Patents

Literature

1717results about How to "Low machining accuracy requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

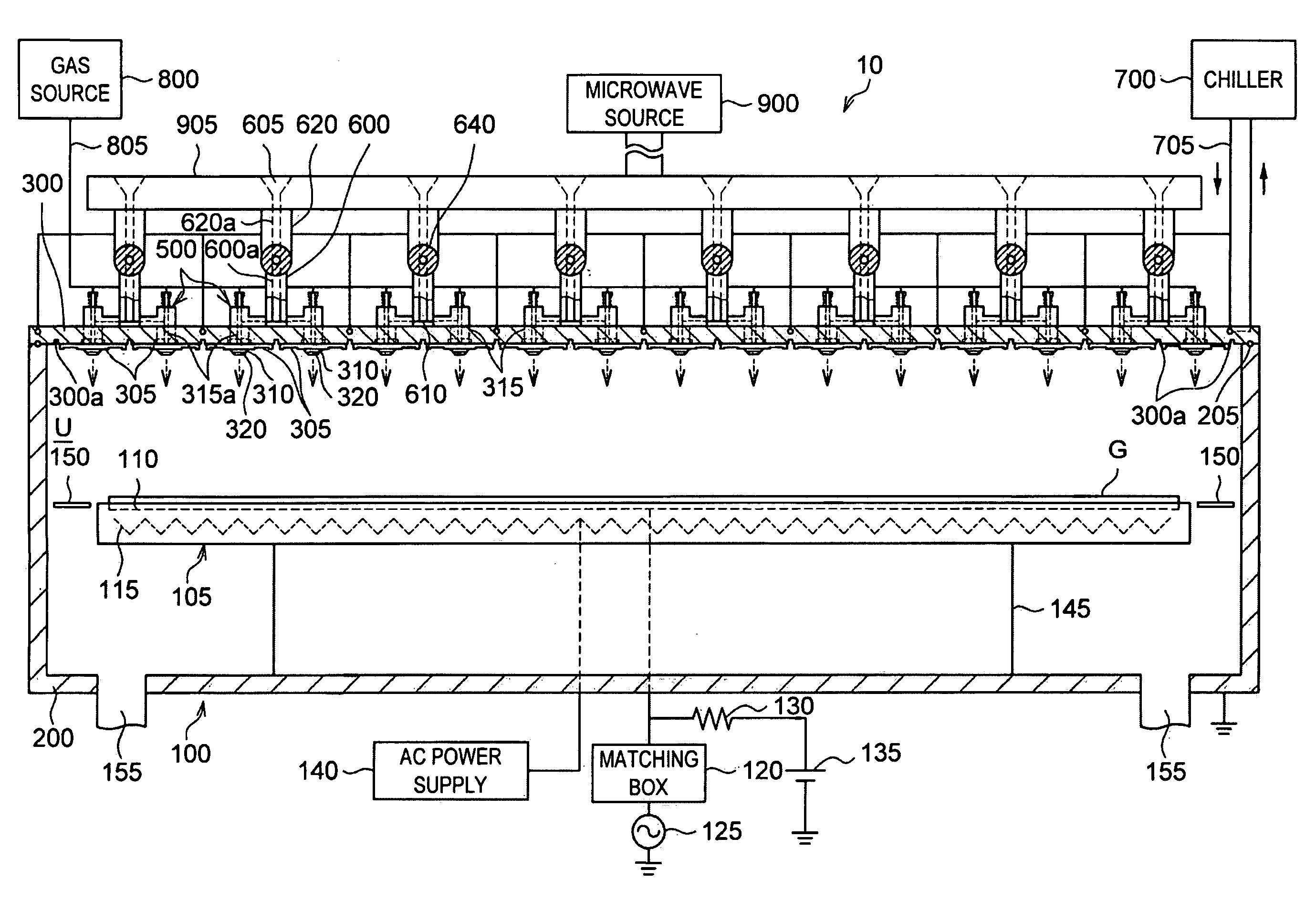

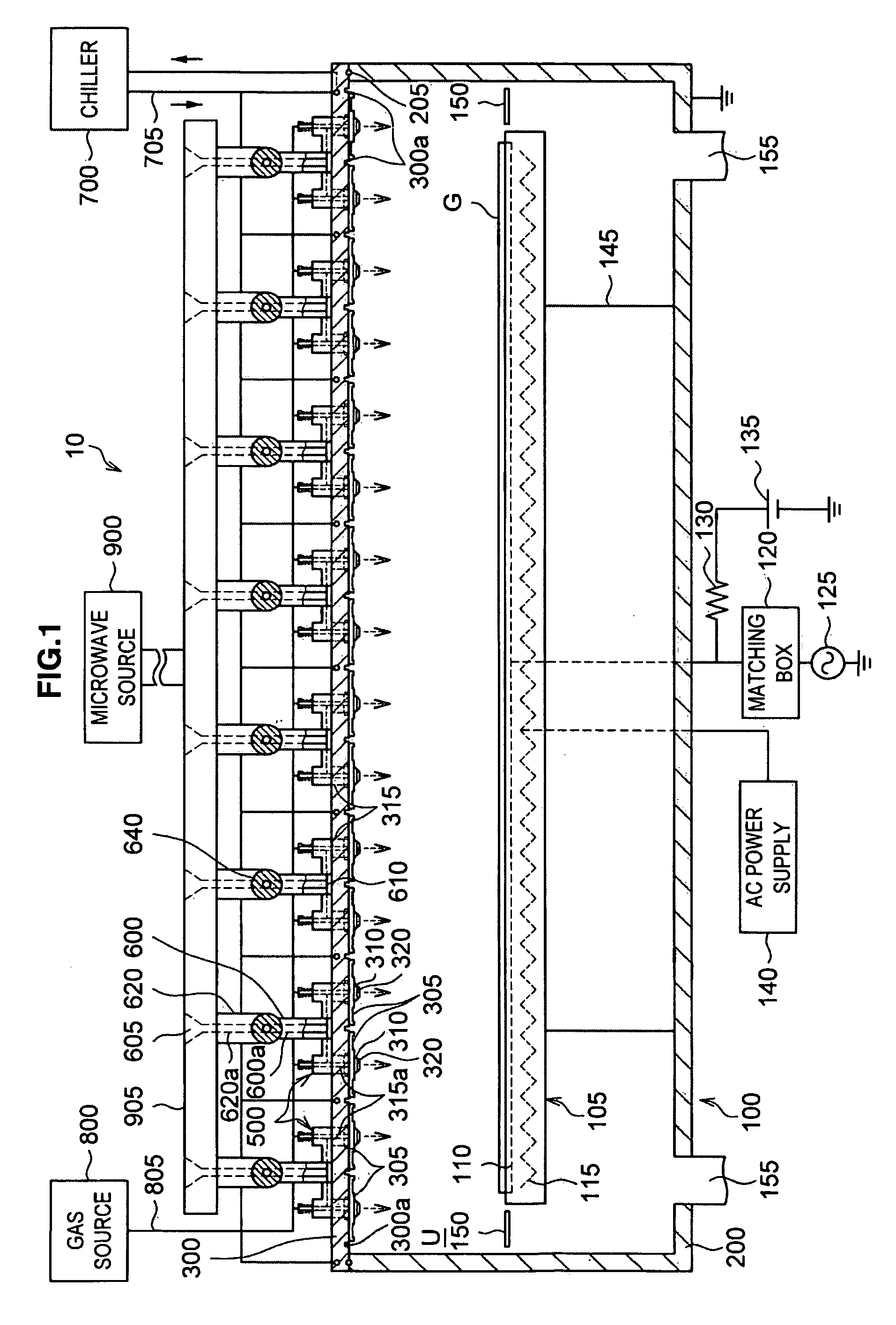

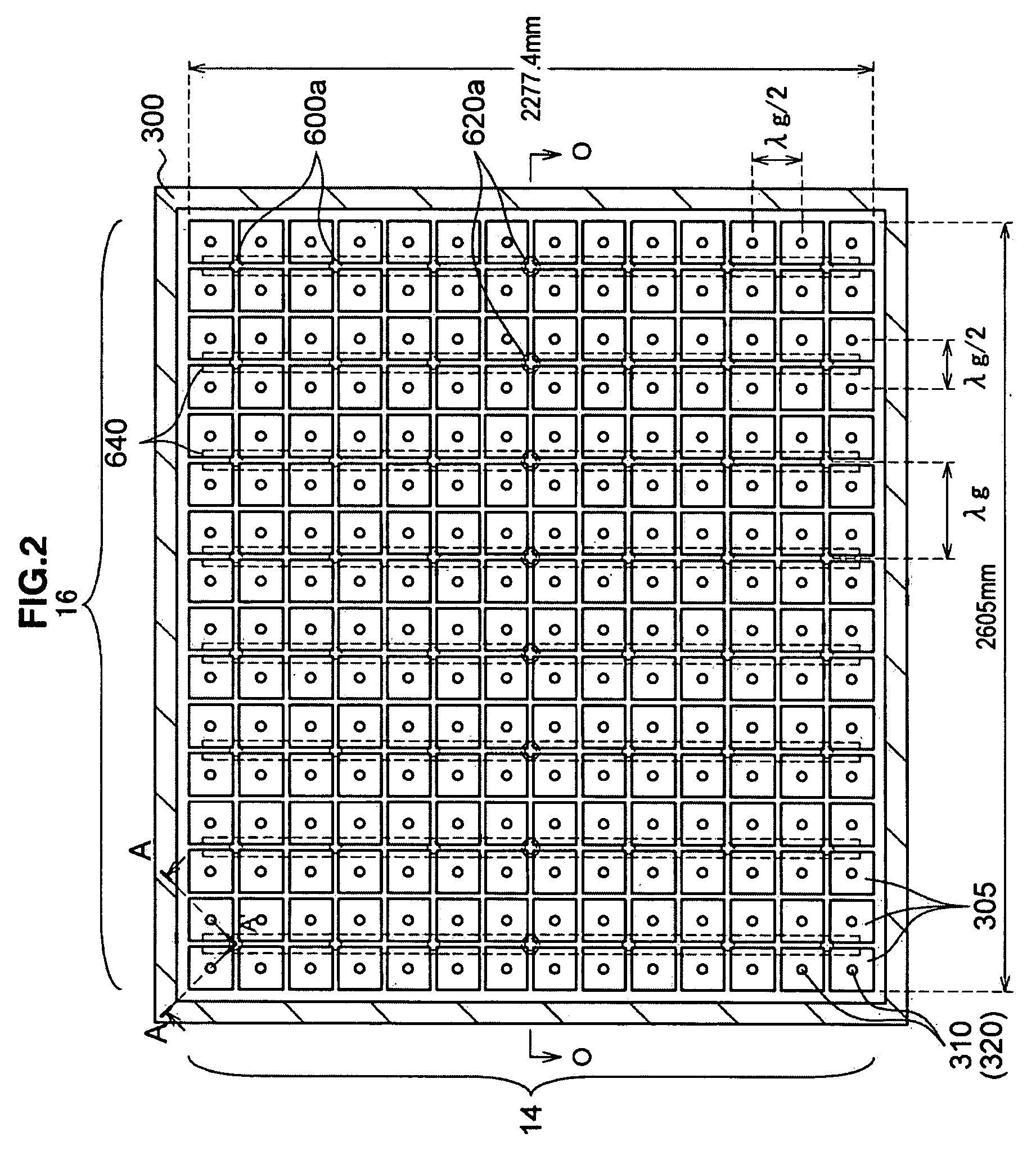

Plasma processing system, antenna, and use of plasma processing system

InactiveUS20080303744A1Reduce the electric fieldImprove uniformityElectric discharge tubesRadiating elements structural formsElectrical conductorDielectric plate

A plasma processing system 10 includes a processing chamber 100, a microwave source 900 that outputs a microwave, an inner conductor of a coaxial waveguide 315a that transfers the microwave, a through-hole 305a, a dielectric plate 305 that transmits the microwave transferred through the inner conductor 315a and discharges it into a processing chamber 100, and a metal electrode 310 that is coupled to the inner conductor 315a via the through-hole 305a, the metal electrode 310 being exposed on the surface of the dielectric plate 305 that faces the substrate with at least a portion of the metal electrode 310 being adjacent to the surface of the dielectric plate 305 that faces the substrate. A surface of the exposed surface of the metal electrode 310 is covered by the dielectric cover 320.

Owner:TOKYO ELECTRON LTD +1

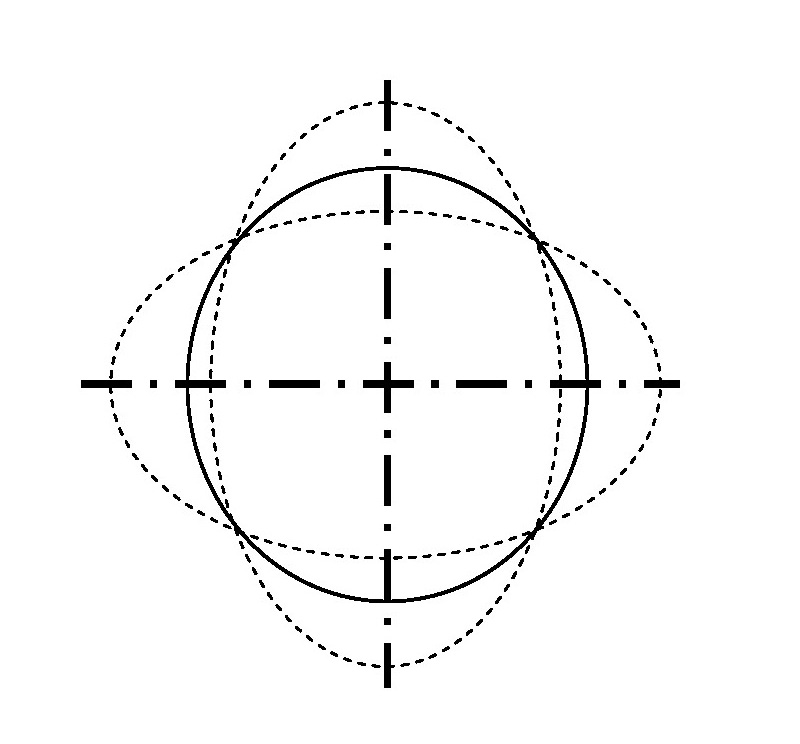

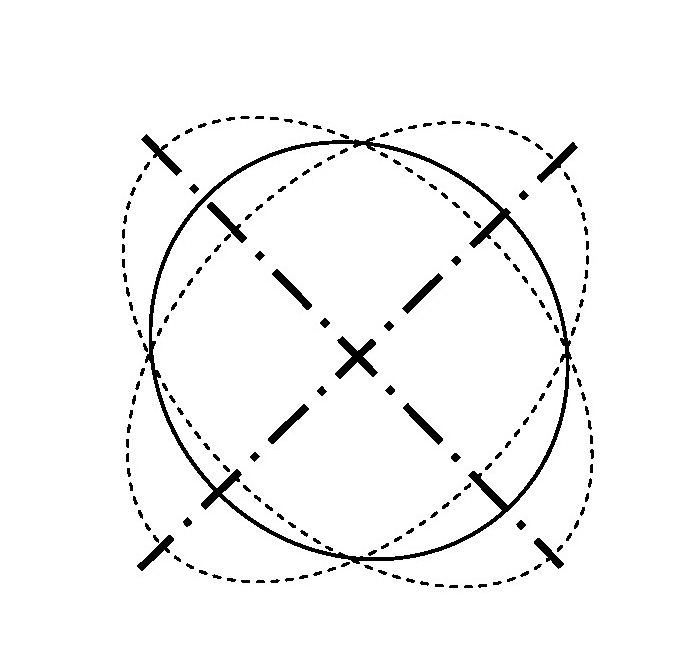

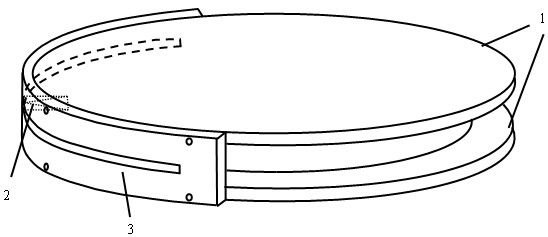

Harmonic oscillator of solid fluctuation gyro and solid fluctuation gyro

ActiveCN101936734ALean structureReduce air dampingSpeed measurement using gyroscopic effectsTurn-sensitive devicesElectricityResonance

The invention discloses a harmonic oscillator of a solid fluctuation gyro, which comprises a resonance ring (1), a resonance transmission part (2), a chassis (3) and a piezoelectric element (4), wherein, the resonance ring (1) is connected with the chassis (3) through the resonance transmission part (2), the resonance transmission part (2) is composed of support beams (21) which are uniformly distributed in the circumferential direction, and the piezoelectric element (4) is arranged on the support beams (21). The invention further discloses the solid fluctuation gyro provided with the harmonic oscillator. The solid fluctuation gyro and the harmonic oscillator of the invention have the advantages of high sensitivity, good sensing effect, convenient machining, low machining cost, simple mechanical balance procedure and the like.

Owner:NAT UNIV OF DEFENSE TECH

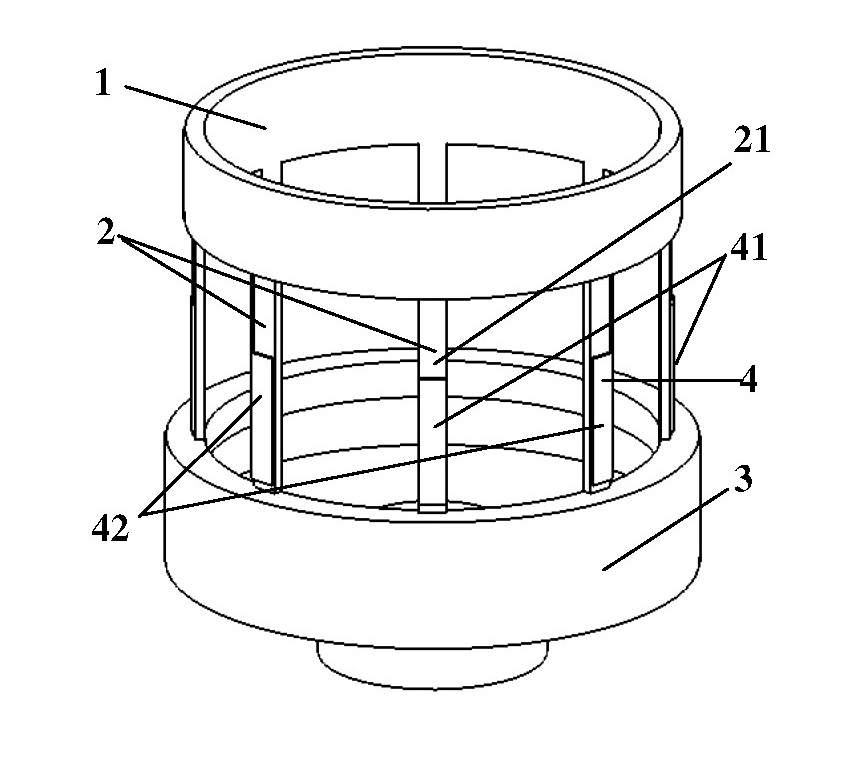

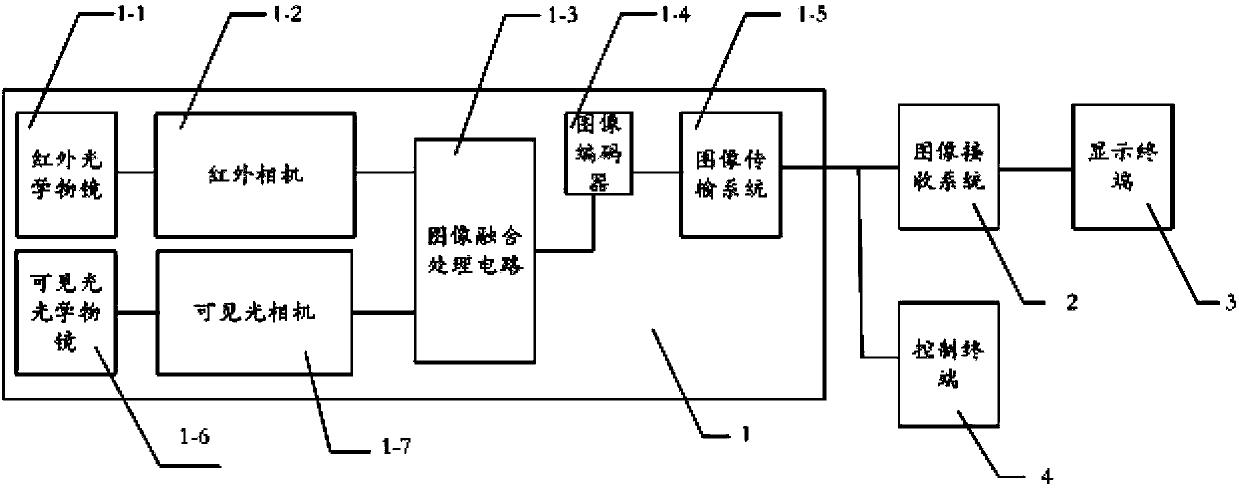

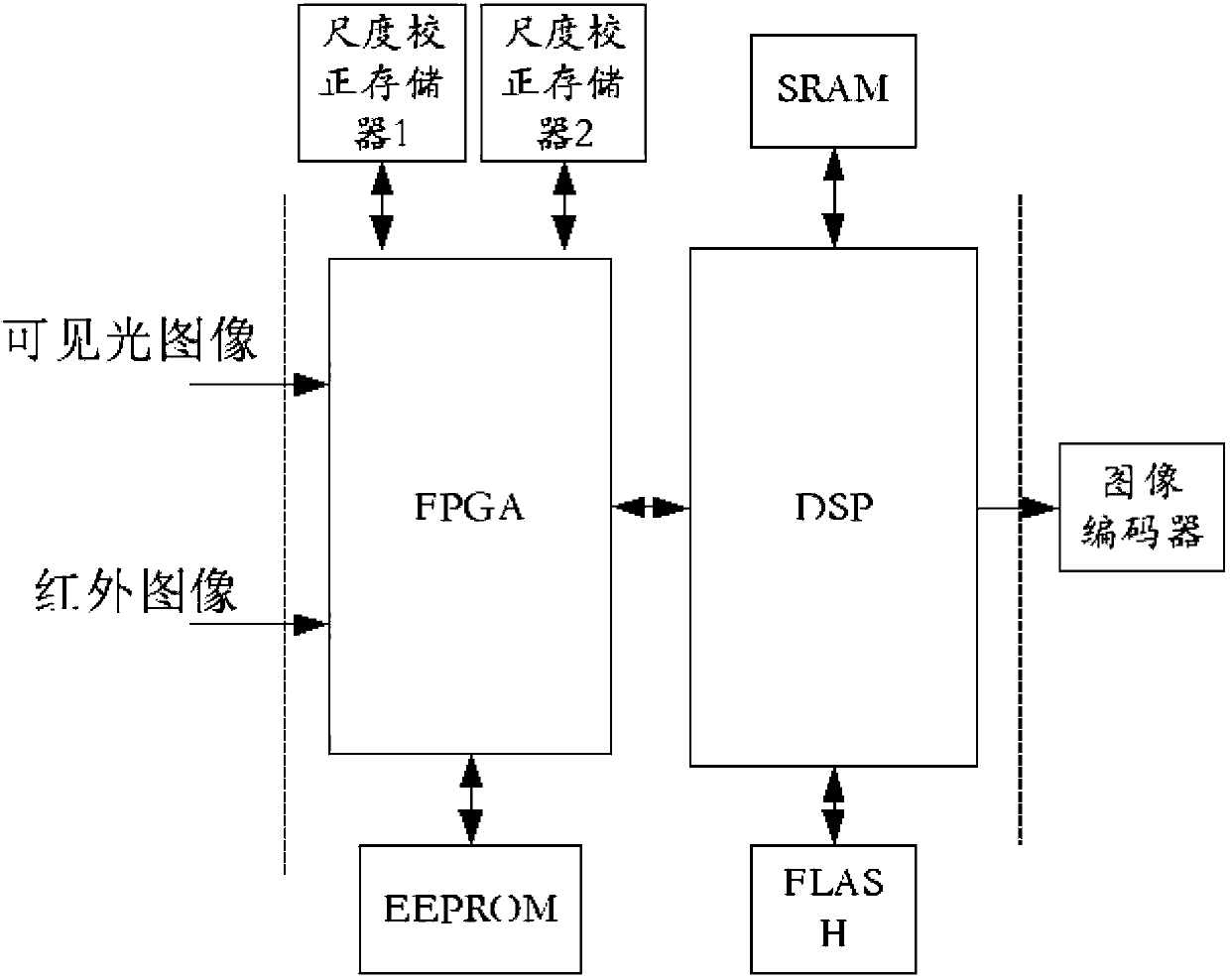

Double-spectrum night vision instrument vehicle-mounted system and double-spectrum fusion design method

The invention discloses a double-spectrum night vision instrument vehicle-mounted system and a double-spectrum fusion design method. The system comprises an infrared double-spectrum imaging die set used for imaging of a visible spectrum and an infrared spectrum and for collection, processing, fusion and transmission of the image data, an image receiving system used for completing the receiving of the image data, a display terminal used for displaying the images for an observer, and a control terminal used for controlling the function and on-off of an imaging mode. Due to the adoption of the system and the method, the problem that coaxial imaging of the double spectrum image is slight bad is solved, the machining precision requirement of the imaging system is reduced, more clear images are provided for forward observation for a train; a fusion method based on a scene moving object provides a reference source for the double-spectrum imaging system, the computation load is reduced, the registering reliability is improved, the imaging on the hardware is convenient, and the real-time performance is possessed; a weight fusion method based on multi-scale bilateral filtering is simple and feasible, improves the imaging detail information and reduces the calculation ability.

