Patents

Literature

182results about How to "Avoid the risk of burns" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

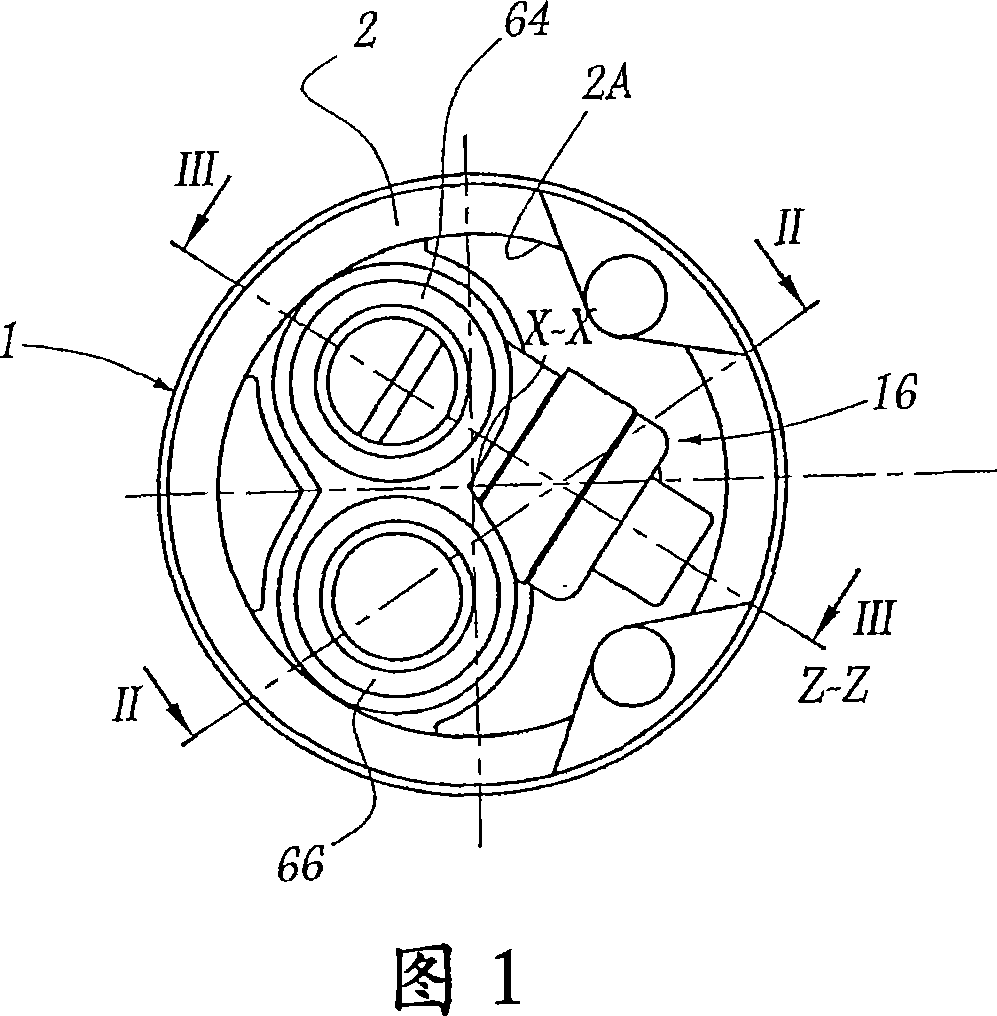

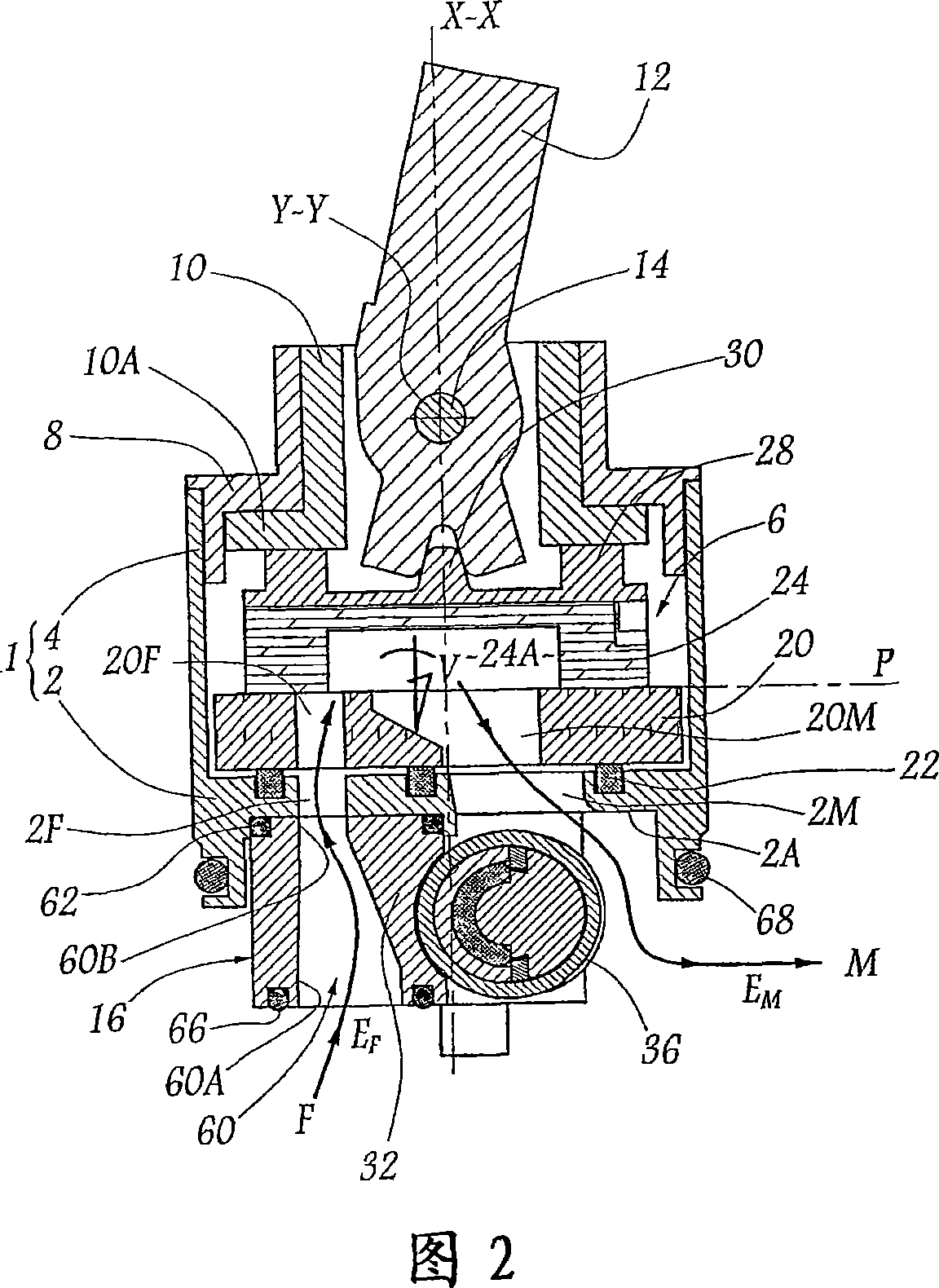

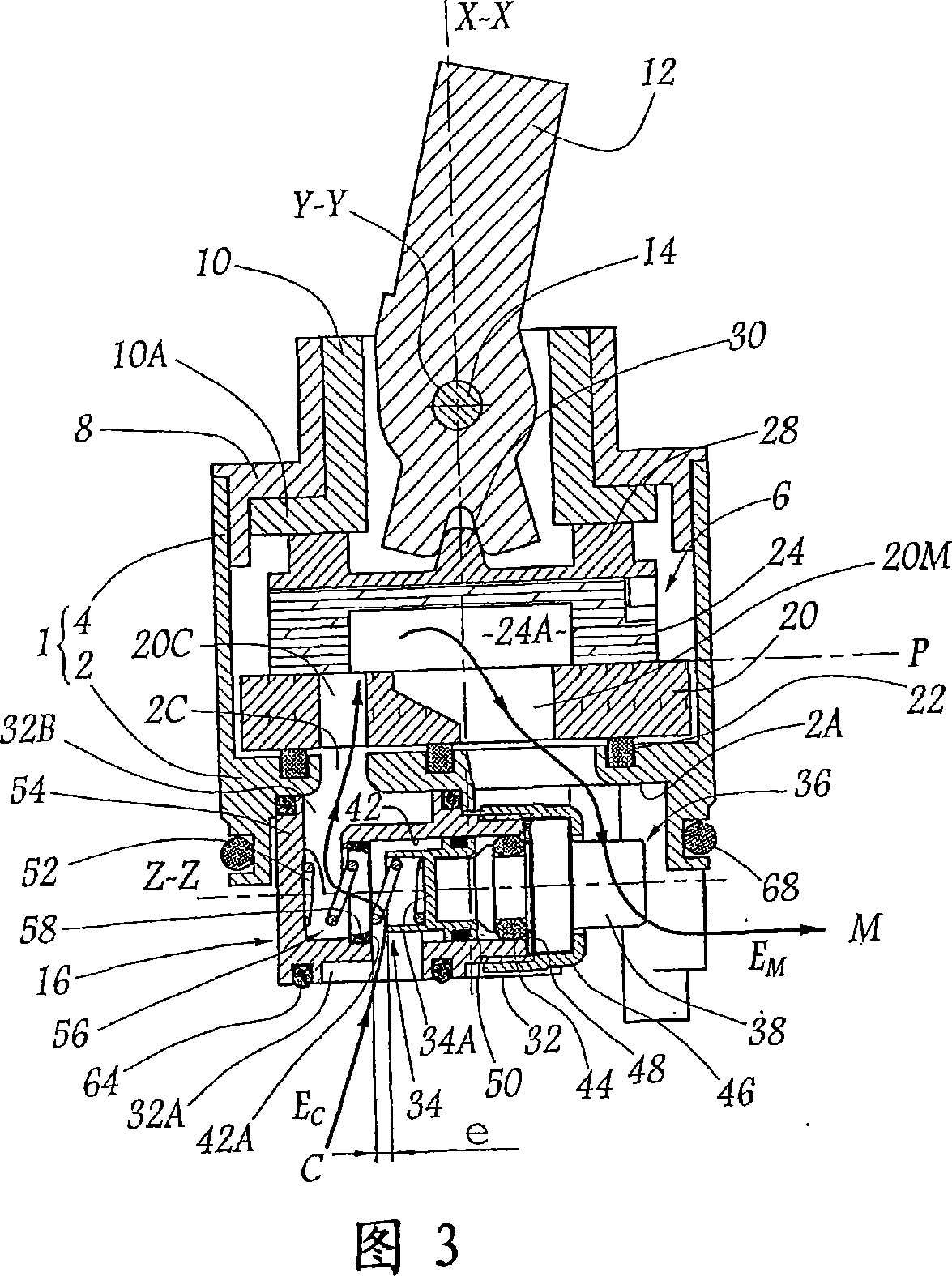

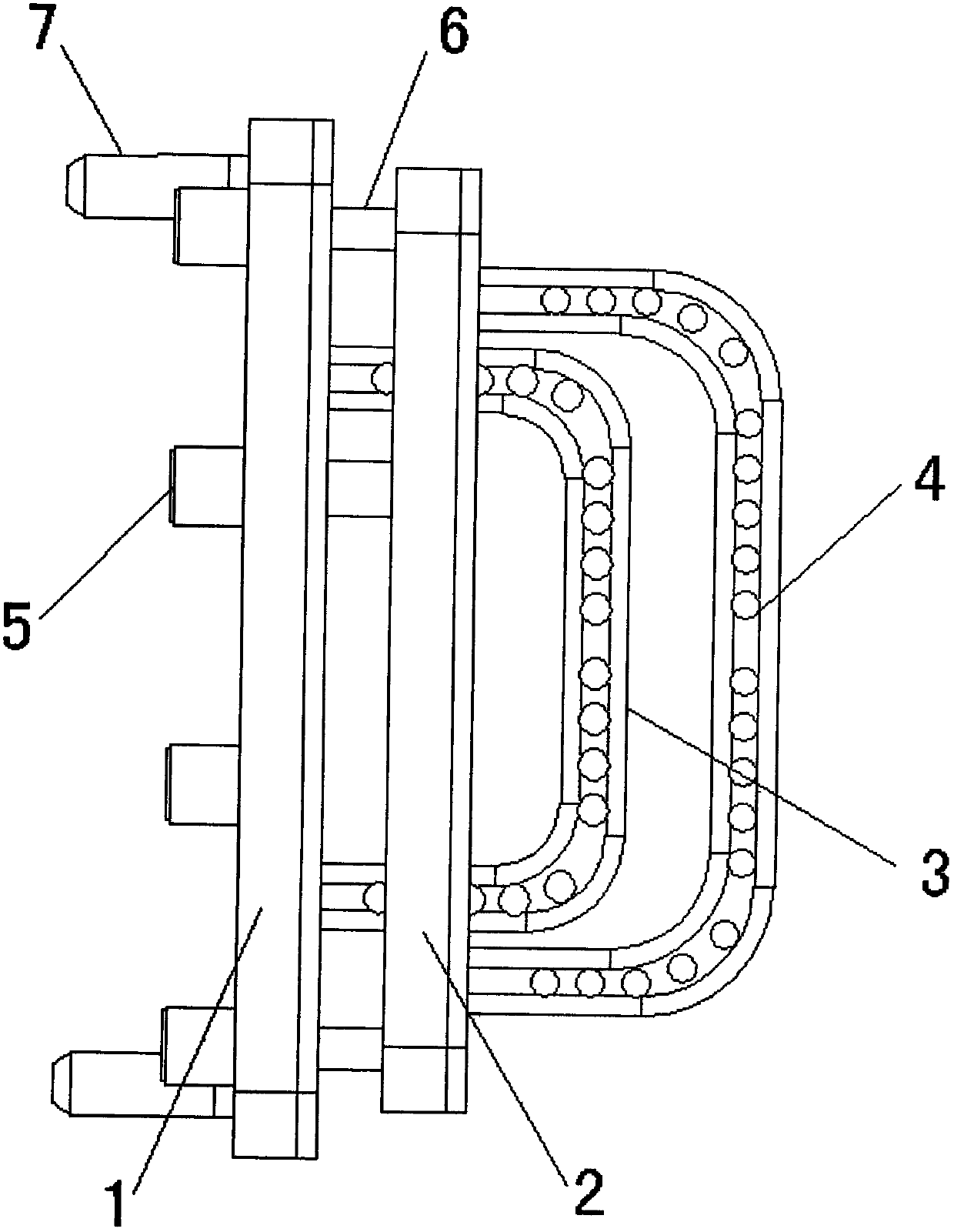

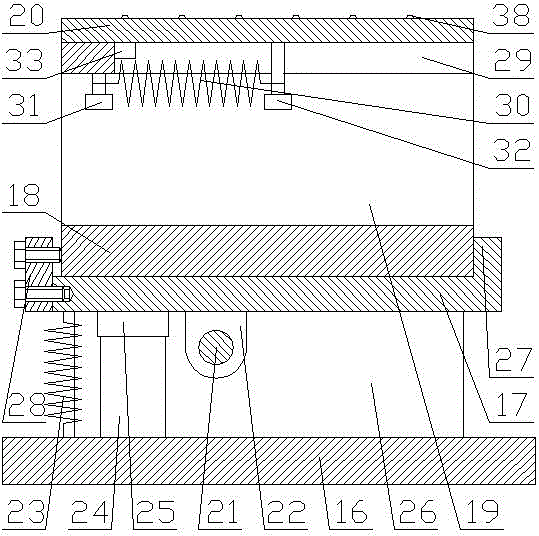

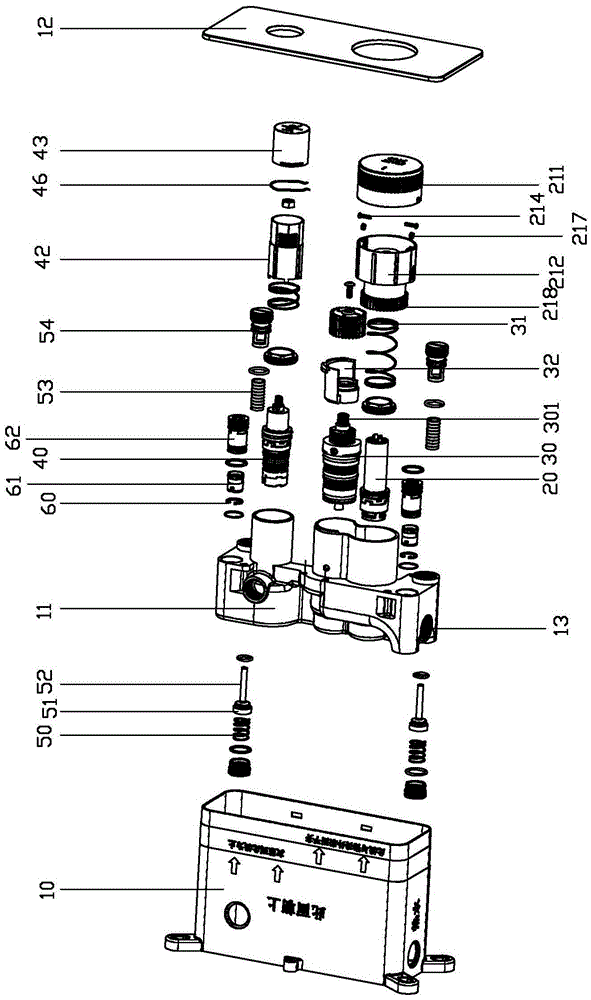

Cartridge for a mixer faucet, faucet comprising a cartridge of this type, and thermostatic assembly to be fitted together with this cartridge

ActiveCN101035954AEasy to useAvoid the risk of burnsOperating means/releasing devices for valvesTemperatue controlEngineeringMechanical engineering

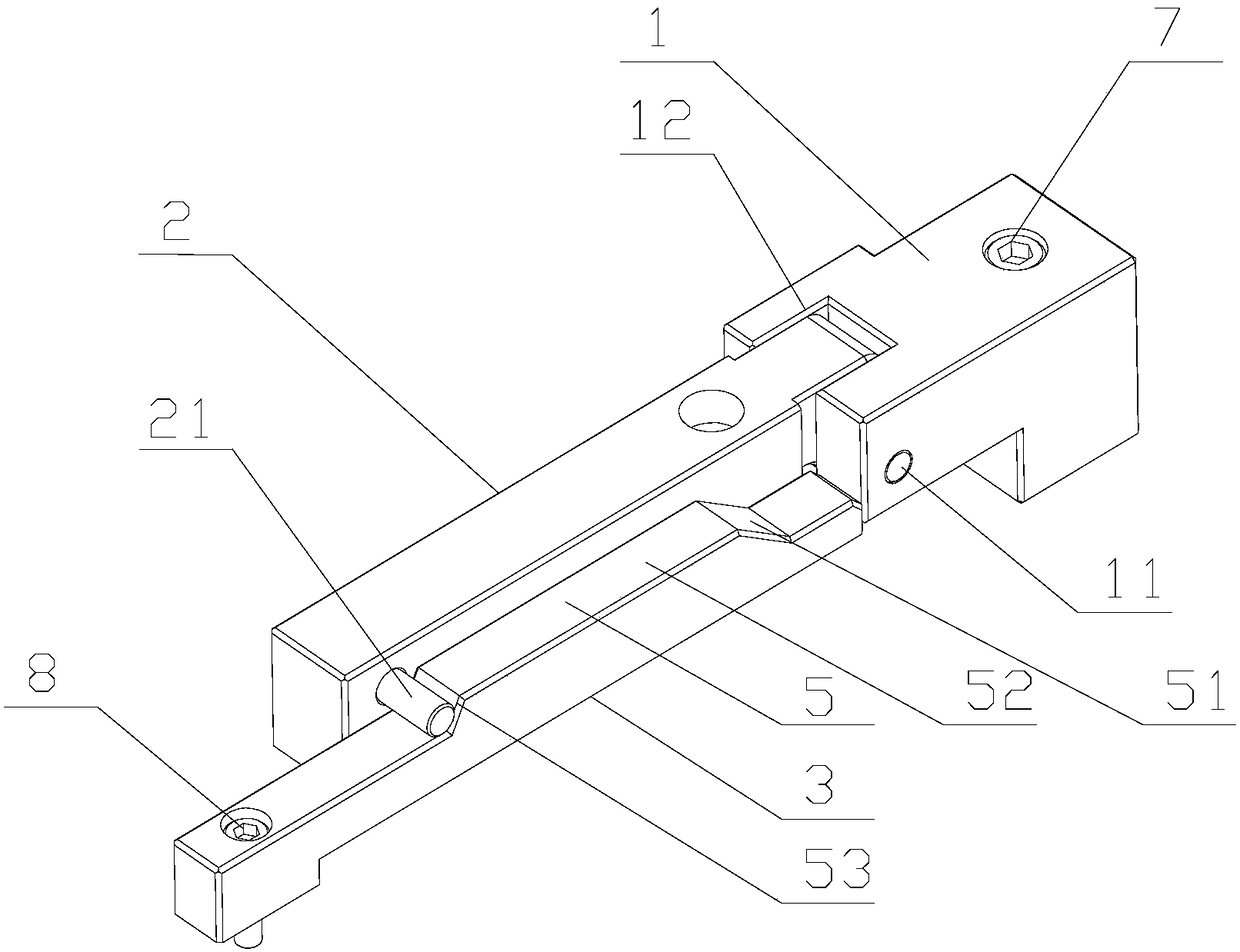

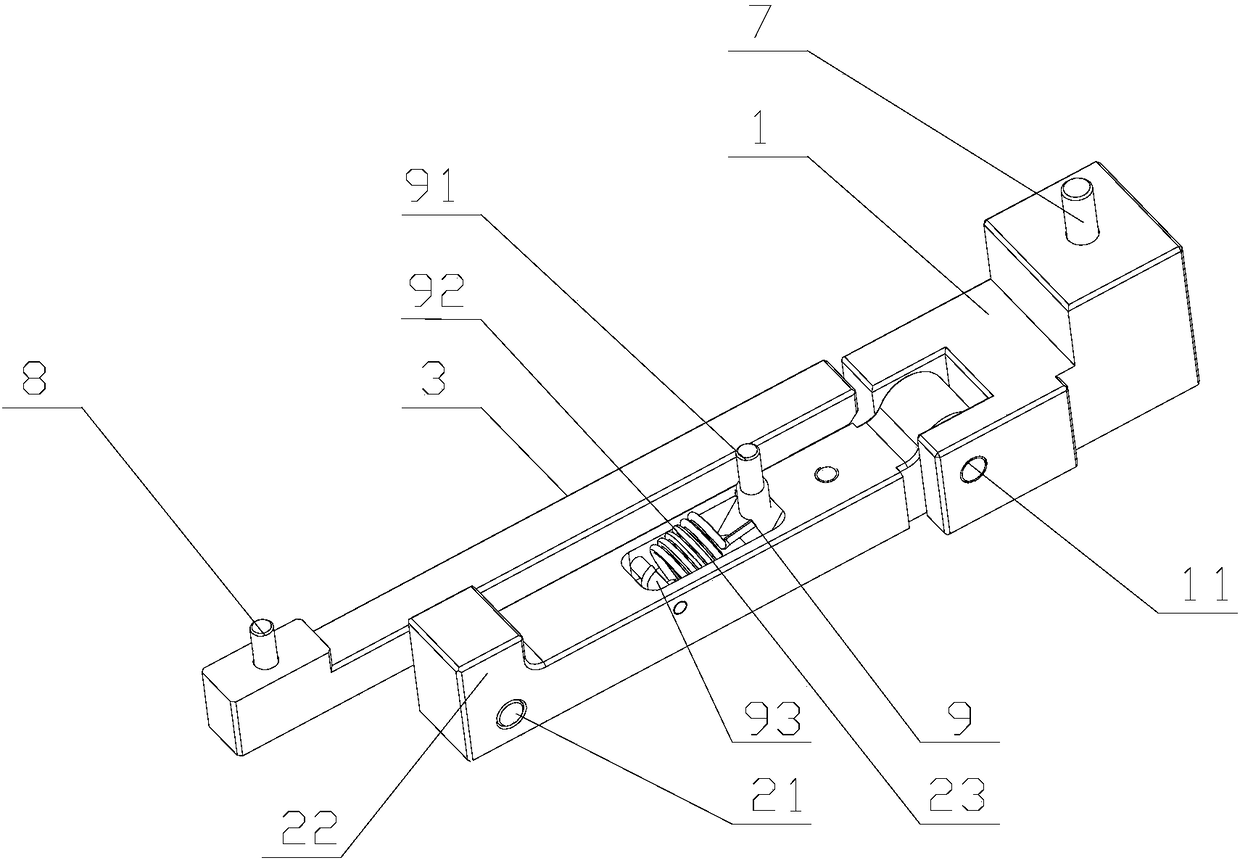

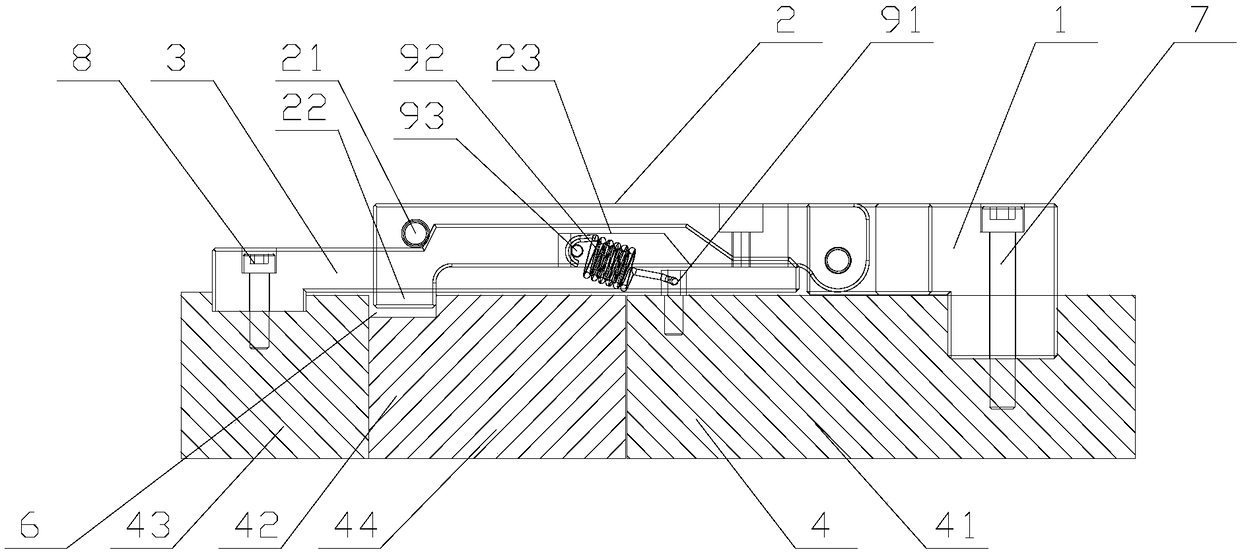

The cartridge comprises two ceramic disks (20, 24) for regulating the temperature and flow of a mixture (M) of two entering fluids. In order to ensure that the temperature of the mixture remains lower than a predetermined value, the cartridge comprises thermostatic means (16) designed for, in the event of a high-temperature mixture, automatically shutting off, upstream from these disks, the circulation of the entering fluid (C) of the highest temperature. In order to limit their size, these means comprise: a closure element (34), which serves to close a passage (56) of the fluid (C) having the highest temperature and which is delimited by the cartridge, and; a thermostatic element (36) including a thermosensitive part (38) placed along the flow path of the mixture and a mobile part (40) connected in translation to the closure element, said closure element being mounted in a manner that enables it to slide in an area (42A) of the passage of the fluid of the highest temperature, with the interposition of a packing seal (58), which is joined to this area and which, when the temperature of the mixture is greater than the predetermined value, is capable of forming a sliding tight contact with the closure element.

