Patents

Literature

31results about How to "Purity unchanged" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

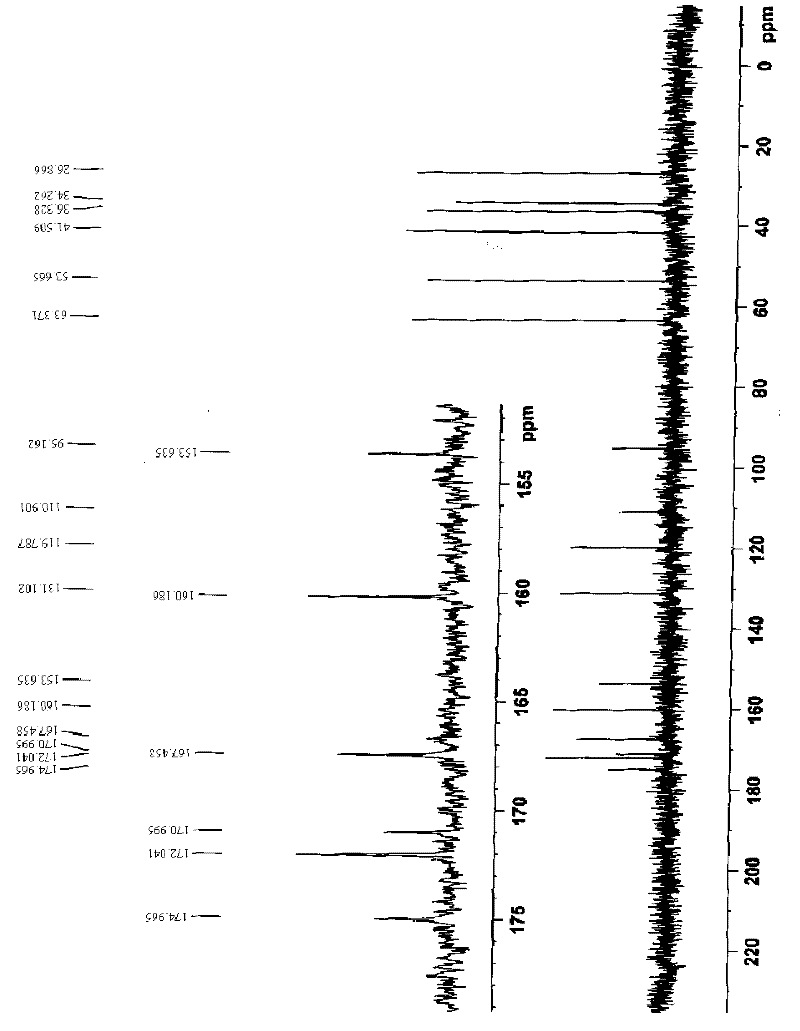

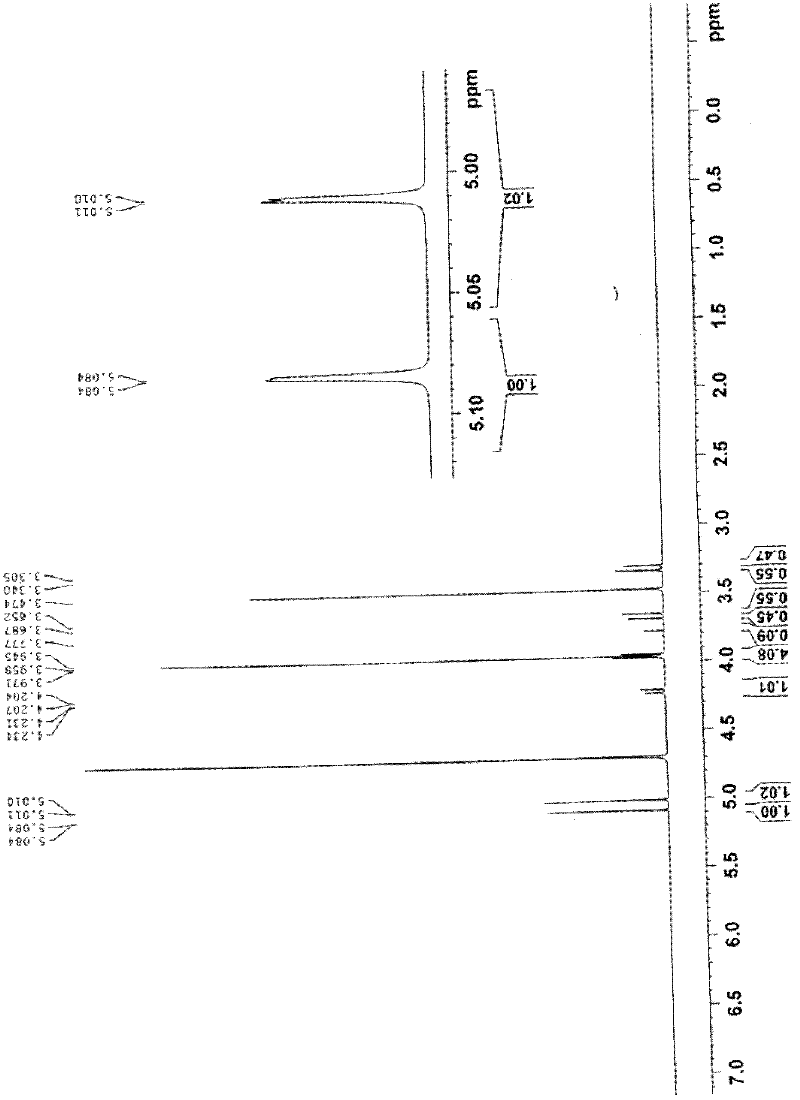

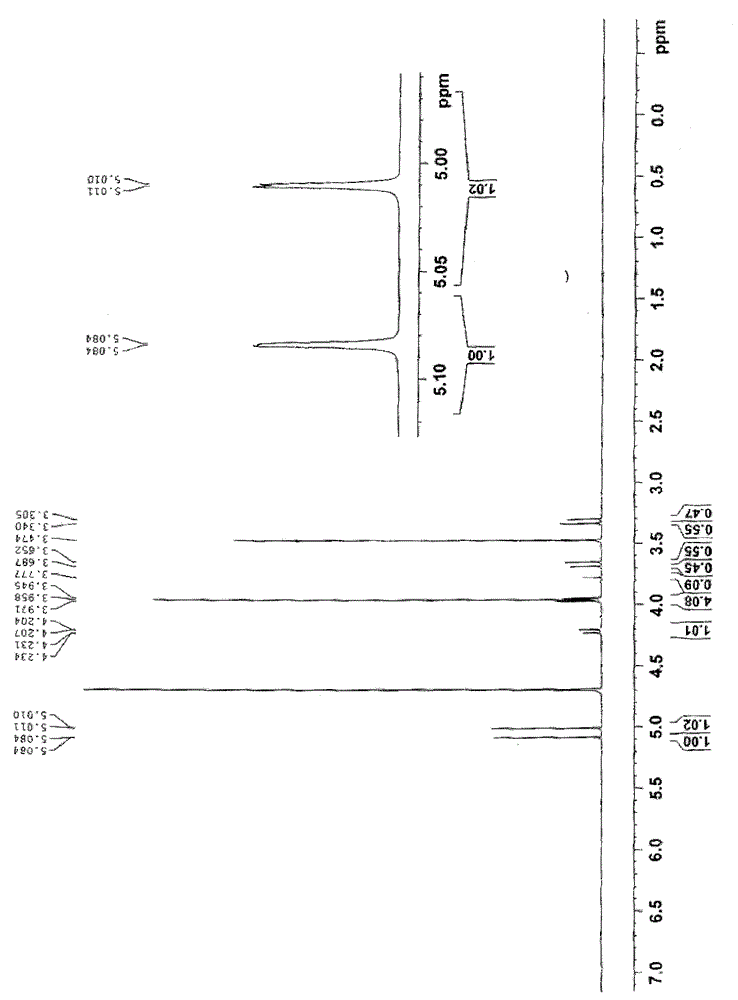

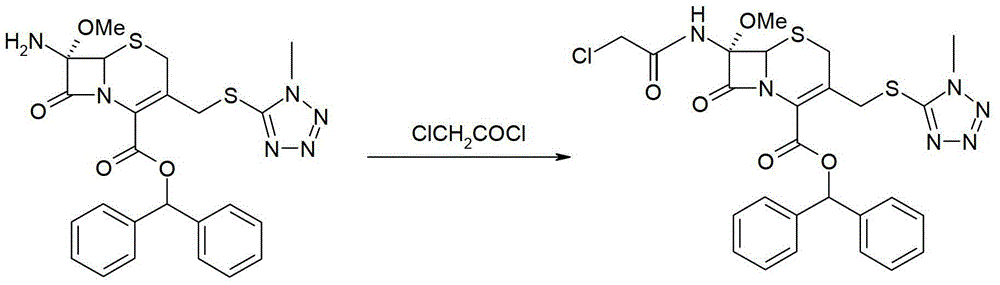

Preparation method of cefotetan

The invention relates to a preparation method of cefotetan. The method comprises the steps of: under an alkaline condition, reacting the starting raw material 7-MAC with chloroacetyl chloride in an organic solvent so as to obtain the intermediate CefoD-1; under nitrogen protection, adding aluminium trichloride into anisole, stirring for dissolving, and leaving the obtained solution for standby application; taking another organic solvent, into which the intermediate CefoD-1 is added under stirring, then adding the standby solution for reacting, thus obtaining the intermediate CefoD-2; reactingthe intermediate CefoD-2 with 3, 5-dithiol-4-isothiazole formic acid trisodium salt until that a sampled cefotetan tautomer is detected less than 4.0%, after the reaction conducting a post-treatment,thus obtaining cefotetan. With improved yield and reduced cost, the method of the invention, without final heating concentration, can generate products with a shallow color and almost invariant purity.

Owner:HAINAN HERUI PHARMA +1

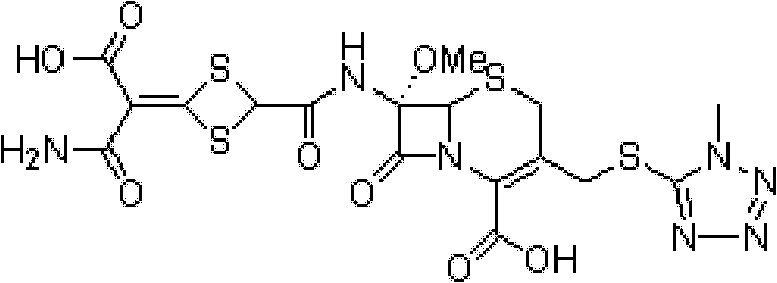

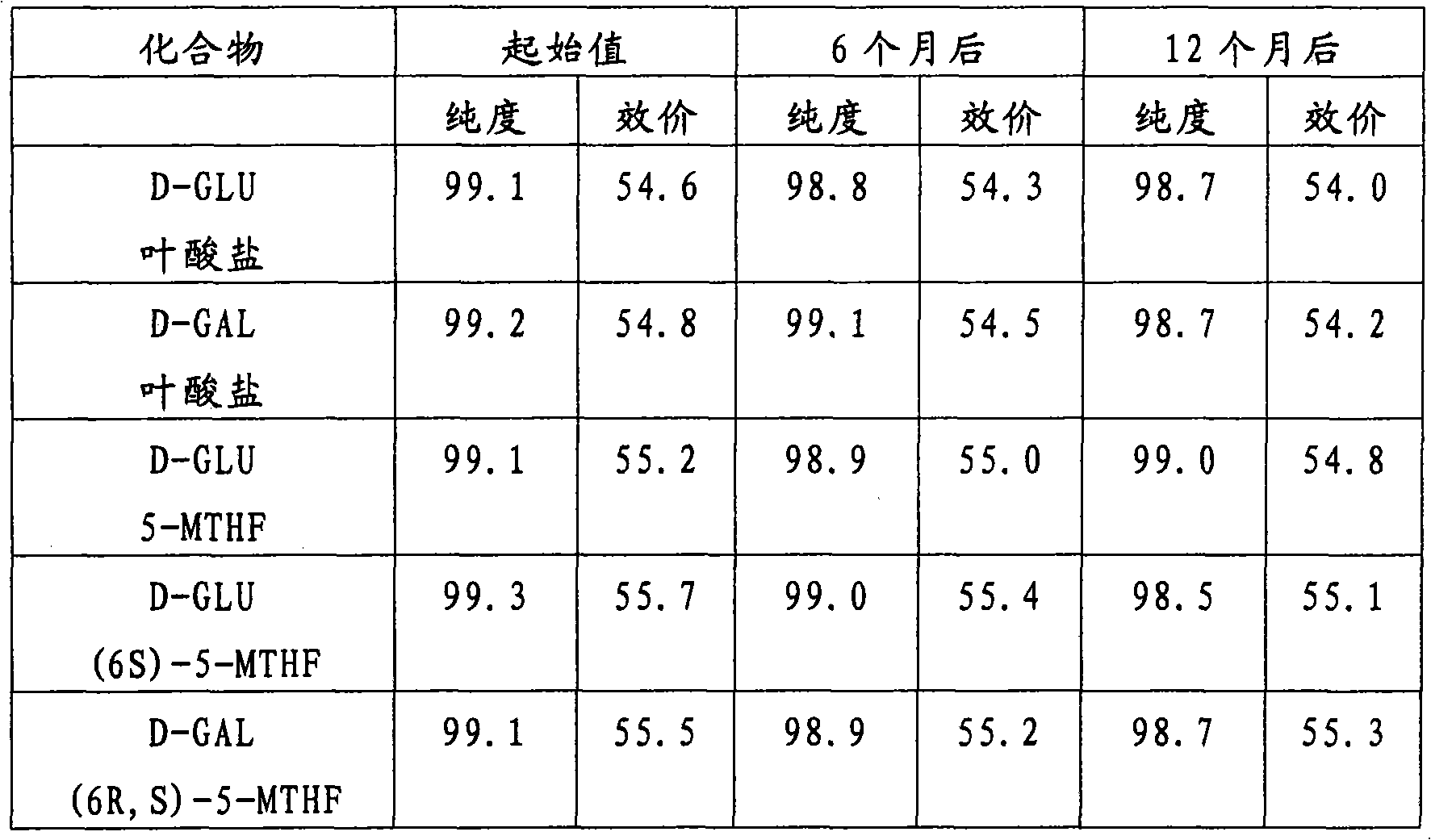

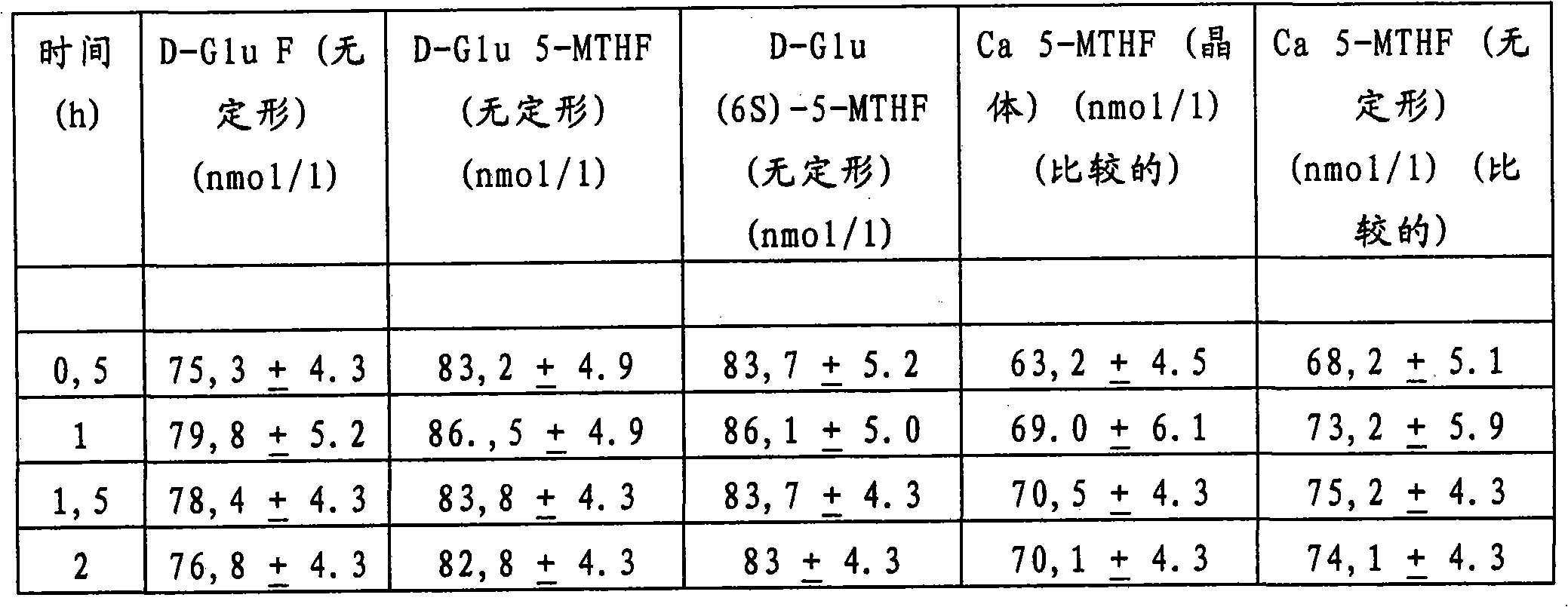

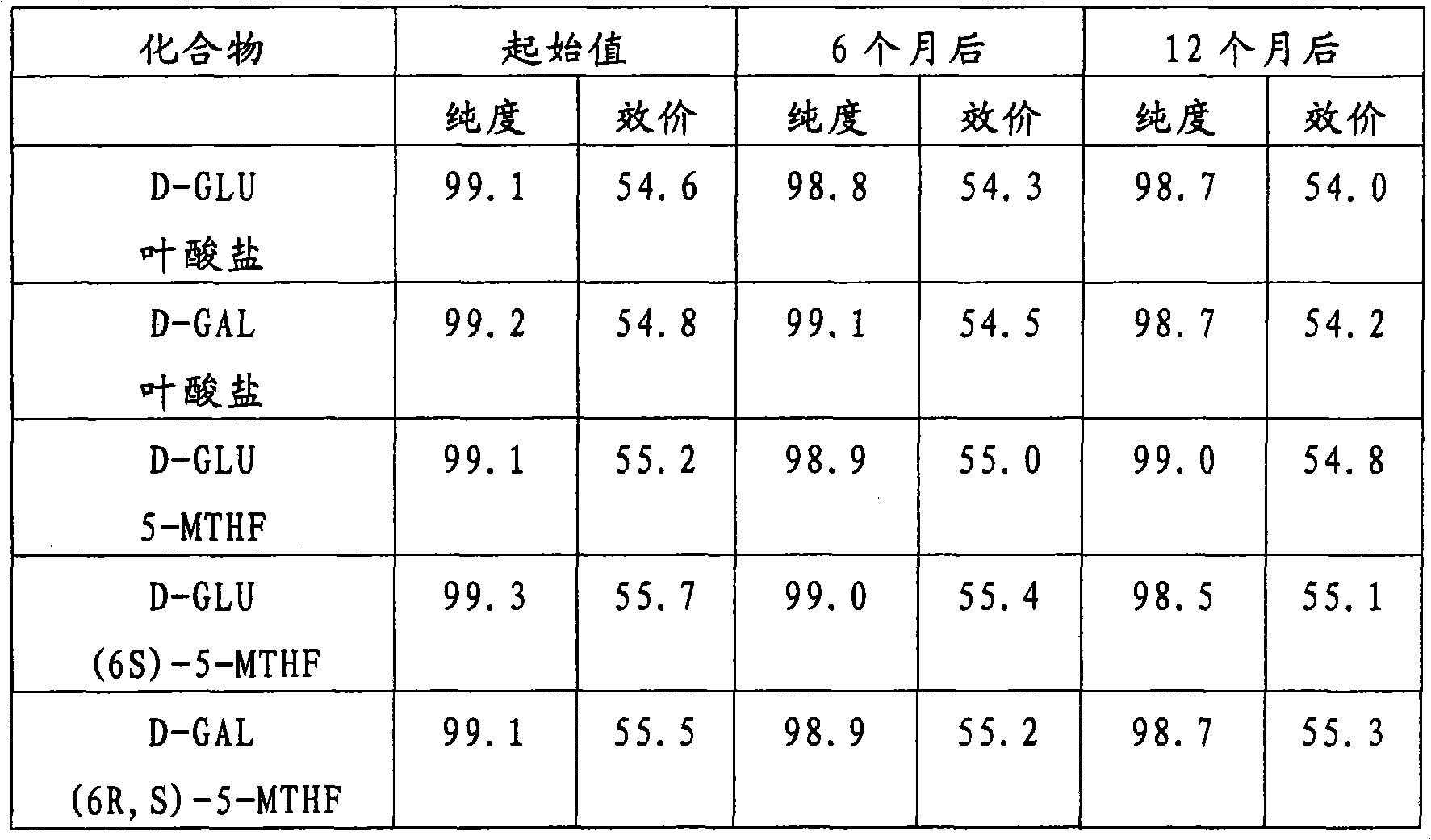

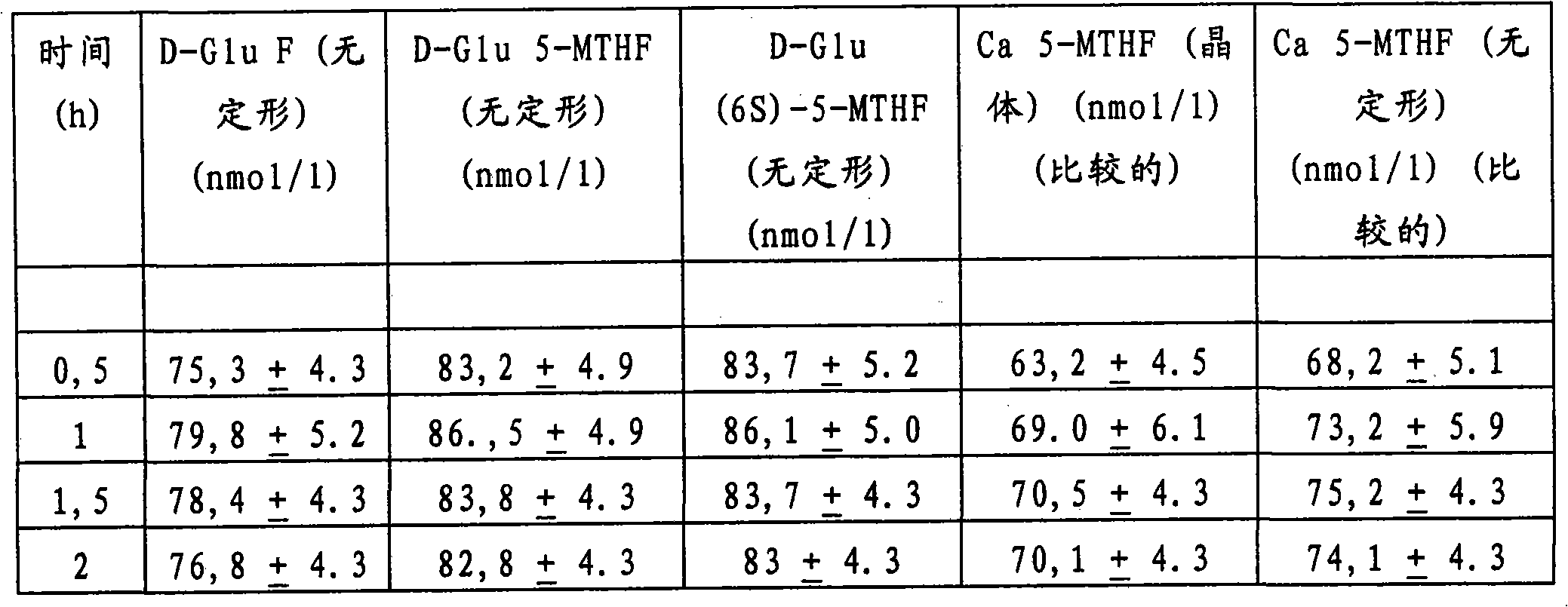

Folates, compositions and uses thereof

ActiveCN101970439AGood water solubilityLong-term chemical stabilityOrganic active ingredientsNervous disorderSolubilityOrganic base

The present invention relates to folates, compositions and uses thereof; In particular, this invention describes a crystalline or amorphous compound which is a substituted or unsubstituted folate or a reduced folate, or the natural or unnatural isomers thereof, of at least one organic base, as well as compositions and uses thereof. The compounds of the invention show a long lasting stability as well as a peculiarly high water-solubility.

