Patents

Literature

882 results about "Layshaft" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A layshaft is an intermediate shaft within a gearbox that carries gears, but does not transfer the primary drive of the gearbox either in or out of the gearbox. Layshafts are best known through their use in car gearboxes, where they were a ubiquitous part of the rear-wheel drive layout. With the shift to front-wheel drive, the use of layshafts is now rarer.

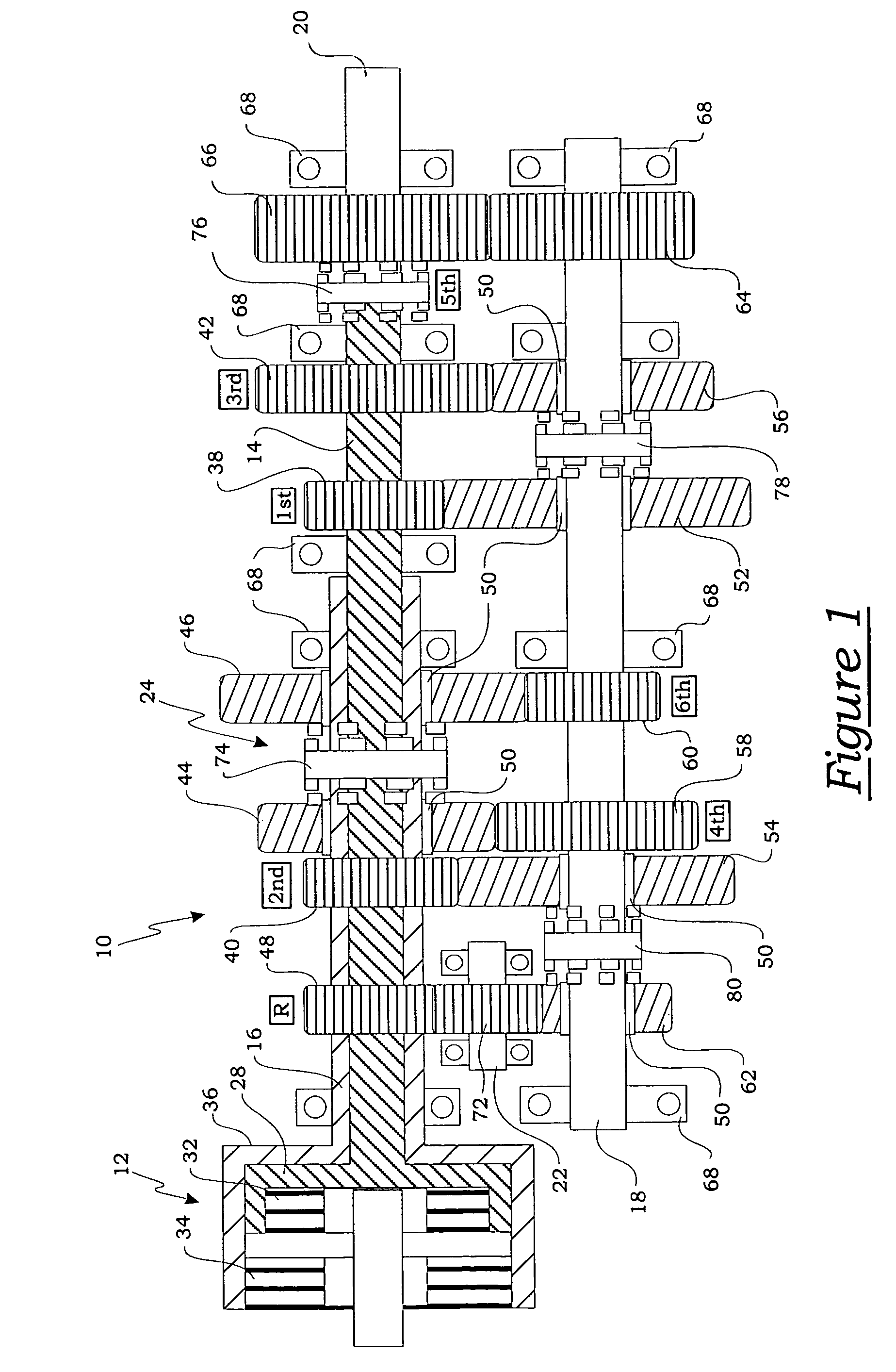

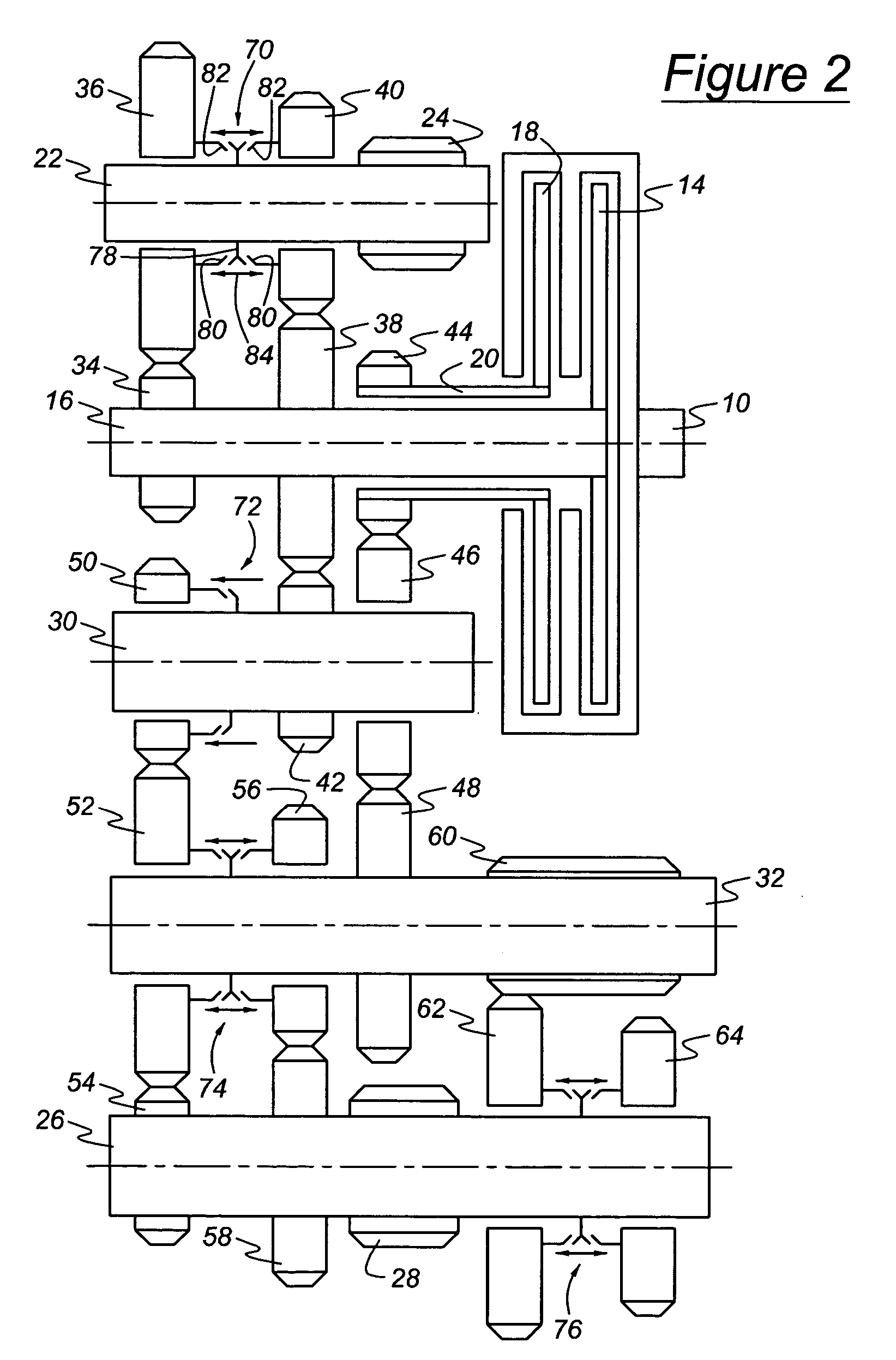

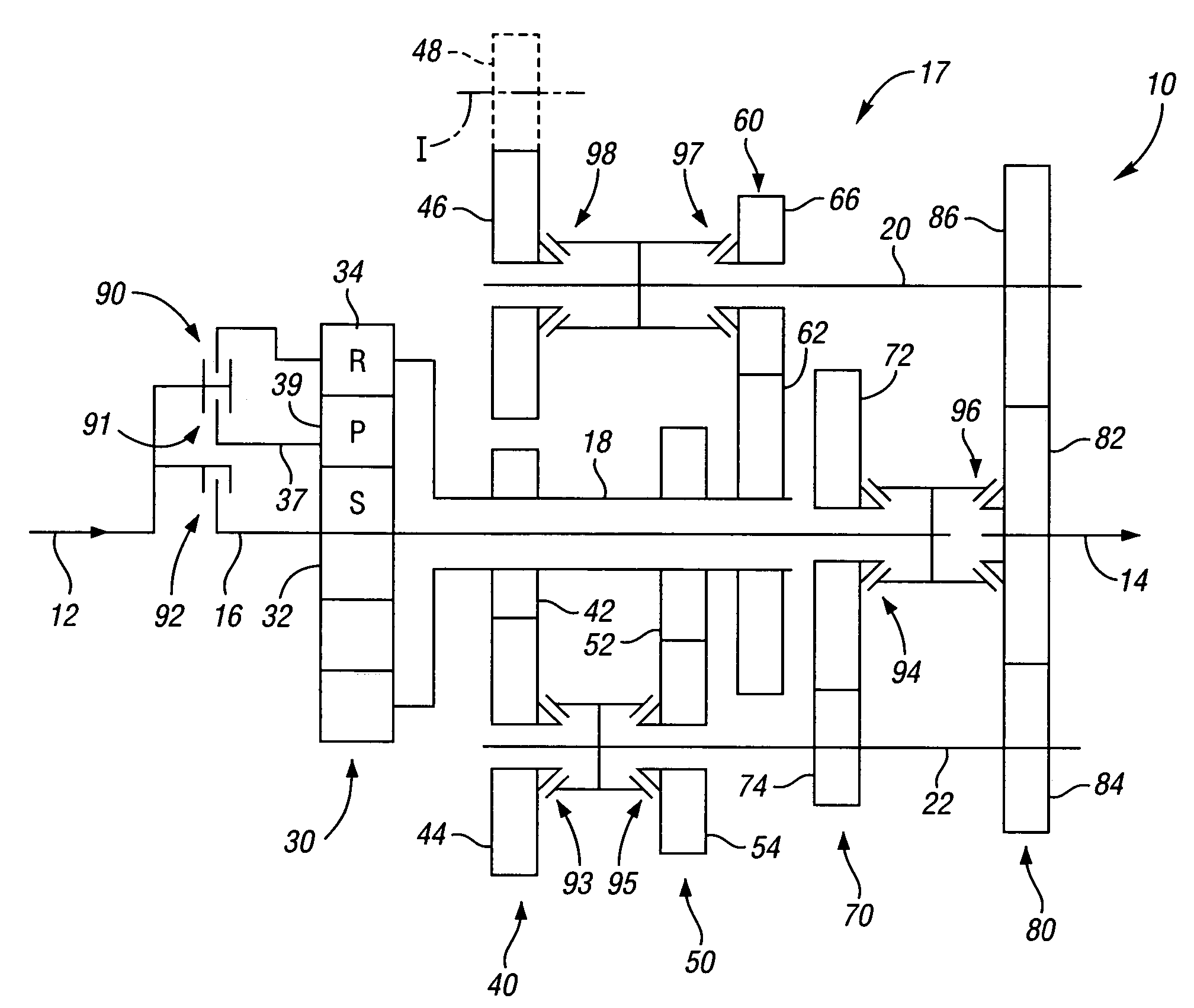

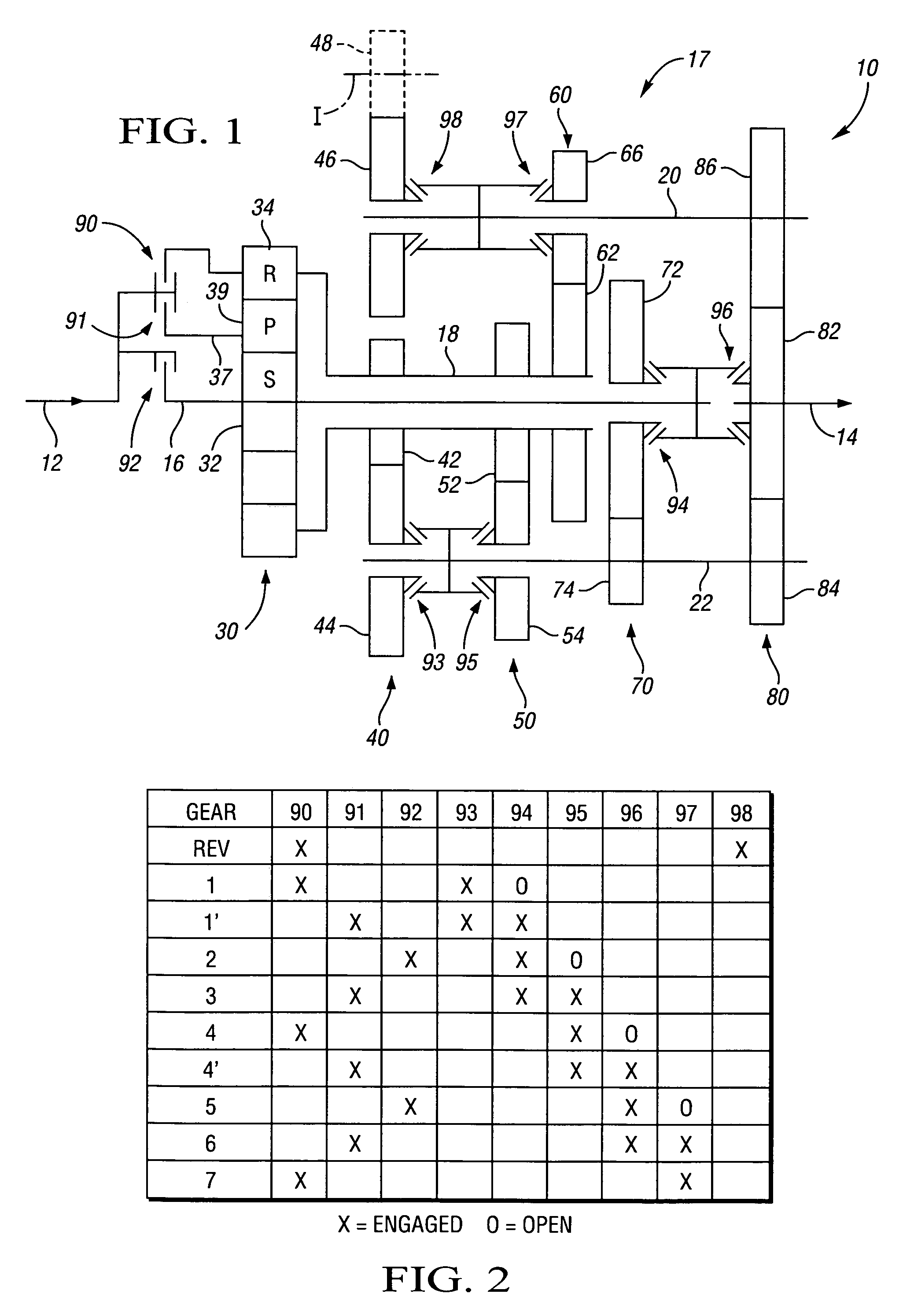

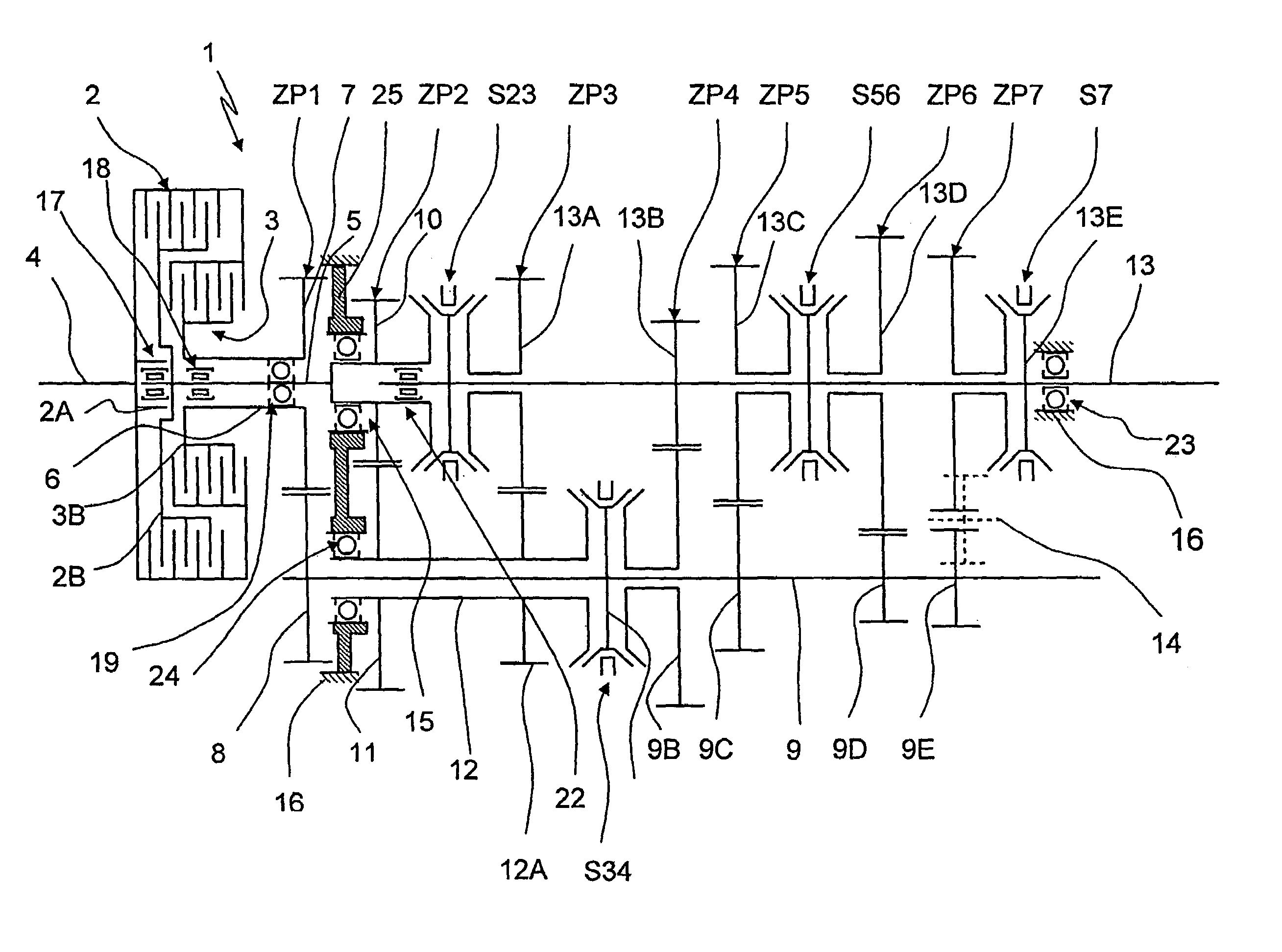

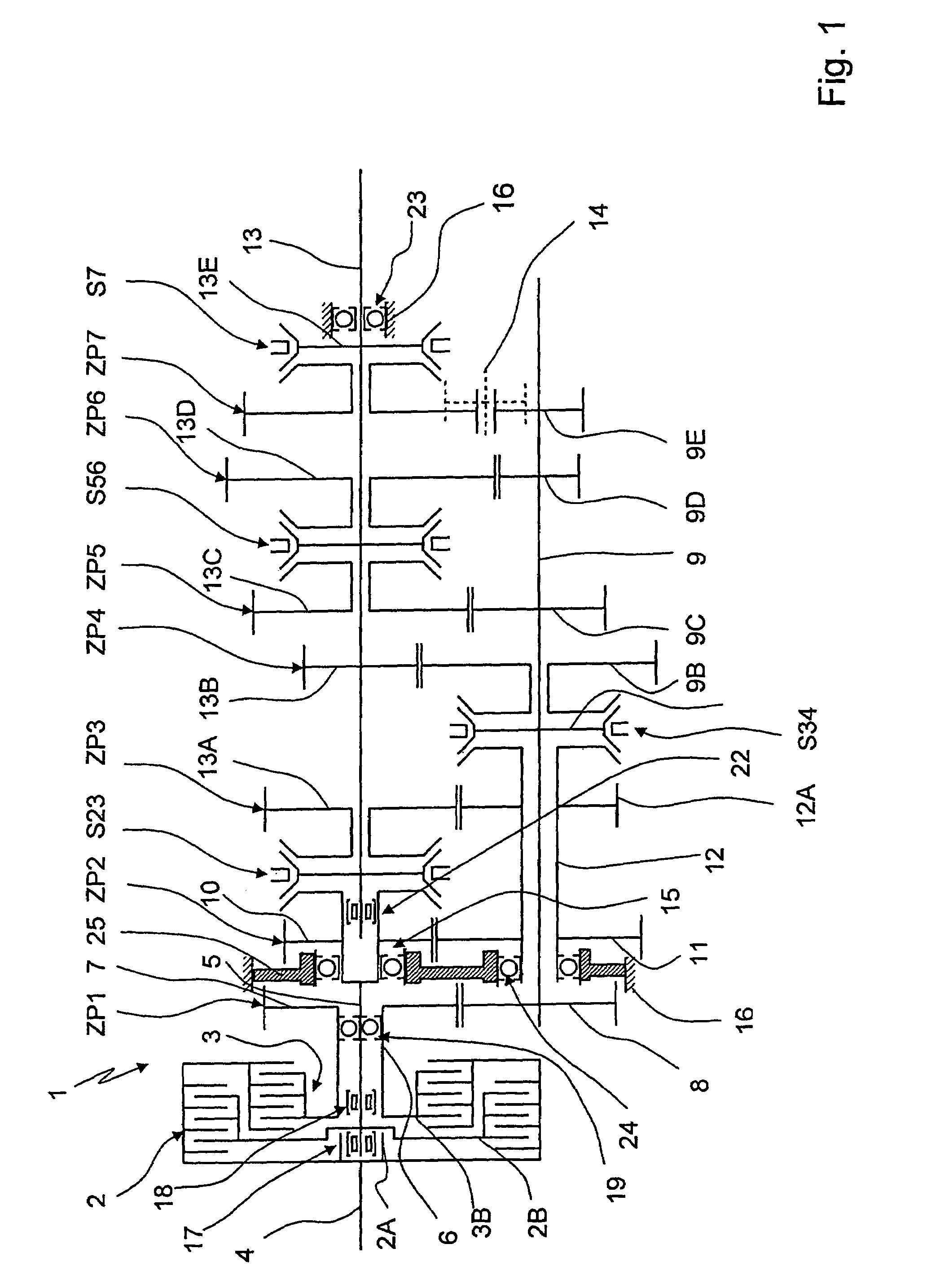

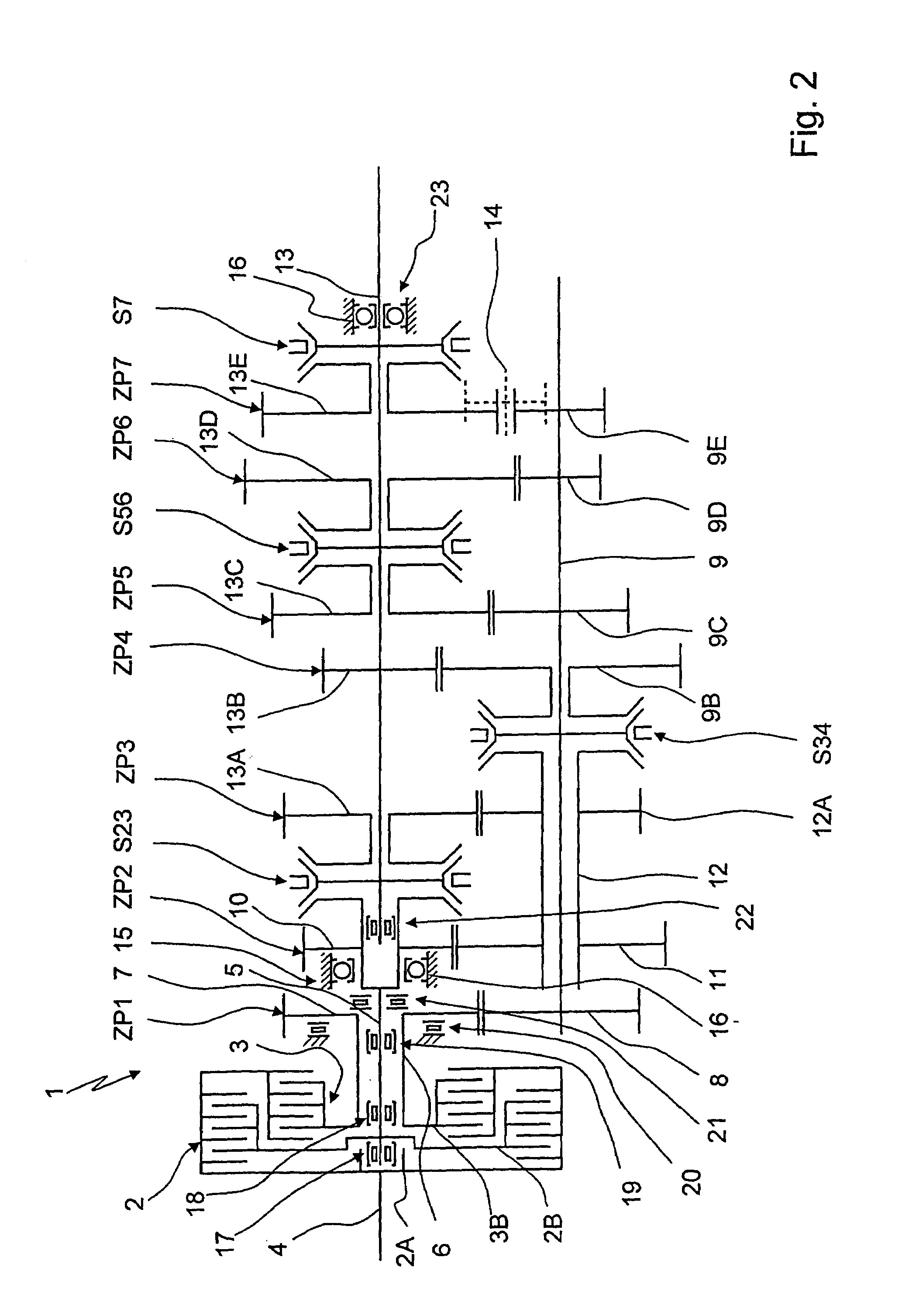

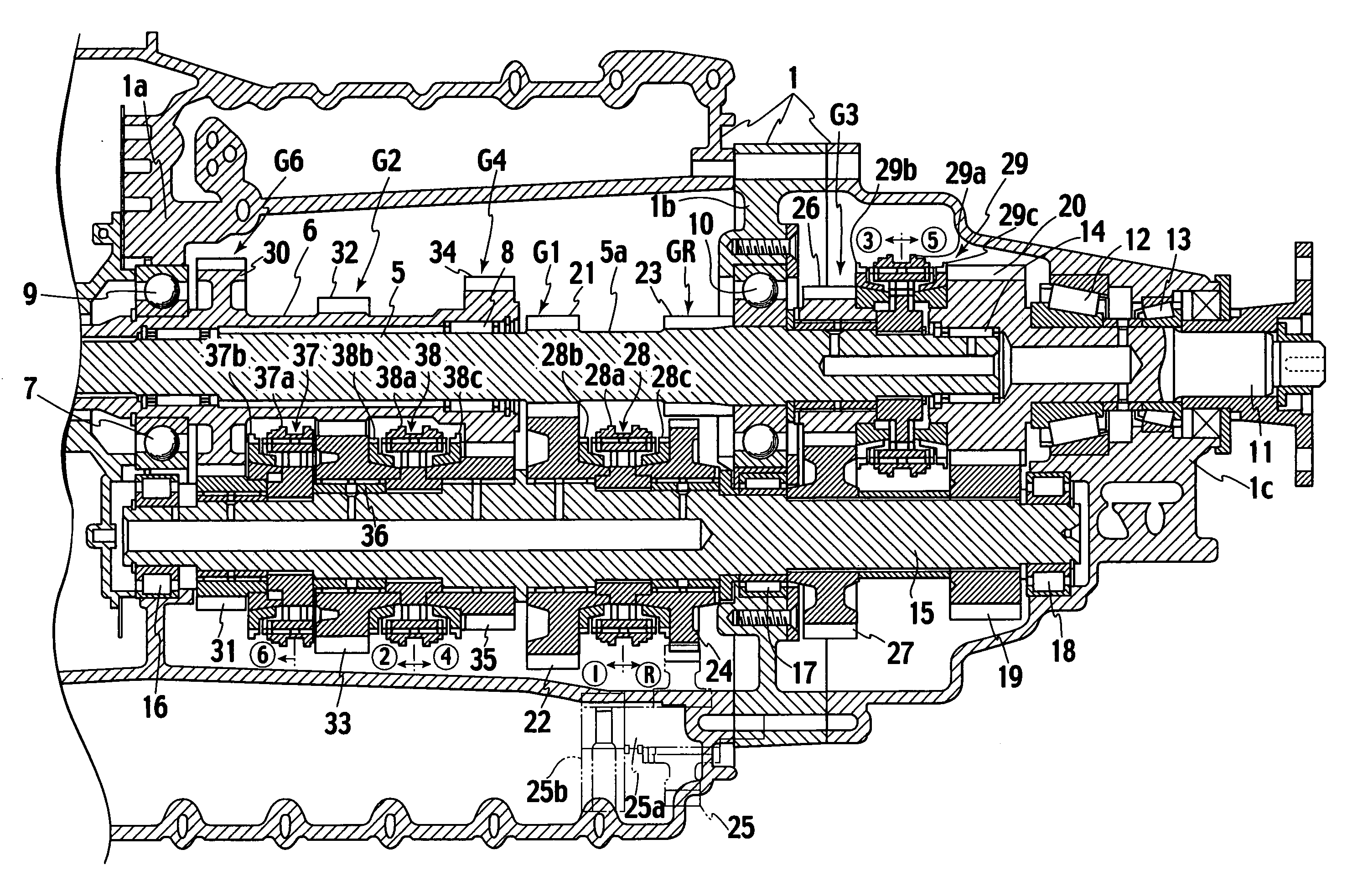

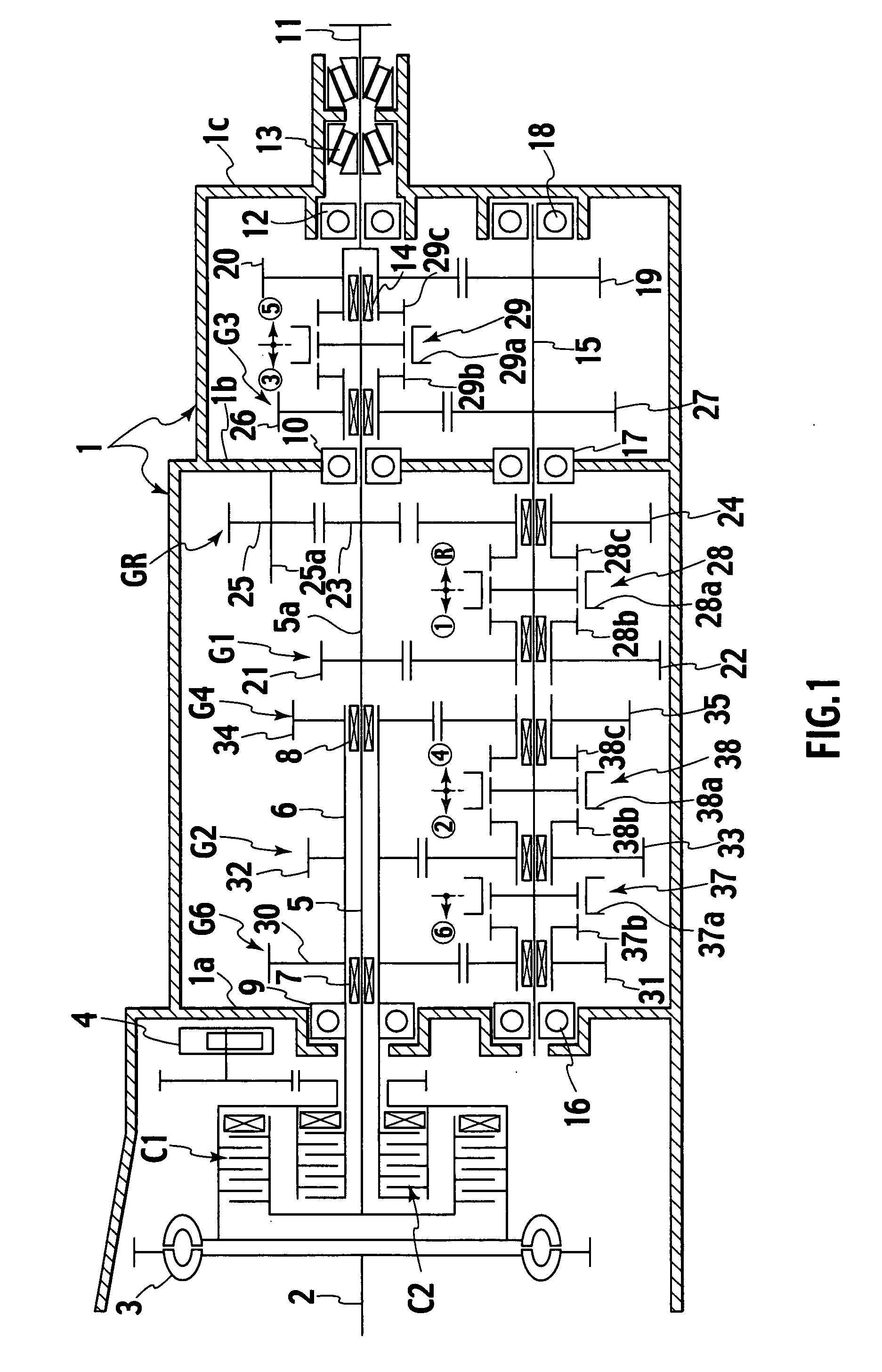

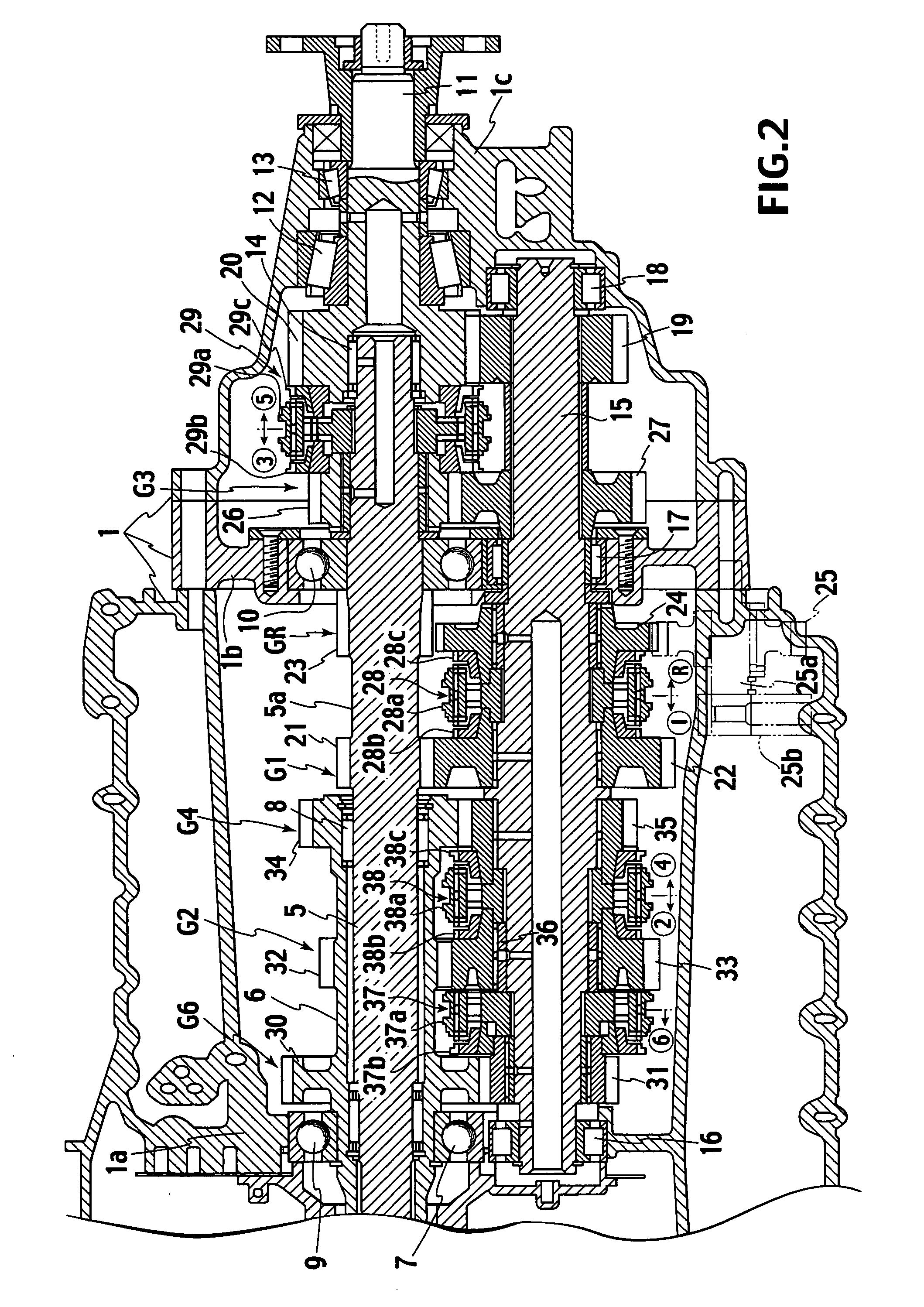

Ranged dual clutch transmission for motor vehicles

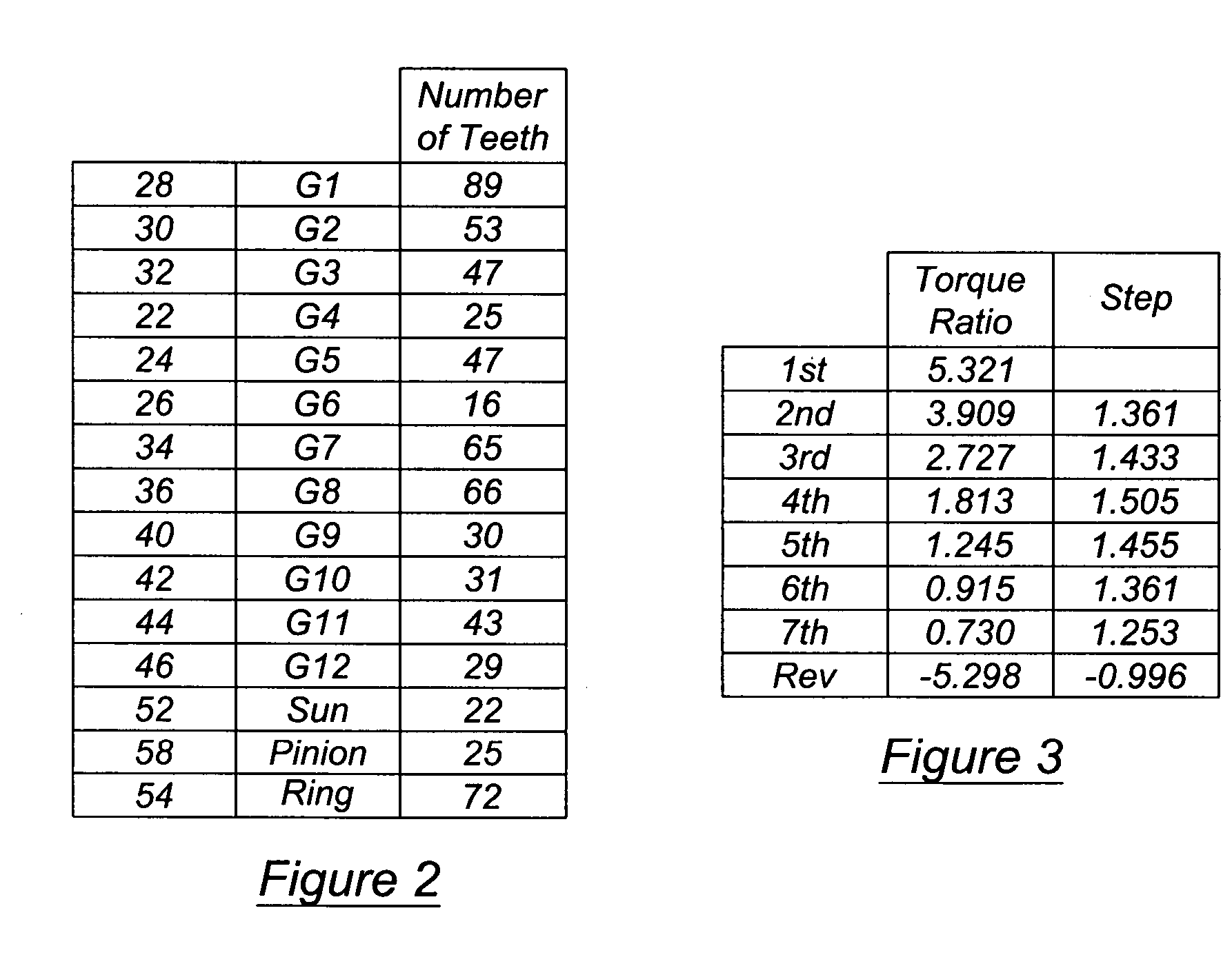

InactiveUS6958028B2Small torque ratioAvoid choiceToothed gearingsTransmission elementsMobile vehicleEngineering

