Patents

Literature

153results about How to "Improve connection rigidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

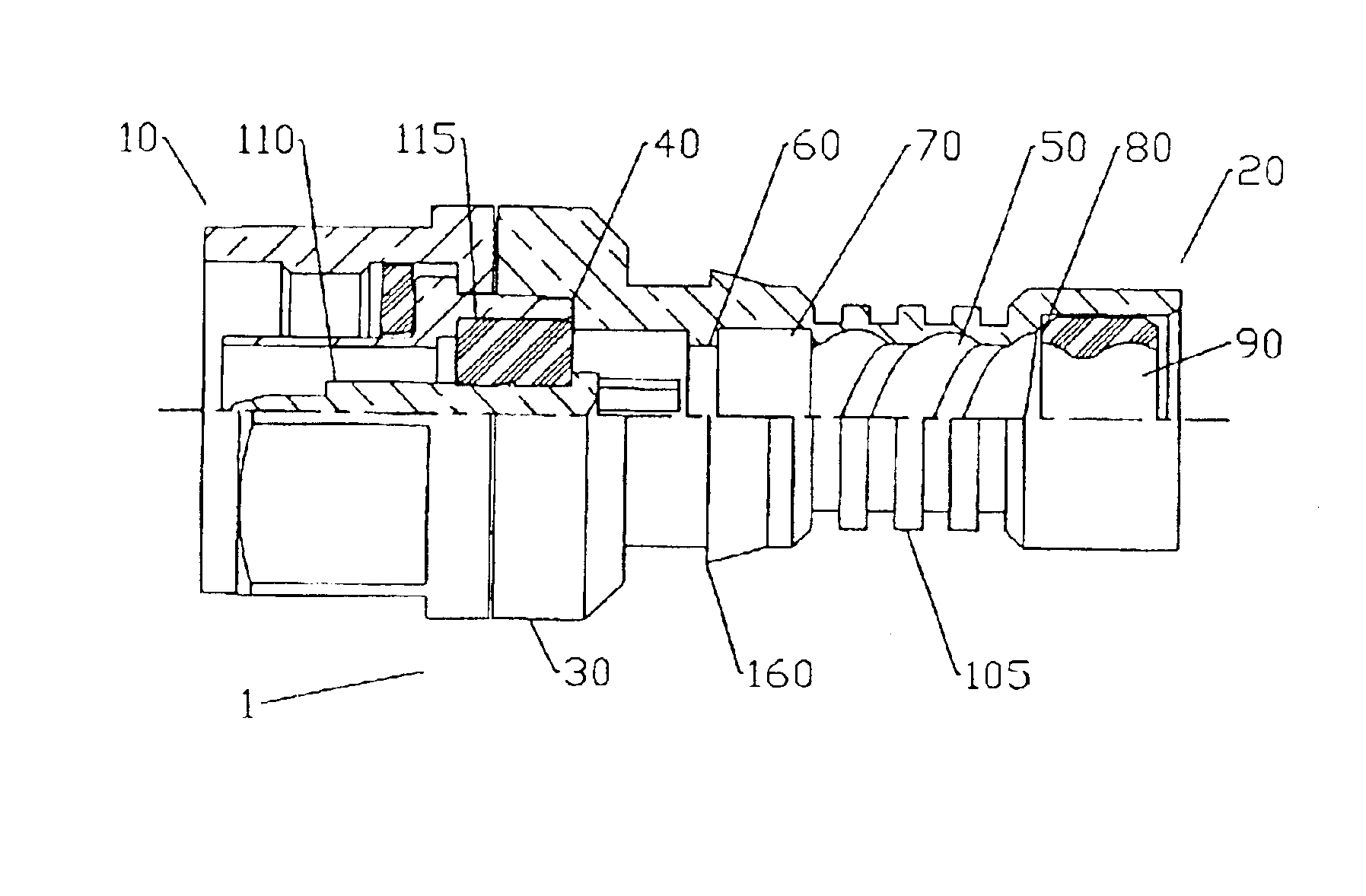

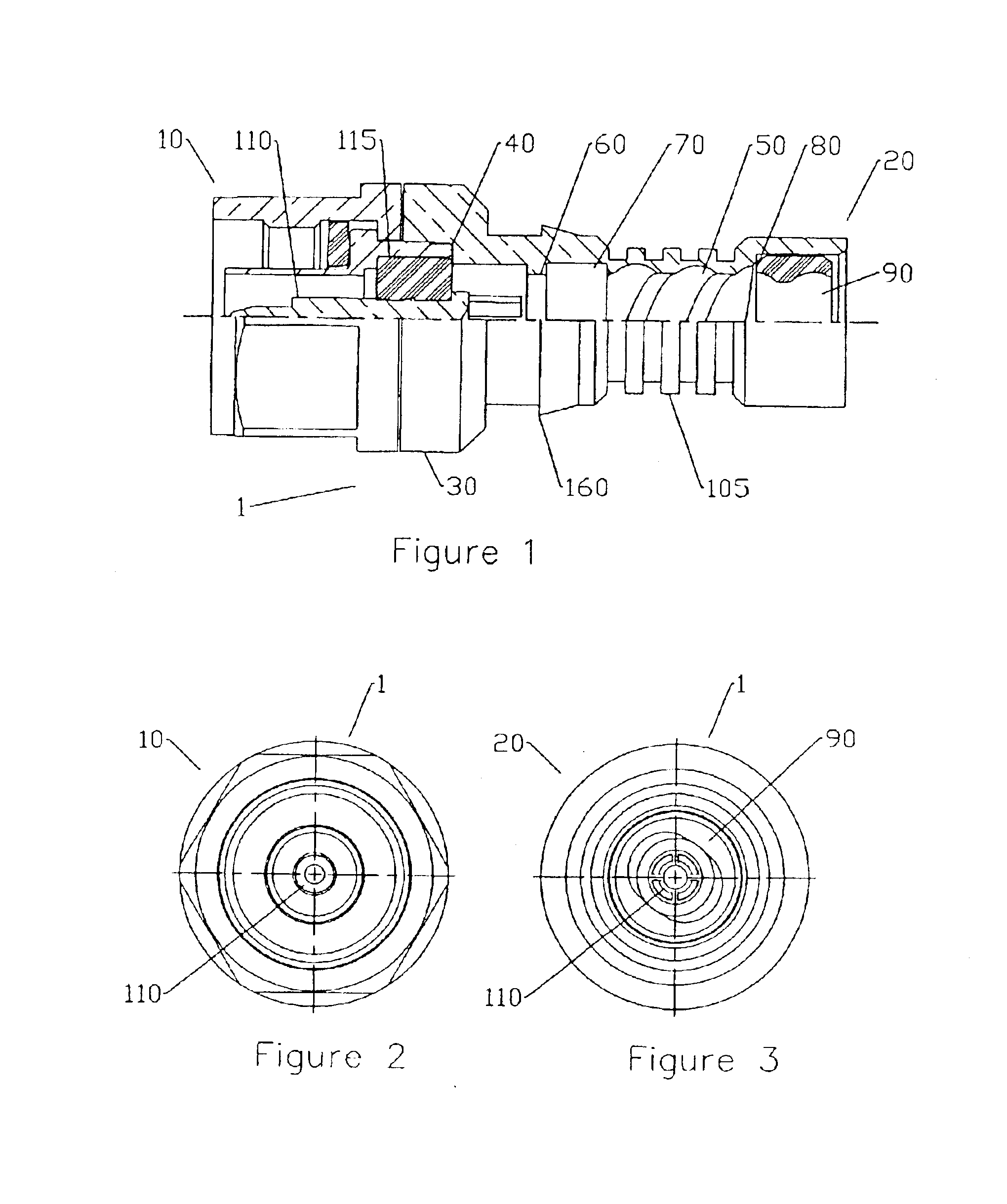

Crimp connector for corrugated cable

InactiveUS6840803B2Minimizing reactionAdvantageous strength and flexibility and weight characteristicElectrically conductive connectionsTwo pole connectionsElectrical conductorCoaxial cable

A corrugated coaxial cable connector, field installable with a hand crimp tool has a connector interface coupled to the connector end of a hollow cylindrical body; an inner surface of the body is adapted to thread onto the helical corrugations on the outer conductor of the cable. A plurality of ridges on an outer surface of the body corresponding to an internal threaded section forms a crimp surface. An inner contact located coaxially within the body has a socket contact section at the cable end dimensioned for insertion of the inner conductor of the cable and electrical connection therewith. A body barb located on the outer surface of the body provides an acute surface for heat shrink tubing to seal against.

Owner:ANDREW LLC

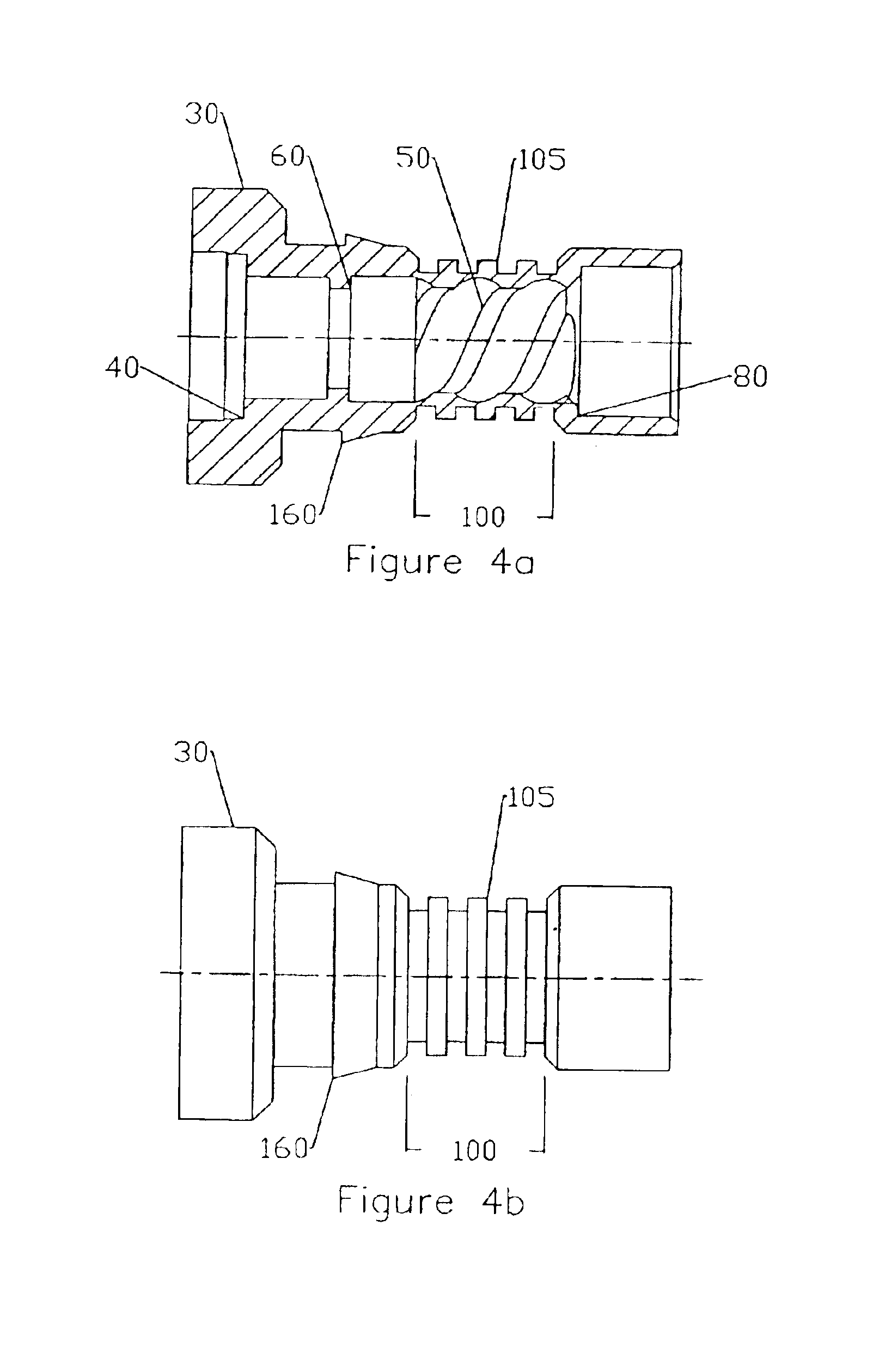

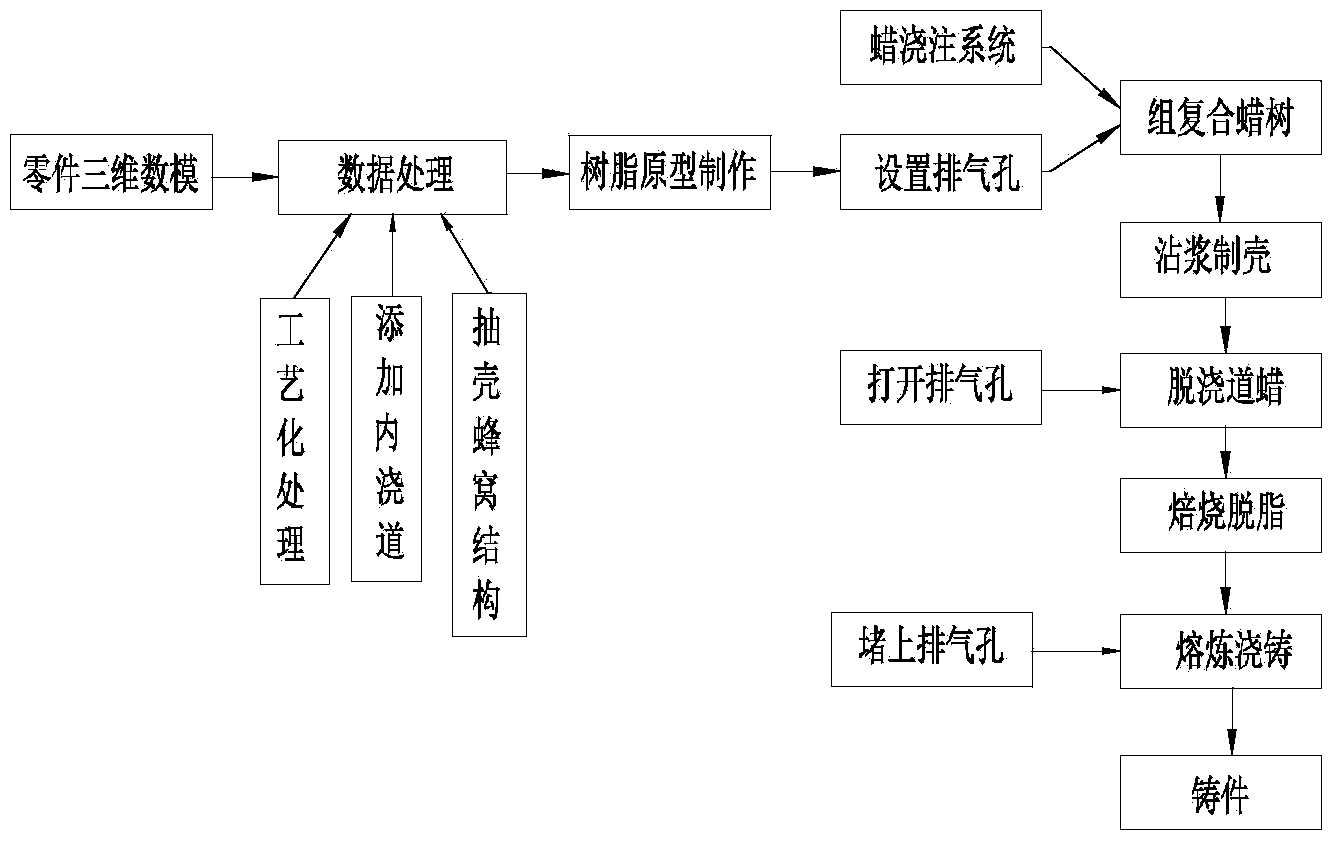

Rapid investment casting method based on stereolithography (SL)

Owner:无锡市交大增智增材制造技术研究院有限公司

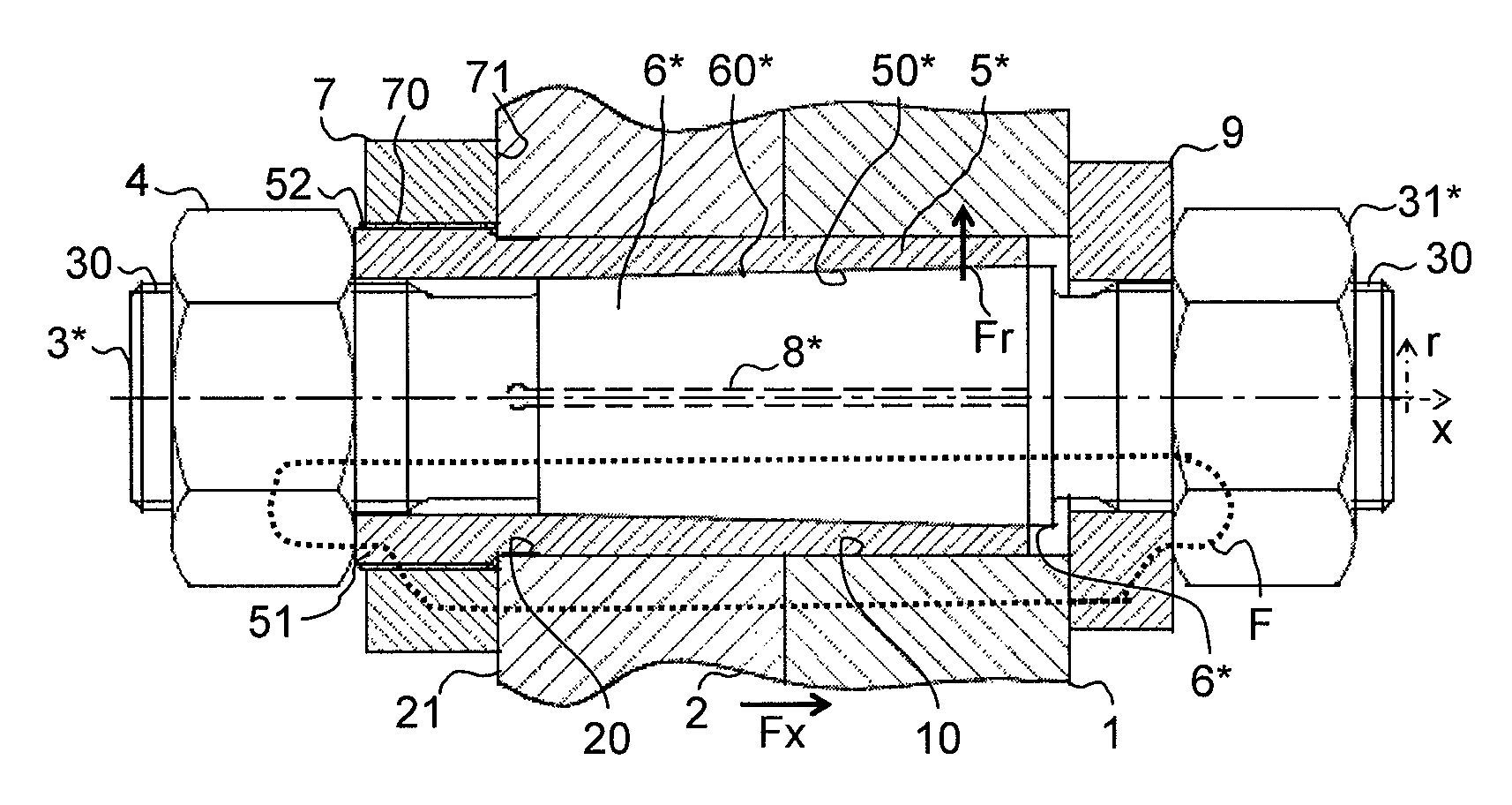

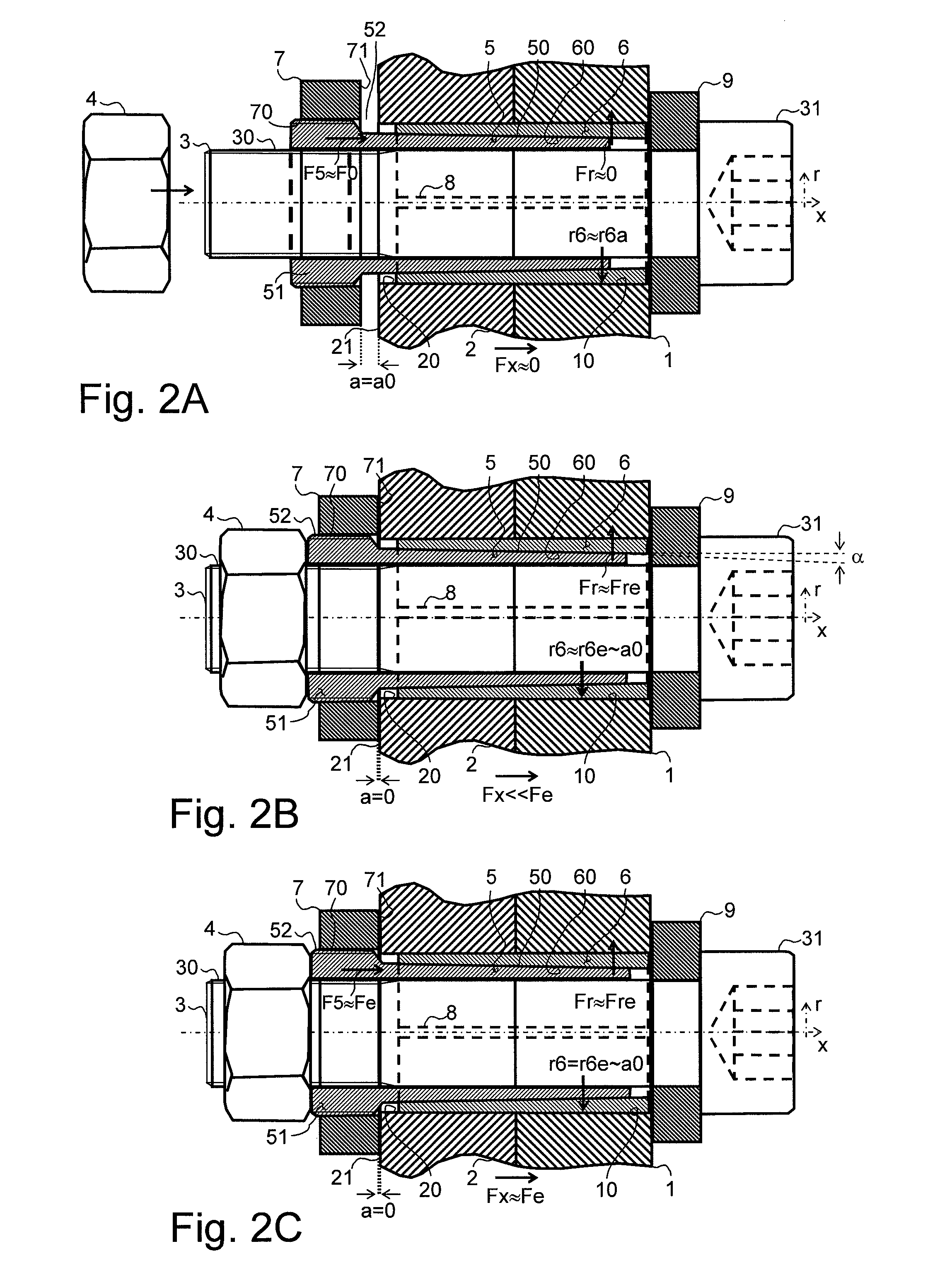

Connecting arrangement and connecting method, in particular by way of non-positive connection on all sides

ActiveUS8496394B2Manufacturing cost be reduceStrong radial forceFlanged jointsKey type connectionsMechanical engineeringEngineering

A method or arrangement for clamping at least one first and one second component to each other with a connection by force on all sides is disclosed. The connecting arrangement comprises a bolt extending from a first component through a through opening in a second component, a clamping nut which is screwed on the bolt for clamping the components, and a cone pair comprising an inner cone with a split and an outer cone. One part of this cone pair is formed as a conical clamping element, which is arranged and axially moveable for radial clamping on the bolt between the components and the clamping nut. A locking nut is screwed on the conical clamping element and clampable against an abutment surface of the second component to limit moveability of the clamping element.

Owner:NORD LOCK AG

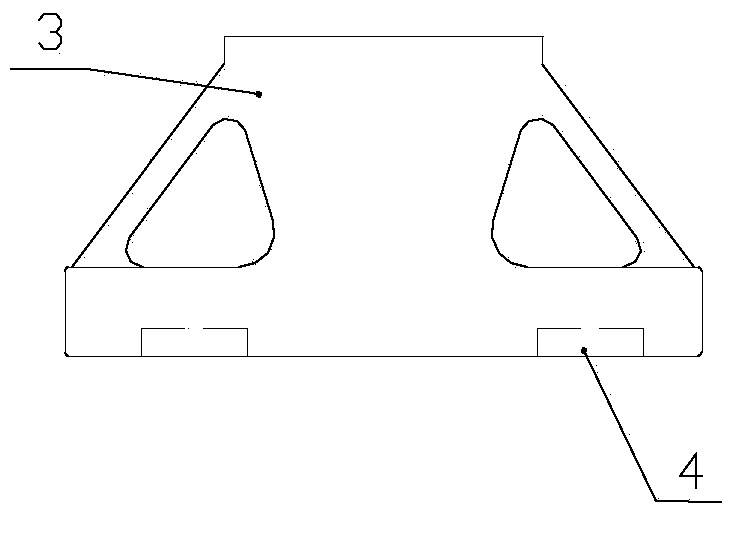

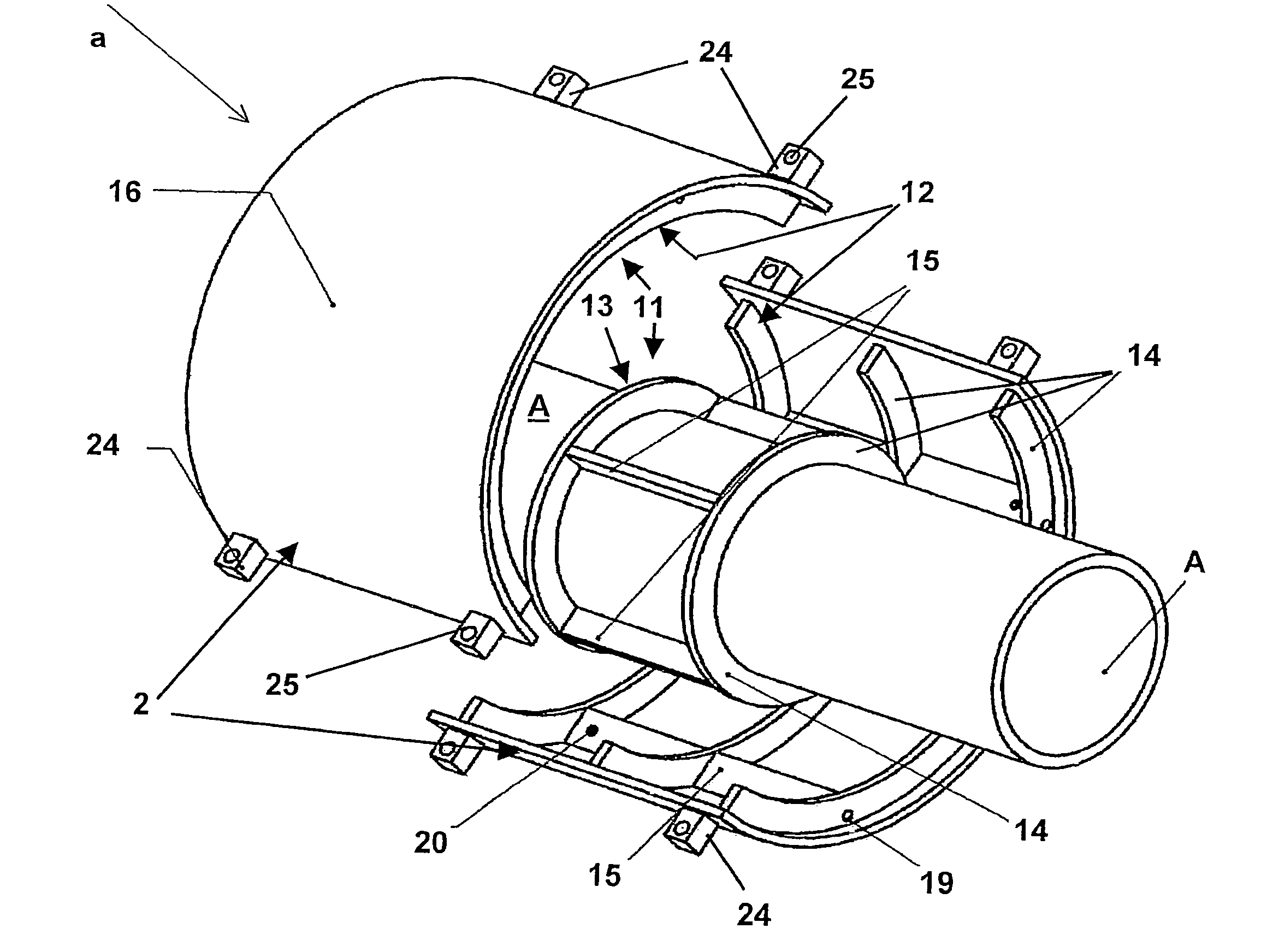

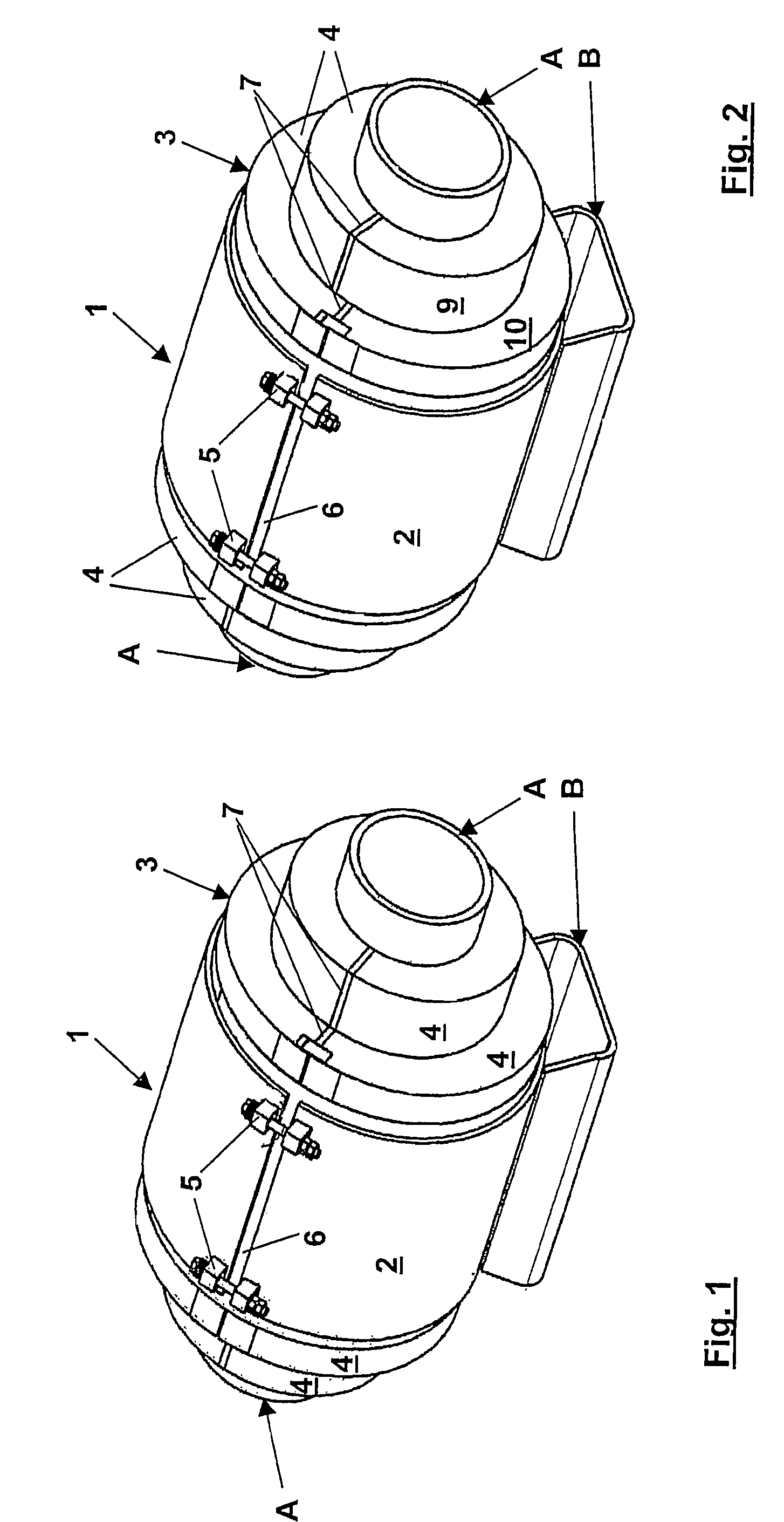

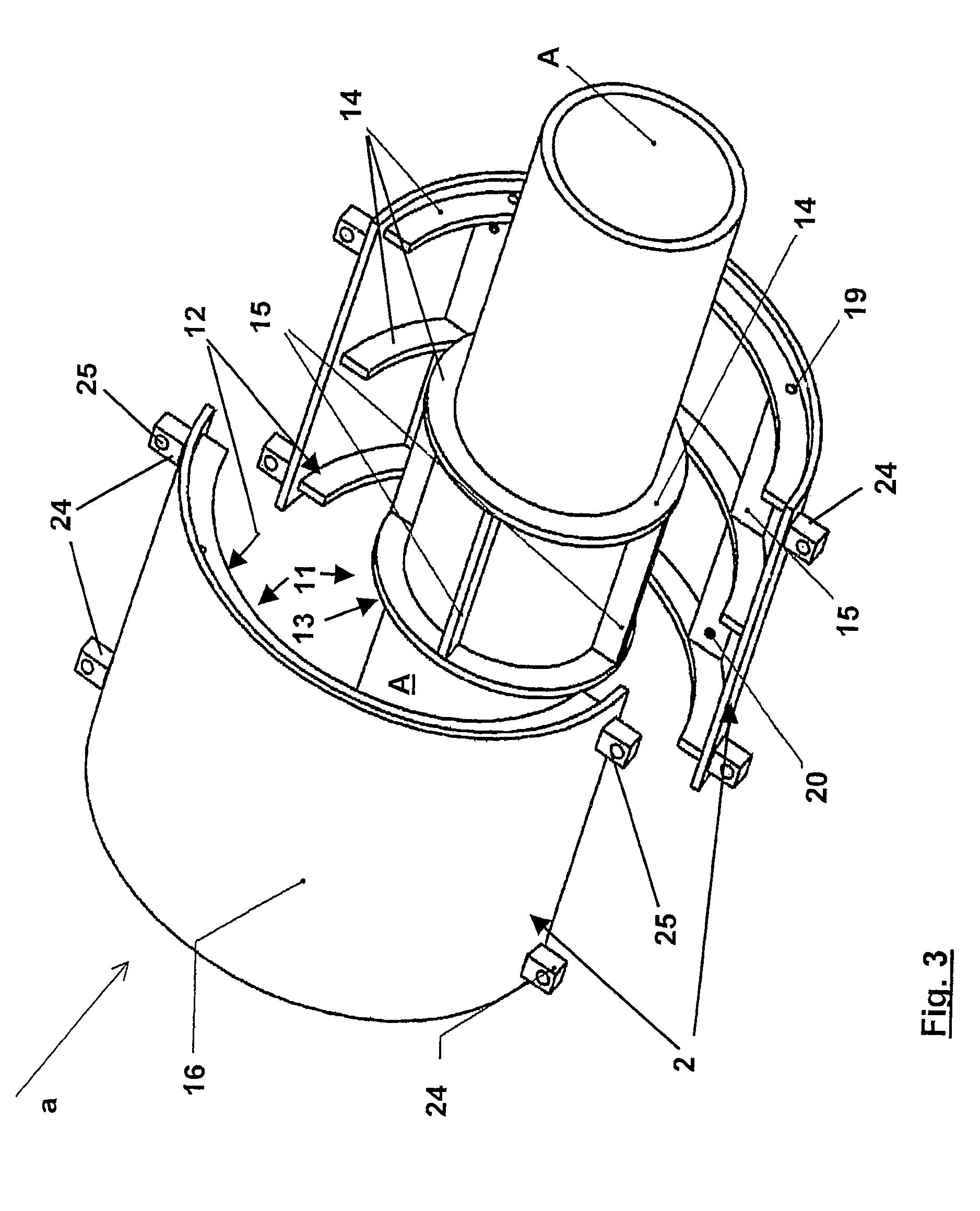

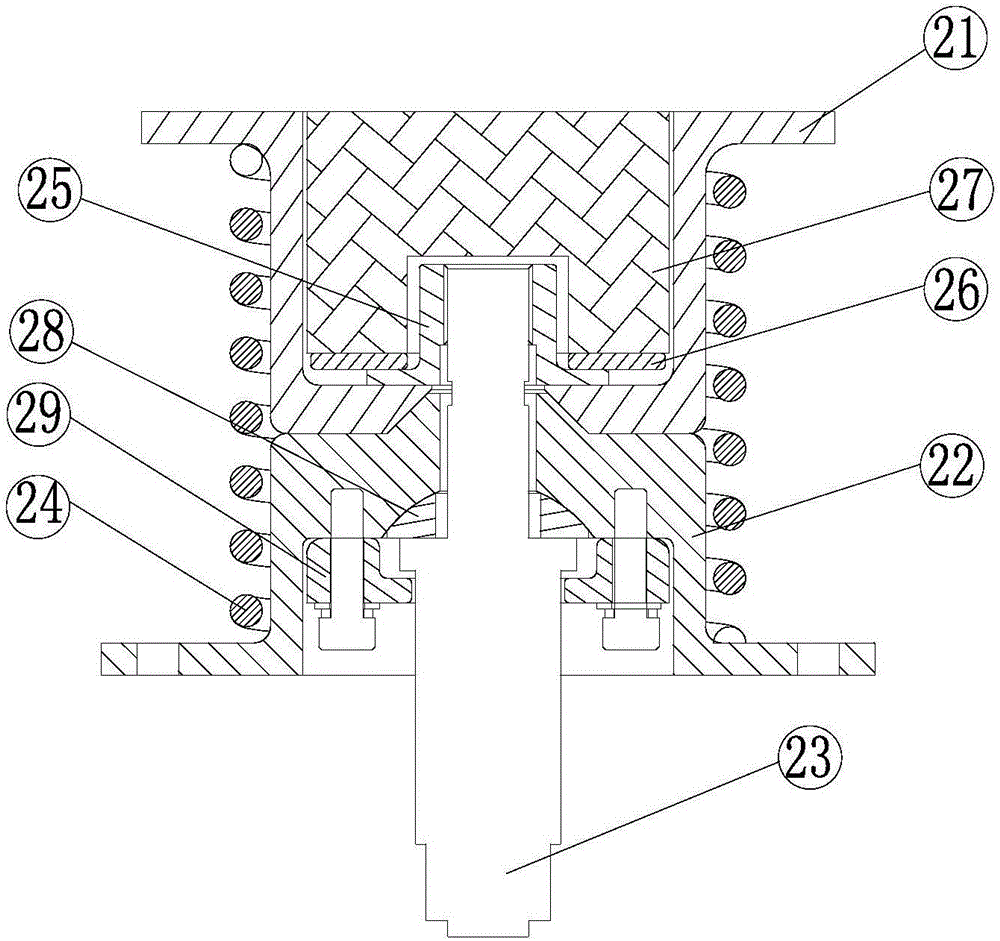

Cold-insulated fixed-point support

ActiveUS7861983B2Great ease of fitting and removingSimple supporting structurePipe supportsMining devicesEngineeringPipe support

The invention relates to a cold-insulated fixed-point pipe support for a low-temperature pipeline which includes an insulating system arranged between an outer shell and a supportable low-temperature pipeline having solid thermal insulating material which thermally insulates the pipeline from the low-temperature environment. A rotation-preventing and displacement-preventing device prevents rotation and displacement of the thermal insulating material with respect to the pipeline and an outer shell. A fixed-point pipe support is adapted to be fitted and removed in a substantially radial direction over the pipeline, and has at least one division with respect to shape with a division plane thereof extending perpendicular to a cross-sectional plane, and having a connecting device for releasable connecting and fixing shaped parts formed by the division.

