Patents

Literature

2809results about "Turn-sensitive devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

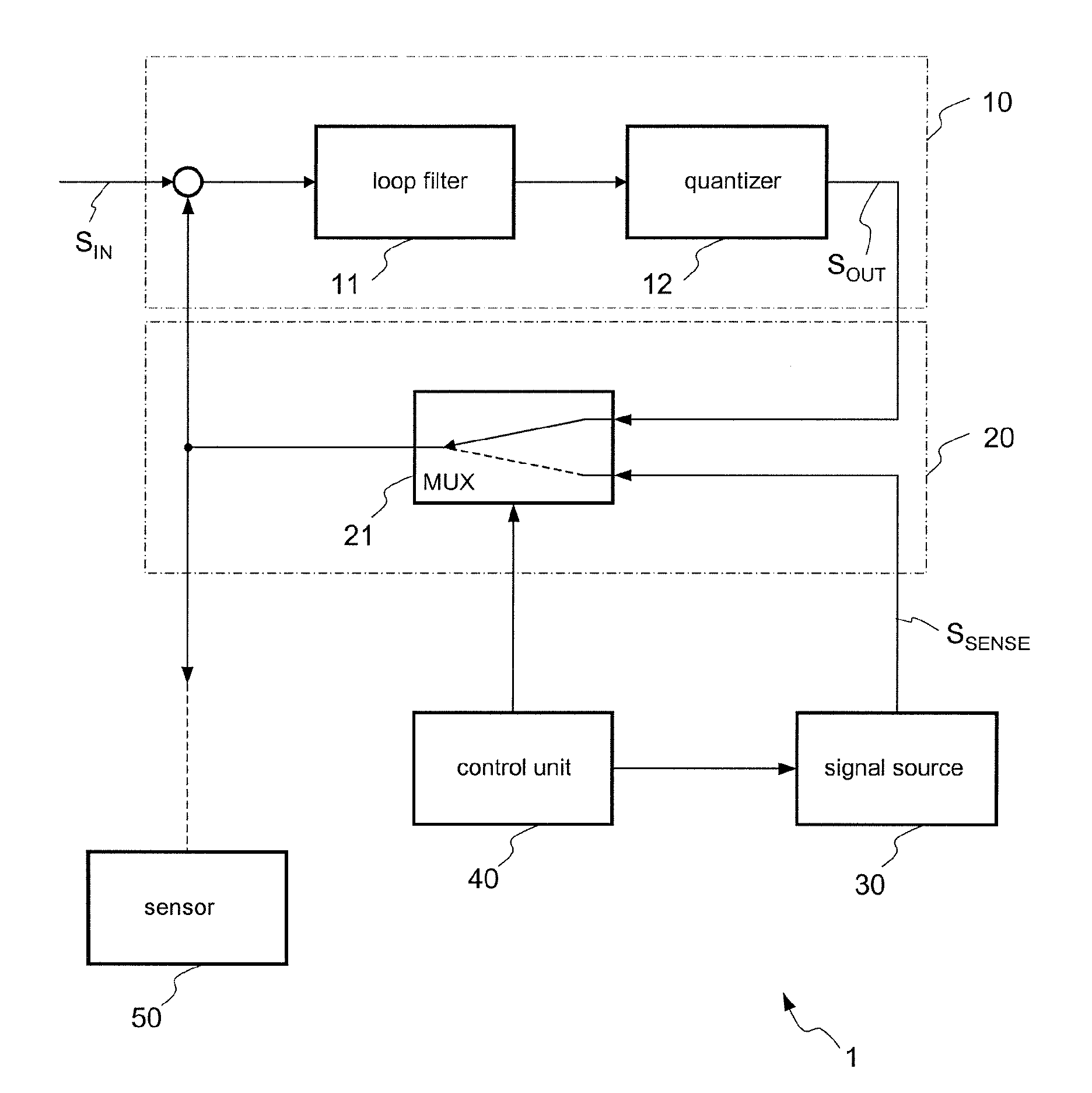

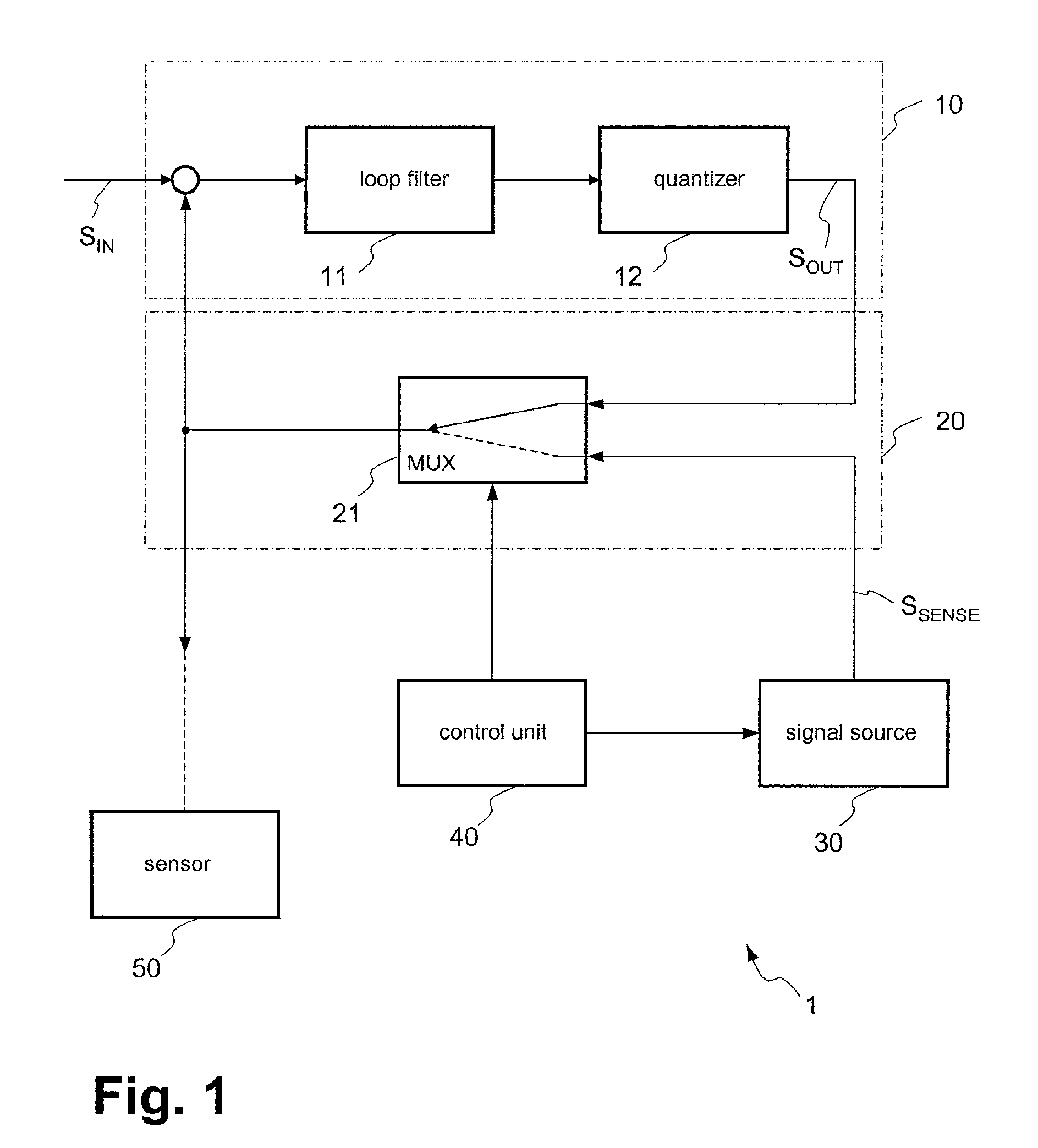

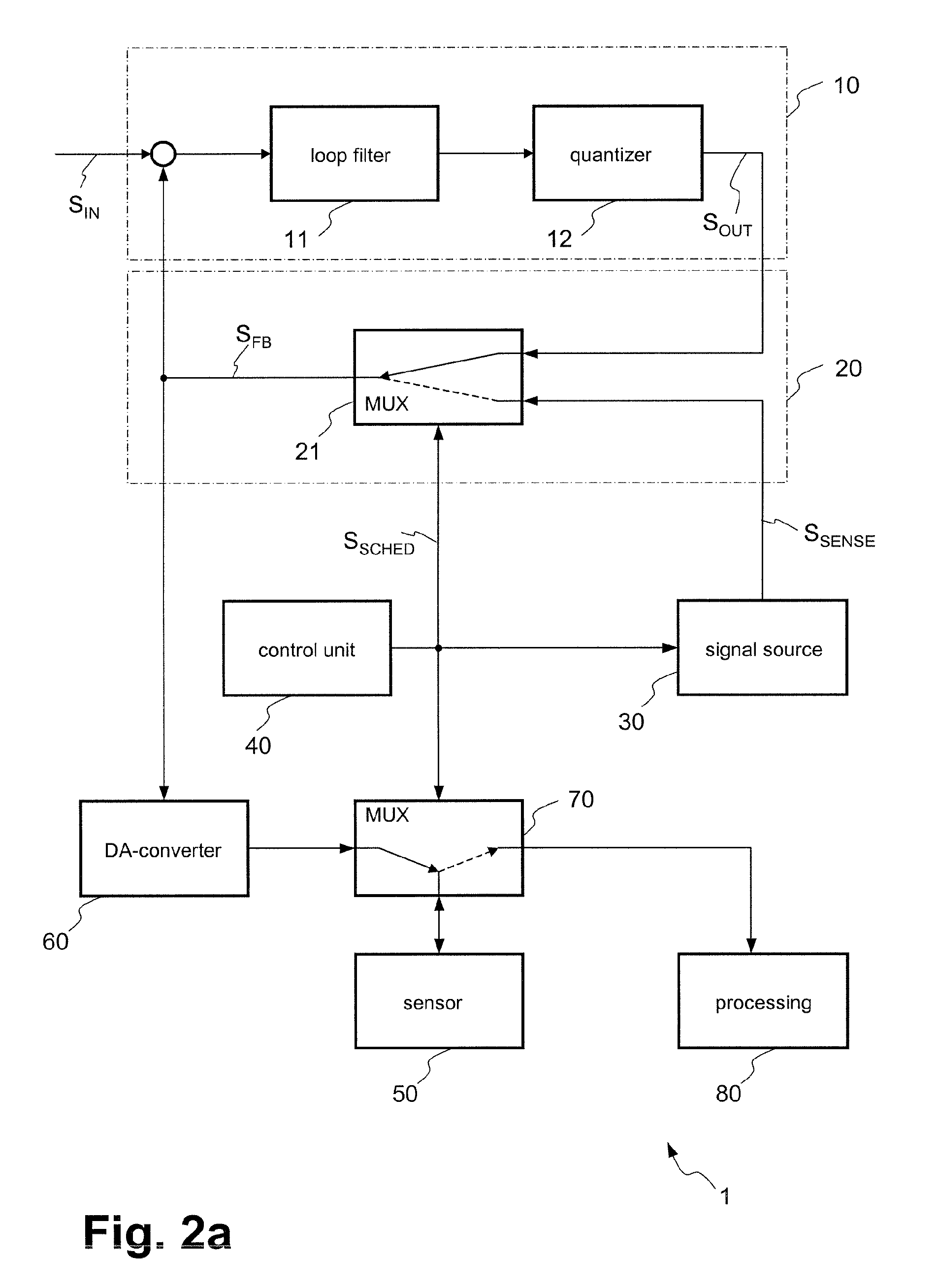

Sigma-delta modulator for operating sensors

InactiveUS7528755B2Electric signal transmission systemsAcceleration measurement using interia forcesLoop filterControl signal

A sigma-delta modulator can be used for actuating a sensor element. The sigma delta modulator includes: a forward branch to which an input signal is fed at an input and which includes a loop filter, a quantizer and an output for providing an output signal. A feedback branch is configured to feed back the output signal of the forward branch at least temporarily to the input of the forward branch. A signal source is configured to generate a readout signal which corresponds to the voltage profile at the sensor element during a measuring process. A control unit is configured to generate a control signal dependent on which either the output signal of the forward branch or the readout signal of the signal source is fed back to the input of the forward branch.

Owner:INFINEON TECH AG

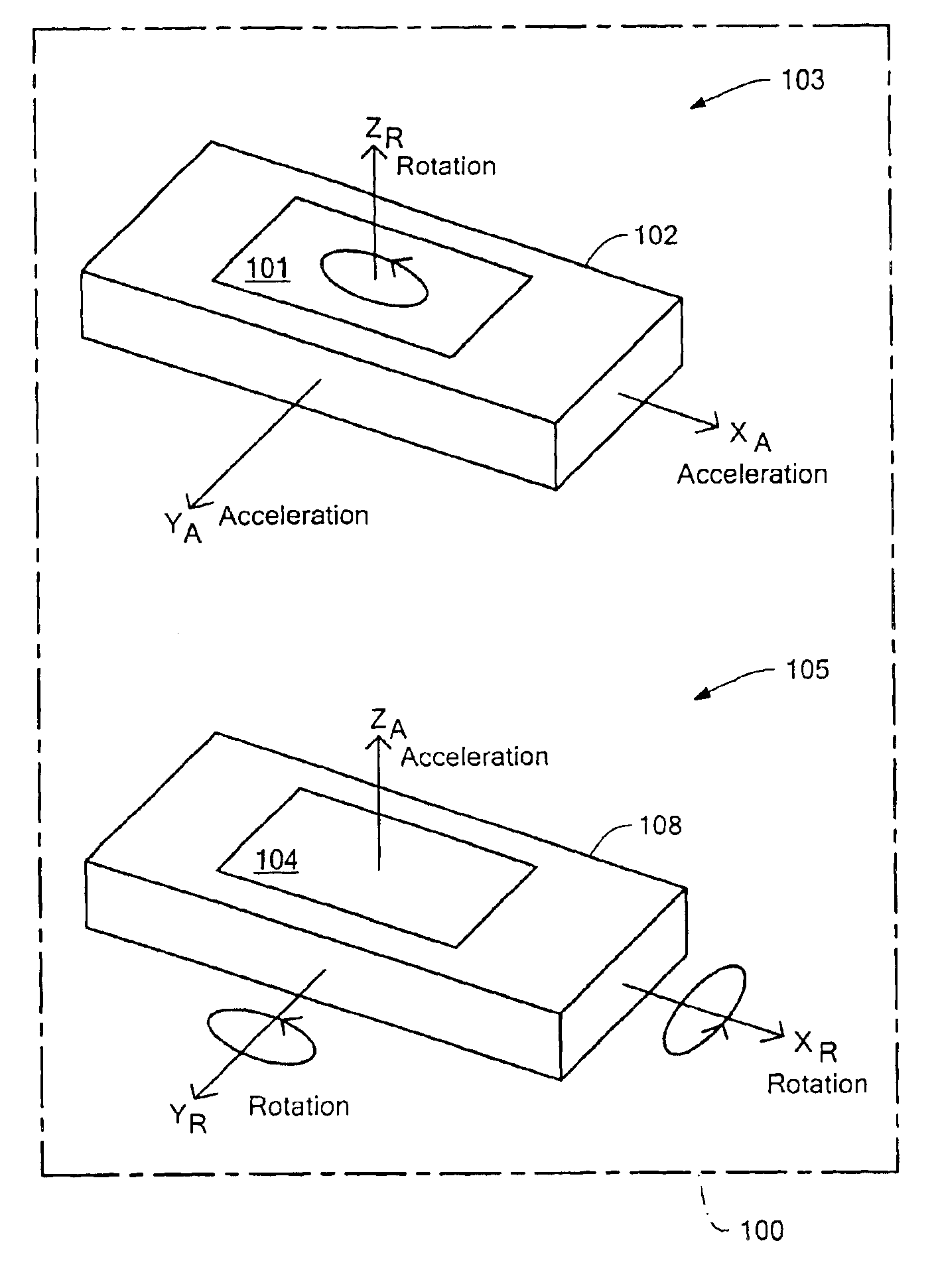

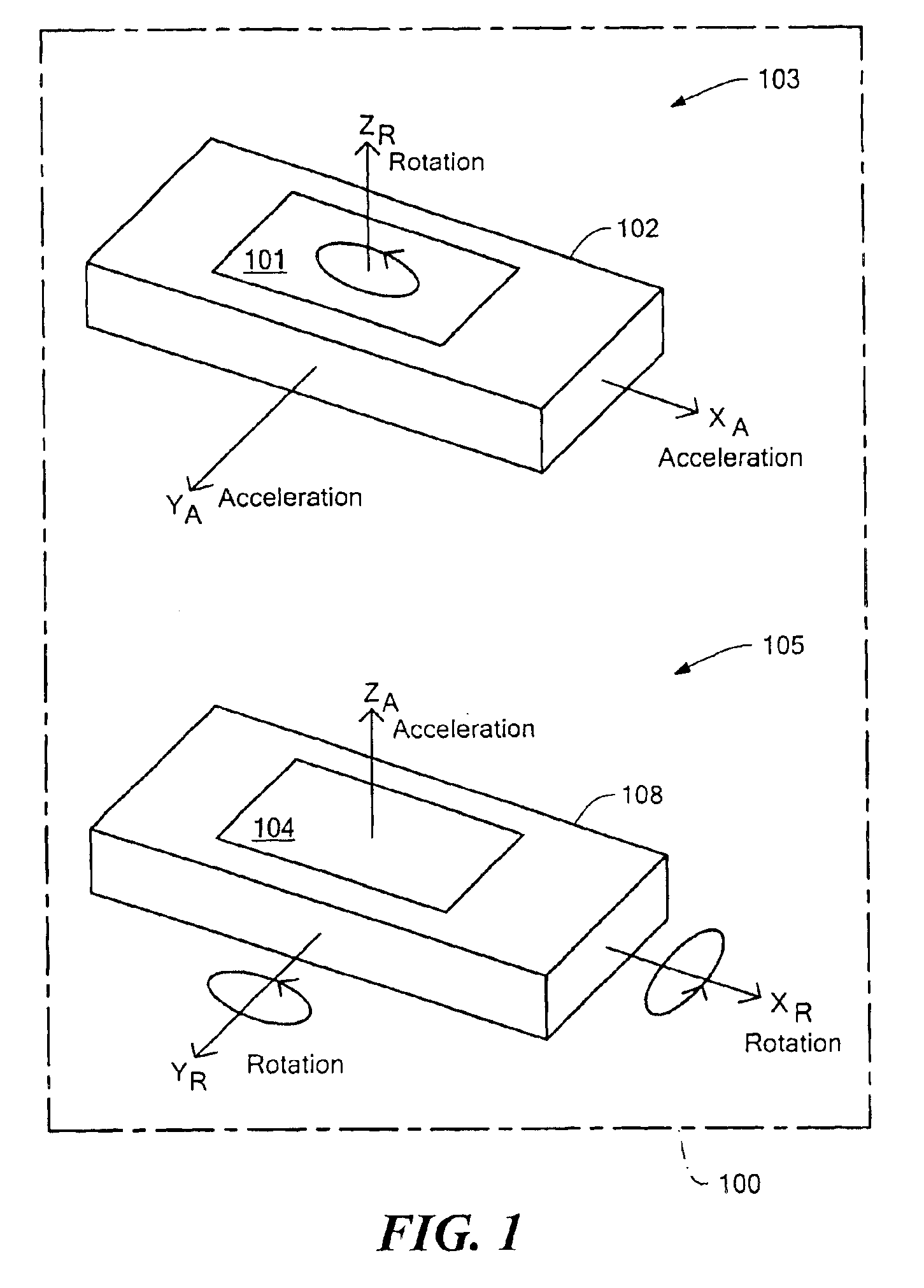

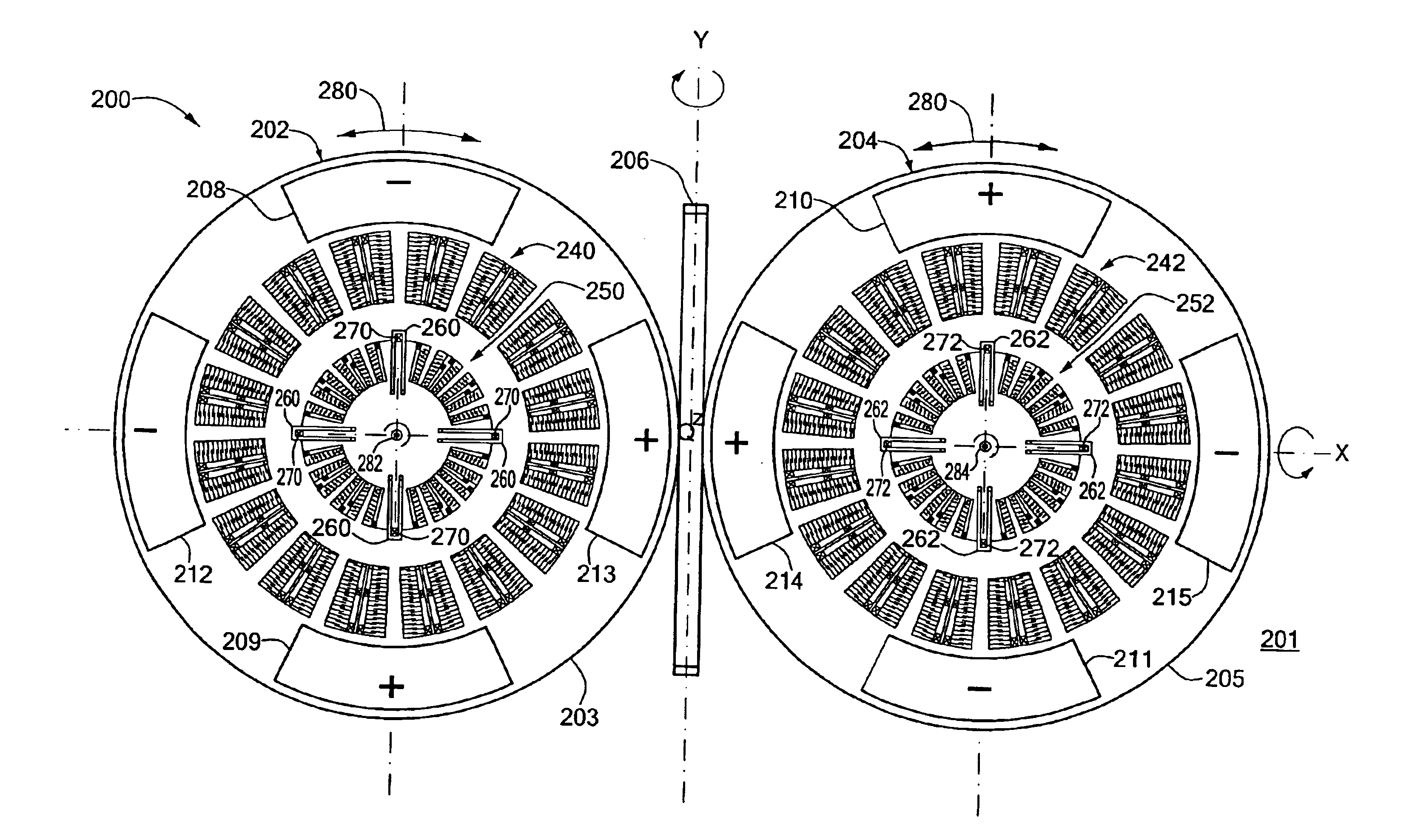

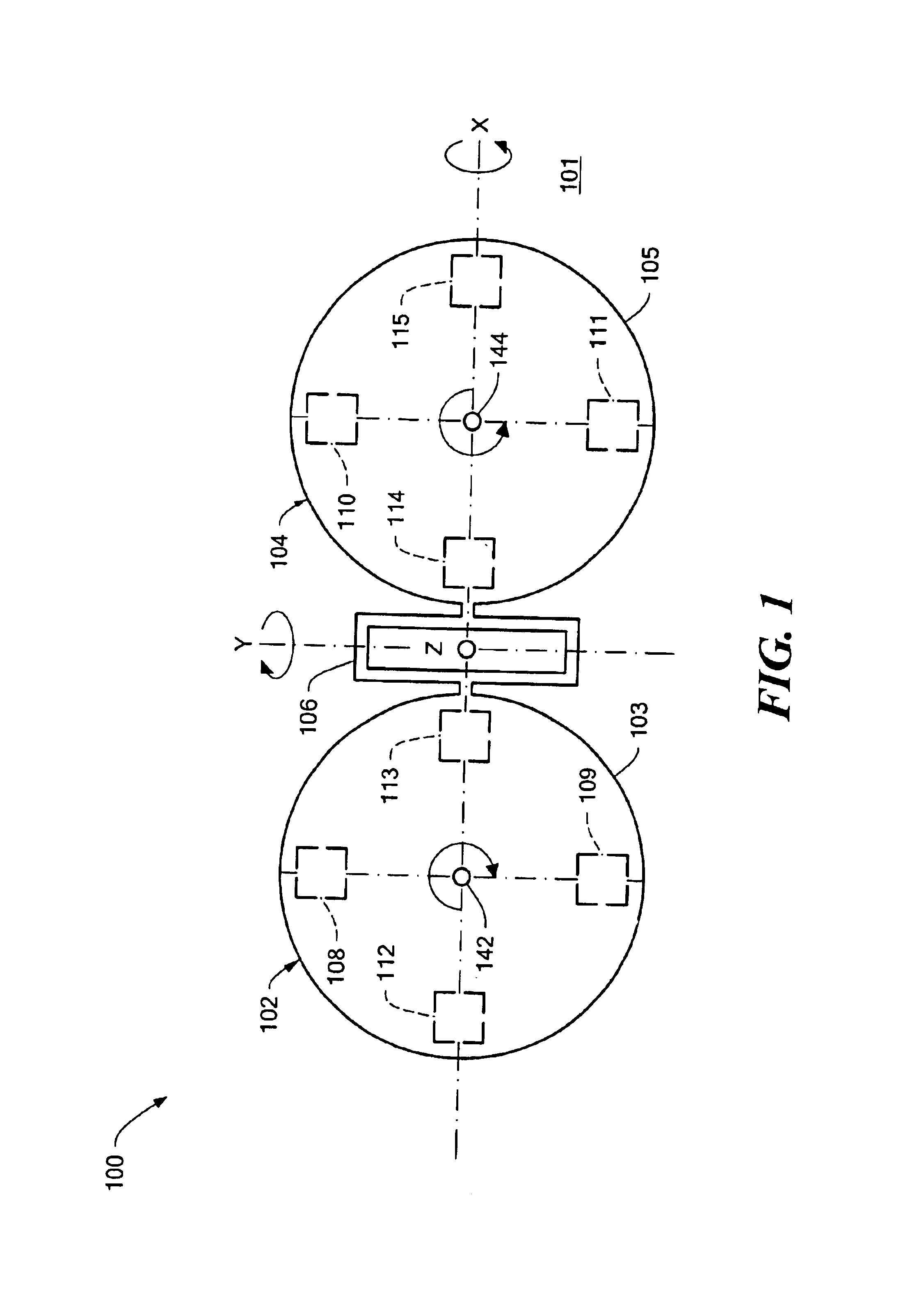

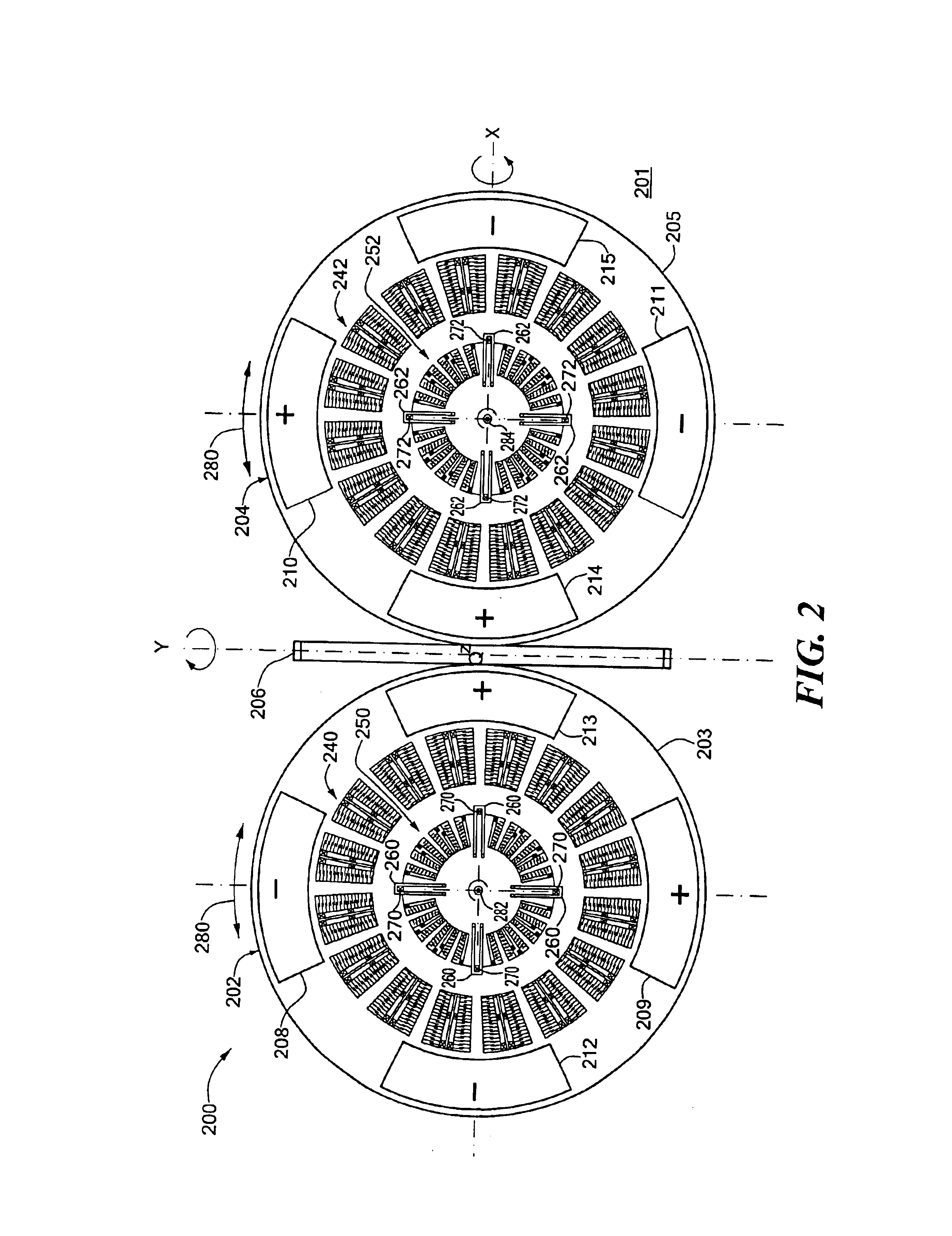

Six degree-of-freedom micro-machined multi-sensor

InactiveUS6848304B2Acceleration measurement using interia forcesSpeed measurement using gyroscopic effectsDegrees of freedomSubstructure

A six degree-of-freedom micro-machined multi-sensor that provides 3-axes of acceleration sensing, and 3-axes of angular rate sensing, in a single multi-sensor device. The six degree-of-freedom multi-sensor device includes a first multi-sensor substructure providing 2-axes of acceleration sensing and 1-axis of angular rate sensing, and a second multi-sensor substructure providing a third axis of acceleration sensing, and second and third axes of angular rate sensing. The first and second multi-sensor substructures are implemented on respective substrates within the six degree-of-freedom multi-sensor device.

Owner:ANALOG DEVICES INC

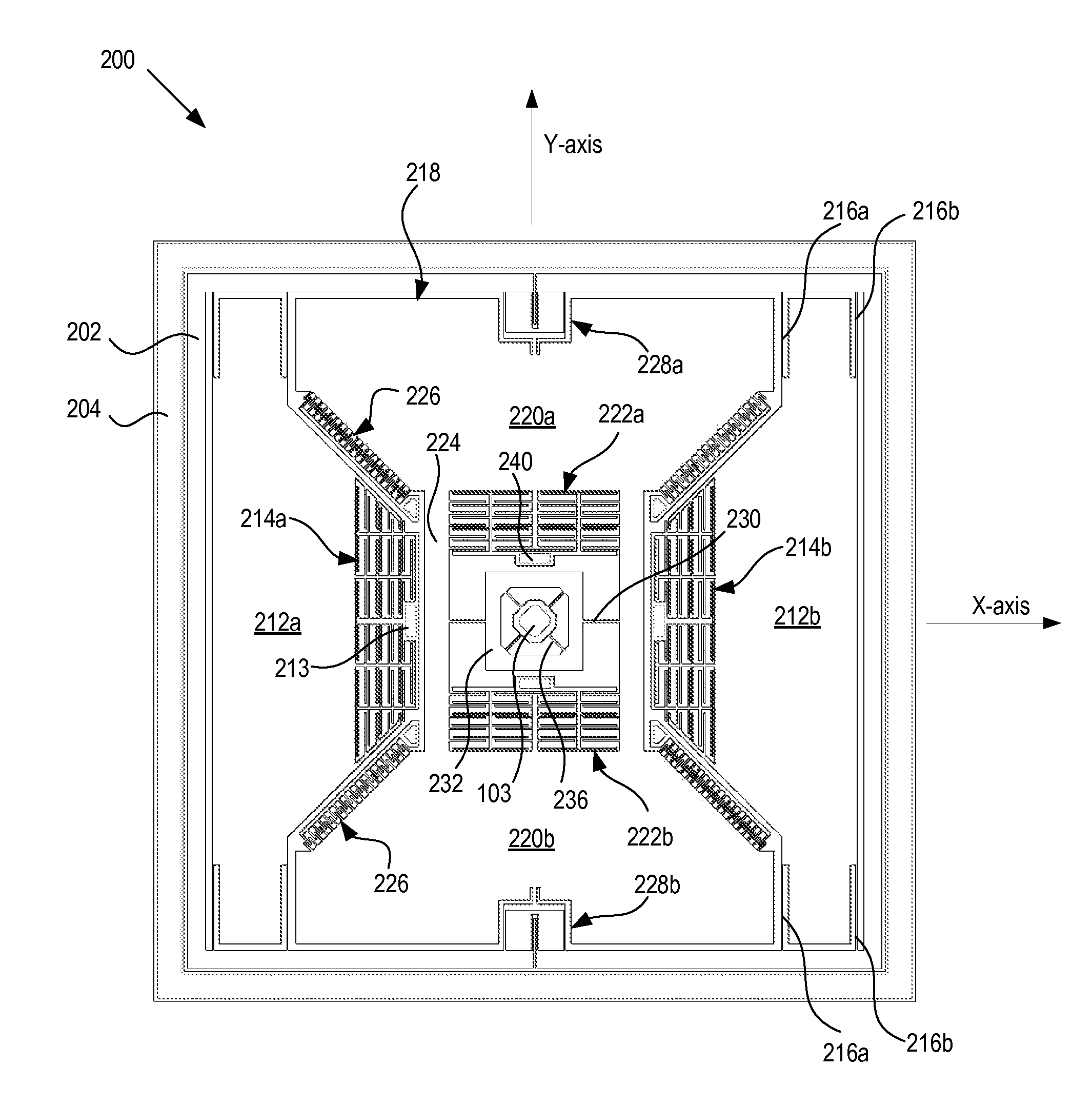

Micromachined inertial sensor devices

ActiveUS20110030473A1Acceleration measurement using interia forcesSolid-state devicesProof massLinear acceleration

A micromachined inertial sensor with a single proof-mass for measuring 6-degree-of-motions. The single proof-mass includes a frame, an x-axis proof mass section attached to the frame by a first flexure, and a y-axis proof mass section attached to the frame by a second flexure. The single proof-mass is formed in a micromachined structural layer and is adapted to measure angular rates about three axes with a single drive motion and linear accelerations about the three axes.

Owner:SEMICON COMPONENTS IND LLC

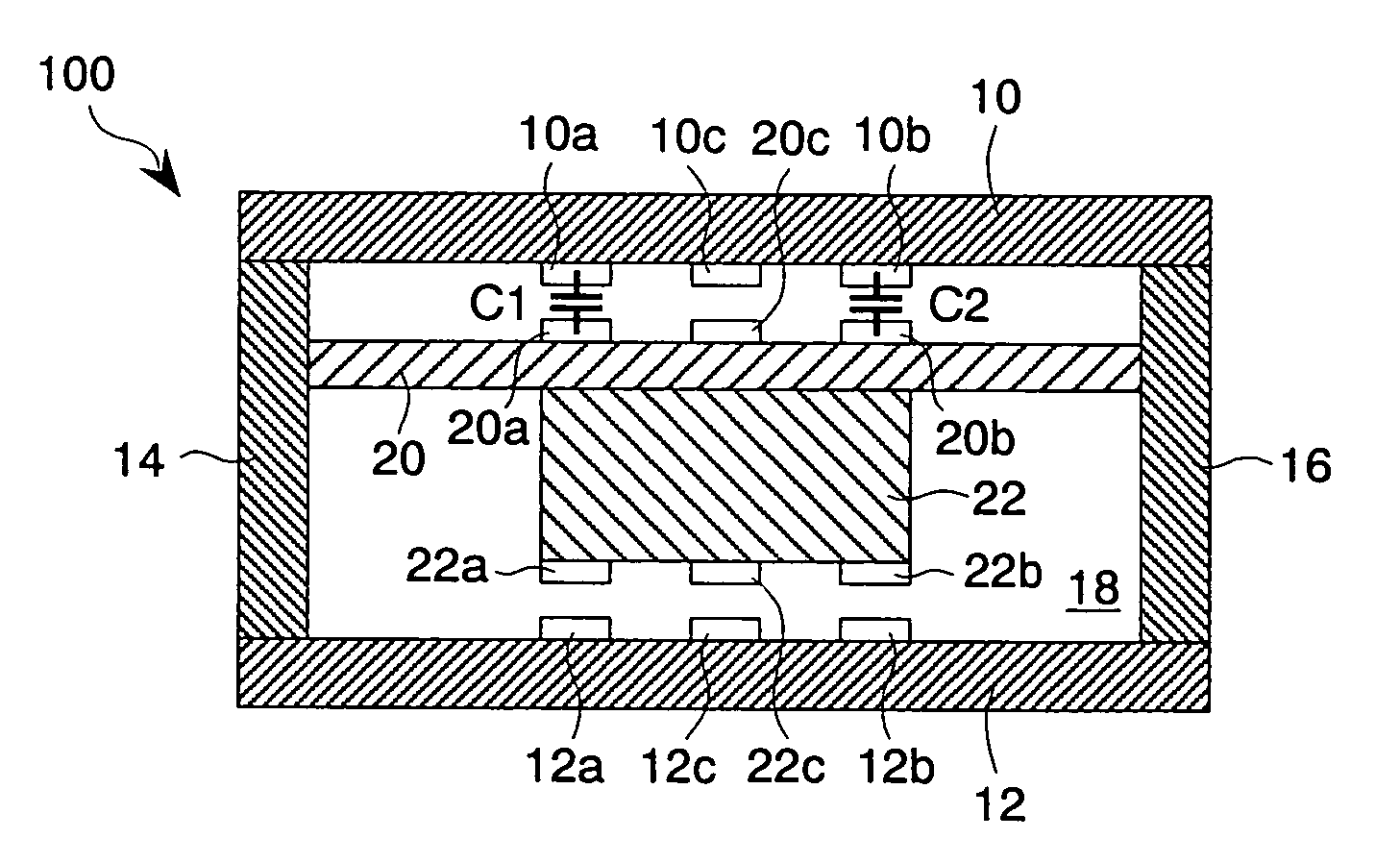

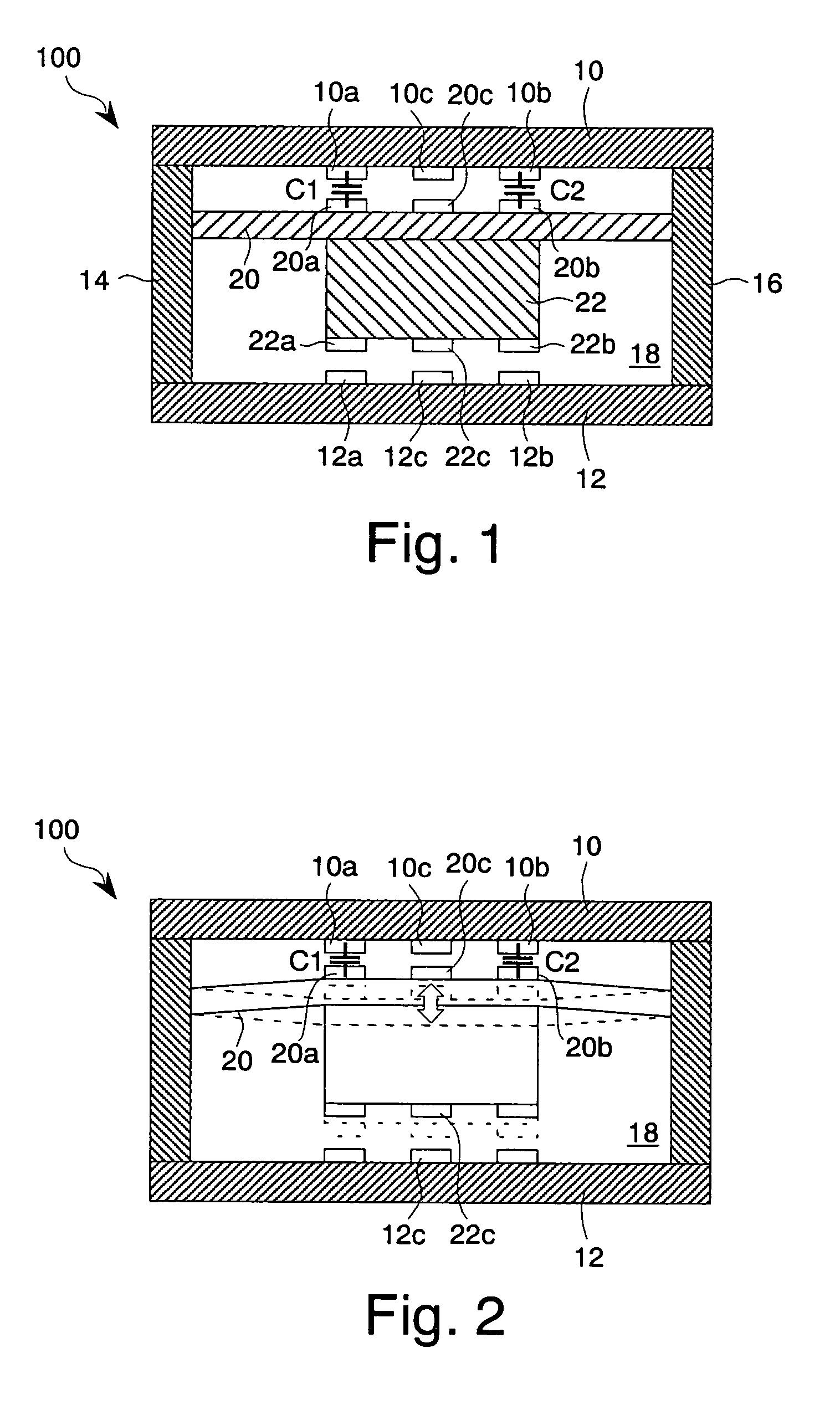

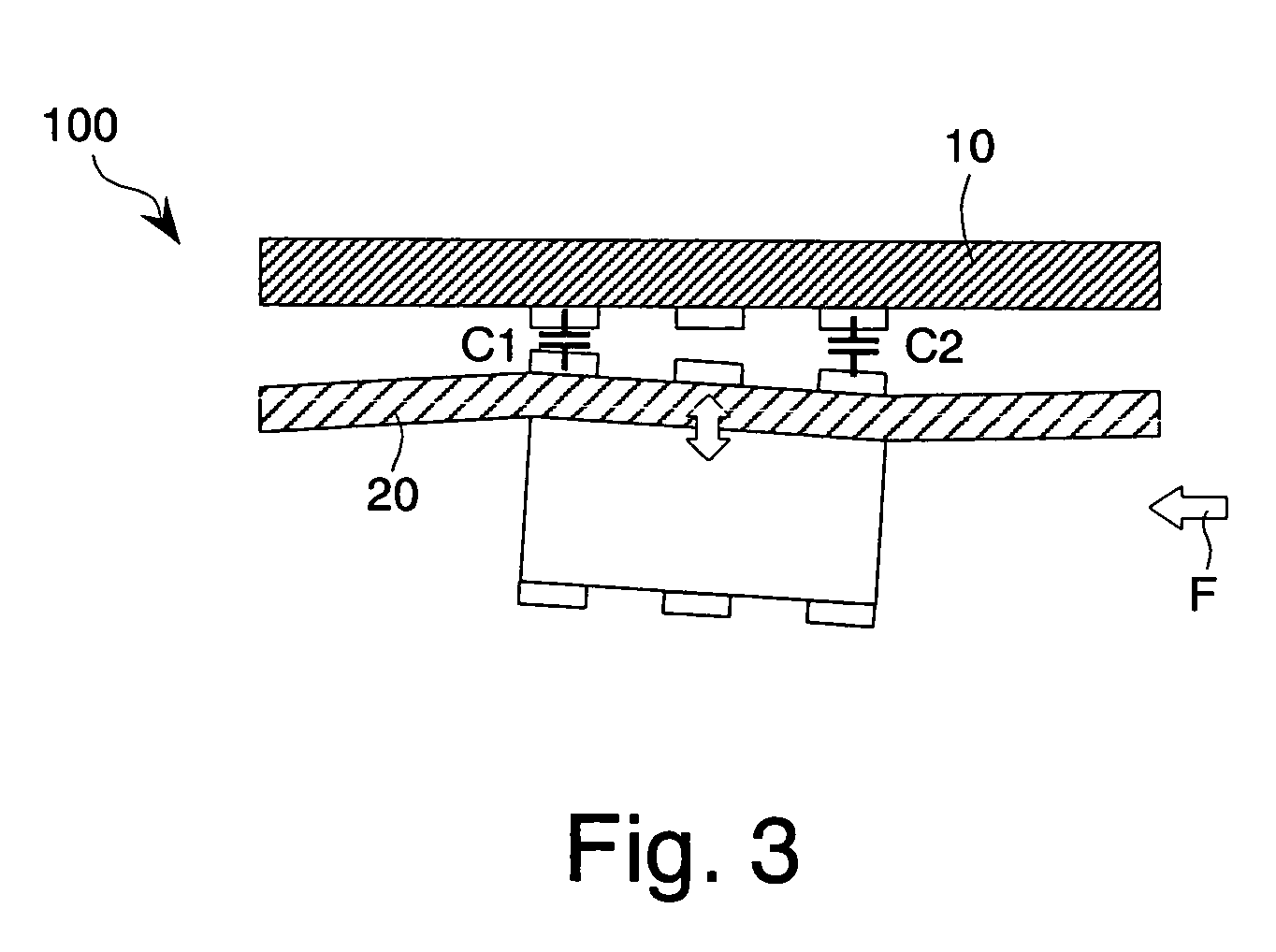

Capacitance difference detecting circuit and MEMS sensor

ActiveUS7119550B2Improve accuracyAcceleration measurement using interia forcesResistance/reactance/impedenceCapacitanceMems sensors

Oscillators have capacitors, respectively, whose capacitances change according to an external force and generate first oscillating signals according to the capacitances. Each of the capacitors is disposed, for example, between a substrate and a mass body that is movably disposed to face the substrate and oscillates in a direction perpendicular to the substrate. A detecting unit detects a relative difference between the capacitances of the capacitors as a difference between frequencies of the first oscillating signals. An angular speed or acceleration applied in a horizontal direction of the substrate is calculated according to the frequency change detected by the detecting unit. Therefore, a capacitance difference detecting circuit and a MEMS sensor that detect a minute change in the capacitances of the two capacitors caused by the external force are formed.

