Patents

Literature

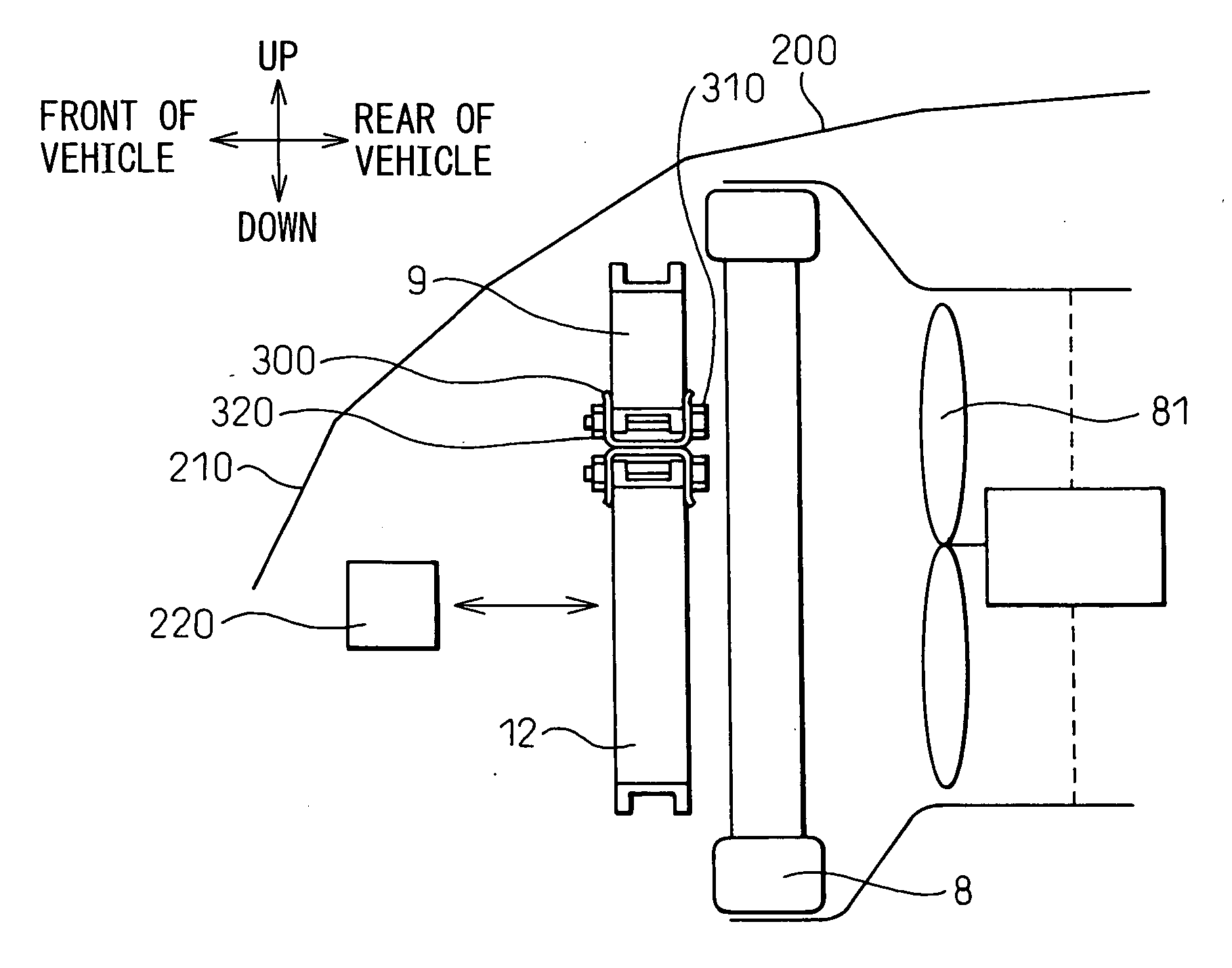

91results about How to "Stable placement effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

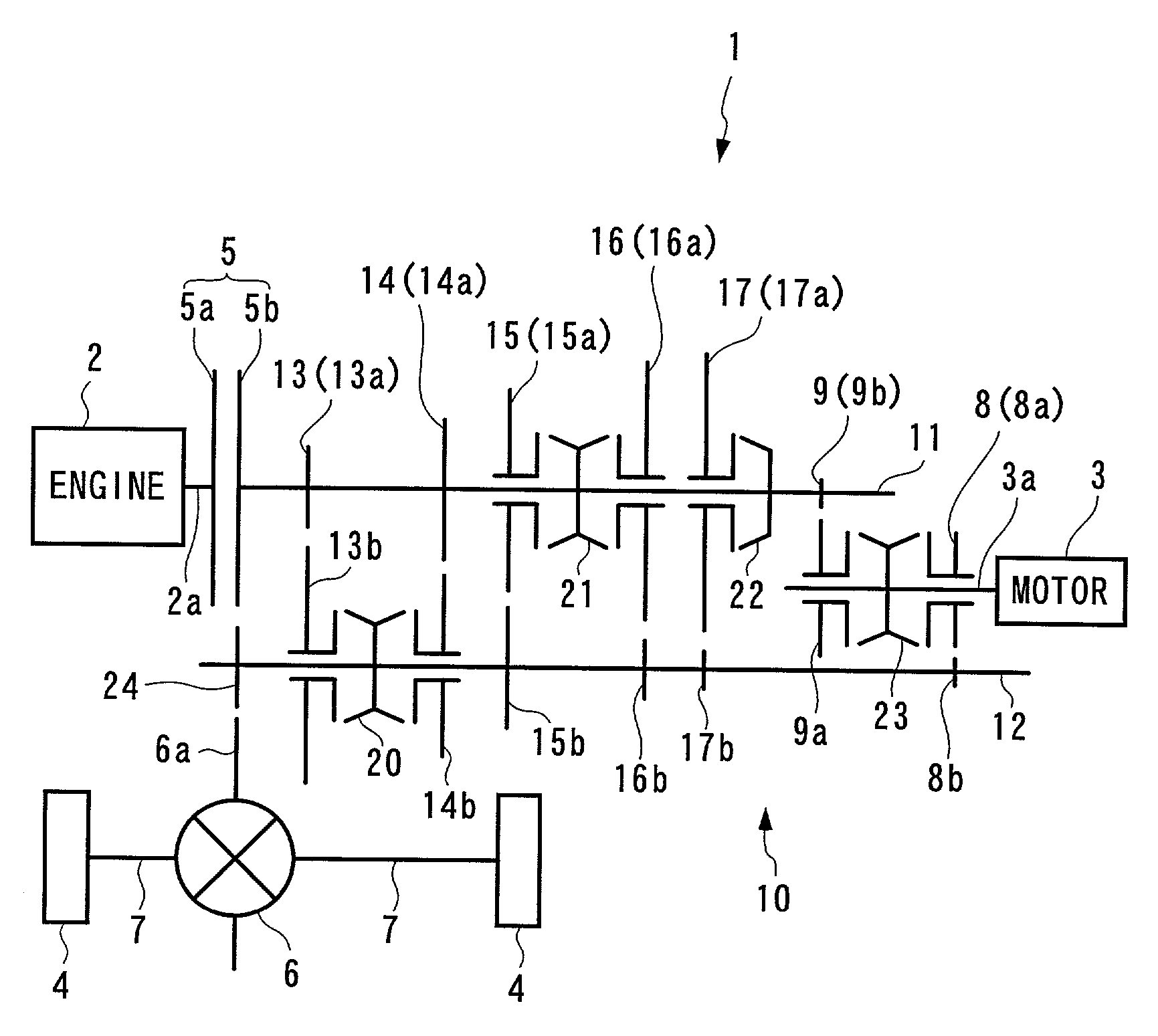

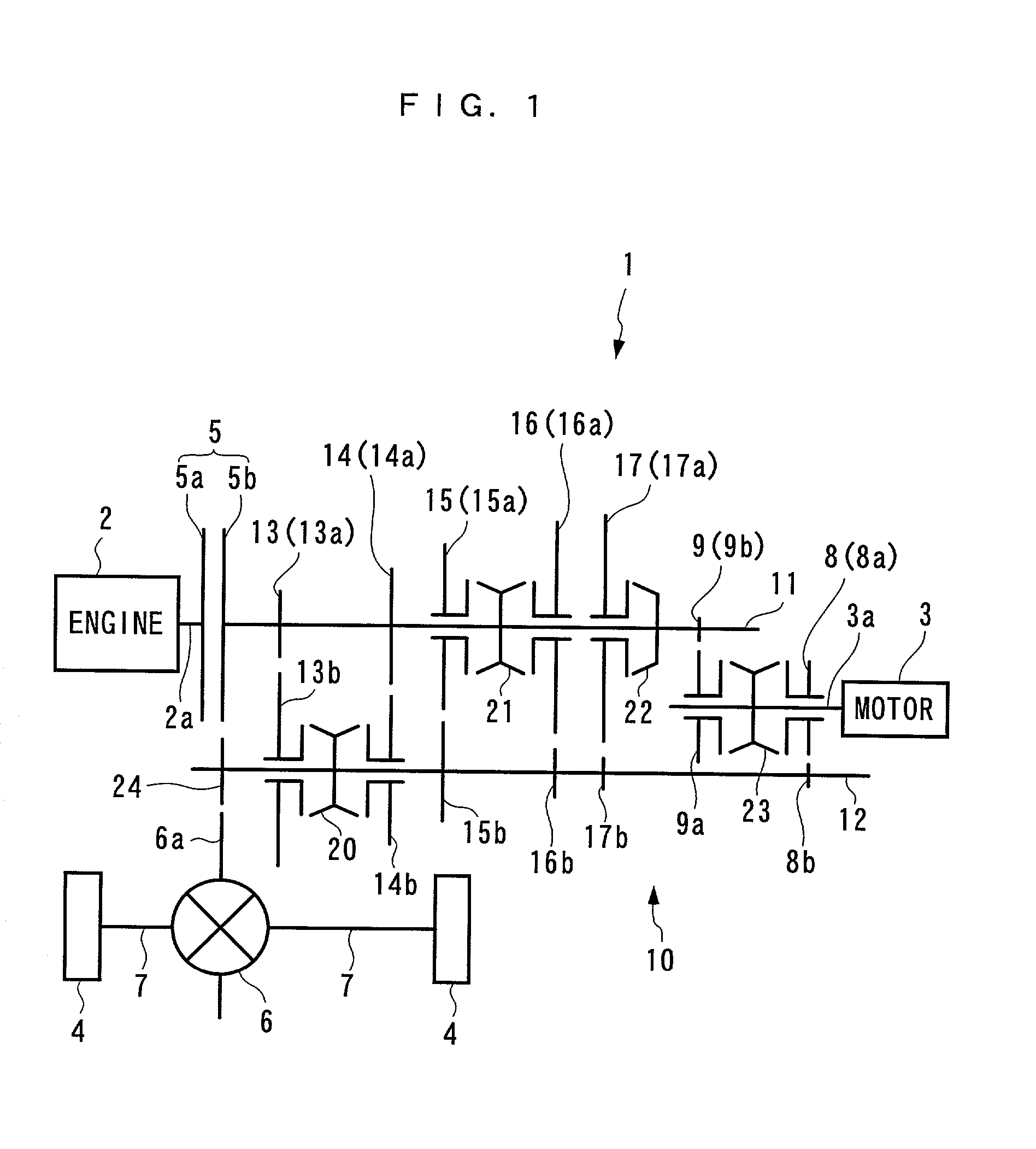

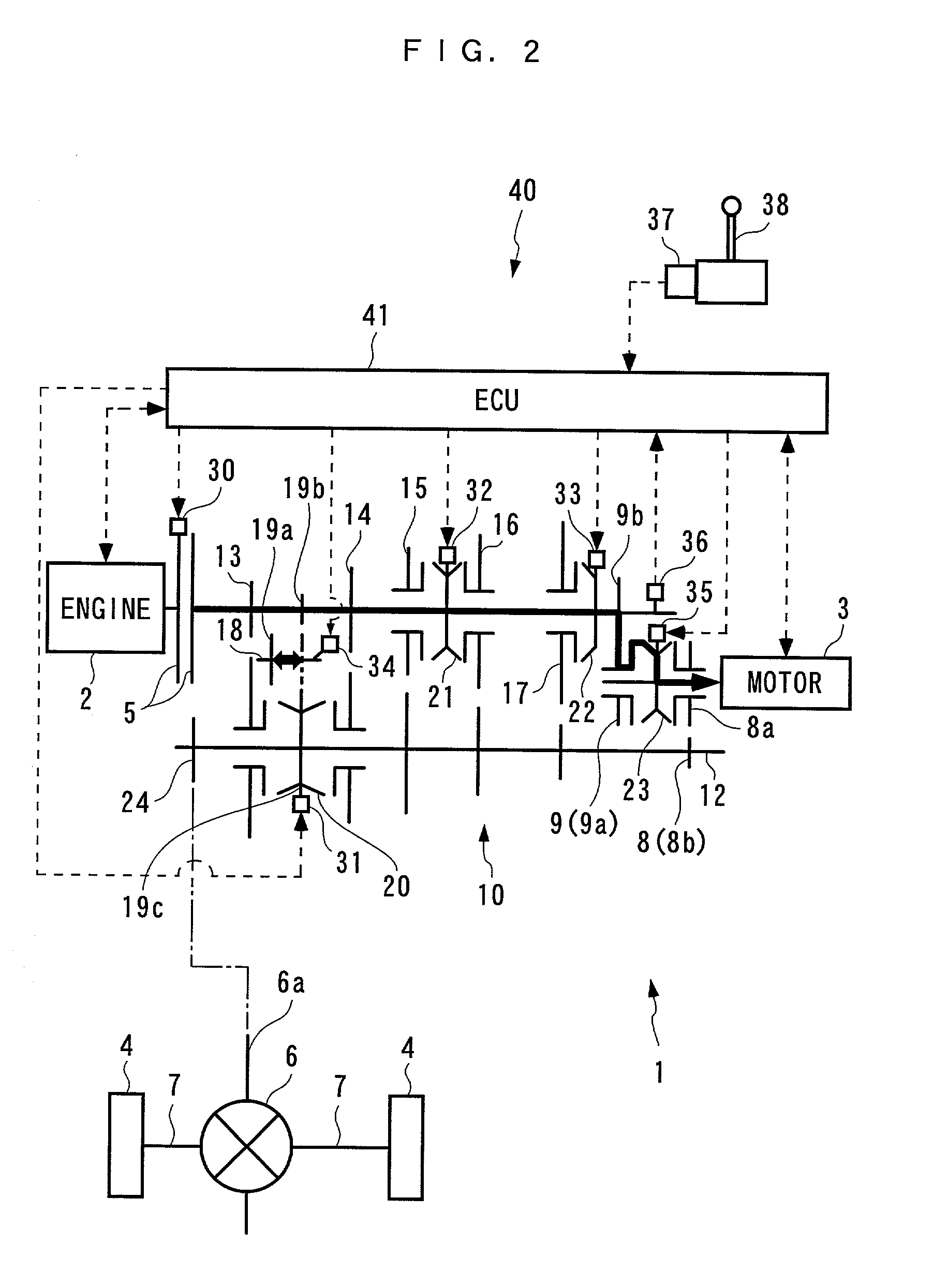

Power transmission mechanism

InactiveUS20020040818A1Stable placement effectPerform operationManual control with multiple controlled membersElectric propulsion mountingDrive wheelDrive shaft

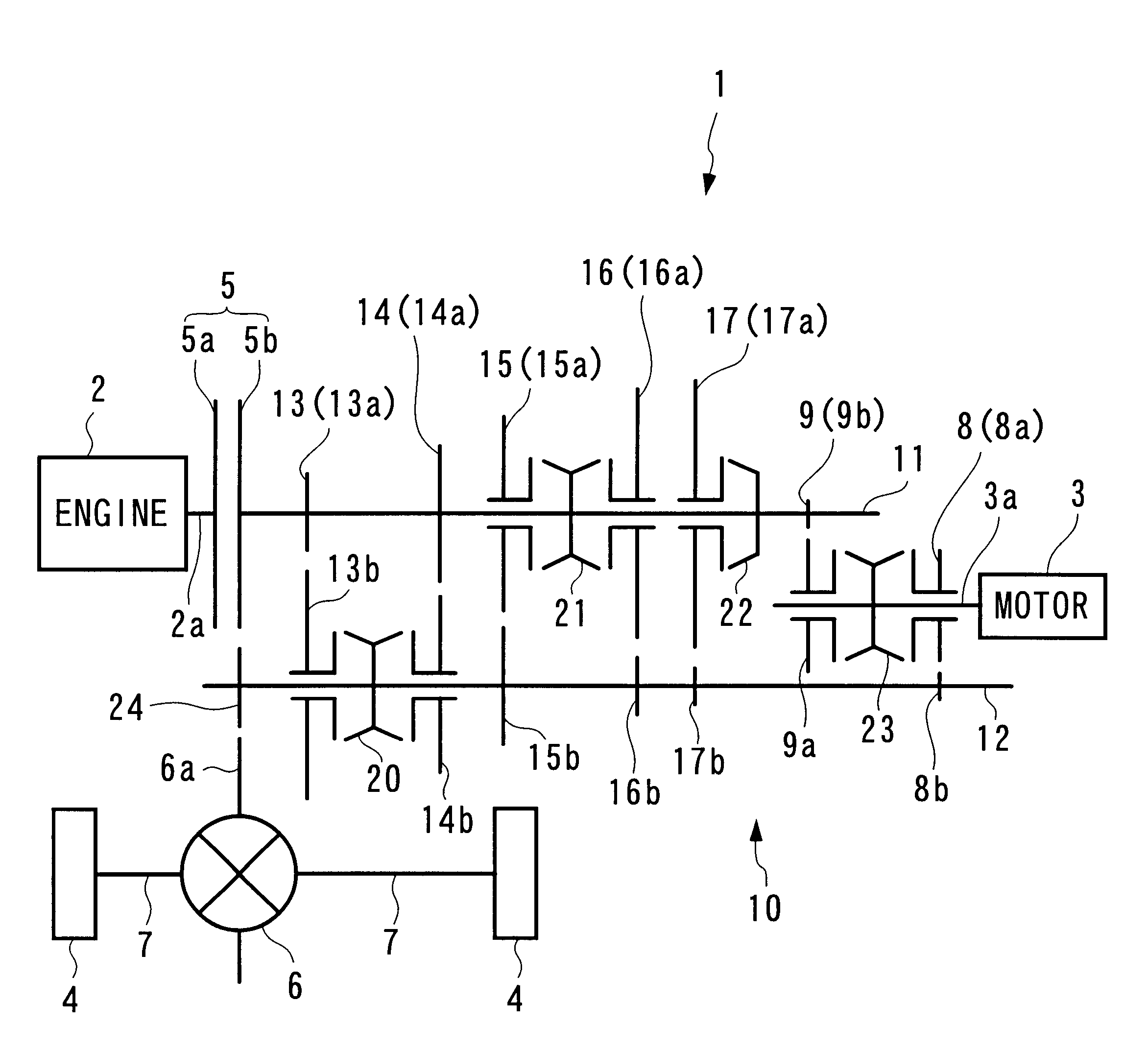

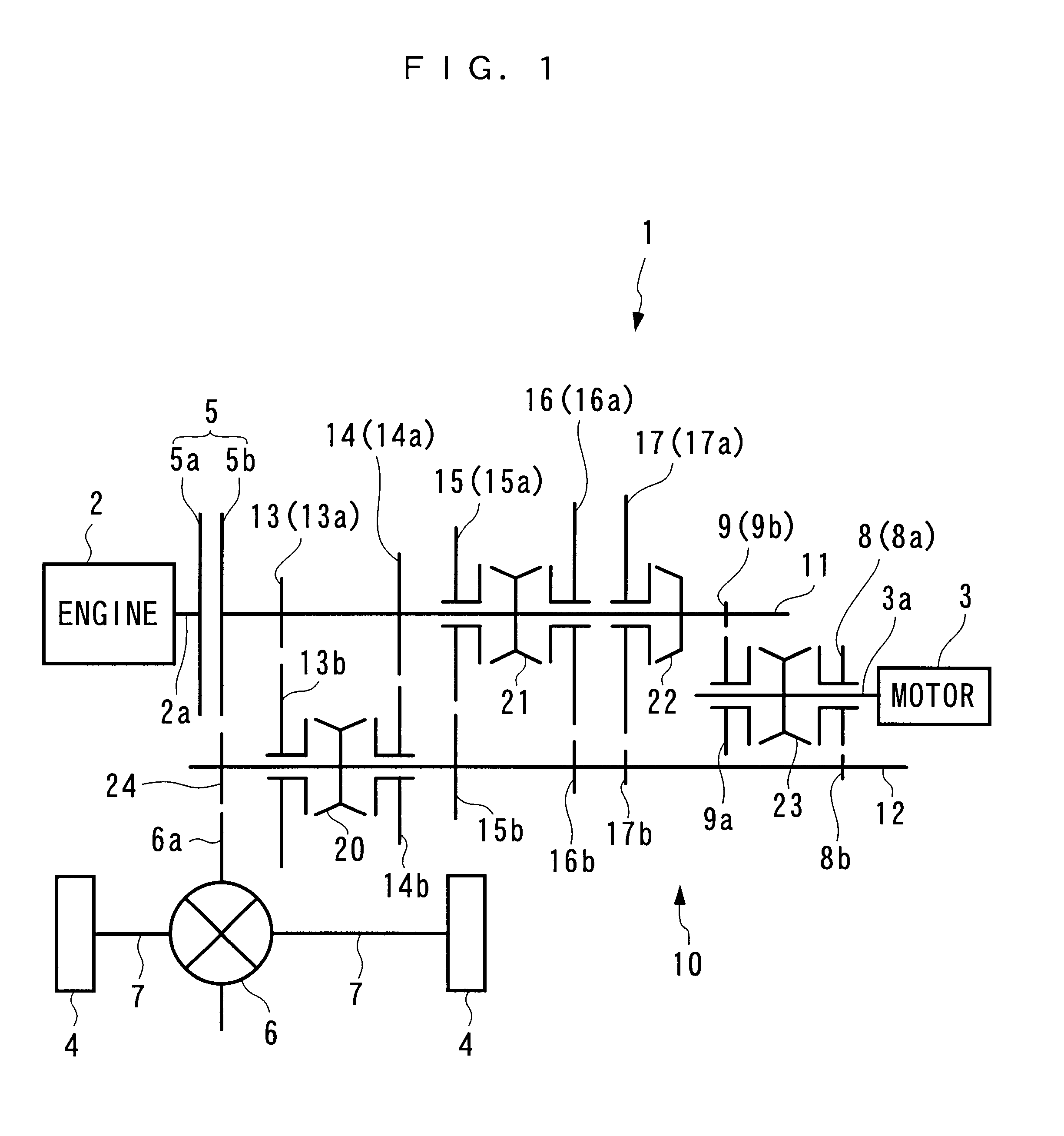

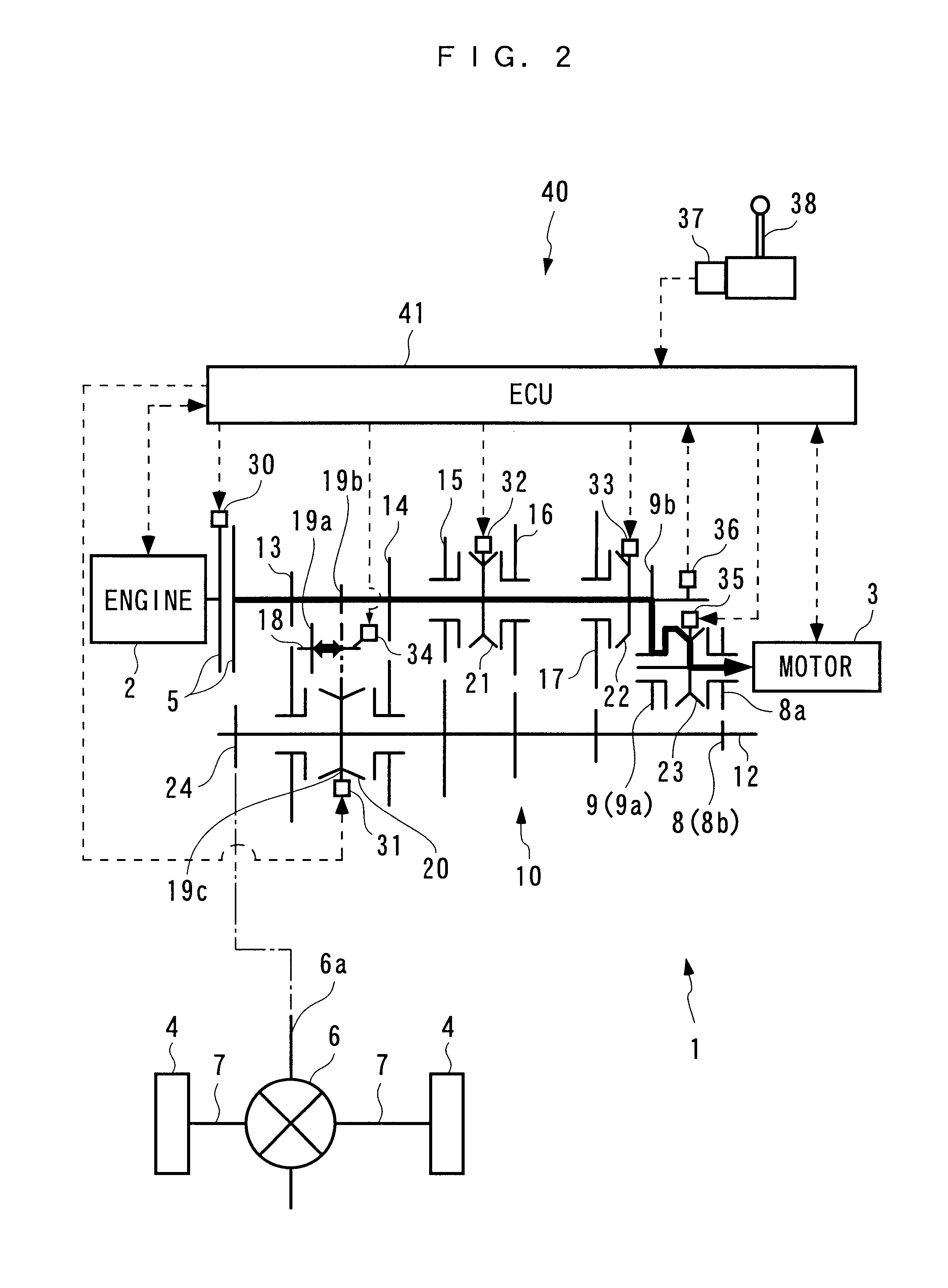

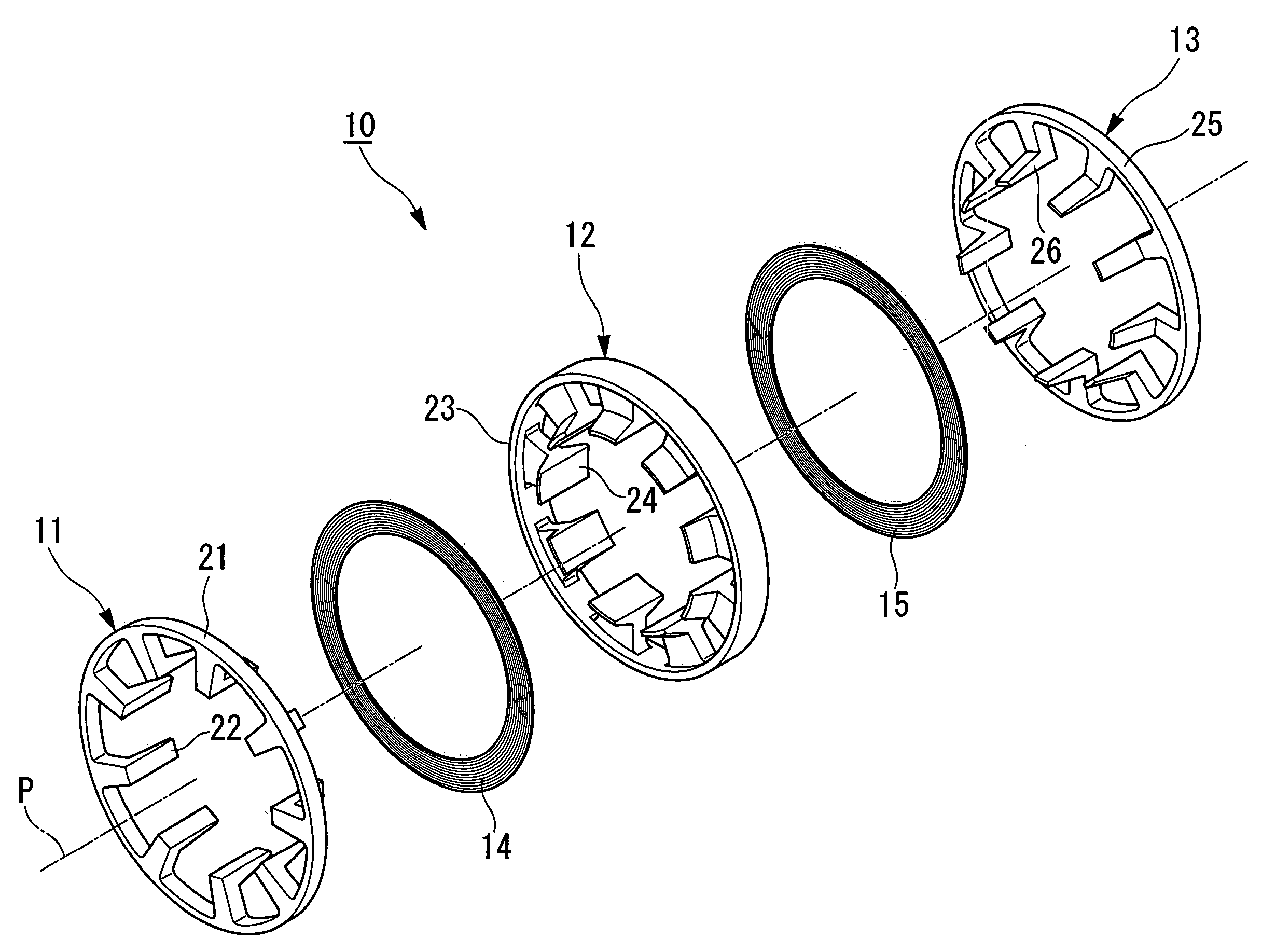

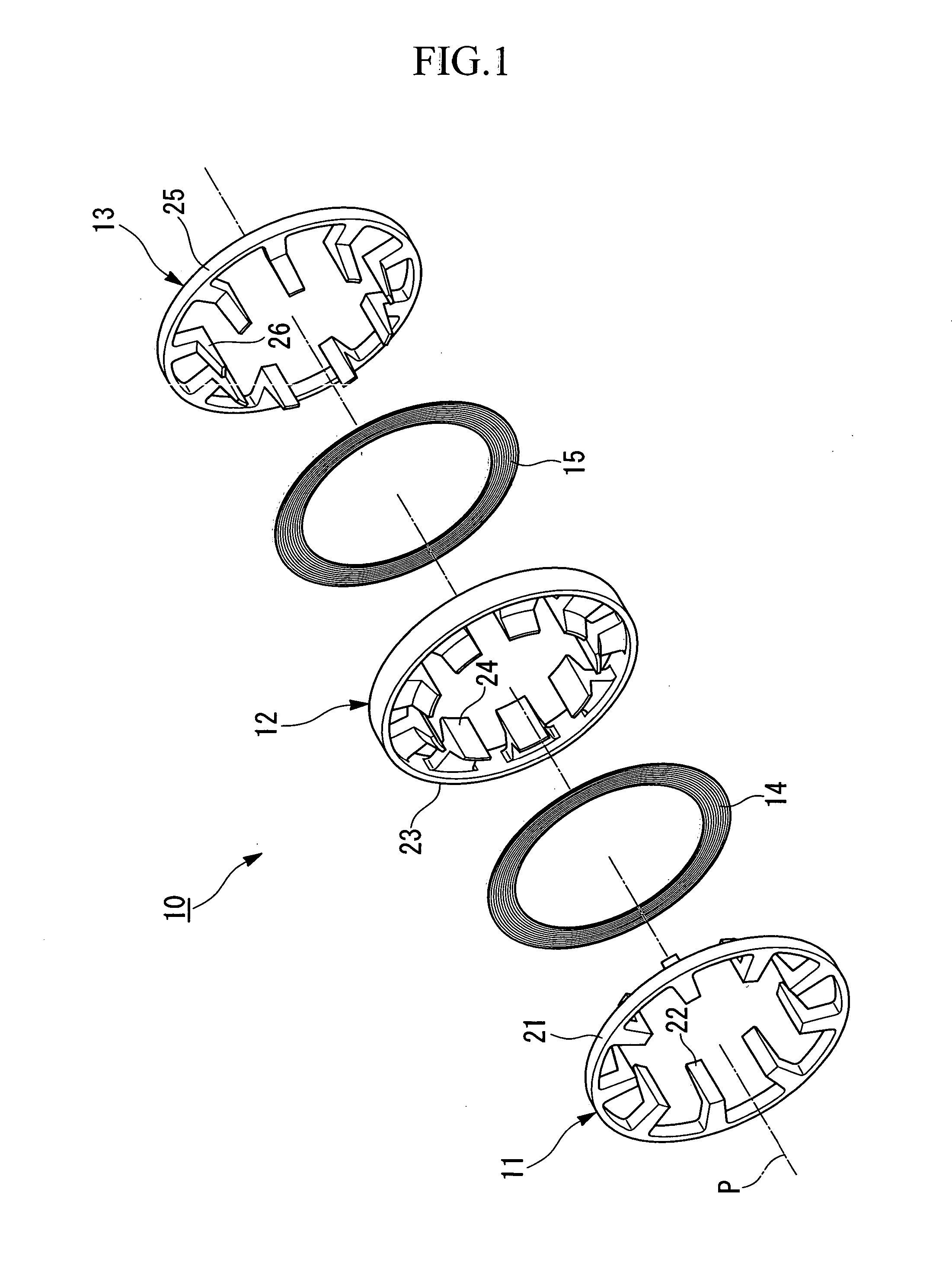

There is provided a power transmission mechanism which is capable of employing one electric motor as a drive source for driving drive wheels and as a drive source for cranking an engine, thereby making it possible to reduce manufacturing costs of the hybrid vehicle, and preventing the motor from offering an extra rotational resistance to the engine when the drive wheels are being driven by the engine, thereby making it possible to enhance fuel economy. In the power transmission mechanism for transmitting the driving force from the engine and / or the electric motor to the drive wheels, when a synchro-clutch for the electric motor, driven by a switching actuator, connects the drive shaft of the electric motor and a driving drive shaft gear to each other, the electric motor is connected to the drive wheels via a meshing gear pair (driving drive shaft gear and driving output shaft gear), whereas when the synchro-clutch connects the drive shaft of the electric motor and a cranking drive shaft gear to each other, the electric motor is connected to the engine via a meshing gear pair (cranking drive shaft gear and cranking input shaft gear), the input shaft of the transmission, and a clutch.