Owner:LISEGA SELSCHAFT

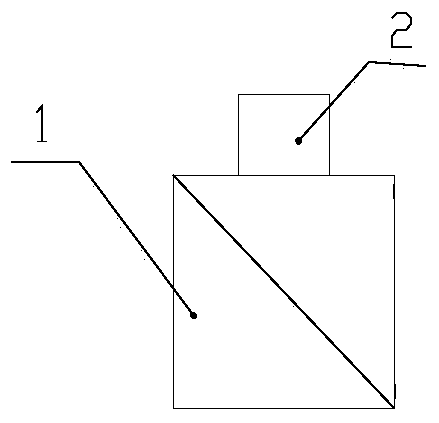

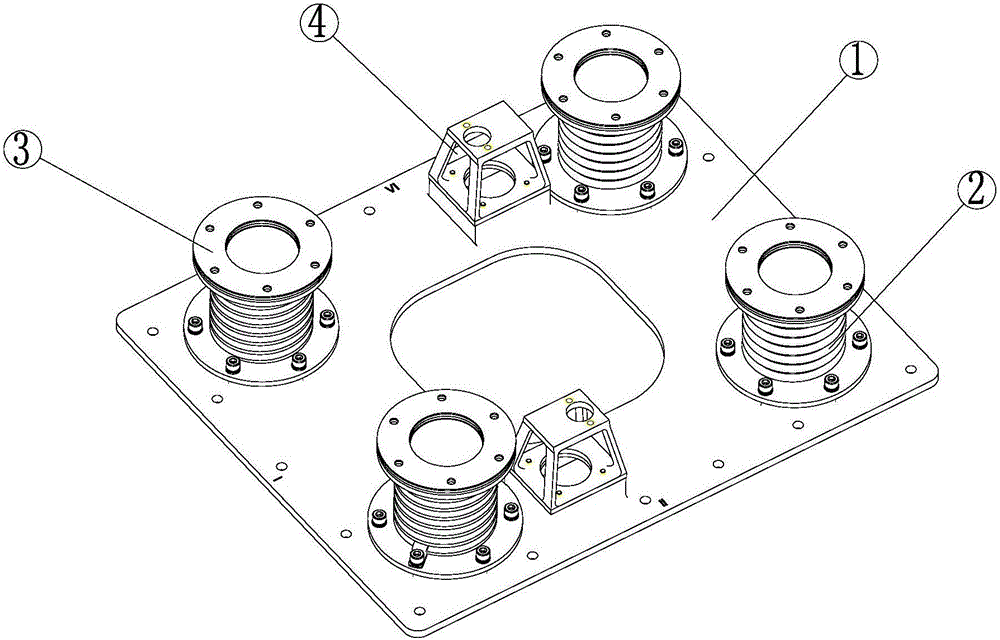

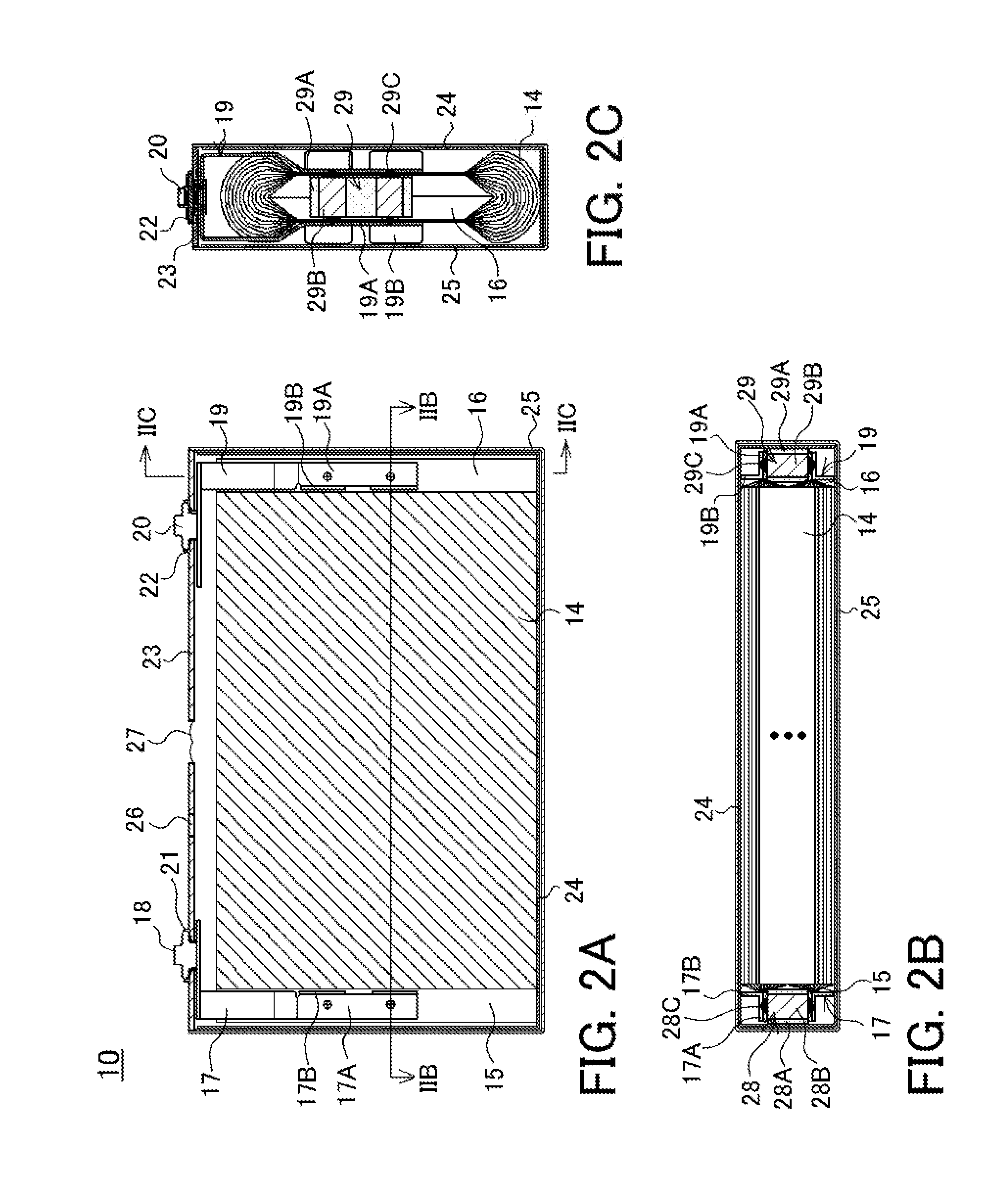

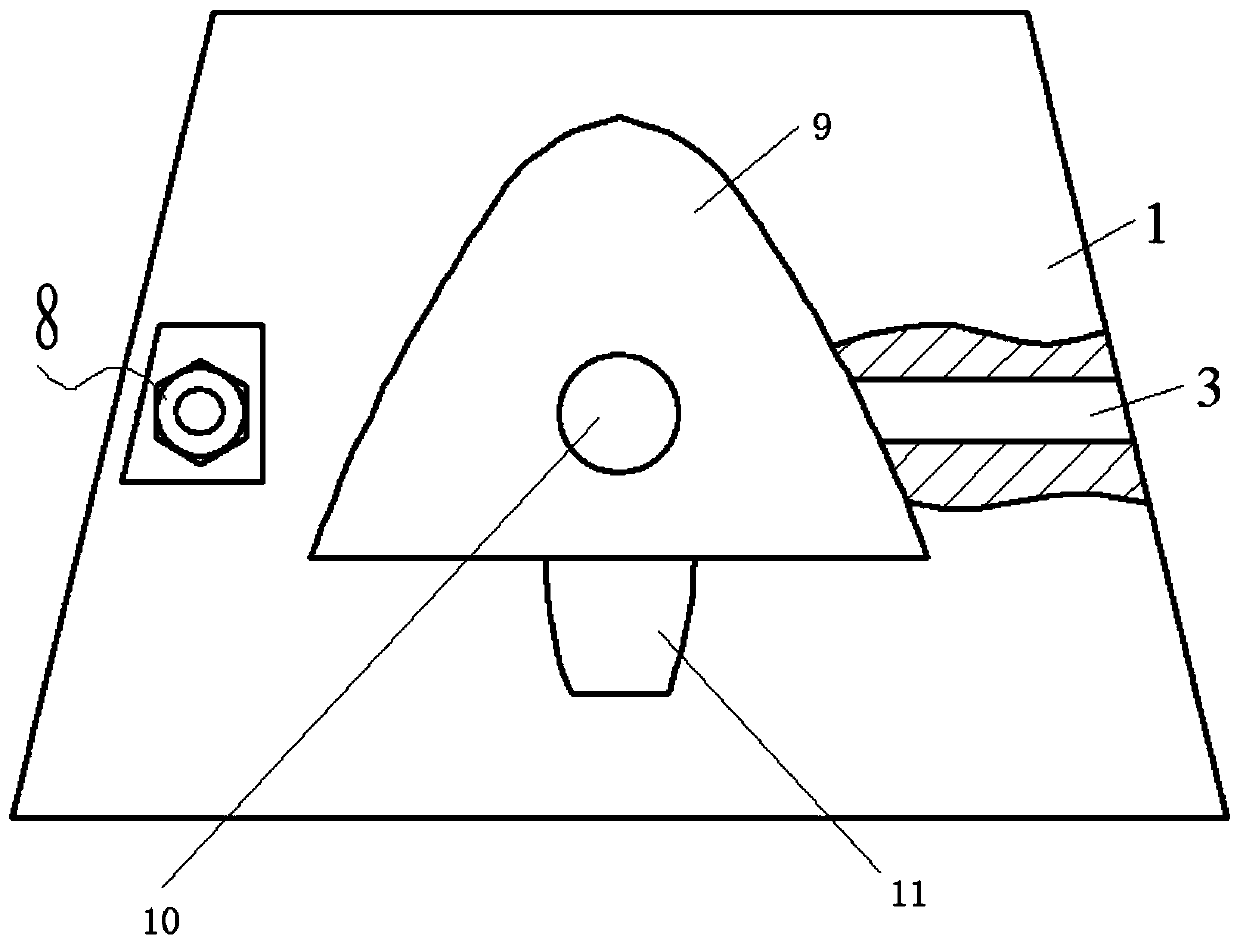

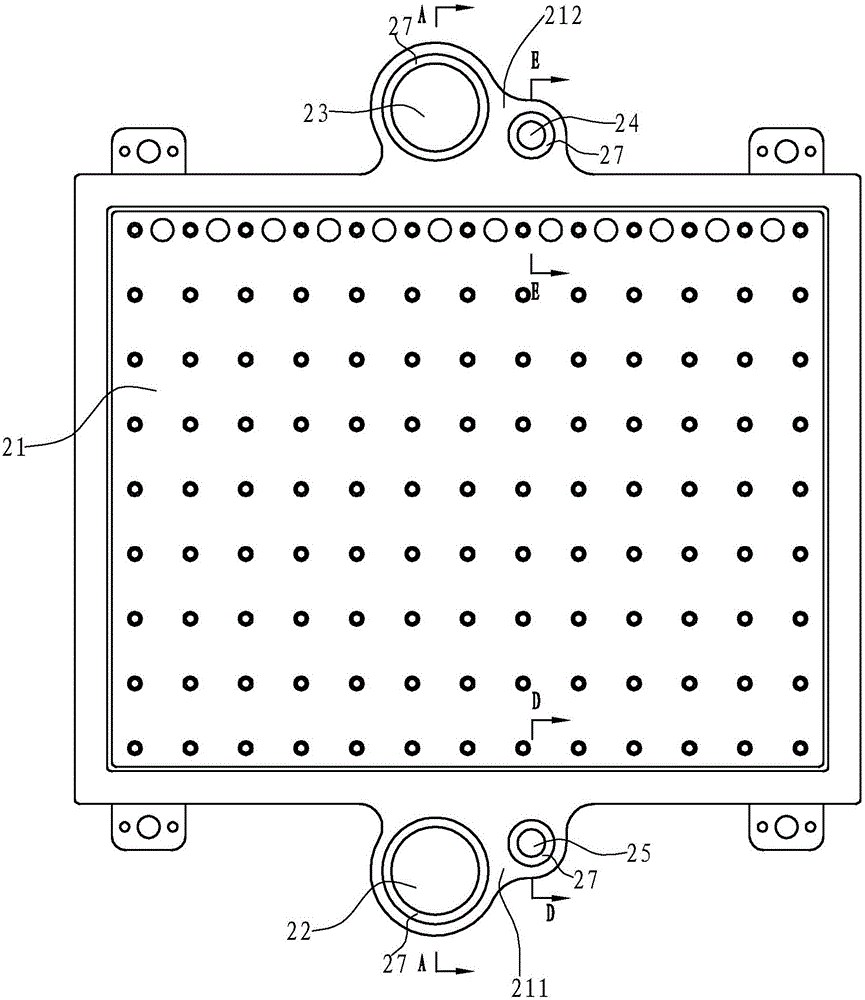

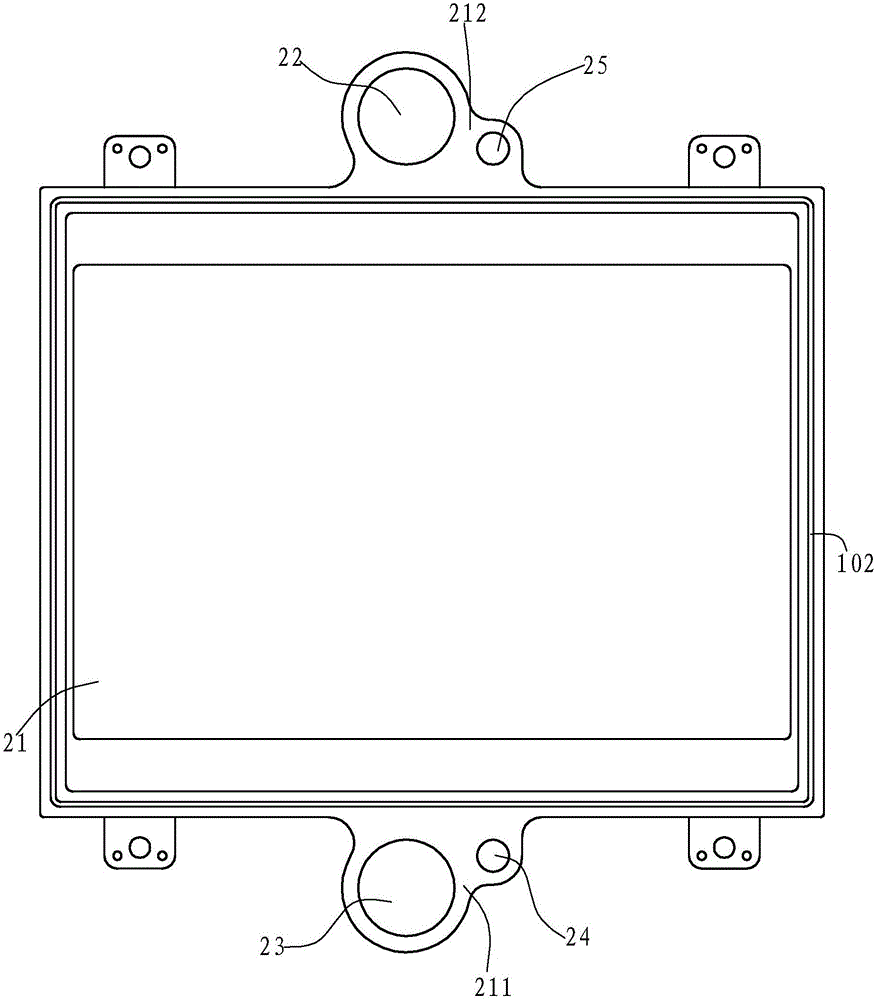

Satellite-rocket point type connection and separation module and device

ActiveCN106052490AAchieve separationImprove connection rigiditySelf-propelled projectilesComputer moduleEngineering

The invention provides a satellite-rocket point type connection and separation module and device. The satellite-rocket point type connection and separation module comprises an upper through connection barrel, a lower through connection barrel, an explosive bolt, a separation spring and a loading nut. The upper through connection barrel and the lower through connection barrel are connected together through the explosive bolt. The free end of the upper through connection barrel is used for being connected with a satellite bottom plate. The portion, connected with the explosive bolt, of the upper through connection barrel is provided with the loading nut. The separation spring is arranged outside the upper through connection barrel and the lower through connection barrel in a sleeving mode and pre-tightened under the effect of the upper through connection barrel and the lower through connection barrel. The satellite-rocket point type connection and separation module and device are good in connection rigidity, low in impact force, high in adaptability, short in research period and low in cost.

Owner:SHANGHAI AEROSPACE SYST ENG INST

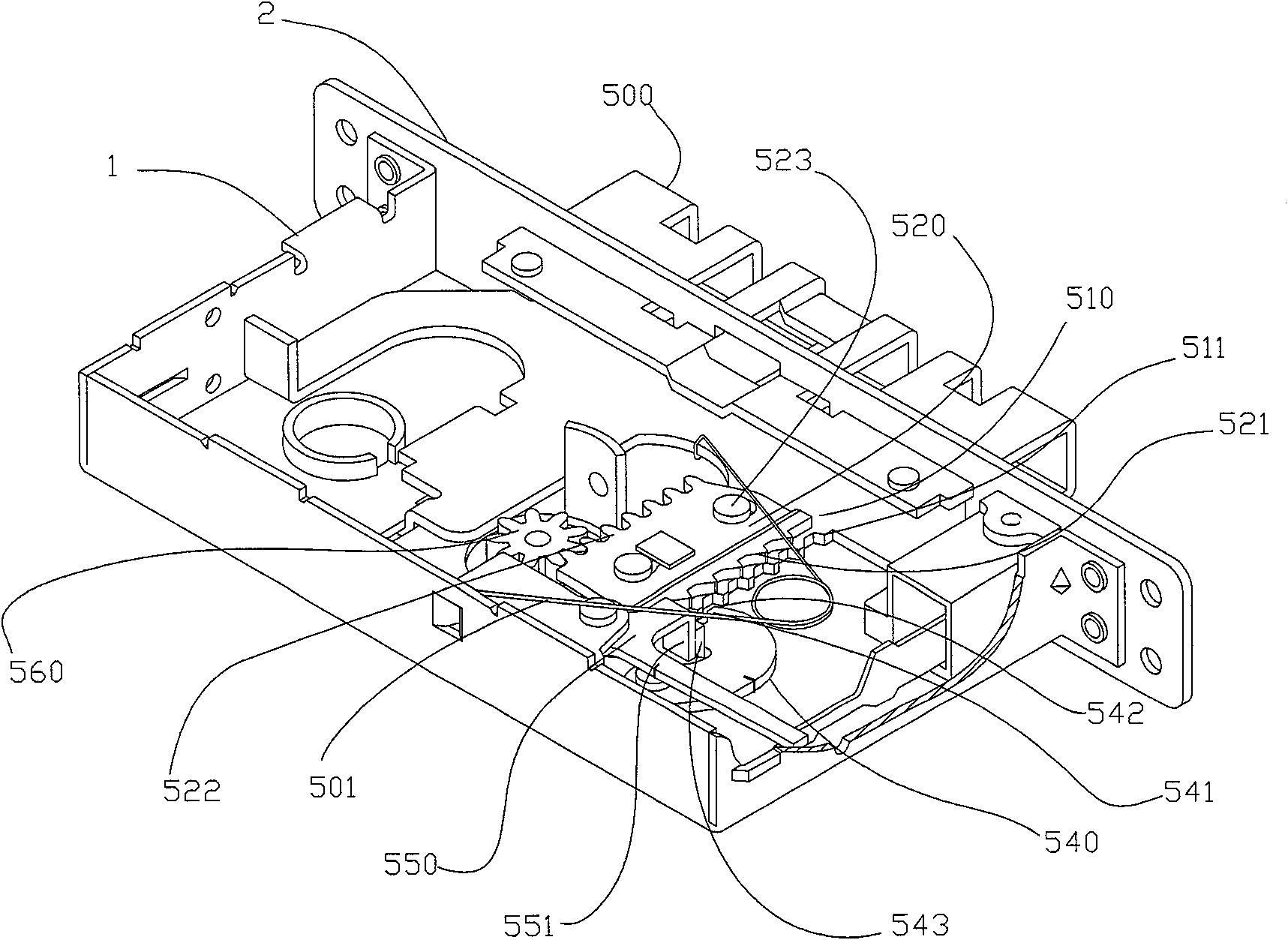

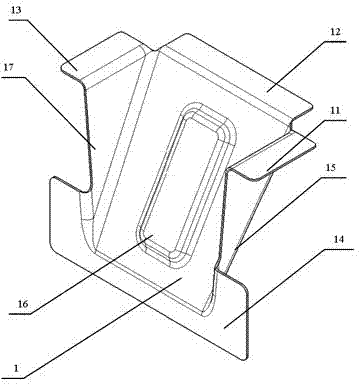

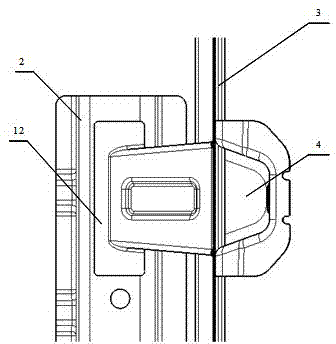

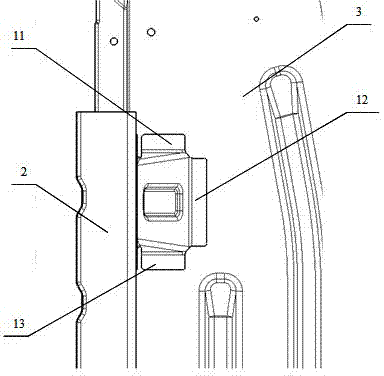

An automatic door lock

ActiveCN101566026ASimple structureCompact structureBuilding locksHandle fastenersLocking mechanismEngineering

The invention provides an automatic door lock, comprising a lock shell having a dead bolt hole molded with dead lock hole; a lock assembly installed on the lock shell panel and the lock shell bottom panel corresponding to a molded lock installation hole; a bolt mechanism installed in the lock shell capable of moving along the direction perpendicular to the lock shell panel; a locking control mechanism for controlling the bolt in the bolt mechanism extruding from and retracting into the panel; and a bolt locking mechanism matched with the door handle operating mechanism. The automatic door lock implements engagement and disengagement of the stop member with a fixed stripe and a movable stripe by coupling of the fixed and the movable stripe, the stop member is capable of engaging with the fixed and the movable stripe at different positions, incomplete unlocking operation due to extrusion of a bolt partially retracted into the shell is prevented.

Owner:WONLY SECURITY & PROTECTION TECH CO LTD

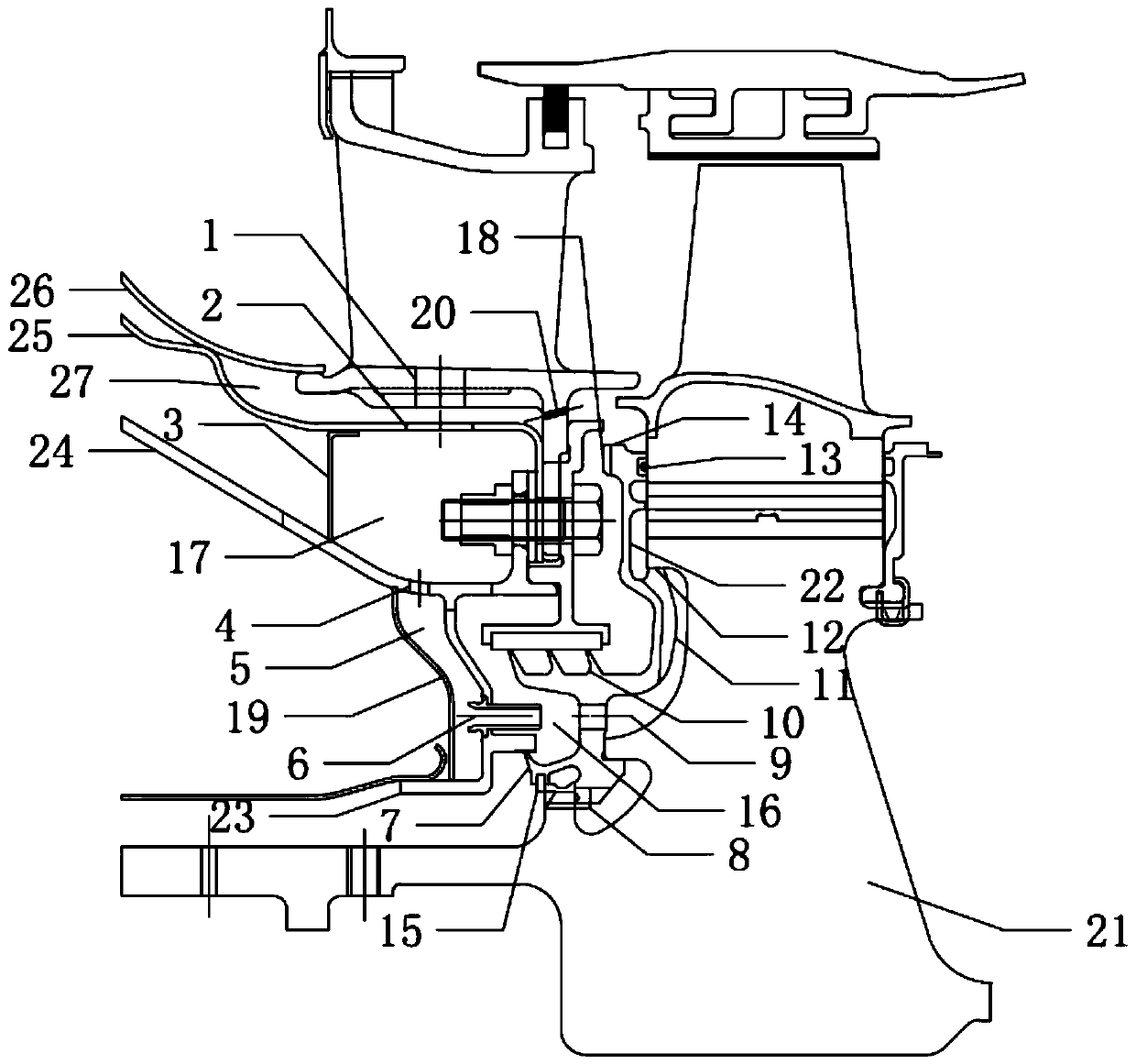

Engine turbine disc cavity structure with pre-rotation nozzle and flow guiding disc

ActiveCN111441828AShorten speedLower the total temperatureBlade accessoriesLeakage preventionEngineeringConvection heat

The invention discloses an engine turbine disc cavity structure with a pre-rotation nozzle and a flow guiding disc. The engine turbine disc cavity structure comprises a turbine disc and further comprises the flow guiding disc and a pre-rotation nozzle ring which are arranged in front of the turbine disc. High-pressure low-temperature two-strand airflow is divided into two strands after entering apre-rotation airflow cavity through the pre-rotation nozzle ring. One strand of airflow passes through pre-rotation cool air receiving holes evenly distributed in the circumferential direction of theflow guiding disc and enters an axial ventilation hole in the bottom of a turbine disc mortise along a radial flow guiding plate on the rear side of the flow guiding disc. The other strand of airflowpasses through a sealed grid tooth ring on the flow guiding disc, and after the other strand of airflow is pre-rotated and pressurized through an inclined flow guiding plate above the front side of the flow guiding disc and is converged with cool air from cool air impact holes evenly distributed in the circumferential direction of the installing edge of a guiding device, the other strand of airflow enters a main runner through a turbine rotor and stator gap. By means of the engine turbine disc cavity structure, the relative total temperature of cool air can be reduced, convection heat exchangeof cool air and the turbine disc is enhanced, pre-rotation pressurizing is conducted on the wheel edge seal gas, the seal effect is improved, and seal gas and main flow mixing losses are reduced.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

