Patents

Literature

270results about How to "Easy resection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

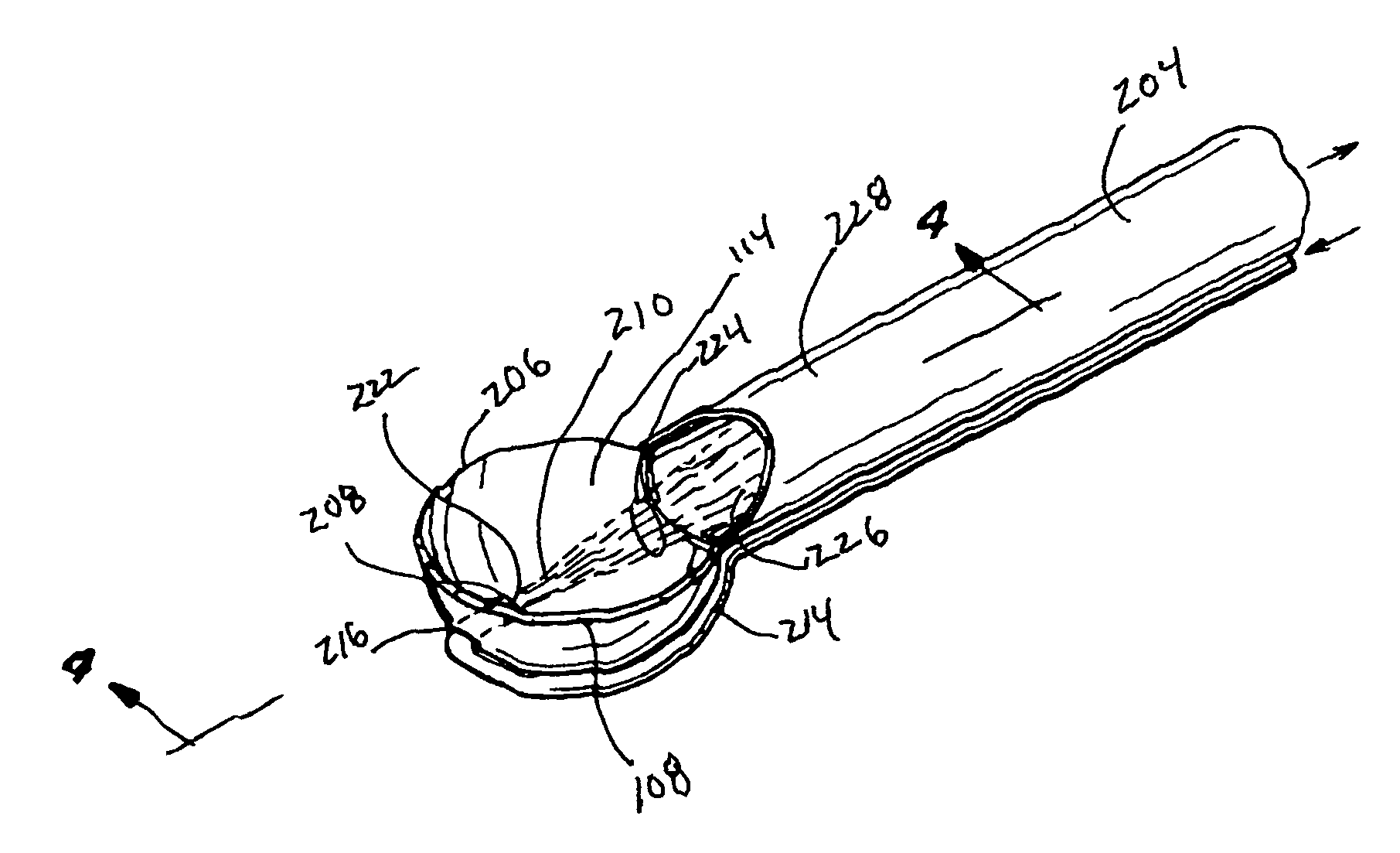

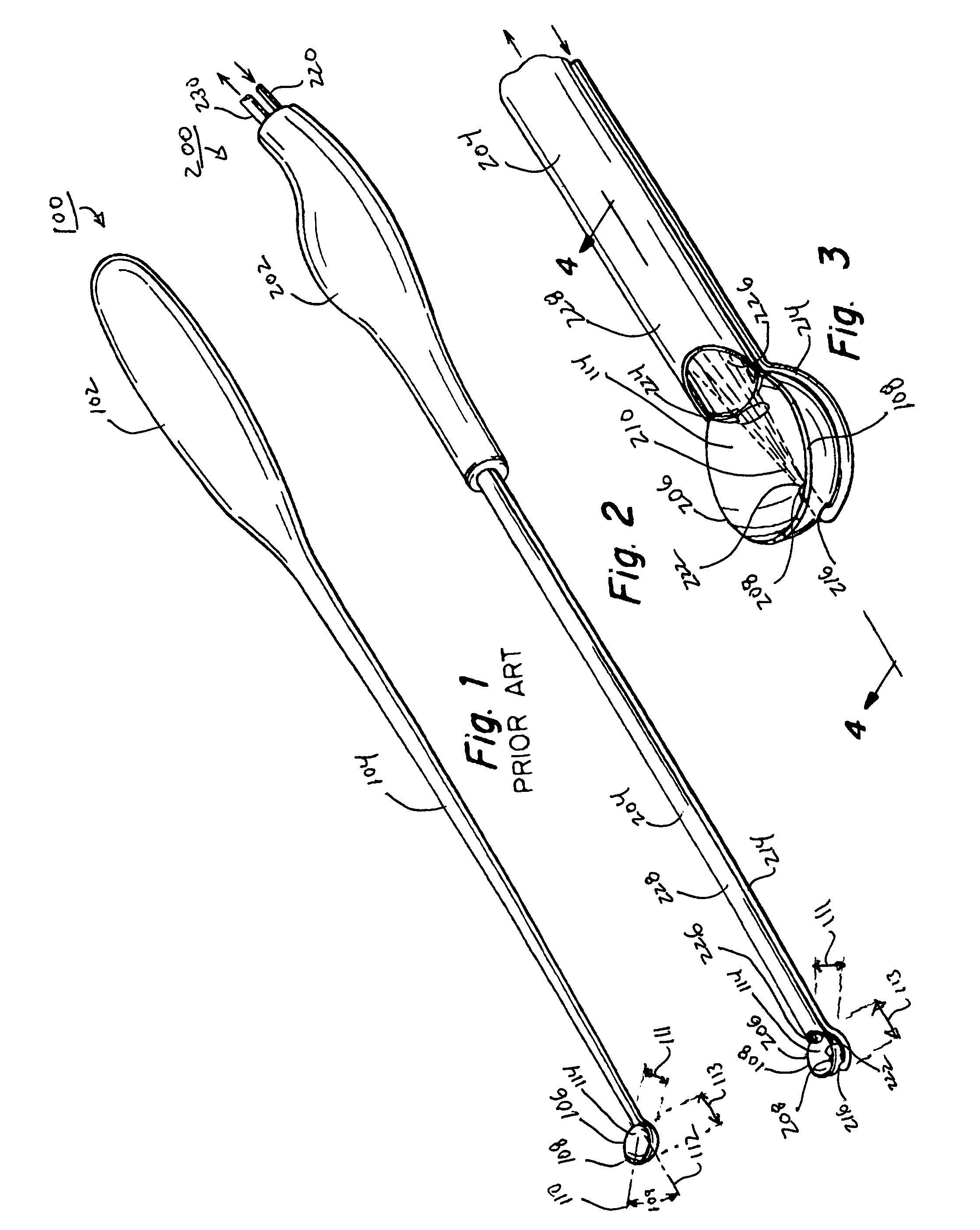

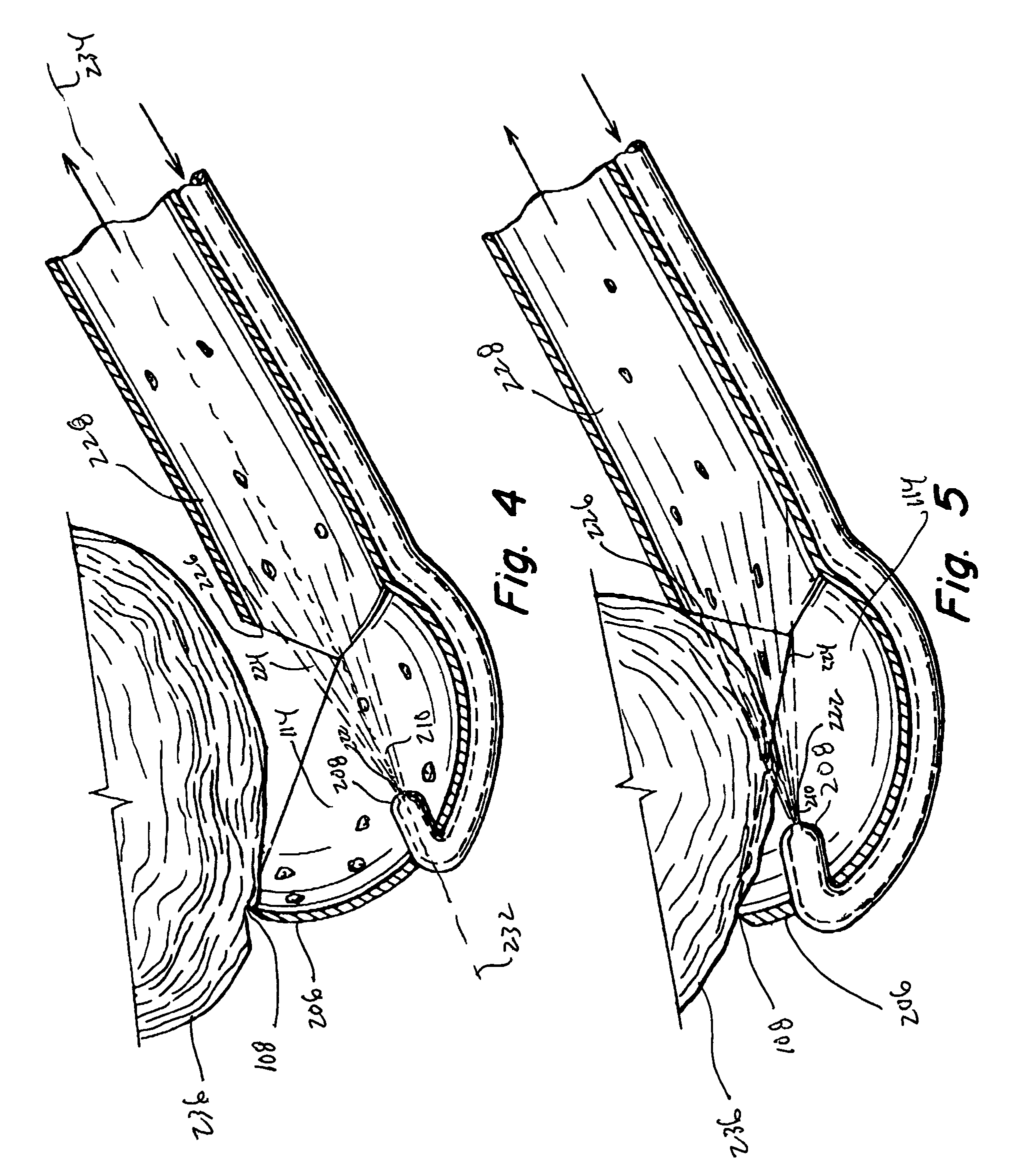

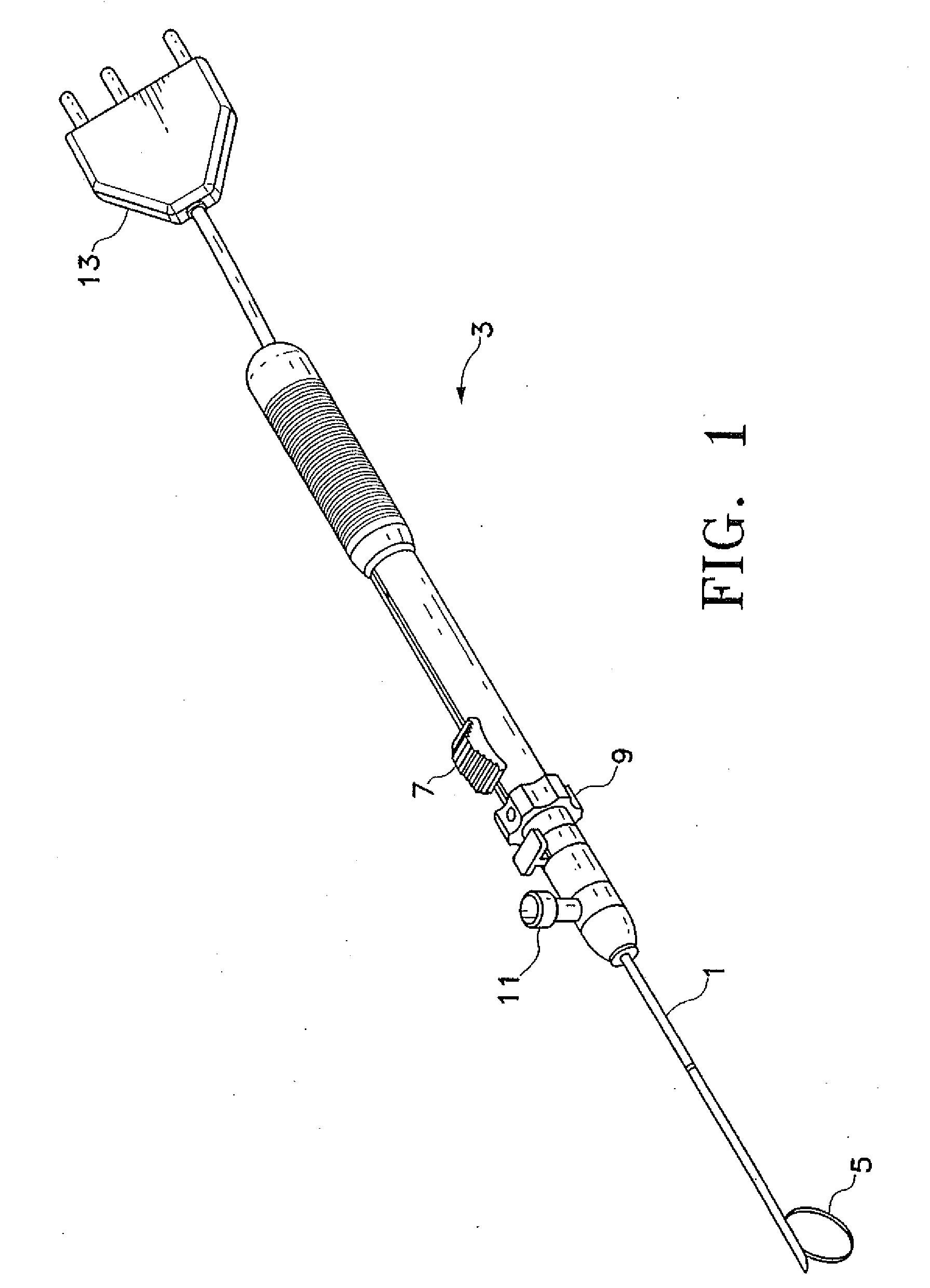

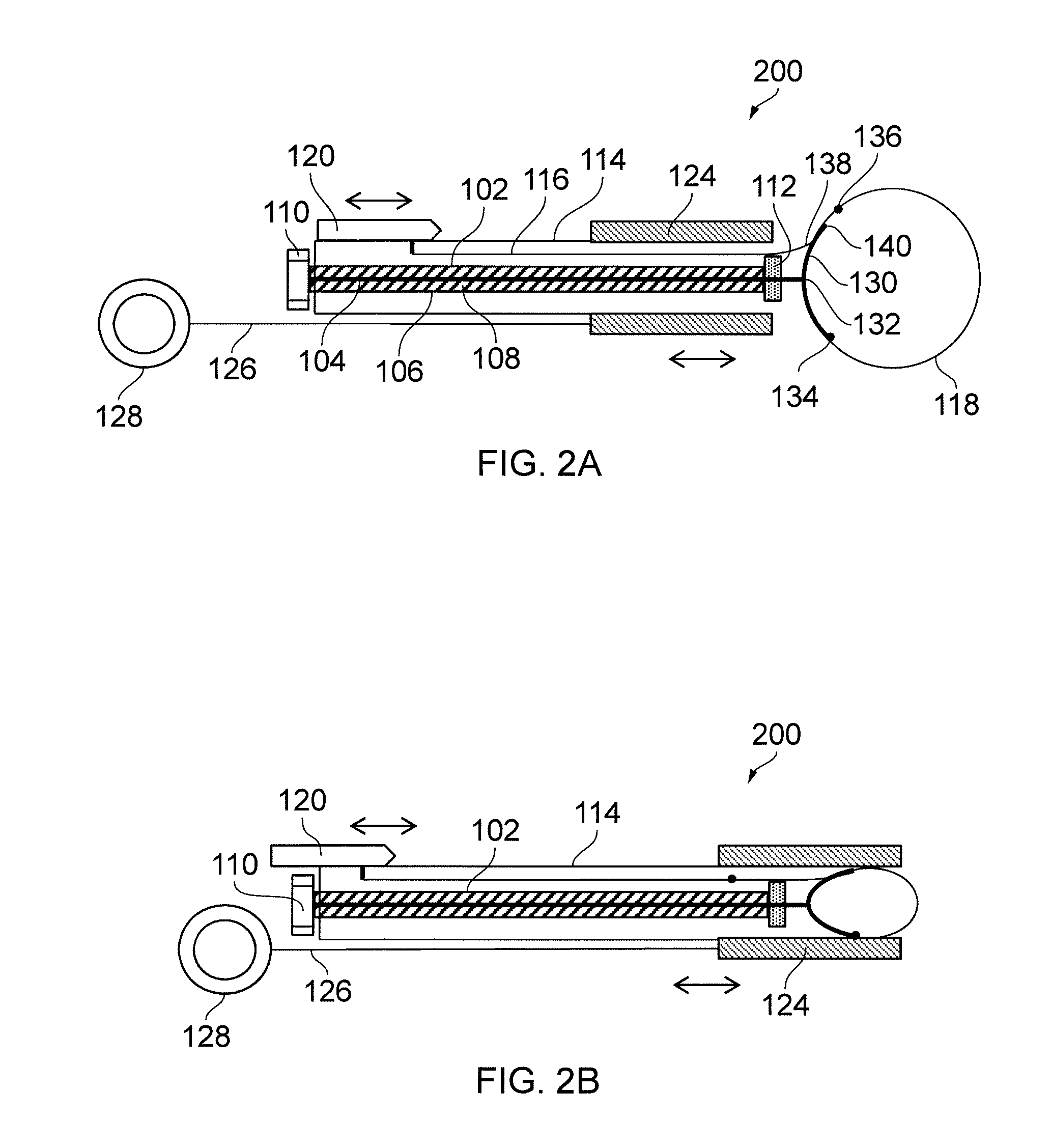

Surgical devices incorporating liquid jet assisted tissue manipulation and methods for their use

ActiveUS8162966B2Improving speed and safetyDecreasing fatigue and workloadCannulasEnemata/irrigatorsSpinal columnLiquid jet

Surgical instruments are disclosed that utilize high-pressure liquid jets to perform a variety of useful functions. In certain embodiments, surgical instruments are described incorporating one or more liquid jets utilized to contact tissue excised by a non-liquid jet tissue-cutting component of the surgical instrument. In certain embodiments, a liquid jet of a surgical instrument can be utilized for the purpose of excising tissue of a patient immobilized and / or manipulated by the surgical instrument. Also described are surgical devices of the type characterized by curettes, rongeurs, bone punches, bone cutting forceps, morcellators, surgical micrograspers, with functionality and performance supplemented by the integration of a liquid jet. Also disclosed are methods of using certain liquid jet-containing surgical instruments for performing surgical procedures, for example surgical procedures on the spinal column of a patient.

