Multi-cavity injection mould hardware mould inputting jig

An injection mold and hardware technology, applied in the field of multi-cavity injection mold hardware into the mold fixture, can solve the problems of high labor cost, low production efficiency, high safety risk, etc., to improve injection molding efficiency, prevent nozzle clogging, and shorten invalid time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

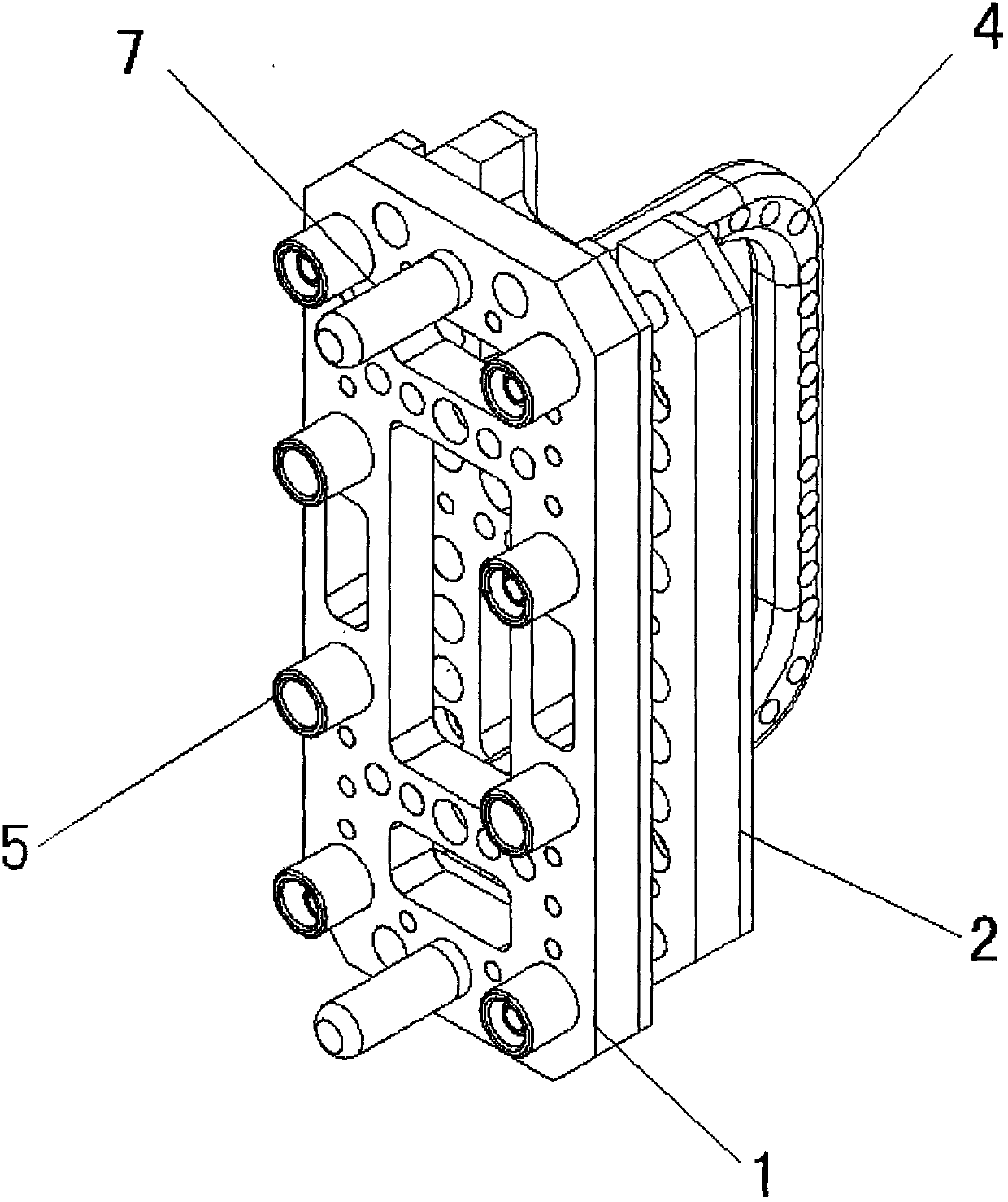

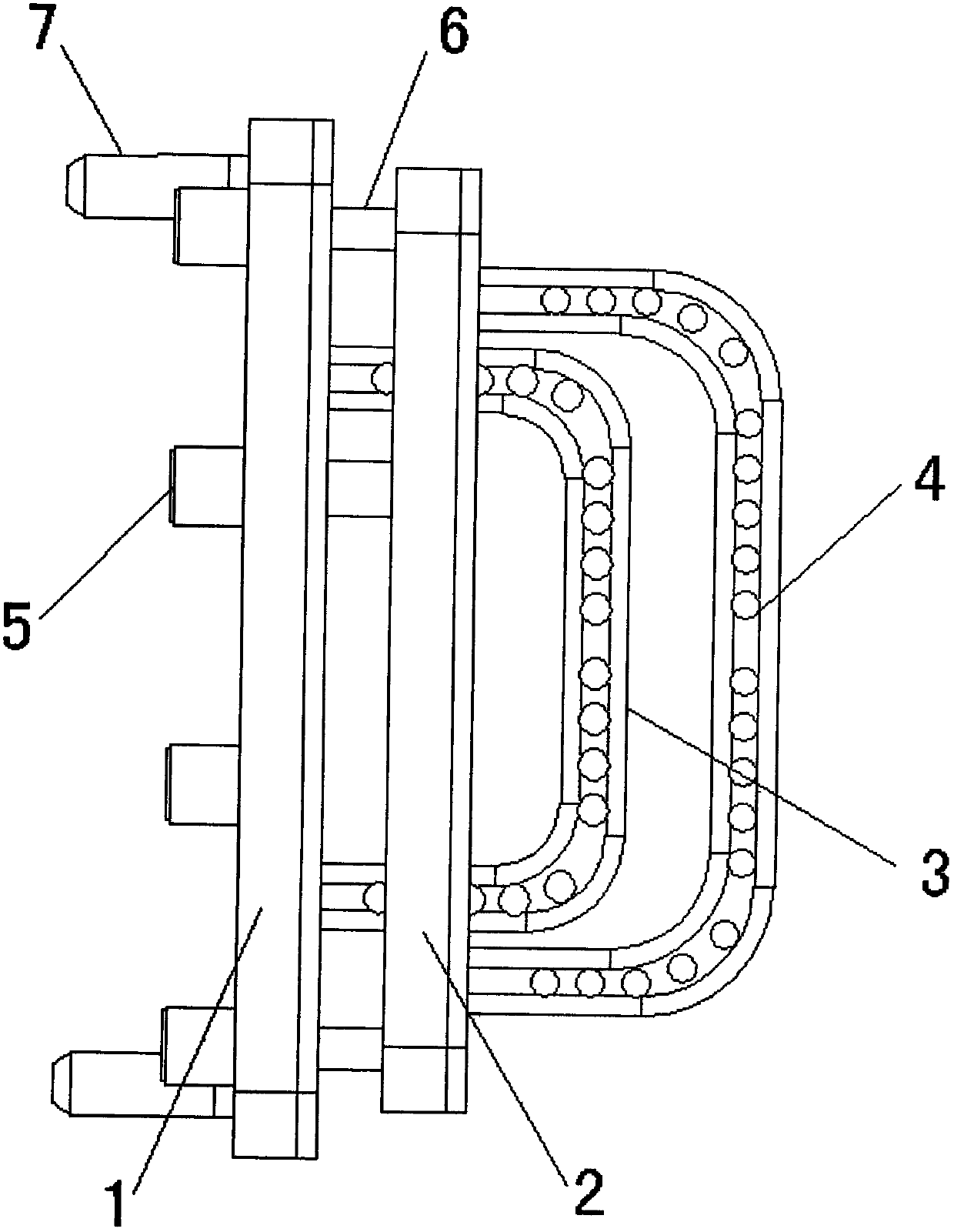

[0013] figure 1 It shows an embodiment of a multi-cavity injection mold hardware entry fixture of the present invention, including a pick-up plate 1 and a mounting plate 2, the mounting plate 2 and the pick-up plate 1 are arranged in parallel, and the mounting plate 2 is arranged on Above the pick-up plate 1, the pick-up plate 1 and the mounting plate 2 are elastically connected by several elastic members, the pick-up plate 1 is provided with a first handle 3, and the mount plate 2 is provided with a second handle 4. There are several evenly distributed insert chucks 5 on the pick-up plate 1, the insert chucks 5 penetrate the pick-up plate 1 and protrude from the bottom surface of the pick-up plate 1, and the insert chucks 5 It is in the shape of a hollow cylinder matching the hardware, and the bottom surface of the corresponding mounting plate 2 is provided with a number of ejector columns 6 inserted into the insert chuck, and two sides of the bottom surface of the pick-up pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com