Patents

Literature

392results about How to "Solve the low detection efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

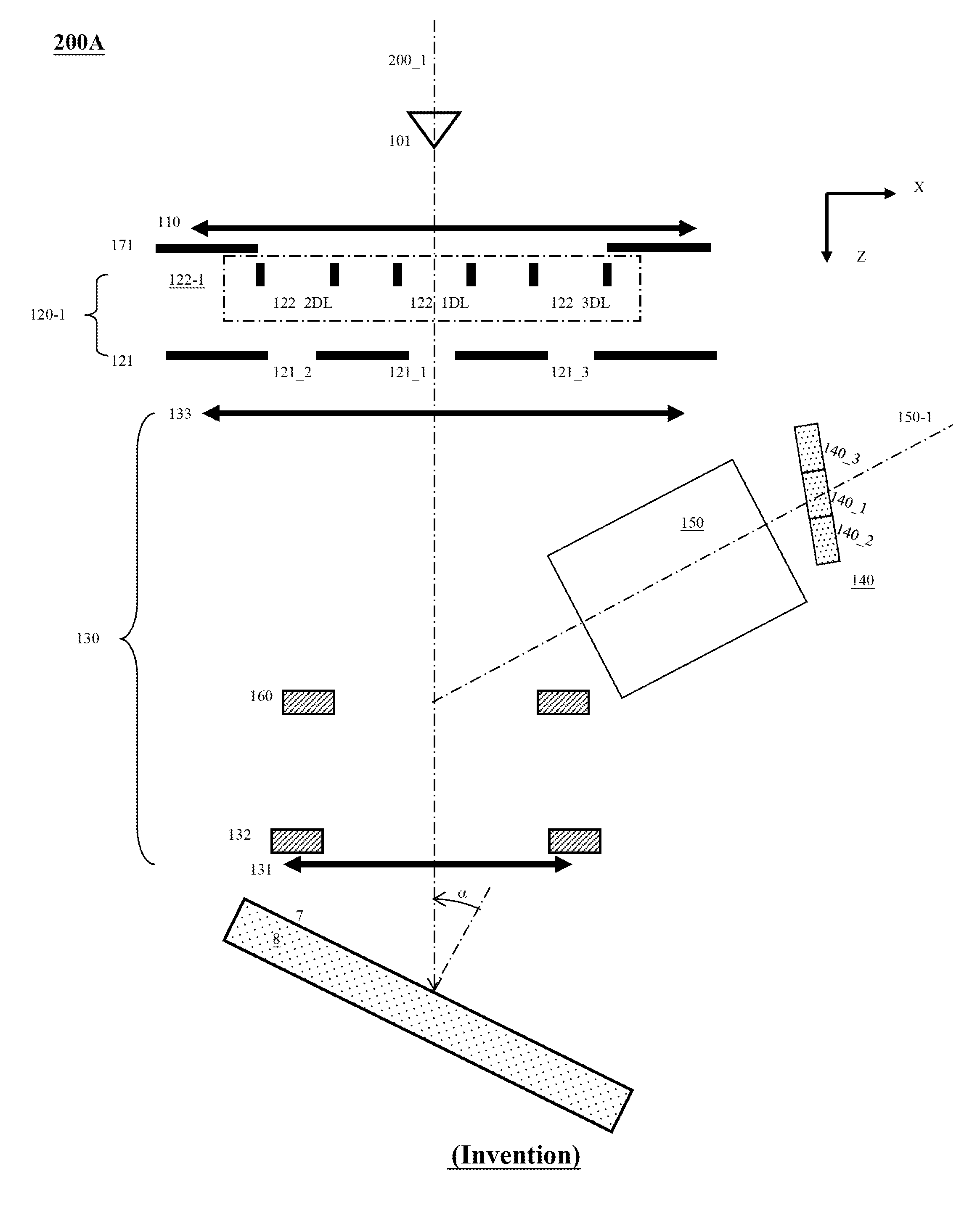

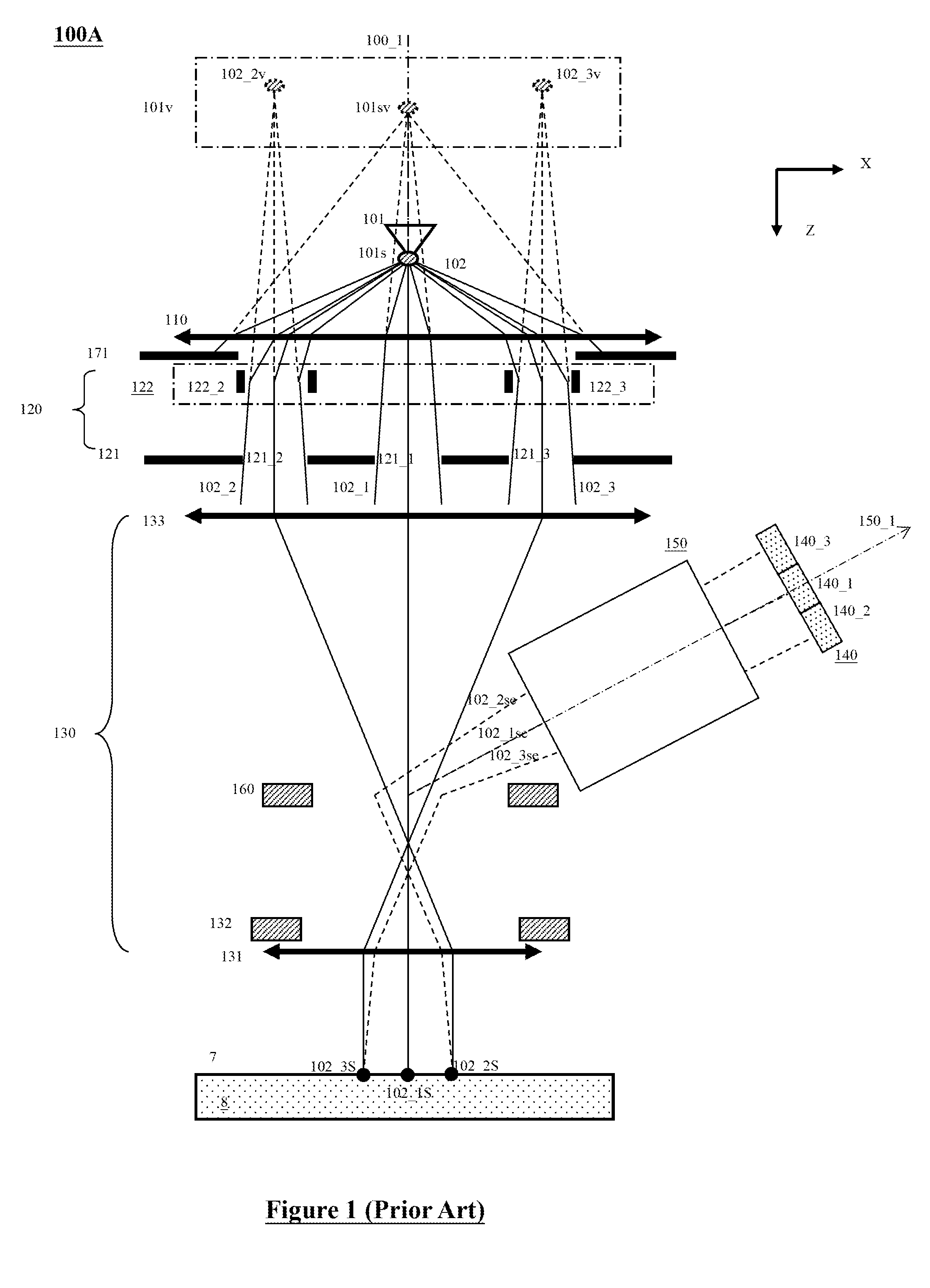

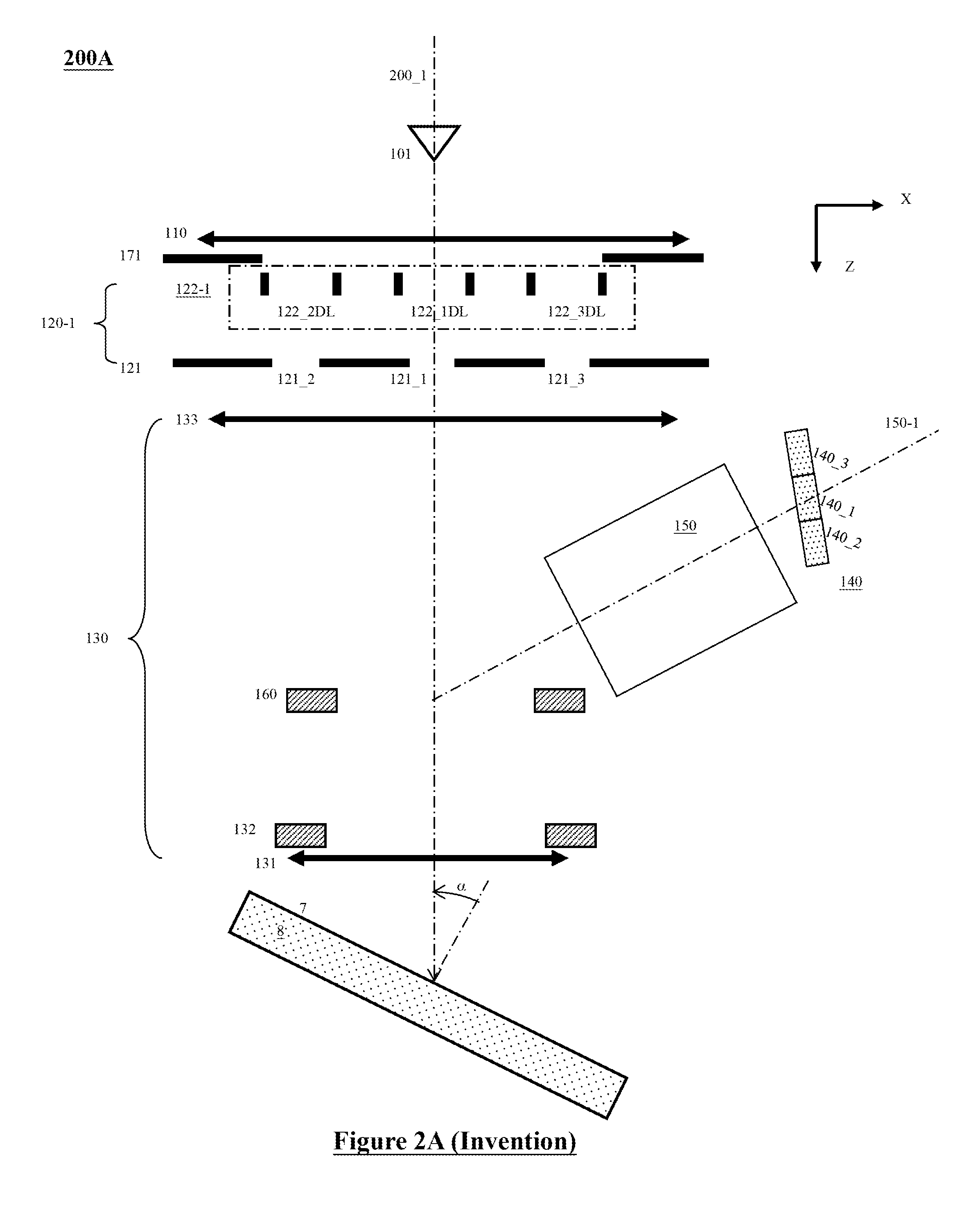

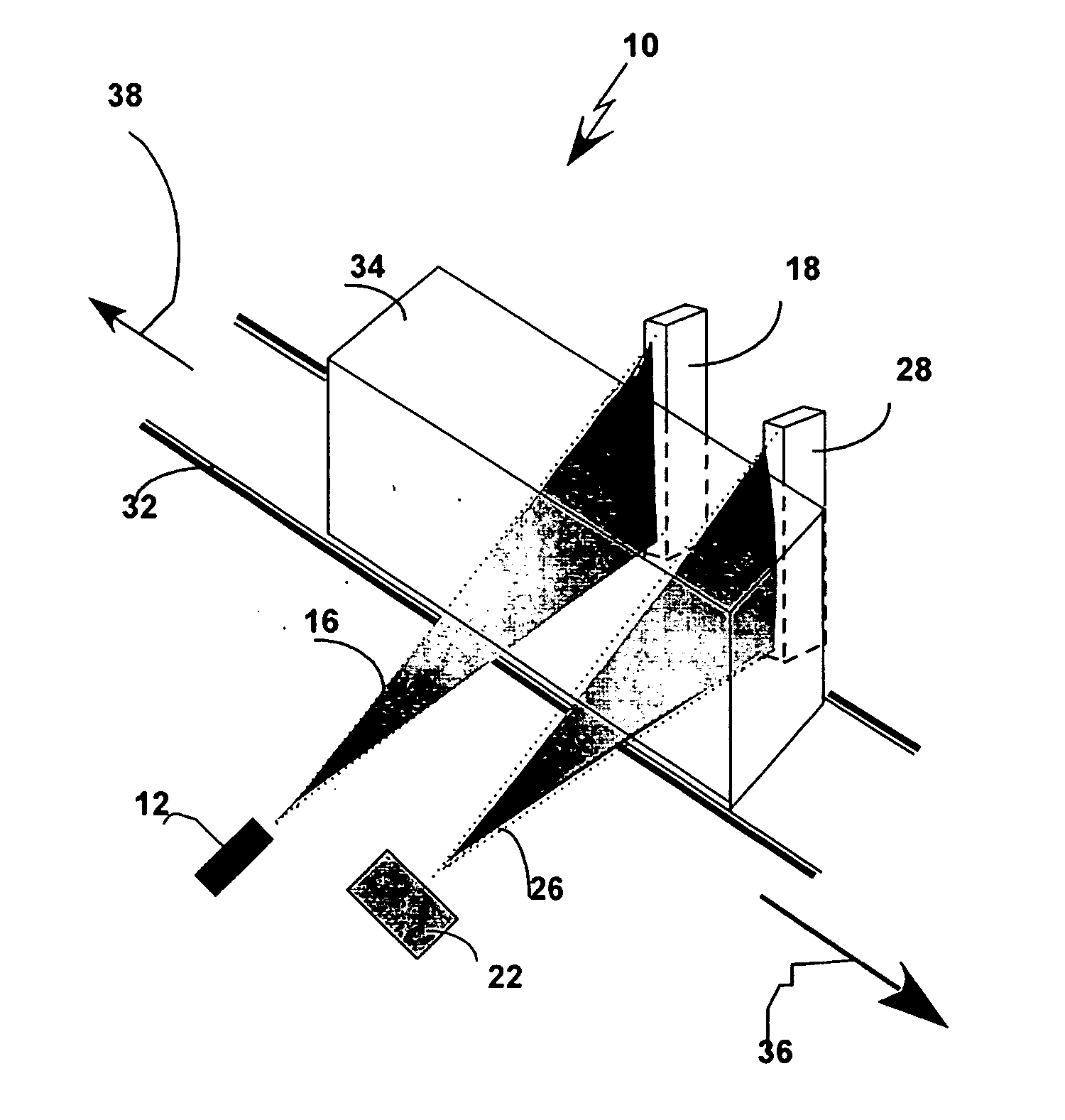

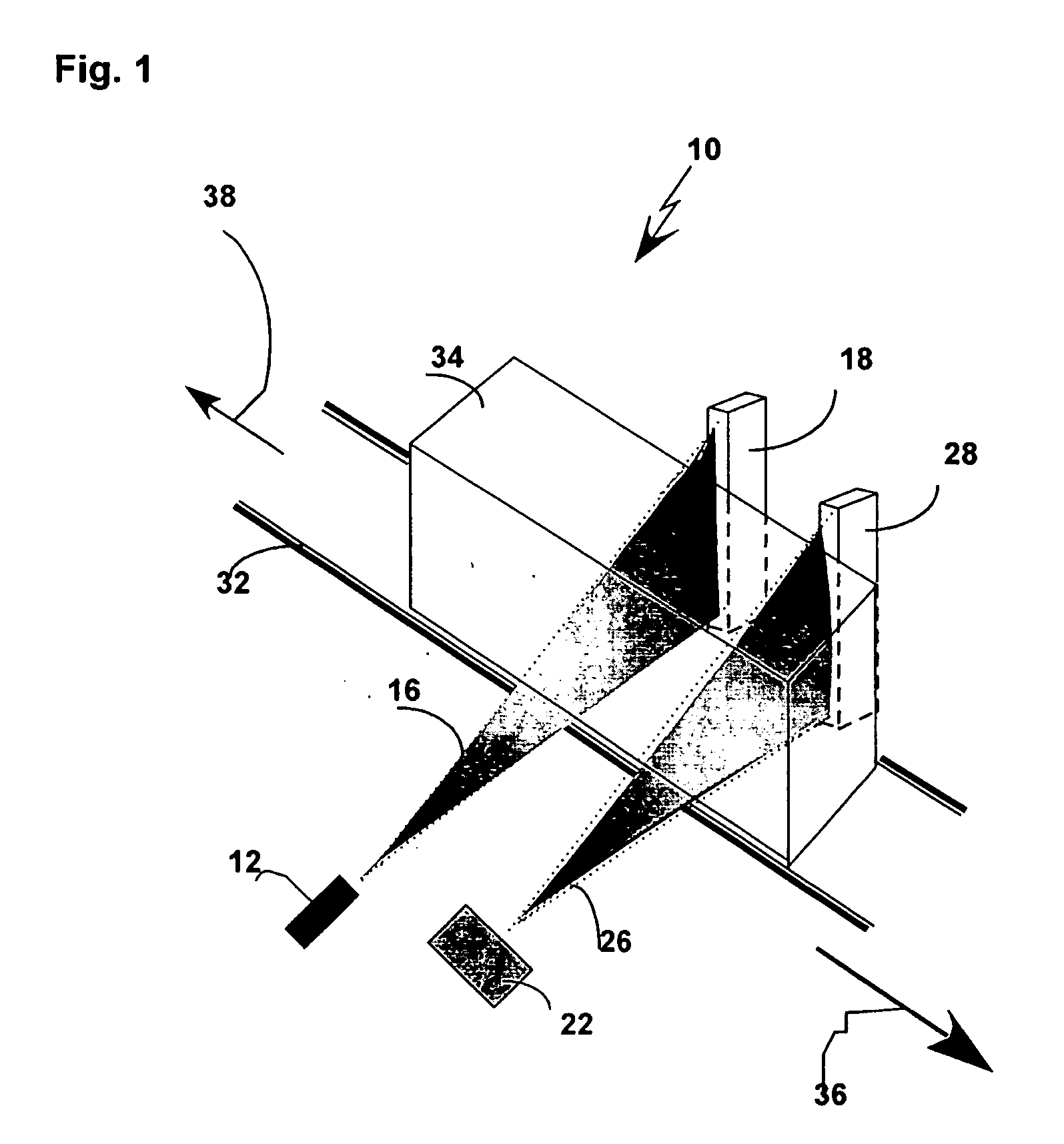

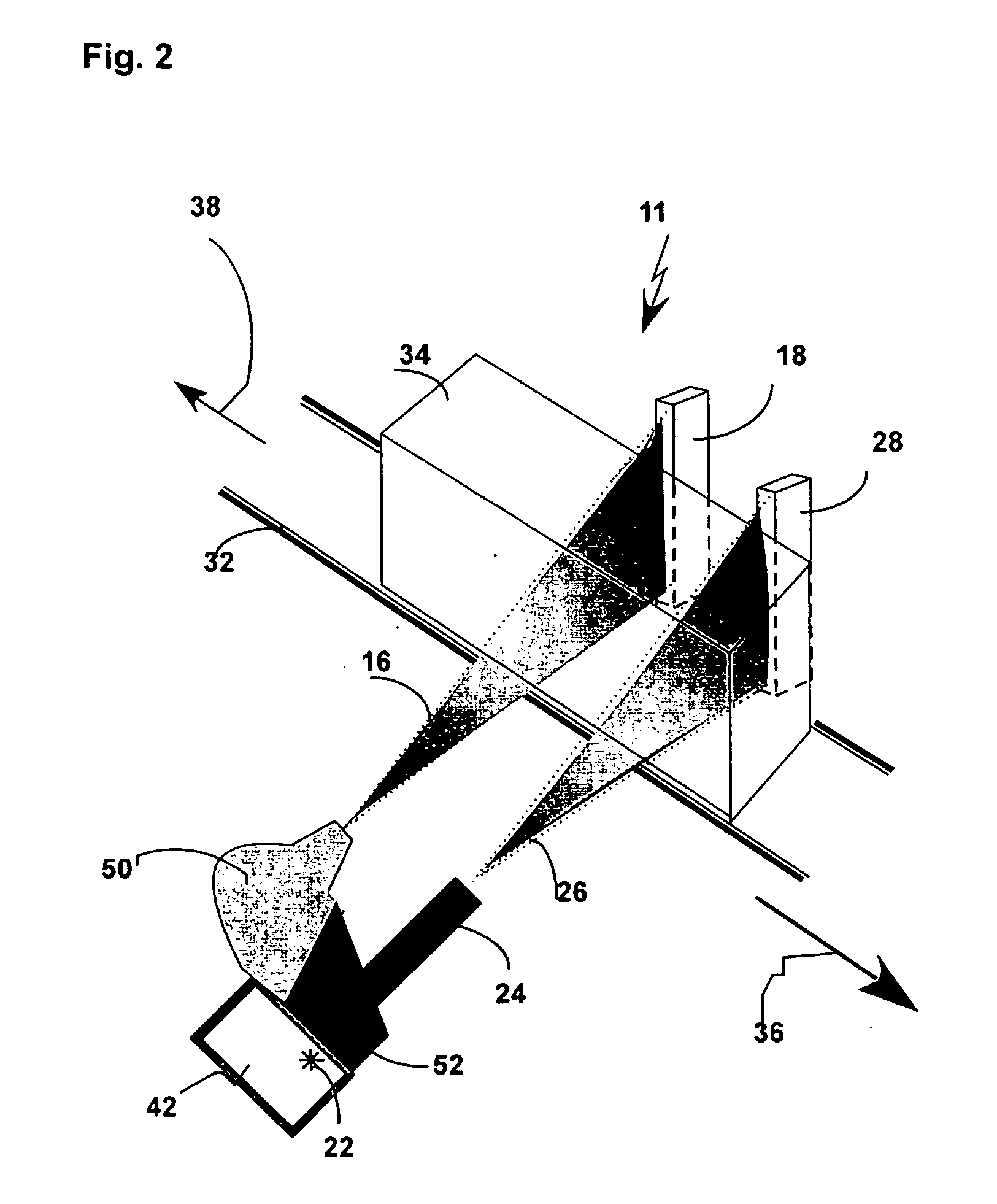

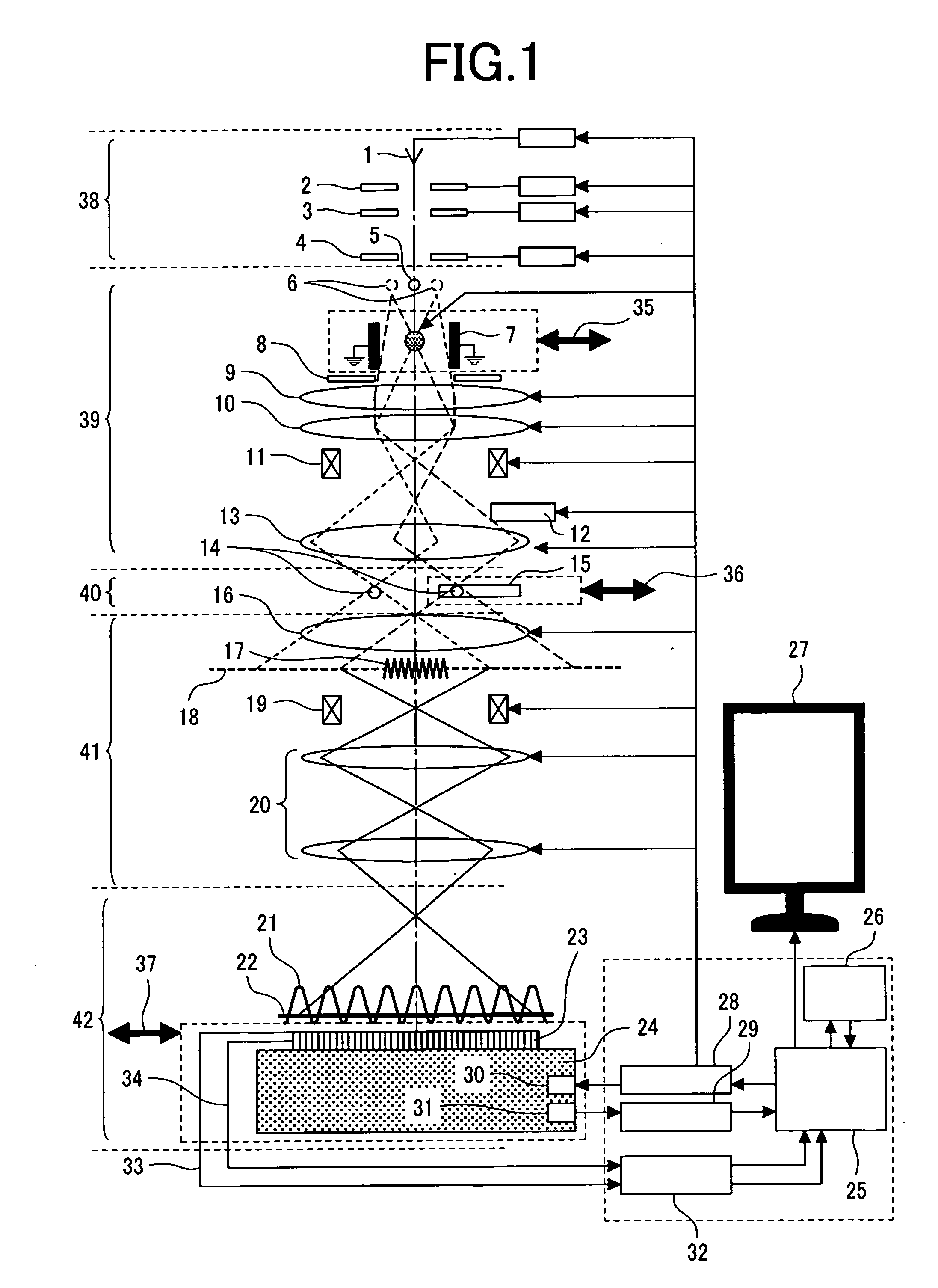

Apparatus of Plural Charged-Particle Beams

ActiveUS20160284505A1High detection efficiencyHigh throughputElectric discharge tubesMolecular physicsCharged particle beam

A multi-beam apparatus for observing a sample with oblique illumination is proposed. In the apparatus, a new source-conversion unit changes a single electron source into a slant virtual multi-source array, a primary projection imaging system projects the array to form plural probe spots on the sample with oblique illumination, and a condenser lens adjusts the currents of the plural probe spots. In the source-conversion unit, the image-forming means not only forms the slant virtual multi-source array, but also compensates the off-axis aberrations of the plurality of probe spots. The apparatus can provide dark-field images and / or bright-field images of the sample.