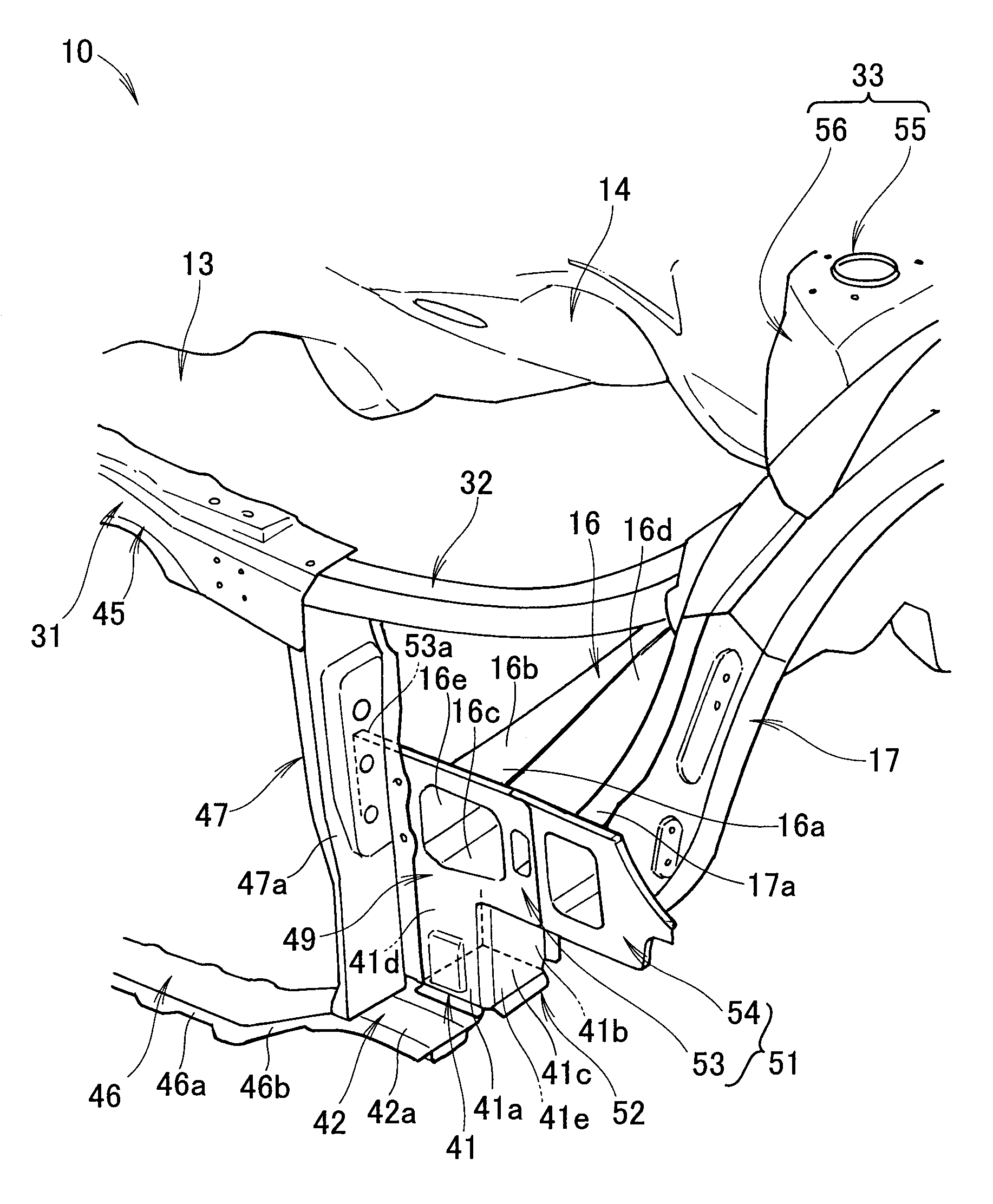

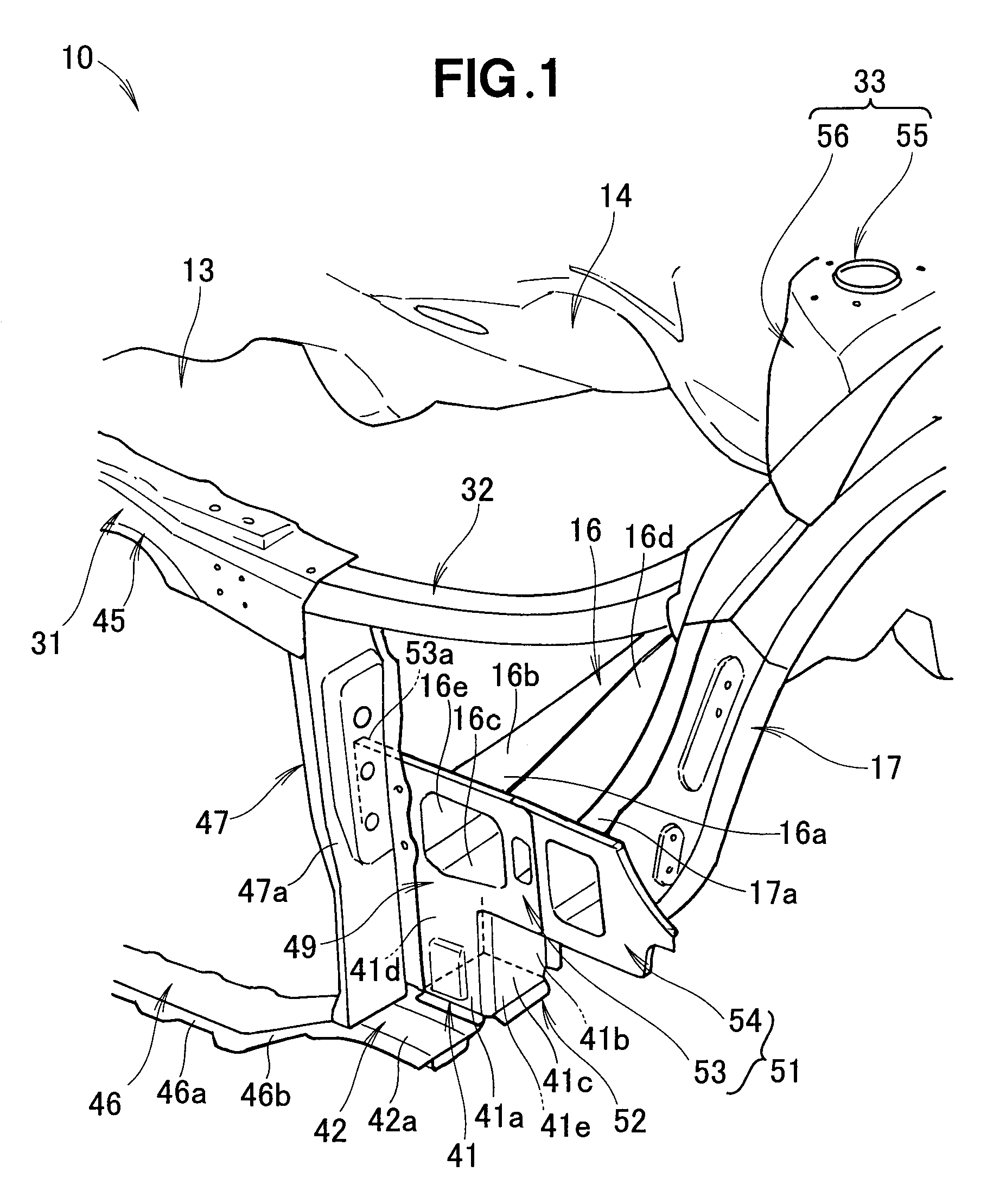

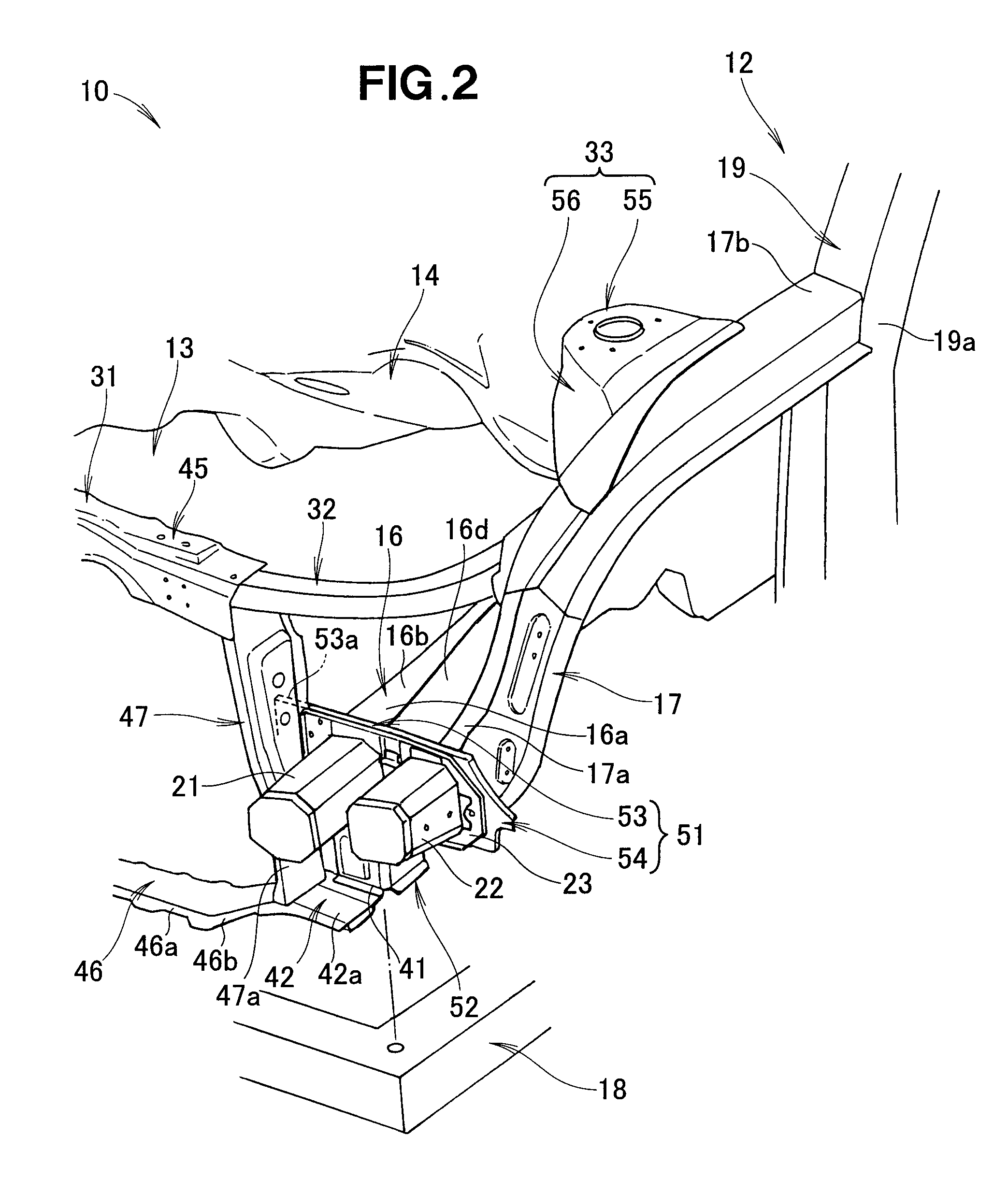

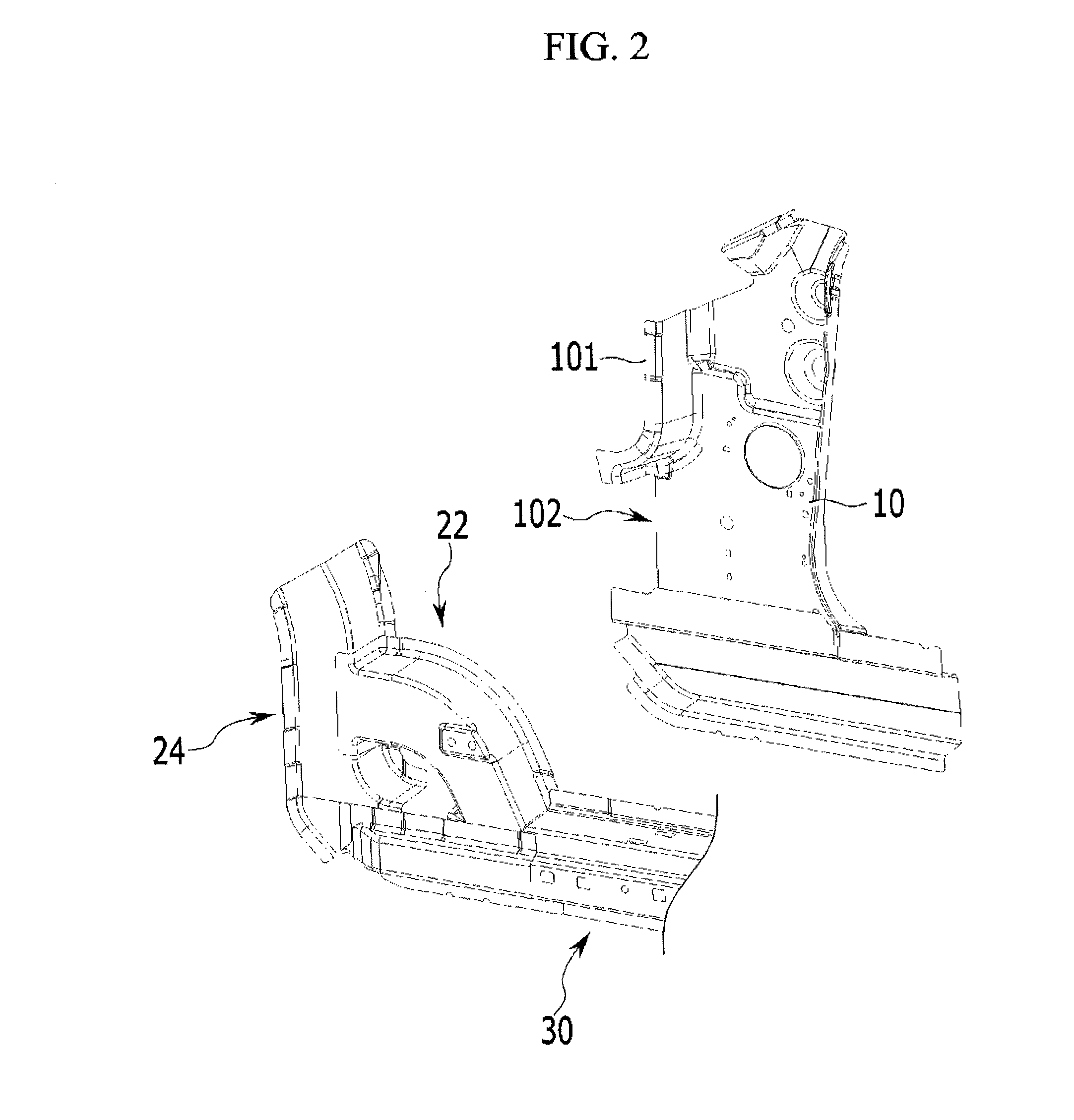

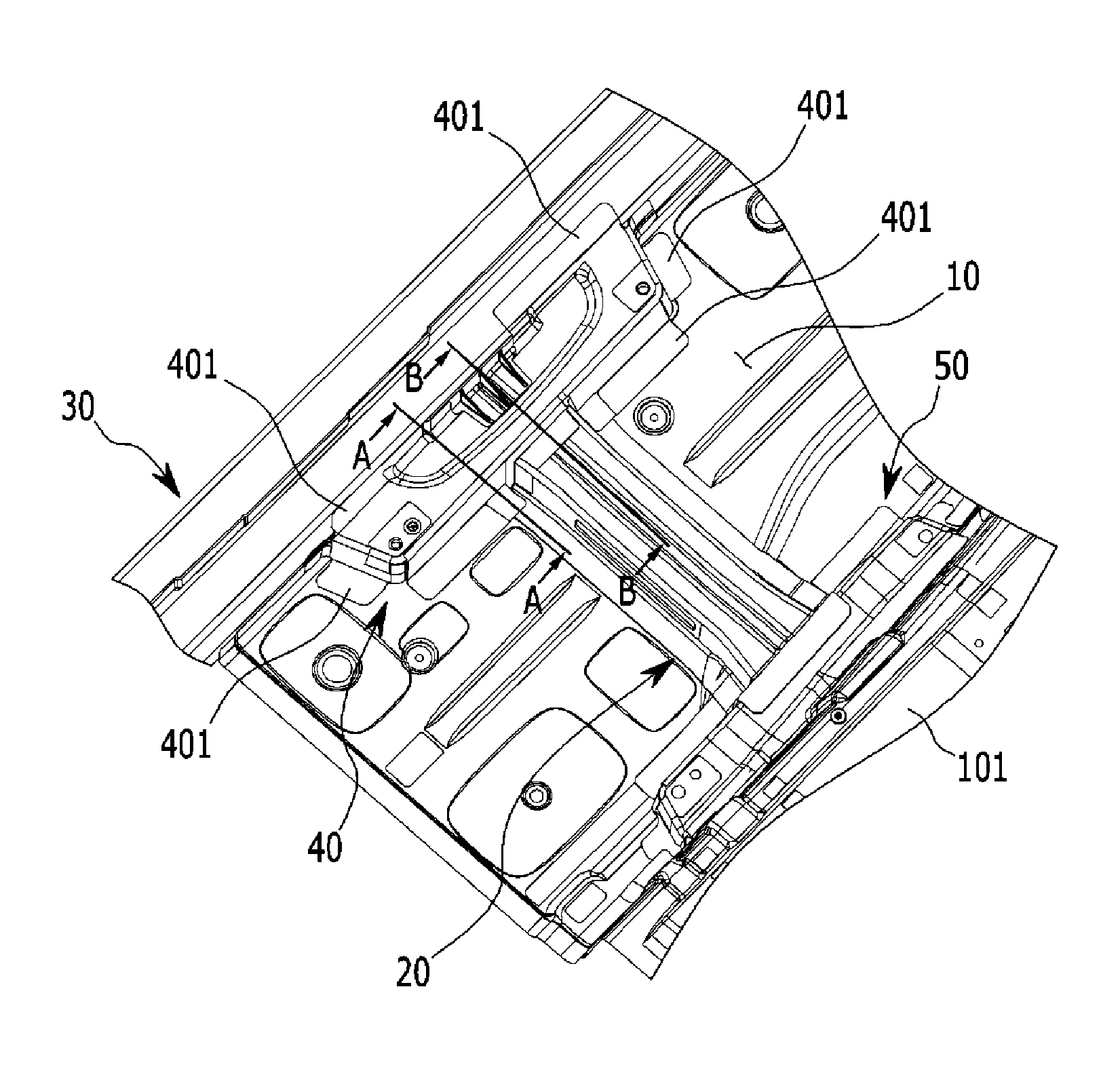

Structure of front section of vehicle body

ActiveUS8764104B2Input of light collision loads to the front bulk head can be slowedImprove connection rigidityVehicle seatsUnderstructuresVehicle frame

Owner:HONDA MOTOR CO LTD

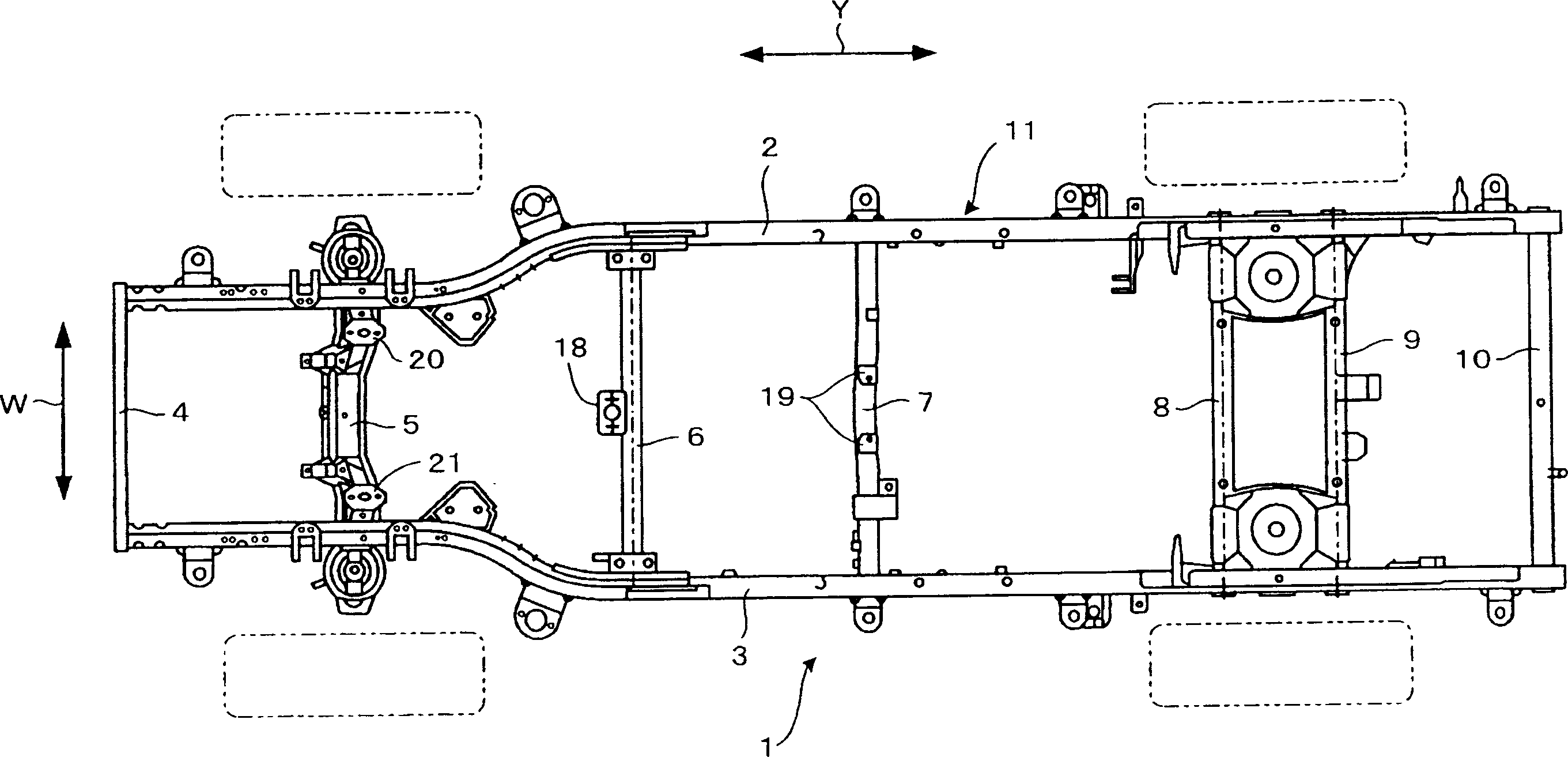

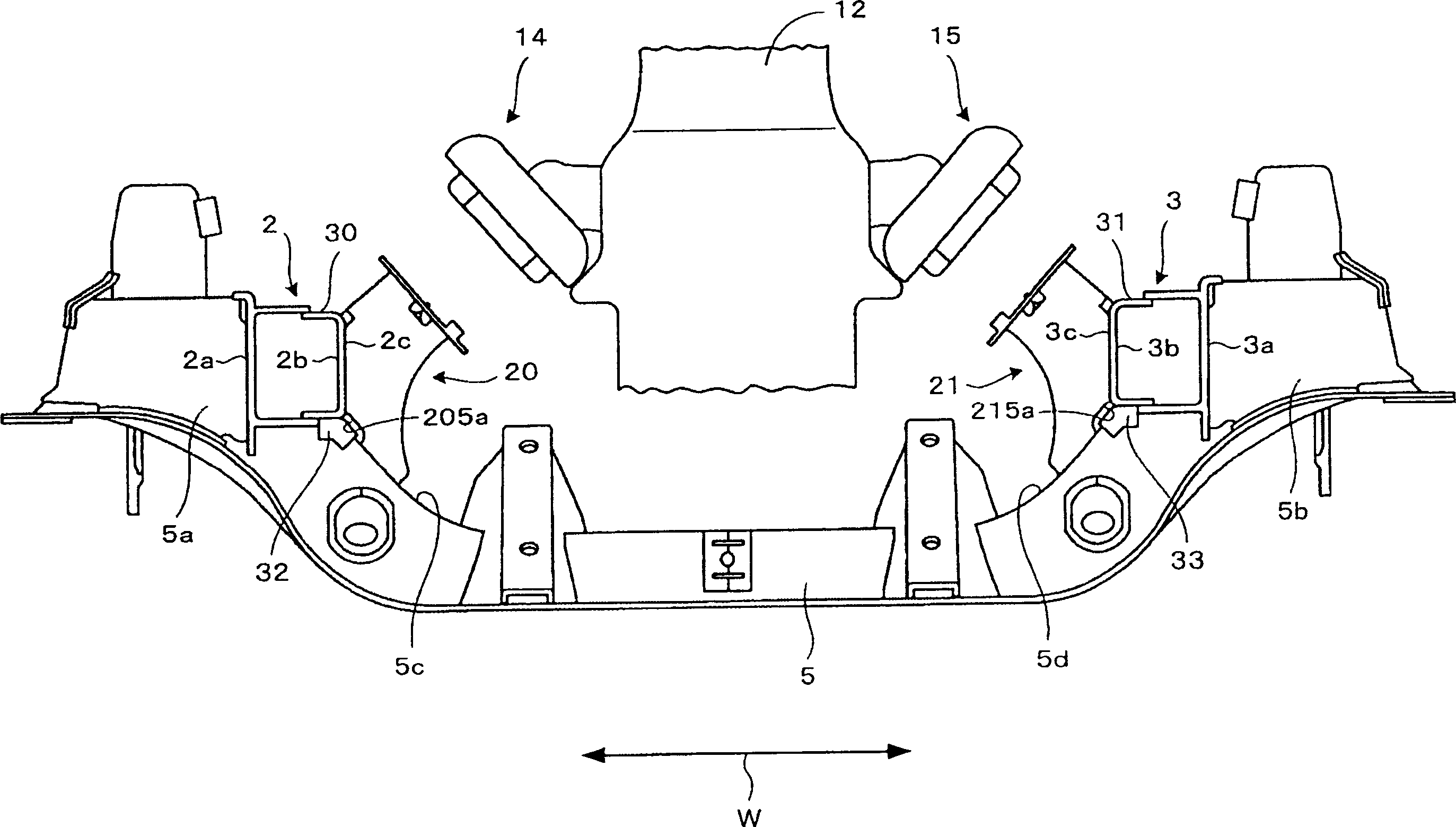

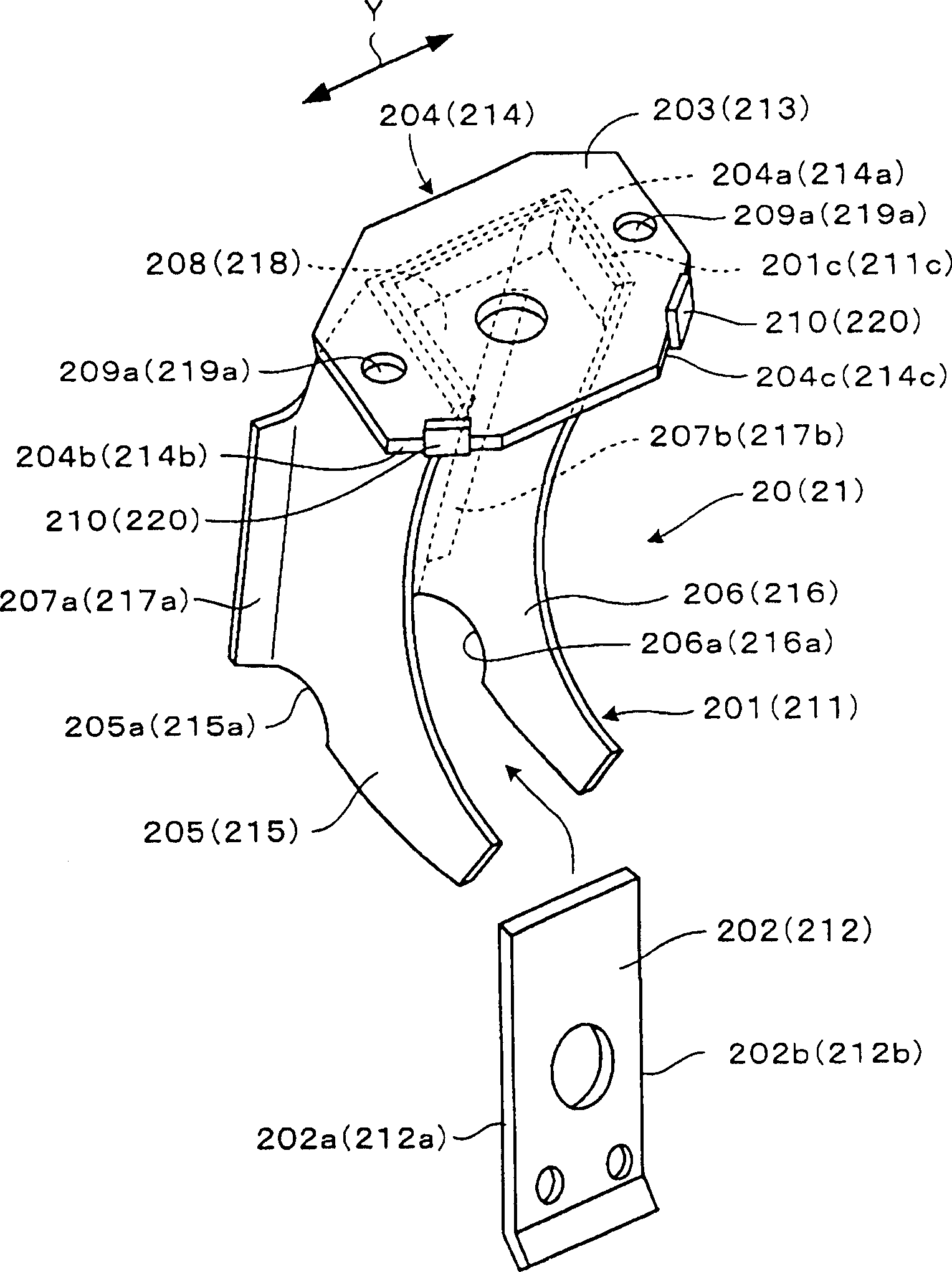

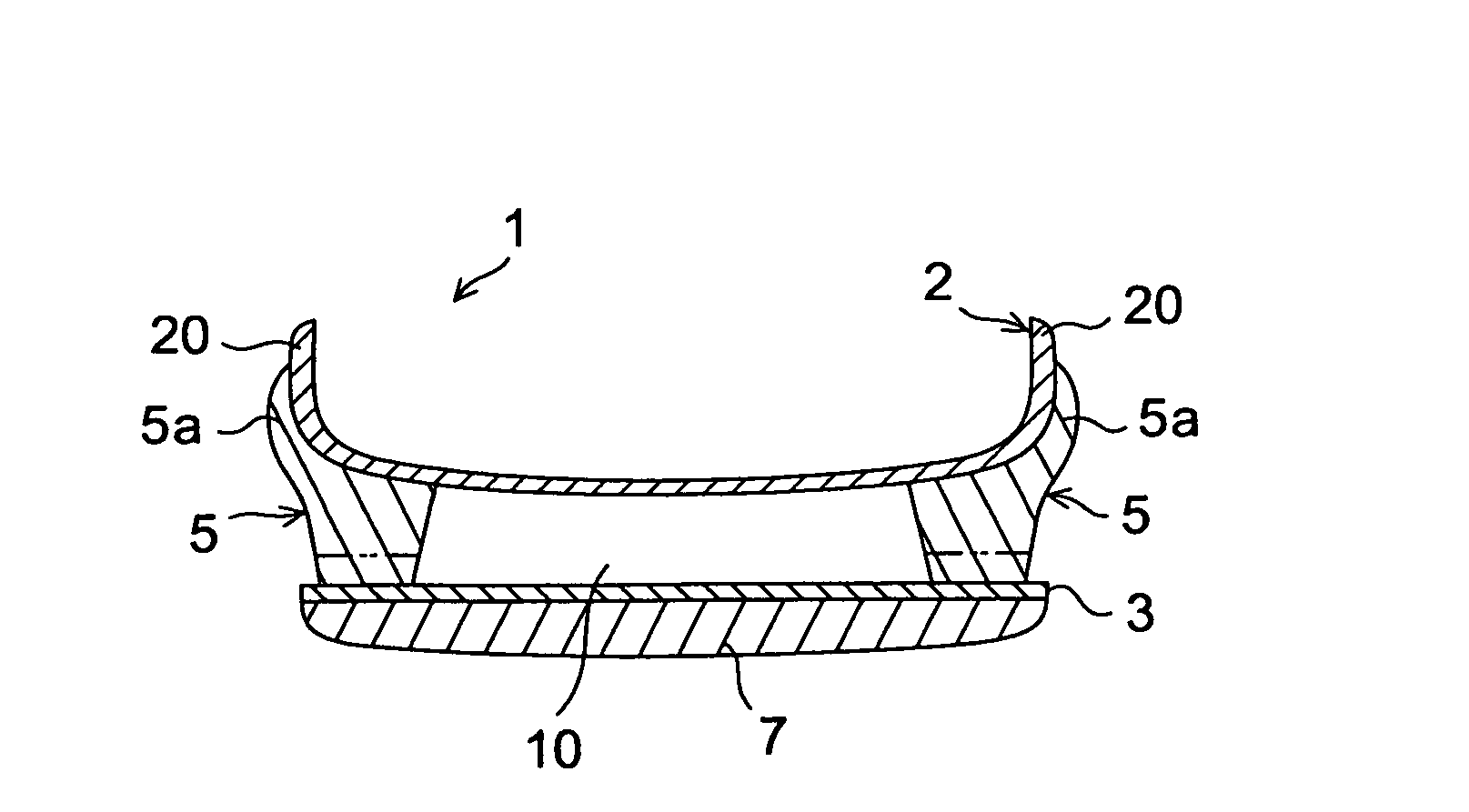

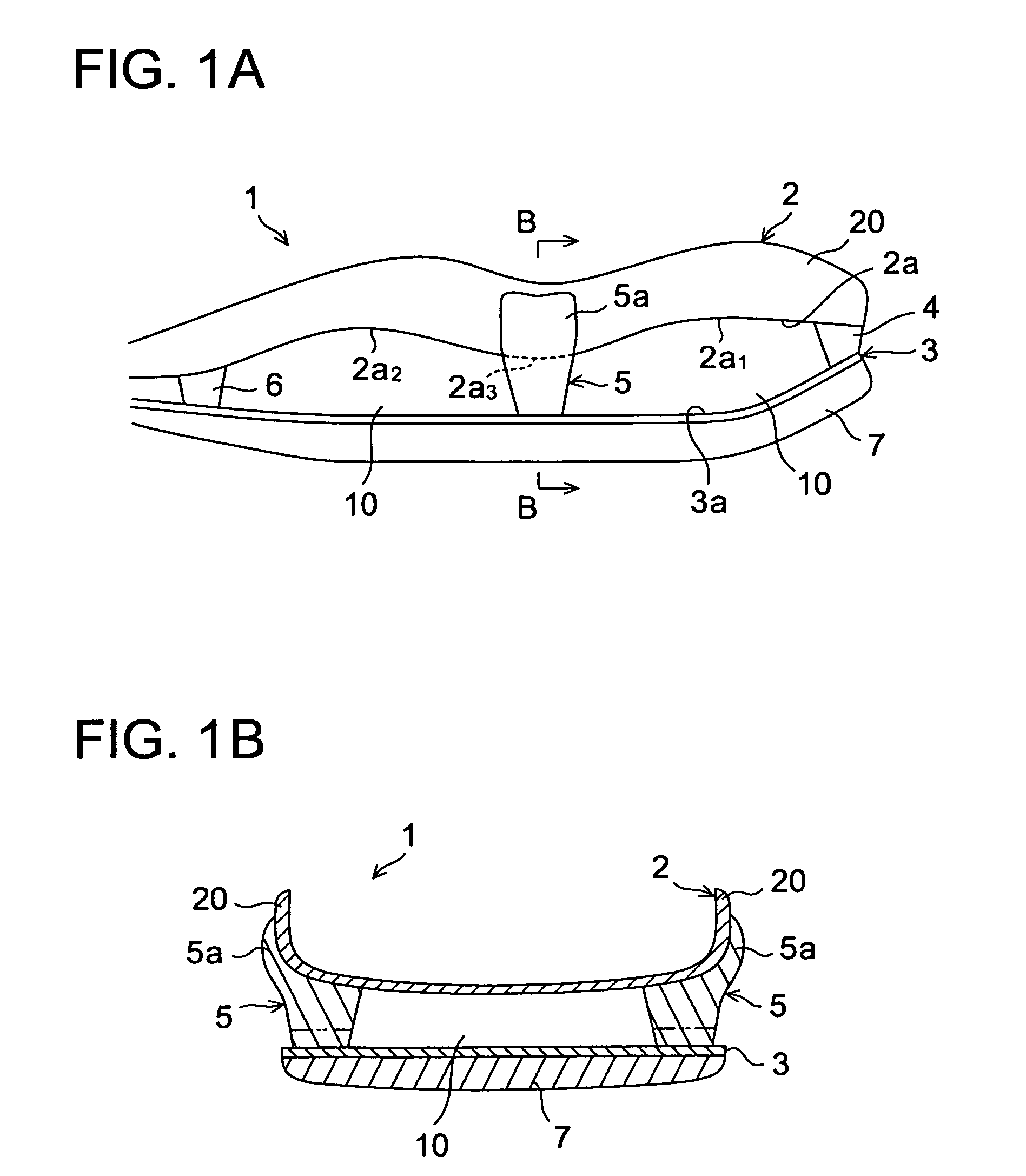

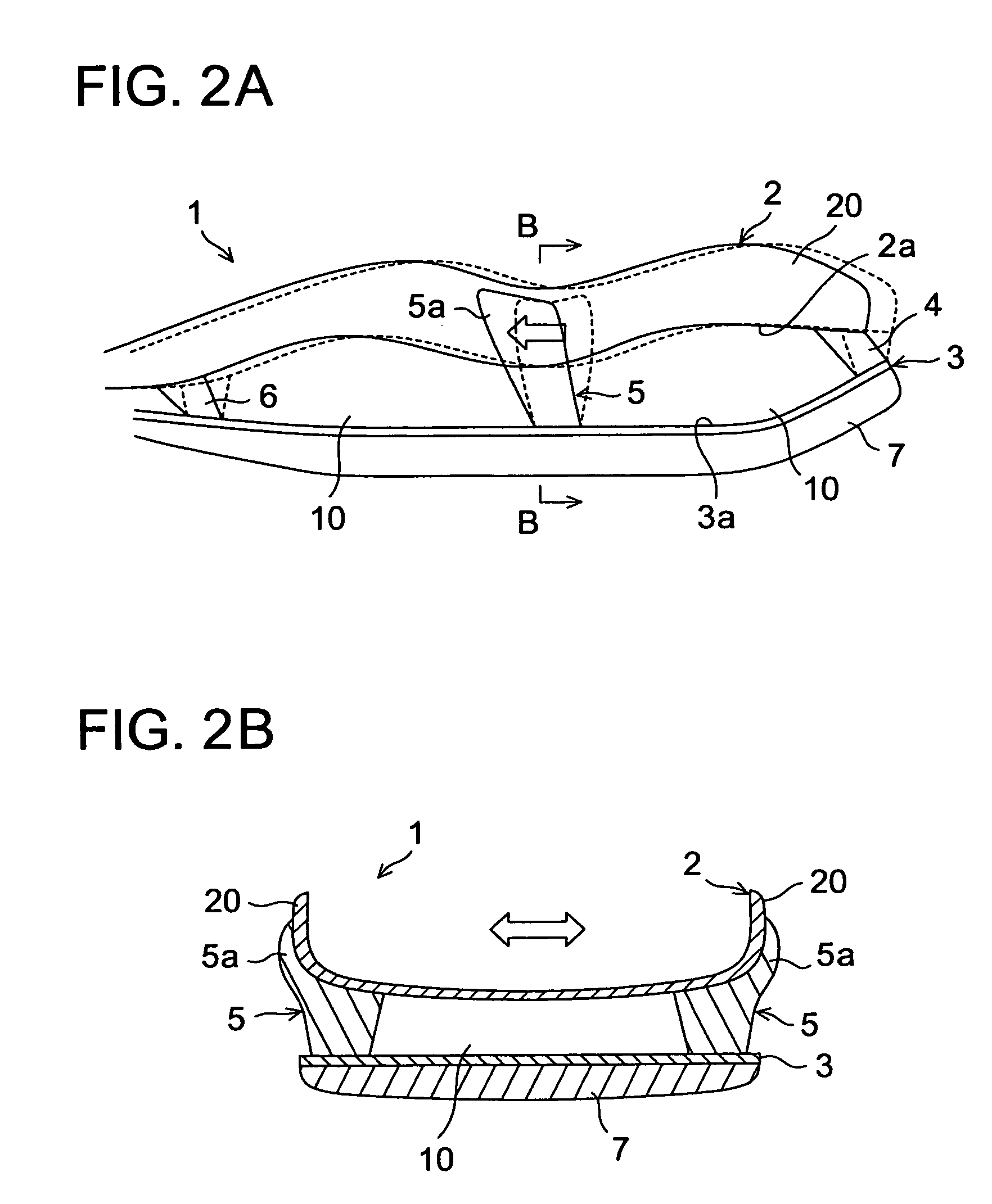

Engine rack structure

ActiveCN1693731AImprove connection rigidityWeight increaseNon-rotating vibration suppressionUnderstructuresEngineeringEngine mount

The invention provides an engine mount structure capable of improving the joint rigidity of a side member and a cross member while suppressing the increase of the weight and cost. The engine mount structure is mounted to an engine 12 arranged between the side members so as to straddle between a pair of side members 2 and 3 that are arranged at an interval in the vehicle width direction W and extend in the longitudinal direction of a vehicle 1 and the cross member 5 of which both end 5a and 5b sides are fixed to respective side members. Engine mount brackets 20 and 21 where engine mount insulators 14 and 15 for elastically supporting the engine are mounted to receiving surfaces 203 and 213 are fixed to the side members 2 and 3 and the cross member 5, and the engine mount insulators 14 and 15 are mounted to receiving surfaces 203 and 213 to support the engine 12.

