Device for continuously and controllably producing hydrogen by virtue of hydrolysis of magnesium hydride and method for producing hydrogen by device

A technology of hydrolysis hydrogen production and hydrogen production equipment, which is applied in the field of energy chemistry and power chemical products, can solve the problems of unstable hydrogen production rate, cumbersome operation, and decreased hydrogen supply rate, and meet the long-term stable requirements and high hydrogen production efficiency , highly controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

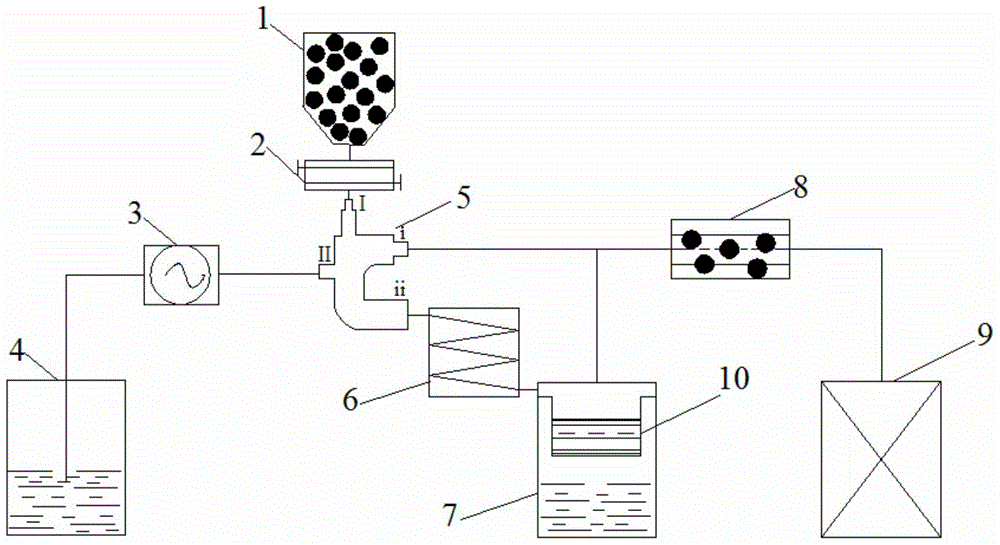

[0030] Embodiment 1: as figure 1 As shown, a hydrogen production device suitable for the micro-dosage reaction of magnesium hydride-magnesium chloride solution system, the device includes a magnesium hydride storage tank 1, a magnesium chloride solution storage tank 4, a hydrogen production reactor 5, a solid-liquid separator 7, and a feeder 2, hydrogen purifier 8 and load 9.

[0031] The magnesium hydride reservoir 1 is connected to the first feed port I of the hydrogen production reactor 5 through the feeder 2 through the pipeline, and the magnesium chloride solution reservoir 4 is connected to the second feed of the hydrogen production reactor 5 through the micro metering pump 3 through the pipeline. Port II; the first outlet i of the hydrogen production reactor 5 is connected to the hydrogen purifier 8 through a pipeline, and the second outlet ii of the hydrogen production reactor 5 is connected to the inlet of the spiral reaction tube 6; the outlet of the spiral reaction ...