Owner:HONDA MOTOR CO LTD

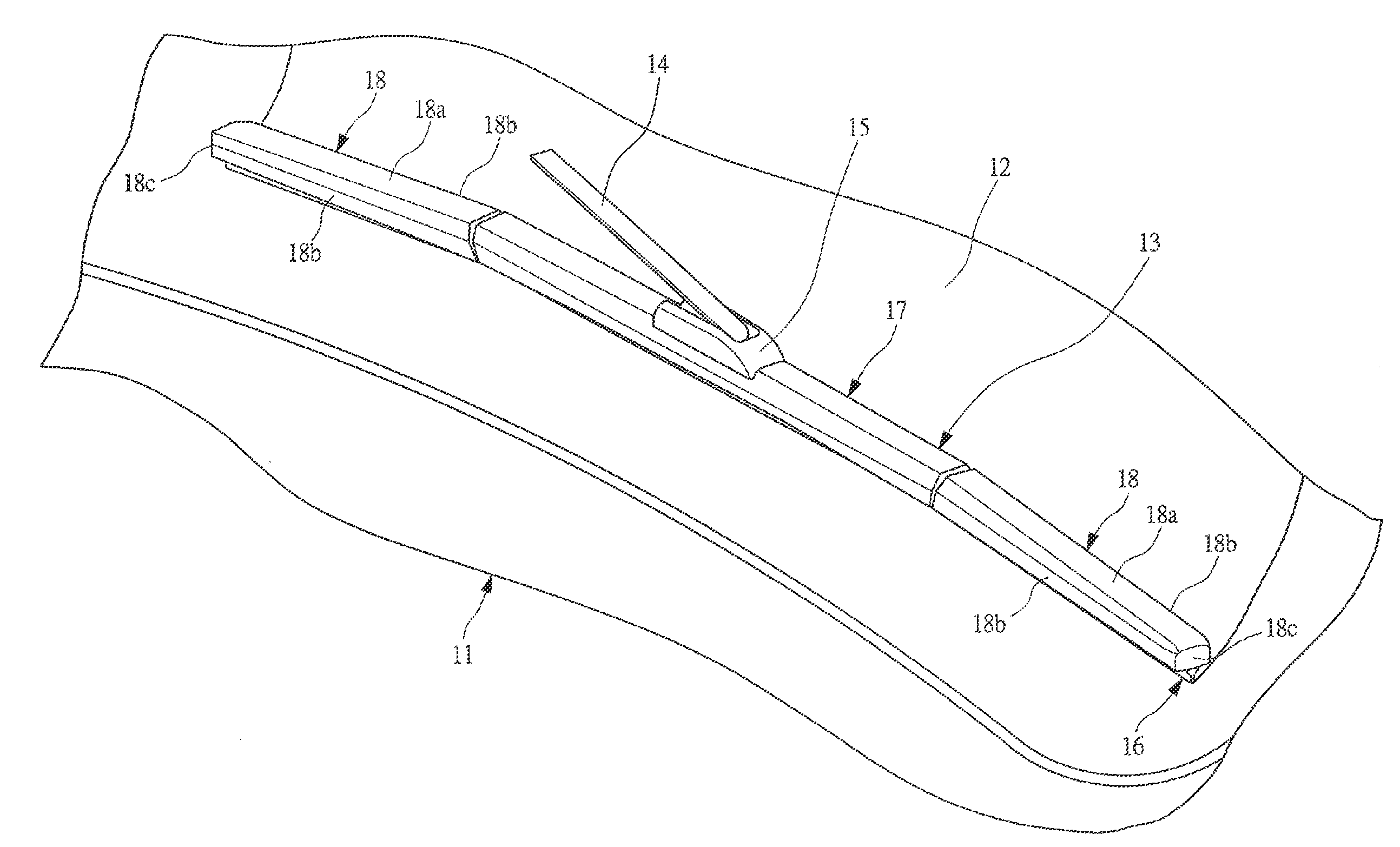

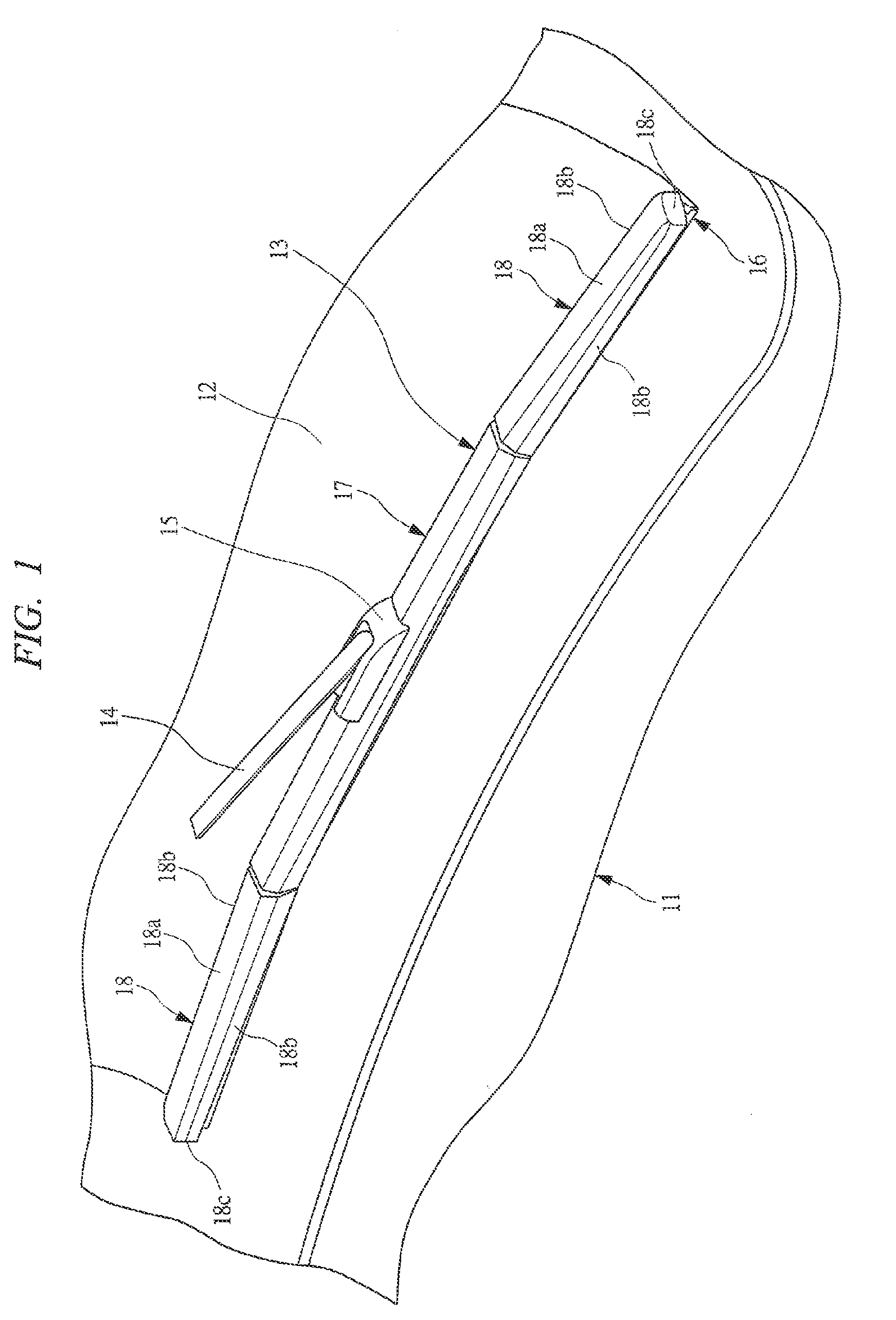

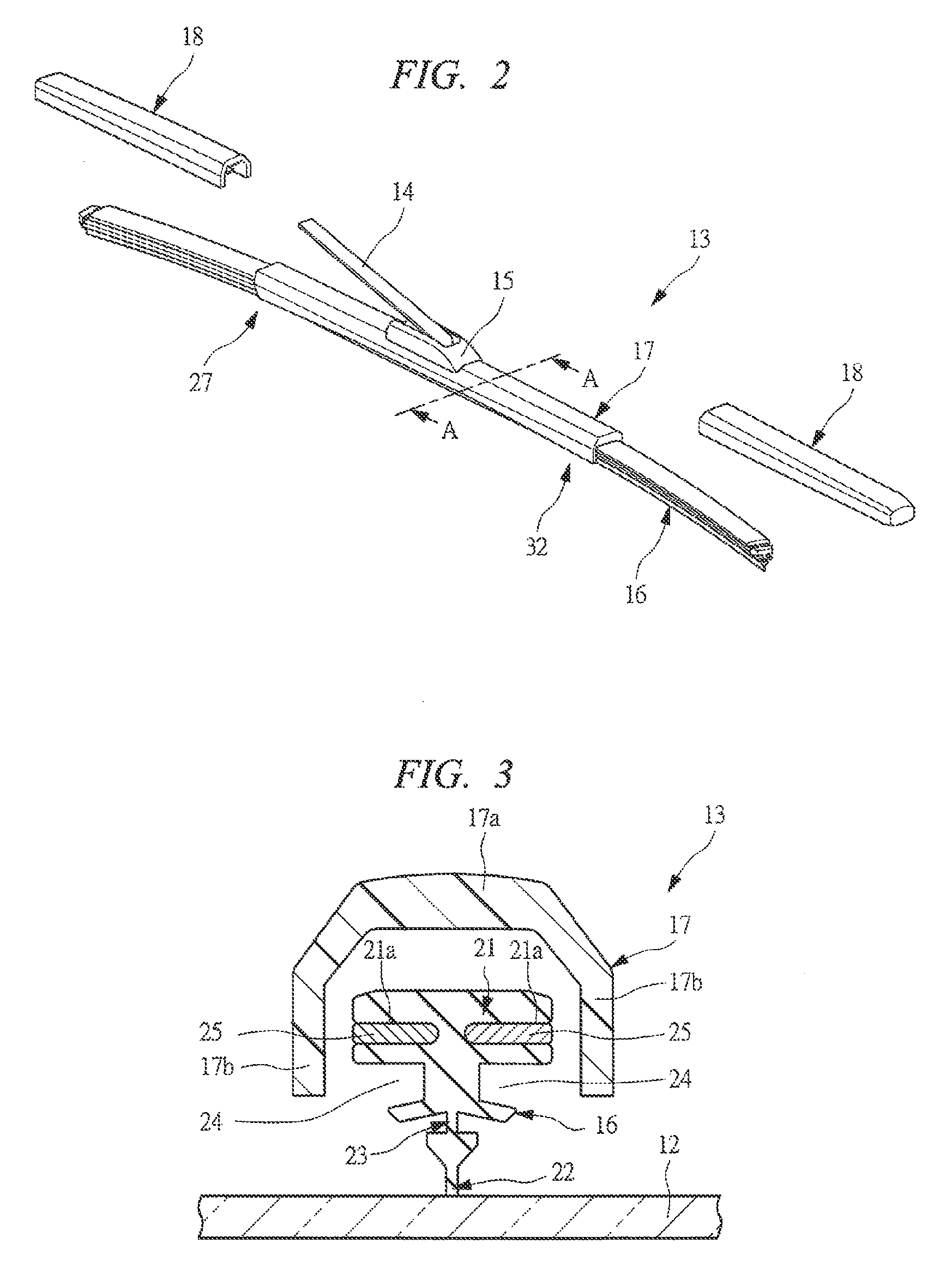

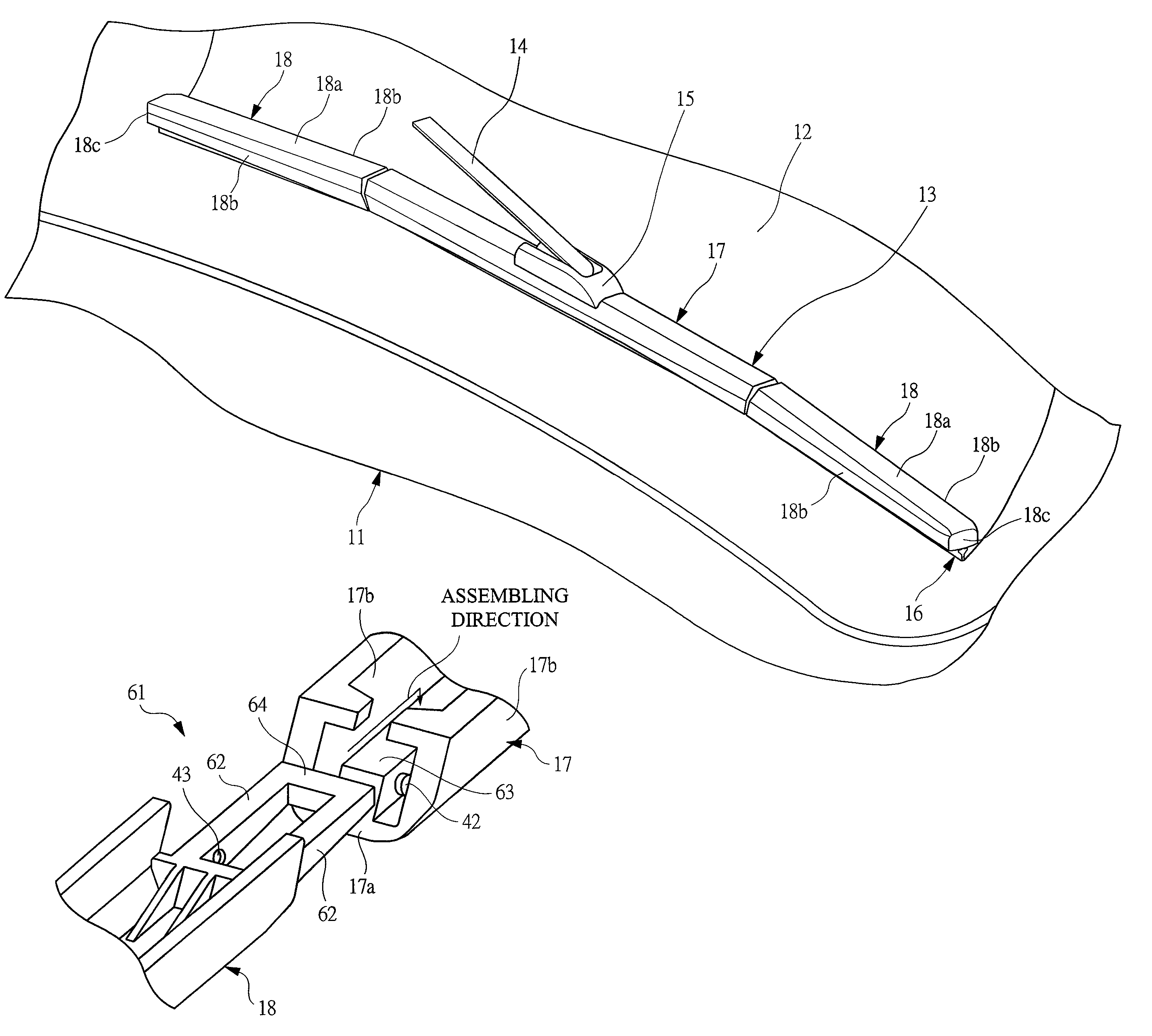

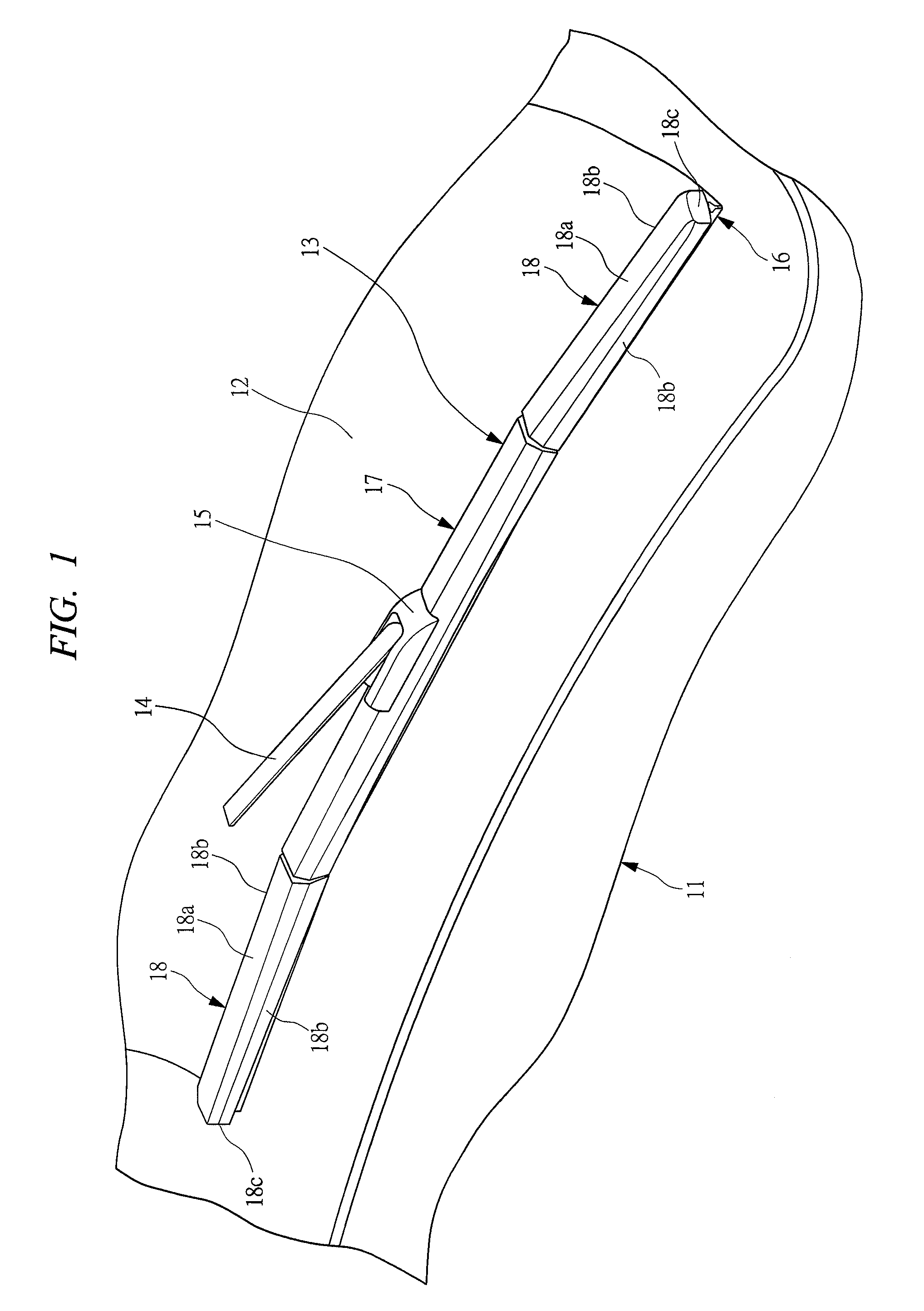

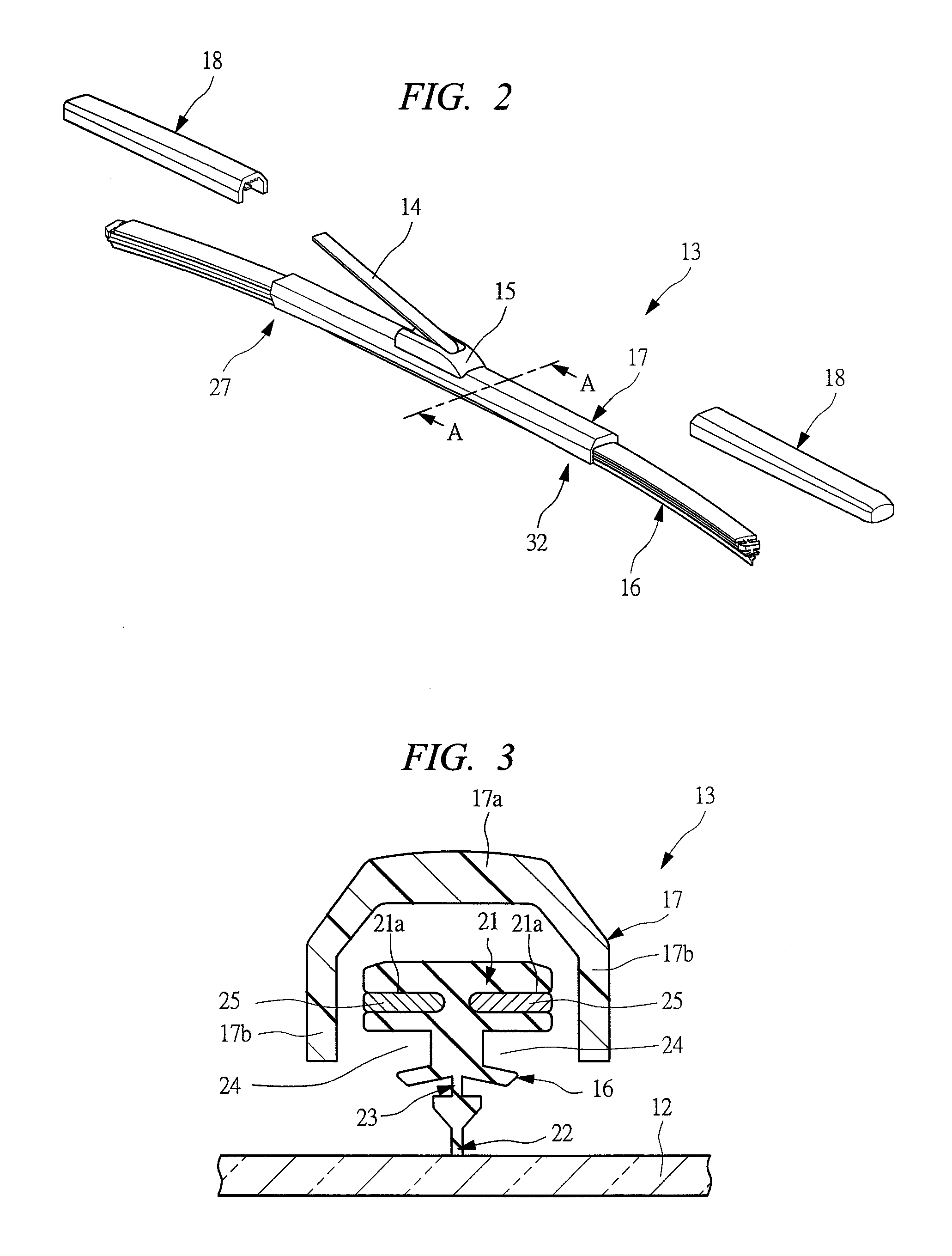

Wiper Blade

ActiveUS20080098559A1Fine appearance be improveEnhance versatilityWindow cleanersVehicle cleaningEngineeringWindshield

A wiper blade 13 comprises a rubber holder 17 attached to a tip of a wiper arm 14 and a blade rubber 16 supported by the rubber holder 17. The rubber holder 17 is formed into a U-shaped cross section, and an intermediate portion of the blade rubber 16 is covered with the rubber holder 17. Also, both sides of the rubber holder 17 are provided with covers 18 in a longitudinal direction in series. Each of the cover 18 becomes rotatable to the rubber holder 17 in a direction perpendicular to a front windshield glass 12, and exposed portions from the rubber holder 17 of the blade rubber 16 are covered with these covers 18 in an elastically deformable state.

Owner:MITSUBA CORP

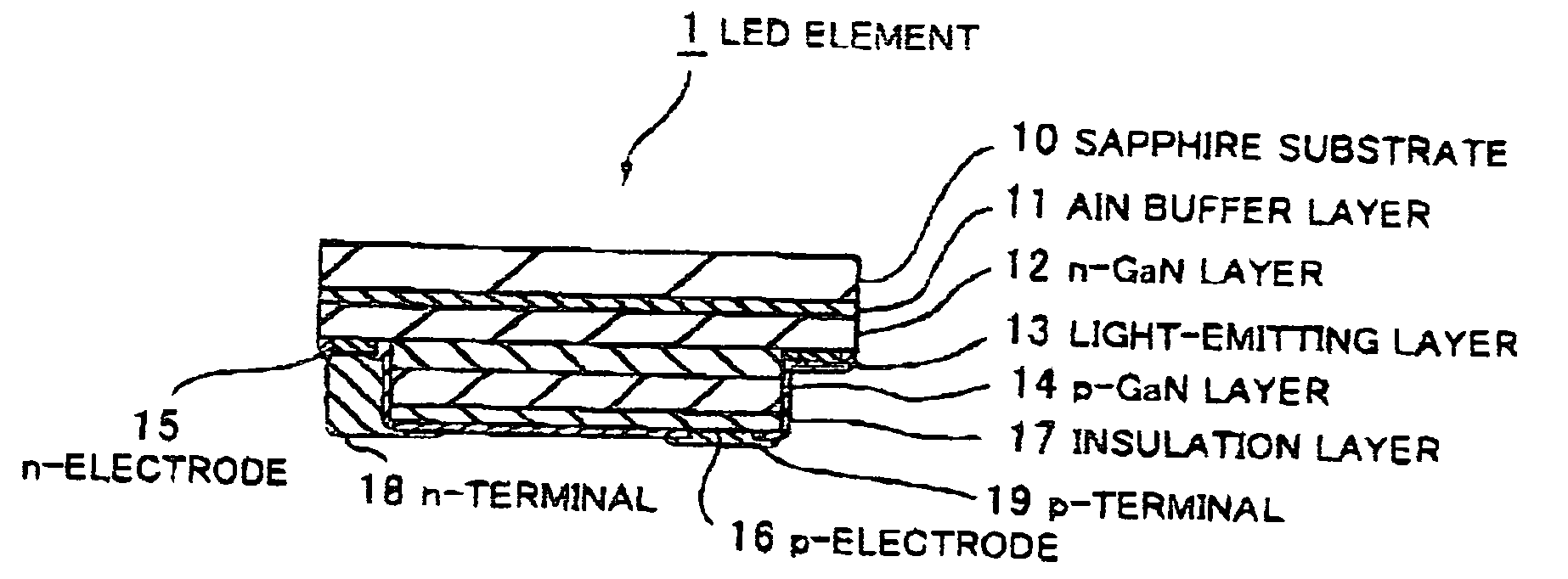

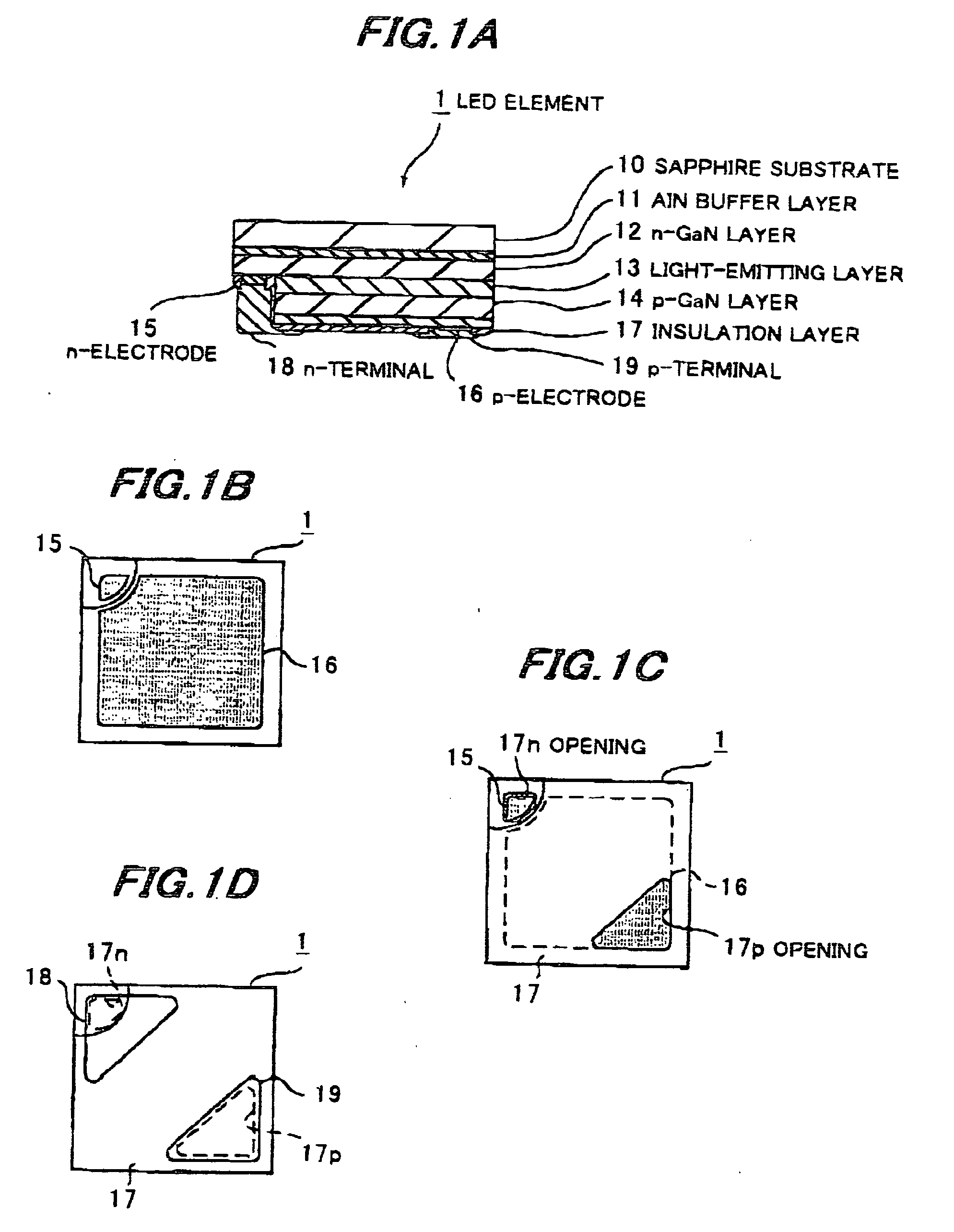

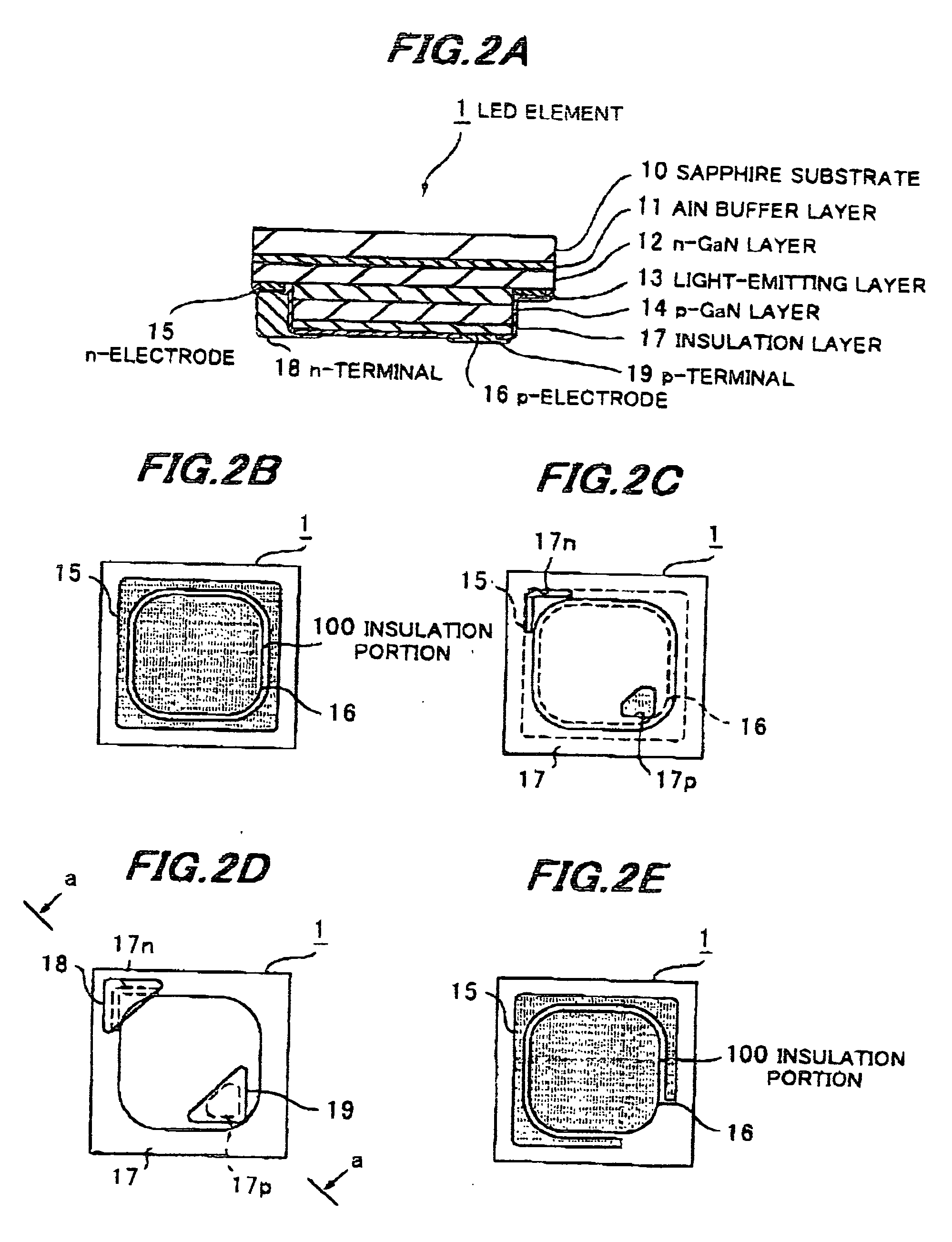

Light emitting element and method of making same

InactiveUS20060001035A1Large discharge areaEven light distributionSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerSemiconductor

A light emitting element has: a semiconductor layer having a light-emitting layer; a first electrode; a second electrode; an insulation layer that is formed on a mounting face side of the semiconductor layer; and a first terminal and a second terminal that are formed on a surface of the insulation layer corresponding to the first electrode and the second electrode, respectively. The first electrode and the second electrode are formed on the mounting face side of the semiconductor layer. The insulation layer has a first opening and a second opening, and the first electrode and the second electrode are electrically connected through the first hole and the second hole, respectively, to the first terminal and the second terminal.