Owner:VERNET SA

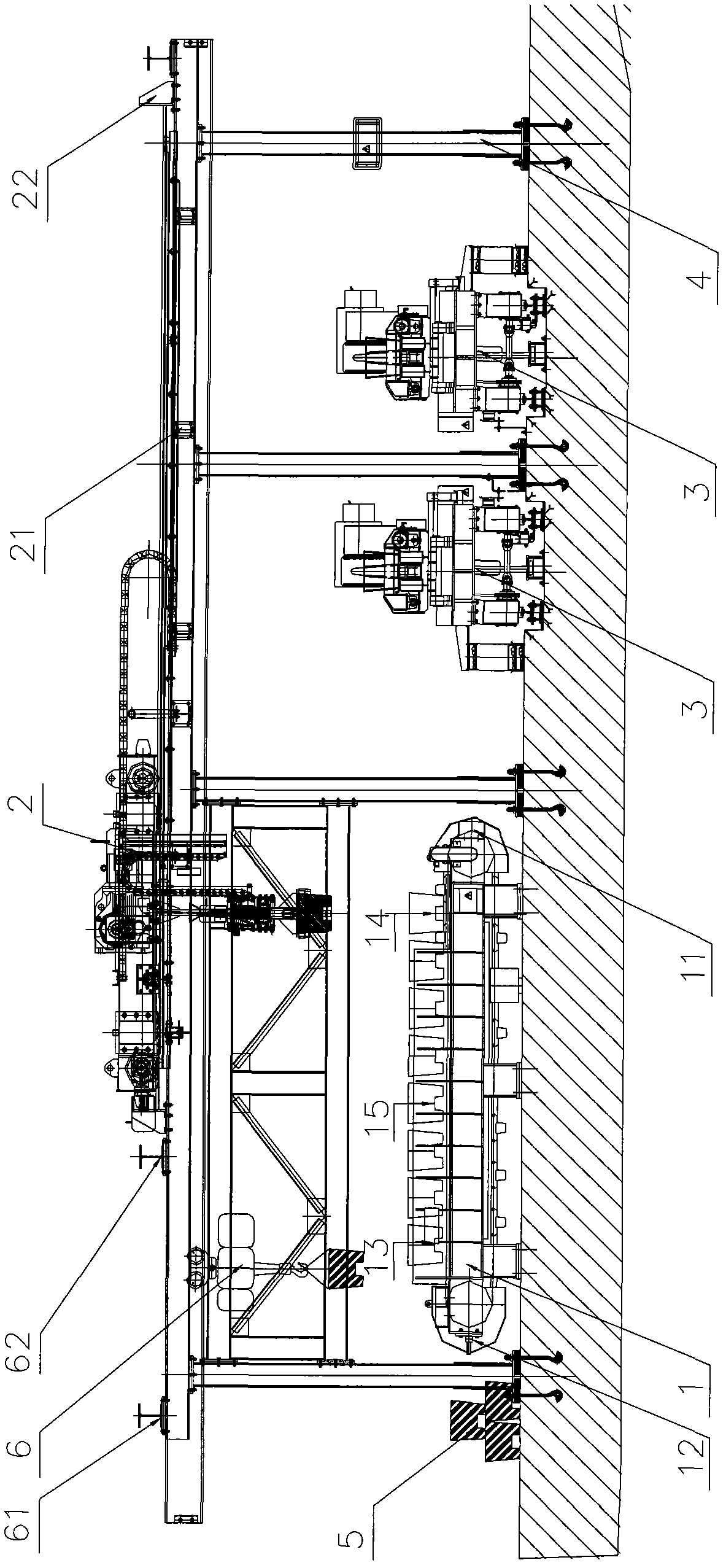

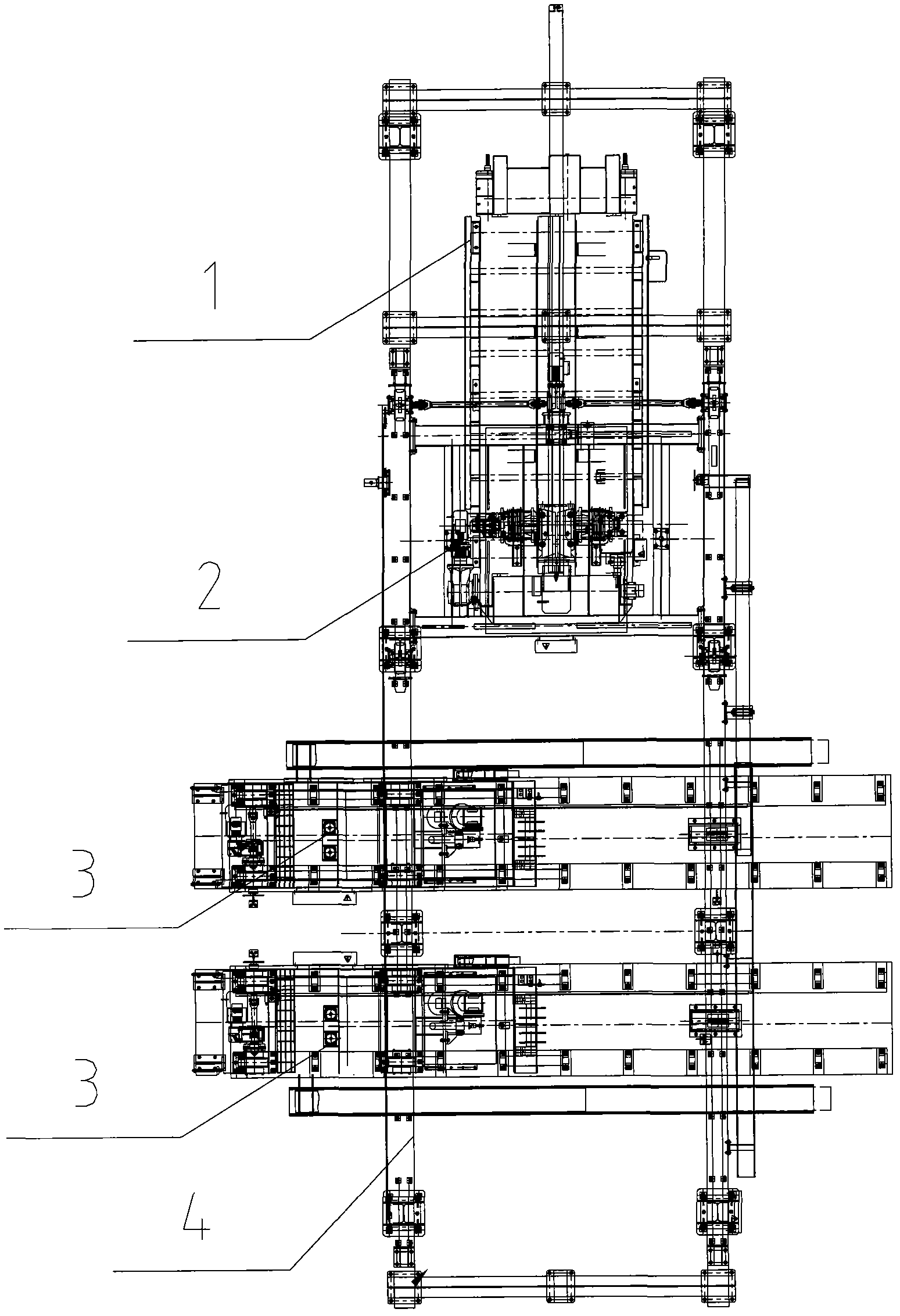

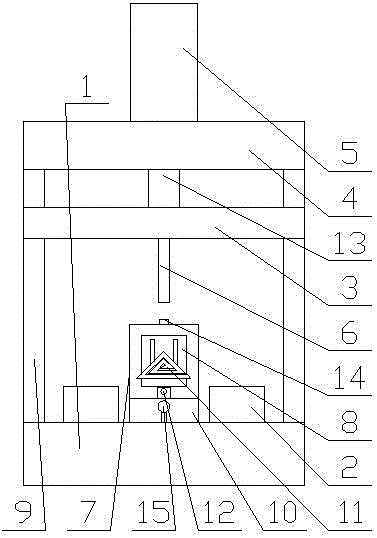

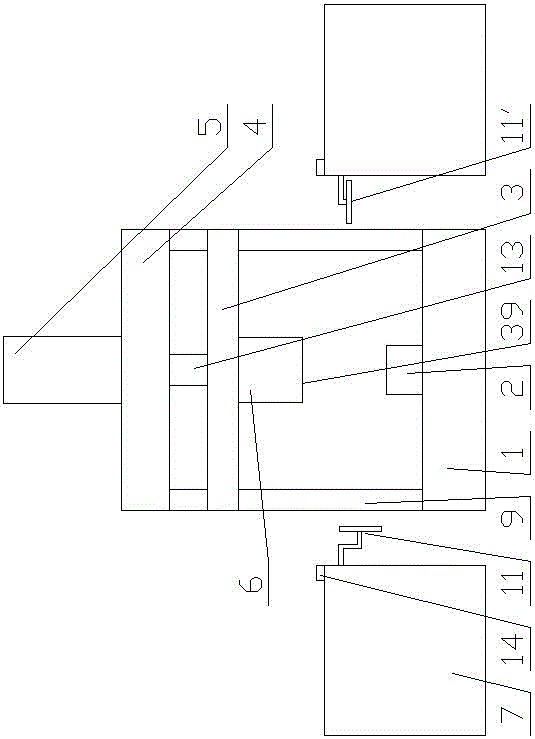

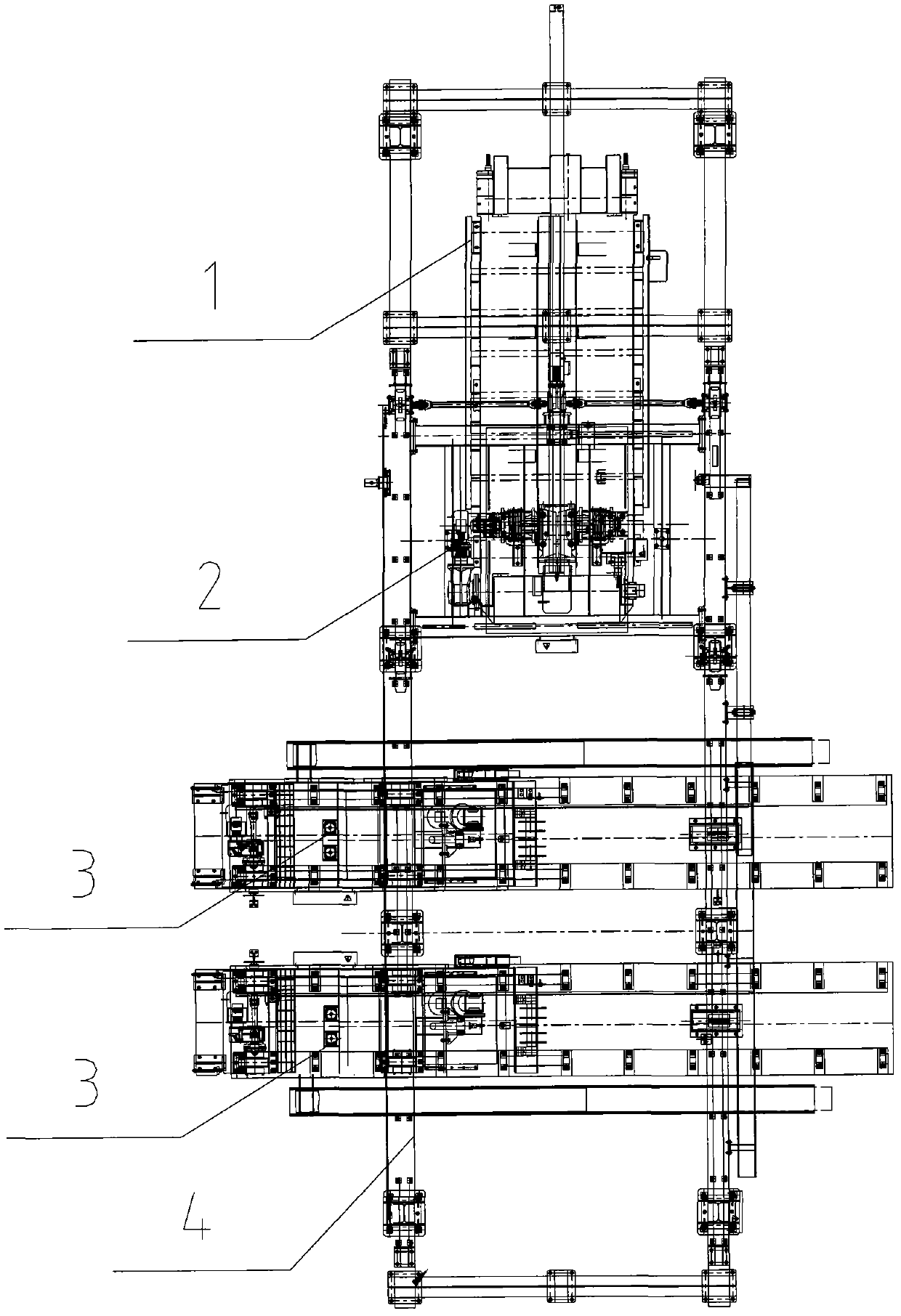

Automatic zincification device and control method thereof

InactiveCN102373391APrevent splashAvoid the risk of burnsHot-dipping/immersion processesProgrammable logic controllerEngineering

The invention discloses an automatic zincification device which comprises a control PLC (Programmable Logic Controller), a bracket, a manipulator device, a conveyer and at least one zincification trolley, wherein the manipulator device is arranged on the bracket and is connected with the control PLC; the conveyer is arranged below the front part of the bracket along the length direction of the bracket and is connected with the control PLC; the zincification trolley is arranged below the rear part of the bracket and moves along a zincification trolley operating track; the zincification trolleyoperating track is vertical to the bracket; and the zincification trolley is connected with the control PLC. Correspondingly, the invention also provides a control method of the automatic zincification device. By the automatic zincification device and the control method thereof, the full automation of the zincification process can be realized.

Owner:BAOSHAN IRON & STEEL CO LTD

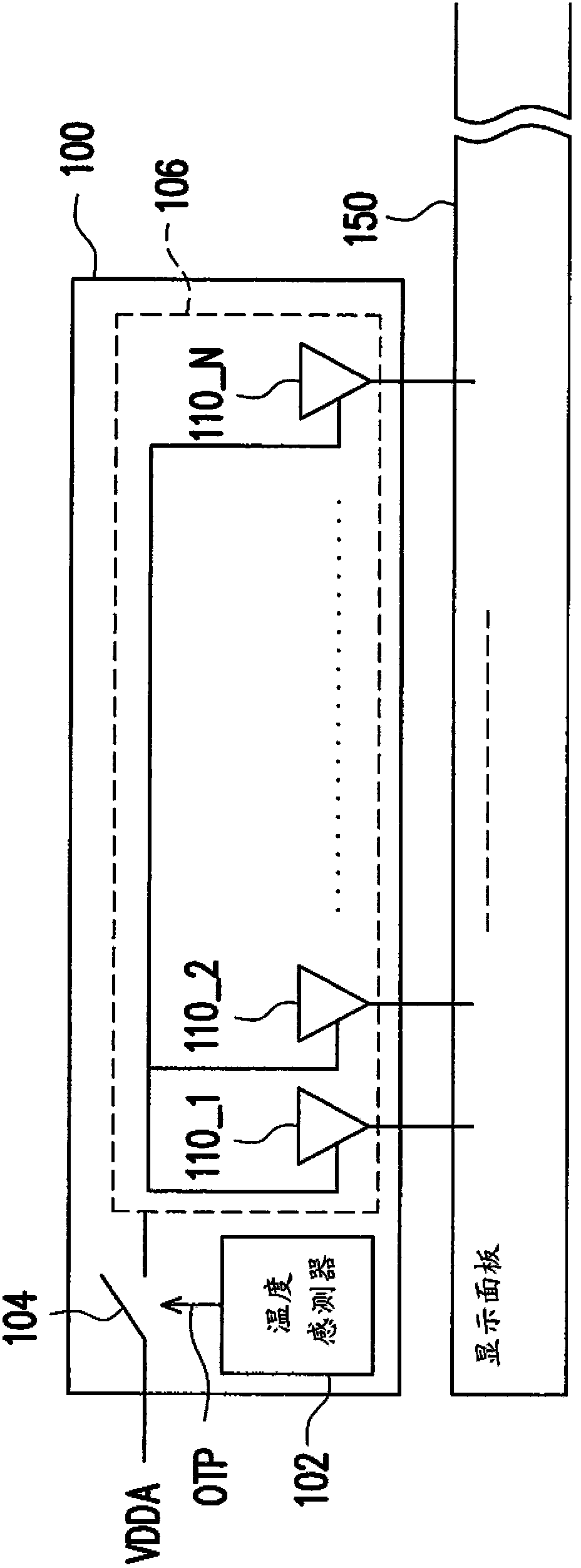

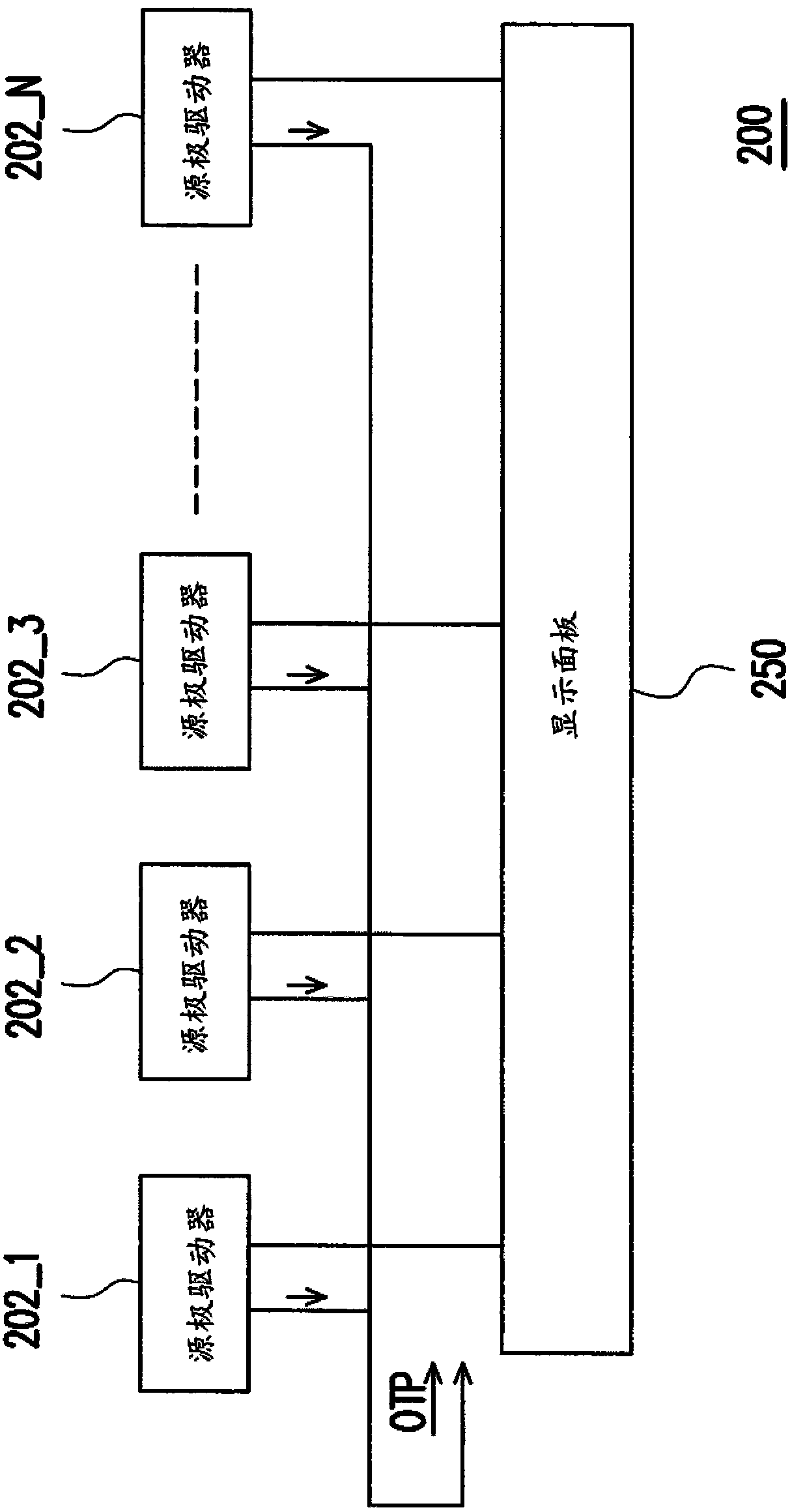

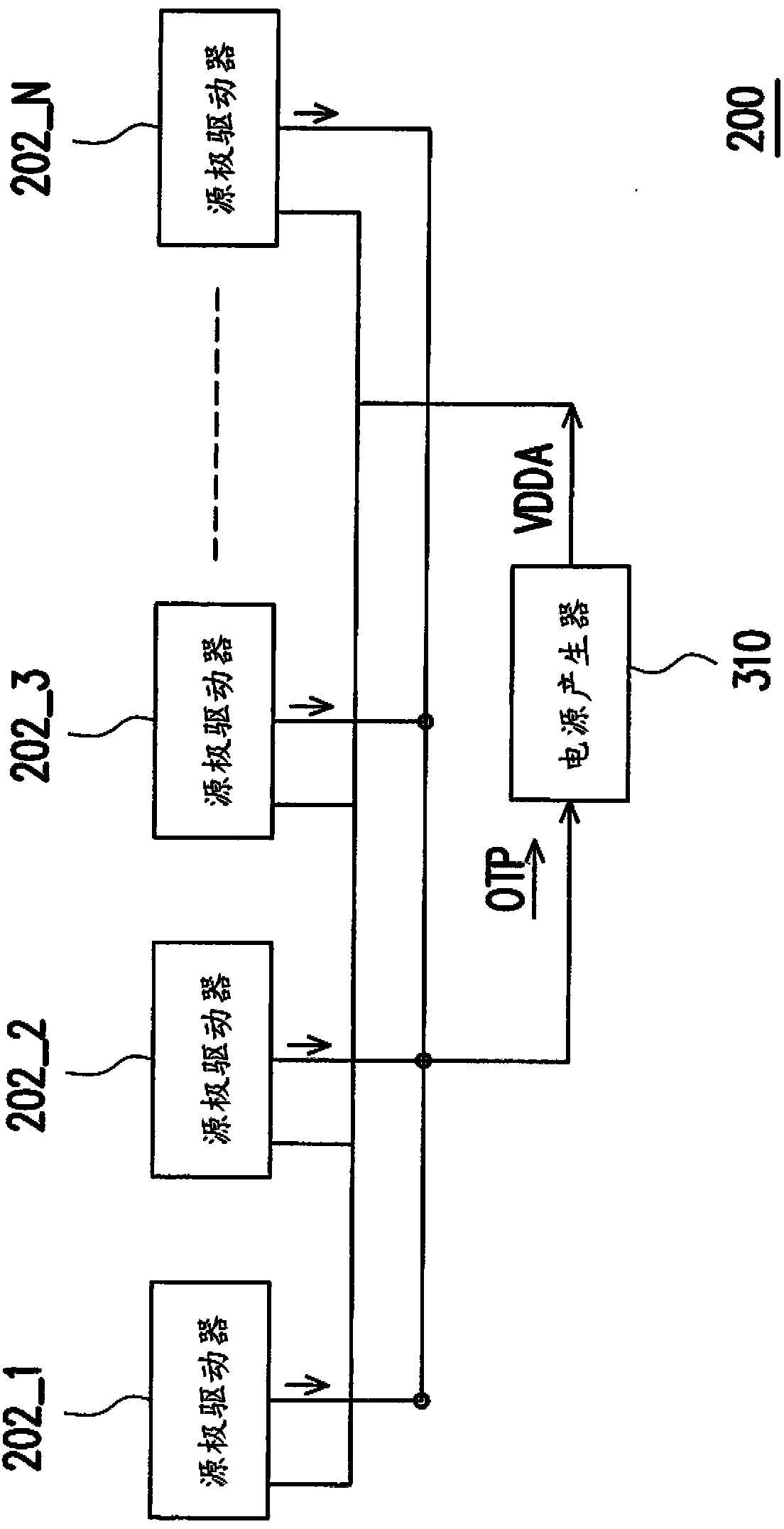

Display device and source electrode driver thereof

InactiveCN104282276AAvoid burningEffective detection of working temperatureStatic indicating devicesStart signalEngineering

The invention provides a display device and a source electrode driver thereof, wherein the source electrode driver comprises a temperature sensor and a power switch. The temperature sensor is used for measuring a first operation temperature of the source electrode driver, and generates an overtemperature protection starting signal through comparing the first operation temperature with a first preset temperature. The power switch is coupled in a power transmission path of a core circuit of the source electrode driver for receiving the operating power. The power switch switches on or off the power transmission power according to the overtemperature protection starting signal.

Owner:NOVATEK MICROELECTRONICS CORP

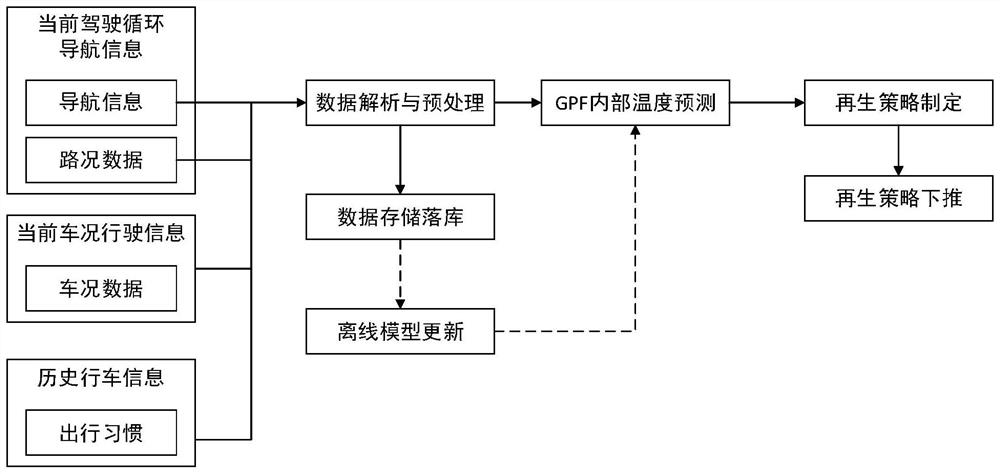

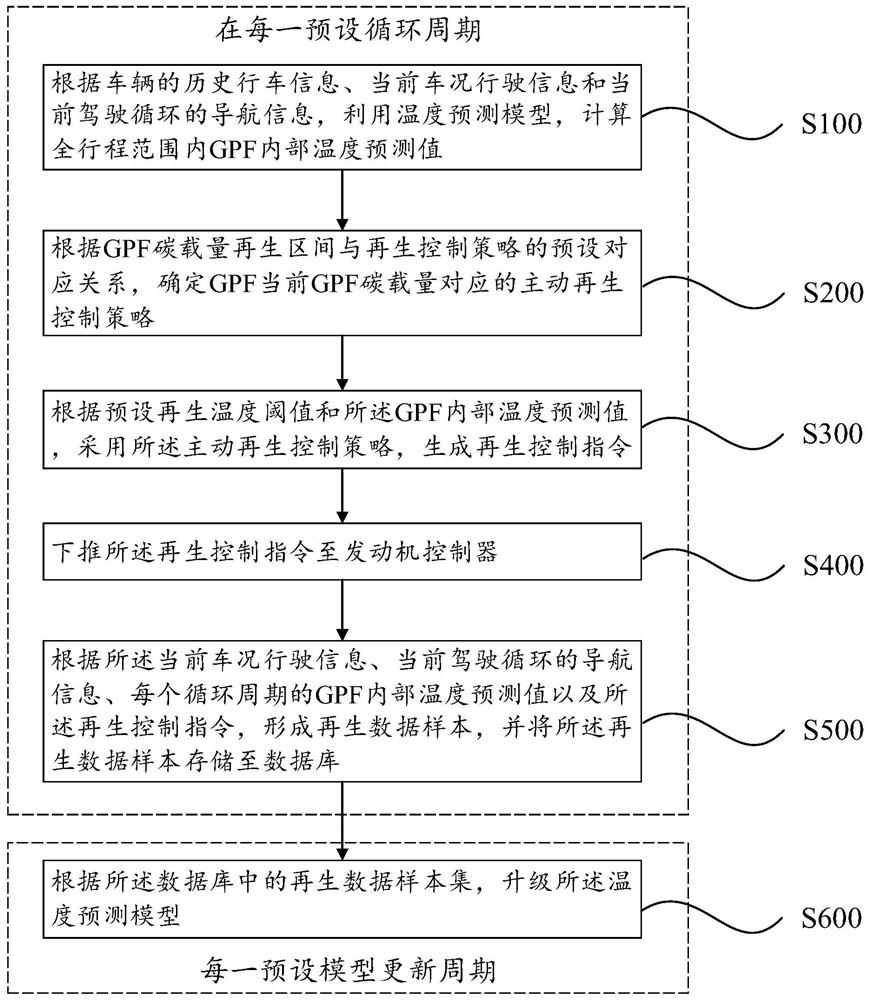

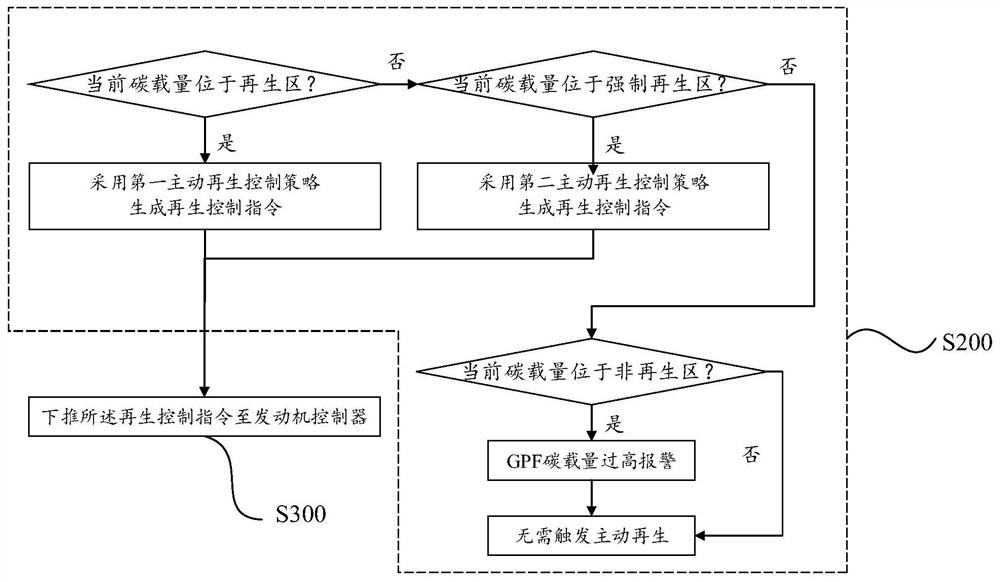

Regeneration control method and system for vehicle particulate matter trap and storage medium

