Internal circulation pressure swing adsorption hydrogen purifier

A pressure swing adsorption and internal circulation technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of large consumption and large amount of hydrogen gas produced from waste gas, and achieve the reduction of production amount and the purity of gas extraction. High, short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, the present invention will be further described in detail through examples and accompanying drawings. But these examples are not limitations on the scope of protection of the present invention, and all changes within the scope of the basic idea of the technical solution of the present invention or substantially equivalent to the technical solution of the present invention are within the scope of protection of the present invention.

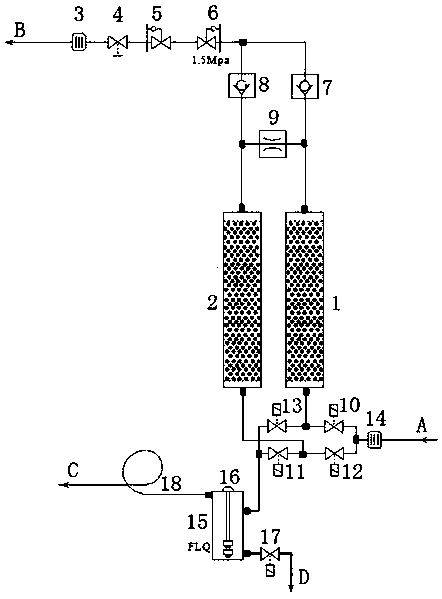

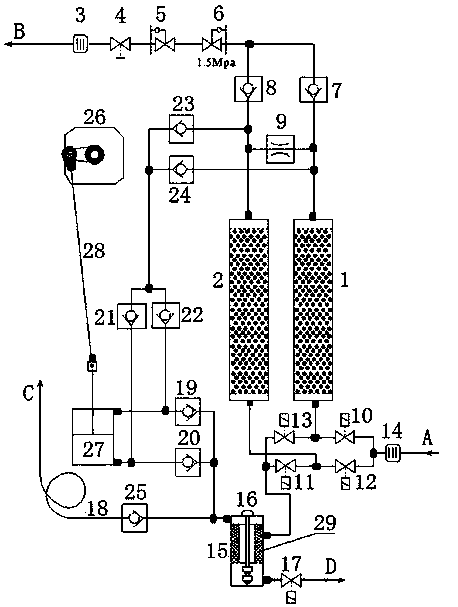

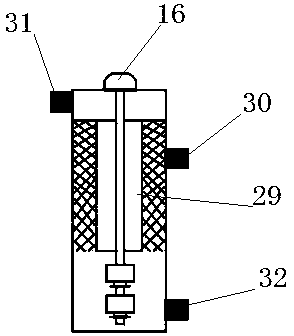

[0031] In order to improve the purity of hydrogen produced by electrolysis of water, that is to reduce the content of water vapor impurities. Utilize the pressure swing adsorption technology of adsorption molecular sieve, through the gas-water separator, realize "adsorption purification" and "desorption regeneration" purification and internal circulation purification, and solve the problem of hydrogen purification. The invention relates to a widely used large-flow gas purification technology of pressure swing adsorption, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com