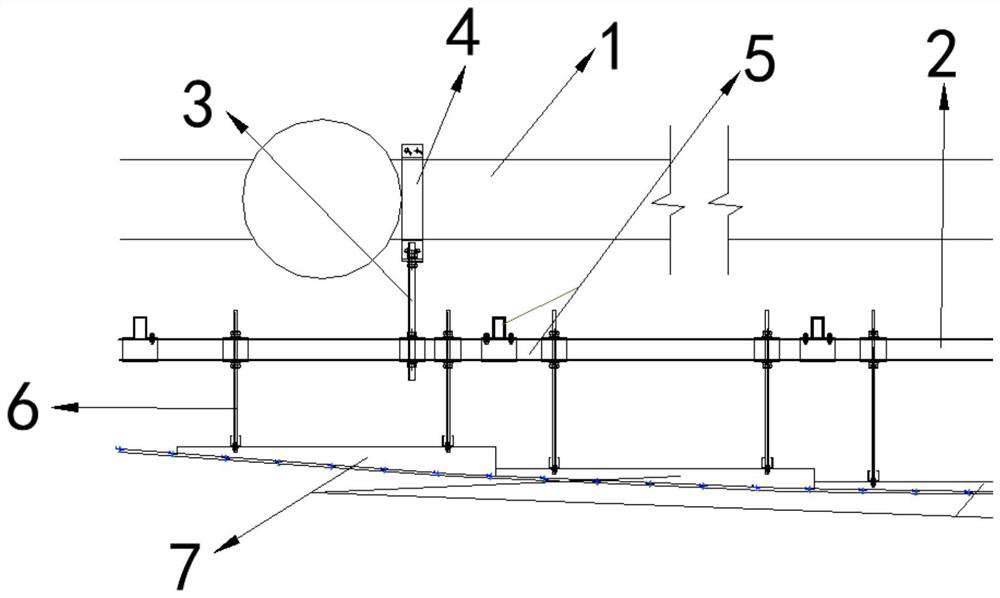

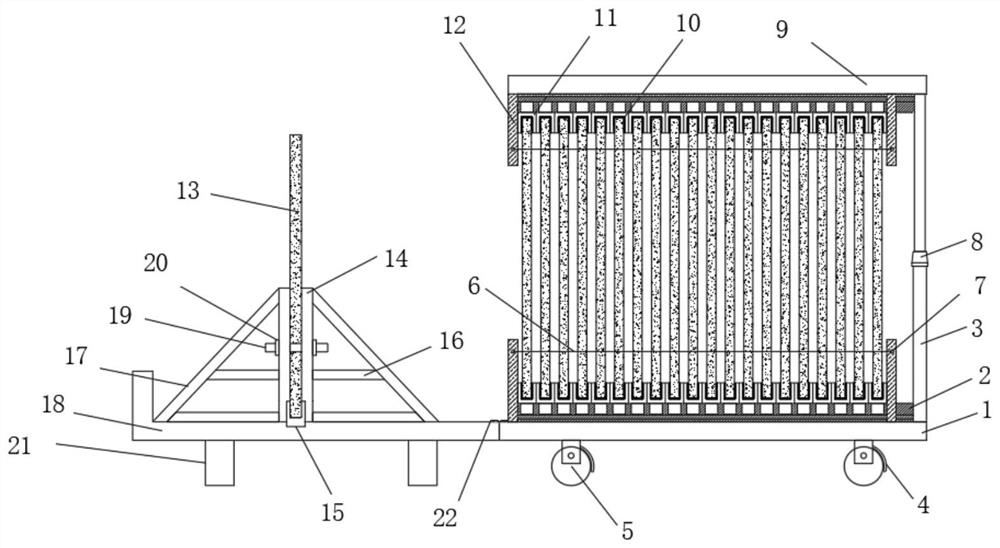

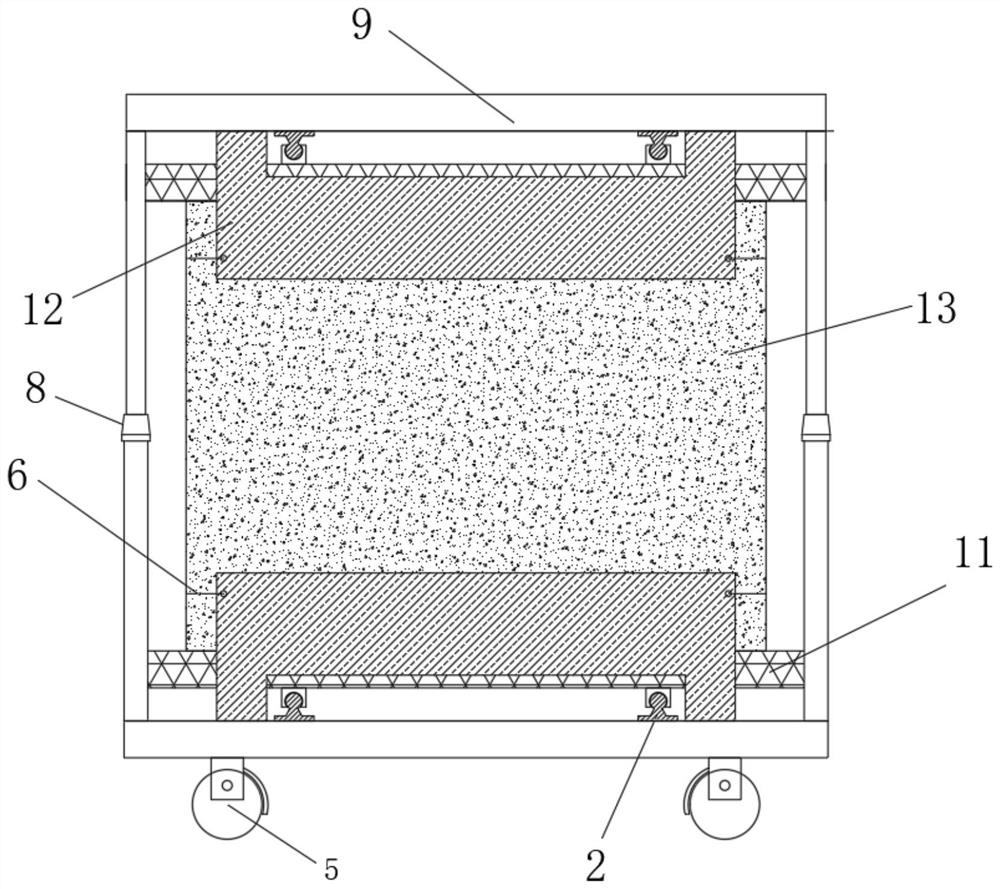

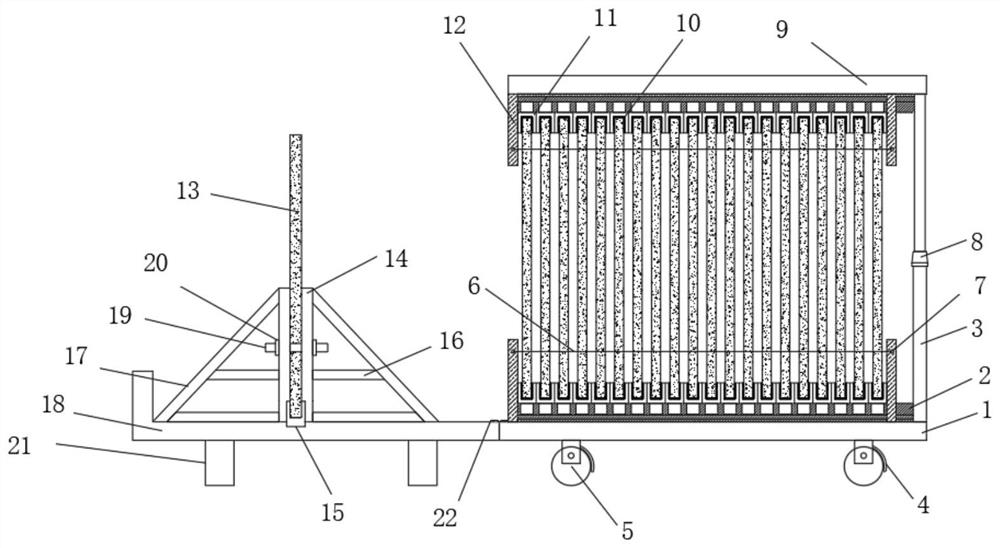

Vertical transport device for construction material between building block layers

InactiveCN104860211AGuaranteed integrityGuaranteed tidyCargo handling apparatusPassenger handling apparatusEngineeringMaterial transport

The invention discloses a vertical transport device for a construction material between building block layers. The vertical transport device comprises a horizontal base, a main mast, a telescopic mast, a rotary sleeve, a rotary mast, a horizontal hanger rod, a first fixed pulley and a winding engine, wherein the main mast is vertically fixed on the horizontal base; the lower end of the telescopic mast is inserted into the upper end in the main mast; the upper end of the telescopic mast is inserted into the lower end in the rotary sleeve; the upper end of the rotary sleeve is inserted into the rotary mast; the top of the rotary mast is vertically and fixedly connected with one end of the horizontal hanger rod; two ends of the horizontal hanger rod are respectively connected with the first fixed pulley and a second fixed pulley to form a pulley; a lifting hook is arranged at one end, which winds the first fixed pulley, of a steel wire rope; one end, which winds the second fixed pulley, of the steel wire rope, is connected with the winding engine; the winding engine is fixedly arranged on the horizontal base. The problem that the building blocks for secondary structure construction of a large-floor height structure is difficult to vertically transport is solved; the vertical transport device has the advantages of being simple, efficient, safe, low in equipment cost, and easy to operate and maintain; the material transportation efficiency and the construction efficiency of a worker are improved; the construction labor intensity is alleviated.

Owner:WUHAN CONSTR ENG

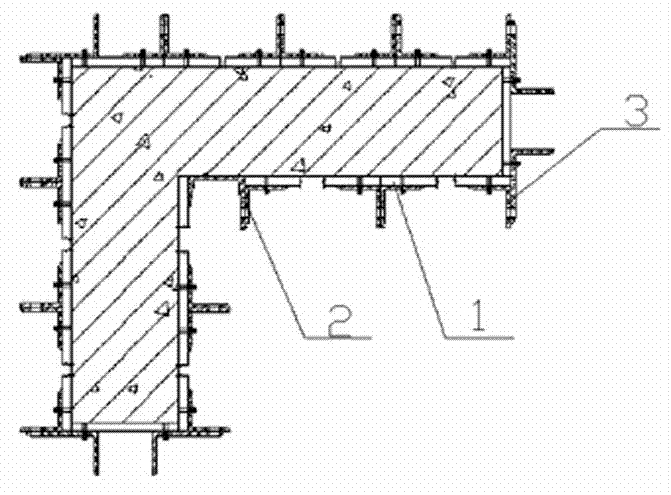

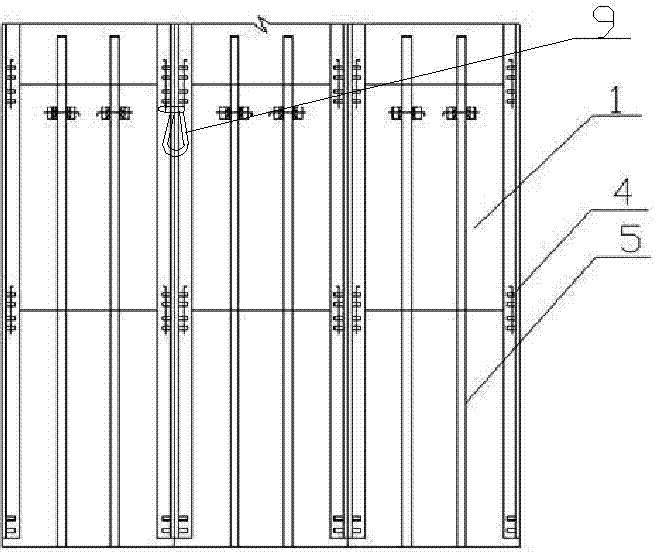

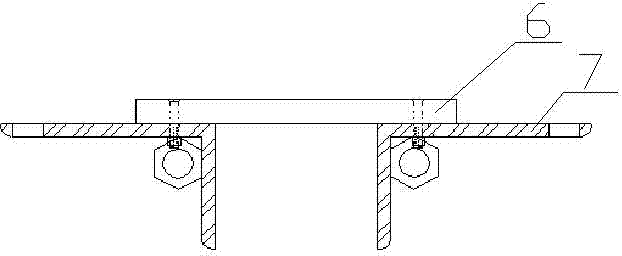

Construction process of metal reinforced frame bamboo plywood fabricated formwork

InactiveCN103615112ALight in massFlexible and convenient assembly and disassemblyBuilding material handlingOccupancy rateWindow opening

The invention discloses a construction process of a metal reinforced frame bamboo plywood fabricated formwork. The construction process comprises the following steps that a, formwork matching and processing are carried out according to a formwork design drawing; b, platform concrete pouring and tamping are carried out, and a scale height and flatness are controlled; c, according to the drawing, a wall body position line and door and window opening position lines are flipped well, formwork limit steel bars are welded, a pre-cast hole and an embedded part are placed, and two lines of release agents are brushed on the surface of the formwork; d, a wallboard formwork on one side is mounted and fixed, a corner formwork is mounted from a wall corner, and the wallboard formwork and the corner formwork are spliced in the perpendicular direction; e, wall penetrating bolts and plastic sleeve tubes are placed; f, a wallboard formwork on the other side is mounted, the wall penetrating bots are screwed, the formworks with holes in two sides are symmetrically arranged, and the wall penetrating bolts are perpendicular to a wall film; g, door and window opening formworks are mounted; h, plane and vertical correction is carried out, reinforcement is carried out through inclined struts, and acceptance check is carried out. The construction process has the advantages that the weight is low, formwork configuration is convenient, the amount of used steel is small, the construction operation is convenient, the circulation rate is high, and the occupancy rate of a tower crane is low.

