Methanol to hydrogen machine system with rapid cold boot

A kind of technology of methanol hydrogen production and hydrogen production machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

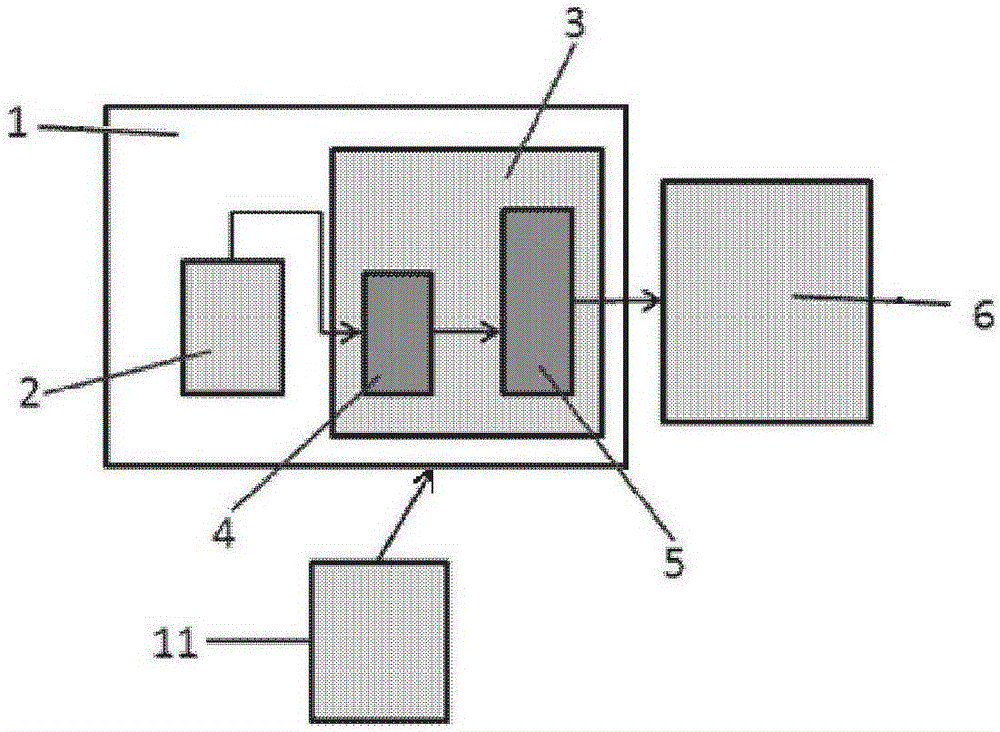

Examples

Embodiment approach

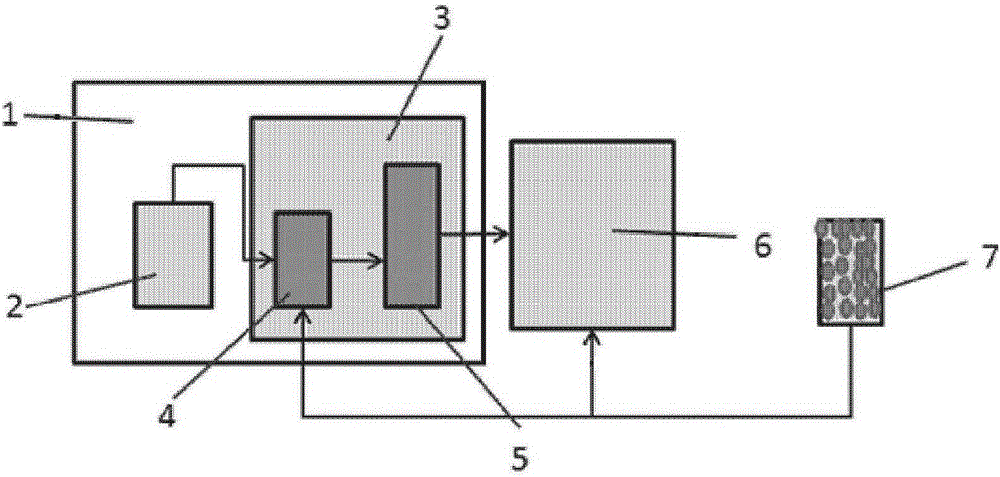

[0043] Preferred option one: if figure 2 As shown, the fast cold start drive unit 11 uses the hydrogen storage material assembly 7 to store hydrogen (pure hydrogen), which is used to heat up the combustion during the cold start of the methanol hydrogen generator system 1 and provide sufficient hydrogen at the initial stage of the client's startup. The hydrogen material components include hydrogen storage materials, high temperature and high pressure resistant shells and hydrogen output valves. Among them, there are many kinds of hydrogen storage materials. According to the storage state of hydrogen, they can be liquid hydrogen storage materials, high-pressure gaseous hydrogen storage materials and solid hydrogen storage materials. The stored hydrogen can be produced by the methanol hydrogen generator according to the present invention, or can also come from other alternative methods (such as high-pressure hydrogen cylinders).

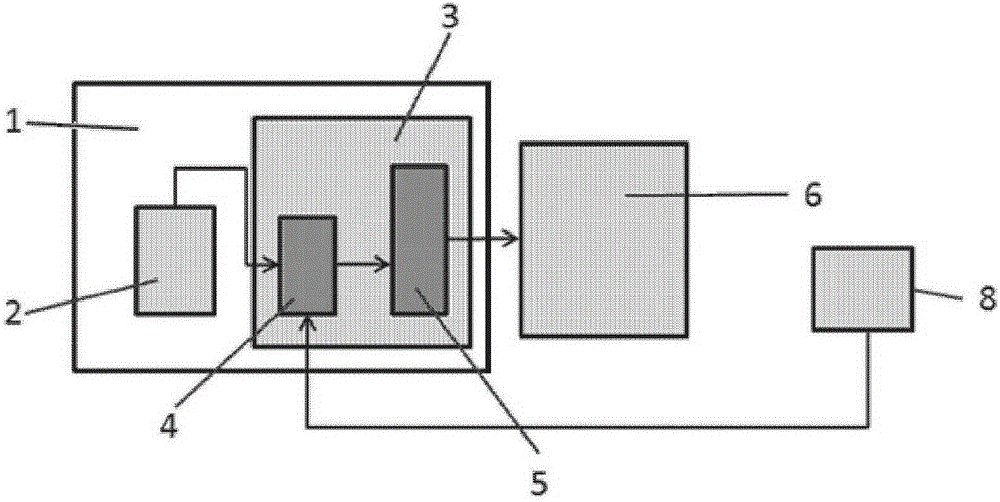

[0044] Preferred option two: if image 3 As sh...

Embodiment 1

[0051] In a preferred embodiment, the metal hydrogen storage material assembly is used as the cold start drive unit. It is calculated that 20.3 mol of hydrogen gas is consumed to meet the heat required by the fuel processor in the methanol hydrogen generator system to increase the temperature from 20°C to 250°C. That is, it needs to consume 40.6g of