Owner:MONTEREY RES LLC

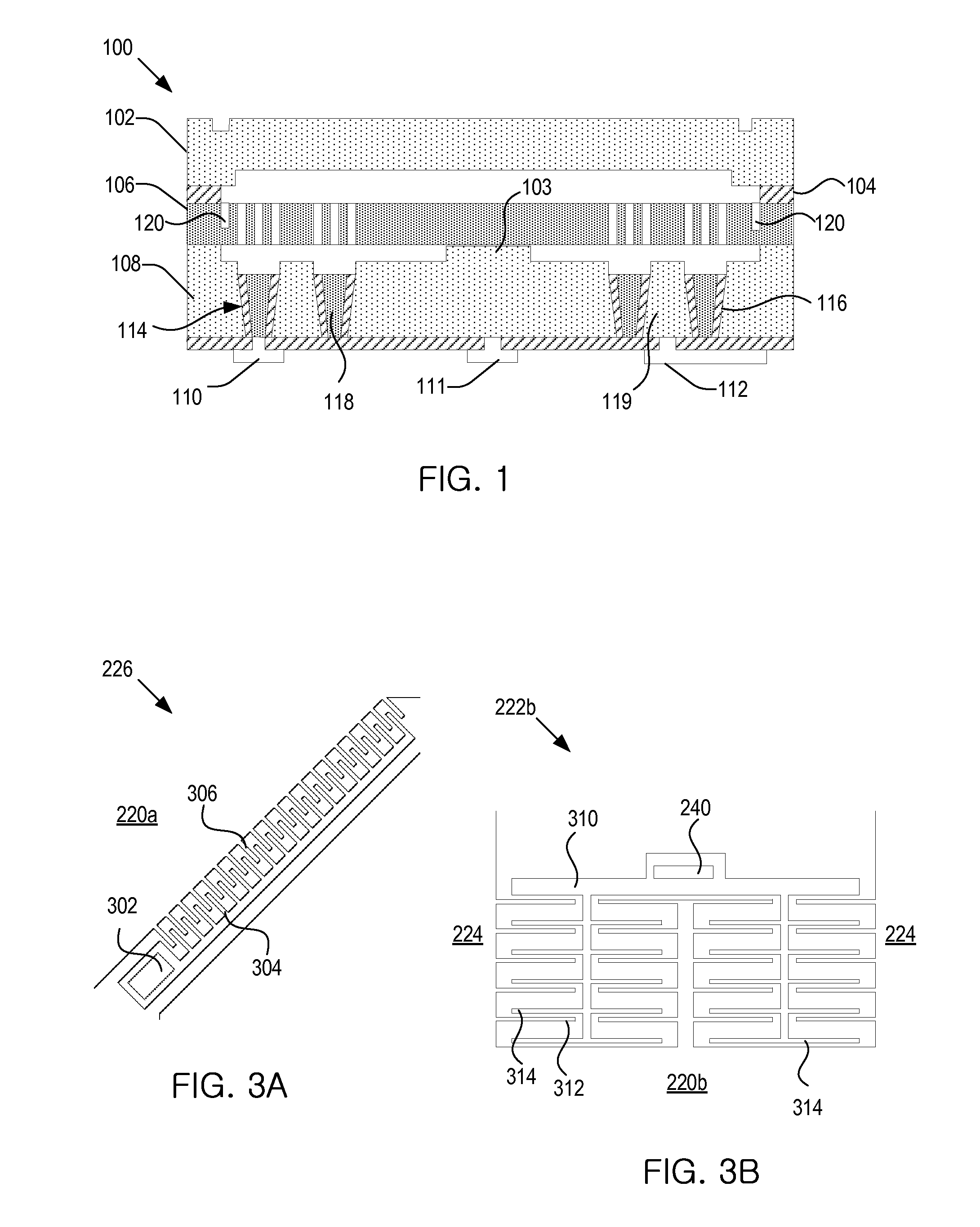

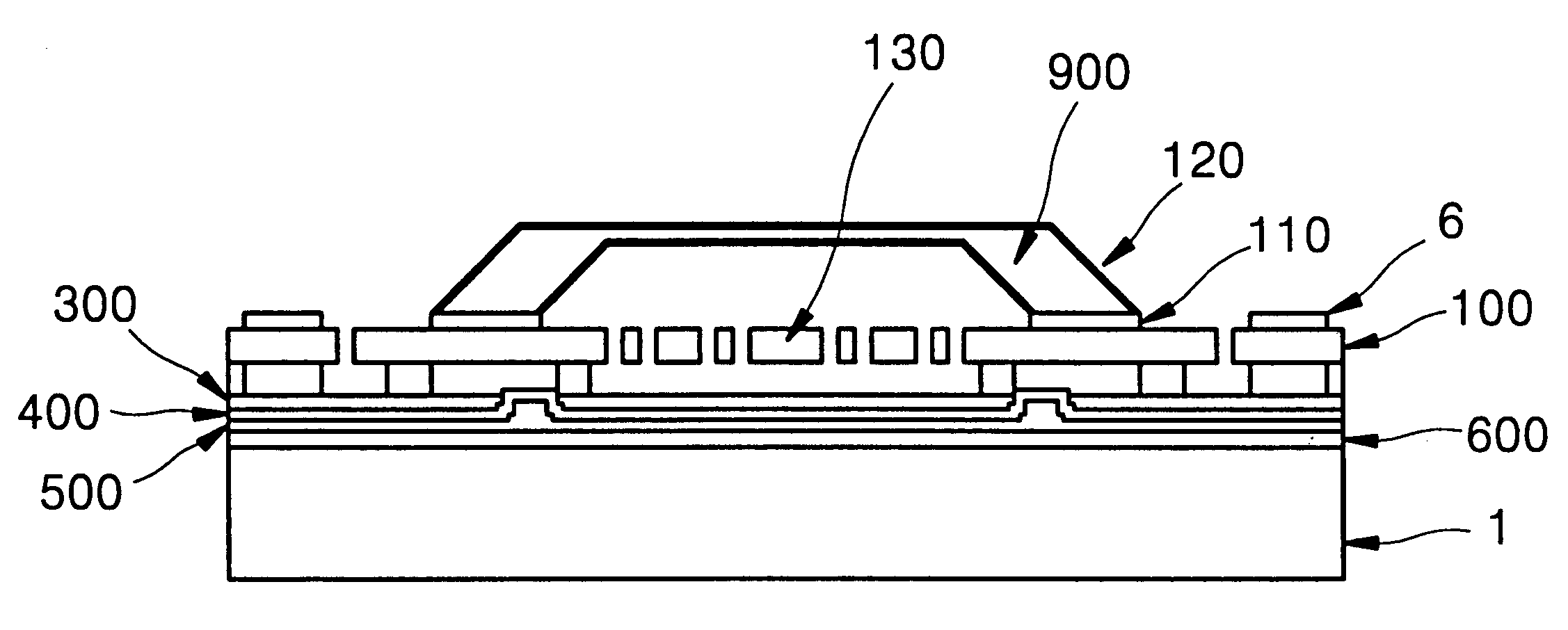

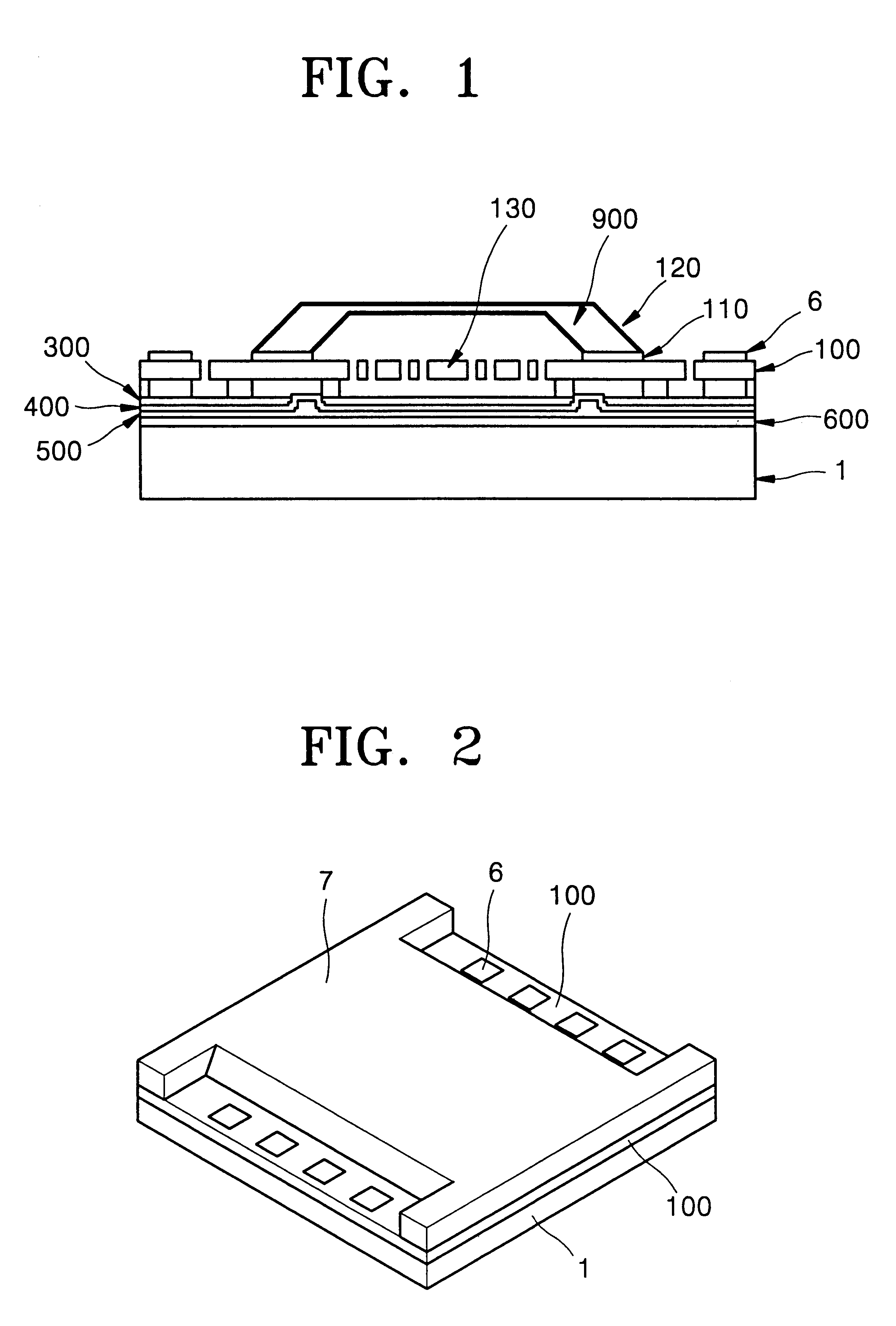

Method of fabricating micro electro mechanical system structure which can be vacuum-packed at wafer level

InactiveUS6391673B1Acceleration measurement using interia forcesSemiconductor/solid-state device detailsVacuum packVacuum level

A method of fabricating a micro electromechanical system (MEMS) structure which can be vacuum-packaged at the wafer level is provided. The method includes the steps of forming a multilayered stack including a signal line on a first wafer; bonding a second wafer to the multilayered stack; polishing the first wafer to a predetermined thickness; forming a MEMS structure in a vacuum area of the first wafer and a pad outside the vacuum area, the MEMS structure and the pad being connected to the signal line; forming a structure in a third wafer to have space corresponding to the vacuum area of the MEMS structure; and bonding the third wafer to the polished surface of the first wafer in a vacuum state. For protection of the structure and maintaining a vacuum level required for operation, the fabricated structure is vacuum-packaged at the wafer level, thereby improving the yield of fabrication. In addition, since a special vacuum packaging process is not necessary, the fabrication can be simplified.

Owner:SAMSUNG ELECTRONICS CO LTD

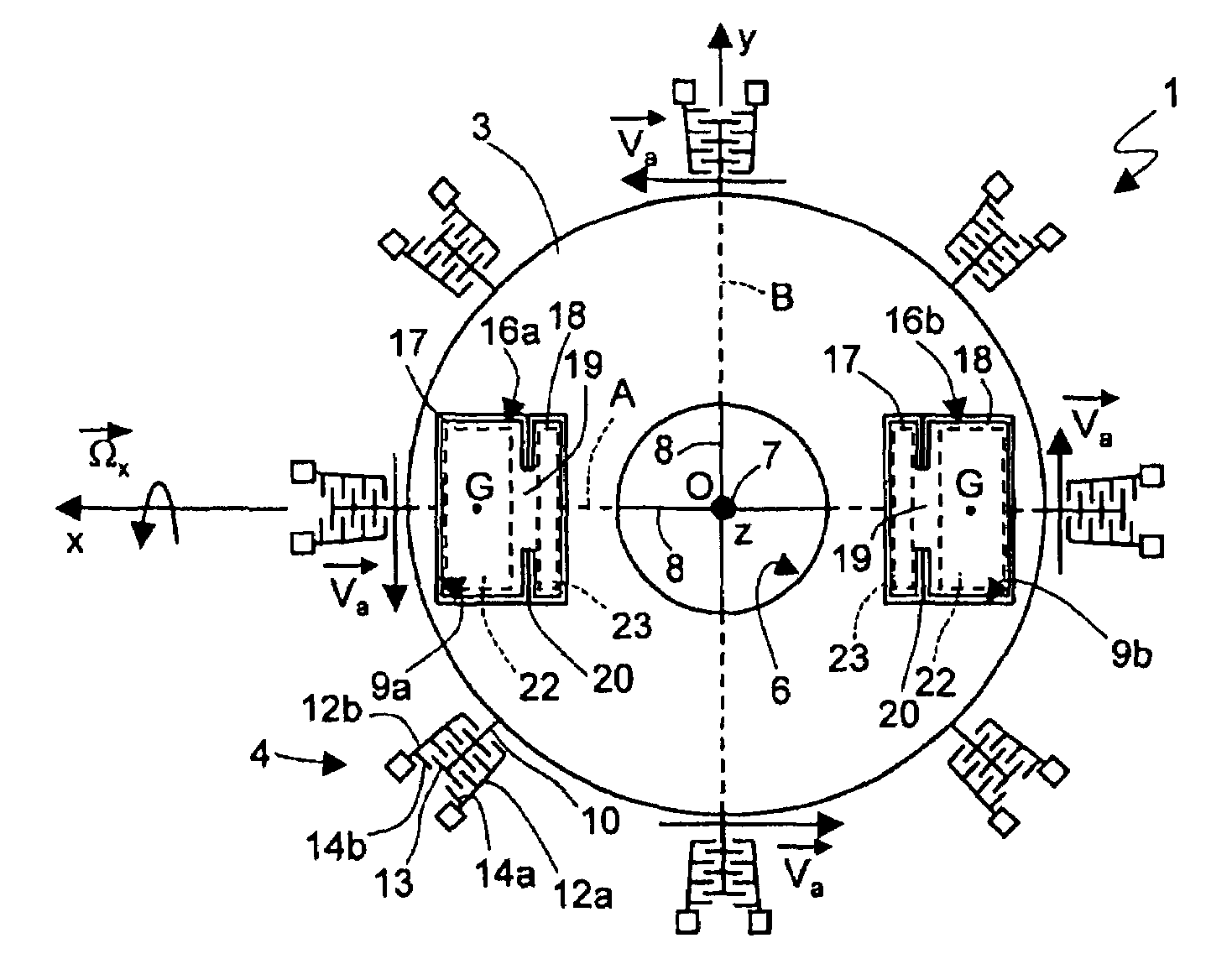

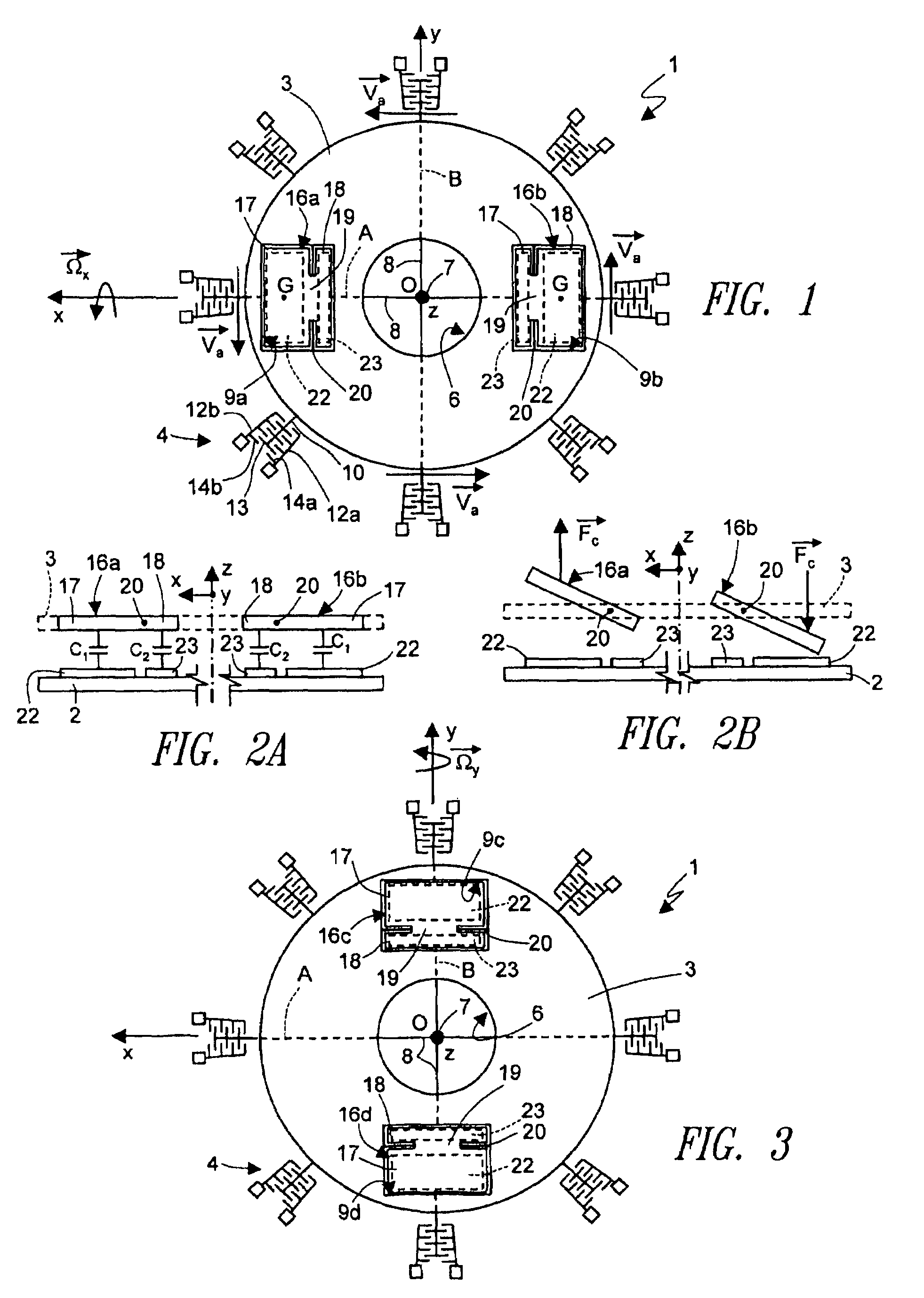

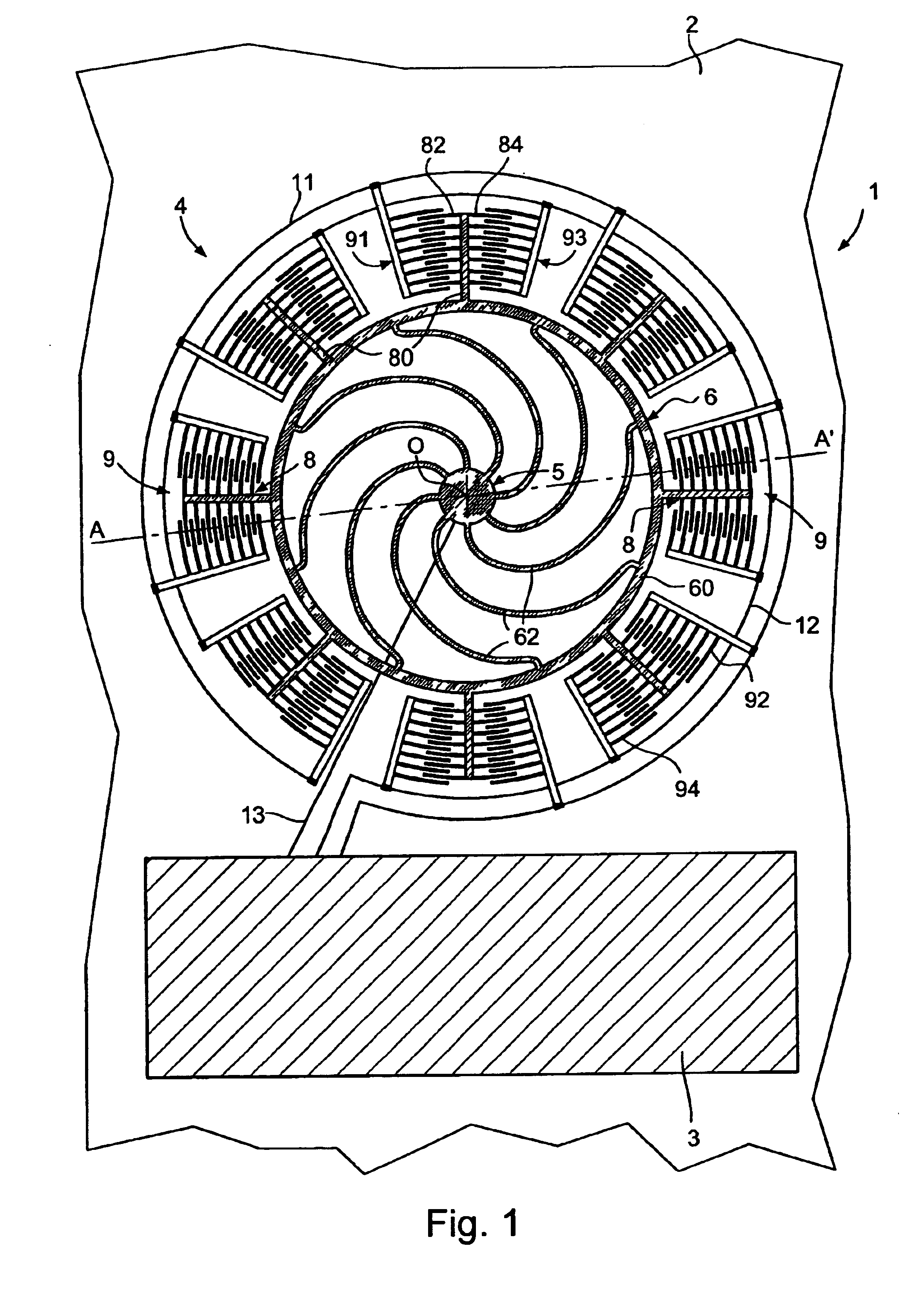

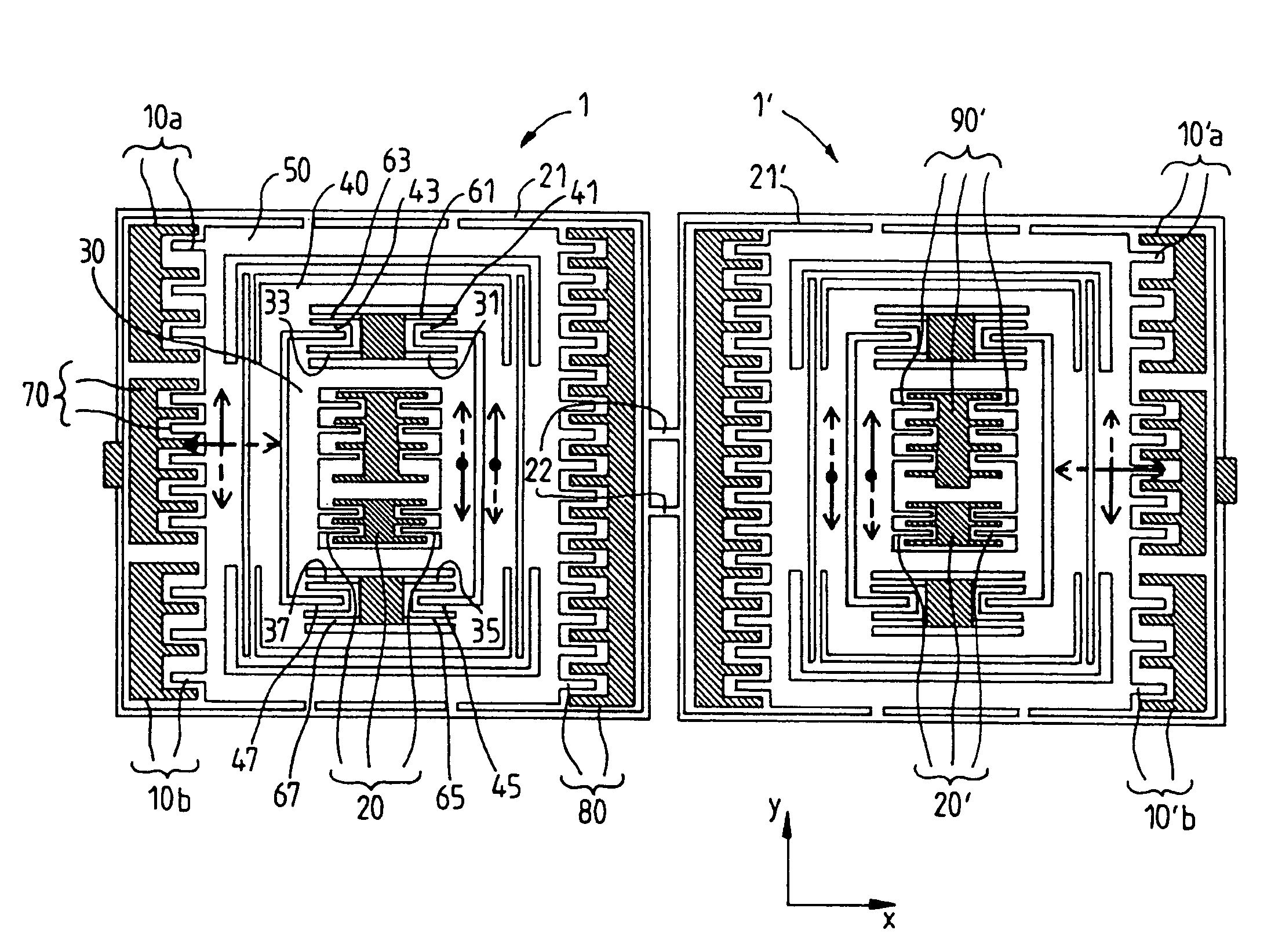

Microelectromechanical integrated sensor structure with rotary driving motion

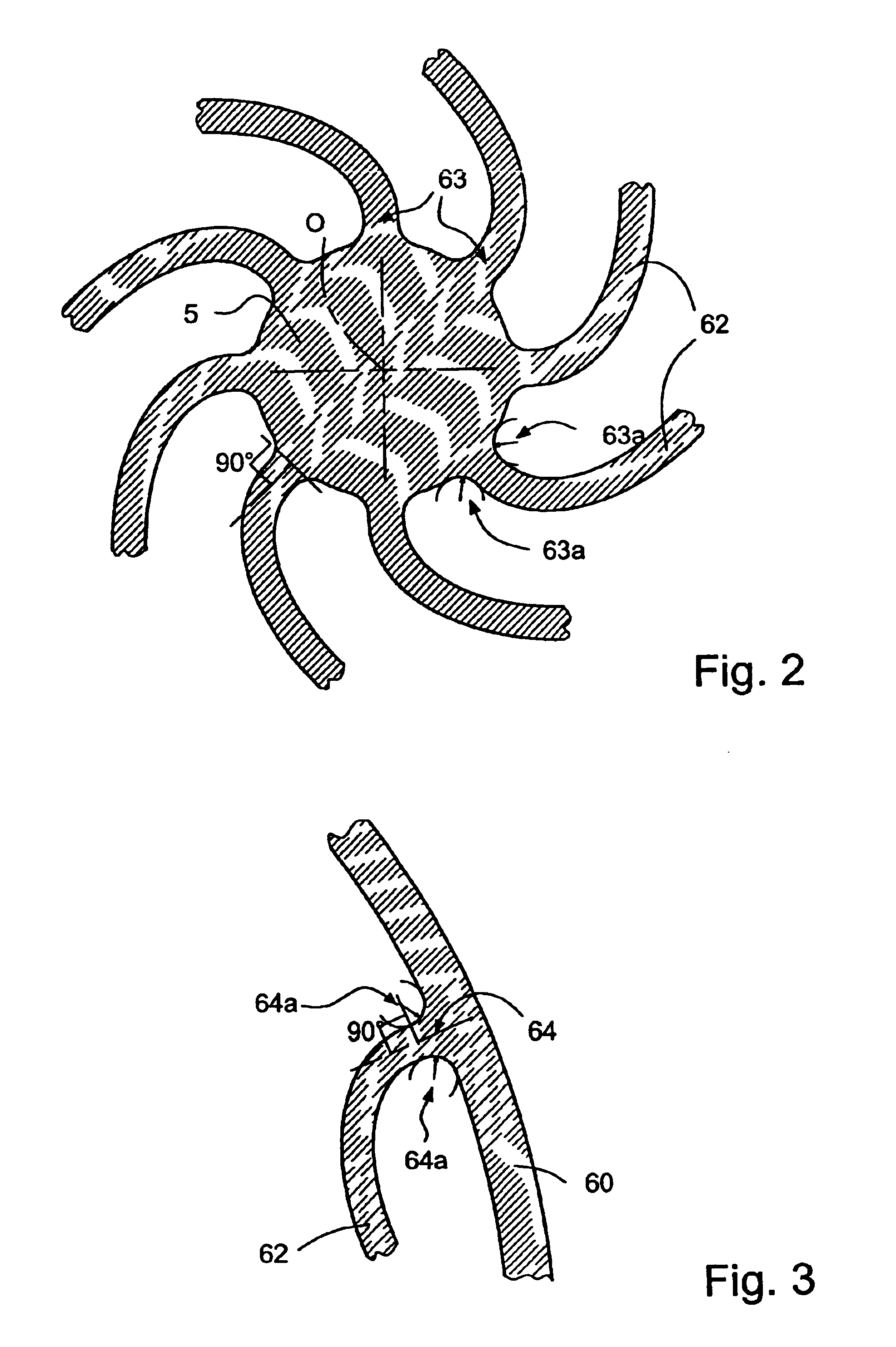

ActiveUS20070214883A1Easy to manufactureSolve the low detection efficiencyAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsLinear motionEngineering

A driving mass of an integrated microelectromechanical structure is moved with a rotary motion about an axis of rotation, and a first sensing mass is connected to the driving mass via elastic supporting elements so as to perform a first detection movement in a presence of a first external stress. The driving mass is anchored to an anchorage arranged along the axis of rotation by elastic anchorage elements. An opening is provided within the driving mass and the first sensing mass is arranged within the opening. The elastic supporting and anchorage elements render the first sensing mass fixed to the driving mass in the rotary motion, and substantially decoupled from the driving mass in the first detection movement. A second sensing mass is connected to the driving mass so as to perform a second detection movement in a presence of a second external stress. A first movement is a rotation about an axis lying in a plane, and a second movement is a linear movement along an axis of the plane.

