Patents

Literature

31results about How to "Reduce operation process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

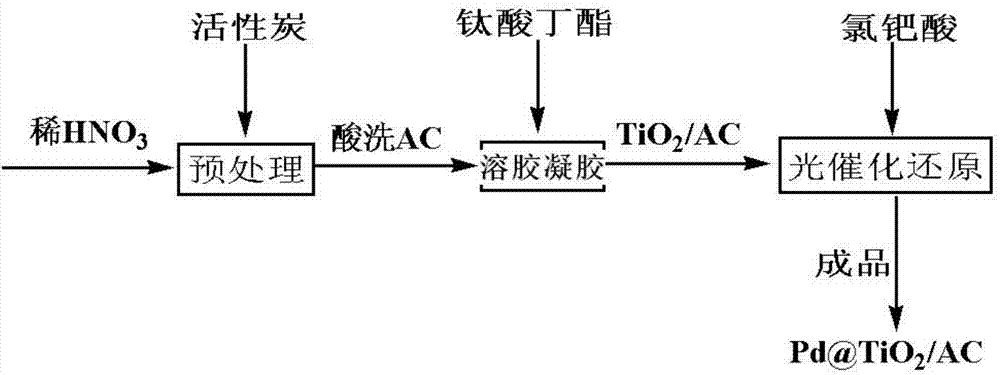

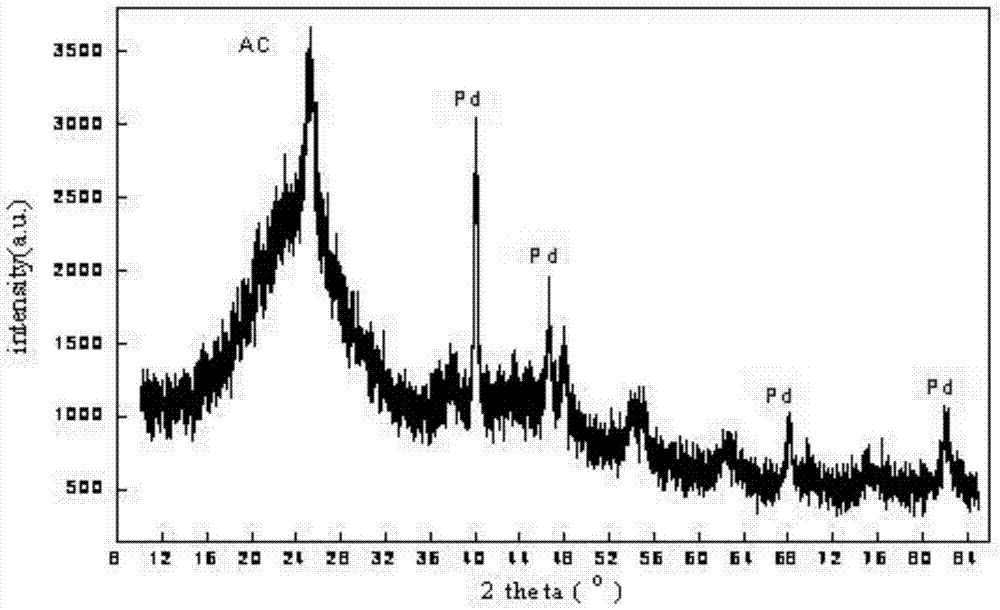

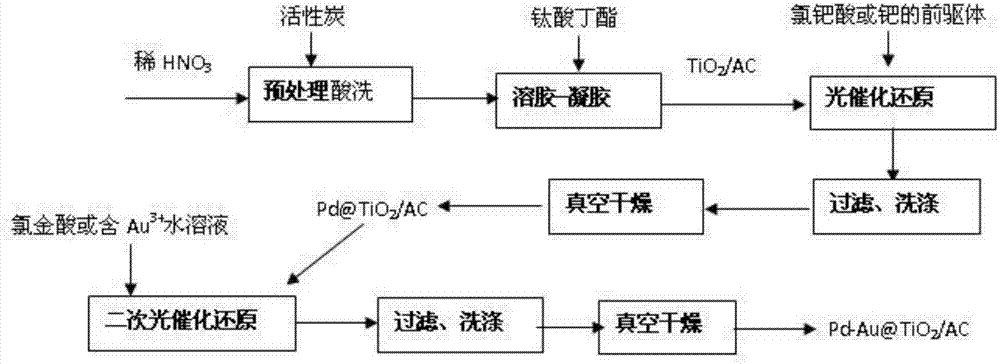

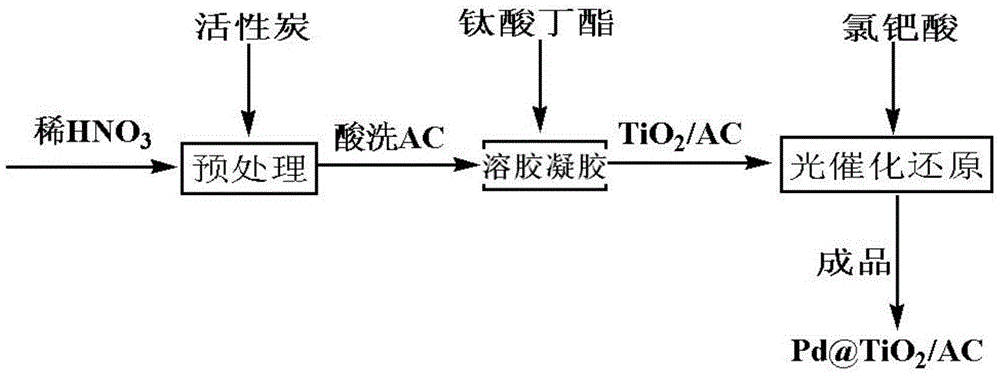

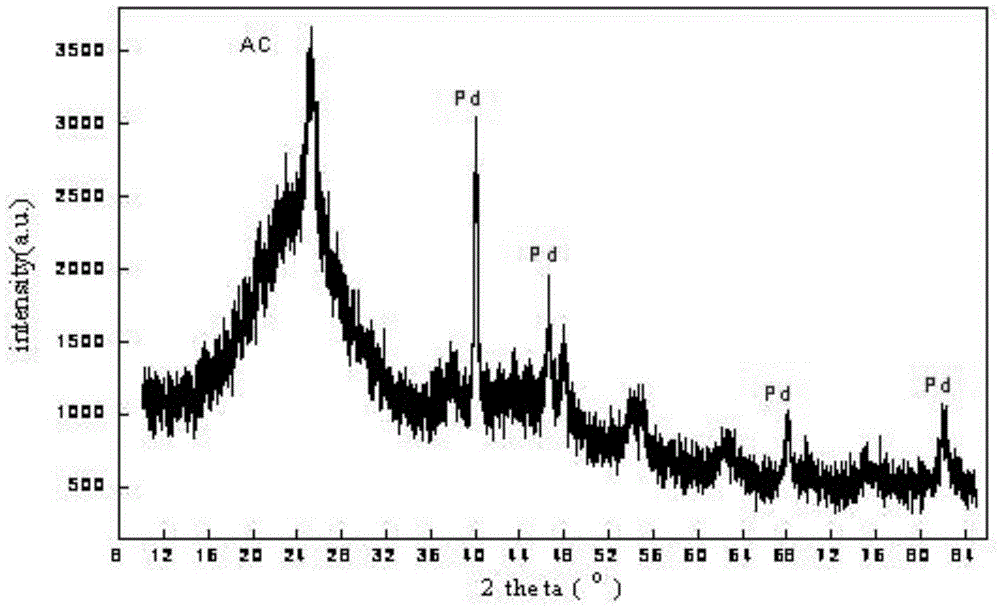

Palladium carbon catalyst as well as preparation method and application thereof

ActiveCN103691431AThe load rate is close to or even fullyFull loadOrganic compound preparationCarbonyl compound preparationActivated carbonPalladium on carbon

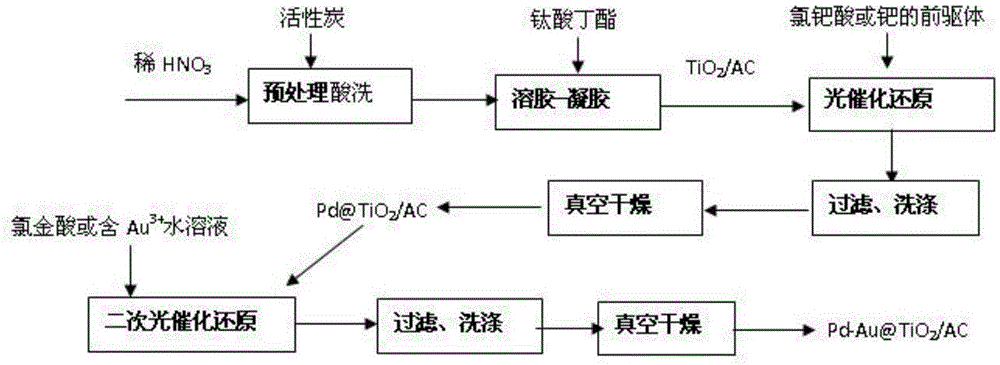

The invention relates to a palladium carbon catalyst which comprises the following components: (1) nanometer TiO2-modified active carbons are used as composite carriers; (2) Pd nanometer particles are used as active components, wherein the strong interaction between metals and the carriers exists in the active components and TiO2 on the composite carriers to form a Pd@TiO2 structure so as to form structural Pd@TiO2 / active carbons of the catalyst.

