Trimming machine for shoes

A technology for trimming machines and shoes, which is applied in the direction of shoemaking machinery, applications, footwear, etc., and can solve the problems of shoes not being positioned, difficult to guarantee quality, and low processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

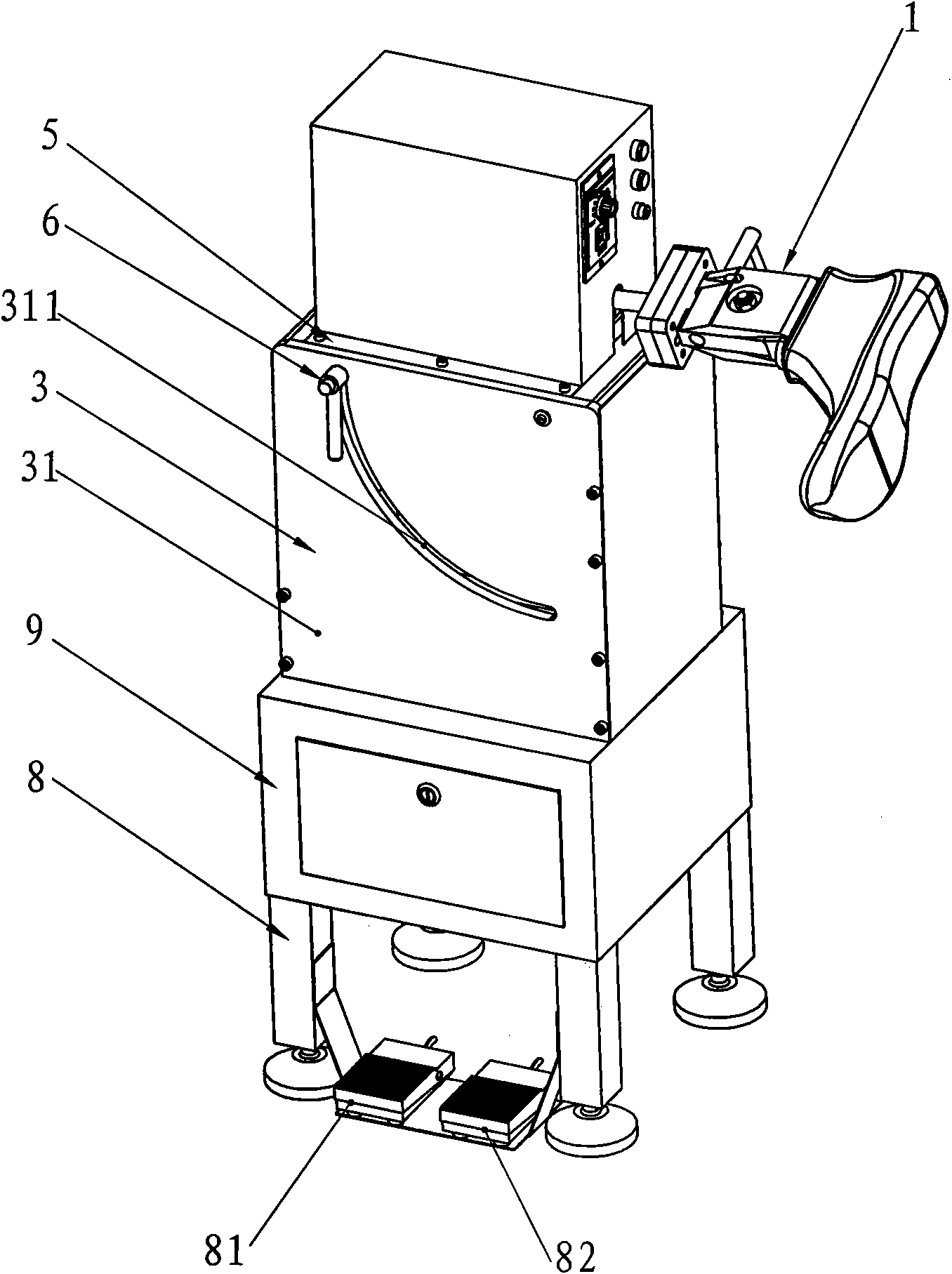

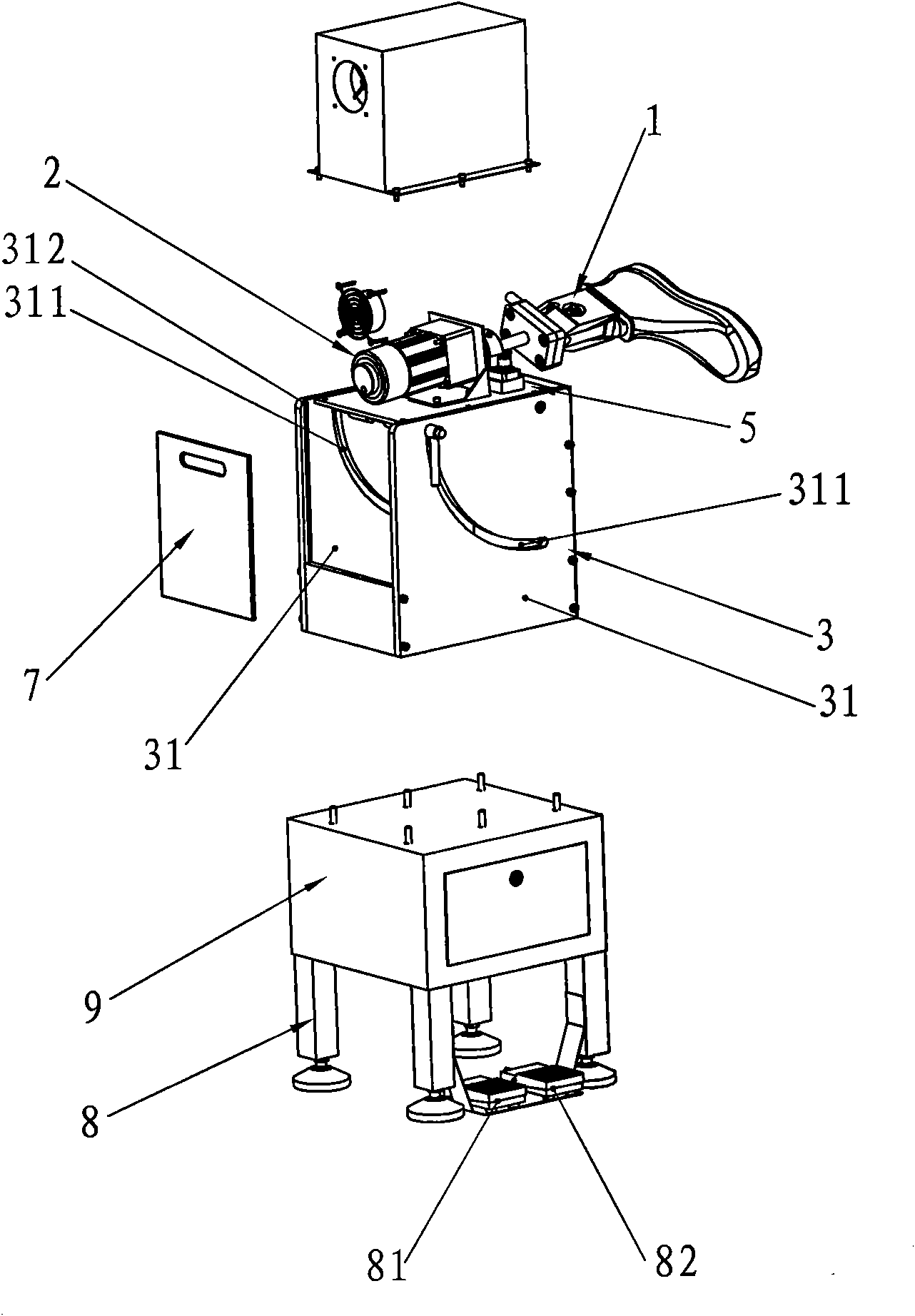

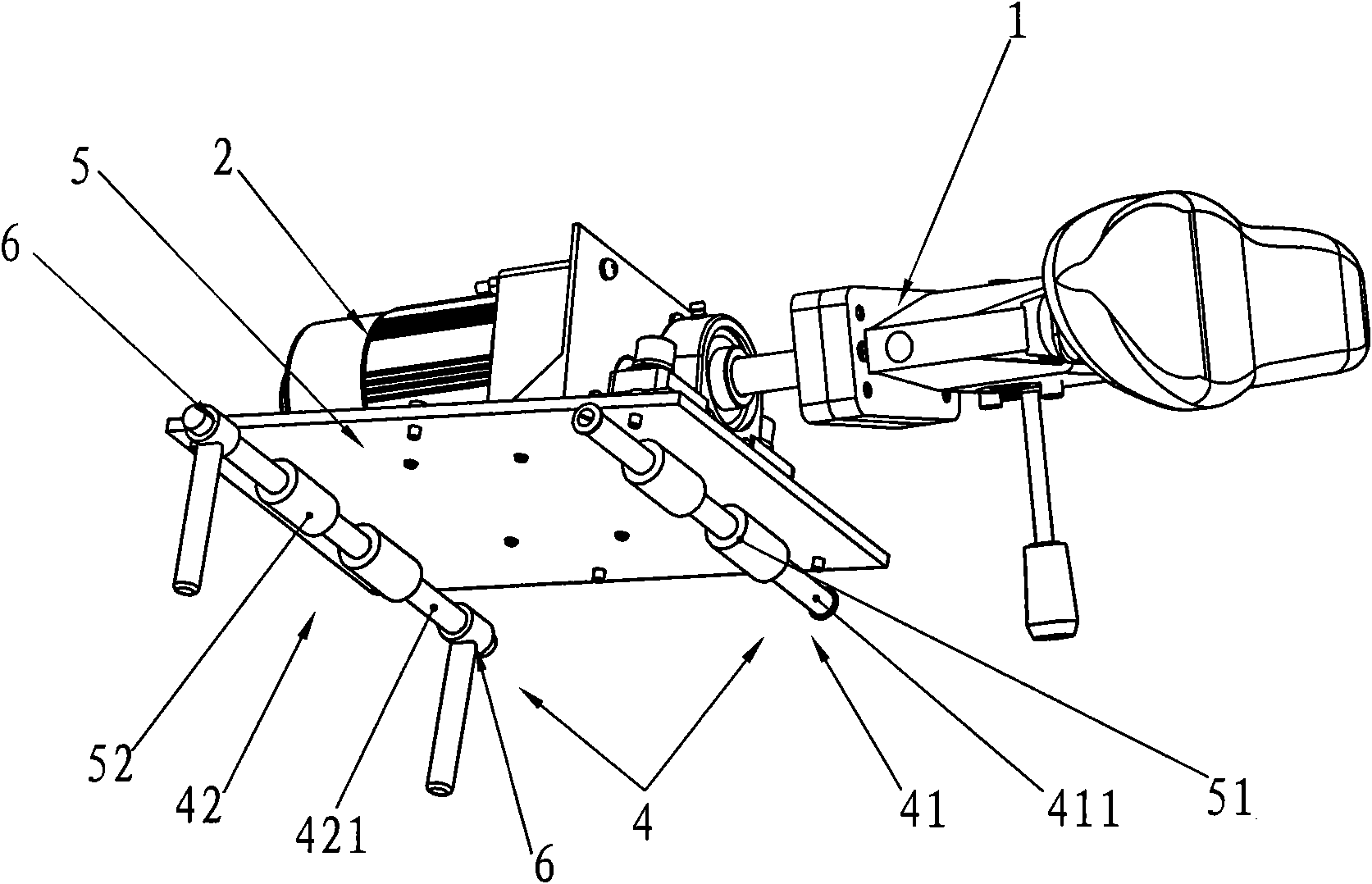

[0018] like Figure 1-Figure 3 A trimming machine for shoes is shown, including a shoe last fixture 1, a motor 2 that is linked with the fixing fixture 1 and constitutes the circumferential rotation of the shoe last fixture 1, a support frame 3 that supports the motor 2 and flips over and cooperates with the motor 2, and The turning mechanism 4 is arranged between the motor 2 and the supporting frame 3 . In the above solution, the shoe to be flashed is placed on the shoe last fixture 1, and the shoe last fixture 1 is linked with the motor 2 to form its circumferential rotation, so that when the motor 2 is running, the shoe will also follow the shoe last fixture for a circle. At this time, the flash can be cut off only by placing the cutter against the flash of the shoe, which is faster and easier to operate, thereby improving the processing efficiency; while the motor 2 is passed through the support frame 3 support, and between the support frame 3 and the motor 2, there is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com