Owner:GNOSIS SPA

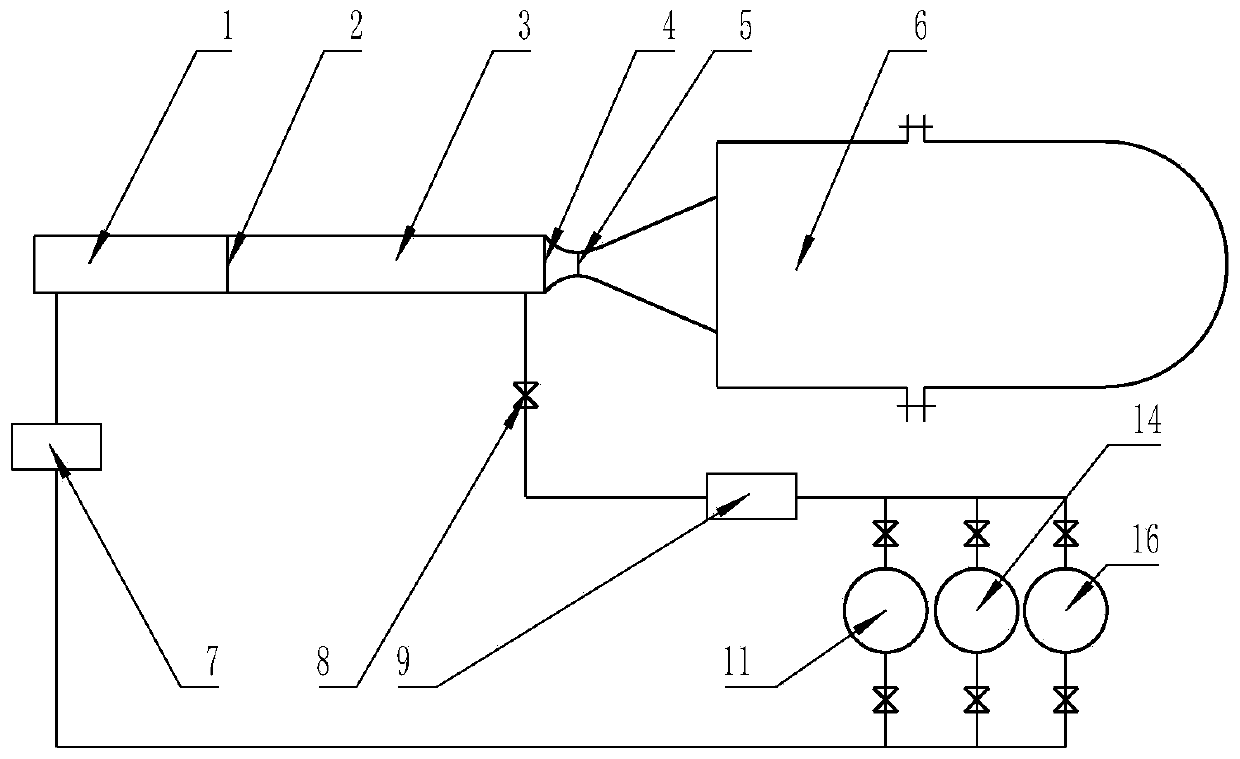

Wind tunnel helium reuse device

The invention discloses a wind tunnel helium reuse device. The device comprises a high pressure section, a membrane I, a low pressure section, a membrane II, a throat valve and a test section, which are sequentially connected along the gas flow direction to form a wind tunnel; the device further comprises a gas flow loop pipeline connected between the high pressure section and a gas storage tankfor flowing from the high pressure section to the gas storage tank and flowing from the gas storage tank to the high pressure section, and an exhaust valve, a low pressure compressor, three groups ofgas storage tanks connected in parallel and a high pressure compressor are sequentially installed on the gas flow loop pipeline in sequence. Helium with different degrees of purity is stored in the gas storage tanks respectively, and the gas storage tank with the similar purity is selected according to the purity of the helium required for the test. The wind tunnel helium reuse device disclosed bythe invention has the advantages of simplicity, high efficiency and low use cost.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

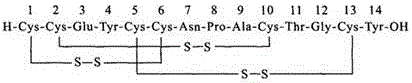

Method for synthesizing linaclotide

InactiveCN105884864APurity unchangedThe cyclization reaction is completePeptide preparation methodsHydroquinone CompoundAmmonium carbonate

The invention discloses a method for synthesizing linaclotide, and relates to the field of medicine synthesis. The method mainly comprises the following steps: improving a linear cyclizing system of linaclotide, cyclizing crude linear peptide by using a ammonium carbonate / DMSO / aqueous solution together with hydroquinone or TCEP so as to obtain a crude linaclotide product, and purifying the crude linaclotide product, thereby obtaining a finished product. By improving the cyclizing system, the yield of linaclotide is increased, the cyclizing time is shortened, the cost of raw materials is lowered, and the method is applicable to industrial production.

Owner:JIANGSU SKYRUN PHARMA CO LTD

De-coloring method of benzoic acid heavy by-product benzyl benzoate

ActiveCN107501098AReduce the color numberImprove solubilityOrganic compound preparationCarboxylic acid esters preparationBenzoic acidThermal insulation

The invention discloses a de-coloring method of benzoic acid heavy by-product benzyl benzoate. The de-coloring method comprises the following steps: 1) producing a benzyl benzoate crude product through reduced-pressure distillation of leftovers from production of benzoic acid through methylbenzene liquid phase air oxidation; 2) adding reactive metal and an acidic solution into the benzyl benzoate crude product for thermal insulation reaction; 3) reducing the temperature to a room temperature after the end of reaction, and filtering and removing the unreacted reactive metal; 4) performing layered treatment on a filtrate to obtain an upper oil layer; and 5) performing reduced-pressure distillation and dehydration on the oil layer, wherein an obtained remaining material is a low-color benzyl benzoate finished product. The de-coloring method disclosed by the invention is advanced in process, convenient to operate and high in yield.

Owner:WUHAN YOUJI IND

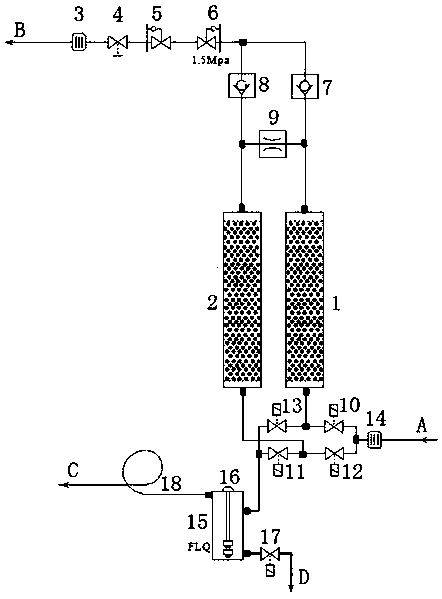

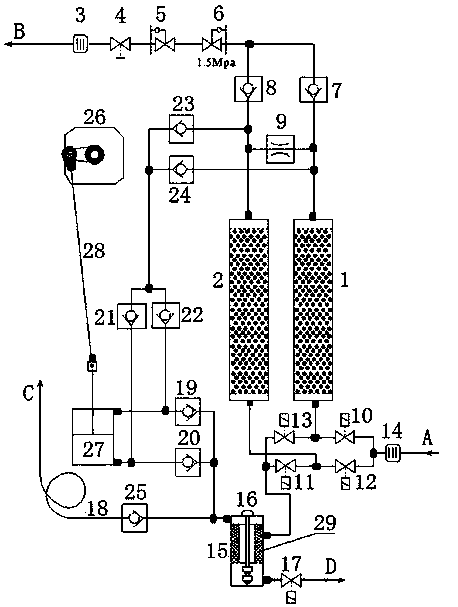

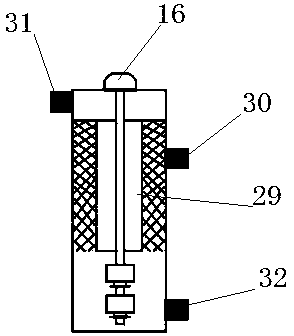

Internal circulation pressure swing adsorption hydrogen purifier

PendingCN107930344AReduce contentImprove utilization efficiencyDispersed particle separationFlame arresterSorbent

The invention provides an internal circulation pressure swing adsorption hydrogen purifier. The internal circulation pressure swing adsorption hydrogen purifier mainly consists of a first adsorption purifying cylinder, a second adsorption purifying cylinder, a gas-water separator, a piston cylinder, a connecting rod driver, a push and pull connecting rod, a throttle valve, an electromagnetic intercepting valve, a ventilation one-way valve, a back pressure valve, a back-fire relief valve and the like, wherein the first adsorption purifying cylinder and the second adsorption purifying cylinder are arranged internally side by side and are filled with an adsorbent. A large-flow internal circulation process accompanied by micro discharge is adopted, and gas purification is realized by changinga gas purification process. Compared with an existing purifier, the purity of purified gas is constant, and the consumption of high purity gas for regeneration is only 4 percent of the existing products. The energy consumption is 3.6 percent of the existing products. The defects of the existing traditional equipment are changed: the consumption of high purity hydrogen gas is high, the production amount of waste hydrogen gas is large and the like. By adopting the internal circulation pressure swing adsorption hydrogen purifier, the production amount of the waste hydrogen gas is reduced, and internal circular use of the high purity hydrogen gas is realized.

Owner:SHANDONG SAIKESAISI HYDROGEN ENERGY

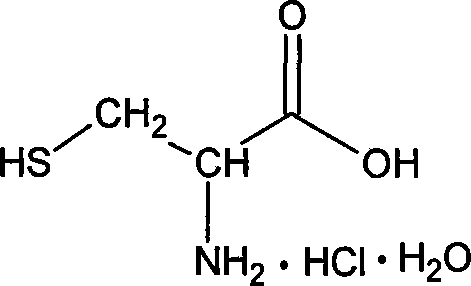

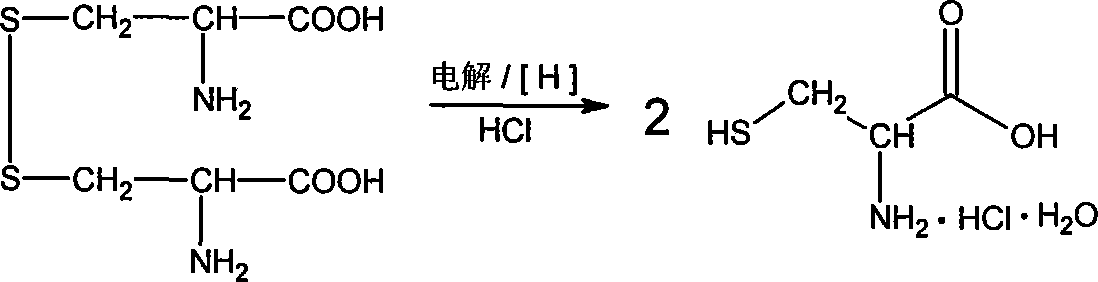

Method for crystallizing L-cysteine muriate high-purity crystal

InactiveCN101074480ACoarse and uniform particle sizeNot easy to mixElectrolysis componentsElectrolytic organic productionImpurityRe crystallization

A method for crystallizing L-beta-mercaptoalanine high-purity crystal is carried out by preparing L-beta-mercaptoalanine cathode electrolytic bath liquid by electrolyzing L-cystine, decompress concentrating for electrolytic bath liquid at 70-80 degree, reaching L-beta-mercaptoalanine equivalent concentration in concentrate to 6-8N, reaching hydrochloric acid equivalent concentration 1.2-2 times of L-beta-mercaptoalanine, agitating at 1-6 degree, lowering temperature to 8-12 degree, laying aside and crystallizing. The crystal grain size is coarse, uniform, transparent, net and diamond, the length is 4-5 mm, and width and thickness are 2-3 mm. It has 5 times re-crystallization and better purity.

Owner:汕头市紫光古汉氨基酸有限公司

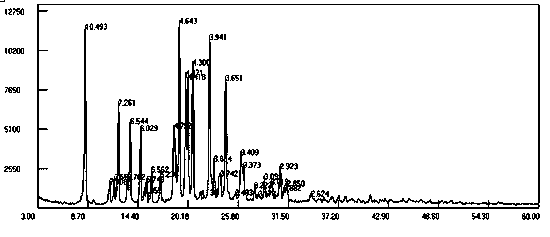

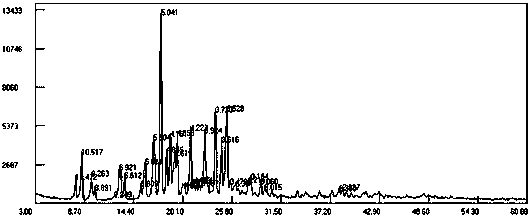

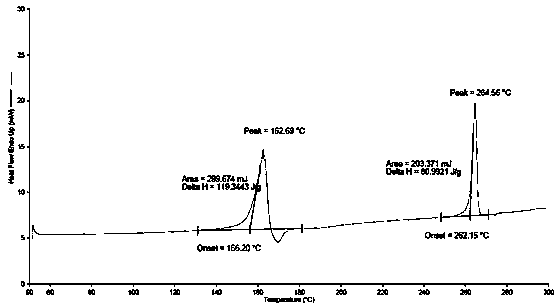

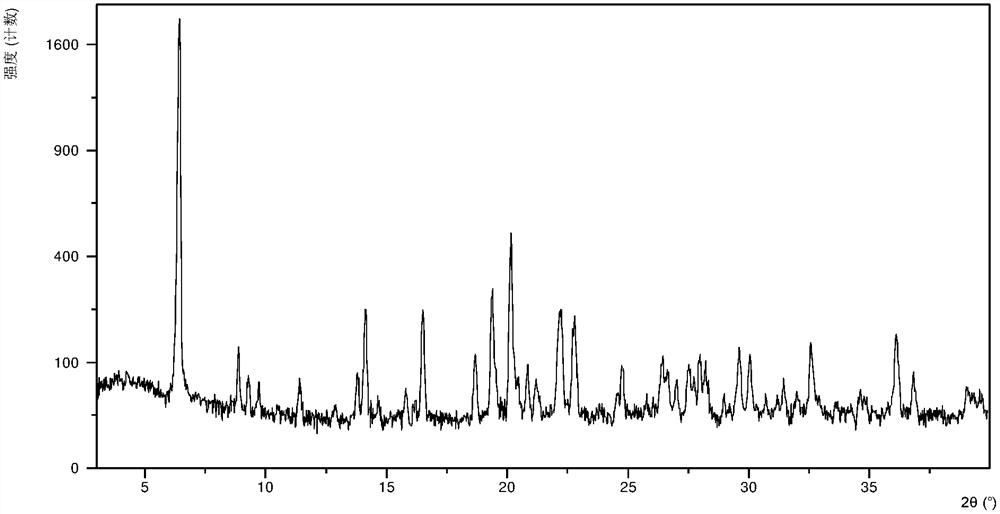

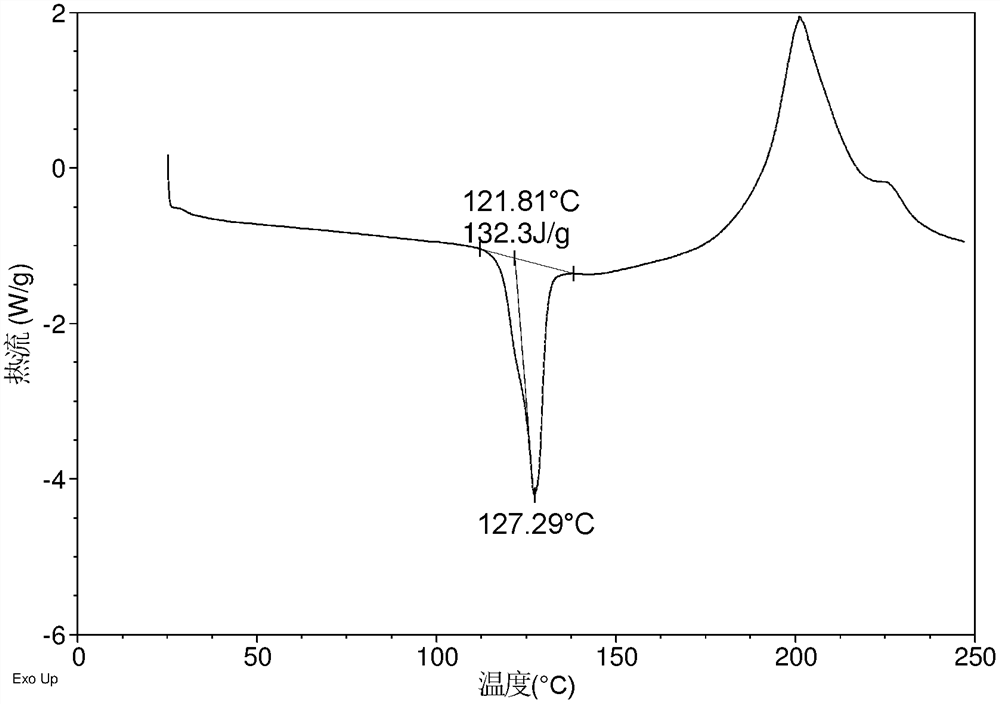

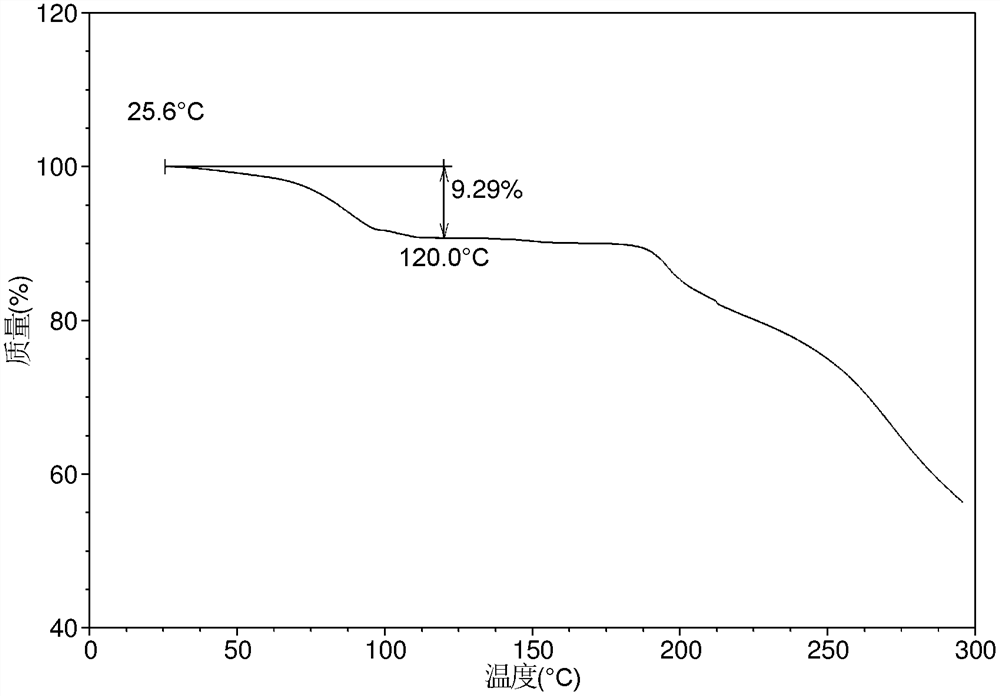

Solvate crystal of 9,9-bis(6-hydroxy naphthalene-2-group) fluorene and preparation thereof