Owner:STMICROELECTRONICS SRL

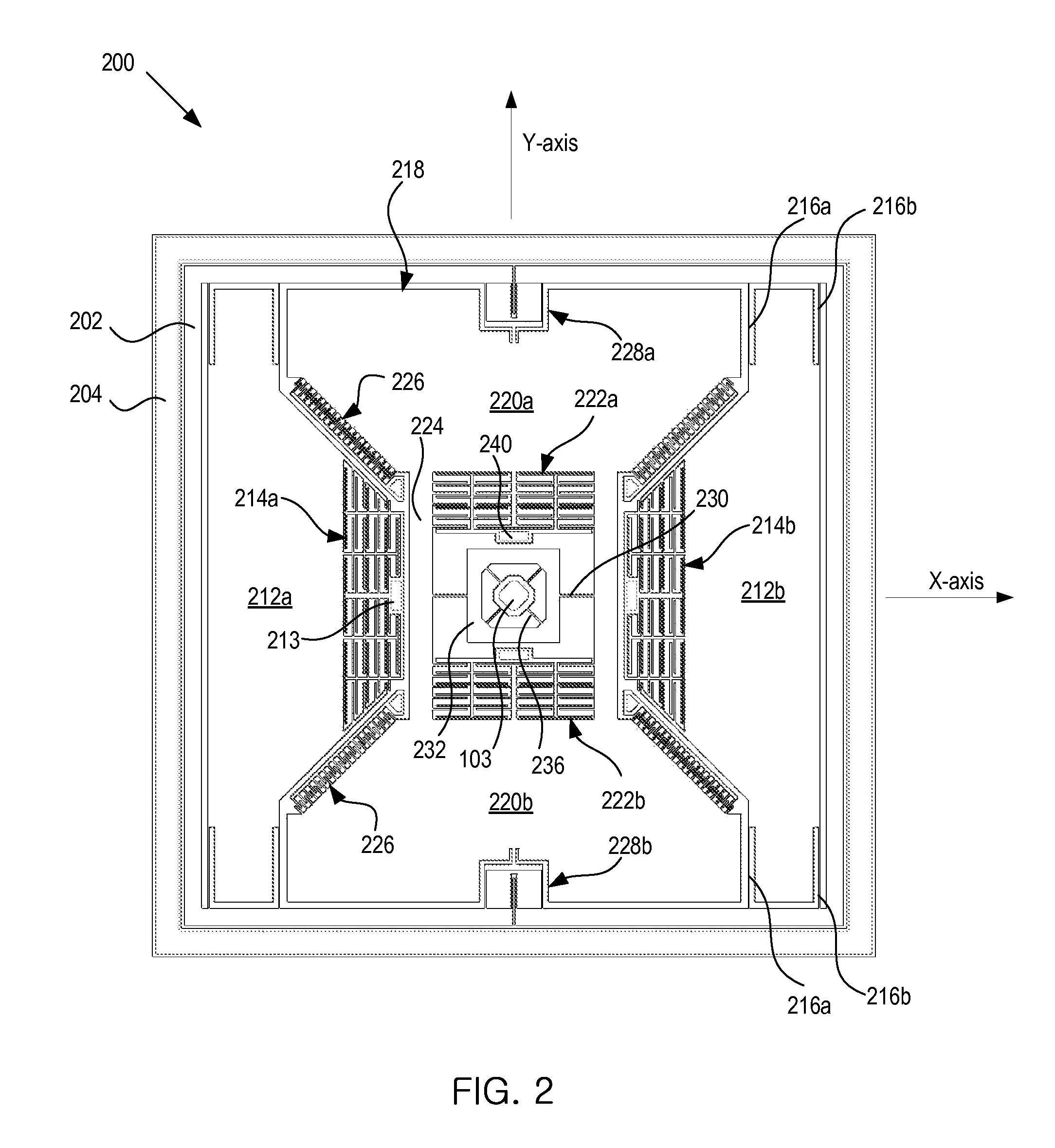

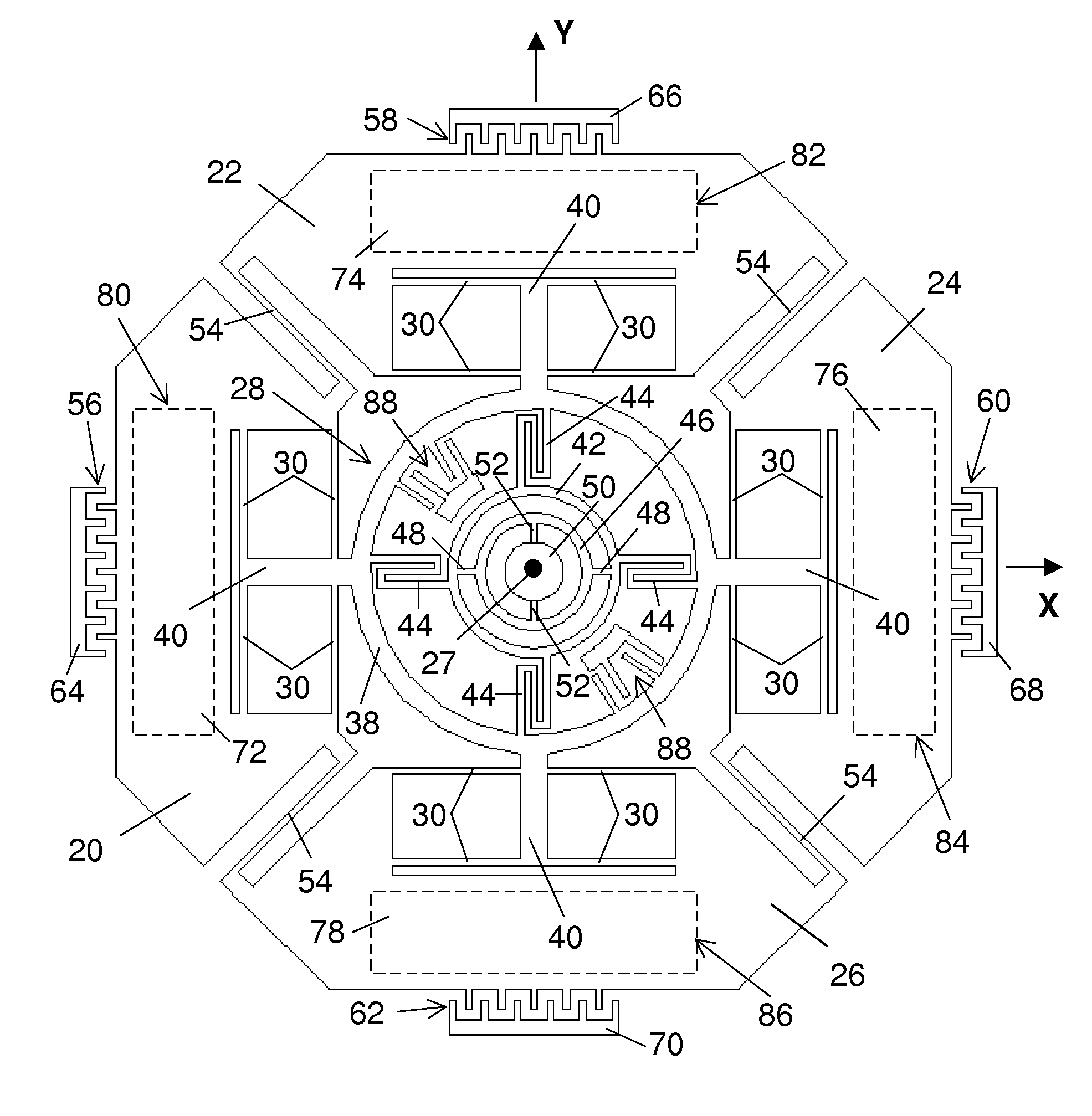

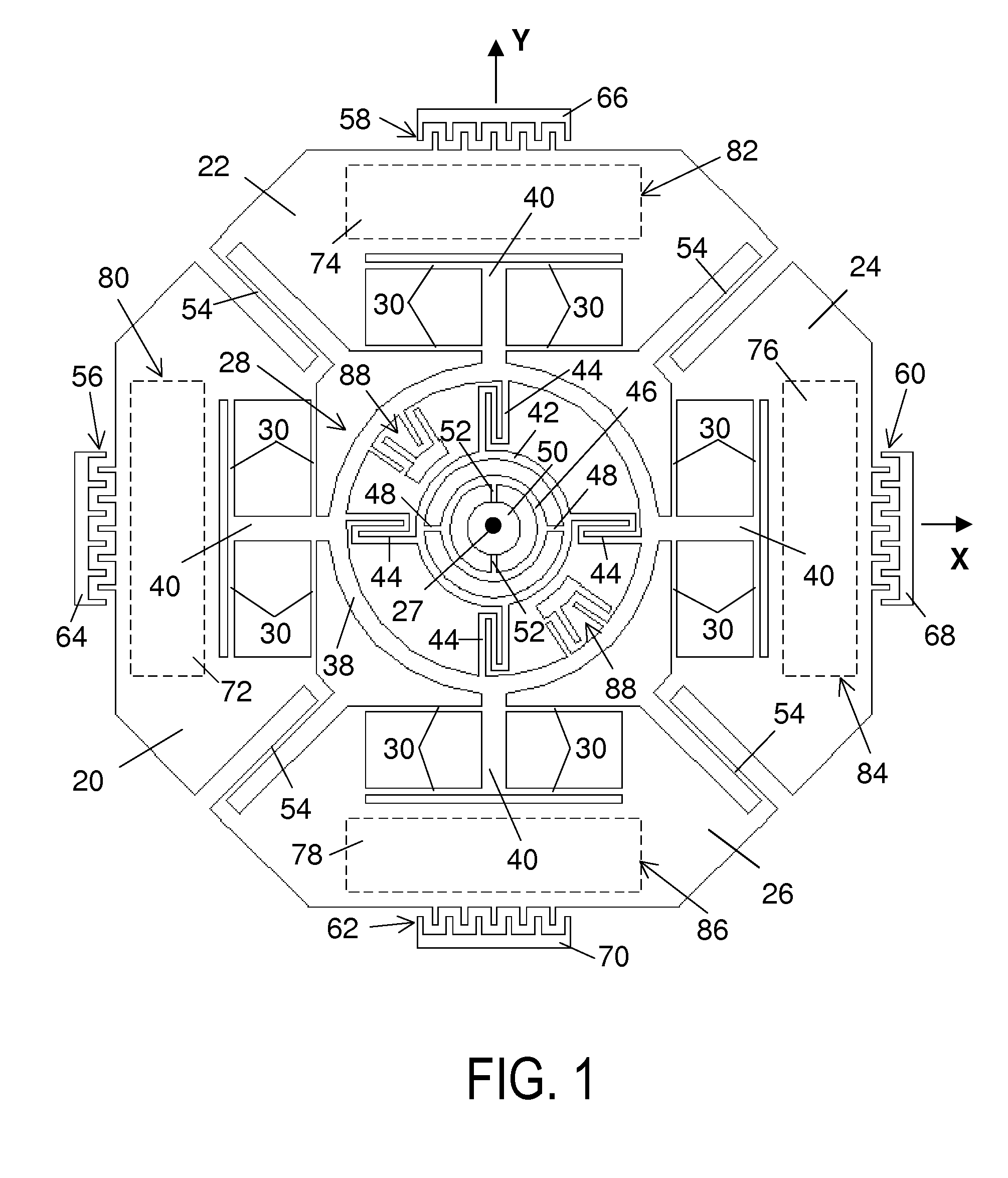

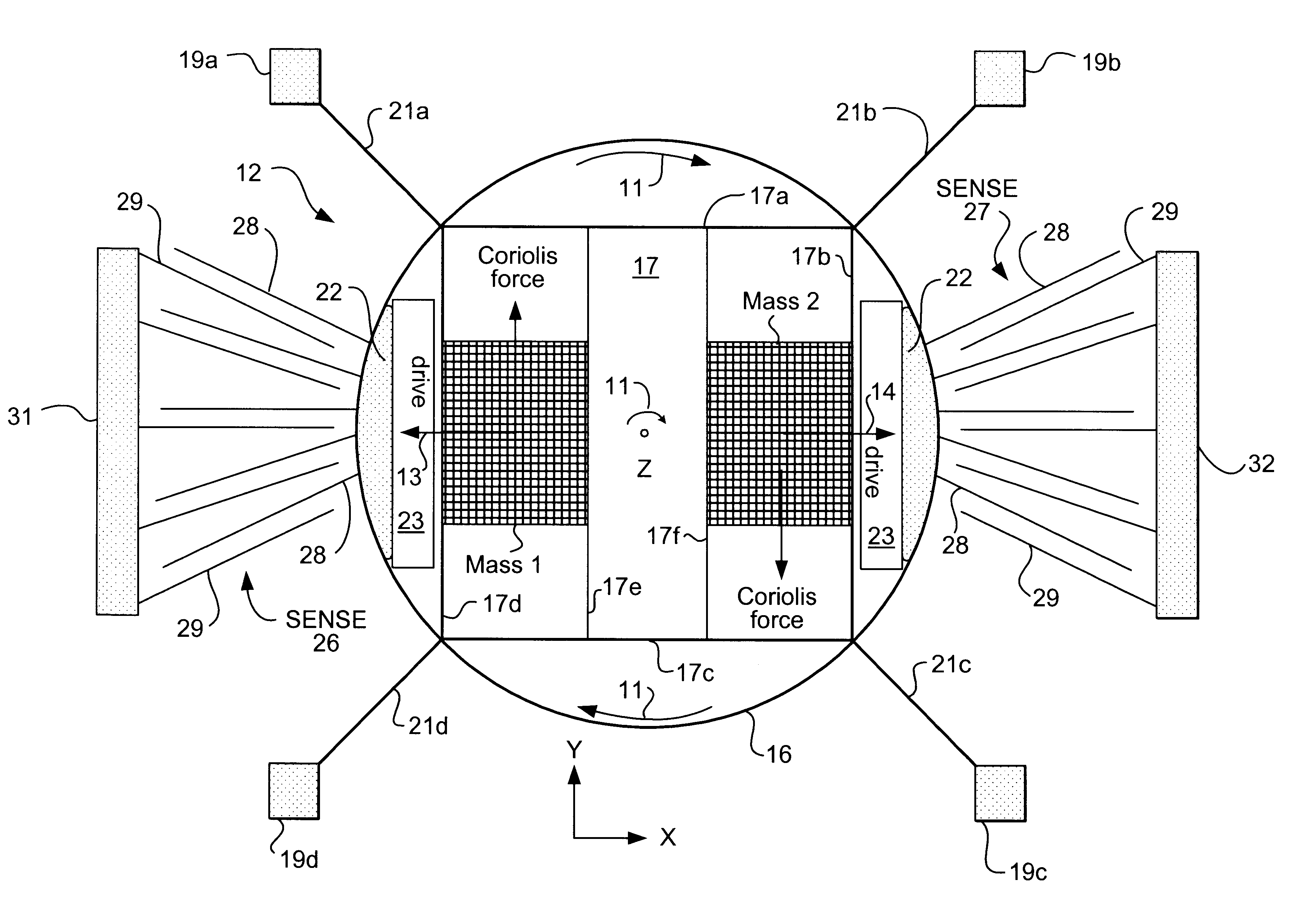

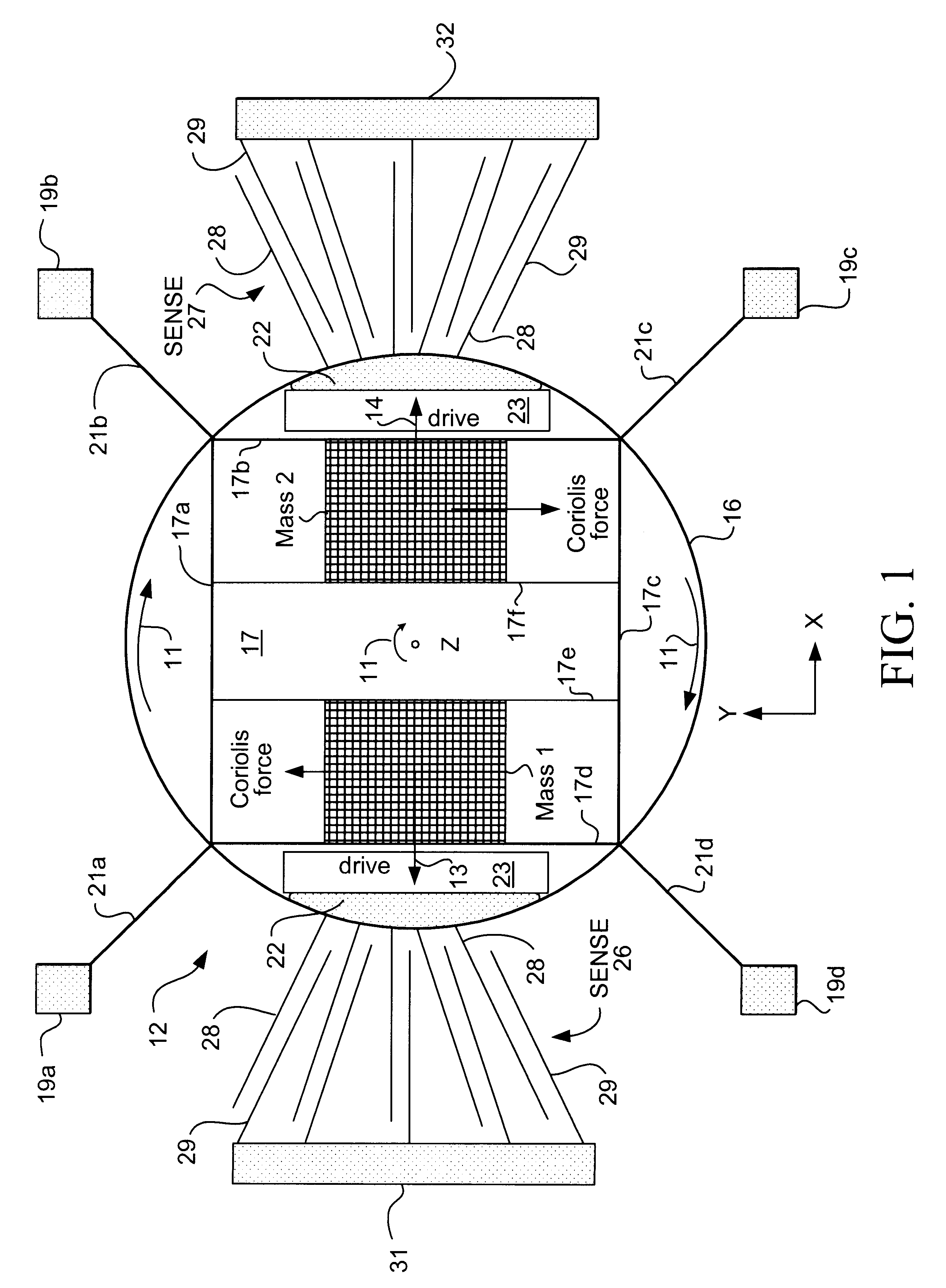

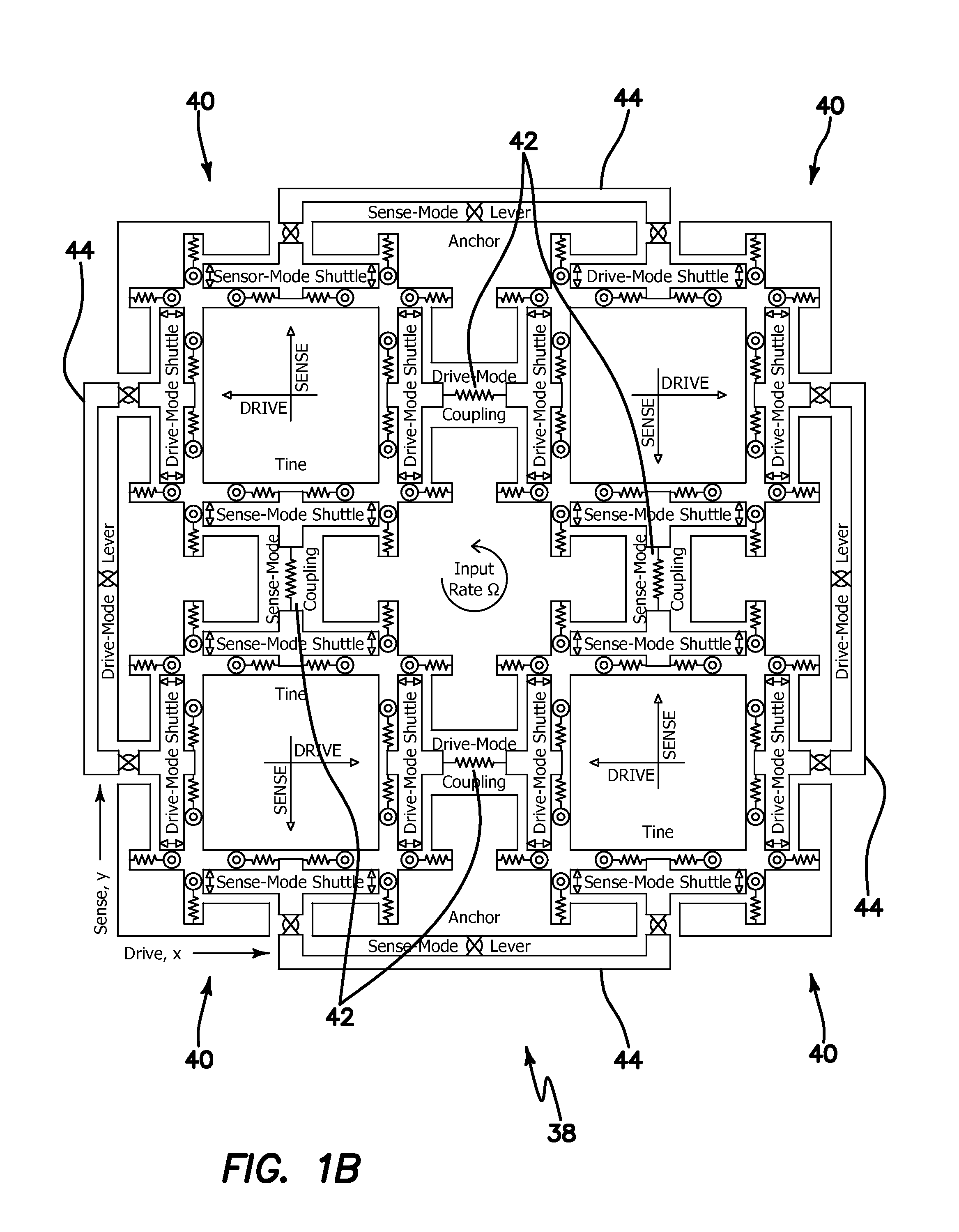

Tri-axis Angular Rate Sensor

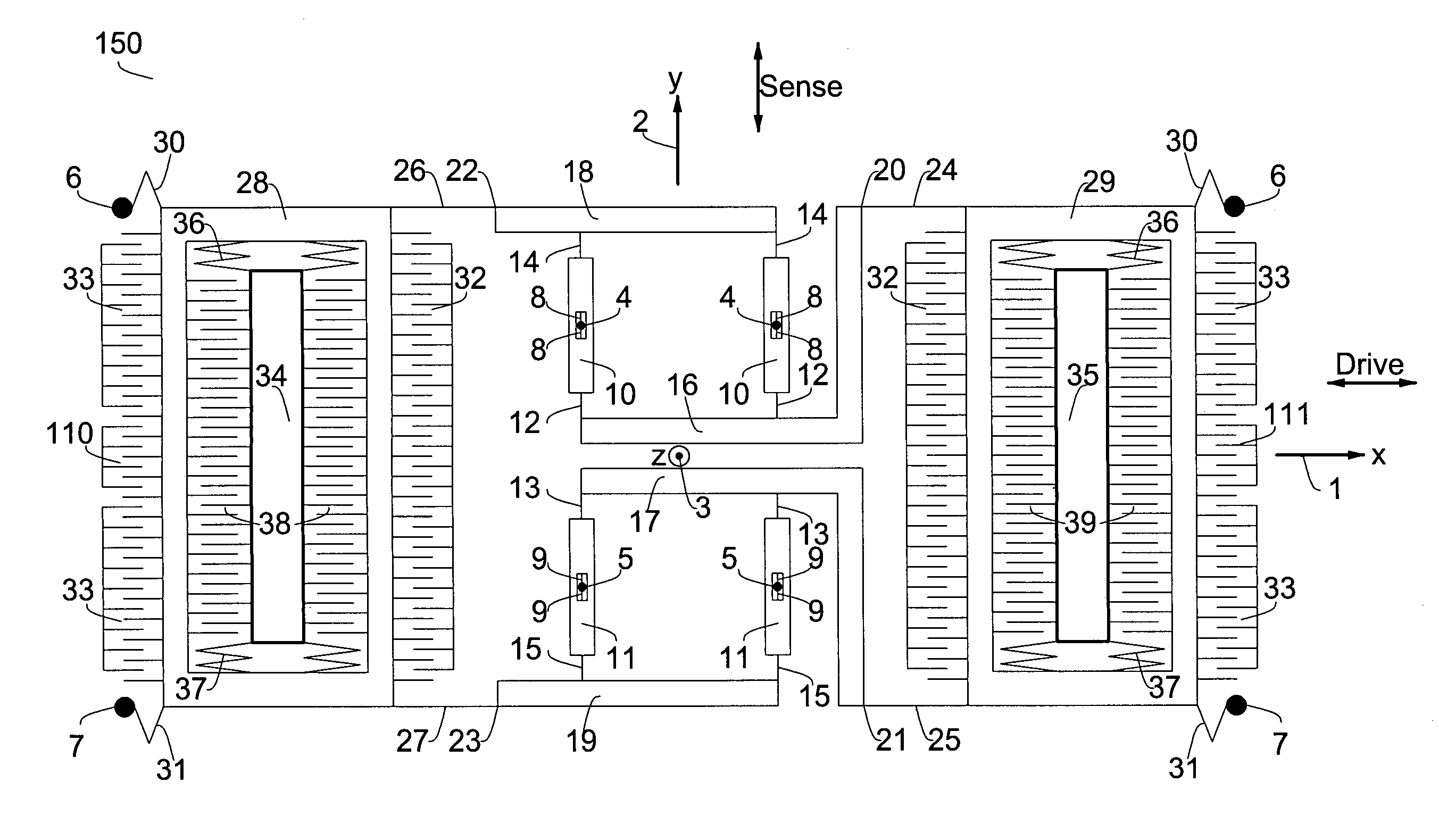

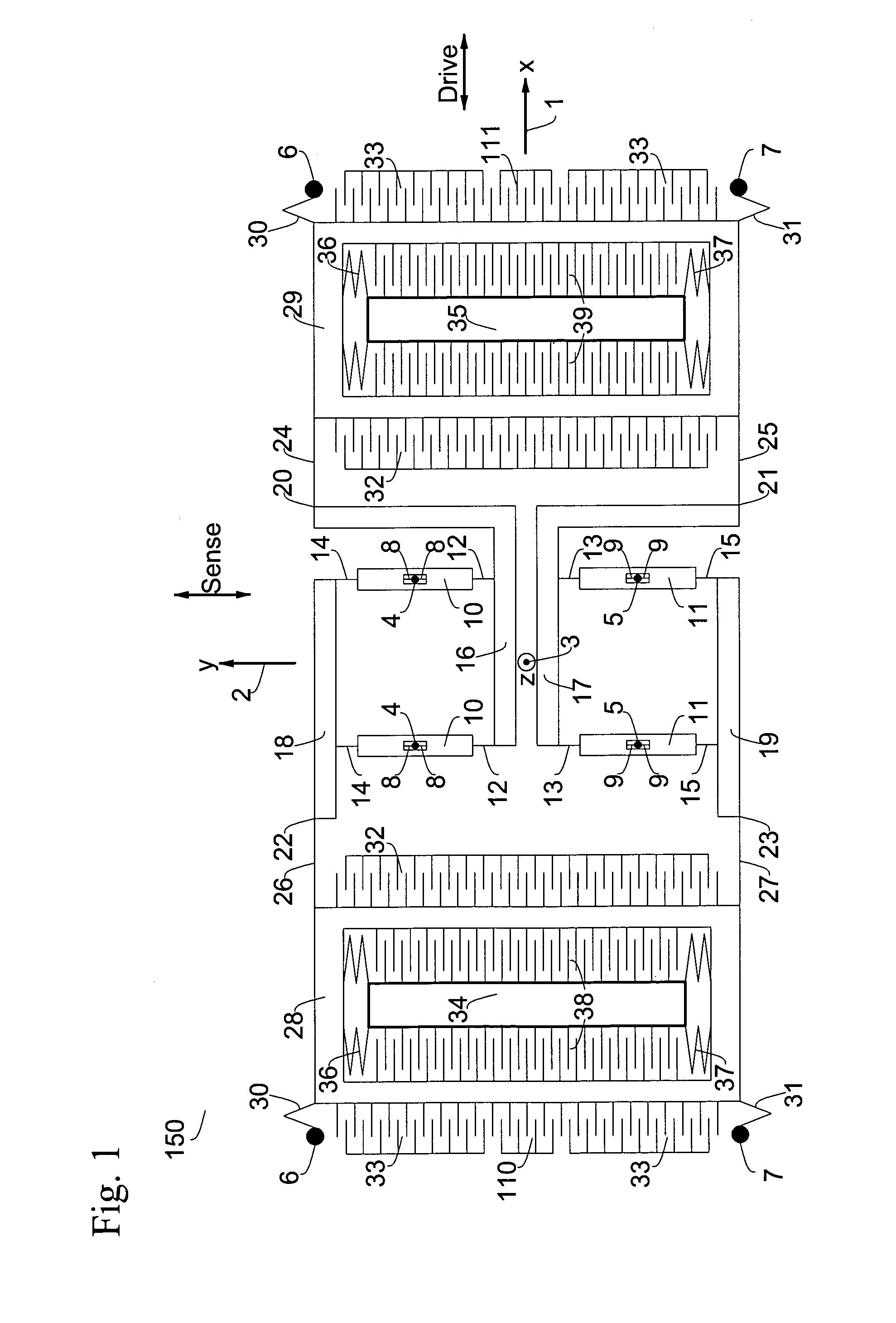

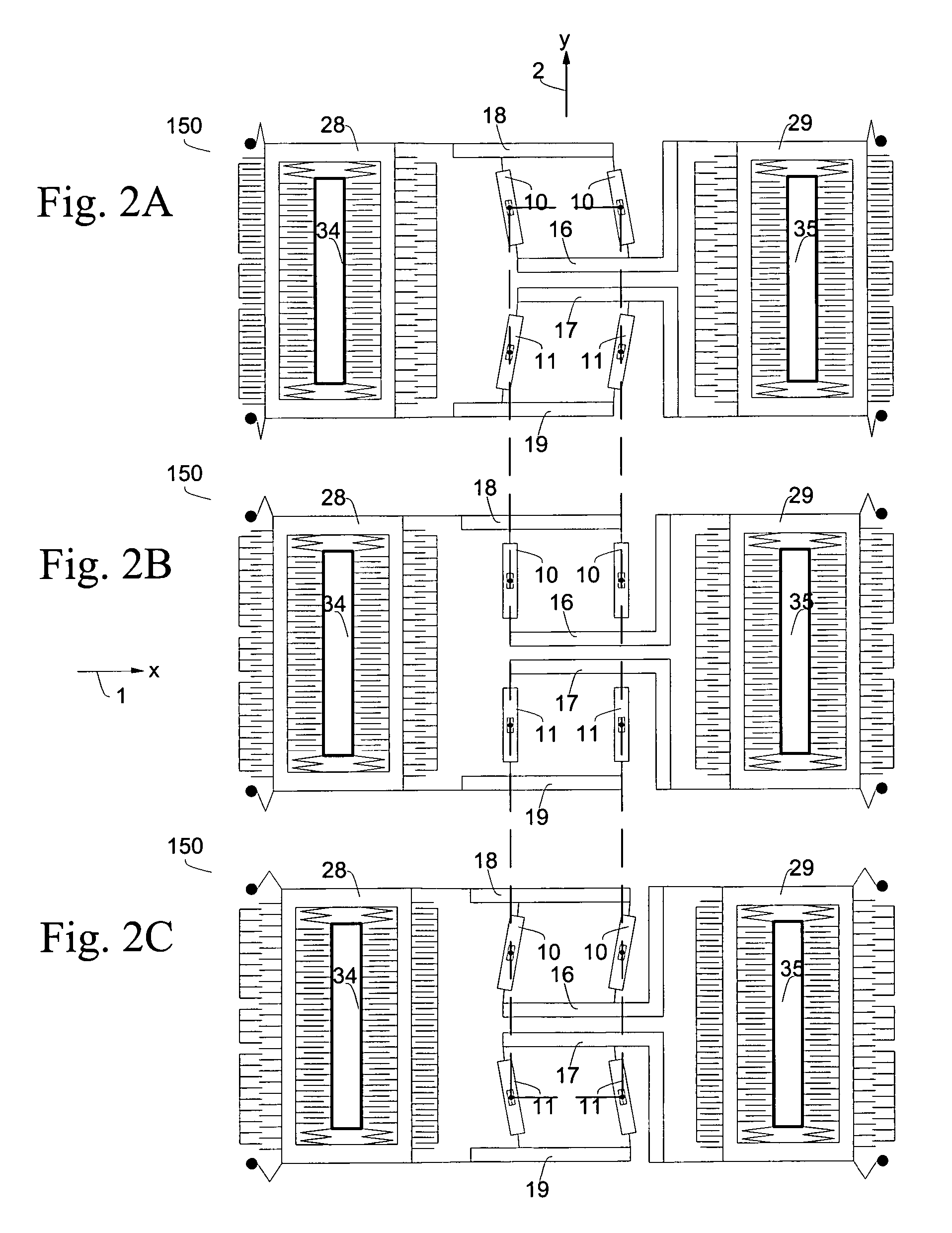

ActiveUS20100236327A1Angular velocity stabilityAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsLinear motionAngular rate sensor

Angular rate sensor for detecting rotation about first, second and third mutually perpendicular input axes having a plurality of generally planar proof masses coupled together for linear drive-mode oscillation along multi-directional drive axes in a plane formed by the first and second input axes. The masses are mounted on a generally planar sense frame for linear movements relative to the sense frame in drive-mode and for rotation together with the sense frame in sense modes. The sense frame is mounted for rotation with the masses in sense modes about the first, second, and third input axes independent of each other, in response to Coriolis forces produced by rotation of the masses about the first, second, and third input axes respectively. And capacitance sensors responsive to the rotational movements of the masses and the sense frame in sense modes are employed for monitoring rate of rotation.

Owner:MEMSLINK TECH CO LTD

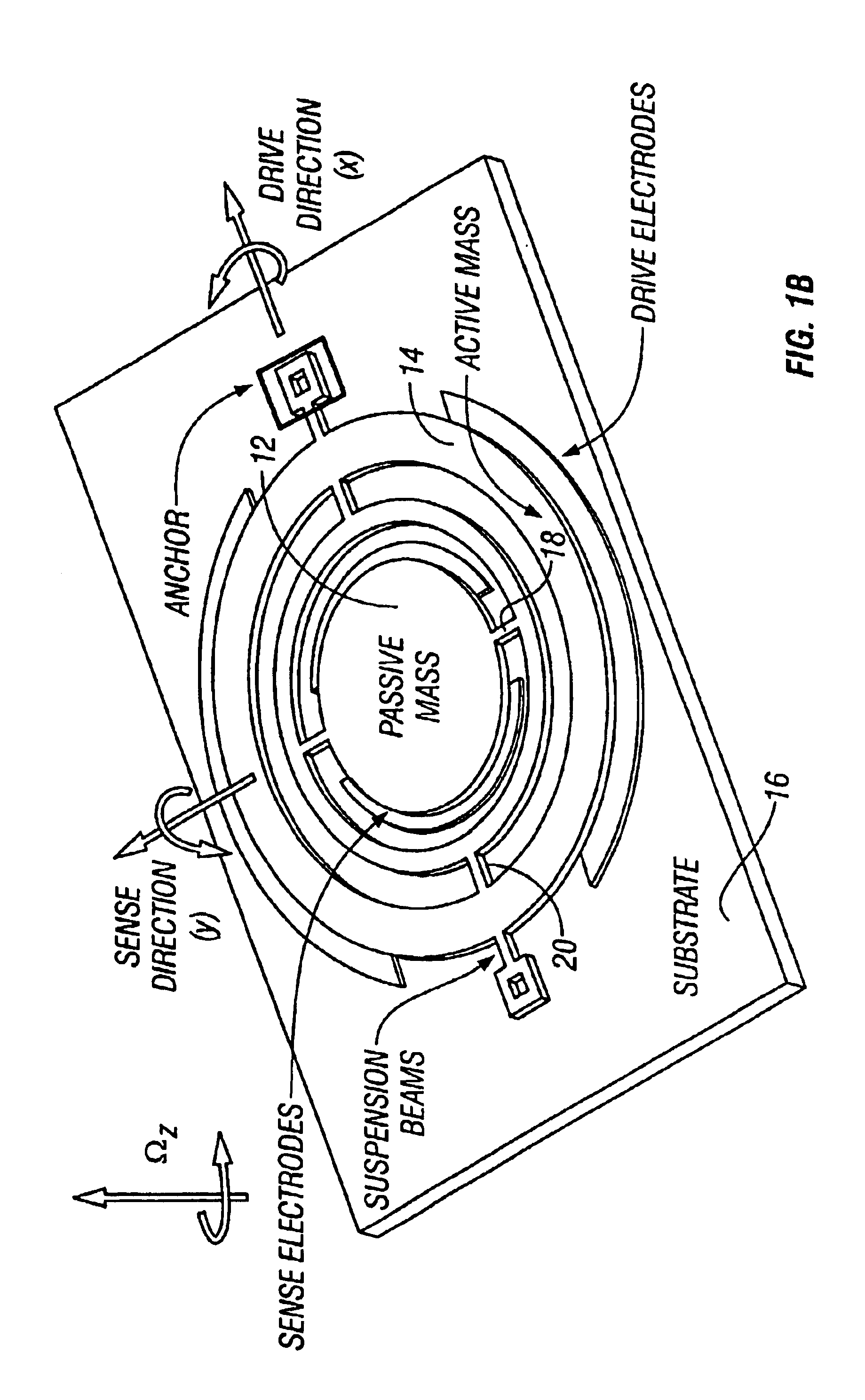

Angular rate sensor made from a structural wafer of single crystal silicon

InactiveUS6189381B1Acceleration measurement using interia forcesSpeed measurement using gyroscopic effectsParallel plateAngular rate sensor

An angular rate sensor made from a structural wafer of single crystal silicon has a pair of proof masses lying in an X-Y plane and supported by a circular frame. The masses are driven into oscillation in the X-direction using an interdigitated comb drive. Rotation of the sensor about the Z-axis induces Coriolis forces which cause the frame to rotate, the rotation of the frame being indicative of the angular rate of the sensor. A parallel plate sensor located outside of the circular frame senses rotation of the frame.

Owner:EMCORE INC

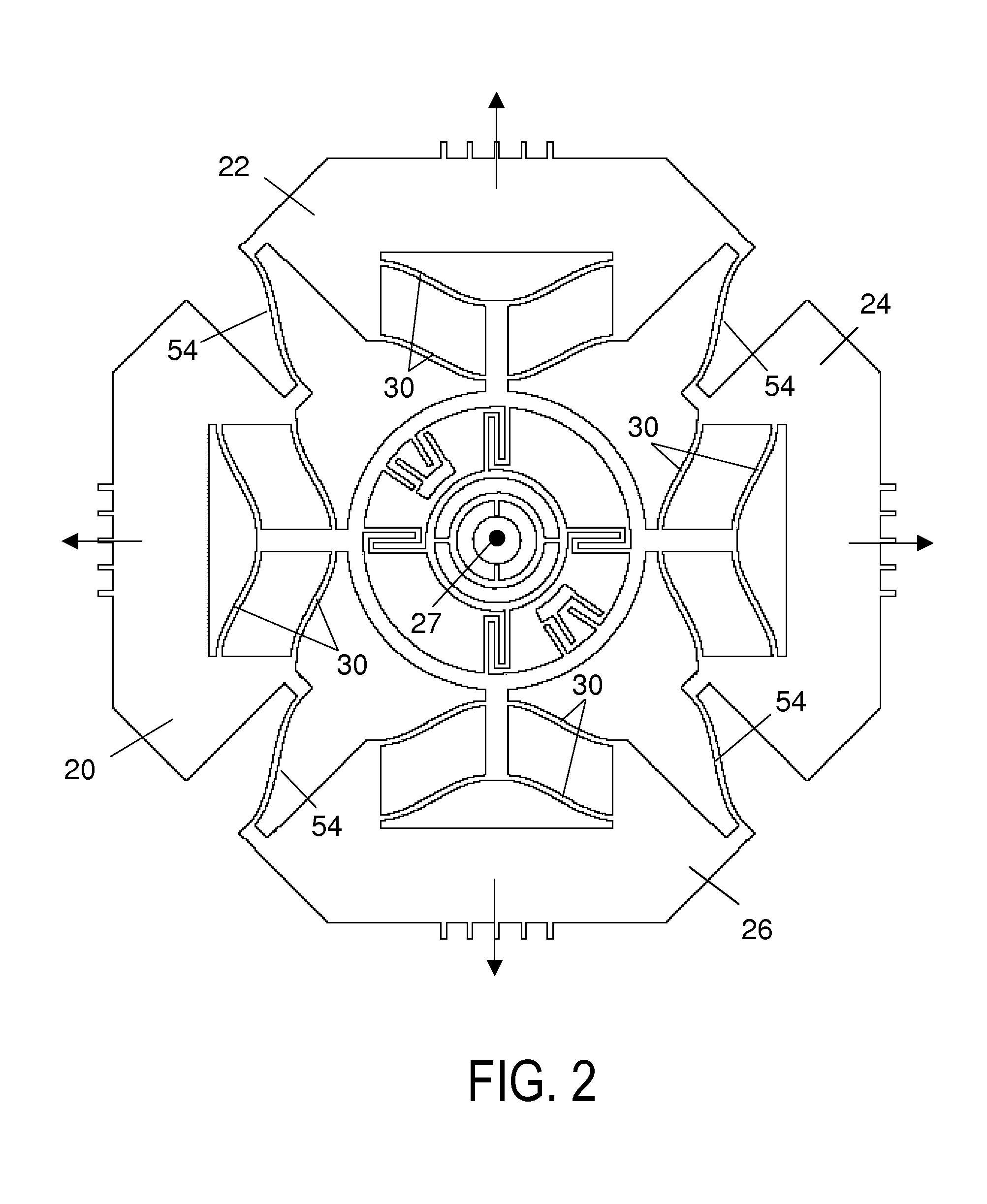

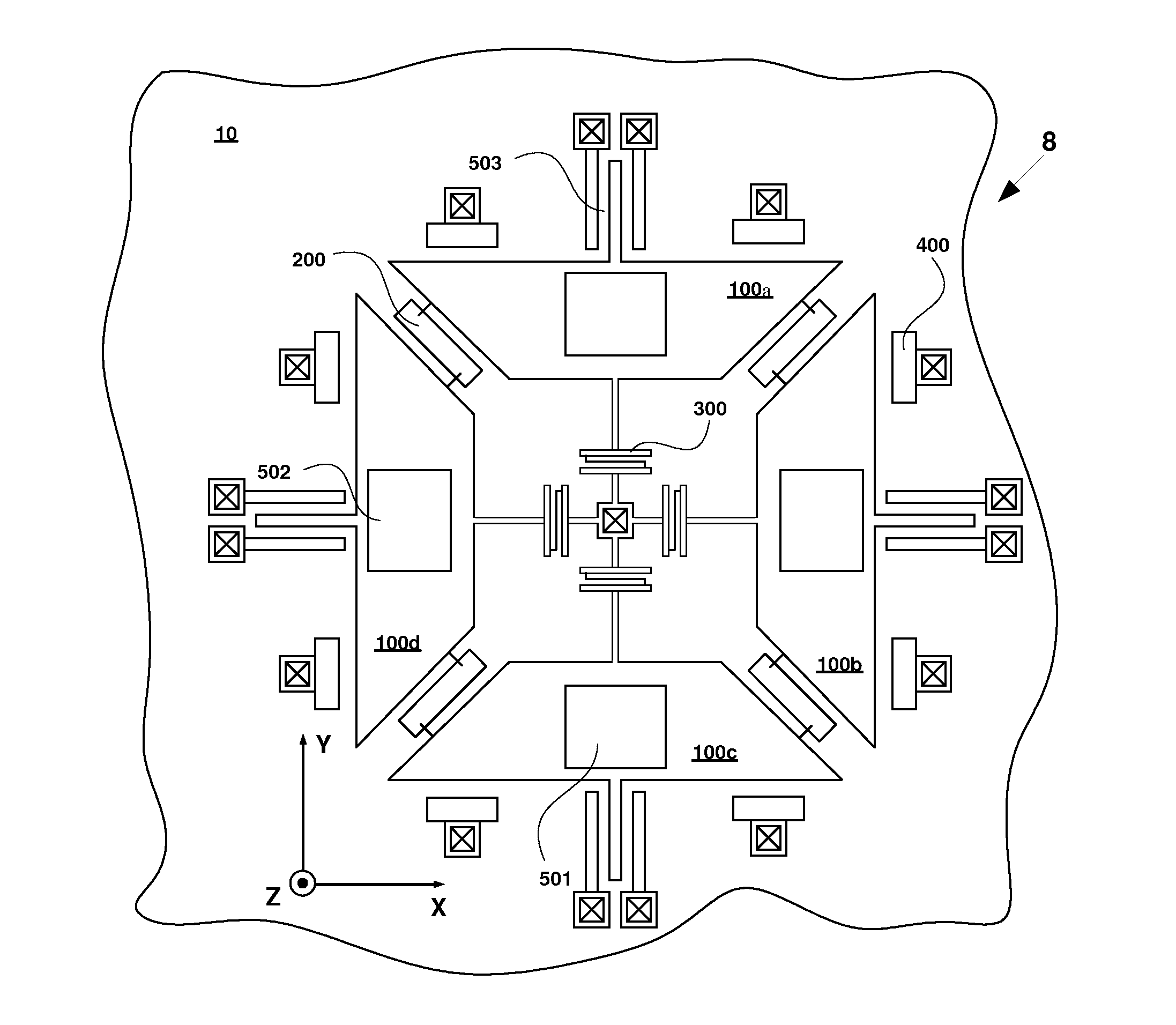

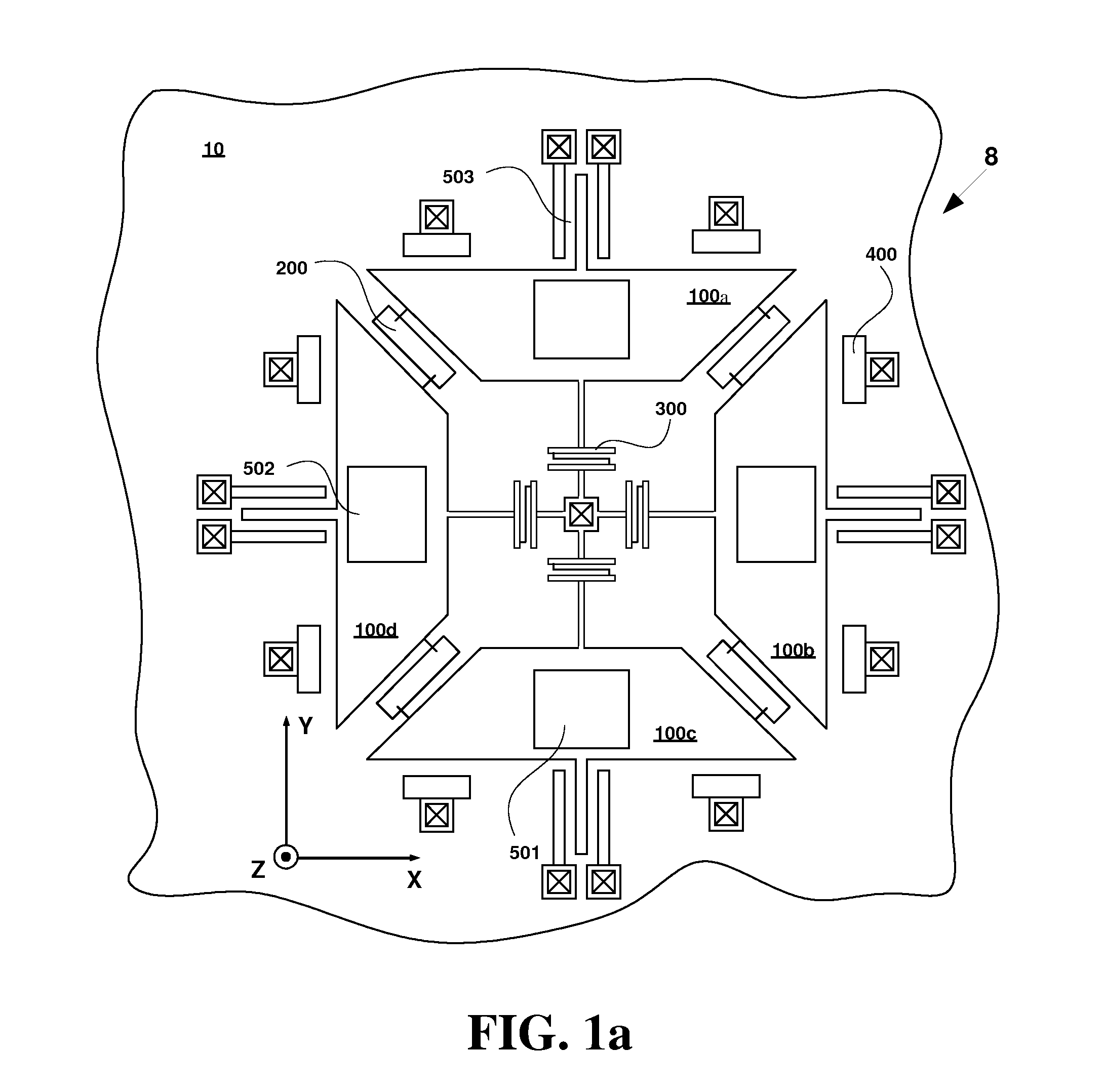

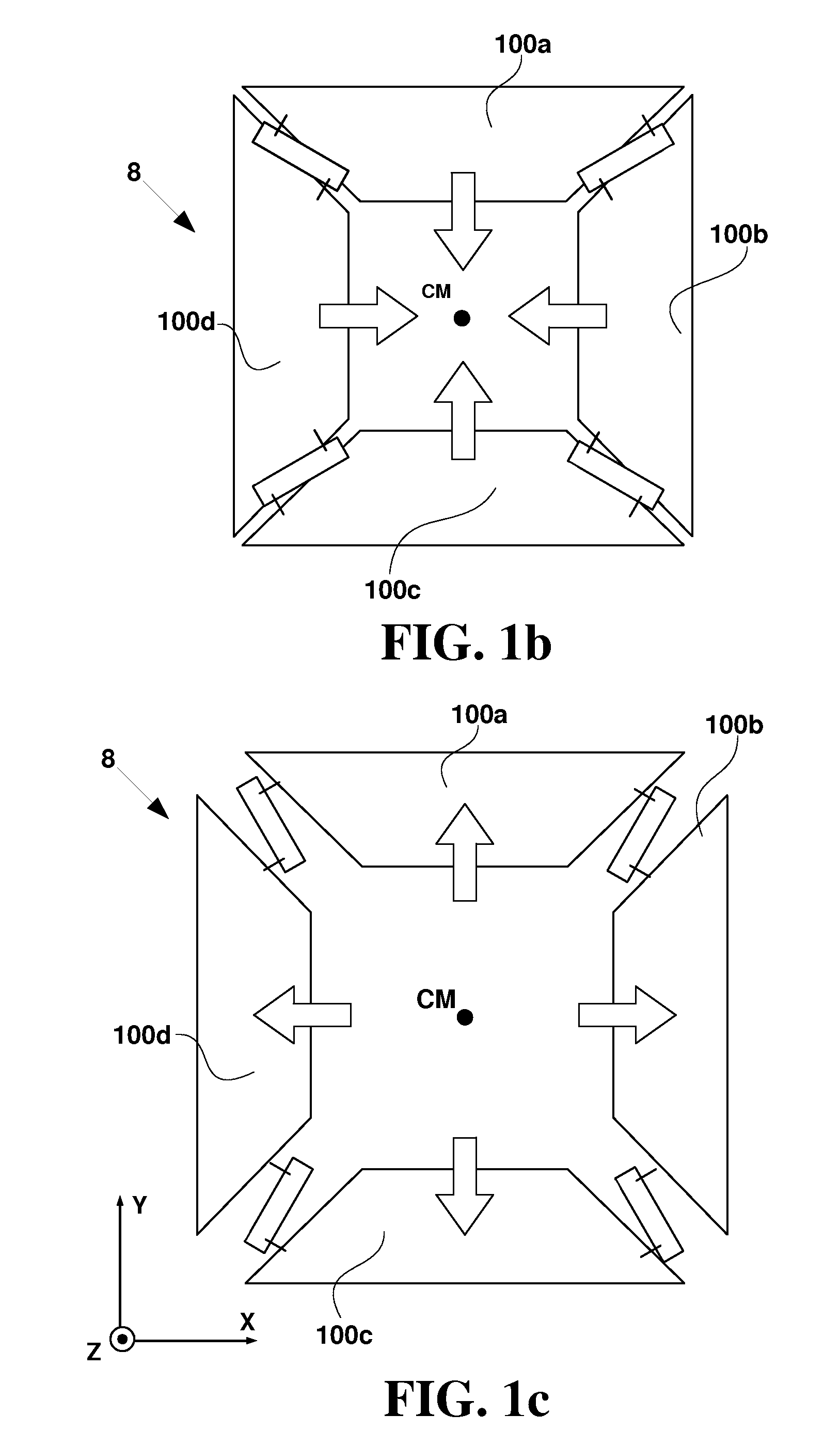

Extension -mode angular velocity sensor

ActiveUS20110061460A1SimplerLow costAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsAngular rate sensorAngular velocity

An angular velocity sensor including a drive extension mode. In one aspect, an angular rate sensor includes a base and at least three masses disposed substantially in a plane parallel to the base, the masses having a center of mass. At least one actuator drives the masses in an extension mode, such that in the extension mode the masses move in the plane simultaneously away or simultaneously towards the center of mass. At least one transducer senses at least one Coriolis force resulting from motion of the masses and angular velocity about at least one input axis of the sensor. Additional embodiments can include a linkage that constrains the masses to move in the extension mode.

