Spraying-free, heat-resistant and weather-resistant high-brightness PMMA alloy material and preparation method thereof

An alloy material, spray-free technology, applied in the field of polymer materials, can solve the problems of decreased gloss of PMMA resin, loss of weather resistance, low toughening efficiency, etc., to save the spraying process, reduce energy consumption, and shorten the injection molding cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

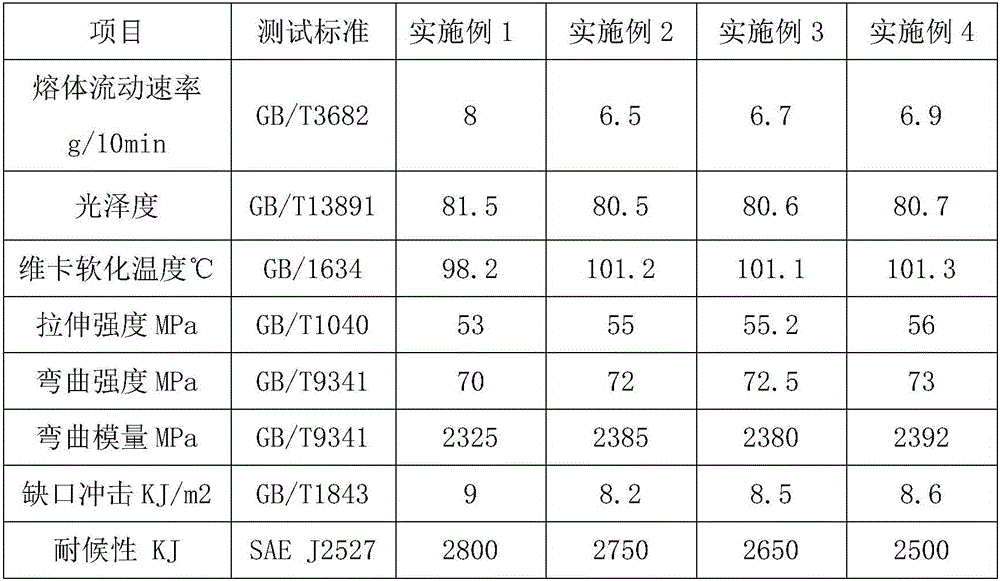

Examples

Embodiment 1

[0025] A spray-free, heat-resistant, weather-resistant high-gloss PMMA alloy material, which is prepared from the following components by weight: PMMA resin: 75 parts, compound toughening agent: 5 parts, heat-resistant agent: 0 parts, light stability Agent: 0.5 part, hindered phenolic antioxidant: 0.5 part, lubricant pentaerythritol stearate: 0.3 part, toner: 1 part.

[0026] Its preparation method comprises the following steps:

[0027] Mix 75 parts of PMMA, 5 parts of compound toughening agent, 0.5 part of hindered phenolic antioxidant, 0.5 part of light stabilizer, 0.3 part of lubricant pentaerythritol stearate, and 1 part of toner, and then add it to the extruder After melting, extrude, cool, air-dry, and pelletize, and then inject in an injection molding machine at a temperature of 230 ° C and a speed of 500 rpm to obtain a spray-free, weather-resistant, weather-resistant high-gloss PMMA alloy material.

Embodiment 2

[0029] A spray-free, heat-resistant, weather-resistant high-gloss PMMA alloy material, which is prepared by weight from the following components: 75 parts of PMMA resin, 20 parts of compound toughening agent, 5 parts of heat-resistant agent, and 0.5 part of light stabilizer , 0.5 parts of phosphite lipid antioxidant, 0.1 part of lubricant N,N-hexylidene bisstearamide, 0.2 part of lubricant oxidized polyethylene wax, and 1 part of toner.

[0030] Its preparation method comprises the following steps:

[0031] 75 parts of PMMA resin, 20 parts of compound toughening agent, 5 parts of heat-resistant agent, 0.5 part of light stabilizer, 0.5 part of phosphite lipid antioxidant, 0.1 part of lubricant N,N-hexene bisstearamide , Lubricant 0.2 part of oxidized polyethylene wax, 1 part of toner, mix evenly, add to the extruder, extrude after melting, cool, air-dry, pelletize, and then in the injection molding machine at a temperature of 240 ℃, Injection molding is carried out at a rotati...

Embodiment 3

[0033] A spray-free, heat-resistant, weather-resistant high-gloss PMMA alloy material, which is prepared by weight from the following components: 75 parts of PMMA resin, 20 parts of compound toughening agent, 5 parts of heat-resistant agent, and 0.3 part of light stabilizer , 0.3 parts of hindered amine antioxidant, 0.1 part of lubricant monoglyceride acid value, 0.1 part of lubricant amide wax, and 1 part of toner.

[0034] Its preparation method comprises the following steps:

[0035] 75 parts of PMMA resin, 20 parts of compound toughening agent, 5 parts of heat-resistant agent, 0.3 part of light stabilizer, 0.3 part of hindered amine antioxidant, 0.1 part of lubricant monoglyceride acid value, 0.1 part of lubricant amide wax 1 part, 1 part of toner, mixed evenly, added to the extruder, extruded after melting, cooled, air-dried, pelletized, and then injected in an injection molding machine at a temperature of 240 ° C and a speed of 500 rpm to obtain Spray-free, heat-resista...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com