Owner:TOYODA GOSEI CO LTD

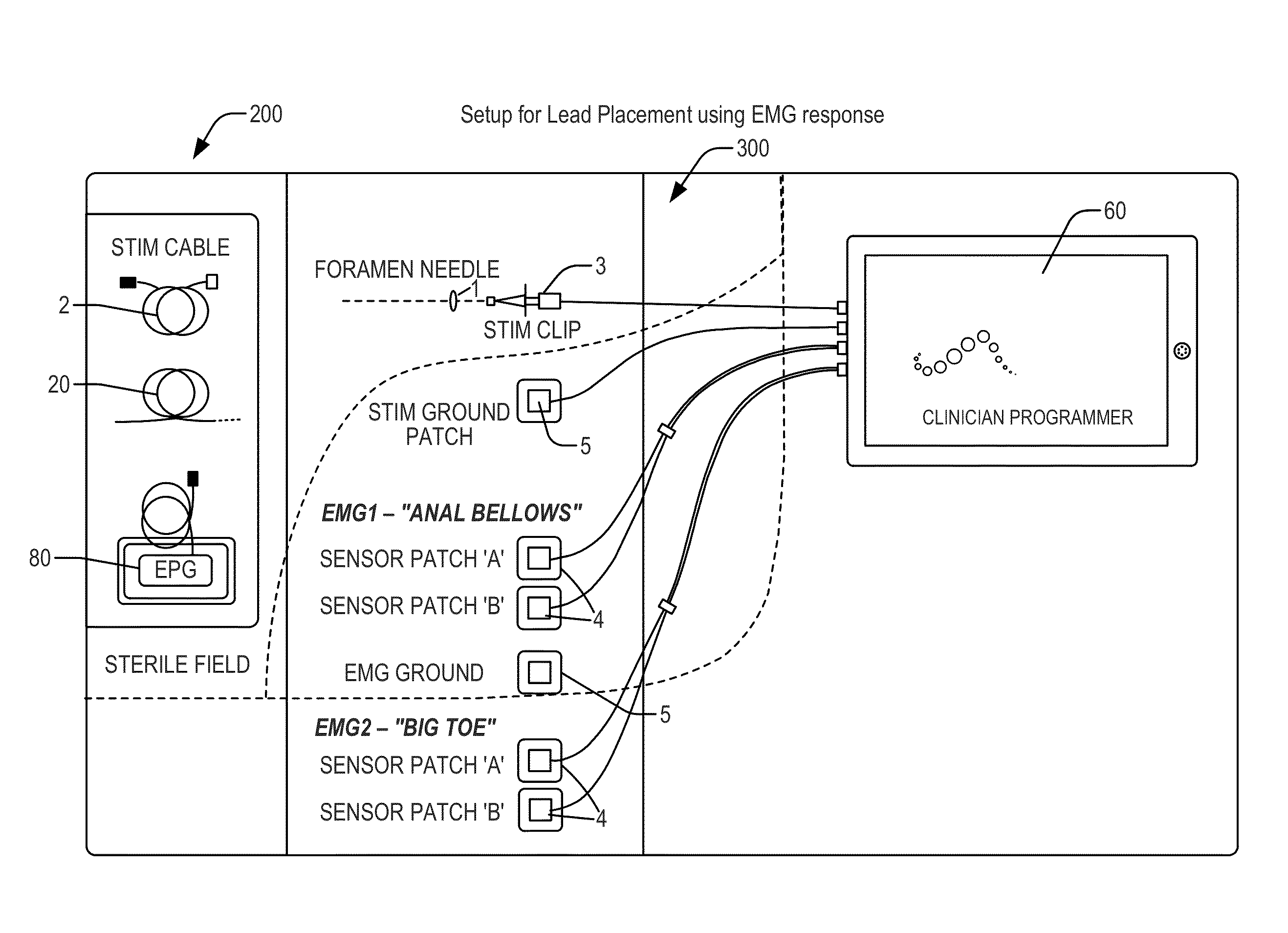

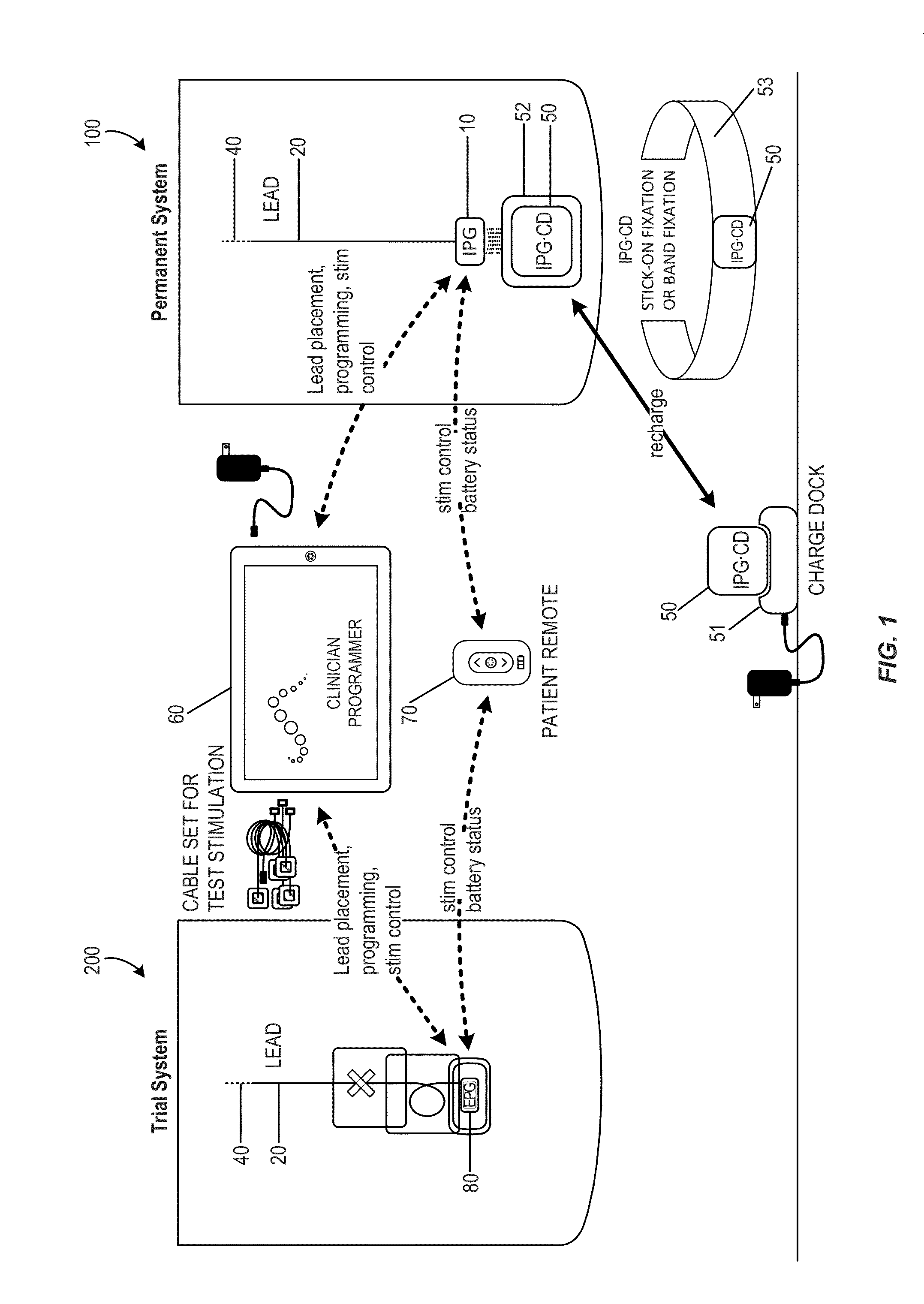

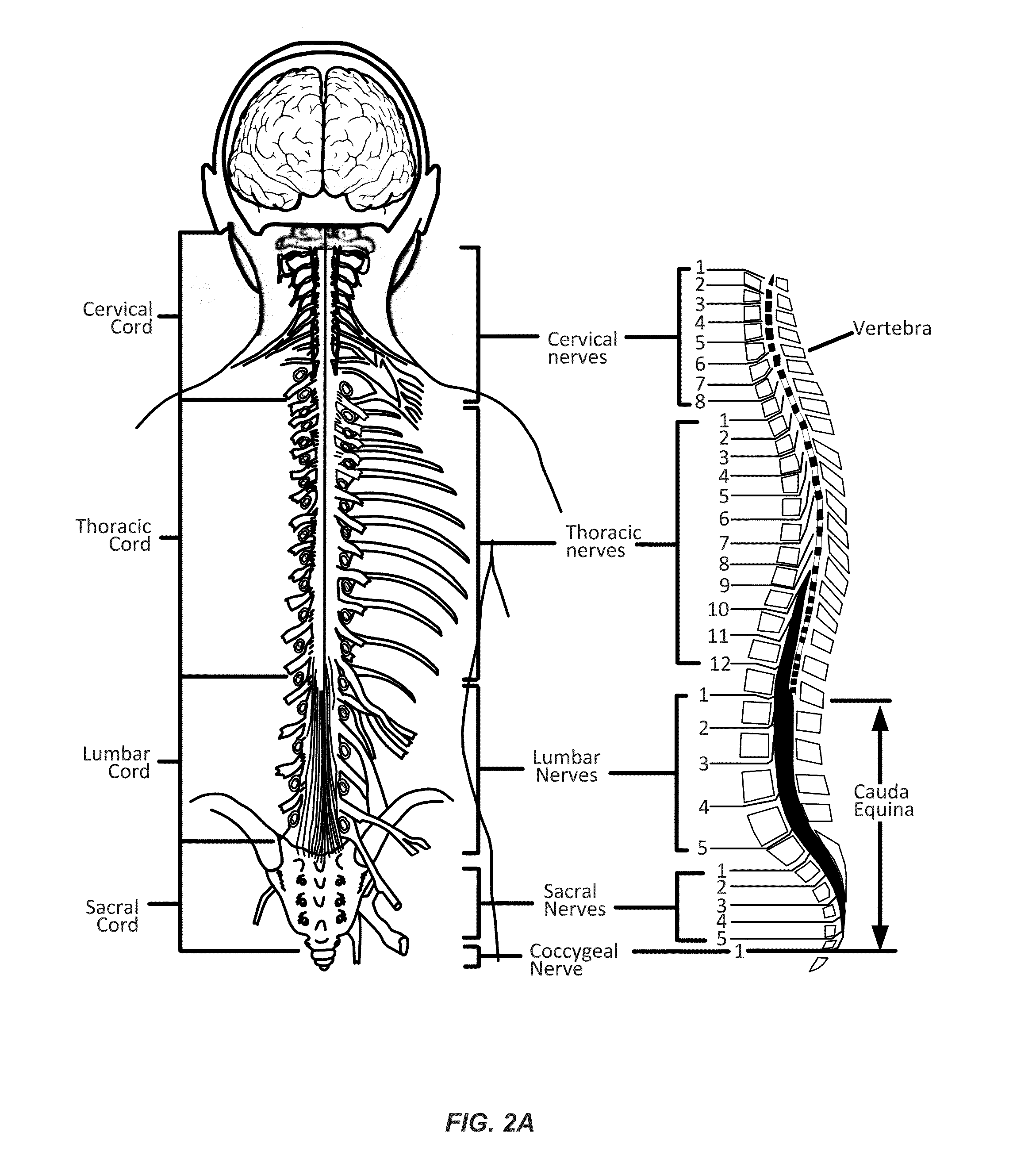

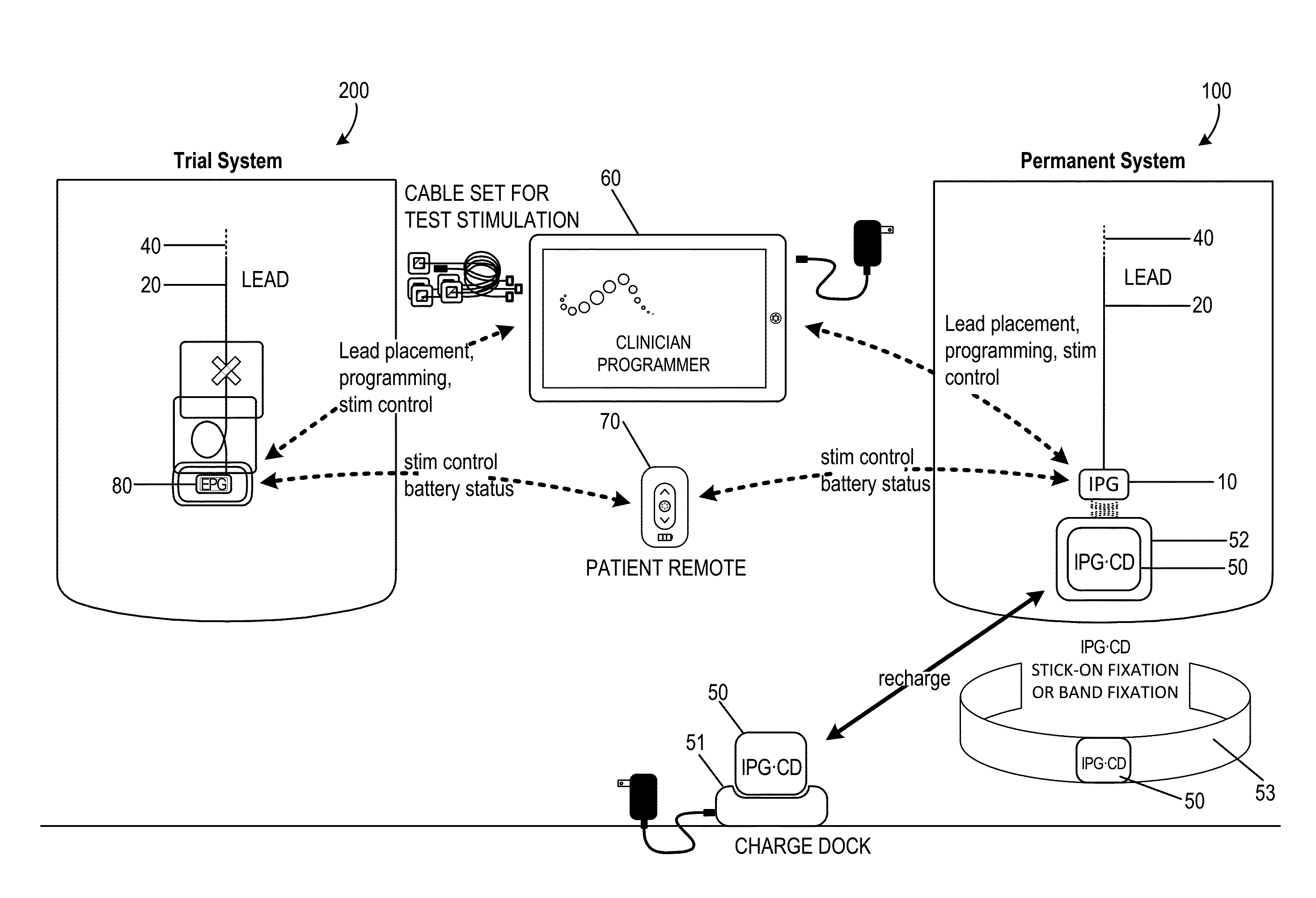

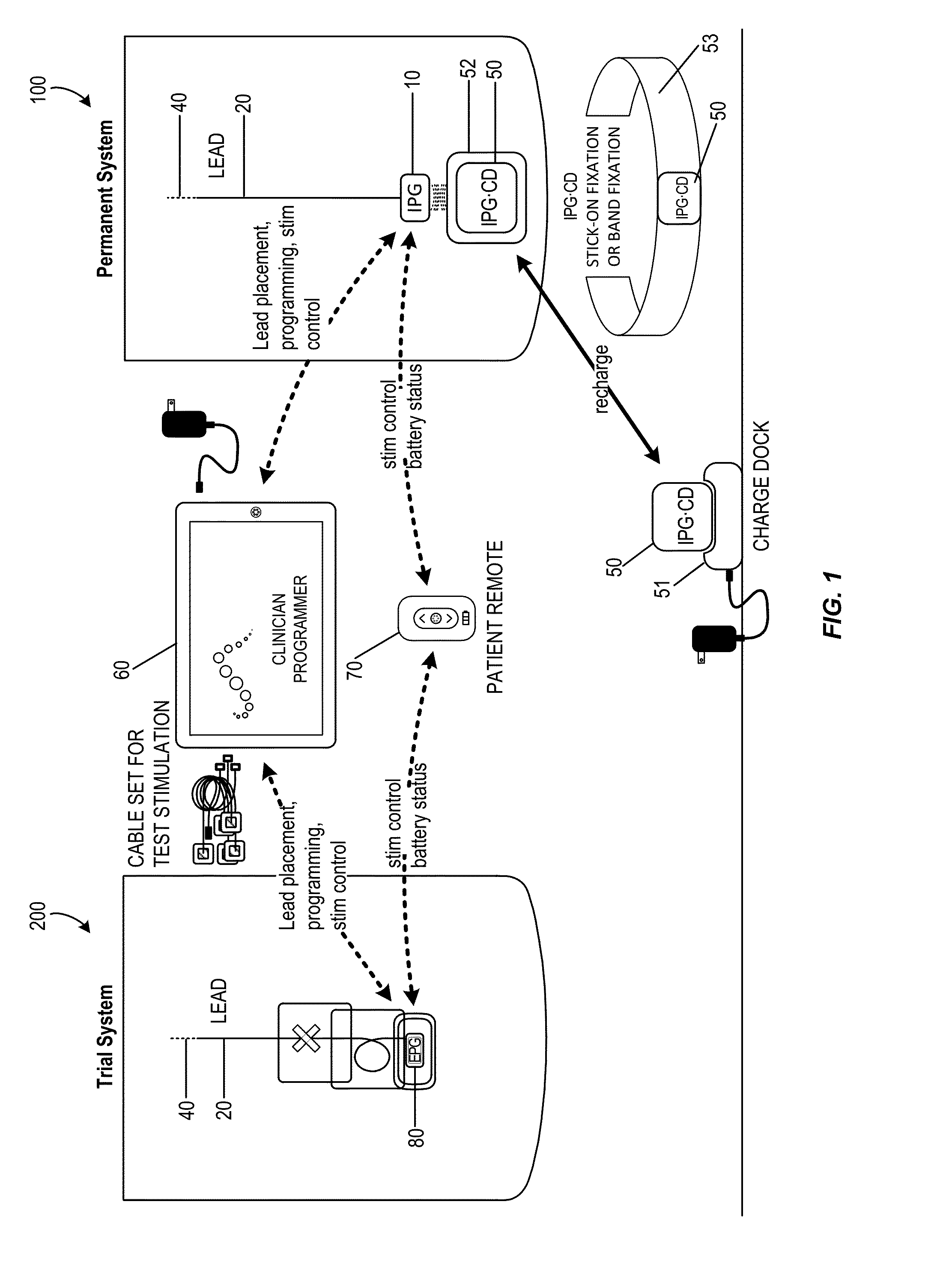

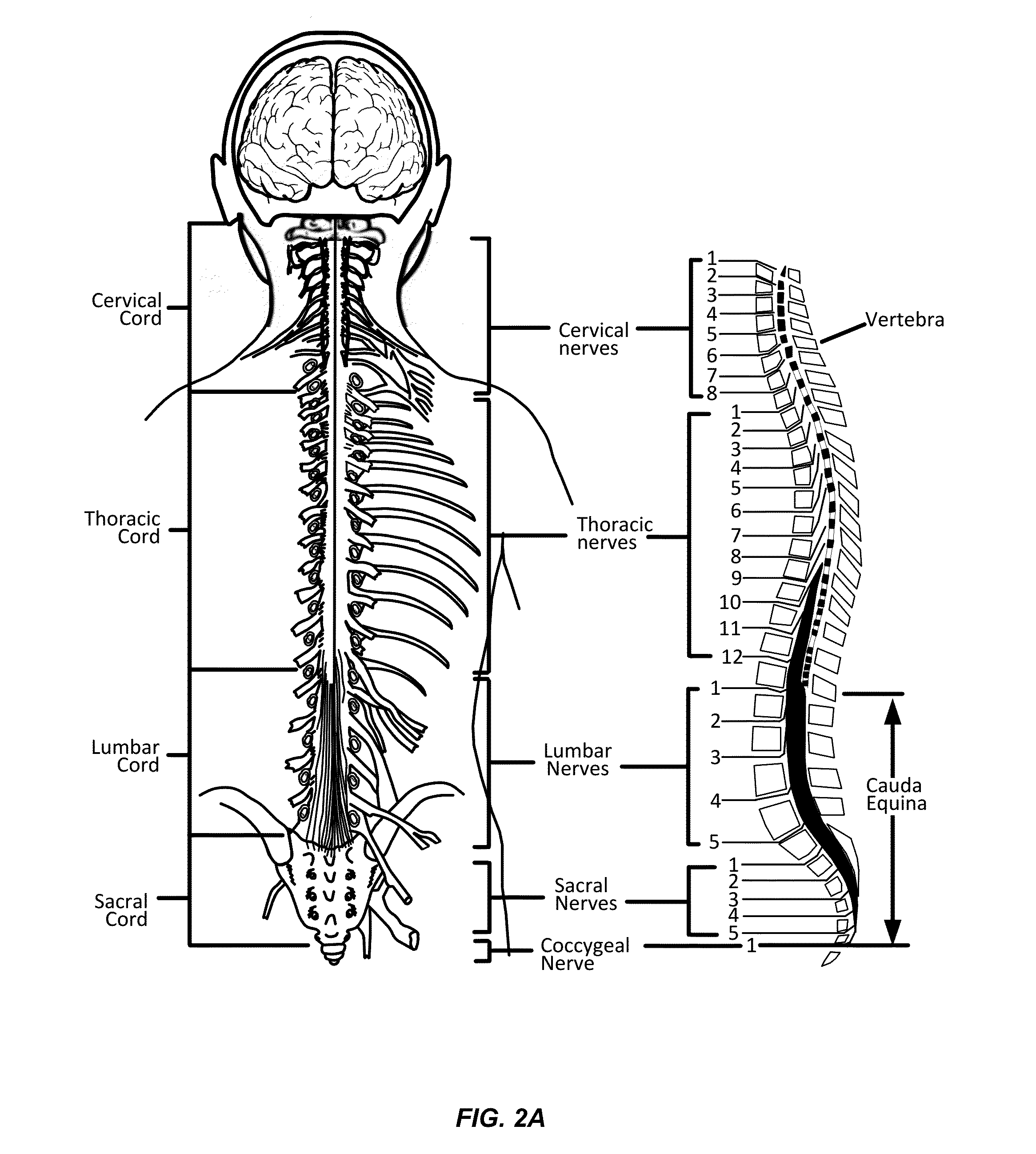

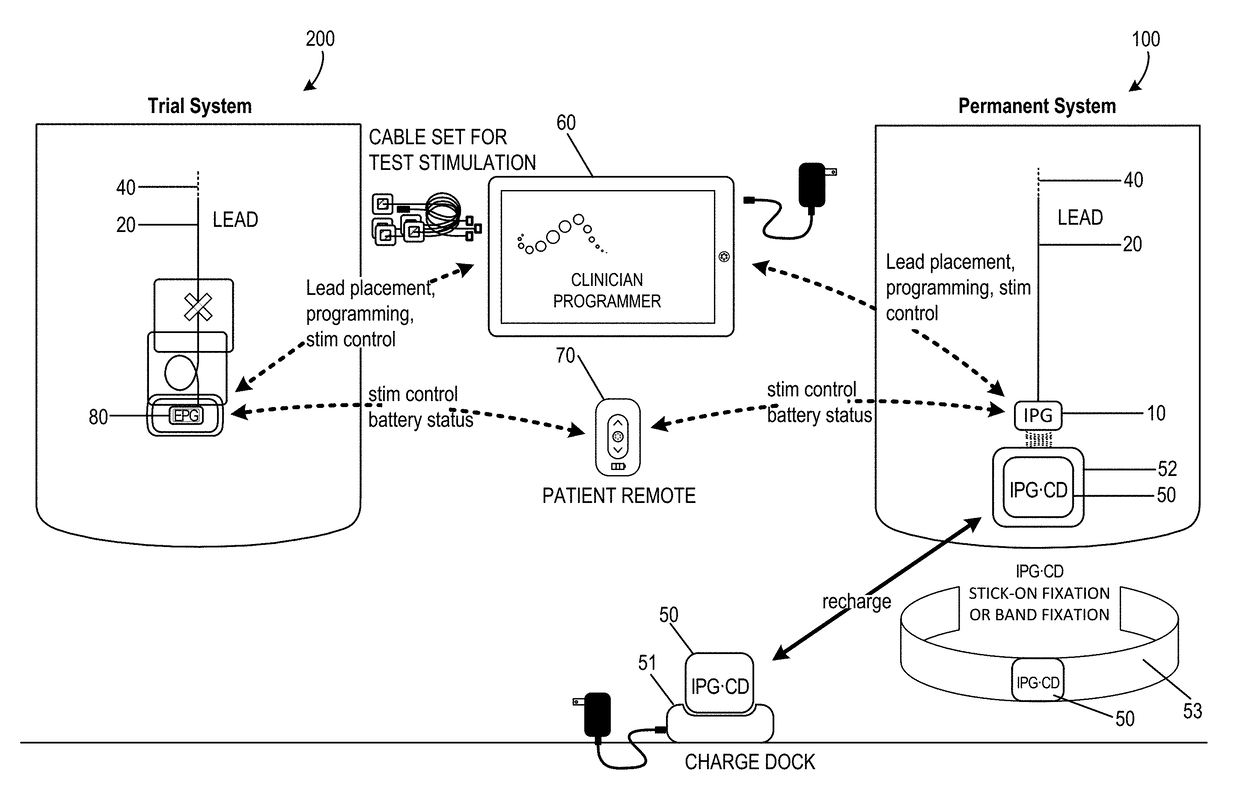

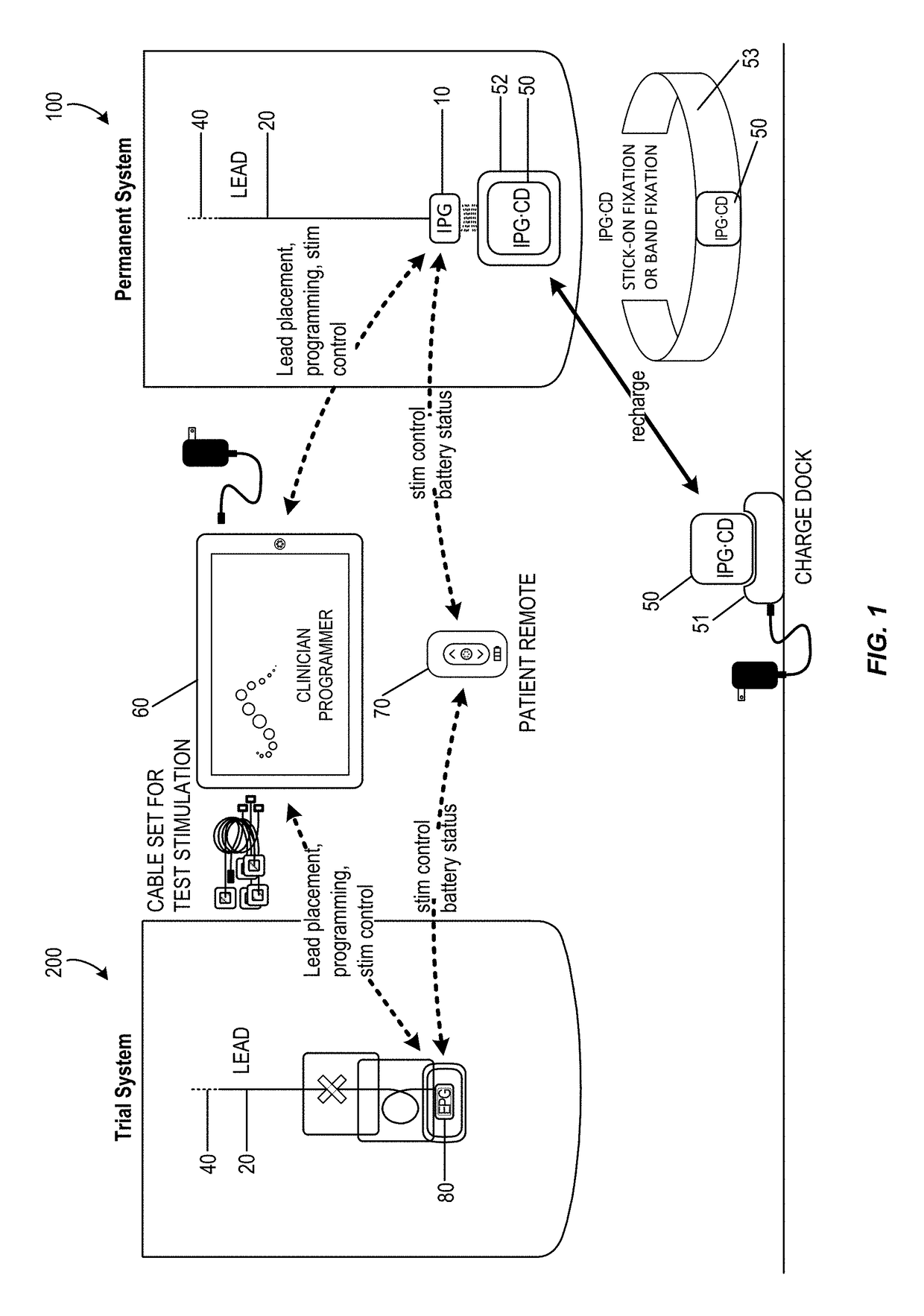

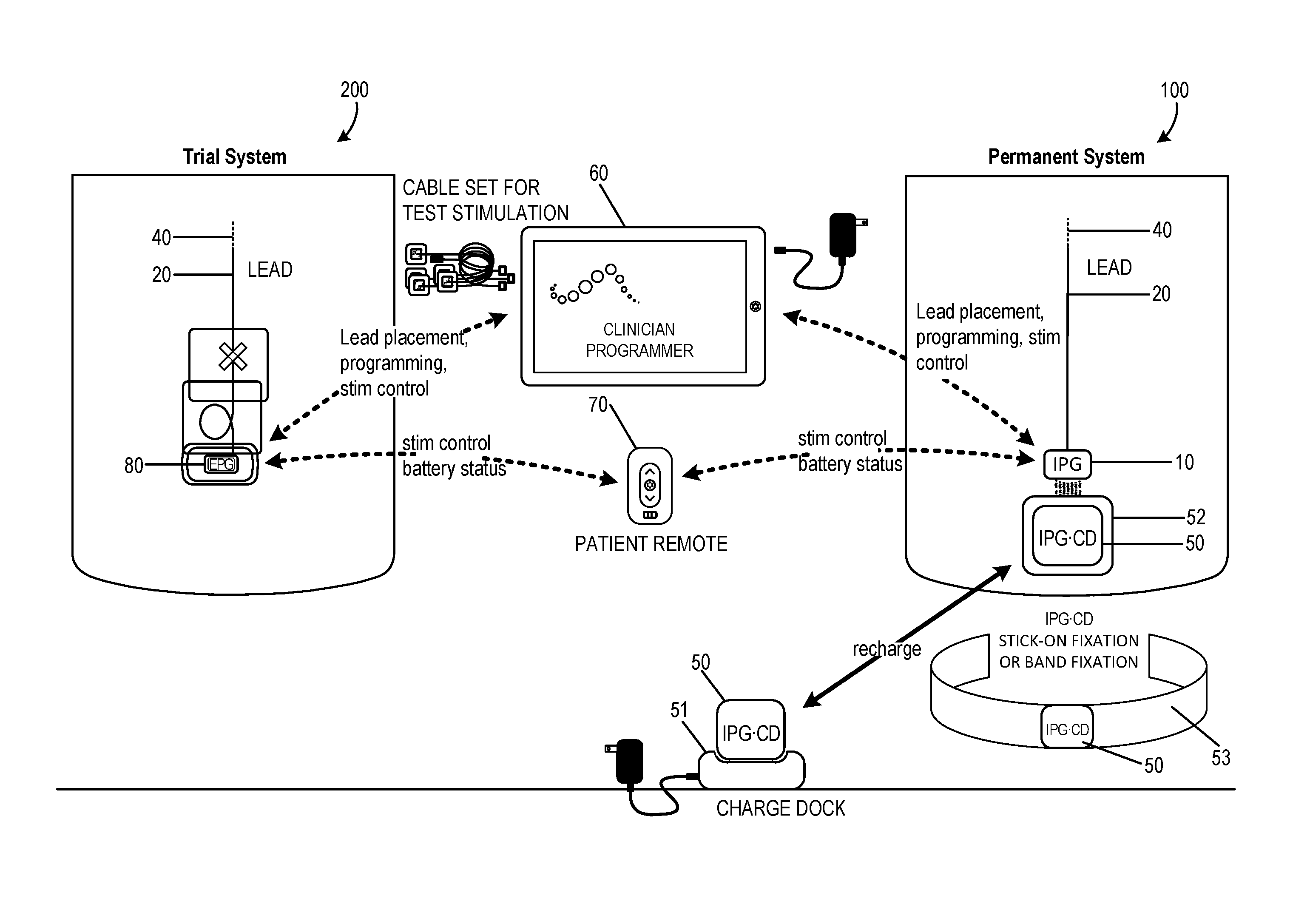

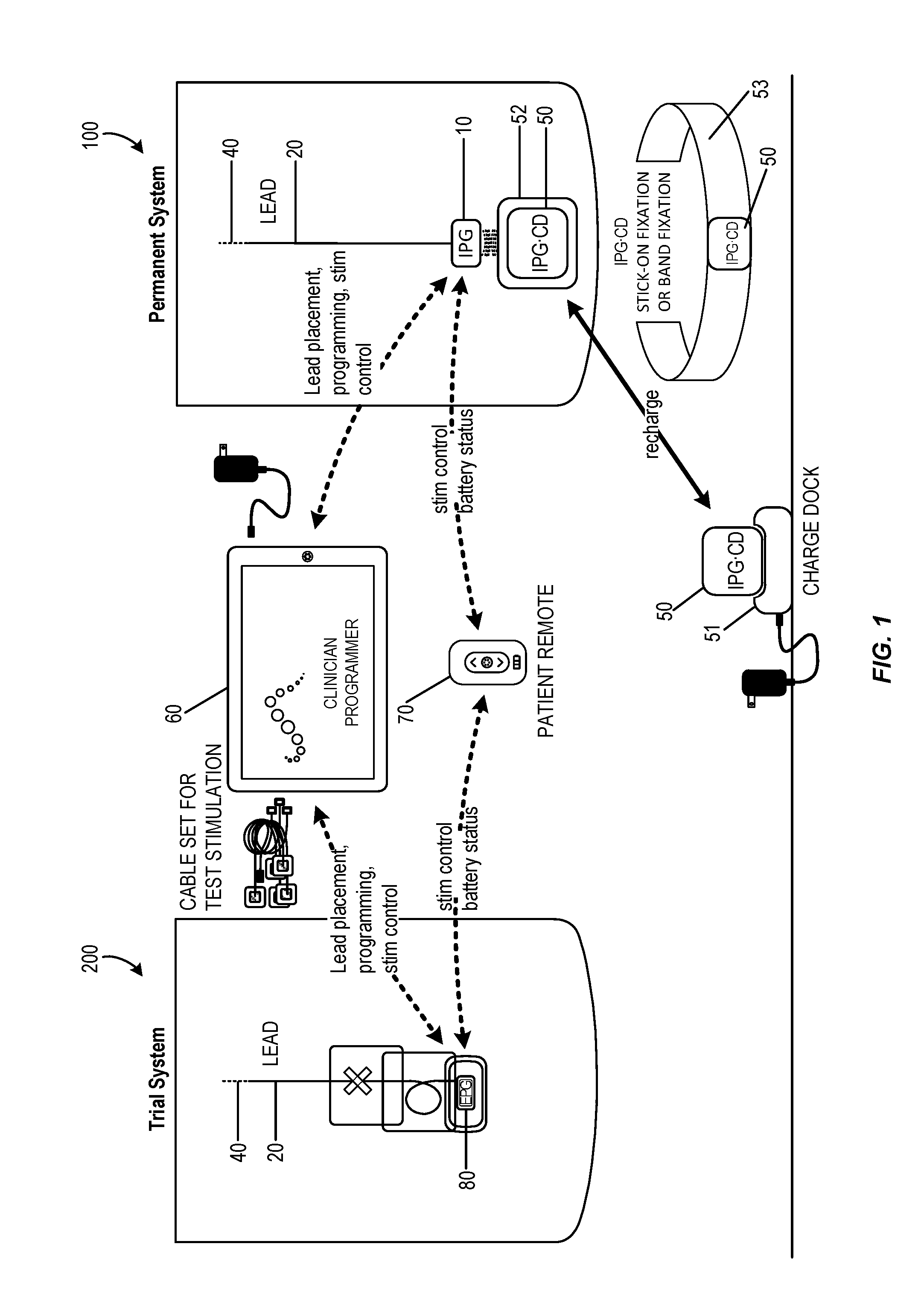

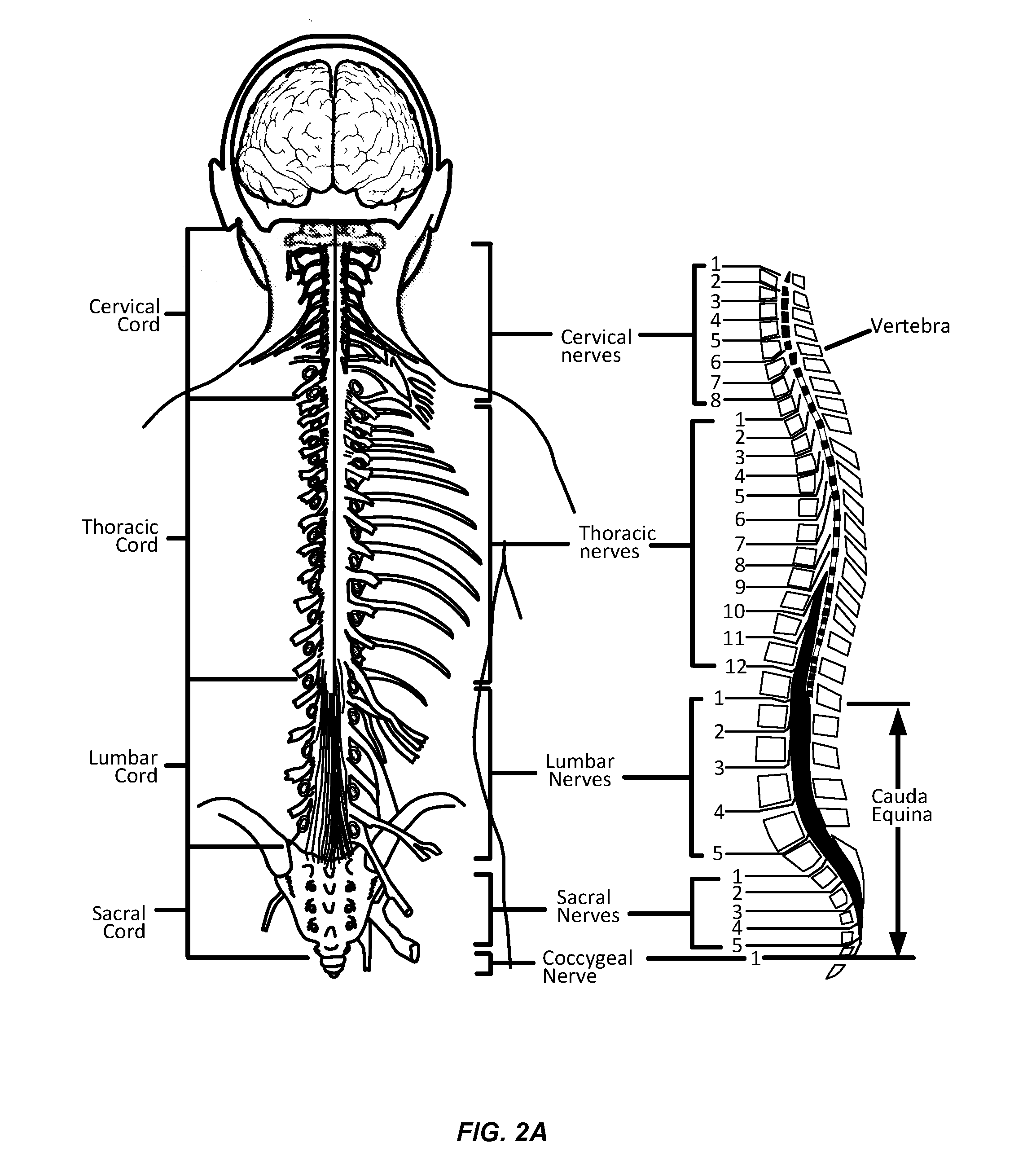

Electromyographic Lead Positioning and Stimulation Titration in a Nerve Stimulation System for Treatment of Overactive Bladder

ActiveUS20160045747A1Reducing subjective assessmentIncrease successSpinal electrodesImplantable neurostimulatorsMedicineHyperactive bladder

The present invention provides improved methods for positioning of an implantable lead in a patient with an integrated EMG and stimulation clinician programmer. The integrated clinician programmer is coupled to the implantable lead, wherein the implantable lead comprises at least four electrodes, and to at least one EMG sensing electrode minimally invasively positioned on a skin surface or within the patient. The method comprises delivering a test stimulation at a stimulation amplitude level from the integrated clinician programmer to a nerve tissue of the patient with a principal electrode of the implantable lead. Test stimulations are delivered at a same stimulation amplitude level for a same period of time sequentially to each of the four electrodes of the implantable lead. A stimulation-induced EMG motor response is recorded with the integrated clinician programmer for each test stimulation on each electrode of the implantable lead via the at least one pair of EMG sensing electrodes so as to facilitate initial positioning of the implantable lead at a target stimulation region.

Owner:AXONICS

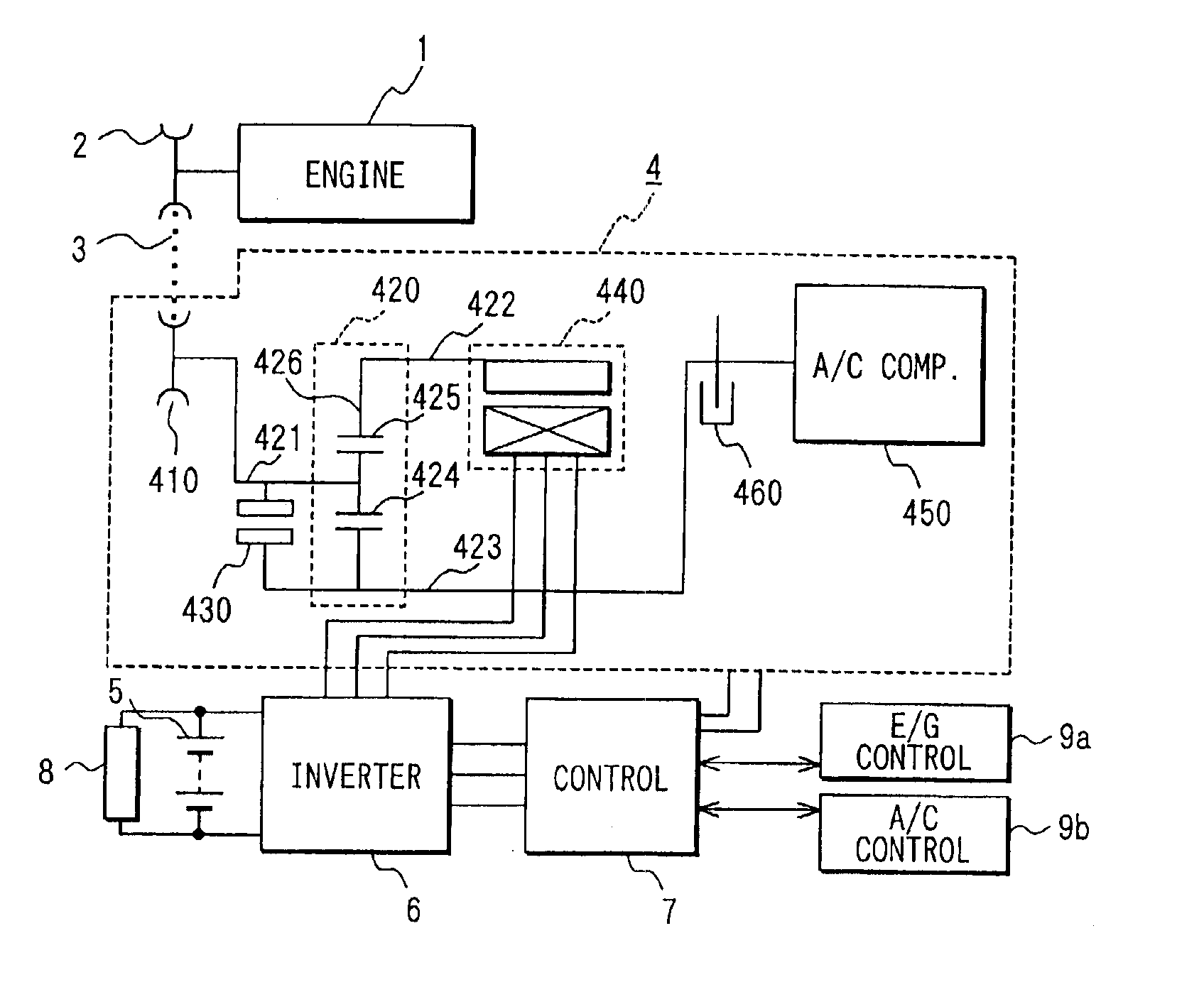

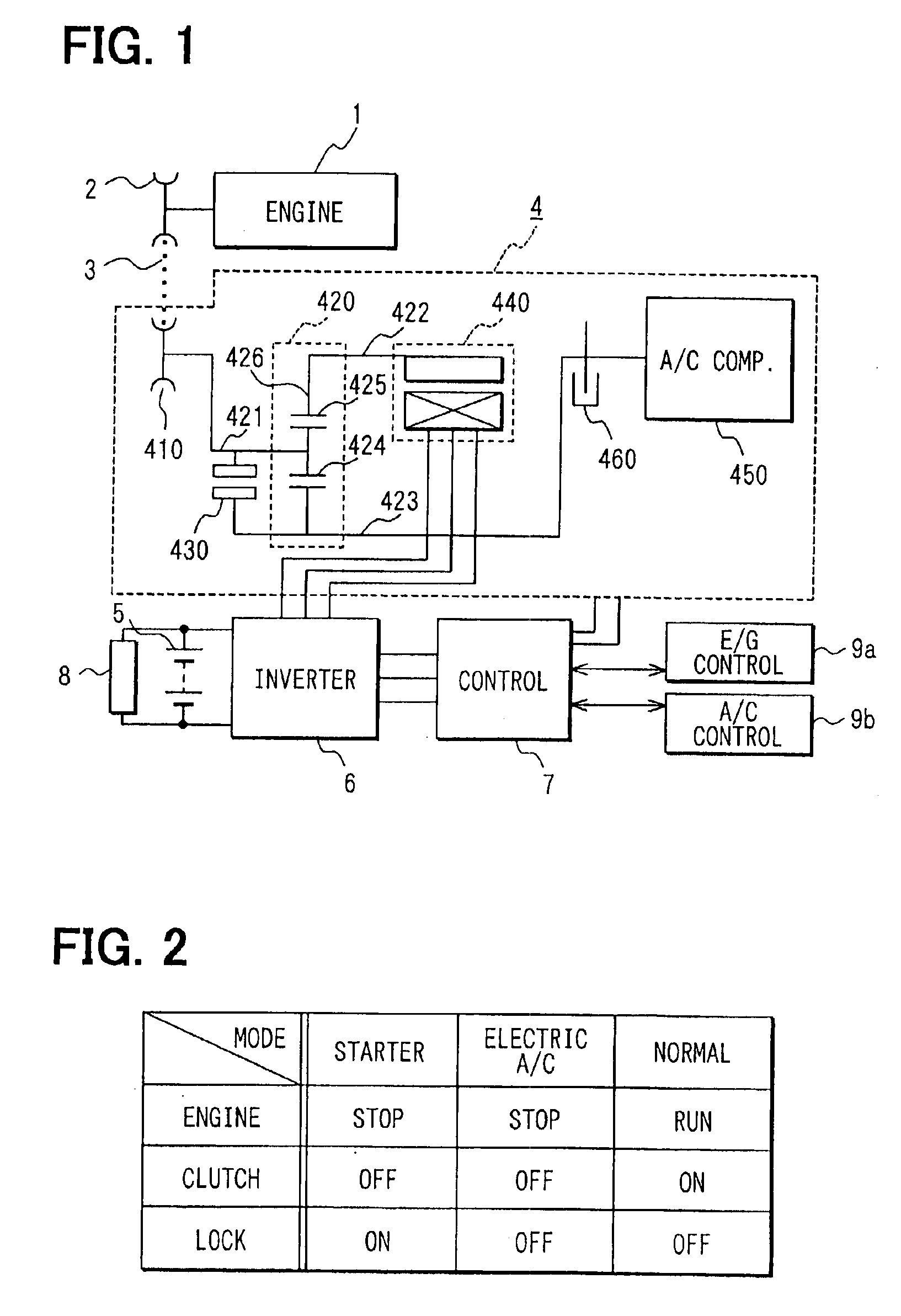

Accessory-driving equipment for an automotive vehicle

InactiveUS6863139B2Low costStable placement effectHybrid vehiclesAuxillary drivesMobile vehicleIdle speed

Accessory-driving equipment connects an engine having an idle stop system, a motor-generator and an accessory including an air-conditioner compressor that is driven even at a time when the idle stop system is operated. The accessory is driven by the engine when the engine is running and driven by the motor-generator when the idle stop system is operated. The accessory-driving equipment includes a first shaft for connecting to the engine, a second shaft for connecting to the motor-generator, a third shaft for connecting to the accessory, a lock device for locking the third shaft and a clutch. The clutch and the lock device are operated so that a torque transmitted from the engine through the first shaft is distributed to the motor-generator and the accessory, or a torque is transmitted from the motor-generator to the engine.