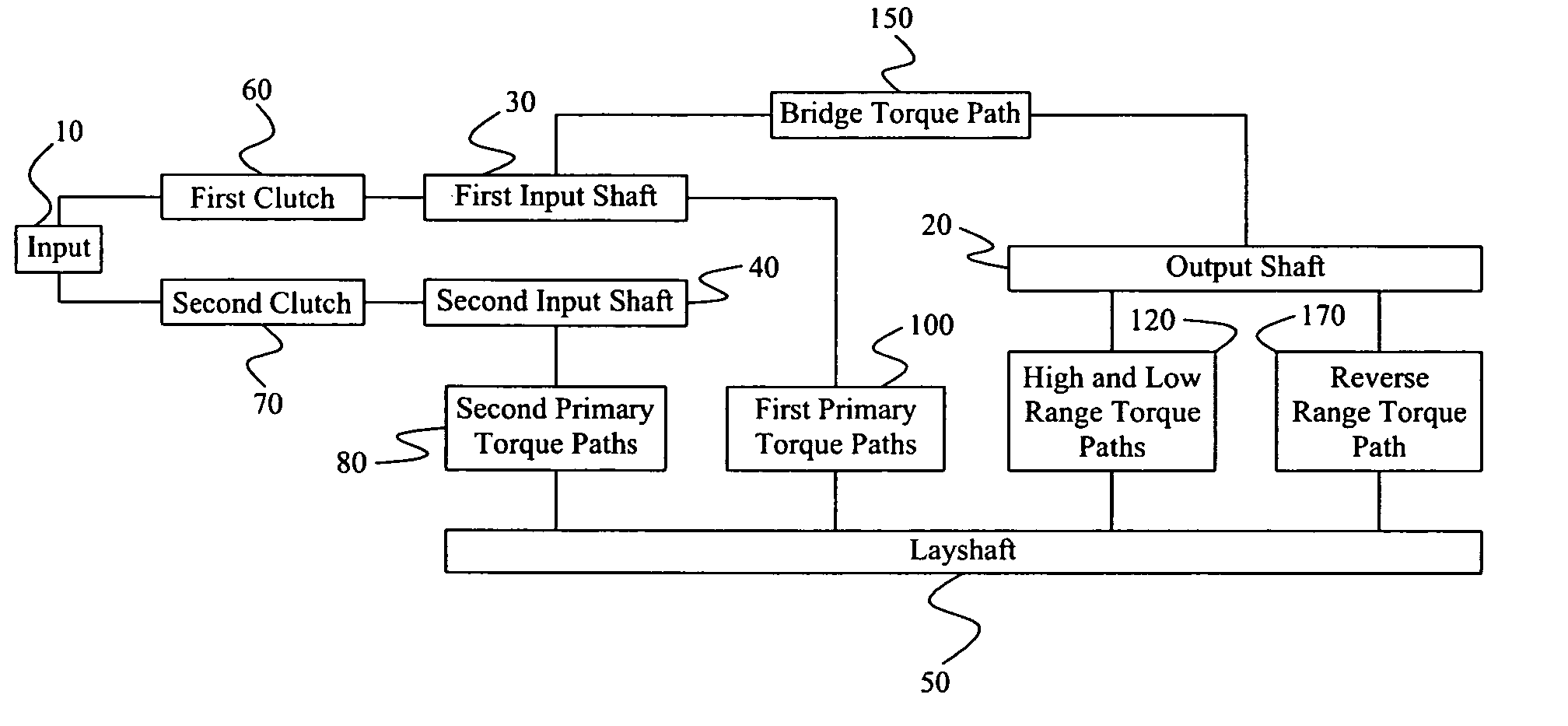

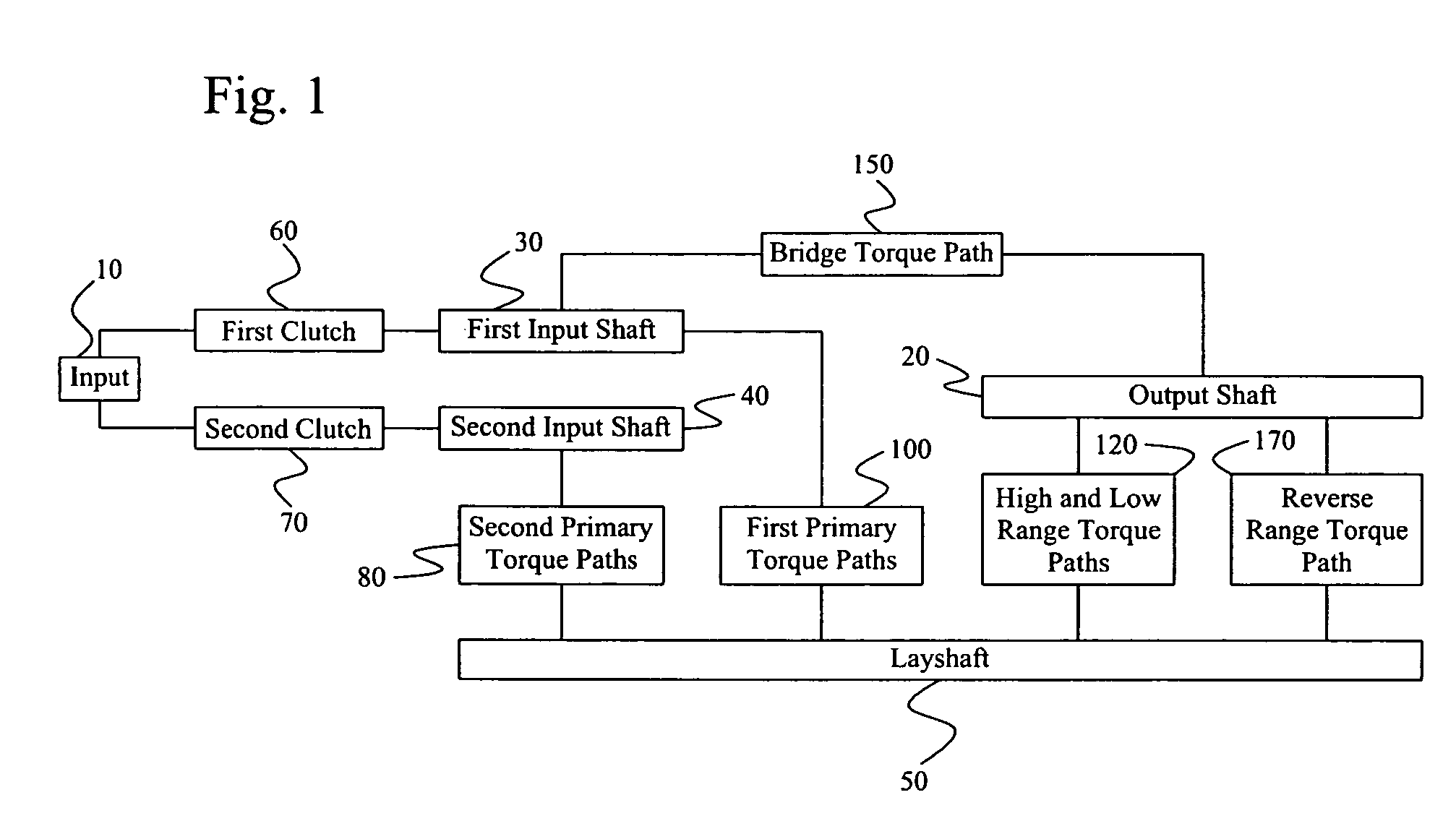

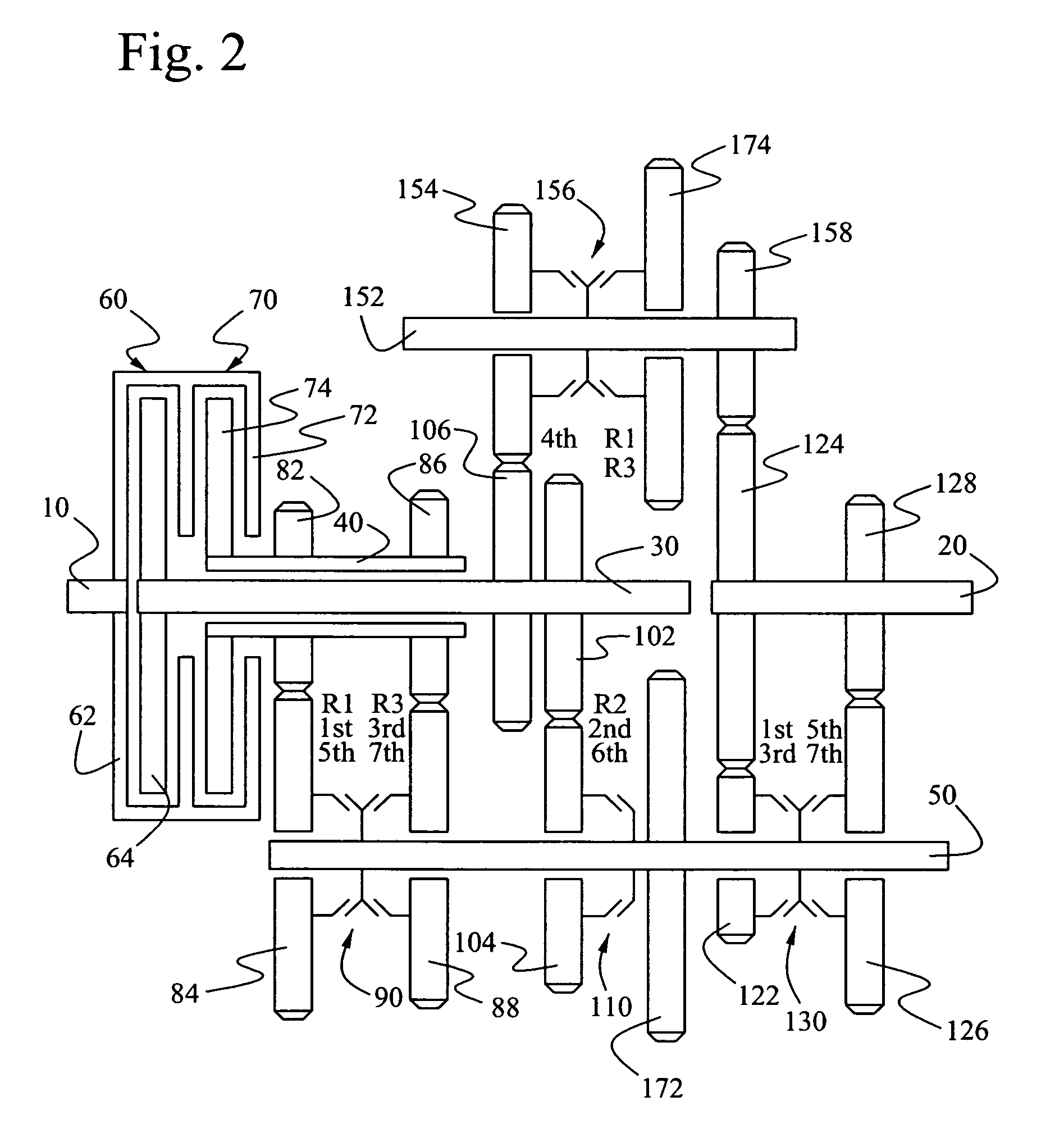

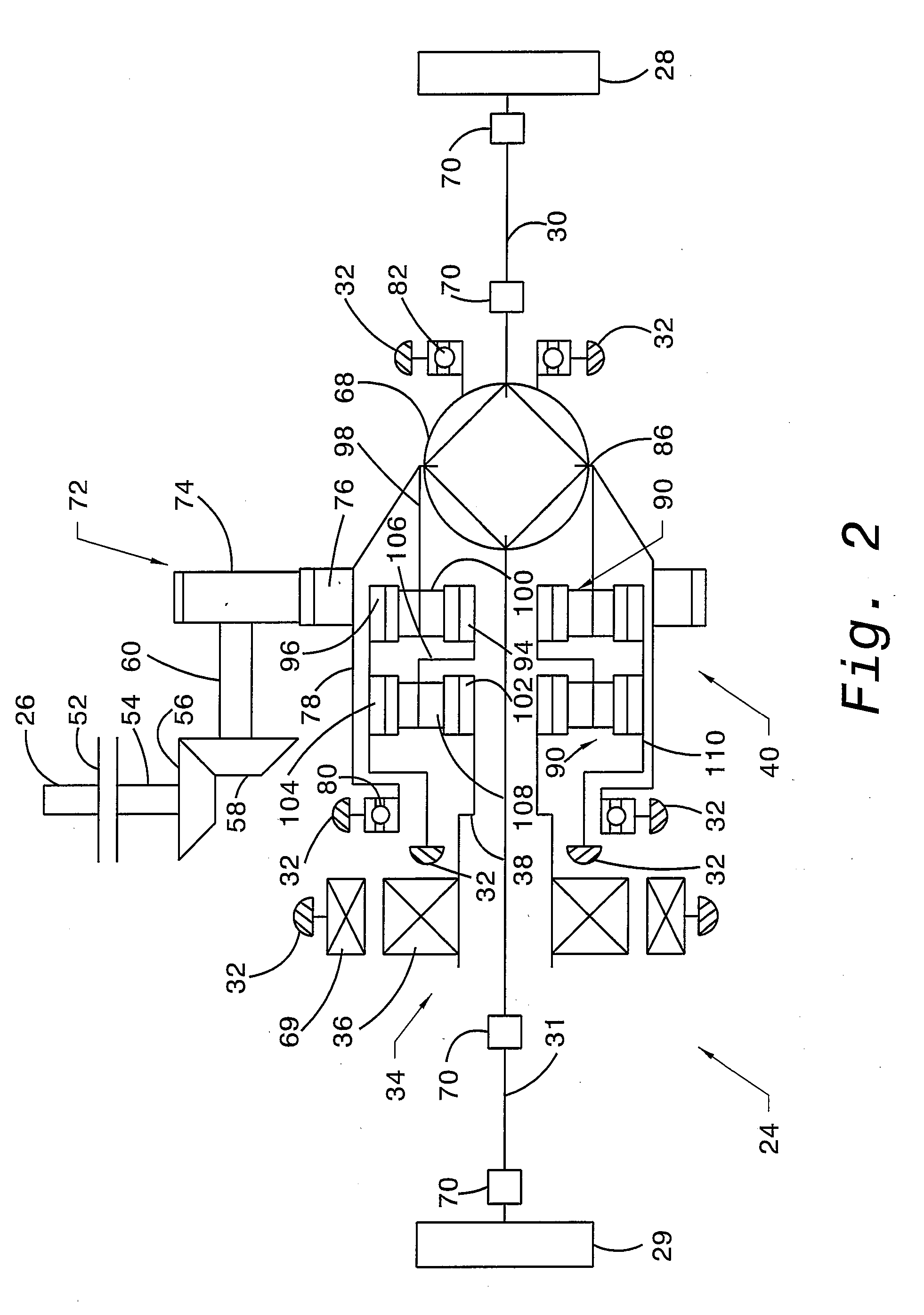

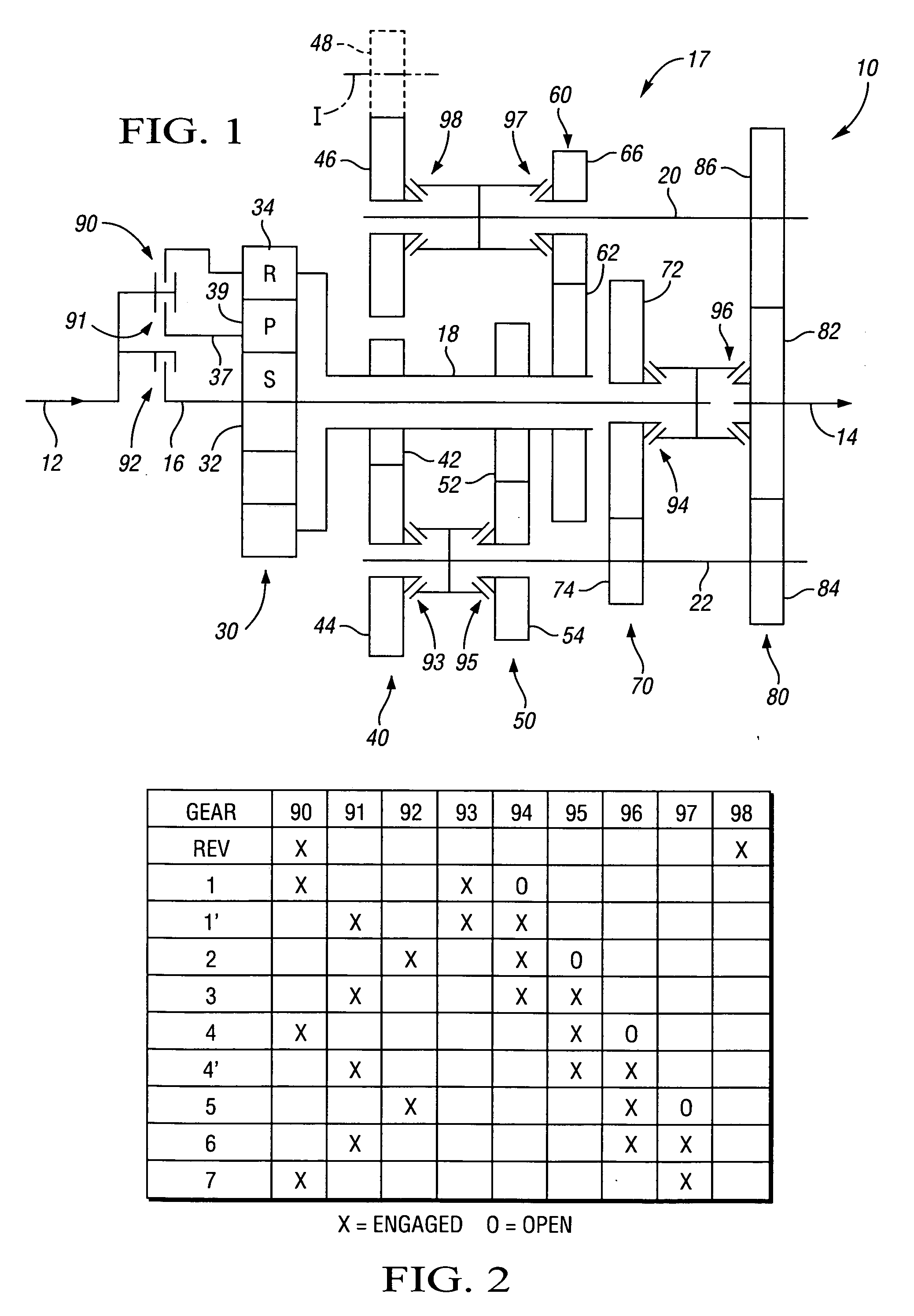

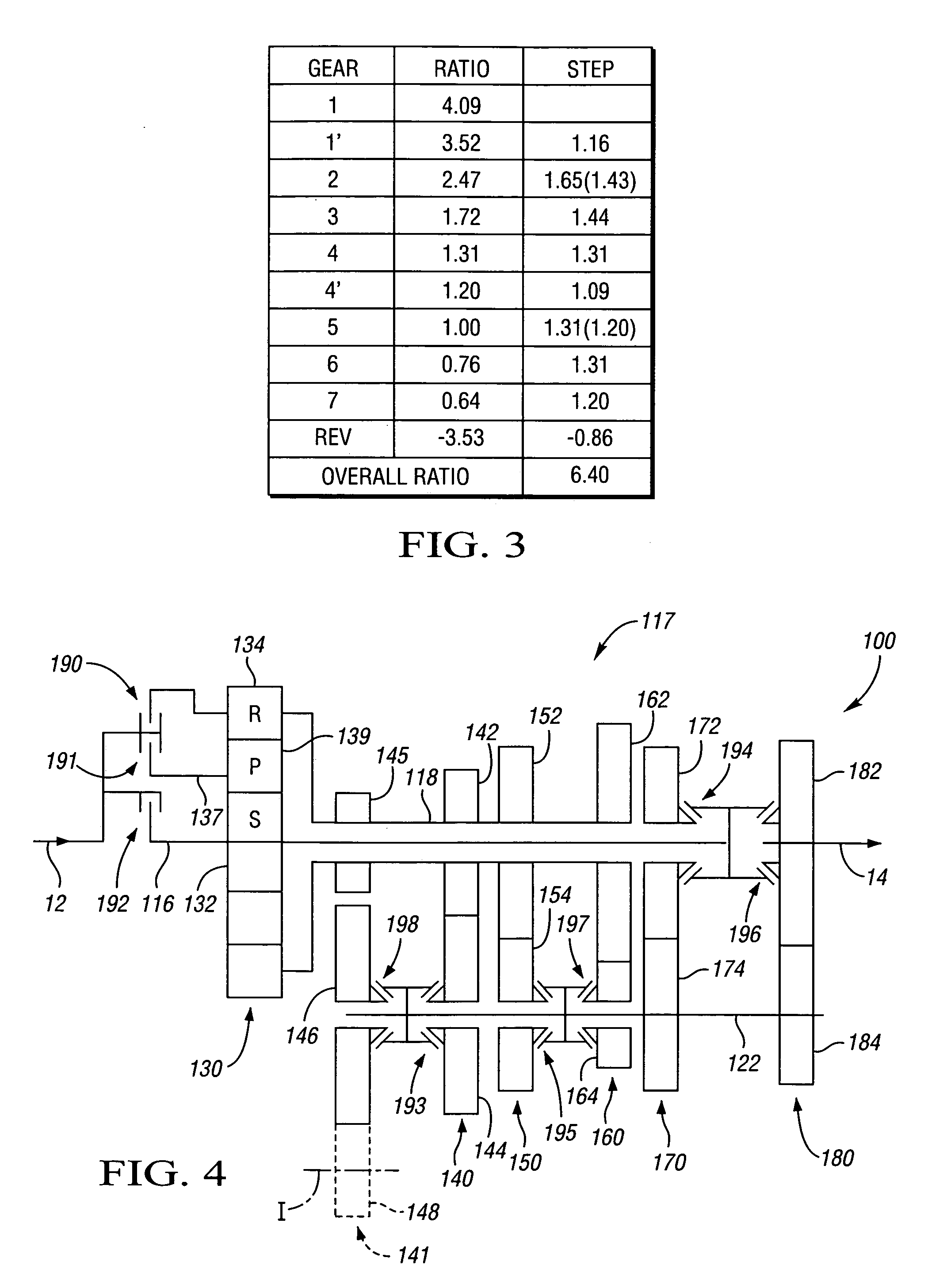

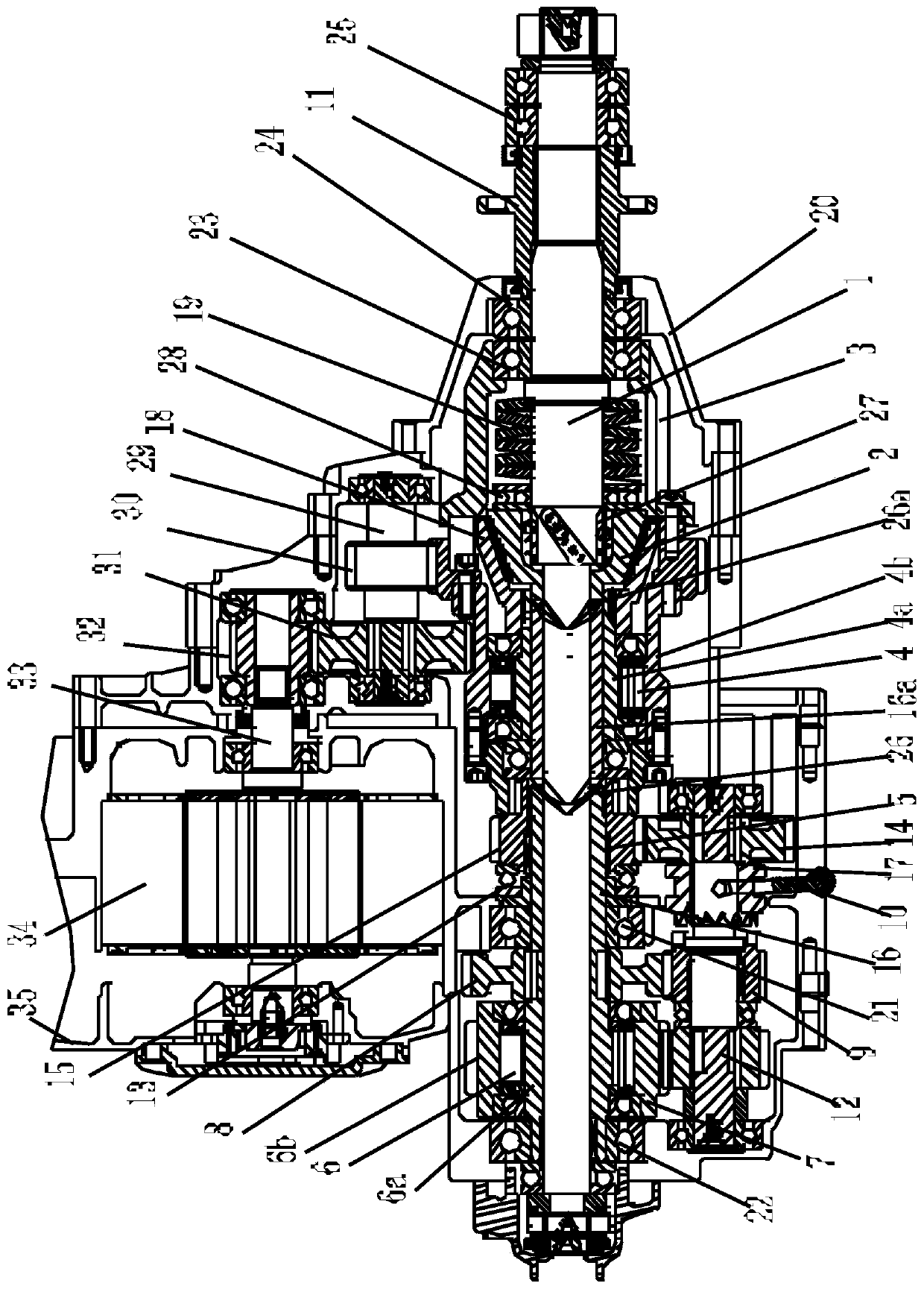

A power transmission for a motor vehicle includes an input, first and second input shafts, a layshaft, drive elements connecting the input shafts to the output and layshaft, couplers, a first clutch for connecting and disconnecting the input and the first input shaft, and a second clutch for connecting and disconnecting the input and the second input shaft. A first torque path driveably connects the first input shaft to the layshaft. A second torque path driveably connects the second input shaft to the layshaft. A third torque path driveably connects the layshaft and output. A bridge torque path driveably connects the first input shaft and the output.

