Patents

Literature

60 results about "Hydrogen purifier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A hydrogen purifier is a device to purify hydrogen if hydrogen production is done from hydrocarbon sources, the ultra-high purified hydrogen is needed for applications like PEM fuel cells .

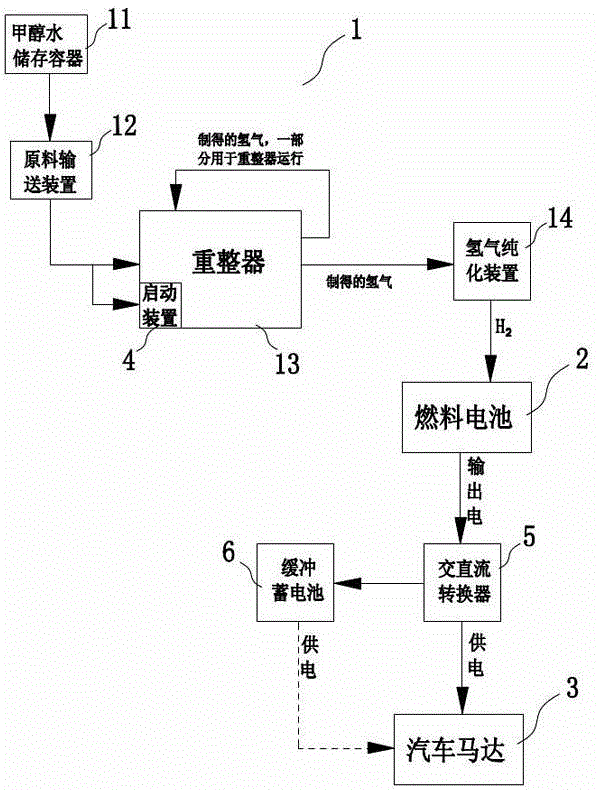

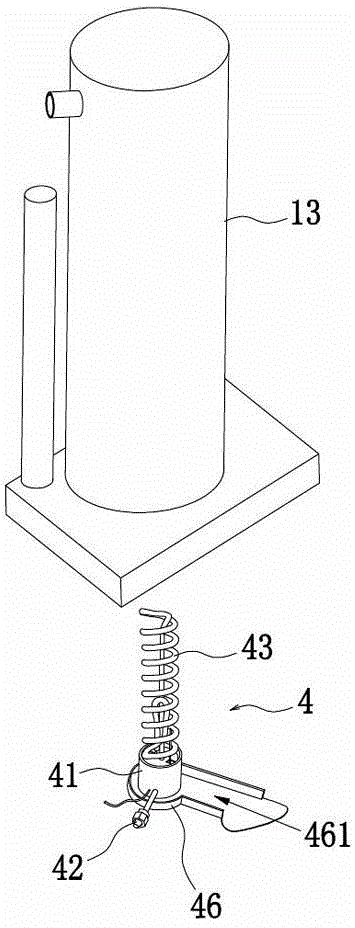

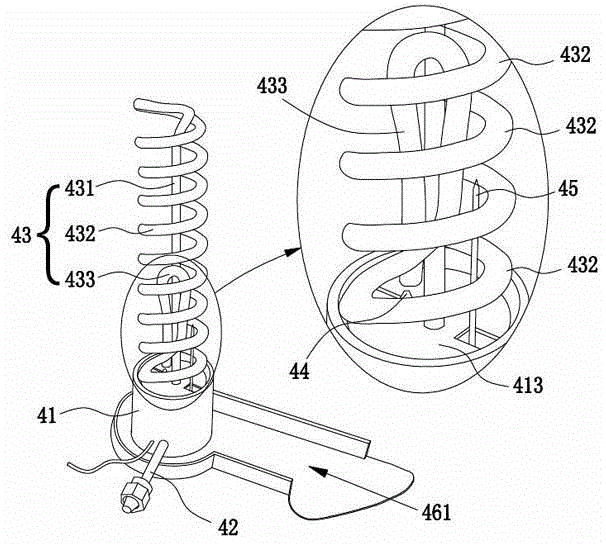

Fuel cell car

ActiveCN104555921AImprove power generation efficiencyIncrease output powerHydrogenVehicular energy storageElectricityElectrochemical response

The invention discloses a fuel cell car. The fuel cell car comprises a methyl alcohol hydrogen producer, a fuel cell and a car motor, wherein the methyl alcohol hydrogen producer comprises a methyl alcohol storage container, a raw material conveyor, a reformer and a hydrogen purifier; the reformer comprises a heat exchanger, a gasifying chamber, a reforming chamber and a separating chamber, and the hydrogen purifier is arranged in the separating chamber; the lower and middle parts of the reforming chamber are at the temperatures of 300-420 DEG C, and the upper part of the reforming chamber is at the temperature of 400-570 DEG C; the temperature in the separating chamber is set into 350-570 DEG C, hydrogen is obtained at the hydrogen producing end of the hydrogen purifier in the separating chamber, and the hydrogen is supplied to the fuel cell after heat exchange is carried out in the heat exchanger; the fuel cell comprises at least two fuel cell groups, and is used for producing electricity through the electrochemical reaction of the hydrogen and oxygen and supplying the car motor with electricity; the car motor is used for driving a car shaft to rotate and accordingly driving the car to run. The methyl alcohol raw material can be converted to the hydrogen at a high speed, the methanol conversion efficiency and utilizing rate are high, and the purification of hydrogen containing gas is easy.

Owner:GUANGDONG HYDROGEN ENERGY SCI & TECH

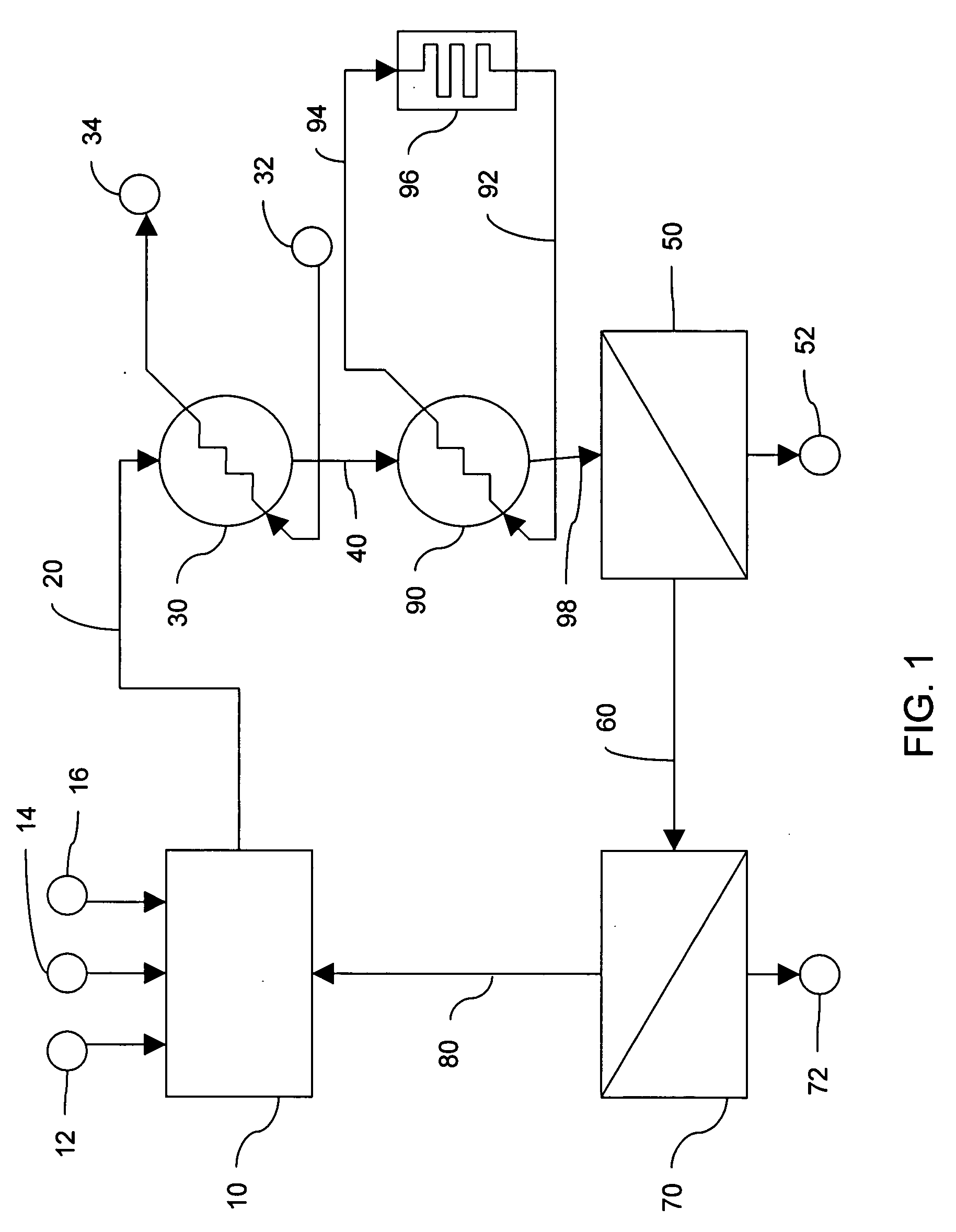

Method and apparatus for cooling in hydrogen plants

InactiveUS20050265919A1Improve efficiencyEasy to operateHydrogen separation using solid contactSteam/vapor condensersHydrogenProcess engineering

A hydrogen plant including a fuel reforming plant configured to receive and process hydrocarbon feedstock and configured to discharge wet reformate including a hydrogen-containing gas stream, and a condenser configured to cool the wet reformate. The hydrogen plant also includes a water separator configured to receive the cooled wet reformate, remove water from the wet reformate, and discharge dry reformate. The hydrogen plant further includes a hydrogen purifier configured to receive the dry reformate, process the dry reformate, and discharge pure or substantially pure hydrogen. A supplemental cooling system is provided in the hydrogen plant to cool the wet reformate in addition to the condenser.

Owner:H2GEN INNOVATIONS INC

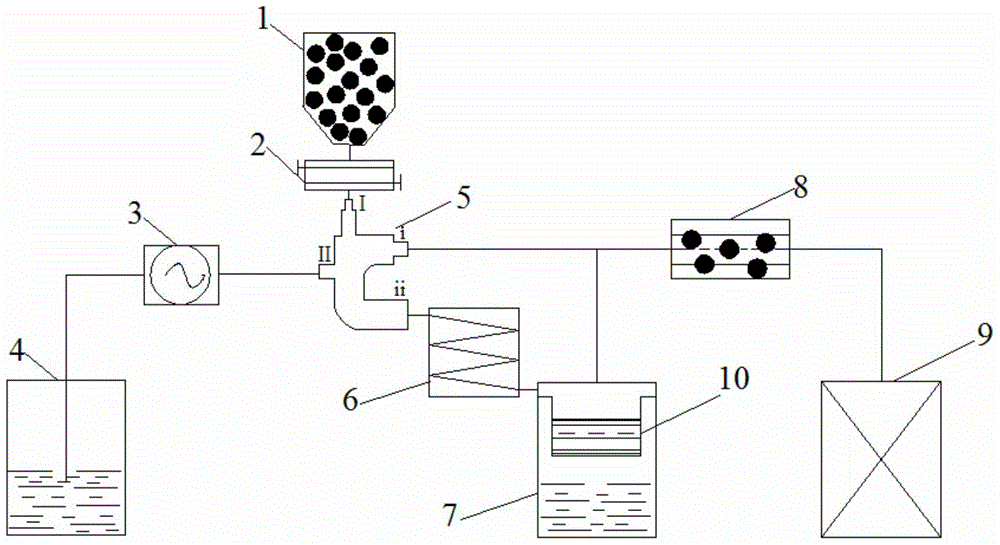

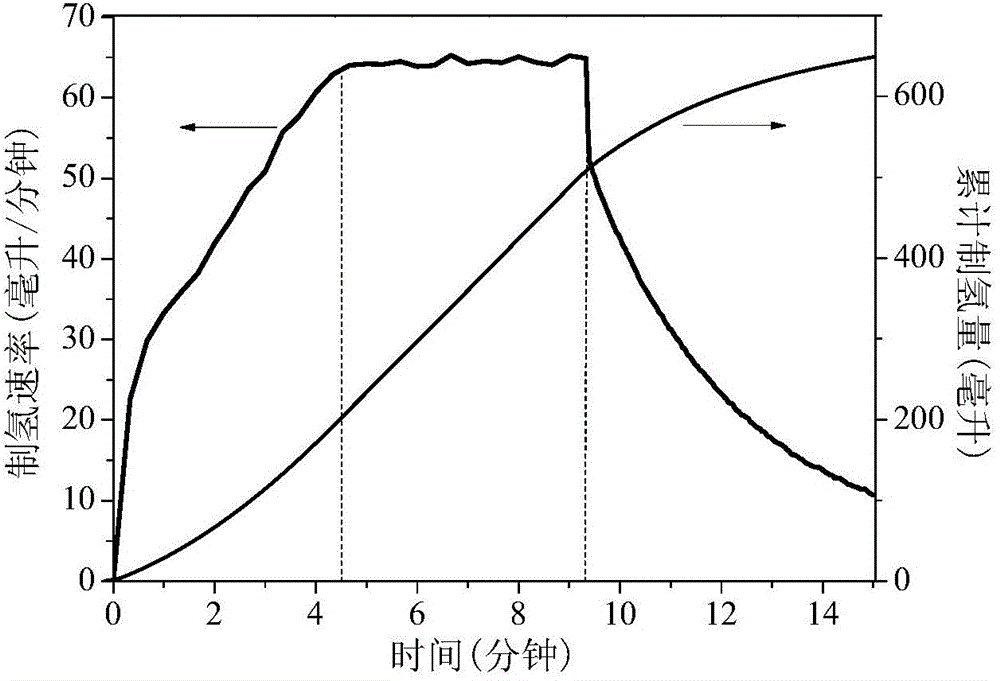

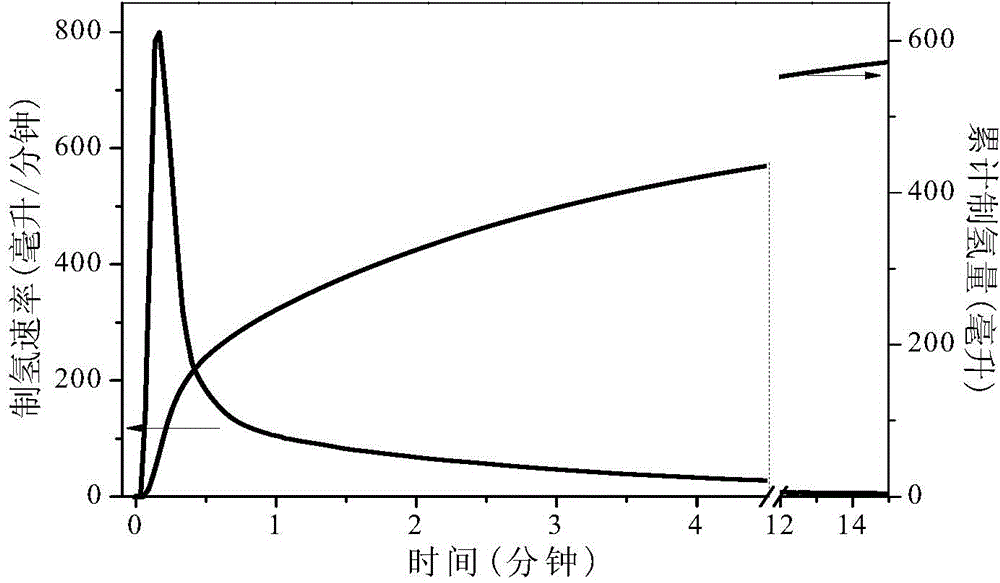

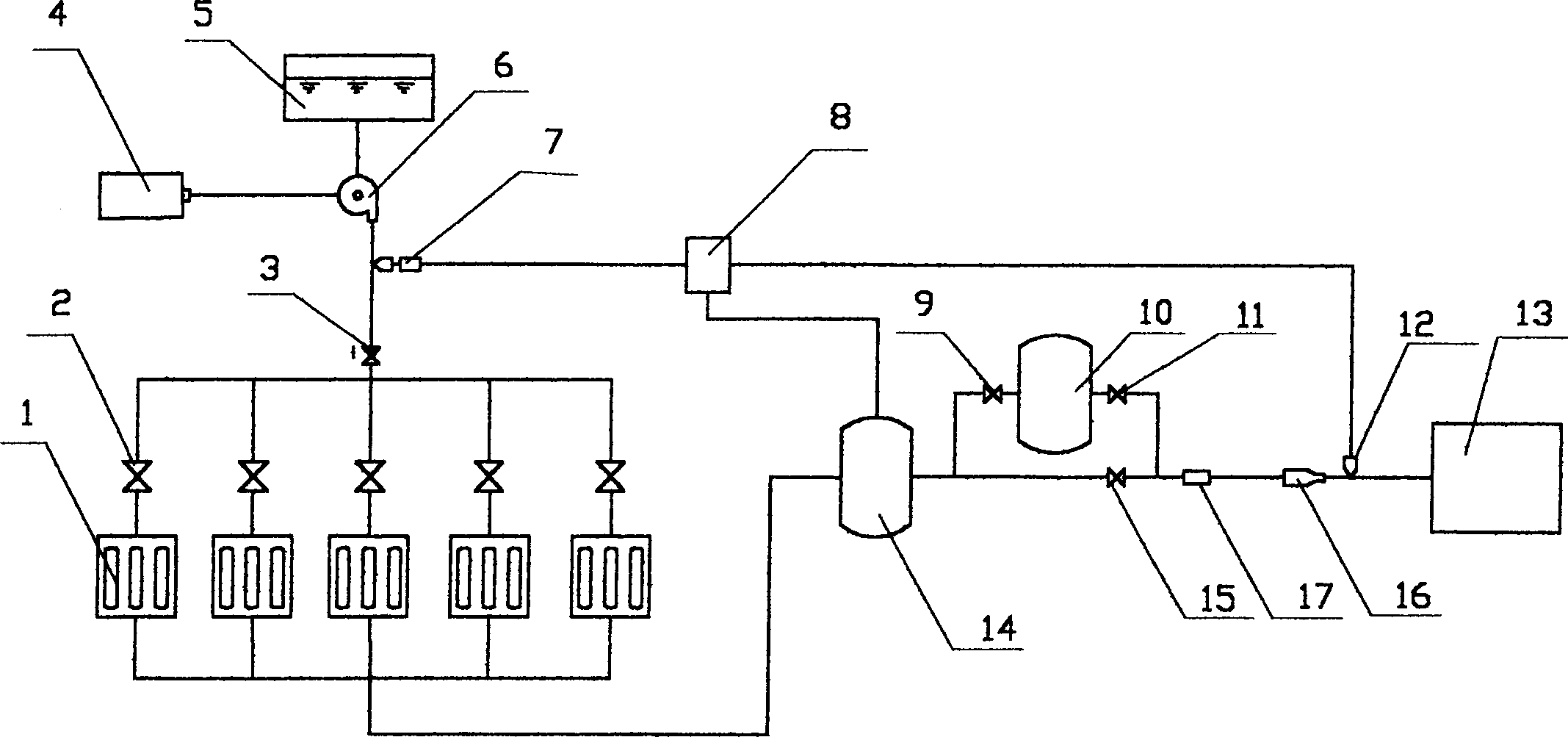

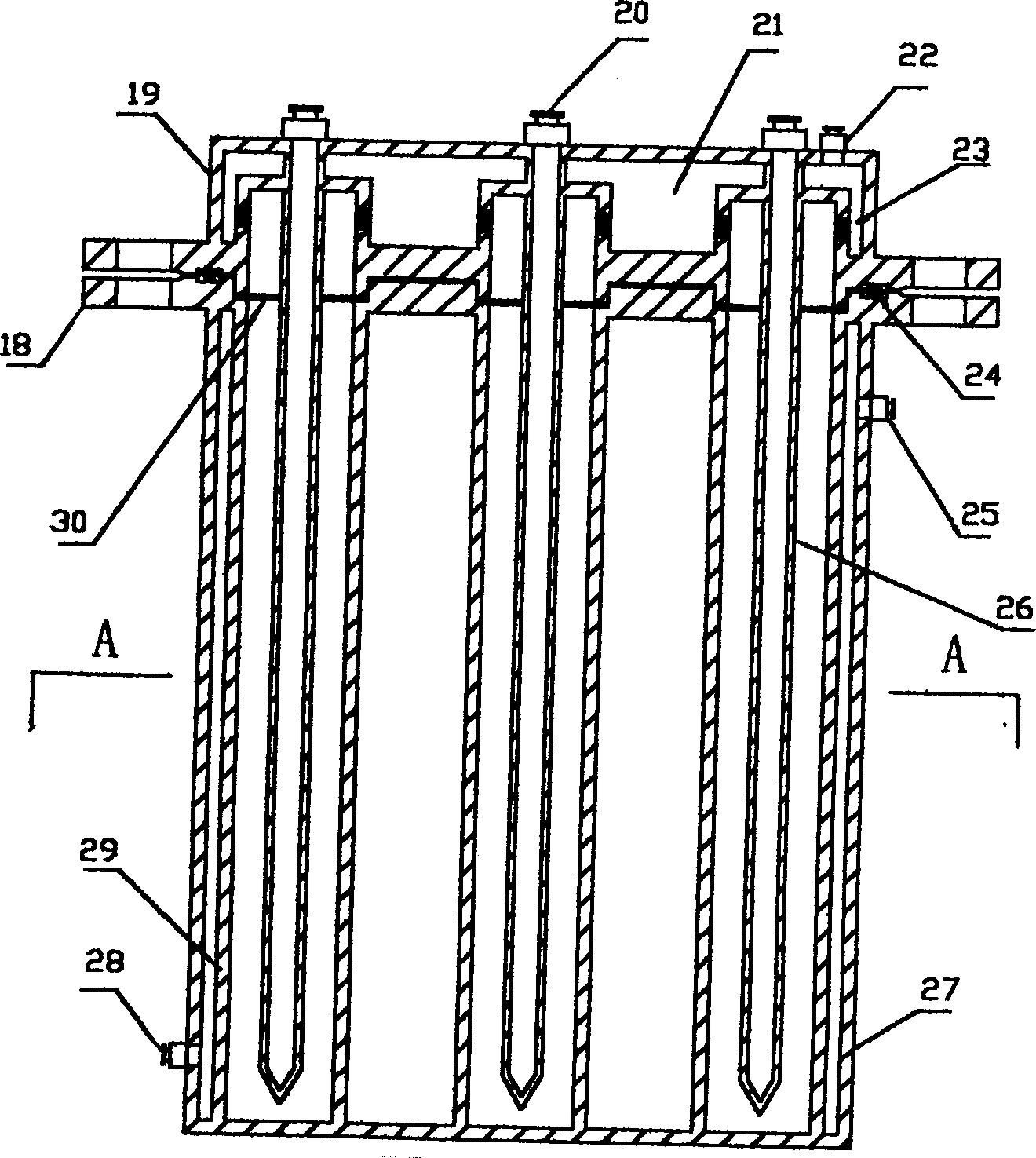

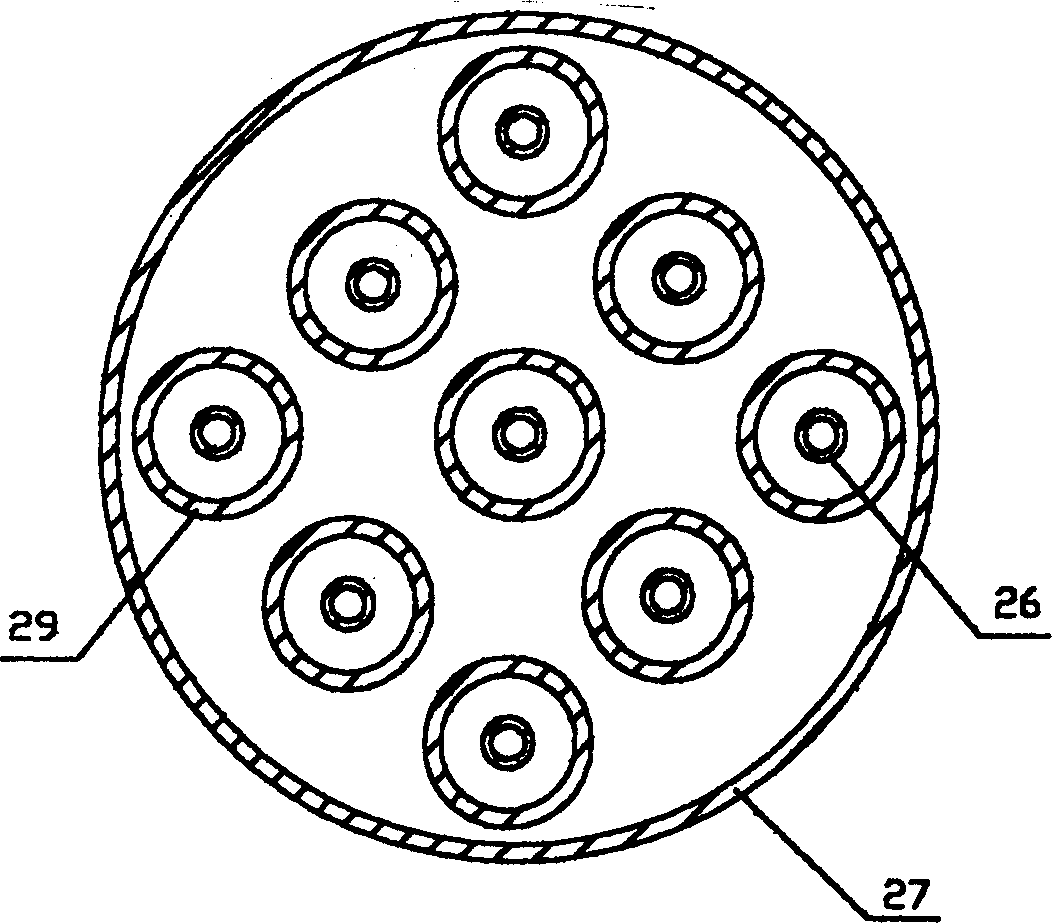

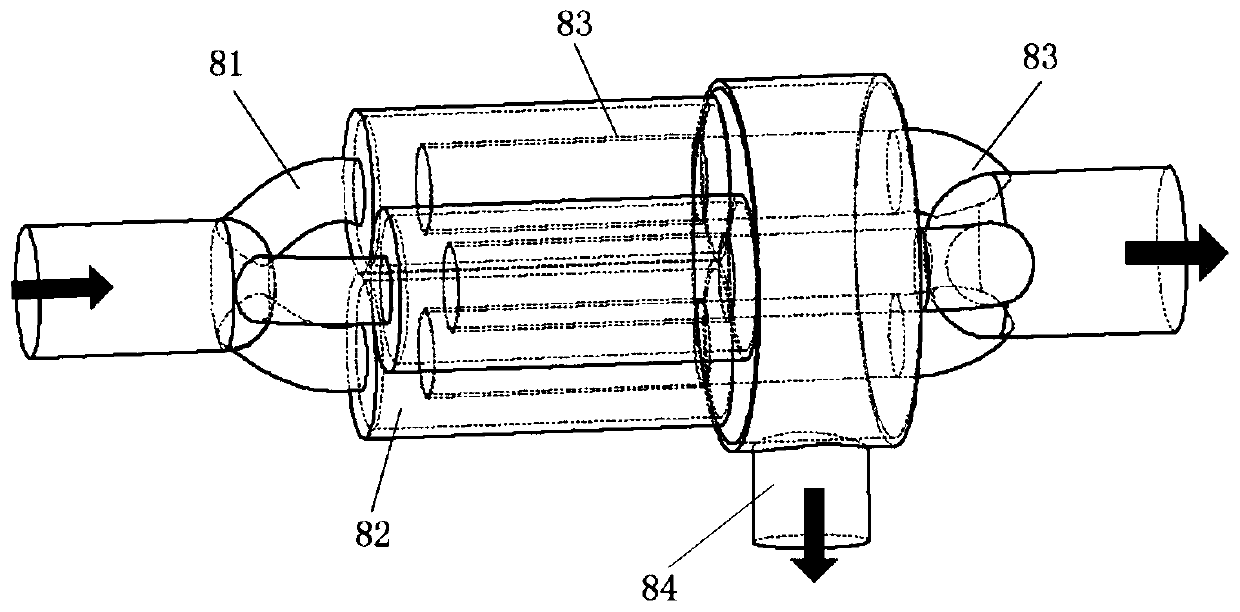

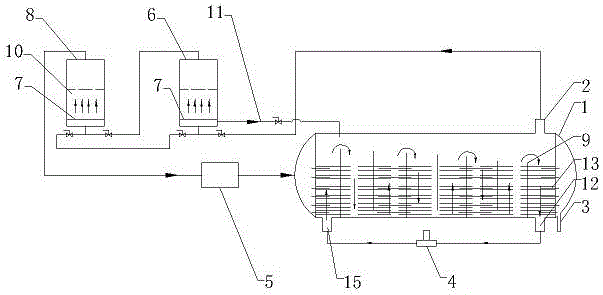

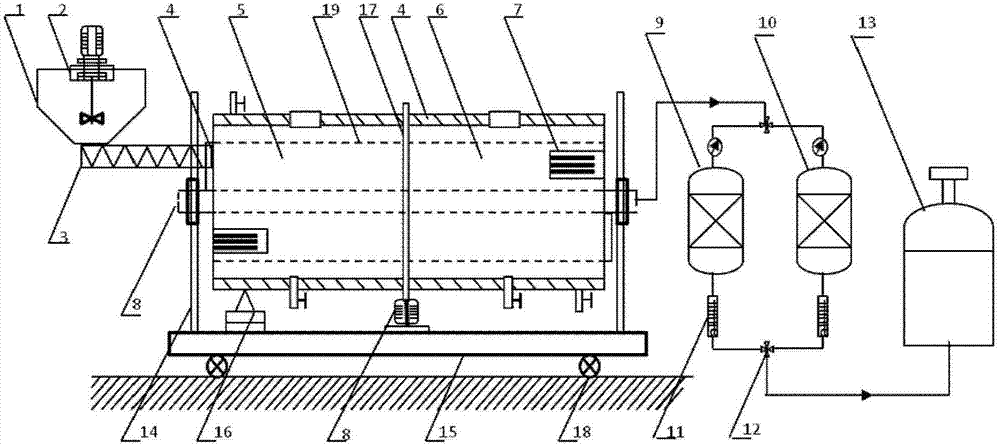

Device for continuously and controllably producing hydrogen by virtue of hydrolysis of magnesium hydride and method for producing hydrogen by device