Owner:DENSO CORP

Integrated Electromyographic Clinician Programmer for Use with an Implantable Neurostimulator

ActiveUS20160045746A1Improve positionAccelerated programSpinal electrodesDiagnostic recording/measuringGraphical user interfaceMedicine

An integrated electromyography (EMG) and signal / stimulation generation clinician programmer may be coupled with an implantable temporary or permanent lead in a patient and at least one EMG sensing electrode minimally invasively positioned on a skin surface or within the patient. Generally, the integrated clinician programmer may comprise a portable housing, a signal / stimulation generator, and EMG signal processor, and a graphical user interface. The housing has an external surface and encloses circuitry at least partially disposed within the housing. The signal / stimulation generator may be disposed within the housing and configured to deliver test stimulation to a nerve tissue of the patient via the implantable lead. The EMG signal processor may be disposed within the housing and configured to record a stimulation-induced EMG motor response for each test stimulation via the at least one EMG sensing electrode. The graphical user interface at least partially comprises the external surface of the housing and has a touch screen display for direct user interaction or for use with a keyboard, mouse, or the like.

Owner:AXONICS

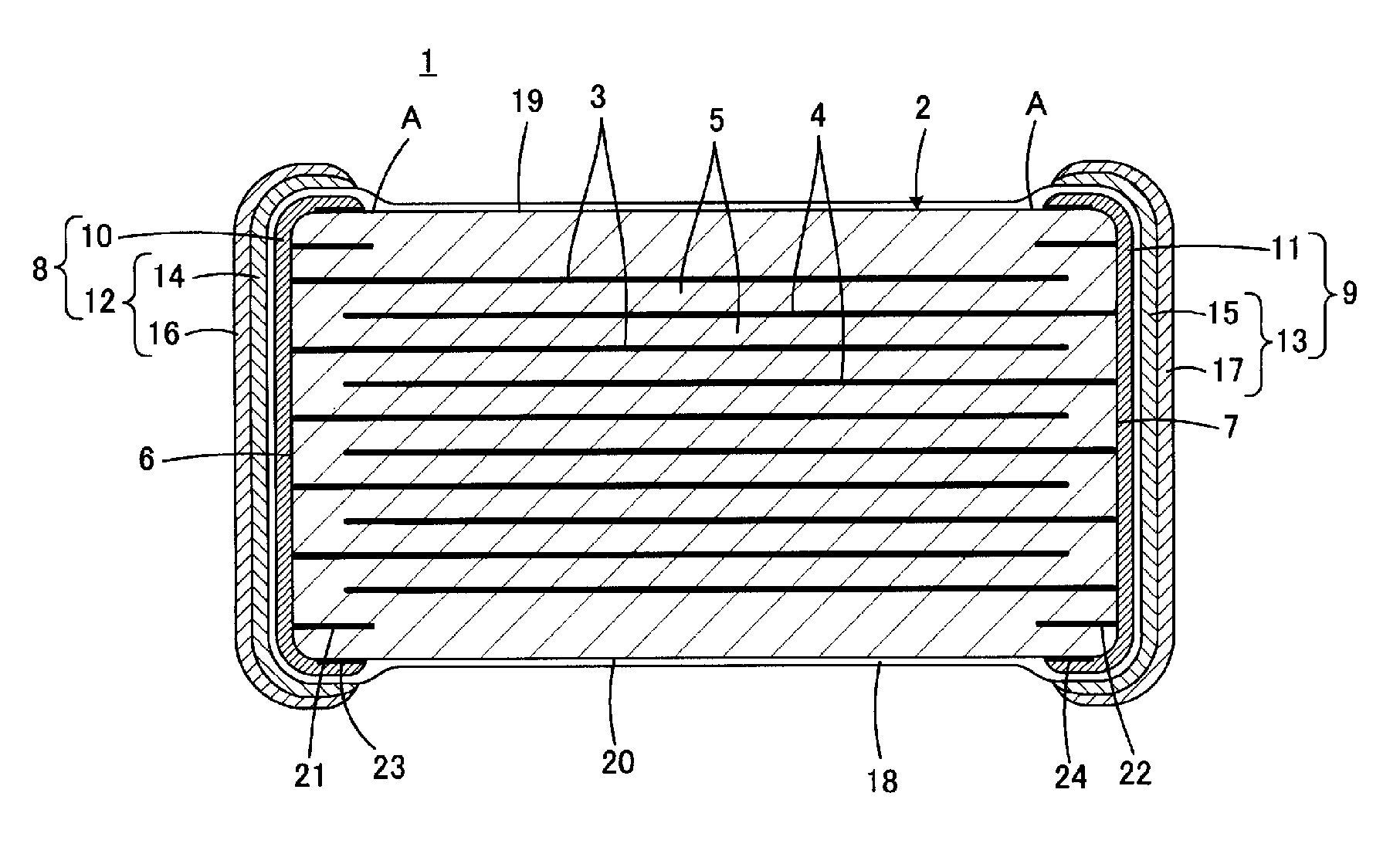

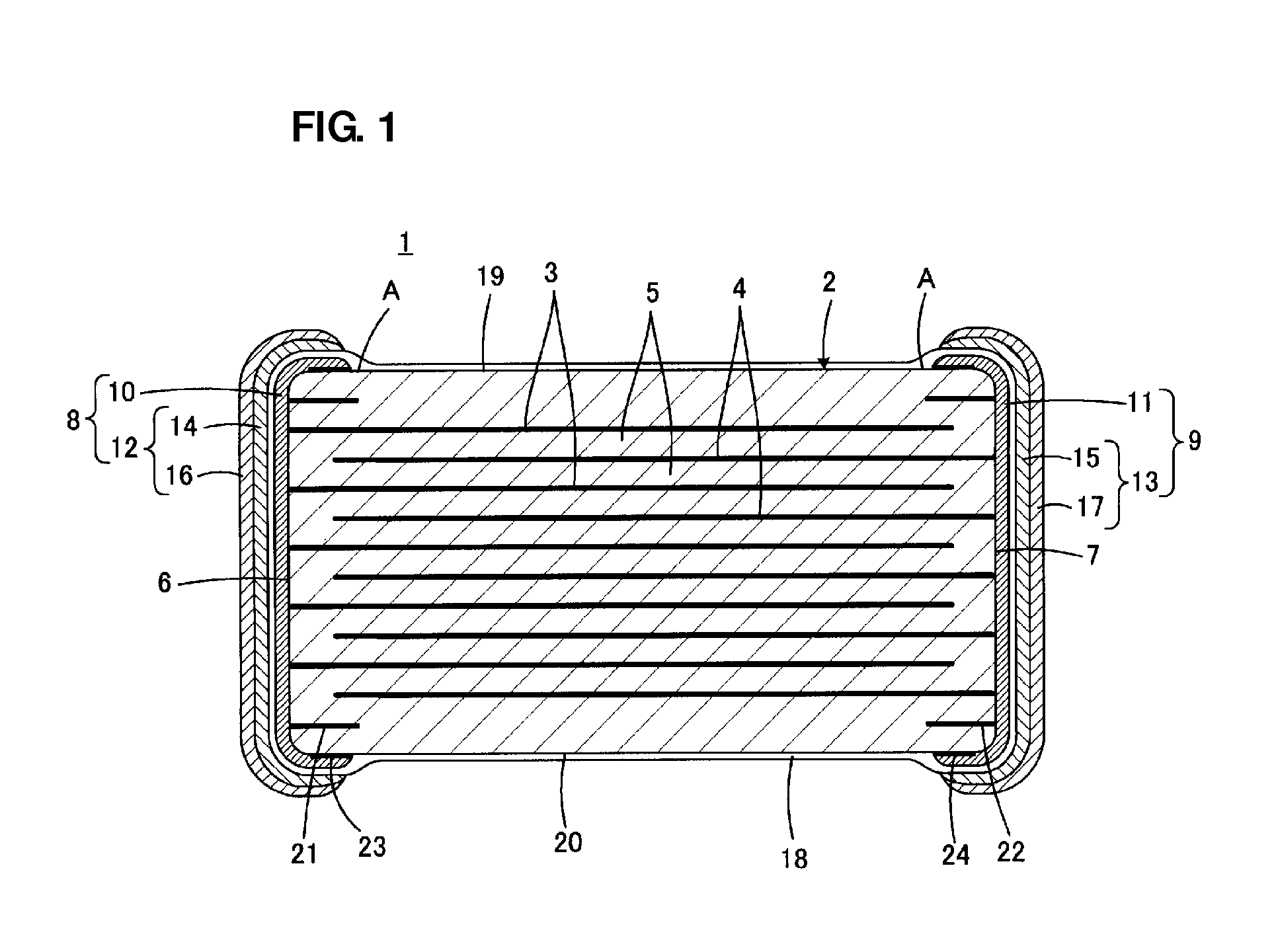

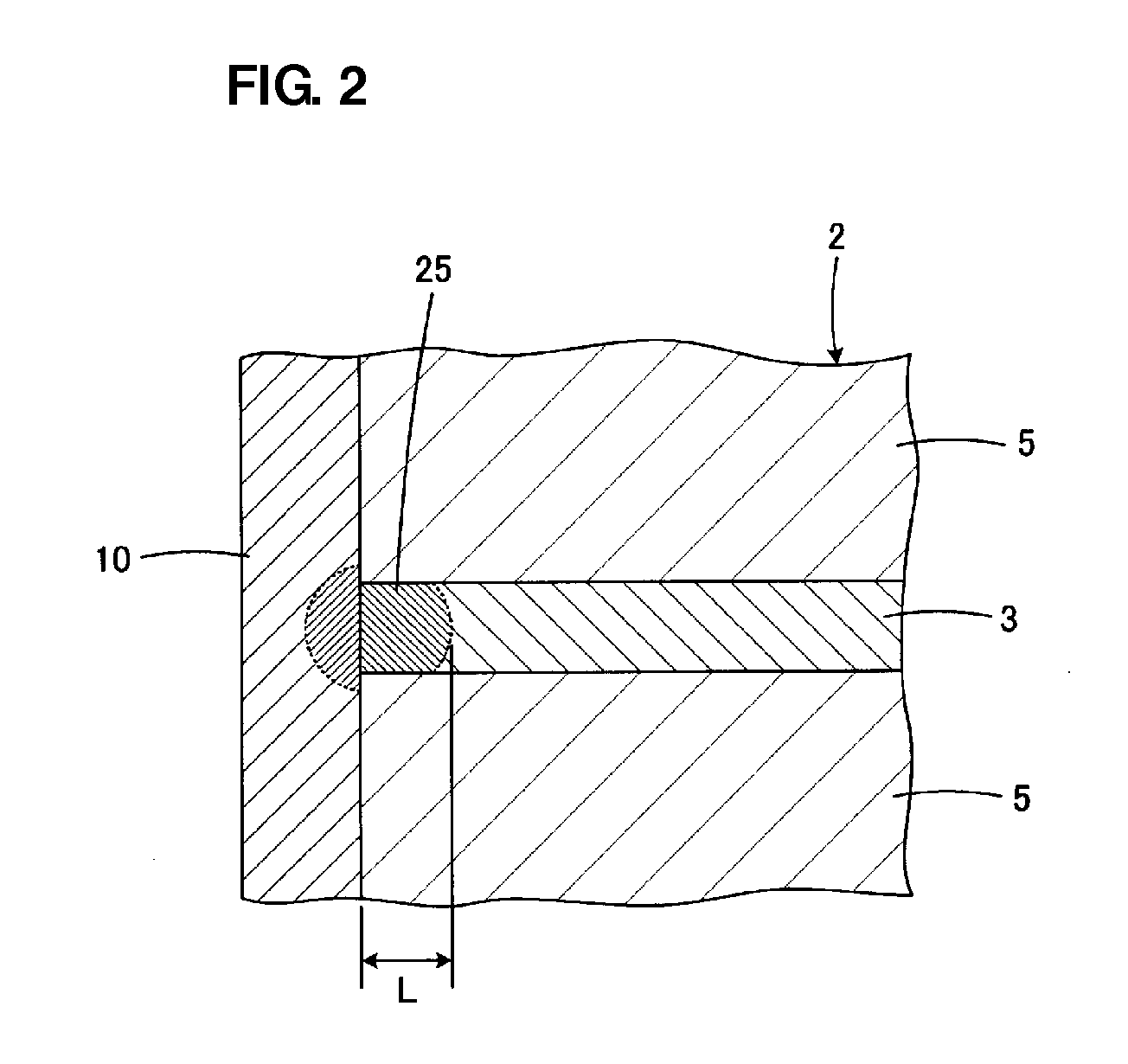

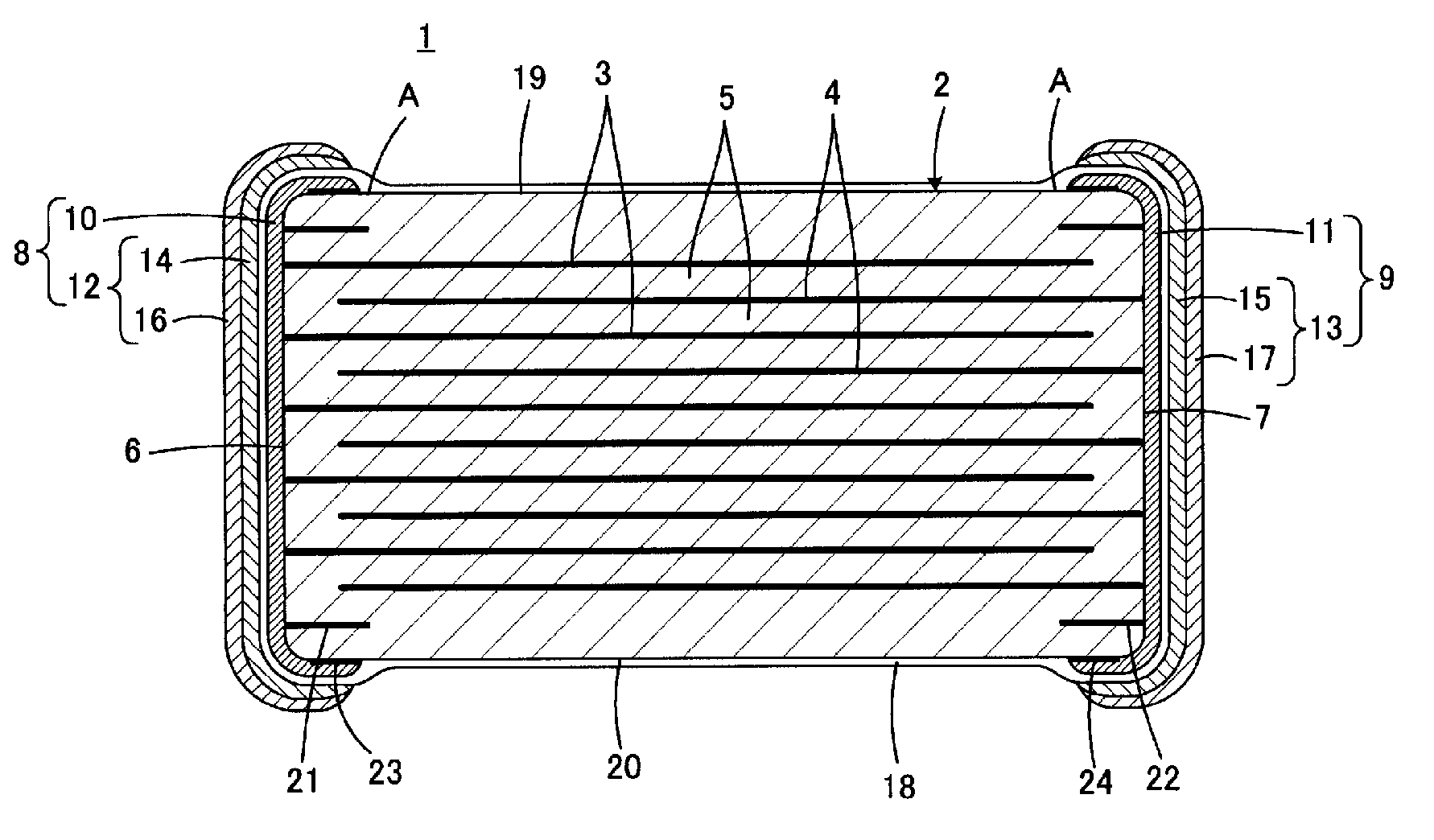

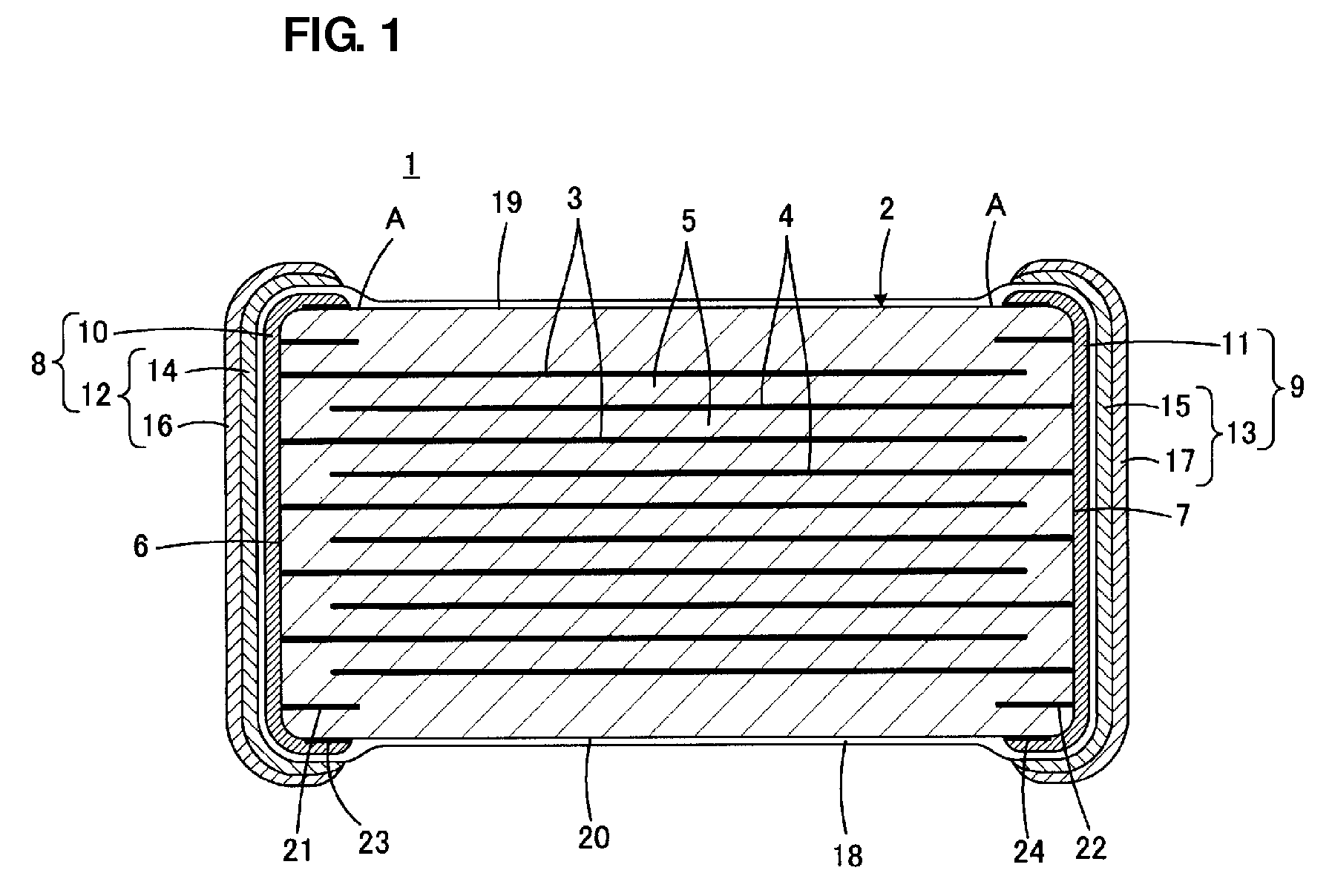

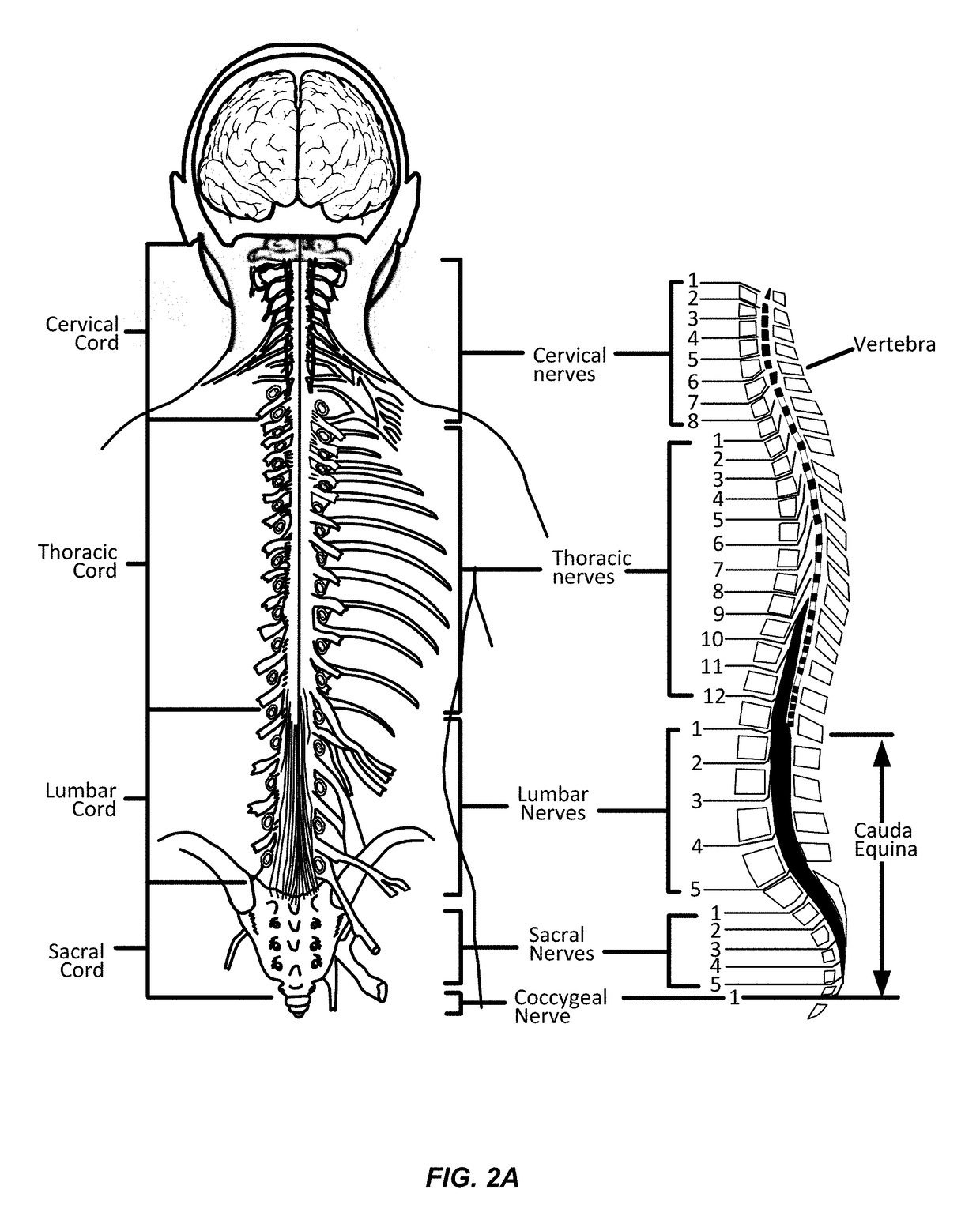

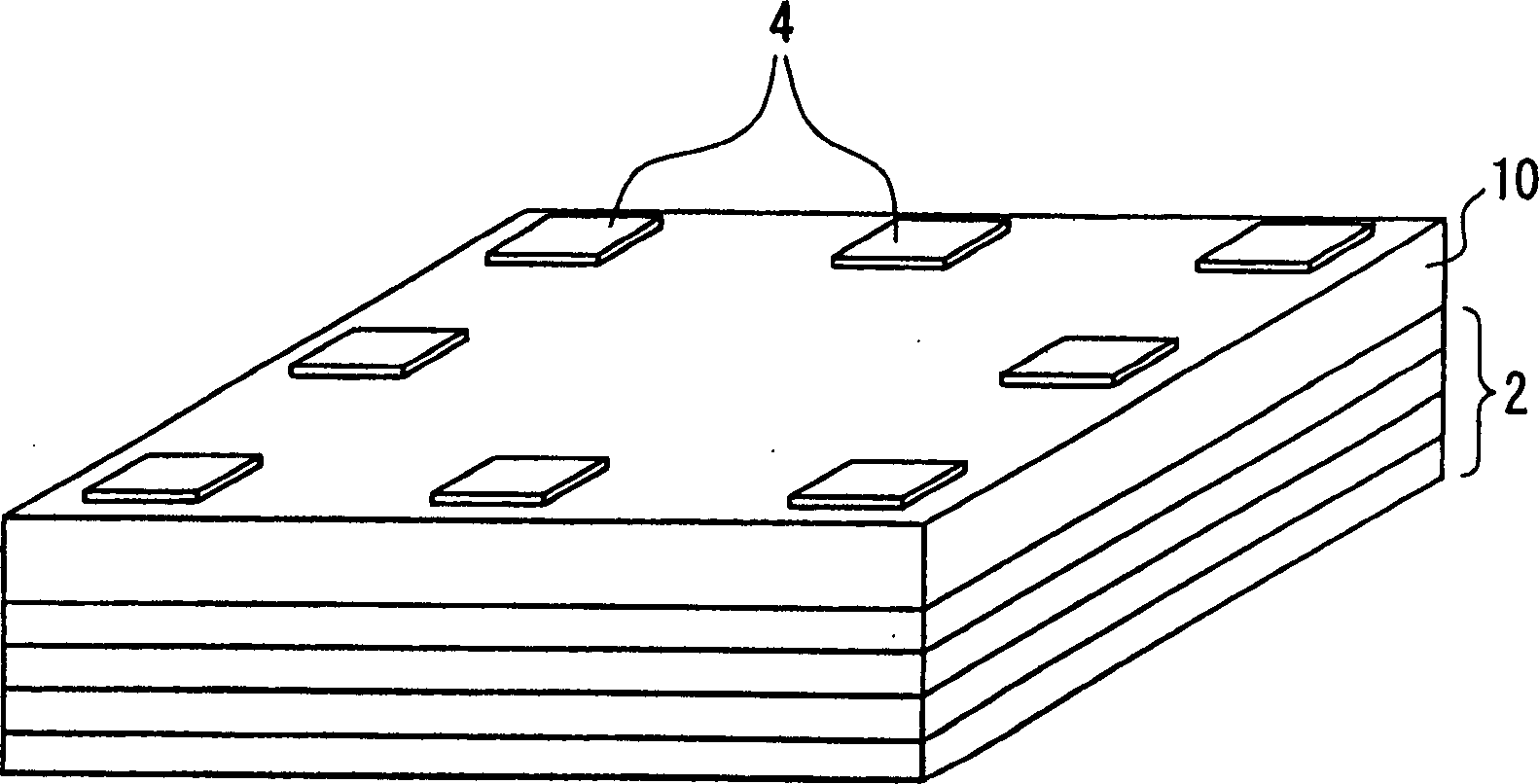

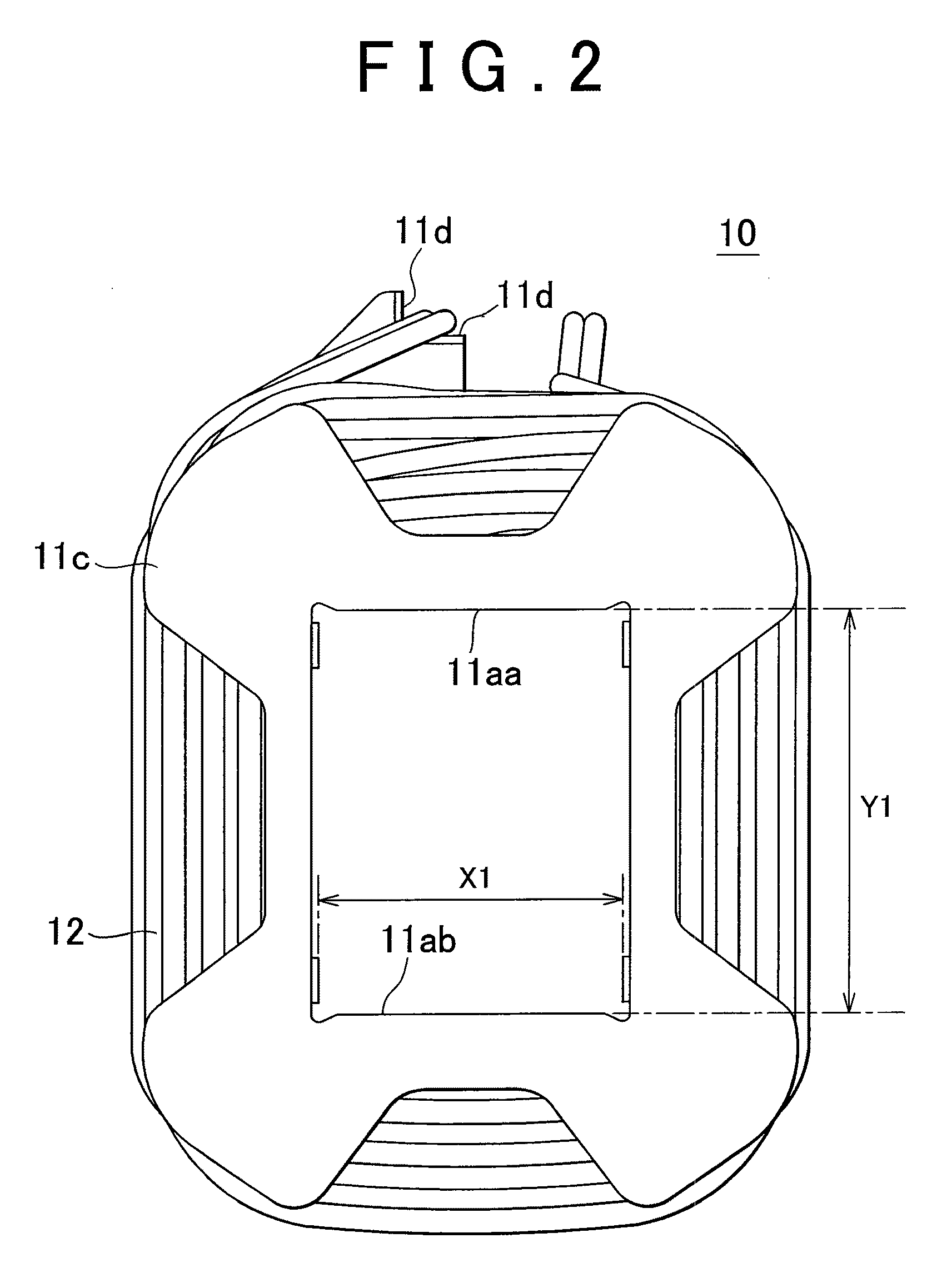

Laminated electronic component and manufacturing method therefor

ActiveUS20100290172A1Reliability be ensureImprove mount propertyFixed capacitor electrodesFixed capacitor dielectricBiomedical engineeringElectronic component

A method for manufacturing a laminated electronic component includes the steps of preparing a component main body having a laminated structure, the component main body including a plurality of internal electrodes formed therein, and each of the internal electrodes being partially exposed on an external surface of the component main body, and forming an external terminal electrode on the external surface of the component main body such that the external terminal electrode is electrically connected to the internal electrodes. The step of forming the external terminal electrode includes the steps of forming a first plating layer on exposed surfaces of the internal electrodes of the component main body, applying a water repellant at least on a surface of the first plating layer and on a section in the external surface of the component main body at which an end edge of the first plating layer is located, and then forming a second plating layer on the first plating layer having the water repellant applied thereon.