Owner:ASML NETHERLANDS BV

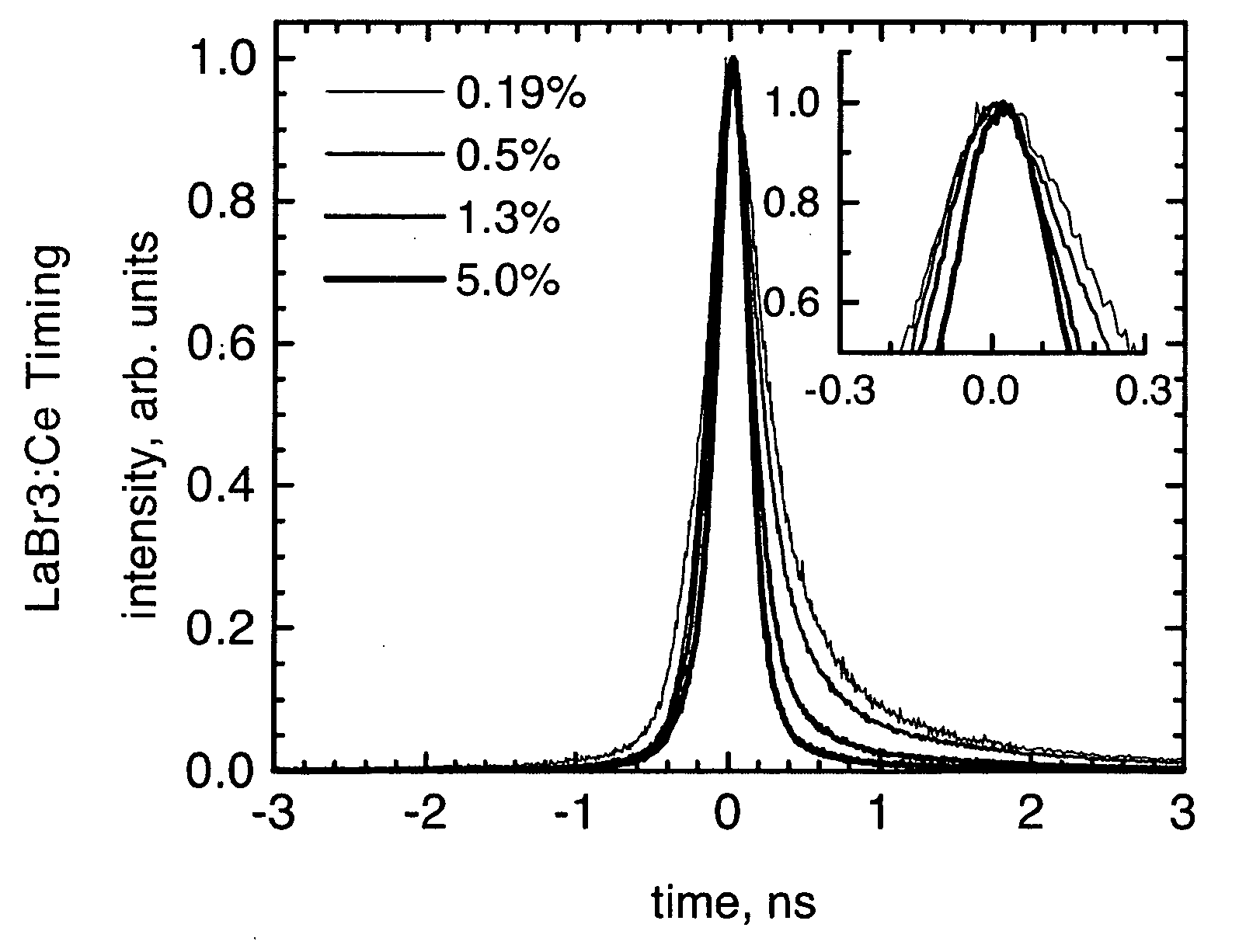

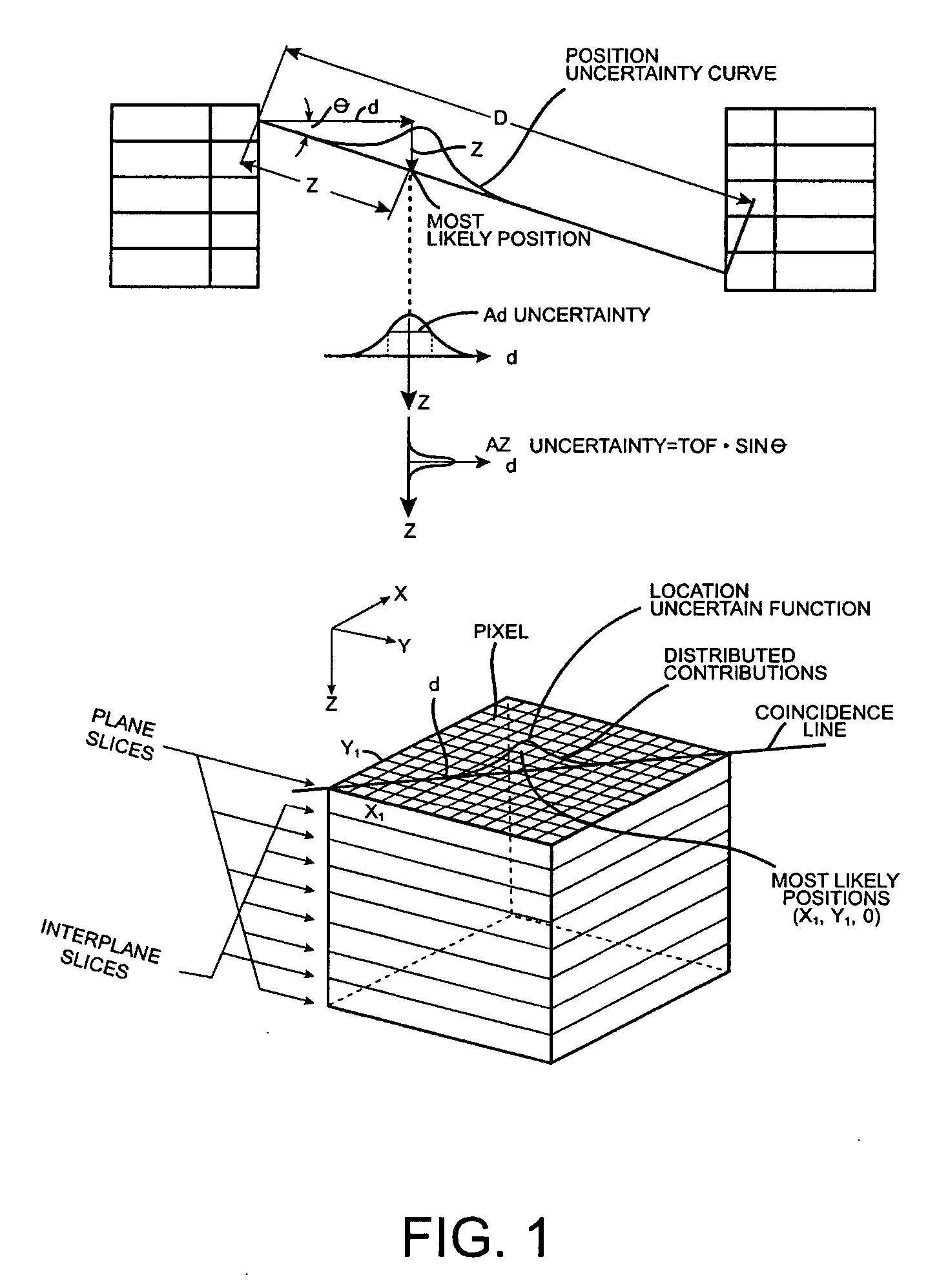

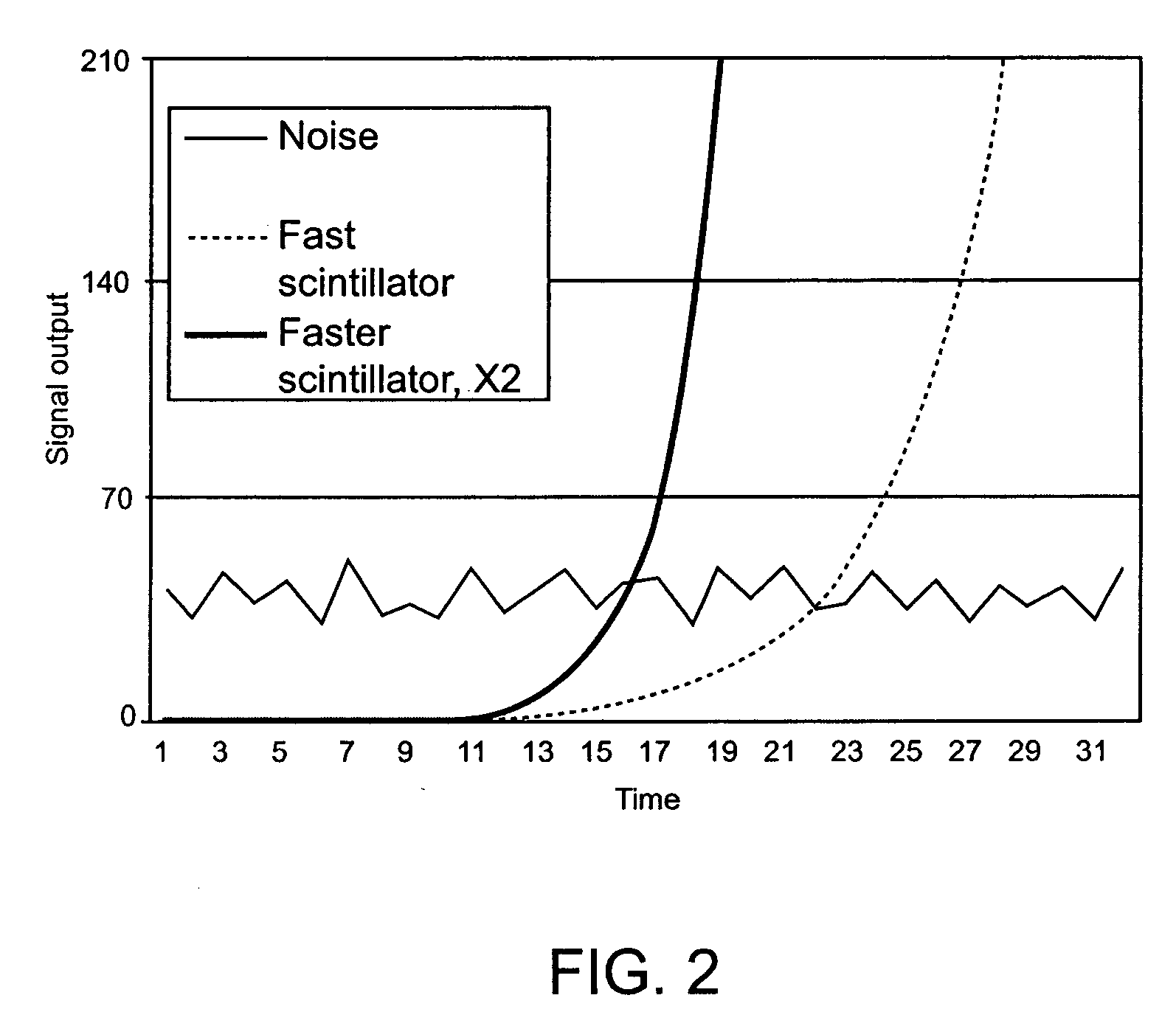

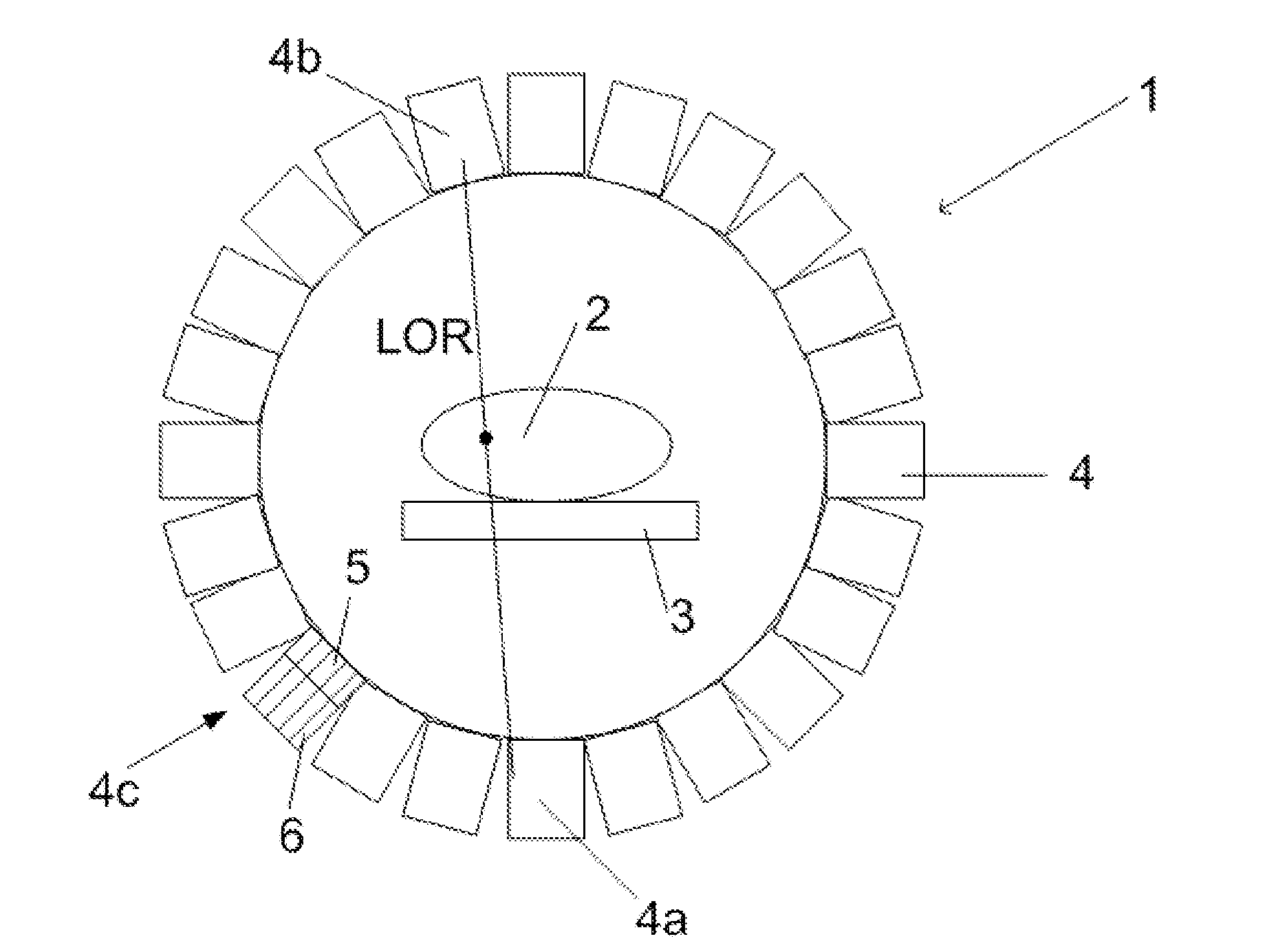

Very fast doped LaBr3 scintillators and time-of-flight PET

ActiveUS20050104001A1High detection efficiencyHigh light outputPolycrystalline material growthMaterial analysis by optical meansImage resolutionRise time

The present invention concerns very fast scintillator materials capable of resolving the position of an annihilation event within a portion of a human body cross-section. In one embodiment, the scintillator material comprises LaBr3 doped with cerium. Particular attention is drawn to LaBr3 doped with a quantity of Ce that is chosen for improving the timing properties, in particular the rise time and resultant timing resolution of the scintillator, and locational capabilities of the scintillator.

Owner:RADIATION MONITORING DEVICES

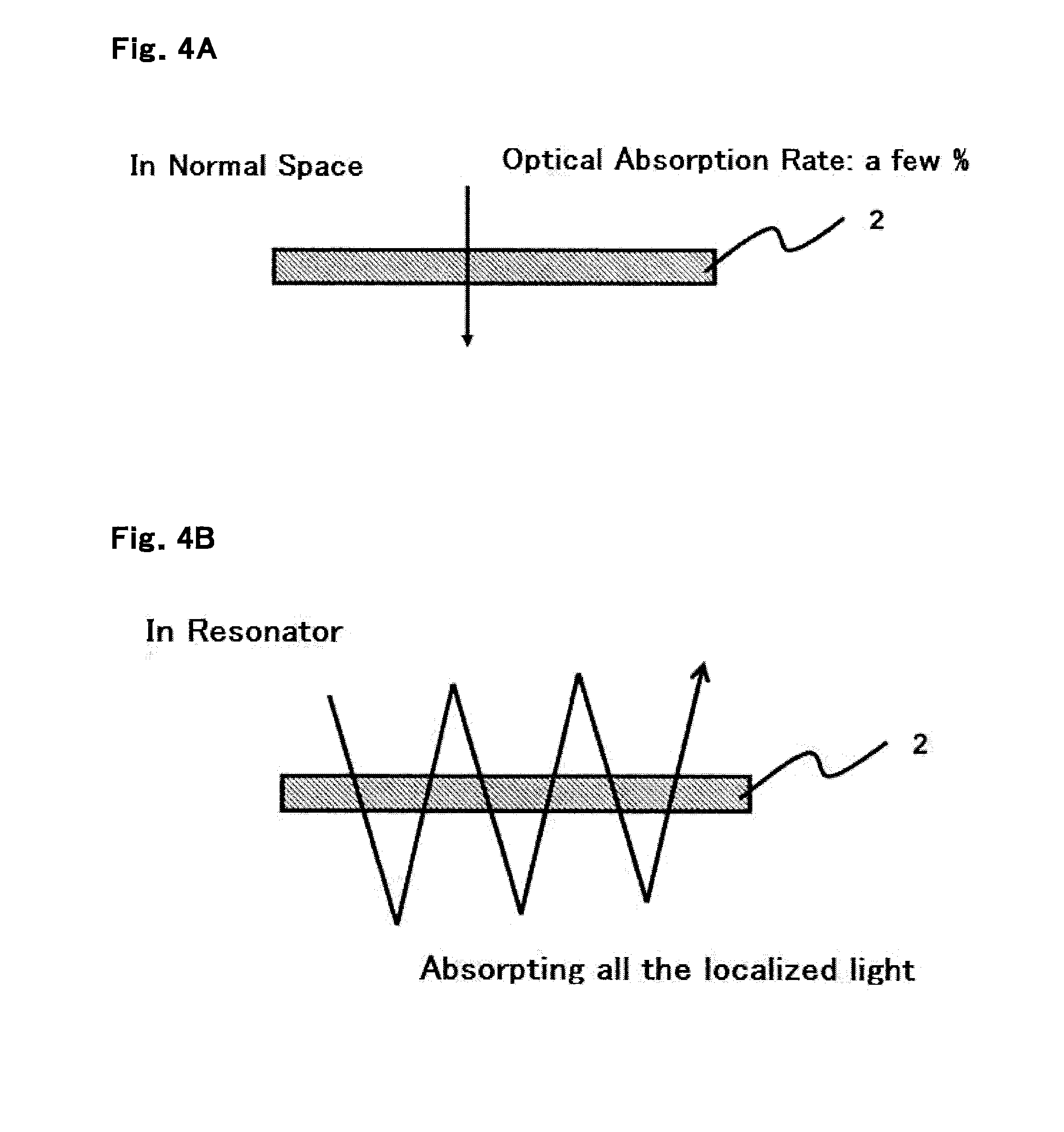

Electromagnetic wave detector and electromagnetic wave detector array

ActiveUS20140319357A1High-sensitivity photodetectionImprove absorption rateSolid-state devicesMaterial analysis by optical meansInter layerSurface plasmon

An electromagnetic wave detector that detects incident light by converting the incident light into an electric signal includes a flat metal layer formed on a supporting substrate, an intermediate layer formed on the metal layer, a graphene layer formed on the intermediate layer, isolated metals periodically formed on the graphene layer, and electrodes arranged oppositely on both sides of the isolated metals. Depending on a size of a planar shape of each of the isolated metals, light having a predetermined wavelength at which surface plasmon occurs is determined out of the incident light, and the light having the predetermined wavelength is absorbed to detect a change in the electric signal generated in the graphene layer.