Owner:HYDROCISION

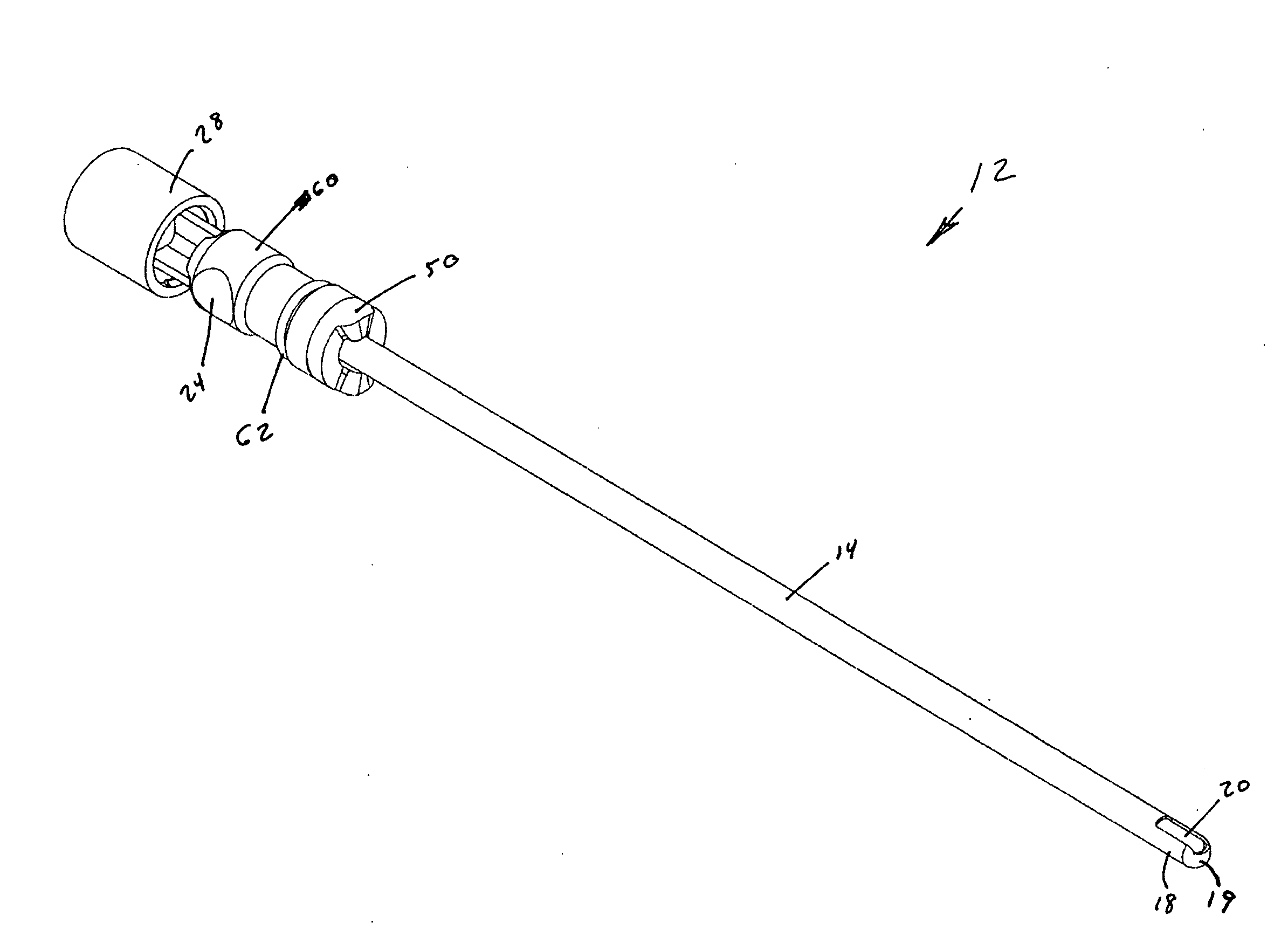

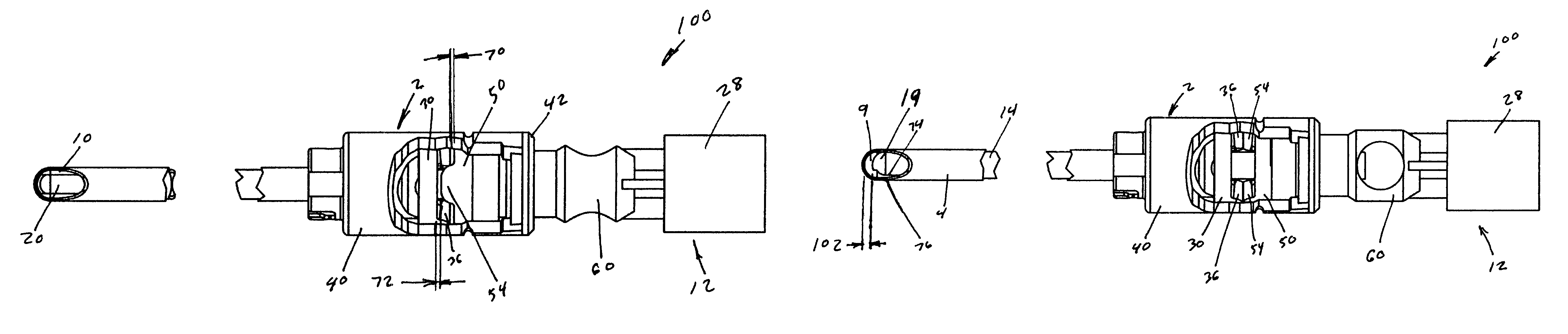

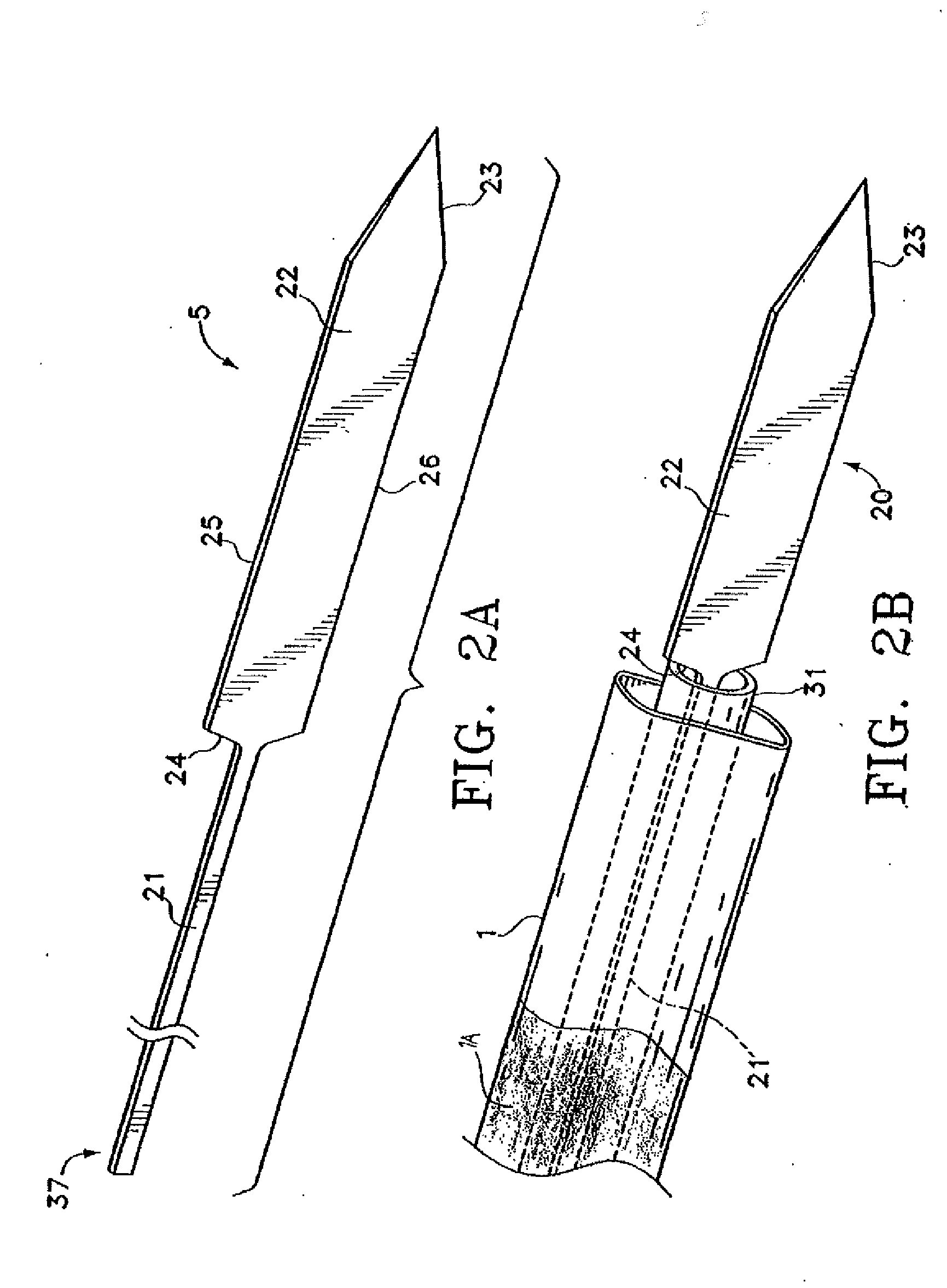

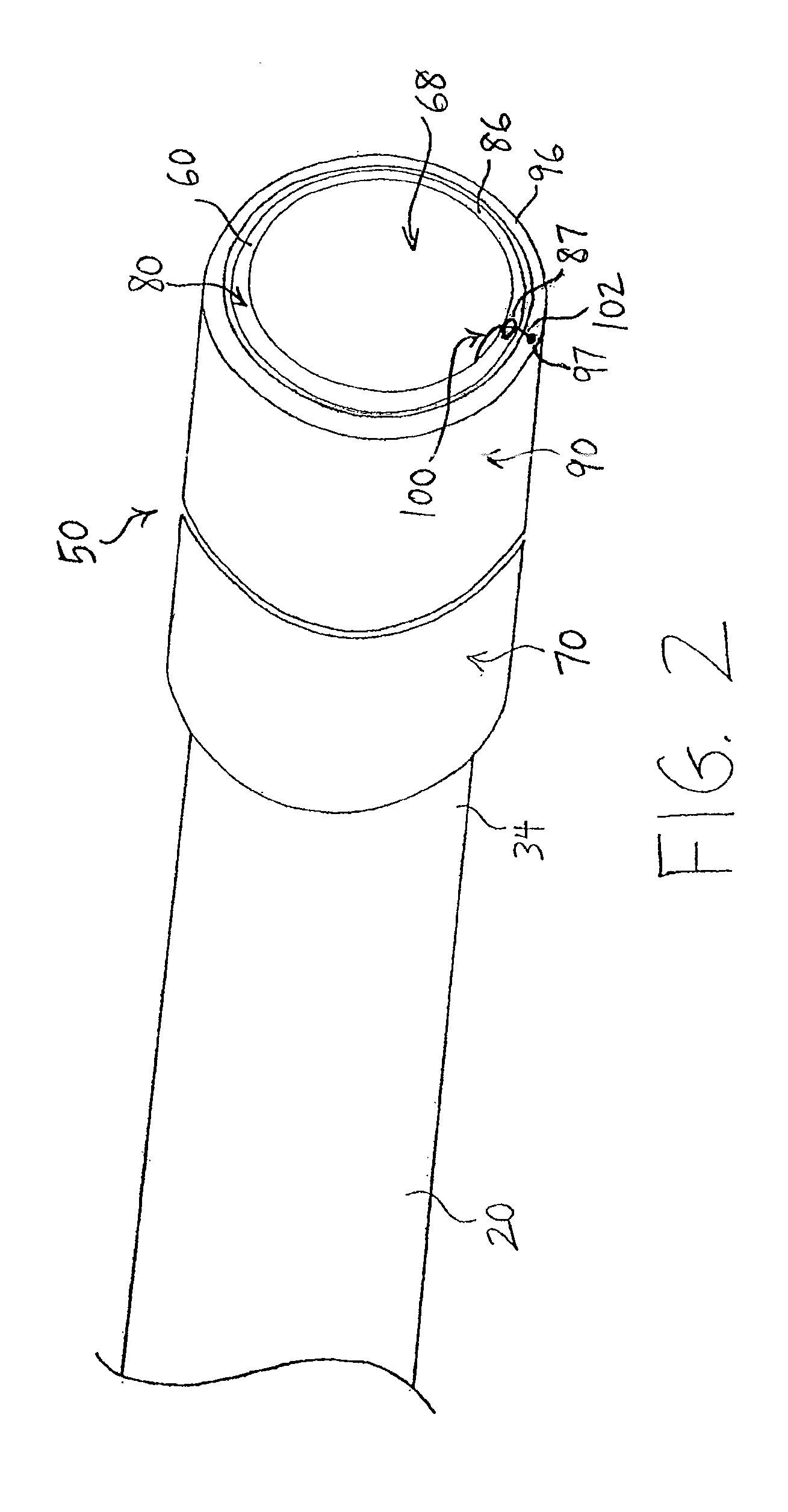

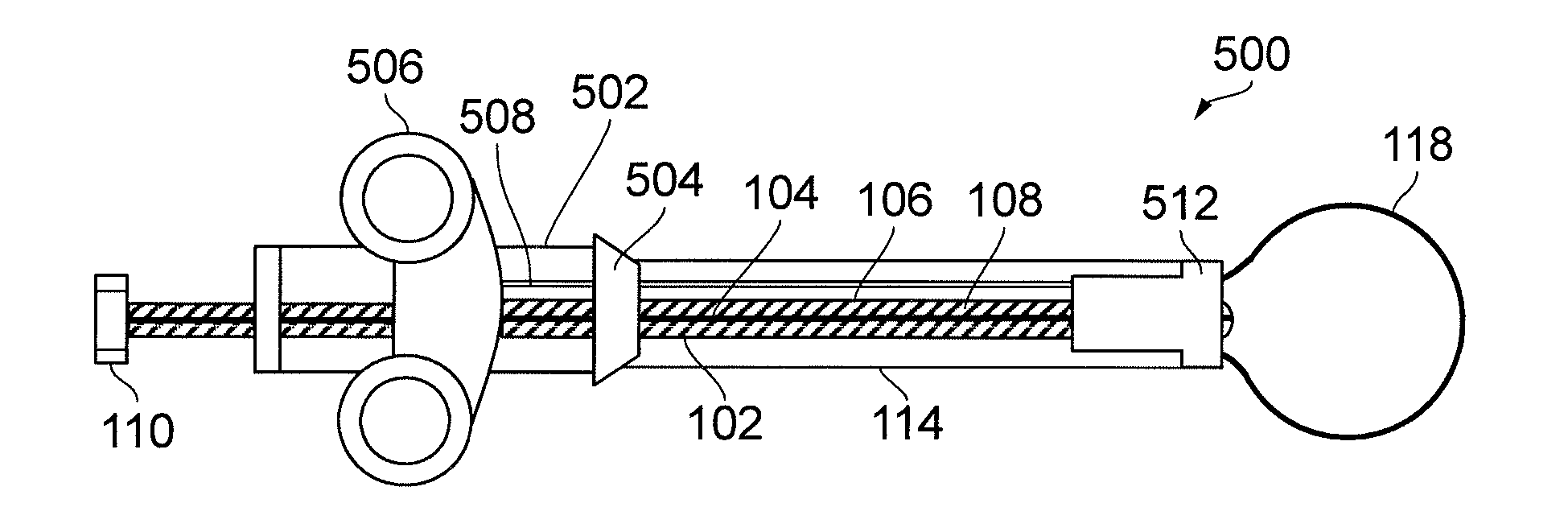

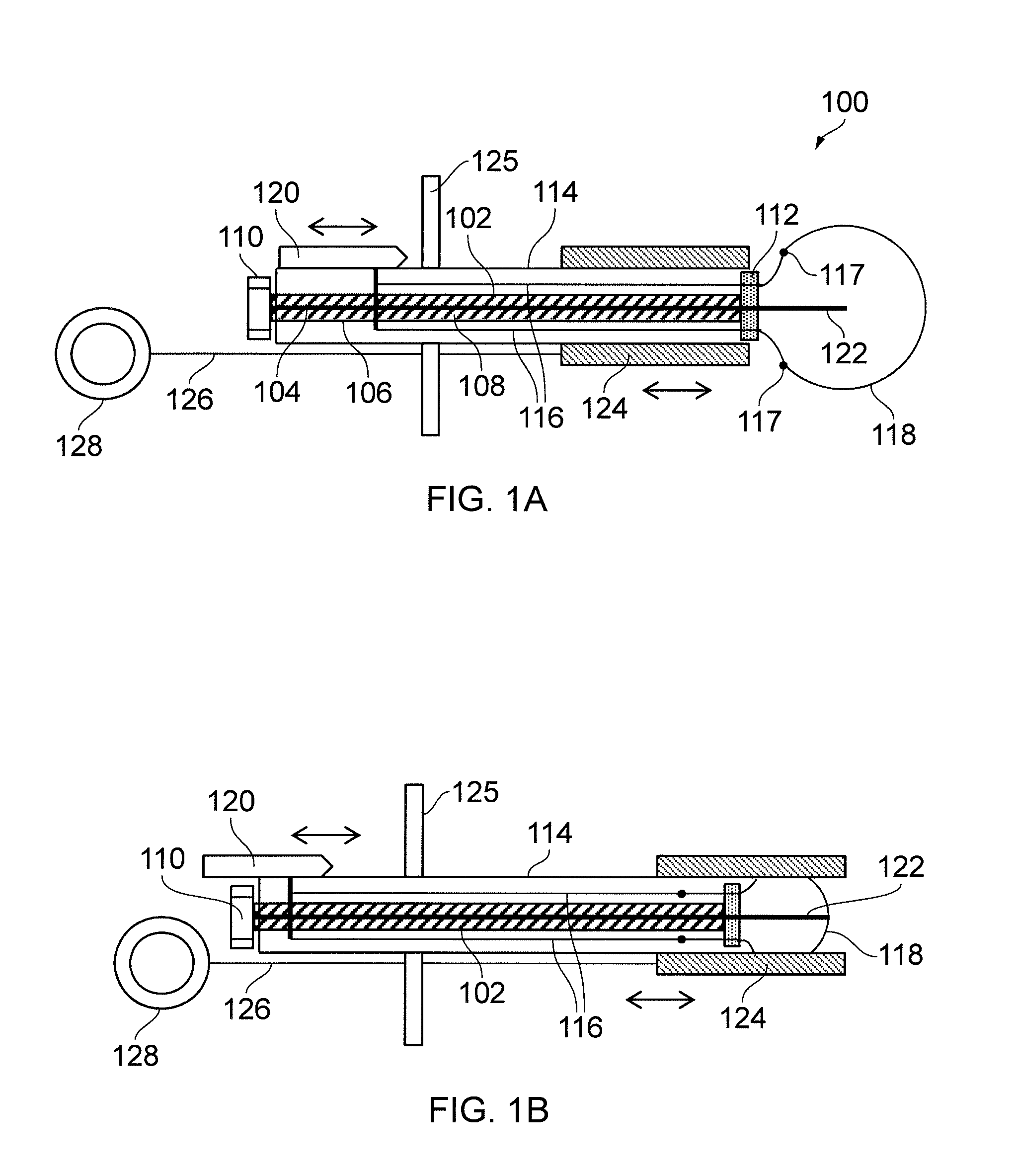

Endoscopic cutting instrument with axial and rotary motion

InactiveUS20080021487A1Improve cutting efficiencyIncrease relative motionExcision instrumentsEndoscopic cutting instrumentsEngineeringEndoscope

Owner:TARGET MEDICAL INNOVATIONS

Endoscopic cutting instrument with axial and rotary motion

InactiveUS7666200B2Improve cutting efficiencyIncrease relative motionExcision instrumentsEndoscopic cutting instrumentsEngineeringEndoscope

Owner:TARGET MEDICAL INNOVATIONS

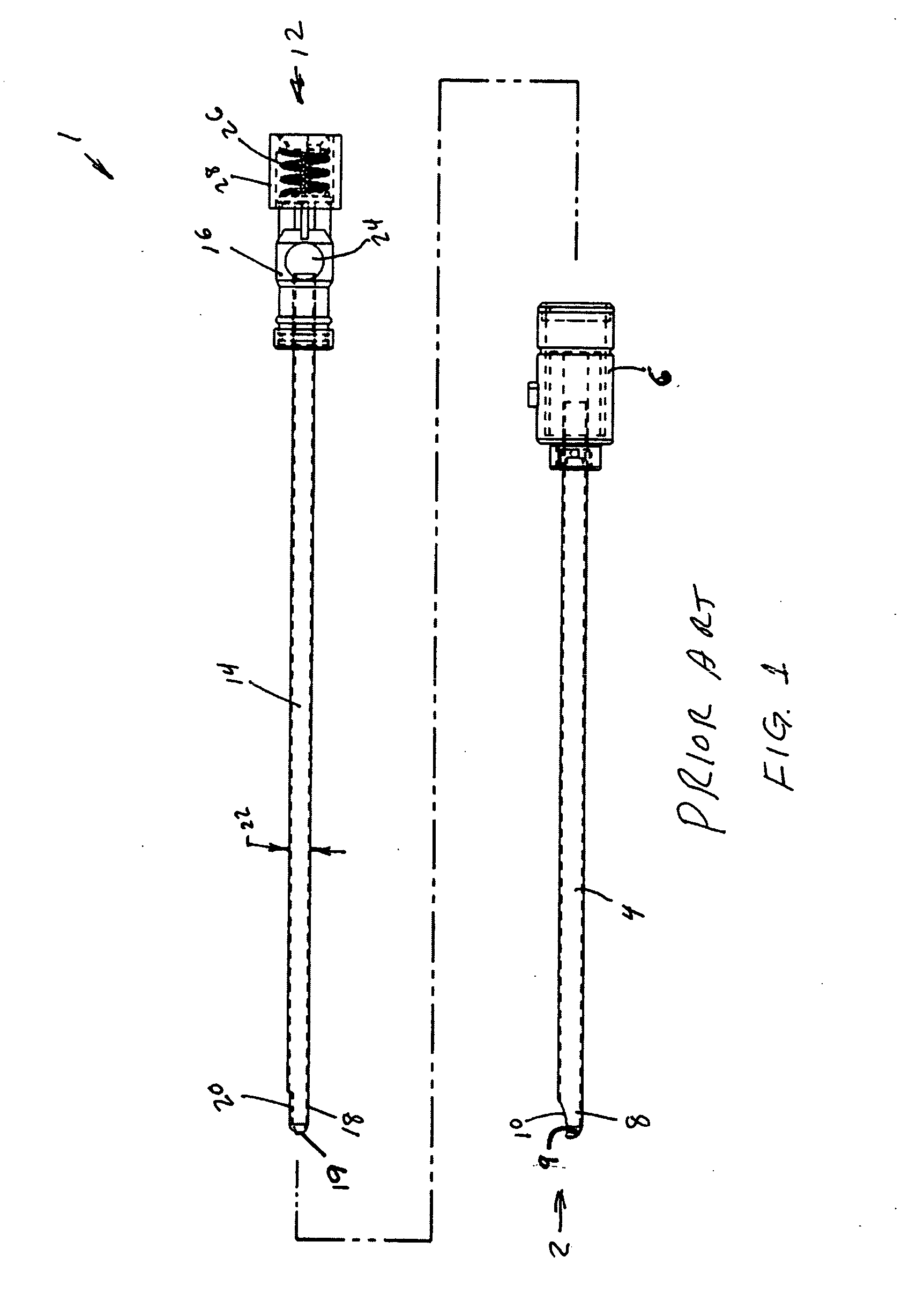

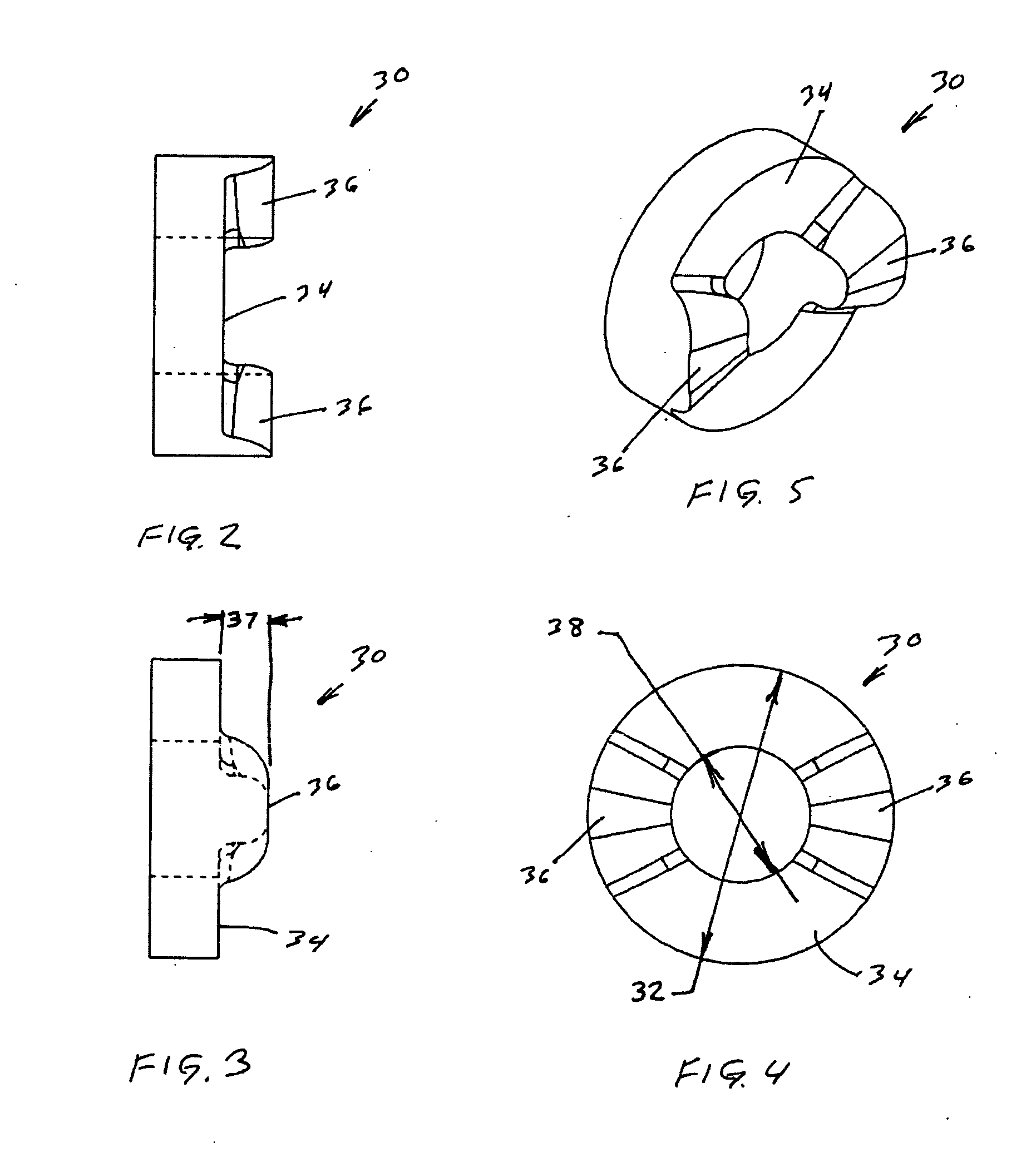

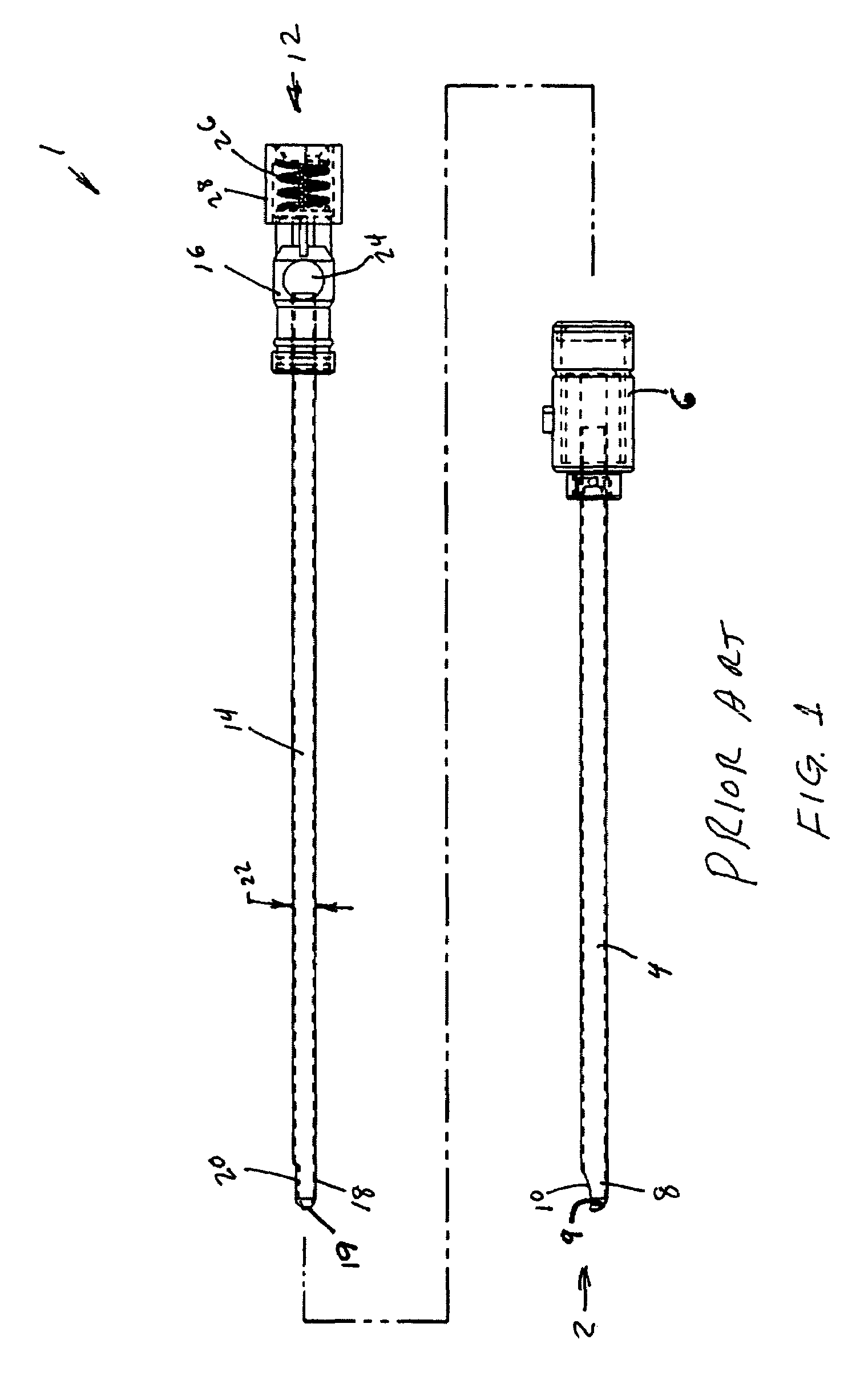

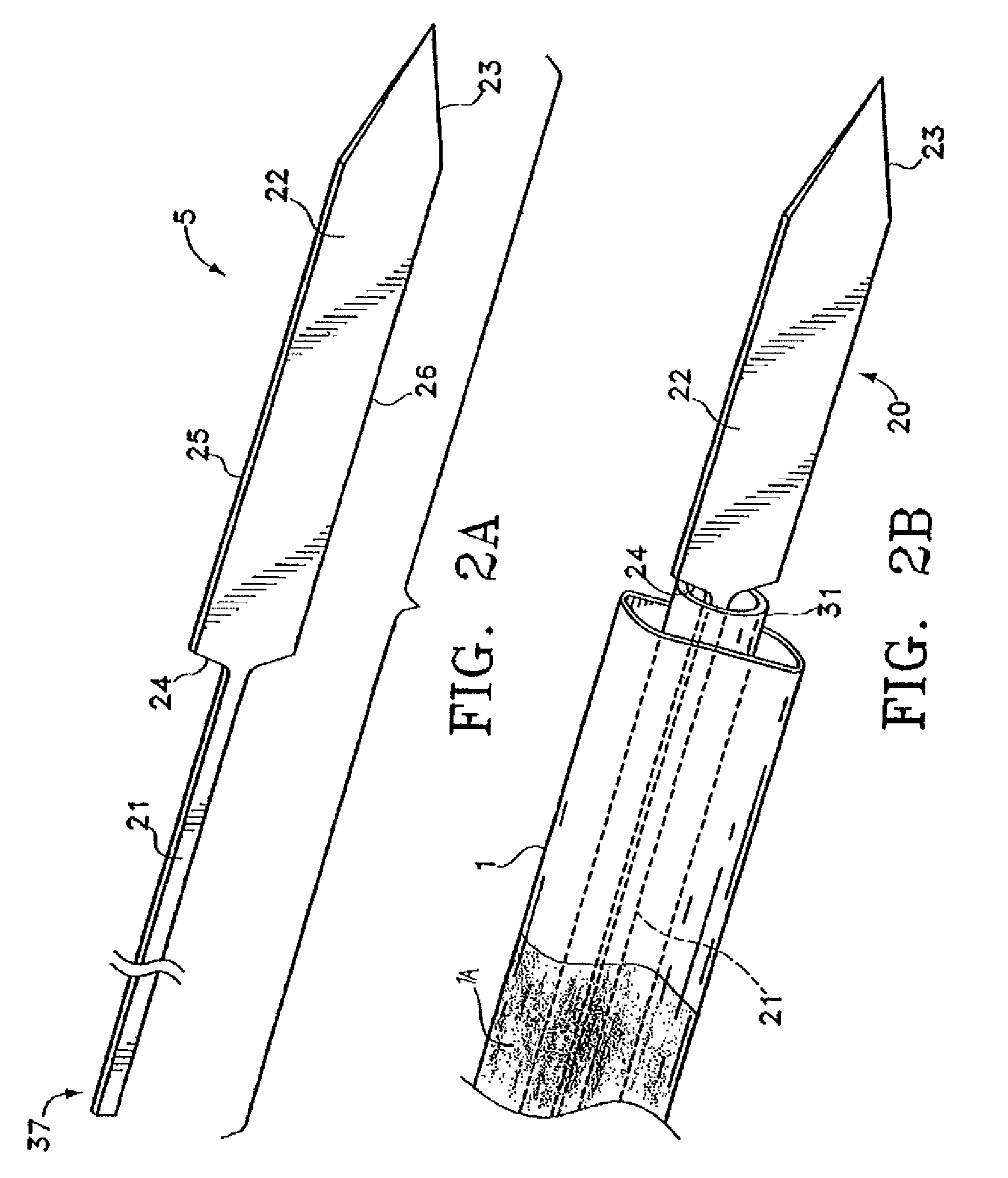

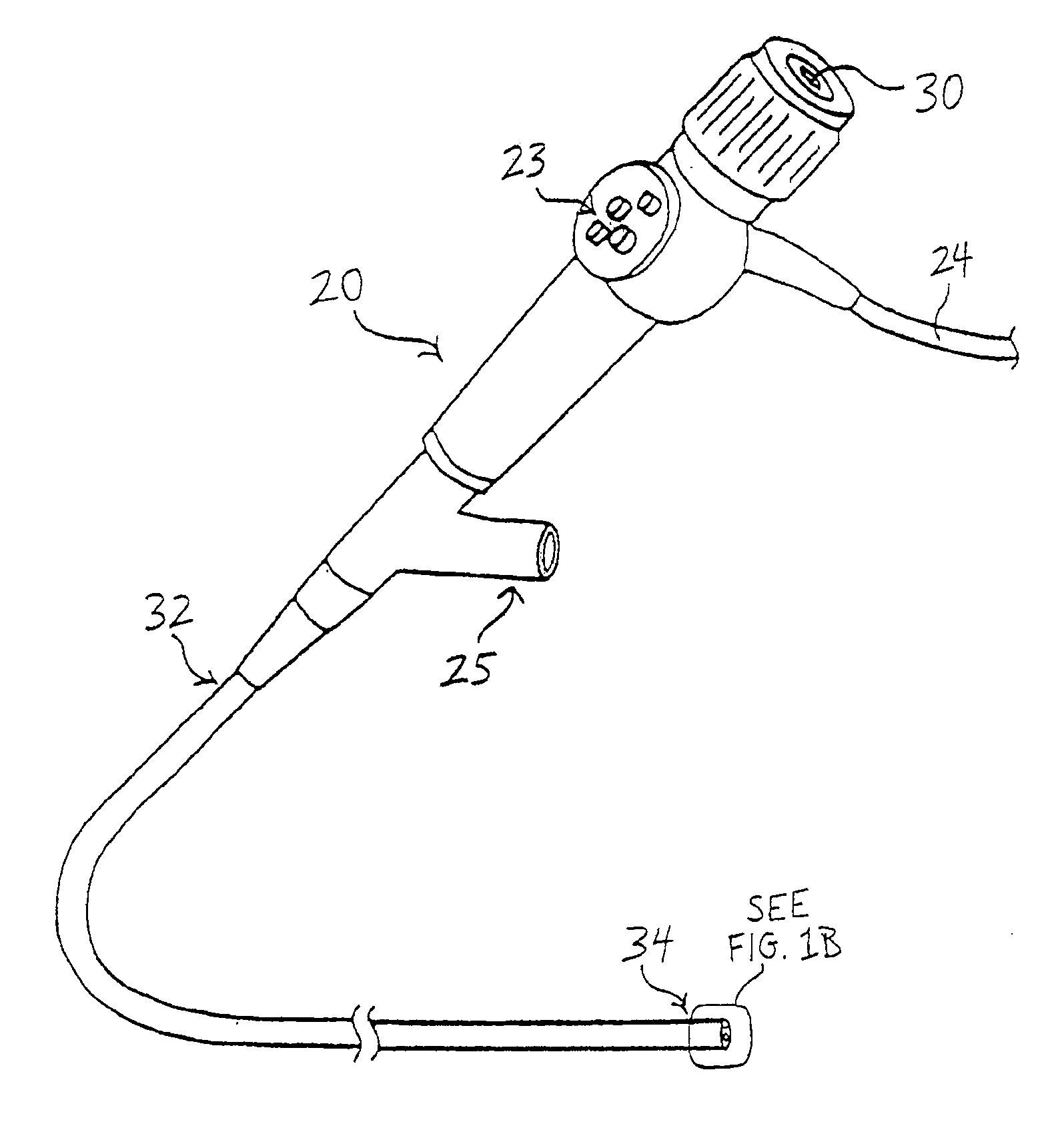

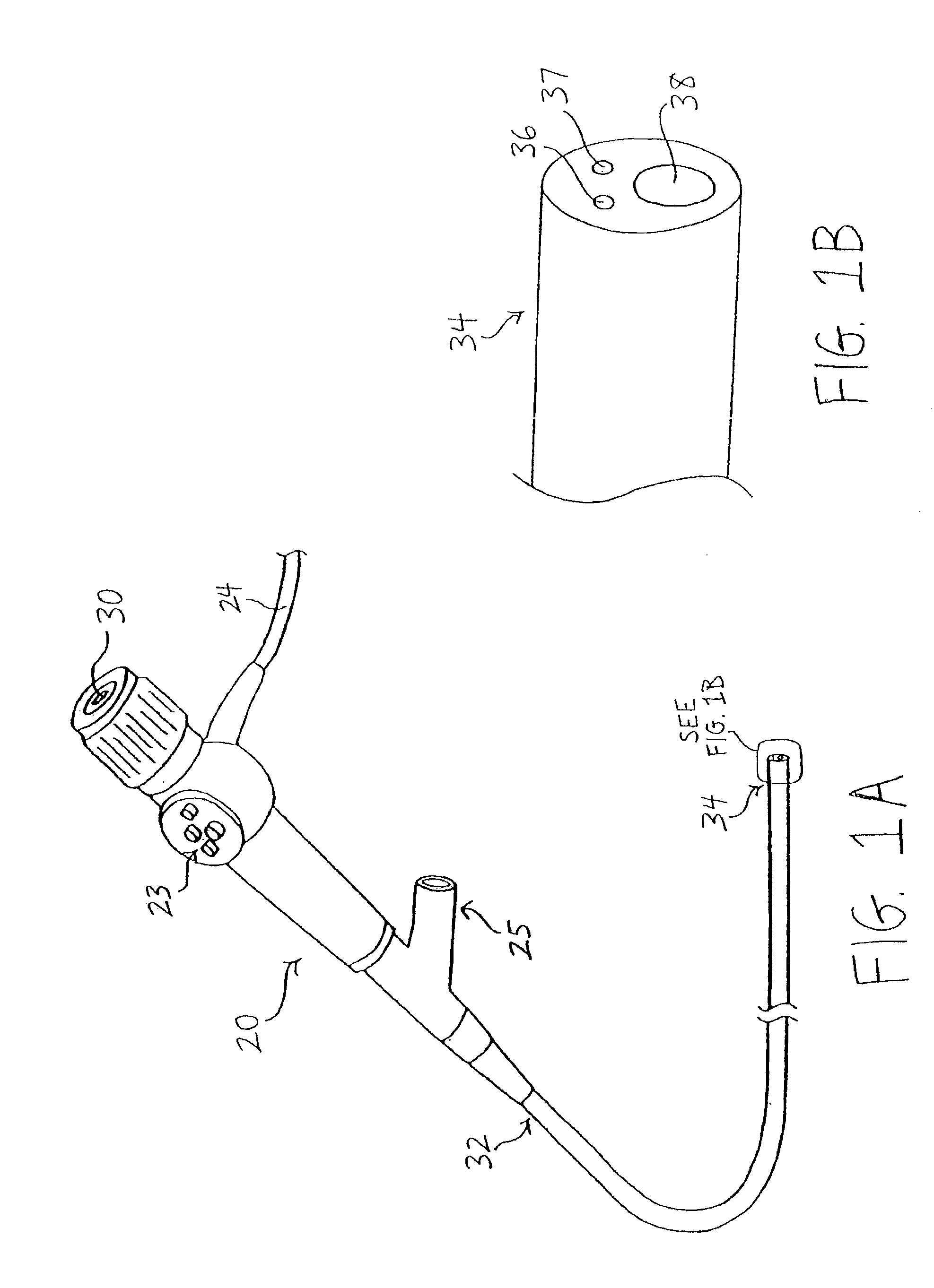

Localization element with energized tip

InactiveUS7468042B2Adequate movementLarge movementSurgical needlesVaccination/ovulation diagnosticsElectricityPower flow

This invention is an improved tissue-localizing device with an electrically energized locator element for fixedly yet removably marking a volume of tissue containing a suspect region for excision. The electrical energizing of the locator element facilitates the penetration of the locator element in to subject's tissue and minimizes resistance due to dense or calcified tissues. At least one locator element is deployed into tissue and assumes a predetermined curvilinear shape to define a tissue border containing a suspect tissue region along a path. Multiple locator elements may be deployed to further define the tissue volume along additional paths defining the tissue volume border that do not penetrate the volume. Delivery of electric current may be achieved through monopolar or bipolar electronic configuration depending on design needs. Various energy sources, e.g. radio frequency, microwave or ultrasound, may be implemented in this energized tissue-localizing device.

