Automatic screwing machine of floor slabs

An automatic locking screw machine, screw locking technology, applied in other manufacturing equipment/tools, drilling/drilling equipment, boring/drilling and other directions, can solve the problem of unfavorable workers' health, environmental noise workers, and finished floor strength. low level issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

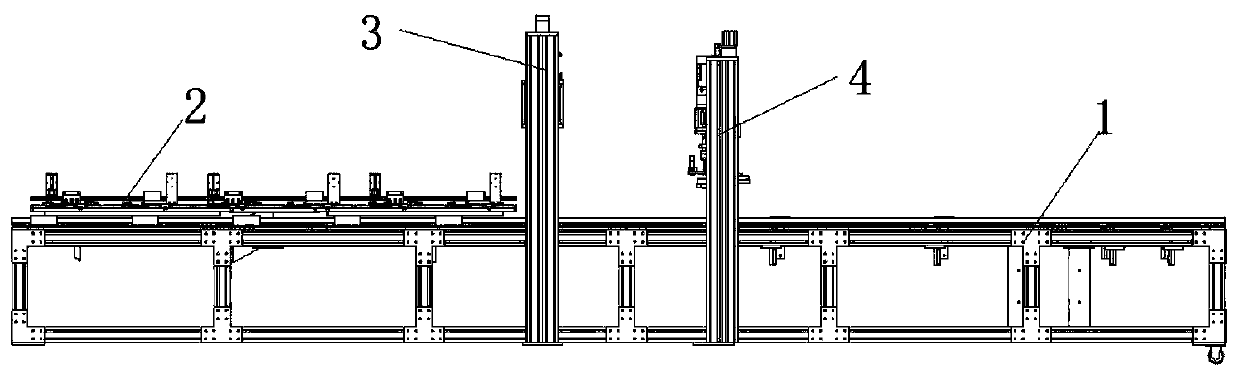

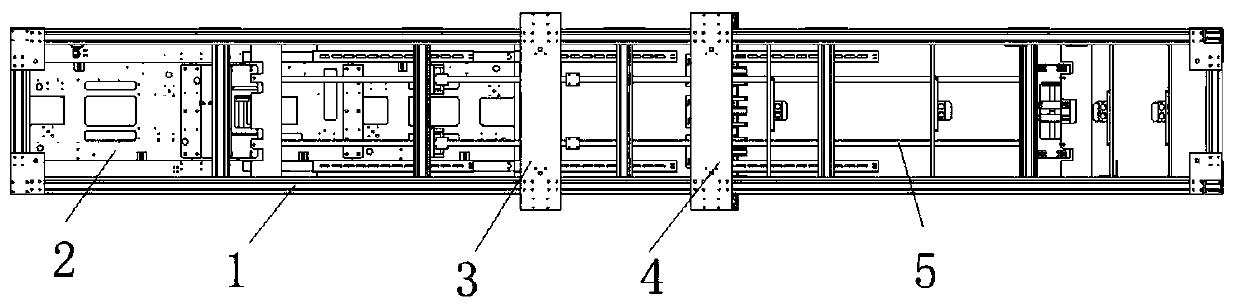

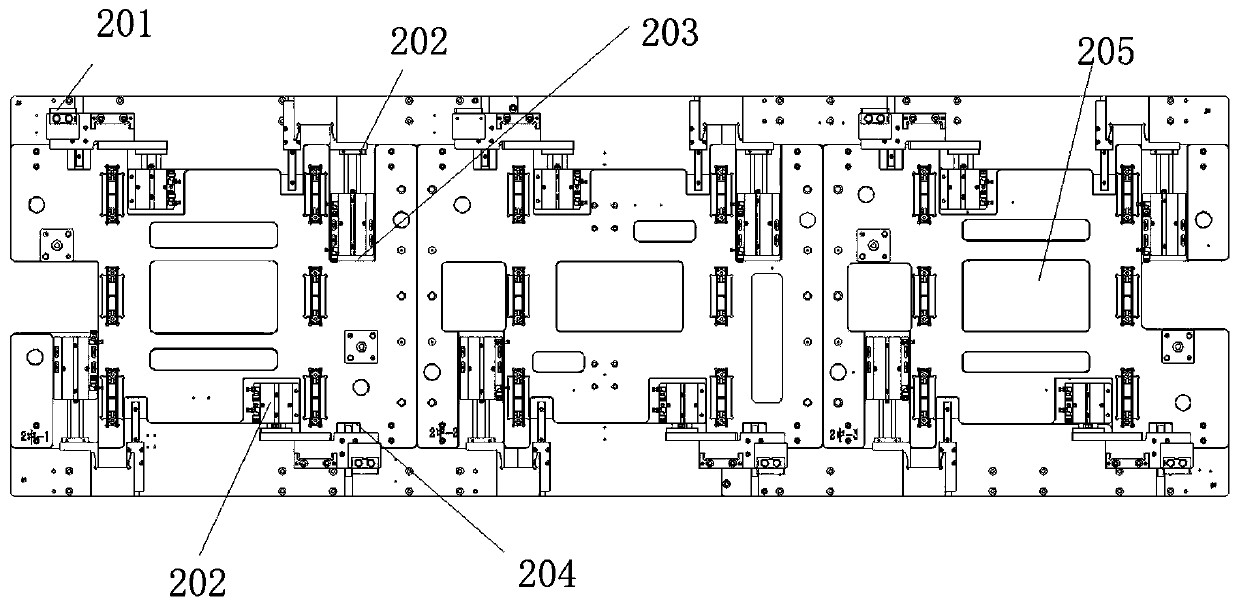

[0024] Such as Figure 1-7 As shown, a floor automatic screw locking machine, the screw locking machine includes a main frame 1, a horizontal workbench is arranged on the main frame 1, and a mold table 2 is arranged on the horizontal workbench; a transmission motor is also arranged on the horizontal workbench , the transmission motor slides along the horizontal workbench through the synchronous belt 5 traction mold table 2; two auxiliary brackets span the horizontal workbench, and an automatic punching unit 3 and an automatic locking unit 4 are respectively installed on the auxiliary brackets; the automatic punching Unit 3 includes a plurality of electric drilling machines, and the automatic locking unit 4 includes a plurality of automatic screw locking machines; the four corners of the mold table 2 and the middle parts of both sides are equipped with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com