Owner:XIAN UNIV OF SCI & TECH

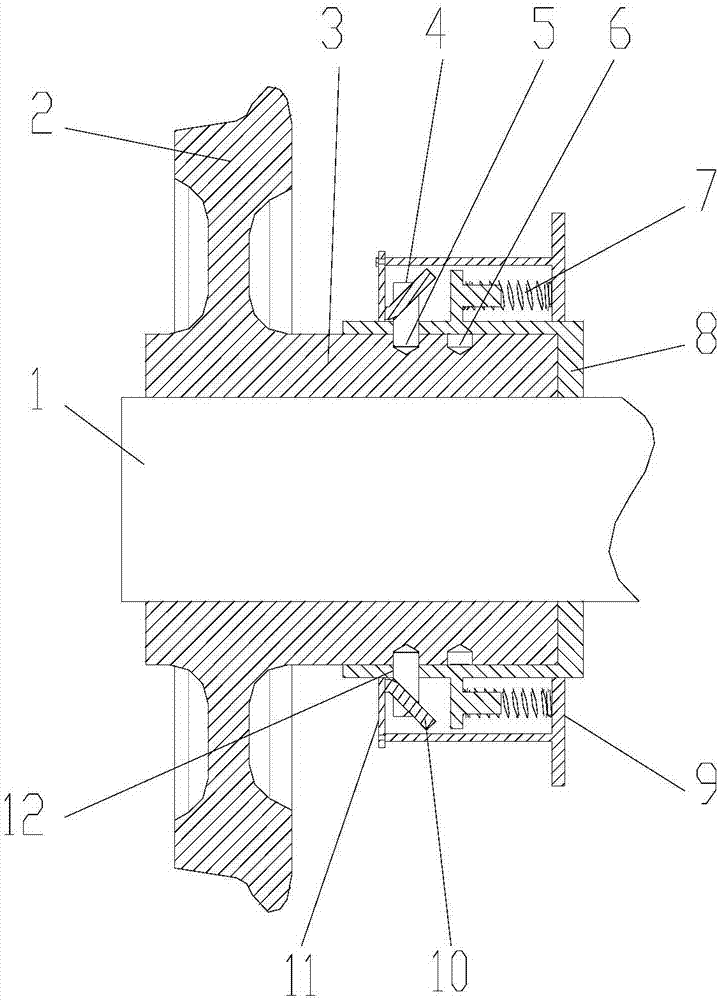

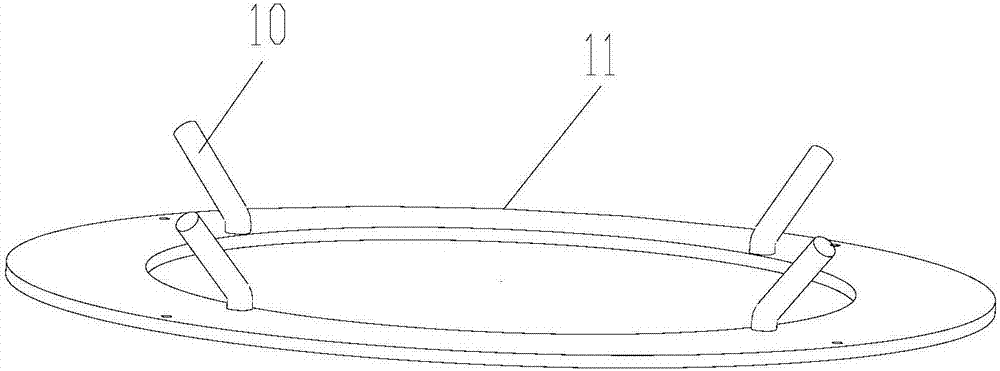

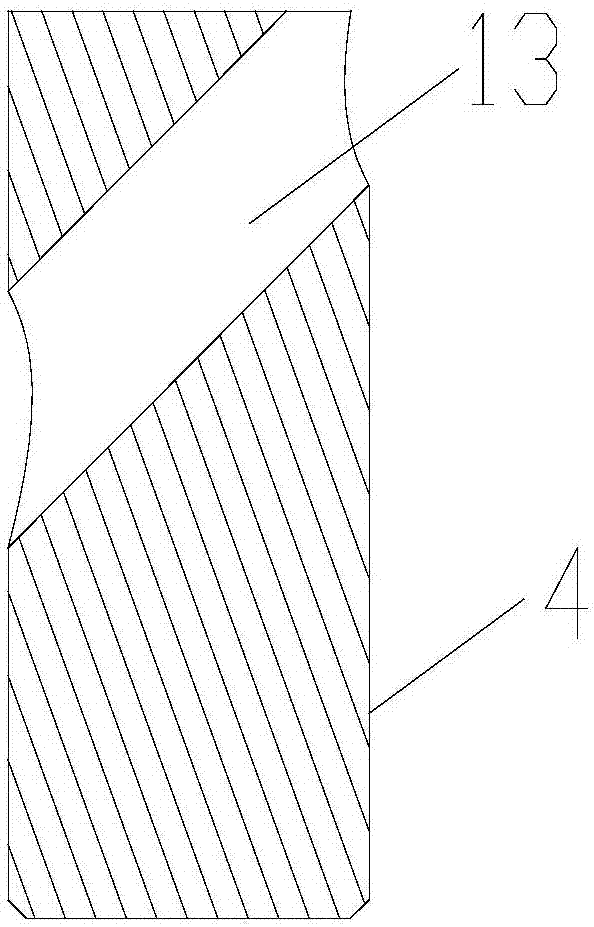

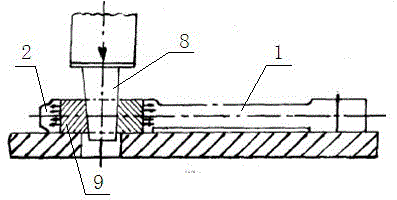

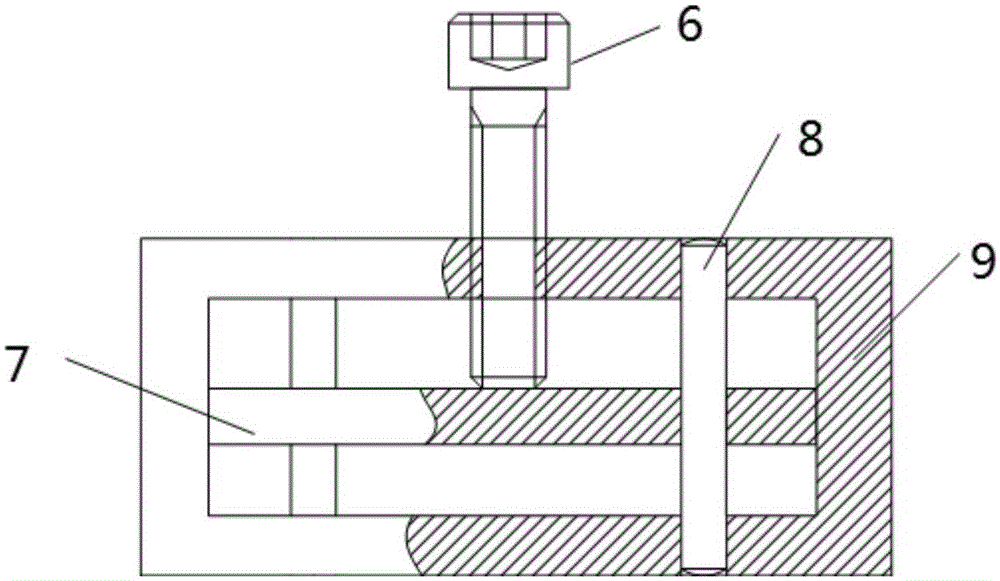

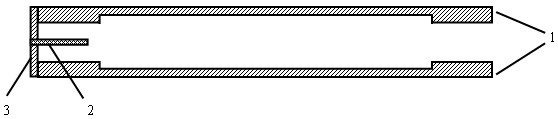

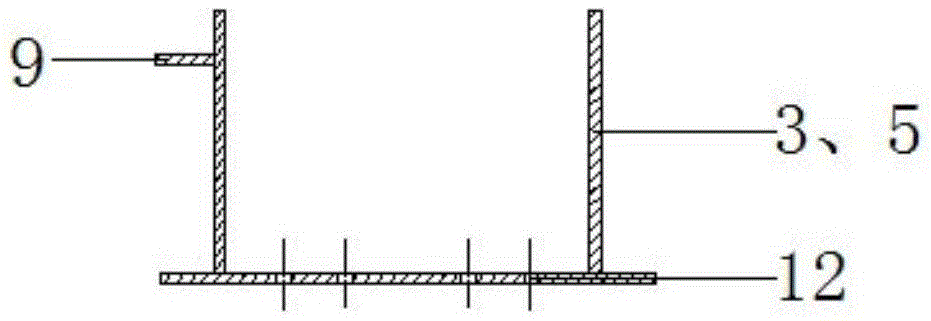

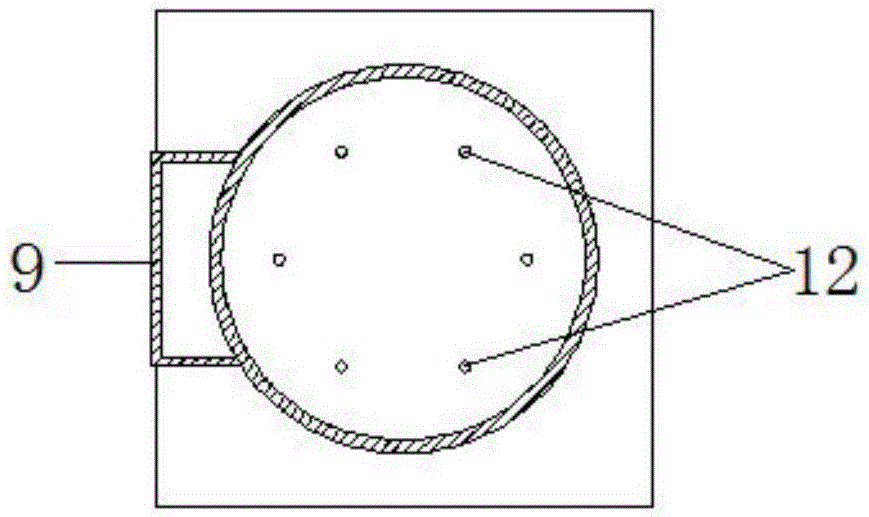

Fishing rod type variable gauge locking mechanism

InactiveCN107187461ALow machining accuracy requirementsEasy to processBogiesDifferent width rail tracksBogieLocking mechanism

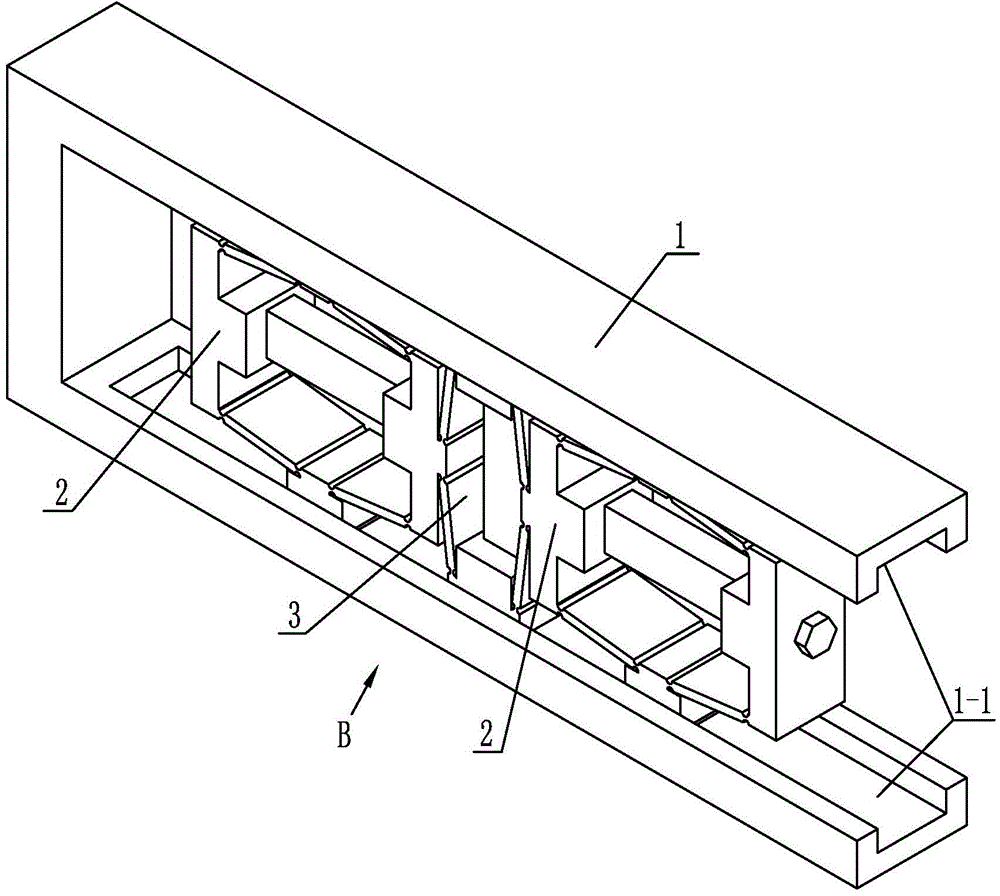

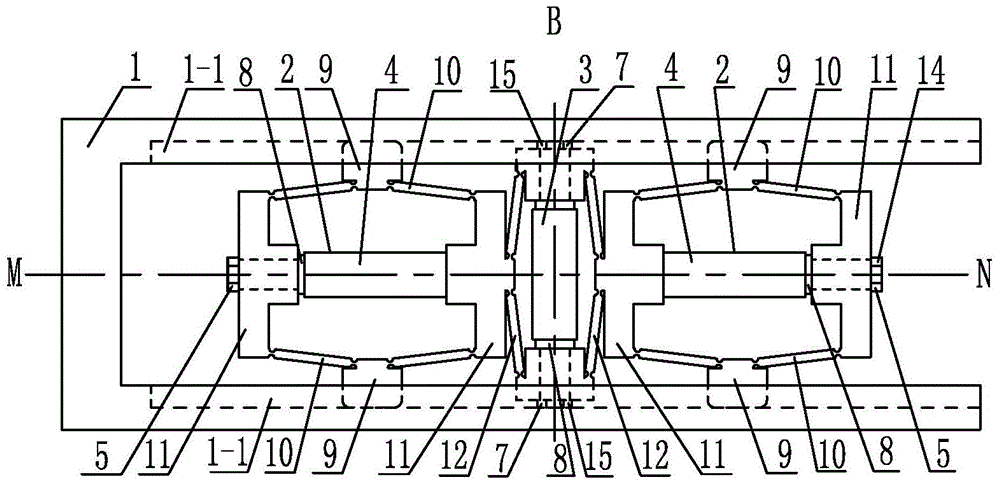

The invention provides a fishing rod type variable gauge locking mechanism, and belongs to the technical field of vehicle bogies. The fishing rod type variable gauge locking mechanism comprises a vehicle axle and wheels, wherein the wheels are separately fixed to two ends of the vehicle axle through a corresponding wheel hub; the axial width of each wheel hub is greater than the thickness of each wheel, and each wheel hub is provided with a narrow gauge and wide gauge limiting structure with a limiting column; a narrow gauge blind hole and a wide gauge blind hole are formed in the outer diameter surface of each wheel hub in the radial direction; sleeves are separately fixed to the wheel axle, on the inner side of each wheel; the inner diameter of each sleeve is in clearance fit with the outer diameter of the corresponding wheel hub; a relieving cylinder is arranged on the outer diameter of each sleeve; a relieving disk is arranged at the end part of each relieving cylinder; oblique fishing rods are uniformly arranged on each relieving disk in the circumferential direction; an axial through hole is formed in the front end of each sleeve along the circumference, and a spring bracket is arranged in the middle part of each sleeve; a relieving spring is arranged between each sleeve and the corresponding relieving cylinder; and an oblique penetrating hole is formed in each limiting column. The fishing rod type variable gauge locking mechanism disclosed by the invention is mainly used in an occasion that a narrow gauge is different from a wide gauge.

Owner:SOUTHWEST JIAOTONG UNIV

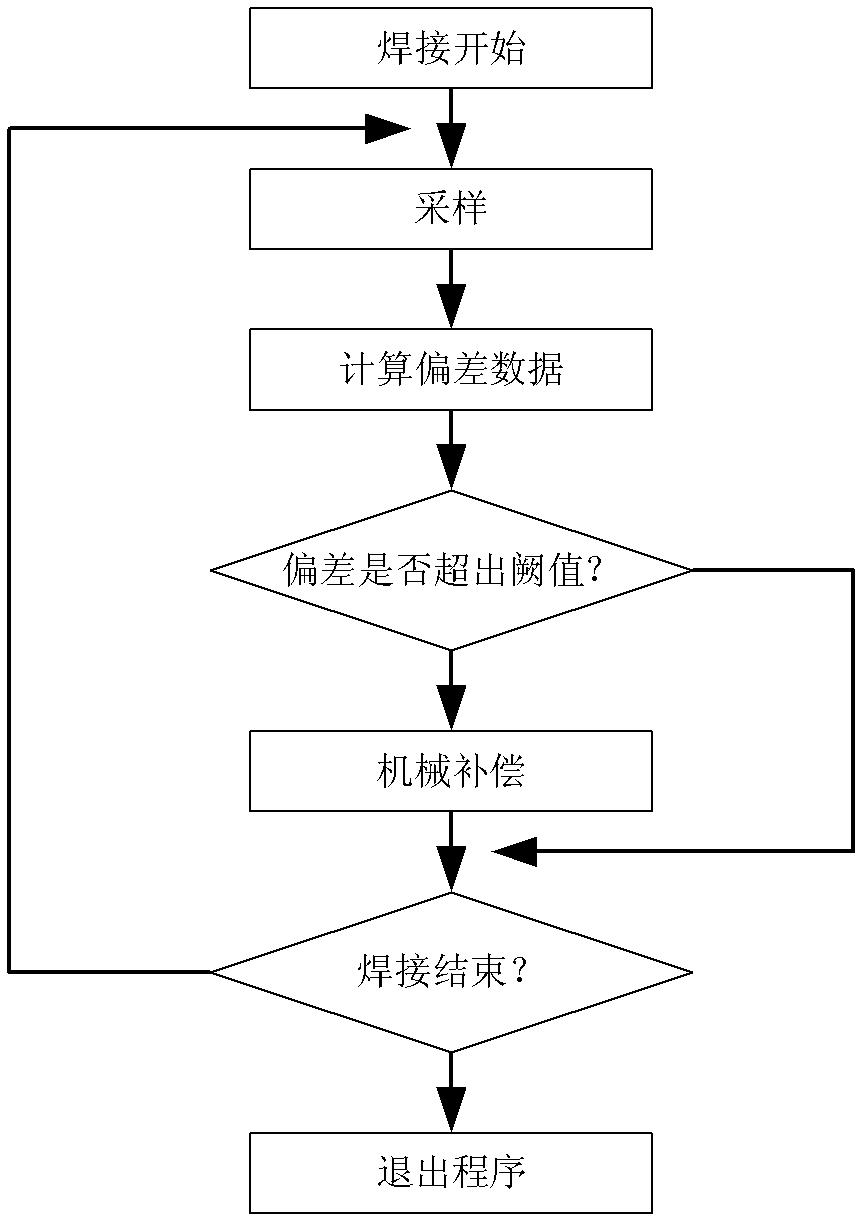

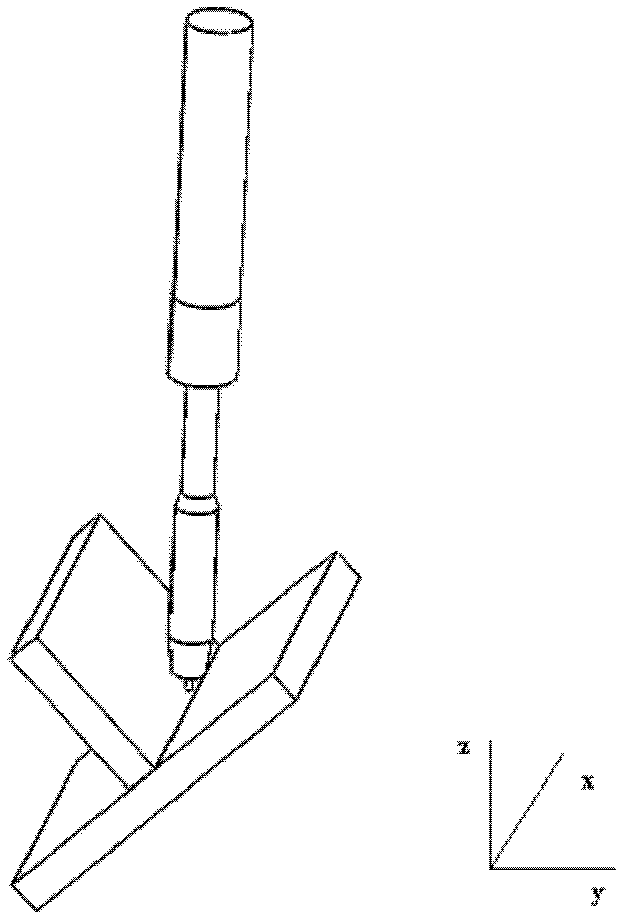

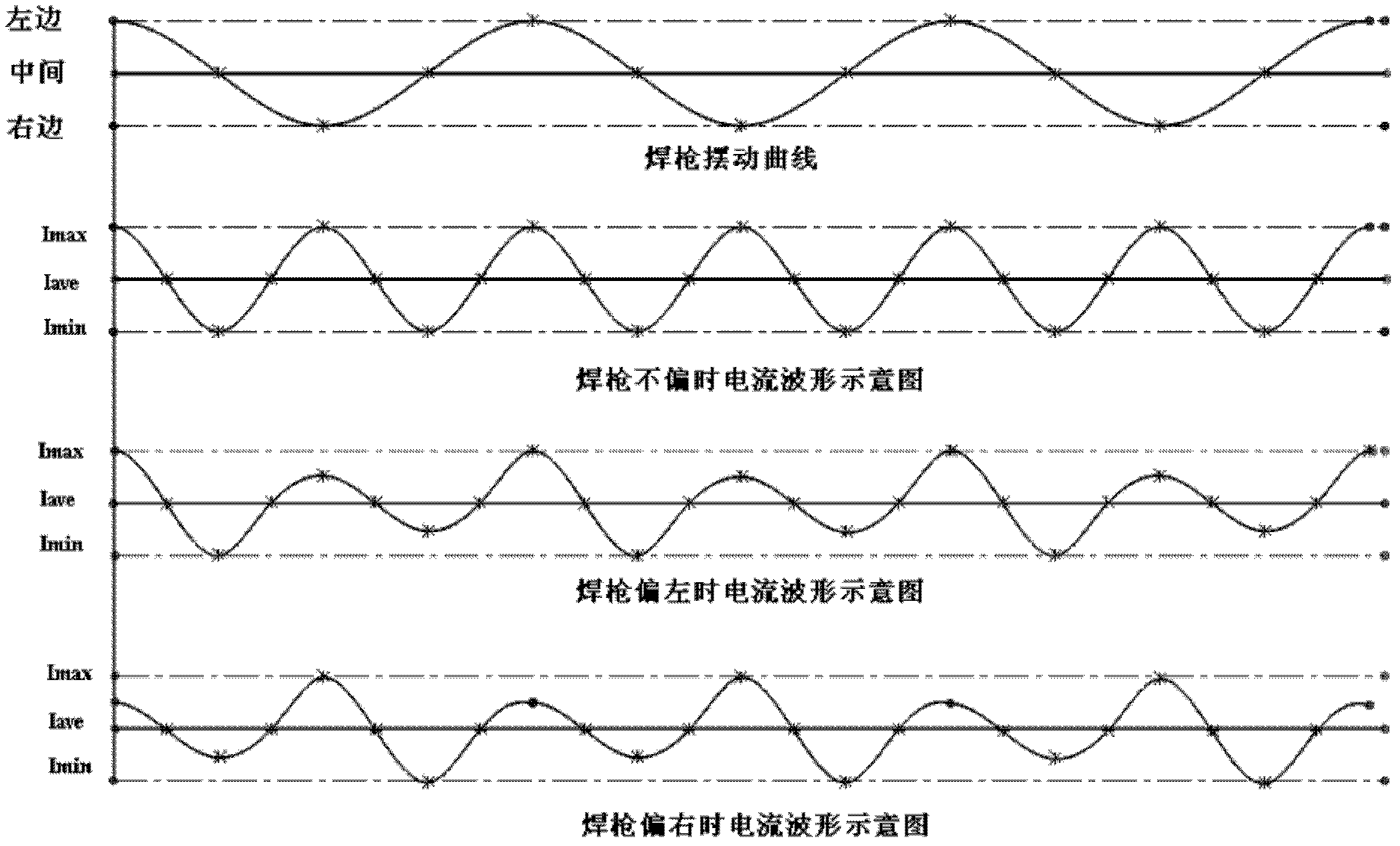

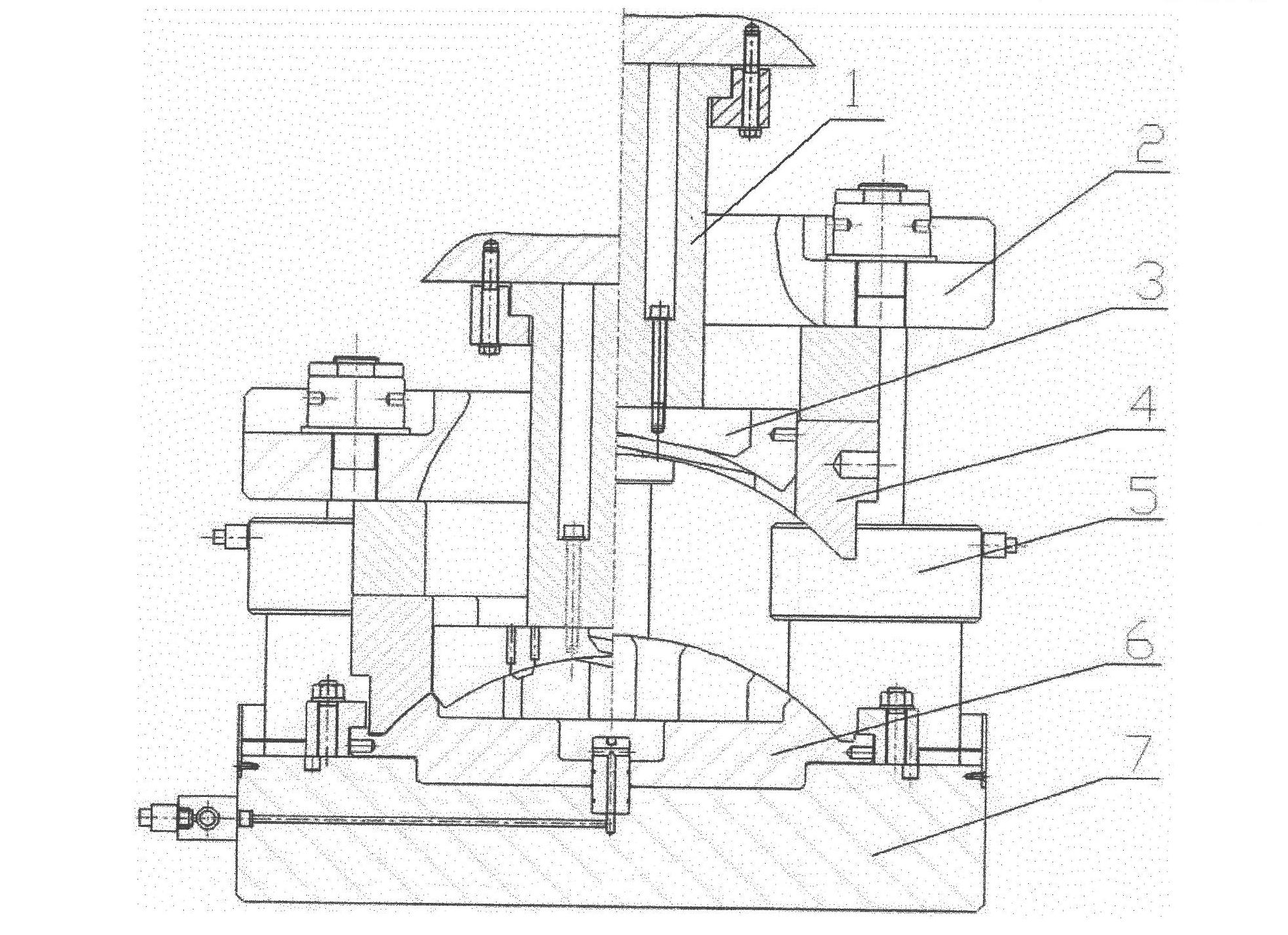

Arc oscillation-based gas shielded welding arc tracking method

ActiveCN103182589AQuick responseImprove tracking accuracyArc welding apparatusPower flowCurrent sensor

The invention relates to an arc oscillation-based gas shielded welding arc tracking method which comprises the following steps that after the welding is started, a welding gun starts doing a periodic oscillation along a direction vertical to a weld joint; a current sensor carries out real-time sampling on a welding current; sampled data is filtrated; filtered data is subjected to deviation judgment and converted into deviation data; and the deviation data is converted into a movement command, and a weld joint track is compensated in real time through a deviation rectifying device. Because sampled signals are filtered by adopting software, the arc oscillation-based gas shielded welding arc tracking method is high in response speed and tracking precision; and due to the adoption of a dual-filtering mode, the signal mutation caused by instable arc is reduced, the deviation compensation dosage is calculated by using known welding parameters, the support of a database or expert system is not needed, the requirement of a welding device on a weldment processing precision is lowered, and thus the arc oscillation-based gas shielded welding arc tracking method is an effective means for realizing the flexible automatic welding.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

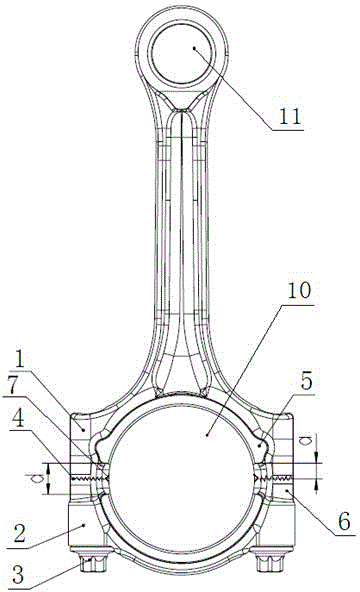

Engine cracking connecting rod and machining method thereof

The invention discloses an engine cracking connecting rod and a machining method of the engine cracking connecting rod. The engine cracking connecting rod comprises a connecting rod body and a connecting rod cover, wherein the connecting rod body is connected with the connecting rod cover in a cracking position of a connecting rod big head through a connecting bolt, U-shaped grooves which are symmetrical relative to a cracking surface are formed in the cracking position of the connecting rod big head, V-shaped splitting grooves are formed in the inner edge, corresponding to the cracking position, of a big head hole of the connecting rod big head, and the V-shaped splitting grooves are symmetrical relative to the cracking surface. The machining method comprises the steps that a forged connecting rod blank with the two symmetrical U-shaped grooves is machined in a rough mode; the connecting rod is cracked into the connecting rod body and the connecting cover; the cracked connecting rod is machined in a fine mode, and a cracking connecting rod finished product is formed. The engine cracking connecting rod and the machining method of the engine cracking connecting rod can lower the cracking difficulty, guarantee the cracking effect, reduce production work procedures, improve reset accuracy after cracking, and guarantee the overall performance of the connecting rod.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