ActiveCN104230671AImprove thermal stabilityHigh bulk densityOrganic compound preparationOrganic chemistry methodsSolventEthyl acetate

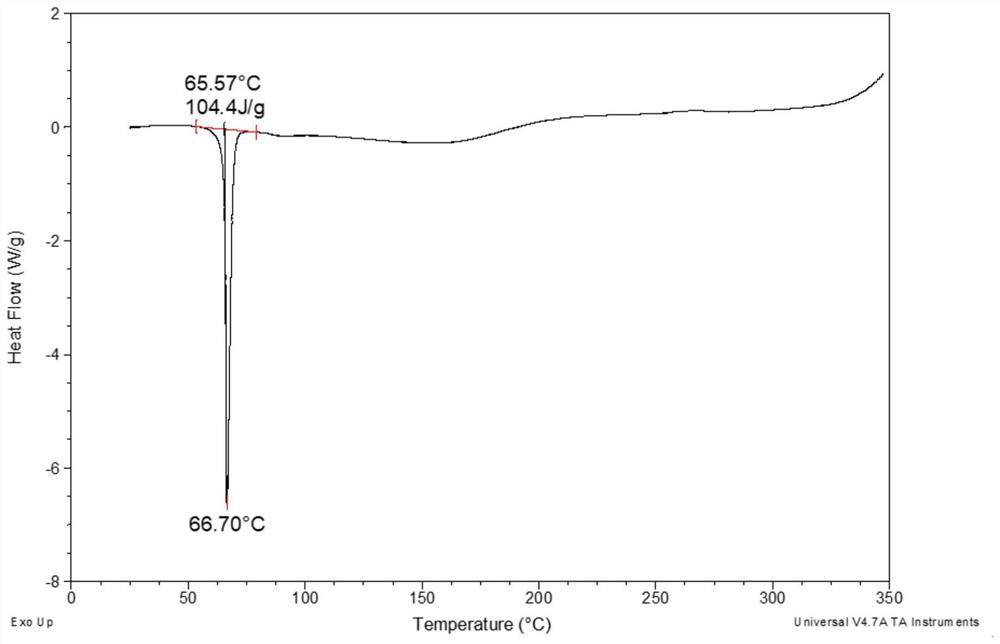

The invention discloses a solvate crystal of 9,9-bis(6-hydroxy naphthalene-2-group) fluorene and preparation thereof. A solvate crystal prepared from the 9,9-bis(6-hydroxy naphthalene-2-group) fluorene and acetonitrile is a solvate crystal I of the 9,9-bis(6-hydroxy naphthalene-2-group) fluorene, and a solvate crystal prepared from the 9,9-bis(6-hydroxy naphthalene-2-group) fluorene and ethyl acetate is a solvate crystal II of the 9,9-bis(6-hydroxy naphthalene-2-group) fluorene. The solvate crystal I and solvate crystal II of the 9,9-bis(6-hydroxy naphthalene-2-group) fluorene, which is prepared through the invention achieve the maximum melting endothermic peaks of 261-266 DEG C and the stacking density of 0.4 g / mL after being desolvated, is basically unchanged in color and purity after being preserved at 40 DEG C for three months due to high heat stability and has the advantages of high stacking density, good flowability and easiness for loaded material transfer.

Owner:JIANGSU EVER GALAXY CHEM CO LTD

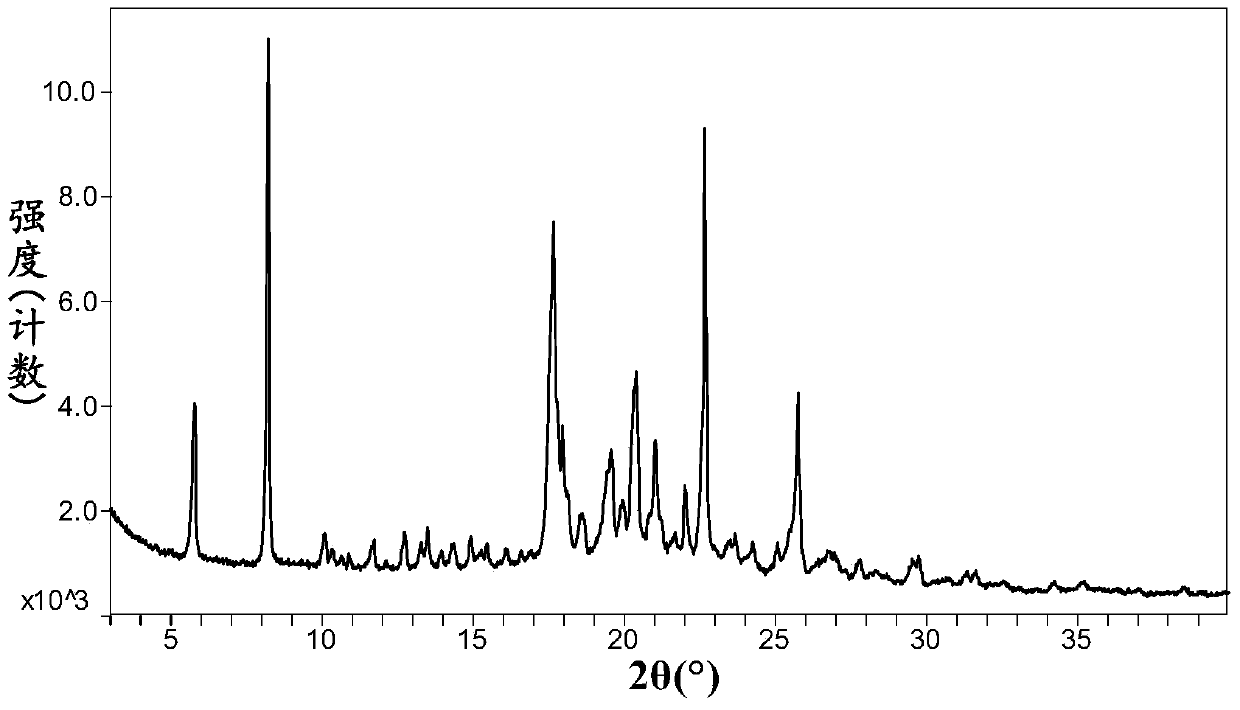

Omarigliptin salt, crystal form products of omarigliptin salt, preparing methods of omarigliptin salt and crystal form products and pharmaceutical composition

ActiveCN106928228AImprove solubilityFast dissolutionOrganic active ingredientsMetabolism disorderPharmaceutical drugBioavailability

The invention relates to novel omarigliptin salt and crystal form products of the omarigliptin salt, and belongs to the technical field of pharmaceutical chemicrystallization. Compared with existing omarigliptin crystal form products, the omarigliptin salt and the crystal form products of the omarigliptin salt have the advantages of being better in crystal form product stability and solubility, higher in dissolving rate and the like, the bioavailability of medicine can be improved, and the omarigliptin salt and the crystal form products of the omarigliptin salt are better suitable for an application of a solid preparation. The invention also relates to the omarigliptin salt, a preparing method of the crystal form products of the omarigliptin salt, a pharmaceutical composition of the omarigliptin salt and applications of the omarigliptin salt to medicine for treating type 2 diabetes mellitus.

Owner:SOLIPHARMA

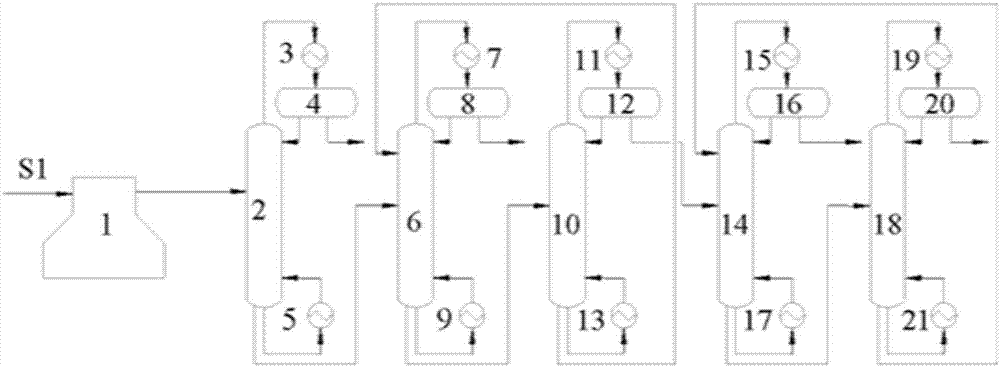

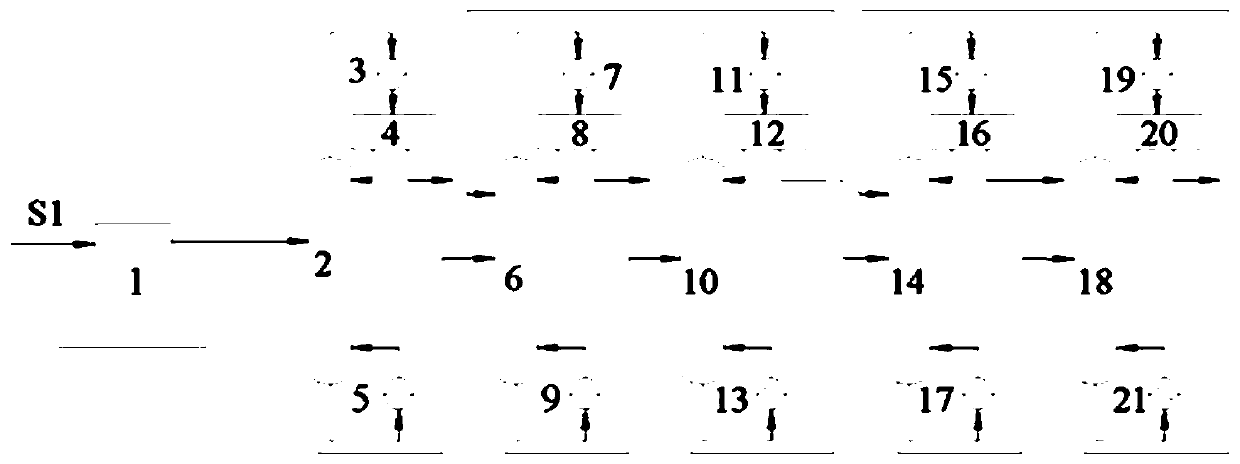

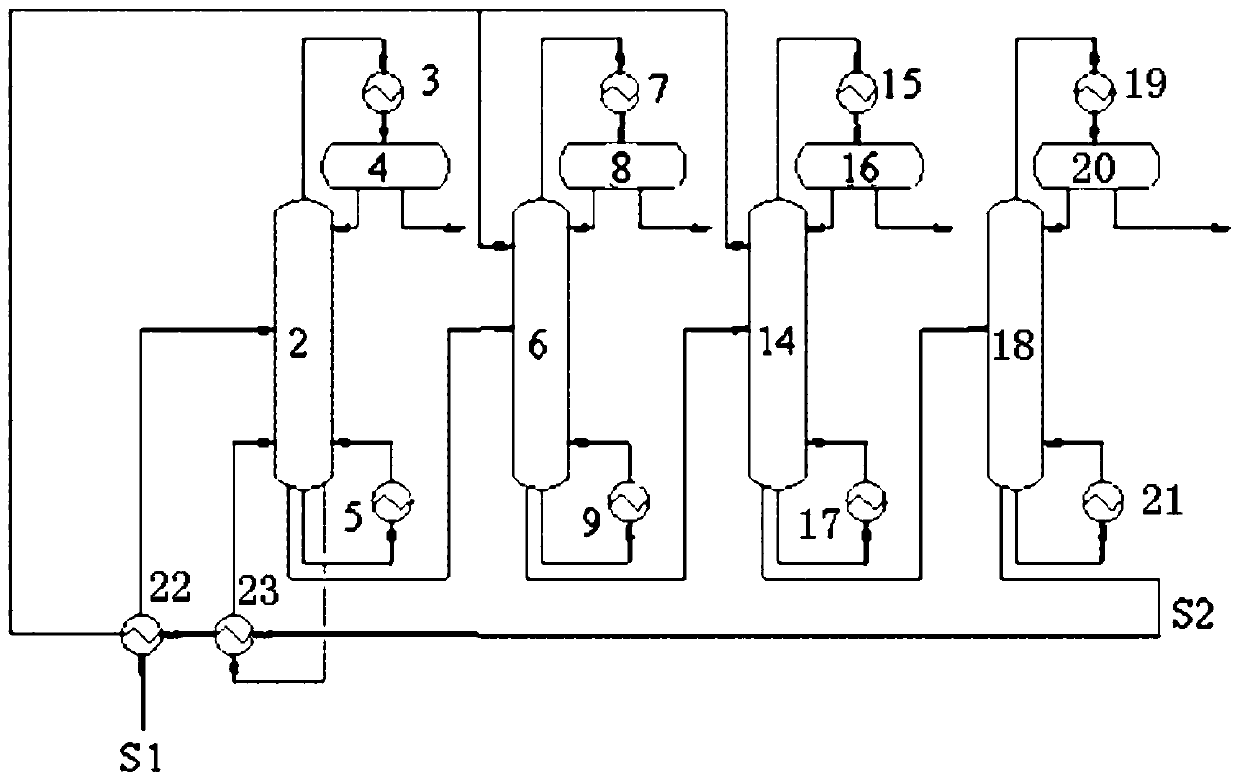

Energy-saving rectification system and method for purifying fusel oil

ActiveCN107488104AOmit investmentReduce energy consumptionOrganic compound preparationChemical industryAlcoholMethanol

The invention discloses an energy-saving rectification system for purifying fusel oil. The system comprises a fusel oil feeding heat exchanger (22), a methanol rectification column (2), an ethanol rectification column (6), a fusel rectification column (14), and an extractant recovery column (18), wherein a methanol rectification column bottom heat exchanger (23) is further arranged at the bottom of the methanol rectification column (2), a fusel oil feeding line (S1) passes through the fusel oil feeding heat exchanger (22) and then is introduced into the methanol rectification column (2), a bottom discharging line of the methanol rectification column (2) is taken as a feeding line of the ethanol rectification column (6), a bottom discharging line of the ethanol rectification column (6) is taken as a feeding line of the fusel oil rectification column (14), a bottom discharging line of the fusel oil rectification column (14) is taken as a feeding line of the extractant recovery column (18), a bottom discharging line (S2) of the extractant recovery column passes through the methanol rectification column bottom heat exchanger (23) at the bottom of the methanol rectification column (2) and the fusel oil feeding heat exchanger (22) in sequence for heat exchange and then is divided into two branches, one of which is introduced to the ethanol rectification column (6) and the other is introduced to the fusel rectification column (14).