Owner:INVENSENSE

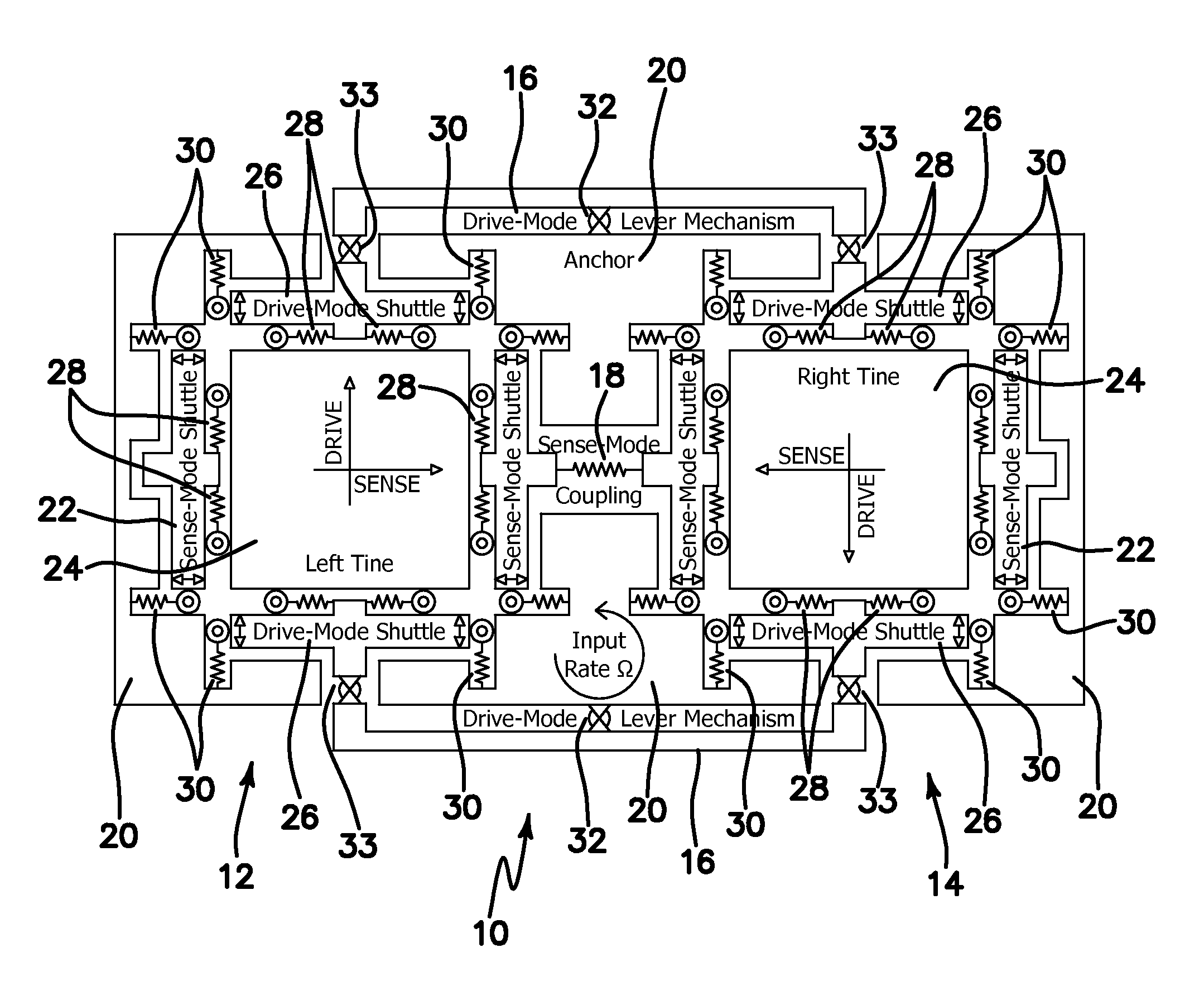

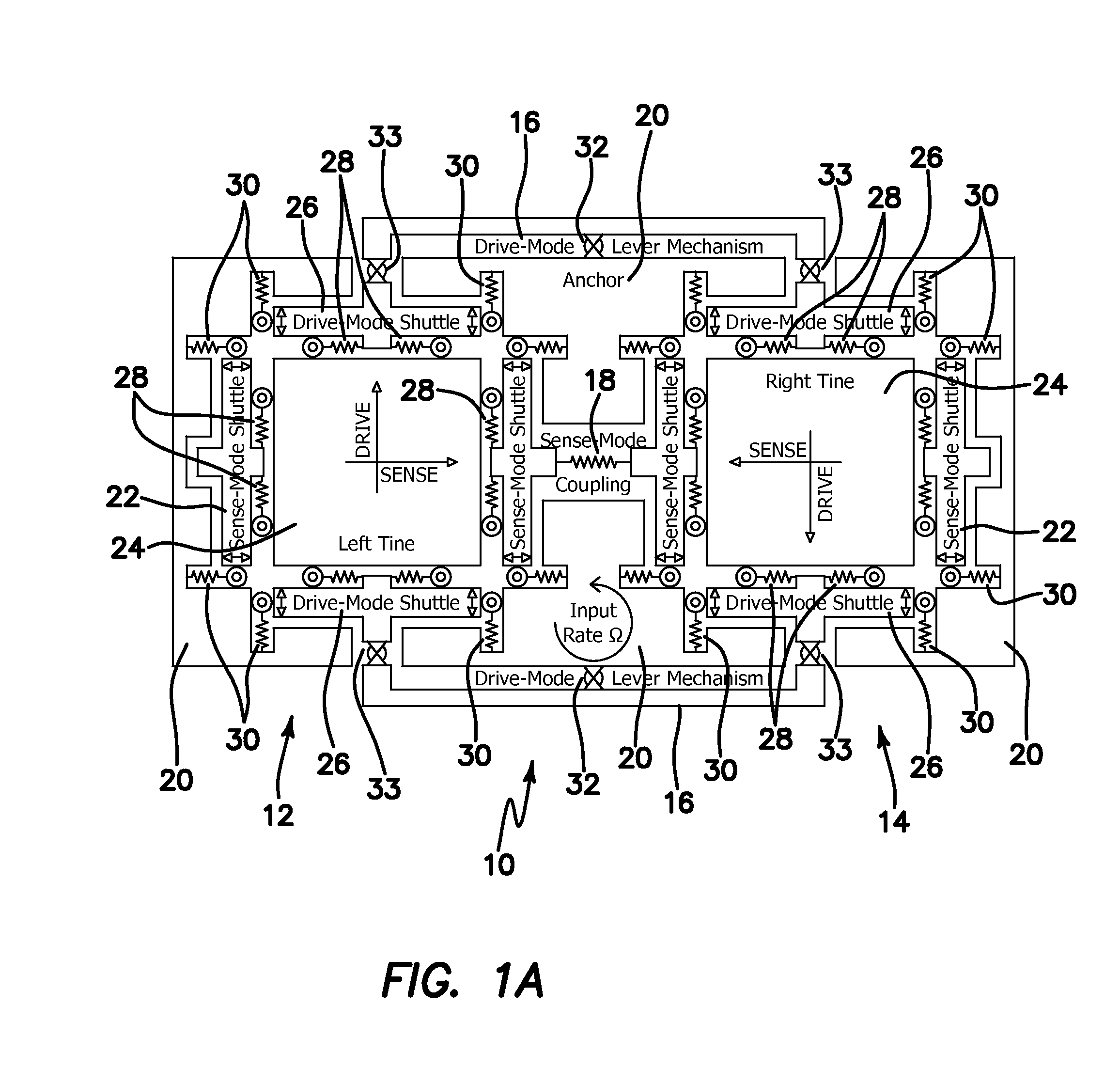

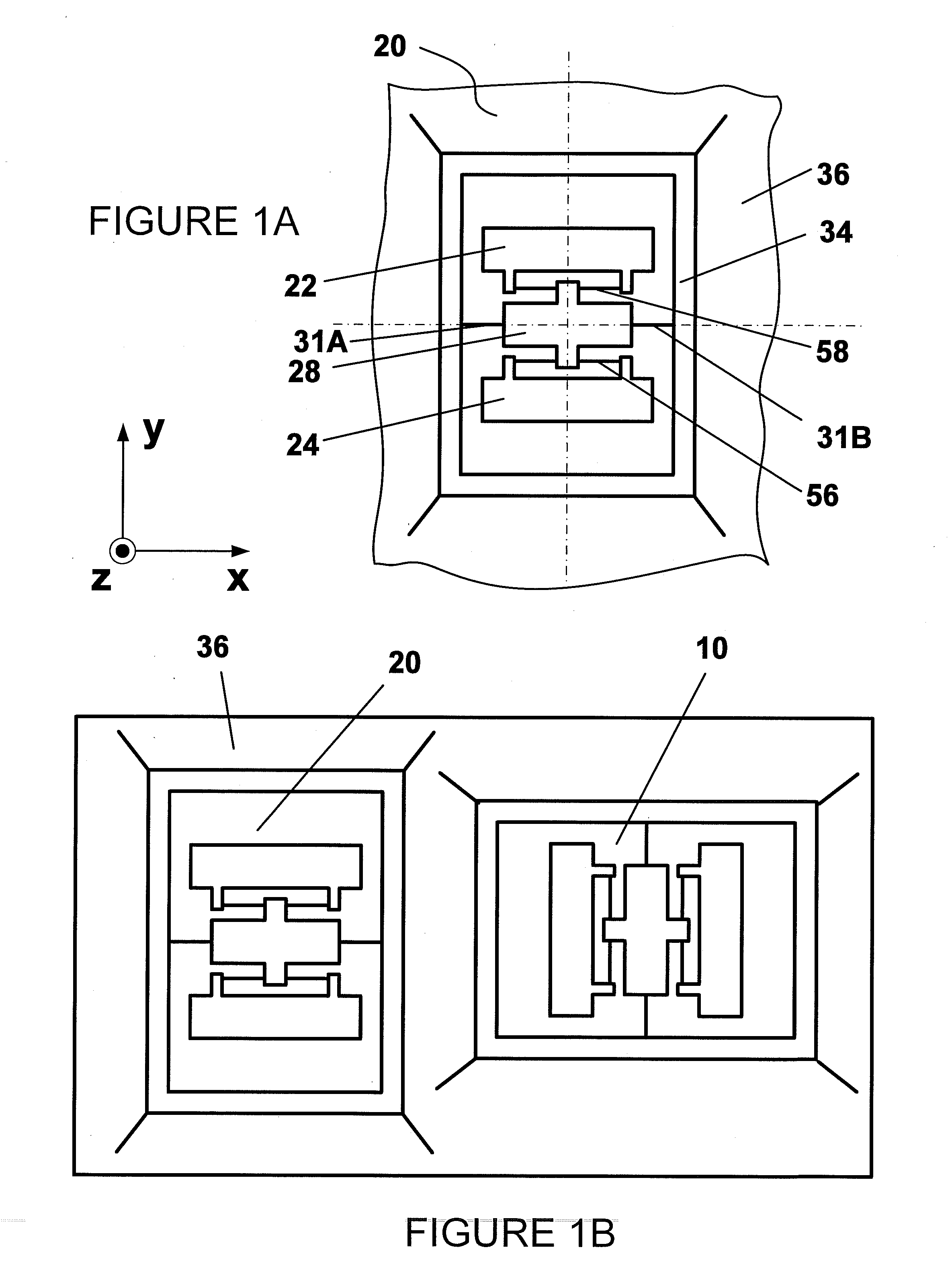

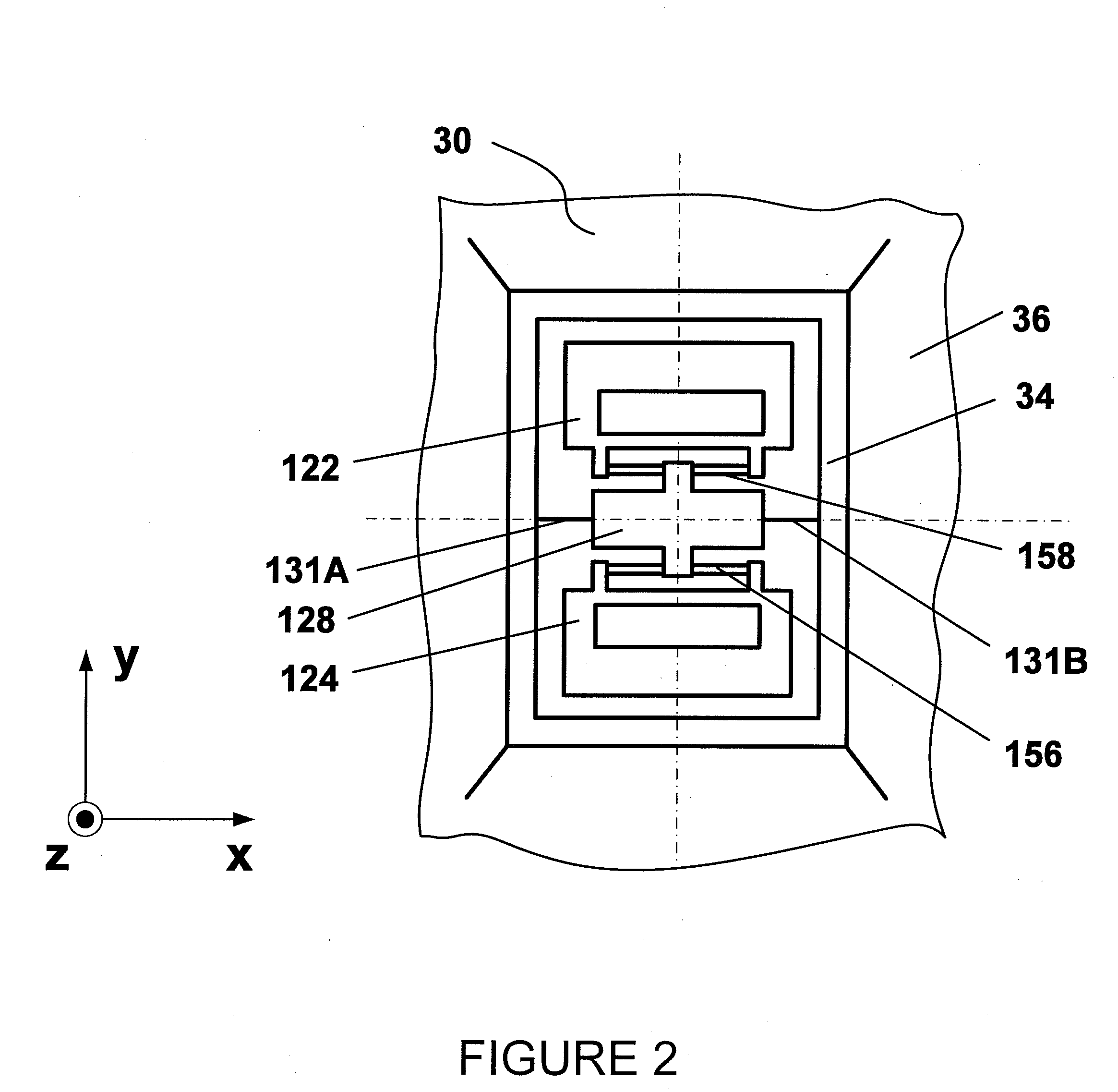

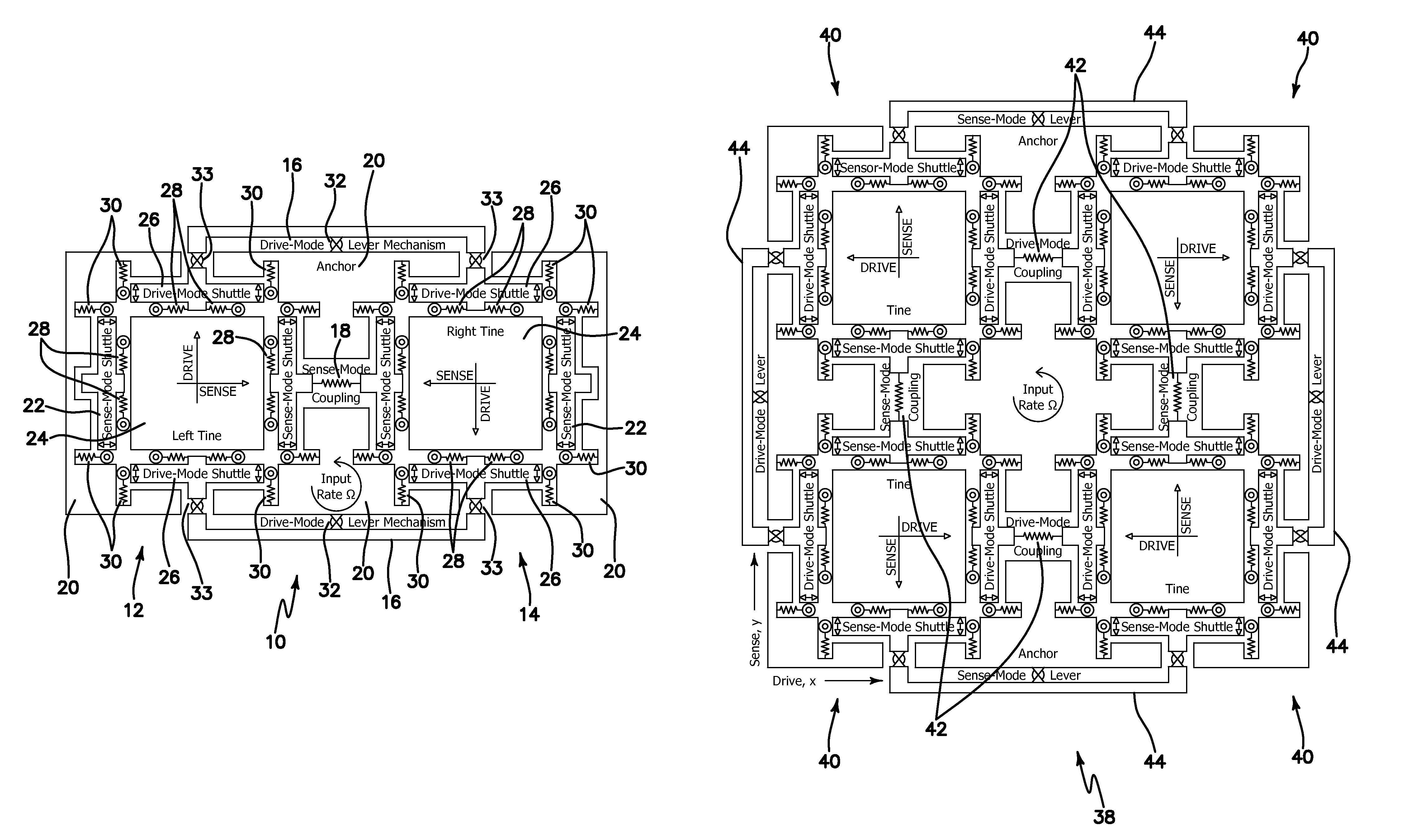

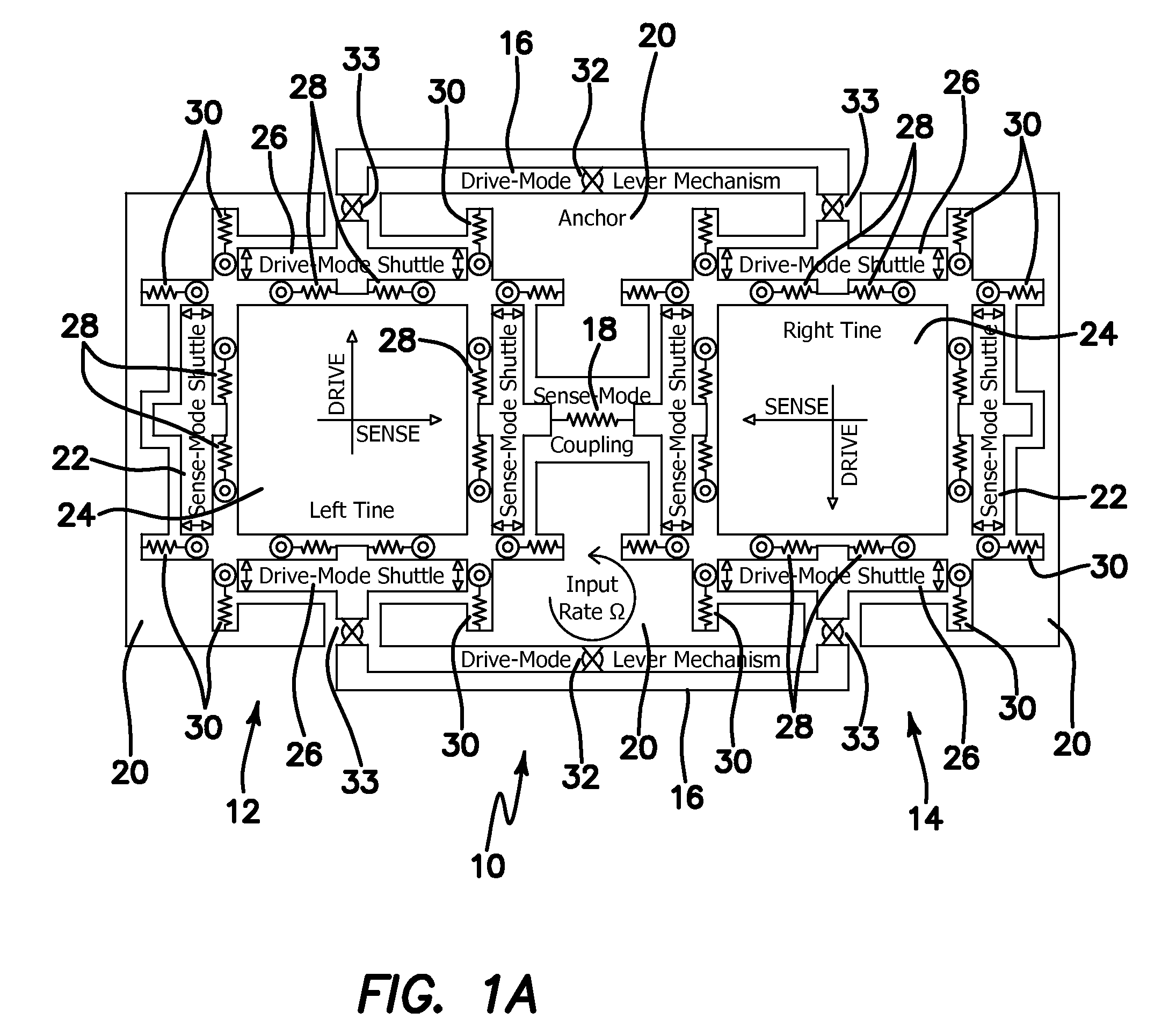

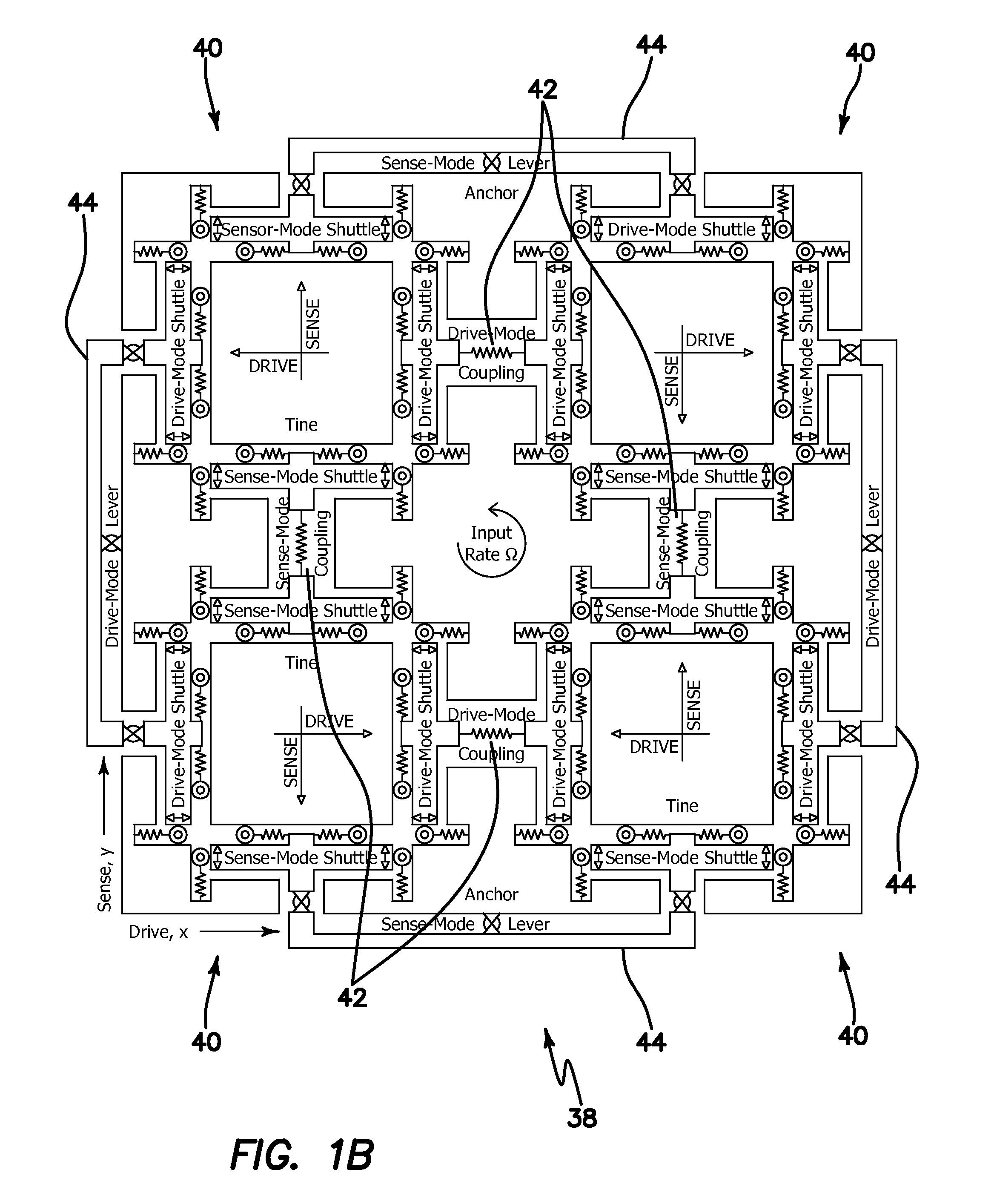

Micromachined tuning fork gyroscopes with ultra-high sensitivity and shock rejection

ActiveUS20100313657A1Eliminate spursEnergy consumption is minimizedAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsTuning forkDynamic balance

A vibratory rate z-axis gyroscope is characterized by drive-mode and sense-mode quality factors and rate sensitivity and is fabricated with at least two decoupled vibratory tines, a levered drive-mode mechanism coupled between the tines to structurally force anti-phase drive-mode motion of the tines at a predetermined drive frequency, to eliminate spurious frequency modes of the anti-phase drive-mode motion of the tines lower than the predetermined drive frequency and to provide synchronization of drive- and sense-mode motion of the tines, and a sense-mode mechanism coupled between the tines arranged and configured to provide a linearly coupled, dynamically balanced anti-phase sense-mode motion of the tines to minimize substrate energy dissipation and to enhance the sense-mode quality factor and rate sensitivity.

Owner:RGT UNIV OF CALIFORNIA

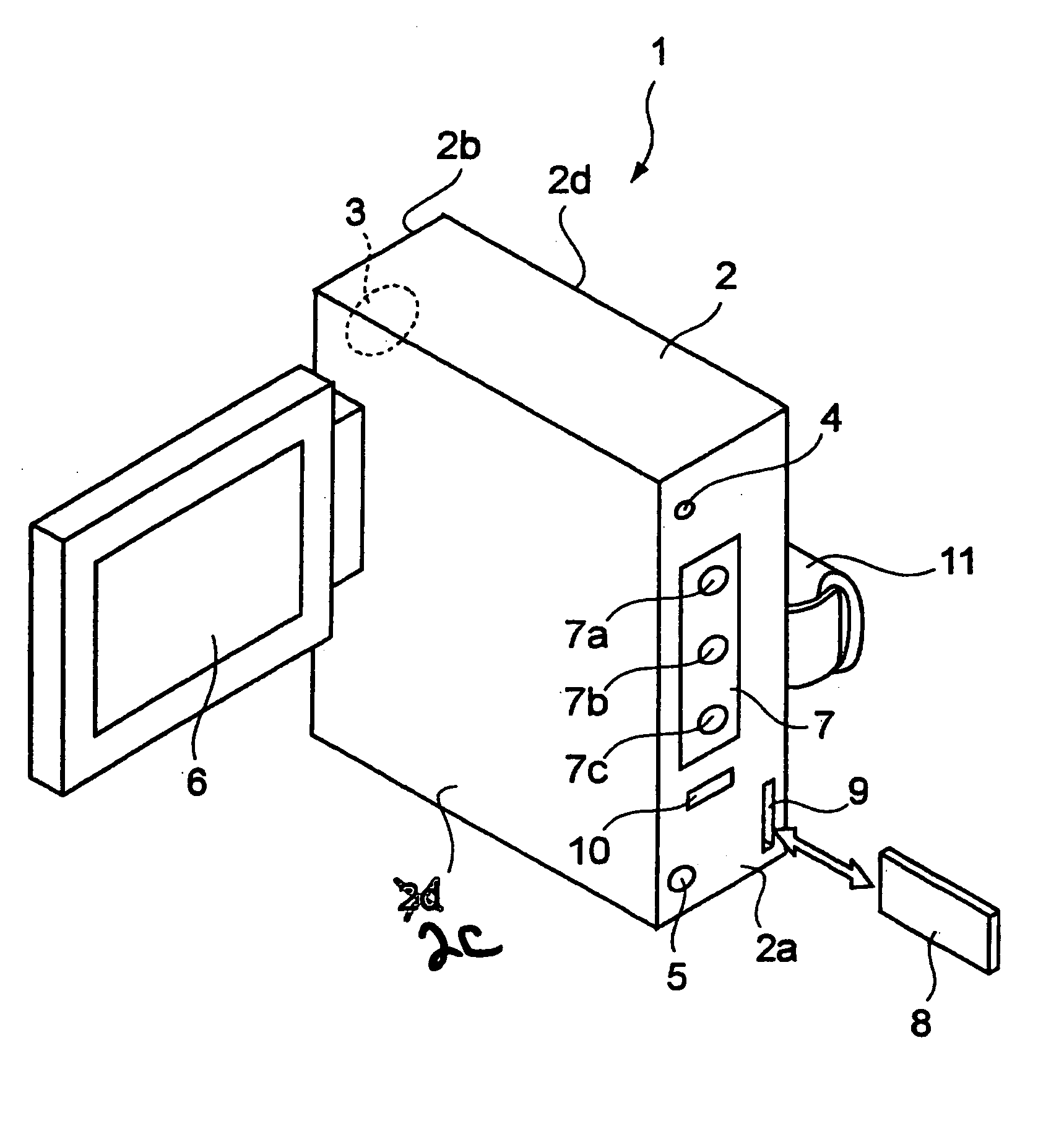

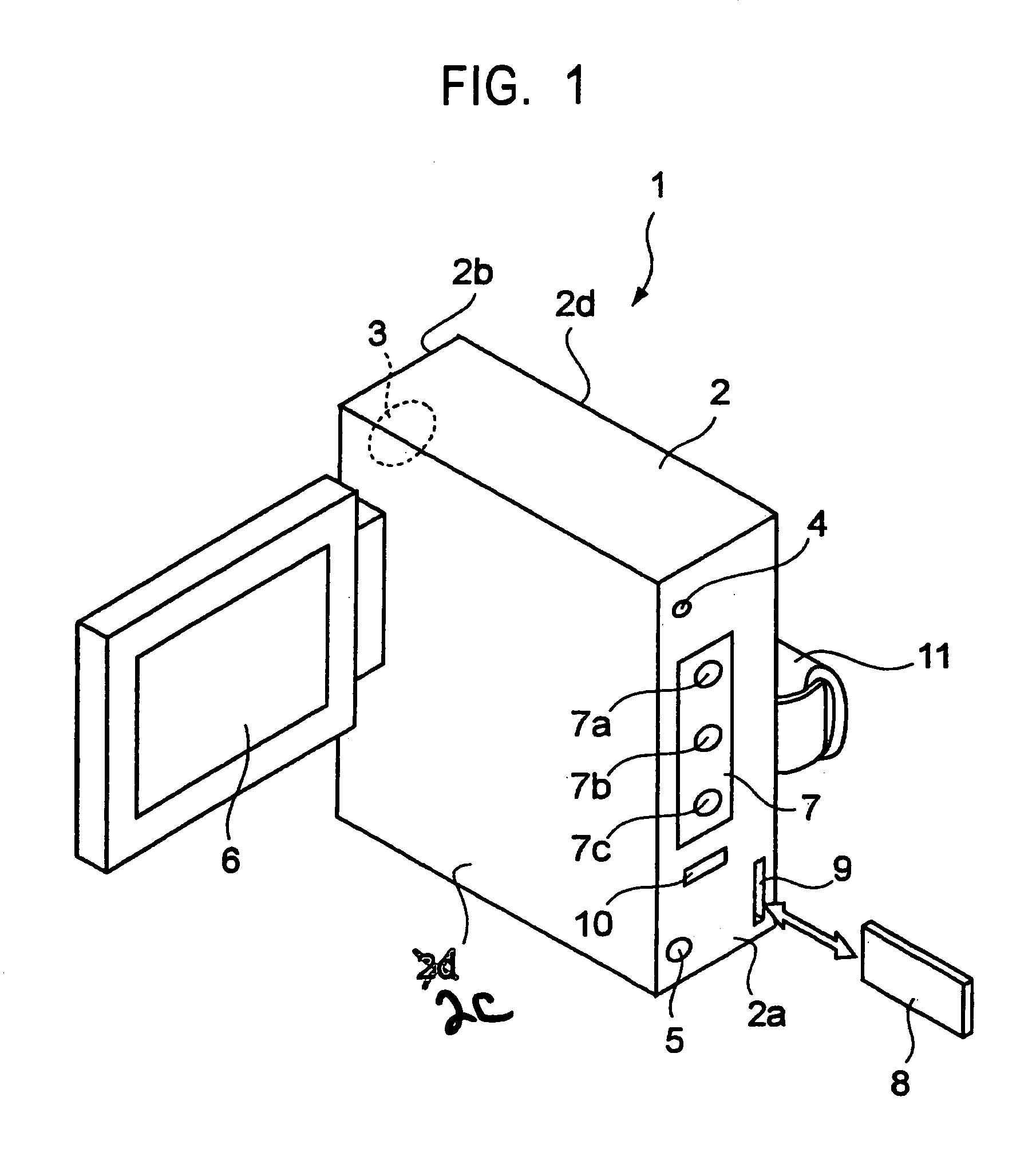

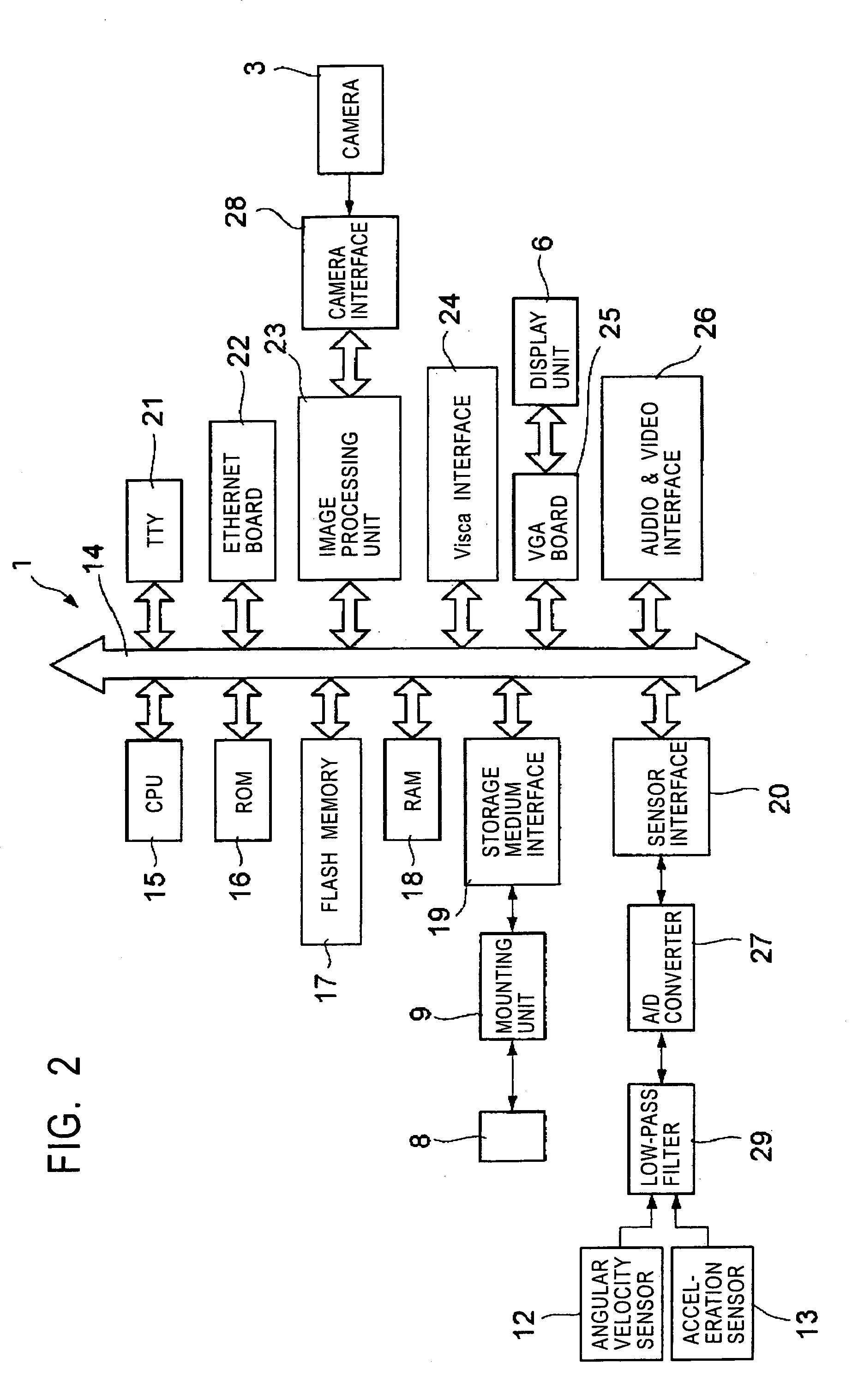

Electronic device, signal compensation device and signal compensation method

InactiveUS7225101B2Reduce processEfficient processingAcceleration measurement using interia forcesPiezoelectric/electrostriction/magnetostriction machinesAngular velocityFailure causes

An electronic device that prevents a failure caused by a temperature drift of an angular velocity sensor, and a signal compensation system and a signal compensation method for compensating for the temperature drift are provided. The present invention provides a mechanism including an angular velocity sensor that outputs a first signal in accordance with a rotational angular velocity. The device stores in advance data of a second signal normally output by the angular velocity sensor while in a stationary state, detects a stationary state and extracts the difference between the first and second signals when the stationary state is detected. The device thereby compensates for the first signal based on the extracted difference signal. A display unit in the device scrolls an image based on the compensated signal. This prevents a failure caused by the temperature drift of the angular velocity sensor.

Owner:SONY CORP

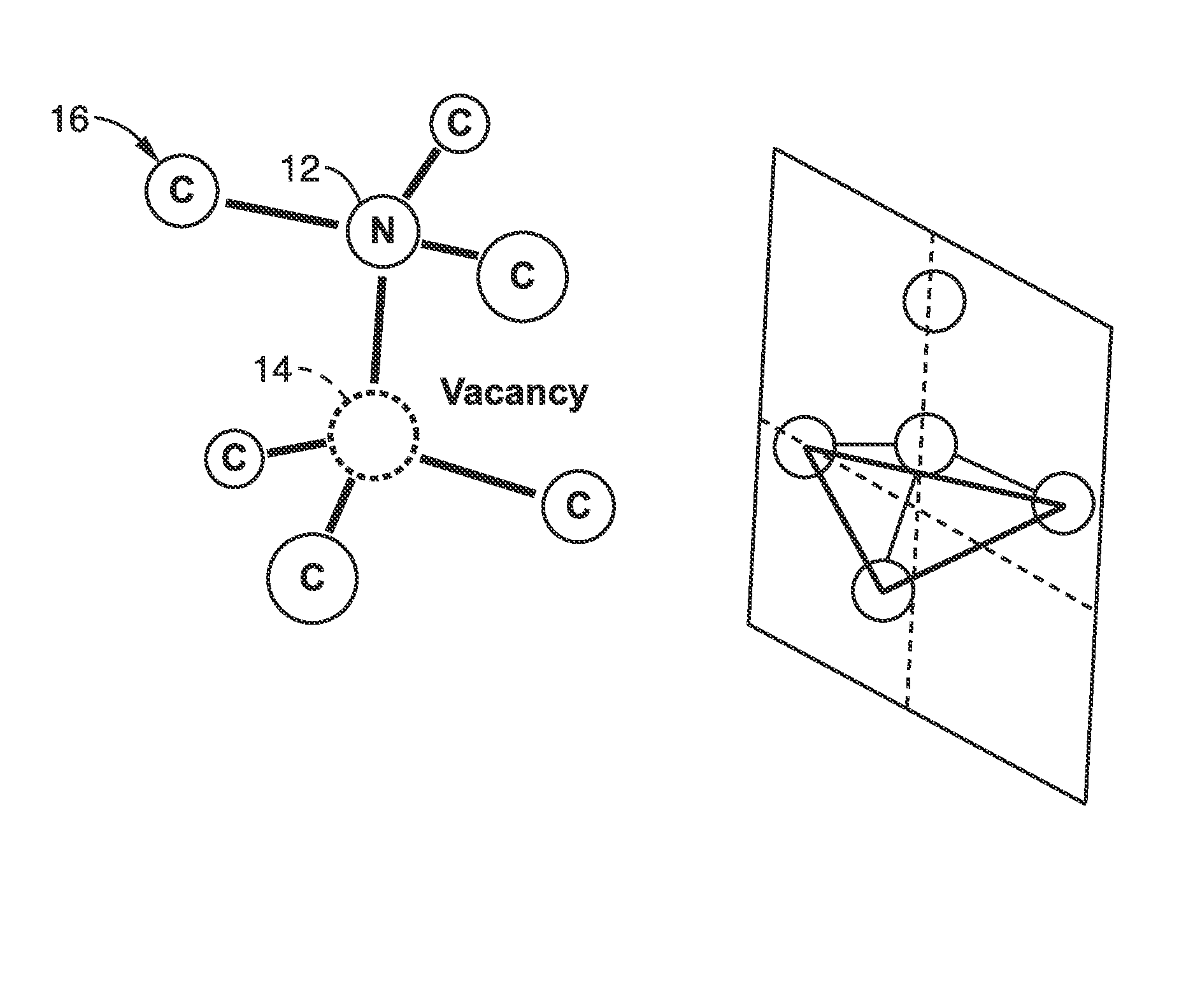

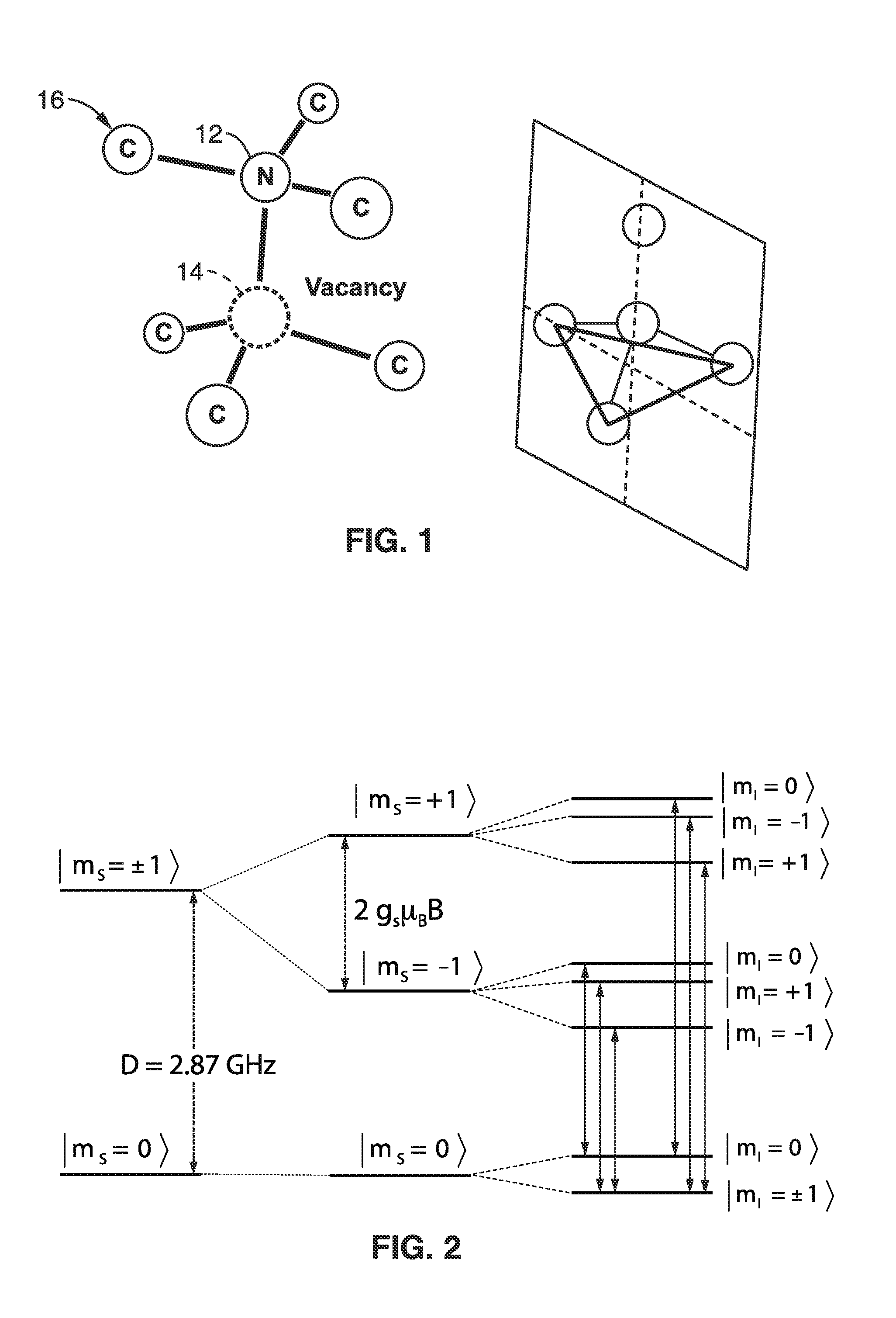

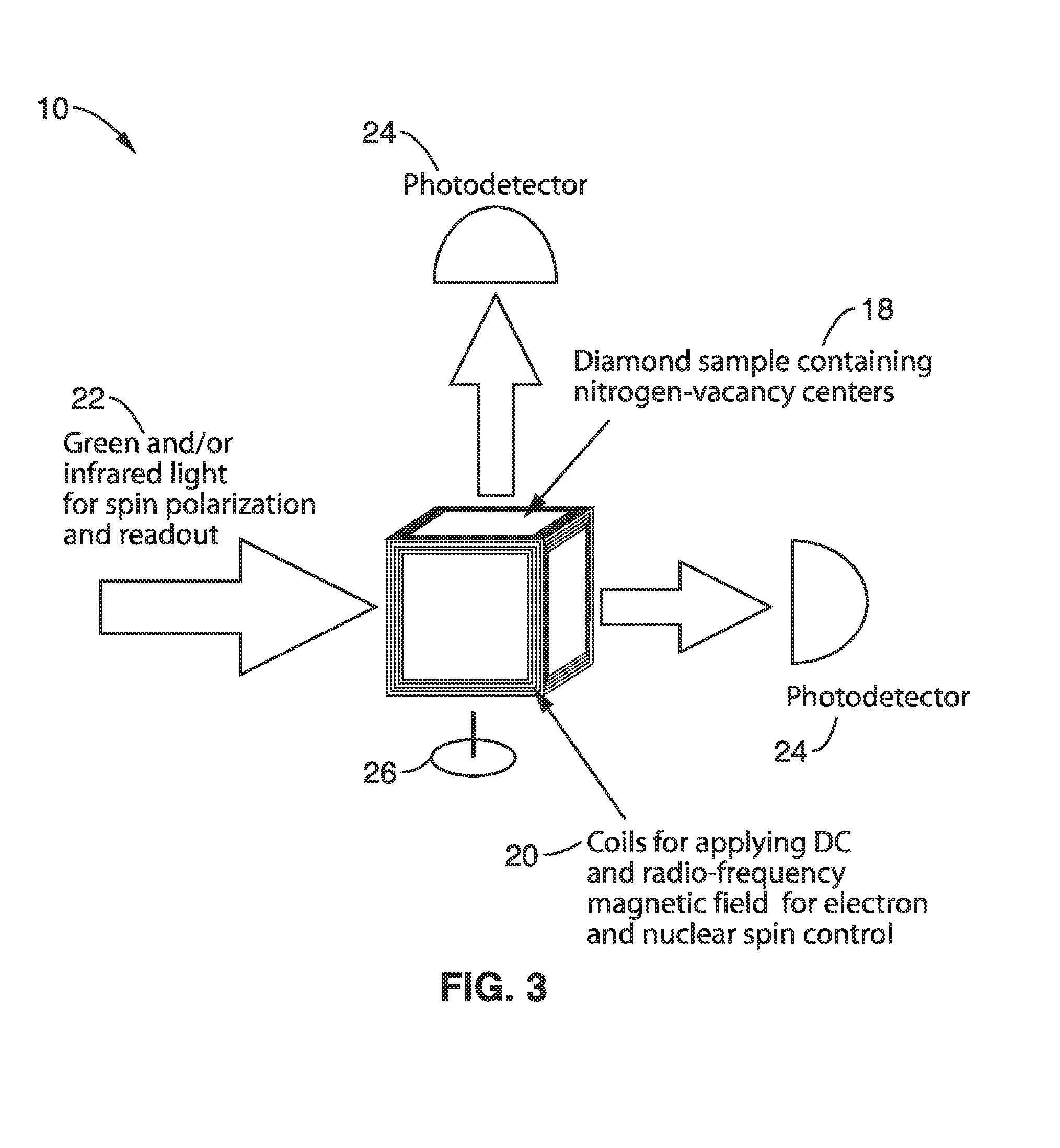

Gyroscopes based on nitrogen-vacancy centers in diamond

ActiveUS20150090033A1Small dimensionThermal robustnessAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsGyroscopePhase shifted

A solid-state gyroscope apparatus based on ensembles of negatively charged nitrogen-vacancy (NV−) centers in diamond and methods of detection are provided. In one method, rotation of the NV− symmetry axis will induce Berry phase shifts in the NV− electronic ground-state coherences proportional to the solid angle subtended by the symmetry axis. A second method uses a modified Ramsey scheme where Berry phase shifts in the 14N hyperfine sublevels are employed.

