Diesel engine cylinder hole water jacket sand core reinforcing method

A water-jacketed sand core and diesel engine technology, applied in cores, additive processing, metal processing equipment, etc., can solve problems affecting the accuracy of sand core forming strength and shape, no solution found, and poor sand core adhesion. Advanced problems, to achieve the effect of simple processing, easy printing, and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

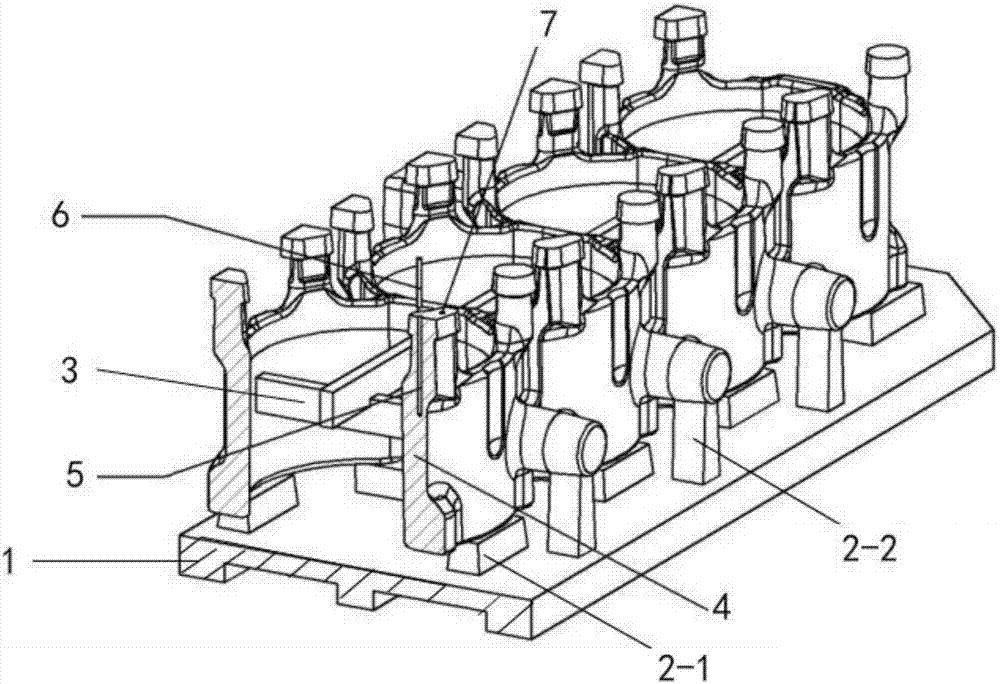

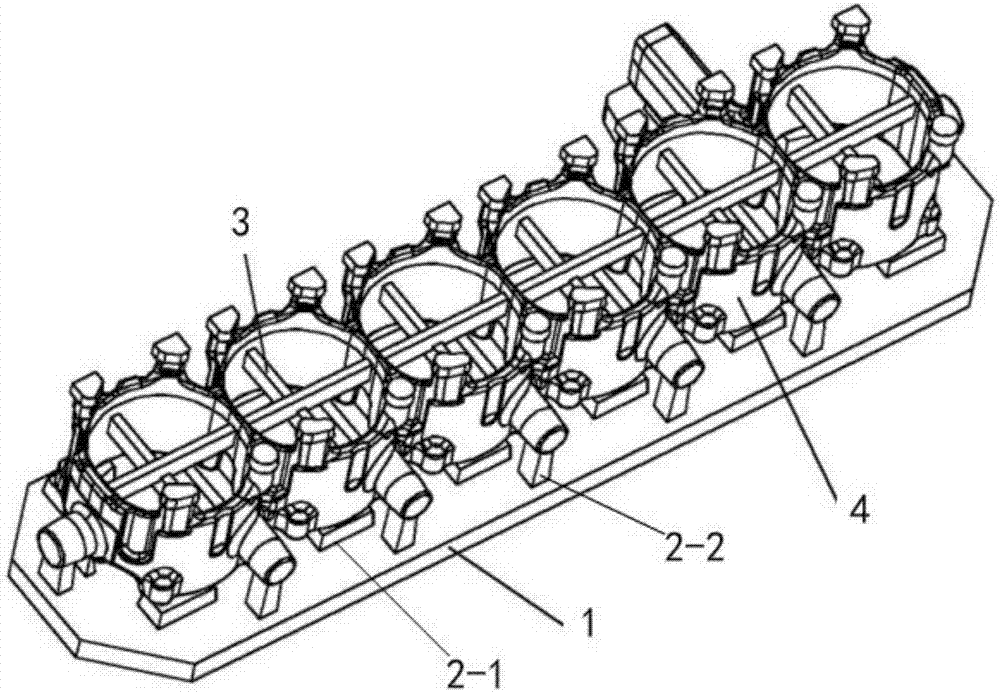

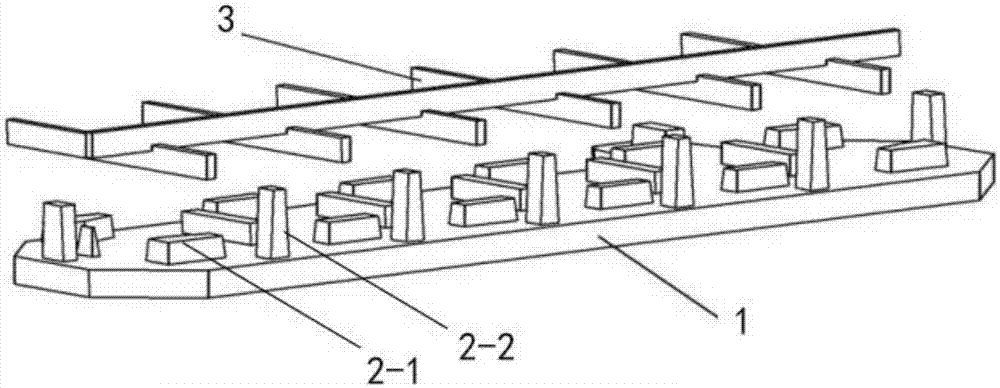

[0028] Such as Figure 1~3 Shown, a kind of diesel engine cylinder bore water jacket sand core reinforcement method, comprises the following steps:

[0029] (1) When 3D printing the cylinder hole water jacket sand core, adopt the 3D printing posture of the cylinder hole water foot of the cylinder hole water jacket sand core 4 facing upwards, first increase the printing boss-like support plate, and then print the cylinder hole The body of the water jacket sand core 4, and a cross-shaped support frame 3 is added to the cylinder hole part of the cylinder hole water jacket sand core 4; the boss-shaped support plate includes a bottom plate 1, and several A cuboid boss, the cuboid boss includes a transverse cuboid boss 2-1 and a longitudinal cuboid boss 2-2; the side of the transverse cuboid boss 2-1 is distributed on the base plate 1; The bottom surface of the longitudinal cuboid-shaped boss 2-2 is distributed on the bottom plate 1; at the same time, four transverse cuboid-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com