Owner:JIANGSU NANTONG SANJIAN CONSTRUCTION GROUP CO LTD

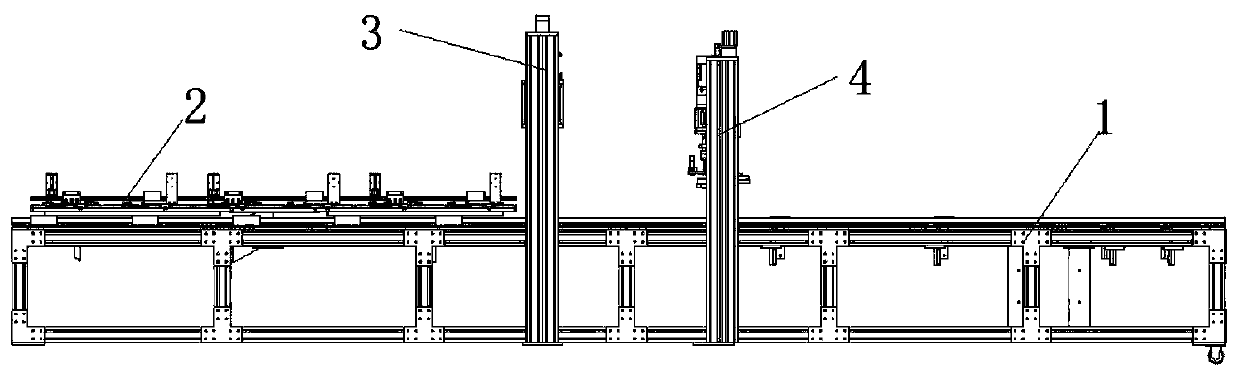

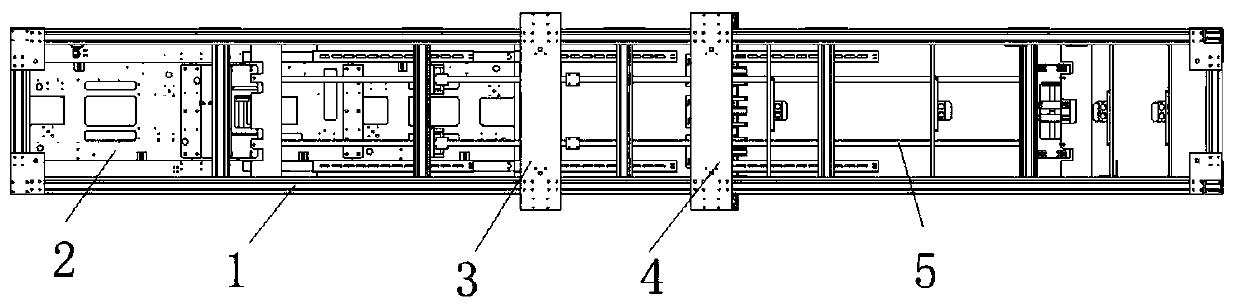

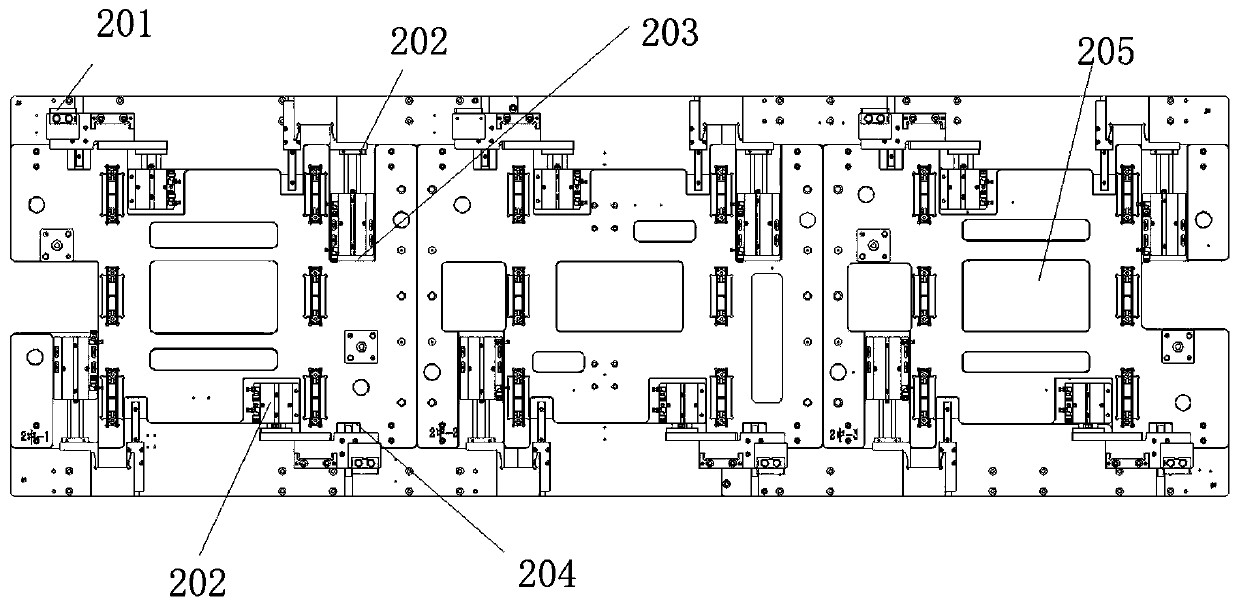

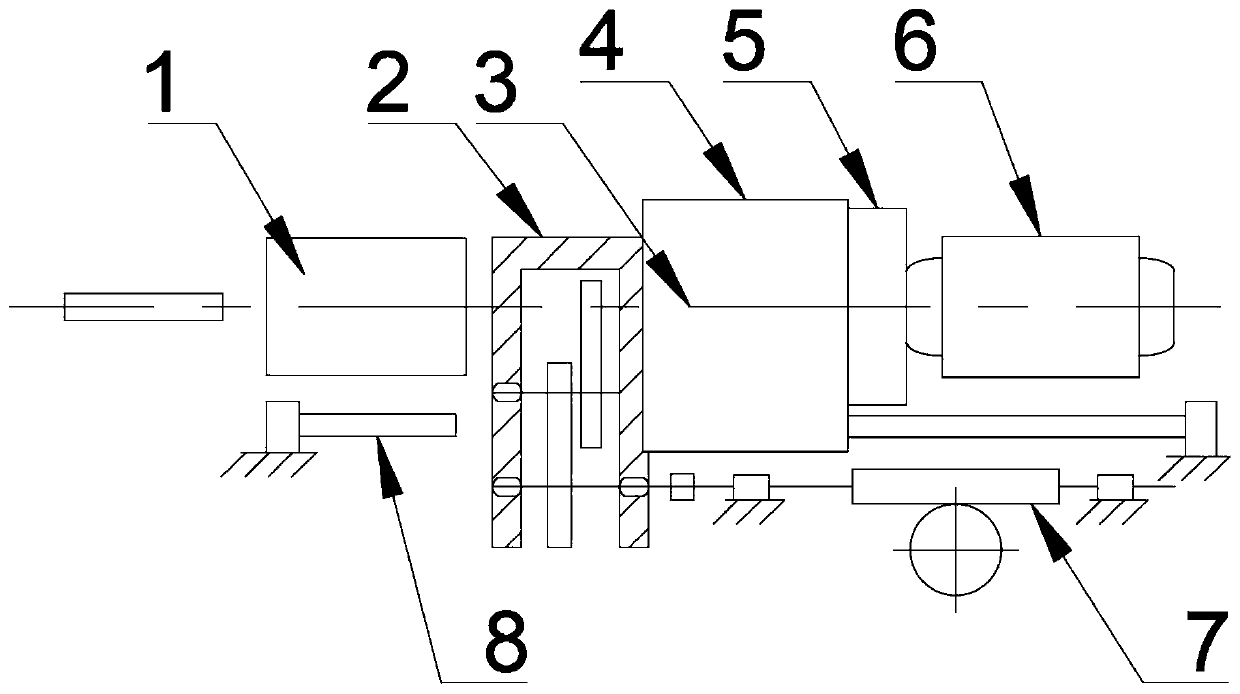

Automatic screwing machine of floor slabs

PendingCN110394638AEasy to reinforceReduce intensityOther manufacturing equipments/toolsMetal working apparatusMetal stripsMotor drive

The invention discloses an automatic screwing machine of floor slabs. The automatic screwing machine comprises a main machine frame, wherein a horizontal workbench is arranged on the main machine frame, and a die table is arranged on the horizontal workbench; a motor is further arranged on the horizontal workbench, and the motor drives the die table to slide along the horizontal workbench throughtraction by a synchronous belt; two auxiliary supports cross the horizontal workbench, and are correspondingly provided with automatic punching units and automatic locking units, the automatic punching units comprise a plurality of electric drilling machines, and the automatic locking units comprise a plurality of automatic screwing machines; and the four corners and the middle parts of the two side edges of the die table are provided with material pressing mechanisms, a plurality of metal strip locking mechanisms are arranged at the two side edges of the die table at equal intervals, and a material ejecting mechanism is arranged at the tail end of the horizontal workbench, and comprises a material ejecting air cylinder and a material ejecting supporting plate. According to the automatic screwing machine, the production process of automatic feeding, screwing and finished product discharging is finished by the machine, the condition of manual screwing is changed, the automatic control performance is high, the efficiency is high, and the operation is safe, easy and convenient.

Owner:多维绿建科技(天津)有限公司 +2

Method for preparing soft-shelled turtle

The invention relates to a method of preparing the turtle, comprising the following steps: 1) pickling: killing a alive turtle, removing skin by putting the turtle in warm water of 60 Deg C for 30 seconds, getting oil by opening stomach and breaking into blocks; b. washing the block, and pickling; 2) preparing soup; 3) preparing process: boiling the soup, adding the pickled turtle, keeping for three to five minutes, and getting out for eating. The process is simpler, and the time is shorter because of the employed process of prepickling and soup preparing, further more, the turtle is delicious and fresh.

Owner:赵国英

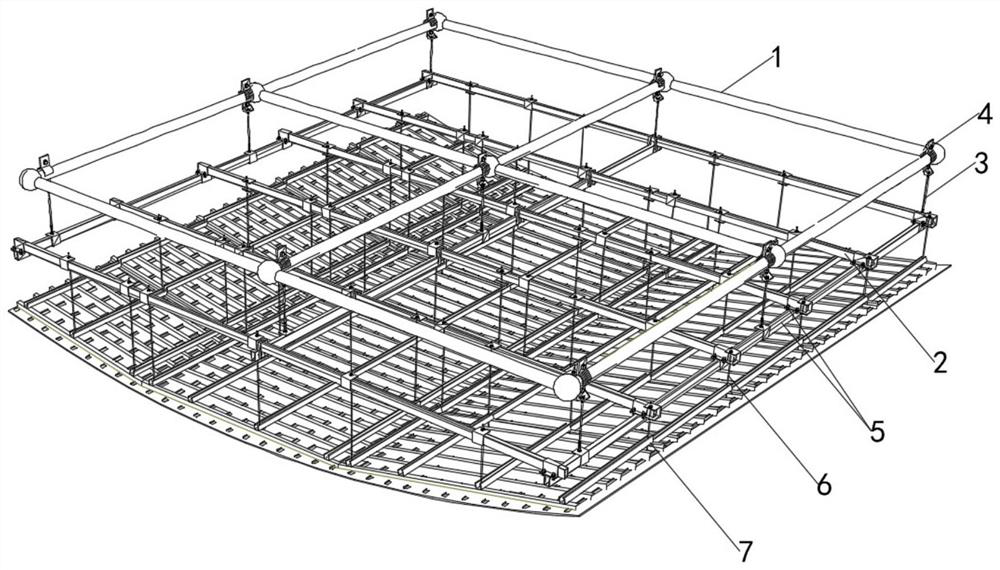

Large-span arc-shaped modeling suspended ceiling construction method

PendingCN113585594AReduce time spent working at heightsImprove construction efficiencyCeilingsCeramic compositeJoist

The invention relates to the technical field of arc-shaped suspended ceiling construction, and particularly discloses a large-span arc-shaped modeling suspended ceiling construction method. The large-span arc-shaped modeling suspended ceiling construction method specifically comprises the following steps that S1, indoor scanning is carried out, and a three-dimensional model is established; S2, according to the three-dimensional model and the indoor actual situation, a suspended ceiling joist is divided into a plurality of ceiling joist units; S3, scaffolds are erected on a construction site, ceiling construction paying-off is carried out, and a supporting frame and the ceiling joist units are mounted in sequence; S4, a silicon ceramic composite board is mounted; S5, putty construction is carried out; and S6, veneer bamboo skin is pasted, and construction is completed. The suspended ceiling joist is divided into the multiple suspended ceiling joist units, and the suspended ceiling joist is mounted in a modularized mode, so that the high-altitude operation time is shortened, the construction efficiency is improved, the labor cost is reduced, and the construction period is shortened.