Owner:RGT UNIV OF CALIFORNIA

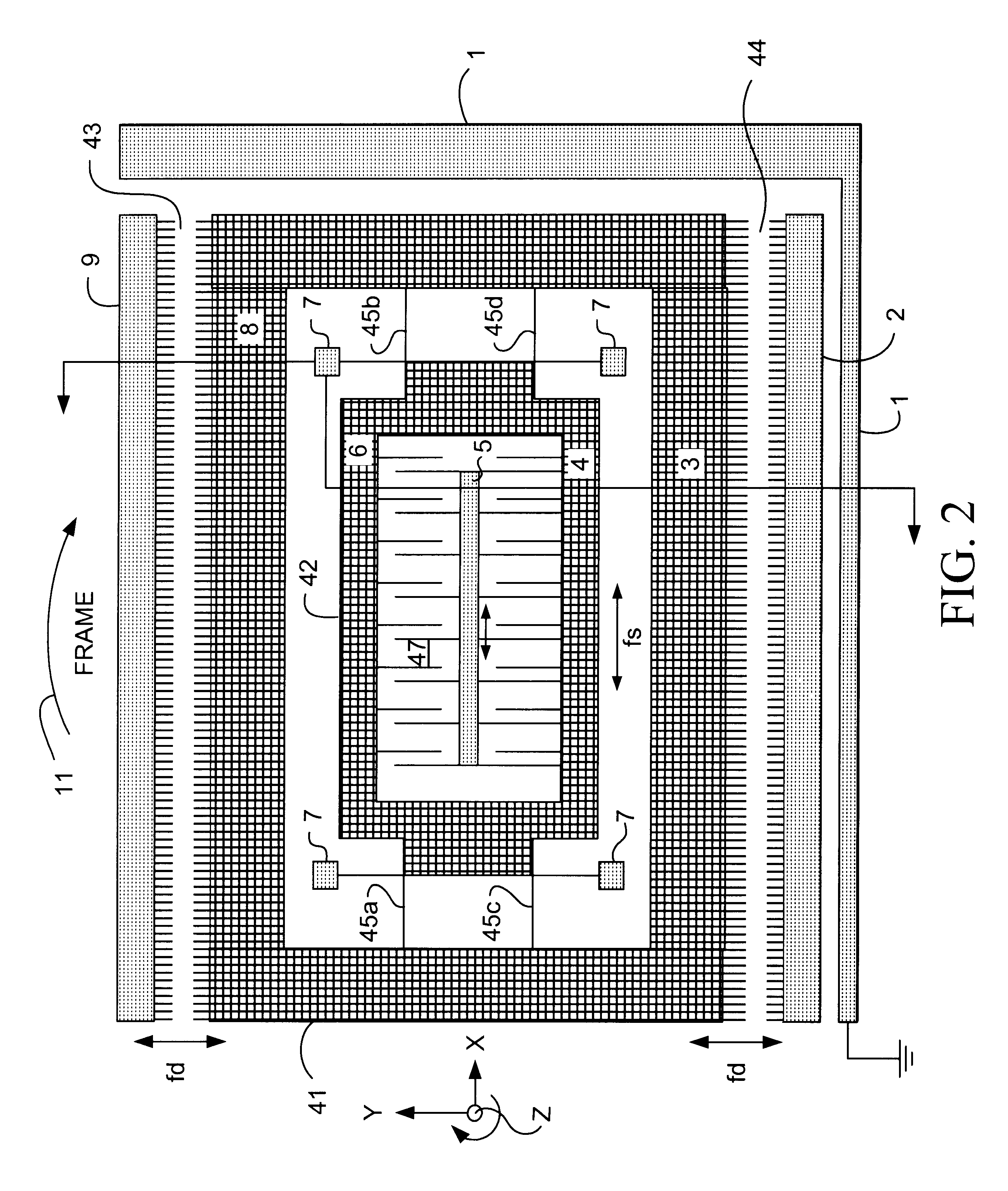

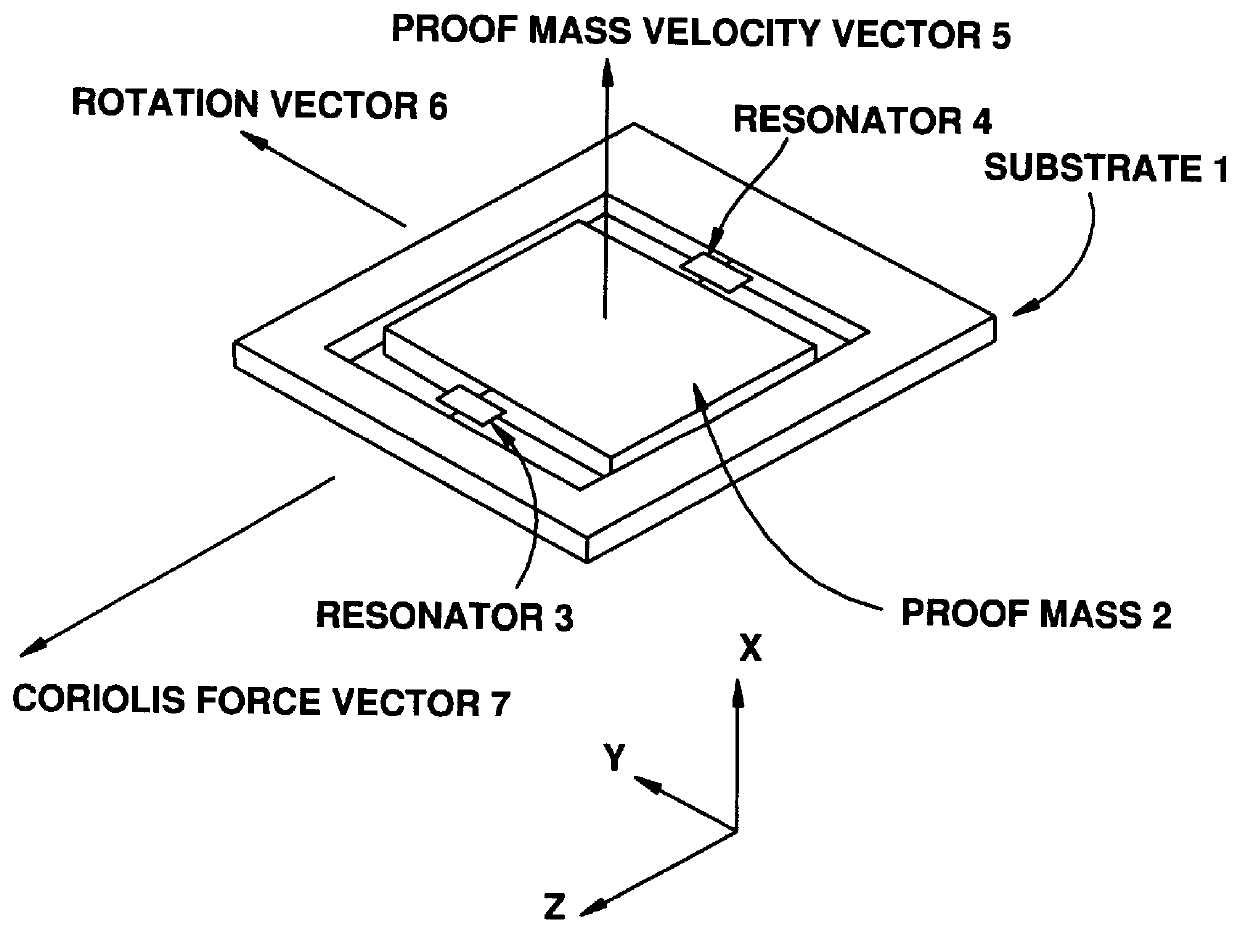

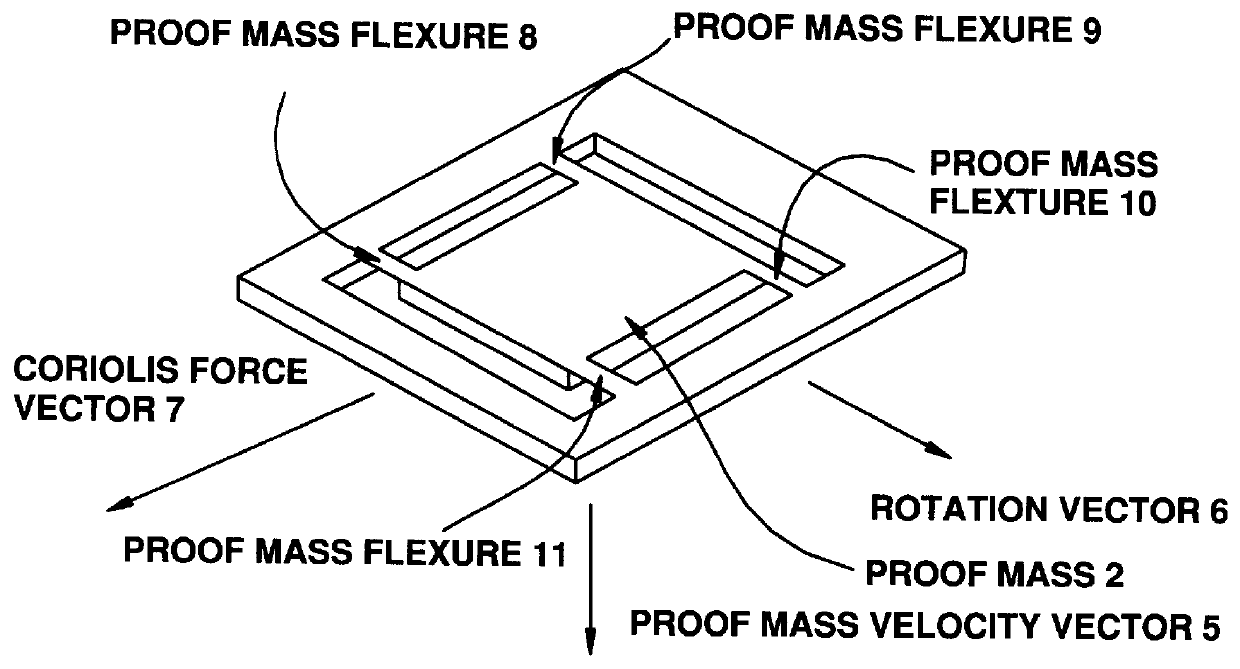

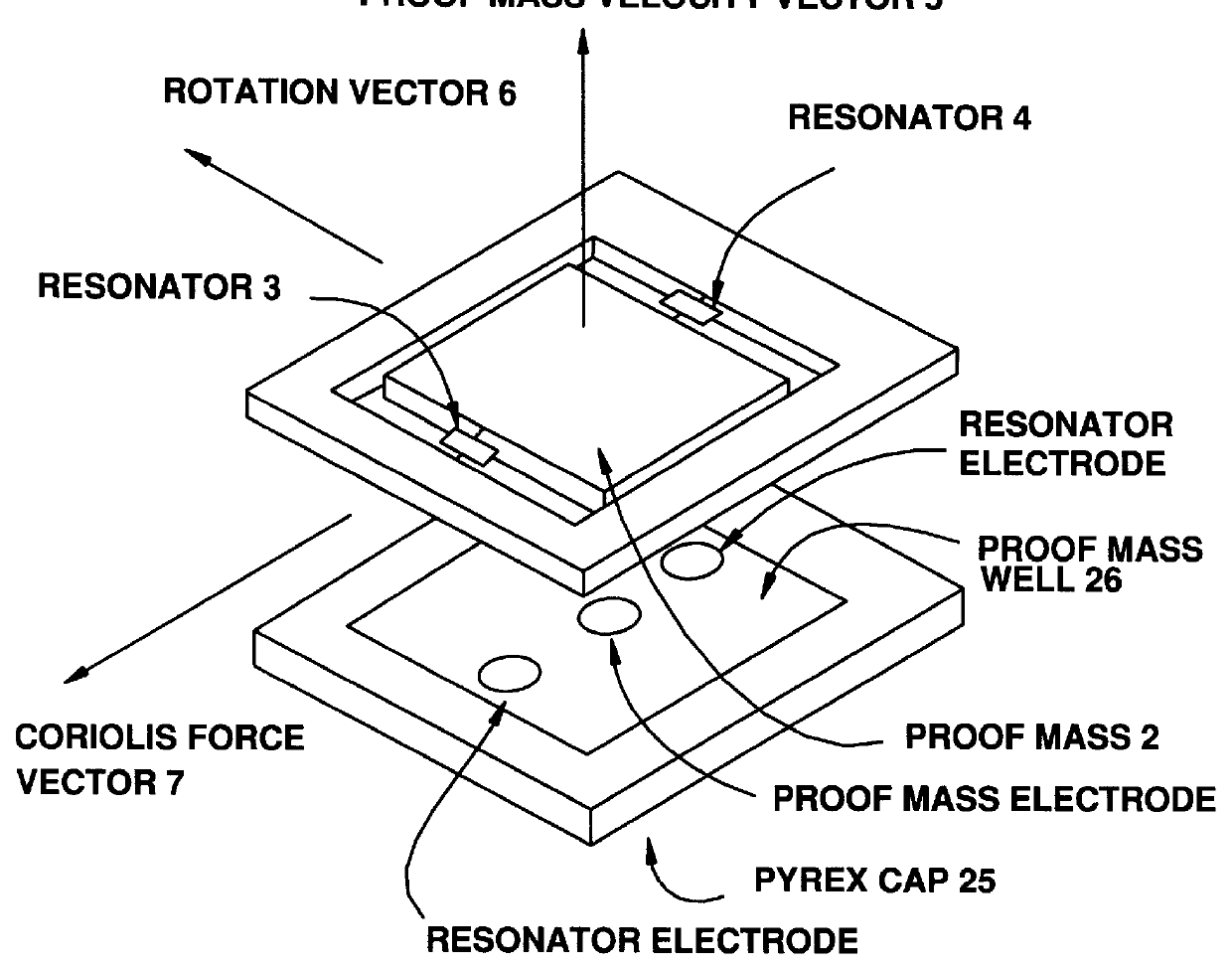

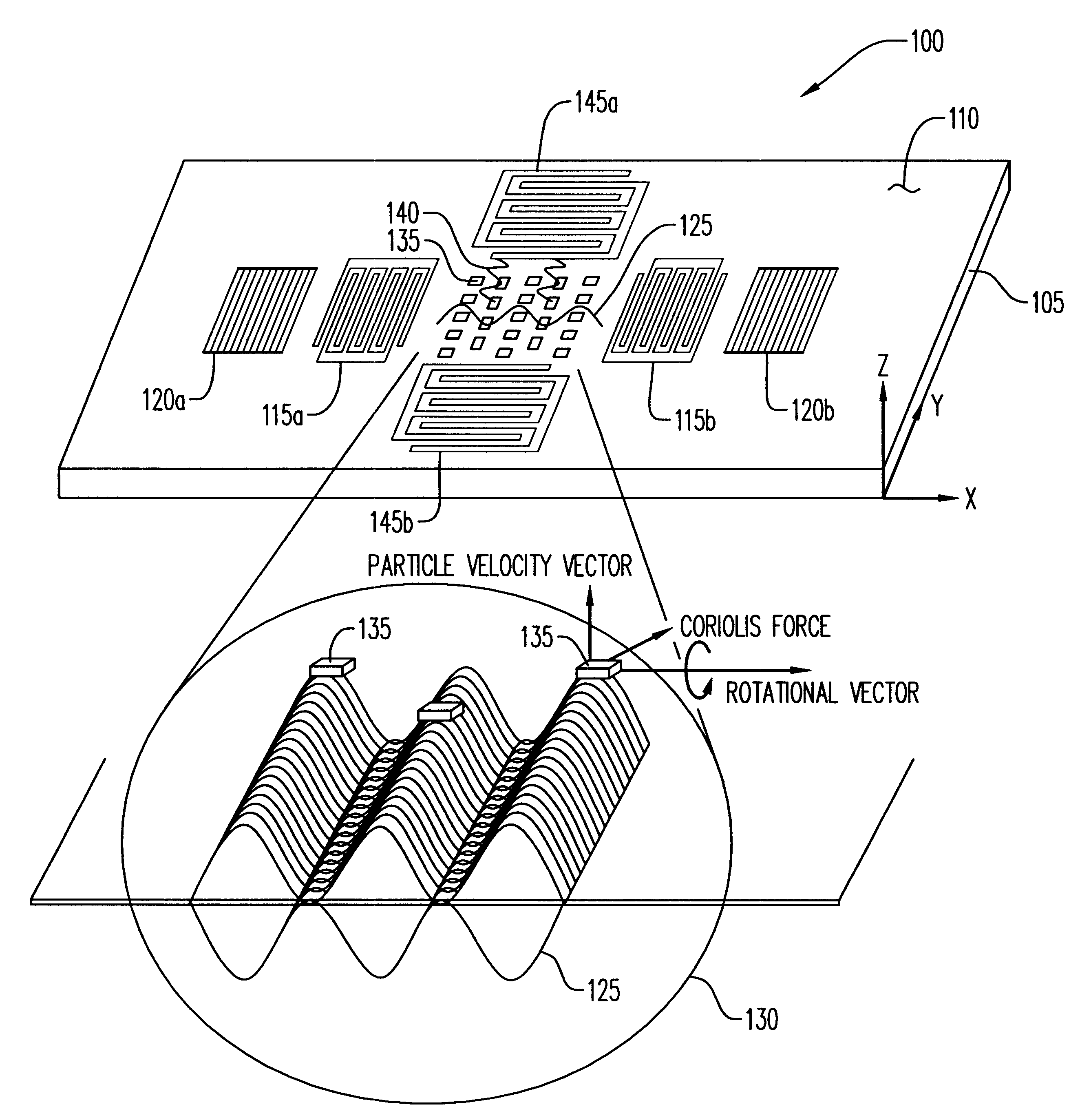

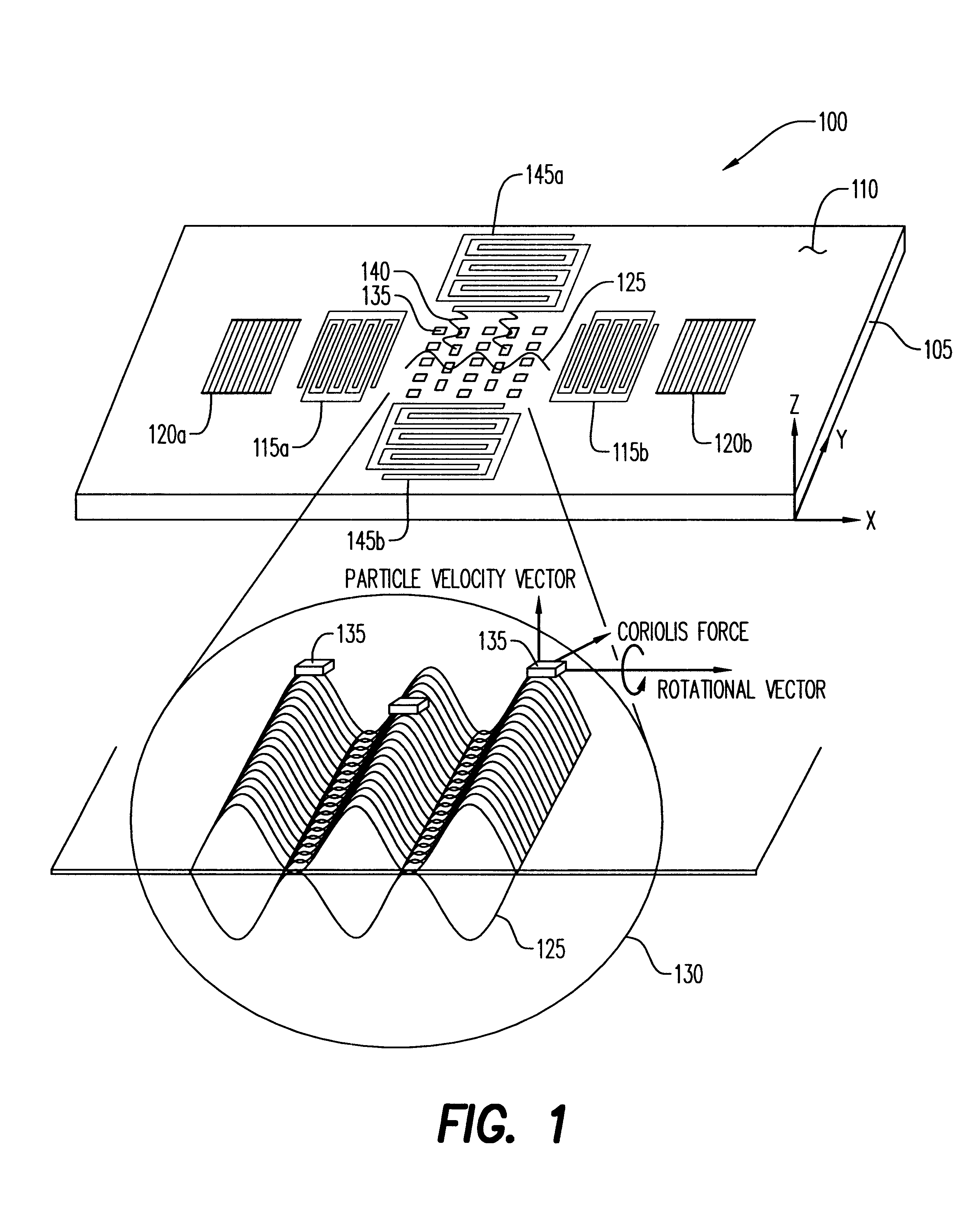

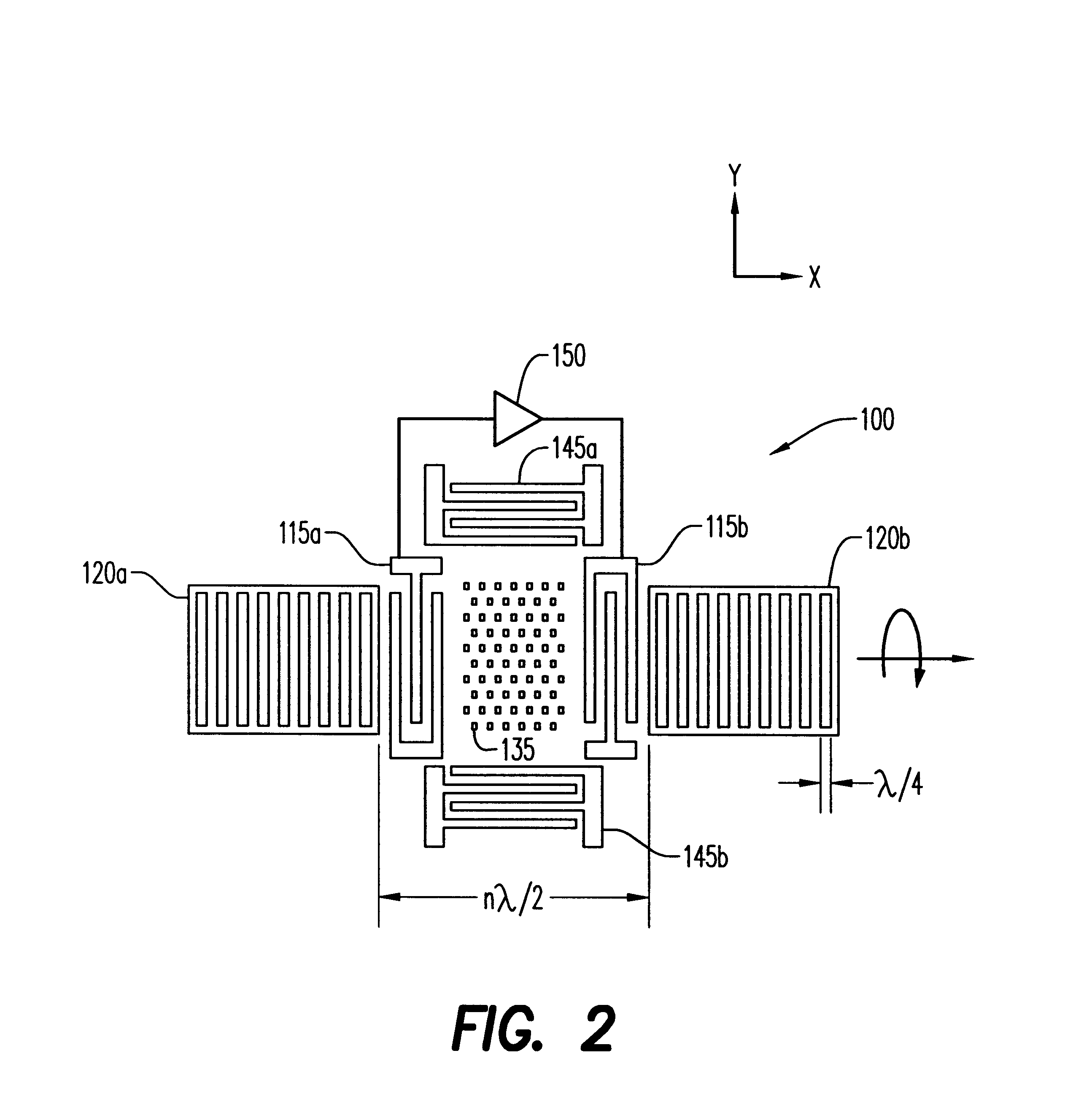

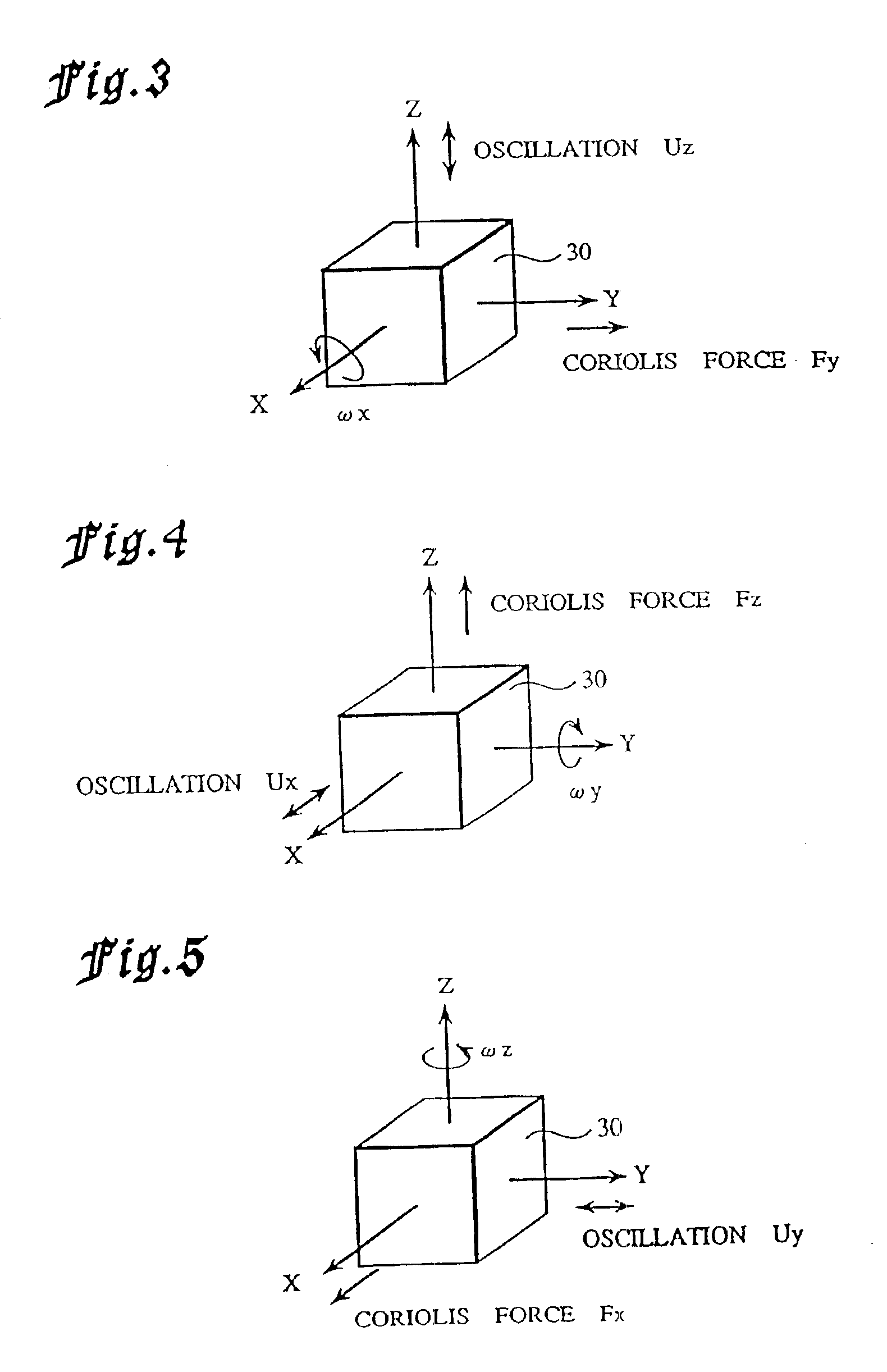

Micromachined acceleration and coriolis sensor

InactiveUS6032531AAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsDual stageGyroscope

A solid state silicon micromachined acceleration and Coriolis (MAC) sensor that measures linear and angular motion. The MAC sensor is a single device that performs the functions of a conventional accelerometer and a gyroscope simultaneously. The MAC sensor is unique in that it is a differential dual stage device using only one micromachined proof mass to measure both linear and angular motions. The single proof mass is connected to opposing electromechanical resonators in a monolithic microstructure made from single crystal silicon. This unique design offers improvements in measurement performance and reductions in fabrication complexity that are beyond the state the art of earlier micromachined inertial sensors.

Owner:KEARFOTT

Integrated multiaxis motion sensor

InactiveUS20100071467A1Acceleration measurement using interia forcesSpeed measurement using gyroscopic effectsIn planeAngular velocity

A system and method describes an inertial sensor assembly, the assembly comprises a substrate parallel to the plane, at least one in-plane angular velocity sensor comprising a pair proof masses that are oscillated in anti-phase fashion along an axis normal to the plane. The first in-plane angular velocity sensor further includes a sensing frame responsive to the angular velocity of the substrate around the first axis parallel to the plane and perpendicular to the axis normal to the plane. The assembly also includes at least one out-of-plane angular velocity sensor comprising a pair of proof masses that are oscillated in anti-phase fashion in the plane parallel to the plane. The out-of-plane angular velocity sensor further comprises a sensing frame responsive to the angular velocity of the substrate around the axis normal to the plane.

Owner:INVENSENSE

Micromachined tuning fork gyroscopes with ultra-high sensitivity and shock rejection

ActiveUS8322213B2Energy consumption is minimizedQuality improvementAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsTuning forkDynamic balance

A vibratory rate z-axis gyroscope is characterized by drive-mode and sense-mode quality factors and rate sensitivity and is fabricated with at least two decoupled vibratory tines, a levered drive-mode mechanism coupled between the tines to structurally force anti-phase drive-mode motion of the tines at a predetermined drive frequency, to eliminate spurious frequency modes of the anti-phase drive-mode motion of the tines lower than the predetermined drive frequency and to provide synchronization of drive- and sense-mode motion of the tines, and a sense-mode mechanism coupled between the tines arranged and configured to provide a linearly coupled, dynamically balanced anti-phase sense-mode motion of the tines to minimize substrate energy dissipation and to enhance the sense-mode quality factor and rate sensitivity.