Owner:高能时代环境(滕州)环保技术有限公司 +1

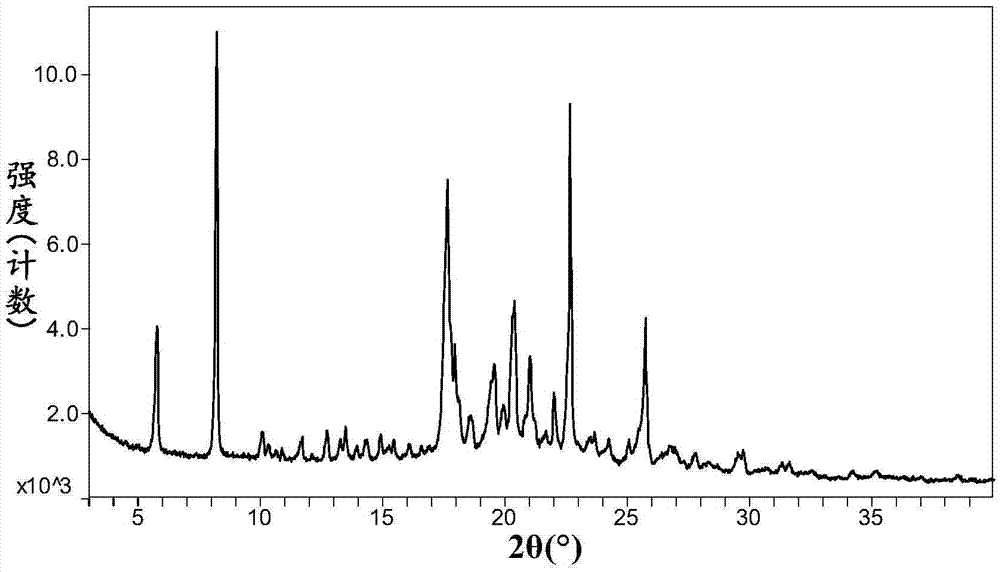

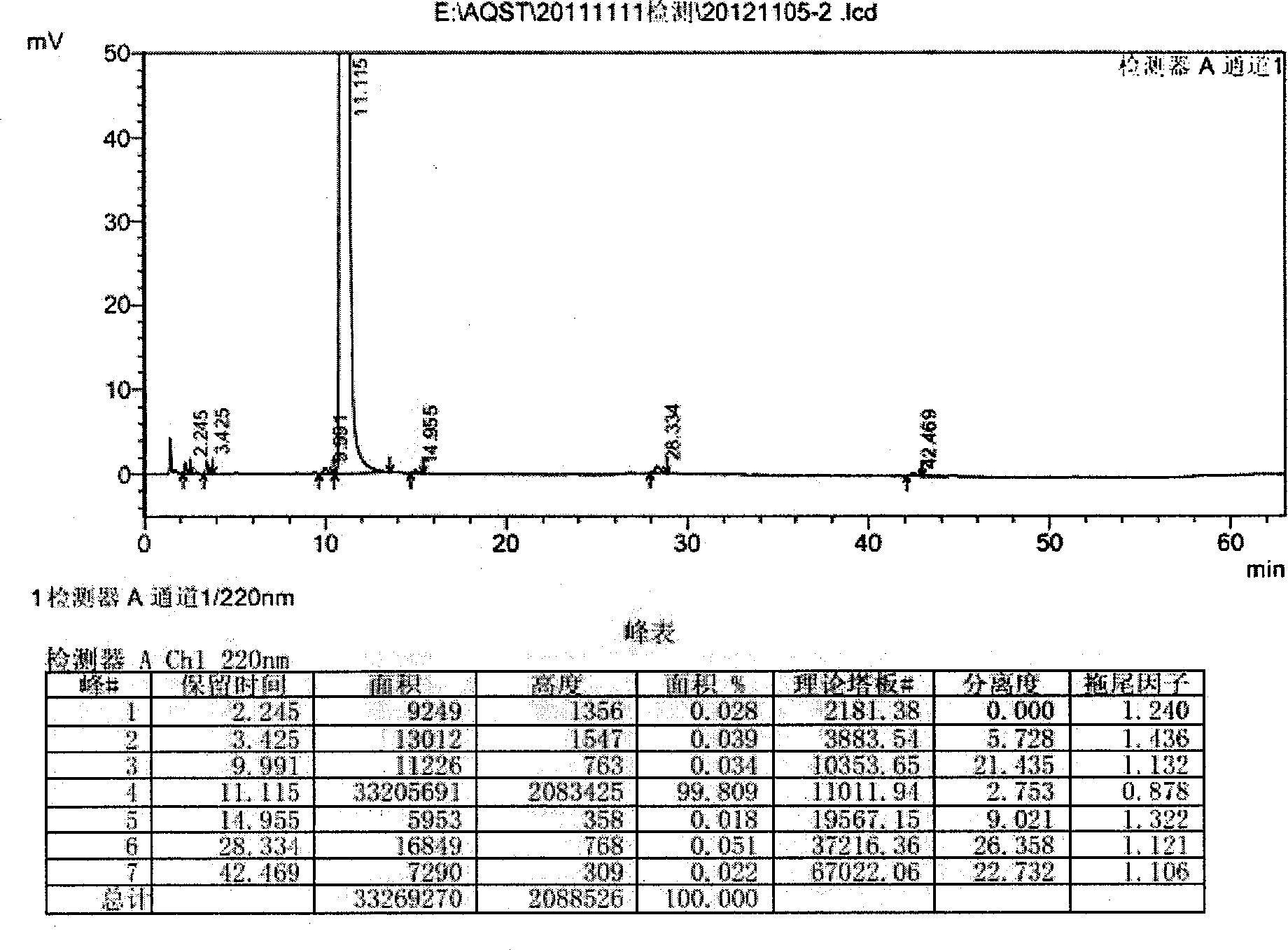

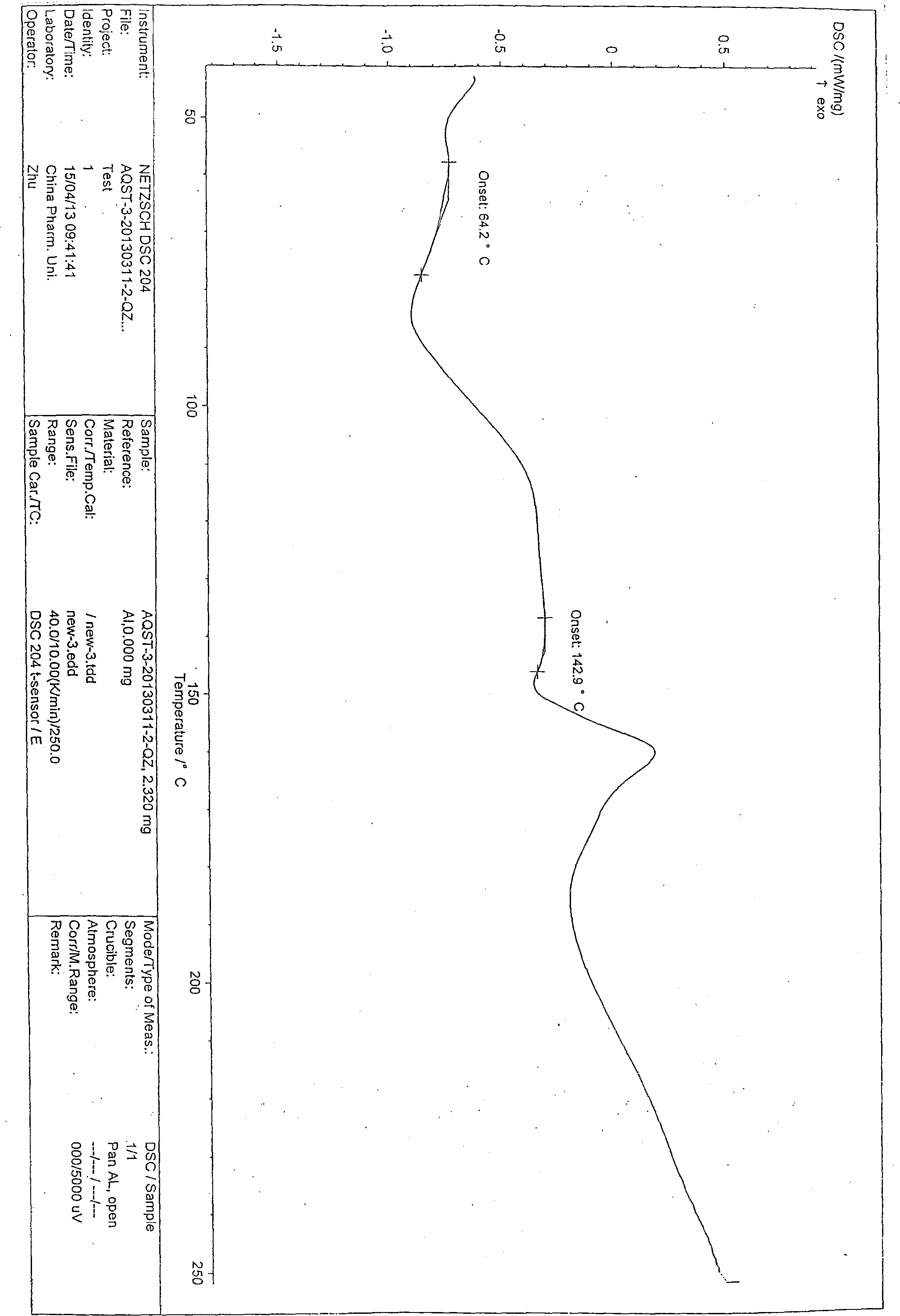

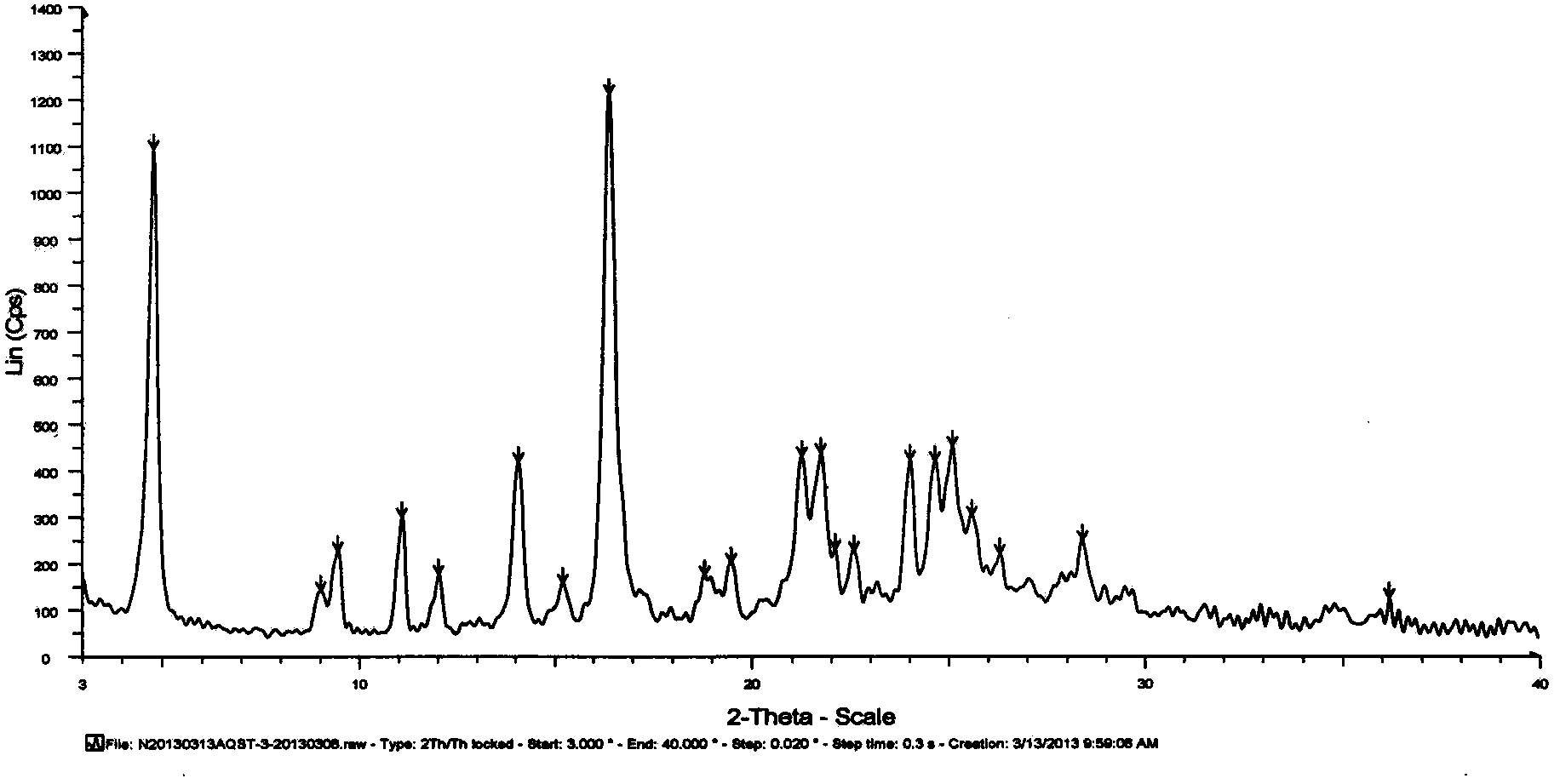

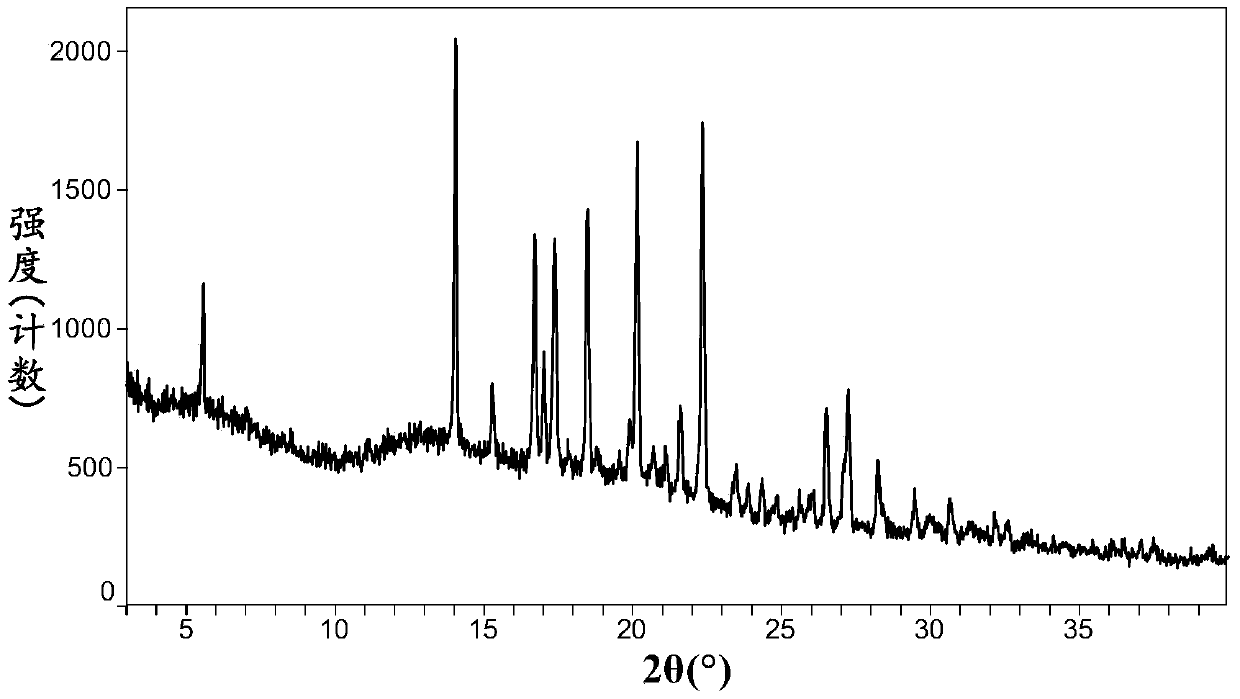

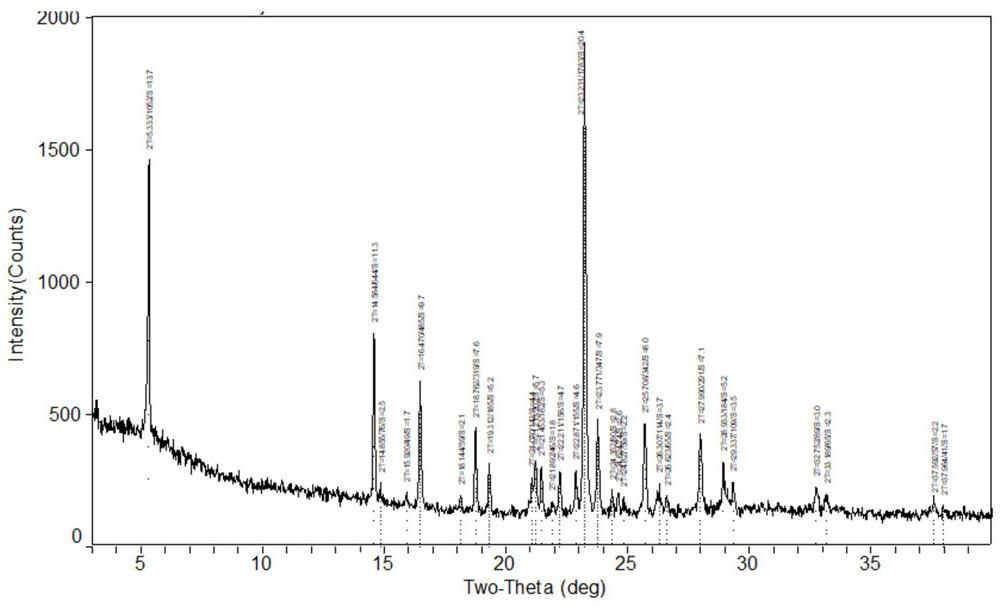

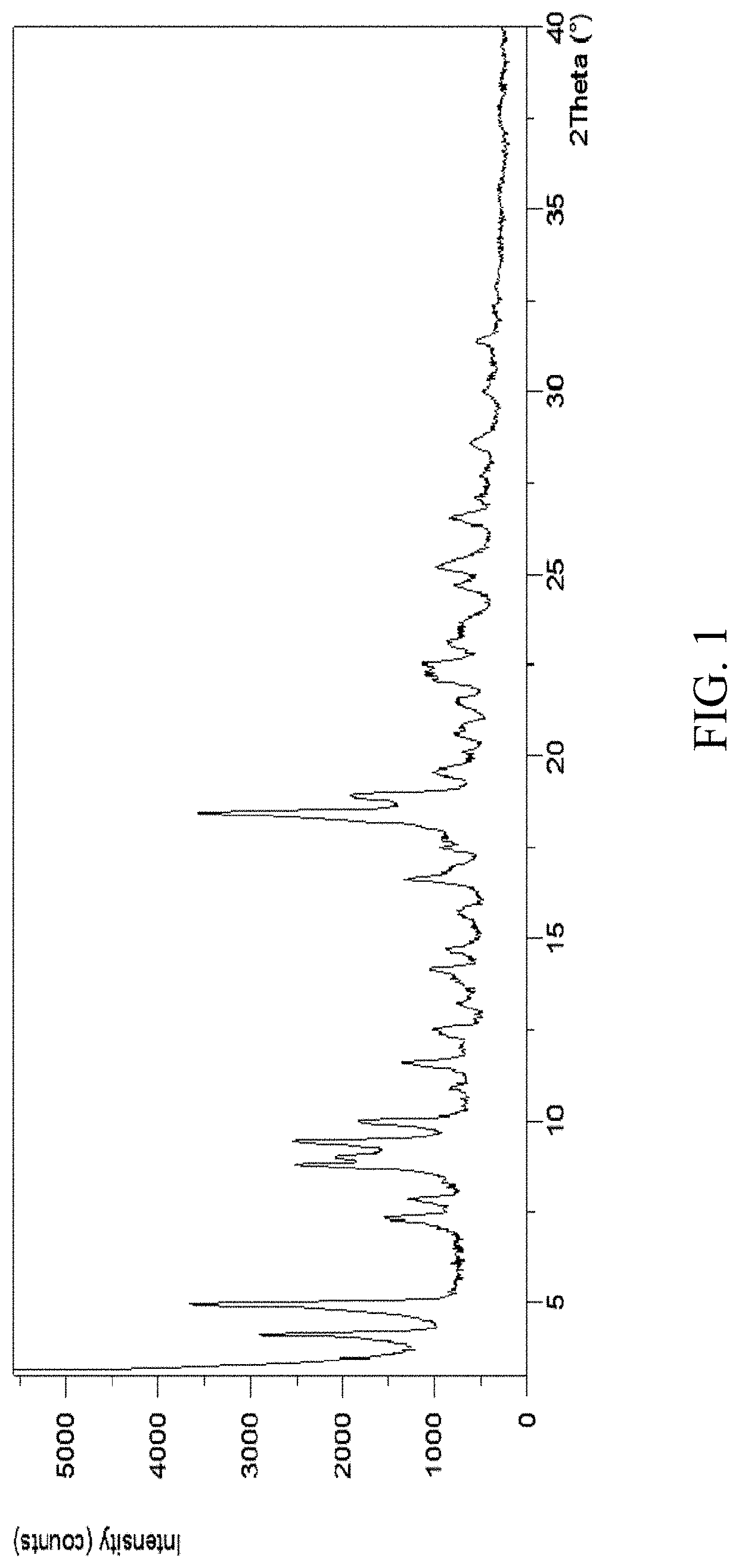

Novel crystal form of azilsartan and preparation method thereof

InactiveCN104341408AGood crystal stabilityHPLC purity unchangedOrganic chemistryPharmaceutical drugCarboxylic acid

The invention relates to a novel crystal form (called form B) of a latest-generation antihypertensive drug, namely, 1-[[2'-(2,5-dihydro-5-oxo-1,2,4oxadiazol-3-yl)[1,1'-biphenyl]-4-yl]methyl]-2-ethoxy-1H-benzimidazole-7-carboxylic acid (generic name: azilsartan), and a preparation method thereof. The azilsartan is found to have a polycrystalline state for the first time, and the novel crystal form is in a semi-stable state. As proved by research, a semi-stable-state product has high crystal form stability, can be preserved at the room temperature for six months, and is free from change in a powder-X diffraction pattern and constant in HPLC (High Performance Liquid Chromatography) purity. The novel crystal form which can be applied to further medicinal development is provided for the project development.

