Patents

Literature

77results about How to "Shorten injection molding cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of antibacterial flame-retardant ABS material

The invention discloses an antibacterial flame-retardant ABS material and a preparation method thereof. The antibacterial flame-retardant ABS material is prepared from ABS resin, a flame-retarding agent, a coordinative flame-retarding agent, an auxiliary flame-retarding agent, a thermal stabilizer, an antibacterial master batch, a compatilizer, an antioxidant and a lubricating agent in parts by weight, wherein the antibacterial master batch is prepared from ABS and at least one of a silver ion type antibacterial agent, zinc oxide and copper oxide by a mass ratio of 10 to 1. According to the ABS material disclosed by the invention, the silver ion type antibacterial agent or the zinc oxide or the copper oxide and the ABS are used for preparing the antibacterial master batch by the mass ratio of 10 to 1, so that the silver ion type antibacterial agent or the zinc oxide or the copper oxide is effectively uniformly dispersed in the ABS resin in order to improve the antibacterial efficiency and achieve a better antibacterial effect than an antibacterial agent which is used independently; and color changes of antibacterial ABS plastic can be effectively prevented, and the antibacterial properties of the antibacterial ABS plastic can be improved.

Owner:ORINKO NEW MATERIAL CO LTD

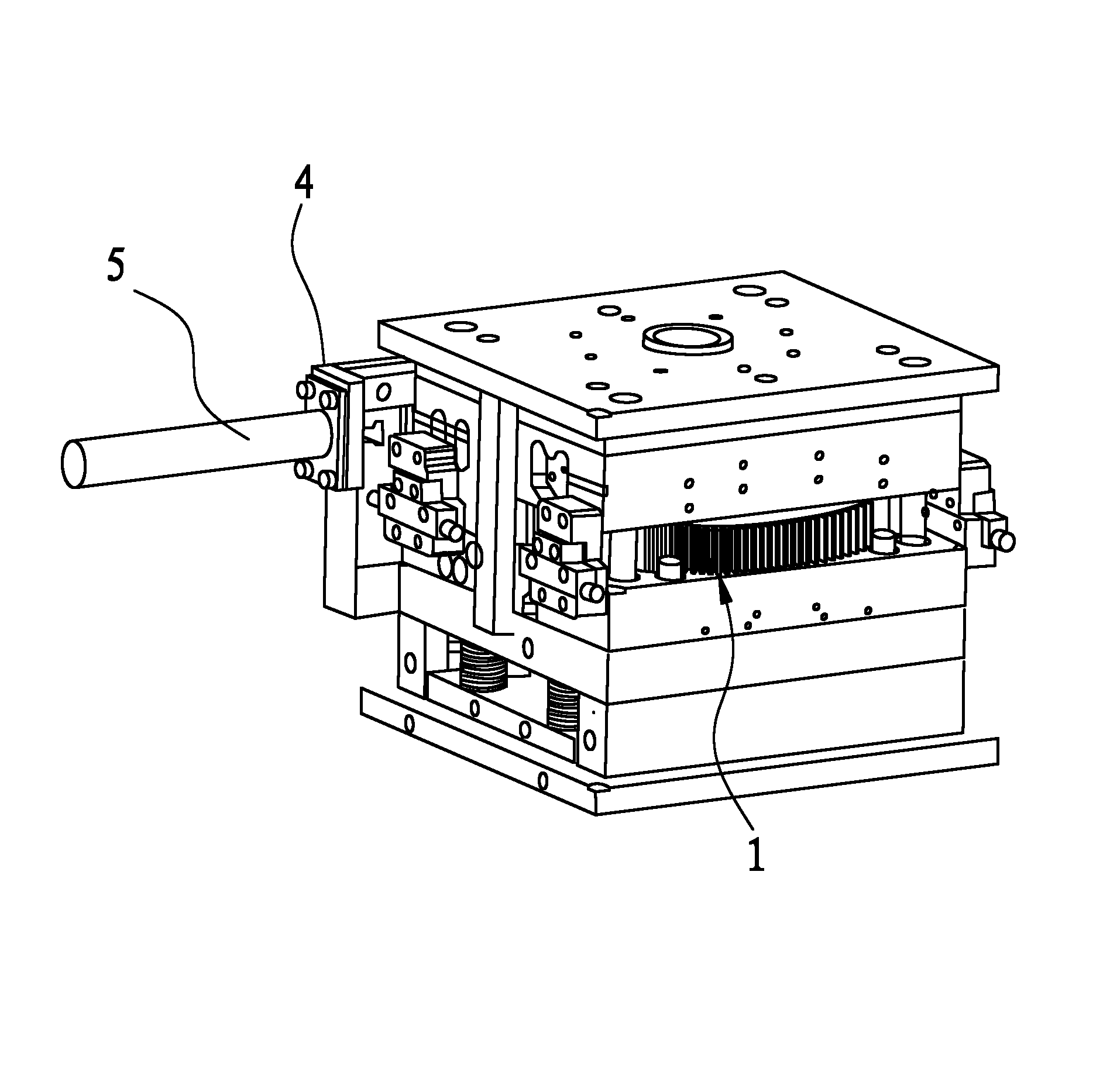

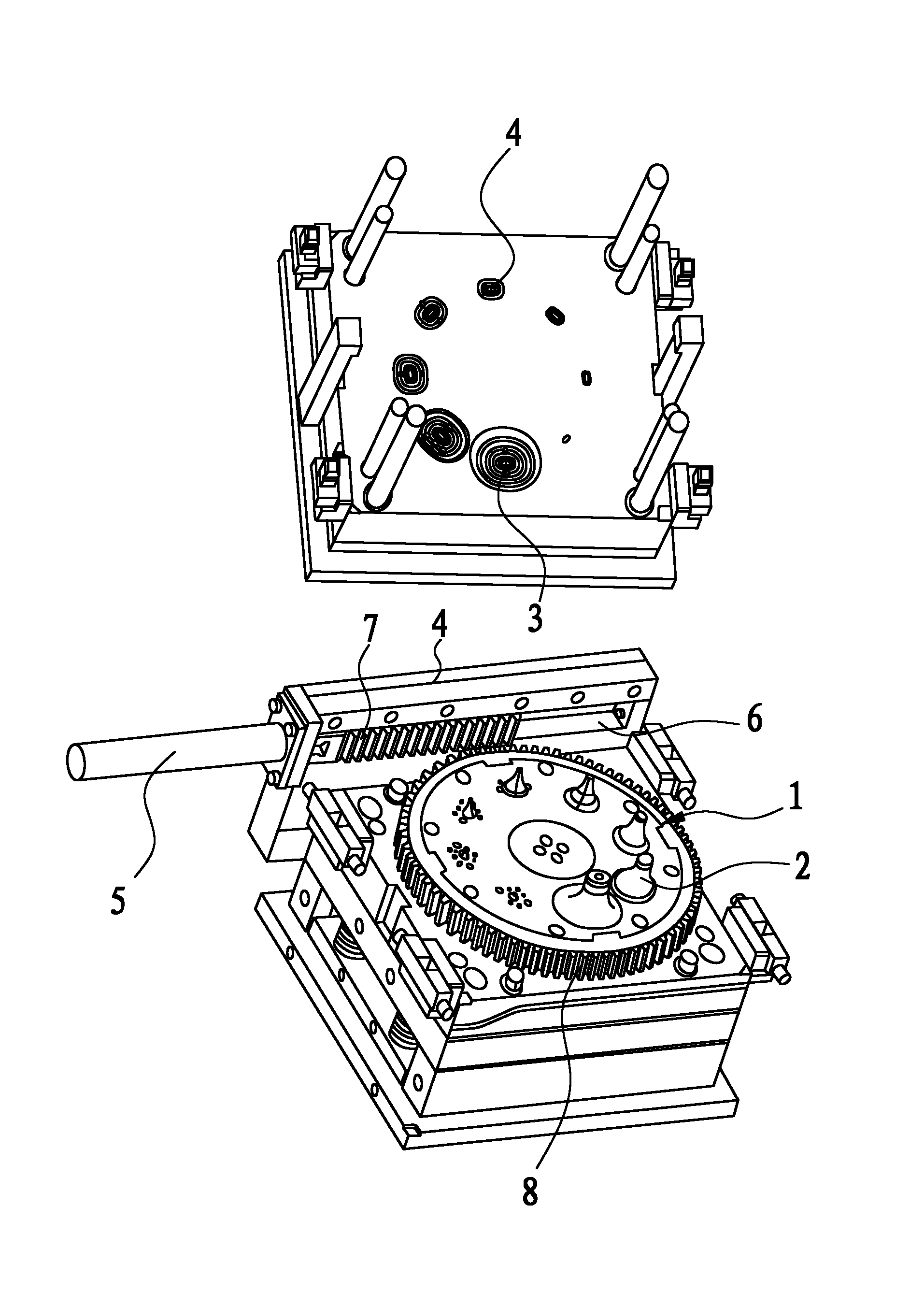

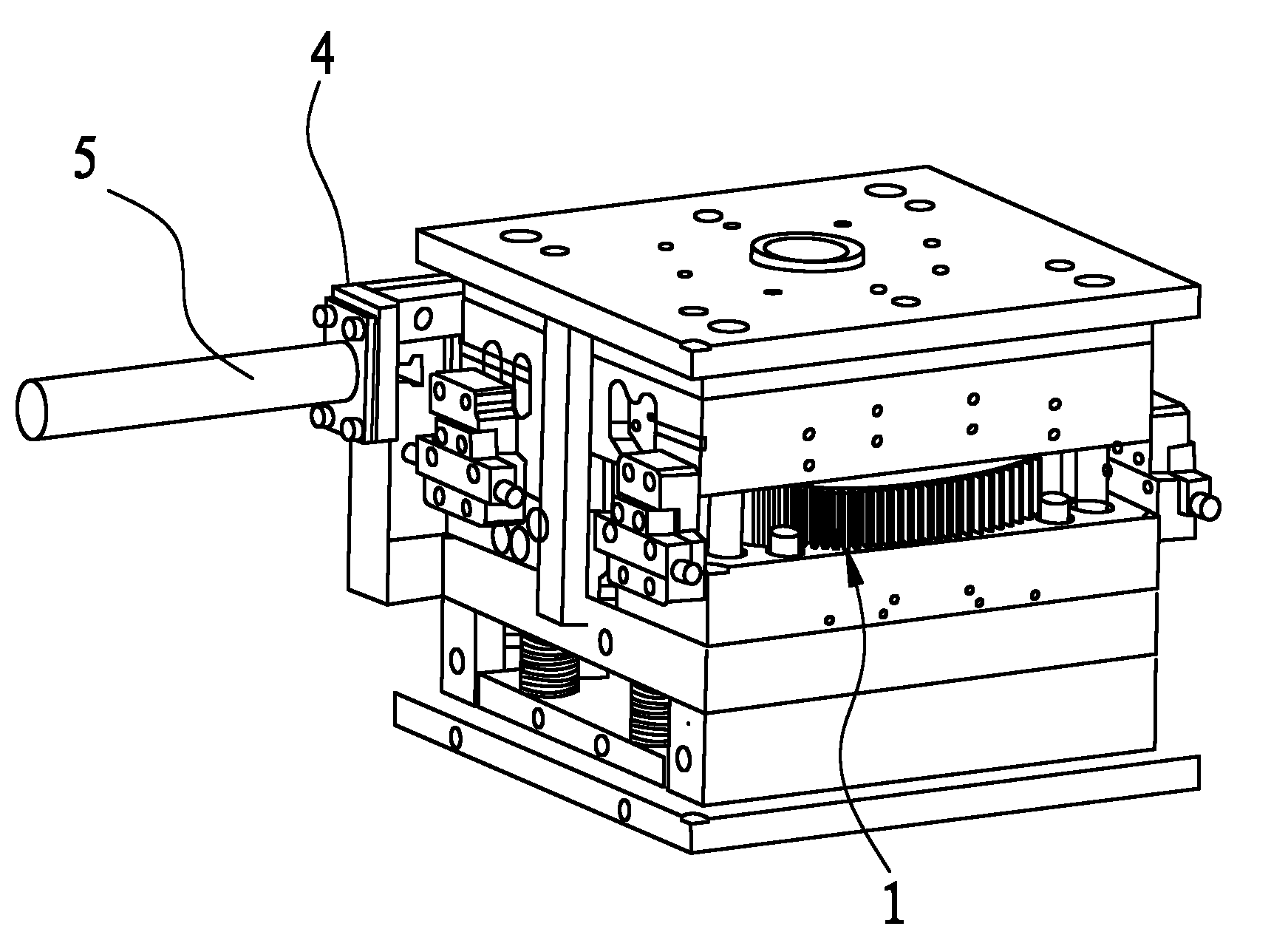

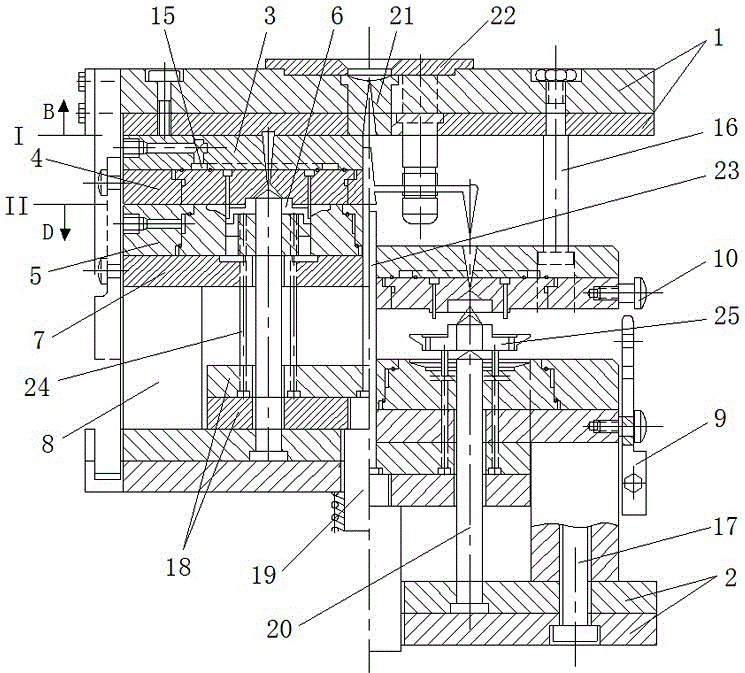

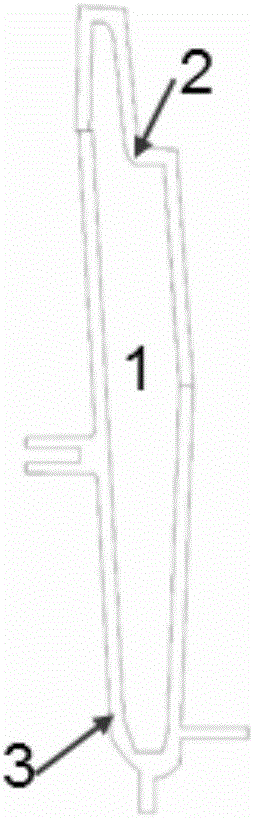

Rotating laminated type injection mould and injection method using same

The invention relates to the technical field of an injection mould, and in particular relates to a rotating laminated type injection mould and an injection method using the same. The mould comprises a fixed mould main body and a movable mould main body, wherein the fixed mould main body comprises a fixed mould plate and a fixed mould chamber, the movable mould main body comprises a movable mould plate, an ejection mechanism and a movable mould chamber, the movable mould chamber is coupled with a rotating disk, one side of the mould is provided with a driving device which drives the rotating disk to rotate, the rotating disk is annularly provided with at least two embedding pieces which are set according to the thickness of a product, and the fixed mould chamber is provided with cavities which are matched with the embedding pieces. As the rotating disk rotates, the embedding pieces arranged at the rotating disk and the cavities arranged at the fixed mould chamber are closed, glued and cooled to be formed and opened, and the transparent product with the special thickness is divided to be subjected to alternated type or laminated type injection at least twice. The invention is reasonable in structure, the size of a mould blank is reduced, the indentation on the surface of the transparent product with the special thickness is controlled, the easily generated air bubble of an inner core is avoided, the injection period is shortened, and the production cost is reduced.

Owner:毅昌金型(东莞)五金制品有限公司

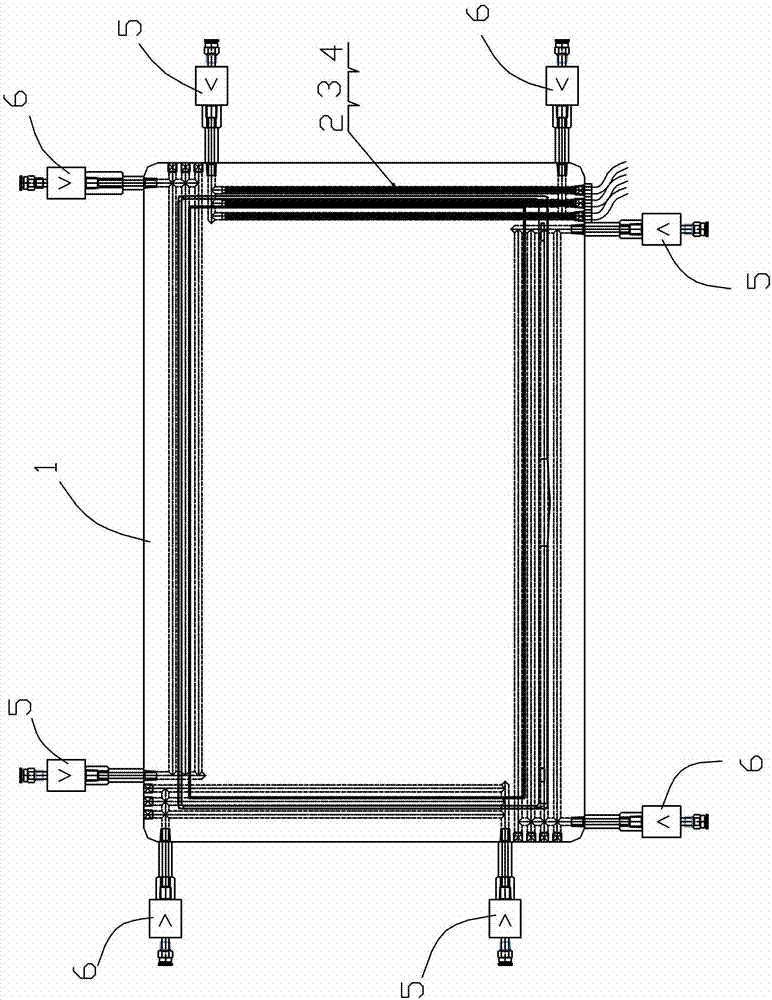

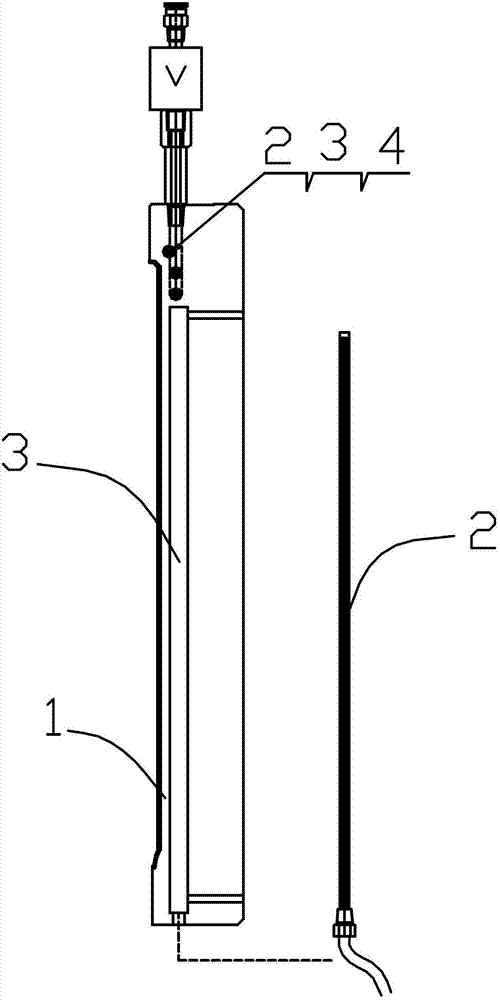

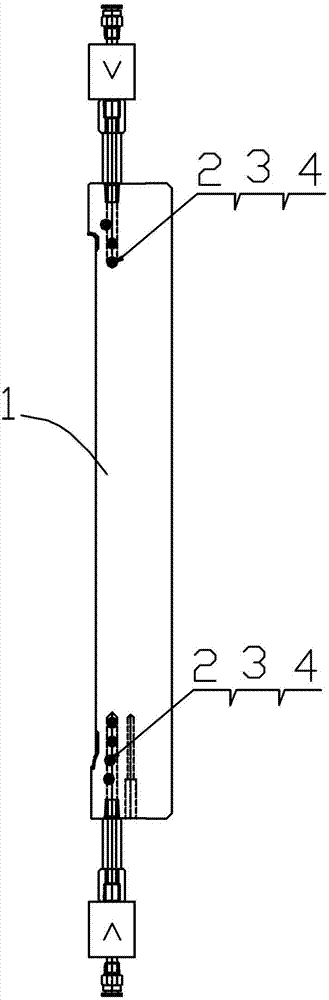

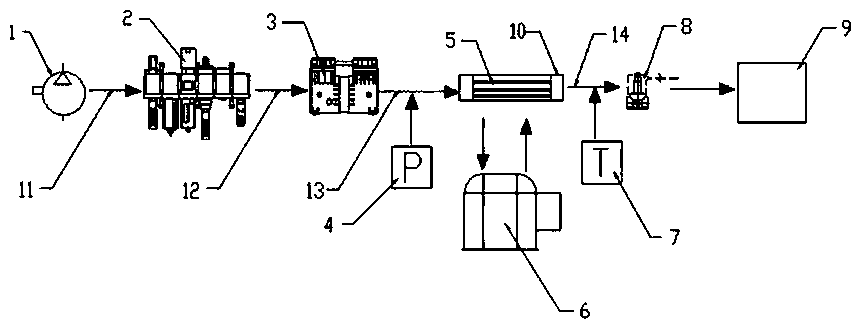

Highlight injection mould heating and cooling device and heating and cooling method thereof

The invention discloses a highlight injection mould heating and cooling device and a heating and cooling method thereof. The heating and cooling device comprises a mould cavity, an electric heating rod, a pump, a heat exchange medium storage container and a controller. The electric heating rod is arranged in a pipeline which is arranged on the mould cavity, a gap for feeding of heat exchange media is reserved between the electric heating rod and the inner wall of the pipeline, a first control valve is arranged at one end of the pipeline, and a second control valve is arranged at the other end of the pipeline. A temperature sensor is arranged on the mould cavity, a pressure sensor is arranged in the pipeline, the temperature sensor and the pressure sensor are connected into the controller, and the pump, the control valves and the electric heating rod are all controlled by the controller. The mould cavity can be heated to higher temperature without external high-pressure boilers and fixed connection pipes, and heat transfer speed and efficiency are high. Further, the highlight injection mould heating and cooling device and the heating and cooling method thereof have the advantages of high safety, reliability and energy conversion efficiency, capability of further shortening injection period and the like.

Owner:QINGDAO HISENSE MOLD

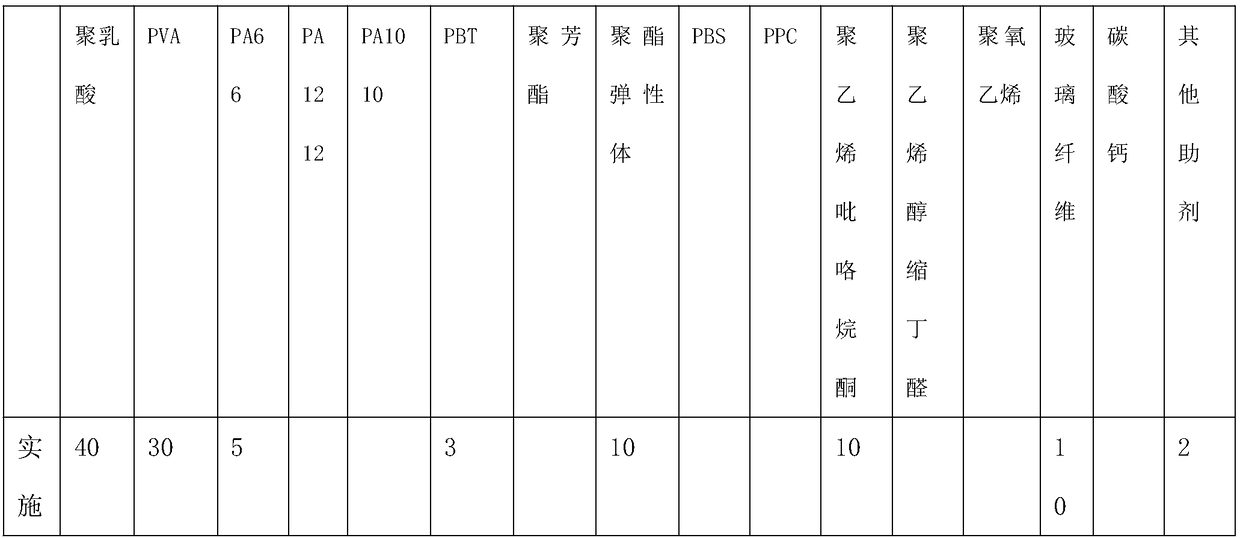

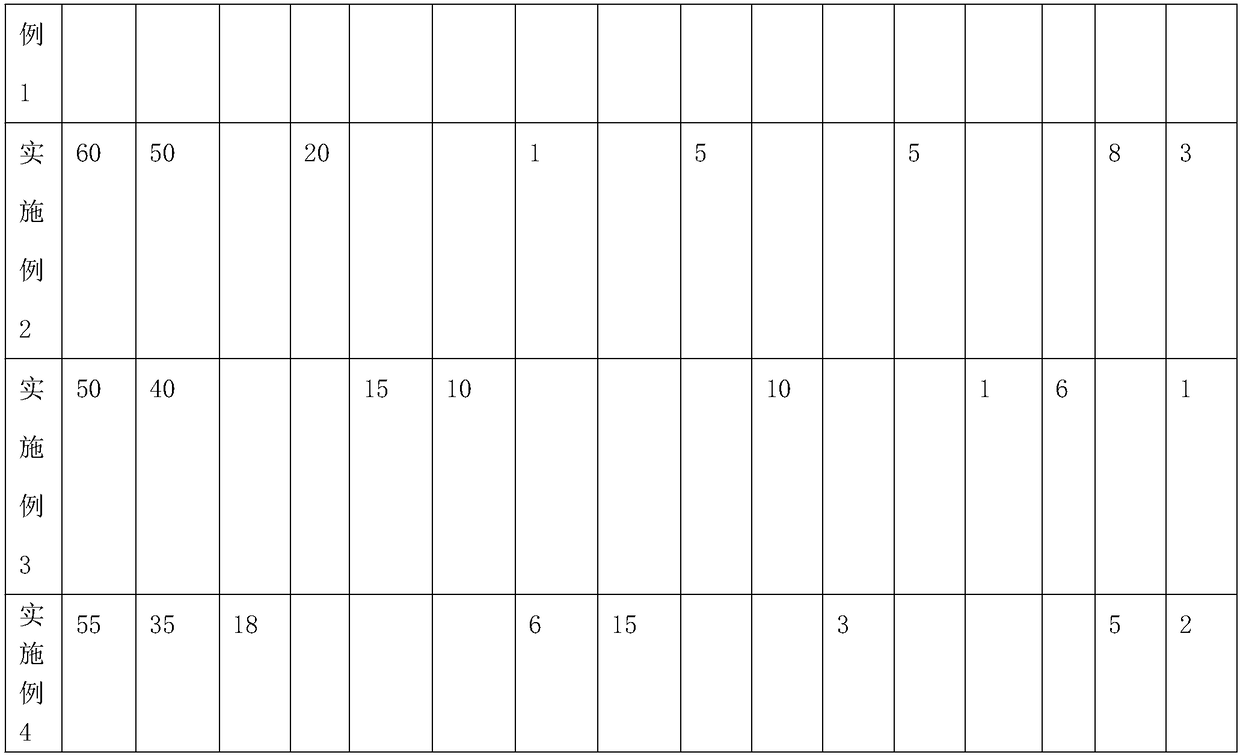

Degradable cable tie material and preparation method thereof

The invention relates to a cable tie material and a preparation method thereof, and in particular discloses a degradable cable tie material and a preparation method thereof. The material comprises thefollowing components in parts by weight: 40-60 parts of polylactic acid, 30-50 parts of polyvinyl alcohol, 5-20 parts of aliphatic polyamide, 1-10 parts of polyester, 5-15 parts of toughener, 5-10 parts of filler, 1-10 parts of degradation synergist and 1-3 parts of other additives. The material has the characteristics of high strength, high elongation, excellent high and low temperature performance, etc., and satisfies requirements of normal use of cable ties at high temperature heat resistance to 85 DEG C, and no fracture at low temperature of extreme weathers of Xinjiang, Heilongjiang, etc.; meanwhile, the material has the advantages of natural easy degradation, good biocompatibility and direct degradation or composting treatment after use, is natural and environmentally friendly, is pollution-free, and meets environmental friendliness requirements; and moreover, the material also has good hydrophilicity and anti-static property, and can meet anti-static requirements of wire harness cable ties of electronic industry.