Owner:MURATA MFG CO LTD

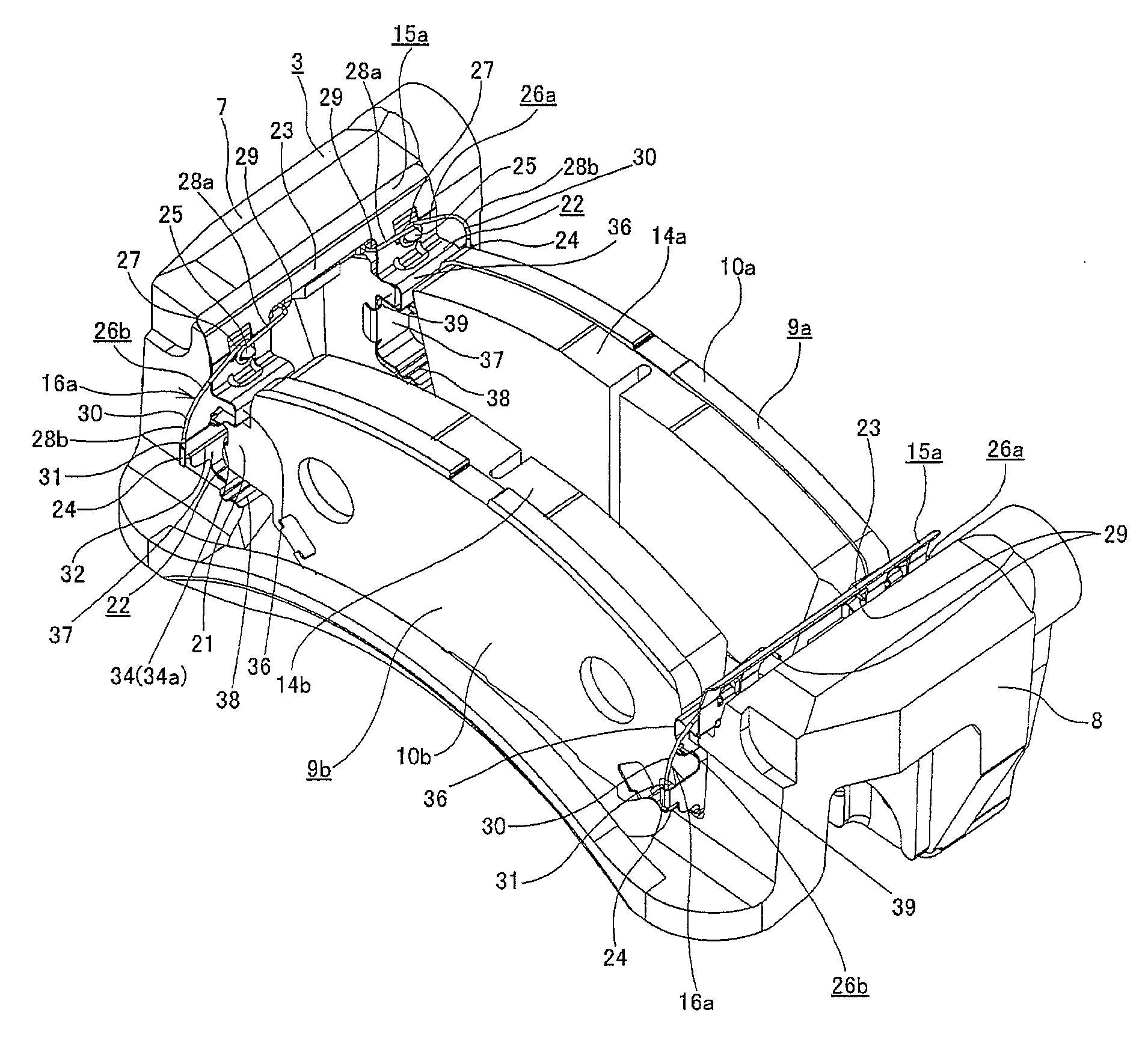

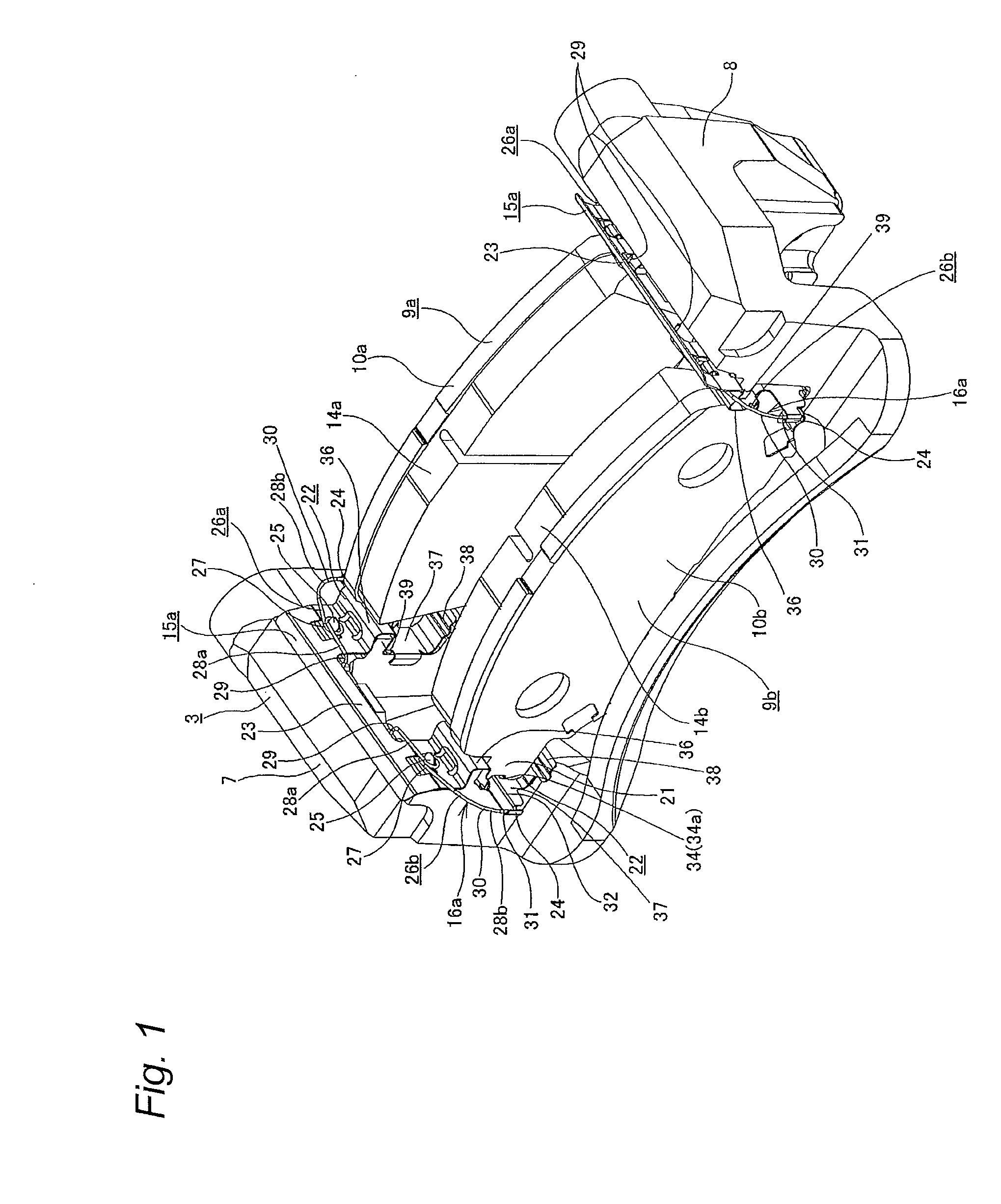

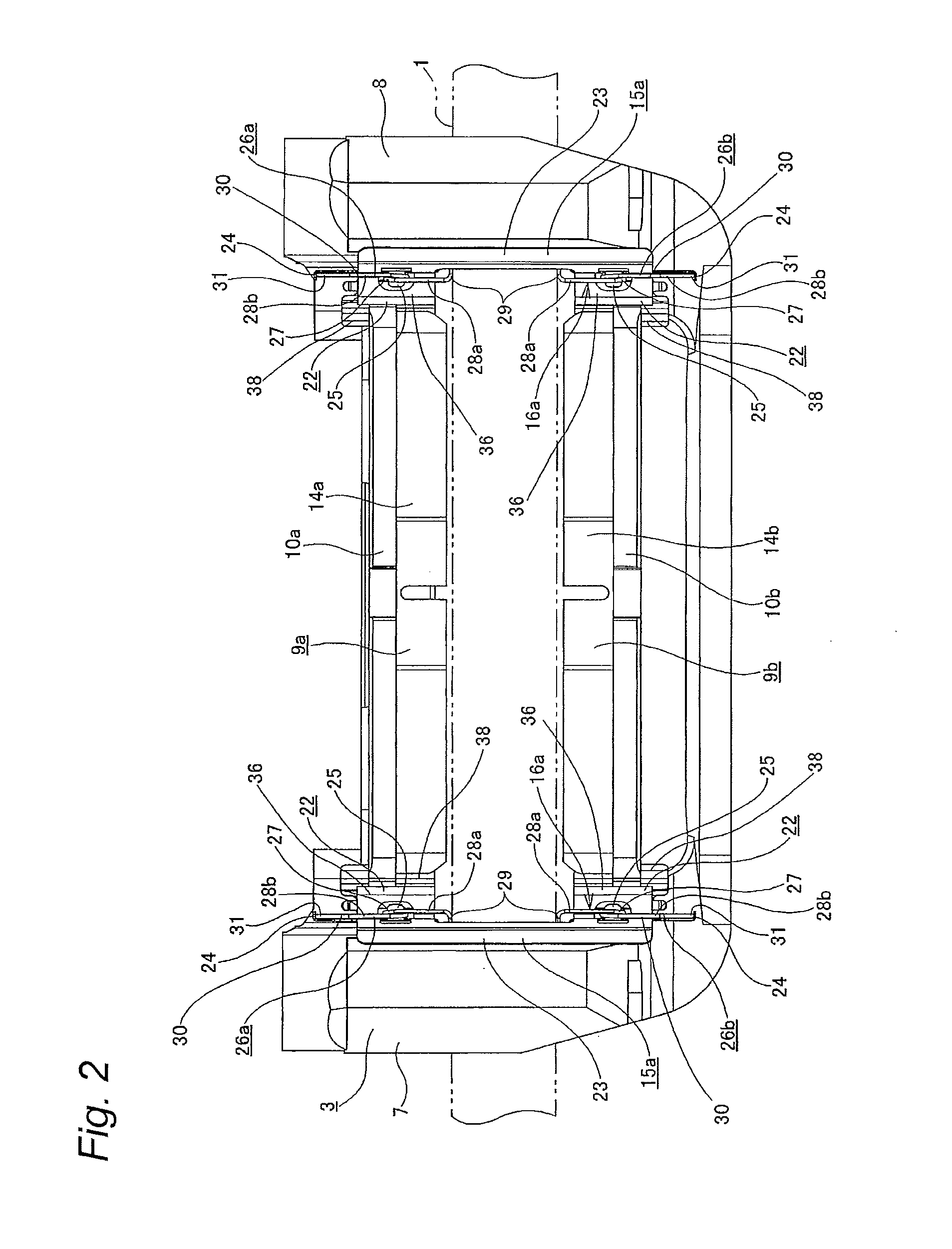

Floating disc brake, method of assembling same, and assemblies consisting of pad clips and return springs

ActiveUS20130025981A1Mounting operability can be improvedReduce material costsBraking element arrangementsAxially engaging brakesEngineeringTorsion spring

Disclosed is a structure such that when pad clips are to be mounted, it is possible to handle return springs and the pad clips as integral articles, thereby facilitating mounting work. Constraining sections are provided at both axial ends of each of the pad clips. Furthermore, the return springs are composed of inner spring elements and outer spring elements. These two types of spring elements are helical torsion springs provided with helical sections. Abutting sections are provided on the spring elements, respectively. The abutting sections are pressed against the inner surfaces of the constraining sections by elastic restoring forces. Moreover, the central axes of the coil sections are substantially oriented in the rotational direction of the rotor.

Owner:AKEBONO BRAKE IND CO LTD

Power transmission mechanism

InactiveUS6640917B2Avoid it happening againReduce manufacturing costManual control with multiple controlled membersElectric propulsion mountingDrive wheelDrive shaft

Owner:HONDA MOTOR CO LTD

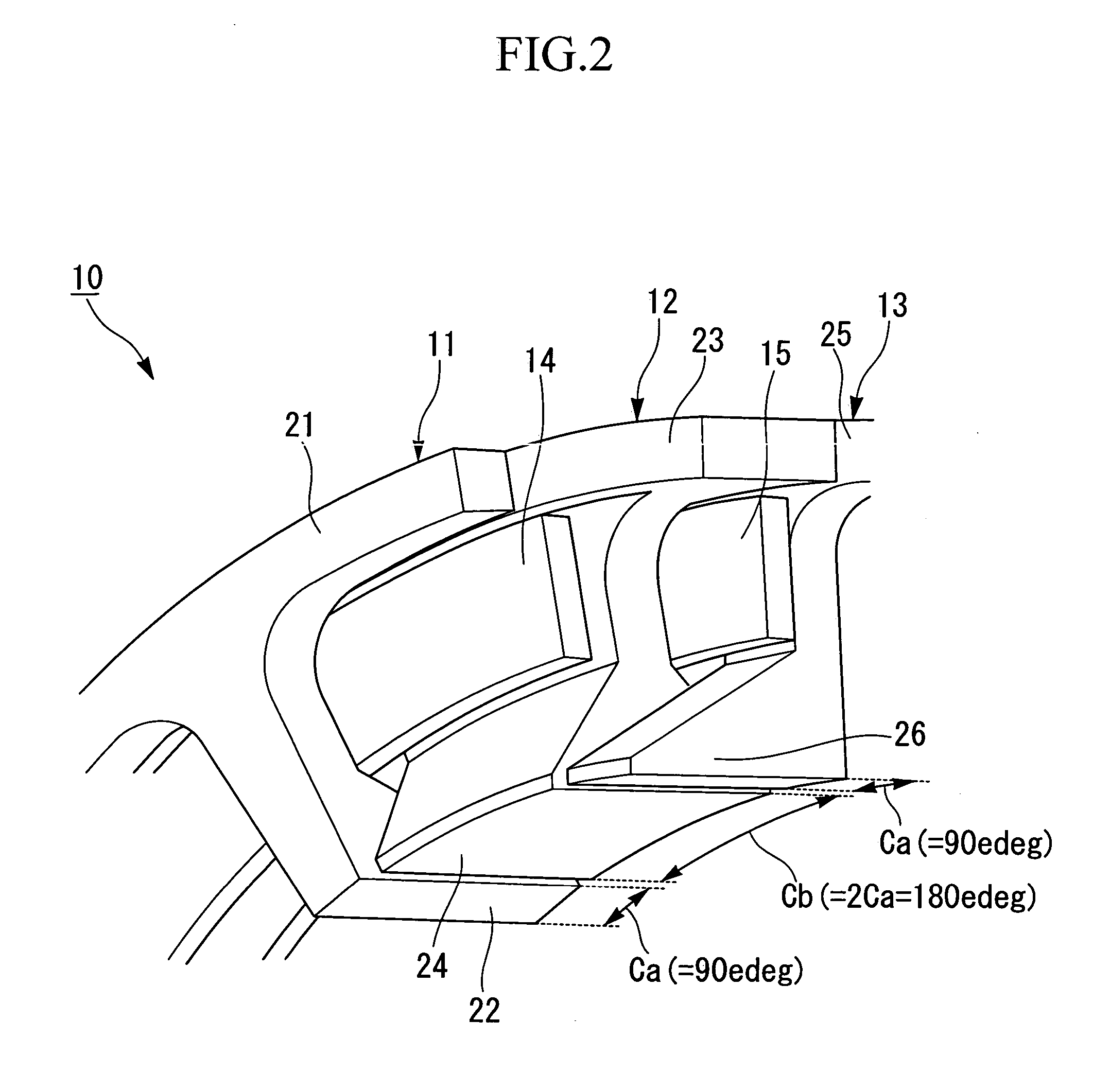

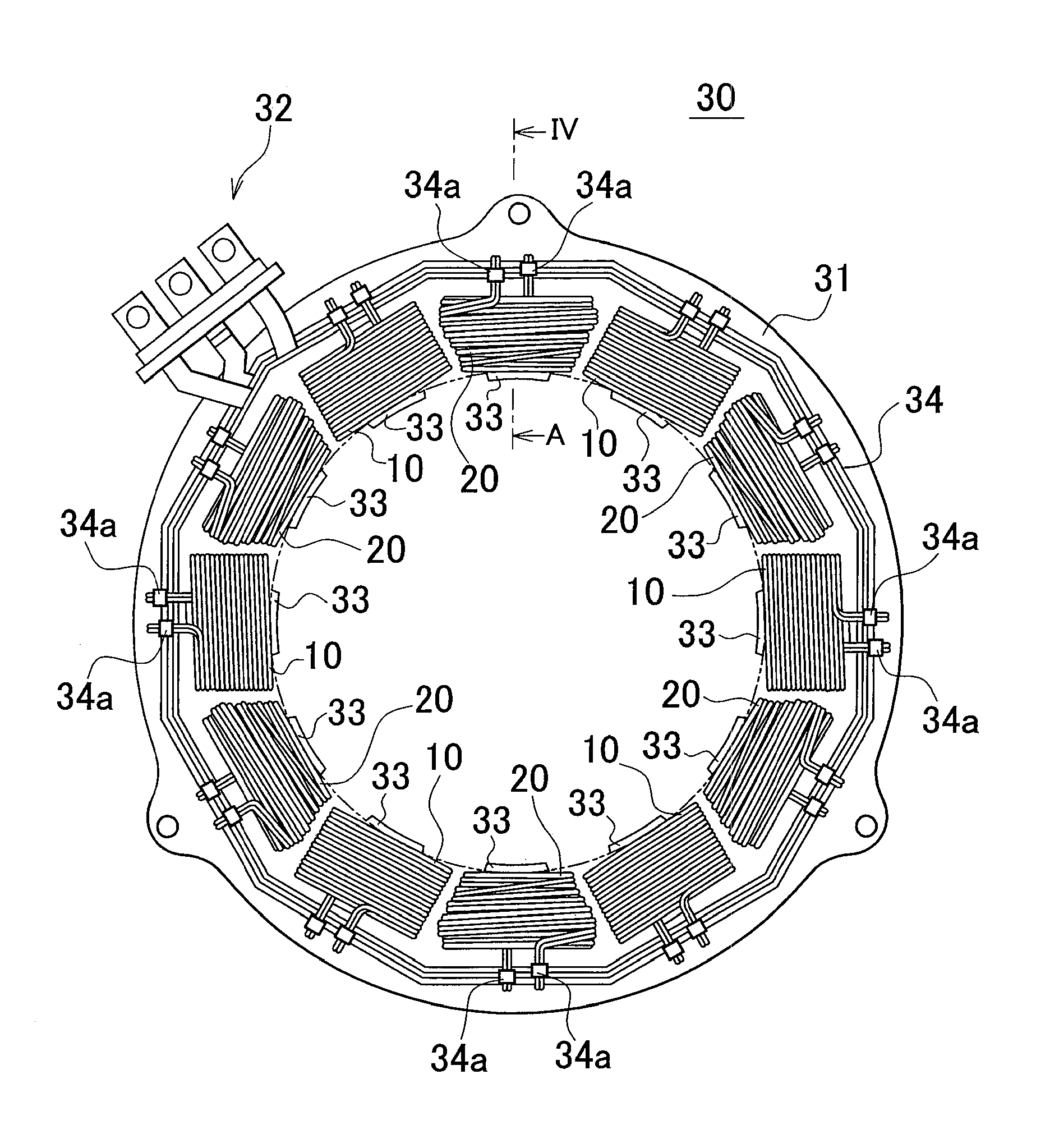

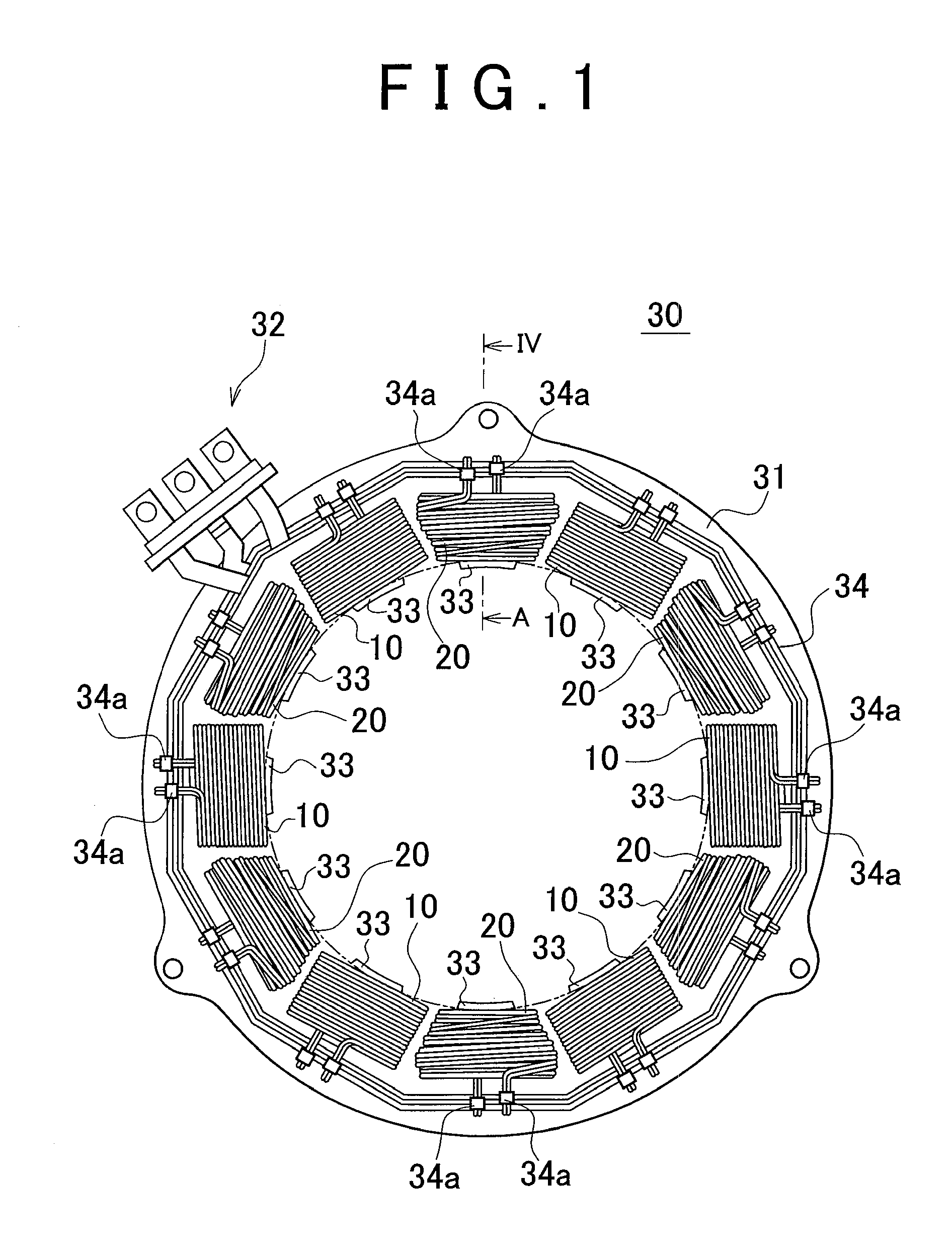

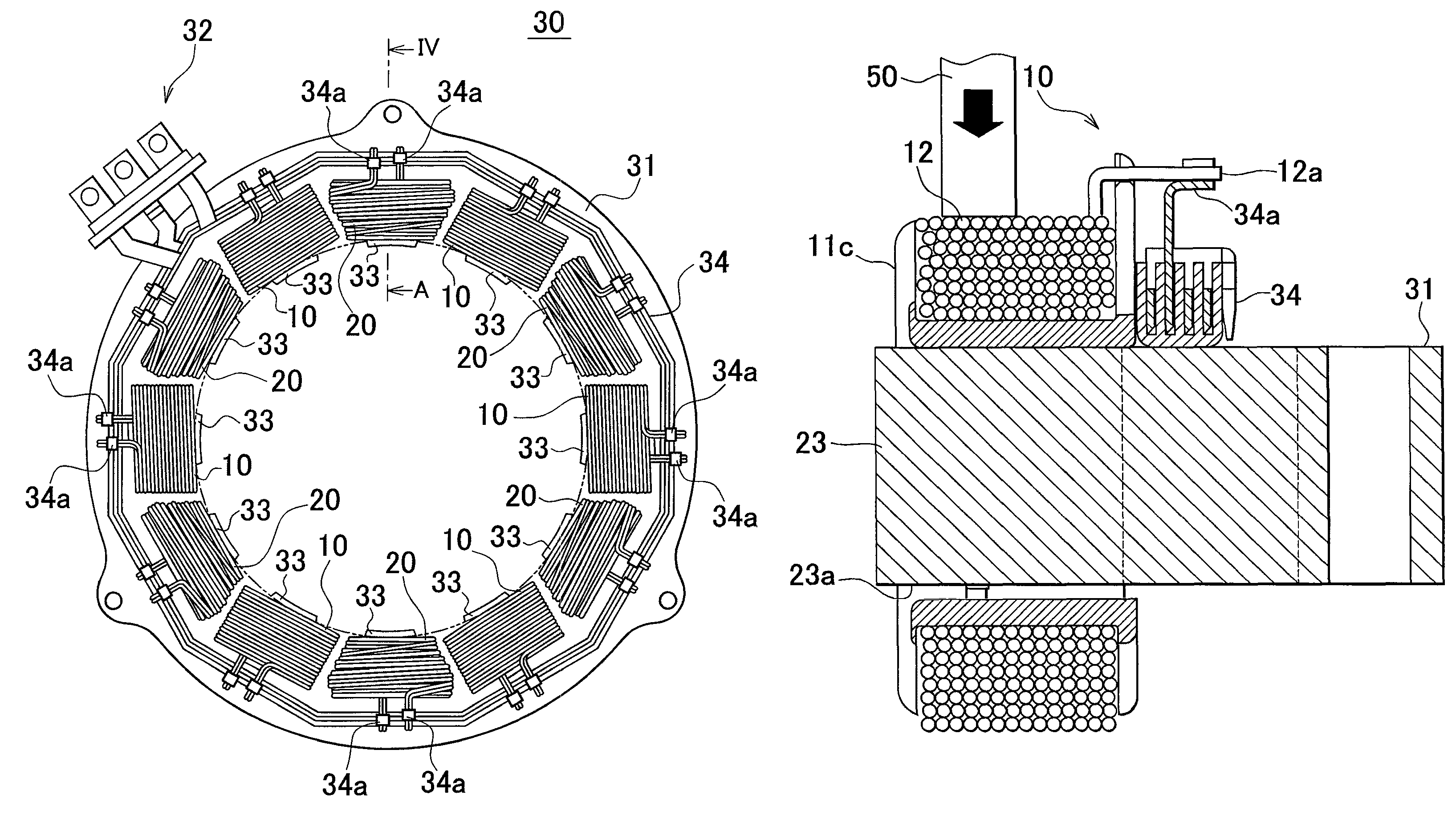

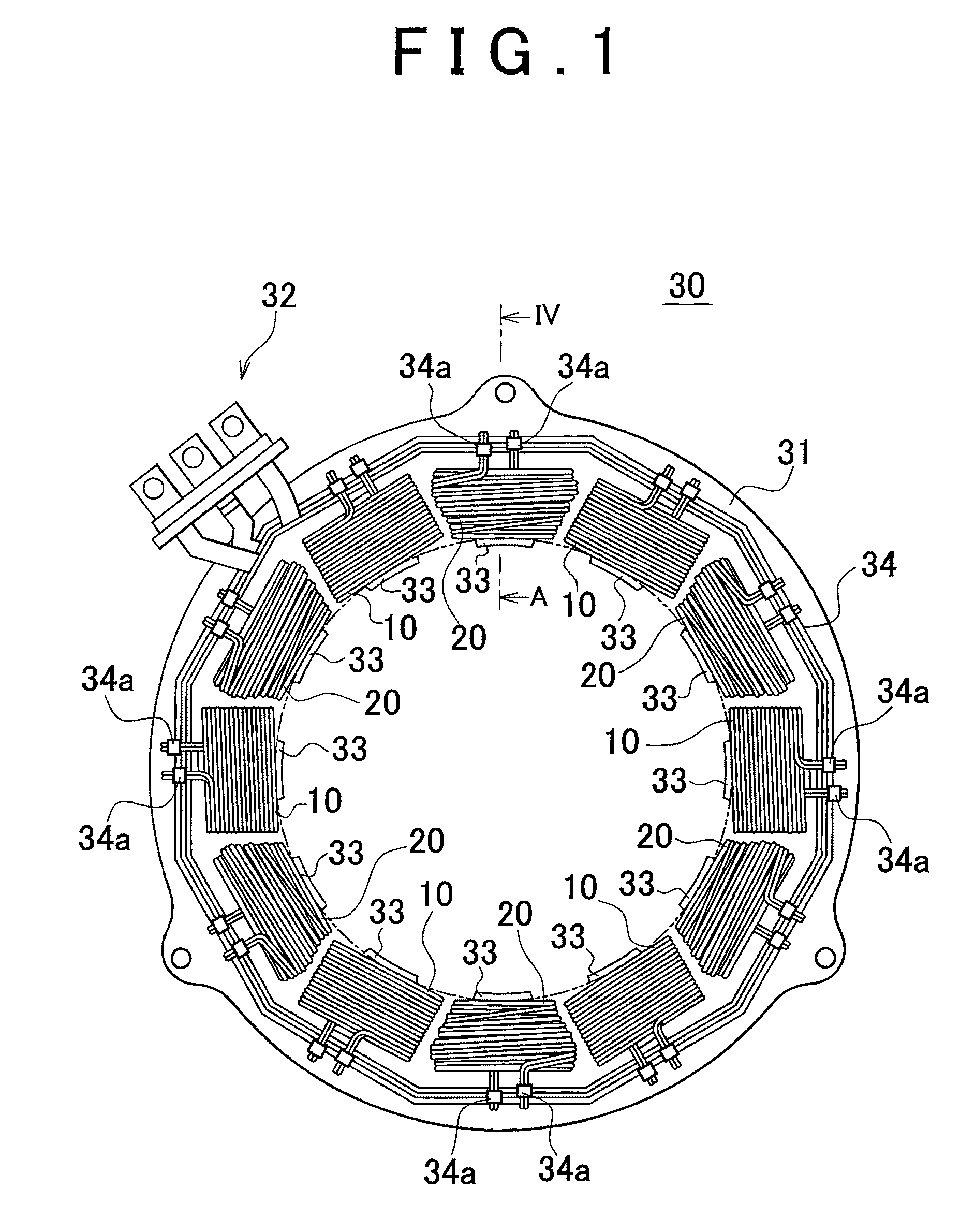

Stator, motor, and method of manufacturing such stator

InactiveUS20060197397A1Simple manufacturing processImprove production efficiencySynchronous generatorsAsynchronous induction motorsThree-phasePhysics

A stator includes mutually independent annular coils and of two phases and teeth and of three phases.

Owner:HONDA MOTOR CO LTD

Wiper blade

ActiveUS8151406B2Good lookingImprove versatilityWindow cleanersVehicle cleaningEngineeringWindshield

A wiper blade 13 comprises a rubber holder 17 attached to a tip of a wiper arm 14 and a blade rubber 16 supported by the rubber holder 17. The rubber holder 17 is formed into a U-shaped cross section, and an intermediate portion of the blade rubber 16 is covered with the rubber holder 17. Also, both sides of the rubber holder 17 are provided with covers 18 in a longitudinal direction in series. Each of the cover 18 becomes rotatable to the rubber holder 17 in a direction perpendicular to a front windshield glass 12, and exposed portions from the rubber holder 17 of the blade rubber 16 are covered with these covers 18 in an elastically deformable state.

Owner:MITSUBA CORP

Laminated electronic component and manufacturing method therefor

ActiveUS8149566B2Additional componentStable placement effectFixed capacitor electrodesFixed capacitor dielectricElectricityElectronic component

A method for manufacturing a laminated electronic component includes the steps of preparing a component main body having a laminated structure, the component main body including a plurality of internal electrodes formed therein, and each of the internal electrodes being partially exposed on an external surface of the component main body, and forming an external terminal electrode on the external surface of the component main body such that the external terminal electrode is electrically connected to the internal electrodes. The step of forming the external terminal electrode includes the steps of forming a first plating layer on exposed surfaces of the internal electrodes of the component main body, applying a water repellant at least on a surface of the first plating layer and on a section in the external surface of the component main body at which an end edge of the first plating layer is located, and then forming a second plating layer on the first plating layer having the water repellant applied thereon.

Owner:MURATA MFG CO LTD

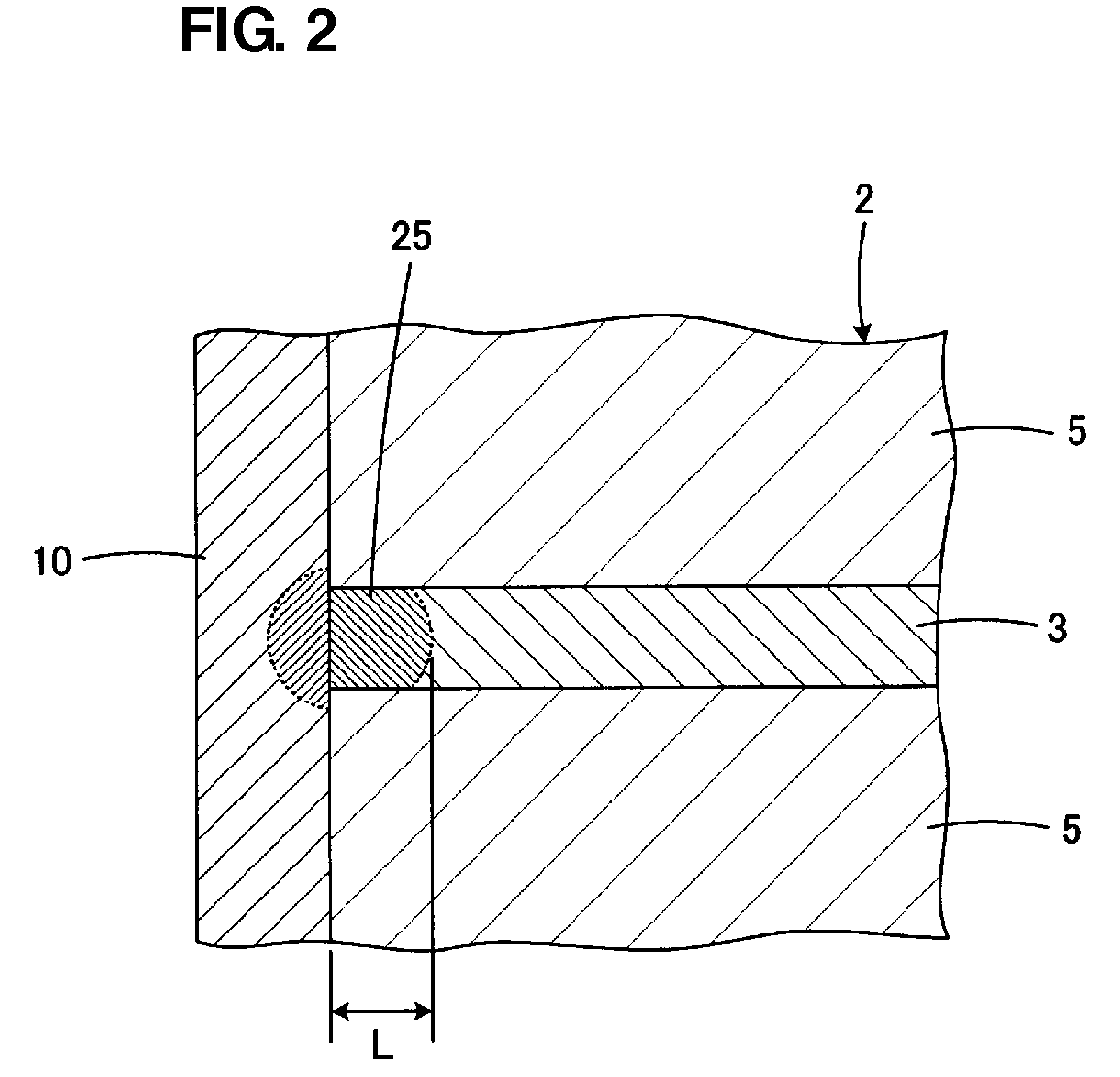

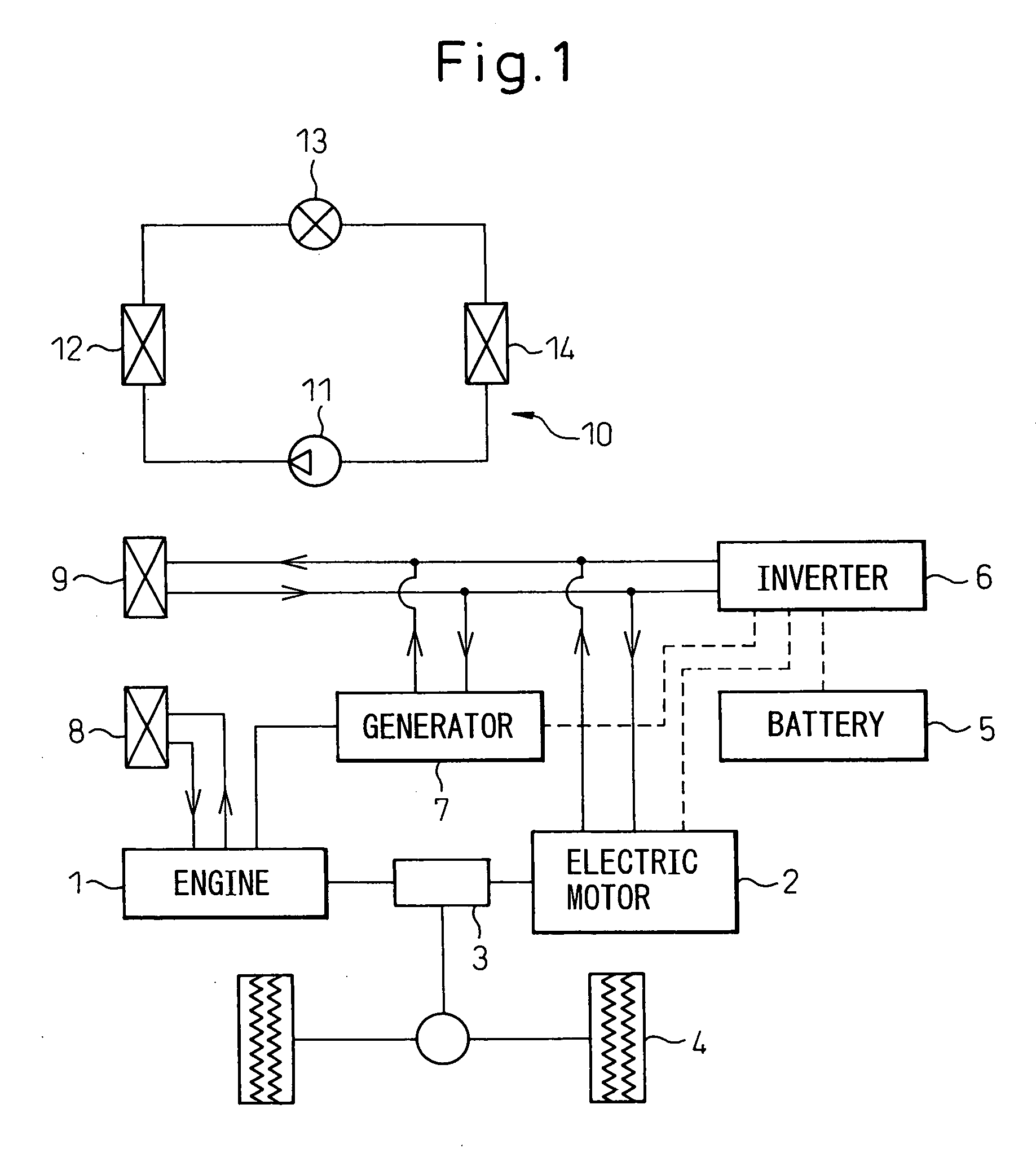

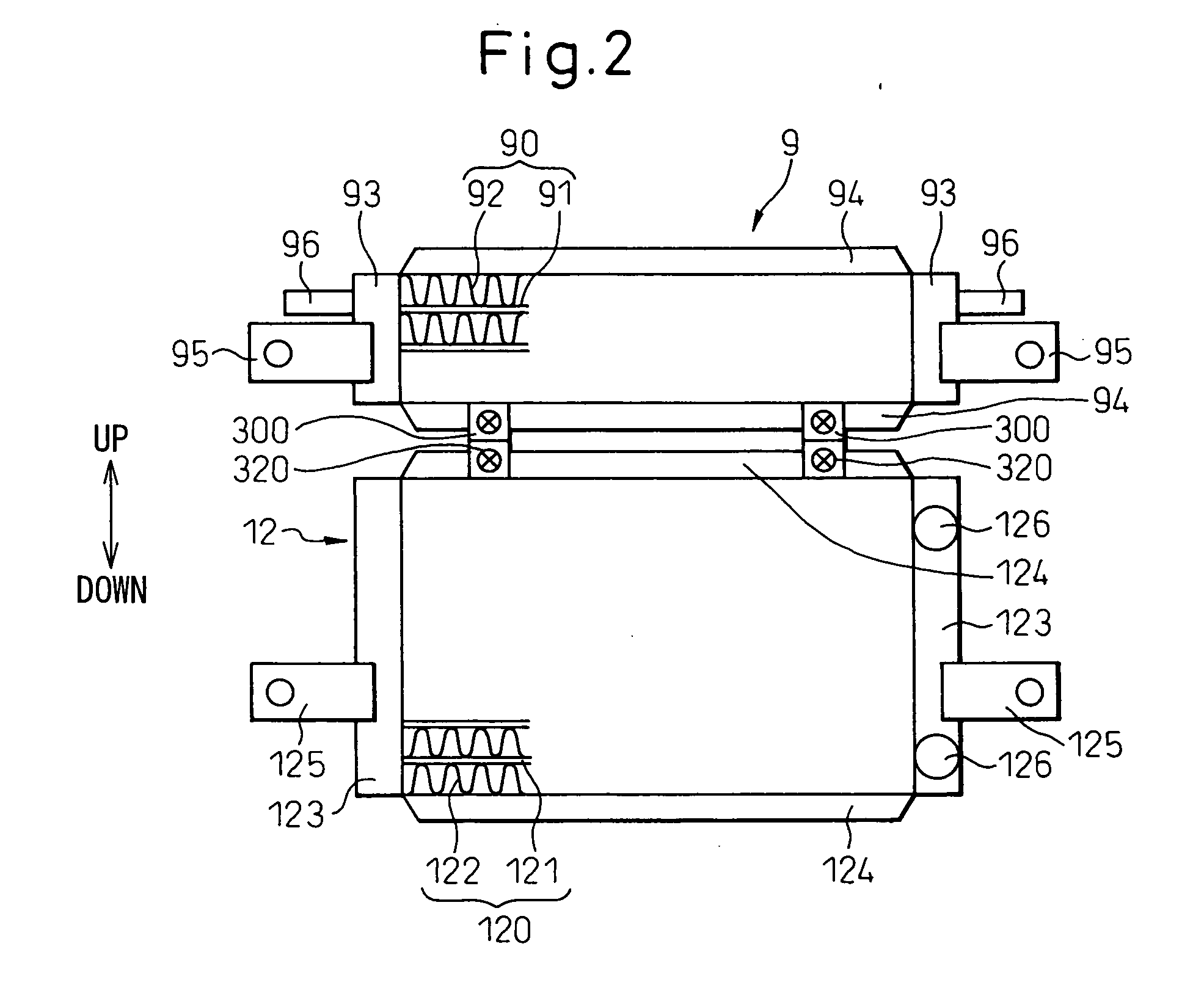

Cooling system used for hybrid-powered automobile

InactiveUS20060278365A1Improve performanceStable placement effectSpeed controllerLiquid coolingTemperature differenceEngineering

A radiator 9 for electric parts use, which cools an inverter and others relating to the control of an electric motor, and a condenser 12 for condensing refrigerant are arranged in parallel with each other with respect to the direction of an air flow on an upstream side of the air flow of a radiator 8 for engine use. Due to the above arrangement, as the air temperatures at the inlets of the radiator 8 for electric parts use and the condenser 12 are low, a temperature difference between air and cooling water and a temperature difference between air and refrigerant are increased, and it becomes possible to enhance the performance of the radiator 8 for electric parts use and the condenser 12.

