Sliding-plate parallel clamping auto tire carrier

An automobile tire and carrier technology, which is applied in the field of automobile carrier and tire-clamping vehicle carrier, can solve the problems of complicated running track of the holding rod, shorten the service life of tires, increase tire wear, etc., so as to reduce the processing difficulty and The effect of low installation accuracy, low processing accuracy and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below through non-limiting embodiments and in conjunction with the accompanying drawings.

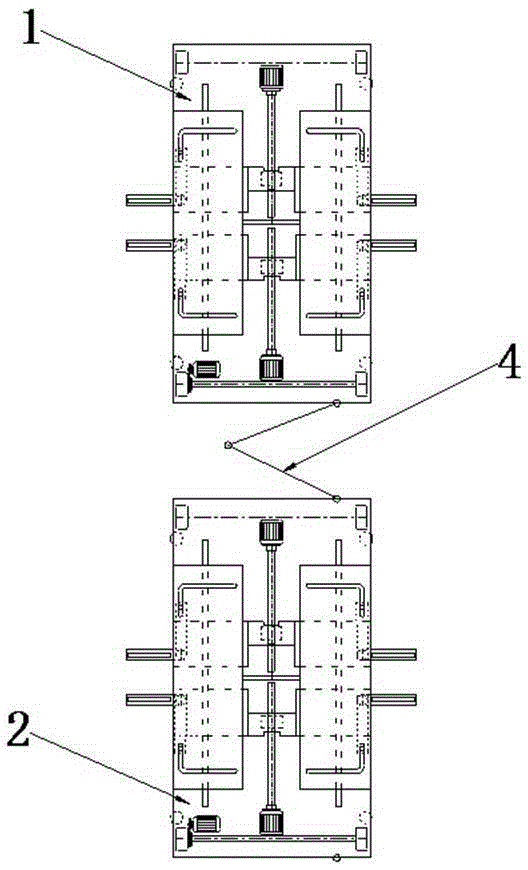

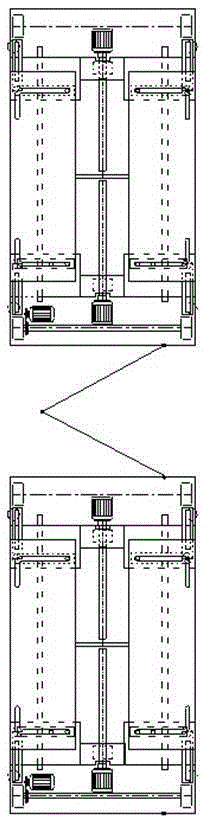

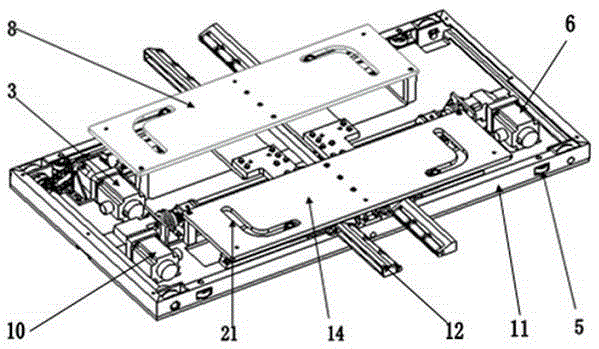

[0053] see Figure 1 to Figure 3 ,in, figure 1 It is a schematic diagram of the structure when the clamping arm of the carrier is unscrewed, figure 2 It is a schematic diagram of the structure when the clamping arm is screwed in and retracted, image 3 It is a structural schematic diagram of one of the chassis of the carrier. As shown in the figure, this embodiment discloses a skateboard-type parallel clamping car tire carrier, which includes two chassis connected by a chassis link 4, which are respectively the first chassis 1 and the second chassis 2. This embodiment For example, each chassis is provided with a traveling mechanism and a positioning device; the traveling mechanism is provided with 1 traveling motor 3, 2 active traveling wheels 23 and 2 passive traveling wheels 23, and the traveling motor 3 drives the chain and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com