Owner:NANJING JULONG SCI&TECH CO LTD

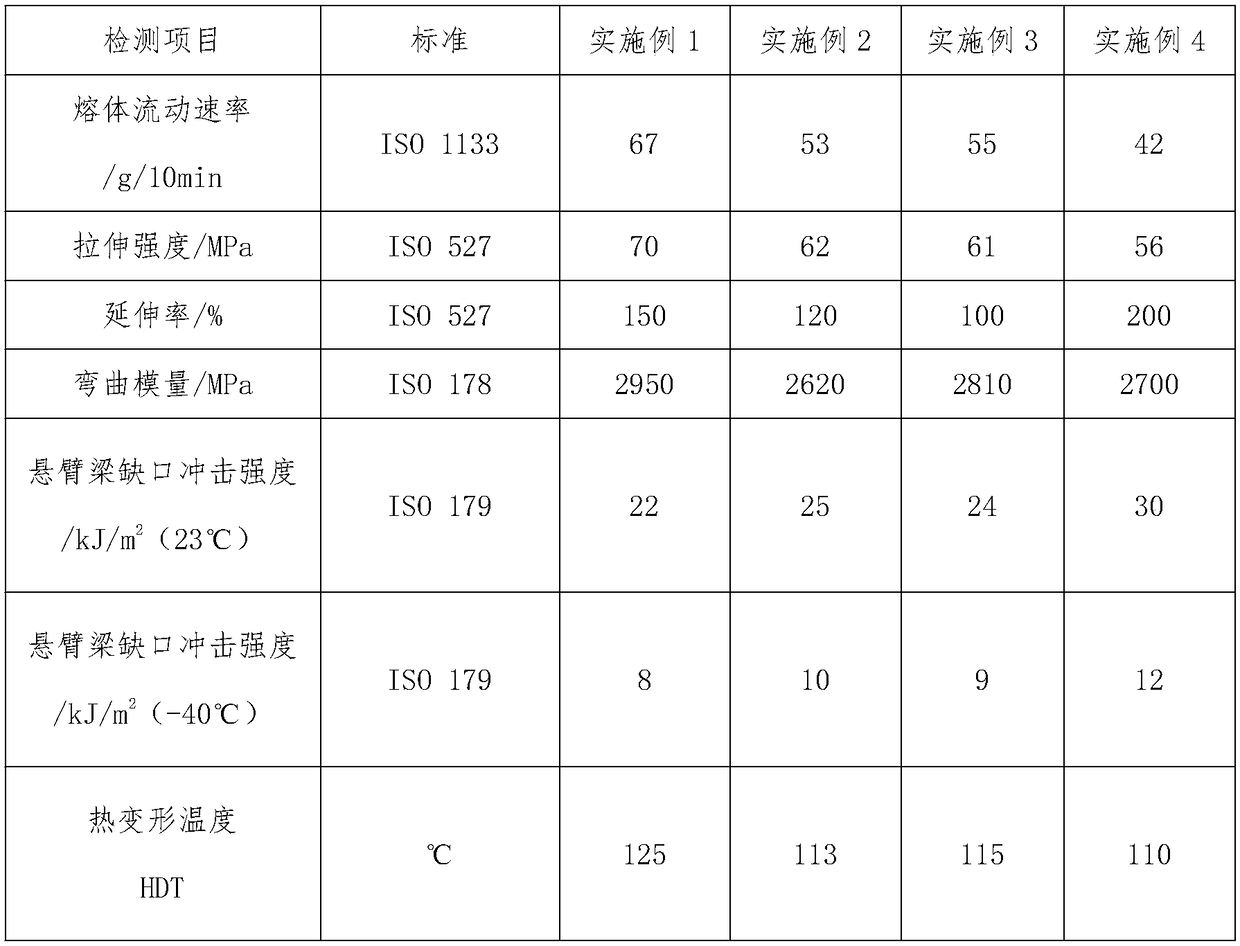

Spraying-free, heat-resistant and weather-resistant high-brightness PMMA alloy material and preparation method thereof

The invention discloses a spraying-free, heat-resistant and weather-resistant high-brightness PMMA alloy material and a preparation method thereof. The spraying-free, heat-resistant and weather-resistant high-brightness PMMA alloy material is prepared from the following components in parts by weight: 70 to 75 parts of PMMA resin, 5 to 20 parts of a compound flexibilizer, 0 to 5 parts of a heat resisting agent, 0.2 to 0.5 part of a light stabilizer, 0.3 to 0.5 part of an antioxidant, 0.2 to 0.3 part of a lubricating agent and 0.5 to 1.0 part of a toner, wherein the compound flexibilizer is prepared by compounding acrylate and organic silicon resin according to a mass ratio of 3 to 1; the heat resisting agent is customized LMPB-g-MAH. By the adding of the crylic acid and organic silicon compound flexibilizer into the PMMA resin, the PMMA resin material is high in impact strength and weather resistance; the heat resisting agent is added into the PMMA resin, the PMMA material is high in heat resistance; therefore, the PMMA material can be molded through one-time injection, and the production efficiency is improved.

Owner:ORINKO NEW MATERIAL CO LTD

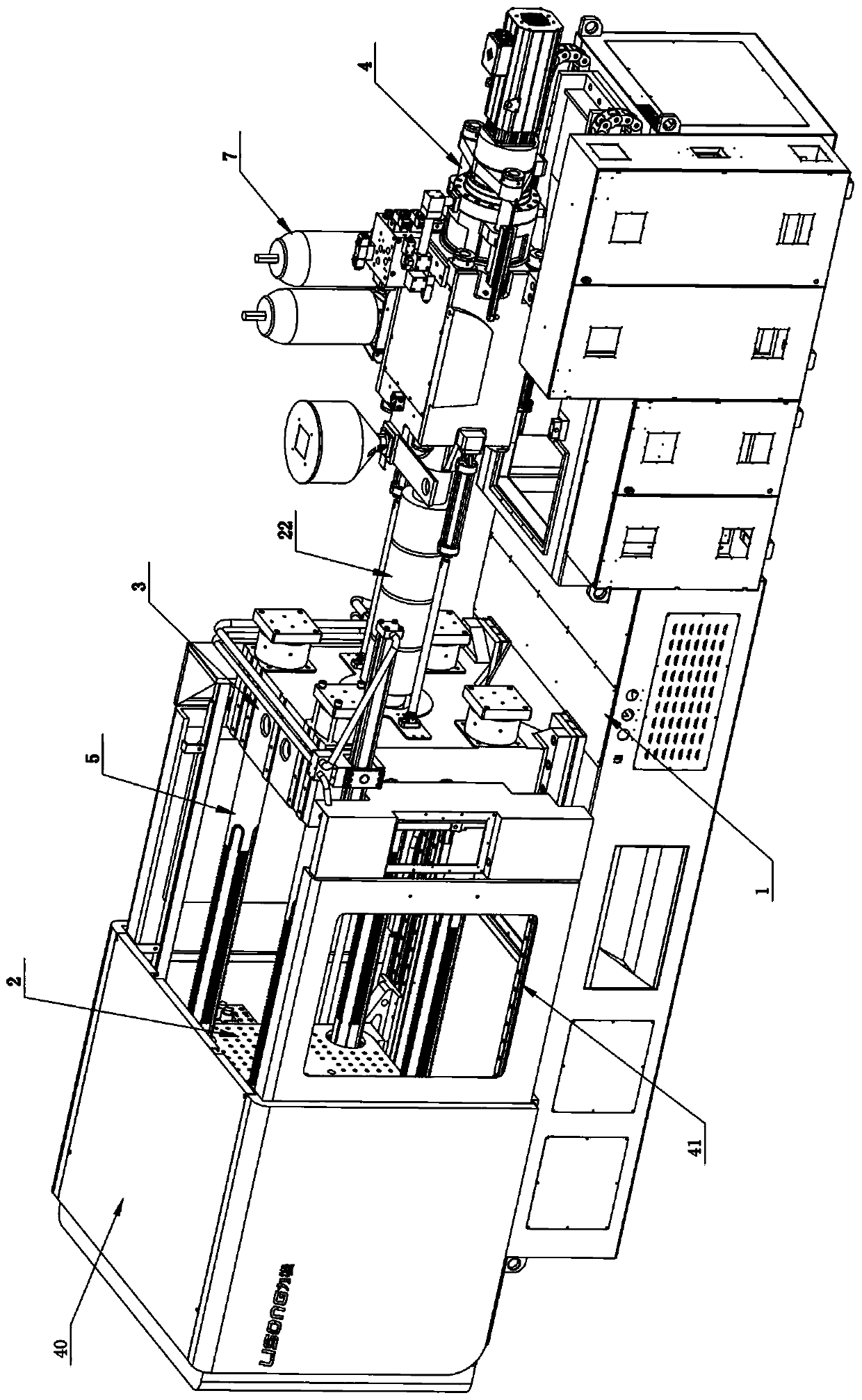

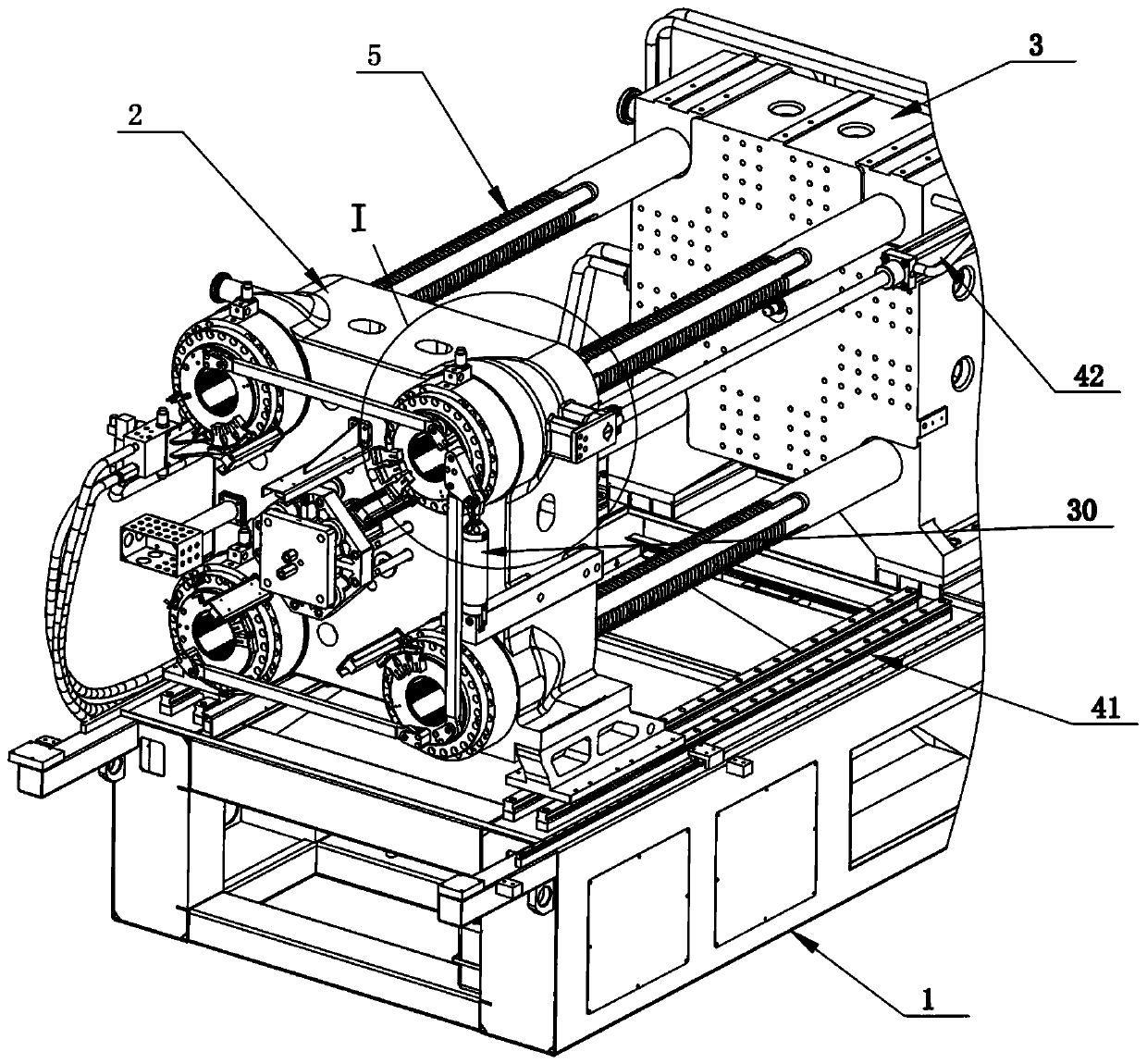

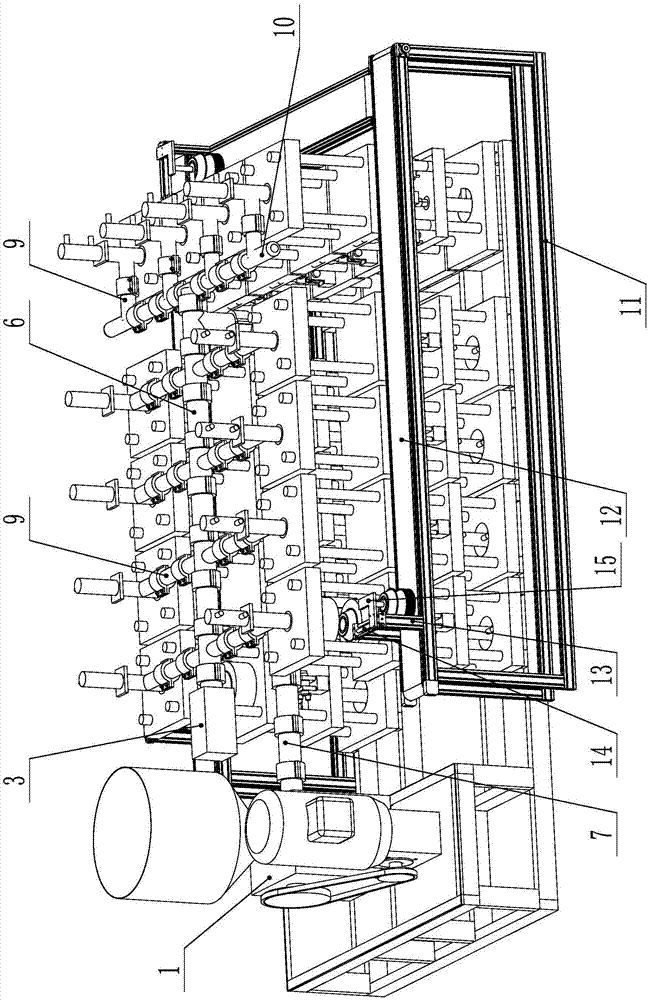

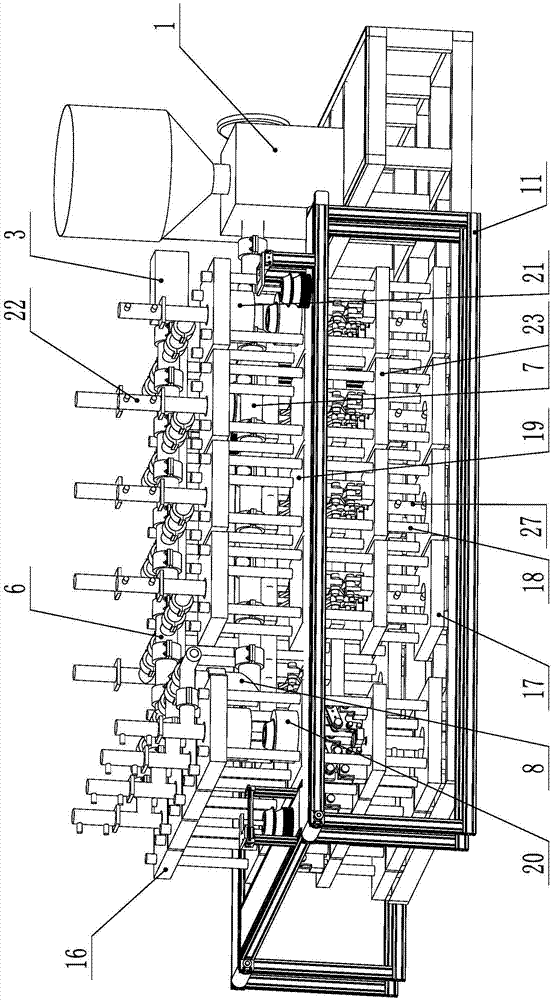

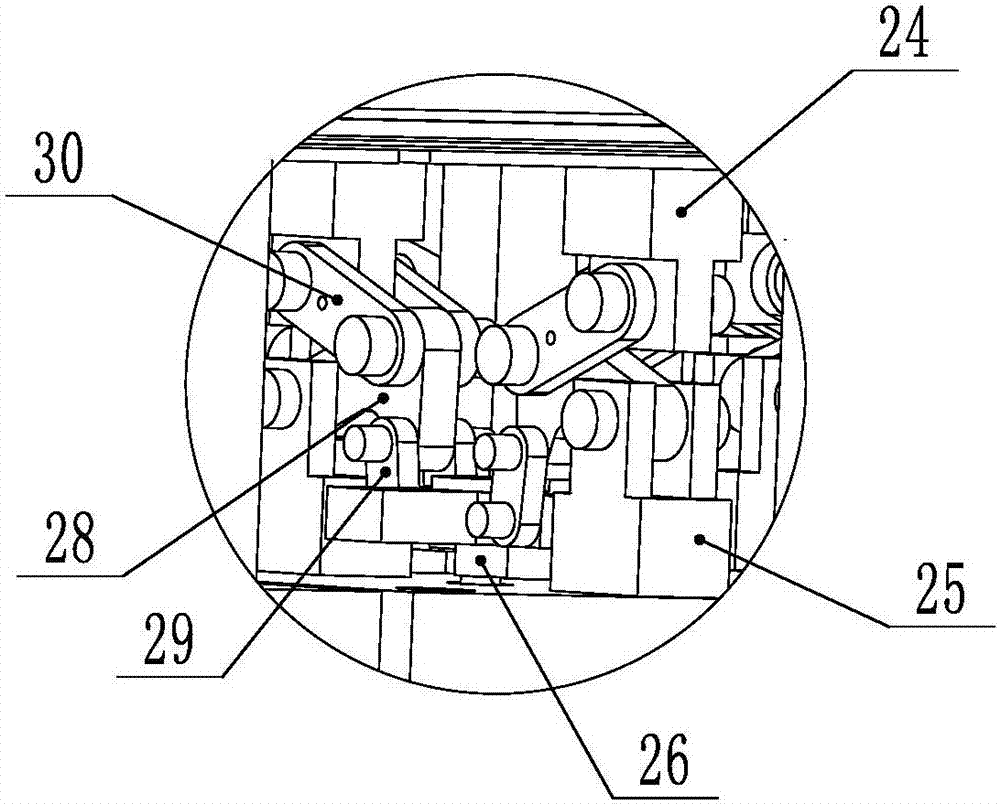

High-precision and high-efficiency injection molding machine

The invention provides a high-precision and high-efficiency injection molding machine. The high-precision and high-efficiency injection molding machine comprises a machine body and further comprises amovable mold plate, a fixed mold plate and an injection mechanism. A plurality of pull rods are mounted between the movable mold plate and the fixed mold plate. A combined contracting brake mechanismcorresponding to the pull rods is mounted on the movable mold plate. A nitrogen auxiliary injection device connected with the injection mechanism is mounted at the side end of the machine body. During mold closing, the combined contracting brake mechanism locks the pull rods. the combined contracting brake mechanism comprises a contracting brake cylinder and a plurality of mold locking pistons. The contracting brake cylinder is connected with one mold locking piston. A piston linkage connecting rod is eccentrically hinged between the two adjacent mold locking pistons. The high-precision and high-efficiency injection molding machine provided by the invention is high in mold replacing speed, good in combined mold locking effect and high in reliability and safety coefficient. The whole high-precision and high-efficiency injection molding machine is high in starting speed, stable in injection rate, high in repeating precision, large in mold containing space, high in production efficiencyand stable and reliable in operation.