Owner:MITSUBISHI ELECTRIC CORP

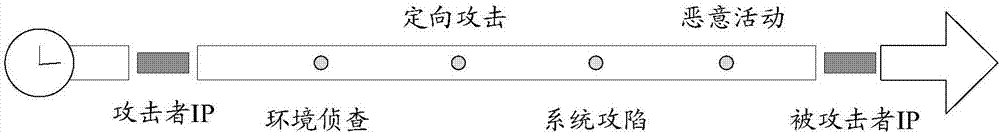

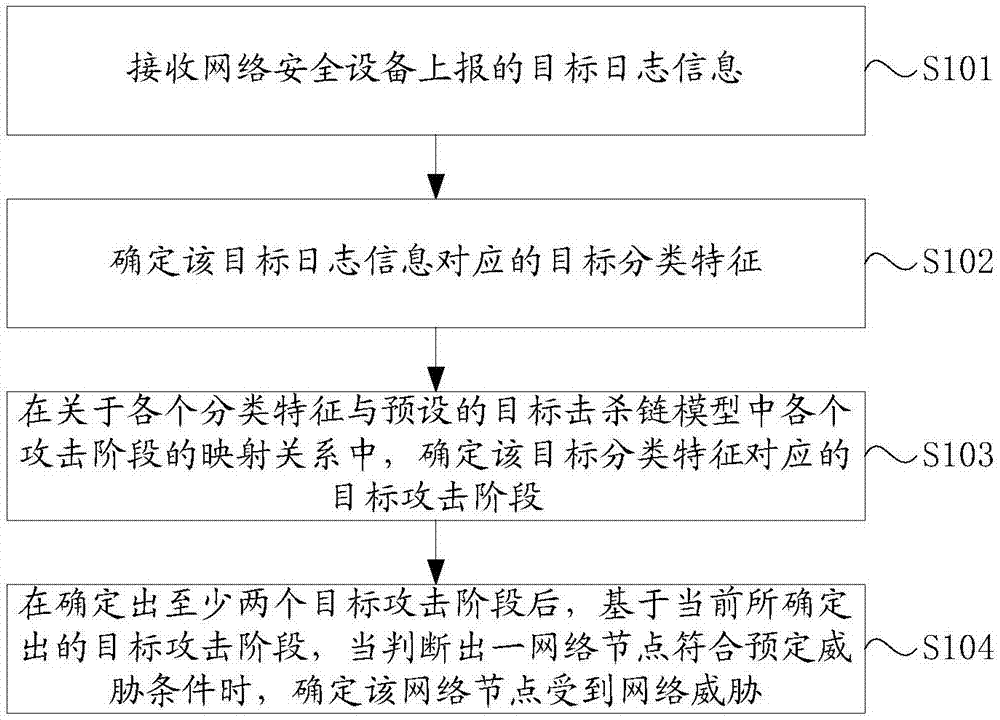

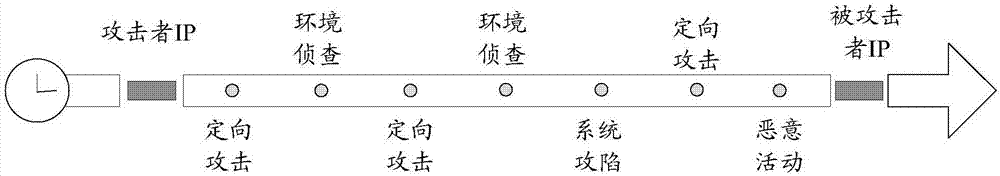

Network threat detection method, device and network management equipment

ActiveCN107888607AMeet the needs of efficient and friendlyRealize automated detectionTransmissionNetwork managementChain model

The application provides a network threat detection method and device, and network management equipment. The method comprises the following steps: receiving target log information reported by networksecurity equipment; determining a target classification feature corresponding to the target log information; determining a target attack stage corresponding to the target classification feature in a mapping relation about each classification feature and each attack state in a preset target kill chain model; and determining a fact that a network node is under network threat when judging that the network node meets the preset threat condition based on the currently determined each target attack stage after determining out at least two target attack stages, wherein the preset threat condition isas follows: generating the stage combination in forward sequence in the target kill chain model according to time order on a time shaft, and the stage combination comprises at least two attack stages.Through the scheme provided by the application, the problem of low detection efficiency in the prior art can be solved.