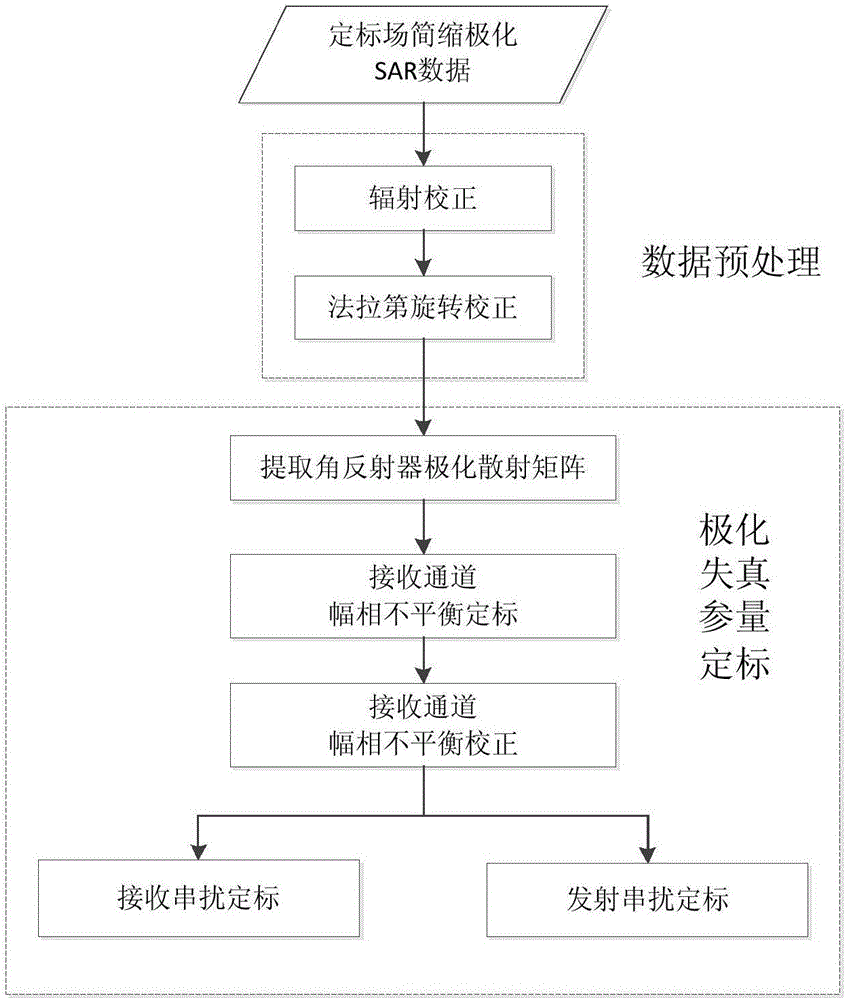

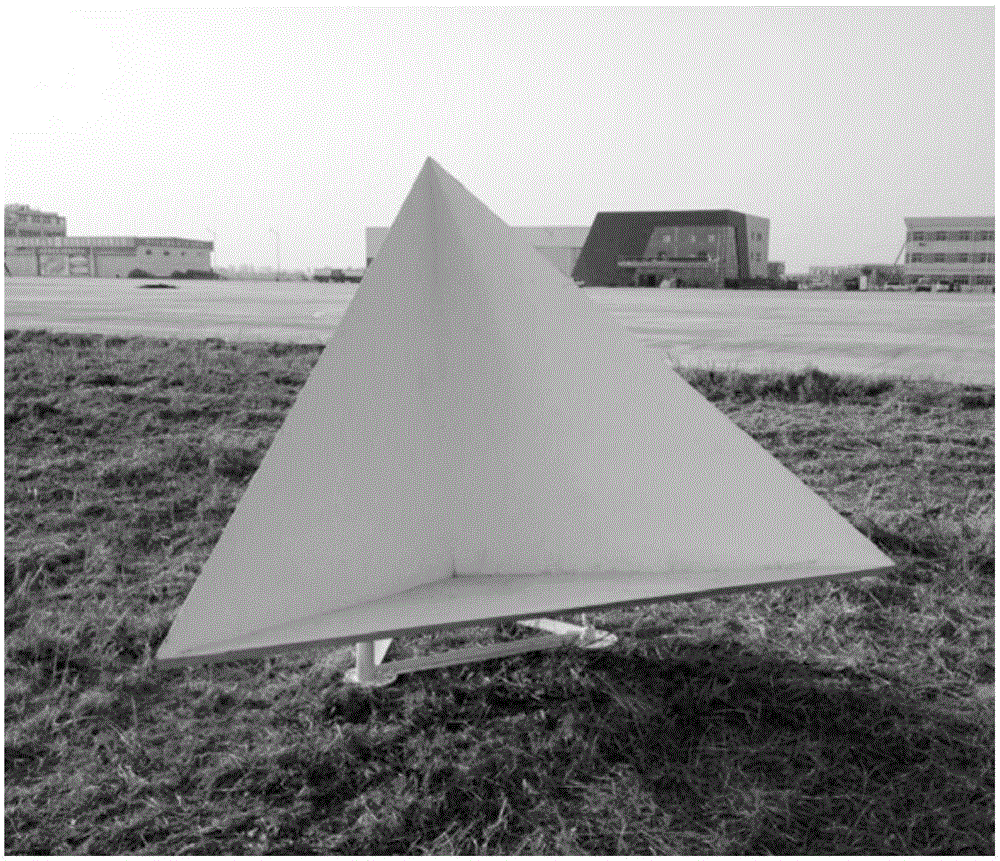

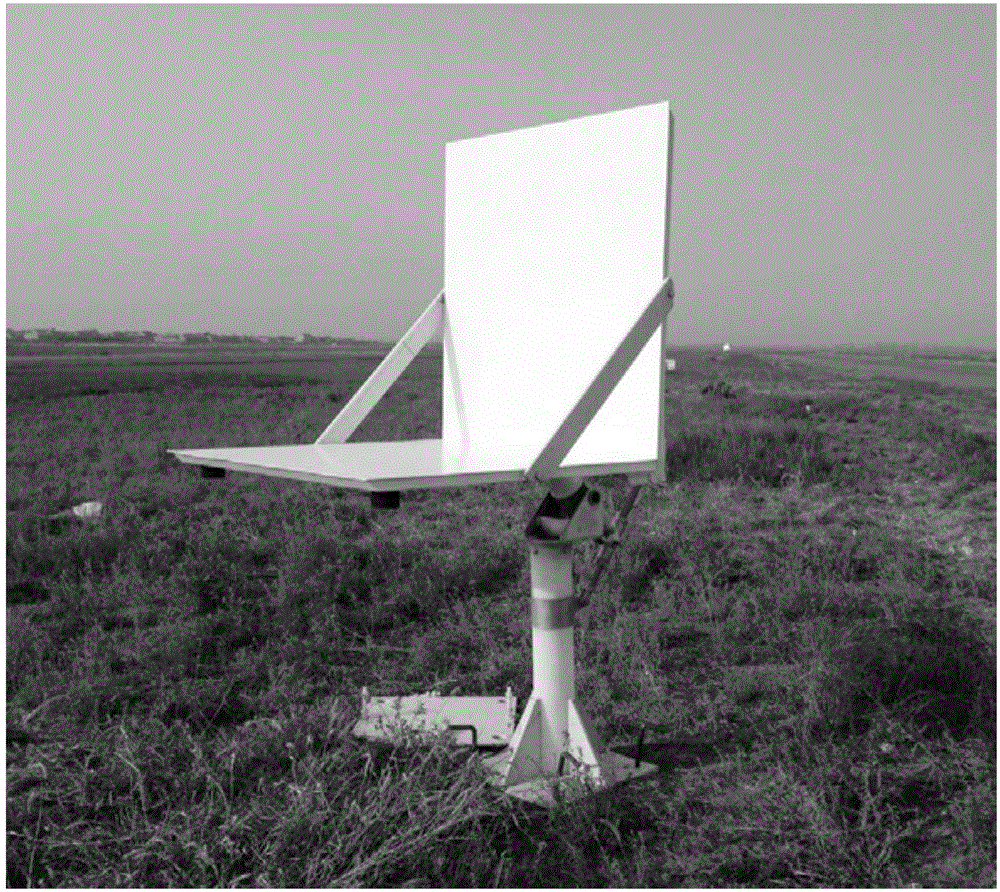

Multi-polarization SAR compact polarimetry calibration method

ActiveCN106405547AReduce weightSimplify requirementsRadio wave reradiation/reflectionPolarimetric sarCalibration algorithm

The invention provides a multi-polarization SAR compact polarimetry calibration method which comprises a calibration field compact polarimetry SAR data preprocessing process and a polarization distortion parameter calibration process. In the calibration field compact polarimetry SAR data preprocessing process, compact polarimetry SAR data radiation correction and Faraday rotation correction are mainly completed. In the polarization distortion parameter calibration process, four different types of common corner reflectors are used as reference calibrators, and a compact polarimetry calibration method (namely, a compact polarimetry polarization distortion parameter calibration method) is deduced based on a calibration model. Through the method, a polarization distortion parameter can be calibrated precisely. The calibration algorithm does not depend on the absolute RCS values of the corner reflectors, and calibration error caused by RCS inconsistency of different corner reflectors can be avoided effectively. The algorithm is of high robustness and practicability.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

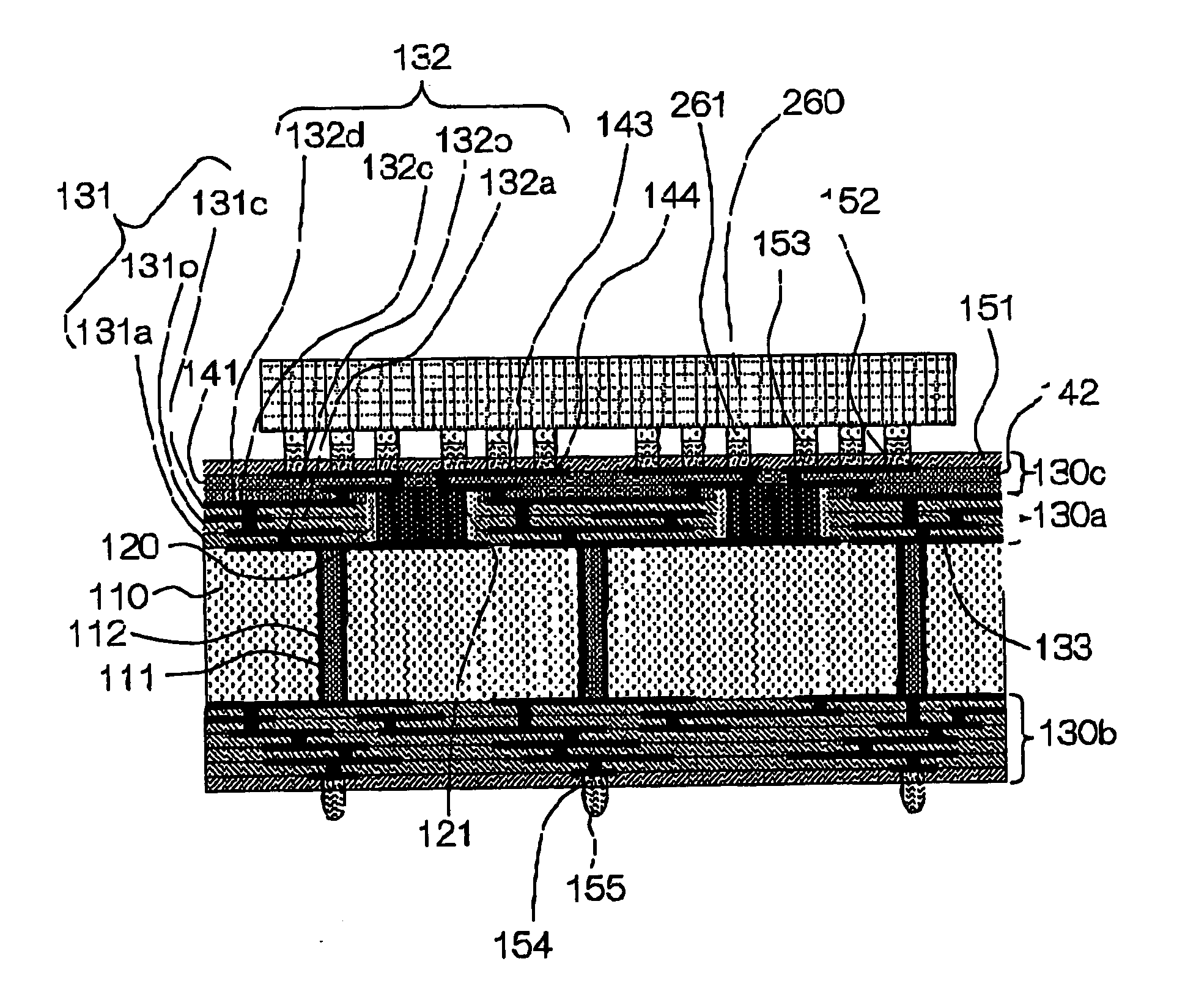

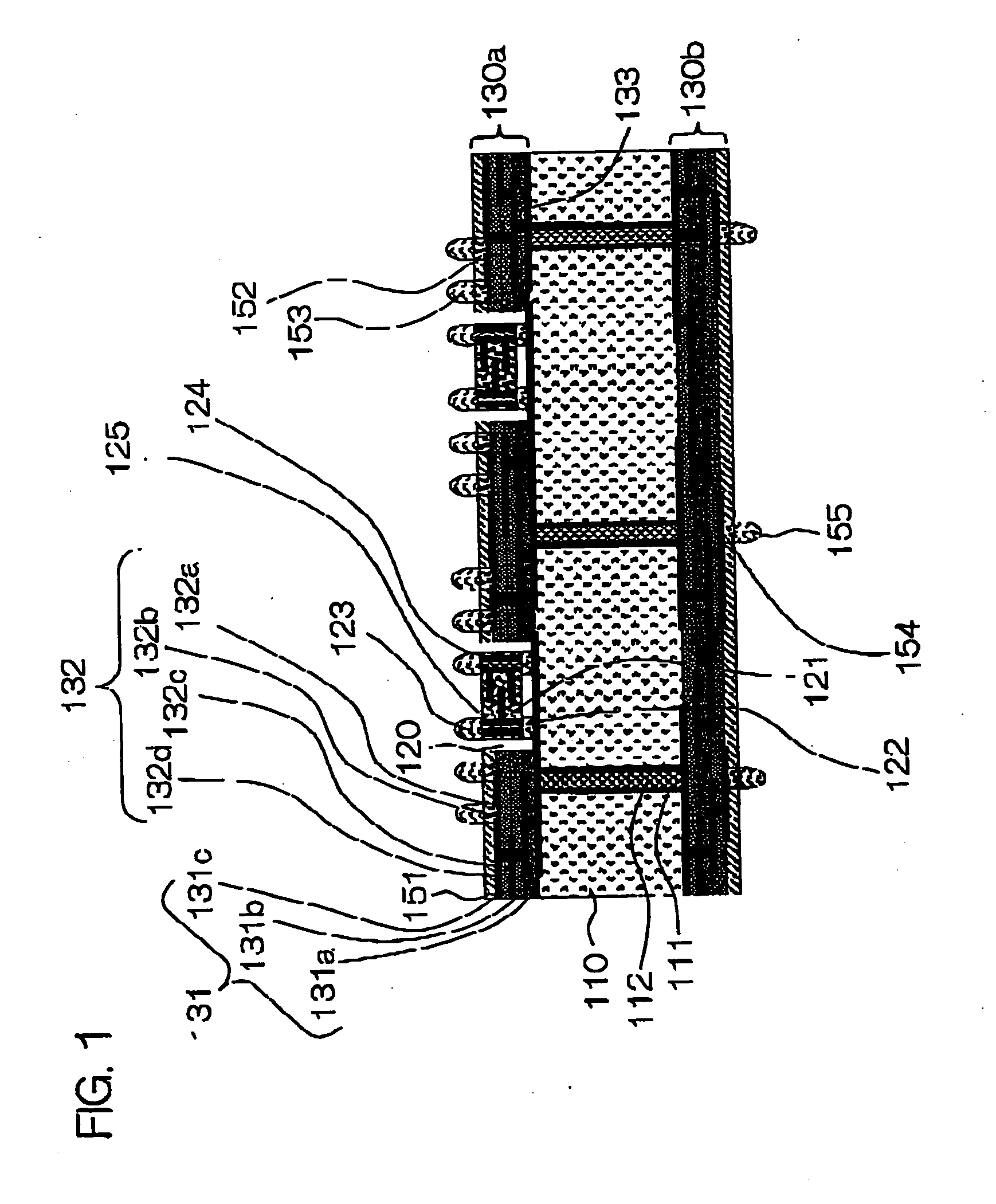

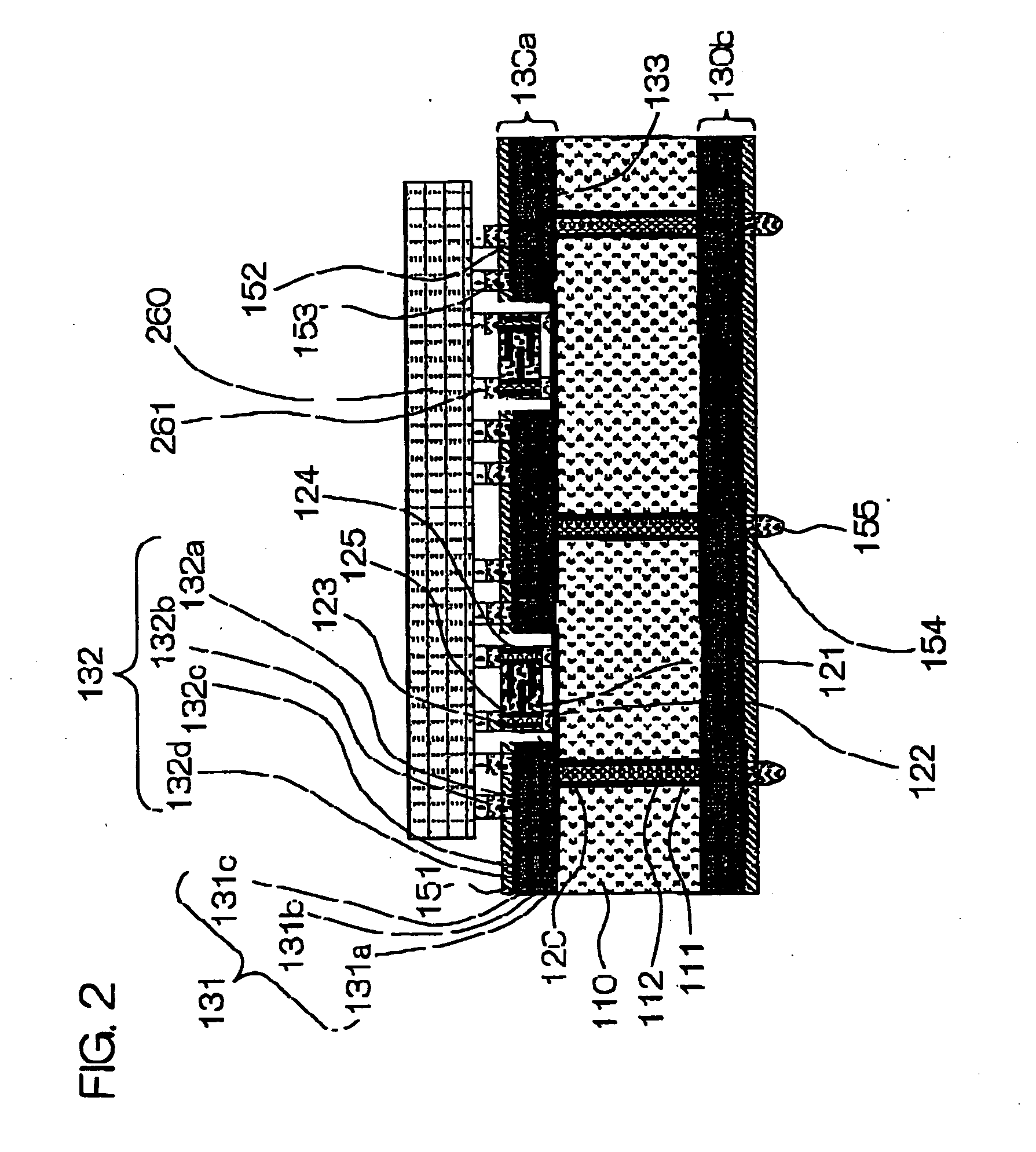

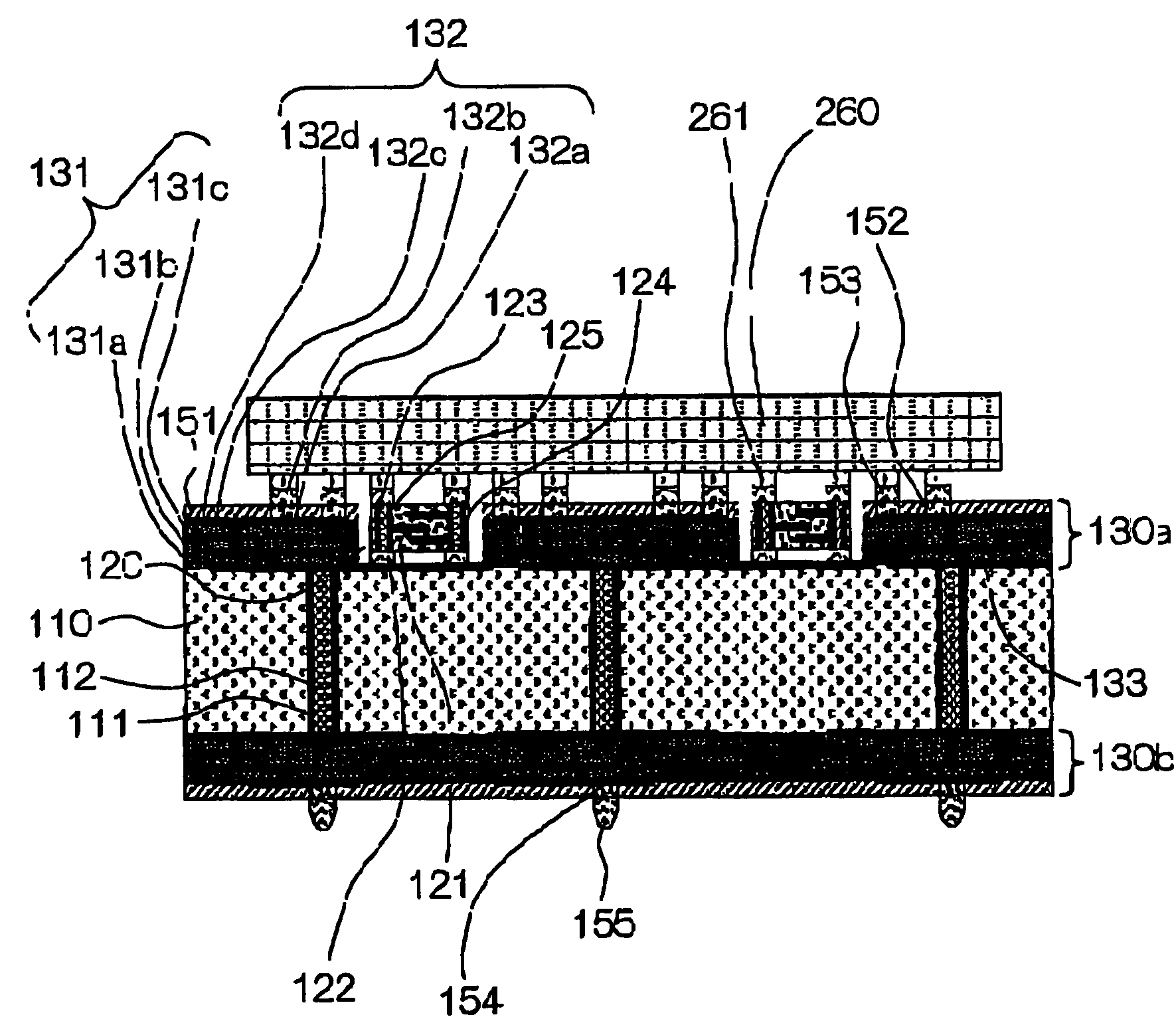

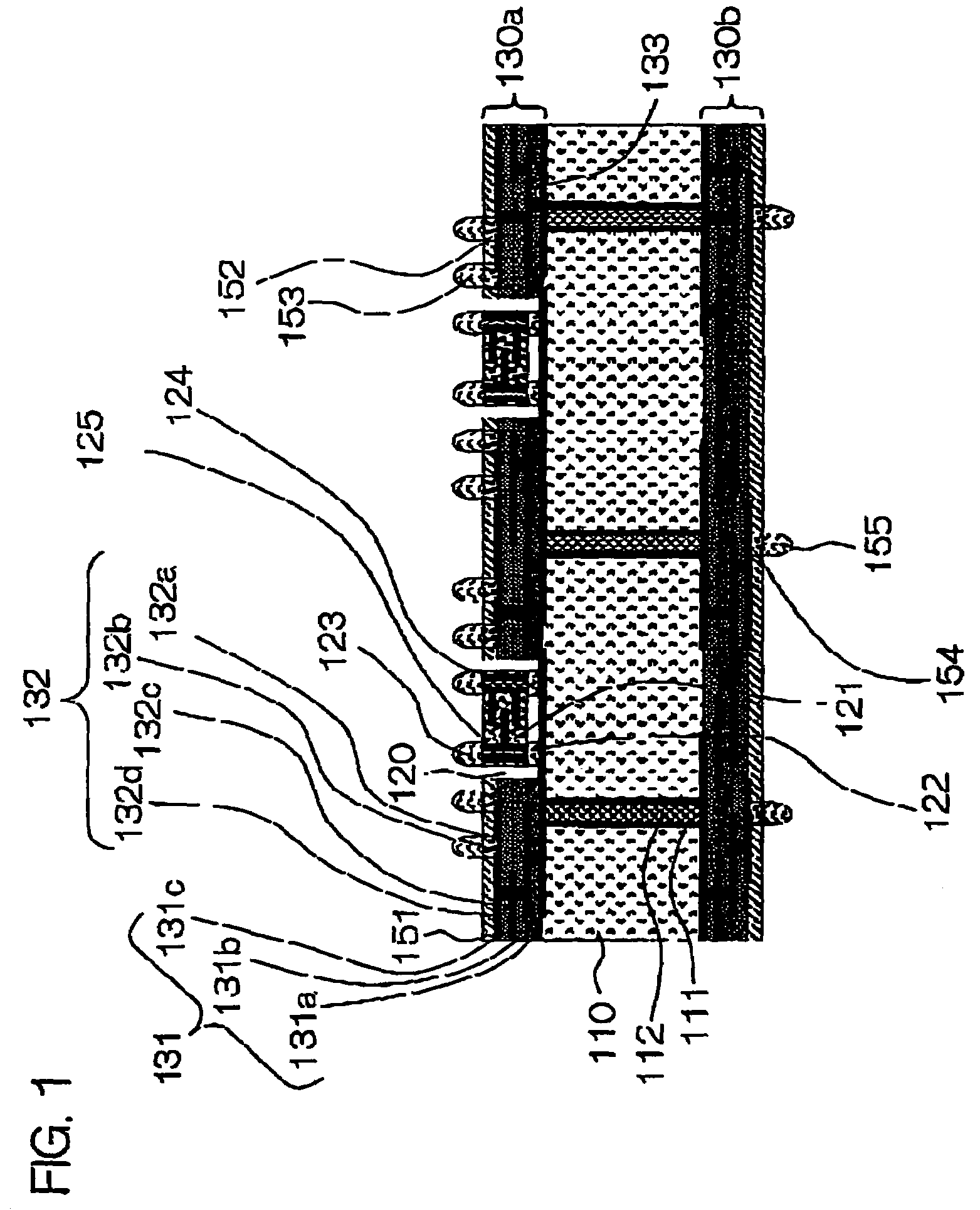

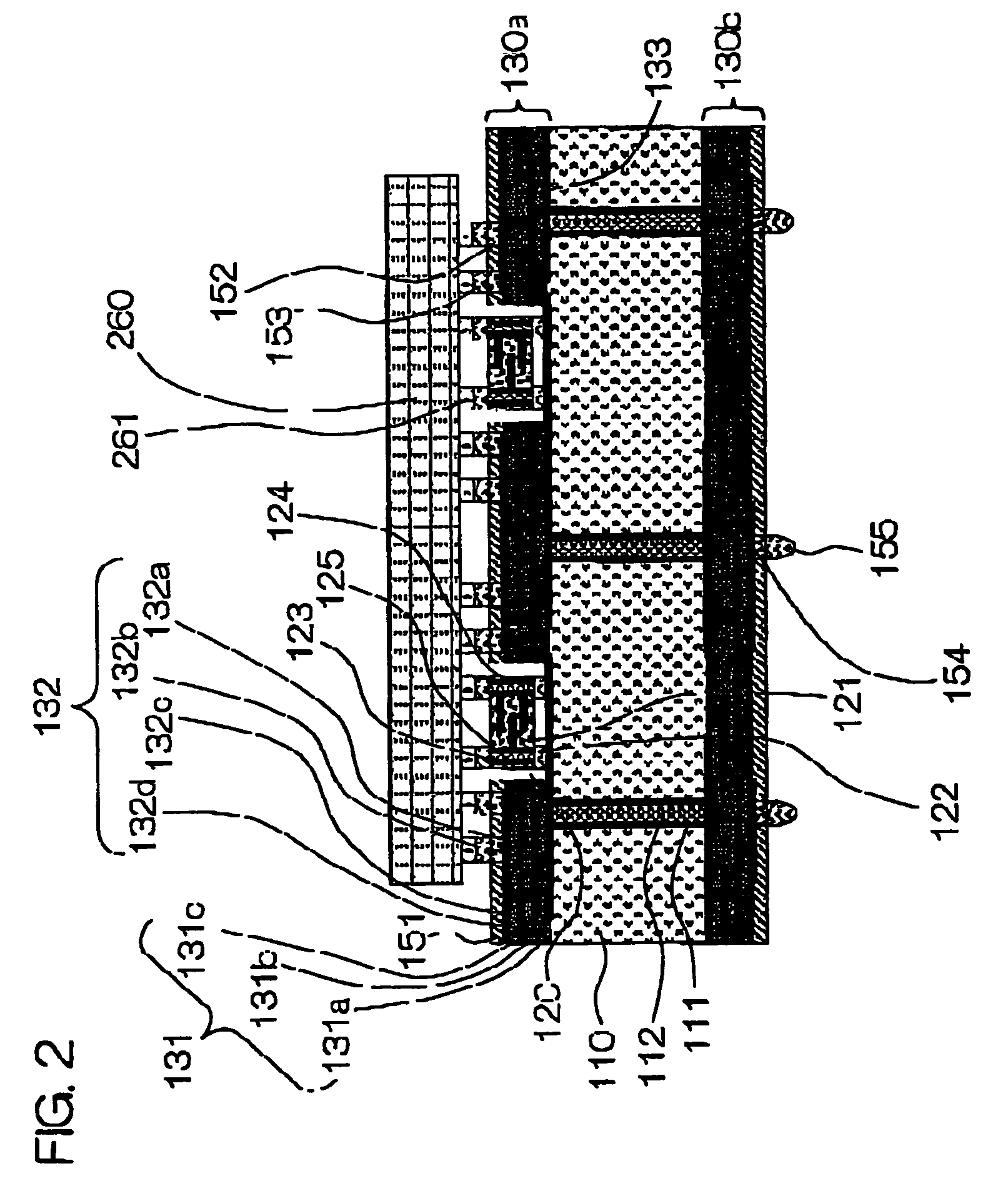

Wiring board and semiconductor device

InactiveUS20050087850A1Fast charge transferLower resistanceSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorDevice material