Owner:TYCO HEALTHCARE GRP LP

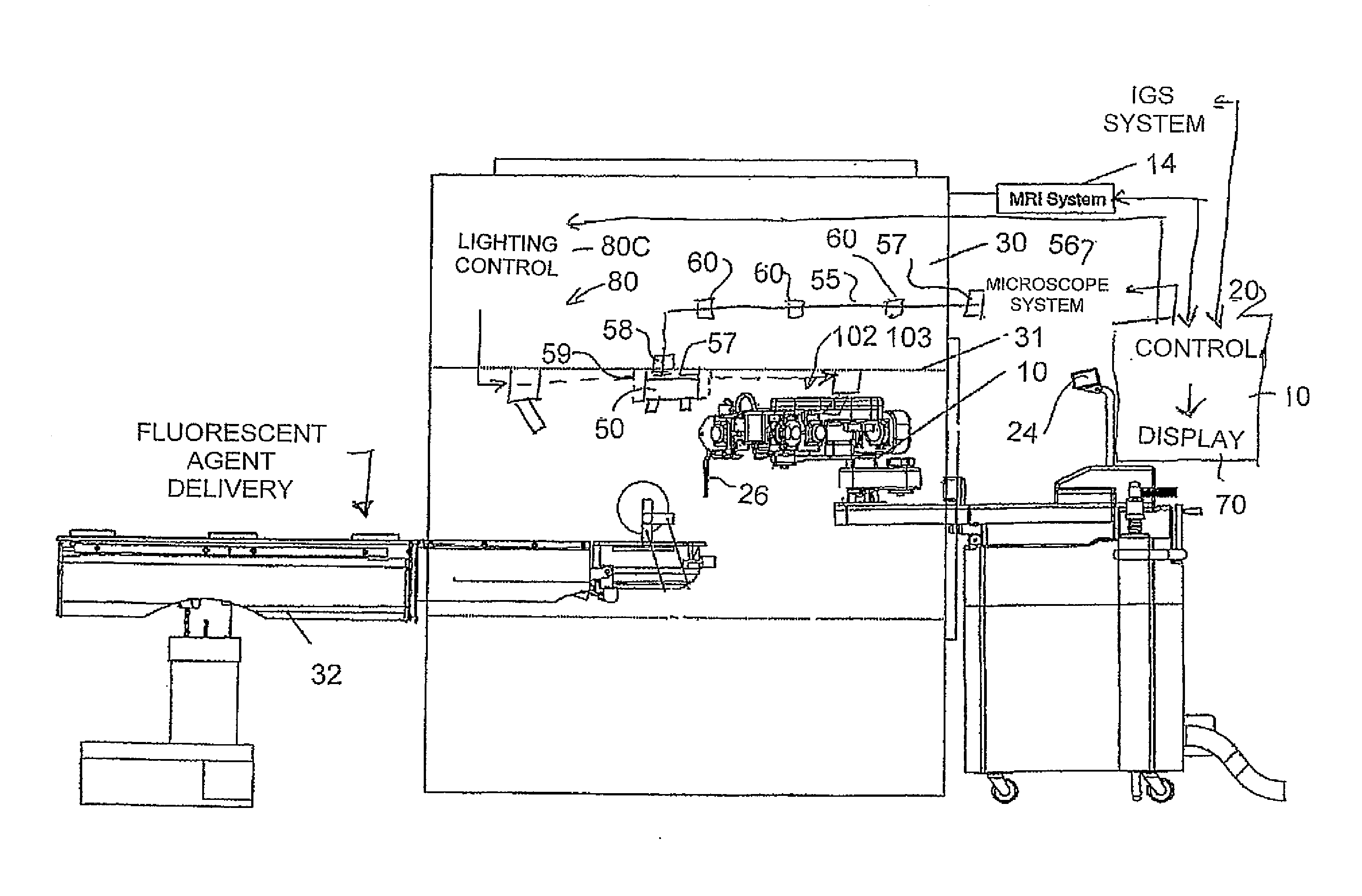

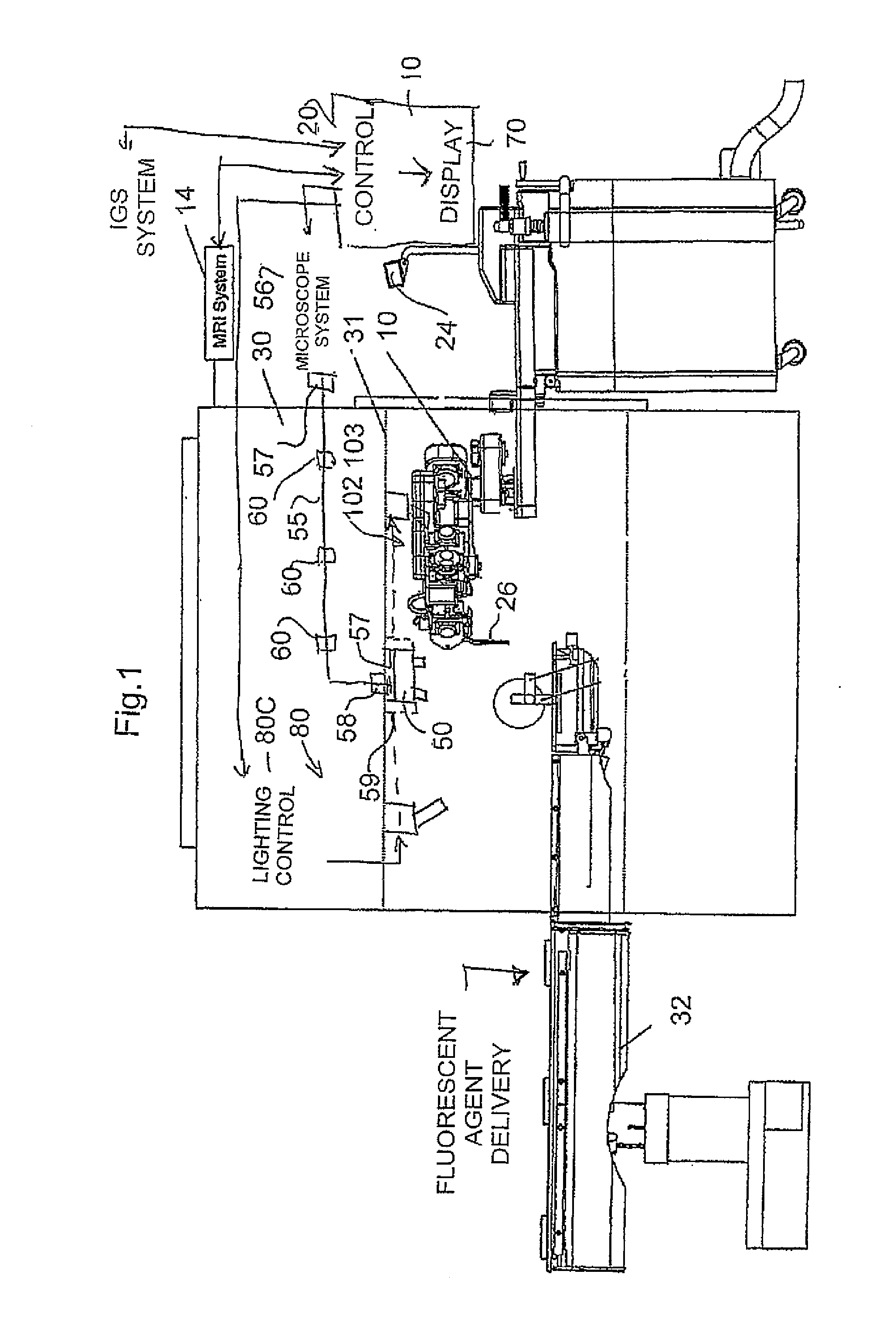

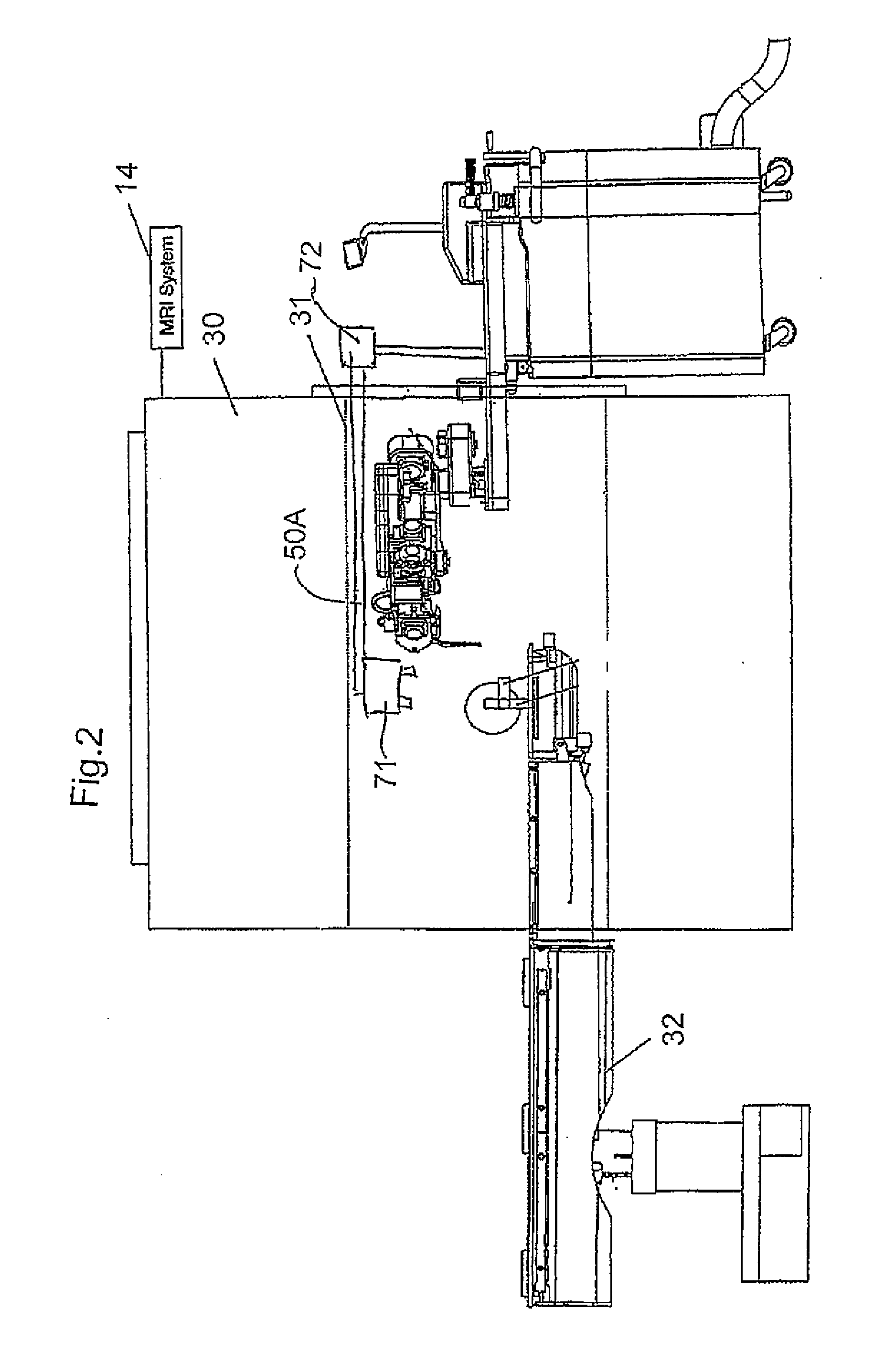

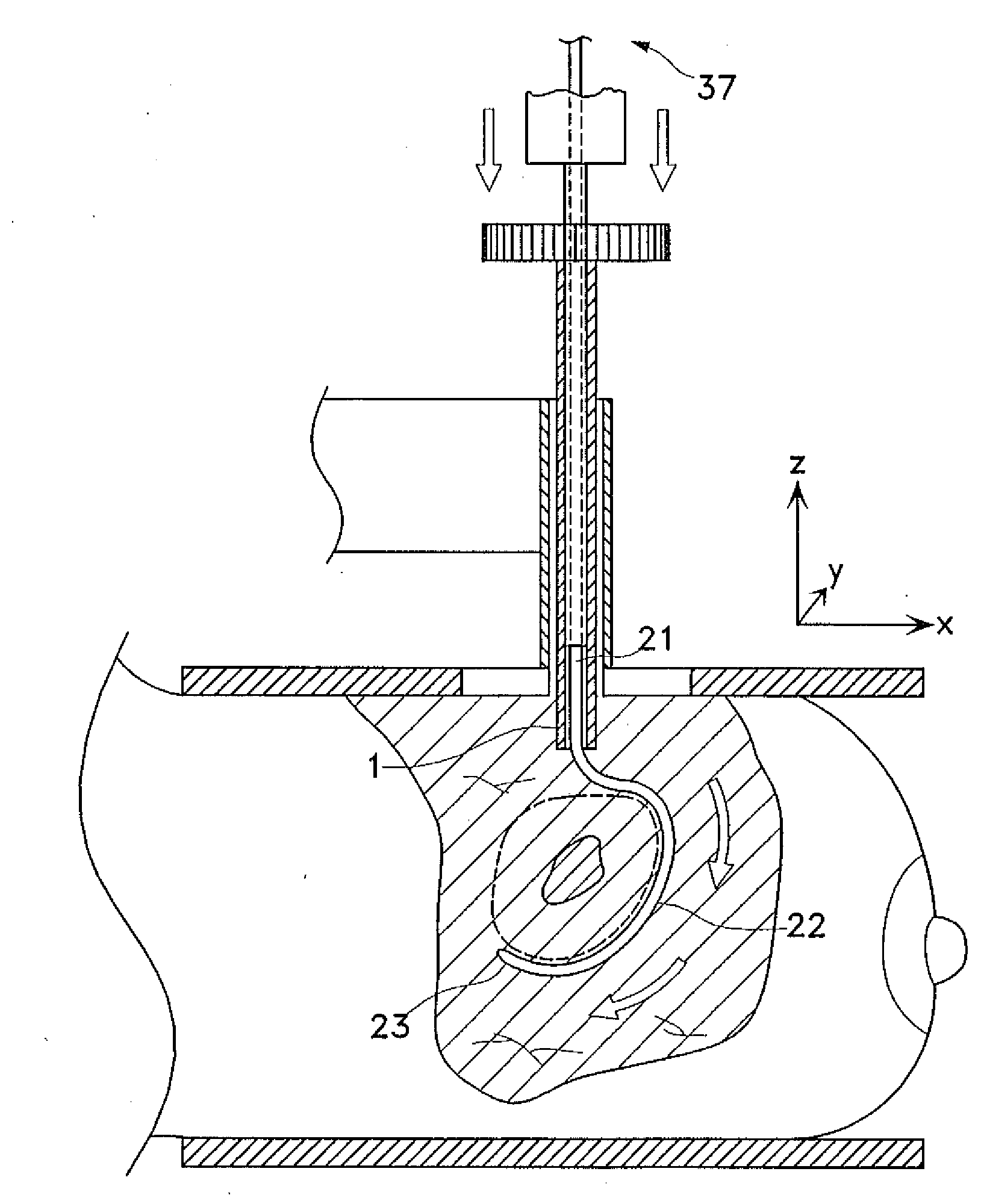

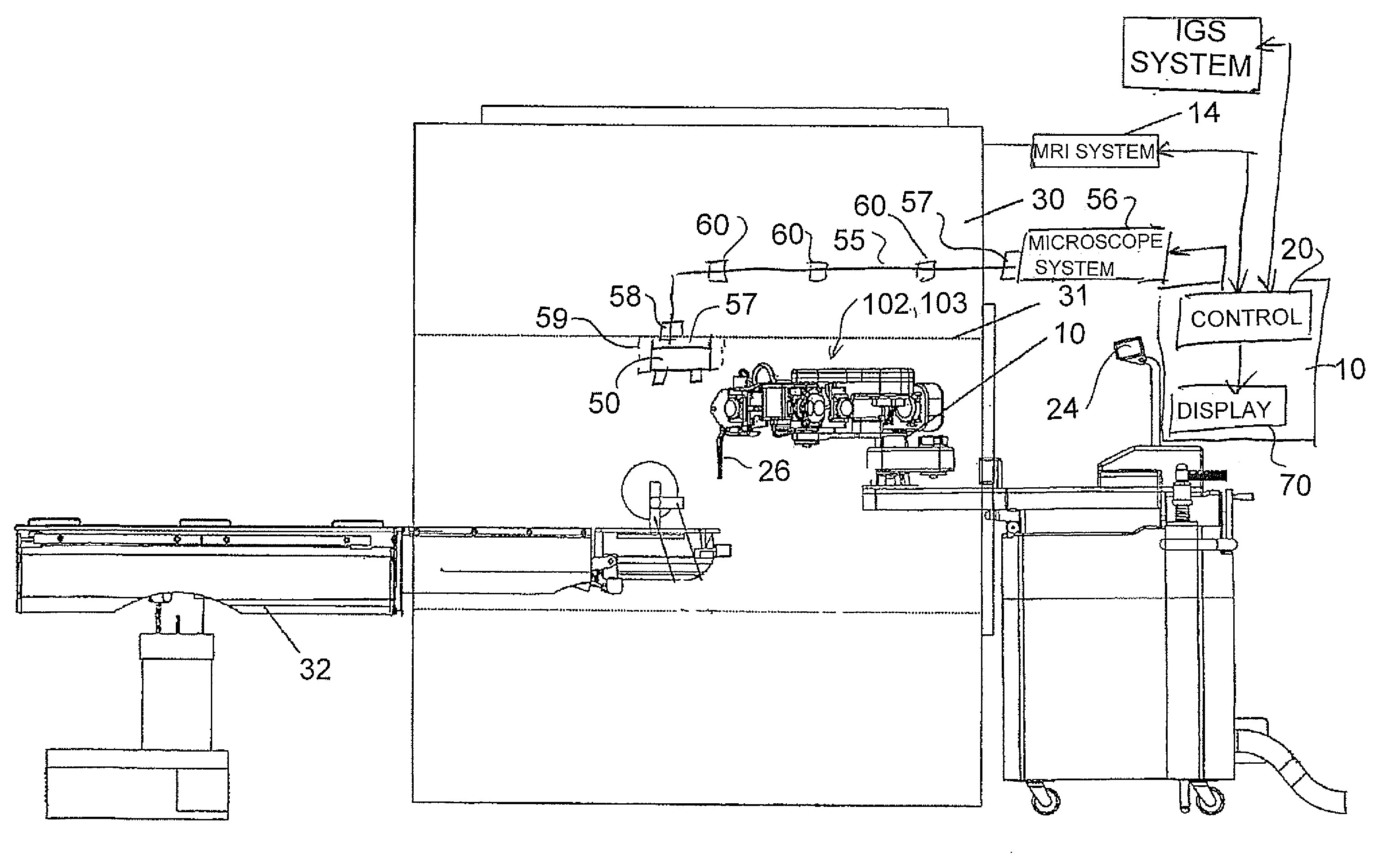

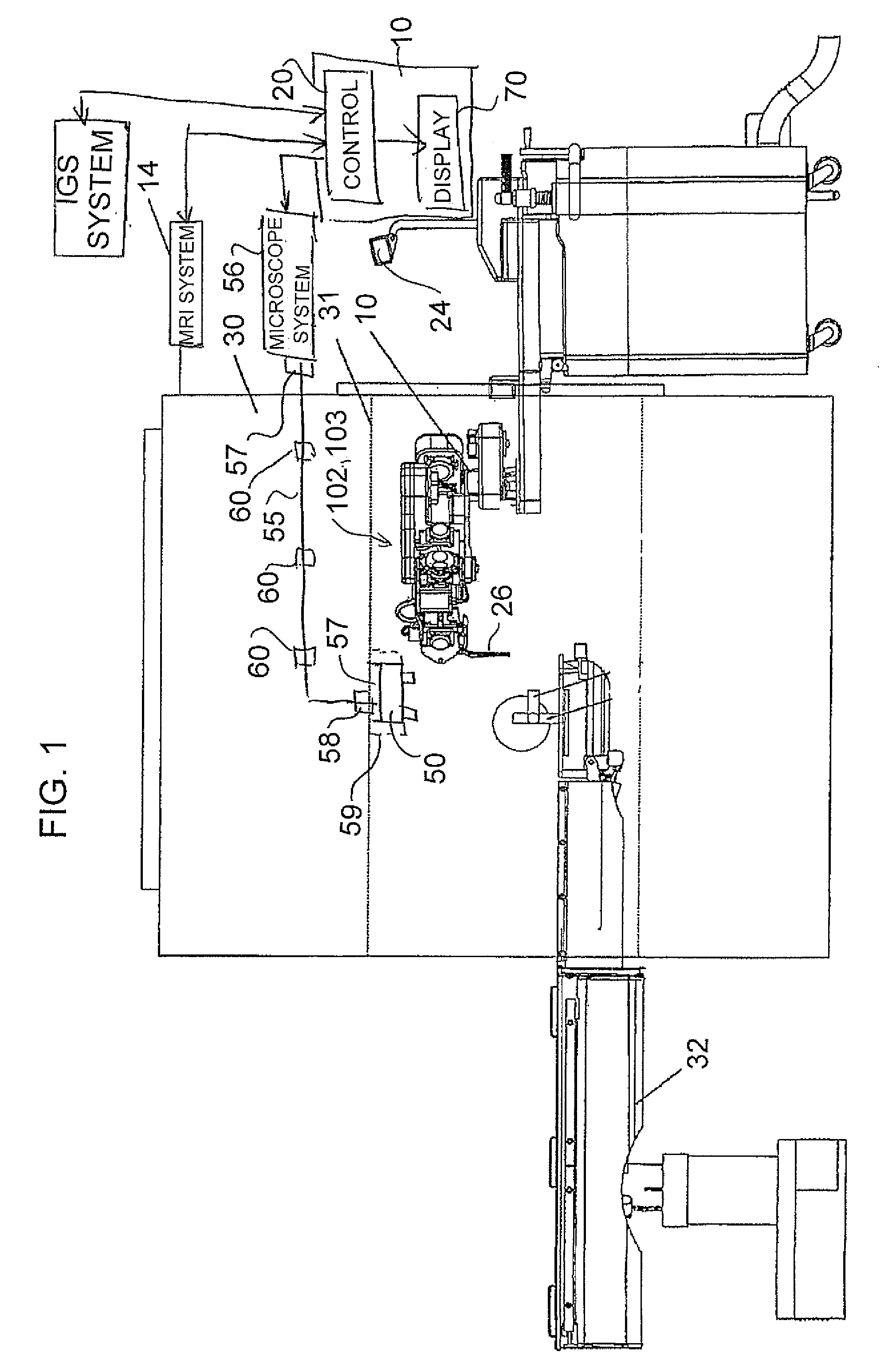

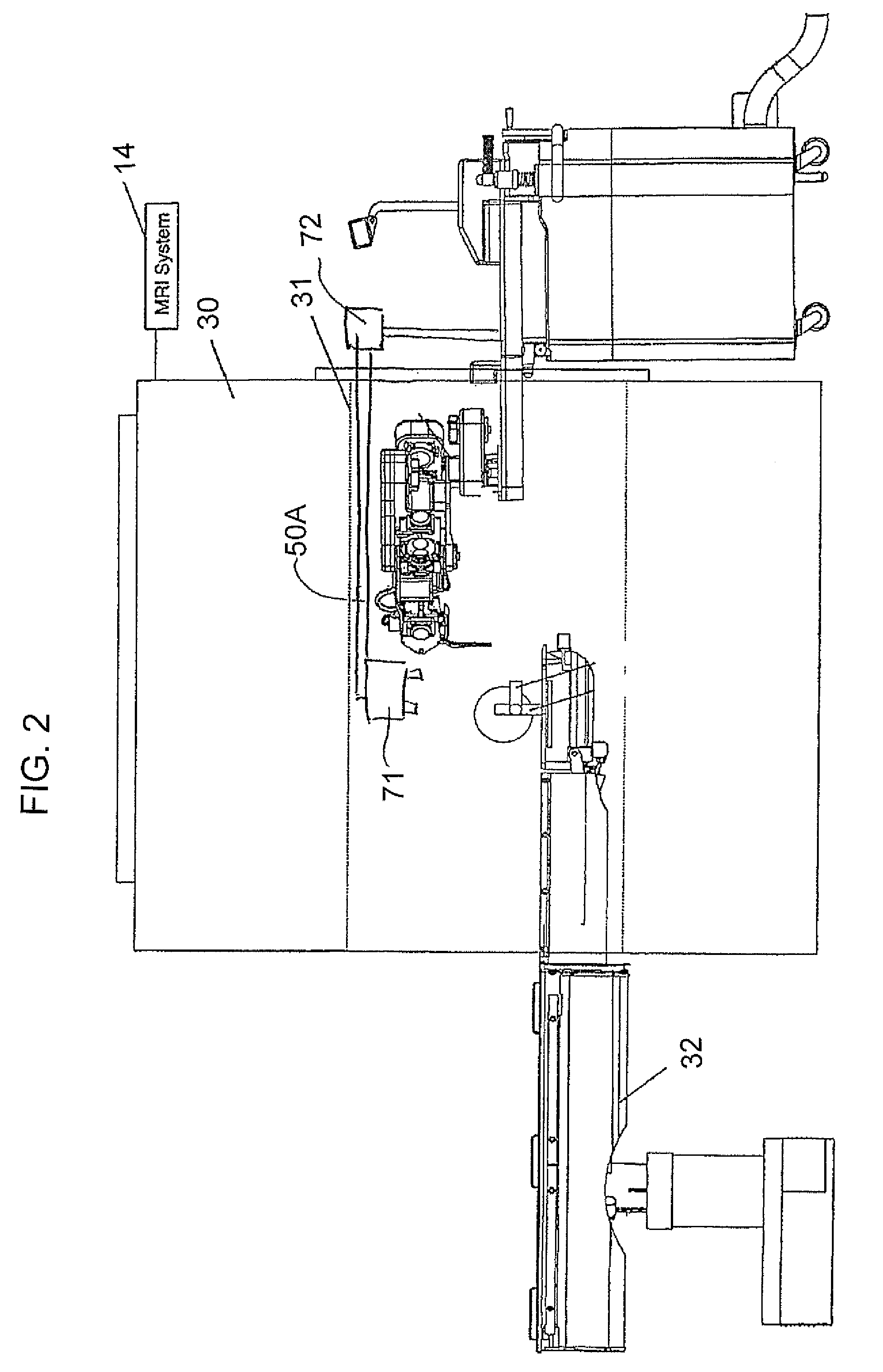

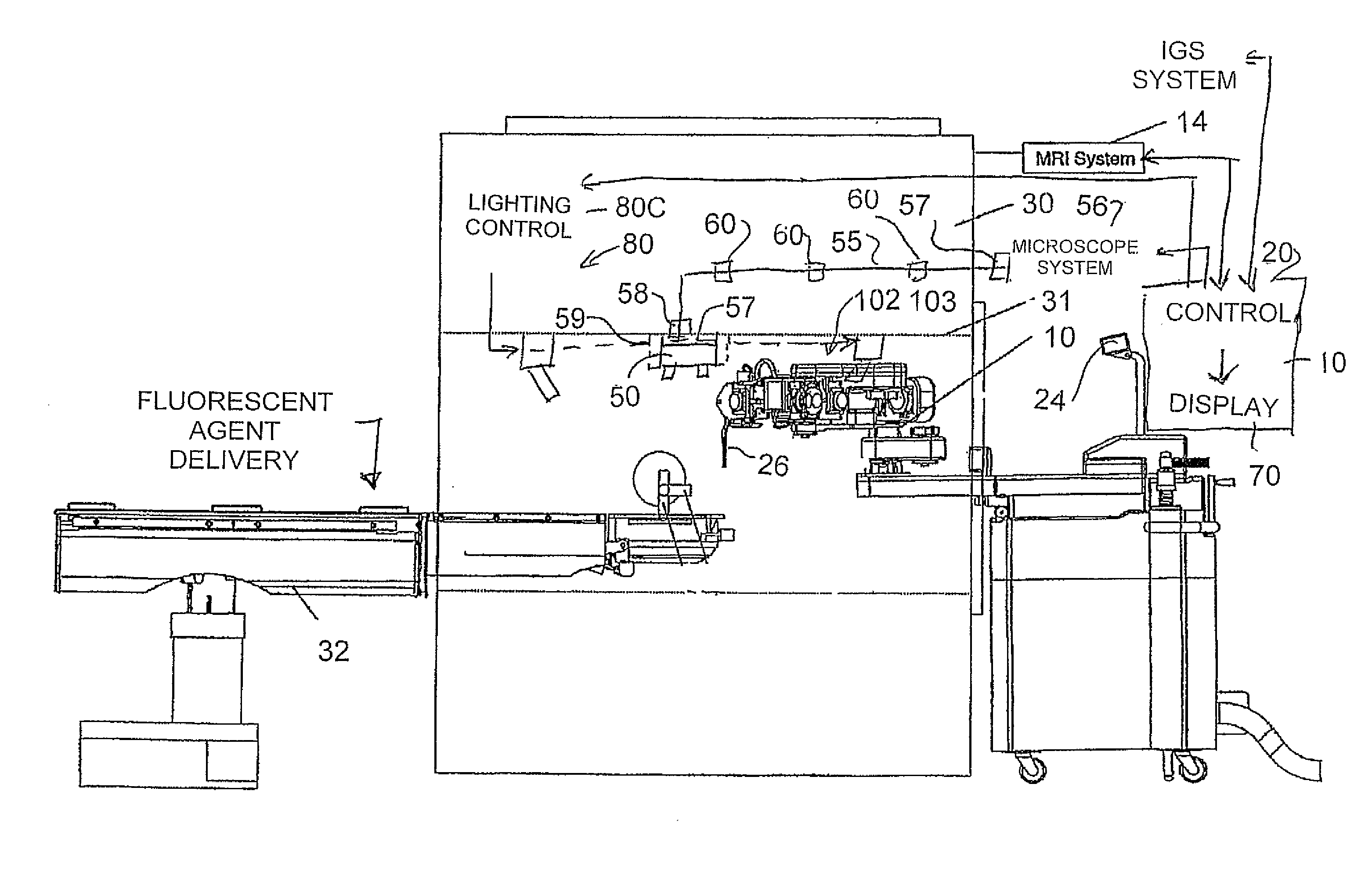

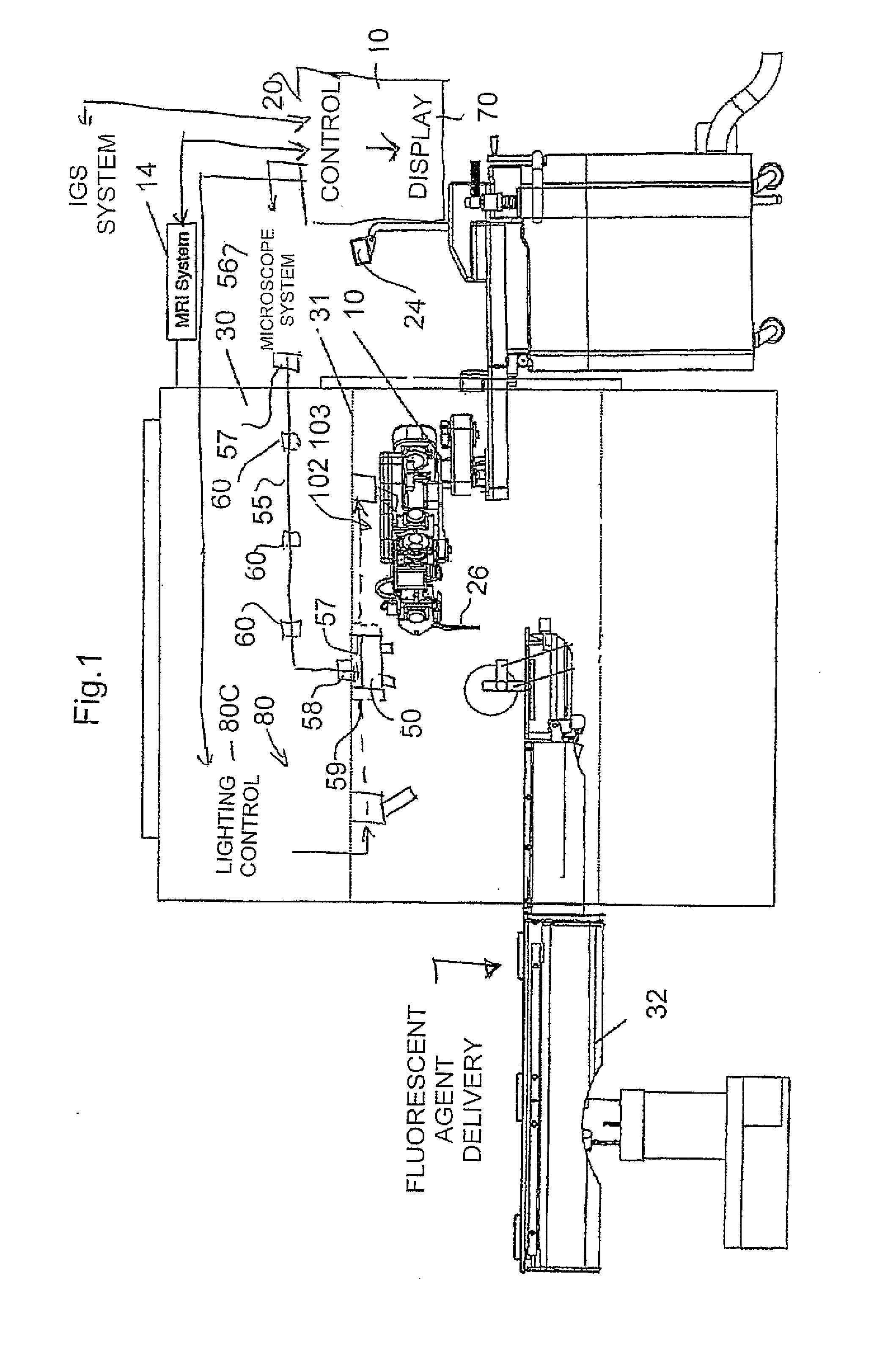

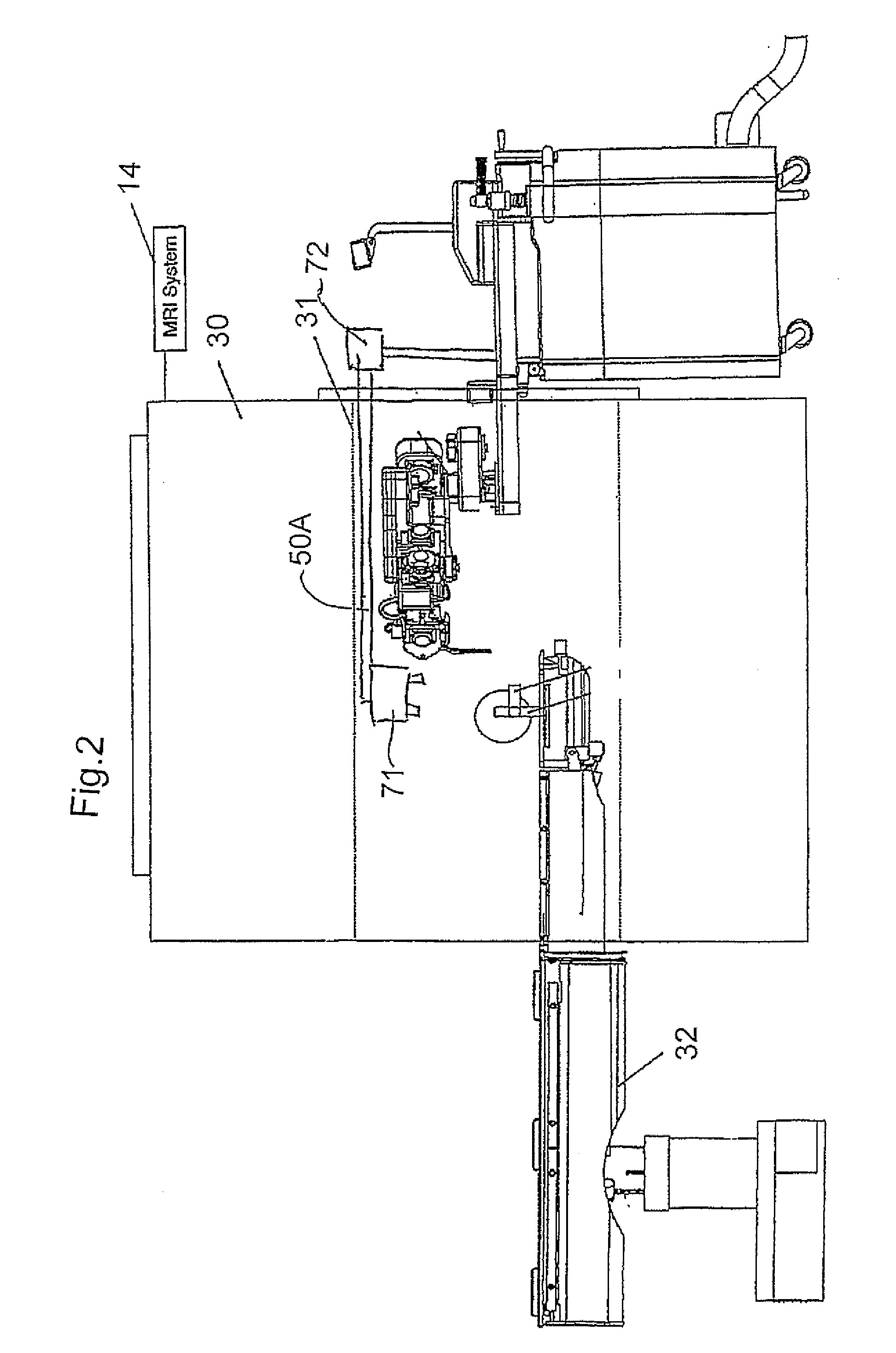

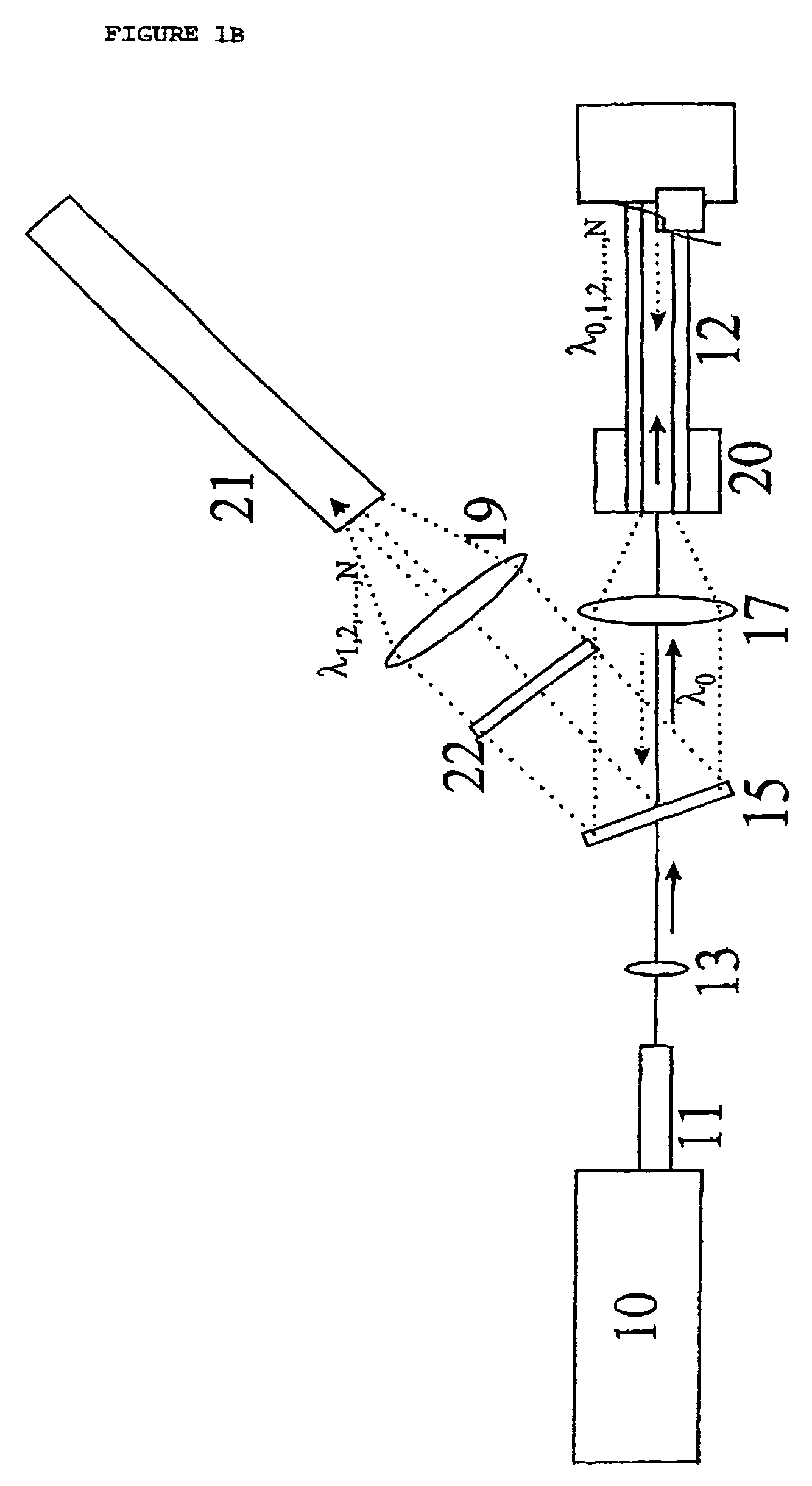

MR Compatible Fluorescence Viewing Device for Use in the Bore of an MR Magnet

InactiveUS20150073433A1Easy resectionDecreased neurological deficitMagnetic measurementsDiagnostics using fluorescence emission3d imageFluorescence

In an MR guided surgical system which is carried out in the bore of an MR magnet and uses fluorescence to detect tumor cells, there is provided a microscope system for viewing the required part of a patient which includes stereoscopic viewing components arranged for use in generating 2D and 3D images displayed to the surgeon. The optical assembly is adjustable to change the view and the visual images are overlaid by the MR images. The visual image can be adjusted in response to movement of the surgical tool and the MR image displayed and / or the image obtained can be modified in response to change in the visual image and / or movement of the tool. The components in the bore are made compatible with the MR environment. A fluorescence delivery system is operated to automatically activate the delivery system in response to detection of the level of fluorescence.

Owner:IMRIS

Localization Element with Energized Tip

InactiveUS20090149850A1Easy to deployEasy to integrateSurgical needlesVaccination/ovulation diagnosticsElectricityMicrowave

This invention is an improved tissue-localizing device with an electrically energized locator element for fixedly yet removably marking a volume of tissue containing a suspect region for excision. The electrical energizing of the locator element facilitates the penetration of the locator element in to subjects tissue and minimizes resistance due to dense or calcified tissues. At least one locator element is deployed into tissue and assumes a predetermined curvilinear shape to define a tissue border containing a suspect tissue region along a path. Multiple locator elements may be deployed to further define the tissue volume along additional paths defining the tissue volume border that do not penetrate the volume. Delivery of electric cut-rent may be achieved through monopolar or bipolar electronic configuration depending on design needs. Various energy sources, e.g., radio frequency, microwave or ultrasound, may be implemented in this energized tissue-localizing device.

Owner:TYCO HEALTHCARE GRP LP

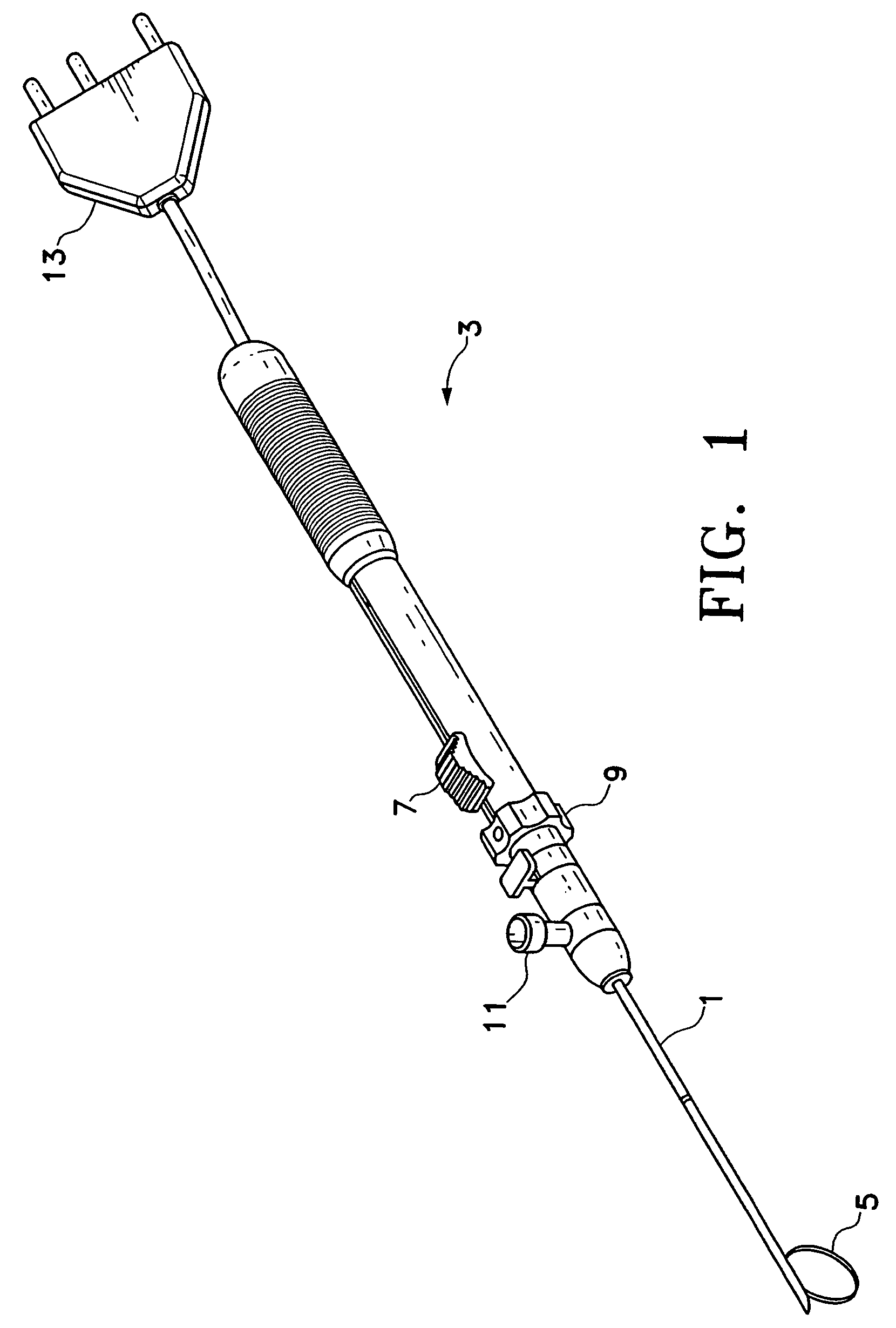

Endoscopic systems and methods for resection of tissue

ActiveUS20130158546A1Quick to useEnhanced tissue biopsySurgical needlesEndoscopesEndoscopic resectionEndoscopy

The present embodiments provide apparatus and methods for facilitating endoscopic resection of tissue. In one embodiment, the apparatus comprises a first tube having proximal and distal regions, and a working lumen disposed within at least a portion of the distal region. A second tube is disposed circumferentially around at least a portion of the distal region of the first tube. A wire has a distal end that is securely attached to a distal region of the second tube. In use, rotation of the second tube relative to the first tube causes the wire to pass circumferentially over a distal face of the first tube to incise tissue disposed within the working lumen of the first tube.

Owner:COOK MEDICAL TECH LLC

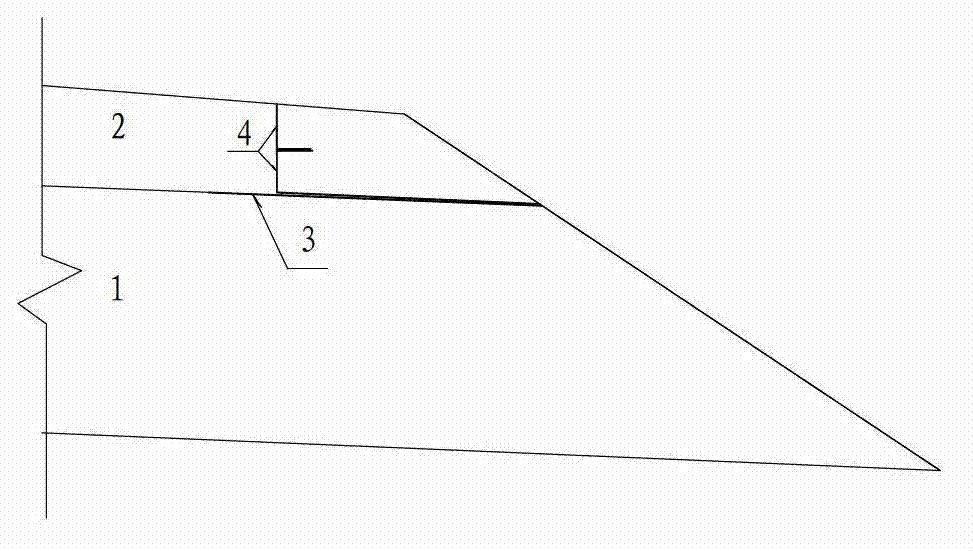

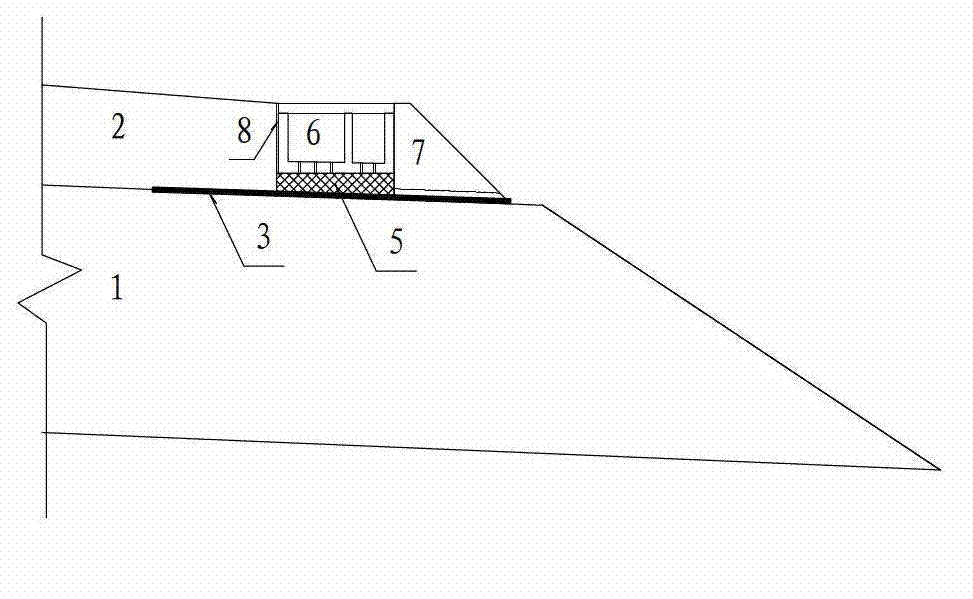

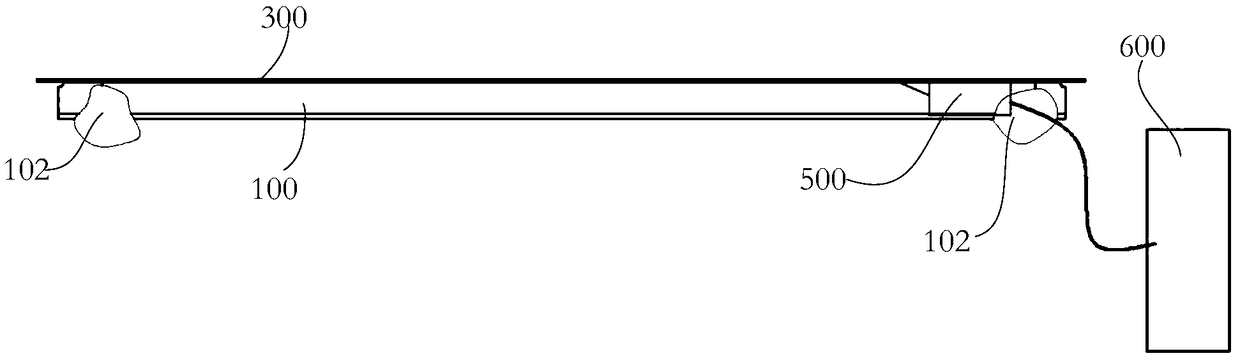

High-speed railroad shoulder and drainage structure