Owner:XIANGTAN UNIV

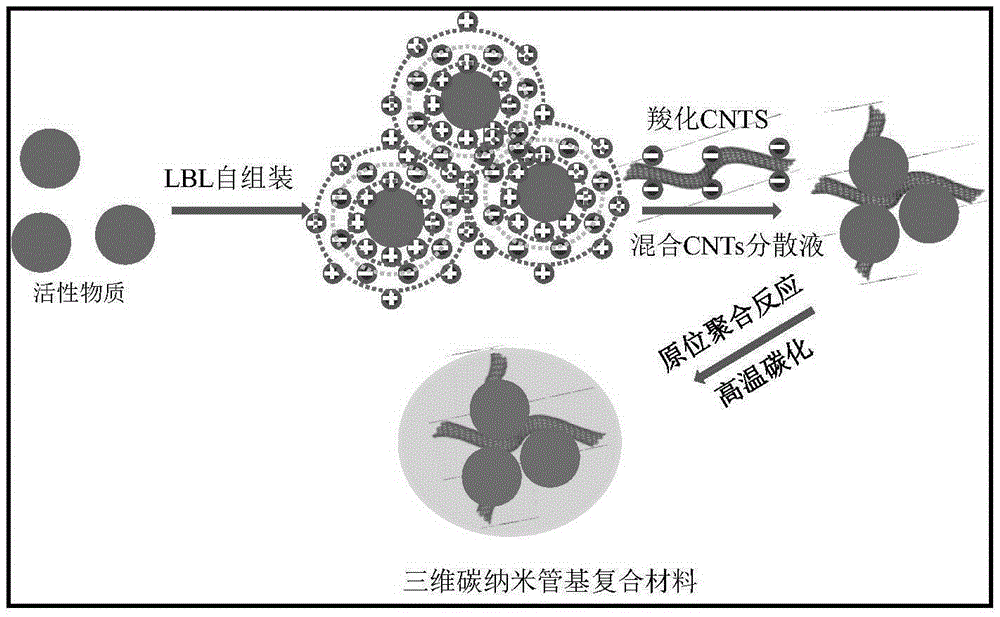

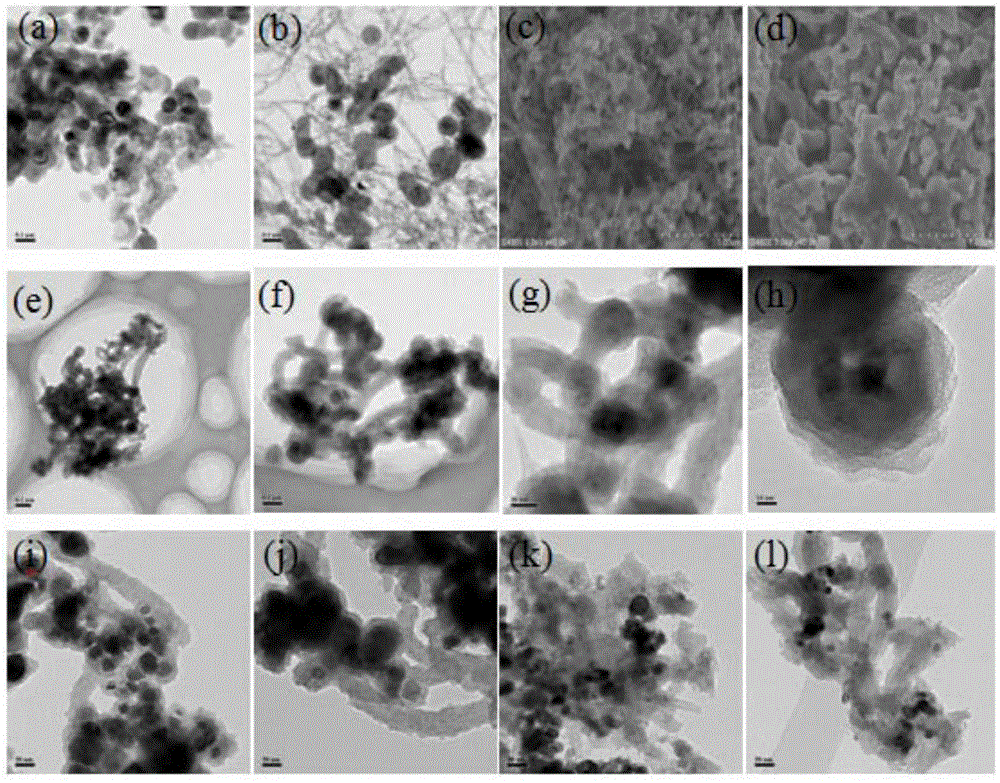

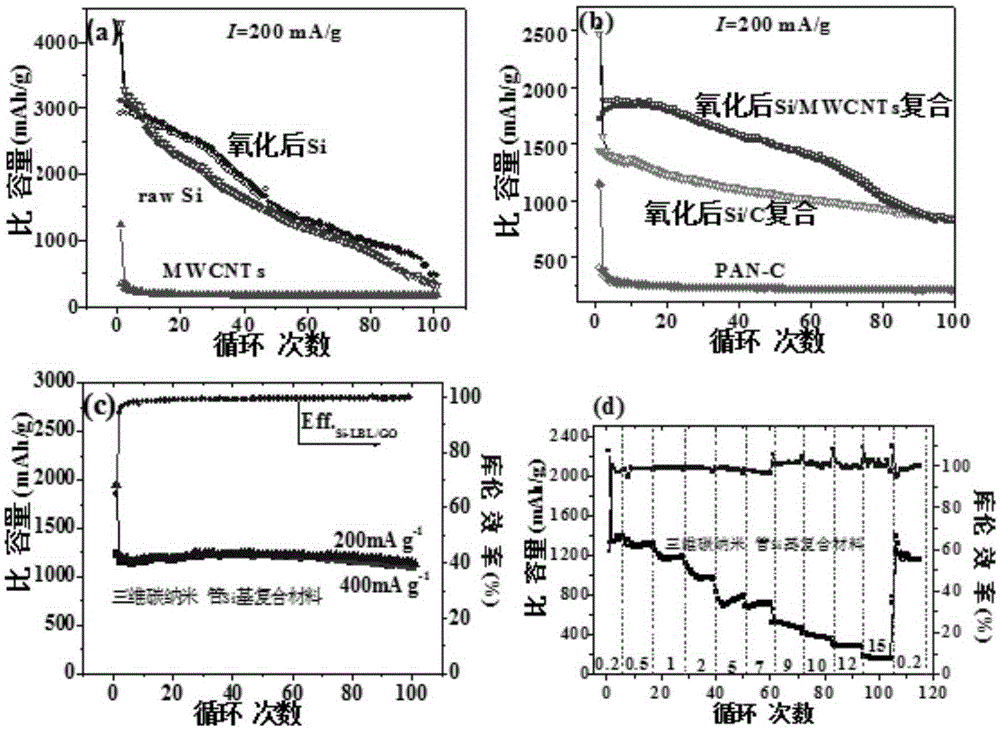

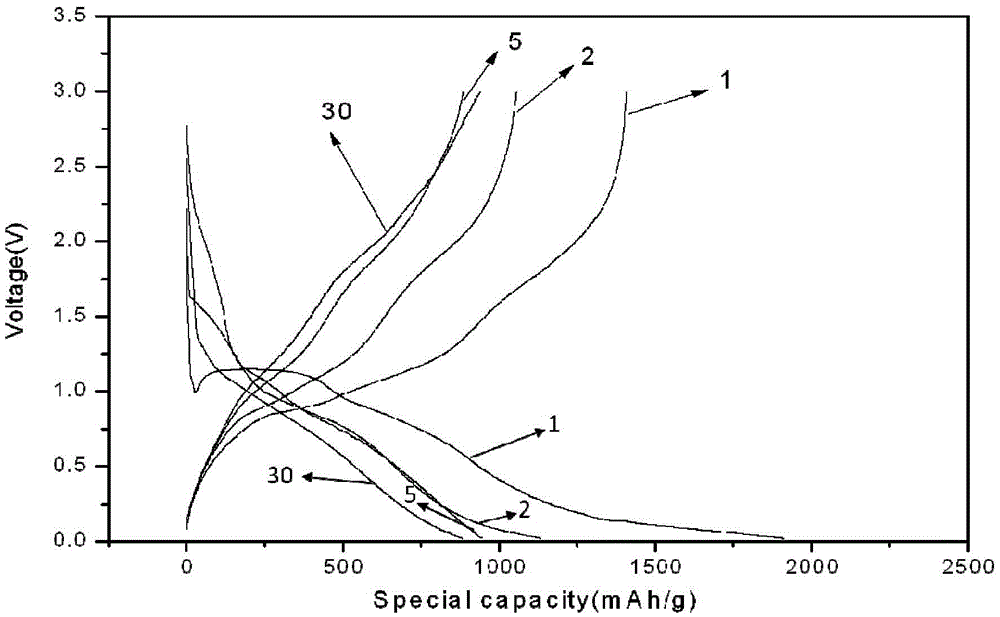

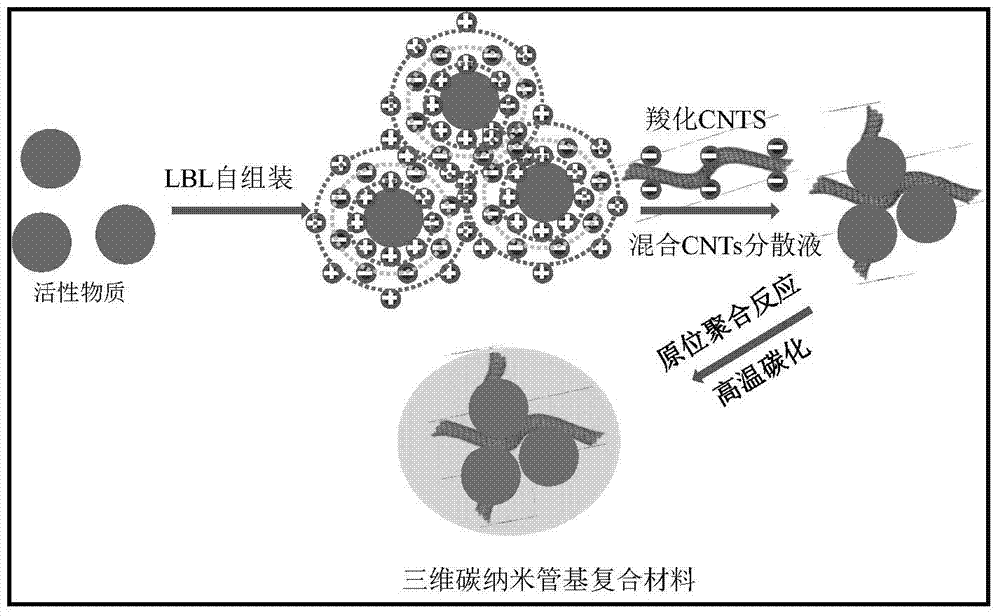

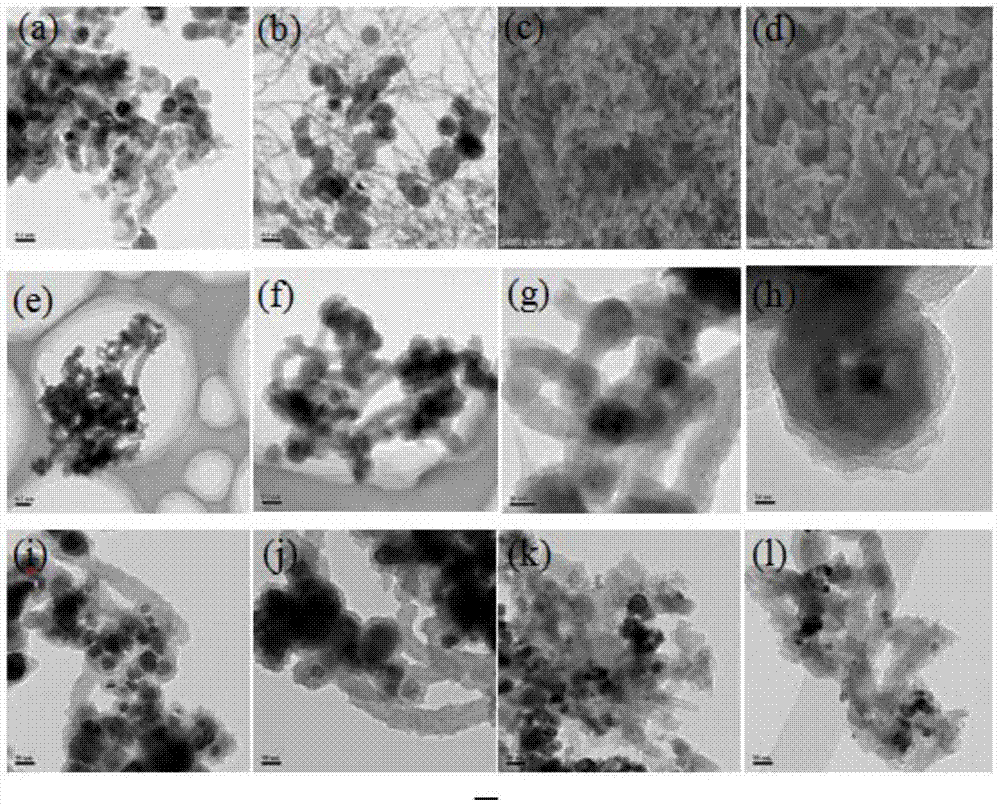

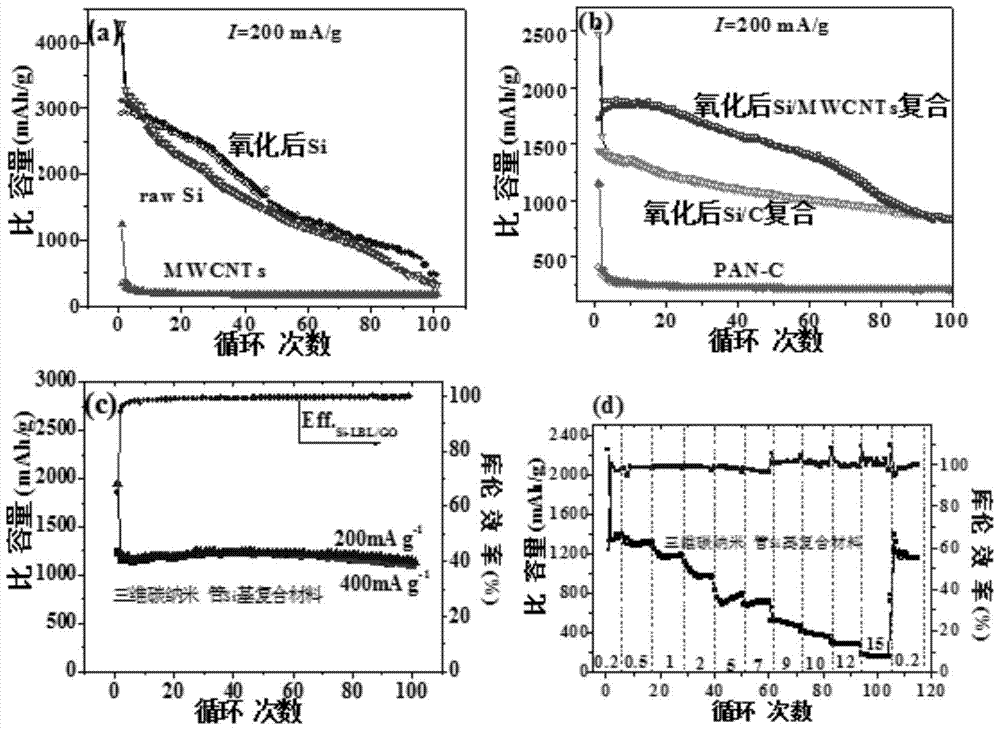

High-performance three-dimensional carbon nanotube composite negative electrode material, preparation method therefor and application thereof

ActiveCN105390687AImprove cycle performanceSignificantly improved cycle performanceMaterial nanotechnologyCell electrodesCarbon nanotubeLayer by layer self assembly

The invention discloses a preparation method for a high-performance three-dimensional carbon nanotube composite negative electrode material. The preparation method comprises: by taking a carboxylated carbon nanotube as a three-dimensional network framework and taking a high-capacity material subjected to layer by layer self-assembly and modification as an active substance, uniformly mixing the carbon nanotube with the active substance under the action of electrostatic attraction; and then performing in-situ coating by taking a mixed element-containing N or S-doped carbon source as a three-dimensional coating layer, and performing high-temperature treatment to obtain the high-performance three-dimensional carbon nanotube composite negative electrode material. The invention furthermore discloses the high-performance three-dimensional carbon nanotube composite negative electrode material and an application thereof. According to the preparation method, the cycle performance of the active substance is remarkably improved, and the capacity of the composite material can be controllably adjusted by controlling a ratio of the carbon nanotube to the active substance. In addition, a solvent used in the method is water, so that the method is environmentally-friendly, good in repeatability and low in cost, and has relatively high potential of large-scale application and good industrialized prospects.

Owner:新疆护翼新材料科技有限公司

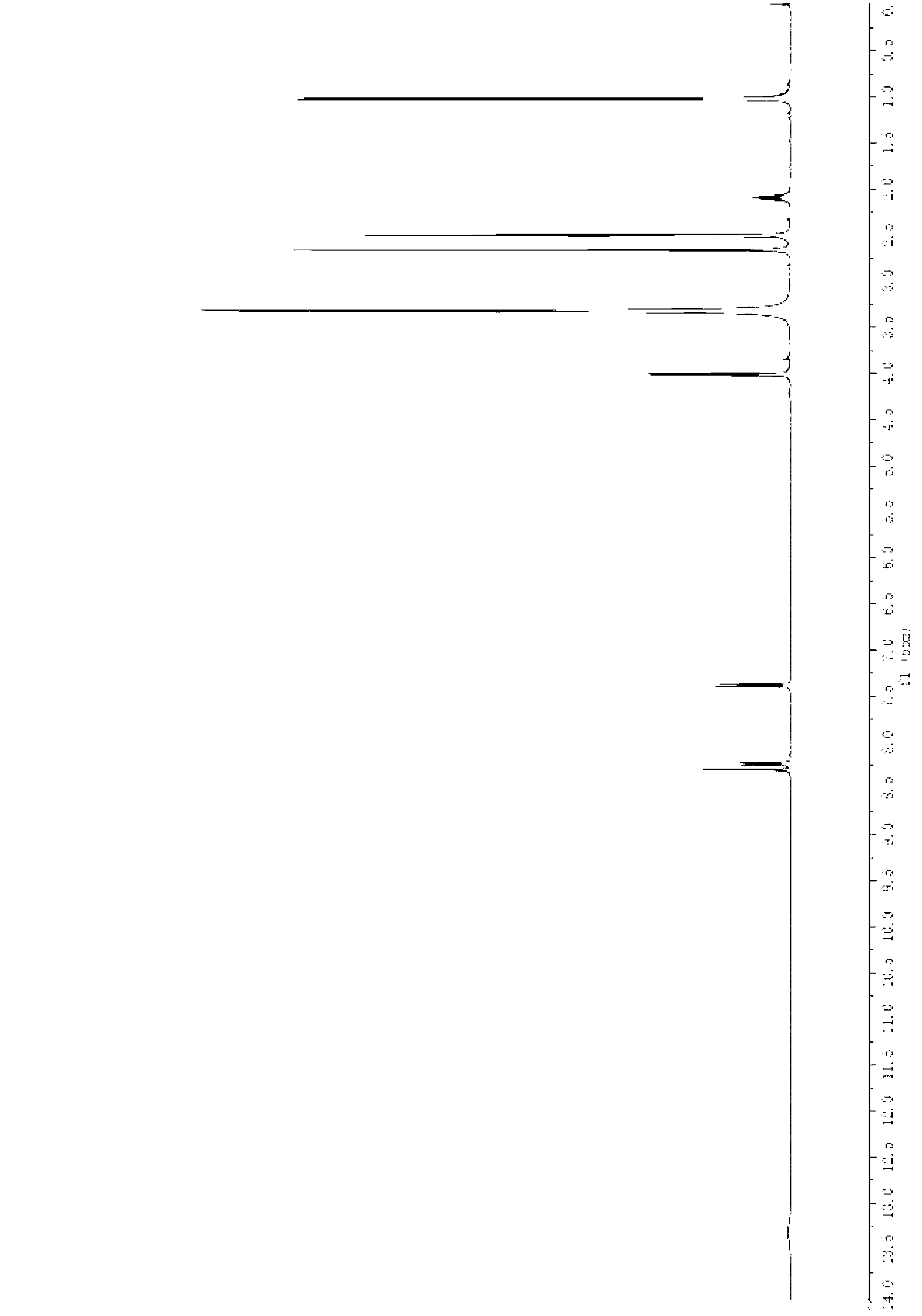

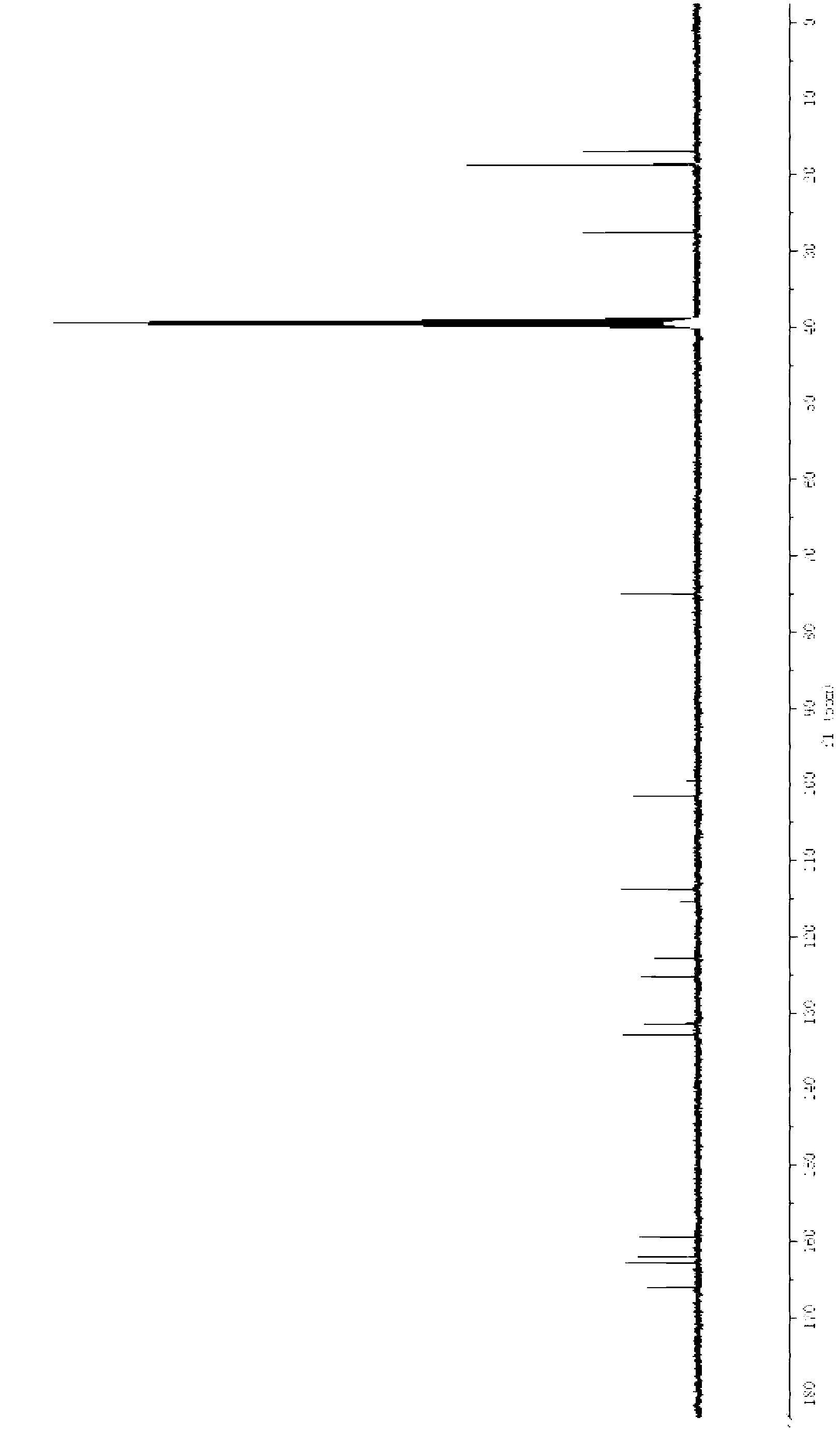

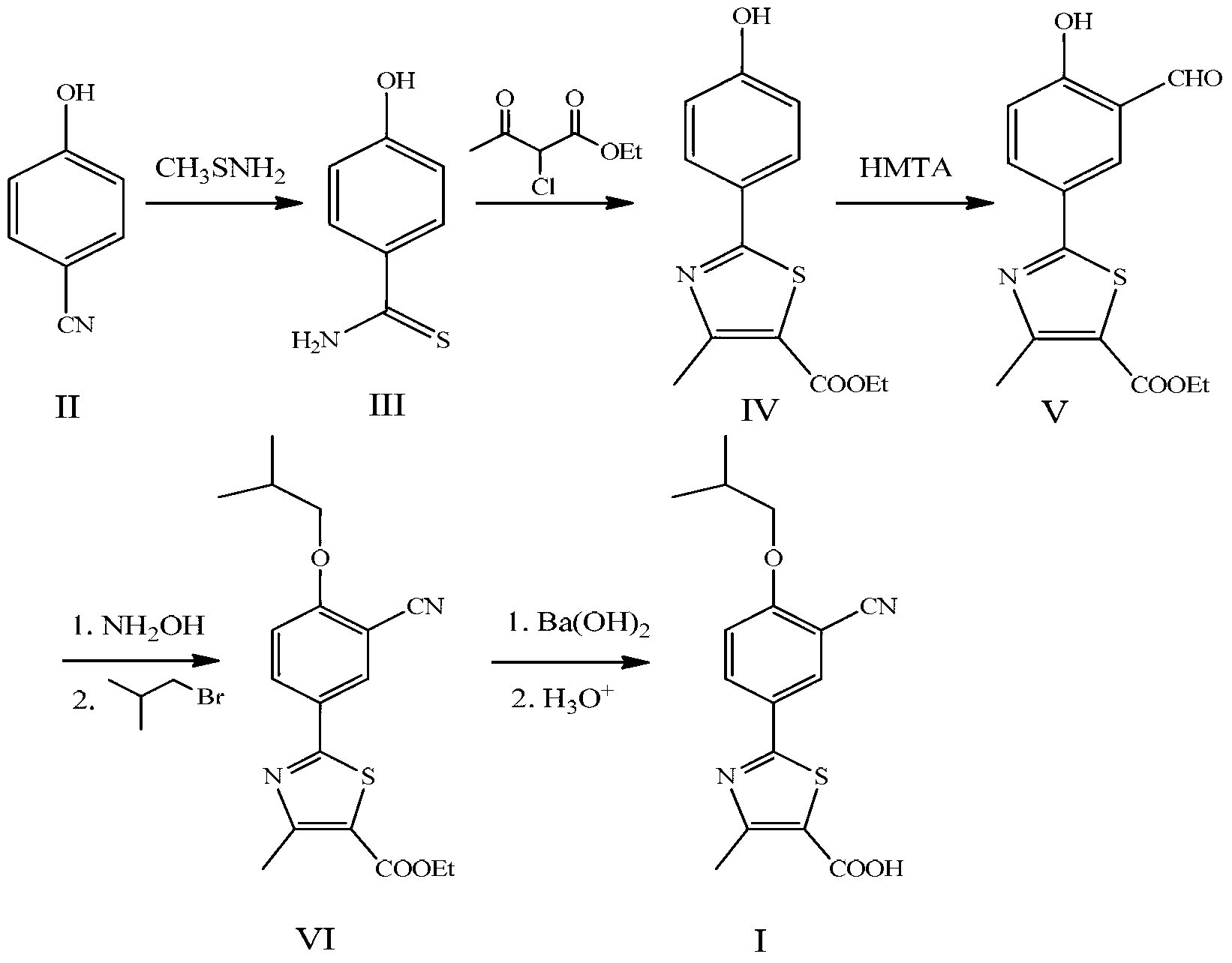

Preparation method for febuxostat

InactiveCN103304512ALow costReduce operation processOrganic chemistryHydroxylamine HydrochlorideToxic material

The invention discloses a preparation method for febuxostat. The preparation method for febuxostat comprises the following steps of: by using 4-hydroxybenzonitrile and thioacetamide as raw materials, and reacting in hydrochloric acid solution to prepare 4-hydroxythiobenzamide; carrying out a reaction on 4-hydroxythiobenzamide and 2-chloroacetoacetic acid ethyl ester to prepare 2-(4-hydroxylphenyl)-4-methylthiazol-5-carboxylic acid ethyl ester; carrying out a reaction on the obtained compound and hexamine in the mixed acid system of methanesulfonic acid and trifluoroacetic acid to prepare 2-(3-formyl-4-hydroxylphenyl)-4-methylthiazole-5-carboxylic acid ethyl ester; synthesising 2-(3-nitrile-4-isobutoxylphenyl) -4-methylthiazole-5-carboxylic acid ethyl ester from the compound, hydroxylamine hydrochloride, potassium carbonate, iso-butyl bromide and the like in a polar protonic solvent via a one-pot method; and finally hydrolyzing in an alkaline condition to obtain the target product, namely, febuxostat. The total yield of the preparation method for febuxostat disclosed by the invention is increased to 66%, the separation steps are reduced, any extremely toxic substance is not involved, and the environmental pollution is less.