Owner:FORD GLOBAL TECH LLC

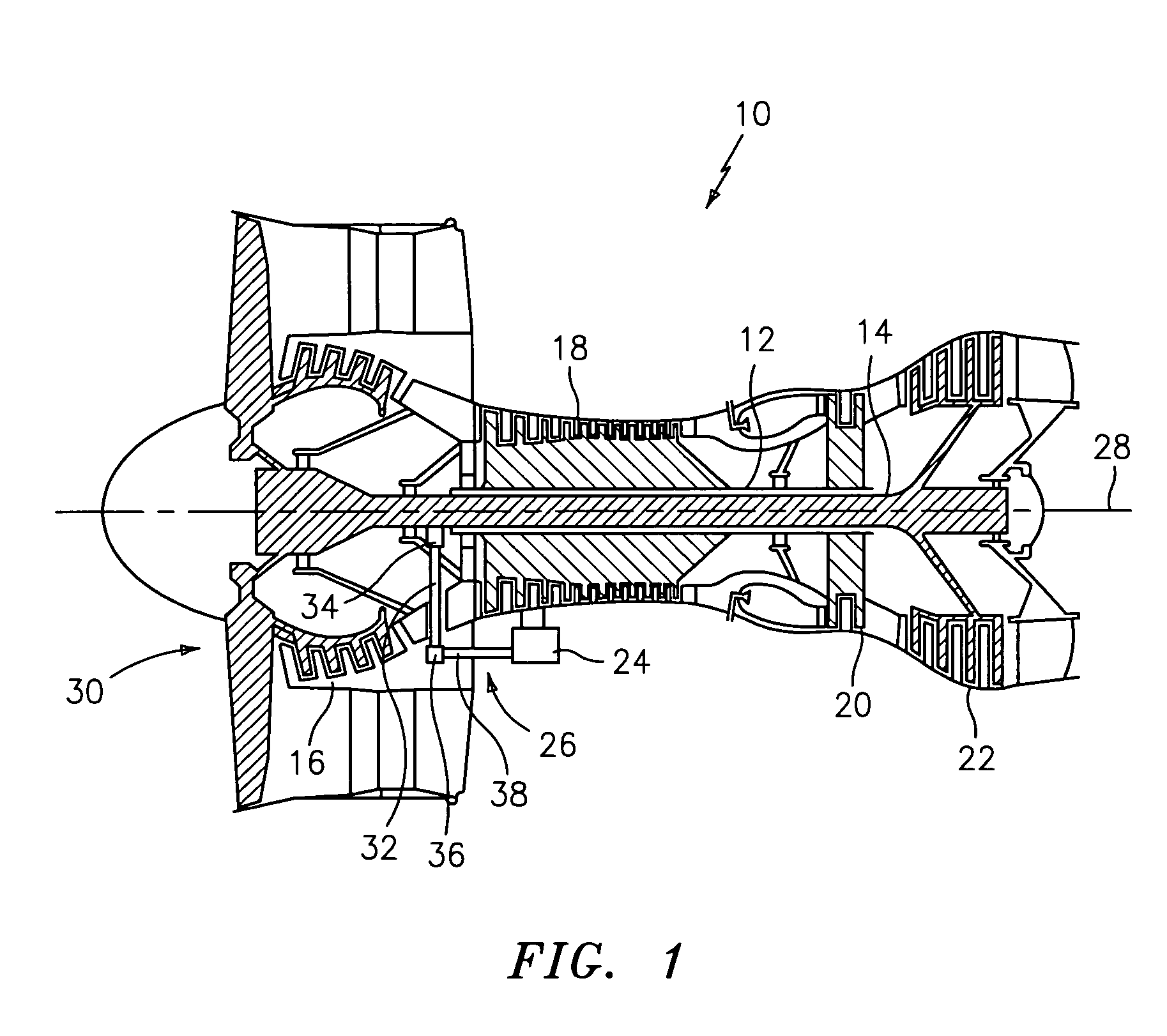

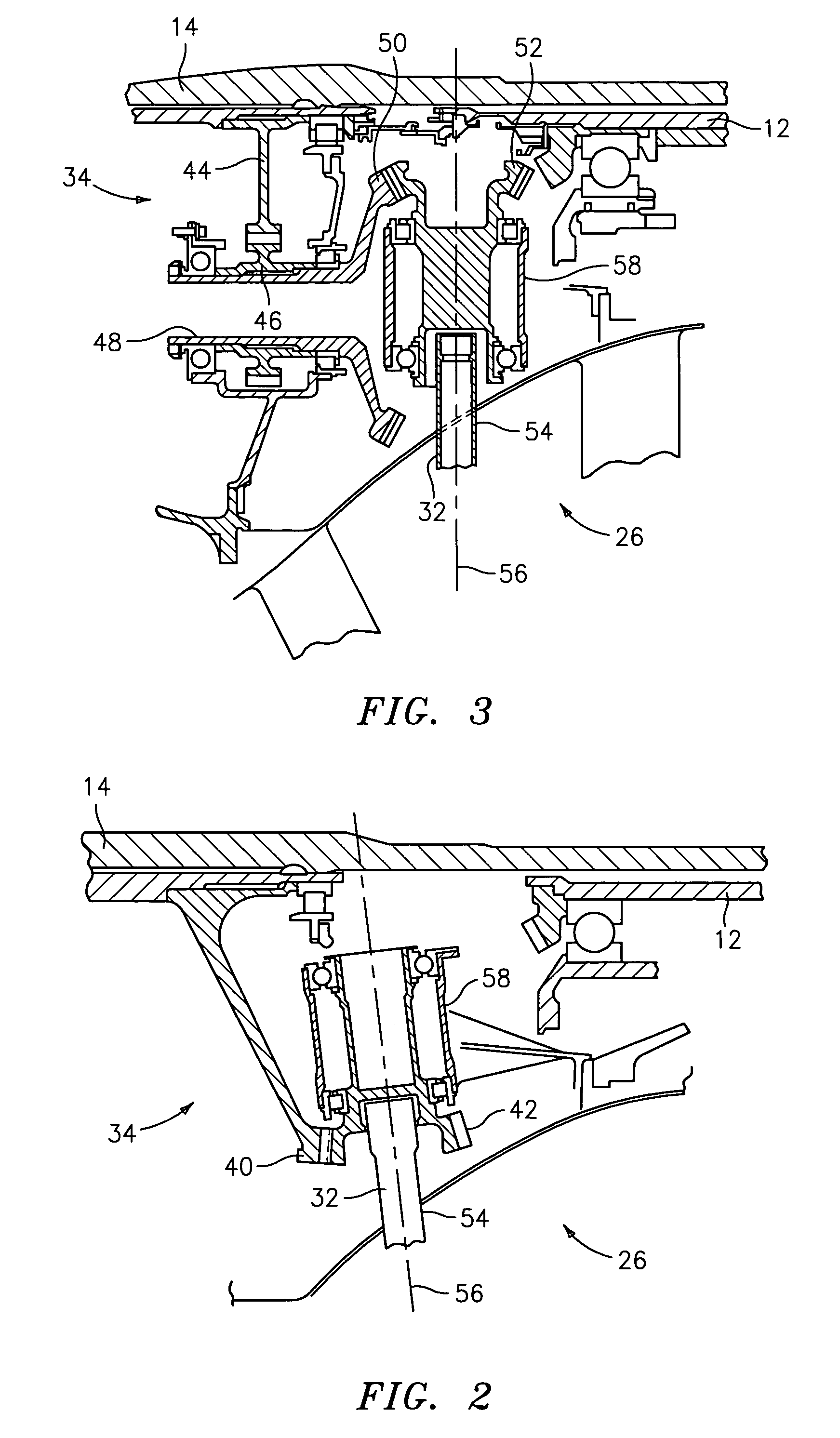

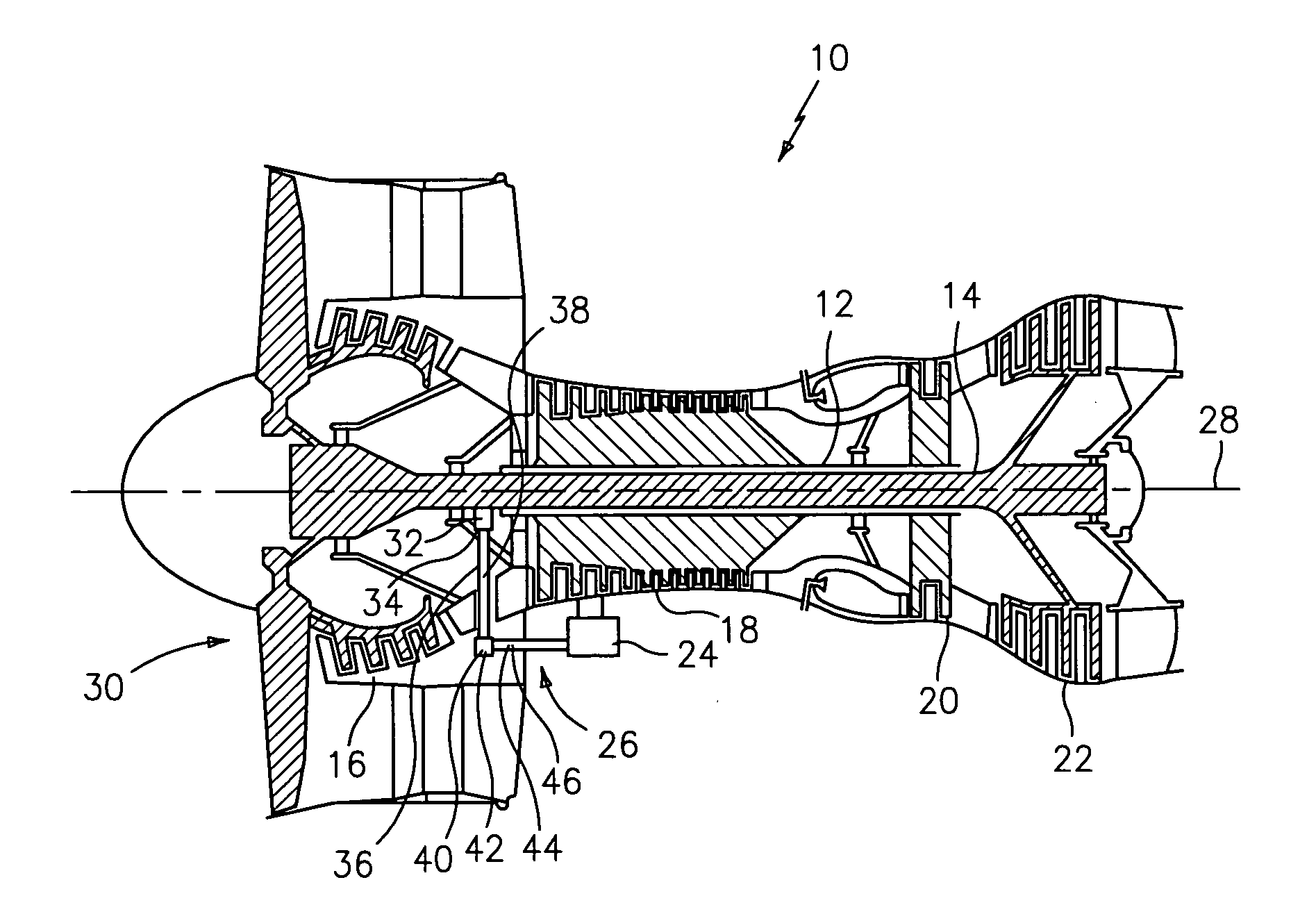

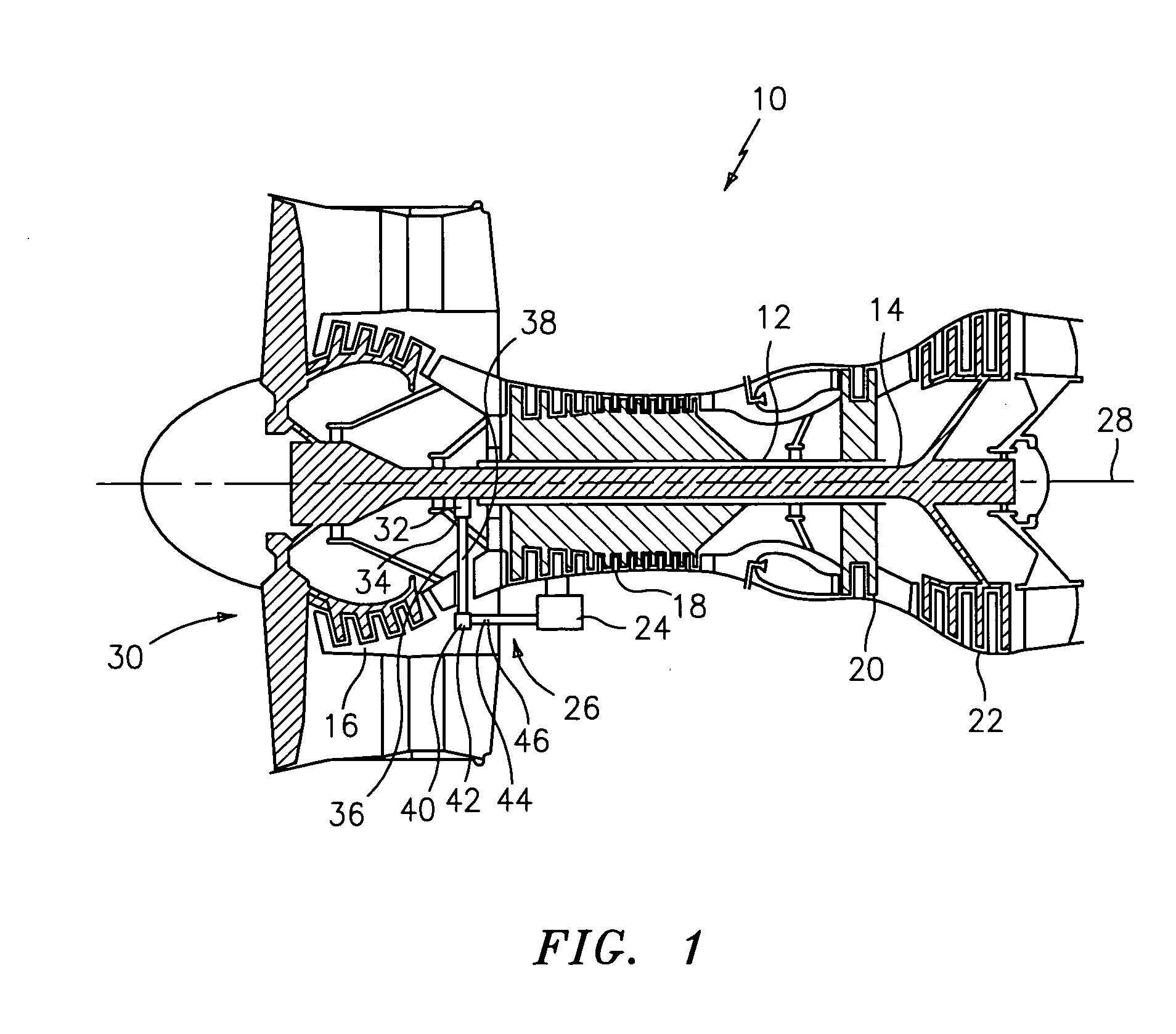

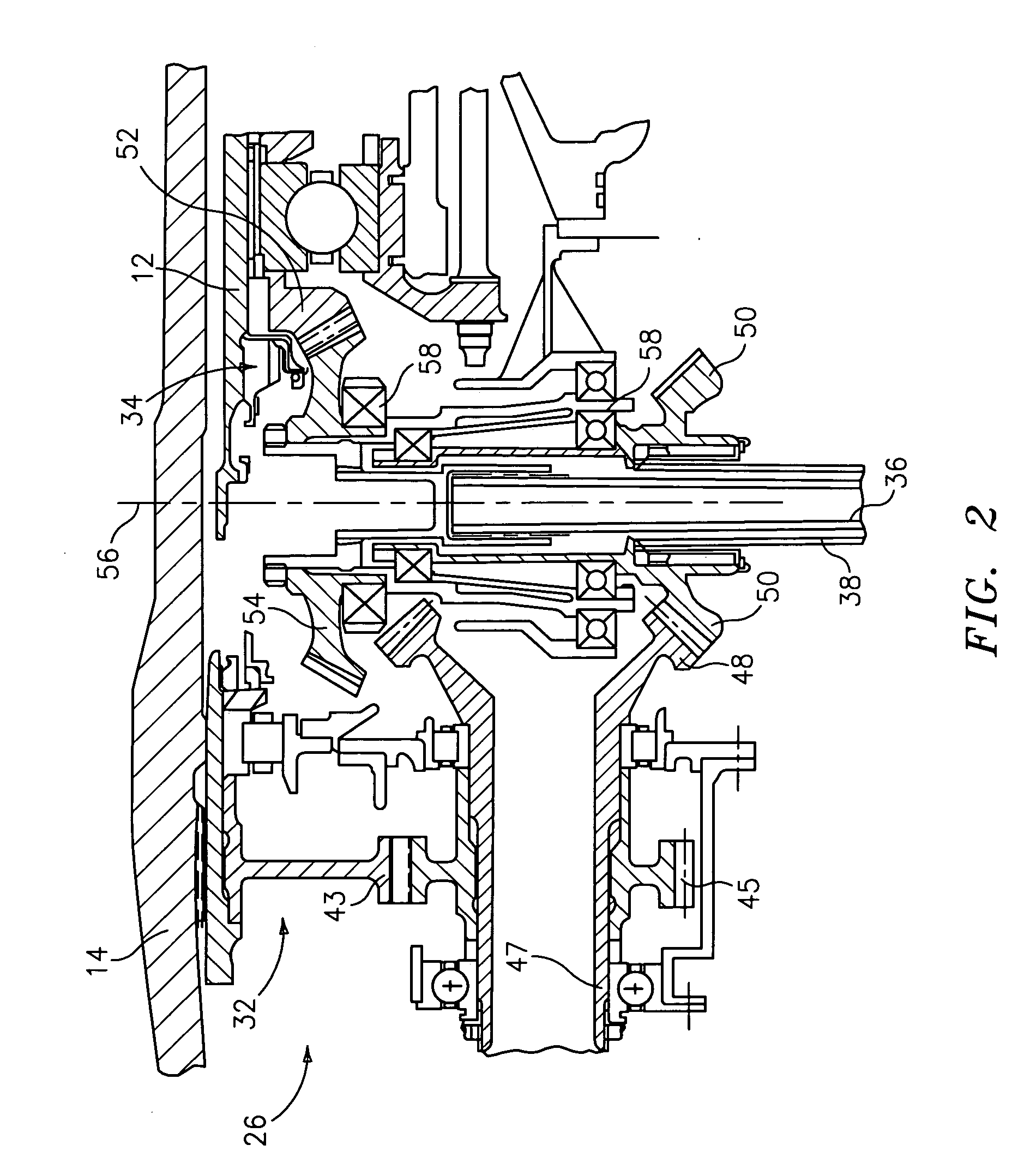

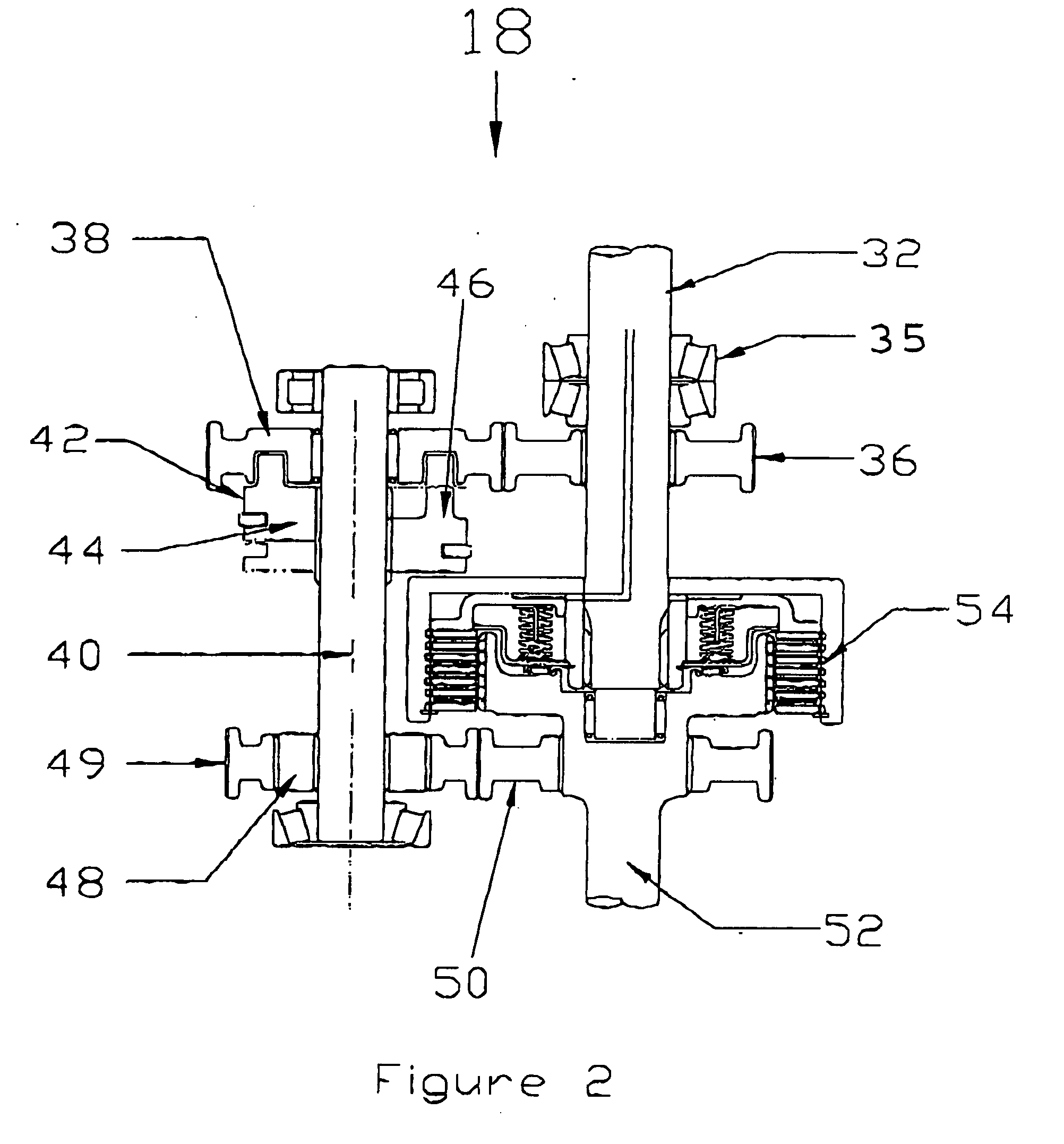

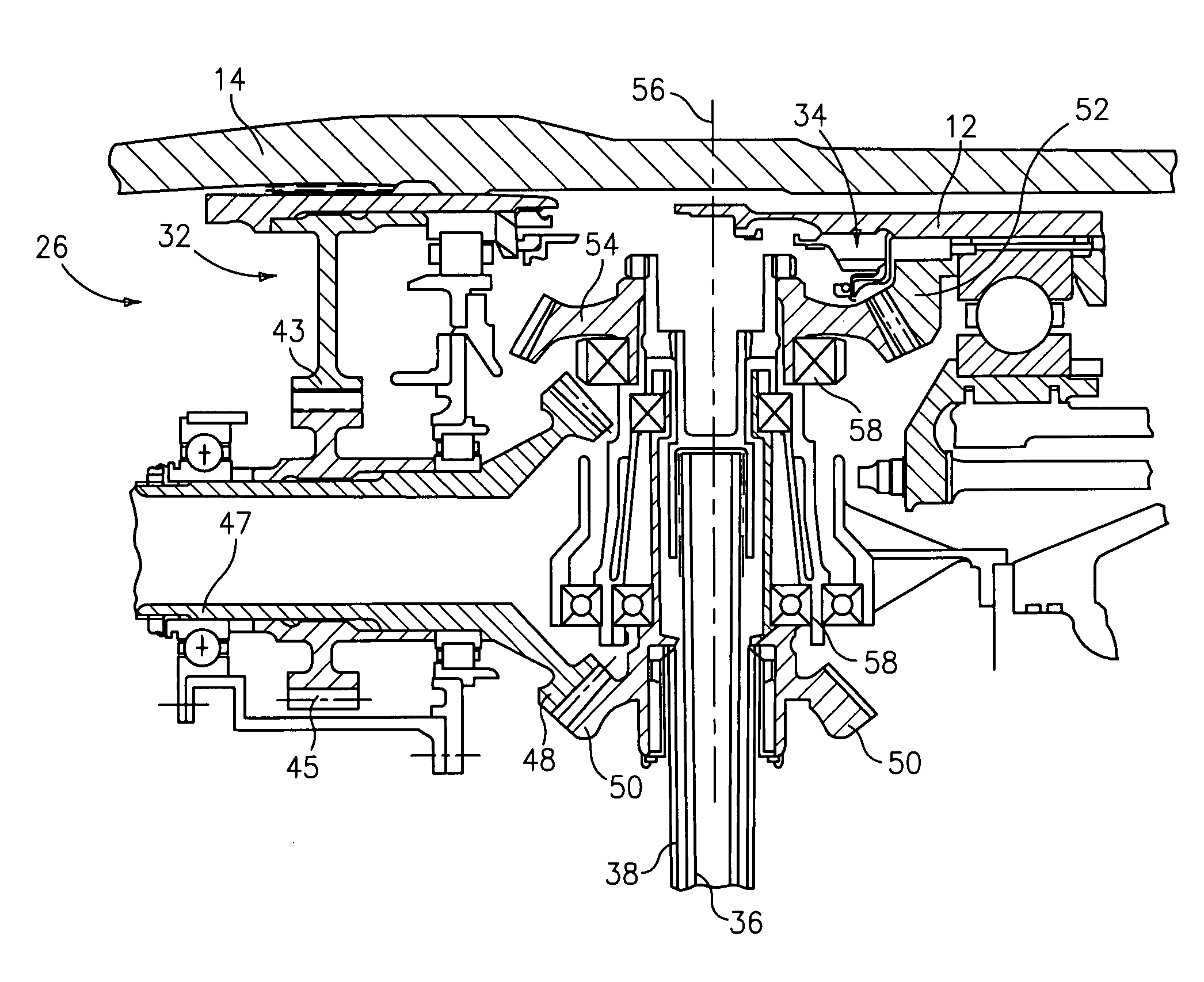

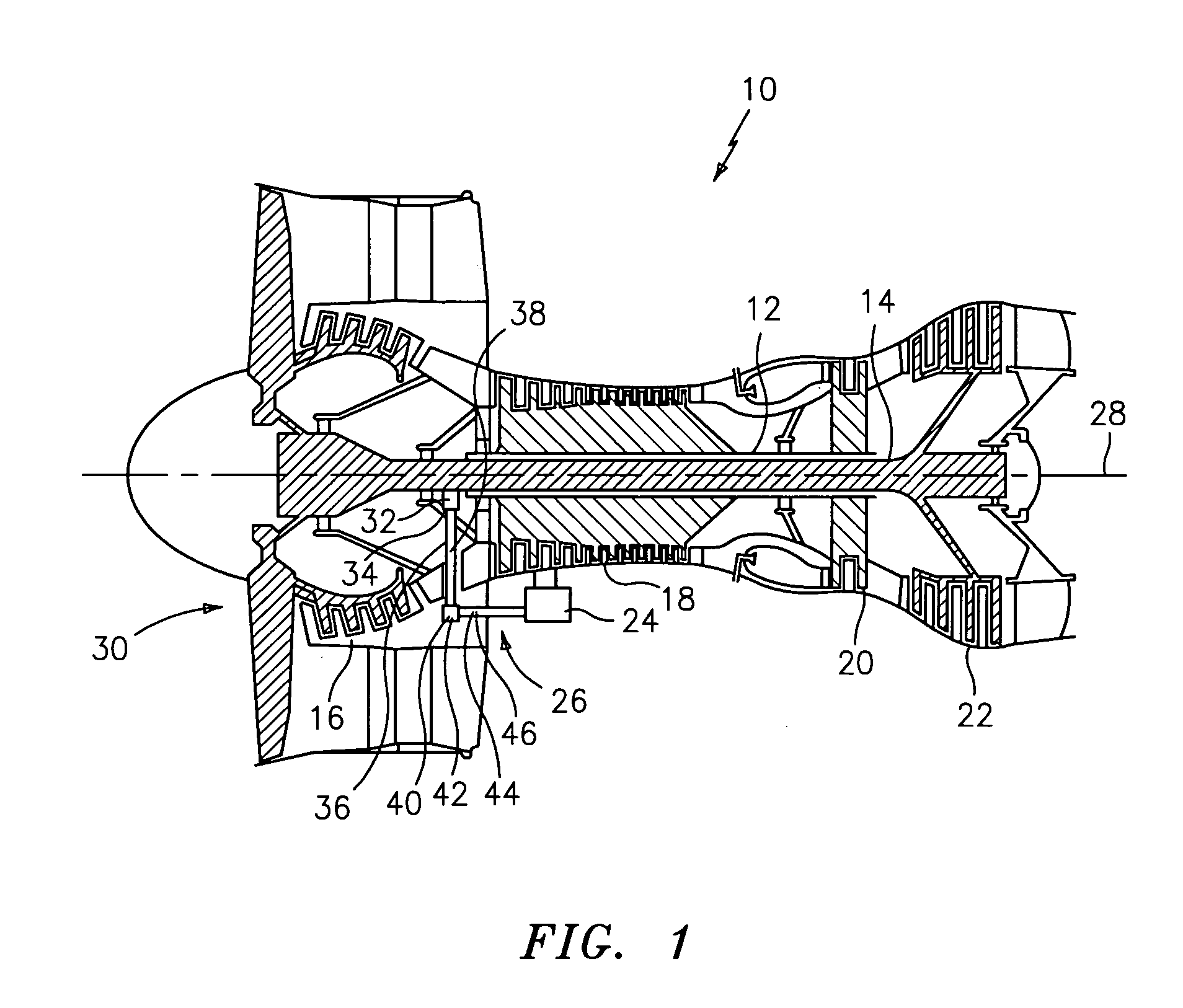

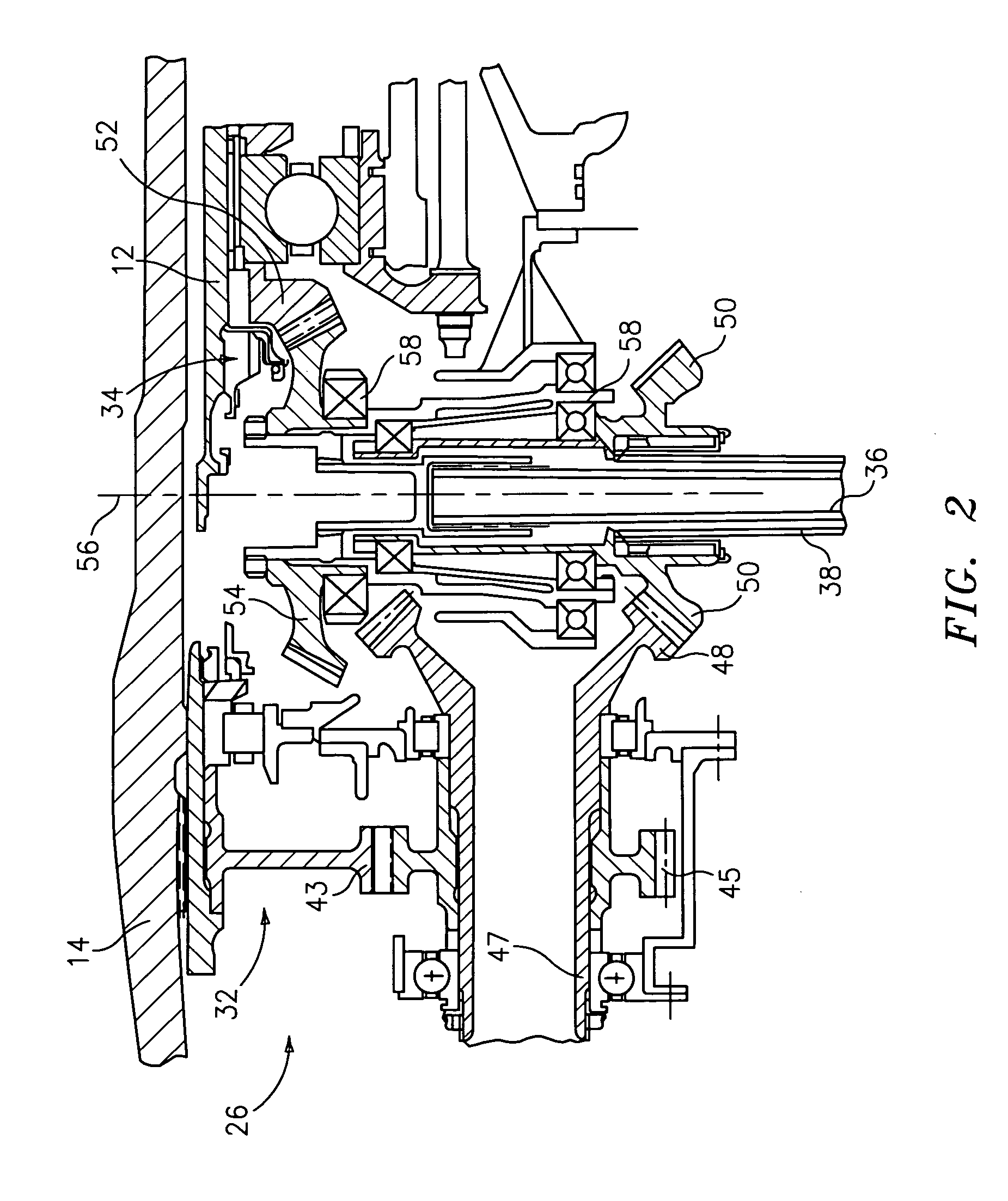

Apparatus for driving an accessory gearbox in a gas turbine engine

InactiveUS7055330B2Increased versatility and capabilityEngine fuctionsToothed gearingsPressure.driveDrive shaft

Owner:UNITED TECH CORP

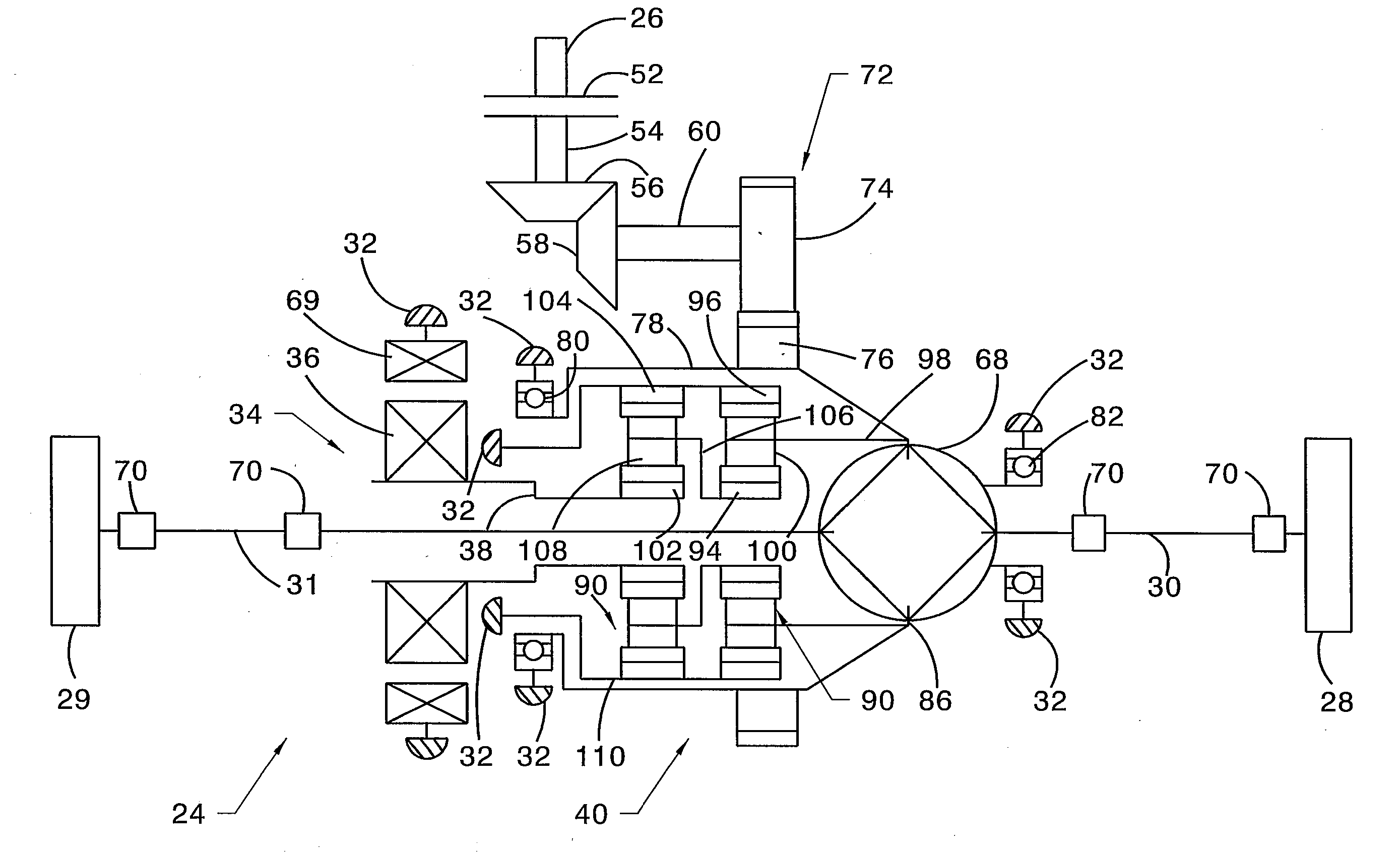

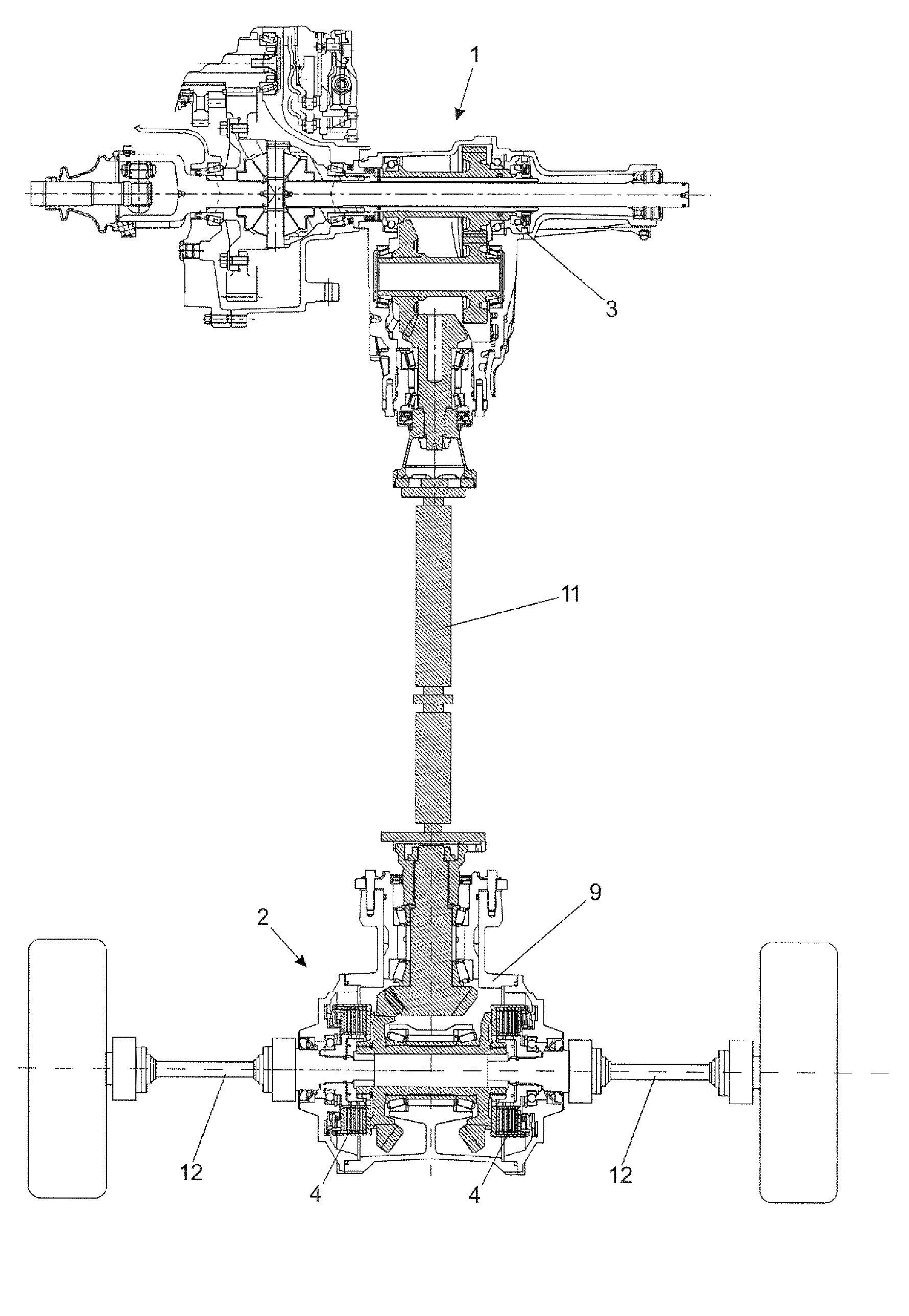

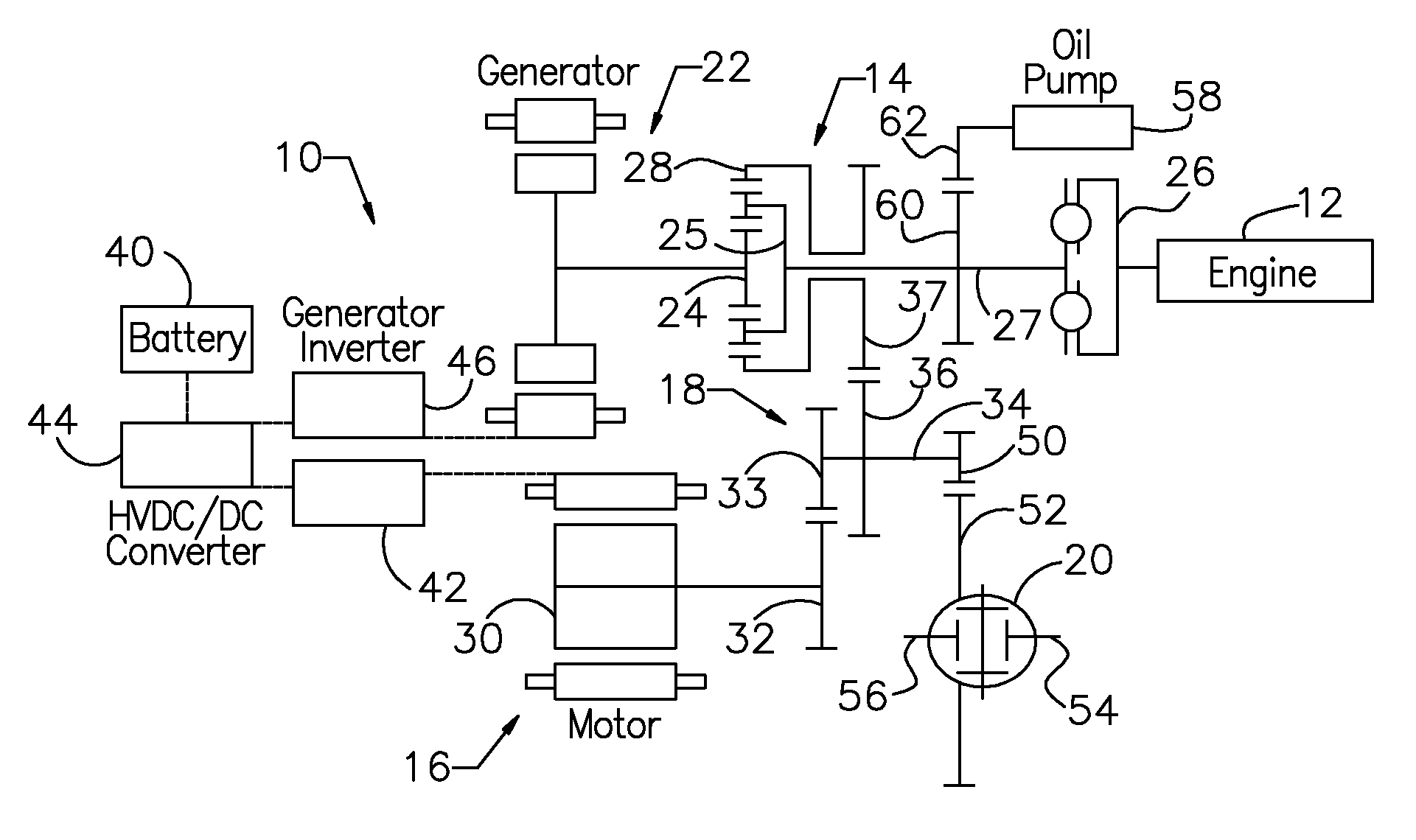

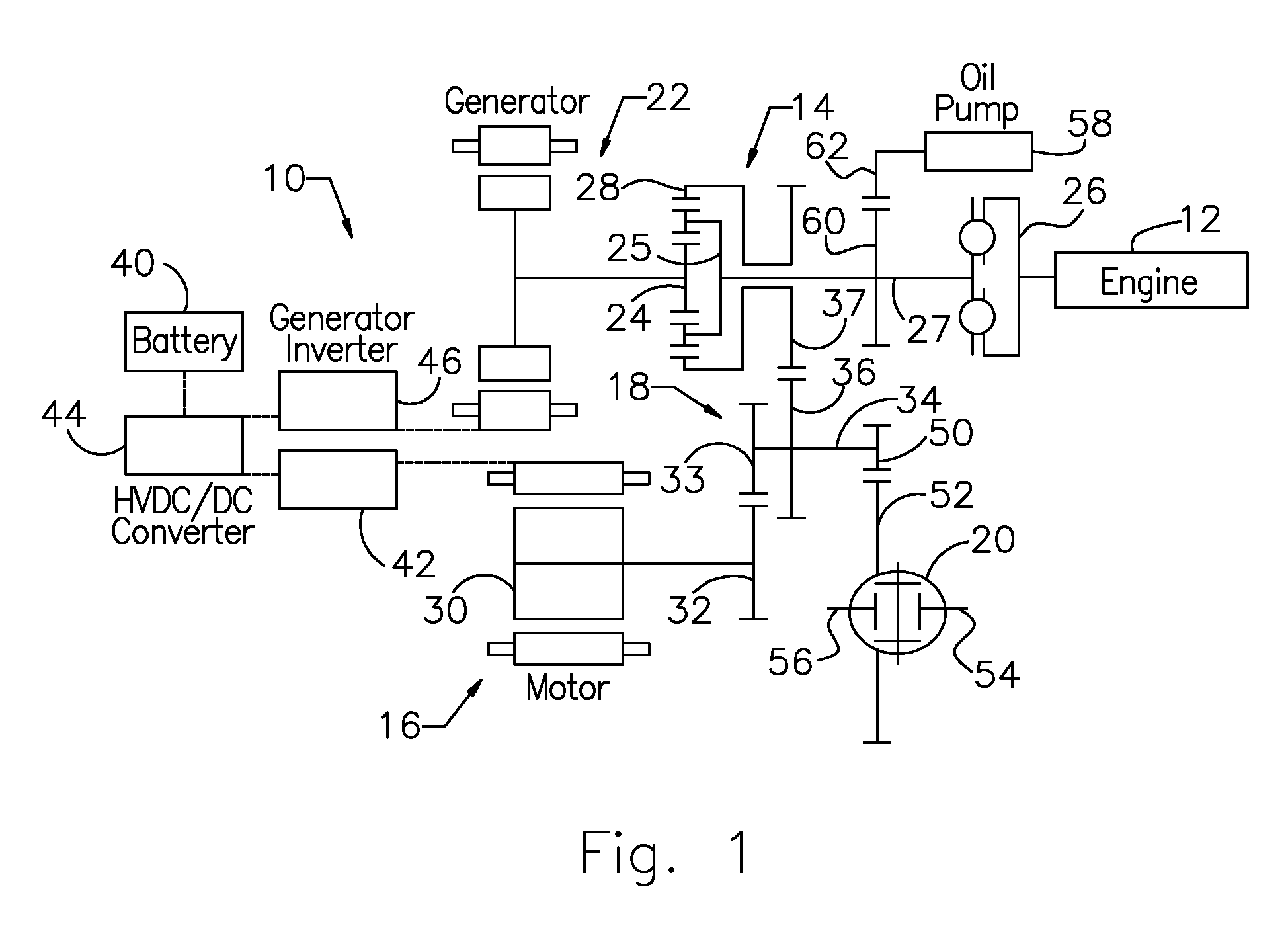

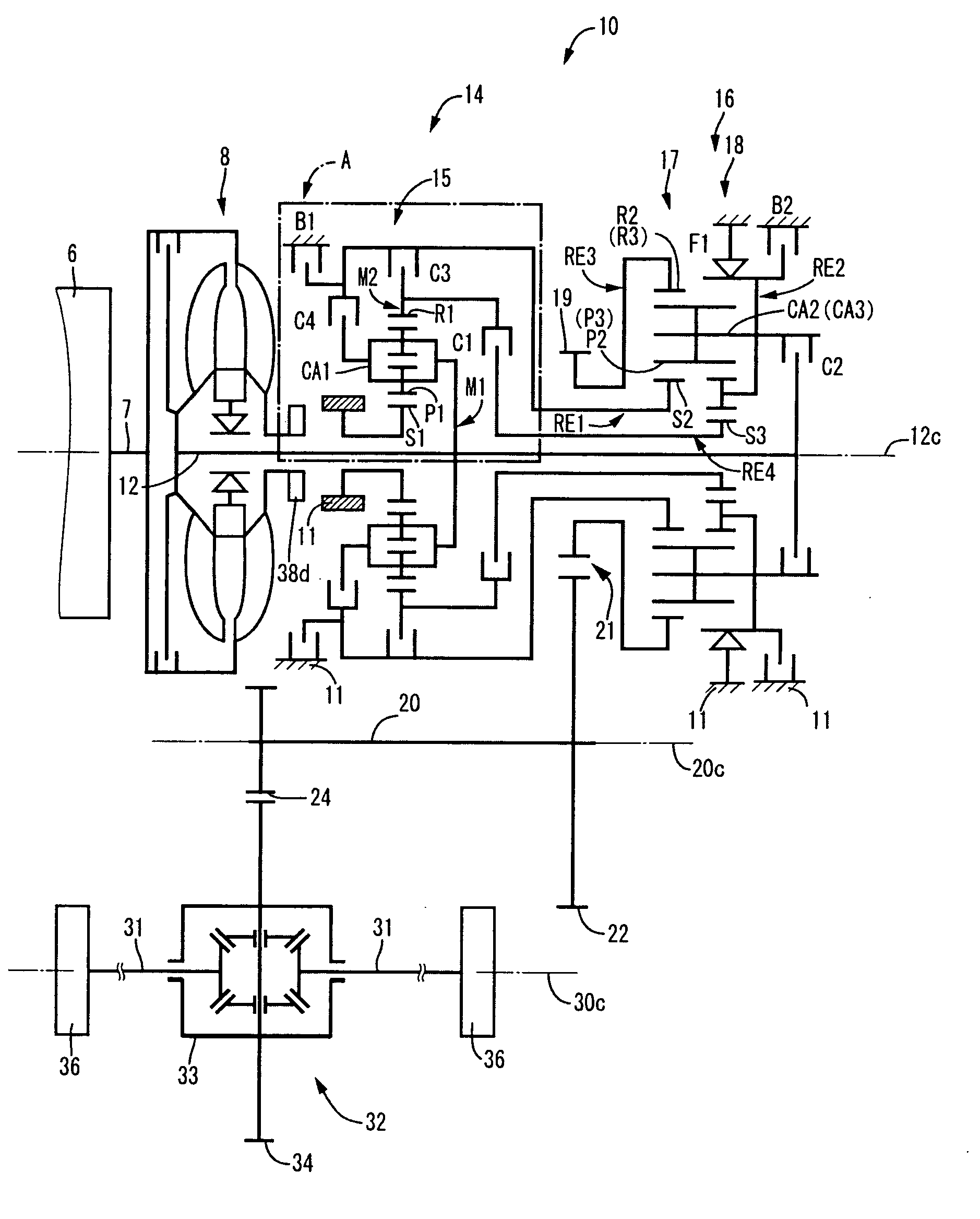

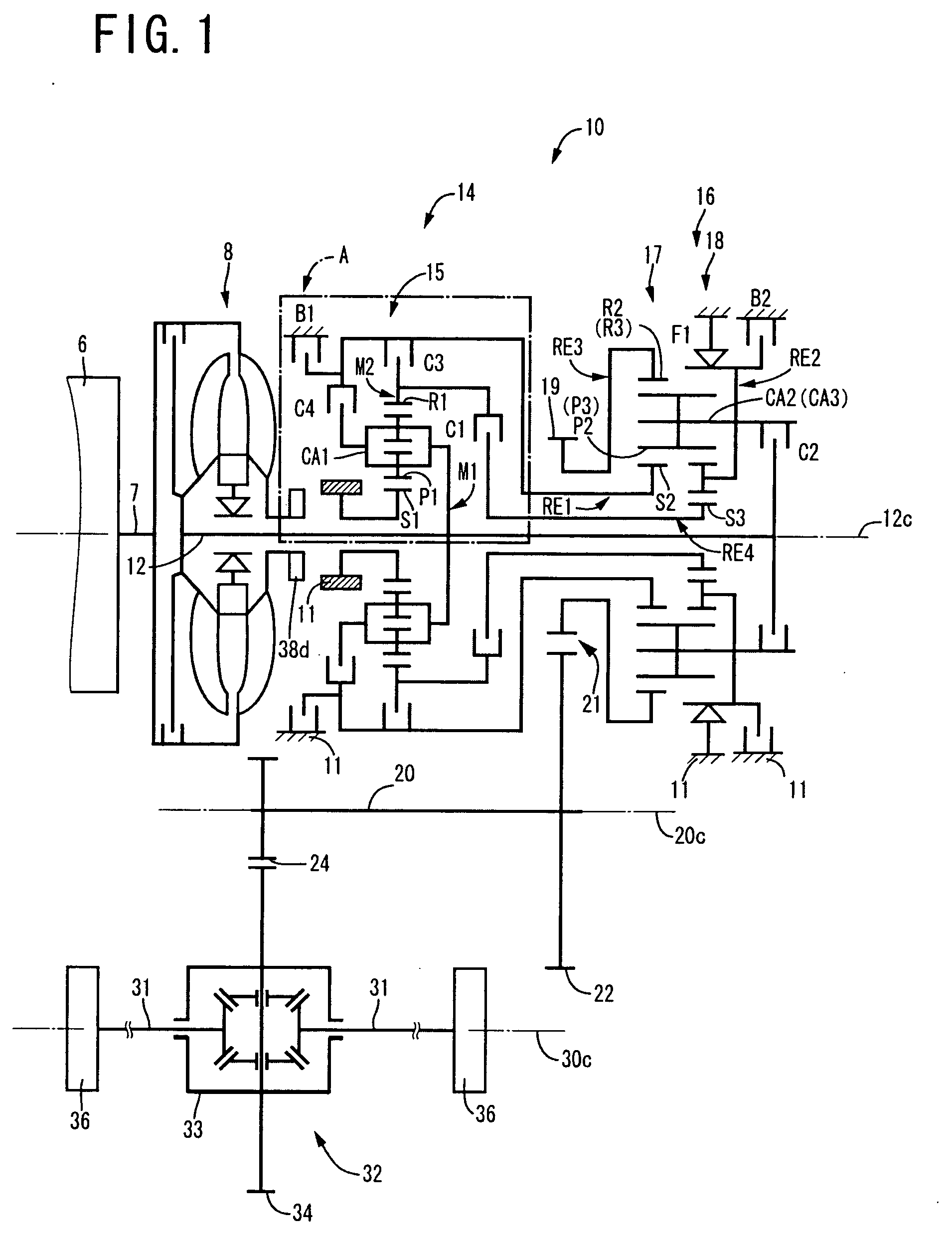

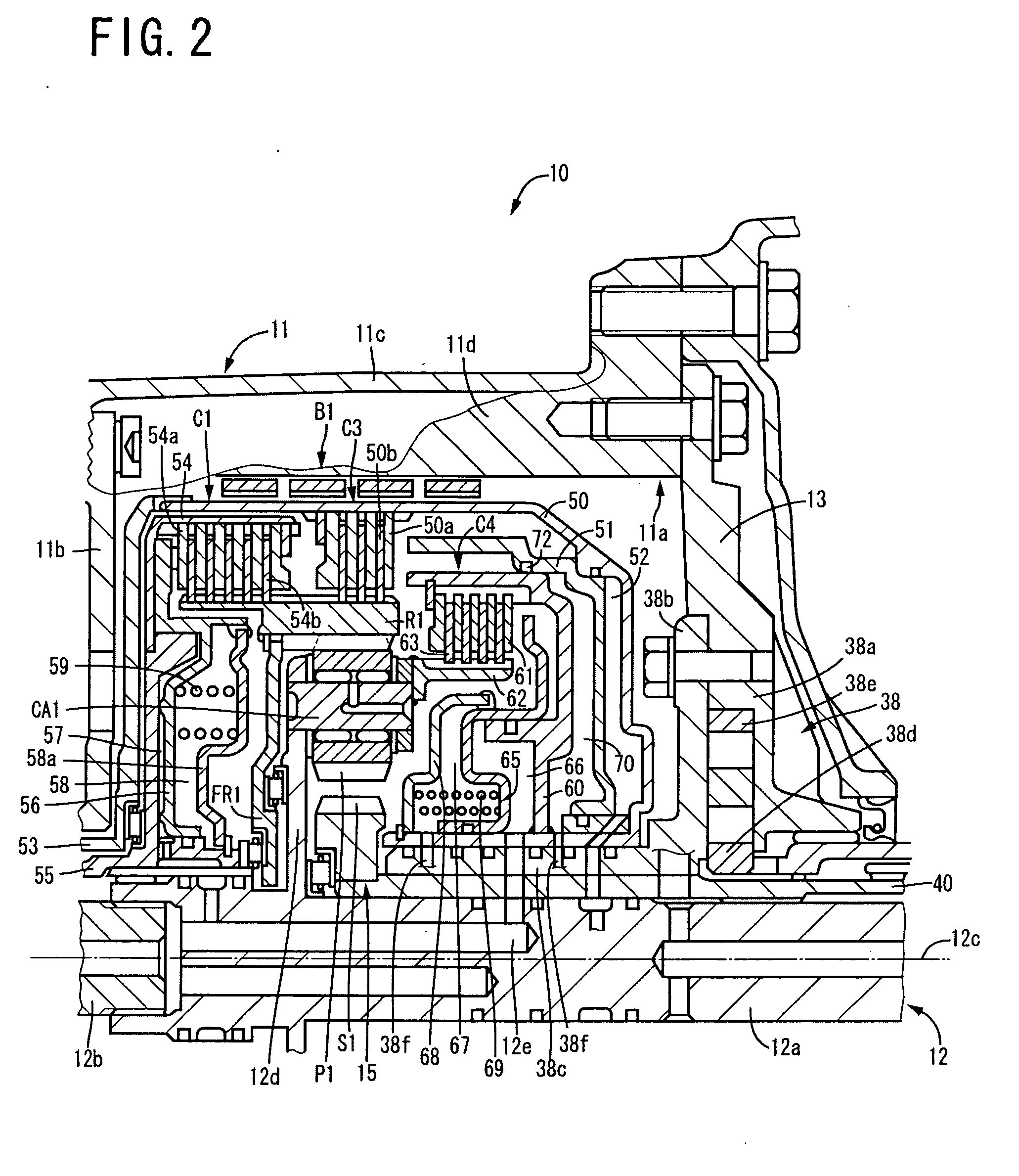

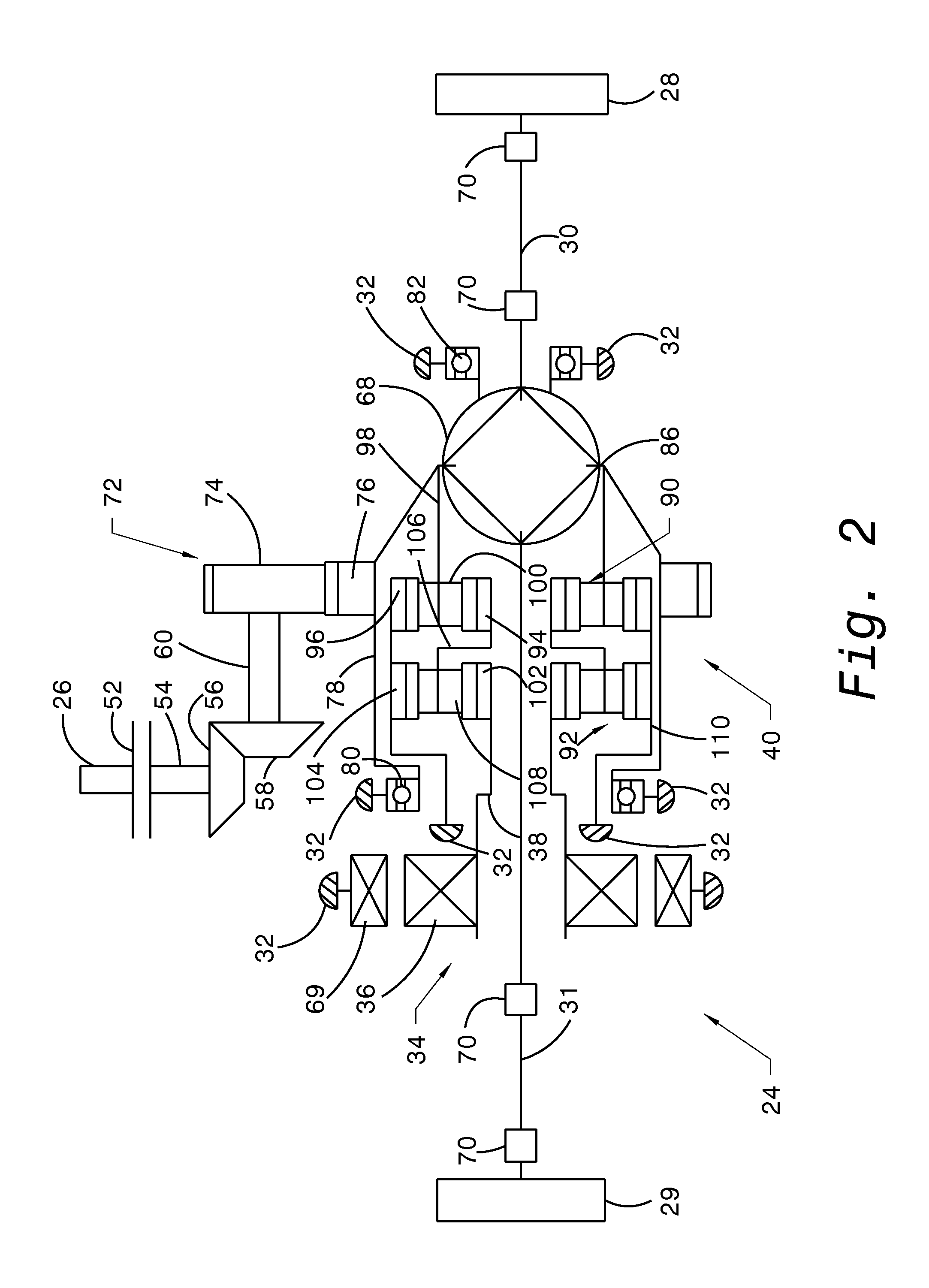

Axle drive unit for a hybrid electric vehicle

ActiveUS20090197727A1Simplifying bearing support requirementClosely positionedMotor/generator/converter stoppersElectric propulsion mountingTransmitted powerElectric machine