Owner:NEW H3C TECH CO LTD

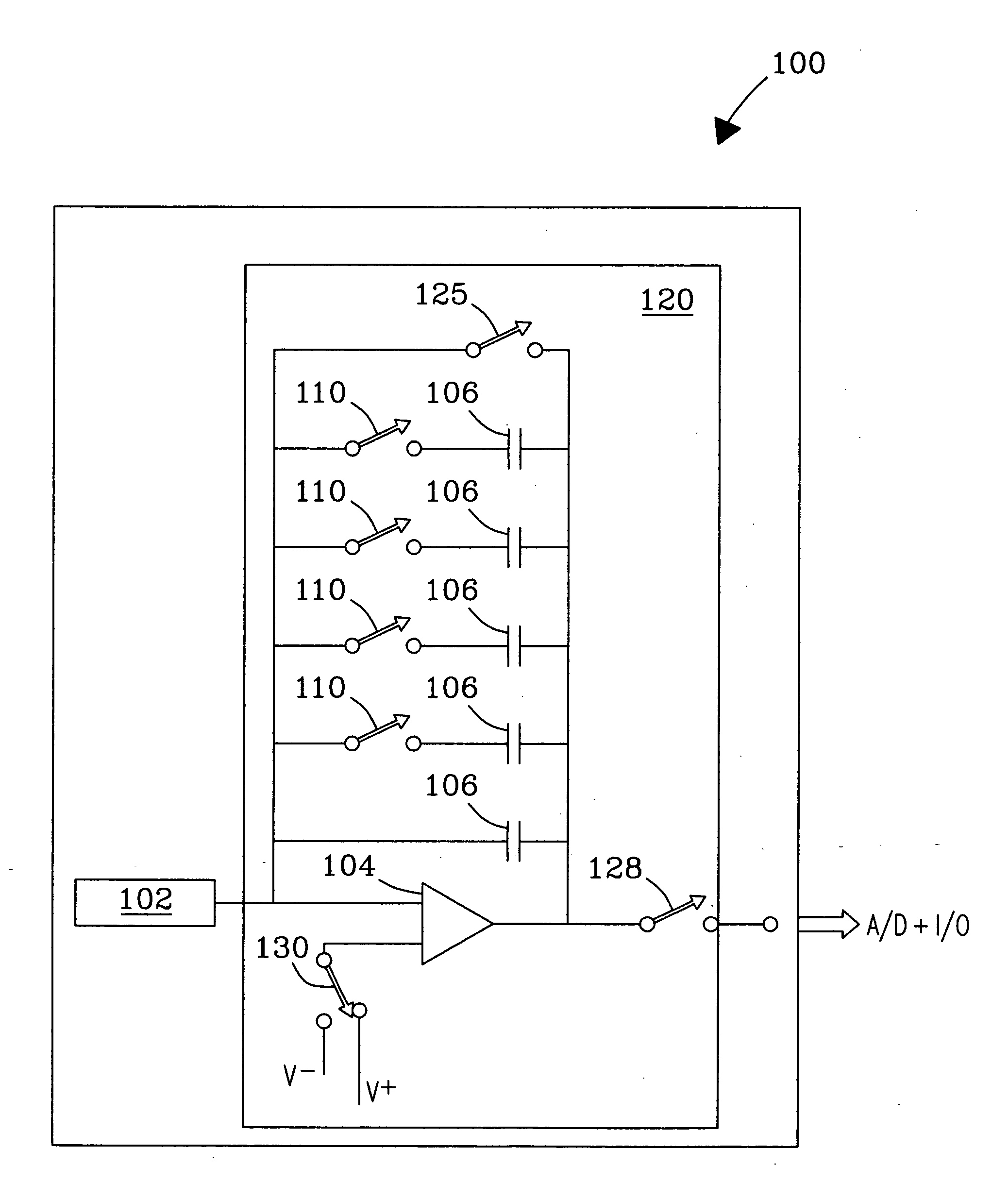

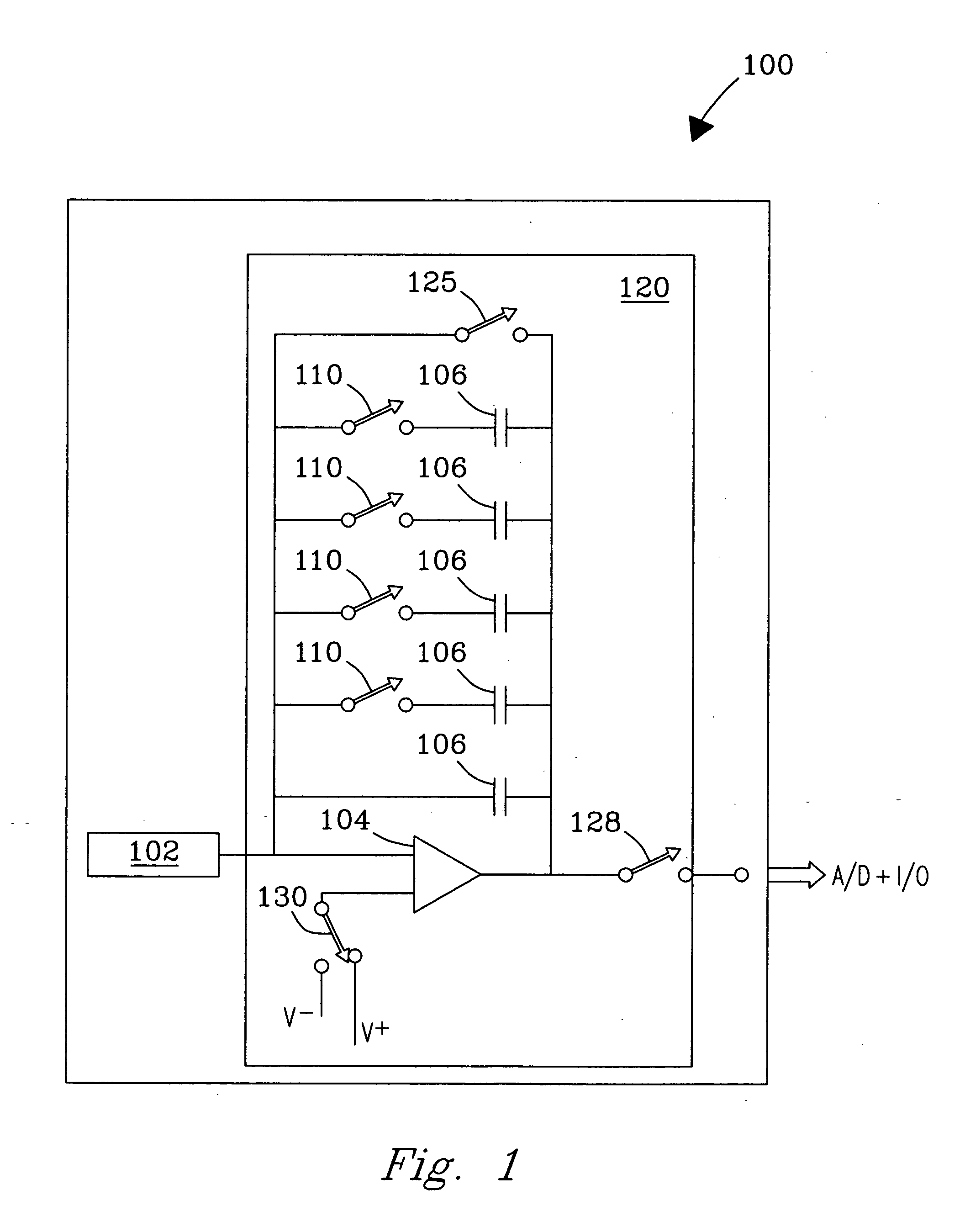

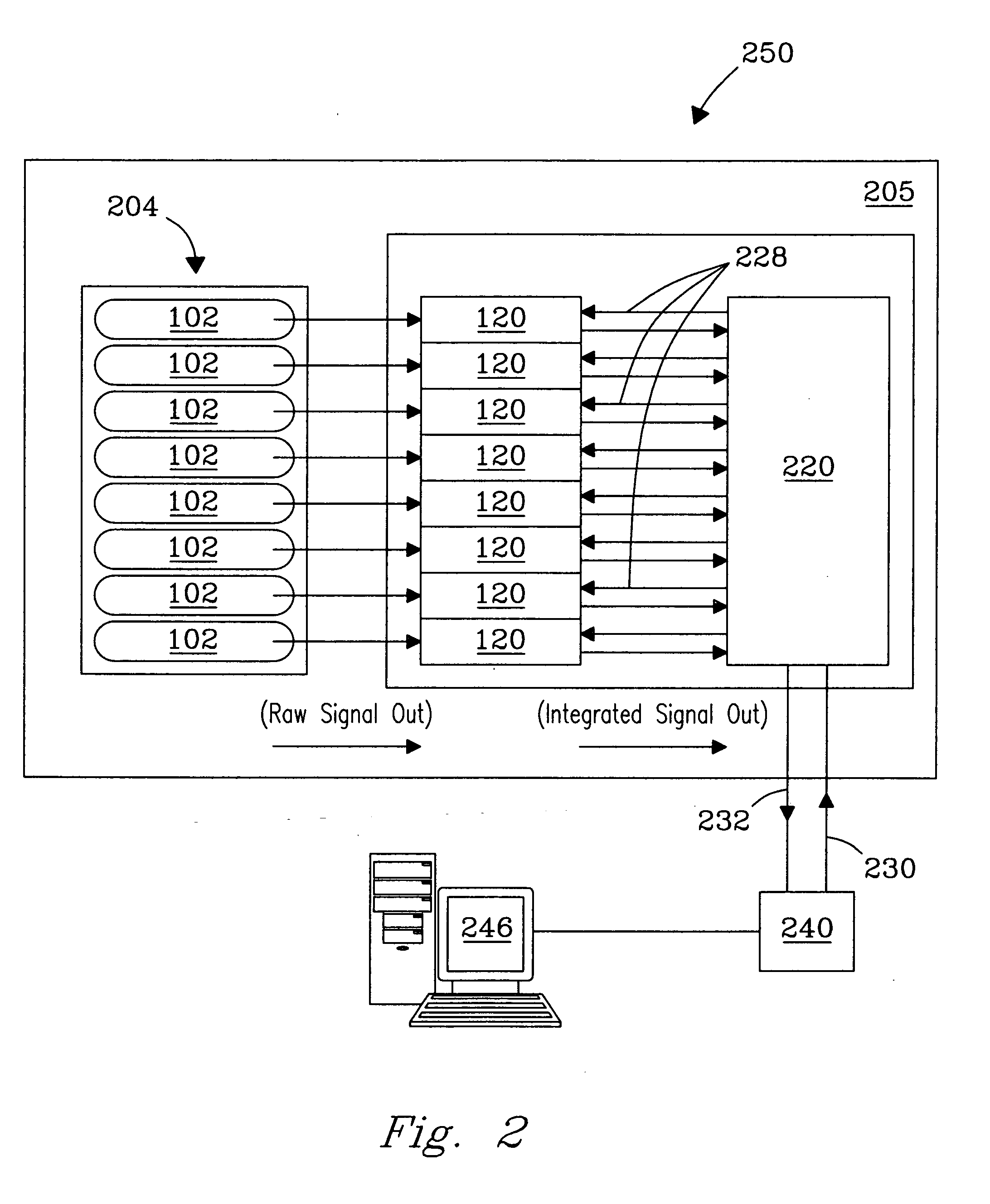

Method and apparatus for simultaneous detection and measurement of charged particles at one or more levels of particle flux for analysis of same

InactiveUS20080073548A1Solve the low detection efficiencyVariation can be minimizedThermometer detailsSpectrometer detectorsCharged particle detectorsParticle physics

A charged particle detector and method are disclosed providing for simultaneous detection and measurement of charged particles at one or more levels of particle flux in a measurement cycle. The detector provides multiple and independently selectable levels of integration and / or gain in a fully addressable readout manner.

Owner:INDIANA UNIV RES & TECH CORP +2

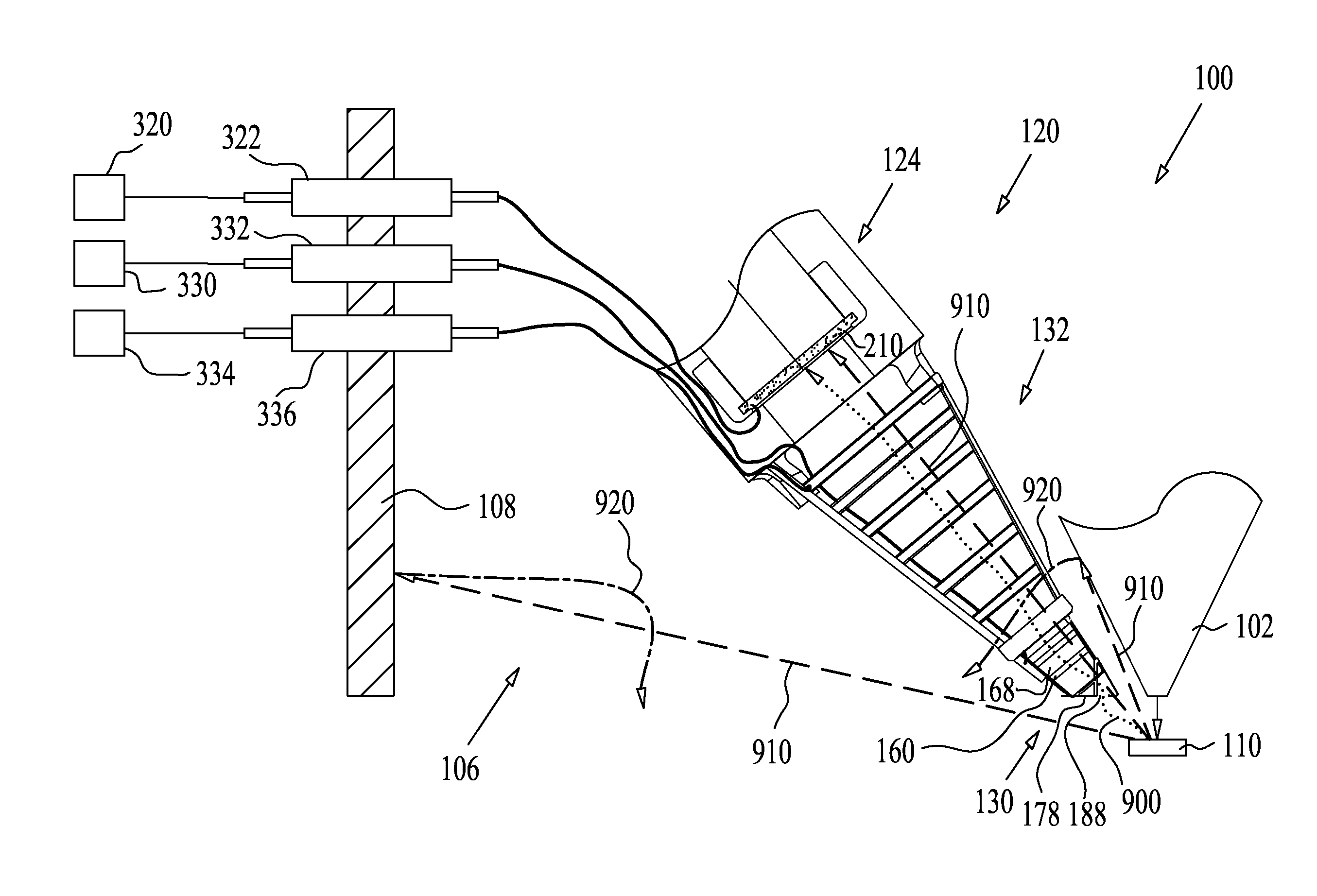

Charged particle detection system and method

ActiveUS20100294931A1High selectivitySolve the low detection efficiencyThermometer detailsMaterial analysis using wave/particle radiationCharged particle detectorsParticle physics

A system for selectively detecting charged particles produced due to operation of a charged particle beam column irradiating a specimen, including a proximal grid being selectively electrically biasable and configured for controllably directing the charged particles by electrically focusing the charged particles to compel selected secondary charged particles, whereupon being selected from the charged particles, to be attracted thereto, and to repel unselected secondary charged particles therefrom, a distal grid spaced apart from the proximal grid and separated therefrom by a gap and being selectively electrically biasable and configured for attracting the selected secondary and / or tertiary charged particles, whereupon being selected from the charged particles, to the distal grid, and to repel unselected tertiary charged particles therefrom, and a charged particle detector configured for detecting selected secondary charged particles attracted to the proximal and / or distal grid and detecting selected tertiary charged particles attracted to the distal grid, that impinge thereupon.