The invention relates to a high-speed railroad shoulder and drainage structure, which aims to solve the problems of graded broken stone cutting at the position of a high-speed railroad shoulder cable channel and effective draining of seepage water in the cable channel, avoid problems of difficult cutting and irregular cutting of graded broken stones at the position of the railroad shoulder cable channel as well as the problem that stability and sedimentation of the filling subgrade are influenced by poor seepage water drainage in the cable channel. The high-speed railroad shoulder and drainage structure comprises a subgrade bed bottom layer filled on the ground or a subgrade body, a subgrade bed surface layer filled on the top of the subgrade bed bottom layer and a cable channel arranged at a railroad shoulder. A composite geomembrane is laid between the subgrade bottom layer and the subgrade bed surface layer, and a geotextile is laid on the internal layer of the subgrade bed surface layer; a seepage material is arranged at the bottom part of the cable channel, and the outer side of the cable channel is provided with a subgrade protection shoulder. An asphalt board is arranged between the cable channel and the subgrade bed surface layer.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

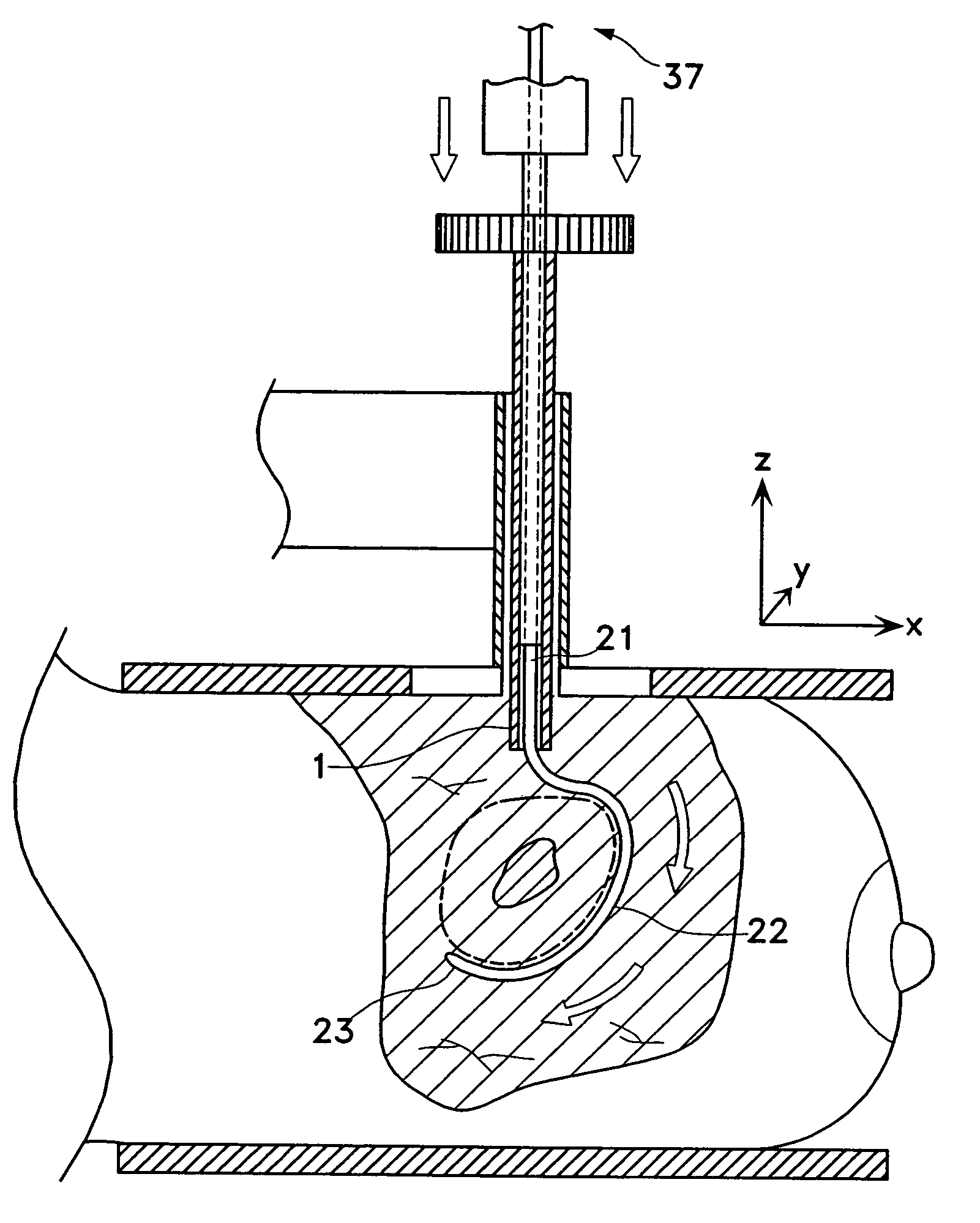

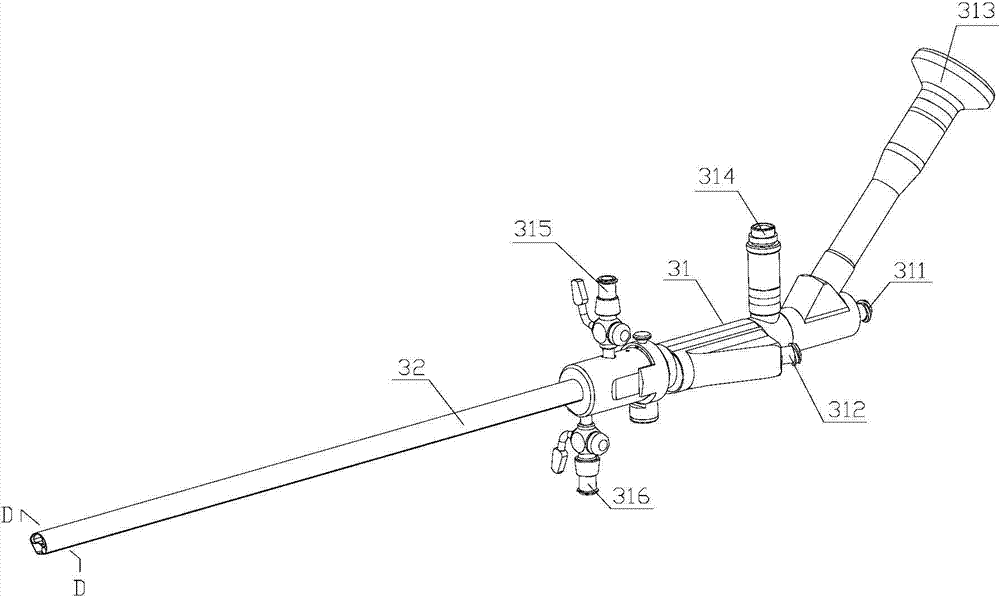

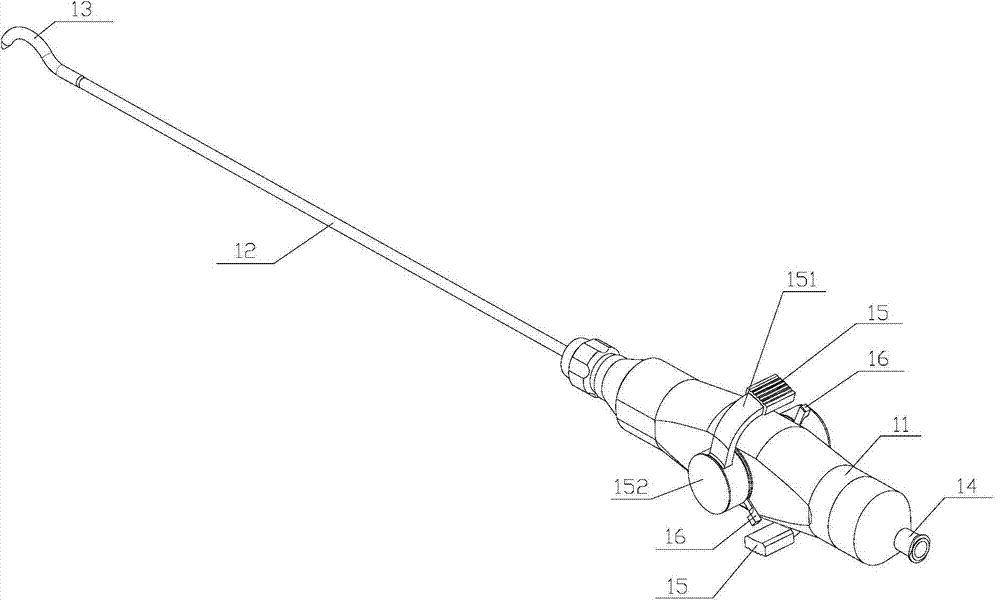

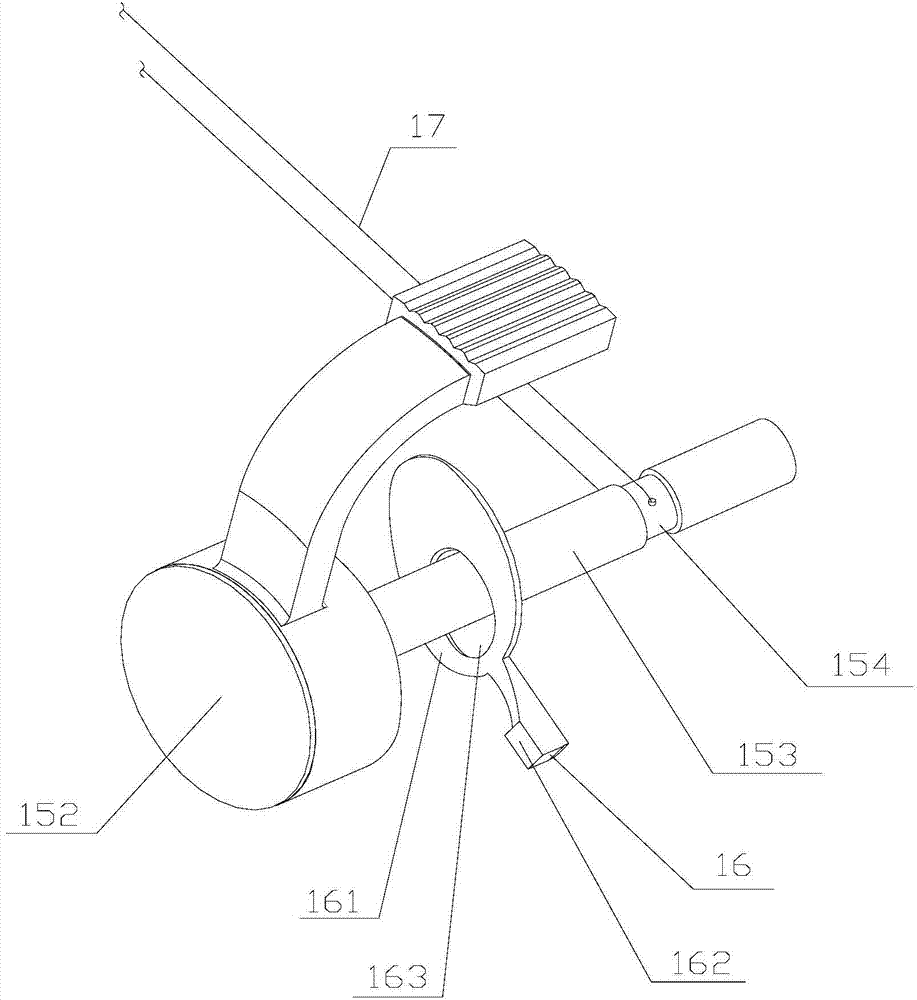

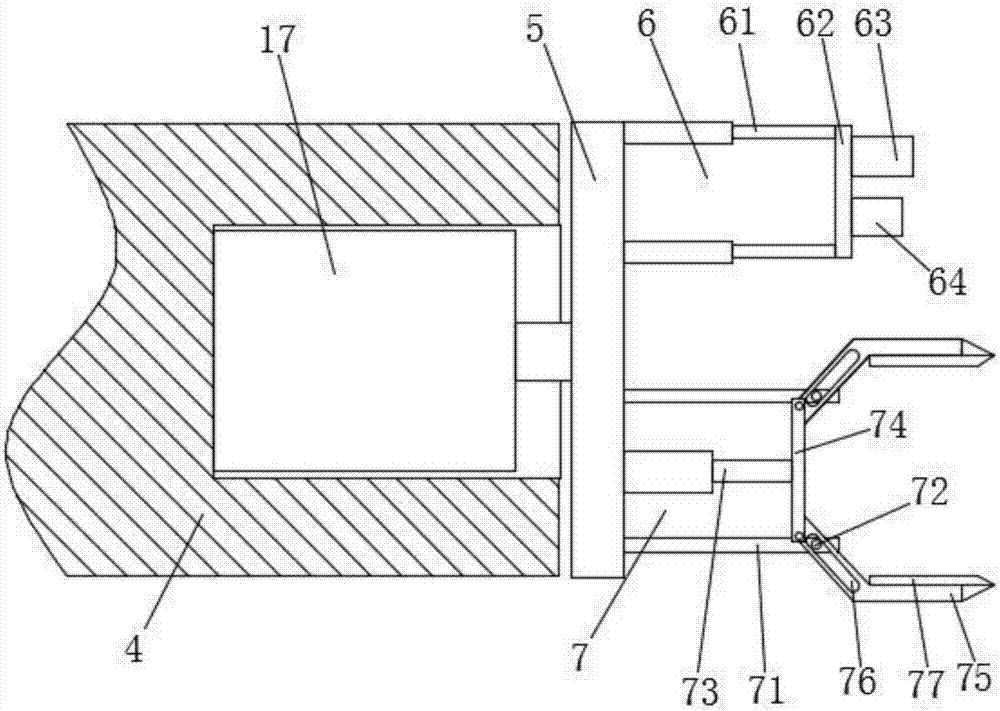

Transurethral intravesical operation instrument system for non-muscle invasive bladder cancer

InactiveCN104490467AIncrease flexibilityEasy resectionSuture equipmentsInternal osteosythesisBlind zoneEngineering

The invention relates to a transurethral intravesical operation instrument system for non-muscle invasive bladder cancer. The system comprises an endoscope with multiple passages, a) a tail end-bendable operation instrument with a bendable joint and / or b) a tail end-bendable operation instrument with a pre-bent pipe structure. According to the system, the tail end-bendable operation instrument with the bendable joint and the tail end-bendable operation instrument with the pre-bent pipe structure are independently matched with the endoscope with the multiple passages for use or the two operation instruments are simultaneously matched with the endoscope with the multiple passages for use, so that operation instrument tail ends in various shapes can be obtained, an encircling operating angle is formed, fine operation is facilitated, and an operated part can be observed in real time; compared with the prior art, the system has the characteristics of fine operation, all-angle operation, no blind zones, complete excision, convenience in the mastering of the excision depth, humanized operation and the like, the cure rate of non-muscle invasive bladder cancer is expected to be increased, operation complications are reduced, and the cancer recurrence rate is lowered.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY +1

MR Compatible Stereoscopic Viewing Device for use in the Bore of an MR Magnet

InactiveUS20120190965A1Increased resection percentageDecreased neurological deficitDiagnostics using lightMagnetic measurementsMagnetMicroscope

In an MR guided surgical system which is carried out in the bore of an MR magnet, there is provided a microscope system for viewing the required part of a patient which includes stereoscopic viewing components arranged for use in generating 2D and 3D images displayed to the surgeon. The optical assembly is adjustable to change the view and the visual images are overlaid by the MR images. The visual image can be adjusted in response to movement of the surgical tool and the MR image displayed and / or the image obtained can be modified in response to change in the visual image and / or movement of the tool. The components in the bore are made compatible with the MR environment.