There is disclosed a wiringboard comprising a core substrate 110, a build-up layer 130a formed on at least one side of main surfaces the core substrate, wherein a cavity 120 for accommodating a chip-type decoupling capacitor 121 is formed in the build-up layer 130a. The capacitor 121 includes electrode terminals on an upper surface thereof that are directly connected to a semiconductor component, and electrode terminals on a back surface of the capacitor 121 is connected to a wiring conductor layer 132a on a bottom surface of the cavity 120. This structure enables decoupling capacitor and the semiconductor component 260 to be connected with low resistance and low inductance.

Owner:KYOCERA CORP

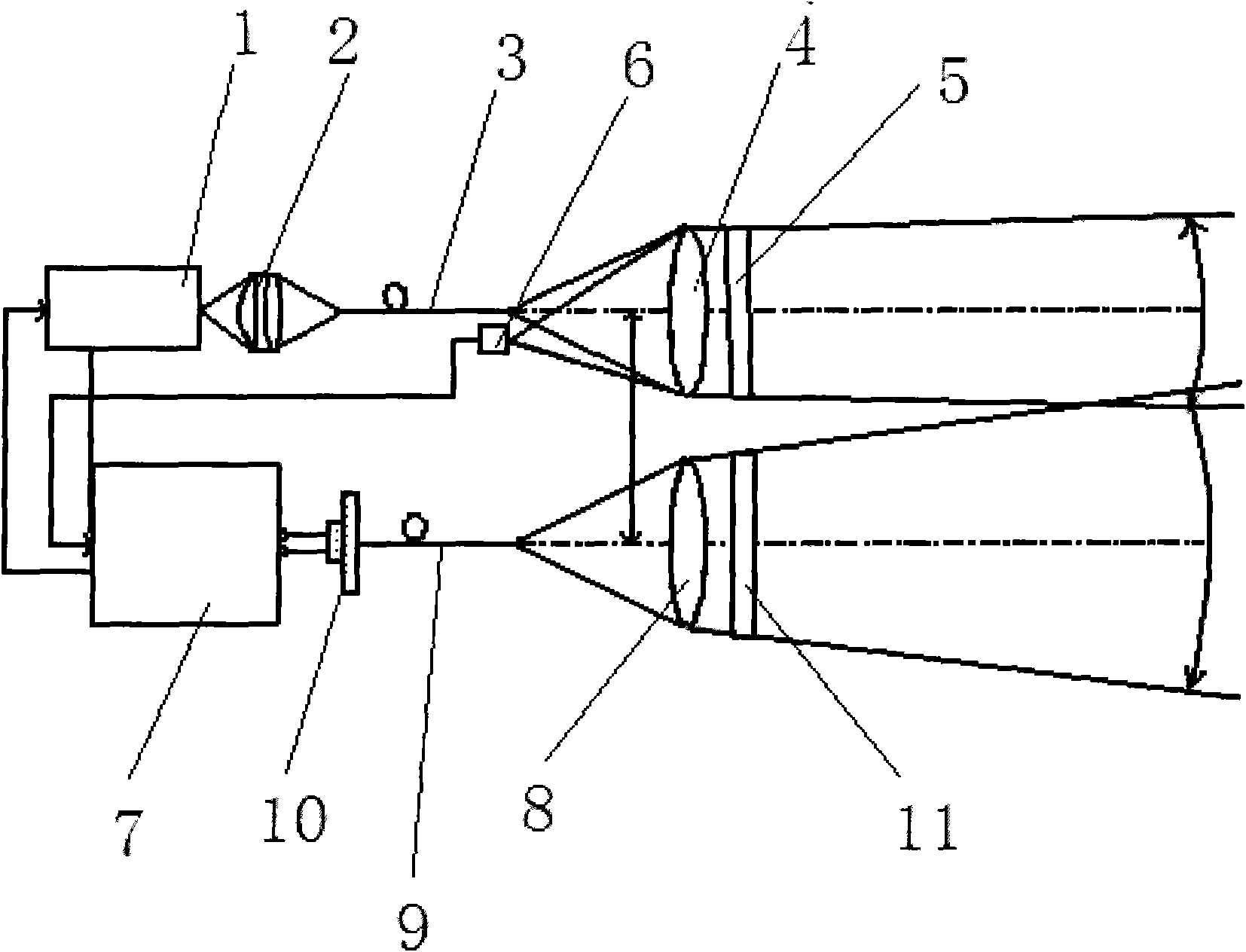

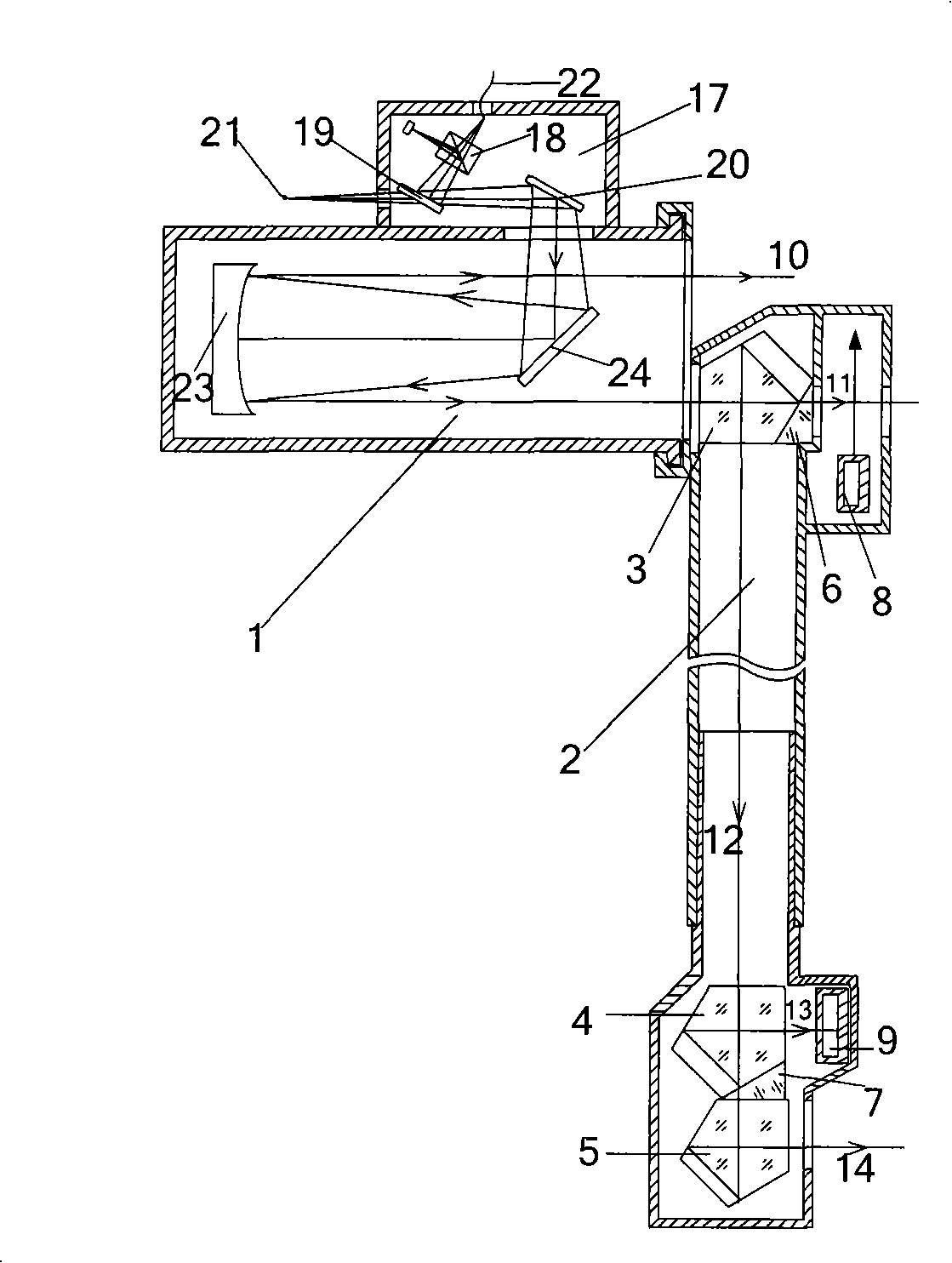

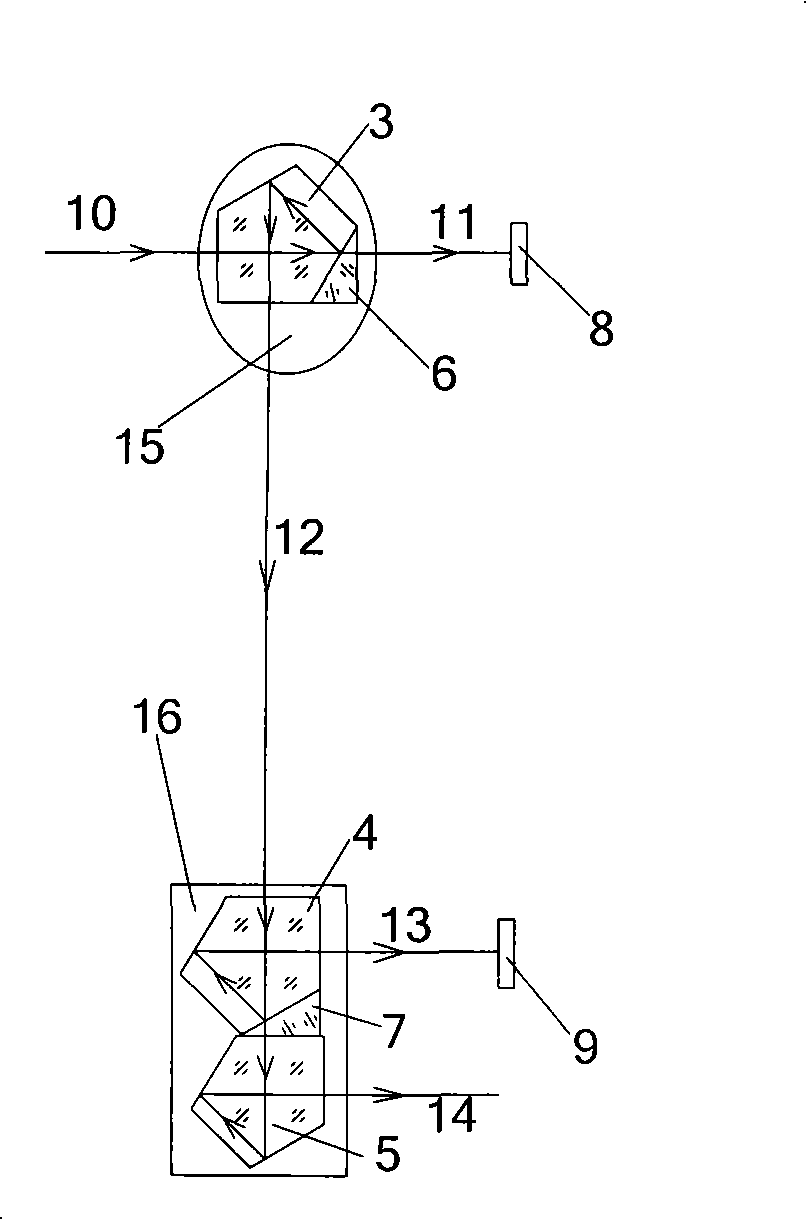

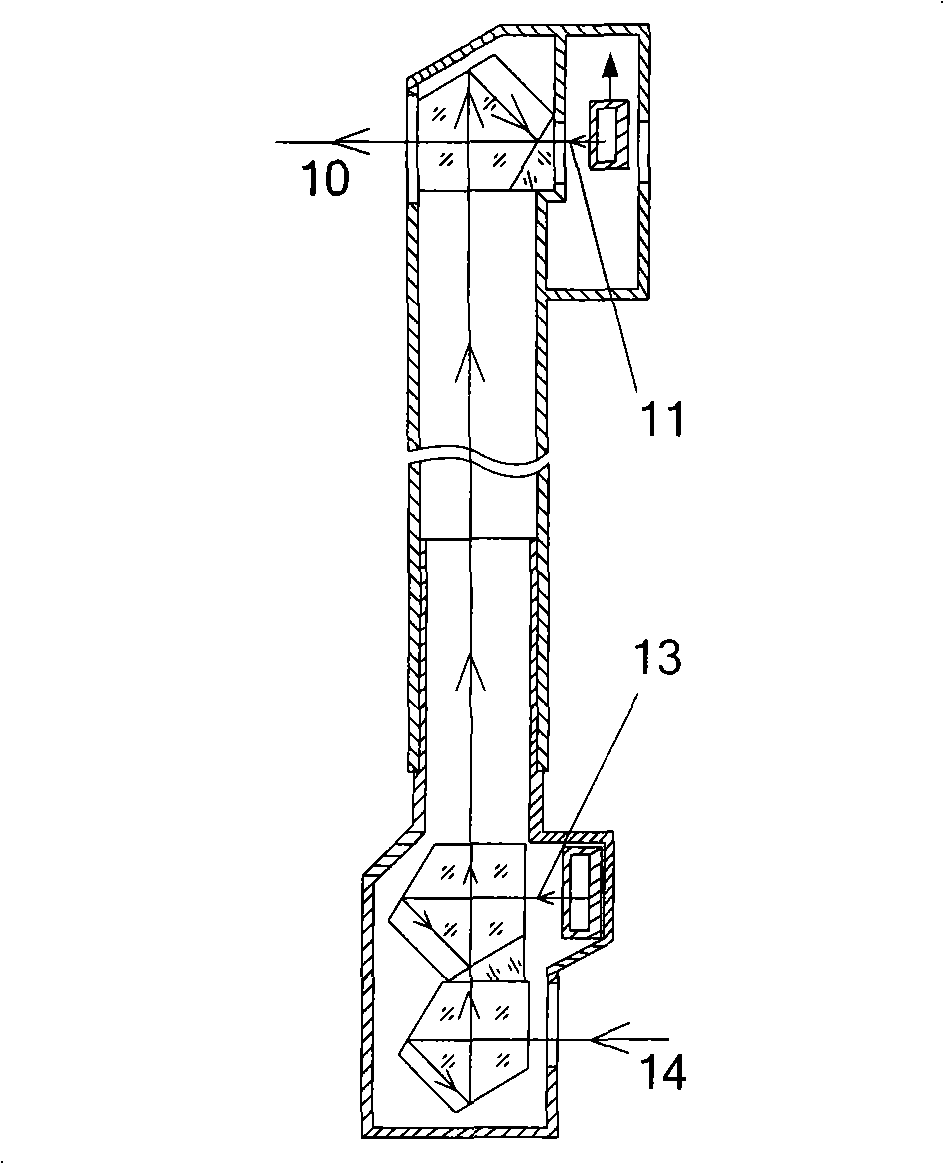

Semiconductor laser radar visibility meter

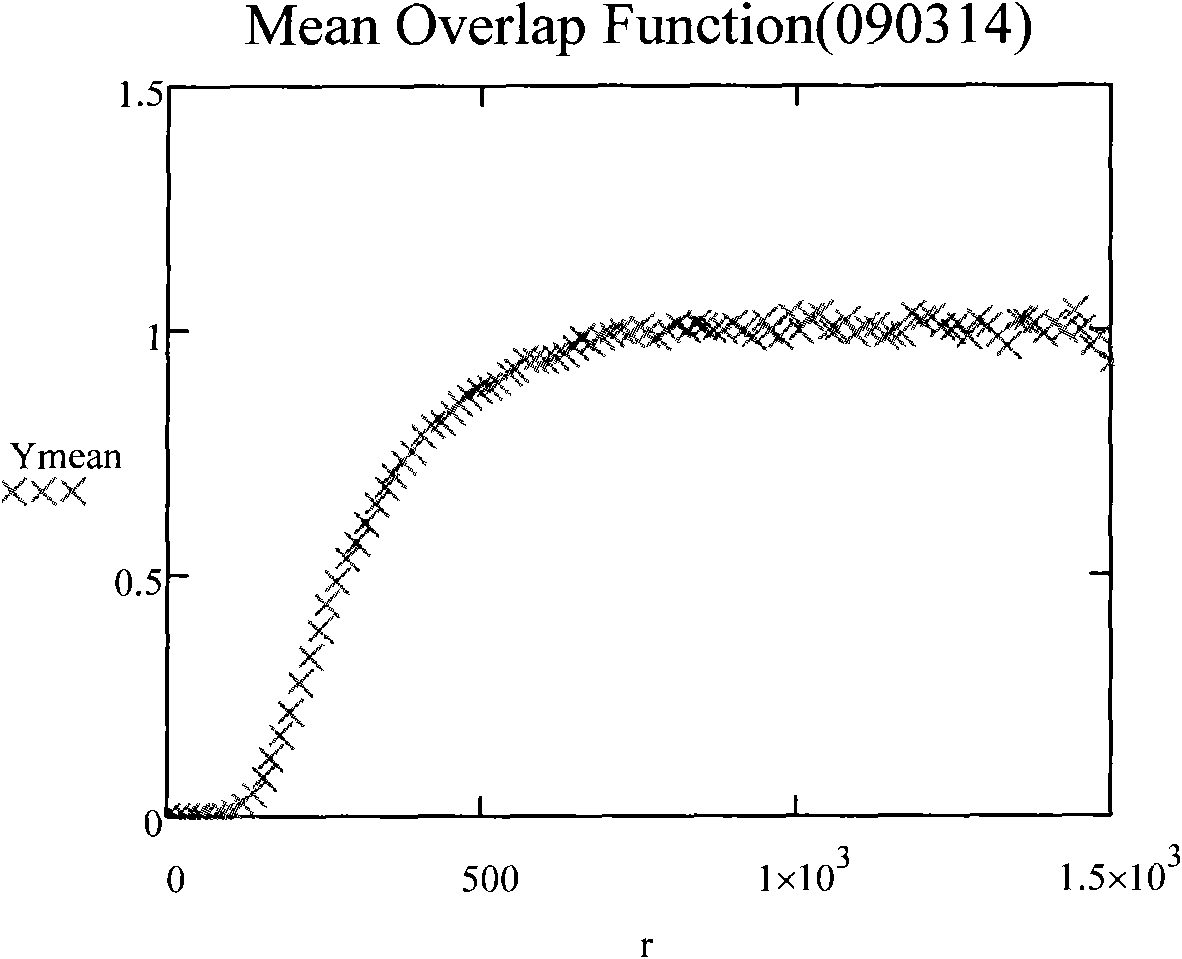

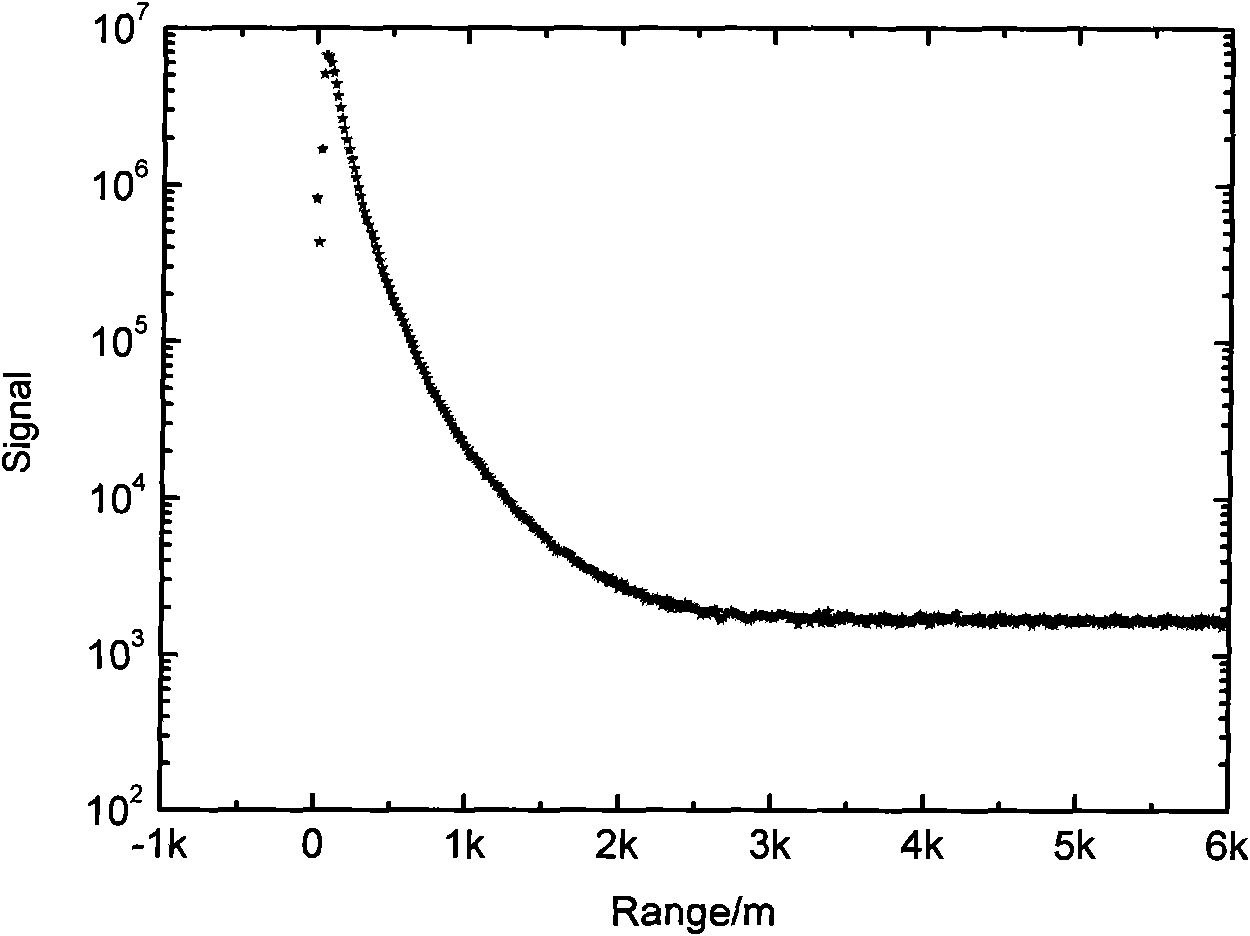

InactiveCN101581786ACompact structureLow machining accuracy requirementsScattering properties measurementsElectromagnetic wave reradiationFlat mirrorVisibility

The invention discloses a semiconductor laser radar visibility meter which comprises a laser emission system, a receiving optical system, and a signal collecting and control system, and is characterized in that: the laser emission system comprises a semiconductor laser, a coupling lens, a first coupling optical fiber, a transmitter-telescope, and a flat mirror with reflection and transmission functions; the receiving optical system comprises a receiving telescope, a second coupling optical fiber, a photodetector, and an amplifier; the signal collecting and control system comprises an AD collecting card, a computer and a door control system; and the AD collecting card is connected with the computer by a stacked way. The visibility meter has small and convenient structure, strong applicability and simple operation, can measure horizontal and slant visibility data in real time, and provides reliable visibility information for the fields of meteorology, transportation, environmental protection and military and the like.

