Assembly shutoff device, anti-backflow method thereof and photovoltaic system

A component and off-state technology, applied in the direction of electrical components, parallel operation of DC power supplies, DC network circuit devices, etc., can solve the problems of easy burning of switch tubes, damage to component switchers, burning of switch tubes, etc., to avoid backflow current. burnt effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

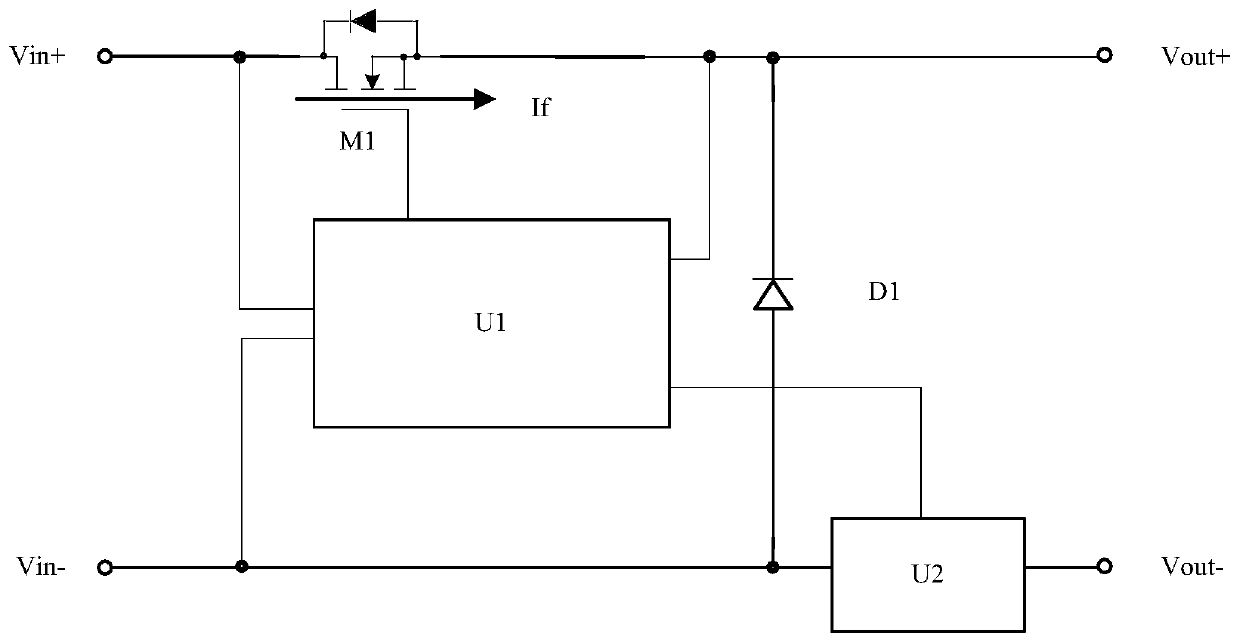

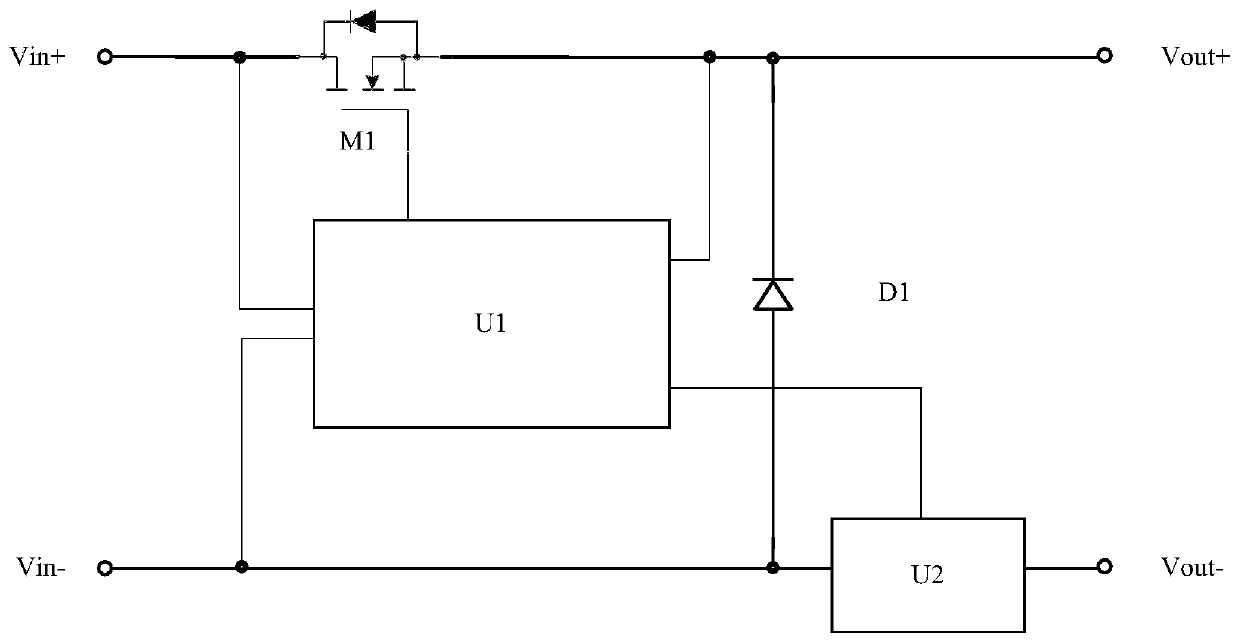

[0043] As mentioned in the background art, in the prior art, when the module switch is in the off state, if the injection current test of the photovoltaic module is performed or the voltage of a certain string of photovoltaic modules is lower than other strings connected in series for some reason, It may happen that the backflow current flows into the component in the way of backflow. At this time, because the component switch is in the off state, the switch tube of the component switch is also in the off state. At this time, the backflow current can easily burn the switch tube. , Resulting in damage to the component switch.

[0044] Specifically, refer to figure 2 , figure 2 It is a schematic diagram of the feasible structure of the traditional component switch, in figure 2 , The component switch includes a switch tube M1, a shutdown control module U1, a communication module U2 and a bypass diode D1, figure 2 Vin+ and Vin- represent the positive and negative interfaces of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com