Owner:宁波力松注塑科技有限公司

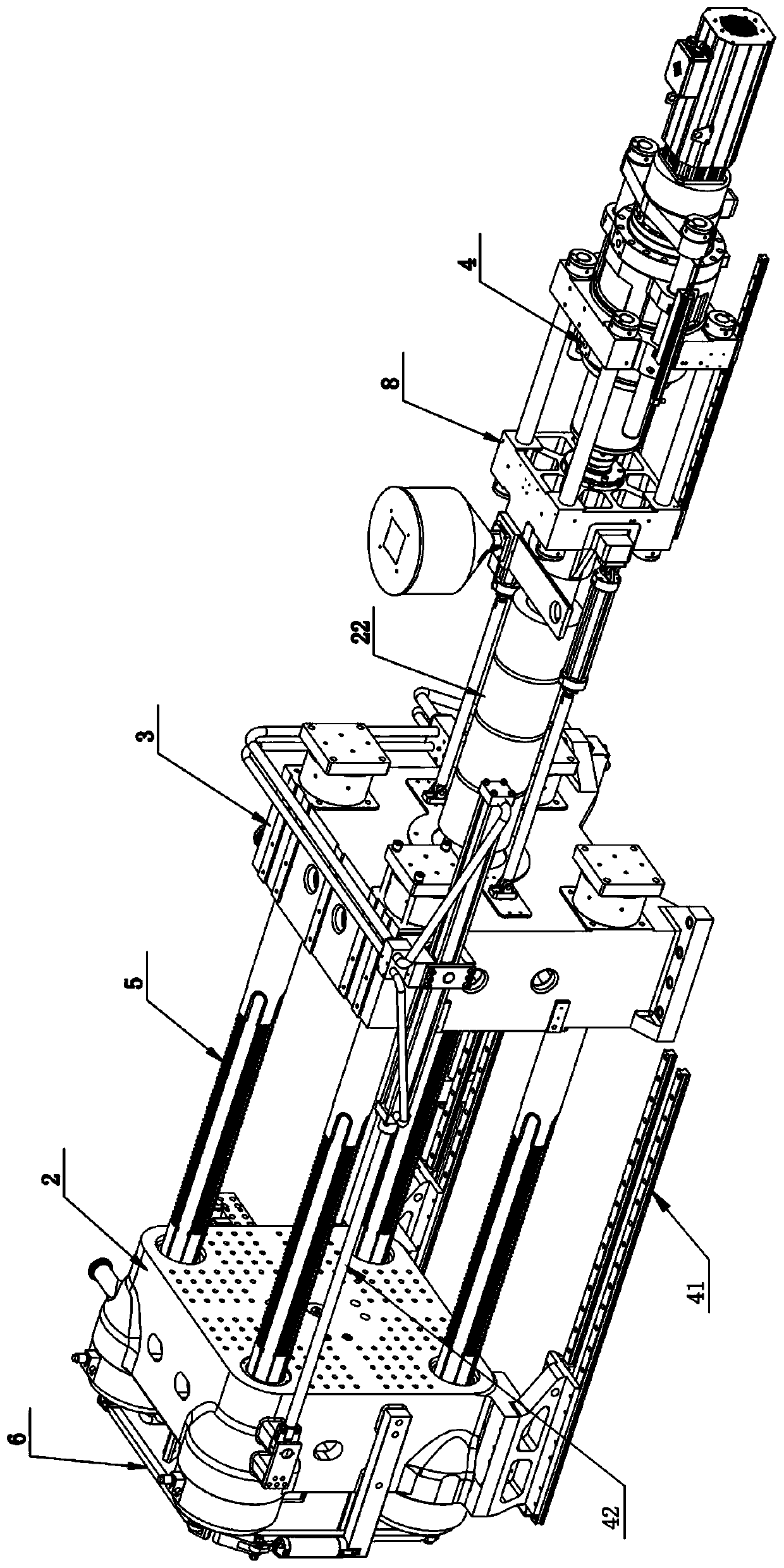

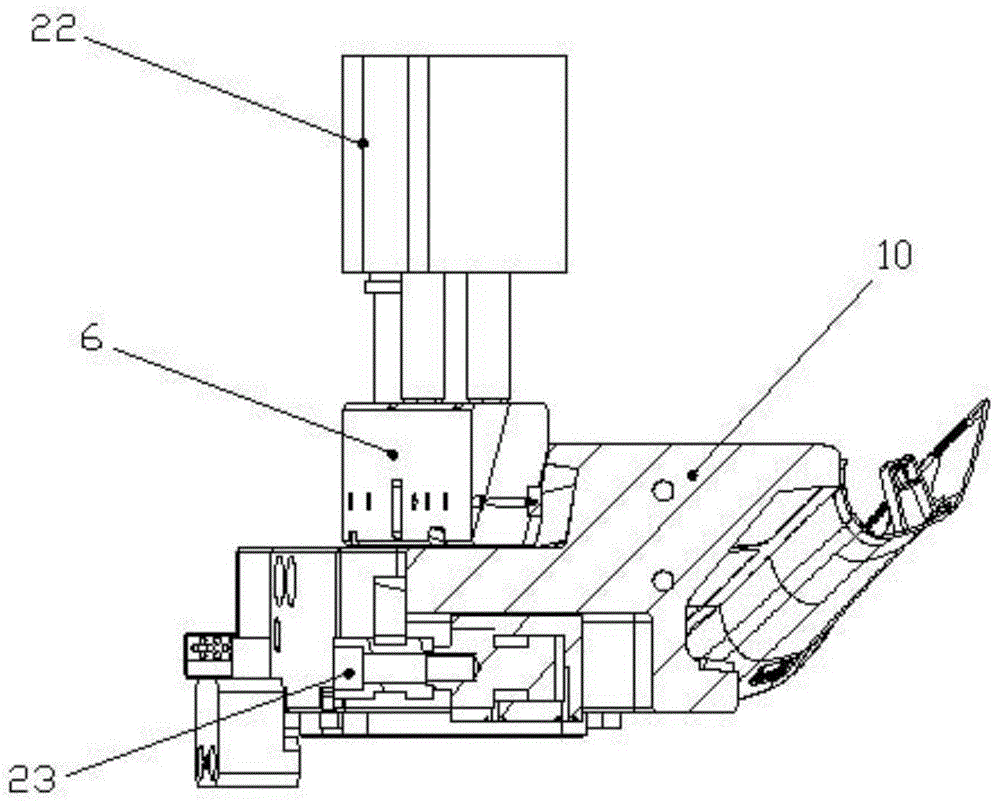

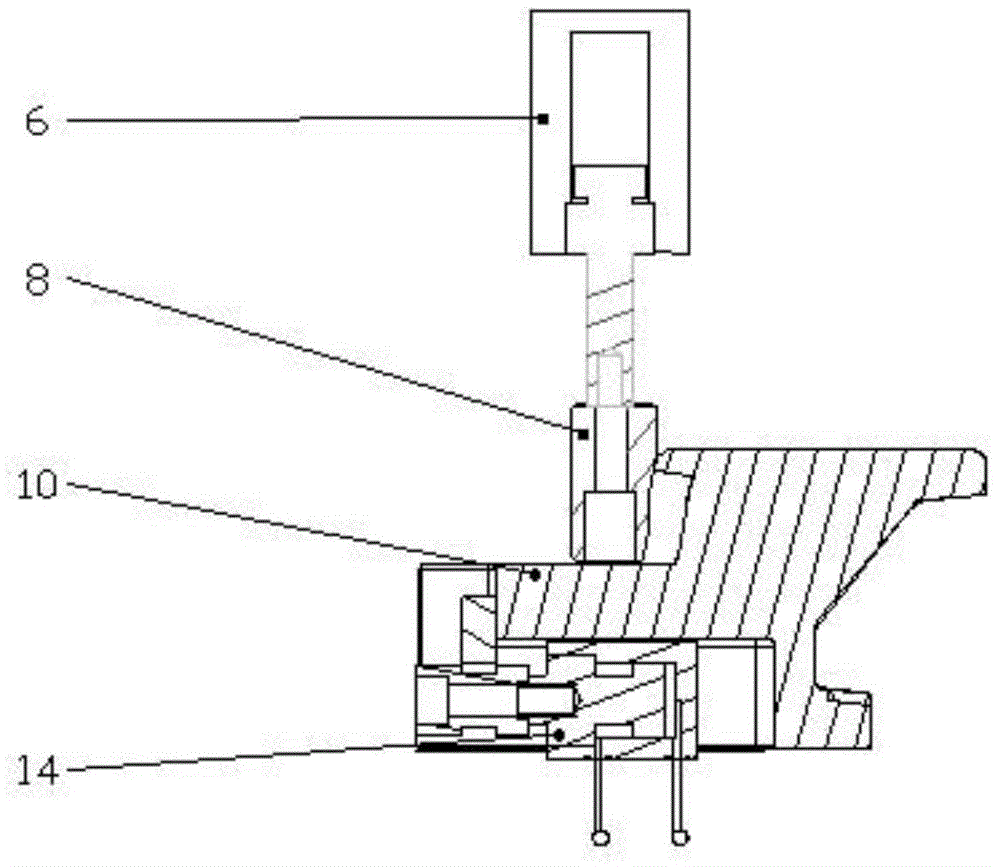

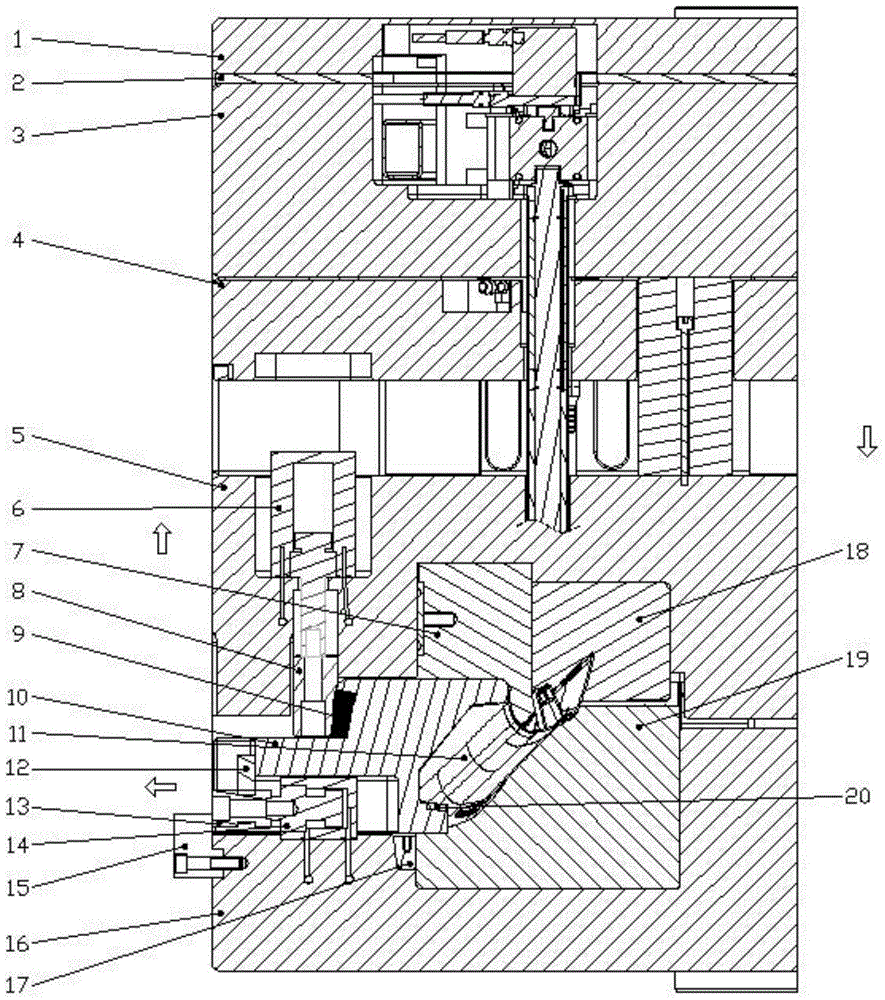

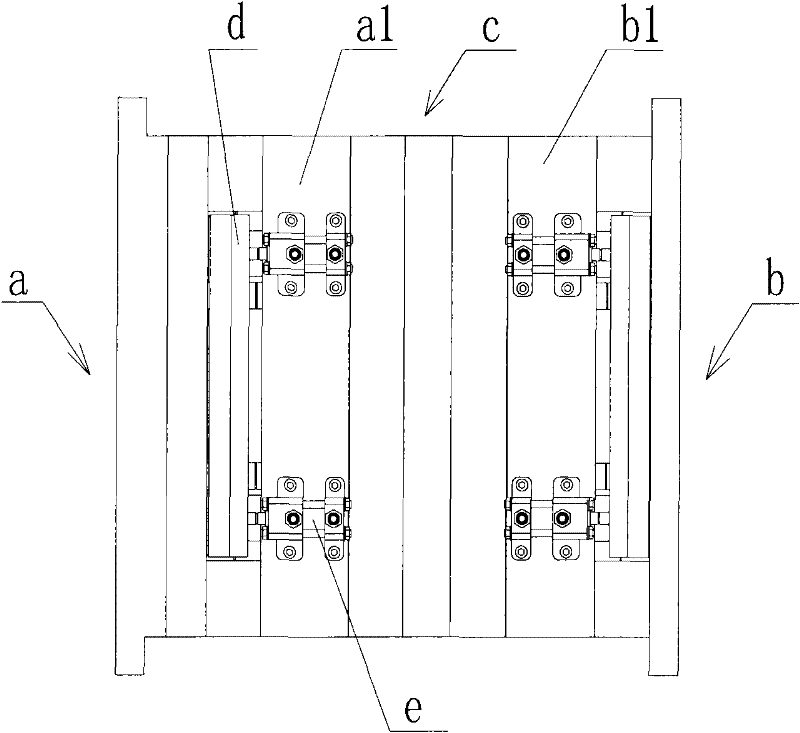

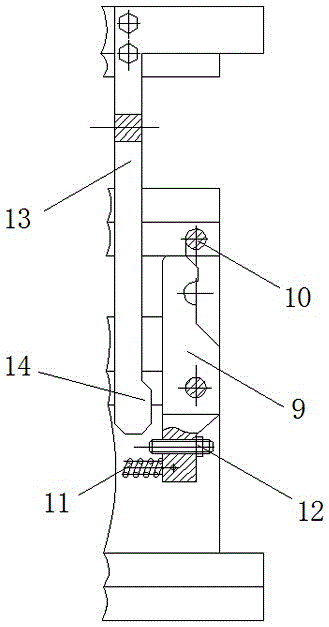

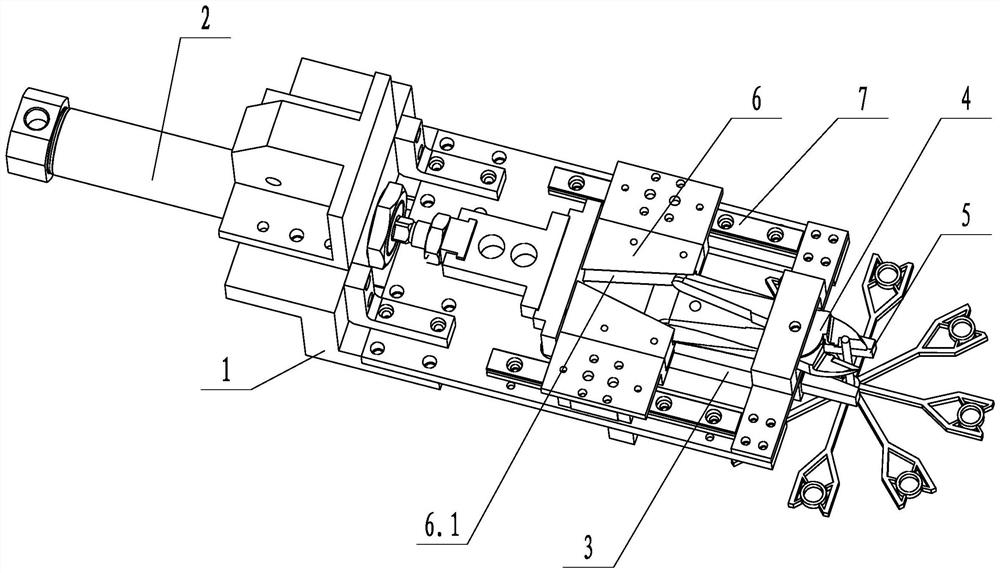

Slide demoulding mechanism for injection mould

ActiveCN105196499ARealize mechanical operationReduce one mold openingEngineeringMechanical engineering

The invention relates to the field of injection moulds, in particular to a slide demoulding mechanism for an in-mould lamination injection mould. The slide demoulding mechanism comprises a slide (10) which forms a mould cavity of the injection mould jointly with a fixed mould core and a movable mould core and is further provided with a heel block (8) used for limiting the position of the slide (10) in the injection mould, a first power mechanism (22) which can drive the heel block (8) to move to relieve limiting of the heel block (8) on the position of the slide (10) in the injection mould and a second power mechanism (23) which can drive the slide (10) to be far away from the mould cavity of the injection mould. According to the slide demoulding mechanism for the in-mould lamination injection mould, the heel block and the slide in the injection mould can be driven by the power mechanisms to be adjusted, so that separation and backoff between the slide and a moulded product can be achieved; compared with the traditional mode that the mould is artificially opened to take the slide out, mechanical operation in the injection mould is achieved, one-time mould opening in the injection process can be reduced, the injection cycle is effectively shortened, and the production efficiency in the injection process is improved.

Owner:KUNDA MOLD SHENZHEN

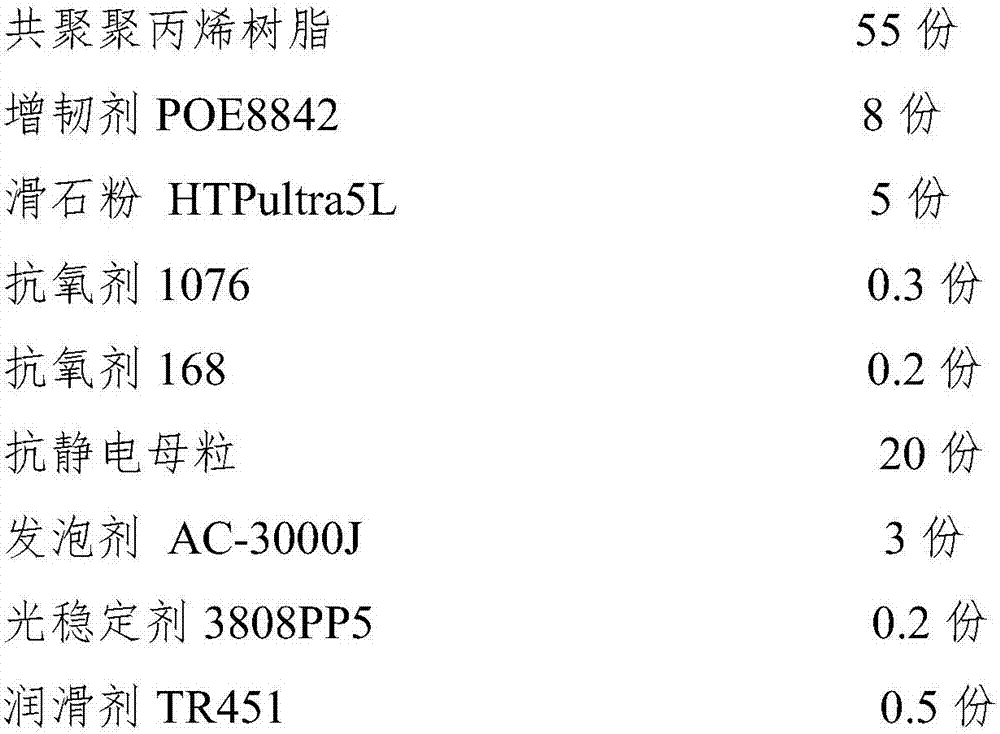

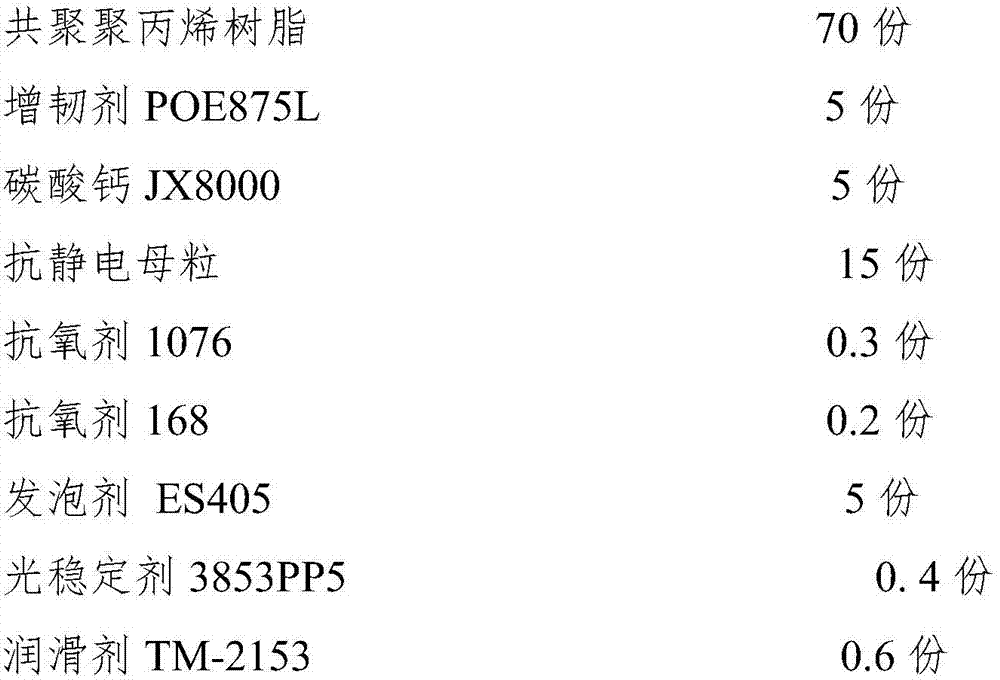

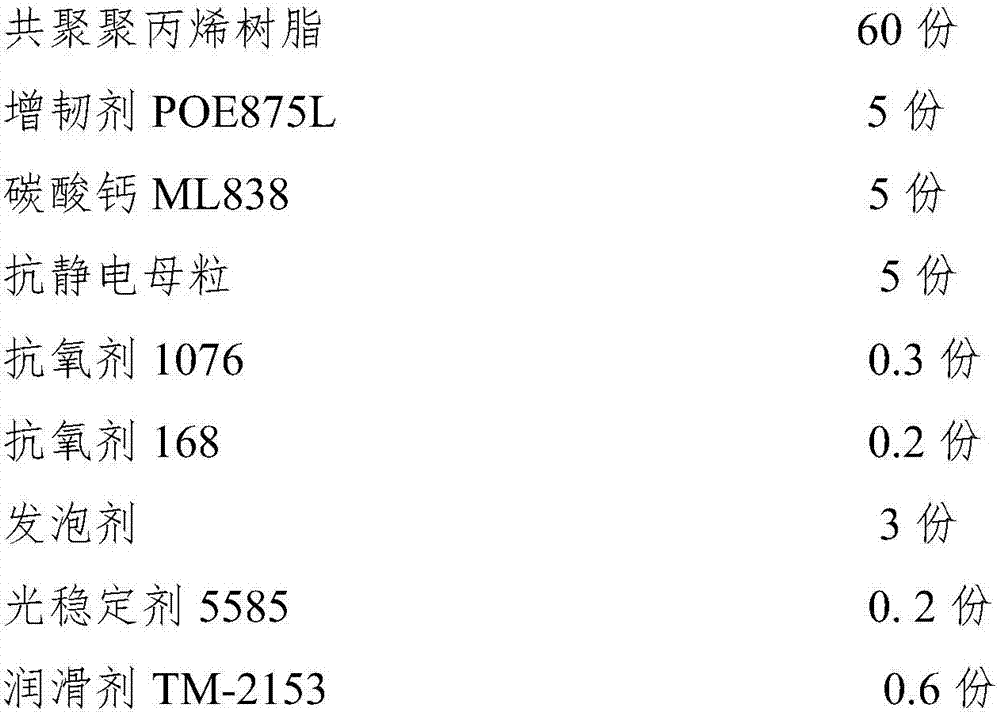

Permanent antistatic micro-foaming polypropylene composite material and preparation method thereof

InactiveCN107446242AImprove thermal stabilityGood chemical resistancePolypropylene compositesPolymer science

The invention provides a permanent antistatic micro-foaming polypropylene composite material and a preparation method thereof, and relates to the technical field of polymer materials. The composite material is prepared from polypropylene resin, a flexibilizer, filler, antistatic master-batches, a foaming agent, an antioxidant, an optical stabilizing agent and a lubricating agent. The polymer permanent antistatic agent can form a polymer network structure in the polymer, is permanently antistatic, still has an antistatic effect in an extremely low humidity environment, and has the advantages of good thermal stability and good chemical resistance.

Owner:ORINKO NEW MATERIAL CO LTD

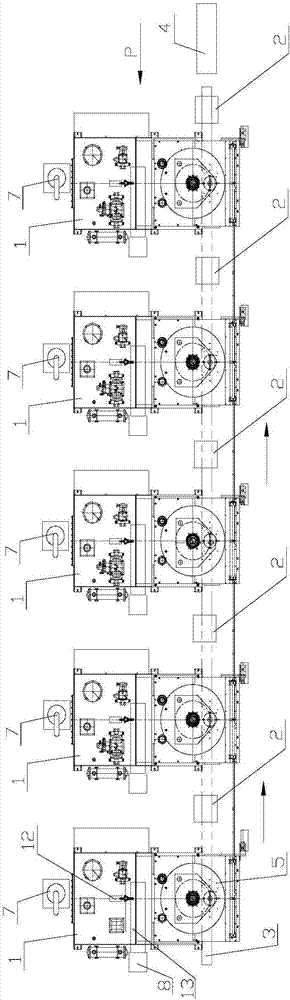

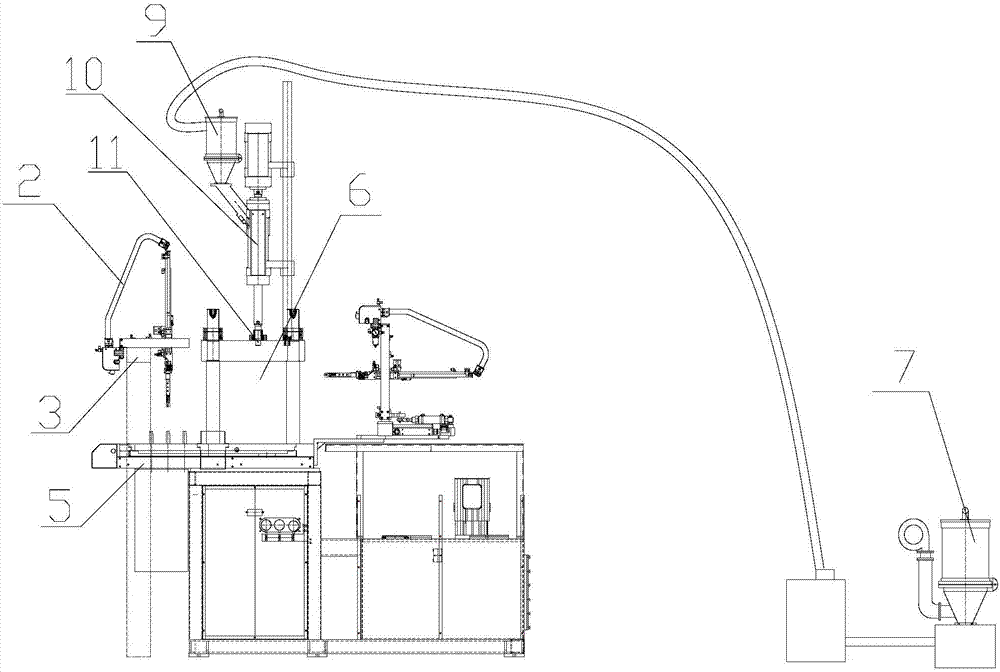

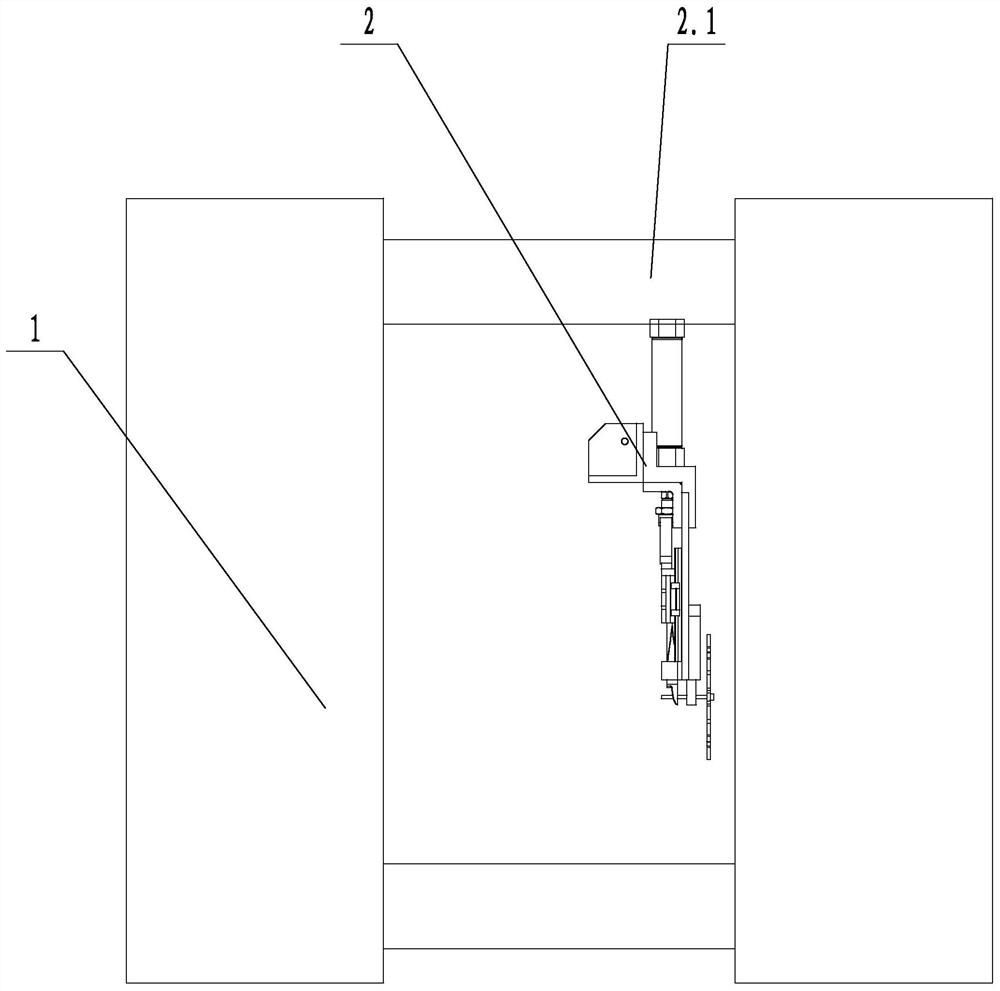

Multi-color automatic integrated production device and method for plastics

InactiveCN106976205AIncrease productivityReduce manual operationsEngineeringInjection molding machine

The invention discloses a multi-color automatic integrated production device and method for plastics. The device is characterized in that a plurality of injection molding machines are distributed in parallel, wherein manipulator mounting guide rails are continuously arranged at one side of each injection molding machine; a cross beam manipulator is arranged at the output end of each injection molding machine, and the cross beam manipulator is arranged on each manipulator mounting guide rail and can move leftwards and rightwards along the manipulator mounting guide rail. The method is characterized in that after being molded through a first injection molding machine, a first-color part of a product is moved out through the first cross beam manipulator and then conveyed into a second injection molding machine; a second-color part is subjected to injection molding on the basis of the first-color part through the second injection molding machine; the molded second-color part is moved out through a second cross beam manipulator and then conveyed into a third injection molding machine to be processed in an injection molding manner; after the final-color part of the product is subjected to injection molding through the last injection molding machine, the product is moved out through the last cross beam manipulator and then conveyed to a product output conveyor belt. With the adoption of the device and the method, the production efficiency can be effectively improved; the manual operation is decreased, and thus the production cost can be decreased greatly.