Owner:CP PHARMA QINGDAO CO LTD

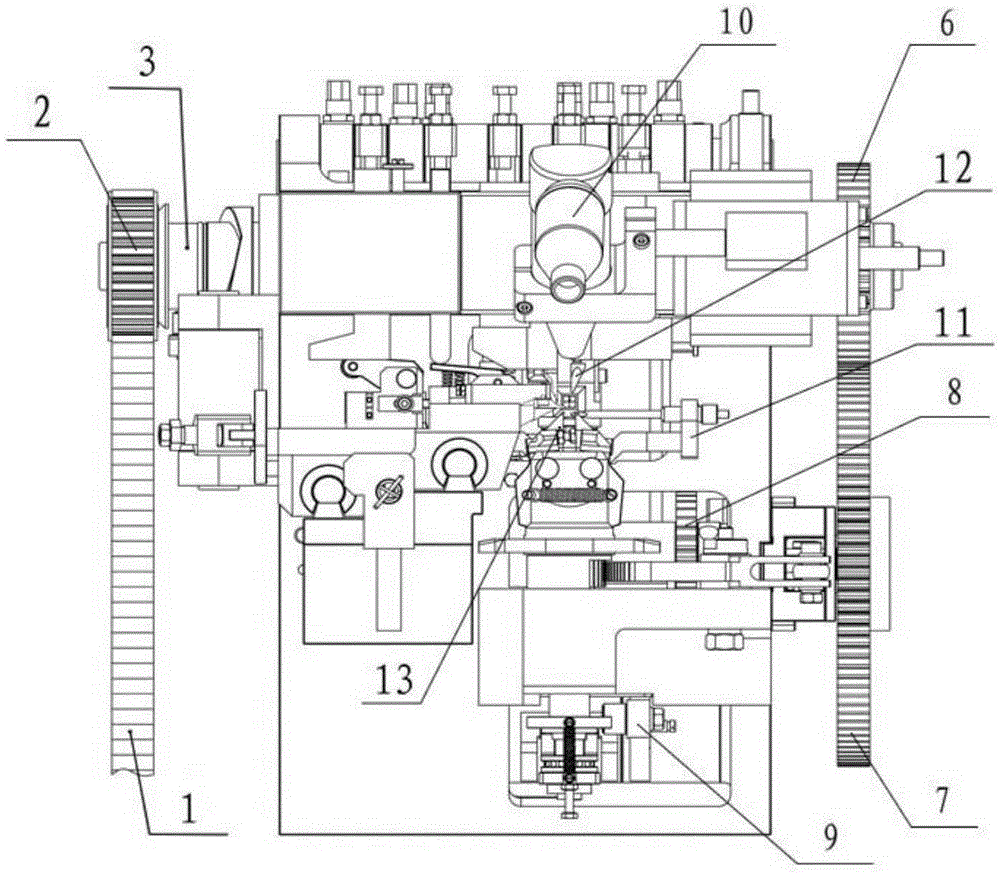

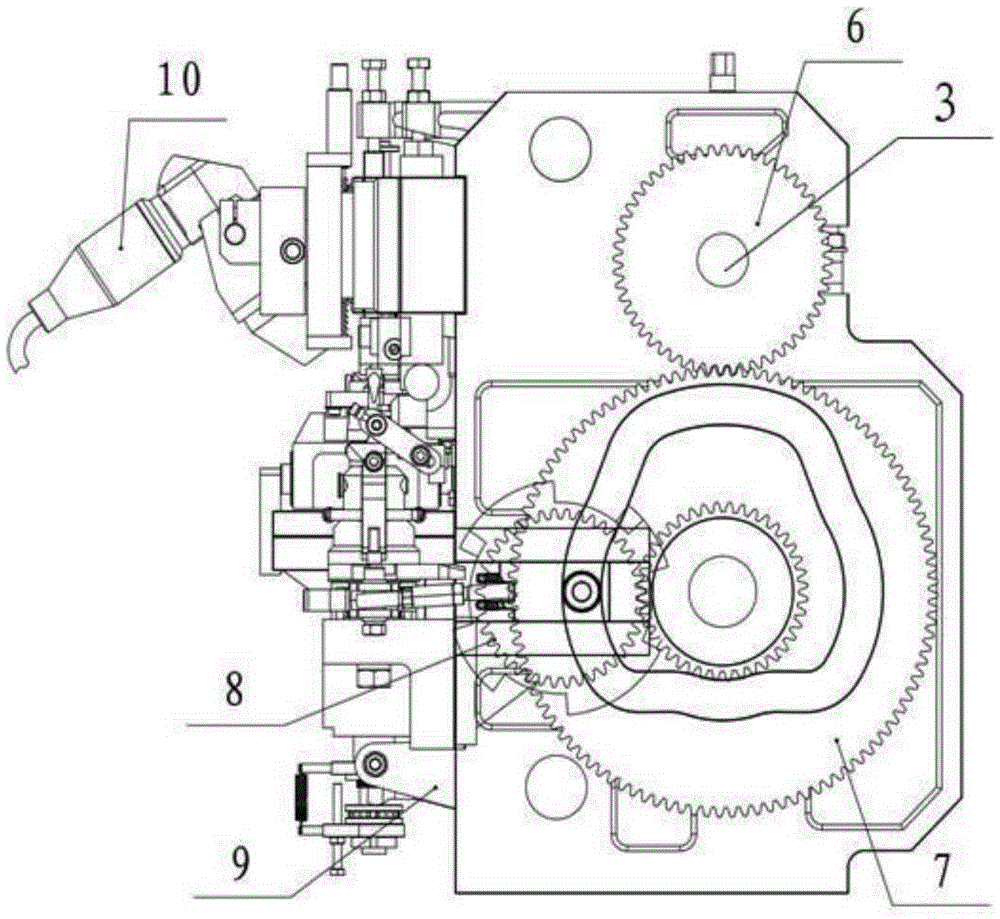

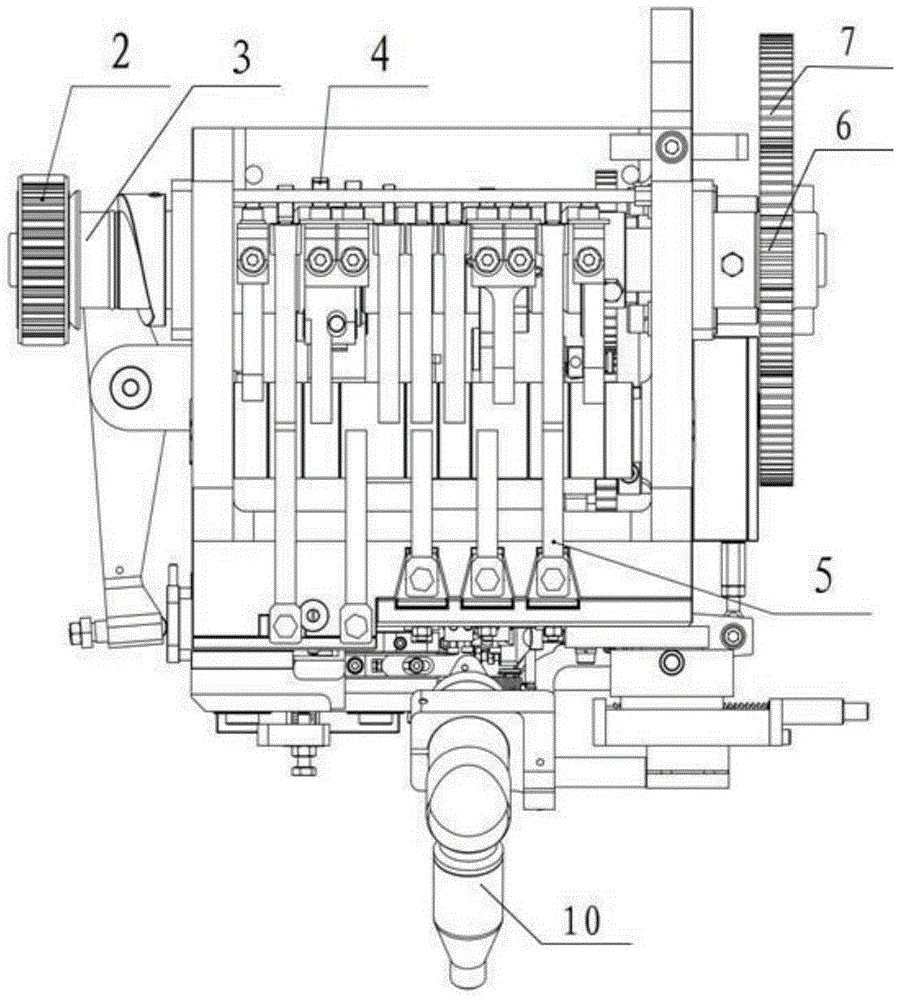

Automatic weaving-chain welding machine

InactiveCN105382549AIncrease productivityImprove productivityOther manufacturing equipments/toolsProduction rateCam

The invention provides an automatic weaving-chain welding machine. A main shaft (3) is installed on the upper portion of the machine, a toothed belt wheel (2) is installed at one side of the main shaft (3), the toothed belt wheel (2) is connected with an engine through a toothed belt (1), a transmission gear (6) is installed at the other end of the main shaft (3), the transmission gear (6) is connected with a disc cam gear (7) through a gear, the disc cam gear (7) is connected with a sector gear (8) through a gear, cams (4) and cam swinging rods (5) are further installed on the main shaft (3), a laser focusing lens (10) is further installed at the outer side of the upper portion of the machine, a swing rod (9) is installed at the bottom of the machine, and the machine further comprises a line feeding mechanism (11), a cutting mechanism (12) and a formation rotary mechanism (13). The automatic weaving-chain welding machine has the advantages that weaving-chain production efficiency is remarkably improved, productivity is greatly raised, and sealing quality is greatly improved.

Owner:浙江立新珠宝科技股份有限公司

Folates, compositions and uses thereof

ActiveCN101970439BLong-term chemical stabilityPurity unchangedOrganic active ingredientsNervous disorderSolubilityOrganic base

The present invention relates to folates, compositions and uses thereof; In particular, this invention describes a crystalline or amorphous compound which is a substituted or unsubstituted folate or a reduced folate, or the natural or unnatural isomers thereof, of at least one organic base, as well as compositions and uses thereof. The compounds of the invention show a long lasting stability as well as a peculiarly high water-solubility.

Owner:GNOSIS SPA

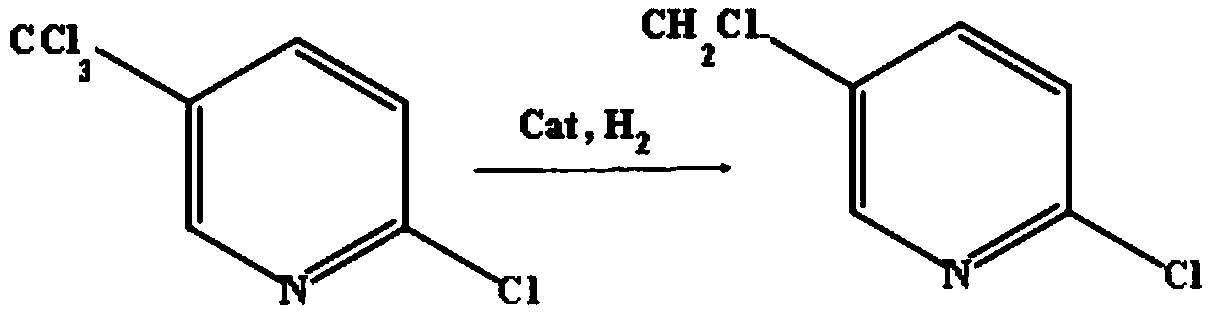

Method for preparing 2-chloro-5-chloromethylpyridine

ActiveCN110577491AAchieve recyclingThorough responseOrganic chemistrySodium phosphatesSynthesis methods

The invention discloses a method for preparing 2-chloro-5-chloromethylpyridine, and the method comprises the following steps: performing selective hydrogenation dechlorination reaction on 2-chloro-5-trichloromethylpyridine serving as a raw material to prepare the 2-chloro-5-chloromethylpyridine; wherein a catalyst is a noble metal catalyst taking activated carbon or aluminum oxide as a carrier, and the mass percentage of a noble metal in the noble metal catalyst is 1%-10%; wherein the mass of the noble metal catalyst is 0.1%-0.5% of the mass of the 2-chloro-5-trichloromethylpyridine; an acid-binding agent is sodium hydroxide, potassium hydroxide, sodium carbonate, potassium carbonate, sodium phosphate, triethylamine, triethanolamine, 2-hydroxyethylamine or ammonia gas; and an organic solvent is toluene, xylene, methyl acetate, ethyl acetate or 2-methyltetrahydrofuran. The yield of the 2-chloro-5-chloromethylpyridine exceeds 82%, the purity of the 2-chloro-5-chloromethylpyridine is 98%or above, the process control is simple, less industrial ''three wastes' 'are generated, and the synthesis method is green and environmentally friendly.

Owner:XIAN CATALYST NEW MATERIALS CO LTD

Alogliptin salt and its crystal form, their preparation method and pharmaceutical composition

ActiveCN106928228BImprove solubilityFast dissolutionOrganic active ingredientsOrganic compound preparationSolubilityAlogliptin

The invention relates to novel omarigliptin salt and crystal form products of the omarigliptin salt, and belongs to the technical field of pharmaceutical chemicrystallization. Compared with existing omarigliptin crystal form products, the omarigliptin salt and the crystal form products of the omarigliptin salt have the advantages of being better in crystal form product stability and solubility, higher in dissolving rate and the like, the bioavailability of medicine can be improved, and the omarigliptin salt and the crystal form products of the omarigliptin salt are better suitable for an application of a solid preparation. The invention also relates to the omarigliptin salt, a preparing method of the crystal form products of the omarigliptin salt, a pharmaceutical composition of the omarigliptin salt and applications of the omarigliptin salt to medicine for treating type 2 diabetes mellitus.

Owner:SOLIPHARMA

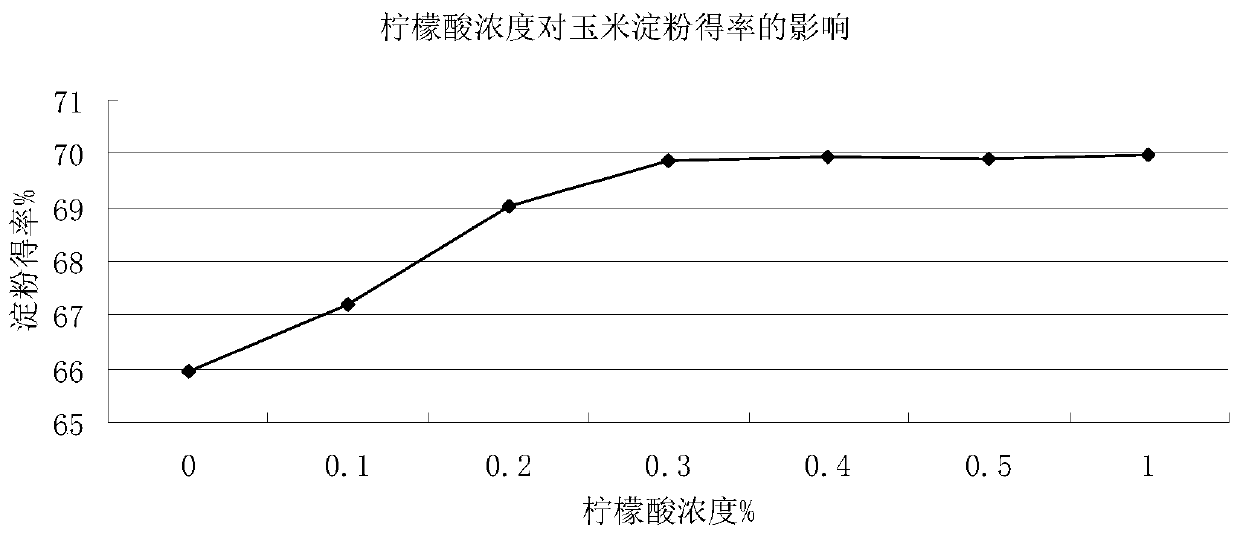

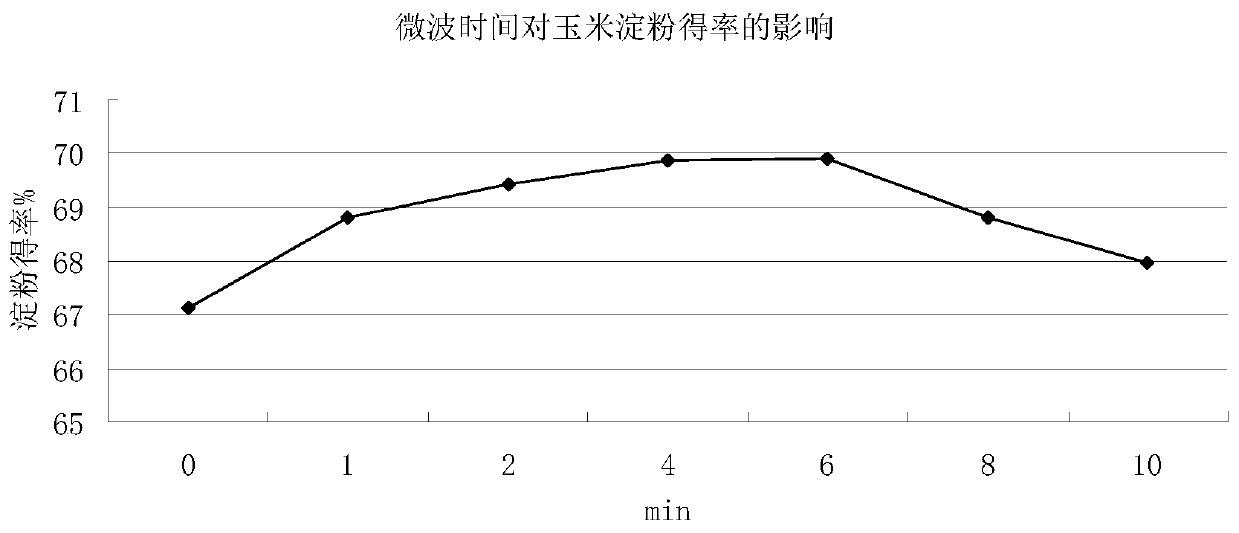

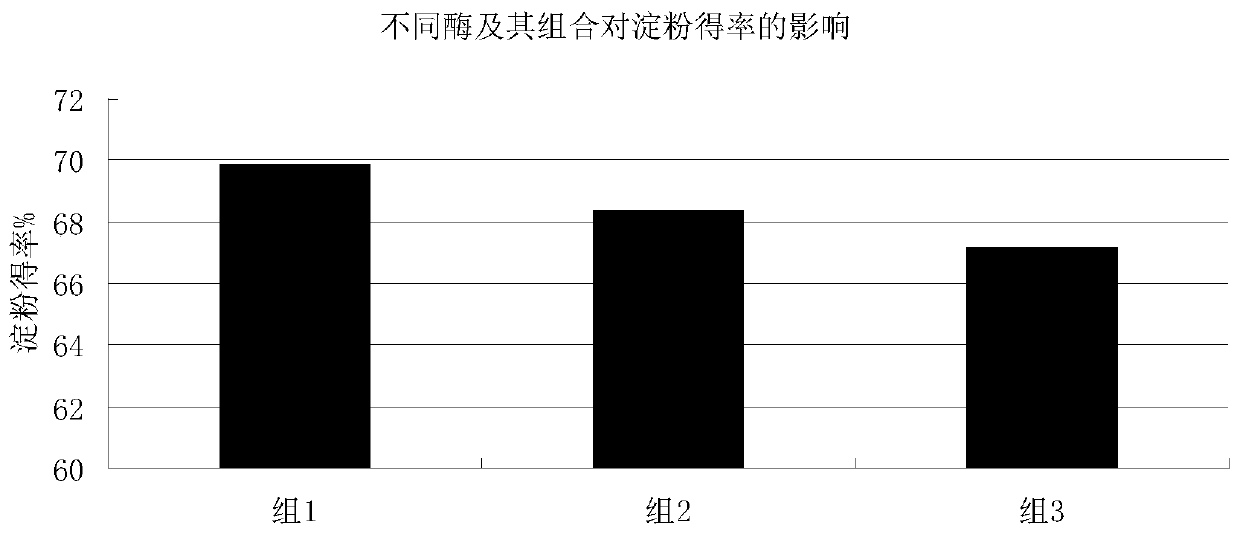

Method for increasing yield of corn starch

InactiveCN110981978AMaintain enzyme activitySavings on industrialization proceduresEngineeringCorn kernel

The invention belongs to the technical field of biology, and particularly discloses a method for increasing the yield of corn starch. The method comprises the following steps: 1) pumping corn kernelsinto a soaking tank, adding an acid solution for soaking and then performing microwave treatment; 2) adding protease into the soaking tank for enzymolysis treatment, and optionally, 3) entering a starch processing procedure. Corn starch is subjected to soaking and multi-stage separation and purification procedures so that the starch yield is increased, the industrial process is saved and the industrial energy consumption is reduced.

Owner:HULUNBEIER NORTHEAST FUFENG BIOTECHNOLOGIES CO LTD

Preparation method of cefotetan

InactiveCN102250125BIncrease contentLess impuritiesOrganic chemistryNitrogen gasChloroacetyl chloride

The invention relates to a preparation method of cefotetan. The method comprises the steps of: under an alkaline condition, reacting the starting raw material 7-MAC with chloroacetyl chloride in an organic solvent so as to obtain the intermediate CefoD-1; under nitrogen protection, adding aluminium trichloride into anisole, stirring for dissolving, and leaving the obtained solution for standby application; taking another organic solvent, into which the intermediate CefoD-1 is added under stirring, then adding the standby solution for reacting, thus obtaining the intermediate CefoD-2; reactingthe intermediate CefoD-2 with 3, 5-dithiol-4-isothiazole formic acid trisodium salt until that a sampled cefotetan tautomer is detected less than 4.0%, after the reaction conducting a post-treatment,thus obtaining cefotetan. With improved yield and reduced cost, the method of the invention, without final heating concentration, can generate products with a shallow color and almost invariant purity.