Owner:CHINA MCC5 GROUP CORP

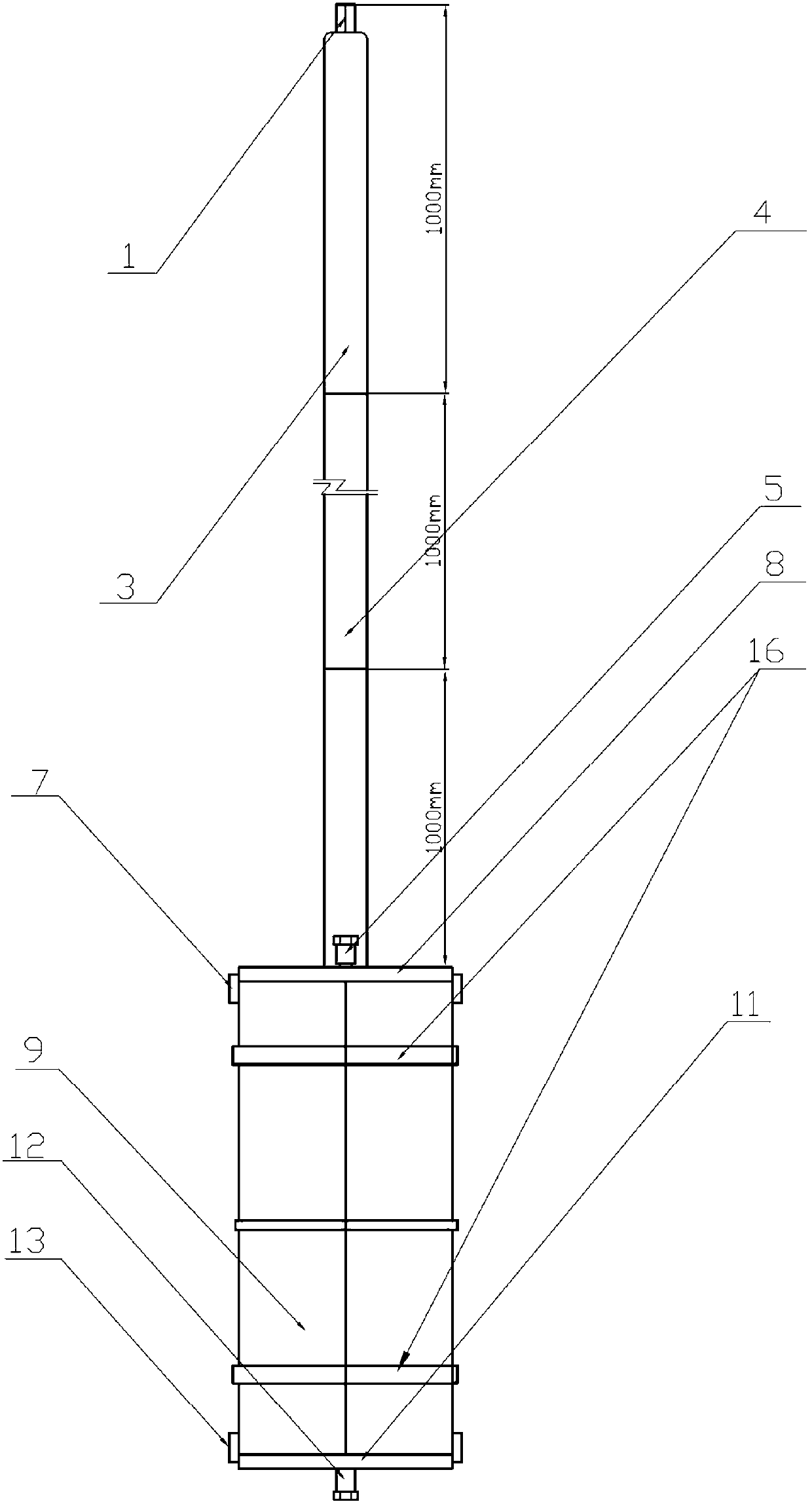

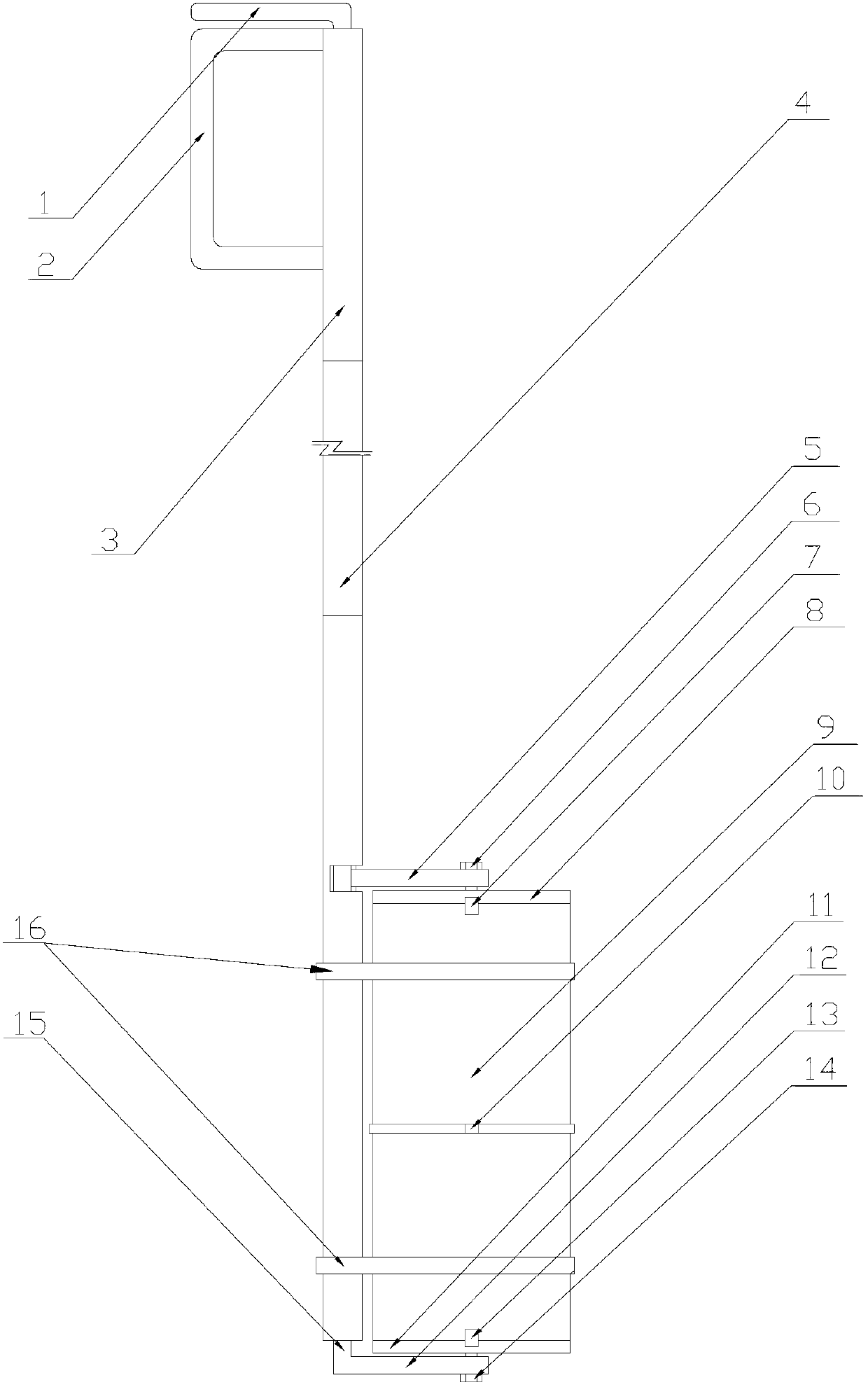

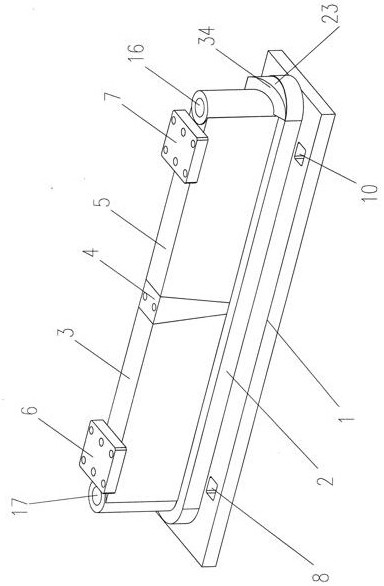

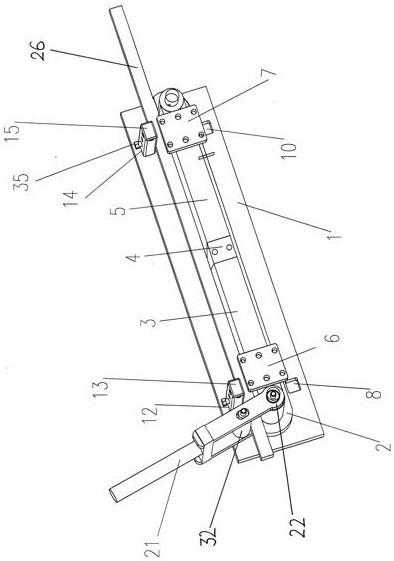

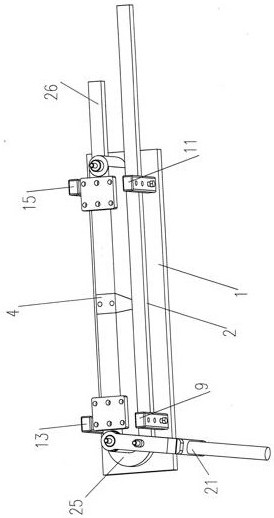

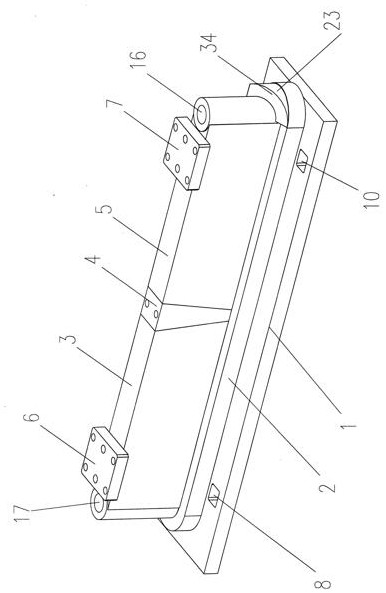

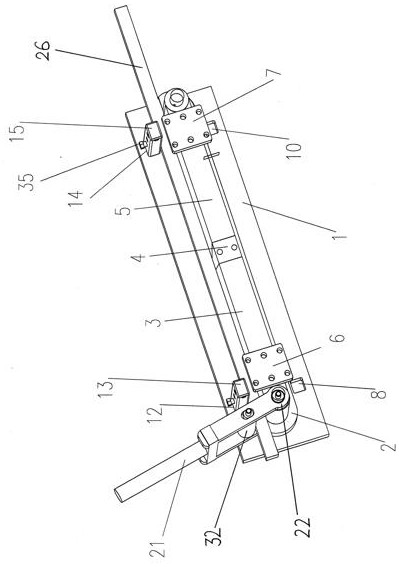

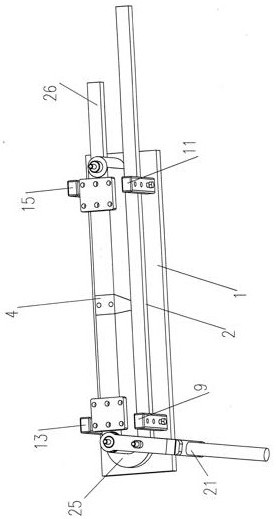

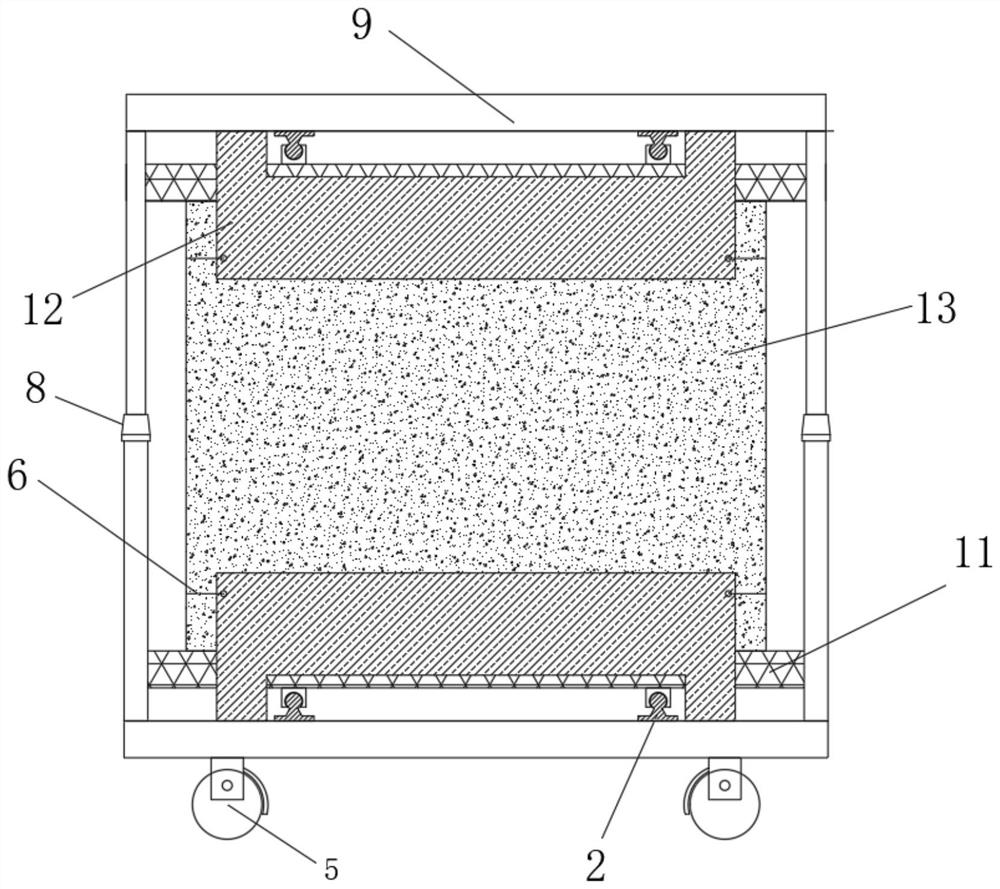

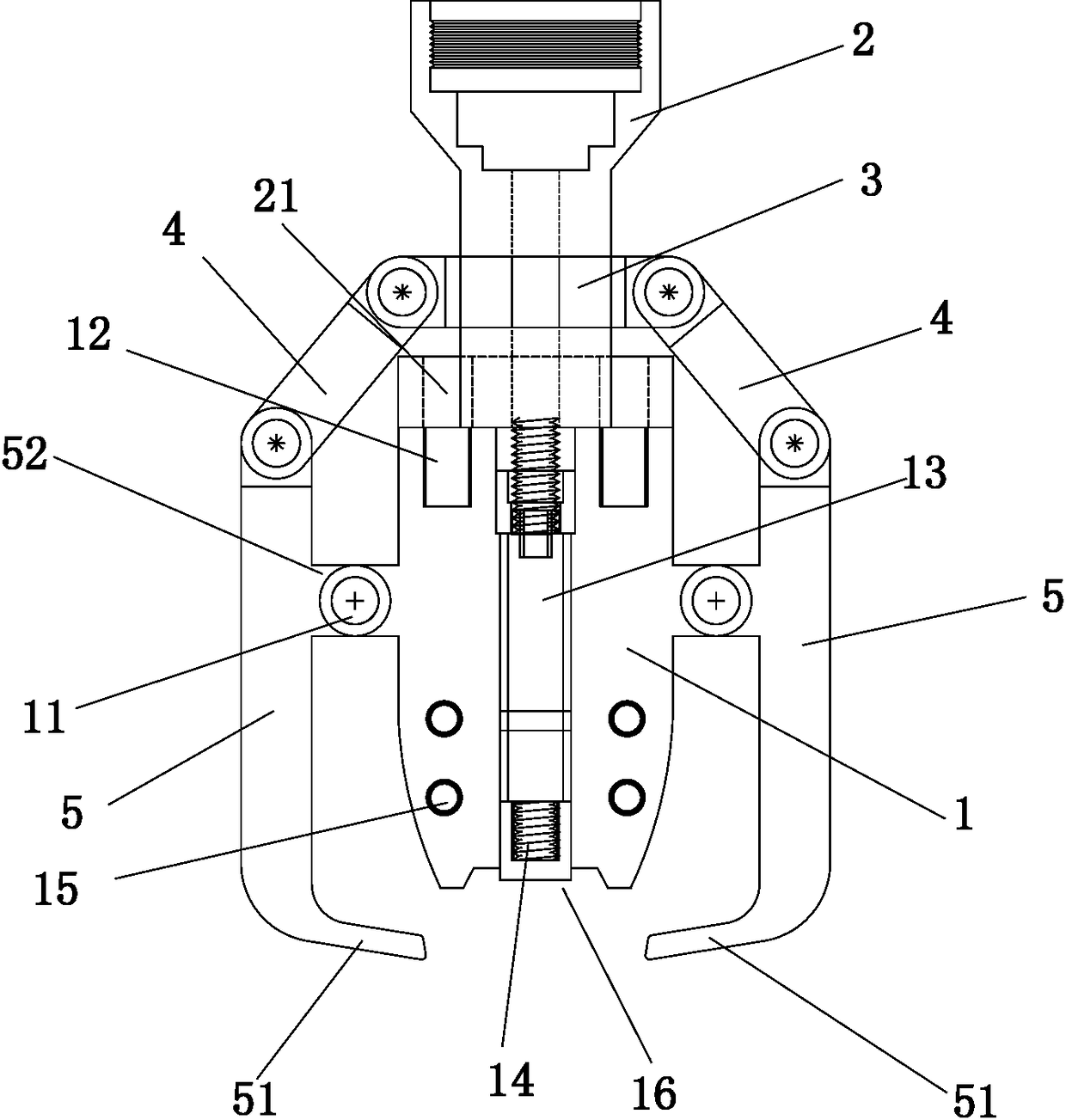

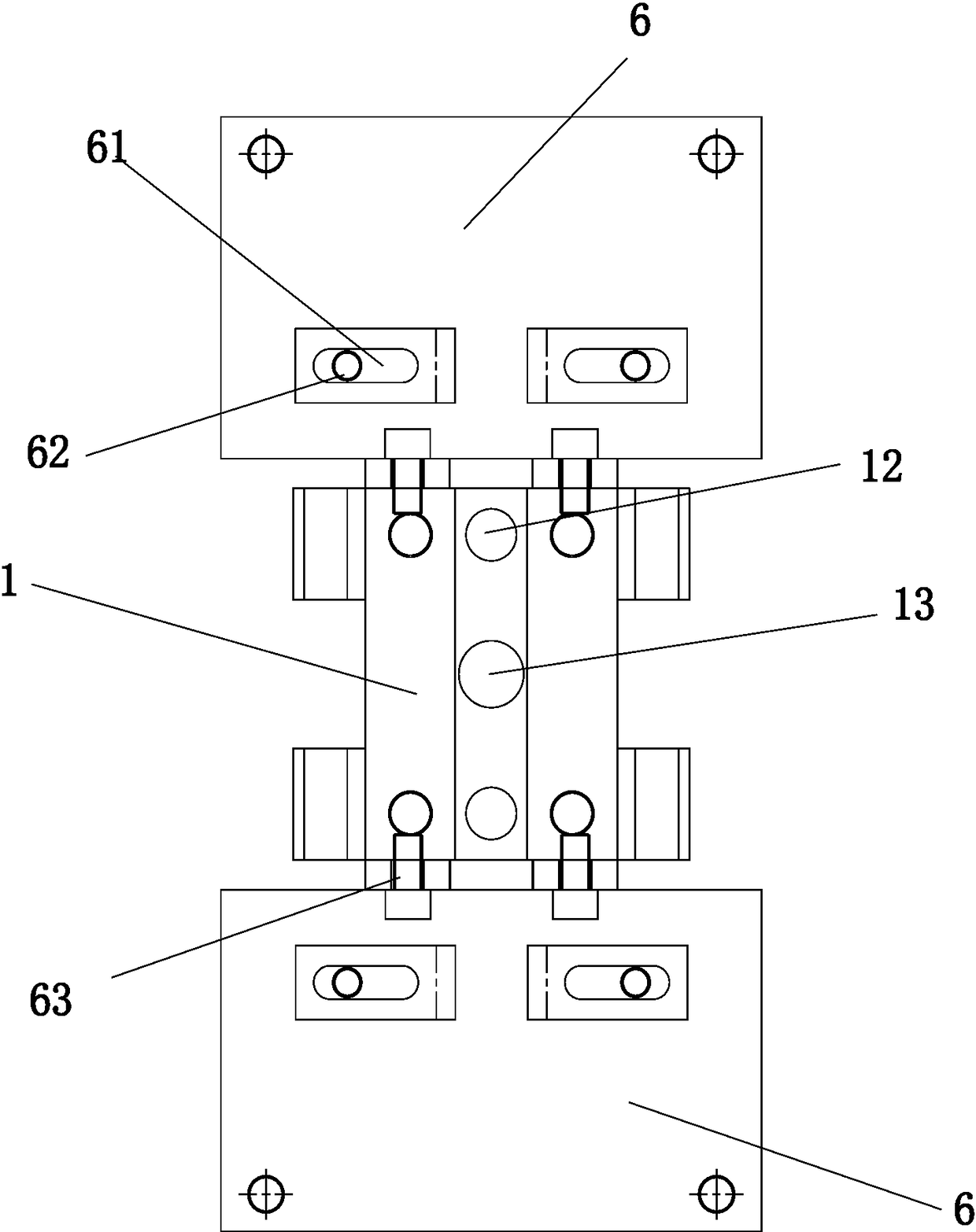

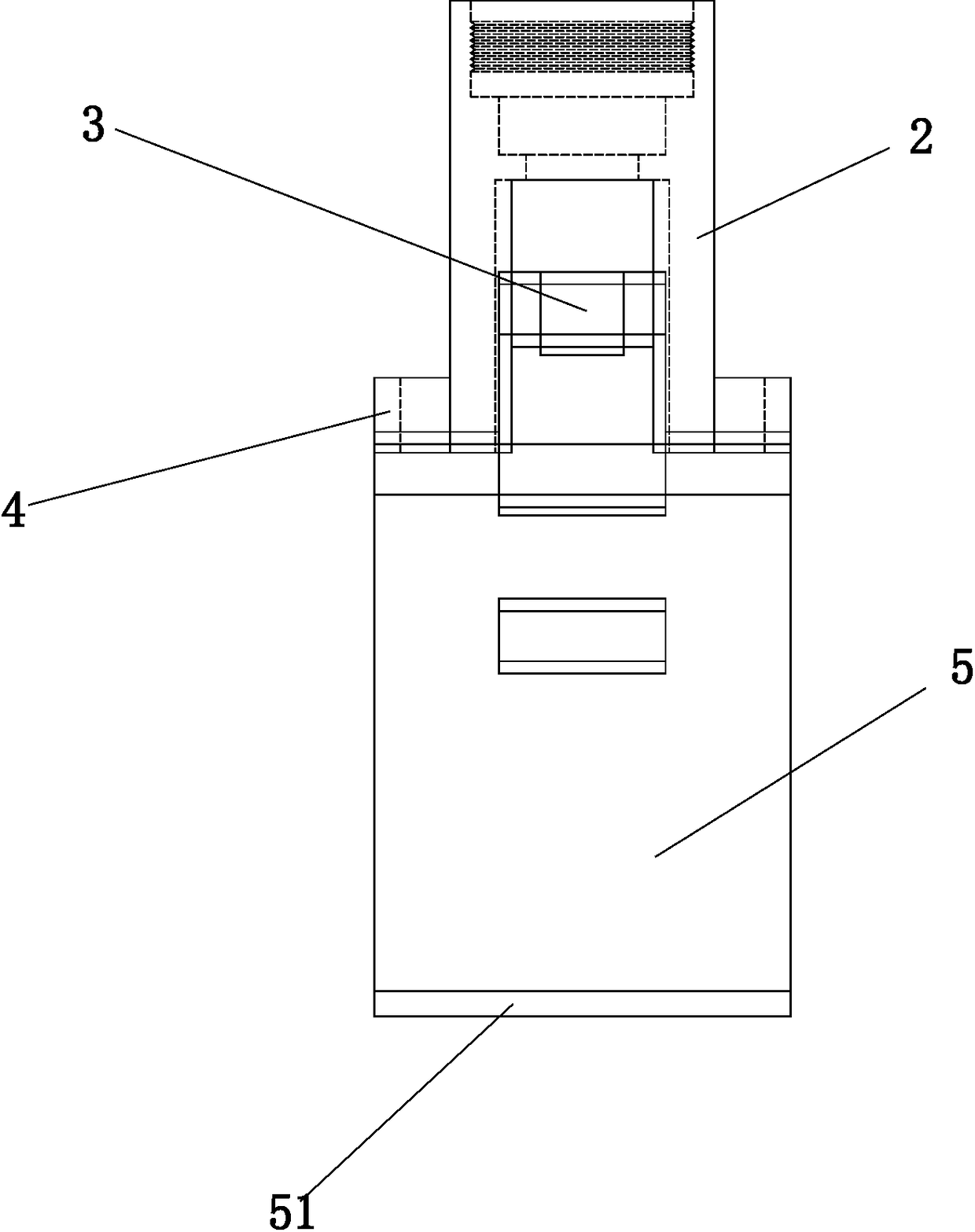

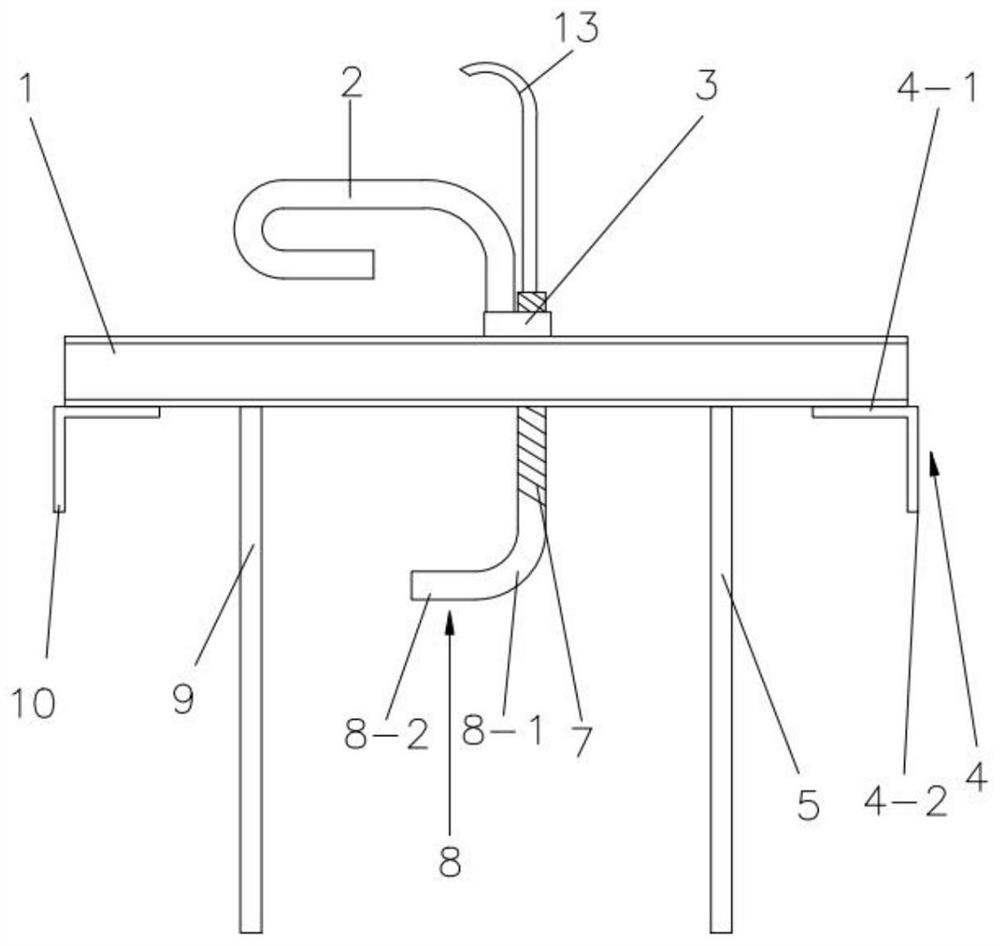

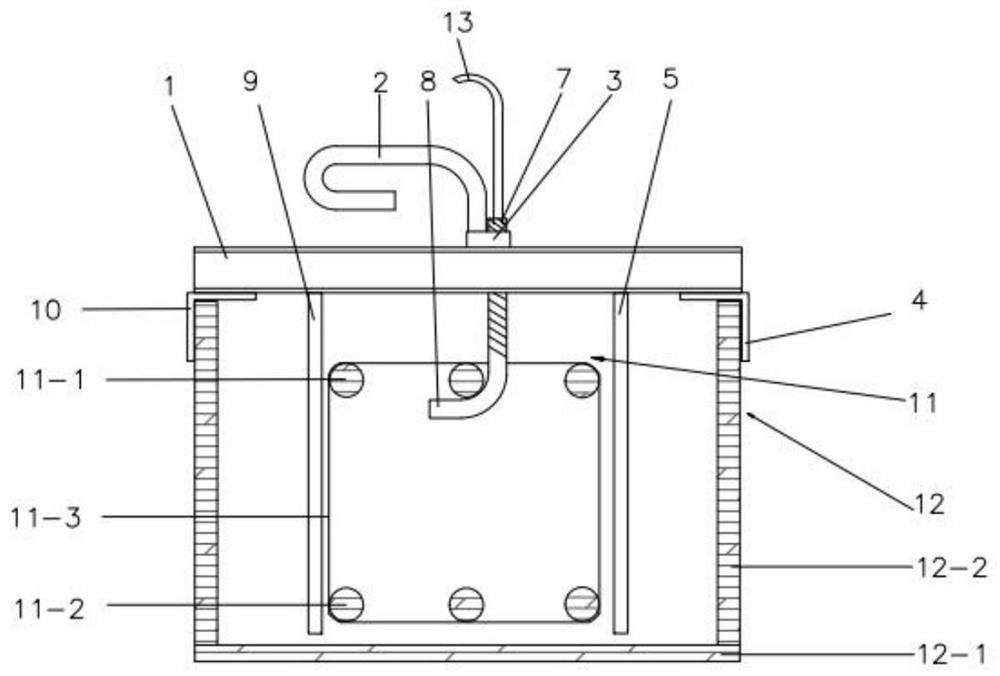

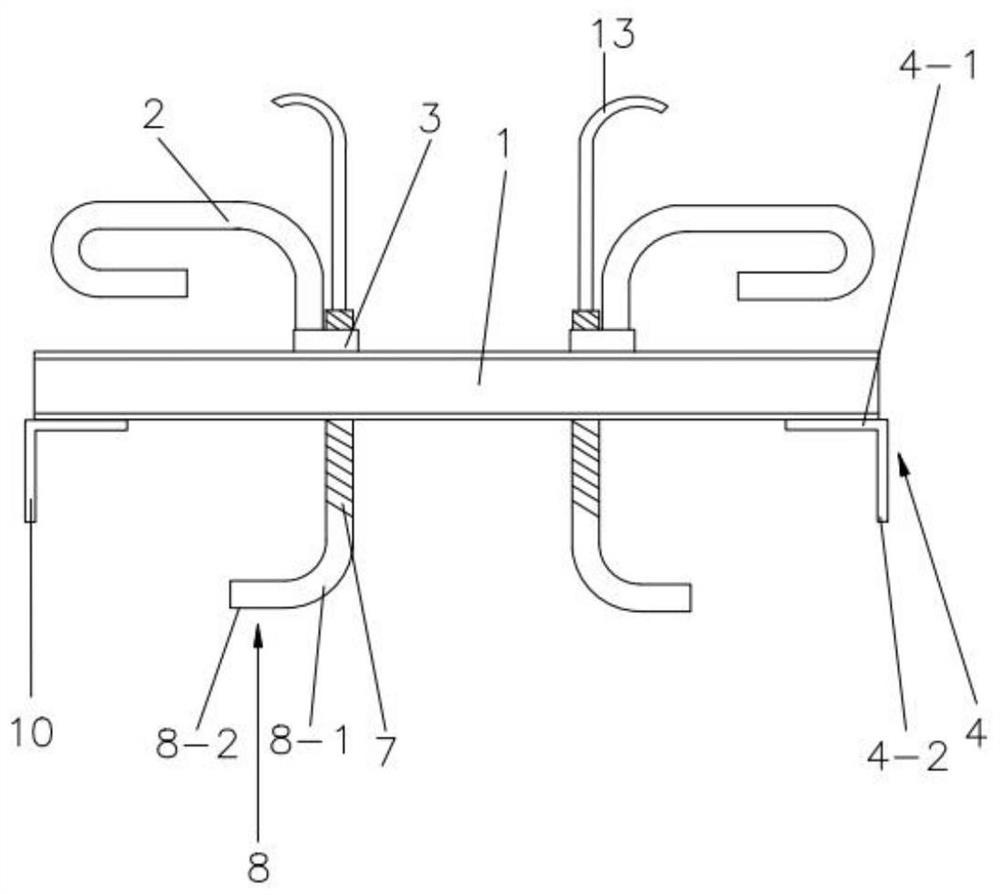

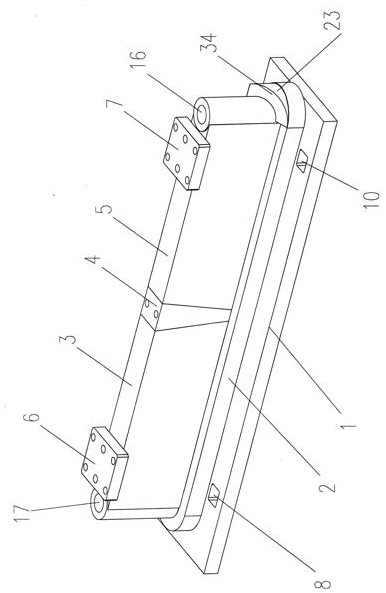

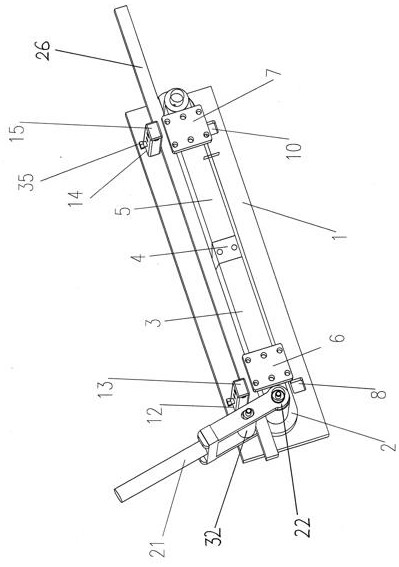

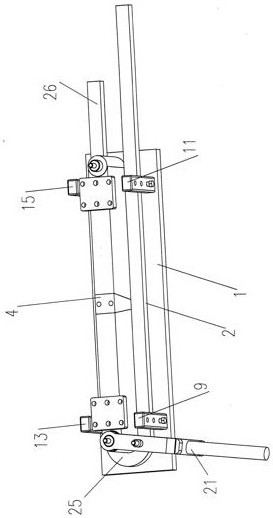

Field sampling device and sampling method of filling slurry

InactiveCN102998147AAccurate placementSimple structureWithdrawing sample devicesControl cellEngineering

The invention provides a field sampling device and a use method of filling slurry. The sampling device comprises a slurry cylinder control unit and a slurry cylinder, wherein the slurry cylinder control unit comprises a sampling rod, an upper transverse rod 5, and a lower transverse rod 12, and a control rod 15 is axially inserted into a main rod 3; the slurry cylinder comprises a slurry cylinder upper baffle 8, a slurry cylinder pipe 9 and a slurry cylinder lower baffle 11; and one end of the upper / lower transverse rod is fixedly connected with the control rod, and the other end of the upper / lower transverse rod is detachably connected with the slurry cylinder upper / lower baffle 8. According to the field sampling device and a sampling method of the filling slurry, the field sampling of the filling slurry is realized by driving the opening and the closing of the upper baffle 8 and the lower baffle 11 by the control rod of the slurry cylinder control unit; and the slurry at a fixed point can be precisely collected, the sampling can not be influenced by low-concentration filling slurry at the upper part of a collecting field in the rising processes of sampled samples, and the property of the filling slurry in the collecting field can be accurately acquired.

Owner:UNIV OF SCI & TECH BEIJING

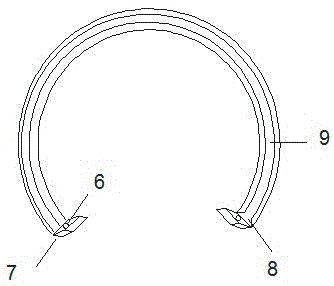

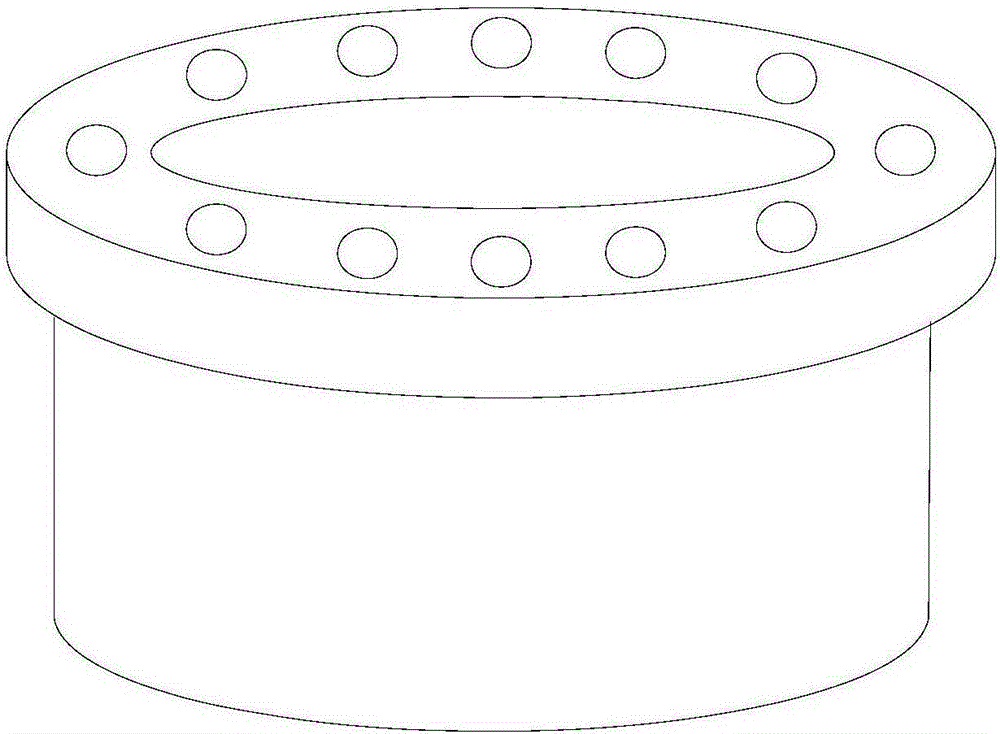

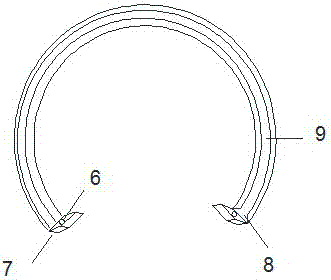

Method for manufacturing site pipeline type expansion joint

InactiveCN103143888AReduce the impactEasy to process on sitePipeline expansion-compensationEngineeringExpansion joint