Owner:丰铁塑机(广州)有限公司

EVA (ethylene-vinyl acetate) microcapsule foaming master batch and preparation technology

The invention relates to an EVA (ethylene-vinyl acetate) microcapsule foaming master batch and a preparation technology, which comprise a material structure of a microcapsule foaming master batch and preparation technology steps of the microcapsule foaming master batch. The material structure of the microcapsule foaming master batch comprises the following materials in percentage by mass: 33 to 50% of EVA copolymer powder, 40 to 65% of microcapsule foaming agent and 2 to 10% of silicone oil. The preparation technology comprises the steps of firstly, grinding the EVA into the powder with particle size no more than 100 micrometers according to the percentage; then, weighing the EVA powder, the microcapsule foaming agent and the silicone oil according to the percentages, and adding the raw materials into a sealed type mixer to mix, wherein the mixing temperature is 50 to 70 DEG C, the mixing speed is 5 to 20r / min, and the mixing time is 8 to 15min; finally, adding the mixed materials into a screw type extrusion granulator, and granulating, wherein the granulating temperature is 50 to 60 DEG C; cooling, so as to obtain the EVA microcapsule foaming master batch.

Owner:泉州市三生橡塑科技有限公司

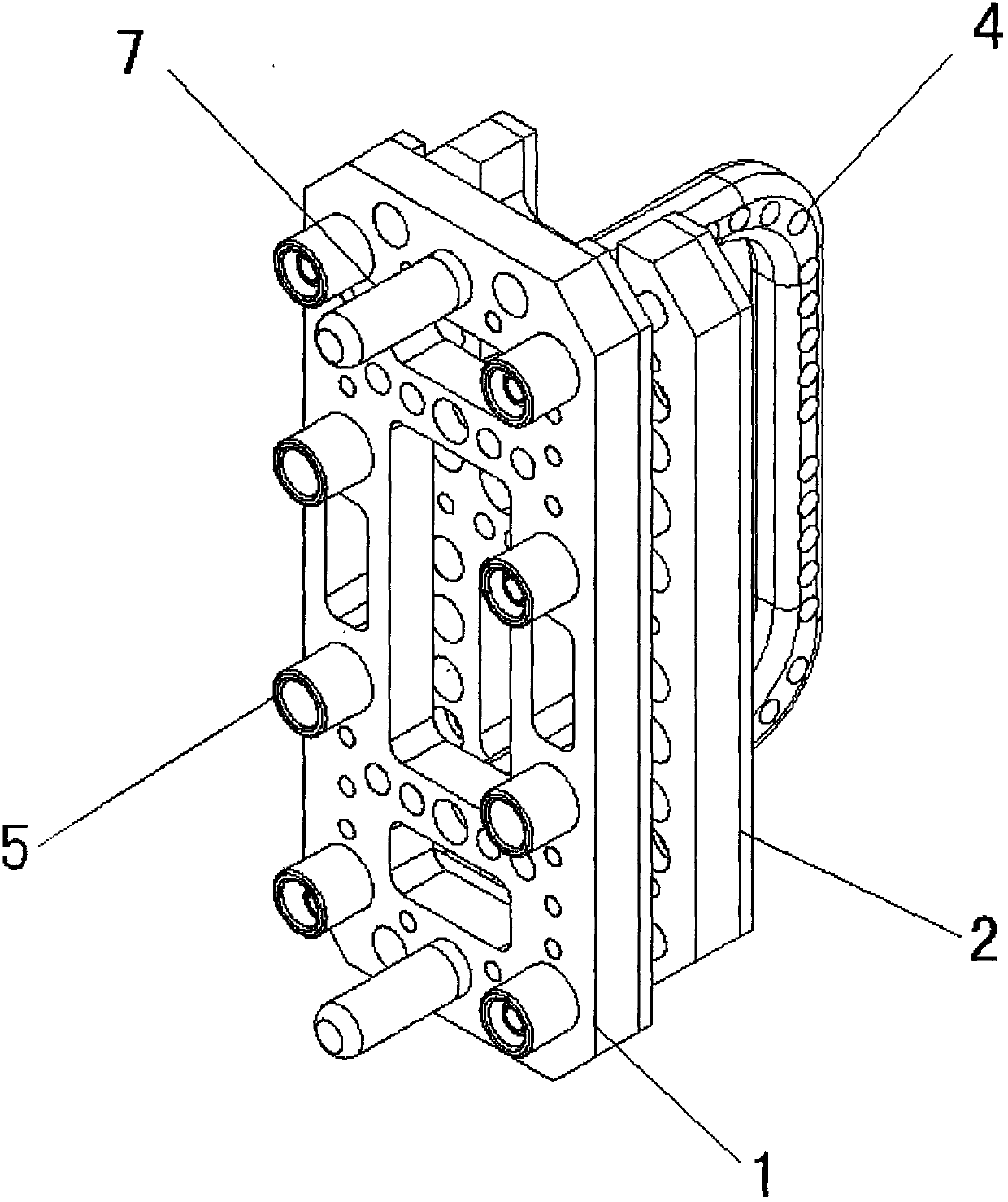

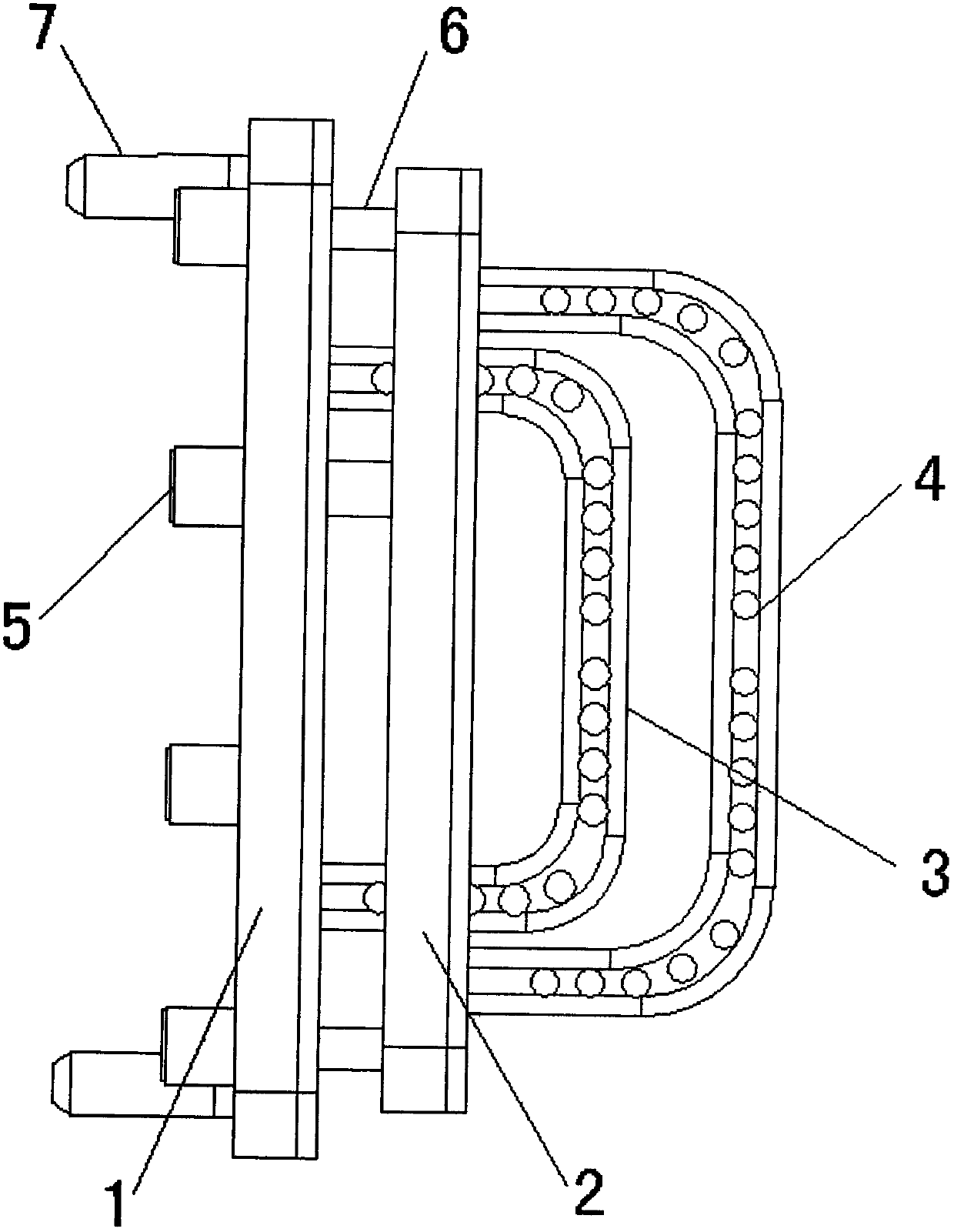

Multi-cavity injection mould hardware mould inputting jig

The invention discloses a multi-cavity injection mould hardware mould inputting jig which comprises an element taking plate and an installation plate in parallel arrangement; the installation plate is installed above the element taking plate; the element taking plate and the installation plate are elastically connected through a plurality of elastomers; a first grip is arranged on the element taking plate; a second grip is installed on the installation plate; the element taking plate is provided with a plurality of embedding element clamp heads which are in uniform distribution; the embedding element clamp heads penetrate through the element taking plate and extend from the bottom surface of the element taking plate; the embedding clamp heads are of a hollow cylindrical shape matched with the shape of a hardware element; and the bottom surfaces (corresponding to the installation plate) of the embedding clamp heads are provided with a plurality of ejection columns inserted into the embedding element clamp heads. The multi-cavity injection mould hardware mould inputting jig has the characteristics that leisure time of operators can be reasonably utilized, the injection molding cycle is shortened, and the injection molding efficiency is improved; the invalid time of the operation of an injection molding machine is shortened, and blocking and chewing can be prevented; hardware can be safely enters a mold by utilizing the jig; and within the original effective time, hardware with the number four times, eight times or even more that of the original hardware can be input.

Owner:KENTA ELECTRONIC MFG KUNSHAN CO LTD

Injection mould with ejection and linkage mechanisms

The invention provides an injection mould with ejection and linkage mechanisms, thus providing a solution to problems of complex oil cylinder structure, high cost and low productivity which exist in present injection moulds employing an oil cylinder ejection mechanism. In the invention, two ejection mechanisms are installed. One end of the ejection mechanisms are connected to liftout plates on the side of the mould core, with the other end connected to one mould side where a cavity is located. The ejection mechanisms are directly driven by mould opening actions of the mould to power the liftout plates so as to eject products. Employing a mechanical structure, the ejection mechanisms of the injection mould are characterized by simple structure, low cost and short injection moulding cycle, and play a key role in achieving fast and efficient manufacturing for the injection mould.

Owner:HAIER GRP CORP +1

Injection mould provided wtih core-pulling mechanism driven by mould opening and closing actions

The invention provides an injection mould provided wtih a core-pulling mechanism driven by mould opening and closing actions, wherein, the injection mould can solve the problems that the core-pulling mechanism adopting a hydraulic cylinder to perform the core-pulling from the lower part of a product has the disadvantages of complicated structure, high cost and bad stability when the core-pulling is carried out in conventional core-pulling manners such as obliquely propping and the like so as to solve an internal inverted buckle existing in the product and so on. The injection mould adopts thetechnical scheme as follows: a driving slide block is connected with a mould movable template in a sliding manner, and the sliding direction is perpendicular to the mould opening direction of the mould; at least one side surface at the front end of the driving slide block takes the shape of a wedge; a driven slide block is inserted in an inserted block; in addition, the driven slide block is provided with a wedged end surface and matched with the driving slide block through an inclined slideway in a sliding manner. The core-pulling mechanism of the injection mould utilizes an inclined guide pillar to drive the slide block when the mould is opened and closed, the core-pulling action is completed in the direction perpendicular to the mould opening and closing direction, the problem of the internal inverted buckle can be solved, the strucutre is simple, the cost is low, the stability of the mould is good, and the injection moulding period is short.

Owner:QINGDAO HAIER MOLDS

Mold local cooling system based on low-temperature high-pressure gas

The invention discloses a mold local cooling system based on low-temperature high-pressure gas. The system comprises an air source capable of providing compressed air, a filter connected with the airsource through a first air pie, a pressurizing pump connected with the filter through a second gas pipe, an exchange refrigeration assembly connected with the pressurizing pump through a third air pipe and capable of refrigerating the pressurized compressed air, a mold internally provided with a cooling air flow way, and a controller. One end of the cooling air flow way is connected with the exchange refrigeration assembly through a fourth air pipe, mold cooling is carried out, and an electromagnetic valve is arranged on the fourth air pipe, and the controller is connected with the pressurizing pump, the exchange refrigeration assembly and the electromagnetic valve for control. Through the above manner, according to the mold local cooling system based on the low-temperature high-pressure gas, the low-temperature high-pressure gas is used for serving as mold cooling media, the gas can reach the mold interior where a common cooling medium cannot arrive, local cooling is rapidly achieved,the injection molding period is shortened, and the pollution is reduced.

Owner:苏州斯泰姆克工业智能科技有限公司

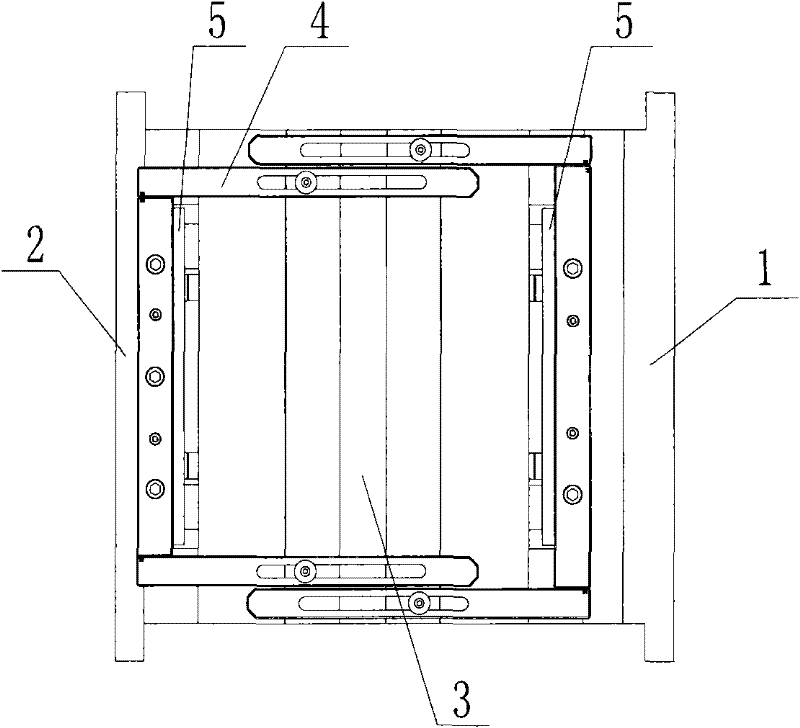

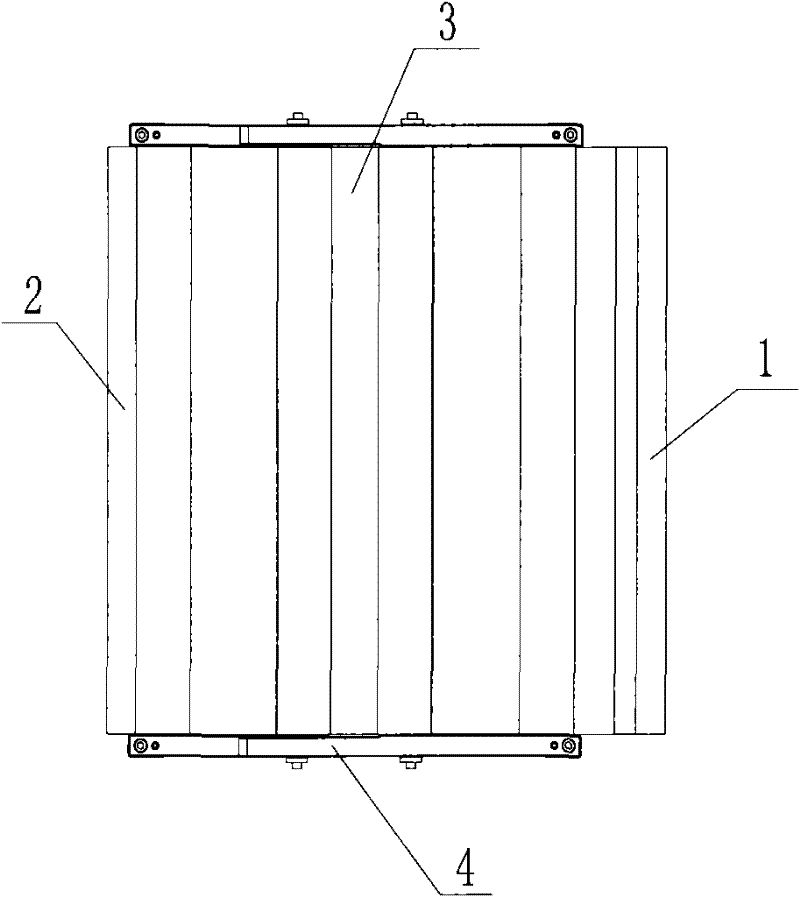

Double-parting-surface structure die capable of achieving stable and rapid parting

The invention relates to a double-parting-surface structure die capable of achieving stable and rapid parting. The double-parting-surface structure die comprises a fixed die plate located on the upper side, and a movable die plate located on the lower side. An upper cooling plate is arranged on the lower side of the fixed die plate. The lower side of the upper cooling plate is provided with a cavity plate connected with the upper cooling plate together. A lower cooling plate is arranged on the lower side of the cavity plate. A cavity used for pouring a product is formed between the cavity plate and the lower cooling plate. A bearing plate is arranged on the lower side of the lower cooling plate. A connecting column is connected between the bearing plate and the movable die plate. The double-parting-surface structure die capable of achieving stable and rapid parting is good in cooling effect, die component losses are reduced, the service life of the die is prolonged, and the injection molding period is shortened; and the production efficiency is improved, the product precision is guaranteed, and the product quality is improved.