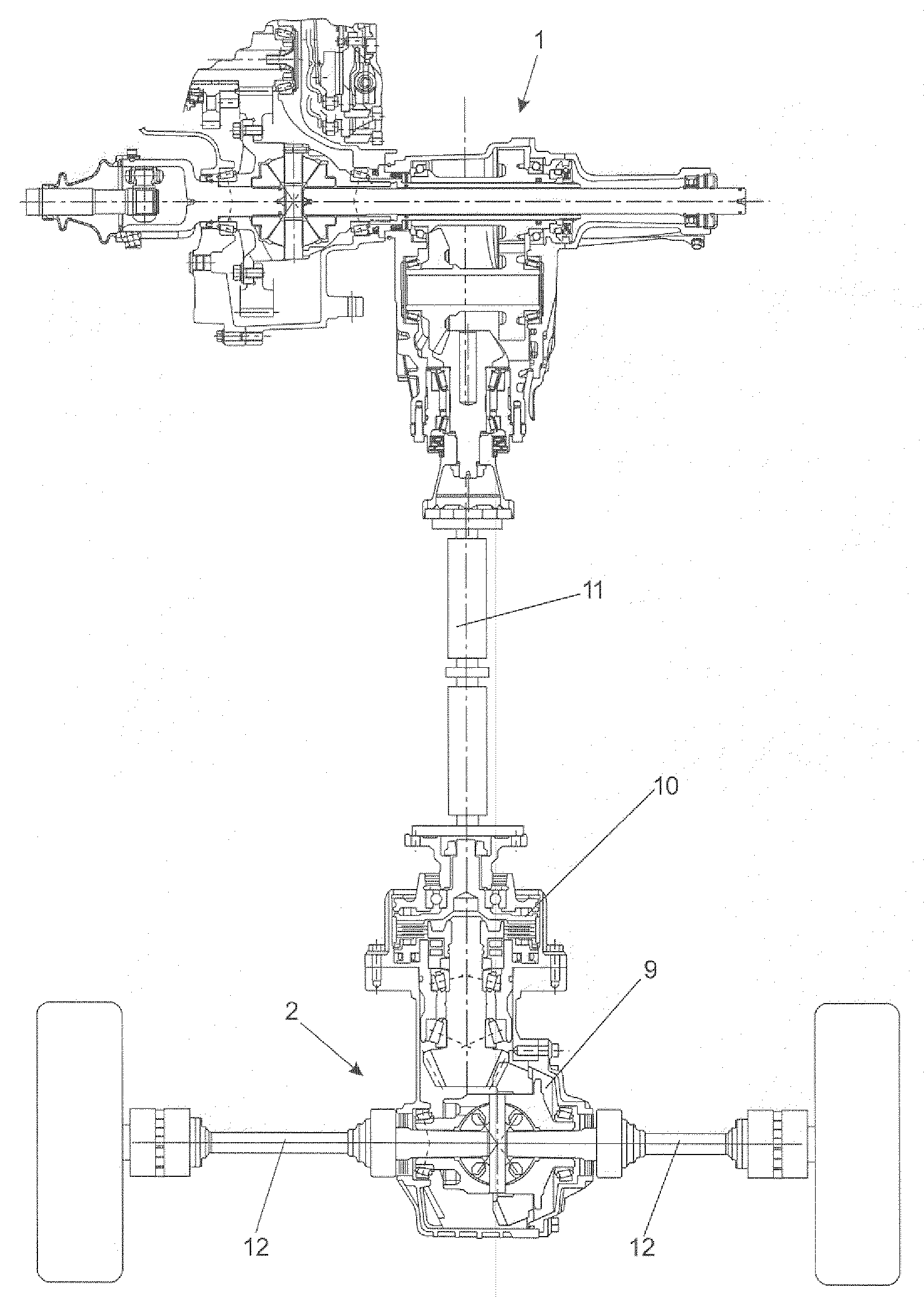

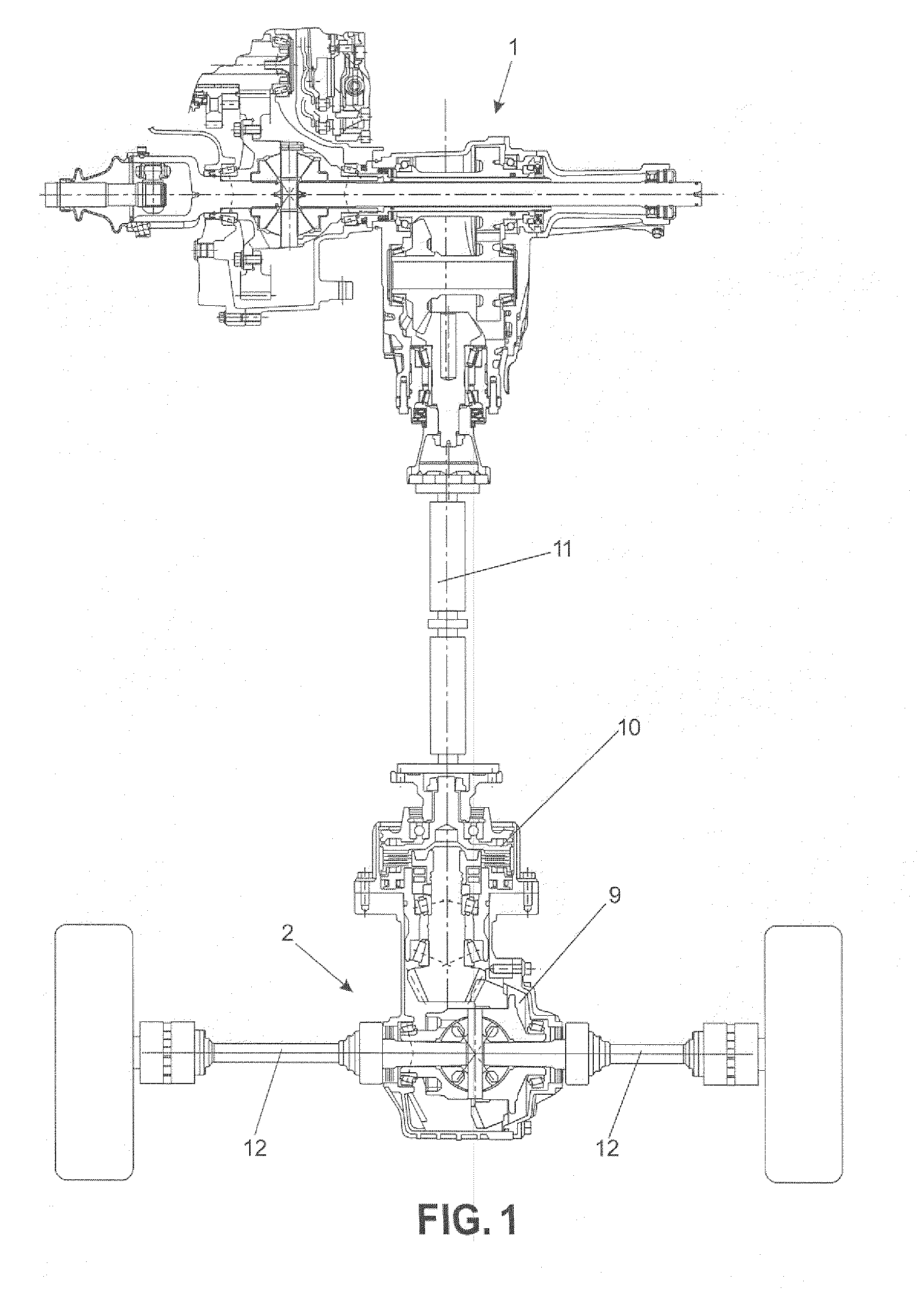

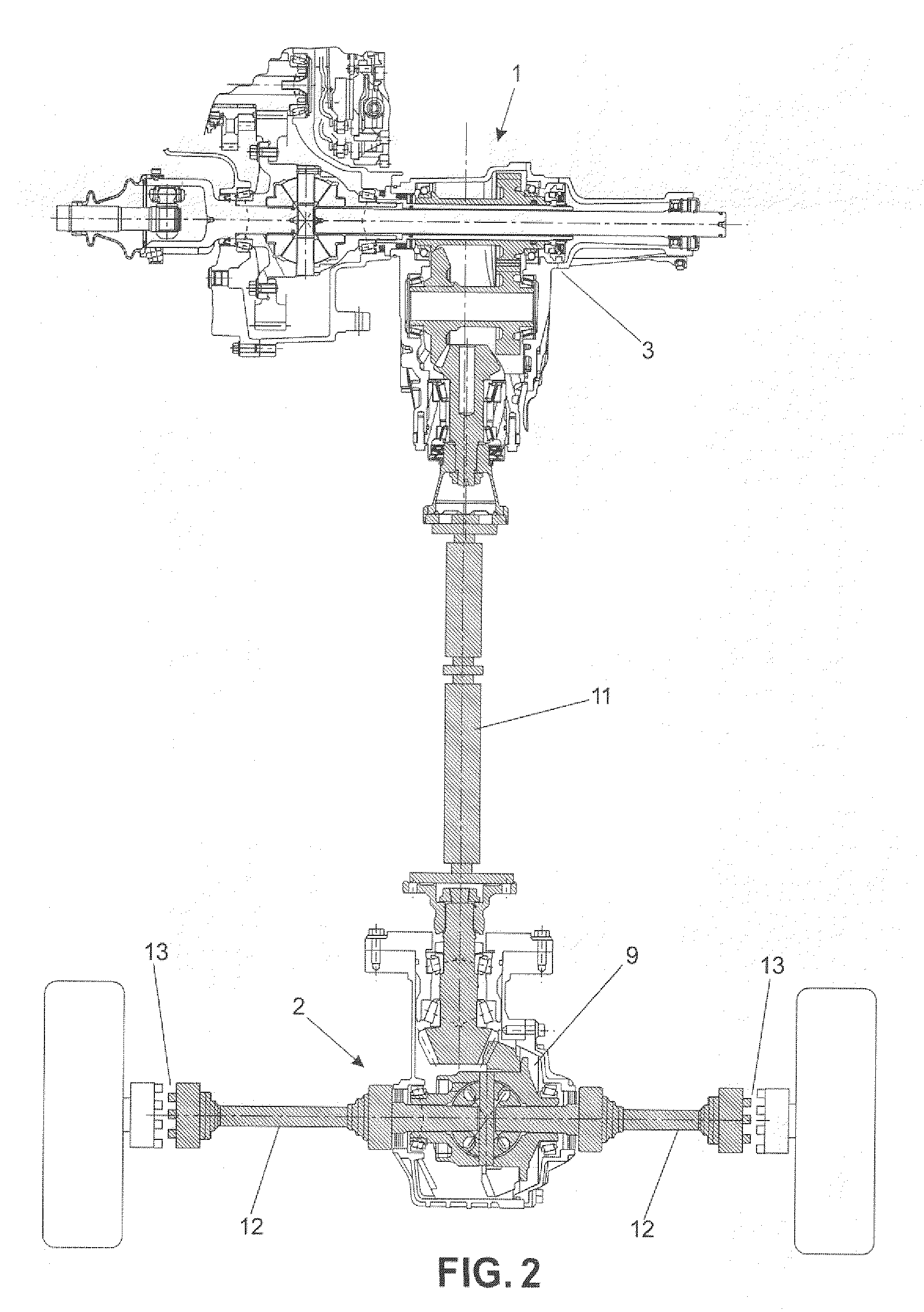

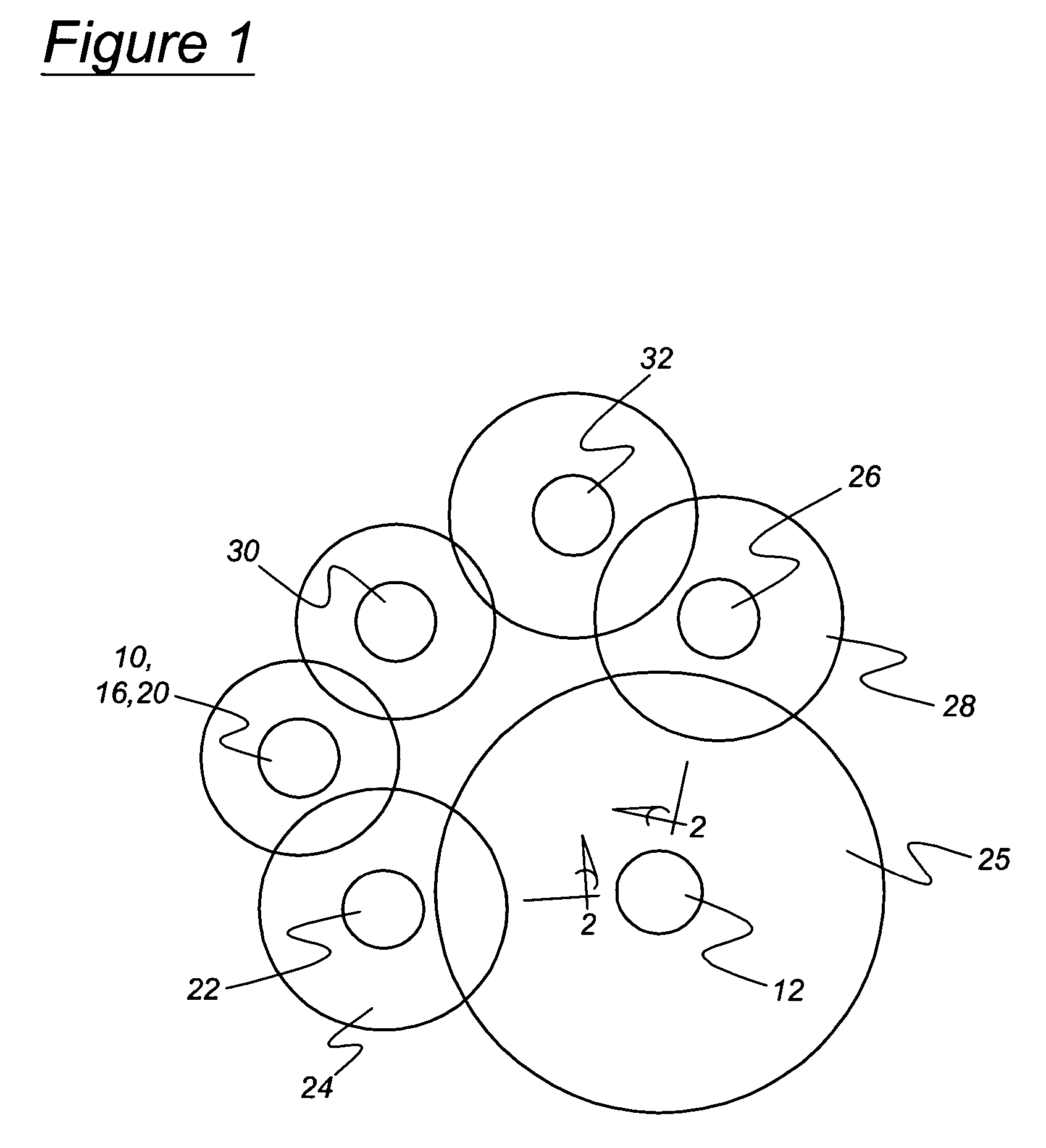

A drive unit for a hybrid electric motor vehicle includes an engine, an electric machine including a rotor, a layshaft gearset including an input driveably connected to the engine and an output, for transmitting power between the input and the output and producing a first speed differential that causes a speed of the input to exceed a speed of the output, first and second driveshafts, a differential mechanism driveably connected to said output, for transmitting power between said output and the driveshafts, and a planetary gear unit driveably connected to the output and the rotor, for transmitting power between said rotor and said output and producing a second speed differential that causes a speed of the rotor to exceed the speed of the output.