Owner:IMRIS

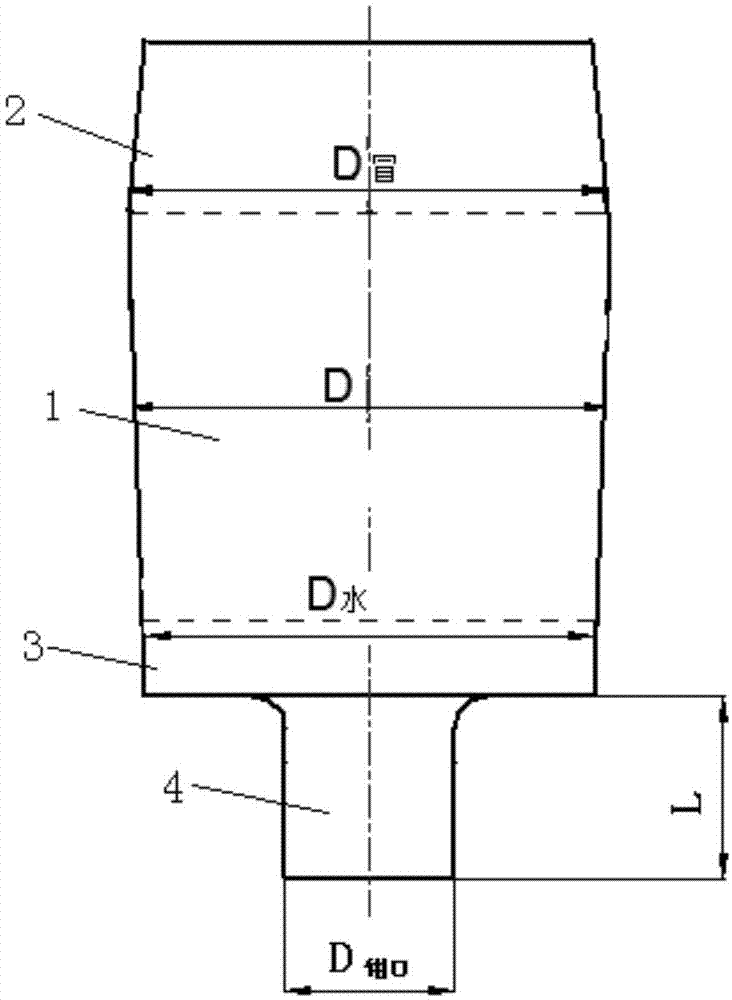

Machining method for effectively improving quality of large forging

The invention discloses a machining method for effectively improving quality of a large forging, belongs to the technical field of smelting and forging, and belongs to an improvement on the smelting and forging of the large forging. The method comprises the steps of firstly, in the smelting process, prefabricating a water gap jaw in the water gap end of an ingot, so the distribution state of water gap deposition cones is changed and the metallurgical quality of the ingot is improved; secondly, adopting riser-free forging in the forging loop and changing the fiber direction of the forging, so the forging quality of the ingot water gap is effectively improved. Through the improvement on the smelting and forging, the hot-working quality of the large forging is effectively improved.

Owner:TIANJIN HEAVY EQUIP ENG RES +1

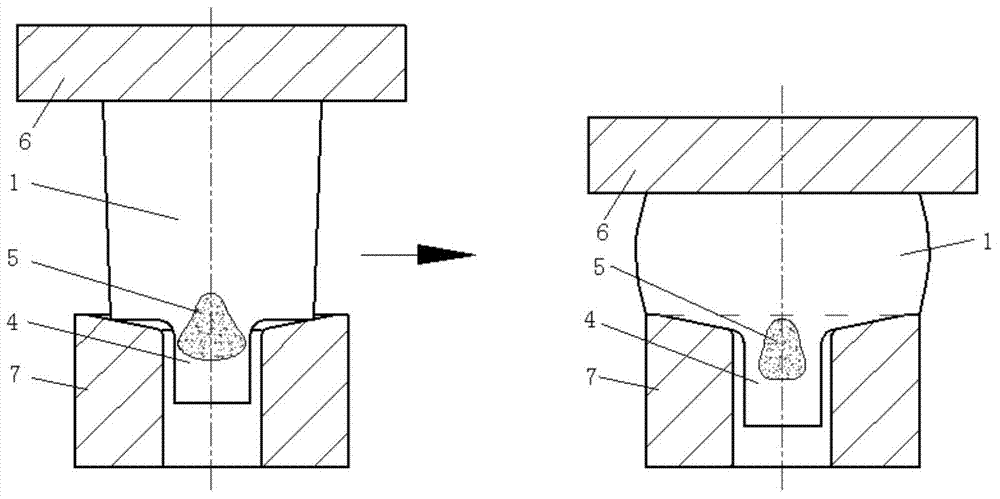

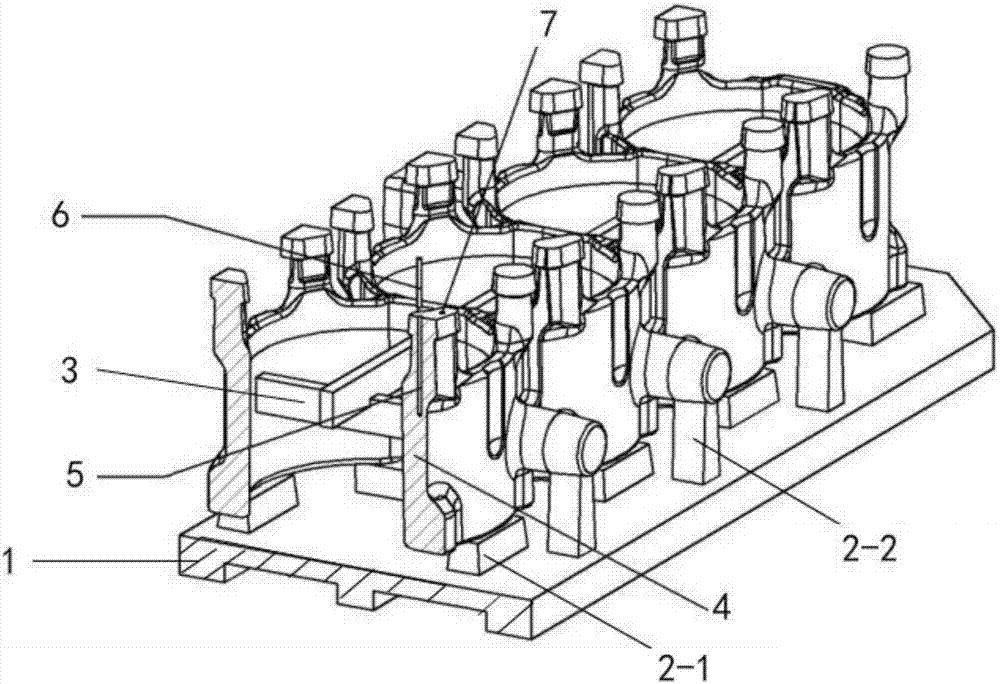

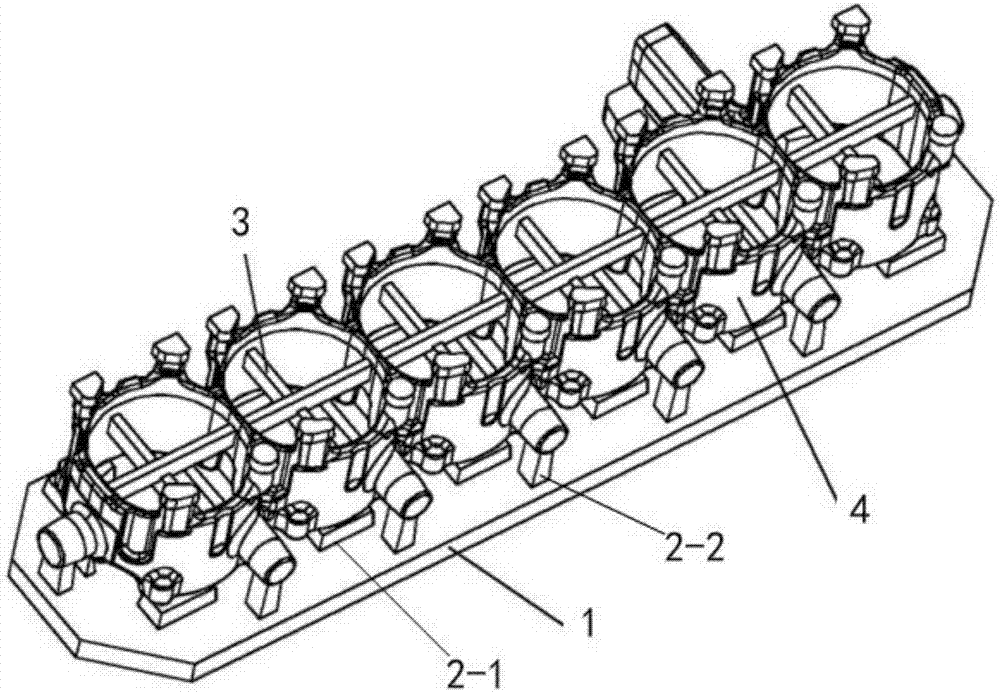

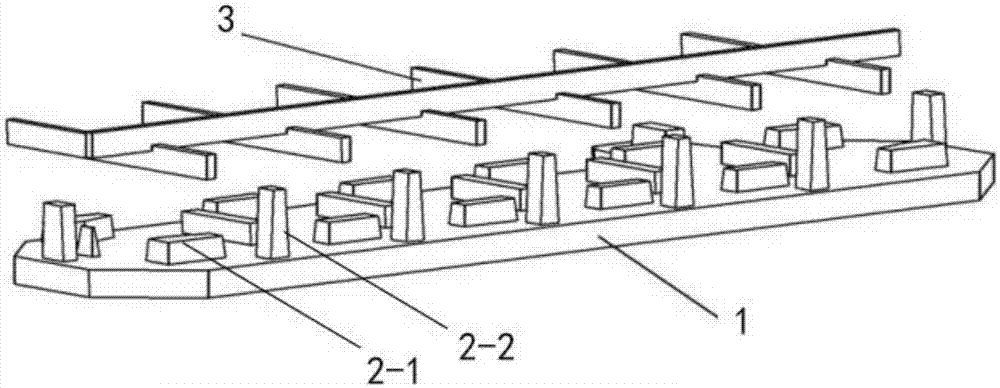

Diesel engine cylinder hole water jacket sand core reinforcing method

ActiveCN107457363AGuaranteed accuracyHigh precisionAdditive manufacturing apparatusFoundry mouldsEngineeringWater jacket

The invention discloses a diesel engine cylinder hole water jacket sand core reinforcing method. The method comprises the following steps that (1) when a cylinder hole water jacket sand core is subjected to 3D printing, a printing supporting mechanism is additionally arranged at first, the cylinder hole water jacket sand core body is printed, and integral forming of the supporting structure and the cylinder hole water jacket sand core is achieved; (2) baking curing is conducted after printing forming; (3) a sand bone hole is longitudinally drilled in a water foot part of the cylinder hole water jacket sand core body; (4) a sand bone matched with the sand bone hole is selected and inserted into the sand bone hole to be fixed; and (5) the supporting structure in the sand core is removed, and the reinforced cylinder hole water jacket sand core with high precision and quality is obtained. The strength of the 3D printed air cylinder block cylinder hole water jacket sand core can be improved, the reinforced sand core can ensure the effect that the positions and shapes of the layers are not changed by dragging during printing, the forming strength and precision of the sand core are ensured, and the practice effect is good.

Owner:GUANGXI YUCHAI MASCH CO LTD

MR Compatible Fluorescence Viewing Device for use in the Bore of an MR Magnet

InactiveUS20120190966A1Increased resection percentageDecreased neurological deficitMagnetic measurementsDiagnostics using fluorescence emissionFluorescenceComputer graphics (images)

In an MR guided surgical system which is carried out in the bore of an MR magnet and uses fluorescence to detect tumor cells, there is provided a microscope system for viewing the required part of a patient which includes stereoscopic viewing components arranged for use in generating 2D and 3D images displayed to the surgeon. The optical assembly is adjustable to change the view and the visual images are overlaid by the MR images. The visual image can be adjusted in response to movement of the surgical tool and the MR image displayed and / or the image obtained can be modified in response to change in the visual image and / or movement of the tool. The components in the bore are made compatible with the MR environment. A fluorescence delivery system is operated to automatically activate the delivery system in response to detection of the level of fluorescence.

Owner:IMRIS

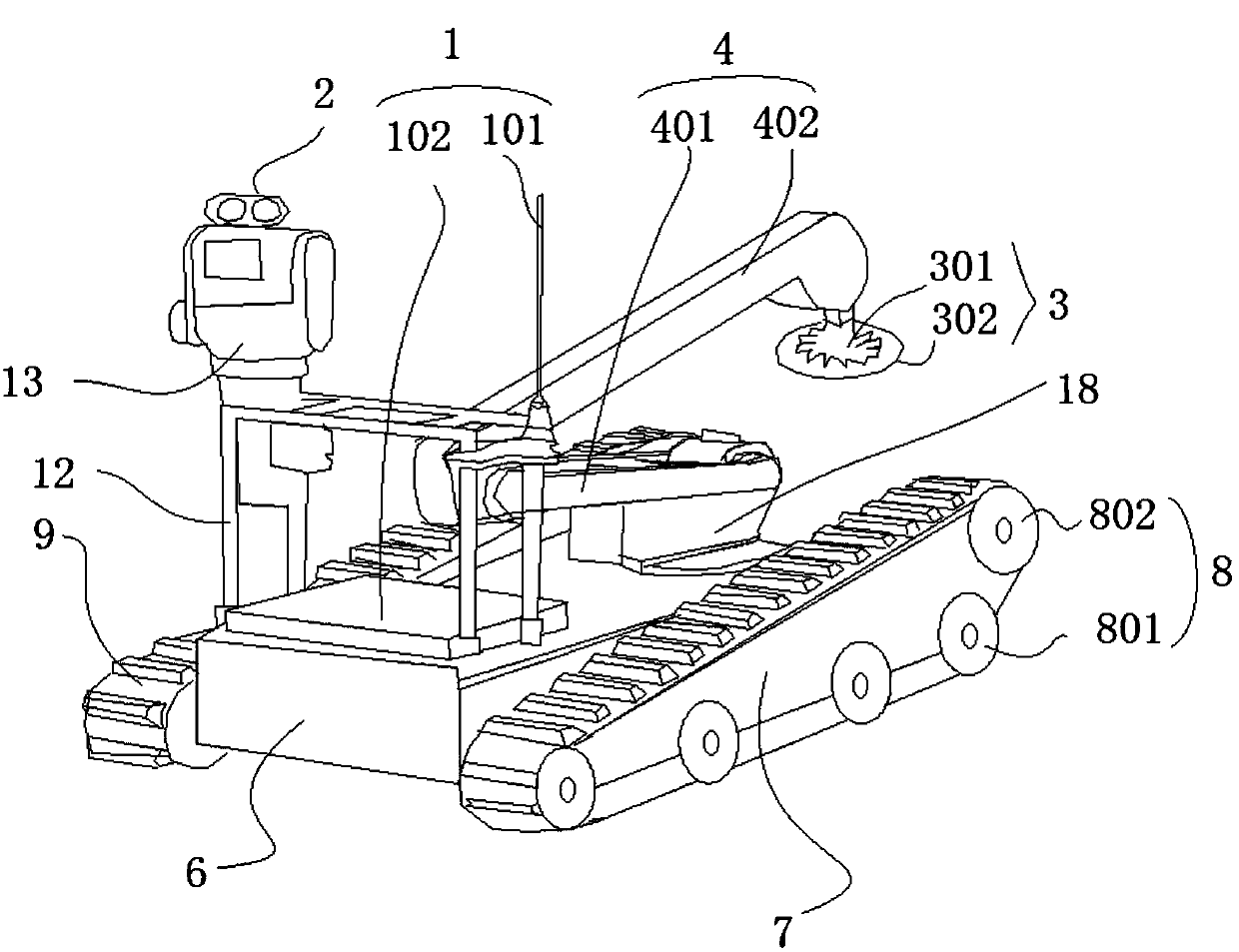

Intelligent weeding robot

InactiveCN109769419APromote growthEasy to moveSoil-working equipmentsWeed killersAutomatic controlEngineering

The invention relates to an intelligent weeding robot. The intelligent weeding robot comprises a cart, a GPS positioning device, a camera used for identifying weeds and a weeding device, wherein the GPS positioning device, the camera and the weeding device are arranged on the cart. The weeding device comprises a cutter head which is mounted at the front end of the cart and used for cutting weeds and a supporting arm which is used for supporting the cutter head; the cart is also provided with a weed burning device used for burning the cut weeds; the cart is internally provided with an automaticcontrol module, and the automatic control module includes a GPS positioning module, an image recognition module, a weed cutting module and a weed burning module; the GPS positioning module, the imagerecognition module, the weed cutting module and the weed burning module are used for controlling the GPS positioning device, the camera, the weeding device and the weed burning device respectively; the automatic control module comprises a control panel and a touch display screen. The intelligent weeding robot can recognize and cut the weeds and then burn off the cut weeds to prevent some weeds from rooting and germinating again, and the weeds are burned into ash and can be used as fertilizer to promote crop growth.

Owner:韩振磊

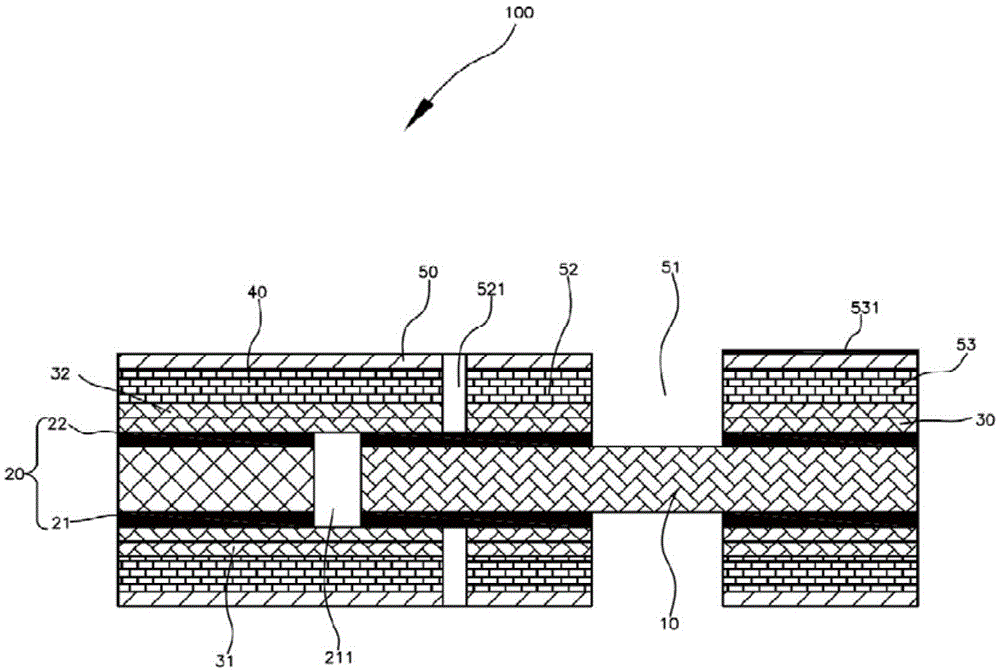

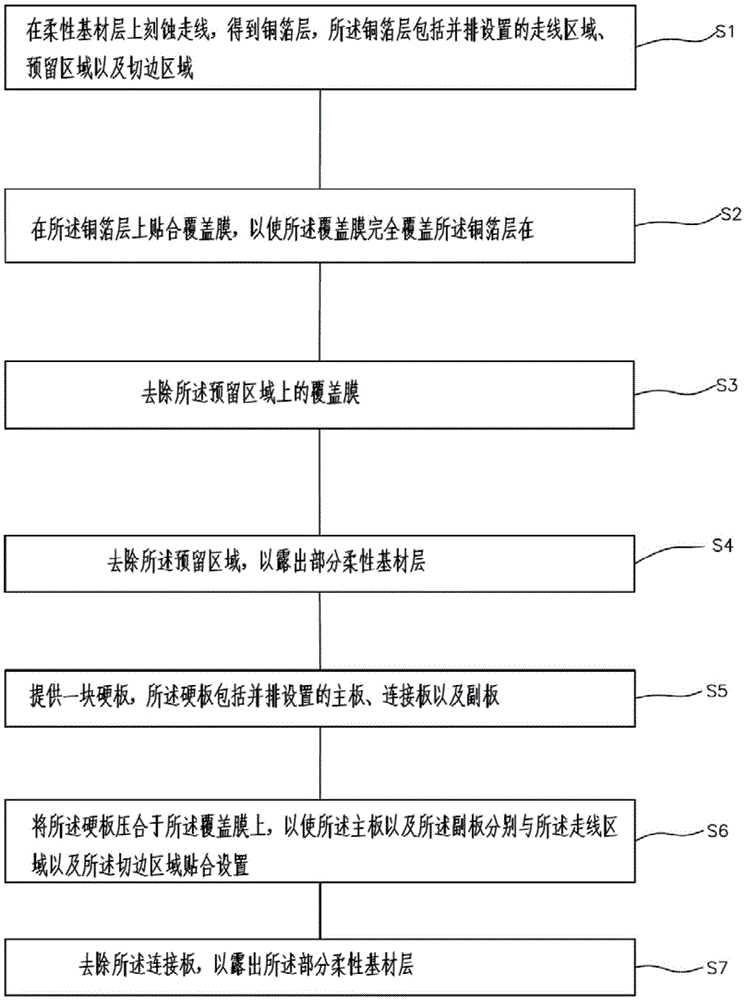

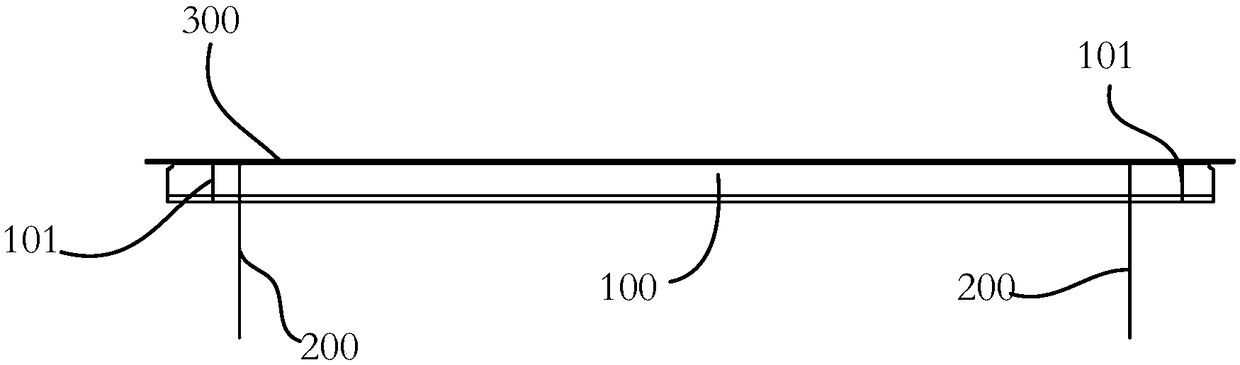

Rigid-flex board and manufacturing method thereof

ActiveCN105578753AAvoid damageExtended service lifePrinted circuit assemblingPrinted circuits structural associationsPunchingCopper foil

The invention discloses a rigid-flex board and a manufacturing method thereof. The rigid-flex board comprises a flexible substrate layer, copper foil layers overlapped on the flexible substrate layer, covering films attached to the copper foil layers, rigid layers overlapped on the covering films and circuit layers overlapped on the rigid layers, wherein each circuit layer is provided with an open window passing through the flexible substrate layer to divide the circuit layer into two oppositely-arranged parts; part of the flexible substrate layer is exposed in the open window; and the flexible substrate layer is connected between two parts of the circuit layer. According to the rigid-flex board and the manufacturing method thereof provided by the embodiment of the invention, through arranging the open window passing through the flexible substrate layer in the circuit layer and using the part exposed in the open window of the flexible substrate layer to connect the two parts of the circuit layer, when board dividing needs to be carried out on the rigid-flex board, a punching die only needs to be adopted to cut off the part, exposed in the open window, of the flexible substrate layer to realize board dividing, the phenomenon that the punching die is likely to be damaged due to cutoff of multiple layers of rigid material can be avoided, and the service life of the punching die is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

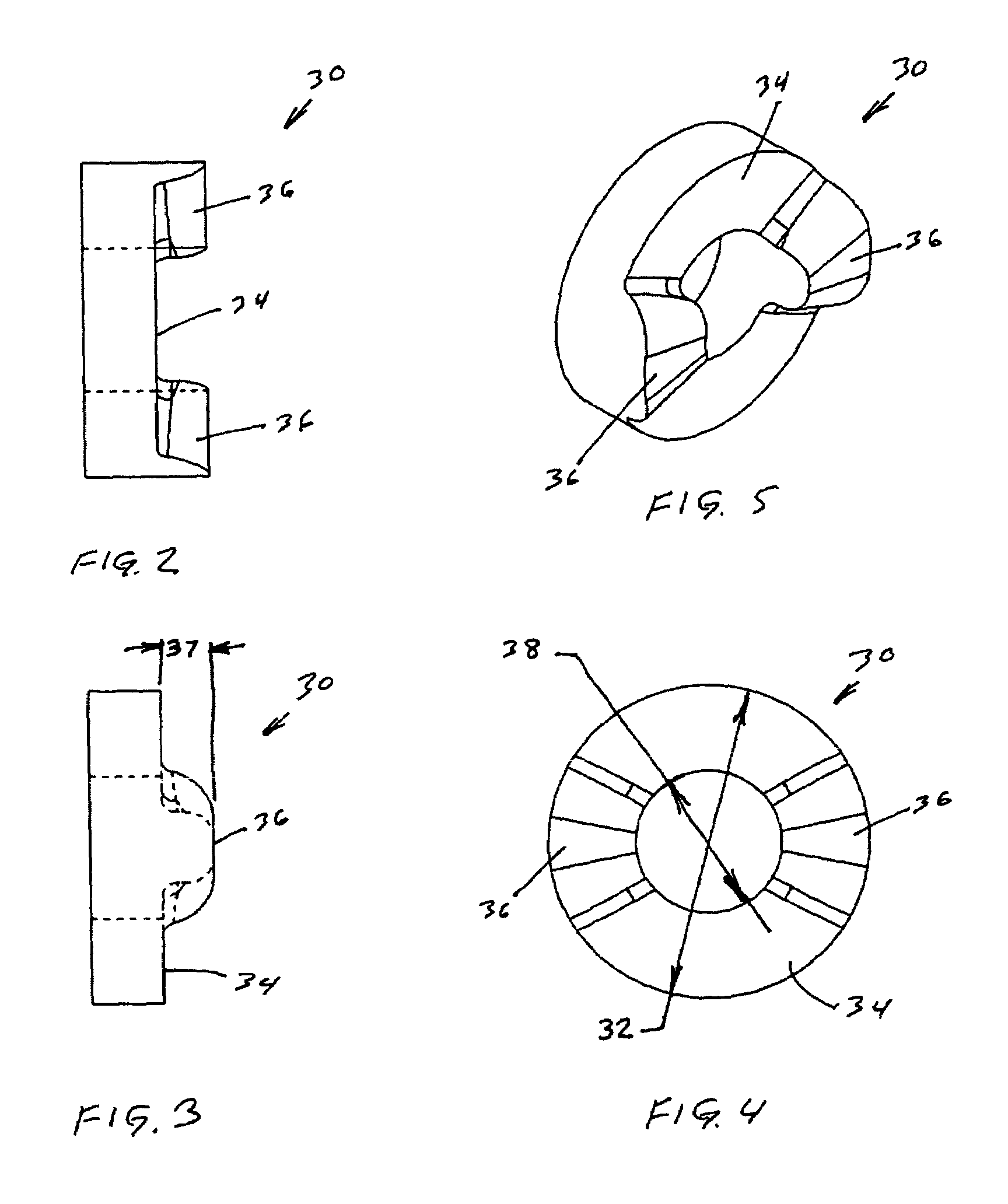

Electrosurgical snare

ActiveUS20160166314A1Reduce riskSmall penetration depthCatheterExcision instrumentsEngineeringEndoscope

An electrosurgical snare, e.g. suitably sized for insertion down the instrument channel of an endoscope, arranged to radiate microwave frequency energy (e.g. having a frequency greater than 1 GHz) from an elongate conductive element within an area encircled by a retractable loop. The elongate conductive element and retractable loop may be independently slidable relative to a snare base at a distal end of a sleeve to provide an appropriate device configuration. By controlling the shape of the emitted microwave field, the risk of collateral thermal damage can be reduced.

Owner:CREO MEDICAL LTD

Submucosal injection solution

InactiveCN107456612AGood liquidityLow viscositySurgeryPharmaceutical delivery mechanismSodium hyaluronatePhysiological function