Owner:FUZHOU UNIV

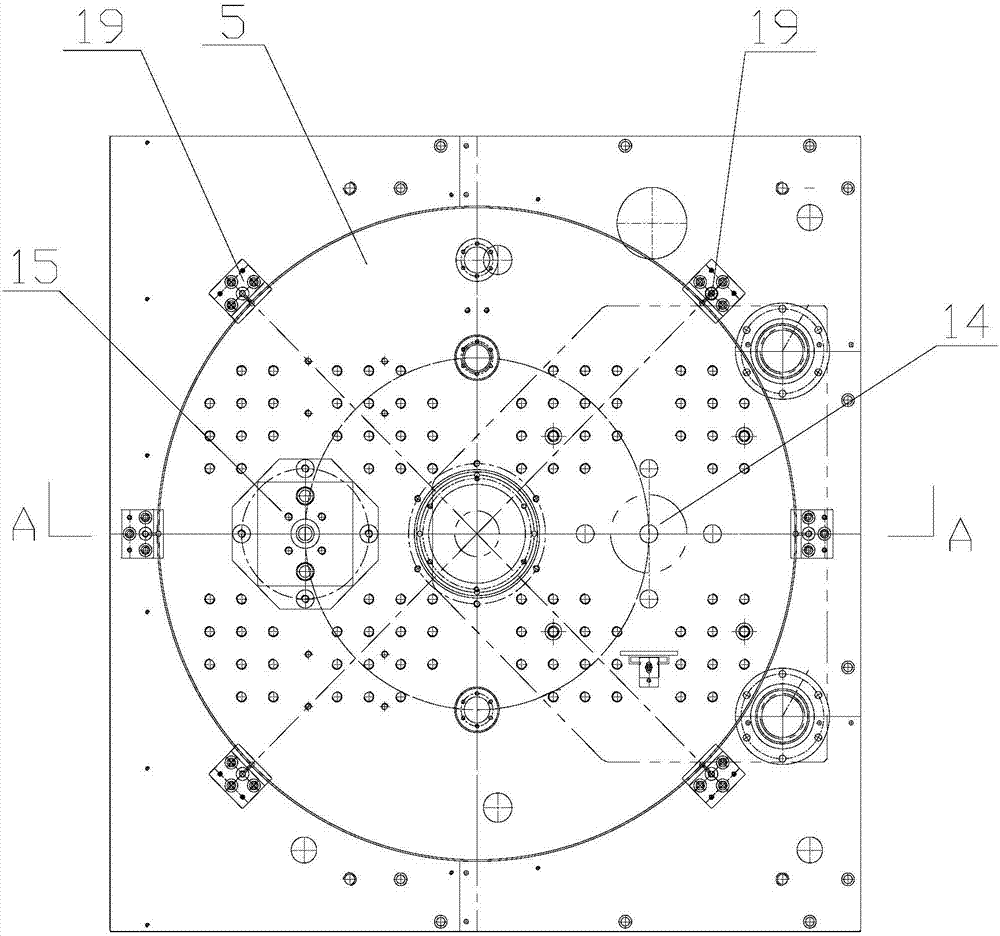

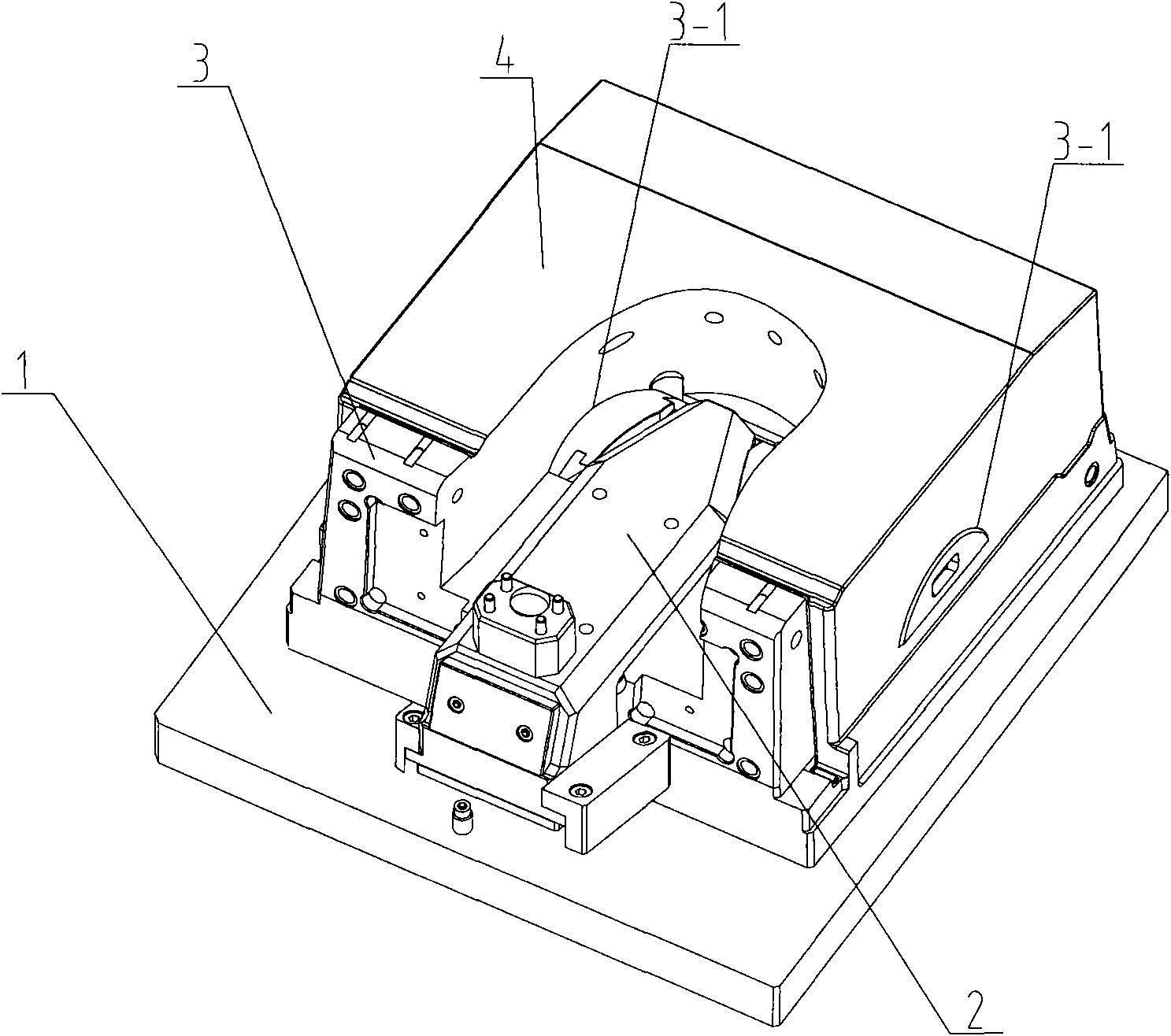

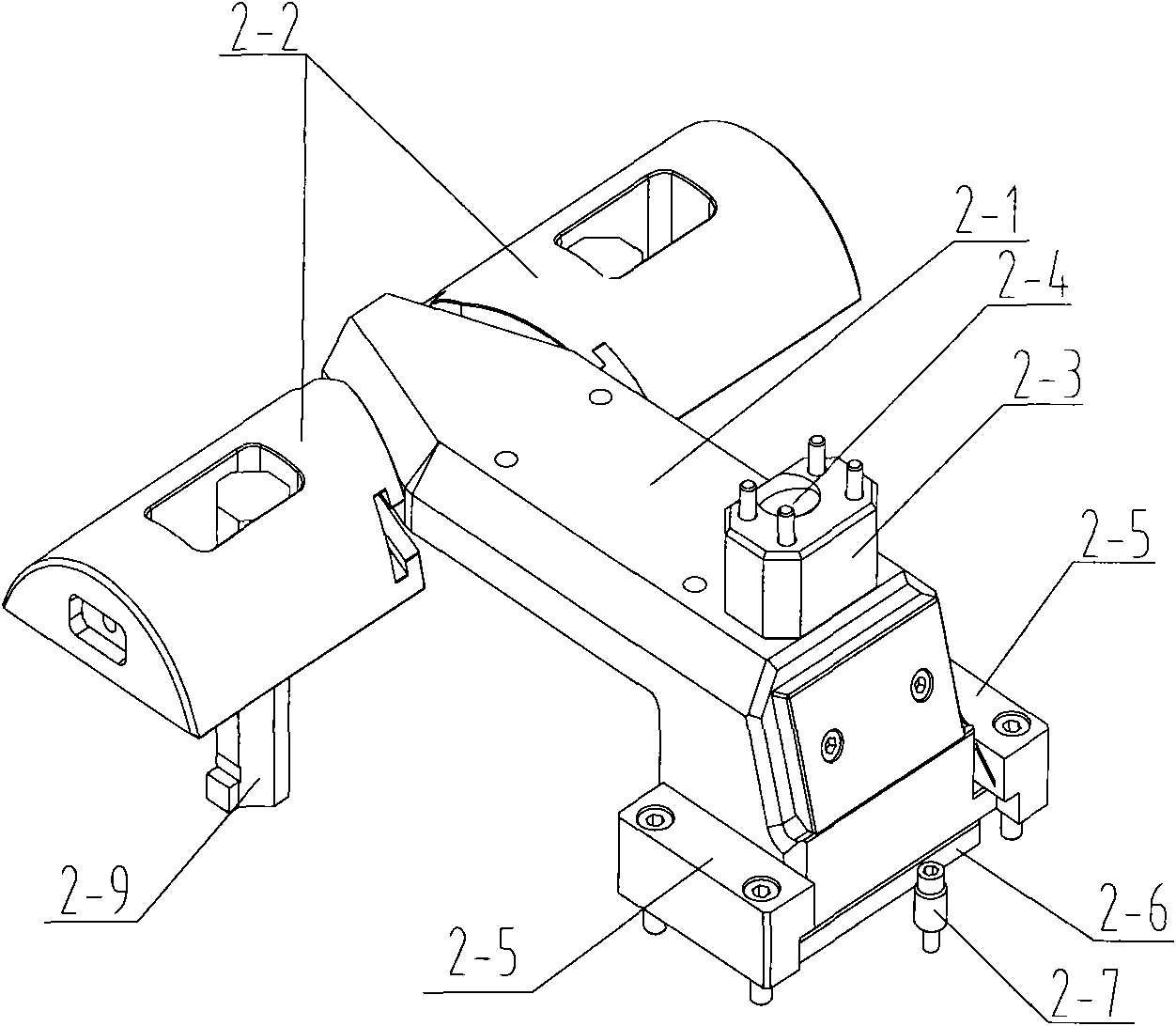

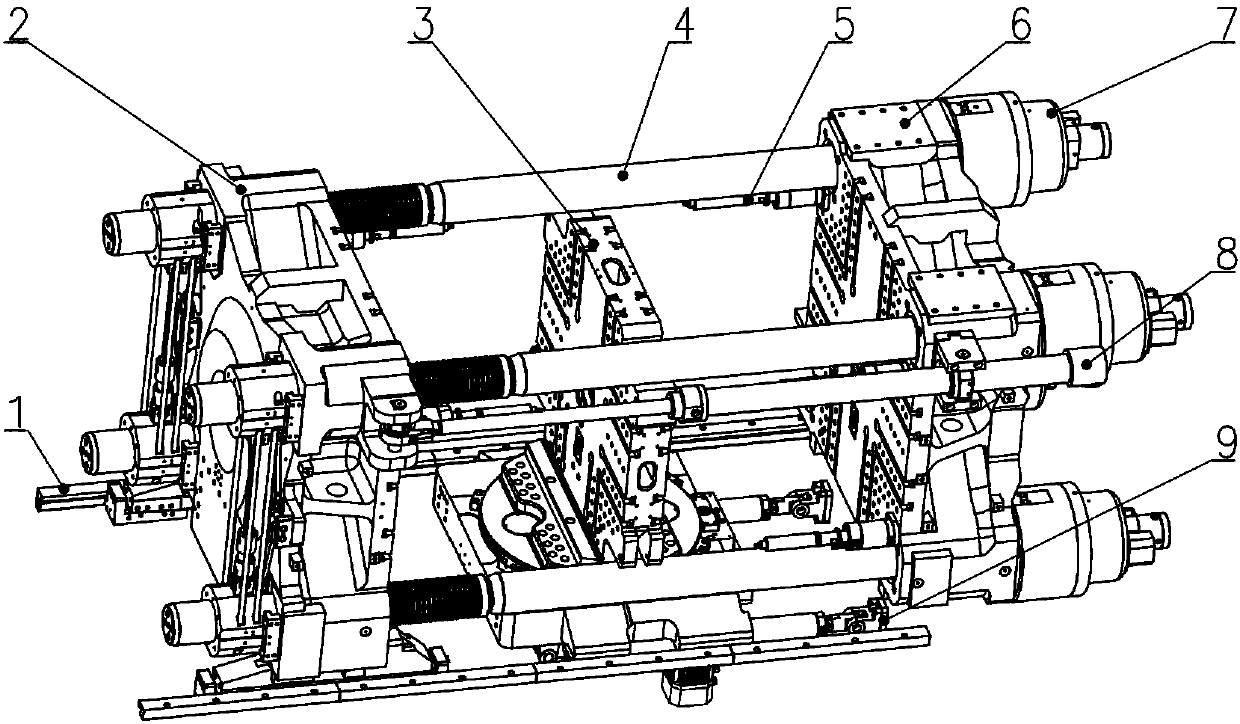

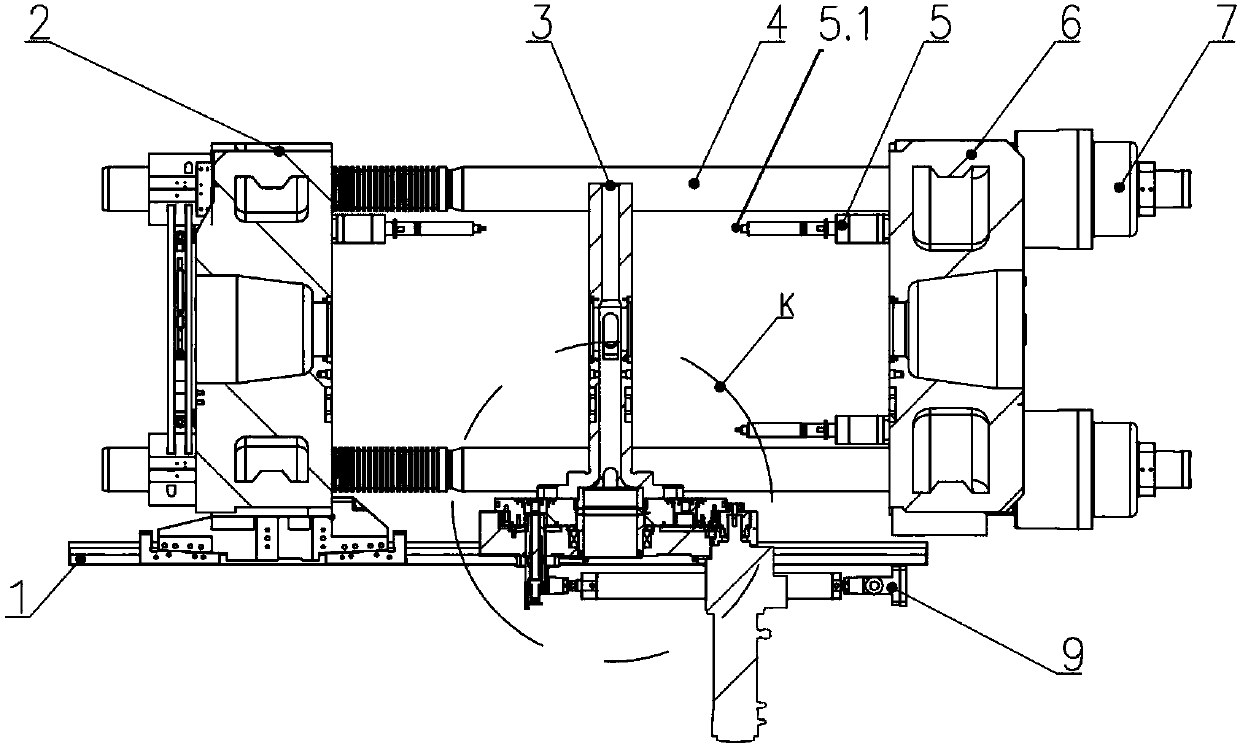

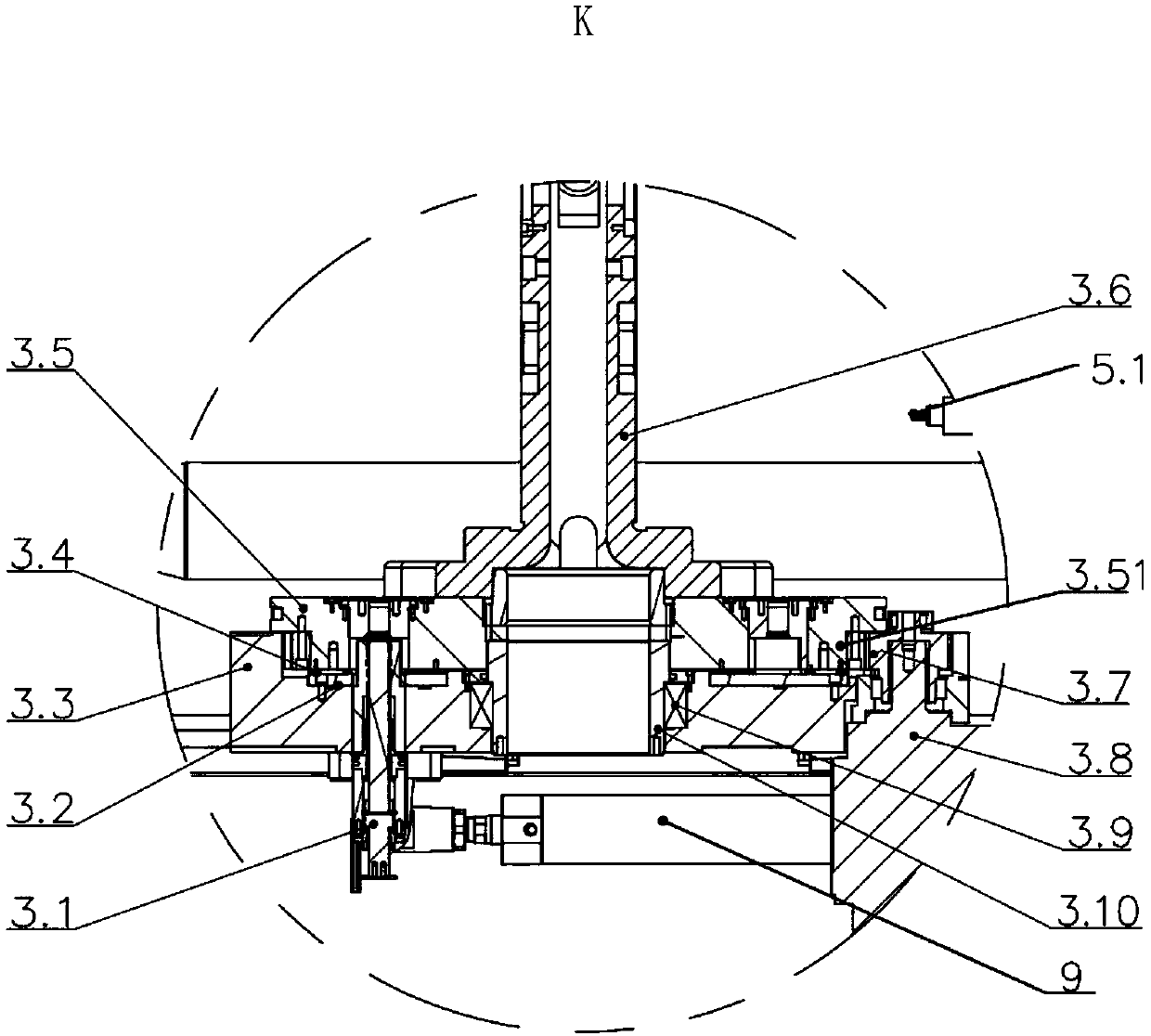

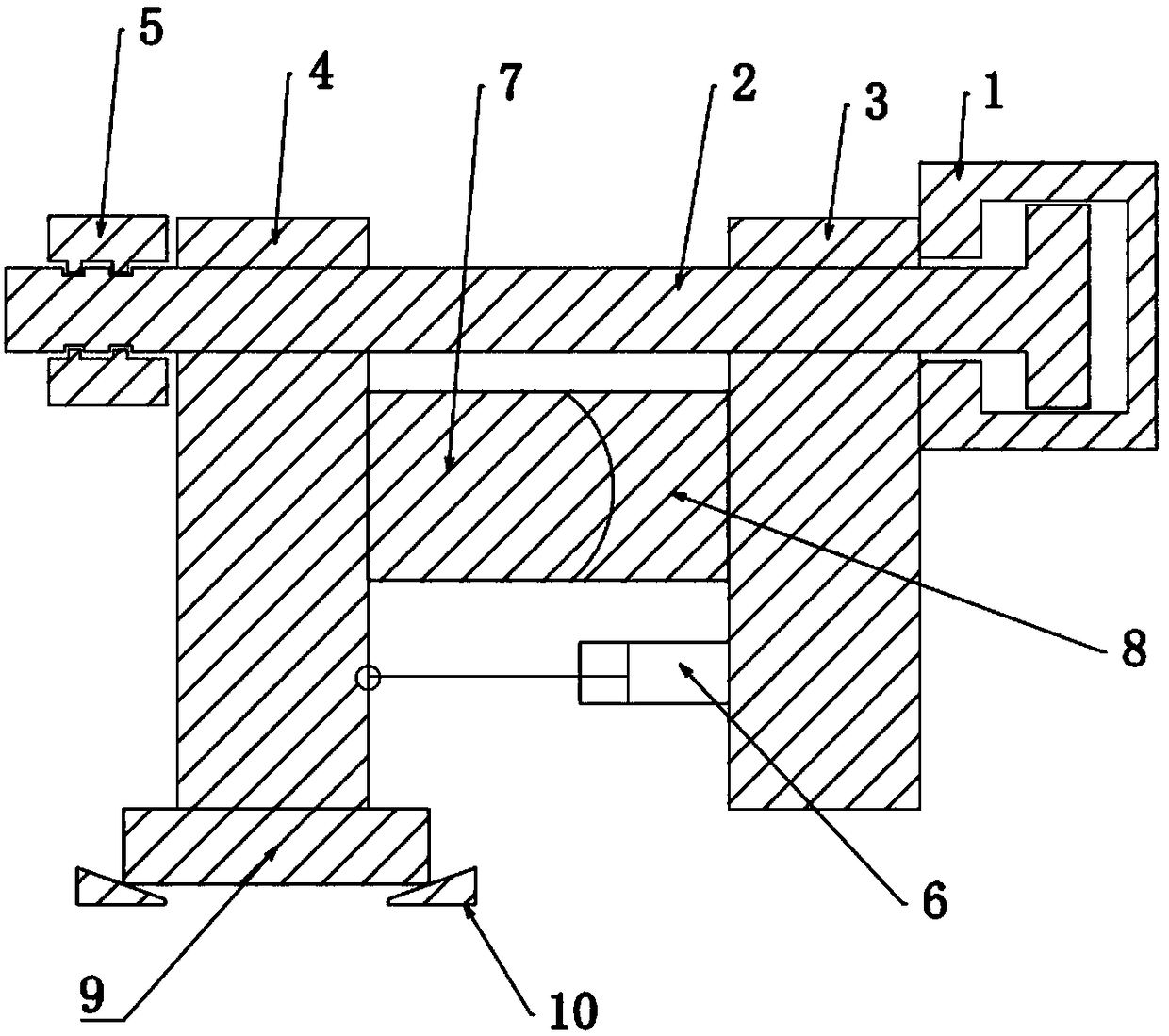

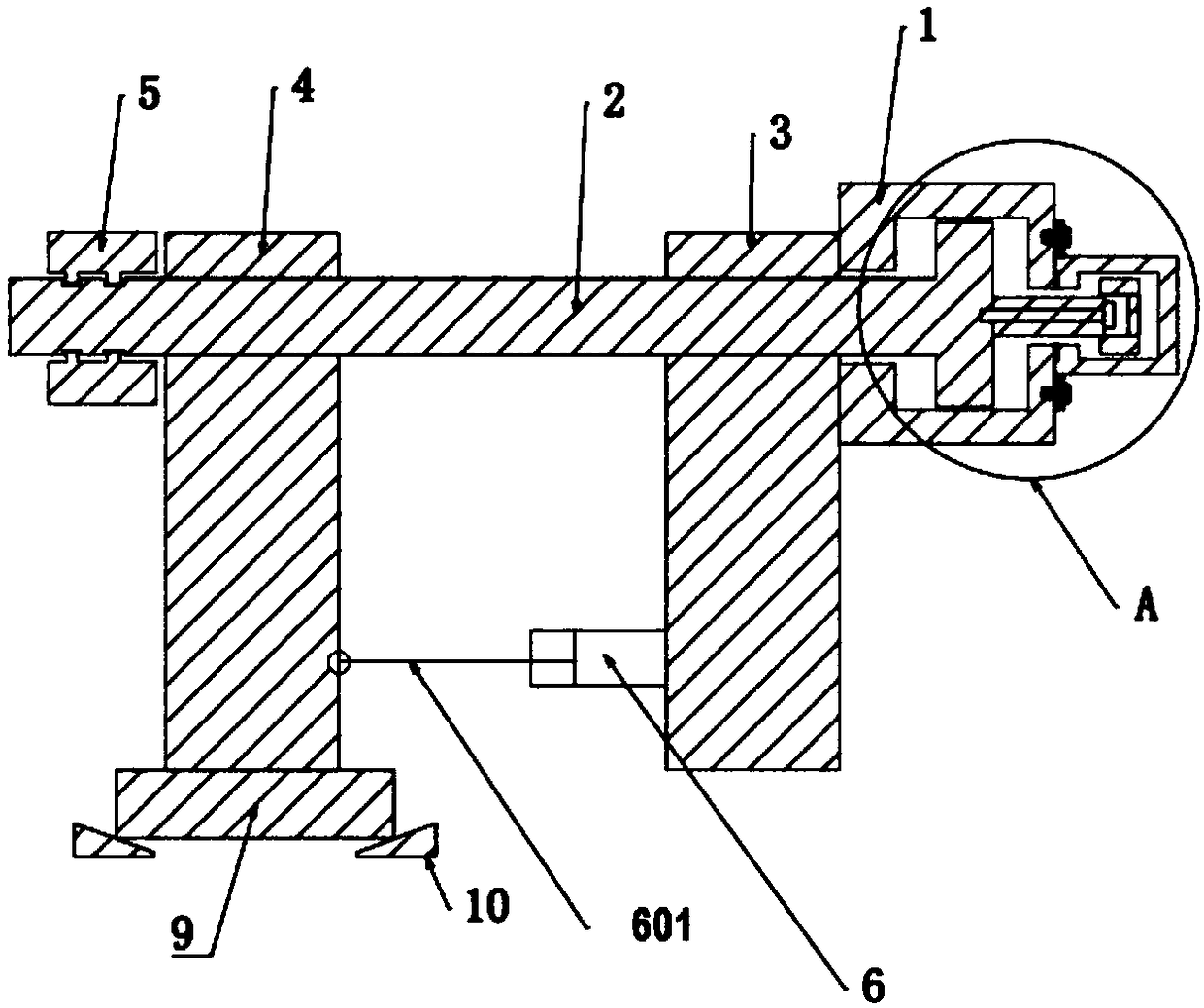

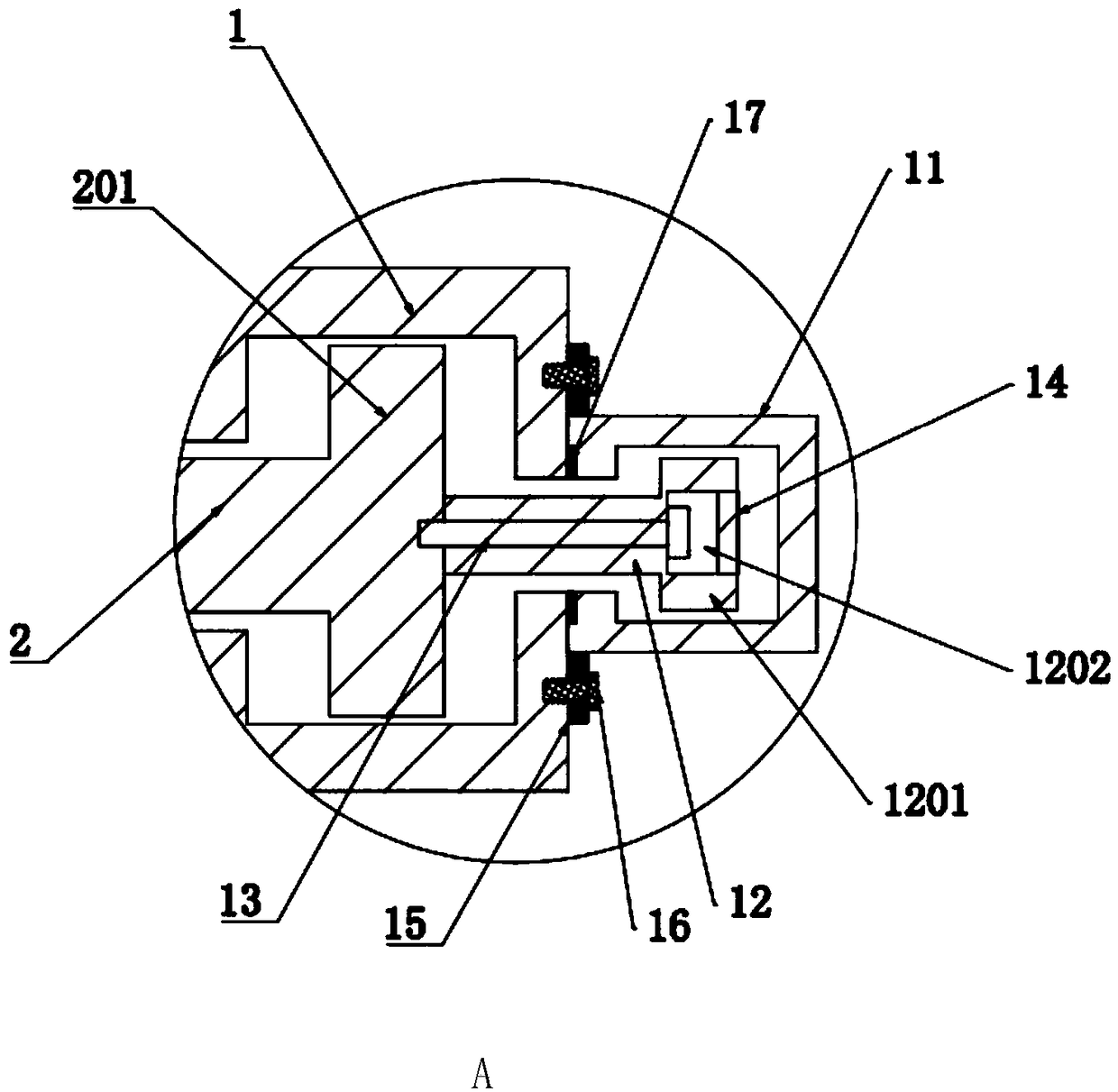

Horizontal rotating mold clamping mechanism of injection molding machine

PendingCN109968617AReduce manufacturing costReduce maintenance costsEngineeringInjection molding machine

The invention discloses a horizontal rotating mold clamping mechanism of an injection molding machine. The horizontal rotating mold clamping mechanism comprises fixed mold plates, movable mold platesand die locking cylinders. The ends of piston rods of the die locking cylinders are connected with pull rods fixed to the fixed die plates. A rotary platform device is arranged between the fixed die plates and the movable die plates. The rotary platform device comprises a movable platform base arranged at the bottom. Rotary platform rapid movement cylinders for driving the mobile platform base todo back and forth motion along a guide block are arranged at the end, close to the fixed die plates, of the inner side of the guide block in a spaced mode. A rotary disk is rotatably arranged at the upper end of the mobile platform base. A rotary die plate synchronously rotating with the rotary disk is vertically arranged at the upper end of the rotary disk. The center of the lower end of the rotary disk is fixedly provided with a gear. A driving device is arranged at the lower end of one side of the mobile platform base. The driving device comprises a motor arranged vertically. The upper needof the motor is provided with a gear shaft engaged with a gear arranged at the lower end of the rotary disk. Through the horizontal rotating mold clamping mechanism of the injection molding machine,the manufacturing and maintenance cost is effectively reduced, and the injection molding efficiency is improved.