InactiveCN104555916AImprove hydrogen production efficiencyImprove controllabilityHydrogen productionHydrogen fuel cellChloride

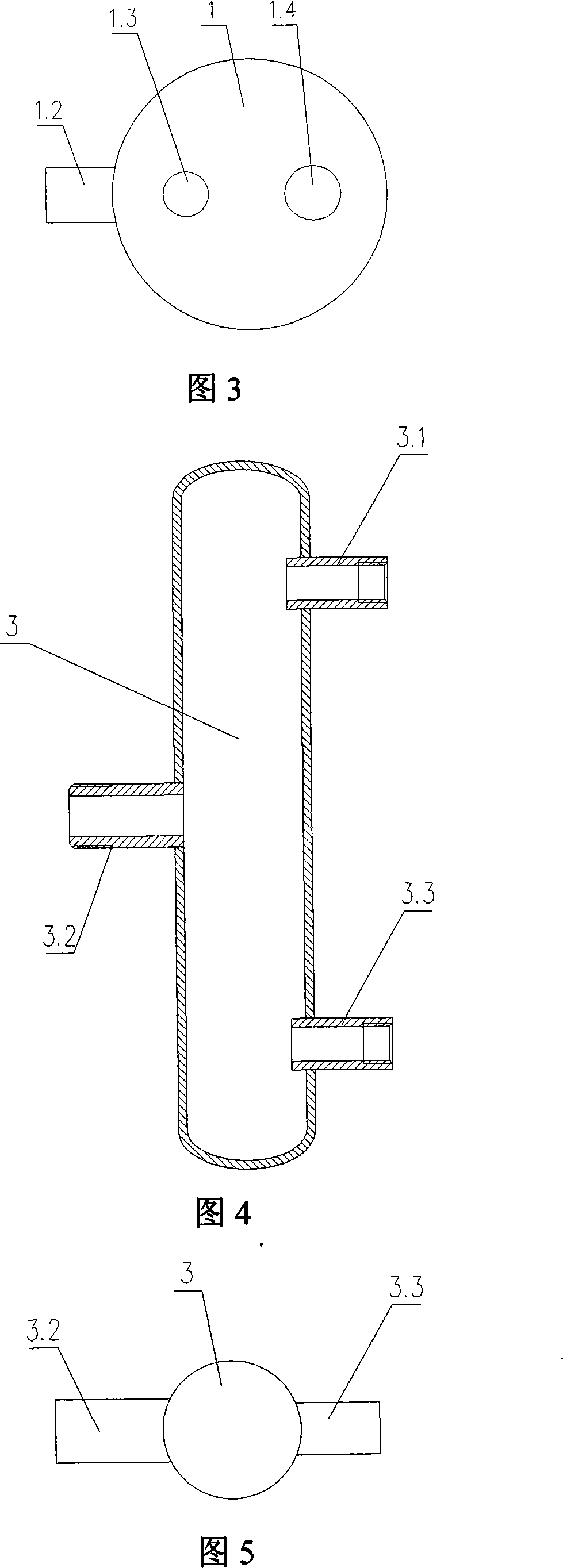

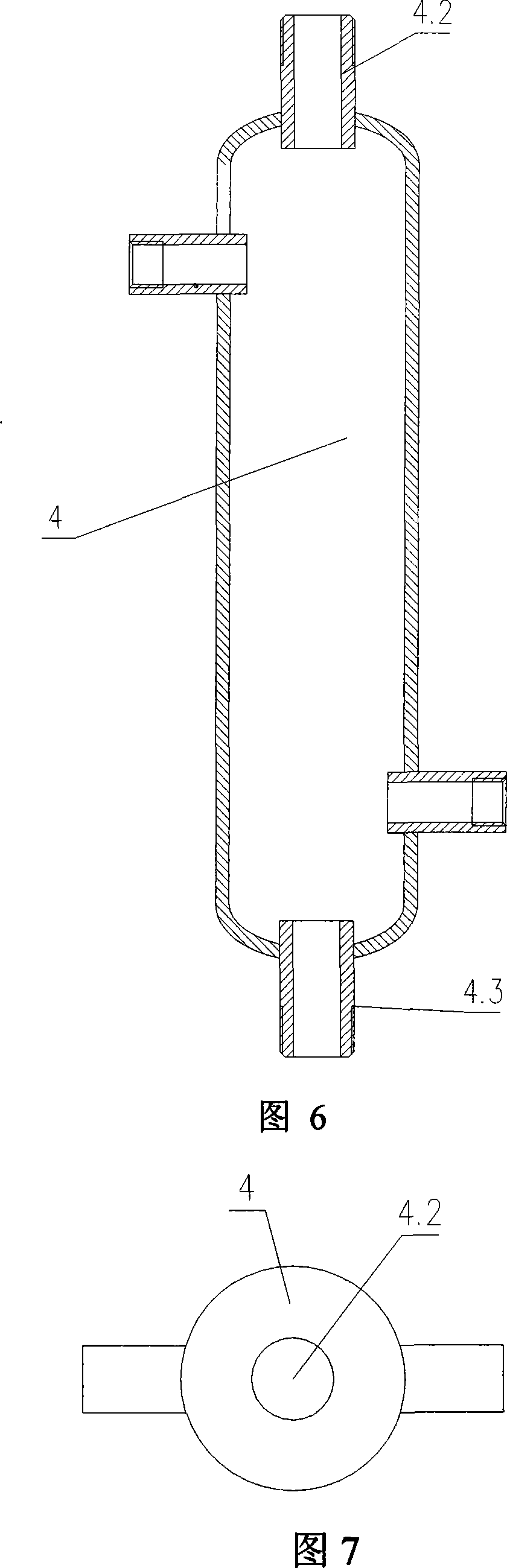

The invention discloses a device for continuously and controllably producing hydrogen by virtue of hydrolysis of magnesium hydride and a method for producing hydrogen by the device. The device comprises a magnesium hydride storage device (1), a magnesium chloride solution storage device (4), a hydrogen production reactor (5 ) and a solid-liquid separator (7), wherein a first material inlet (I) of the hydrogen production reactor (5 ) is connected with the magnesium hydride storage device (1), a second material inlet (I) of the hydrogen production reactor is connected with the magnesium chloride solution storage device (4), a first guide outlet (I) of the hydrogen production reactor is connected with a hydrogen purifier (8), a second guide outlet (II) of the hydrogen production reactor is connected with an inlet of the solid-liquid separator (7) through a spiral reaction pipe (6) and an outlet of the solid-liquid separator (7) is connected with the hydrogen purifier (8). By the device for producing hydrogen, hydrogen can be efficiently, controllably and continuously stably output and the device has the advantages of strong operability, high safety and is easy to increase and amplify and can meet the requirements of hydrogen fuel cells with different powers on online hydrogen sources.

Owner:NANJING UNIV OF TECH

Vehicular hydrogen preparing method and device

InactiveCN1384043AReduce manufacturing costHigh degree of automationHydrogen productionVehicular energy storageFuel cellsHydrogen

The present invention relates to the preparation of hydrogen. In the vehicular hydrogen preparing process, solid matter CaH2 a / o NaBH4, catalyst containing active matter Fe, Co, Ni, Cu or Mn and water are subjected to reaction. The hydrogen preparing apparatus includes reactors, liquid tanks, buffering tank, hydrogen purifier, depressing valve, flow rate measuring meter, pressure sensor, cooling tank with temperature sensor, etc. connected together, and the control signal from the circuit is fed to the controller. The present invented process is low in hydrogen preparation cost, high in safety and the apparatus is simple in structure, and is especially suitable for in automobile with fuel battery.

Owner:天津海蓝德能源技术发展有限公司

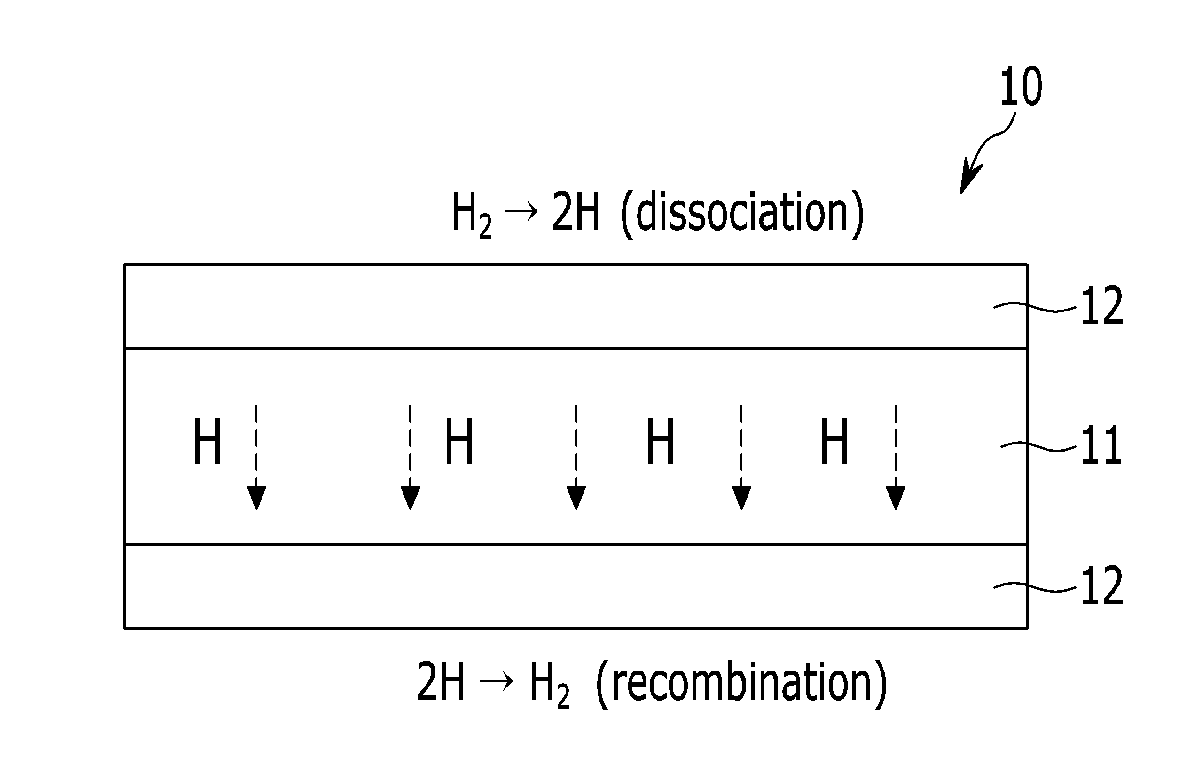

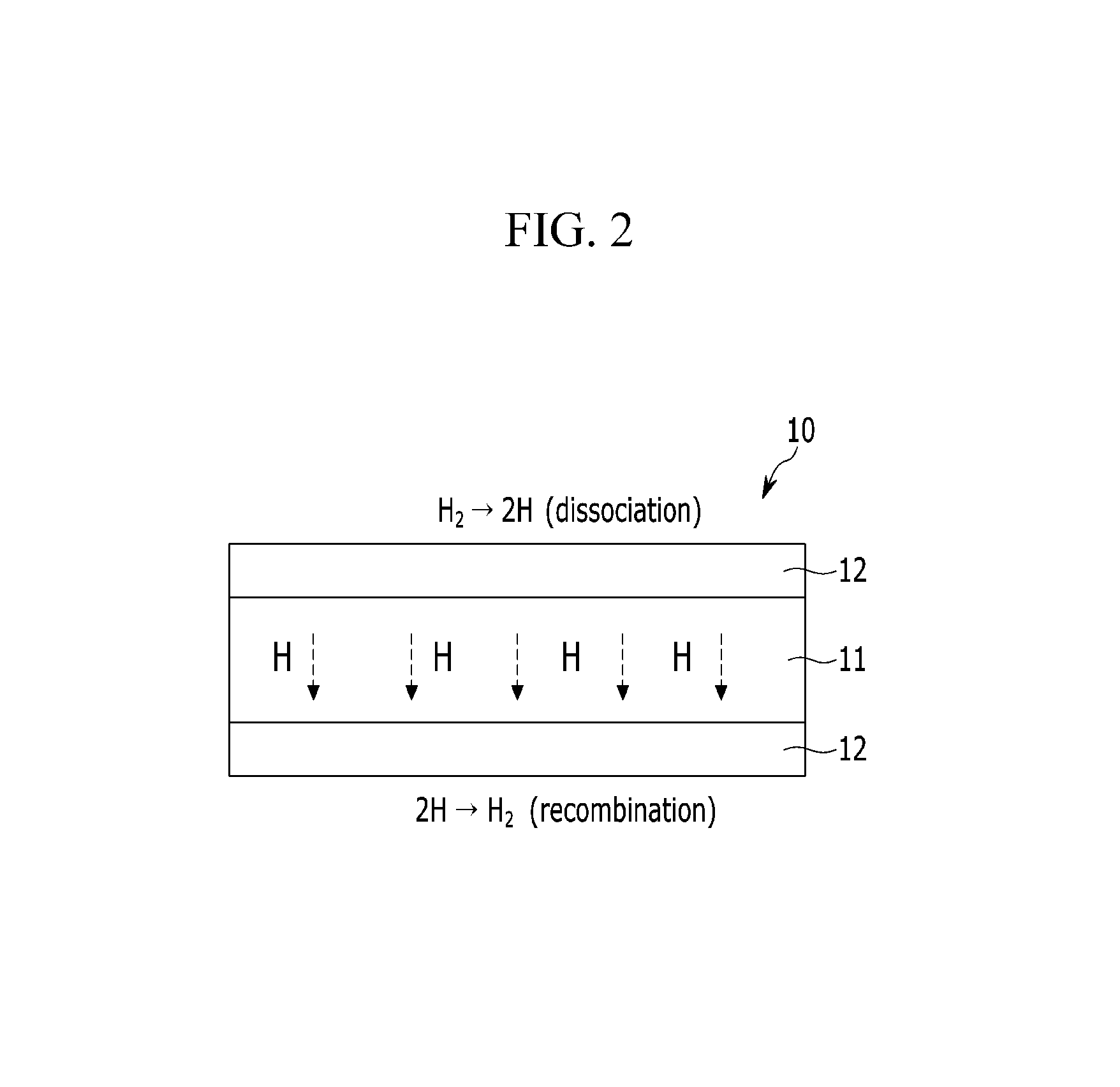

Permeable film for separating hydrogen

ActiveUS20060213368A1Improves high-temperature amorphous stabilityGuaranteed stabilityMembranesSemi-permeable membranesHydrogenNiobium

A hydrogen permeable membrane which has an excellent high-temperature amorphous stability and a long lifetime under high-temperature heating operation and which can be miniaturized for use in a high-performance hydrogen purifier. The hydrogen permeable membrane is made of a non-crystalline nickel-zirconium alloy or zirconium-nickel alloy composed of 44 to 75 atom % of nickel or zirconium; and 0.2 to 16 atom % of aluminum, 0.2 to 12 atom % of vanadium and / or niobium, or 0.2 to 12 atom % of niobium and 0.1 to 10 atom % of phosphorus (provided that the combined amount of niobium and phosphorus is not more than 18 atom %); with the balance being zirconium or nickel and unavoidable impurities.

Owner:MAGNUM OIL TOOLS +2

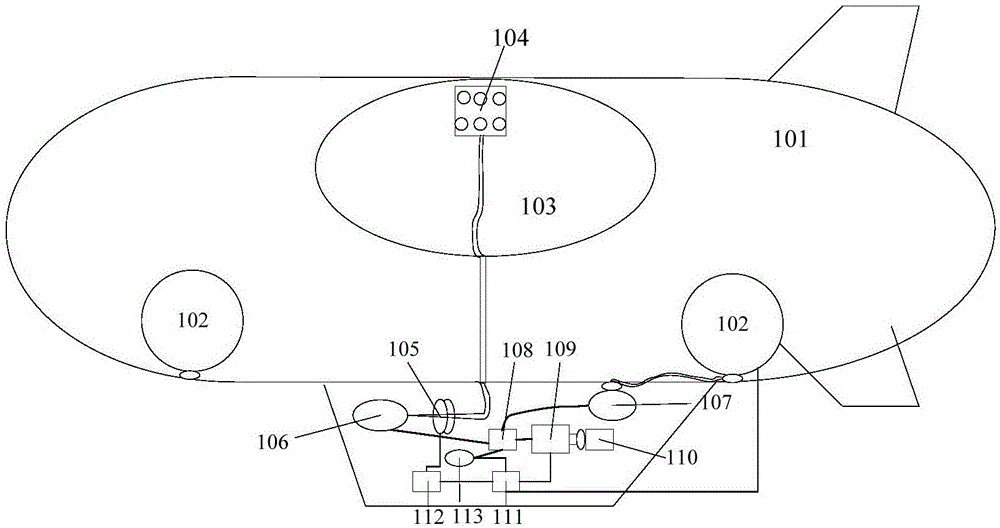

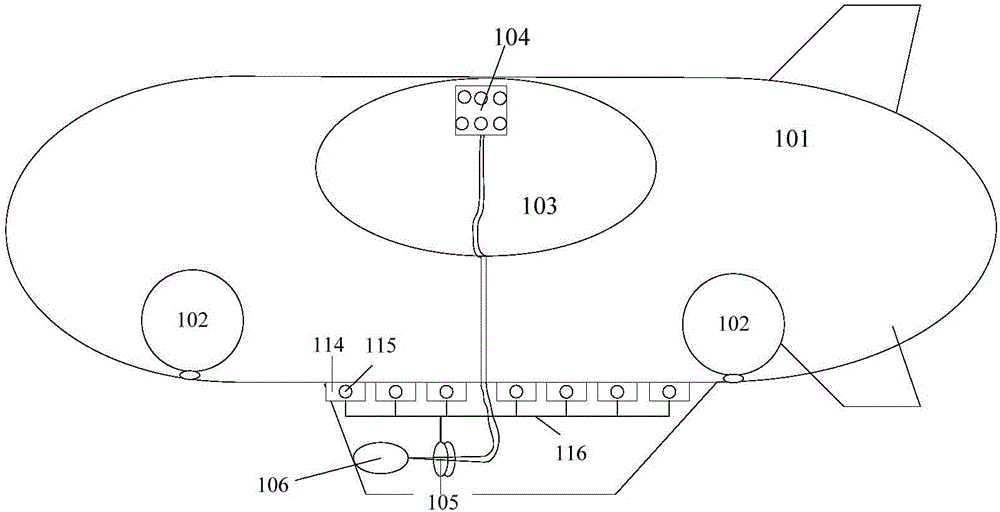

Stratospheric airship with hydrogen adjusting device

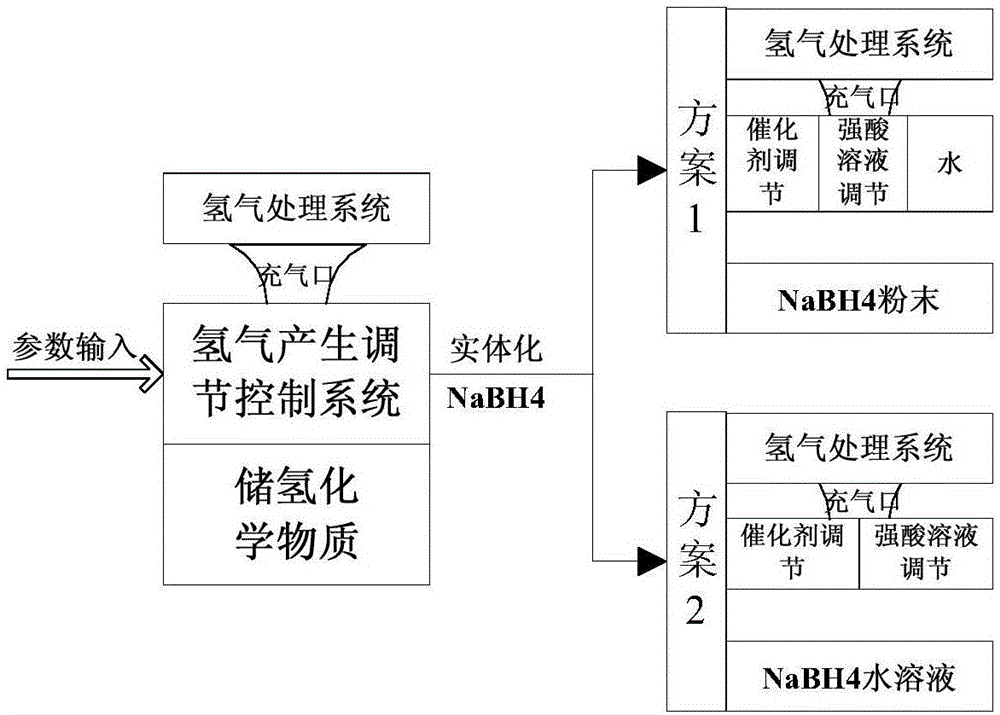

The invention relates to a stratospheric airship with a hydrogen adjusting device, and belongs to the technical field of buoyancy adjusting of stratospheric airships. A hydrogen bag and air bags are included in an airship body in the stratospheric airship, a hood is included in the hydrogen bag, and a pressure sensor is included in the hood. A buoyancy lift adjusting system and a hydrogen storage ballast are included in a pod in the stratospheric airship. A buoyancy adjusting system comprises a hydrogen treatment system, a fuel storage box, an air storer, a fuel battery, an energy management system, a lithium battery, a water electrolyzer, a hydrogen purifier and a water storer. A hydrogen generation device is a container, and the middle of the container is divided by separation plates into four cavities. The hydrogen generation device is fixedly connected to the outside of the pod through a separating and unlocking device, and the hydrogen generation device is thrown out from the pod when the separating and unlocking device is opened.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

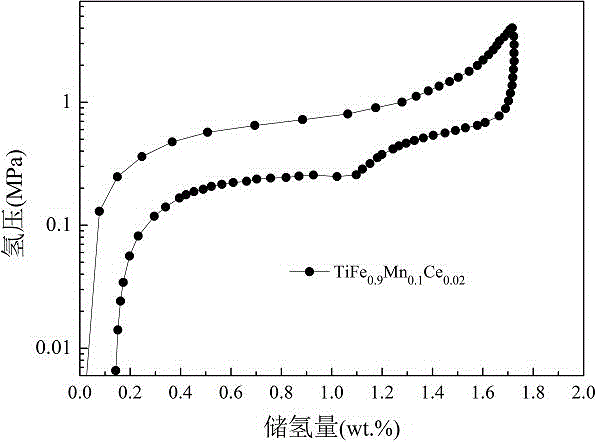

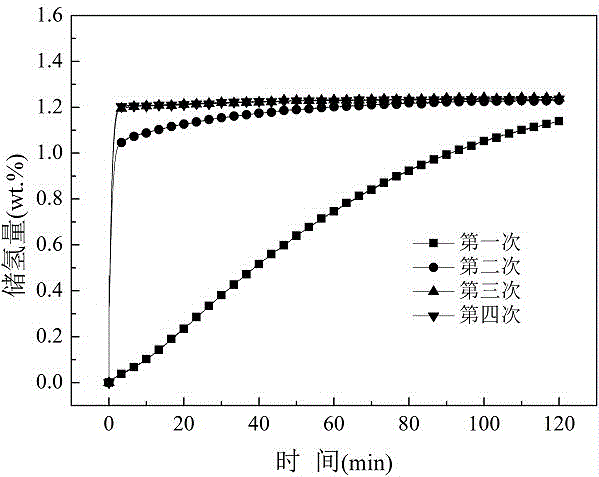

Ferrotitanium-based hydrogen storage alloy

InactiveCN105779848AImprove the activation effectChanges in thermodynamic propertiesHydrogen fuelHydrogen purifier

The invention relates to a ferrotitanium-based hydrogen storage alloy and belongs to the technical field of hydrogen storage alloy materials. The ferrotitanium-based hydrogen storage alloy has a general chemical formula of TiFe(1-x)MnyCozCen, wherein x is larger than 0 but smaller than or equal to 0.20, x is the sum of y and z, y is larger than 0 but smaller than or equal to 0.15, z is larger than or equal to 0 but smaller than or equal to 0.08, and n is larger than 0 but smaller than or equal to 0.10. The hydrogen storage alloy can be smelted by a vacuum medium-frequency sensing furnace; the smelted alloy can absorb hydrogen directly and has a good activation property; and a hydrogen absorbing and releasing platform of the alloy is flat, the hydrogen storage quantity is high, cost is low, and the alloy is particularly suitable for being applied to mobile or portable hydrogen storage devices such as a hydrogen purifier and a hydrogen fuel tank.