Owner:SHANDONG WEIGAO PHARM CO LTD

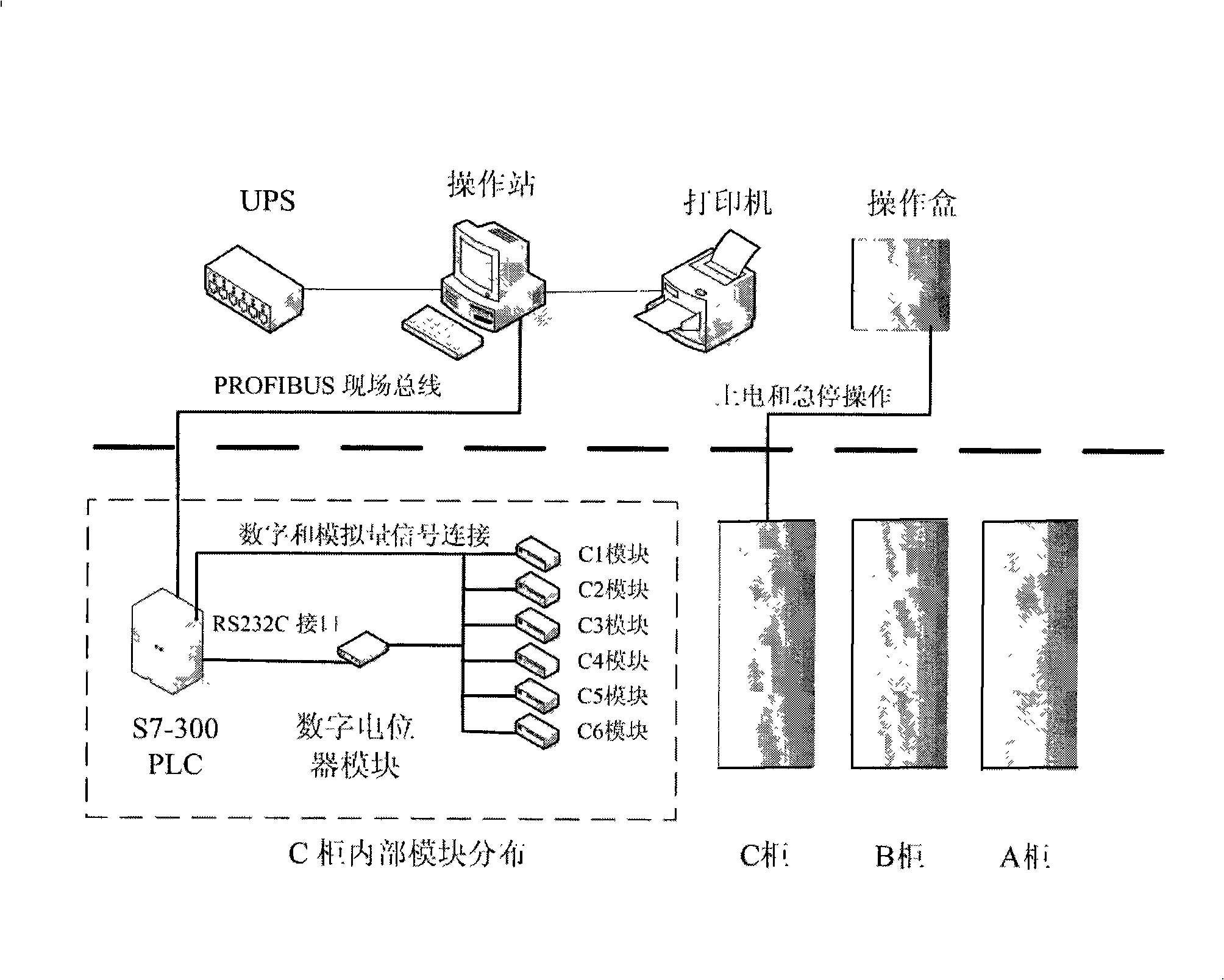

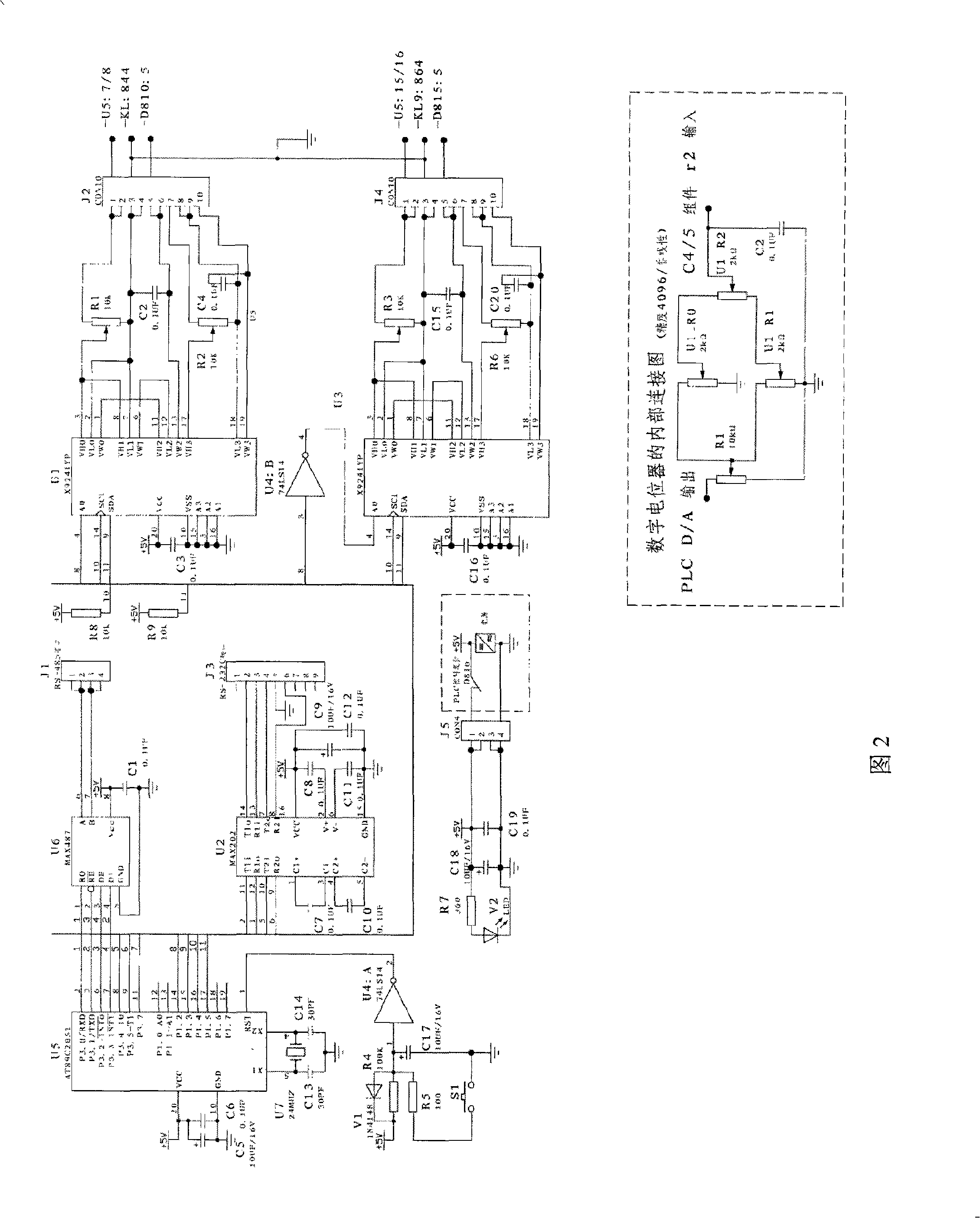

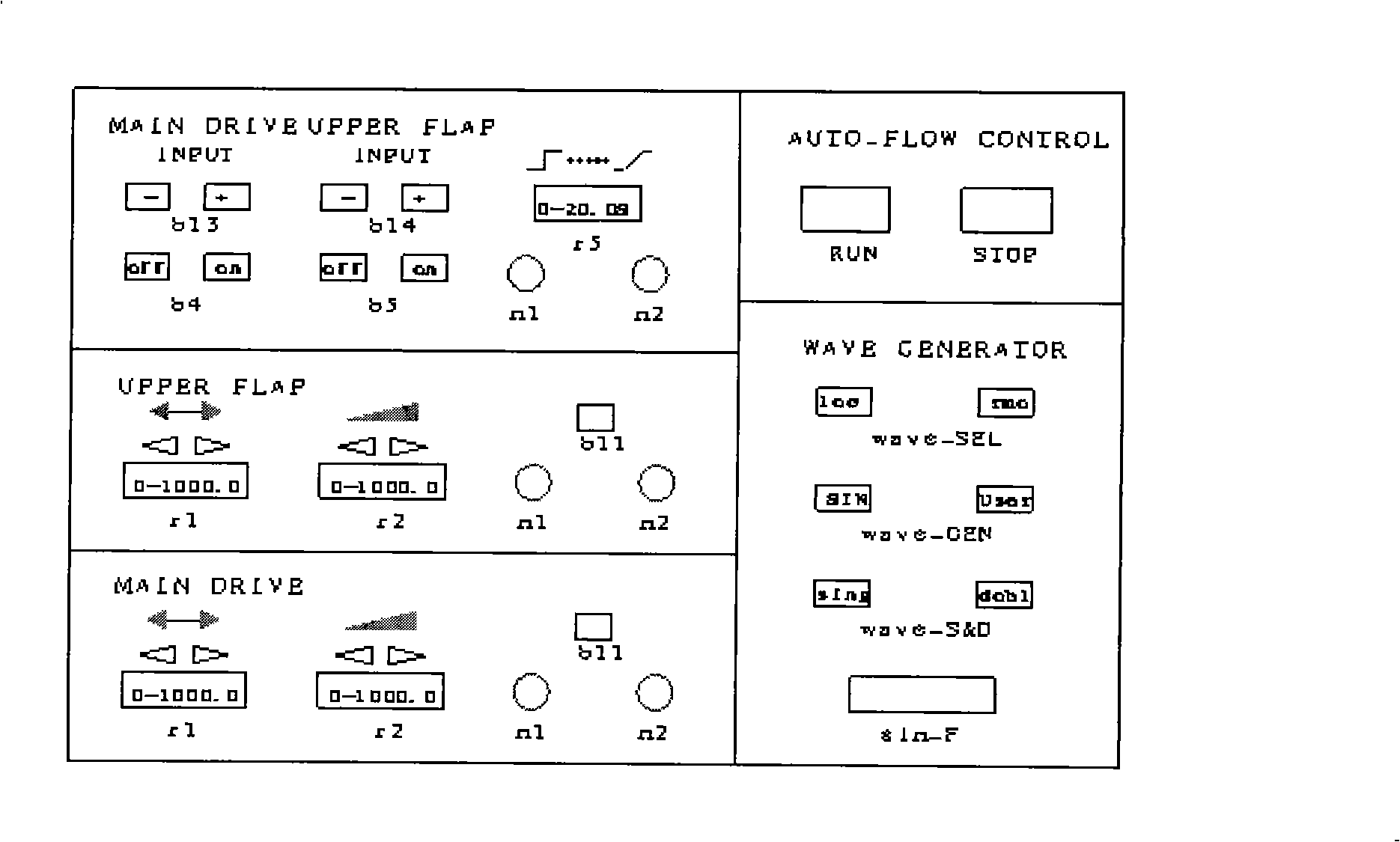

Remote observing and controlling system for oceanography engineering pond wave generator

InactiveCN101344782AImprove accuracyVersatileTotal factory controlProgramme control in sequence/logic controllersEngineeringInput/output

The invention discloses a remote measurement and control system for pool wave makers in ocean engineering, consisting essentially of a measurement and control regulation cabinet (cabinet C), a PLC and a computer graph measurement and control system. The PLC is arranged in the measurement and control regulation cabinet of the wave maker and used for signal acquisition and input / output control of the cabinet. Remote measurement and control of the wave maker is realized through bus communication with the computer graph measurement and control system. The system of the invention can be used for remote control and parameter test of pool wave makers in ocean engineering of national key ocean engineering laboratories so as to improve the control capacity of the wave makers and also the accuracy of data test.

Owner:SHANGHAI MARITIME UNIVERSITY

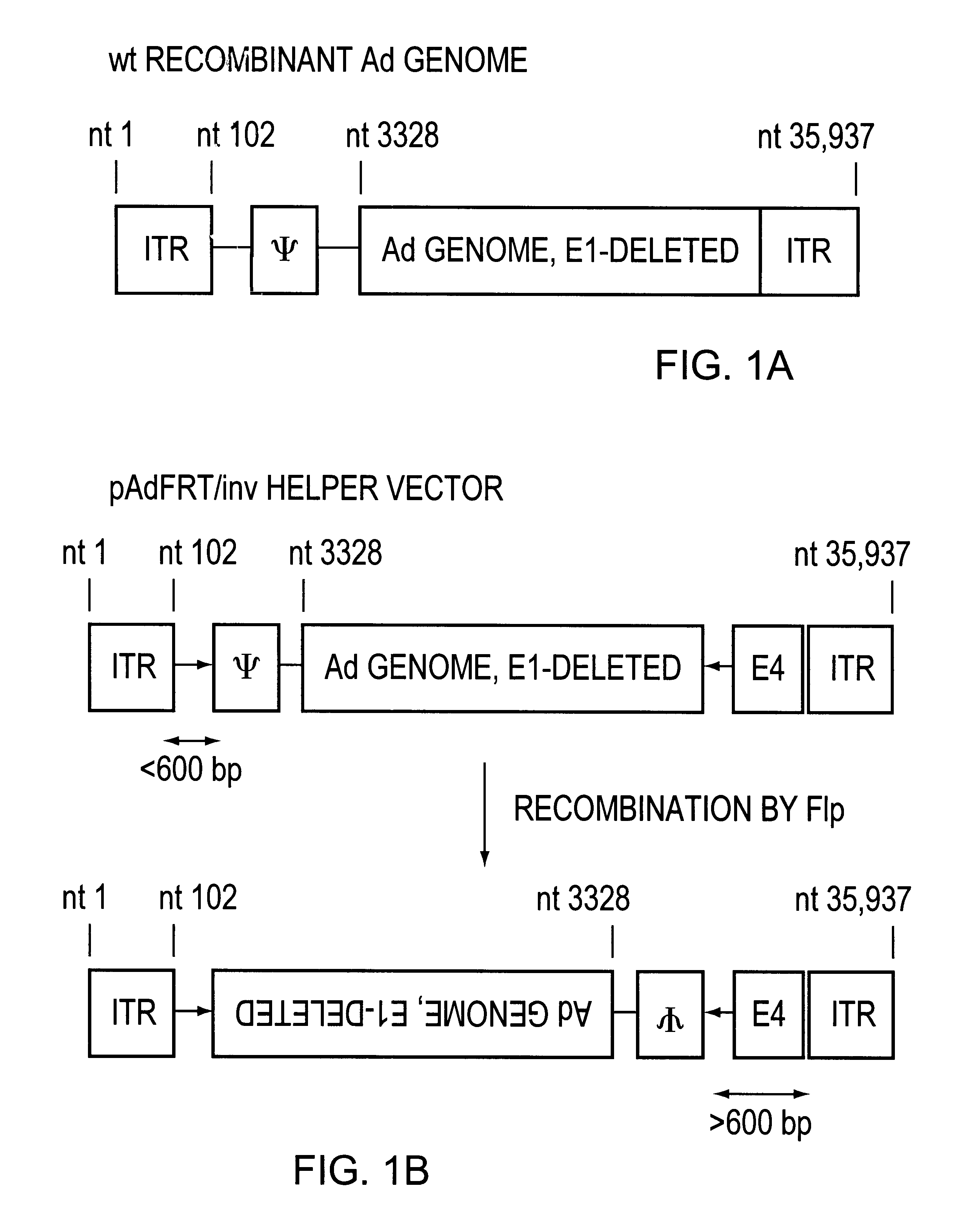

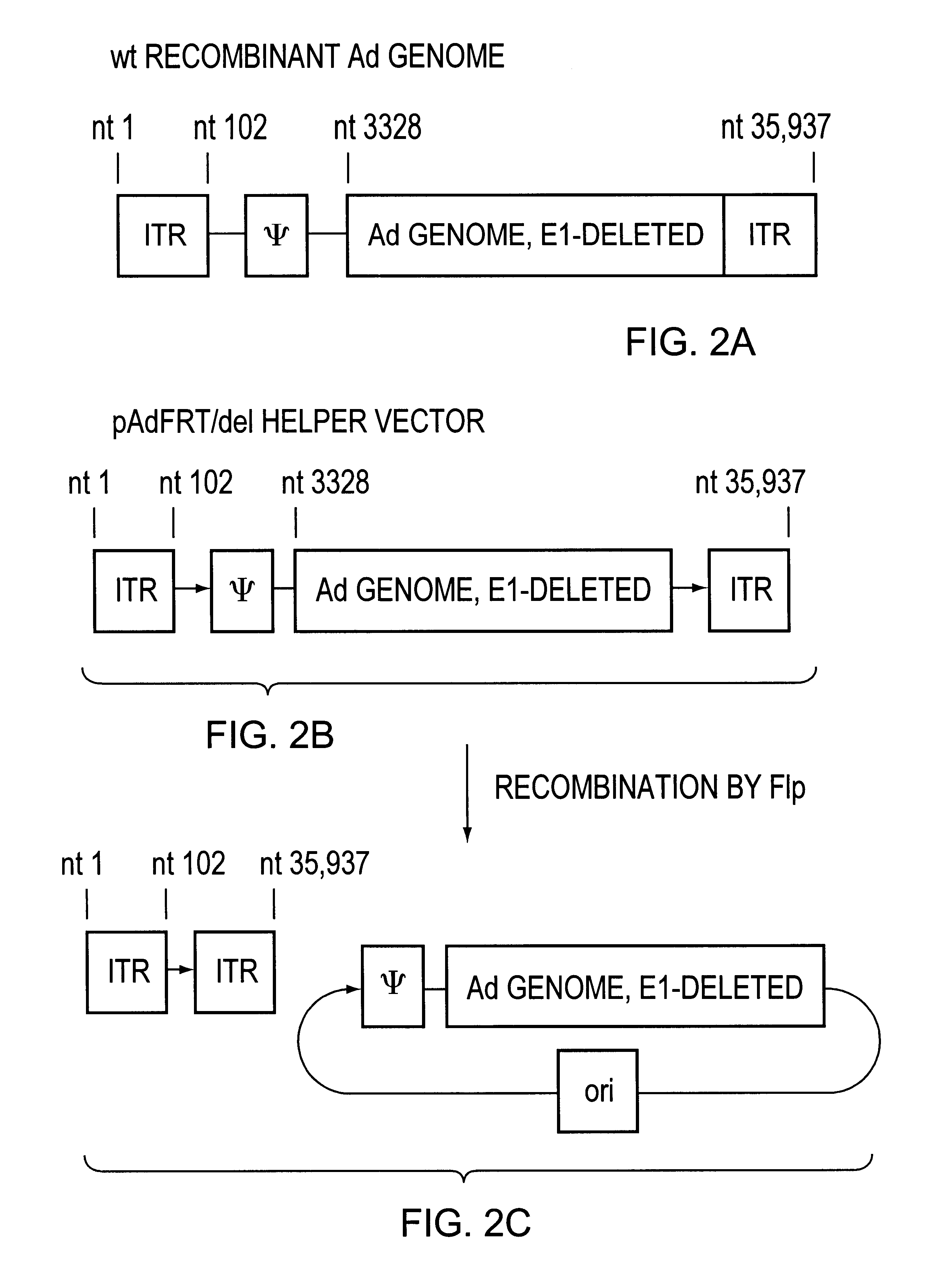

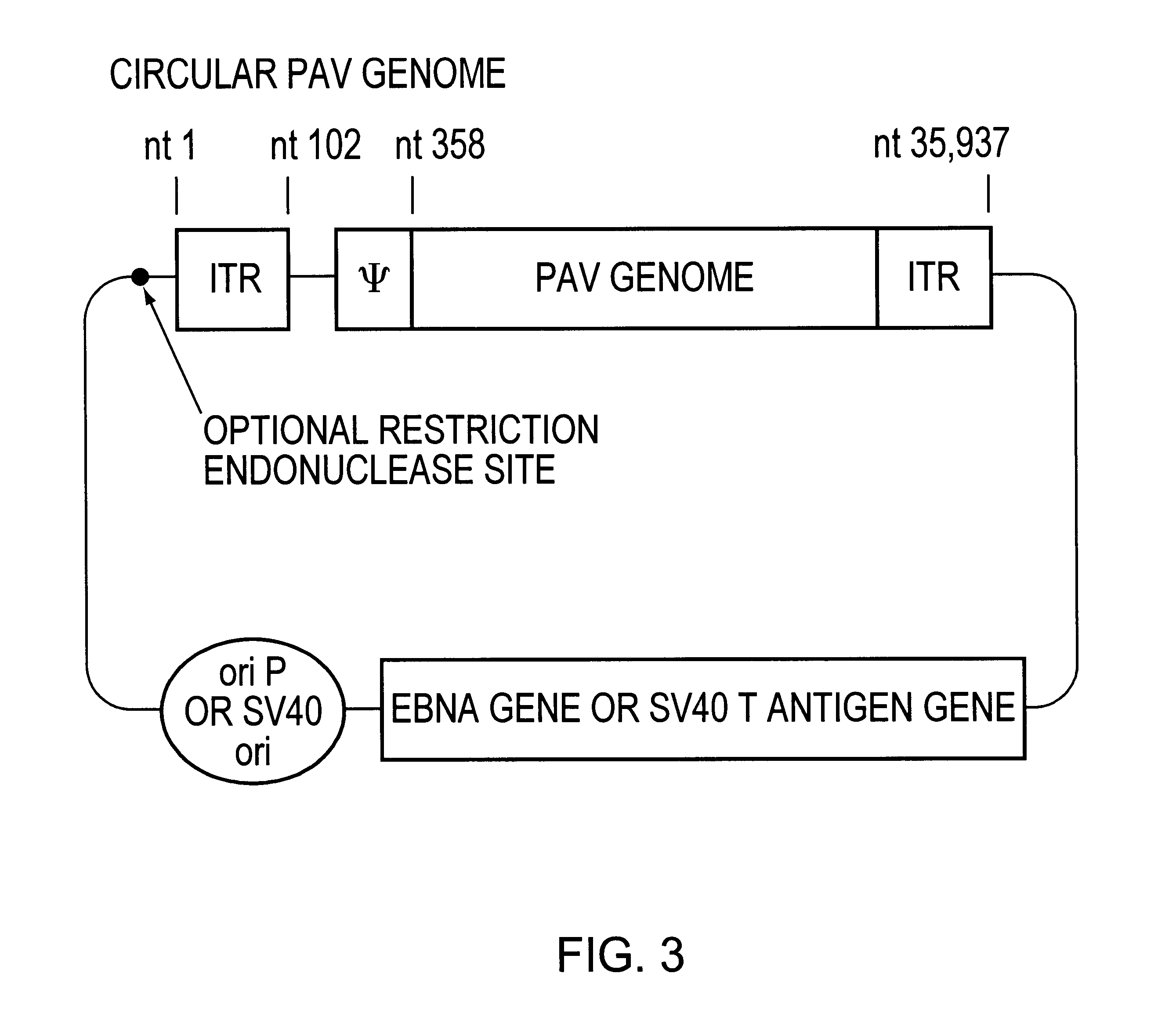

Adenoviral helper vectors

InactiveUS6541245B1Improve efficiencyImprove securityBiocideGenetic material ingredientsRecognition sequenceRecombinase

The present invention is directed to improved helper vectors and cell lines for the production of pseudoadenoviral (PAV) vectors containing substantially reduced levels of contaminating helper vector. The invention provides for helper vectors for the production of substantially helper vector-free PAV stocks comprising phag C31 recombinase recognition sequences which, depending upon their arrangement within the helper vector, can prevent helper vector packaging. The invention also provides for improved cell lines for the production of substantially helper vector-free PAV stocks comprising a stably introduced novel circular PAV genome into the cell.

Owner:GENZYME CORP

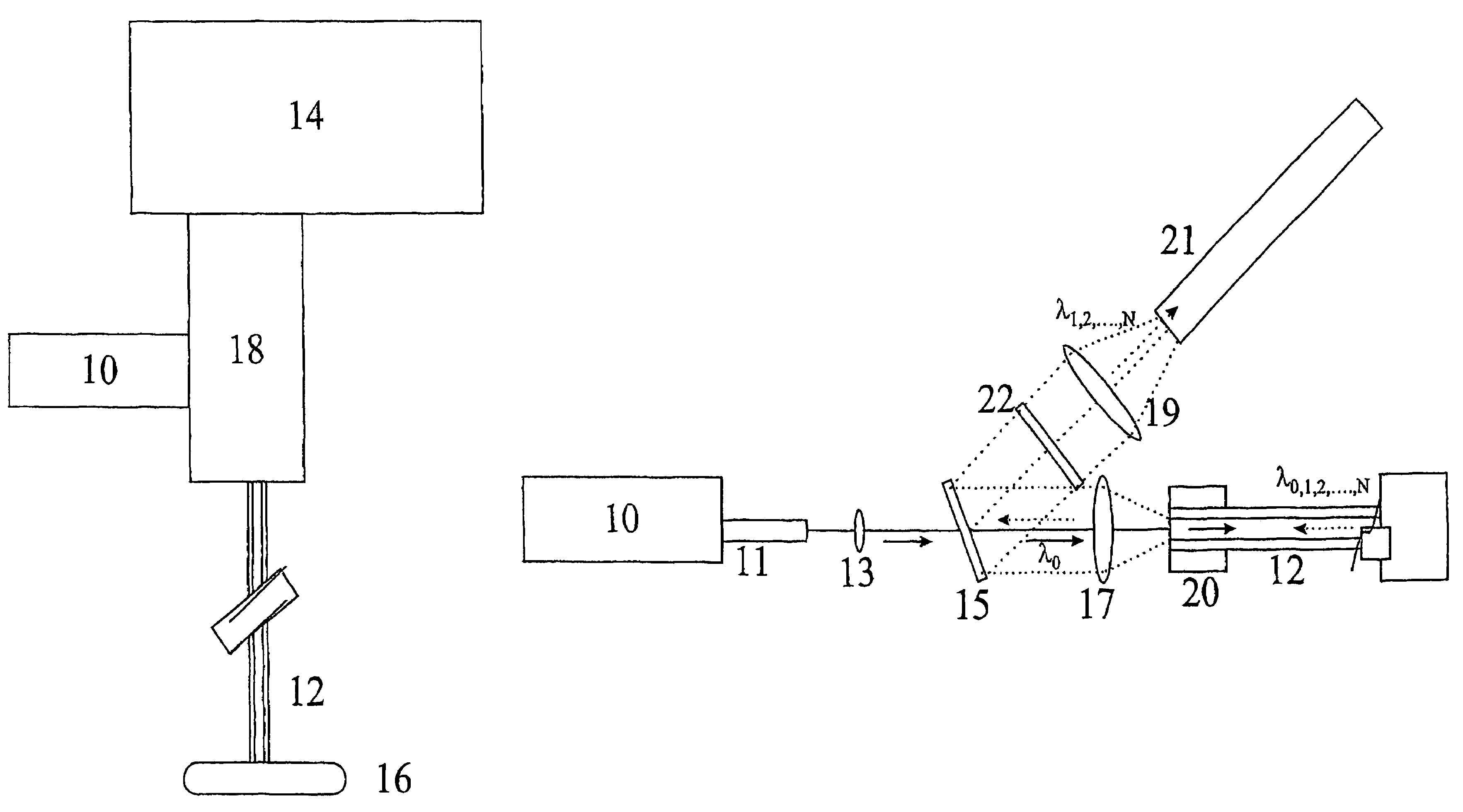

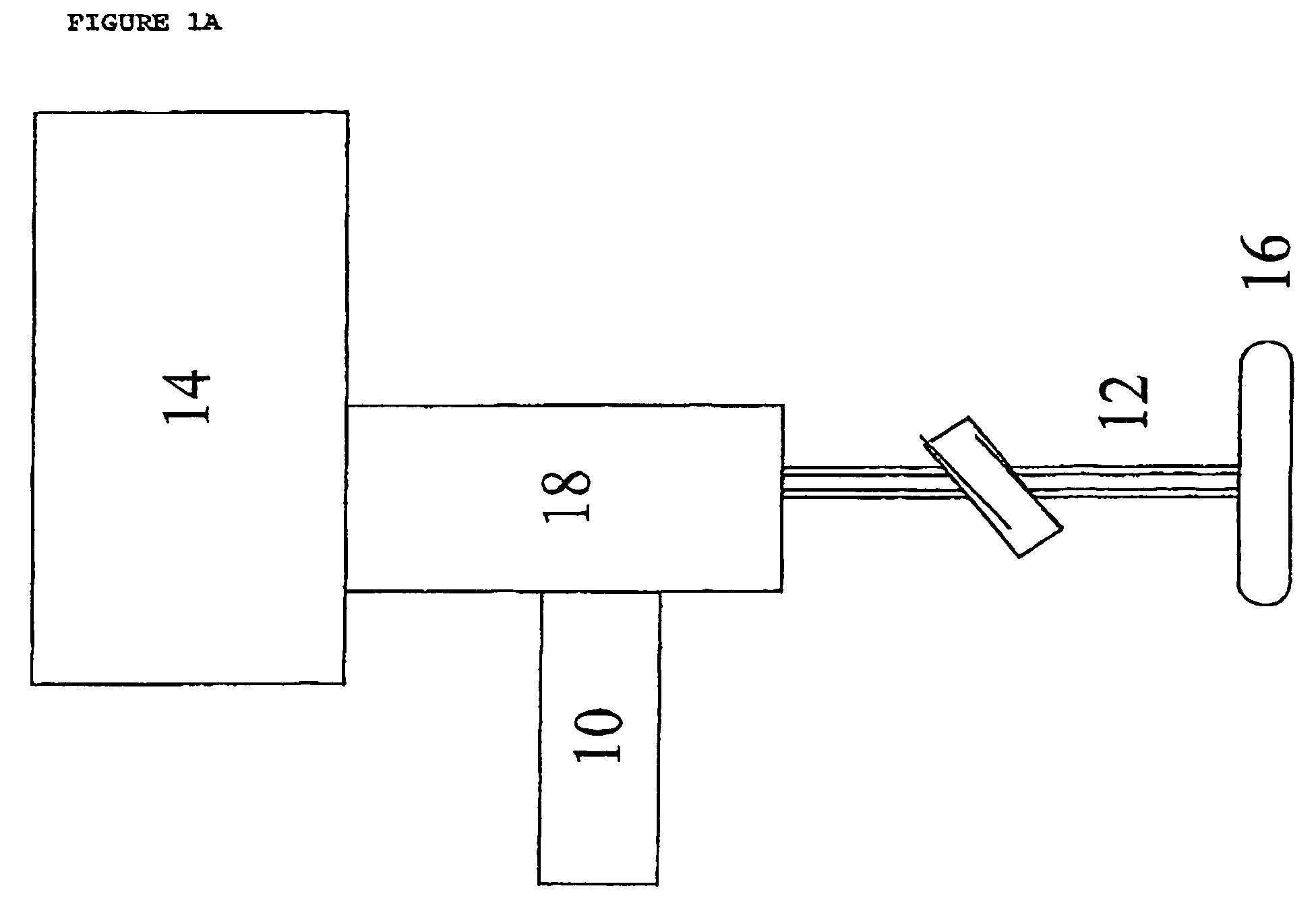

Spectrometer for measuring inelastically scattered light

InactiveUS7110108B2Raise the possibilityEasy constructionRadiation pyrometryMaterial analysis by observing effect on chemical indicatorSpectral analysisSpectrometer

The spectrum of light, inelastically scattered by a sample (16) is measured. The light is guided through a capillary (12) from and to the sample, at least in one of these directions, through the channel no inelastic scattering of light occurs which can form an interfering background when measuring on the sample. By guiding the light through the channel, inelastic scattering of this light is prevented and it becomes possible to guide scattered light back through the channel to spectral analysis equipment (14) without problems with inelastic scattering during the guidance of the light. Preferably, the light is guided through the channel of the capillary in both directions.

Owner:RIVER DIAGNOSTICS

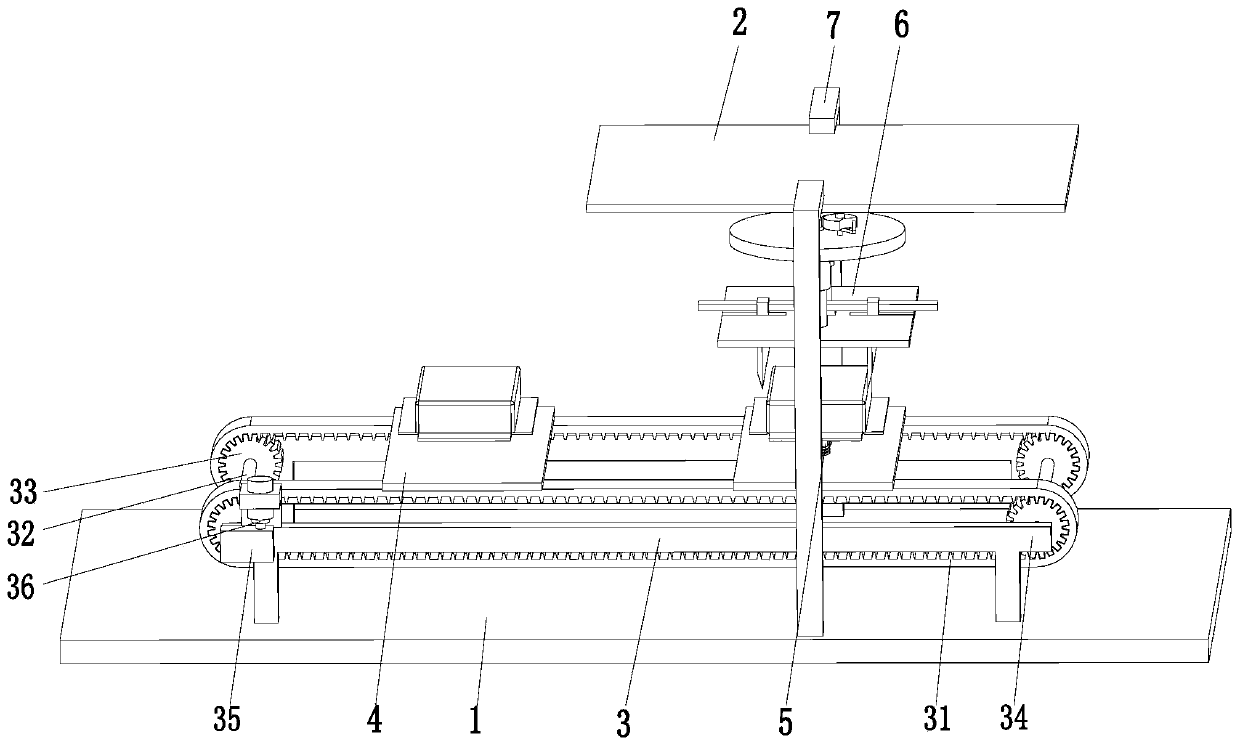

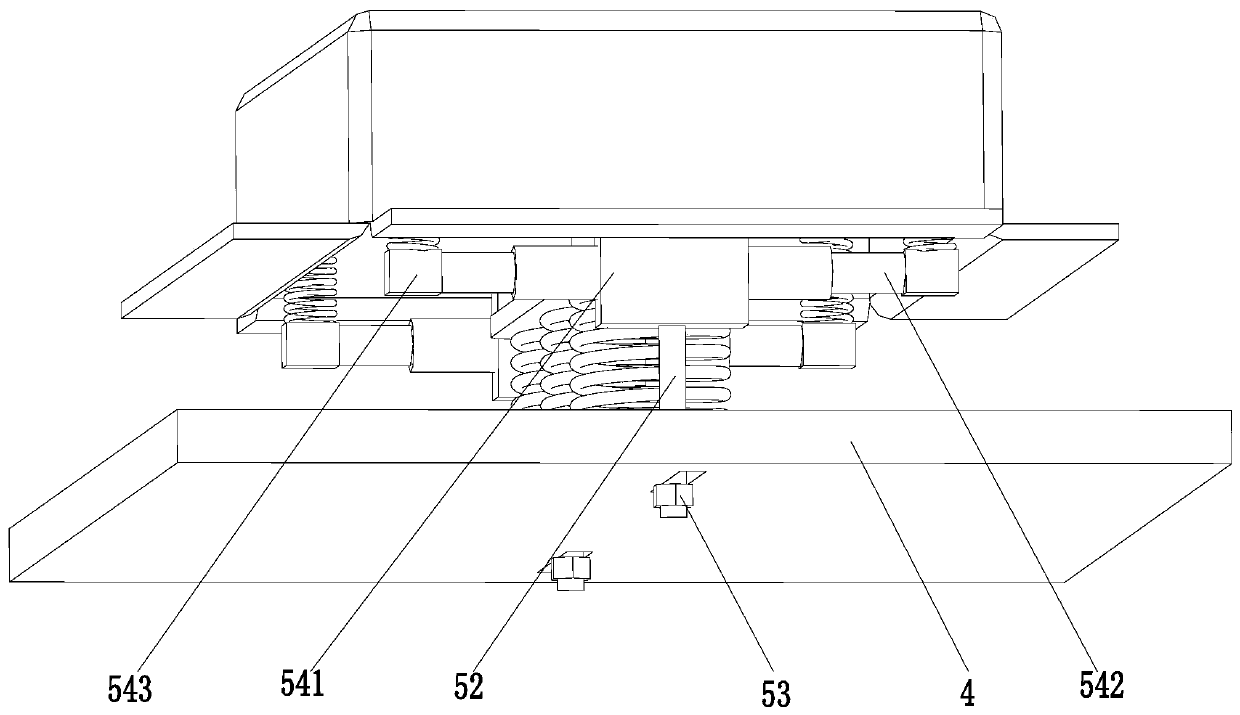

Transparent plastic packaging box manufacturing die cutting device

ActiveCN110757558ASolve efficiency problemsSolve the problem of high error rateDomestic articlesMetal working apparatusPlastic packagingEngineering

The invention relates to a transparent plastic packaging box manufacturing die cutting device. The transparent plastic packaging box manufacturing die cutting device comprises a bottom plate, a top plate, a conveying mechanism, workbenches, fixing devices, a cutting device and top plate supports. The top plate is located above the bottom plate, and the front end and the rear end of the top plate are installed at the top end of the bottom plate through the top plate supports. The conveying mechanism is arranged on the top of the bottom plate, and the workbenches are evenly arranged on the top end face of the conveying mechanism. The fixing devices are arranged on the tops of the workbenches, and the bottom surfaces of the fixing devices are installed on the top end faces of the workbenches.The cutting device is located above the fixing devices, and the top end of the cutting device is installed in the center of the bottom surface of the top plate. The transparent plastic packaging boxmanufacturing die cutting device can solve the problems that when the excessive material die cutting is conducted on plastic boxes through manual operation, the working efficiency is low, the error and omission rate is high, and an existing die cutting machine only can conduct die cutting on single plastic boxes and cannot meet the processing requirements of multiple plastic boxes in the market.