Owner:FORD GLOBAL TECH LLC

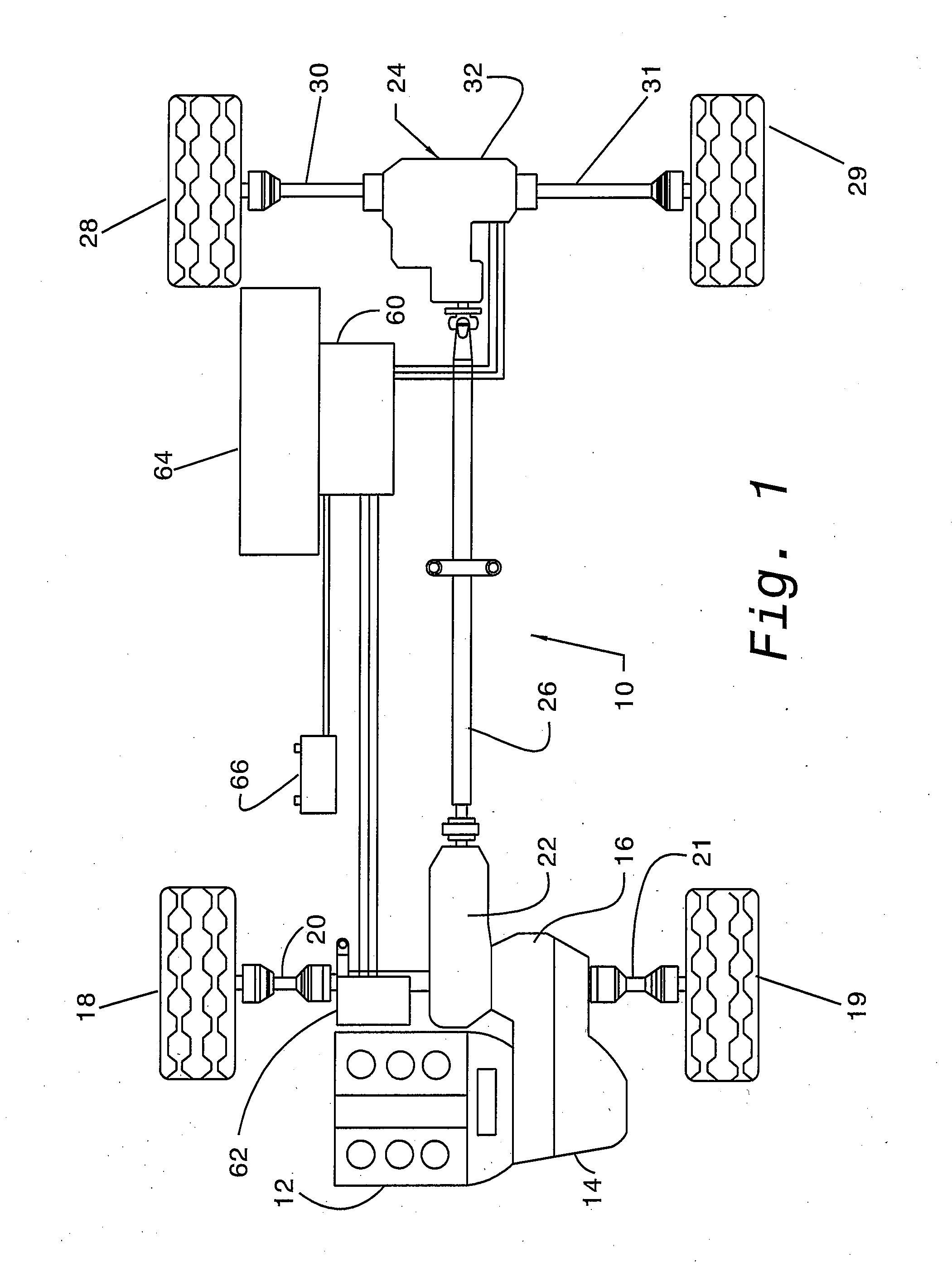

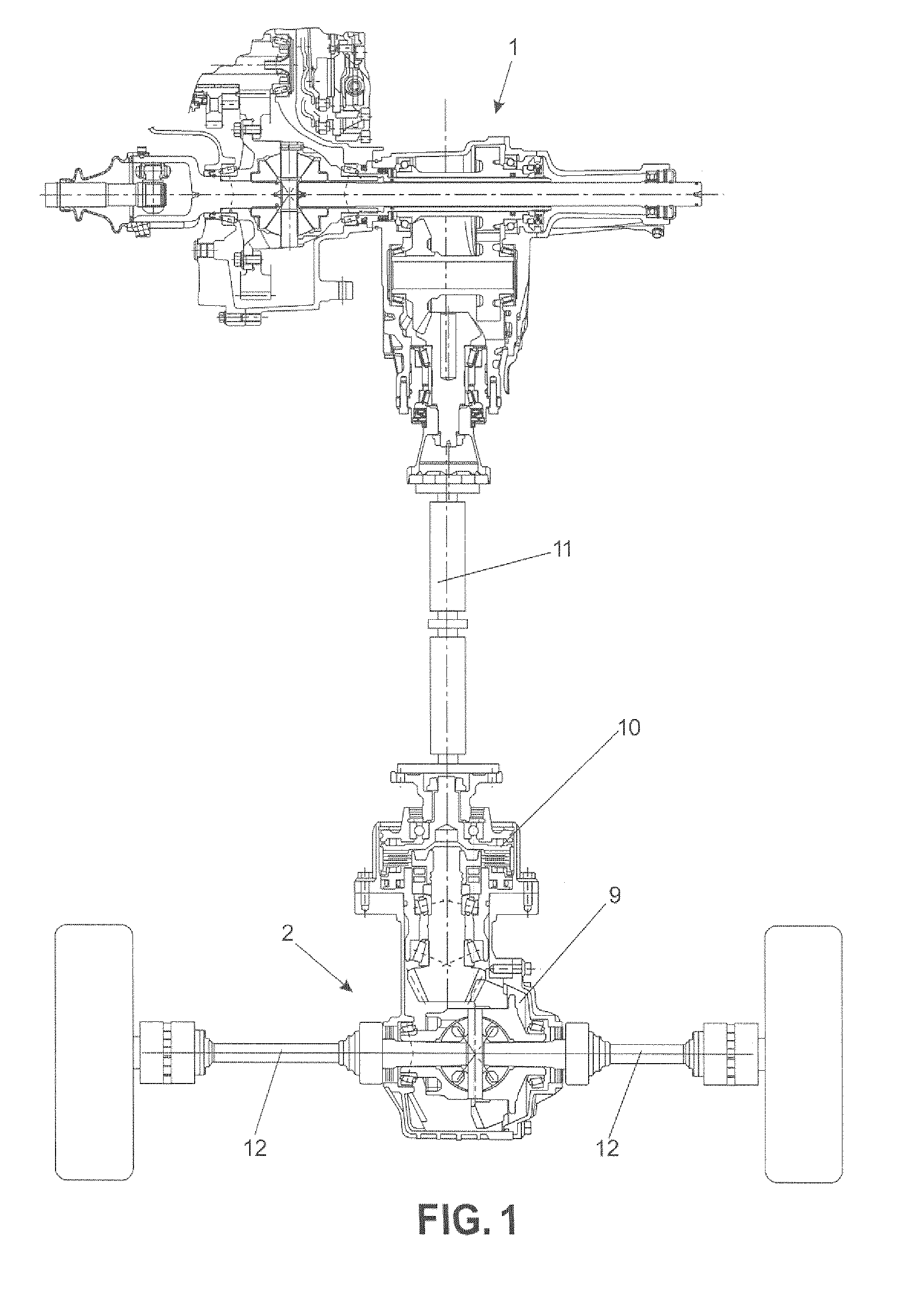

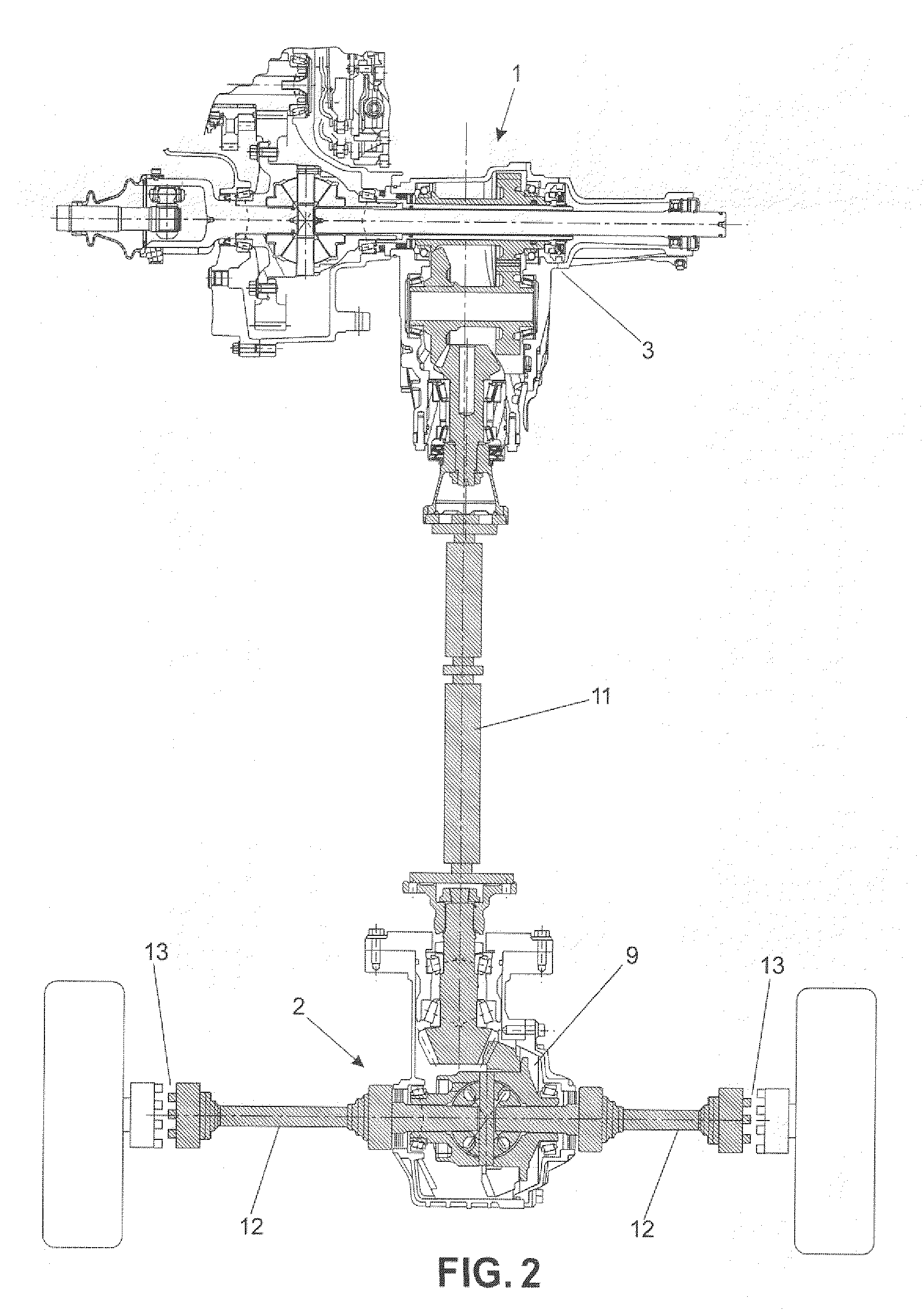

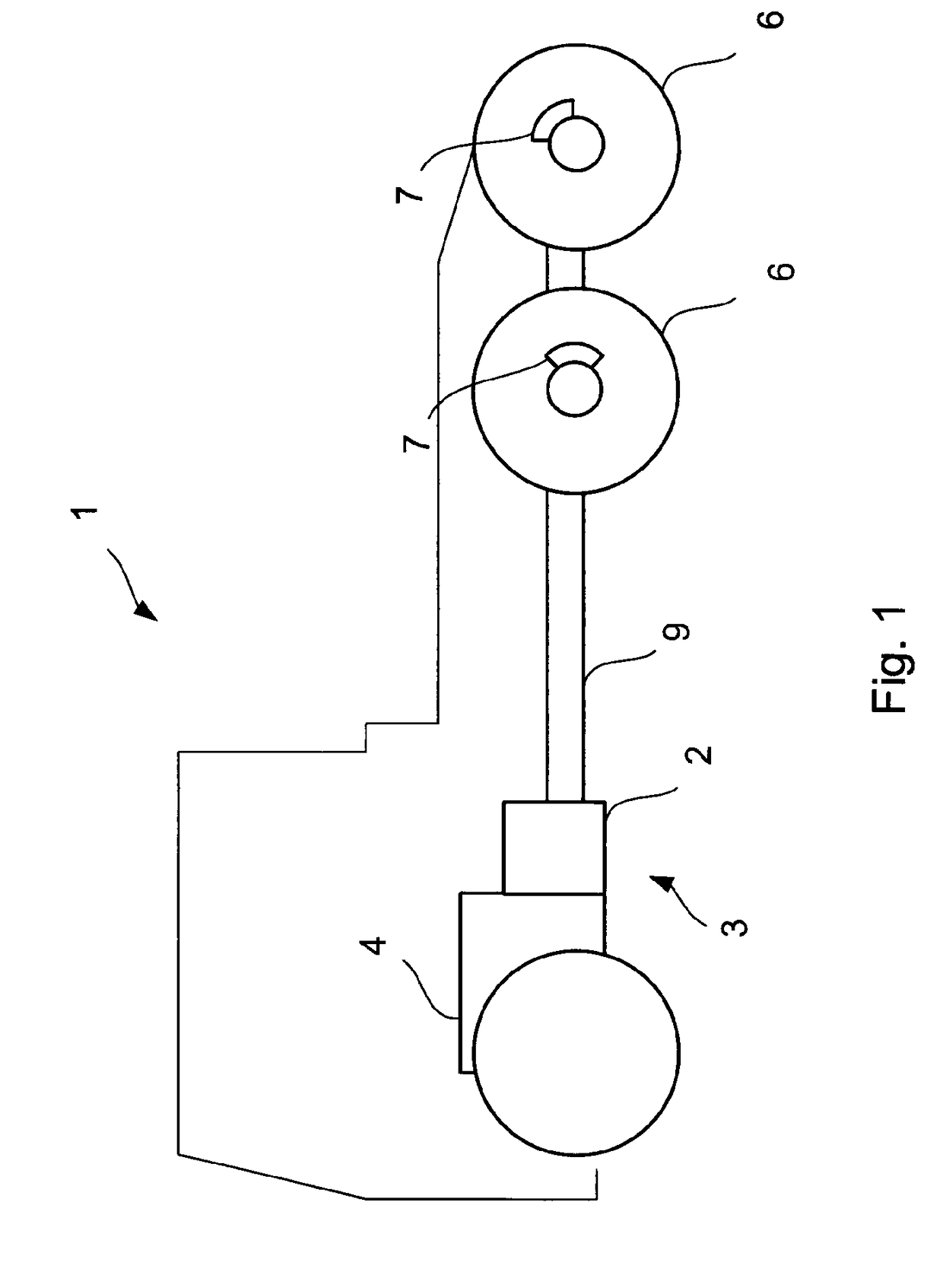

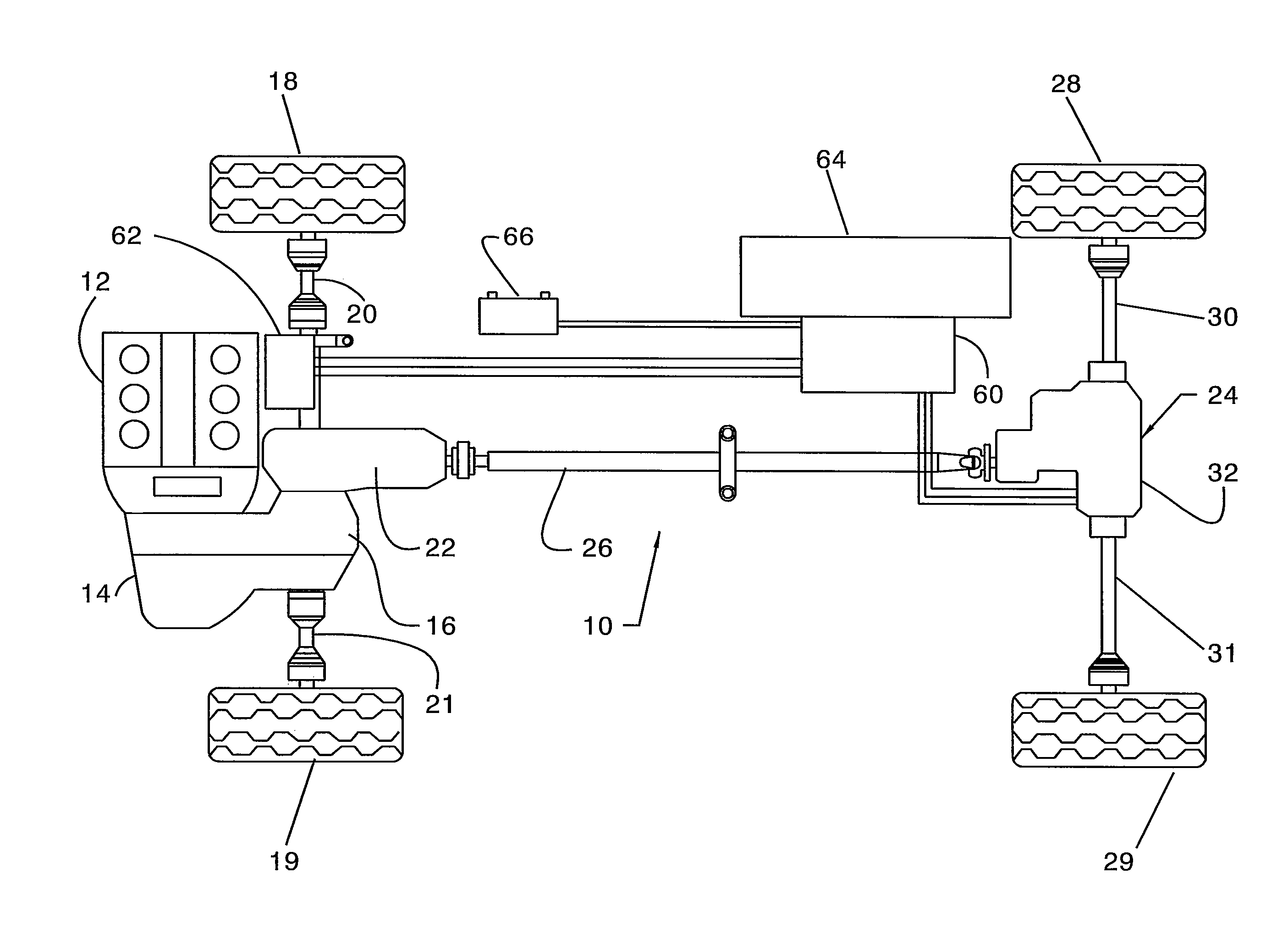

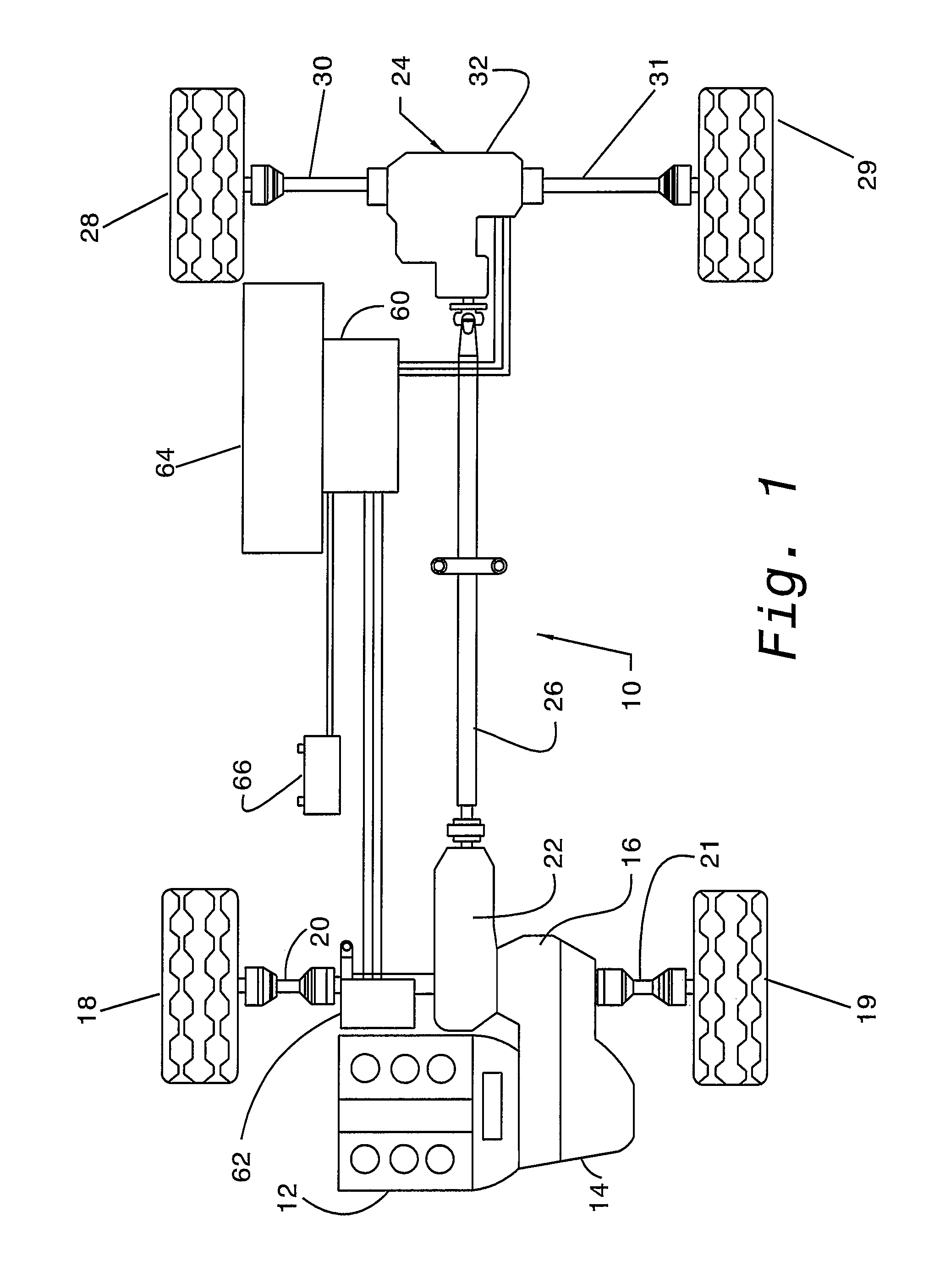

Drive train for a vehicle with connectable secondary axle

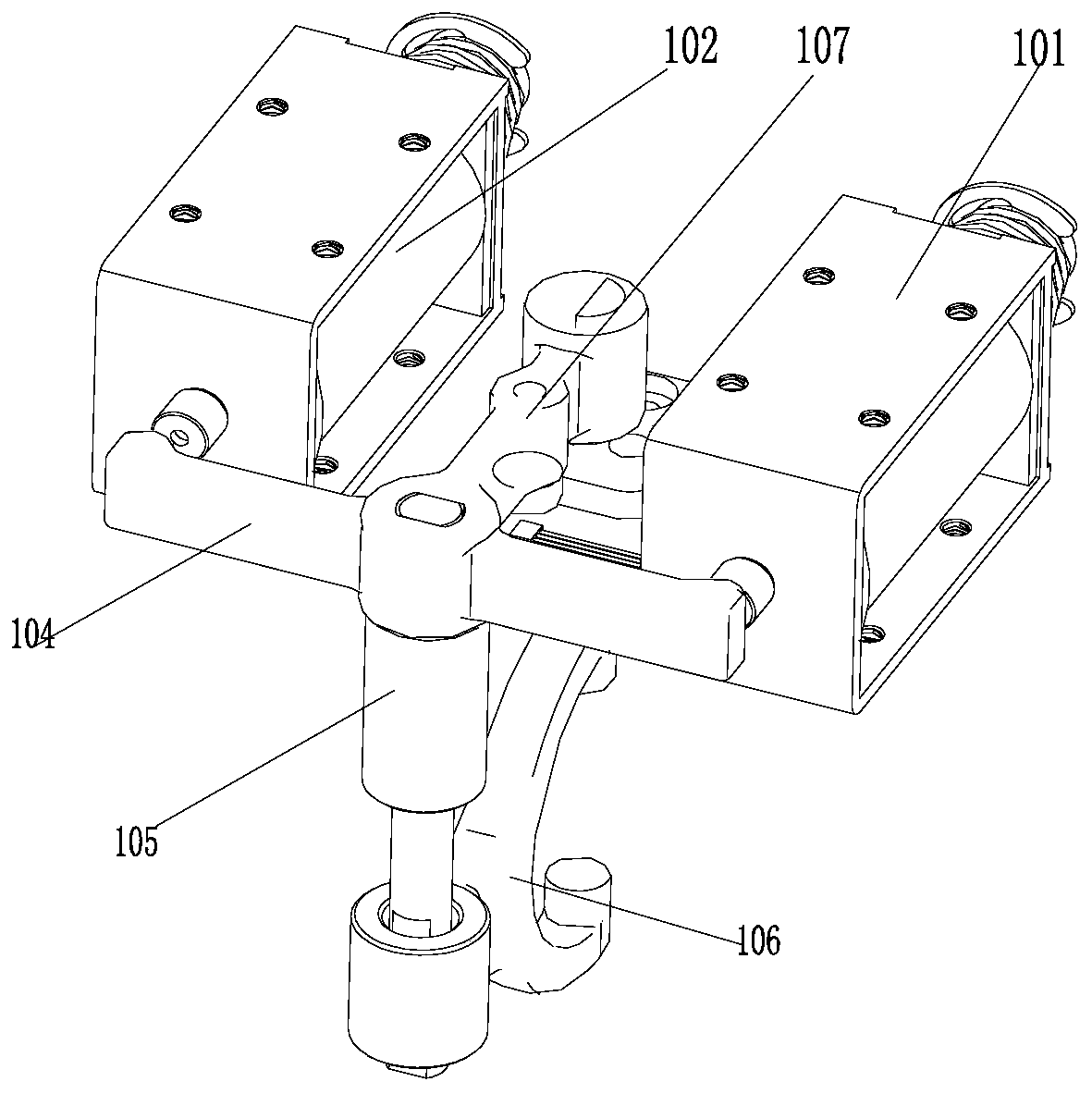

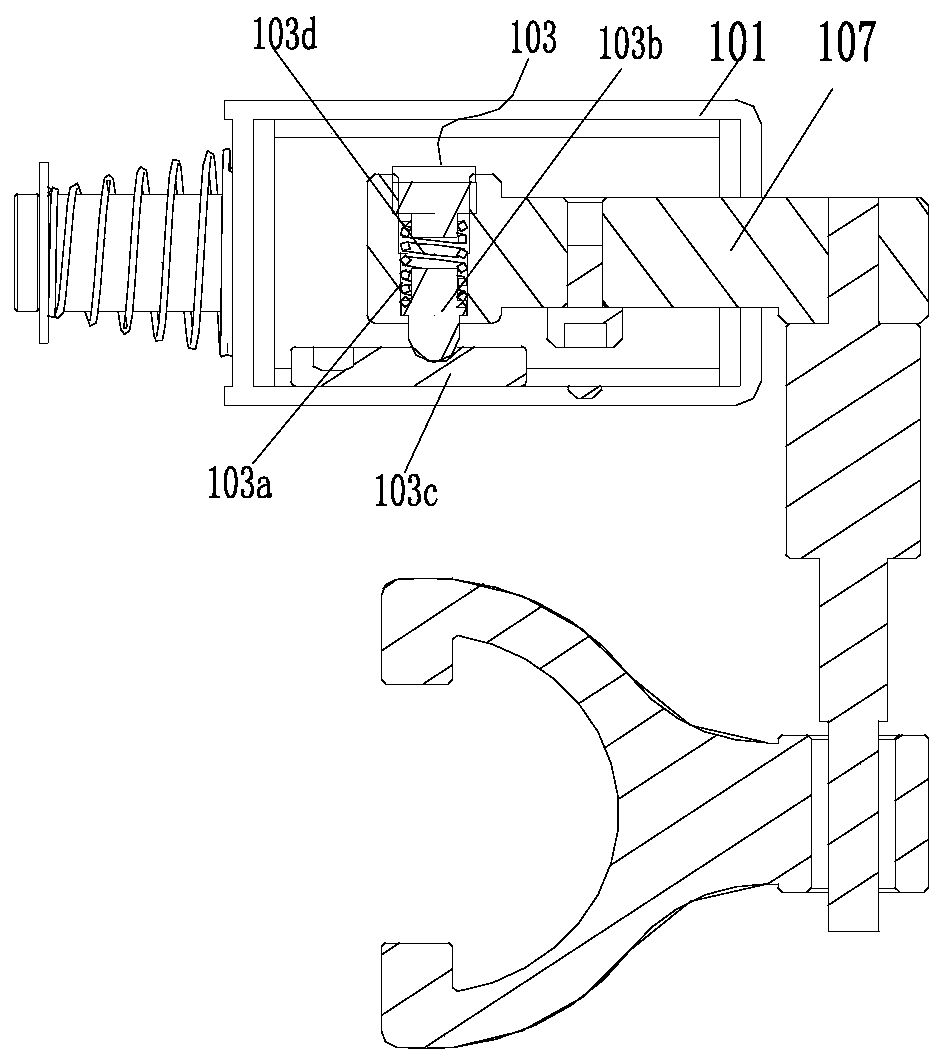

ActiveUS20090277711A1Reduce additional structural costPower Loss MinimizationControl devicesDrive wheelCoupling

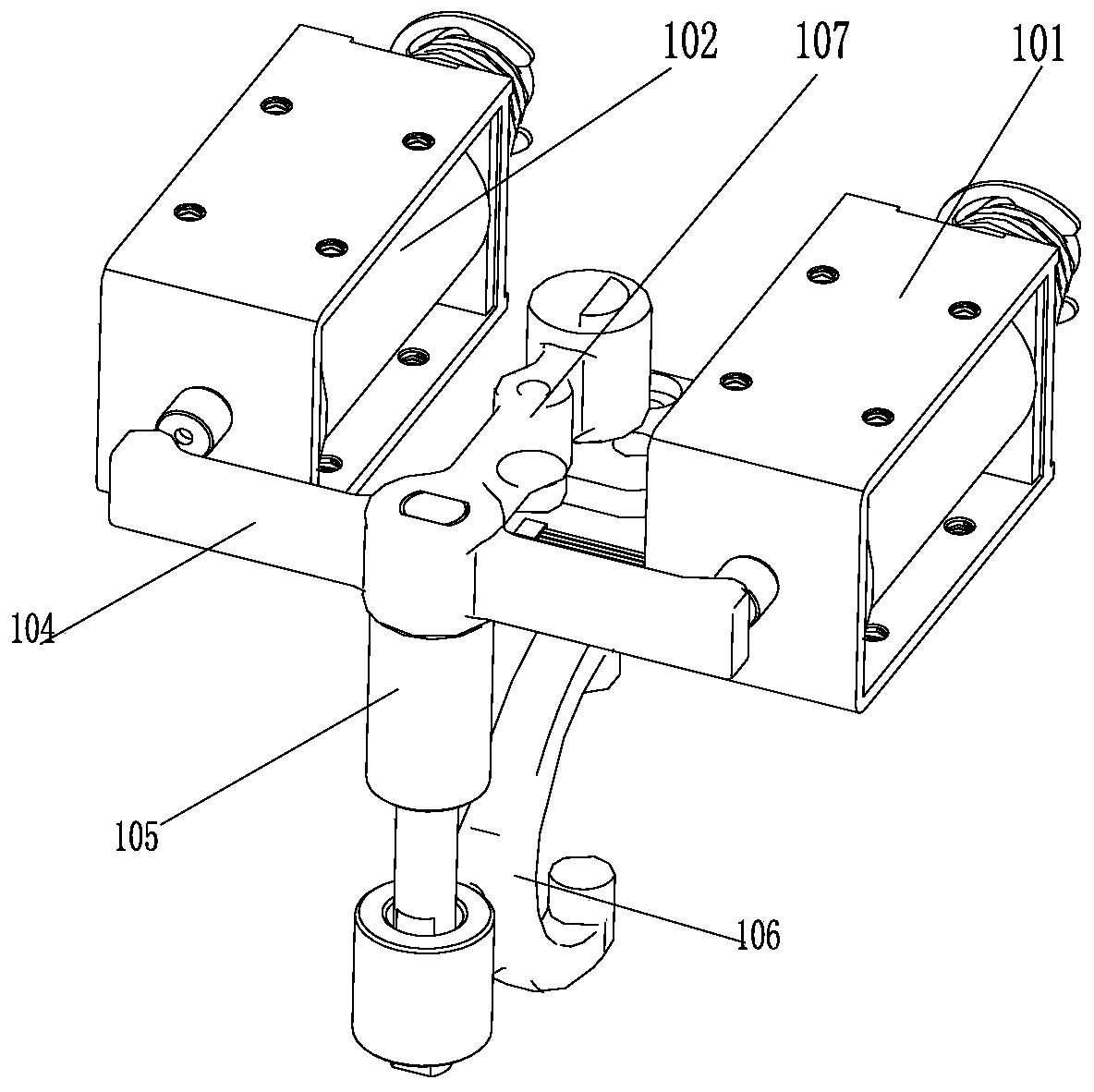

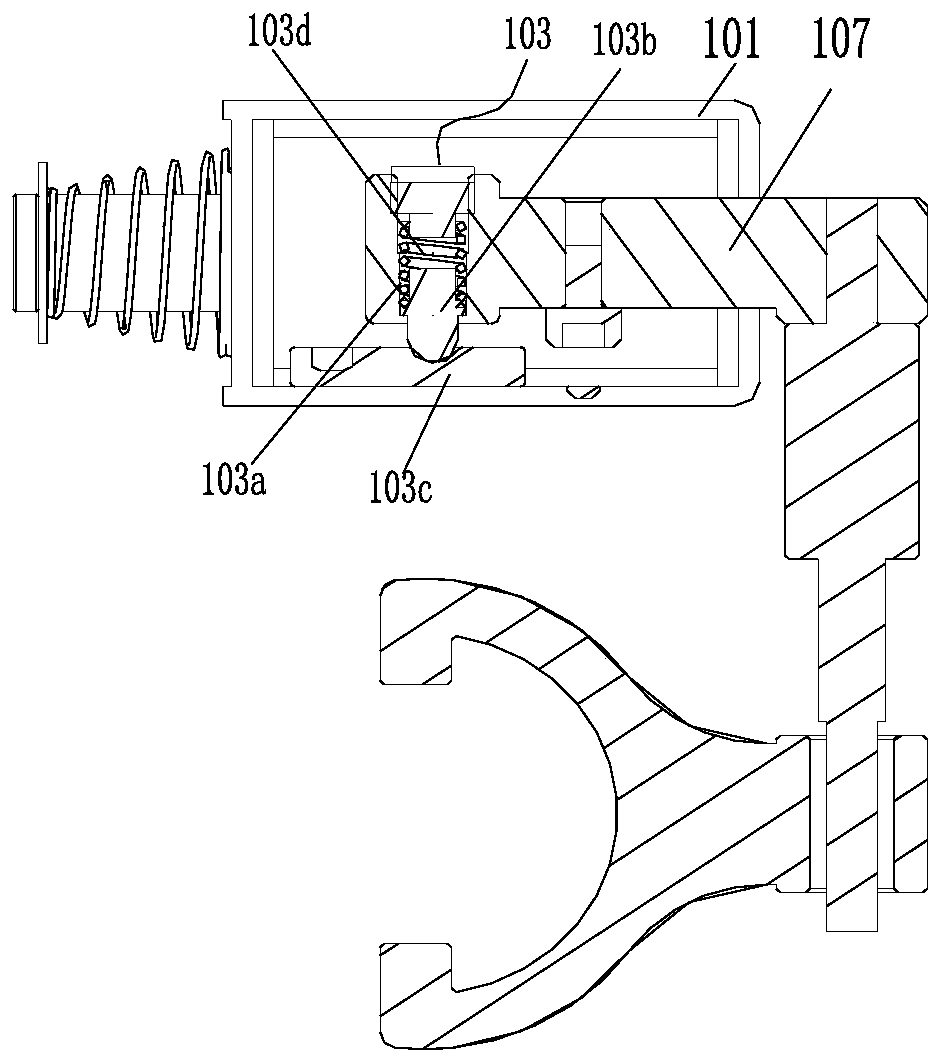

The invention relates to a drive train of a vehicle, comprising a permanently driven primary axle and a secondary axle connectable to the primary axle via a switch-on device with a switch-on mechanism, whereby the secondary drive train output via side shaft couplings is transferred to the drive wheels of the secondary axle.A disadvantage to these drive trains is that also when the secondary axles are not connected their components are dragged along by the vehicle drive or by the drive wheels rolling away on the roadway, causing power losses. Complete shutdown of the secondary drive train to date is executed only by manually switchable wheel hub couplings which are however a disadvantage with respect to ease of use and practicability.Because the switch-on mechanism and / or the side shaft couplings have frictionally engaged couplings, it can be that when the secondary axle is uncoupled the section of the secondary drive train located between the switch-on device and the side shaft couplings is uncoupled both from the primary axle and from the secondary drive wheels, such that there is no more power loss in this secondary drive train section, whereby connecting the secondary drive train during travel is possible all the same and losses in comfort and practicability do not have to be tolerated.

Owner:GETRAG DRIVELINE SYST +1

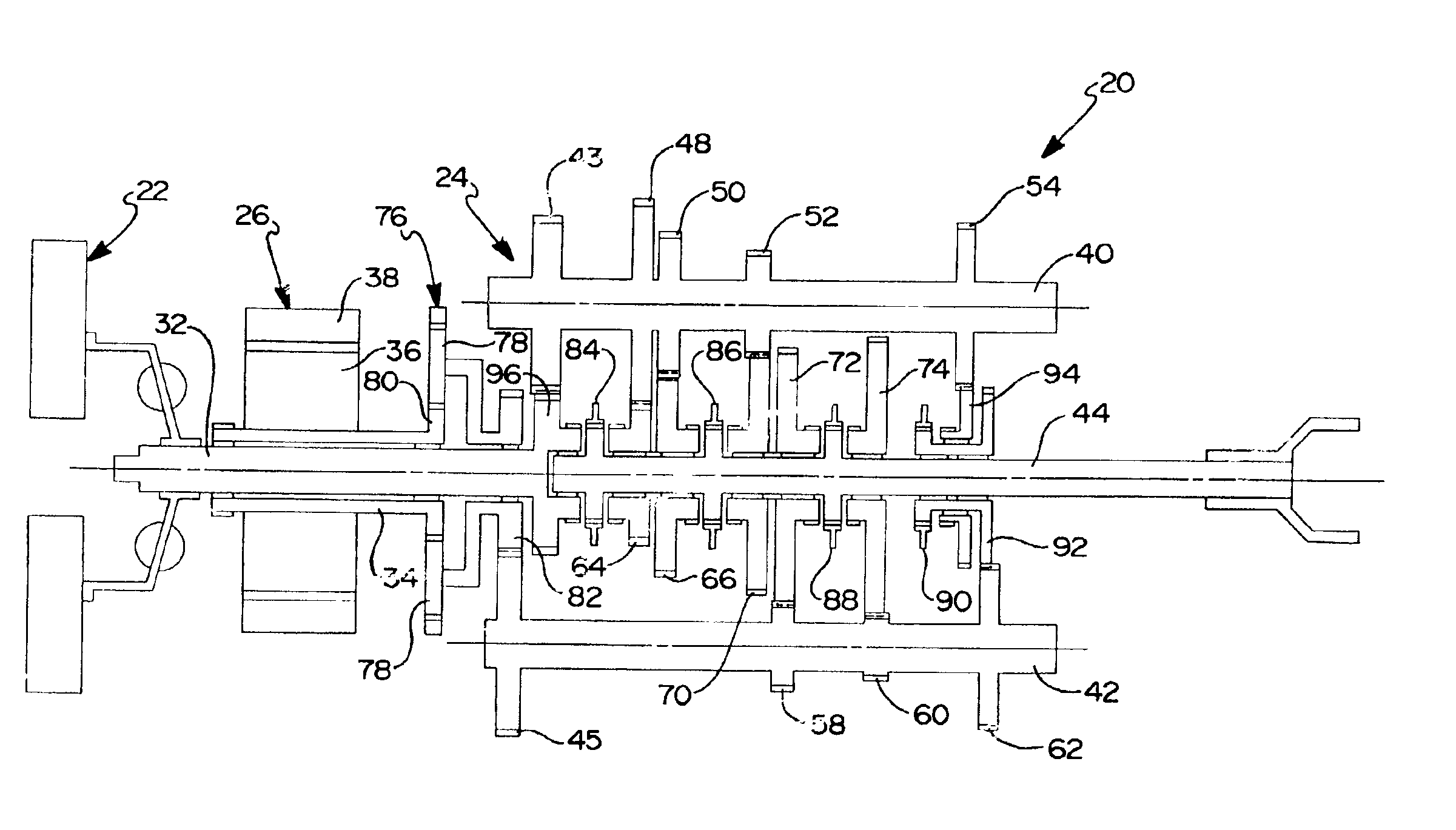

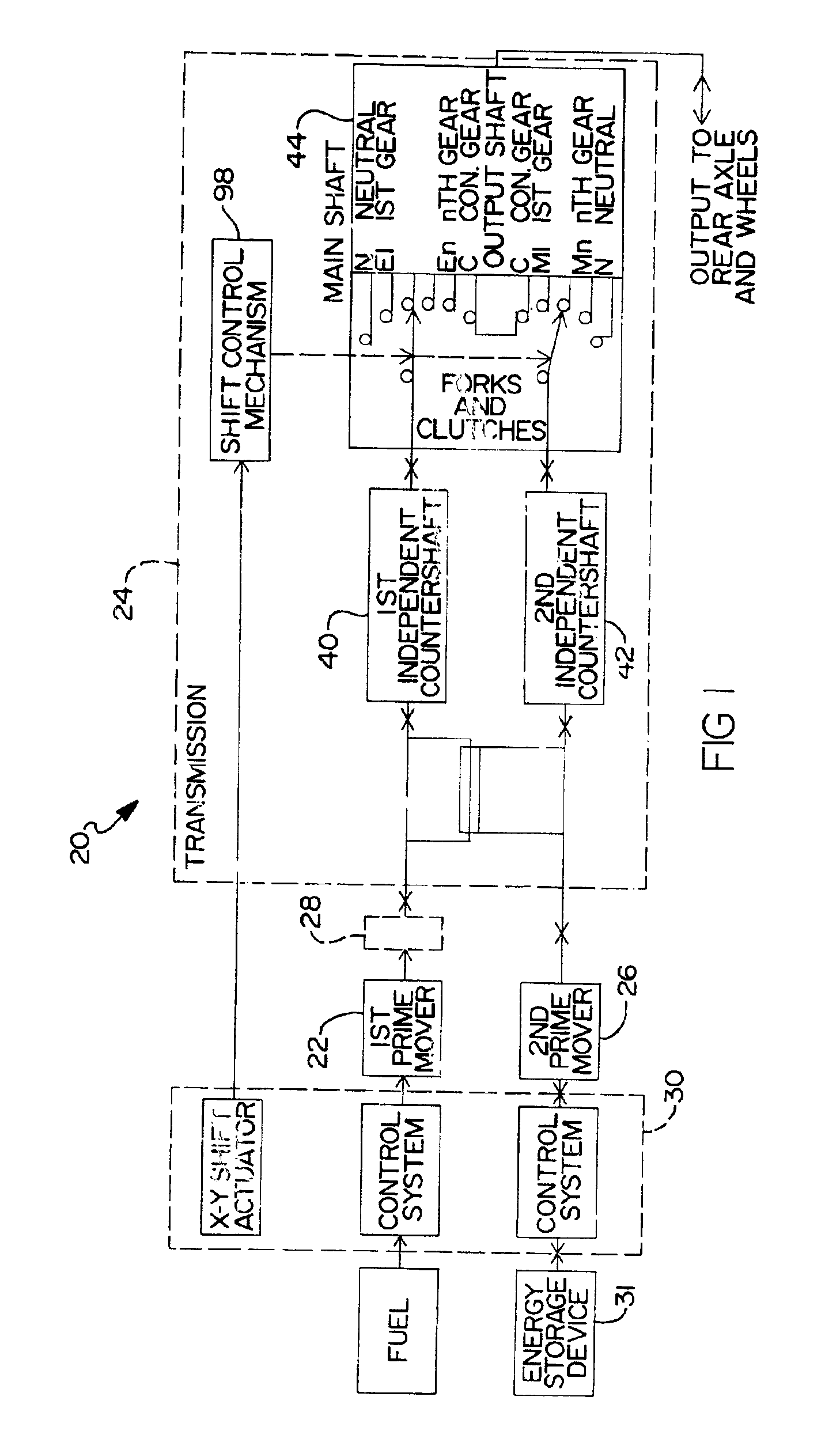

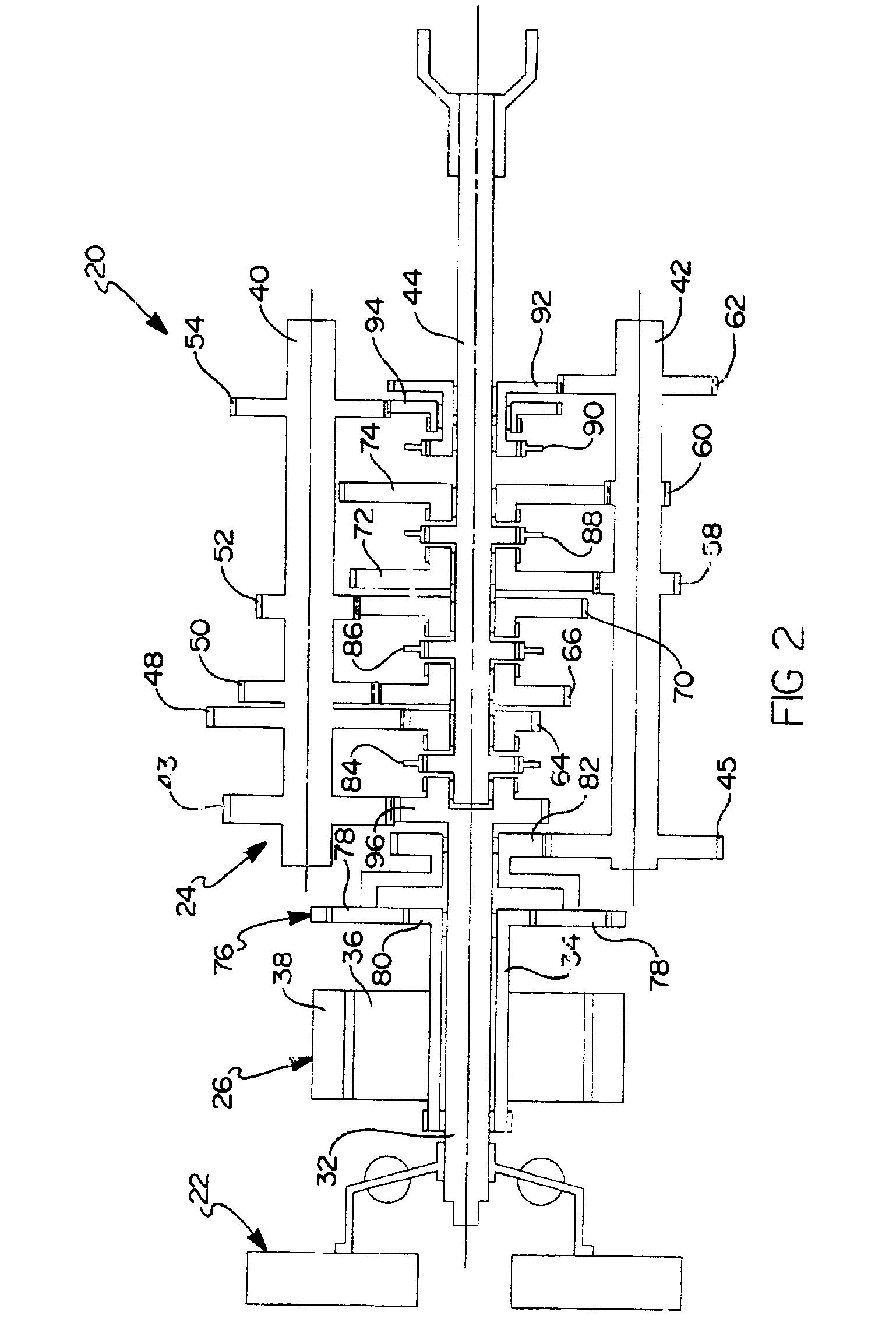

Hybrid powertrain system

InactiveUS6945893B2Improved shift qualityMaintaining torqueGas pressure propulsion mountingToothed gearingsControl theoryHybrid powertrain

A hybrid powertrain system is provided that includes a first prime mover having a rotational output, a second prime mover having a rotational output, and a transmission having a main shaft supporting at least two main shaft gears thereon. The transmission includes a first independent countershaft drivingly connected to the first prime mover and including at least one ratio gear supported thereon that meshes with a respective main shaft gear. A second independent countershaft is drivingly connected to the second prime mover and includes at least one ratio gear supported thereon that meshes with a respective main shaft gear. The ratio gears on the first and second countershafts cooperate with the main shaft gears to provide at least one gear ratio between the first and second countershafts and the main shaft. A shift control mechanism selectively engages and disengages the first and second countershafts for rotation with the main shaft.

Owner:EATON CORP

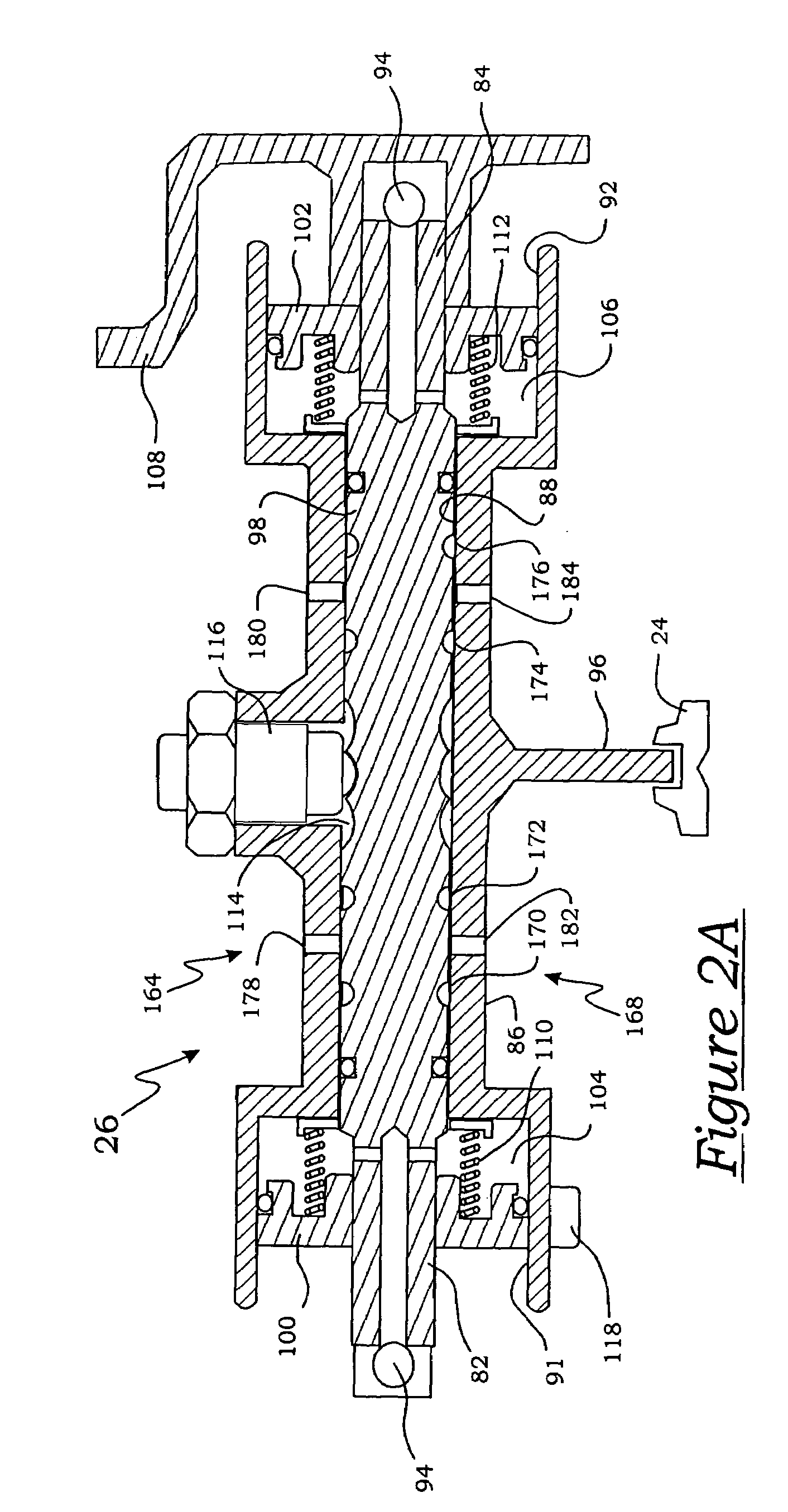

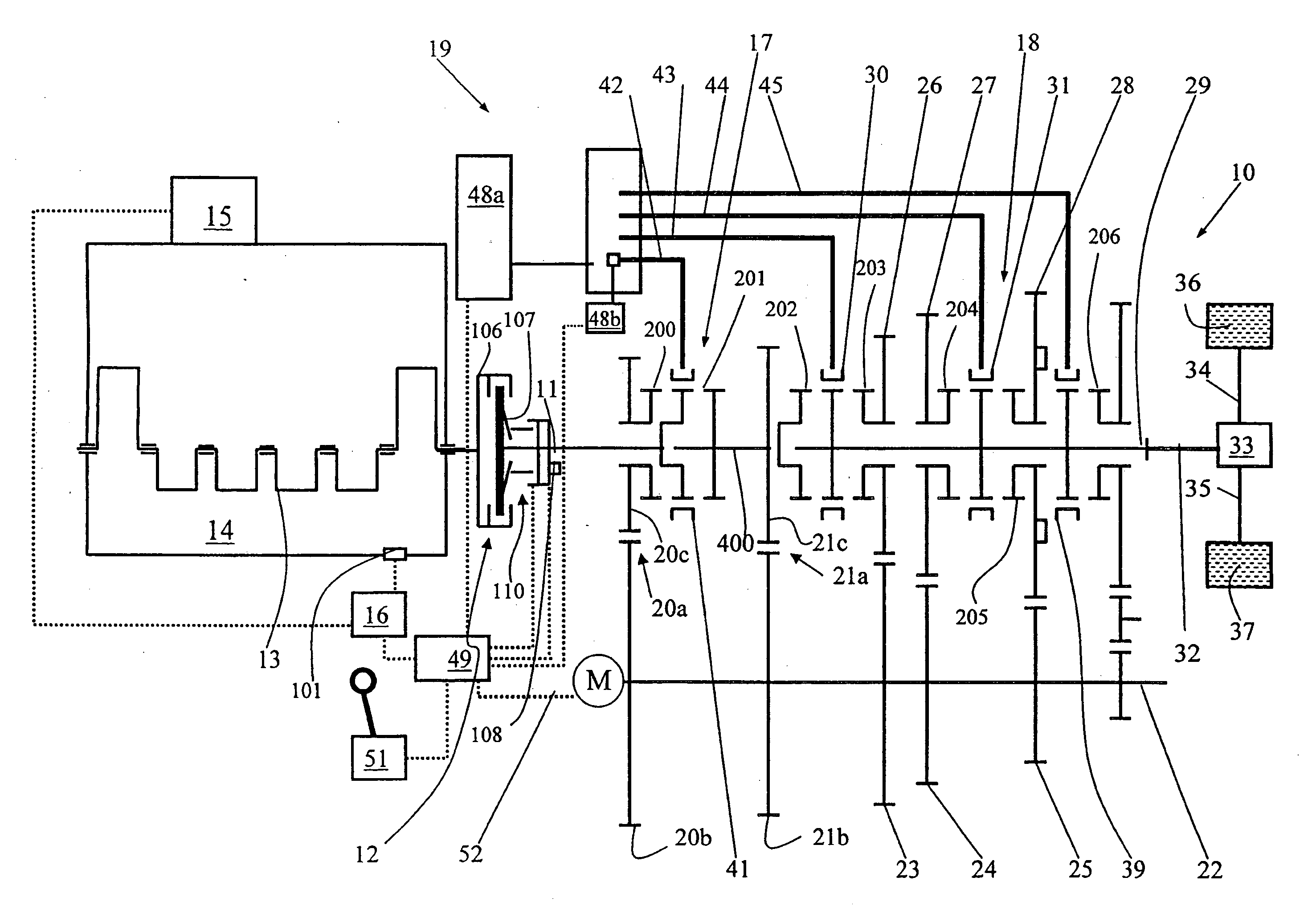

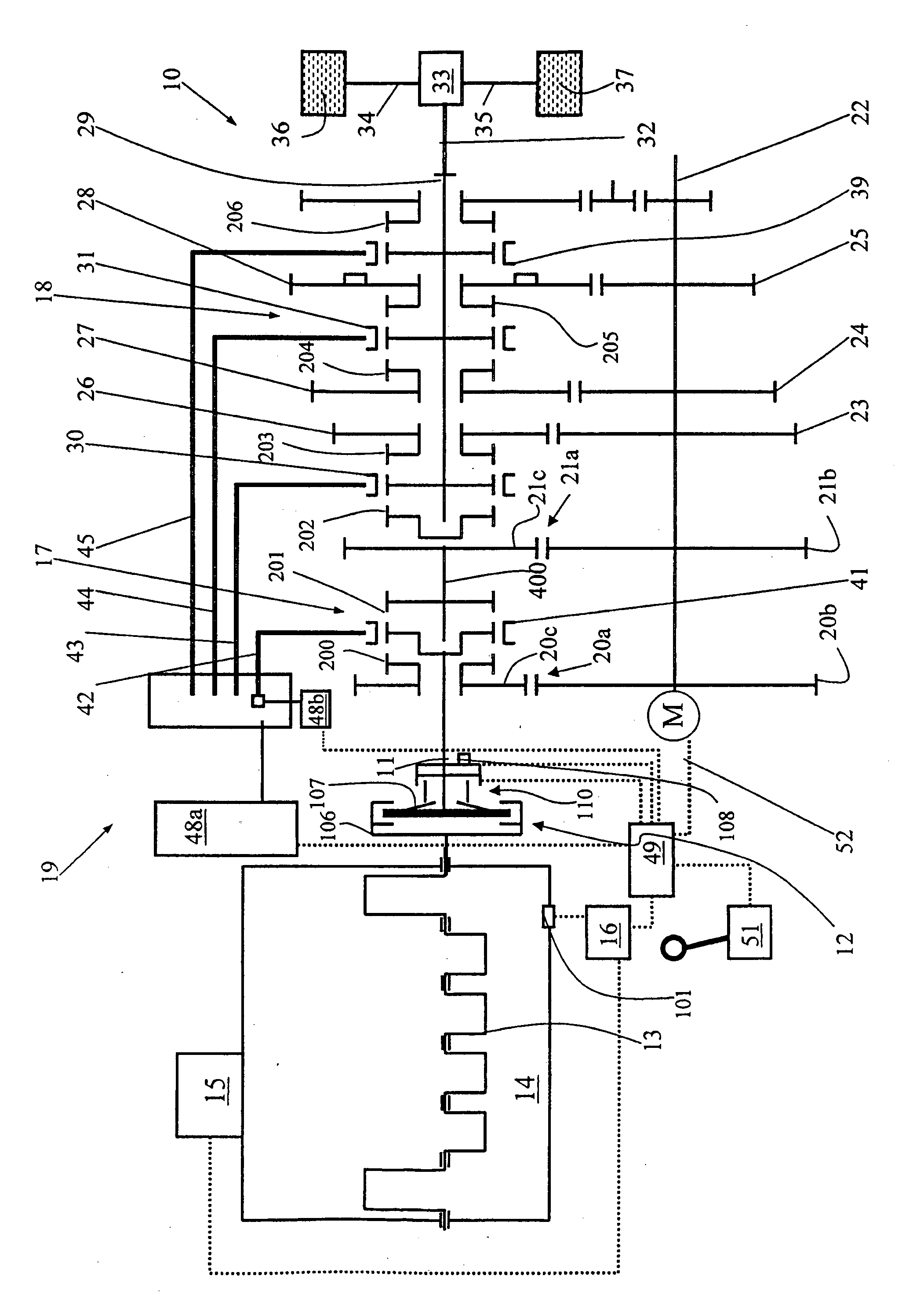

Dual clutch transmission having a synchronizer actuation interlock circuit

ActiveUS7155993B2Overcome limitationsAvoid catastrophic failureToothed gearingsGearing controlMobile vehicleEngineering

A dual clutch transmission for a motor vehicle having a synchronizer actuation interlock system includes two input shafts, a counter shaft, and a plurality of gear sets rotatively disposed on the shafts. The gear sets are adapted to be operatively engaged to and disengaged from their respective shafts. A plurality of synchronizers are disposed about the gear sets and the synchronizers are adapted to operatively engage and disengage the gear sets to and from their respective shafts. A plurality of hydraulically actuated shift actuators are each operatively connected to one of the plurality of synchronizers. Each shift actuator is adapted to cause its respective synchronizer to engage and disengage its respective gear sets to and from their respective shaft and further adapted to provide a hydraulic interlock that prevents an associated shift actuator on the same shaft from hydraulically actuating when the shift actuator is already engaged.

Owner:BORGWARNER INC

Dual clutch transmission having low gear mesh loss

InactiveUS7083540B2Weakening rangeLow magnitudeToothed gearingsTransmission elementsMobile vehicleEngineering

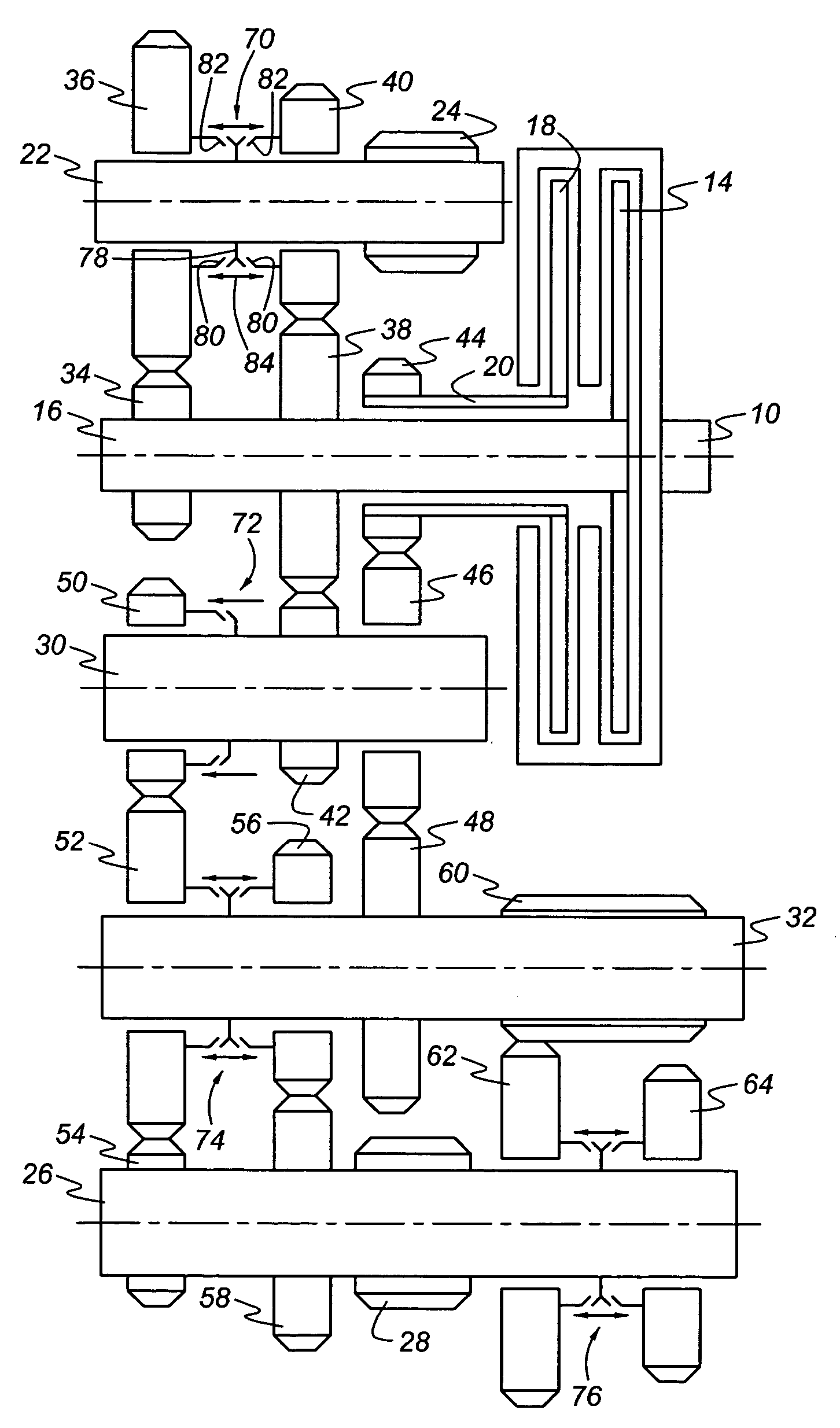

A power transmission for a motor vehicle In realizing these advantages, a power transmission according to this invention includes an input shaft, an output, and a layshaft disposed parallel to the input shaft. A pair of drive elements includes a first element secured to the input shaft, and a second element journalled on the layshaft and driveably connected to the first element. A first coupler is secured to the layshaft for releasably coupling the second element and the layshaft. A planetary gear unit driveably connecting the layshaft and the output, includies a sun gear secured to the layshaft, a ring gear surrounding the sun gear and fixed against rotation, a carrier driveably connected to the output, and a set of planet pinions meshing with the sun gear and ring gear and rotatably supported on the carrier.