Owner:SHANGHAI UNIV

Mobile hydrogen-generating hydrogen-storing integrated device and hydrogen supplying method thereof

InactiveCN101186275AWide variety of sourcesSimple structureHydrogen productionTemperature controlChemical reaction

The invention relates to a movable integrated device for generation and storage of hydrogen and a hydrogen supply method, which belongs to the hydrogen preparation technical field. The movable integrated device for generation and storage of hydrogen comprises a hydrogen generator and a hydrogen storage tank. The device is characterized in that: the hydrogen generator is connected with a gas-water separator through a pipeline, and the gas-water separator is connected with a hydrogen purifier through a pipeline; the hydrogen purifier is connected with the hydrogen storage tank through a pipeline, and the hydrogen storage tank is provided with a temperature controlling apparatus. The hydrogen supply method is that: chemical reaction happens in the hydrogen generator to produce hydrogen, and the water and the hydrogen are separated by the gas-water separator; then purified by the hydrogen purifier, the hydrogen is stored into the storage tank after temperature regulated; while the hydrogen is needed, the hydrogen storage tank supplies the hydrogen through controlling the temperature. The invention has the advantages of simple structure, low construction cost, reliable technique, safety, high hydrogen generating speed, high purity of the hydrogen, less energy consumption and no pollution, etc., and is particularly applicable to movable situations.

Owner:天津海蓝德能源技术发展有限公司

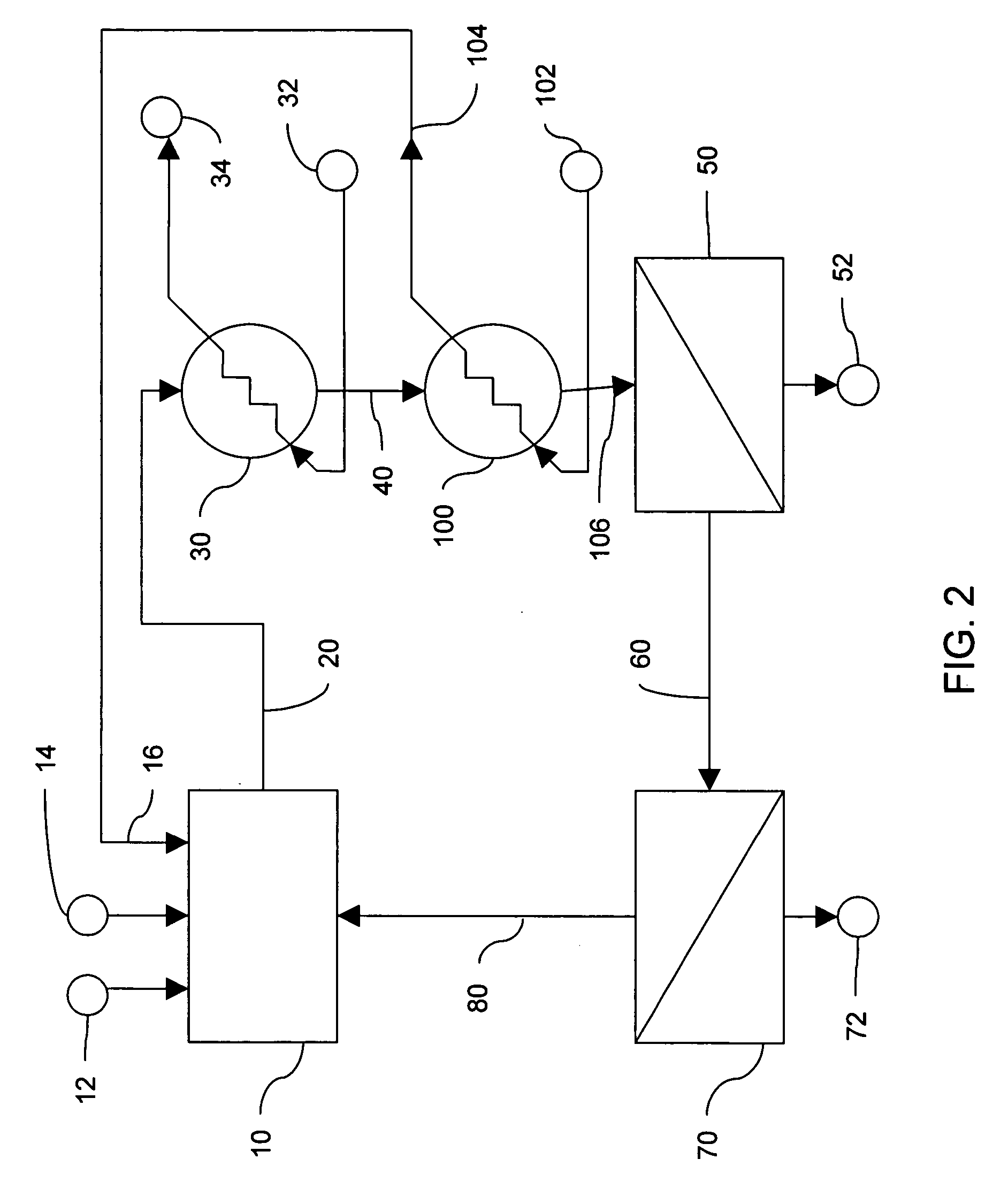

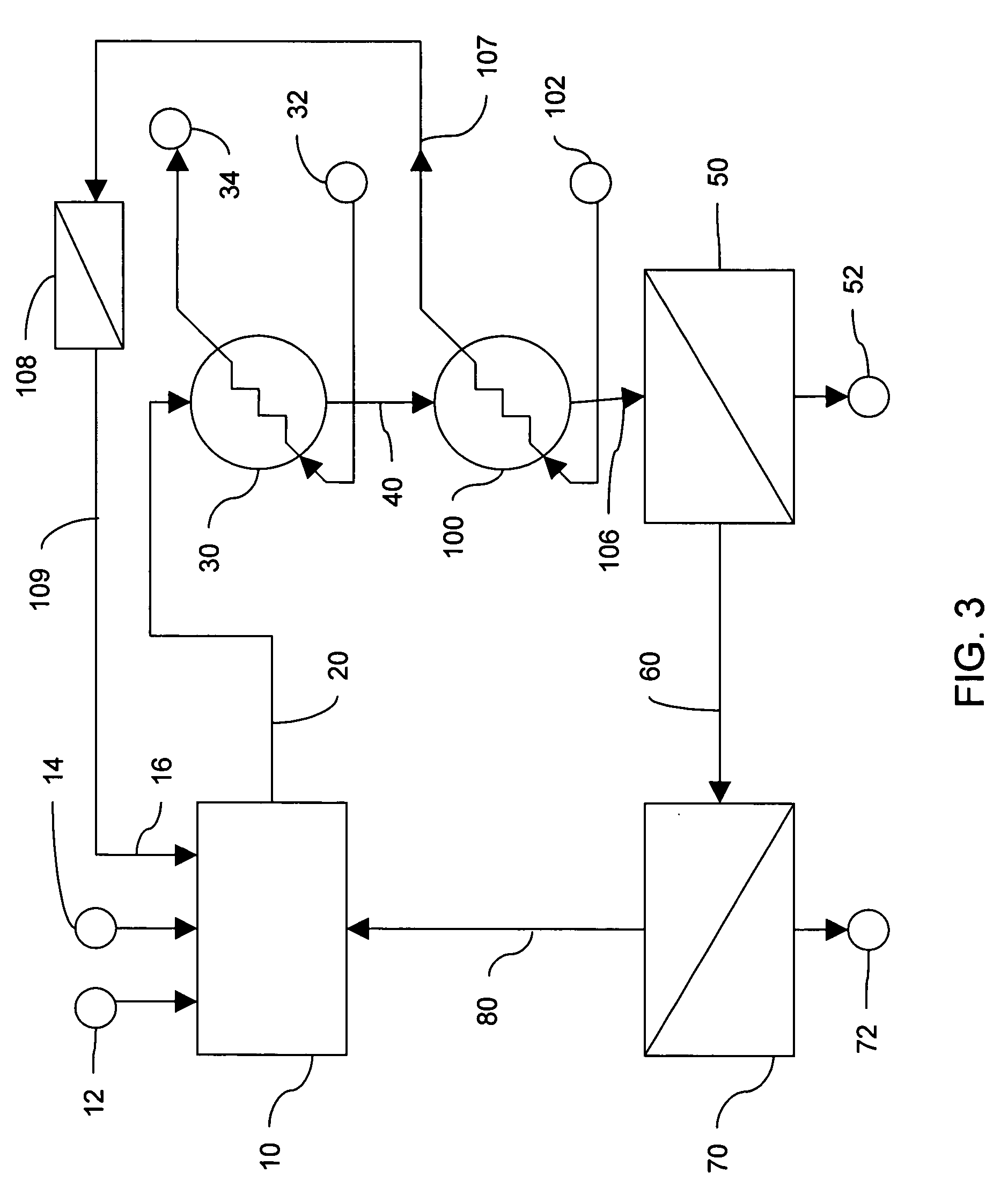

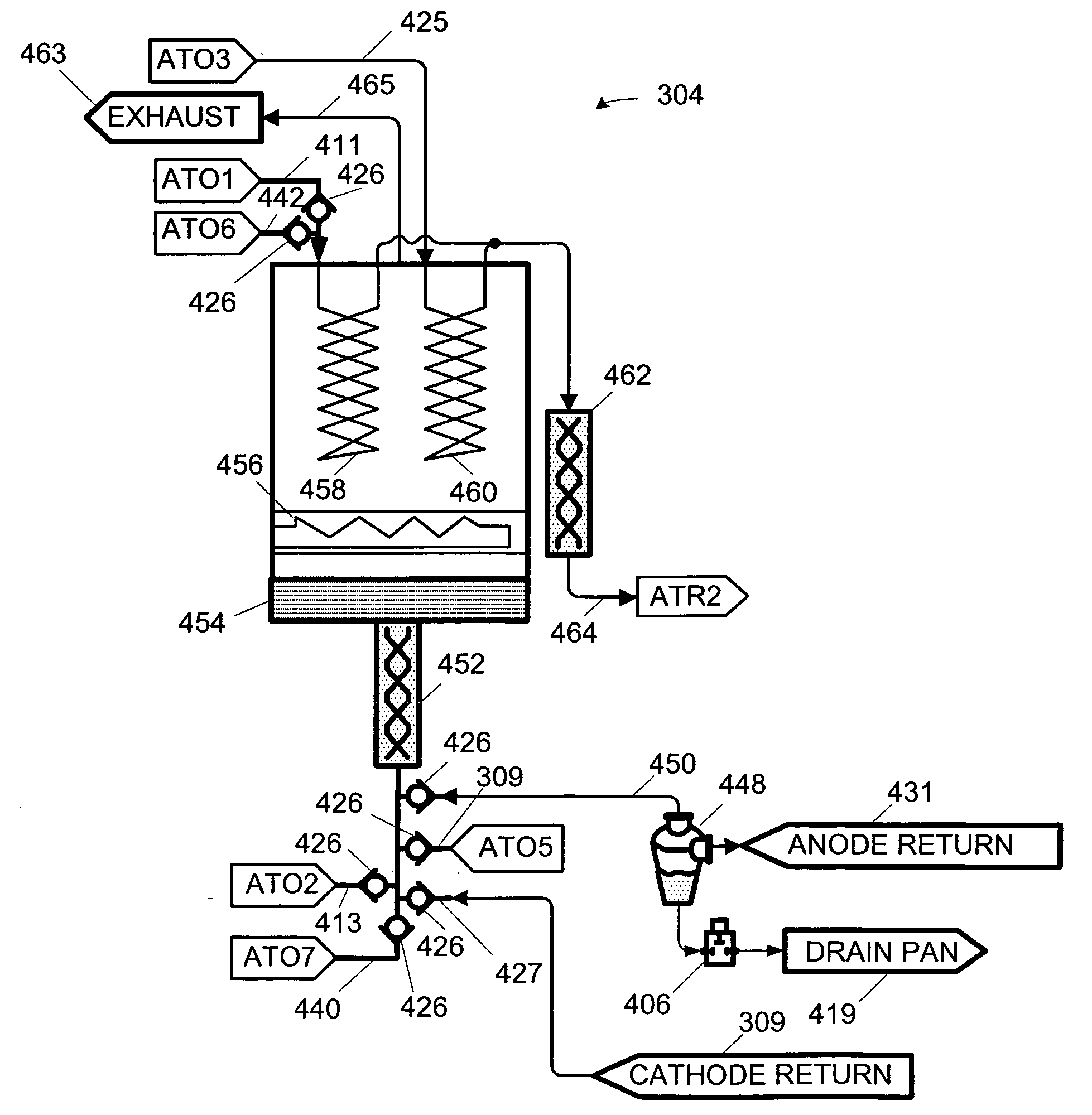

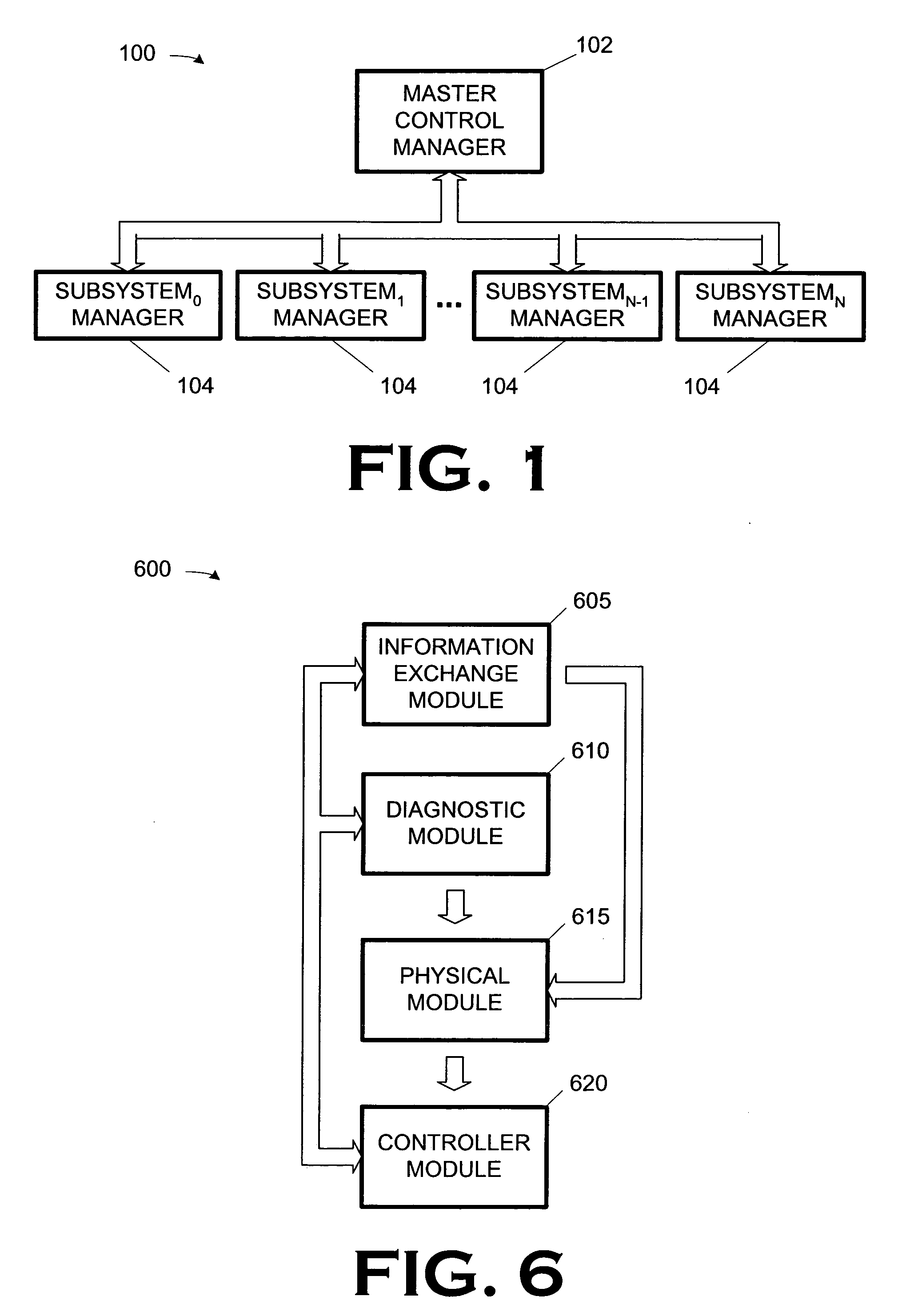

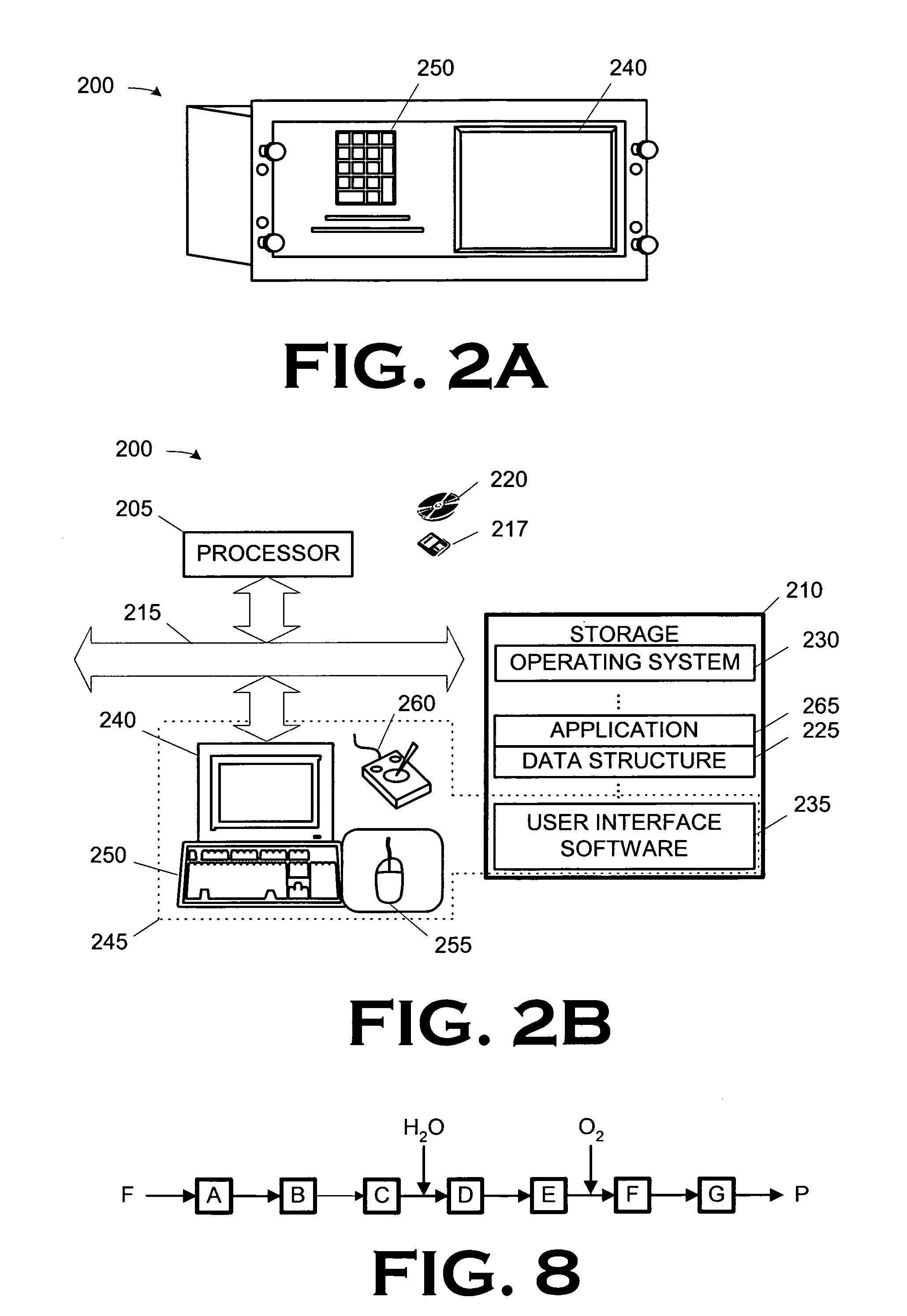

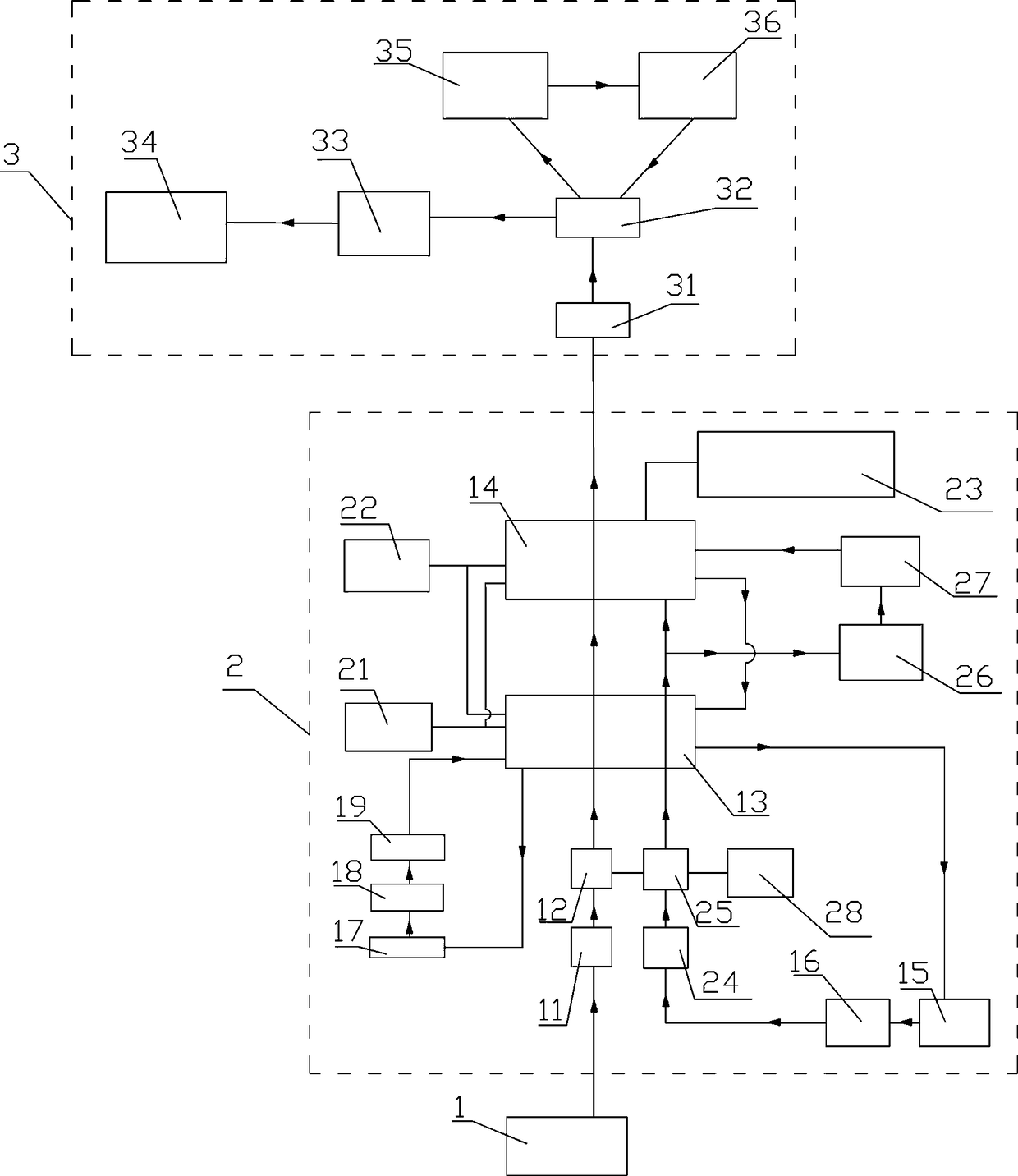

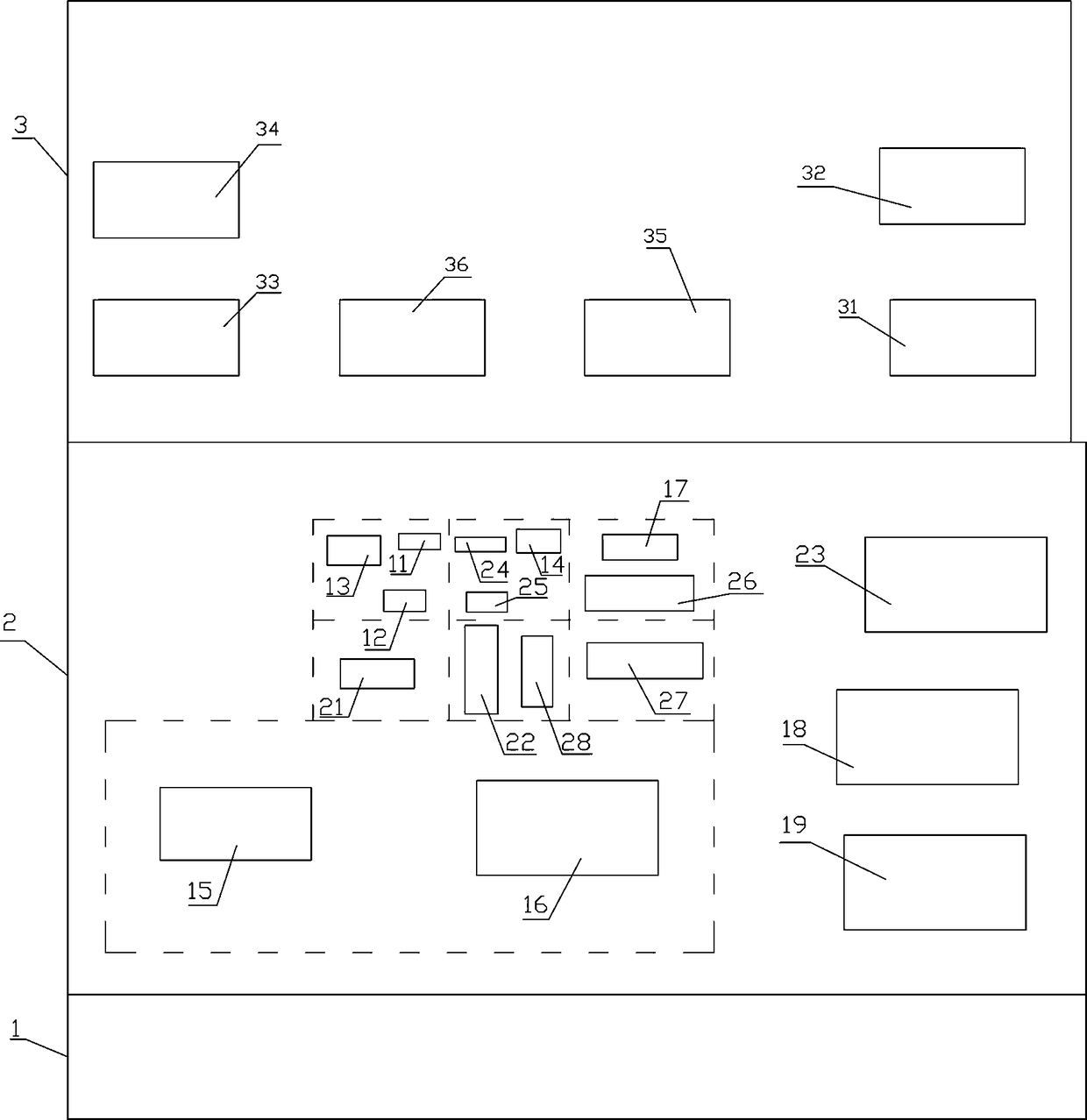

Control system for a hydrogen generator

A method and apparatus for use in generating hydrogen are disclosed. The apparatus includes a fuel processor capable of producing a reformate from a fuel; a hydrogen purifier capable of generating a purified hydrogen gas stream from the reformate; a compressor capable of providing the reformate from the fuel processor to the pressure swing adsorption unit at a desired pressure; and a control system capable of integrating and controlling the operation of the fuel processor, the pressure swing adsorption unit, and the compressor. In another aspect, the invention includes a method for controlling the operation of a purified hydrogen generator, the method comprising: controlling the operation of a hydrogen generator; controlling the operation of a hydrogen purifier; and synchronizing the controlled operation of the hydrogen generator with the controlled operation of the hydrogen purifier.