Owner:SANADA RYOUICHI +2

Stator mounting method

InactiveUS20090230793A1Reduce in quantityReduce dispersionSynchronous generatorsWindingsEngineeringLower face

In a stator mounting method in which a coil unit is inserted into a stator core and a lead wire protruding from the coil unit is inserted into and mounted on a terminal portion of the stator core, the lead wire is passed through a lead wire pullout portion located at a predetermined position of a coil frame body, a height from an inner peripheral upper face of the coil frame body to the lead wire pullout portion is equalized with a distance from a core upper face of the stator core to a lead wire insertion position inner peripheral lower face of the terminal portion, and the core upper face of the stator core is held in contact with an inner peripheral upper face of the coil frame body after the lead wire is inserted into the terminal portion.

Owner:TOYOTA JIDOSHA KK

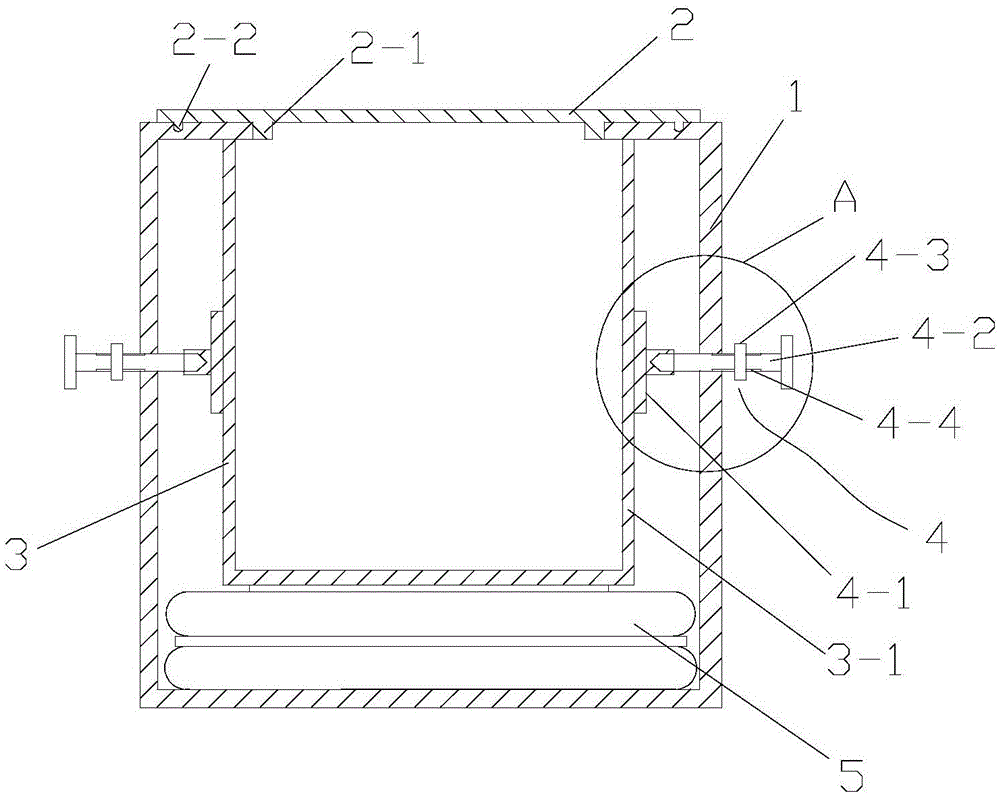

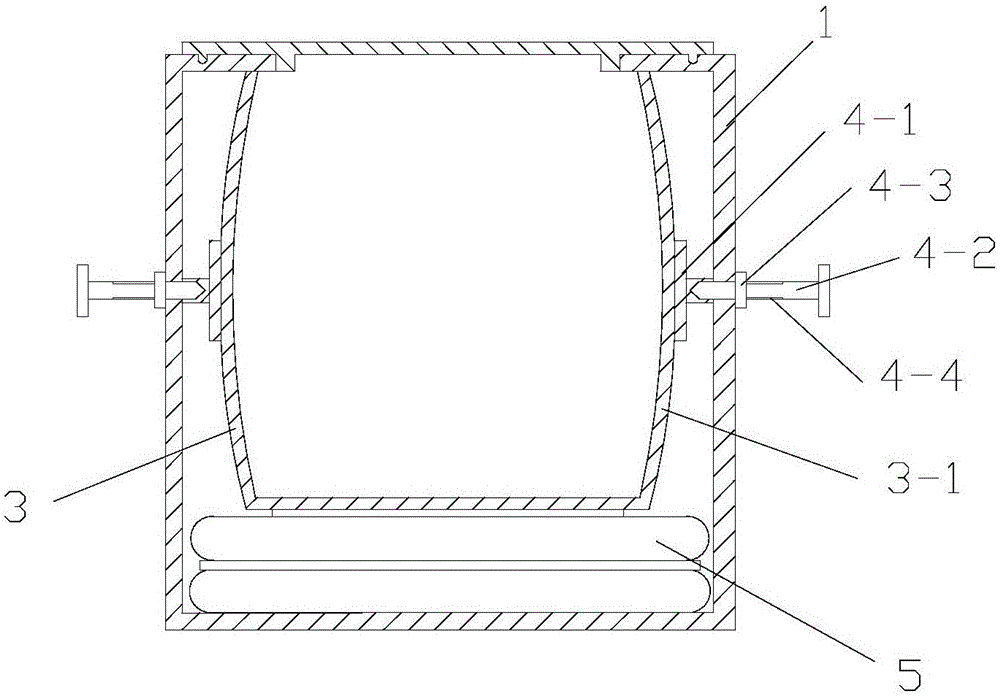

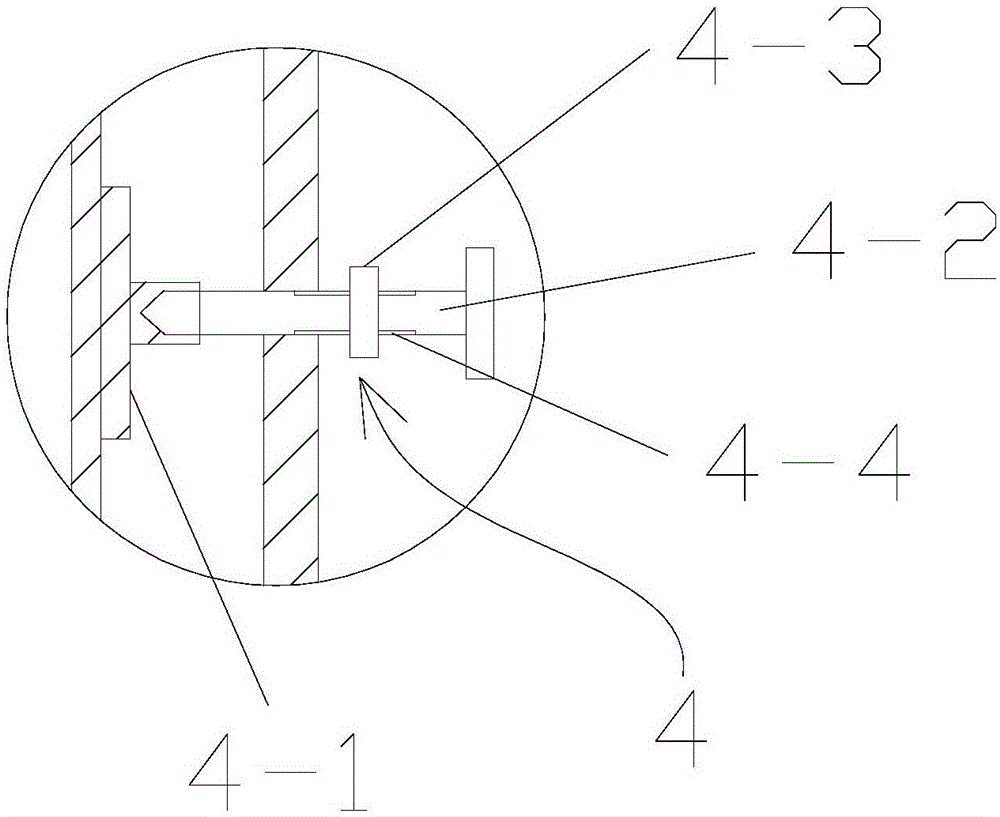

Shock absorption packaging box

InactiveCN105151482AStable placement effectGood shockproof effectContainers to prevent mechanical damageInternal fittingsAir springAbsorption effect

The invention discloses a shock absorption packaging box. The shock absorption packaging box comprises box bodies and a box cover. The box bodies include the inner box body and the outer box body. The lateral walls of the inner box body and the lateral walls of the outer box body are separated, and at least one lateral wall of the inner box body is an elastic plate capable of deforming in an arc shape and expanding outwards. The shock absorption packaging box further comprises an outward pulling part used for outwards pulling the elastic plate to deform the elastic plate. The shock absorption packaging box comprises an air spring which is arranged between the bottom wall of the inner box body and the bottom wall of the outer box body and used for shock absorption. The elastic plate needs to restore due to the elasticity, thereby forming certain squeezing force toward the inside of the box body to filled objects. The gaps among the objects are adjusted through the squeezing force, the objects are prevented from moving relatively, a whole is roughly formed, and therefore a stable placement effect is achieved, and collision and damage to the objects caused by relative movement of the objects are avoided. In addition, the air spring is arranged, so that longitudinally upward shock on the inner box body is absorbed. The shock absorption effect is good, and the objects are prevented from being damaged.

Owner:重庆市合川区华丰包装有限公司

Integrated electromyographic clinician programmer for use with an implantable neurostimulator

ActiveUS10092762B2Improve utility and successStable placement effectSpinal electrodesDiagnostic recording/measuringGraphical user interfaceMedicine

An integrated electromyography (EMG) and signal / stimulation generation clinician programmer may be coupled with an implantable temporary or permanent lead in a patient and at least one EMG sensing electrode minimally invasively positioned on a skin surface or within the patient. Generally, the integrated clinician programmer may comprise a portable housing, a signal / stimulation generator, and EMG signal processor, and a graphical user interface. The signal / stimulation generator may be disposed within the housing and configured to deliver test stimulation to a nerve tissue of the patient via the implantable lead. The EMG signal processor may be disposed within the housing and configured to record a stimulation-induced EMG motor response for each test stimulation via the at least one EMG sensing electrode. The graphical user interface at least partially comprises the external surface of the housing and has a touch screen display for direct user interaction or a keyboard, mouse, or the like.

Owner:AXONICS

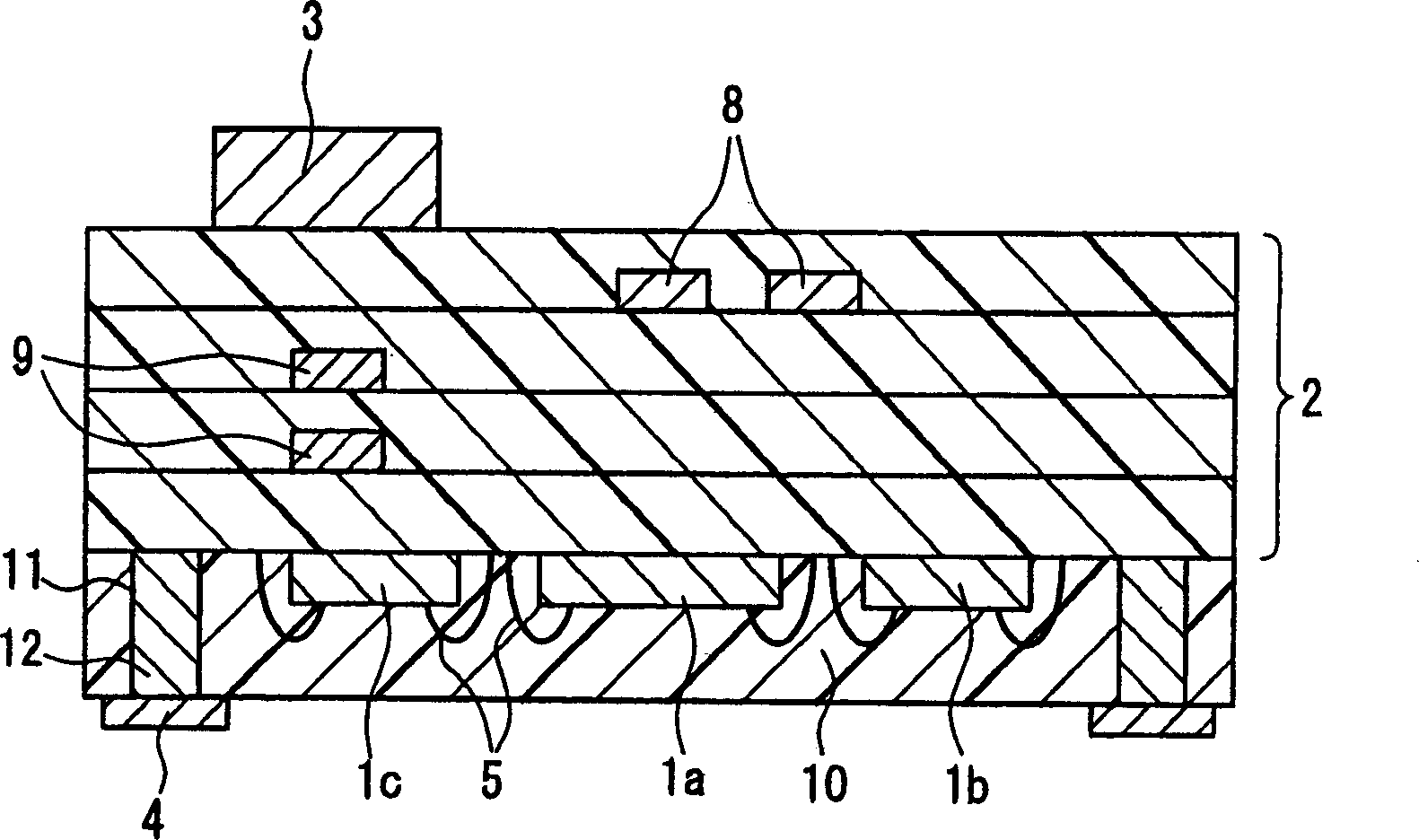

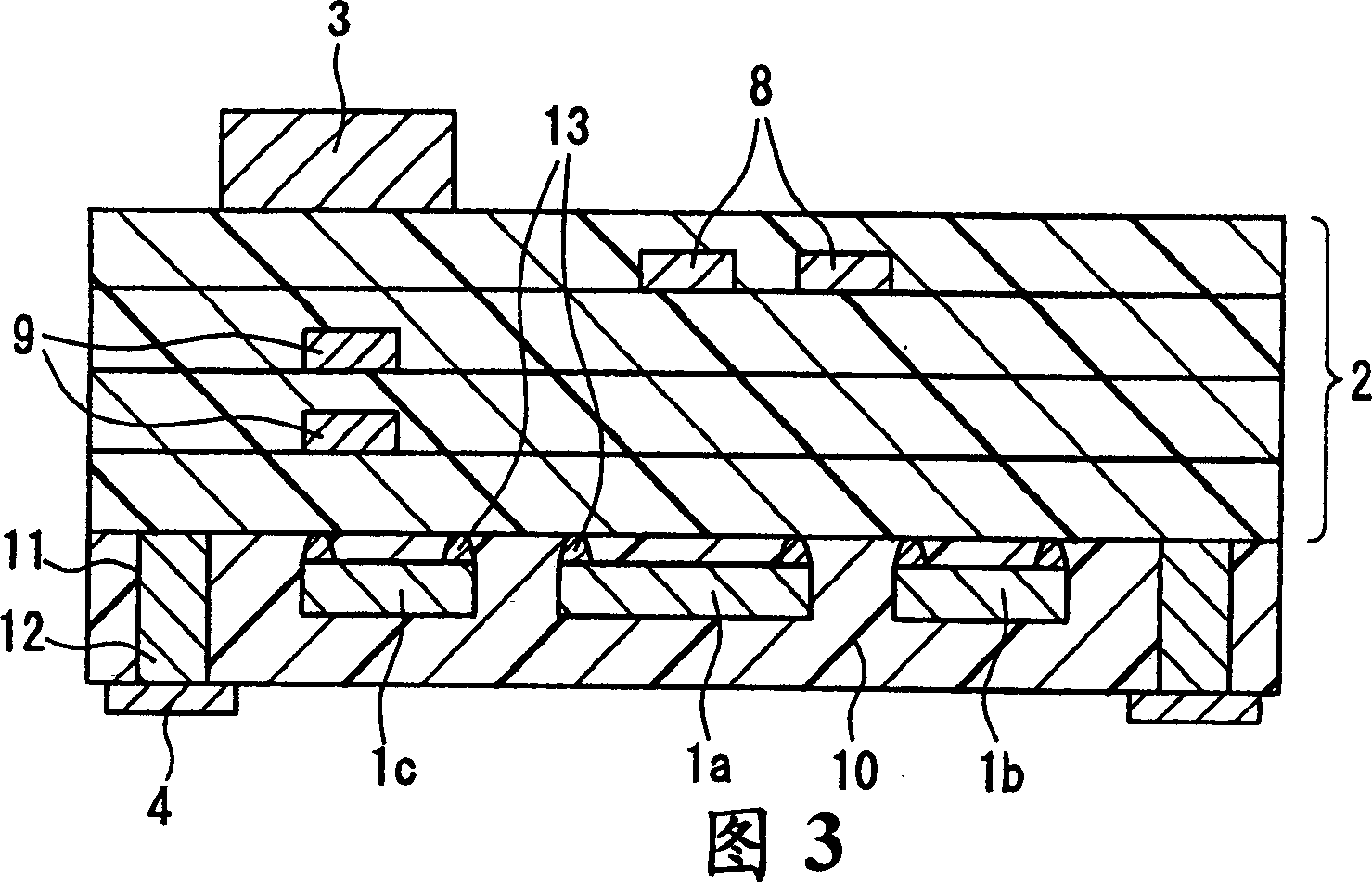

High frequency semiconductor device

InactiveCN1412838AImproved resistance to mechanical shockImprove moisture resistanceSemiconductor/solid-state device detailsSolid-state devicesEpoxyDevice material

The invention relates to a high-frequency semiconductor device comprising a ceramic substrate (2); an element group (1a,1b,1c) including semiconductor elements and passive components mounted onto a bottom portion of the ceramic substrate (2); and a composite resin material layer formed on the bottom portion of the ceramic substrate so as to bury the element group; wherein the composite resin material layer(10) is formed by a composite resin material including an epoxy resin and an inorganic filler material, and the composite resin material layer has a flat bottom surface on which electrodes (4) for connecting to the outside are formed.