The invention discloses a method for manufacturing a site pipeline type expansion joint in the environment with larger environmental temperature change and strong corrosivity, which has the characteristic of convenience in overhauling and maintenance. The method comprises the following steps: step A, selecting a reinforcement plate material and a roll bending material; step B, cutting the reinforcement plate material into a circular-ring-shaped reinforcement plate, wherein the inner diameter of the reinforcement plate is equal to the outside diameter of a pipeline; step C, enabling an inner diameter part of the reinforcement plate to be clung to the outer circumference of the pipeline so as to enable the inner diameter part of the reinforcement plate to be sealed and welded with the outer circumference of the pipeline to cause the reinforcement plate to protrude outside the pipeline; step D, cutting the roll bending material into a roll bending plate of which the width is equal to the distance between two adjacent reinforcement plates; and step E, performing sealing and welding on a long side part of the roll bending plate and an outer circumference part of the two adjacent reinforcement plates to enable the roll bending plate and the two reinforcement plates to form a pipeline type expansion joint waviness with a cavity. According to the method, the material of the expansion joint can be selected according to the environment; multiple times of repair, local replacement and repeated use can be realized; and the site pipeline type expansion joint can replace a finished stainless steel waviness expansion joint.

Owner:CHINA 19TH METALLURGICAL CORP

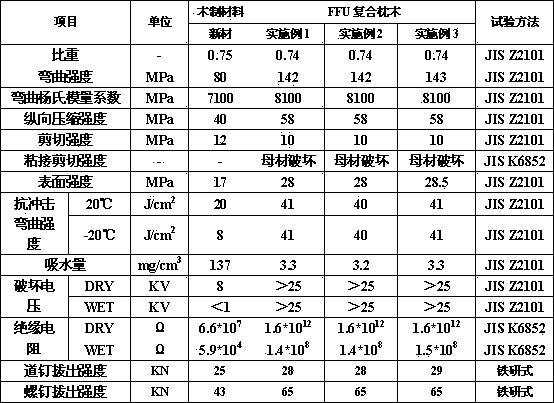

FFU (Fiber Reinforce-Foamed-Urethane) composite sleeper

The invention discloses an FFU (Fiber Reinforce-Foamed-Urethane) composite sleeper. The FFU composite sleeper is characterized by being molded by using a light corrosion-resistant structural material which is made by reinforcing synthetic resin foam through glass long fibers, wherein the glass long fibers are 20-35 nanometers in diameters, and are 2-8 centimeters in lengths; and the synthetic resin foam is made by performing chemical reaction foaming on hard ethyl carbamate resin. The FFU composite sleeper provided by the invention is a glass fiber-reinforced hard FFU microporous elastomer, has the excellent performance of high specific strength, shock absorption, noise reduction, electric insulation resistance, high durability and the like, is light in weight, is high in application property, and can be processed like wood; and the FFU composite sleeper contributes to environmental protection, and is recyclable.