Owner:TEXACO INC & TEXACO DEV CORP

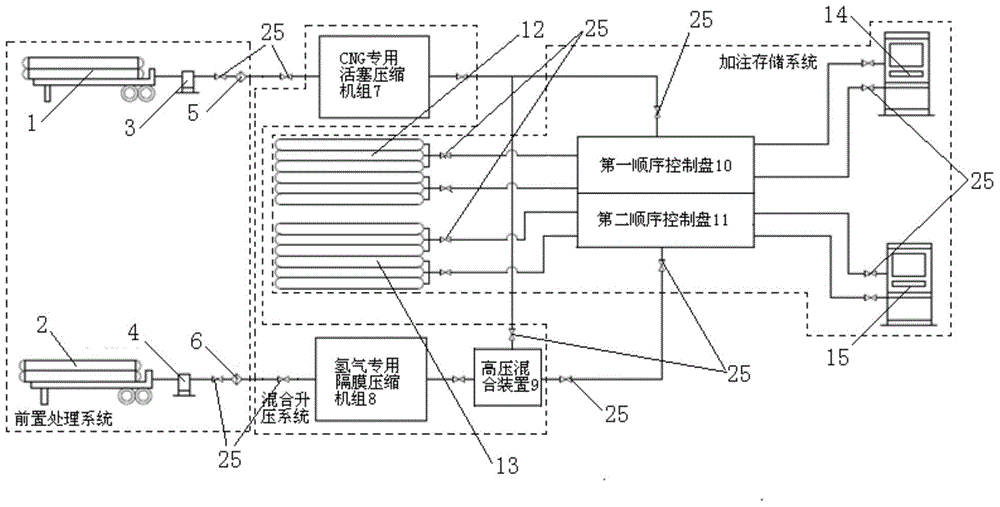

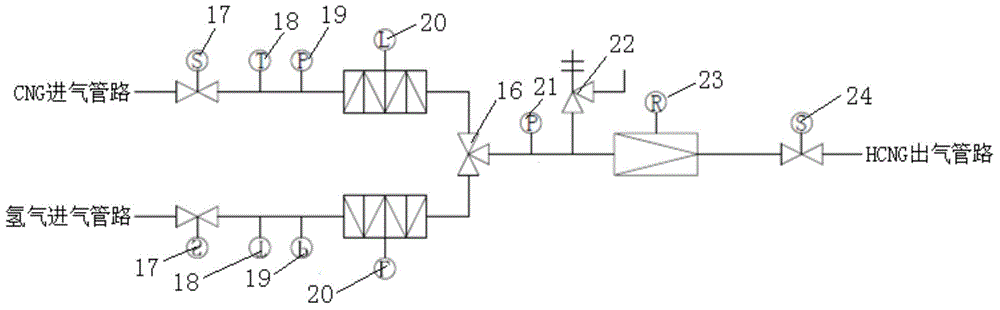

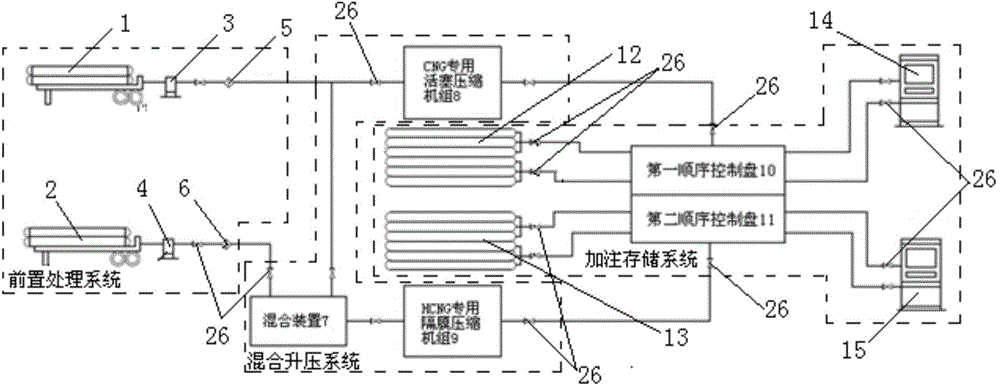

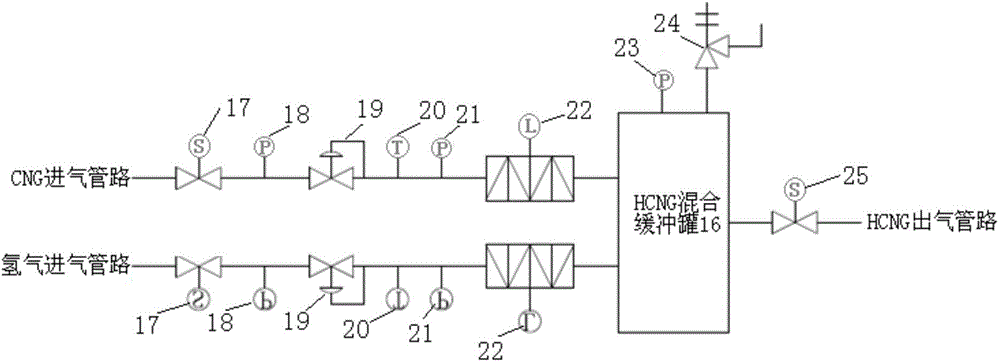

Mixed gas filling device and mixed gas filling method of CNG and HCNG

ActiveCN104456067ALow costEasy procedurePipeline systemsContainer discharging methodsProcess engineeringHigh pressure

The invention relates to a mixed gas filling device and a mixed gas filling method of CNG and HCNG. The device comprises a pre-processing system, a mixed pressure raising system and a filling and storing system, wherein the pre-processing system is connected with the mixed pressure raising system and the filling and storing system and comprises a tube bundle CNG conveying trailer, a tube bundle hydrogen conveying trailer, a CNG gas discharging column, a hydrogen discharging column, a CNG purifier and a hydrogen purifier; the mixed pressure raising system comprises a special piston compressor unit for CNG, a special diaphragm compressor unit for hydrogen and a high pressure mixing device; the gas inlet of the special piston compressor unit for CNG is connected with the gas outlet of the CNG purifier, and the gas outlet of the special piston compressor unit for CNG is connected with the CNG gas inlet pipeline of the high pressure mixing device; the gas inlet of the special diaphragm compressor unit for hydrogen is connected with the gas outlet of the hydrogen purifier, and the gas outlet of the special diaphragm compressor unit for hydrogen is connected with a hydrogen inlet pipeline of the high pressure mixing device; and an HCNG gas outlet pipeline of the high pressure mixing device is connected with the filling and storing system. The mixed gas filling device and the mixed gas filling method provided by the invention can be widely applied to gas stations of HCNG automobiles and CNG automobiles.