Owner:PANASONIC CORP

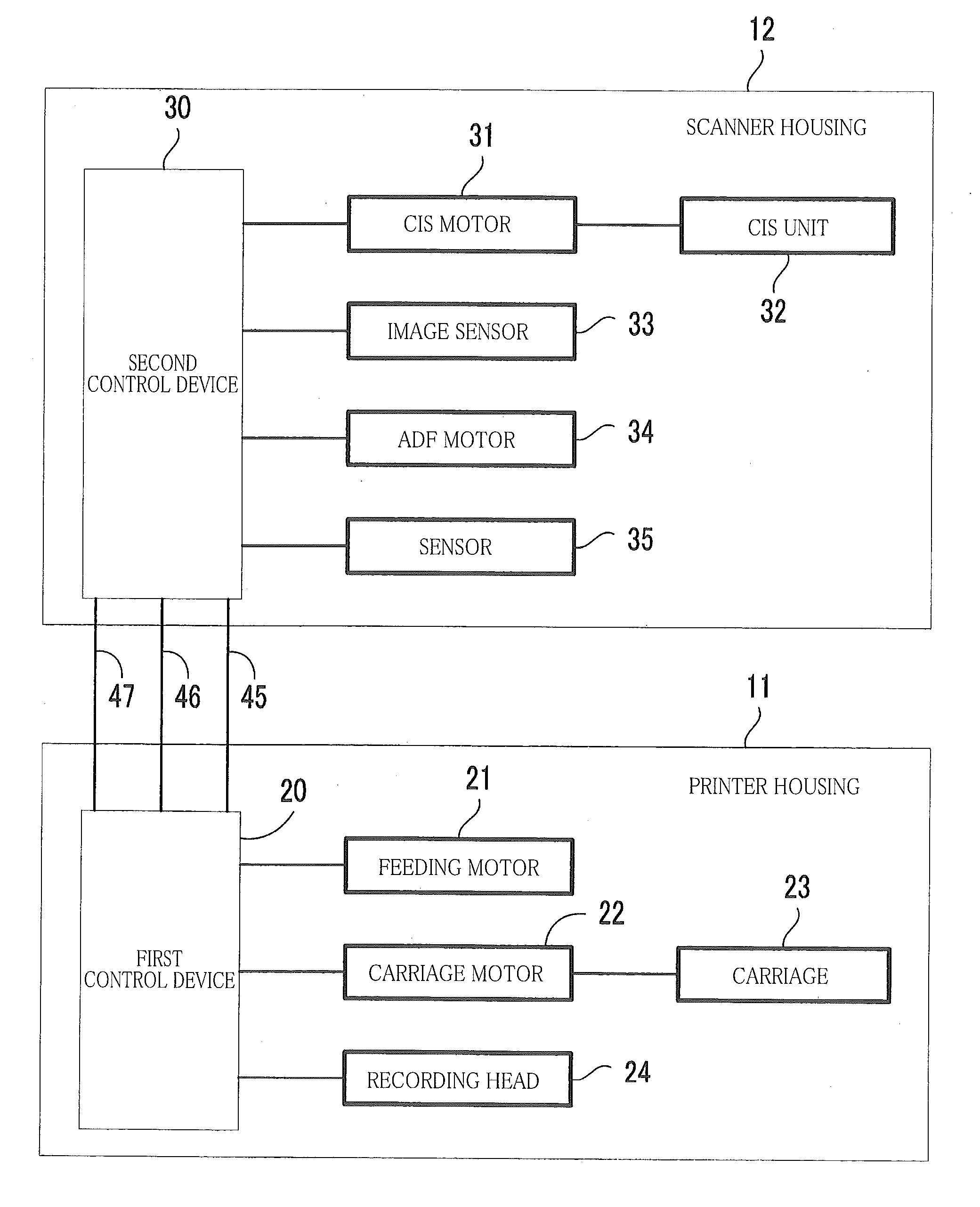

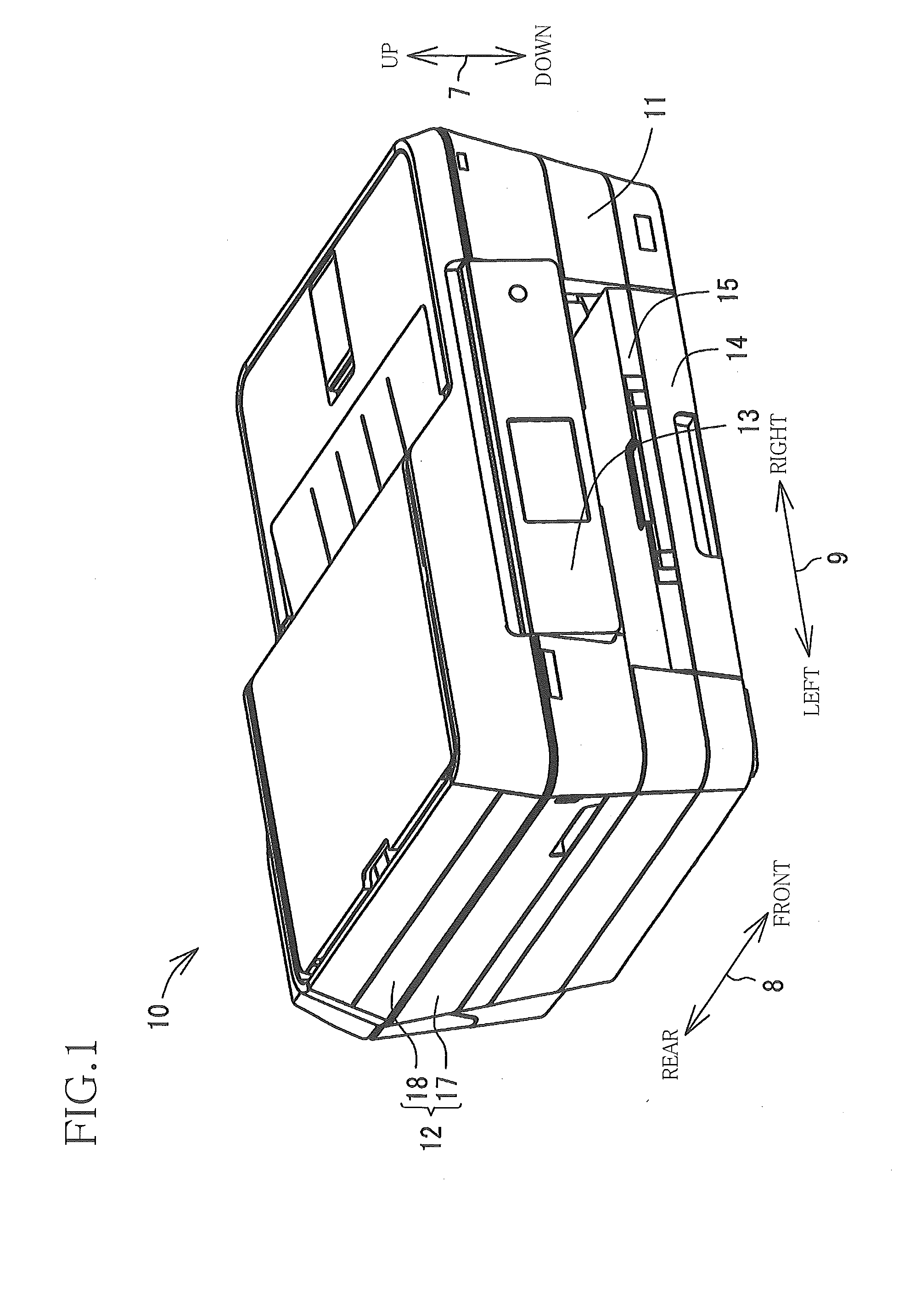

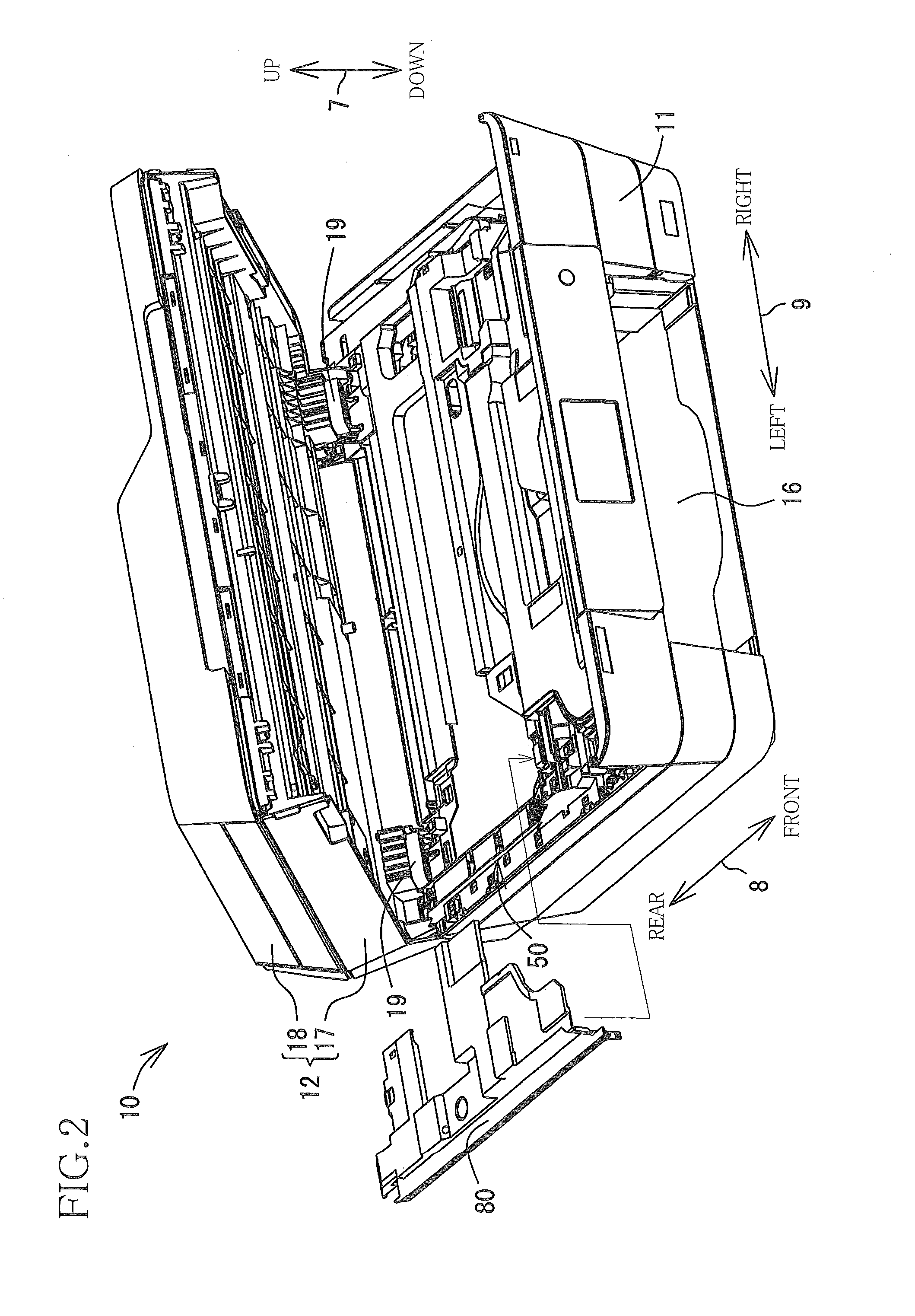

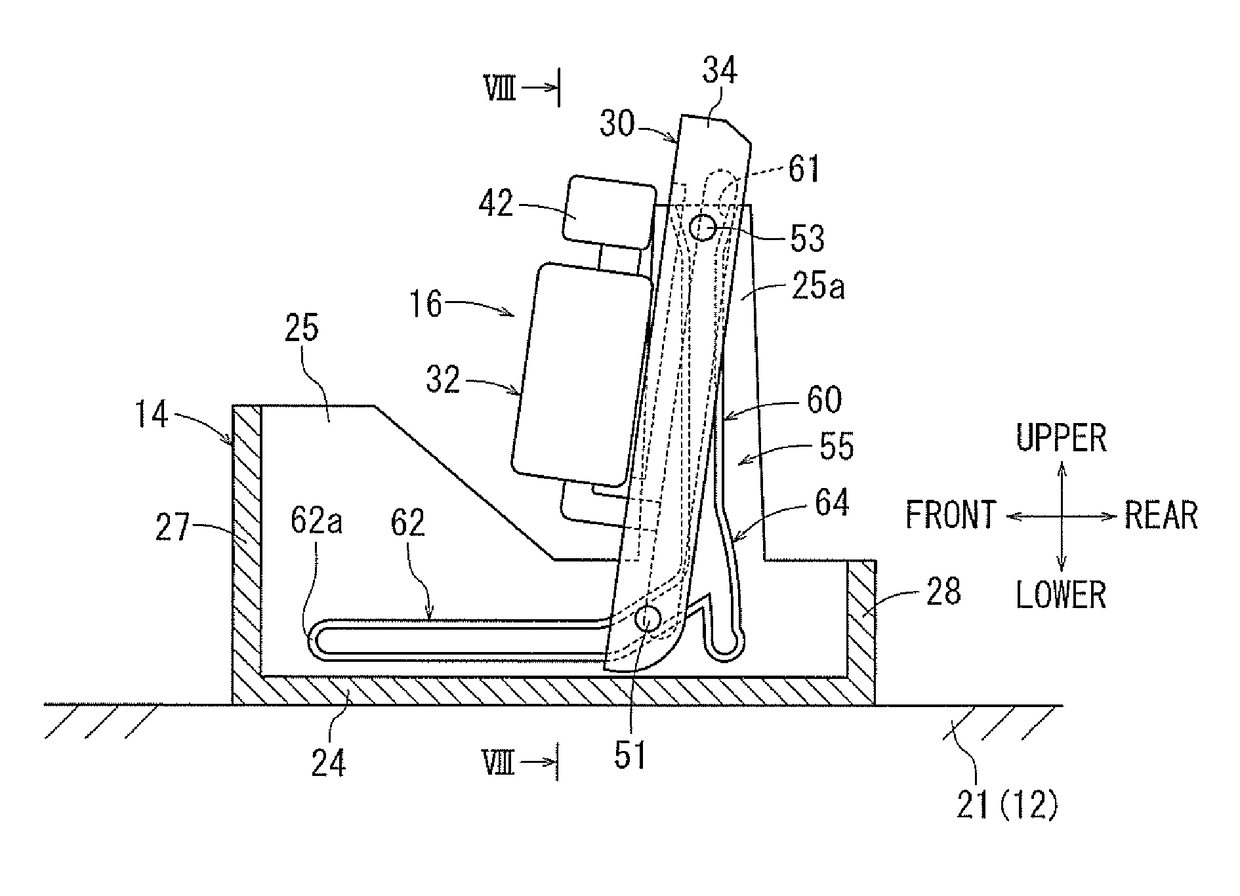

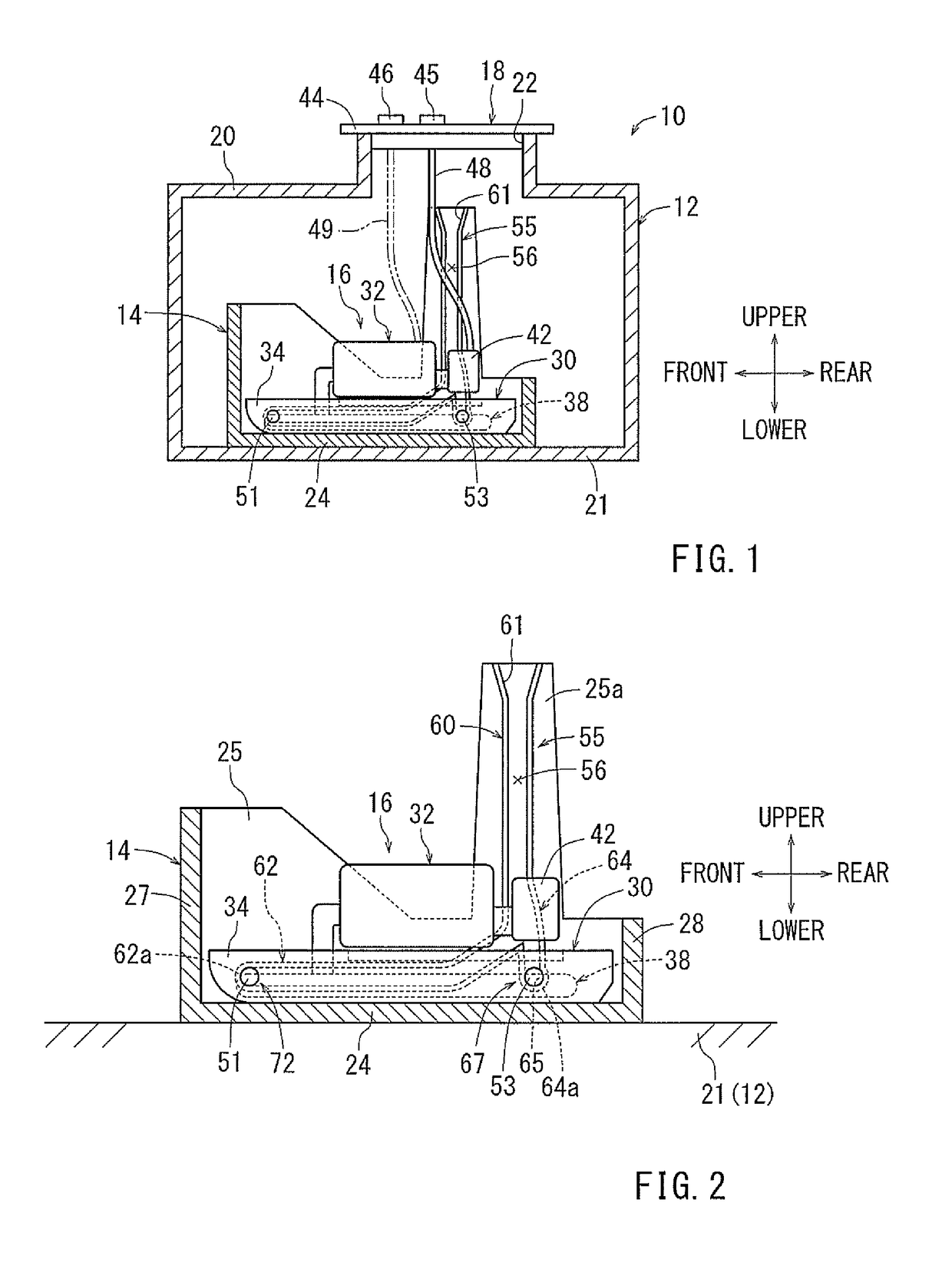

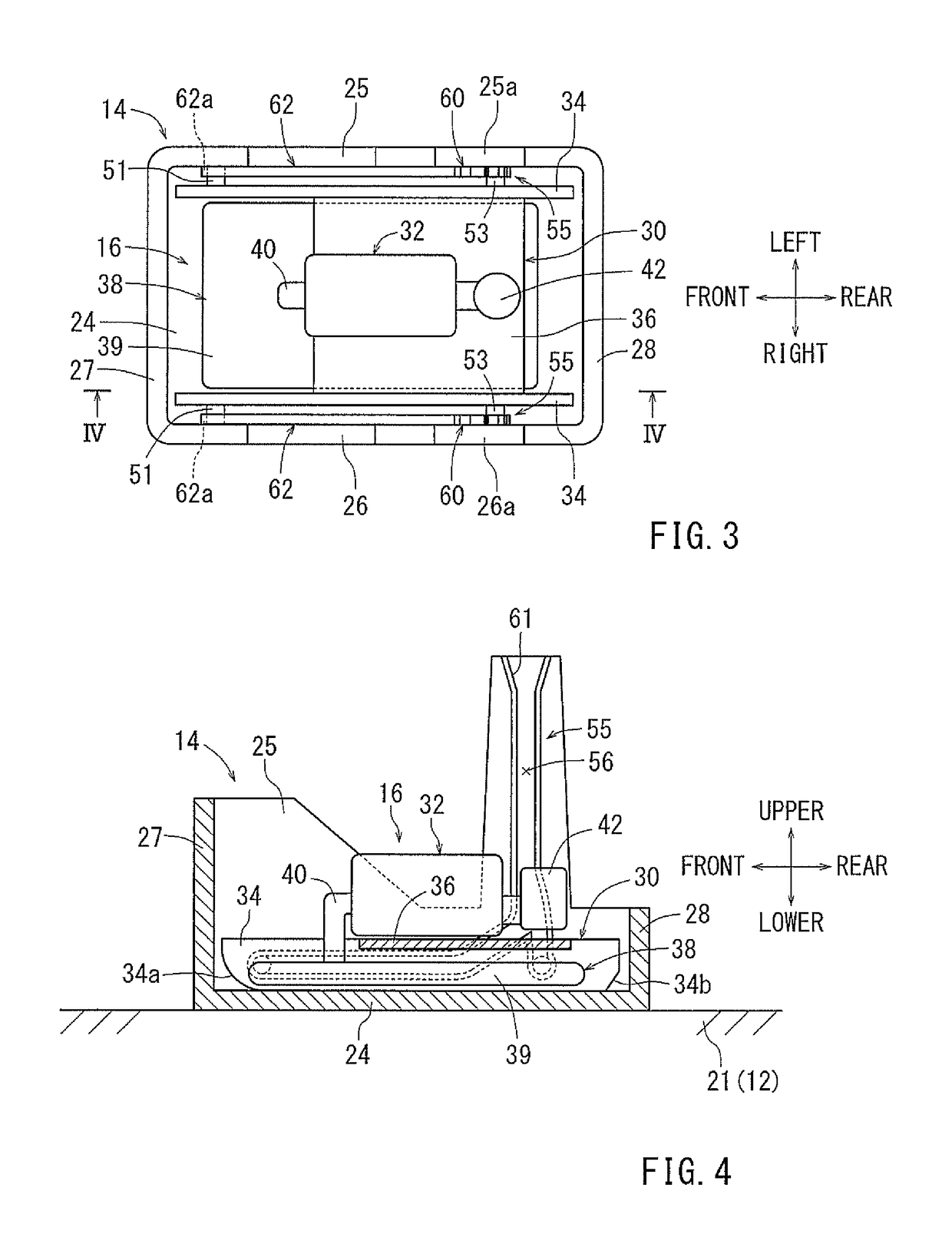

Image Recording Apparatus

ActiveUS20140169823A1Stable placement effectReduce impactElectrographic process apparatusImage recordingEngineering

An image recording apparatus includes: a first housing comprising a recording portion and a first control device; a second housing comprising a second control device and supported by the first housing to be rotationally movable between a close position and a distant position by rotationally moving about a first axis extending in a first direction; a first cable and a second cable electrically connecting the first control device to the second control device; and a holder having a supported portion and holding the first cable and the second cable. In the first housing, at least a part of the holder extends in a second direction and the holder holds the first cable and the second cable such that the first cable and the second cable extend in the second direction and are respectively disposed at positions different from each other in the first direction and in a third direction.

Owner:BROTHER KOGYO KK

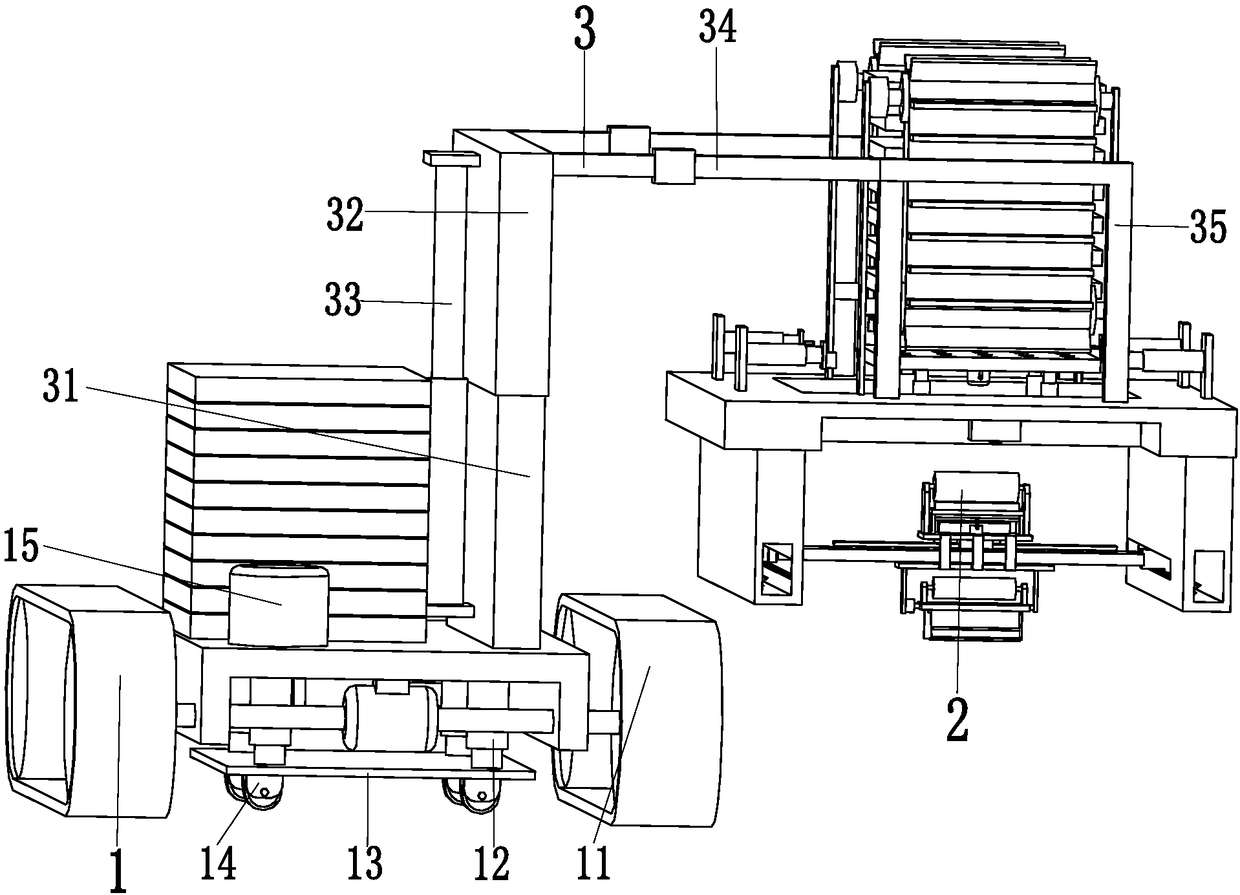

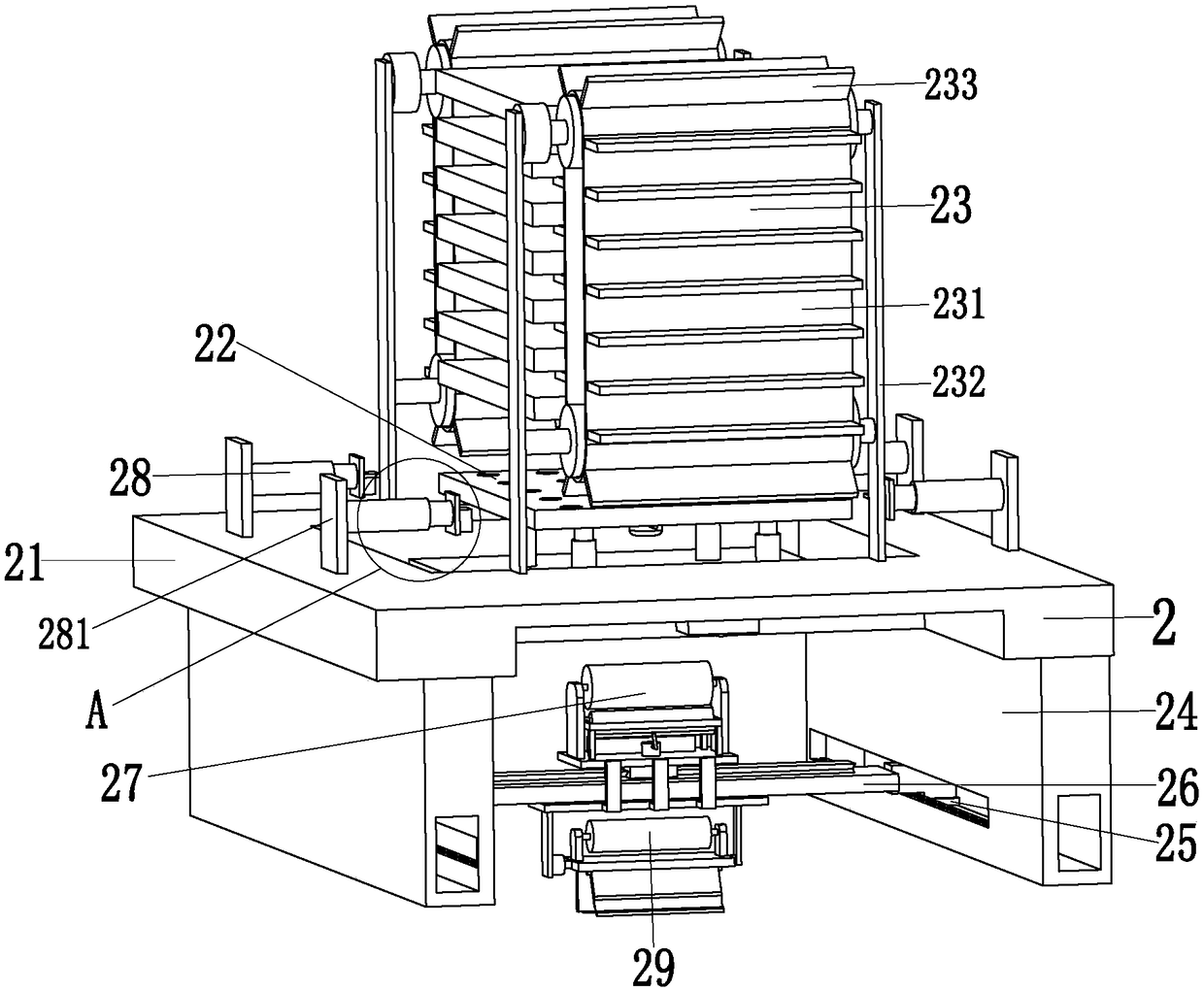

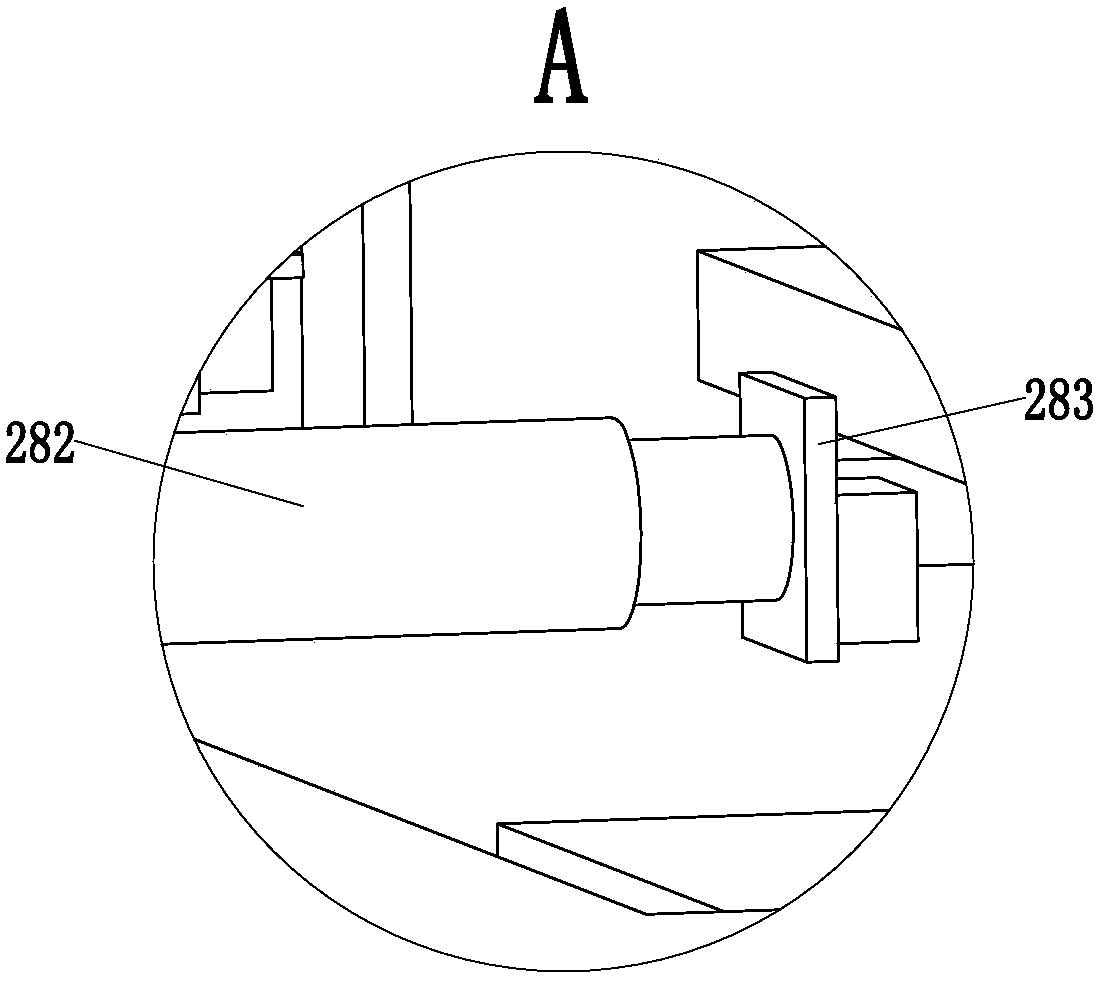

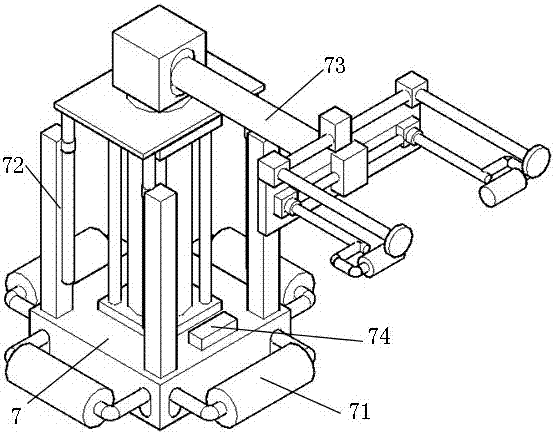

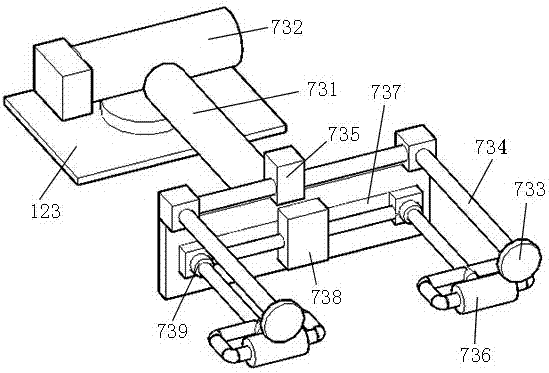

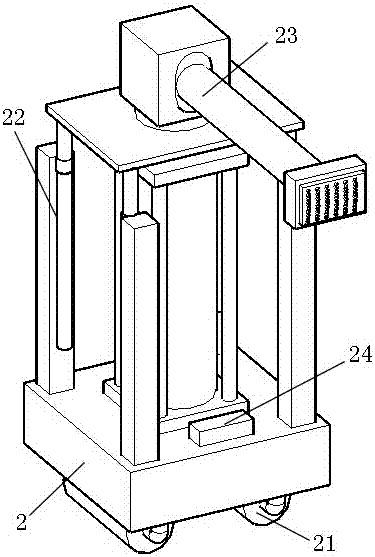

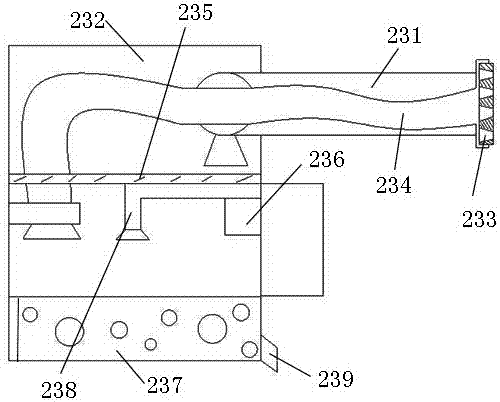

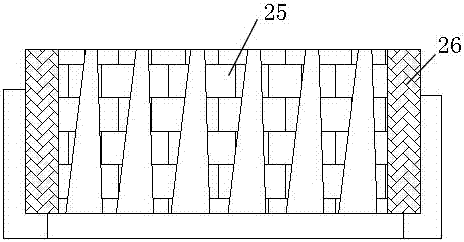

Building decoration equipment for automatic fixing and mounting of soft ceramic tiles

ActiveCN108590141AImplement automatic transferImprove work efficiencyBuilding constructionsAdhesiveEngineering

The invention relates to building decoration equipment for automatic fixing and mounting of soft ceramic tiles. The building decoration equipment comprises a moving device, a fixing and mounting device and a supporting mechanism, wherein the bottom of the left end of the supporting mechanism is mounted at the top of the moving device, and the fixing and mounting device is installed at the bottom of the right end of the supporting mechanism; the moving device comprises a moving platform, a moving push rod, a moving bottom plate, walking wheels and a counterweight; and the fixing and mounting device comprises a fixing and mounting supporting frame, a fixing and mounting suction mechanism, a conveying mechanism, a smearing moving frame, a moving frame sliding block, a smearing supporting plate, a smearing mechanism, a limiting mechanism and a scraping sweeping and rolling mechanism. The building decoration equipment can solve the problems of low working efficiency, need of manual handlingof the soft ceramic tiles, poor effect of manual applying adhesive on the soft ceramic tiles, deviation of the position of manual mounting of the soft ceramic tiles, need of manual cleaning of the fixing and mounting ground, dripping everywhere of adhesive liquid of adhesive applied soft ceramic tiles, need of manual rolling of the fixed and mounted soft ceramic tiles existing in the conventionalfixing and mounting of the soft ceramic tiles.

Owner:聊城泽润装饰工程有限公司

Electromyographic Lead Positioning and Stimulation Titration in a Nerve Stimulation System for Treatment of Overactive Bladder

ActiveUS20160121123A1Improve utility and successStable placement effectSpinal electrodesImplantable neurostimulatorsMedicineHyperactive bladder

The present invention provides improved methods for positioning of an implantable lead in a patient with an integrated EMG and stimulation clinician programmer. The integrated clinician programmer is coupled to the implantable lead, wherein the implantable lead comprises at least four electrodes, and to at least one EMG sensing electrode minimally invasively positioned on a skin surface or within the patient. The method comprises delivering a test stimulation at a stimulation amplitude level from the integrated clinician programmer to a nerve tissue of the patient with a principal electrode of the implantable lead. Test stimulations are delivered at a same stimulation amplitude level for a same period of time sequentially to each of the four electrodes of the implantable lead. A stimulation-induced EMG motor response is recorded with the integrated clinician programmer for each test stimulation on each electrode of the implantable lead via the at least one pair of EMG sensing electrodes so as to facilitate initial positioning of the implantable lead at a target stimulation region.

Owner:AXONICS

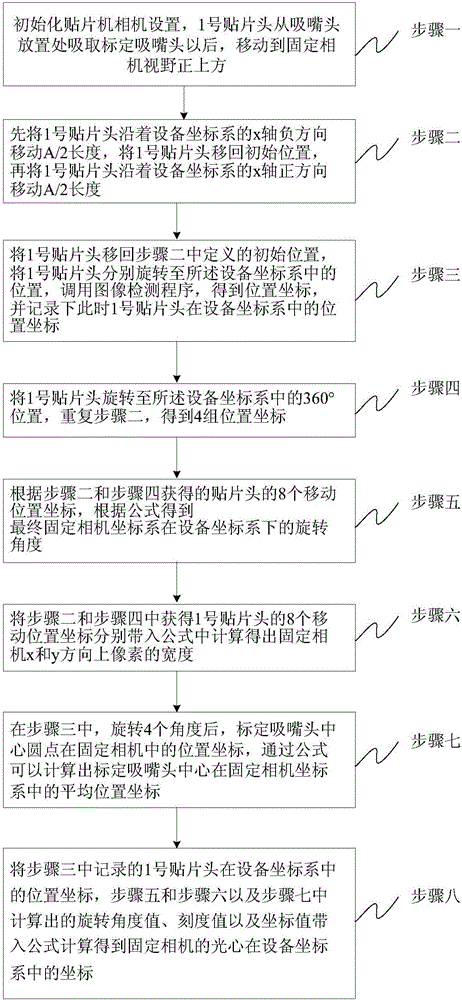

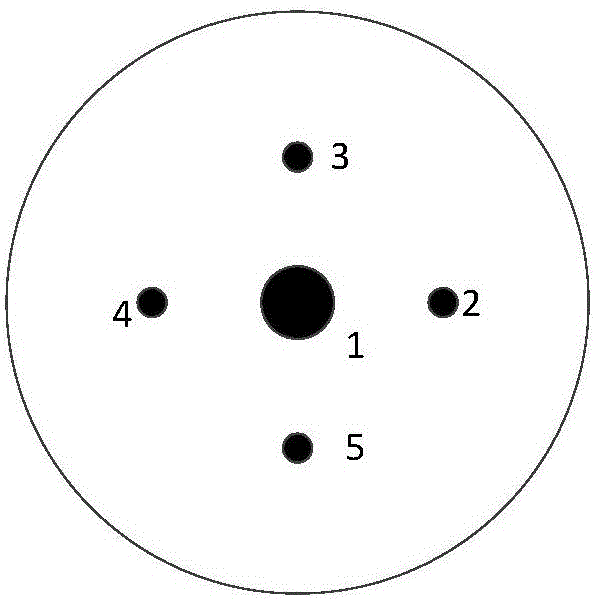

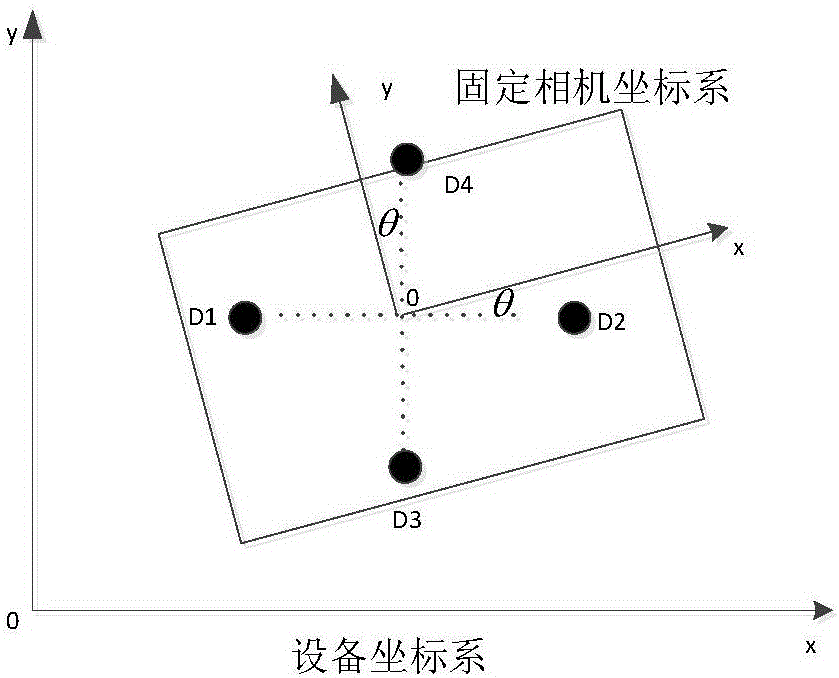

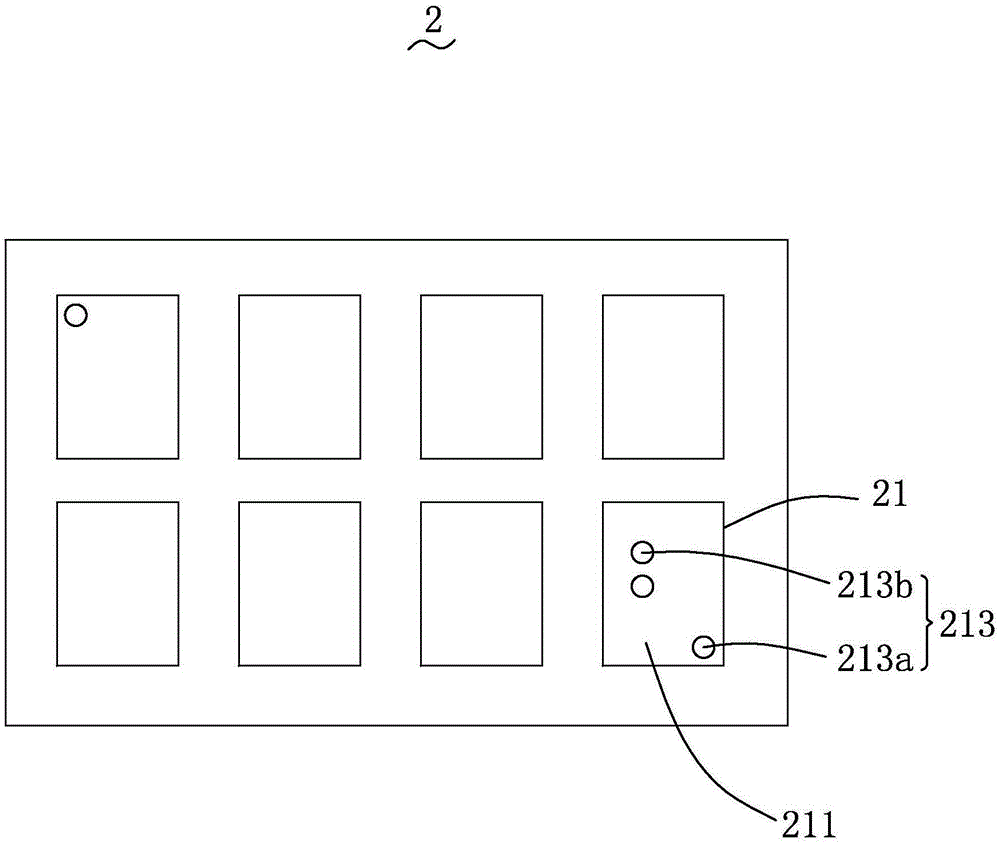

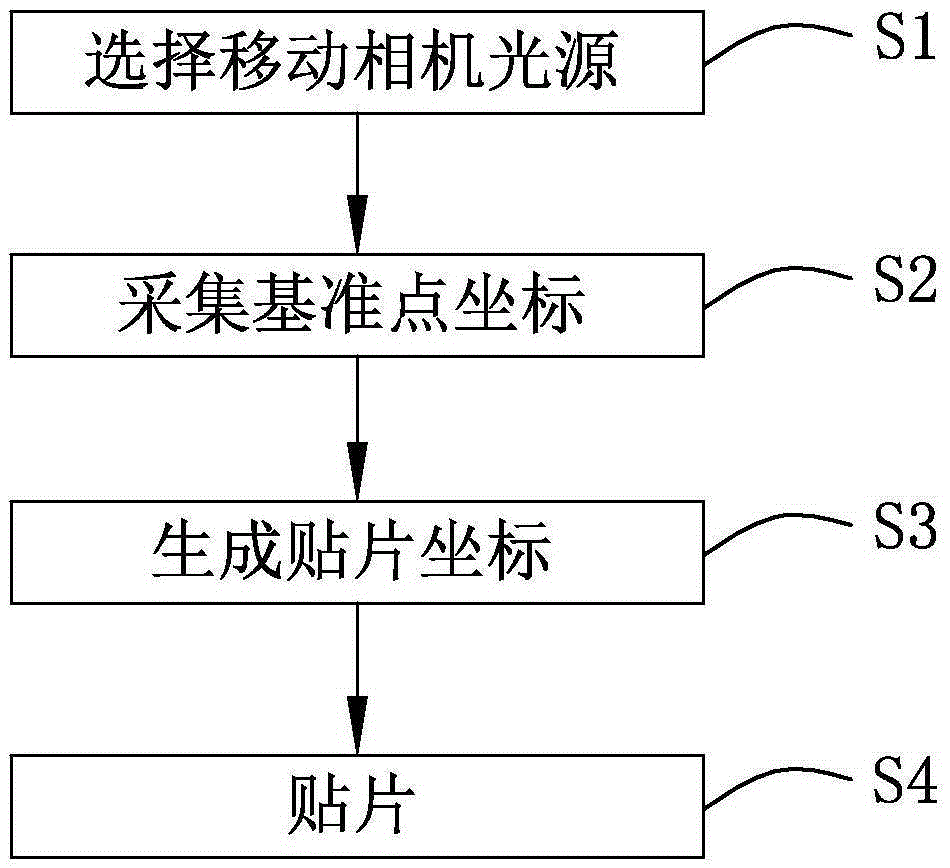

Fixed camera calibration method

ActiveCN106341956AHigh precisionStable placement effectPrinted circuit assemblingElectrical componentsCorrection methodNozzle

The invention discloses a fixed camera correction method, belongs to the machine vision localization detection field and is applied to the high-accuracy correction process of a surface mounting machine. The main objective of the invention is to solve the problem that the location, scale and rotation angle of the fixed camera of an existing surface mounting machine cannot be accurately measured in an equipment coordinate system when the fixed camera of the surface mounting machine is mechanically installed. According to the method of the invention, the positional relationship of a surface mounting head in a fixed camera is determined according to a calibration suction nozzle; a conversion relation between two coordinate systems is calculated and derived; the scale of the fixed camera is calculated through the position coordinates of a center; and the rotation angle of the fixed camera in an equipment coordinate system is calculated according to the position coordinates of the surface mounting head and the value coordinates of the surface mounting head. The coordinates, the rotation angle and the scale of the fixed camera are corrected, so that deviation in a detection process caused by manual installation can be offset, the calibration point detection and positioning accuracy of the surface mounting machine can be improved, and the surface mounting effect of the surface mounting machine can be improved. The fixed camera correction method of the invention is suitable for the machine vision precision correction field.