ActiveCN113202607AGood flexibilityThe regeneration process is stableInternal combustion piston enginesExhaust apparatusProcess engineeringDriving cycle

The invention provides a regeneration control method and system for a vehicle particulate matter trap and a storage medium. The regeneration control method comprises the following steps of in each preset cycle period, executing the following steps of according to historical driving information of a vehicle, current vehicle condition driving information and navigation information of a current driving cycle, utilizing a temperature prediction model to calculate a GPF internal temperature prediction value in a whole travel range; determining an active regeneration control strategy, corresponding to current GPF carbon loading capacity, of the GPF according to a preset corresponding relation between a GPF carbon loading capacity regeneration interval and a regeneration control strategy; according to a preset regeneration temperature threshold value and the GPF internal temperature predicted value, adopting the active regeneration control strategy to generate a regeneration control instruction; and pushing down the regeneration control instruction to an engine controller. According to the regeneration control method and system and the storage medium, no hardware cost needs to be increased, a GPF regeneration process can be accurately controlled, the regeneration accuracy and rationality can be remarkably improved, and the regeneration efficiency is improved.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

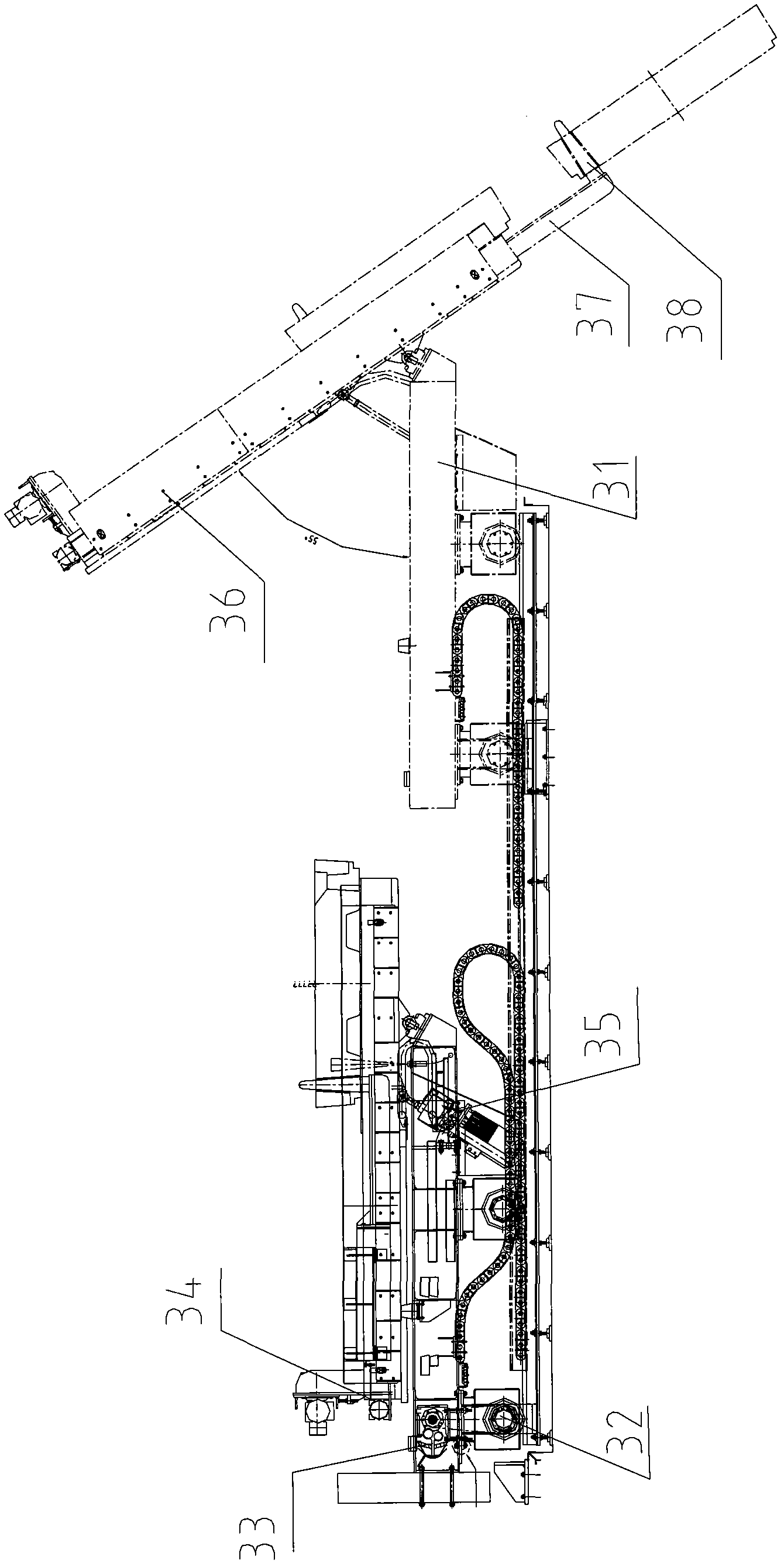

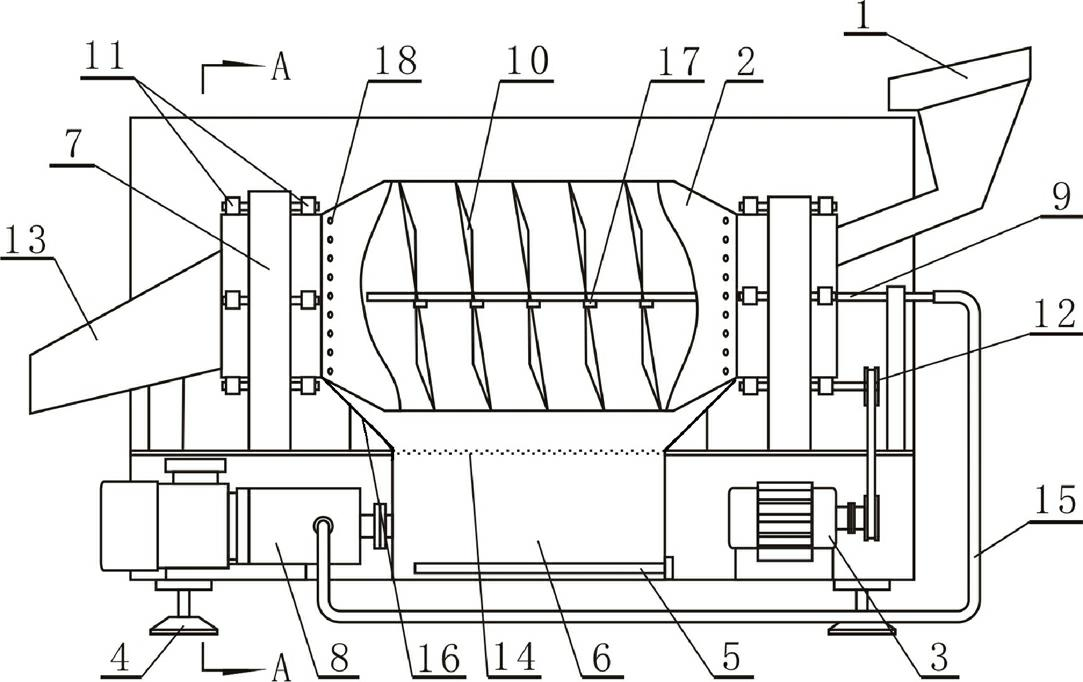

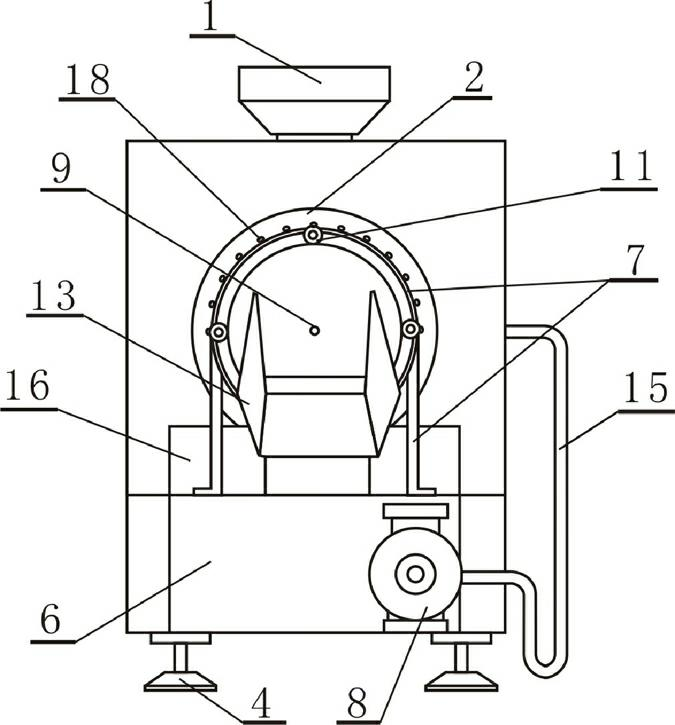

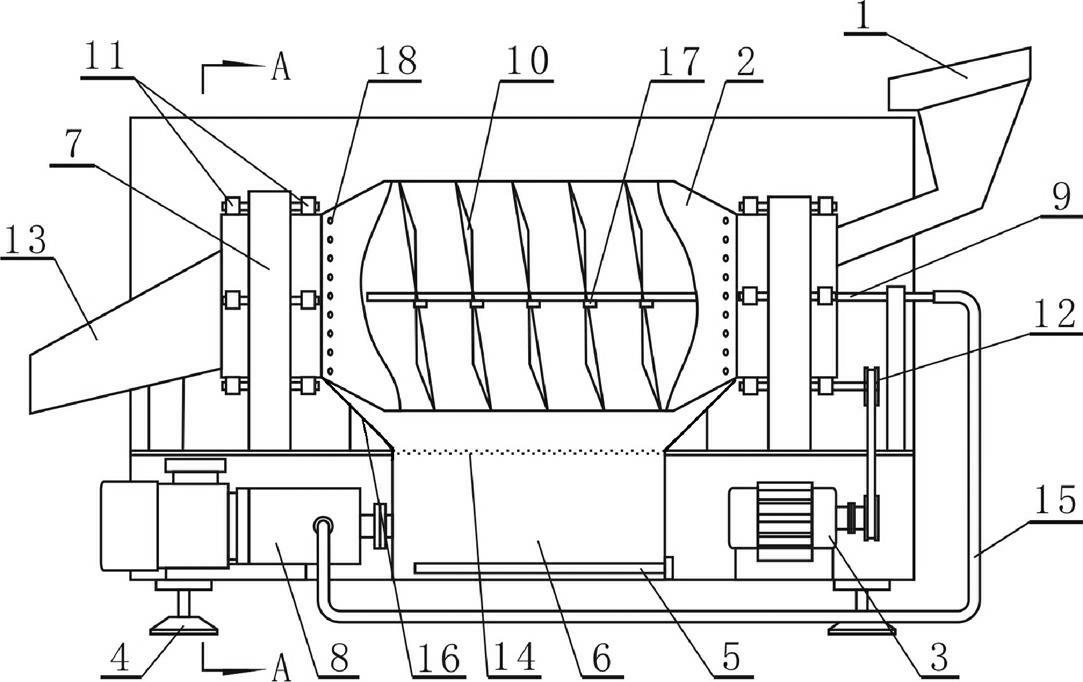

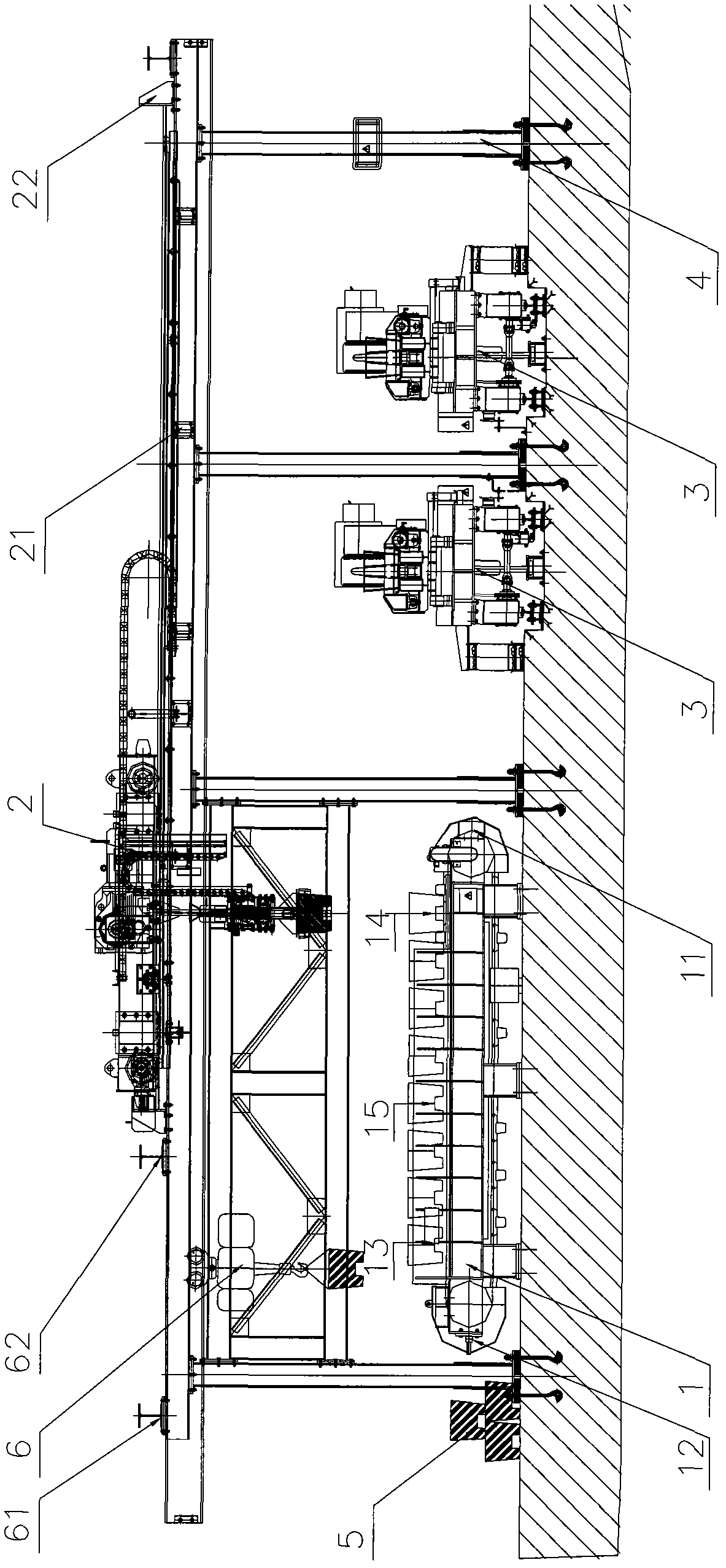

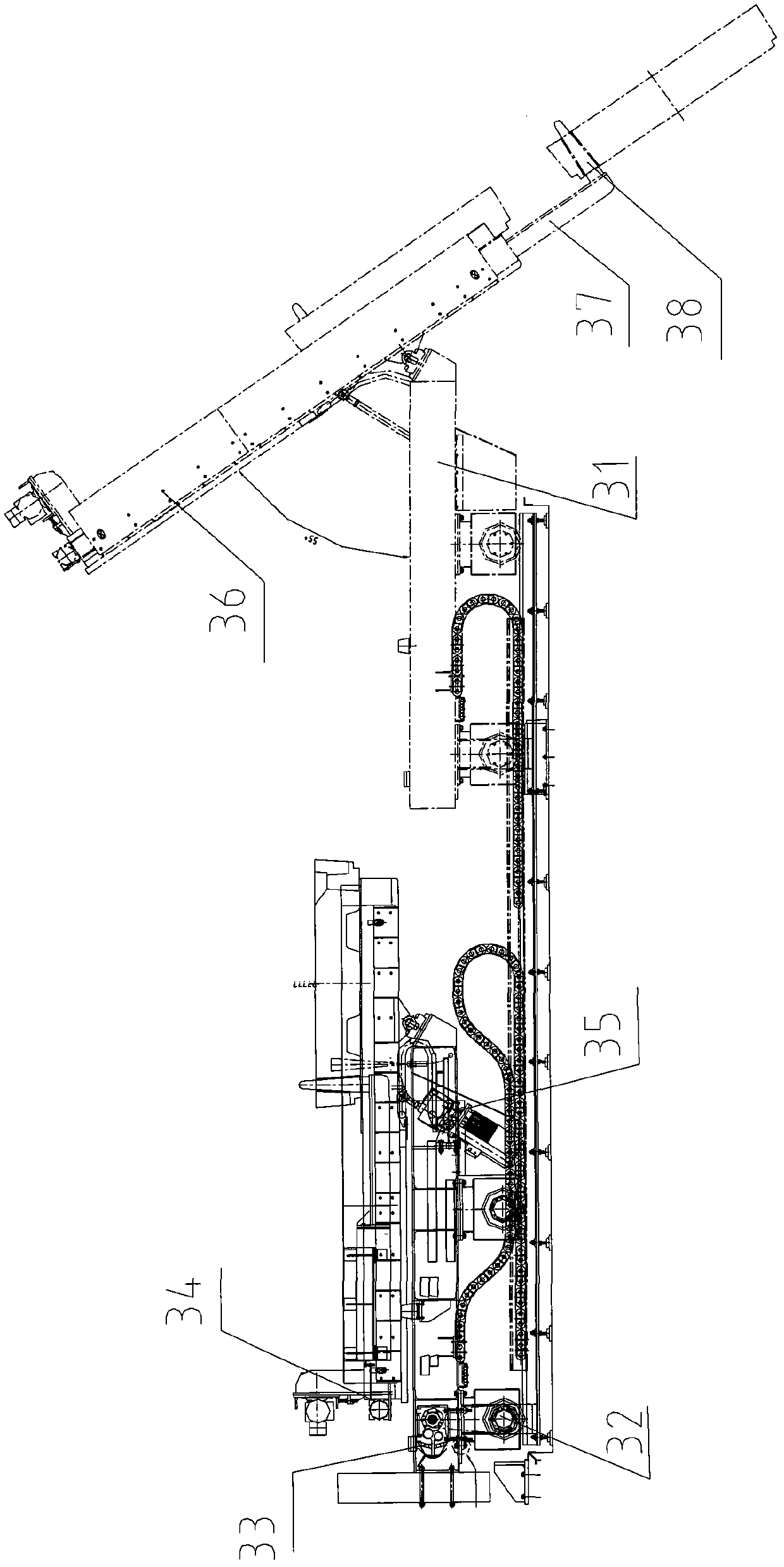

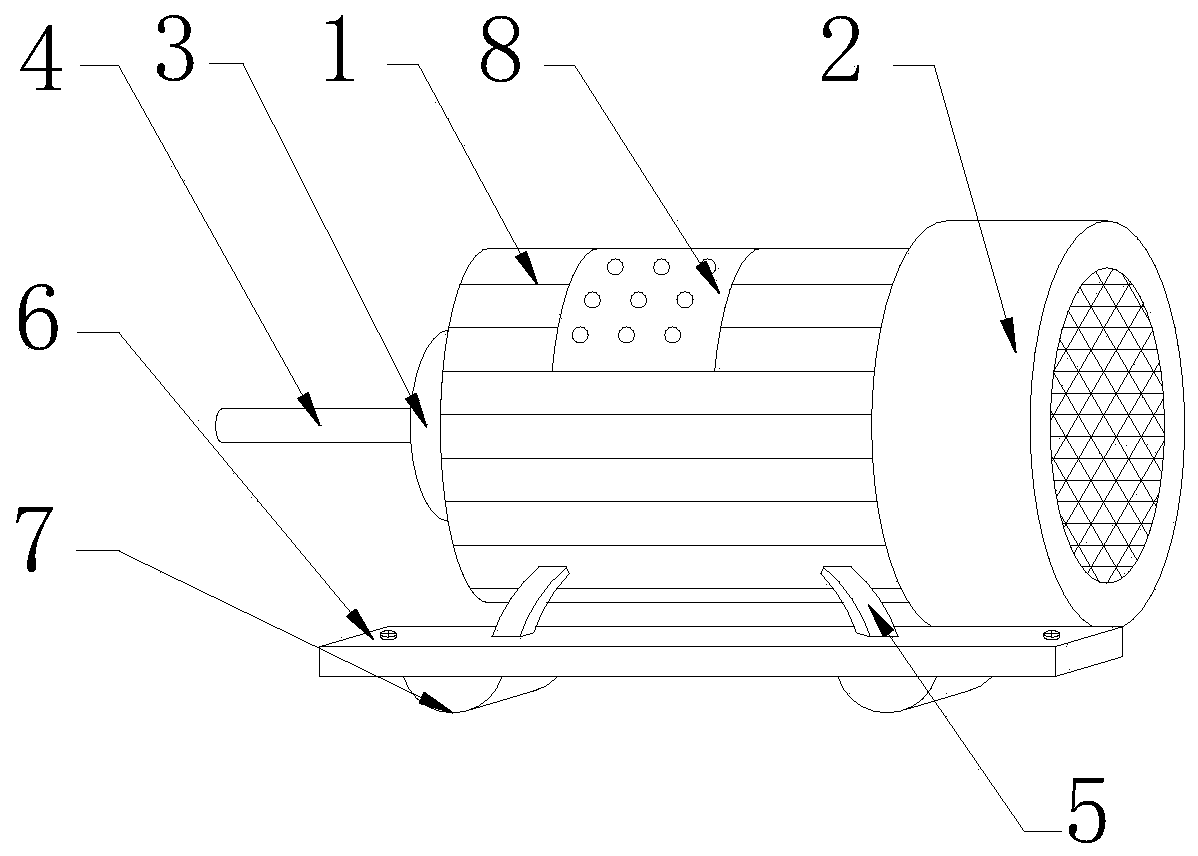

Continuous operation type soaking device before peeling of plant nuts

InactiveCN102423102AAvoid the risk of burnsRealize automatic entry and exitHuskingHullingAutomatic controlElectric machinery

The invention discloses a continuous operation type soaking device before peeling of plant nuts. The continuous operation type soaking device comprises a machine frame, a soaking roller, a driving device and a spraying device, wherein the driving device comprises a motor and a roller bracket; a roller group is arranged on the roller bracket; two ends of the soaking roller are matched with the roller group; the roller group is driven by the motor; the spraying device comprises a water supply device and a spraying pipe; a heating device is arranged in the water supply device; and the water supply device is connected with and extends into the spraying pipe in the soaking roller. A pot-shaped soaking container in the prior art is replaced by the soaking roller type soaking device and materials are soaked and propelled towards the outlet end by a push flow plate in the soaking roller, so that the technical aims of automatic feeding and discharging of the materials and line production are fulfilled. The continuous operation type soaking device has a simple structure and simple work, and realizes automatic control easily. Closed operation is basically realized, and an operator is prevented from being scalded by hot water. Production efficiency is improved and production cost is reduced.

Owner:YUNNAN MOER GARDEN BIOLOGICAL SCI & TECH DEV

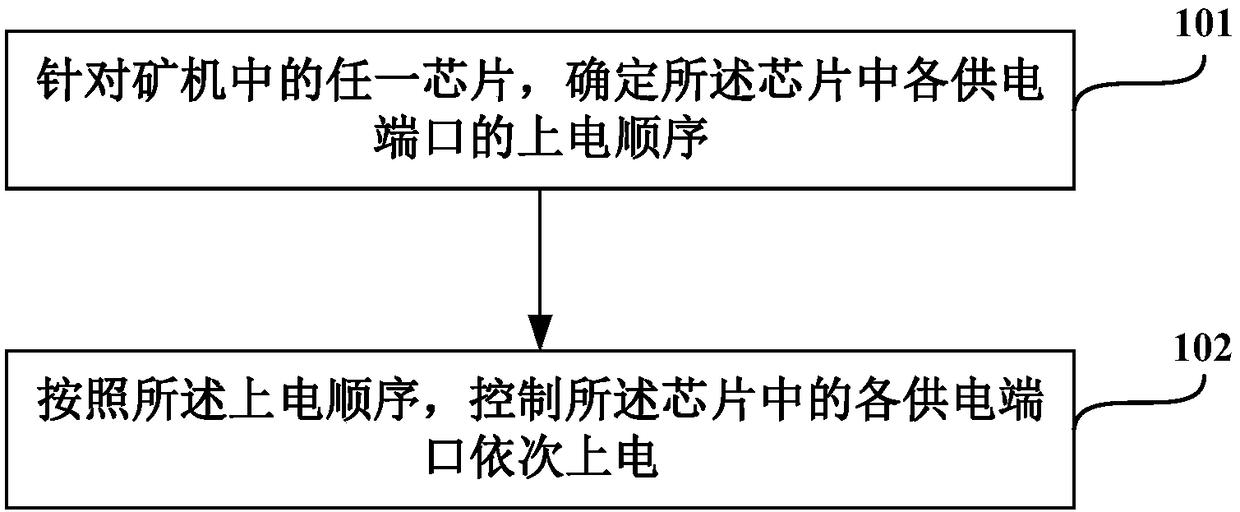

Chip control method and device, computer equipment and computer storage medium

InactiveCN108519806AEnsure safetyAvoid the risk of burnsVolume/mass flow measurementPower supply for data processingElectricityEmbedded system

The embodiment of the invention discloses a chip control method and device, computer equipment and a computer storage medium. the chip control method is applied to a mine machine for mining digital cash. The mine machine comprises one or more chips, and each chip comprises three or more power supply ports. The chip control method comprises the steps that for any one chip in the mine machine, the power-on sequence of all the power supply ports in the corresponding chip is determined; according to the power-on sequence, all the power supply ports in the corresponding chip are controlled to be powered on in sequence. Compared with the prior art, all the power supply ports in each chip in the mine machine can be powered on in sequence according to the preset power-on sequence, the safety of the chips and the mine machine can be guaranteed accordingly, and the burn-down risk of the chips and the mine machine is avoided.

