Large-scale paraboloid antenna surface operation angle control and loading measurement system

A parabolic antenna, working angle technology, applied in the direction of antenna, antenna parts, antenna support/installation device, etc., can solve the problems such as impossible to ensure the horizontal state of the theodolite, complex structure of large-diameter parabolic antenna, affecting the measurement accuracy of the reflector, etc. , to achieve the effect of simple structure, reliable and effective fixation, and error avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

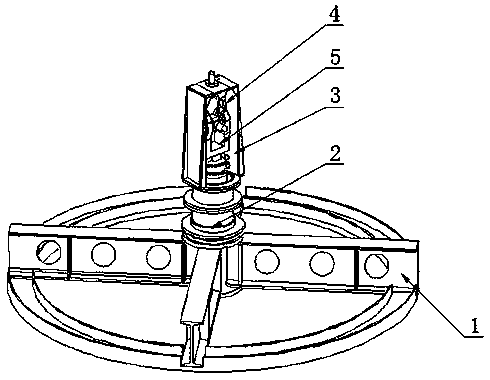

[0034] Such as figure 1 As shown, a large-scale parabolic antenna profile working angle control and loading measurement system includes a high-strength bracket 1, a rotating head 2, an afterburner cover 3, a handle combination 4 and a theodolite 5, and the rotating head 2 is installed on a high-strength On the bracket 1, the booster cover 3 is installed on the swivel head 2 through threaded connection, theodolite 5 is installed on the swivel head 2 through threaded connection, the theodolite 5 is located in the booster cover 3, and the handle combination 4 is installed on the booster cover through threaded connection 3, handle combination 4 is connected with theodolite 5;

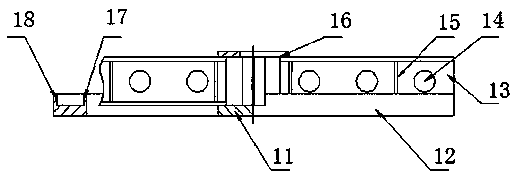

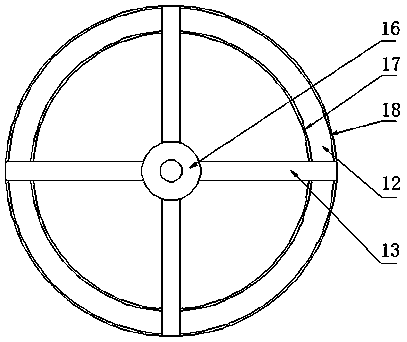

[0035] Such as figure 2 , 3 As shown, wherein the high-strength support 1 includes a positioning plate 12, several support f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com