Patents

Literature

162results about How to "Reduce gear ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

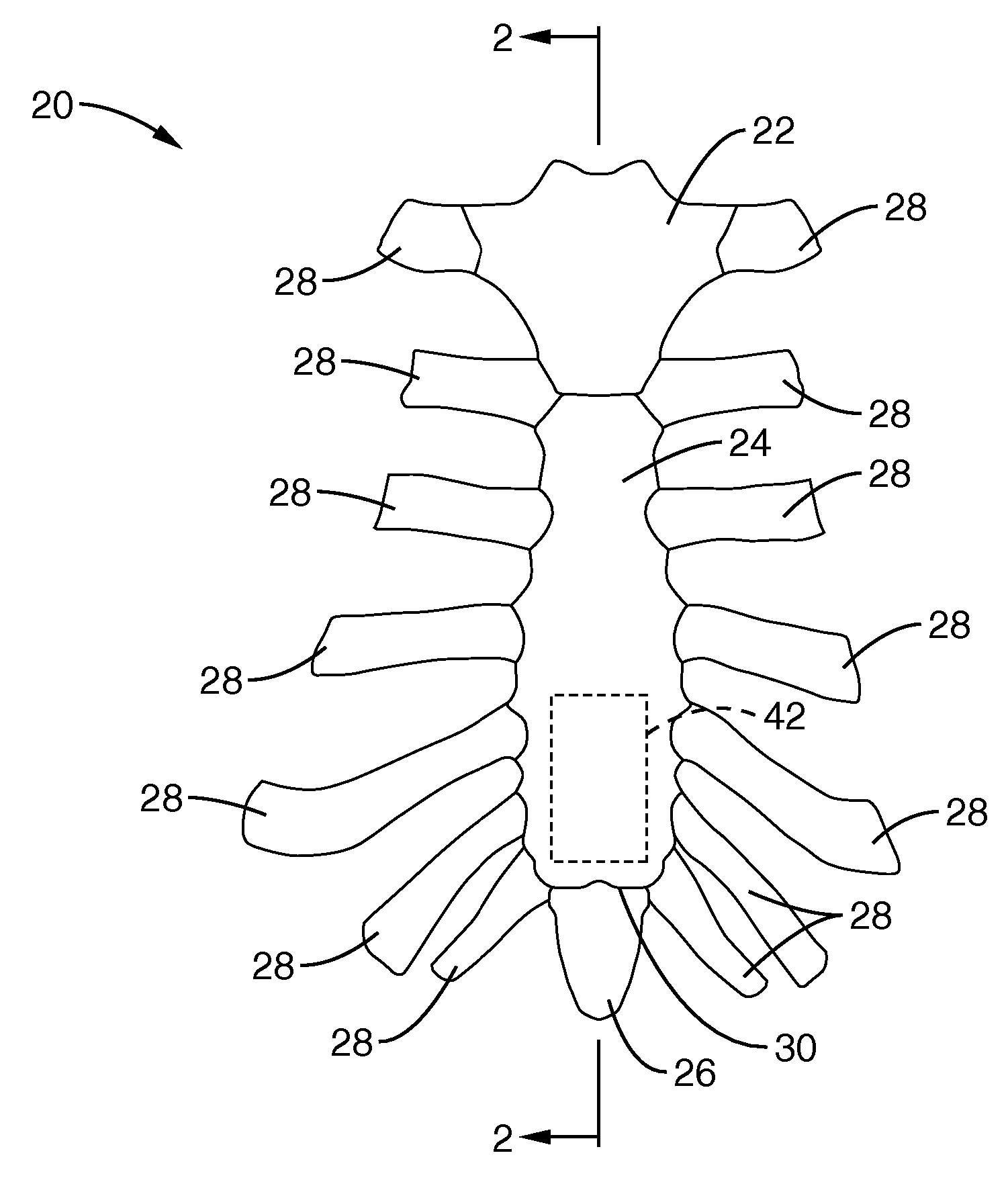

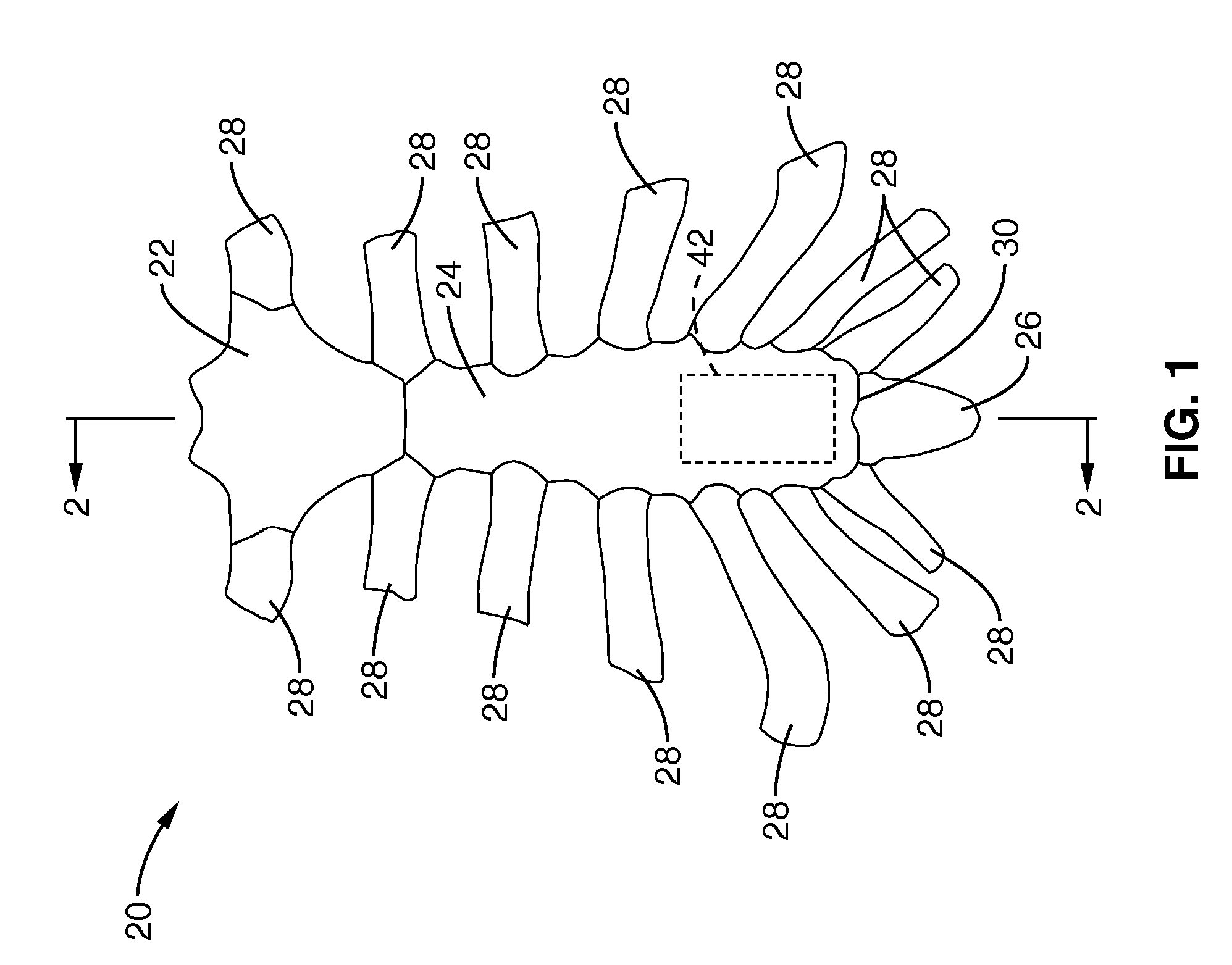

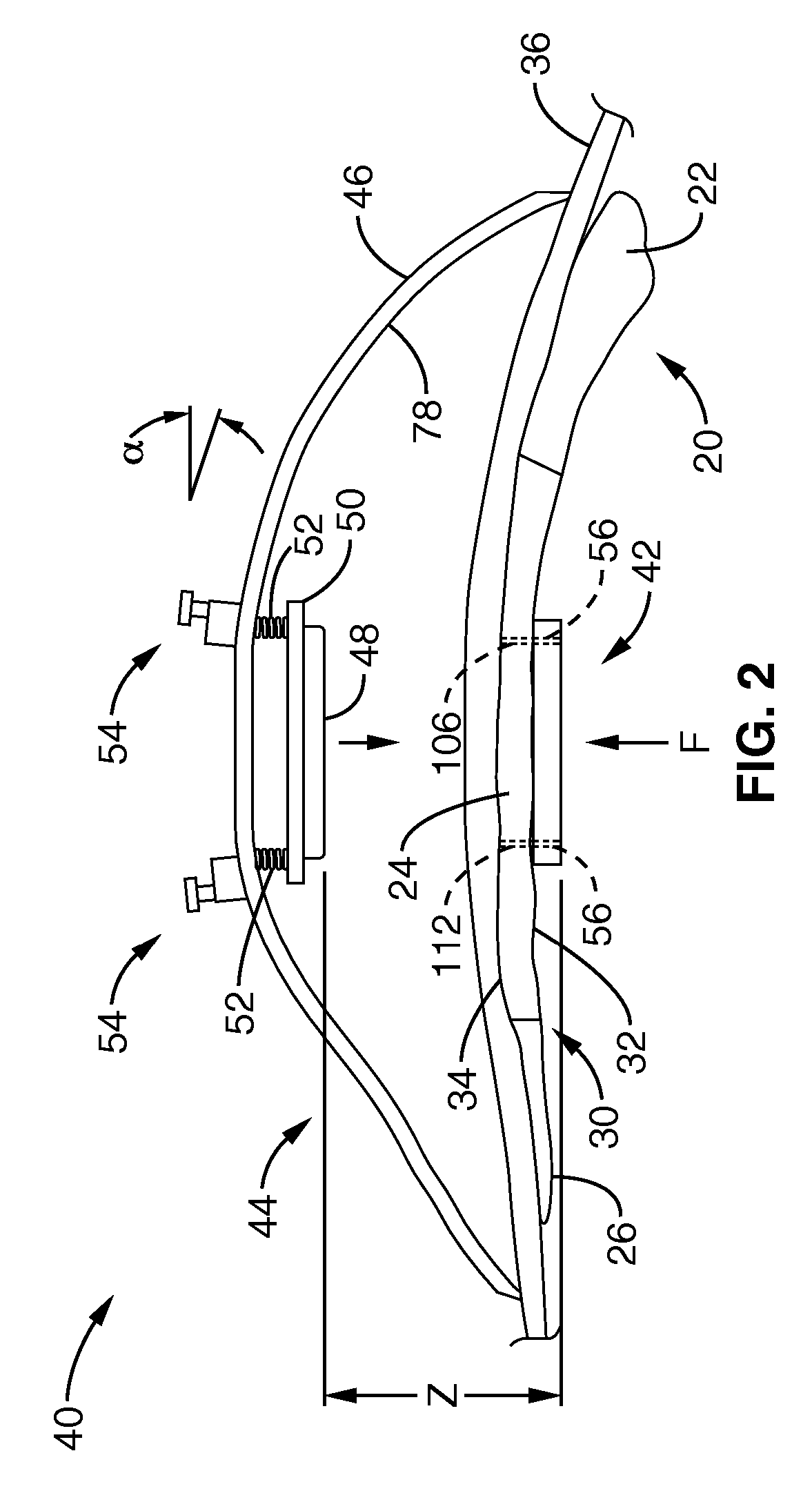

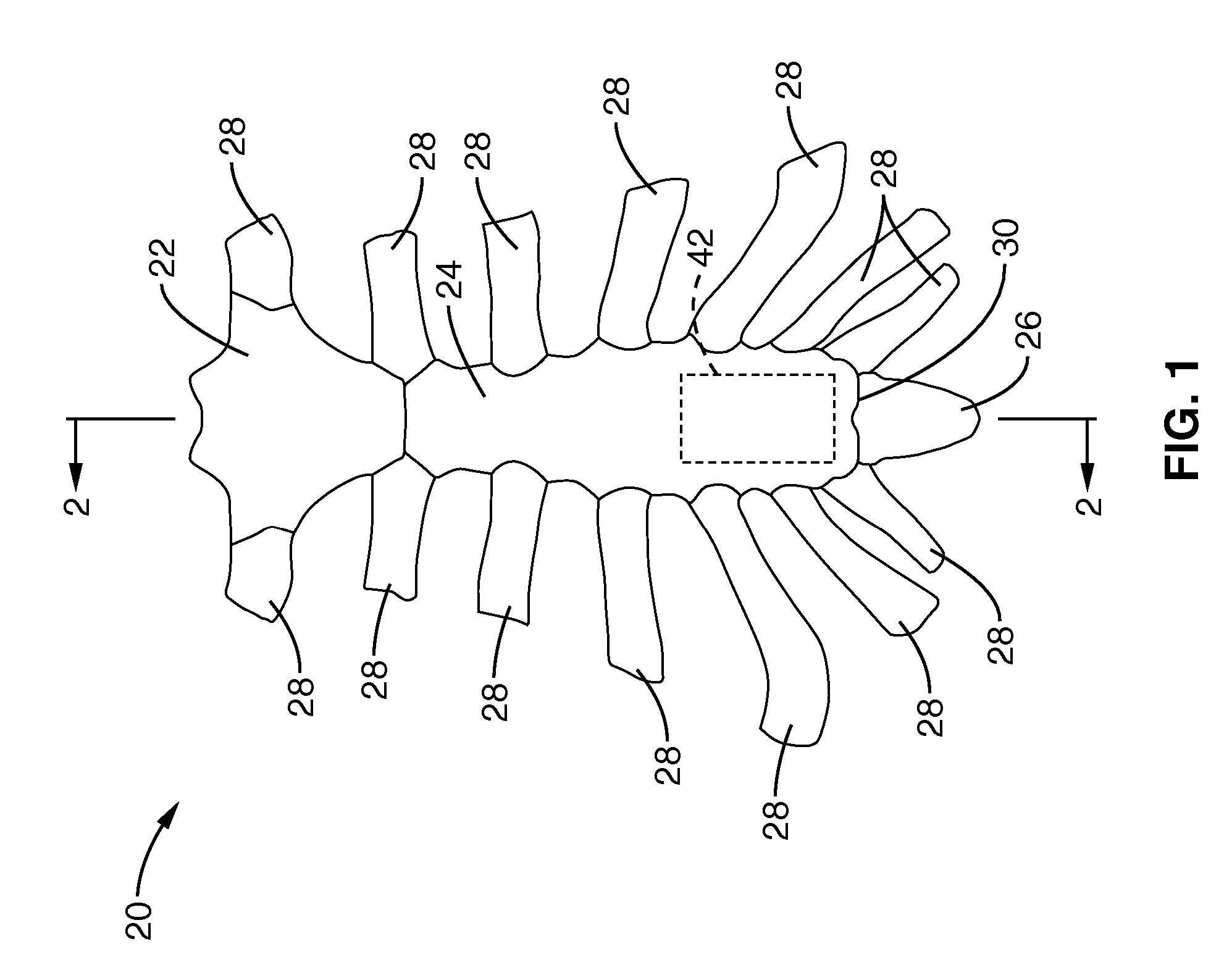

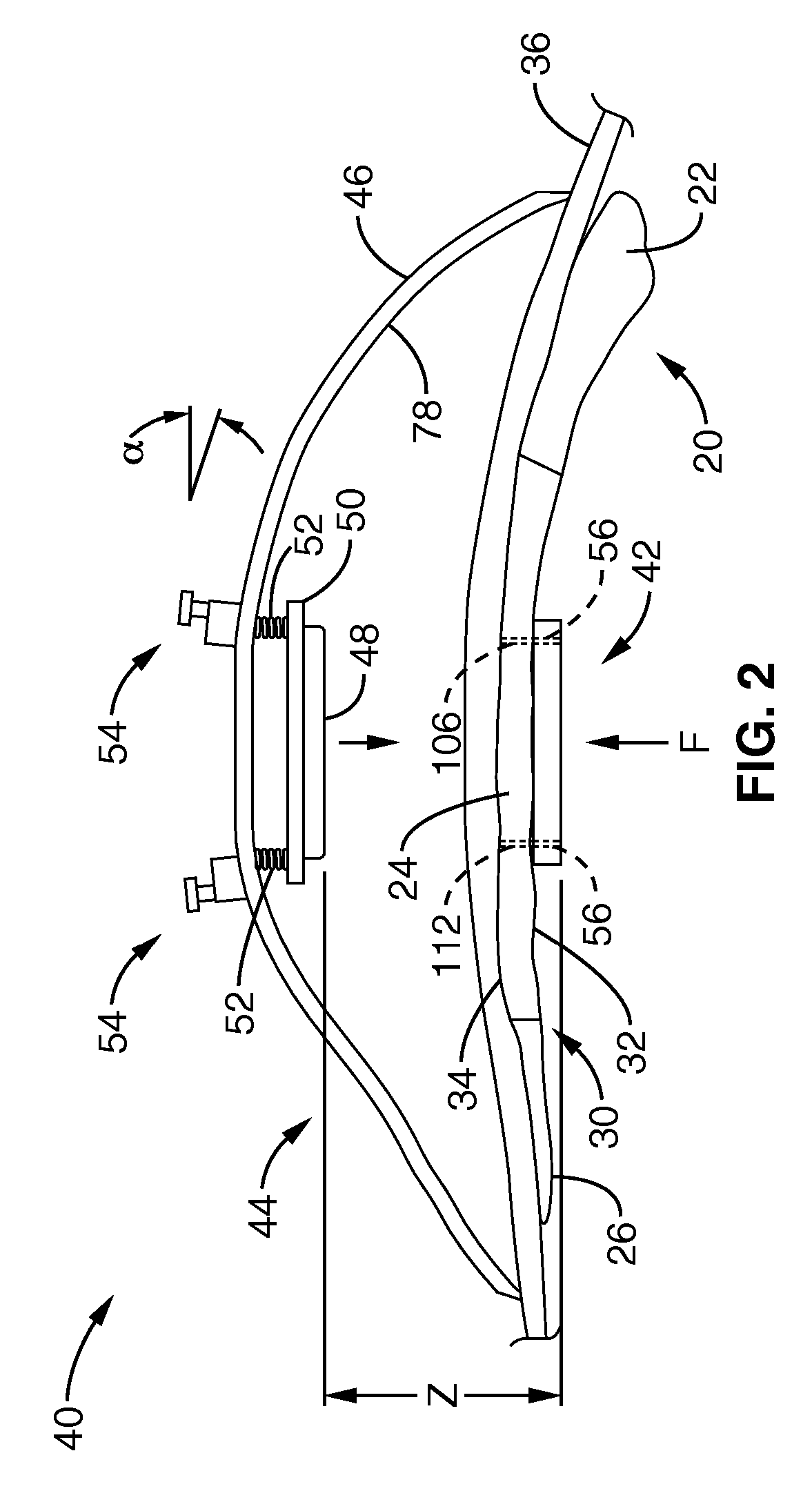

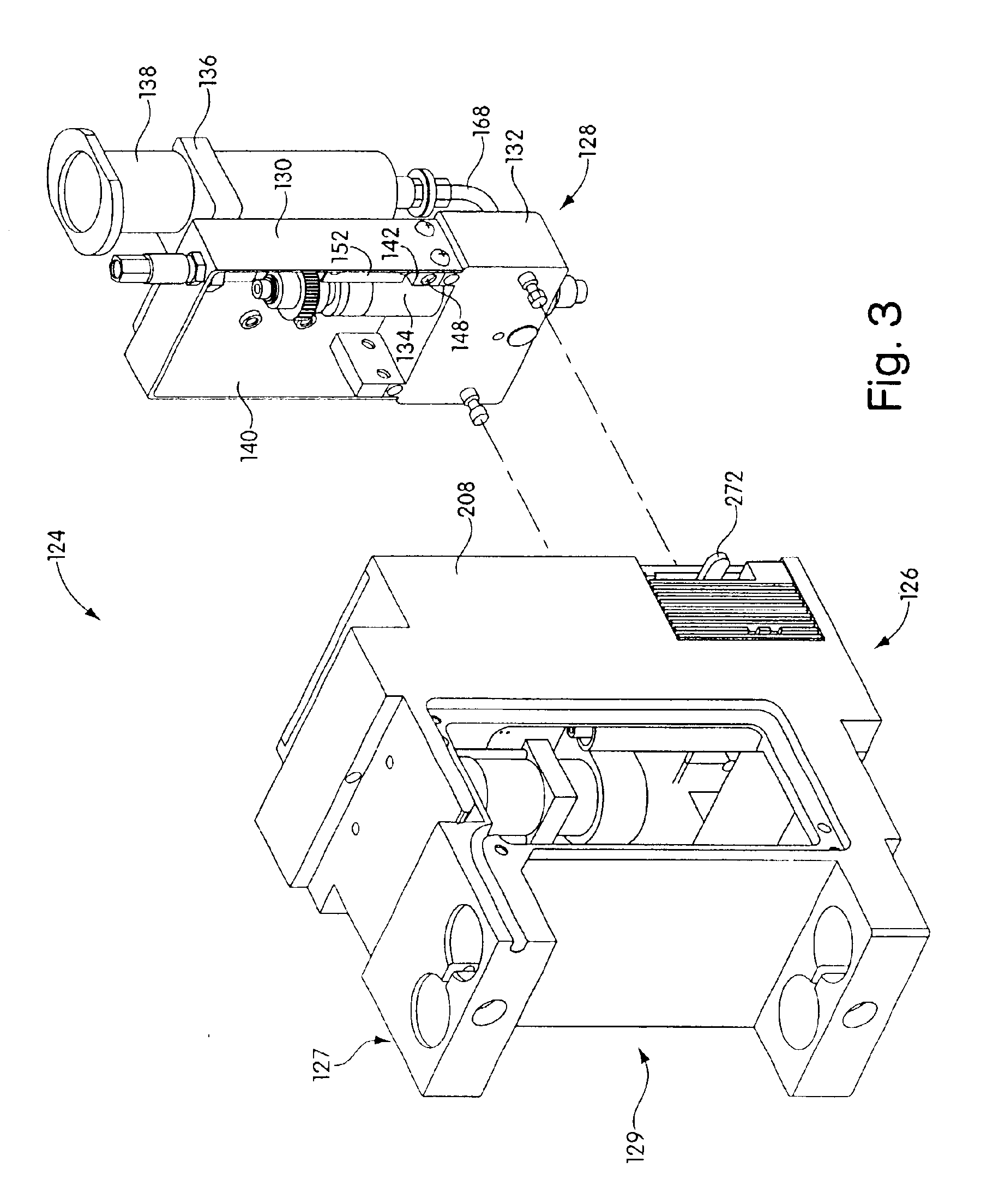

Apparatus and methods for magnetic alteration of anatomical features

ActiveUS20070276378A1Reduce gear ratioSuture equipmentsInternal osteosythesisAnatomical structuresJackscrew

Systems and methods are disclosed for manipulating an anatomical feature within the body of the patient. An implant such as an internal jackscrew is implanted at the anatomical and has first and second attachment points that secure to spaced-apart locations on the anatomical feature, an internal rotor coupled to the jackscrew, and is configured to drive motion of the jackscrew to manipulate the anatomical feature. The system further includes an external rotor that is magnetically coupled to the internal rotor such that rotation of the external rotor at an exterior location to the patient's body affects a corresponding internal rotation of the internal rotor to manipulate the anatomical feature.

Owner:RGT UNIV OF CALIFORNIA

Apparatus and methods for magnetic alteration of anatomical features

ActiveUS8439915B2Reduce gear ratioSuture equipmentsInternal osteosythesisAnatomical structuresJackscrew

Systems and methods are disclosed for manipulating an anatomical feature within the body of the patient. An implant such as an internal jackscrew is implanted at the anatomical and has first and second attachment points that secure to spaced-apart locations on the anatomical feature, an internal rotor coupled to the jackscrew, and is configured to drive motion of the jackscrew to manipulate the anatomical feature. The system further includes an external rotor that is magnetically coupled to the internal rotor such that rotation of the external rotor at an exterior location to the patient's body affects a corresponding internal rotation of the internal rotor to manipulate the anatomical feature.

Owner:RGT UNIV OF CALIFORNIA

Dispensing system and method

InactiveUS6866881B2Increase the number ofReduce gear ratioLarge containersPretreated surfacesMotor unitElectric motor

A dispensing system and method for dispensing material onto a substrate. The dispensing system includes a frame, a support, coupled to the frame, that supports the substrate at a dispensing position in the dispensing system, and a dispensing head, coupled to the frame, that dispenses the material onto the substrate. The dispensing head includes a motor unit having a first motor coupled to an output drive mechanism, and a dispensing unit, removably coupled to the motor unit, having a material outlet from which the dispensing material is dispensed, the dispensing unit having a dispensing mechanism coupled to the material outlet and coupled to the output drive mechanism of the motor unit such that operation of the first motor causes the dispensing mechanism to dispense material through the outlet. The dispensing head may be controlled for deposition of dots of material having diameters smaller than a dispensing needle of the dispensing unit.

Owner:KPS SPECIAL SITUATIONS FUND II LP

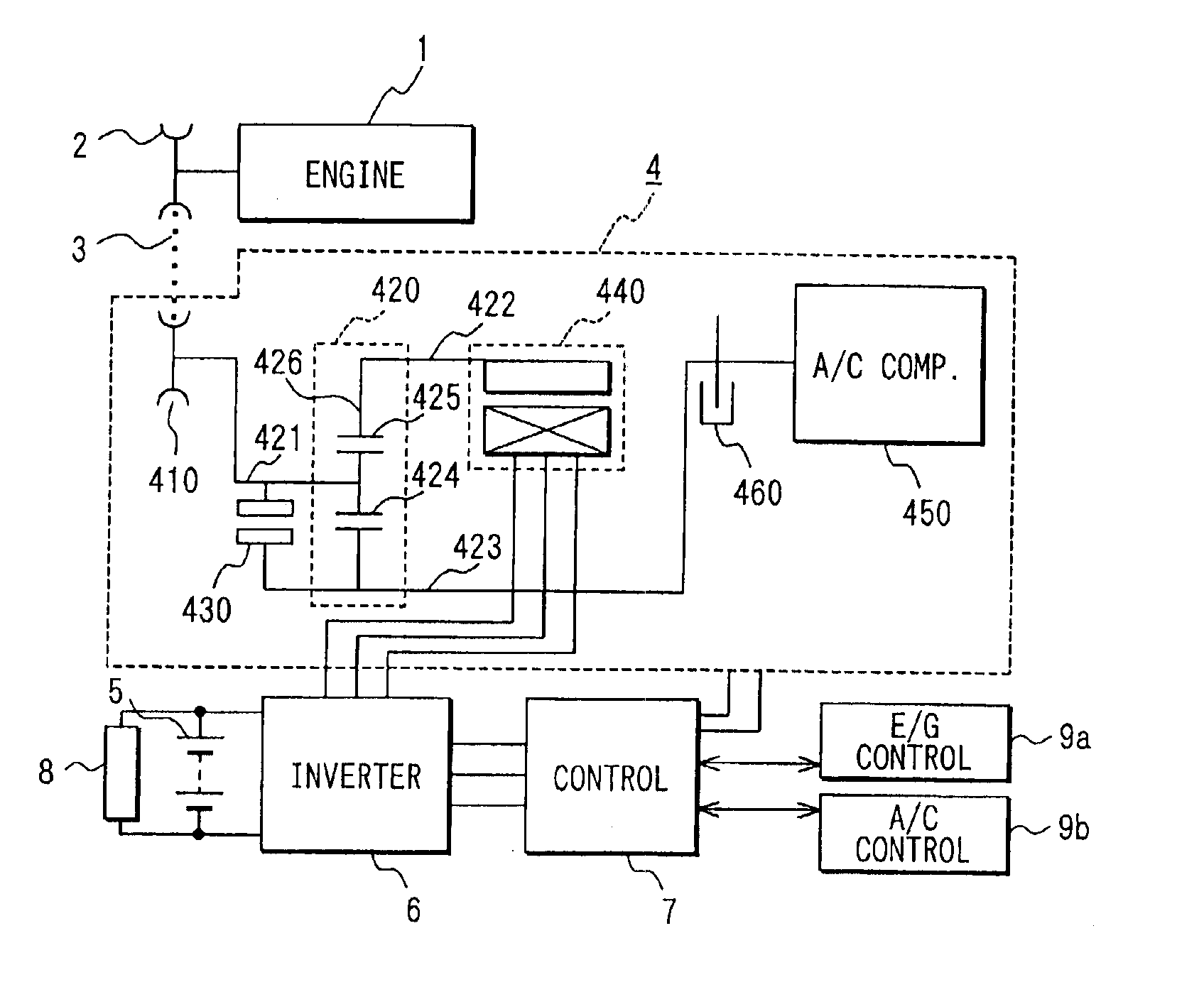

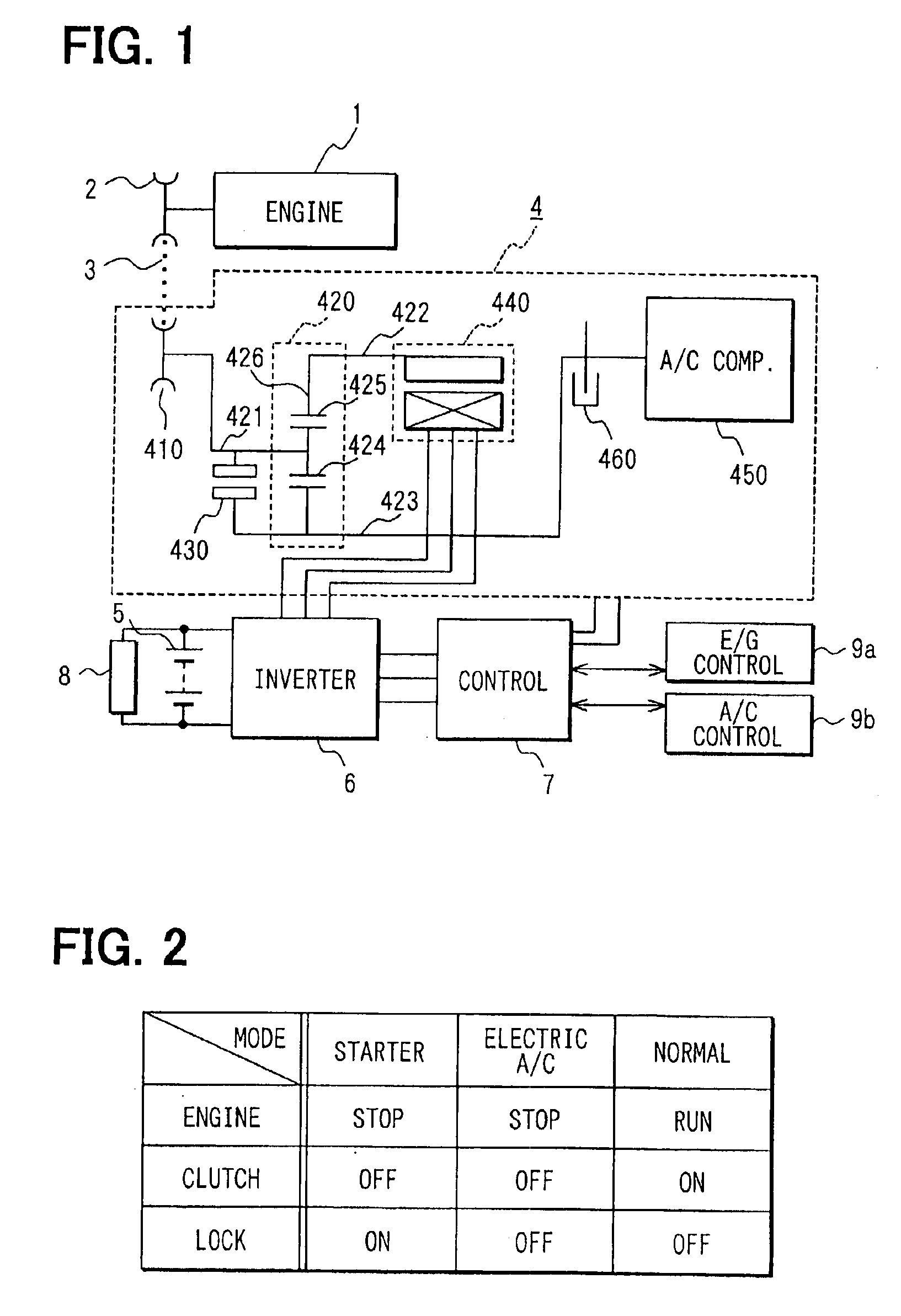

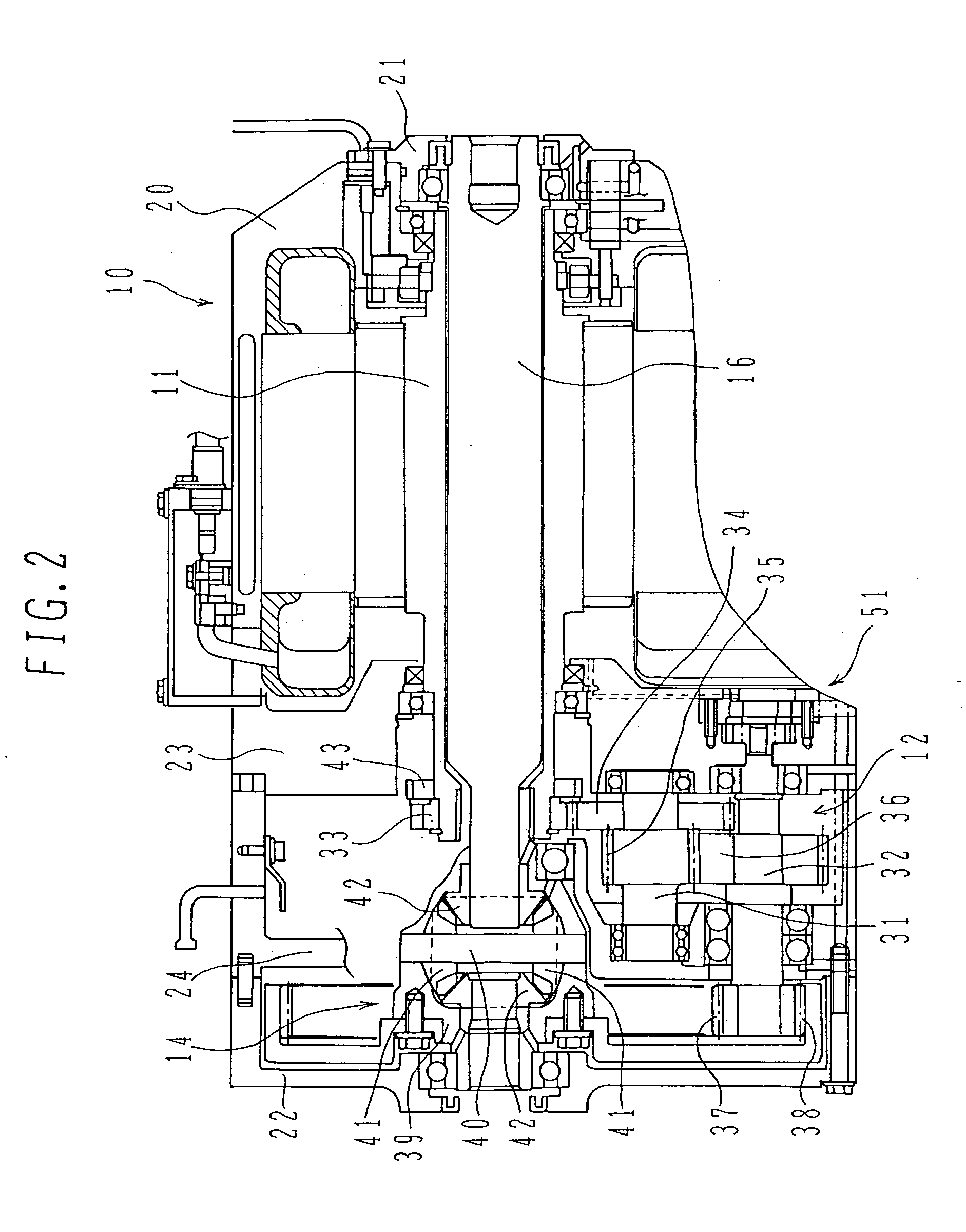

Accessory-driving equipment for an automotive vehicle

InactiveUS6863139B2Low costStable placement effectHybrid vehiclesAuxillary drivesMobile vehicleIdle speed

Accessory-driving equipment connects an engine having an idle stop system, a motor-generator and an accessory including an air-conditioner compressor that is driven even at a time when the idle stop system is operated. The accessory is driven by the engine when the engine is running and driven by the motor-generator when the idle stop system is operated. The accessory-driving equipment includes a first shaft for connecting to the engine, a second shaft for connecting to the motor-generator, a third shaft for connecting to the accessory, a lock device for locking the third shaft and a clutch. The clutch and the lock device are operated so that a torque transmitted from the engine through the first shaft is distributed to the motor-generator and the accessory, or a torque is transmitted from the motor-generator to the engine.