Owner:BEIJING BITMAIN TECH LTD

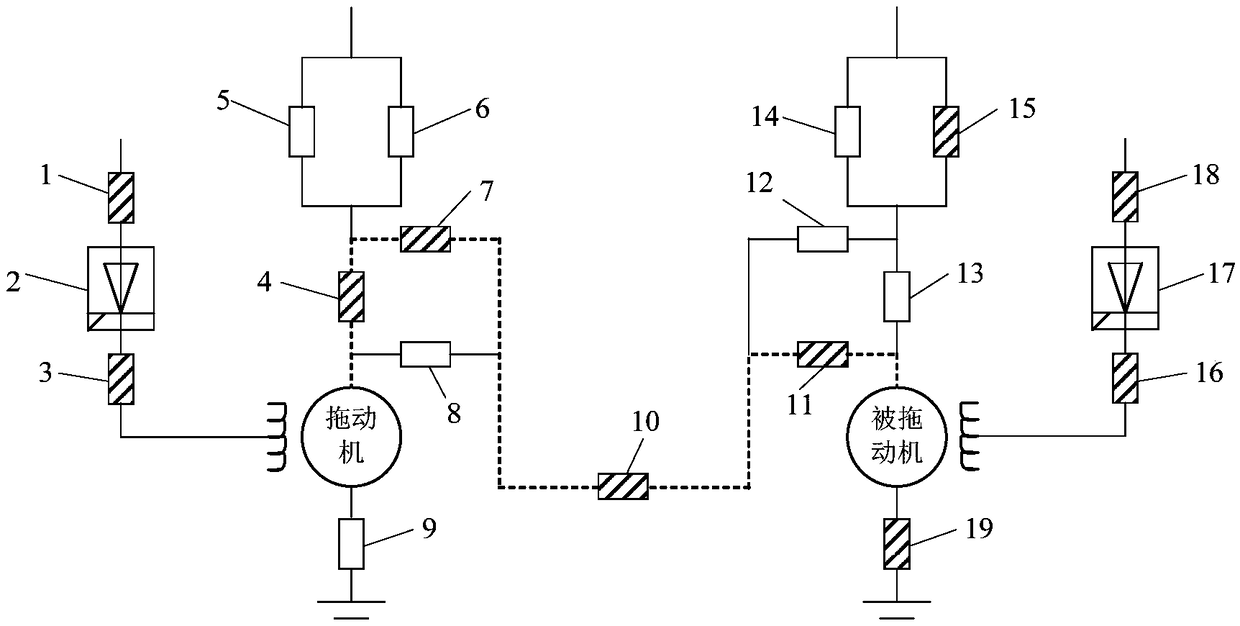

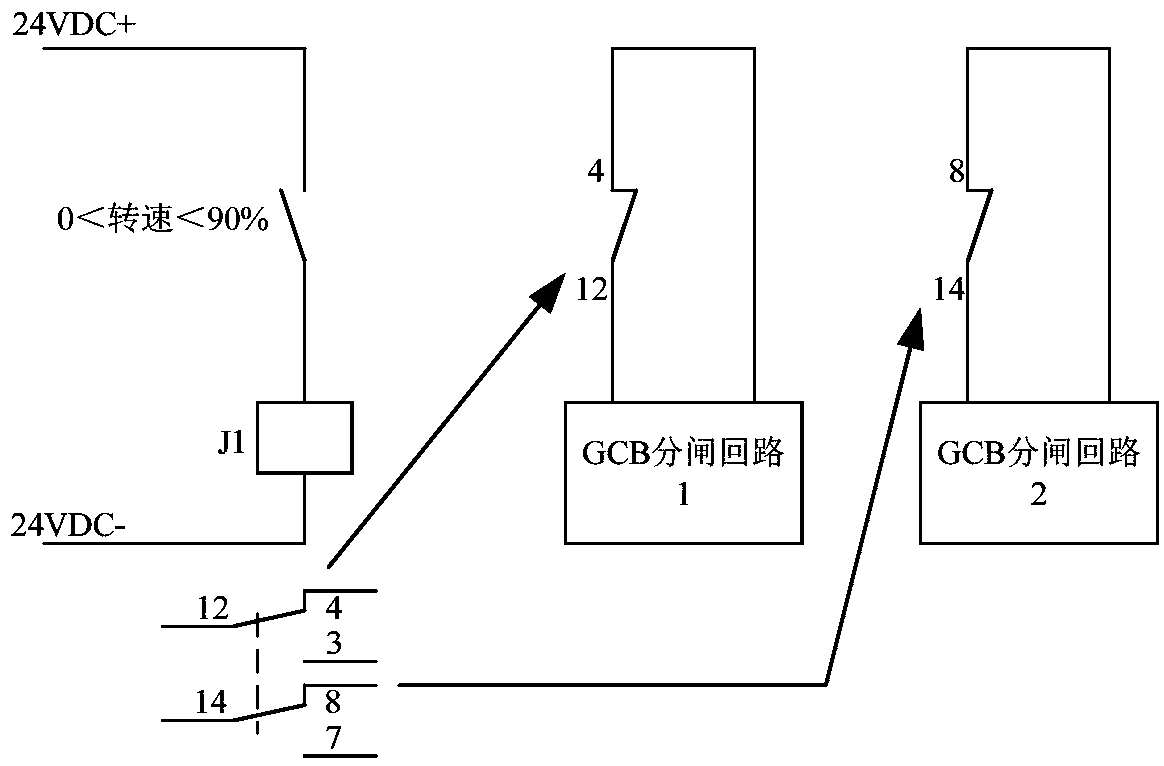

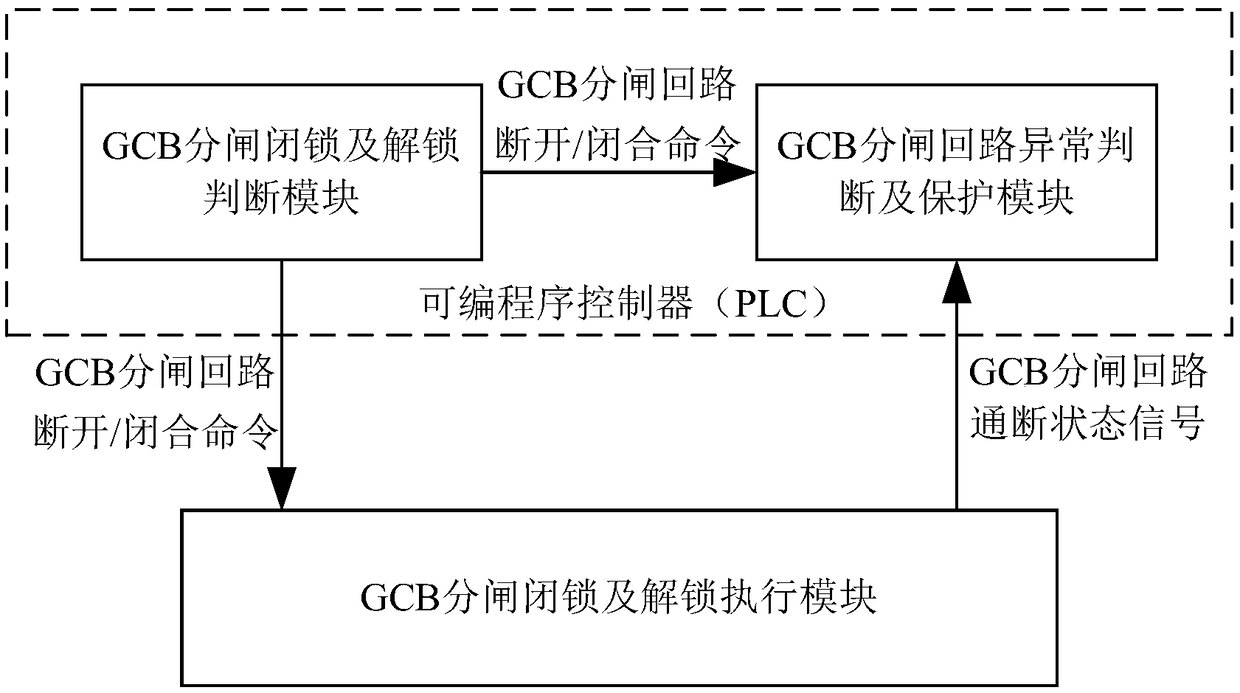

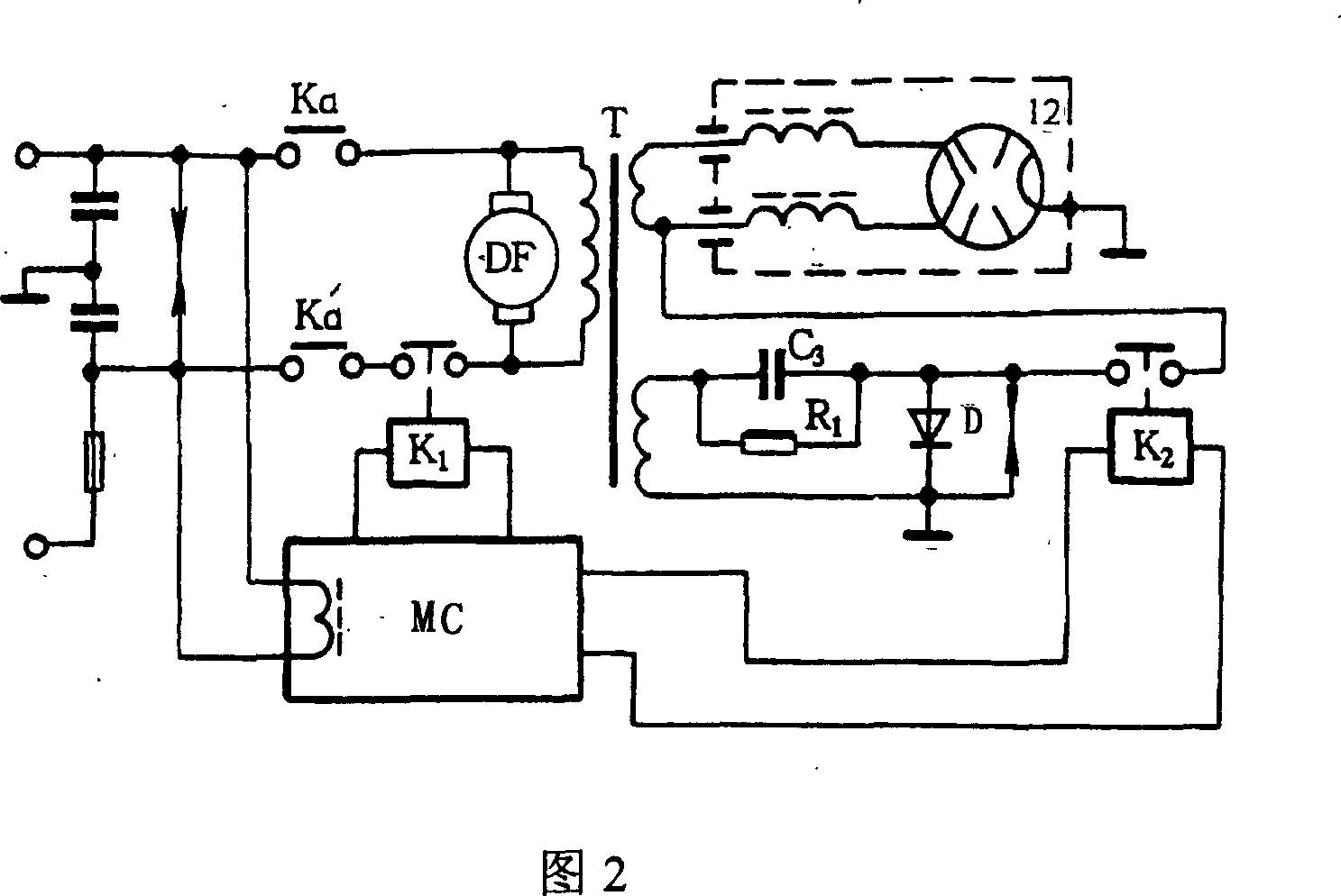

GCB breaking locking and unlocking system and method of pumped storage machine set

ActiveCN108880337AImprove securitySpeed up execution of device operationsPolyphase induction motor starterEmbedded system

The invention discloses a GCB breaking locking and unlocking system and method of a pumped storage machine set. The system comprises a GCB breaking locking and unlocking judgment module, a GCB breaking loop abnormality judgment and protection module and a GCB breaking locking and unlocking execution module, wherein the GCB breaking locking and unlocking judgment module is used for judging whethera GCB breaking loop is needed to be locked or unlocked or not and sending a GCB breaking loop disconnection or closing command out, the GCB breaking loop abnormality judgment and protection module isused for comprehensively judging whether the GCB breaking locking function and the breaking function are failure not or and taking corresponding safety protection measure, and the GCB breaking lockingand unlocking execution module is used for executing GCB breaking locking and unlocking operation and feeding an on / off state back to the GCB breaking loop abnormality judgment and protection module.By the system, the functions that GCB breaking is locked at a low rotational speed of a back-to-back drag machine and the GCB breaking is unlocked when the machine set reaches a high rotational speedstate or excitation of two machine sets exits due to trip of the back-to-back drag machine can be achieved, and the necessary measure also can be timely taken to protect the safety of equipment whenthe GCB breaking locking function and the breaking function are failure.

Owner:QINGYUAN PUMPED STORAGE POWER GENERATION CO LTD +1

Shell for filling gelatinized solid-liquid phase mixed fuel with stirring function

ActiveCN112414233ATotal energy guaranteeMeet PowerdesignAmmunition testingNuclear energy generationFluid phaseEngineering

The invention discloses a shell for filling gelatinized solid-liquid phase mixed fuel with a stirring function. The shell is characterized in that the lower end of an eighth outer cylindrical surfaceof an annular motion stirring disc is provided with eight eighth lower end cylindrical bosses which are uniformly distributed in the circumferential direction, the axis of each eighth lower end cylindrical boss of the annular motion stirring disc is vertical to the axis of a revolving body of the annular motion stirring disc, an eighth annular groove is formed in the middle of an eighth outer cylindrical surface of the annular motion stirring disc, and the inner side surface of the eighth annular groove of the annular motion stirring disc is an eighth middle outer cylindrical surface. The warhead shell has the function of stirring internal fuel, and solid-phase fuel, liquid-phase fuel and gel are stirred in the warhead shell until the solid-phase fuel, the liquid-phase fuel and the gel areuniformly mixed; air is prevented from being in contact with the gelatinized solid-liquid phase mixed fuel, no air exists in the fuel finally, and the power design of the warhead is met; and the riskof combustion is avoided, and the safety of the warhead is ensured.

Owner:XIAN MODERN CHEM RES INST

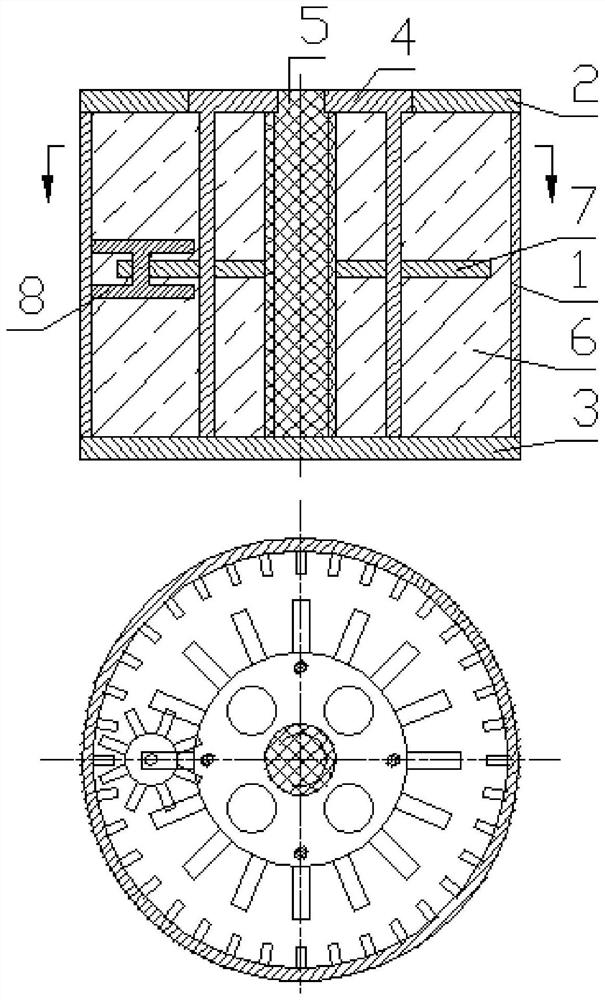

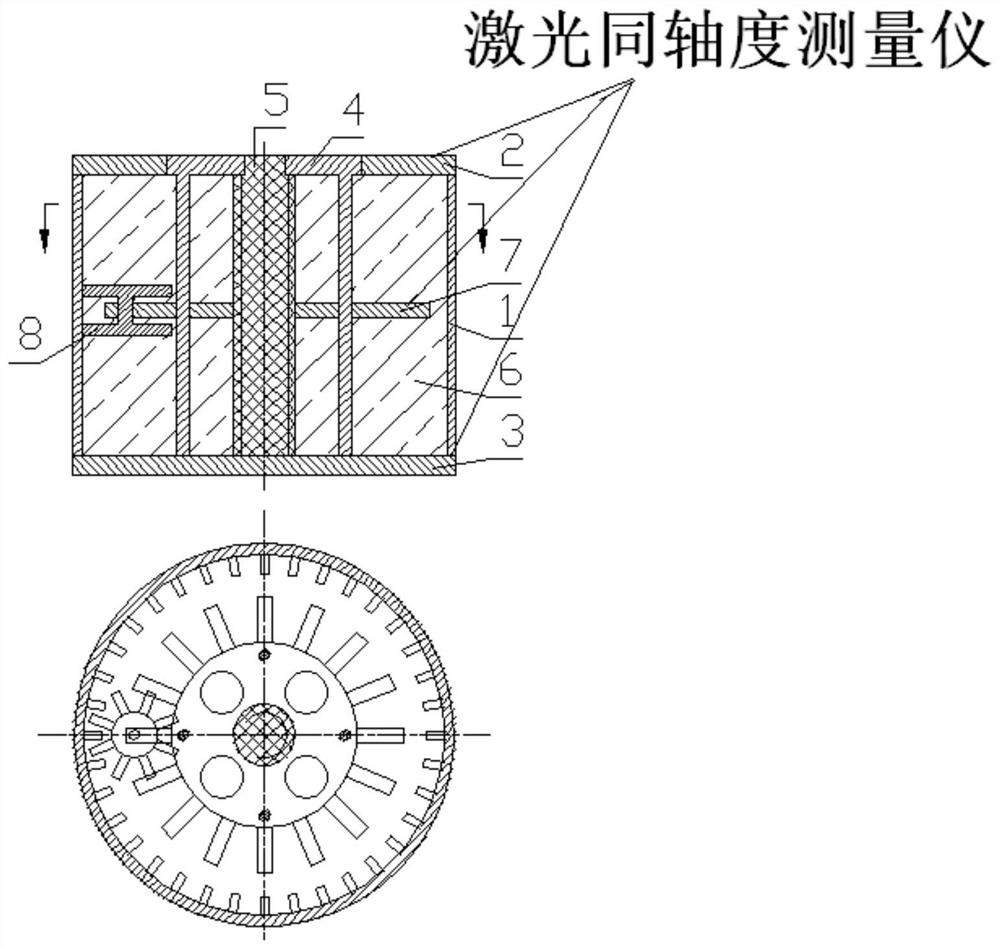

Warhead shell capable of improving filling ratio based on laser coaxiality measuring instrument

ActiveCN112390693ATotal energy guaranteeMeet PowerdesignExplosive working-up apparatusMeasuring instrumentEngineering

The invention discloses a warhead shell capable of improving the filling ratio based on a laser coaxiality measuring instrument, which is characterized in that the axis of a revolving body of a support frame 4 coincides with the axis of a revolving body of a shell 1, the support frame 4 is positioned inside the shell 1, and the fourth upper end concentric ring surface of the support frame 4 is coplanar with the second upper end concentric ring surface of an upper end cover 2; and the fourth outer cylindrical surface of the support frame 4 is in running fit contact with the second inner cylindrical surface of the upper end cover 2, and the lower ends of four fourth cylinders of the support frame 4 are in sliding fit contact with the third upper end circular plane of a lower end cover 3. Airis prevented from making contact with the gelatinized solid-liquid phase mixed fuel, no air exists in the fuel finally, and the power design of the warhead is met. The risk of combustion is avoided,and the safety of the warhead is ensured.

Owner:XIAN MODERN CHEM RES INST +1

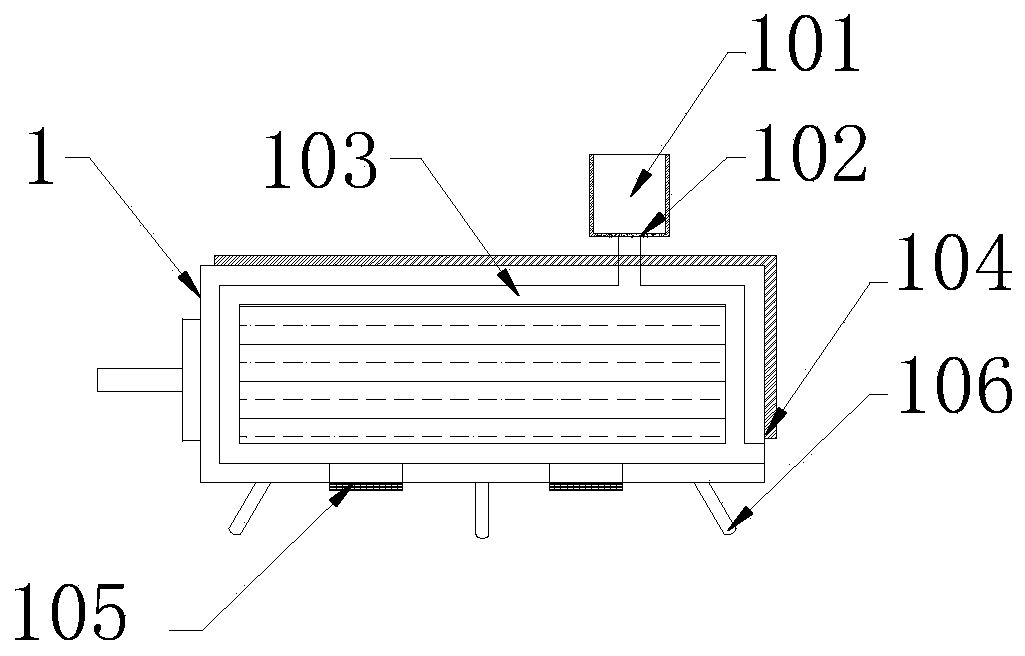

Horizontal type heat conduction oil heating furnace and method thereof

ActiveCN108088078AImprove heating efficiencySimple structureStorage heatersCombustion chamberHeating furnace

The invention discloses a horizontal type heat conduction oil heating furnace. The furnace comprises a horizontal type furnace body, a left smoke guide pipe, a right smoke guide pipe, a smoke collecting box and a main smoke discharging pipe; the smoke collecting box is supported and arranged above the outer wall of the horizontal type furnace body through a plurality of box bodies, and the smoke collecting box is arranged in the middle of the upper side of the horizontal type furnace body; the smoke inlet end of the left smoke guide pipe communicates with the smoke discharging end at the leftend of the horizontal type furnace body, and the smoke inlet end of the right smoke guide pipe communicates with the smoke discharging end at the right end of the horizontal type furnace body; the smoke discharging end of the left smoke guide pipe and the smoke discharging end of the right smoke guide pipe jointly communicate with the smoke collecting box; and the smoke outlet end of the smoke collecting box communicates with the main smoke discharging pipe. According to the furnace, the structure is simple, a main combustion chamber structure is arranged in a furnace core, so that quadruple heating of fed heat conduction oil is realized with the cooperation of an external auxiliary combustion chamber structure, and the heating efficiency of a heating pipe is effectively improved.

