Trimming mechanism of plastic oil tank and method of trimming oil tank

A technology for plastic fuel tanks and fuel tanks, which is applied in the field of fuel tank trimming and plastic fuel tank trimming mechanisms, which can solve the problems of large total weight, inability to increase speed, and affect the efficiency of production lines, etc., and achieve the effect of small load and faster moving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

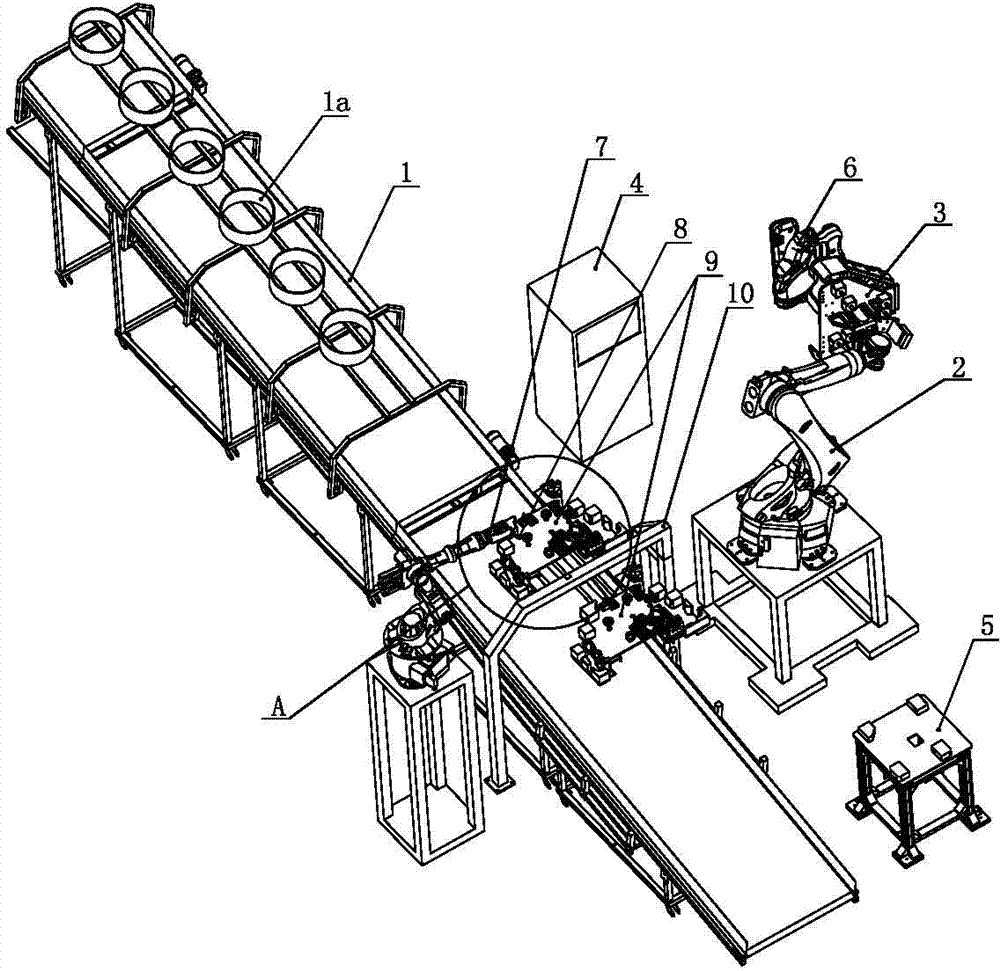

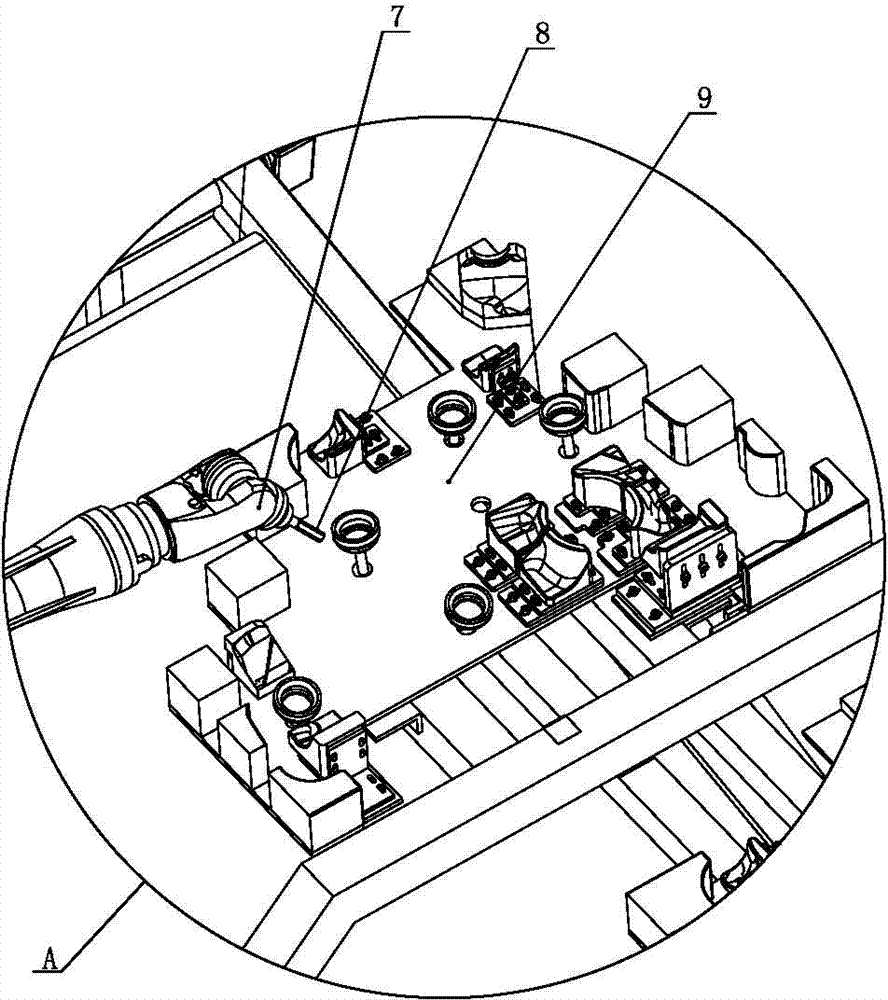

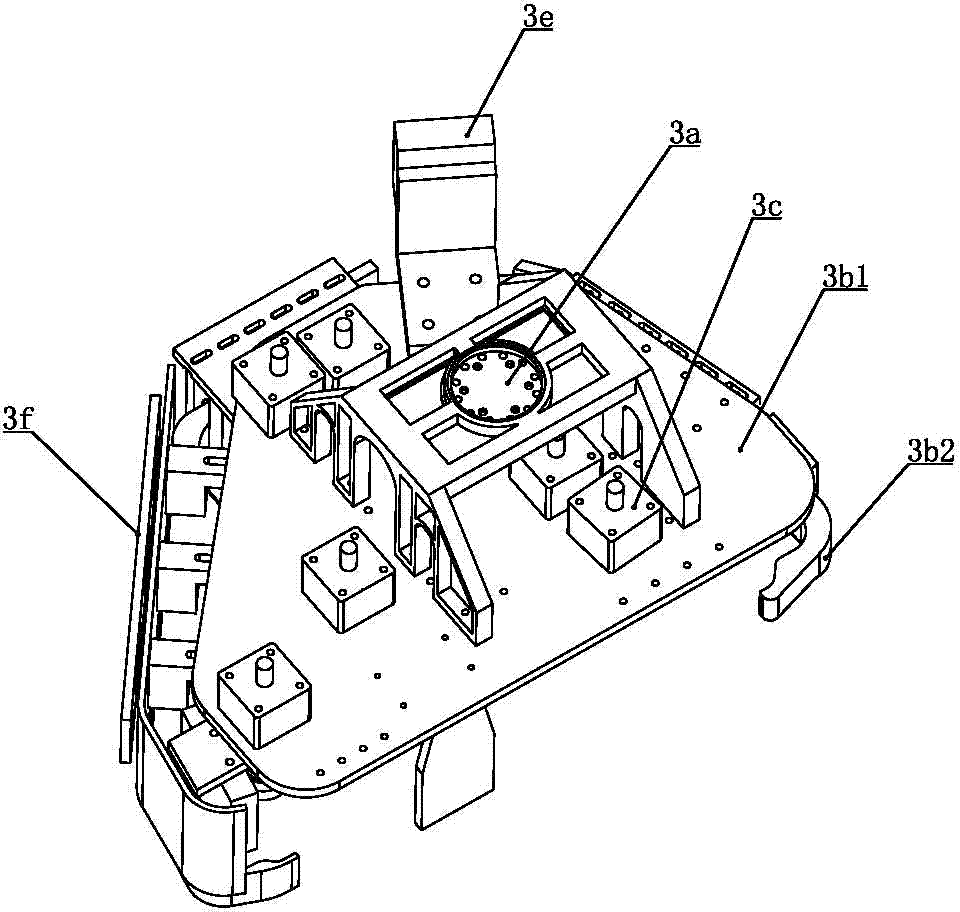

[0026] Such as Figure 1 to Figure 5 As shown, the plastic fuel tank trimming mechanism of the present invention includes a large robot 2, a bar code machine 4, a weighing platform 5 and a flash conveying line 1, and the large robot 2, a bar code machine 4 and a weighing platform 5 are all located at the flash conveying line 1 On the right side of the big robot 2, the end of the mechanical arm of the big robot 2 is equipped with a fuel tank grasping mechanism 3 that can grab a plastic fuel tank. Within the working stroke range of the arm, a small robot 7 is installed on the left side of the flash conveying line 1 opposite to the big robot 2, and the end of the mechanical arm of the small robot 7 is equipped with a tool that can cut off the flash of the plastic fuel tank clamping line. Trimming knife 8, two trimming platforms 9 with consistent shape and size are arranged side by side between the big robot and the small robot, and the two trimming platforms 9 are all fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com