Owner:MITSUBISHI MOTORS CORP

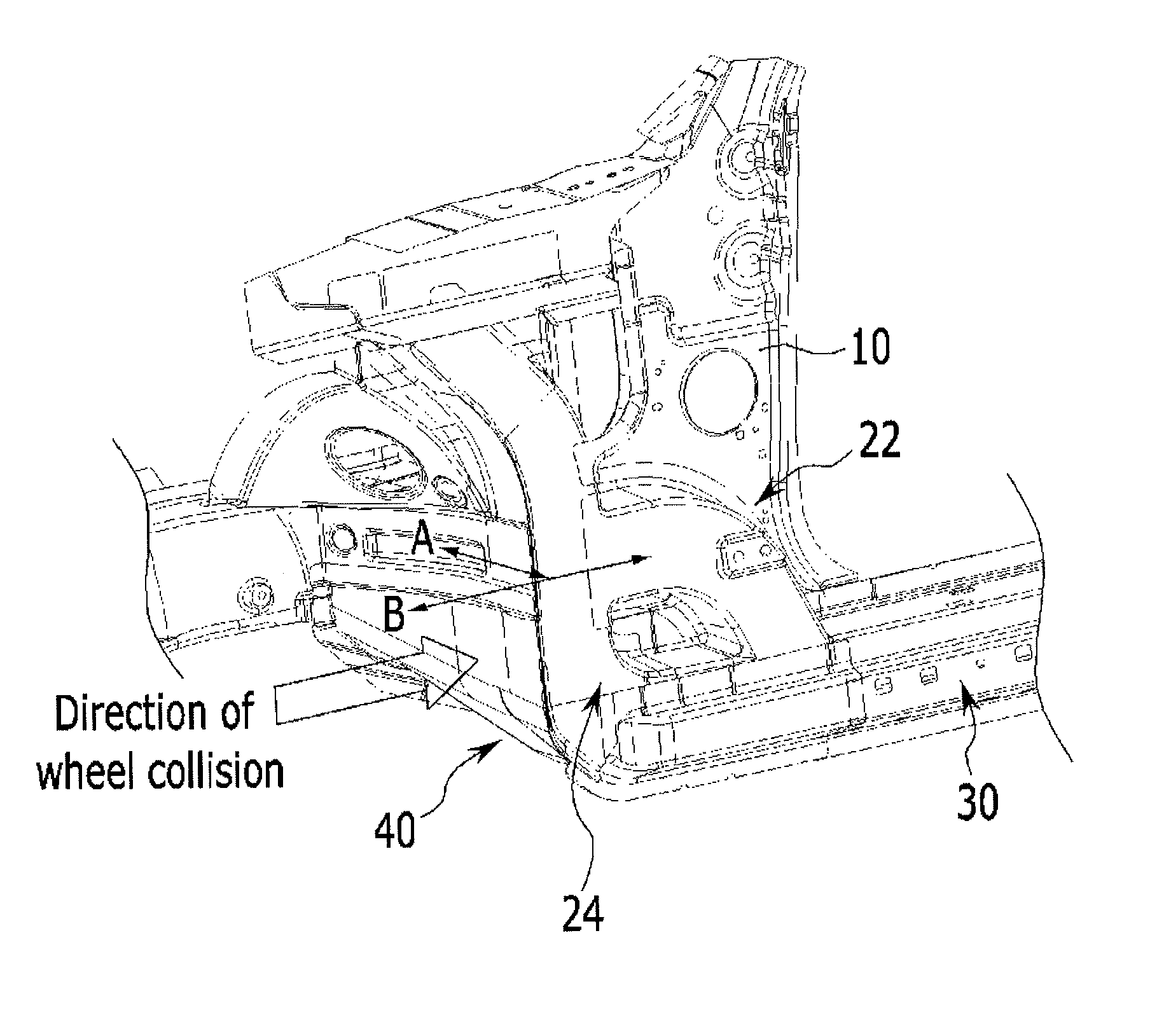

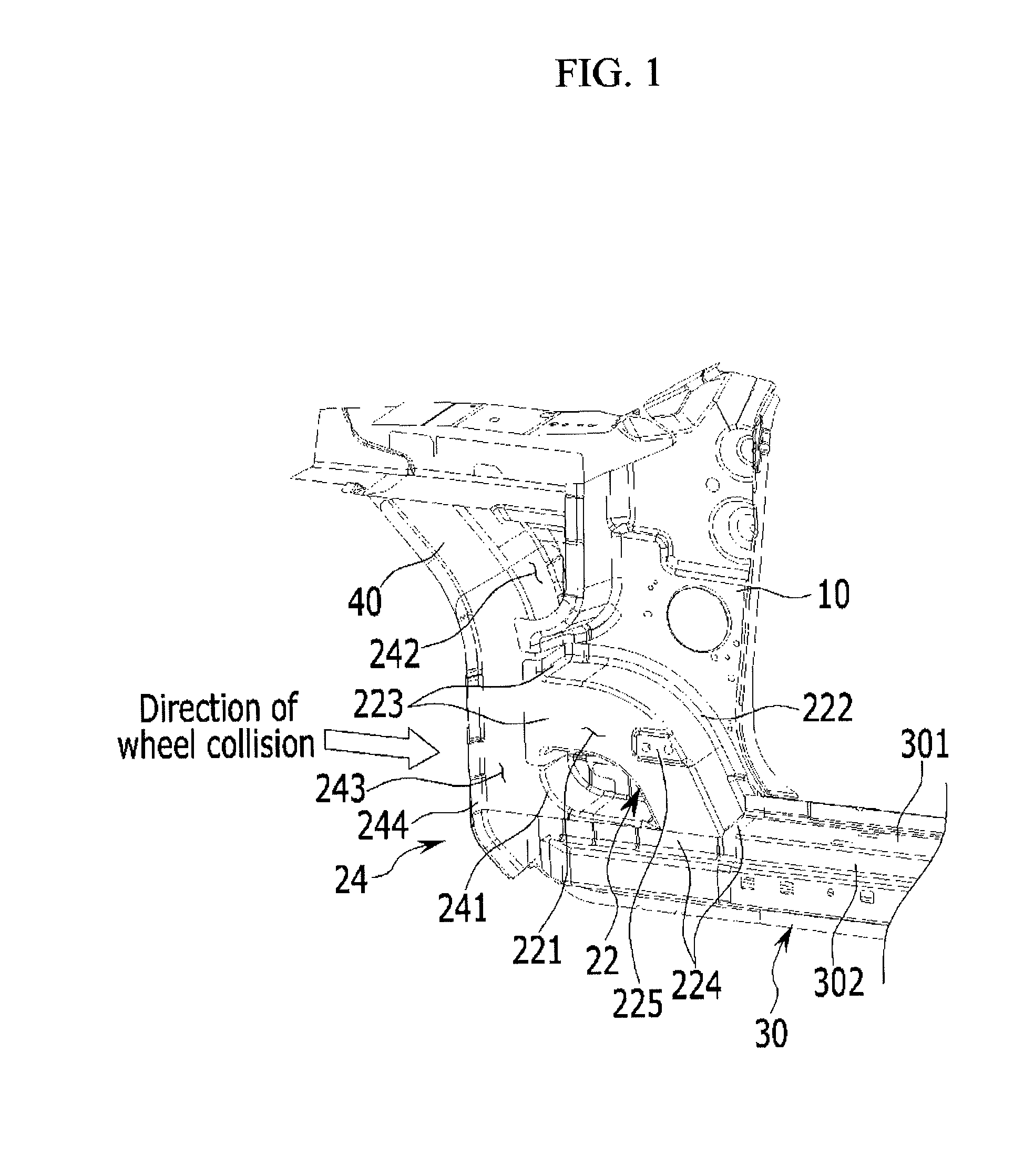

Vehicle body reinforcing structure

ActiveUS20150166112A1Avoid damageSecurityVehicle seatsSuperstructure subunitsEngineeringMechanical engineering

Owner:HYUNDAI MOTOR CO LTD

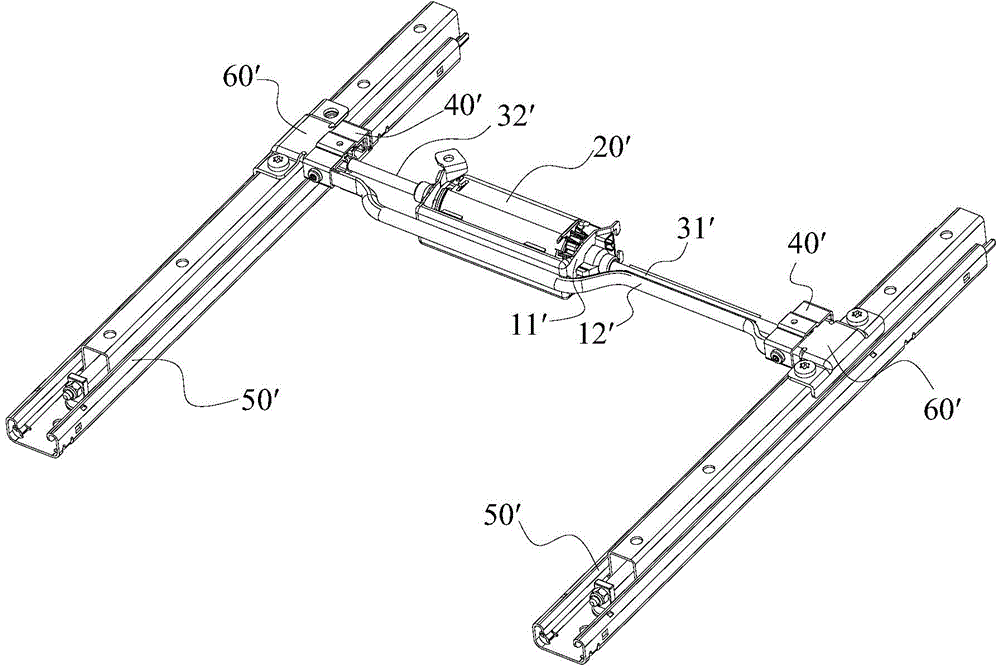

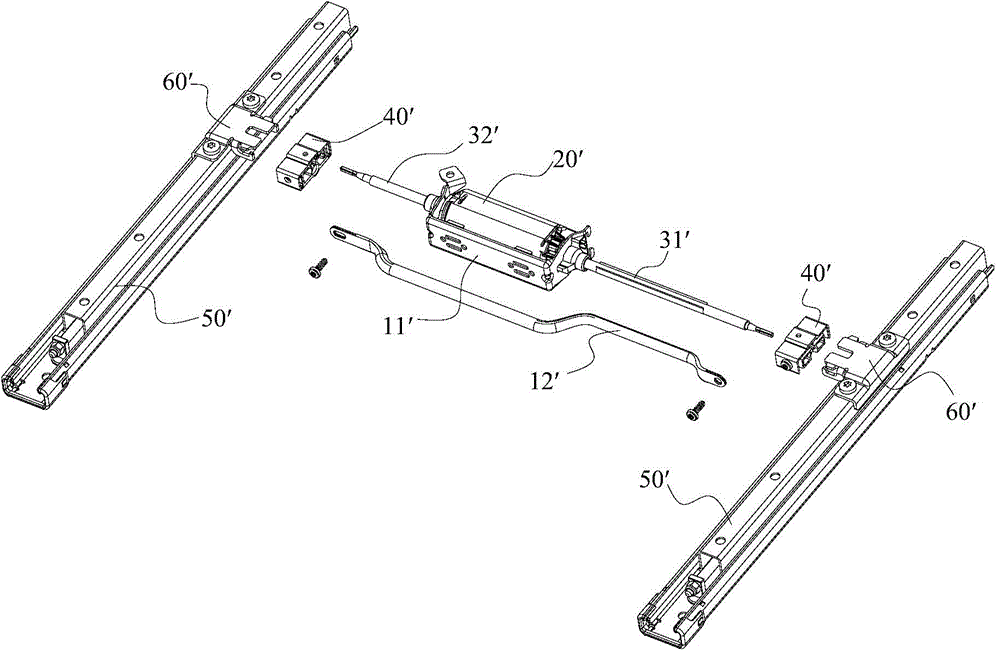

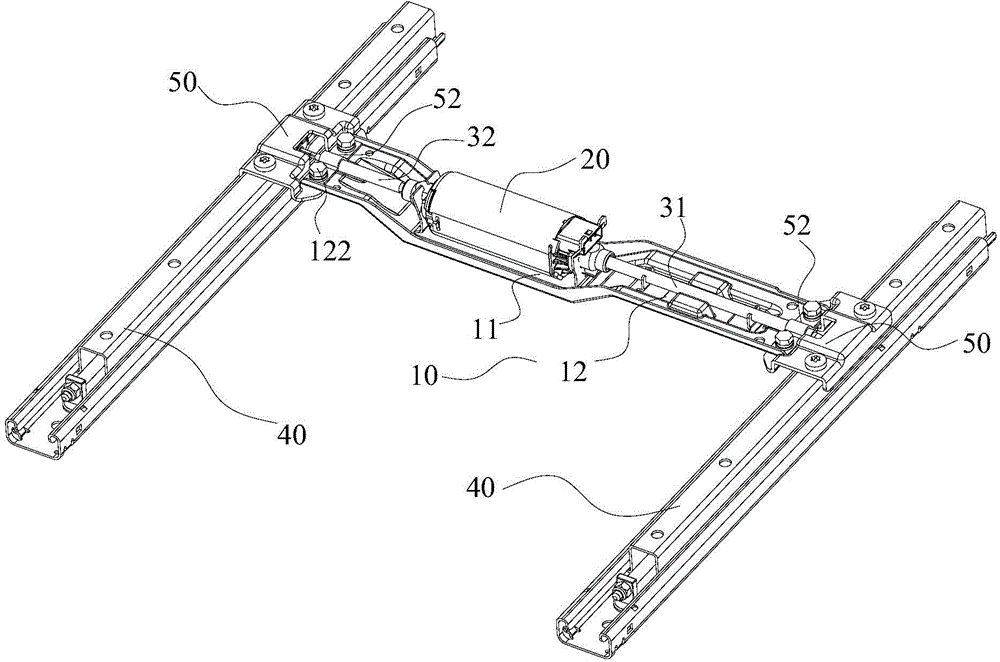

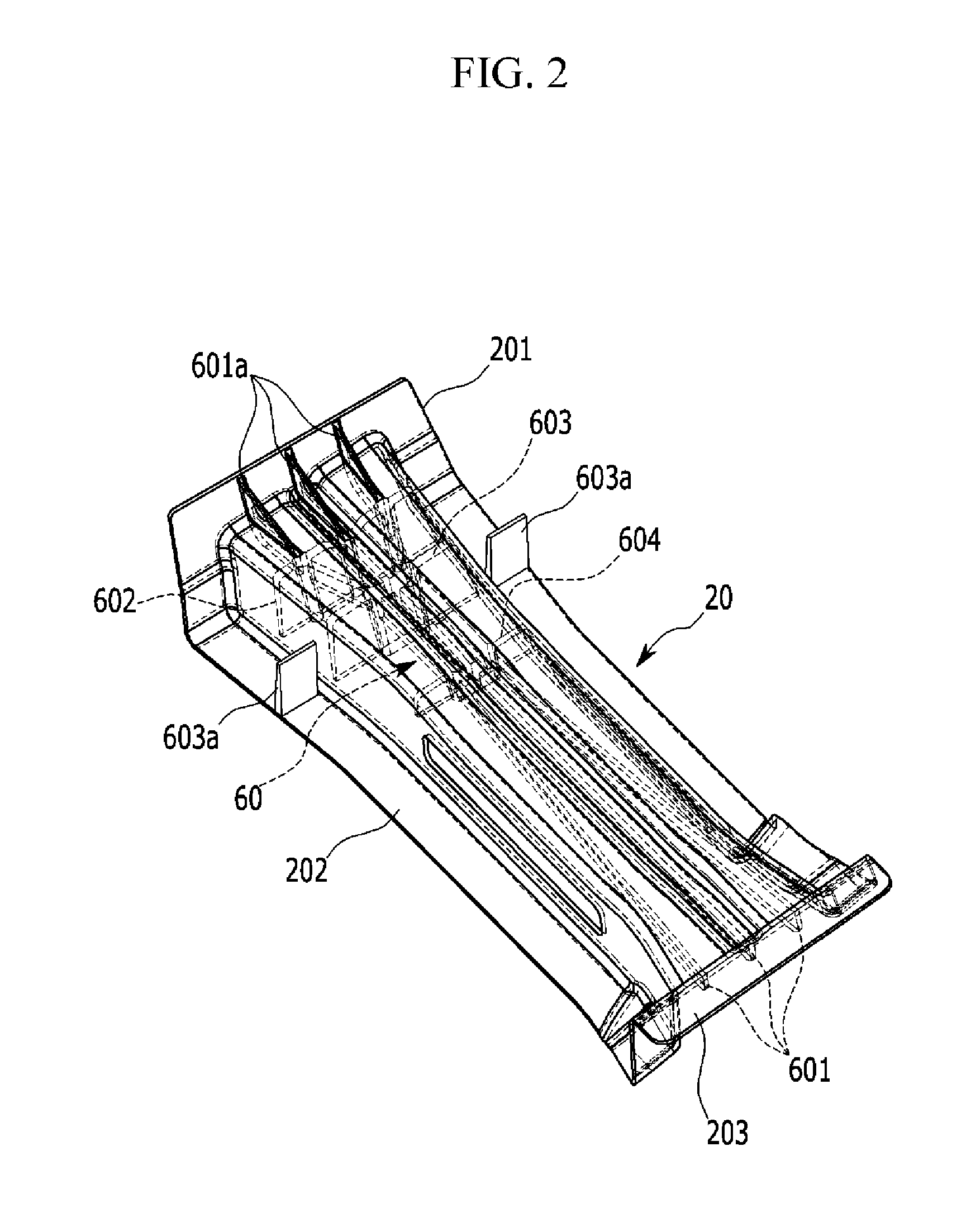

Automobile sliding rail assembly and motor bracket thereof

InactiveCN104802667AHigh strengthImprove connection rigidityMovable seatsElectric machineryEngineering

The invention discloses a motor bracket. The motor bracket is used for supporting a sliding rail motor; the sliding rail motor is fixedly connected between two parallel sliding rails; the motor bracket is of a plate-shaped structure, and comprises a supporting plate and a connecting plate which are fixedly connected with each other; the supporting plate supports and fixes the sliding rail motor; the two ends of the connecting plate are respectively connected with the two sliding rails which are arranged in parallel. Through an optimal design of the structure, the fixing and supporting strength of the motor bracket to the sliding rail motor is improved; the connecting rigidity of an automobile seat is improved; the reliable and stable connection is ensured. On the basis, the invention also provides an automobile sliding rail assembly which is provided with the motor bracket.