Owner:FORD GLOBAL TECH LLC

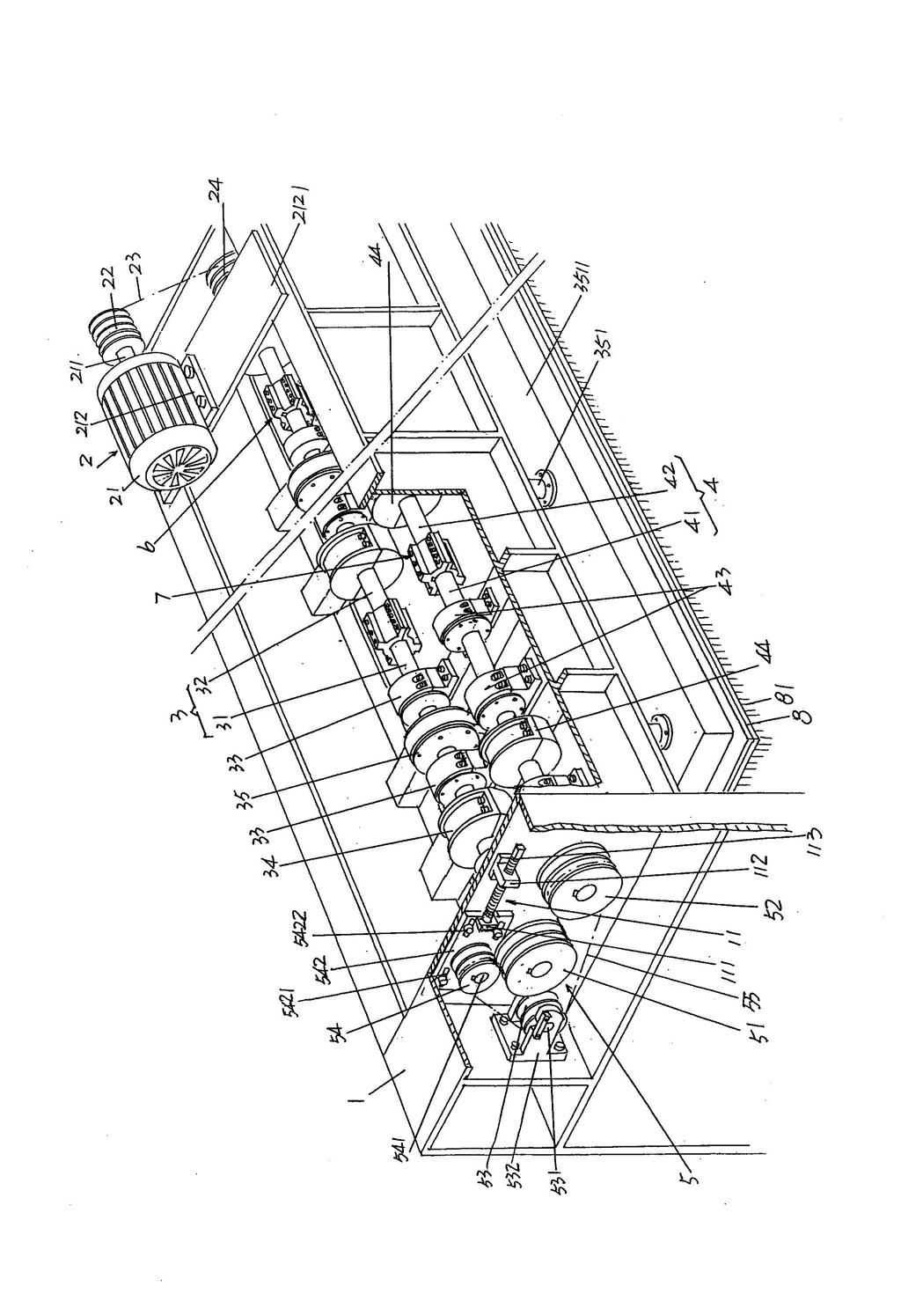

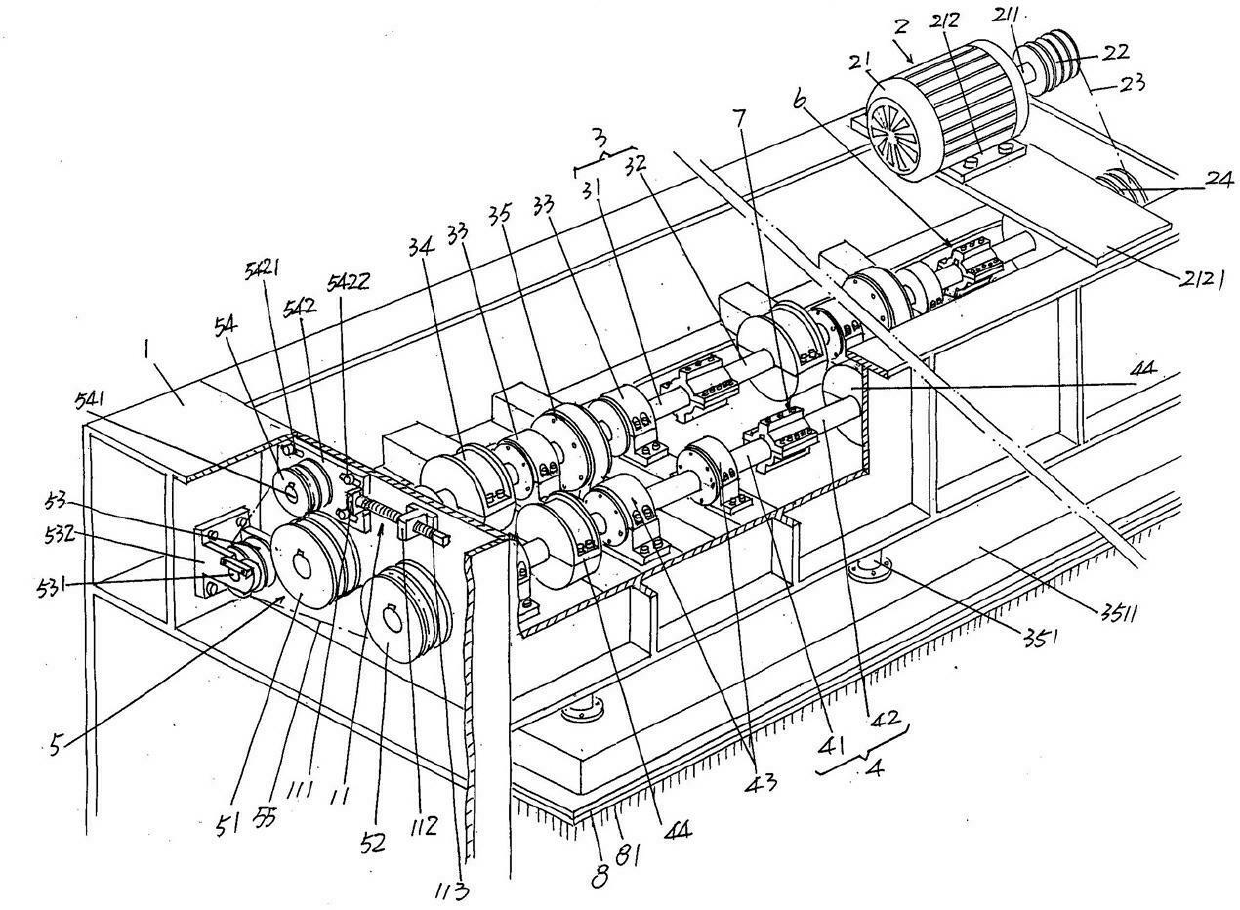

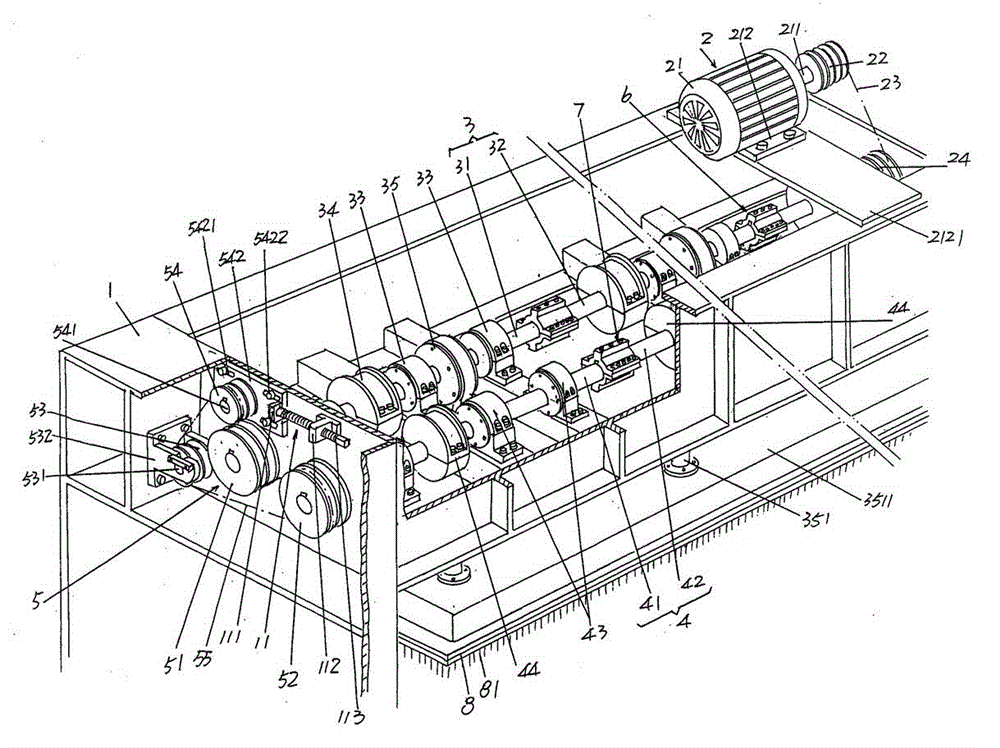

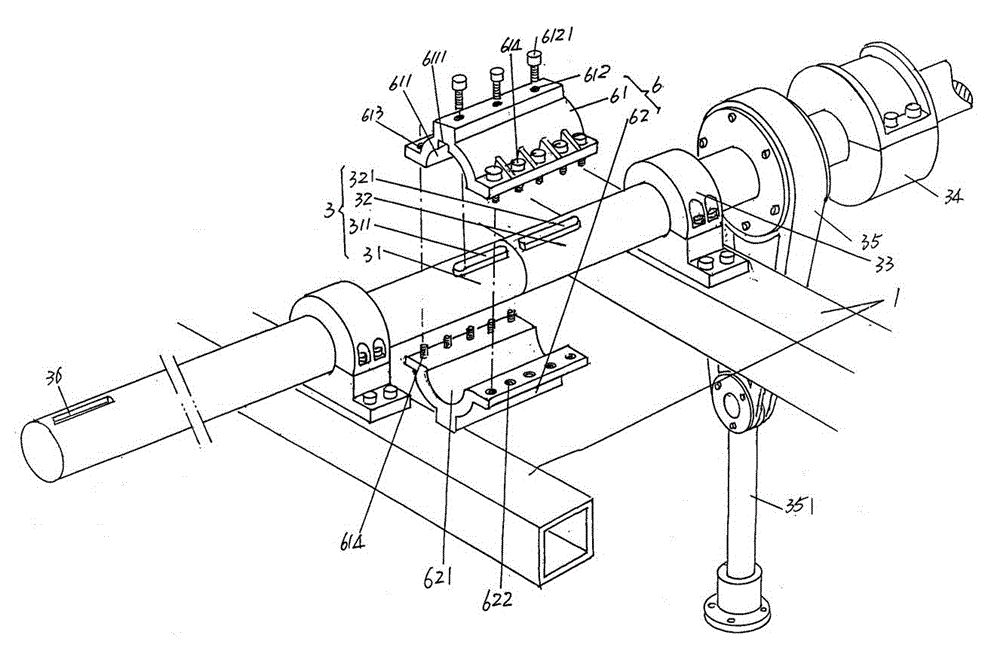

Double-shaft needling machine

The invention discloses a double-shaft needling machine, belonging to the technical field of non-woven textile machinery. The machine comprises a rack, a power transmission mechanism, a main shaft, an auxiliary shaft and an auxiliary shaft transition transmission mechanism. The machine is characterized in that the auxiliary shaft transition transmission mechanism comprises a first belt wheel, a second belt wheel, a transition belt wheel, a tension belt wheel and a transmission belt, wherein the first belt wheel is fixed at the other end part of the main shaft; the second belt wheel is fixed on the auxiliary shaft and corresponds to the first belt wheel; the transition belt wheel and the tension belt wheel are arranged on the rack; the transmission belt is sleeved on the first and second belt wheels, the transition belt wheel and the tension belt wheel; and the transition belt wheel, the tension belt wheel and the first belt wheel are in a triangular positional relation. The double-shaft needling machine disclosed by the invention has the advantages of avoiding noise, reducing the manufacturing and mounting difficulty, being beneficial to maintaining and replacing a bearing, shortening the shutdown time, ensuring the operation efficiency, saving resources and lowering the cost.

Owner:常熟市伟成非织造成套设备有限公司

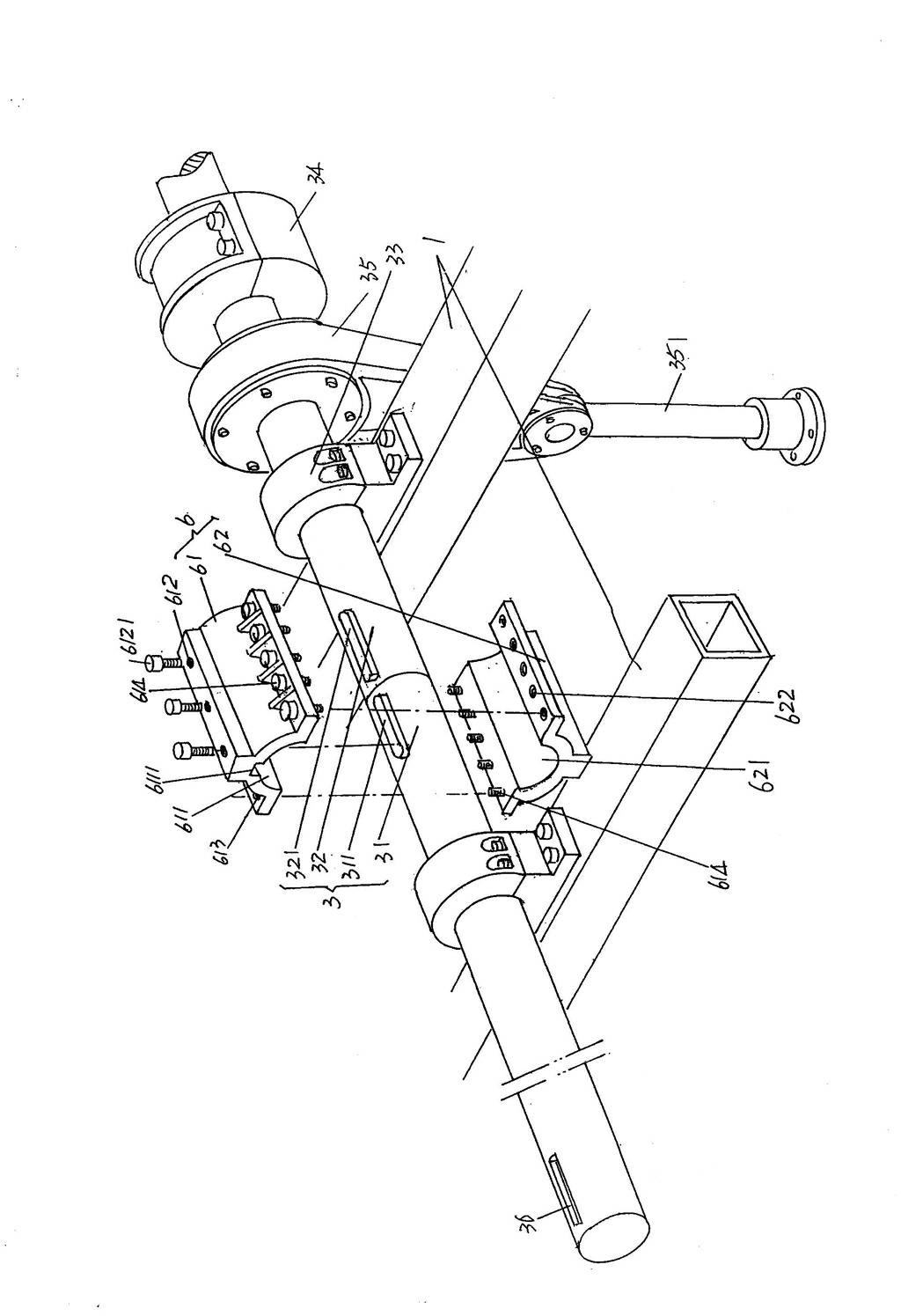

Improved-structure double-shaft needling machine

The utility model relates to a structurally improved double-shaft needle loom, which belongs to the technical field of non-woven machinery. Including frame, power transmission mechanism, main shaft, auxiliary shaft and auxiliary shaft transition transmission mechanism, features: auxiliary shaft transition transmission mechanism includes first and second pulleys, transition pulleys, tension pulleys and transmission belts, the first pulley is fixed on the main shaft The end of the second pulley is fixed on the auxiliary shaft, the transition pulley and the tension pulley are set on the frame; the transition pulley is set on the transition pulley shaft seat, and the transition pulley shaft seat is fixed on the frame; the tension pulley is set on On the shaft seat of the tensioning pulley, an adjusting device for the shaft seat of the tensioning pulley is arranged on the frame; a pair of adjusting screw slots are respectively set on the upper and lower parts of the shaft seat of the tensioning pulley, and adjusting screws are arranged at the positions of each adjusting screw slot; The tensioning pulley shaft seat adjusting device comprises a screw nut, a screw seat and a screw rod. Advantages: Avoid noise and improve the environment of the job site.

Owner:常熟市伟成非织造成套设备有限公司

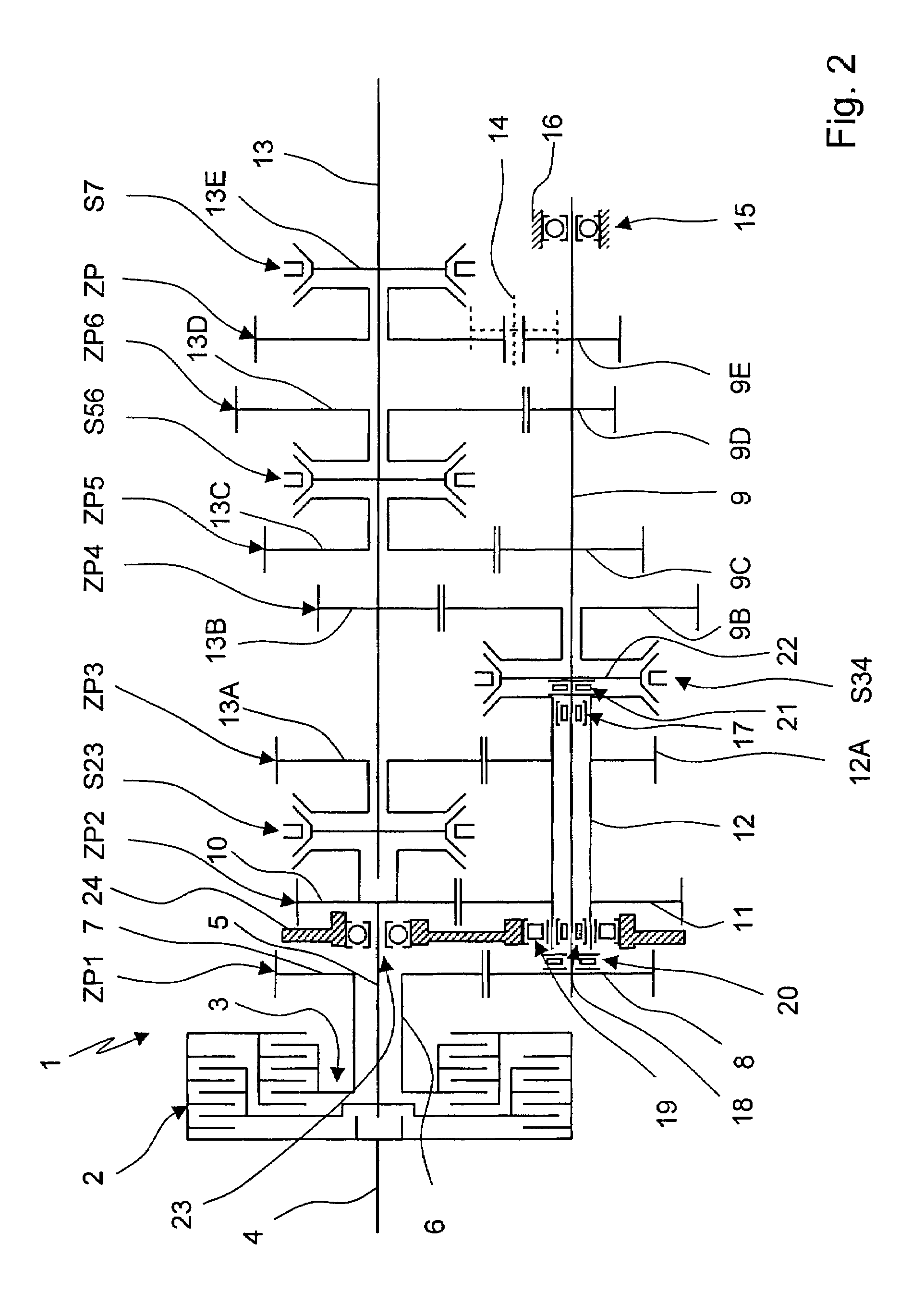

Shifting claw transmission and shifting method therefor

InactiveUS20080314176A1Easy transferAvoid problemsToothed gearingsGearing controlFree rotationGear wheel

In a shifting claw transmission for a motor vehicle including a main shaft and a countershaft and an electric motor for rotating the countershaft or being rotated thereby with freely rotatable gear wheels supported on the counter shaft and engageable with the countershaft by claw engagement structures, the speed of the countershaft is adjustable by the electric motor to be close to, but somewhat different from, the speed of the freely rotatable gear wheels to be engaged in order to facilitate shifting but avoid a tooth-on-tooth problem which would inhibit shifting.

Owner:DAIMLER AG

Speed changing gearbox with dual path input

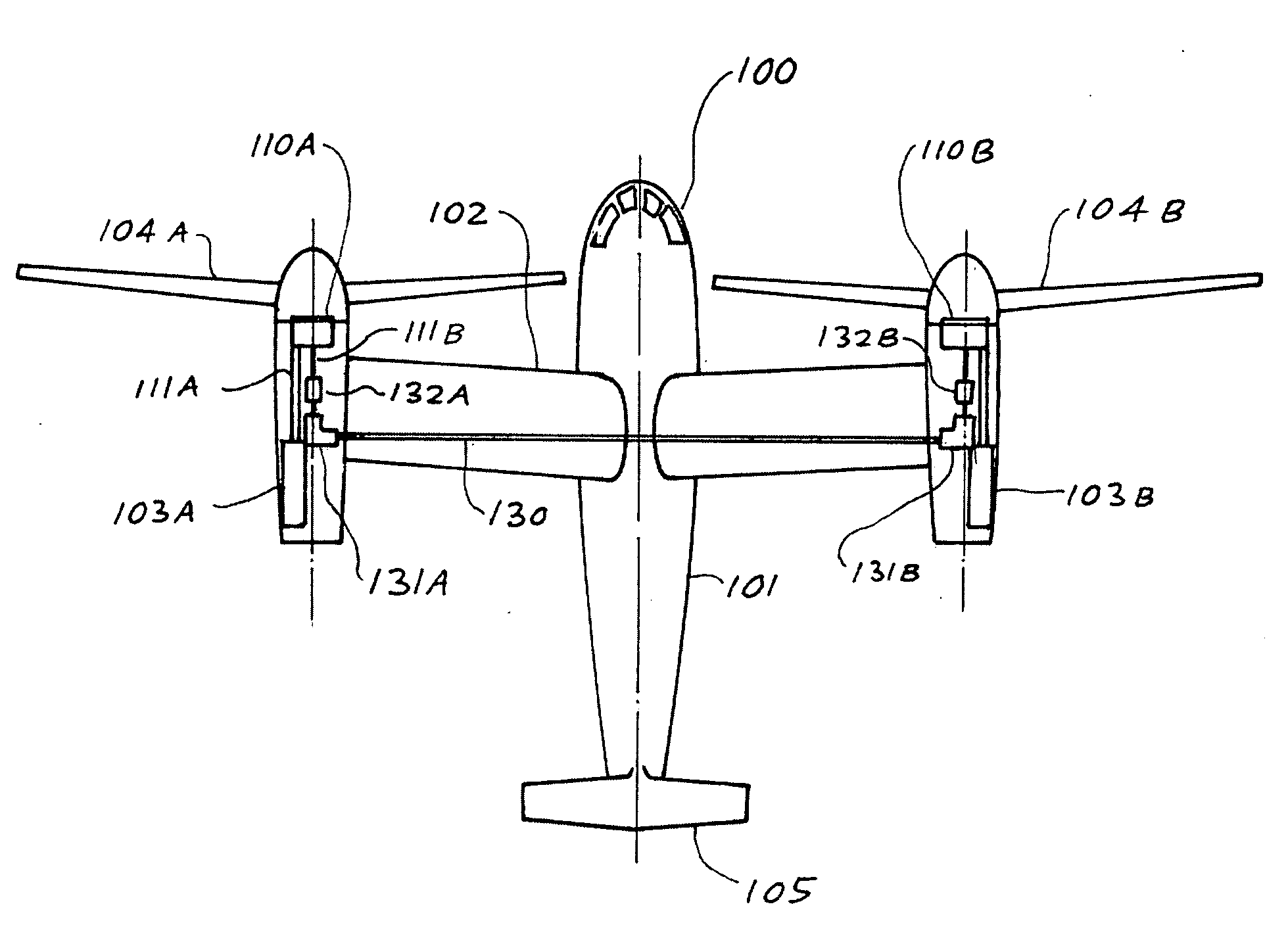

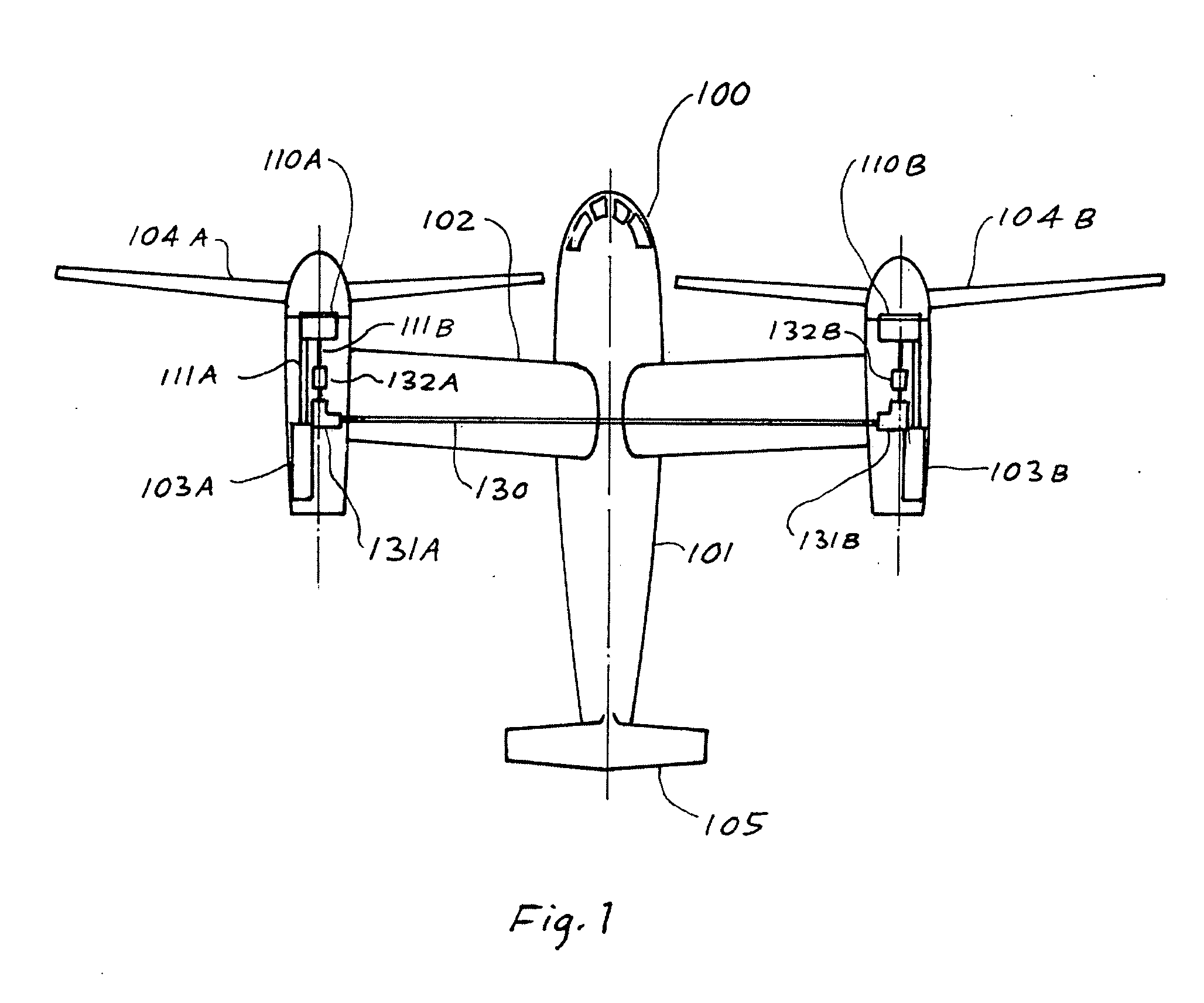

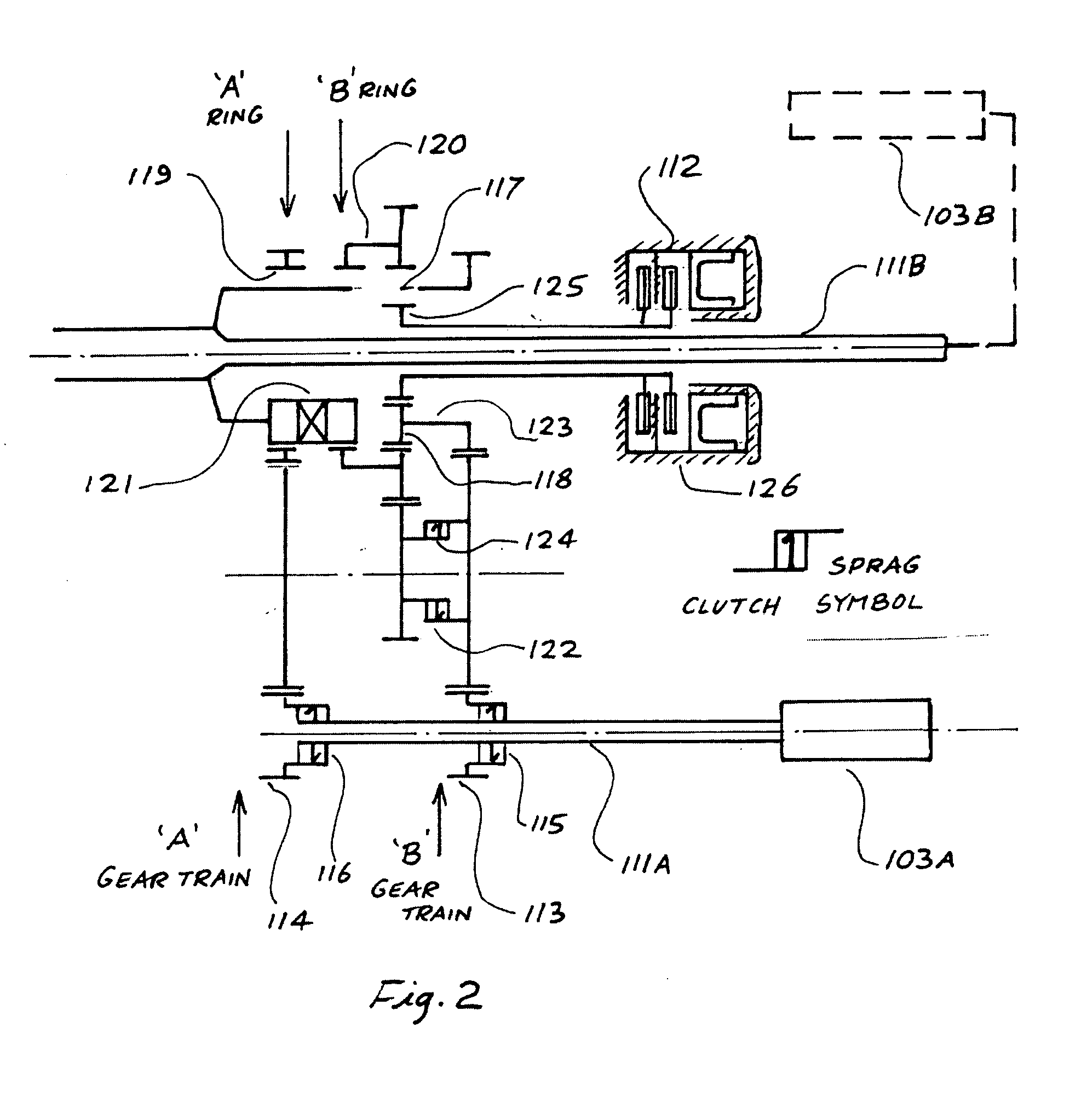

InactiveUS20070205321A1Large weightReduce peripheral speedGearingDepending on number of propellersGear wheelTransmitted power

Contemplated gearboxes provide first and second power-balanced paths in which a speed changer is configured to operate with only one path. Most preferably, the gearbox includes a friction clutch and a sprag clutch arranged such that, together with a layshaft and spur-gear differential, gear shifting can be done while transmitting power.

Owner:KAREM AIRCRAFT INC

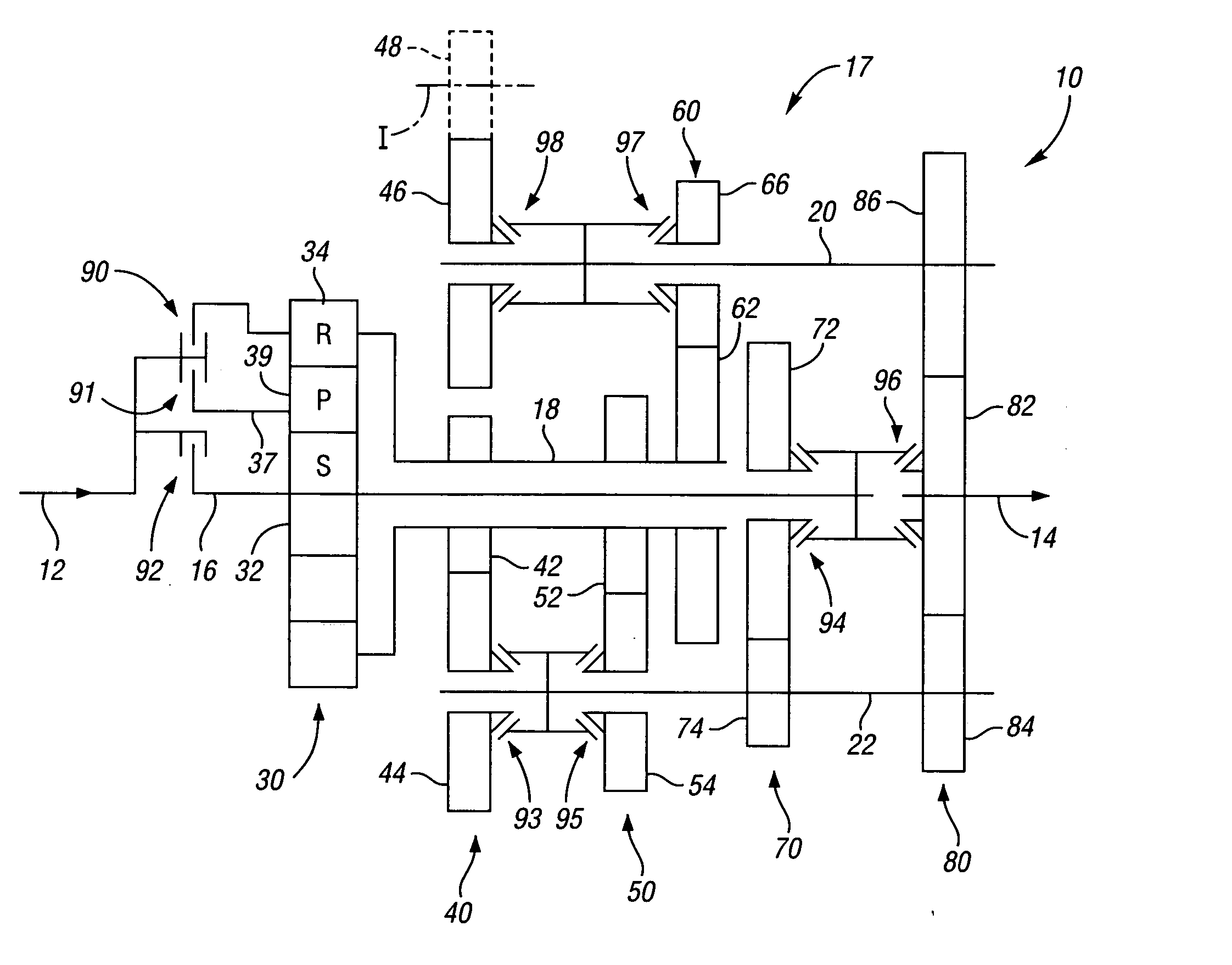

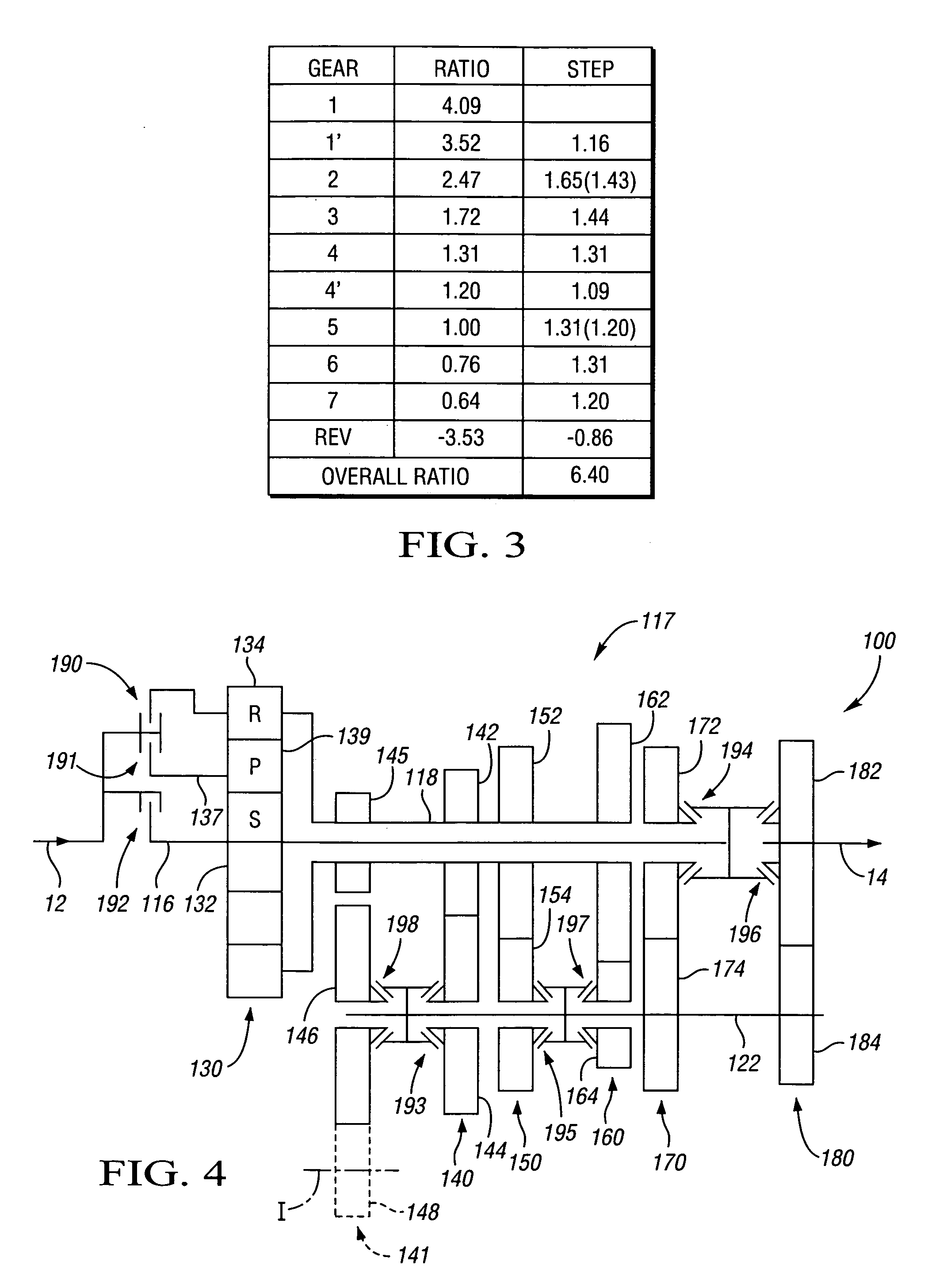

Multi-speed transmission with differential gear set and countershaft gearing

InactiveUS20070131046A1Reduce in quantityShorten the axial lengthToothed gearingsTransmission elementsGear wheelEngineering

A transmission is provided having a differential gear set with three input torque-transmitting mechanisms, such as friction clutches, to achieve torque flow through the differential gear set to a countershaft gearing arrangement. The transmission utilizes power-on shifts. By utilizing the torque ratio of the differential gear set, additional forward ratios are available with good step progression, reducing the number of countershaft gear sets and synchronizers necessary in comparison to a dual-clutch transmission providing the same number of ratios. A shorter axial length is thus attainable.