Owner:DENSO CORP

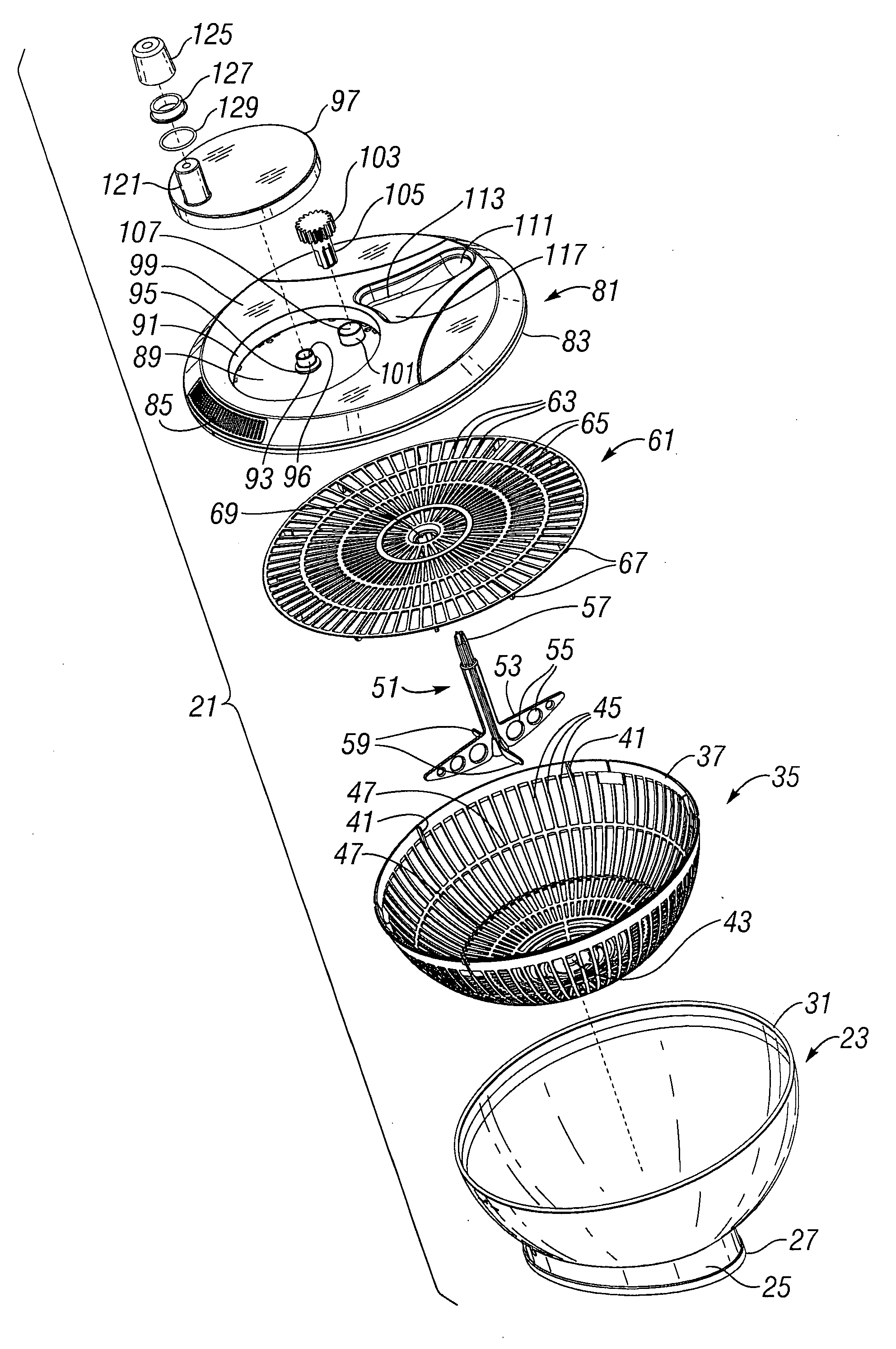

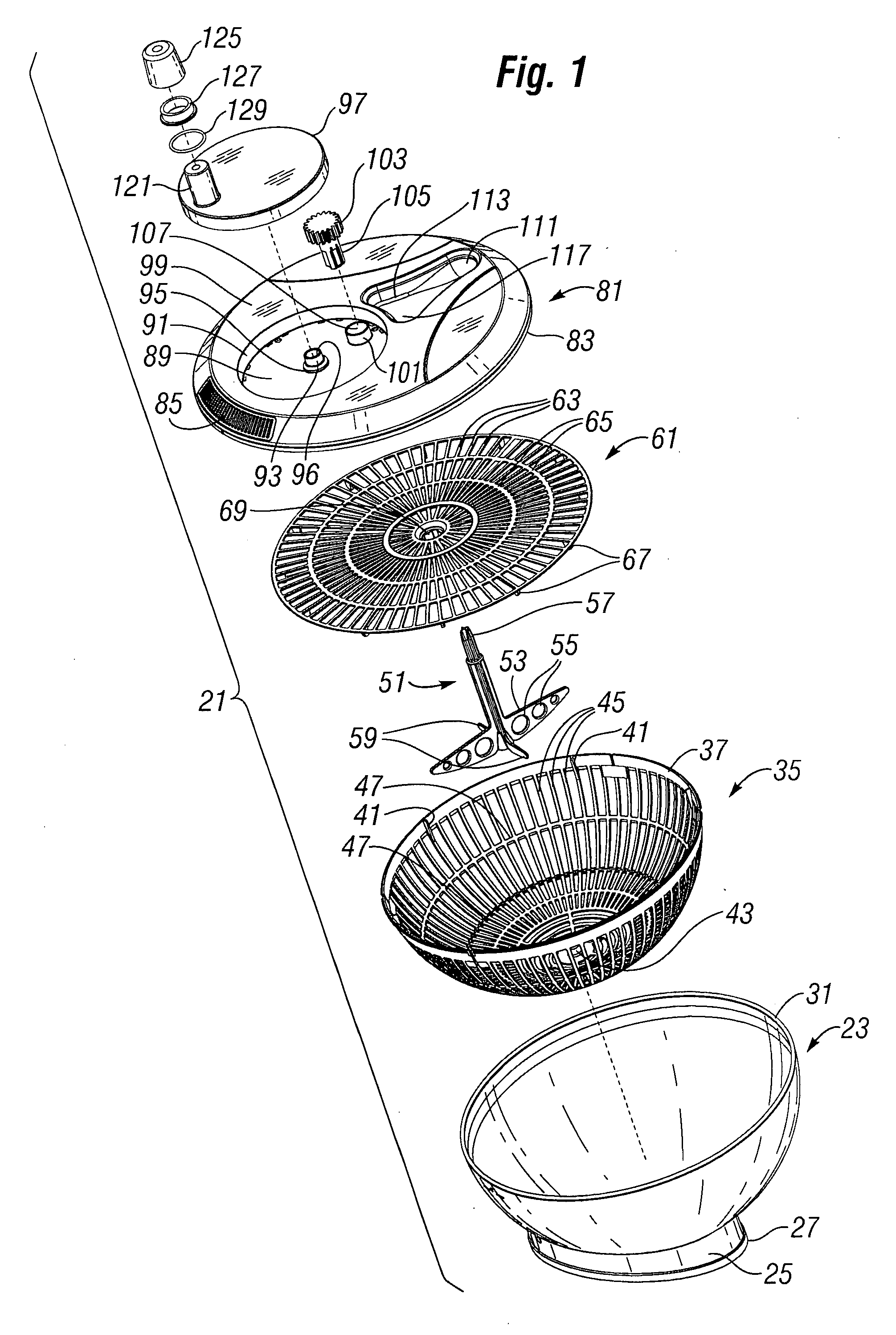

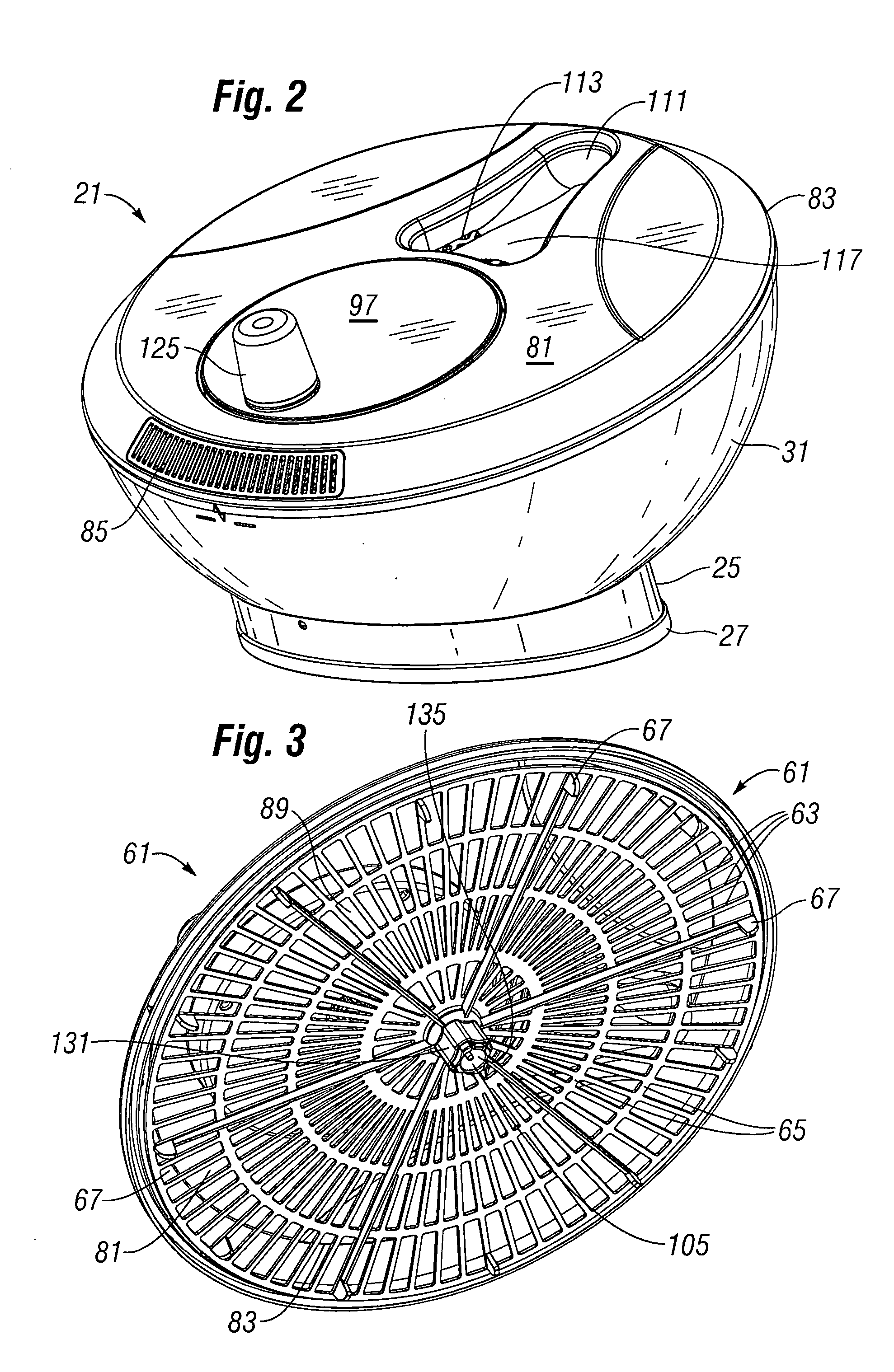

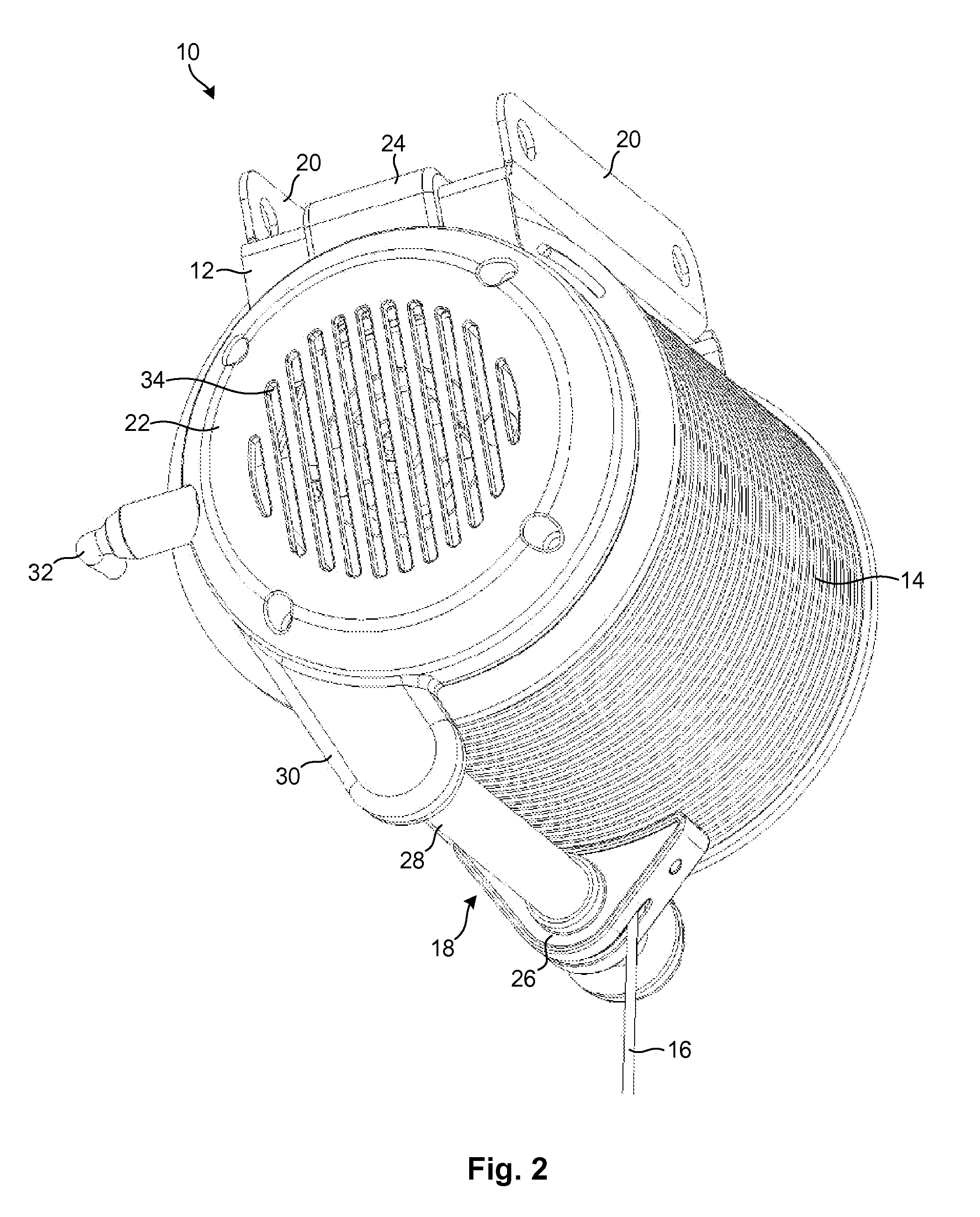

Salad, rice and other foods washer and spinner

InactiveUS20100263555A1Slow downReduce gear ratioJuice extractionEggs preservationWater bottleWaste management

A salad, rice and other foods washer and spinner includes an angled bowl and cover with a cranking handle that turns a basket and basket lid inside the bowl via a gear set. A twin speed gear set is disclosed which allows a different velocity of spin when the cranking handle is turned in one direction than when it is turned in the other direction. A bowl is angled with respect to a base member and a covering lid includes water inlet on a higher side of the lid that allows water from a faucet or jug to be directed through the cover and onto the basket lid where it is dispersed into the basket volume via holes in the basket lid, with water escaping, if desired through an outlet grille.

Owner:DAKA RESEARCH INC

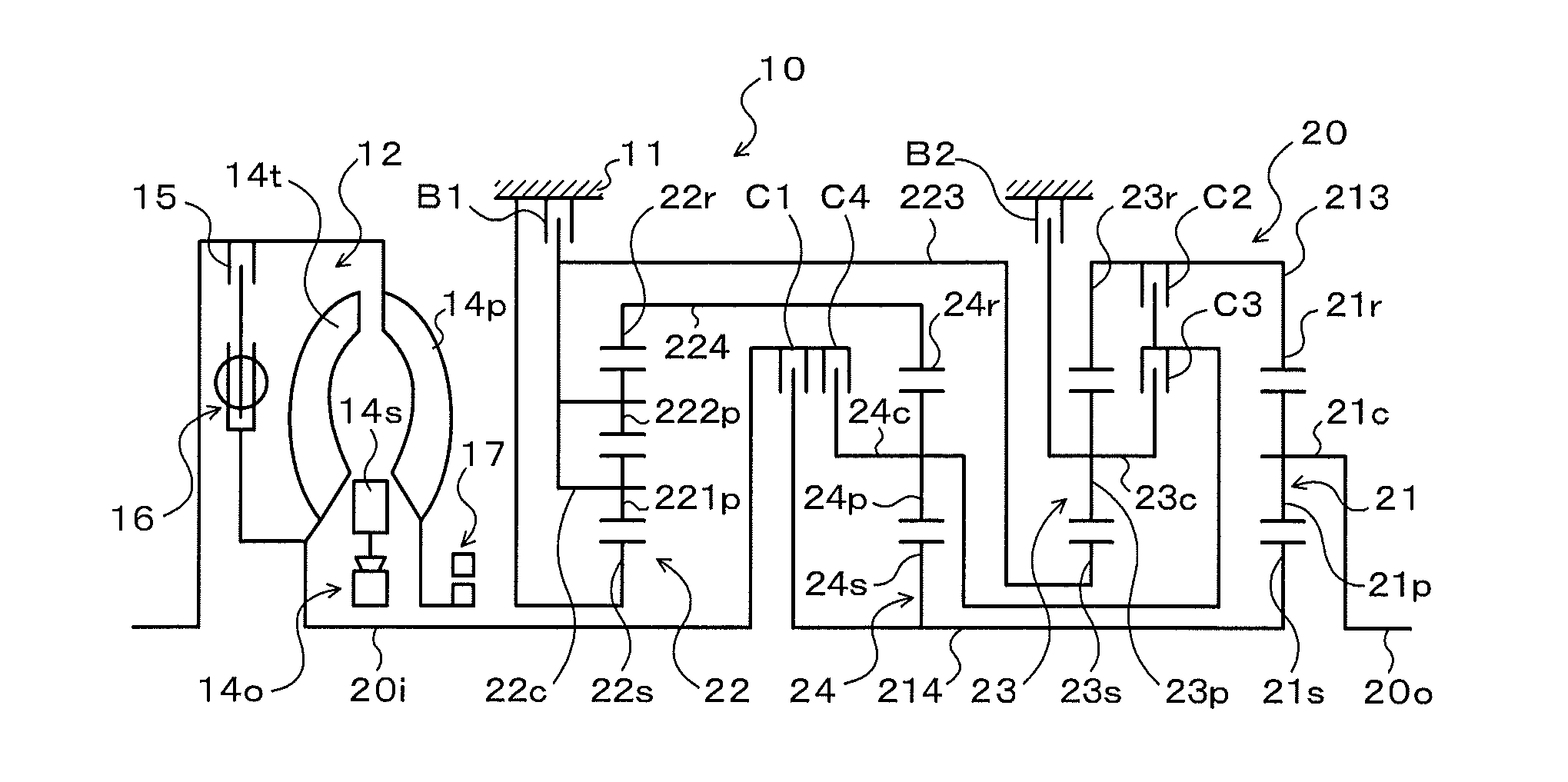

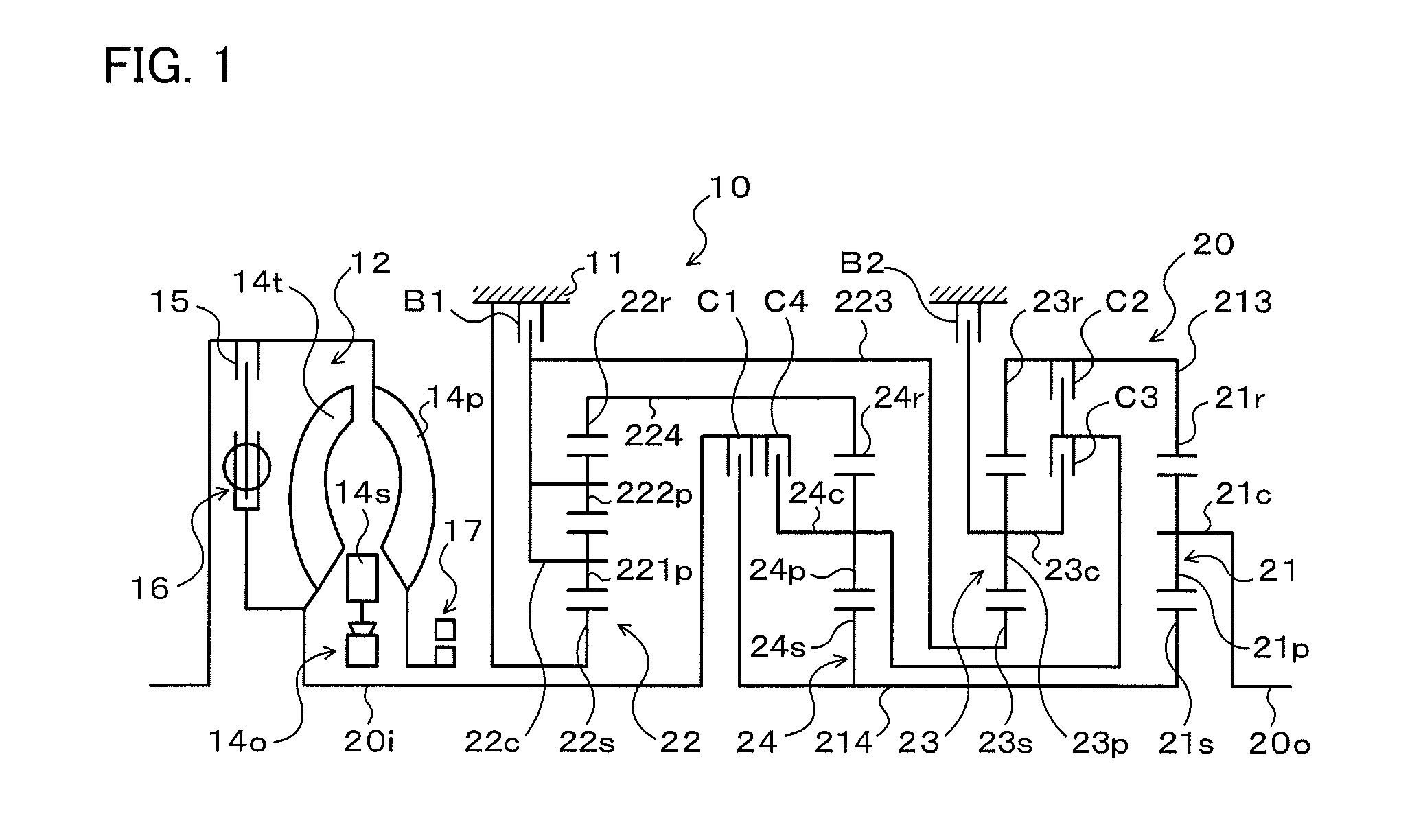

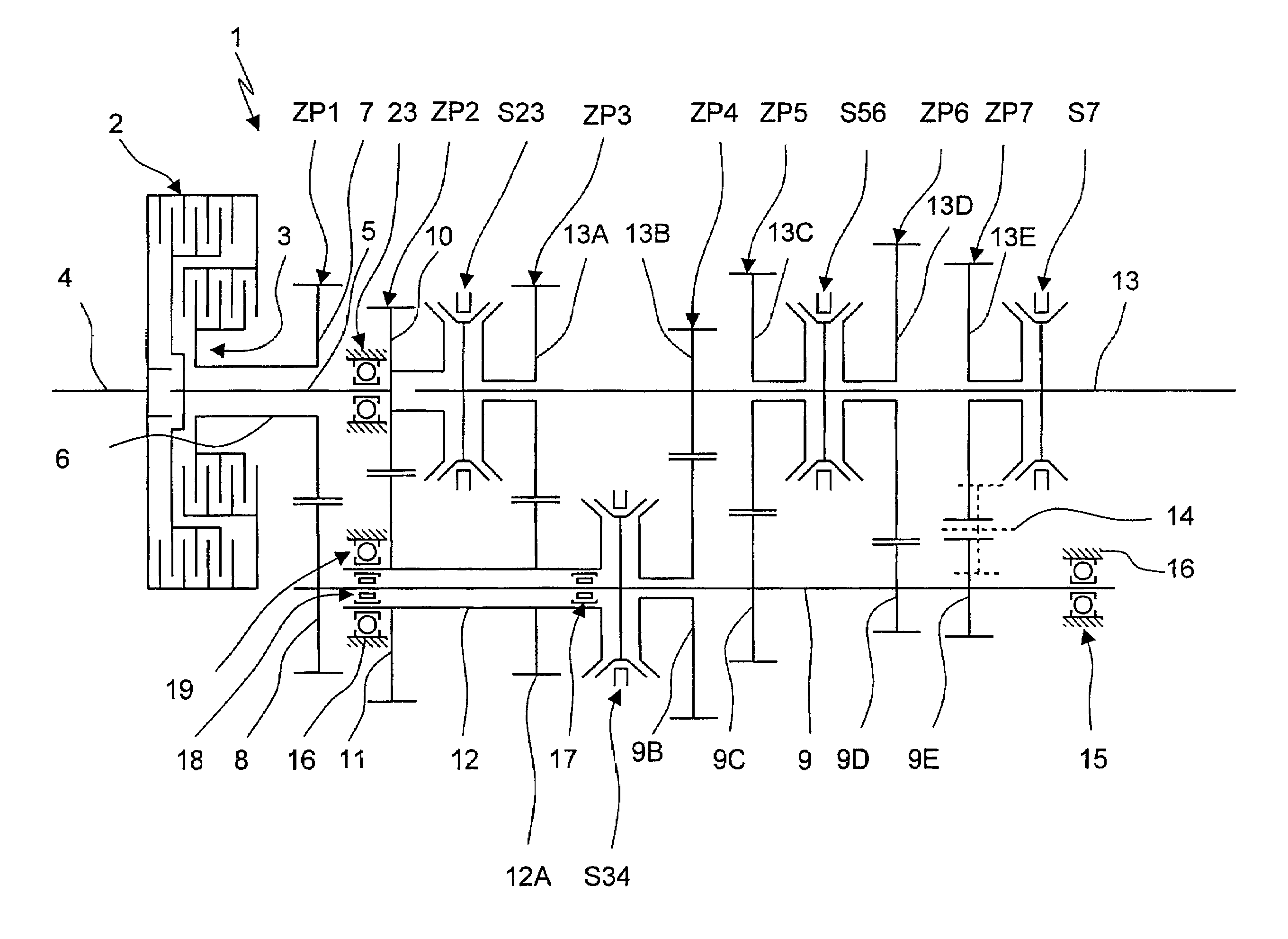

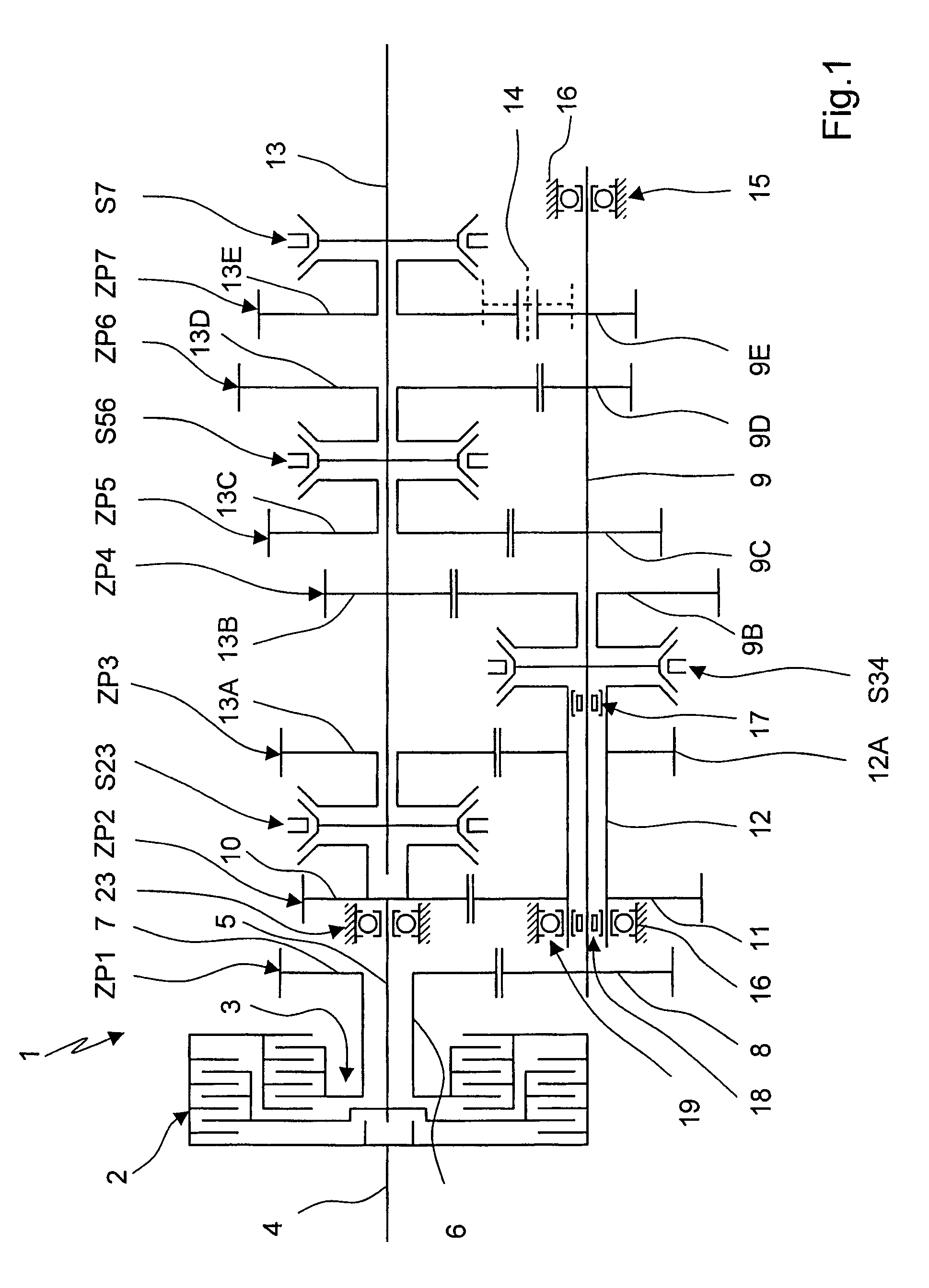

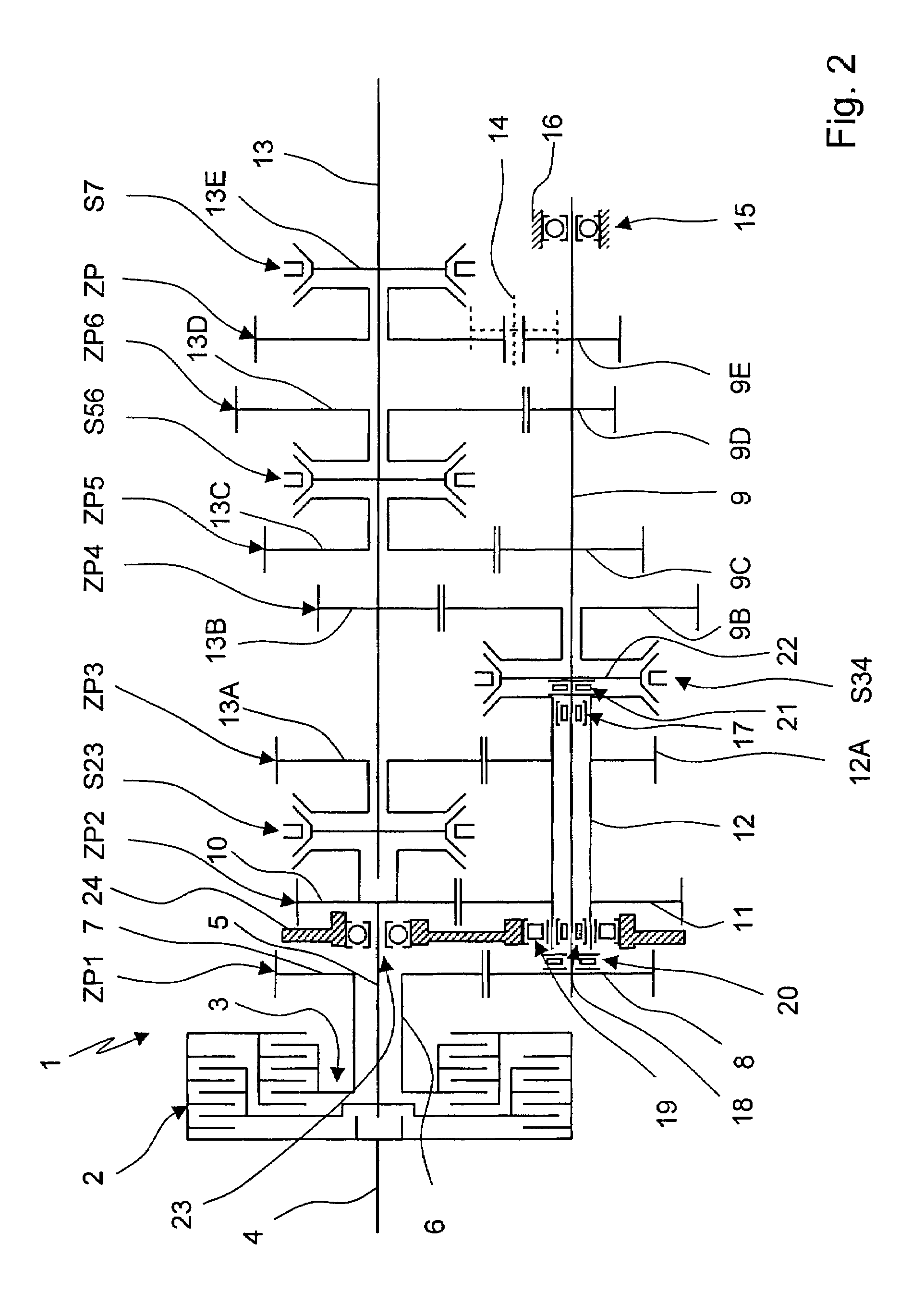

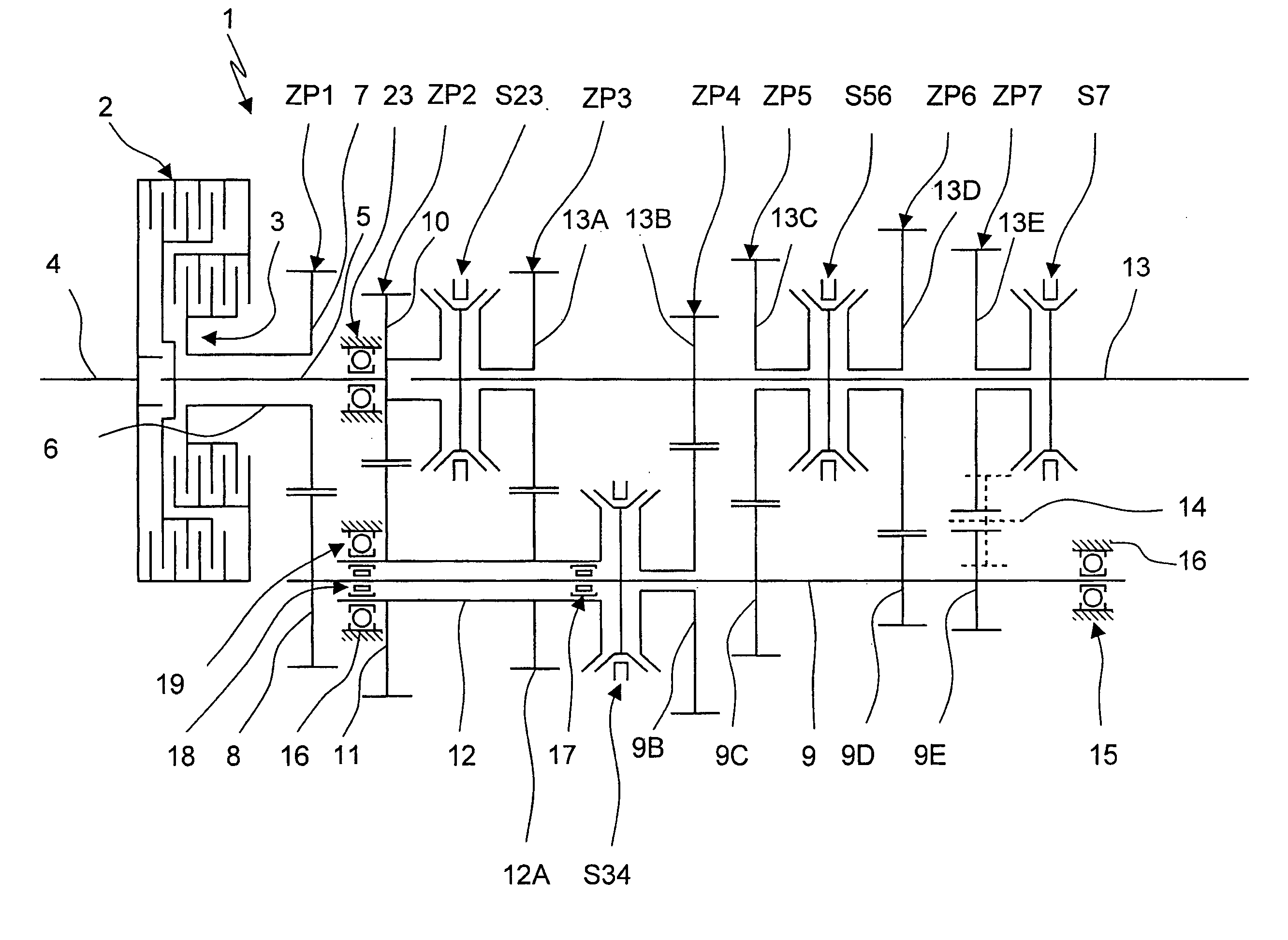

Multi-speed transmission

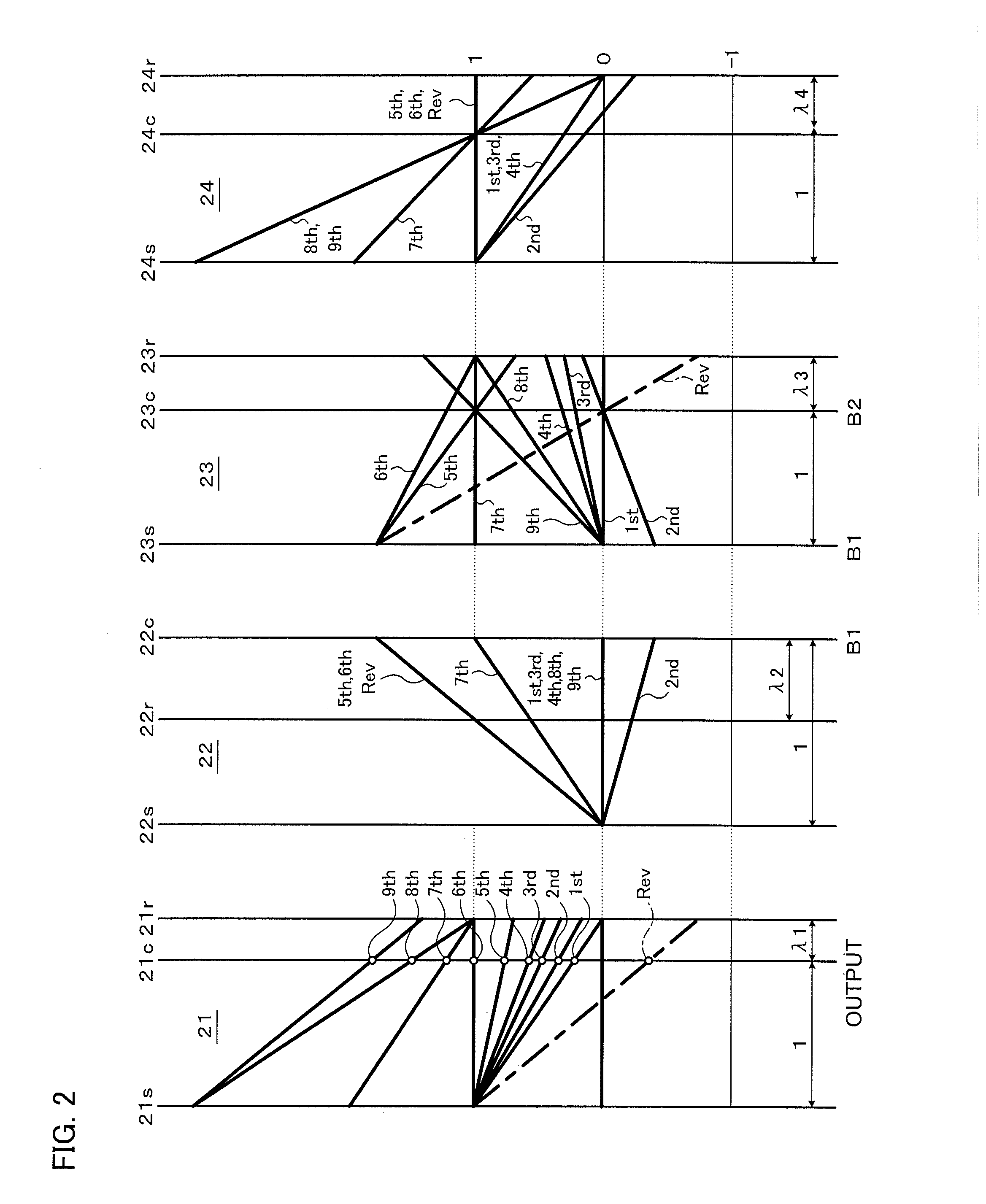

InactiveUS20160341289A1Improve vehicle efficiencyEasy to spreadToothed gearingsTransmission elementsAutomatic transmissionEngineering

An automatic transmission includes a single-pinion first planetary gear, a double-pinion second planetary gear, a single-pinion third planetary gear, a single-pinion fourth planetary gear, clutches C1, C2, C3, and C4, and brakes B1 and B2. First to ninth forward speeds and a reverse speed are established by engaging three of the clutches C1 to C4 and the brakes B1 and B2 and disengaging the remaining three clutches and brakes.

Owner:AISIN AW CO LTD +1

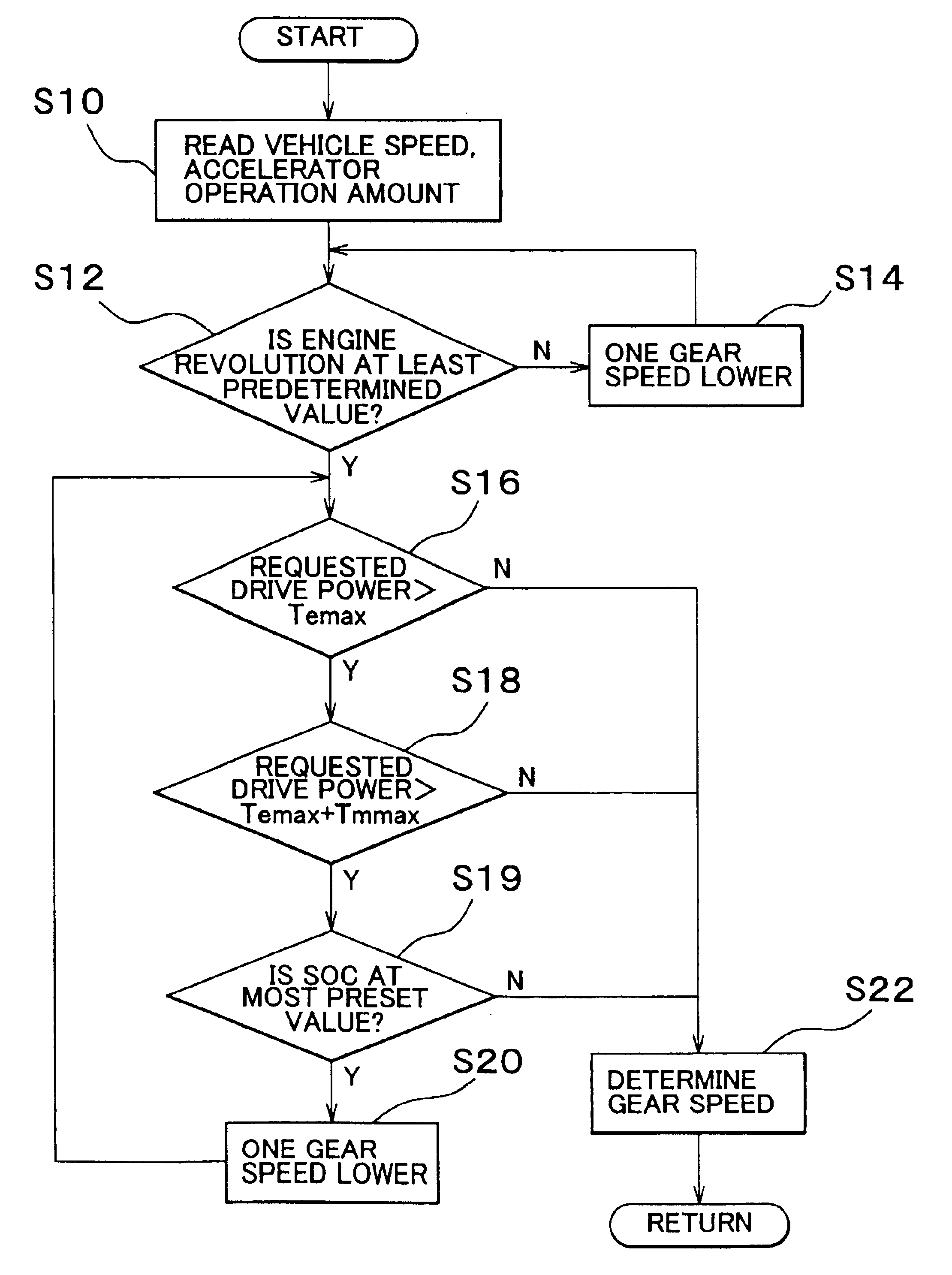

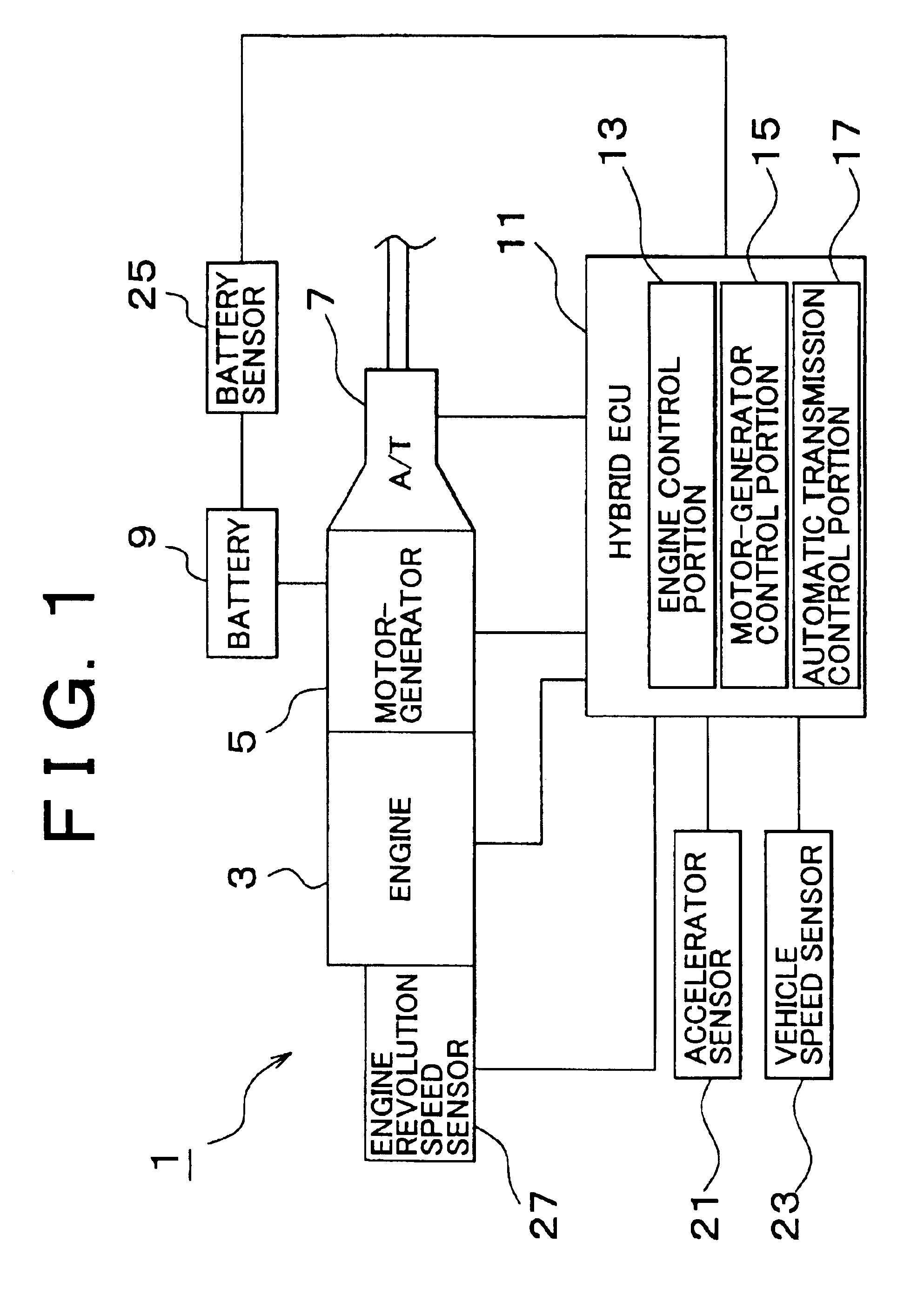

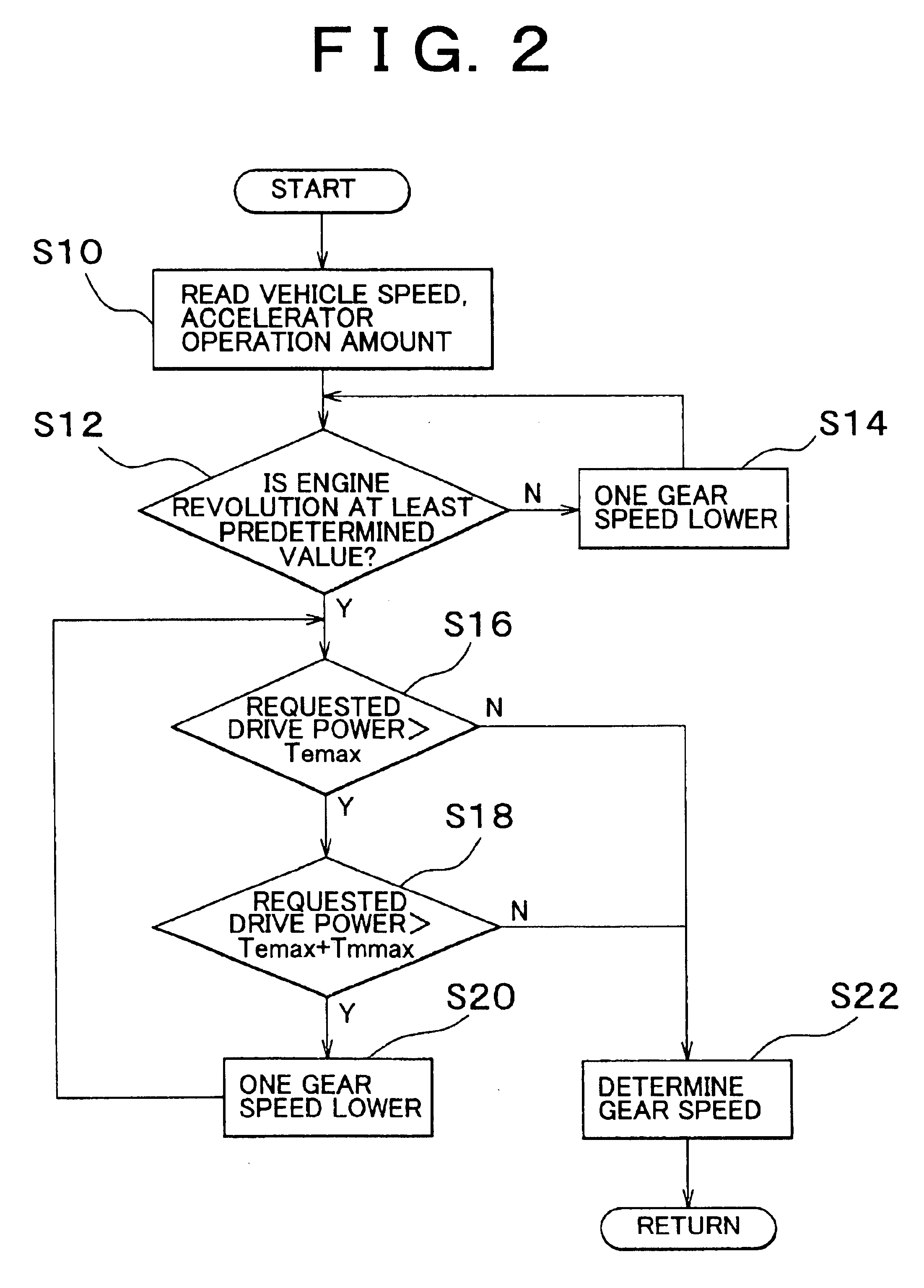

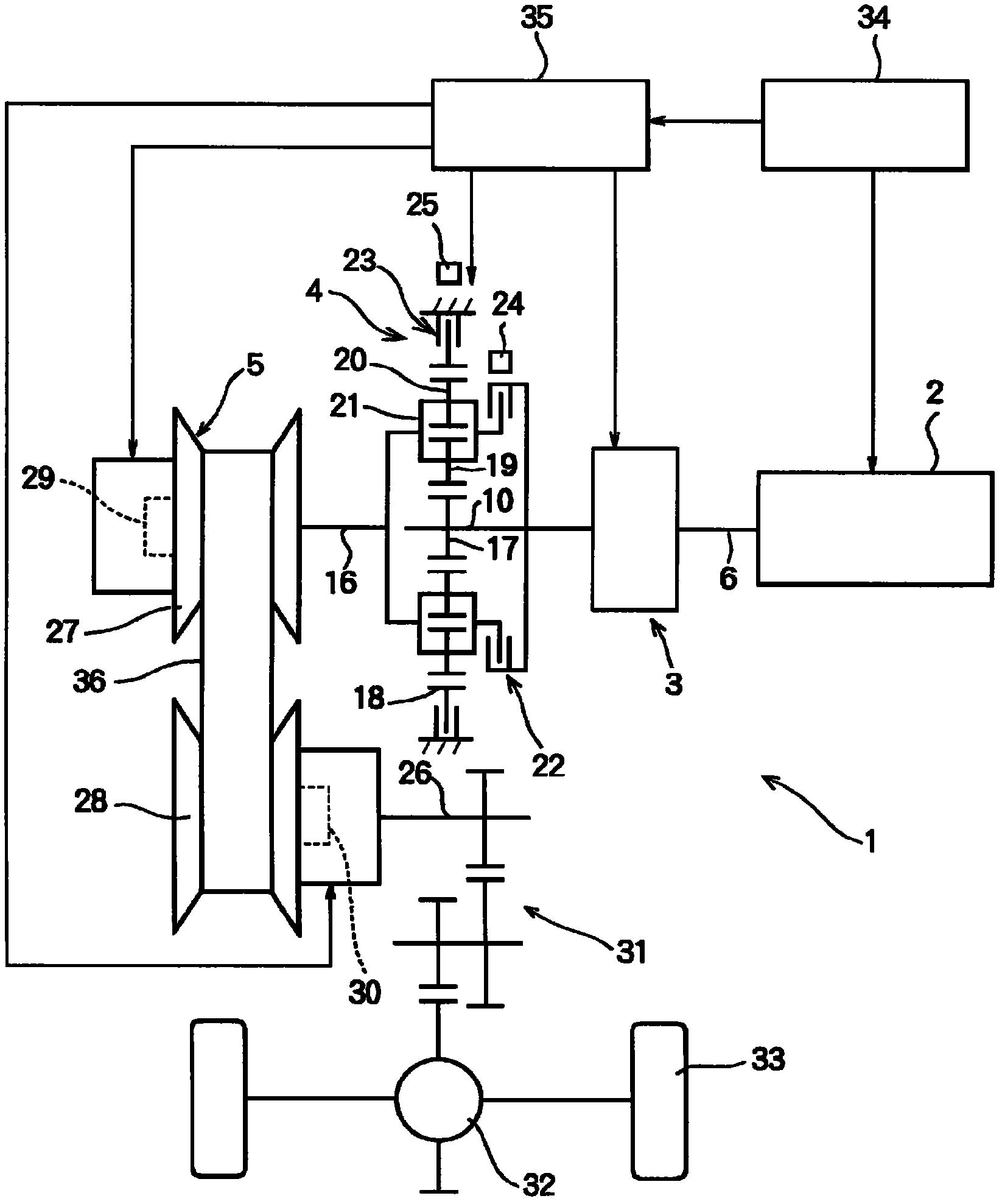

Control apparatus for transmission-equipped hybrid vehicle, and control method for the same