Owner:TSINGHUA UNIV

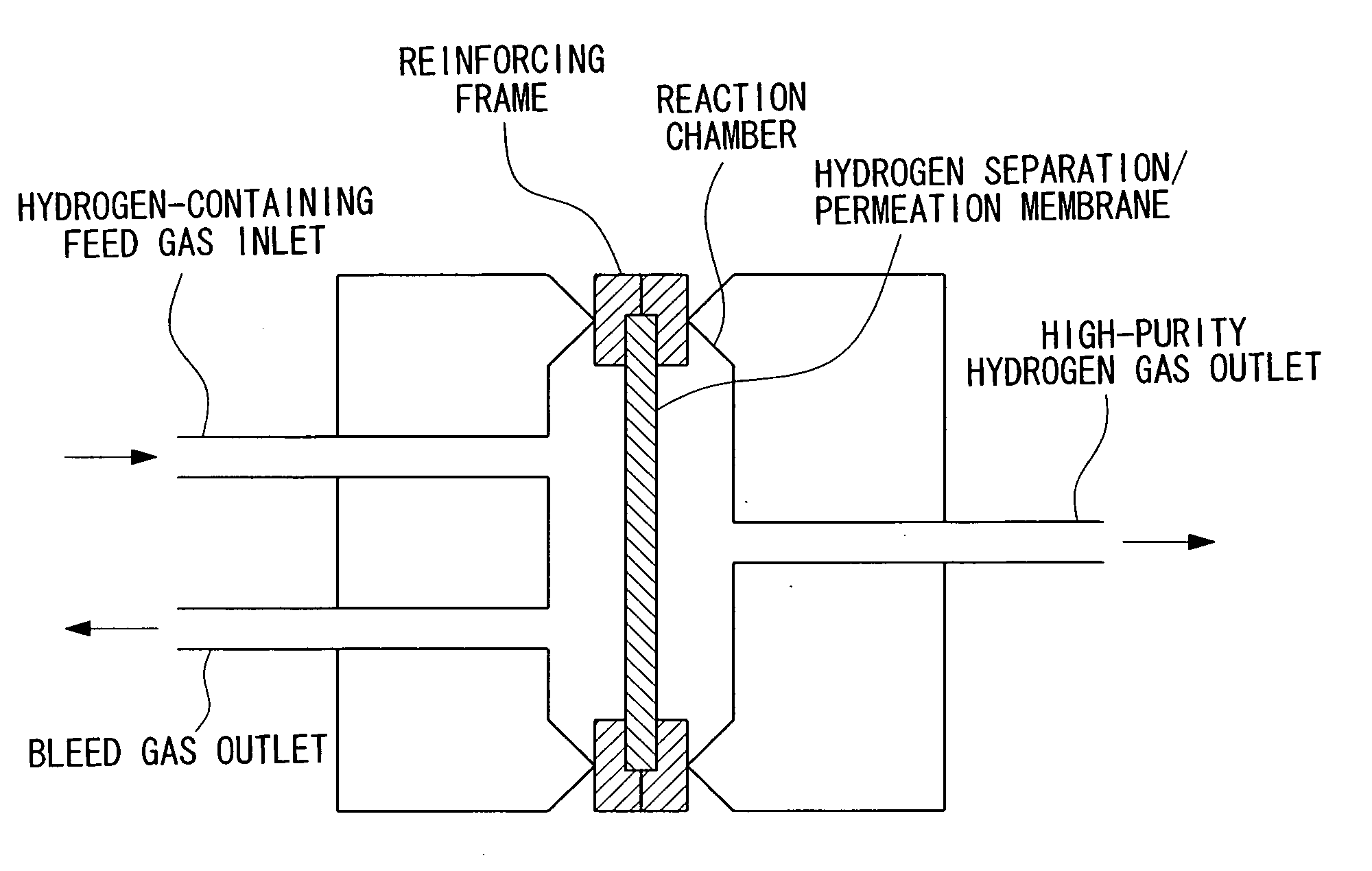

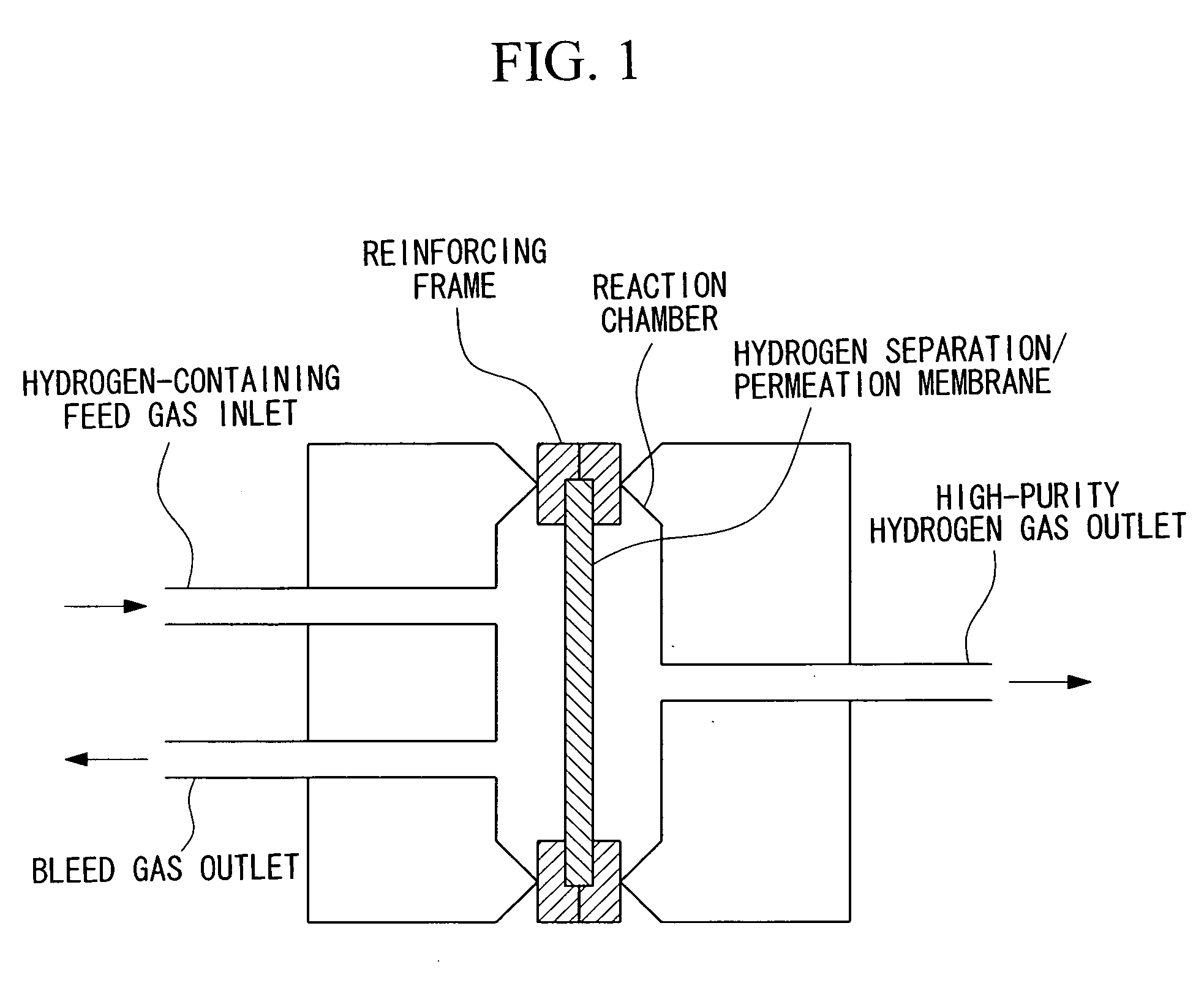

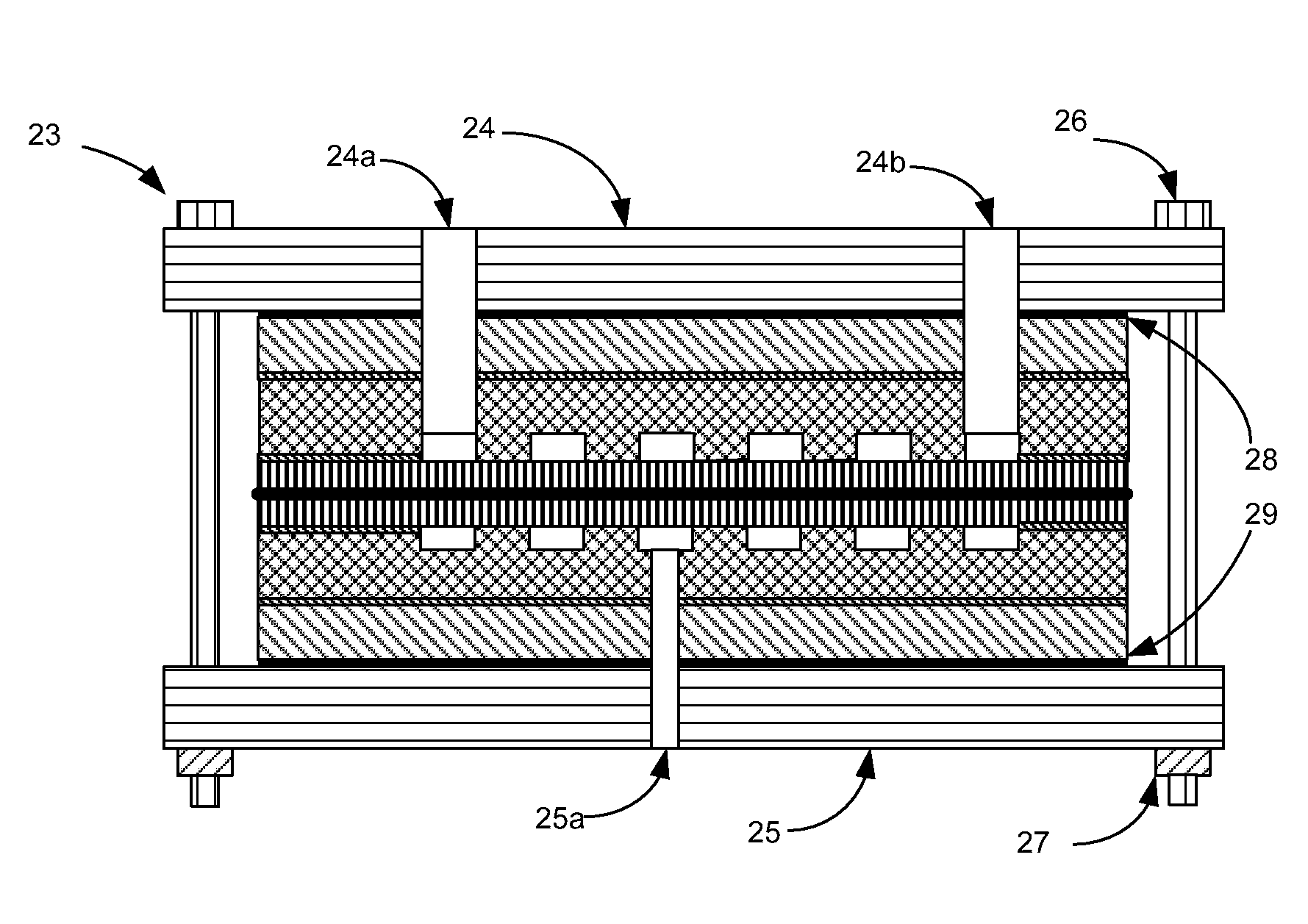

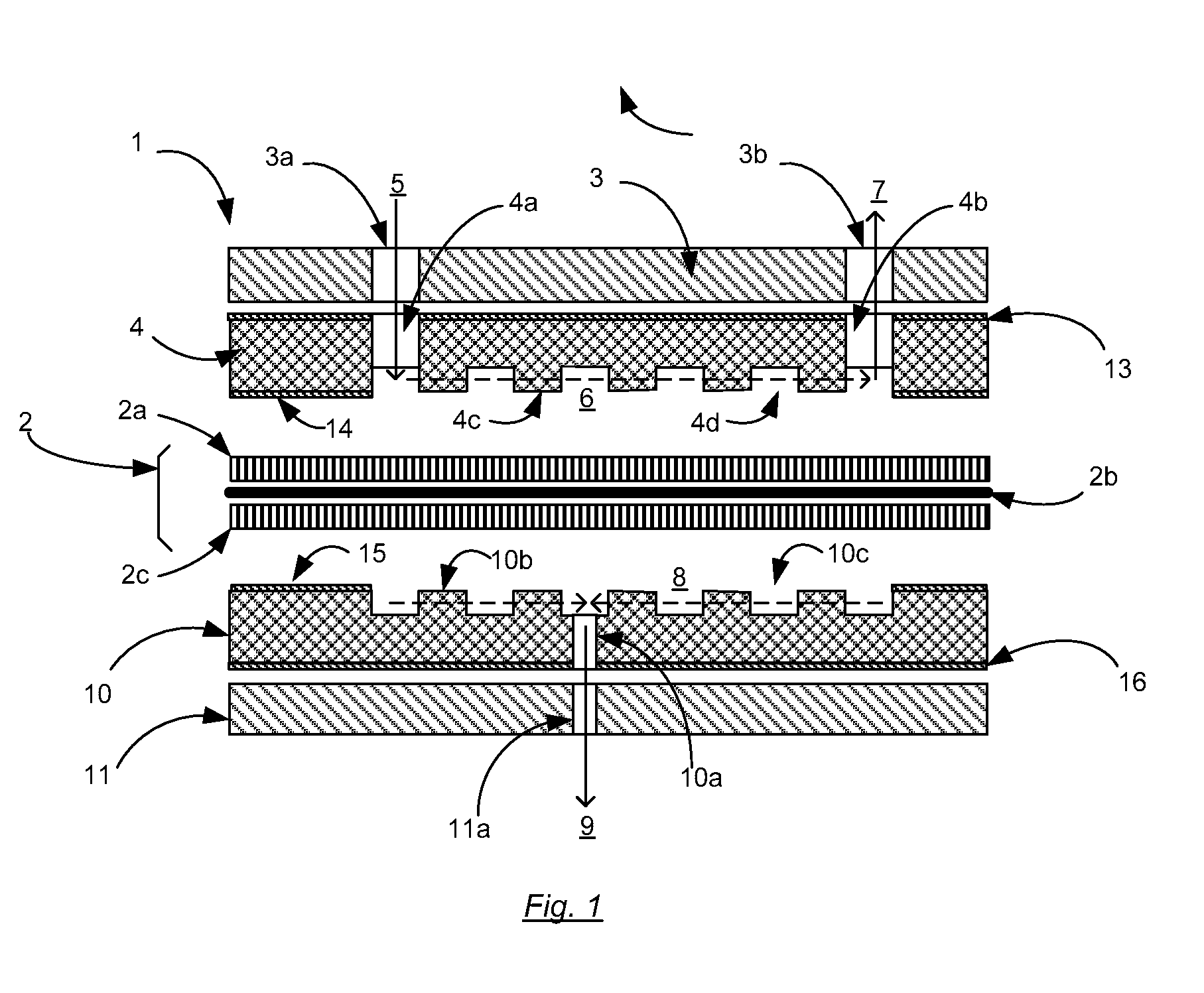

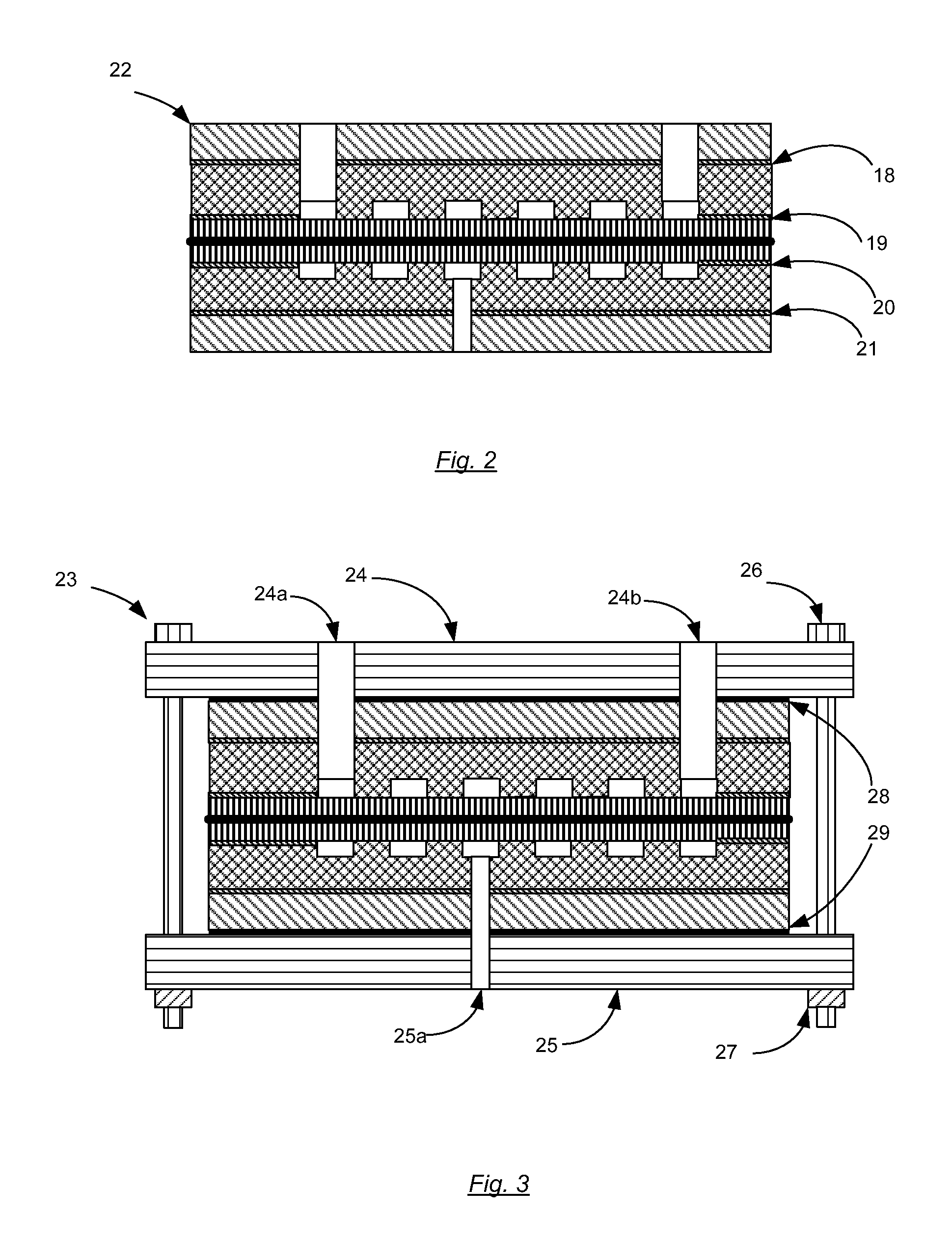

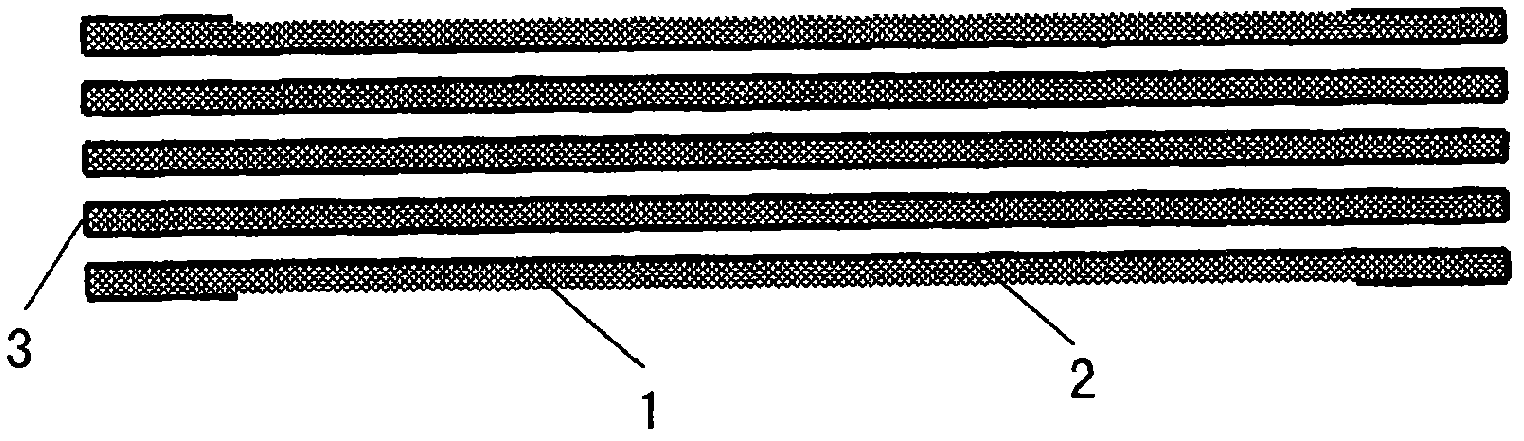

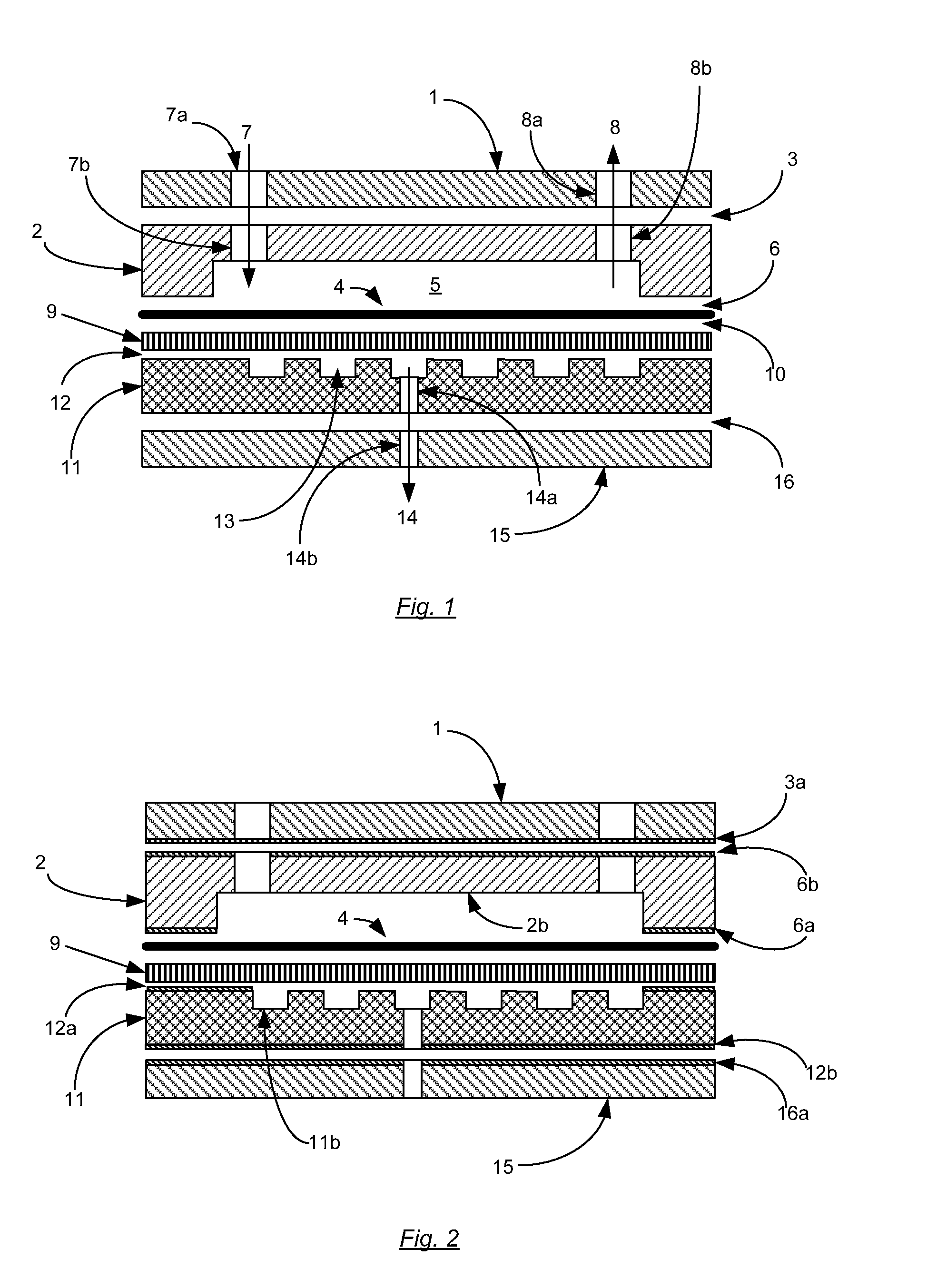

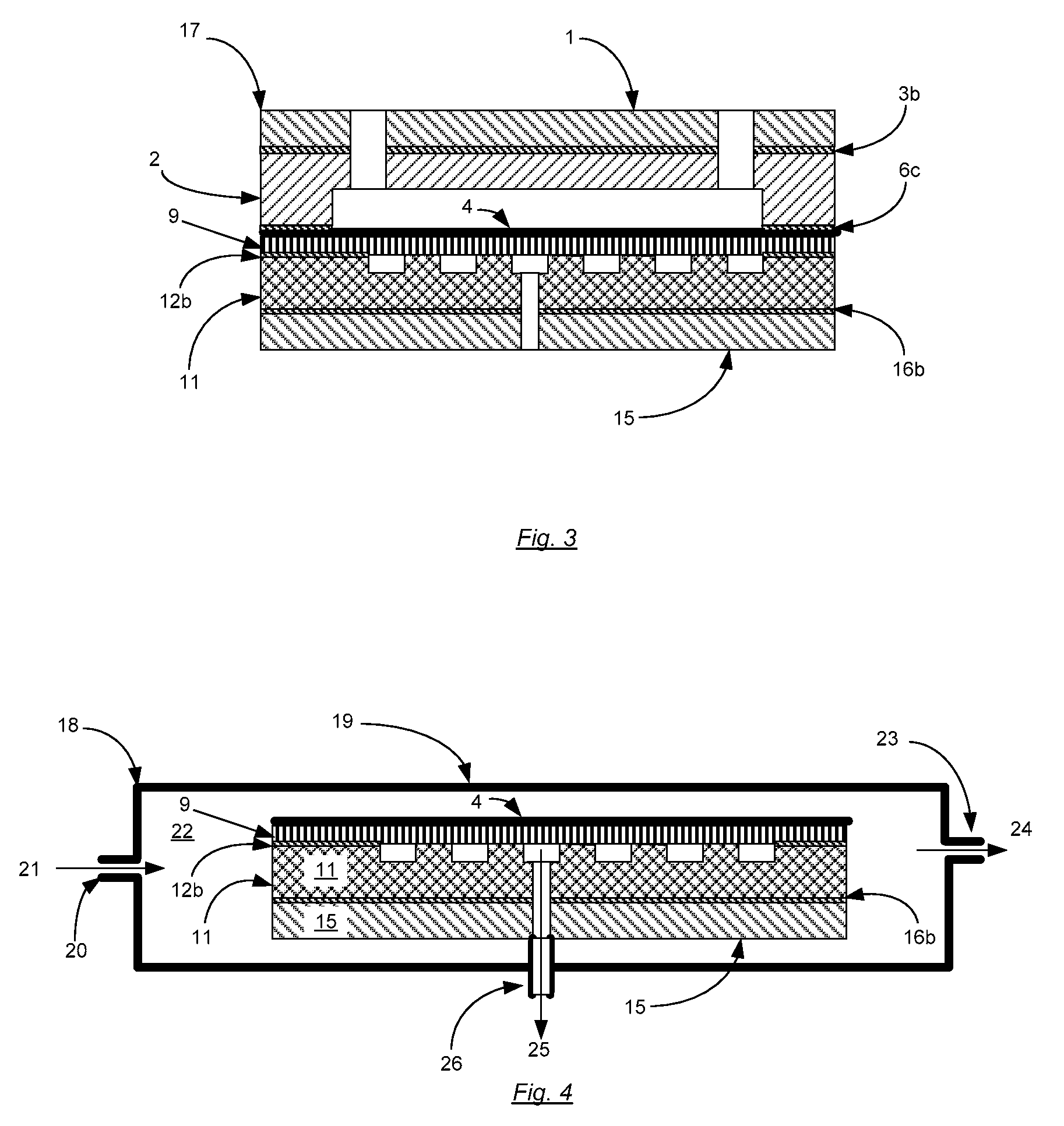

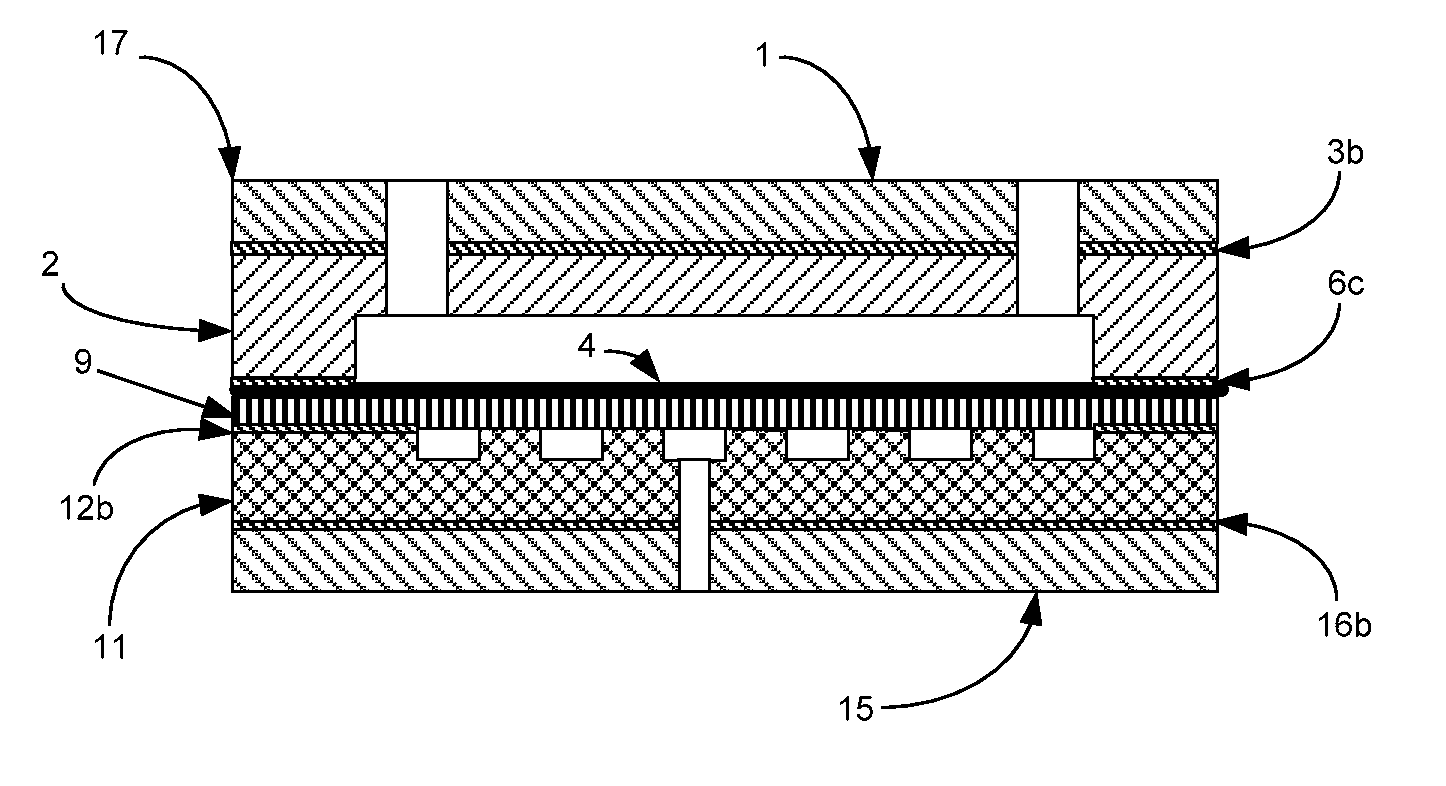

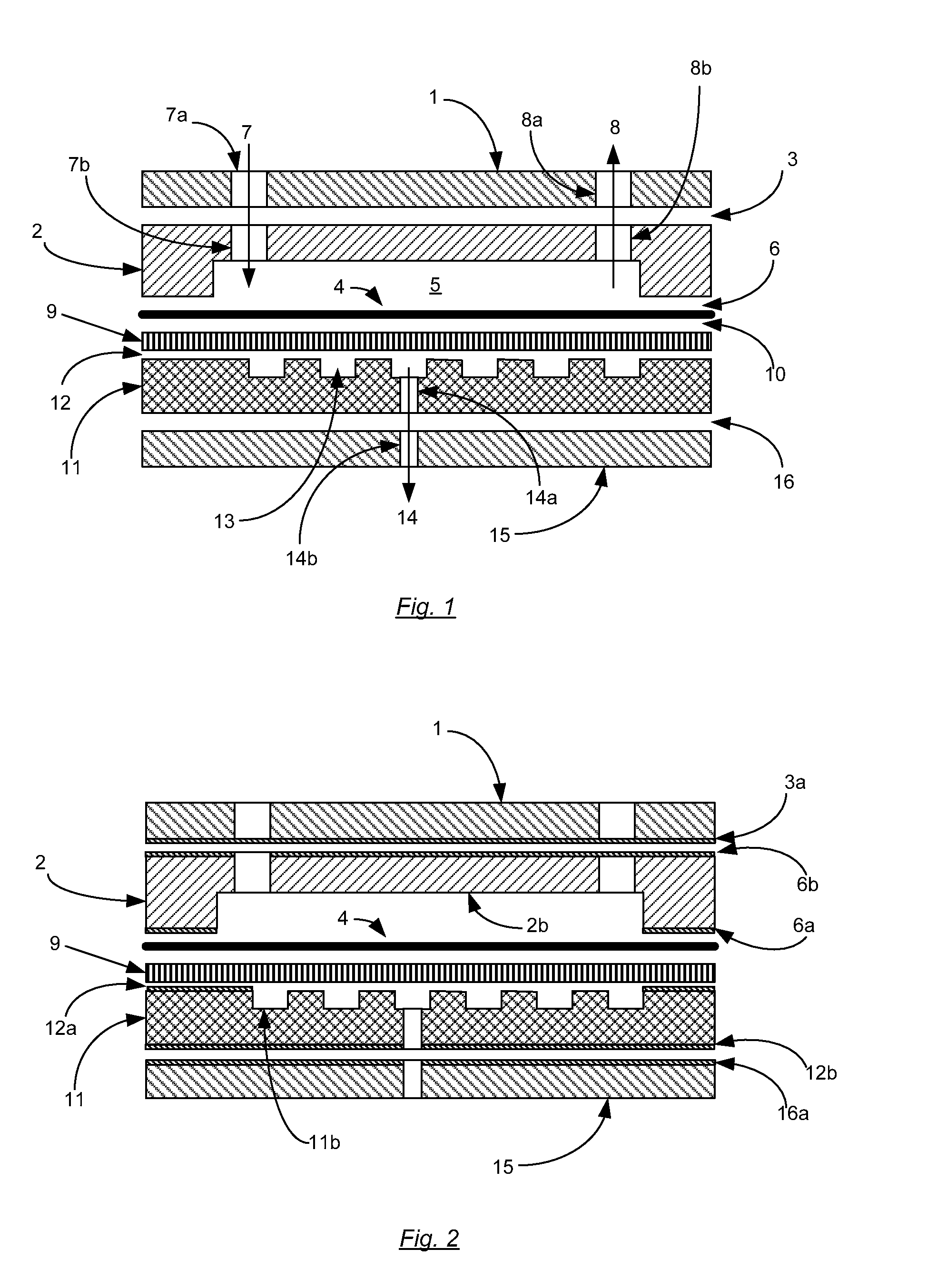

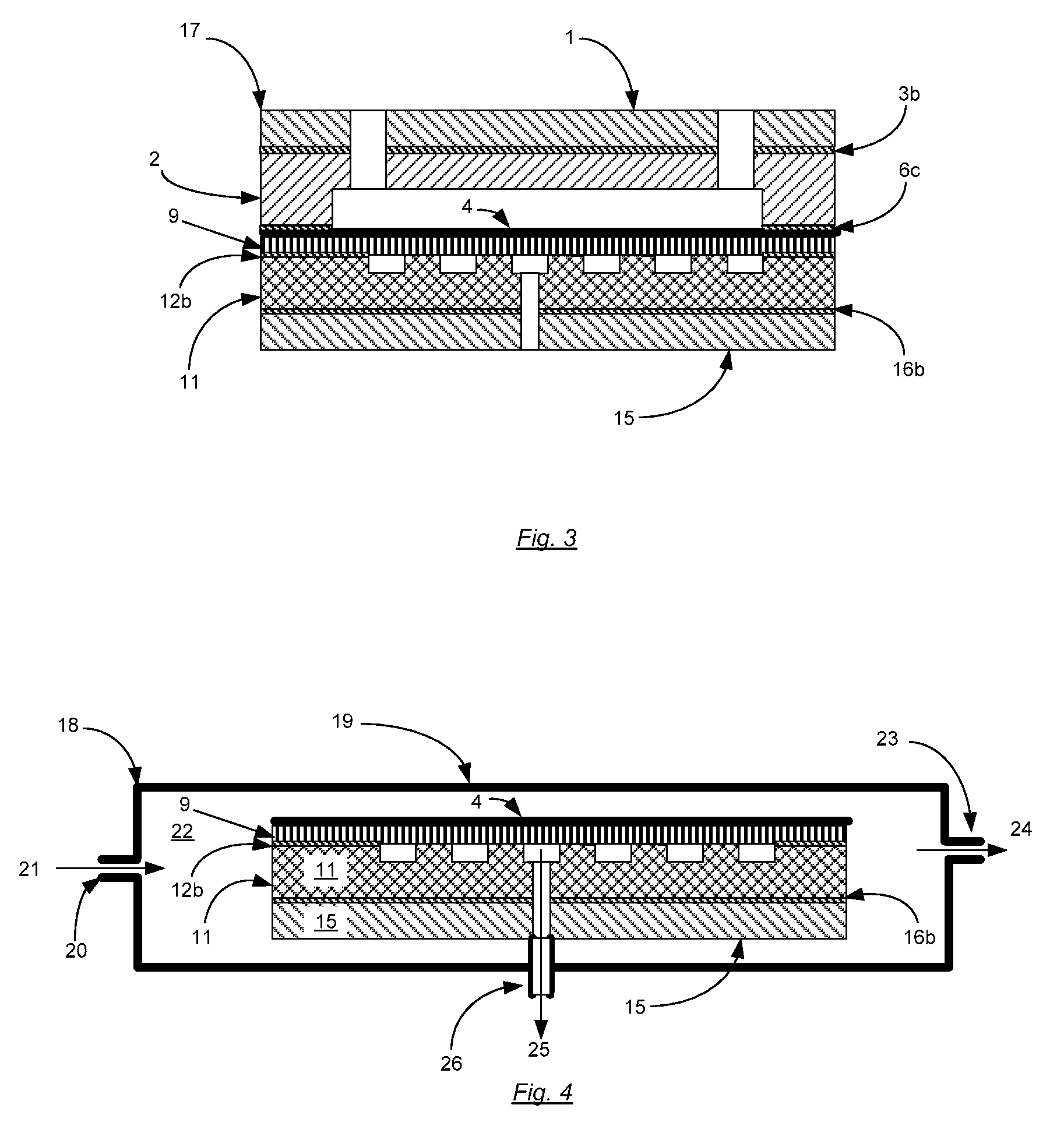

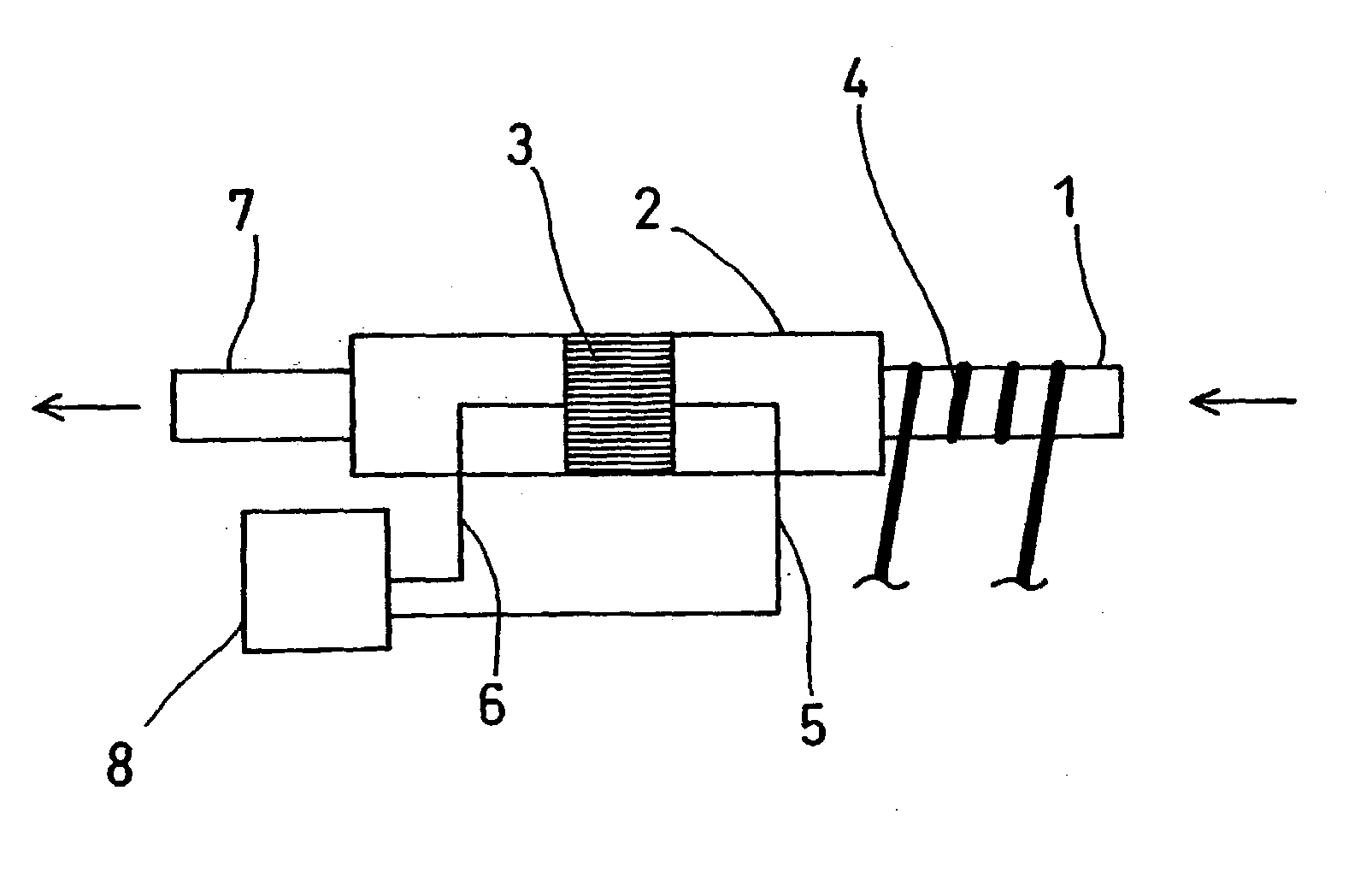

Hydrogen Purifier Module with Membrane Support

ActiveUS20100282085A1Increased durabilityPrevents the membrane from wrinklingSemi-permeable membranesMembranesHydrogenPhysical chemistry

A hydrogen purifier utilizing a hydrogen-permeable membrane to purify hydrogen from mixed gases containing hydrogen is disclosed. Improved mechanical support for the permeable membrane is described, enabling forward or reverse differential pressurization of the membrane, which further stabilizes the membrane from wrinkling upon hydrogen uptake.

Owner:JIANGSU QINGNENG NEW ENERGY TECHNOLOGIES CO LTD +1

Mobile hydrolyzed-aluminum hydrogen production device

InactiveCN101525119AEasy to useSafe, convenient and reliable to useHydrogen productionElectrolysisHydrogen purifier

The invention relates to a mobile hydrolyzed-aluminum hydrogen production device, which belongs to the technical field of hydrogen production, aims to be used for transportation means and consists of a recycling-use hydrogen production bucket, a hydrogen supply part and a hot-water supply part, wherein reaction materials used in the invention are water and hydrolyzed aluminum developed by the applicant; the hydrolyzed aluminum reacts in hot water at a temperature of between 60 and 95 DEG C to form hydrogen and alumina; the alumina is reduced into aluminum through electrolysis and then prepared into the hydrolyzed aluminum for recycling use; the hydrogen supply part uses hydrogen-transmitting pipe to combine the hydrogen production bucket, a condensate filter, a hydrogen-storing device, a constant-pressure hydrogen-supplying device and a hydrogen purifier and then supplies hydrogen to a hydrogen-using device; and the hot-water supply part uses a water pipe to supply the remaining hot water of the hydrogen-using device to the hydrogen production bucket through a water pump, an electronic-control tee proportioning valve, an electric heater and the like. The mass ratio of the hydrogen production bucket to the hydrogen yield thereof is about 20 to 1, and is about one quarter of that of a metal hydrogen-storing tank to hydrogen storage capacity. A working medium used in the invention is free from toxicity, harm and smell, safe and convenient to use and cheaper than gasoline. The hydrogen production device has the advantages of simple structure and implementation convenience.