Owner:CHENGGONG GASOLINEEUM SCI & TECH DONGYING

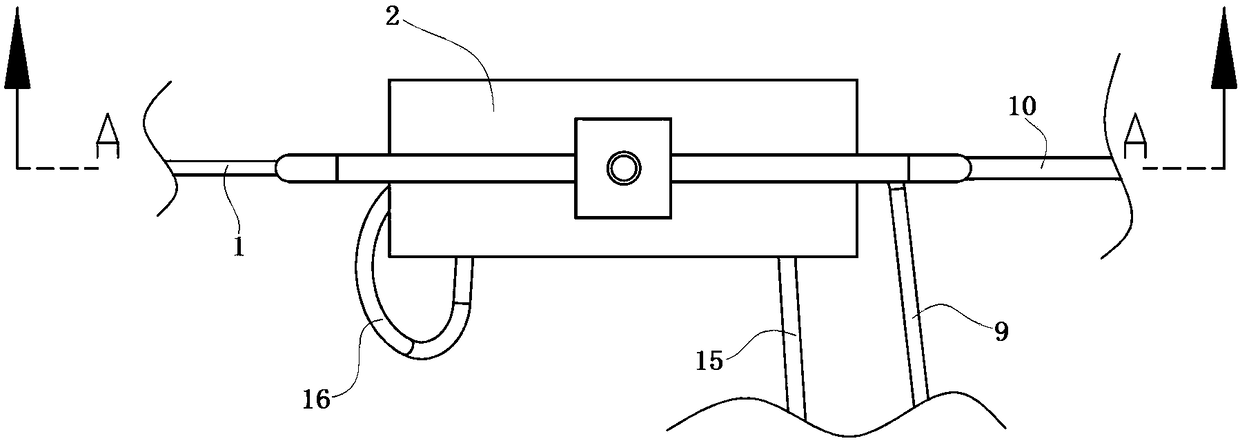

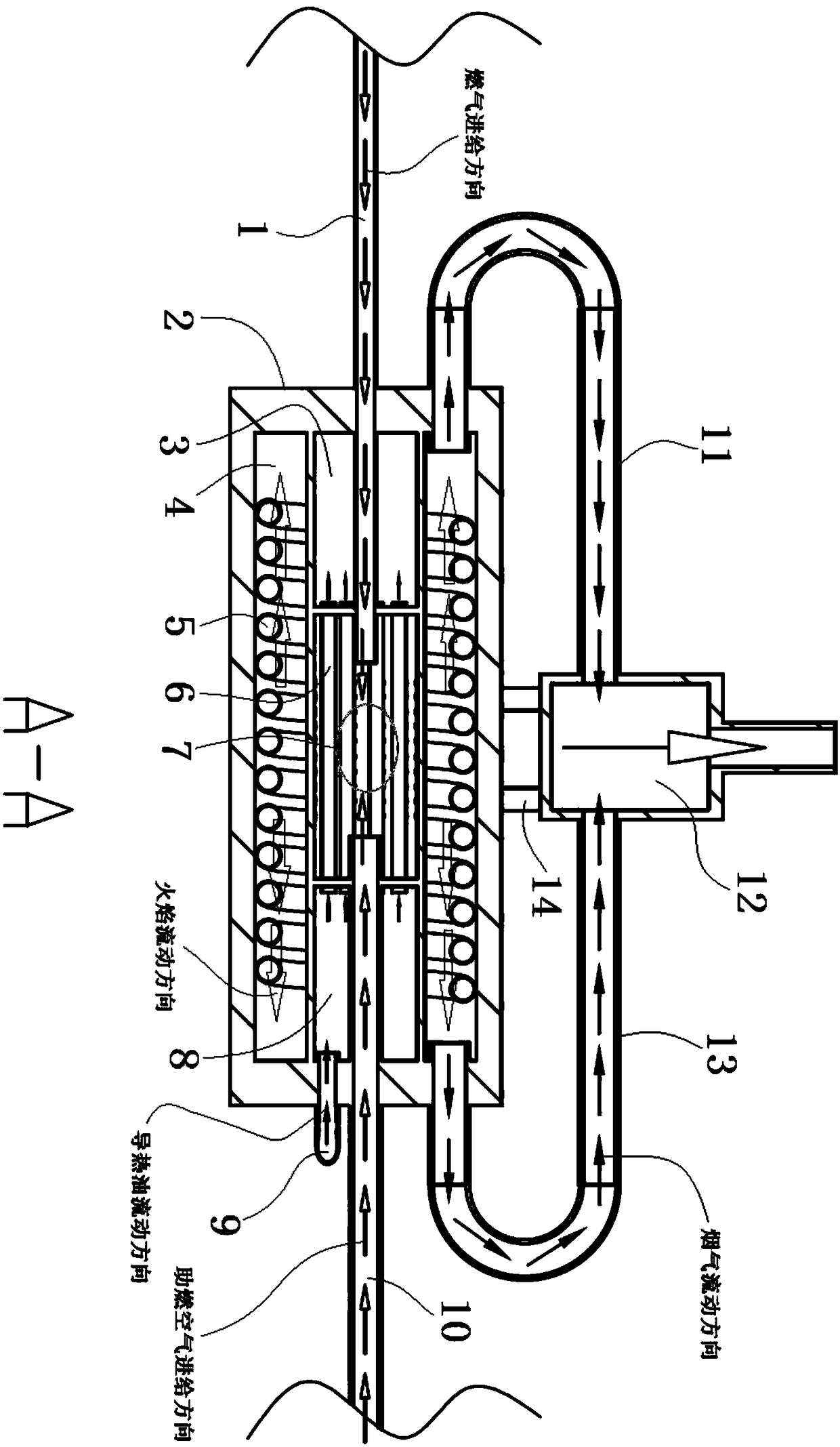

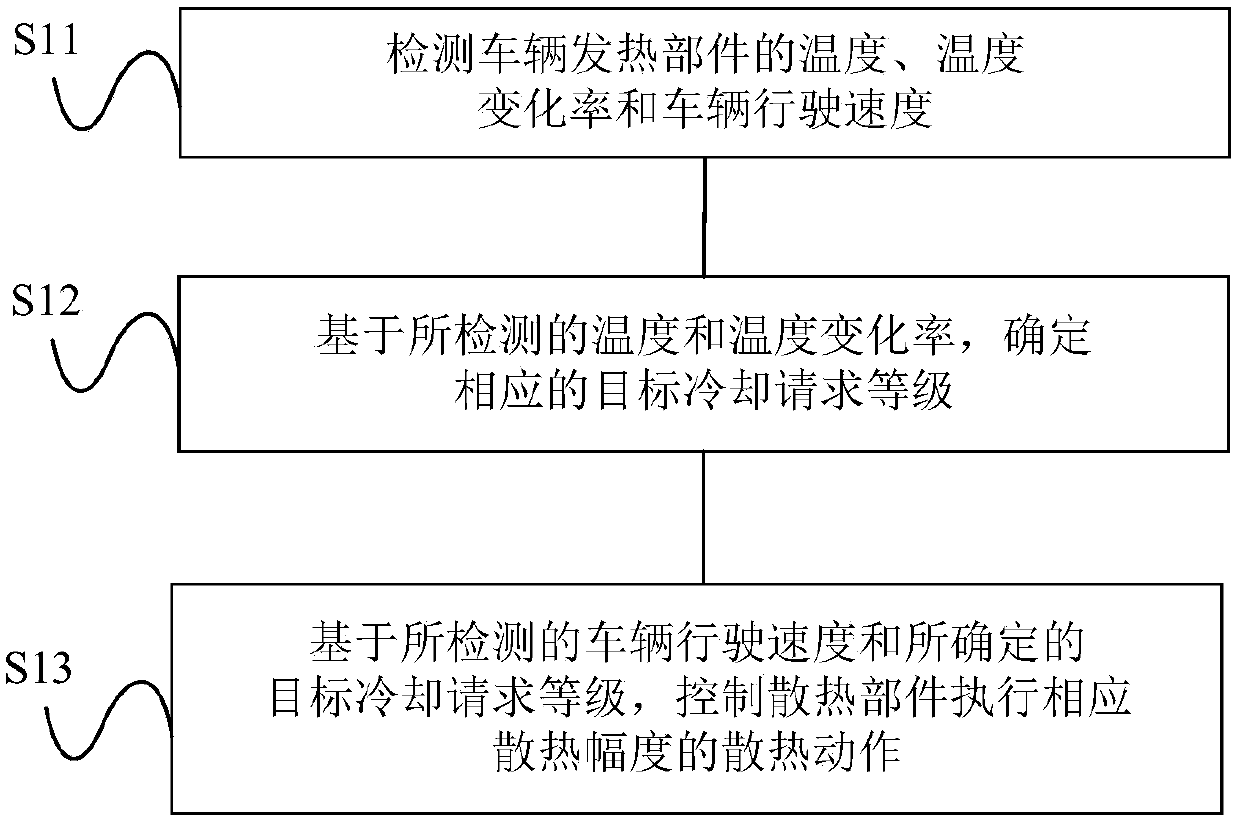

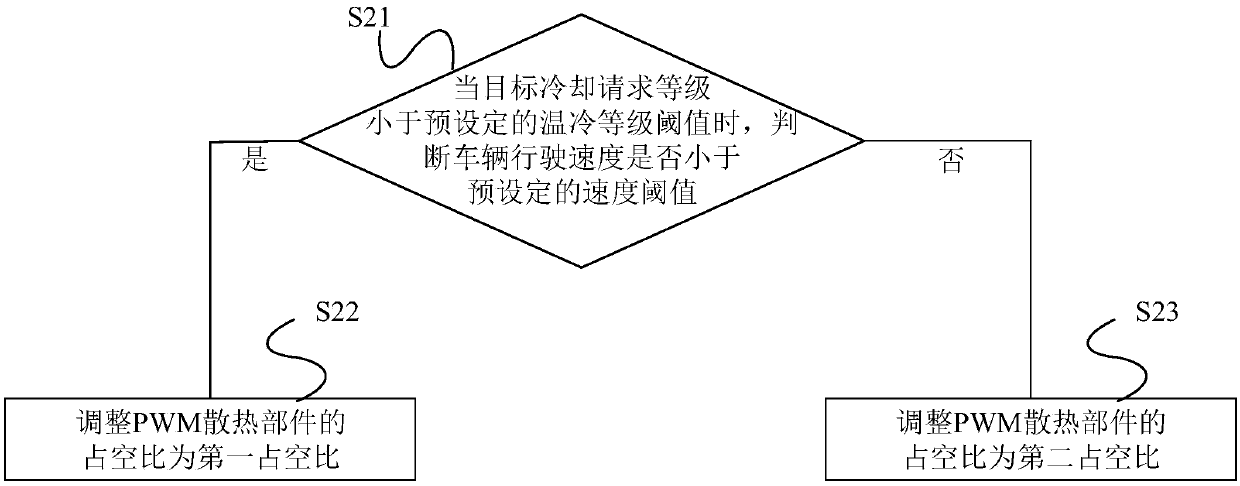

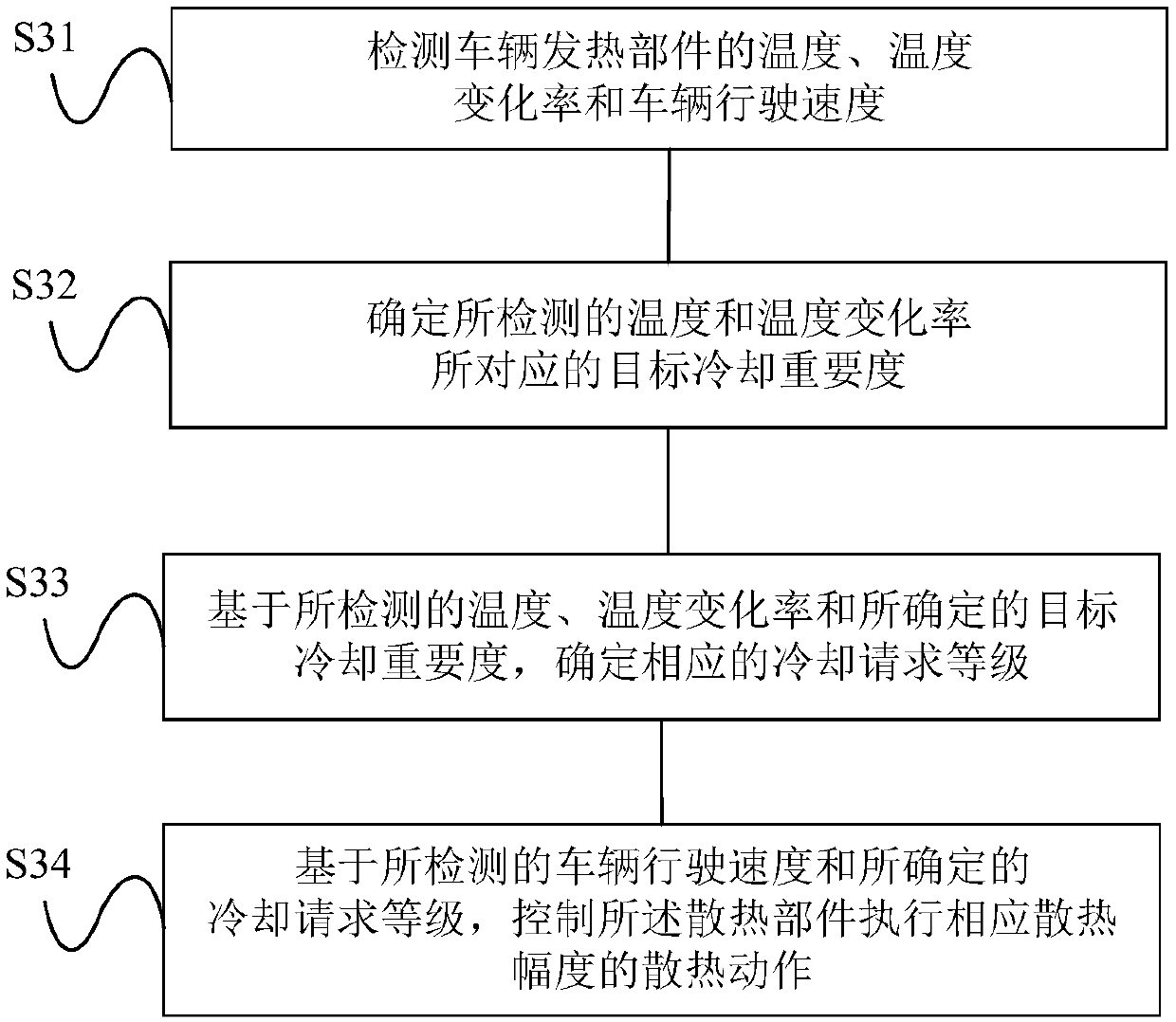

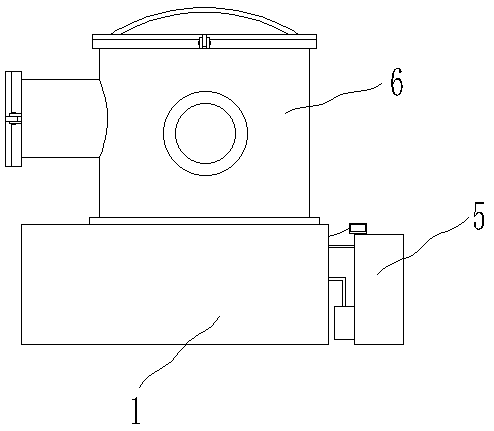

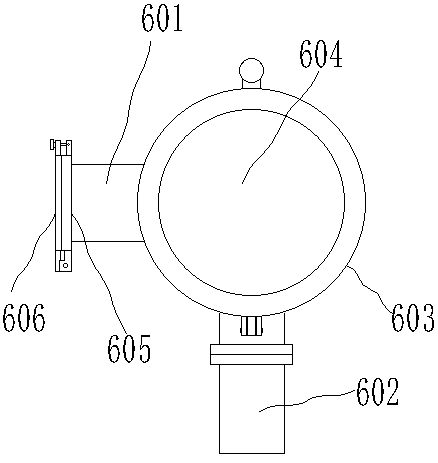

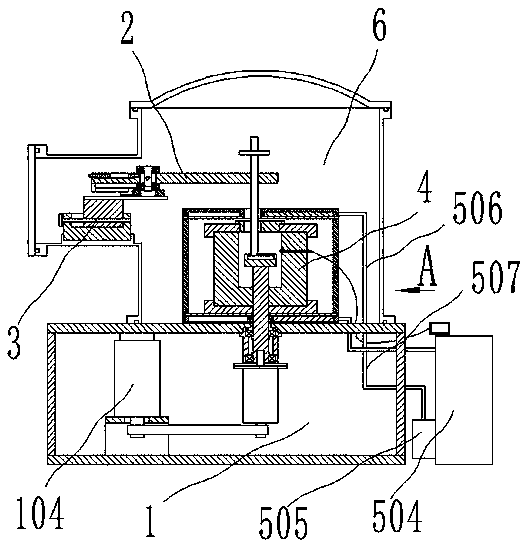

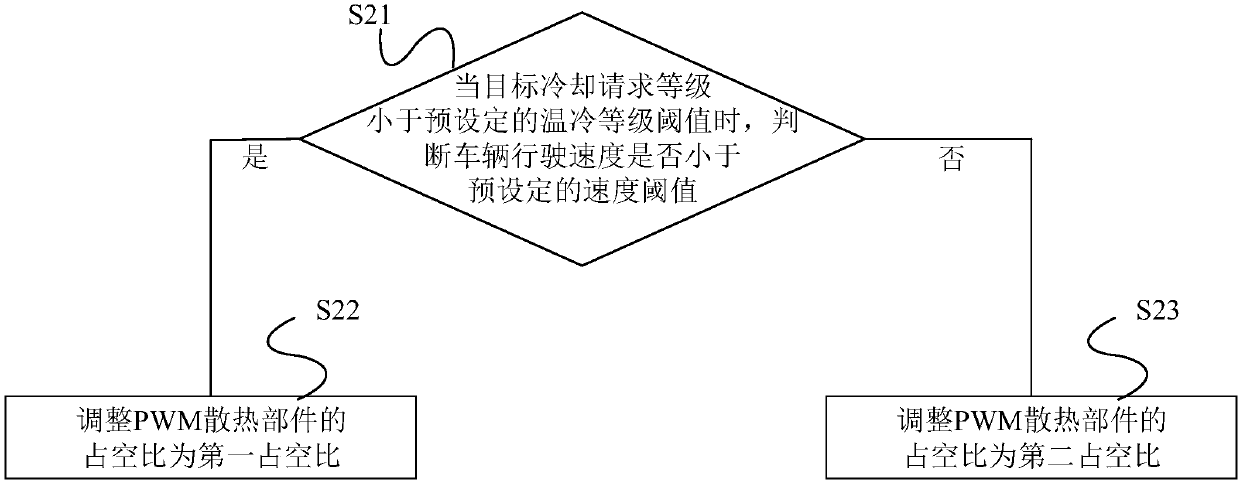

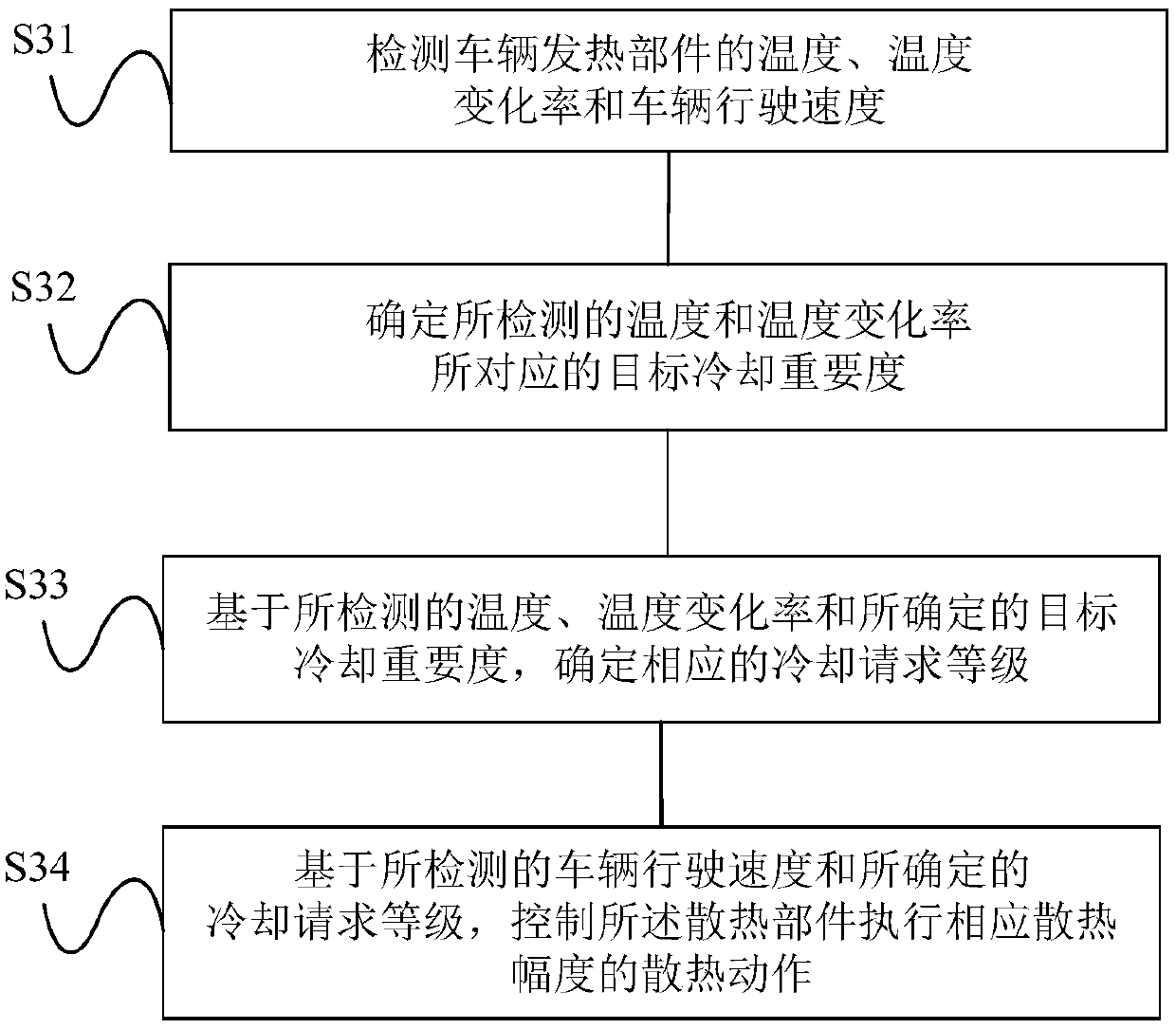

Vehicle heat dissipation control method and system

ActiveCN111376709AAvoid the risk of burnsThermal management for safetyPump controlPositive-displacement liquid enginesThermodynamicsHeat management

The invention relates to the technical field of vehicle heat dissipation, and provides a vehicle heat dissipation control method and system. The vehicle heat dissipation control method comprises the steps of detecting the temperature of a heating component of a vehicle, the temperature change rate, and the vehicle running speed; determining a target cooling importance degree corresponding to the detected temperature and the temperature change rate, wherein the cooling importance degree indicates an importance degree of cooling the heating component of the vehicle; determining a corresponding cooling request level based on the detected temperature, the temperature change rate and the determined target cooling importance degree; and based on the detected vehicle running speed and the determined cooling request level, controlling a heat dissipation component to execute a heat dissipation action of a corresponding heat dissipation amplitude, wherein the heat dissipation amplitude is in positive correlation with the running speed of the vehicle and the cooling request level. Therefore, the risk that the heating component is burnt down due to the fact that the temperature rises too fastduring high-speed driving and is not reduced in time is avoided, and safe heat management on important heating components in the vehicle heat dissipation control process is guaranteed.

Owner:GREAT WALL MOTOR CO LTD

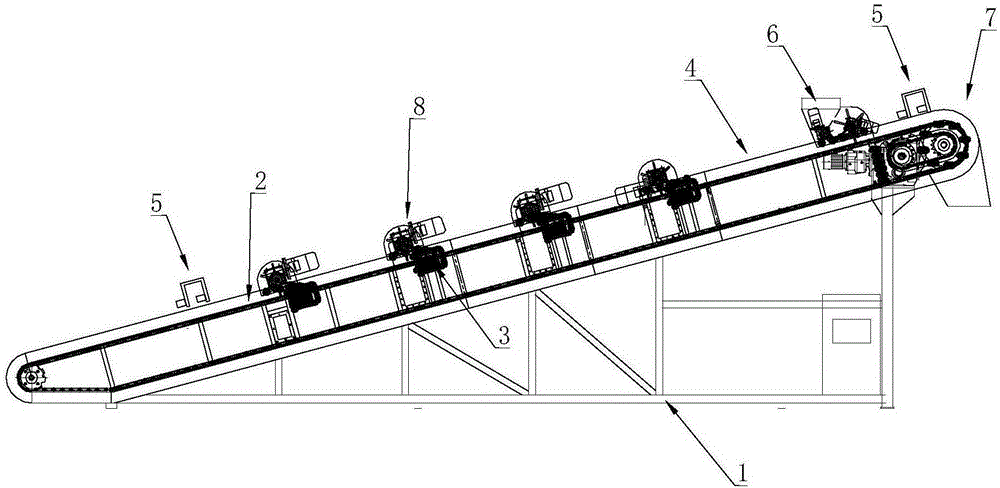

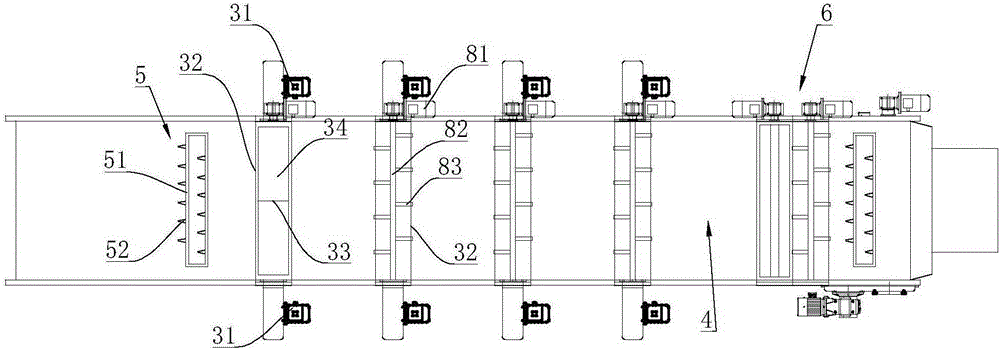

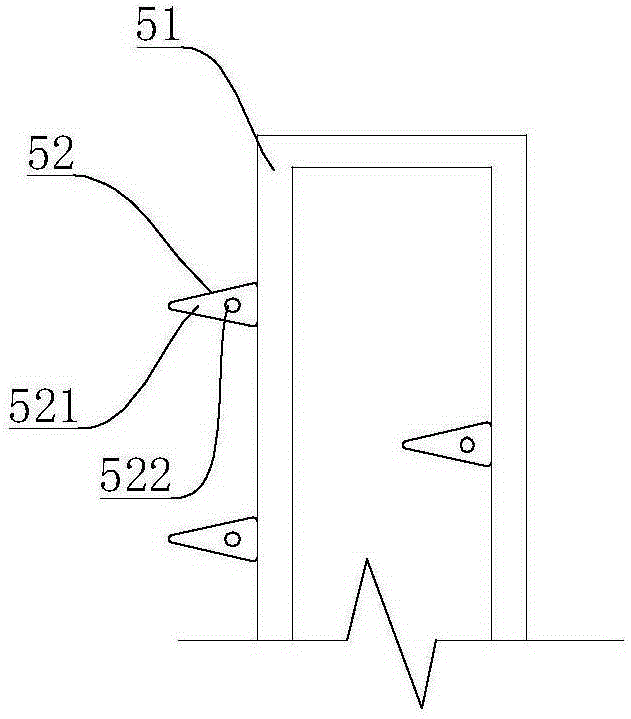

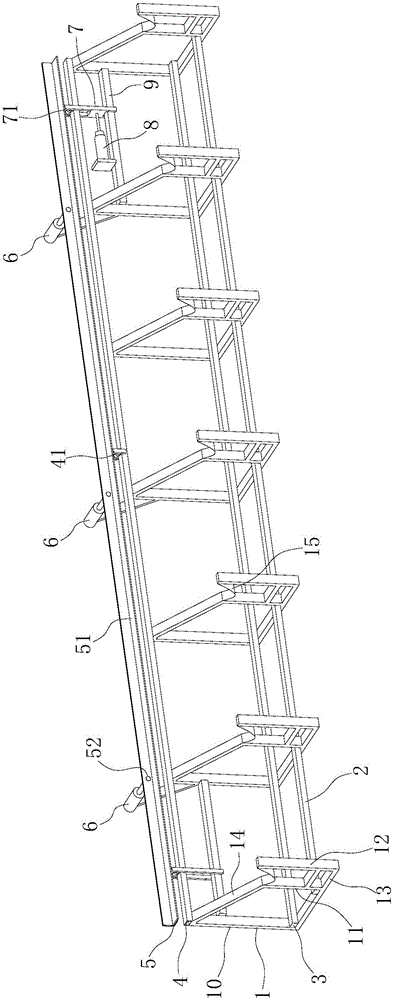

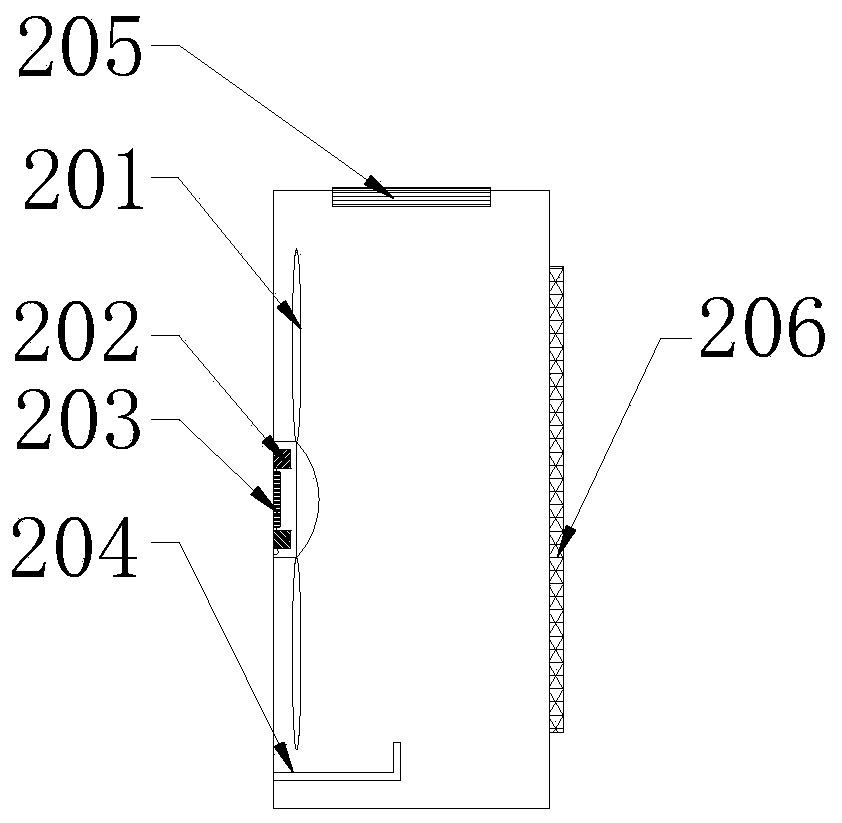

Airing bed used for solid fermentation of food

ActiveCN105176792AEasy to controlAvoid pollutionBioreactor/fermenter combinationsBiological substance pretreatmentsSurface moistureClosed loop

The invention relates to an airing bed used for solid fermentation of food. The airing bed comprises a bracing frame which is provided with a conveying mesh belt laid out in a closed loop manner and a driving mechanism used for driving running of the conveying mesh belt; and the airing bed also comprises a set of an air supply system and a material turning system which are mutually cooperated, wherein the air supply system comprises a fan and an air supply pipe which are mutually connected, the air supply pipe is arranged below the conveying mesh belt, the upper part of the air supply pipe is provided with an air outlet, the air outlet points to the conveying mesh belt, and a material turning area of the material turning system is located in an upper surface area of the conveying mesh belt to which the air outlet points. The airing bed provided by the invention conveys a material by using the conveying mesh belt; the material is stirred and turned by the air supply system and the material turning system, so the material is cooled and surface moisture is rapidly volatilized; an accessory material adding system can add accessory materials into the material; a dynamic material temperature measurer can detect the temperature of the material in real time; and the whole process does not need direct participation of workers, so the material is prevented from pollution and the workers are prevented from risks of burns.

Owner:四川华宇瑞得科技有限公司

Vacuum high-temperature friction-wear tester

PendingCN111380766AImprove accuracyEasy to operateInvestigating abrasion/wear resistanceEngineeringMachine

The invention relates to material surface performance test equipment, and particularly relates to a vacuum high-temperature friction-wear tester. The tester is characterized in that a vacuum cover isarranged above a machine base, a force measuring assembly, an adjusting support, a heating furnace assembly and a cooling circulation system are arranged in the vacuum cover, the cooling circulation system is connected above the machine base, the heating furnace assembly is arranged in the cooling circulation system, a supporting connecting pipe is arranged at the left end of the vacuum cover, theadjusting support is connected in the supporting connecting pipe, the left end of the force measuring assembly is connected to the adjusting support, the right end of the force measuring assembly isconnected with a loading rod, the loading rod penetrates through the force measuring assembly, the heating furnace assembly comprises a furnace body, a heating cavity is formed in the furnace body, the loading rod is inserted into the heating cavity, a friction disc is arranged in the heating cavity, a detection piece is clamped between the loading rod and the friction disc, the lower end of the friction disc is connected with a rotating shaft, the rotating shaft penetrates through the heating furnace assembly and the cooling circulation system, the lower end of the rotating shaft is rotationally connected into the machine base, and the side wall of the vacuum cover is further connected with a molecular pump unit.

Owner:兰州华汇仪器科技有限公司

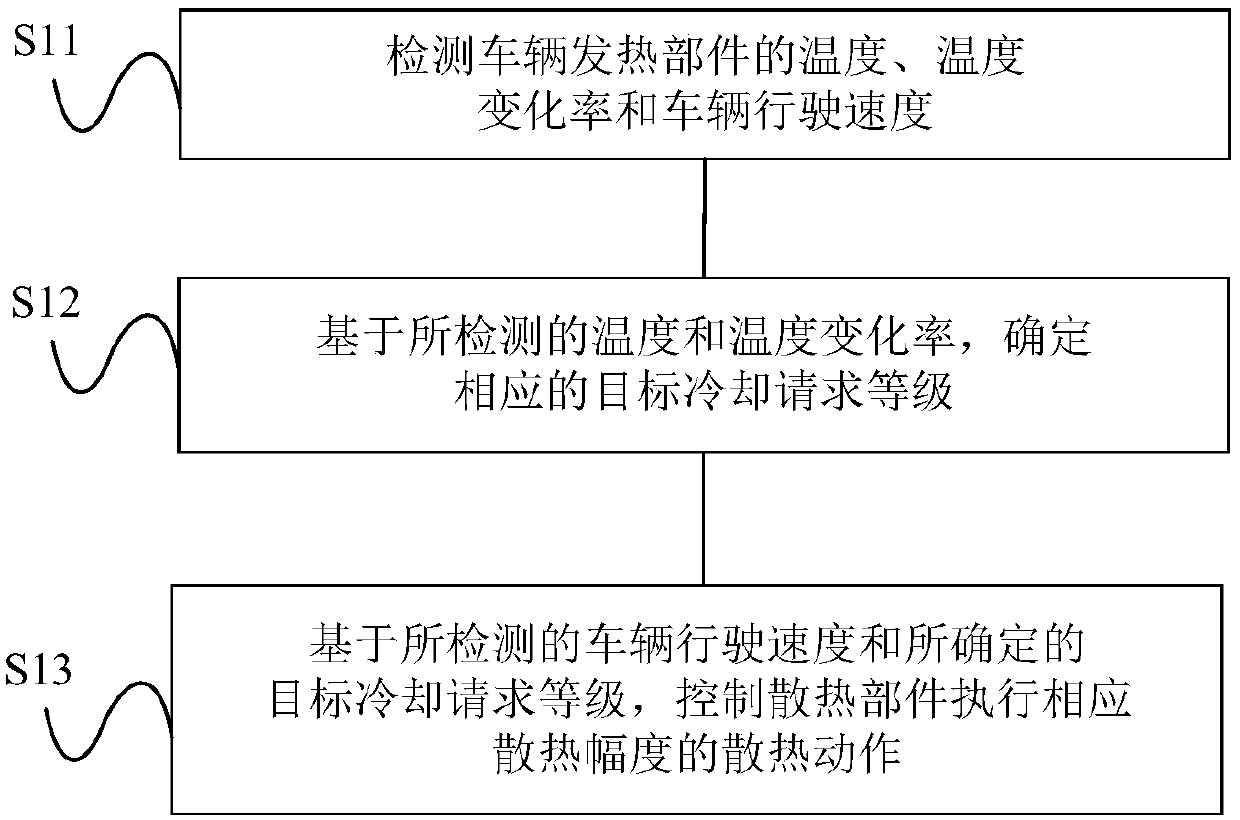

Vehicle heat dissipation control method and system

ActiveCN111376710AAvoid the risk of burnsSolve the cooling effectPropulsion coolingThermodynamicsAutomotive engineering

The invention relates to the field of vehicle heat dissipation, and provides a vehicle heat dissipation control method and system. The vehicle heat dissipation control method comprises the steps of detecting the temperature of a heating component of a vehicle, the temperature change rate, and the vehicle running speed; determining a corresponding target cooling request level based on the detectedtemperature and the temperature change rate; and controlling a heat dissipation component to execute a heat dissipation action of a corresponding heat dissipation amplitude based on the detected vehicle running speed and the determined target cooling request level, wherein the heat dissipation amplitude is in positive correlation with the vehicle running speed and the target cooling request level.Therefore, the vehicle speed is also considered in addition to the temperature and the temperature change rate of the heating component in the heat dissipation process, heat dissipation treatment should be conducted even if the temperature is low and the driving speed is high, and the risk that the heating component is burnt down due to the fact that cooling is not conducted in time when the driving temperature rise is too high can be avoided.

