High-precision and high-efficiency injection molding machine

An injection molding machine, high-precision technology, applied in the field of injection molding machines, can solve the problems of inability to meet various specifications and sizes of plastic barrels, long injection molding processing cycle, inconvenient mold disassembly and installation, etc., to achieve fast mold change speed and reliability. And the effect of high safety factor and improved injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

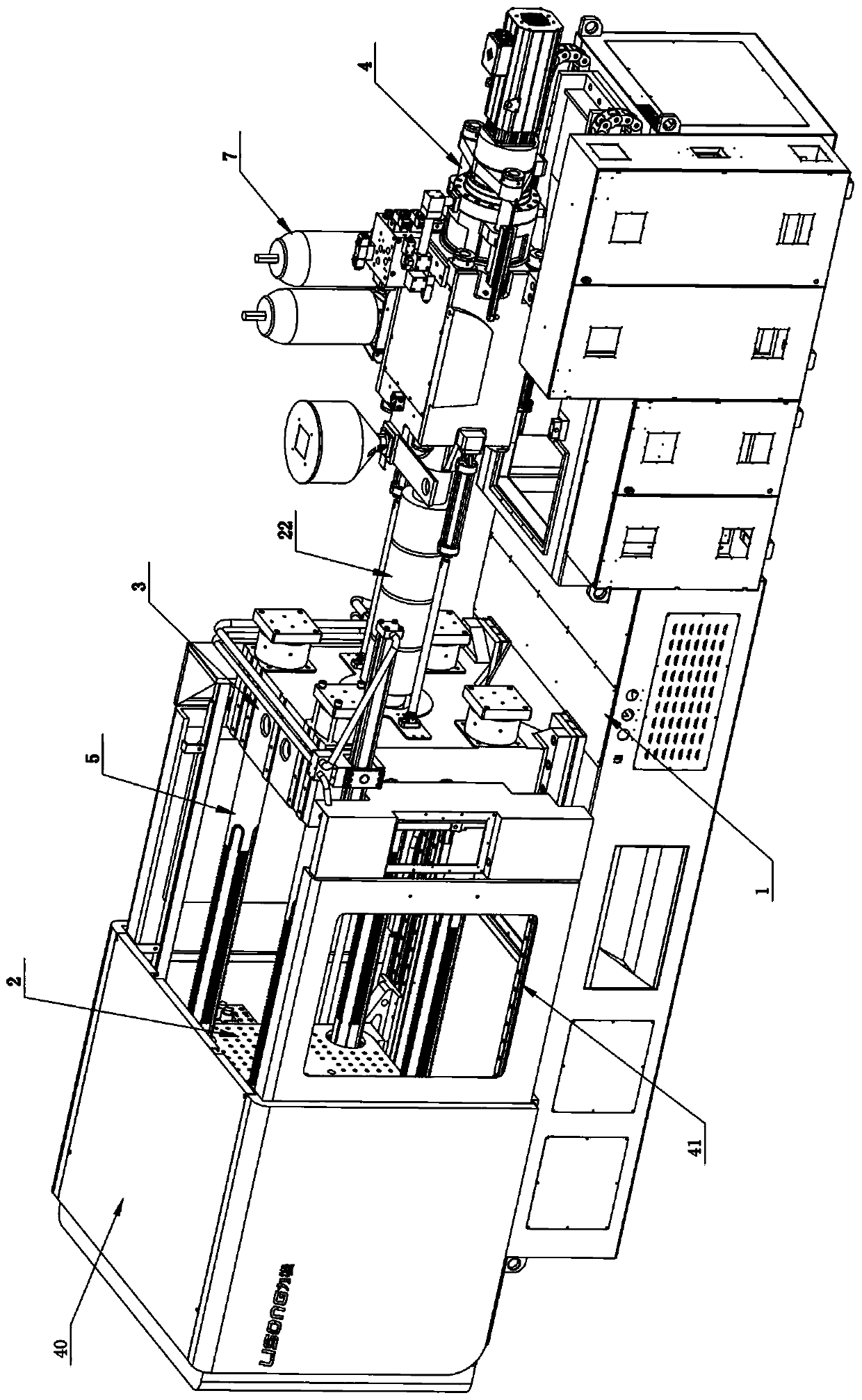