Owner:RGT UNIV OF CALIFORNIA

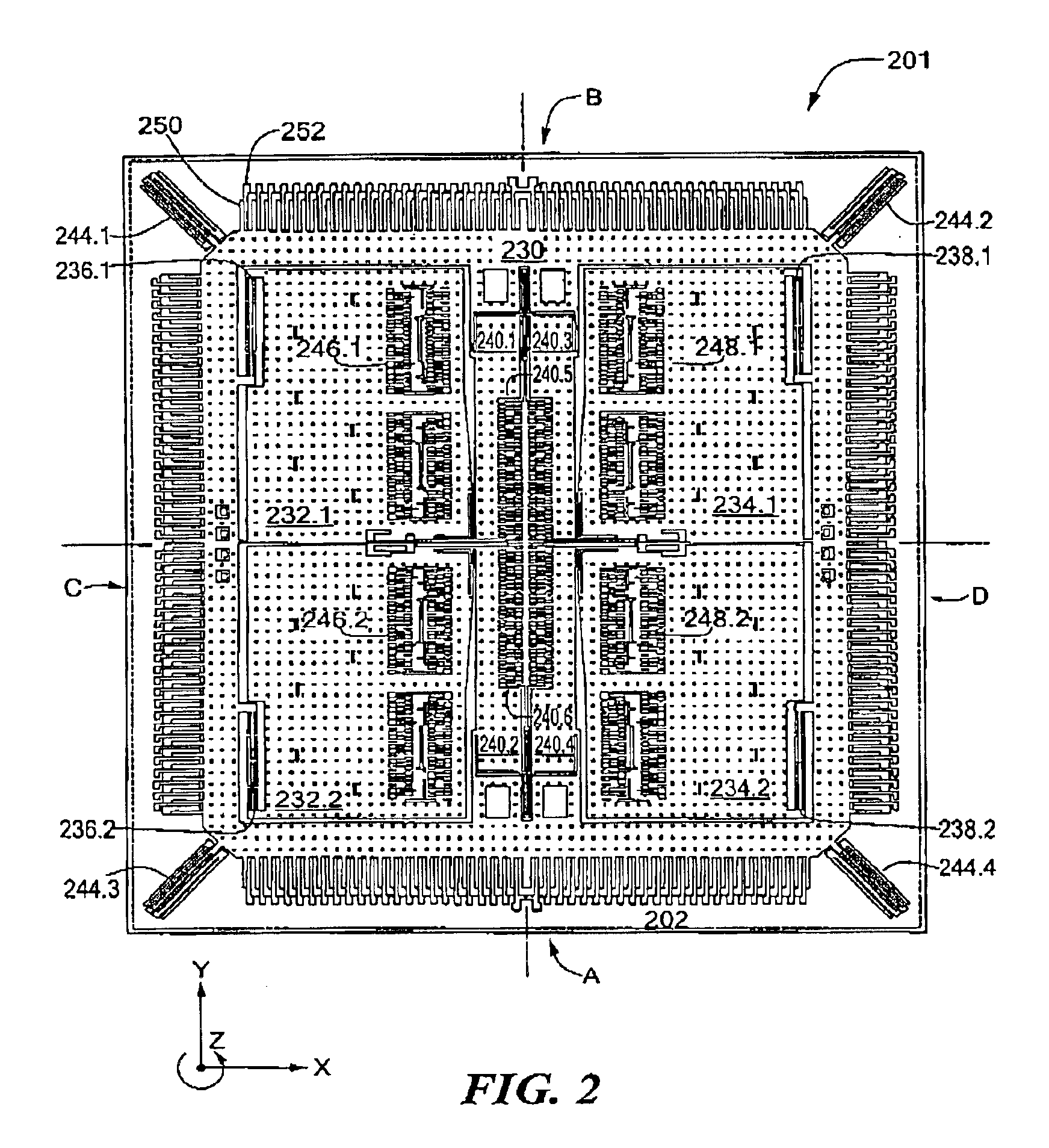

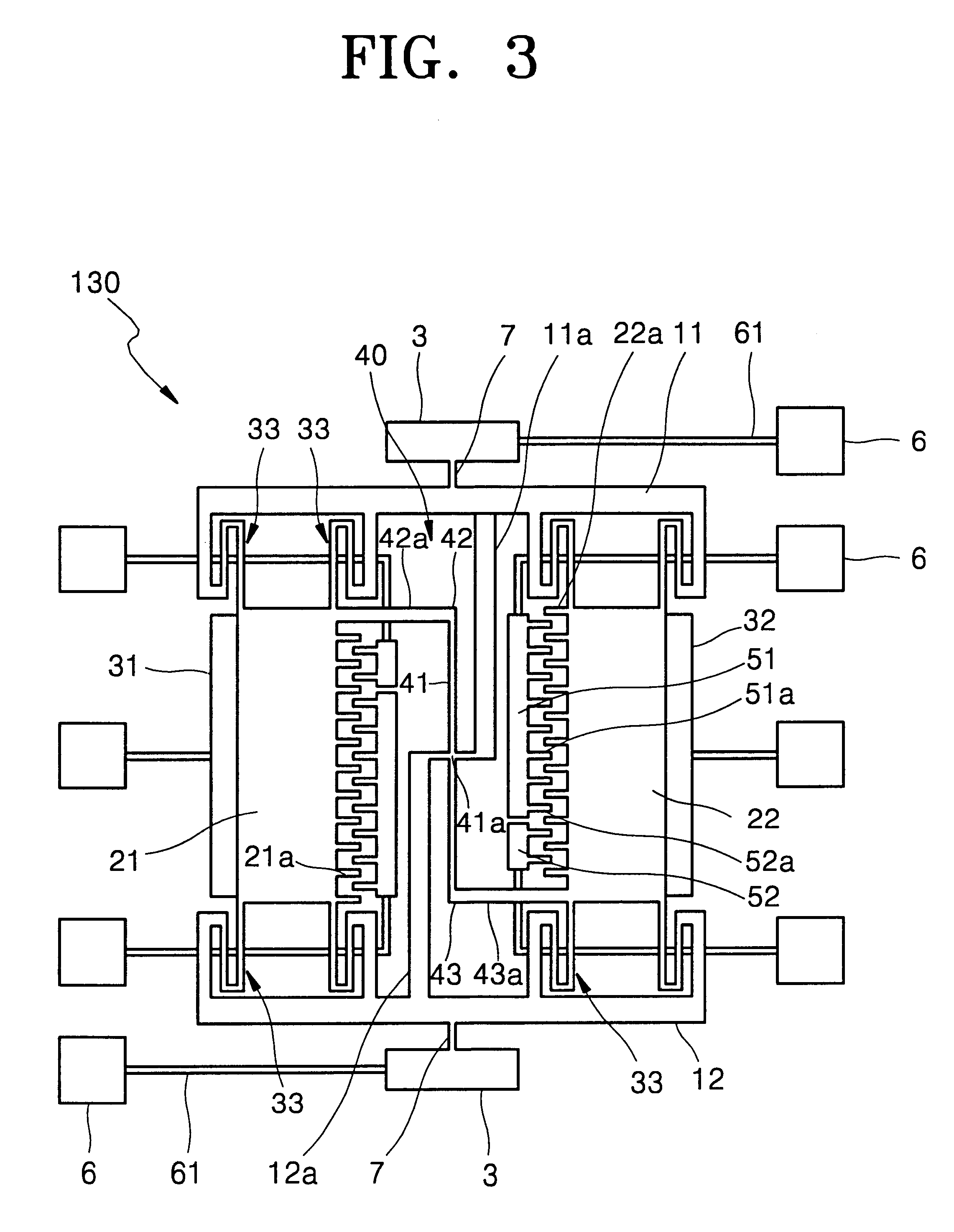

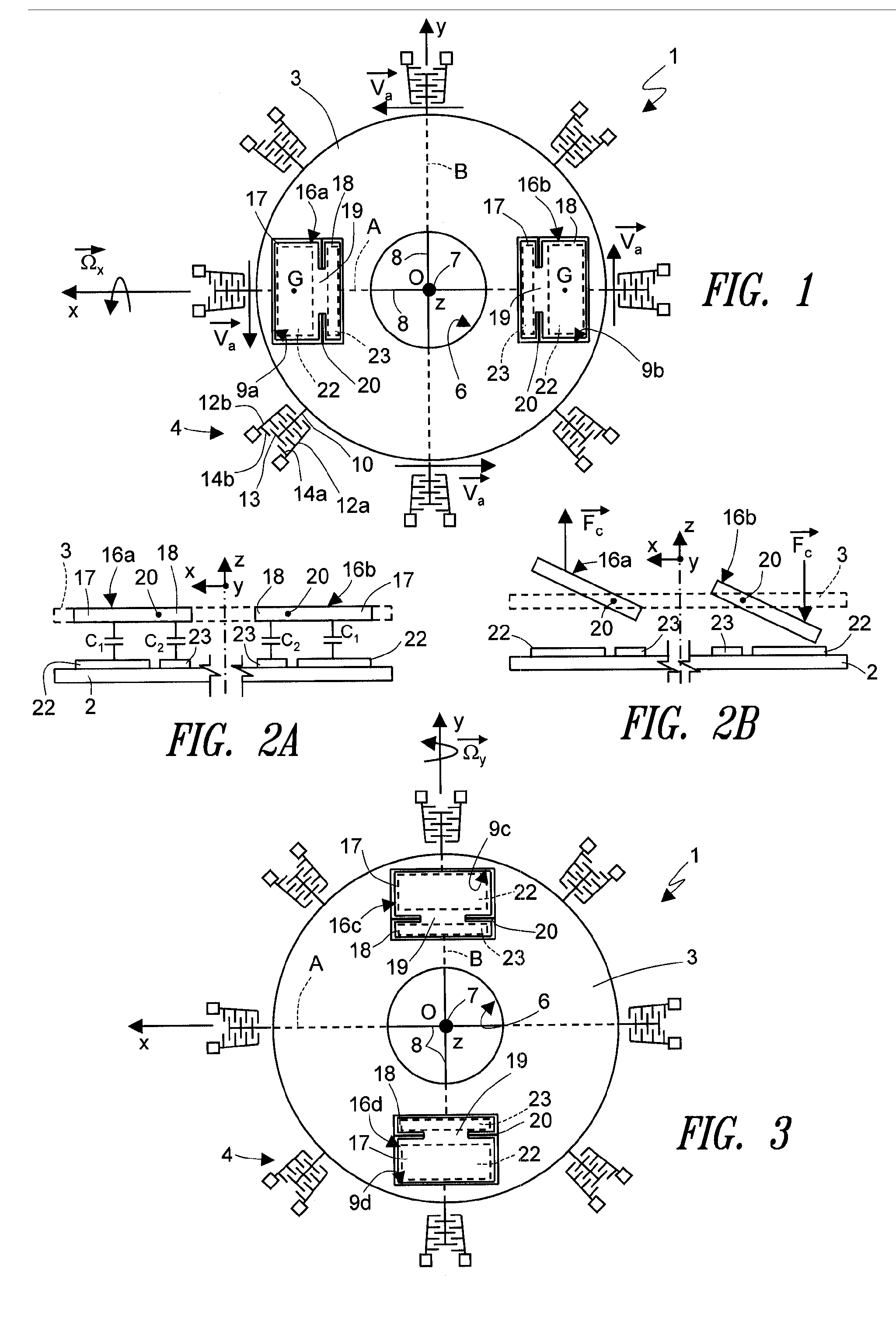

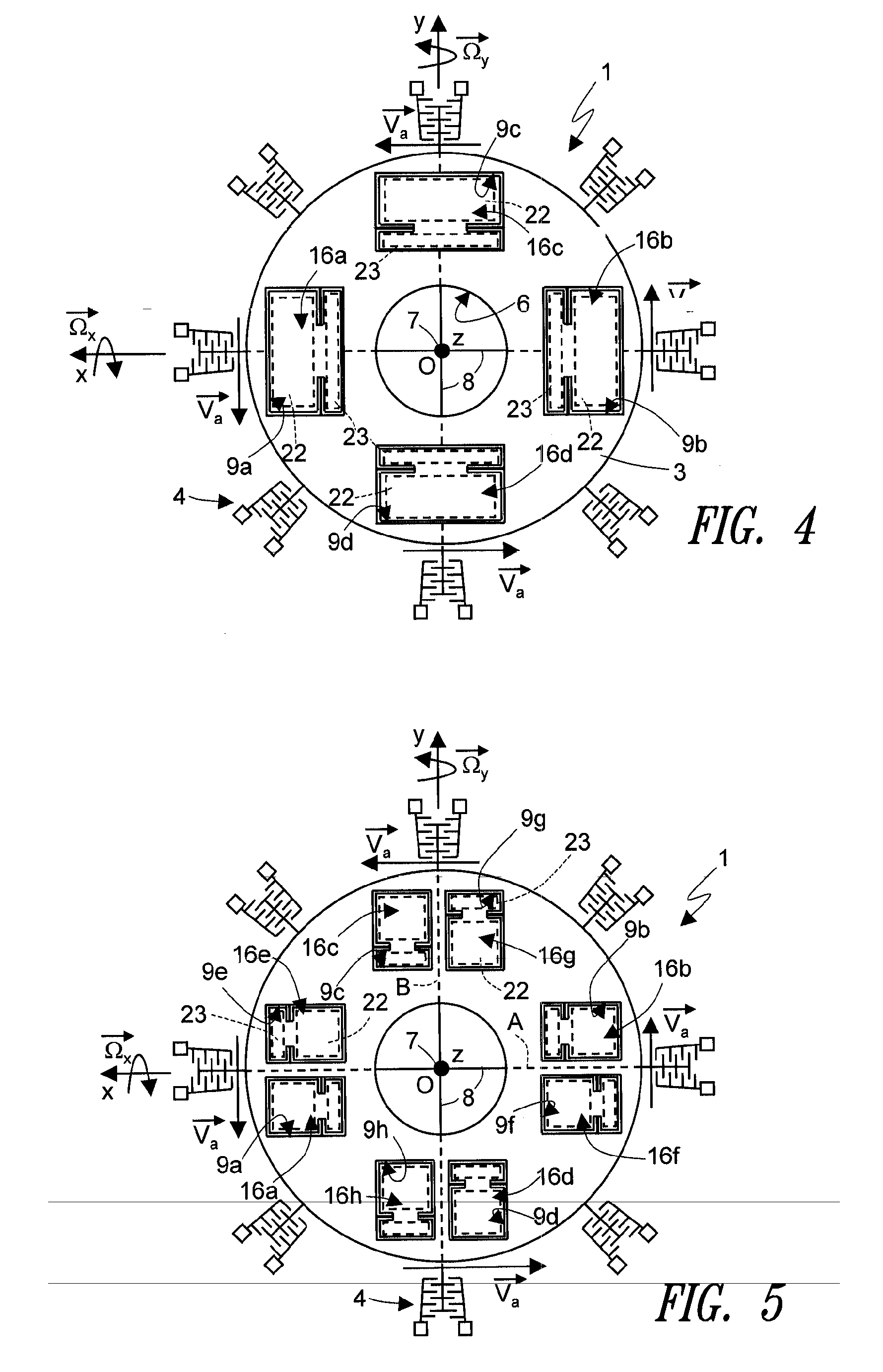

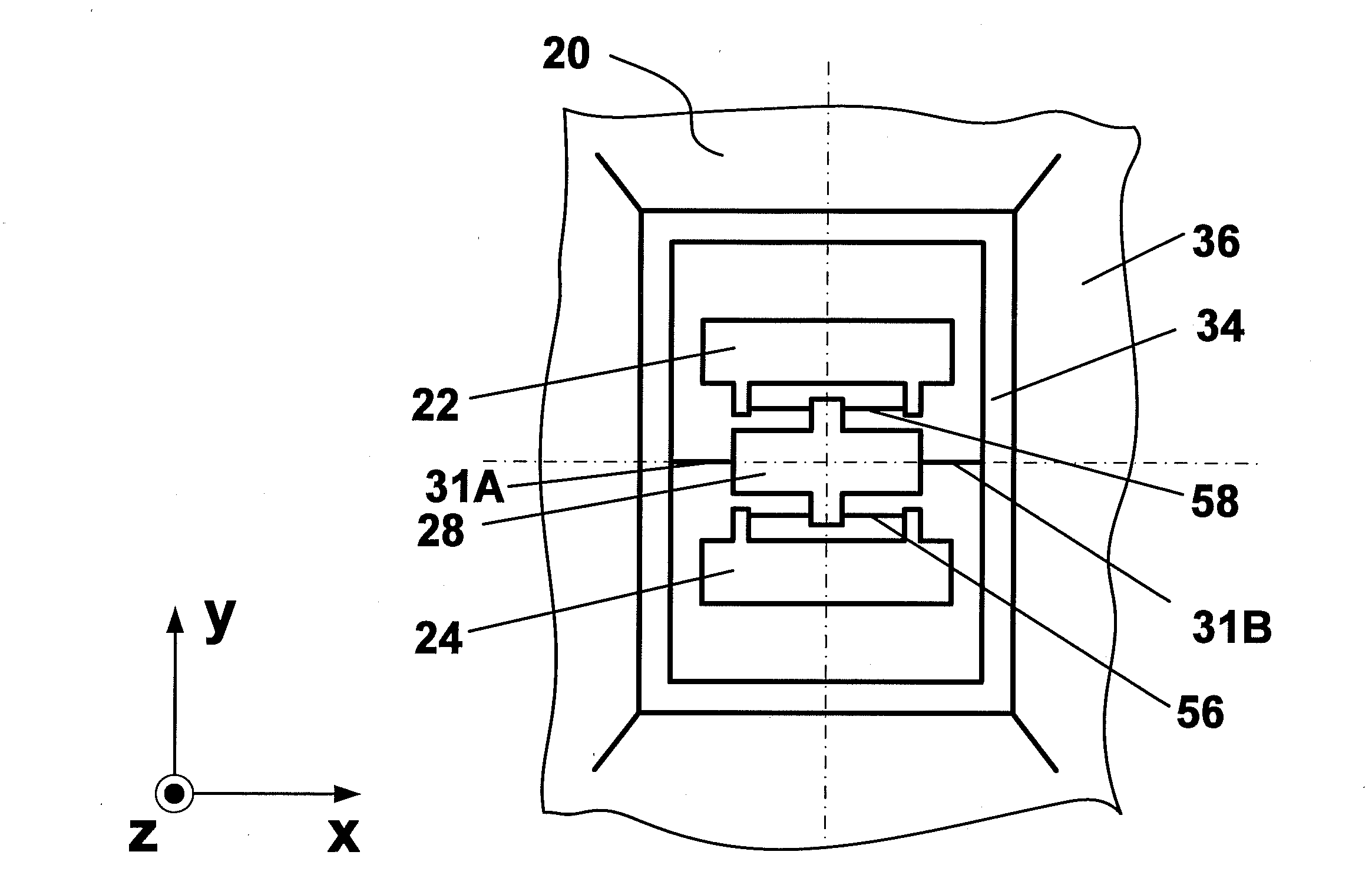

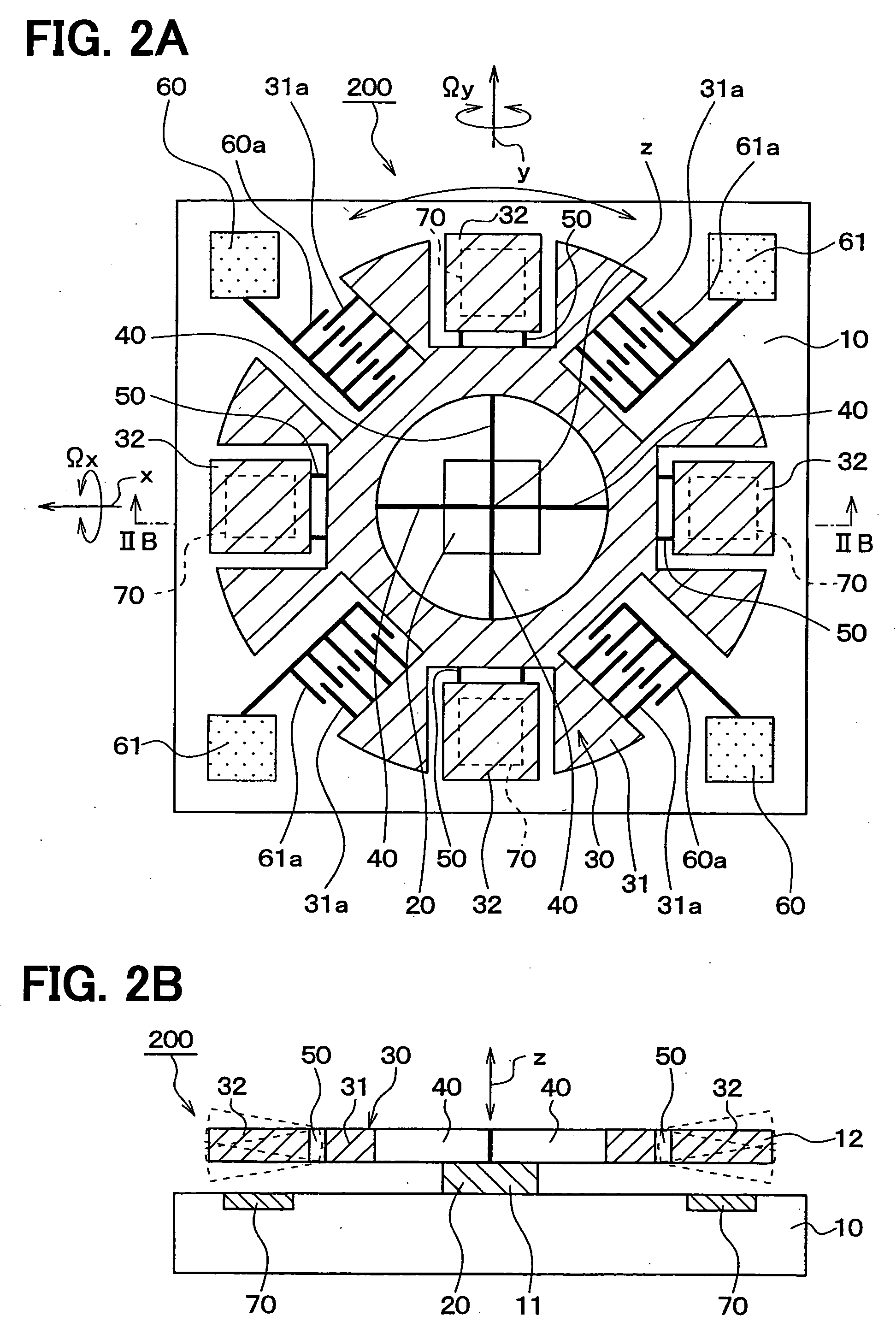

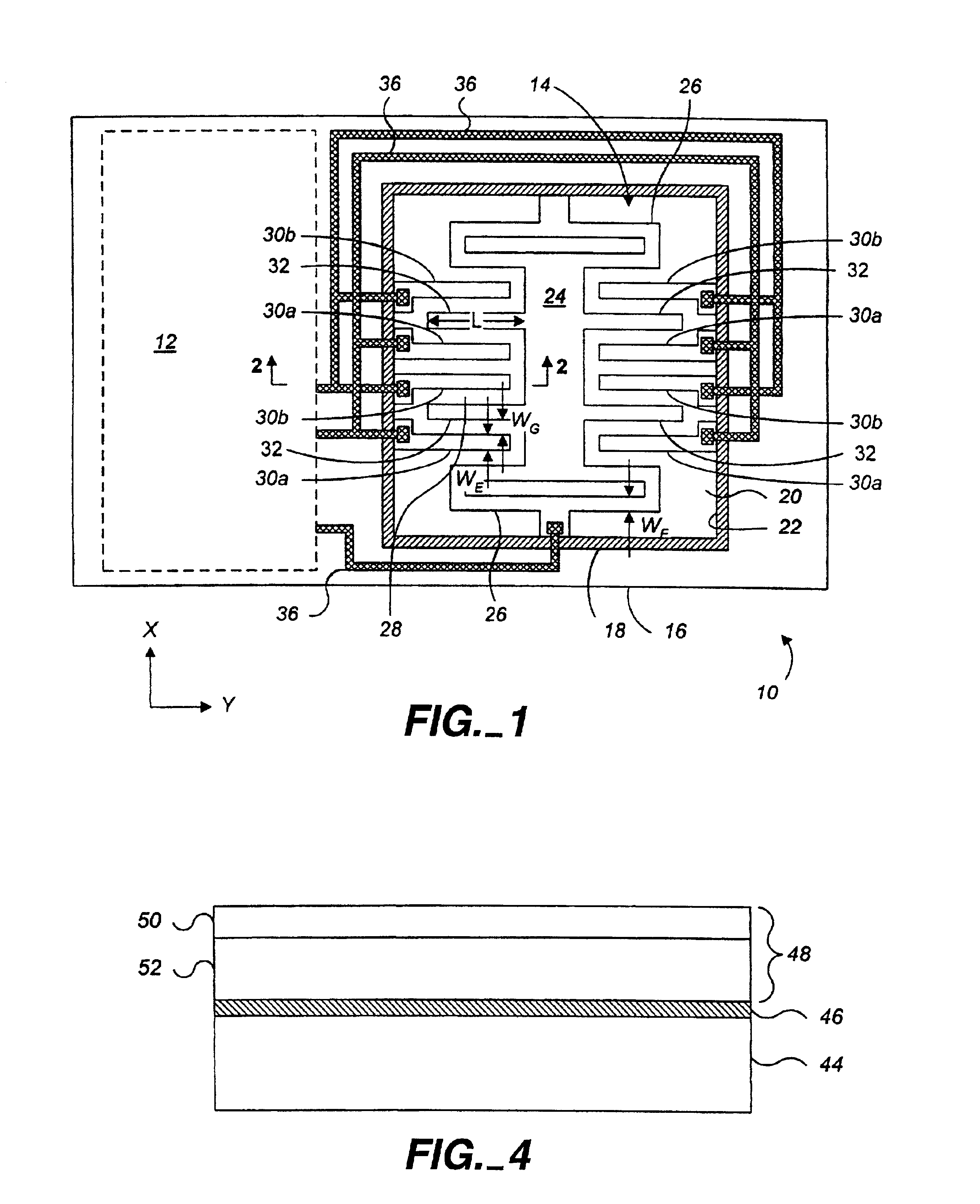

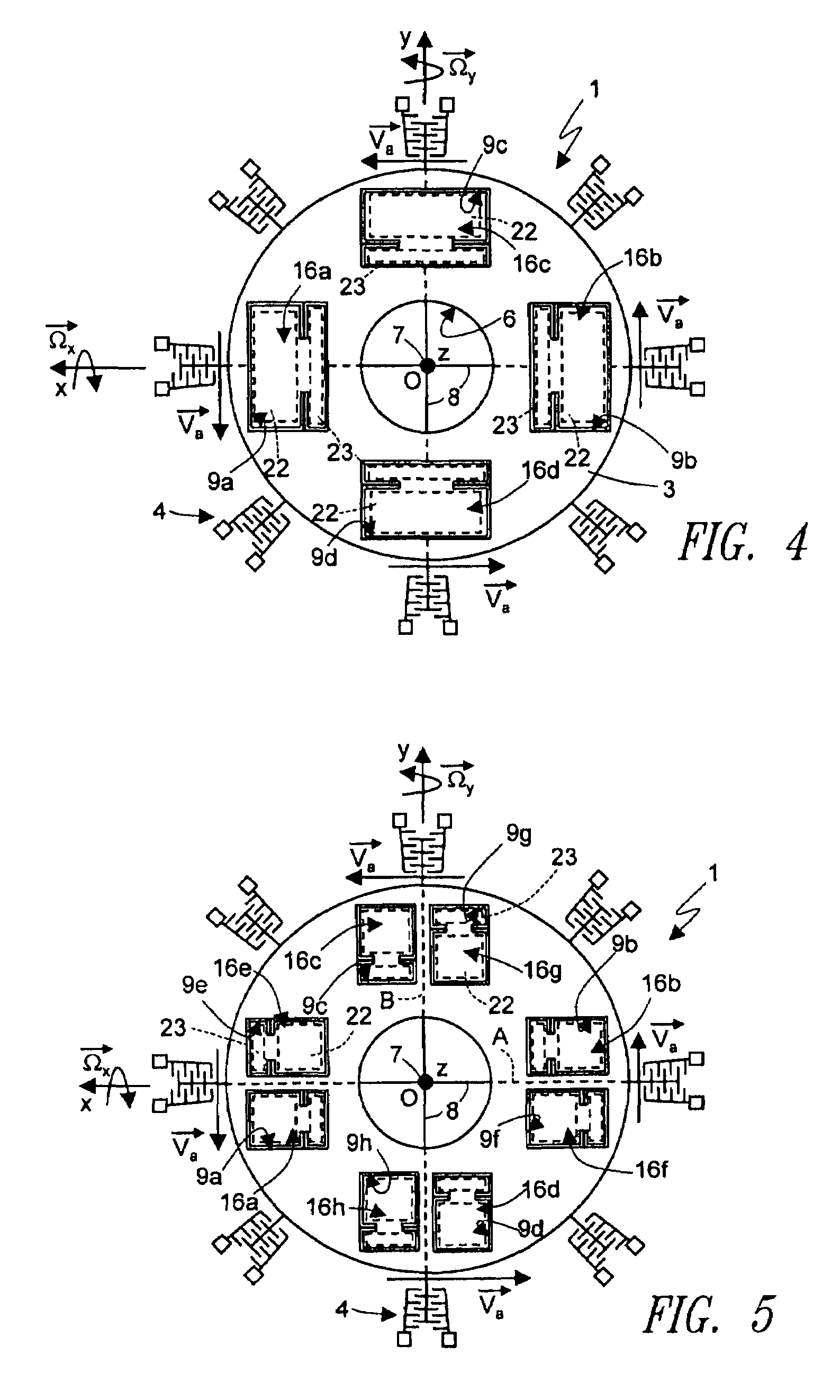

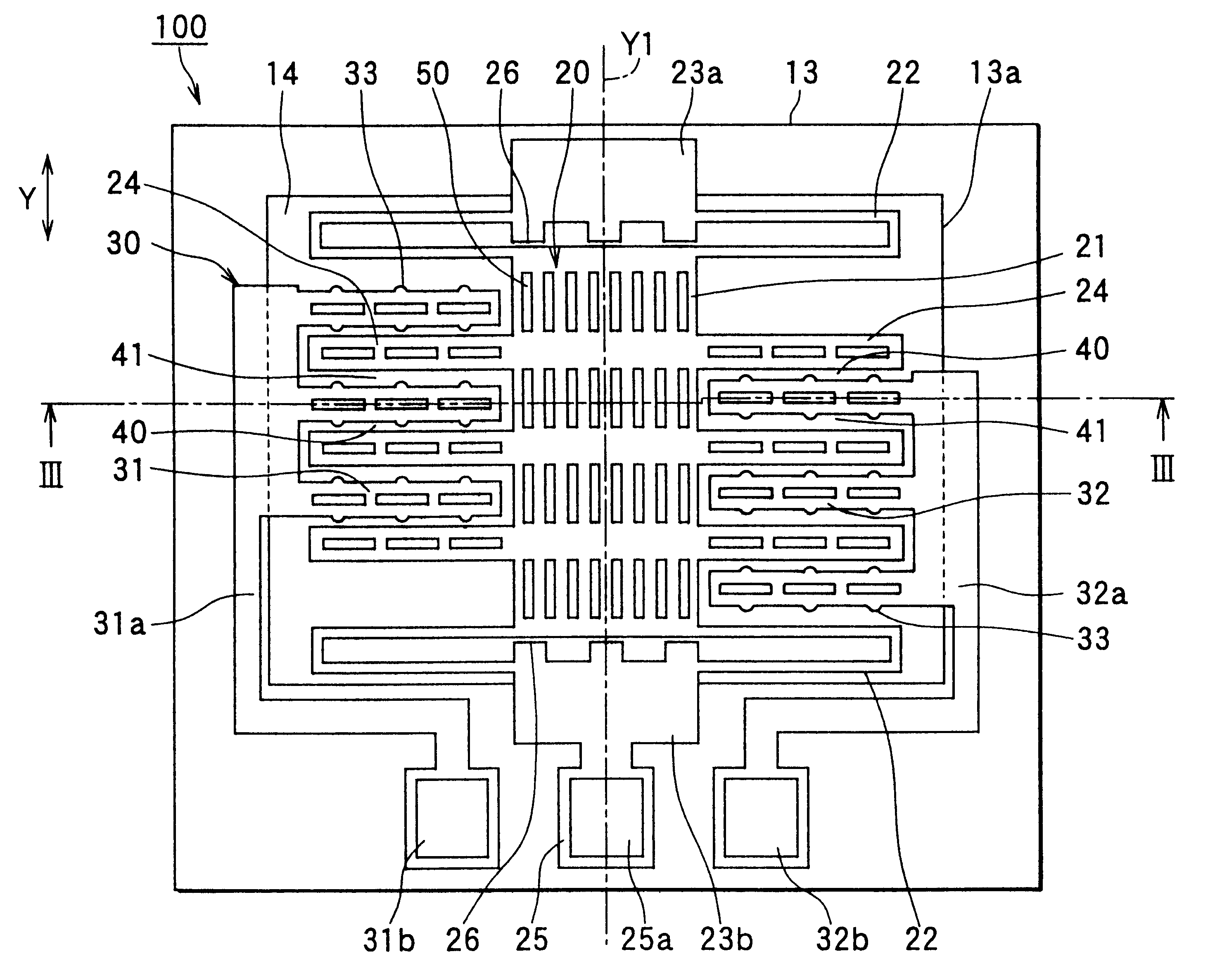

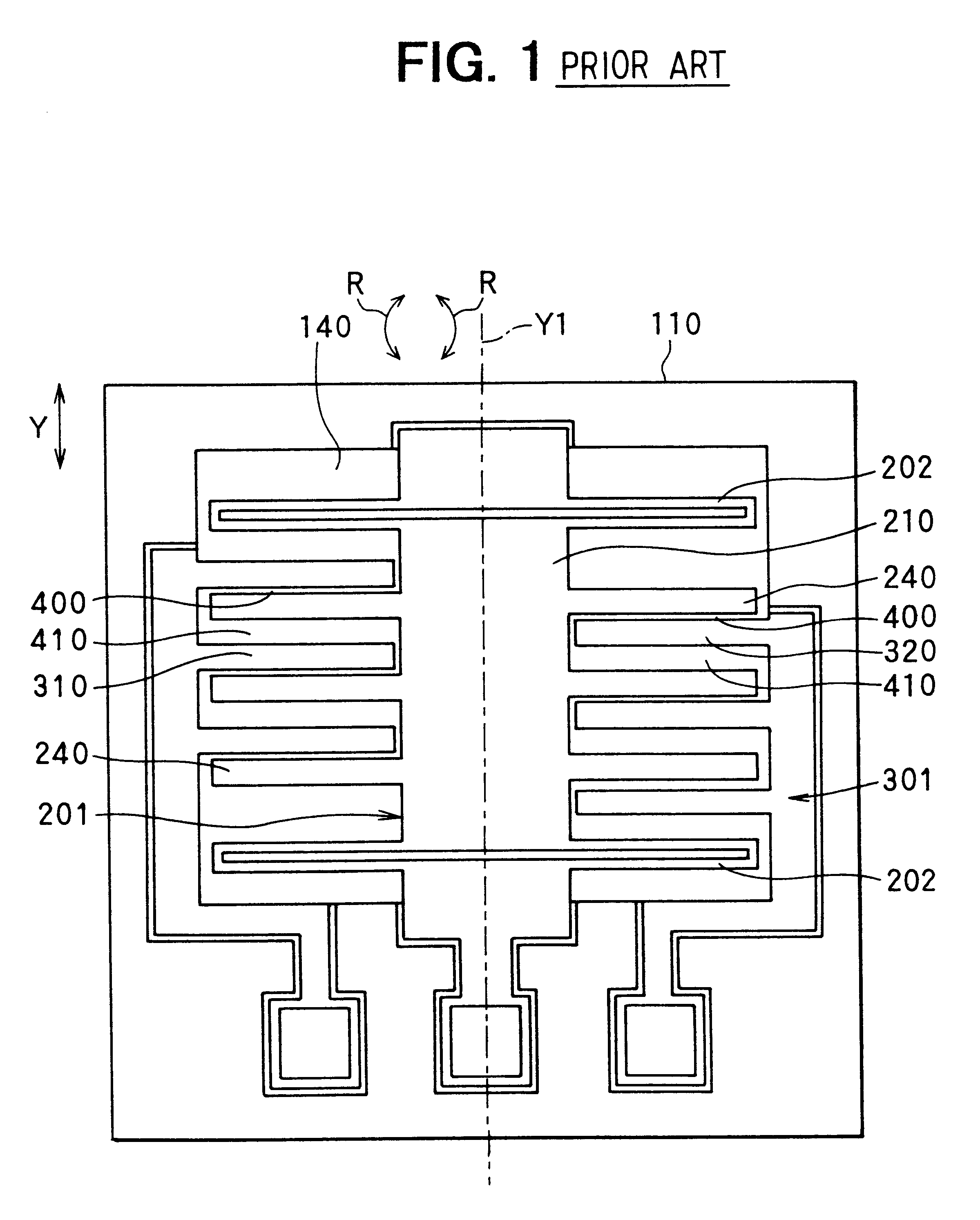

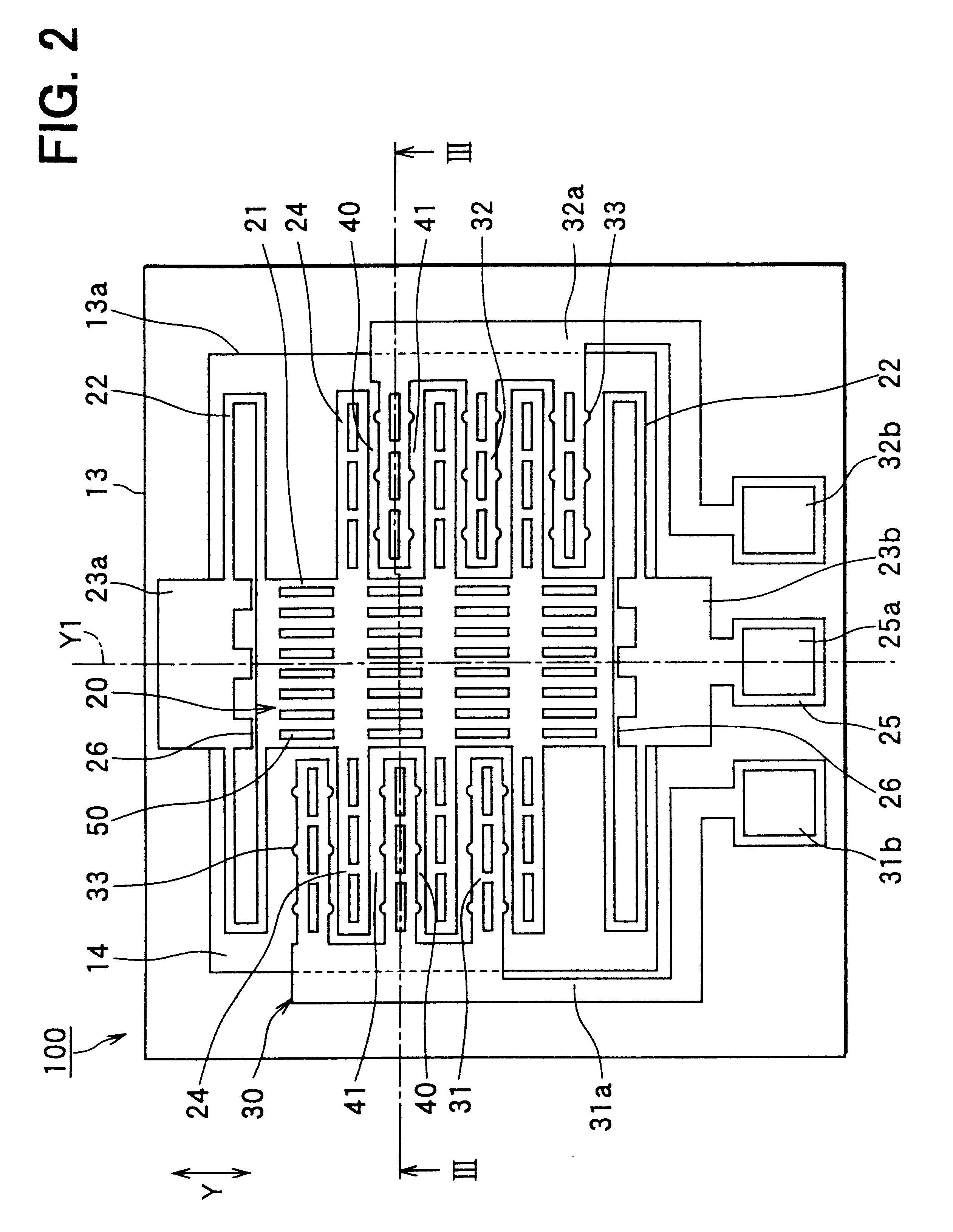

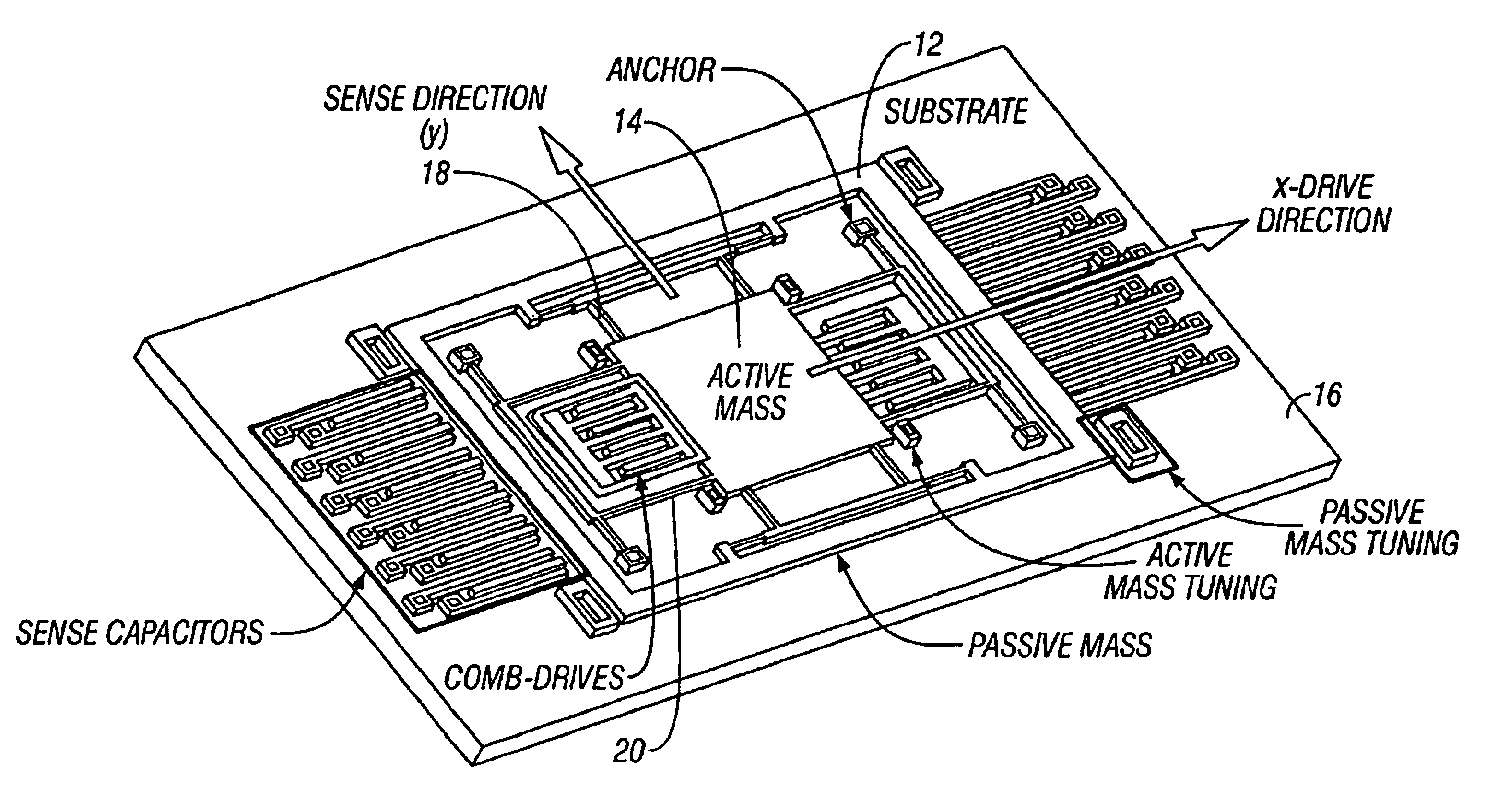

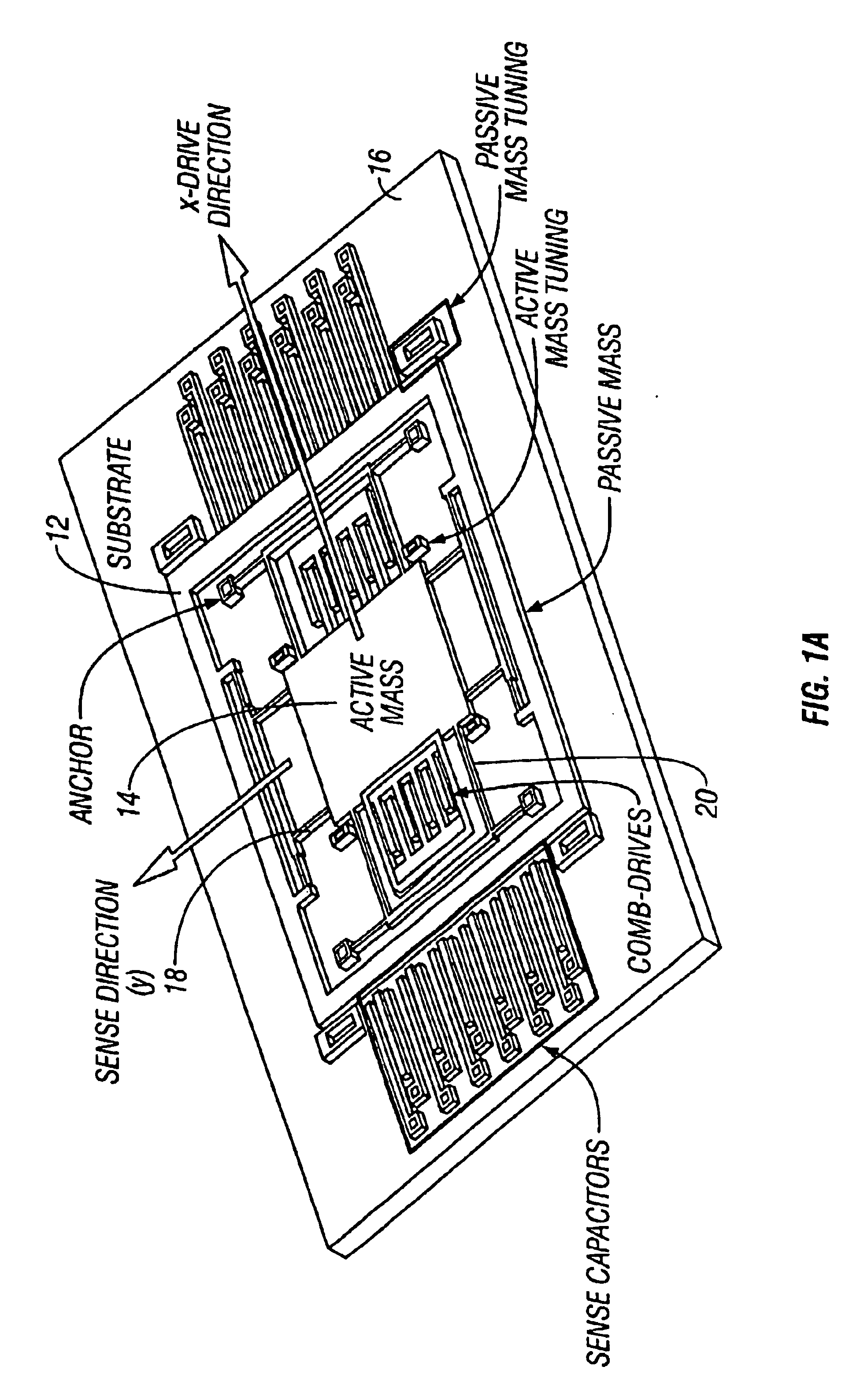

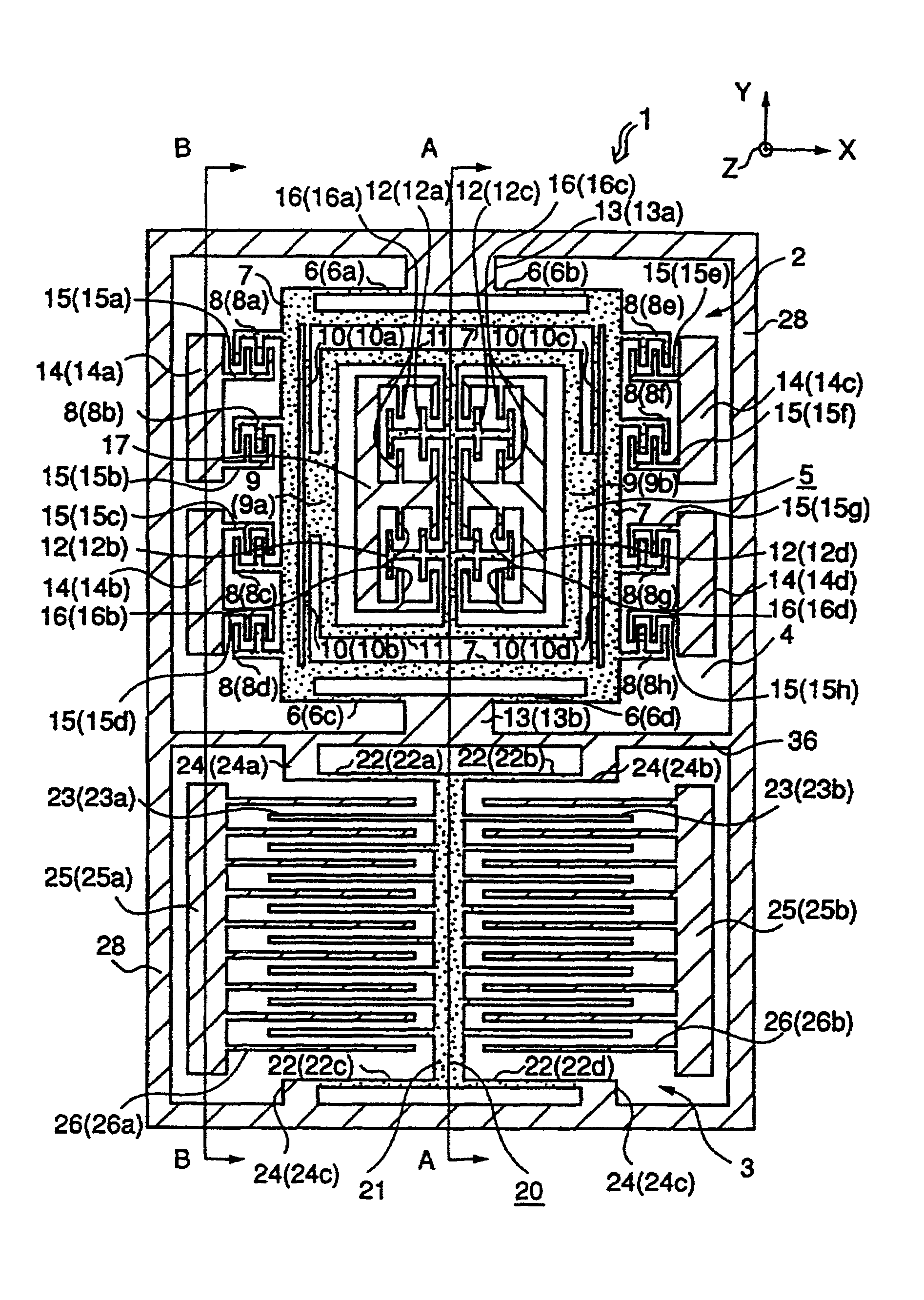

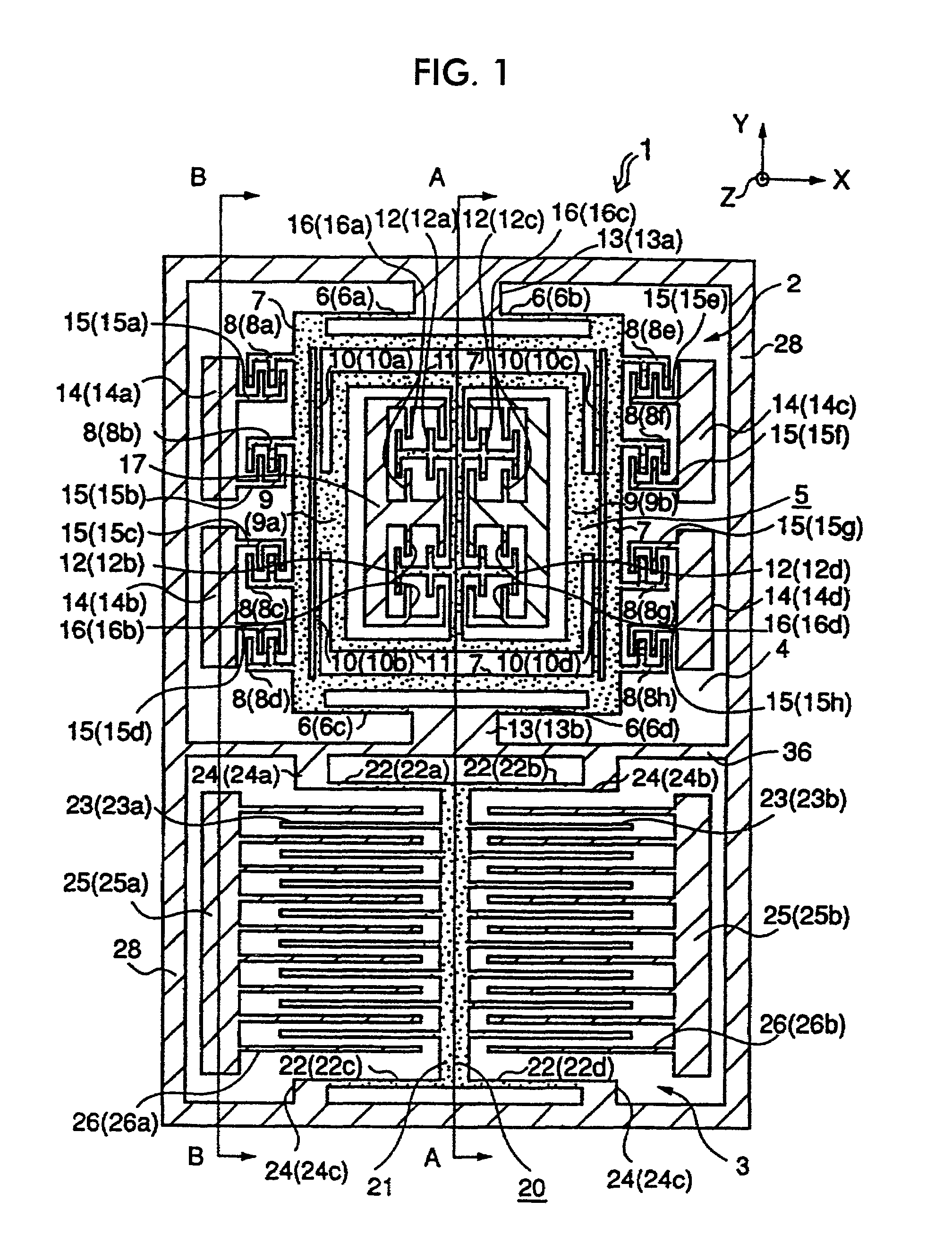

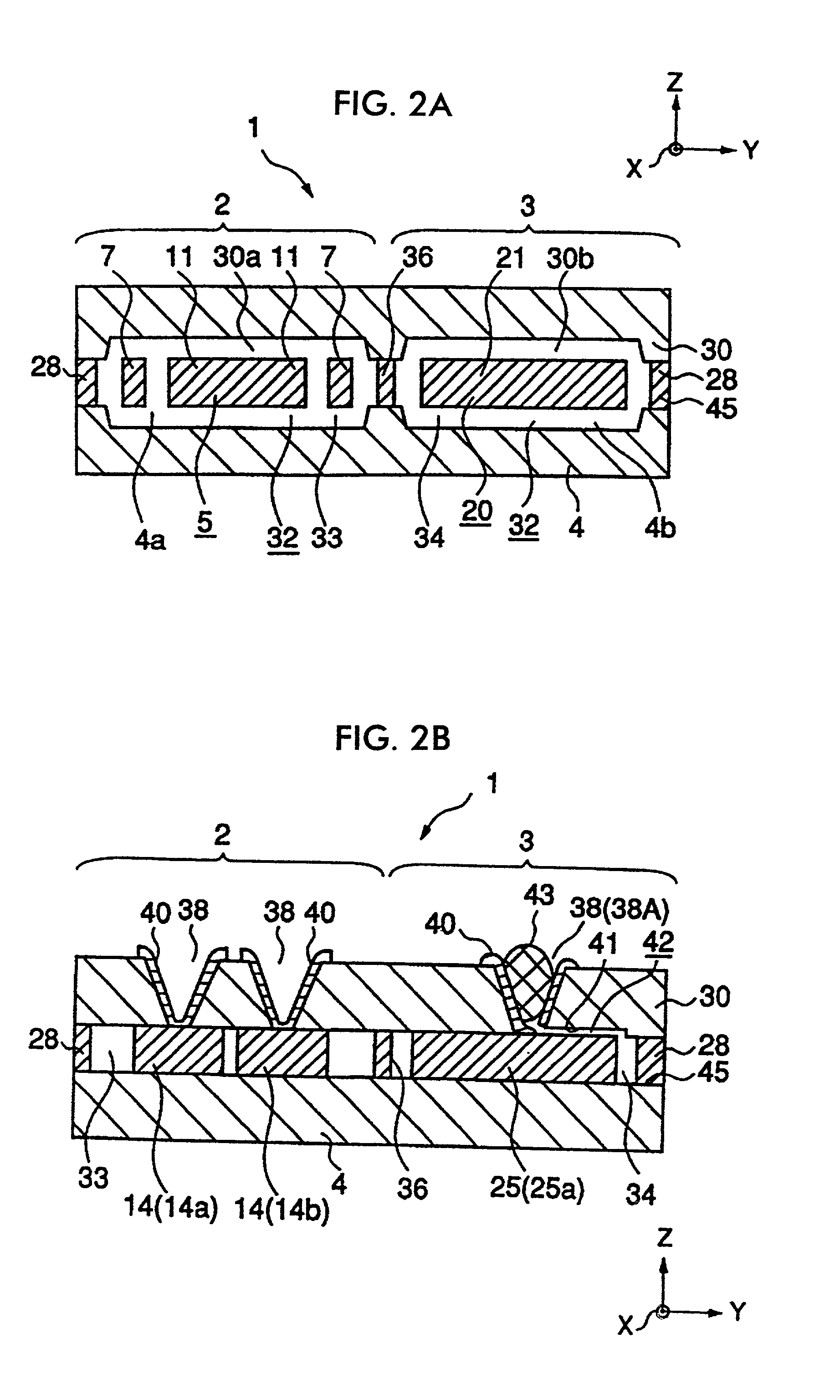

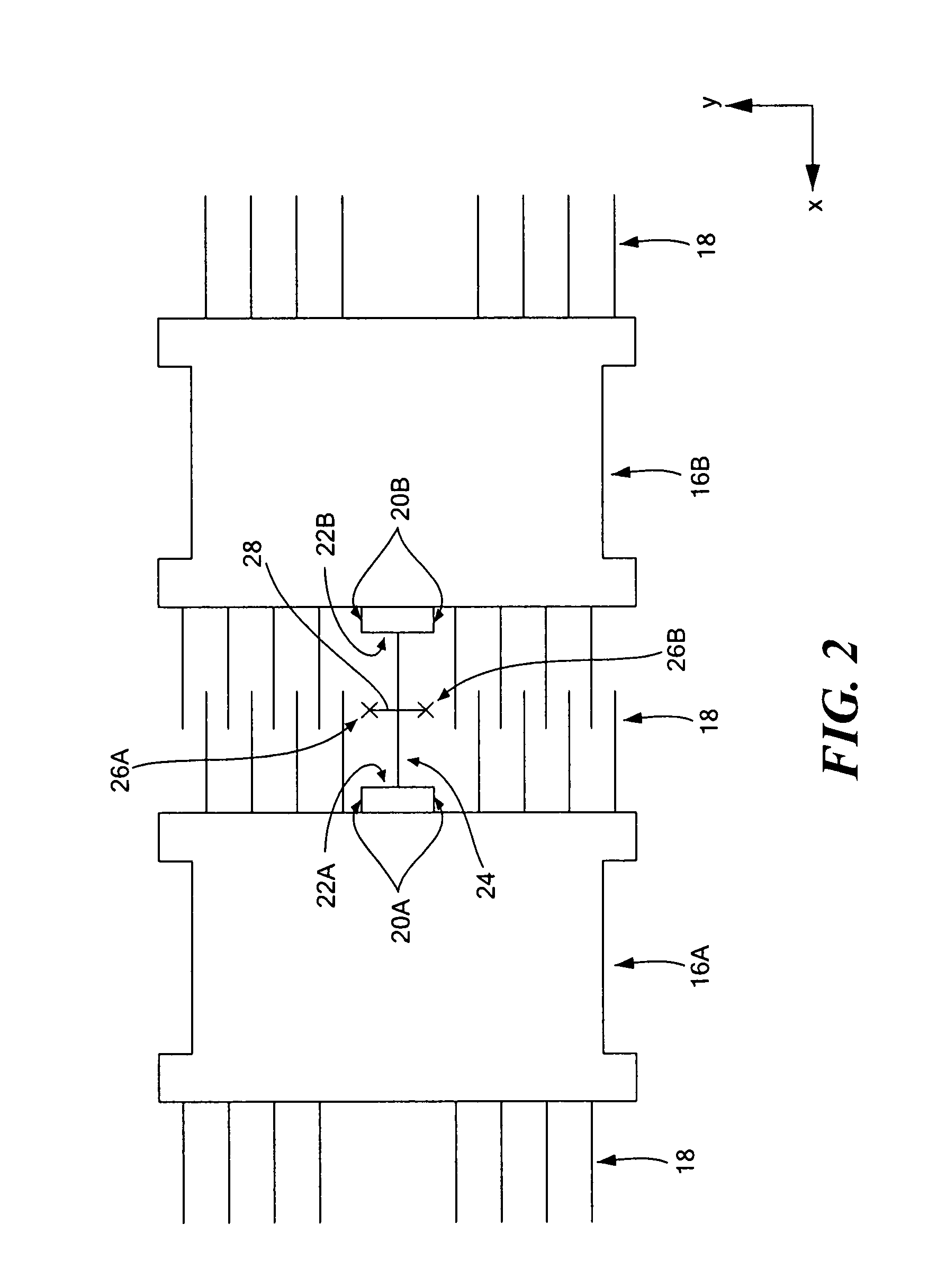

Micro-machined multi-sensor providing 1-axis of acceleration sensing and 2-axes of angular rate sensing

InactiveUS6837107B2Easy to centerReduce adverse effectsAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsAccelerometerClassical mechanics

A micro-machined multi-sensor that provides 1-axis of acceleration sensing and 2-axes of angular rate sensing. The multi-sensor includes a plurality of accelerometers, each including a mass anchored to and suspended over a substrate by a plurality of flexures. Each accelerometer further includes acceleration sense electrode structures disposed along lateral and longitudinal axes of the respective mass. The multi-sensor includes a fork member coupling the masses to allow relative antiphase movement, and to resist in phase movement, of the masses, and a drive electrode structure for rotationally vibrating the masses in antiphase. The multi-sensor provides electrically independent acceleration sense signals along the lateral and longitudinal axes of the respective masses, which are added and / or subtracted to obtain 1-axis of acceleration sensing and 2-axes of angular rate sensing.

Owner:ANALOG DEVICES INC

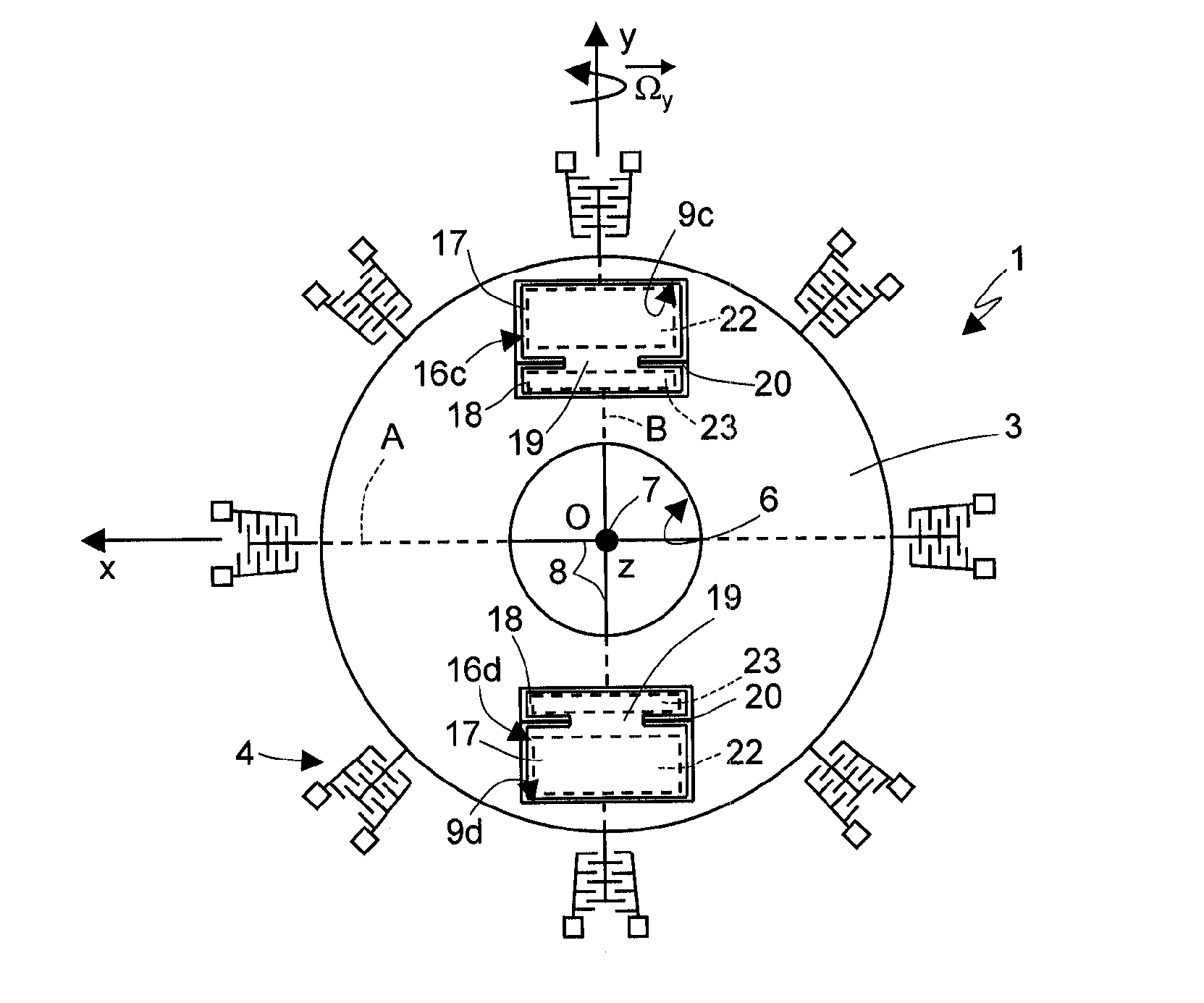

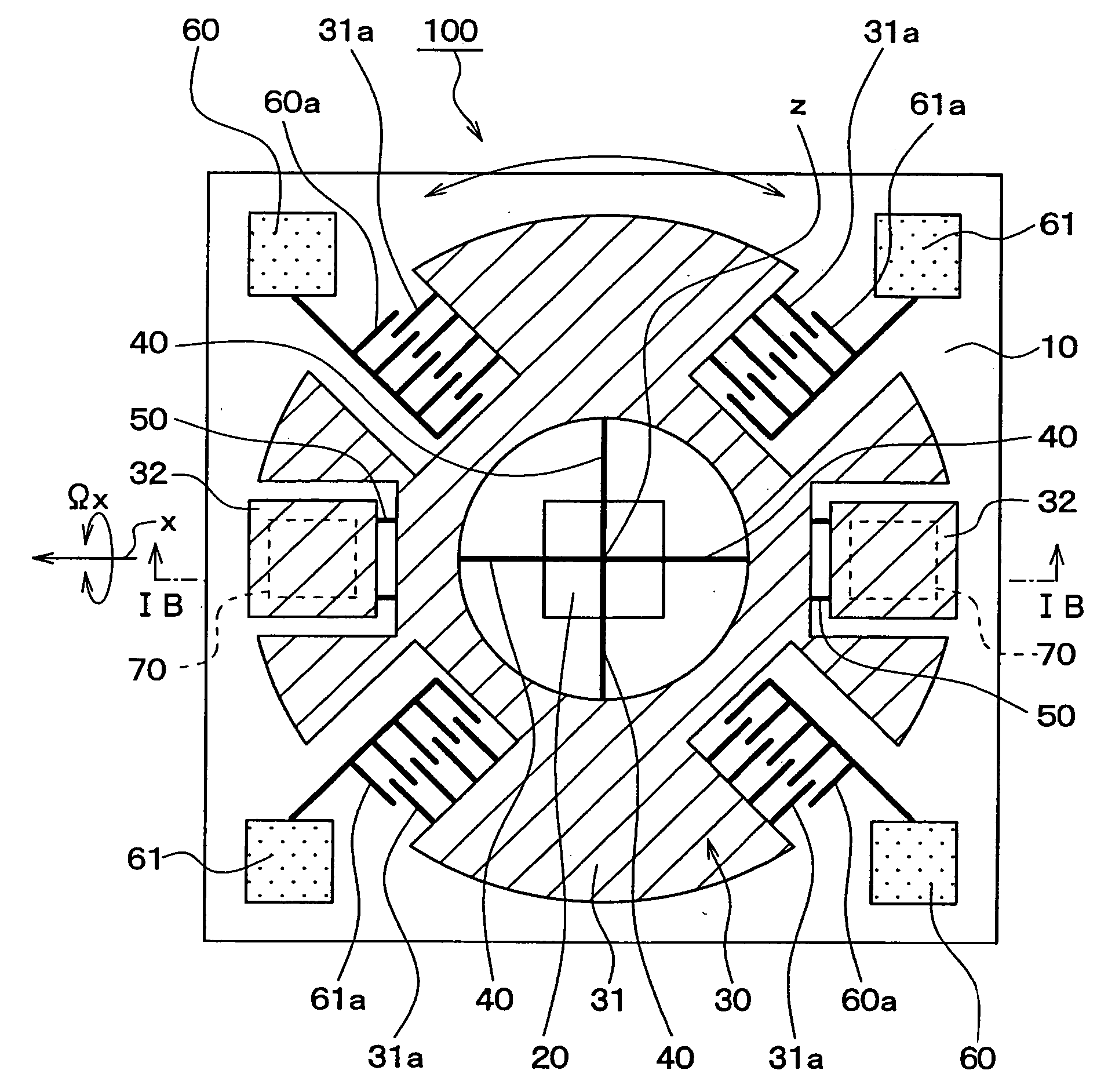

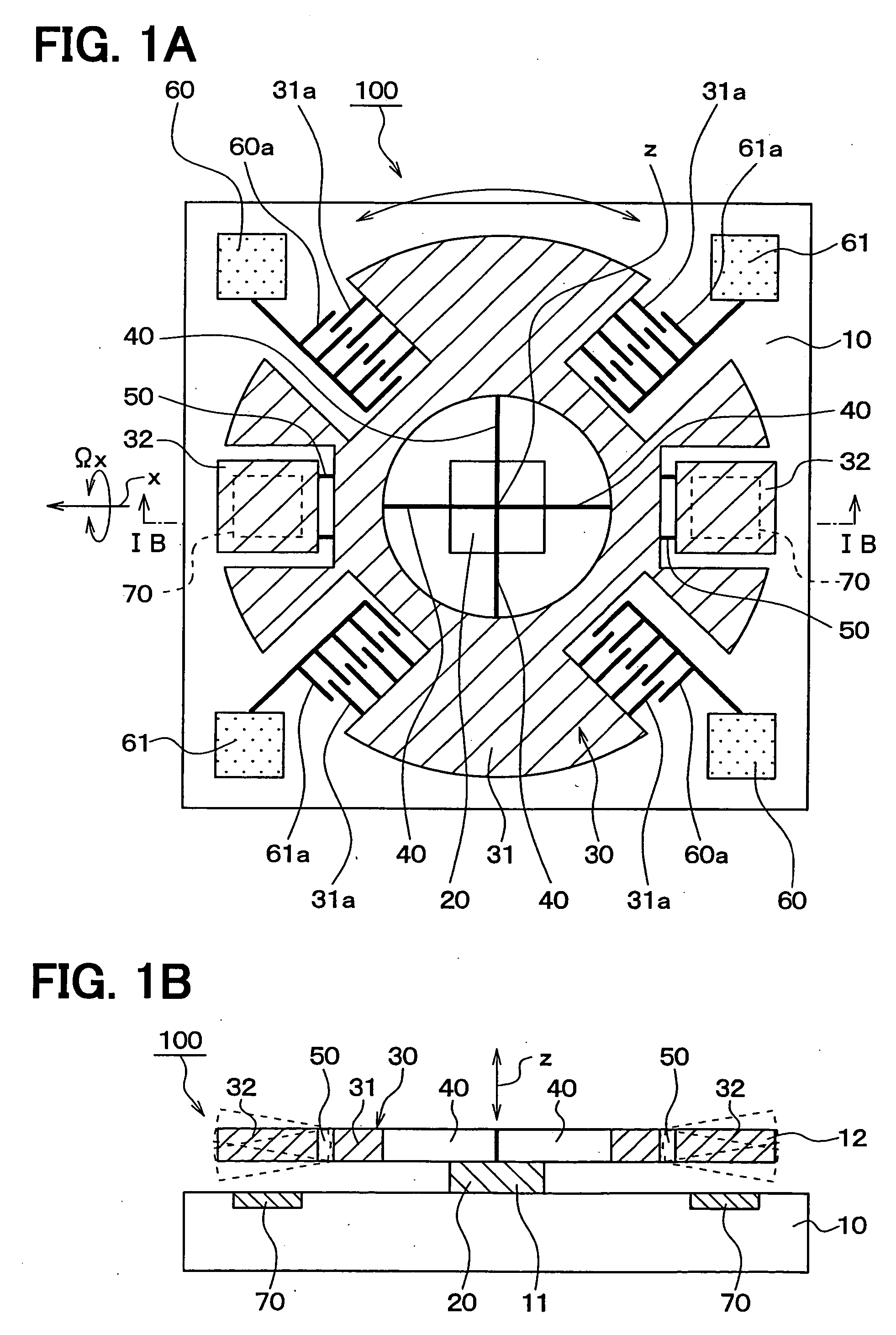

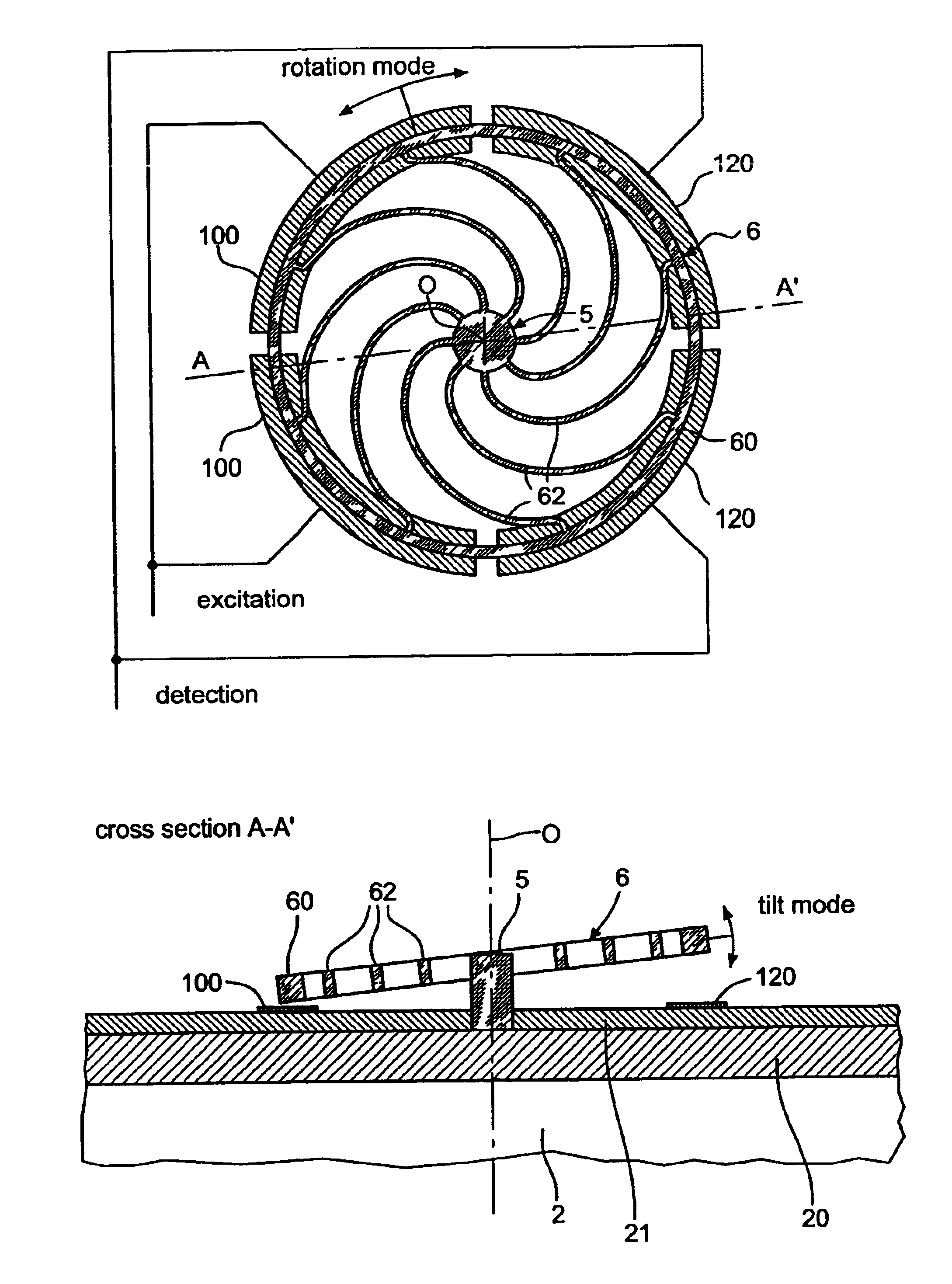

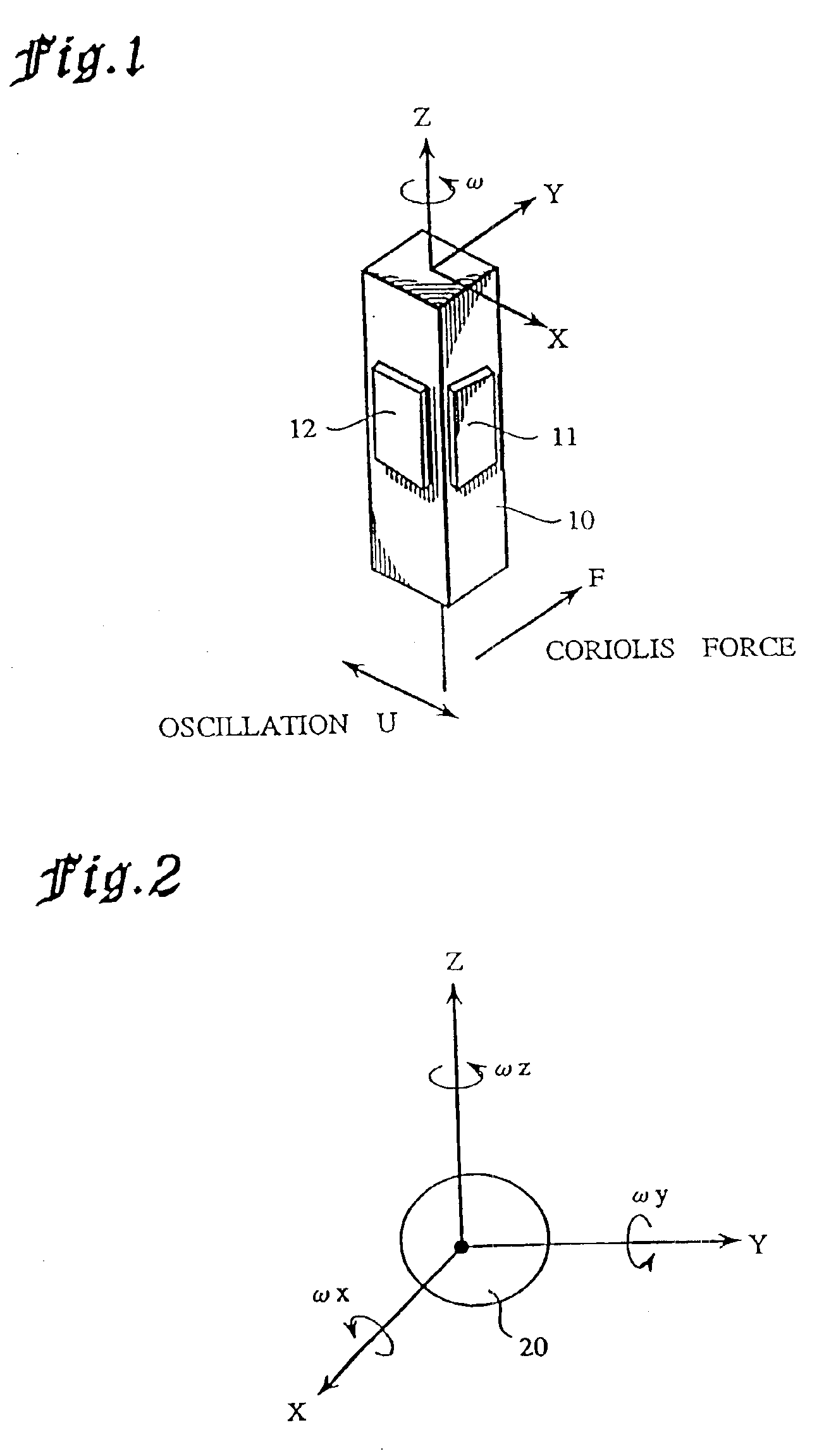

Angular velocity detector having inertial mass oscillating in rotational direction

InactiveUS20060112764A1Simple designEasy to manufactureAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsCapacitanceInertial mass

An angular velocity detector includes a disk-shaped inertial mass supported on a substrate via driving beams and a second mass connected to the inertial mass via detecting beams. The inertial mass is oscillated in its rotational direction around a center axis (z) by an electrostatic force. When an angular velocity around a detection axis (x), which is perpendicular to the center axis (z), is imposed on the second mass while the inertial mass is oscillating, the second mass displaces in the direction parallel to the center axis (z). A capacitance between the second mass and the substrate changes according to the displacement of the second mass. The angular velocity is detected based on the changes in the capacitance. Since the driving beams allow the inertial mass to oscillate only in the rotational direction, the driving beams can be easily designed and manufactured.