Owner:GREAT WALL MOTOR CO LTD

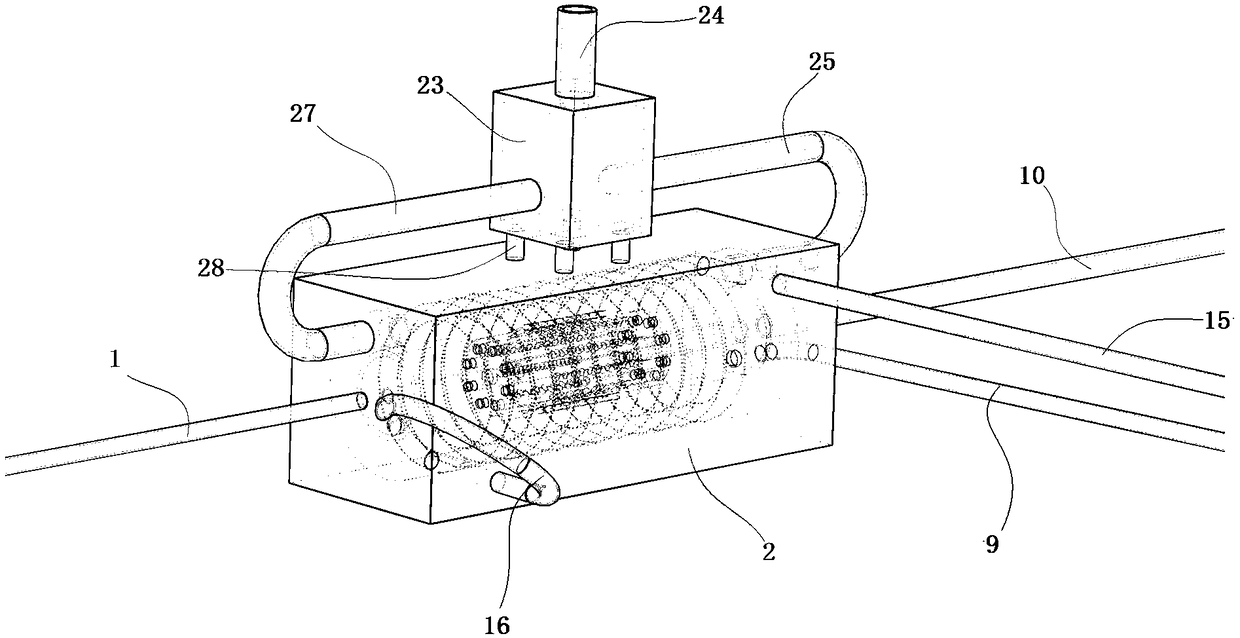

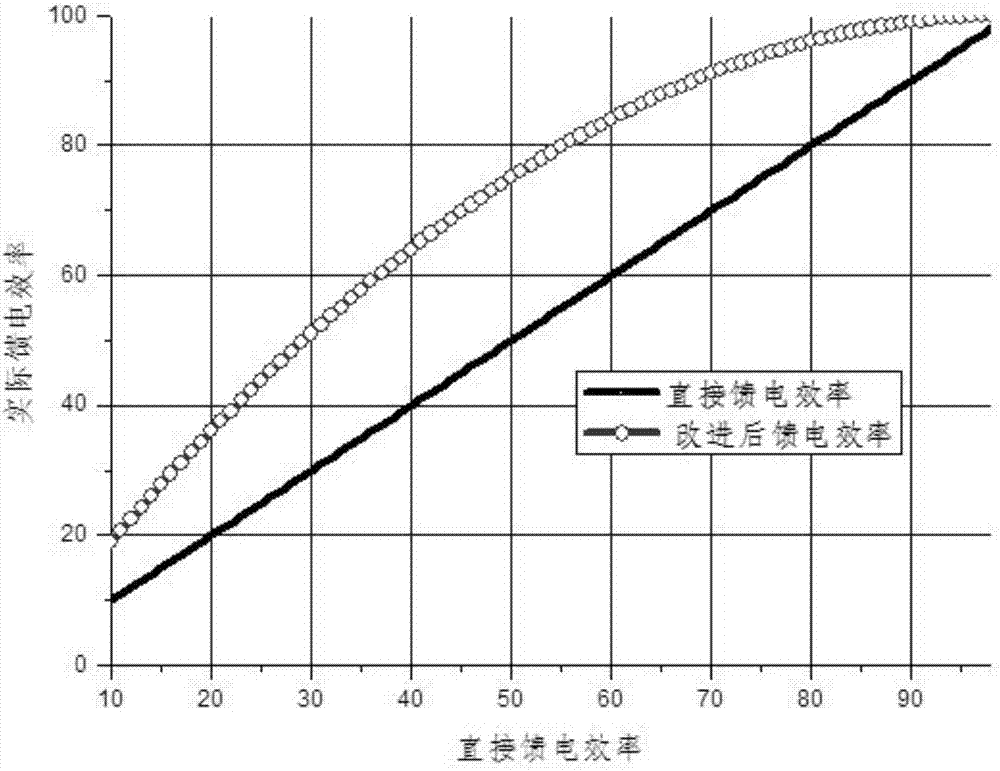

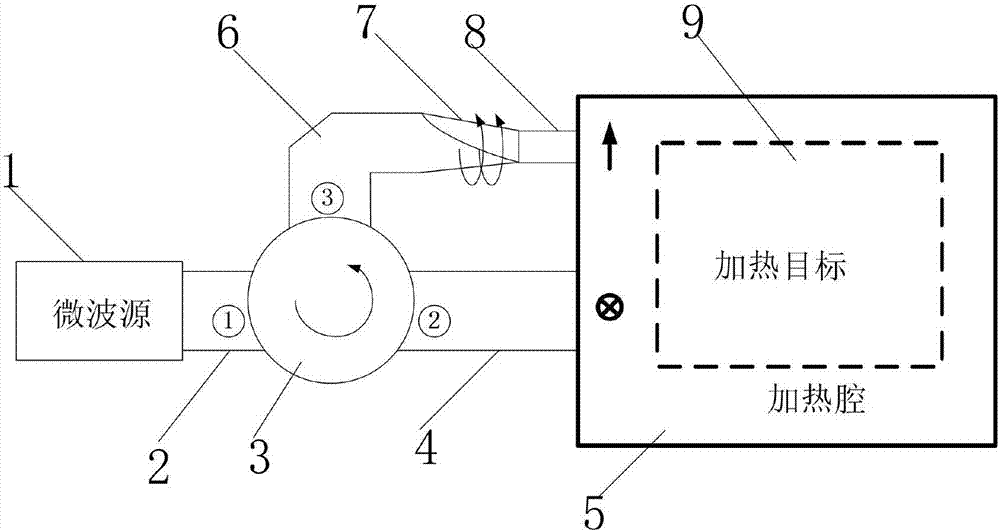

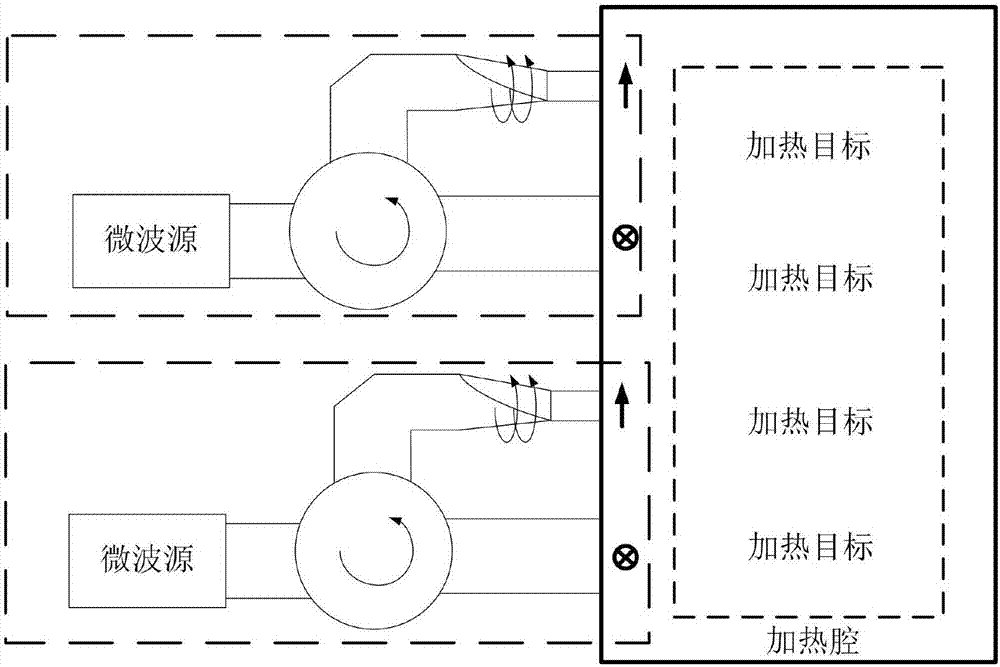

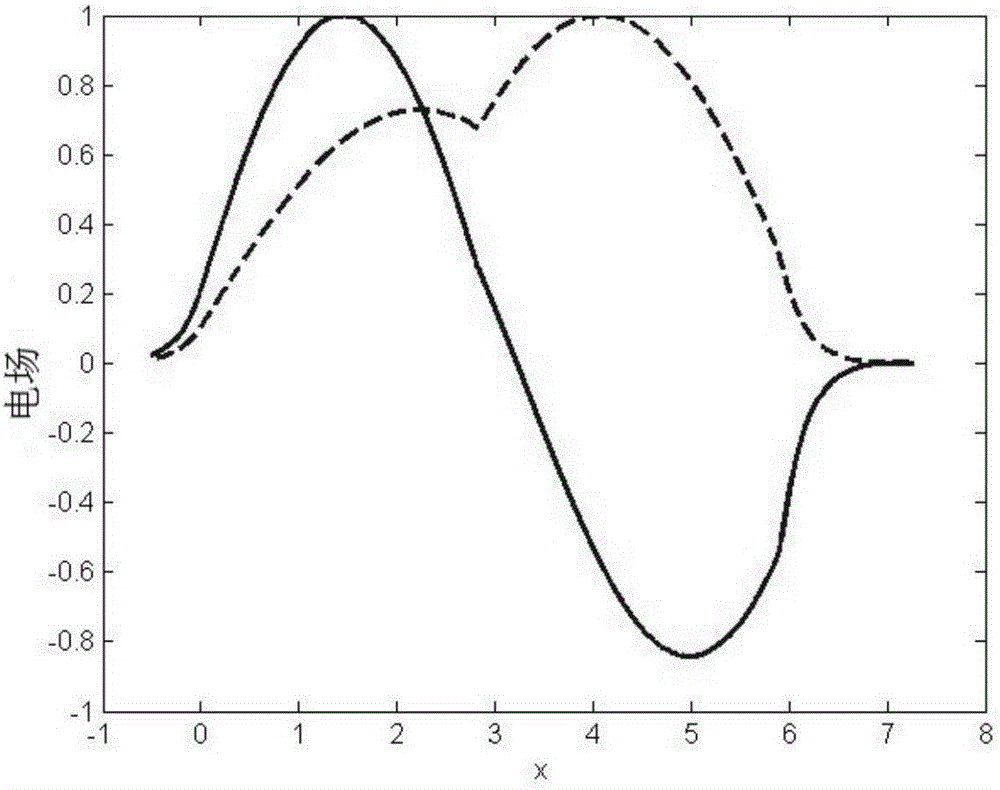

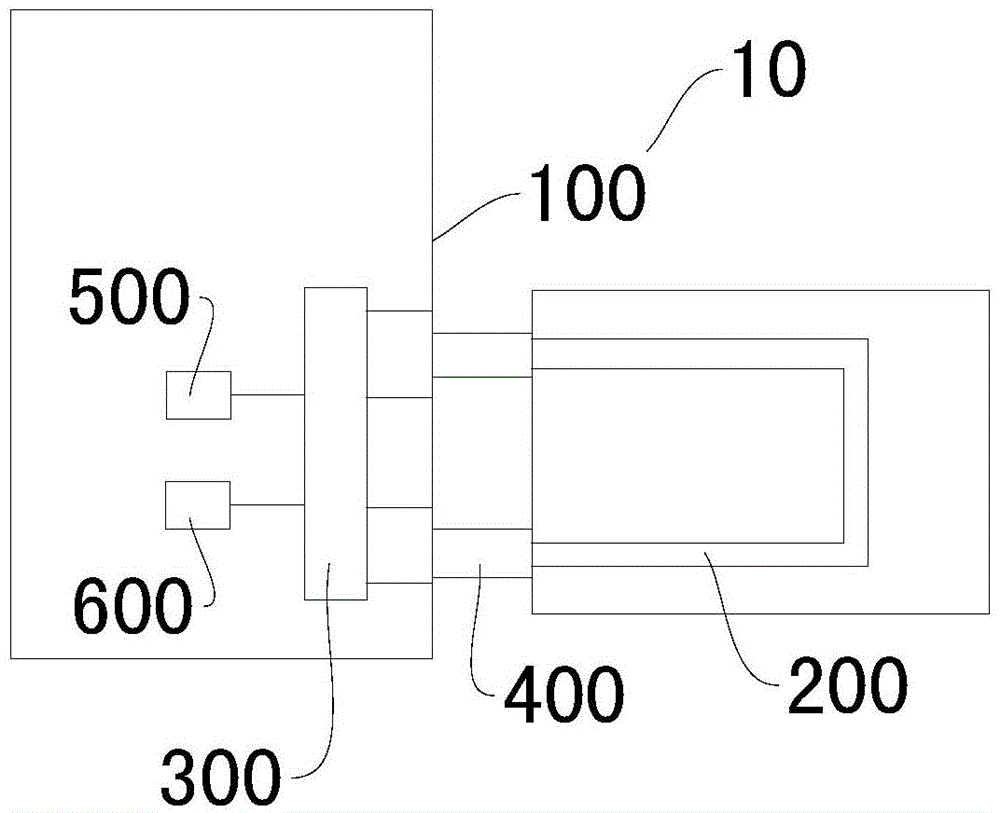

High efficiency microwave feed excitation system for heating cavity

InactiveCN107371289AImprove heating uniformityImprove energy efficiencyMicrowave heatingMicrowaveEnergy absorption

The invention belongs to the field of microwave heating application technology and discloses a high efficiency microwave feed excitation system for a heating cavity. The system includes a microwave excitation source. An output port of the microwave excitation source is connected to a first port of a circulator through a first connection waveguide. A second port of the circulator is connected with the heating cavity through connecting with a second connection waveguide. A third port of the circulator is connected with one end of a chamfer curved waveguide. The other end of the chamfer curved waveguide is connected with one end of a polarization reversing waveguide. The other end of the polarization reversing waveguide is connected with the heating cavity through connecting with a third connection waveguide. According to the invention, the efficiency of energy feed from the microwave excitation source to the heating cavity and the efficiency of microwave energy absorption of a target are improved substantially.

Owner:XIAN ENBIENS PHOTOELECTRIC

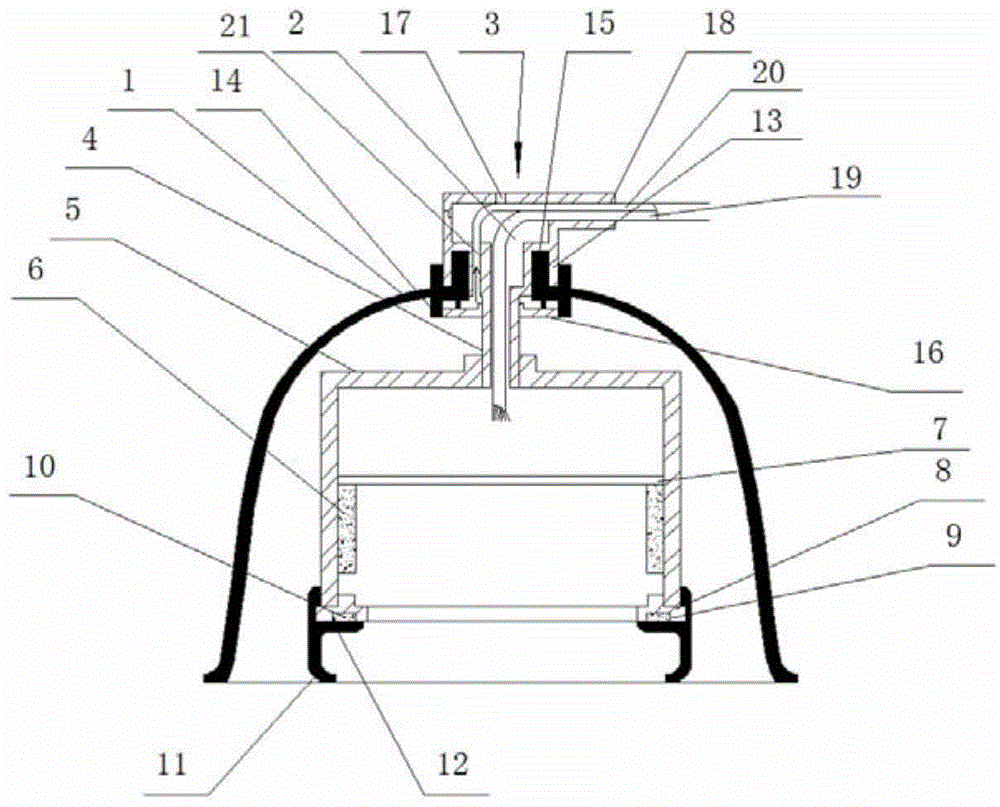

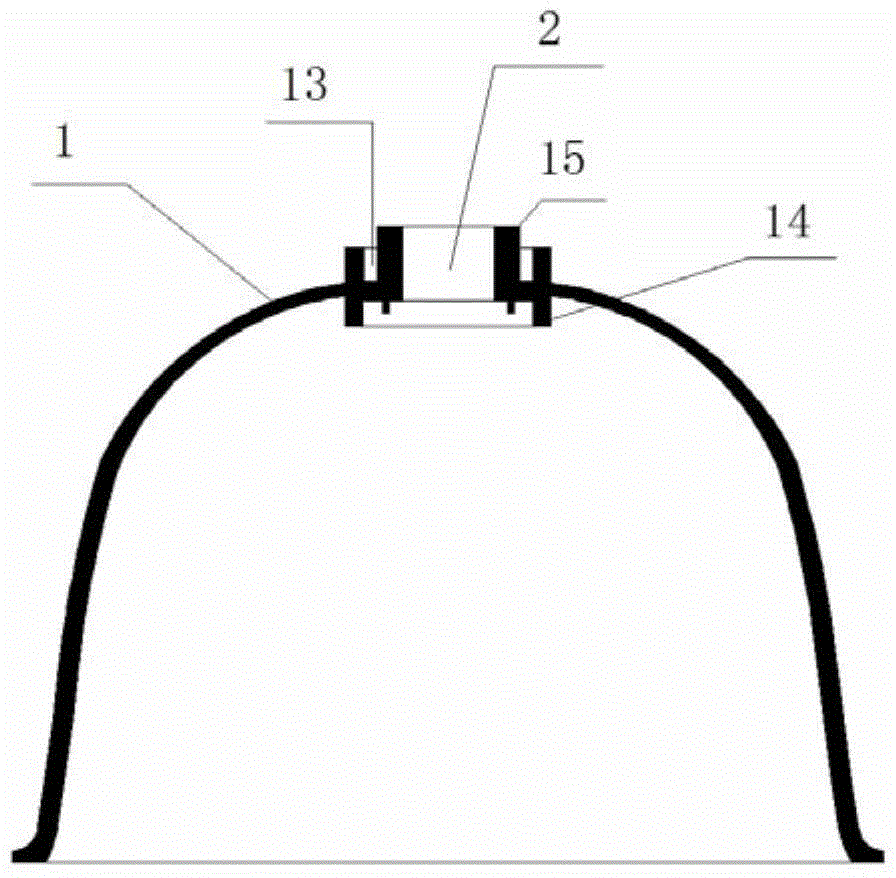

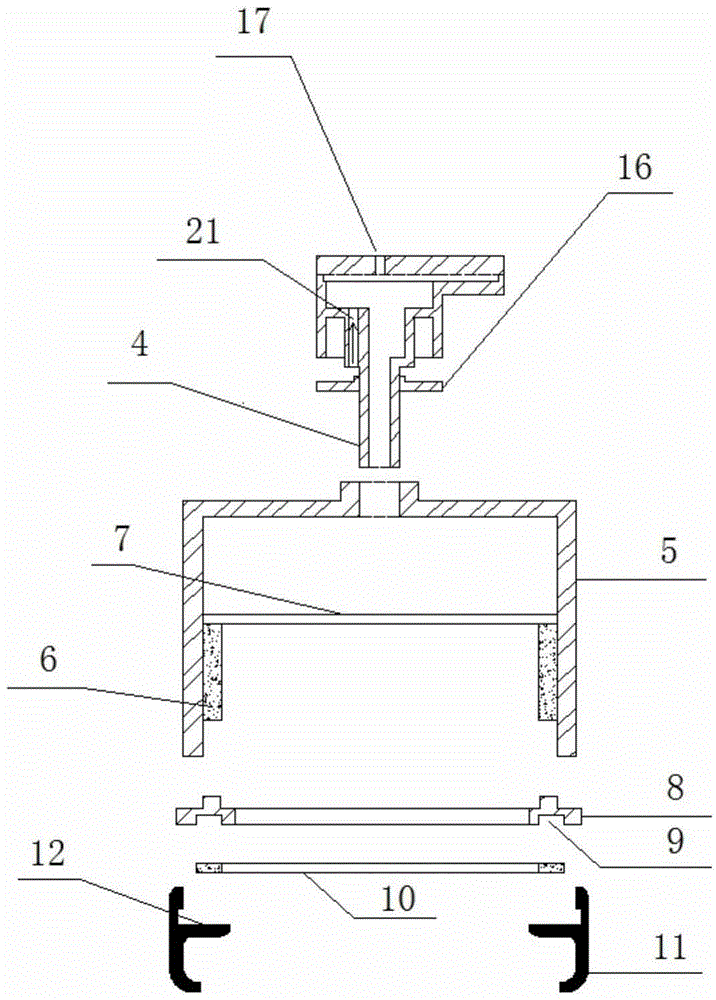

Adsorption type moxibustion head fixing device

ActiveCN104146864AGuaranteed distanceSolve the problem of strong adsorptionDevices for heating/cooling reflex pointsEngineeringSilica gel

The invention discloses an adsorption type moxibustion head fixing device which is a bowl-shaped cover. A moxibustion head fixing base is arranged above a center hole in the top of a cover body. A lead wire channel and a single-way air extracting channel are arranged in the moxibustion head fixing base. The lead wire channel extends into the cover body downwards through a moxibustion head fixing pipe. A moxibustion head is arranged at the bottom end of the moxibustion head fixing pipe. An annular magnet and a heating piece are embedded in the outer shell of the moxibustion head. An annular groove is formed in the moxibustion head outer shell. A copper ring is embedded into the annular groove. A sleeve-pipe-shaped conducting silica gel base is arranged at the bottom of the moxibustion head outer shell. An annular lower end cover covering cover is arranged on the inner wall of the conducting silica gel base. The adsorption type moxibustion head fixing device has the advantages that during electrotherapy, acanthesthesia can be removed, adsorbing firmness is very stable, and scalding is effectively avoided.