Owner:HAINAN HERUI PHARMA +1

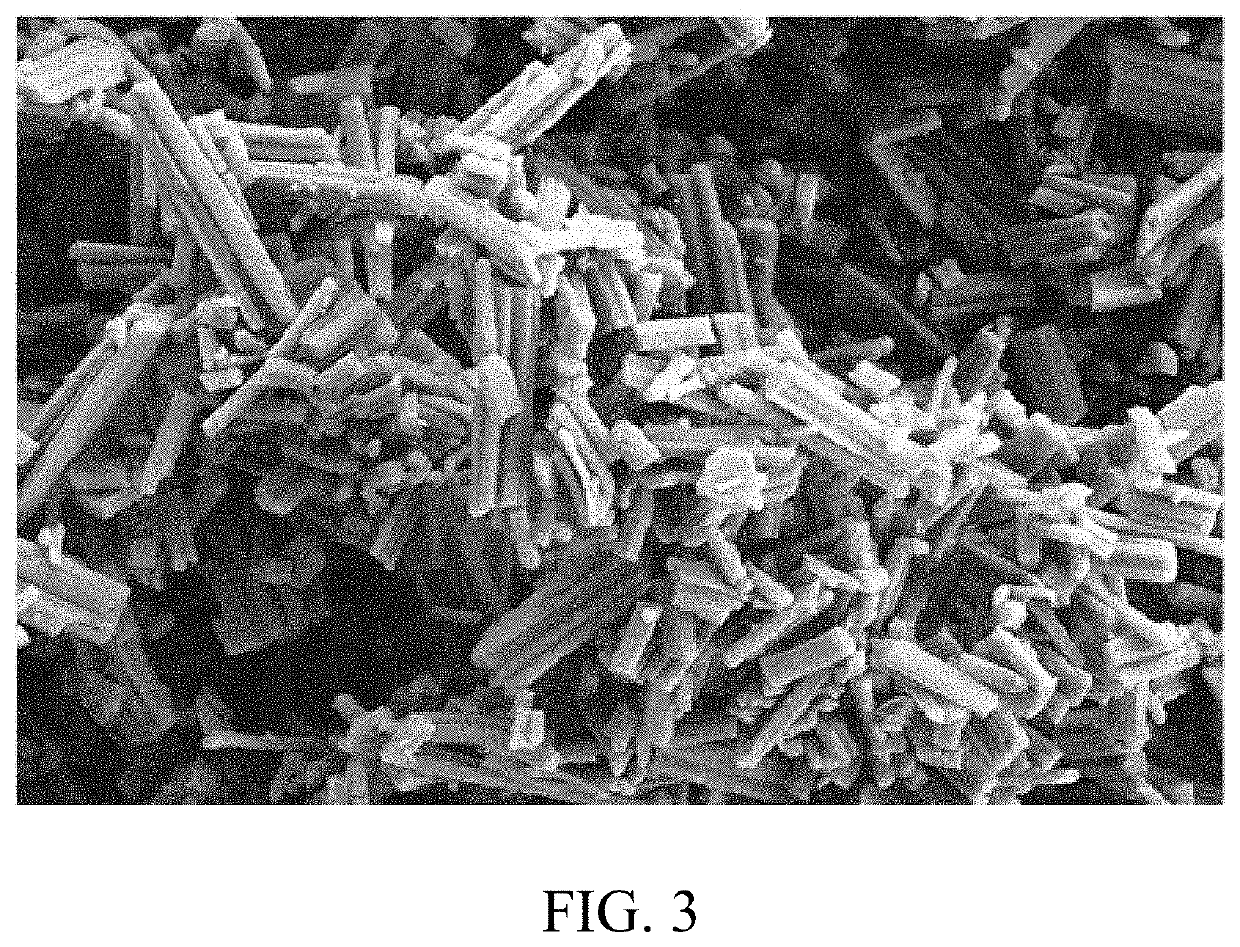

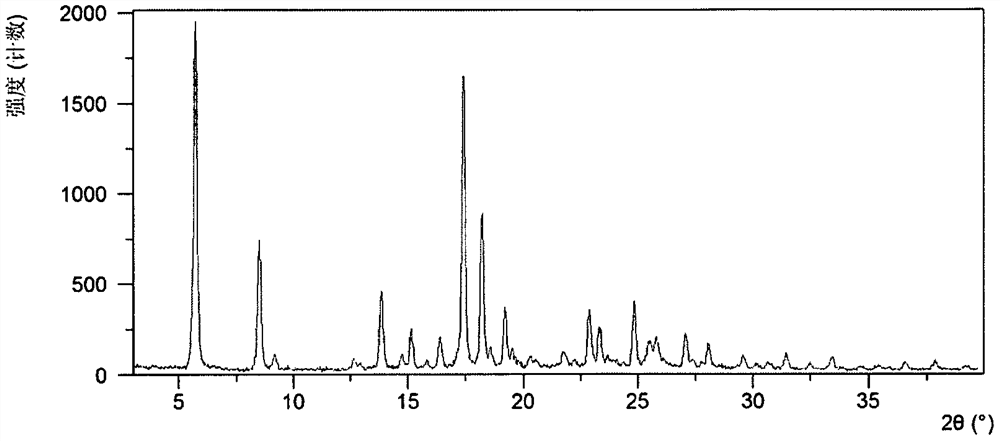

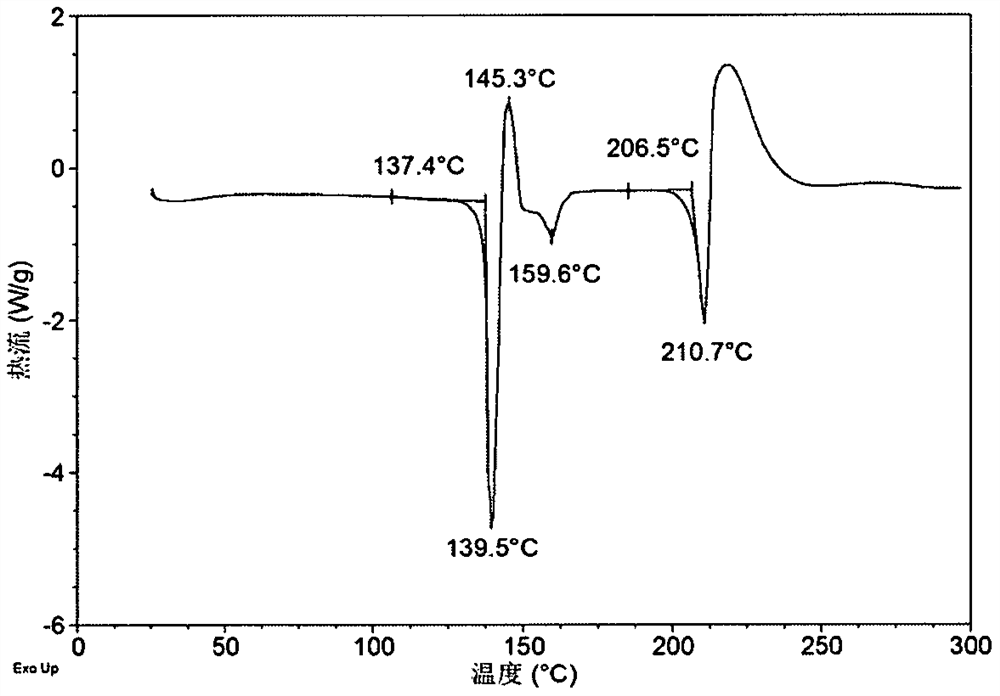

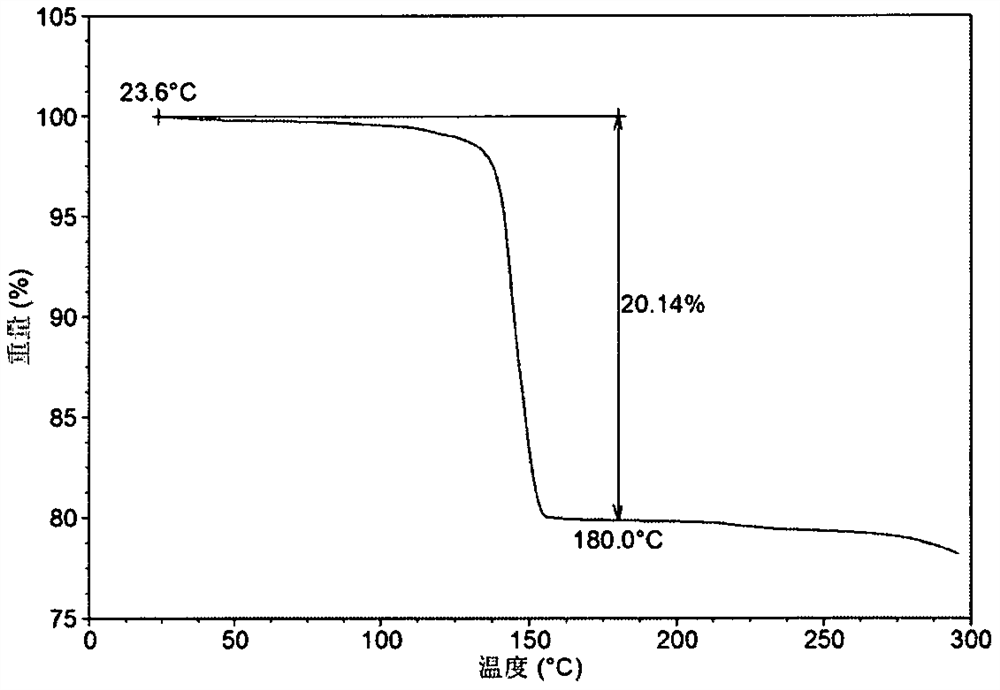

Crystal form of Crisabole solvate and preparation method and application of crystal form

PendingCN113620982AGood water solubilityImprove bioavailabilityAntipyreticOrganic chemistry methodsEfficacyPharmaceutical Aids

The invention discloses a crystal form of a Crisabole solvate and a preparation method and application of the crystal form. The crystal form has better water solubility, and the significantly improved water solubility is helpful for improving the bioavailability of the medicine, thereby improving the druggability and efficacy of the medicine. In addition, a preparation prepared from the crystal form has relatively good stability, and particularly has high crystal form stability in a pharmaceutical preparation taking pyridine or 1, 3-propylene glycol as an auxiliary material.

Owner:SOLIPHARMA

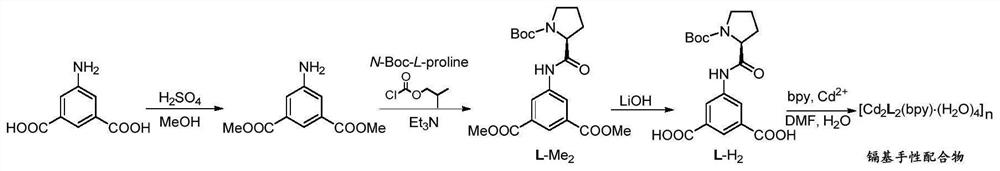

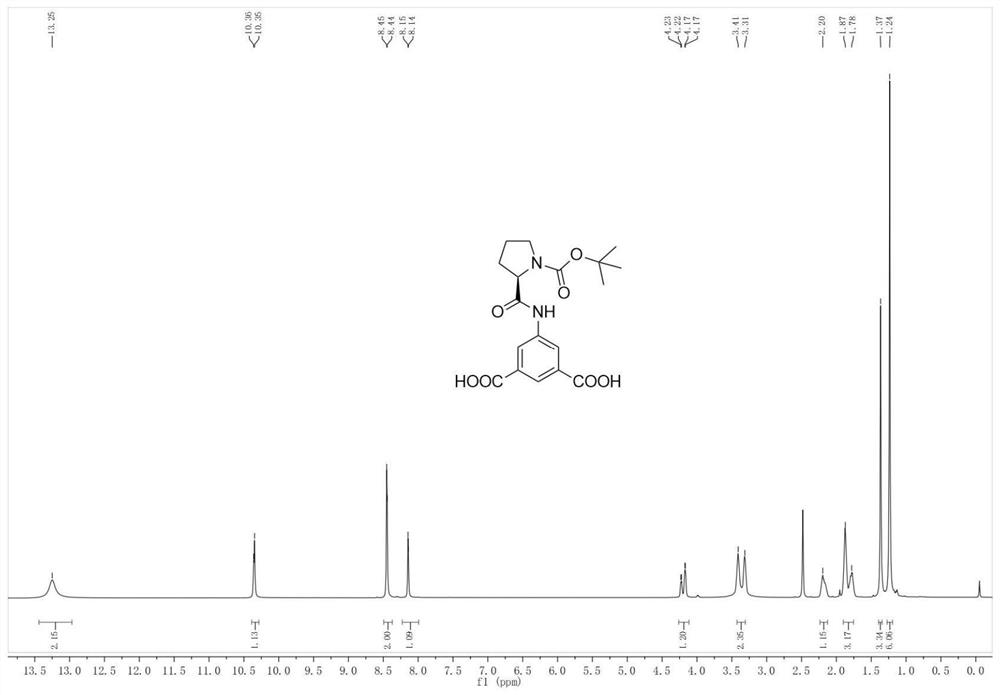

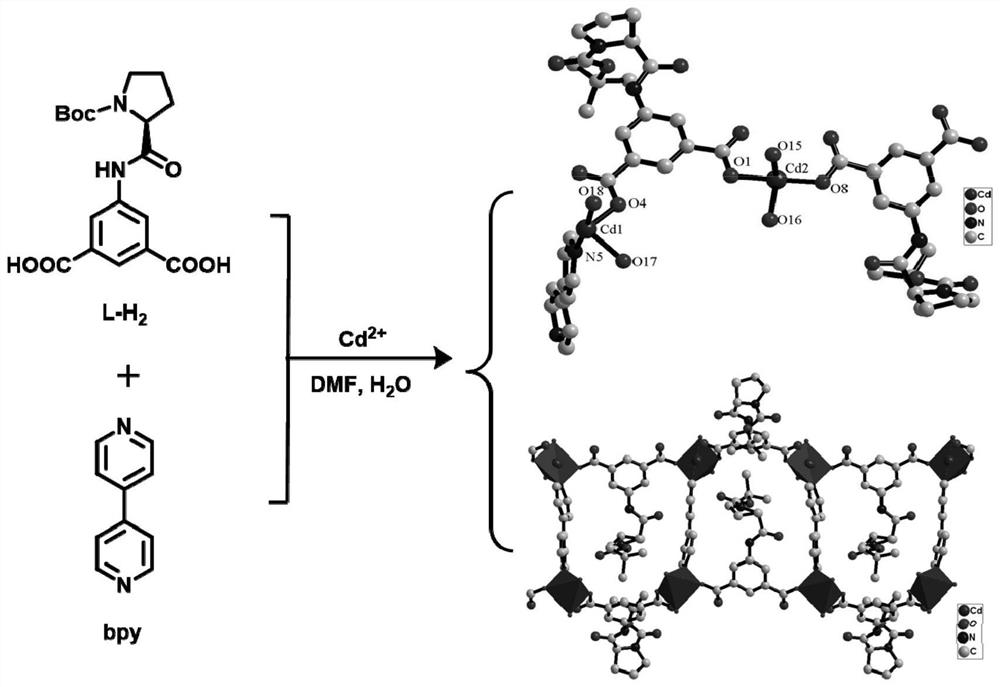

V-shaped chiral carboxylic acid ligand, preparation method and application thereof

PendingCN113185439AOvercoming Difficulties in Assembling Chiral ComplexesReduce manufacturing costOrganic chemistry methodsAmino acidCombinatorial chemistry

The invention discloses a V-shaped chiral carboxylic acid ligand L-H2, relates to the technical field of synthetic chemistry and coordination chemistry, and also provides a preparation method of the ligand and an application of the ligand in assembling chiral complexes. The preparation method has the beneficial effects that the prepared V-shaped chiral carboxylic acid ligand is cheap in synthesis raw materials, simple in preparation method and suitable for large-scale preparation, has proper ligand rigidity and special coordination guidance and is beneficial to overcoming the flexibility of a framework of amino acid and the flexibility of a coordination mode. Therefore, a complex material with a chiral structure is easy to assemble.

Owner:HEFEI UNIV OF TECH

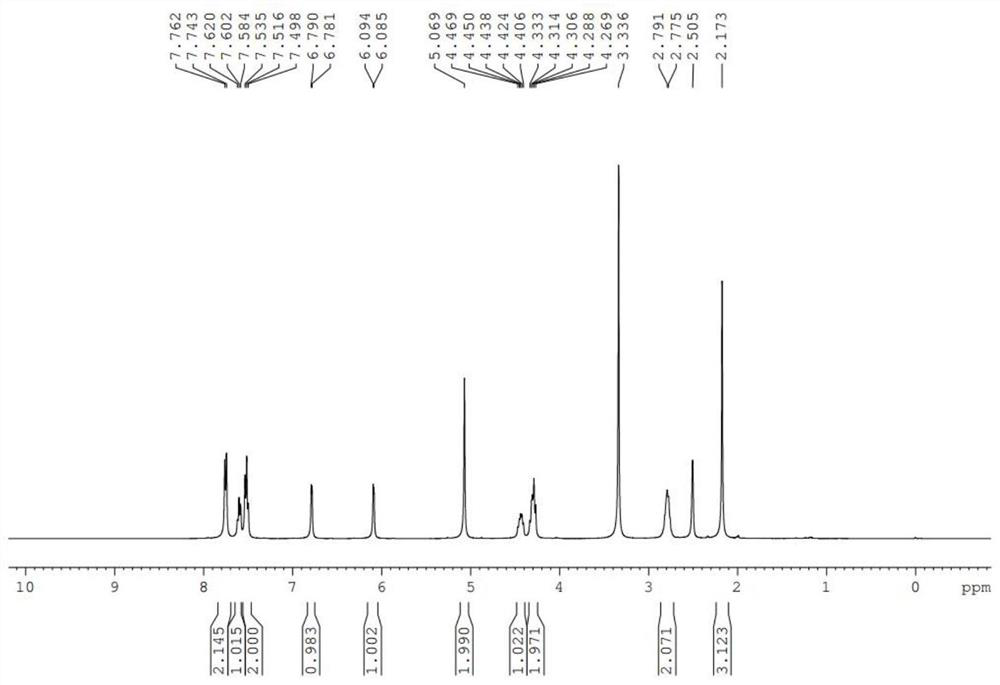

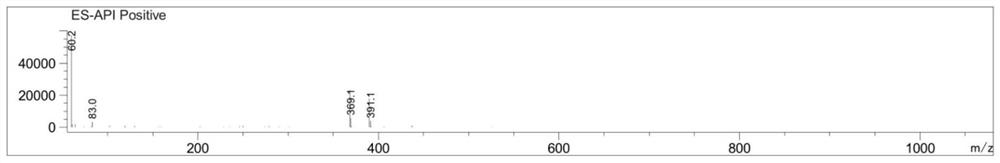

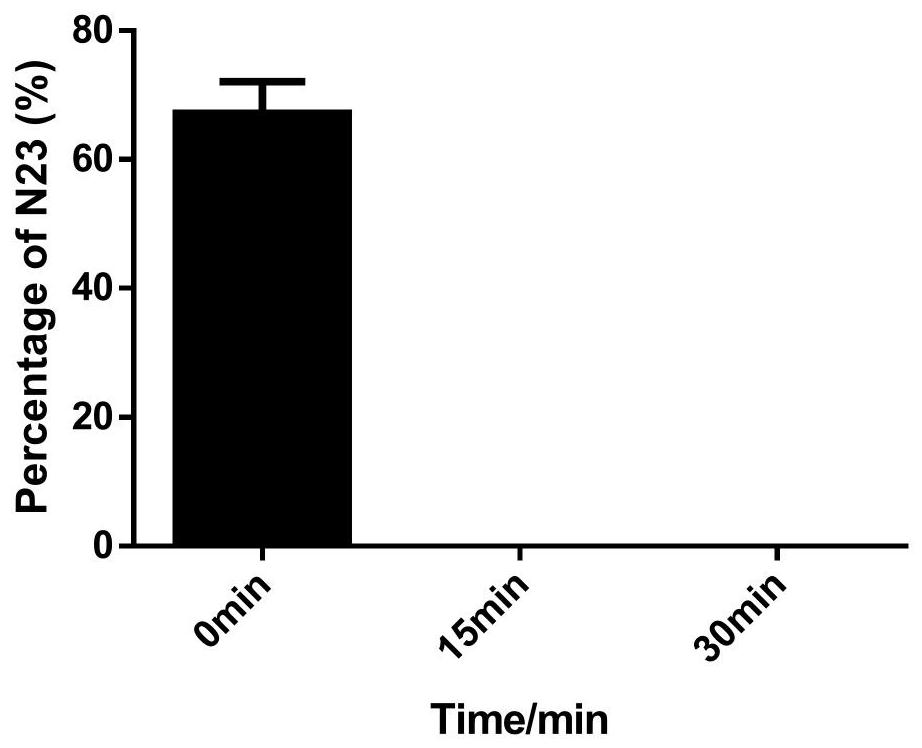

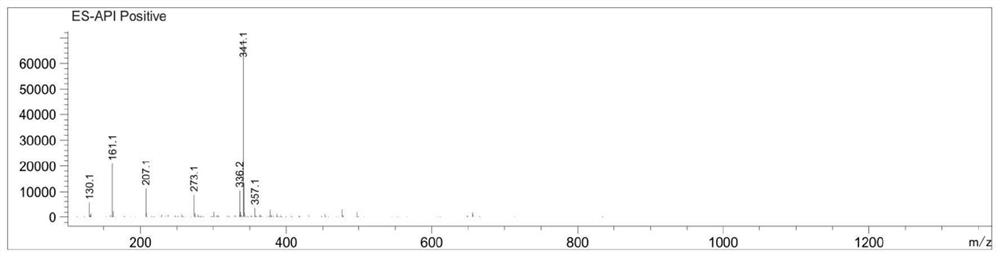

Ketorolac derivative as well as preparation method and application thereof

ActiveCN114380834AOvercoming the short half-lifeOvercome stabilityOrganic active ingredientsNervous disorderKetorolacCarboxyl radical

The invention relates to a ketorolac derivative as well as a preparation method and application thereof. The ketorolac derivative N23 and the levorotatory enantiomer N23 (S) thereof are obtained by derivatizing carboxyl of ketorolac, and the problems of short half-life period, poor stability, irritation, compatibility and the like of ketorolac are solved. In-vivo rat tests show that the compound has good pharmacokinetic properties.

Owner:NANJING HERON PHARMA SCI & TECH CO LTD

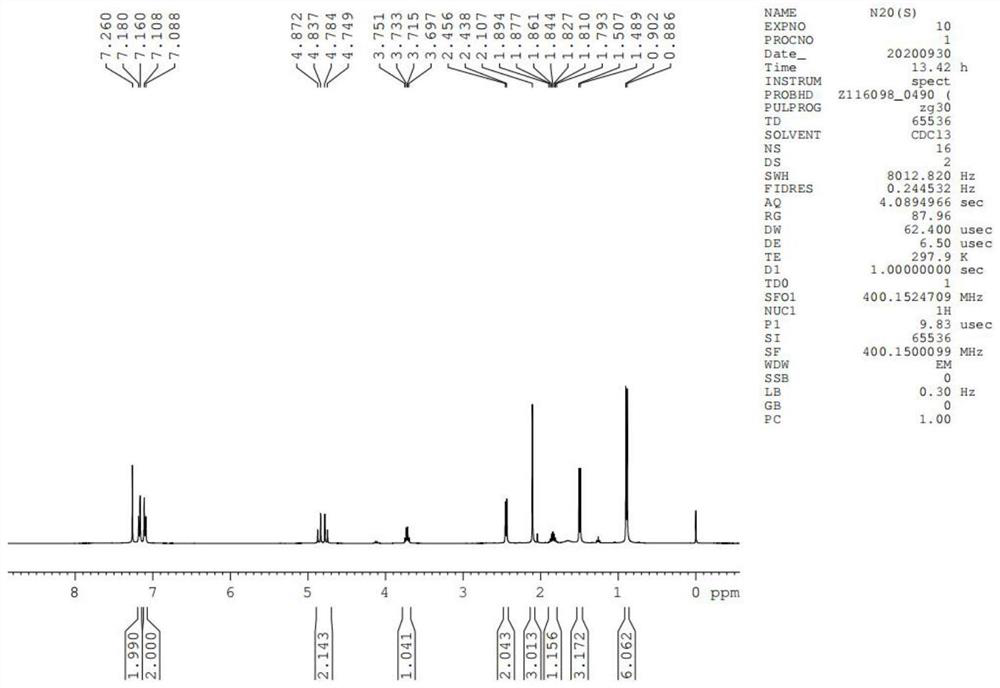

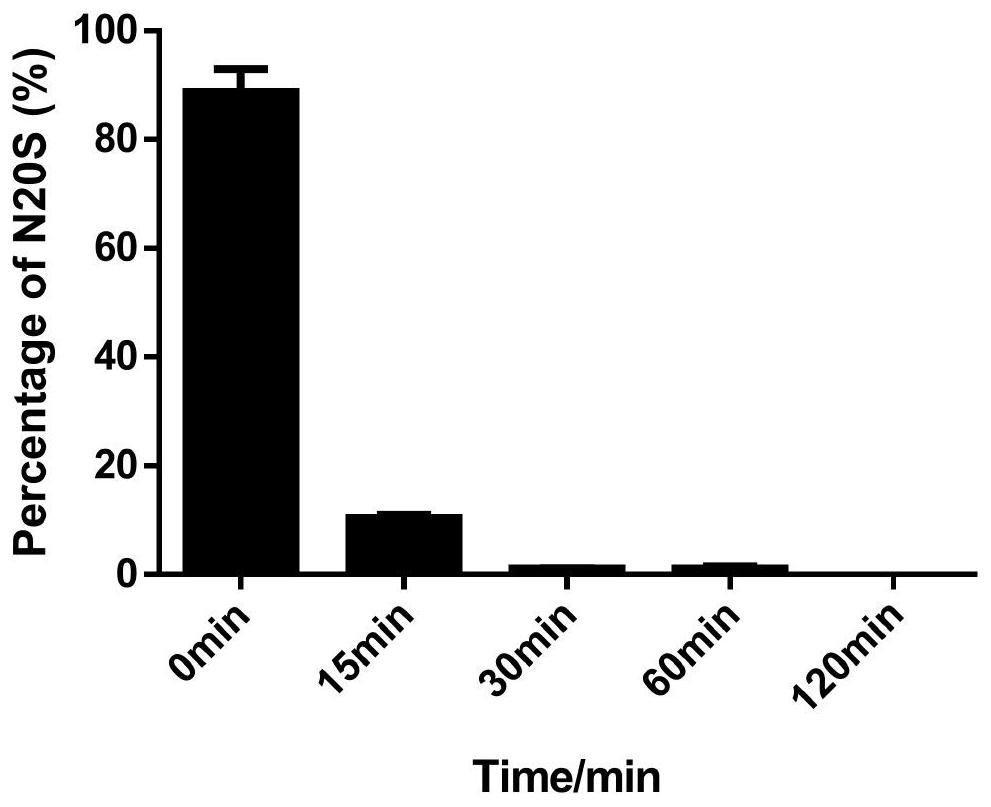

Ibuprofen derivative as well as preparation method and application thereof

PendingCN114380785AOvercoming the short half-lifeOvercome stabilityOrganic active ingredientsNervous disorderCarboxyl radicalIrritation

The invention relates to an ibuprofen derivative as well as a preparation method and application thereof. The ibuprofen derivative N20 and the dextrorotatory enantiomer N20 (S) thereof are obtained by derivatizing carboxyl of racemic ibuprofen or S-ibuprofen, and the problems of short half-life period, poor stability, irritation, compatibility and the like of ibuprofen are solved. In-vitro plasma and in-vivo rat tests show that the compound has good pharmacokinetic properties.