Owner:浙江汉东塑胶新材料有限公司

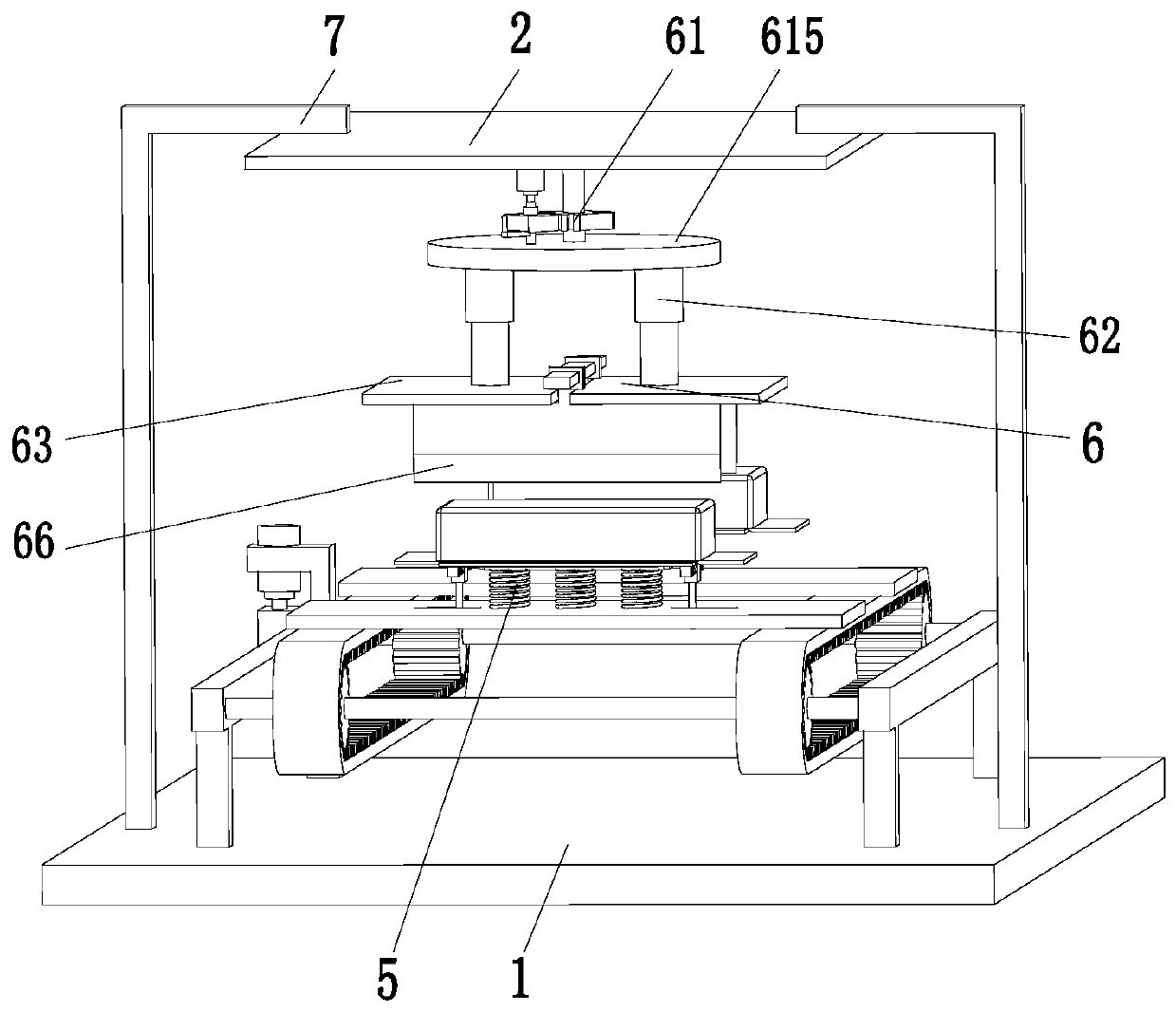

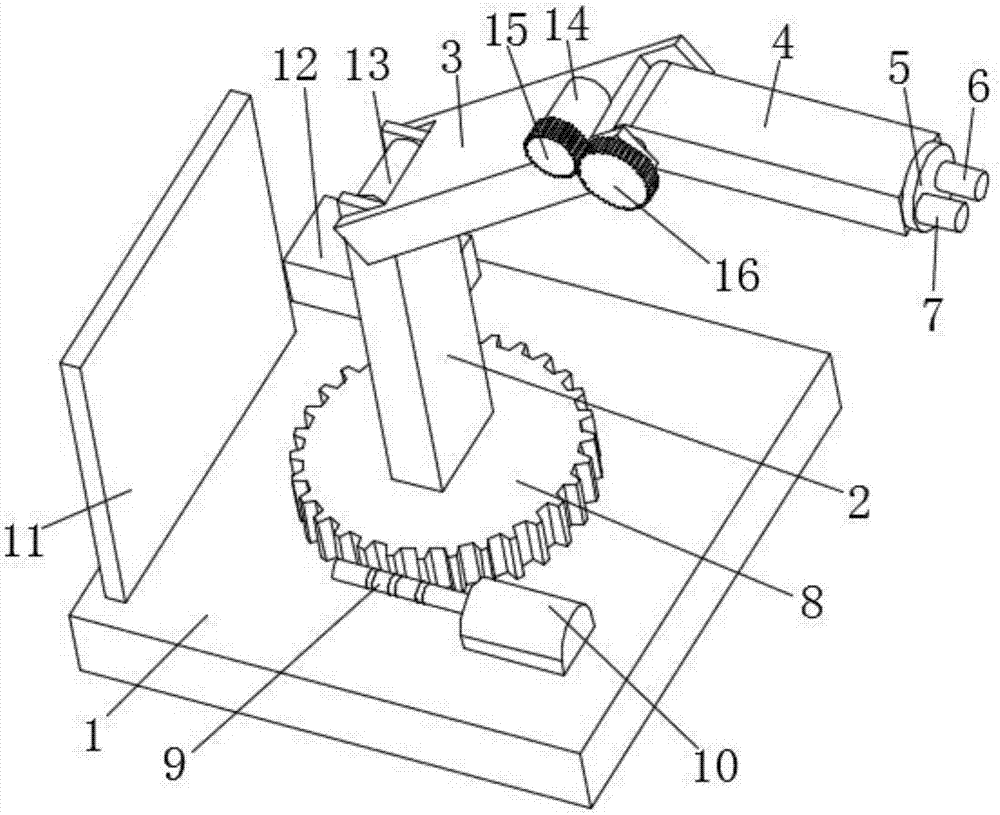

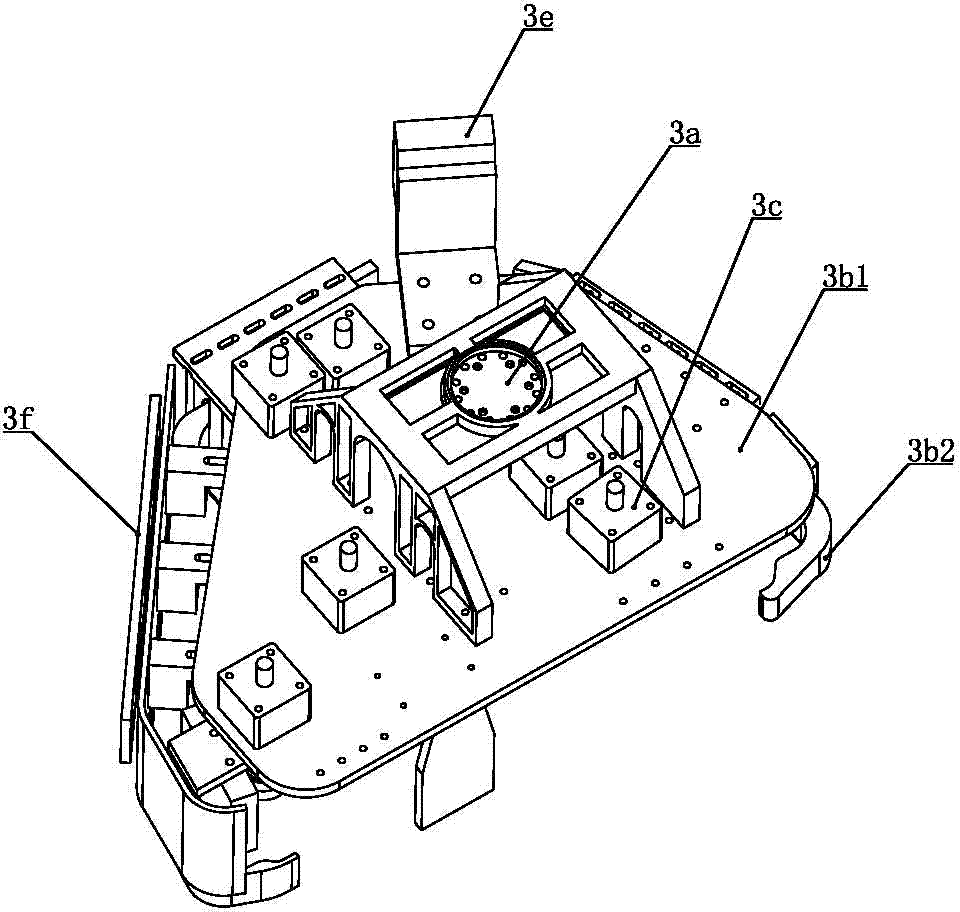

Robot for assisting celiac minimally invasive surgery

The invention discloses a robot for assisting celiac minimally invasive surgery. The robot comprises a base, wherein a worm wheel, a display, a PLC and a first motor are arranged on the upper surface of the base; the PLC is electrically connected with an external power supply; the first motor is electrically connected with the PLC; the display is electrically connected with the PLC; the worm wheel is mounted at the center of the upper surface of the base in a rotatable manner; and a worm is mounted on an output shaft of the first motor. The robot for assisting the celiac minimally invasive surgery is provided with a clamping device and an observing device; the clamping device can assist a doctor in clamping a diseased tissue in an abdominal cavity in an operation process, so that the doctor can excise or shape the diseased tissue; the observing device can transmit a condition in the abdominal cavity onto the display through a camera, so that the doctor can perform preoperative analysis on a prevalence situation in the abdominal cavity; furthermore, the observing device can further assist the doctor in observing an operation condition more conveniently in the operation process; and a provided lighting lamp is used for lighting an environment in the abdominal cavity, thus facilitating observation.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

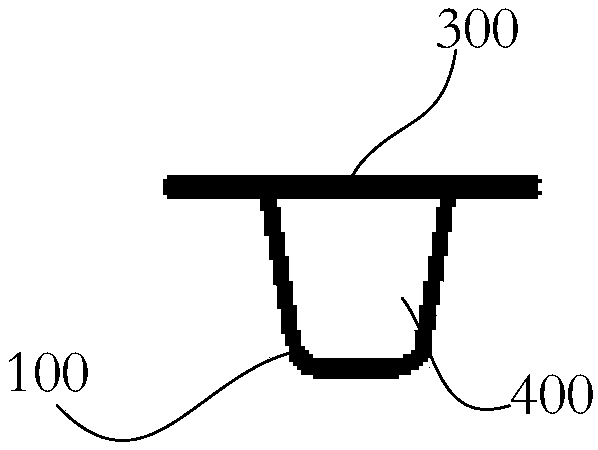

Method and steel box girder for supplementing internal weld at joint of U-rib of steel box girder and panel

ActiveCN109024223AExtended service lifeEnsure driving safetyBridge erection/assemblyBridge strengtheningEngineeringSurface plate

The invention relates to a method for supplementing an internal weld at the joint of a U rib of a steel box girder and a panel, and a steel box girder. The method comprises the following steps: S1, aprofiling hole is arranged on the steel box girder; S2, the welding system of the internal weld supplementary equipment enters the enclosed space formed by the U rib and the panel in the steel box girder from the position of the copying hole; S3, the welding system travels along the length direction of the U rib, and simultaneously welds the U rib and the panel from the inside of the U rib; S4, after the welding is completed, the position of the copying hole is filled. The invention opens a profiling hole in the steel box girder so that the welding system enters between the U rib and the panel, Adding internal weld to U-rib of existing steel bridge can strengthen the opening defects in U-rib, prolong the service life of bridge, ensure the safety of driving, increase the social and economicbenefits of bridge operation, reduce the maintenance cost of bridge, and the direct and indirect losses caused by closed traffic during the maintenance period.

Owner:WUHAN LIXIN AUTOMATION TECH CO LTD

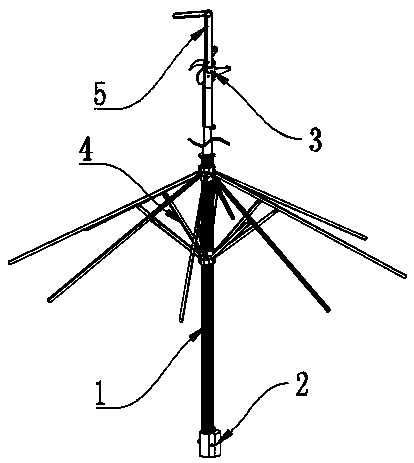

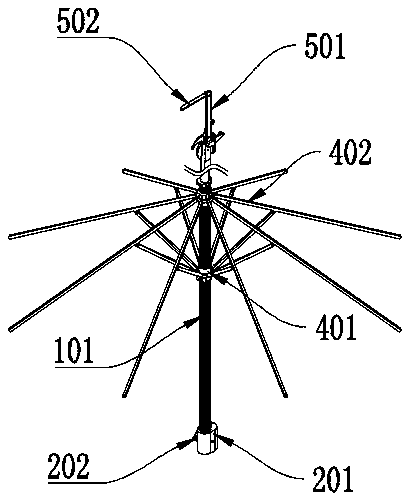

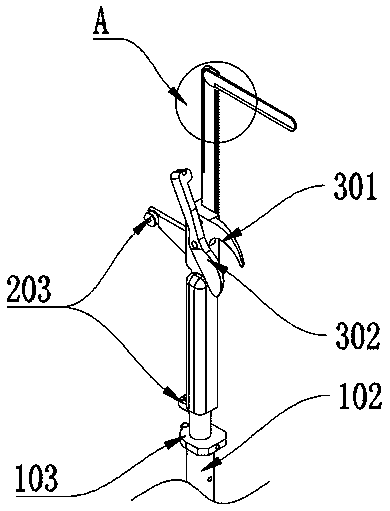

Tree barrier cleaning equipment for field maintenance of electric power

InactiveCN110915455AEnsure safetyEasy to trimSecateursCuttersStructural engineeringMechanical engineering

The invention provides tree barrier cleaning equipment for field maintenance of electric power. The tree barrier cleaning equipment comprises a main supporting rod mechanism, wherein a bottom tightening mechanism is arranged at the root of the main supporting rod mechanism; a protecting device is connected to the outer wall of the main supporting rod mechanism in a sliding and sleeving manner; a trimming device is arranged at the top end of the main supporting rod mechanism; protecting supporting rods are connected to connecting mounting rings on the outer walls of sliding mounting blocks in ahinging manner; the top and bottom sliding mounting blocks are arranged; the protecting supporting rods are also connected to the sliding mounting block at the lower end; each protecting supporting rod at the lower end is connected to the middle inner end of the corresponding protecting supporting rod at the upper end; and fixed clamping holes of which the sizes are the same as those of clampingblocks are formed in the two sliding mounting blocks, so that the two sliding mounting blocks can respectively fixed to the corresponding positions. According to the tree barrier cleaning equipment disclosed by the invention, a transparent plastic cloth or a net cloth can be additionally arranged on the protecting supporting rods, so that the protecting device integrally adopts the shape of an umbrella; and when branches are trimmed, the protecting device can block the falling branches to guarantee the safety of trimming workers at the lower part.

Owner:肖安南

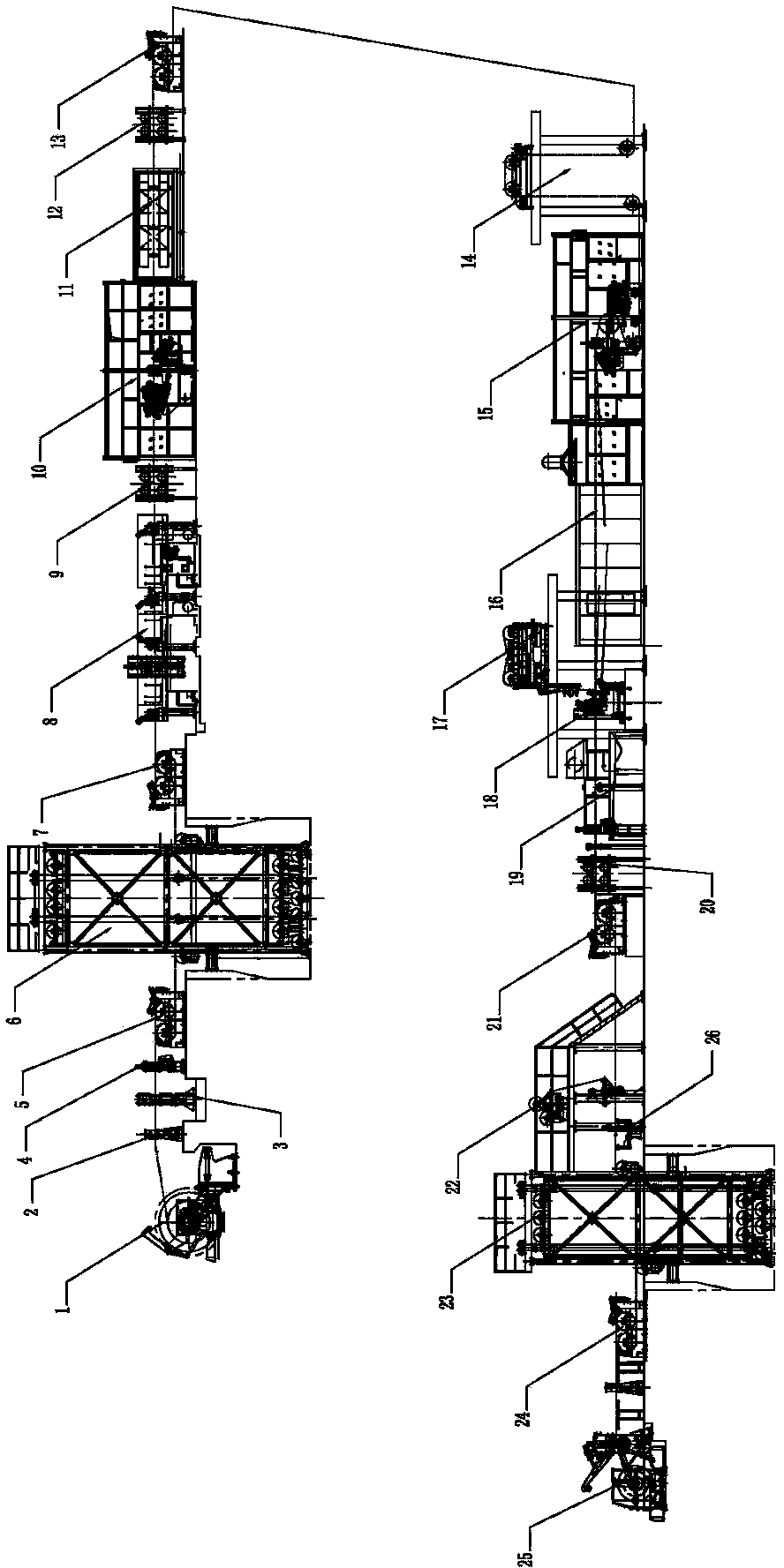

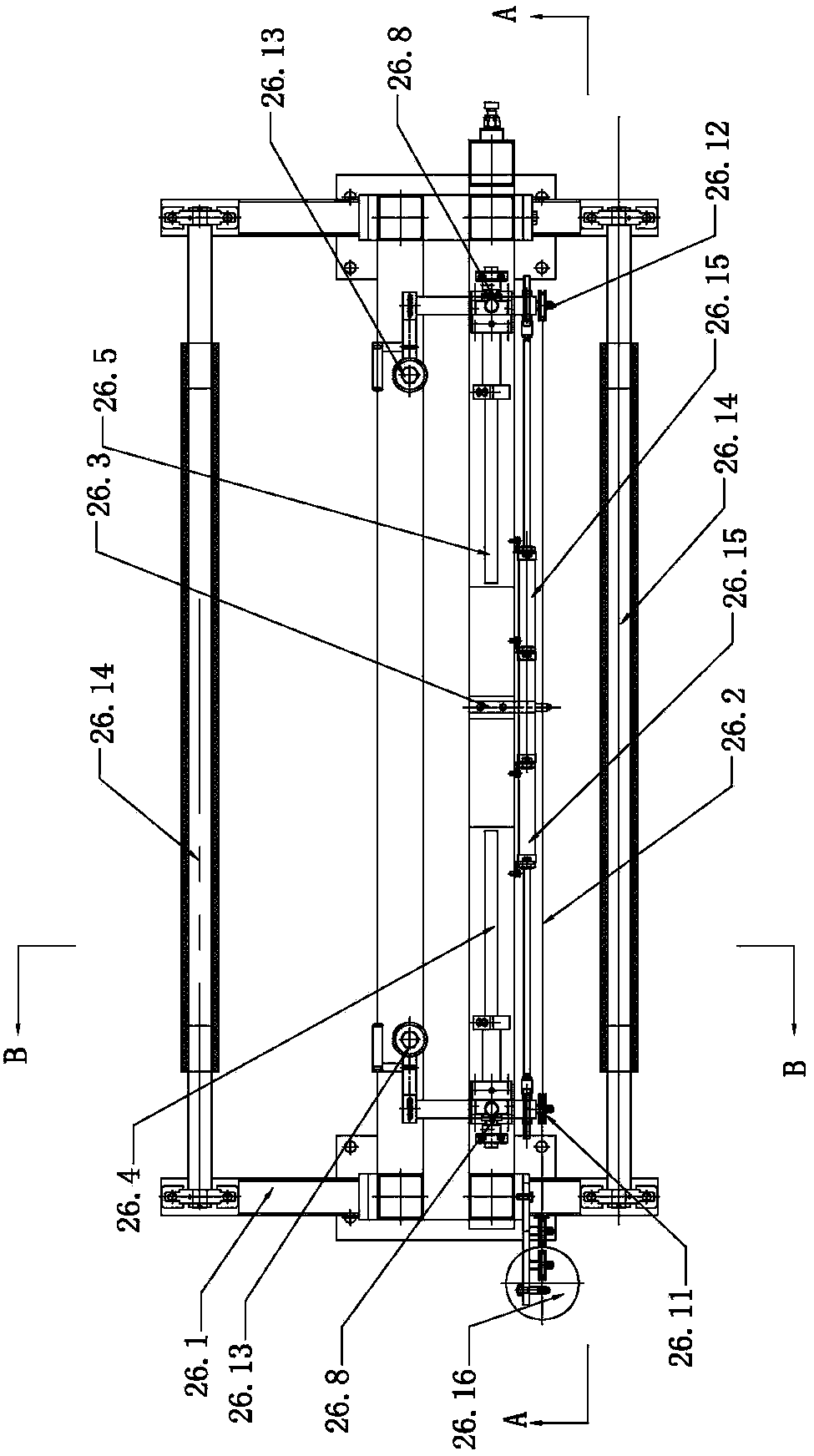

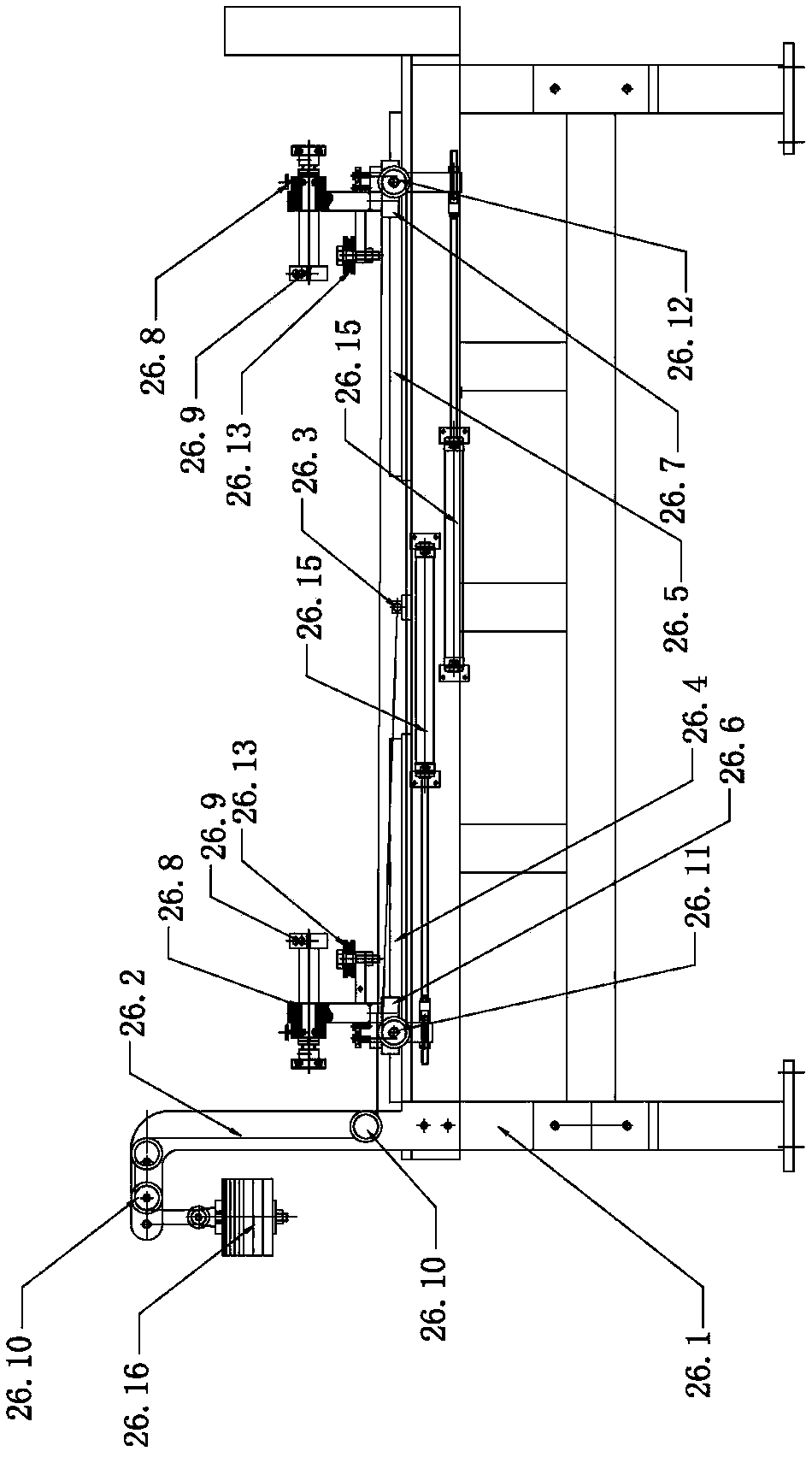

Filmed plate production line

InactiveCN104191787ASmall footprintOverall small sizeLaminationLamination apparatusProduction linePolyvinyl chloride

The invention relates to a filmed plate production line which comprises an uncoiling machine, a sewing machine, a flattening machine, a tightening machine I, a front storage rack, a tightening machine II, a front processor, a thermal flashing machine, a coating machine, a moisture drying machine, a cold flashing machine, a tightening machine III, a centering machine, a primary coating machine, a primary coating curing furnace, a PVC (Polyvinyl Chloride) filming guide machine, a PVC filming machine, a fine coating compulsive cooling machine, a wiping centering machine, a tightening machine IV, a protecting film coating machine, a rear storage rack, a tightening machine V and a coiling machine which are densely arranged in sequence. The filmed plate production line is characterized by further comprising a film trimming machine, wherein the film trimming machine is arranged between the protecting film coating machine and the rear storage rack. The filmed plate production line has the advantages that redundant films on two sides of a filmed metal plate in the production line can be cut off, the time and the labor are saved, and the use reliability is high.

Owner:JIANGYIN GANGLI AUTOMATION EQUIP

Cleaning method for removing metal oxide deposited on surface of ceramic

PendingCN112563111AReduce particulate pollutionExtend the time of single useElectric discharge tubesSand blastingPotassium hydroxide

The invention relates to a cleaning method for removing metal oxide deposited on the surface of ceramic. The cleaning method comprises the following steps: incoming inspection; soaking in pure water;wiping with scouring pads; washing with pure water; soaking in isopropanol; surface sand blasting; cleaning with potassium hydroxide and hydrogen peroxide; cleaning with nitric acid and hydrofluoric acid; soaking in pure water; baking at high temperature; washing under high pressure; ultrasonic cleaning; nitrogen purging; and drying. Aluminum oxide sand blasting treatment is adopted, the roughnessof the surface of a ceramic component is improved, the sediment adsorption capacity is improved, permeation pollutants in micropores of the ceramic component can be cut off easily through a high-temperature baking process, the surface of the ceramic component is cleaned through ultrasonic cleaning and nitrogen, and particle pollutants on the surface of the ceramic component are greatly reduced. Particle pollutants and deposited pollutants on the surface of the ceramic part and in micropores can be completely removed, the single use time of the ceramic part is doubled, the use frequency of theceramic part is increased, and the use cost of customers is reduced.