Owner:齐齐哈尔市祥和中医器械有限责任公司

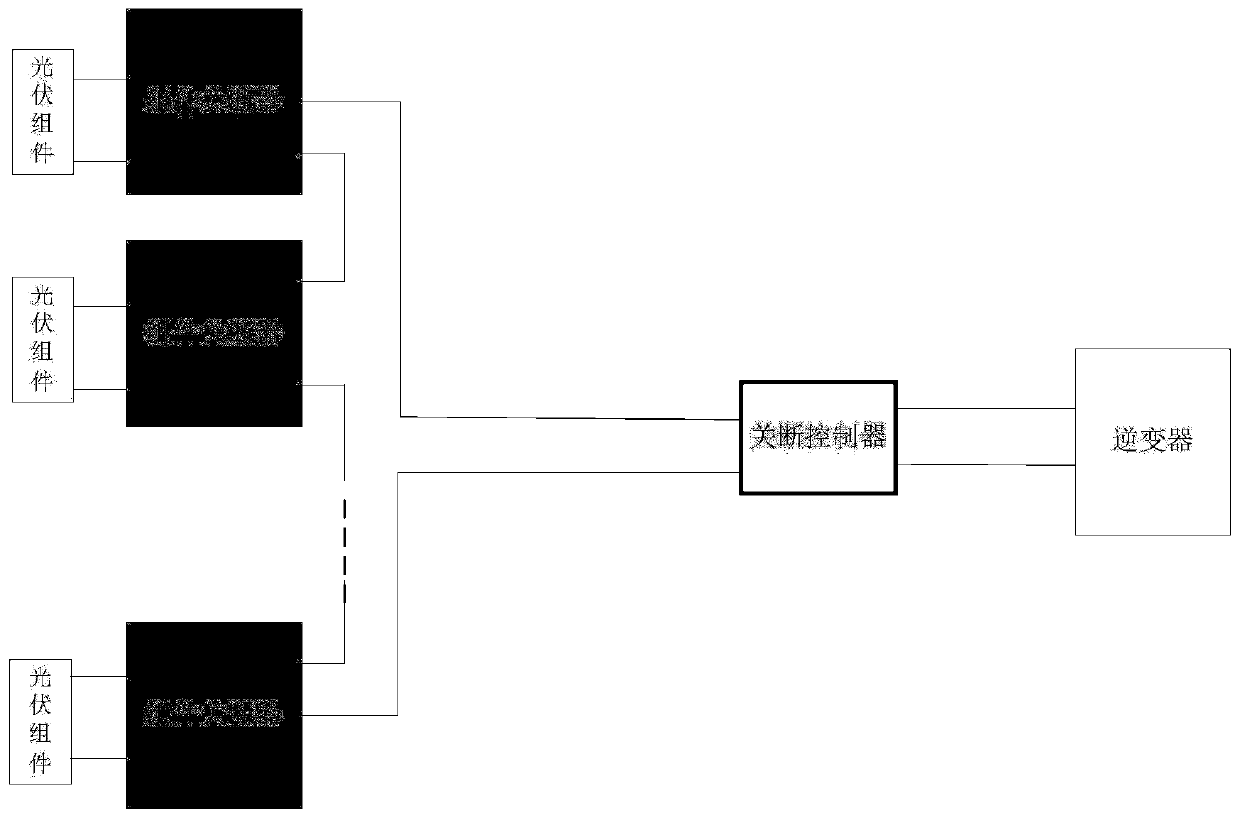

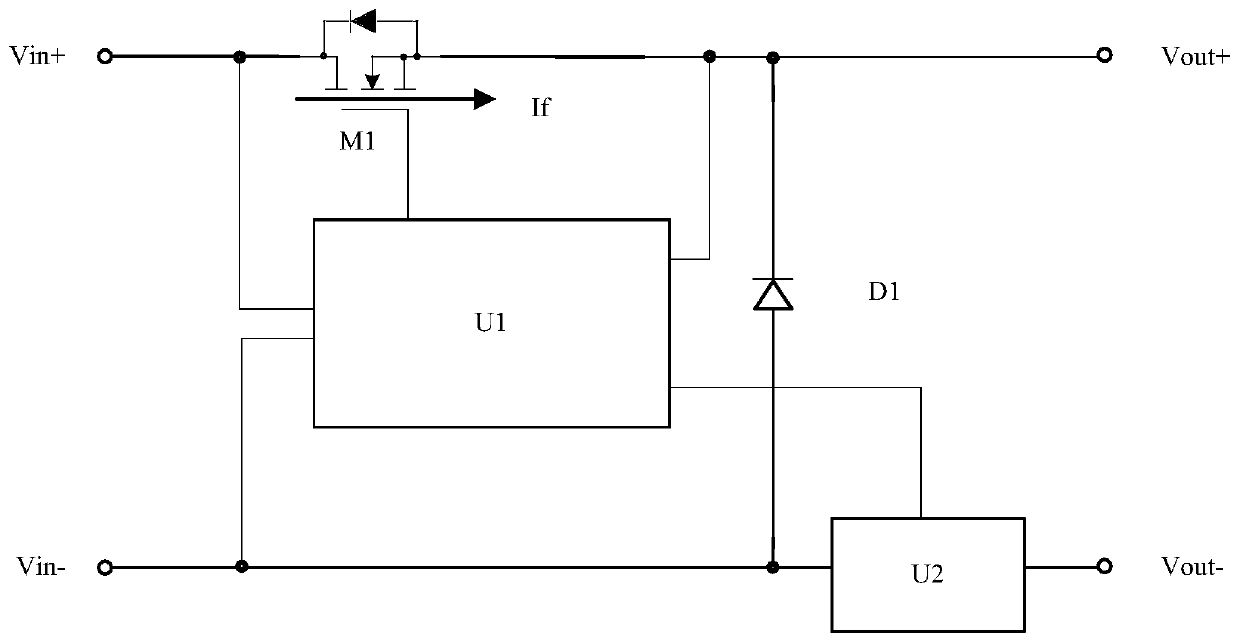

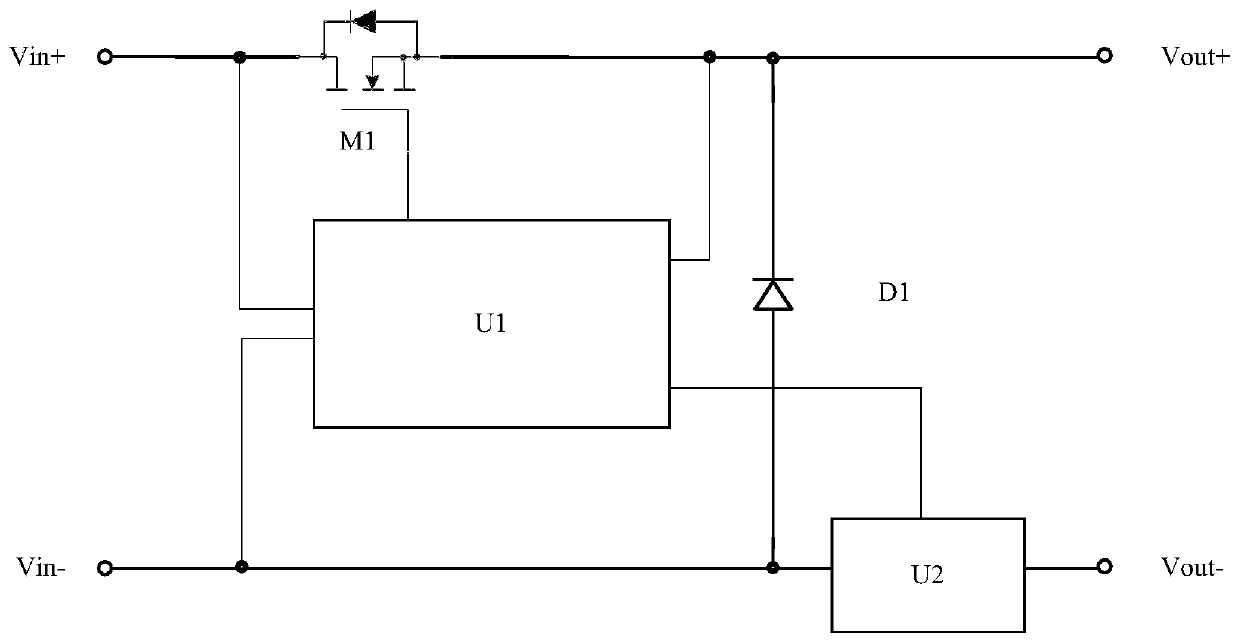

Assembly shutoff device, anti-backflow method thereof and photovoltaic system

The invention discloses an assembly shutoff device, an anti-backflow method thereof and a photovoltaic system. A control module of the assembly shutoff device is used for acquiring a detection voltagebetween a second connecting end and a third connecting end in real time when the assembly shutoff device is shutoff; the detection voltage represents the voltage states of two ends of a source electrode and a drain electrode of a first switch tube; when the detection voltage exceeds a first threshold voltage, it is considered that backflow current passes through a body diode of the first switch tube and reversely passes through the first switch tube; at the moment, the control module outputs a driving signal through a first connecting end to control the first switch tube to be switched on, sothat backflow current reversely passes through the conducted first switch tube, and the risk that the first switch tube is burnt by the backflow current is avoided.

Owner:ZHEJIANG INTEPOWER ELECTRONIC CO LTD

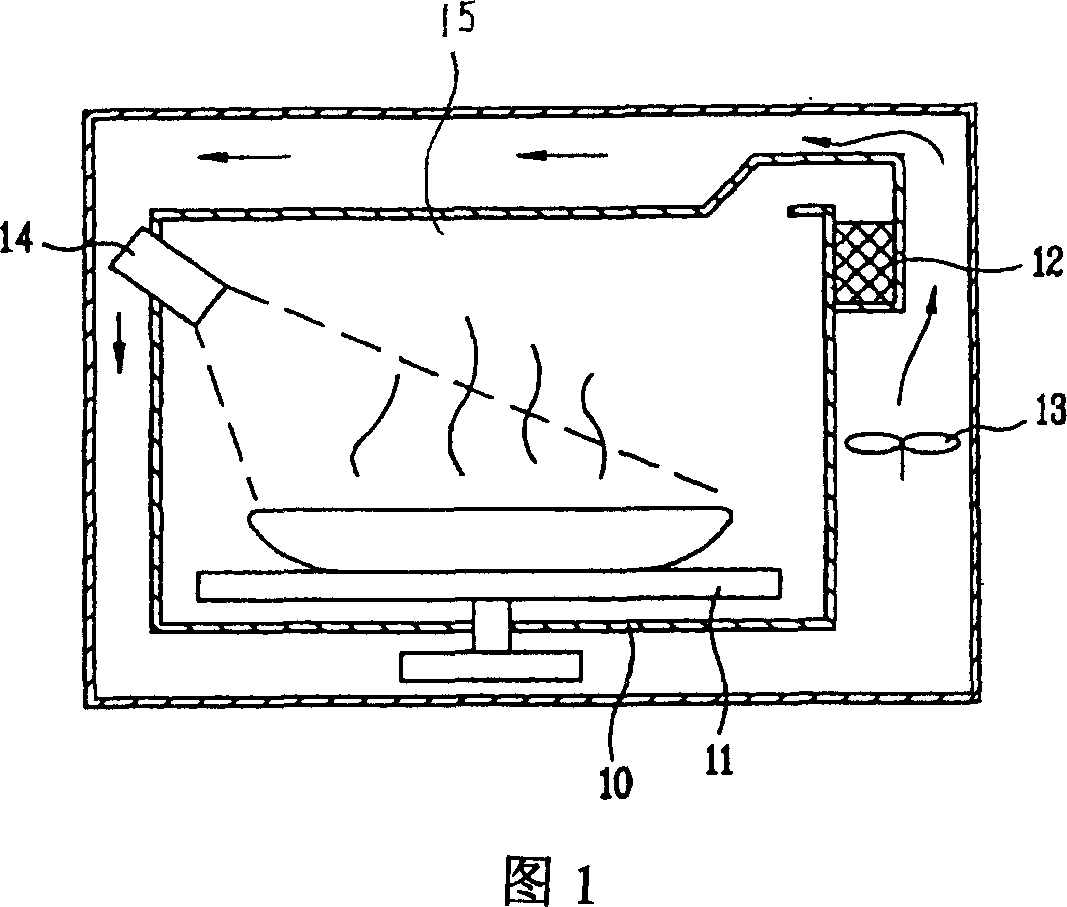

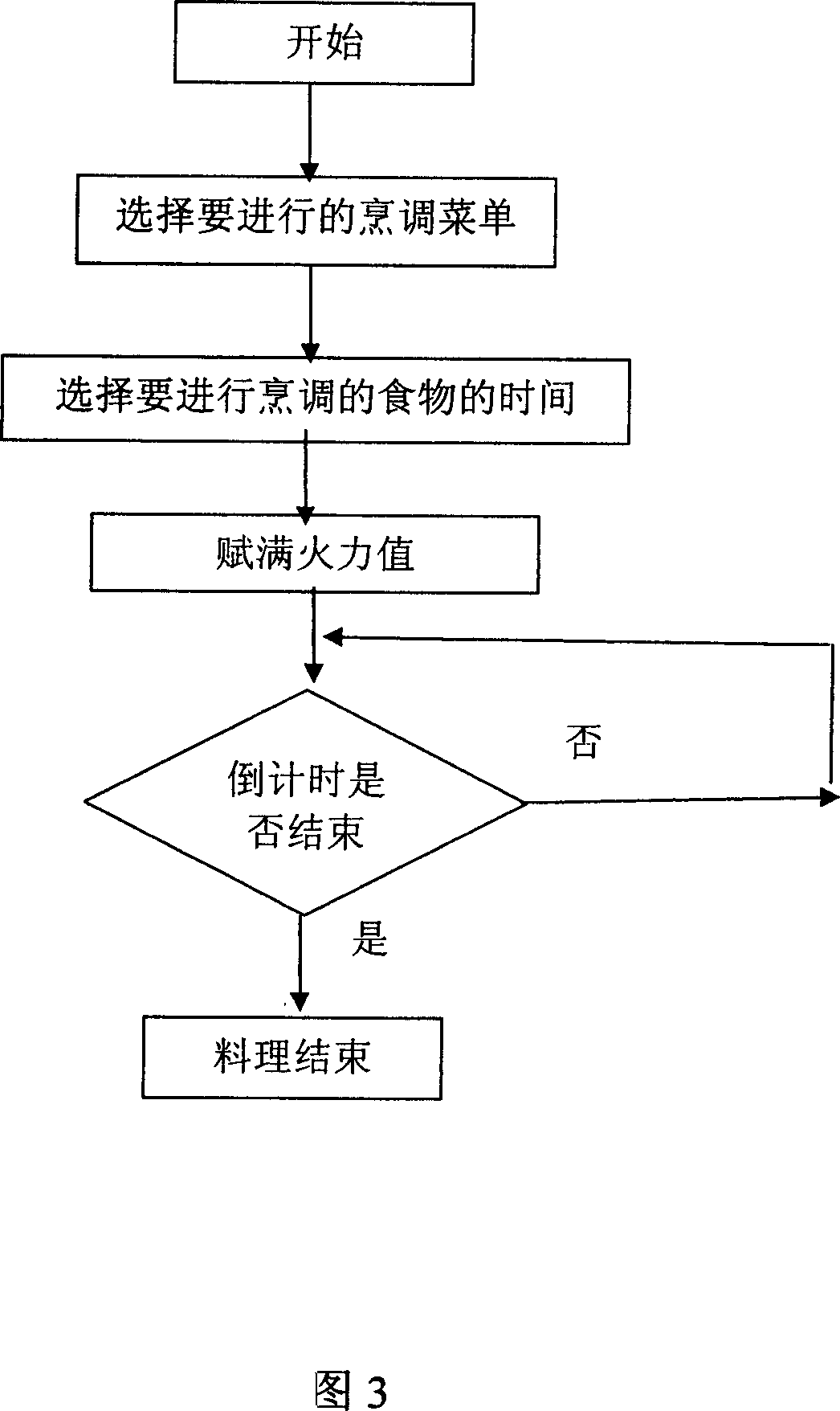

Control method of food roasting procedure of microwave oven

InactiveCN1955553AAvoid the risk of burnsDomestic stoves or rangesLighting and heating apparatusMicrowave ovenProcess engineering

A control method for the food roosting program of microwave oven includes such steps as choosing roast menu, inputting total cooking time and fire power distribution for different stages according to chosen menu, and pressing beginning button to start cooking.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Fluid anti-gravity flowing device driven by air cushion

The invention discloses a fluid anti-gravity flowing device driven by an air cushion. A third upper end cylinder and a third lower end cylinder have the same shape and are coaxial, the upper end of a third spring is connected with the lower end of the third upper end cylinder, the lower end of the third spring is connected with the upper end of the third upper end cylinder, the third spring is divided into three layers from outside to inside, and each layer of third springs are uniformly distributed along the circumference of the axis of a revolving body of a buffer layer. Gelatinized solid-liquid phase mixed fuel is loaded into a body detonation warhead shell from bottom to top in the anti-gravity direction under the pressure effect, the gelatinized solid-liquid phase mixed fuel is driven by the pressure air cushion, the air cushion has the buffering function, the fuel loading process is stable, the fuel flows into the body detonation warhead shell from the lower end, air in the shell of a body detonation warhead is exhausted from the upper portion, bubbles formed by convection motion of the air and the gelatinized solid-liquid phase mixed fuel are avoided, and the explosive power of a warhead is guaranteed.

Owner:XIAN MODERN CHEM RES INST

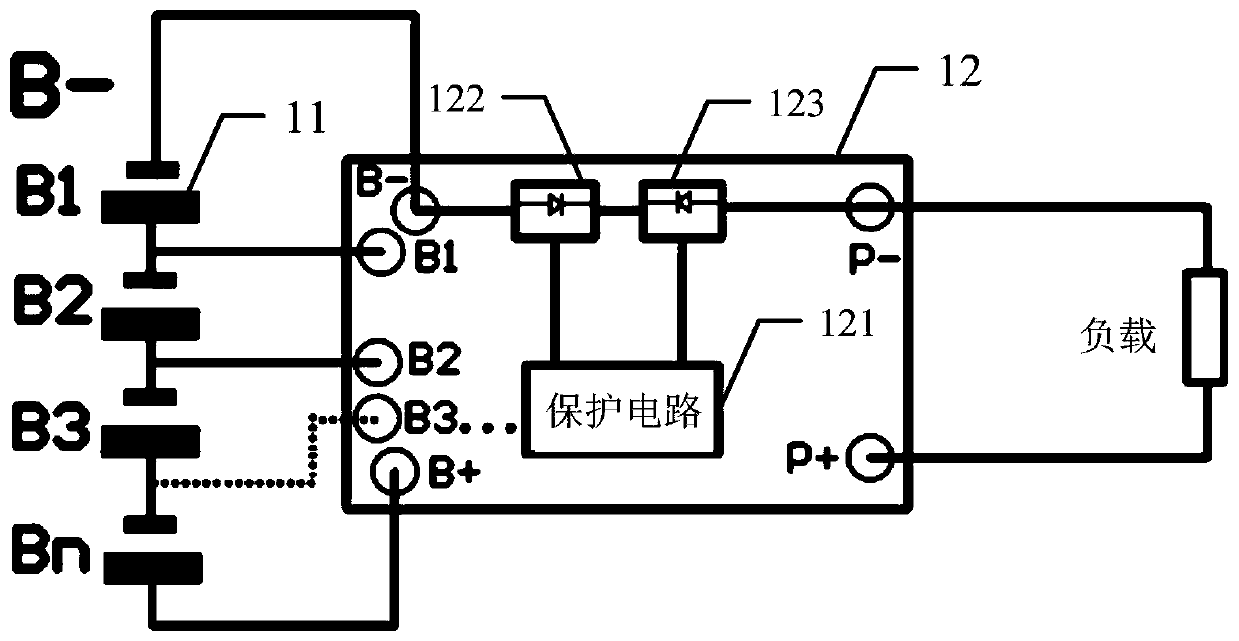

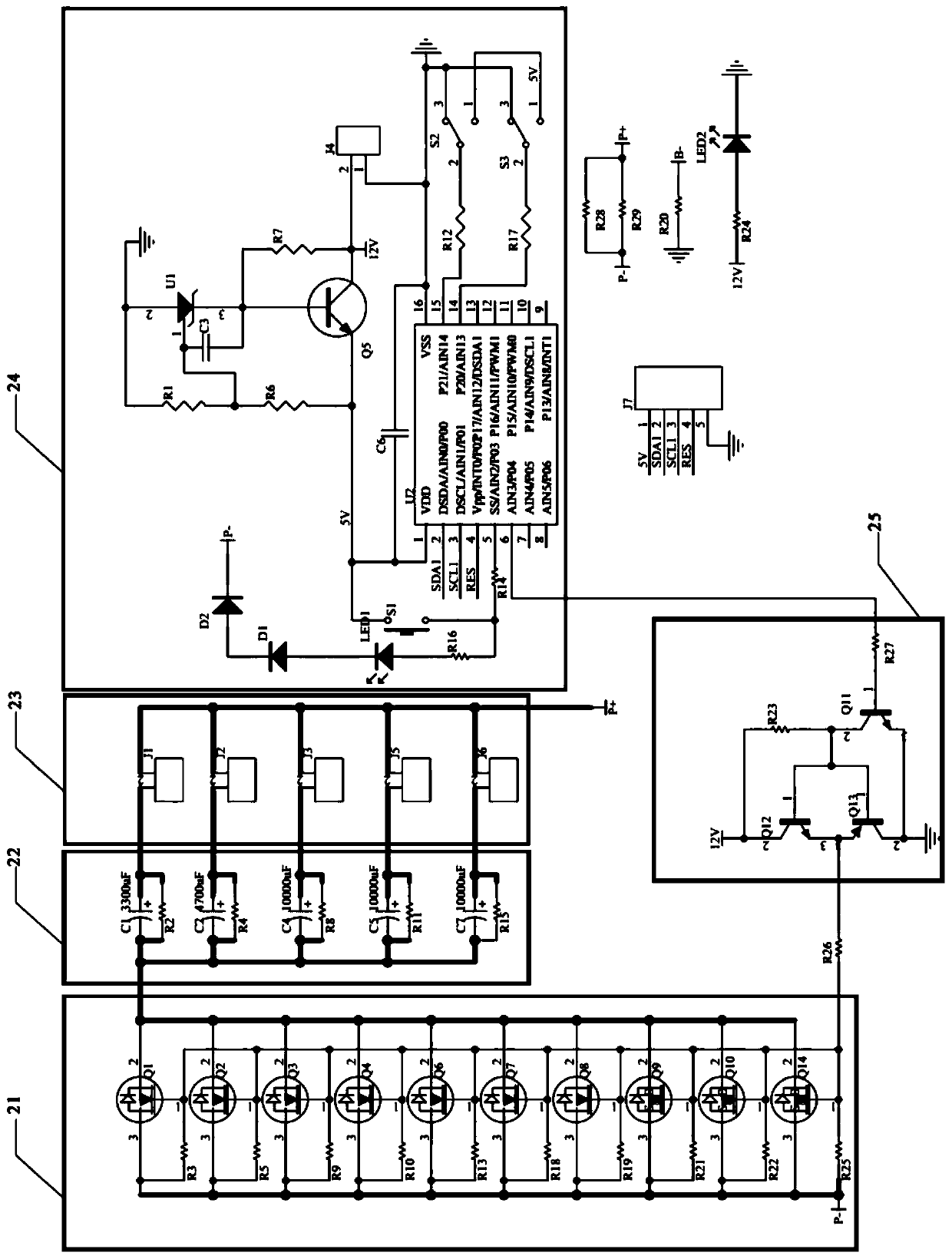

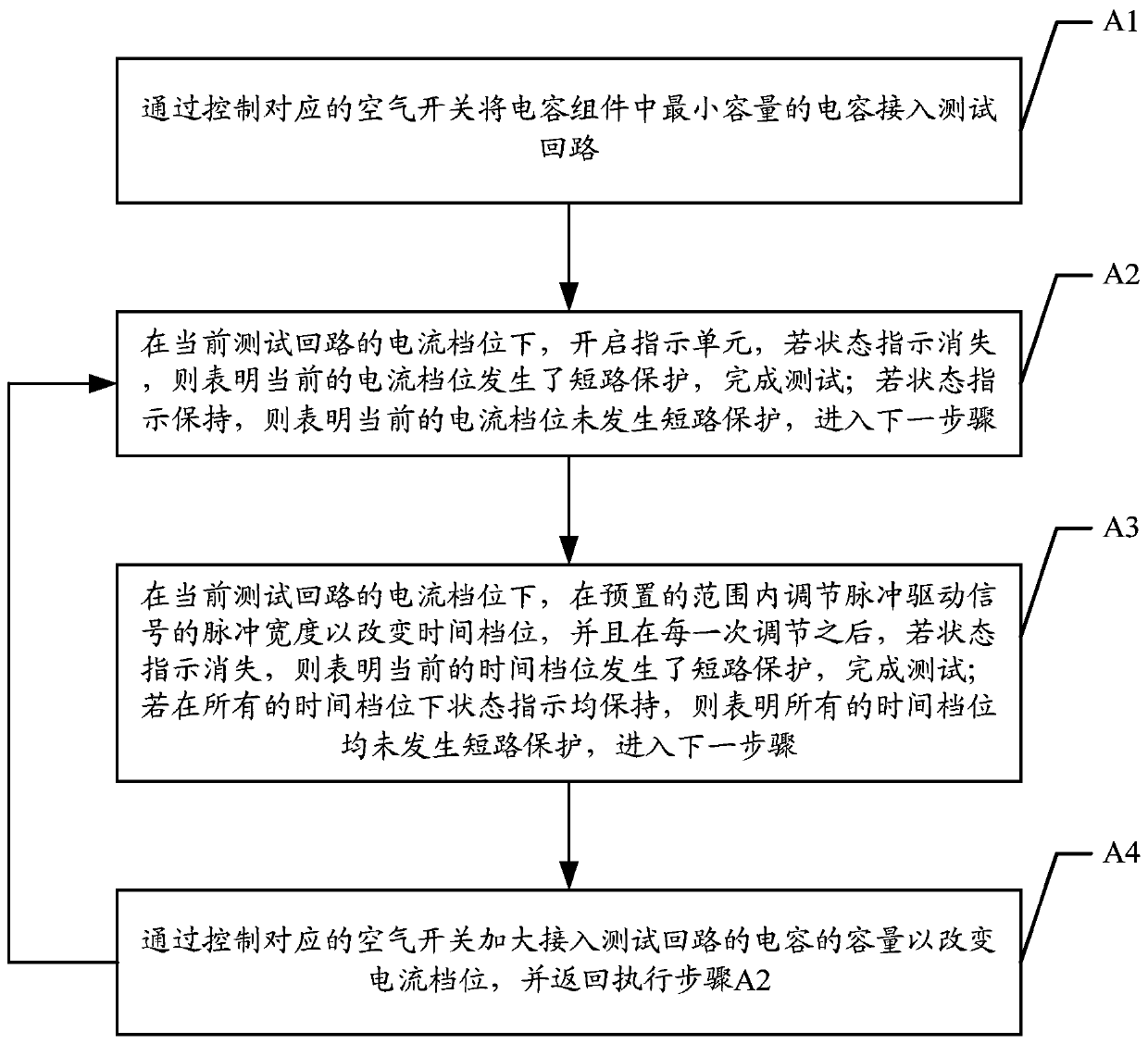

Short-circuit test circuit, tester and method for negative electrode protection type lithium battery protection board

PendingCN110736917ASimple structure and stable and reliableAvoid the risk of burnsShort-circuit testingElectronic protection circuit testingCapacitanceCell controller

The invention is suitable for the technical field of lithium battery product testing, and provides a short-circuit test circuit, a tester and a method for a negative electrode protection type lithiumbattery protection board. The short-circuit test circuit comprises a short-circuit starting switch tube assembly, a capacitor assembly, an air switch group, an indication unit capable of being manually switched on and off, a controller and a level conversion circuit. The capacitor assembly comprises a plurality of high-capacity capacitors which can be independently controlled to be switched on; the pulse width of the pulse driving signal output by the controller can also be set; different short-circuit test thresholds are realized by controlling the specific capacity of the switched-on high-capacity capacitor or the pulse width of the pulse driving signal; and whether the short-circuit protection function of the battery protection board is effective or not is judged by combining the stateindication of the prompt unit, and the short-circuit test threshold can be adjusted from low to high, so that the risk of burning the battery protection board and the battery pack during direct high-threshold test short circuit is avoided.