Owner:SOUTH CHINA UNIV OF TECH

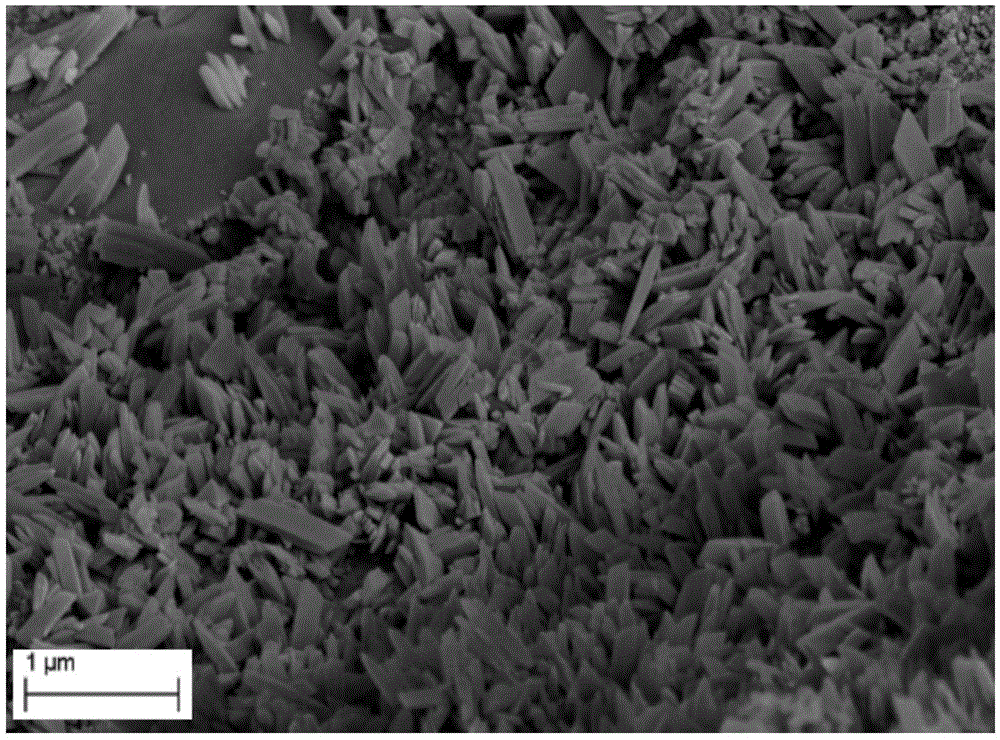

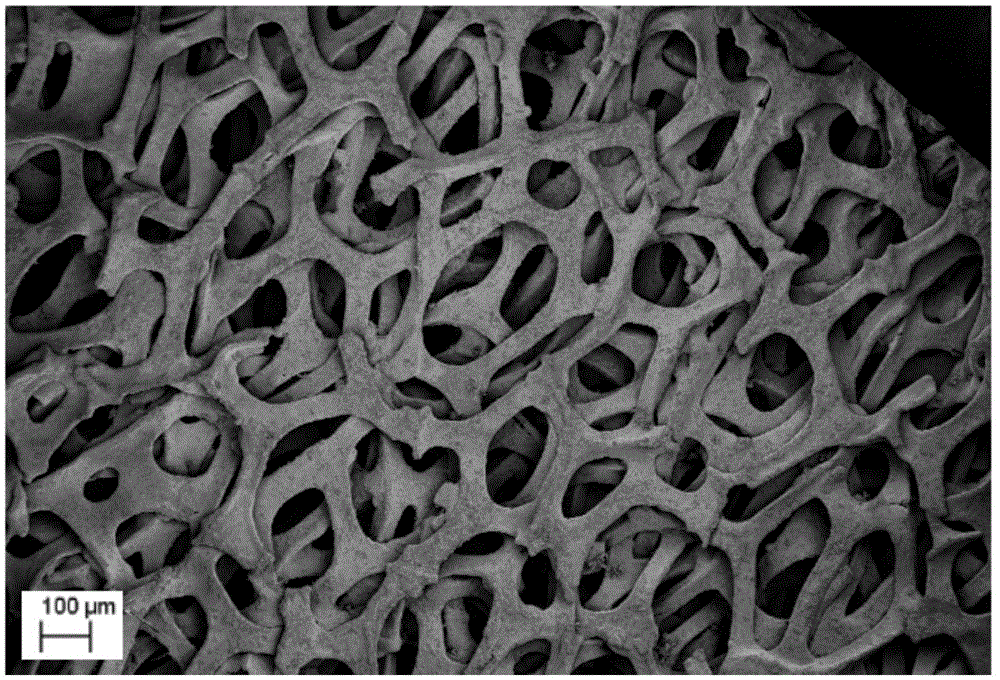

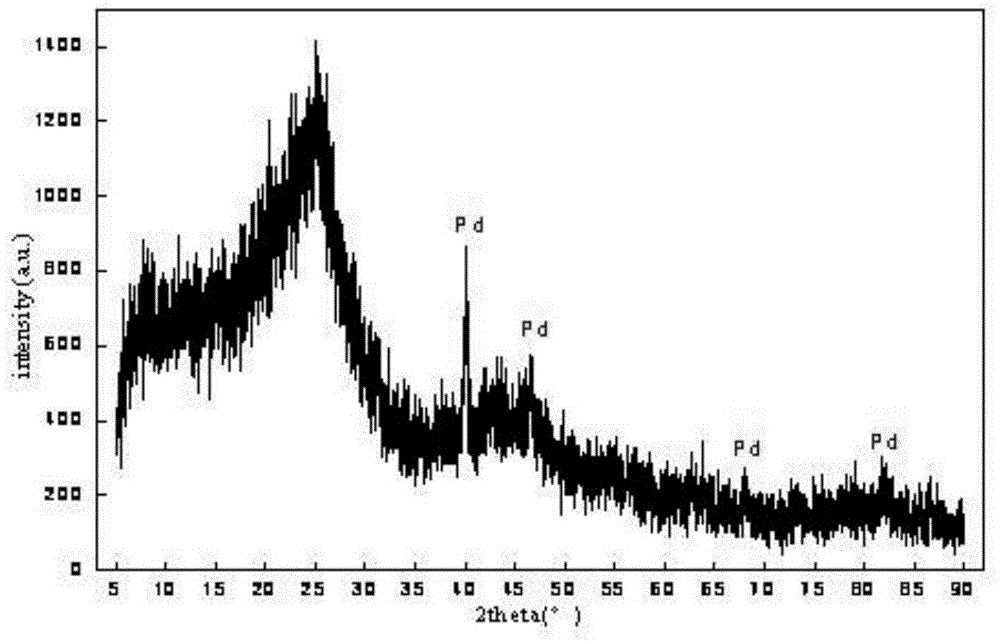

Metal catalyst, preparation method and application

ActiveCN103691434AThe load rate is close to or even fullyAvoid reunionOrganic compound preparationCarbonyl compound preparationCyclohexanoneActive component

The invention relates to a metal catalyst which comprises: 1) a nano TiO2 modified porous material as a composite carrier, and 2) a nano particle of at least one out of Pd and other transition metals as an active component, wherein the active component and TiO2 in the composite carrier have strong metal-carrier interaction to form a Pd@TiO2 structure or a Pd-M@TiO2 structure, thereby forming the Pd-M@TiO2 / porous carrier catalyst, and M is at least one out of the transition metals except Pd. The invention further relates to a preparation method of the catalyst, and an application of the catalyst in preparing cyclohexanone through selective phenol hydrogenation.

Owner:XIANGTAN UNIV

Lithium ion battery cathode and preparation method thereof

InactiveCN105489899ALarge specific surface areaImprove conductivityElectrode carriers/collectorsSecondary cellsTerephthalic acidLithium electrode

The invention relates to the field of lithium ion batteries, in particular to a lithium ion battery cathode and a preparation method thereof. According to the lithium ion battery cathode, a foam copper sheet serves as a current collector, and terephthalate cobalt serves as active substances. The lithium ion battery cathode is prepared from the foam copper sheet, terephthalic acid, cobalt-nitrate hexahydrate, N,N-dimethyl-formamide, anhydrous ethanol and deionized water. A hydrothermal reaction method is adopted for the preparation method, the active substances can directly grow on the surface of the foam cupper sheet and in pores, a traditional complicated coating technology is not needed, and the cathode applicable to lithium ion batteries can be further obtained. When the method is used for preparing the batteries, cost is low, operation is easy, and the prepared batteries are light and high in specific capacity.