Owner:富乐德科技发展(天津)有限公司

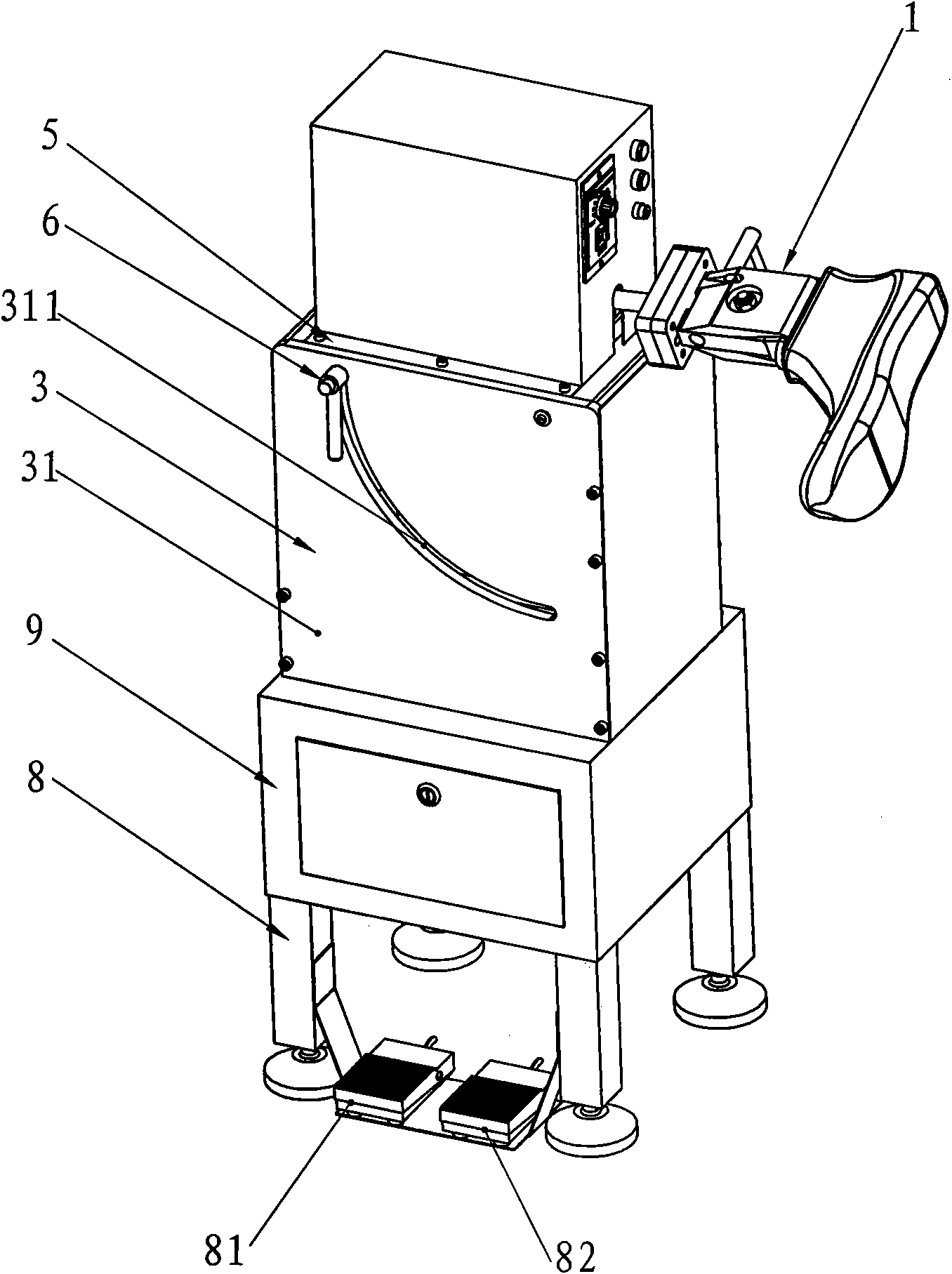

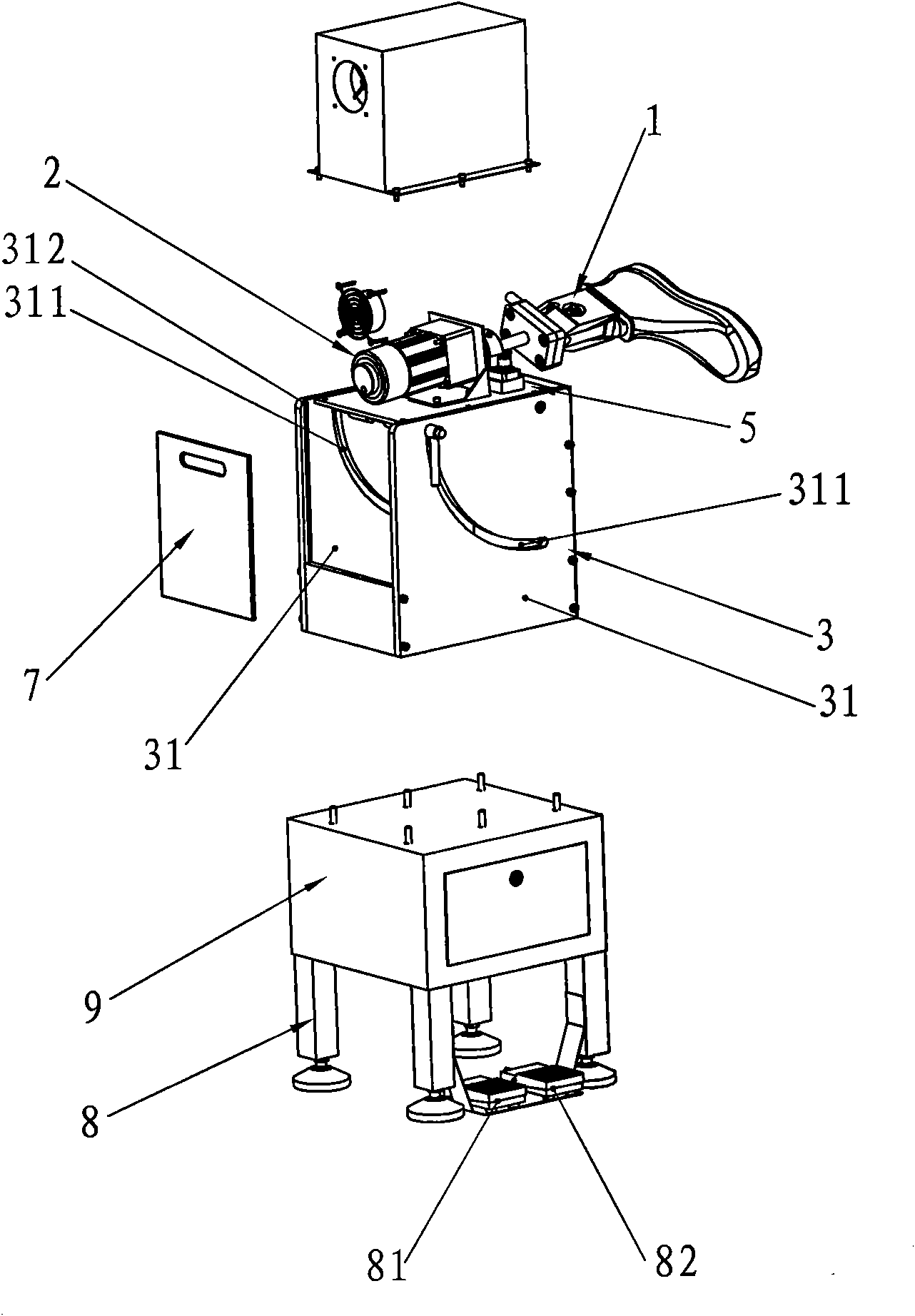

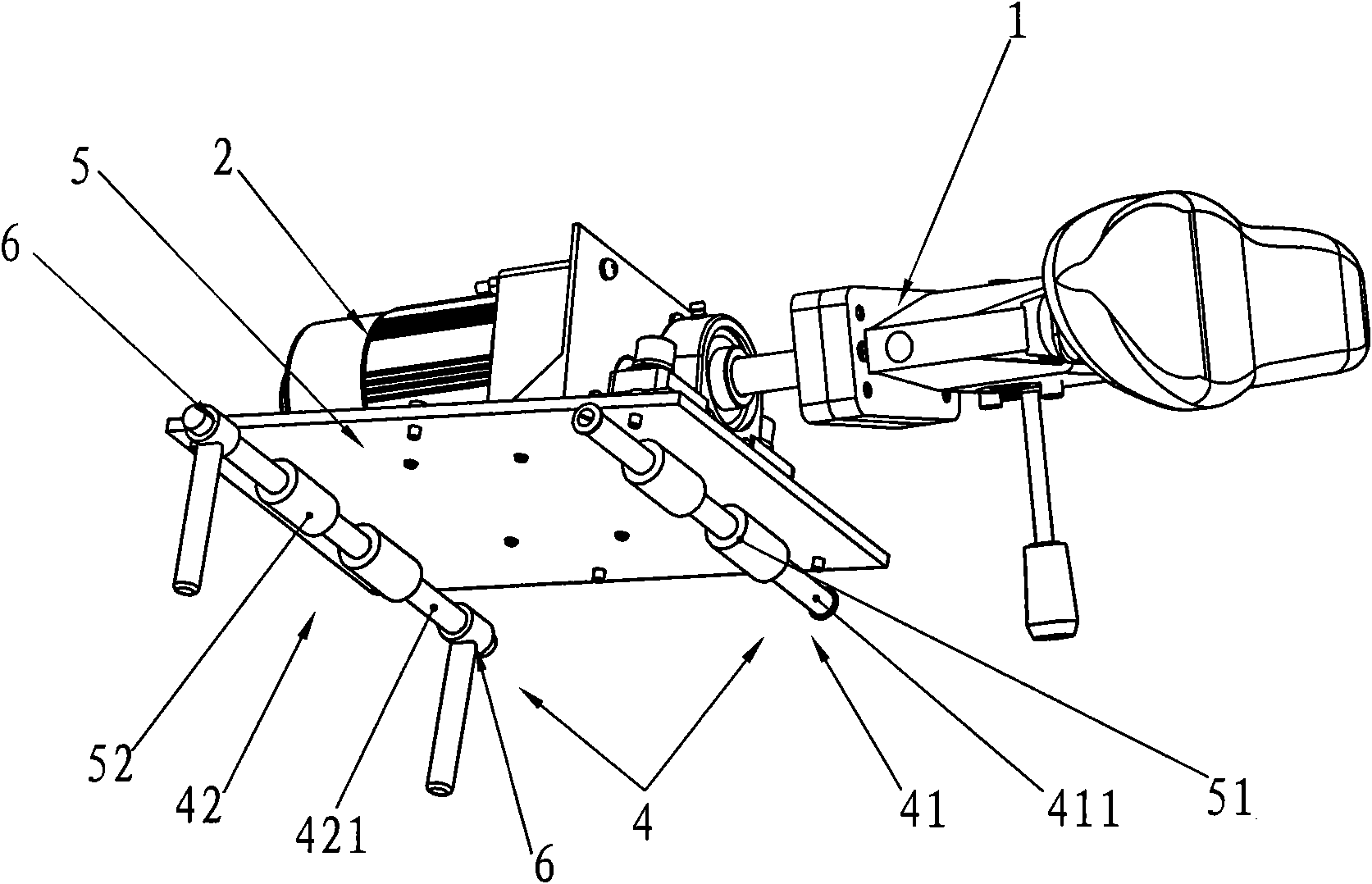

Trimming machine for shoes

The invention relates to a trimming machine for shoes, which adopts the technical scheme as follows: the trimming machine for shoes comprises a shoe tree fixture, a motor, a carriage and a turnover mechanism, wherein the shoe tree fixture is in linkage with the shoe tree fixture and drives the shoe tree fixture to rotate along the circumferential direction, the carriage supports the motor and is in overturn fit with the motor, and the overturn mechanism is arranged between the motor and the carriage. By adopting the technical scheme, the trimming machine for shoes capable of positioning and rotating shoes and improving processing efficiency is provided.

Owner:WENZHOU MENGLANI SHOES

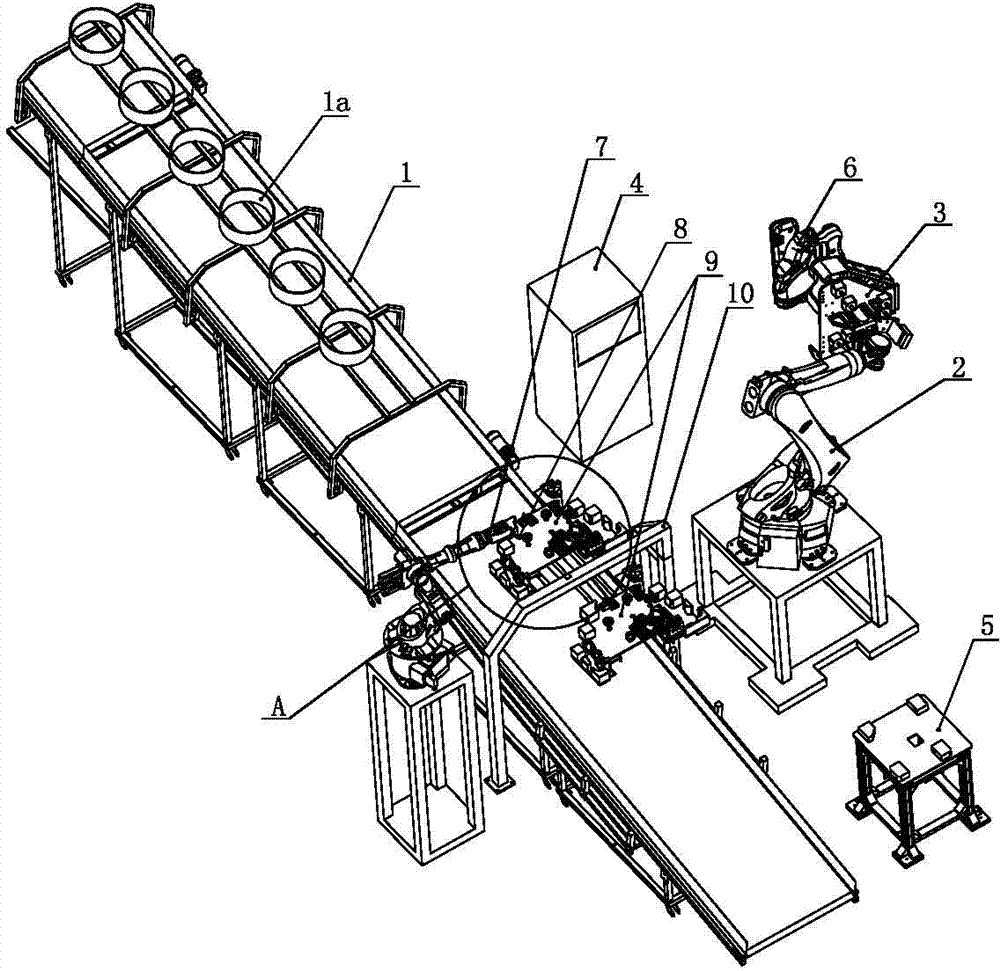

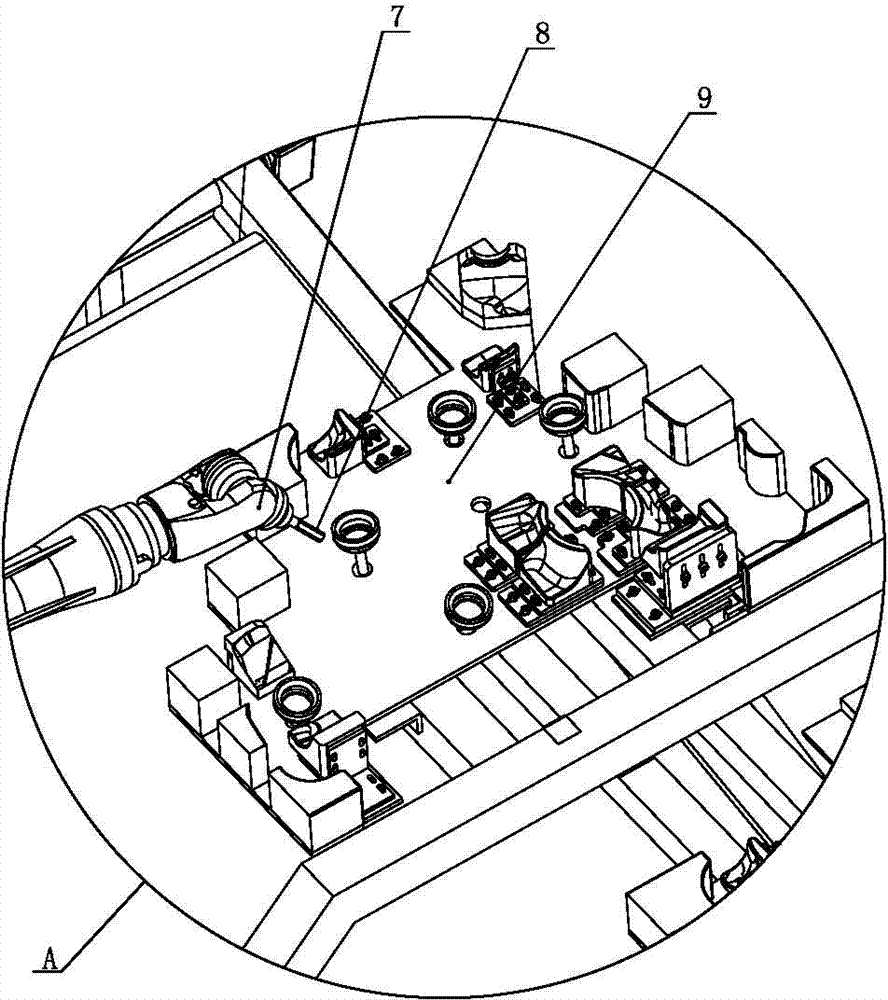

Trimming mechanism of plastic oil tank and method of trimming oil tank

The invention relates to a trimming mechanism of a plastic oil tank and a method of trimming the oil tank. The trimming mechanism comprises a big robot, a barcode printer, a weighing table and a trimming conveying line, wherein the big robot, the barcode printer and the weighing table are all located at the right side of the trimming conveying line, an oil tank grasping mechanism capable of grasping the plastic oil tank is arranged on the end of a mechanical arm of the big robot, the barcode printer and the weighing table are respectively arranged in a working travel range of the mechanical arm of the big robot, a small robot is arranged on a position, which is opposite to the big robot, at the left side of the trimming conveying line, a trimming knife capable of cutting trimmings of joint lines of the plastic oil tank is arranged on the end of a mechanical arm of the small robot, two trimming tables with the consistent shape and size are arranged between the big robot and the small robot in parallel, and the two trimming table are both fixed above the trimming conveying line. When one plastic oil tank is trimmed by the small robot, waiting, grasping, barcode pasting and weighing of another plastic oil tank can be completed by the big robot, and the trimming speed is quick, so that the production period is shortened, and the production efficiency is improved.

Owner:YAPP AUTOMOTIVE PARTS

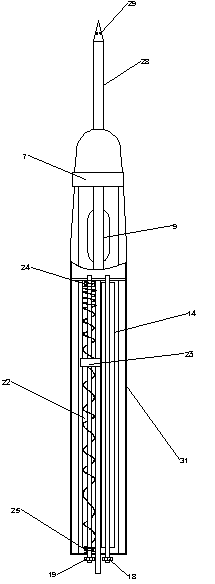

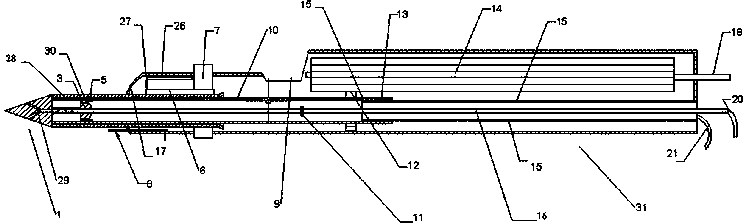

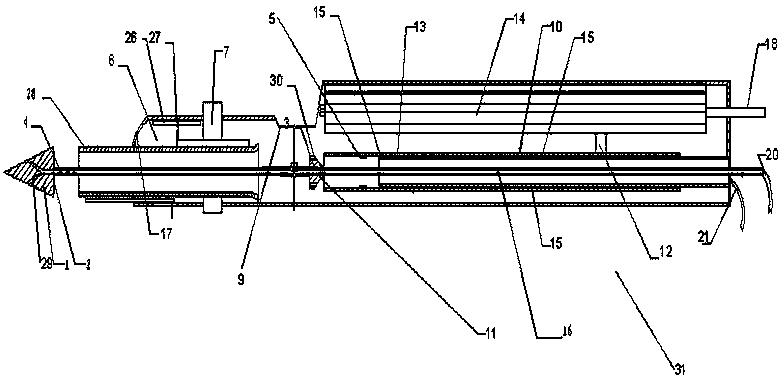

Adjustable scalpel head for minimally invasive soft tissue central biopsy

The invention discloses an adjustable scalpel head for minimally invasive soft tissue central biopsy. The scalpel head comprises a shell, one end of the shell is provided with a scalpel tip for puncture, a negative pressure cutting device for cutting human body tissues is arranged in the shell, and a driving device for driving the negative pressure cutting device to cut the tissues is arranged in the shell. The prism-shaped front end of the scalpel tip transits backwards into a cone shape.

Owner:陈政

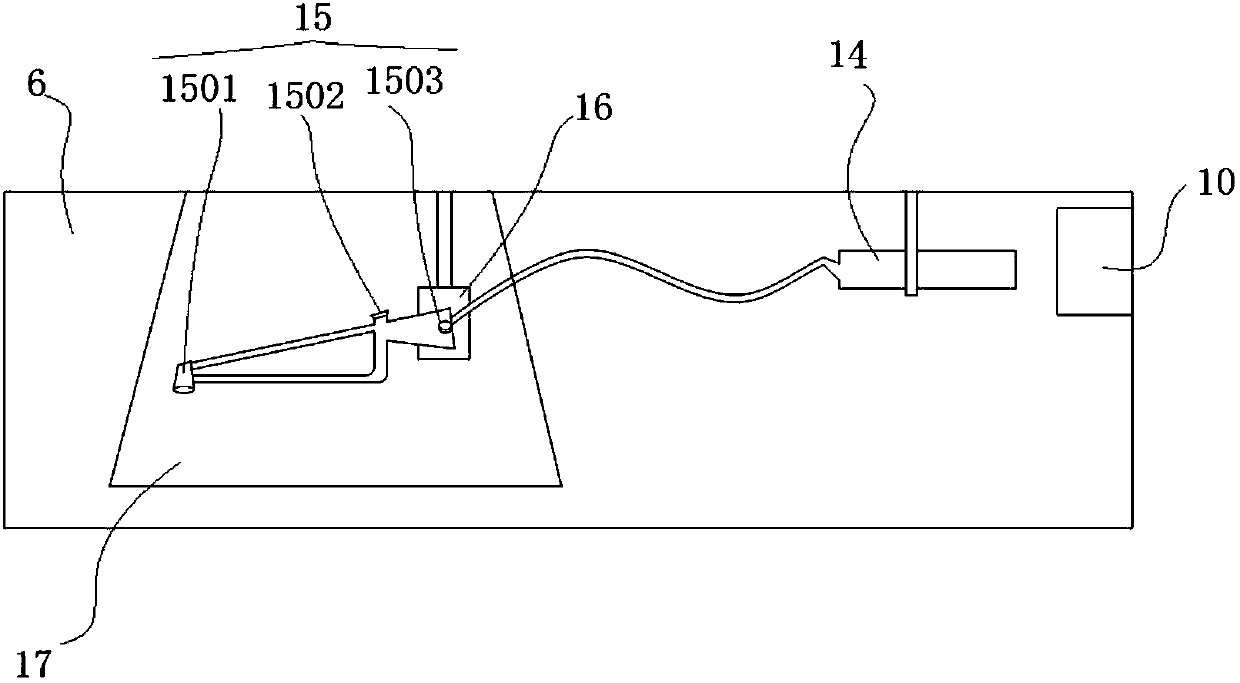

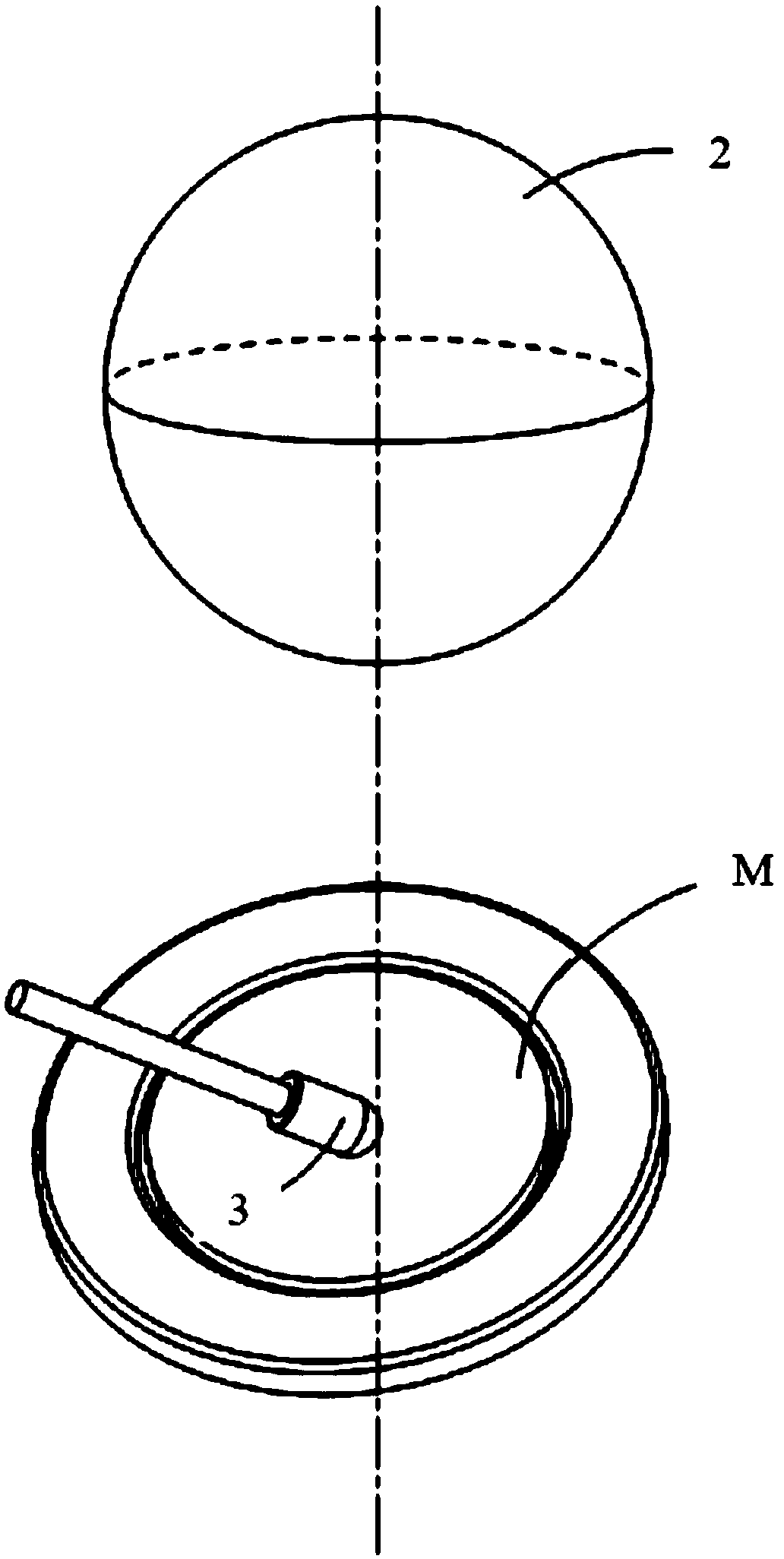

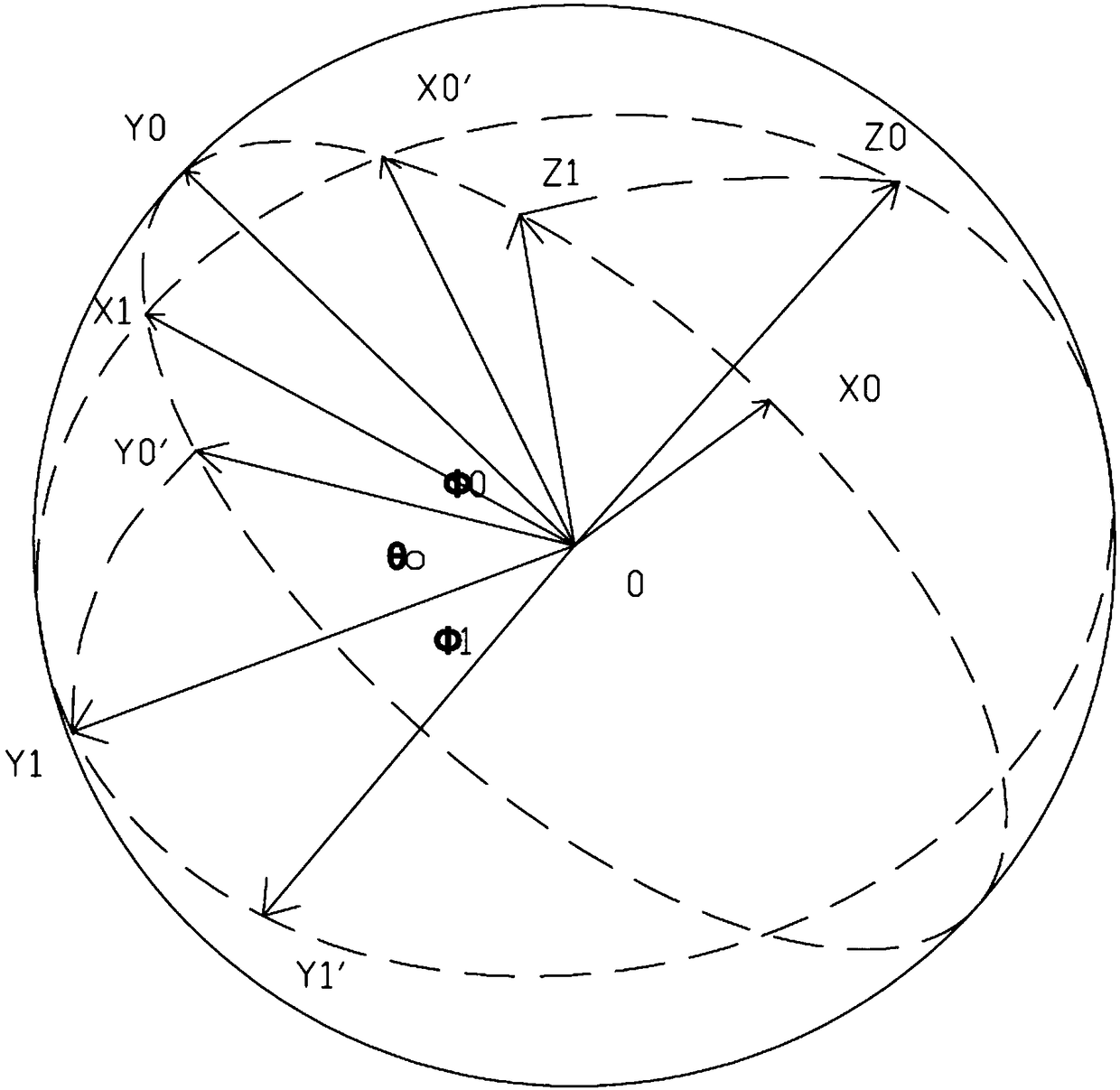

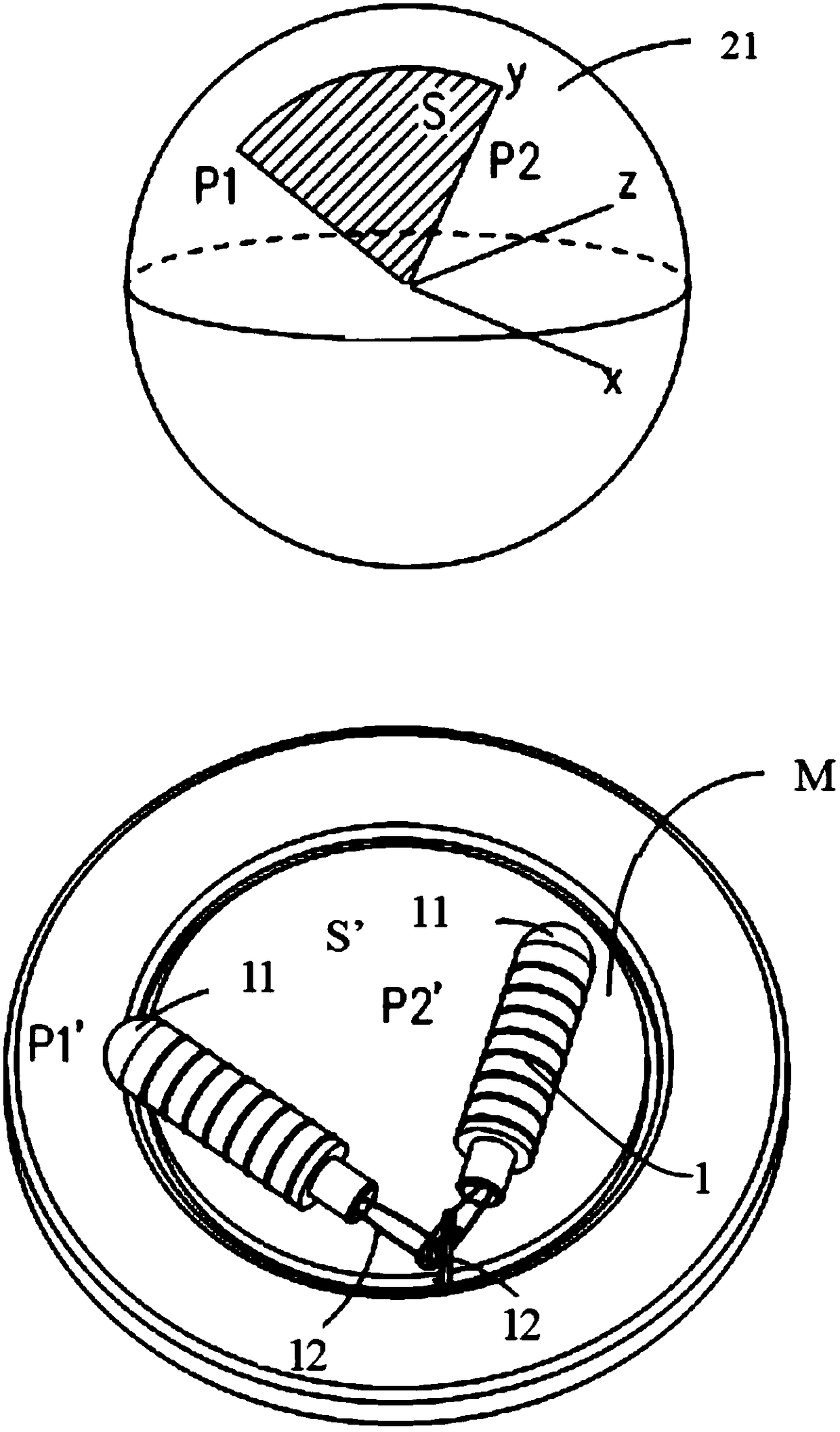

Minimally invasive surgery assisting device and control method thereof

ActiveCN109288549AHigh torqueEasy roll operationSurgical manipulatorsSurgical robotsLess invasive surgeryMedicine

The invention provides a minimally invasive surgery assisting device. The minimally invasive surgery assisting device comprises an in-vitro device, an in-vivo device, a positioning probe and a controlsystem, wherein the in-vitro device comprises an in-vitro magnetism generating device and a driving mechanism, the in-vitro magnetism generating device provides a rotating magnetic field, and the driving mechanism drives the in-vitro magnetism generating device to move and / or rotate; the in-vivo device comprises a magnetic assisting part and a fixing clamp connected with the magnetic assisting part; the positioning probe comprises a magnetic field sensor detecting the magnetic field intensity of the in-vitro magnetism generating device; the control system is directly or indirectly communicated with the driving mechanism and the positioning probe. The minimally invasive surgery assisting device has the advantages that the rolling angle of the to-be-stripped mucosa in any spatial facing direction can be easy to control, operation repeatability is high, speed is high, and safety and reliability are realized.

Owner:ANKON MEDICAL TECH (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com