Owner:陈世敏

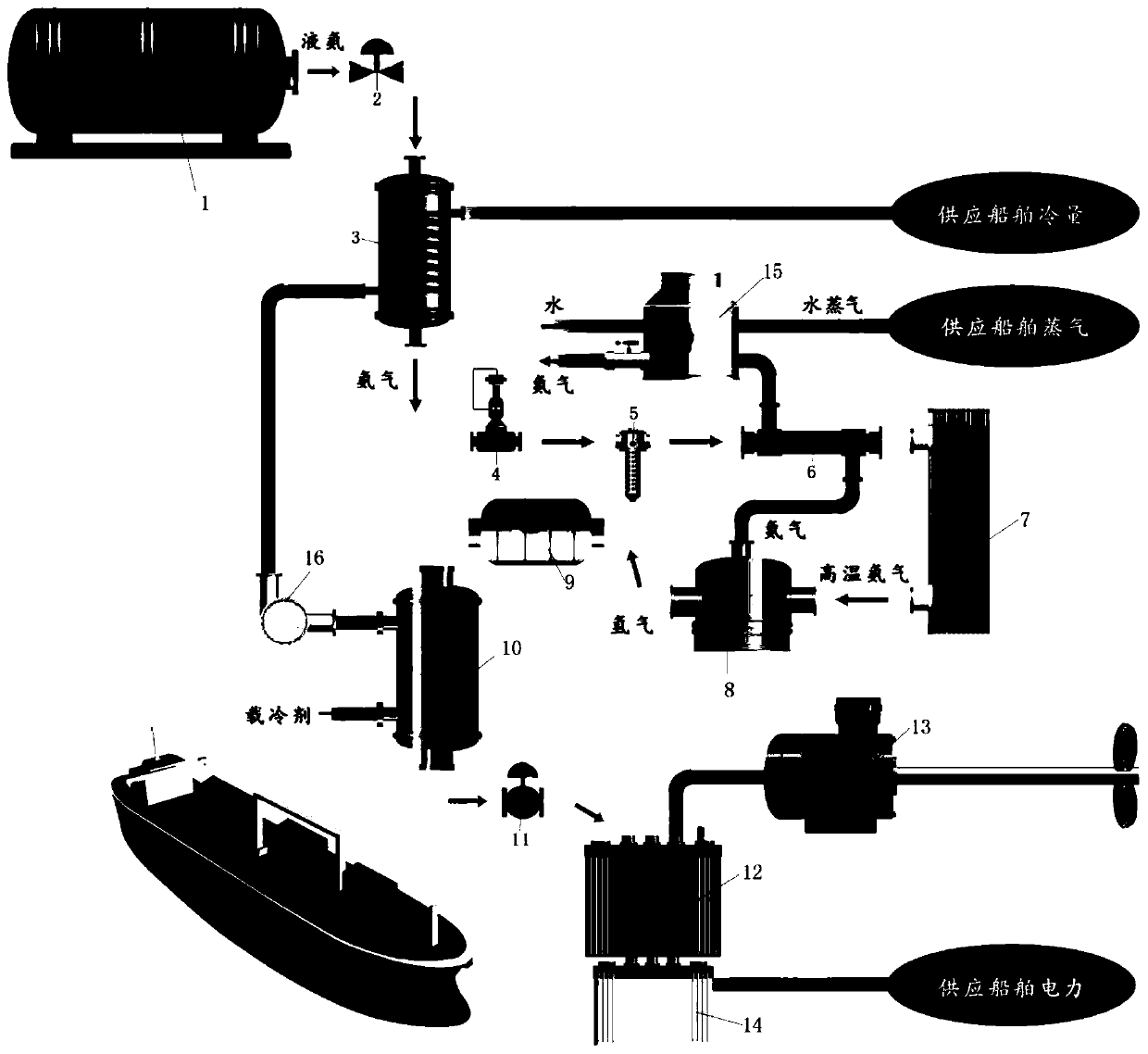

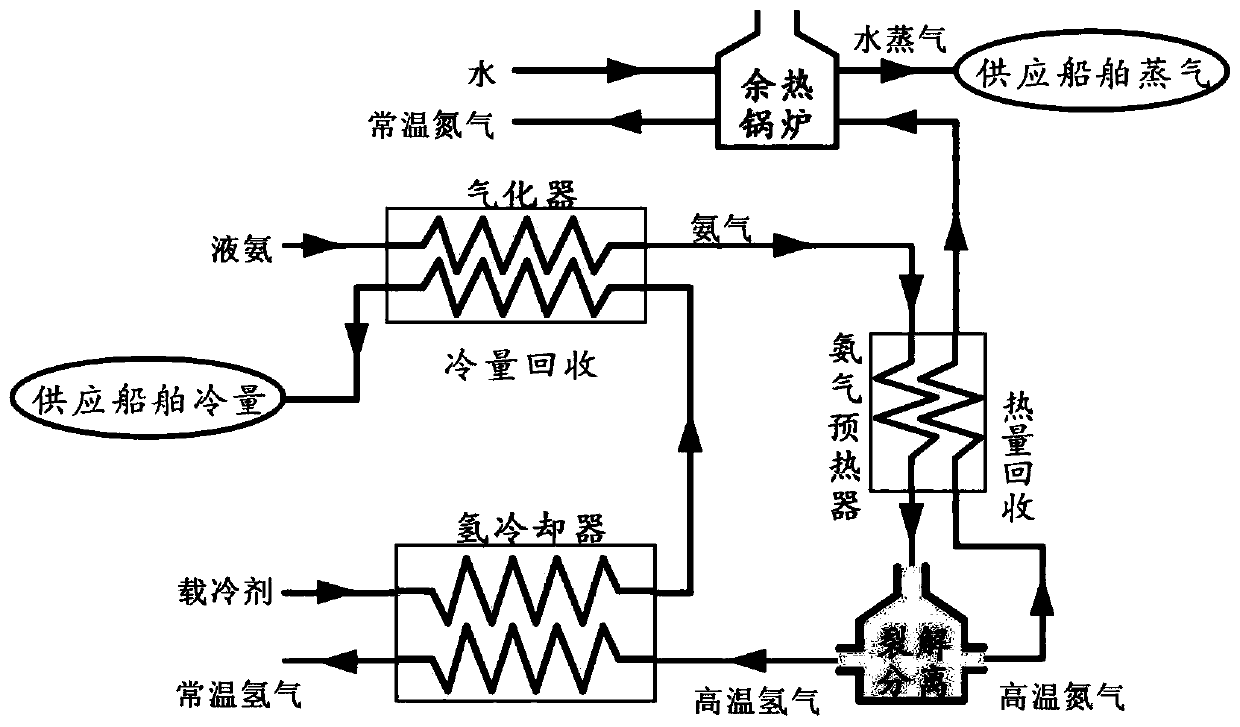

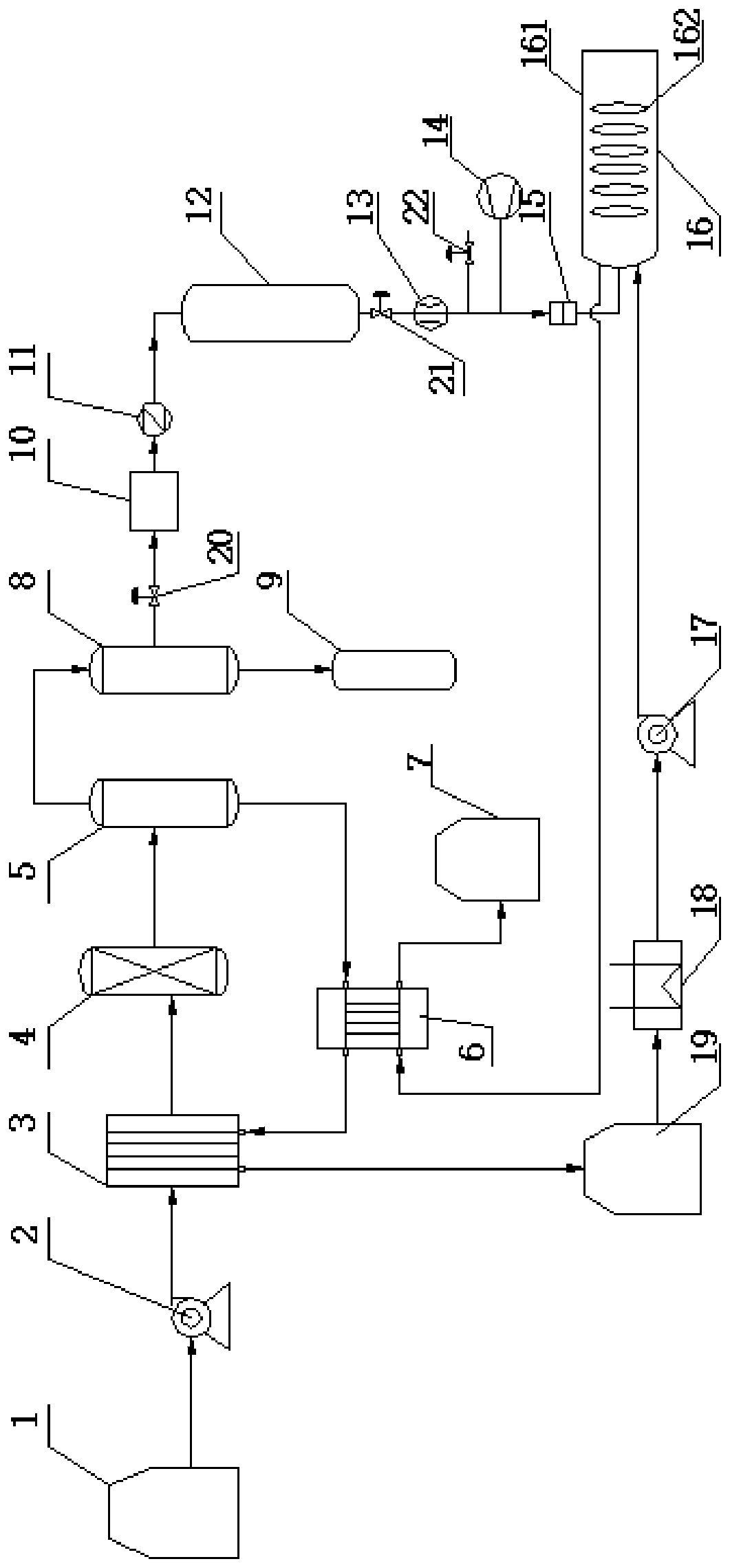

Combined cooling, heating and power composite system based on ammonia energy ship and power supply method

ActiveCN111170273AOvercome costsOvercome the shortcomings of flammable and explosiveAuxillariesHydrogen productionCatalytic decompositionHydrogen purifier

The invention provides a combined cooling, heating and power composite system based on an ammonia energy ship. The combined cooling, heating and power composite system comprises a hydrogen productionsystem, a ship power supply system and a cooling, heating and heat exchange circulating system. The hydrogen production system comprises a marine liquid ammonia storage tank, a flow regulating valve bank, a gasifier, a pressure regulating valve bank, a drying filter, an ammonia preheater, an electric heater, an ammonia catalytic decomposition hydrogen separation unit, a hydrogen purifier, a hydrogen cooler and a hydrogen pressure flow control valve bank which are communicated in sequence; the ship power supply system comprises a hydrogen-air fuel cell, a motor propeller and a storage battery.The cooling, heating and heat exchange circulating system comprises a waste heat boiler and a secondary refrigerant pump; the waste heat boiler is used for generating saturated steam to meet the heatrequirements of ship auxiliary machines and passenger cabins. The secondary refrigerant pump is used for cooling the ship equipment and supplying related cooling capacity to the ship. The problem thata large amount of energy is consumed due to the fact that an existing hydrogen production-hydrogen storage technology cuts off the hydrogen production technology and the hydrogen storage technology is solved.

Owner:DALIAN MARITIME UNIVERSITY

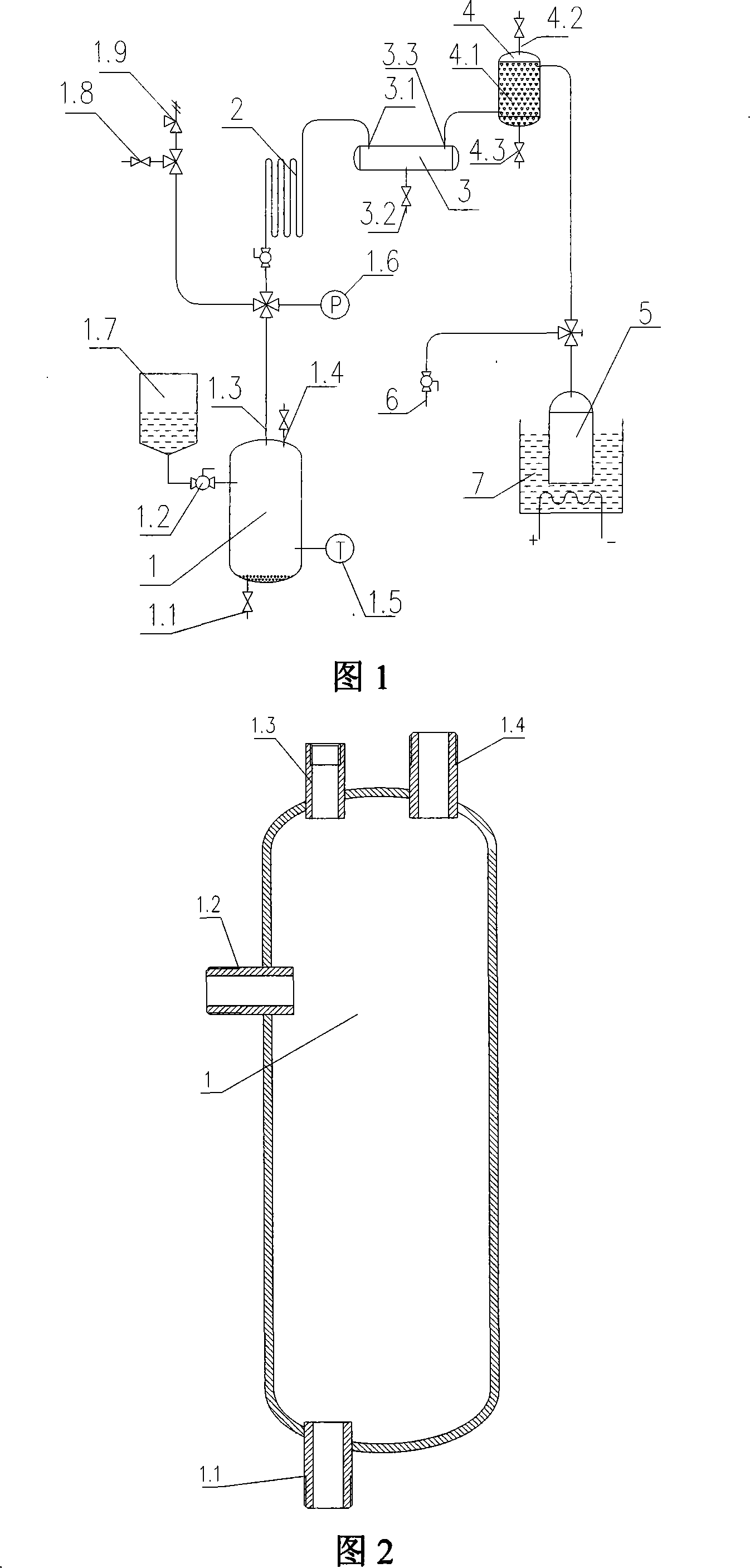

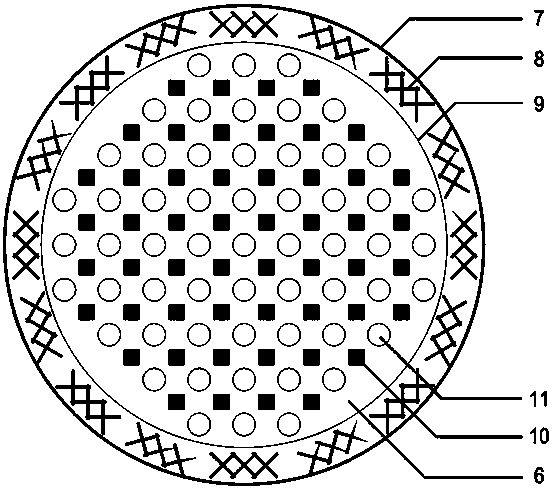

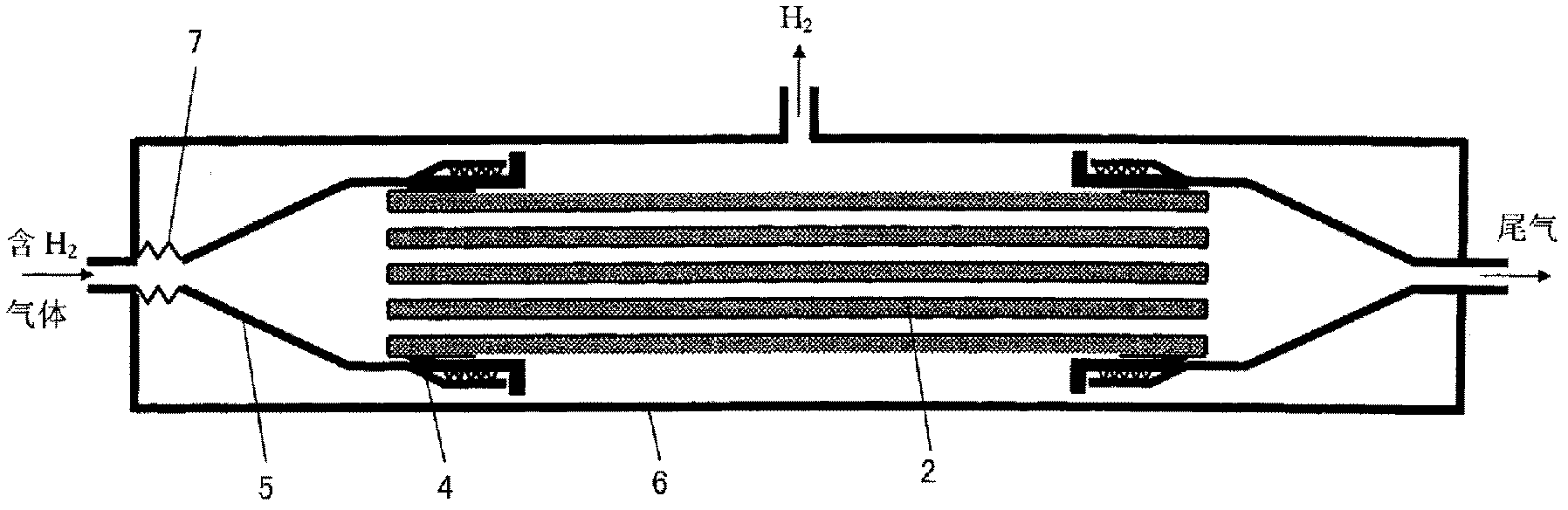

Hydrogen purifier

PendingCN108328577AImprove securityImprove purification efficiencyHydrogen separation by selective and reversible uptakeGas-discharge lampPurification methods

The invention discloses a hydrogen purifier, which comprises a main body purifying device, an automatic controller, a heat exchange device and a waste gas treating device, wherein the main body purifying device comprises a gas inlet pipe, a gas inlet pump, a gas inlet valve, a gas inlet cut-off valve, a reaction tank, a gas discharge cut-off valve, a gas discharge valve, a gas discharge pump, a gas discharge pipe, a bypass valve, a reversing gas pipe, a gas discharge reversing valve and a waste gas discharge pipe, the reaction tank comprises a reaction tank outer wall, a reaction tank interlayer, a reaction tank inner wall, a hydrogen storage alloy reaction bed body, a pressure gauge and a filter, and the heat exchange device comprises a hot water box, a cold water box, a two-way water pump and a heat exchanger. According to the present invention, hydrogen purification is performed by using the characteristics of the hydrogen storage alloy; and the hydrogen purifier has characteristicsof small size, low cost, simple process and direct online / offline use, and has great advantages compared to other hydrogen purification methods.

Owner:BEIJING CHINA POWER UNITED TECH

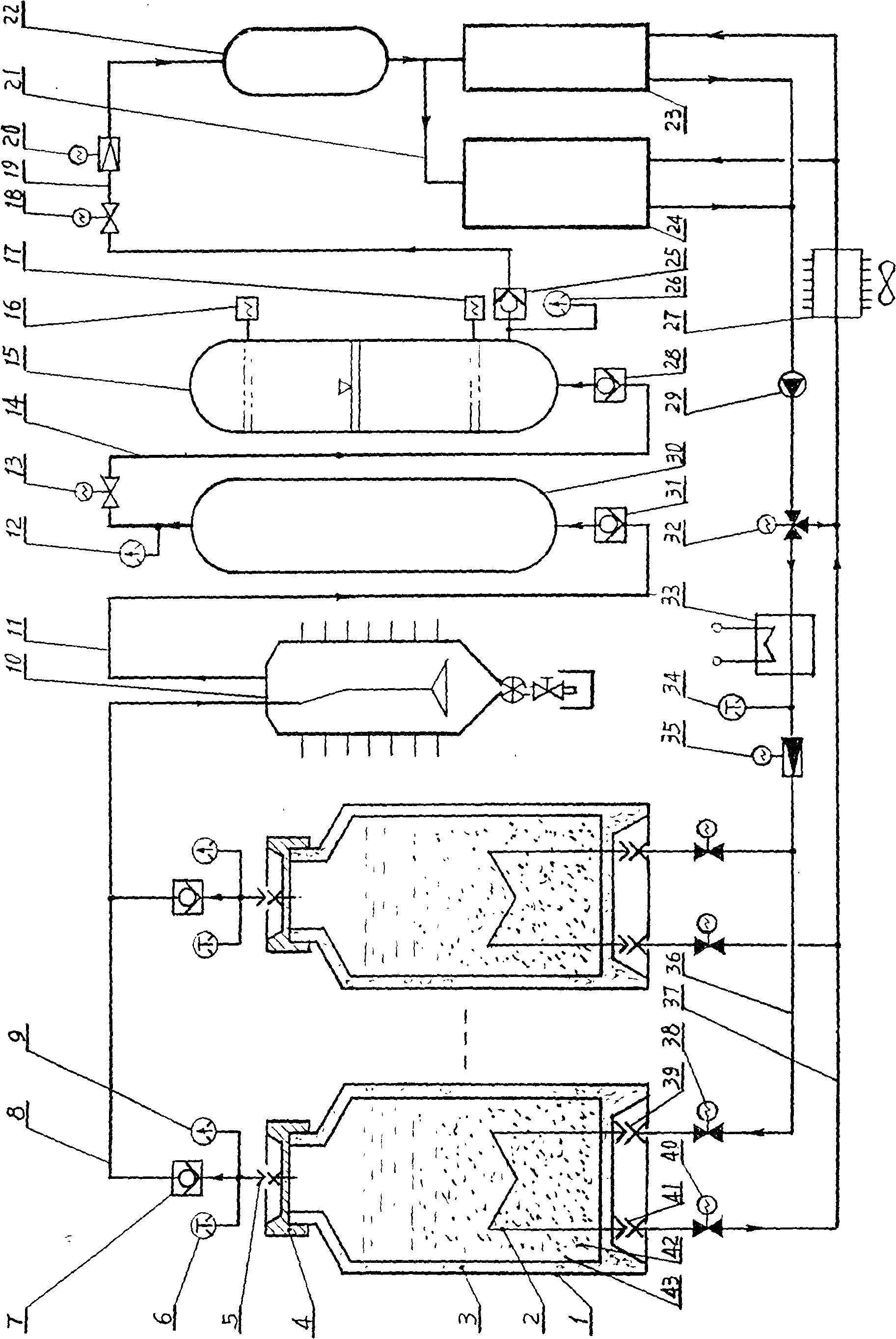

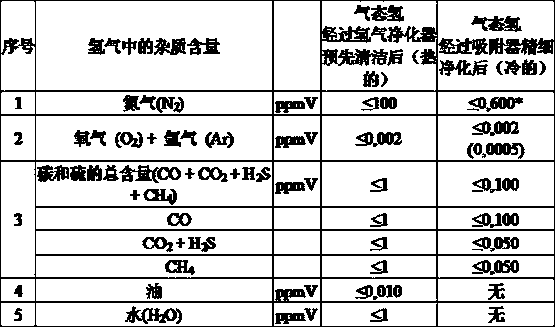

Recycling hydrogen purification processing method for producing polysilicon by reducing trichlorosilane

InactiveCN102328906AHigh purityQuality improvementHydrogen separation using solid contactChemical industryHydrogenHydrogen purifier

The invention discloses a recycling hydrogen purification processing method for producing polysilicon by reducing trichlorosilane. Two groups of metal palladium composite membrane hydrogen purifiers which are serially connected are adopted for carrying out purification processing on recycling hydrogen obtained by trichlorosilane reduction, wherein the first group of metal palladium composite membrane hydrogen purifiers are relatively larger, the ultra-pure hydrogen (H2 purity is more than 99.9999%) after purification processing is returned to a reducing furnace and used as a raw material gas for trichlorosilane reduction; and the second group of hydrogen purifiers are relatively smaller, and the high-pure hydrogen (H2 purity is 99.999%) after purification processing is transmitted to a hydrogen cooling chemical section and used as a raw material gas. The recovery ratio of the recycling hydrogen after the purification processing by adopting the method disclosed by the invention can reach 99%. When hydrogen chloride content is higher in the recycling hydrogen, a necessary dechlorination measure is adopted for lowering HCl content below 0.5 ppm. By adopting the hydrogen purified by the method disclosed by the invention to produce the polysilicon, purity and quality of the polysilicon products can be obviously improved, and an obvious energy-saving emission reduction effect is achieved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