Owner:SHAANXI TIANDI FOUND BUILDING NEW MATERIAL TECH

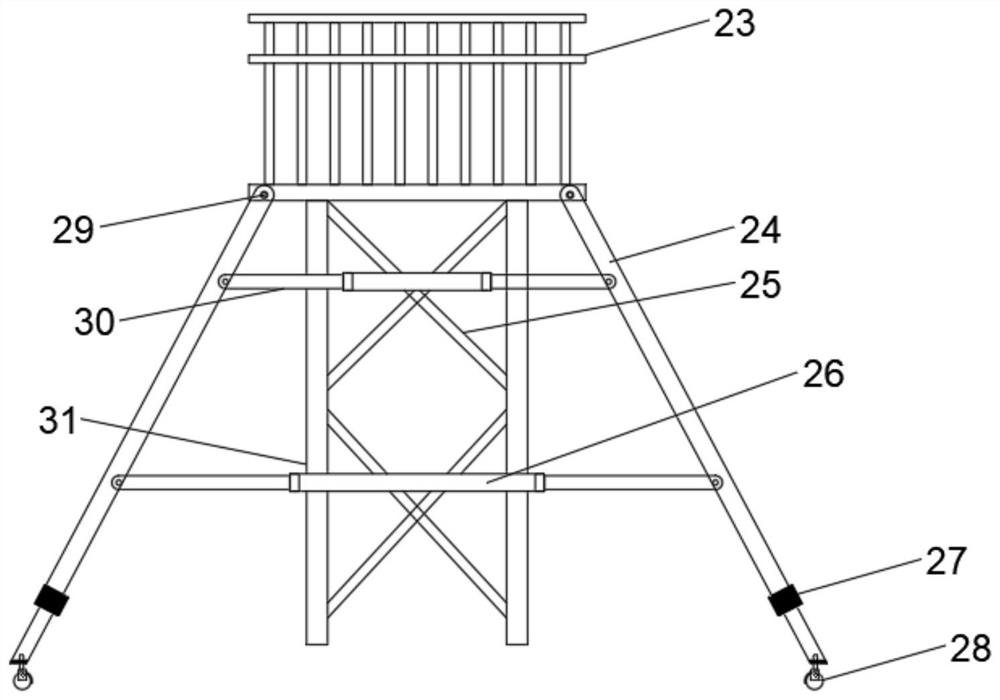

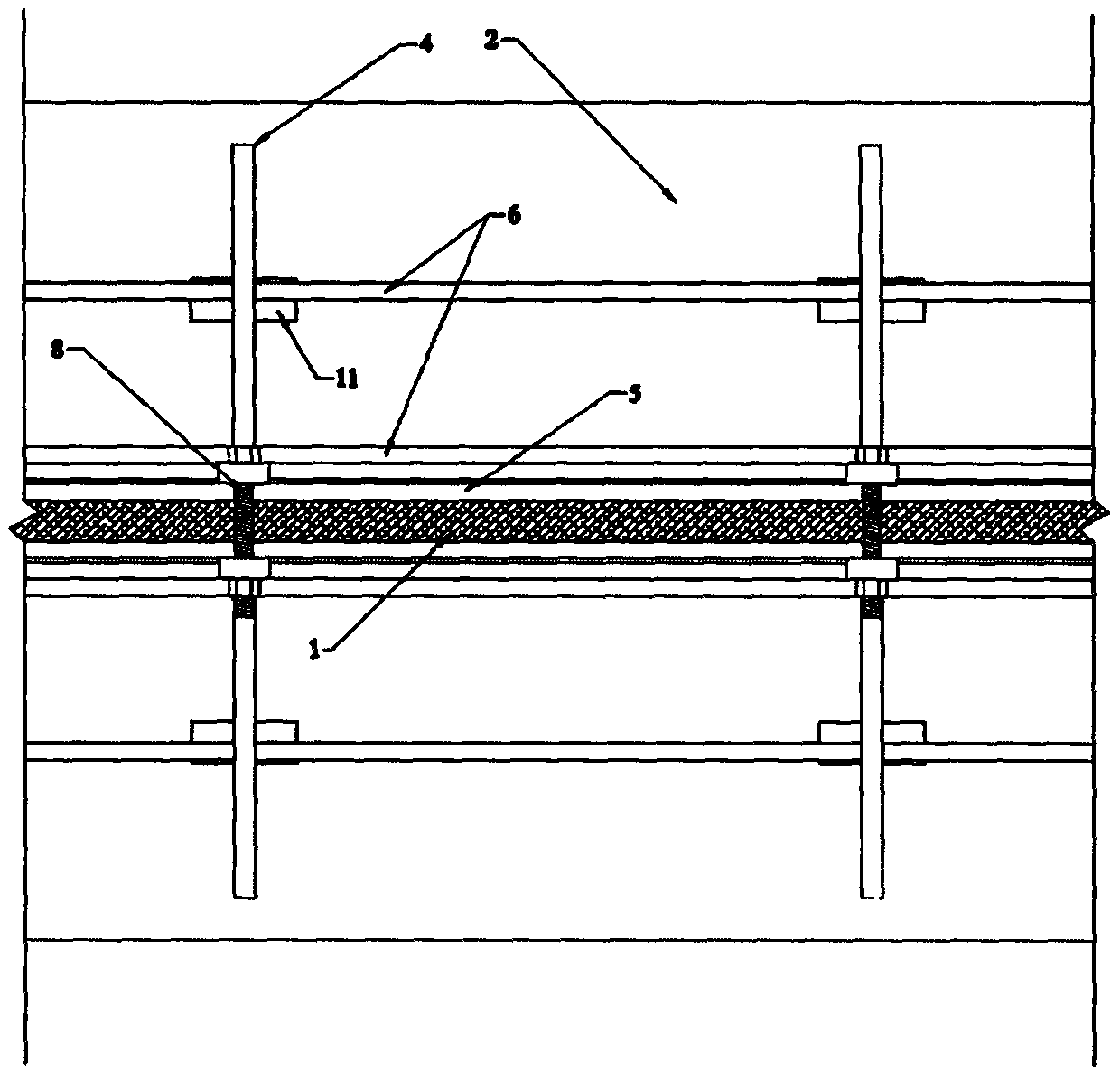

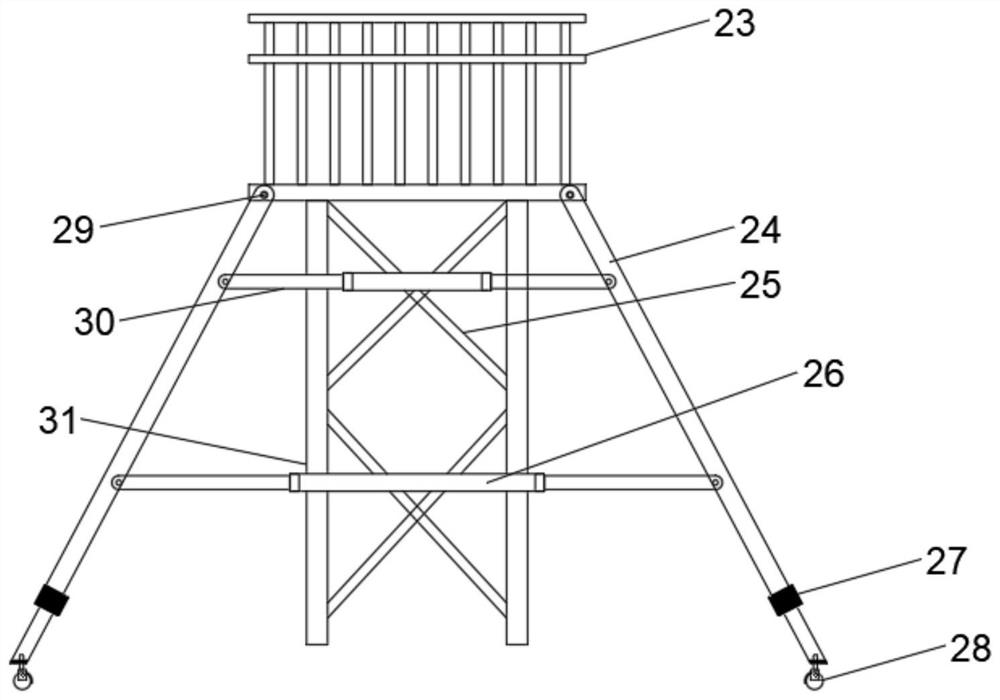

Dry-hanging stone wall surface and construction method thereof

ActiveCN112065048AEasy to process on siteSmall footprintCovering/liningsBuilding material handlingStone wallArchitectural engineering

The invention provides a dry-hanging stone wall surface and a construction method thereof. The construction method comprises the following steps of stone selecting and carrying; movable type shaping operation support erecting; vertical channel steel keel mounting; transverse keel mounting; stone grooving; bottom stone temporary support mounting; stone mounting; and coping cover plate construction;bottom stone temporary support dismounting and the like. The stone carrying and machining efficiency can be greatly improved, the occupied area of stone stacking is reduced, the dry-hanging stone construction efficiency is improved, the stone bottom elevation is flexibly adjusted, the stability of the dry-hanging stone wall surface structure is enhanced, and building materials are saved.

Owner:SHENZHEN JIANYI DECORATION GROUP

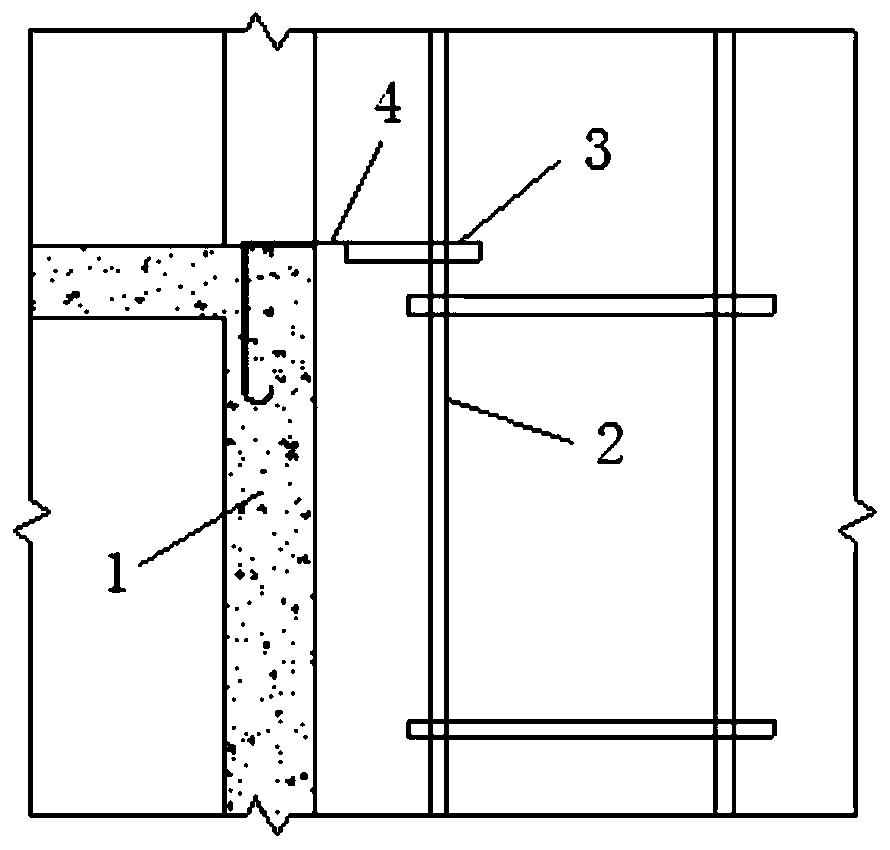

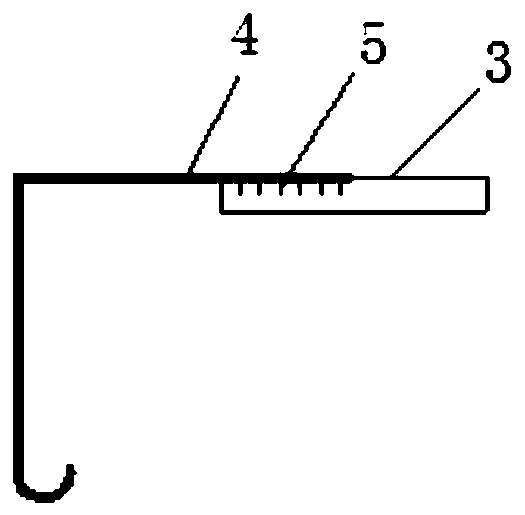

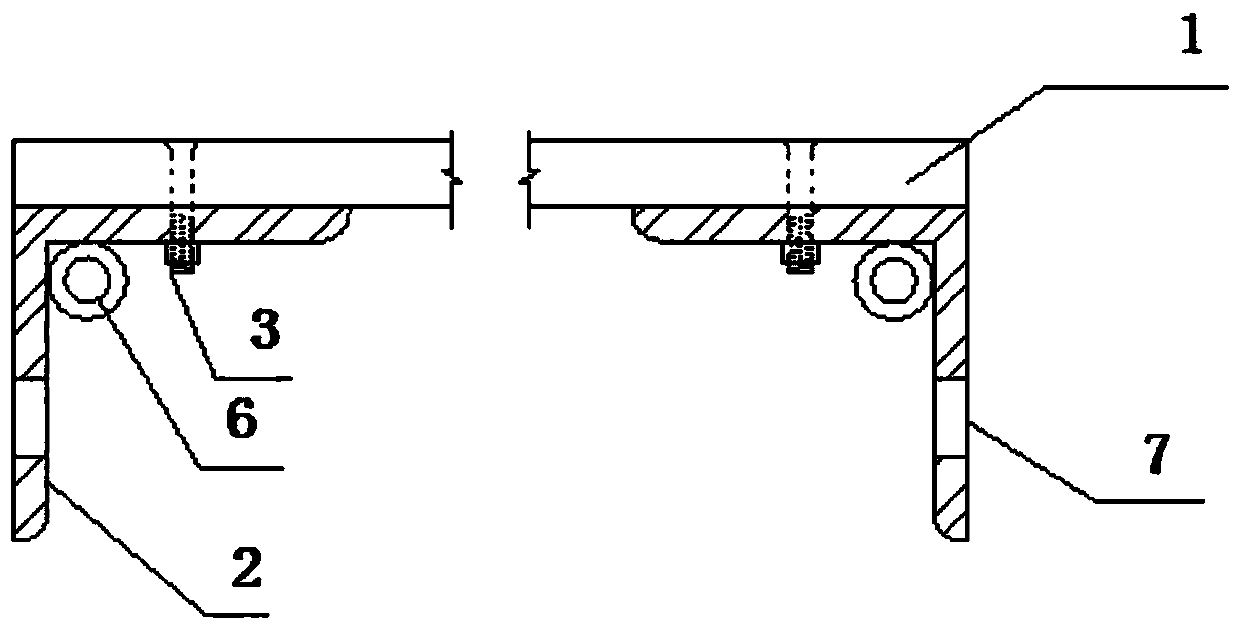

Shear wall external scaffolding tie point structure and manufacturing method thereof

PendingCN109898834ASatisfies the requirements of tie-knot rigid jointsEasy to process on siteScaffold accessoriesSteel tubeRebar

The invention discloses a shear wall external scaffolding tie point structure and a manufacturing method thereof. A tie point structure comprises a structural outer wall panel, an external scaffolding, a scaffold short steel tube andround steel, one end of the round steel is bent to form a hook, the plain and straight section of the round steel is bent at an intermediate position into a vertical section and a horizontal section of 90 degrees, and the hook is located at the bottom of the vertical section of the round steel; the horizontal section is welded to one end of the scaffold short steeltube, the vertical section of the round steel is embedded in the structural outer wall panel and fixed with a structural steel bar in the structural outer wall panel, and the other end of the scaffold short steel tube is fixedly connected witha vertical pole in the external scaffold. According to the shear wall external scaffolding tie point structure and the manufacturing method thereof, can avoid the hole on the structural shear wall is avoided, at the same time the requirements of thescaffolding rigid tie pointcan be met by relying on the tensile and compressive performance of the round steel, on-site processing is convenient, and the construction operation is also convenient and quick.