Owner:CHANGAN UNIV

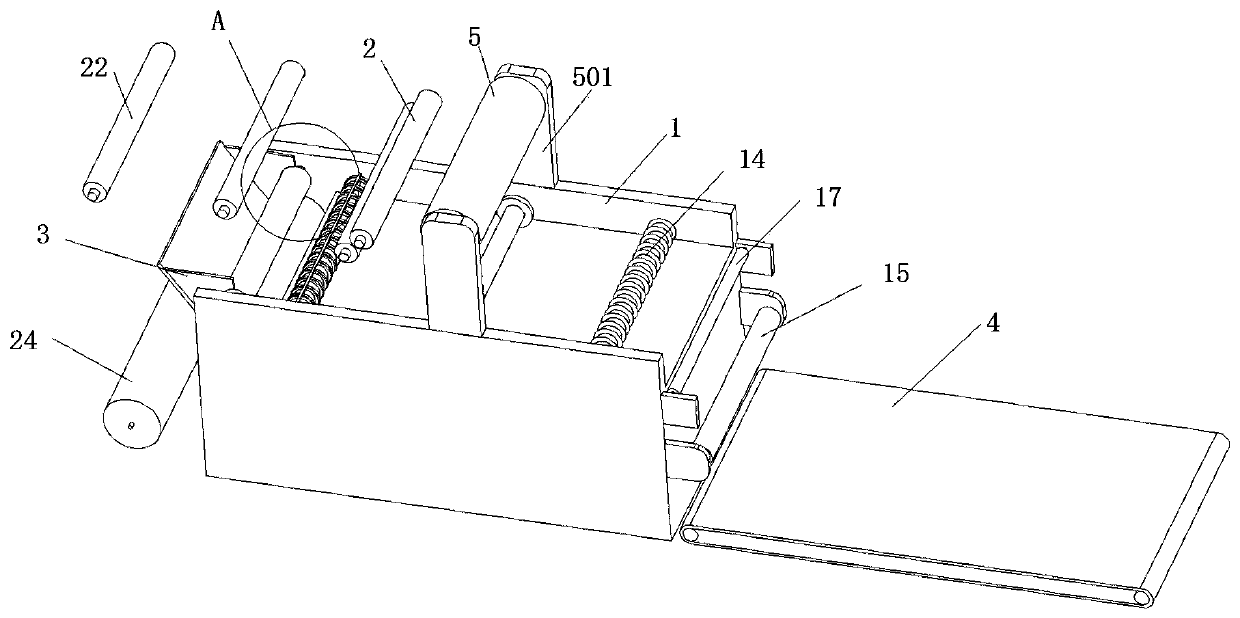

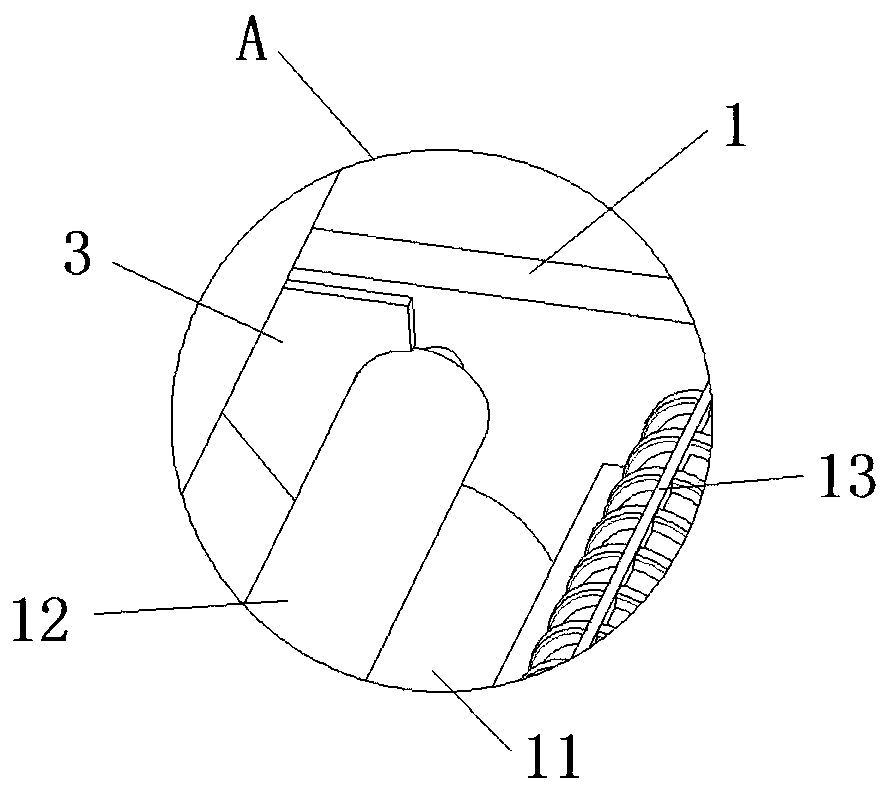

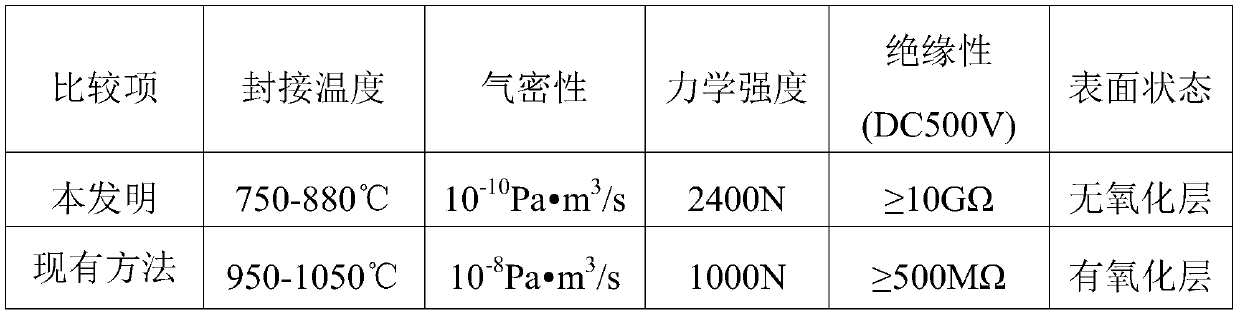

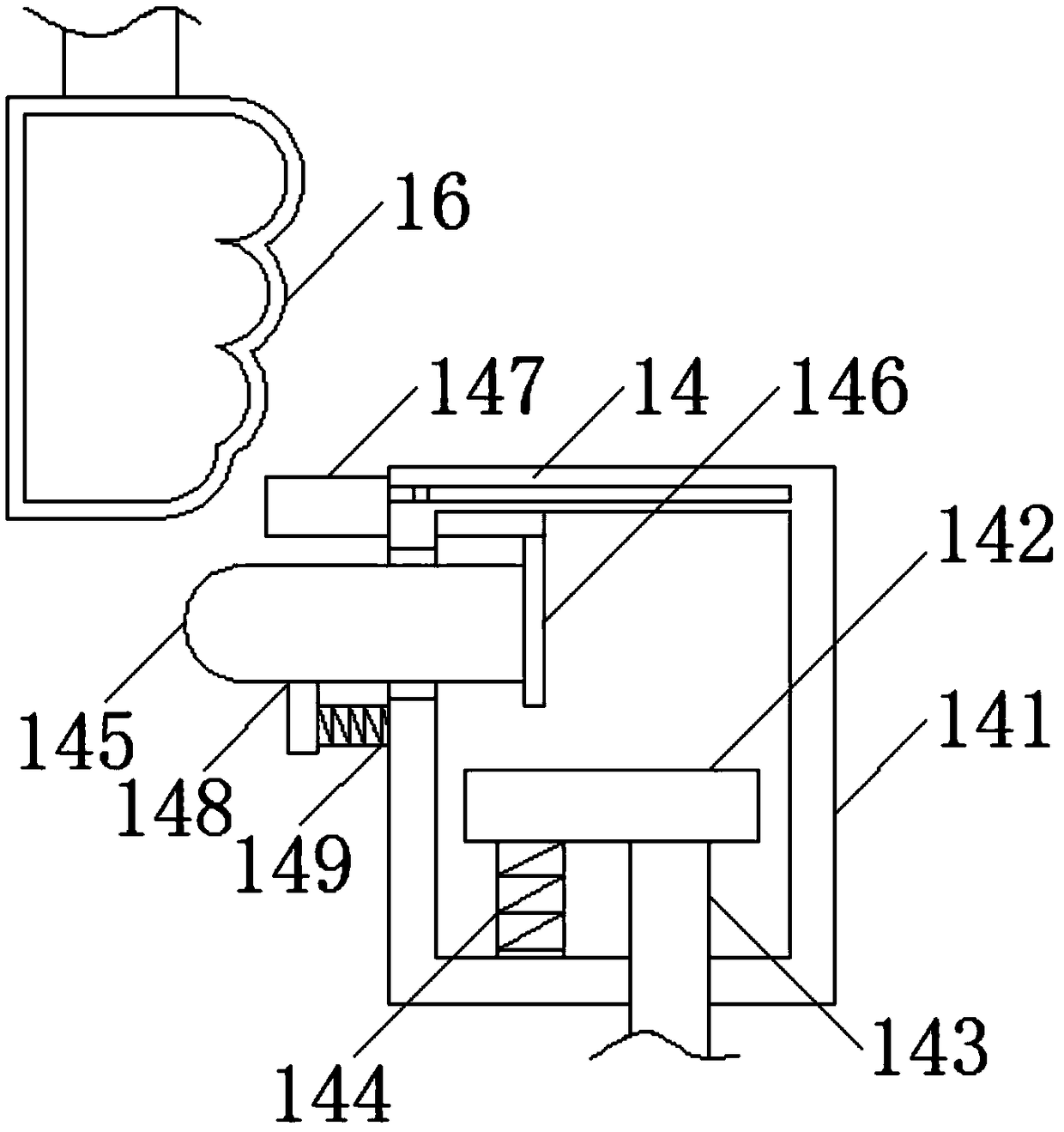

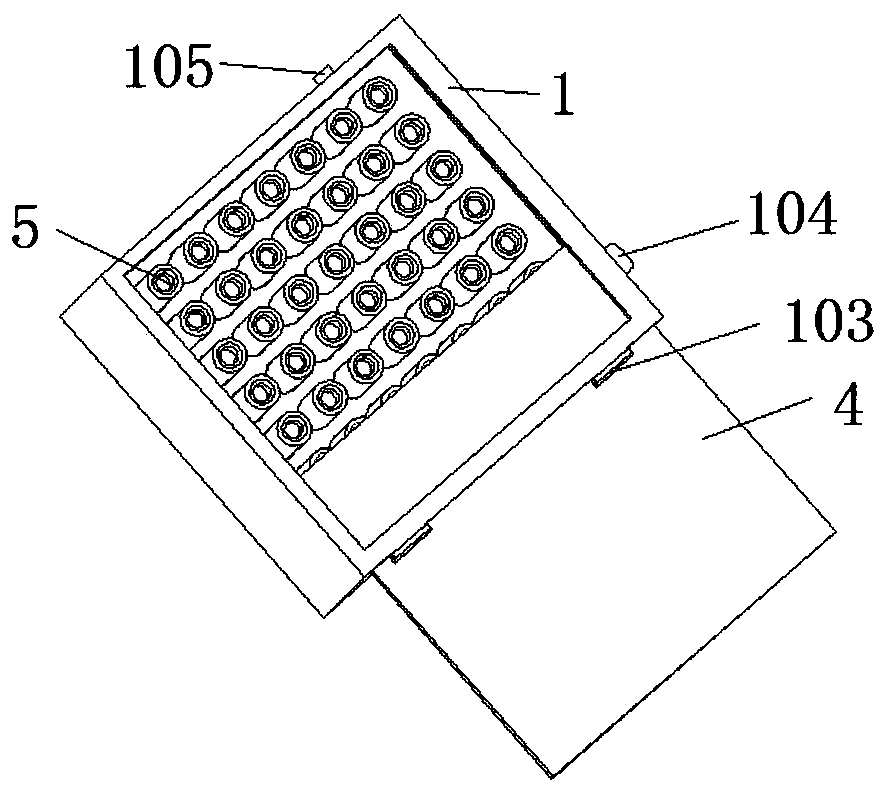

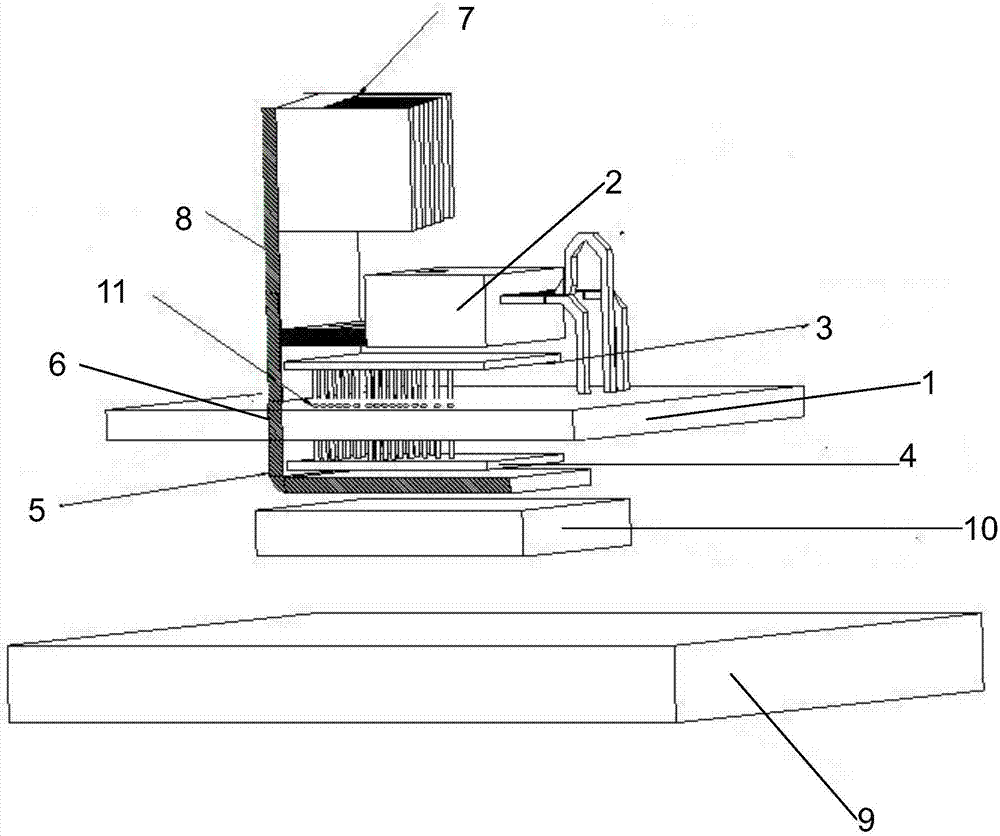

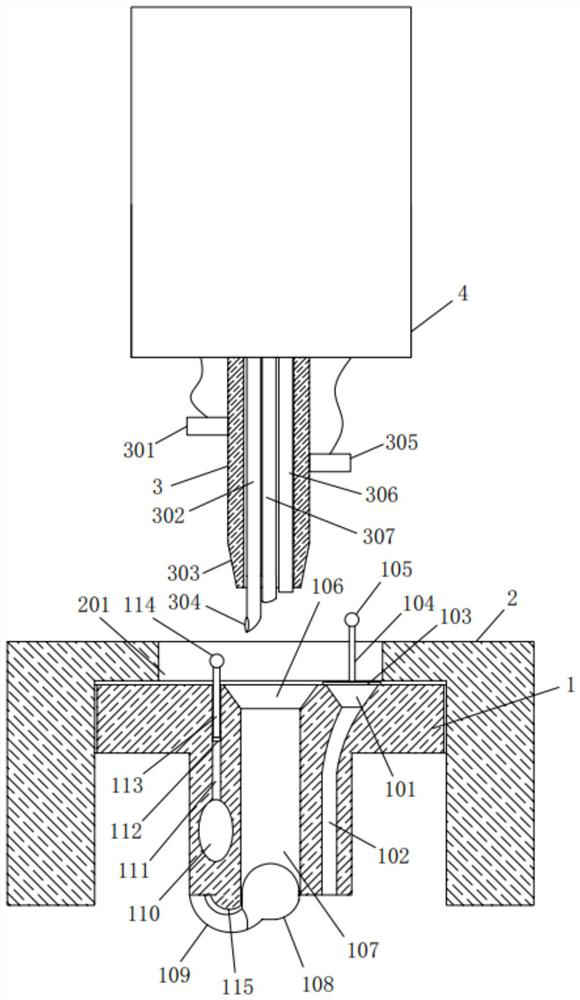

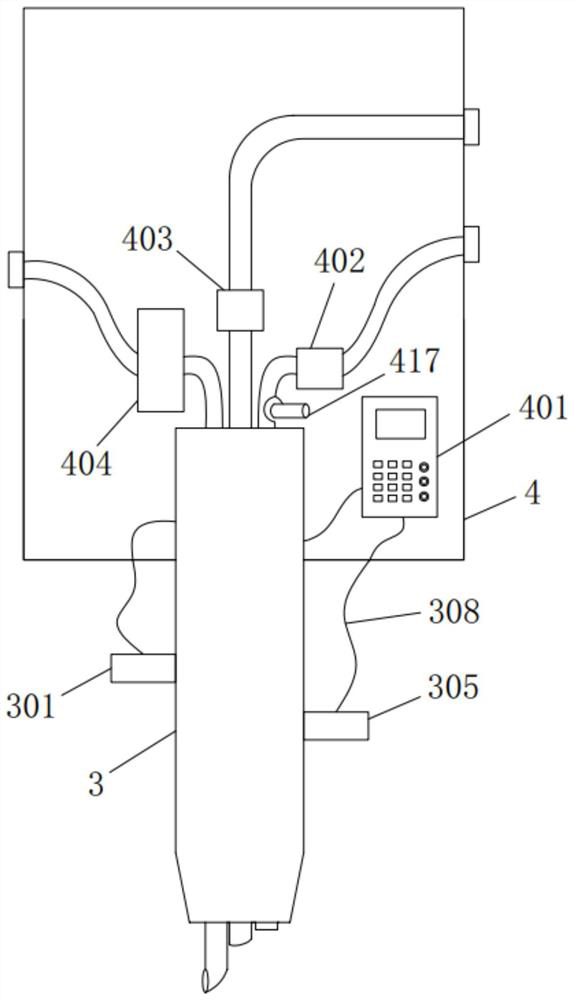

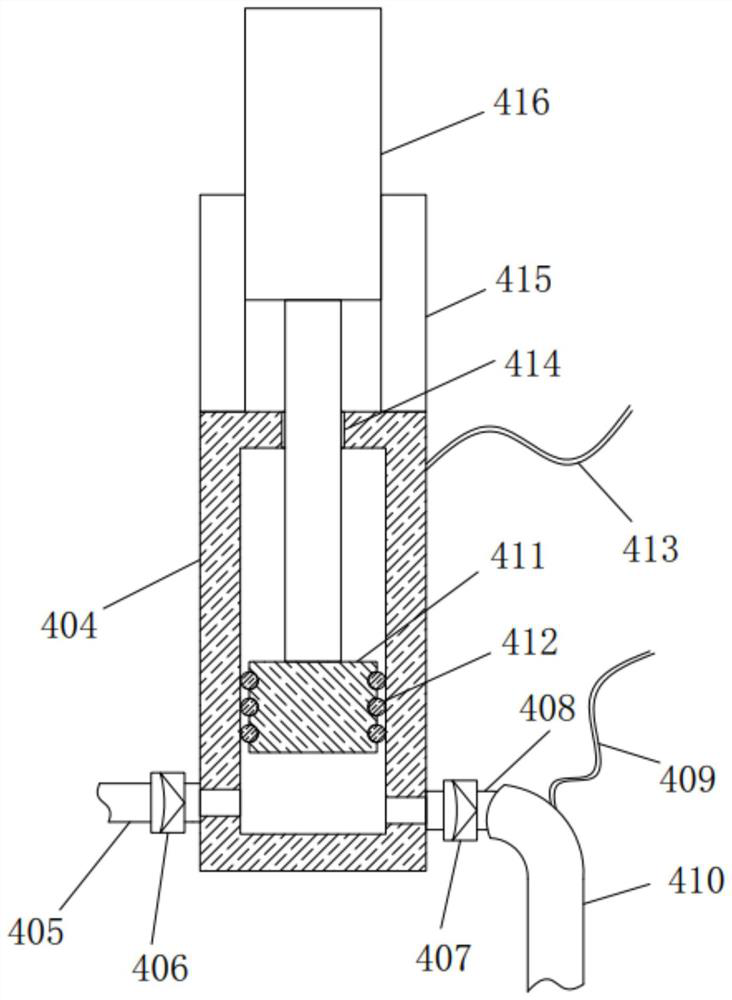

Cold application patch and production device thereof

PendingCN110025426AIncrease productivityShorten the processing flowLamination ancillary operationsPersonal careCold compressesEngineering

The invention discloses a cold application patch and a production device thereof. The device comprises a machine base body, a separation mechanism and a feeding mechanism; an unreeling machine is fixed at the upper part of the machine base body, and the unreeling machine separates a backing adhesive tape into an upper non-woven fabric gluing layer and a lower isolating layer; and the feeding mechanism is arranged at one end part of the machine base body, a driving roller is arranged below the feeding mechanism, and a pressing roller, an embossing roller and a cutter roller are sequentially arranged on the upper end surface of the machine base body from right to left. In the device, the backing adhesive tape is directly divided into an upper part and a lower part, a hydrogel layer is arranged between the upper layer and the lower layer of the backing adhesive tape, the upper part and the lower part of the backing adhesive tape are pressed and laminate by the pressing roller, and segmented cutting is carried out, so that a single block-shaped cold application patch structure is formed; and the whole device realizes one-step synthesis of the cold compress paste from raw material processing to cutting, so that the production efficiency is greatly improved.

Owner:安徽省纳胜生物科技有限公司

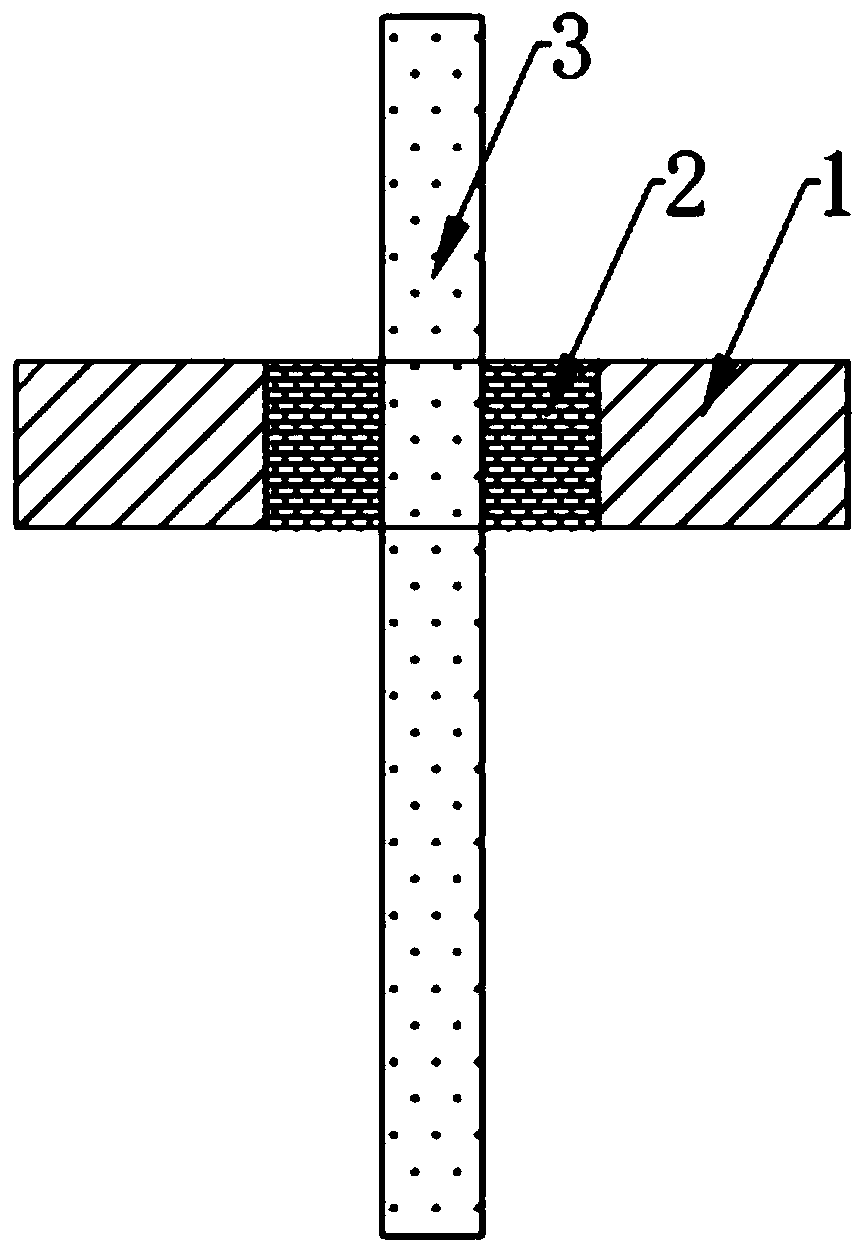

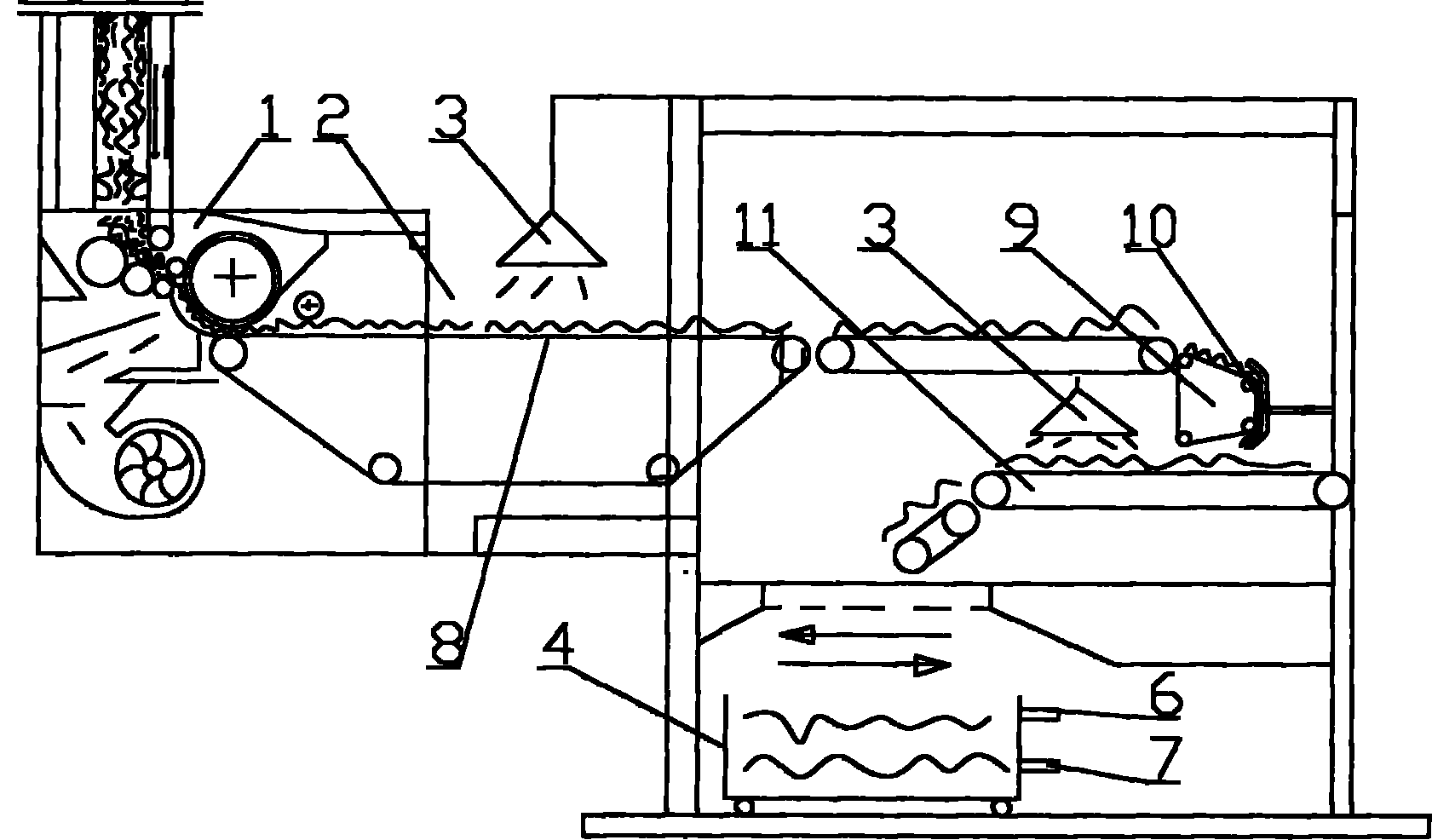

Sealing method for titanium-glass seal assembly

PendingCN110981224AStress reliefEliminate potential safety hazardsSolid state diffusion coatingElectrical conductorOver oxidation

The invention discloses a sealing method for a titanium-glass seal assembly. A to-be-sealed titanium metal shell and metal conductor core column are respectively pre-oxidized at the temperature of 300-500 DEG C, so the wettability of metal and glass is improved, and the problem that the wettability of titanium and a titanium alloy with glass is poor is solved; a low-temperature oxidation layer isused as a protective layer to prevent the metal from being excessively oxidized at high temperature; the consistency of a sintered assembly is further ensured, and subsequent surface treatment is facilitated; a sealing mold provided with a sealing part into a sintering furnace for sintering; nitrogen and hydrogen binary atmosphere is introduced as protective gas; the formation of nitrides and oxides on the metal surfaces of titanium and the titanium alloy is eliminated, and the seal assembly surface treatment process is eliminated; the sintered sealing part is subjected to heat preservation atthe temperature of 500-550 DEG C so as to eliminate stress in the seal assembly, potential safety hazards in the using process of the seal assembly are eliminated, then the titanium-glass seal assembly can be obtained after the seal assembly is cooled to the room temperature, and the process is simple.

Owner:XIAN SEAL ELECTRONICS MATERIAL TECH CO LTD

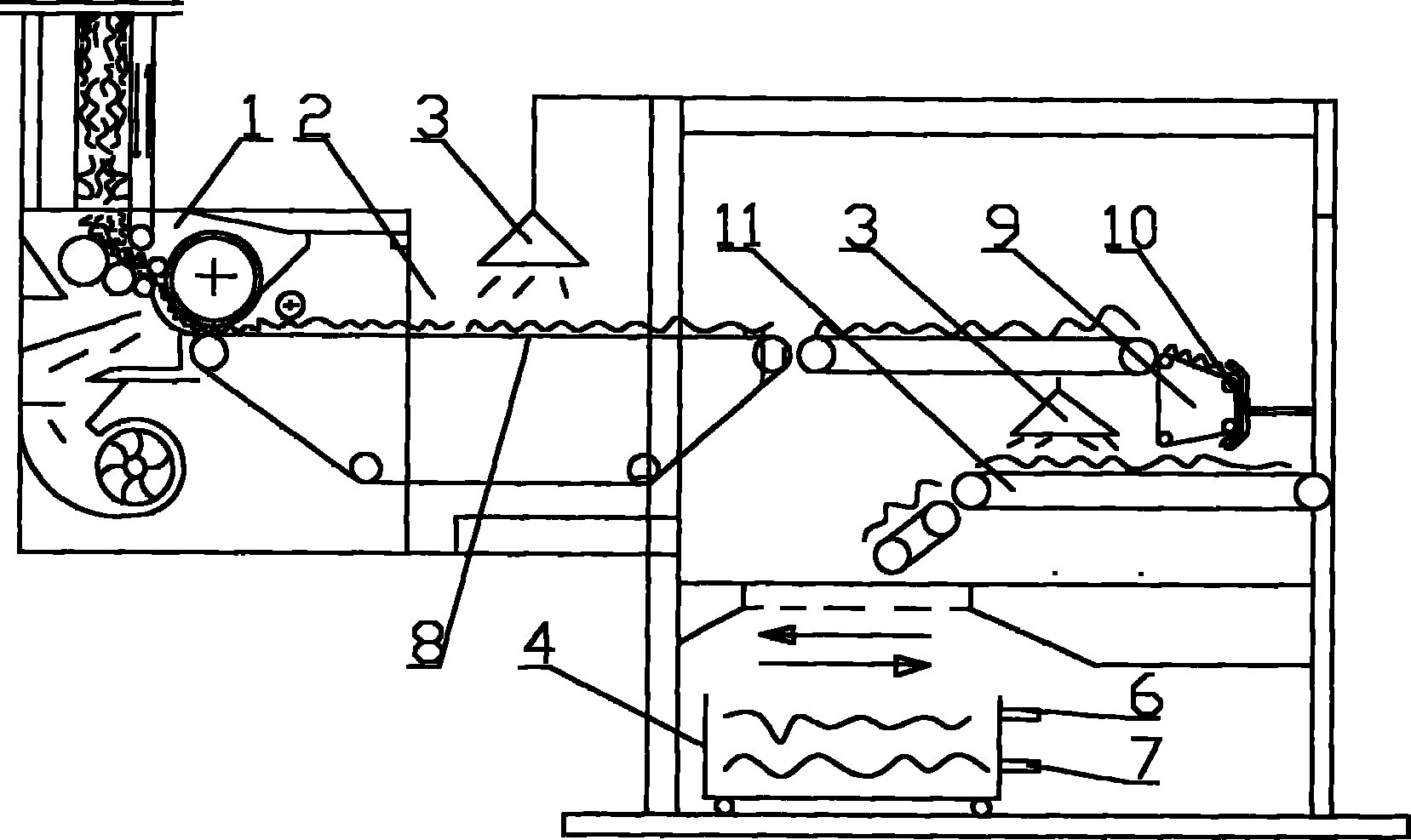

Integrated production method and device for plant fiber mattress

InactiveCN102079497AStacking effect is goodReduce operation processUpholstery manufactureStuffed mattressesFiberEngineering

The invention discloses an integrated production method and device for a plant fiber mattress, the method comprises the manufacturing of plant fiber elastic sheets and the method is characterized by spraying glue on two sides of each plant fiber elastic sheet, uniformly laying the elastic sheets on which the glue is sprayed in a die, compressing the laid elastic sheets through a hot press of the die, and introducing hot air; and shaping. In the method, the manufactured plant fiber elastic sheets are directly placed into the die, and one-time hot pressing shaping is performed, thereby reducing the manual stacking process, reducing the waste of scraps, enabling the quality of the mattress to be more stable and ensuring better comfortableness.