InactiveUS6867509B1Efficient executionMaximize efficiencyInternal combustion piston enginesGearing controlLower limitControl theory

Owner:TOYOTA JIDOSHA KK

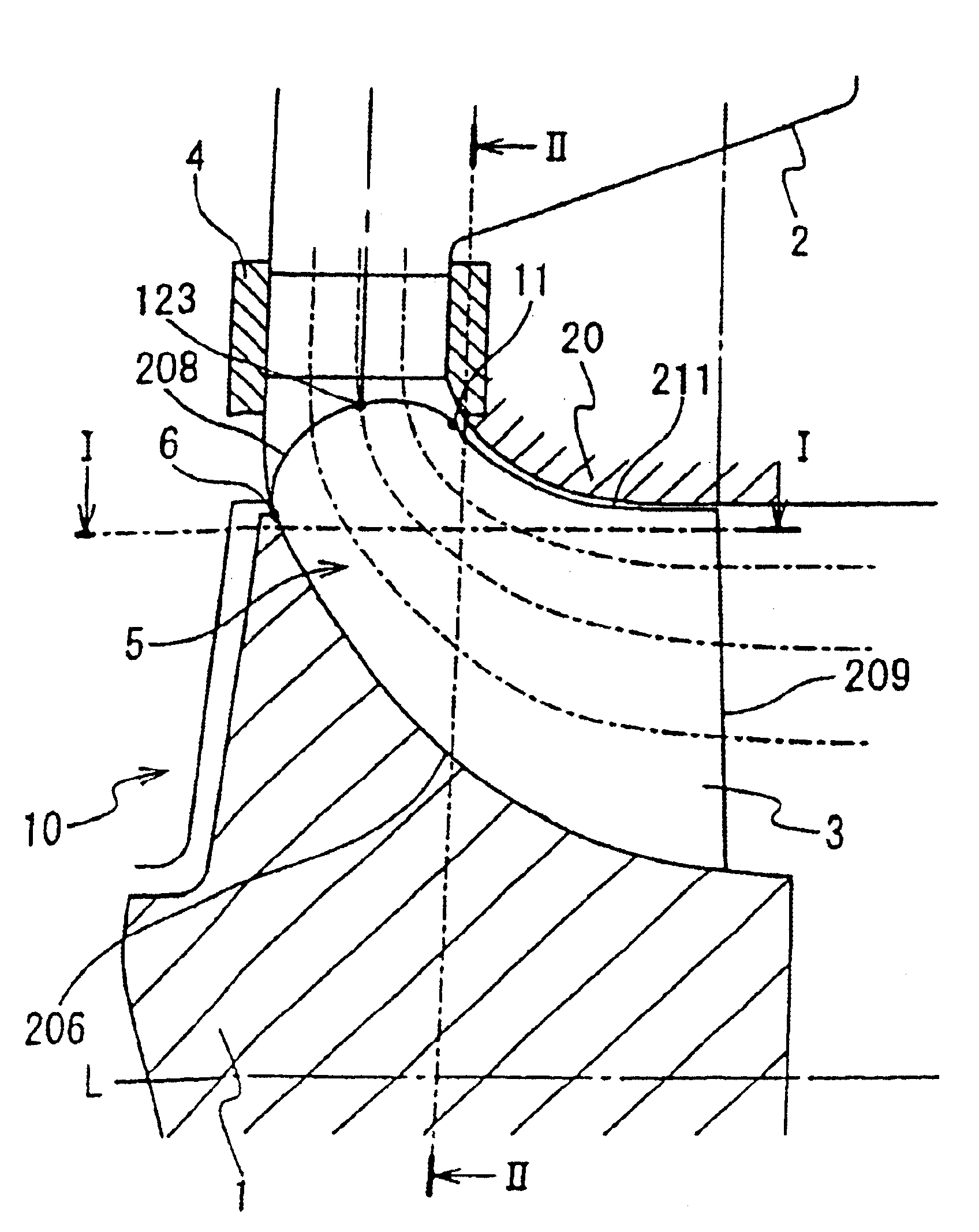

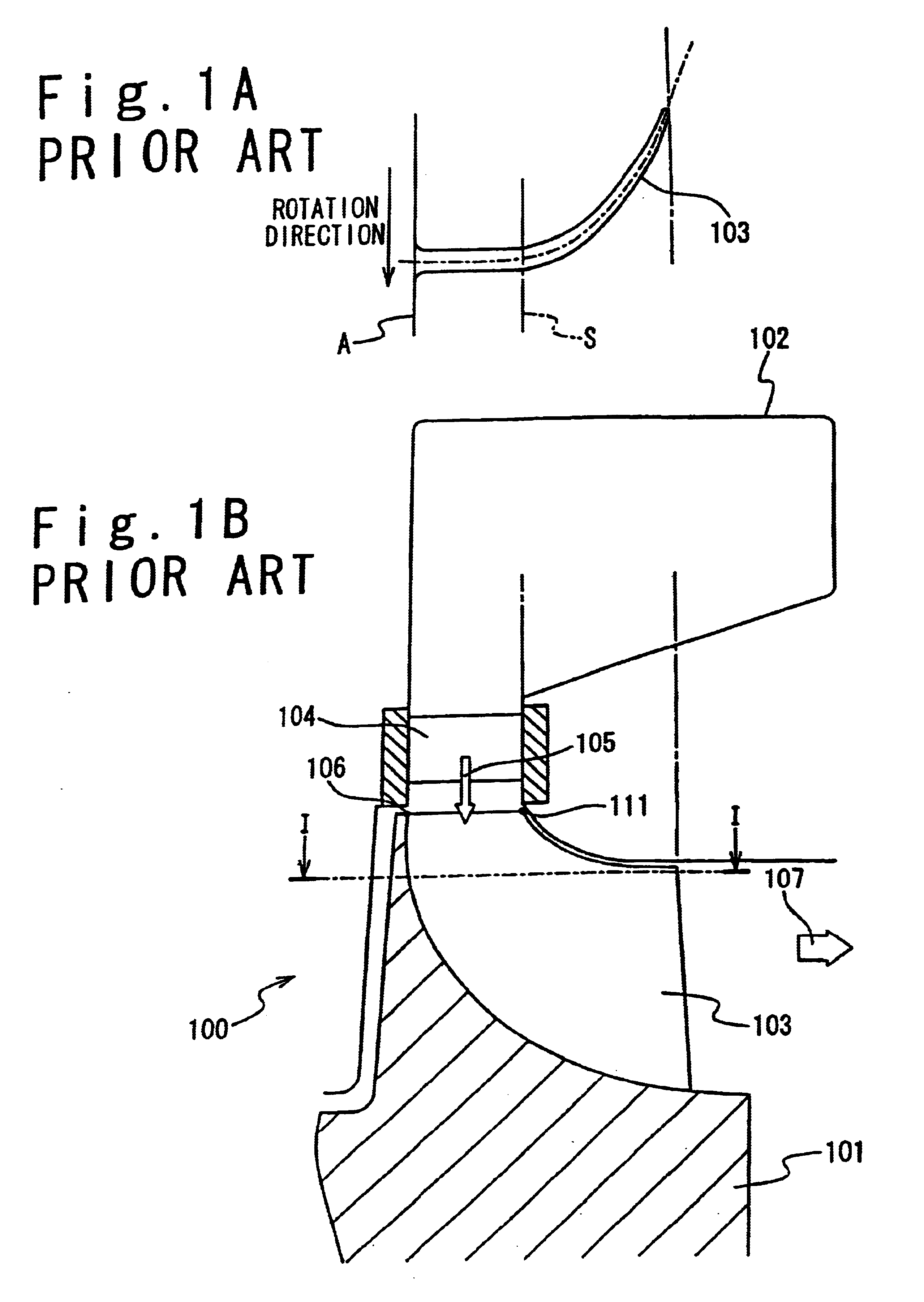

Mixed flow turbine and mixed flow turbine rotor blade

InactiveUS6877955B2Improve efficiencyReduce gear ratioPropellersRotary propellersMixed flowCurve shape

A mixed flow turbine includes a hub attached to a rotation axis and a plurality of rotor blades. Each of the plurality of rotor blades is attached to the hub in a radial direction, and the hub is rotated based on fluid supplied to a rotation region of the plurality of rotor blades. Each of the plurality of rotor blades has a curved shape that convexly swells on a supply side of the fluid.

Owner:MITSUBISHI HEAVY IND LTD

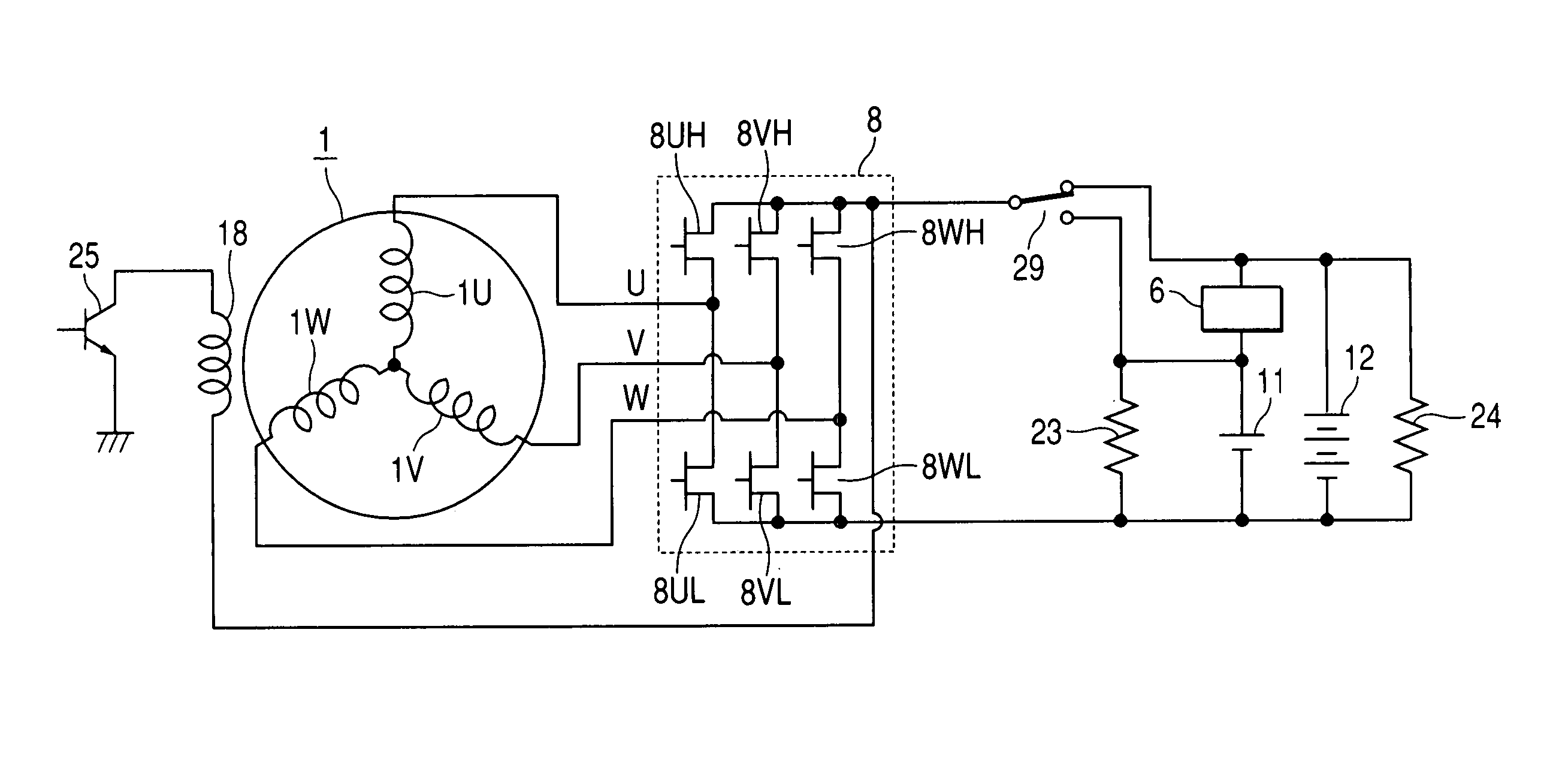

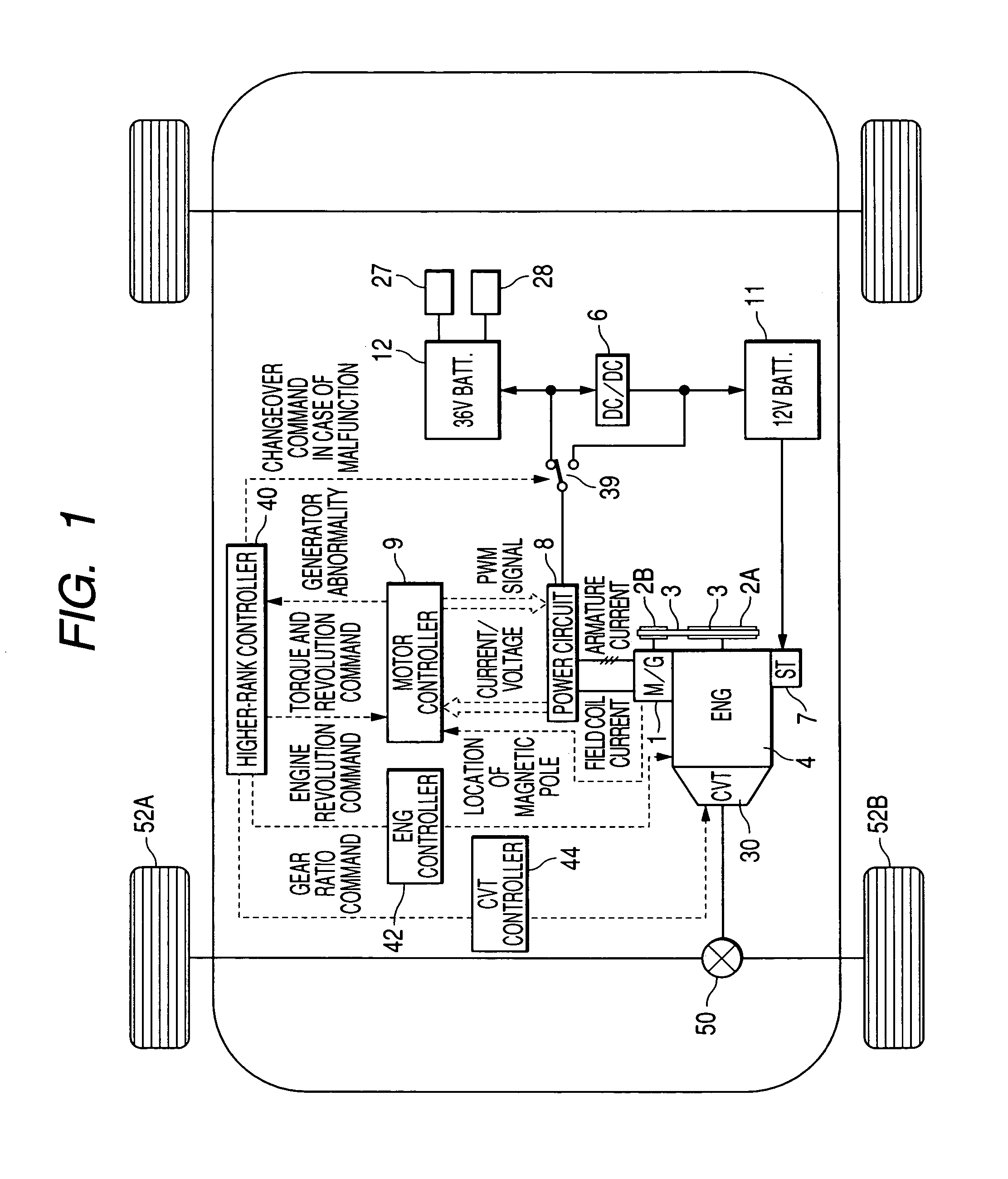

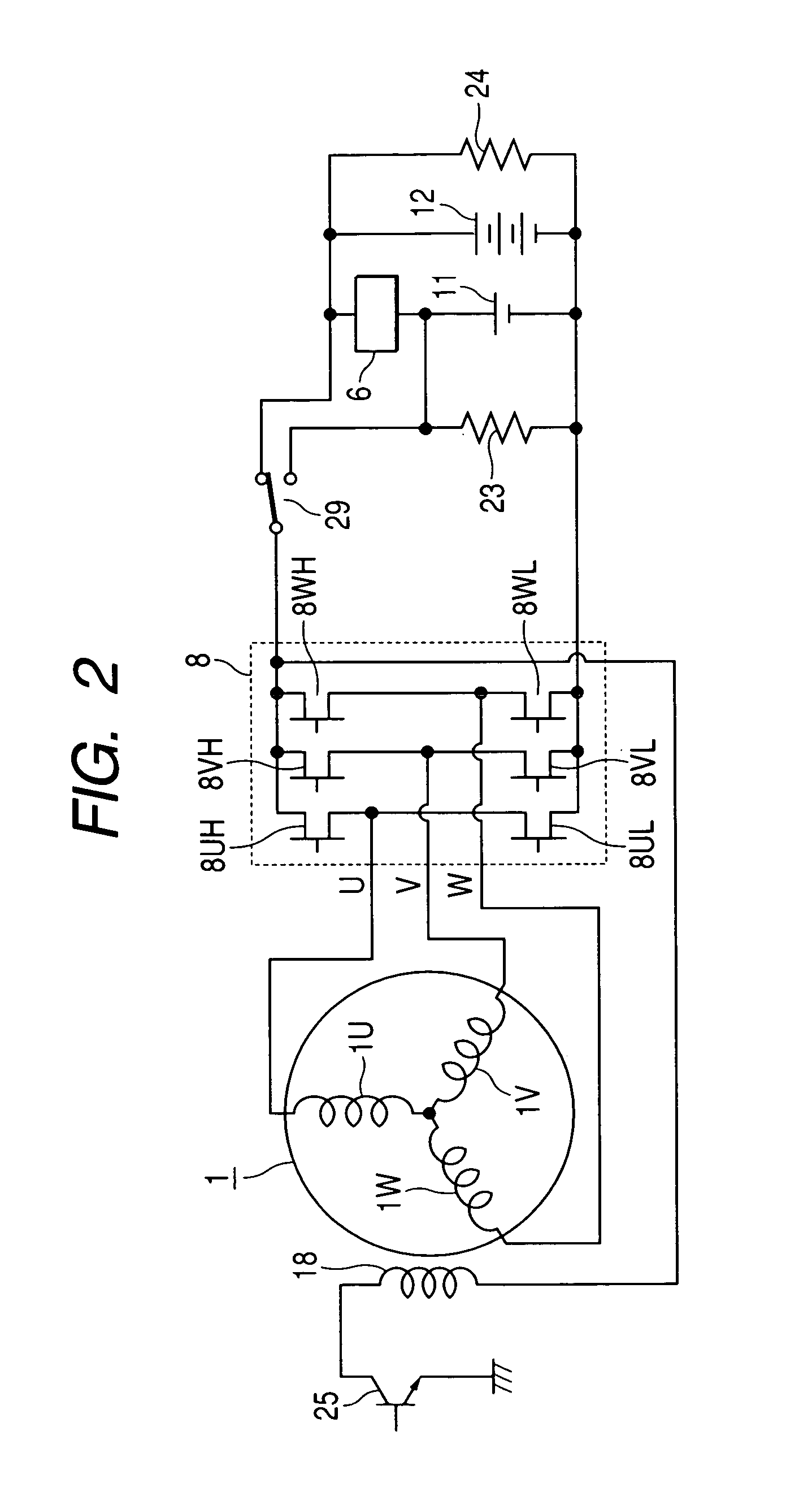

Power supply system for vehicle

InactiveUS7215034B2Electric power generatedDriving is possibleHybrid vehiclesAuxillary drivesDriver/operatorLow voltage

An A.C. generator has a rotor that is equipped with a permanent magnet and a field coil. The output of the A.C. generator charges the high-voltage battery. Voltage of the high-voltage battery is stepped-down by a DC / DC converter and supplied to the low-voltage battery. When the motor controller detects that the field coil has not been energized, the higher-rank controller switches so as to generate power by means of the permanent magnet of the A.C. generator and charge the low-voltage battery. This mechanism enables power to be generated when a circuit malfunctions.Thereby, a power supply system for vehicle can generate power when a circuit malfunctions so that the driver on the vehicle can drive the vehicle to a repair shop.

Owner:HITACHI LTD

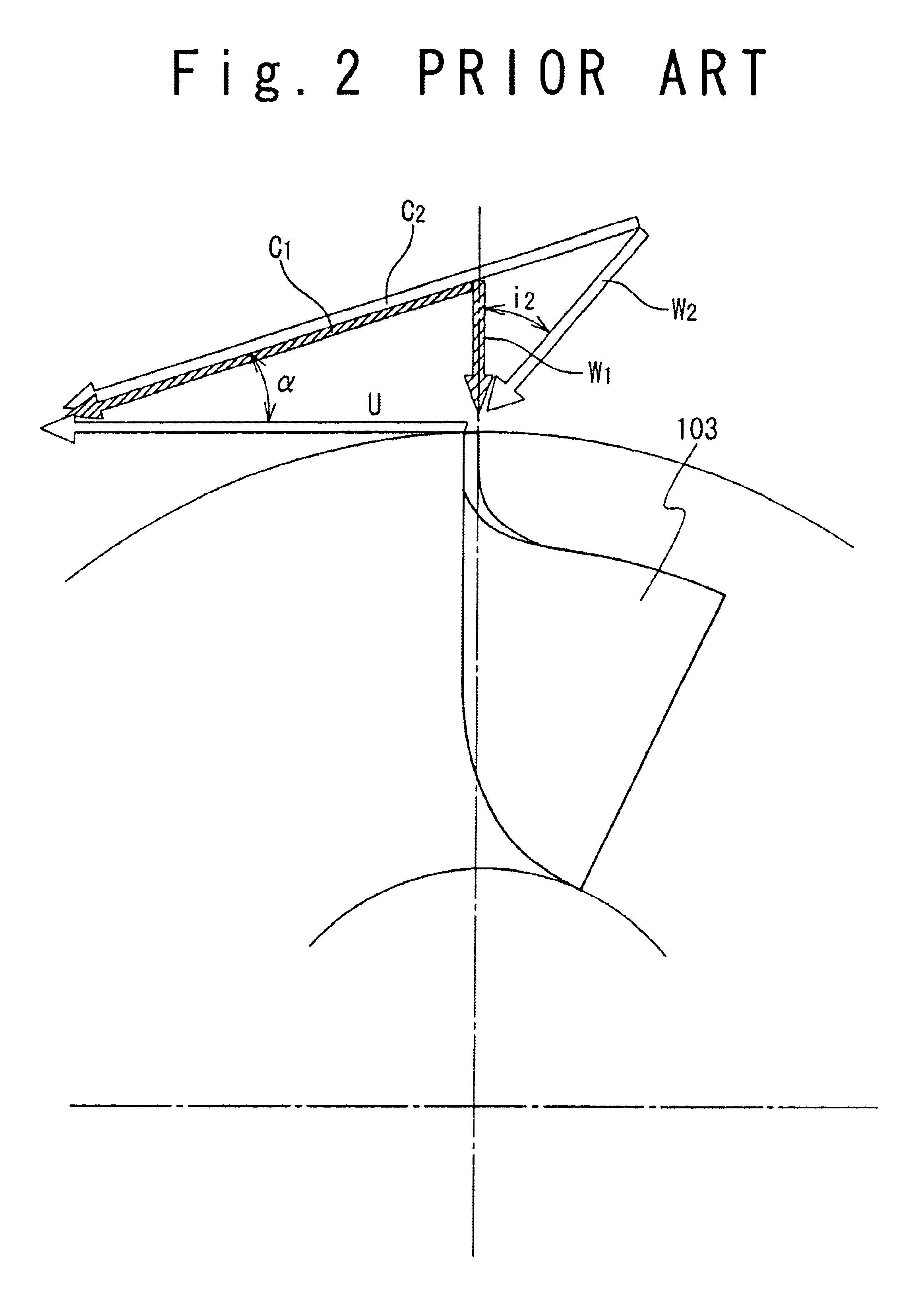

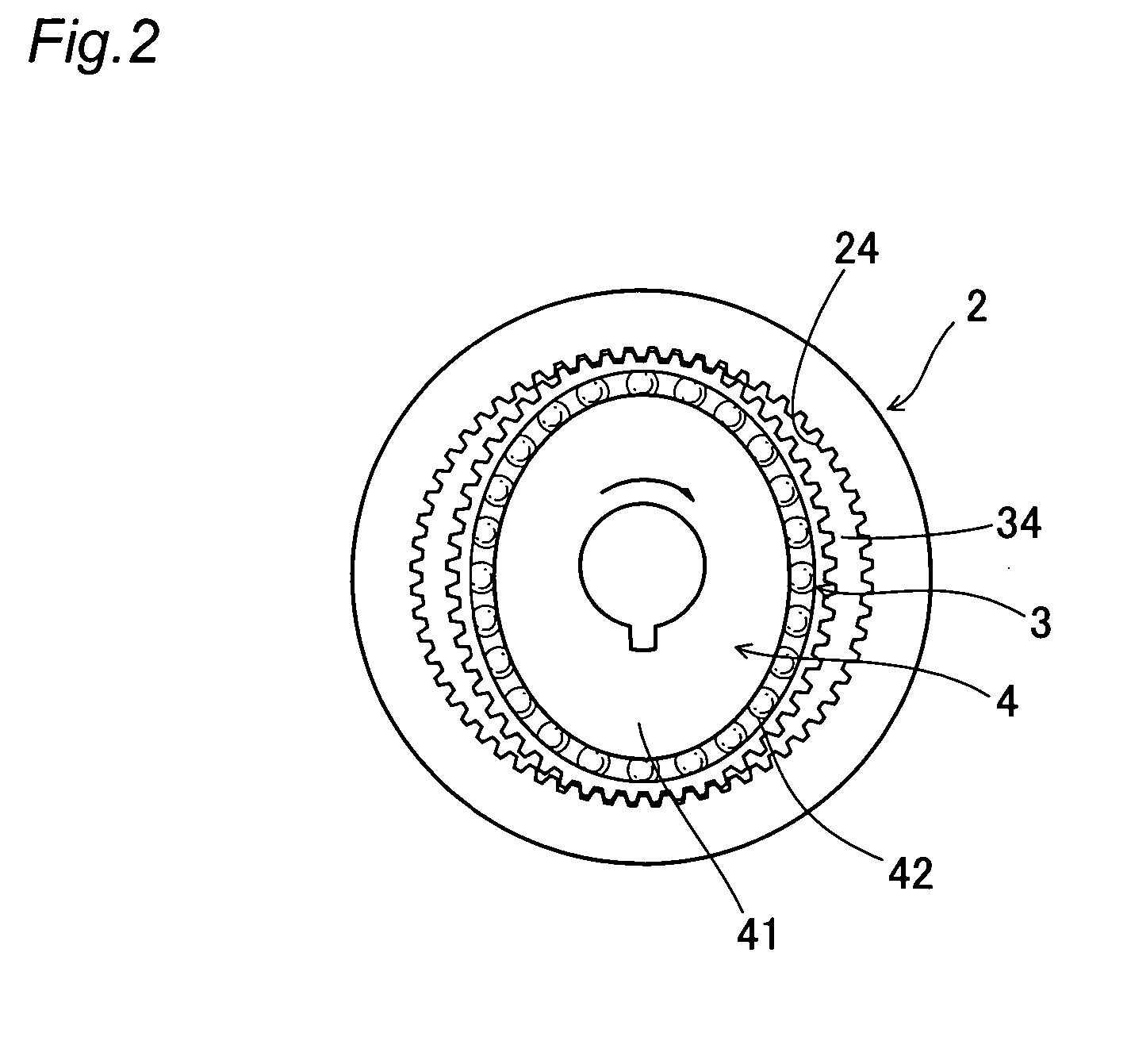

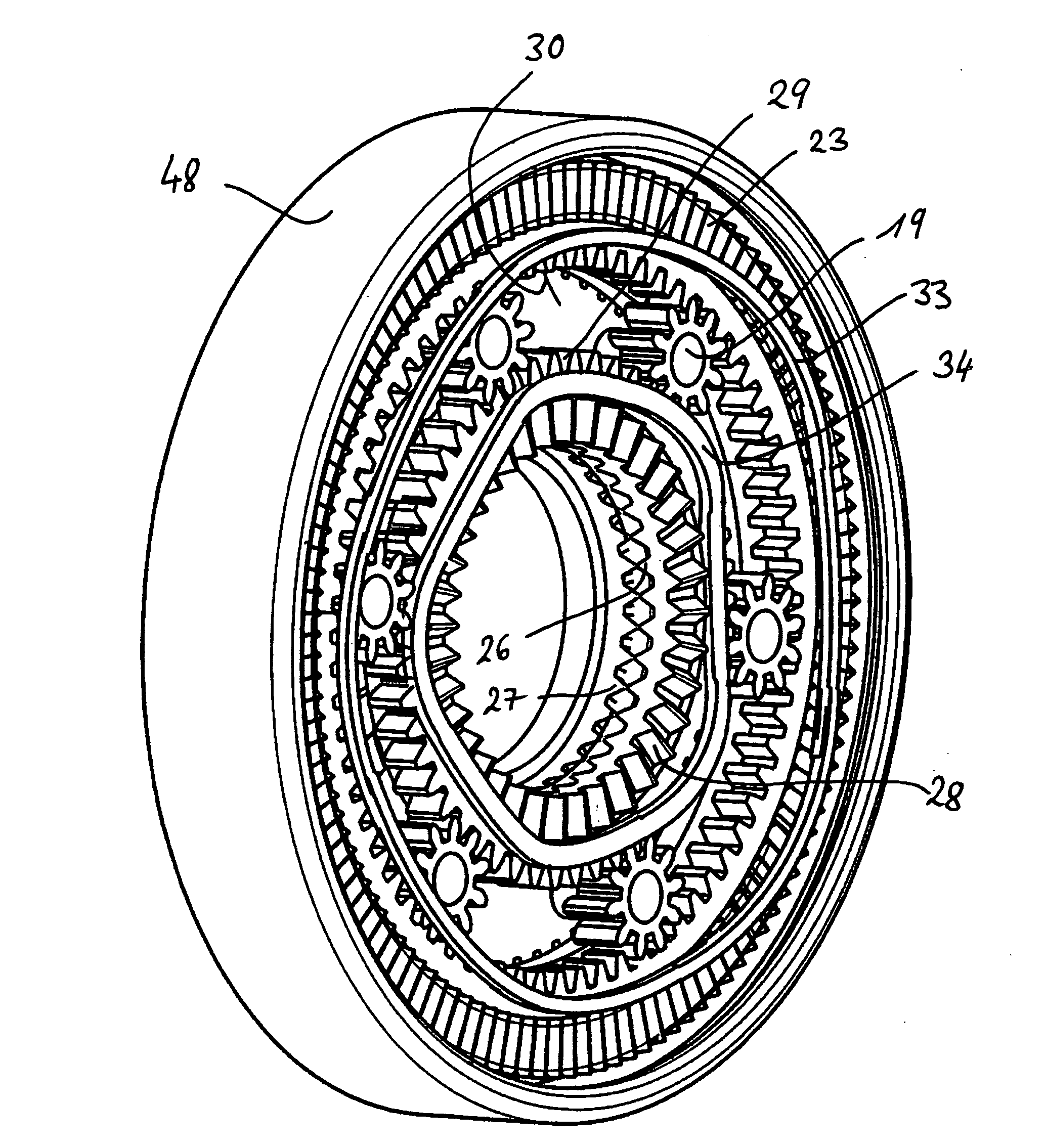

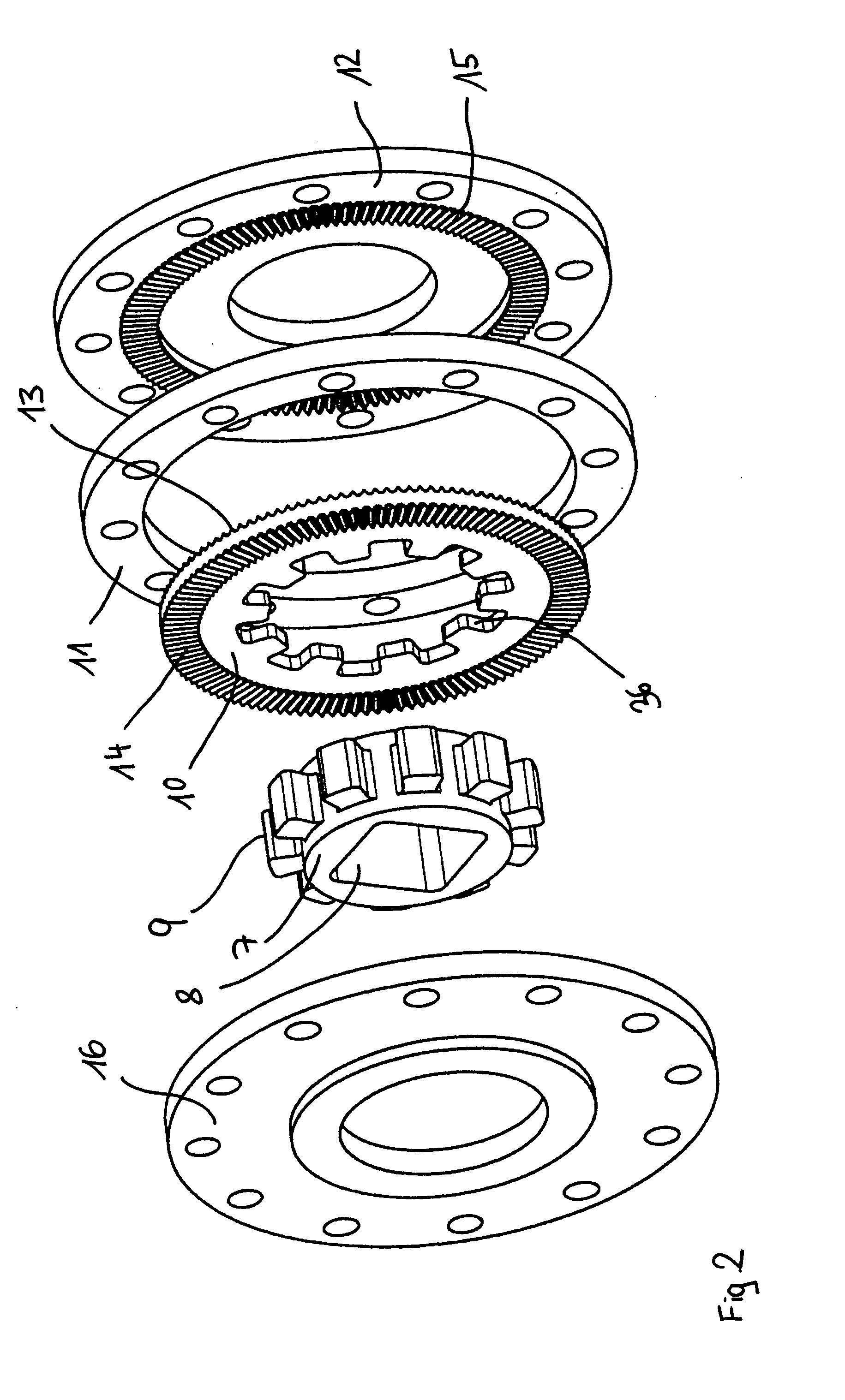

Wave gear device

InactiveUS20050066769A1Increasing the thicknessPrevent degradationPortable liftingToothed gearingsGear wheelEngineering

A wave gear device has a rigid internal gear, a flexible external gear, and a wave generator. The tooth profiles of both gears are initially defined by a basic rack tooth profile shape. The lower parts of the dedendum portions of these tooth profiles are modified by curves C2 and C3 having pressure angles α2 and α3 that are less than the standard pressure angle α1 of the basic rack tooth profile shape C1. An increase in thickness of the tooth bottom side can be minimized even if the tooth depth is increased and the tooth thickness / tooth space ratio changed to increase the tooth thickness. Hence, the ratcheting torque of a wave gear device having a high reduction gear ratio can be increased without reducing the service life and strength of a pinion cutter for the rigid internal gear, or the fatigue strength of the flexible external gear.