Owner:HAITIAN PLASTICS MACHINERY GRP

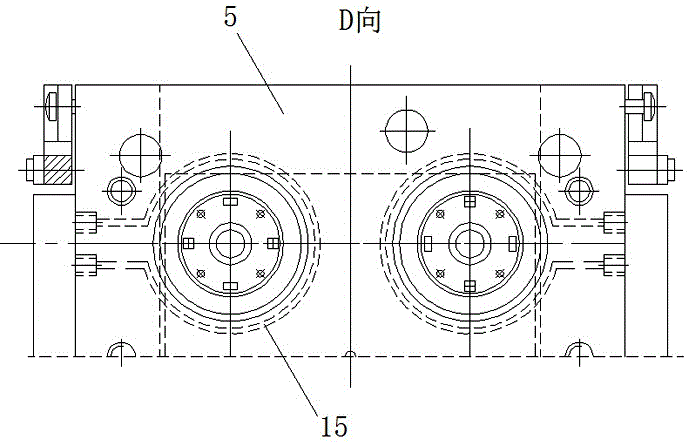

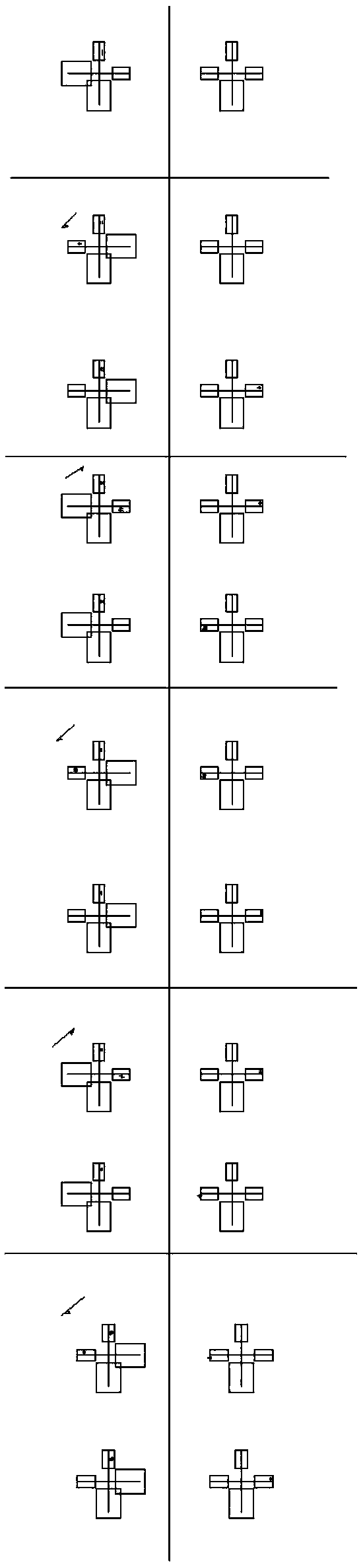

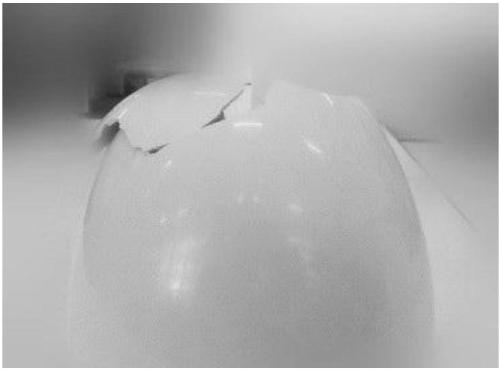

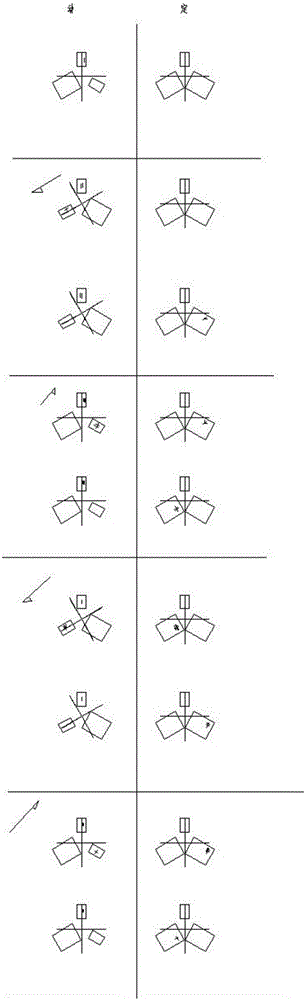

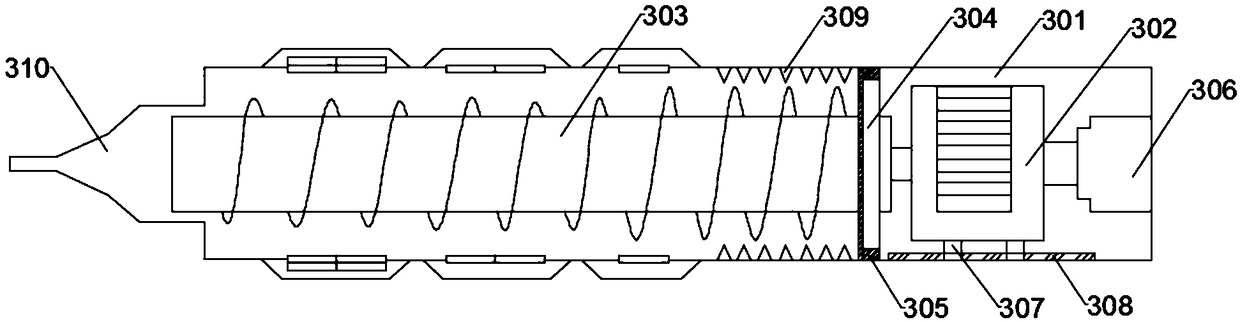

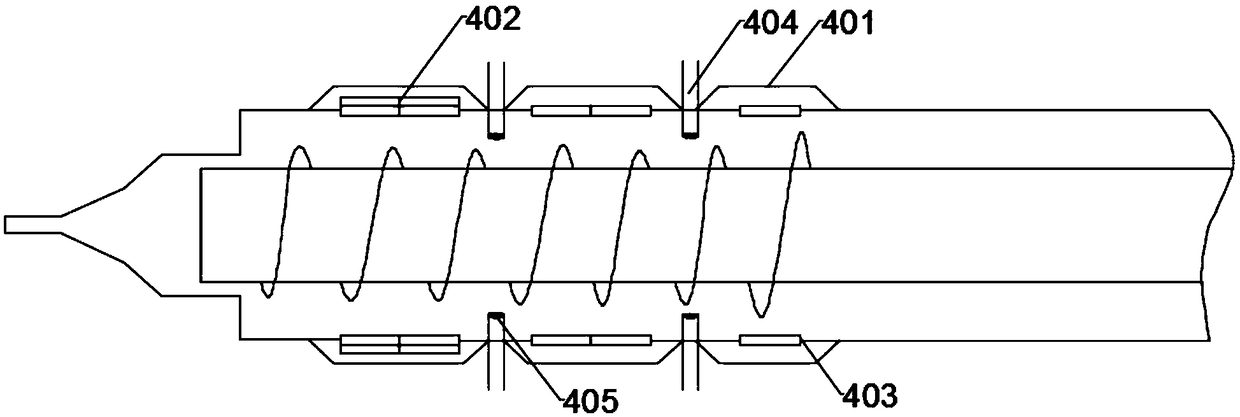

A method for realizing three-layer four-station injection molding of thick-walled parts

ActiveCN106738597BInjection waiting time reducedShorten the timeDomestic articlesThick wallMaterials science

The invention discloses an implementation method for three-layer four-station injection molding of a thick-wall part. According to the sequence of injection molding, injection molding is conducted on a middle layer at first, then, injection molding is conducted on the upper side of the periphery of the middle layer, and finally, the lower side of the periphery of the middle layer is subjected to injection molding; injection molding is implemented by arranging fixed molds and movable molds; and the fixed molds are uniformly arranged at four stations and are perpendicular to one another, and the movable molds are uniformly arranged at four stations and are perpendicular to one another. According to the implementation method, the movable molds and the fixed molds of the product exchange and stay through repeated rotating, the injection mold period is shortened, and the part precision is improved.

Owner:HASCO VISION TECHNOLOGY CO LTD

Mold clamping mechanism of two-plate injection molding machine

The invention discloses a mold clamping mechanism of a two-plate injection molding machine. The clamping mechanism comprises a movable mold plate and a fixed mold plate that are arranged in parallel and at an interval, wherein a mold locking oil cylinder is arranged on one side, far away from the movable mold plate, of the fixed mold plate; the end part of a mold locking piston rod penetrates through the fixed mold plate and then is connected with the movable mold plate; a mold moving mechanism used for driving the movable mold plate to move along the mold locking piston rod is arranged between the movable mold plate and the fixed mold plate; a half-and-half brake nut capable of locking or unlocking the mold locking piston rod is arranged on one side, far away from the fixed mold plate, ofthe movable mold plate; a fine adjustment oil cylinder is fixedly arranged at one end, far away from the fixed mold plate, of the mold locking oil cylinder; the area of the cross section of the fineadjustment oil cylinder is smaller than that of the mold locking oil cylinder; a fine adjustment piston rod is arranged in the fine adjustment oil cylinder; the end part of the fine adjustment pistonrod is fixedly connected with a mold locking piston. The mold clamping mechanism of the two-plate injection molding machine has the advantages of being high in linkage degree, production efficiency and product quality.

Owner:HAITIAN PLASTICS MACHINERY GRP

Improved toy shell material and preparation method thereof

The invention discloses an improved toy shell material. The improved toy shell material is prepared from a component A and a component B, and the weight ratio of the component A to the component B is1:(0.8-1.2), wherein the component a comprises the following components in percentage by mass: 18-22% of ethylene vinyl acetate (EVA), 2-4% of zinc stearate and 74-80% of calcium carbonate, and the component B comprises the following components in percentage by mass: 58-62% of calcium carbonate, 12-18% of a lubricant and 20-30% of EVA. The invention further discloses a preparation method of the improved toy shell material. The toy shell material can be easily cracked by pushing, a packaged finished product is not easily cracked in a transportation process, sharp points or edges are avoided after the shell material is broken, and thus children are prevented from being scratched.

Owner:PACIFIC INDAL ZHONGSHAN

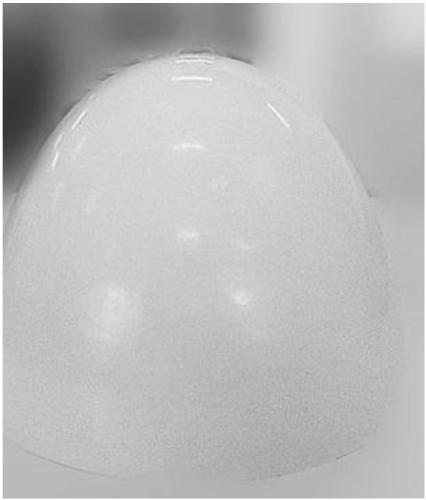

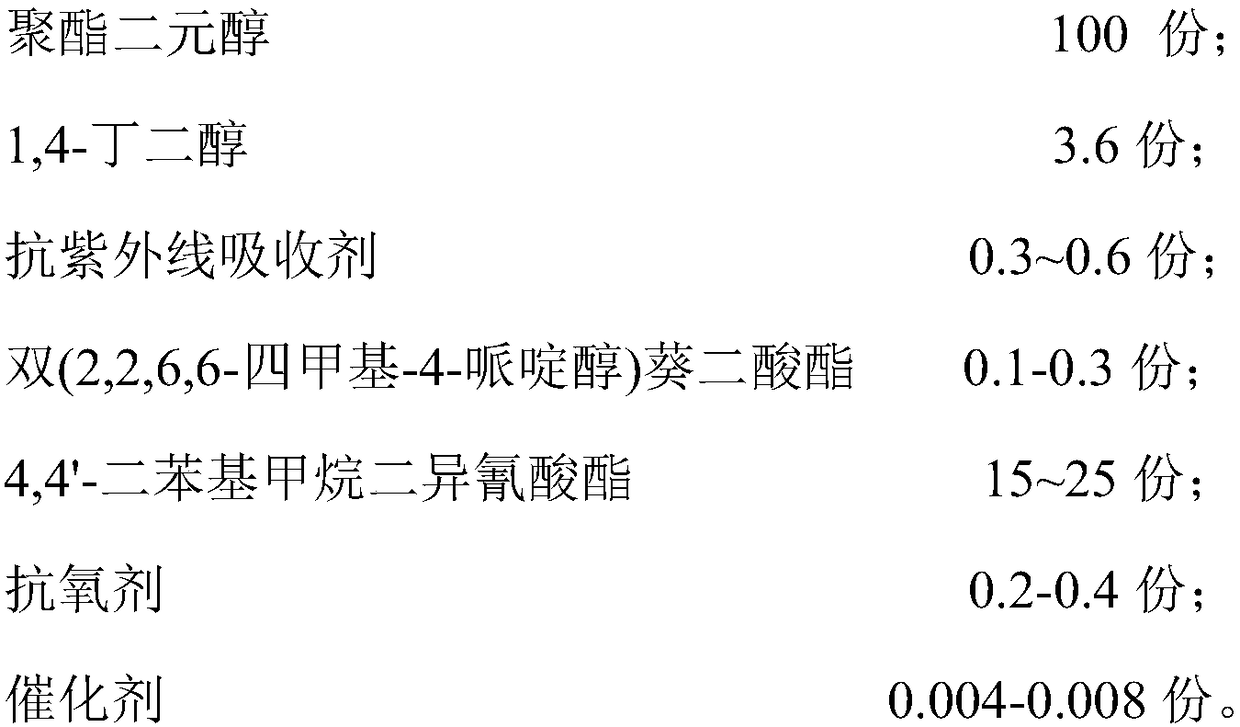

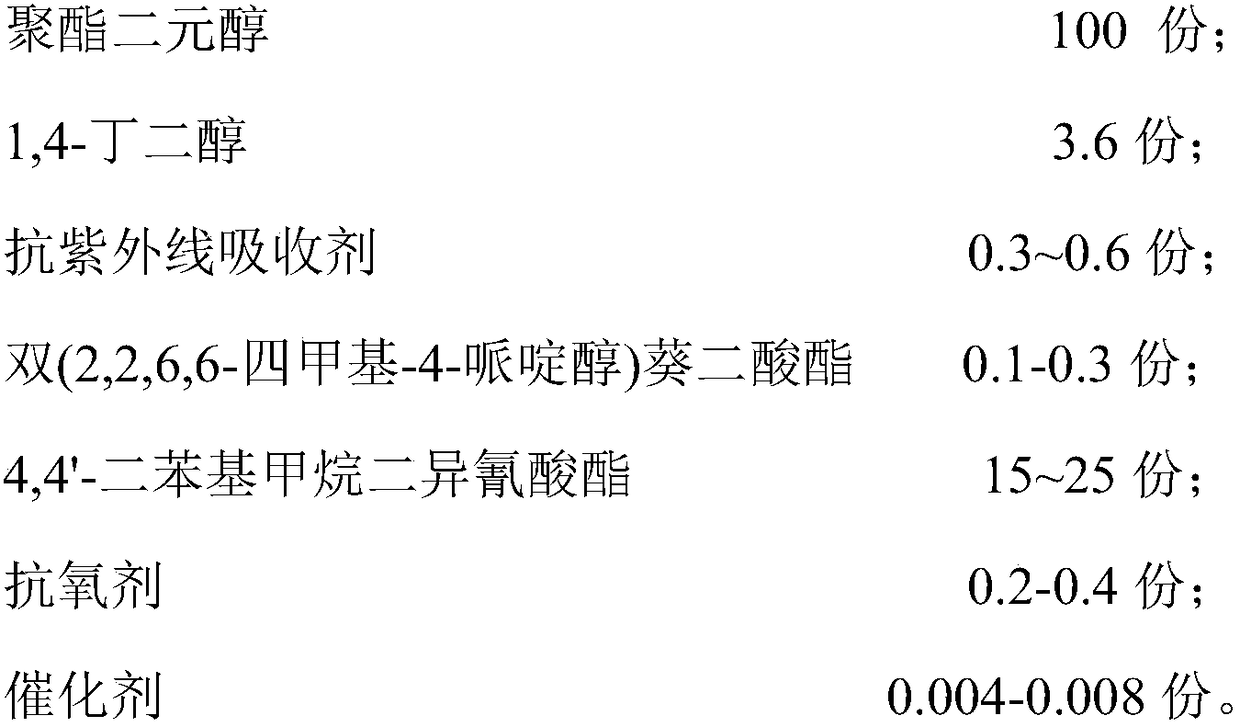

Anti-yellowing thermoplastic polyurethane elastomer and preparation method thereof

InactiveCN108164676AGood yellowing resistanceThe preparation method is economical and environmentally friendlyPolyesterAntioxidant

The invention discloses an anti-yellowing thermoplastic polyurethane elastomer and a preparation method thereof. The polyurethane elastomer has shore hardness of 60 to 75 A. The polyurethane elastomeris prepared from the following raw materials: polyester glycol, 1,4-butanediol, an anti-ultraviolet absorbent, di(2,2,6,6-tetramethyl-4-pipradrol)sebacic acid ester, 4,4'-diphenylmethane diisocyanate, an antioxidant and a catalyst. According to the anti-yellowing thermoplastic polyurethane elastomer and the preparation method thereof, the shore hardness of the thermoplastic polyurethane elastomeris up to 60 to 75 A, and the injection molding period is effectively shortened, so that a phenomenon of sticking of a mold during processing is avoided. Furthermore, due to addition of the anti-ultraviolet absorbent, the polyurethane elastomer disclosed by the invention is excellent in anti-yellowing property. Moreover, the injection molding period and the intensity of the thermoplastic polyurethane elastomer can be balanced by regulating and controlling the use amount of a catalyst. The preparation method of the polyurethane elastomer is environmentally friendly, economical, high in weatherresistance, high in injection molding speed and high in processing efficiency, and can be widely applied to injection molding of products such as a shoe material, a triangular belt and sheet rubber.

Owner:清远新力化机有限公司

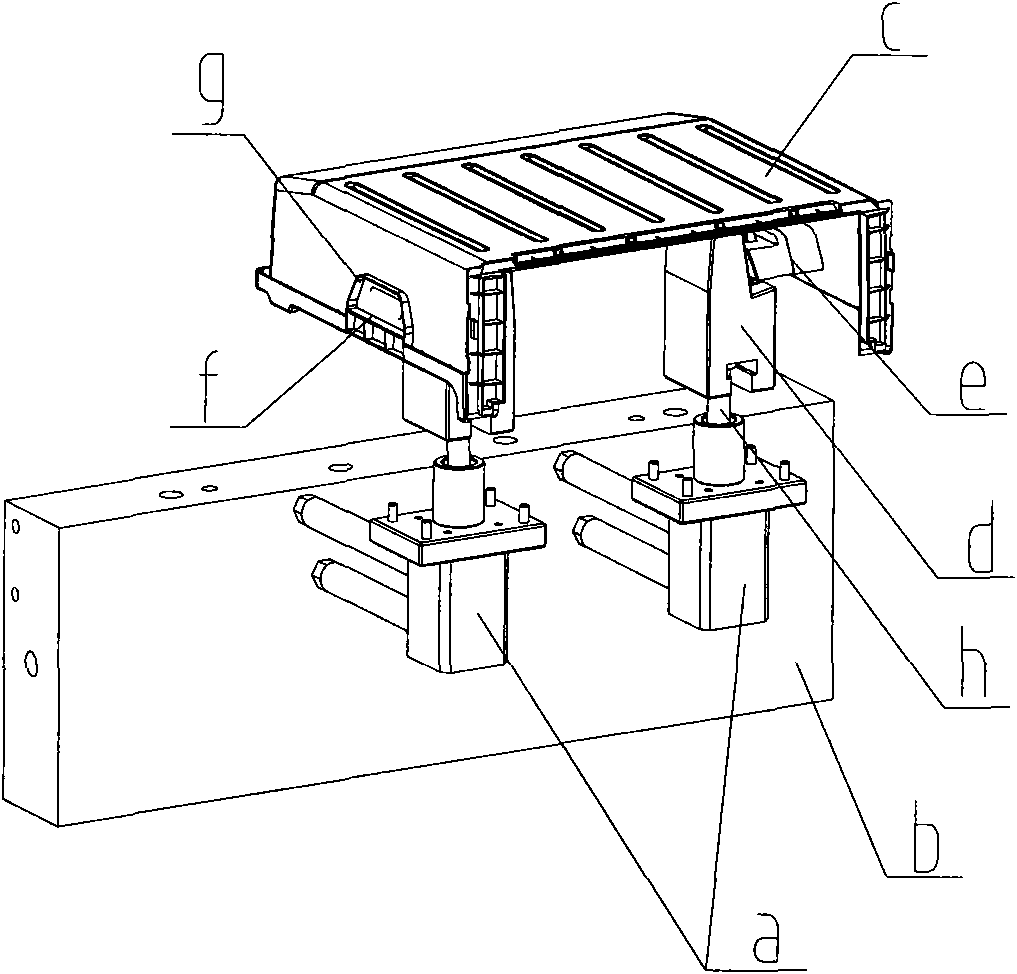

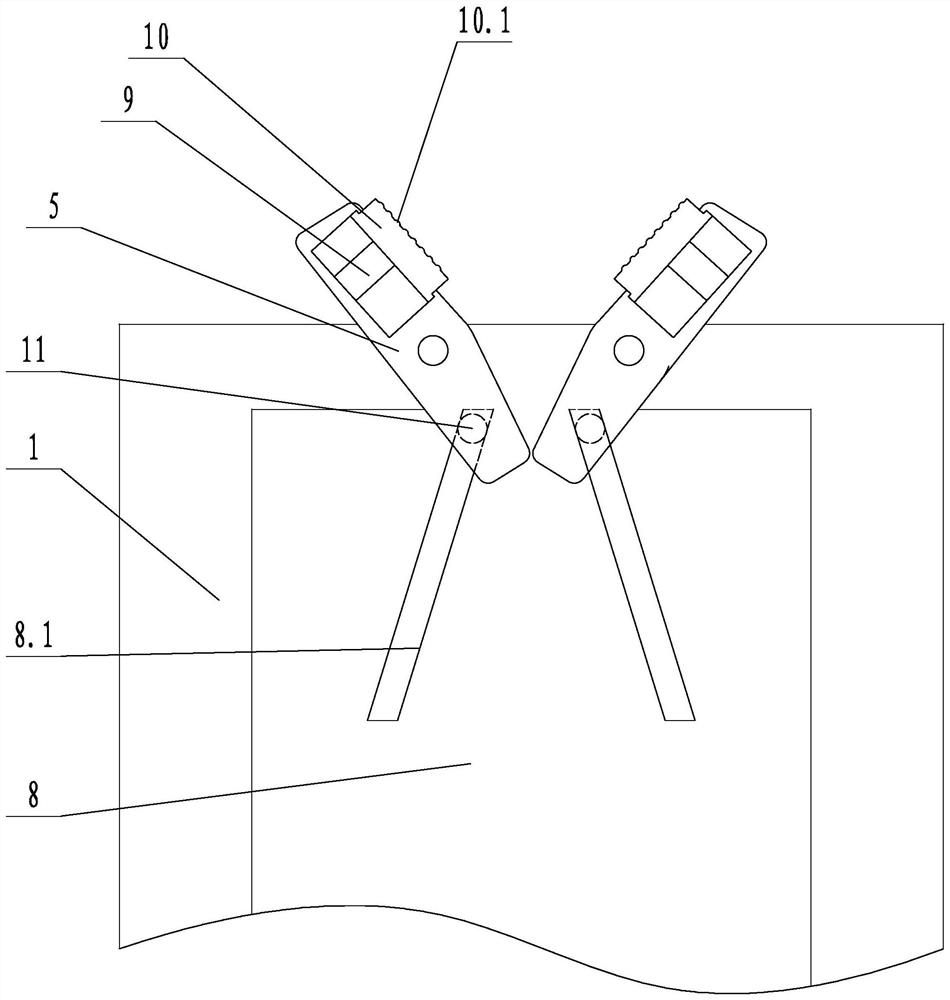

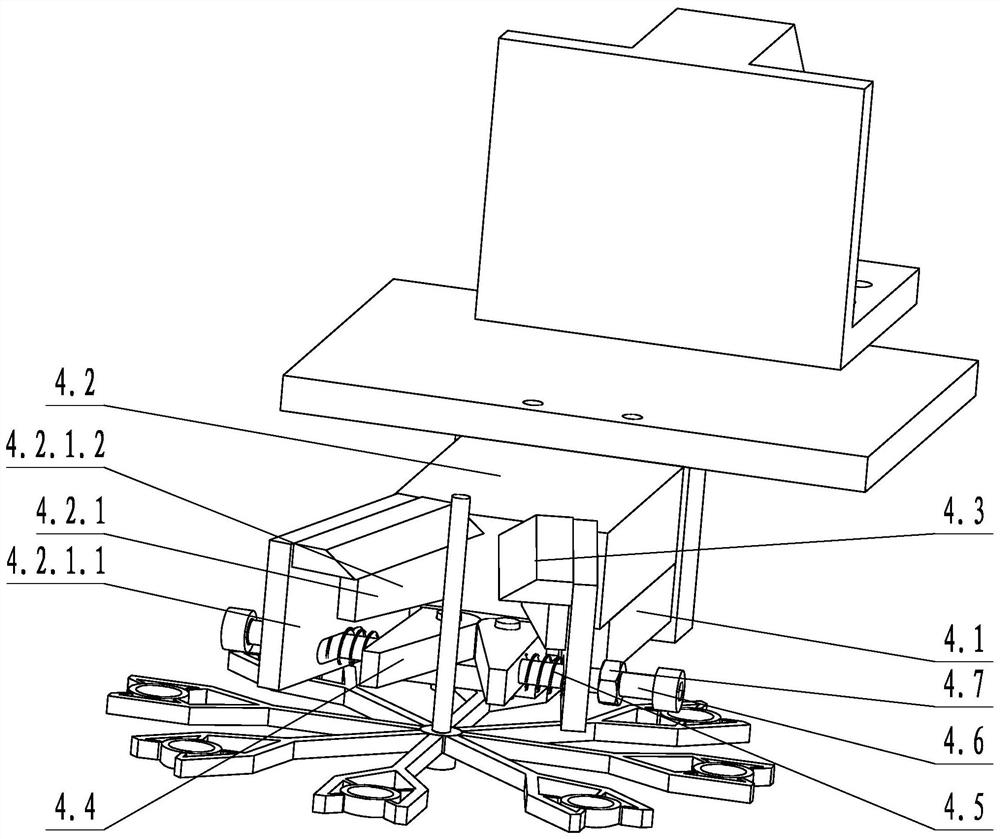

Double-acting clamping jig with shearing function

PendingCN113858543AAvoid pinchingAvoid interferenceMetal working apparatusPunchingStructural engineering

The invention discloses a double-acting clamping jig with a shearing function. The double-acting clamping jig comprises a fixing frame, a first driving mechanism, a second driving mechanism, scissors, a clamping jaw block and a first inclined pushing block; and the first driving mechanism, the second driving mechanism and the scissors are arranged on the fixing frame, the clamping jaw block is arranged below the scissors, the first inclined pushing block is in sliding connection with the fixing frame, the first driving mechanism drives the first inclined pushing block to slide, a first guide groove is formed in the first inclined pushing block and is of a V-shaped structure, a large opening of the first guide groove faces the scissors, a handle of the scissors makes contact with the side wall of the first guide groove, and the second driving mechanism drives the clamping jaw block to move. According to the double-acting clamping jig with the shearing function, a material rod of an injection molding product is shorn, so that possible interference between the material rod and a punch of a punching machine due to deformation of the material rod is avoided, and further shortening of the injection molding period becomes reality.