Owner:HUBEI AVIATION PRECISION MASCH TECH CO LTD

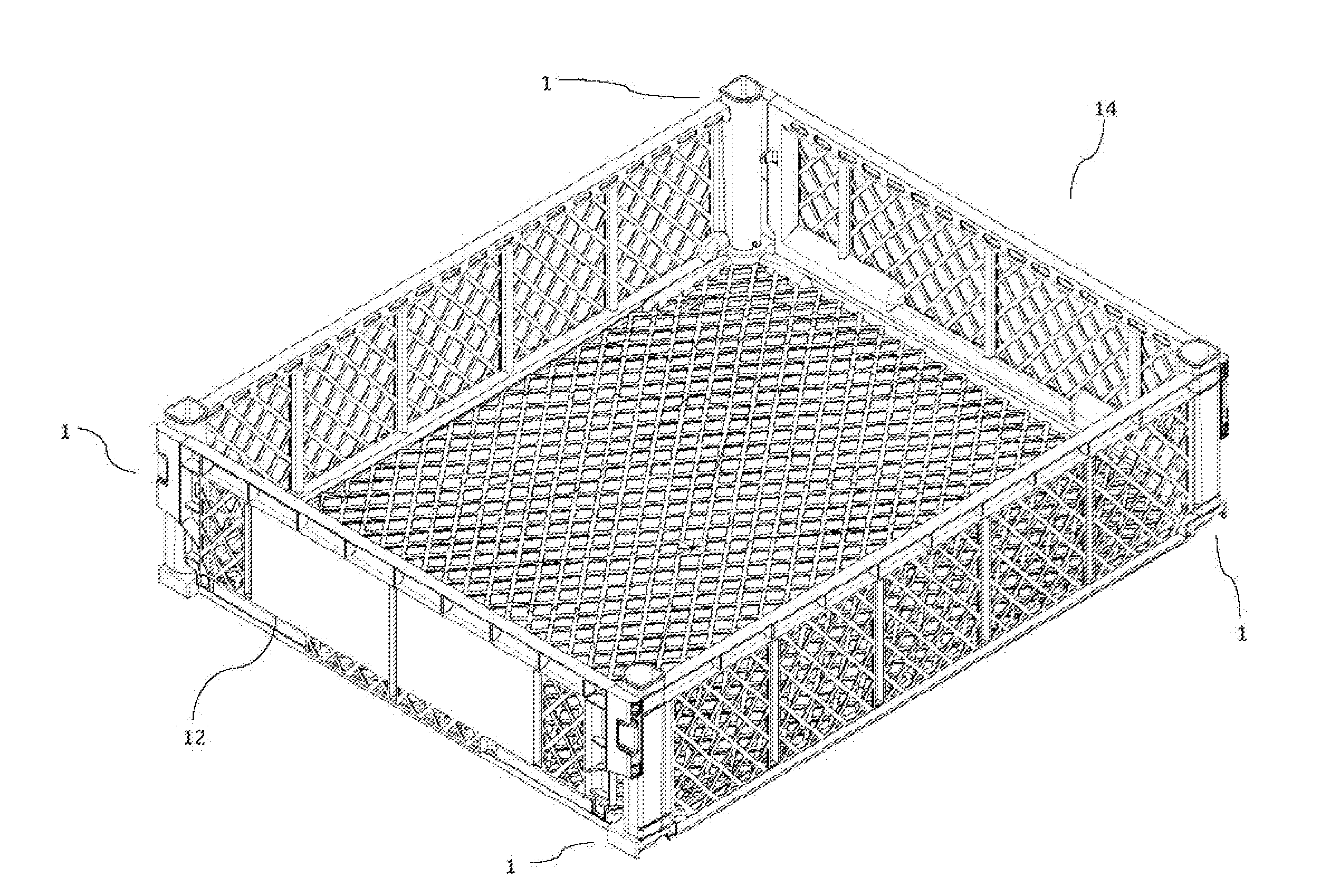

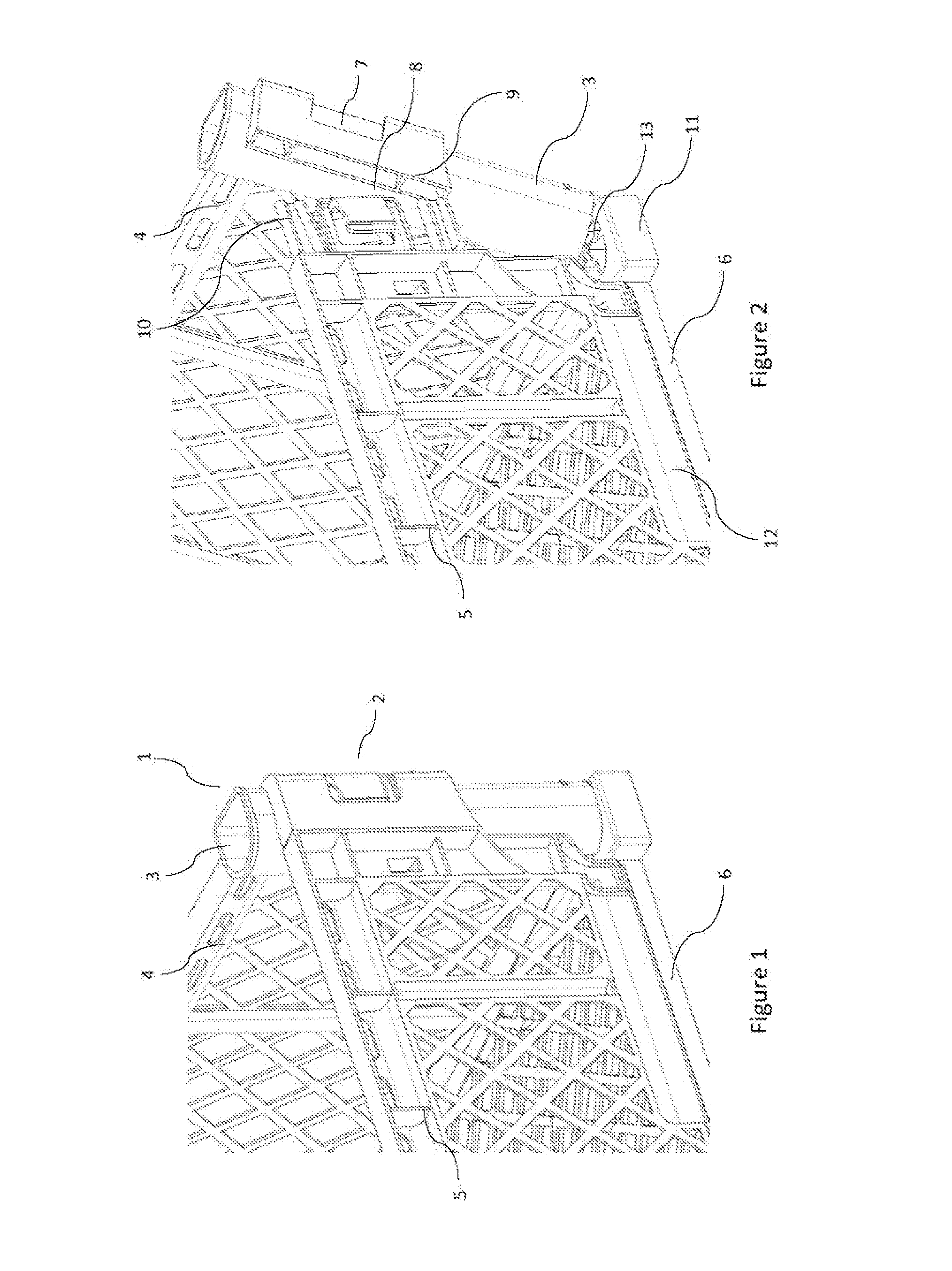

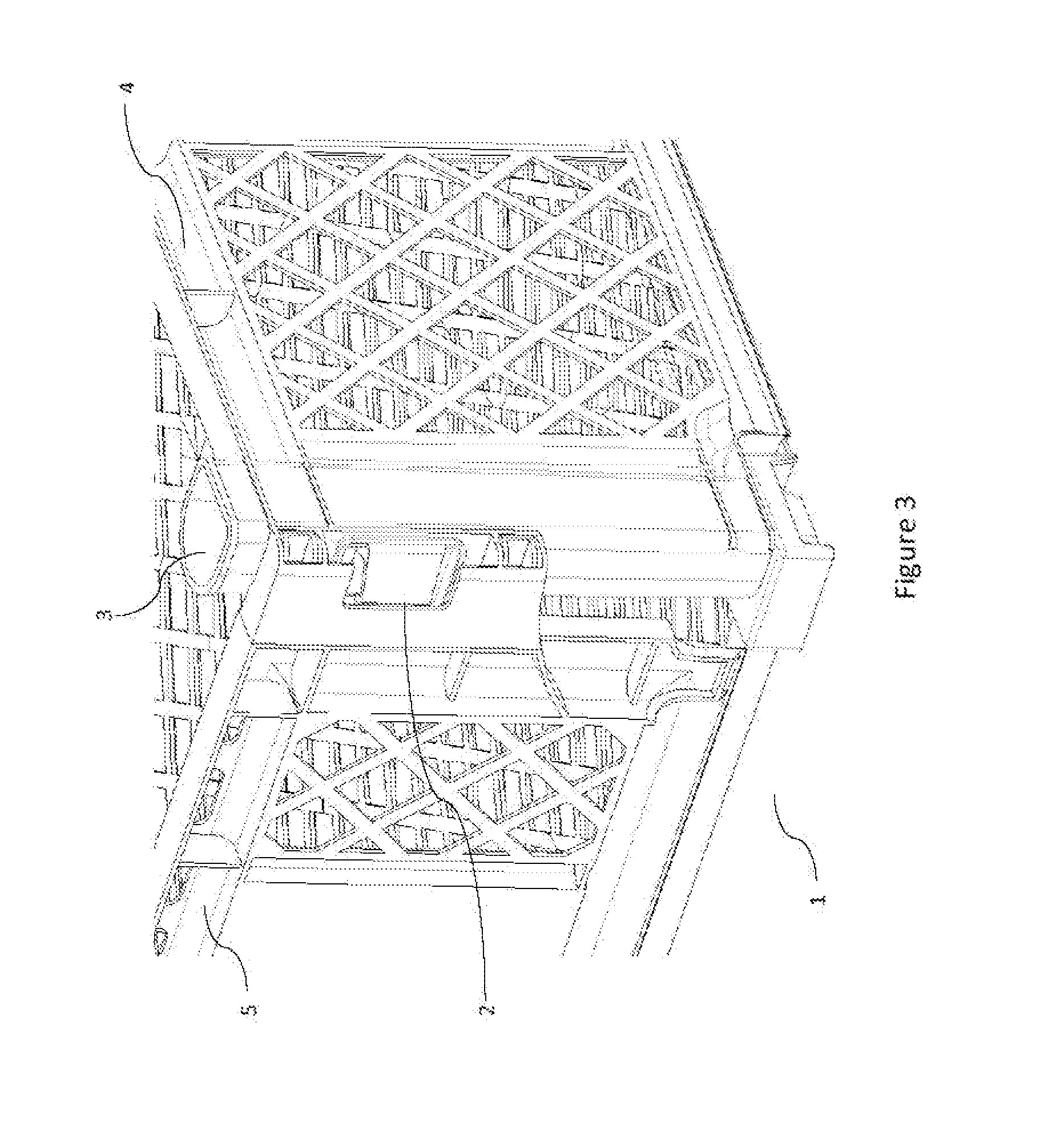

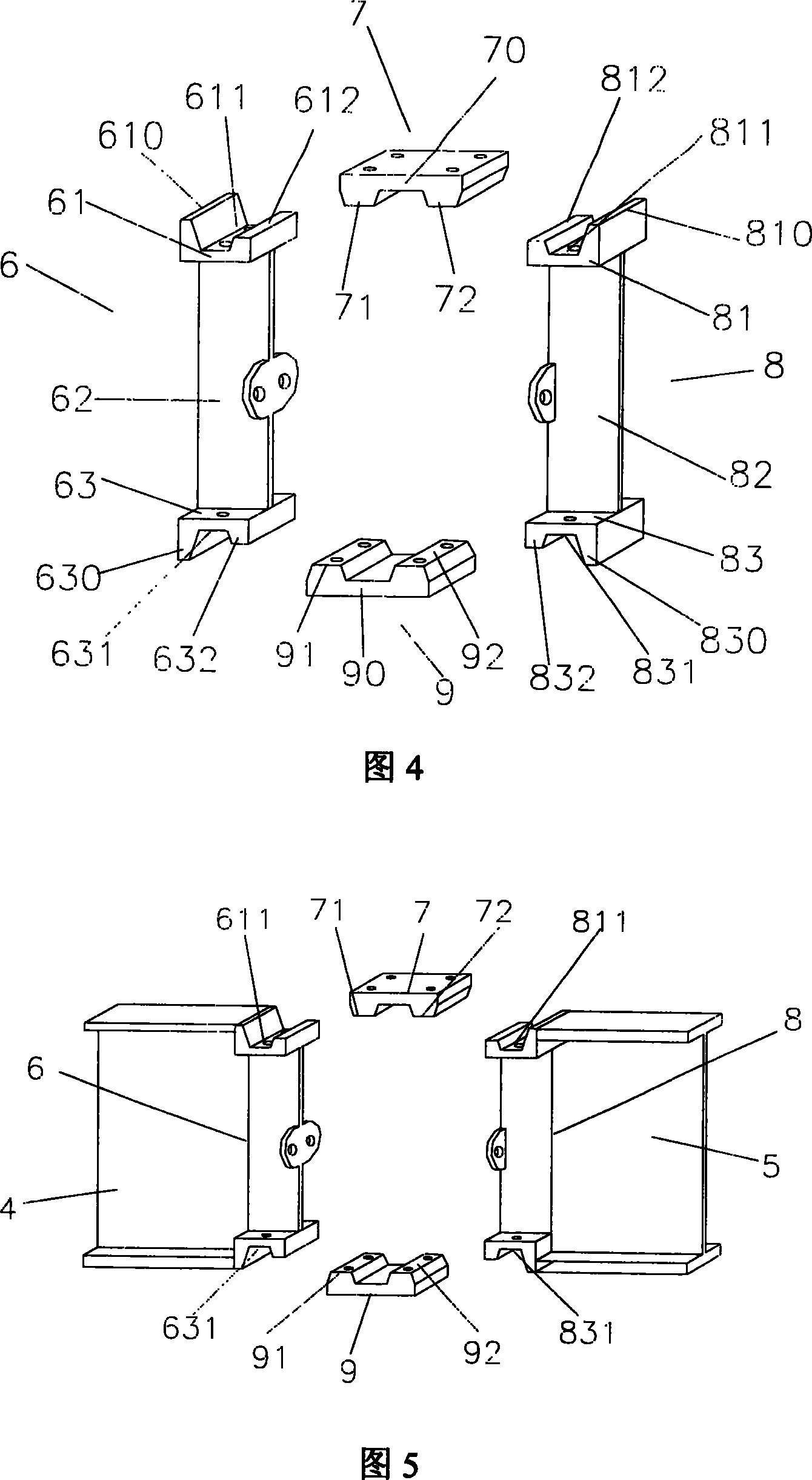

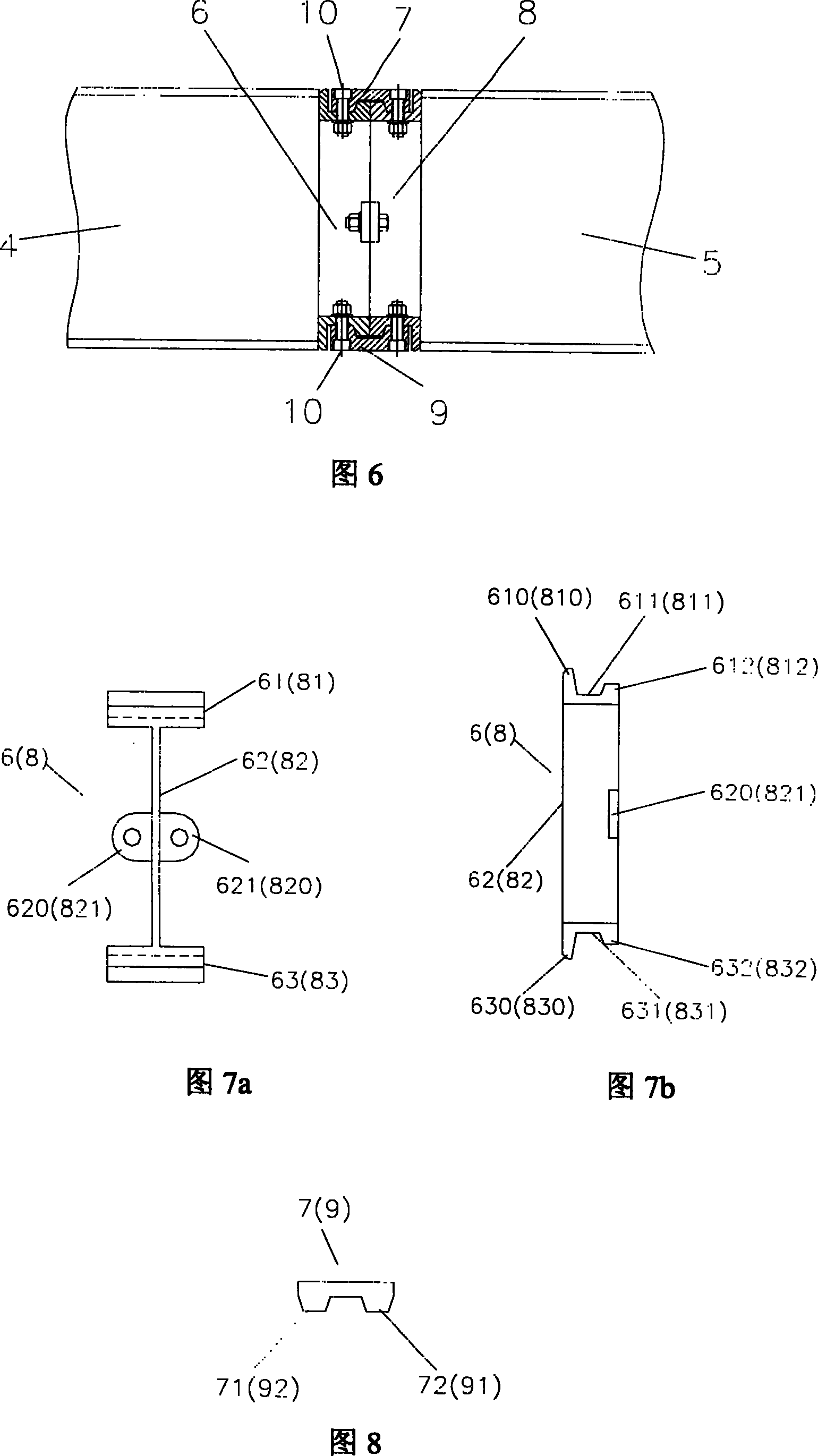

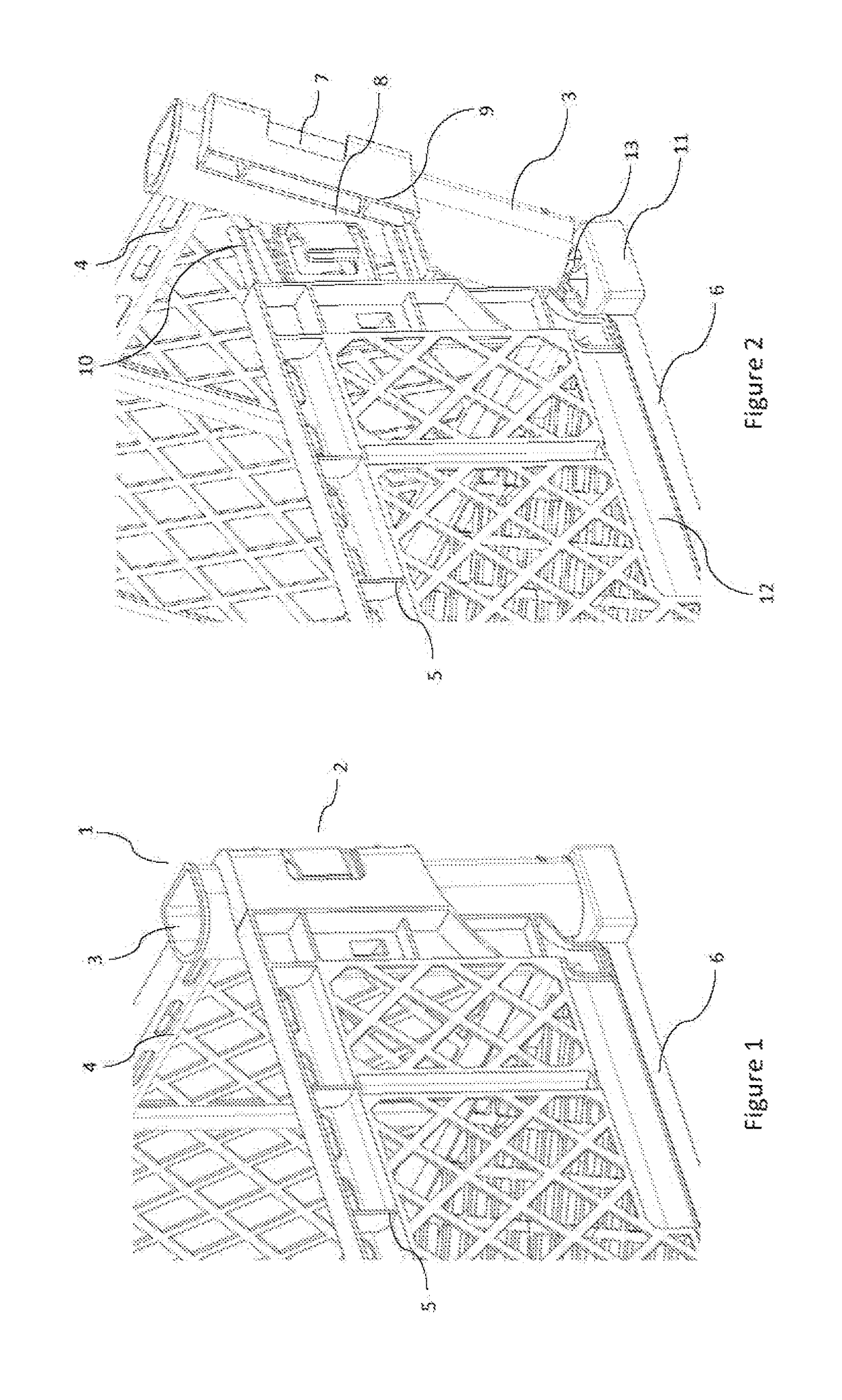

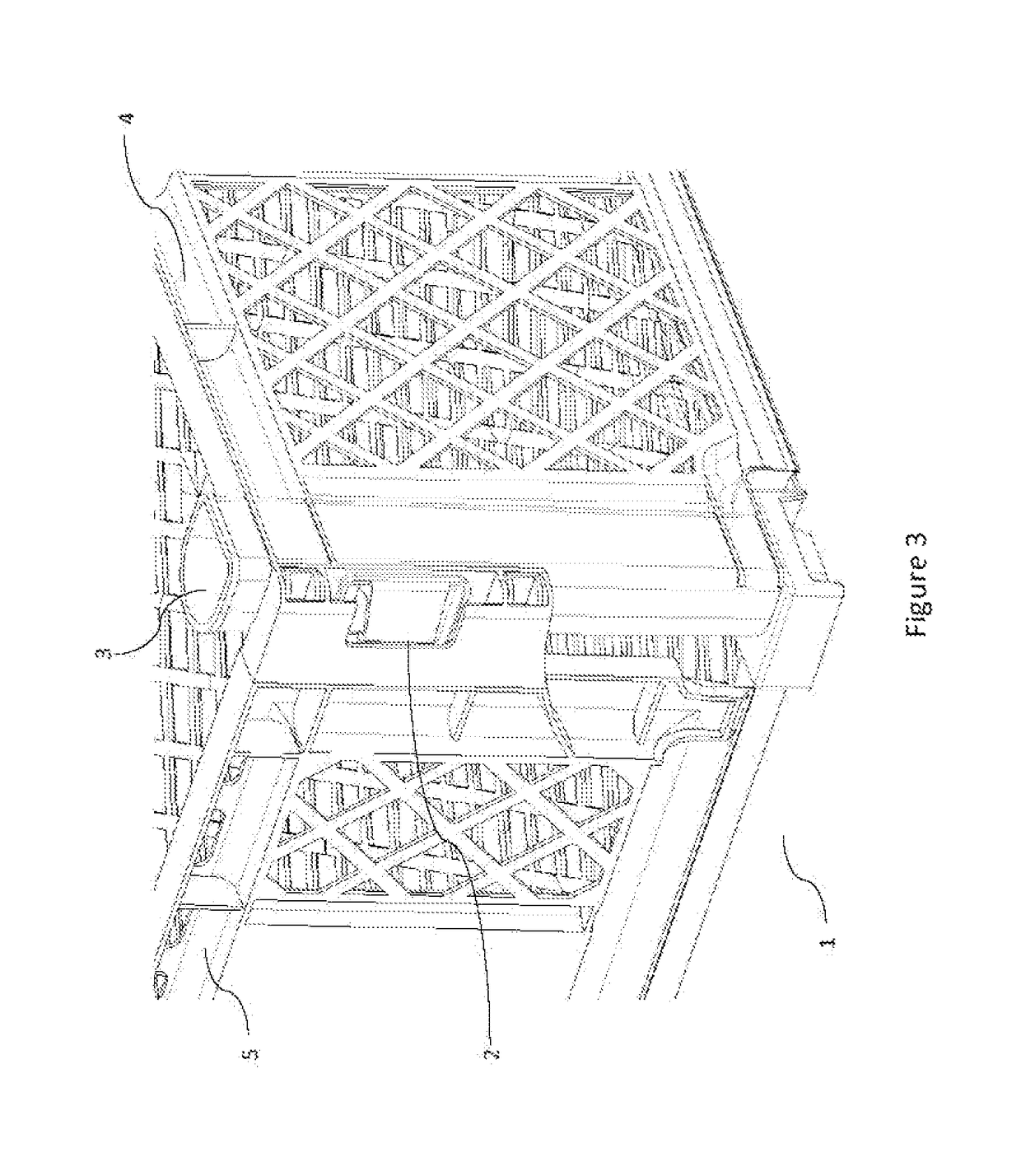

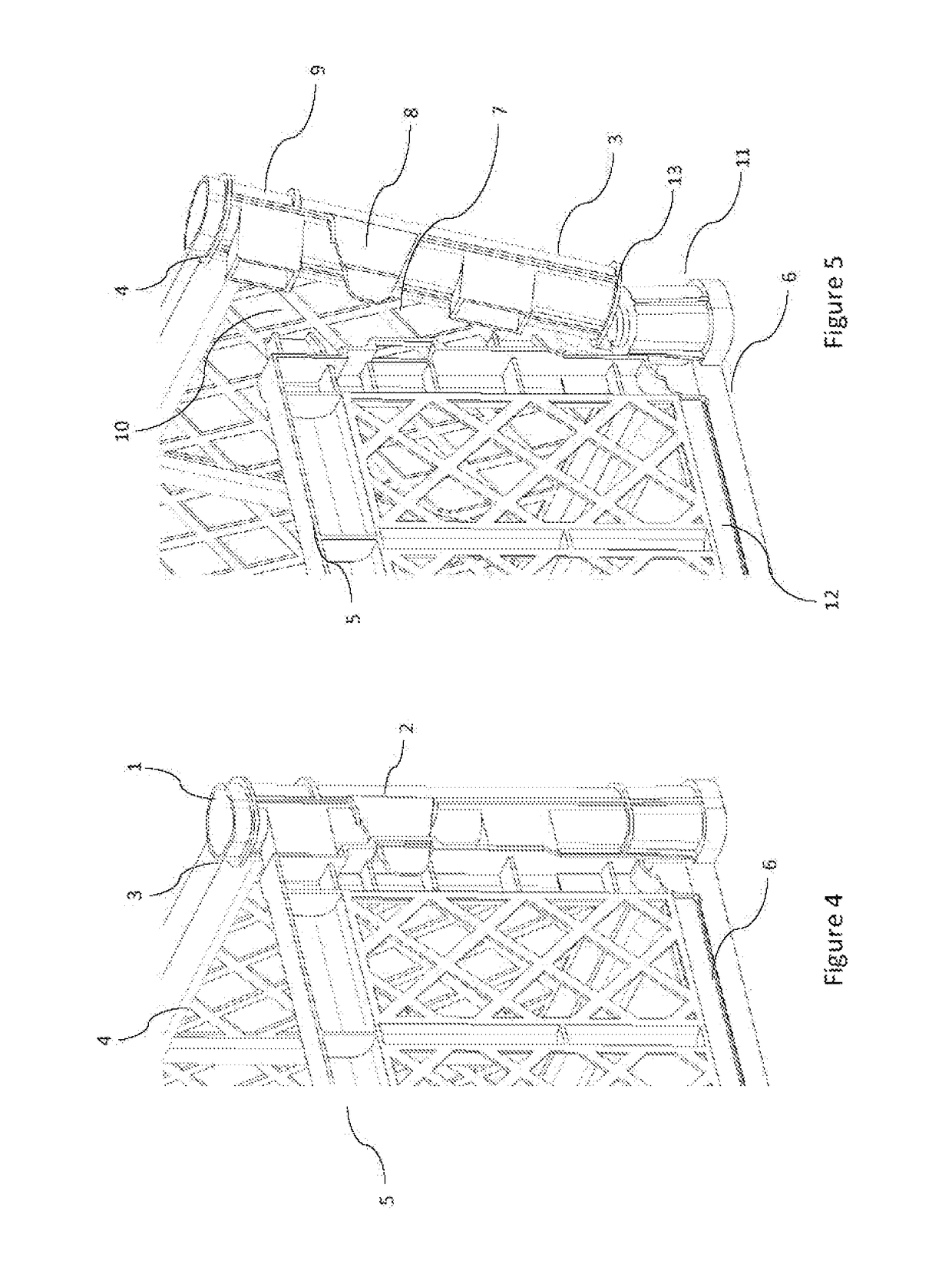

Light and integrated junction system of the walls of a collapsible container

ActiveUS20150284135A1Improve the immunityReduce weightDomestic articlesTray containersHigh intensityEngineering

The present invention comprises a junction system of structures, preferably for container walls, which is light and is integrated to the structures to be joined providing high strength and rigidity reducing the weight of the joint, which comprises at least a closing device having at least a pair of closing means, a male closing mean and a female closing mean, wherein said closing means join at least two structures together, or two adjacent faces of a container for fruit and vegetable products, preferably the side faces, being fixed to said structures or faces; further comprising a column fixed to one of said structures, wherein said column is configured as a hollow cylindrical body which in turn is integrated to at least one of said closing means. Furthermore, the invention comprises an associated container and its manufacturing process.

Owner:WENCO

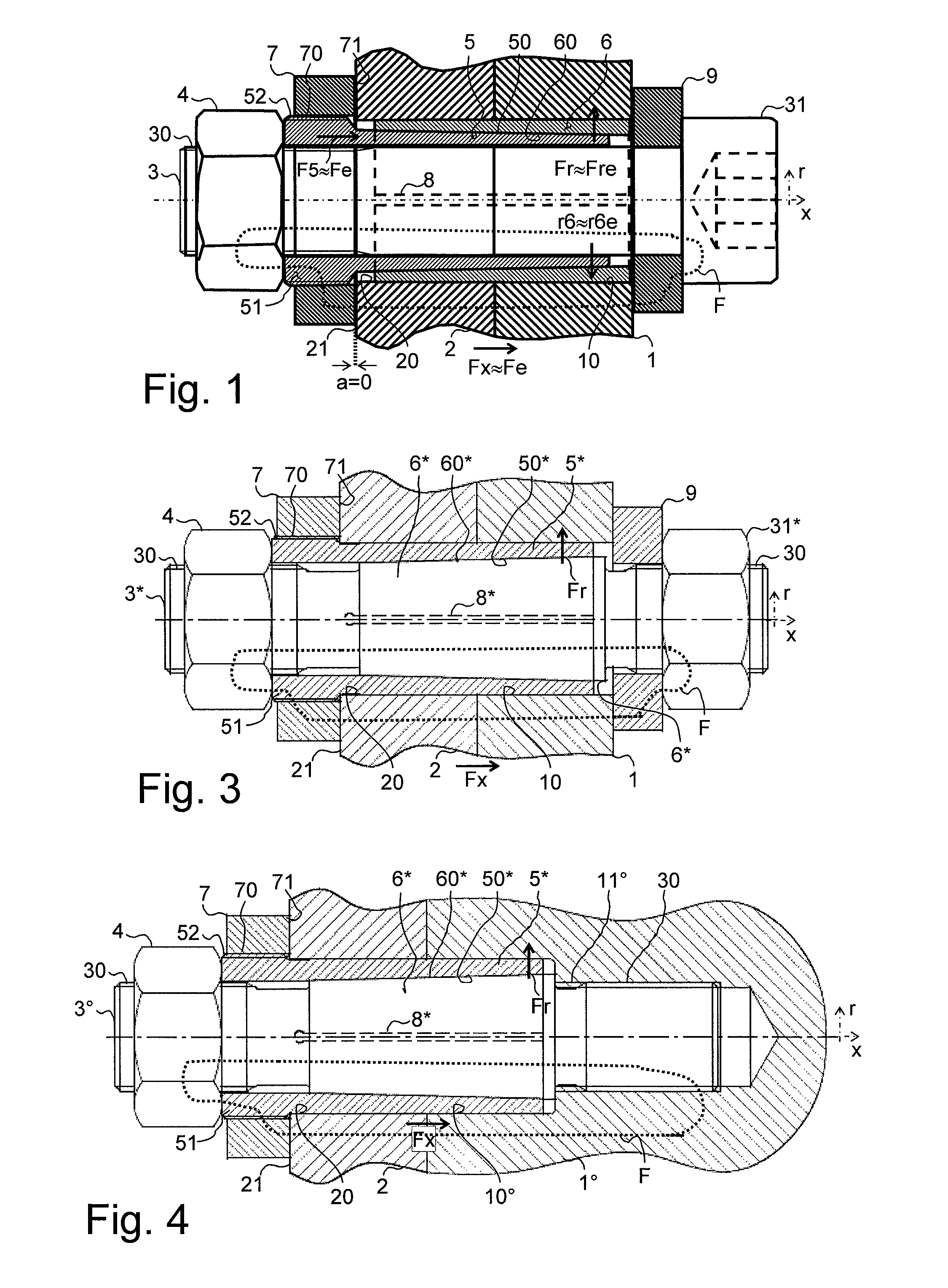

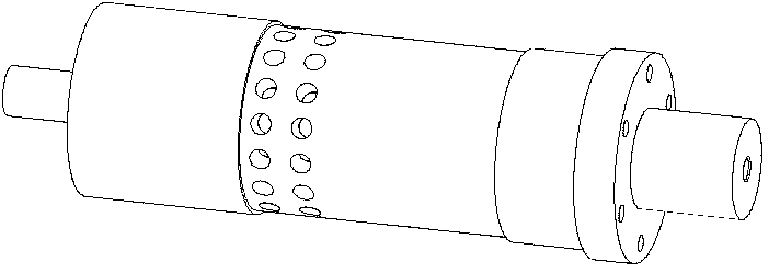

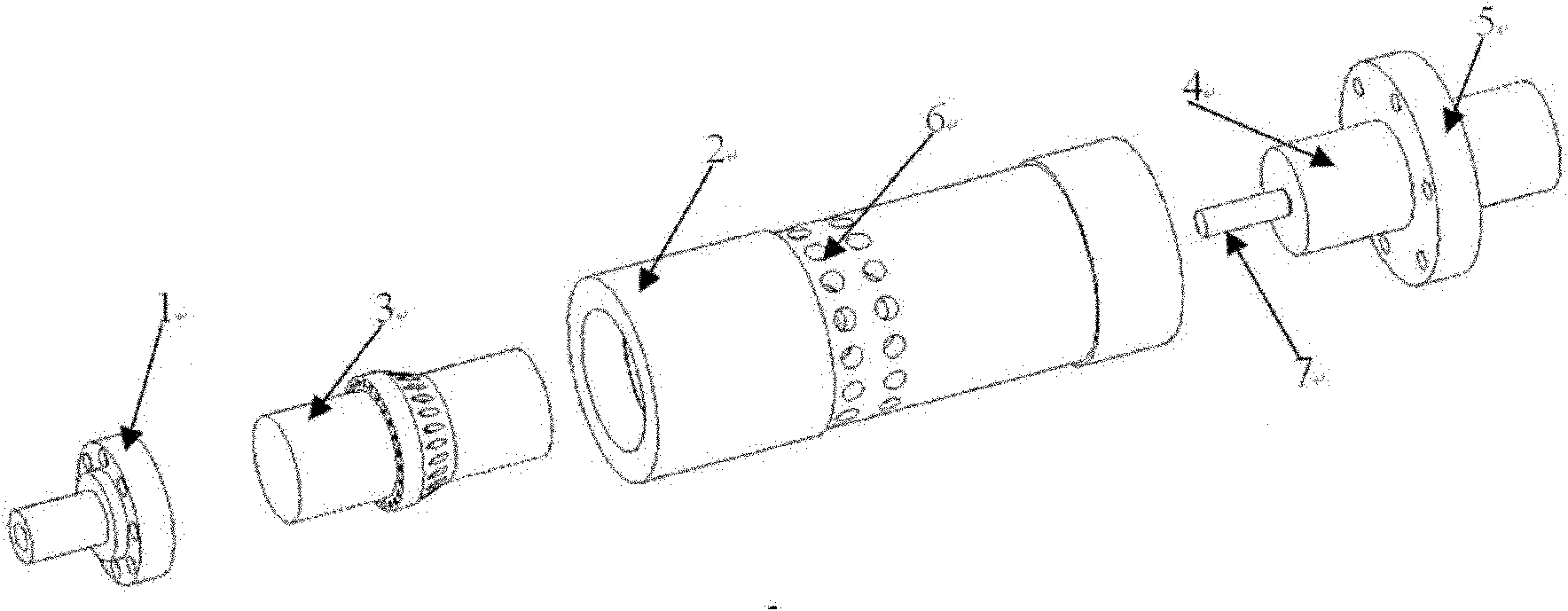

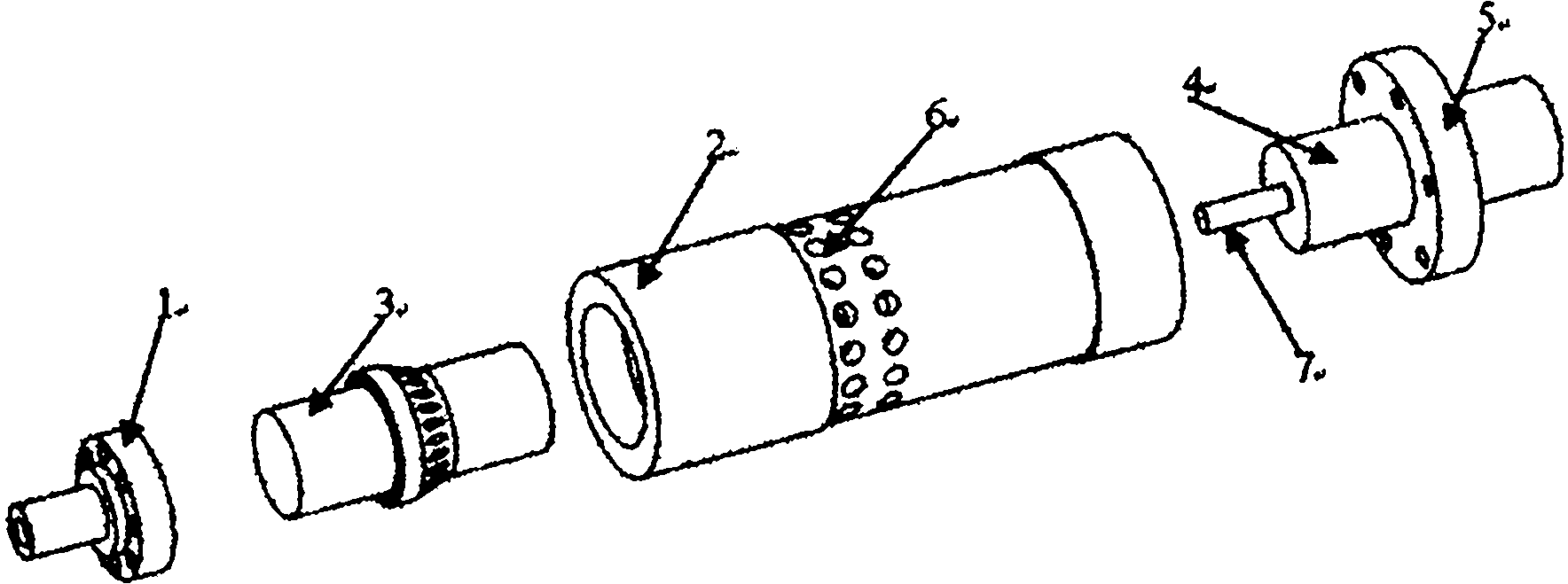

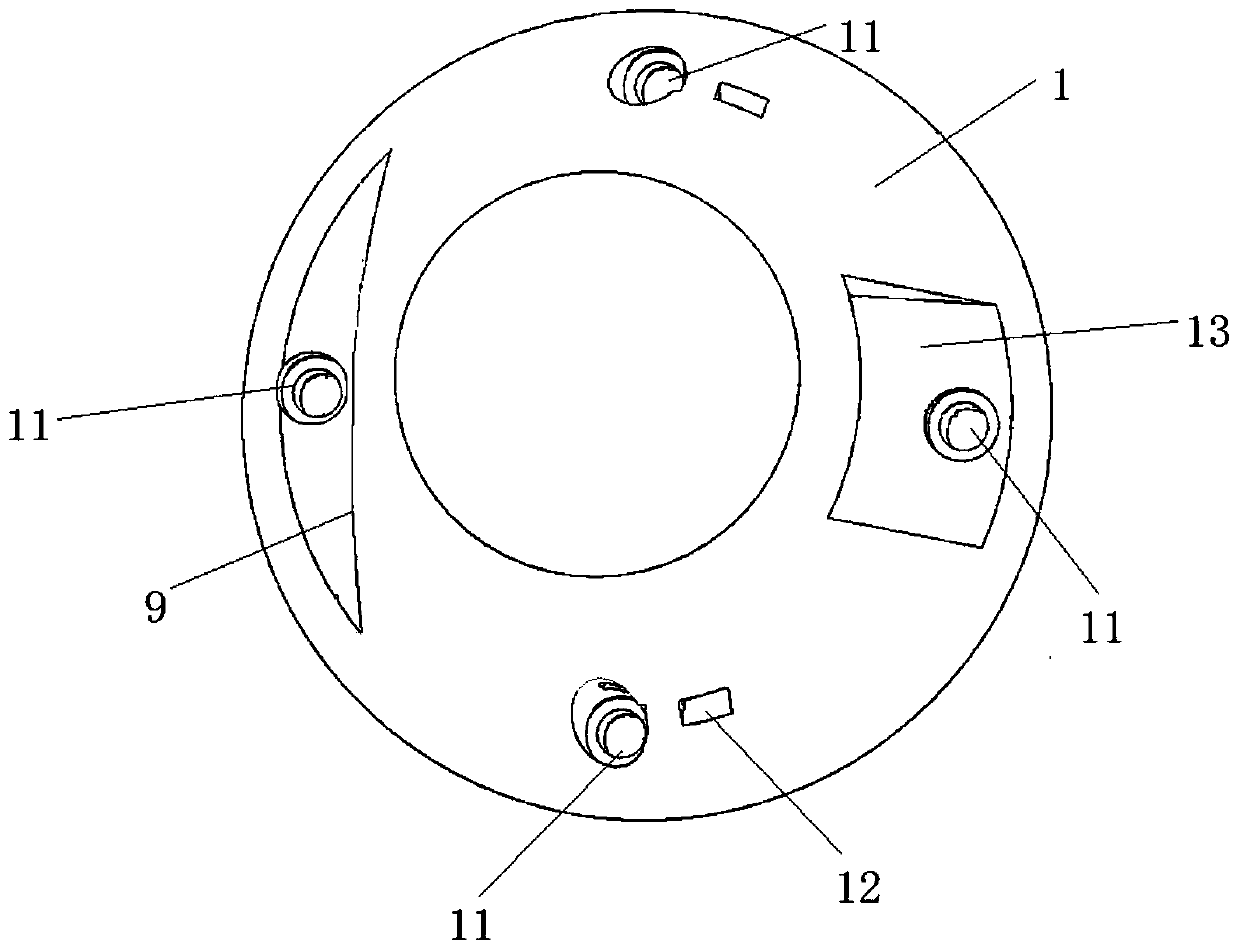

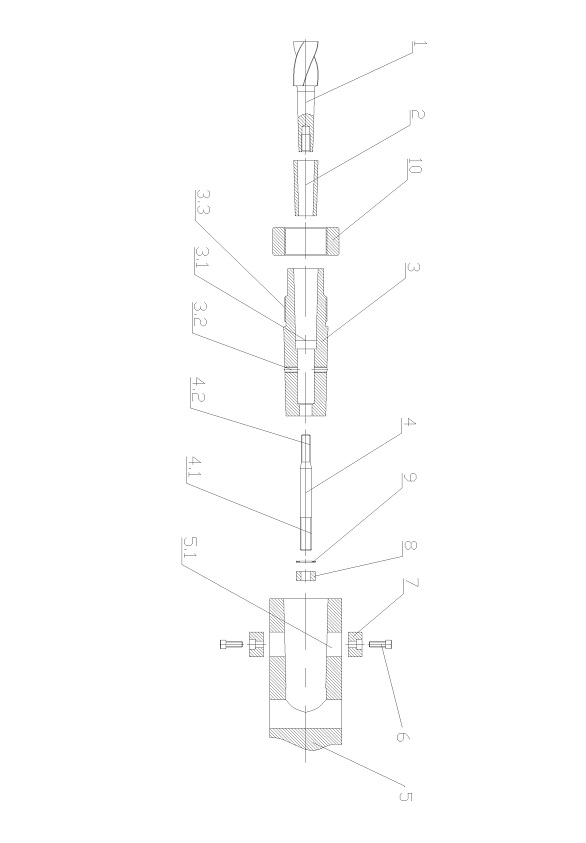

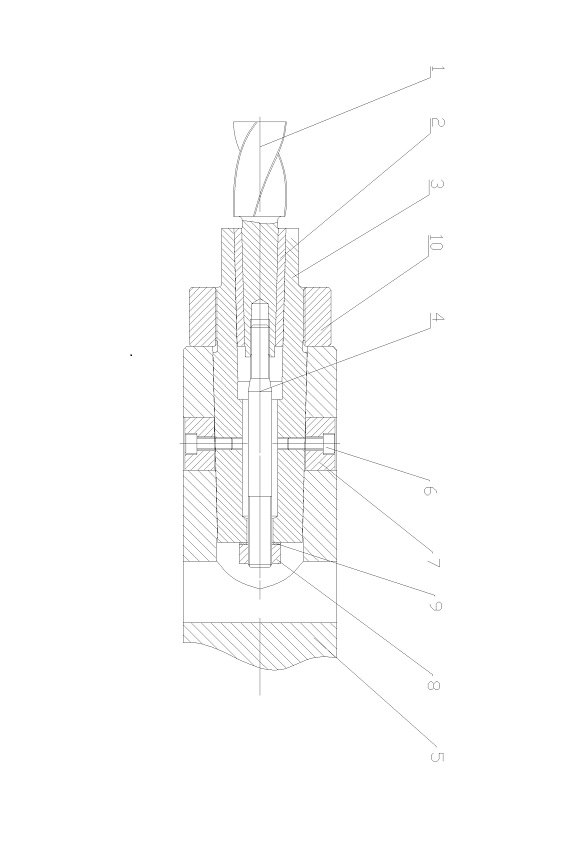

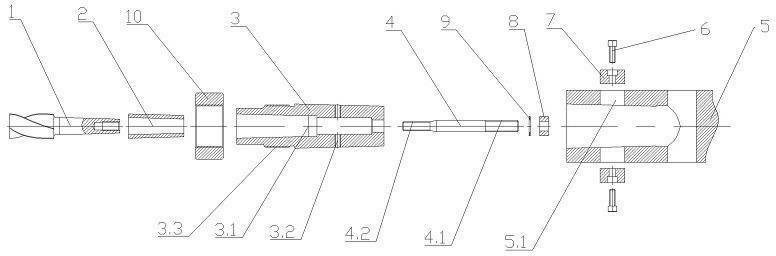

Ultrasonic transducer and amplitude modulator combined piece

InactiveCN102172574AThe transmission direction of ultrasonic vibration is stableImprove reliabilityMechanical vibrations separationNon-electric welding apparatusEnergy consumptionUltrasonic vibration

The invention discloses an ultrasonic transducer and amplitude modulator combined piece, which comprises a top cover, a shell, an ultrasonic transducer, an amplitude modulator and a positioning ring, wherein the ultrasonic transducer, the amplitude modulator and the positioning ring are fixed in the shell; the amplitude modulator is connected with one end of the shell; the other end of the shell is connected with the top cover through clearance fit; the positioning ring and the amplitude modulator are fastened and connected together; and the ultrasonic transducer and the amplitude modulator are fixed, sealed and connected into one piece. The ultrasonic transducer and amplitude modulator combined piece can improve the accuracy and reliability of ultrasonic vibration processing and solve the problems of the clamping rigidity difference between the conventional ultrasonic transducer and amplitude modulator, difficulty in node finding and large energy consumption in a transmission process and is greatly improved in dust prevention, clamping, precision and energy transmission efficiency.

Owner:SHANGHAI JIAO TONG UNIV +1

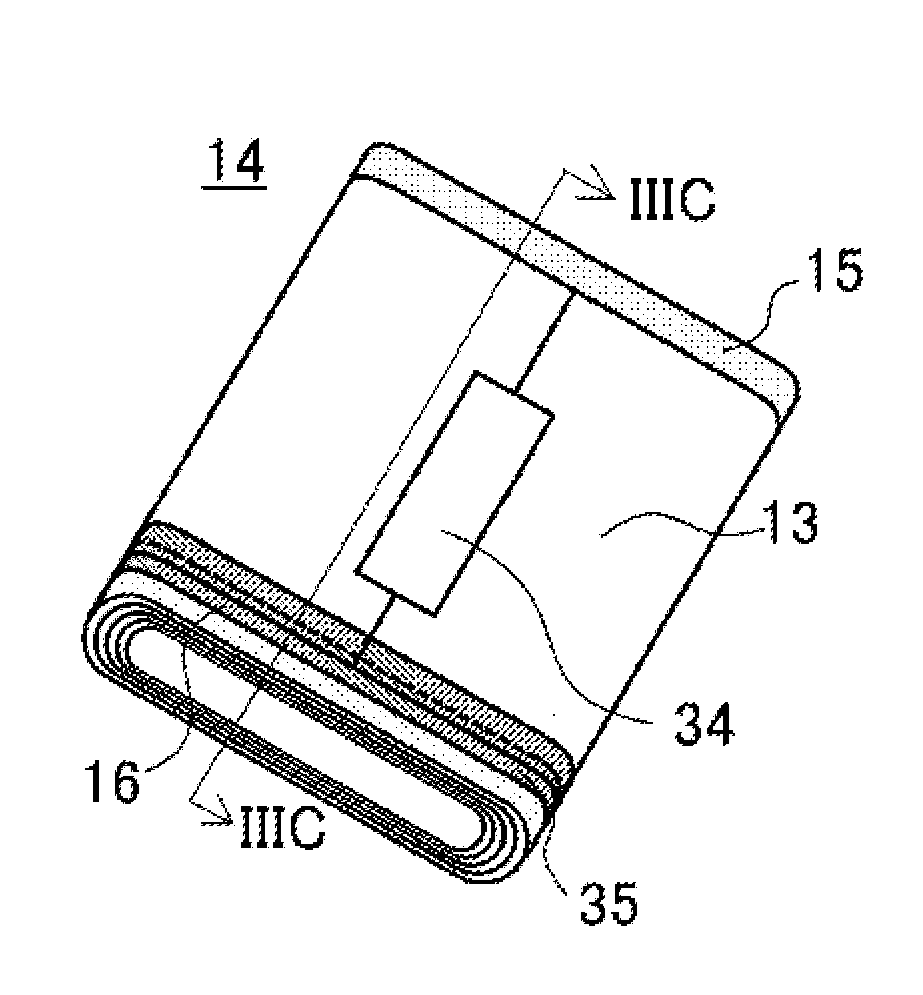

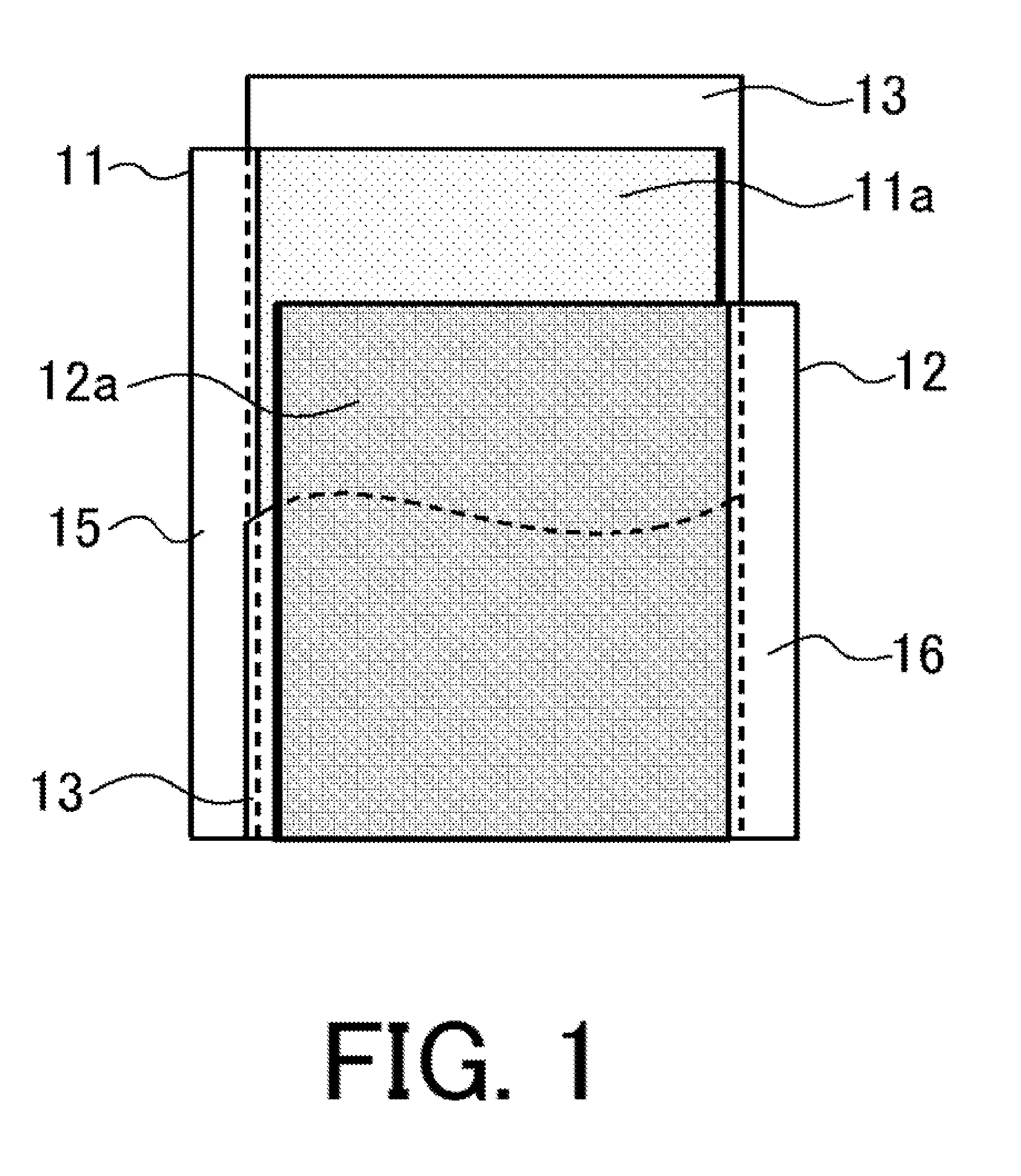

Secondary battery

InactiveUS20130084479A1Improve reliabilityRelieve pressureFinal product manufactureElectrode carriers/collectorsEngineeringCentral Site

A secondary battery with a flat wound electrode assembly includes a positive and negative electrode substrate exposed portions formed on the first and second end thereof, respectively. An end portion of a negative electrode active material mixture layer of a negative electrode plate on the negative electrode substrate exposed portion side protrudes more than an end portion of positive electrode active material mixture layer of an adjacent positive electrode plate. The negative electrode substrate exposed portion is converged on the central site in the thickness direction of the electrode assembly. A separator is located at the outermost surface of the electrode assembly, and the separator and the negative electrode substrate exposed portion of the adjacent negative electrode plate are fixed integrally with a fixing member. Thereby, semi-floating and peeling of the negative electrode active material mixture layer hardly occur at the end side of the negative electrode substrate exposed portion.