Embodiment 2

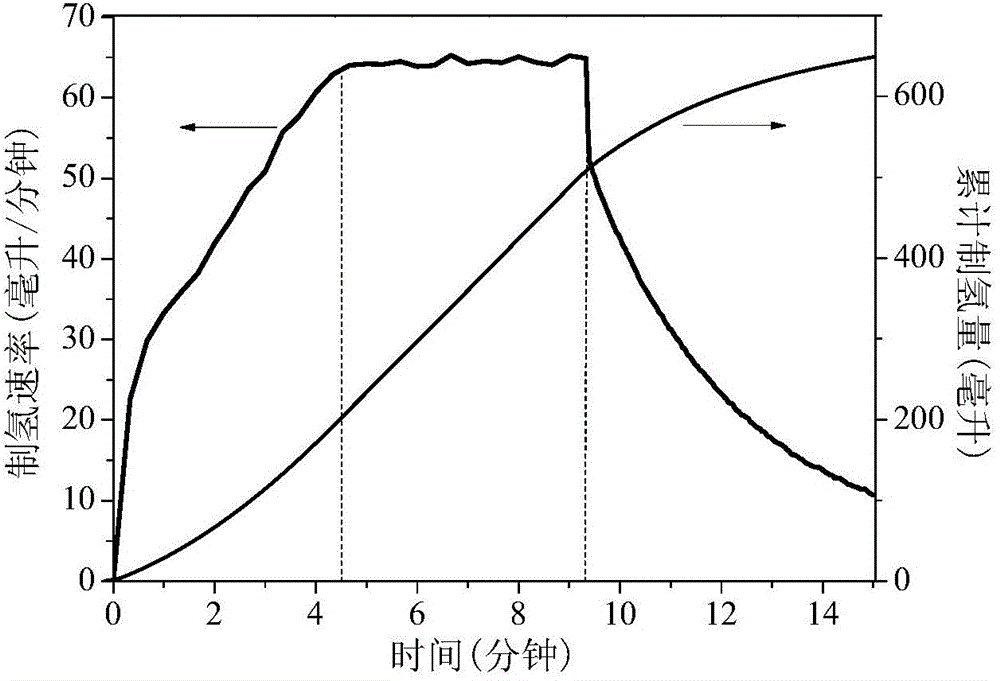

[0034] The magnesium hydride was pretreated by ball milling activation, the ball milling activation time was 3.0h, the rotation speed was 400rpm, the ball-to-material ratio was 40:1, and dry powder granulation was made into 20mg cylindrical granules. The above-mentioned micro-dose cylindrical particles are reacted with a magnesium chloride solution at a temperature of 60° C. and a concentration of 0.5 mol / L. The feeding dose of each magnesium hydride is 20mg, the feeding time interval of each tablet is 20s, the feeding dose of magnesium chloride solution is 0.1mL / s, and the solid-liquid dosage ratio is 1:5g / mL.

[0035] Magnesium hydride particles are introduced from the first feed port I of the reactor, magnesium chloride solution is introduced from the second feed port II, and the solid-liquid two-phase reactant reacts rapidly in the hydrogen production reactor to generate hydrogen gas, and the hydrogen gas comes from the hydrogen production reactor. It is exported from the ...

Embodiment 3

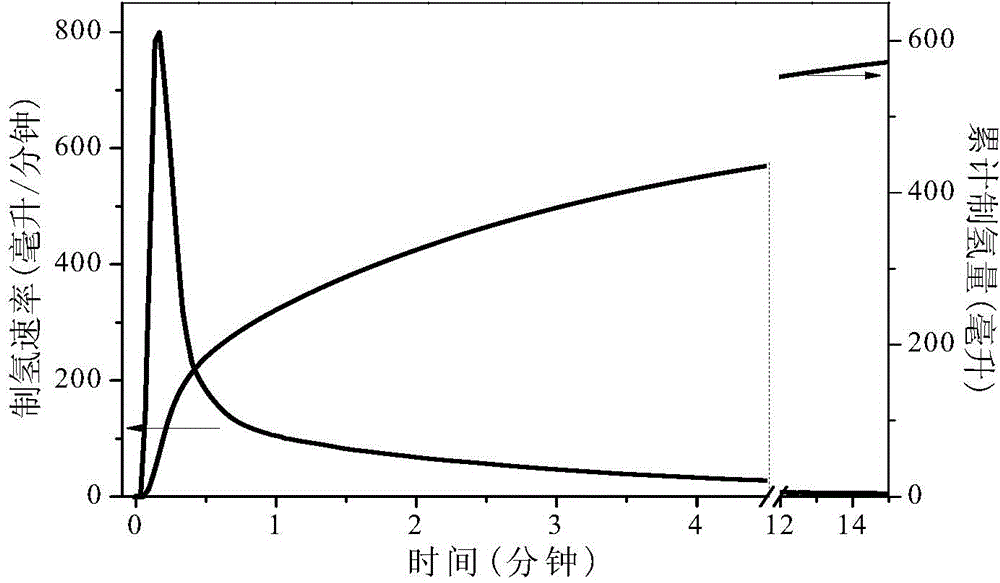

[0037] The magnesium hydride was subjected to ball milling activation pretreatment, the ball milling activation time was 4h, the rotation speed was 300rpm, the ball-to-material ratio was 30:1, and dry powder granulation was made into 50mg cylindrical granules. The above-mentioned micro-dose cylindrical particles are reacted with a magnesium chloride solution at a temperature of 60° C. and a concentration of 0.5 mol / L. The feeding dose of each magnesium hydride is 50mg, the feeding time interval of each pellet is 20s, the feeding dose of magnesium chloride solution is 0.1mL / s, and the solid-liquid dosage ratio is 1:5g / mL.

[0038] Magnesium hydride particles are introduced from the first feed port I of the reactor, magnesium chloride solution is introduced from the second feed port II, and the solid-liquid two-phase reactant reacts quickly in the hydrogen production reactor to generate hydrogen gas, and the hydrogen gas comes from the hydrogen production reactor. It is exported...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com