Owner:ANHUI INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Method of cryogenic surface activation direct bonding for preparation of quartz glass capillary tube

InactiveCN105016632ARequirements for lower machining accuracySmooth inner wallPlasma treatmentMicrometer

The present invention discloses a method of cryogenic surface activation direct bonding for preparation of a quartz glass capillary tube. According to the method, a wet chemical method is used to activate a quartz glass surface, and the manner of direct bonding of a stack of multiple layers of glass is applied, so as to prepare the quartz glass capillary tube at a lower temperature with a proper pressure. A steel needle of a specific size is added to a model and used to define a size and location of the capillary tube. The minimum diameter of the capillary tube prepared can reach as small as 200 micrometers ,and the bonding strength can reach 5 MPa. According to the method, the operation of cryogenic surface activation bonding is simple, the requirement on the glass sheet surface roughness is low, and no clean room or expensive ultra-high vacuum plasma treatment device is required. The method overcomes the problems of the pipe collapse, the device superficial devitrification and the inner wall roughness that may be caused by the conventionally prepared capillary tubes. The capillary tube produced has the smooth inner wall, increases the viewable region of the sample in the capillary tube, and dramatically improves chip performance.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

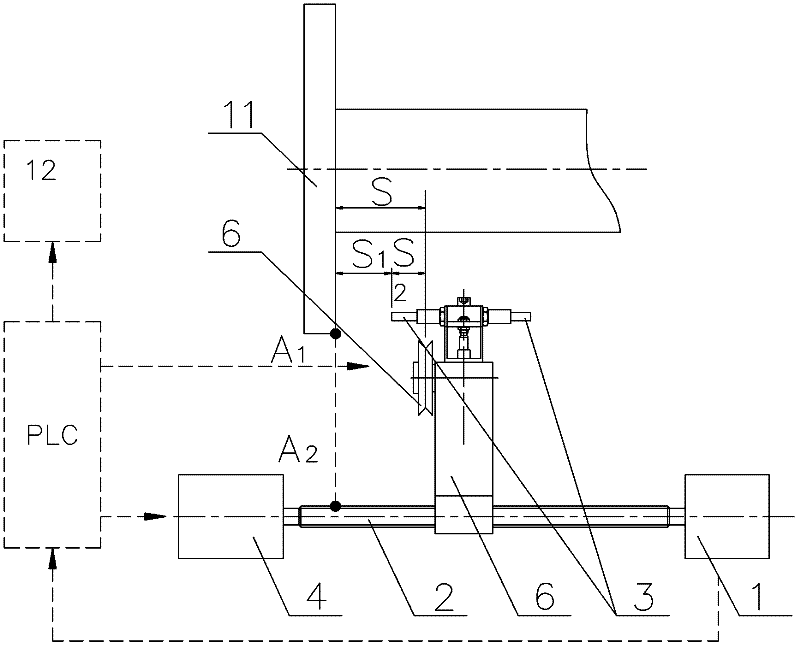

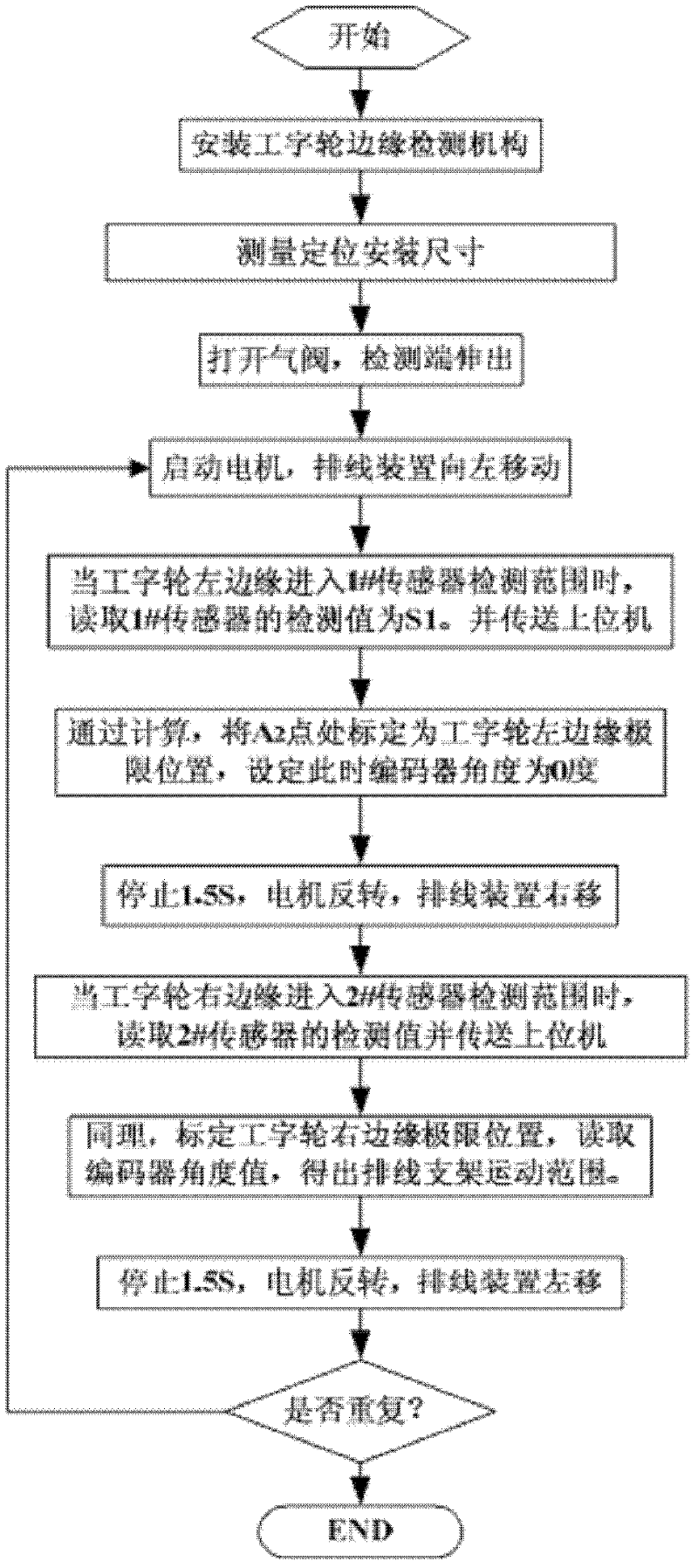

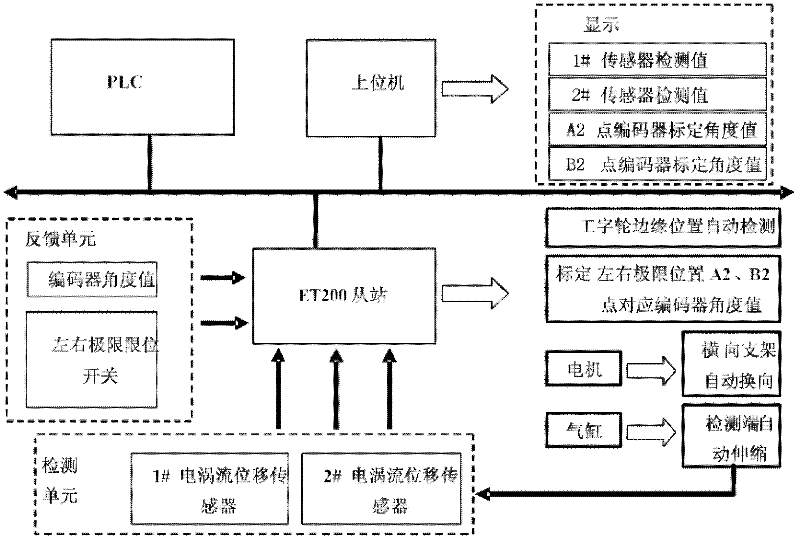

Position detecting system for edge of winding-up H-shaped wheel of wire drawing machine and control method thereof

ActiveCN102506678ASimple structureImprove detection accuracyUsing electrical meansProgramme control in sequence/logic controllersElectric machineEngineering

The invention discloses a position detecting system for the edge of a winding-up H-shaped wheel of a wire drawing machine and a control method thereof. The method comprises the following steps that: (1) two extreme positions are calibrated; in the process that a controller adopts a motor to drive a bracket to move on a lead screw, the controller acquires distances from displacement sensors to theinner edge of the H-shaped wheel by the two displacement sensors and calibrates the two extreme positions according to the distances; angle values of encoders corresponding to the two extreme positions are acquired; and (2) the bracket is controlled to do reciprocating movement between the two extreme positions, and the controller drives the bracket to move along the lead screw by the motor, and controls the motor to rotate reversely when the bracket reaches the extreme positions, so that the purpose that the bracket moves between the two extreme positions in a reciprocating manner till the wire arranging procedure on the H-shaped wheel is finished. The position detecting system has the characteristics of high detection accuracy and easiness in implementation and the like and can effectively avoid the phenomenon of wire stacking at the edge of the H-shaped wheel.

Owner:CENT SOUTH UNIV

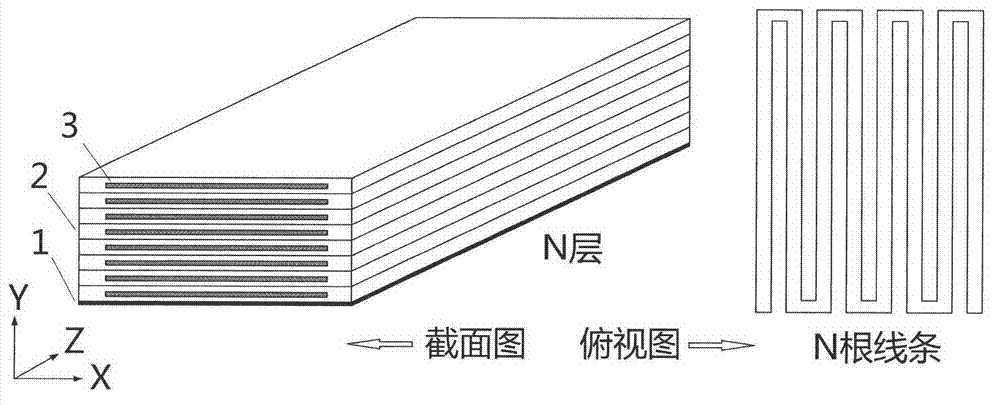

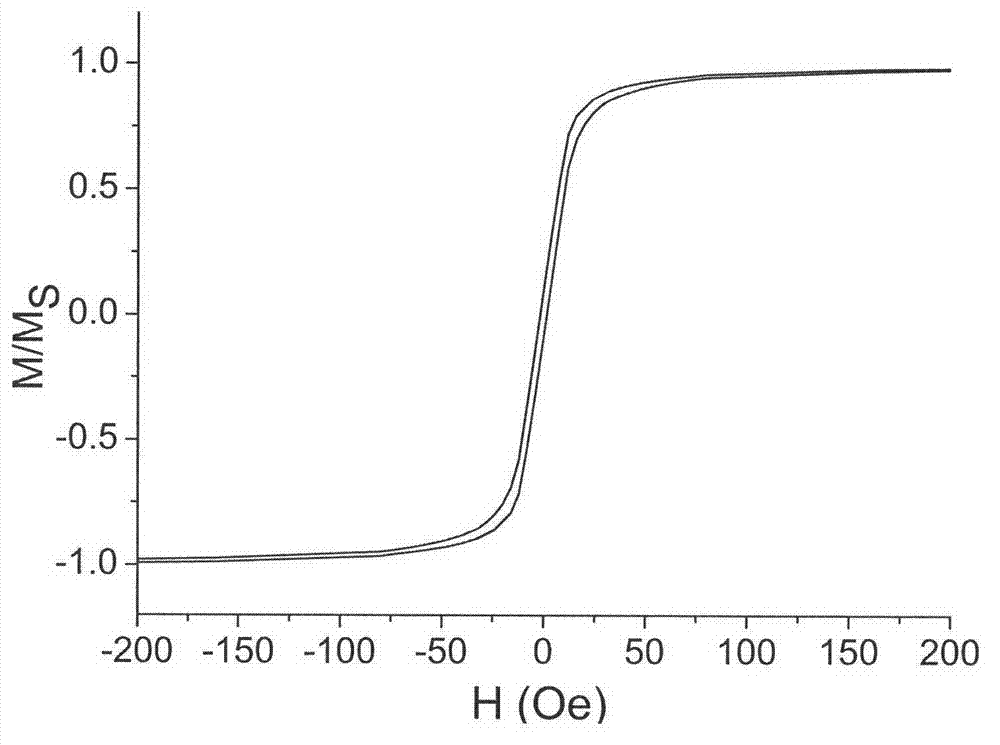

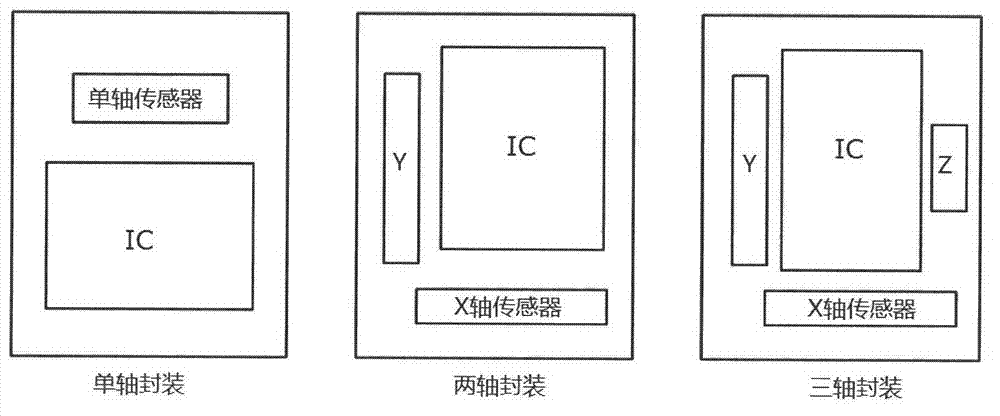

Design and manufacture technology of sensor chip for detecting magnetic field and acceleration

InactiveCN103076577ASimple processHigh sensitivityAcceleration measurement using interia forcesMagnetic measurementsManufacturing technologyEngineering

The invention discloses a design and manufacture technology of a sensing unit of a sensor and one or more types of sensor chips consisting of the sensing unit, in particular to one or more types of sensor chips capable of detecting the magnetic field parallel and vertical to the surface of the chip and the acceleration of an object. The invention has the advantages that the process is simple and easy, the sensitivity is high, and batched production is easily realized; the sensing unit of the sensor comprises a wafer substrate, a seed layer, a soft magnetic material layer, a conducting layer and a N-layer structure; the conducting layer is wrapped by the soft magnetic material layer; the N-layer structure is formed by combination of the soft magnetic material layer and the conducting layer; and simultaneously a bent structure is formed by N long lines in the plane (the sensing unit is a single-strip-shaped structure when N is equal to 1). The sensing unit of the sensor realizes single-axis, double-axis and three-axis magnetic field detection by different packaging forms. Simultaneously, due to the combination of the sensing unit of the sensor and a cantilever structure with magnetic mass blocks, the single-axis, double-axis and three-axis acceleration detection can be realized.

Owner:陈磊

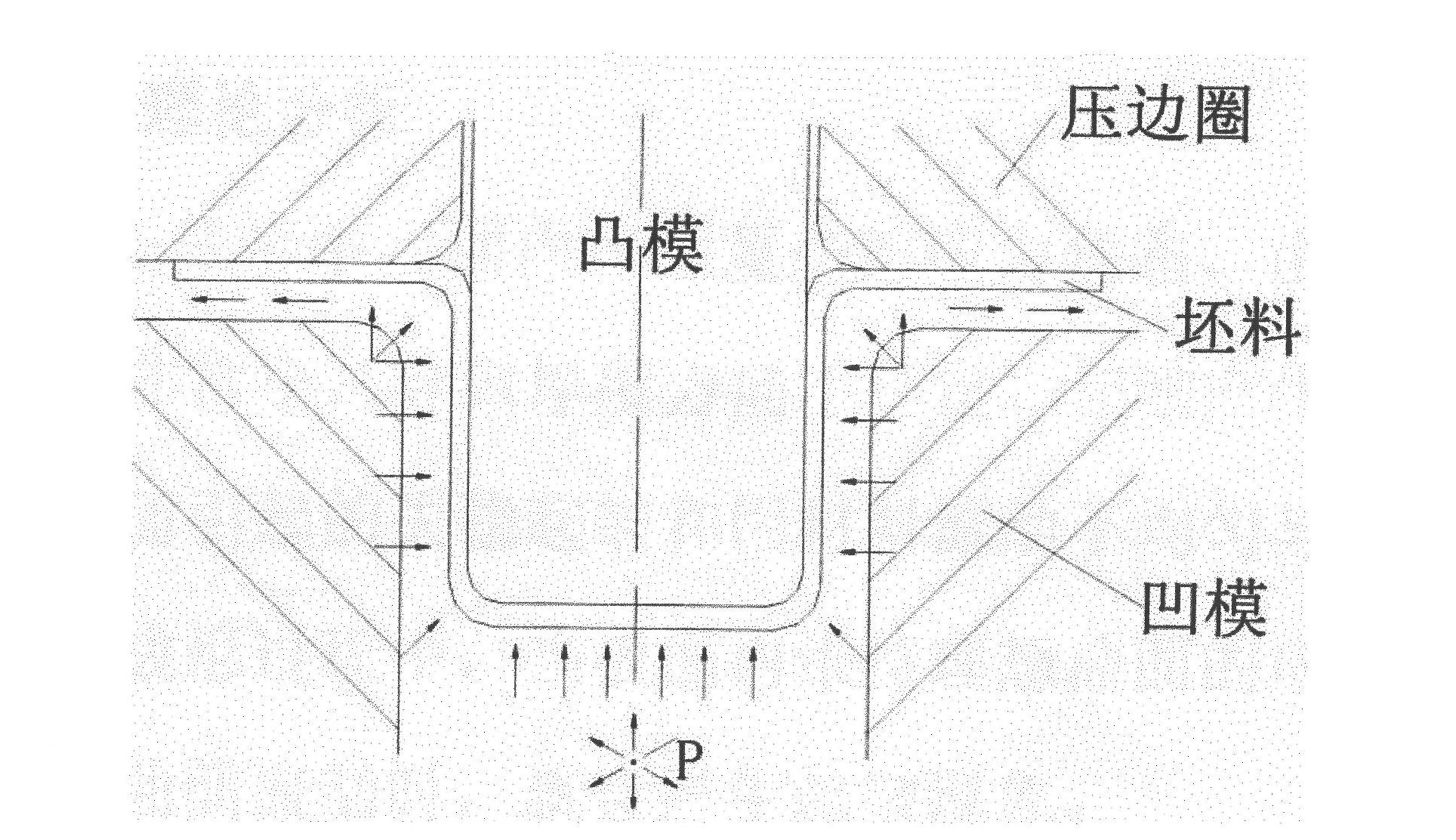

Method for forming thin-walled parts through stamping and drawing

The invention discloses a method for forming thin-walled parts through stamping and drawing, which is used for reducing the thicknesses (0.4-2mm) of raw materials to 50-100% of the original thicknesses the raw materials; the raw materials comprise magnesium alloys, aluminum alloys, titanium alloys, high temperature alloys and complex splice-welded plates; and the method specifically comprises the following steps that: a flexible forming technique is adopted with the aid of moulds and a hydraulic machine, wherein the moulds are in concave-convex fit with the hydraulic machine; upper and lower blank holders and concave and convex moulds are respectively subjected to hydraulic pressure exertion control; the nominal pressure of a main hydraulic cylinder exerted on the concave and convex moulds is 25000-4500 KN, and the nominal pressure of a side-pressing hydraulic cylinder accounts for 50-67% of the nominal pressure of the main hydraulic cylinder; and the maximum operating pressure of a liquid chamber is 150MPa. By using the method disclosed by the invention, an expected effect is obtained, and the qualification rates and efficiencies of parts are obviously improved; and meanwhile, the hydroforming technology fills in the gaps in industry application, and lays a solid foundation for the thorough solving of technical bottlenecks existing in actuating cylinder cover forming and the research and preparation of future novel thin-wall parts and sheet metal forming parts.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

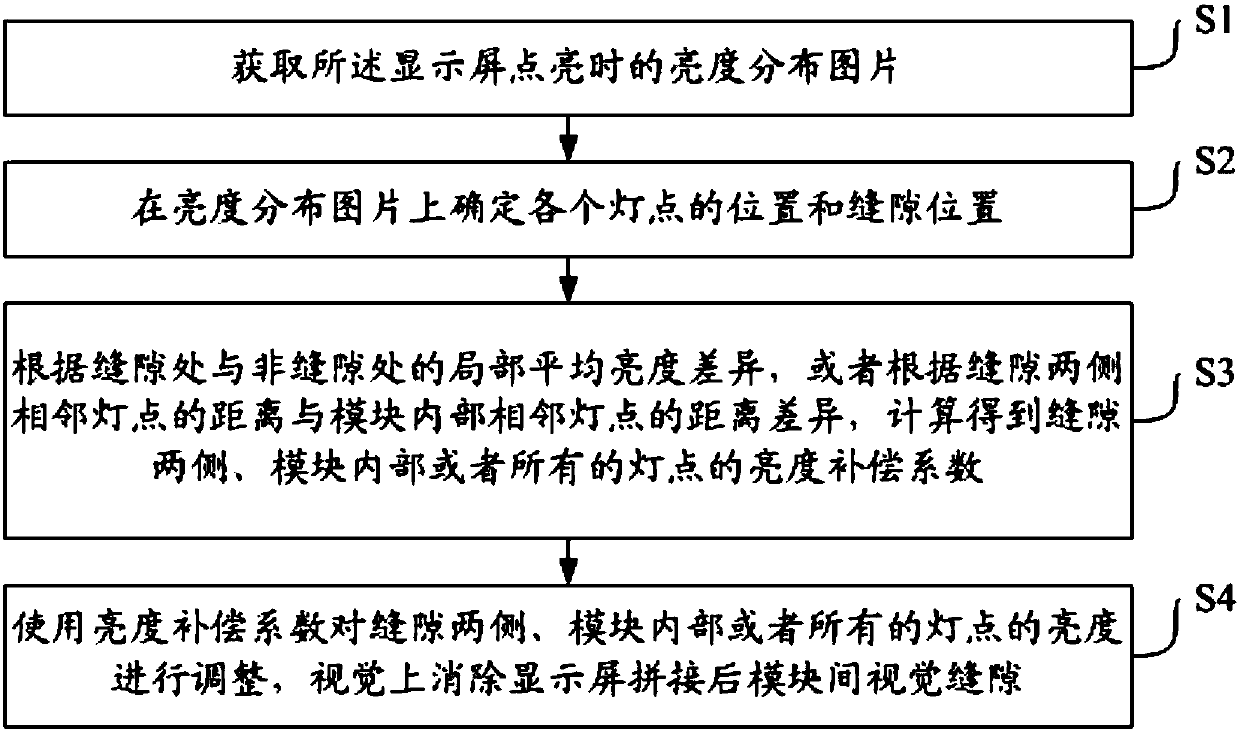

Method for removing visual gaps among modules after display screen is spliced and display method

ActiveCN107742511ALow processing technology requirementsLow machining accuracy requirementsCathode-ray tube indicatorsLocal averageComputer science

The invention discloses a method for removing visual gaps among modules after a display screen is spliced and a display method, and belongs to the field of display screens. The method comprises the steps of S1, obtaining a brightness distribution picture when the display screen is lightened; S2, determining the positions and gap positions of all light points on the brightness distribution picture;S3, calculating to obtain brightness compensation coefficients of the light points at the two sides of each gap and inside each module or all the light points according to the local average brightness difference of the gaps or the non-gaps, or according to the distance of adjacent light points at the two sides of each gap and the distance difference of adjacent light points inside each module; S4, using the brightness compensation coefficients to adjust the brightness of the light points at the two sides of each gap and inside each module or all the light points to visually remove the visualgaps among the modules after the display screen is spliced. Bright and dark lines in gaps among display units of the spliced display screen are visually removed, the visual effect is obviously improved, the achievement steps are simple, and the splicing and installation difficulty and installation cost are lowered.

Owner:颜色空间(北京)科技有限公司

Method for manufacturing high-luminous-efficacy focusing solar Fresnel lens

ActiveCN102230980AExtended service lifeLow machining accuracy requirementsLensFresnel lensOptical axis

The invention relates to a method for manufacturing a high-luminous-efficacy focusing solar Fresnel lens. The method comprises the following five steps of: 1, improving a ripple surface, wherein a vertical surface (15) of each ripple is changed into an inner inclined surface (9); an inclination angle of an intersection between the inner inclined surface (9) and a bottom surface (2) is reduced along with the increasing of a vertical distance between the intersection and a central optical axis (7); the degree di of each inclination angle can be calculated by an inverse trigonometric function; and a ripple bottom is changed into a narrow flat bottom; 2, selecting flat-panel quartz glass and silica gel as materials; 3, changing a single-layer mirror body into a glass and silica gel double-layer compound mirror body; 4, moulding; and 5, treating the surface of glass, performing rubber injection and compound forming, trimming the edge and inspecting so as to manufacture the improved Fresnellens. The lens manufactured by the method has high luminous efficacy, a low light precision requirement, high light transmission performance and anti-aging performance, low manufacturing cost and long service life. The compound lens has high material performance complementarity; furthermore, the processing difficulty of the die and the mirror body is reduced; and the service life of the die is prolonged.