Owner:SHANGHAI NO 7 CONSTR

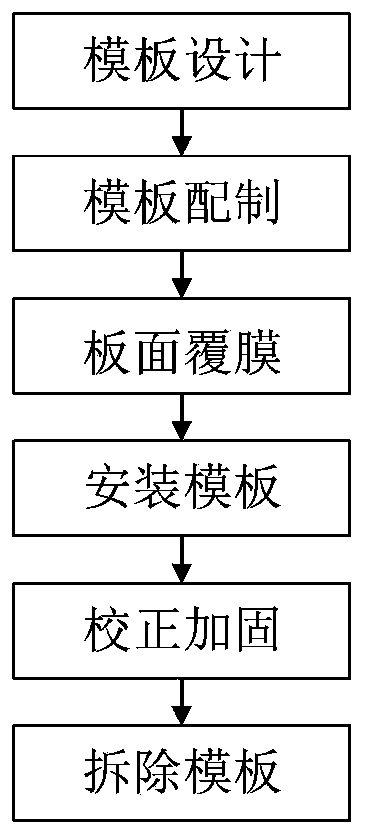

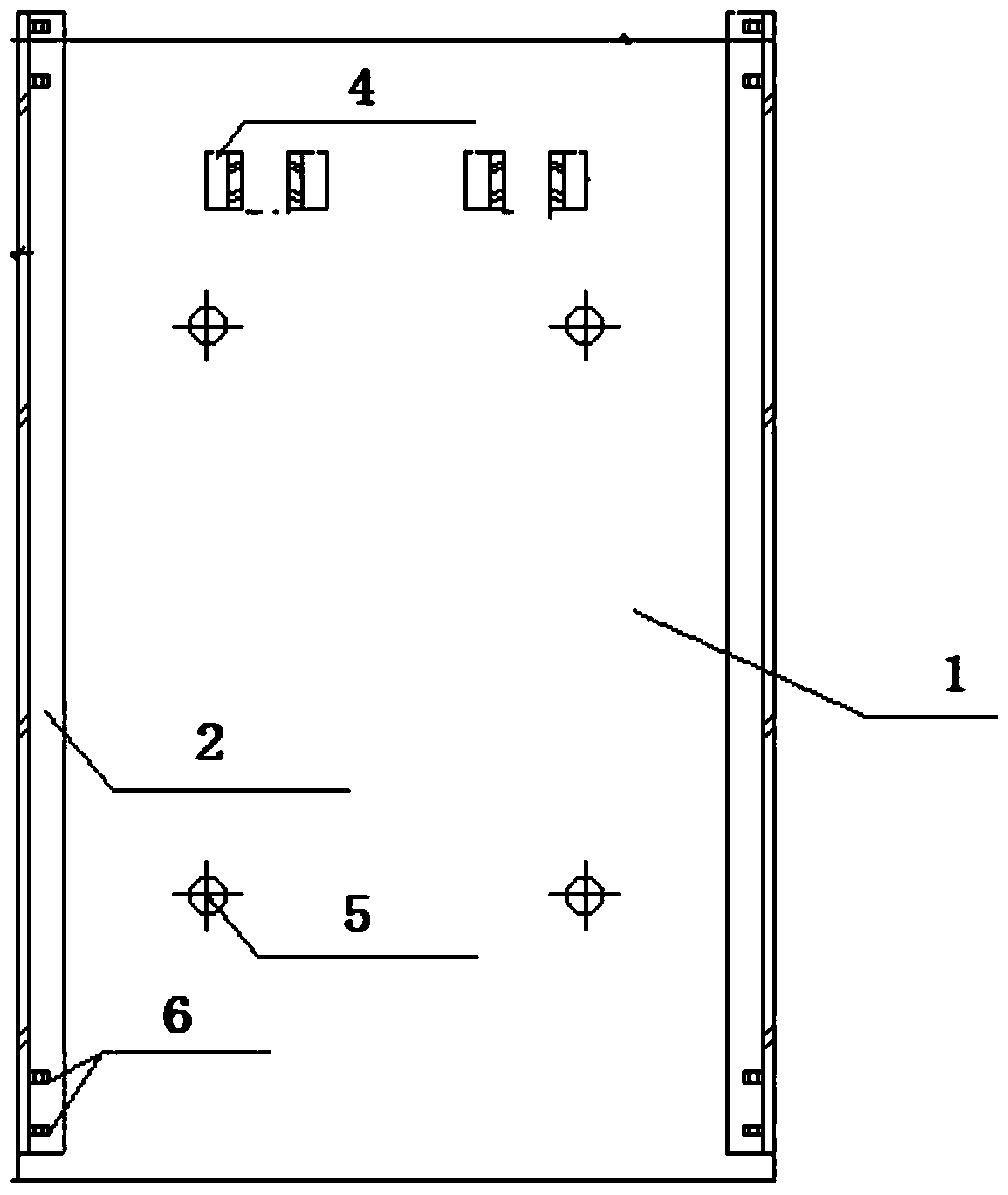

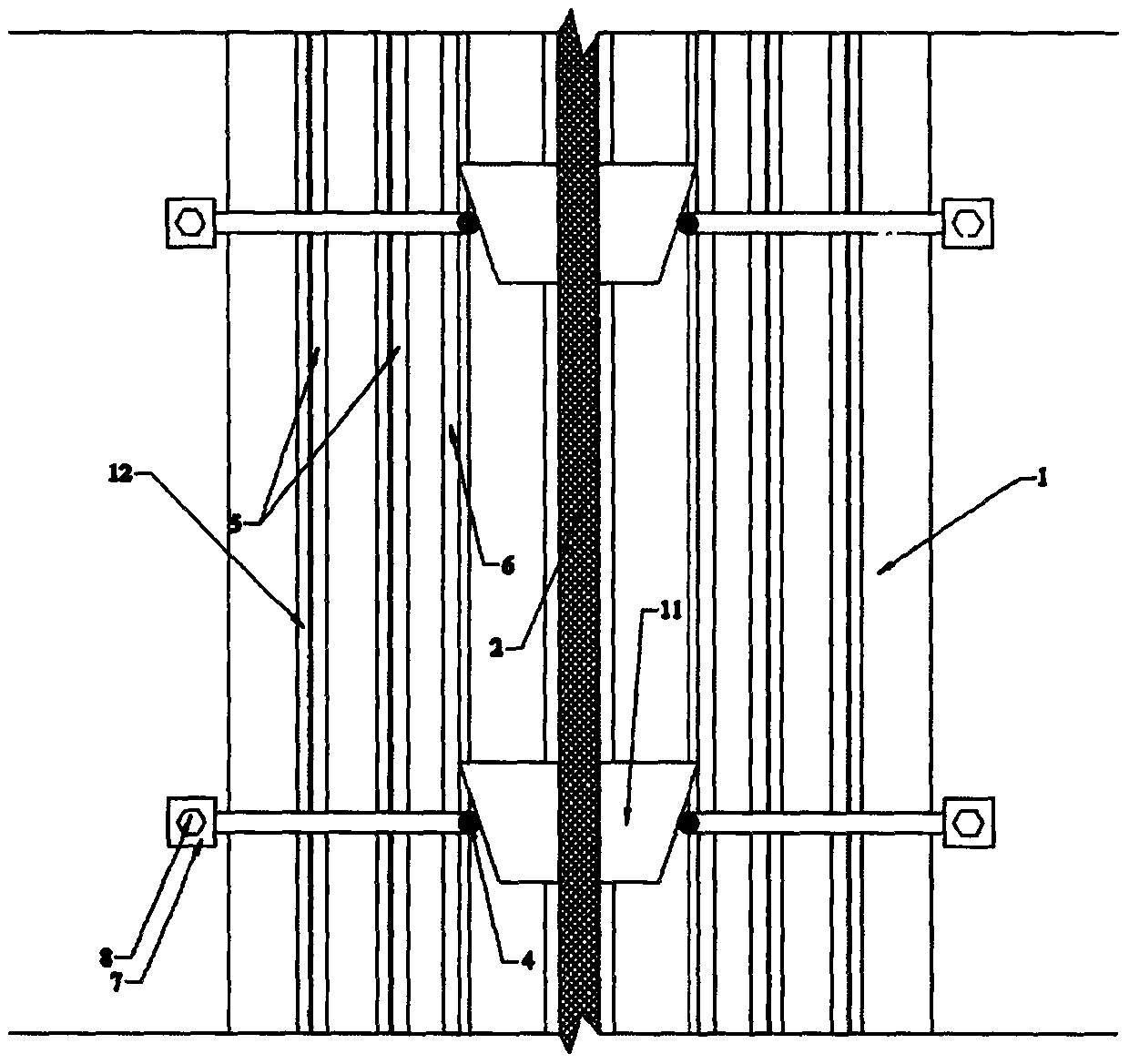

Construction method of assembling high turnover rate steel-coated plywood lightweight formwork system

InactiveCN110439257AReduce weightEasy to process on siteAuxillary members of forms/shuttering/falseworksForming/stuttering elementsHigh turnoverCoating

The invention discloses a construction method of an assembling high turnover rate steel-coated plywood lightweight formwork system. The construction method comprises the following steps of formwork design, formwork preparation, panel coating, formwork installation, correction reinforcement and formwork removing, wherein the step of formwork design is design of standard formworks, non-standard formworks, external corner formworks and internal corner formworks. The construction method has the advantages of flexible assembly, good impression quality, fast construction progress and high turnover rate.

Owner:CHONGQING NO 3 CONSTR +1

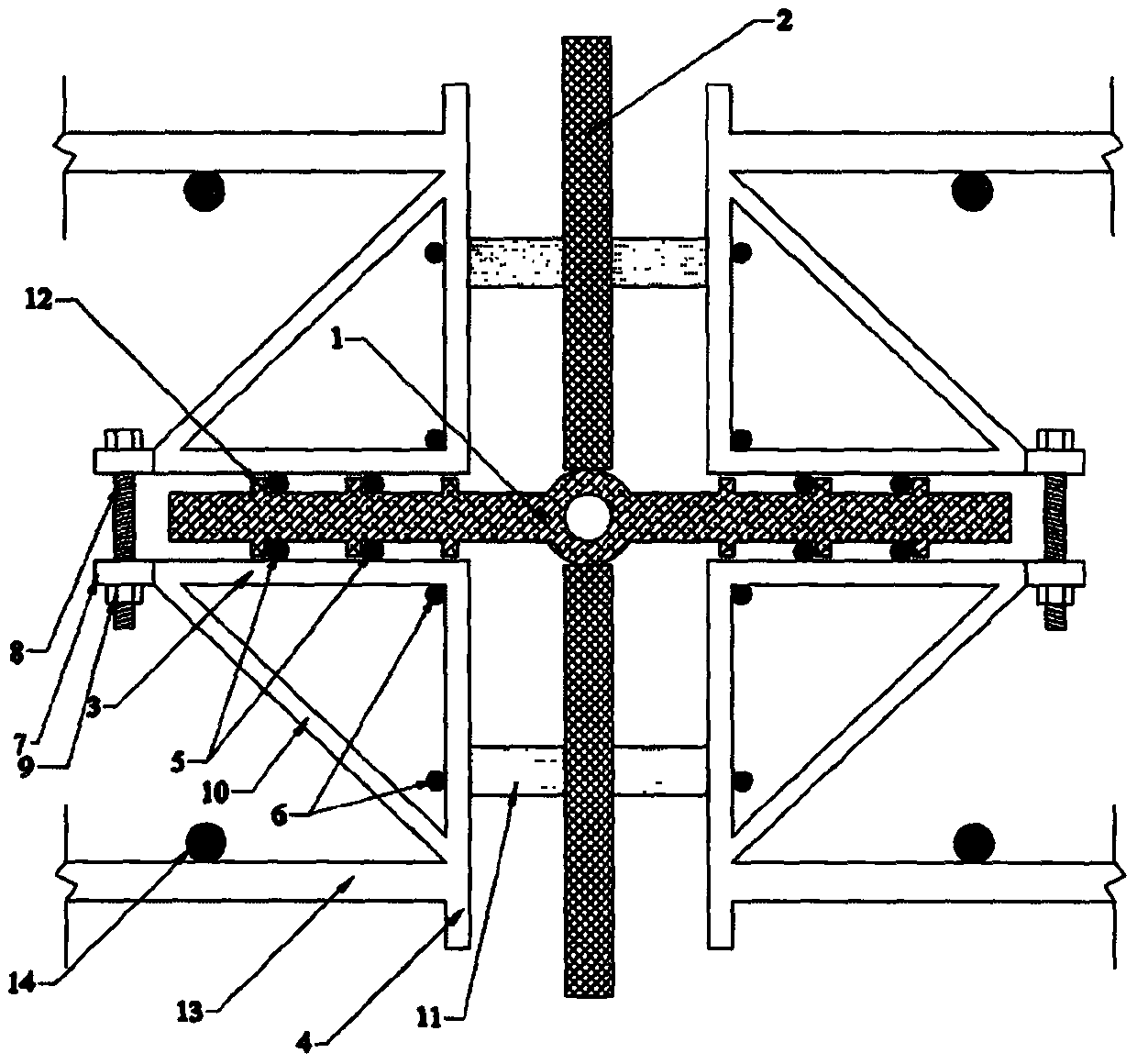

Rubber waterstop and foam board fixing device for box culvert continuous placement and using method thereof

The invention discloses a rubber waterstop and foam board fixing device for box culvert continuous placement and a using method thereof. The fixing device involves a rubber waterstop, foam boards, steel bar supports, bolts and mortar cushion blocks, the rubber waterstop is of a rectangular sheet-shaped structure, anti-skid protrusions are arranged on the two faces of the rubber waterstop, each steel bar support comprises a waterstop fixing rib, a foam board fixing rib, a rubber water-stopping anti-skid distribution rib, a connecting rib, a steel plate with a hole and an inclined supporting ribwhich are welded together to play a role of a fixing support, the bolts comprise screw rods and nuts and play a role in connecting the steel bar supports on the two sides of the waterstop to clamp and position the waterstop, and the mortar cushion blocks are trapezoidal mortar cushion blocks, are bound on the foam board fixing ribs and cooperate with the supports to play a role in fixing the foamboards. The fixing device has the advantages that the fixing problem of the rubber waterstop and the foam boards during box culvert continuous placement is solved, moreover, the structure is simple,fixing and connecting are convenient, on-site machining is facilitated.

Owner:BEIJING HANJIANHESHAN PIPELINE CO LTD +1

Antirust agent for autoclaved sand aerated concrete slab reinforcement and preparation method

ActiveCN108003708BSimple preparation processEasy to process on siteCarboxyl rubber coatingsAnti-corrosive paintsTap waterRebar

The invention discloses a rust inhibitor for a steel bar for an autoclaved sand aerated concrete board and a preparation method. The rust inhibitor is prepared from the following components in percentage by weight: 53 to 57 percent of carboxylic butadiene-styrene latex, 1.2 to 1.7 percent of iron oxide red, 8 to 11 percent of slaked lime, 3.2 to 3.7 percent of high-efficiency thickener, 18 to 22 percent of quartz sand, 5 to 10 percent of sand aerated concrete board waste material and 3 to 7 percent of tap water. Raw materials of the rust inhibitor provided by the invention are easily purchased, and the rust inhibitor has a low cost and a simple confecting process, can be abundantly confected once to be stored and used, has high adhesive force with the steel bar and is environmentally friendly and pollution-free.

Owner:SHAANXI NITYA NEW MATERIALS TECH CO LTD

One-time winding forming method for commutation pole coil of direct-current propulsion motor

ActiveCN114094787AEasy demoulding structureIngenious demoulding structureManufacturing dynamo-electric machinesElectric machineJackscrew

The invention discloses a one-time winding forming method for a commutation pole coil of a direct-current propulsion motor. The problem of one-time winding forming of a large-section sudden transposition coil is solved. Like a combined tool, the winding tool is designed into a combined assembly type, and a tool main body part is formed by combining and assembling a rectangular base plate, a long-strip barrel-shaped lower die holder, a long-strip three-dimensional die core, cantilever type pressing blocks on the two sides of the upper end and front and rear plug-in type pressing stand columns and a swing arm type bending wrench, an arc-shaped transposition block with a wedge-shaped inclined plane, an interlayer gap base plate and a jackscrew of a winding straight line edge form a combined accessory for winding the winding. All the components can be partially replaced according to the specifications of winding coils, the whole tool is convenient to assemble, disassemble and combine, and can be suitable for winding the reversing pole coils of various specifications, and the coils can be wound at a time. The tool die is combined, assembly, disassembly and combination are convenient, the tool cost is low, and on-site machining is easy.

Owner:SHANXI FENXI HEAVY IND

Method for cooking soft-shelled turtle

The present invention relates to a method for cooking a soft-shelled turtle. According to the present invention, the method for cooking the soft-shelled turtle includes the steps of pre-pickling, soup processing and the like, so that the in-site processing is easier, and the processing time is shorter. Besides, soft-shelled turtle soup made by using the method provided by the present invention is delicious in taste, and the soft-shelled turtle is fresh and tender in texture.