Owner:HARMONIC DRIVE SYST IND CO LTD

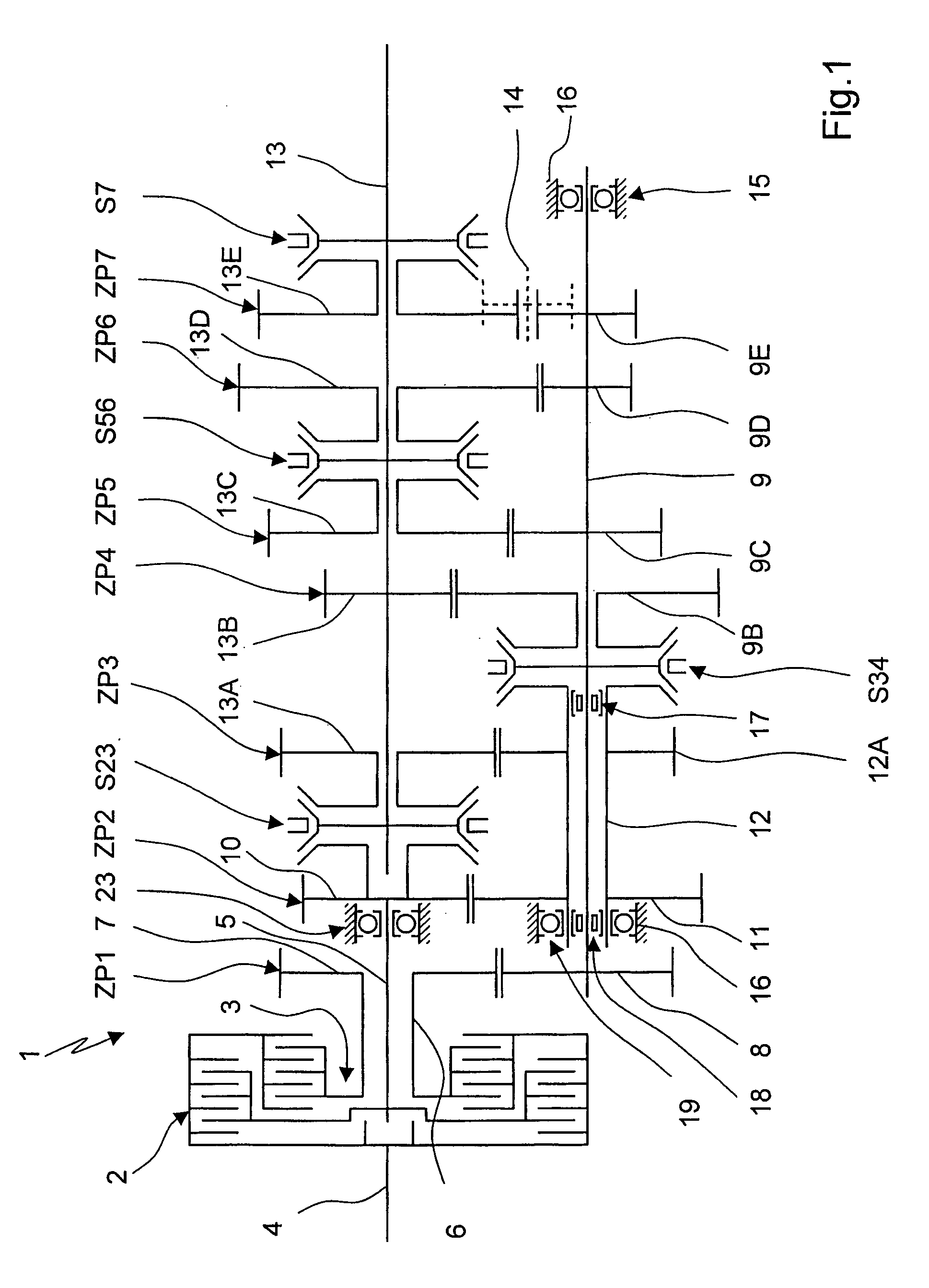

Multistep transmission of a layshaft type

InactiveUS7267022B2Reduce gear ratioIncrease valueRolling contact bearingsToothed gearingsPower flowGear wheel

A multi-speed transmission of countershaft design having a main countershaft and a hollow countershaft arranged concentrically and having likewise two load-shift elements. A first half of the shift elements is connected with a drive unit and a second half of the shift elements is connected to a gearbox input shaft. The gearbox input shafts and countershafts are mounted in a housing and connected to gear wheels, which intermesh in pairs as gear wheel pairs and can be connected or disconnected in order to reduce the overall gear ratio in the power flow. The main countershaft is mounted directly on the housing in the area of its first end and in the hollow countershaft in the area of its second end. The hollow countershaft is mounted in the housing in the area of its end that faces toward the end of the main countershaft that is mounted in the hollow countershaft.

Owner:ZF FRIEDRICHSHAFEN AG

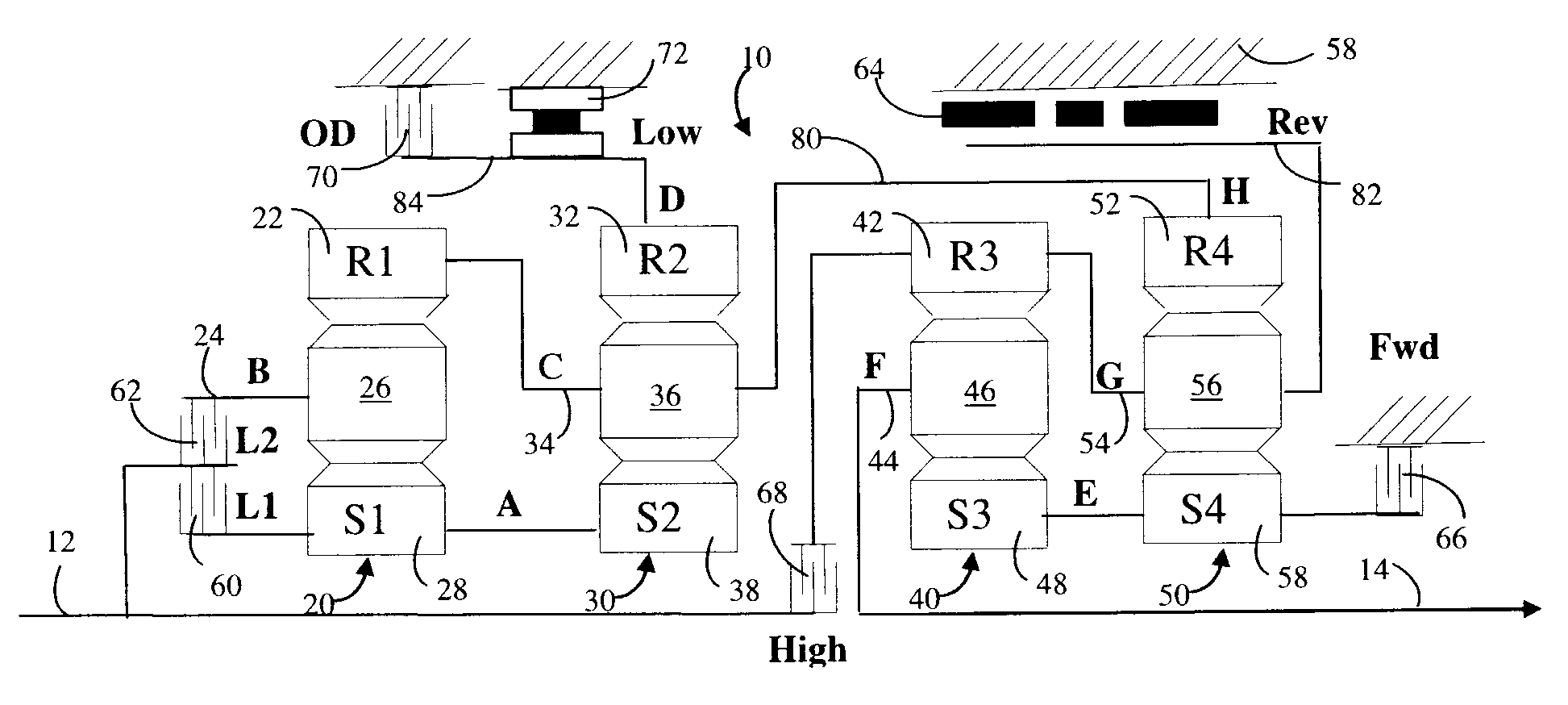

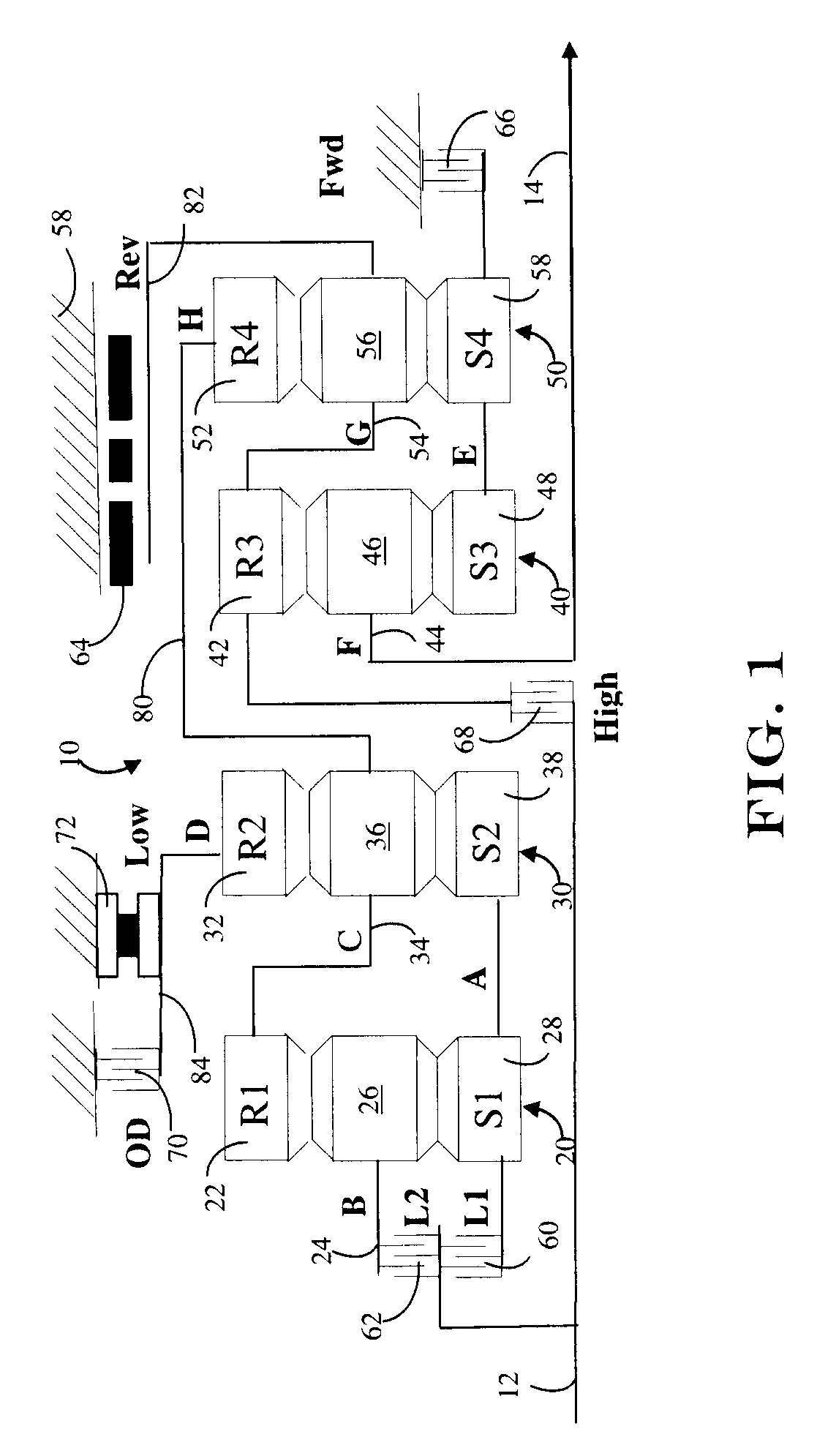

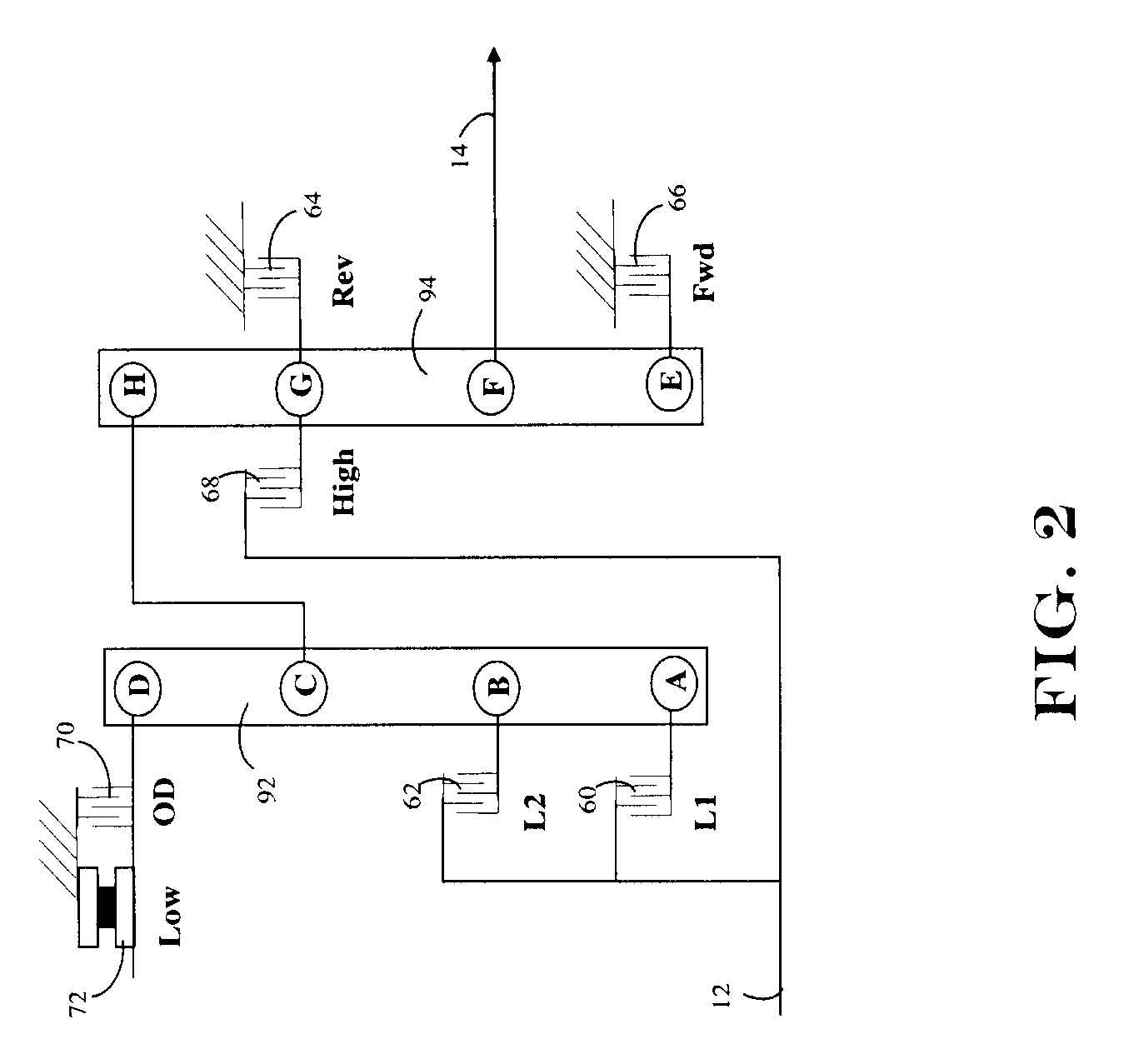

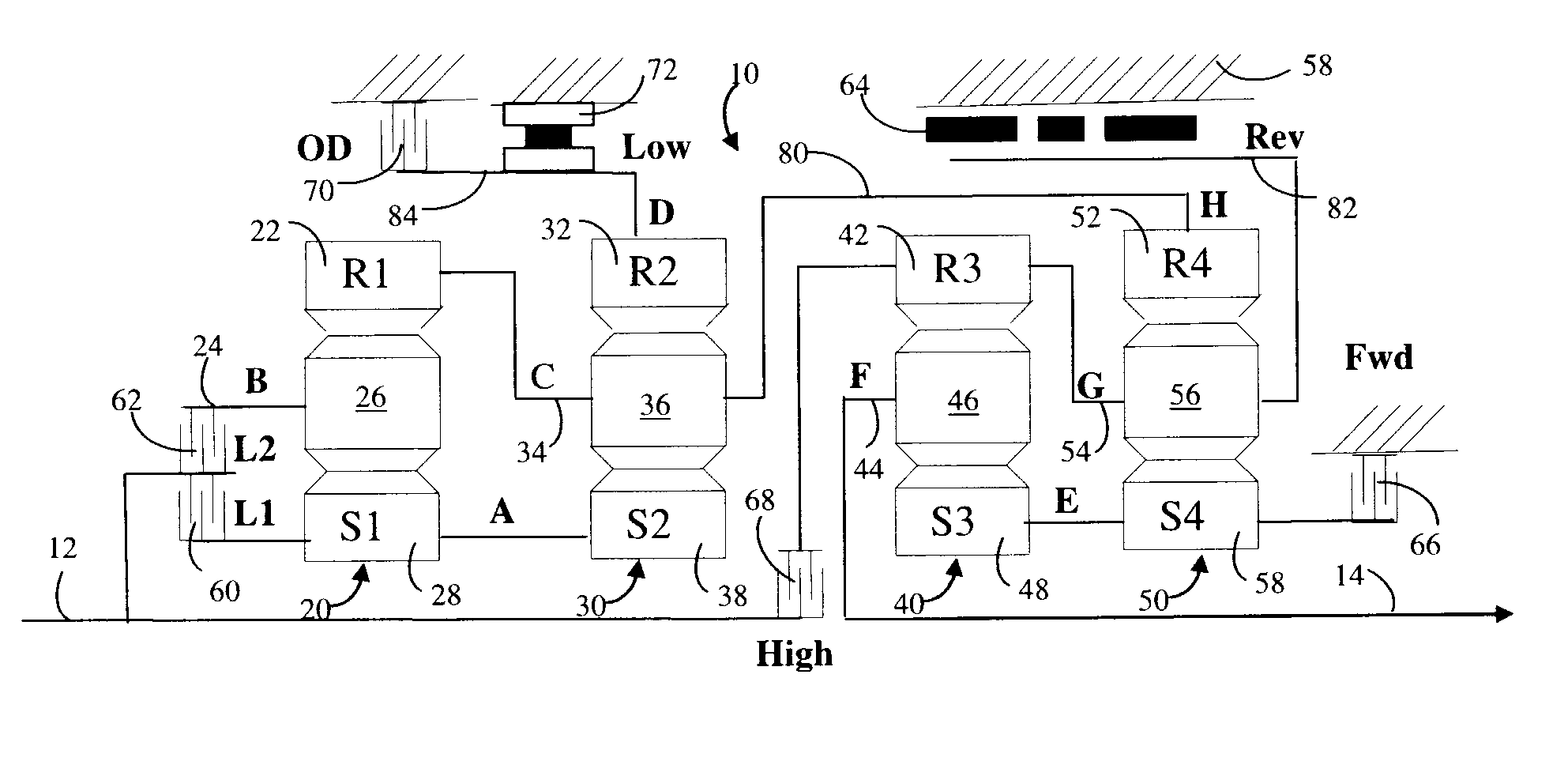

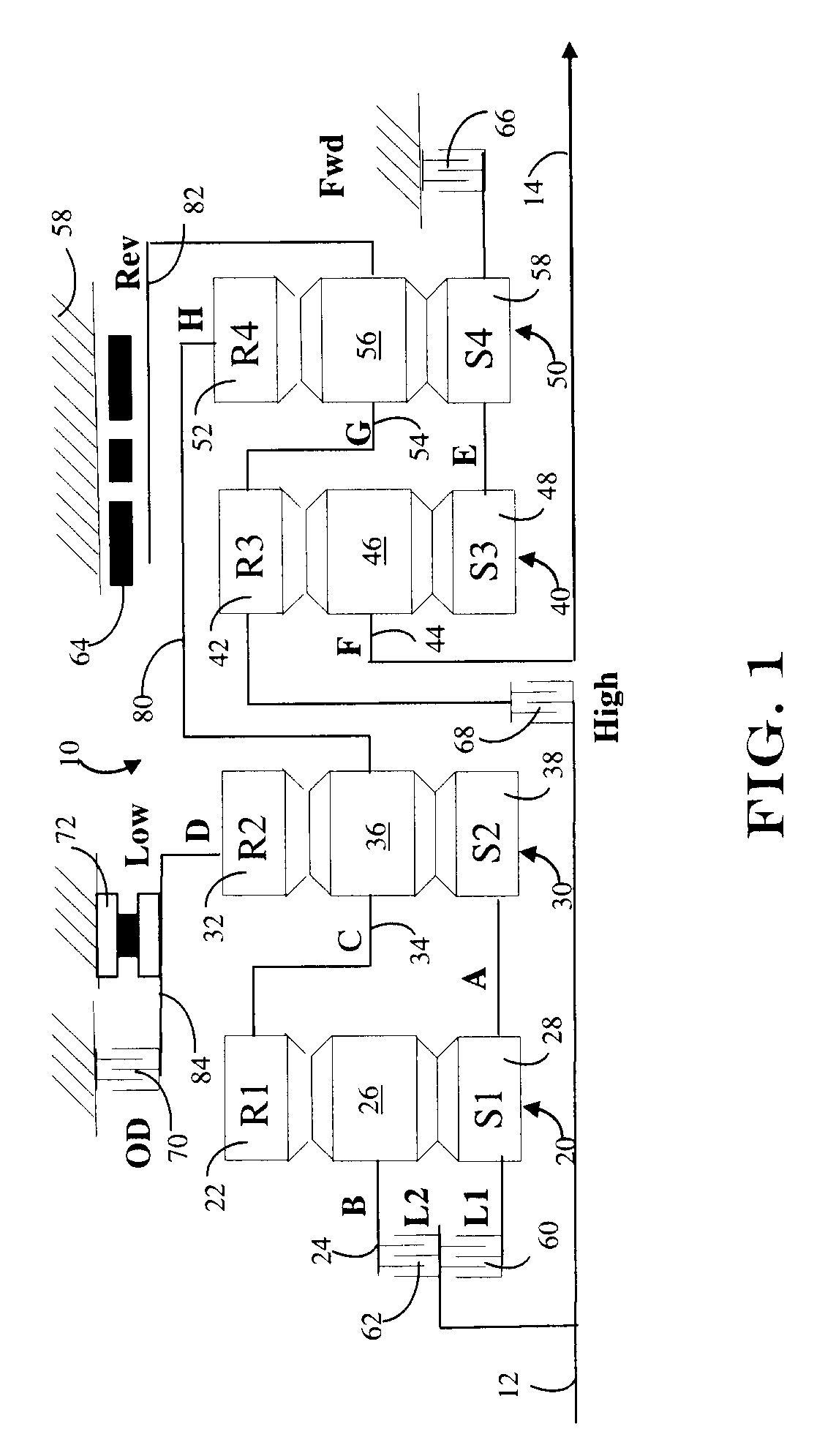

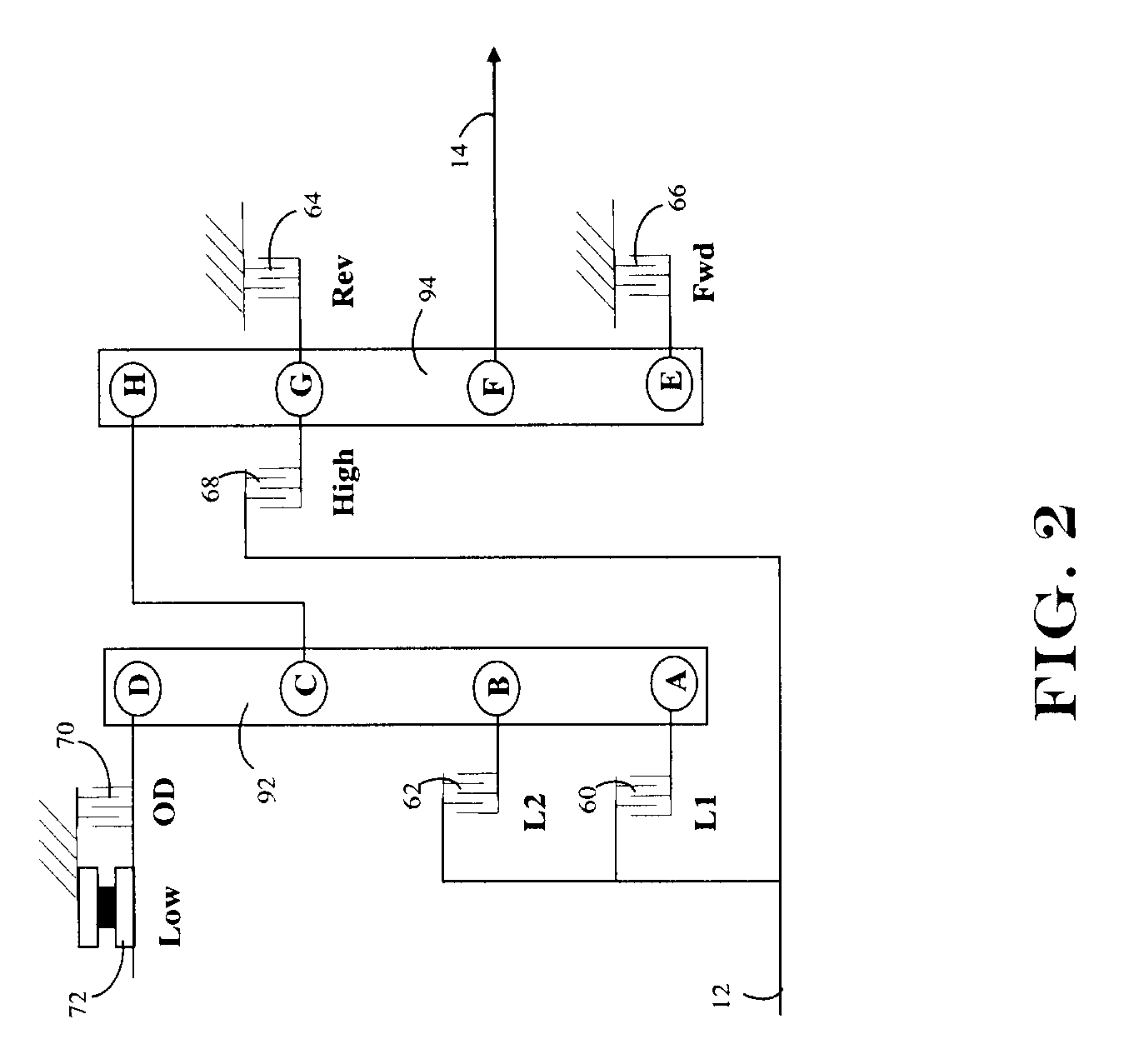

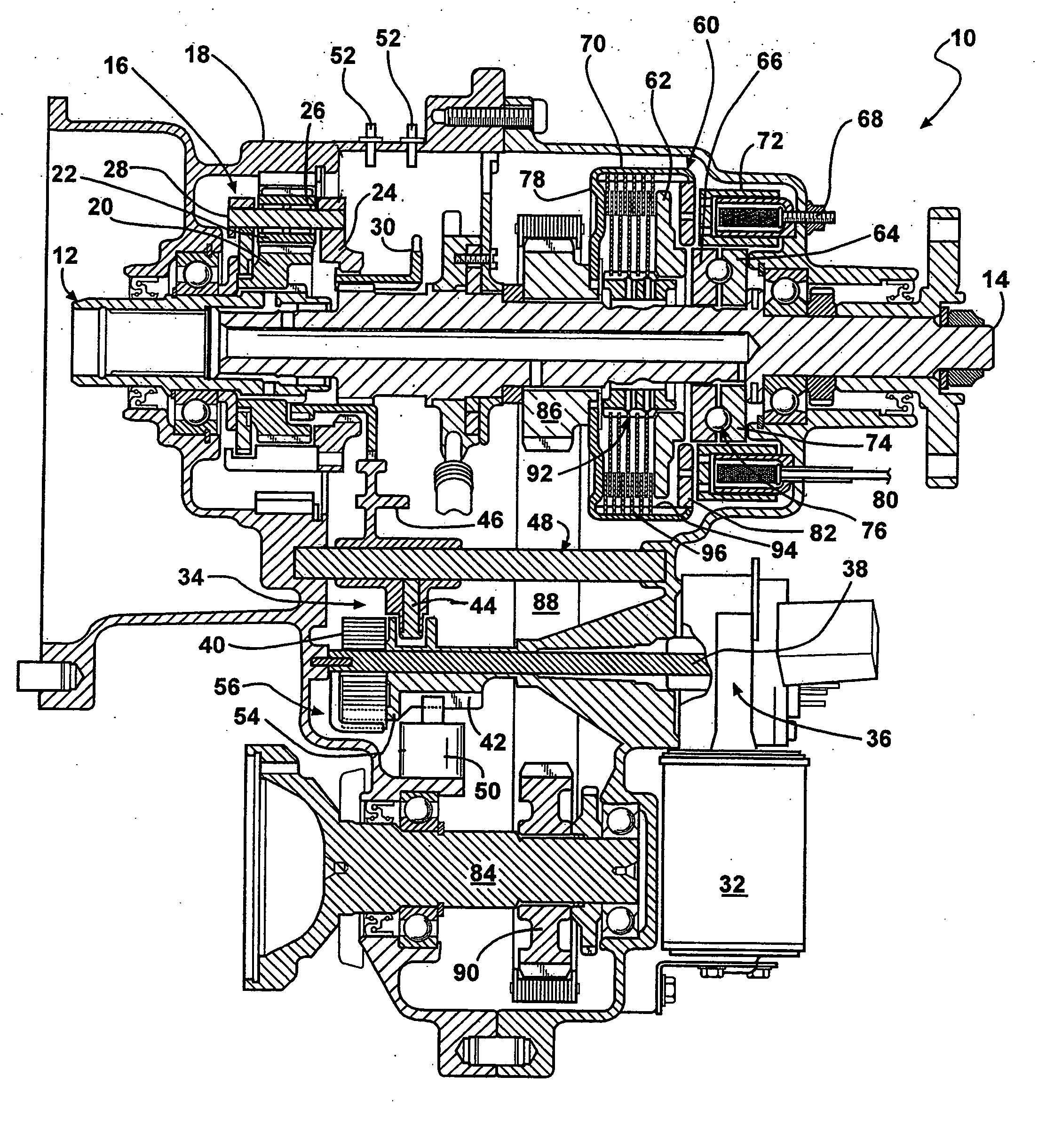

Multiple speed automatic transmission

ActiveUS20090088289A1Eliminate the problemReduce gear ratioToothed gearingsTransmission elementsAutomatic transmissionGear wheel

A multiple speed transmission includes an input and output; a first, second, third and fourth planetary gear sets, each gear set including a sun gear, a ring gear, a carrier, and pinions supported on the carrier and meshing with the sun gear and the ring gear; a first epicyclic gearing assembly including the first gear set, the second gear set, a first clutch, a second clutch, a first brake, and first, second, third and fourth rotating members, said first clutch being operable to couple said first rotating member to the input, said second clutch being operable to couple said second rotating member to the input, and said first brake being operable to hold said fourth rotating member against rotation; and a second epicyclic gearing assembly including the third gear set, the fourth gear set, a third clutch, a second brake, a third brake, and fifth, sixth, seventh and eighth rotating members, the third rotating member being secured to the eighth rotating member, said third clutch being operable to couple said seventh rotating member to the input, said second brake being operable to hold said seventh rotating member against rotation, said third brake being operable to hold said fifth rotating member against rotation, and said sixth rotating member being secured for rotation to the output.

Owner:FORD GLOBAL TECH LLC

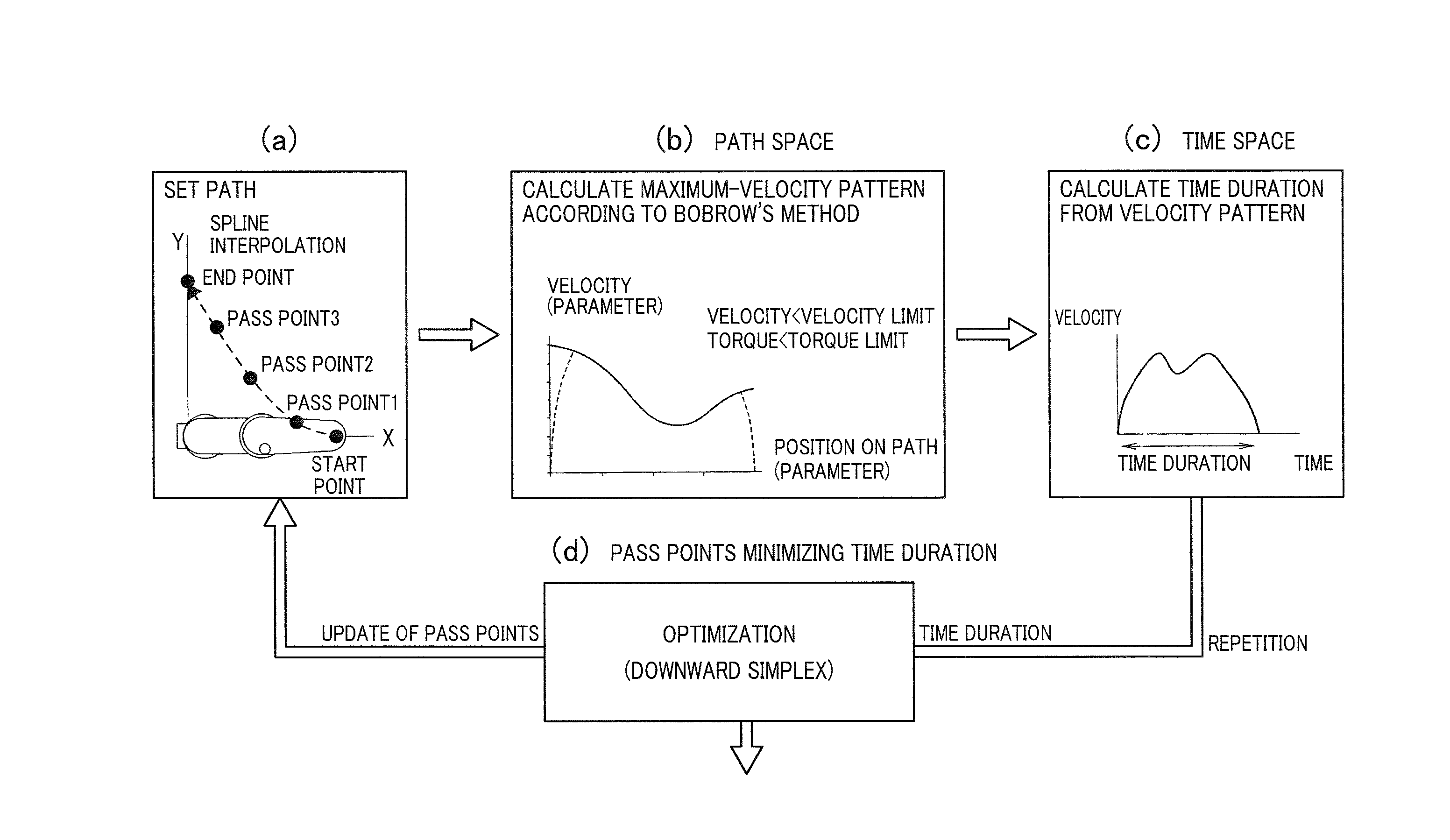

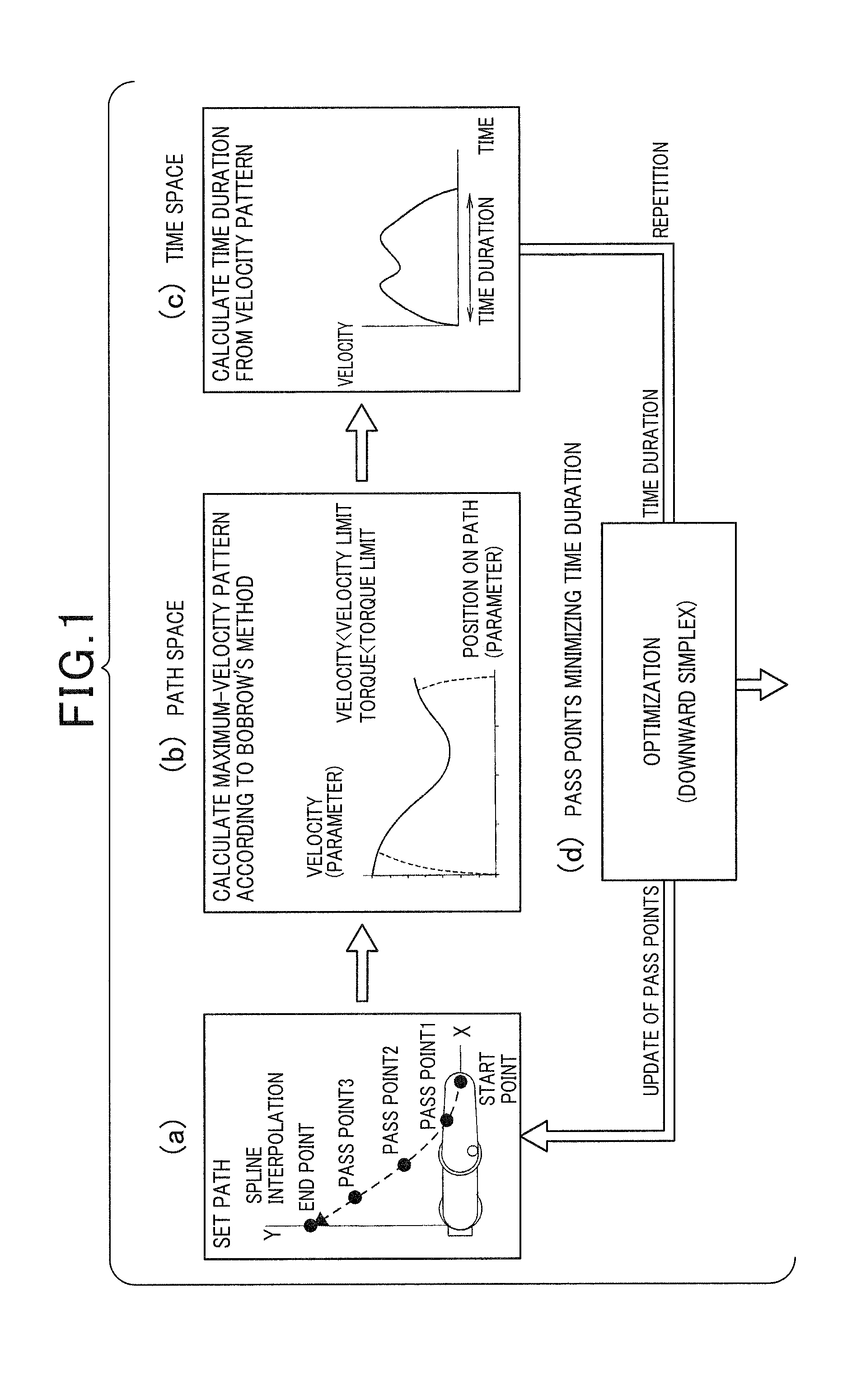

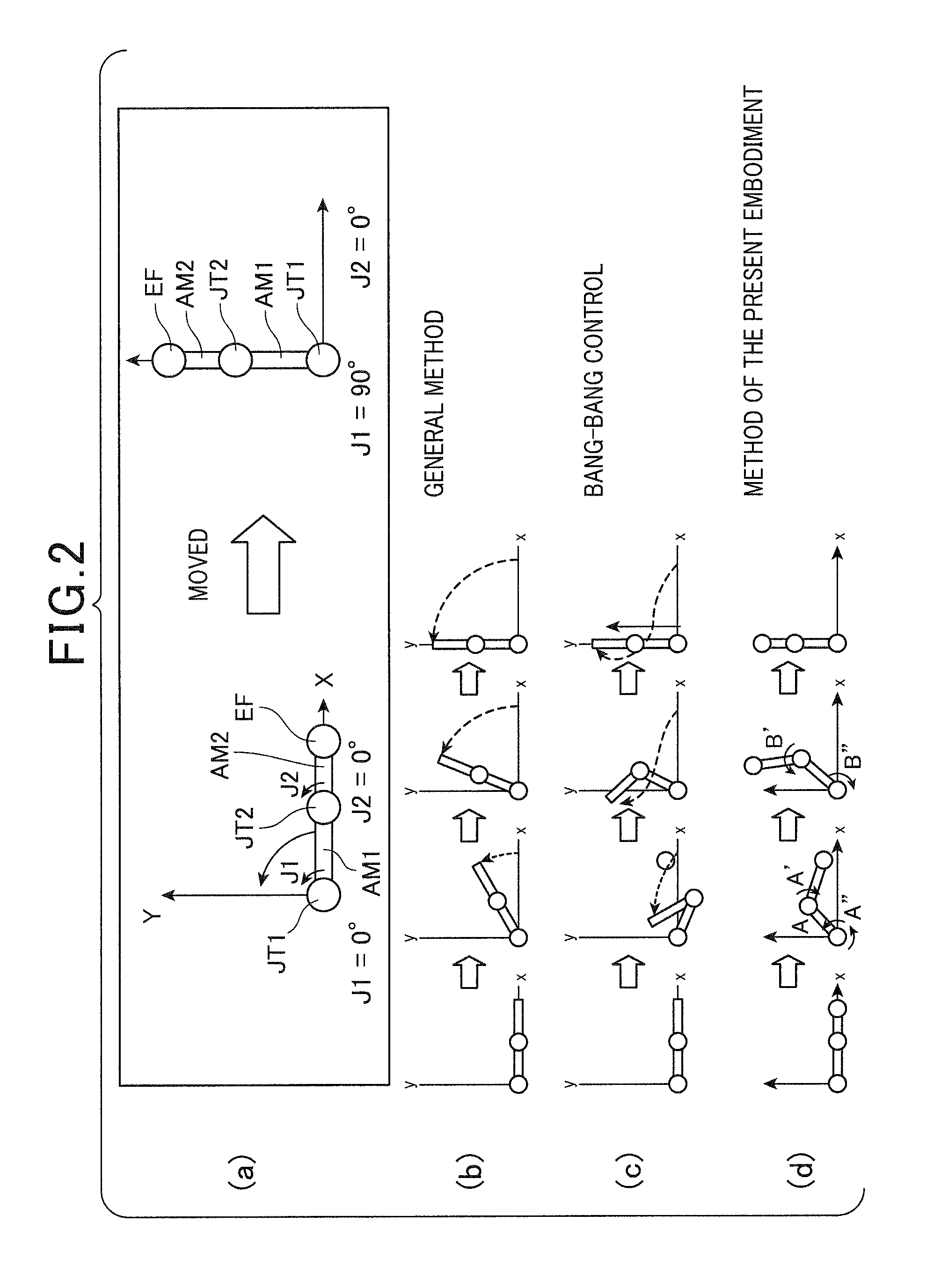

Method of generating path of multiaxial robot and control apparatus for the multiaxial robot

ActiveUS20140297030A1Avoid movement speedShortening duration of timeProgramme-controlled manipulatorSpecial data processing applicationsEngineeringActuator

In a multiaxial robot, a path along which the end effector of the robot moves in the shortest time duration is generated. The robot includes a first link and a second link positioned closer to an end effector than the first link. Start and end points are specified, and velocity patterns are generated for joints driving the first and second links based on the specified start end points. The velocity patterns enable a movement of the second link to cause i) a reaction for increasing an acceleration force generated by the first joint when the end effector is started to be moved from the start point toward the end point, and ii) a reaction for increasing a deceleration force generated by the first joint when the end effector is stopping to the end point.