Owner:SANYO ELECTRIC CO LTD

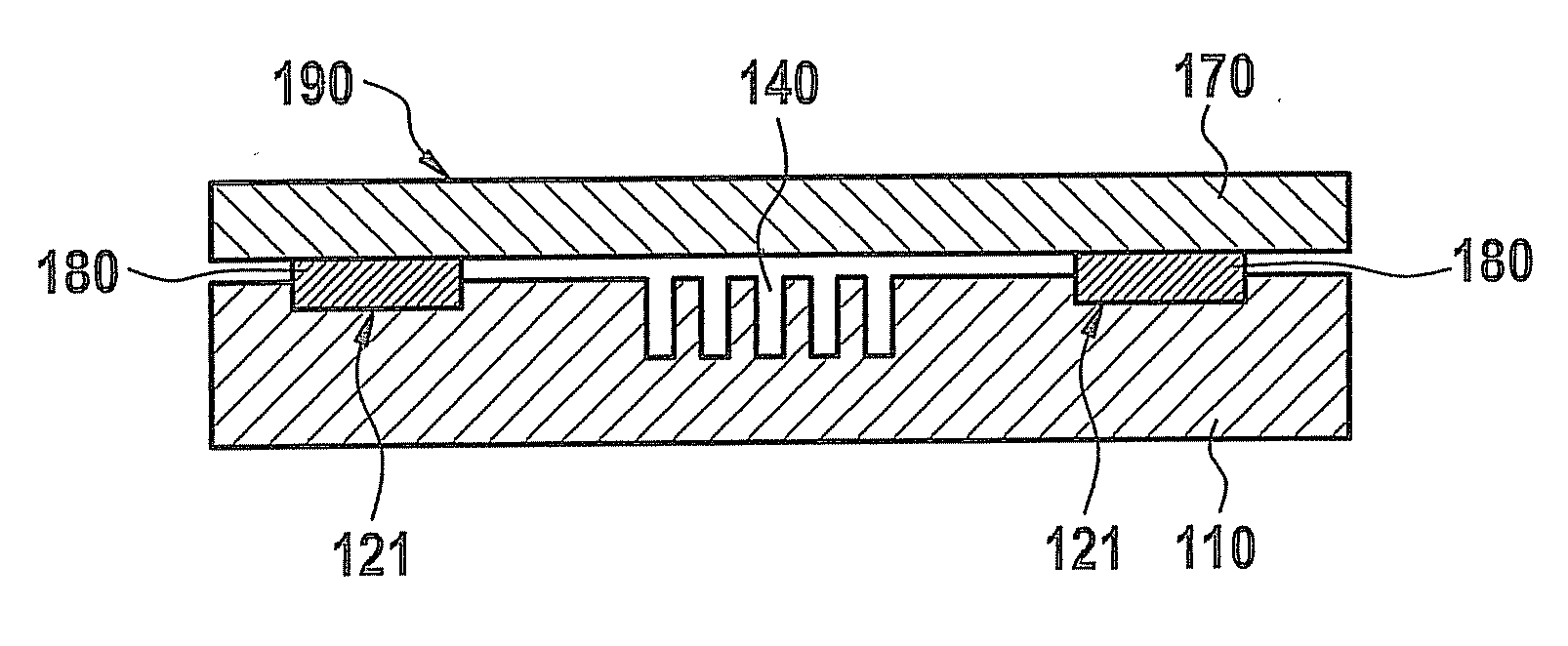

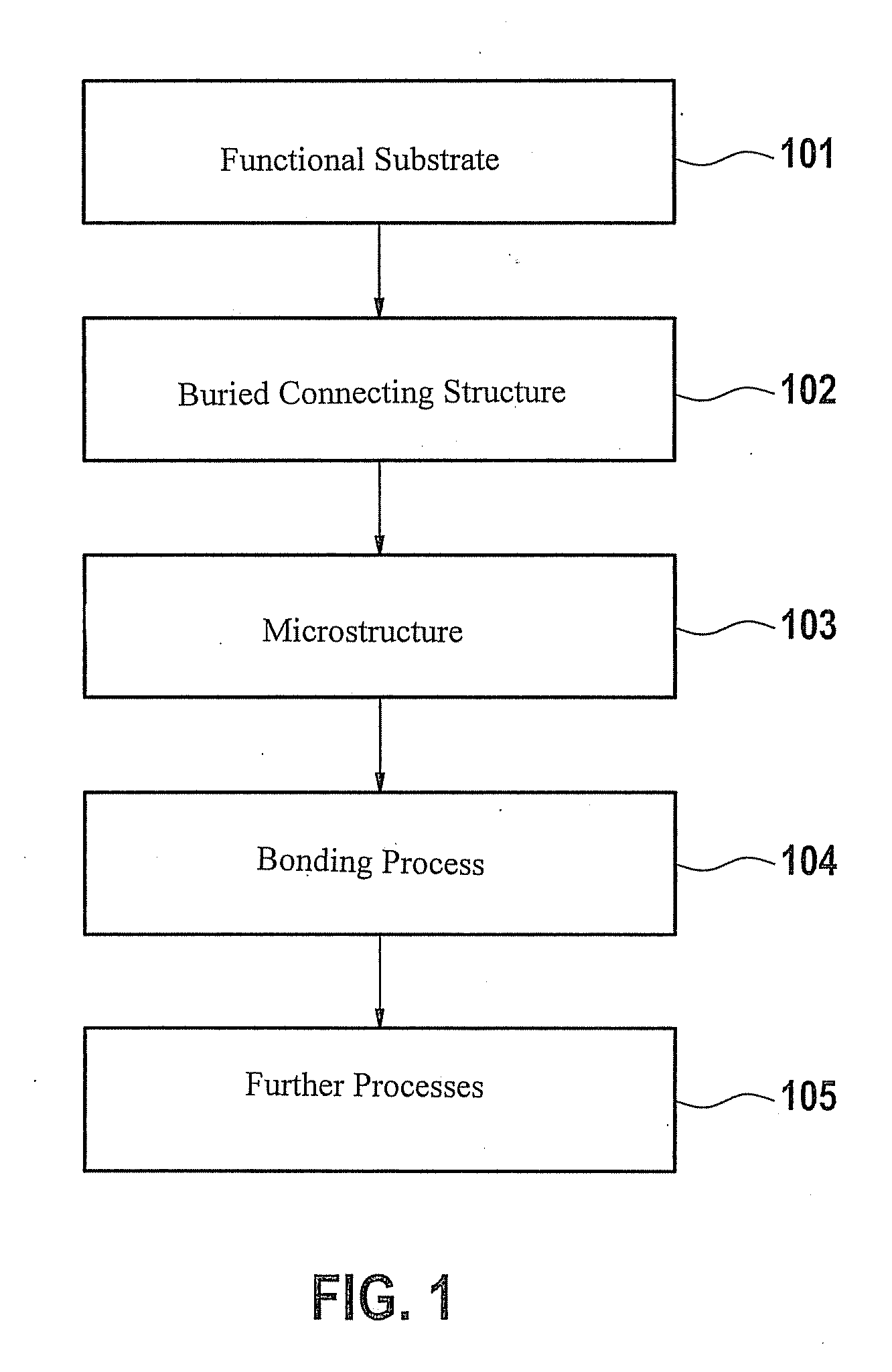

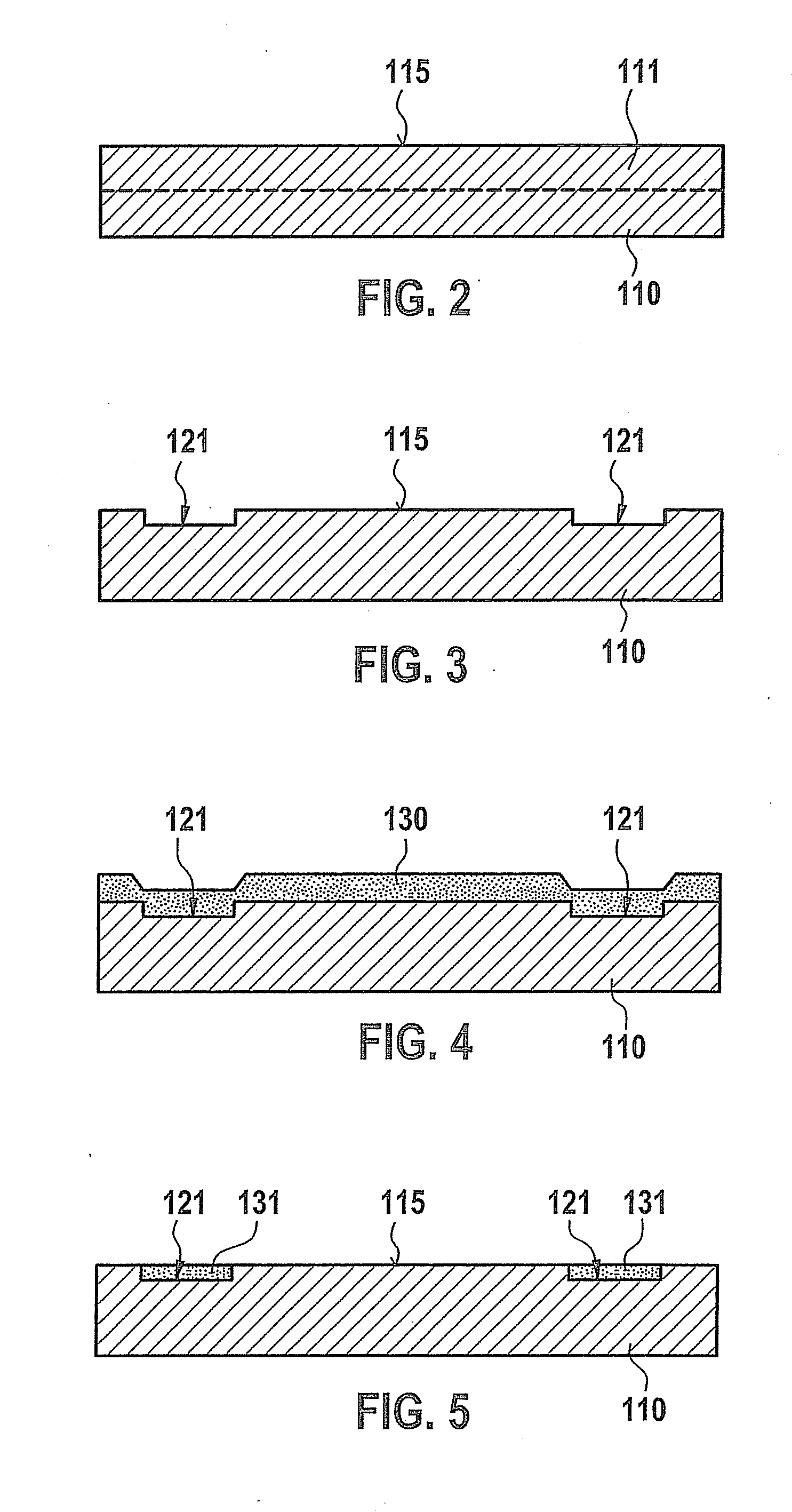

Micromechanical Component

ActiveUS20110298063A1Reliable removalLow costFixed microstructural devicesSemiconductor/solid-state device detailsBonding processEngineering

A method is described for manufacturing a micromechanical component. The method includes providing a first substrate, forming a first connecting structure on the first substrate, and forming a microstructure on the first substrate after forming the first connecting structure. The microstructure has at least one movable functional element. The method further includes providing a second substrate having a second connecting structure, and joining the first and second substrates by carrying out a bonding process, the first and second connecting structures being joined to form a common connecting structure, and a sealed cavity being formed in the region of the microstructure. The method provides that the first connecting structure takes the form of a buried connecting structure extending up to an upper surface of the first substrate. Also described is a related micromechanical component.

Owner:ROBERT BOSCH GMBH

Sole structure for a shoe

Owner:MIZUNO CORPORATION

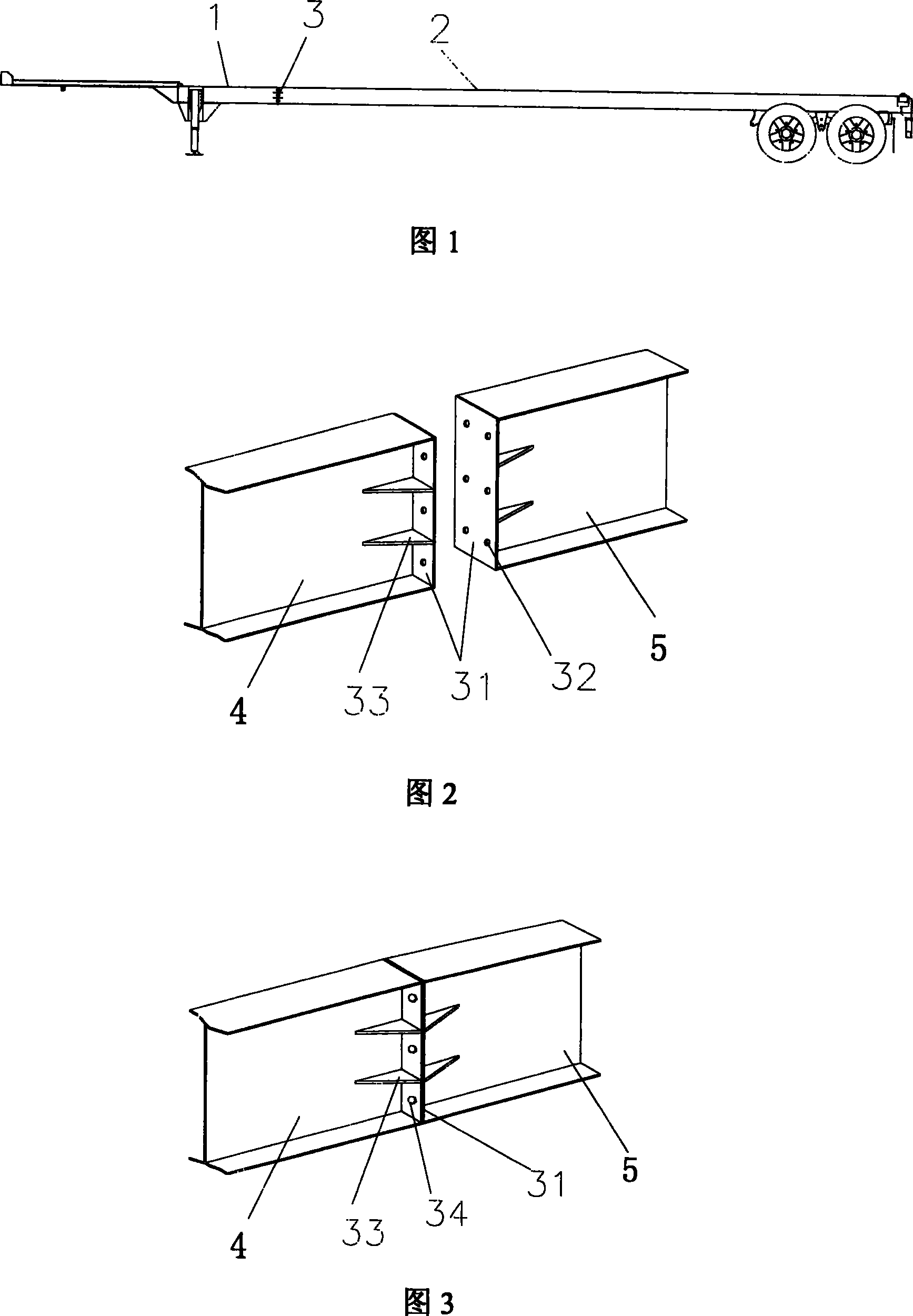

Composite type connector lug in use for beam of car frame

The invention relates to combined type connector lug used in carriage beam. It is divided into fixing part and connecting part. The connecting seat of the former is connected with the carriage main beam to be a whole. The connecting piece of the latter is connected with the connecting seat to be a whole. It has the advantages of using connecting piece to bear bending stress and tensile stress, big connect area to increase fastening function and connecting rigidity, high reliability, suiting for containerized transport semi-trailer with multiplex type main beam structure etc.

Owner:CIMC VEHICLES (GROUP) CO LTD

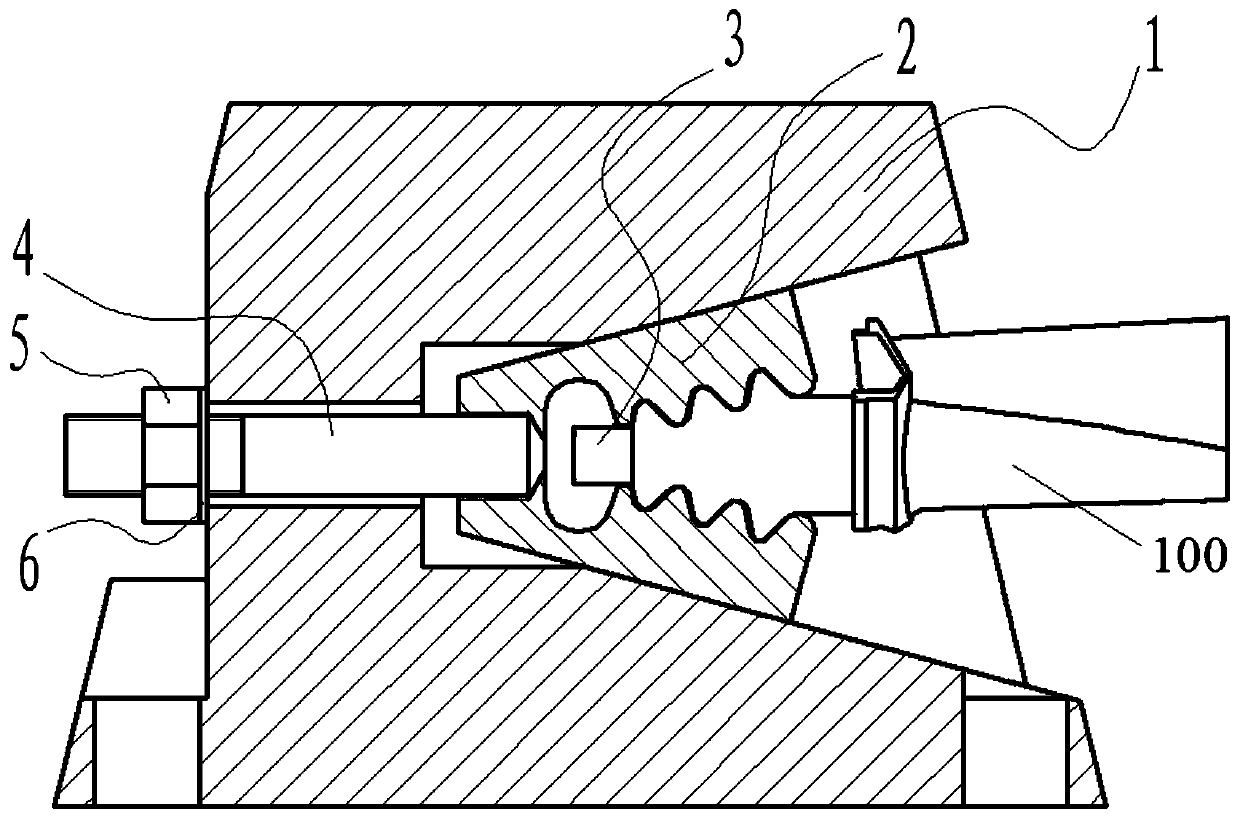

Turbine blade vibration test tool and turbine blade clamping method

InactiveCN111256934ASimple structureFirmly connectedVibration testingTurbine bladeClassical mechanics

The invention discloses a turbine blade vibration test tool and a turbine blade clamping method, the vibration test tool comprises a main body, the main body is internally provided with an opening alignment chute inner cavity and a force application step hole, the included angle of the opening alignment chute inner cavity is the same as the included angle of blade tenon teeth, and the opening alignment chute inner cavity is used for placing a clamping block; the clamping block is provided with a clamping mortise and a large arc transition hollow elastic section, one end of the clamping block is provided with a threaded hole communicated with the hollow elastic section, and the threaded hole is used for installing a stress application screw. The other end of the connecting rod is connectedwith the nut; the stop block tightly abuts against the tenon bottom of the blade under the action of the adjusting bolt. The stress application screw penetrates through a stress application stepped hole in the main body and extends into the threaded hole of the clamping block, the stop block penetrates through the main body and the clamping block, and an adjusting bolt used for adjusting the position of the stop block is installed on the main body. According to the structure, the blade tenon is fixedly held through the combined action of pressing and jacking, so that the attachment area of thetenon tooth surface of the blade and a tool mortise is large, the contact is uniform, the fixedly holding rigidity is high, and the consistency is good.

Owner:AECC AVIATION POWER CO LTD

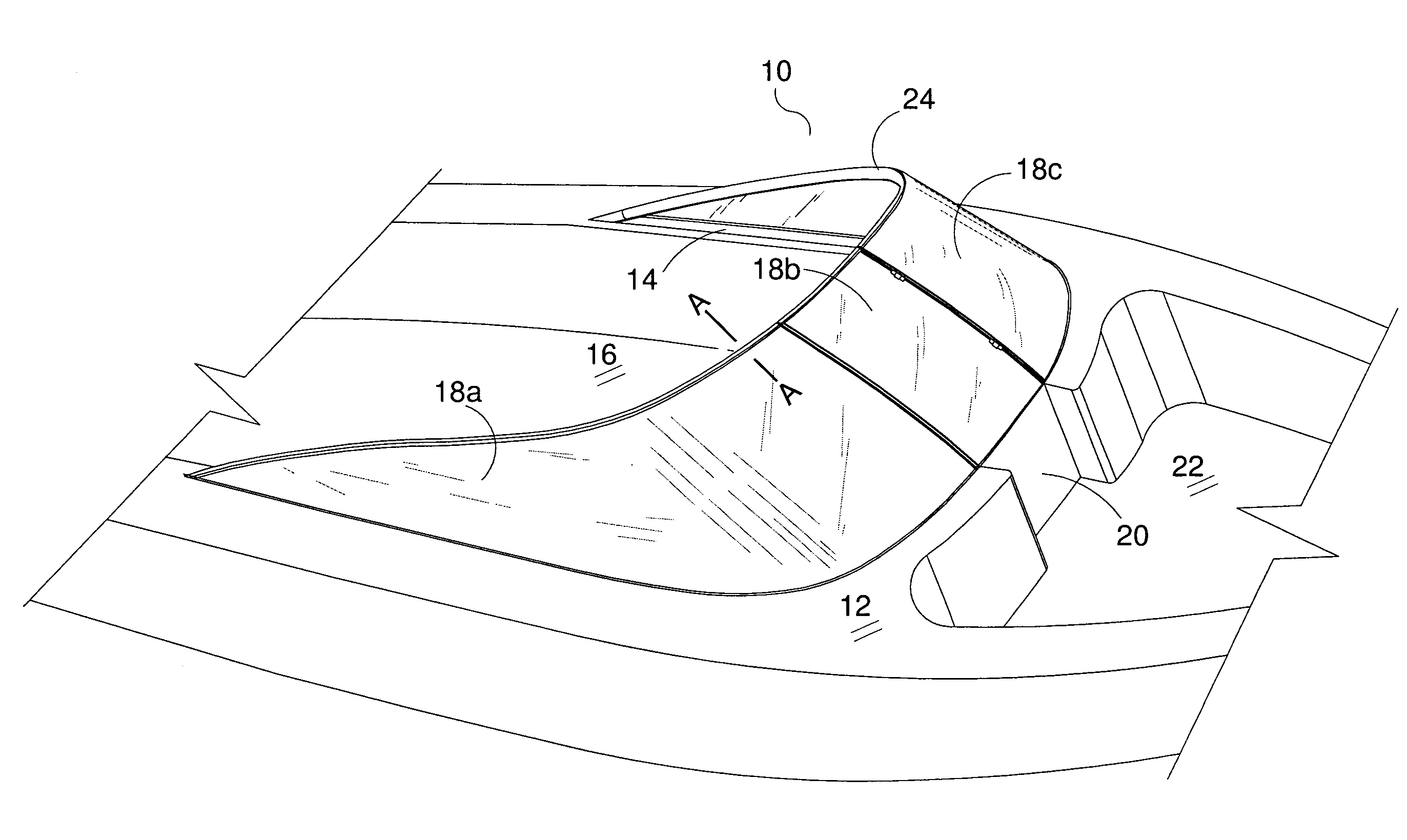

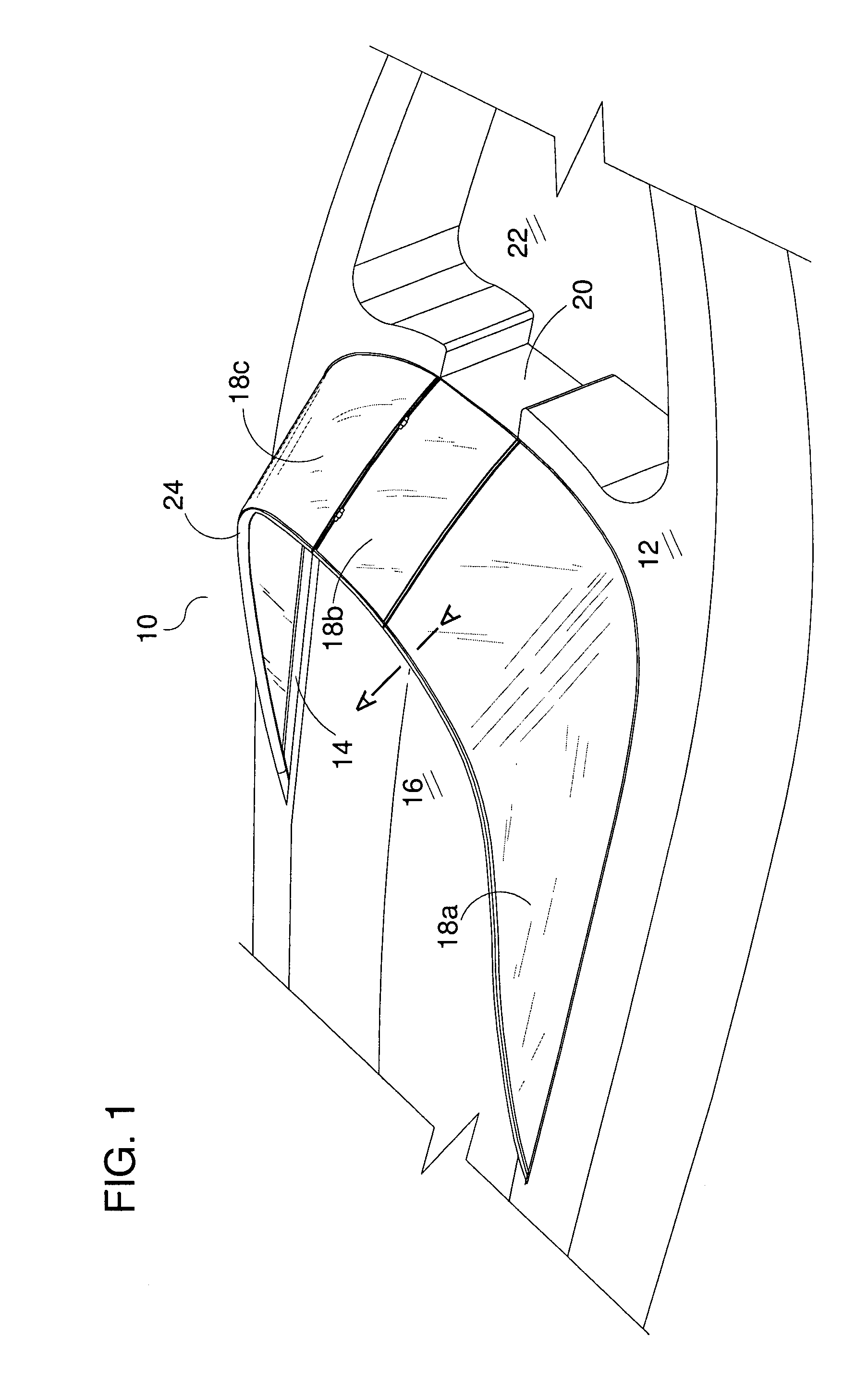

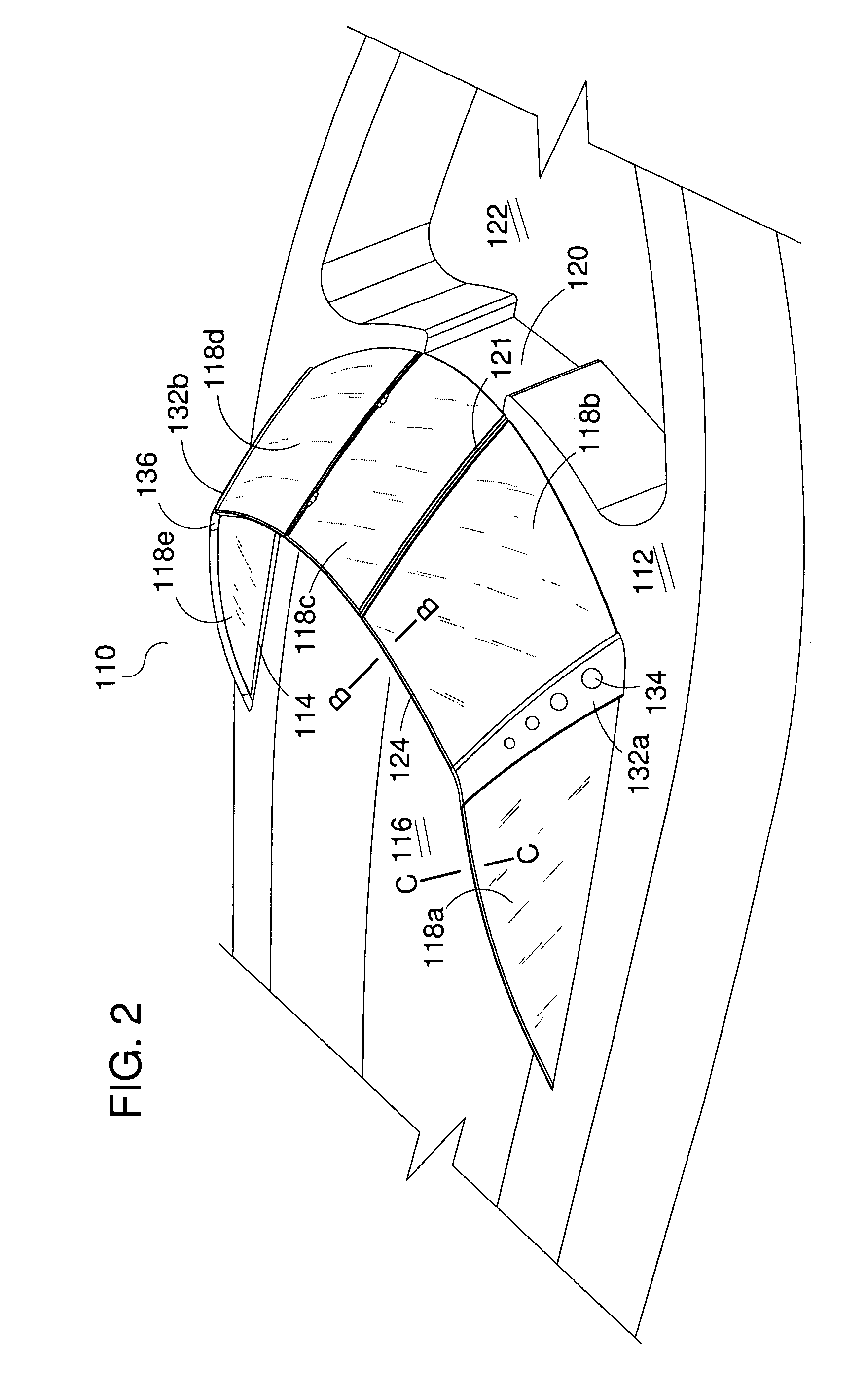

Marine windshield frame and method of manufacture

InactiveUS20080245288A1Complexity of partManufactured smallClear-view screensFloating buildingsAdhesiveDie casting

A marine windshield frame for curved or straight windshield glass having a top frame rail mounted inward of the windshield glass and substantially flush with frontal surface of the windshield glass. The top frame rail is mounted onto the windshield glass edge by adhesive. The windshield frame may also include a pair of vertically oriented corner posts. The corner posts are preferably manufactured by die-cast molding. An alternate manufacturing method is to stretch-form an aluminum alloy extrusion, machining vent holes therein, and machined a taper thereon an edge.