Owner:徐小芹

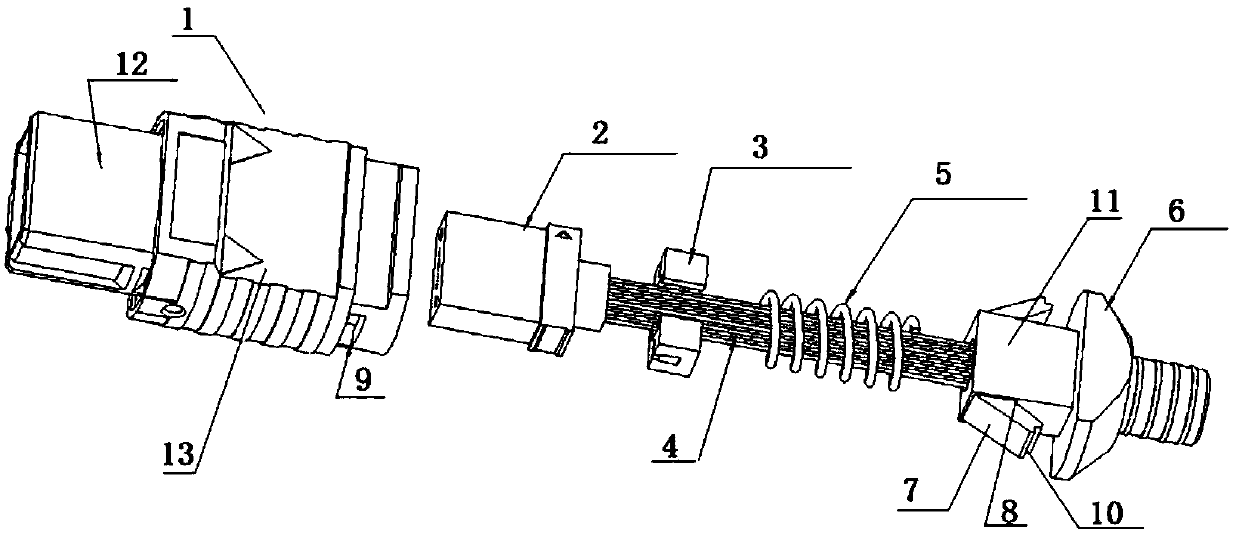

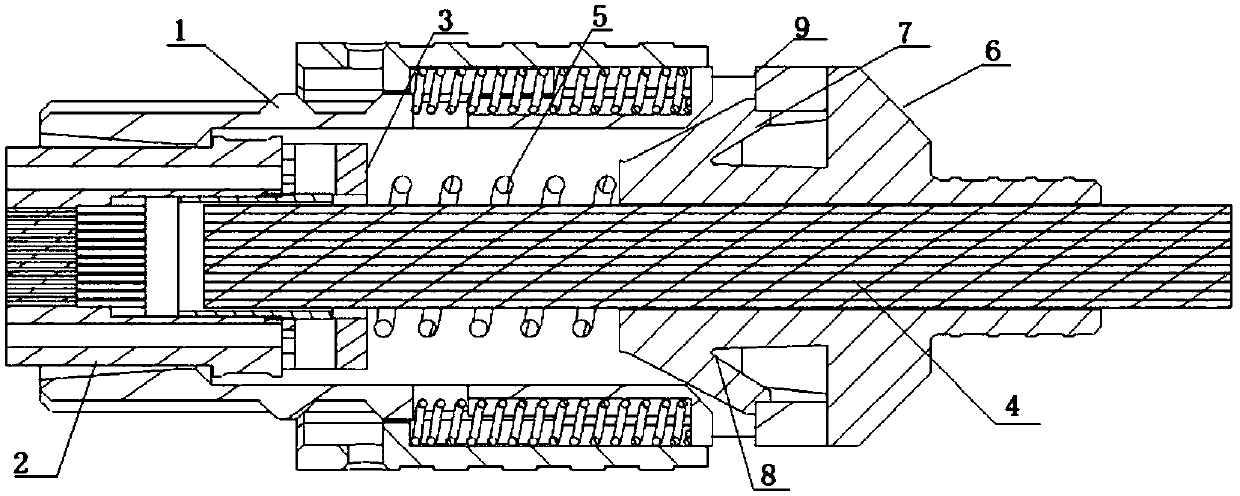

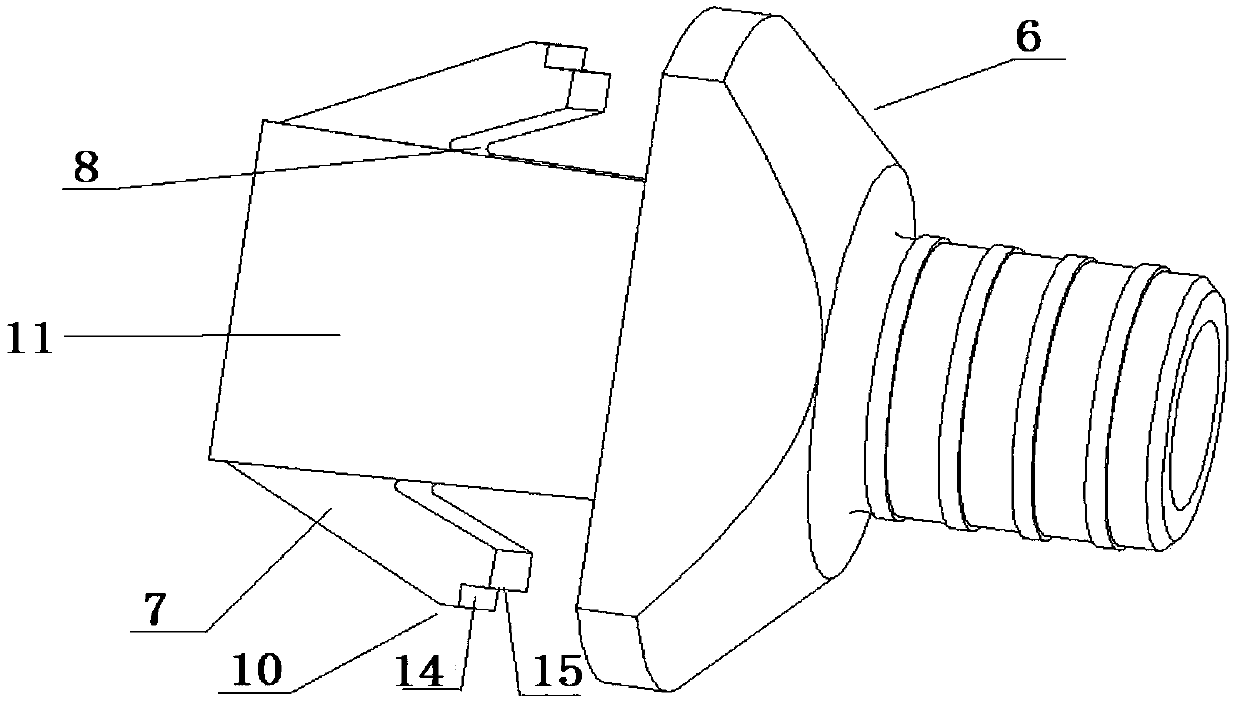

Optical fiber connector

ActiveCN110618496AWon't fall offEasy to processCoupling light guidesEngineeringOptical fiber connector

The invention relates to an optical fiber connector comprising a housing component, wherein a ferrule and a spring for pushing the ferrule forward are arranged in the housing component, a spring holding seat for limiting the spring is connected to the rear portion of the housing component, the spring holding seat comprises a holding seat body, an elastic cantilever is provided on the holding seatbody and is overhung by backward lean in the form that its rear end is close to the radial outer side of the housing component, and an overhanging end of the elastic cantilever is in stopper cooperation backward with the housing component. The above technical solution solves the problem that the hook between the spring holding seat and the housing component in the prior art is easily loosened, resulting in connection failure.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

One-time winding forming method of commutation pole coil of DC propulsion motor

ActiveCN114094787BEasy demoulding structureIngenious demoulding structureManufacturing dynamo-electric machinesElectric machineControl theory

The invention discloses a one-time winding and forming method for the reversing pole coil of a DC propulsion motor, which solves the problem of one-time winding and forming of a large-section emergency transposition coil; like a combined tool, the invention's The winding winding tooling is designed as a combined assembly. The main part of the tooling is composed of a rectangular base plate, a long barrel-shaped lower mold base, a long three-dimensional mold core, cantilevered pressing blocks on both sides of the upper end, and plug-in pressing blocks on the front and rear sides. Tightening columns are combined to form the main body of the tooling; the swing arm bending wrench, the arc-shaped transposition block with a wedge-shaped inclined surface, the interlayer gap backing plate and the top wire on the straight side of the winding form the winding winding. Combination accessories; the above components can be partially replaced according to the specifications of the winding coil. The whole tooling is convenient to assemble and disassemble. It is suitable for winding commutation pole coils of various specifications, so that the coil can be wound at one time. The tooling mold is combined, easy to assemble and disassemble, low tooling cost, and easy to process on site.

Owner:SHANXI FENXI HEAVY IND

Method for preparing soft-shelled turtle

The invention relates to a method of preparing the turtle, comprising the following steps: 1) pickling: killing a alive turtle, removing skin by putting the turtle in warm water of 60 Deg C for 30 seconds, getting oil by opening stomach and breaking into blocks; b. washing the block, and pickling; 2) preparing soup; 3) preparing process: boiling the soup, adding the pickled turtle, keeping for three to five minutes, and getting out for eating. The process is simpler, and the time is shorter because of the employed process of prepickling and soup preparing, further more, the turtle is delicious and fresh.

Owner:赵国英

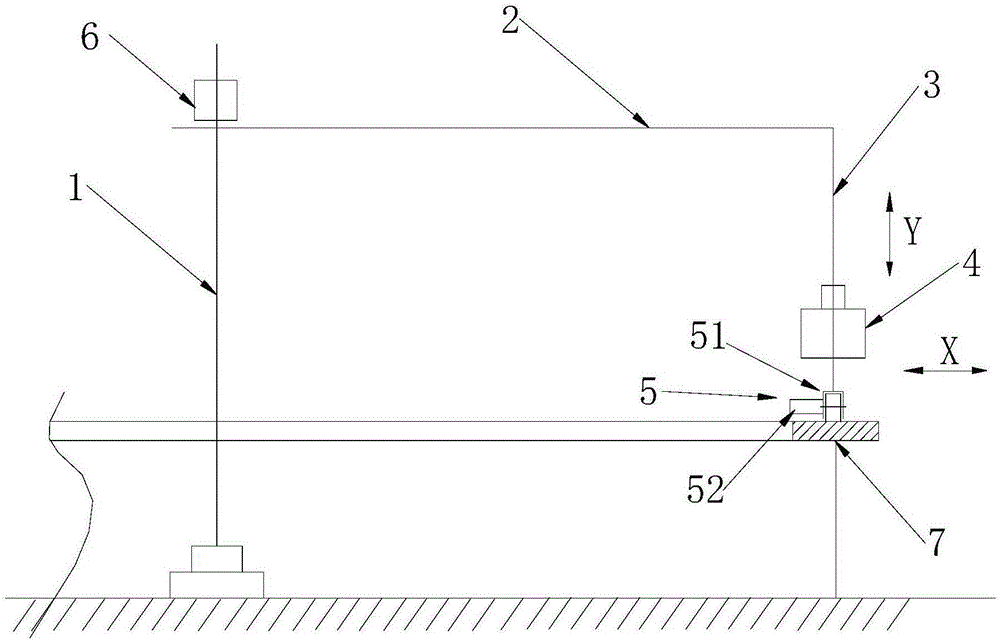

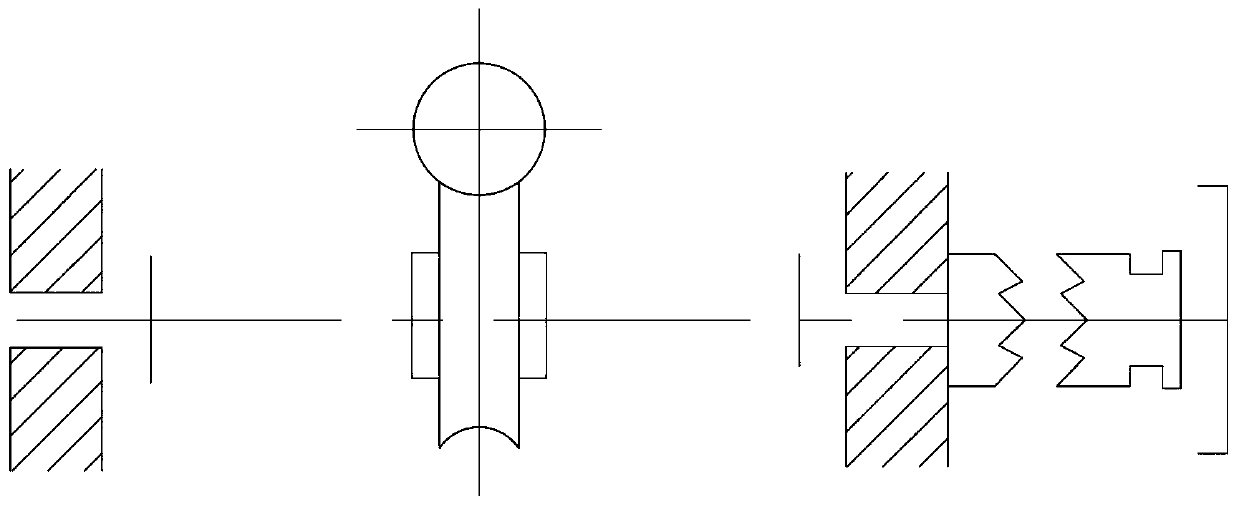

A Dividable Combined Turning, Milling and Boring Machine

ActiveCN104759885BGuaranteed machining accuracySimple structurePrecision positioning equipmentOther manufacturing equipments/toolsEngineeringAngle of rotation

The invention relates to a separable combined turning / milling / boring machine. The separable combined turning / milling / boring machine is characterized by comprising a positioning shaft fixed in the position of the central axis of a workpiece to be machined, a beam comprising a cross beam, a power head arranged on the beam in a sliding manner and comprising a main driver, a power box and a cutting tool bit, an indexing detection device for detecting the angle of rotation of the beam, and an indexing control device for receiving information fed back by the indexing detection device and controlling the beam to stop at a specified angle, wherein the cross beam is horizontally and rotatably fixed on the positioning shaft; the power head is capable of moving in the horizontal and vertical directions. As the indexing detection device and the indexing control device are adopted to control indexing, the separable combined turning / milling / boring machine is high in indexing precision, convenient to operate, and full-automatic; the production efficiency is improved and the machining period is shortened; the separable combined turning / milling / boring machine is suitable for indexing machining and the like of large workpieces.

Owner:FOSHAN XINCHENG HONGDING MACHINERY TECH CO LTD

A Simple Supporting Method for Concrete Cylindrical Formwork

ActiveCN105569331BEasy to processImprove turnover rateForms/shuttering/falseworksSteel tubeMaterials science

The invention discloses a simple supporting method for a cylindrical concrete formwork, and belongs to the technical field of building concrete formworks. An inner flat iron hoop, supporting steel tubes and an outer flat iron hoop are involved in the method. The method is characterized in that a bamboo wood formwork is further involved in the method and is of a cylindrical structure formed by splicing two or more composite bamboo glue formworks; the inner flat iron hoop is fixedly installed on the periphery of the bamboo wood formwork, and the supporting steel tubes are fixed to the inner flat iron hoop through steel tube fasteners and are sleeved with the outer flat iron hoop. The cylindrical concrete formwork is compact in structure, easy to machine, not prone to deformation, light in weight and low in cost, the surface of poured concrete is smooth, and dimension errors are small; the supporting components are high in circulation rate, convenient to assemble and disassemble and high in working efficiency; no complex outer supporting structure is needed, and the cylindrical concrete formwork is suitable for narrow sites and is convenient to maintain and clean after being dismantled.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

A dry-hanging stone wall surface and its construction method

ActiveCN112065048BEasy to process on siteSmall footprintCovering/liningsBuilding material handlingStone wallSupport removal

The invention provides a dry-hanging stone wall surface and a construction method, comprising the following steps: selecting and transporting stone materials; setting up mobile stereotyped operation supports; installing vertical channel steel keels; installing horizontal keels; Support installation; stone installation; top cover construction; bottom stone temporary support removal and other steps can greatly improve the stone handling and processing efficiency, reduce the occupied area of stone stacking, improve the construction efficiency of dry-hanging stone materials, and flexibly adjust the bottom elevation of stone materials. Enhance the stability of the dry-hanging stone wall structure and save building materials.