Owner:DENSO WAVE INC

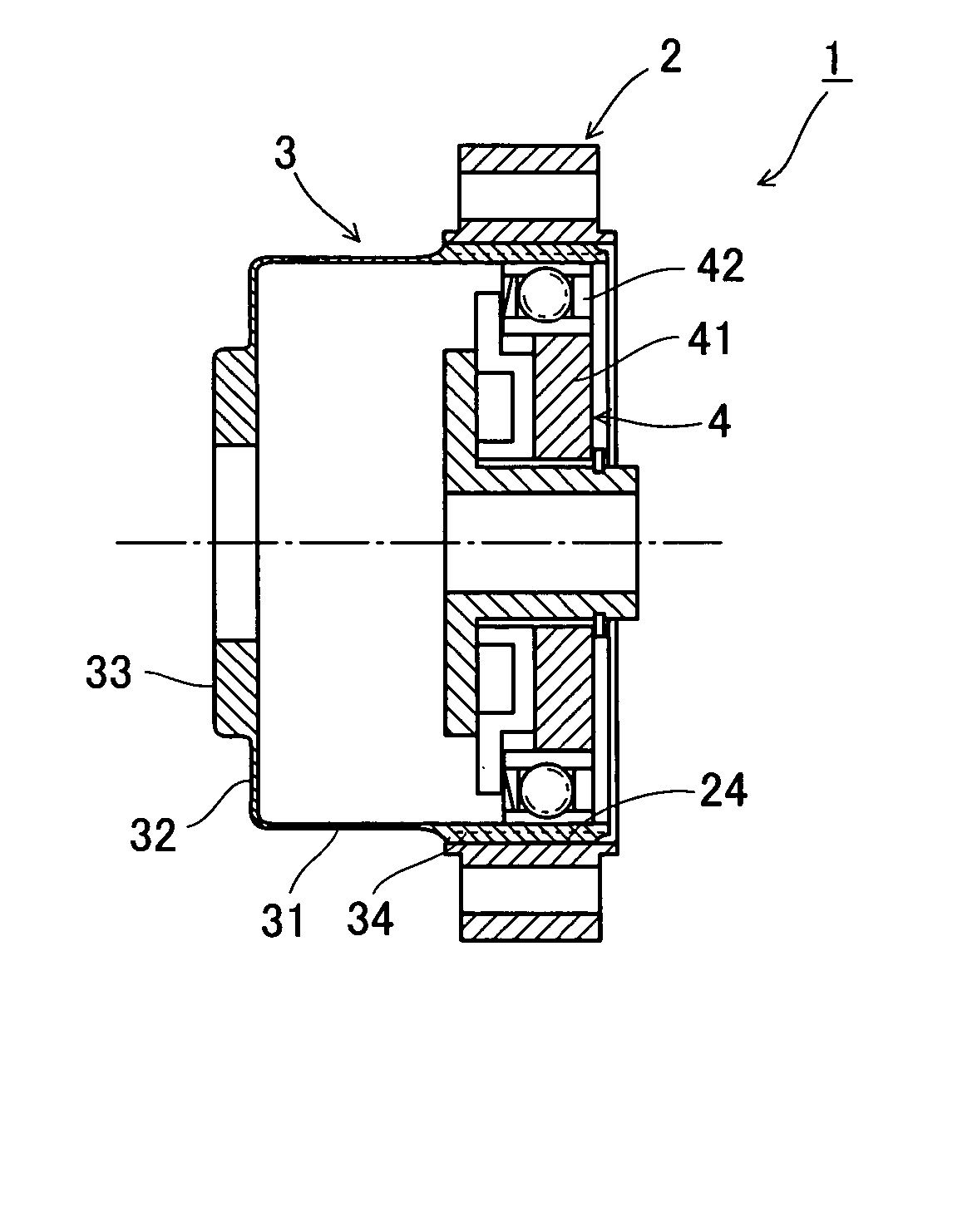

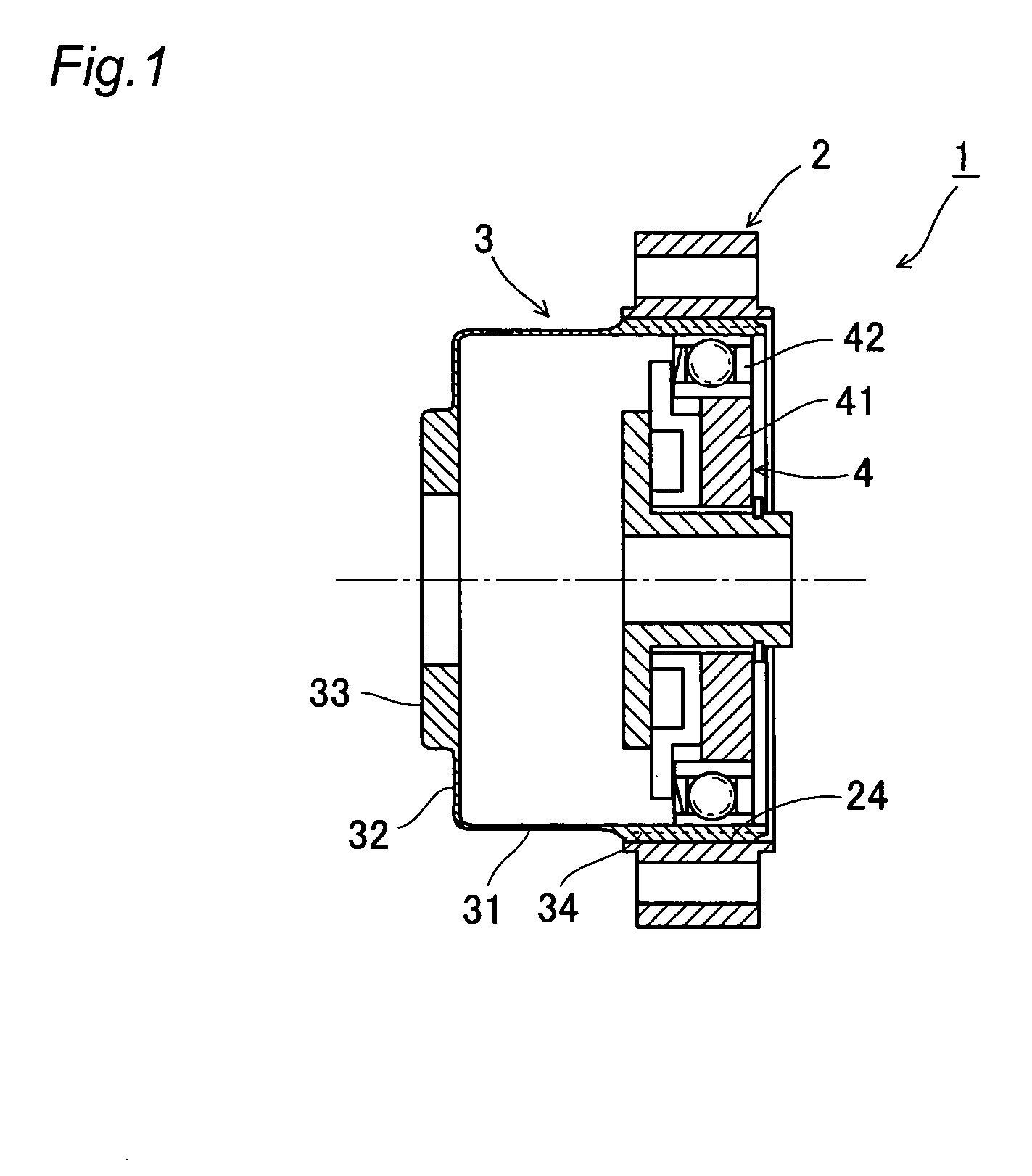

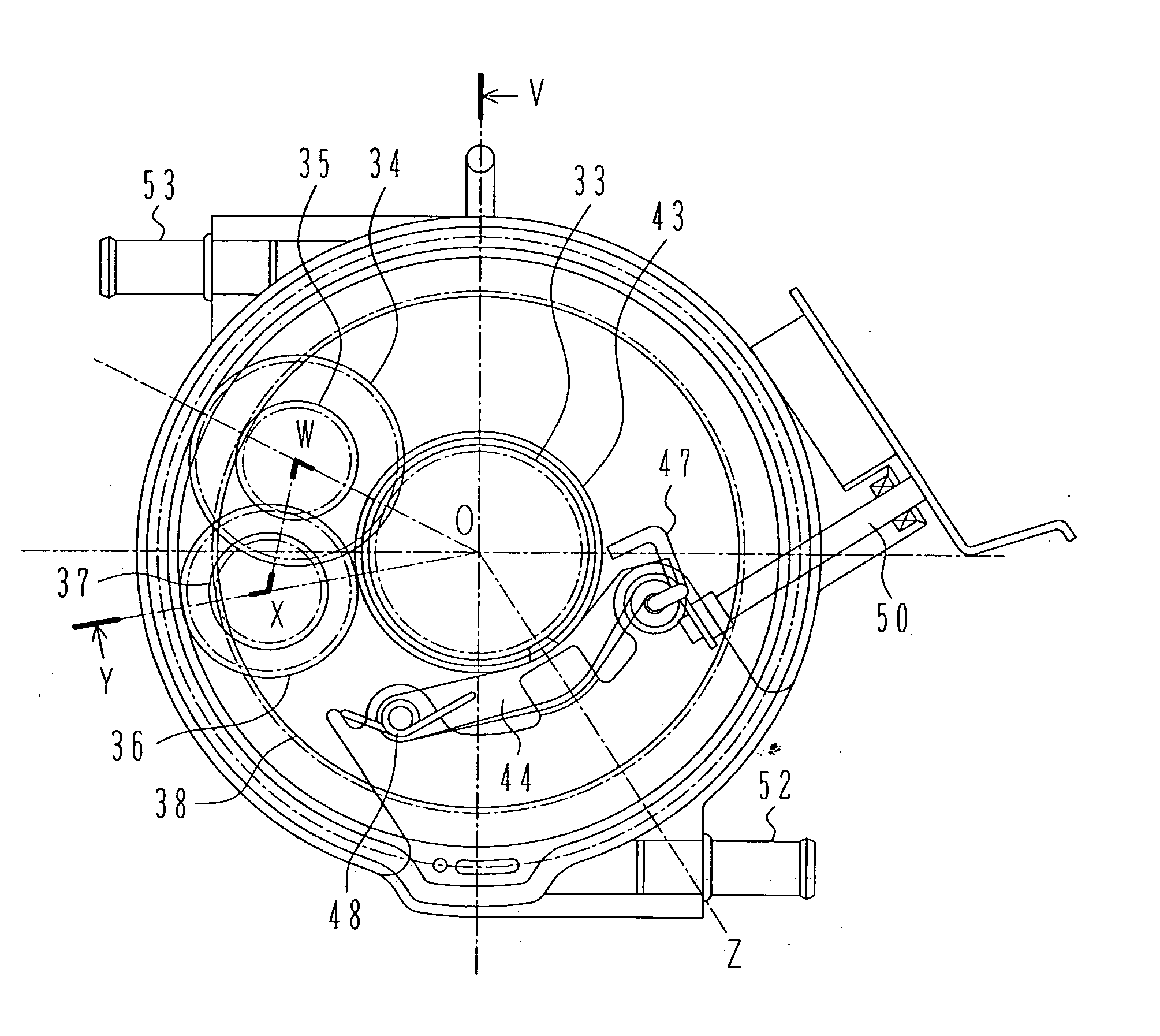

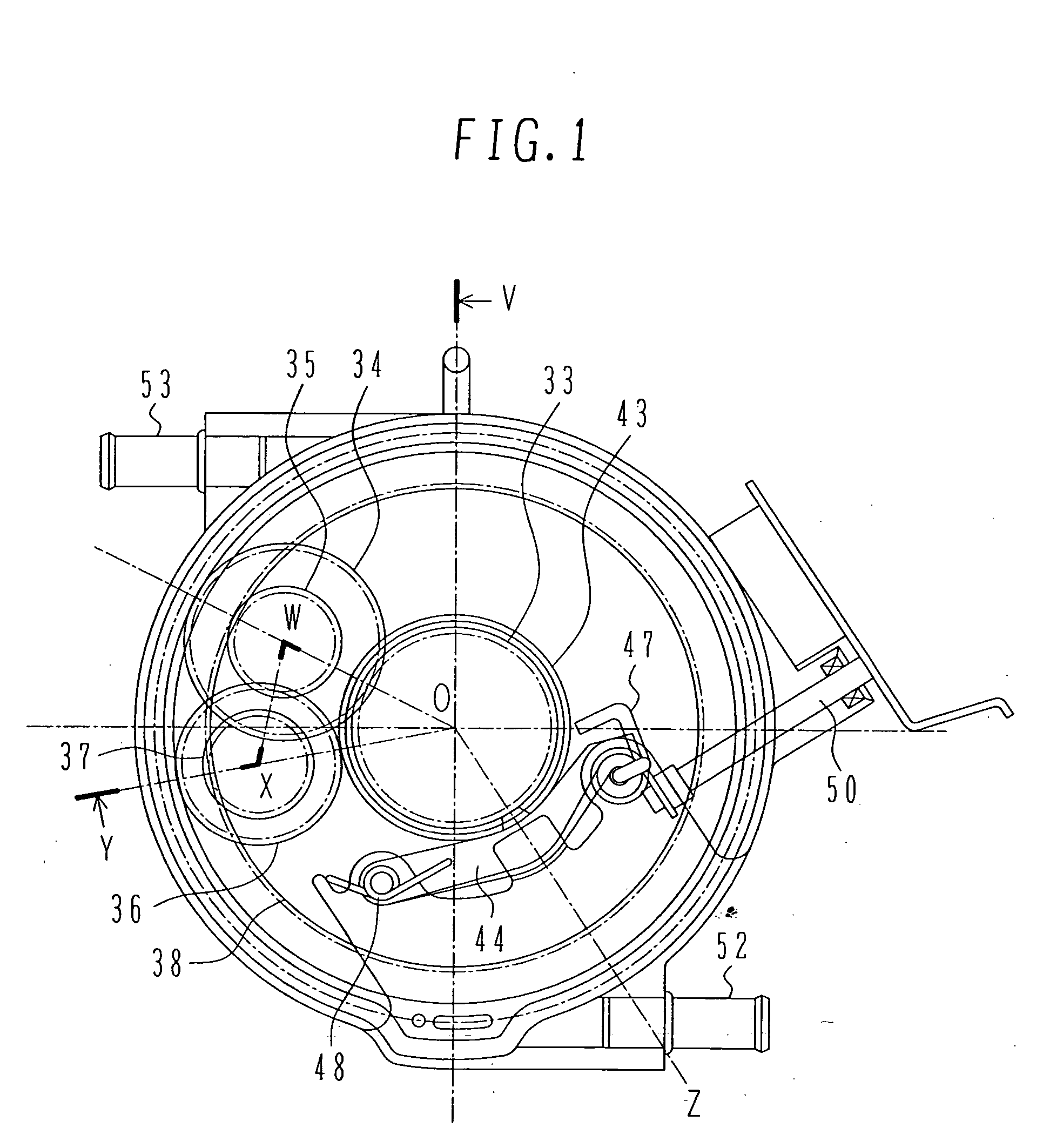

Power transmission apparatus for vehicle and vehicle-driving electric machinery system using the same

InactiveUS20050143210A1Power transmission efficiency is reducedReduce transmission efficiencyElectric propulsion mountingToothed gearingsGear ratioFixed position

The invention provides a power transmission apparatus for vehicle which can realize a high torque transmission efficiency and a high reduction gear ratio of a reduction gear unit with a more compact structure, and a vehicle-driving electric machinery system using the power transmission apparatus for vehicle. The power transmission apparatus for vehicle comprises a motor, a reduction gear unit for decelerating power outputted from the motor, and a differential gear unit for distributing the power decelerated by the reduction gear unit to left and right wheels. The reduction gear unit is a reduction gear mechanism including a plurality of gears mounted over a shaft which is rotatably held by a housing in a fixed position. The reduction gear unit and the differential gear unit are arranged within an area in oppositely facing relation to an axial end surface of the motor.

Owner:HITACHI LTD

Speed limiting for rotary driven sprinkler

InactiveUS7232078B2Speed is limitedReduce speedWatering devicesMovable spraying apparatusViscous dampingLow speed

A speed limiting mechanisms for turbine-driven fluid distribution apparatus usable with compressible fluid such as compressed air and incompressible fluid such as water. Dynamic viscous damping of the turbine output power train is used to control the rotational speed of the turbine. This prevents overspeeding when the turbine is air driven, and also when the turbine is water driven, under abnormal conditions such as blockage of a bypass area designed to control the turbine speed by limiting flow to the turbine. The same mechanism can be used to impose a lower rotational speed in the turbine during normal operation in conjunction with a turbine optimized for lower speed operation to reduce the required gear reduction in the power train.

Owner:KAH JR CARL L

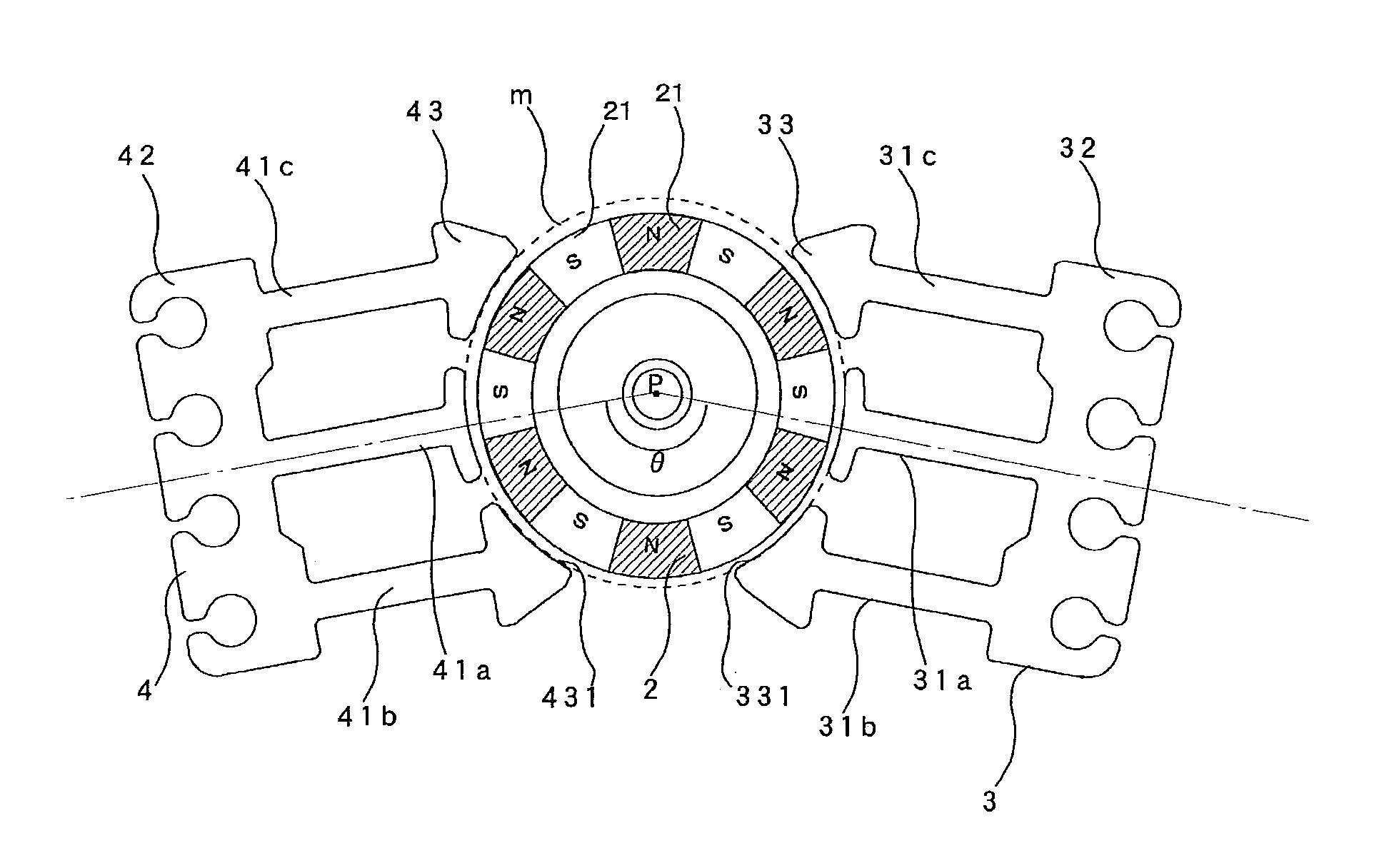

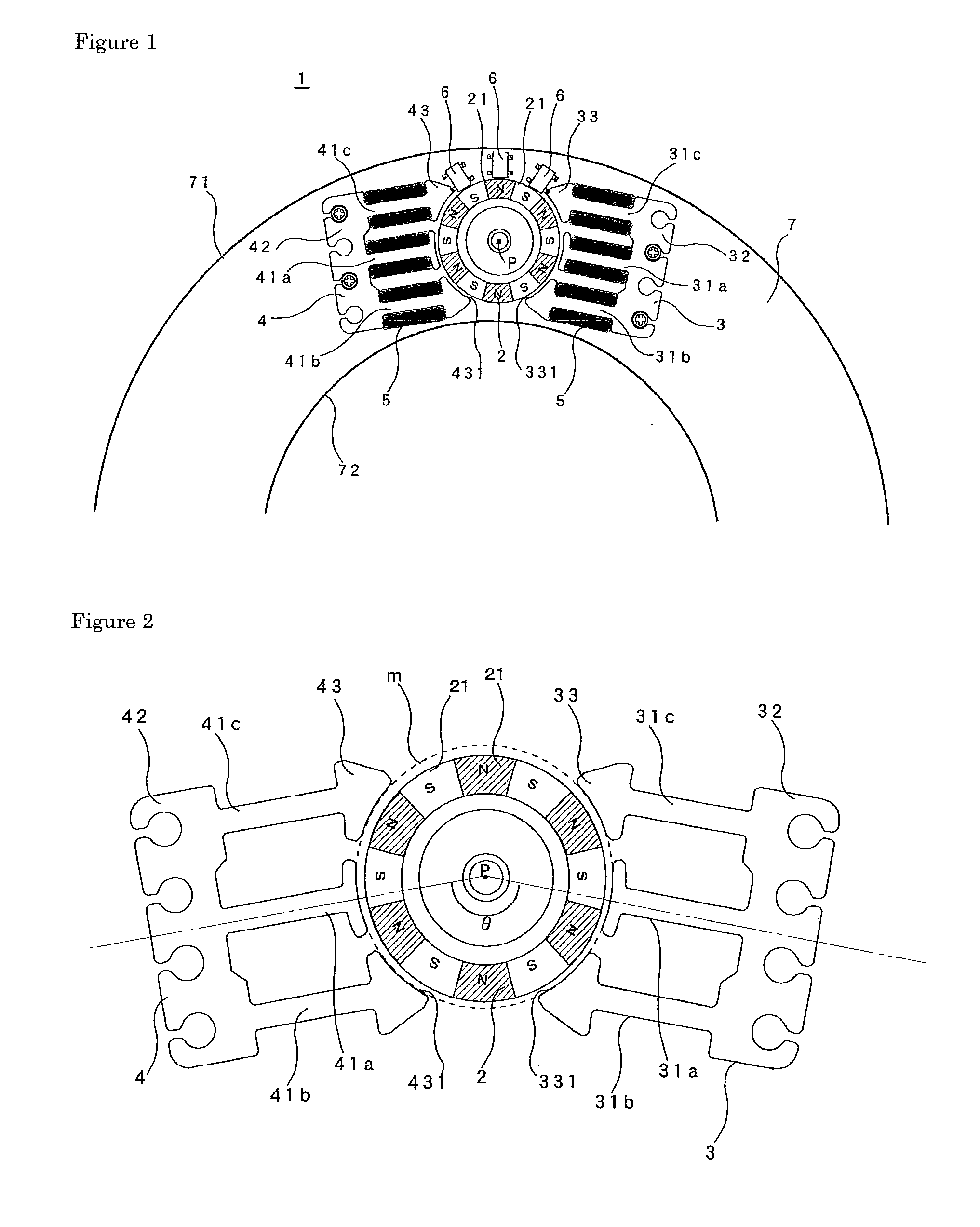

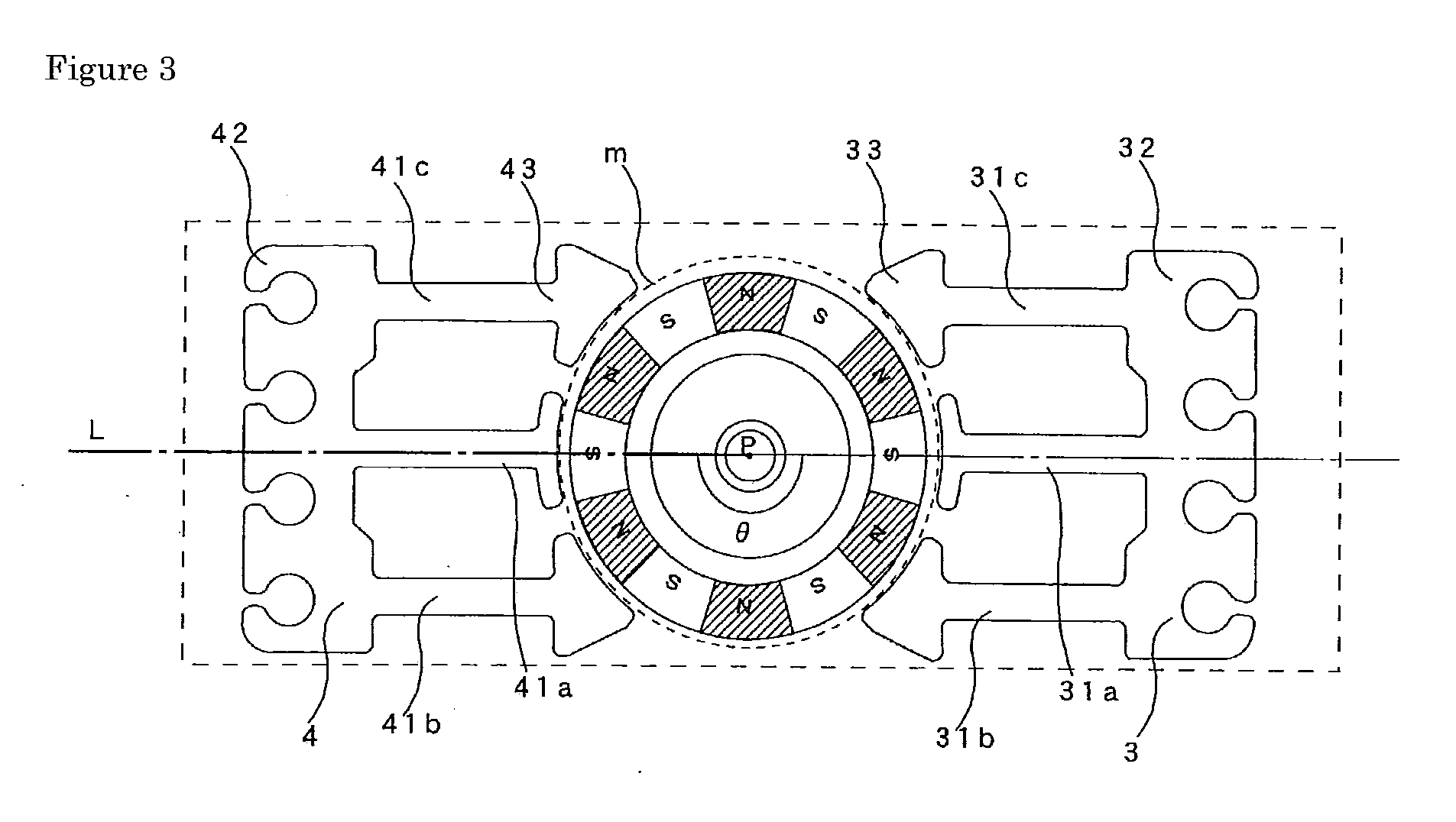

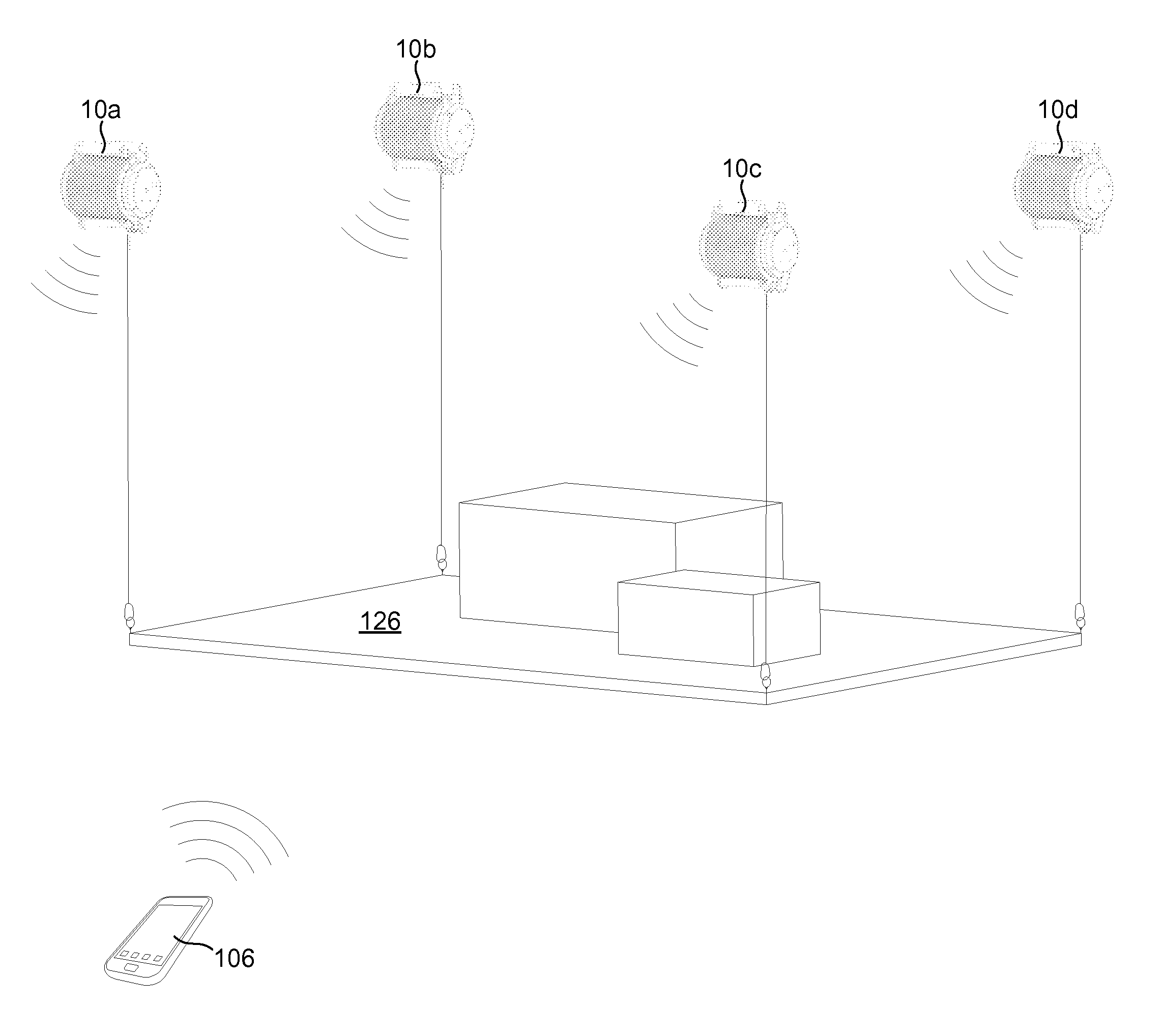

Three-Phase Brushless DC Motor

InactiveUS20100314962A1Increase torqueReduce noiseMagnetic circuitMaster clocksMagnetic polesThree-phase

An object of the present invention is to provide a three-phase brushless DC motor providing a high torque and performs stable operations which can be used even when an installation space is restricted. To achieve the object, the present invention adopts an inner rotor-type three-phase brushless DC motor in which an inner rotor-type three-phase brushless DC motor comprising a rotor provided with a plurality of magnetic poles divided equally in a circumferential direction at an outer peripheral of the rotor and a stator separately arranged along an outer peripheral of the rotor, wherein the stator is provided with M−n (wherein, n is an integer equal to or larger than 1) of stator sections each provided with three stator poles each having different phases, and the relationship between number of magnetic poles provided in the rotor and the total number of stator poles is made different from the conventional one.

Owner:TAMRON

Multiple speed automatic transmission

ActiveUS8177674B2Eliminate the problemReduce gear ratioToothed gearingsTransmission elementsAutomatic transmissionGear wheel

A multiple speed transmission includes an input and output; a first, second, third and fourth planetary gear sets, each gear set including a sun gear, a ring gear, a carrier, and pinions supported on the carrier and meshing with the sun gear and the ring gear; a first epicyclic gearing assembly including the first gear set, the second gear set, a first clutch, a second clutch, a first brake, and first, second, third and fourth rotating members, said first clutch being operable to couple said first rotating member to the input, said second clutch being operable to couple said second rotating member to the input, and said first brake being operable to hold said fourth rotating member against rotation; and a second epicyclic gearing assembly including the third gear set, the fourth gear set, a third clutch, a second brake, a third brake, and fifth, sixth, seventh and eighth rotating members, the third rotating member being secured to the eighth rotating member, said third clutch being operable to couple said seventh rotating member to the input, said second brake being operable to hold said seventh rotating member against rotation, said third brake being operable to hold said fifth rotating member against rotation, and said sixth rotating member being secured for rotation to the output.

Owner:FORD GLOBAL TECH LLC

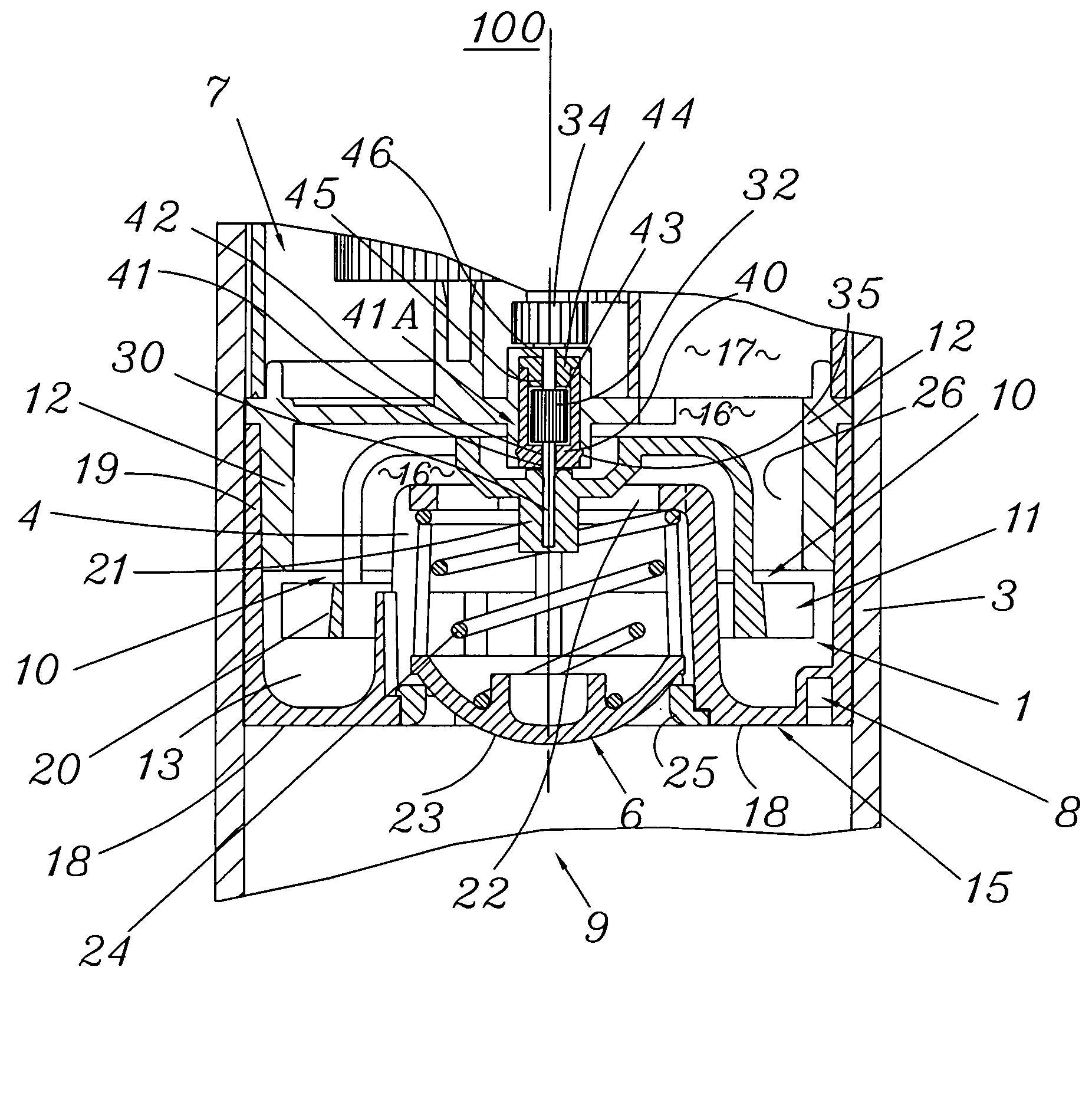

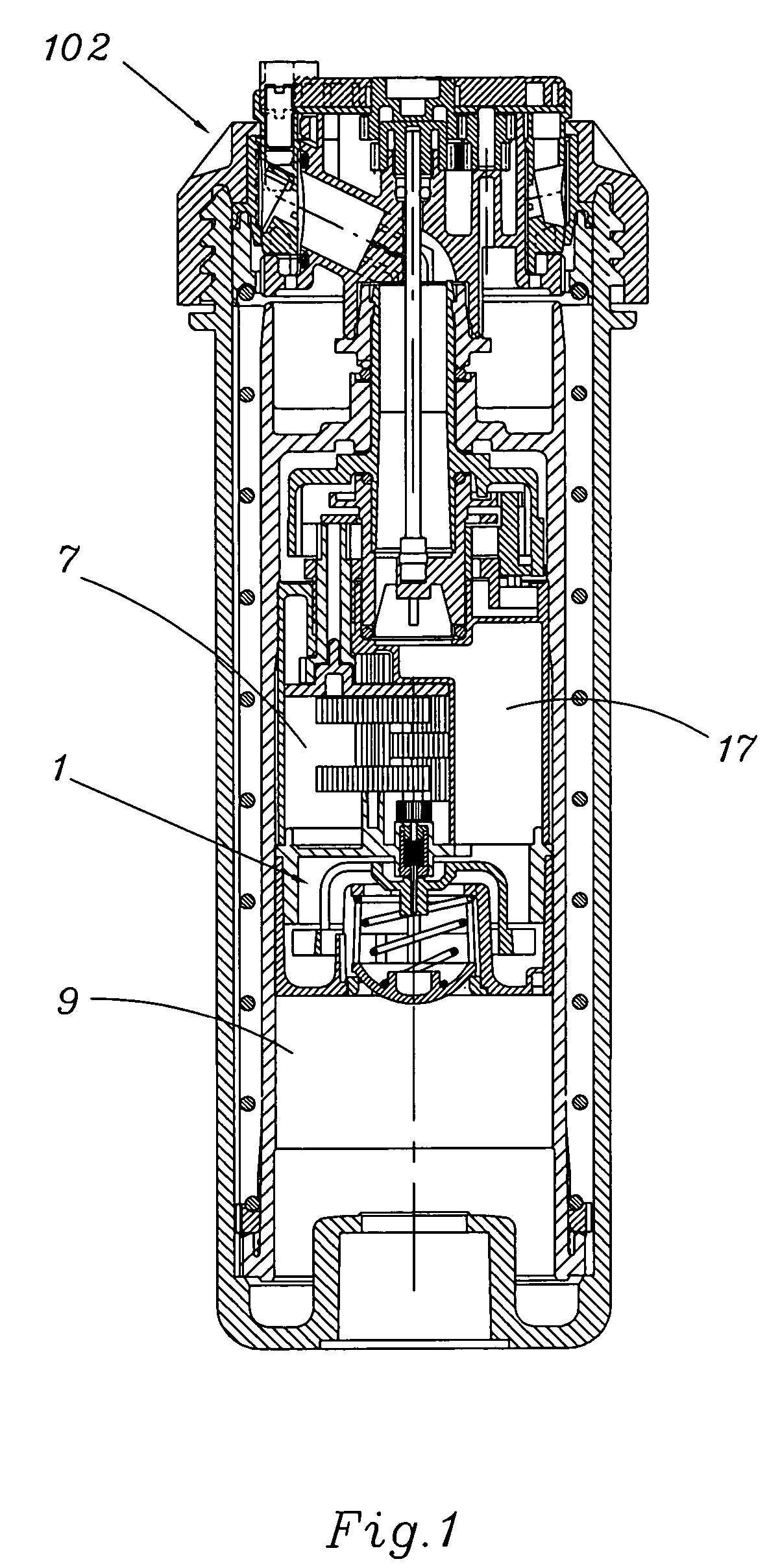

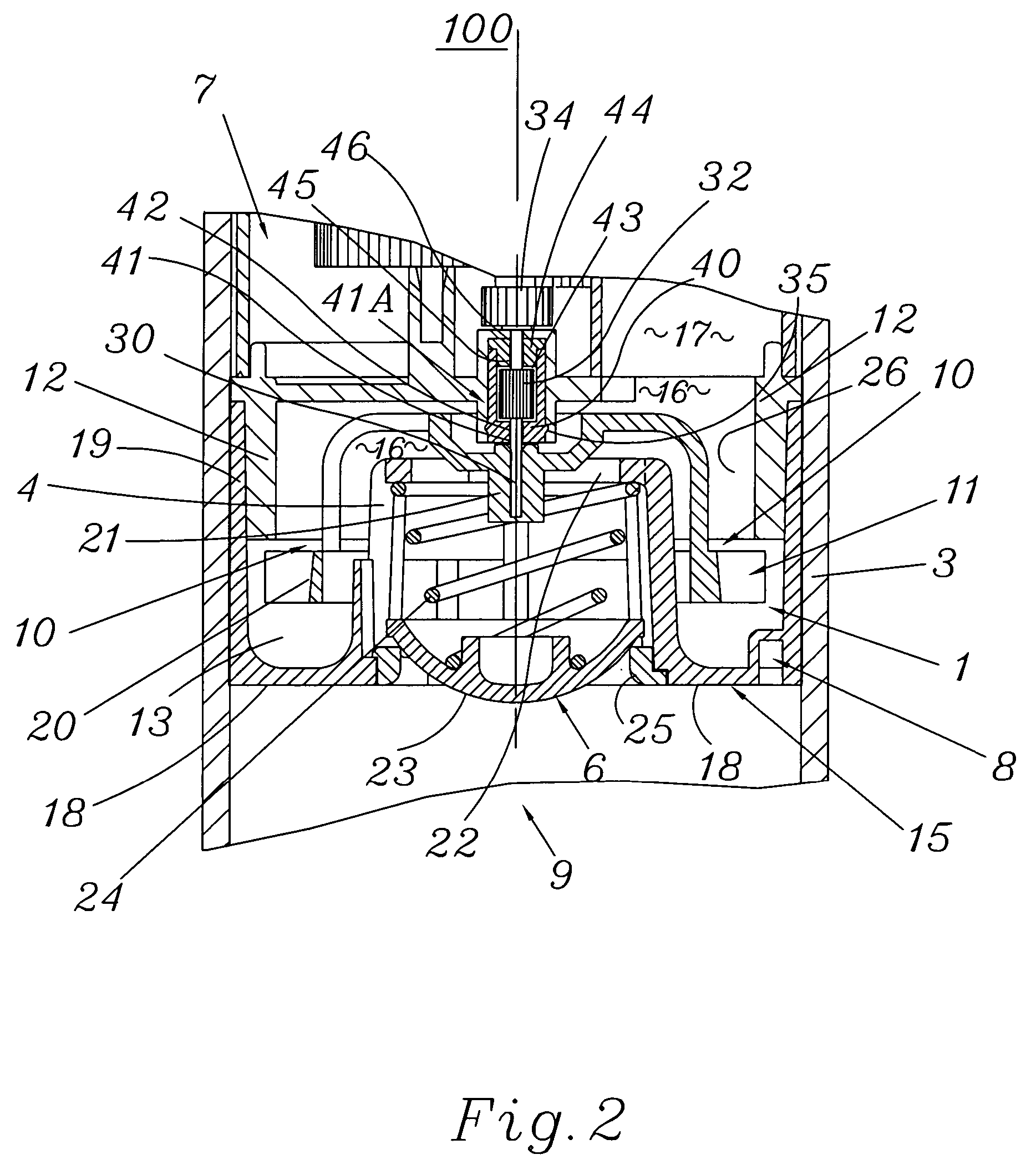

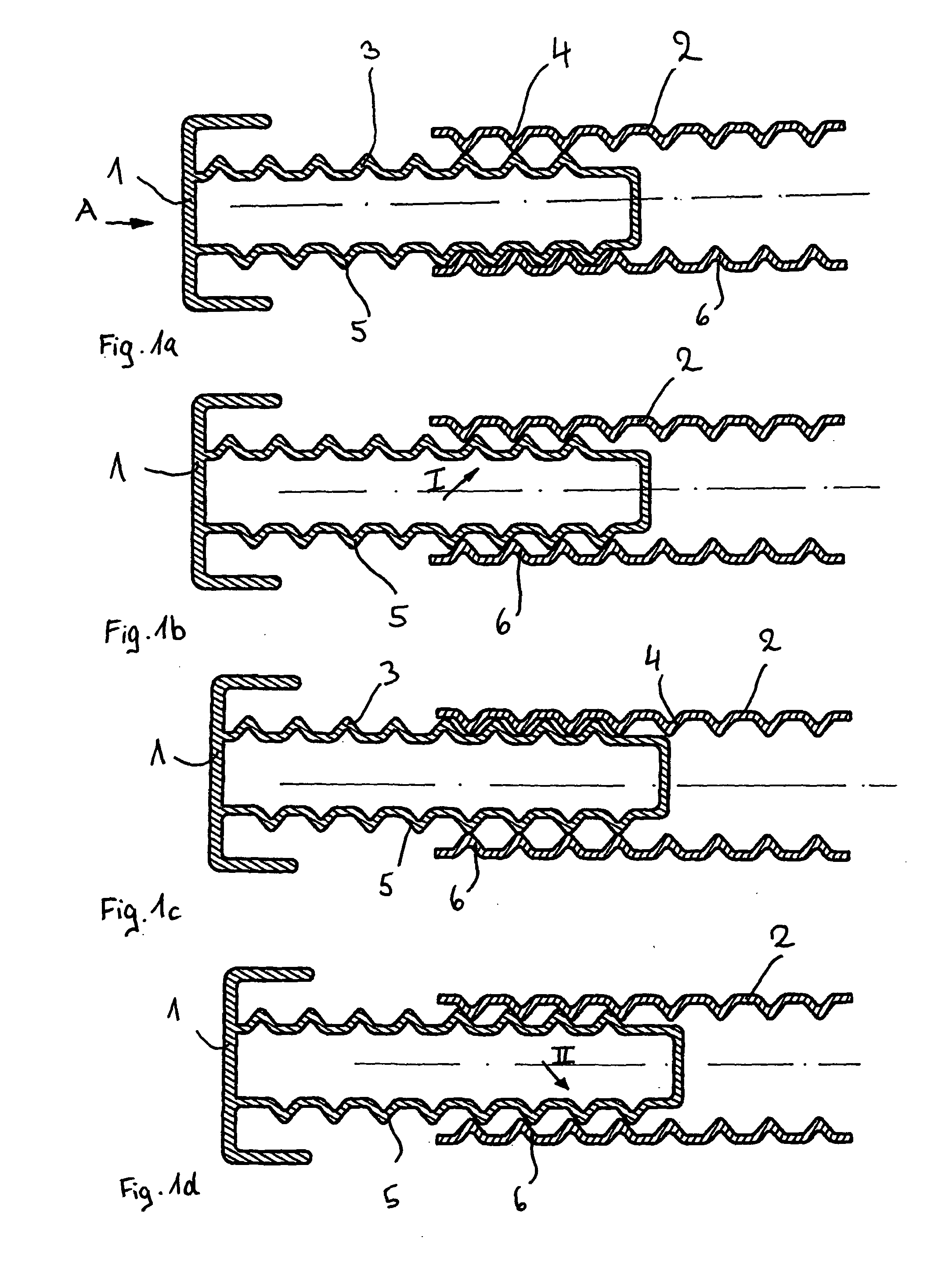

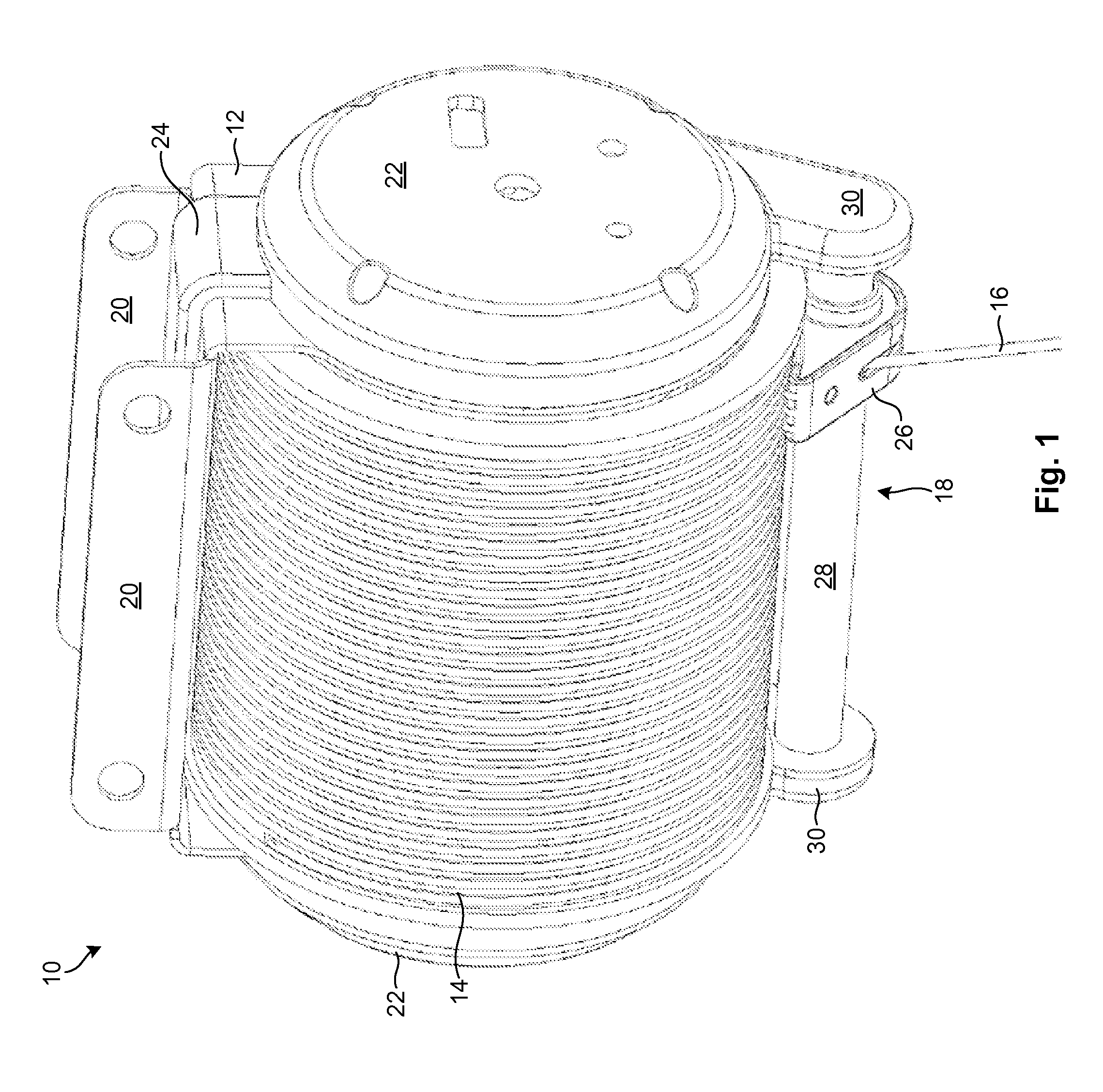

Force Limiting Device for a Motor Vehicle

ActiveUS20110172054A1Good chanceSimple and compactBelt retractorsToothed gearingsEngineeringMotorized vehicle

