Filmed plate production line

A film-coated board and production line technology, applied in the direction of layered products, lamination devices, lamination, etc., can solve the problems of danger, poor consistency of manual operation, etc., achieve high reliability, small size and footprint, reduce The effect of floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

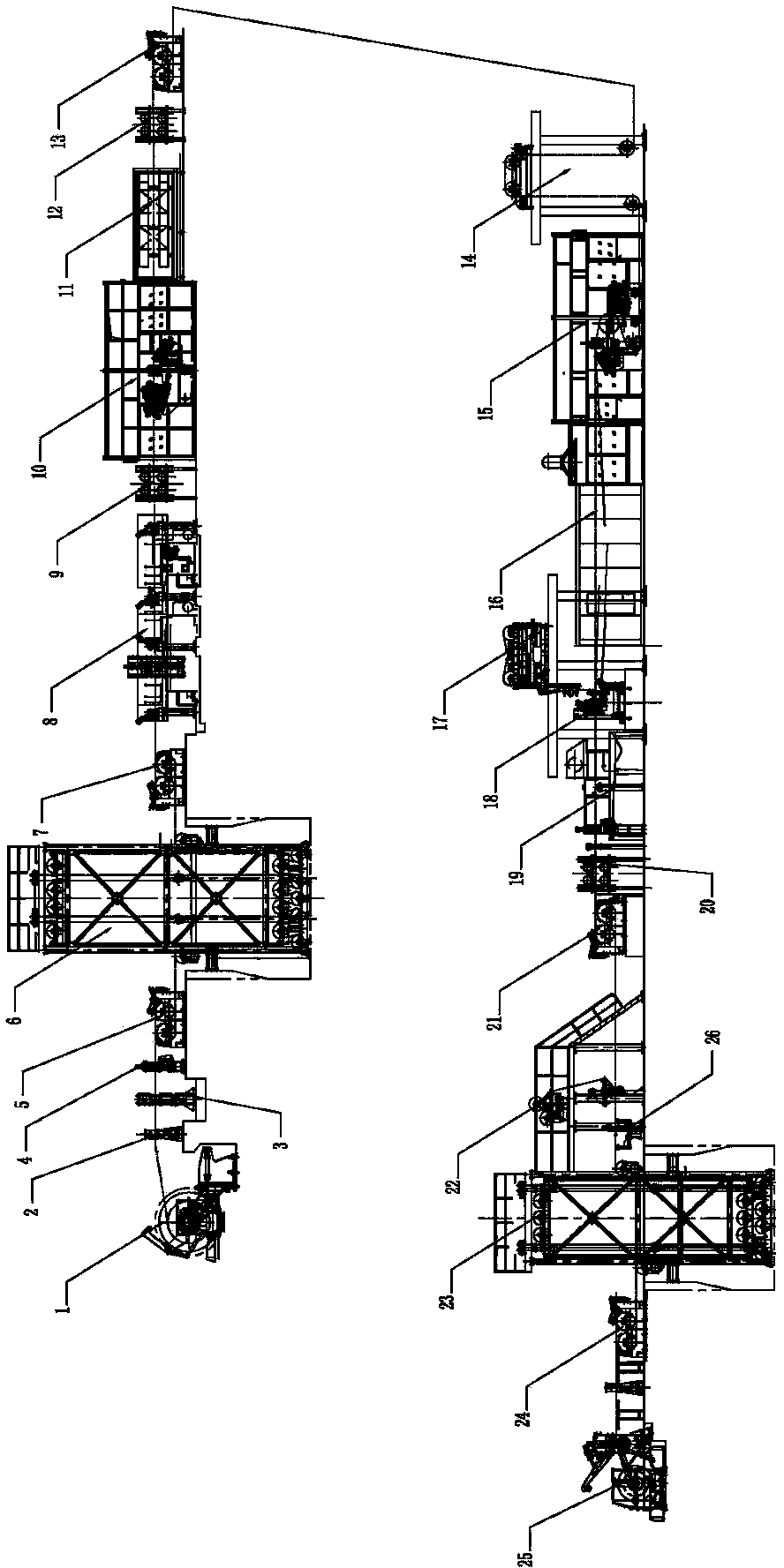

[0014] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the film-coated board processing production line includes uncoiler 1, shearing machine 2, sewing machine 3, flattening machine 4, tensioner Ⅰ5, front storage rack 6, tensioner Ⅱ7, pre-processing machine 8, heating Purging machine 9, chemical coating machine 10, water vapor dryer 11, cold purging machine 12, tensioning machine III 13, centering machine 14, initial coating machine 15, initial coating curing furnace 16, PVC film guide machine 17, PVC laminating machine 18, fine coating strong cooling machine 19, squeezing machine 20, tensioning machine Ⅳ 21, protective film laminating machine 22, rear storage rack 23, tensioning machine Ⅴ 24 and winder 25 front and rear closely arranged in sequence;