Owner:HANGZHOU XINENG NEW MATERIAL CO LTD

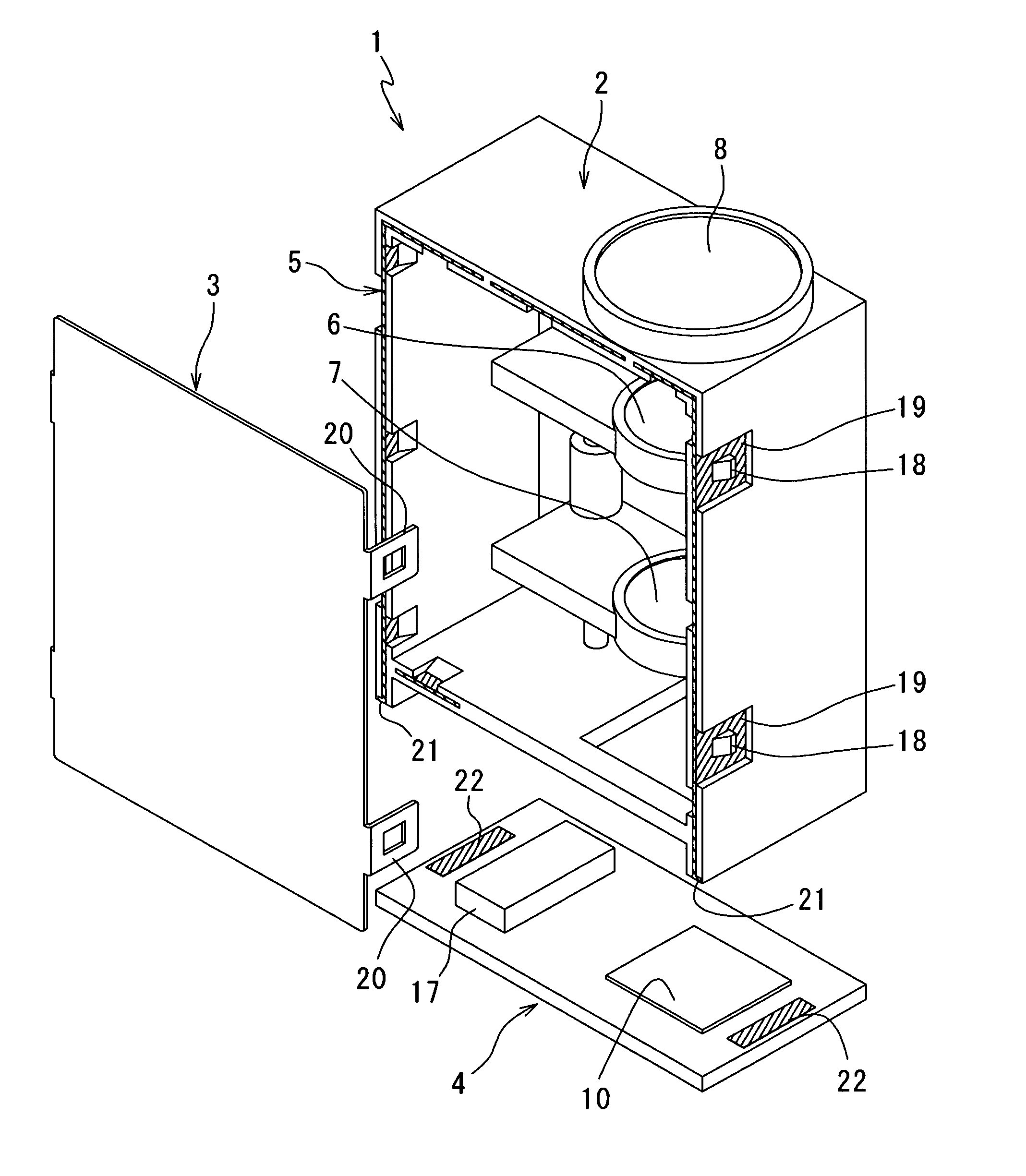

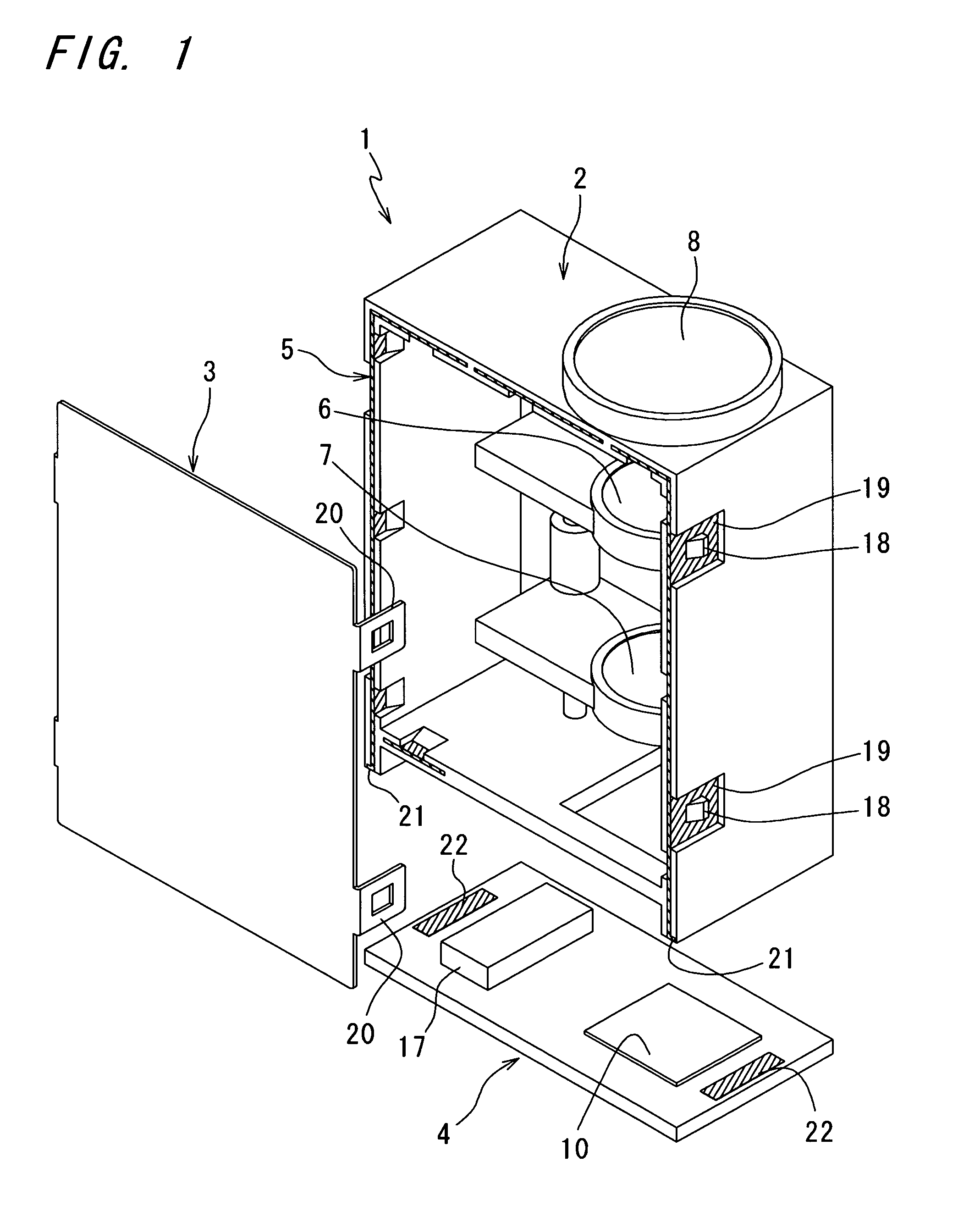

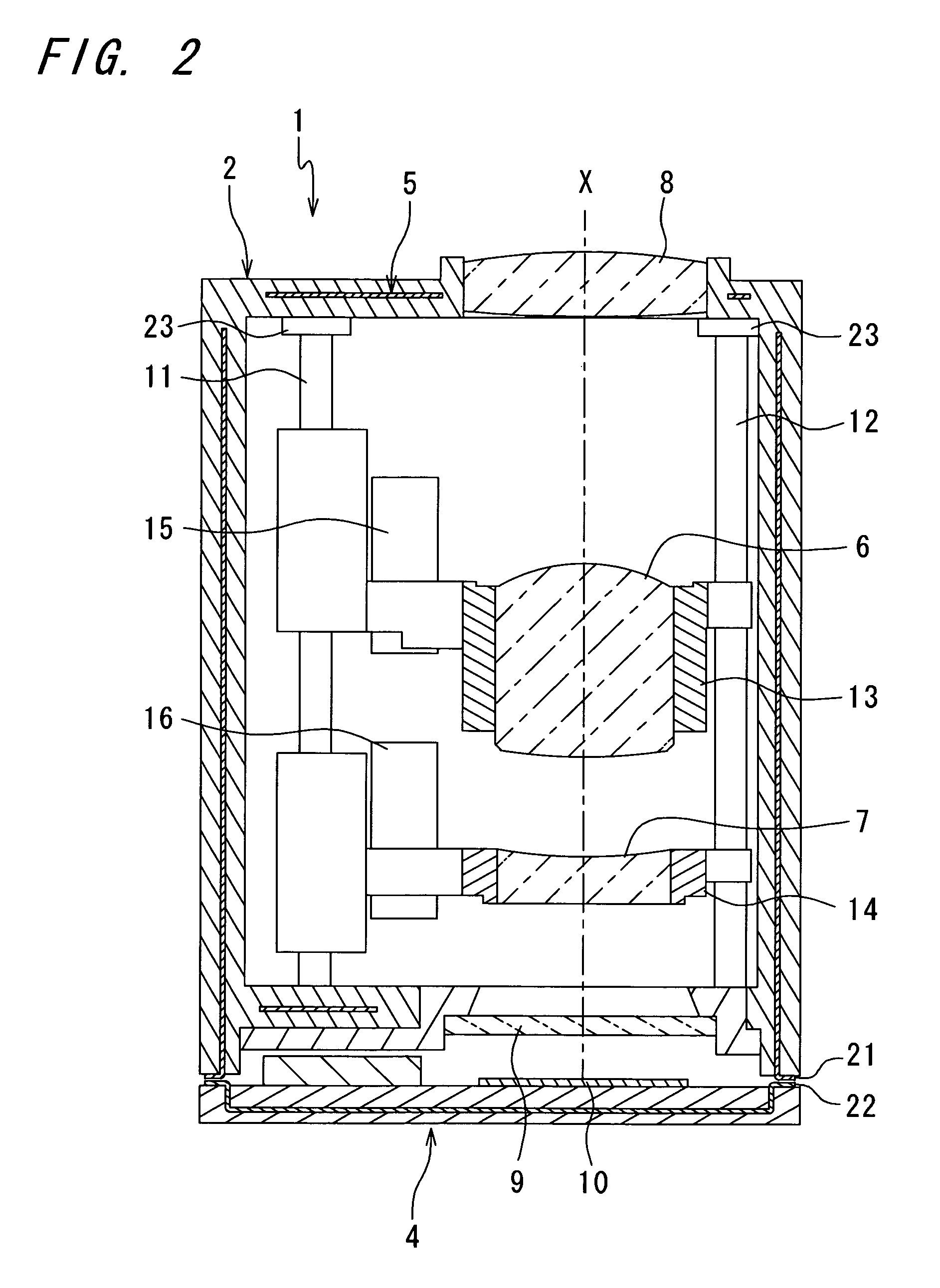

Camera module and electronic device

InactiveUS7805071B2High dimensional accuracyLow machining accuracy requirementsTelevision system detailsColor television detailsComputer moduleConductive materials

There is provided an inexpensive camera module 1 having shieldability. The camera module 1 has a housing 2 which is molded from resin so that layers of the resin are formed on both sides of a metal plate 5 and in which an inside space for accommodating a group of lenses 6, 7 is formed and which is opened at least in one direction, a lid 3 for sealing the opened part of the housing 2, and a substrate 4 on which an imaging element 10 is mounted. In the housing 2, the metal plate 5 is partially exposed, and the lid 3 composed of conductive material and ground patterns 22 on the substrate 4 are in conductive contact with exposed parts 19, 21 of the metal plate 5.

Owner:KONICA MINOLTA OPTO

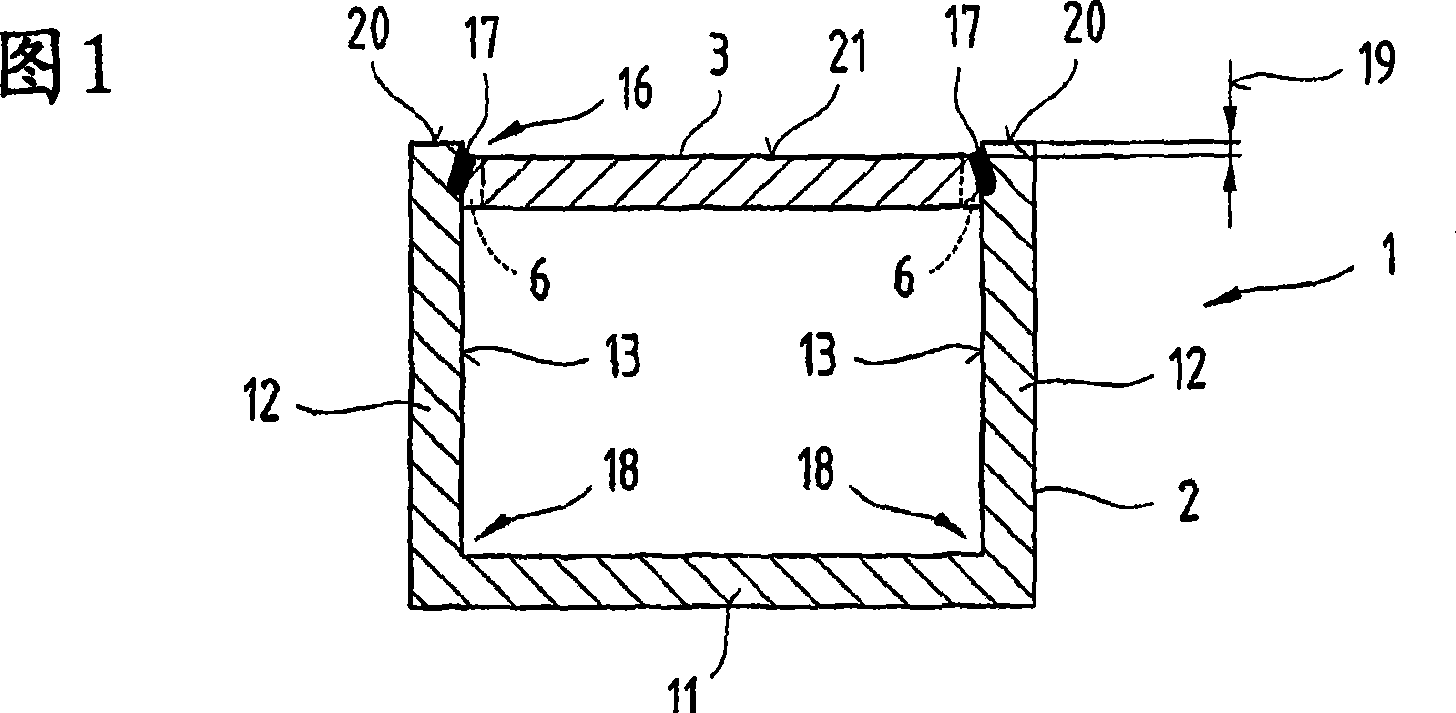

Multi-piece part composed of metal element and manufacturing method thereof

InactiveCN101048257APrevent agingAvoid brittlenessThin material handlingLaser beam welding apparatusCold formedButt joint

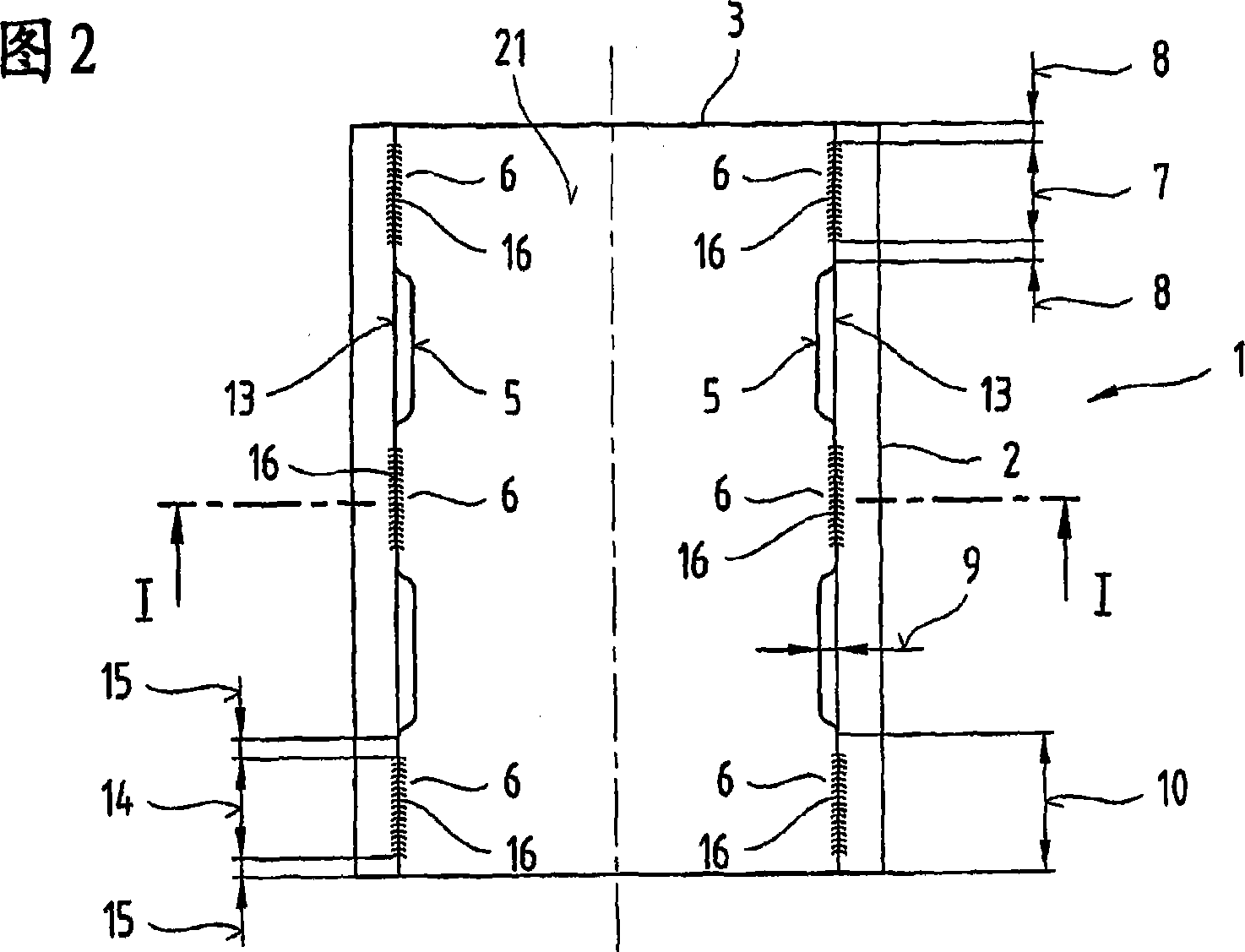

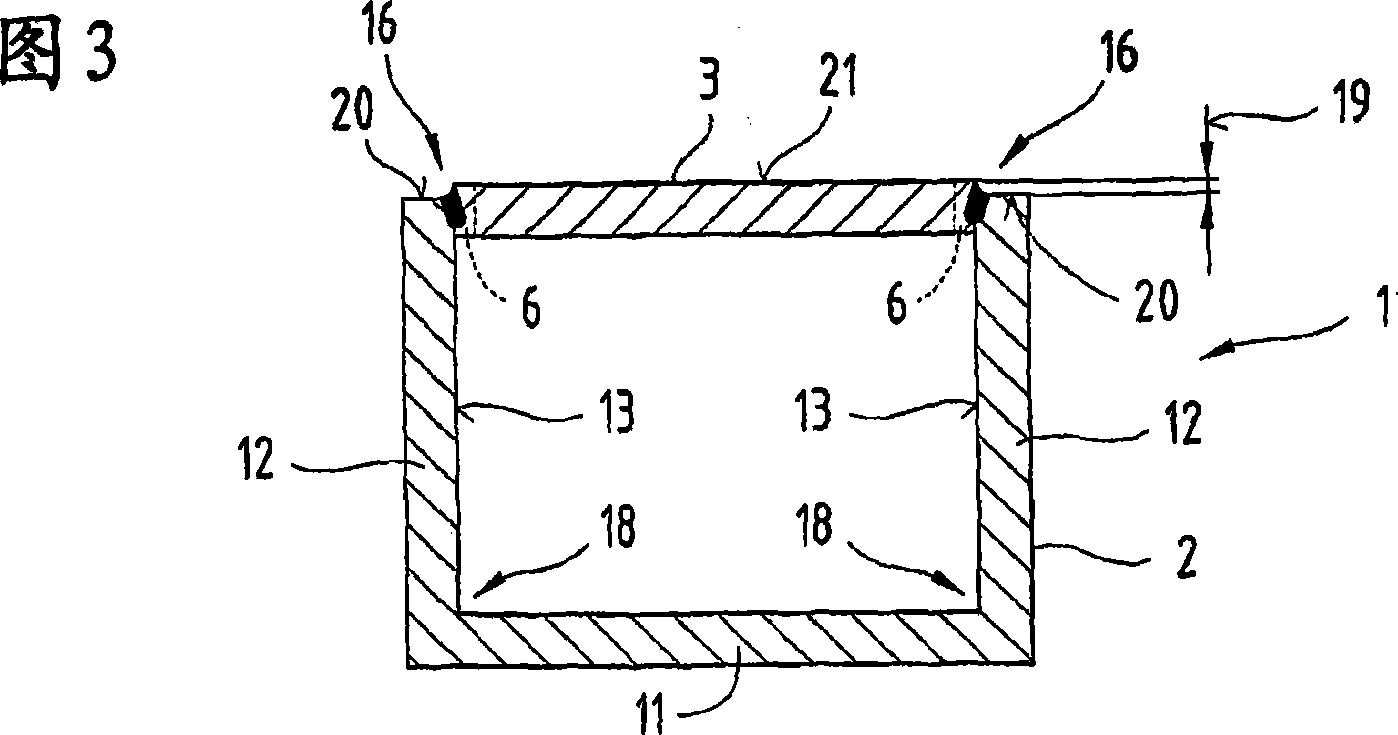

The invention relates to a subassembly (1) and a method for the production thereof. Said subassembly (1) comprises a first and a second part (2, 3), the first (2, 3) of which is cold-formed. Said parts (2, 3) are provided with parallel planar pieces (20, 21) and contact areas that extend at an angle therefrom in order to place the two parts (2, 3) against each other without leaving a gap therebetween while being joined to each other at the butt joint (16) via a welded seam (17) created by means of beam welding. The planar pieces (20, 21) are disposed so as to be misaligned relative to each other by an offset (19). One of the parts (2, 3) is provided with a contacting projection (6) which embodies the contact area of the first part (2). The parts (2, 3) are positioned relative to each other in such a way that the second part (3) forms the butt joint (16) along with the first part (2) in the section of the first part (2) in which an offset thickness of the basic material is smaller than the offset thickness of the structure in a deformation zone (18) created on the first part (2) by cold forming.

Owner:STIWA HLDG

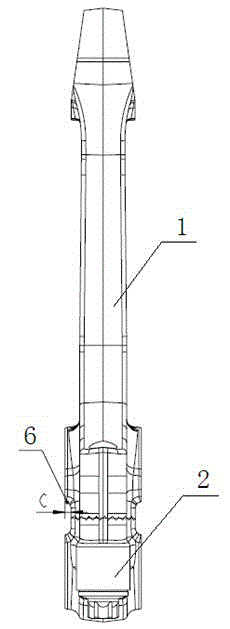

Inner driving type passive clamping piezoelectric actuator

ActiveCN104167953ARealize internal driveAchieve relaxationPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsSelf locking

The invention relates to a piezoelectric actuator, in particular to an inner driving type passive clamping piezoelectric actuator. The problems that according to an existing inner driving type clamping piezoelectric actuator, self locking cannot be achieved during outage, a driver is slow in running speed, and requirements for machining accuracy of a clamping body and a guiding track are high are solved. The inner driving type passive clamping piezoelectric actuator comprises a guiding track, driving bodies, a driving piezoelectric stack, two clamping piezoelectric stacks and two clamping bodies. Each clamping body comprises a piezoelectric stack pre-tightening piece, two clamping triangle amplified flexible hinges, two clamping piezoelectric stack supporting bodies and two clamping heads. Each driving body comprises two driving triangle amplified flexible hinges, two driving piezoelectric stack supporting bodies and two driving piezoelectric stack pre-tightening pieces. The driving bodies connected with the clamping bodies are arranged between the two clamping bodies. The driving bodies and the clamping bodies are placed in grooves of two arms of the guiding track. The piezoelectric actuator is used in a micro-driving process.

Owner:HARBIN INST OF TECH

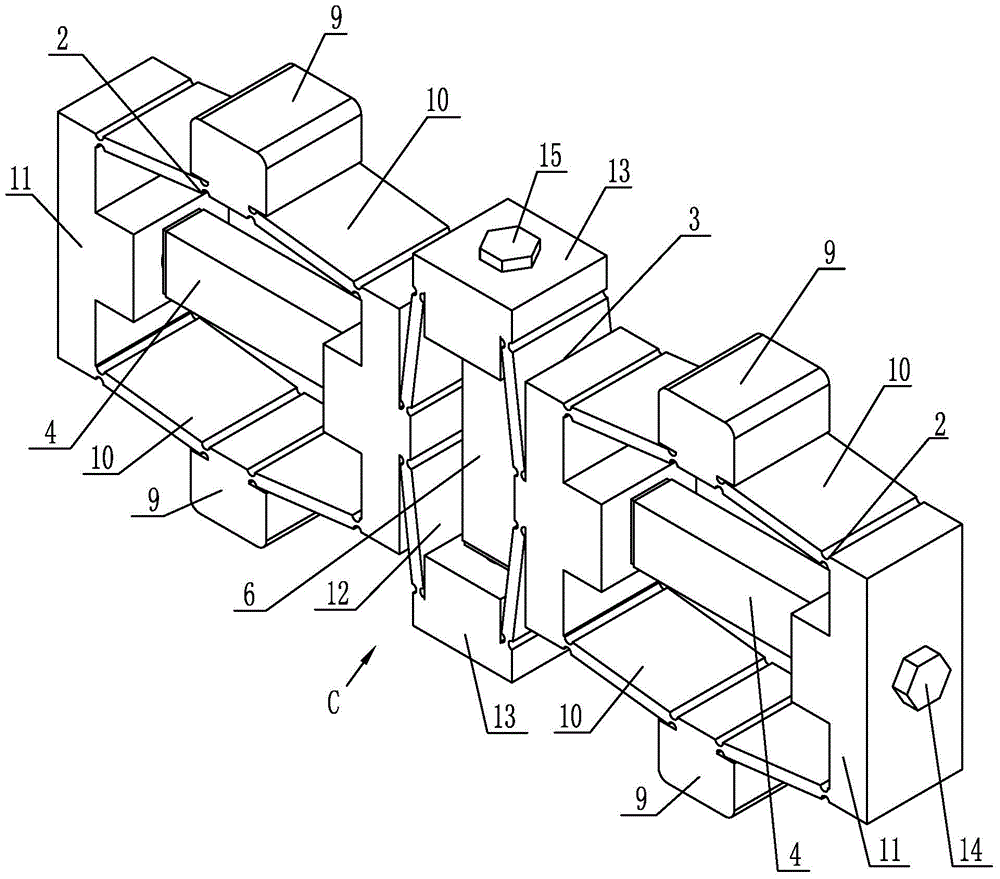

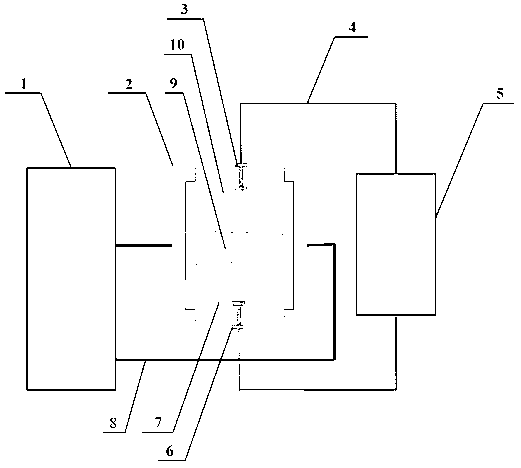

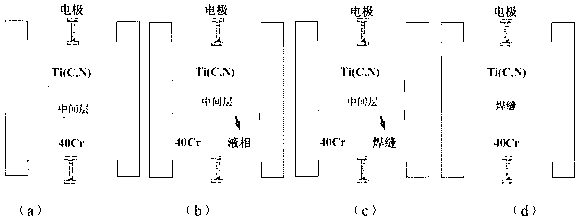

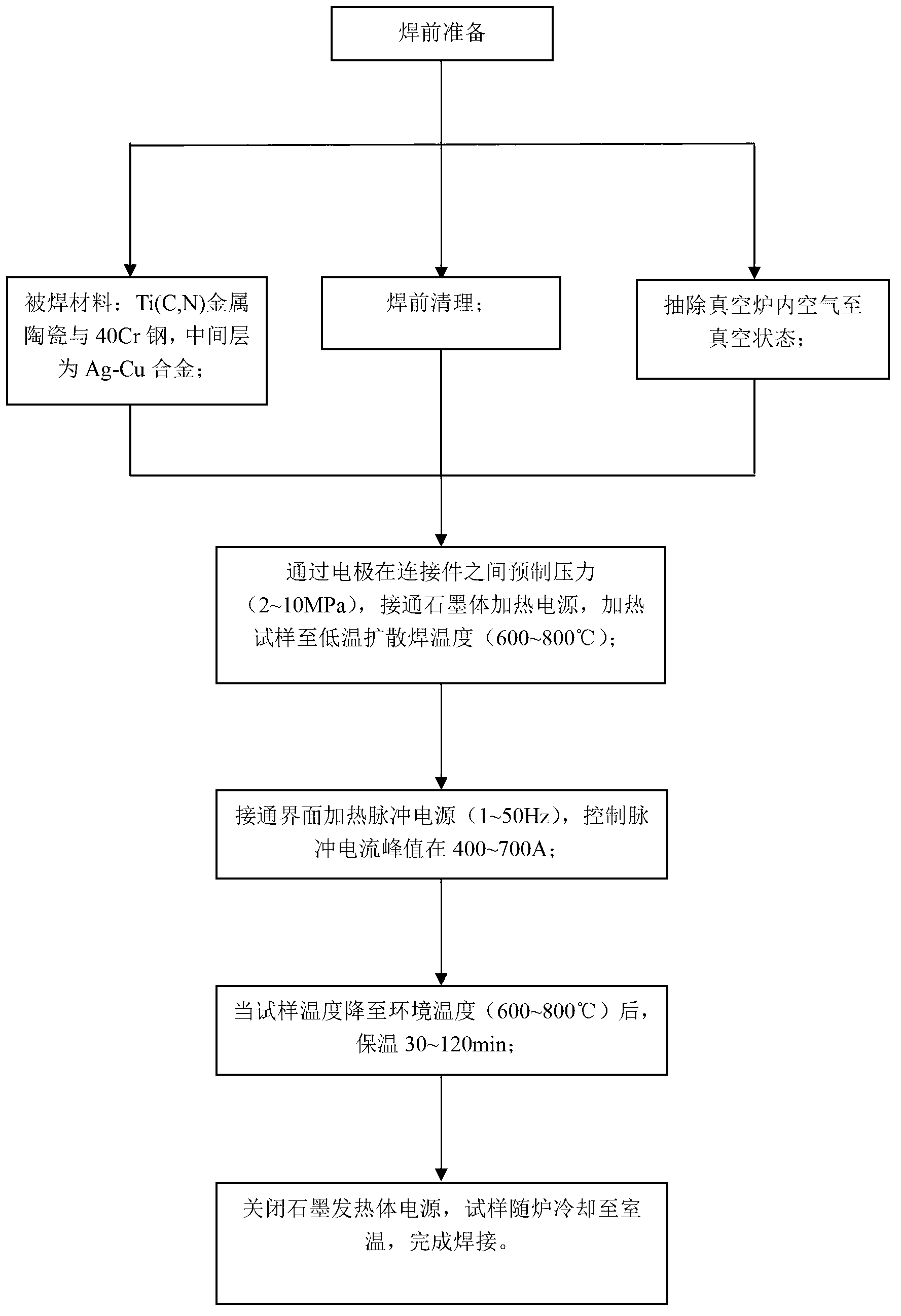

Low-temperature rapid diffusion welding device and method based on pulse current auxiliary heating

ActiveCN102699520APromote fragmentationLow machining accuracy requirementsNon-electric welding apparatusRadiant heatPulse power supply

The invention discloses a low-temperature rapid diffusion welding device and method based on pulse current auxiliary heating. The device comprises a graphite body heating power supply, a graphite body, electrodes, an interface heating pulse power supply and a sample. According to the method, graphite body radiant heat is mainly used, welding interface contact resistance heat and discharge heat are used as accessory, an original liquid phase is formed by the resistance heat and discharge heat which are formed at an interface to be connected by the pulse current, and diffusion welding is realized by virtue of less externally-applied extrusion force. The device and the method can be used for reducing the residual stress, obviously shortening the welding time, requiring smaller applied pressure and preventing workpieces from being subjected to serious deformation in a pressurization direction, are conductive to crushing oxidation films on the surfaces of materials and simultaneously can be used for reducing the material surface processing precision requirement; and the device disclosed by the invention is simple in process, smart in design and convenient in use, and can be widely applied to the diffusion welding of various nonmetals and metals.