Owner:VONTRON TECH CO LTD

A high-performance three-dimensional carbon nanotube composite negative electrode material and its preparation method and application

ActiveCN105390687BImprove cycle performanceSignificantly improved cycle performanceMaterial nanotechnologyCell electrodesCarbon nanotubeCarboxylic group

The invention discloses a preparation method for a high-performance three-dimensional carbon nanotube composite negative electrode material. The preparation method comprises: by taking a carboxylated carbon nanotube as a three-dimensional network framework and taking a high-capacity material subjected to layer by layer self-assembly and modification as an active substance, uniformly mixing the carbon nanotube with the active substance under the action of electrostatic attraction; and then performing in-situ coating by taking a mixed element-containing N or S-doped carbon source as a three-dimensional coating layer, and performing high-temperature treatment to obtain the high-performance three-dimensional carbon nanotube composite negative electrode material. The invention furthermore discloses the high-performance three-dimensional carbon nanotube composite negative electrode material and an application thereof. According to the preparation method, the cycle performance of the active substance is remarkably improved, and the capacity of the composite material can be controllably adjusted by controlling a ratio of the carbon nanotube to the active substance. In addition, a solvent used in the method is water, so that the method is environmentally-friendly, good in repeatability and low in cost, and has relatively high potential of large-scale application and good industrialized prospects.

Owner:新疆护翼新材料科技有限公司

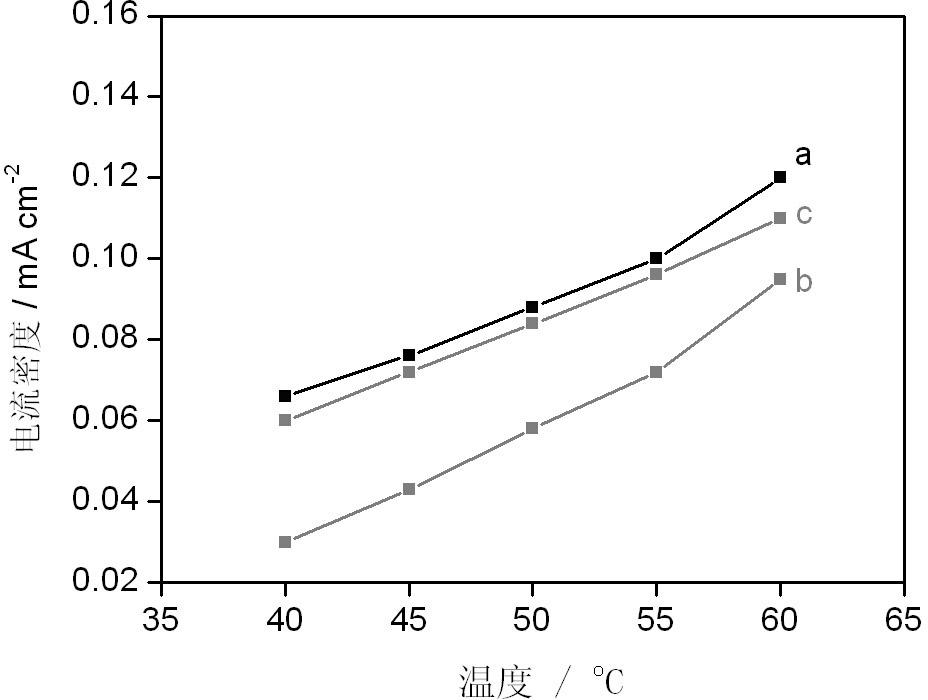

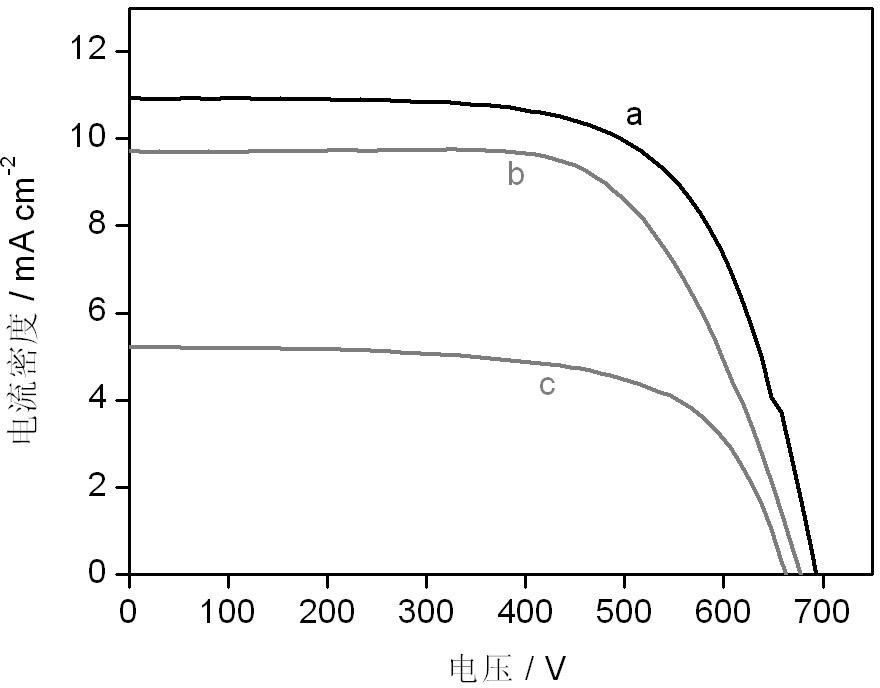

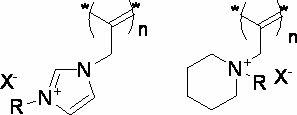

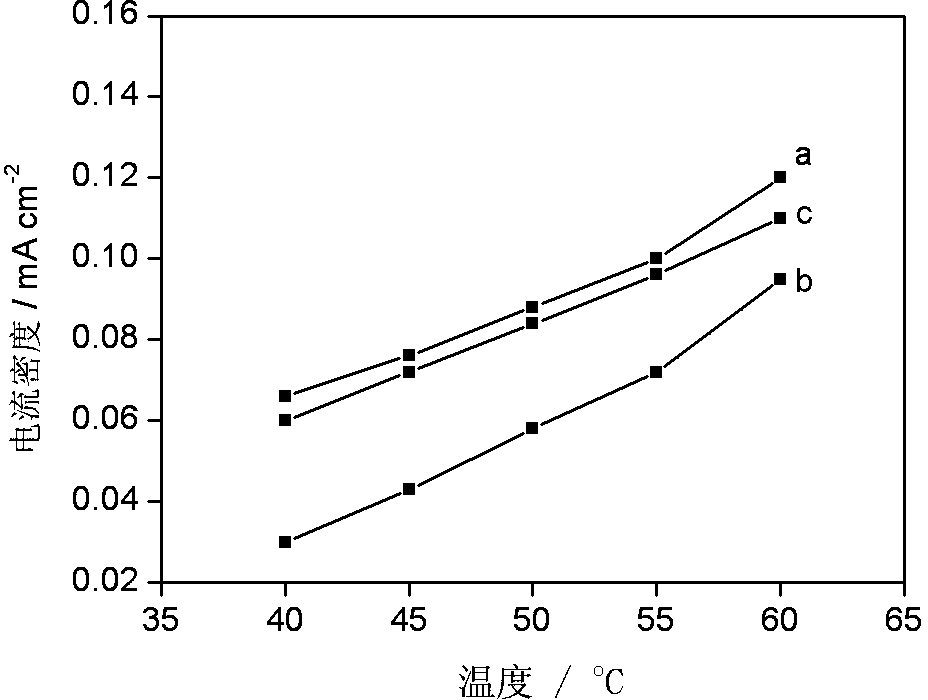

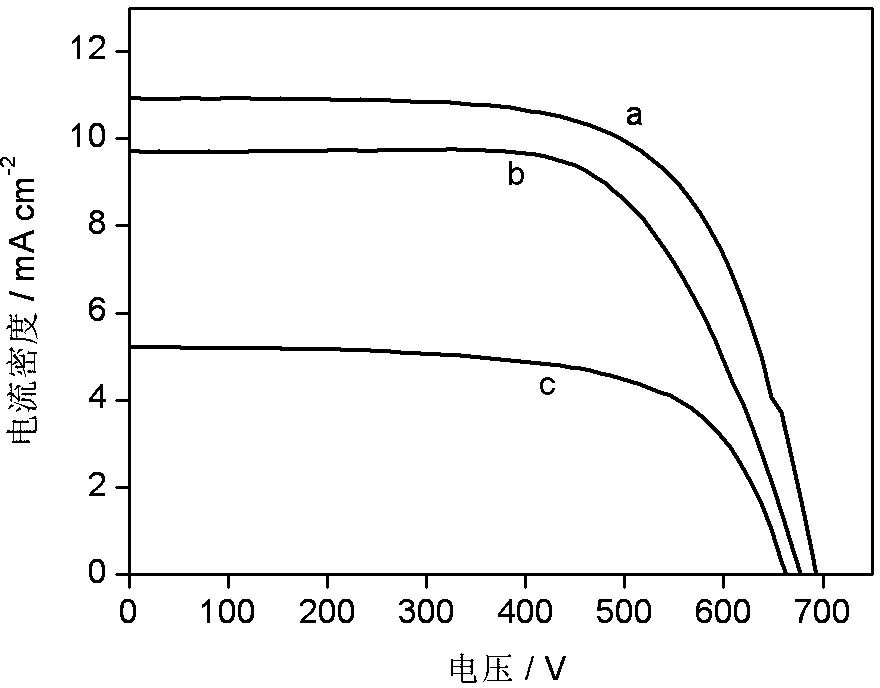

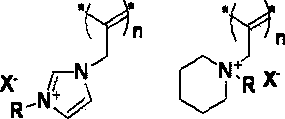

Ionic liquid modified carbine, preparation method for same and application thereof

InactiveCN102633927AEasy to prepareRaw materials are cheap and easy to getLight-sensitive devicesOrganic chemistryPtru catalystElectrical battery

The invention belongs to the technical field of solar cells, and particularly relates to ionic liquid modified carbine, a preparation method for the same and application thereof. The preparation method for the ionic liquid modified carbine employs autocatalysis and auto polymerization without any catalyst. The melting point of the ionic liquid modified carbine exceeds 80 DEG C so as to accord with the highest use temperature of a dye-sensitized solar cell. Ionic liquid is high in electric conductivity at the room temperature, and the electric conductivity at the room temperature reaches 40mS / cm. The ionic liquid modified carbine is applied to the all-solid dye-sensitized solar cell with energy conversion efficiency of 6.25%. The preparation method is simple, raw materials are inexpensive and available, operation process is simplified and cost of the cell is reduced by applying the carbine to the all-solid dye-sensitized solar cell, and the cell is high in stability and suitable for mass production.

Owner:FUDAN UNIV

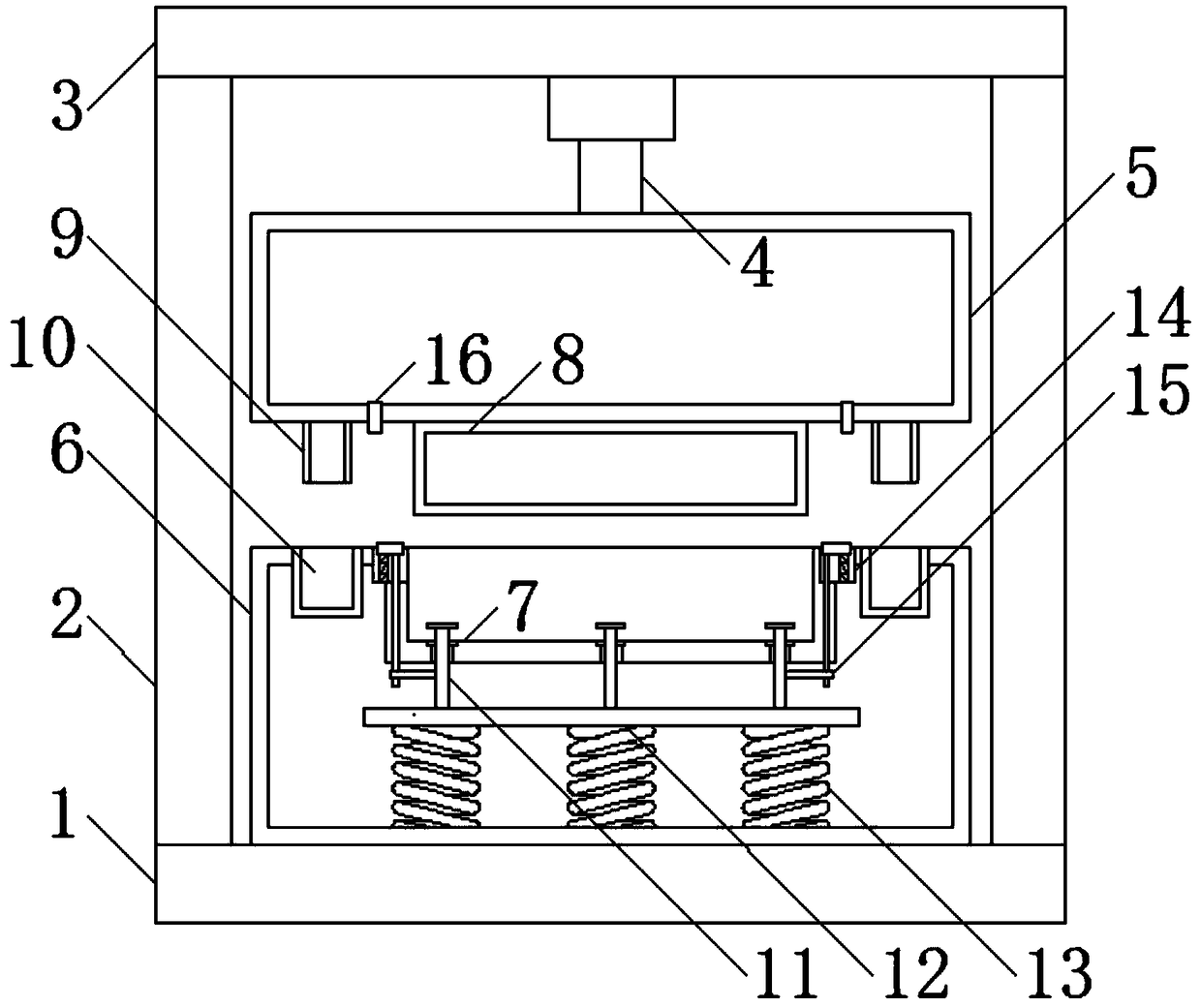

Stamping die for casting of metal product

InactiveCN108714674ASimple molding processReduce operation processForging/hammering/pressing machinesHandling devicesEngineering

The invention discloses a stamping die for casting of a metal product, and belongs to the technical field of metal products. The stamping die comprises a lower die plate. Supporting rods are arrangedon the left side and the right side of the top of the lower die plate correspondingly. A fixing plate is arranged at the tops of the supporting rods. The bottom of the fixing plate is connected with ahydraulic telescopic rod. The bottom of the hydraulic telescopic rod is connected with a movable die plate. A fixed die plate is arranged at the top of the lower die plate. A mold cavity is formed inthe top of the fixed die plate. A mold core matched with the mold cavity is arranged at the bottom of the movable die plate. Guiding columns are arranged on the left side and the right side of the bottom of the movable die plate correspondingly. Guiding sleeves matched with the guiding columns are arranged on the left side and the right side of the top of the fixed die plate correspondingly. Three sets of jacking rods are movably arranged in an inner cavity of the fixed die plate. The bottoms of the jacking rods are connected with a supporting plate. The bottom of the supporting plate is connected with a telescopic spring. Thus, a metal material forming technology is simpler, an operation technology adopted after the metal product is formed is reduced, the forming efficiency of the metalproduct is improved, the structure is simple, and using is convenient.

Owner:扬州市金阳光铸造有限公司

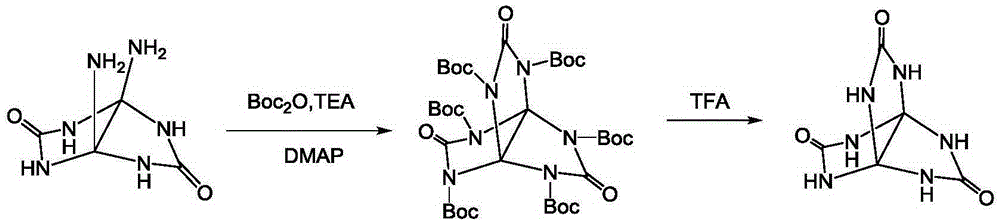

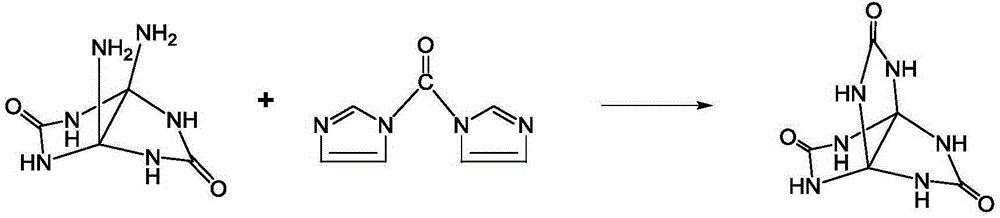

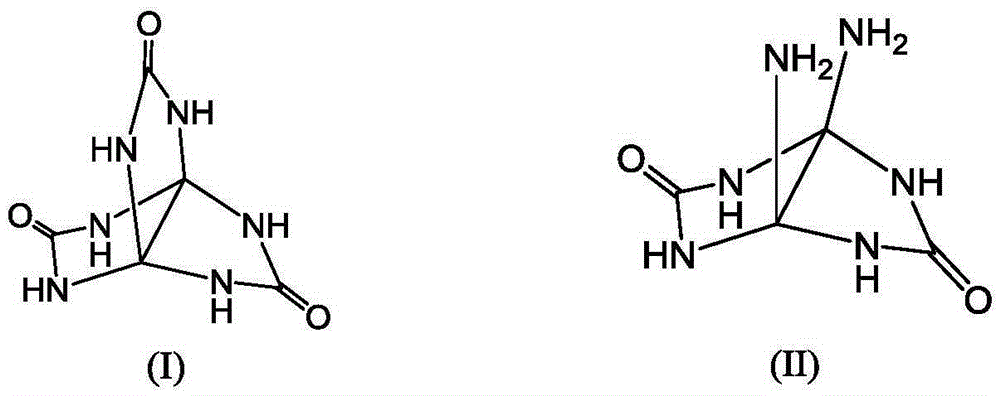

Synthetic method for 3,7,10-trioxo-2,4,6,8,9,11-hexa aza(3,3,3)propellane

The invention discloses a synthetic method for 3,7,10-trioxo-2,4,6,8,9,11-hexa aza(3,3,3)propellane. The method comprises the following steps that at the temperature of 15 DEG C-30 DEG C, diamino glycoluril and N,N'-carbonyldiimidazole are added into dimethyl sulfoxide in a stirred mode, after feeding is finished, the reaction is carried out for 50-80 h, then reaction liquid is poured into acetone and filtered, filter cake is washed with methyl alcohol and dried to obtain 3,7,10-tri oxo-2,4,6,8,9,11-hexa aza(3,3,3)propellane, the molar ratio of diamino glycoluril to N,N'-carbonyldiimidazole is 1:1.05-1.3, and the mass ratio of diamino glycoluril to N,N'-carbonyldiimidazole is 1:18-25.