Owner:NANJING HERON PHARMA SCI & TECH CO LTD

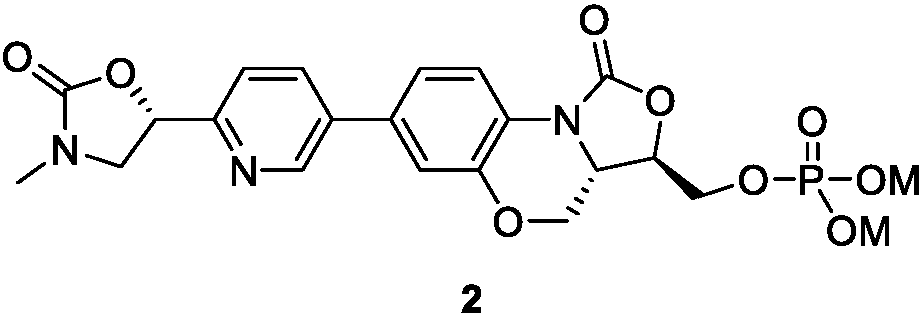

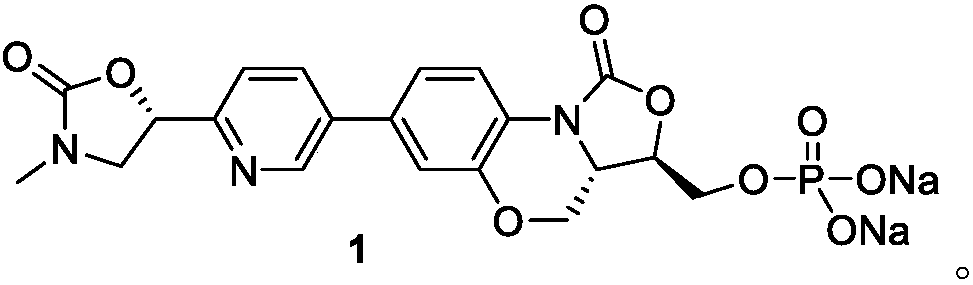

Polymorphic form of compound, preparation method and use thereof

ActiveUS10662198B2Improve stabilityImprove liquidityOrganic chemistry methodsAntiviralsThiazoleFormate

Owner:QILU PHARMA CO LTD

A preparation method of high-performance biomedical amorphous calcium phosphate 3D printing material

ActiveCN109734066BHigh purityPlay a role in wrappingAdditive manufacturing apparatusNanotechnologySilicic acidAluminum silicate

The invention discloses a preparation method of high-performance biomedical amorphous calcium phosphate 3D printing materials. First, rare earth substances, silica sol, soluble magnesium salts, soluble aluminum salts, fluorine salts, etc. are used as raw materials, and are prepared by high-temperature hydrothermal reaction. Obtain zero-charge magnesium aluminum silicate additives, and participate in the high-temperature water phase reaction of calcium source and phosphorus source, so as to prepare amorphous calcium phosphate nanopowder material with high purity and stable performance; it will be processed by 3D printing The bone material solid finished product with excellent mechanical and mechanical properties can be obtained, and the industrial application prospect is extremely bright.

Owner:ZHONGSHAN POLYTECHNIC

The decolorization method of benzoic acid heavy by-product benzyl benzoate

ActiveCN107501098BReduce the color numberImprove solubilityOrganic compound preparationCarboxylic acid esters preparationBenzoic acidBenzyl benzoat

The invention discloses a de-coloring method of benzoic acid heavy by-product benzyl benzoate. The de-coloring method comprises the following steps: 1) producing a benzyl benzoate crude product through reduced-pressure distillation of leftovers from production of benzoic acid through methylbenzene liquid phase air oxidation; 2) adding reactive metal and an acidic solution into the benzyl benzoate crude product for thermal insulation reaction; 3) reducing the temperature to a room temperature after the end of reaction, and filtering and removing the unreacted reactive metal; 4) performing layered treatment on a filtrate to obtain an upper oil layer; and 5) performing reduced-pressure distillation and dehydration on the oil layer, wherein an obtained remaining material is a low-color benzyl benzoate finished product. The de-coloring method disclosed by the invention is advanced in process, convenient to operate and high in yield.

Owner:WUHAN YOUJI IND

New crystal form of acalabrutinib and its preparation method and use

ActiveCN111527089BImprove physical stabilityImprove long-term stabilityOrganic active ingredientsOrganic chemistry methodsTyrosine-kinase inhibitorTyrosine

The invention relates to a new crystal form of Acalabrutinib and a preparation method thereof, a pharmaceutical composition containing the crystal form, and an application of the crystal form in preparing Bruton's tyrosine kinase inhibitors and pharmaceutical preparations for treating mantle cell lymphoma. The crystal form of Acalabrutinib provided by the present invention has one or more improved properties compared with the prior art, and is of great value to the optimization and development of the drug in the future.

Owner:CRYSTAL PHARMA CO LTD

Crystal form of salt of sb-939 and its preparation method and use

ActiveCN110291071BFor long-term storageGood for quantitative accuracyOrganic active ingredientsOrganic chemistryMechanical stabilityCombinatorial chemistry

The present invention relates to the crystal form of the salt of compound (I) and its preparation method and application. The new crystal forms CS7, CS9, CS1 and CS3 provided by the present invention have low hygroscopicity, good stability, high purity, low degradation, high solubility and good mechanical stability. It provides new and better options for the preparation of drugs containing compound (I), and is of great significance for drug development.

Owner:CRYSTAL PHARMA CO LTD

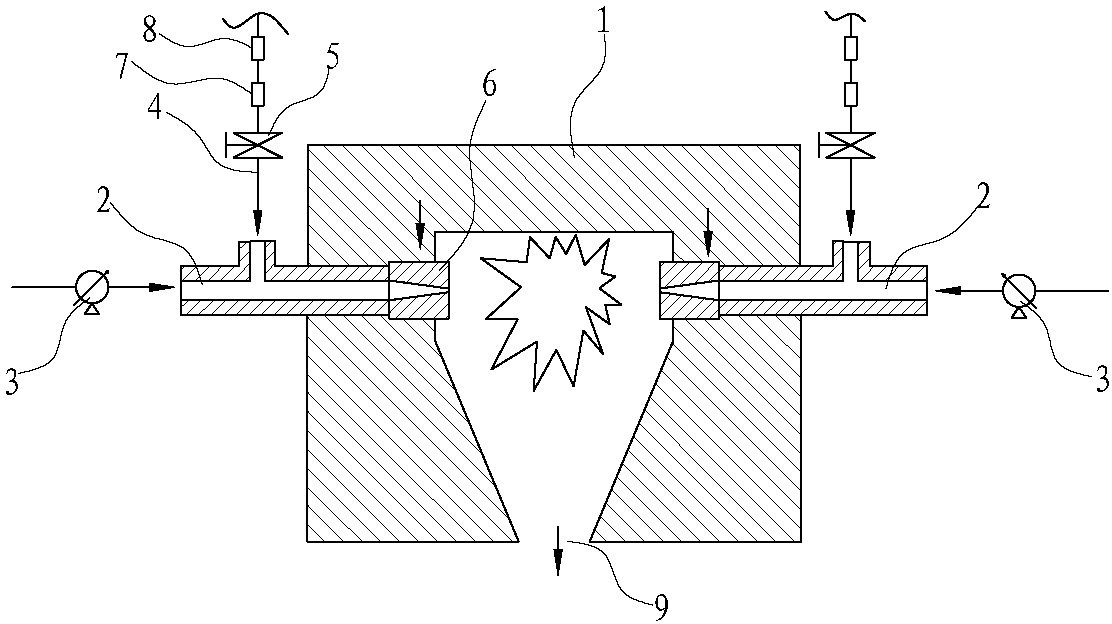

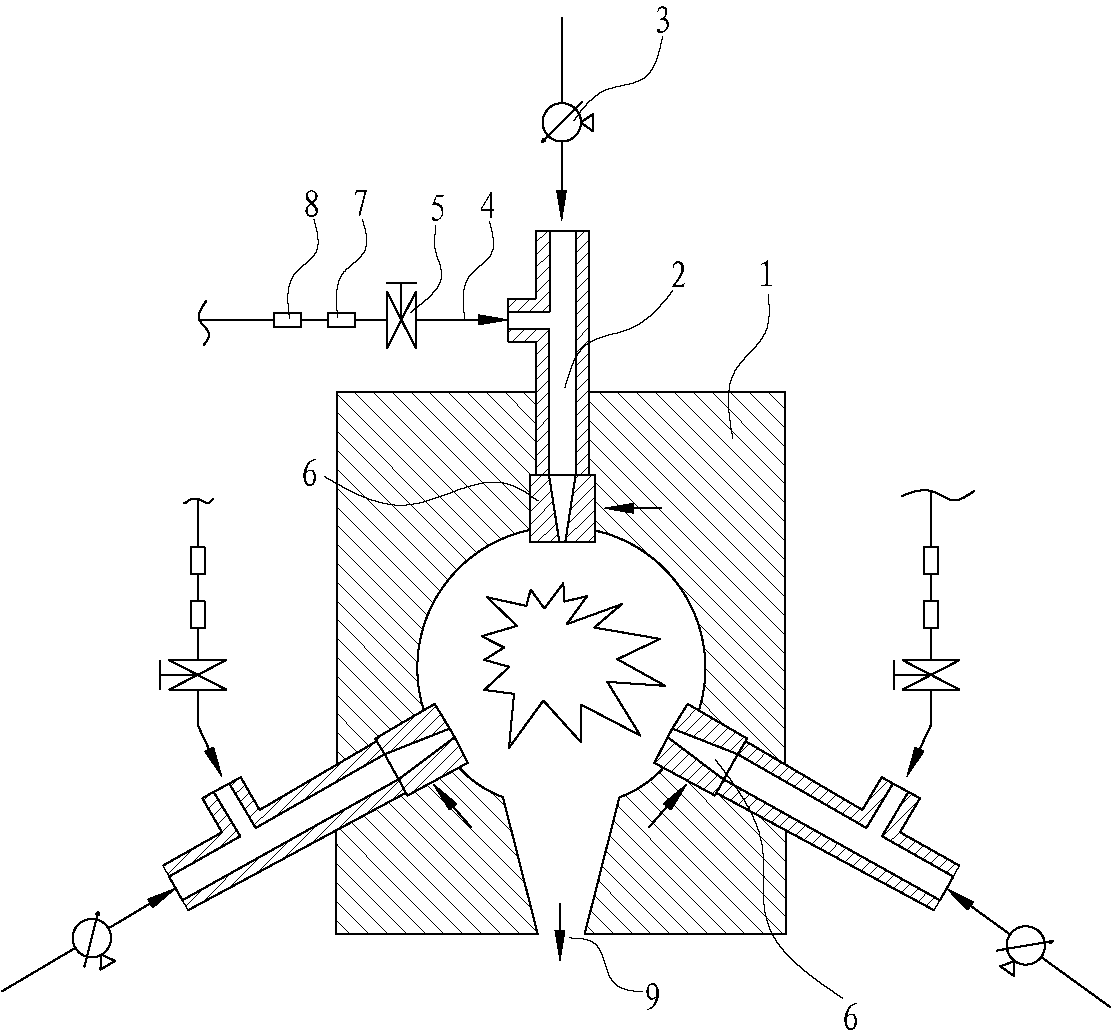

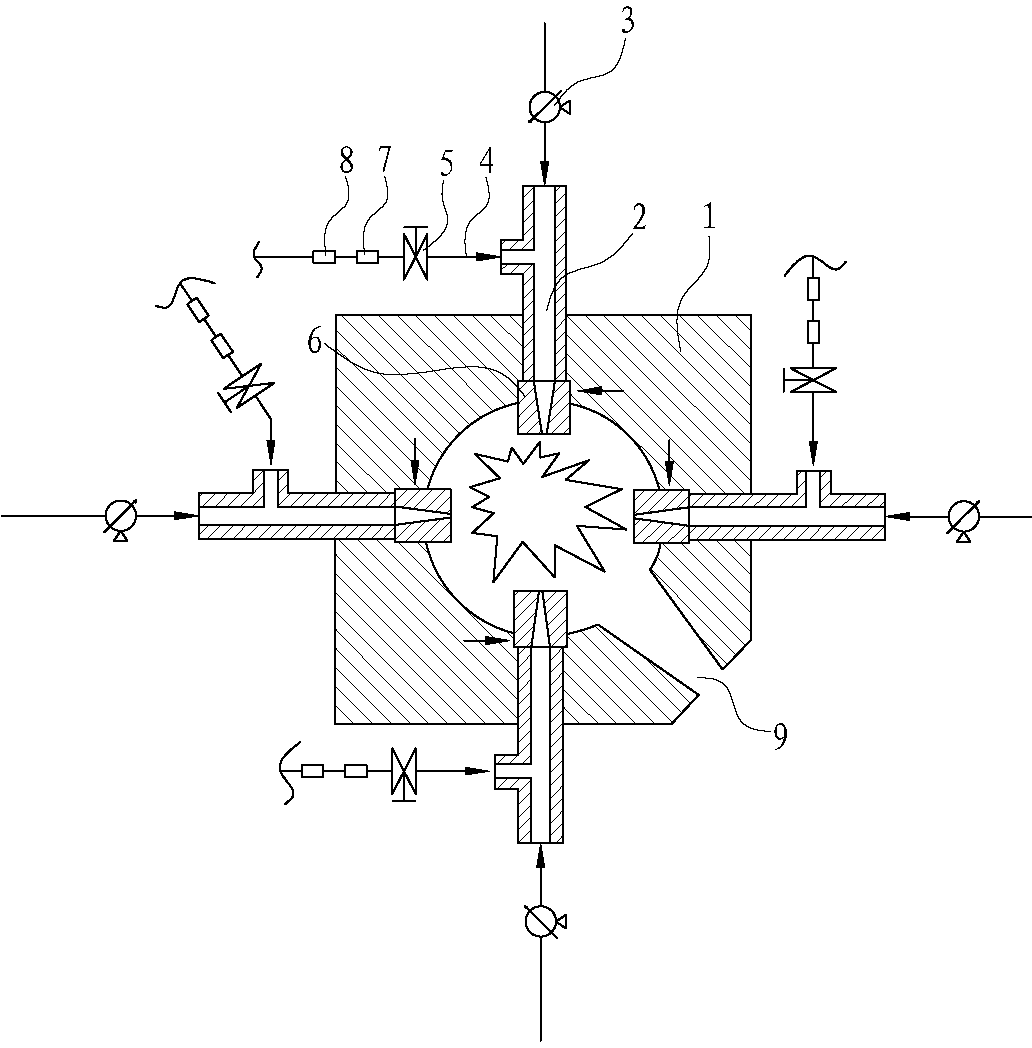

Multi-shaft common-rail pulse liquid micro-refinement apparatus

InactiveCN103394300AUnique craftCompact structureFlow mixersTransportation and packagingLiquid stateCommon rail

The invention discloses a multi-shaft common-rail pulse liquid micro-refinement apparatus. The apparatus comprises a refinement chamber, above two pipelines and a high pressure pump; the refinement chamber is provided with the above two pipelines, one ends of the pipelines are positioned outside the refinement chamber, have three-way structures, and are connected with the high pressure pump and a slurry raw material tube respectively, the slurry raw material tube is provided with a valve, the other ends of the pipelines are positioned in the refinement chamber and are provided with nozzles, the central shafts of the nozzles intersect in the refinement chamber, and the refinement chamber is provided with a material outlet. The apparatus which rapidly breaks and refines the material through utilizing the superposed energy has the characteristics of unique technology, compact structure, stable performances, strong effect, multifunction and the like. The apparatus is mainly used for the controllable refinement treatment of the material in a liquid state, and has the compounding, surface treatment and emulsification functions, and the obtained treated product has a smallest particle size reaching above 1nm nanometer level dimension, has particle size specification uniformity reaching above 80% and an improved functionality.

Owner:XIAMEN TENGYUAN RESOURCE APPL TECH DEV

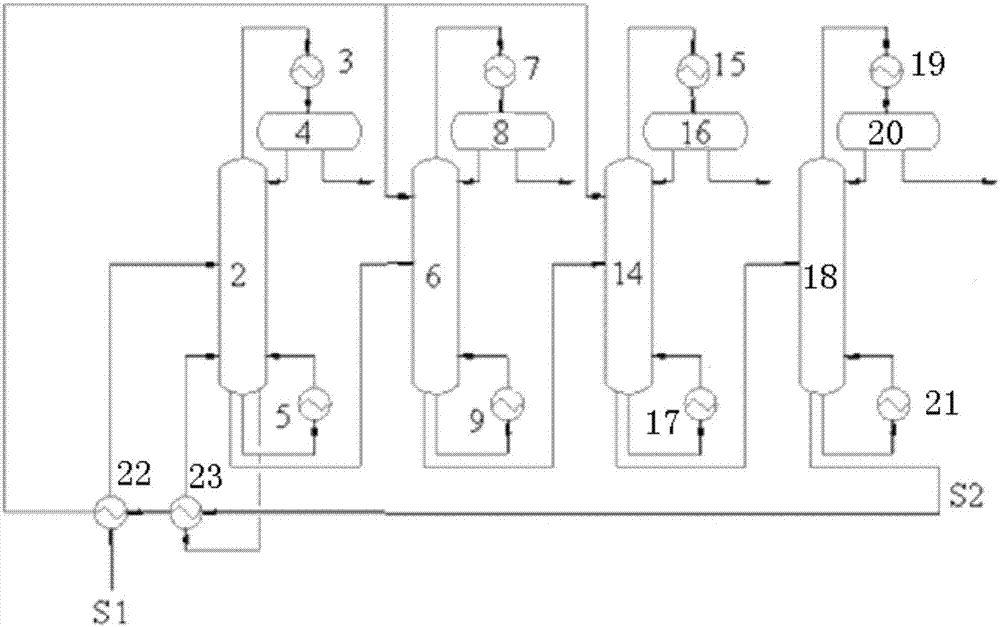

Energy-saving rectification system and energy-saving rectification method for purifying fusel oil

ActiveCN107488104BOmit investmentReduce energy consumptionOrganic compound preparationChemical industryPhysical chemistryDistillation method

The invention discloses an energy-saving rectification system for purifying fusel oil. The system comprises a fusel oil feeding heat exchanger (22), a methanol rectification column (2), an ethanol rectification column (6), a fusel rectification column (14), and an extractant recovery column (18), wherein a methanol rectification column bottom heat exchanger (23) is further arranged at the bottom of the methanol rectification column (2), a fusel oil feeding line (S1) passes through the fusel oil feeding heat exchanger (22) and then is introduced into the methanol rectification column (2), a bottom discharging line of the methanol rectification column (2) is taken as a feeding line of the ethanol rectification column (6), a bottom discharging line of the ethanol rectification column (6) is taken as a feeding line of the fusel oil rectification column (14), a bottom discharging line of the fusel oil rectification column (14) is taken as a feeding line of the extractant recovery column (18), a bottom discharging line (S2) of the extractant recovery column passes through the methanol rectification column bottom heat exchanger (23) at the bottom of the methanol rectification column (2) and the fusel oil feeding heat exchanger (22) in sequence for heat exchange and then is divided into two branches, one of which is introduced to the ethanol rectification column (6) and the other is introduced to the fusel rectification column (14).