Owner:深圳市电将军科技有限公司

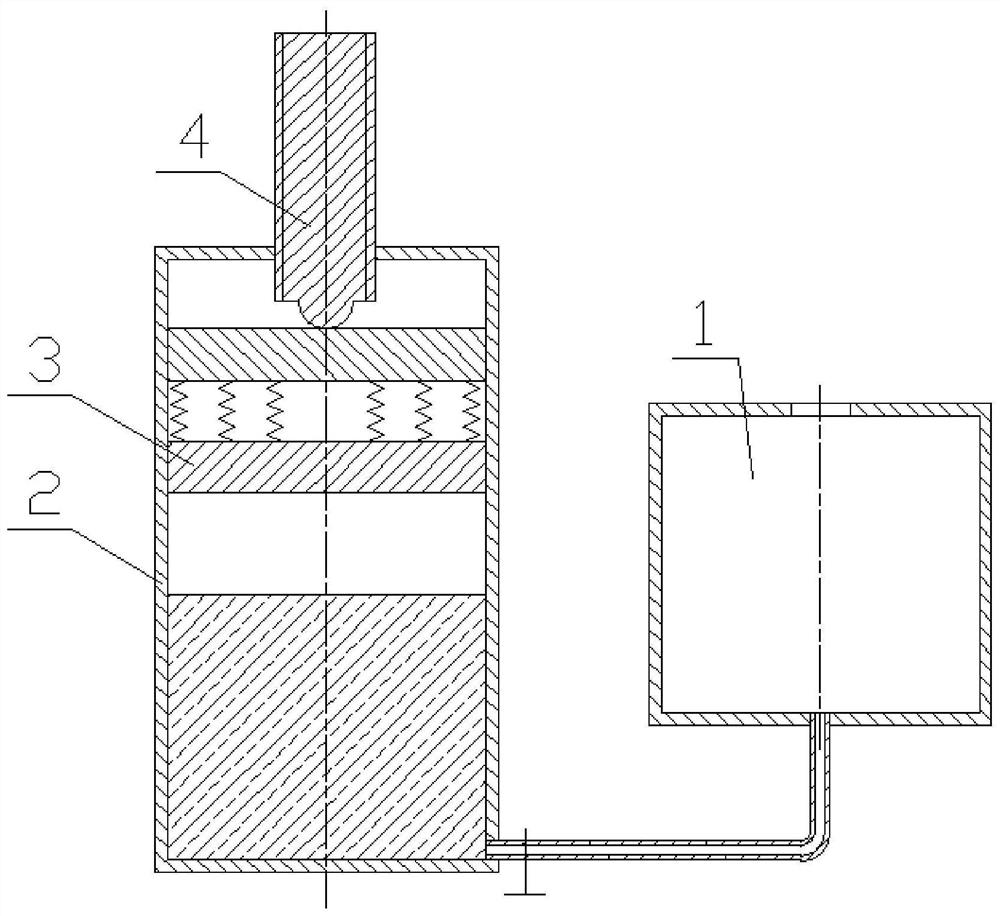

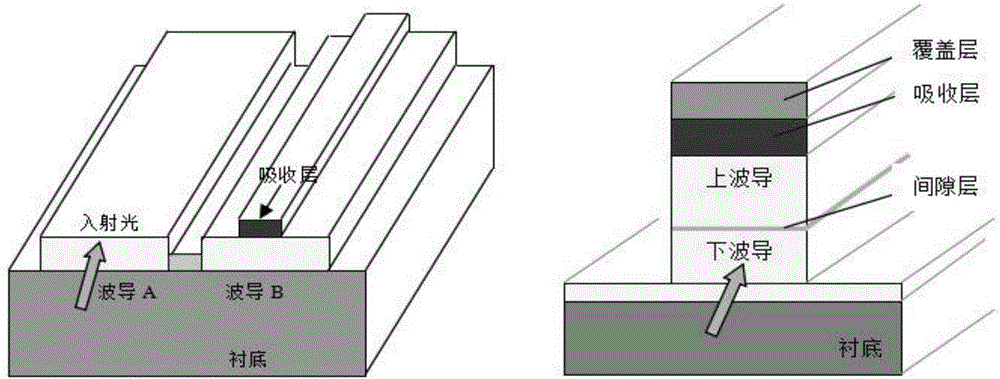

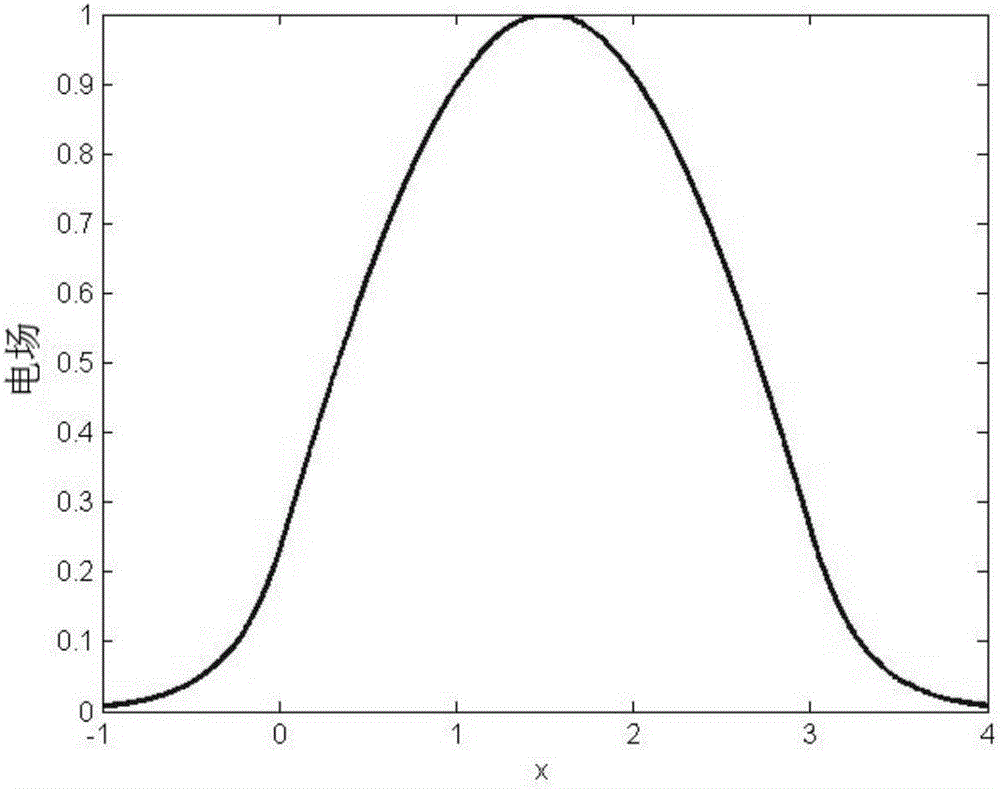

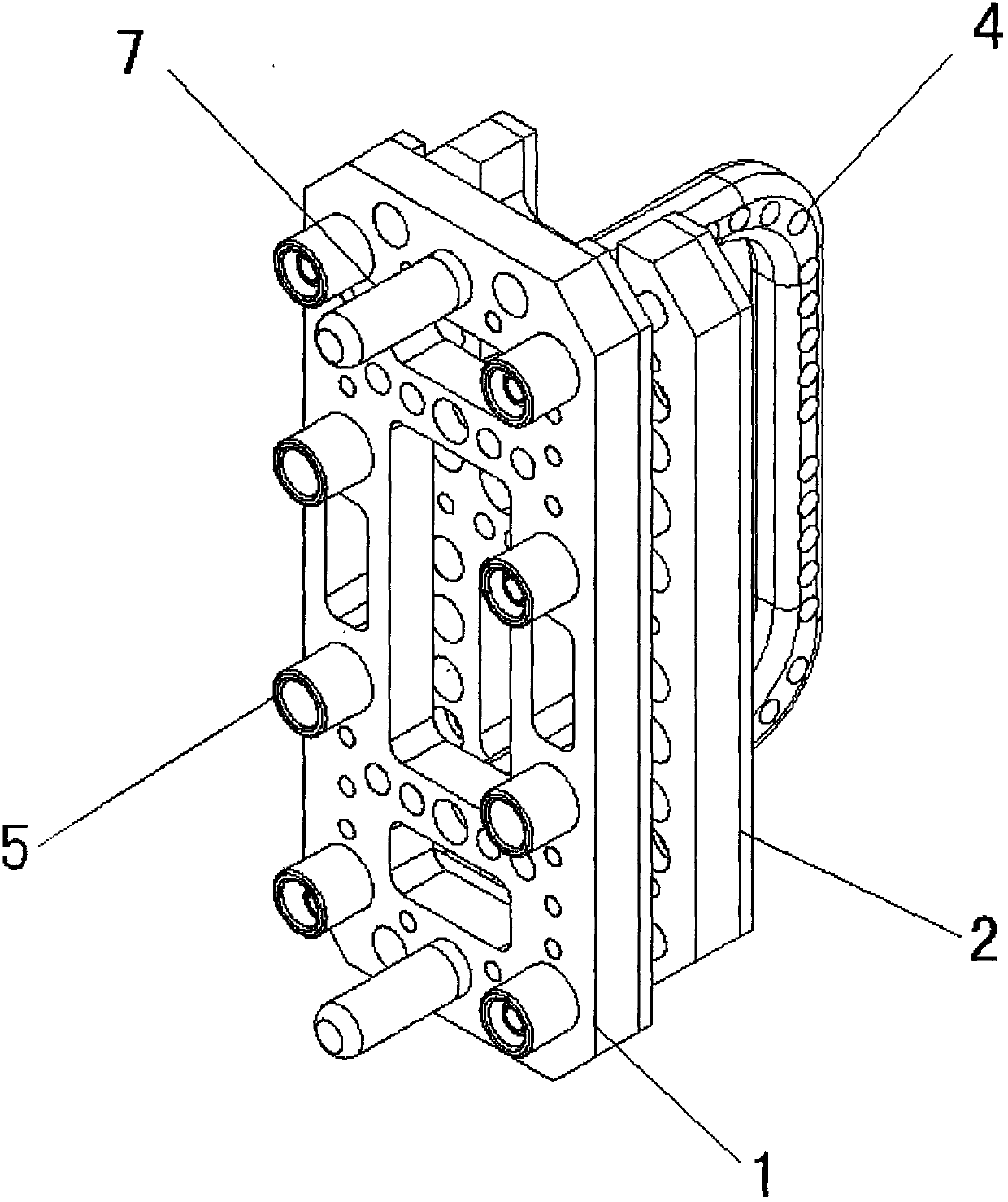

High-order supermode direction coupling waveguide detector with symmetric horizontal directions

ActiveCN106842421AImprove responsivenessIncrease photocurrentOptical waveguide light guideLight spotMicrometer

The invention discloses a high-order supermode direction coupling waveguide detector with symmetric horizontal directions. The high-order supermode direction coupling waveguide detector sequentially comprises a substrate layer (1), a waveguide layer (2), an absorbing layer (3) and a covering layer (4) from bottom to top, wherein the waveguide layer (2) consists of a left waveguide (21), a middle waveguide (22) and a right waveguide (23) in parallel; the left waveguide (22) and the right waveguide (23) are of the same structure, and are symmetrically distributed. The high-order supermode direction coupling waveguide detector has the advantages that the problem of over-small incident light spot due to over-small cross section in the existing direction coupling waveguide detector, the vertical direction coupling waveguide detector and the symmetric structure type vertical direction coupling waveguide detector is solved; the diameter of the incident light spot is increased from 3 micrometers to 5 micrometers, so as to increase the photocurrent of the detector, and effectively improve the optical coupling efficiency from an optical fiber to waveguide.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Automatic polishing machine discharging mechanism with protection function

ActiveCN106272047AReasonable structureHigh degree of automationGrinding machine componentsPolishing machinesSteel tubeEngineering

The invention discloses an automatic polishing machine discharging mechanism with a protection function. The mechanism comprises a plurality of discharging supports, a front reinforcing connecting rod and a rear reinforcing connecting rod which are used for fixedly connecting the discharging supports, rolling support rods fixedly installed at the upper ends of the discharging supports, a backup plate, steel pipe pushing cylinders, pushing plates, a backup plate pushing cylinder and pushing plate slide rails; the pushing plate slide rails are connected between rear stand columns of the adjacent discharging supports at the left end and the right end of the mechanism respectively, the pushing plates are movably connected to the pushing plate slide rails respectively, the backup plate pushing cylinder is fixedly installed on one pushing plate slide rail, the front end of a pushing rod of the backup plate pushing cylinder is fixedly connected with the pushing plate of the corresponding pushing plate slide rail, rolling wheels are rotatably connected to the pushing plates, the backup plate is fixedly connected to the uppermost ends of the pushing plates, and the steel pipe pushing cylinders are fixedly connected to a part of the discharging supports. According to the automatic polishing machine discharging mechanism with the protection function, automatic nondestructive discharging is achieved, and the surface quality of steel pipes is improved while the labor intensity is reduced.

Owner:浙江义腾特种钢管有限公司

Multi-cavity injection mould hardware mould inputting jig

The invention discloses a multi-cavity injection mould hardware mould inputting jig which comprises an element taking plate and an installation plate in parallel arrangement; the installation plate is installed above the element taking plate; the element taking plate and the installation plate are elastically connected through a plurality of elastomers; a first grip is arranged on the element taking plate; a second grip is installed on the installation plate; the element taking plate is provided with a plurality of embedding element clamp heads which are in uniform distribution; the embedding element clamp heads penetrate through the element taking plate and extend from the bottom surface of the element taking plate; the embedding clamp heads are of a hollow cylindrical shape matched with the shape of a hardware element; and the bottom surfaces (corresponding to the installation plate) of the embedding clamp heads are provided with a plurality of ejection columns inserted into the embedding element clamp heads. The multi-cavity injection mould hardware mould inputting jig has the characteristics that leisure time of operators can be reasonably utilized, the injection molding cycle is shortened, and the injection molding efficiency is improved; the invalid time of the operation of an injection molding machine is shortened, and blocking and chewing can be prevented; hardware can be safely enters a mold by utilizing the jig; and within the original effective time, hardware with the number four times, eight times or even more that of the original hardware can be input.

Owner:KENTA ELECTRONIC MFG KUNSHAN CO LTD

Large-size angle steel high-frequency heating single-face bending machine used for extra-high voltage iron tower

The invention discloses a large-size angle steel high-frequency heating single-face bending machine used for an extra-high voltage iron tower. The large-size angle steel high-frequency heating single-face bending machine comprises a base. Workpiece placing racks are symmetrically fixed to the front end and the back end of the top surface of the base. A pressing block is connected to the position above the workpiece placing racks in an up-down movement mode. A bending pressing die is fixed to the bottom surface of the pressing block and located between the workpiece placing racks. The pressing block provides the driving force through a hydraulic piston which is fixed to a top plate. The top plate is fixed to the base through vertical posts. High-frequency heating machines are arranged on the left side and the right side of the base correspondingly. The shape defined by heating coils of the high-frequency heating machines is the same as that of a bent and deformed region of a workpiece. By means of the structure of the large-size angle steel high-frequency heating single-face bending machine, the high-frequency heating machines and the bending mechanism are combined together, and after being heated, the workpiece can be bent immediately without turnover, so that the heat loss is avoided, and energy consumption is reduced; and meanwhile workpiece turnover is omitted, the production efficiency is improved, and the hidden danger that an operator is scalded by the workpiece in the workpiece turnover process is also avoided.

Owner:JIANGSU FLIGHT ELECTRIC EQUIP MFG

Automatic zincification device and control method thereof

InactiveCN102373391BPrevent splashAvoid the risk of burnsHot-dipping/immersion processesProgrammable logic controllerManipulator

The invention discloses an automatic zincification device which comprises a control PLC (Programmable Logic Controller), a bracket, a manipulator device, a conveyer and at least one zincification trolley, wherein the manipulator device is arranged on the bracket and is connected with the control PLC; the conveyer is arranged below the front part of the bracket along the length direction of the bracket and is connected with the control PLC; the zincification trolley is arranged below the rear part of the bracket and moves along a zincification trolley operating track; the zincification trolleyoperating track is vertical to the bracket; and the zincification trolley is connected with the control PLC. Correspondingly, the invention also provides a control method of the automatic zincification device. By the automatic zincification device and the control method thereof, the full automation of the zincification process can be realized.

Owner:BAOSHAN IRON & STEEL CO LTD

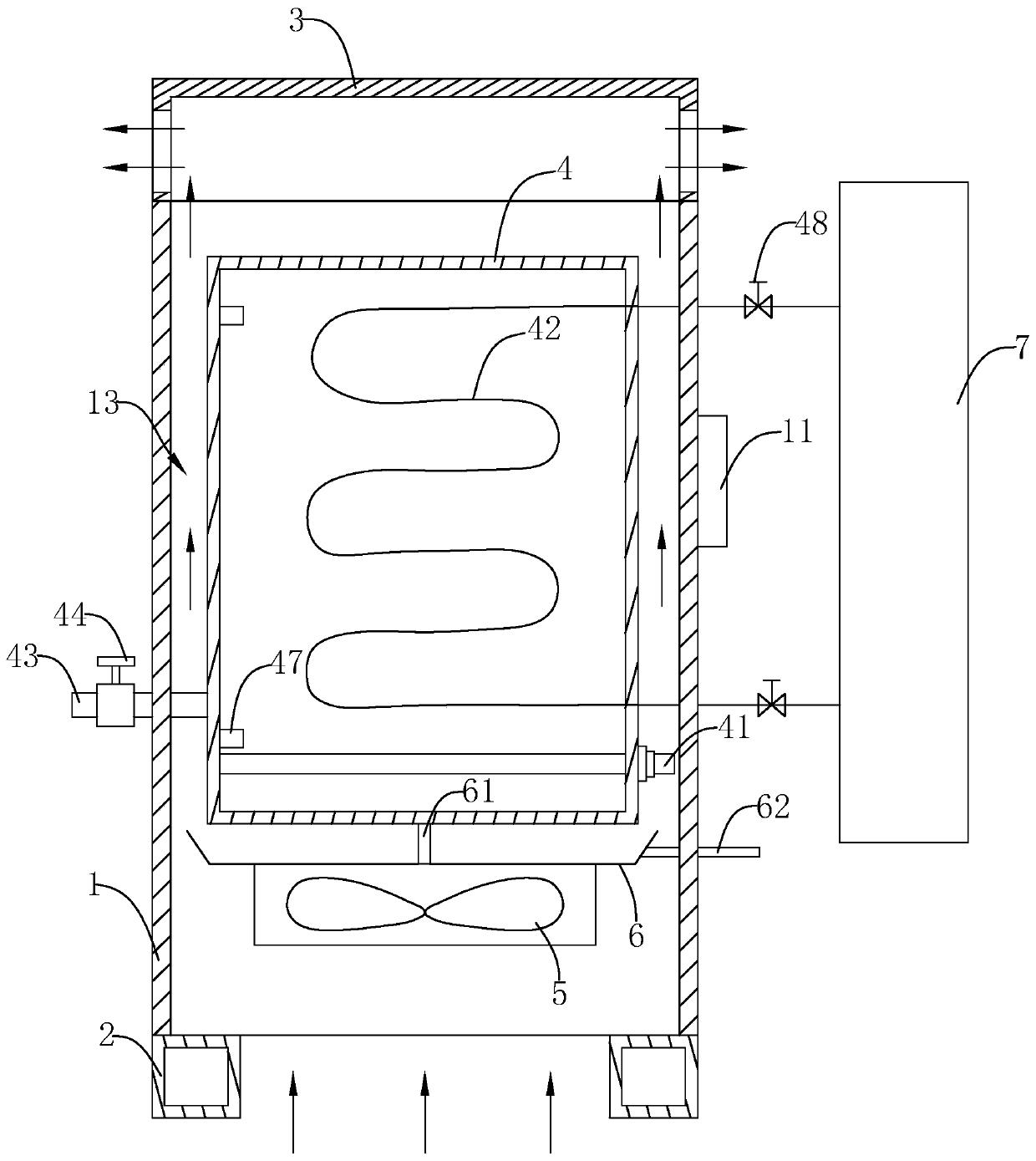

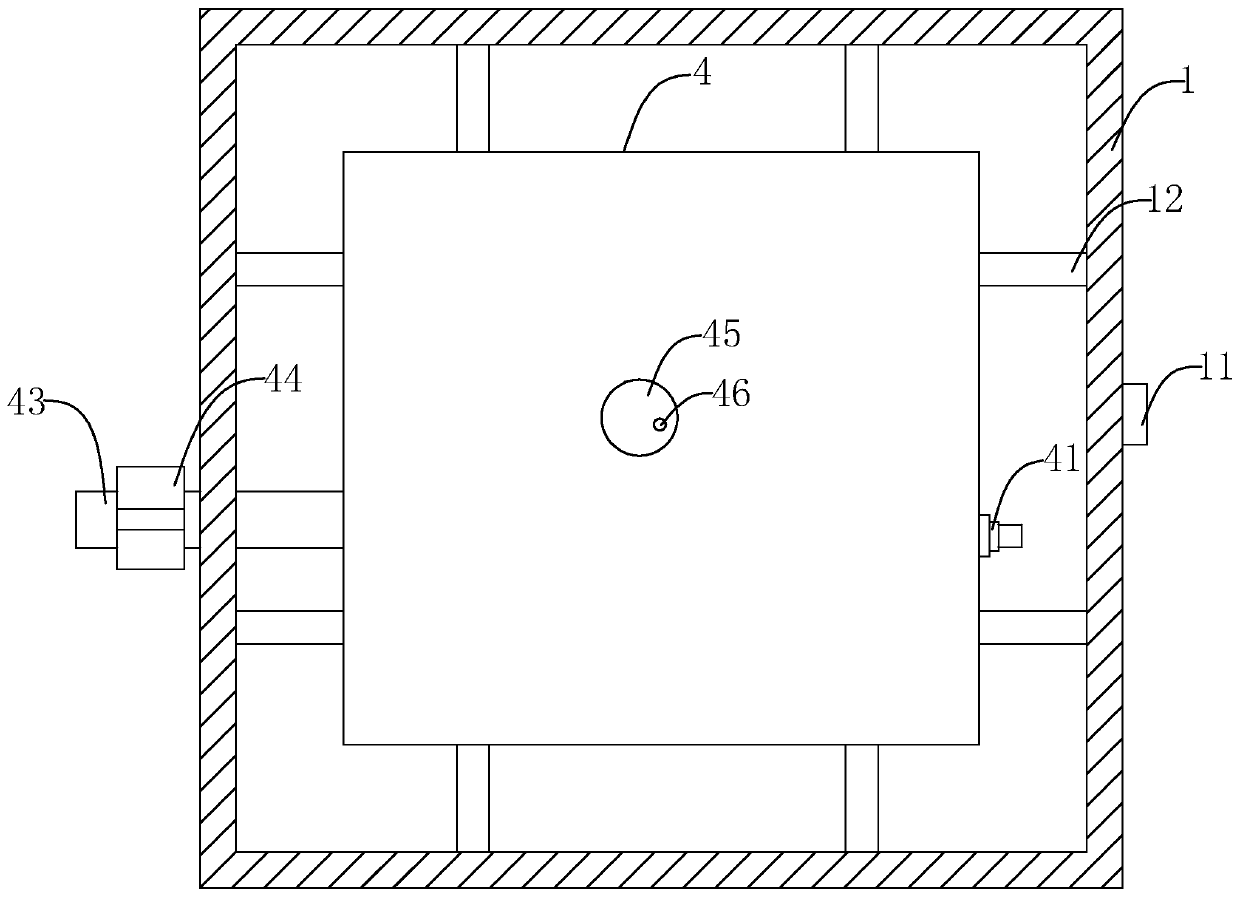

Air source heat pump cold and hot double-storage air conditioning device

PendingCN110500683AAvoid circulationSmall heat releaseHeat pumpsCondensate preventionEngineeringAir conditioning

The invention relates to an air source heat pump cold and hot double-storage air conditioning device. The device comprises two parts of a heat pump type air conditioner outdoor device and a heat pumptype air conditioner indoor device, wherein the heat pump type air conditioner indoor device comprises a shell hollowed and opened at the two ends, a base fixedly connected to the bottom of the shelland communicating with the external, an electric heating device arranged in a water tank, a refrigerant-water heat exchanger arranged in the water tank and used for heating or cooling water, and a fanmounted under the water tank; an air way for enabling air currents to pass through is formed between the shell and the water tank; an air cap is arranged at the end, far from the base, of the shell;and air outlets are formed around the air cap. The device has the advantages of capability of realizing room-stage cold and hot storage, simple structure, low mounting cost and high safety and reliability, and provides excellent solutions for such important demands as cleaning and warming in cold regions, power grid load balance, heating and cooling operation cost reduction and cleaning energy consumption.

Owner:BEIJING ZETA MECHANICAL & ELECTRICAL EQUIP ENG CO LTD

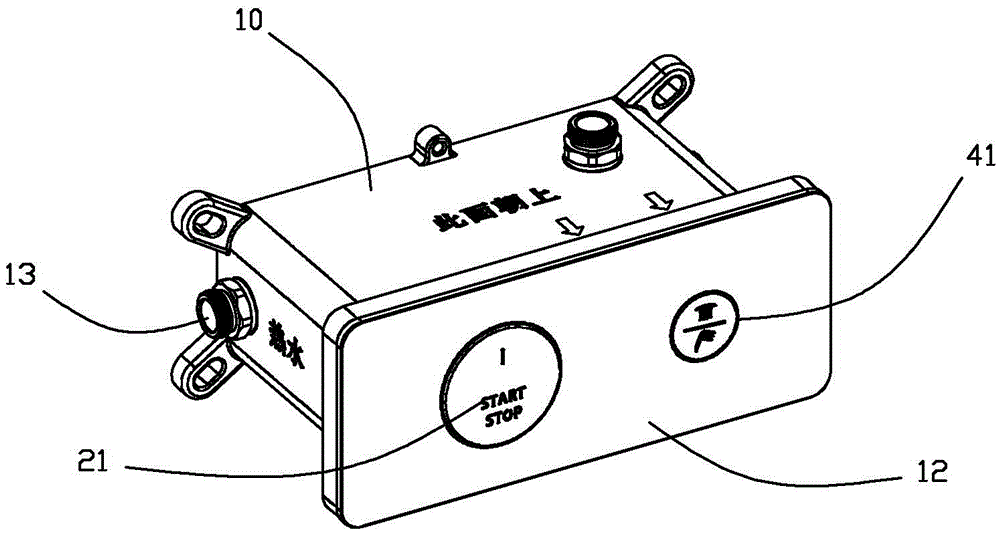

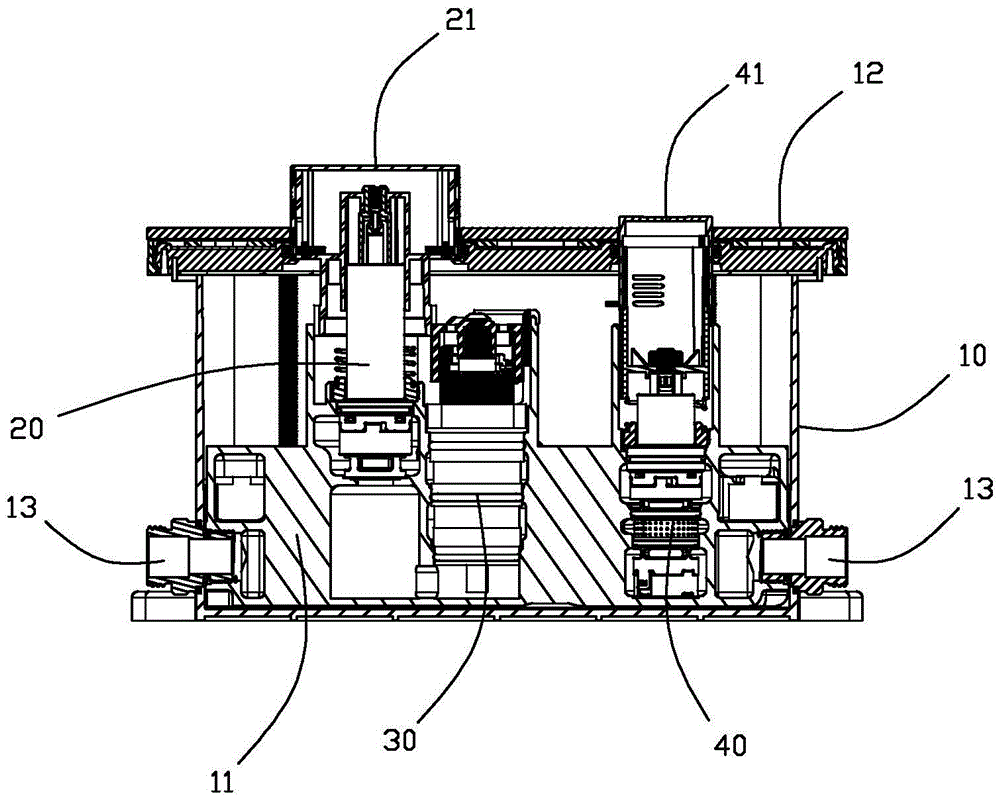

Barrier-free used concealedly-installed control valve

ActiveCN106015651AEasy to openEasy to operateOperating means/releasing devices for valvesMultiple way valvesInlet channelControl valves

The invention relates to a barrier-free used concealedly-installed control valve. The control valve comprises a concealedly-installed box, a concealedly-installed body and a rotary-control type thermostatic valve. The thermostatic valve is installed in the concealedly-installed body and arranged between a water inlet channel and a water outlet channel of the concealedly-installed body. The concealedly-installed body is installed in the concealedly-installed box. A pressing type switch valve is arranged between the thermostatic valve and the water inlet channel. A rotary hand wheel is arranged at the end of the switch valve. Linkage is achieved between the rotary hand wheel and a thermoregulation assembly of the thermostatic valve. The rotary hand wheel is pressed once, the switch valve is closed, the thermostatic valve and the water inlet channel are blocked, and the rotary hand wheel is not higher than a panel of the concealedly-installed box. The rotary hand wheel is pressed again, the switch valve is opened, the thermostatic valve communicates with the water inlet channel, and the rotary hand wheel extends out of the panel of the concealedly-installed box. According to the barrier-free used concealedly-installed control valve, barrier-free operation can be conducted. The control valve has anti-scalding and anti-cold functions and a secondary starting anti-scalding function, and anti-scalding and anti-cold effects are both achieved through arrangement of exceeding prompting tap positions, namely, the possibility that water temperature is adjusted to be low due to the fact that the hand wheel is accidentally driven by clothes, a bath towel and the like to rotate is avoided completely.

Owner:FUJIAN XIHE SANITARY WARE TECH

Generator convenient for thermal dissipation

InactiveCN110048540AImprove securityGood heat insulationCooling/ventillation arrangementSupports/enclosures/casingsThermal insulationOperability

The invention discloses a generator convenient for thermal dissipation. The generator comprises a generator main body, a thermal dissipation end board and a front end cover, a water injection cavity is embedded into the top end of the generator main body, a water diversion film is tightly attached to the middle part of the interior of the water injection cavity, the bottom end of the water injection cavity is fixedly connected with a thermal conduction pipe, the bottom end of the thermal conduction pipe is fixedly connected with a superheated steam outlet, the periphery of the generator main body is fixedly connected with a reflector, a rubber sleeve is tightly attached to the top end of the generator main body, the rubber sleeve has good thermal insulation capability, thus scald risk is avoided, the reflector well ensures the practicability of the generator, a shock absorption support can buffer shock generated by the generator main body to a certain degree, operability of the generator is well improved, the service life of the generator is well prolonged through the superheated steam outlet, the thermal dissipation performance of the generator is further improved through the cooling fan, and the generator is suitable for being used and has wide development prospects in the future.

Owner:诸暨市合纵科技有限公司

Anesthesia machine

The invention discloses an anesthesia machine which comprises a shell, a breathing circuit, a heating source and heat-insulation components. The breathing circuit is arranged on the outside of the shell; the heating source is arranged in the shell and is connected with the breathing circuit; one end of each heat-insulation component is connected with the heating source, and the other end of each heat-insulation component is detachably connected with the breathing circuit. The anesthesia machine in an embodiment of the invention has the advantages that the anesthesia machine is excellent in safety performance, and the breathing circuit is convenient to mount and detach.

Owner:BEIJING AEONMED

High temperature mold locking device and operation method

The invention discloses a high temperature mold locking device and an operation method. The high temperature mold locking device comprises a fixing seat, a swinging hook and an inserting plate. The fixing seat is fixed on the side surface of a moving die, one end of the swinging hook is rotatably connected to the fixing seat, and the other end of the swinging hook is detachably connected with a fixed die. One end of the inserting plate is fixed to the side surface of the fixed die, and the bottom of the other end of the inserting plate is in contact with the side surface of the moving die. Theswinging hook and the inserting plate are parallel and in contact with each other, and the swinging hook can be moved along the top contour of the swinging hook to be connected with the fixed die orseparated from the fixed die. The high temperature mold locking device and the operation method have the advantages that the function of locking the moving die and the fixed die of a high temperaturemold is realized, and the locking firmness of the high temperature mold locking device to the moving die and the fixed die is improved; the automation degree of the high temperature mold locking device is improved, and the risk of being burnt by the high temperature mold due to human operation is avoided; and the mold opening sequence of the high temperature mold is determined, and the situationsthat the product or the fixed die is deformed due to the fact that the product adheres to the fixed die due to violation of the mold opening sequence by workers are avoided.

Owner:昆山艾比塑胶模具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com