Owner:JIANGSU UNIV OF SCI & TECH

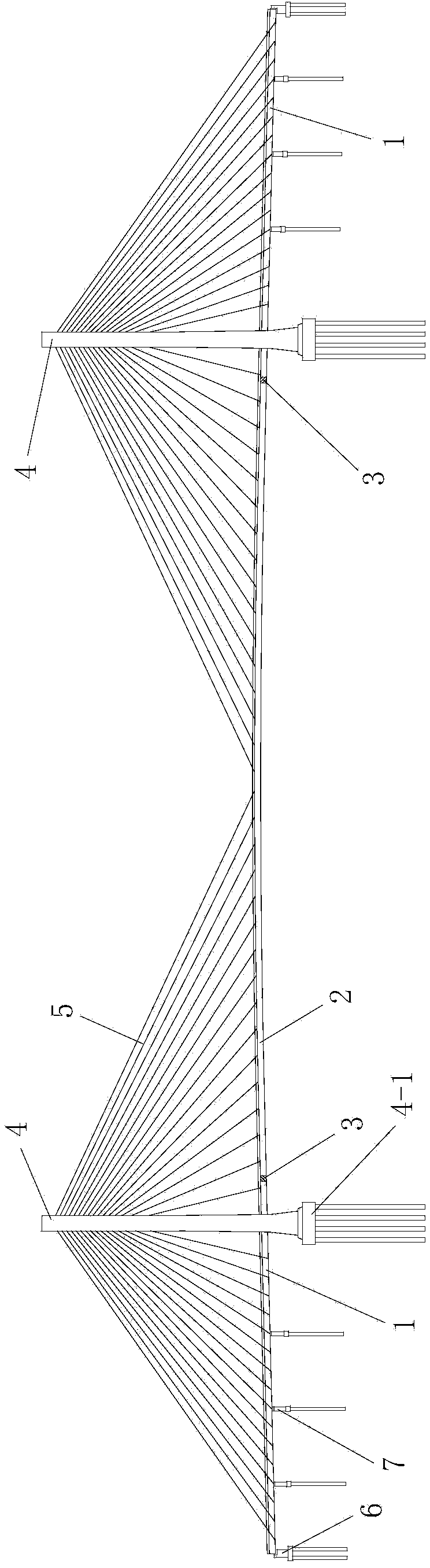

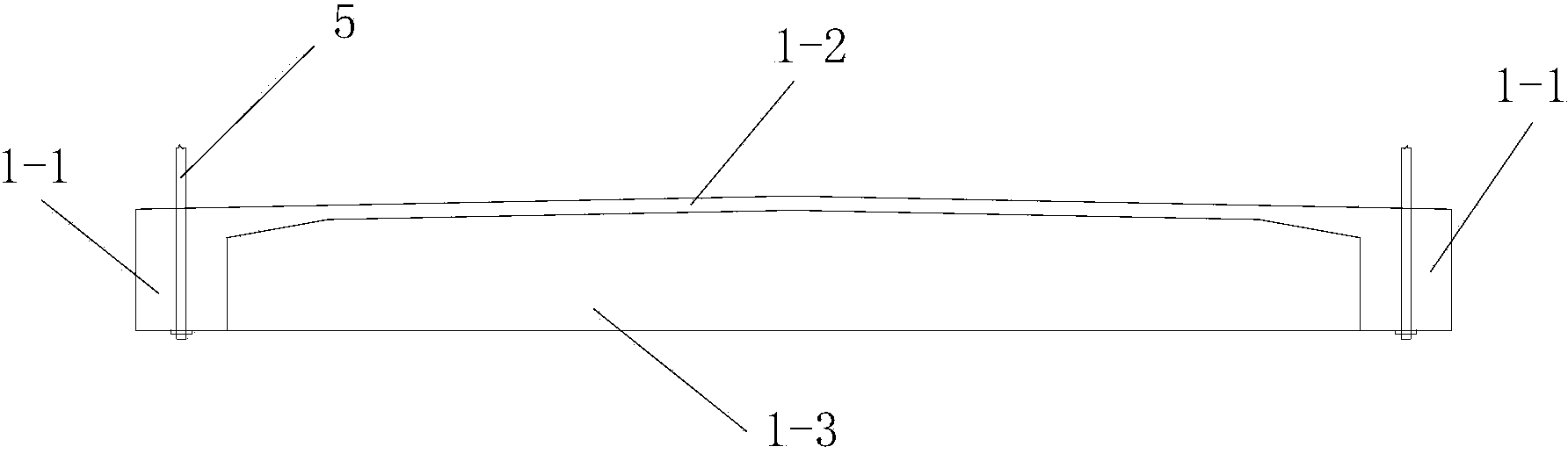

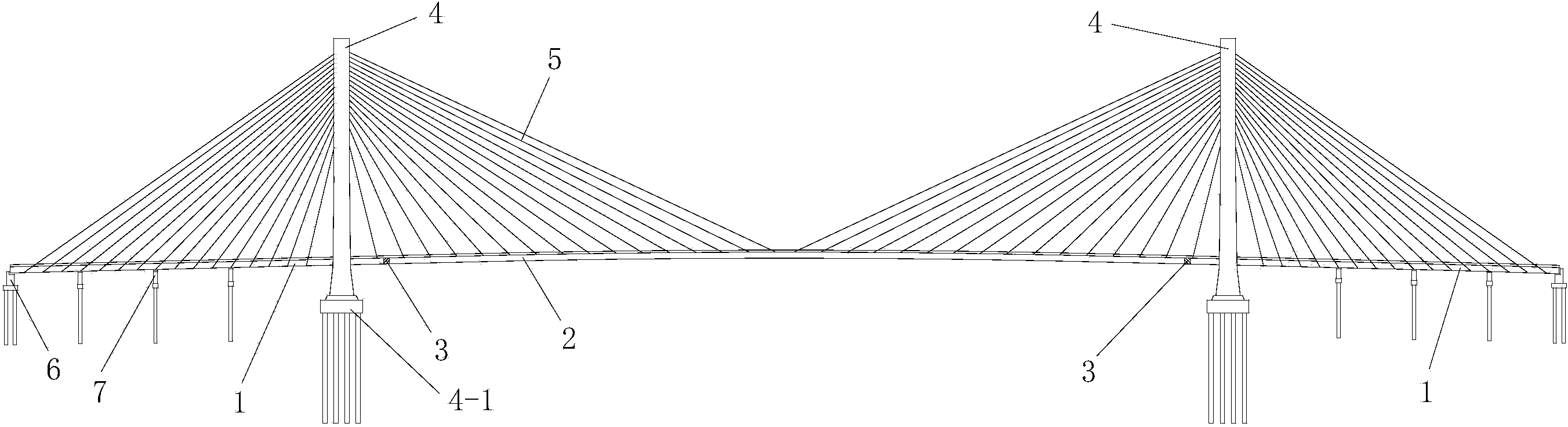

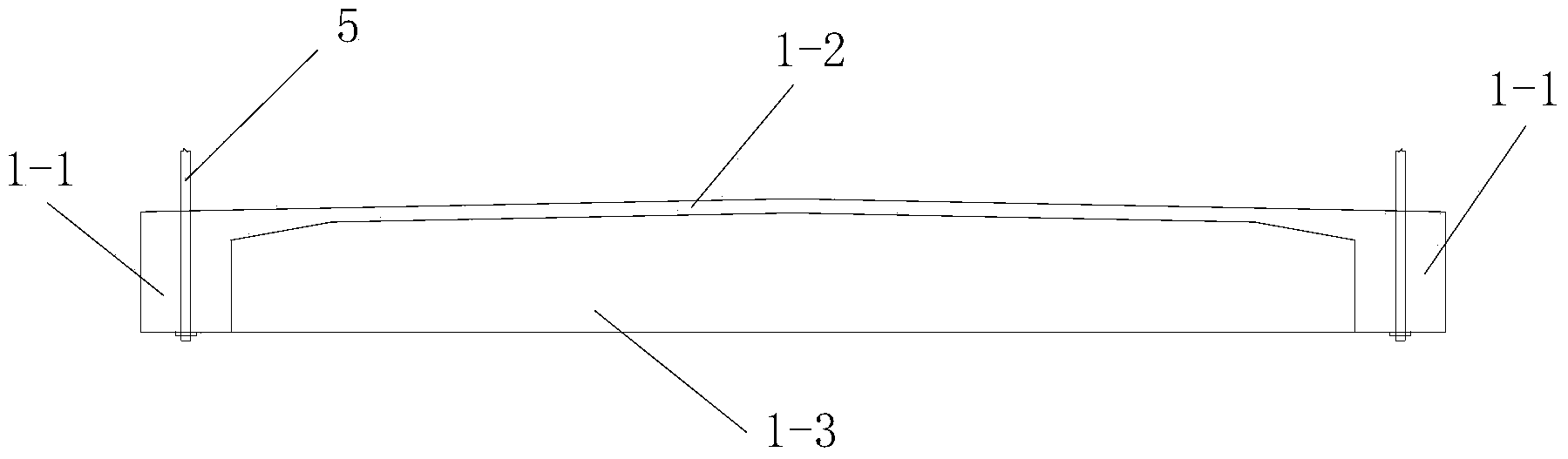

Double-tower hybrid beam cable-stayed bridge system and construction method thereof

InactiveCN104294747ASimple structureReasonable designCable-stayed bridgeBridge erection/assemblyCable stayedConcrete beams

The invention discloses a double-tower hybrid beam cable-stayed bridge system. The double-tower hybrid beam cable-stayed bridge system comprises a hybrid beam composed of a concrete beam and a composite beam. The concrete beam and the composite beam are connected through a joint section. The concrete beam is a bilateral ribbed beam and comprises two concrete beam ribs. The composite beam comprises two main steel beams, and the main steel beams are each of an I shape and each comprise a main steel beam top plate, a main steel beam bottom plate and a main beam steel web. The joint section comprises a concrete beam rib-main steel beam connection structure composed of a front pressure bearing plate, a rear pressure bearing plate and a joint section steel web, and the main steel beam top plates and the main steel beam bottom plates stretch into the concrete beam ribs. The double-tower hybrid beam cable-stayed bridge system is reasonable in structural design, convenient to construct, high in construction speed, good in use effect and good in connection effect of a steel-concrete joint part. Meanwhile, the invention further discloses a construction method of the double-tower hybrid beam cable-stayed bridge system. The construction method includes the steps of lower portion supporting structure and main tower construction and hybrid beam construction. The construction method is simple, easy to implement, short in construction period and good in construction effect.

Owner:TONGJI UNIV

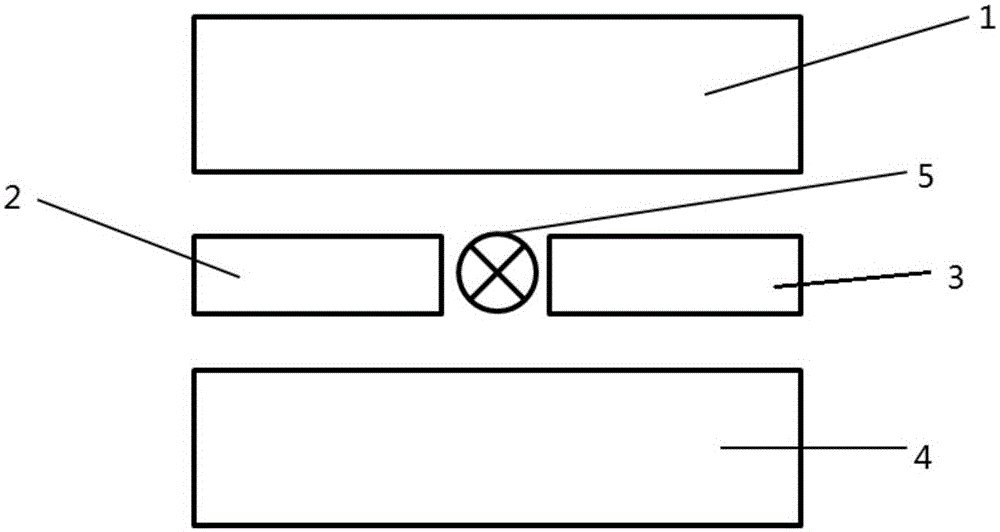

Air dielectric cylindrical lens antenna

The invention discloses an air dielectric cylindrical lens antenna. The air dielectric cylindrical lens antenna comprises a metal disc-shaped parallel plate waveguide, a feed source antenna and arc-shaped metal support plates, wherein the metal disc-shaped parallel plate waveguide comprises an upper metal disc and a lower metal disc, the upper and the lower inner surfaces of the metal disc-shaped parallel plate waveguide are planes or arc-shaped surfaces, a central cavity of the metal disc-shaped parallel plate waveguide forms an air dielectric cylindrical lens, an annular boss is arranged below the edge of the upper disc of the metal disc-shaped parallel plate waveguide, the annular boss is arranged above the edge of the lower disc of the metal disc-shaped parallel plate waveguide, the feed source antenna is arranged between the two annular bosses, the feed source antenna is embedded in an arc-shaped groove between the arc-shaped metal support plates on the edges of the two metal discs, and the arc-shaped metal support plates are connected with the two metal discs through screws. The feed source antenna is a horizontal polarization gradient groove antenna or a horizontal polarization gradient groove antenna array.

Owner:ZHEJIANG UNIV

Wiring substrate for mounting semiconductor components

InactiveUS7271476B2Fast charge transferLower resistanceSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorLow inductance

Owner:KYOCERA CORP

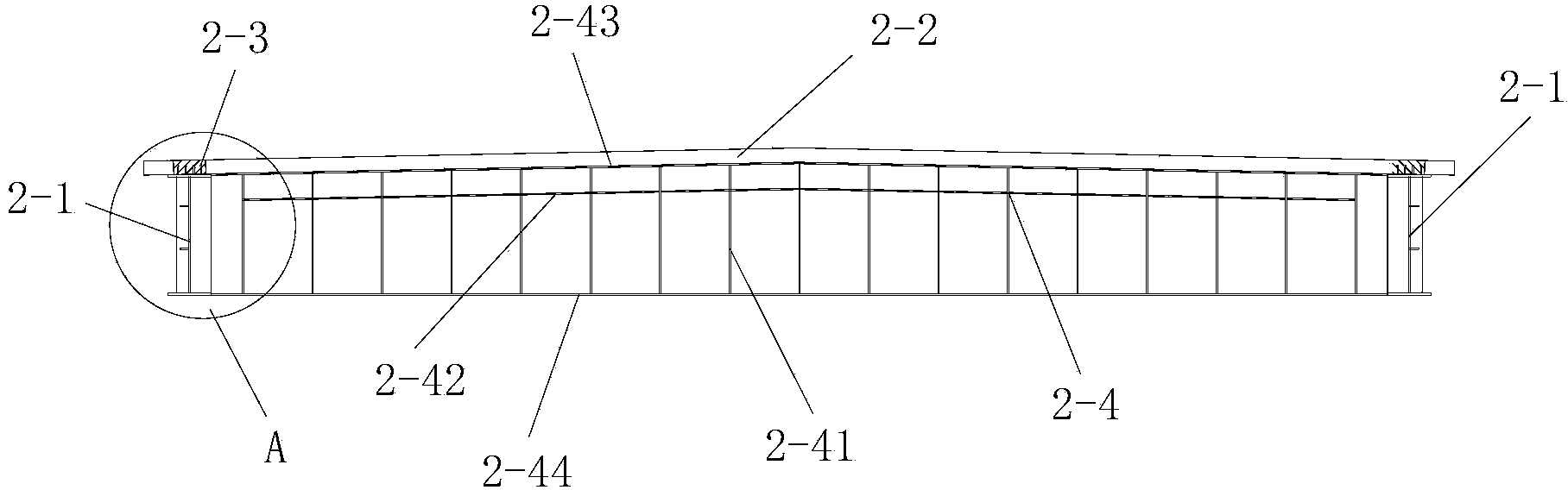

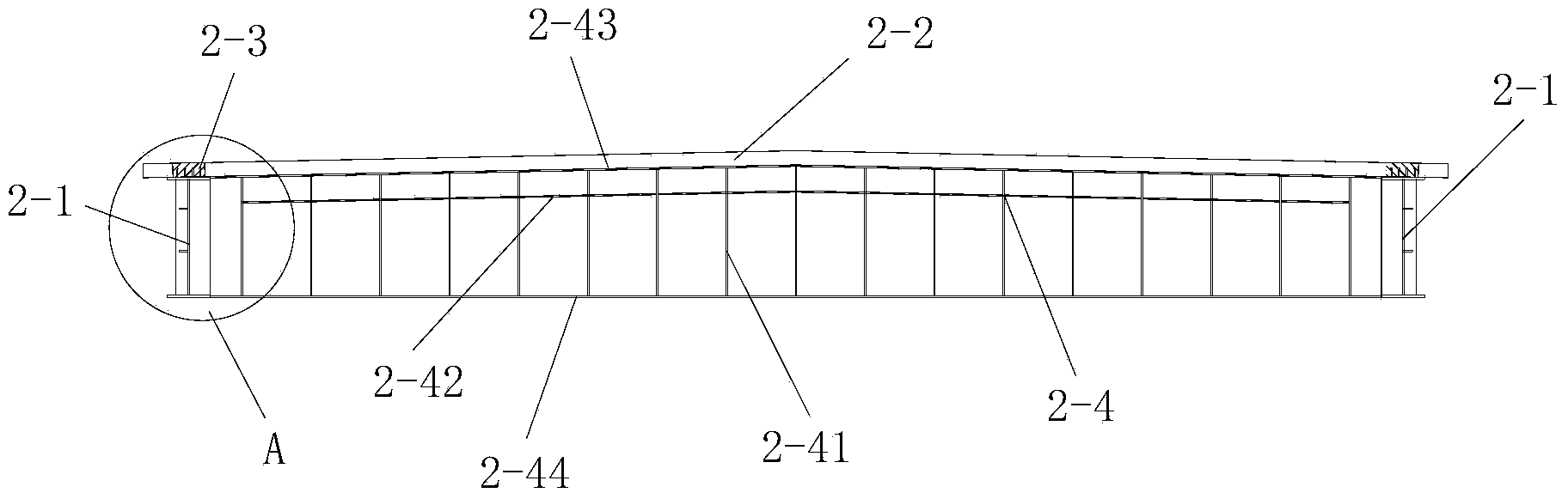

Joint section structure for hybrid beam cable-stayed bridge and construction method thereof

InactiveCN104294748ASimple structureReasonable designCable-stayed bridgeBridge structural detailsConcrete beamsCable stayed

The invention discloses a joint section structure for a hybrid beam cable-stayed bridge. The joint section structure comprises a concrete beam-combined beam connecting structure connected between a concrete beam and a combined beam, wherein the combined beam comprises steel girders distributed in the longitudinal direction of the bridge, the steel girders are I-shaped and comprise steel girder top plates, steel girder base plates and steel girder web plates. The steel girder top plates and the steel girder base plates extend into the concrete beam, and the concrete beam-combined beam connecting structure comprises a front pressure bearing plate, a rear pressure bearing plate and a joint section steel web plate. The joint section structure is simple, reasonable in design, high in construction speed and good in using effect, and the problems of complicated structure, poor joint effect and the like existing in a steel-concrete joint portion structure can be solved. The invention further discloses a construction method of the joint section structure. The construction method comprises the steps of 1 erecting a construction support; 2 hoisting a steel structure; 3 constructing the concrete beam-combined beam connecting structure; 4 casting concrete. The construction method is simple in step, reasonable in design, convenient to construct, high in construction speed and good in construction effect.

Owner:TONGJI UNIV

Device for detecting wide distance light beam parallelism

The invention relates to a wide distance beam parallelism detecting apparatus, comprising a photoelectric auto-collimator and a diameter-expanding collimating arm. The apparatus can detect the parallelism of the wide distance parallel beams and the detecting distance can reach 1.5m; and two parallel beams do not need to be contained into the caliber of the photoelectric auto-collimator so as to reduce the caliber of the photoelectric auto-collimator and largely reduce the manufacturing cost of the photoelectric auto-collimator. Simultaneously, the adoption of pentaprism and optical wedge largely reduces the processing precision requirement of the pentaprism and has no impact on the detecting precision of the whole apparatus and higher precision can be provided. The use of an optical splitting system in the photoelectric auto-collimator leads the detecting wave band of the apparatus to be expanded to the laser and infrared spectrum band from the white spectrum band so as to become a multi-spectrum optical system.

Owner:CHANGCHUN UNIV OF SCI & TECH

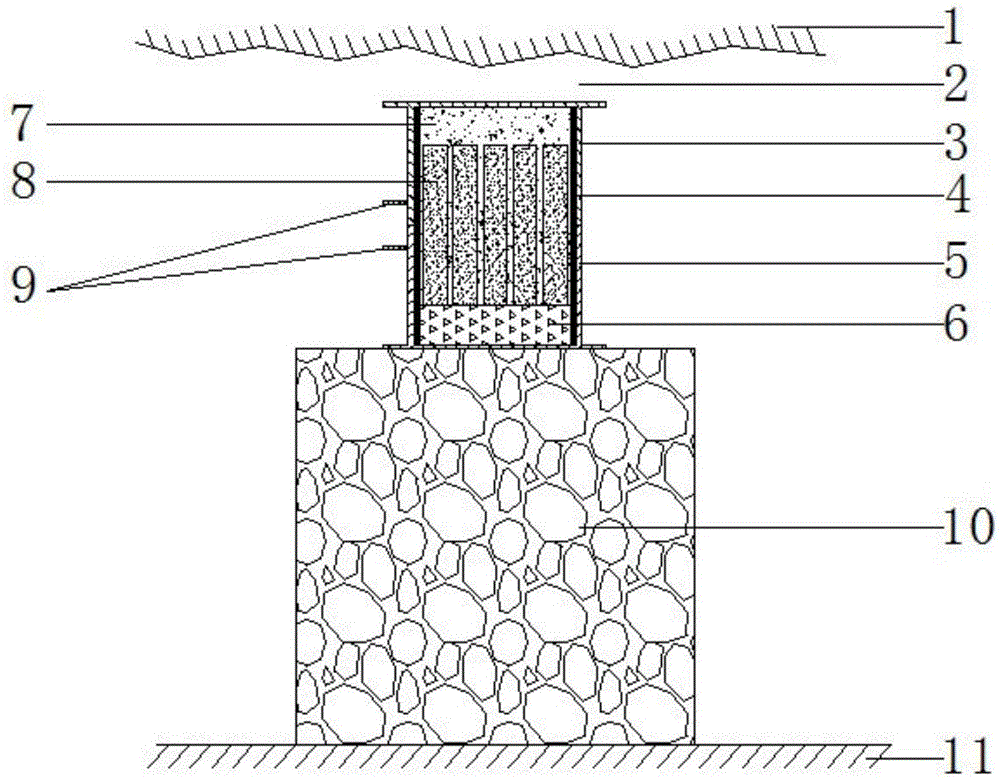

Underground stope artificial pillar expansion jacking device and construction method

The invention discloses an underground stope artificial pillar expansion jacking device mounted between an artificial pillar foundation and a stope top plate. The underground stope artificial pillar expansion jacking device comprises an upper cover barrel, an inner sleeve and a lower cover barrel; the inner sleeve is positioned between the upper cover barrel and the lower cover barrel; the upper cover barrel has a barrel bottom I and a barrel wall I; the lower cover barrel has a barrel bottom II and a barrel wall II; the upper cover barrel is arranged above the inner sleeve; the outer wall of the inner sleeve is in clearance fit with the inner wall of the barrel wall I; the lower cover barrel covers the lower side of the inner sleeve; the outer wall of the inner sleeve is in clearance fit with the inner wall of the barrel wall II; a gravel cushion layer and an expansion agent cartridge are arranged in the inner sleeve from bottom to top in sequence; and gravels fill the expansion agent cartridge; and water drainage exhaust holes are respectively formed in the barrel bottom I and the barrel bottom II. The underground stope artificial pillar expansion jacking device has such advantages as simple structure, low production cost, convenience for use, capability of quickly and actively jacking, good jacking effect and high support force.

Owner:NORTHEASTERN UNIV

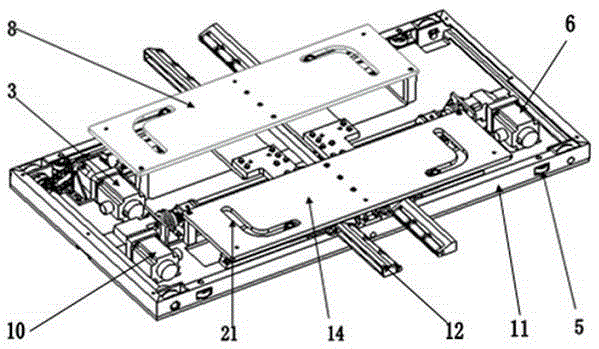

Sliding-plate parallel clamping auto tire carrier

The invention discloses a sliding-plate parallel clamping auto tire carrier which comprises at least two mutually connected chassis, wherein traveling mechanisms and positioning devices are arranged on the chassis; a clamping mechanism is arranged on each chassis and comprises a pair of sliding plates and a sliding plate driving mechanism, and the sliding plates are connected with the chassis in a sliding way; clamping arms are movably connected with the sliding plates; and a left guiding groove plate and a right guiding groove plate are fixed on each chassis. Through the interaction and cooperation of the sliding plates, L-shaped guiding grooves in the guiding groove plates and the clamping arms, the siding plates perform linear motion under the guidance of the L-shaped guiding grooves so as to force the clamping arms to perform rotary and linear motion, so that the rotating, unfolding and folding motion of the clamping arms is realized, and then the effect that working arms parallelly clamp tires to carry an auto is realized through the linear motion; a clamping arm driving motor is omitted, the system structure is simplified, and the reliability is improved; the clamping arms parallelly and oppositely push the clamped tires so as to avoid damaging the auto; and meanwhile, the sliding-plate parallel clamping auto tire carrier is simple in structure, convenient to mount, low in cost and high in reliability.