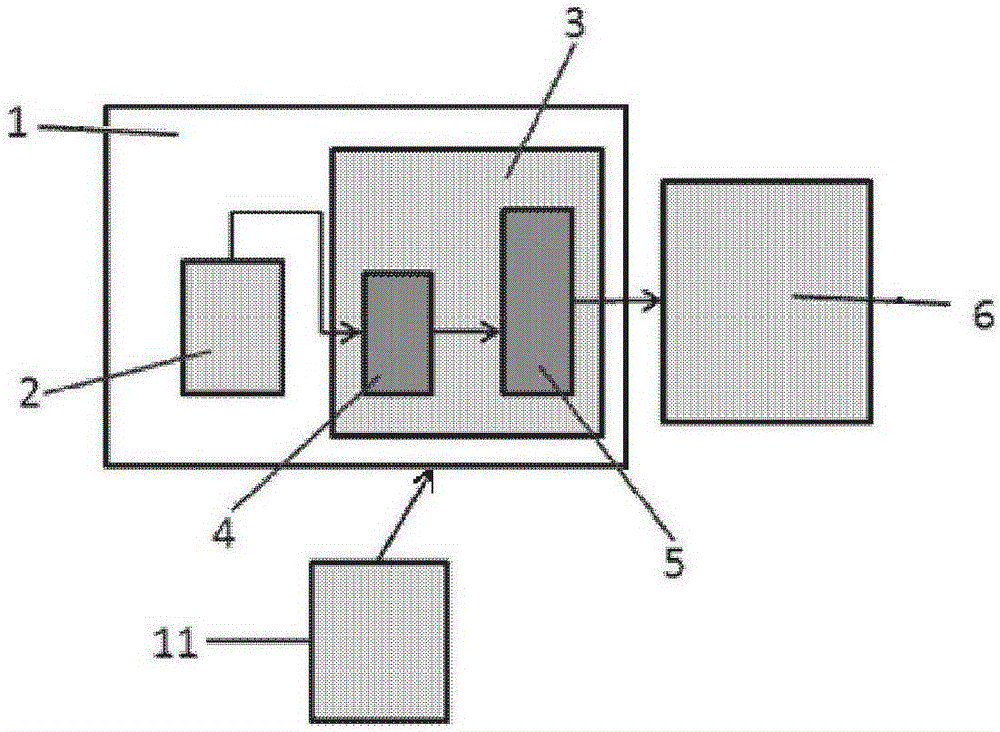

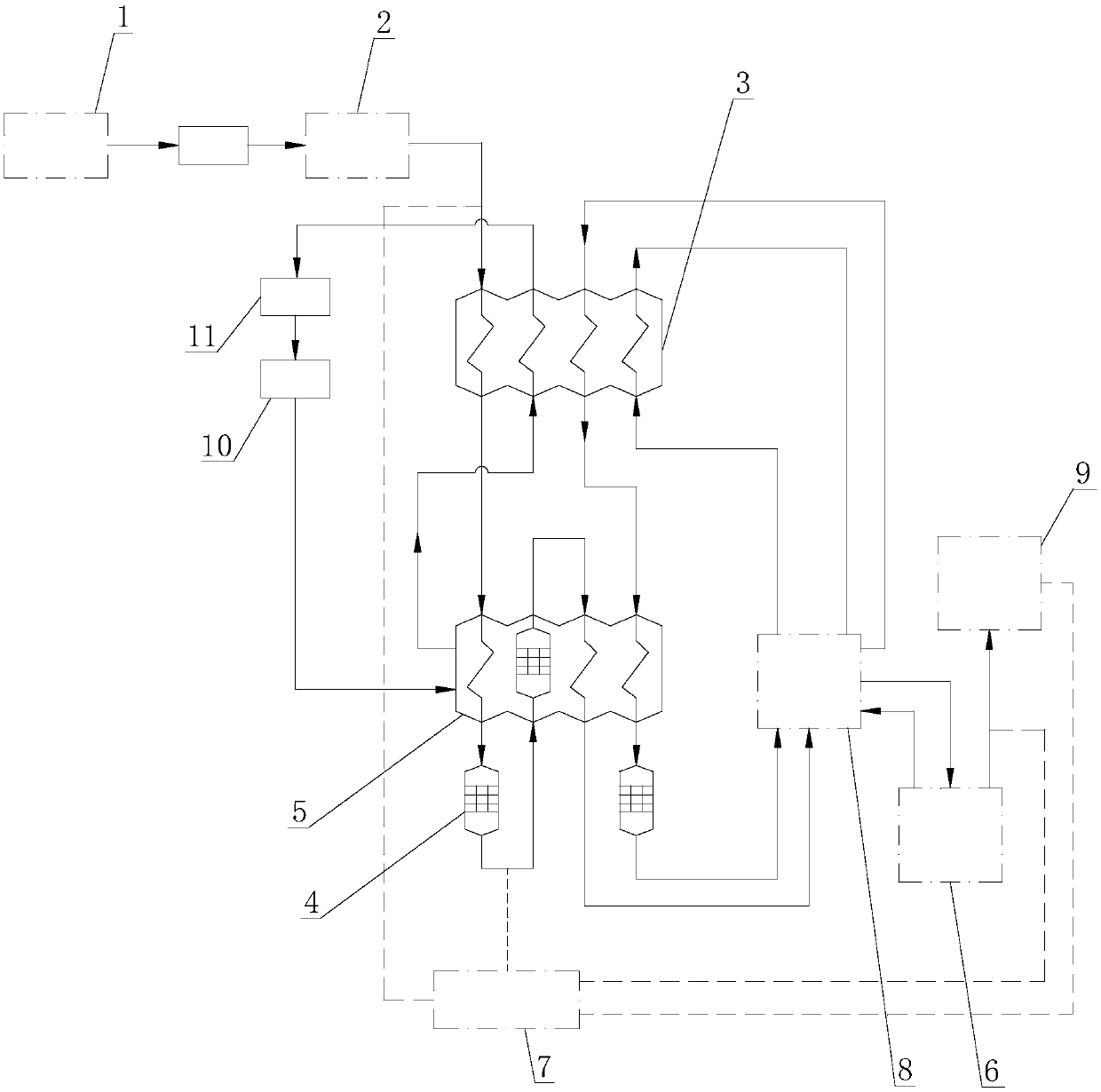

Methanol to hydrogen machine system with rapid cold boot

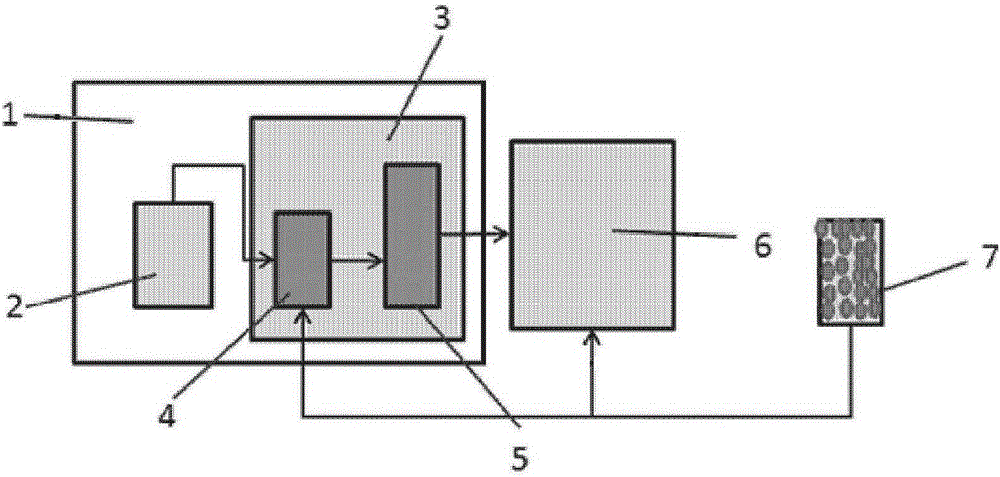

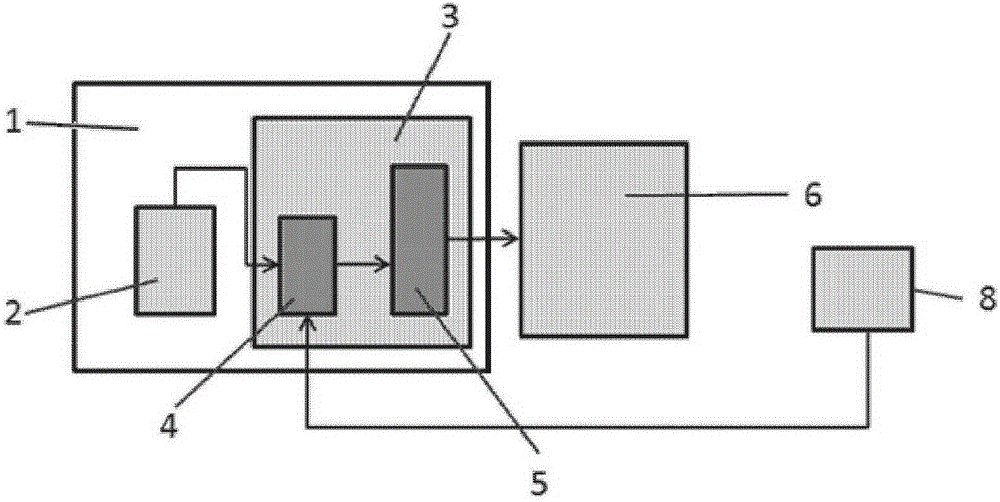

The invention provides a methanol to hydrogen machine system (1), which includes a fuel module (2) and a methanol to hydrogen module (3). The fuel module (2) includes a fuel storage device and a fuel conveying device; the methanol to hydrogen module (3) includes a fuel processor (4) for processing the fuel and producing hydrogen and a hydrogen purifier (5) used to purify hydrogen; the methanol to hydrogen module (3) is connected to the fuel module and a client (6). The methanol to hydrogen machine system (1) is characterized by further comprising a rapid cold boot driving unit (11), which is a device used to accelerate the cold boot of the methanol to hydrogen machine system (1). On the other hand, the invention provides a methanol fuel cell system, which uses the rapid cold boot driving unit (11) of the methanol to hydrogen machine system (1) as a cold boot driving device.

Owner:BEIJING NOWOGEN TECH CO LTD

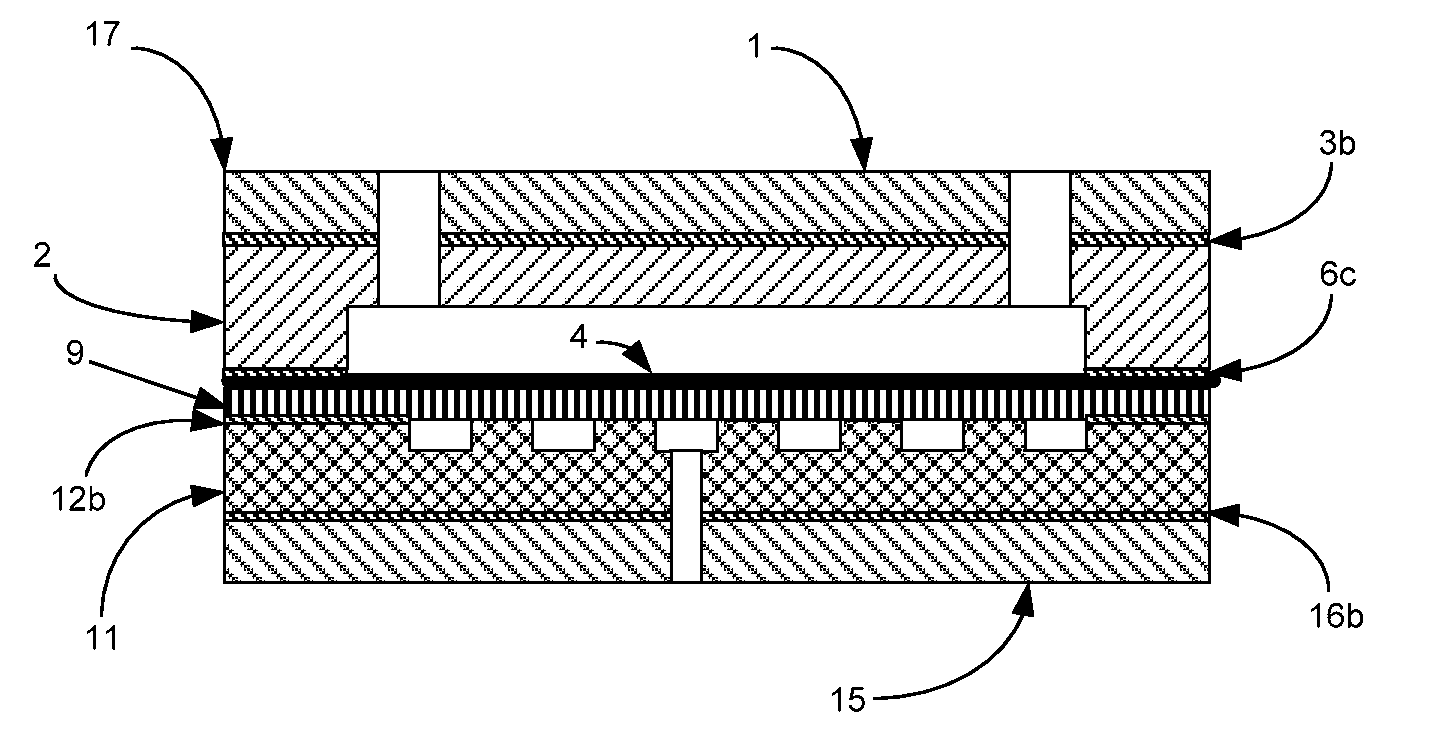

Hydrogen Purifier Module and Method for Forming the Same

ActiveUS20100263538A1Improve sealingLimiting the fabrication temperature required to form the sealsMembranesSemi-permeable membranesHydrogenWorking temperature

A hydrogen purifier utilizing a hydrogen-permeable membrane to purify hydrogen from mixed gases containing hydrogen is disclosed, with improved sealing means where the seals are formed by first melting a metal with a low temperature melting point, and then allowing the metal to form a subsequent alloy which has a melting temperature above the operational temperature of the purifier. The improved seal allows for the fabrication of hydrogen purifiers at lower temperatures than conventional methods such as brazing. Various metallurgical combinations and methods for achieving the seal are disclosed.

Owner:JIANGSU QINGNENG NEW ENERGY TECHNOLOGIES CO LTD +1

CNG and HCNG mixing and refilling device and method

ActiveCN104534271AHelp drive adoptionLow costContainer discharging methodsContainer filling under pressureHydrogenProcess engineering

The invention relates to a CNG and HCNG mixing and refilling device and a CNG and HCNG mixing and refilling method. The device comprises a prepositioned treatment system, a mixing and pressurizing system and a filling and storing system, wherein the prepositioned treatment system is connected with the filling and storing system by the mixing and pressurizing system; the prepositioned treatment system comprises a pipe bundle CNG conveying trailer, a pipe bundle hydrogen gas conveying trailer, a CNG unloading column, a hydrogen gas unloading column, a CNG purifier and a hydrogen gas purifier; the mixing and pressurizing system comprises a mixing device, a CNG special piston compressor set and an HCNG special diaphragm compressor set; a gas inlet of the CNG special piston compressor set is connected with a gas outlet of the CNG purifier; the gas outlet of the CNG special piston compressor set is connected with the filling and storing system; a hydrogen gas inlet pipeline of the mixing device is connected with the gas outlet of the hydrogen gas purifier; a CNG inlet pipeline is connected with the gas outlet of the CNG purifier; an HCNG outlet pipeline is connected with the gas inlet of the HCNG special diaphragm compressor set; and the gas outlet of the HCNG special diaphragm compressor set is connected with the filling and storing system. The CNG and HCNG mixing and refilling device and the CNG and HCNG mixing and refilling method can be widely applied to gas stations of HCNG cars and CNG cars.

Owner:TSINGHUA UNIV

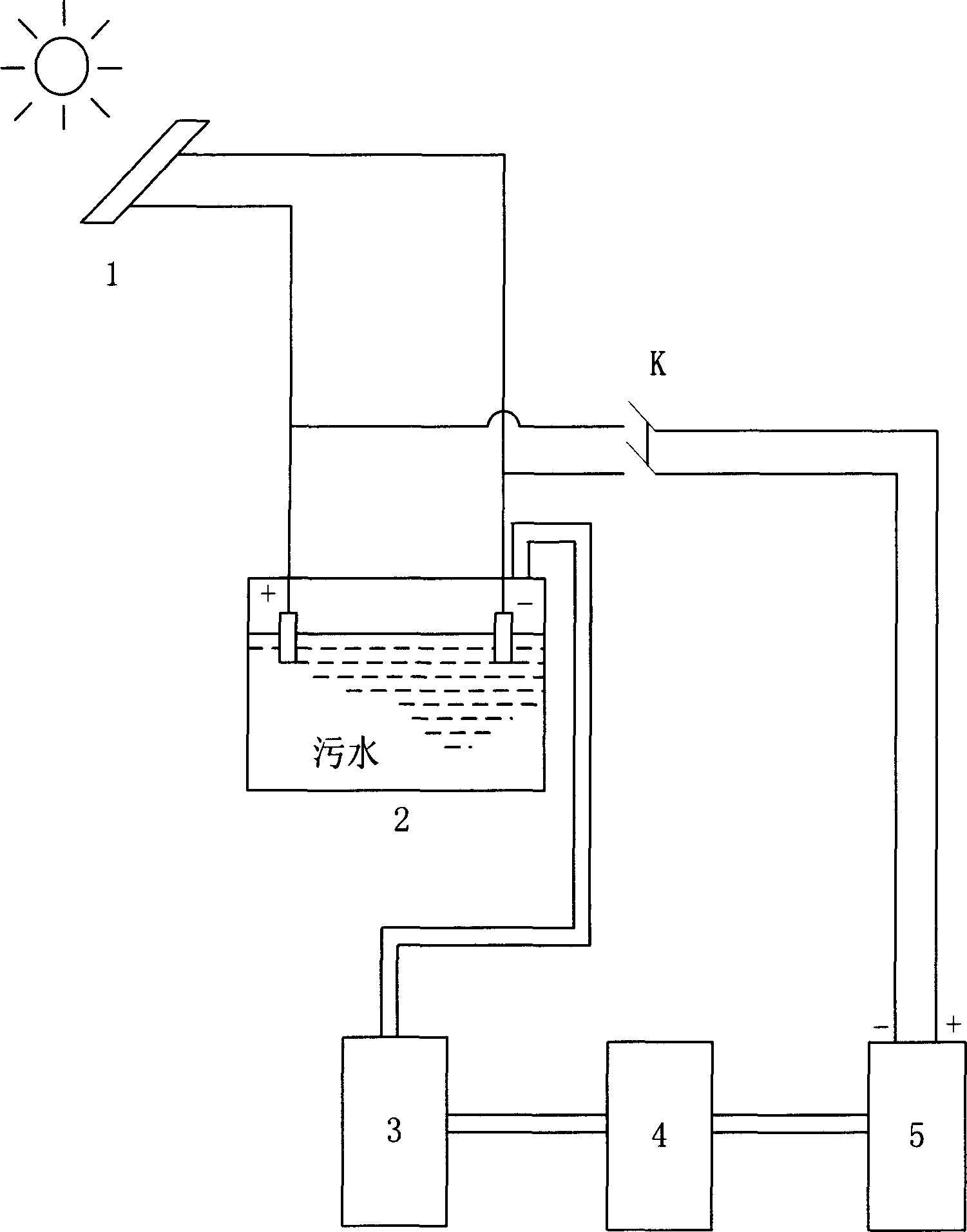

Sewage treatment system for regenerative resource power supply

InactiveCN1778699ASave electricityImprove matchElectrolysis componentsEnergy inputElectrolysisElectrical battery

A sewage treating system for power supply by re-generative resources consists of electrolytic sewage sewage-treating tank with at least solar cell, hydrogen purifier, hydrogen storage tank and fuel battery set. The top outlet of cathode cavity of electrolytic sewage-treating tank is communicated with hydrogen purifier and hydrogen storage tank by pipeline, then connected with fuel inlet of fuel battery set, and the said electrode of electrolytic sewage-treating tank is communicated with paralleled solar cell and fuel battery set. It can be used to supply power by solar energy, collect and purify the generated hydrogen as resources of fuel battery set and convert hydrogen energy into electric energy. It has electric power saving and no environmental pollution.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

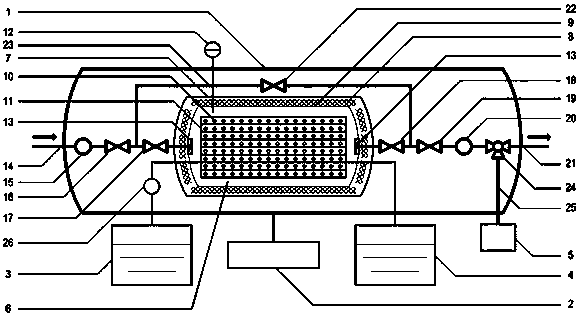

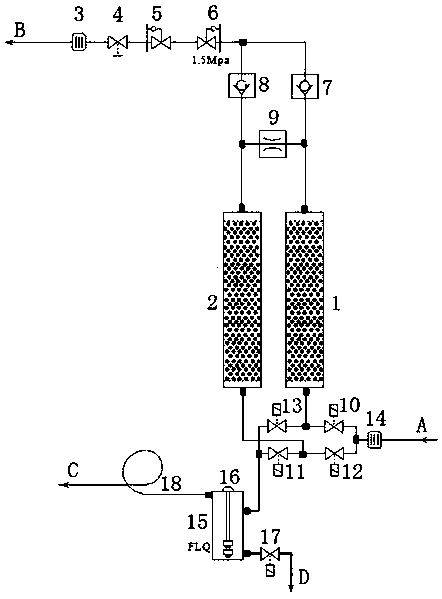

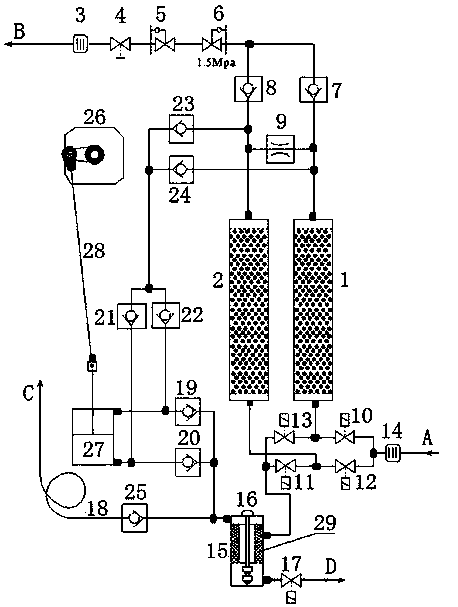

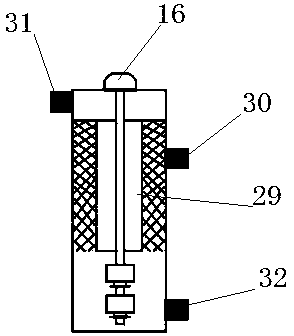

Internal circulation pressure swing adsorption hydrogen purifier

PendingCN107930344AReduce contentImprove utilization efficiencyDispersed particle separationFlame arresterSorbent

The invention provides an internal circulation pressure swing adsorption hydrogen purifier. The internal circulation pressure swing adsorption hydrogen purifier mainly consists of a first adsorption purifying cylinder, a second adsorption purifying cylinder, a gas-water separator, a piston cylinder, a connecting rod driver, a push and pull connecting rod, a throttle valve, an electromagnetic intercepting valve, a ventilation one-way valve, a back pressure valve, a back-fire relief valve and the like, wherein the first adsorption purifying cylinder and the second adsorption purifying cylinder are arranged internally side by side and are filled with an adsorbent. A large-flow internal circulation process accompanied by micro discharge is adopted, and gas purification is realized by changinga gas purification process. Compared with an existing purifier, the purity of purified gas is constant, and the consumption of high purity gas for regeneration is only 4 percent of the existing products. The energy consumption is 3.6 percent of the existing products. The defects of the existing traditional equipment are changed: the consumption of high purity hydrogen gas is high, the production amount of waste hydrogen gas is large and the like. By adopting the internal circulation pressure swing adsorption hydrogen purifier, the production amount of the waste hydrogen gas is reduced, and internal circular use of the high purity hydrogen gas is realized.