A load limiting mechanism for a motor vehicle, comprising at least two parts (1, 2, 10, 12, 16, 20, 21, 46, 22, 40) controlled relative to one another with a frequency controlled oscillating movement. The parts (1, 2, 10, 12, 16, 20, 21, 46, 22, 40) moving relative to one another comprise interlocking gears (3, 4, 13, 15, 24, 25, 26, 27) and the frequency controlled oscillating movement results thereby that at least one of the parts (1, 10, 21, 22) compared to the other part (2, 12, 16, 20, 40, 46) executes a wavelike oscillating feed motion, in which the gears (3, 4, 13, 15, 24, 25, 26, 27) alternately become engaged and disengaged thereby dissipating energy.

Owner:AUTOLIV DEV AB

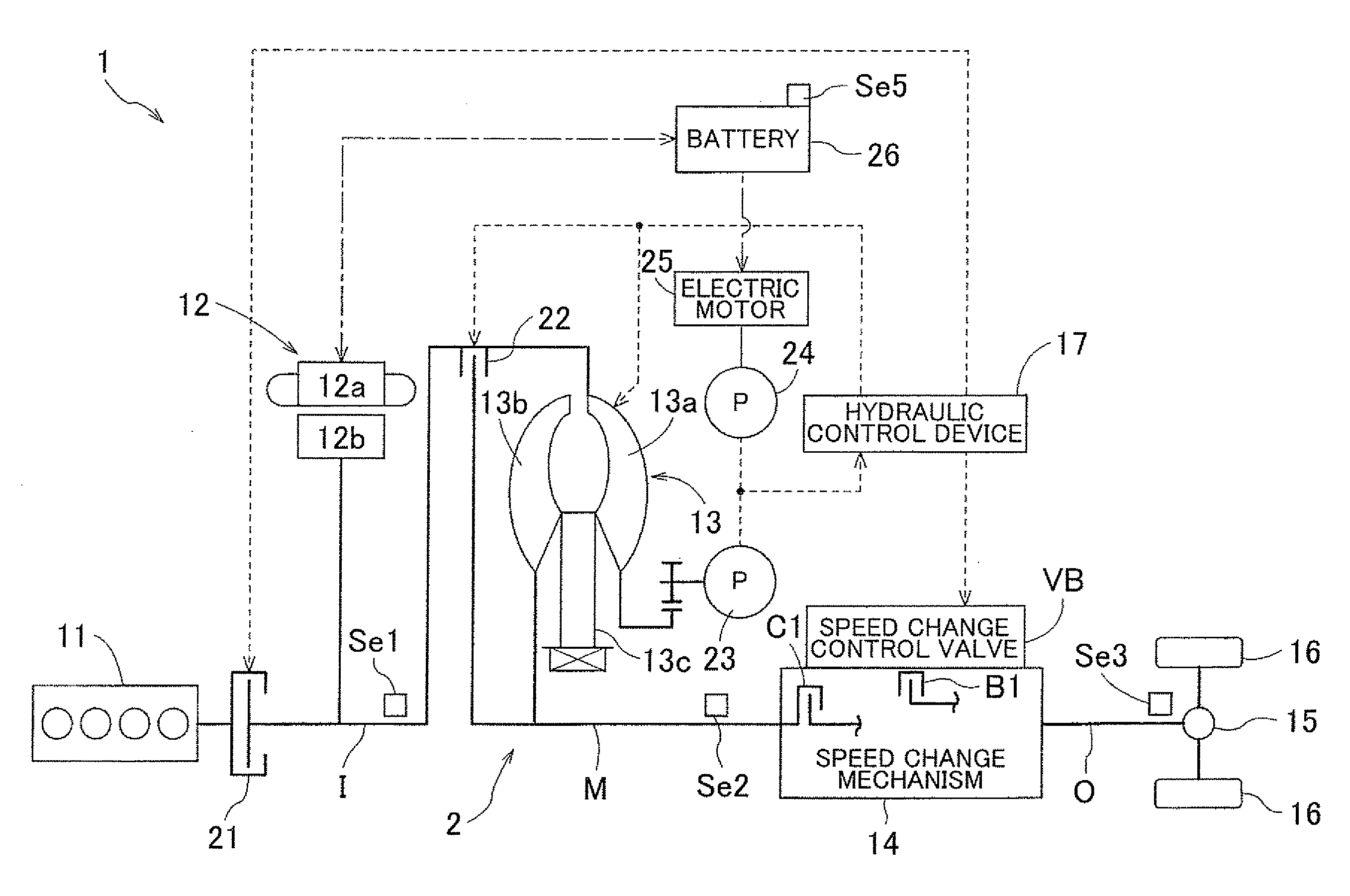

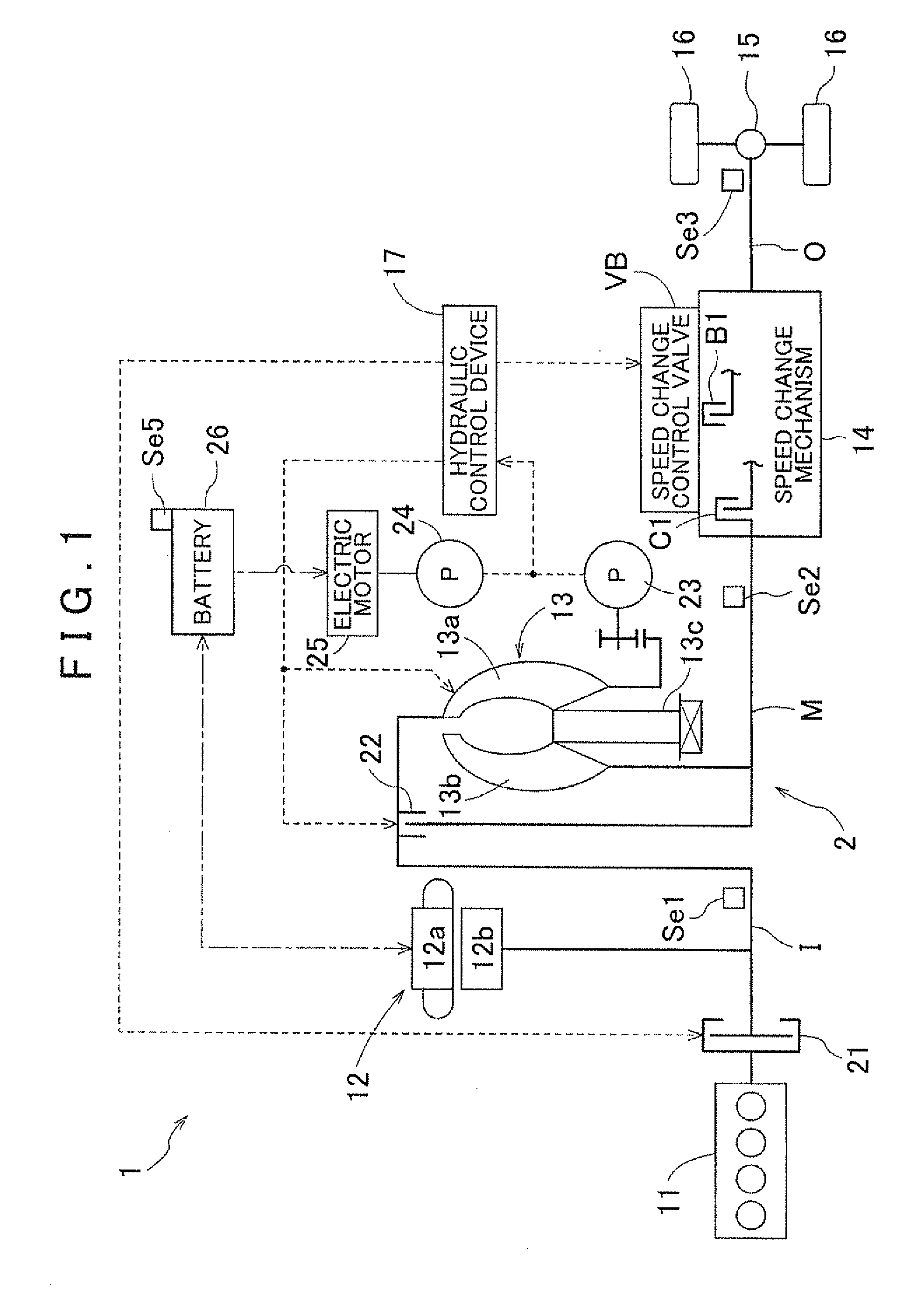

Control device

ActiveUS20110246009A1Reduce the amount requiredReduce the ratioDigital data processing detailsGas pressure propulsion mountingLow speedChange control

A control device for controlling a transmission configured such that when the speed change mechanism performs switching to a shift speed with a lower speed ratio in a negative torque prediction established state in which predicted input torque is negative, the predicted input torque being a predicted value of input torque input to the input member a predetermined determination reference time later, and being derived on the basis of variations in the input torque, special speed change control is executed in which a disengagement hydraulic pressure is lowered to cause a disengagement element to slip, and the disengagement element is maintained in a slipping state over an entire speed change process, which extends from a time point when the disengagement element starts slipping to a time point when a rotational speed is synchronized with a rotational speed of the input member.