Owner:NINGBO BEILONG PRECISION MOLDING

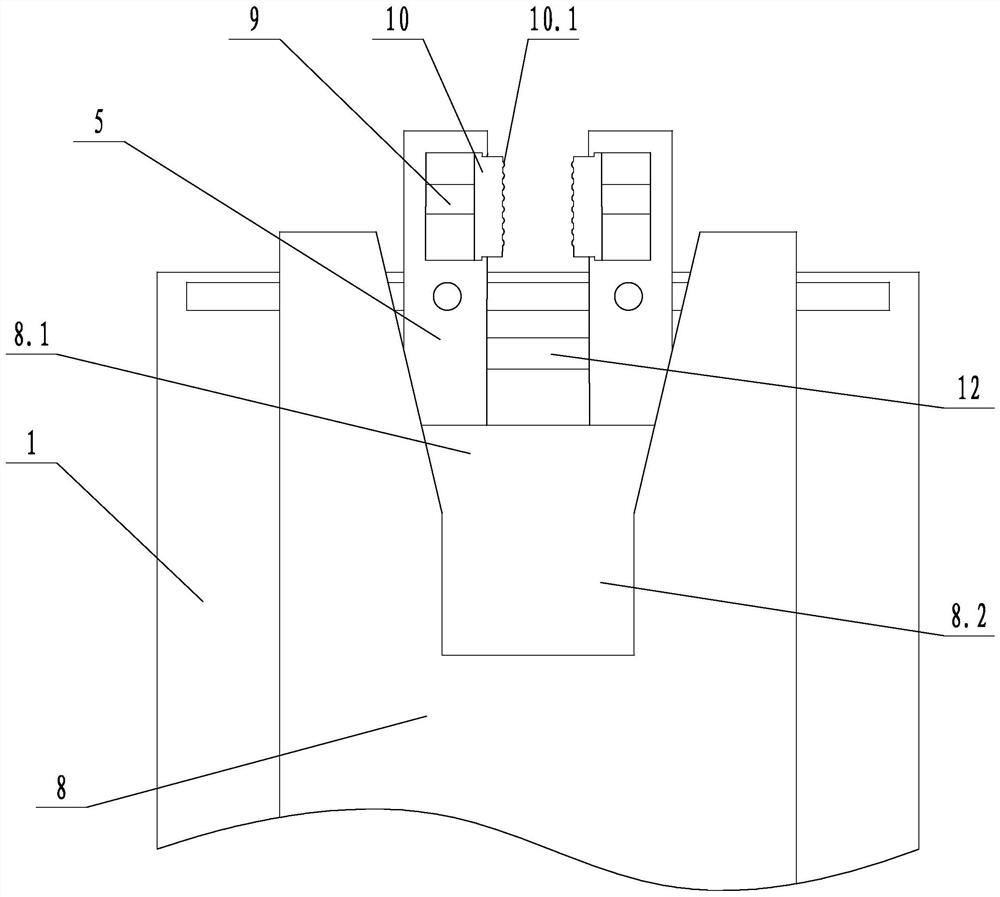

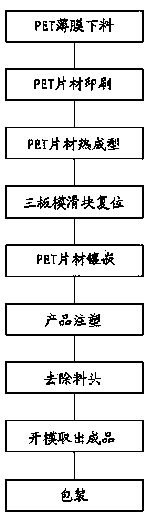

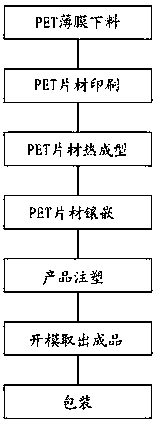

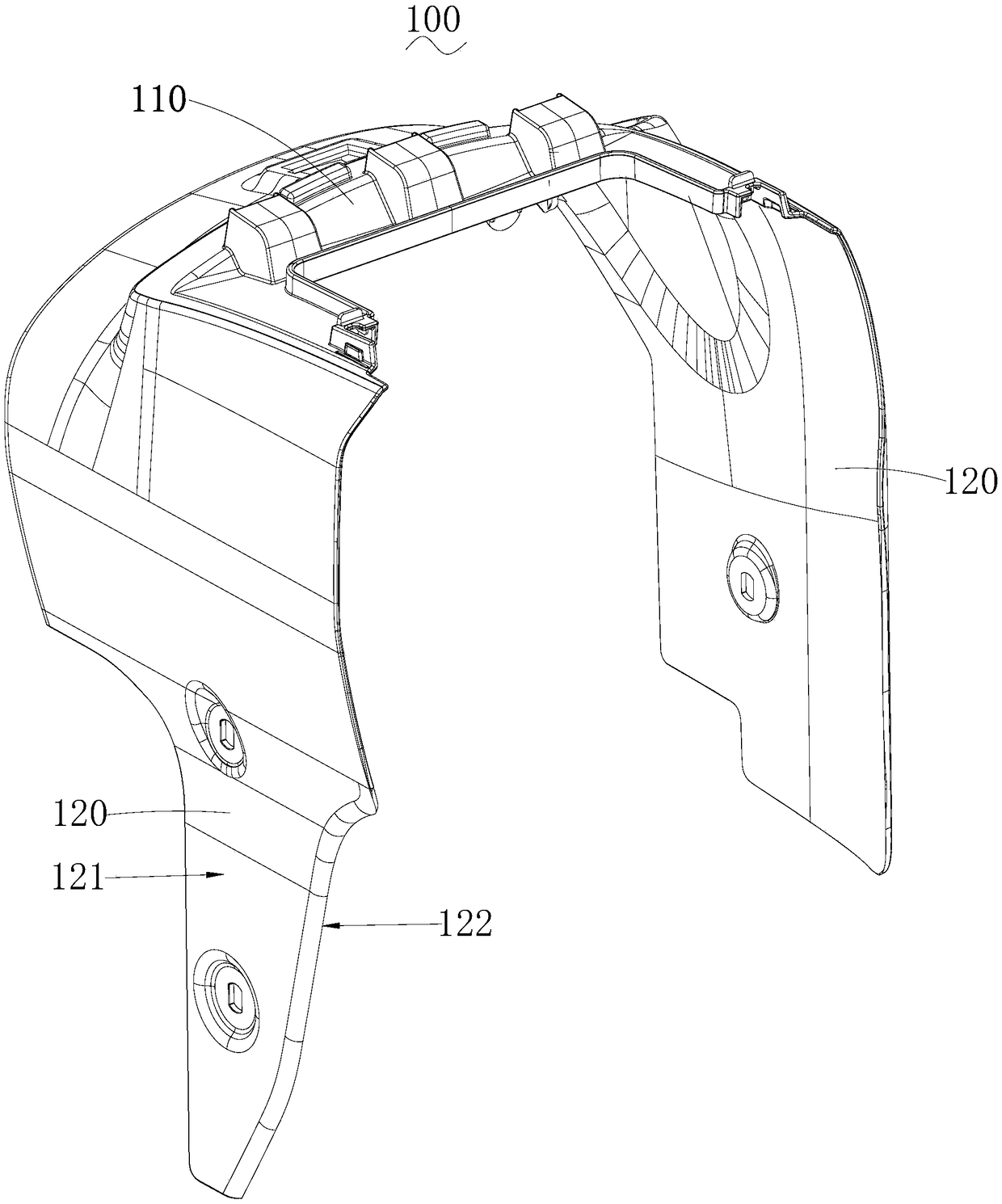

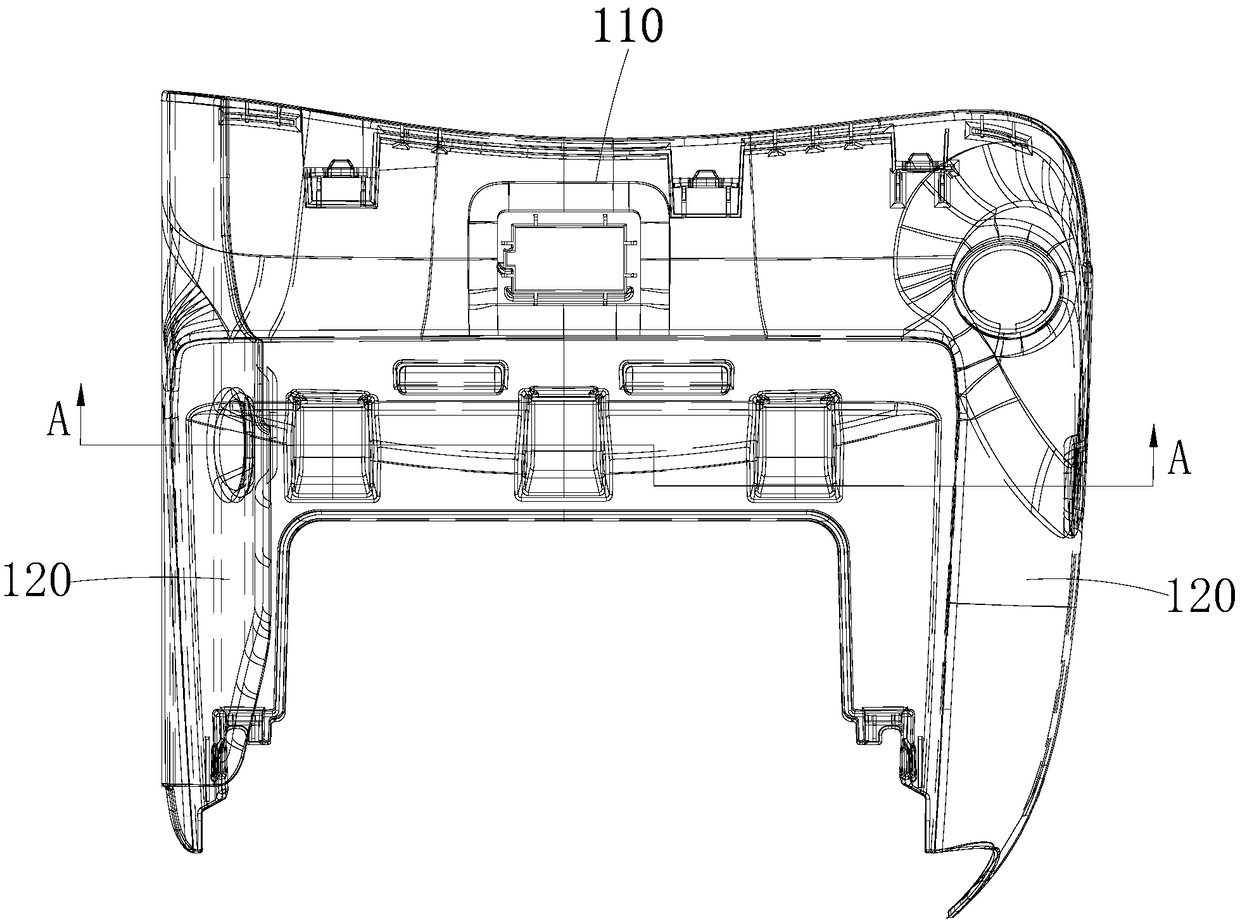

IML reverse covering process of laundry machine panel

InactiveCN104385525AShorten injection molding cycleReduce weightFlat articlesDomestic articlesLaundryEngineering

The invention discloses an IML reverse covering process of a laundry machine panel. The process comprises the following steps: discharging a PET film, and cutting the PET film into a PET sheet of the corresponding size according to product appearance; printing the PET sheet, namely printing patterns on the PET sheet through a screen printing machine; thermally forming the PET sheet, namely performing thermal forming on the printed PET sheet through a thermal forming machine; inlaying the PET sheet, namely placing the thermally formed PET sheet to a movable mold cavity of an injection molding mold, wherein the printing surface of the PET sheet faces downwards and is positioned; performing product injection molding, namely performing injection molding on the product by using a two-plate mold, and fusing the PET sheet to the surface of a plastic piece through high-temperature high-pressure injection molding; opening the mold and taking out the finished product; and packaging. The process has the advantages that the production cycle is shortened, the waste of remnants is reduced, and the quality of the product is ensured.

Owner:江苏坤达电器装饰有限公司

Multi-station injection moulding machine

PendingCN107471538AReduce manufacturing costReduce labor costsInjection molding machineInjection moulding

The invention belongs to the technical field of injection moulding equipment, and particularly relates to a multi-station injection moulding machine. The multi-station injection moulding machine comprises an extruder; a material outlet of the extruder is connected with a material storage cylinder through a material conveying main pipe; a plurality of material outlets are formed in the material conveying main pipe; each material outlet is connected with a mould assembly rack; and a plurality of mould assembly racks are arrayed along at least one side of the extruder. According to the multi-station injection moulding machine, melt raw materials of one extruder are distributed to the multiple mould assembly racks for injection moulding through the material conveying main pipe and the material storage cylinder, so that a technique of multi-station injection integral moulding through distribution of one extruder is realized; production cost and labor cost are lowered; injection moulding efficiency is improved; and an injection moulding cycle is shortened.

Owner:林士顺

Implementing method of three-layer three-position injection molding for thick-wall part

ActiveCN106799811AInjection waiting time reducedReduce injection molding timeOptical articlesMaterials science

Owner:HASCO VISION TECHNOLOGY CO LTD

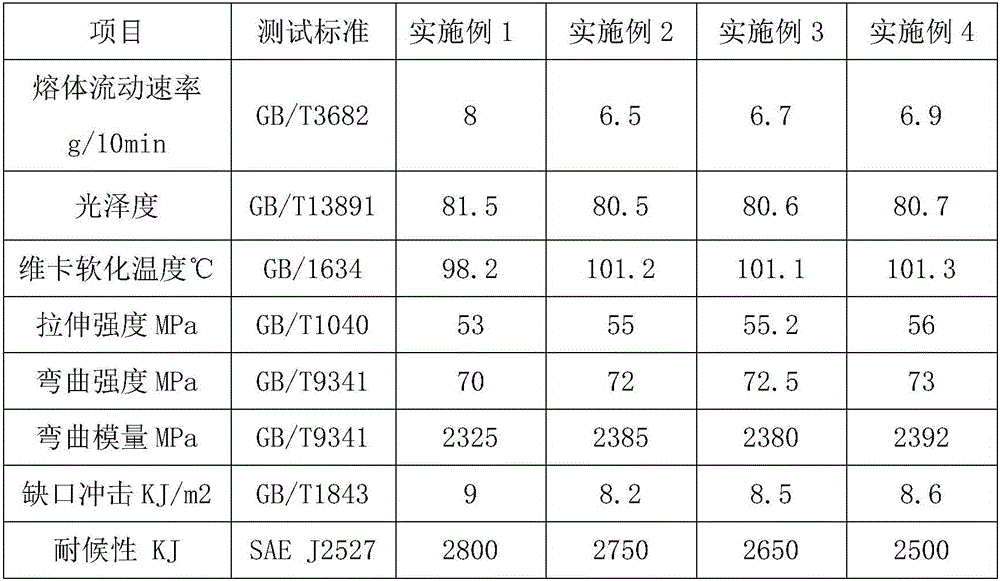

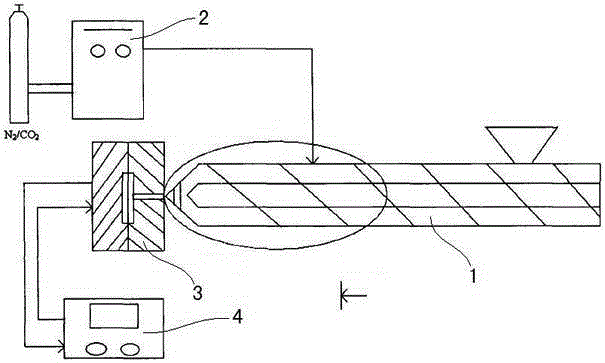

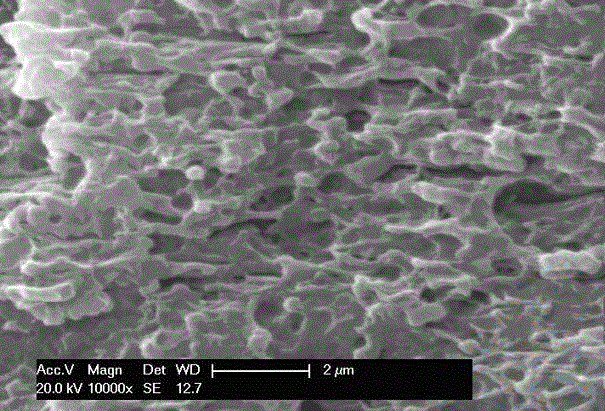

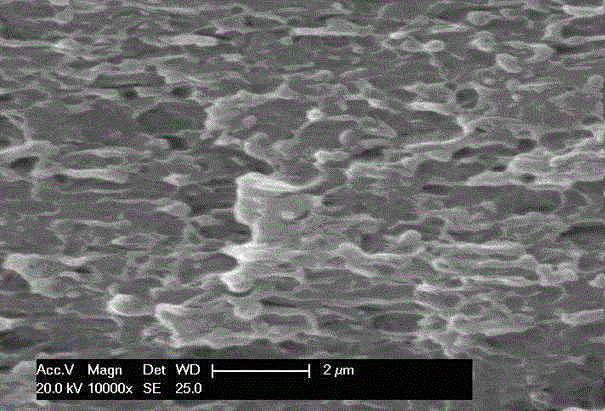

A kind of microporous pc/abs alloy and preparation method thereof

The invention relates to a microporous PC / ABS alloy and a preparation method thereof. The average micropore diameter of the microporous PC / ABS alloy is less than 1 μm, and the number of cells is greater than 109 / cm3; Reduced by more than 10%, the impact strength increased by about 2 times. The preparation method uses supercritical nitrogen as a foaming agent and injection molding to obtain a microporous PC / ABS alloy with small cell diameter, high density and uniform distribution; supercritical nitrogen foaming is combined with injection molding methods, supercritical nitrogen It can reduce the viscosity of the resin, reduce the clamping force in injection molding, reduce the burrs and internal stress of the product, prolong the life of the mold, and increase the dimensional stability of the product; it can also reduce the defects such as warpage and shrinkage marks of the product, and improve product quality. In addition, because the pressure-holding stage in traditional injection molding is not required, the injection molding cycle is shortened, the production efficiency is improved, and the cost is reduced.

Owner:FUZHOU UNIV

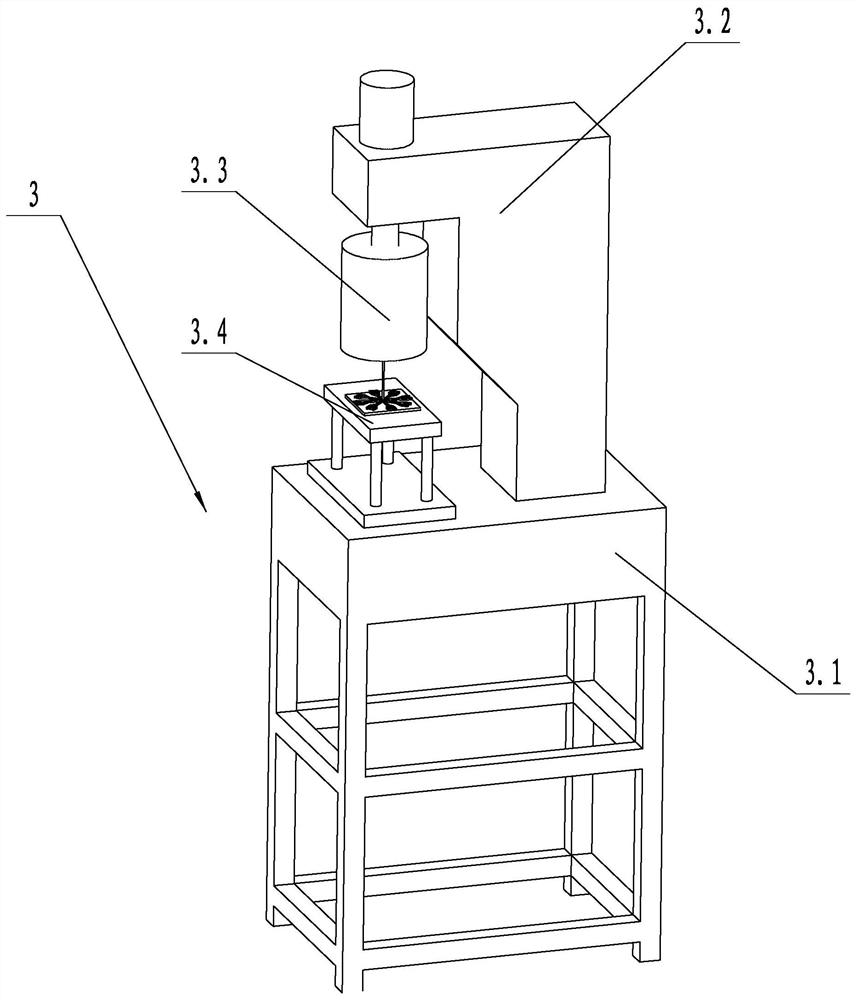

Production equipment for shortening production cycle of small injection molded part

PendingCN113878788AAvoid interferenceShorten injection molding cyclePunchingInjection molding machine

The invention discloses production equipment for shortening the production cycle of a small injection molded part. The production equipment comprises an injection molding machine, clamping equipment and a punching machine, wherein the injection molding machine is used for injection molding to form a semi-finished product; the clamping equipment is used for clamping the semi-finished product and cutting off a material rod on the semi-finished product, and the punching machine is used for separating a product on the semi-finished product from waste and punching to form the product; the punching machine comprises a support, a power mechanism, an ultrasonic punching head and a punching clamp, the power mechanism and the punching clamp are fixed to the support, the ultrasonic punching head is fixed to the power mechanism, and a material rod avoiding hole is formed in the ultrasonic punching head; and the punching machine can separate the product and the waste on the punching clamp through the ultrasonic punching head. According to the production equipment for shortening the production cycle of the small injection molded part, the material rod of the injection molded product is cut short, so that possible interference between the material rod and a punch of the punching machine due to deformation of the material rod is avoided, and therefore the injection molding cycle is shortened.