Owner:SAN DIEGO VENTURES

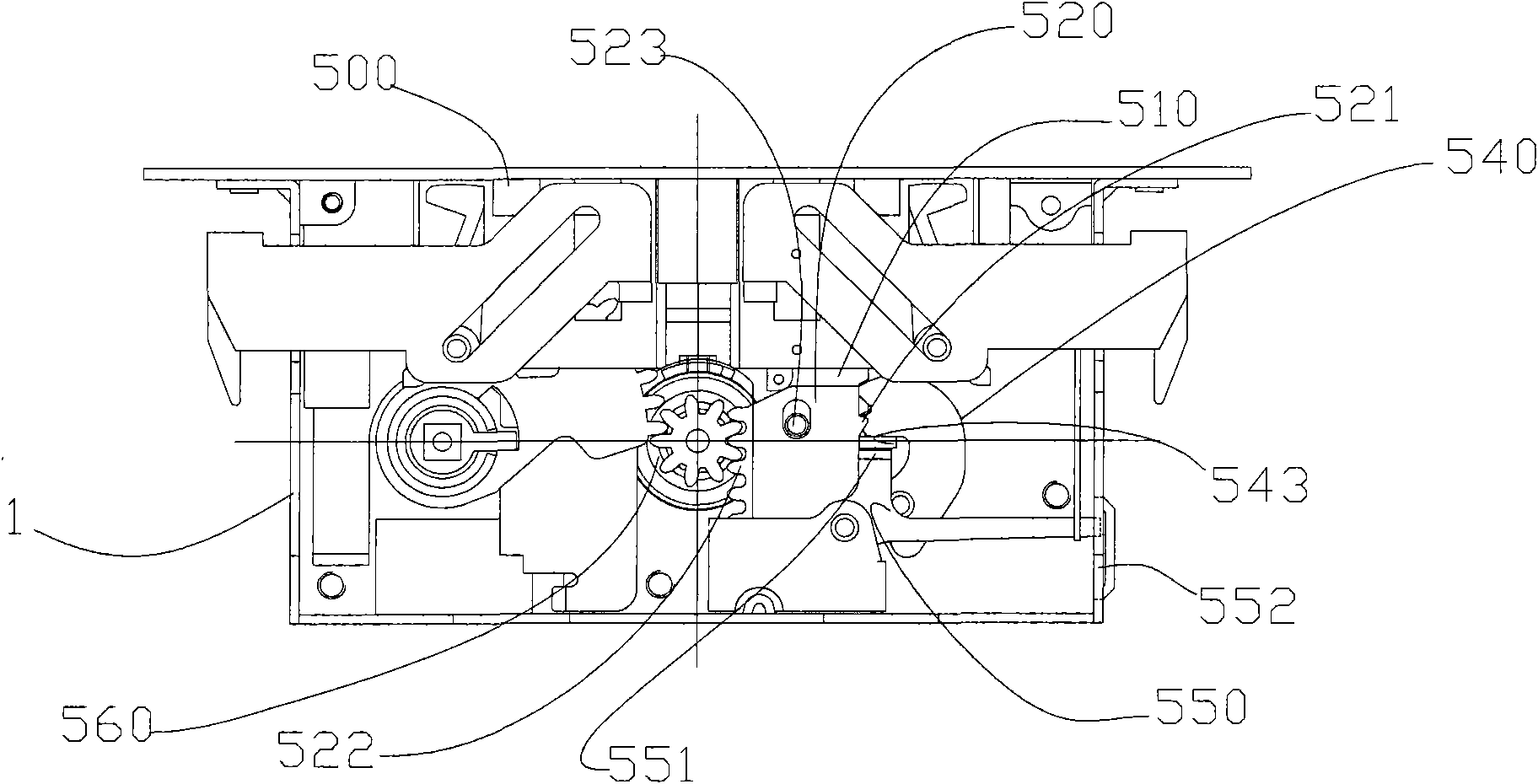

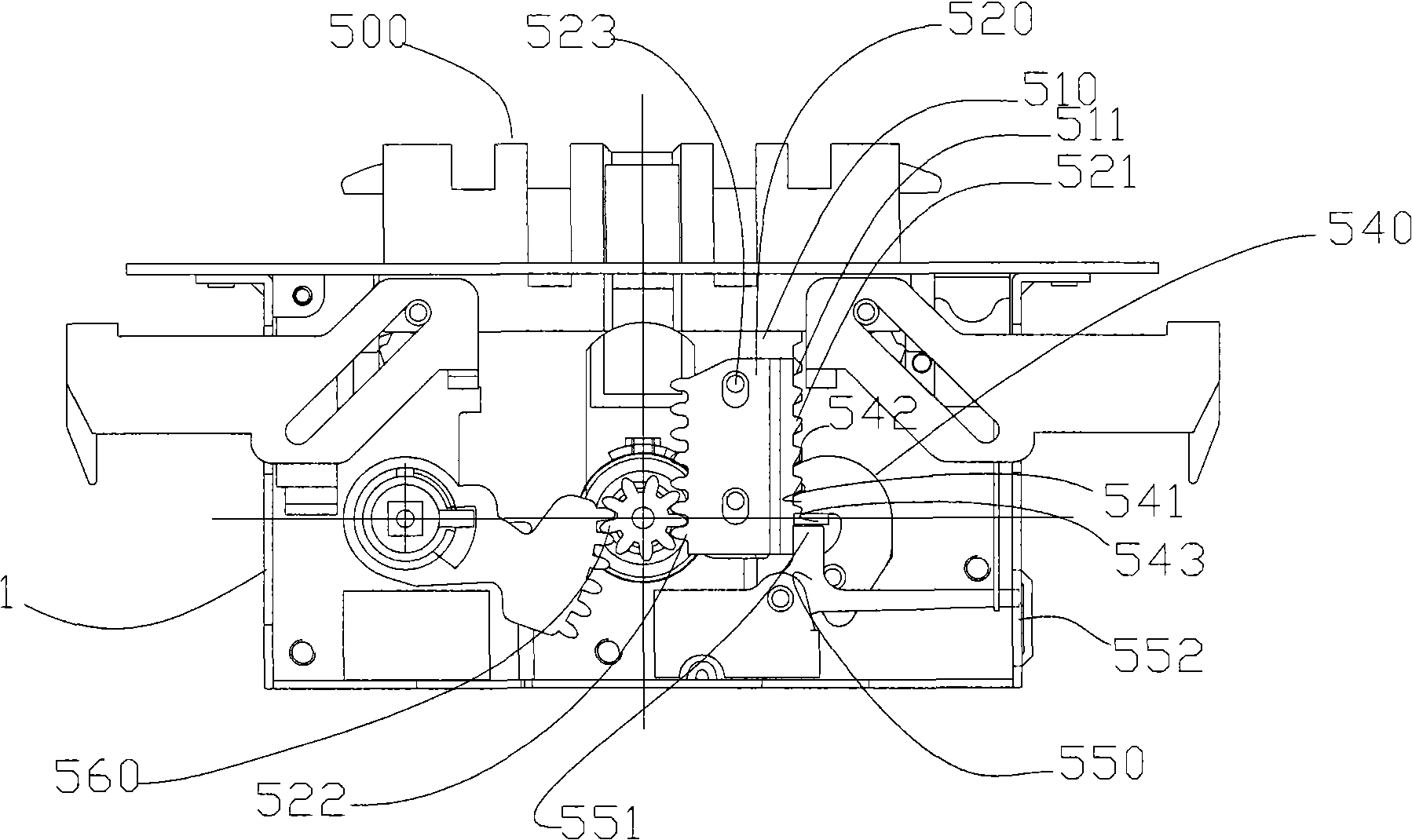

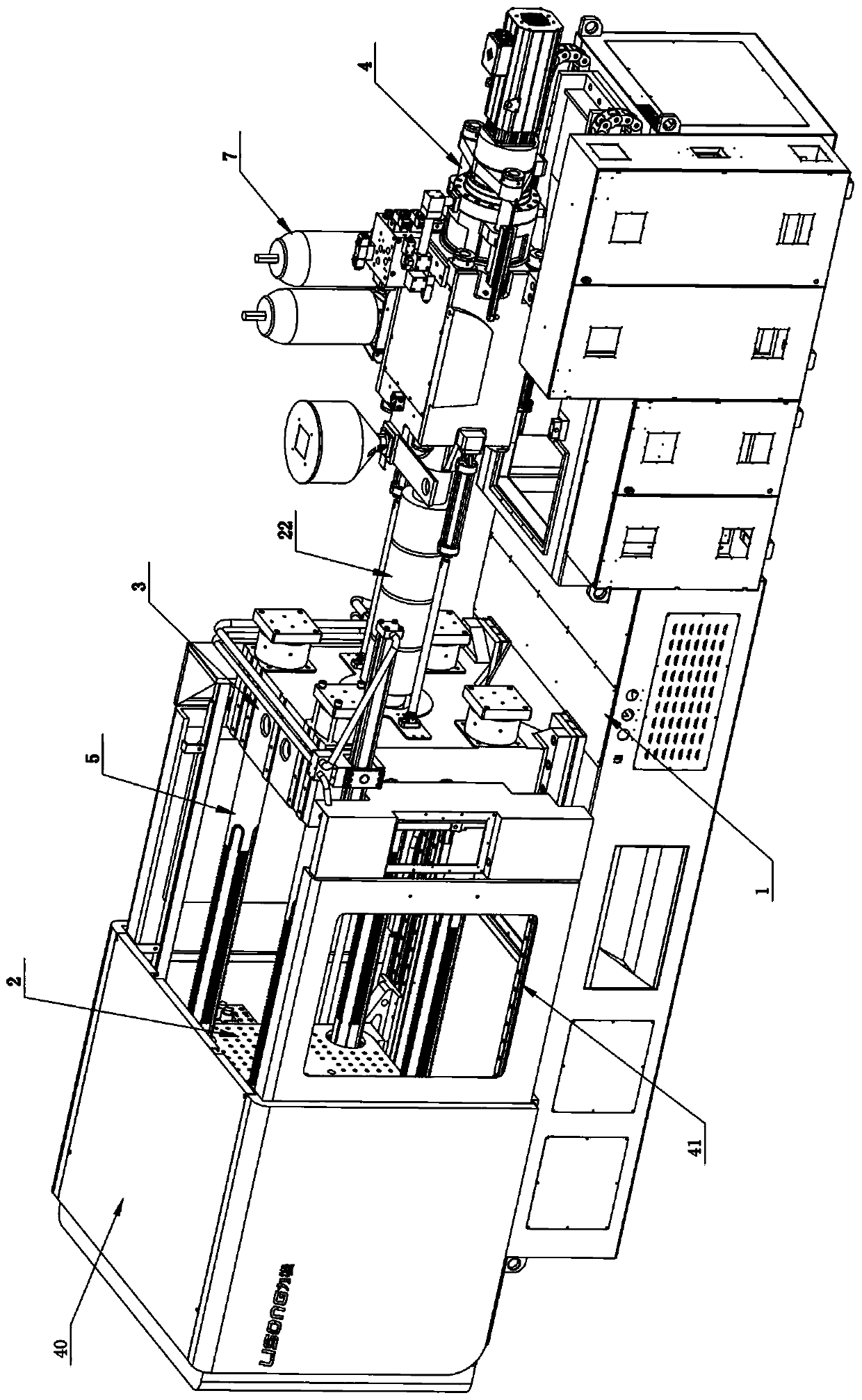

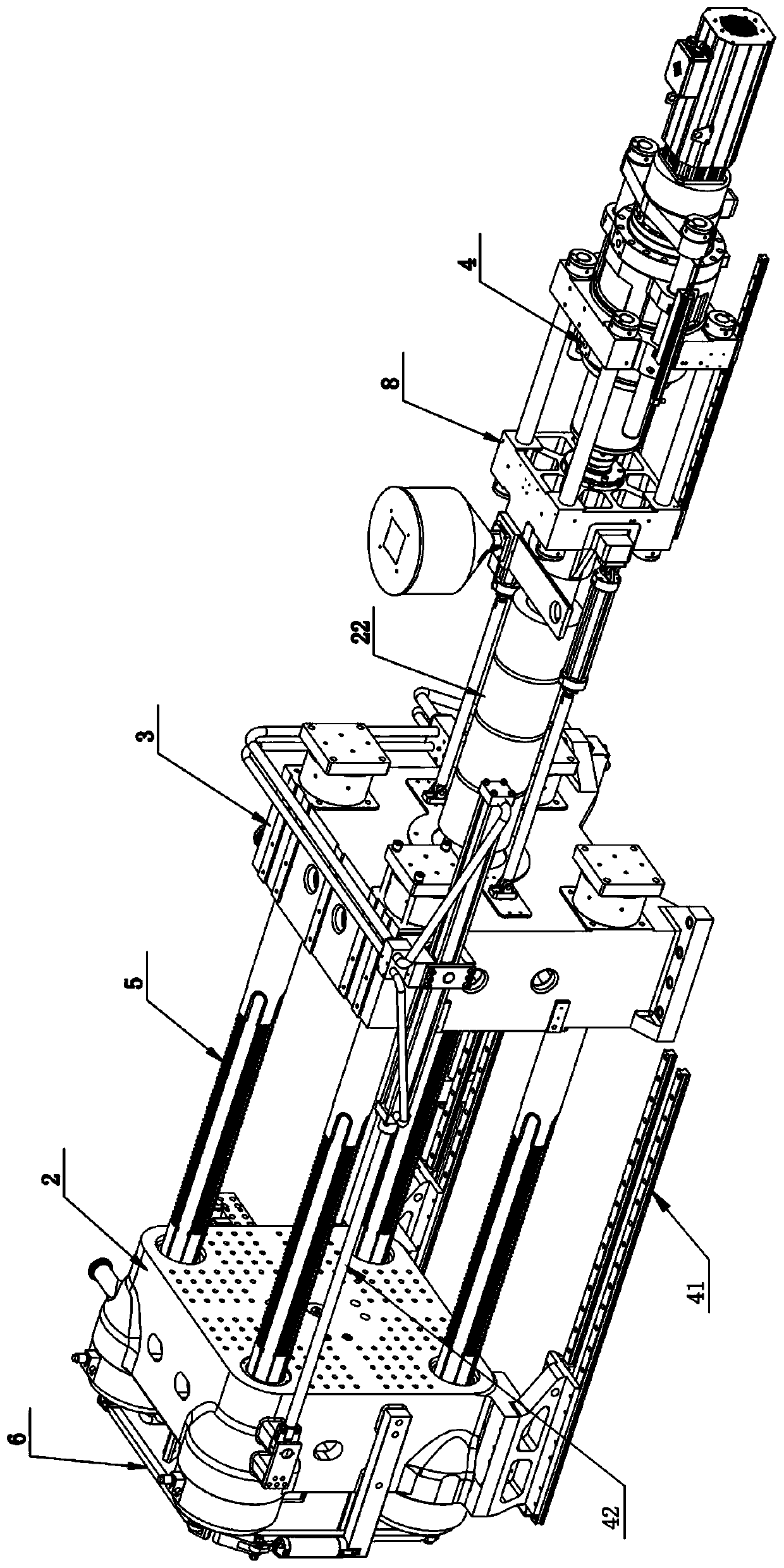

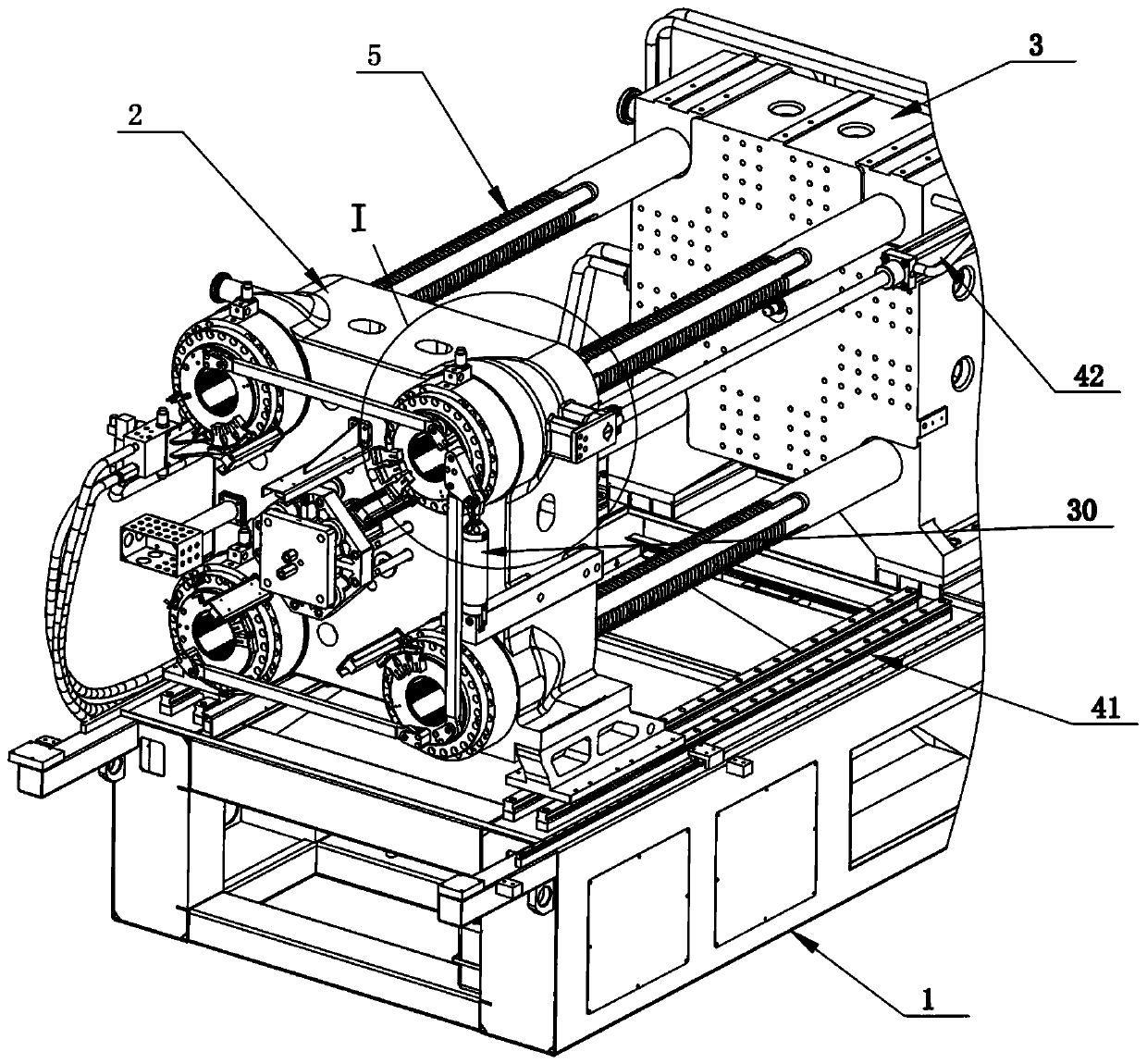

High-precision and high-efficiency injection molding machine

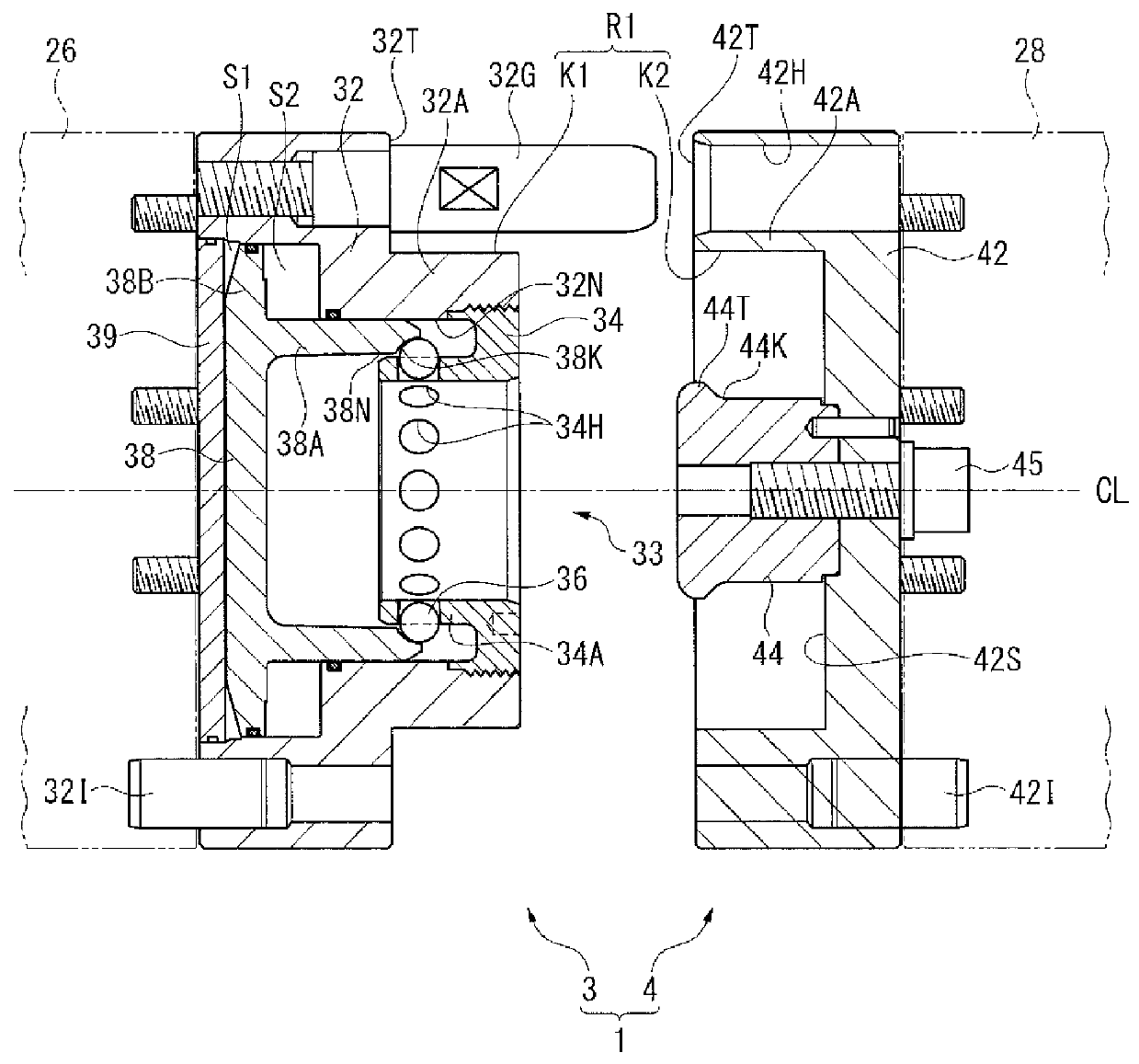

The invention provides a high-precision and high-efficiency injection molding machine. The high-precision and high-efficiency injection molding machine comprises a machine body and further comprises amovable mold plate, a fixed mold plate and an injection mechanism. A plurality of pull rods are mounted between the movable mold plate and the fixed mold plate. A combined contracting brake mechanismcorresponding to the pull rods is mounted on the movable mold plate. A nitrogen auxiliary injection device connected with the injection mechanism is mounted at the side end of the machine body. During mold closing, the combined contracting brake mechanism locks the pull rods. the combined contracting brake mechanism comprises a contracting brake cylinder and a plurality of mold locking pistons. The contracting brake cylinder is connected with one mold locking piston. A piston linkage connecting rod is eccentrically hinged between the two adjacent mold locking pistons. The high-precision and high-efficiency injection molding machine provided by the invention is high in mold replacing speed, good in combined mold locking effect and high in reliability and safety coefficient. The whole high-precision and high-efficiency injection molding machine is high in starting speed, stable in injection rate, high in repeating precision, large in mold containing space, high in production efficiencyand stable and reliable in operation.

Owner:宁波力松注塑科技有限公司

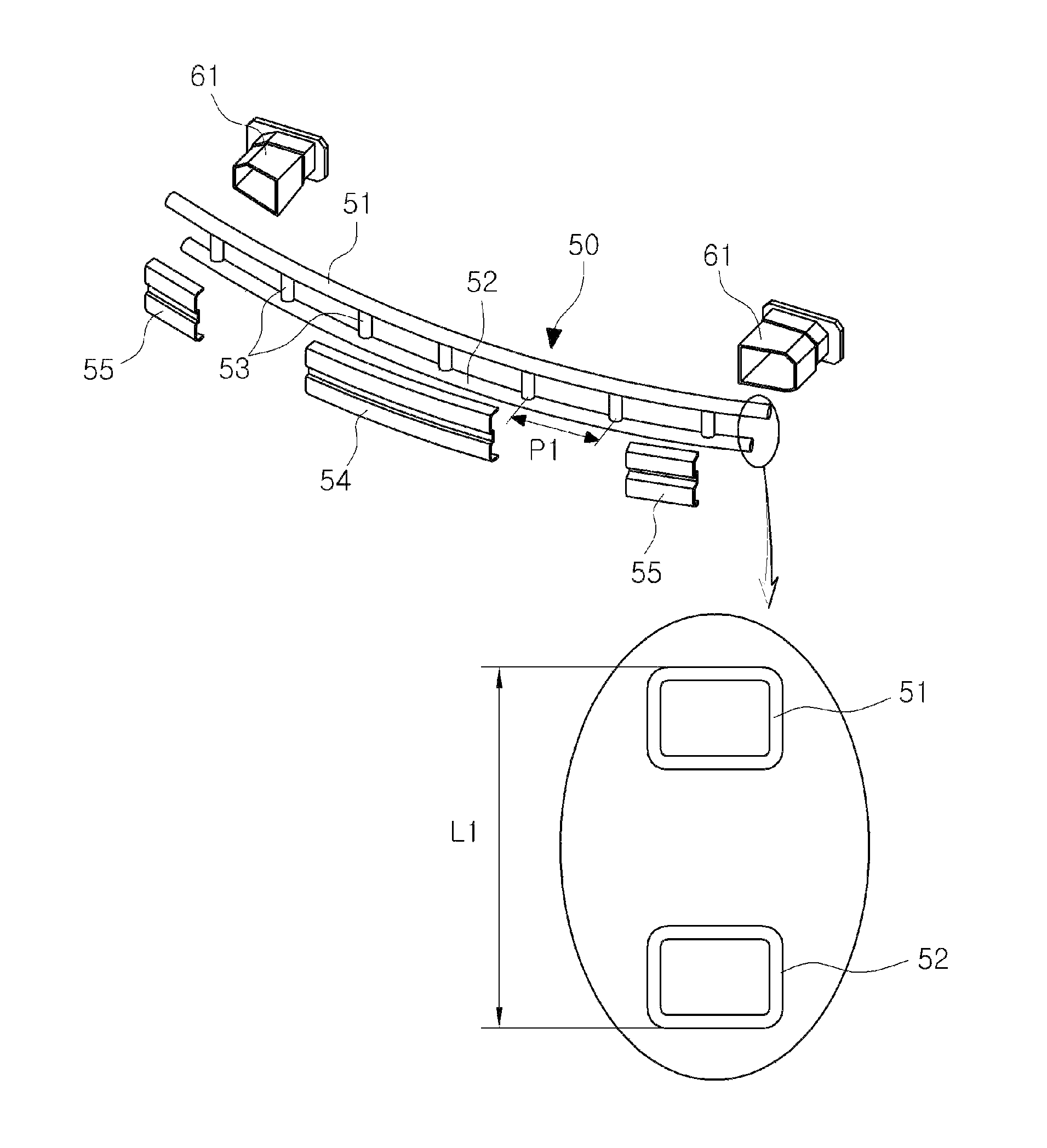

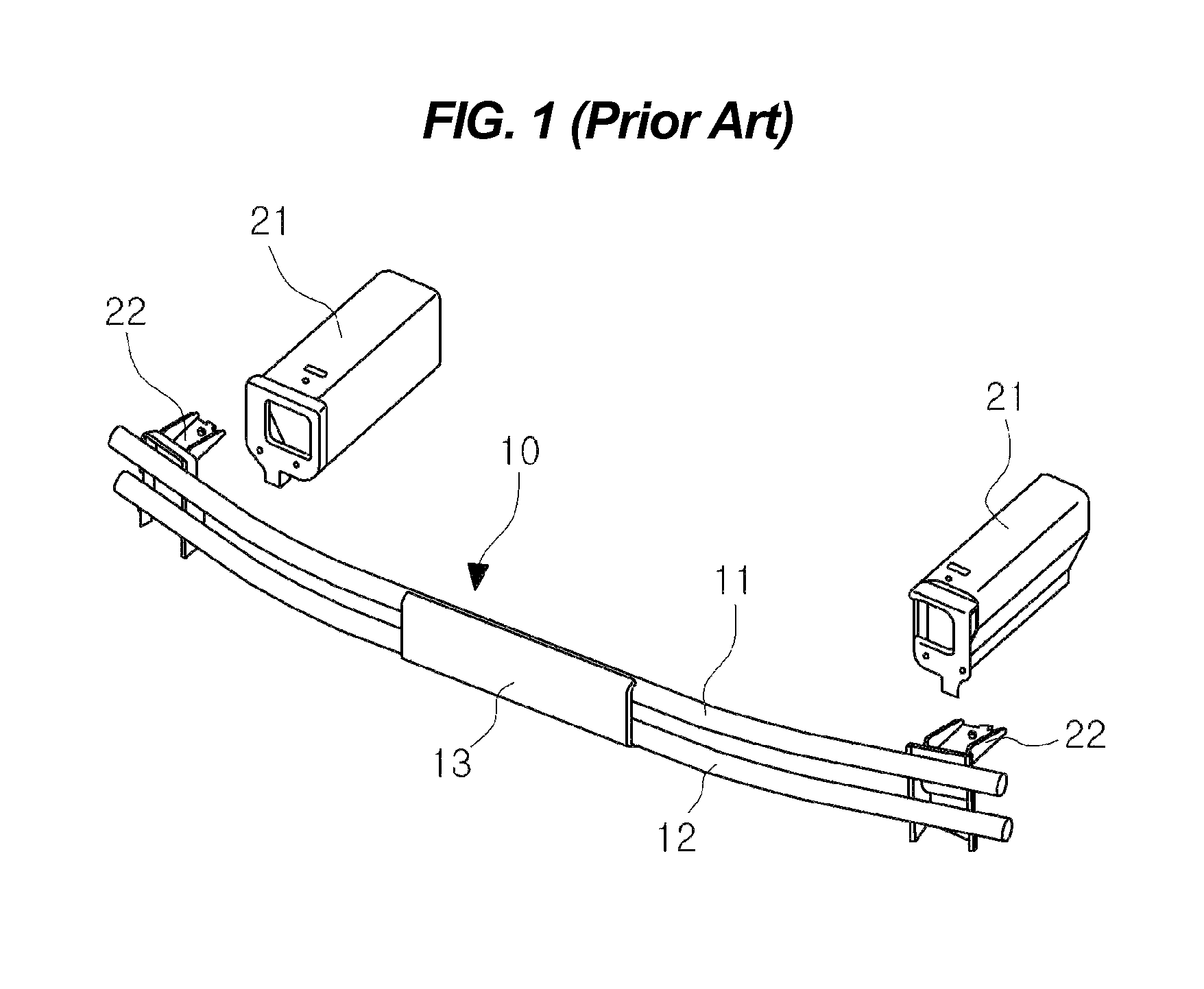

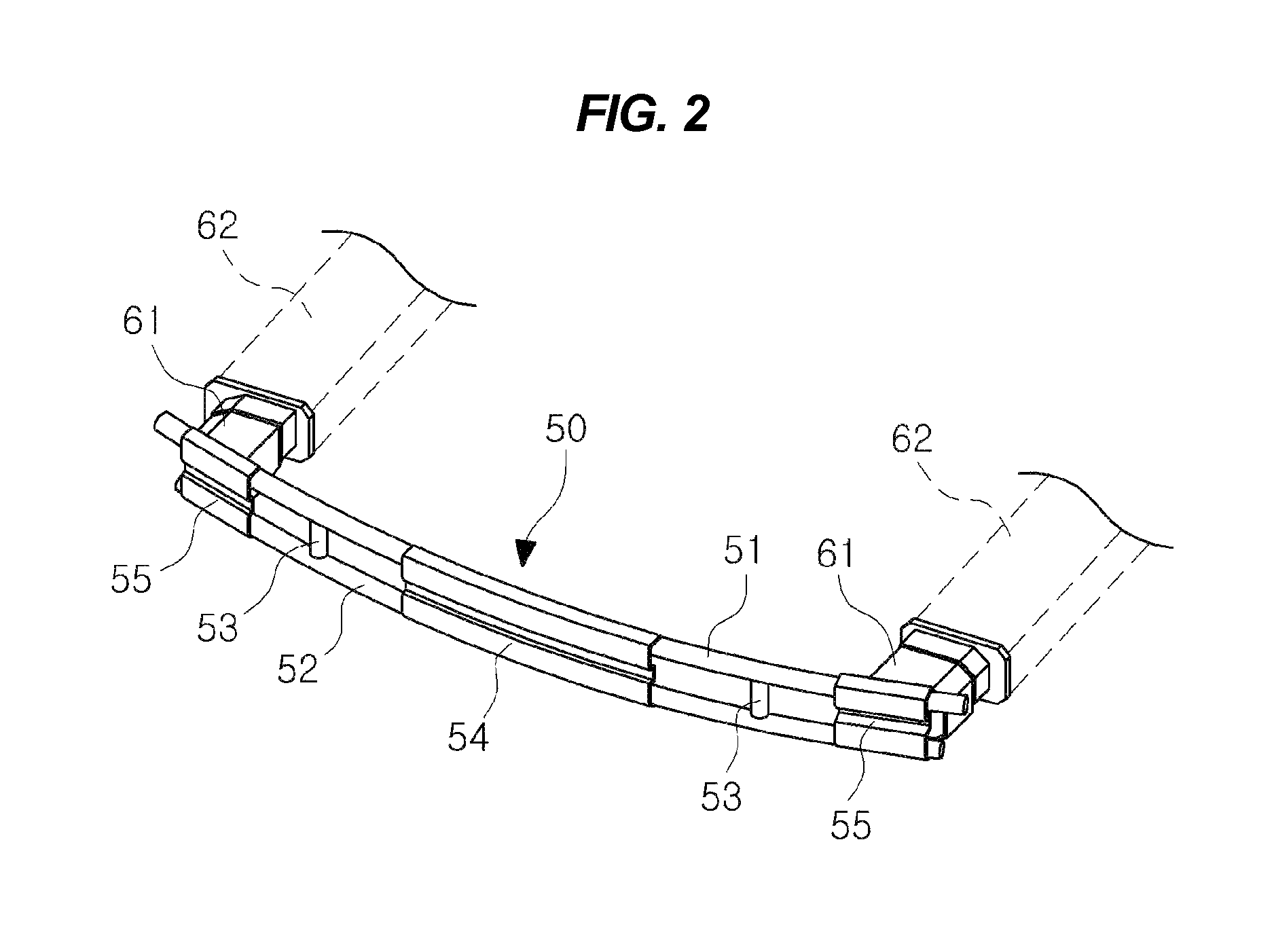

Tubular back beam for vehicle

ActiveUS8864198B2Improve connection rigidityAvoid separationVehicle seatsDashboardsEngineeringCrashworthiness

Owner:HYUNDAI MOTOR CO LTD +1

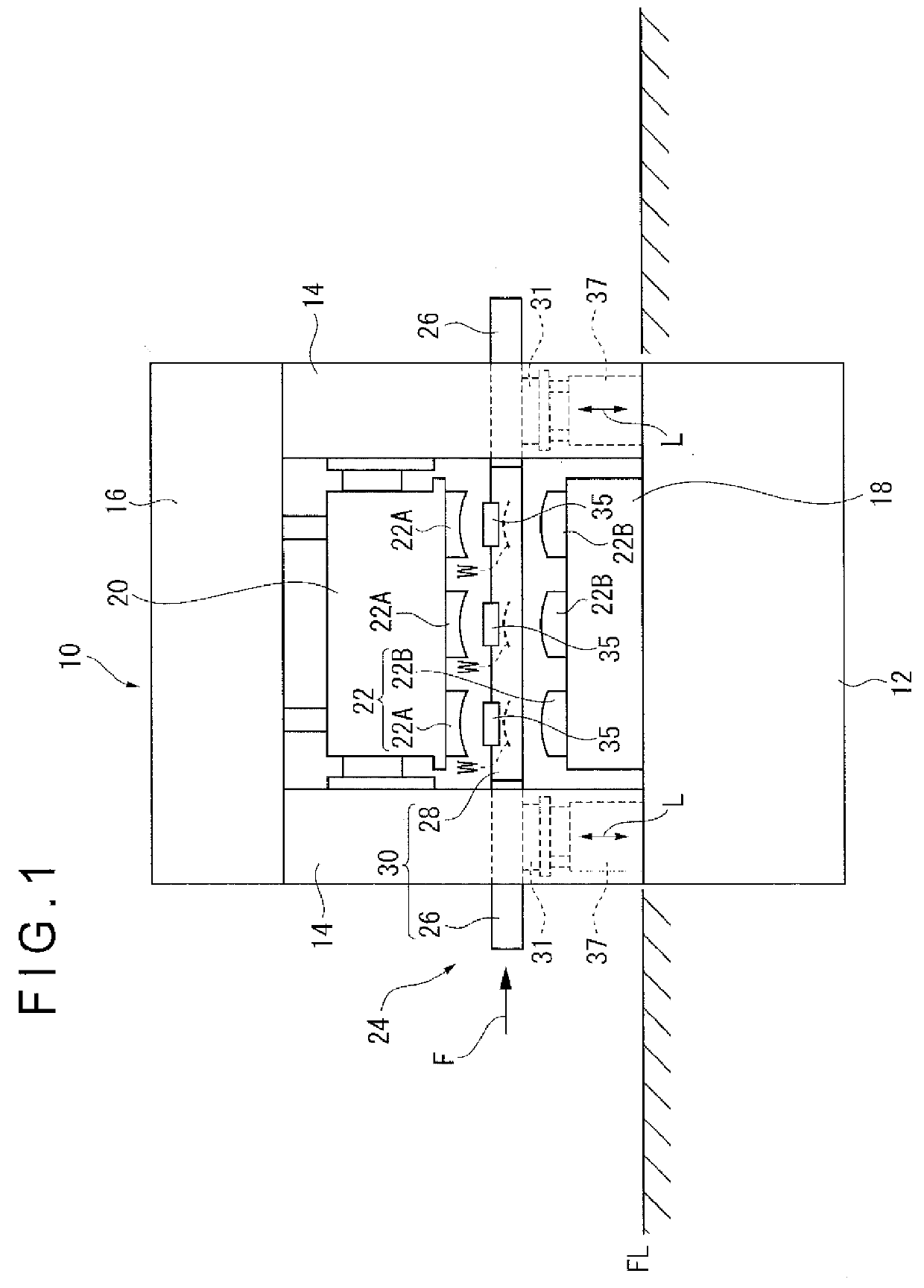

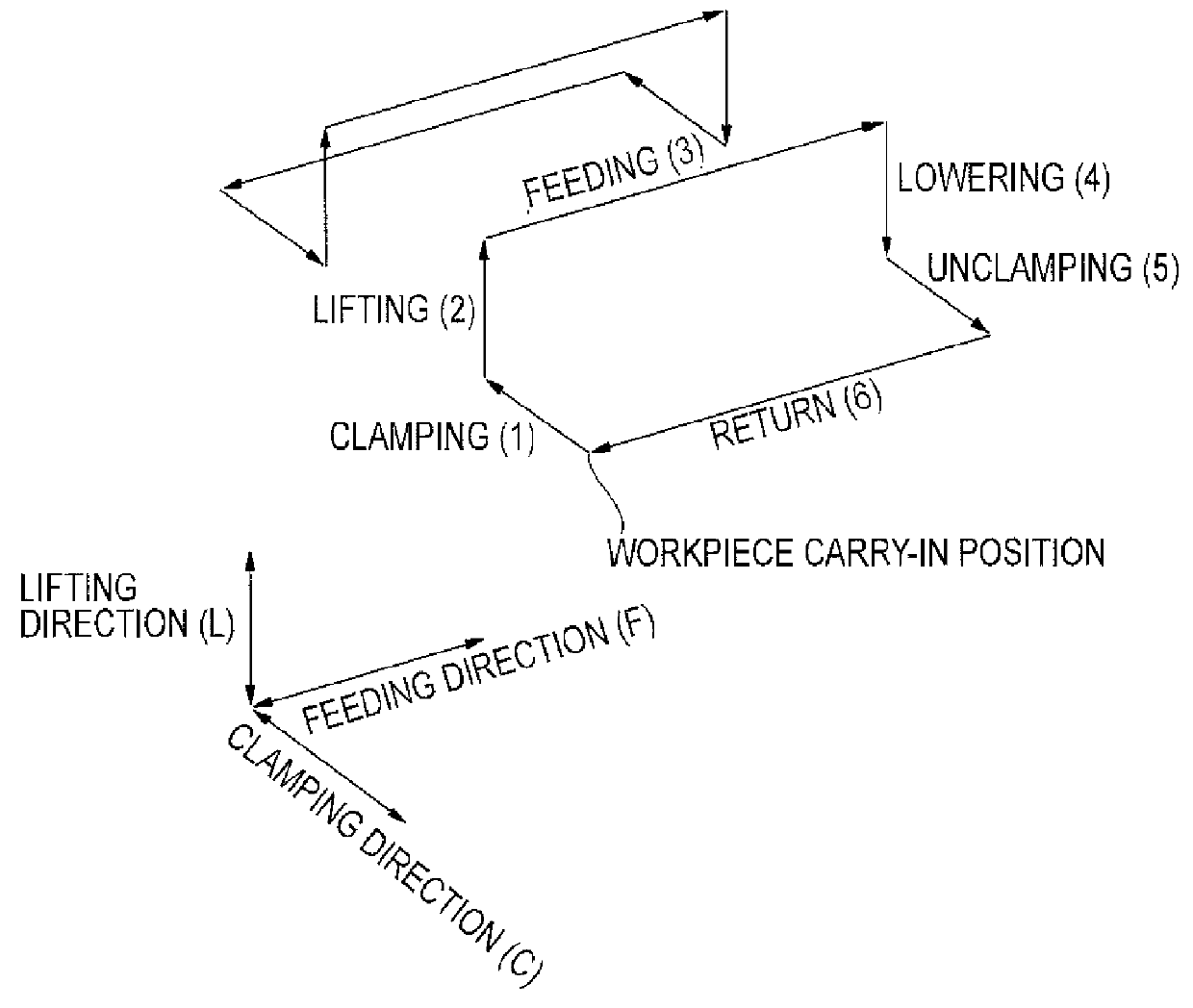

Transfer bar

ActiveUS8857239B2Improve connection rigidityIncrease speedConveyorsMetal-working feeding devicesEngineeringMechanical engineering

Owner:KOMATSU LTD +2

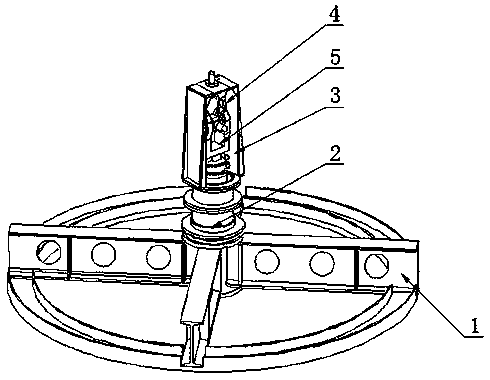

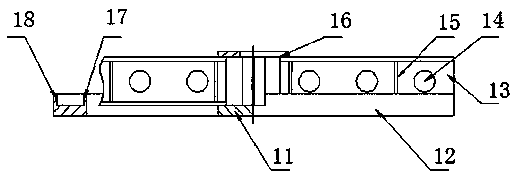

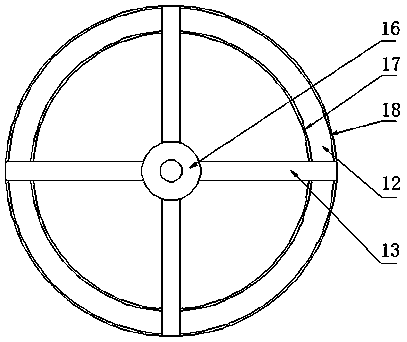

Large-scale paraboloid antenna surface operation angle control and loading measurement system

InactiveCN105375097AImprove installation accuracyStrong connectionAntenna supports/mountingsTheodoliteEngineering

The present invention discloses a large-scale paraboloid antenna surface operation angle control and loading measurement system. The large-scale paraboloid antenna surface operation angle control and loading measurement system comprises a high-strength support (1), a rotating head (2), a reinforcing cover (3), a handle combination (4) and a theodolite (5). The rotating head (2) is installed on the high-strength support (1) through threaded connection; the reinforcing cover (3) is installed on the rotating head (2) through threaded connection; the theodolite (5) is installed on the rotating head (2) through threaded connection; the theodolite (5) is located in the reinforcing cover (3); the handle combination (4) is installed on the reinforcing cover (3) through threaded connection; and the handle combination (4) is connected with the theodolite (5). The large-scale paraboloid antenna surface operation angle control and loading measurement system is able to measure and control the operation angle of the large-scale paraboloid antenna surface, eliminate measurement errors caused by factors such as wind loading, dead weight, positioning error and the like, and ensure the measurement precision. Moreover the large-scale paraboloid antenna surface operation angle control and loading measurement system is able to effectively fix a theodolite and allow the theodolite to perform inclination measurement which cannot be realized in the prior art.