Owner:XIAN MODERN CHEM RES INST

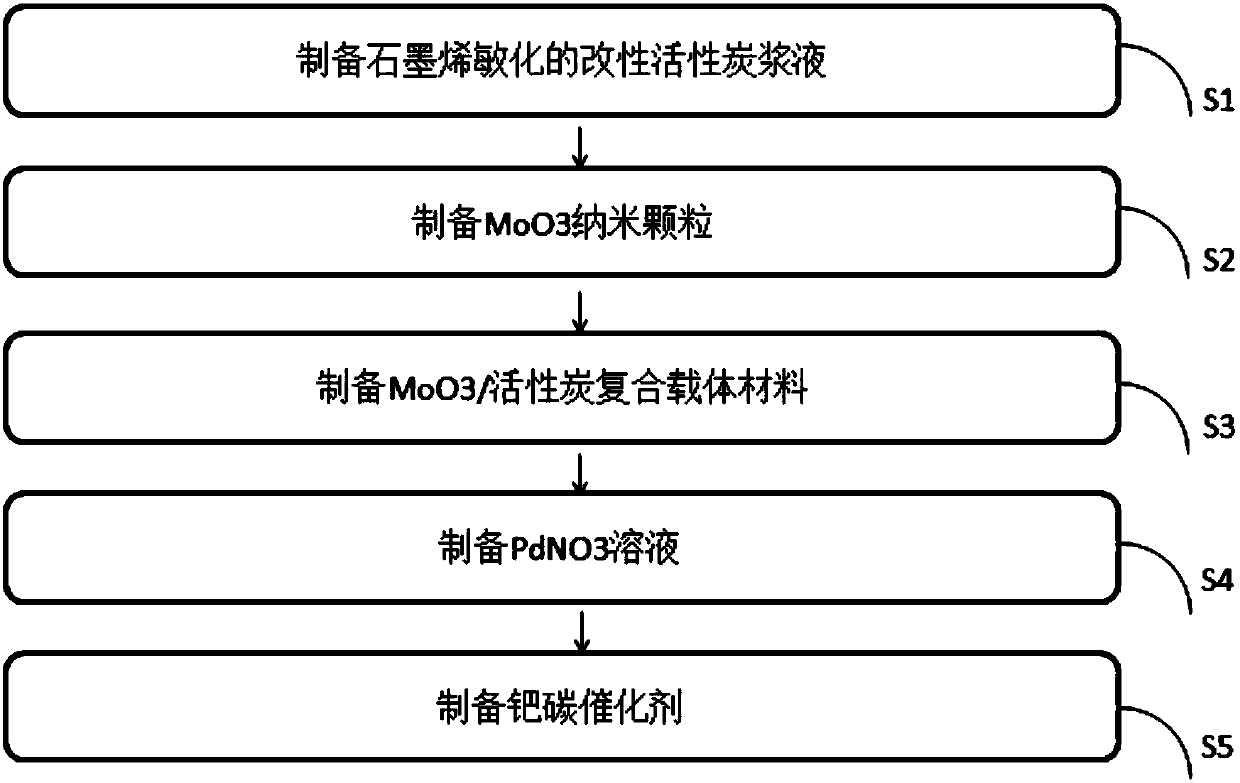

Graphene palladium carbon catalyst

InactiveCN107790126AReduce operation processAvoid agglomeration or sinteringCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsCvd grapheneChemistry

The invention relates to the technical field of preparation and application of graphene, in particular to a graphene palladium carbon catalyst. A preparation method of the graphene palladium carbon catalyst comprises the following steps: S1, preparing modified activated carbon slurry sensitized by the graphene; S2, preparing MoO3 nano particles; S3, preparing a MoO3 / activated carbon composite carrier material; S4, preparing a PdNO3 solution; S5, preparing a palladium carbon catalyst. The graphene palladium carbon catalyst, prepared by the preparation method disclosed by the invention, has theadvantages that palladium microcrystalline particles as an active component are small to nanometer scale, the content is high and more surface atoms are exposed; in addition, the specific surface areais large and the active component has good dispersity on the surface of a carrier.

Owner:NANJING XUYURUI MATERIAL TECH CO LTD

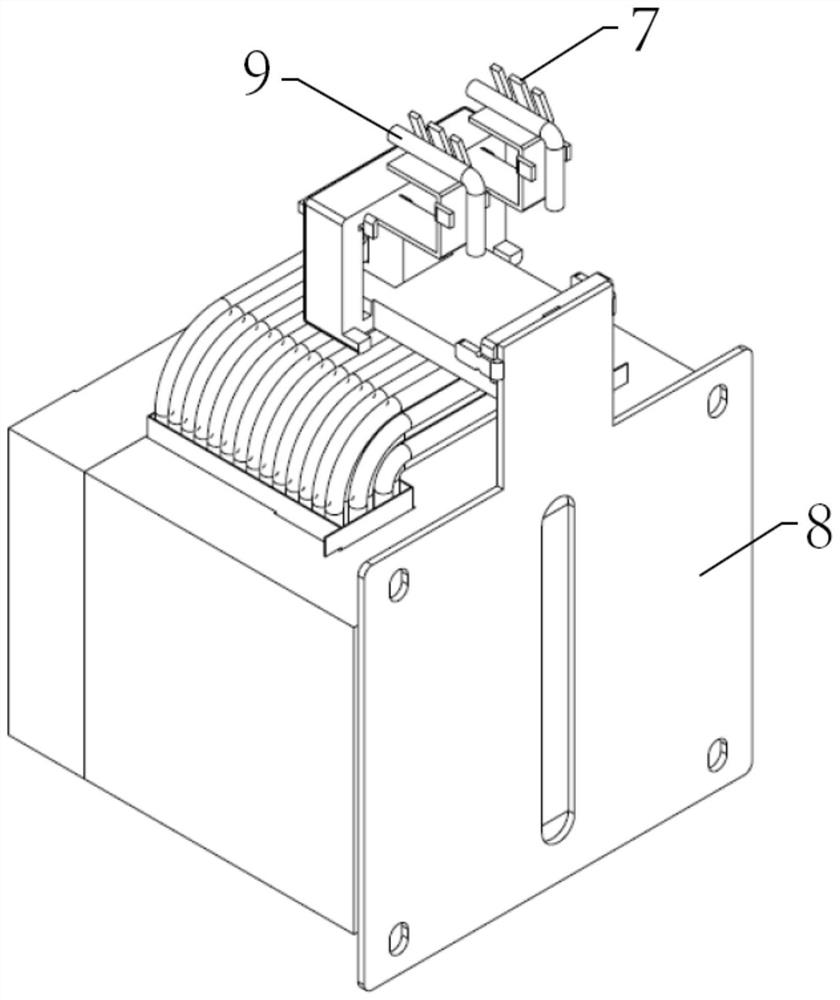

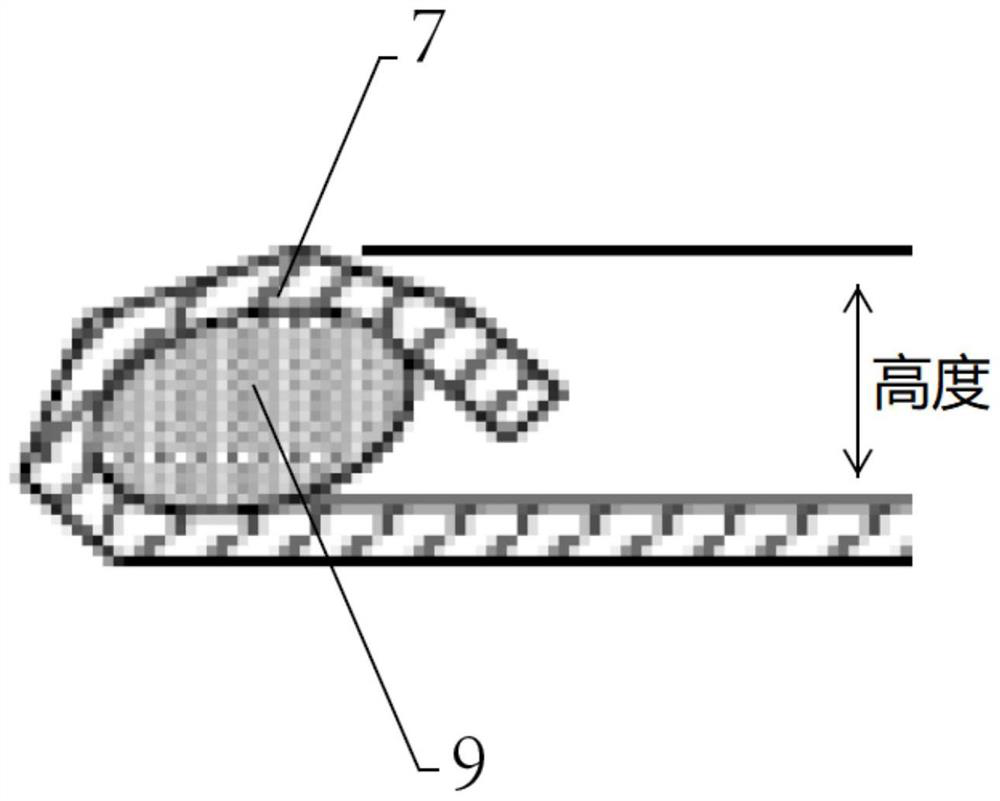

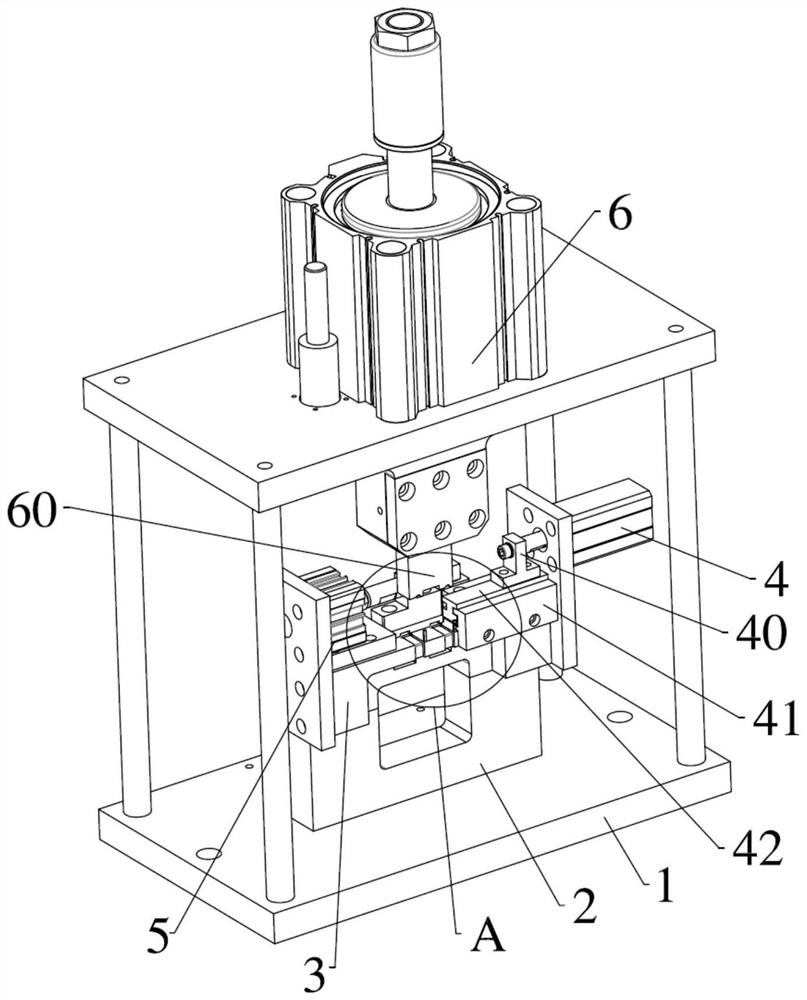

Variable-frequency electric reactor claw terminal crimping device

PendingCN112072438AReduce investmentReduce dependenceLine/current collector detailsElectrical performanceMechanical engineering

The invention relates to the technical field of terminal crimping jigs, in particular to a variable-frequency reactor claw terminal crimping device, which comprises a mounting frame, a reactor fixingseat and a terminal claw positioning base, and is characterized in that the reactor fixing seat is fixed on a bottom plate of the mounting frame, and the terminal claw positioning base is mounted on the reactor fixing seat; pushing and flattening structures used for pushing and flattening the clamping jaws and wire fixing structures used for pulling wires are installed on the portions, located atthe two ends of the terminal clamping jaw positioning base, of the electric reactor fixing base respectively, and flattening structures used for flattening the clamping jaws after the pushing and flattening structures push and flatten the clamping jaws are installed on a top plate of the mounting frame. According to the invention, the working efficiency is greatly improved, and the labor intensityof operators is reduced; the manufactured variable-frequency electric reactor clamping jaw covered wire product is high in appearance consistency, the connecting wire is almost prevented from fallingoff, and the product quality is improved; and the high-voltage and impedance qualification rate is high, and the electrical performance is very stable.

Owner:HEFEI ECRIEE TAMURA ELECTRIC

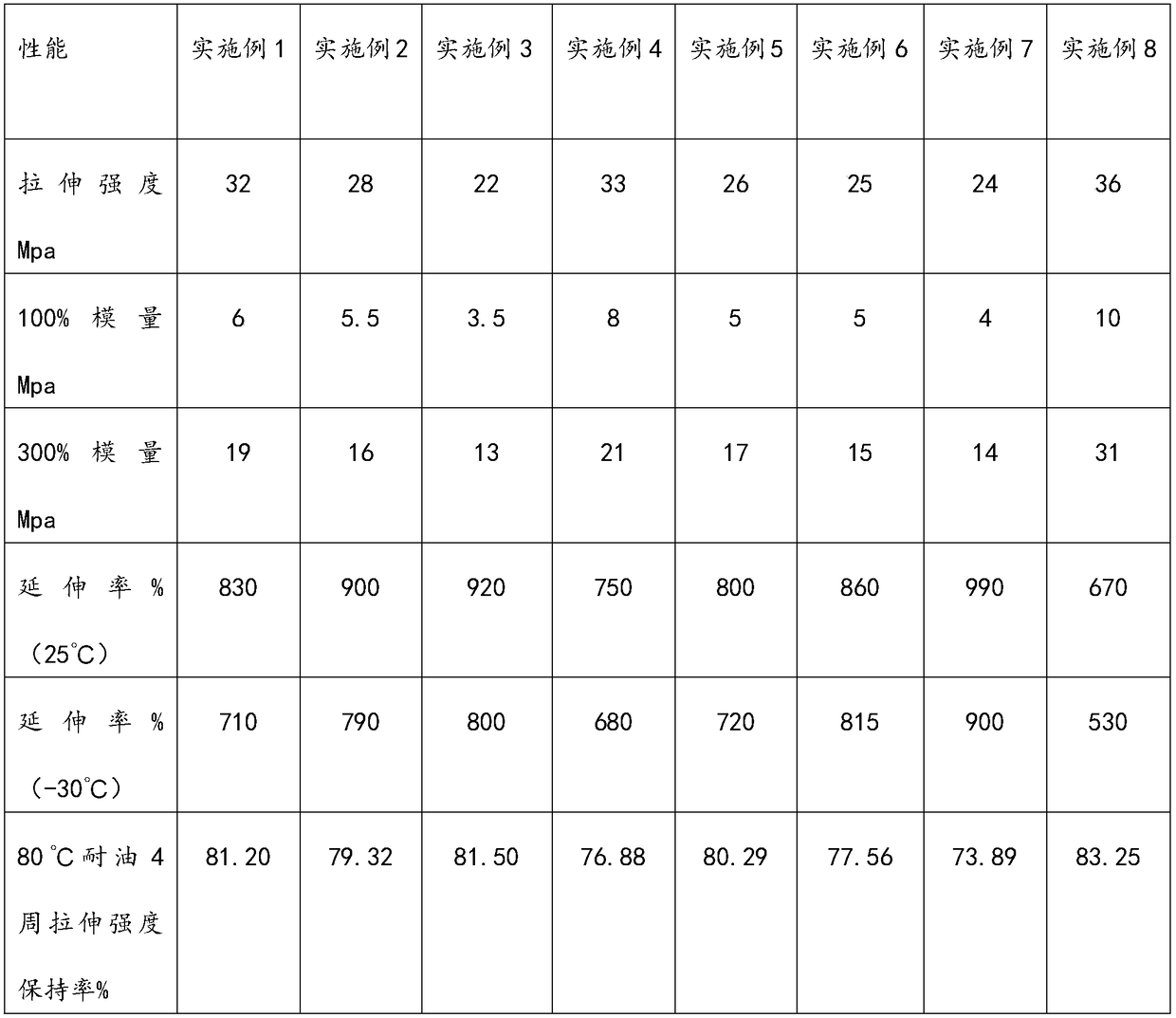

A preparation process of polycarbonate-ether polyol and oil-resistant and low-temperature resistant polyurethane elastomer

ActiveCN106750233BGood flexibility at low temperatureImprove low temperature resistancePolyurethane elastomerPolyol

The present invention relates to a kind of preparation technology of polycarbonate-ether polyol, it is characterized in that, comprises the following steps: 1) the system that will contain the aliphatic dihydric alcohol of 8 carbon atoms, polyether polyol and reaction catalyst is heated up to Stir at 90-100°C, add organic carbonate to it at a constant flow rate in an inert atmosphere, and carry out transesterification at a constant temperature; Polyhydric alcohol, constant temperature reaction; 3) carry out constant temperature polycondensation after decompression to -0.085 to -0.09Mpa, to obtain final product. The polyurethane elastomer prepared based on the reaction between the polycarbonate-ether polyol and diisocyanate has excellent comprehensive properties such as oil resistance and low temperature resistance, and can broaden the application field of the polycarbonate polyurethane elastomer.

