Preparation method of selenide/graphite-phase carbon nitride composite photocatalyst material

A graphitic carbon nitride and selenide technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as application of composite materials, and achieve simple preparation process, convenient operation, and synthesis. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

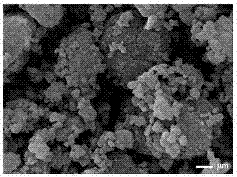

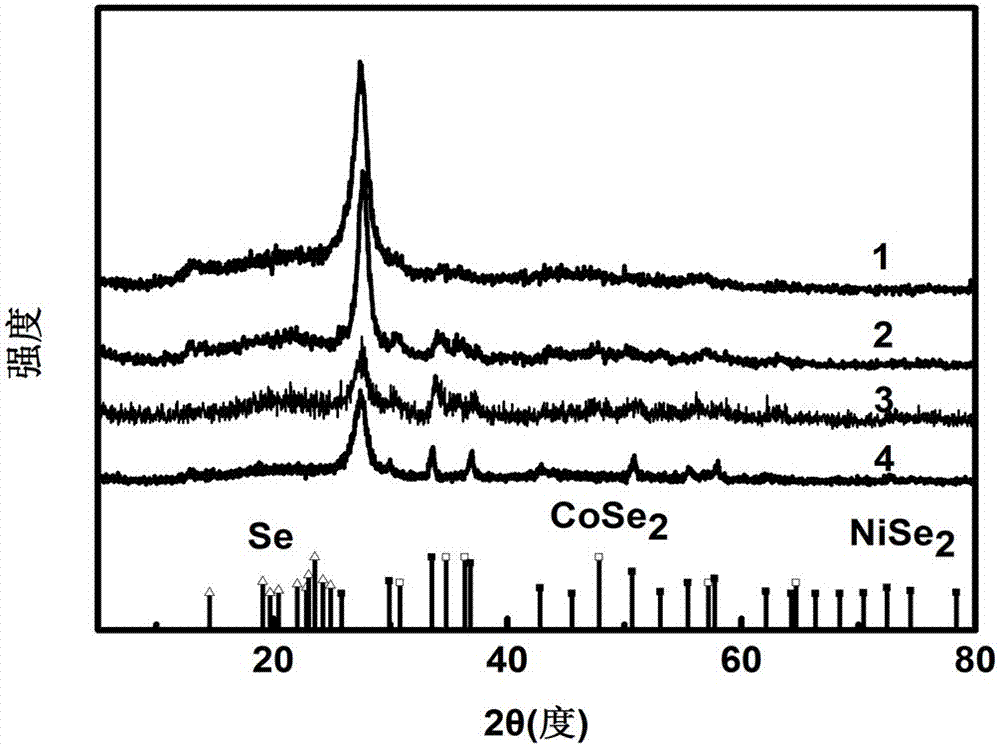

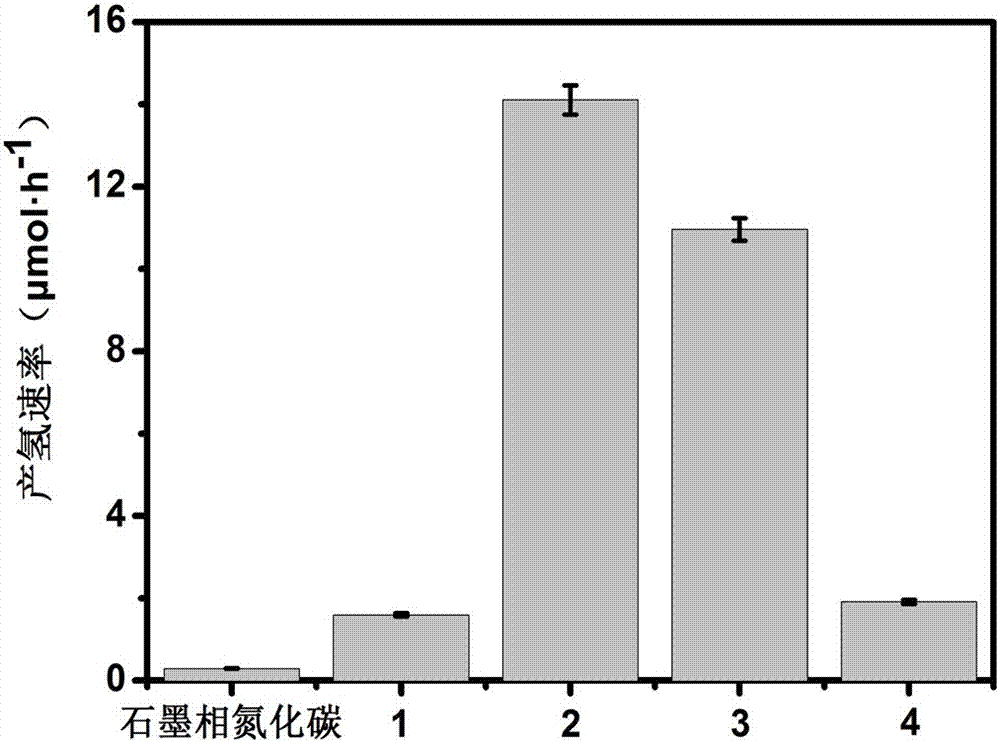

specific Embodiment 1

[0019] Mix the ZIF-67CoNi zeolite imidazolate framework material with the graphite phase carbon nitride powder, so that the mass ratio of the ZIF-67CoNi zeolite imidazolate framework material is 2.5%, and add the same mass of ZIF-67CoNi zeolite imidazolate framework material Selenium powder, ground in an agate mortar for 15 min, in N 2 Under the atmosphere, the temperature was raised to 350 °C at a rate of 5 °C / min for 2 hours, and then naturally cooled to room temperature.

specific Embodiment 2

[0020] Mix the ZIF-67CoNi zeolite imidazolate framework material with the graphite phase carbon nitride powder, so that the mass ratio of the ZIF-67CoNi zeolite imidazolate framework material is 5%, and add the same quality as the ZIF-67CoNi zeolite imidazolate framework material Selenium powder, ground in an agate mortar for 15 min, in N 2 Under the atmosphere, the temperature was raised to 350 °C at a rate of 5 °C / min for 2 hours, and then naturally cooled to room temperature.

specific Embodiment 3

[0021] Mix the ZIF-67CoNi zeolite imidazolate framework material with the graphite phase carbon nitride powder, so that the mass ratio of the ZIF-67CoNi zeolite imidazolate framework material is 10%, and add the same quality as the ZIF-67CoNi zeolite imidazolate framework material Selenium powder, ground in an agate mortar for 15 min, in N 2 Under the atmosphere, the temperature was raised to 350 °C at a rate of 5 °C / min for 2 hours, and then naturally cooled to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com