Owner:CHENGDU JINJIANG ELECTRONICS SYST ENG

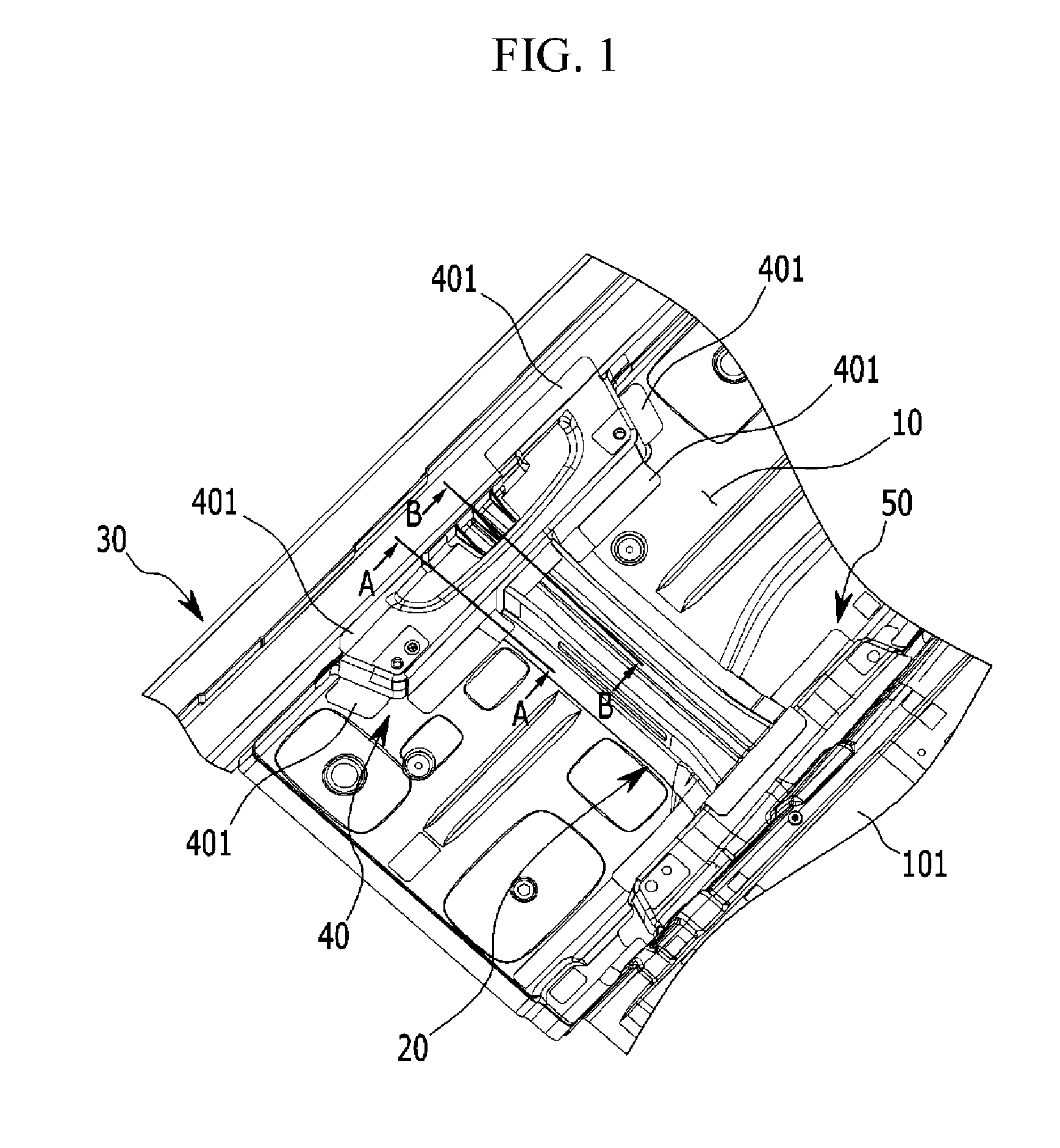

Side connecting component for automobile floor

InactiveCN102358351AIncrease stiffnessImprove connection rigiditySuperstructure subunitsEngineeringUltimate tensile strength

The invention discloses a side connecting component for an automobile floor. In the side connecting component for the automobile floor, a body is an integrally punched component; and the side connecting component for the automobile floor is characterized in that: a main plane of the body is rectangular; the upper part of the main plane is bent backwards and rightwards to form an upper connecting part; a right triangular supporting plate of which the vertex angle is downward is vertically connected on the right side of the main plane; the upper part of the right triangular supporting plate is bent rightwards to form a right connecting part; a left triangular supporting plate of which the vertex angle is downward is vertically connected on the left side of the main plane; the upper part of the left triangular supporting plate is bent leftwards to form a left connecting part; a concave lower connecting part is connected with the lower part of the right triangular supporting plate, the lower part of the left triangular supporting plate and the lower edge of the main plane; and the upper connecting part, the right connecting part, the left connecting part and the lower connecting part are planes. By the side connecting component for the automobile floor, the connecting rigidity and the connecting strength between a chair installing component and the floor are improved; through experimental verification, the local mode of a chair installing position is improved; and through fixture sample vehicle verification, the structural form and the installation mode of the side connecting component for the automobile floor are applicable to various automobile models.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Structure for reinforcing seat mounting portion of vehicle body

ActiveUS9272637B2Provide stabilityImprove securityVehicle seatsSuperstructure subunitsEngineeringMechanical engineering

Owner:HYUNDAI MOTOR CO LTD

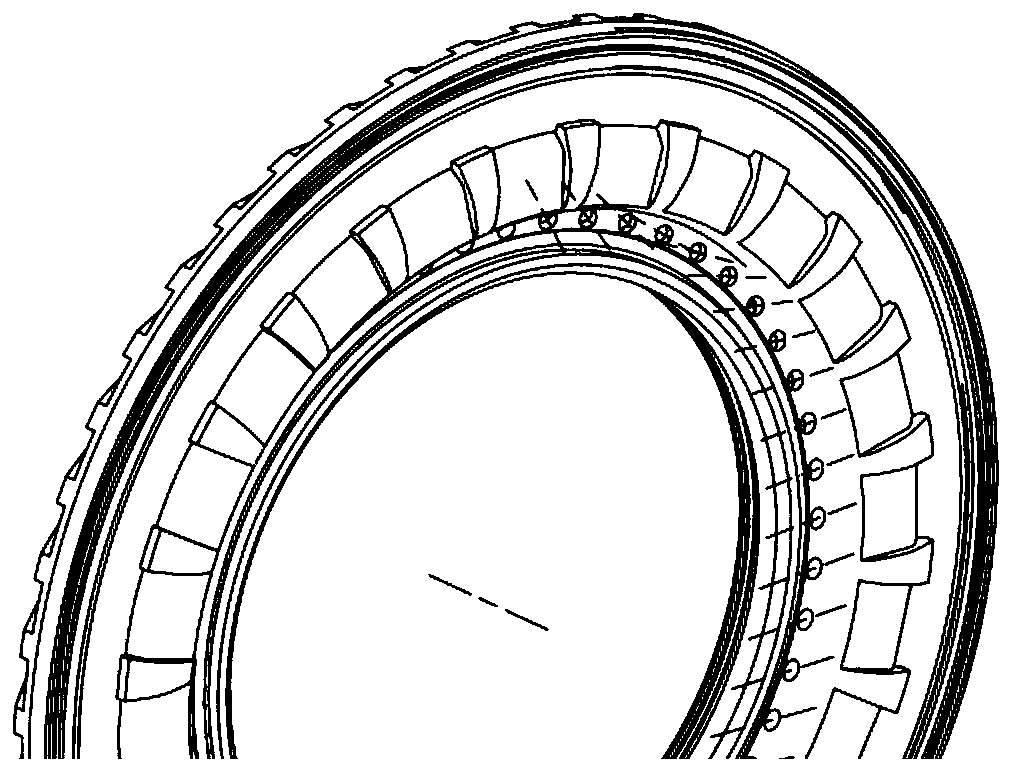

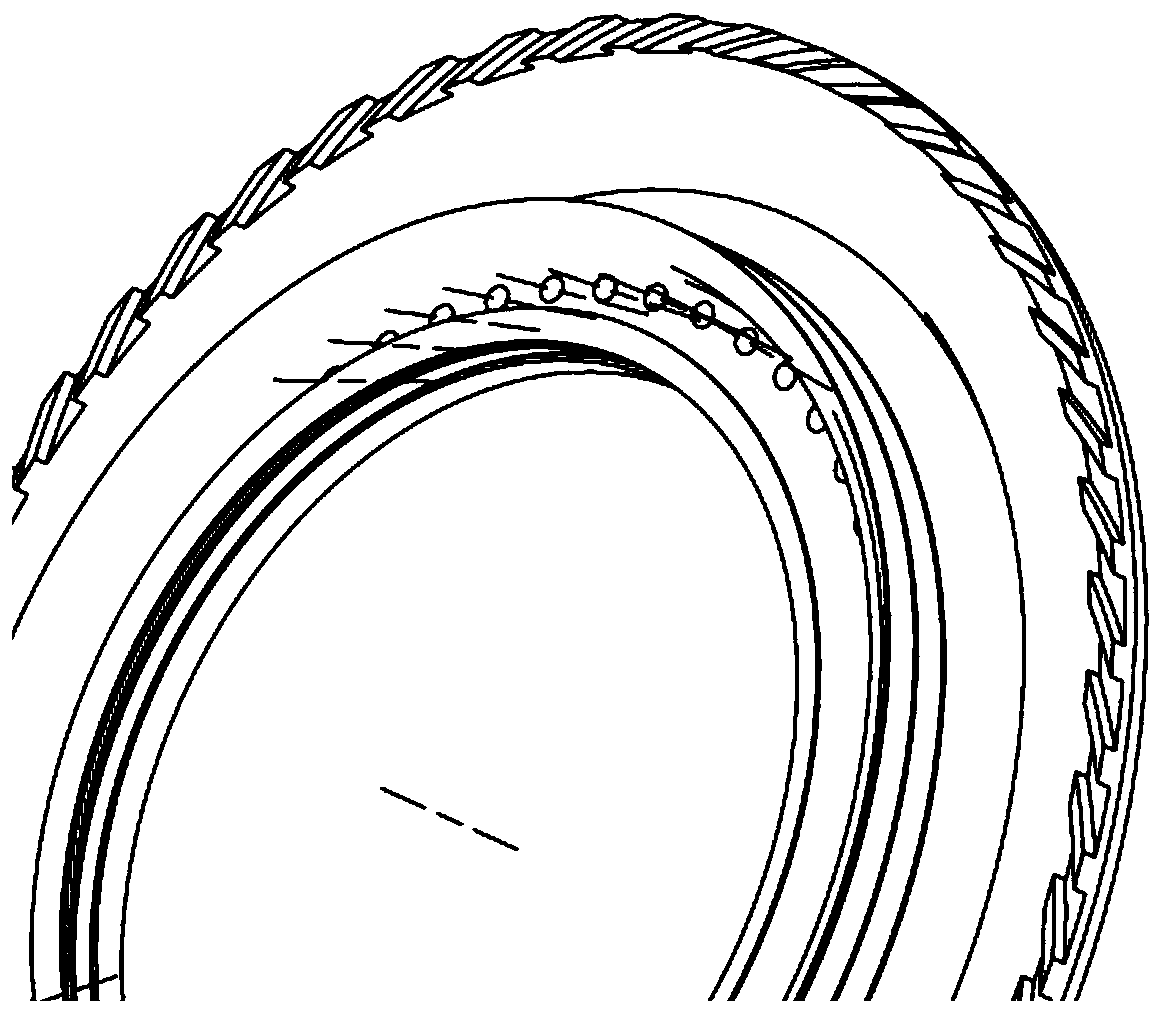

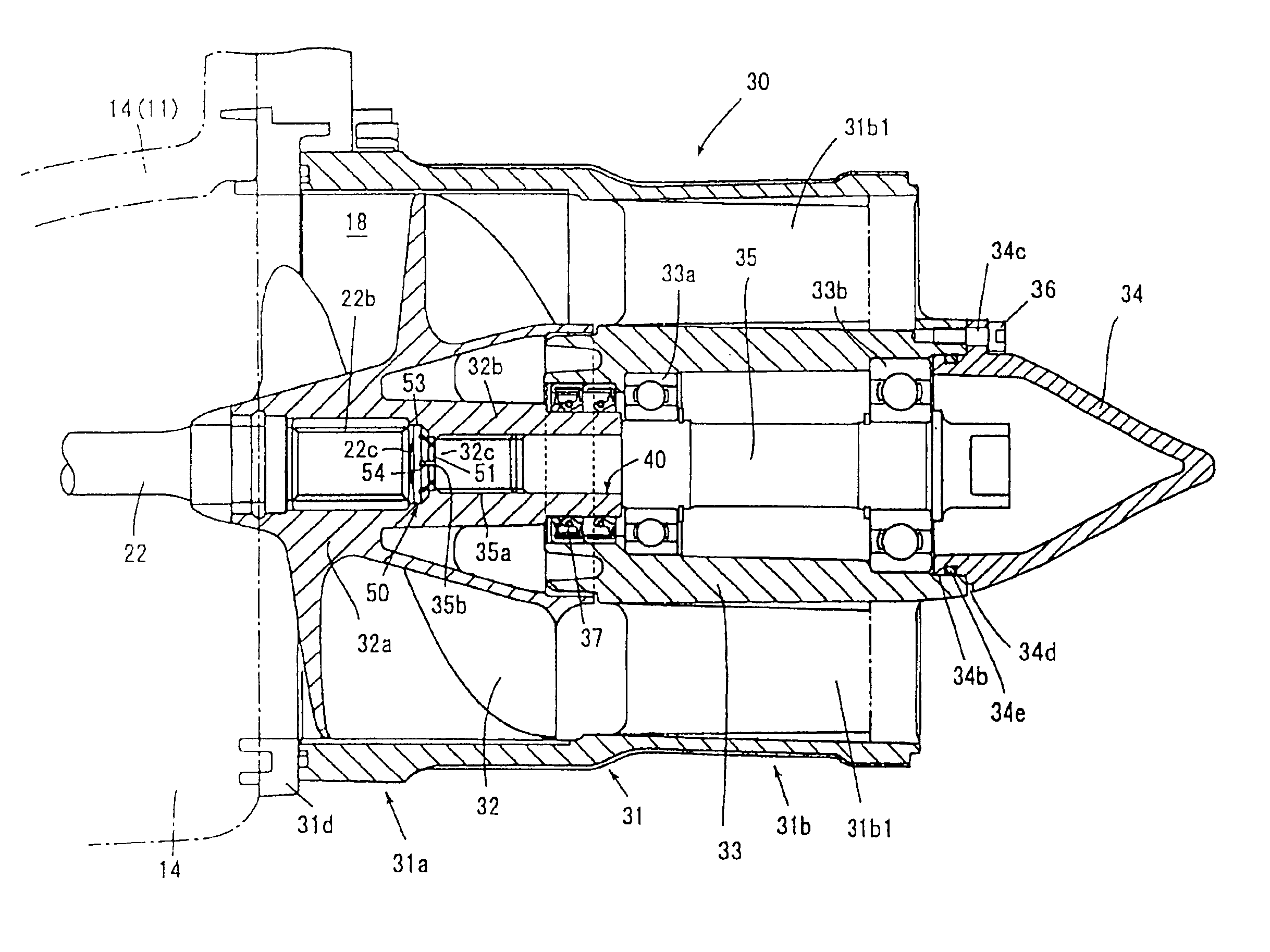

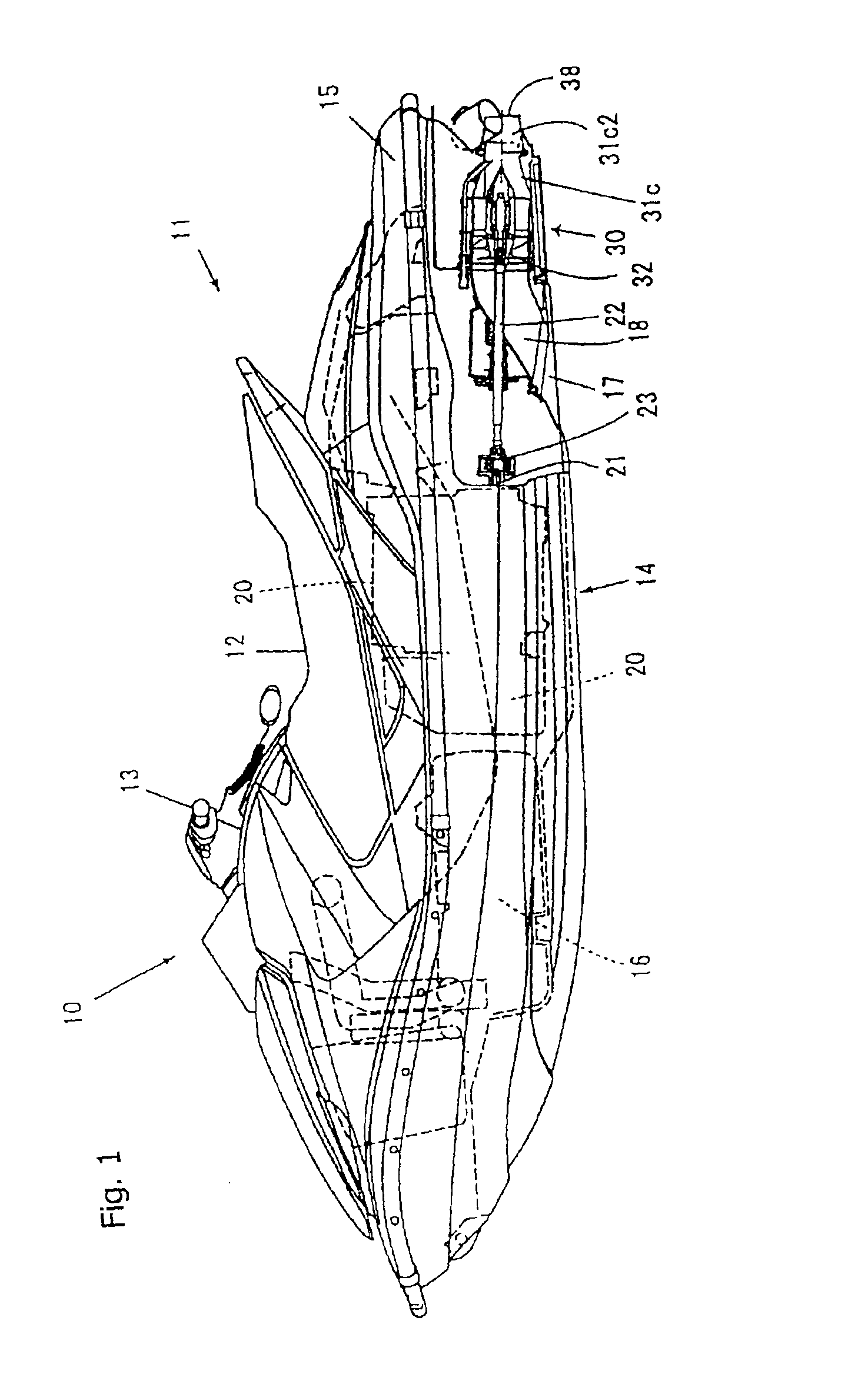

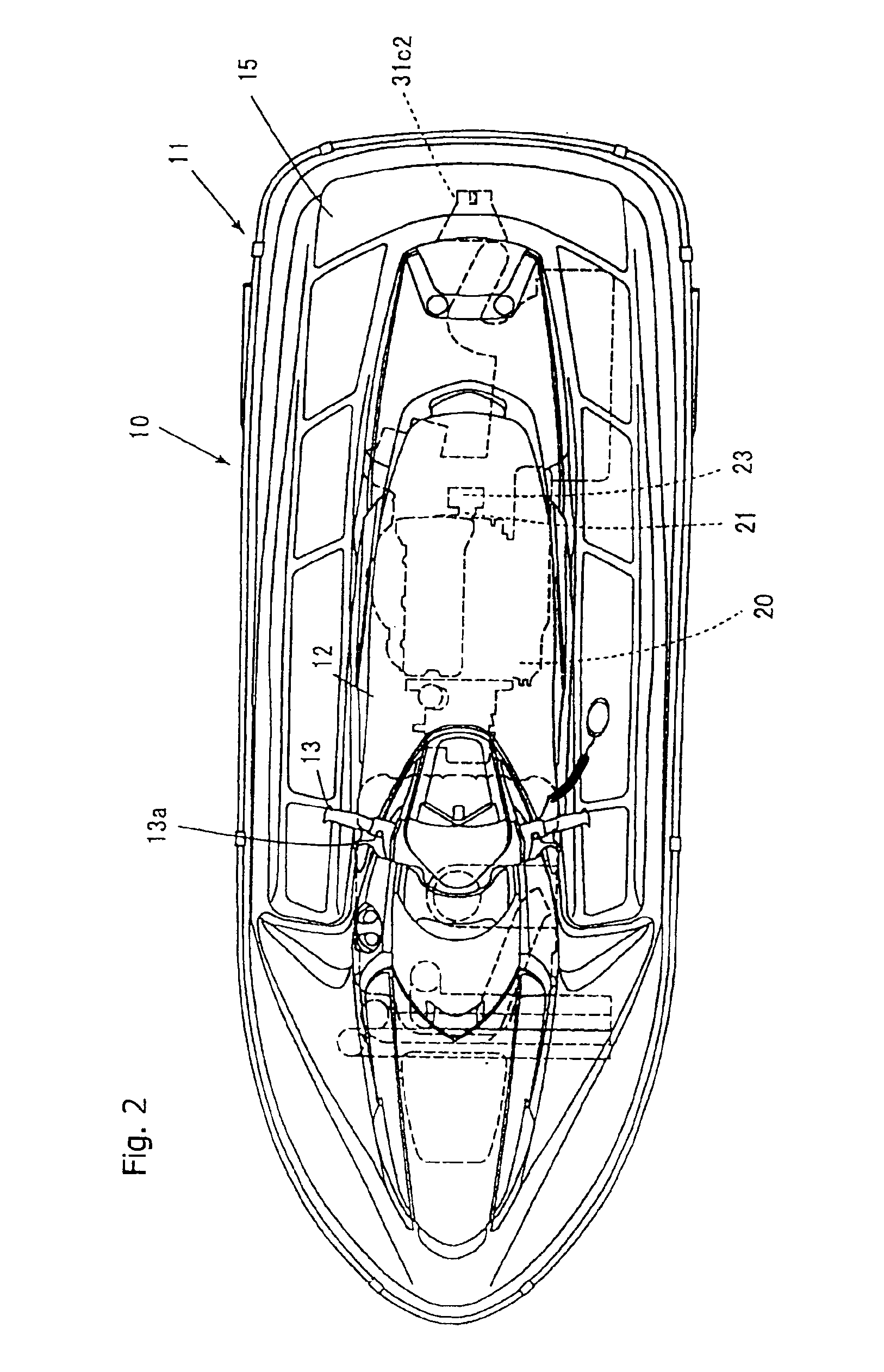

Water jet propeller apparatus for a personal watercraft

ActiveUS6872110B2Reduce corrosionMinimizing intrusion of waterRubber-like material springsWater acting propulsive elementsImpellerDrive shaft

A jet pump for a personal watercraft is designed to prevent water from contacting an impeller shaft therein. The apparatus includes a stator 31 with a channel 18 formed therein. An impeller 32 and an impeller shaft 35 are rotatably disposed in the stator 31, and are connected to one another by a threaded connection therebetween. A collar 40 is integrally formed with the impeller 32, and a water-resistant seal 37 is provided between the collar 40 and the stator. The impeller shaft 35 is constructed so that a drive shaft 22 is connectable to the front thereof by a spline fit. A shock-absorbing member 50 is provided for placement between the impeller shaft and the drive shaft, and the shock-absorbing member includes structure adapted to allow air or grease to pass toward the drive shaft side thereof, when the impeller is screwed on to the impeller shaft.

Owner:HONDA MOTOR CO LTD

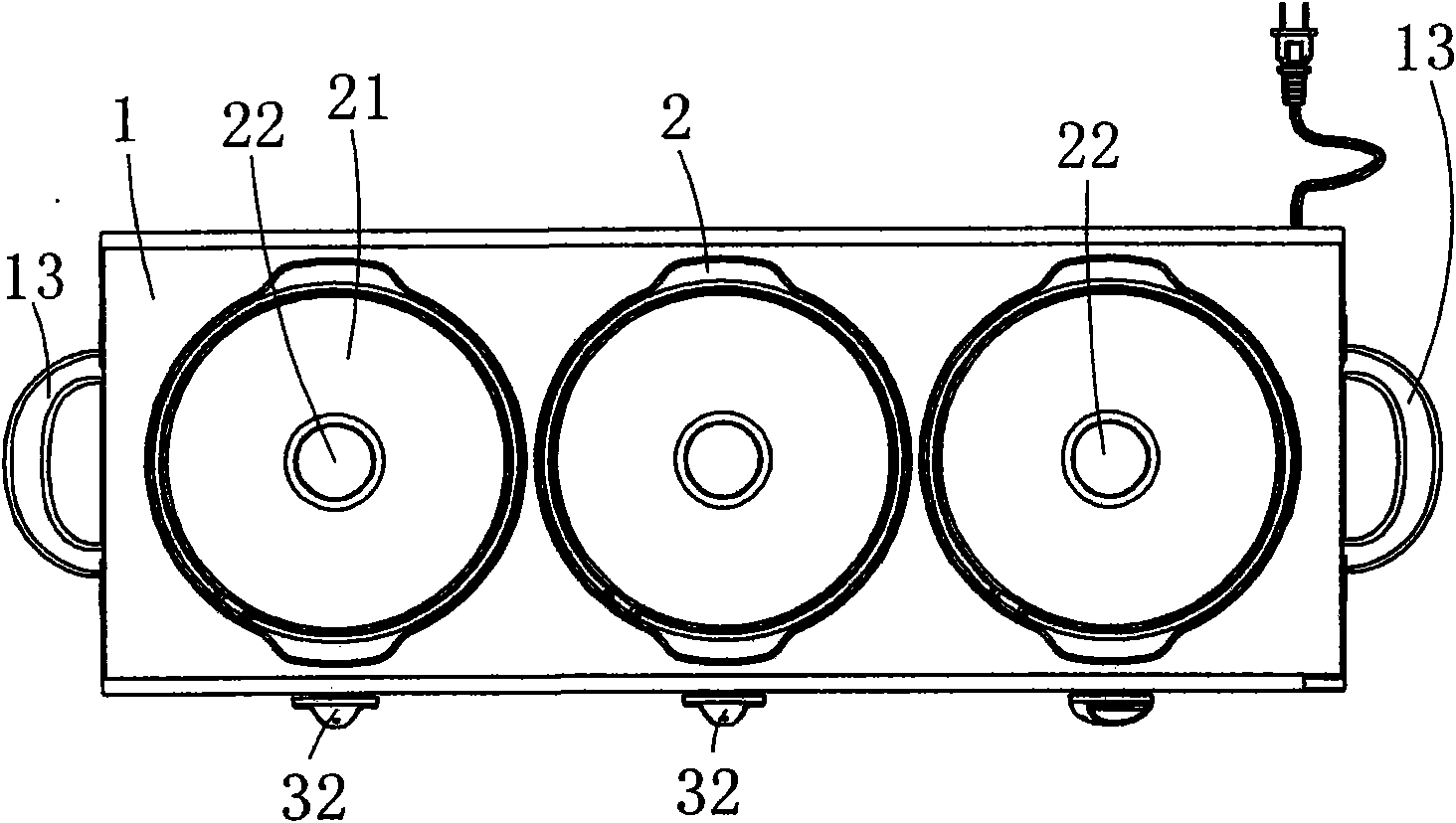

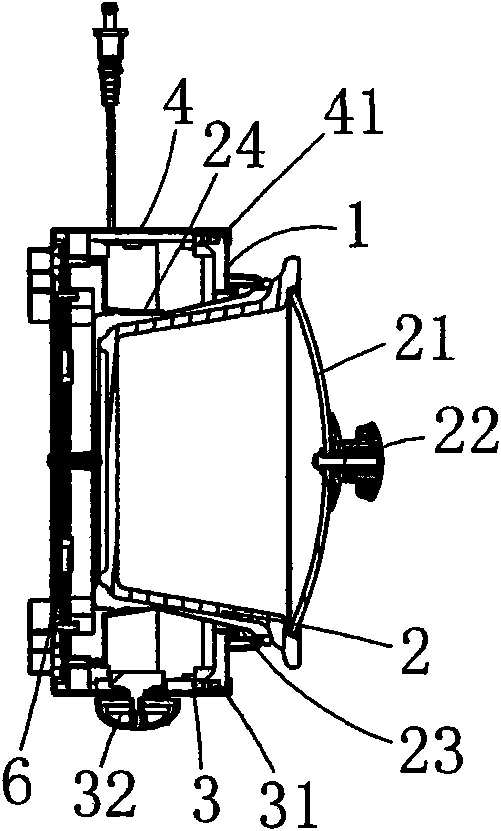

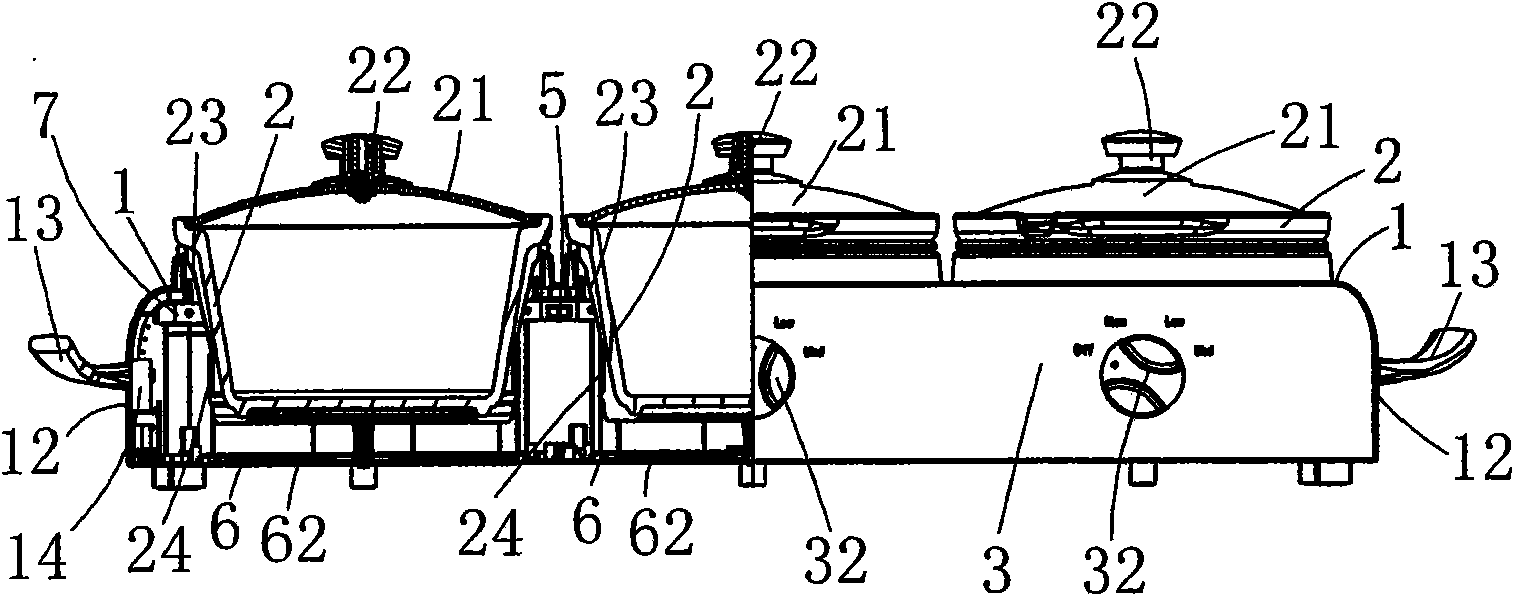

Combinative structure slow cooker

InactiveCN101564269AEasy to installImprove connection rigidityMultiple-unit cooking vesselsWarming devicesEngineeringCooker

The invention discloses a combinative structure slow cooker, which comprises a faceplate body. The middle of the faceplate body is provided with at least three parallelly arranged cooker holes and the left side and right side thereof are both provided with flange bodies extending downwards; the cooker holes are all internally embedded with cooker bodies, the front face part of the faceplate is assembled with a front faceplate, and the assembly edge between the front faceplate and the faceplate body is embedded with a front sealing strip; the back face part of the faceplate body is assembled with a back faceplate, and the assembly edge between the back faceplate and the faceplate body is embedded with a back sealing strip; a lining medium plate is connected at the middle position between the back faceplate and the front faceplate; the lower part of the faceplate body is assembled with a bottom plate which is also assembled with the lower edge of the back faceplate and the lower edge of the front faceplate; three parallel cooker bodies are designed with simple structure and are convenient and quick for installation; an electrical heating mode is used to heat each cooker that is strong in operation independence and beneficial to energy saving; a horizontal manual supporting plate and a lining side plate are arranged to enhance the connection rigidity and firmness between the front faceplate and the back faceplate; and a casing handle is assembled to facilitate carrying.

Owner:浙江亿达控股集团有限公司

Tool positioning-clamping mechanism for milling machine

InactiveCN102581668ASmooth rotationNot easy to fall offPositioning apparatusMetal-working holdersEngineeringMachine

The invention discloses a tool positioning-clamping mechanism for a milling machine, which comprises a tool (1), a tool shank (3) and a pull bar (4). The tool shank (3) is partially contained in a machine spindle (5) and fixed to the same, the tool shank (3) is provided with a center hole (3.1), the tool (1) is nested into the center hole (3.1), the pull bar (4) is contained in the center hole (3.1), one end of the pull bar (4) is connected with the tool shank (3) and axially limited, the other end of the pull bar (4) is fixedly connected with the tool (1), and accordingly the tool (1) is fixedly connected with the machine spindle (5). The connection way is higher in connection rigidity than the original Morse taper connection way, connection is more stable, and clamping is better. When the machine spindle is in high-speed rotation, the tool is more stable in rotation and less apt to fall from the spindle, and safety factor is higher.

Owner:宁波远达船机配件有限公司

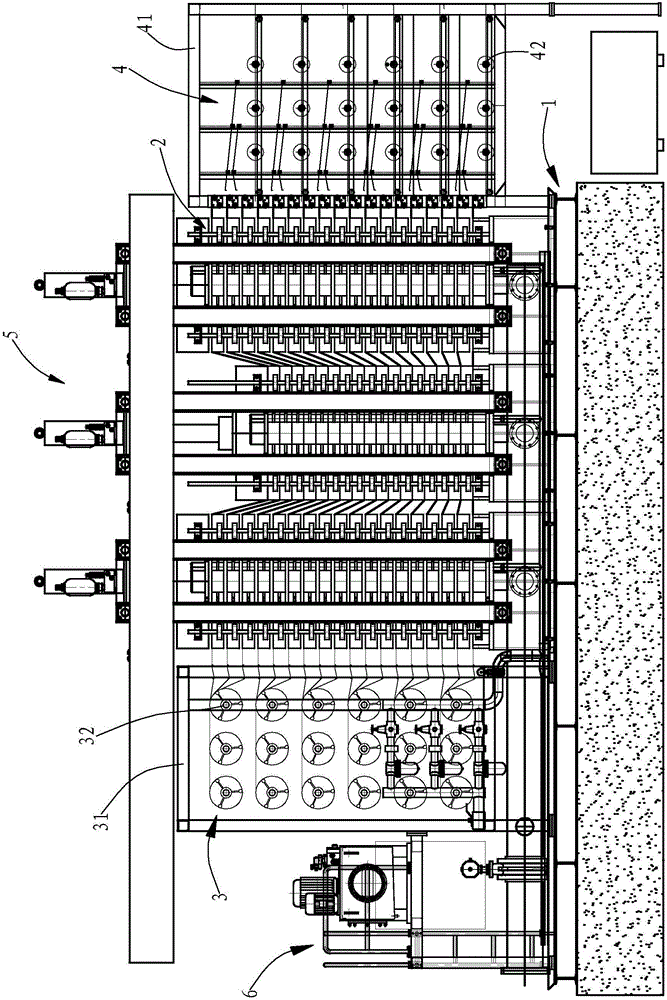

Rubber tube-free precise plate-type filtering machine

ActiveCN105854368AImprove sealingGuaranteed tightnessMembrane filtersFiltration separationPulp and paper industryFilter paper

The invention relates to a rubber tube-free precise plate-type filtering machine. The rubber tube-free precise plate-type filtering machine comprises a rack and a filter box, a paper feeding mechanism, a paper discharging mechanism, a hydraulic device and an electric control device which are installed on the rack; the paper feeding mechanism and the paper discharging mechanism are located on the two sides of the filter box so as to drive filter paper to complete filtering work in the filter box, the hydraulic device cooperates with the filter box to conduct the filtering work, and the paper feeding mechanism, the paper discharging mechanism and the hydraulic device are connected with the electric control device and controlled by the electric control device. The filter box in the rubber tube-free precise plate-type filtering machine is good in sealing property and reliable in sealing, the hydraulic device is low in energy consumption and long in service life, a support assembly is reliable in installation and good in rigid strength, and the electric control device is high in operating flexibility.

Owner:NINGBO CHUANGLI HYDRAULIC MACHINERY MFG CO LTD

Light and integrated junction system of the walls of a collapsible container

ActiveUS10232978B2Improve the immunityReduce weightDomestic articlesRigid containersHigh intensityEngineering

The present invention comprises a junction system of structures, preferably for container walls, which is light and is integrated to the structures to be joined providing high strength and rigidity reducing the weight of the joint, which comprises at least a closing device having at least a pair of closing means, a male closing mean and a female closing mean, wherein said closing means join at least two structures together, or two adjacent faces of a container for fruit and vegetable products, preferably the side faces, being fixed to said structures or faces; further comprising a column fixed to one of said structures, wherein said column is configured as a hollow cylindrical body which in turn is integrated to at least one of said closing means. Furthermore, the invention comprises an associated container and its manufacturing process.

Owner:WENCO SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com