Owner:SHANDONG TIANCHEN INTELLIGENT PARKING EQUIPMENT CO LTD

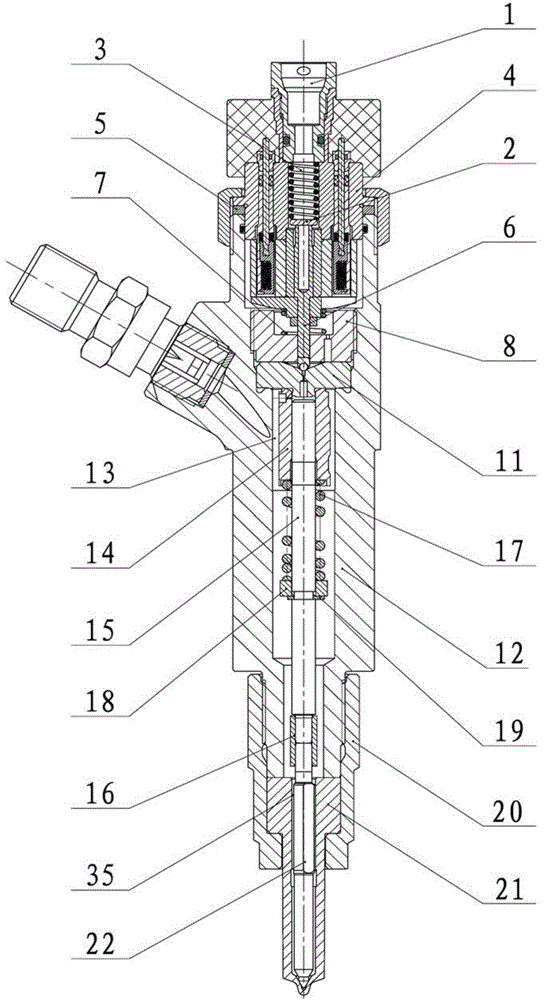

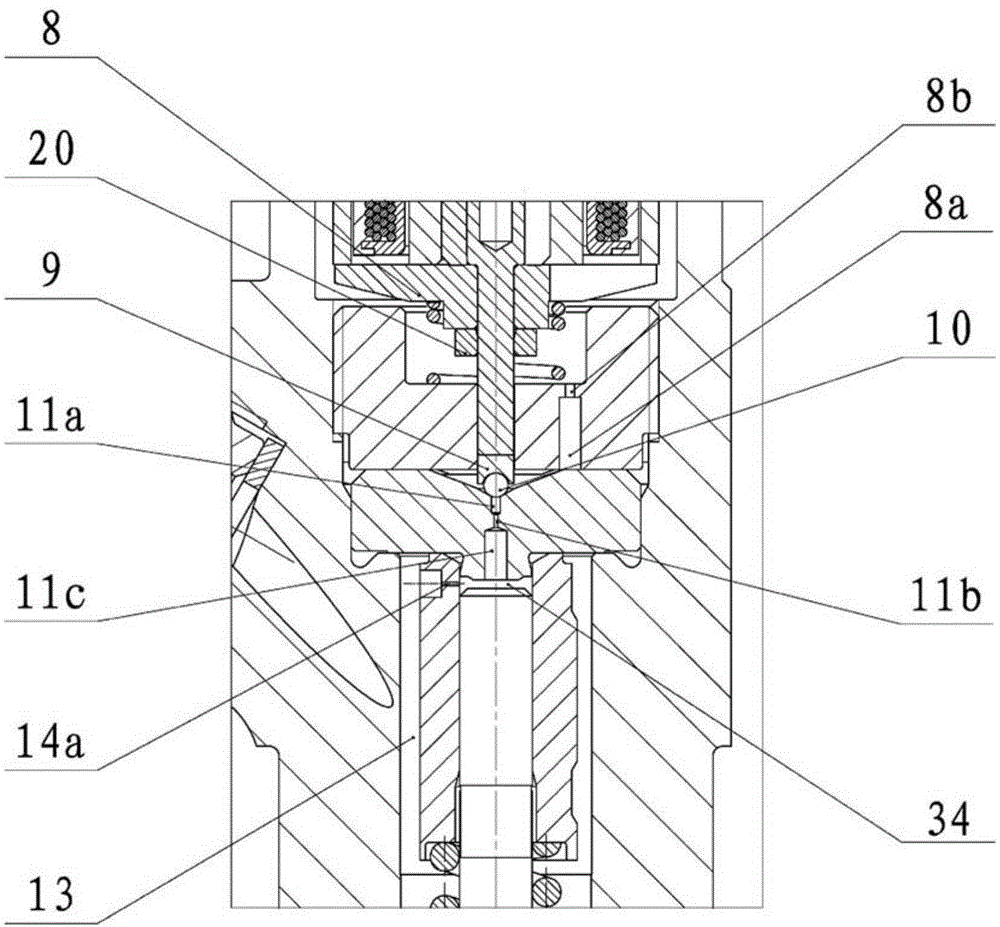

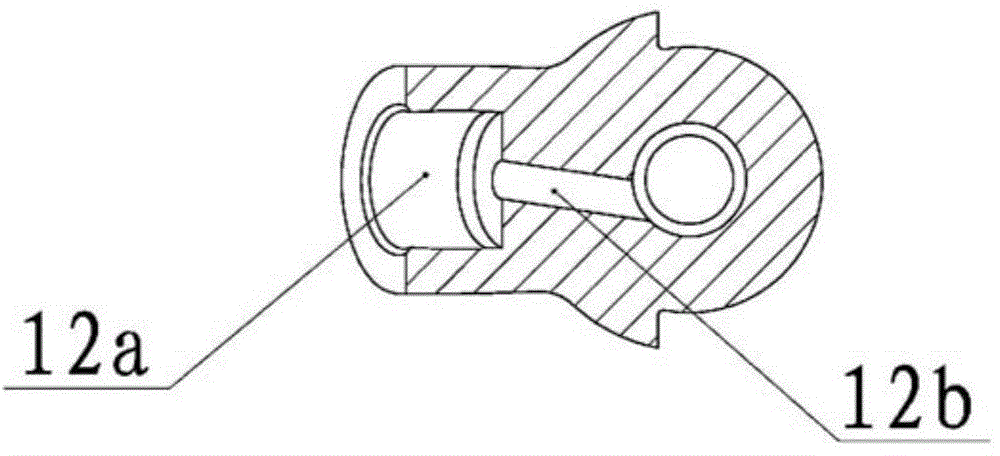

Middle hole pressure storage static leakage-free oil sprayer

ActiveCN104314725ASimple structureImprove sealingFuel injection apparatusMachines/enginesSolenoid valvePlunger

The invention discloses a middle hole pressure storage static leakage-free oil sprayer, comprising a high speed solenoid valve, a locking screw sleeve, a tapered surface ball valve type switch valve, a control plunger and barrel assembly, an oil sprayer spring, a spring seat, an opening check ring, an oil sprayer body, an oil sprayer assembly and an oil nozzle locking cap; the tapered surface ball valve type switch valve is arranged in a concave cavity in the upper end of the oil sprayer body; the upper end of the oil sprayer body is connected with the high speed solenoid valve by a locking nut; the lower end of the oil sprayer body is connected with the oil nozzle assembly by the oil nozzle locking cap; the control pole plunger and barrel assembly is arranged in a central hole formed along the axis of the oil sprayer body; the central hole of the oil sprayer body and the control pole plunger and barrel assembly form a middle hole pressure storage cavity. The oil sprayer is simple in structure, low in machining cost and convenient to mount, so the production efficiency and product percent of pass are improved.

Owner:钧风电控科技(大连)有限责任公司

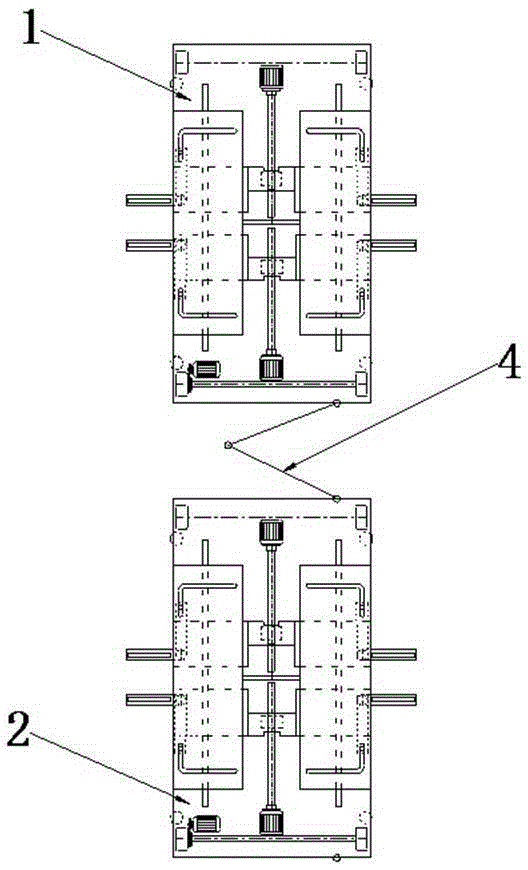

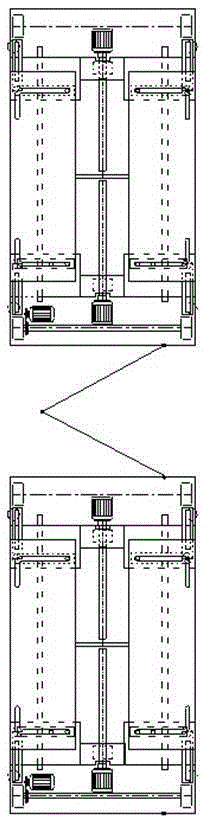

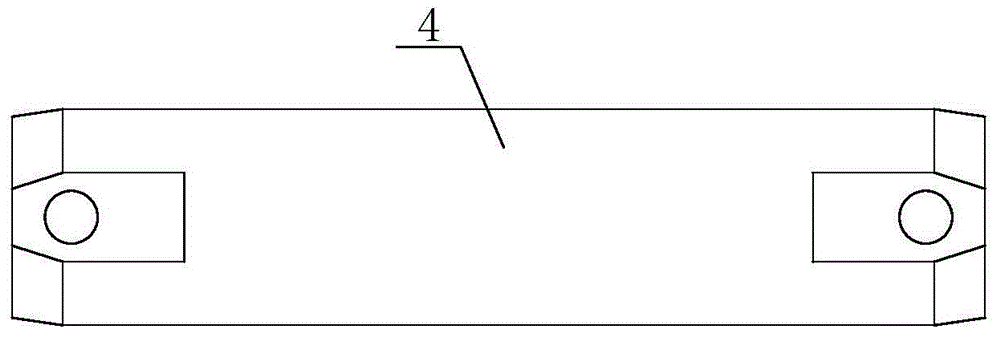

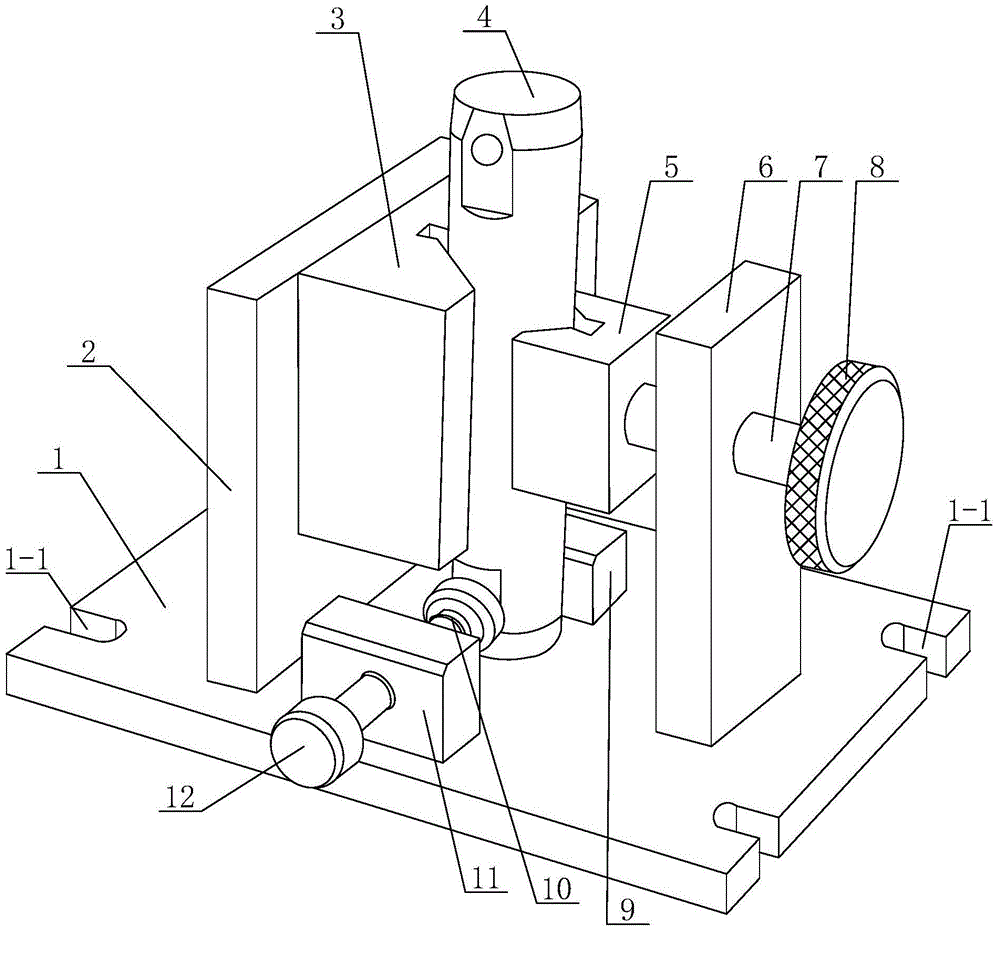

Cylindrical workpiece end flat-milling and clamping device

InactiveCN105666177AReasonable designSimple structurePositioning apparatusMetal-working holdersEngineeringMachining

The invention discloses a cylindrical workpiece end flat-milling and clamping device which comprises a bottom plate, a V-shaped groove sizing block, a V-shaped groove pressure head, a driving threaded rod and a positioning block. A first vertical plate and a second vertical plate are fixedly arranged on the upper side of the bottom plate. The V-shaped groove sizing block is fixedly arranged on one side of the first vertical plate. The driving threaded rod is arranged on the second vertical plate. The V-shaped groove pressure head is hinged to one end of the driving threaded rod. A circular handle is fixedly mounted at the other end of the driving threaded rod. The positioning block and a support are fixedly arranged on the upper side of the bottom plate and located between the V-shaped groove sizing block and the V-shaped groove pressure head. A pressing shaft used for rapidly and tightly pressing a workpiece is mounted in an unthreaded hole in the middle of the support in a sliding mode. An elastic element is arranged between the end of the pressing shaft and the support. The cylindrical workpiece end flat-milling and clamping device has the following characteristics of quick positioning, good positioning accuracy, high machining precision, reasonable design, simple structure and convenient clamping.

Owner:XIAN ZHIYUE ELECTROMECHANICAL TECH

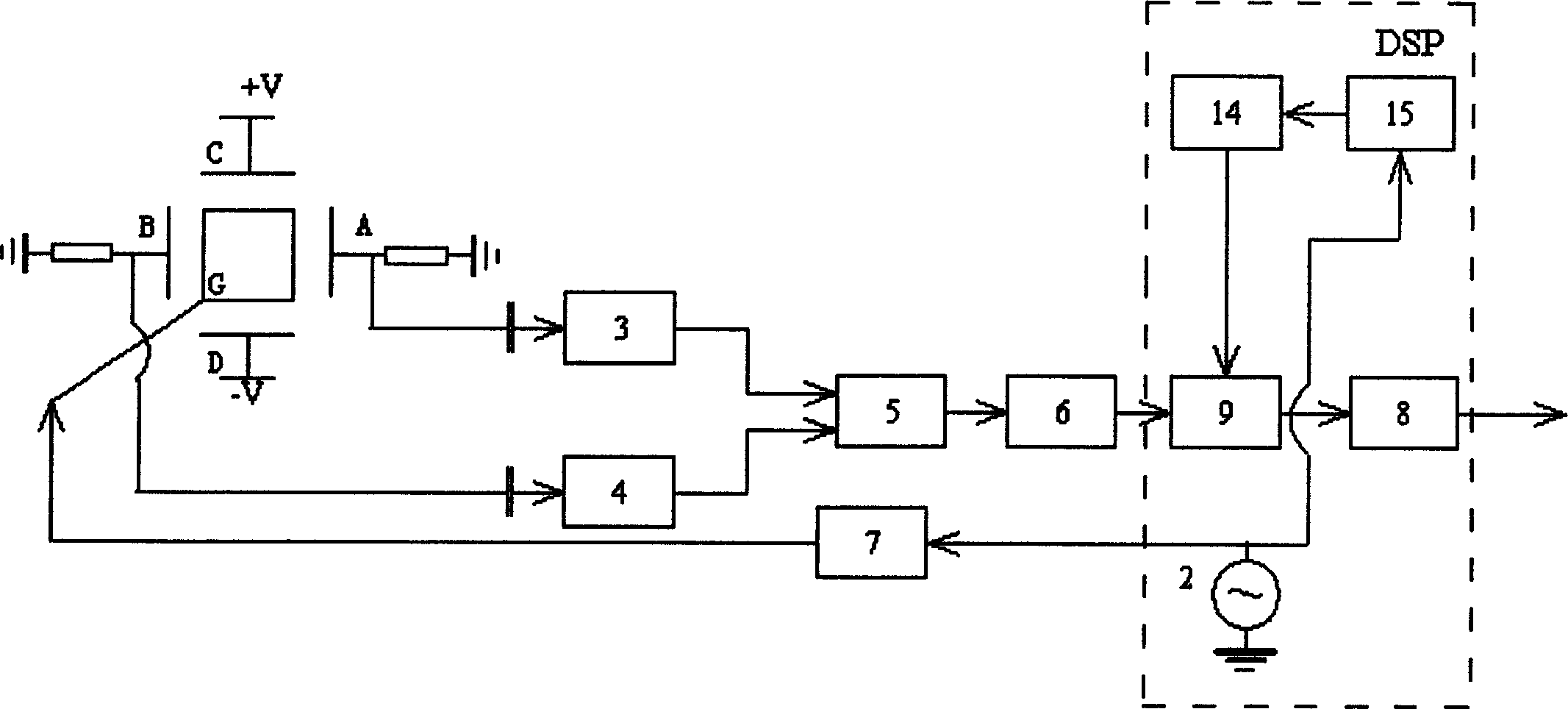

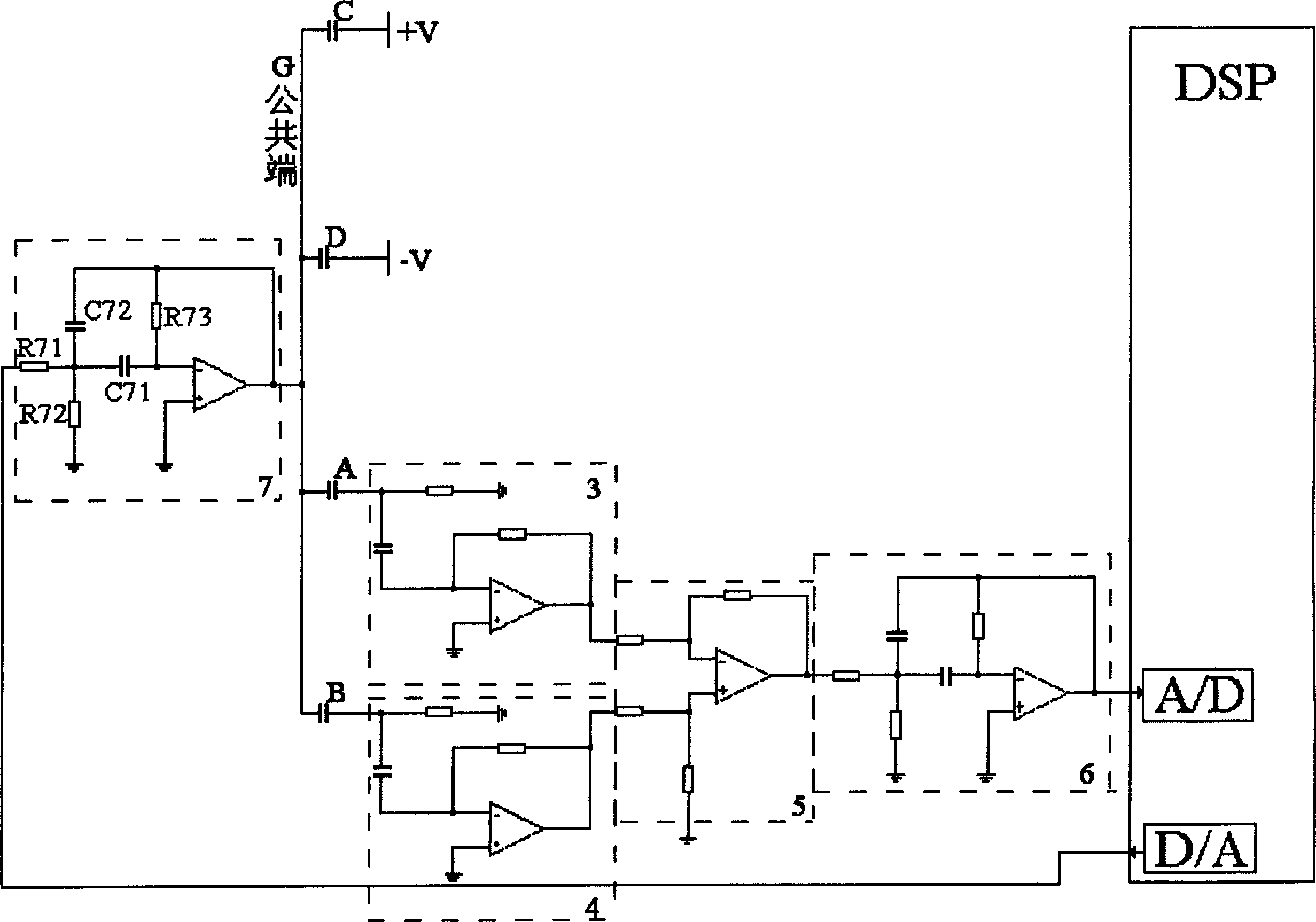

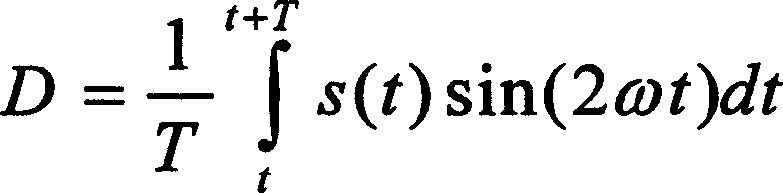

Method for extracting one-way harmonic wave of condenser type micro-gyroscope responsive signals and extraction apparatus therefor

InactiveCN1595063AMechanical vibration stabilityStable open loop driveSpeed measurement using gyroscopic effectsTurn-sensitive devicesCapacitanceControl signal

It is a harmonic wave extraction method and its apparatus of capacitor micro gyro single-path sensitive signals. The basic wave signals are output to the micro gyro capacitor electrode after magnification and let its positive and negative direct current separately bias located and connected to the ground. The sensitive capacitor electrode is connected to the ground and separately extracts sensitive signals from the electrode and differential amplify the signals by the amplifier after the anti-phase amplifier. The output signals can be turned into micro gyro sensitive signals after phase-sensitive rectifier and low magnification. The basic wave signals from the said basic signal generator serves as the control signals of the phase reference end of the phase-sensitive rectifier after double frequency and phase deviation and its apparatus comprises the public capacitor electrode with micro gyro, drive capacitor electrode and sensitive capacitor electrode.

Owner:SOUTHEAST UNIV

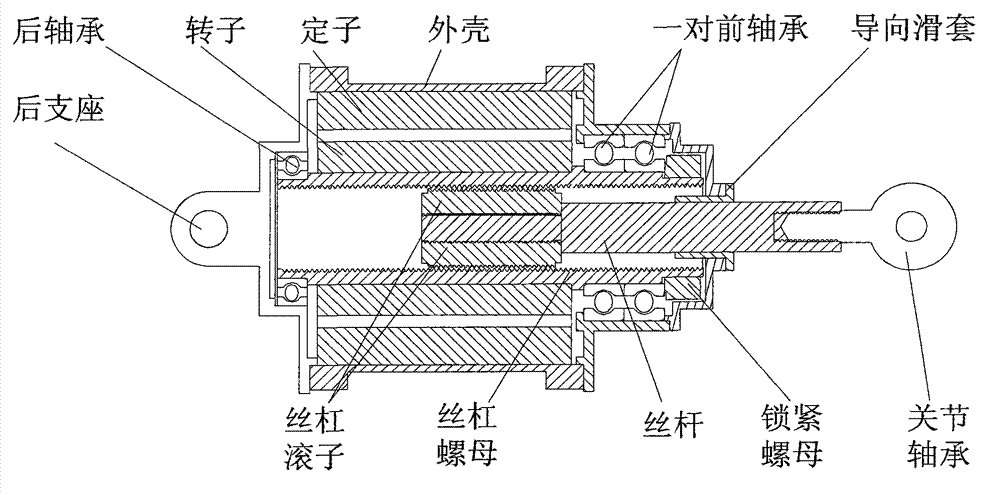

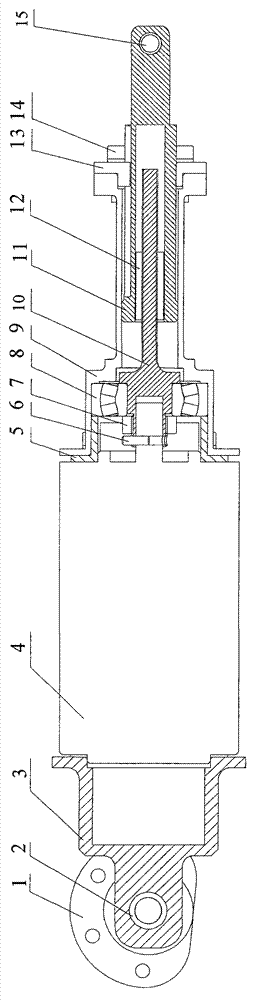

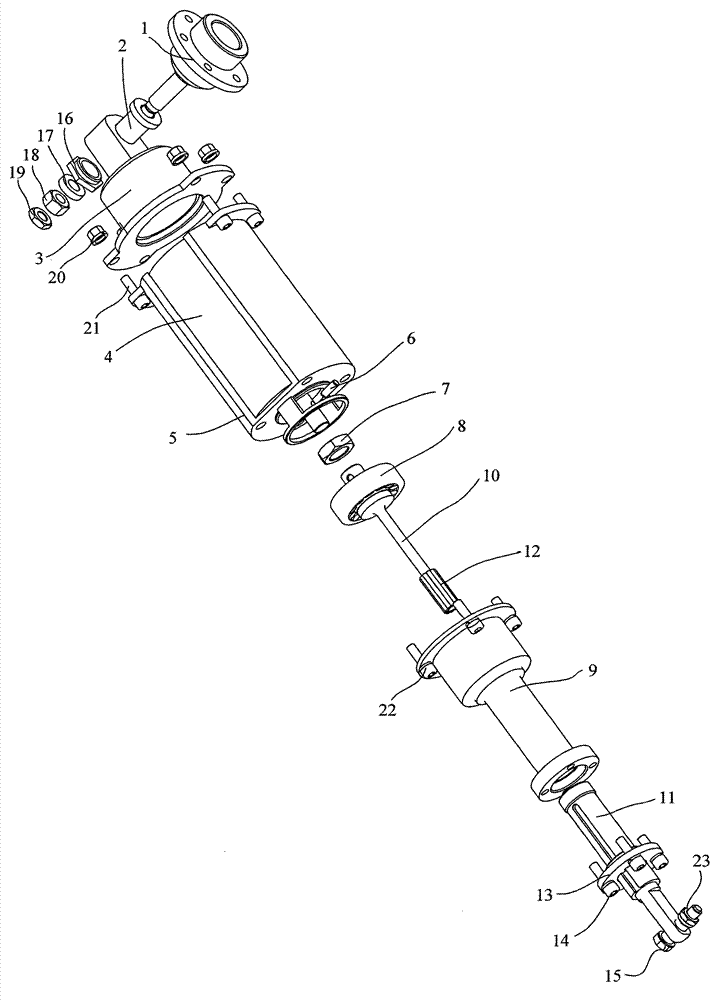

Compact electric servo mechanism for linear displacement

ActiveCN102931760AReduce design difficultyGuaranteed integrityGearingMechanical energy handlingBall screwElectric machine

The invention provides a compact electric servo mechanism for linear displacement. The compact electric servo mechanism comprises a support saddle, a sliding bearing, a motor connector, a motor, a motor shell, a self-aligning roller bearing, a screw support shell, a ball screw, a ball screw nut, a screw roller, a guide element, an output shaft and a sliding bearing end cover. According to the compact electric servo mechanism, the integrity of the motor structure is ensured by a combined design of the screw and the motor; the motor does not need to be independently designed; the design difficulty of the motor is reduced; the motor is directly connected with the ball screw to achieve direct drive, and the screw nut moves forwards and backwards when the motor rotates, so that the screw nut does not need to adopt the structure of a long thread hole, and a guide groove is designed on the screw nut to be used along with the guide element. Therefore, the accurate servo control of linear displacement is achieved, and the linear output of the mechanism does not need the assistance of an external structure.

Owner:BEIJING AUTOMATION CONTROL EQUIP INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com