Owner:GM GLOBAL TECH OPERATIONS LLC

Dual clutch automatic transaxle

InactiveUS7044014B2Shorten the lengthSolve the lack of spaceToothed gearingsTransmission elementsControl theoryLayshaft

A multiple speed transaxle includes first and second input shafts, first and second output shafts, a layshaft, an idler shaft, a first set of selectable torque paths between the first input shaft and first output shaft, a second set of selectable torque paths between the second input shaft and the second output shaft, the second set including the layshaft and idler shaft, and a selectable torque path between the first input shaft and second output shaft including the layshaft and idler shaft.

Owner:FORD GLOBAL TECH LLC

Drive train for a vehicle with connectable secondary axle

A drive train of a vehicle is disclosed which comprises a permanently driven primary axle and a secondary axle connectable to the primary axle via a switch-on device with a switch-on mechanism, whereby the secondary drive train output via side shaft couplings is transferred to the drive wheels of the secondary axle. Because the switch-on mechanism and / or the side shaft couplings have frictionally engaged couplings, it can be that when the secondary axle is uncoupled, the shutdown section of the secondary drive train located between the switch-on device and the side shaft couplings is uncoupled both from the primary axle and from the secondary drive wheels, such that there is no more power loss in this shutdown section, whereby connecting the secondary drive train during travel is possible all the same and losses in comfort and practicability do not have to be tolerated.

Owner:GETRAG DRIVELINE SYST +1

Multi-speed transmission with differential gear set and countershaft gearing

InactiveUS7311630B2Reduce in quantityEliminate needToothed gearingsTransmission elementsGear wheelControl theory

Owner:GM GLOBAL TECH OPERATIONS LLC

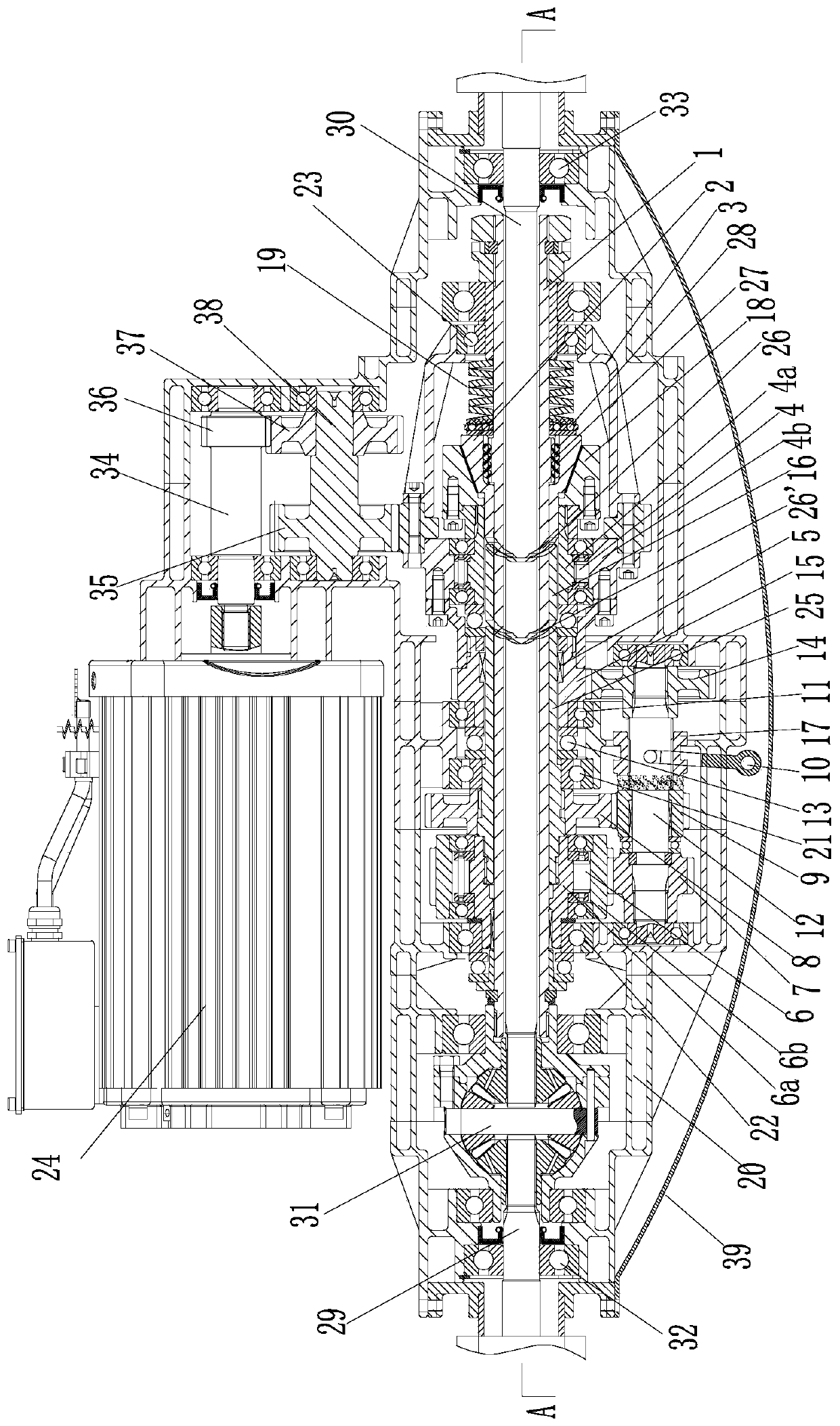

Mechanical double-overrunning clutch adaptive automatic transmission external motor drive axle

ActiveCN109910604ASmooth load changeAchieve balance controlElectric propulsion mountingToothed gearingsAutomatic transmissionMotor drive

The invention discloses a mechanical double-overrunning clutch adaptive automatic transmission external motor drive axle. The drive axle comprises an axle shell, a drive motor is externally arranged,a transmission system is located in the axle shell and comprises a low gear transmission mechanism, a reverse gear transmission mechanism and an adaptive transmission assembly; the reverse gear mechanism has a transmission ratio I which transmits a reverse gear power from an auxiliary shaft to a main shaft, the low gear transmission mechanism has a transmission ration II which transmits a low gearpower from the auxiliary shaft to the main shaft, and the transmission ratio I is greater than or equal to the transmission ratio II. According to the mechanical double-overrunning clutch adaptive automatic transmission external motor drive axle, reasonable cooperation of two overrunning clutches is utilized, so that the overall structure is simple and compact, a transmission line is shared by reverse gear transmission, low gear transmission and fast gear transmission, and no interference is produced, the overall performance is ensured, the adaptive capacity is relatively strong, the cooperation with the adaptive automatic transmission mechanism is smooth and natural, the overall efficiency is improved, the whole transmission system is located in the axle shell, the overall structure is compact, the strength and rigidity of the whole axle is improved, and the occupying volume is small.

Owner:SOUTHWEST UNIVERSITY

Split power transmission to include a variable drive

InactiveUS7396309B2Eliminates an additional starting gearReduce necessityGearingDrive shaftGear wheel

A split power transmission with a variable drive, a brake, a clutch, an integrating transmission containing a planetary set, the internal gear forming the output of the transmission, and an additional planetary set located between the drive shaft and the transmission. A portion of the transmission drive shaft power is transferable to the transmission which includes a secondary shaft located axially parallel to the variable drive. The power of the variable drive is directed towards the integrating transmission via the secondary shaft by using a defined transmission ratio. Torque division in the low cruising range and is achieved by locking the brake connecting the internal gear of the planetary set located between the drive shaft, and the transmission to the unit. Whereas in the high cruising range, by engaging the clutch the sun gear of the transmission is interlocked with the internal gear of the transmission.

Owner:ZF FRIEDRICHSHAFEN AG

Transmission device of layshaft type

Owner:ZF FRIEDRICHSHAFEN AG

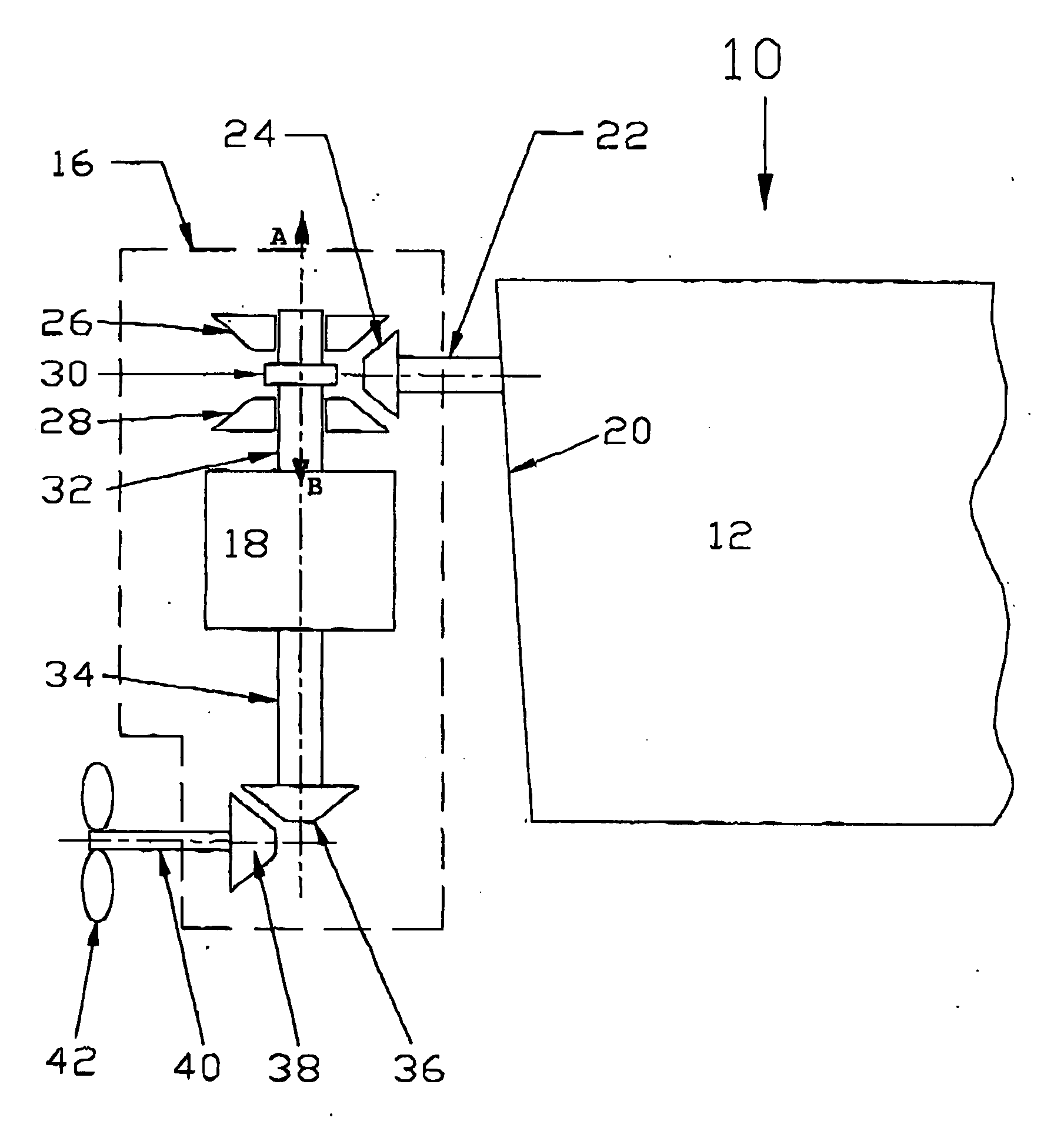

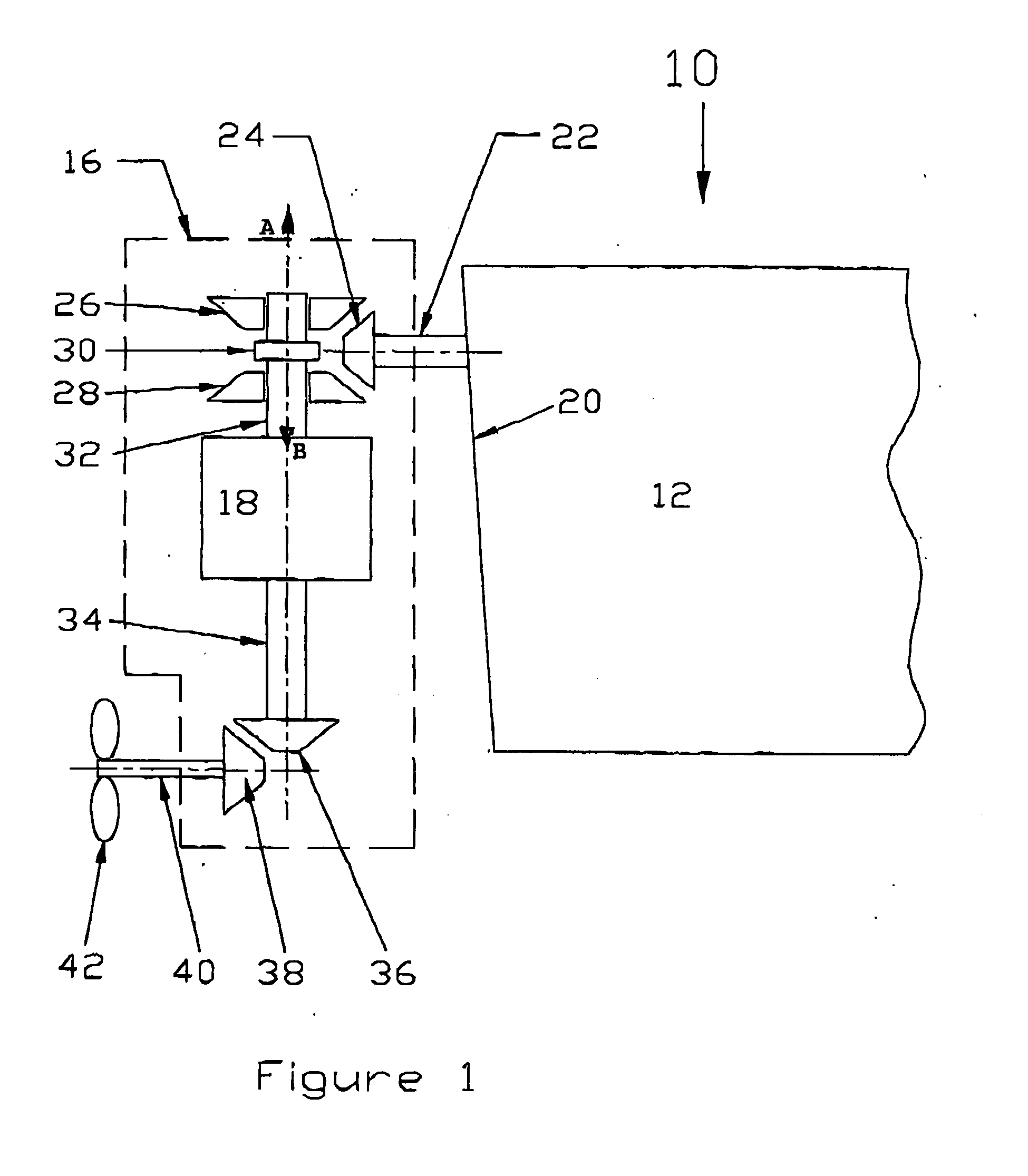

Apparatus for driving an accessory gearbox in a gas turbine engine

InactiveUS20050183540A1Improve versatilityImprove rendering capabilitiesEngine fuctionsToothed gearingsDrive shaftPressure.drive

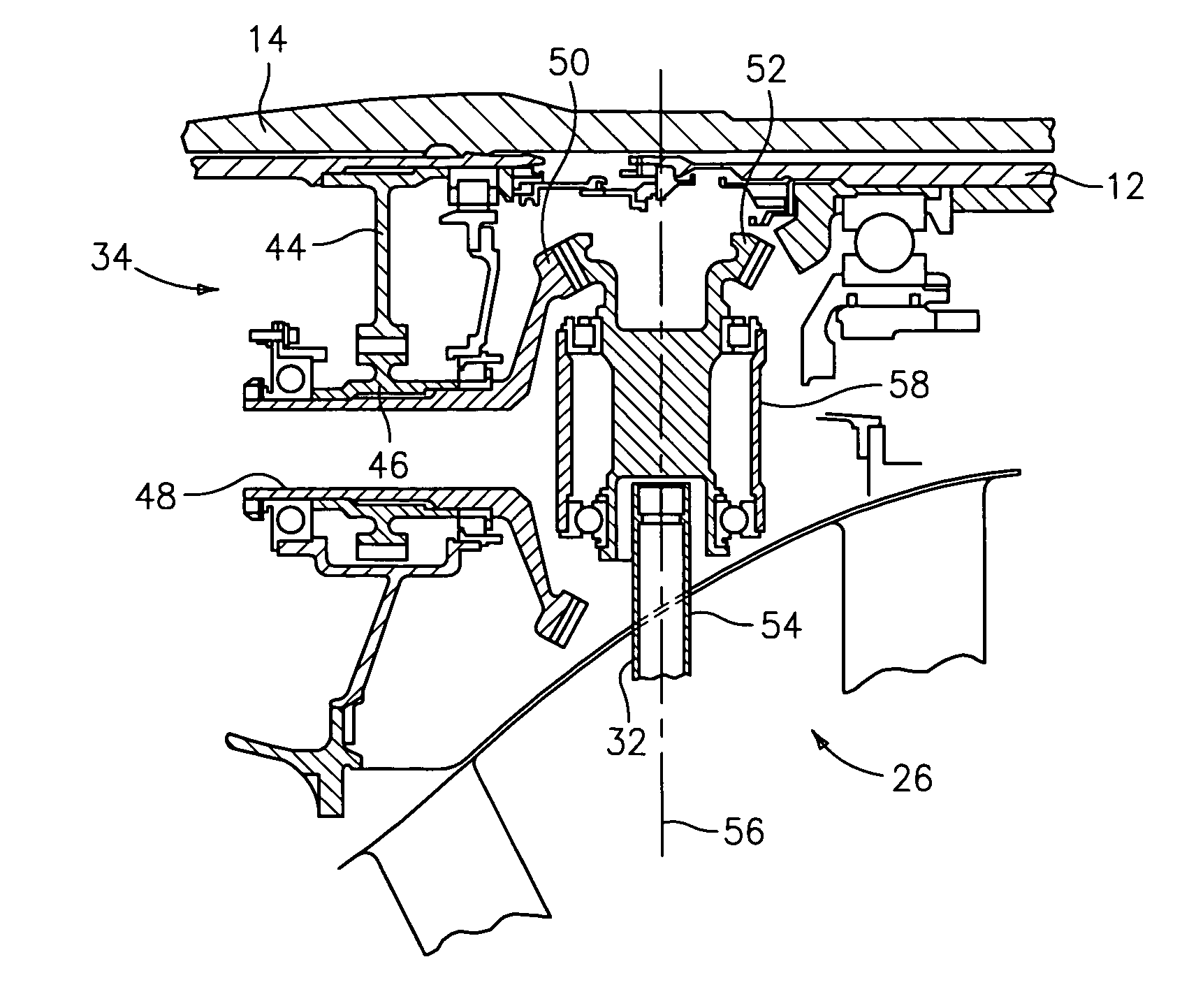

A mechanical drive system for an accessory gearbox of a gas turbine engine is provided. The engine has a high-pressure drive shaft and a low-pressure drive shaft. The mechanical drive system includes a first tower shaft, a second tower shaft, a first lay shaft, and a second lay shaft. The first tower shaft is driven by the high-pressure drive shaft. The second tower shaft is driven by the low-pressure drive shaft. The first lay shaft is driven by the first tower shaft, and is connected to the accessory gearbox. The second lay shaft is driven by the second tower shaft, and is connected to the accessory gearbox.

Owner:UNITED TECH CORP

Multi-Mode Powersplit Powertrain for Electric Vehicle

ActiveUS20130012347A1Improve driveabilityImprove fuel economyHybrid vehiclesToothed gearingsElectric machineEngineering

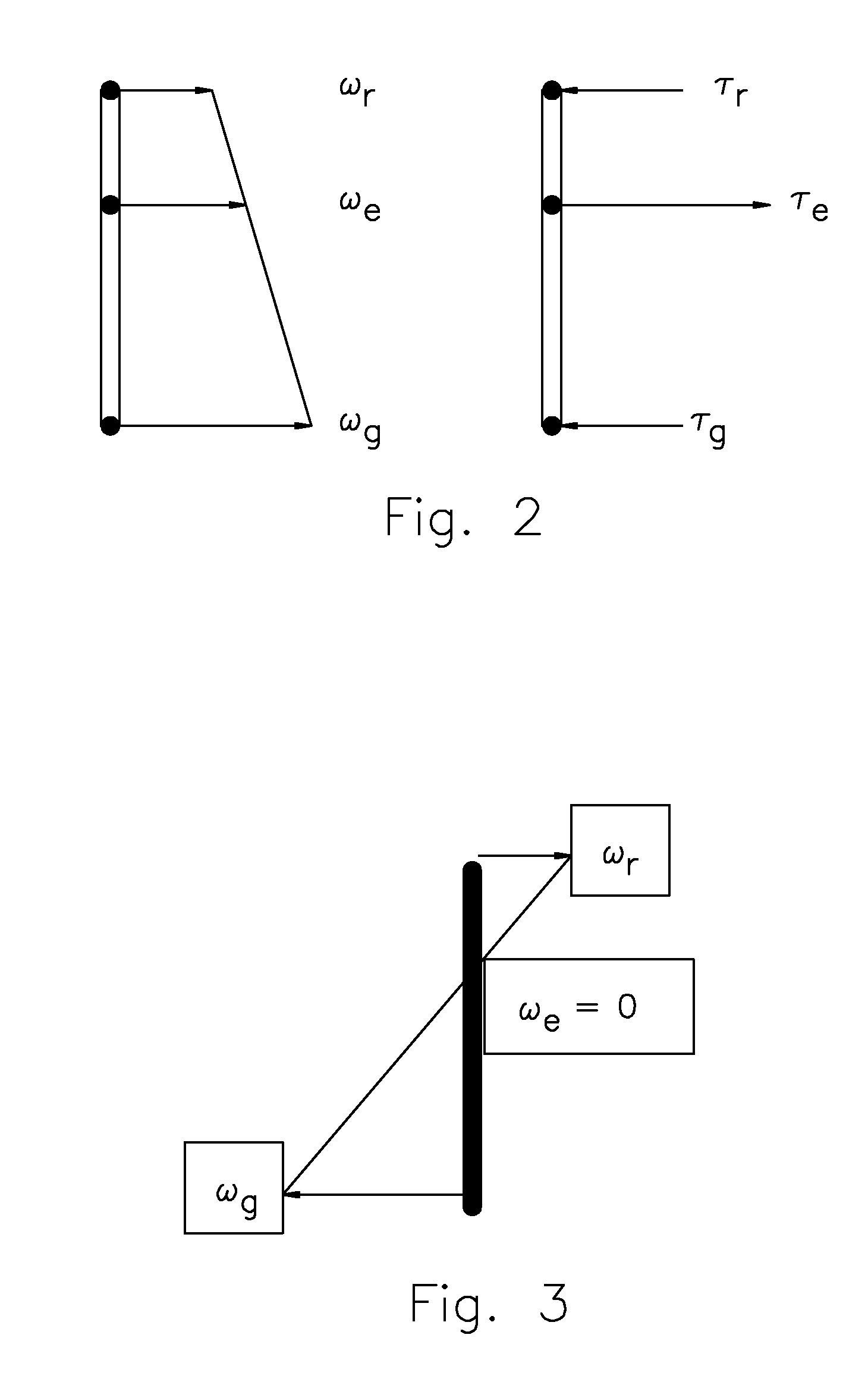

A powertrain includes a countershaft, a gearset including a sun gear, a carrier connected to an engine, a ring gear releaseably held against rotation and connectable to the countershaft, and pinions supported on the carrier and meshing with the sun gear and ring gear, an electric machine connected to the sun gear and connectable to the countershaft, and a second electric machine driveably connected to the countershaft.

Owner:FORD GLOBAL TECH LLC

Planetary gear type multistage transmission for vehicle

ActiveUS20070184932A1Easy constructionWide range of speed ratioToothed gearingsTransmission elementsEngineeringLayshaft

A small-sized vehicular planetary gear type step-variable transmission having seven or more forward drive gear positions with a wide range speed ratio and suitable for use on a vehicle. A transmission includes three planetary gear sets, four clutches, and two brakes to provide seven or more forward drive gear positions with a wide range speed ratio. A counter gear pair is constituted by an output gear disposed between a first transmission portion and a second transmission portion, and a driven gear which is mounted on a counter shaft rotatably about a second axis parallel to a first axis and which is held in meshing engagement with the output gear. A fourth clutch reduces an amount of increase of an axial length of the transmission, so that the transmission is small-sized and used on the vehicle.

Owner:TOYOTA JIDOSHA KK

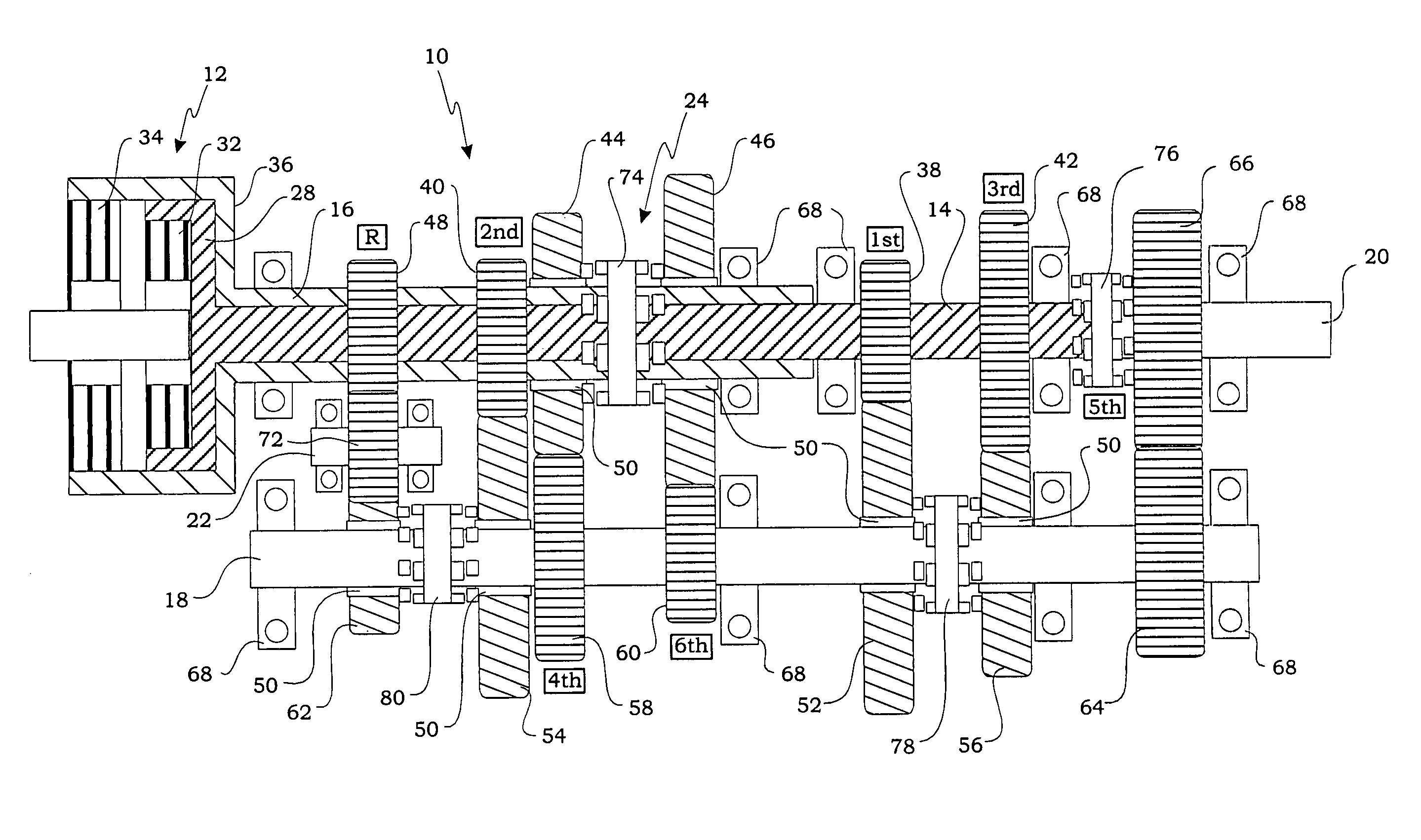

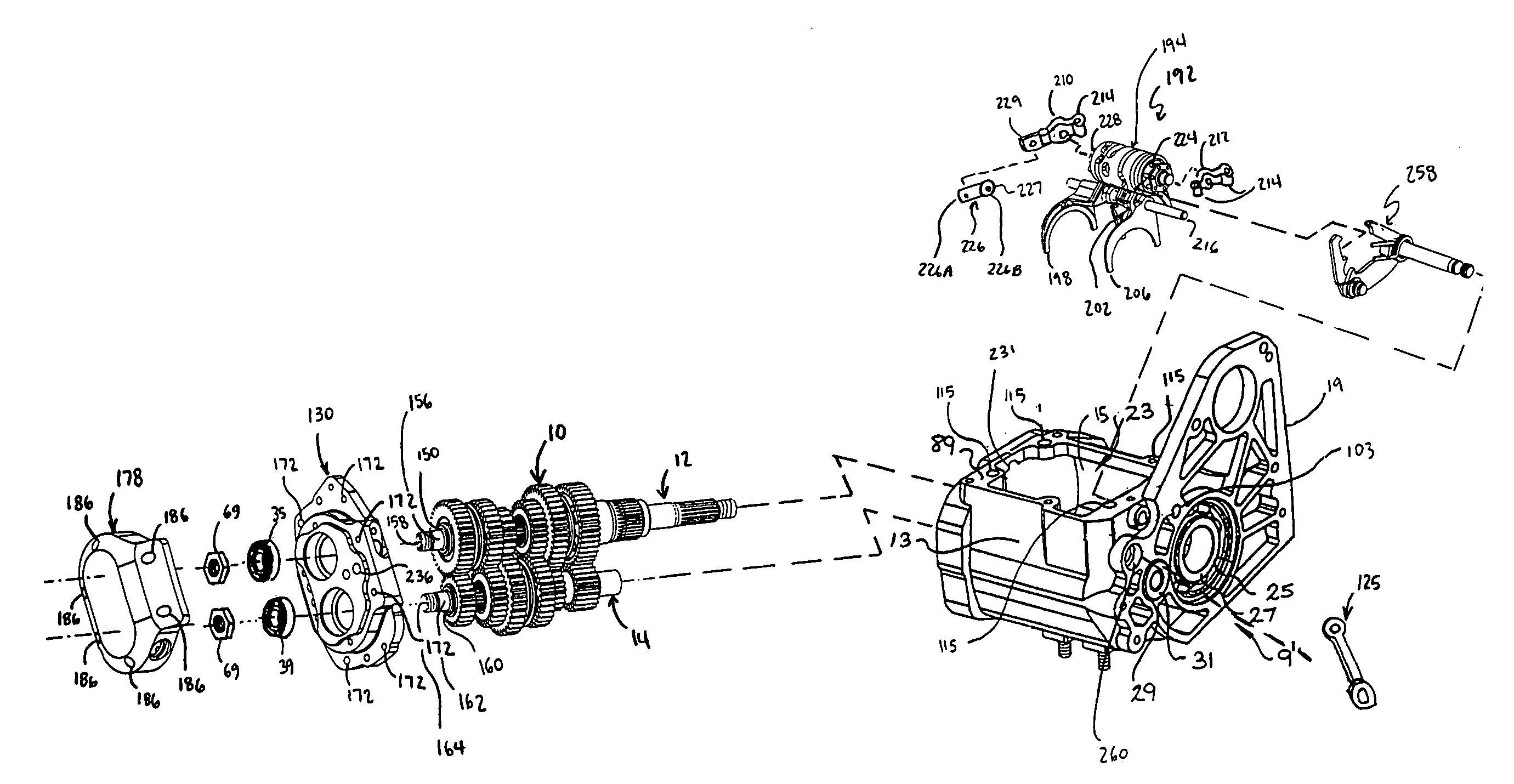

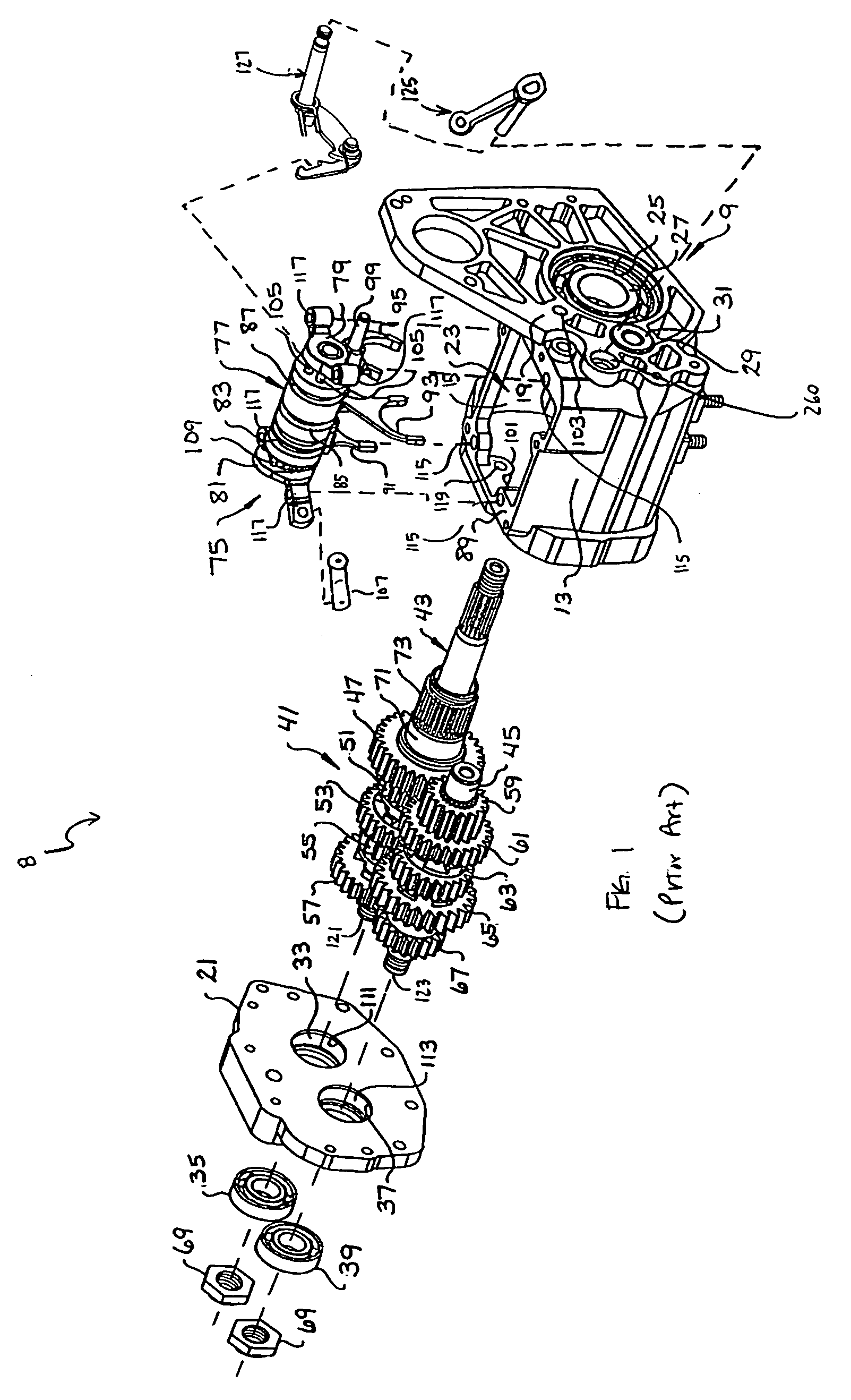

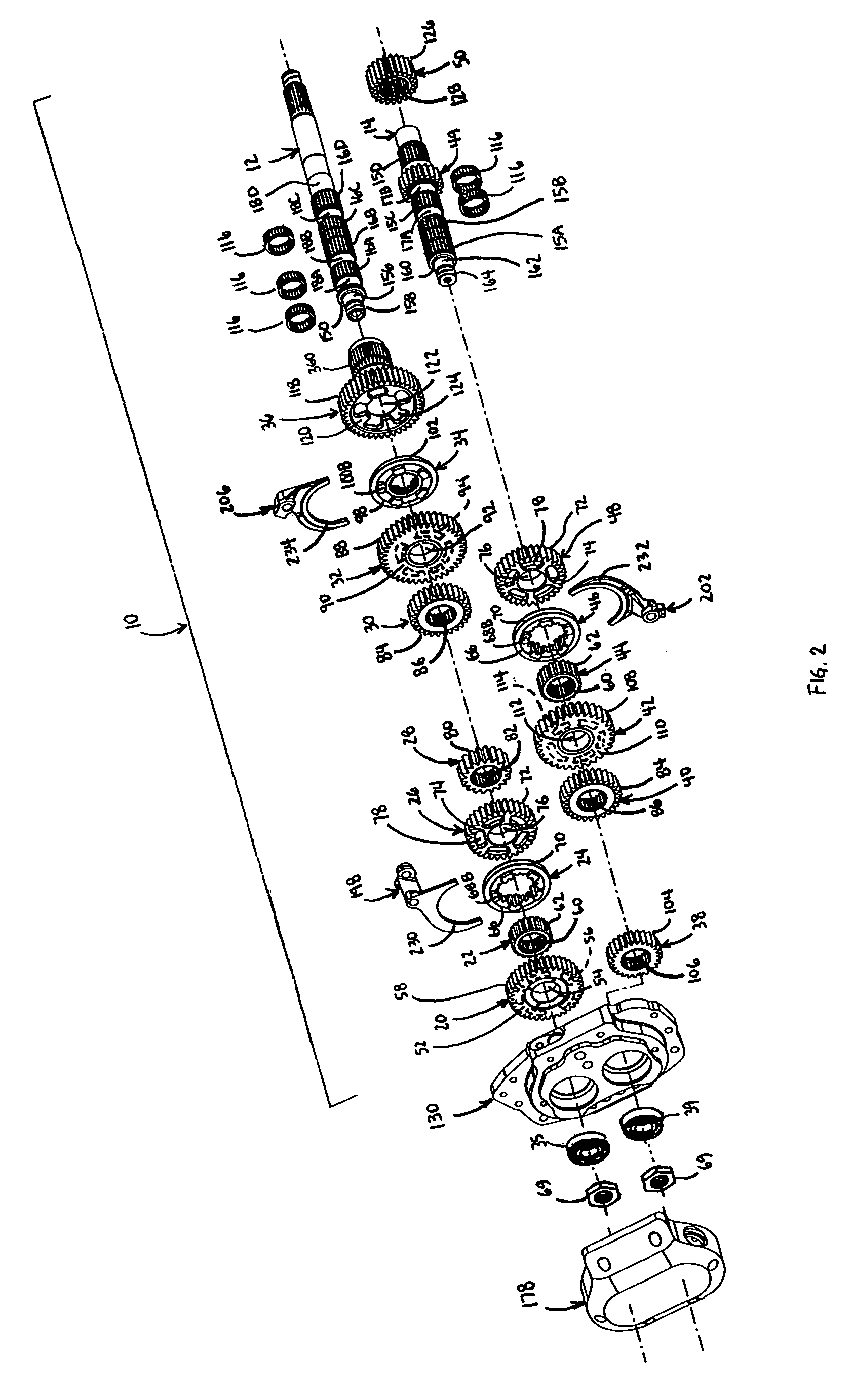

Six speed motorcycle transmission

A six speed gear assembly for a motorcycle transmission is provided that includes a mainshaft gear shaft with a plurality of mainshaft gears mounted in sequence thereon, wherein the sequence includes a mainshaft 4th gear, a mainshaft 3rd gear, one of a mainshaft 1st gear and a mainshaft 2nd gear, the other of the mainshaft 1st gear and the mainshaft 2nd gear, a mainshaft 6th gear, and a mainshaft 5th gear. The six speed gear assembly also includes a countershaft gear shaft with a plurality of countershaft gears mounted in sequence thereon, wherein the sequence includes a countershaft 4th gear, a countershaft 3rd gear, one of a countershaft 1st countershaft 1st gear and a countershaft 2nd gear, the other of the countershaft 1st gear and the countershaft 2nd gear, a countershaft 6th gear, and a countershaft 5th gear.