Owner:HARBIN INST OF TECH

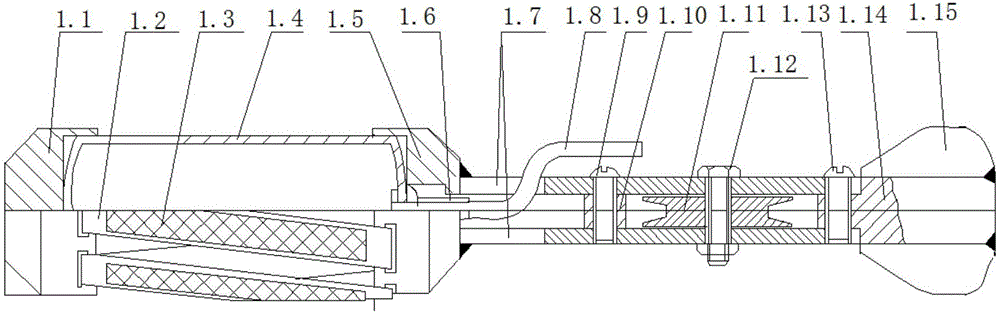

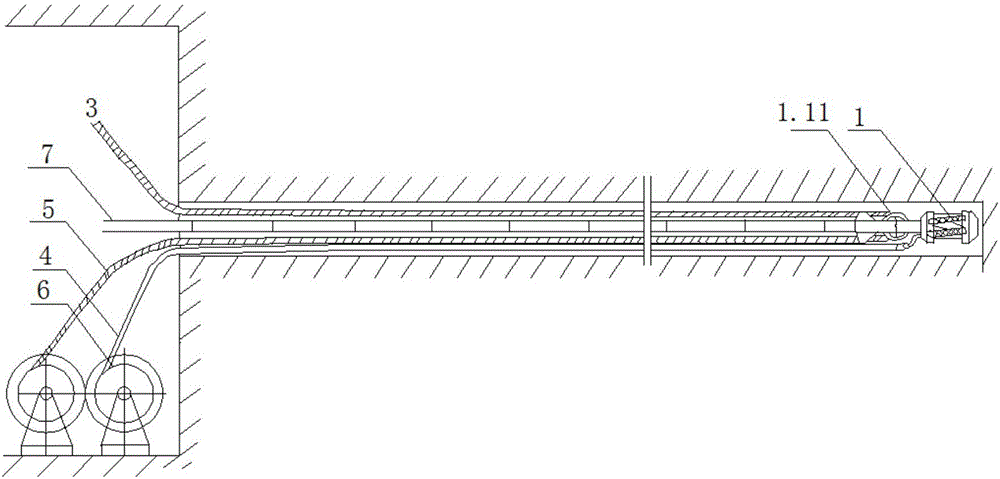

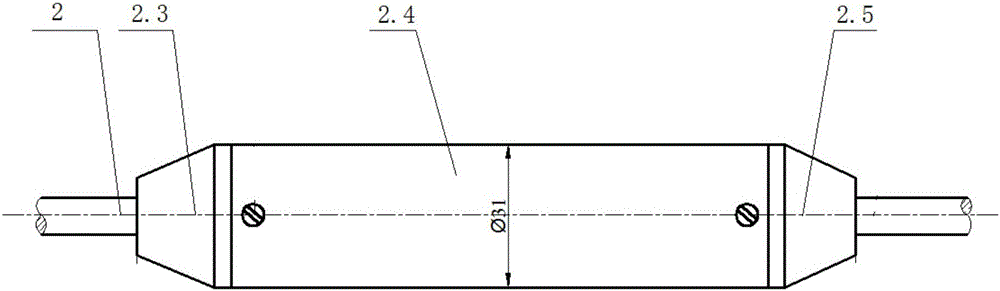

Coal-mine underground horizontal deep-hole multichannel passive detector system and embedded method thereof

InactiveCN106526663AStable placement effectEnhanced couplingSeismic signal receiversSeismology for water-loggingEngineeringCoal

The invention relates to a passive detector system and an embedded method, belongs to the underground construction equipment field and especially relates to a coal-mine underground horizontal deep-hole multichannel passive detector system and an embedded method thereof. The system comprises a traction head and a detector apparatus, wherein the traction head is provided with a traction pulley and a traction head inflation air bag used for fixing the traction head in a hole after air inflation; the detector apparatus includes several detectors which are connected in series through a connection device; the detectors are provided with detector inflation air bags used for fixing the detectors in the hole after the air inflation; and one end of the connection device is winded around and arranged on the traction pulley. By using the system and the method, a current situation of coal-mine underground seismic exploration construction is greatly improved, which promotes development and application of a coal-mine underground seismic exploration technology.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

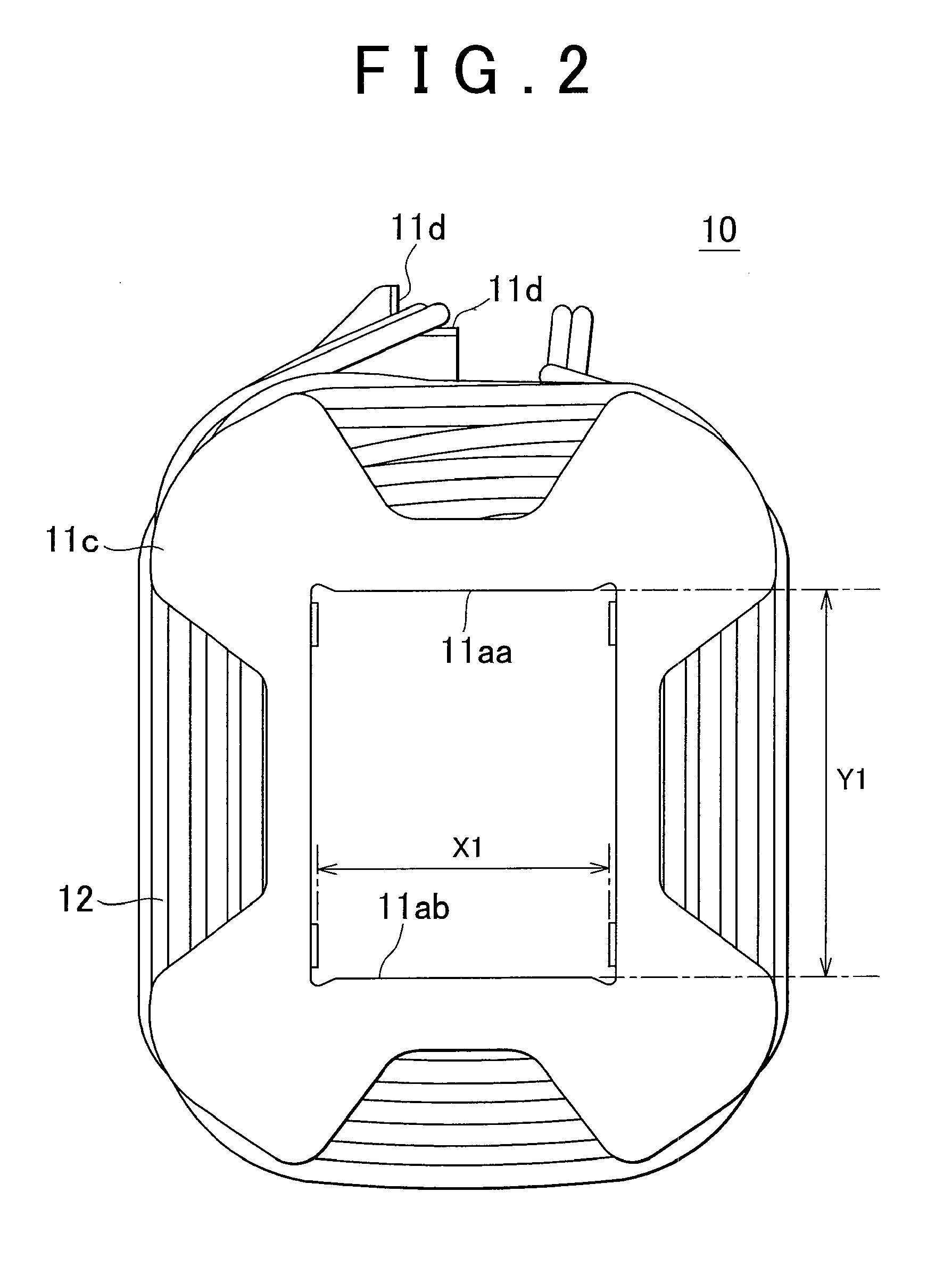

Fuel tank

InactiveUS9752543B2Move preciselyStable placement effectMachines/enginesLiquid fuel feedersFuel tankEngineering

Owner:AISAN IND CO LTD

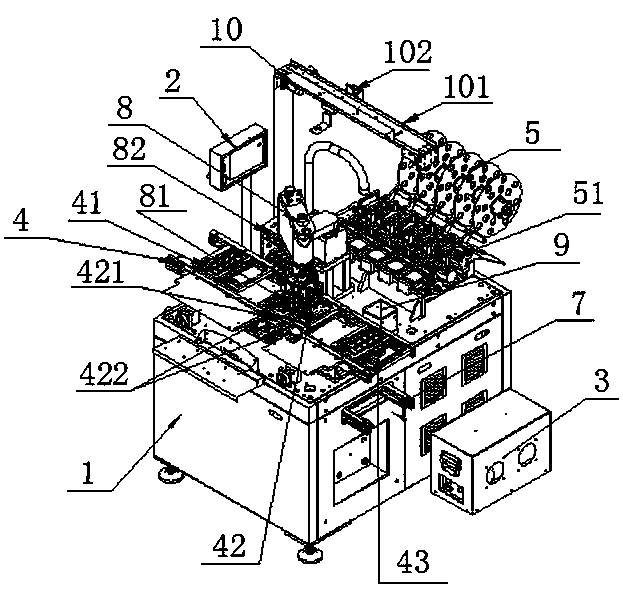

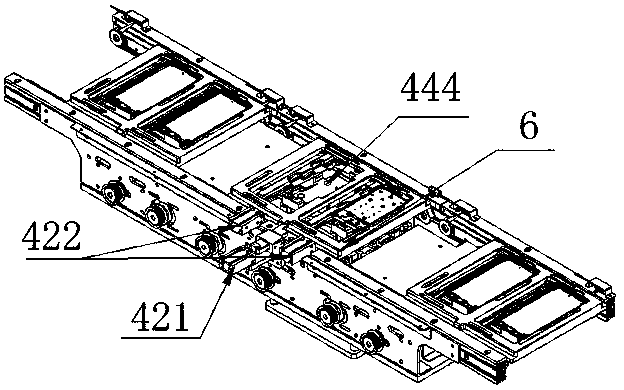

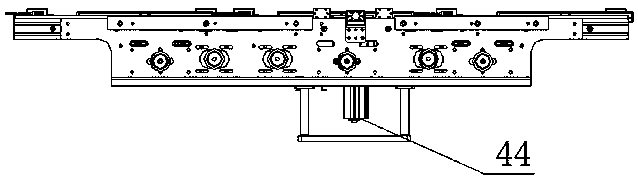

Multi-material automatic pasting equipment

PendingCN107756027ALow machining accuracy requirementsUniqueness guaranteedAssembly machinesMetal working apparatusRobot handData signal

The invention relates to multi-material automatic pasting equipment. The multi-material automatic pasting equipment comprises an operation touch display screen, a vacuum pump, a jig feeding rail, a stopping air cylinder, a jig positioning air cylinder, a product bonding mechanism, an auxiliary feeder feeding device, a product flowing jig, a jig reverse backflow rail, a pasting robot, a waste material collecting box, a camera movement mechanical arm and a CCD camera. According to the multi-material automatic pasting equipment, different kinds of materials can be subject to CCD detection, the pasting robot can achieve accurate material sucking according to data signals detected by the pasting robot and enables the product bonding mechanism to be capable of conducting accurate product positioning according to data signals detected by the product bonding mechanism, product positioning achieves standard unification, the product assembling position uniqueness is guaranteed, the requirement for the machining accuracy of the product flowing jig is reduced, cost is saved, and the product pasting accuracy is guaranteed to be high; and the product flowing jig achieves circulated and automaticbackflow and use through the jig reverse backflow rail, and space occupied by plane rotation is reduced.

Owner:DONGGUAN SHANZE INTELLIGENT TECH

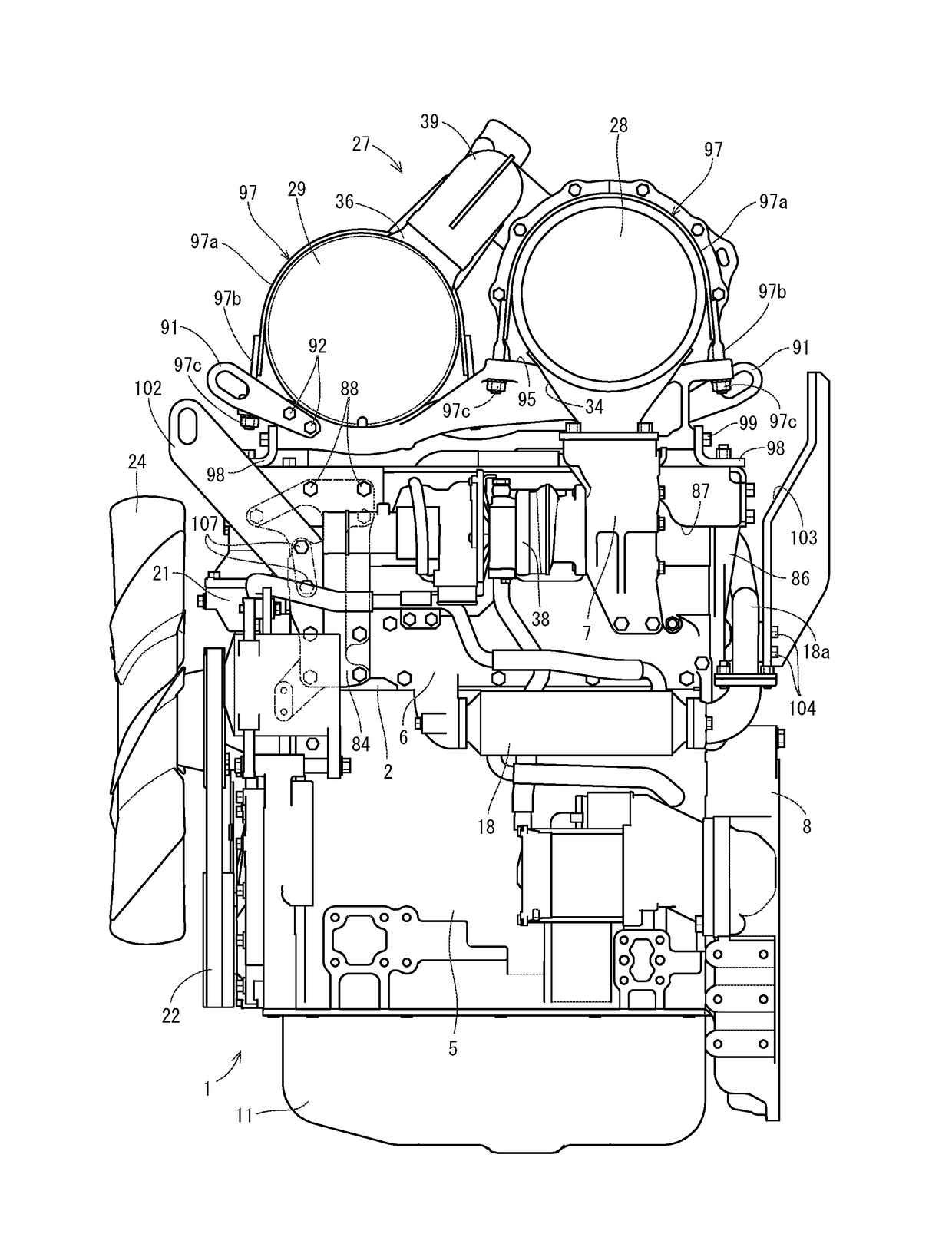

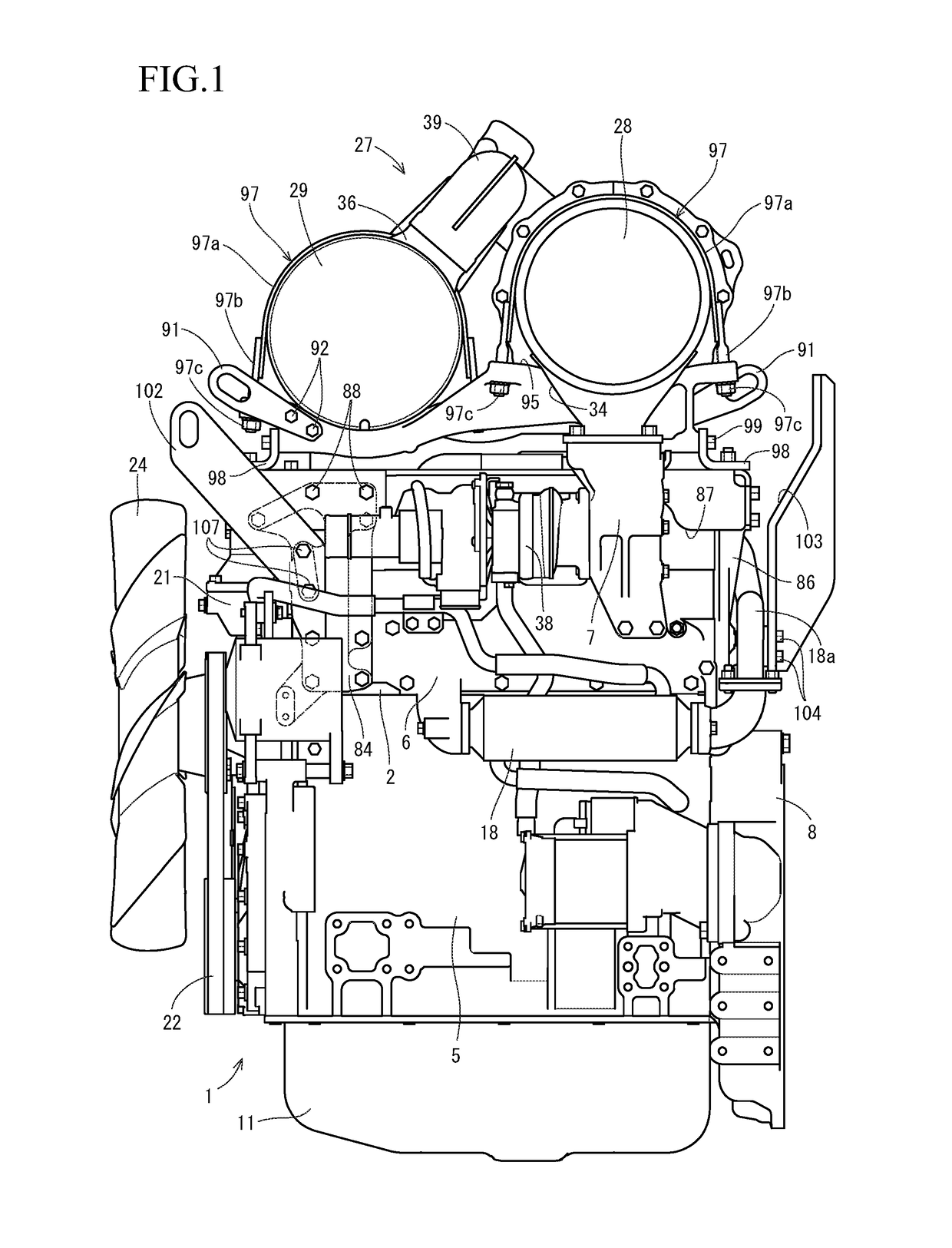

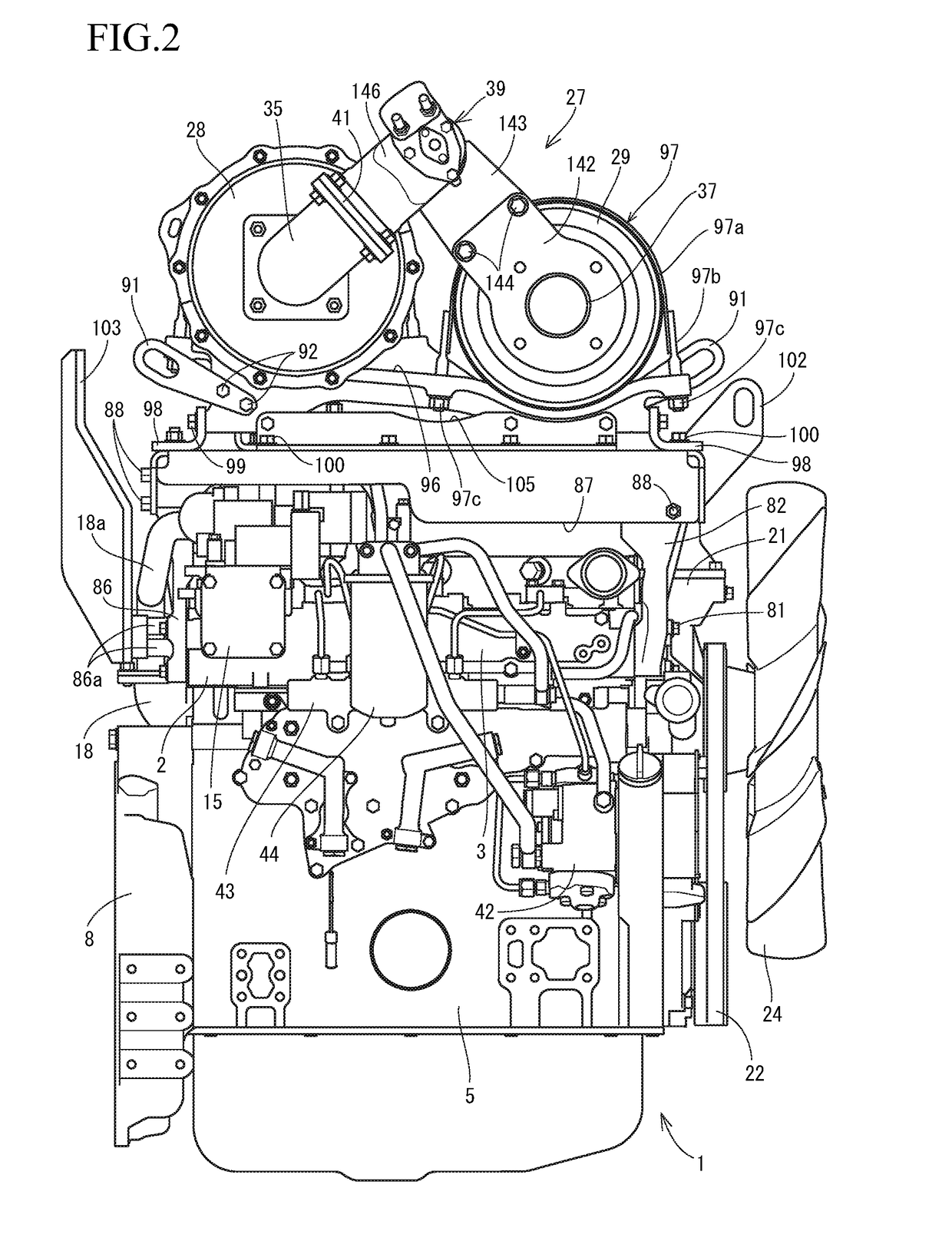

Engine device

ActiveUS20170204770A1Reduce oscillationStable placement effectAgricultural vehiclesInternal combustion piston enginesParticulatesNitrogen oxide

In the engine device having an exhaust gas purification device which removes particulate matters in exhaust gas of the engine or nitrogen oxides in the exhaust gas of the engine, the exhaust gas purification device is firmly fixed to a support base, and an exhaust gas outlet pipe of the engine is provided with an exhaust connection portion which connects an exhaust gas inlet of the exhaust gas purification device, and a support base connection portion which connects the support base.

Owner:YANMAR POWER TECHNOLOGY CO LTD

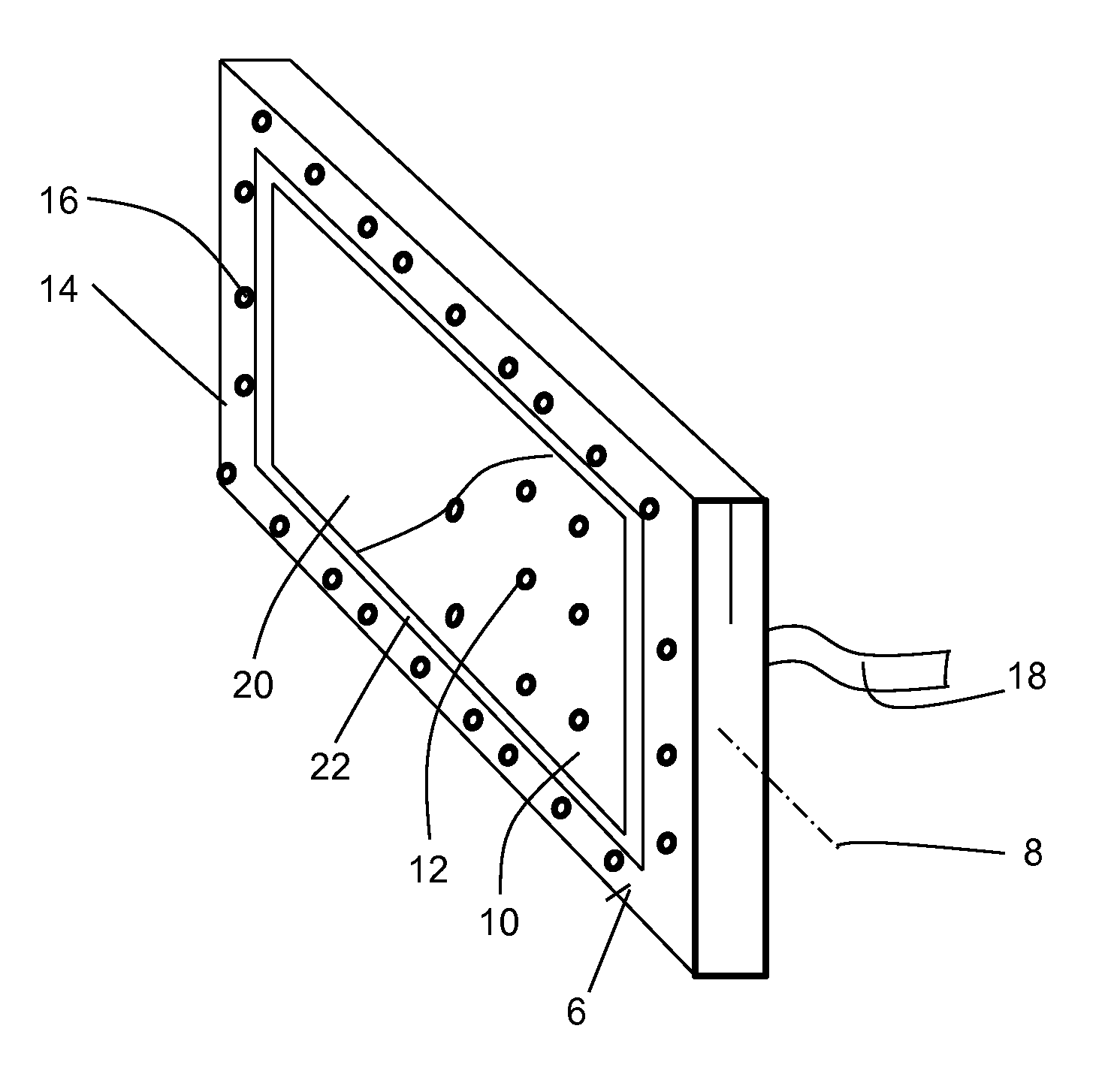

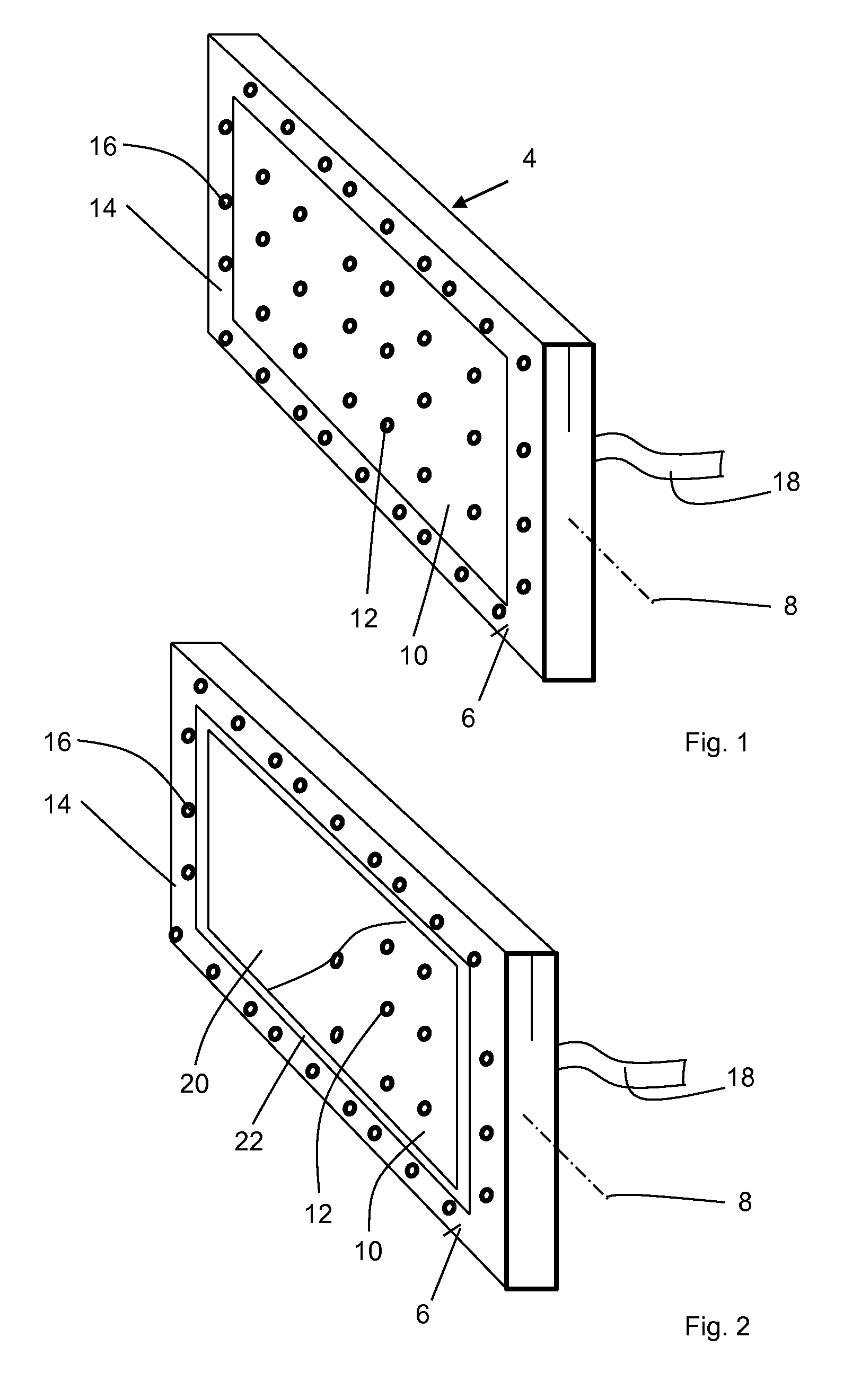

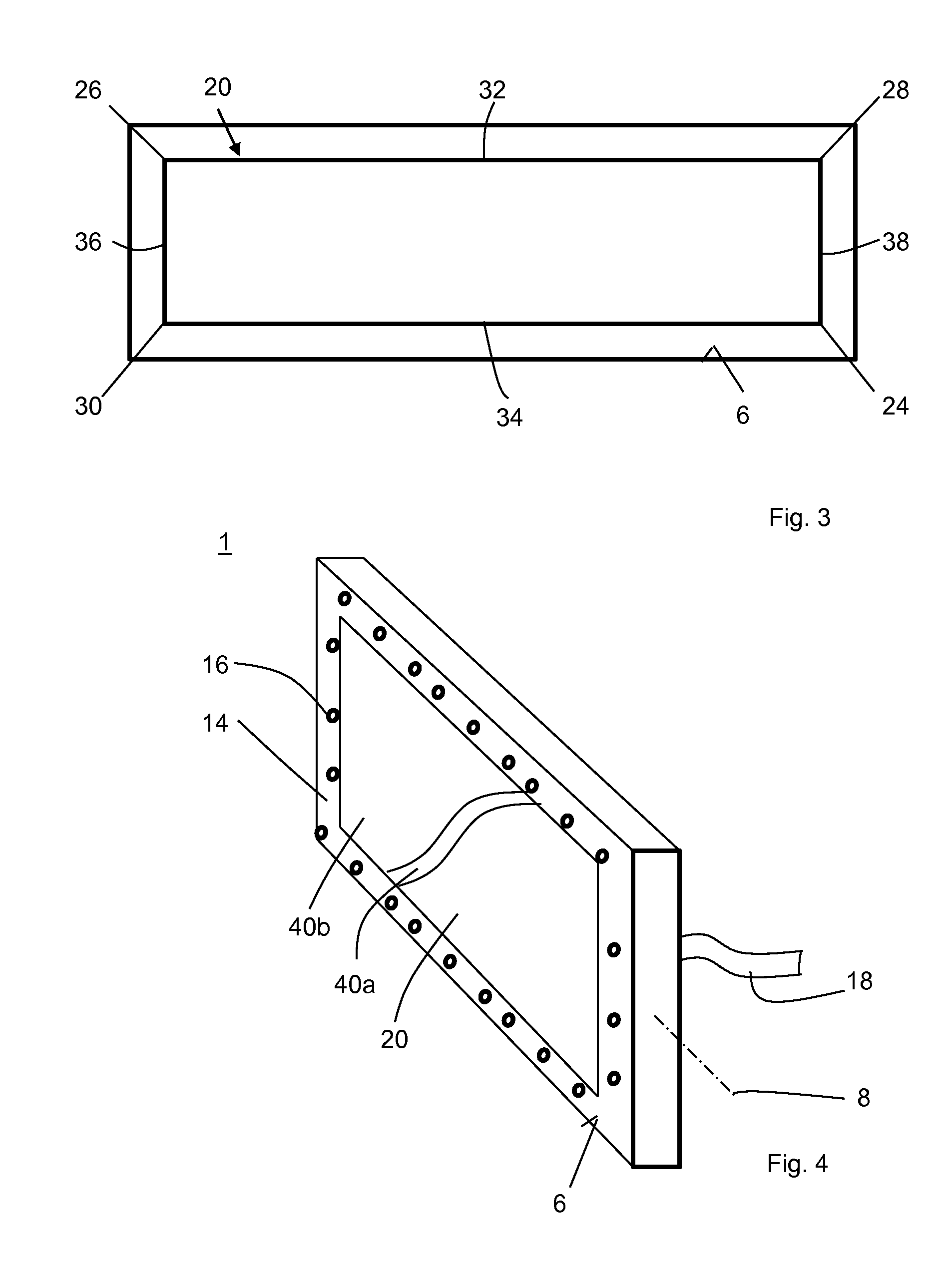

A method and a placement tool for the manufacture of a non-crimp fabric

ActiveUS20120279649A1Improve placement performanceEliminate the effects ofMechanical working/deformationLaminationEngineeringWork in process

Disclosed is a method for placing fibre-reinforced, pre-impregnated, planar semi-finished products on a placement tool for the manufacture of a non-crimp fabric, wherein a placement film is clamped on the placement tool for purposes of holding the non-crimp fabric, and by means of evacuation and / or the application of pressure is fixed in position on the placement tool and / or can be released from the latter. Also disclosed is a placement tool for the execution of such a method.

Owner:AIRBUS OPERATIONS GMBH

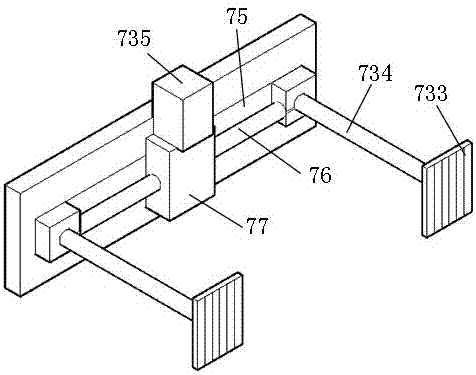

Wall paper adhering device for wall paper adhering system

InactiveCN107444000AShorten the timeSave manpower for placementPaperhangingAdhesivePulp and paper industry

The invention relates to the technical field of adhesive product installation, in particular to a wall sticker device used in a wallpaper sticker system. A wall sticker device for a wallpaper sticking system, comprising a sticker body, a sticker moving mechanism, a sticker lifting mechanism, a wall sticker mechanism and a sticker controller arranged on the sticker fuselage; the wall sticker The mechanism includes a sticker arm, one end of the sticker arm is connected to the sticker arm shaft driven by the sticker arm shaft motor, and the other end is connected to the sticker board, and the sticker board is provided with a wallpaper adsorption assembly and a wallpaper pressing assembly; the strong paper The adsorption assembly includes a symmetrically arranged electrostatic adsorption disc, an expansion rod of the adsorption disc and a drive motor for the expansion rod of the adsorption disc, and the electrostatic adsorption disc is electrically connected with the electrostatic generator. The wall sticker device of the present invention can assist the wallpaper sticking system to automatically stick the wallpaper on the wall after the wall is glued, saving the time and manpower for sticking the wallpaper, and improving the effect of sticking the wallpaper.

Owner:浙江绿洲胶粘制品有限公司

Automated wall surface cleaning device for wallpaper mounting system

InactiveCN107411652AShorten the timeSave manpower for placementCarpet cleanersFloor cleanersSurface cleaningDrive motor

The invention relates to the technical field of adhesive product installation, in particular to a wall surface cleaning device of an automatic wallpaper mounting system. A wall cleaning device of an automated wallpaper mounting system, comprising a cleaning body, a cleaning moving mechanism arranged on the cleaning body, a cleaning lifting mechanism, a wall cleaning mechanism and a cleaning controller; the cleaning moving mechanism includes The first cleaning moving wheel and the second cleaning moving wheel, the first cleaning moving wheel is provided with a first supporting wheel frame, and the second cleaning moving wheel is provided with a second supporting wheel frame, and the first supporting wheel frame and The first moving wheel direction shaft is connected, the first moving wheel direction shaft is connected with the first moving wheel direction shaft driving motor, and the second supporting wheel frame is connected with the second moving wheel direction shaft. The wall surface cleaning device of the present invention can assist the wallpaper mounting system to automatically clean the scraped wall surface, save the wallpaper mounting time and manpower, and improve the wallpaper mounting effect.

Owner:浙江绿洲胶粘制品有限公司

Stator mounting method

InactiveUS7930818B2Reduce in quantityReduce dispersionSynchronous generatorsWindingsLower faceElectrical and Electronics engineering

In a stator mounting method in which a coil unit is inserted into a stator core and a lead wire protruding from the coil unit is inserted into and mounted on a terminal portion of the stator core, the lead wire is passed through a lead wire pullout portion located at a predetermined position of a coil frame body, a height from an inner peripheral upper face of the coil frame body to the lead wire pullout portion is equalized with a distance from a core upper face of the stator core to a lead wire insertion position inner peripheral lower face of the terminal portion, and the core upper face of the stator core is held in contact with an inner peripheral upper face of the coil frame body after the lead wire is inserted into the terminal portion.

Owner:TOYOTA JIDOSHA KK

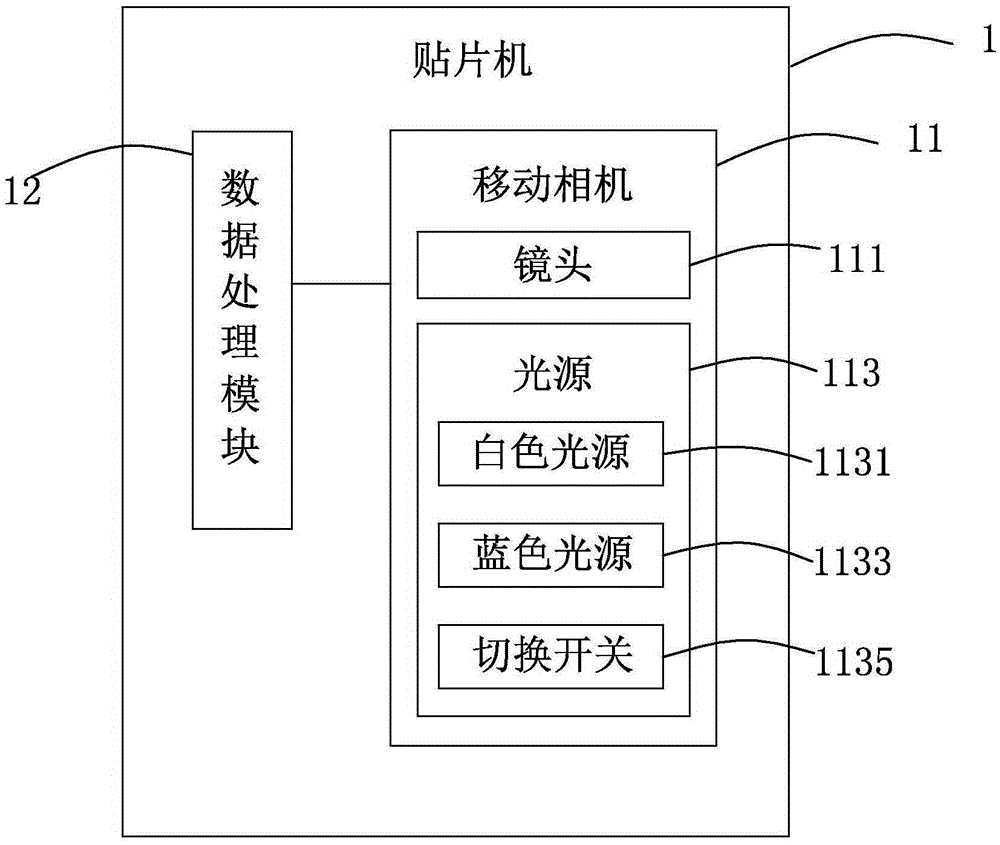

Surface mounting machine and surface mounting method thereof

InactiveCN105407654AShorten recognition timeIncrease contrastPrinted circuit assemblingMobile cameraElectricity

The invention provides a surface mounting machine. The surface mounting machine comprises a mobile camera and a data processing module. The mobile camera is electrically connected with the data processing module. The mobile camera is used for identifying the reference points on circuit boards. The data processing module is used for analyzing reference point information to generate surface mounting coordinates. The mobile camera comprises a lens and a light source. The light source comprises a blue light source. The light source is used for irradiating the circuit boards. The lens is aligned with the circuit boards. The invention also provides a surface mounting method applying the surface mounting machine. According to the surface mounting method, the blue light source of the surface mounting machine is utilized to perform component surface mounting of circuit board splicing boards. Compared with machines in the prior art, the surface mounting machine has high identification capacity for solder paste, and the surface mounting method significantly enhances efficiency of surface mounting and significantly reduces the defects of surface mounting.

Owner:DONGGUAN HAOYUAN ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com