Field sampling device and sampling method of filling slurry

A technology of on-site sampling and filling slurry, applied in sampling devices and other directions, can solve problems such as insufficient research on flow characteristics, settling characteristics and strength distribution characteristics, restricting the settling characteristics of filling aggregates, binder distribution characteristics, and difficulty in being representative. , to achieve the effect of optimizing the stope structure size, facilitating on-site processing and production, and scientific sampling methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

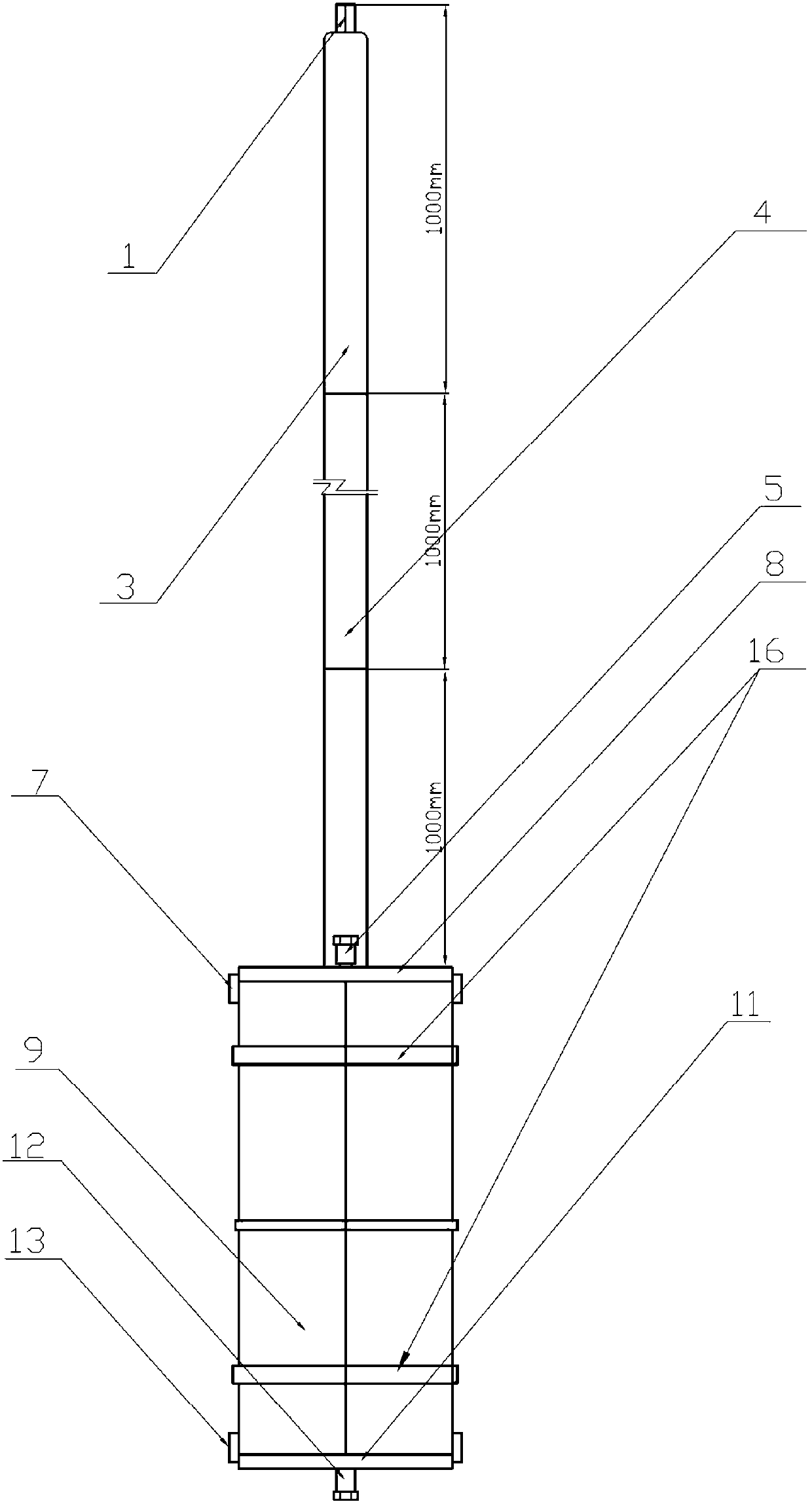

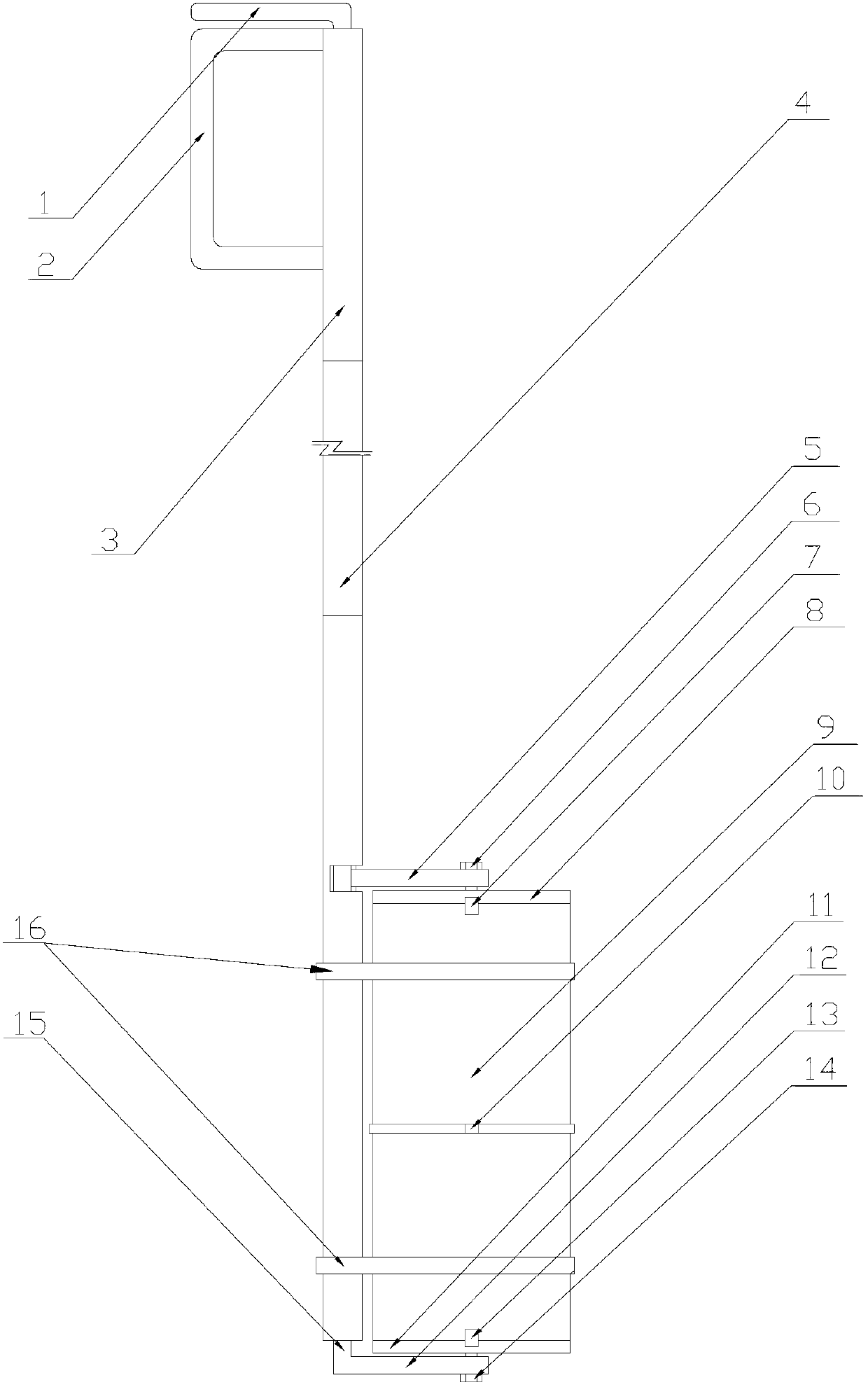

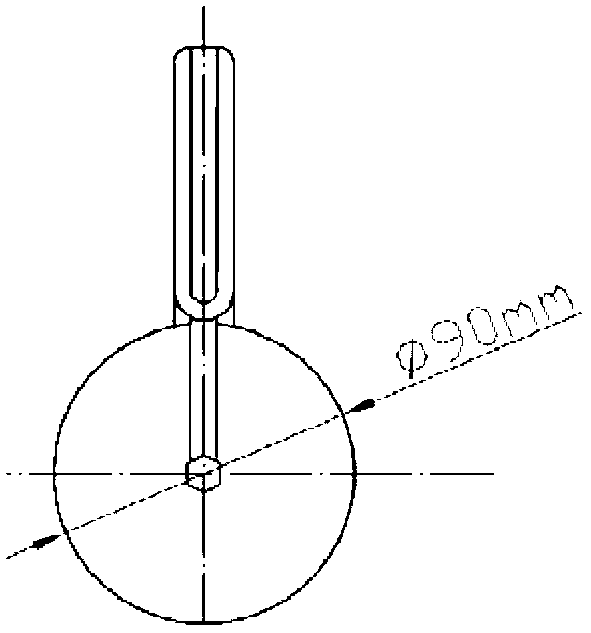

[0038] The on-site sampling device for filling slurry provided by the present invention includes a slurry cylinder control unit and a slurry cylinder, see figure 1 - As shown in Figure 7, the purpose of the slurry cylinder control unit is to place the slurry cylinder to a predetermined sampling position, and to control the opening and closing of the upper baffle (8) and the lower baffle (11) of the slurry cylinder for flexible sampling The main function of the slurry tank is to fill the slurry. There are various connecting components in the slurry tank to fix and connect the various parts of the slurry tank to prevent the slurry from flowing out.

[0039] Slurry tank control unit

[0040] Such as Figure 1-3As shown, the slurry cylinder control unit includes a sampling rod, an upper cross rod (5), and a lower cross rod (12), wherein the sampling rod is composed of a main rod (3) and a control rod (15); in the main rod (3) 1. The top of the control rod (15) can also be prov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com