Owner:DENSO CORP

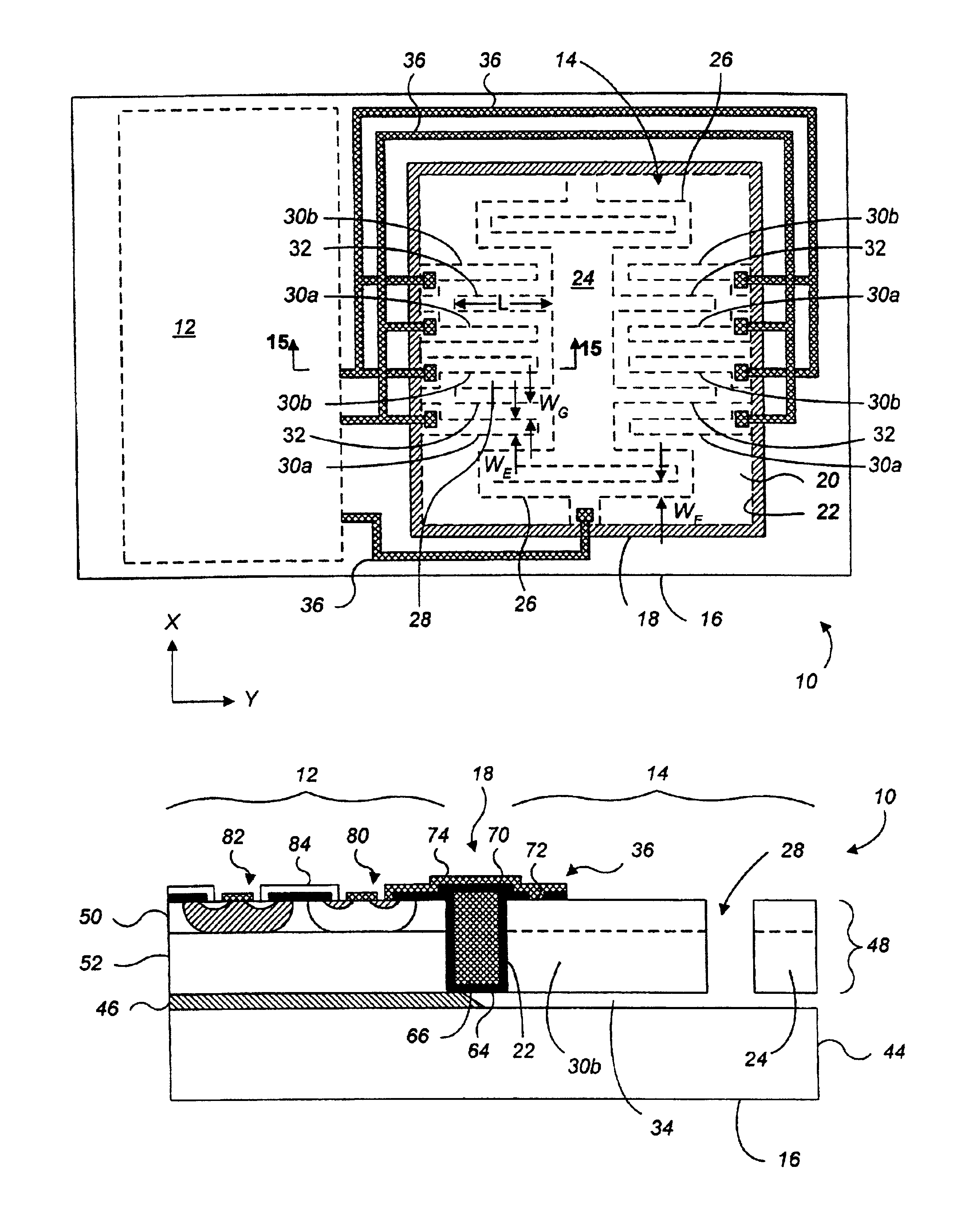

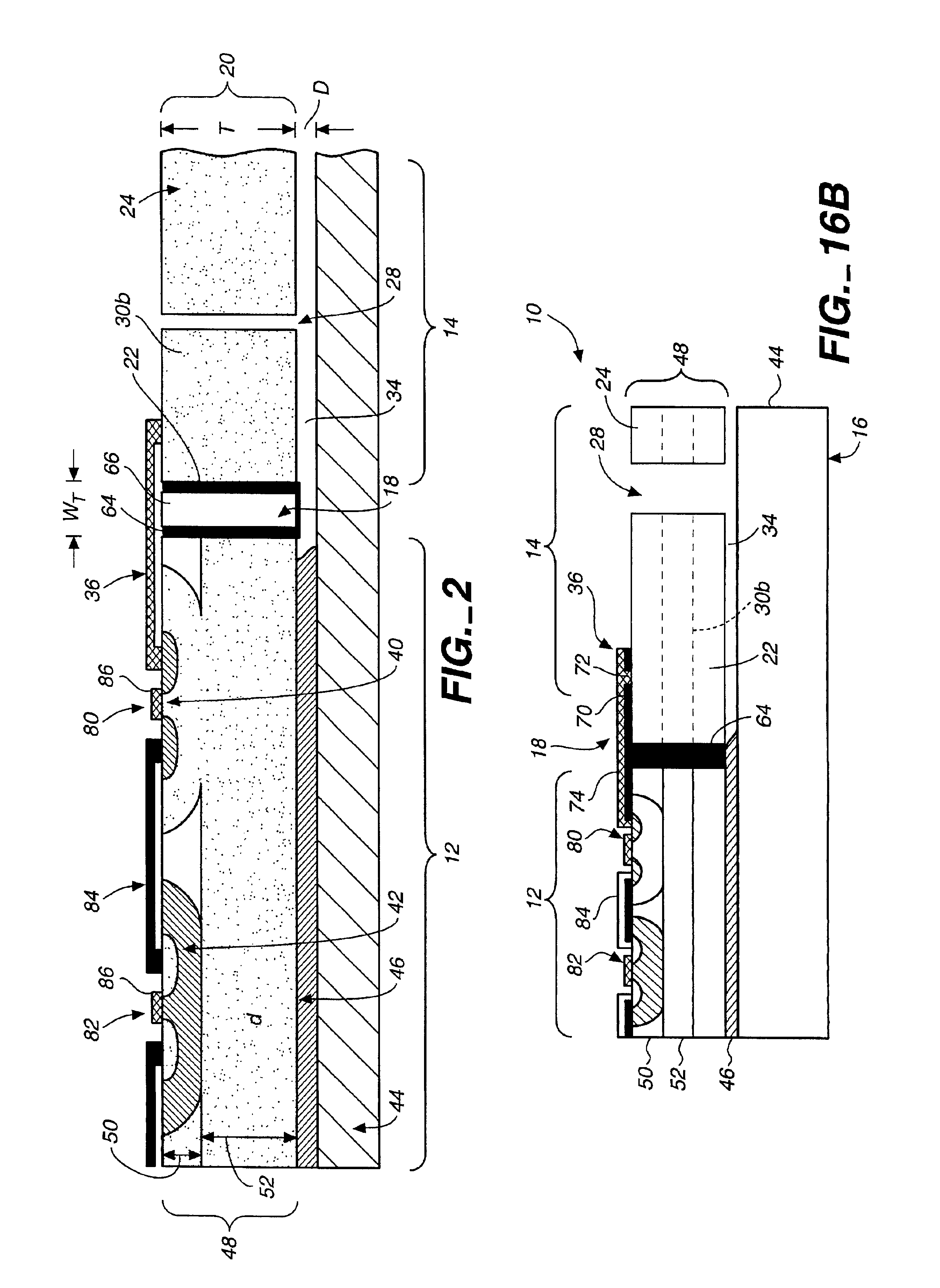

Method of fabricating a microfabricated high aspect ratio device with electrical isolation

InactiveUS6960488B2High aspect ratioLarge sense capacitanceTelevision system detailsAcceleration measurement using interia forcesInterconnectionMicrostructure

A microfabricated device having a high vertical aspect ratio and electrical isolation between a structure region and a circuit region. The device may be fabricated on a single substrate and may include electrical interconnections between the structure region and the circuit region. The device includes a substrate and an isolation trench surrounding a structure region in the substrate. The isolation trench includes a lining of a dielectric insulative material. A plurality of microstructure elements are located in the structure region and are laterally anchored to the isolation trench.

Owner:RGT UNIV OF CALIFORNIA

Microelectromechanical integrated sensor structure with rotary driving motion

ActiveUS7694563B2Easy to manufactureStrong configurabilityAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsLinear motionEngineering

A driving mass of an integrated microelectromechanical structure is moved with a rotary motion about an axis of rotation, and a first sensing mass is connected to the driving mass via elastic supporting elements so as to perform a first detection movement in a presence of a first external stress. The driving mass is anchored to an anchorage arranged along the axis of rotation by elastic anchorage elements. An opening is provided within the driving mass and the first sensing mass is arranged within the opening. The elastic supporting and anchorage elements render the first sensing mass fixed to the driving mass in the rotary motion, and substantially decoupled from the driving mass in the first detection movement. A second sensing mass is connected to the driving mass so as to perform a second detection movement in a presence of a second external stress. A first movement is a rotation about an axis lying in a plane, and a second movement is a linear movement along an axis of the plane.

Owner:STMICROELECTRONICS SRL

Micro-electro-mechanical gyroscope

InactiveUS6516665B1High sensitivityEasy to detectPiezoelectric/electrostriction/magnetostriction machinesImpedence networksElectricityGyroscope

A gyroscope comprises a piezoelectric substrate having a surface. Disposed on the surface are a resonator transducer, a pair of reflectors, a structure such as a metallic dot, and a sensor transducer. The resonator transducer creates a first surface acoustic wave on the surface. The pair of reflectors reflects the first surface acoustic wave to form a standing wave within a region of the surface between the pair of reflectors. The structure is disposed on the surface within the region, wherein a Coriolis force acting upon the structure creates a second surface acoustic wave. The sensor senses the second surface acoustic wave and provides an output indicative thereof.