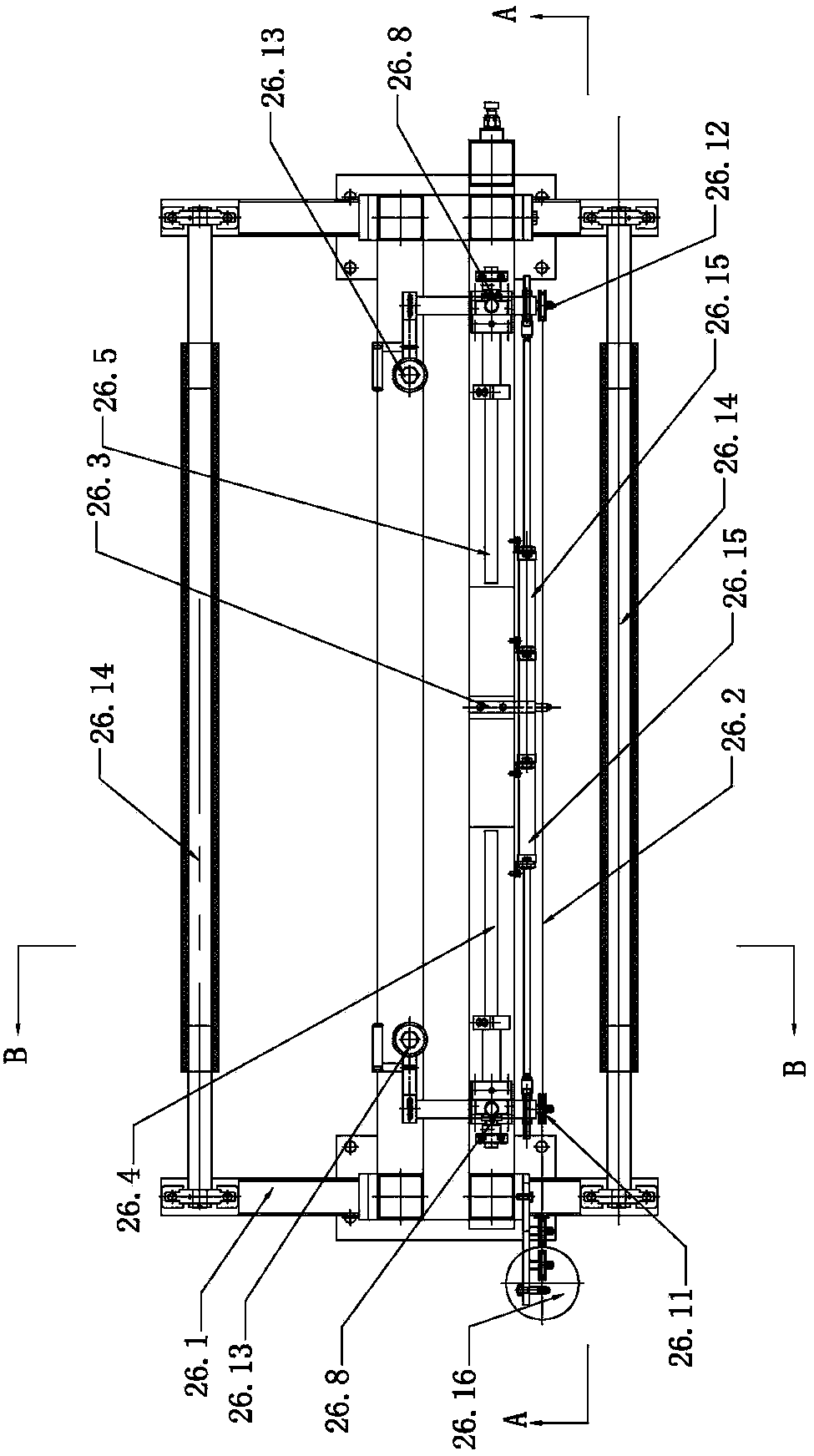

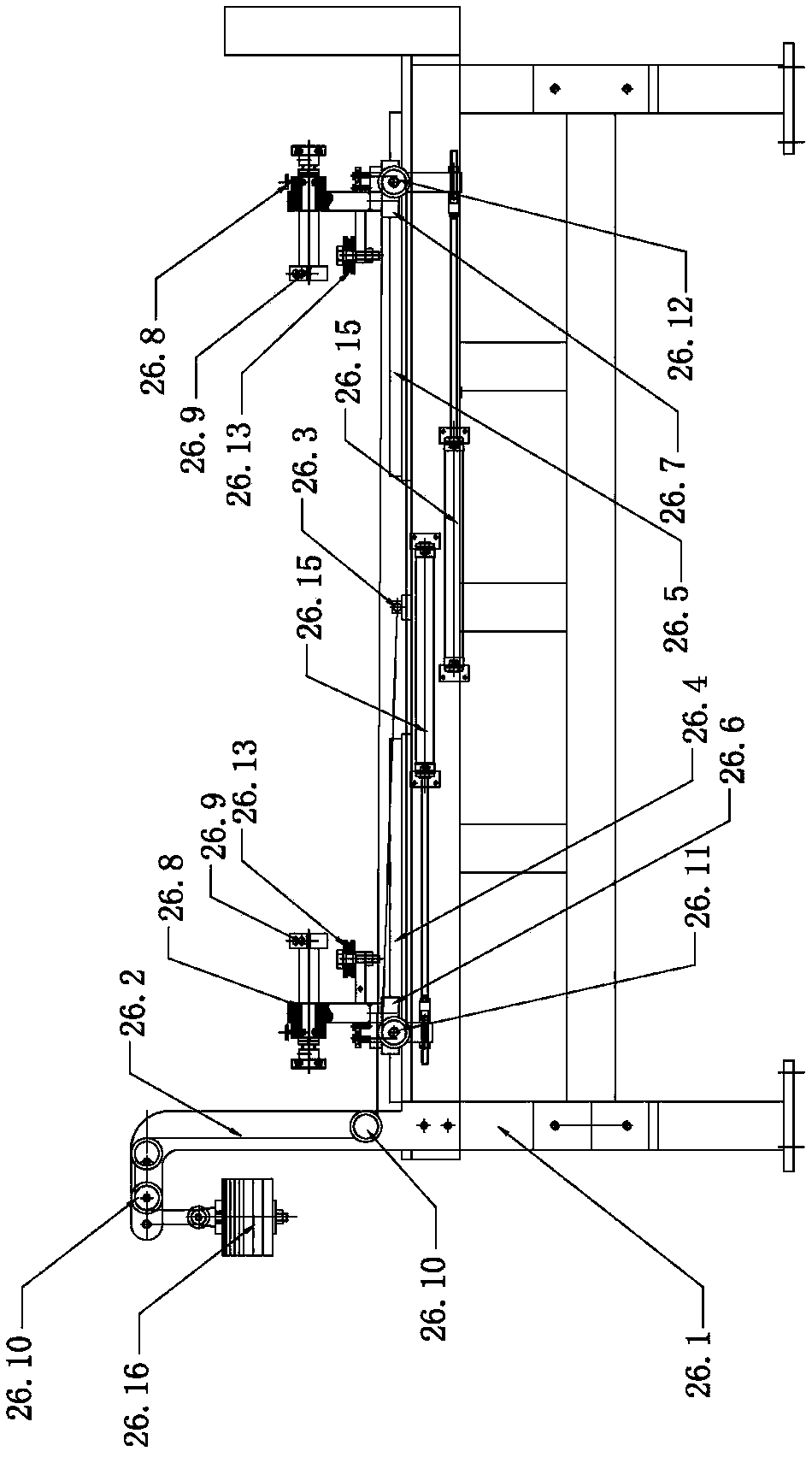

[0015] It is characterized in that it also includes a film trimming machine 26, and the film trimming machine 26 is arranged between the protective film laminating machine 22 and the rear storage rack 23, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com