Owner:MIRACLL CHEM

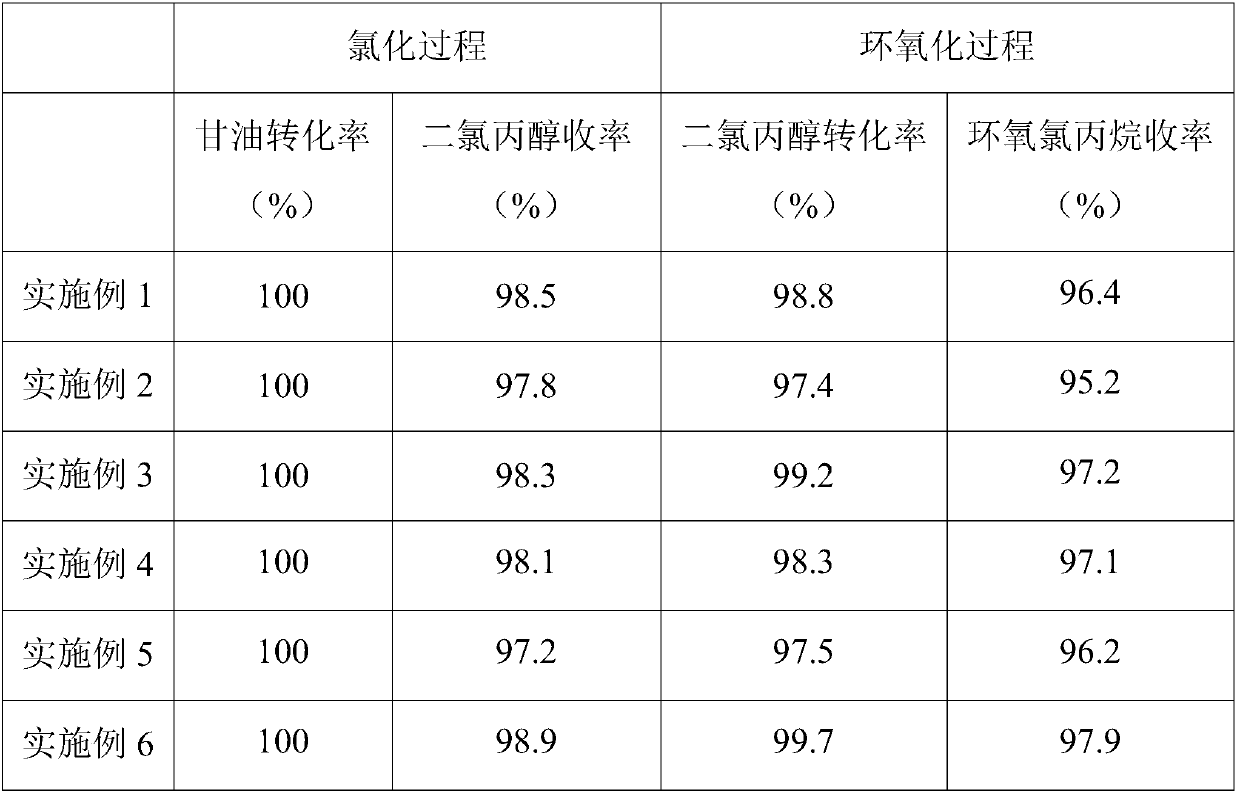

Method for preparing chloropropylene oxide from biomass glycerol

The invention provides a method for preparing chloropropylene oxide from biomass glycerol. The method comprises the following steps: first mixing biomass glycerol with organic acid, carrying out heating to 90-140 DEG C, maintaining the temperature, introducing hydrogen chloride gas into the obtained system and starting a bubbling reaction, wherein tail gas is absorbed with alkali liquor; cooling amaterial obtained in the previous step to room temperature, then transferring the material to another reactor, heating the material to 30-90 DEG C, and adding a KOH solution with a concentration of 6-10 mol / L for a reaction; and at the end of the reaction, removing solids through filtration so as to obtain a filtrate which is a chloropropylene oxide solution. The method of the invention has the advantages of simple process, easy availability of raw materials, low cost and good industrialization prospects.

Owner:JIANGSU SOPO GRP +1

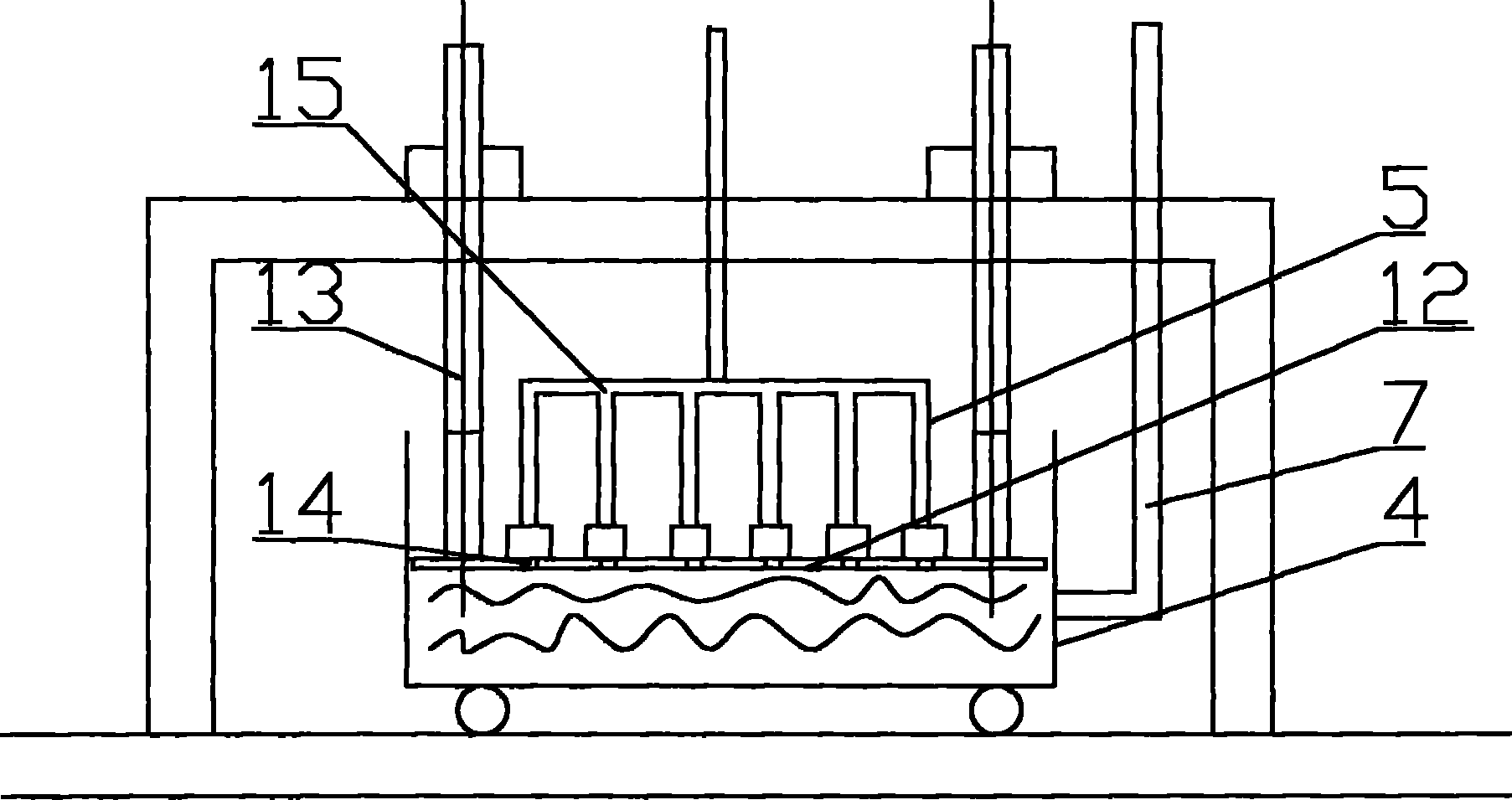

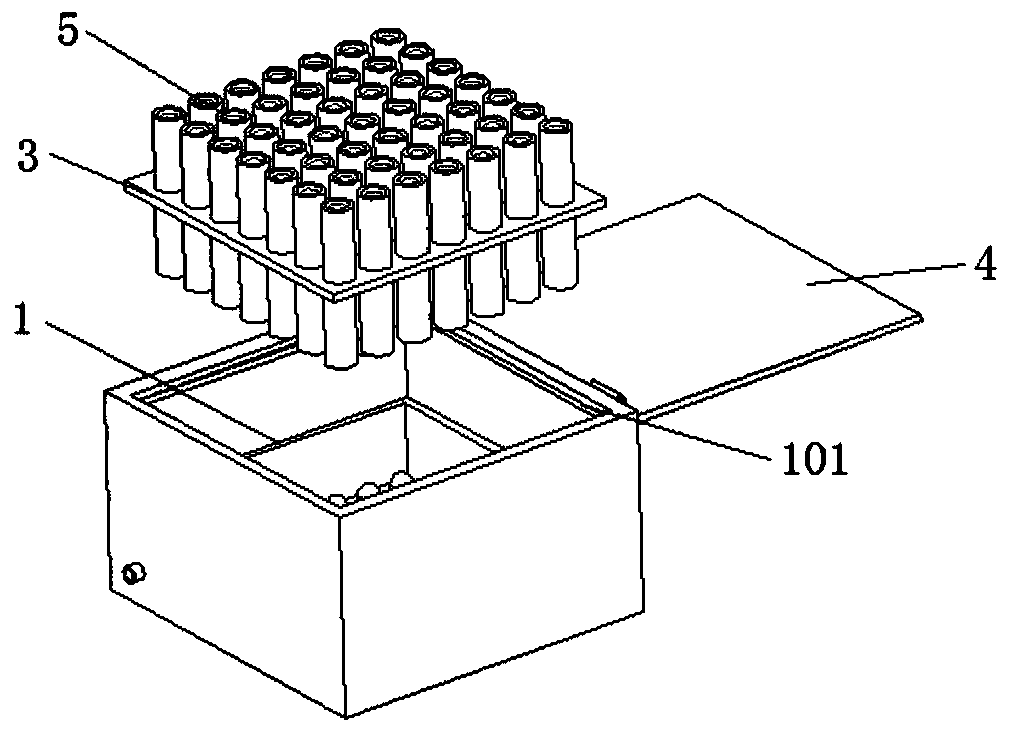

Manufacturing technology of high thermal shock resistance graphite electrode and production device thereof

InactiveCN109761609AImprove antioxidant capacityImprove cohesionMaterials preparationManufacturing technology

The invention discloses a manufacturing technology of a high thermal shock resistance graphite electrode and a production device thereof. The technology comprises the following steps of (1) material preparation; (2) burning; (3) grinding; (4) stirring; (5) rolling; (6) calcination; (7) forming; (8) dipping and (9) graphitization. The production device comprises a dipping box body, a fixing plate and a covering plate; the dipping box body is of a box structure with the upper end face being open, bases are evenly distributed at the bottom of a filter tank body, the fixing plate is arranged in the middle of the filter tank body, a clamping groove is formed to extend outwards from one end face of the upper end face of the dipping box body, and inward sinking tanks are formed in the inner sidesof the other three upper end faces of the dipping box body. The preparation technology is characterized in that the formed graphite electrode is placed into the dipping box to be dipped, so that thedipping liquid can completely wet a whole green body of the graphite electrode, then graphitezation is conducted, the cohesion of the graphite electrode is improved, breakage prone to occurring in thegraphitization process of the graphite electrode is reduced, and the integral thermal shock resistance of the graphite electrode is enhanced.

Owner:HEFEI CARBON CO LTD

Low performance compound potassium powder additive

Disclosed is a low performance composite potassium powder additive for fireworks and firecrackers which is prepared from charging 30-50 wt% potassium chloride and -50-70 wt% sodium chlorate through mixing homogeneously, reacting 3-5 hours at the condition of 100 deg. C steam, cooling down the product, separating sodium chloride to obtain half-finished potassium chlorate product, immersing the potassium chlorate for second dissolution, charging potassium nitrate and barium nitrate 10-40% of weight of potassium chlorate, reacting 2-4 hours at the condition of 100 deg. C steam, natural cooling for crystallization, scouring, centrifugally separating, drying and chalking to 200-250 mesh, charging light calcium carbonate 5-10% of weight of disintegrated article, and mixing homogeneously.

Owner:张龙替

A kind of palladium carbon catalyst and preparation method and application

ActiveCN103691431BThe load rate is close to or even fullyFull loadOrganic compound preparationCarbonyl compound preparationPalladium on carbonActivated carbon

The invention relates to a palladium carbon catalyst which comprises the following components: (1) nanometer TiO2-modified active carbons are used as composite carriers; (2) Pd nanometer particles are used as active components, wherein the strong interaction between metals and the carriers exists in the active components and TiO2 on the composite carriers to form a Pd@TiO2 structure so as to form structural Pd@TiO2 / active carbons of the catalyst.

Owner:XIANGTAN UNIV

Printed circuit board

PendingCN107426913AGood dispersionImprove cooling effectPrinted circuit aspectsCircuit thermal arrangementsCopper coatingElectronic component

The present invention relates to a printed circuit board. The printed circuit board comprises a PCB, a power electronic component installed at one surface of the PCB and capable of heating at work, a metal cooling fin strip is arranged at the other surface of the PCB, the PCB is provided with the insertion hole of the metal cooling fin strip, and the metal cooling fin strip is bended and then passes through the PCB through the insertion hole to be stretched into the heating area of the heating power electronic component. The heat emitted by the power electronic component can be directly conducted on the metal cooling fin strip at the other surface of the PCB through the metal cooling fin strip to perform heat radiation on the metal cooling fin strip with no need for a structure of laying one layer of insulation heat conduction materials and copper coating on an aluminum plate for heat radiation so as to solve the technical problems that the current printed circuit board is complex in technology, the product disability rate is high and the maintenance is not convenient.

Owner:SHENZHEN GOLD POWER TECH

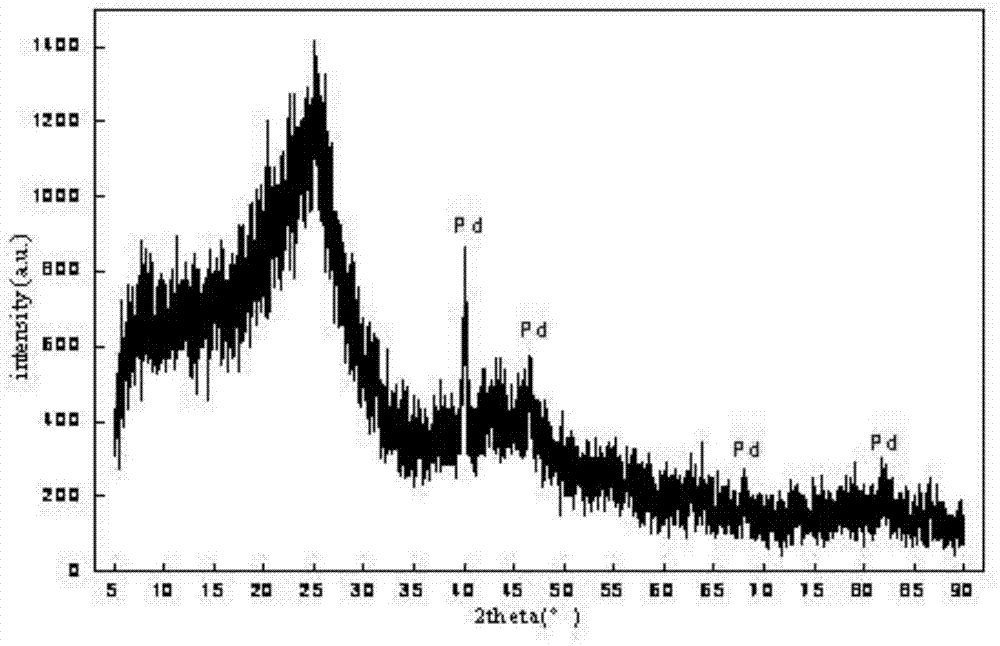

A kind of metal catalyst and preparation method and application

ActiveCN103691434BThe load rate is close to or even fullyAvoid reunionOrganic compound preparationCarbonyl compound preparationCyclohexanoneNanoparticle

The invention relates to a metal catalyst which comprises: 1) a nano TiO2 modified porous material as a composite carrier, and 2) a nano particle of at least one out of Pd and other transition metals as an active component, wherein the active component and TiO2 in the composite carrier have strong metal-carrier interaction to form a Pd@TiO2 structure or a Pd-M@TiO2 structure, thereby forming the Pd-M@TiO2 / porous carrier catalyst, and M is at least one out of the transition metals except Pd. The invention further relates to a preparation method of the catalyst, and an application of the catalyst in preparing cyclohexanone through selective phenol hydrogenation.

Owner:XIANGTAN UNIV

Ionic liquid modified carbine, preparation method for same and application thereof

InactiveCN102633927BEasy to prepareRaw materials are cheap and easy to getOrganic chemistryLight-sensitive devicesPtru catalystElectrical battery

The invention belongs to the technical field of solar cells, and particularly relates to ionic liquid modified carbine, a preparation method for the same and application thereof. The preparation method for the ionic liquid modified carbine employs autocatalysis and auto polymerization without any catalyst. The melting point of the ionic liquid modified carbine exceeds 80 DEG C so as to accord with the highest use temperature of a dye-sensitized solar cell. Ionic liquid is high in electric conductivity at the room temperature, and the electric conductivity at the room temperature reaches 40mS / cm. The ionic liquid modified carbine is applied to the all-solid dye-sensitized solar cell with energy conversion efficiency of 6.25%. The preparation method is simple, raw materials are inexpensive and available, operation process is simplified and cost of the cell is reduced by applying the carbine to the all-solid dye-sensitized solar cell, and the cell is high in stability and suitable for mass production.