Owner:PENN STATE RES FOUND

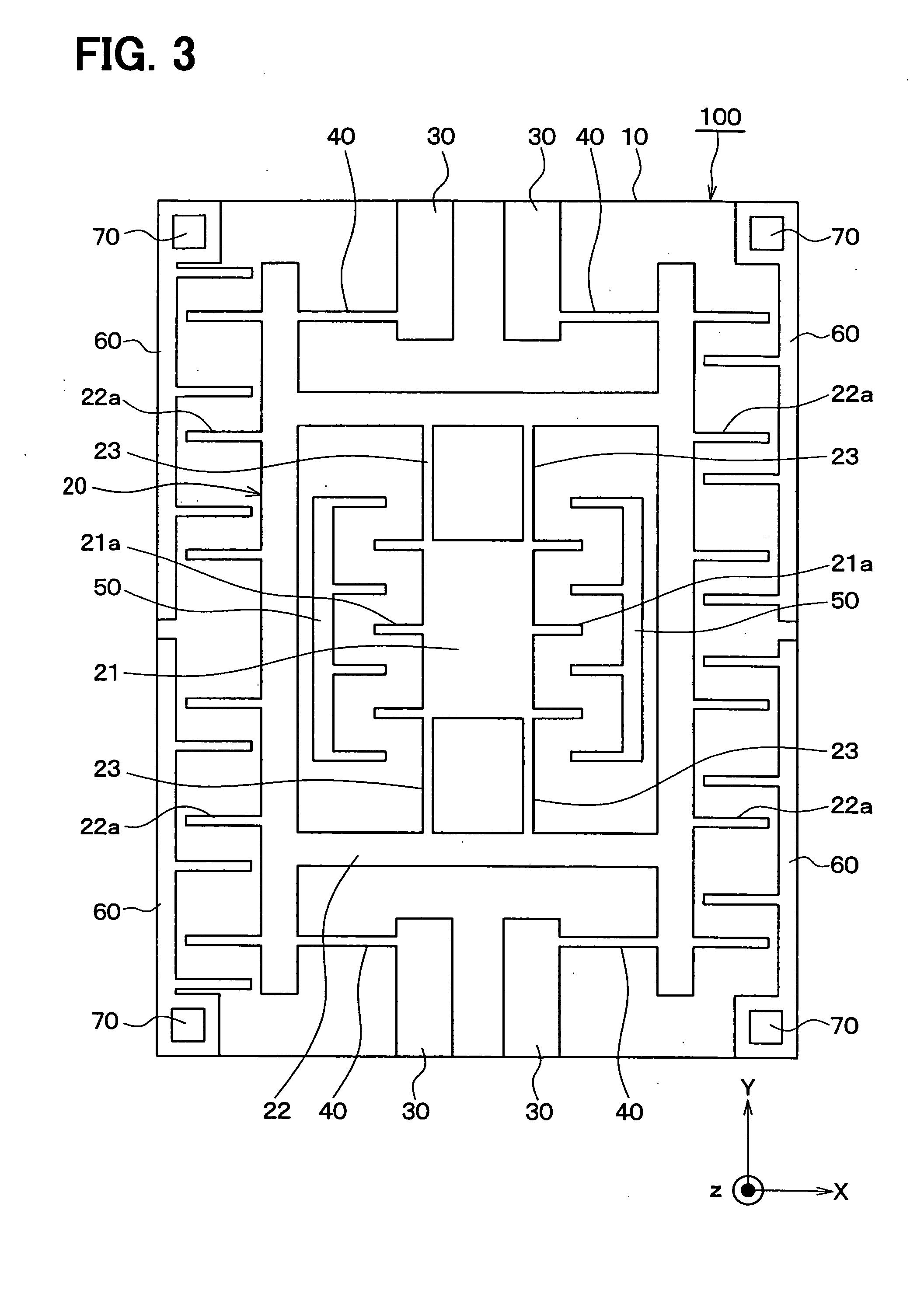

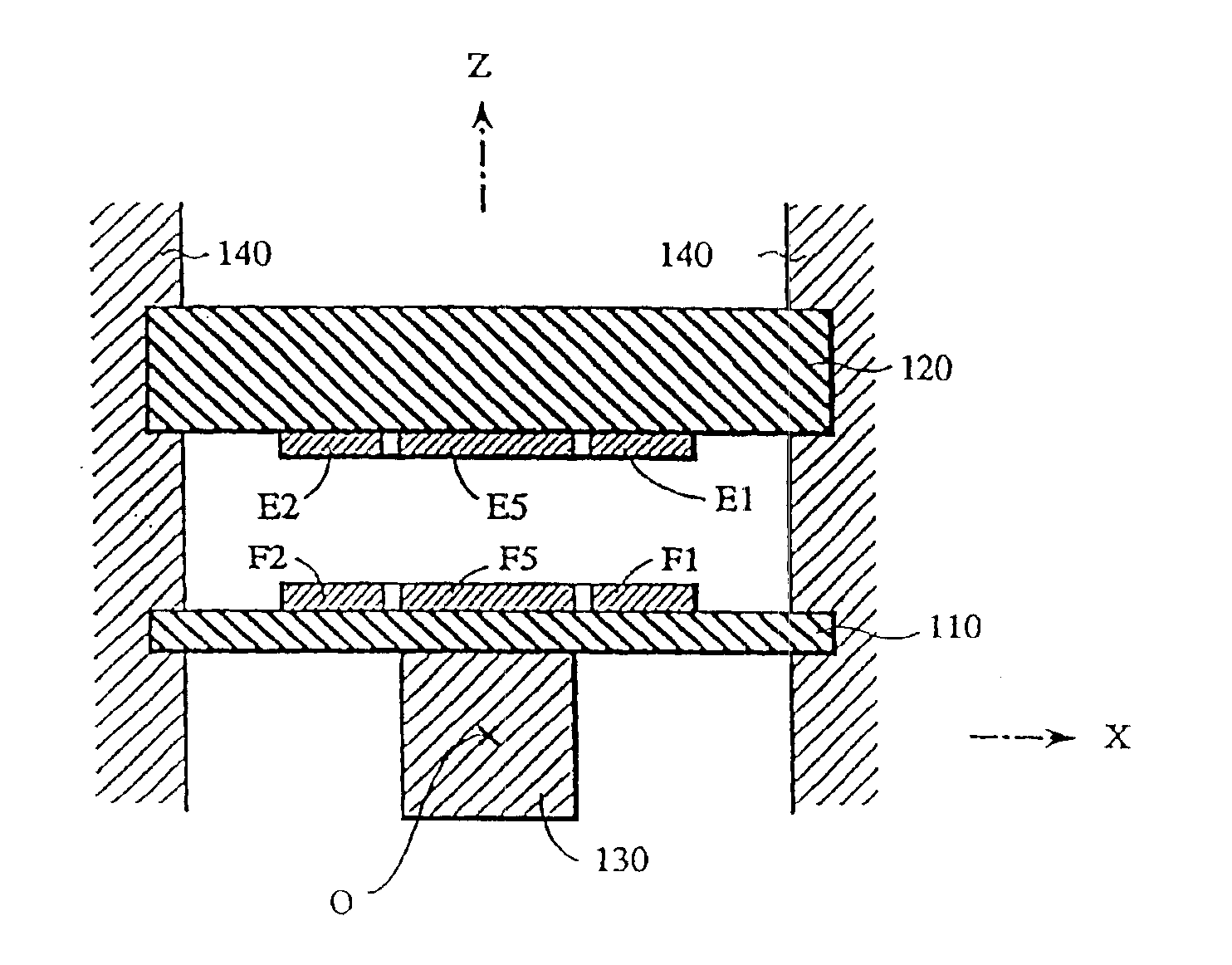

Semiconductor physical quantity sensor

A semiconductor acceleration sensor, which prevents an adhesion of a movable electrode to a first or second fixed electrode due to an electrostatic attracting force generated therebetween. The sensor has a weight portion and movable electrodes formed on both sides of which, and first and second fixed electrodes each engaging with the each of the movable electrodes. Each of the first and second fixed electrodes is disposed in parallel with each of the movable electrodes so that side faces thereof determine a detection interval and non-detection interval larger than the detection interval with side faces of adjoining two of the movable electrodes. Protrusions are formed on both of the side faces of each of the first and second fixed electrodes. These protrusions prevent the movable electrodes from adhering to the first or second fixed electrode in both of the detection interval and non-detection interval.

Owner:DENSO CORP

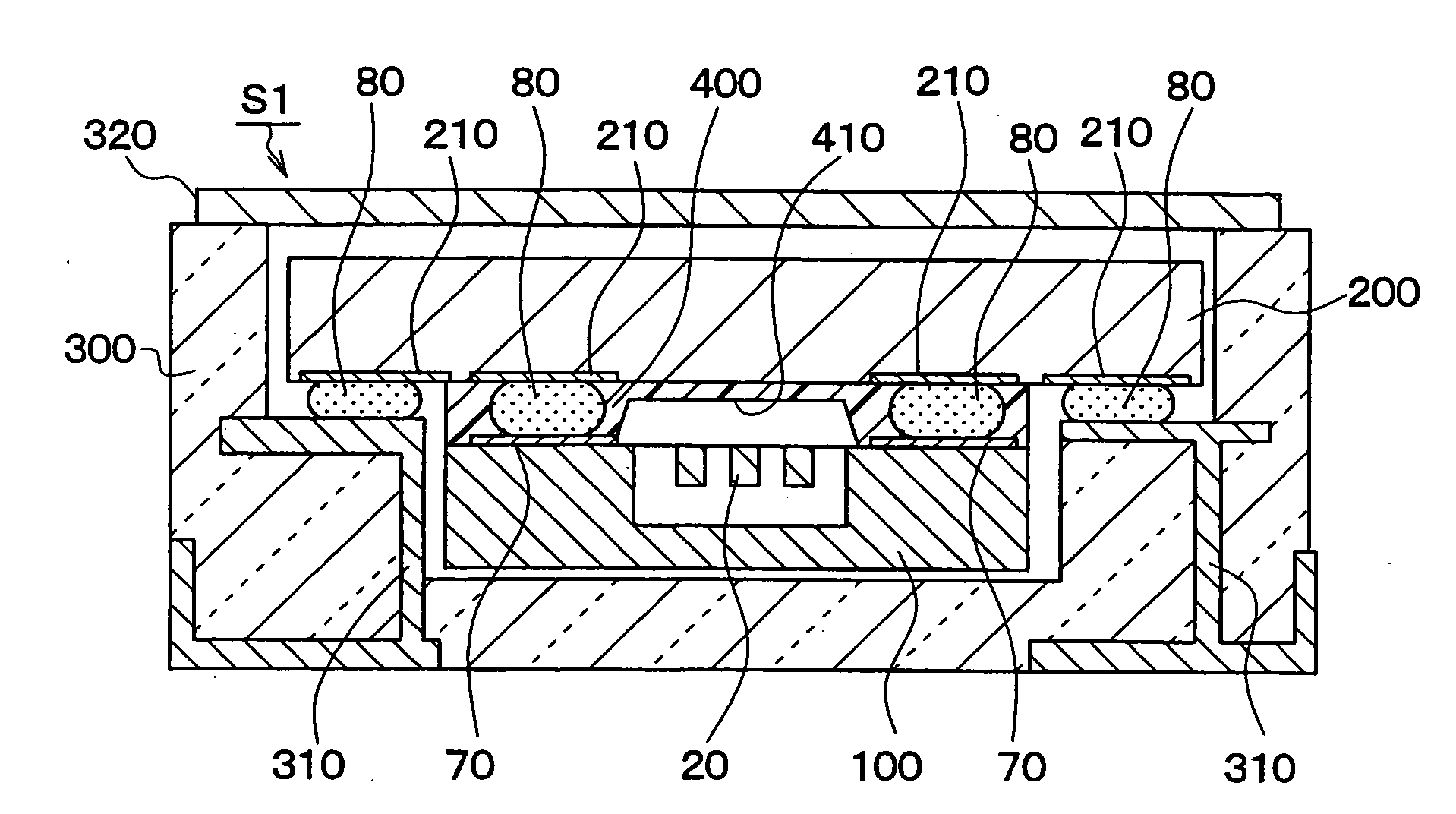

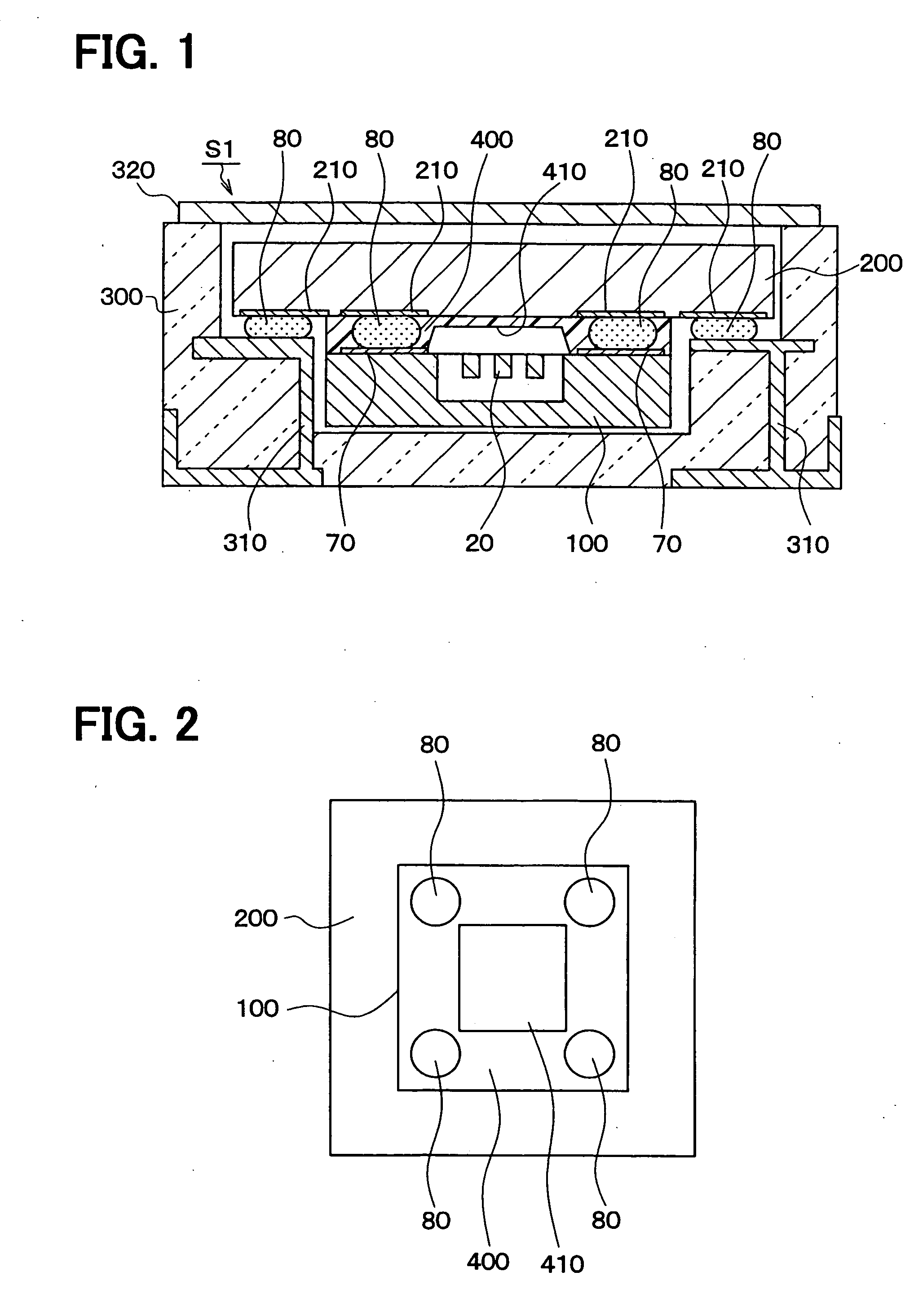

Sensor device

InactiveUS20060097331A1Limited their electrical capabilitiesReduce capacityAcceleration measurement using interia forcesSemiconductor/solid-state device detailsAngular velocityParasitic capacitance

A sensor device includes a sensor chip having a movable portion on one surface, a circuit chip laminated with the sensor chip to be opposite to the movable portion of the sensor chip, and a bump located between the sensor chip and the circuit chip. In the sensor device, the sensor chip and the circuit chip are electrically connected through the bump, and the movable portion of the sensor chip is separated from the circuit chip by a space using the bump. Accordingly, it can effectively restrict parasitic capacity of an electric connecting portion between both the chips from being changed by an impact. For example, the sensor device can be used as an angular velocity sensor device having a vibrator as the movable portion.

Owner:DENSO CORP

Temperature compensation mechanism for a micromechanical ring resonator

InactiveUS6859113B2Additional requirementAcceleration measurement using interia forcesImpedence networksVIT signalsAtomic physics

A time base including a resonator (4) and an integrated electronic circuit (3) for driving the resonator into oscillation and for producing, in response to the oscillation, a signal having a determined frequency. The resonator is an integrated micromechanical ring resonator supported above a substrate (2) and adapted to oscillate in a first oscillation mode. The ring resonator includes a free-standing oscillating structure (6). Electrodes (100, 120; 130, 150) are positioned under the free-standing oscillating structure in such a way as to drive and sense a second oscillation mode in a plane substantially perpendicular to the substrate and having a resonant frequency which is different from the resonant frequency of the first oscillation mode, a frequency difference between the resonant frequencies of both oscillation modes being used for compensating for the effect of temperature on the frequency of the signal produced by the time base.

Owner:ETA SA MFG HORLOGERE SUISSE

Z-axis angular rate sensor

ActiveUS7036372B2Acceleration measurement using interia forcesSpeed measurement using gyroscopic effectsTuning forkAngular rate sensor

An oscillatory rate sensor is described for sensing rotation about the “z-axis”. It is tuning-fork in nature with structural linkages and dynamics such that fundamental anti-phase oscillation of two proof masses is accomplished by virtue of the mechanical linkages.

Owner:ROHM CO LTD

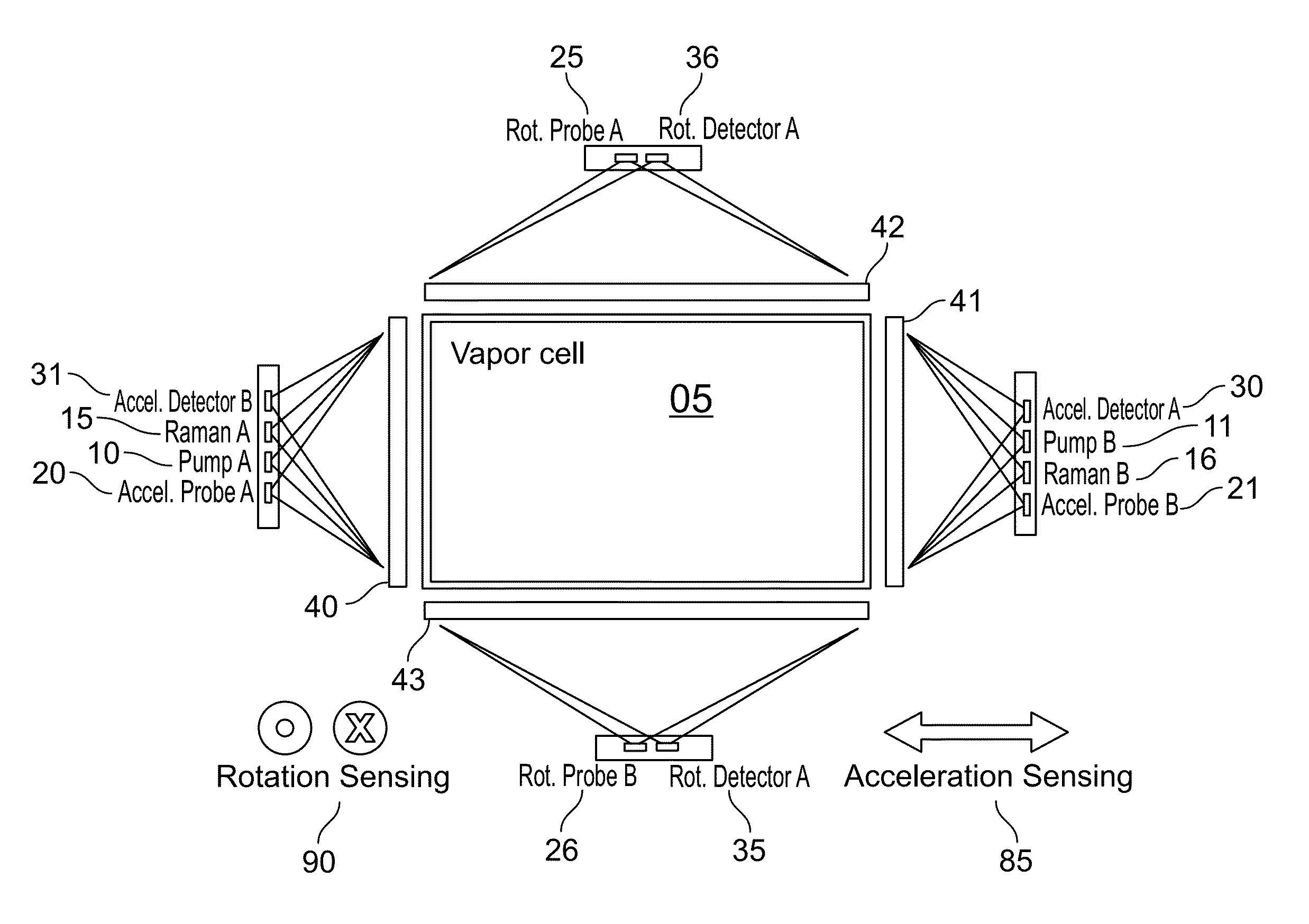

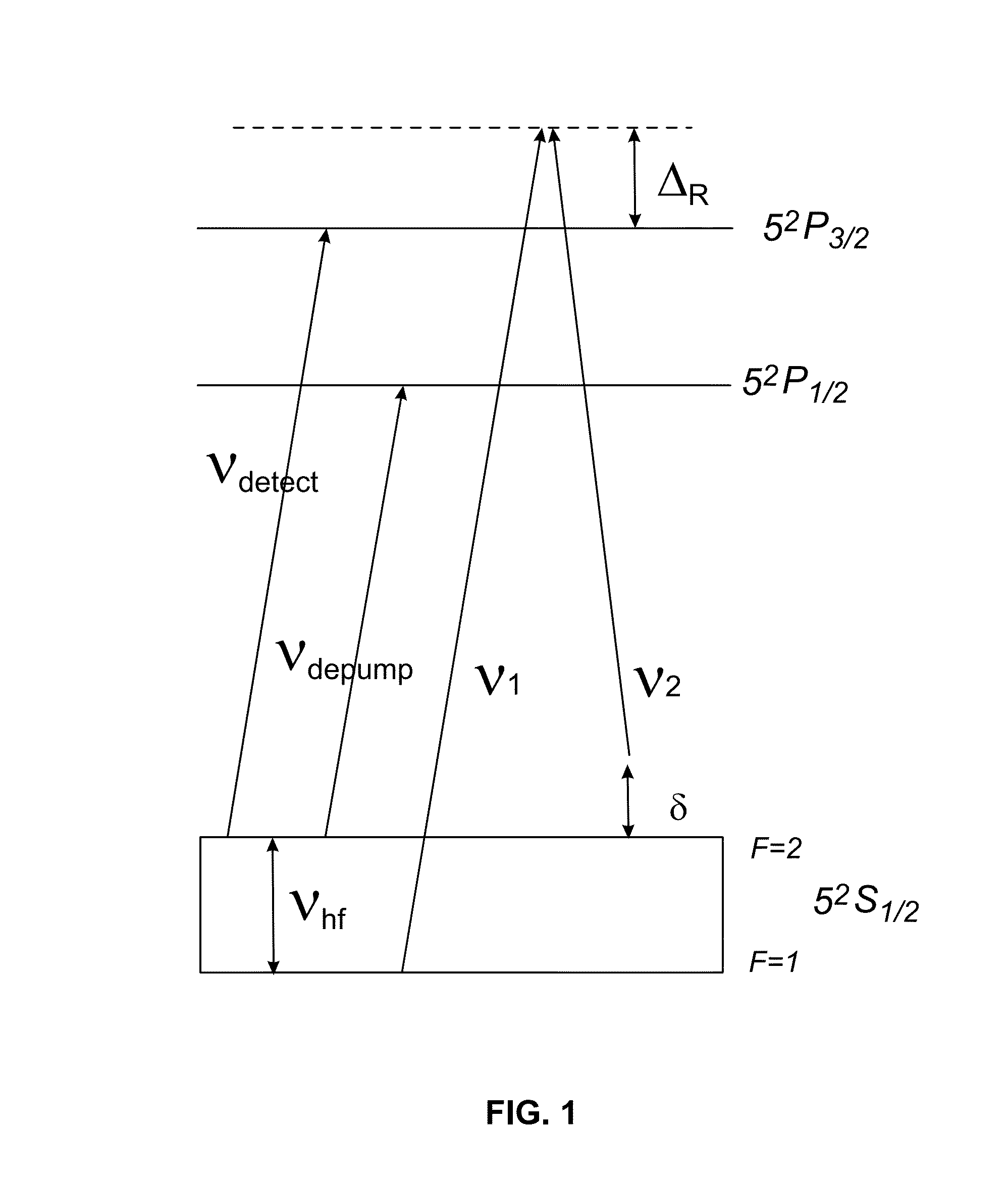

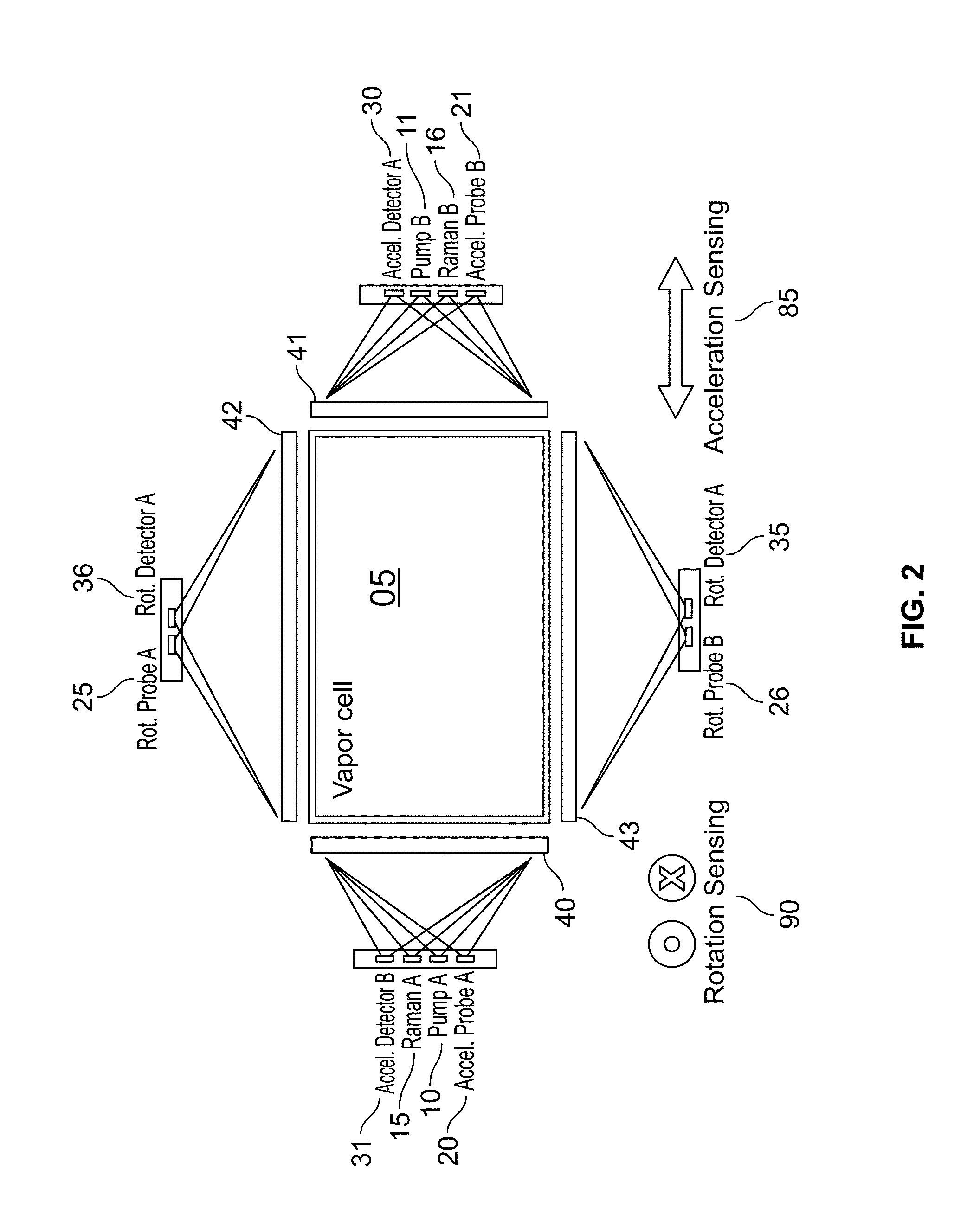

Light-pulse atom interferometric device

ActiveUS9291508B1Optical measurementsAcceleration measurement using interia forcesChemical speciesOptic system

An atomic interferometric device useful, e.g., for measuring acceleration or rotation is provided. The device comprises at least one vapor cell containing a Raman-active chemical species, an optical system, and at least one detector. The optical system is conformed to implement a Raman pulse interferometer in which Raman transitions are stimulated in a warm vapor of the Raman-active chemical species. The detector is conformed to detect changes in the populations of different internal states of atoms that have been irradiated by the optical system.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Non-resonant four degrees-of-freedom micromachined gyroscope

InactiveUS6845669B2WideOscillation amplitude is largeMechanical apparatusAcceleration measurement using interia forcesGyroscopeEngineering

A micromachined design and method with inherent disturbance-rejection capabilities is based on increasing the degrees-of-freedom (DOF) of the oscillatory system by the use of two independently oscillating proof masses. Utilizing dynamical amplification in the 4-degrees-of-freedom system, inherent disturbance rejection is achieved, providing reduced sensitivity to structural and thermal parameter fluctuations and damping changes over the operating time of the device. In the proposed system, the first mass is forced to oscillate in the drive direction, and the response of the second mass in the orthogonal direction is sensed. The response has two resonant peaks and a flat region between peaks. Operation is in the flat region, where the gain is insensitive to frequency fluctuations. An over 15 times increase in the bandwidth of the system is achieved due to the use of the proposed architecture. In addition, the gain in the operation region has low sensitivity to damping changes. Consequently, by utilizing the disturbance-rejection capability of the dynamical system, improved robustness is achieved, which can relax tight fabrication tolerances and packaging requirements and thus result in reducing production cost of micromachined methods.

Owner:RGT UNIV OF CALIFORNIA

Angular velocity sensor

InactiveUS6941810B2Simple structureAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsCapacitanceAngular velocity

An angular velocity sensor for detecting an angular velocity component includes an oscillator having mass, a sensor casing for accommodating the oscillator therewithin, a flexible member for connecting the oscillator to the sensor casing so that the oscillator can be moved with respect to the sensor casing, and capacitance elements including a first electrode provided on a surface of the oscillator and a second electrode provided on a surface of a fixed member fixed to the sensor casing.

Owner:WAKO CO LTD

Composite sensor device and method of producing the same

InactiveUS7004025B2High detection sensitivityAvoid vibrationAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsAngular velocityAtmospheric pressure

A plane vibrator of an angular velocity sensor and a movable member of an acceleration sensor are provided in a spaced floating state on the same substrate. A lid is formed so as to cover and be spaced from the upper side of the plane vibrator and the movable member. A space defined by the substrate and the lid is sectioned into a angular velocity sensor space and an acceleration sensor space by use of a sectioning wall. The angular velocity sensor space is hermetically sealed to be in the vacuum state. The acceleration sensor space is hermetically sealed to be under atmospheric pressure. The plane vibrator is vibrated at a high frequency and a large amplitude so that the angular velocity detection sensitivity is enhanced. The movable member, even if vibration of the plane vibrator is transmitted thereto, is prevented from vibrating at a high frequency and a large amplitude, due to the damping effect of air. Thus, the acceleration detection sensitivity is enhanced.

Owner:MURATA MFG CO LTD

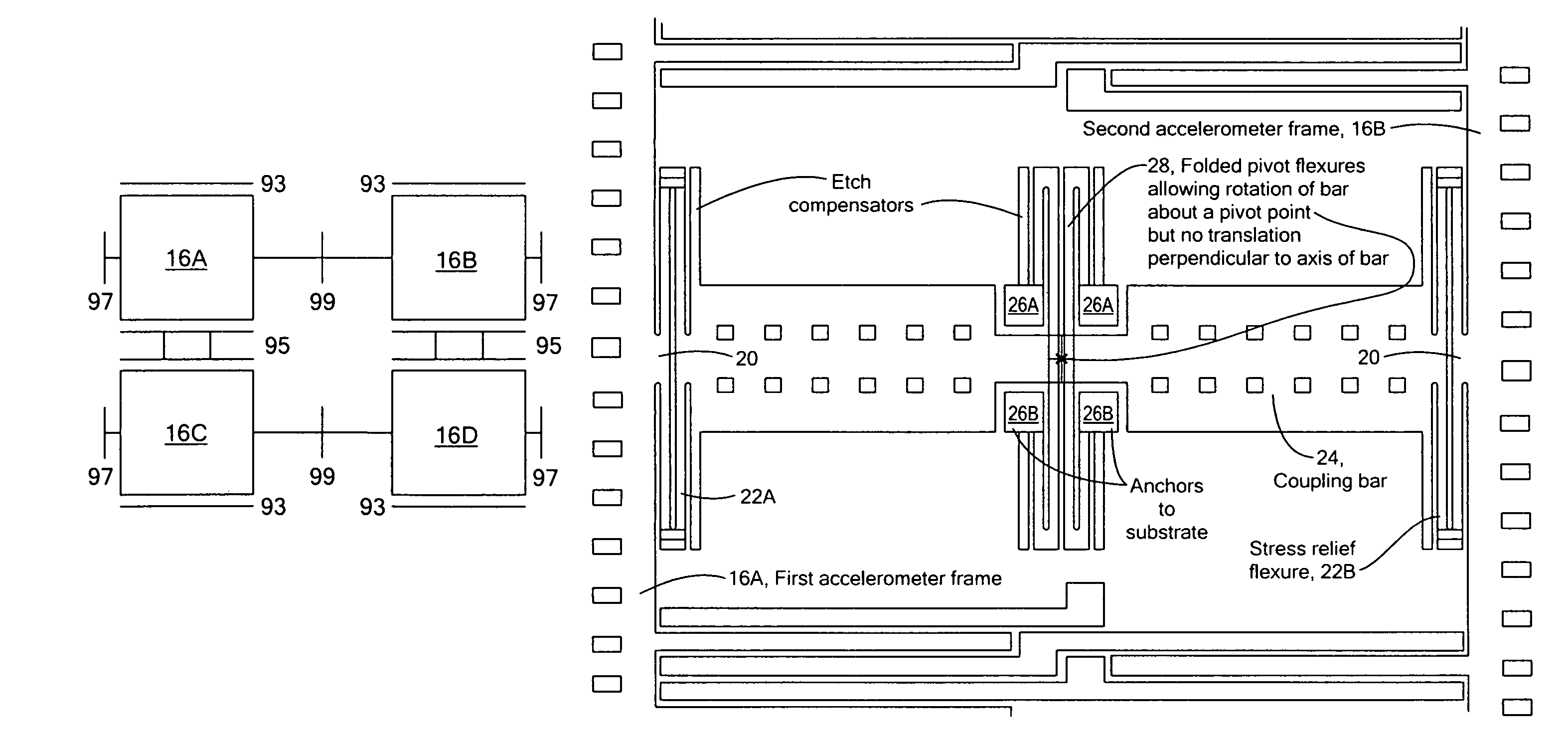

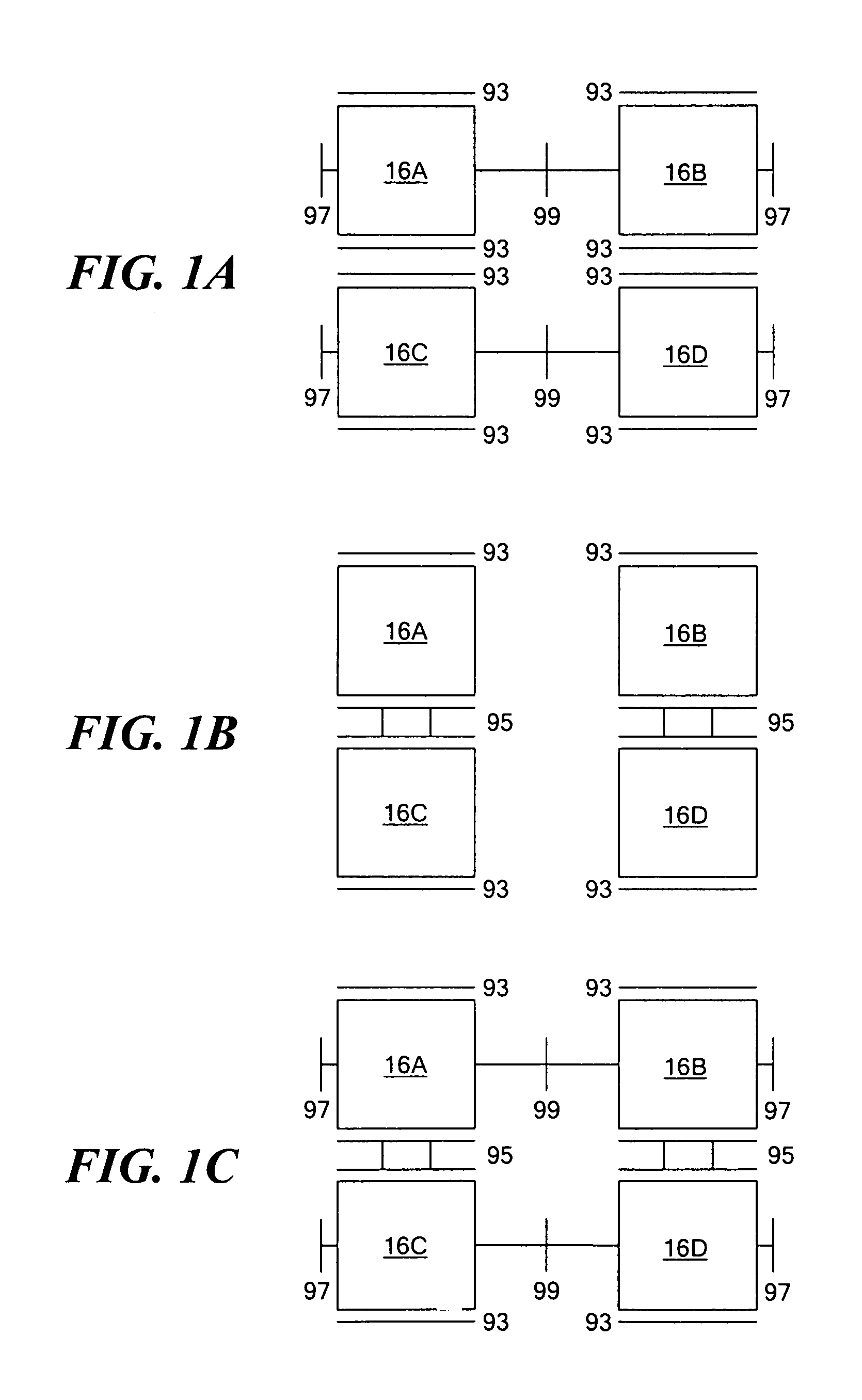

Cross-quad and vertically coupled inertial sensors

ActiveUS7421897B2Prevent movementAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsFully coupledEngineering

Owner:ANALOG DEVICES INC

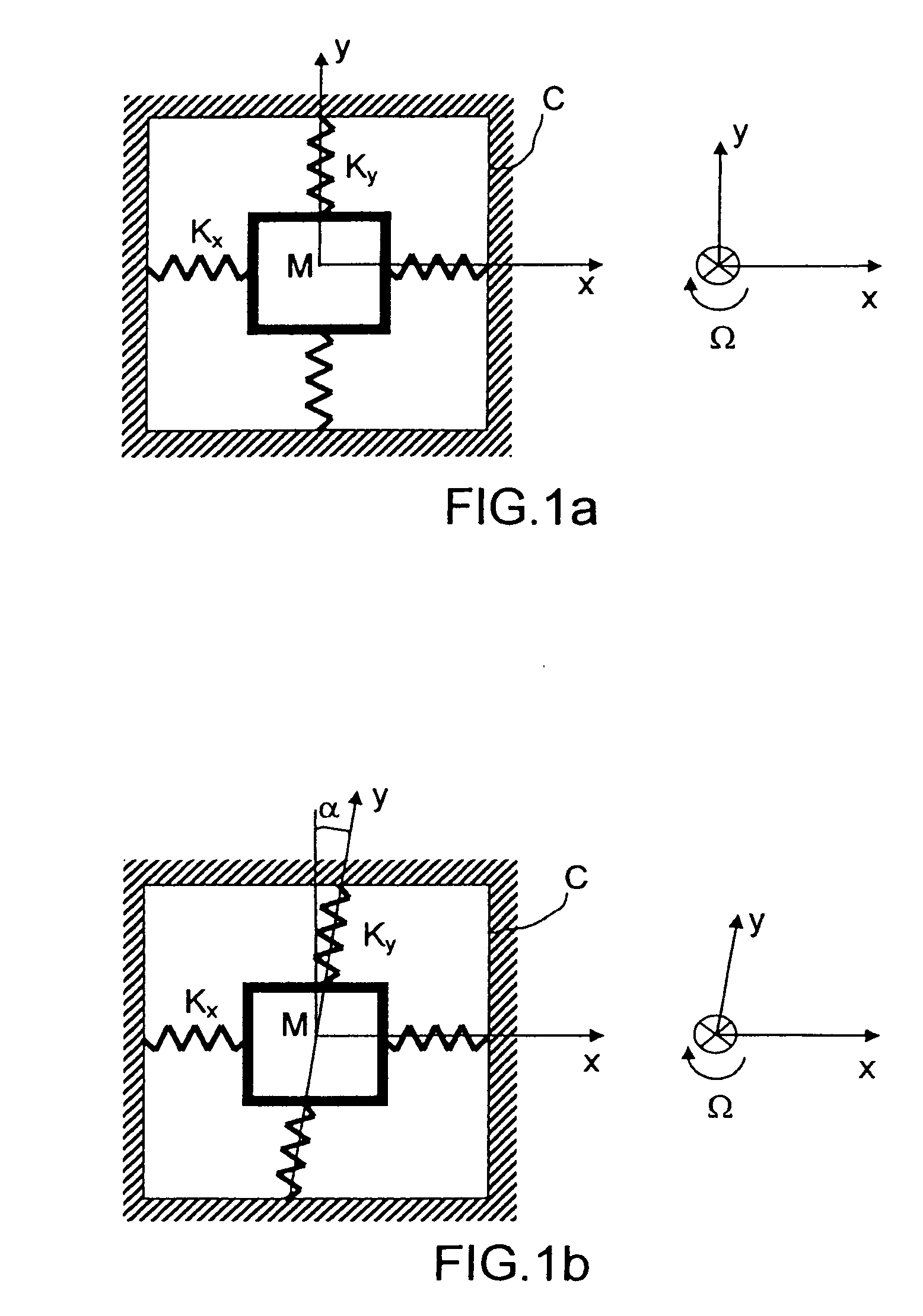

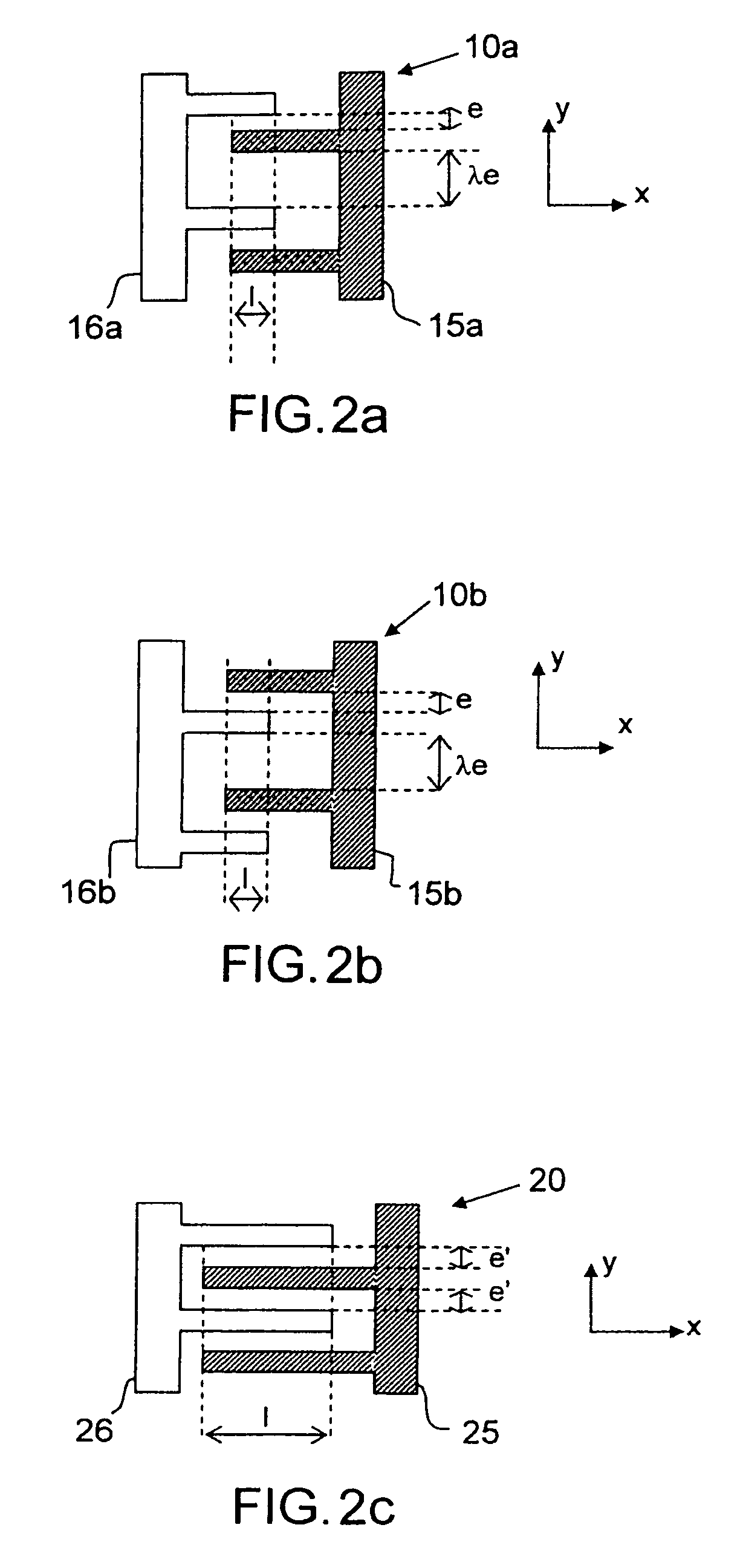

Vibratory Gyroscope Balanced by an Electrostatic Device

ActiveUS20080282833A1Mechanical apparatusSpeed measurement using gyroscopic effectsAdjustable stiffnessDc voltage

The invention relates to a gyroscope with a vibrating structure, produced by micromachining in a thin wafer, which comprises a movable inertial assembly (1) comprising at least one movable mass (50) able to vibrate in the plane of the wafer along a drive axis x and along a sense axis y roughly perpendicular to the x-axis, an interdigital sensor comb (90) and an interdigital drive comb (70). It furthermore comprises at least one additional interdigital comb (10a), called the quadrature-error compensation comb, connected to the mass (50) and which has two asymmetric air gaps e and λe, λ being a positive real number, for subjecting the mass to an adjustable electrostatic stiffness due to coupling between the x-axis and the y-axis by applying a variable DC voltage V to this comb, the adjustable stiffness allowing compensation for the quadrature error of the gyroscope.

Owner:THALES SA

Popular searches

Analogue conversion Turn-sensitive devices Analogue-digital converters Devices using electric/magnetic means Devices characerised by mechanical means Acceleration measurement in multiple dimensions Semiconductor devices Converting sensor output electrically/magnetically Soldering apparatus Photomechanical apparatus

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com