Owner:SHANDONG SAIKESAISI HYDROGEN ENERGY

Separation membrane, hydrogen separation membrane including the separation membrane, and hydrogen purifier including the hydrogen separation membrane

ActiveUS20130206002A1Improve Oxidation StabilitySuppress hydrogen embrittlement fracturesSemi-permeable membranesMembranesHydrogenAlloy

Owner:SAMSUNG ELECTRONICS CO LTD

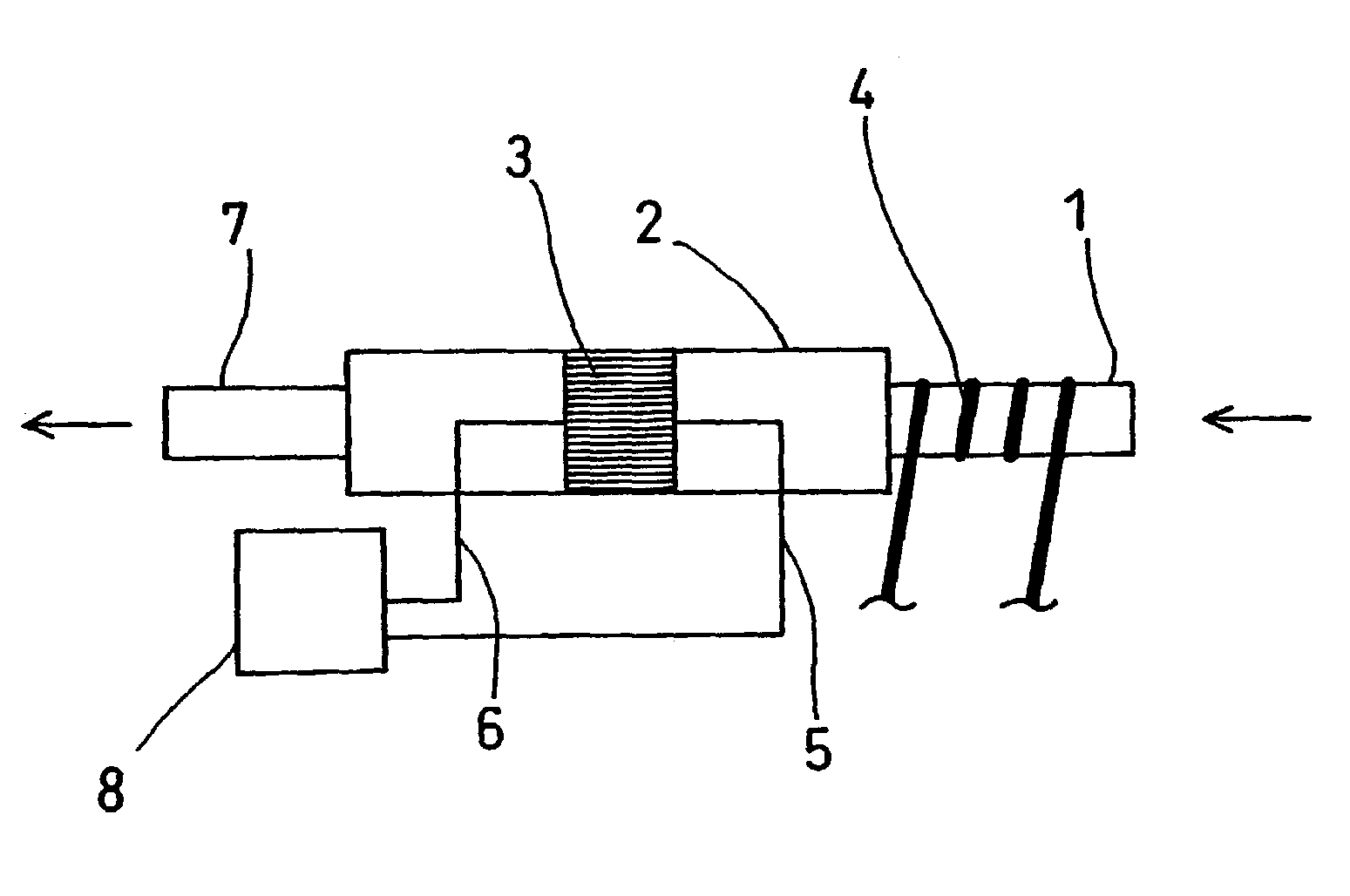

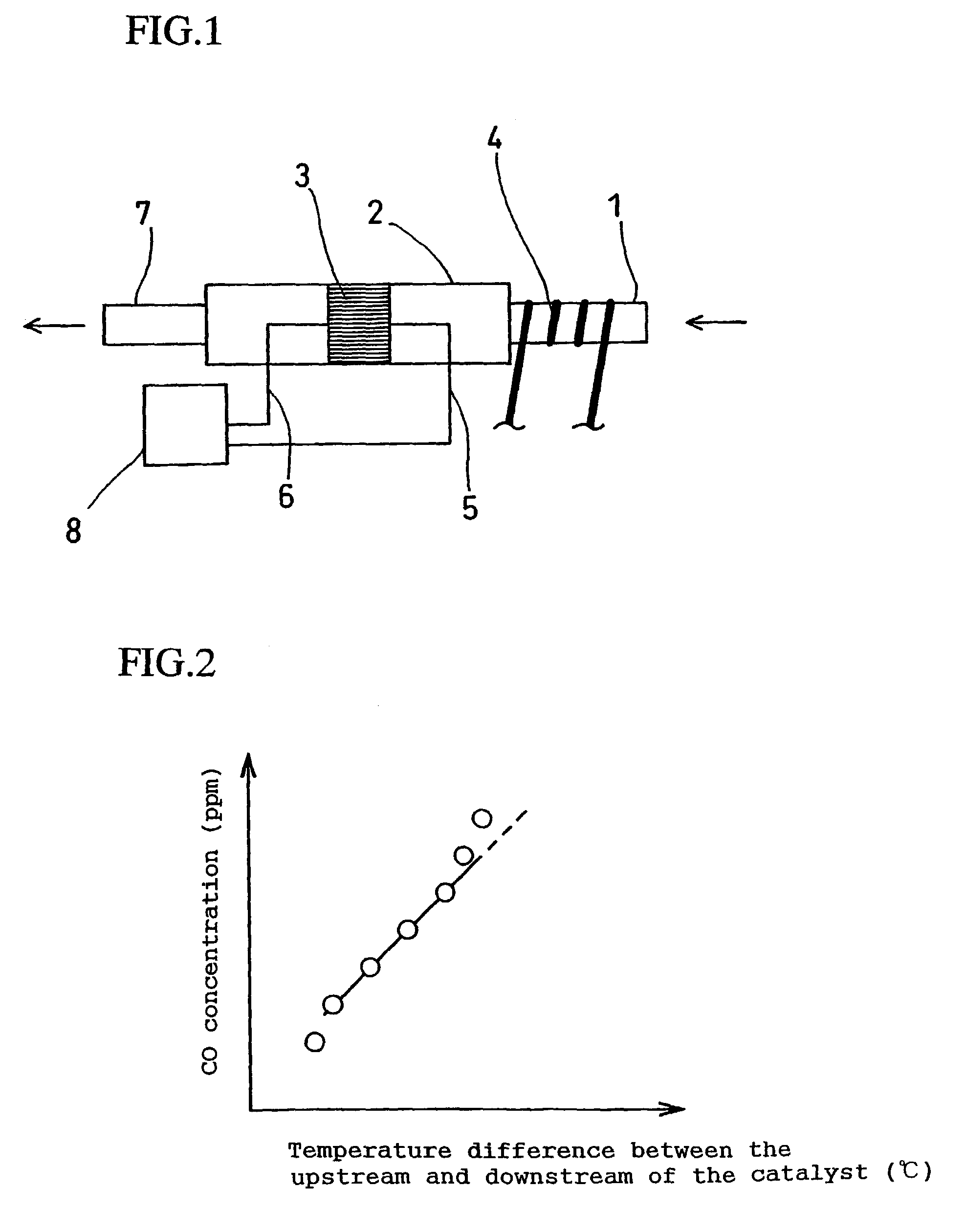

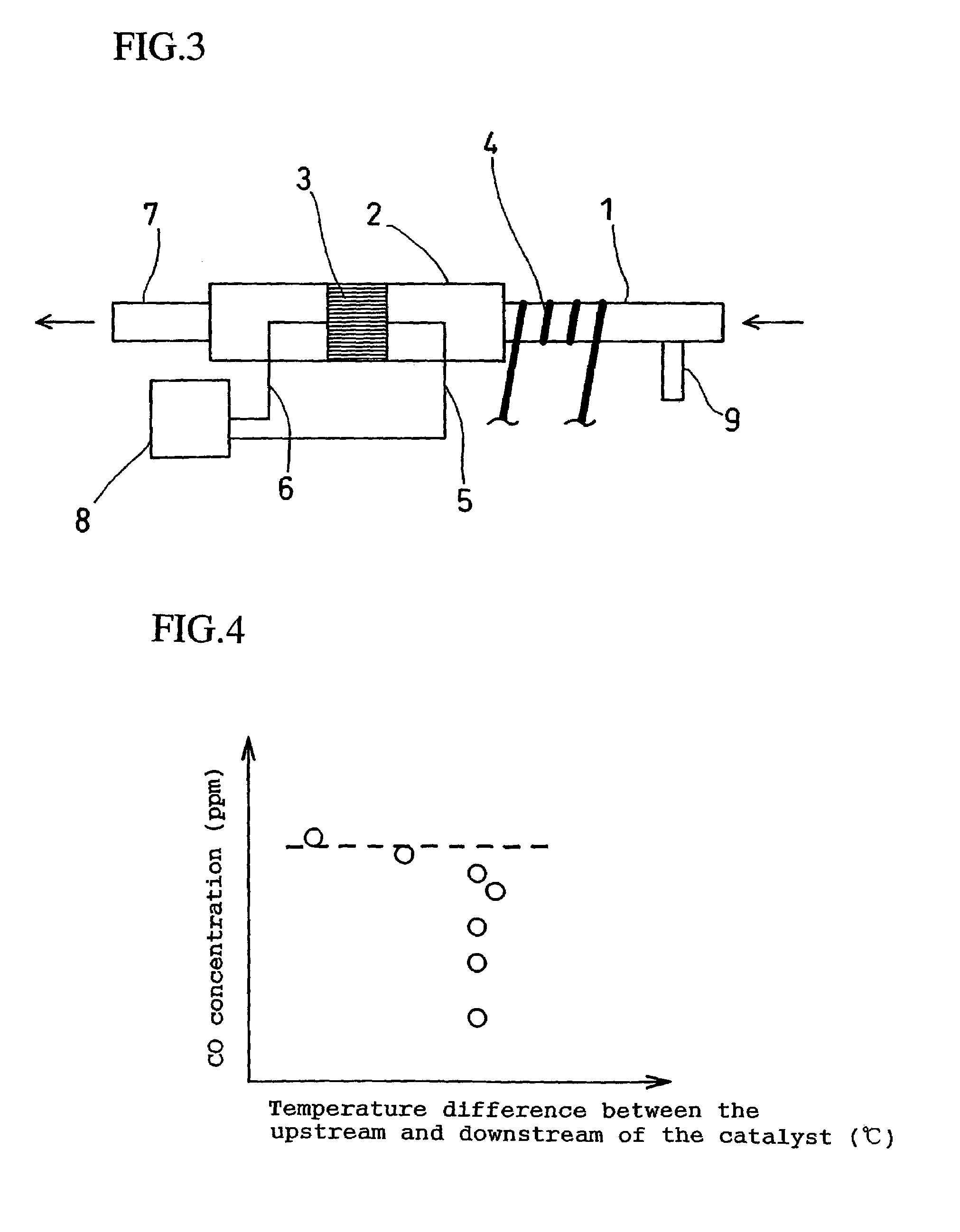

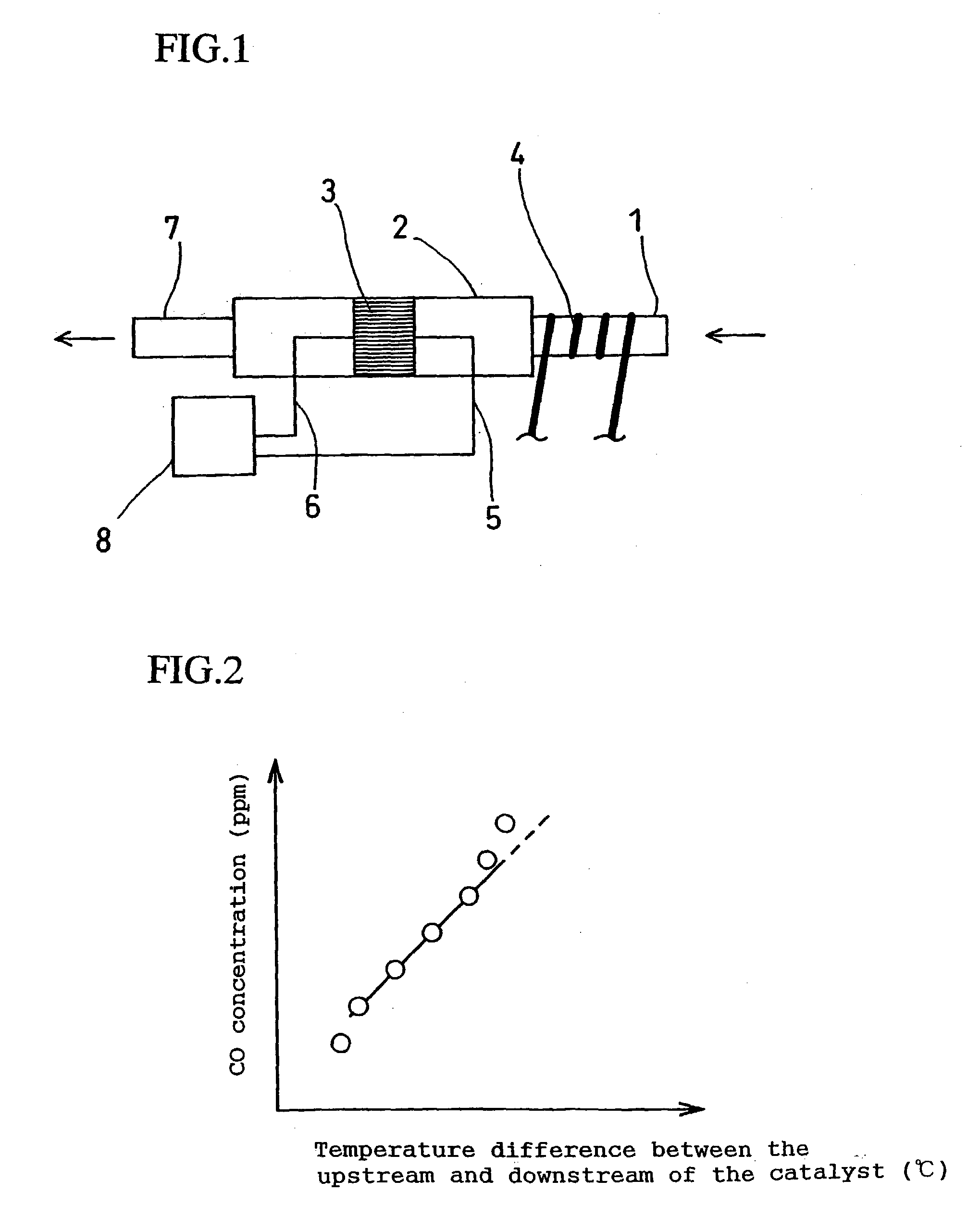

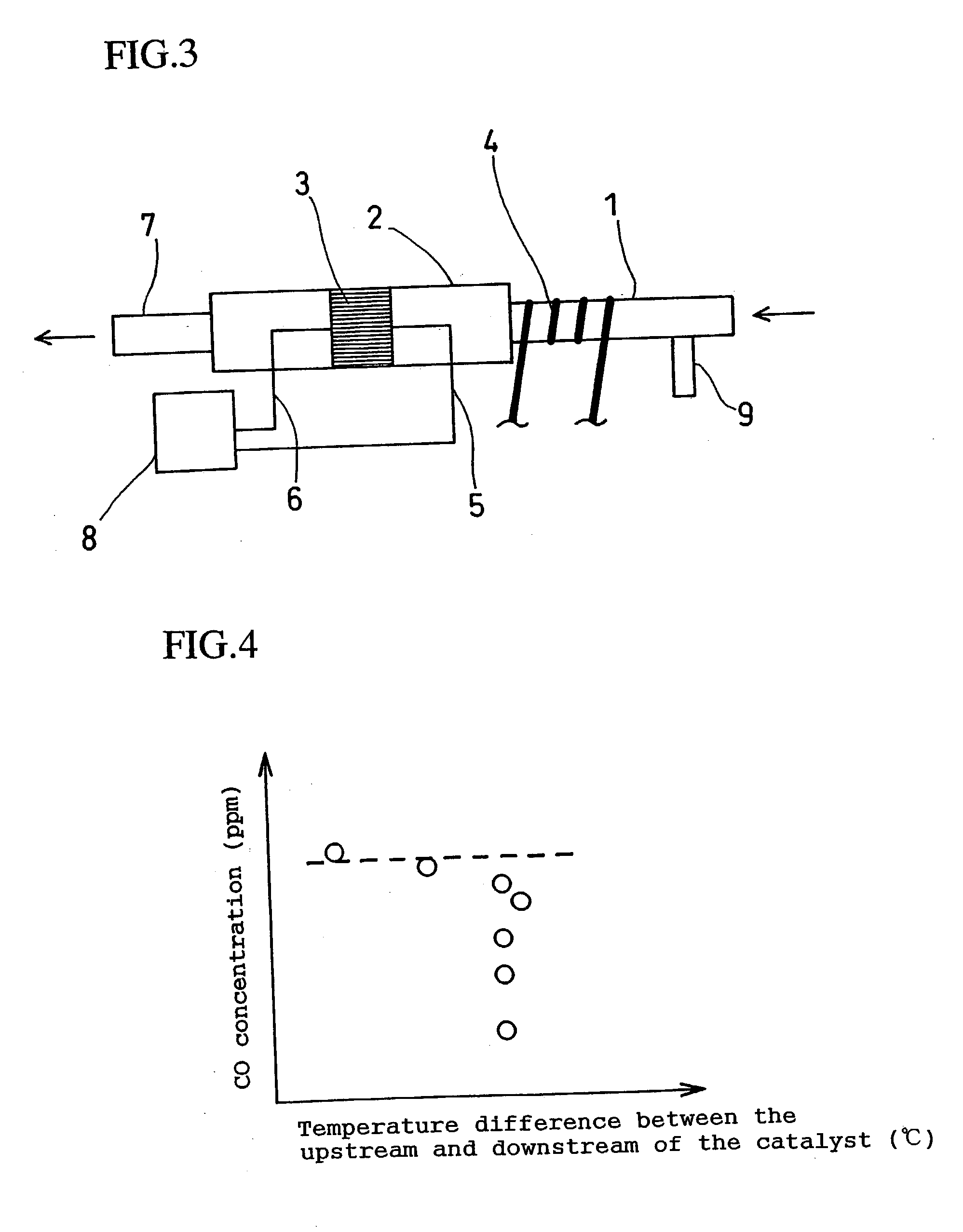

Gas concentration sensor, hydrogen purification unit using this and fuel cell system

InactiveUS7357015B2Analysing fluids using sonic/ultrasonic/infrasonic wavesFuel cell auxillariesHydrogenFuel cells

In order to provide a step capable of reliably detecting a CO concentration in a reformed gas at low cost and a hydrogen purifier capable of fully exerting a function of a CO purifying catalyst, a gas concentration detector comprising a reaction chamber which has a catalyst layer and a gas temperature detector and capable of detecting the concentration of carbon monoxide in the gas by means of a signal of the temperature detector referring to a reformed gas passing along through the reaction chamber.

Owner:PANASONIC CORP

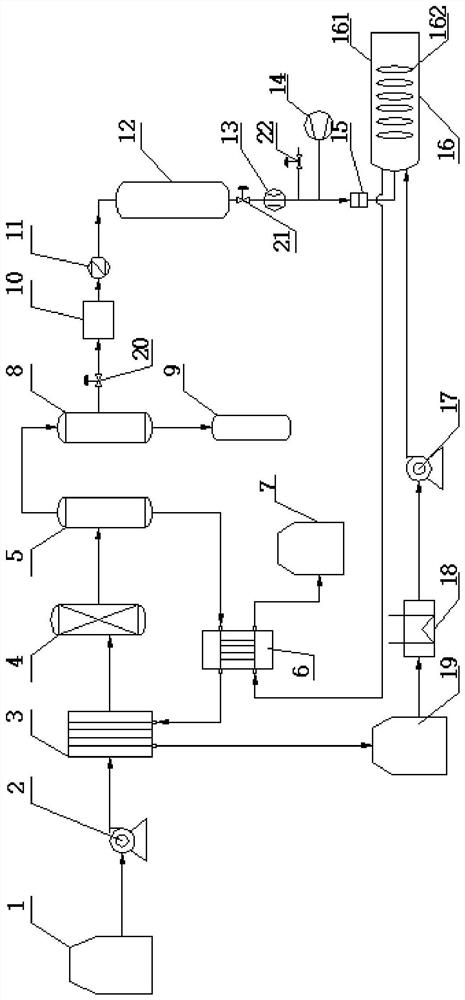

Liquid hydrogen production line

PendingCN108534462AIncrease productivityReduce consumptionSolidificationLiquefactionAir preheaterProduction line

The invention discloses a liquid hydrogen production line comprising a hydrogen intensively-containing grid charging workshop, a hydrogen processing workshop and a liquid hydrogen storing workshop. Ahydrogen purifier, a hydrogen filter, a first heat exchanger group, a second heat exchanger group, a circulating hydrogen low-pressure compressor, a circulating hydrogen high-pressure compressor, a circulating hydrogen purifier, a circulating hydrogen filter, a first circulating hydrogen expansion unit, a second circulating hydrogen expansion unit, a nitrogen compressor, a liquid nitrogen air preheater, a liquid hydrogen storage tank, an ice maker system, a cold box vacuum system, a diffusing device and an electric heater are arranged in the hydrogen processing workshop. A liquid hydrogen pump, a liquid hydrogen storage tank, a liquid hydrogen truck-loading arm, a liquid hydrogen tank box, a BOGC compressor and a BOG air pre-heater are arranged in the liquid hydrogen storage workshop. Theliquid hydrogen production line is high in production efficiency and low in production cost.

Owner:ZHANGJIAGANG RES INST OF HYDROGEN ENERGY CO LTD

Hydrogen purifier module and method for forming the same

ActiveUS8110022B2Improve sealingLimiting the fabrication temperature required to form the sealsDispersed particle filtrationPretreated surfacesHydrogenAlloy

A hydrogen purifier utilizing a hydrogen permeable membrane, and a gas-tight seal, where the seal is uses a low temperature melting point metal, which upon heating above the melting point subsequently forms a seal alloy with adjacent metals, where the alloy has a melting point above the operational temperature of the purifier. The purifier further is constructed such that a degree of isolation exists between the metal that melts to form the seal and the active area of the purifier membrane, so that the active area of the purifier membrane is not corrupted. A method of forming a hydrogen purifier utilizing a hydrogen permeable membrane with a seal of the same type is also disclosed.

Owner:JIANGSU QINGNENG NEW ENERGY TECHNOLOGIES CO LTD +1

Gas concentration sensor, hydrogen purification unit using this and fuel cell system

InactiveUS20030129463A1Temperature controlAnalysing fluids using sonic/ultrasonic/infrasonic wavesFuel cell auxillariesFuel cellsHydrogen

In order to provide a step capable of reliably detecting a CO concentration in a reformed gas at low cost and a hydrogen purifier capable of fully exerting a function of a CO purifying catalyst, a gas concentration detector comprising a reaction chamber which has a catalyst layer and a gas temperature detector and capable of detecting the concentration of carbon monoxide in the gas by means of a signal of the temperature detector referring to a reformed gas passing along through the reaction chamber.

Owner:PANASONIC CORP

Heat self-recycled offshore alloy hydrogen storage and hydrogen supply system and method

ActiveCN111536418AImprove work efficiencyHigh hydrogen storage densityVessel mounting detailsWaterborne vesselsVapor–liquid separatorOrganic liquids

The invention relates to the technical field of hydrogen energy, in particular to a heat self-recycled offshore alloy hydrogen storage and hydrogen supply system and method. The supply system comprises an organic liquid storage tank, wherein a discharge port of the organic liquid storage tank is connected with a feed port of a preheater through a liquid conveying pipeline, and a discharge port ofthe preheater is connected with a feed port of a dehydrogenation reactor through a liquid conveying pipeline; and a discharge port of the dehydrogenation reactor is connected with a feed port of a gas-liquid separator, a gas outlet at the upper part of the gas-liquid separator is connected with a hydrogen purifier gas inlet through a gas transmission pipe, and a discharge port at the lower part ofthe gas-liquid separator is connected with a feed port of a heat exchanger through a liquid conveying pipeline. The supply method comprises the steps of preparing work, starting a circulating coolingunit, filling hydrogen and closing the supply system. According to the supply system and method, an underwater vehicle can be prevented from frequently returning to a specific port base for hydrogensupply, and the working efficiency of the underwater vehicle is improved.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

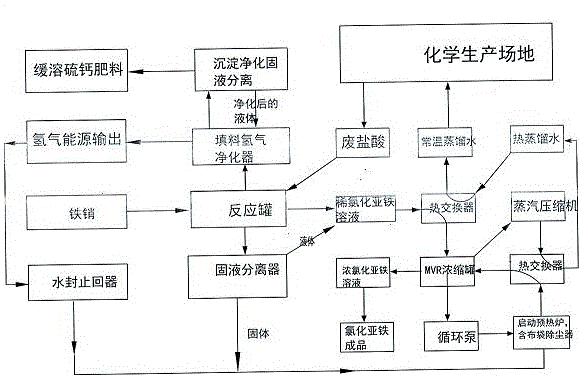

Technology for comprehensive utilization treatment of chemical plant waste hydrochloric acid and special MVR evaporation concentrator thereof

InactiveCN106241887AWill not be easily dischargedLow costChemical industrySulfur compoundsEvaporationHydrogen purifier

The invention relates to a technology for comprehensive utilization treatment of chemical plant waste hydrochloric acid and a special MVR evaporation concentrator thereof; the technology for comprehensive utilization treatment of the chemical plant waste hydrochloric acid comprises the following steps: allowing chemical produced waste hydrochloric acid to enter a reaction tank placed with iron scraps, and carrying out a reaction of the hydrochloric acid and iron to generate ferrous chloride and hydrogen gas, wherein the specific reaction is as follows: 2HCL+Fe->FeCL2+H2 (gas); and after treating the hydrogen gas by a packing hydrogen gas purifier, outputting and sending the treated hydrogen gas as a hydrogen gas energy source to a preheating furnace to be used as fuel for making up loss of equipment heat. The useless hydrochloric acid is treated, the economic benefits are obtained in the treatment process, and the by-products hydrogen gas and carbon powder are used as energy supplement during equipment operation.

Owner:SHANDONG HAOBANG ENVIRONMENTAL PROTECTION TECH

Small-sized hydrogen methane fuel gas generation device for residents in villages and towns and using method

InactiveCN102876410AStart fastGuaranteed uptimeGas production bioreactorsGaseous fuelsProcess engineeringEngineering

The invention relates to a small-sized hydrogen methane fuel gas generation device for residents in villages and towns, wherein a garbage crushing and conveying device is connected with a feed port of a hydrogen methane generator through a packing auger; the crushed garbage is subjected to anaerobic fermentation in the hydrogen methane generator; a one-way openable valve of an anaerobic methane generation chamber is arranged between an anaerobic hydrogen generation chamber and the anaerobic methane generation chamber; the gas outlet end of a nanoceramic coating rolling shaft which runs through the center of the hydrogen methane generator is connected with a hydrogen purifier and a methane purifier respectively; purified hydrogen and purified methane are controlled by a gas mixing valve to be mixed and then are conveyed to a hydrogen storage tank; the hydrogen methane generator is arranged on a pedestal; a gravity lifting device is arranged between the pedestal and the hydrogen methane generator; a 360-degree rotatable universal wheel is arranged at the lower part of the pedestal; and brackets are arranged on two sides of the pedestal and are respectively used for fixing the packing auger, the hydrogen purifier and the methane purifier. The invention further provides a method for preparing hydrogen methane fuel gas by using the hydrogen methane generation device.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Hydrogen liquefaction system with hydrogen element detection function

PendingCN108679929AImprove liquefaction efficiencyLow investment costSolidificationLiquefactionLiquid hydrogenGaseous hydrogen

The invention discloses a hydrogen liquefaction system with a hydrogen element detection function. An outlet of a gaseous hydrogen source communicates with an inlet of a heat exchanger through a hydrogen purifier. An outlet of the heat exchanger communicates with an inlet of an absorber. An outlet of the absorber communicates with an inlet of a first hydrogen ortho-para conversion reactor. An outlet of the first hydrogen ortho-para conversion reactor communicates with an inlet of a hydrogen cooling circulation system. An outlet of the hydrogen cooling circulation system communicates with an inlet of a second hydrogen ortho-para conversion reactor. An outlet of the second hydrogen ortho-para conversion reactor communicates with an inlet of a liquid hydrogen filling and delivery unit. The inlet of the heat exchanger, the outlet of the absorber, the outlet of the second hydrogen ortho-para conversion reactor and the liquid hydrogen filling and delivery unit are all connected with a hydrogen element detection and analysis module. The hydrogen liquefaction system with the hydrogen element detection function has the advantages that the liquid liquefaction efficiency is high, the investment cost is low, and the quality of liquid hydrogen is good.

Owner:ZHANGJIAGANG RES INST OF HYDROGEN ENERGY CO LTD

A hydrogen replenishment system and method for offshore alloy hydrogen storage and hydrogen supply using heat self-circulation

ActiveCN111536418BImprove work efficiencyHigh hydrogen storage densityVessel mounting detailsWaterborne vesselsVapor–liquid separatorOrganic liquids

The invention relates to the technical field of hydrogen energy, in particular to a hydrogen replenishment system and method for offshore alloy hydrogen storage and hydrogen supply using heat self-circulation. The replenishment system of the present invention includes an organic liquid storage tank, the discharge port of the organic liquid storage tank is connected to the feed port of the preheater through the infusion pipeline, and the discharge port of the preheater is connected to the feed port of the dehydrogenation reactor through the transfusion pipeline The outlet of the dehydrogenation reactor is connected to the inlet of the gas-liquid separator, the gas outlet on the upper part of the gas-liquid separator is connected to the inlet of the hydrogen purifier through a gas pipeline, and the outlet on the lower part of the gas-liquid separator is connected through an infusion pipeline The feed port of the heat exchanger; the replenishment method of the present invention includes several steps of preparation work, start-up of the circulating cooling unit, hydrogen filling and closing of the replenishment system. The invention can prevent the underwater vehicle from frequently returning to a specific port base for hydrogen supply, and improves the working efficiency of the underwater vehicle.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com