Owner:THIESSEN PRODS

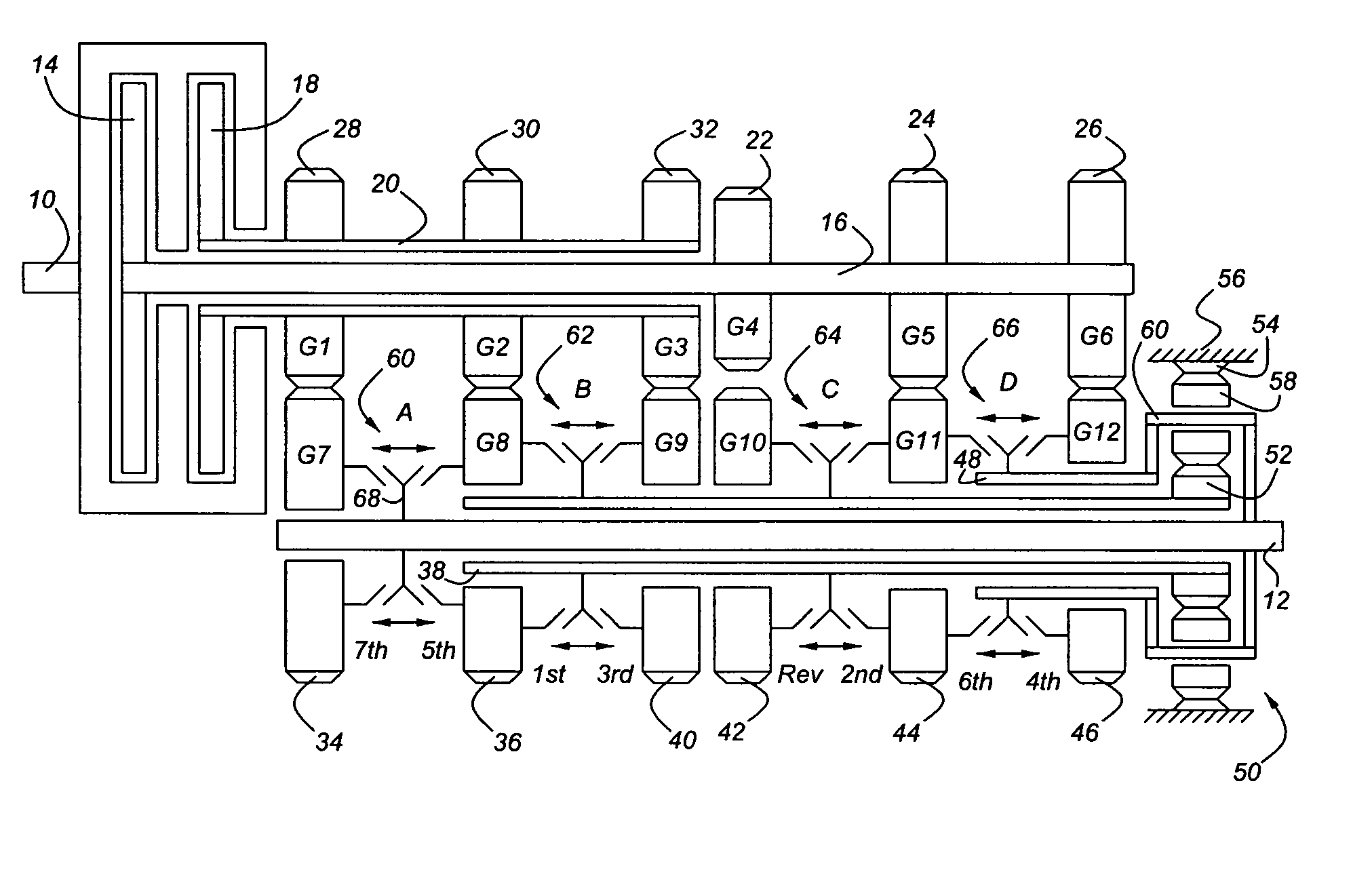

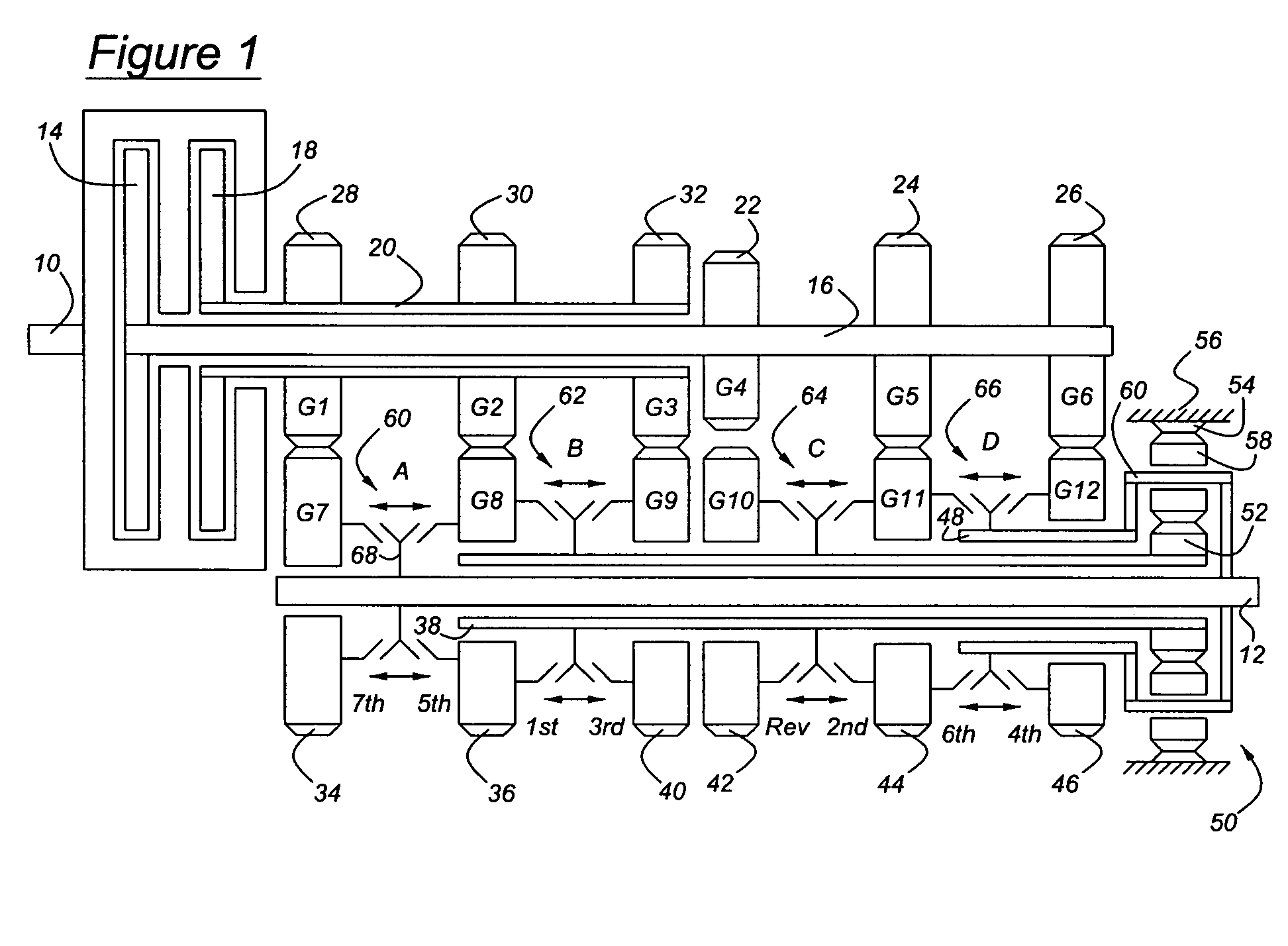

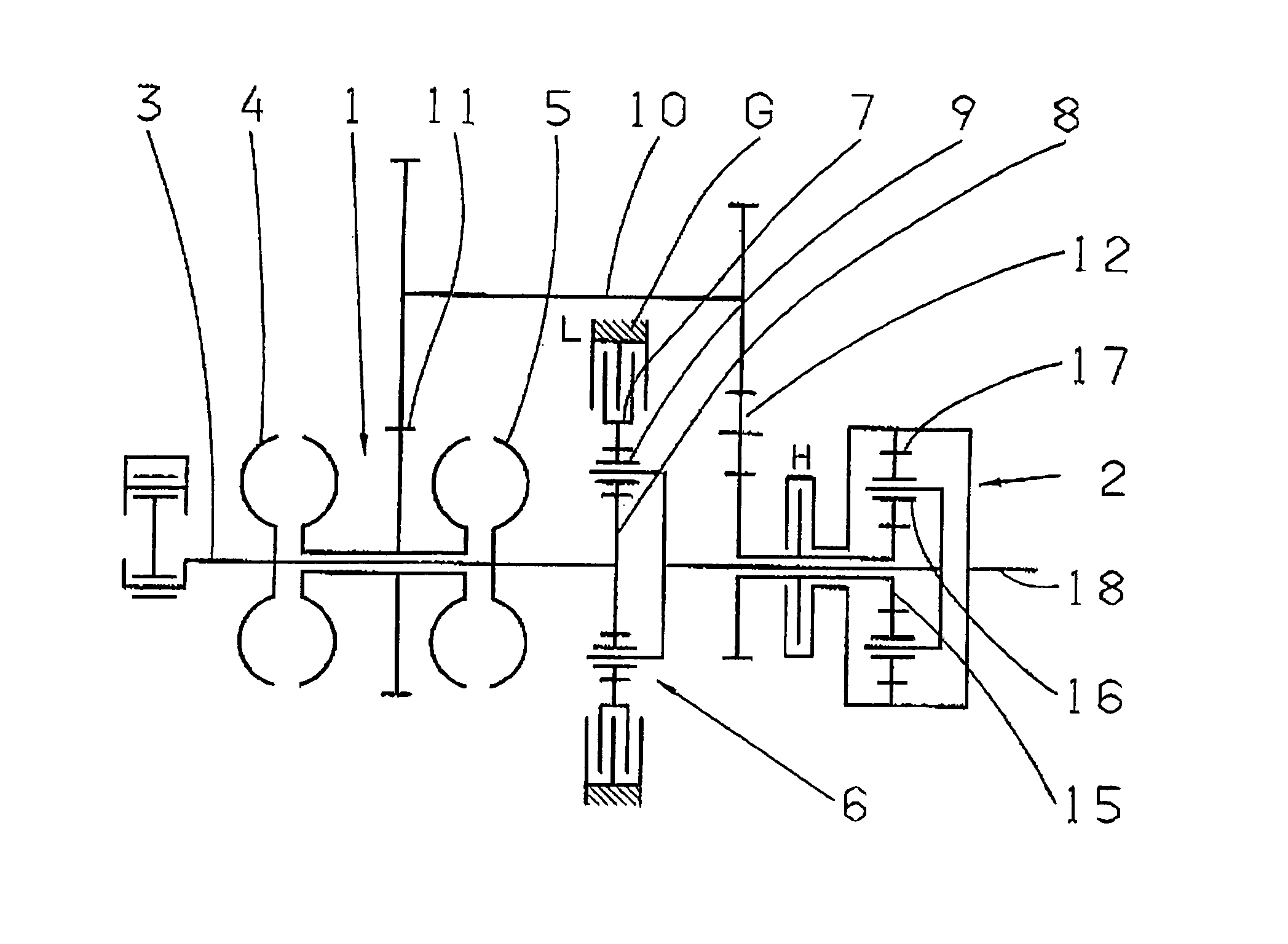

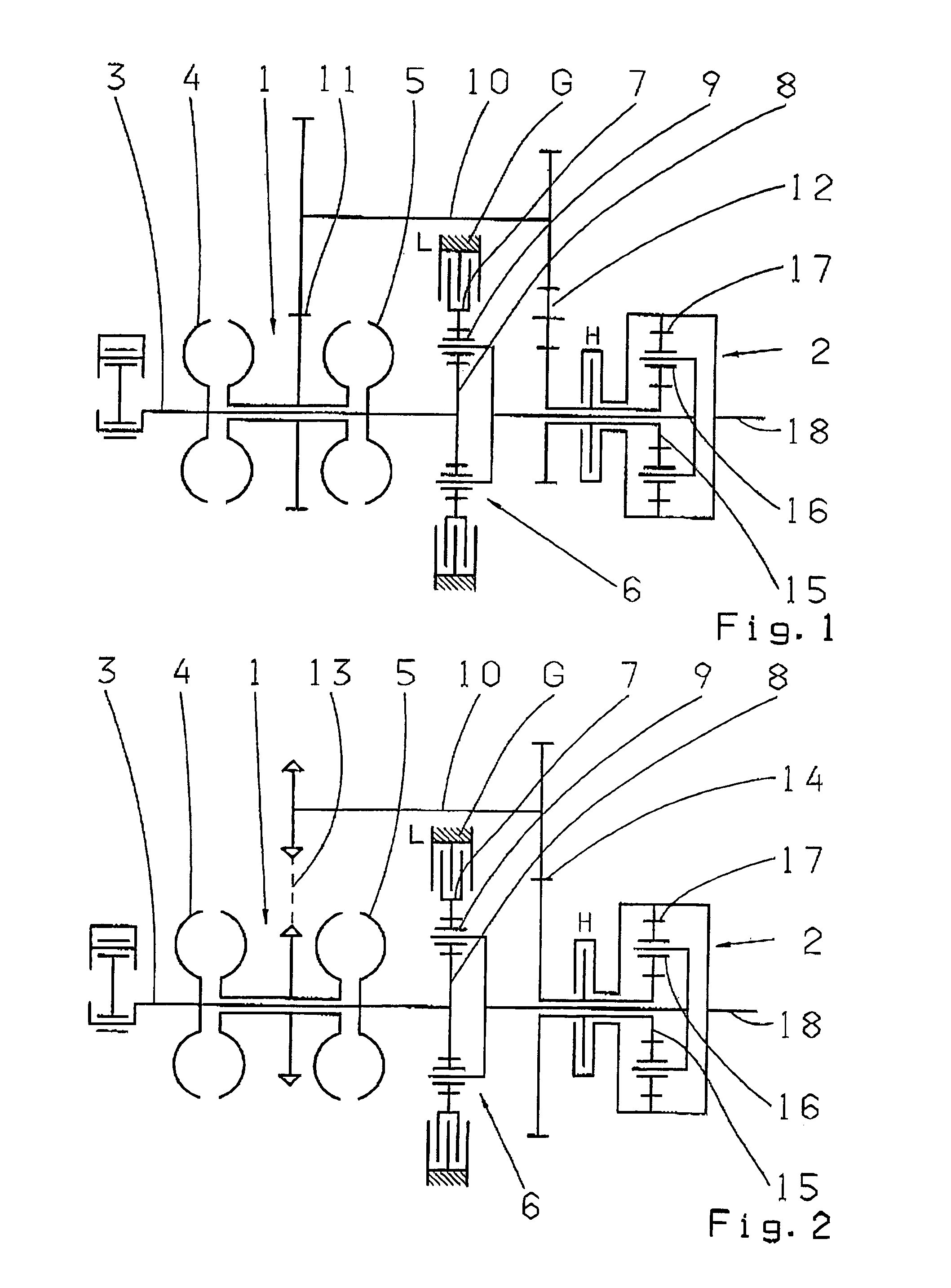

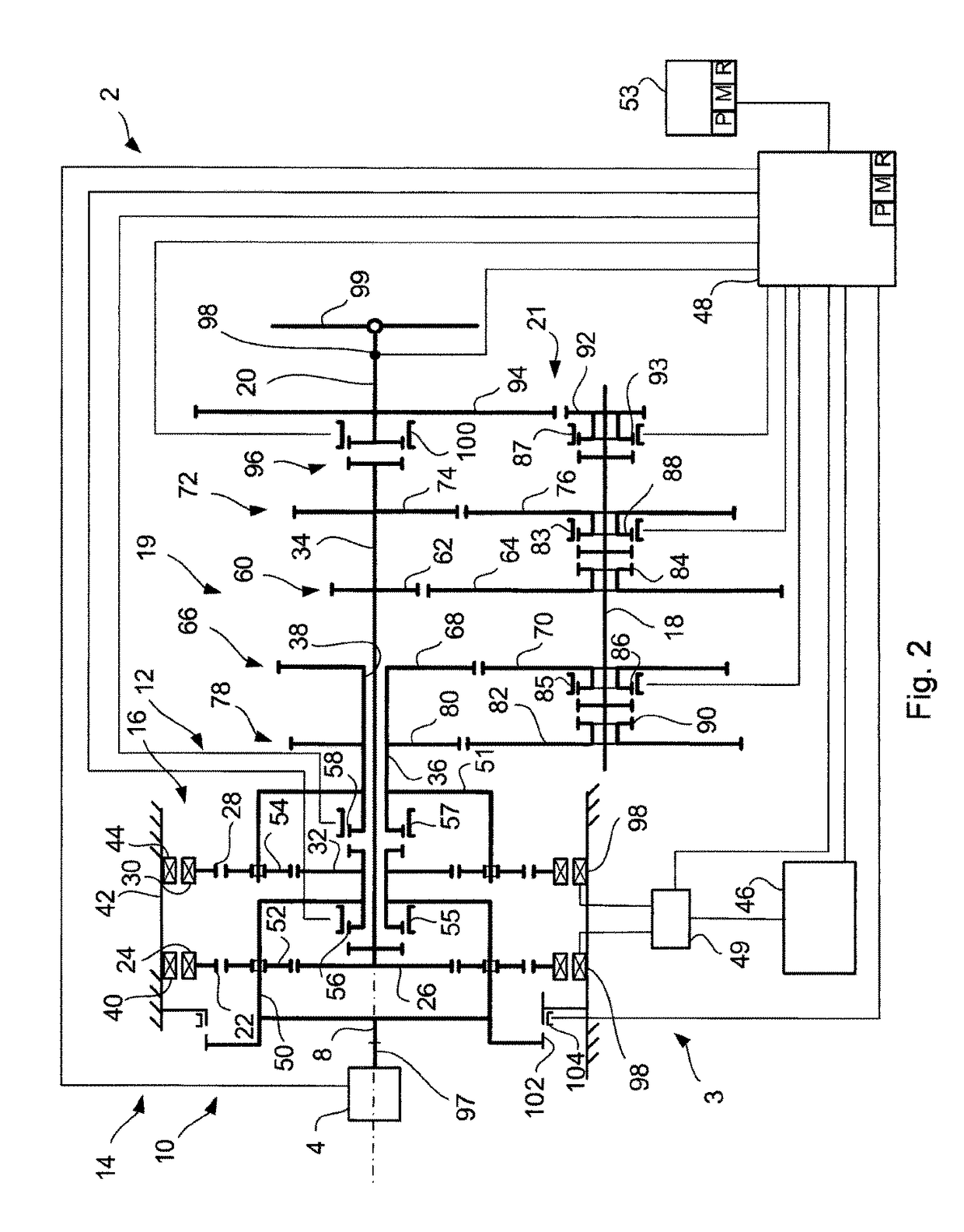

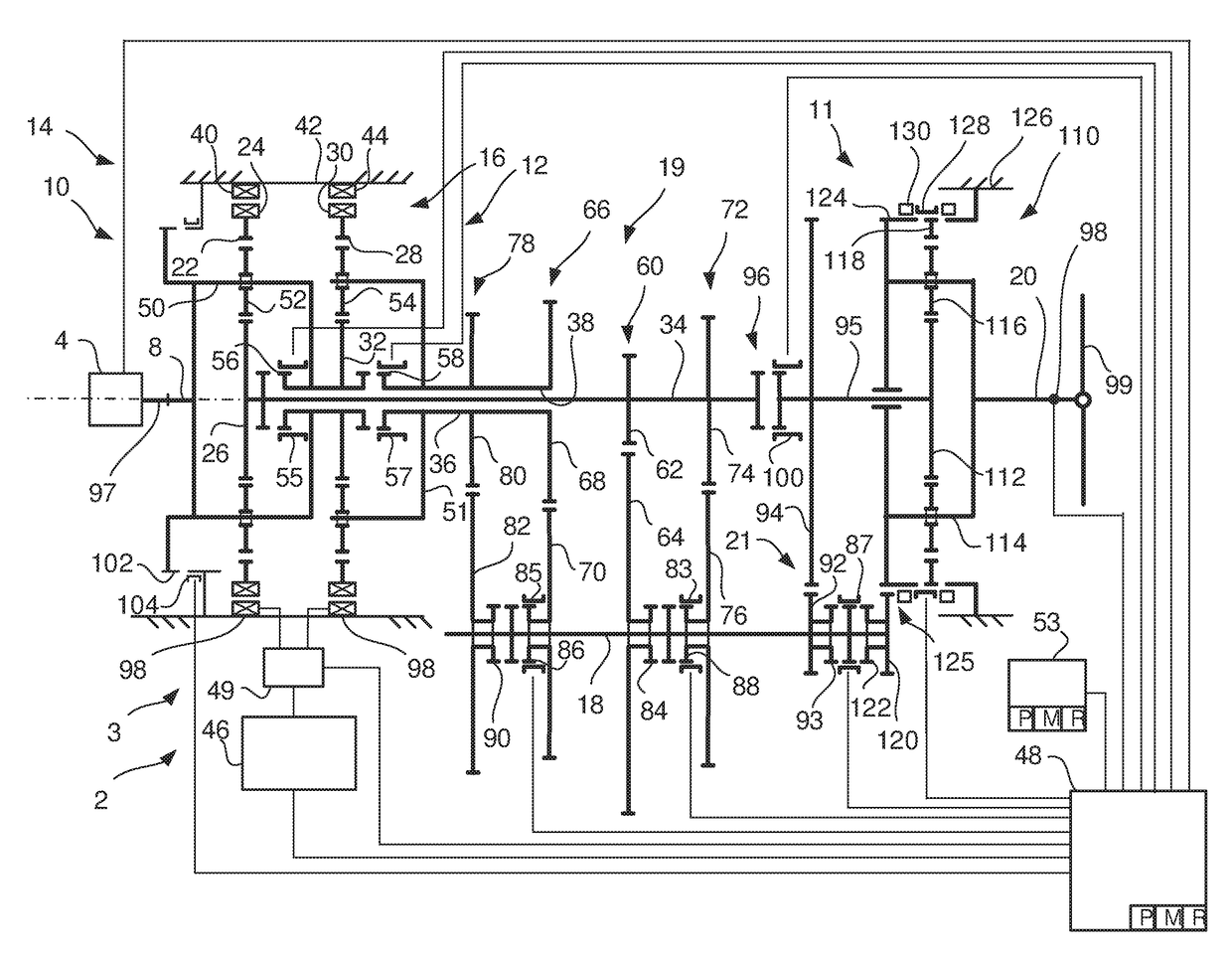

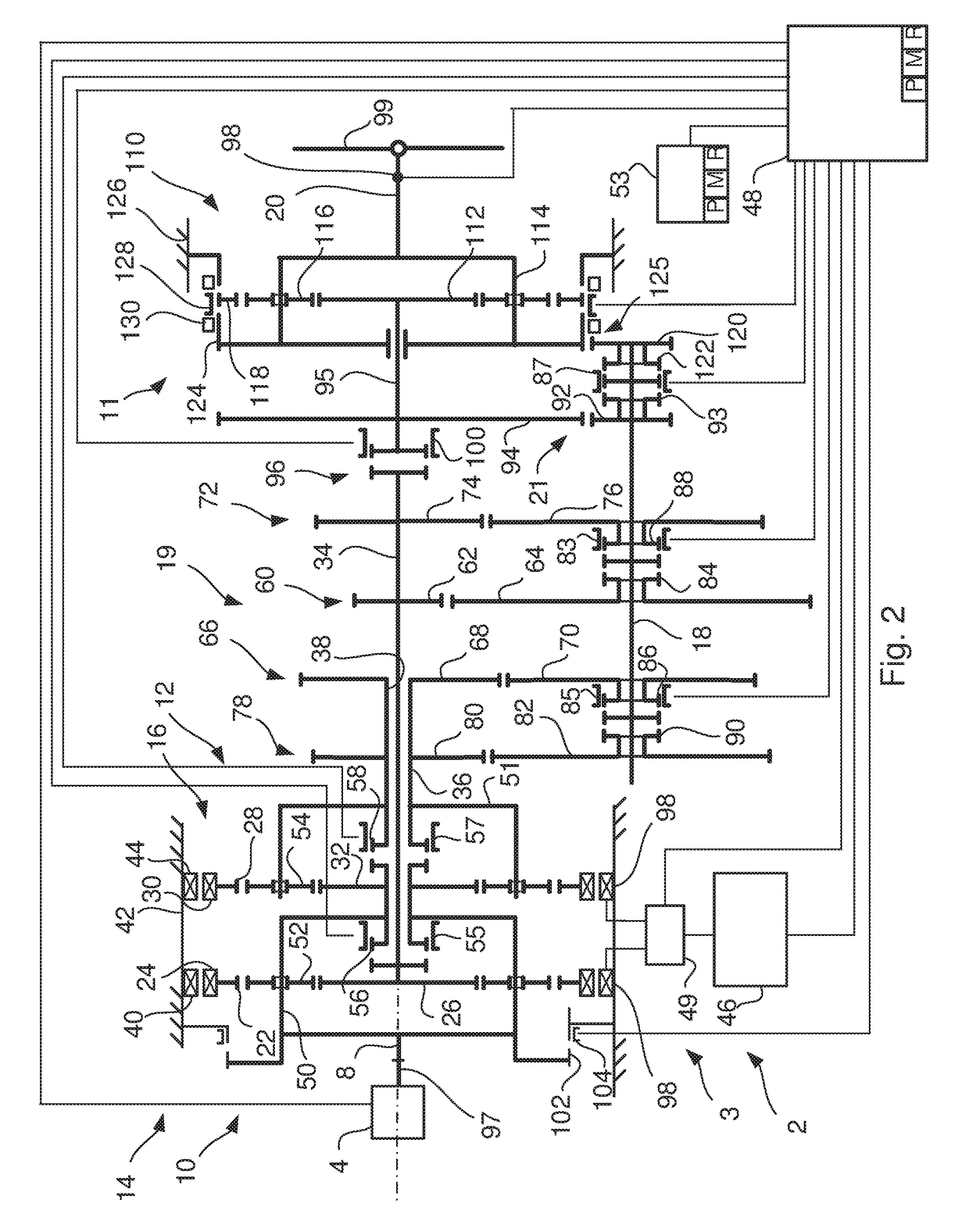

Hybrid powertrain with a gearbox and method to control the hybrid drivetrain

ActiveUS9770969B2Promote regenerationEfficient and reliable wayHybrid vehiclesElectric propulsion mountingDrivetrainElectric machine

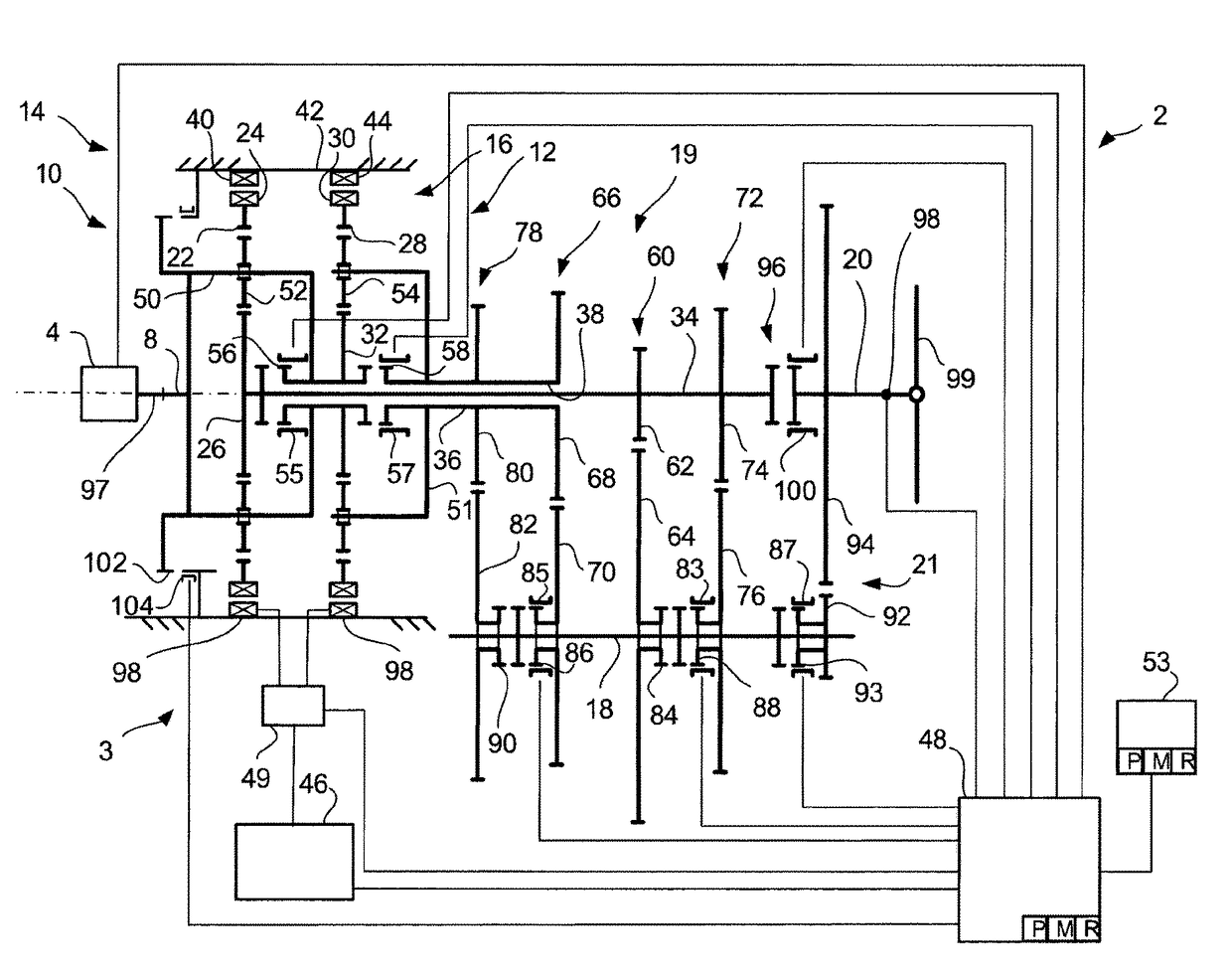

A hybrid powertrain that includes a combustion engine (4); a gearbox (2) with an input shaft (8) and an output shaft (20); a first planetary gear (10) connected to the input shaft (8) a second planetary gear (12) connected to the first planetary gear (10); a first electrical machine (14) connected to the first planetary gear (10); a second electrical machine (16) connected to the second planetary gear (12); a first gear pair (G1, 60) and a third gear pair (G1, 72) situated between the first planetary gear (10) and the output shaft (20); and a second gear pair (66) and a fourth gear pair (G2, 78) situated between the second planetary gear (12) and the output shaft (20); a countershaft (18) provided between the respective first and the second planetary gears (10, 12) and the output shaft (2), and (18) connected to the output shaft (20) via a fifth gear pair (G3M 21). Also, disclosed is a method for controlling the hybrid powertrain. Also a method for controlling a hybrid powertrain (3) and a computer program (P) for controlling the hybrid powertrain (3).

Owner:SCANIA CV AB

Single clutch transmission

InactiveUS20070125192A1Reduce resistancePropulsion power plantsOutboard propulsion unitsLow speedGear train

A two speed transmission includes an input shaft; a lay shaft spaced from the input shaft; a first gear train connecting the input shaft to the lay shaft; a second gear train connecting the lay shaft to an output shaft the gear train including a one way clutch or similar; and a clutch for engaging the input shaft with the output shaft. The transmission is arranged such that when the output shaft is disengaged from the input shaft power is transmitted to the output shaft via the first and second gear trains and the lay shaft. When the clutch is disengaged, power is transmitted from the input shaft via the gear trains and the lay shaft via the one way clutch to the output shaft which typically provides first or low gear for use in low speed maneuvering or where greater torque is required. With the clutch engaged, power may be transmitted from the input shaft directly to the output shaft to provide a second gear for when the watercraft is cruising. This transmission system has the advantage of being extremely compact and since, it requires only a single clutch, provides reduced drag compared with transmission systems incorporating more than one clutch. Advantageously, the default for the transmission has the one way clutch or similar in the first or lower gear, with the clutch normally on, so that if the system fails, it is always possible for the boat owner to get the boat home albeit at a slower speed.

Owner:CONSULTING INT

Apparatus for driving an accessory gearbox in a gas turbine engine

ActiveUS20050183529A1Increased versatility and capabilityEngine fuctionsToothed gearingsDrive shaftPressure.drive

A mechanical drive system for an accessory gearbox of a gas turbine engine is provided. The engine has a high-pressure drive shaft and a low-pressure drive shaft. The mechanical drive system includes a first tower shaft, a second tower shaft, a first lay shaft, and a second lay shaft. The first tower shaft is driven by the high-pressure drive shaft. The second tower shaft is driven by the low-pressure drive shaft. The first lay shaft is driven by the first tower shaft, and is connected to the accessory gearbox. The second lay shaft is driven by the second tower shaft, and is connected to the accessory gearbox.

Owner:RTX CORP

Twin-clutch manual transmission

A twin-clutch manual transmission including: first and second input shafts provided with respective clutches; a counter shaft parallel to these input shafts; gear sets of an odd-numbered gear range group disposed between the rear end portion of the first input shaft and the counter shaft; gear sets of the even-numbered gear range group disposed between the second input shaft and the counter shaft; an output shaft being concentric with and abutting on a rear end of the first input shaft; and a synchronizer provided between the rear end of the first input shaft and the output shaft to provide a direct-coupling gear range. The odd-numbered gear range group includes the direct-coupling gear range.

Owner:NISSAN MOTOR CO LTD

Hybrid powertrain and a vehicle with such a hybrid powertrain

ActiveUS20170282700A1Easy transferPromote regenerationHybrid vehiclesElectric propulsion mountingInternal combustion engineHybrid powertrain

The present invention relates to a hybrid powertrain, comprising an internal combustion engine; a gearbox with an input shaft and an output shaft; a first planetary gear, connected to the input shaft; a second planetary gear, connected to the first planetary gear; a first electrical machine, connected to the first planetary gear; a second electrical machine, connected to the second planetary gear; at least one gear pair, connected with the first planetary gear and the output shaft; and at least one gear pair, connected with the second planetary gear and the output shaft, wherein the internal combustion engine is connected with the first planetary gear via the input shaft, wherein a countershaft is arranged between the respective first and second planetary gears and the output shaft; and the countershaft is connected with the output shaft via a range gearbox.

Owner:SCANIA CV AB

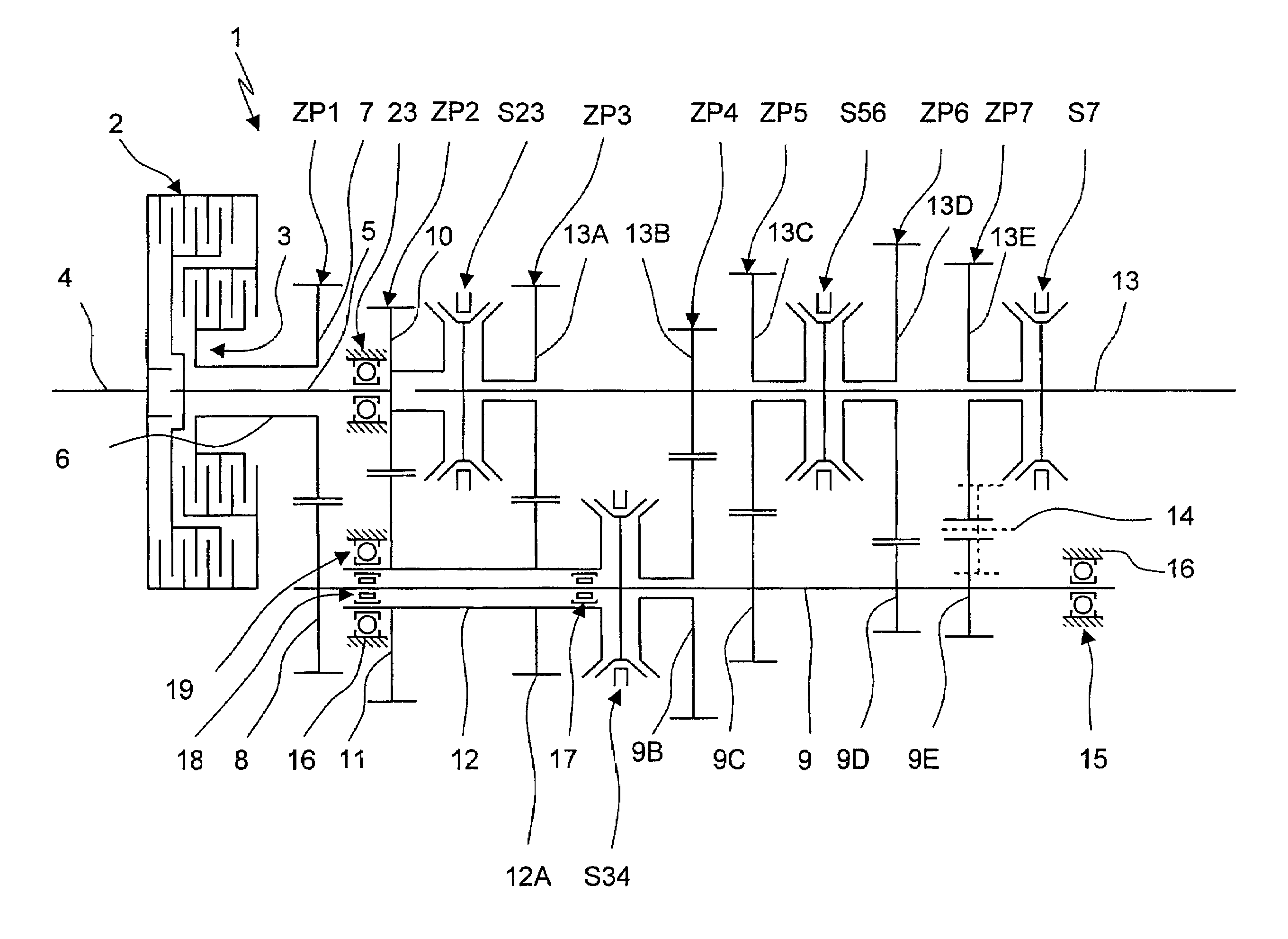

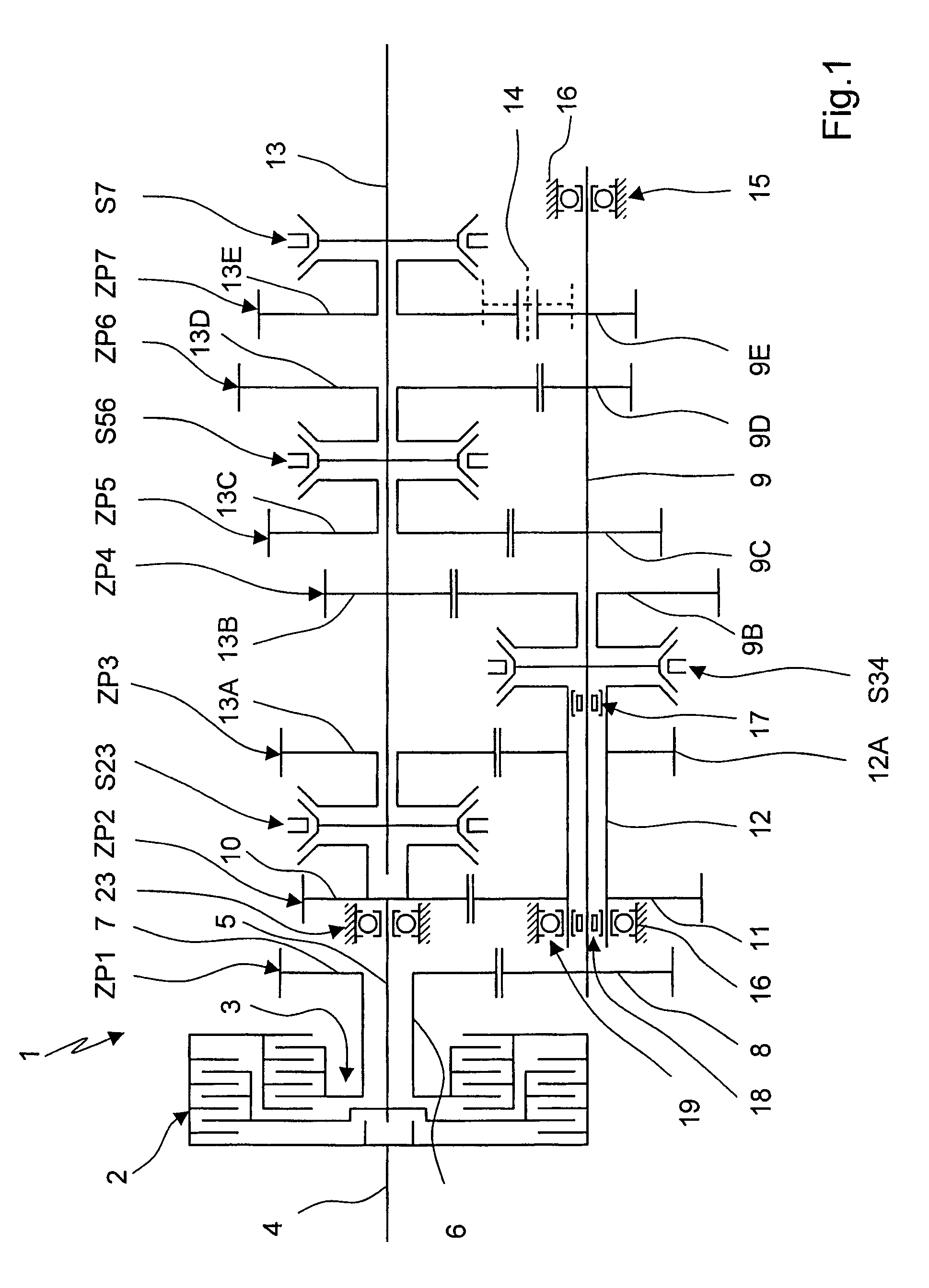

Multistep transmission of a layshaft type

InactiveUS7267022B2Reduce gear ratioIncrease valueRolling contact bearingsToothed gearingsPower flowGear wheel

A multi-speed transmission of countershaft design having a main countershaft and a hollow countershaft arranged concentrically and having likewise two load-shift elements. A first half of the shift elements is connected with a drive unit and a second half of the shift elements is connected to a gearbox input shaft. The gearbox input shafts and countershafts are mounted in a housing and connected to gear wheels, which intermesh in pairs as gear wheel pairs and can be connected or disconnected in order to reduce the overall gear ratio in the power flow. The main countershaft is mounted directly on the housing in the area of its first end and in the hollow countershaft in the area of its second end. The hollow countershaft is mounted in the housing in the area of its end that faces toward the end of the main countershaft that is mounted in the hollow countershaft.

Owner:ZF FRIEDRICHSHAFEN AG

Axle drive unit for a hybrid electric vehicle

ActiveUS7762366B2Closely positionedSimple supportMotor/generator/converter stoppersElectric propulsion mountingTransmitted powerElectric machine

A drive unit for a hybrid electric motor vehicle includes an engine, an electric machine including a rotor, a layshaft gearset including an input driveably connected to the engine and an output, for transmitting power between the input and the output and producing a first speed differential that causes a speed of the input to exceed a speed of the output, first and second driveshafts, a differential mechanism driveably connected to the output, for transmitting power between the output and the driveshafts, and a planetary gear unit driveably connected to the output and the rotor, for transmitting power between the rotor and the output and producing a second speed differential that causes a speed of the rotor to exceed the speed of the output.

Owner:FORD GLOBAL TECH LLC

Mechanical double-overrunning clutch main shaft outputting adaptive automatic transmission high speed motor wheel chair hub

ActiveCN109910601ASmooth load changeAchieve balance controlMotor depositionElectric energy managementAutomatic transmissionElectric cars

The invention discloses a mechanical double-overrunning clutch main shaft outputting adaptive automatic transmission high speed motor wheel chair hub. A reverse gear mechanism has a transmission ratioI which transmits a reverse gear power from an auxiliary shaft to a main shaft, a low gear transmission mechanism has a transmission ration II which transmits a low gear power from the auxiliary shaft to the main shaft, and the transmission ratio I is greater than or equal to the transmission ratio II. According to the mechanical double-overrunning clutch main shaft outputting adaptive automatictransmission high speed motor wheel chair hub, reasonable cooperation of two overrunning clutches is utilized, reasonable set of the transmission ratios are realized on the reverse gear structure andthe low gear mechanism, so that the overall structure is simple and compact, a transmission line is shared by reverse gear transmission, low gear transmission and fast gear transmission, and no interference is produced, the overall performance of the mechanical adaptive automatic transmission provided by the invention is ensured, the adaptive capacity is relatively strong, the cooperation with theadaptive automatic transmission mechanism is smooth and natural, the mechanical adaptive automatic transmission is applicable to the field of electric cars, meanwhile, a reducing input structure is utilized, the mechanical adaptive automatic transmission is suitable for power input of the high speed motor, and the overall efficiency is improved.

Owner:SOUTHWEST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com