Owner:AISIN AW CO LTD

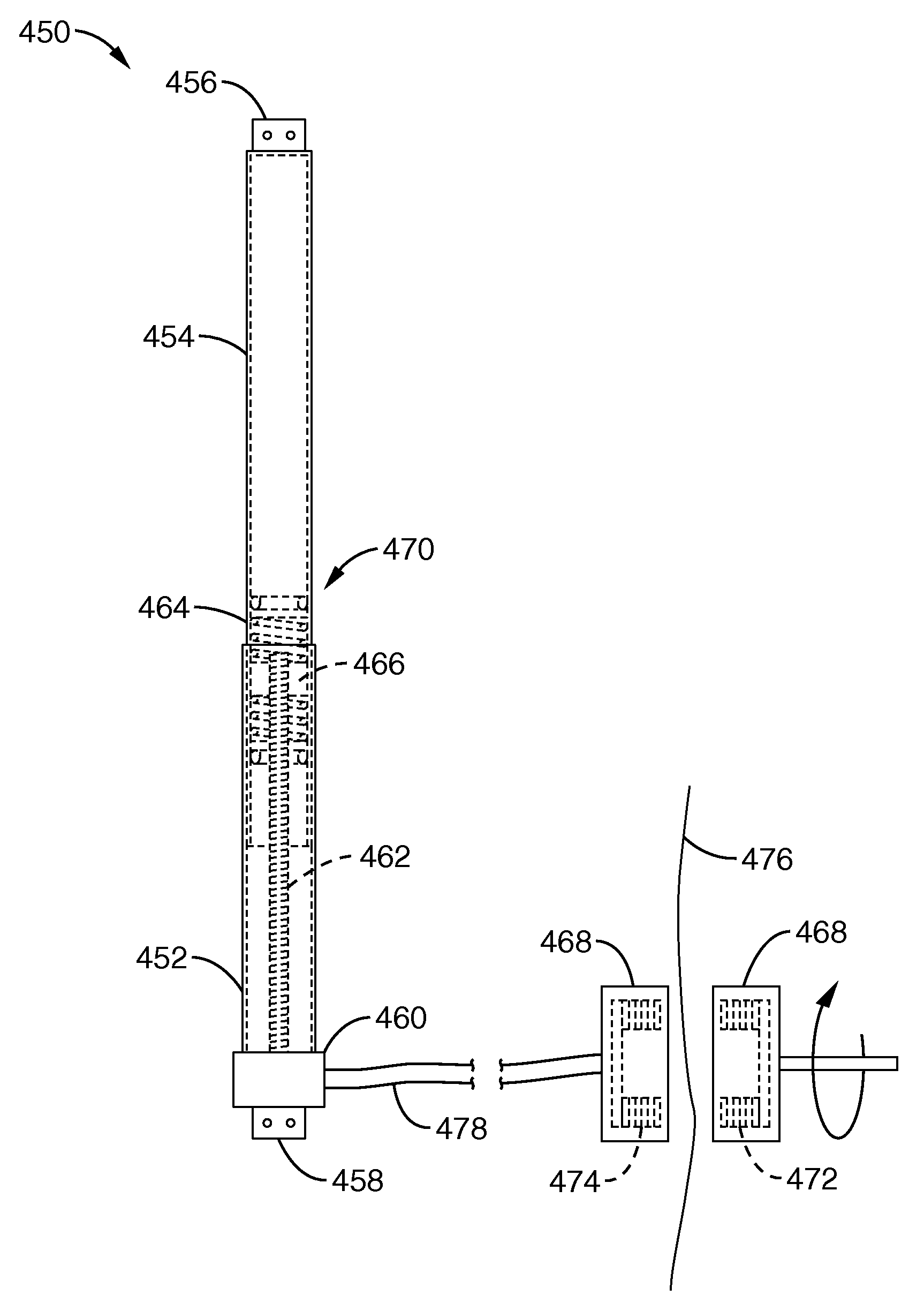

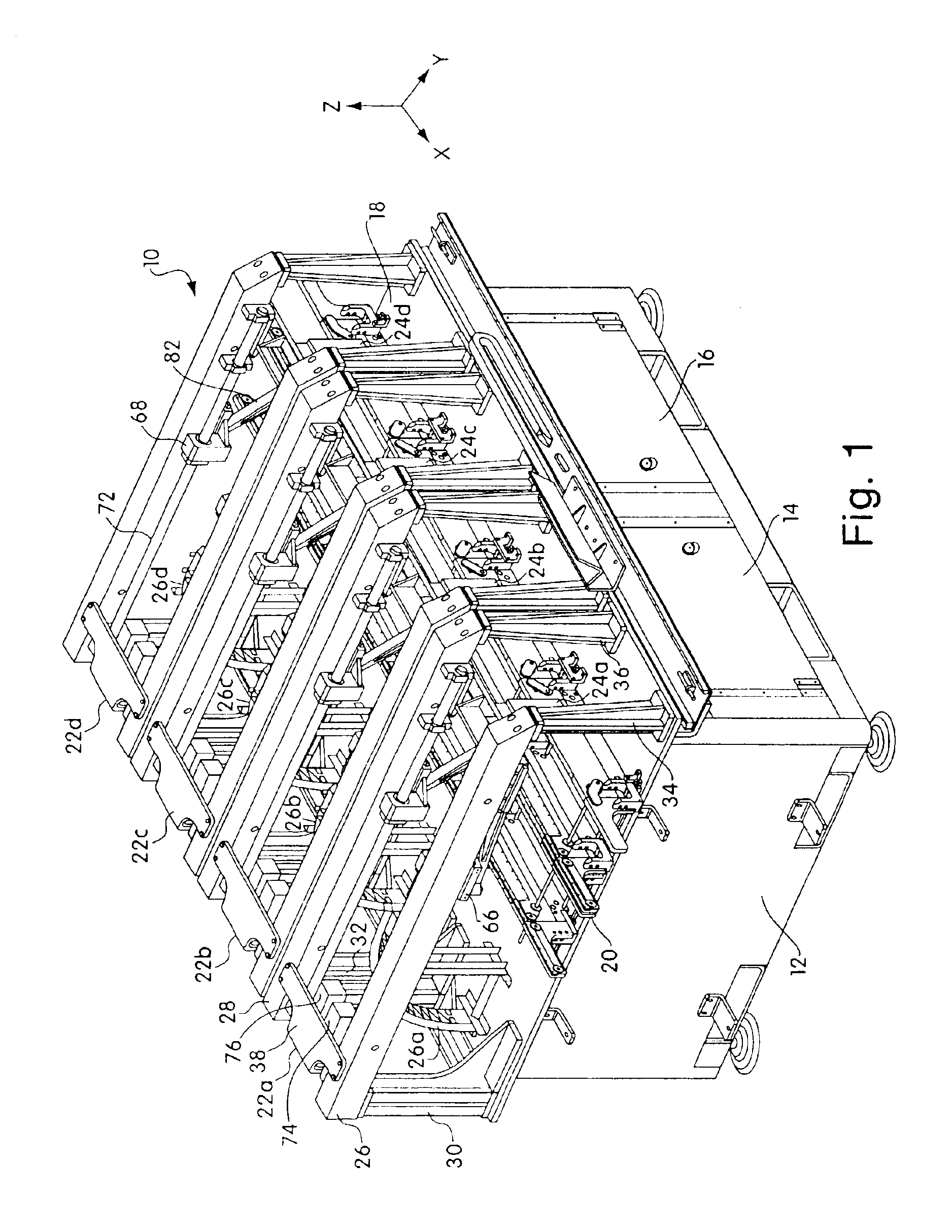

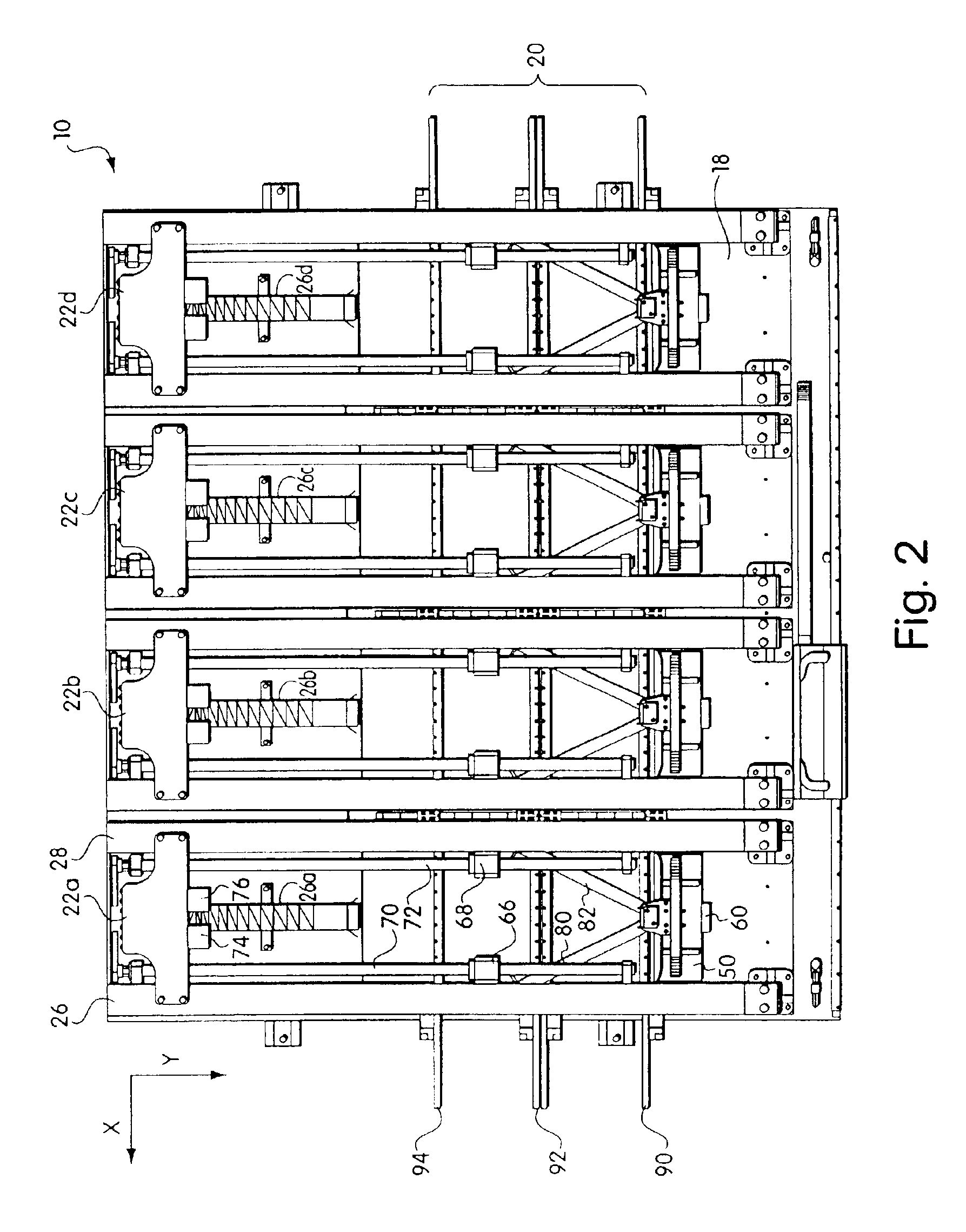

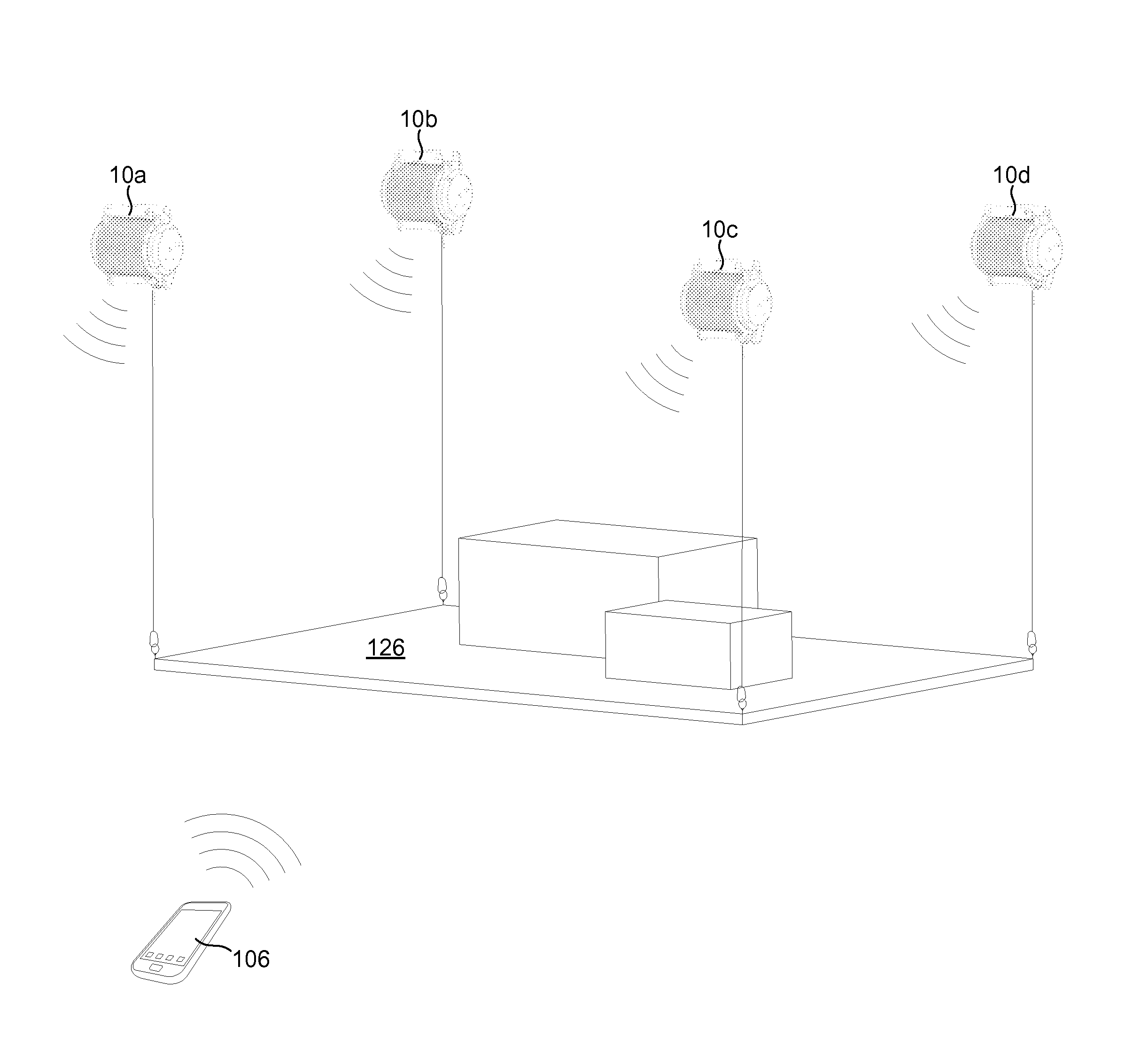

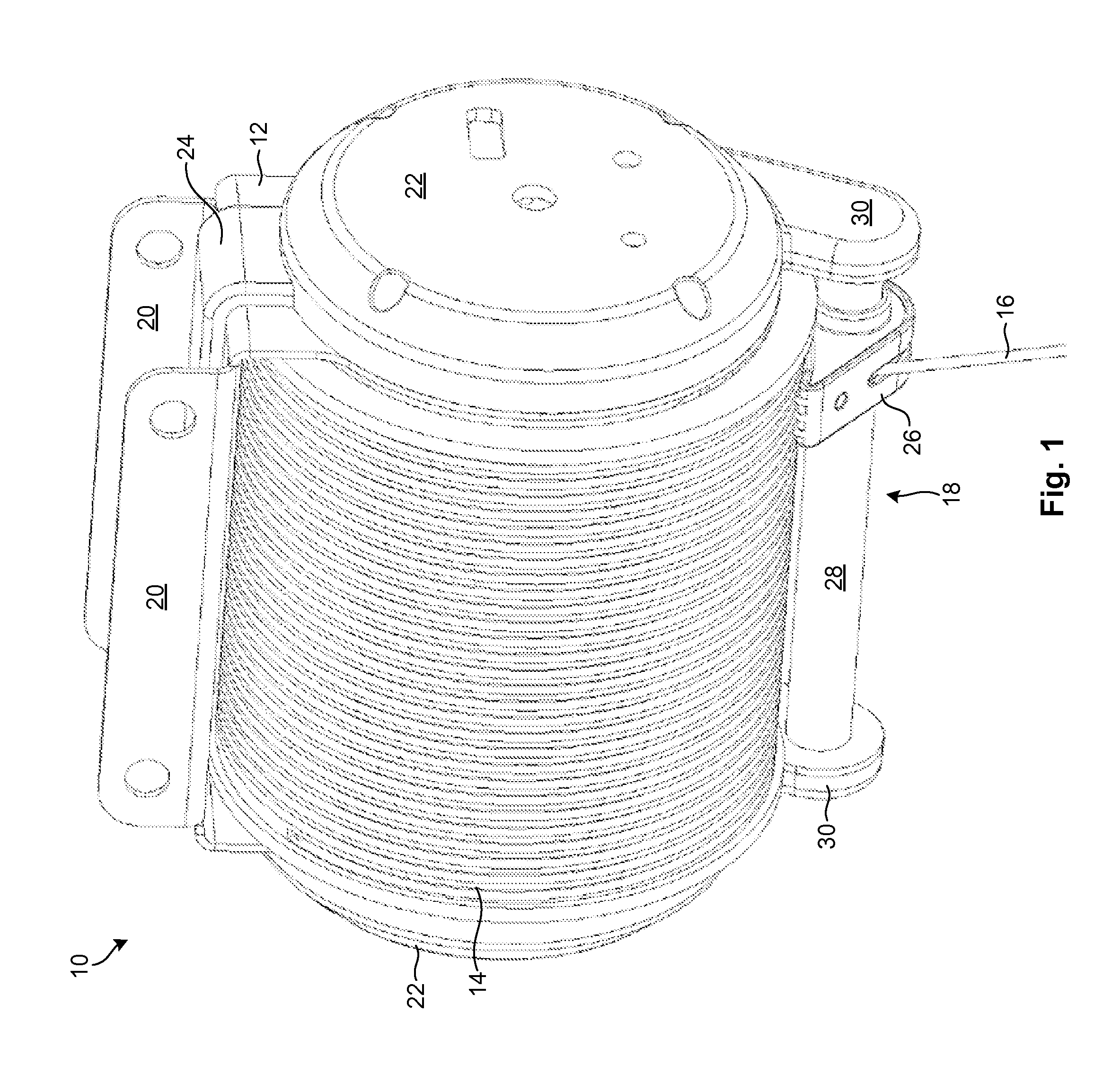

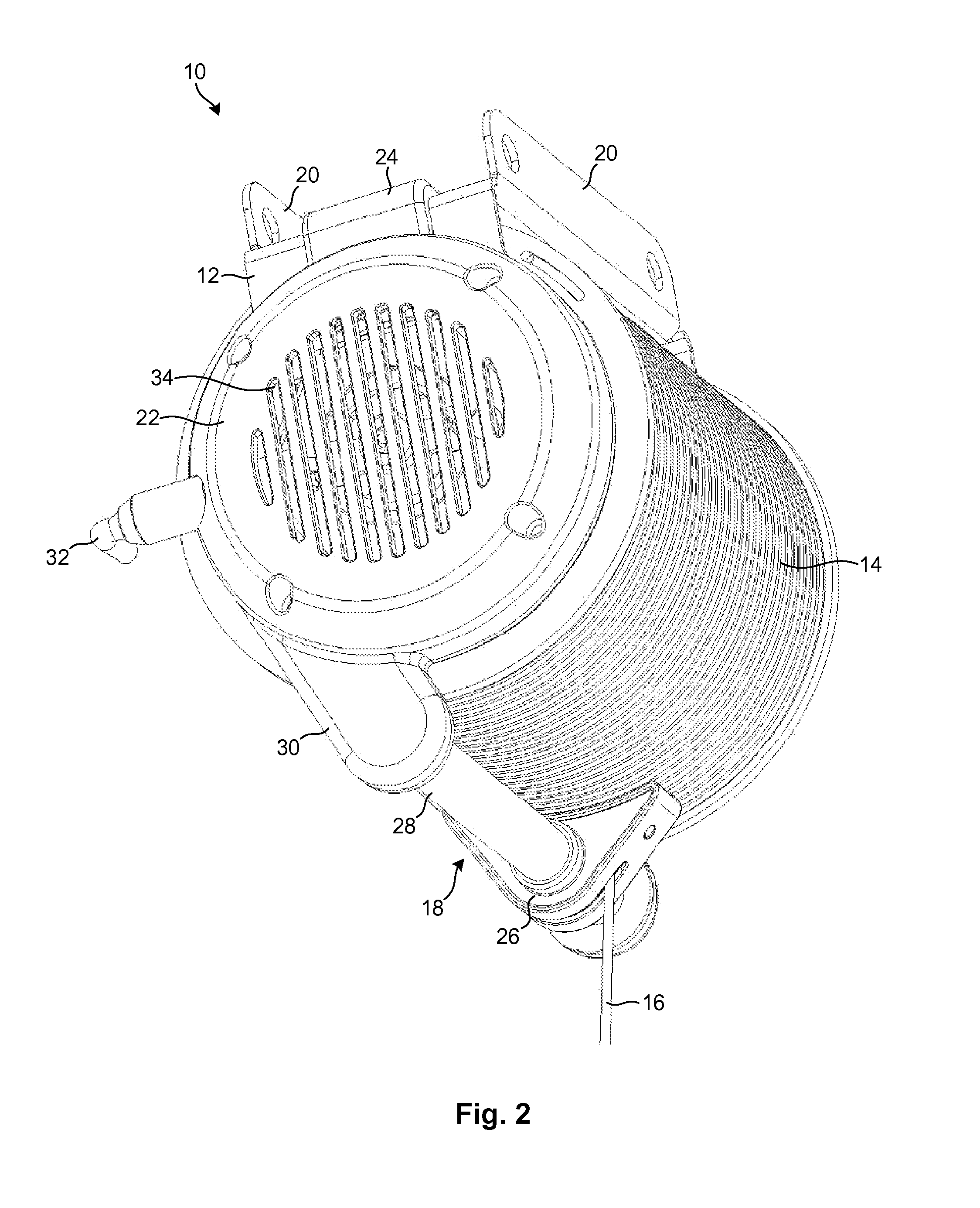

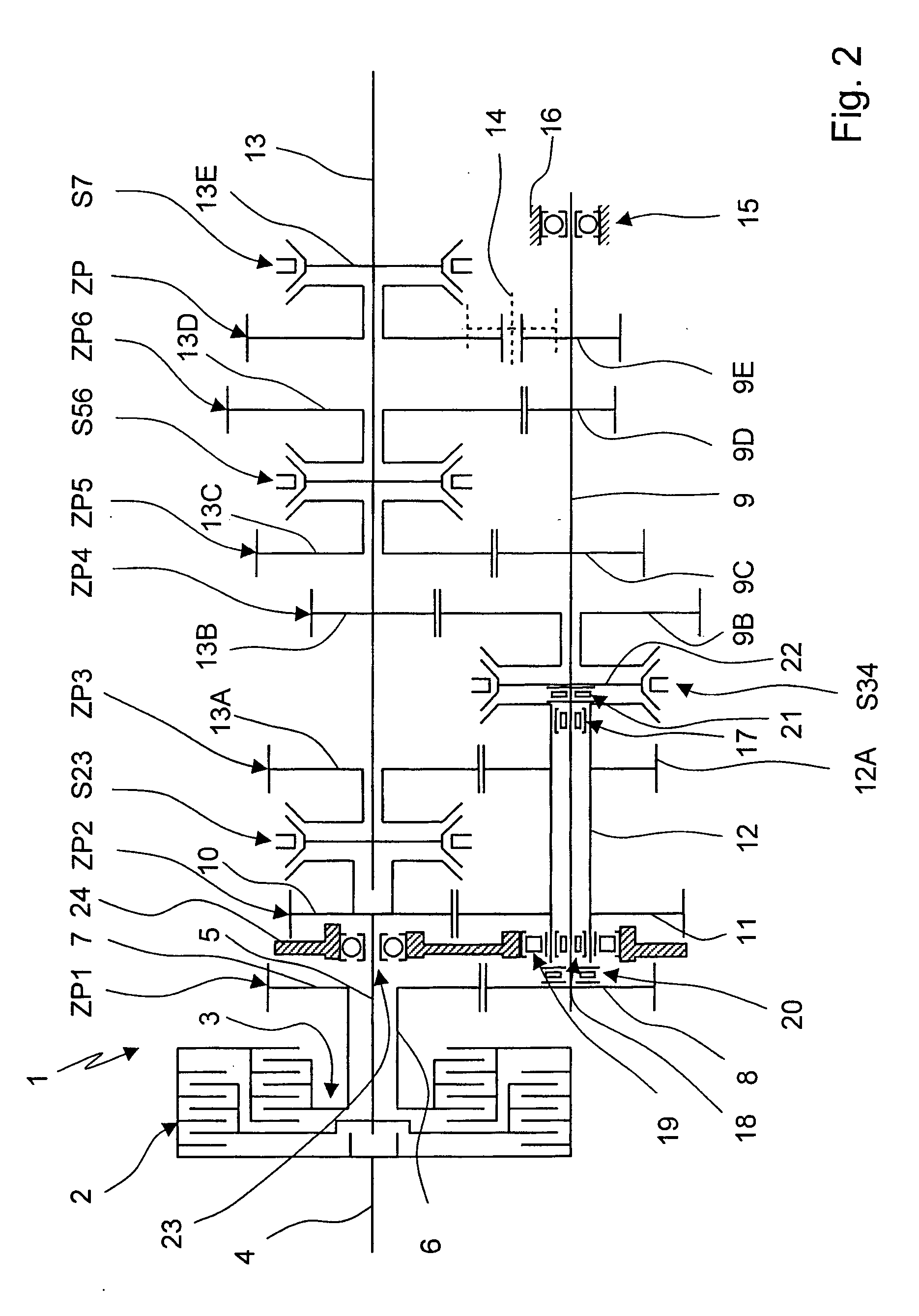

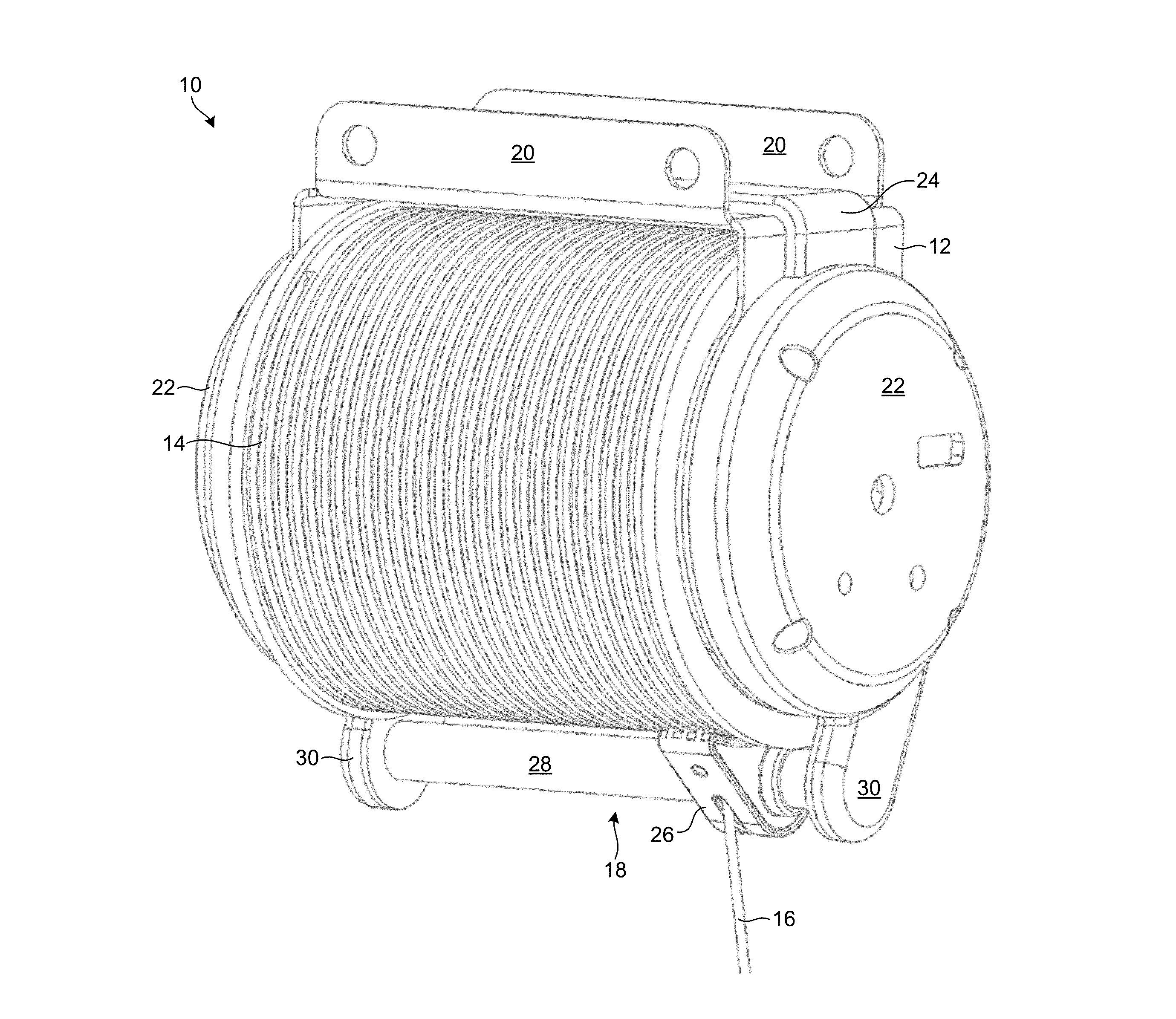

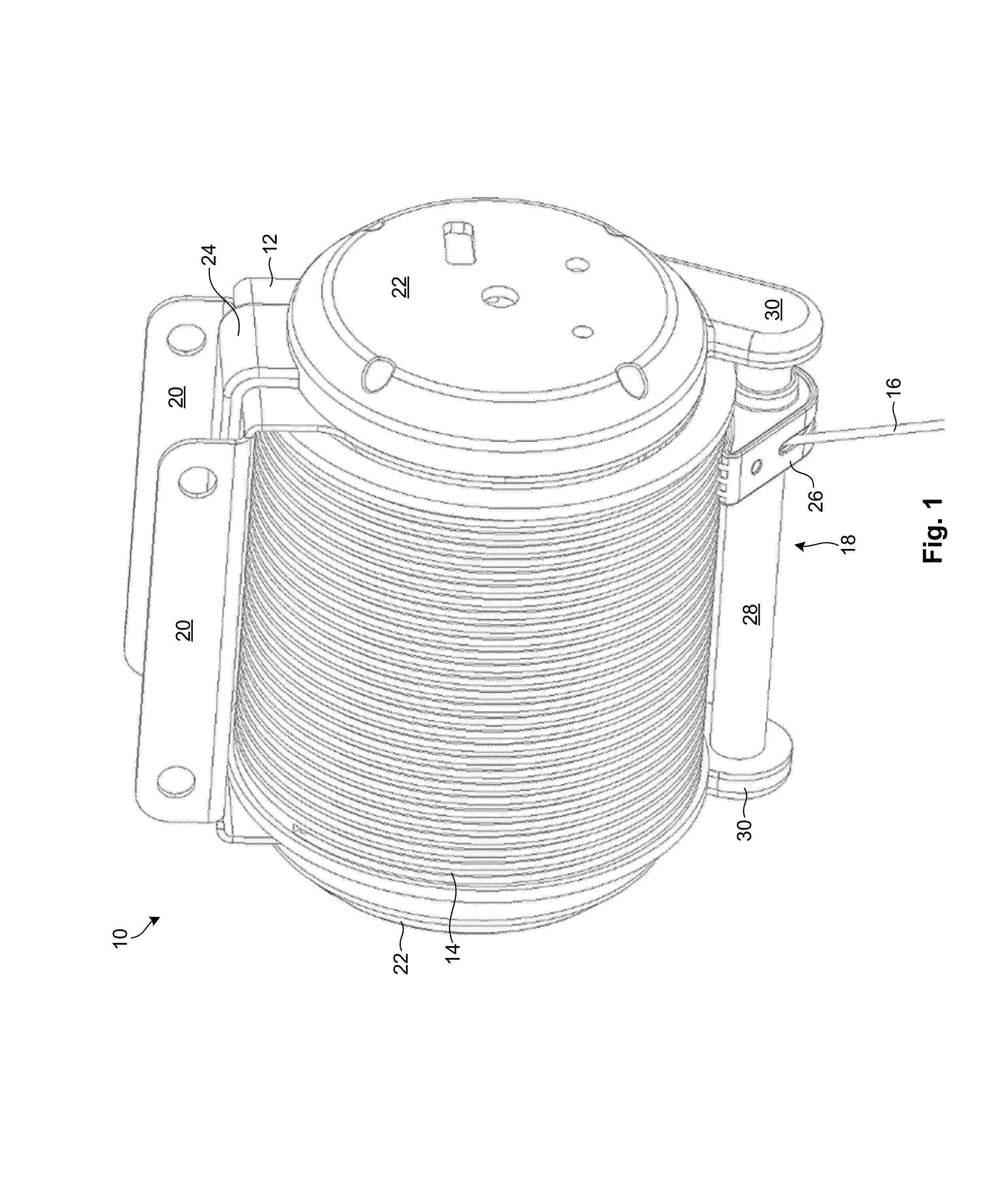

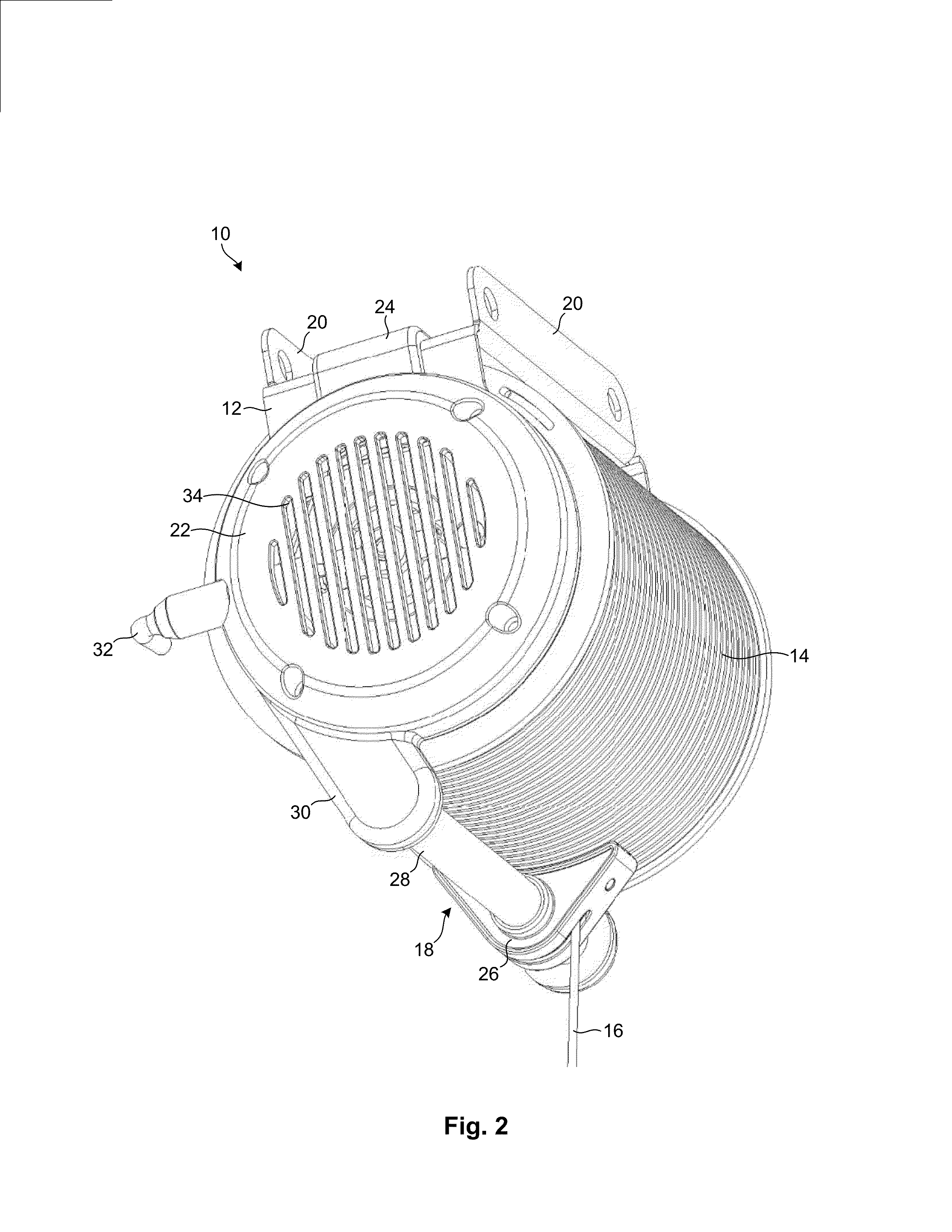

Synchronized Motorized Lifting Devices for Lifting Shared Loads

ActiveUS20150284225A1Reduce gear ratioPrevent rotationLifting framesWinding mechanismsLine tubingIndustrial engineering

A system includes multiple lifting devices, where each lifting device includes a drum to draw in or let out a line, and a motor and transmission coupled to the drum to apply a torque thereto. A grouping module is provided to group the lifting devices for synchronized operation. A synchronization module monitors an amount of line that is drawn in or let out from each of the lifting devices and, based on the amount, adjusts operating parameters (e.g., position, speed, etc.) of one or more of the lifting devices in the group to substantially synchronize the amount of line drawn in or let out with other lifting devices in the group.

Owner:HALL LABS LLC

Multistep transmission of a layshaft type

InactiveUS20060048593A1Easy to installReduce gear ratioRolling contact bearingsToothed gearingsPower flowGear wheel

A multi-speed transmission of countershaft design having a main countershaft and a hollow countershaft arranged concentrically and having likewise two load-shift elements. A first half of the shift elements is connected with a drive unit and a second half of the shift elements is connected to a gearbox input shaft. The gearbox input shafts and countershafts are mounted in a housing and connected to gear wheels, which intermesh in pairs as gear wheel pairs and can be connected or disconnected in order to reduce the overall gear ratio in the power flow. The main countershaft is mounted directly on the housing in the area of its first end and in the hollow countershaft in the area of its second end. The hollow countershaft is mounted in the housing in the area of its end that faces toward the end of the main countershaft that is mounted in the hollow countershaft.

Owner:ZF FRIEDRICHSHAFEN AG

Load Distribution Management for Groups of Motorized Lifting Devices

ActiveUS20150284226A1Reduce gear ratioPrevent rotationSemiconductor/solid-state device manufacturingLifting framesSimulationComputer module

A system includes multiple lifting devices, where each lifting device includes a drum to draw in or let out a line, and a motor and transmission coupled to the drum to apply a torque thereto. A grouping module groups the lifting devices for synchronized operation in lifting a shared load. A load distribution management module monitors an amount of weight carried by each of the grouped lifting devices and provides feedback to a user to enable more optimal distribution of the shared load amongst the grouped lifting devices.

Owner:HALL LABS LLC

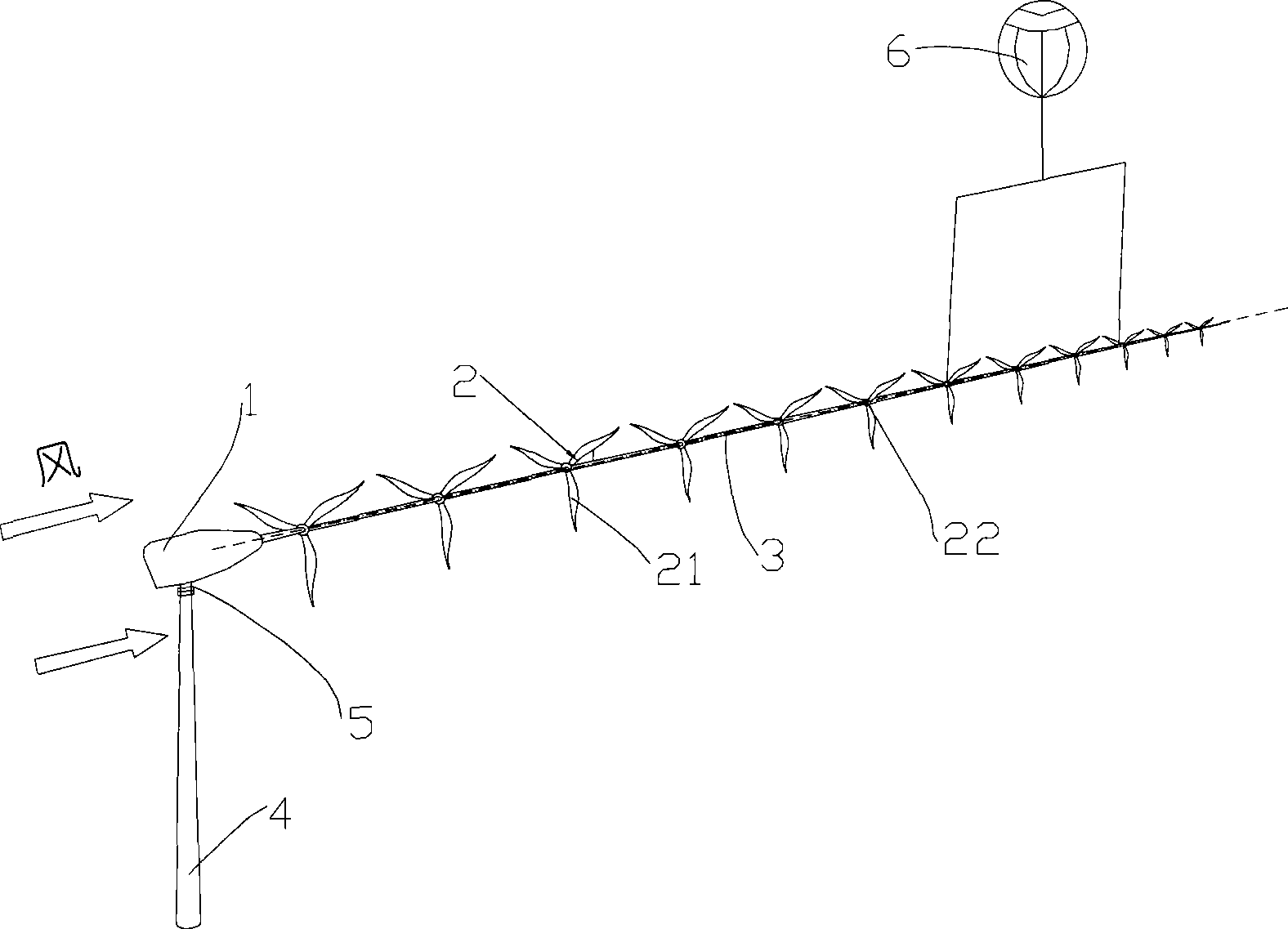

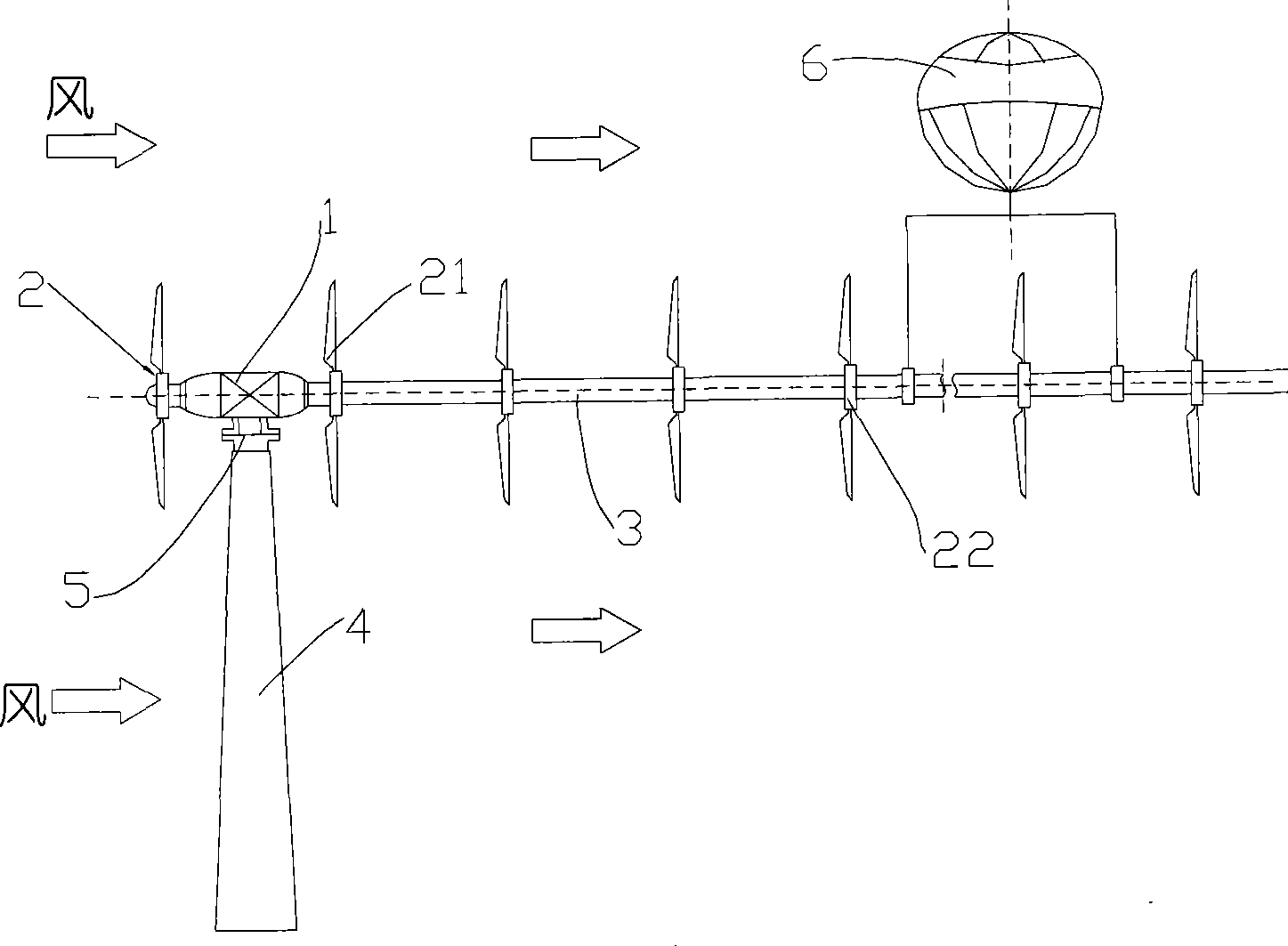

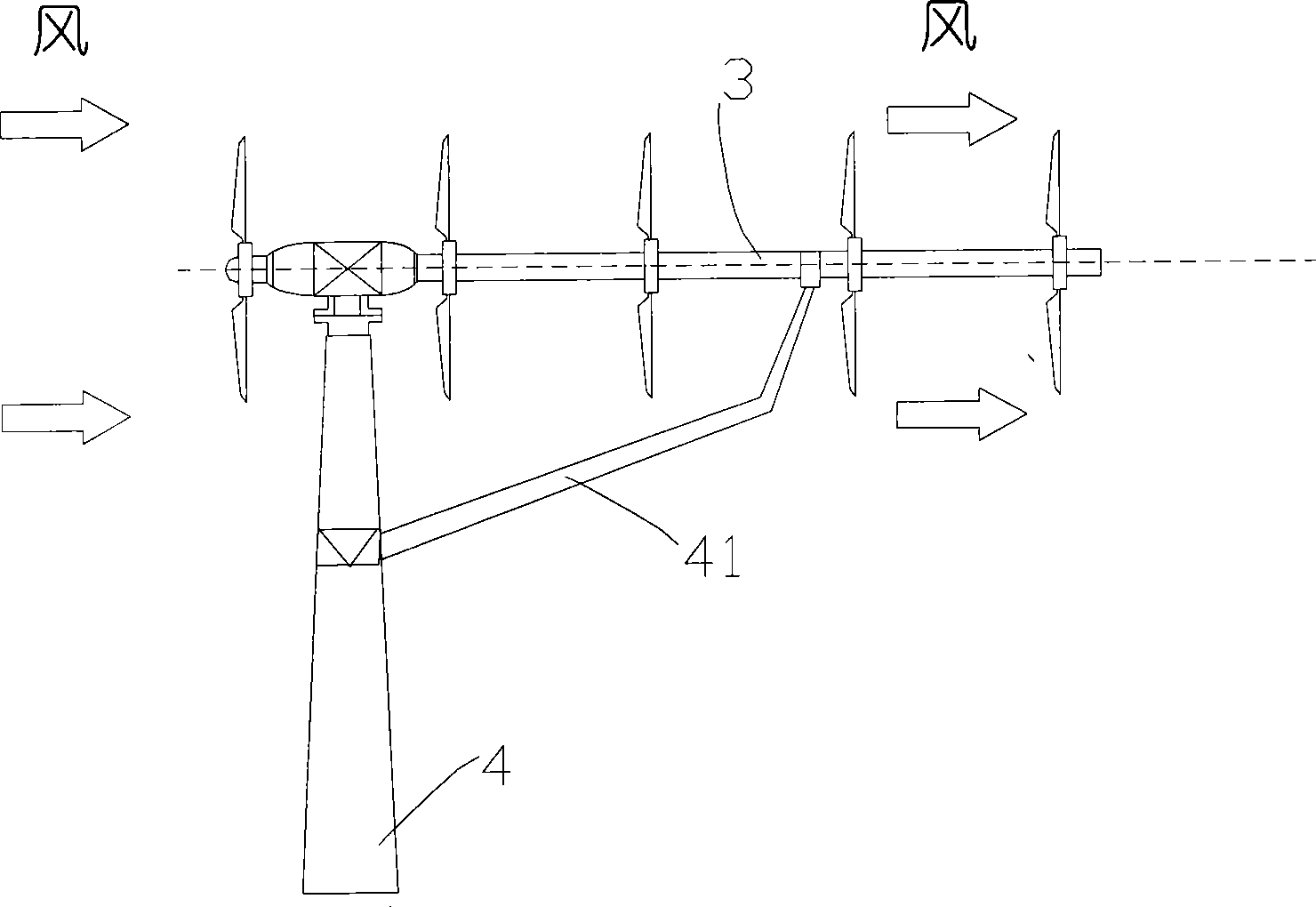

Wind generator system

InactiveCN101446270AImprove economyEase of mass productionFinal product manufactureWind motor supports/mountsDrive shaftTower

The invention discloses a wind generator system which comprises a tower, a generator assembly which is arranged on the tower, a transmission shaft which is connected with the generator assembly, and multi-stage wind wheels which are movably arranged and spaced along the axial direction of the transmission shaft. The multi-stage wind wheels with small blades are arranged on the same shaft to replace a single wind wheel with huge blades, thus overcoming various disadvantages which are caused by huge blades of the existing huge wind generator, enhancing wind energy utilization efficiency, and universality and economical efficiency of the application of the wind electric power generation. In addition, for the generators with the same power, decrease of diameter of the wind wheels causes corresponding increase of rotation speed of the wind wheels so that transmission ratio of a gear box is reduced, manufacturing and installation cost of the gear box is reduced, which can further enhance economical efficiency of the generator system. The system has the advantages of low cost, high wind energy utilization ratio, convenient and easy manufacture, installation and maintenance, wide application field range, and can greatly reduce the diameter and whole size of the wind wheels of the existing big and small wind generators to facilitate transportation.

Owner:刘运科

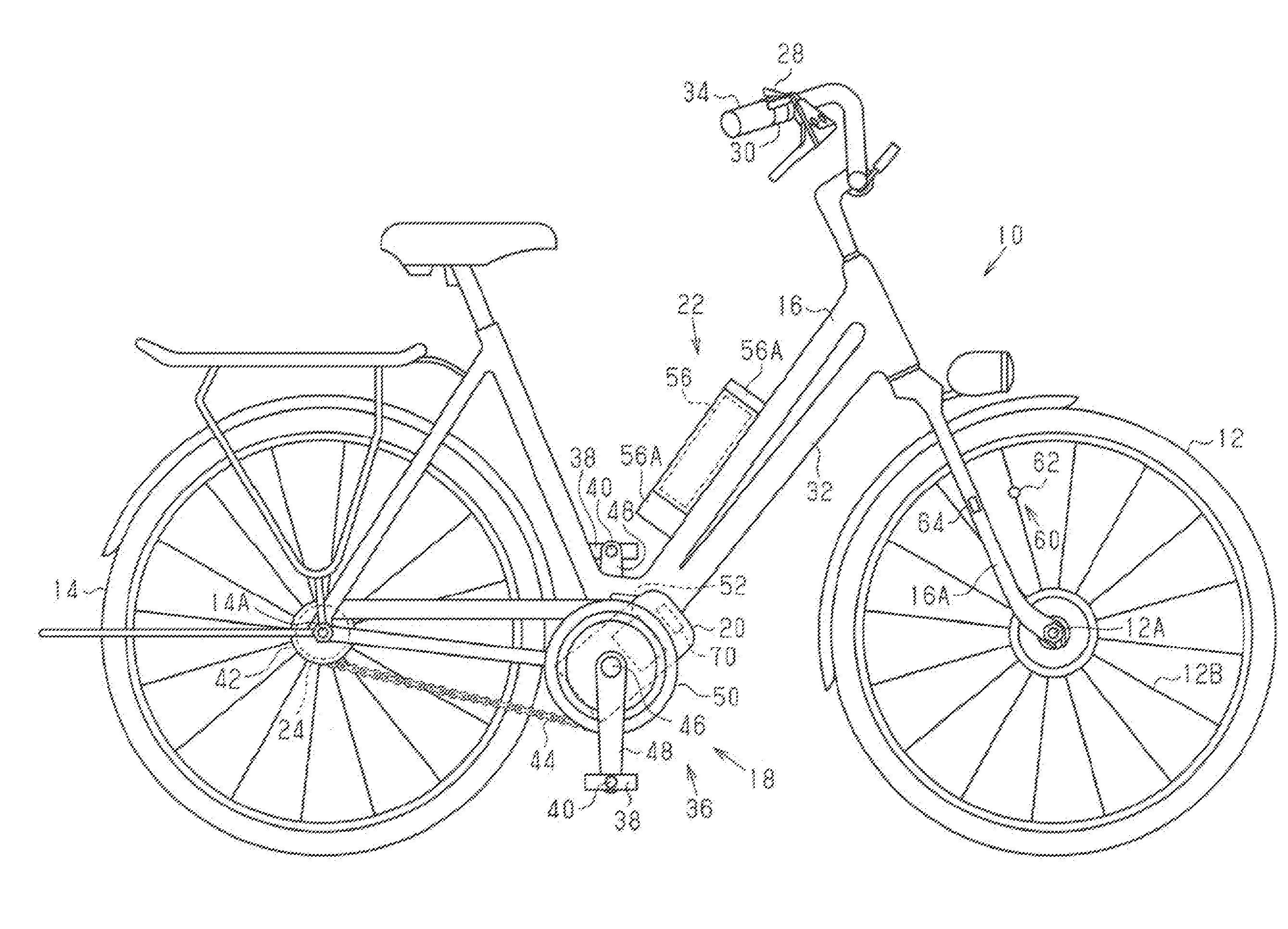

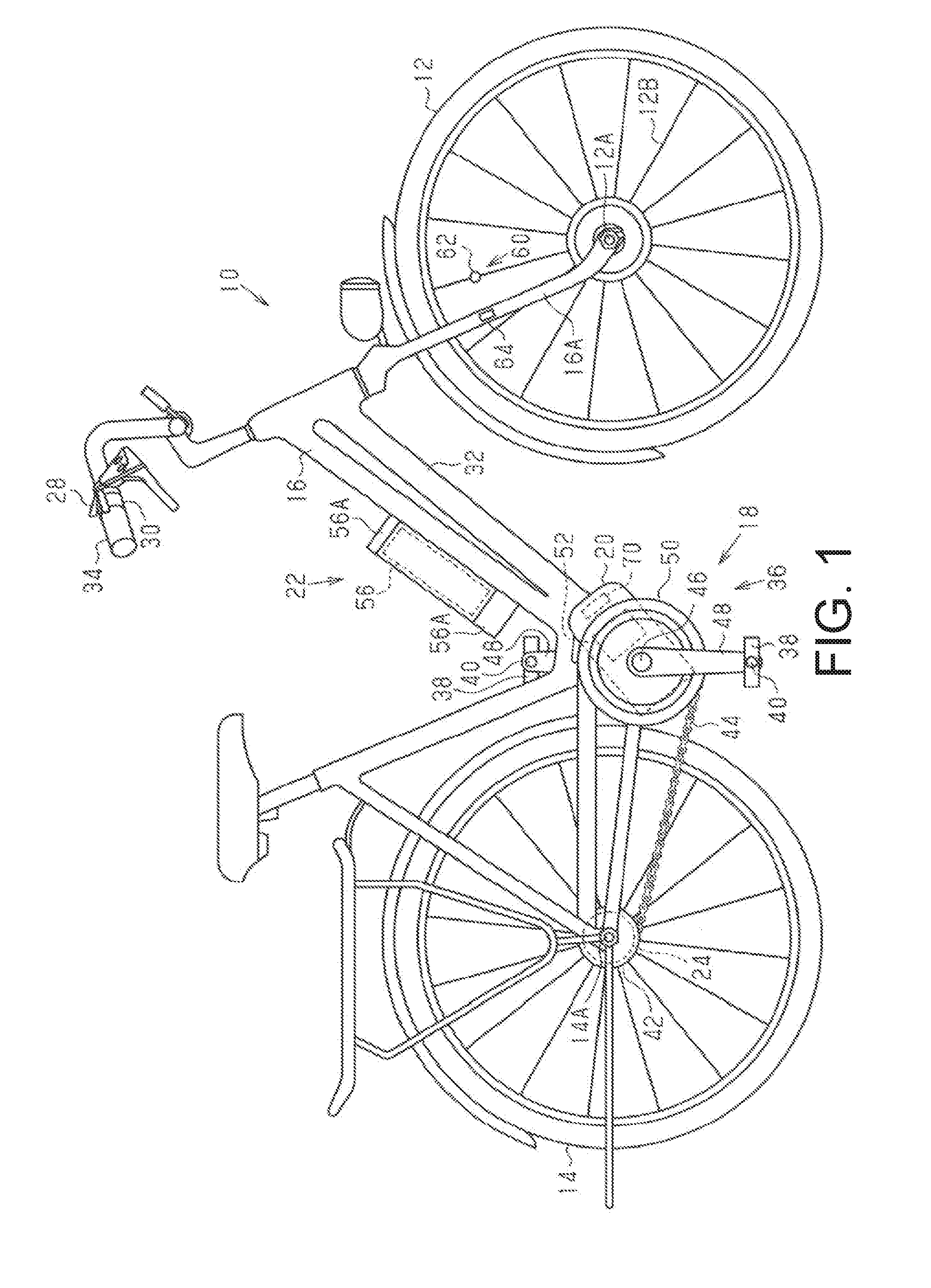

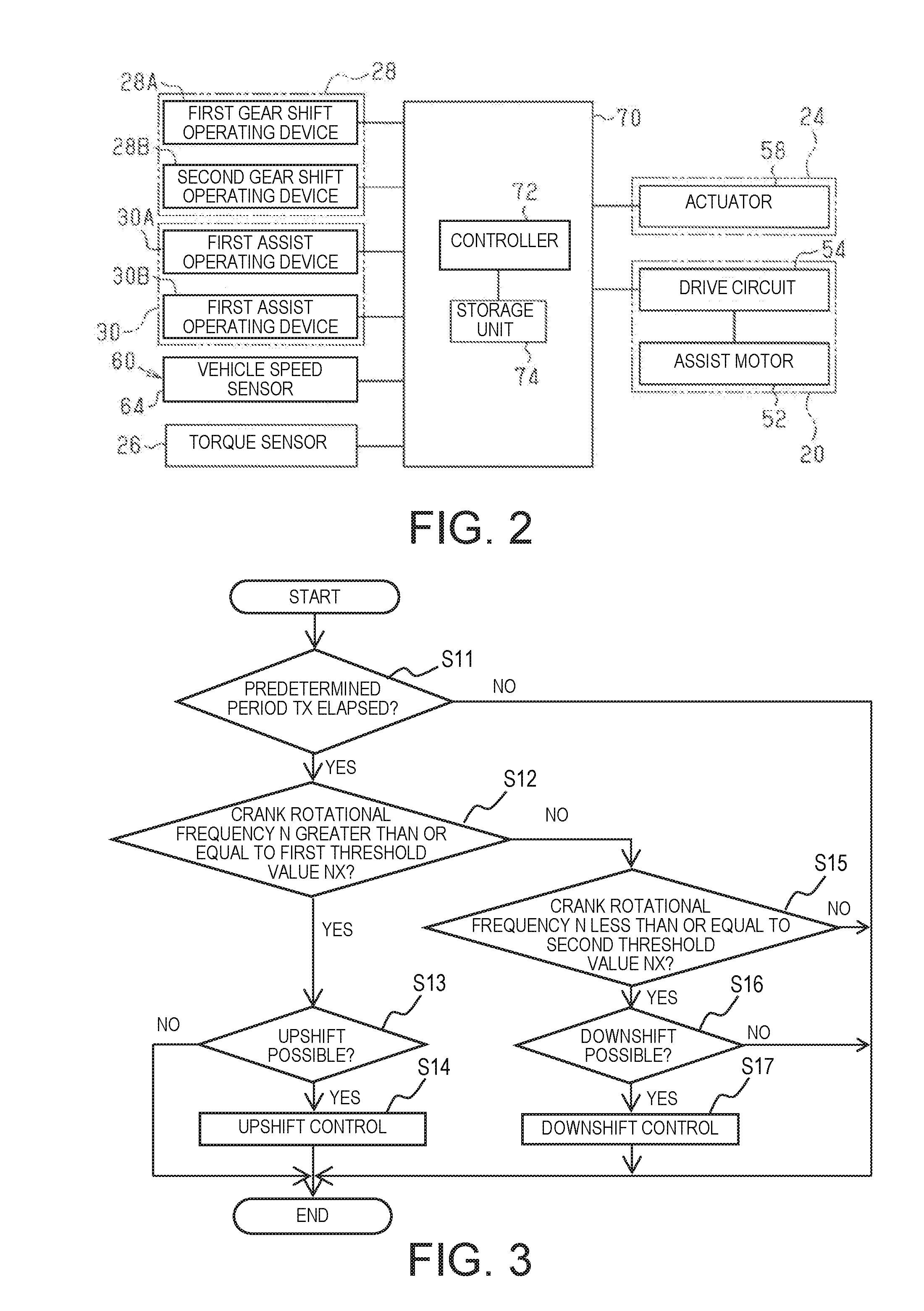

Bicycle control system

ActiveUS20170001687A1Easy to controlIncrease gear ratioWheel based transmissionChain/belt transmissionState dependentOperating point

A bicycle control system is provided that is configured to control a bicycle component using a threshold value that is appropriate for the rider. The bicycle control system includes a controller for controlling a bicycle component based on a threshold value and a parameter related to a running state of a bicycle. The controller changes the threshold value when an operating unit is operated, and the change amount of the threshold value when the operating unit is operated is determined based on an operating state of the operating unit.

Owner:SHIMANO INC

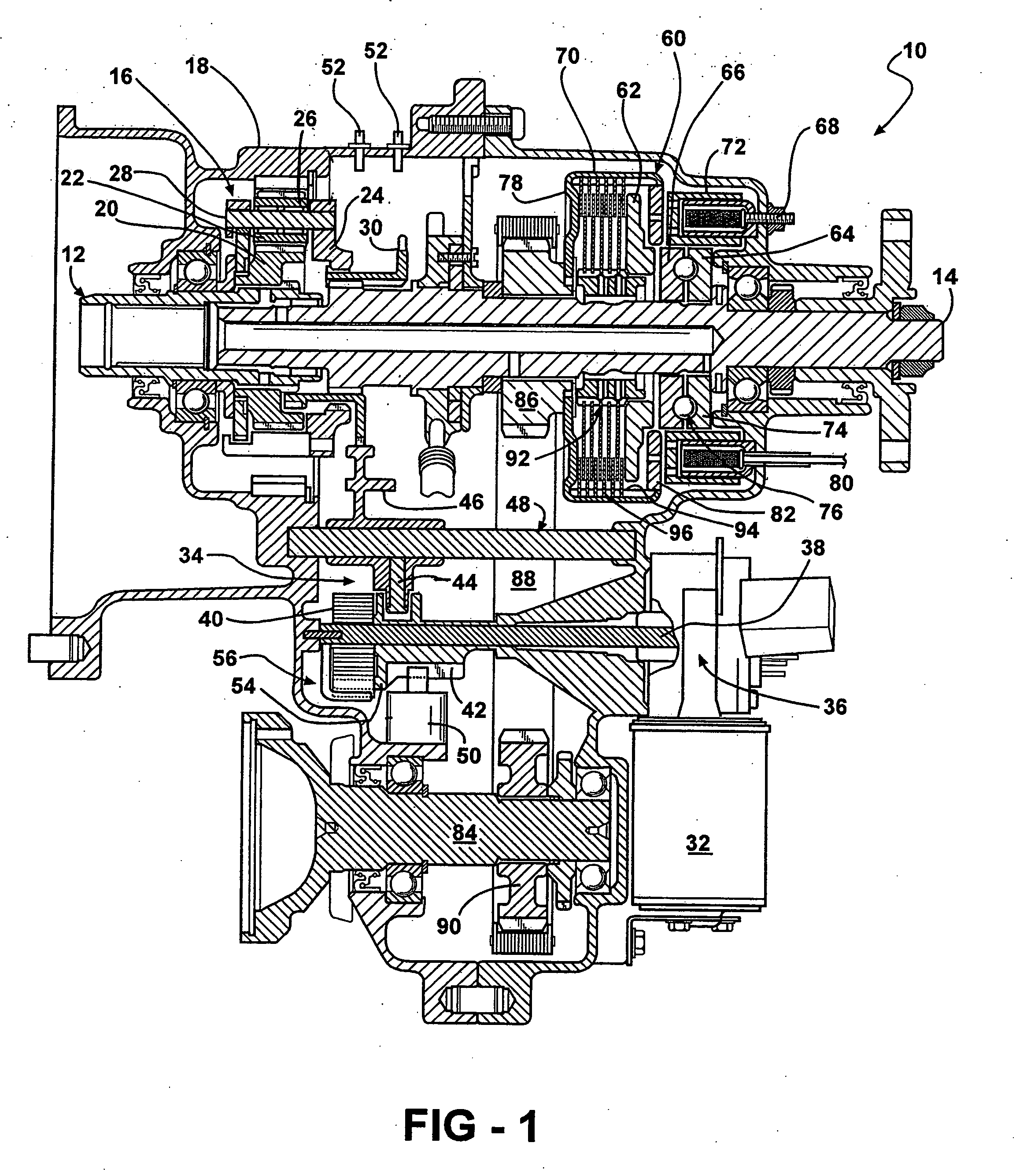

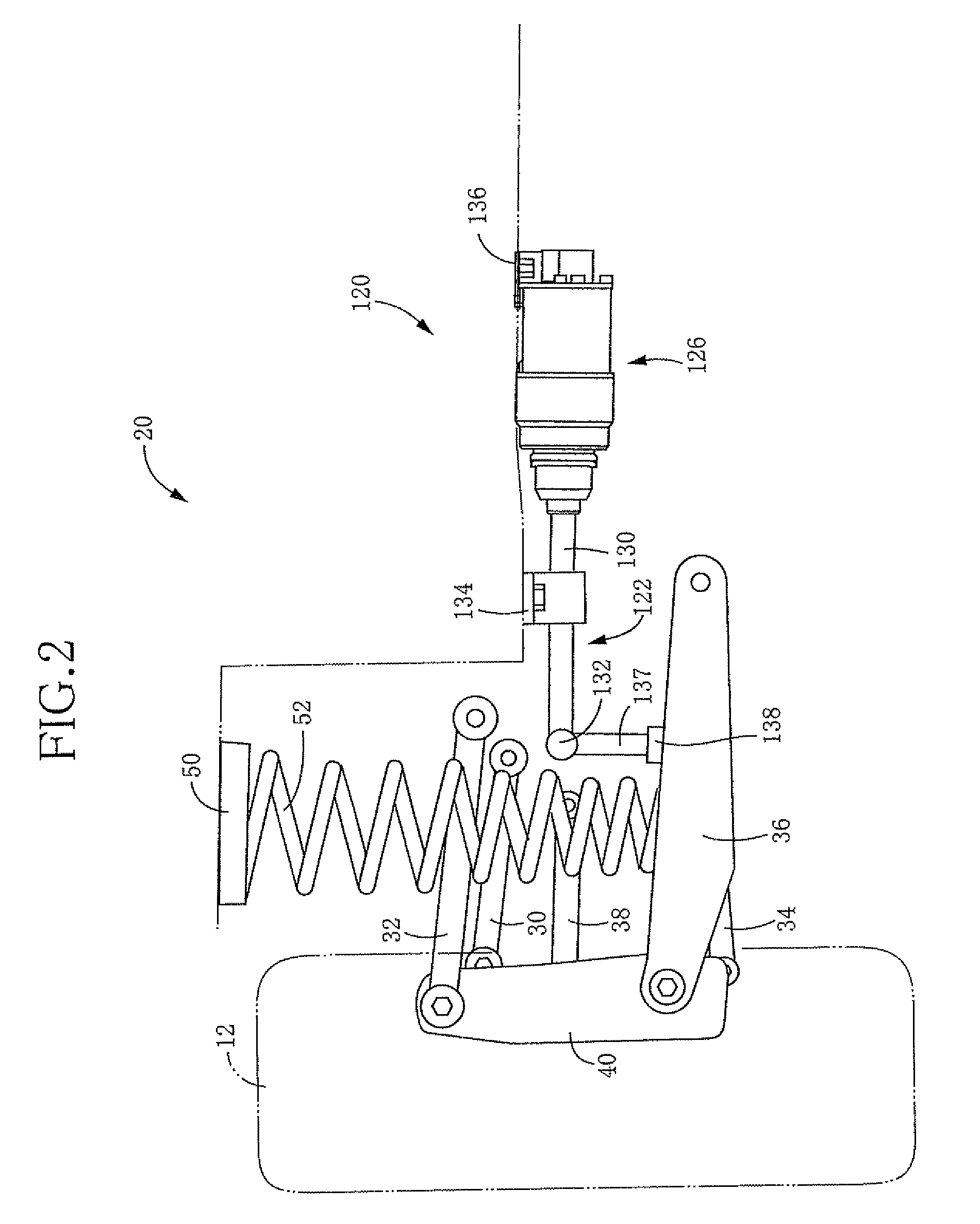

Electric shift transfer case

A shift fork restrictor operably disposed in a transfer case for the purpose of allowing the shift motor to transfer energy to the currently existing double wound spring, where the energy is stored until the shift motor sensor indicates that the motor is in the proper range location. When the motor is in the proper range location, the stored energy in the spring is released by the shift fork restrictor releasing the cam allowing for maximum torque and speed to be provided through the secondary rail, cam, and shift fork to complete the requested range shift. This configuration can be used to, among other things, select a high or low range in the transfer case, as well as couple the input and output shafts together, which have different gear ratios.