Owner:高能时代环境(滕州)环保技术有限公司 +1

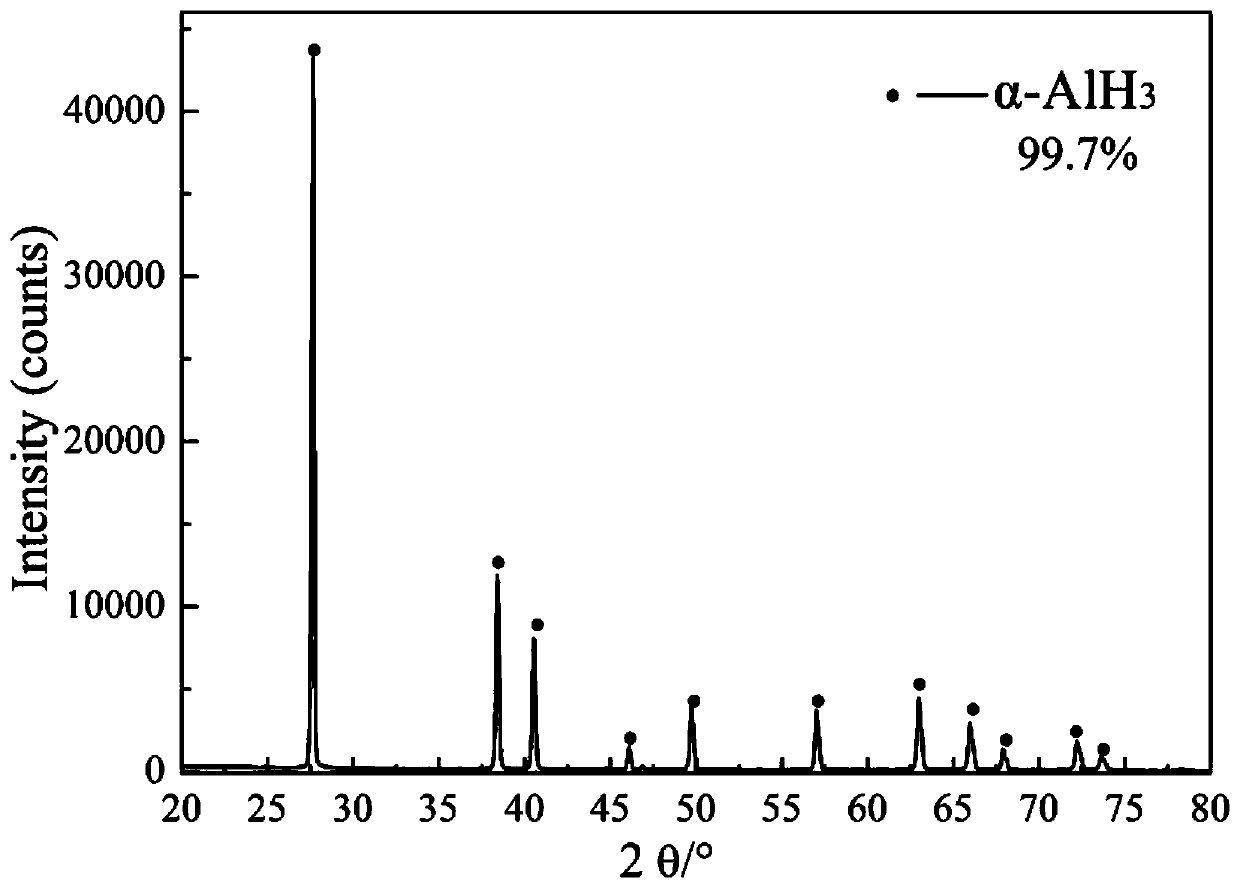

A kind of process method for preparing α-aluminum trihydride with sodium borohydride catalysis

ActiveCN107032302BReduce operation processLess impuritiesMonoborane/diborane hydridesMetal/metal-oxides/metal-hydroxide catalystsCalcium borohydrideFuel cells

The invention discloses a process method for preparing alpha-aluminum hydride by sodium borohydride catalysis. The method comprises a step (1) of preparing a catalyst solution; a step (2) of preparation of alpha-aluminum hydride; and a step (3) of product aftertreatment. The process method for preparing alpha-aluminum hydride by sodium borohydride catalysis can be implemented at a low temperature and normal pressure, and is suitable for industrial production. The obtained alpha-aluminum hydride is single in crystal form, the single-batch conversion rate is 86.5% or above, the purity reaches 98%, the thermal stability is high, and the alpha-aluminum hydride is favorable for being applied to fields of energetic materials, propellants and fuel cells and the like.

Owner:河南纳宇新材料有限公司

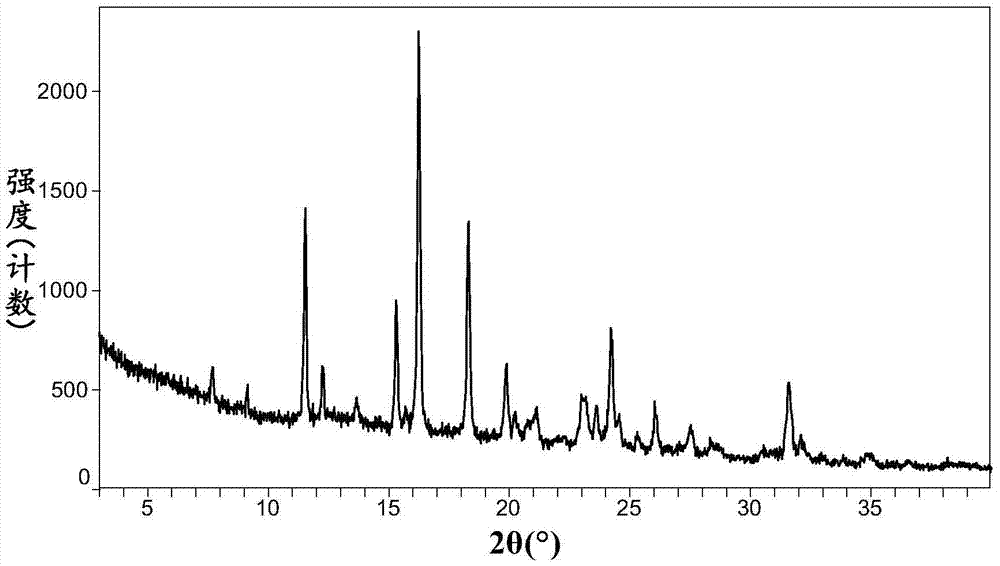

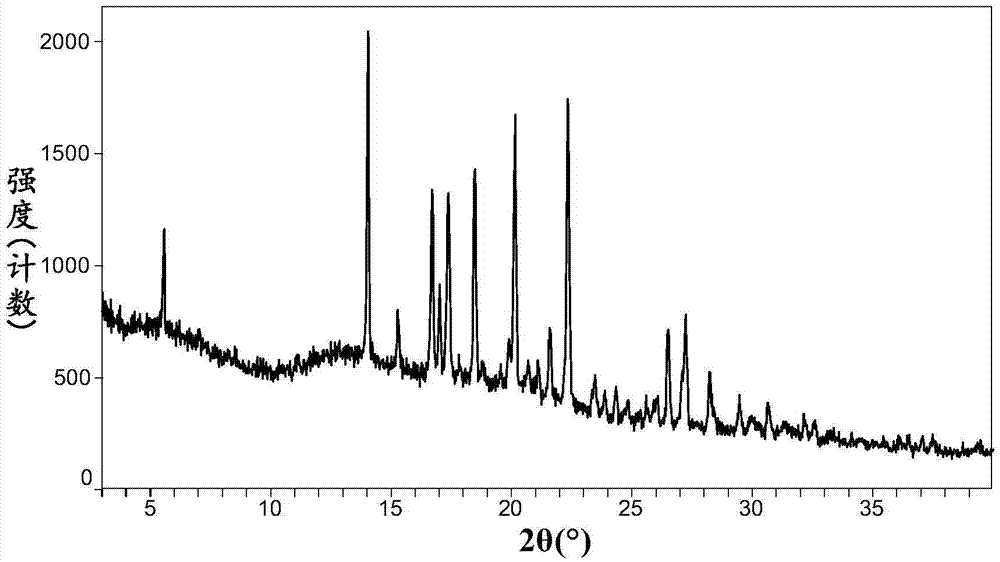

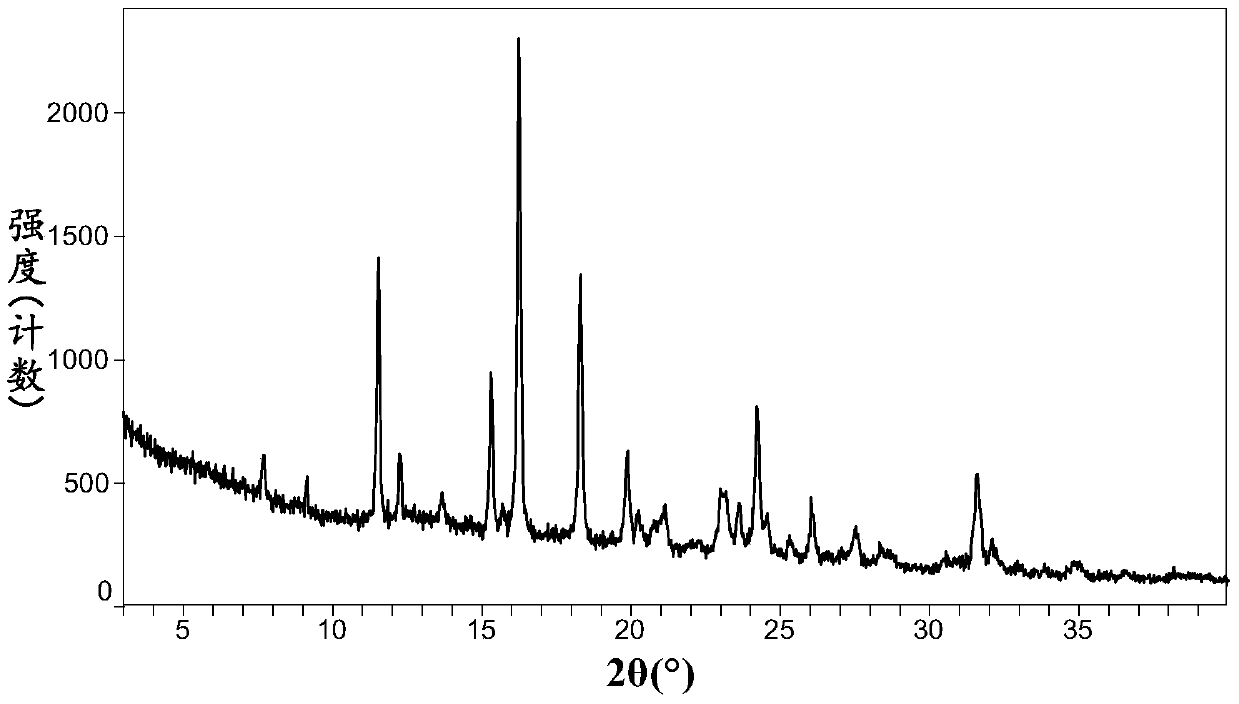

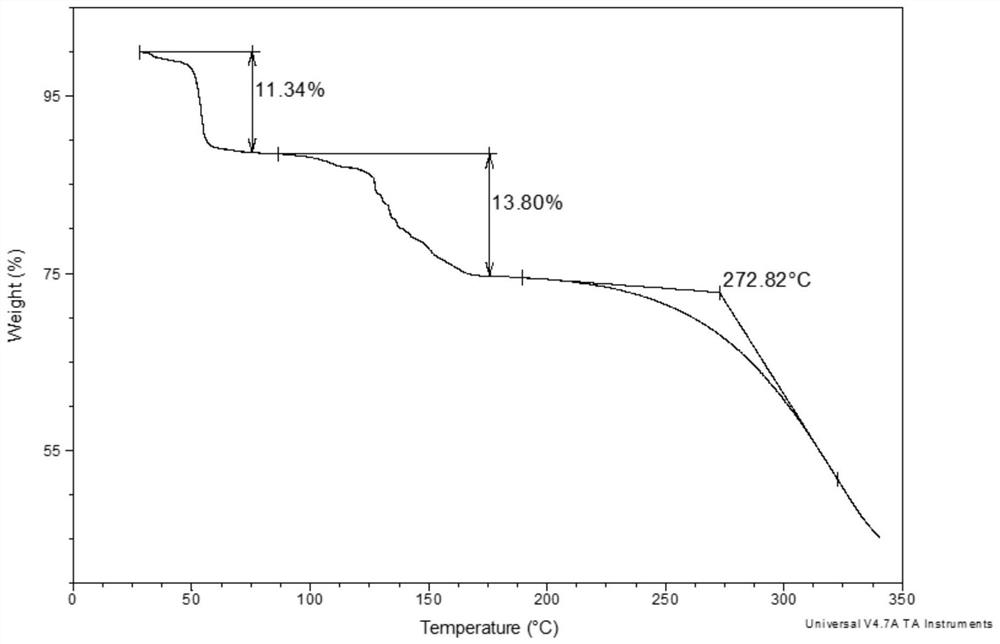

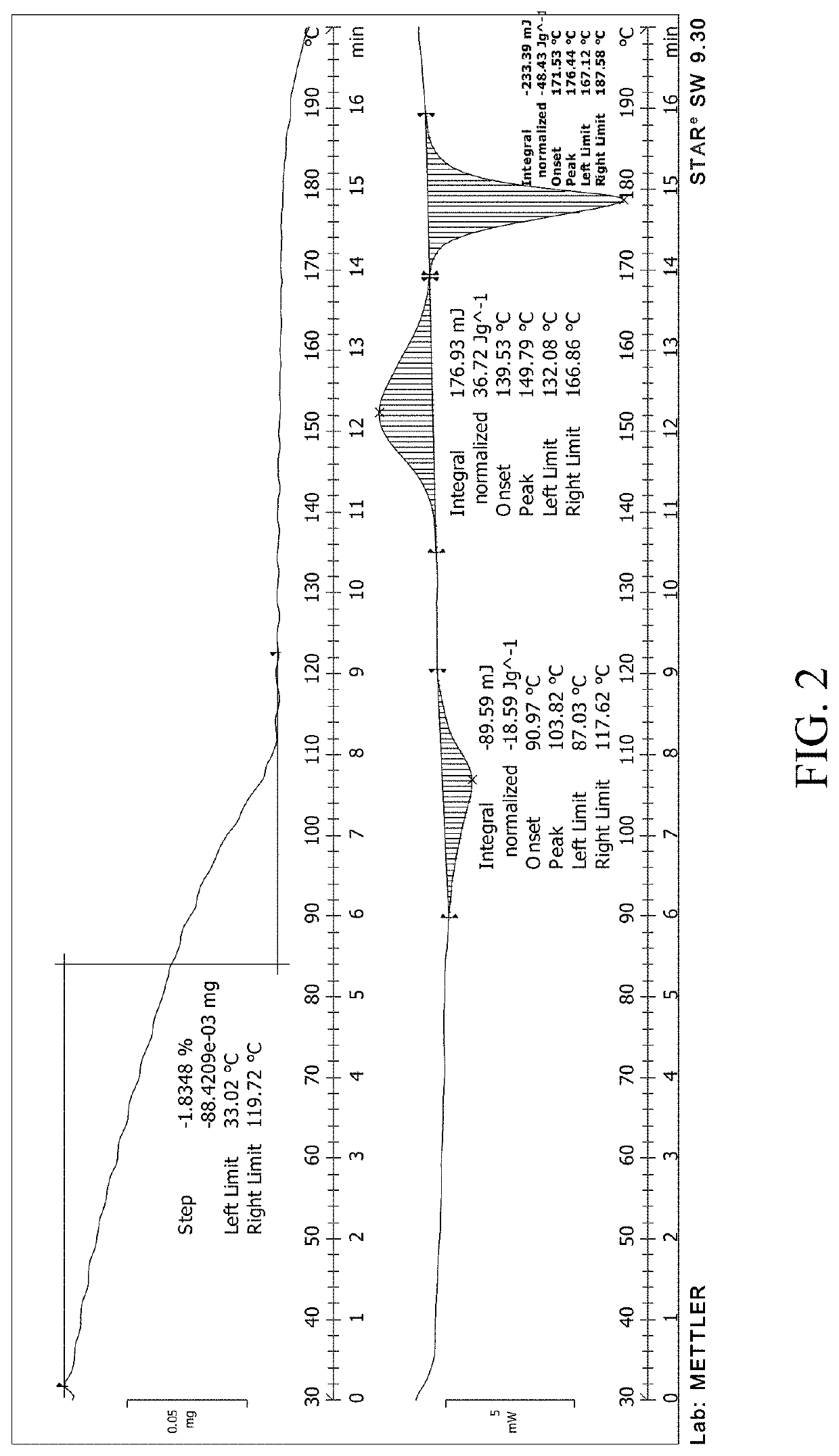

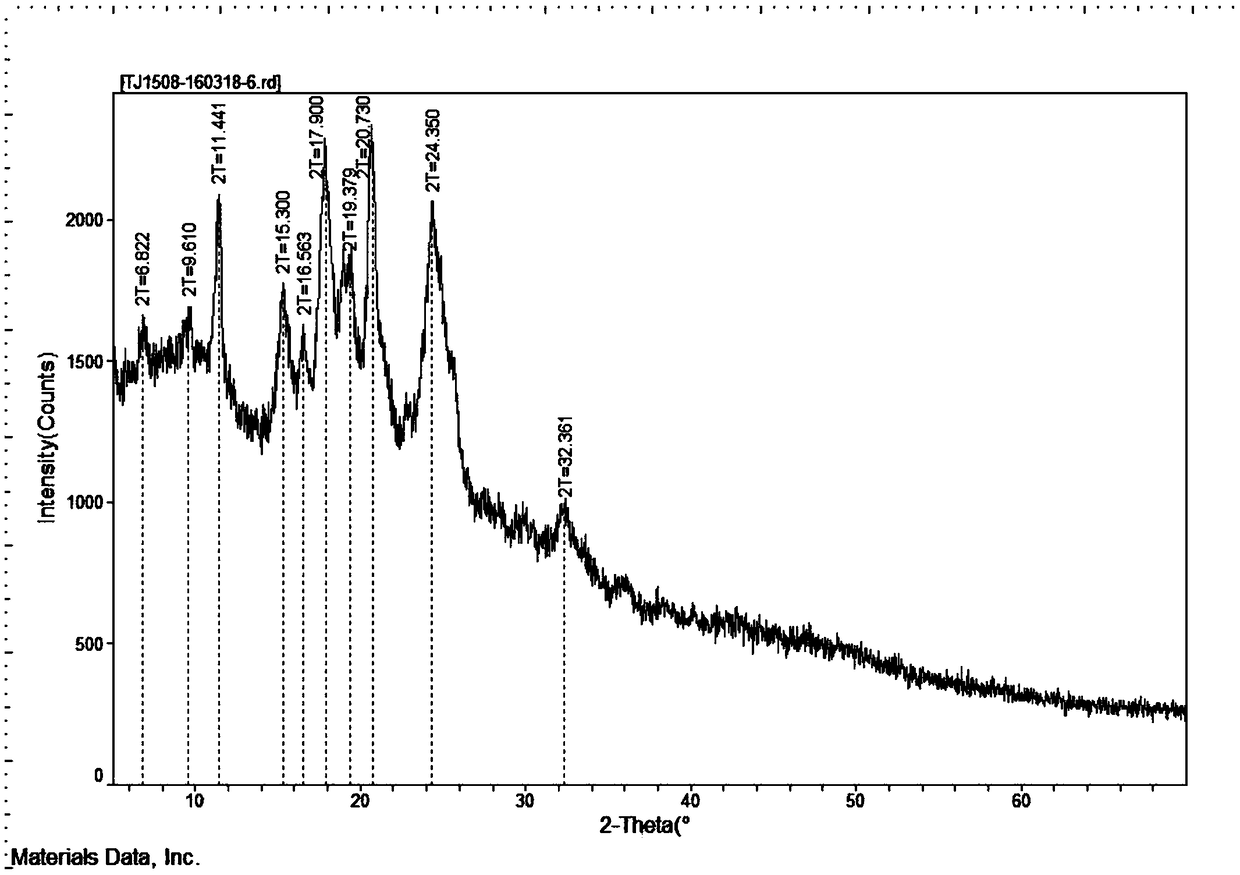

A kind of crystalline form b of sodium salt of oxazolidinone antibacterial drugs and its preparation method and application

InactiveCN106749321BPurity unchangedImprove stabilityAntibacterial agentsOrganic chemistry methodsChemical industryOrganic solvent

The invention discloses an oxazolidinone type antibacterial medicine sodium salt crystal form B, and a preparation method and application thereof, and belongs to the field of medicine chemical industry. The crystal form B comprises the following 2 theta reflection angle measuring characteristic peaks in an X-ray powder diffraction spectrum: 11.4+ / -0.2 degrees, 15.3+ / -0.2 degrees, 16.6+ / -0.2 degrees, 17.9+ / -0.2 degrees, 20.7+ / -0.2 degrees and 24.4+ / -0.2 degrees. The crystal form has the advantages that better stability is realized; the organic solvent residue is lower; the moisture absorption is avoided; better flowability and preparation processing performance are realized; important application significance is realized in the antibiotic medicine preparation.

Owner:SHANGHAI INST OF MATERIA MEDICA CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com