Owner:NINGBO BEILONG PRECISION MOLDING

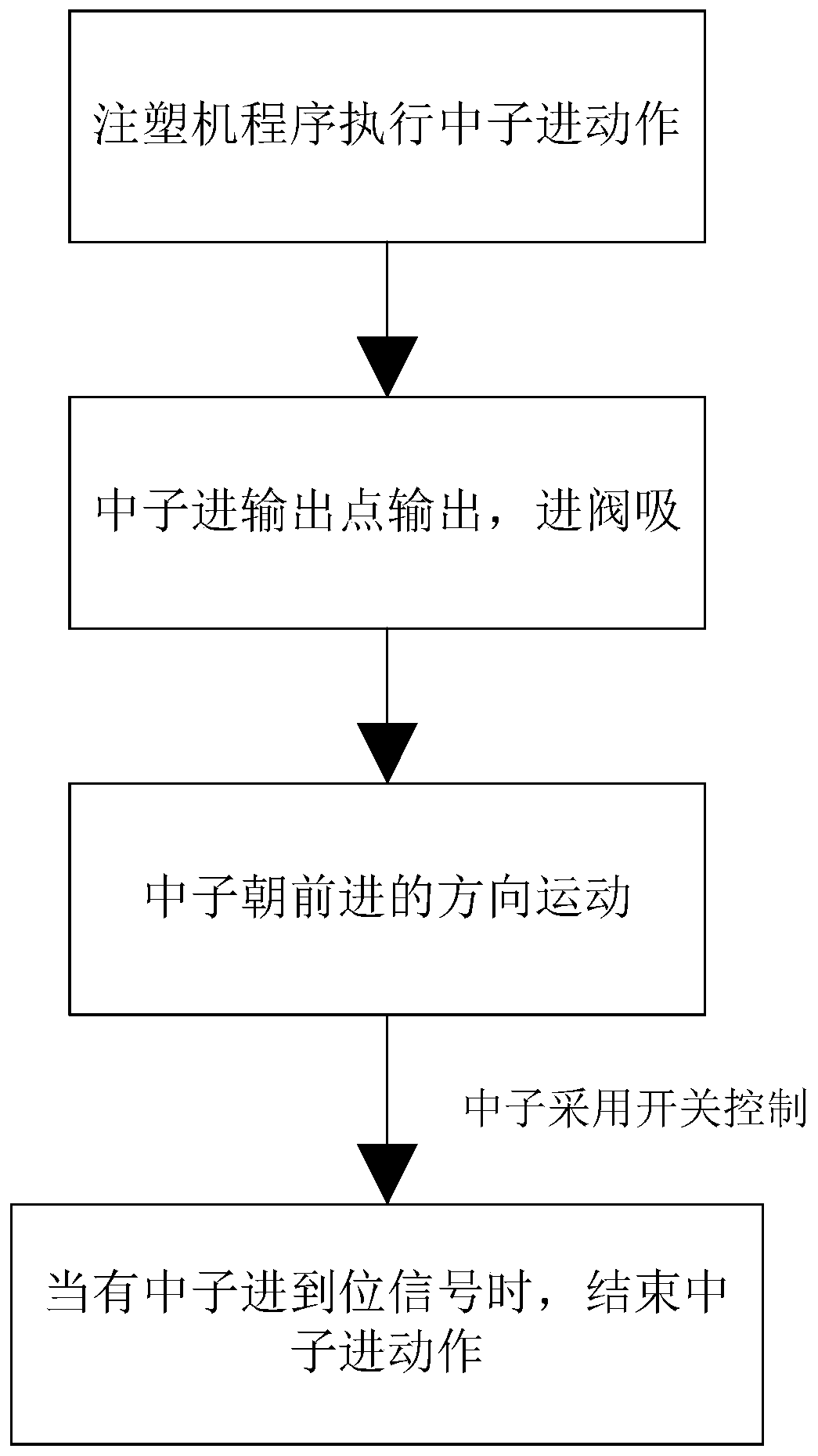

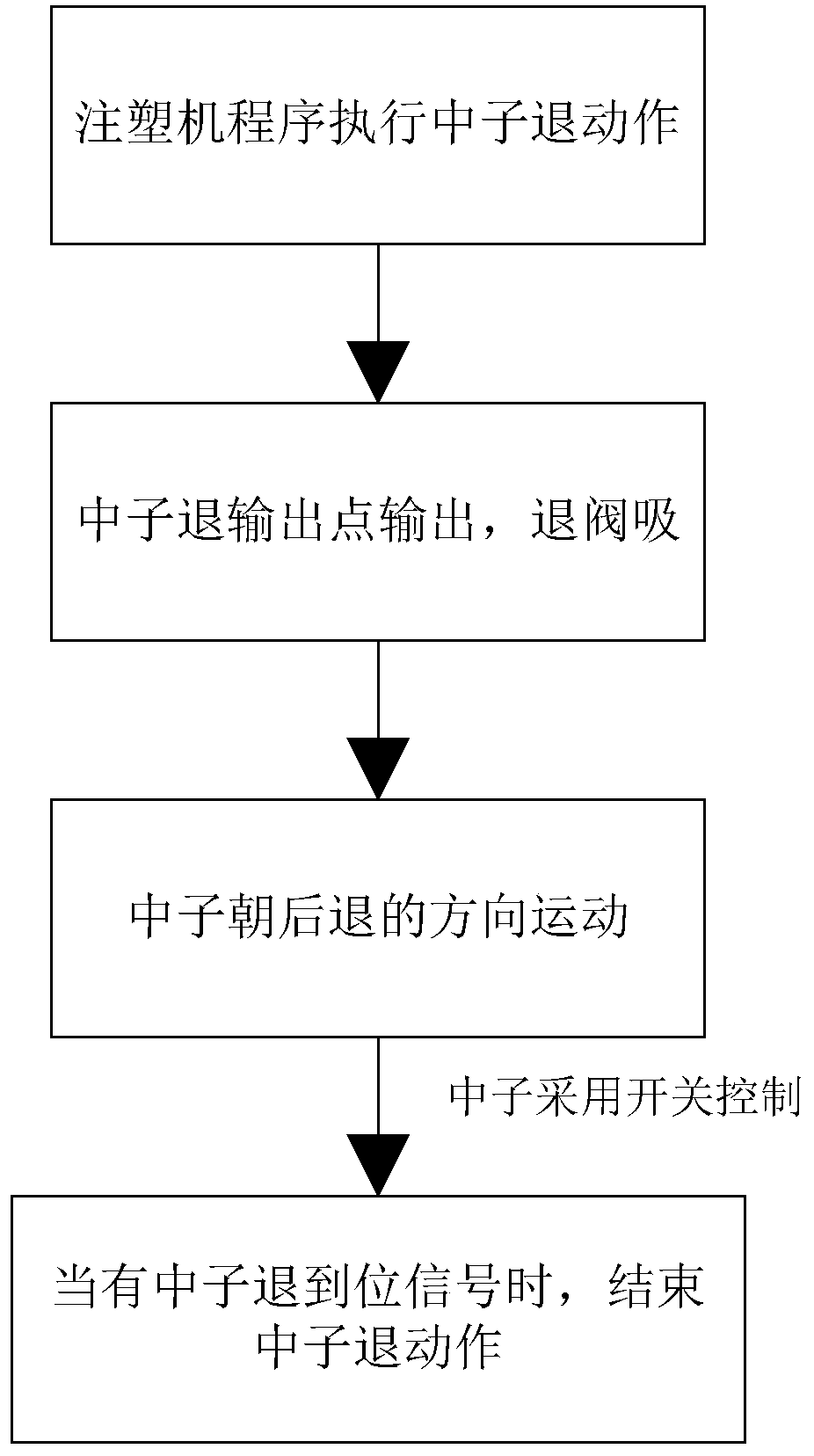

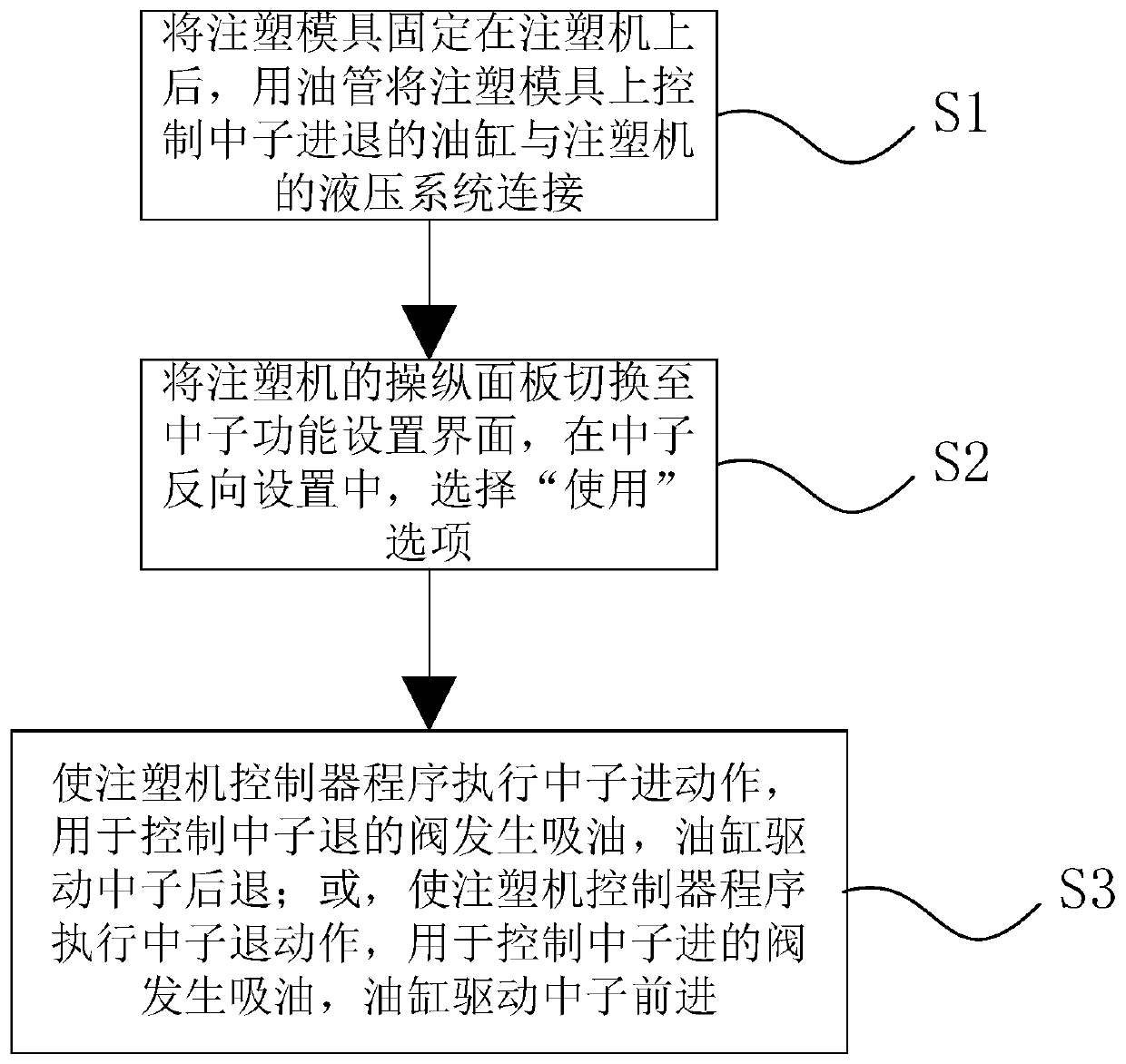

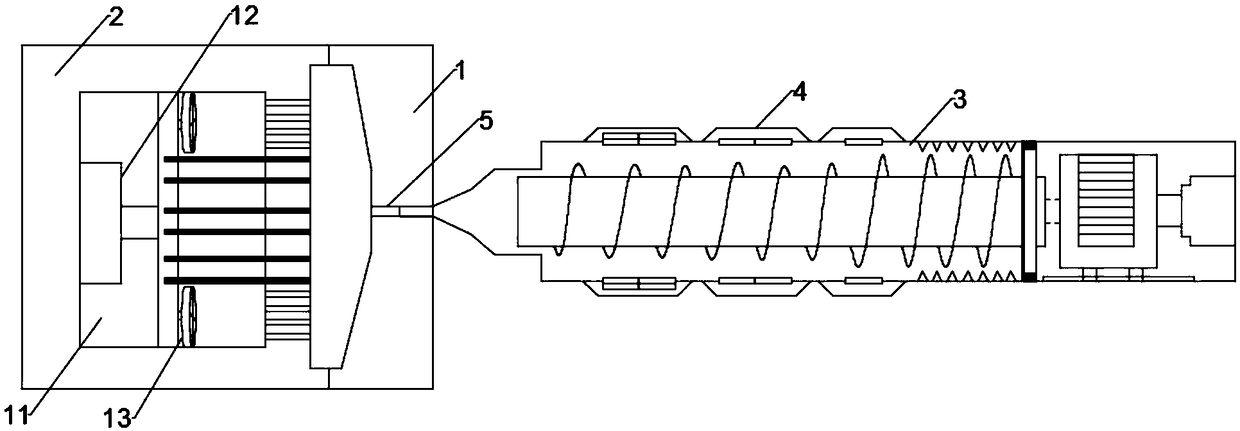

Reverse control method for neutron action of injection molding machine

The invention relates to the technical field of injection molding machines and discloses a reverse control method for neutron action of an injection molding machine. The reverse control method comprises the following steps of fixing an injection molding die on the injection molding machine, and then connecting an oil cylinder for controlling neutrons to advance and retreat on the injection moldingdie with a hydraulic system of the injection molding machine; switching a control panel of the injection molding machine to a neutron function setting interface, and selecting a use option in the reverse setting of the neutrons; executing the advancing action of the neutrons by using injection molding machine controller programs, absorbing by using a valve for controlling the neutrons to retreat,and driving the neutrons to retreat by using the oil cylinder; or performing the neutrons retreating action by using the injection molding machine controller programs, absorbing the oil by using a valve for controlling the neutrons to advance, and driving the neutrons to advance by using the oil cylinder. The reverse control method disclosed by the invention has the advantages that the injectionmolding machine has the neutron reversing function, and a high-pressure oil pipe does not need to be exchanged, so that personal security is ensured; and in addition, information interference to othermolds is avoided.

Owner:HAITIAN PLASTICS MACHINERY GRP

Plastic slipper injection molding injection mold and method

ActiveCN108790232AAvoid Burnt SituationsIncrease the amount of foamDomestic footwearSurface mountingDrive motor

The invention discloses a PVC blowing slipper injection mold which comprises a fixed mold base, a movable mold base and a plastic mixing crushing mechanism, wherein the plastic mixing crushing mechanism comprises an accommodating reaction cylinder and a drive motor; the drive motor is connected with a squeezing screw; a thermal insulating panel is arranged at one end of the squeezing screw and isconnected with a displacement air cylinder; a movable sliding block is mounted on the lower surface of the drive motor; a sliding rail is further arranged on the inner wall of the accommodating reaction cylinder; the squeezing screw is sequentially divided into a crushing section, a melting stirring section and a squeezing section from right to left; the accommodating reaction cylinder is providedwith a friction bulge; the accommodating reaction cylinder is provided with subsection heating mechanisms at the melting stirring section and the squeezing section separately; and an air blowing pipeis further arranged on the accommodating reaction cylinder. The subsection heating manner is adopted to avoid the situation that plastic is burnt; an air blowing mechanism is added to increase the foaming quantity; and water-cooling and air-cooling manners are adopted to carry out air blowing foaming treatment and efficient cooling function, so that the injection molding period is shortened and the operating convenience is also improved.

Owner:定州市鼎足鞋业有限公司

Injection molds for the manufacture of cantilevered structural products

The invention belongs to the field of a mold structure and especially relates to an injection mold for manufacturing a cantilever structure product. When the mold is assembled, a front inner mold and a rear inner mold are encircled and formed into an injection chamber for forming a main body of the cantilever structure product; and the rear inner mold and a rear mold sliding block are encircled and formed into an injection chamber for forming a reverse buckling cantilever. After injection molding, an injection molding machine is used for opening the mold, the rear mold sliding block slides and separates from the reverse buckling cantilever, the tail end of the reverse buckling cantilever is outward turned by a drawing mechanism, the reverse buckling cantilever is plastically deformed, and the rear mold sliding block is separated from the rear inner mold; the product packaging force is small, and a simplified jacking mechanism is adopted for pushing the main body away from the rear inner mold, so that the mold stripping is realized; and the rear mold sliding block is reset and the mold is assembled, so as to prepare for the next injection molding. The injection mold is suitable for manufacturing a large-scale cantilever structure product which can be separated from the mold without fully separating the product reverse buckle, and the separating structure configured for the reverse buckling cantilever of the present mold is not required, so that the mold structure is simplified, the rear mold has the space for arranging a more reasonable water channel, the injection molding period is reduced, the mold quality is high, and the production cost is low.

Owner:FOSHAN CITY SHUNDE DISTRICT BAINIAN TECH CO LTD

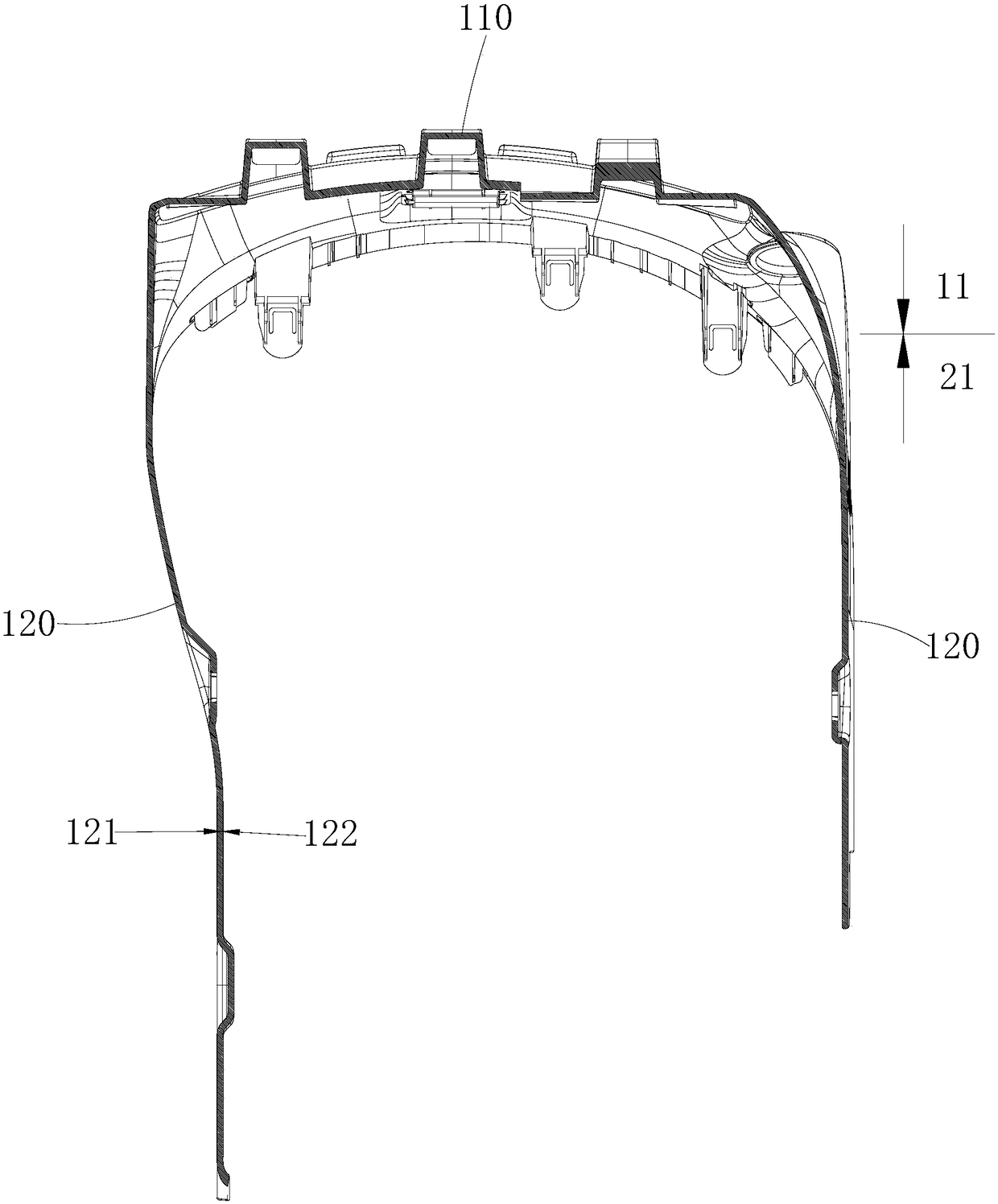

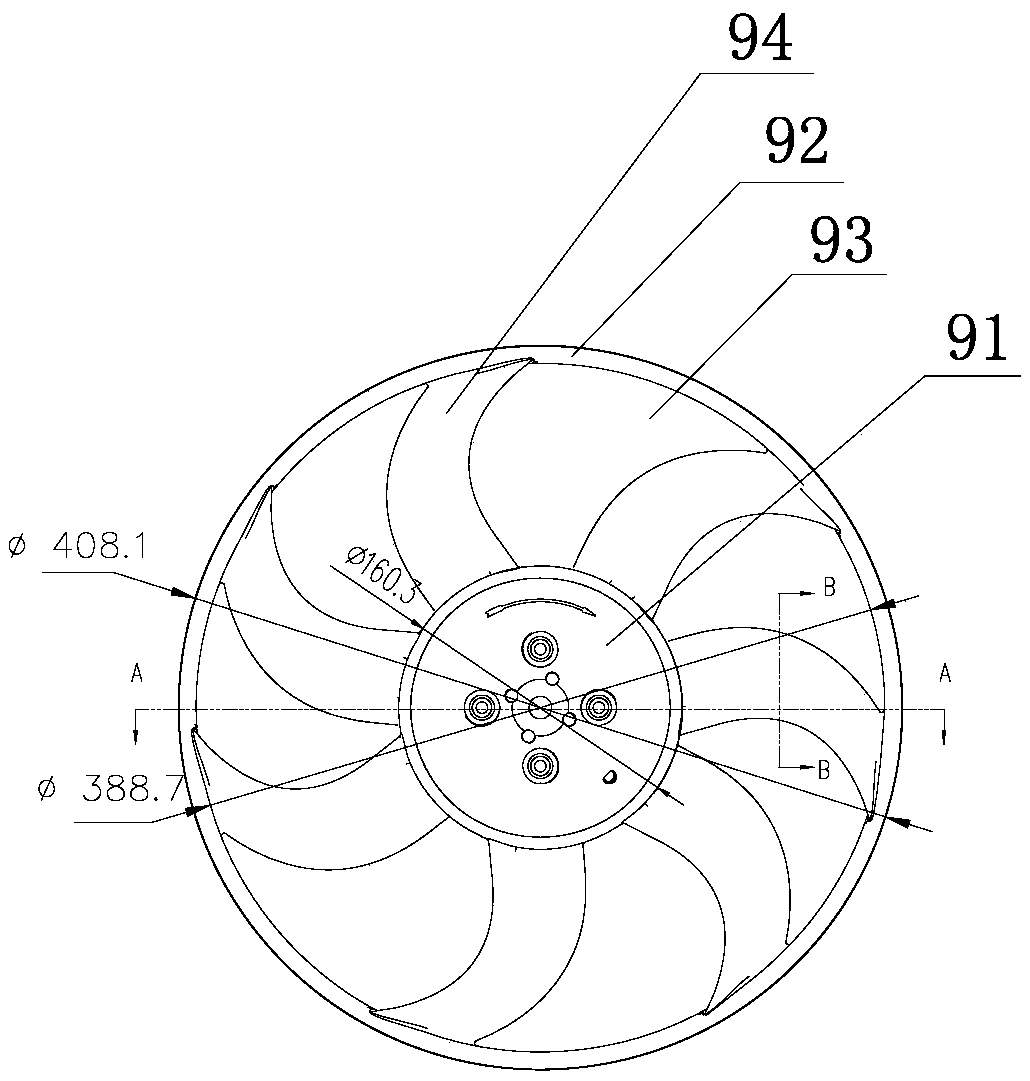

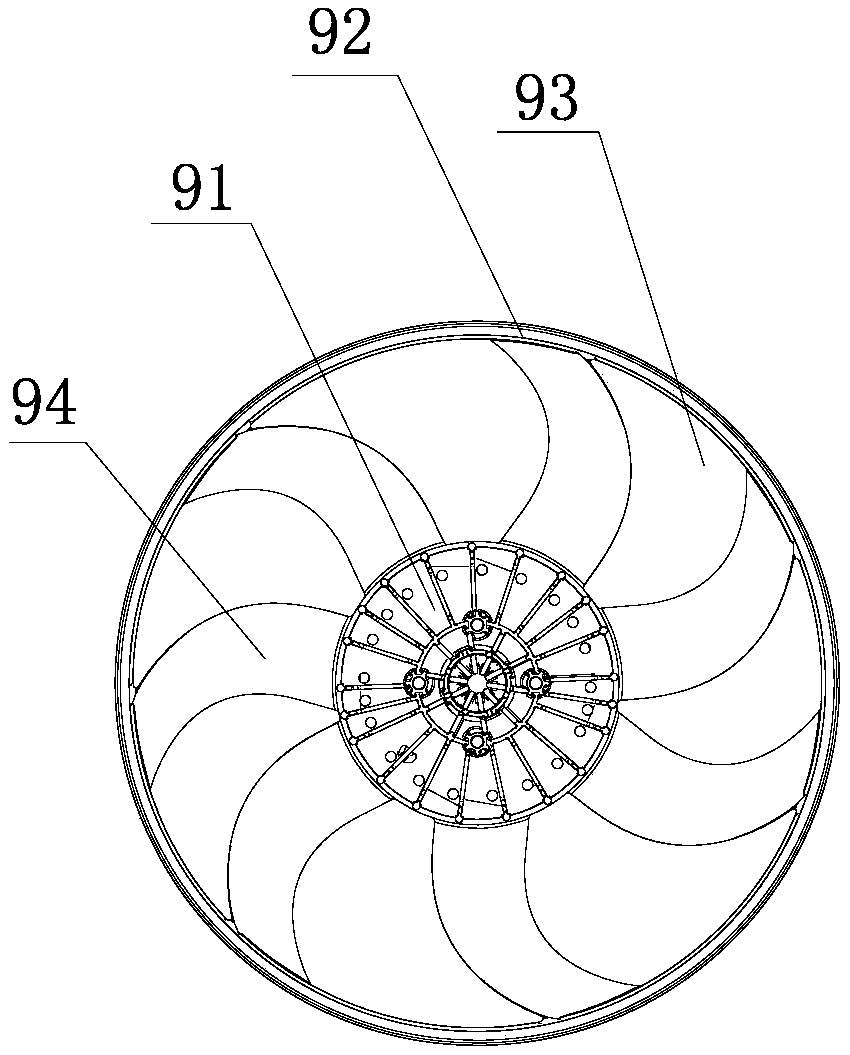

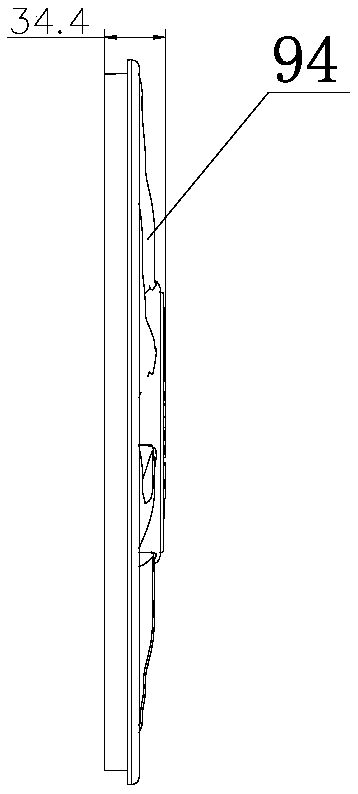

Cooling water channel structure of automobile engine cooling fan mold

The invention discloses a cooling water channel structure of an automobile engine cooling fan mold. The cooling water channel structure is composed of a fixed mold side water channel arranged on the back side of a fixed mold side fan mold cavity and a movable mold side water channel arranged on the back side of a movable mold side fan mold cavity. The fixed mold side water channel comprises a plurality of independent fixed mold side well type water channels. Each fixed mold side well type water channel is arranged on the back side of a blade cavity in the fixed mold side fan mold cavity. Eachfixed mold side well type water channel is provided with an inlet and an outlet. The movable mold side water channel comprises a plurality of independent movable mold side well type water channels. Each movable mold side well type water channel is arranged on the back side of a blade cavity in the movable mold side fan mold cavity. Each movable mold side well type water channel is provided with aninlet and an outlet. The cooling water channel structure has the advantages that the cooling effect is good; the shape of the curved surface of each injection molded fan blade can reach the expectedideal shape; the injection molding period can be shortened; and the injection molding production efficiency is greatly improved.

Owner:NINGBO TIANLONG ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com