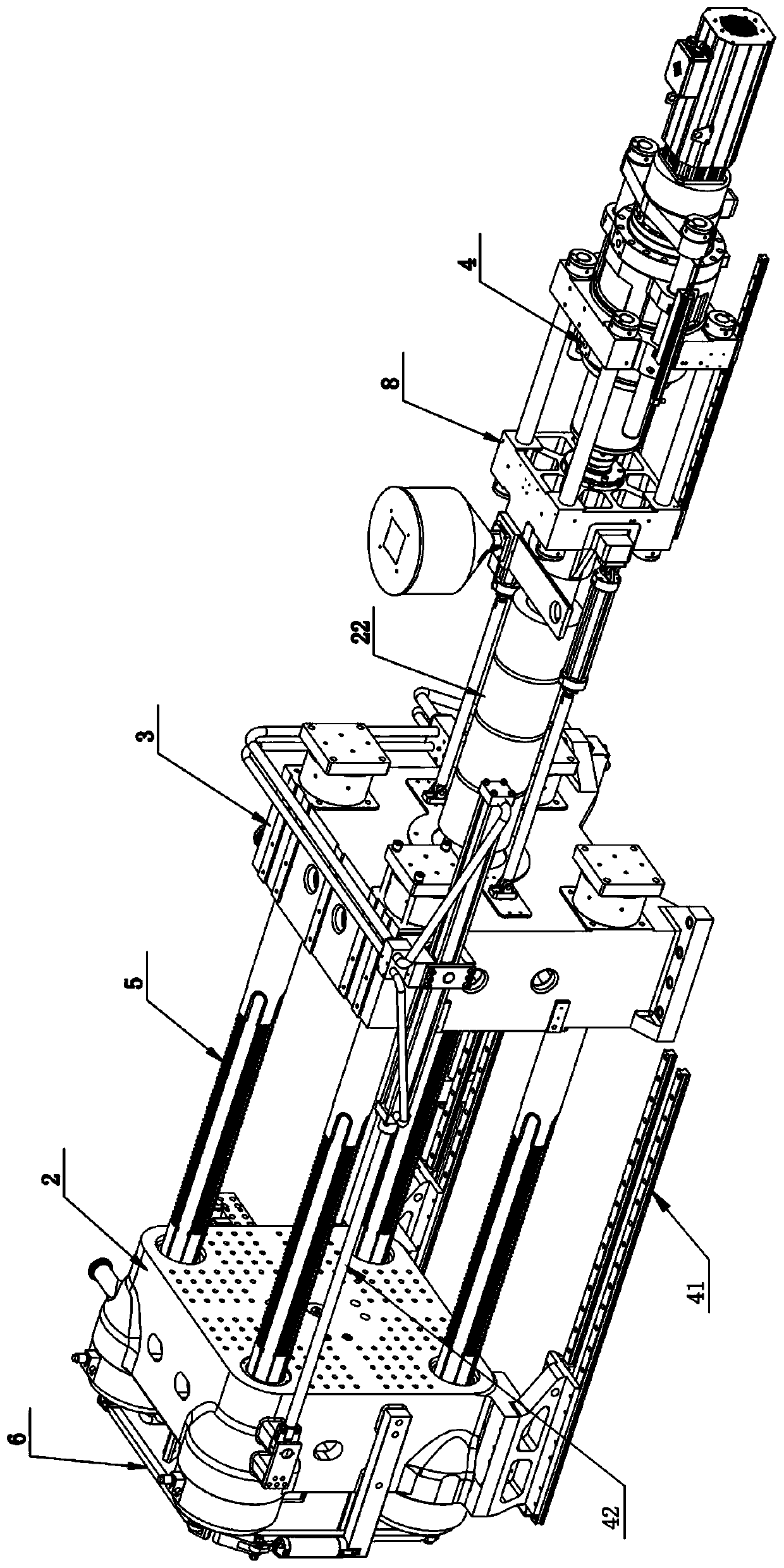

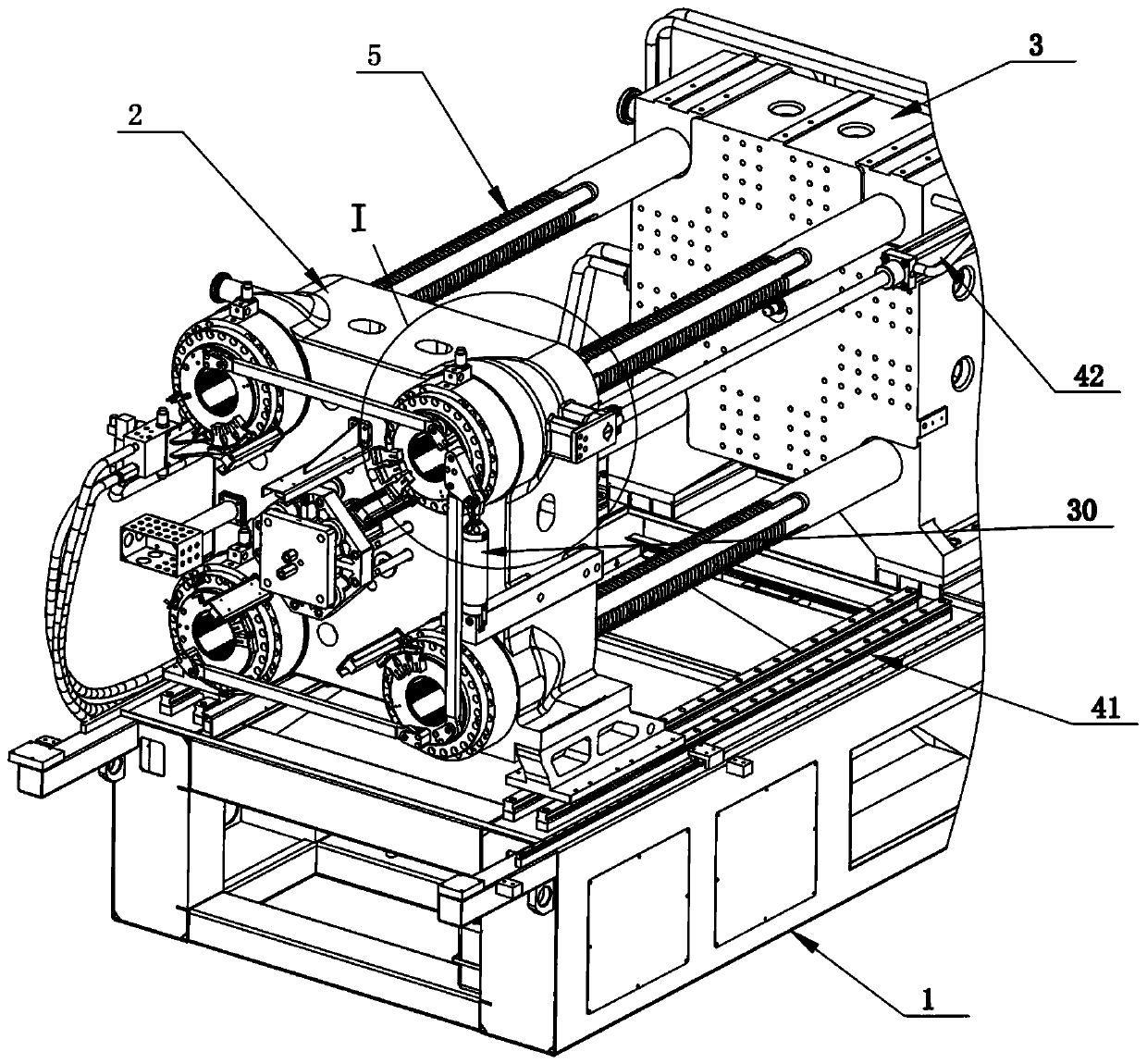

[0031] refer to Figure 1 to Figure 11 , the present invention provides a high-precision and high-efficiency injection molding machine, comprising: a body 1 and a movable platen 2, a fixed platen 3 and an injection mechanism 4 respectively installed on the body 1; multiple tie rods are installed between the movable platen 2 and the fixed platen 3 5. The movable template 2 is thickened, with good rigidity, less elastic deformation, can withstand high cavity pressure impact, less probability of mold expansion, and effectively protects the mold; the movable template 2 is equipped with a combined brake mechanism 6 corresponding to the tie rod 5; The side end of the body 1 is equipped with a nitrogen auxiliary injection device 7 connected to the injection mechanism 4. The nitrogen auxiliary injection device 7 is used to assist the injection mechanism 4 to facilitate rapid injection, prevent raw materials from solidifying, and improve injection molding efficiency and injection moldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com