Owner:SHENZHEN JIANYI DECORATION GROUP

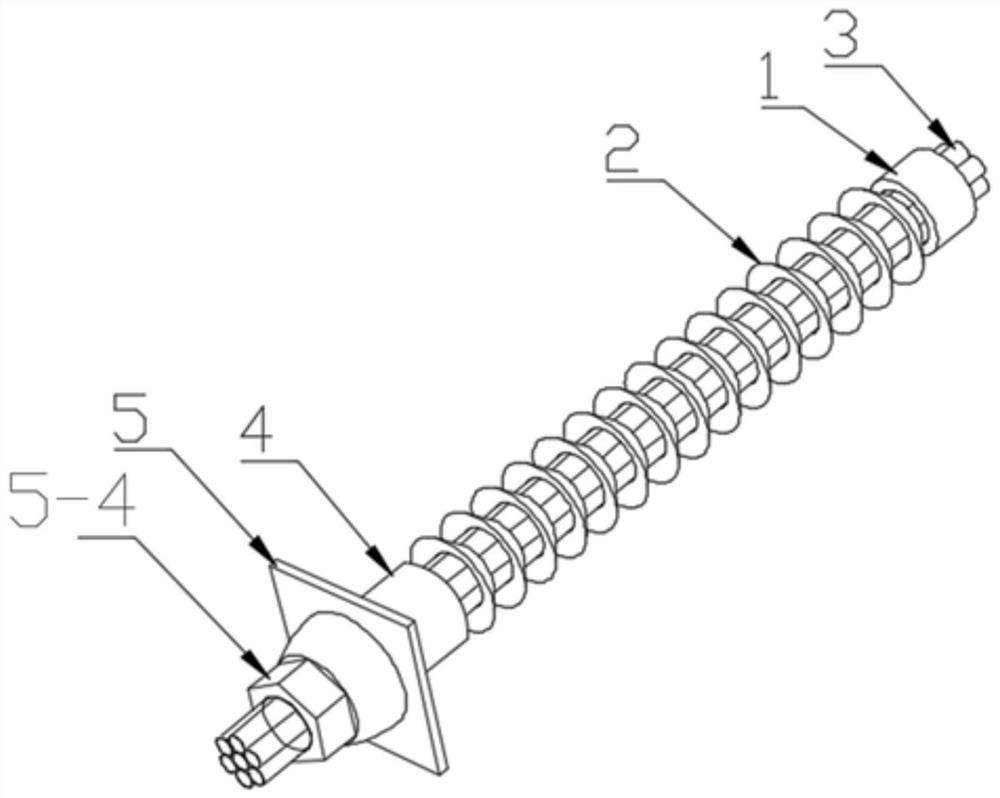

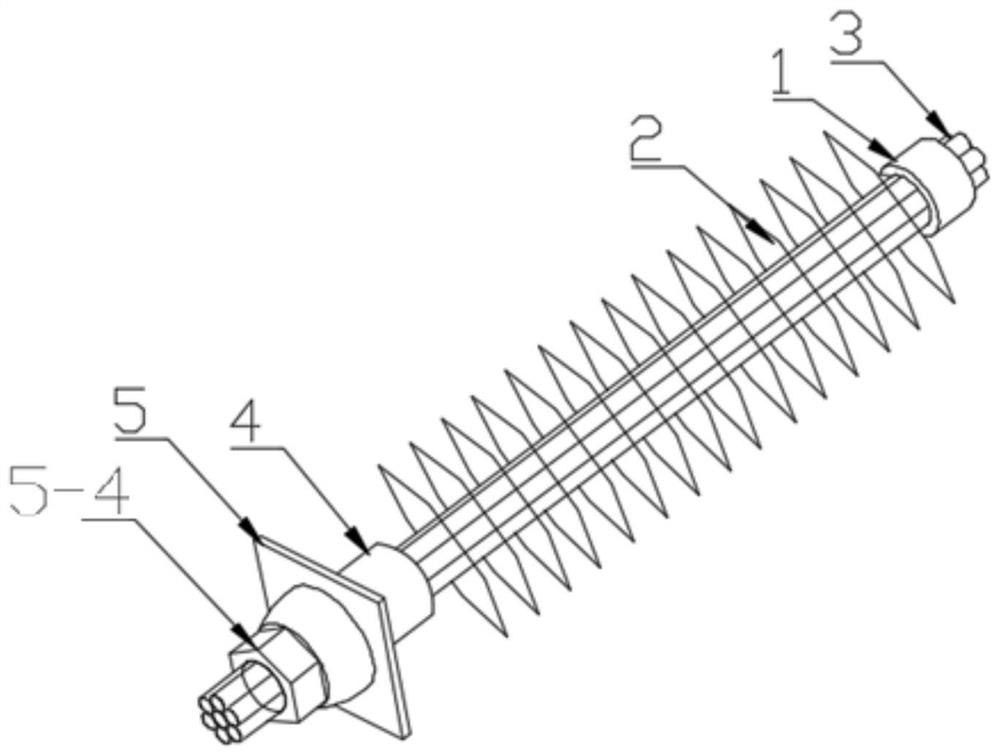

Radial internal expansion resistance-increasing anchor cable supporting device and method

InactiveCN112879058AAvoid failureImprove tensile propertiesAnchoring boltsEngineering supportRock bolt

The invention provides a radial internal expansion resistance-increasing anchor cable supporting device and method, and relates to the technical field of geotechnical engineering supporting. High-performance anchoring can be achieved, the supporting performance of a single anchor cable is enhanced, the structure is exquisite, the construction speed is high, and the self-expansion effect is achieved. The device comprises a steel strand bundle, and one end of the steel strand bundle sequentially penetrates through a fixed connecting sleeve, a plurality of resistance-increasing pieces and a steel sleeve; the steel strand bundle is fixedly connected with the fixed connecting sleeve, the resistance-increasing pieces and the steel sleeve; a tray structure is arranged at the other end of the steel strand bundle; the resistance-increasing pieces are of a hollow structure and are in an inwards-convex sheet shape as a whole, and the inwards-convex faces are close to the end provided with the tray structure; and when the device is subjected to the huge drawing force effect, pressure relief is achieved through self expansion, meanwhile, the tensile resistance is increased, and anchor cable anchoring failure is avoided. The technical scheme is suitable for the rock stratum supporting process.

Owner:UNIV OF SCI & TECH BEIJING

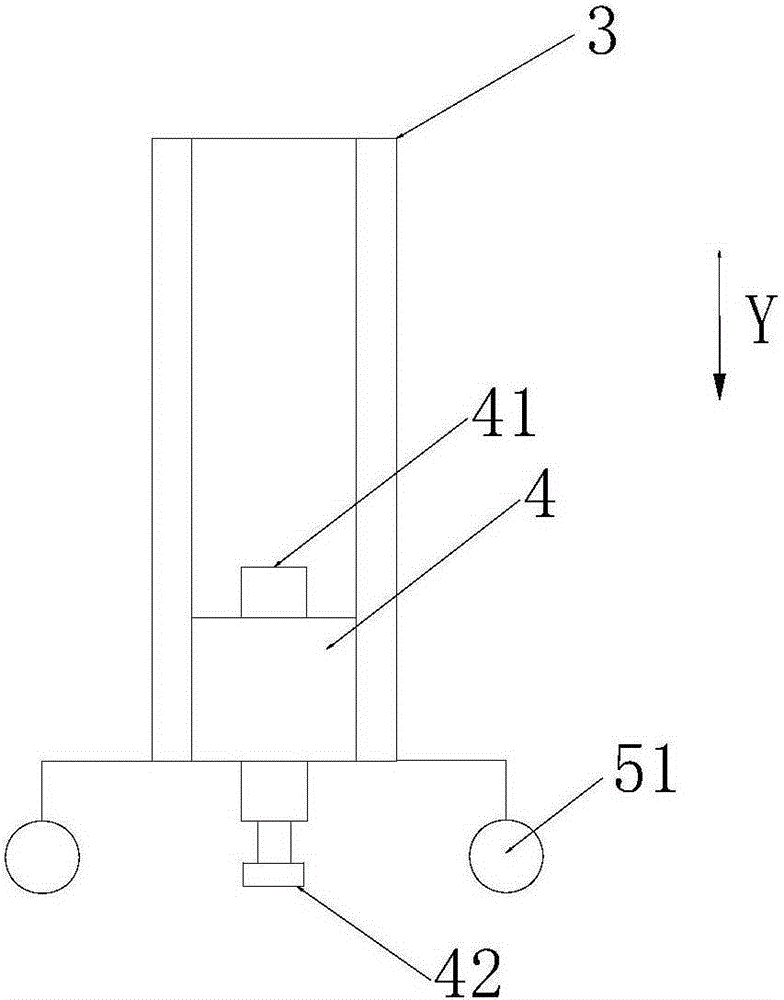

Novel semi-automatic feed mechanism of threading machine

InactiveCN110814445AImprove processing efficiencyReduce volumeThread cutting machinesDrive wheelReduction drive

The invention discloses a novel semi-automatic feed mechanism of a threading machine. The novel semi-automatic feed mechanism comprises a thread cutting device, a gear box, a main shaft, a sliding machine base, a speed reducer, a motor, a worm pair and round guide rails. According to the thread cutting device, four movable threading die type cutters are installed in a cylindrical cutter supportingframe, one end of the thread cutting device is connected with the main shaft through a coupler, the gear box is arranged between the thread cutting device and the sliding machine base and fixed to one end of the sliding machine base, the main shaft is a driven wheel output shaft in the gear box and fixedly connected with a driven wheel through a key groove structure, the sliding machine base is arranged at one end of the gear box, the two round guide rails are arranged at the bottom end of the sliding machine base, and the sliding machine base is connected with the round guide rails in a clearance fit mode through shaft sleeves. According to the novel semi-automatic feed mechanism of the threading machine, a worm mechanism is adopted as motion and power output of thread cutting, and meanwhile the advantages that an original machine is high in machining efficiency, small in size, compact in structure, low in weight, capable of facilitating field machining and the like are kept.

Owner:JIANGSU XINPENG ENERGY TECH

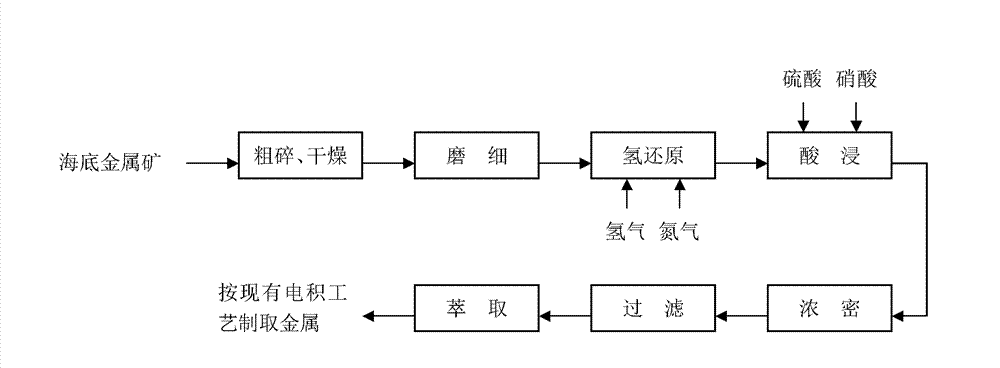

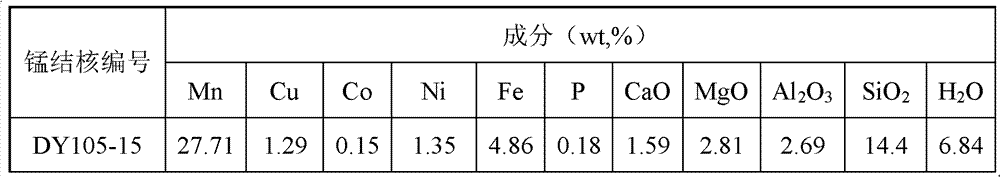

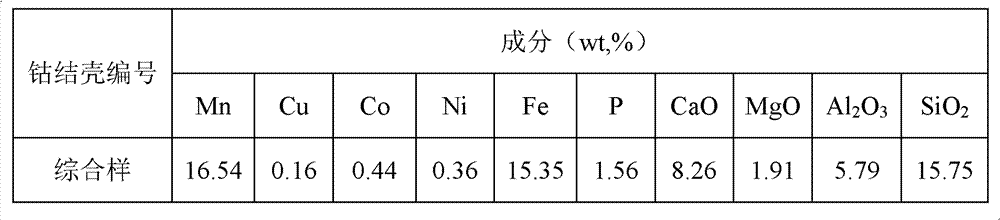

Method for extracting valuable metal from submarine metallic ore

ActiveCN102358919BImprove leaching rateReduce shipping costsProcess efficiency improvementHydrogenFiltration

The invention discloses a method for extracting valuable metal from submarine metallic ore, which comprises the following steps: coarsely crushing submarine metallic ore, drying the coarsely crushed ore materials; levigating the dried ore materials to obtain ore powder; placing the ore powder in a reaction bed, injecting hydrogen under a heating condition to perform a reduction reaction; adding the reduced discharged material into an acid solution for acid leaching; concentrating the leached ore pulp after acid leaching, collecting the supernatant, performing pressure filtration of the concentrated underflow, combining the filtrate and the supernatant, removing impurities, extracting, and recovering valuable metal by an electrodeposition method. The method of the invention has the advantages of resource saving, low energy consumption, low pollution, zero carbon discharge capacity, high reduction and leaching rates, and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Electric hydraulic modeling clamp

The invention relates to the field of buildings, in particular to an electric hydraulic modeling clamp. The electric hydraulic modeling clamp comprises a support. A pressure bearing piece is arrangedat the top of the support, provided with a detachable pressure applying device and further provided with a pressure bearing plate which bears the pressure conducted by the pressure bearing piece. Thepressure bearing plate is arranged above the support, and the two ends of the pressure bearing plate are connected with transmission strips which are provided with extruding pieces. The extruding pieces and the support are in transmission connection with each other, and extruding heads are arranged at the bottoms of the extruding pieces. A return spring matched with the pressure bearing piece is arranged in the support. Compared with the prior art, a color steel tile can be quickly modeled, the color steel tile is evenly stressed during modeling, the strength loss is small, breakage is avoided, a photovoltaic device can be mounted directly, and the problems that during mounting of the photovoltaic device, punching needs to be conducted on the color steel tile, the time and labor are wasted, and water leakage hidden danger exists are solved.

Owner:宁波建工建乐工程有限公司

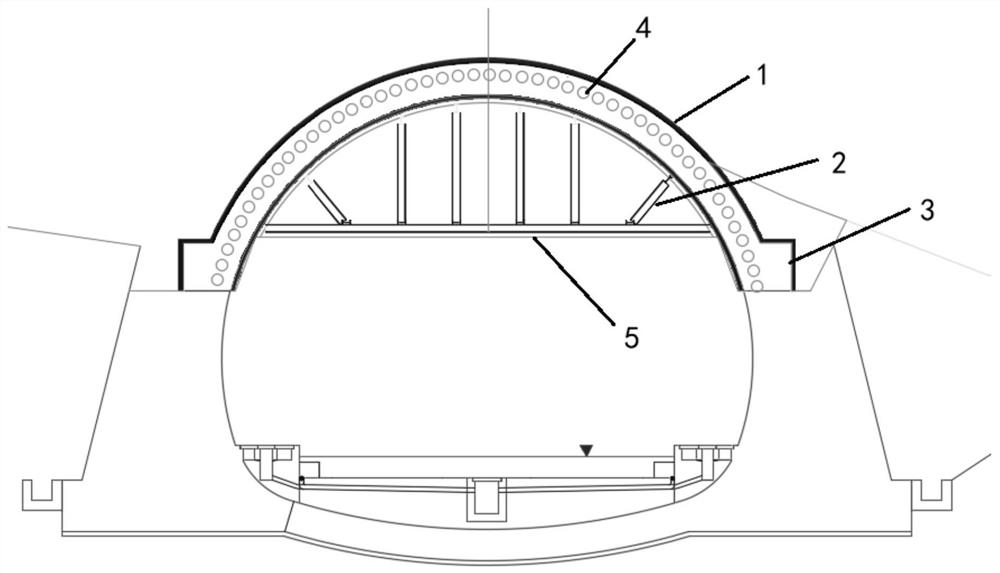

Rapid supporting structure for tunnel guide wall formwork and construction method

PendingCN111911198AIncrease profitImprove construction qualityUnderground chambersForms/shuttering/falseworksSupporting systemFalsework

The invention discloses a rapid supporting structure for a tunnel guide wall formwork and a construction method. The rapid supporting structure comprises a guide wall and a supporting system; a guidepipe is arranged in the guide wall, the inclination angle of the guide pipe is 1-3 degrees, and arch feet are arranged at the two ends of the guide wall; and the supporting system comprises a transverse supporting pipe and an oblique supporting pipe, and the two ends of the oblique supporting pipe are connected with the transverse supporting pipe and the guide wall respectively. According to the construction method, potential safety hazards in the installation process of a steel pipe bowl opening scaffold are avoided, equipment investment is reduced, the utilization rate of existing materialsis increased, the construction cost is saved, and the construction period is shortened; and the outstanding effects of high safety, high economy and high construction speed are achieved.

Owner:ROAD & BRIDGE INT +1

A method of manufacturing prefabricated components

ActiveCN112536910BThe preparation method is simple and easyEasy constructionMould fastening meansConstruction engineeringRebar

The invention discloses a method for making a prefabricated component, which comprises the following steps: 1. Welding the steel frame; 2. Installing the formwork support and positioning fixture; 3. Adjusting the steel frame; 4. Pouring concrete and removing the positioning fixture , to obtain concrete prefabricated components. The method of the invention has simple steps, convenient construction, and easy operation by workers. By supporting the formwork on the outside of the reinforcement frame and installing a plurality of positioning fixtures on the top of the formwork, the distance between the reinforcement frame and the bottom of the formwork is adjusted by the positioning fixtures to meet the requirements of the concrete protection layer. fixed value, and then realize the positioning of the bottom of the steel skeleton, and facilitate the formation of a steel protection layer at the bottom of the steel skeleton. On the one hand, it saves the support and binding of multiple concrete pads, and on the other hand, it reduces the consumption of concrete pad materials. Thereby increasing the overall strength of the concrete precast member.

Owner:CHINA RAILWAY FIRST GRP CO LTD

One-time winding and forming combined tooling for commutating pole coils of DC propulsion motors

ActiveCN114094786BEasy demoulding structureIngenious demoulding structureElectric machinesManufacturing dynamo-electric machinesElectric machineControl theory

The invention discloses a combined tooling for one-time winding and forming of commutation pole coils of DC propulsion motors, which solves the problem of one-time winding and forming of large-section emergency transposition coils; The invented winding tooling is designed to be combined and assembled. The main part of the tooling is composed of a rectangular base plate, a long barrel-shaped lower mold base, a long three-dimensional mold core, cantilevered pressing blocks on both sides of the upper end, and front and rear side plugs. The main body of the tooling is formed by combined assembly; the swing arm bending wrench, the arc-shaped transposition block with a wedge-shaped inclined surface, the interlayer gap backing plate and the top wire on the straight side of the winding form the winding winding system. The combination accessories used; the above parts can be partially replaced according to the specifications of the winding coils. The whole tooling is convenient to assemble and disassemble. It is suitable for winding commutation pole coils of various specifications, so that the coils can be wound at one time. The tooling mold is combined, easy to assemble and disassemble, low tooling cost, and easy to process on site.

Owner:SHANXI FENXI HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com