Owner:BORG WARNER INC

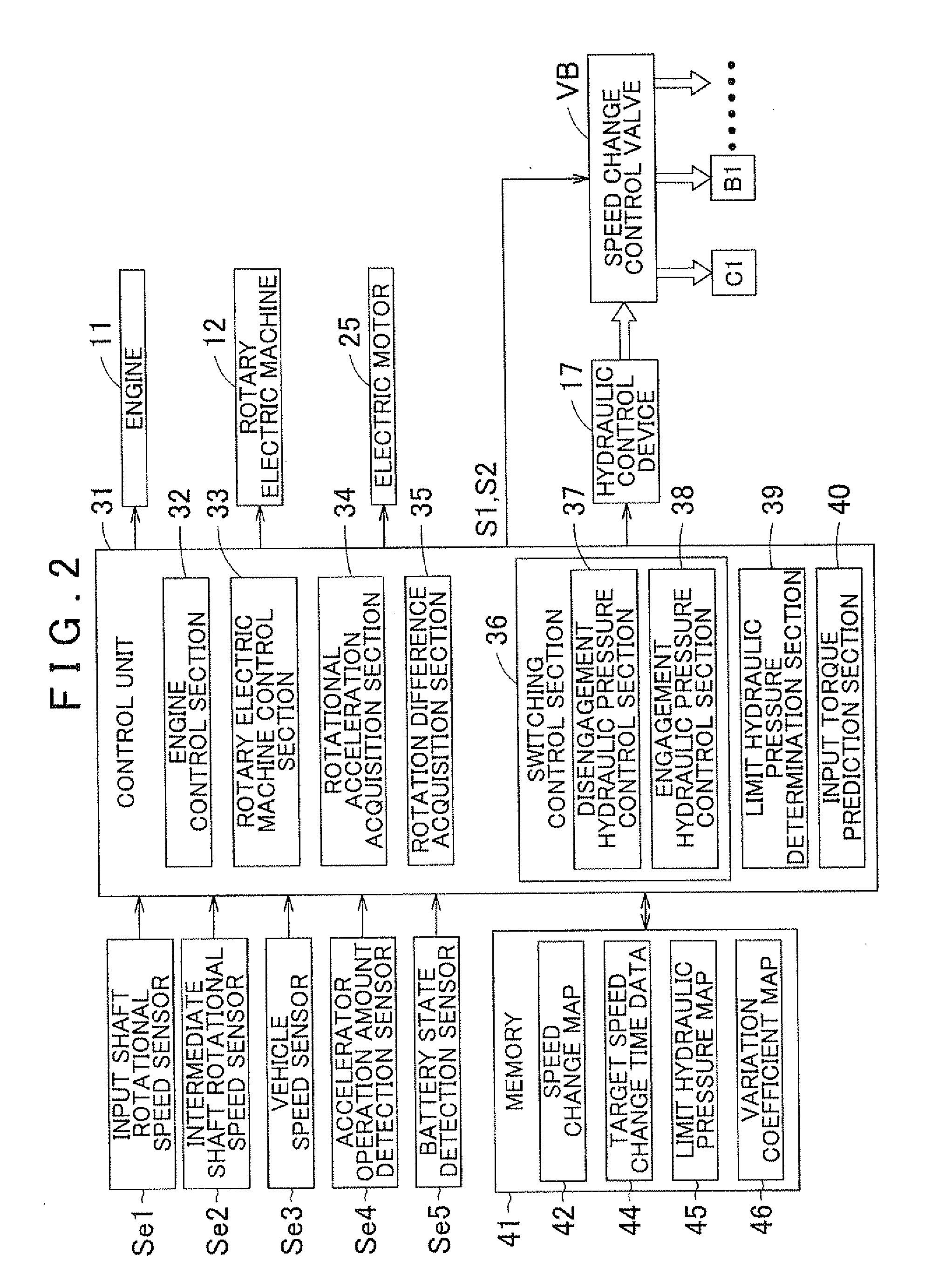

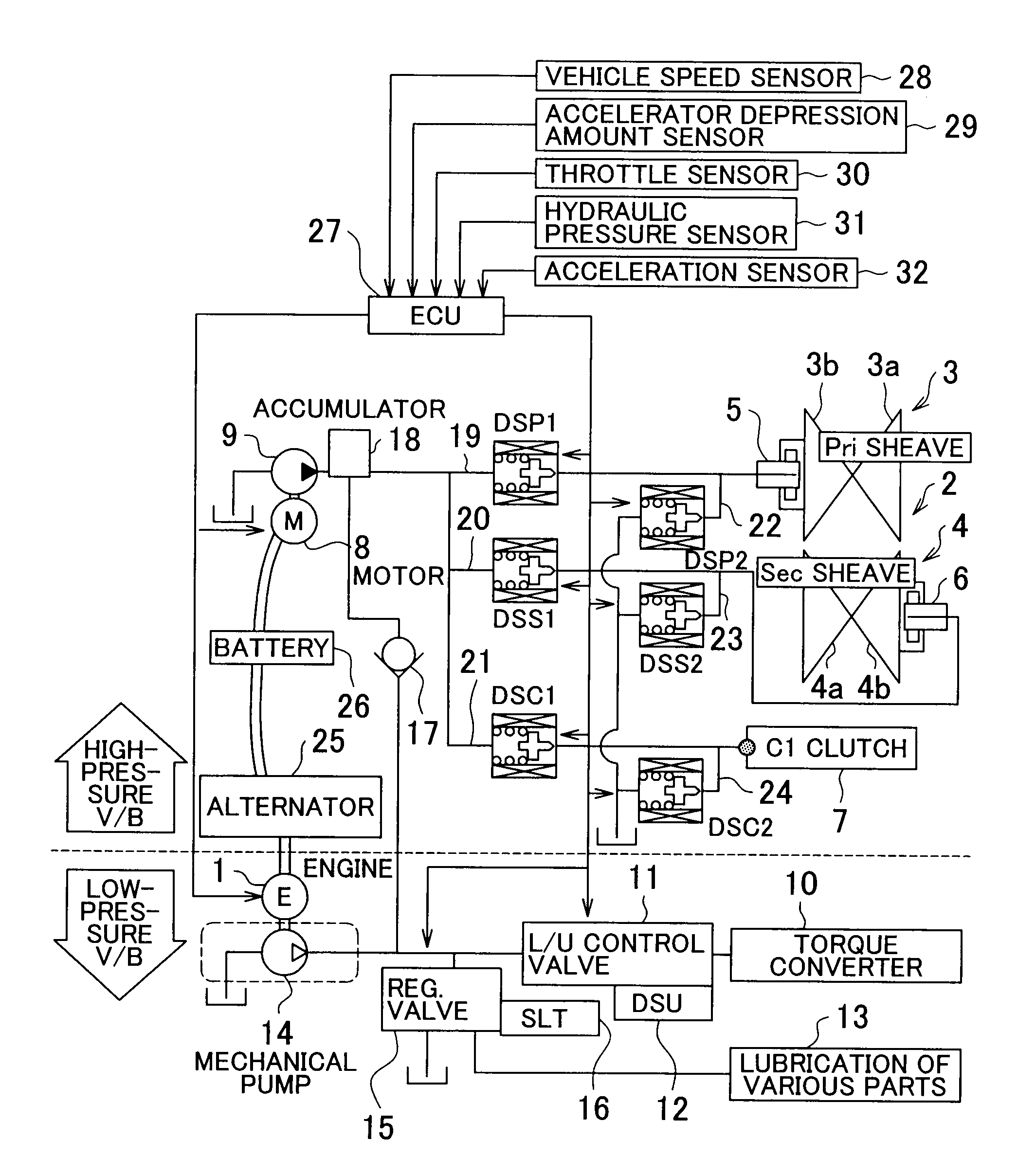

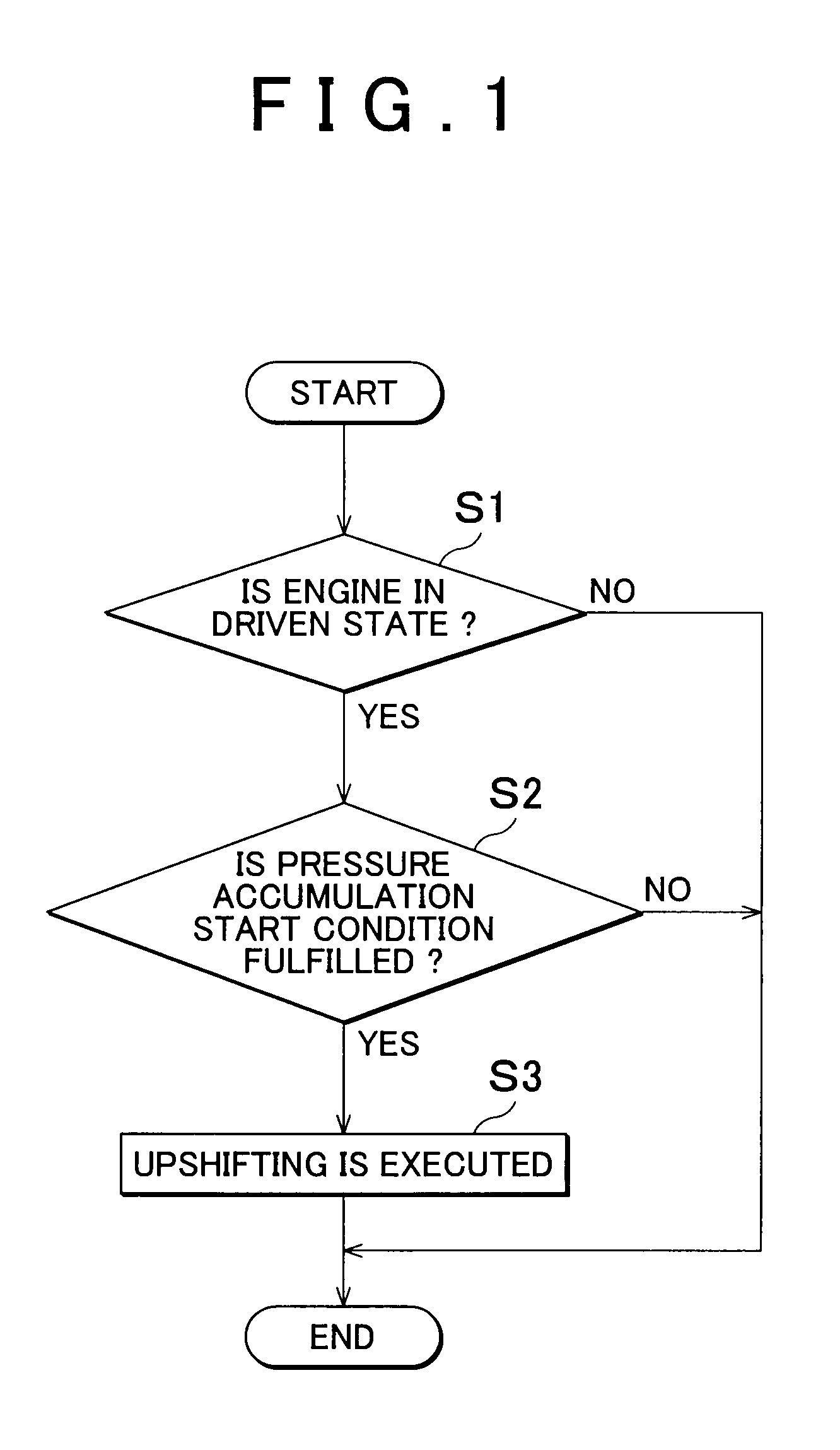

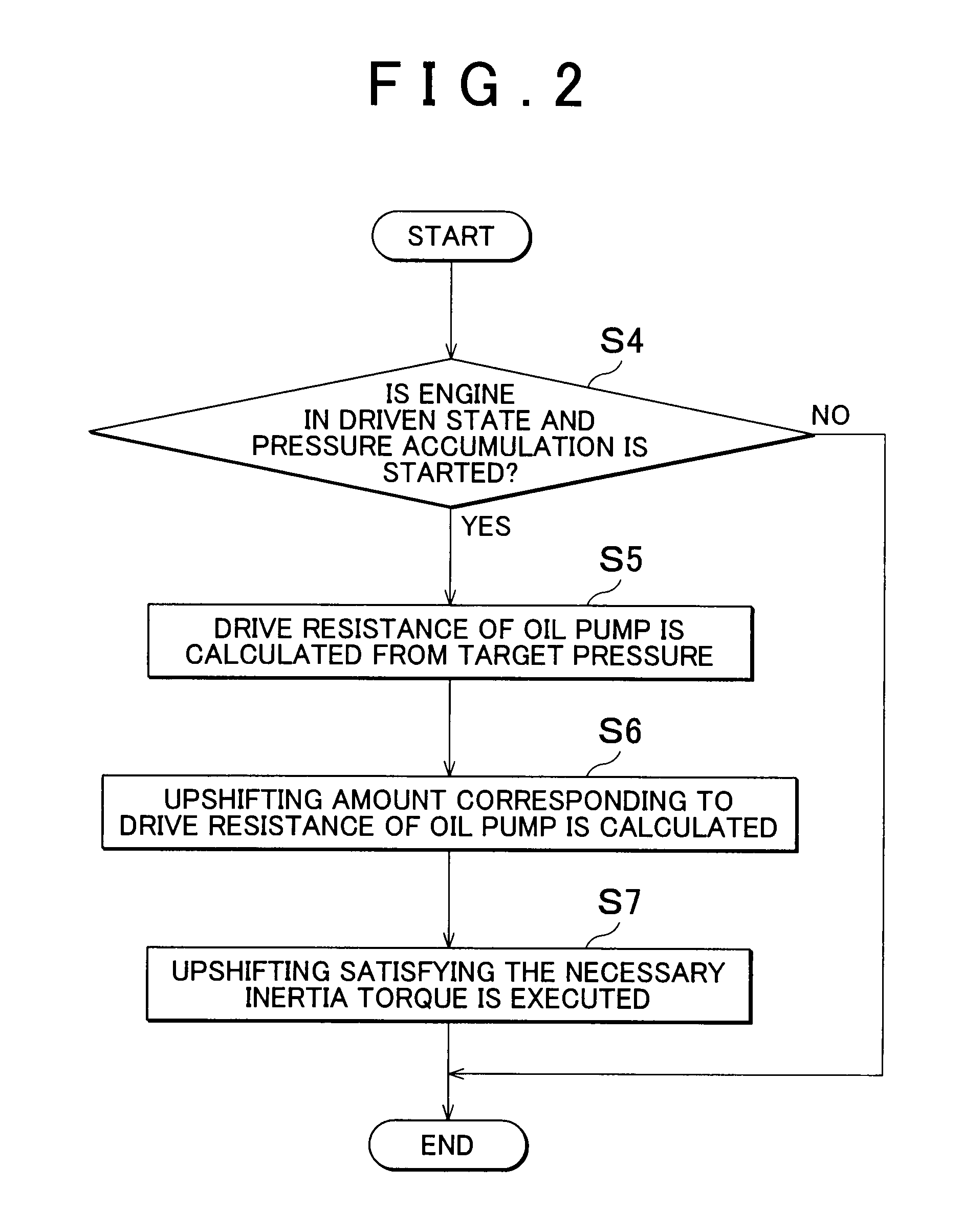

Shift controller and shift control method for automatic transmission mechanism

InactiveUS20100210413A1Reduce gear ratioReduce hydraulic pressureFluid couplingsRoad transportAutomatic transmissionHydraulic pump

A shift controller for an automatic transmission mechanism is configured such that when the engine is in a driven state in which the engine is driven by a travel inertia force or the like and an accumulated pressure amount of the accumulator is equal to or less than a predetermined threshold, the excessive engine brake force, which is generated due to the accumulation of at least a portion of the hydraulic pressure generated from the mechanical hydraulic pump in the accumulator, is inhibited or reduced by conducting upshifting that relatively decreases the gear ratio of the automatic transmission mechanism. Therefore, the generation of the excessive engine brake force can be inhibited or reduced even when the engine is in the driven state and pressure accumulation is performed.

Owner:TOYOTA JIDOSHA KK

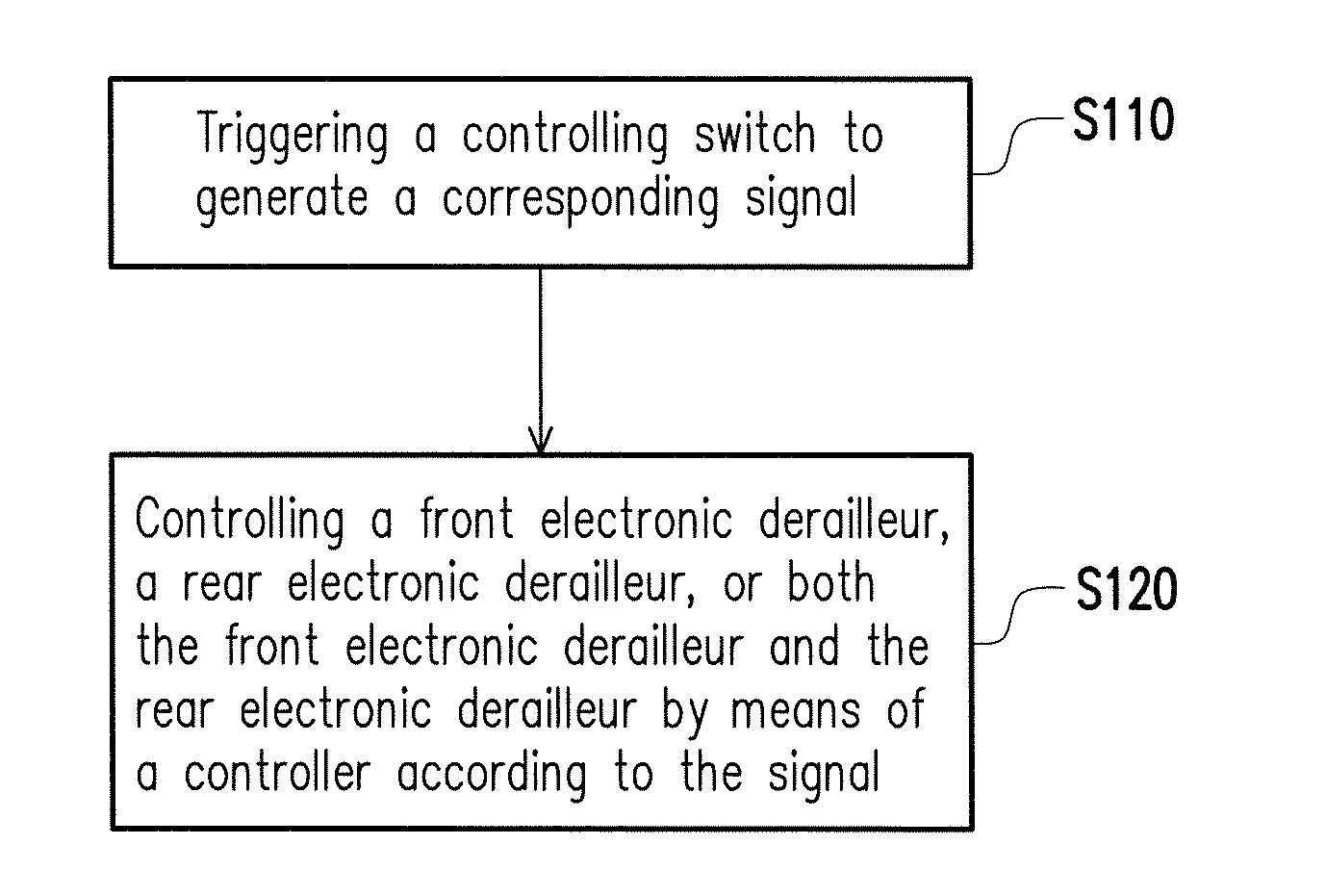

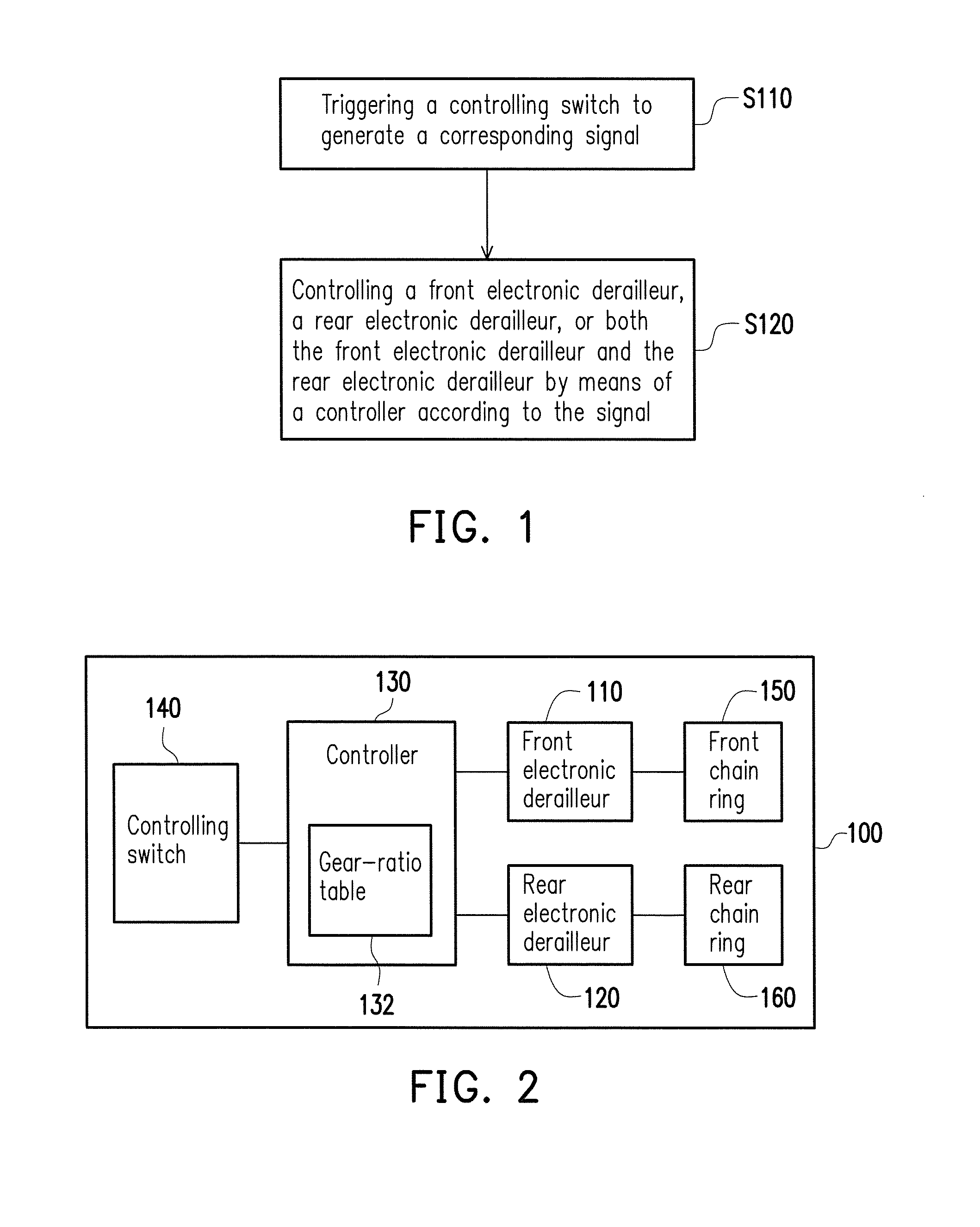

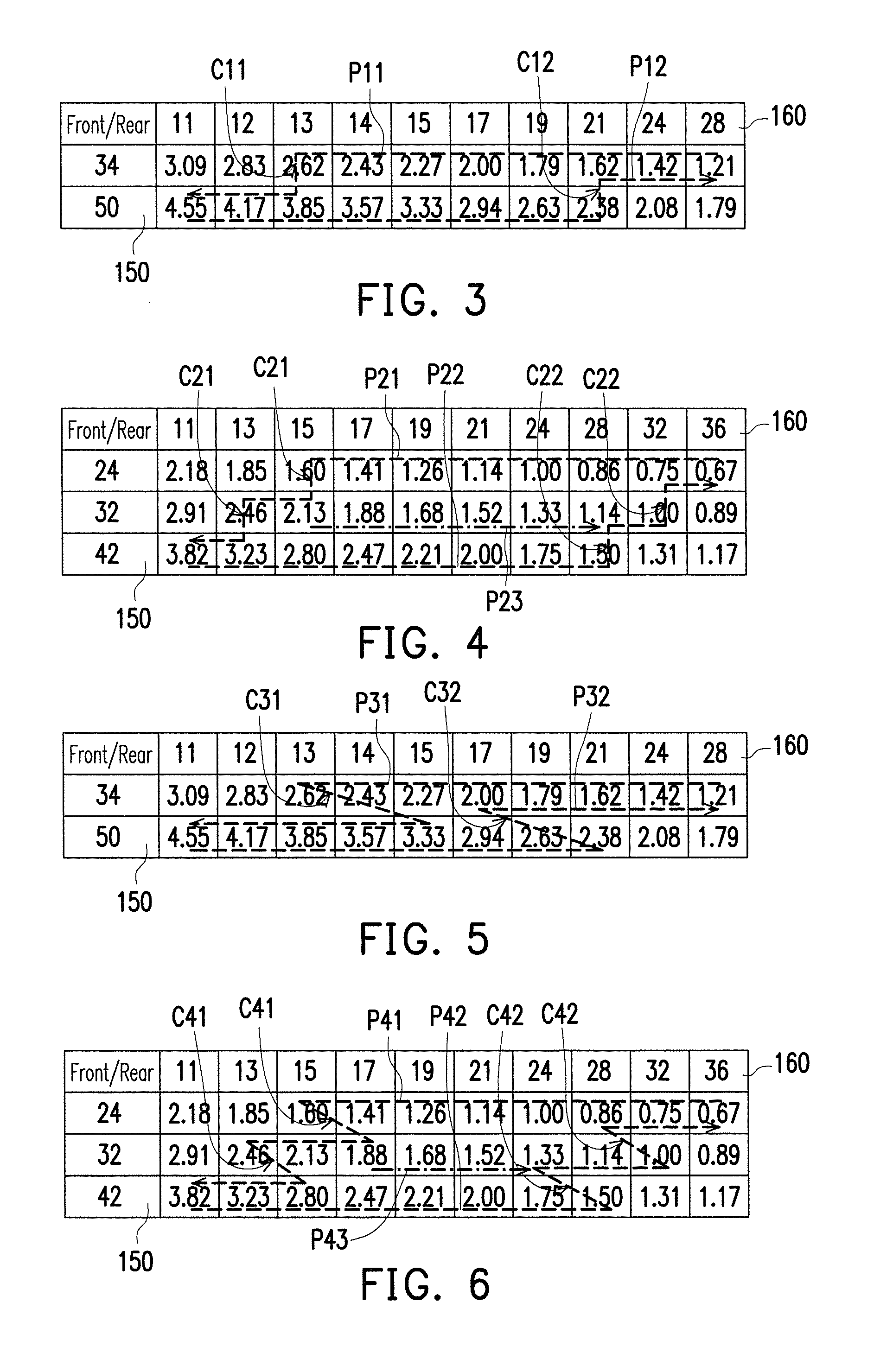

Bicycle shifting method

ActiveUS8712656B2Reduce harmGuarantee the riding comfortDigital data processing detailsGearing controlControl switchControl theory

A bicycle shifting method suitable for controlling a gear ratio of a front chain ring and a rear chain ring of the bicycle is provided. The bicycle has a front electronic derailleur, a rear electronic derailleur, a controller, and a controlling switch, and the controller stores a gear-ratio table. The bicycle shifting method includes following steps. The controlling switch is triggered to generate a corresponding signal. One or both of the electronic derailleurs are controlled by the controller according the signal. When the signal is a speed-increasing signal, the controller controls the electronic derailleurs to increase the gear ratio along a speed-increasing path of the gear-ratio table. When the signal is a laborsaving signal, the controller controls the electronic derailleurs to decrease the gear ratio along a laborsaving path of the gear-ratio table. The speed-increasing path is different from the laborsaving path.

Owner:GIANT MFG

Grooved drum and associated roller for motorized lifting device

ActiveUS9399566B2Reduce gear ratioPrevent rotationMachine supportsCycle standsEngineeringMechanical engineering

Owner:HALL LABS LLC

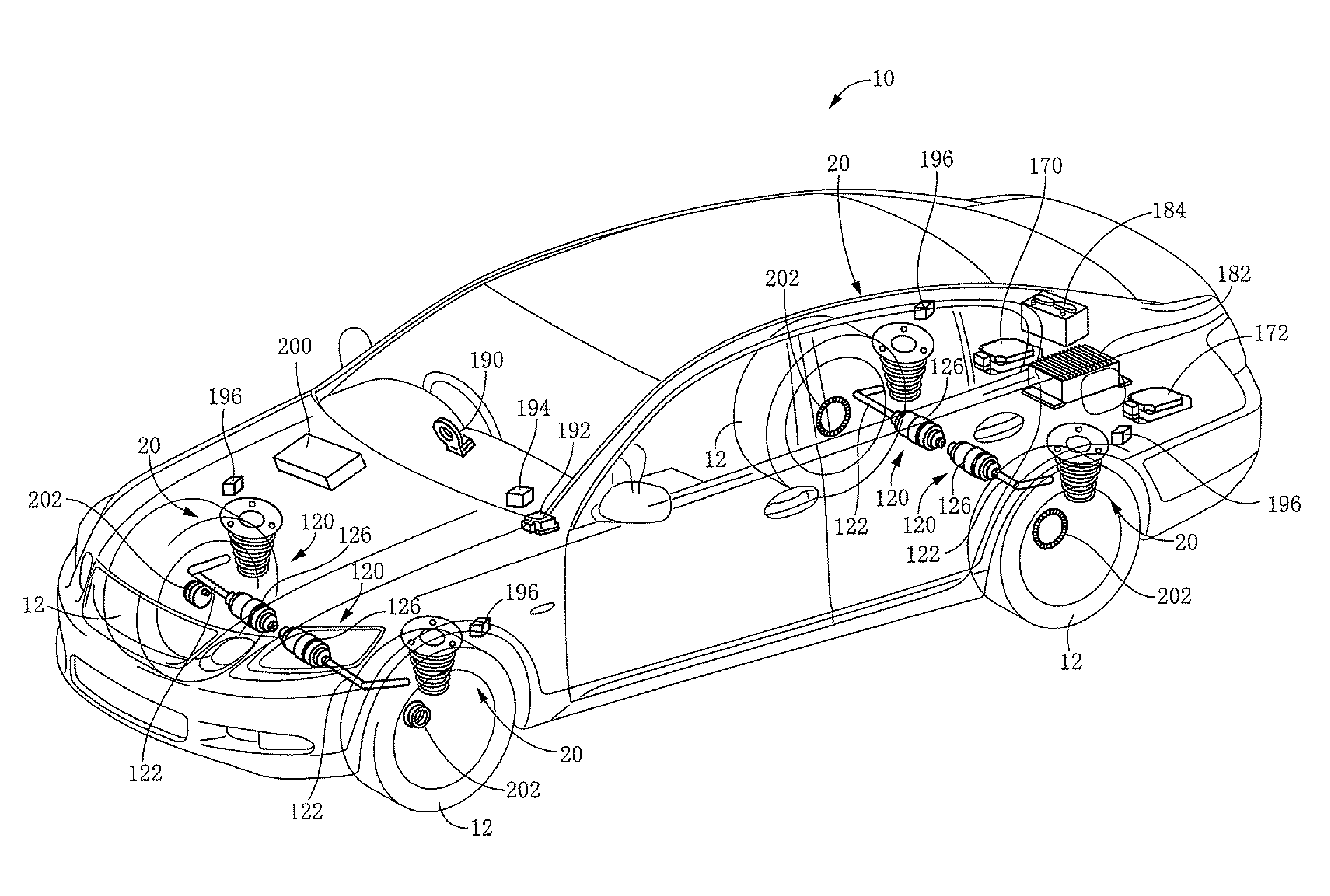

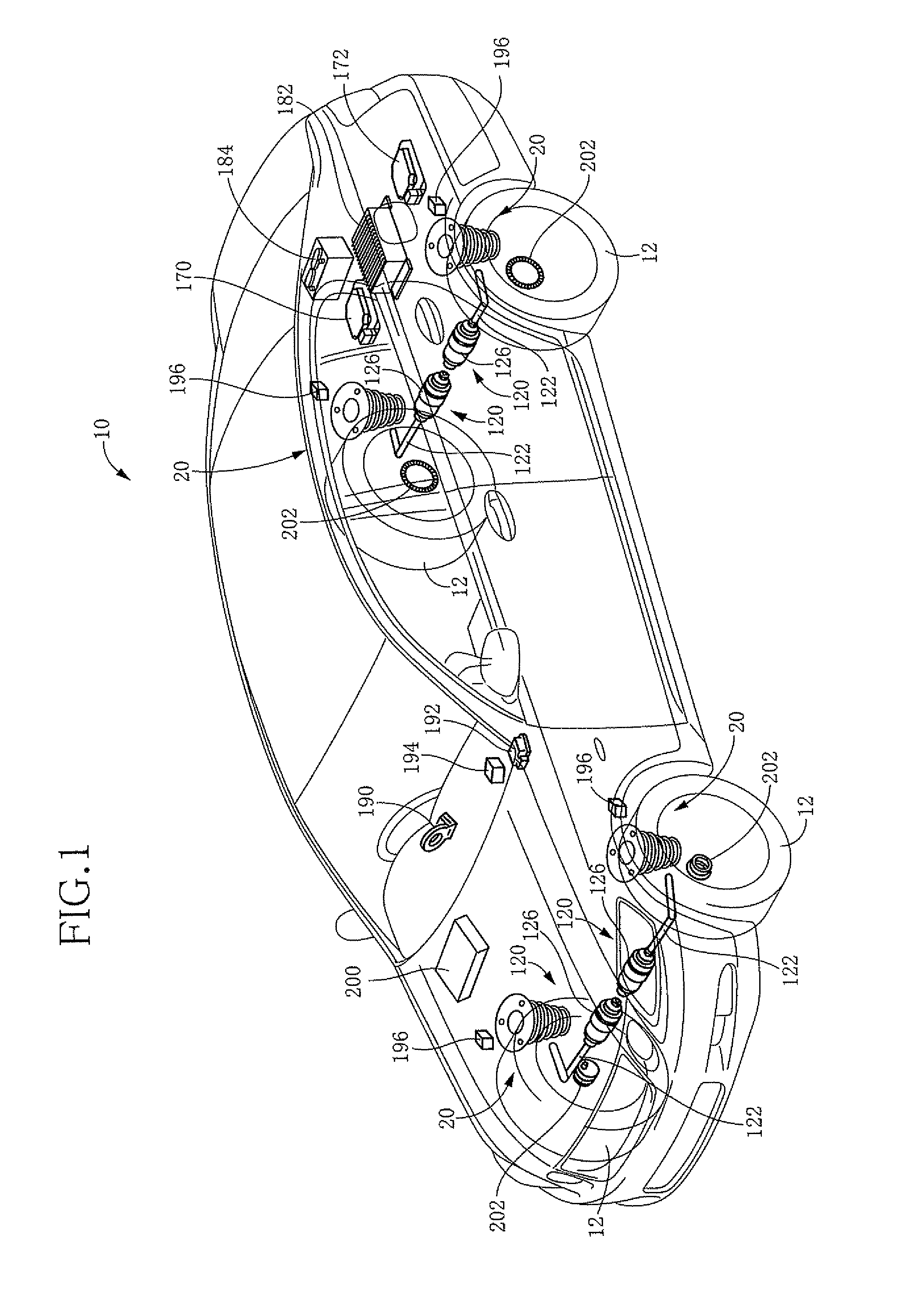

Suspension system for vehicle

InactiveUS8240679B2Reduce impactMinimizing damping forceLiquid based dampersInterconnection systemsResonanceEngineering

A suspension system for a vehicle, including: (a) a suspension spring; (b) a hydraulic damper; (c) a displacement force generator disposed in parallel with the suspension spring and the damper; and (d) a controller including a damping-force controlling portion for controlling a damping force of the damper and a displacement-force controlling portion for controlling a displacement force of the displacement force generator. The displacement-force controlling portion is configured to execute a sprung-portion vibration damping control for controlling the displacement force, such that the generated displacement force acts as a damping force against sprung-portion vibration. The damping-force controlling portion is configured, upon execution of the sprung-portion vibration damping control, to execute a damping force reducing control for reducing the damping force that is to be generated by the damper, depending on an intensity of unsprung-portion resonance frequency vibration which occurs in the vehicle and which has a resonance frequency of the unsprung portion.

Owner:TOYOTA JIDOSHA KK

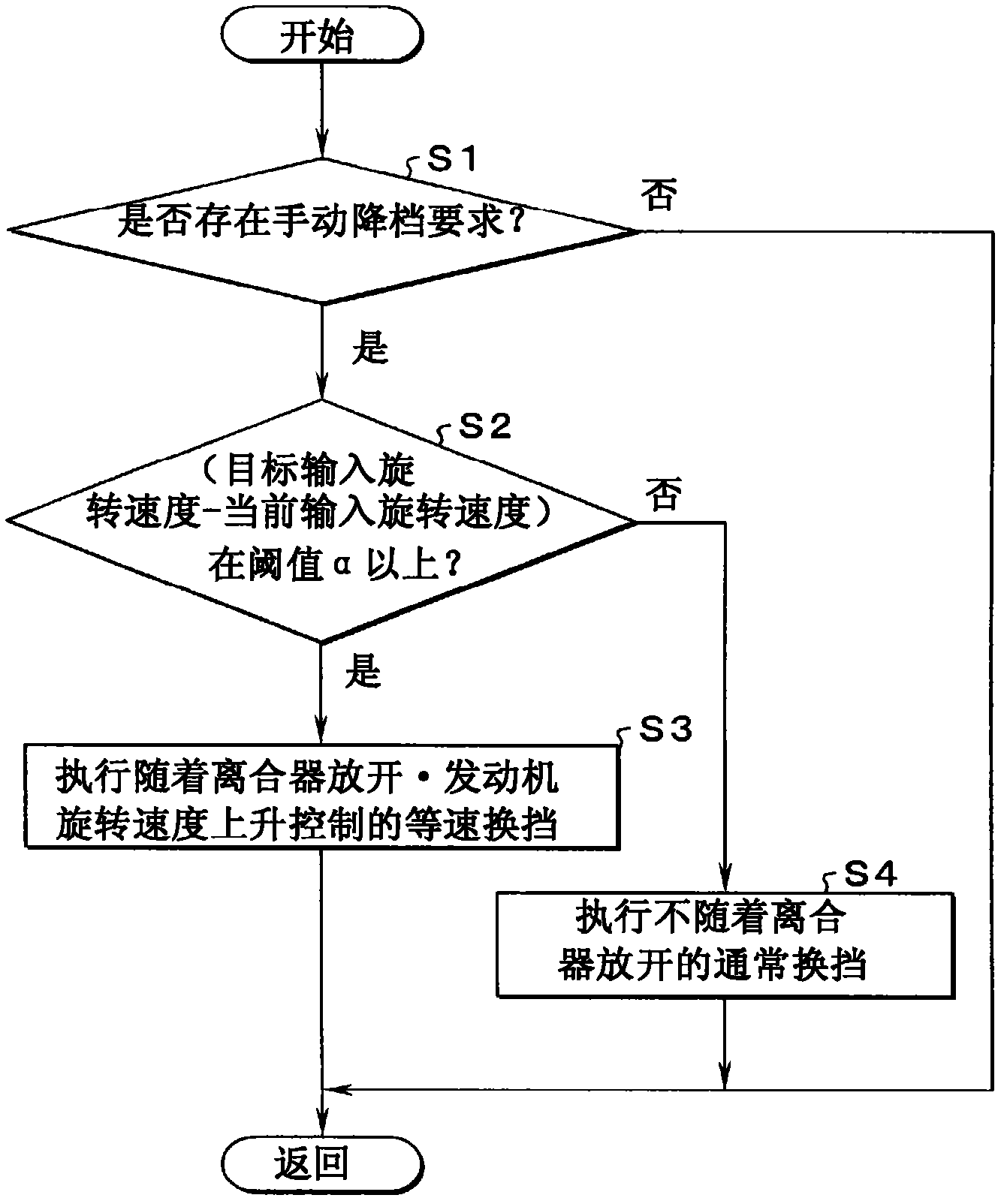

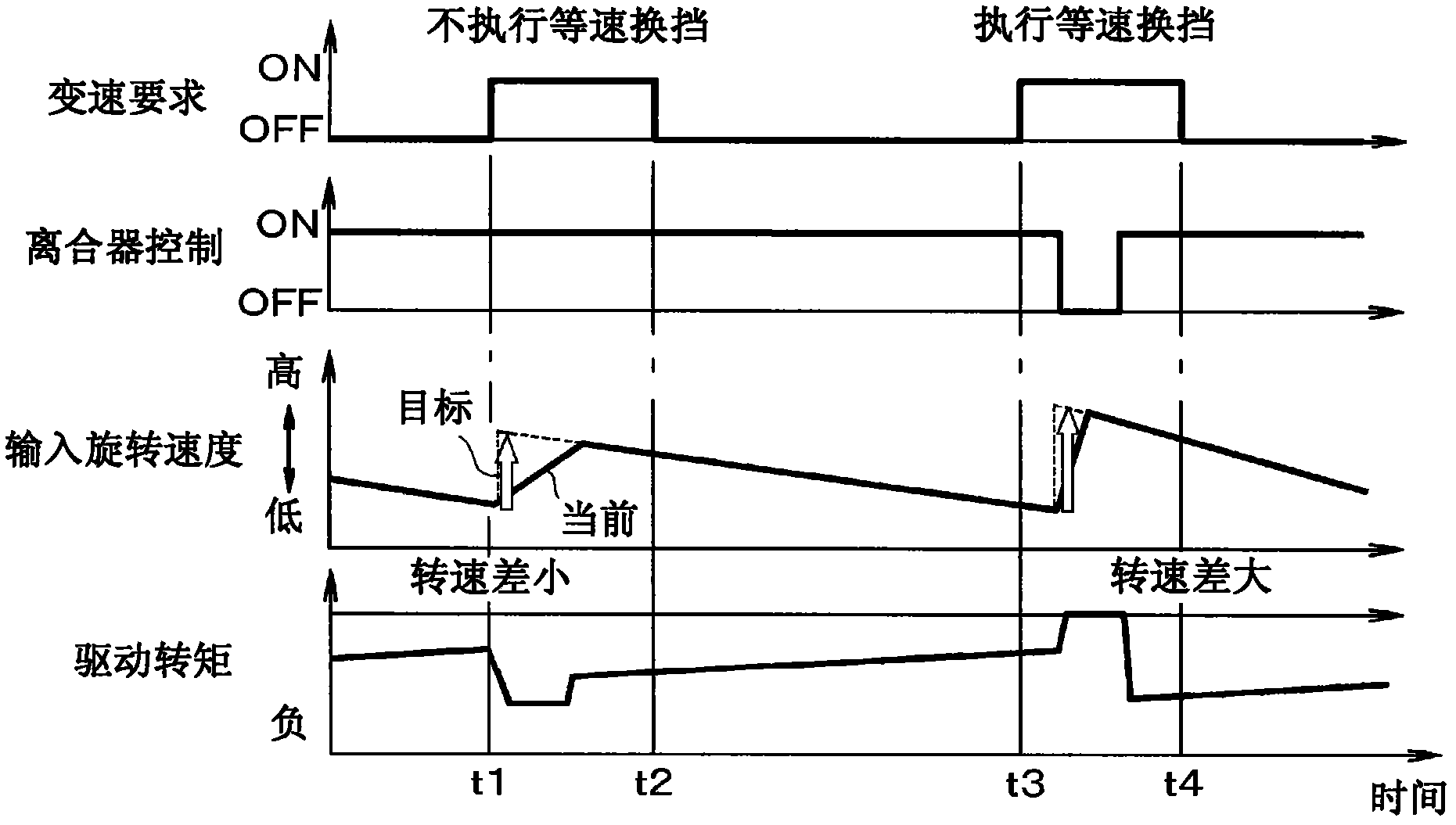

Driving force control device

InactiveCN102361787ASmall torque capacityAvoid equivalent inertial mass increaseGearingGearing controlEngineeringInternal combustion engine

Provided is a driving force control device capable of suppressing shifting shocks when a speed ratio is stepwise changed by a continuously variable transmission. The driving force control device has the continuously variable transmission connected in a power transmittable manner to the output shaft of an internal combustion engine through a clutch so that the device can change the speed ratio of the continuously variable transmission stepwise. The driving force control device comprises a shift deciding means (Step S1) for deciding whether or not the torque capacity of the clutch is relatively high and whether or not the speed ratio of the continuously variable transmission is stepwise changed while the vehicle is running, and a first shifting means (Step S3) for lowering the torque capacity of the clutch, when the speed ratio of the continuously variable transmission is stepwise changed, before the speed ratio is changed by the continuously variable transmission, synchronizing the rotating speed of the internal combustion engine, while the speed ratio is being changed by the continuously variable transmission, with the input rotating speed after the speed ratio is changed by the continuously variable transmission, and raising the torque capacity of the clutch after the speed ratio is changed by the continuously variable transmission.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com