Owner:FUDAN UNIV

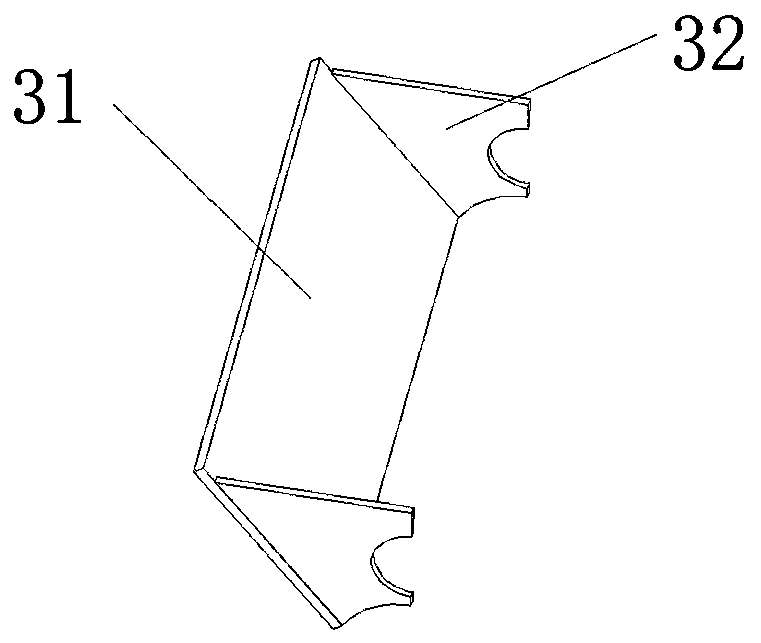

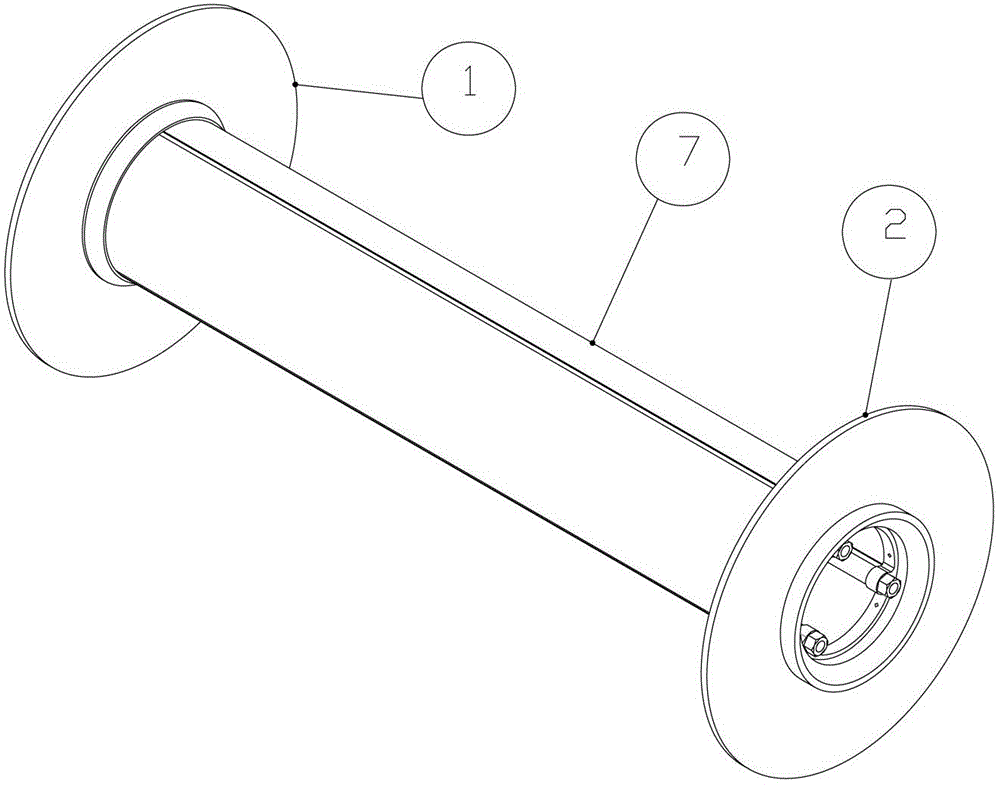

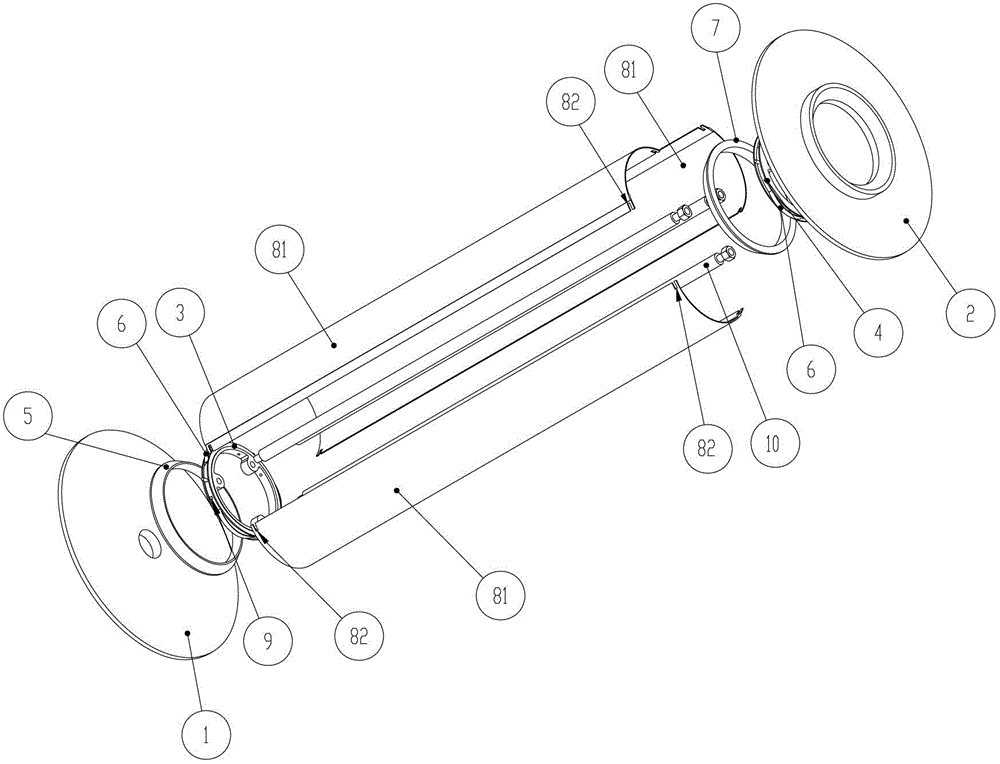

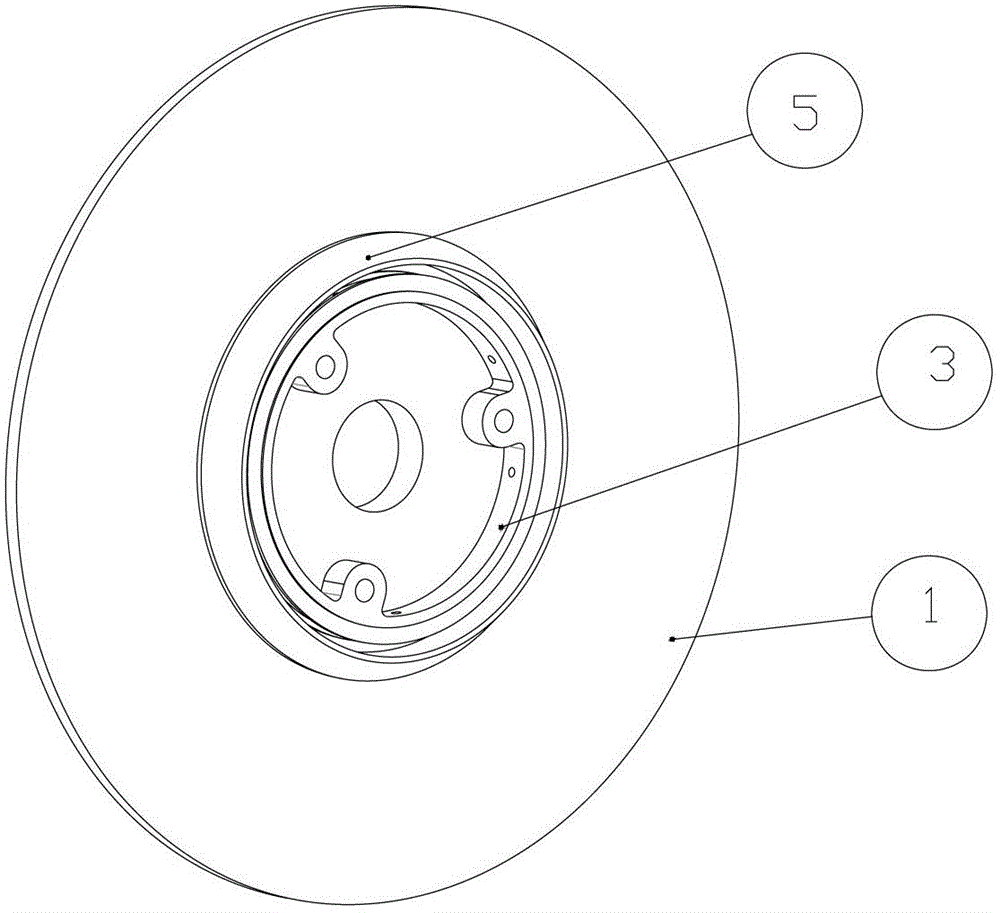

A bobbin and a dyeing process applied to the bobbin

ActiveCN104120575BReduce use costReduce processing costsTextile treatment carriersLiquid/gas/vapor yarns/filaments treatmentBobbinMaximum diameter

The invention discloses a yarn reel and a dyeing process applied to the yarn reel. The yarn reel includes a cylinder body for winding cloth to be dyed, and a first side plate and a second side plate respectively arranged at two ends of the cylinder body. plate, the cylinder is composed of a plurality of cylinder members, the cylinder members are sequentially connected end to end along the circumferential direction of the cylinder to form the cylinder, and, along the circumference of the cylinder, the distance between adjacent cylinder components can be Adjustment; an inner positioning sleeve is arranged in the cylinder body, and the cylinder body and the inner positioning sleeve are coaxially arranged, and a return spring for adjusting the distance between the cylinder body and the inner positioning sleeve is arranged between the cylinder body and the inner positioning sleeve. It can be seen that the bobbin can shrink or expand within a certain range in the radial direction. When the cloth to be dyed is wound on the bobbin of the bobbin, the bobbin of the bobbin maintains the maximum diameter. When the cloth shrinks during the dyeing process , the cylinder can automatically shrink radially inward. Compared with the prior art, the present invention saves the process cost more and reduces the operation process.

Owner:ZHEJIANG WEIXING IND DEV

Low performance compound potassium powder additive

Disclosed is a low performance composite potassium powder additive for fireworks and firecrackers which is prepared from charging 30-50 wt% potassium chloride and -50-70 wt% sodium chlorate through mixing homogeneously, reacting 3-5 hours at the condition of 100 deg. C steam, cooling down the product, separating sodium chloride to obtain half-finished potassium chlorate product, immersing the potassium chlorate for second dissolution, charging potassium nitrate and barium nitrate 10-40% of weight of potassium chlorate, reacting 2-4 hours at the condition of 100 deg. C steam, natural cooling for crystallization, scouring, centrifugally separating, drying and chalking to 200-250 mesh, charging light calcium carbonate 5-10% of weight of disintegrated article, and mixing homogeneously.

Owner:张龙替

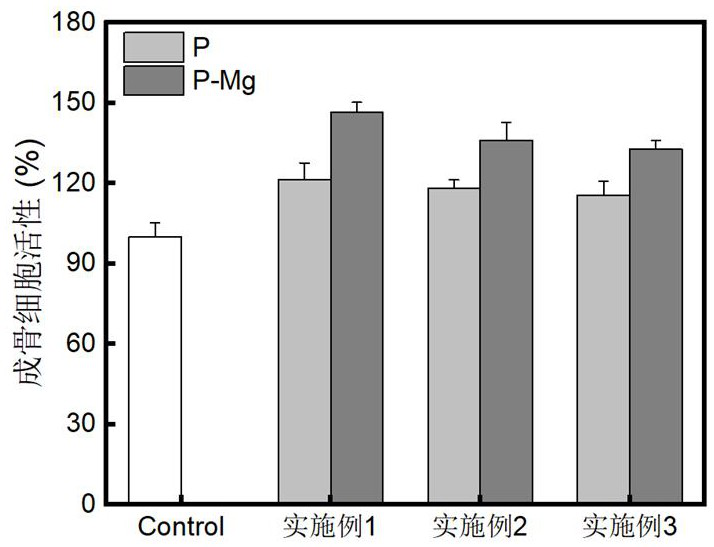

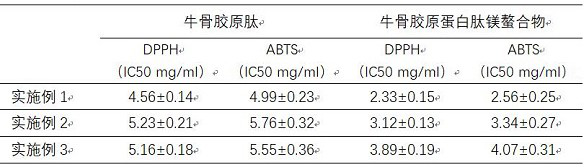

Preparation method and application of collagen peptide magnesium chelate

PendingCN114767838ALow costReduce operation processCosmetic preparationsConnective tissue peptidesPeptideEnzyme

The invention relates to a preparation method and application of a collagen peptide magnesium chelate. The preparation method comprises the following steps: step 1, preparing bovine bone collagen peptide; and step 2, preparing the bovine bone collagen peptide magnesium chelate. According to the method, cattle bones which are wide in source are used as raw materials, the cattle bone collagen peptide is prepared through double-enzyme composite enzymolysis, and the collagen peptide magnesium chelate is prepared through chelation of the cattle bone collagen peptide and magnesium ions. The collagen peptide magnesium chelate has significantly improved antioxidant activity and osteoblast promoting activity, can play a positive effect on prevention and treatment of osteoporosis, and provides a new thought for development and utilization of novel peptide magnesium chelate products.

Owner:BEIJING UNIV OF CHEM TECH

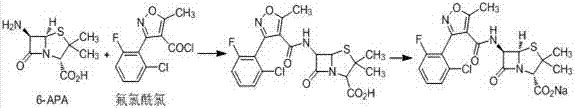

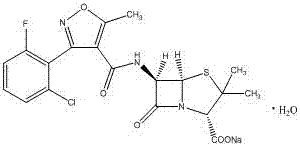

A kind of synthetic method of flucloxacillin sodium monohydrate

ActiveCN104910183BReduce pollutionReduce the use effectOrganic chemistryFlucloxacillinDocumentation procedure

The invention discloses a method for compounding flucloxacillin sodium-hydrate, which belongs to the technical field of drug synthesis, and comprises the steps: 6-aminopenicillanic acid (6-APA) is salified, then 3-(2-chloro-6-fluorophenyl)-5- methyl isoxazole-4-formyl chloride or equivalents thereof are added to do an acylation reaction, and then acids are added drop by drop to adjust a potential of hydrogen (pH) value to obtain flucloxacillin acid aqueous solutions. Organic solution is used to extract, and organic phases are washed, dried and filtered to obtain flucloxacillin acid solutions through saturated salt water, then white solids are dissolved out in the flucloxacillin acid solutions which are added with sodium iso-octoate solutions, and products are obtained by controlling temperature and crystallizing. The method for compounding the flucloxacillin sodium-hydrate does not separate intermediate flucloxacillin acids, obtained flucloxacillin acids are directly salified with sodium iso-octoate after being extracted trough the organic solution, reduces separation steps and operation process, also reduces usage amount and times of organic solution simultaneously, greatly reduces discharge amount of organic solution relative to patent documentation CN 102964356A, reduces production cost above 20%, and obviously improves economic and environmental values.

Owner:CHENGDU LIKAI CHIRAL TECH

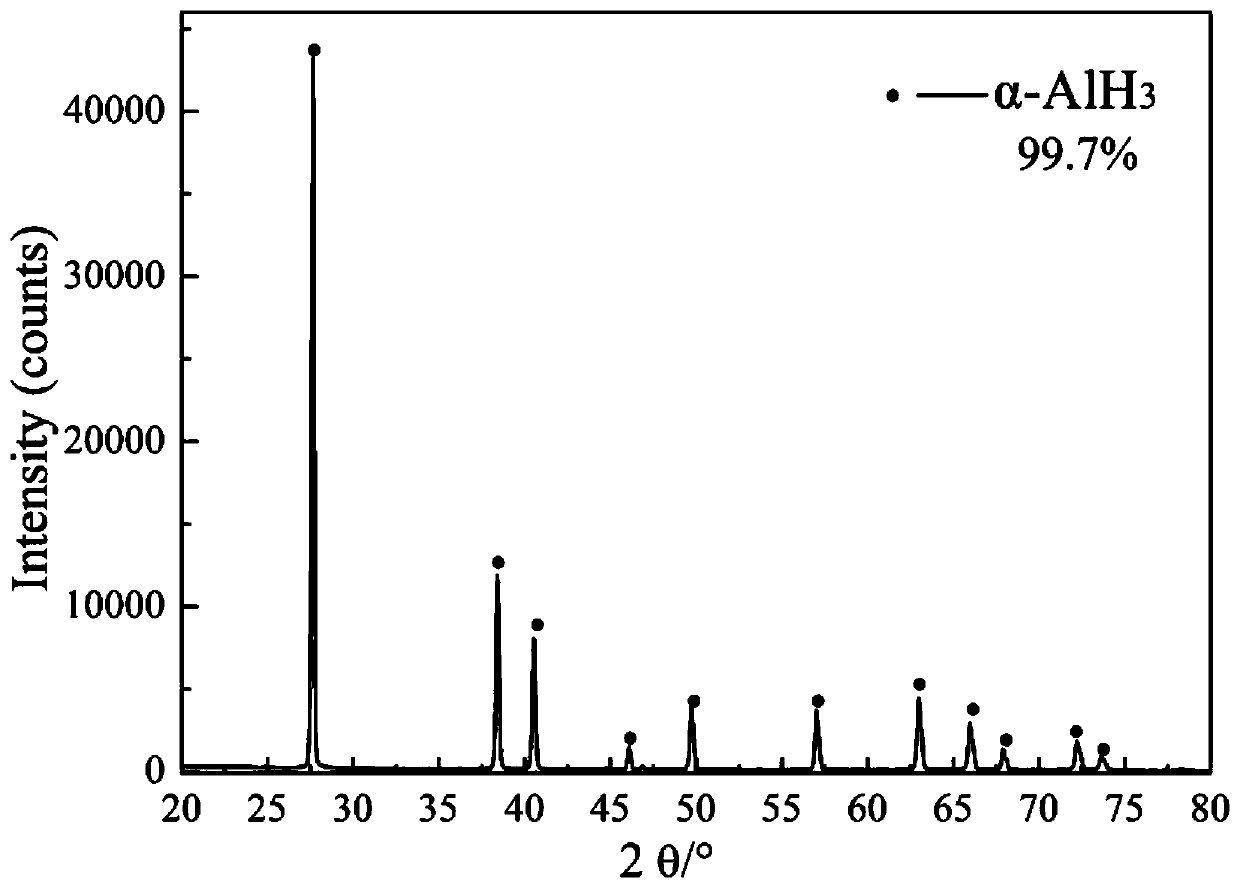

A kind of process method for preparing α-aluminum trihydride with sodium borohydride catalysis

ActiveCN107032302BReduce operation processLess impuritiesMonoborane/diborane hydridesMetal/metal-oxides/metal-hydroxide catalystsCalcium borohydrideFuel cells

The invention discloses a process method for preparing alpha-aluminum hydride by sodium borohydride catalysis. The method comprises a step (1) of preparing a catalyst solution; a step (2) of preparation of alpha-aluminum hydride; and a step (3) of product aftertreatment. The process method for preparing alpha-aluminum hydride by sodium borohydride catalysis can be implemented at a low temperature and normal pressure, and is suitable for industrial production. The obtained alpha-aluminum hydride is single in crystal form, the single-batch conversion rate is 86.5% or above, the purity reaches 98%, the thermal stability is high, and the alpha-aluminum hydride is favorable for being applied to fields of energetic materials, propellants and fuel cells and the like.

Owner:河南纳宇新材料有限公司

An automatic filling process

ActiveCN112320740BEasy to fillEasy to detectBottle/container closureBottle-handling machinesVacuum pumpingEngineering

The invention relates to an automatic filling process, comprising a filling sleeve, an inner cover and an outer cover used in cooperation with the filling sleeve; the two sides of the filling sleeve are fixedly connected with a first contact piece and a second contact piece, and the shell The inner seal is connected with the dispensing tube, the vacuum pumping tube and the filling tube, the vacuum degree detection head is installed on the vacuum pumping tube, the upper end of the insulation cylinder is fixedly connected with an electric push rod through the second connecting rod, and the injection plug is sealed and slidably installed in the insulation cylinder; An airbag is installed inside the inner cover, a movable ejector rod is fixedly connected to the upper part of the piston, a second contact head is fixedly connected to the upper end of the movable ejector rod, and a rubber sheet is fixedly connected to the top of the conical groove. In the present invention, it is convenient to carry out tightness detection before and after filling; it is convenient to realize automatic filling operation, and the vacuuming, filling and sealing are all concentrated on the filling head, which saves the operation process and improves the work efficiency; It reduces the space occupied by other equipment and saves costs.

Owner:福州幽力克生物科技有限公司

Preparation method of manganese-series hydrogen sulfide removing agent in normal-temperature environment

The invention belongs to the technical field of chemical engineering, and relates to a preparation method of a manganese-based hydrogen sulfide removing agent in a normal-temperature environment. Themethod comprises the following steps of: (1) washing activated carbon with absolute ethyl alcohol, carrying out suction filtration to obtain filter residues, and carrying out drying to obtain an activated adsorbent; (2) crushing aluminum oxide and manganese dioxide to obtain mixed powder with the particle size of 0.5-0.8 mu m, weighing a certain amount of nitrate of one or more compounds of copper, nickel, zinc, magnesium and cerium, dissolving the nitrate in water to form a solution, adding the mixed powder into the solution, adding alkali liquor, and carrying out stirring to obtain a mixed solution; and (3) adding the active adsorbent obtained in the step (1) into the mixed solution obtained in the step (2), adding an auxiliary agent, carrying out stirring, still standing and filtering sequentially, putting filter residues into a drying oven, drying the filter residues , and roasting the filter residues to obtain the desulfurizing agent. The method of the invention reduces the production cost and simplifies the operation process; and the prepared manganese-series hydrogen sulfide removing agent has the advantages of high desulfurization precision at normal temperature, long service life, good mechanical strength, no influence on material chromaticity and the like.

Owner:SINOPEC YANGZI PETROCHEM +1

Secondary baking and heat pressing technique of heat pressing hemp fibre board for vehicle inner decoration

InactiveCN101434079BReduce smokeAvoid the risk of burnsWood veneer joiningDrying machines with progressive movementsEngineeringBonding strength

The invention discloses a secondary baking and hot-pressing process for hot-pressing hemp fiber boards. Two conveying and receiving meshes which alternately input and output are arranged in a baking oven, the temperature of the baking oven is adjusted to be between 140 and 150 DEG C, and hemp fiber boards are placed on the conveying receiving meshes, are subjected to first baking and exit the baking oven to be cooled, and then are directly paved with fabrics and PVC skin for hot press after secondary baking. The invention is a secondary baking, the first baking is preheating, and the secondary baking is to ensure that the heat is easier to penetrate the hemp fiber boards, thereby ensuring that the hemp fiber boards can achieve the softening requirement of hot-pressing composite molding further to guarantee the composite bonding strength of the skin and the hemp fiber boards, reducing dense smoke and pungent odor produced by the hemp fiber boards after the baking further to improve thework environment, and avoiding the risk of burning the hemp fiber boards due to sharp fire baking; during the hot-pressing, a tension process of the fabrics and the PVC skin on a frame tooling can becanceled, and no defect of folds after the hot-pressing can not generate, thereby reducing one operation process.

Owner:YANFENG AUTOMOTIVE TRIM SYST CHONGQING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com