hydrogen. If the hydrogen flow rate is 1.4g / min for heating, it only takes 30 minutes to heat up to 250°C. If the client is a fuel cell with a stack power of 6kW as an example, from the moment the stack starts up until the methanol hydrogen generator can supply hydrogen, the stack needs to consume 3.1mol / min of hydrogen in terms of full power. A total of 113.3 mol of hydrogen is required from the start-up of the methanol hydrogen generator system until the methanol hydrogen generator can supply hydrogen. In this embodiment, the metal hydride hydrogen storage device HYM-100S / A (purchased from Beijing Haoyun Jinneng Technology Co., L...

Embodiment 2

[0053] In another preferred embodiment, the high-pressure hydrogen cylinder is used as the cold-start driving unit. After calculation and testing, it needs to consume 20.3 mol of hydrogen to meet the heat required by the fuel processor in the methanol hydrogen generator system to raise the temperature from 20°C to 250°C. , that is, it needs to consume 40.6g of hydrogen. If the hydrogen flow rate of 1.4g / min is used for heating, it only takes 30 minutes to heat up to 250°C. If the client is a fuel cell with a stack power of 6kW as an example, from the moment the stack starts up until the methanol hydrogen generator can supply hydrogen, the stack needs to consume 3.1mol / min of hydrogen in terms of full power. A total of 113.3 mol of hydrogen is required from the start-up of the methanol hydrogen generator system until the methanol hydrogen generator can supply hydrogen. Taking hydrogen storage in a hydrogen cylinder compressed to 15MPa as an example, only a container of less tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com