Owner:EL MUL TECH

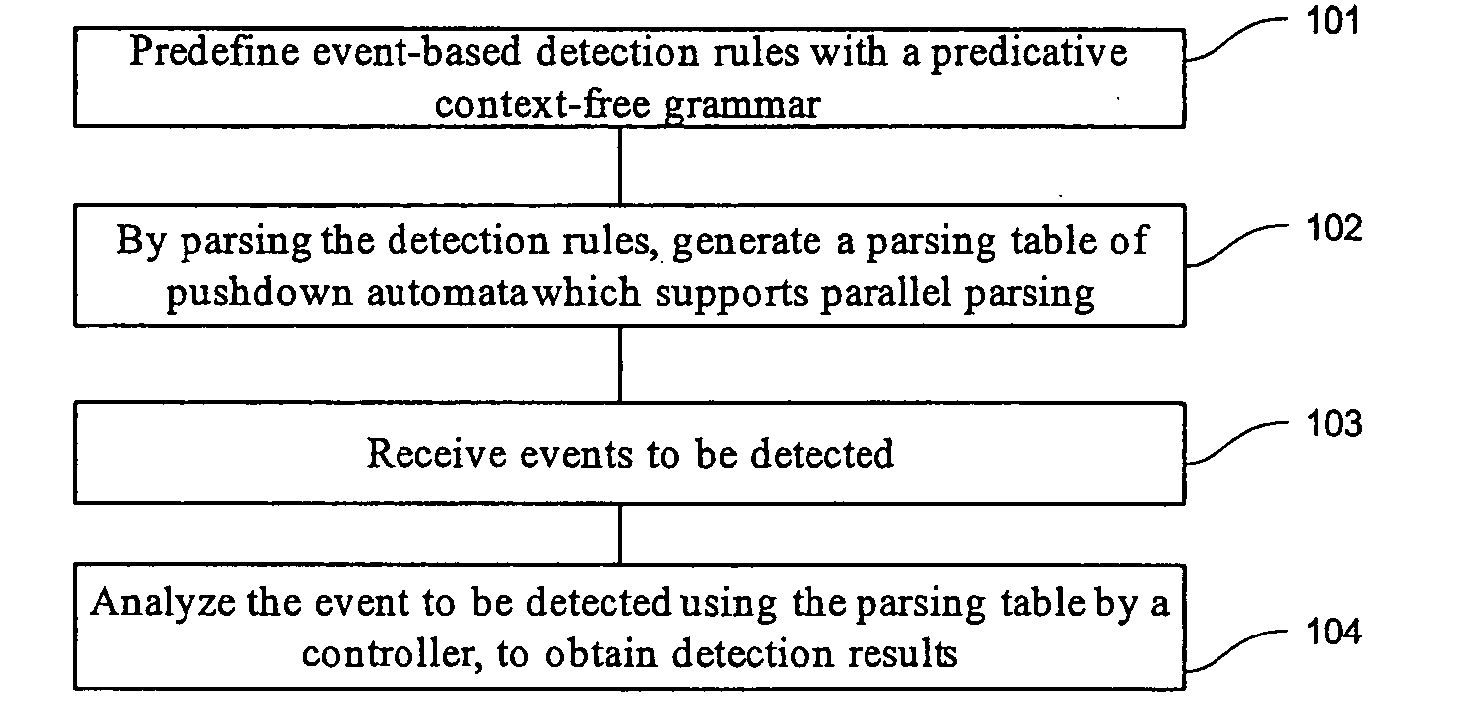

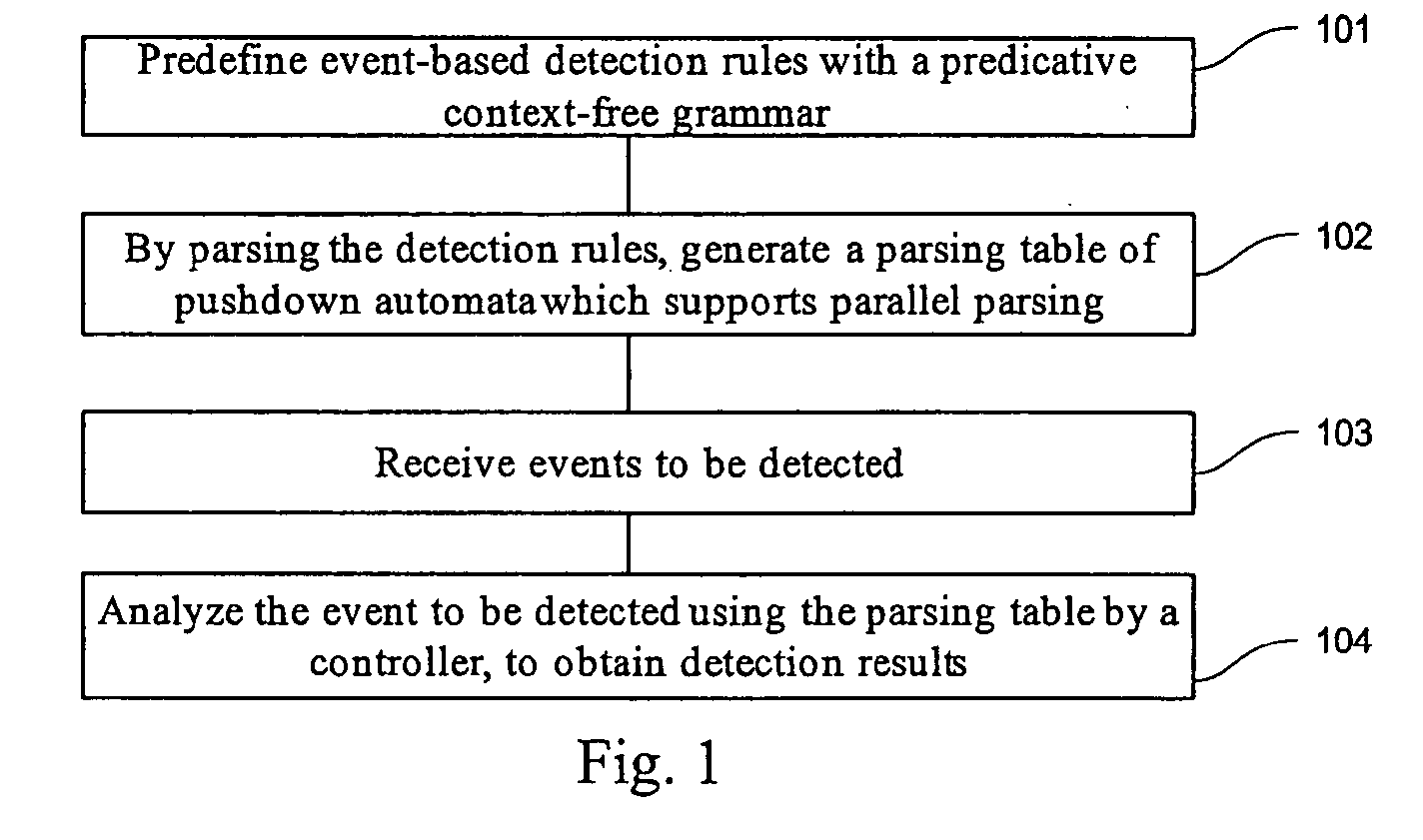

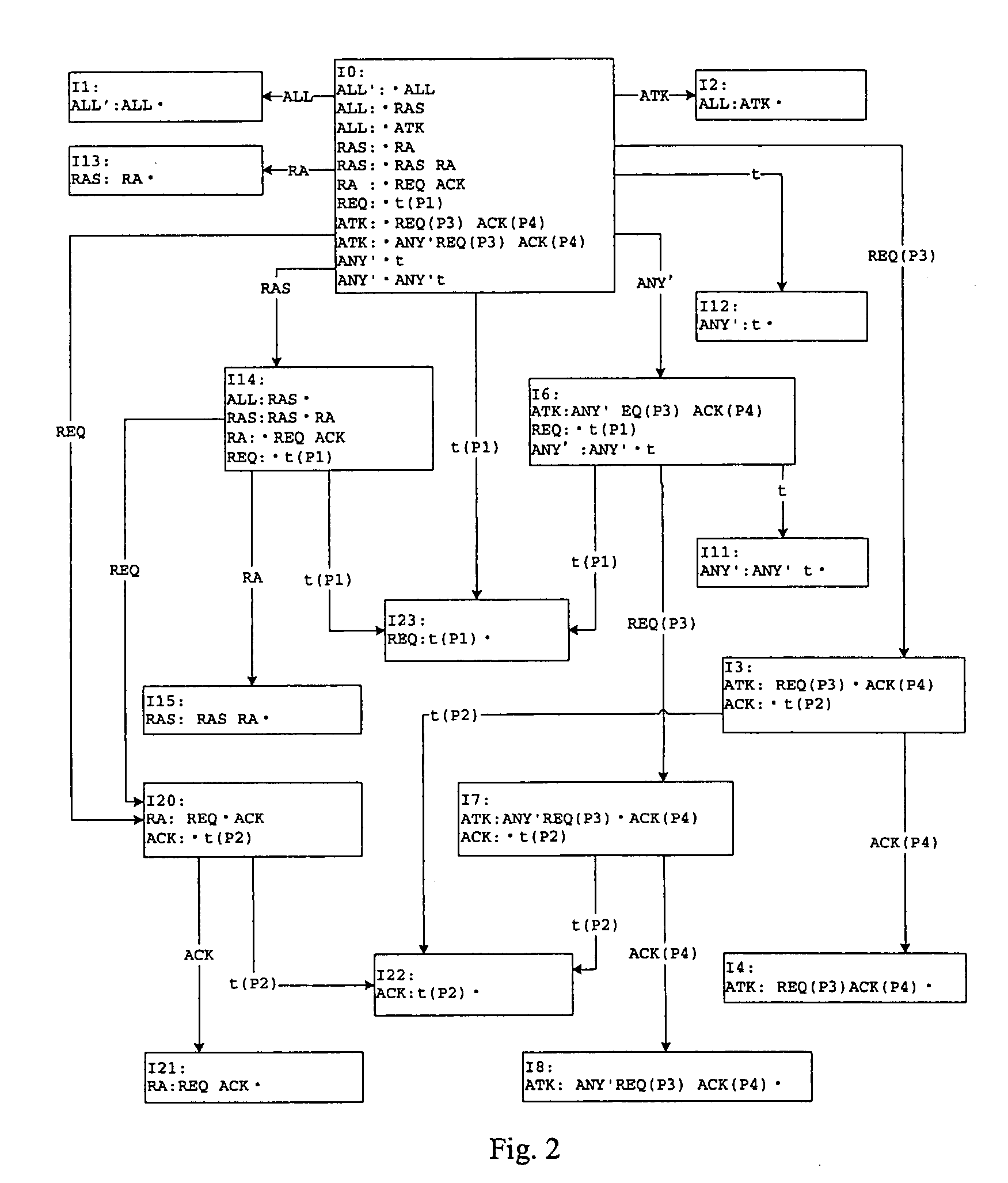

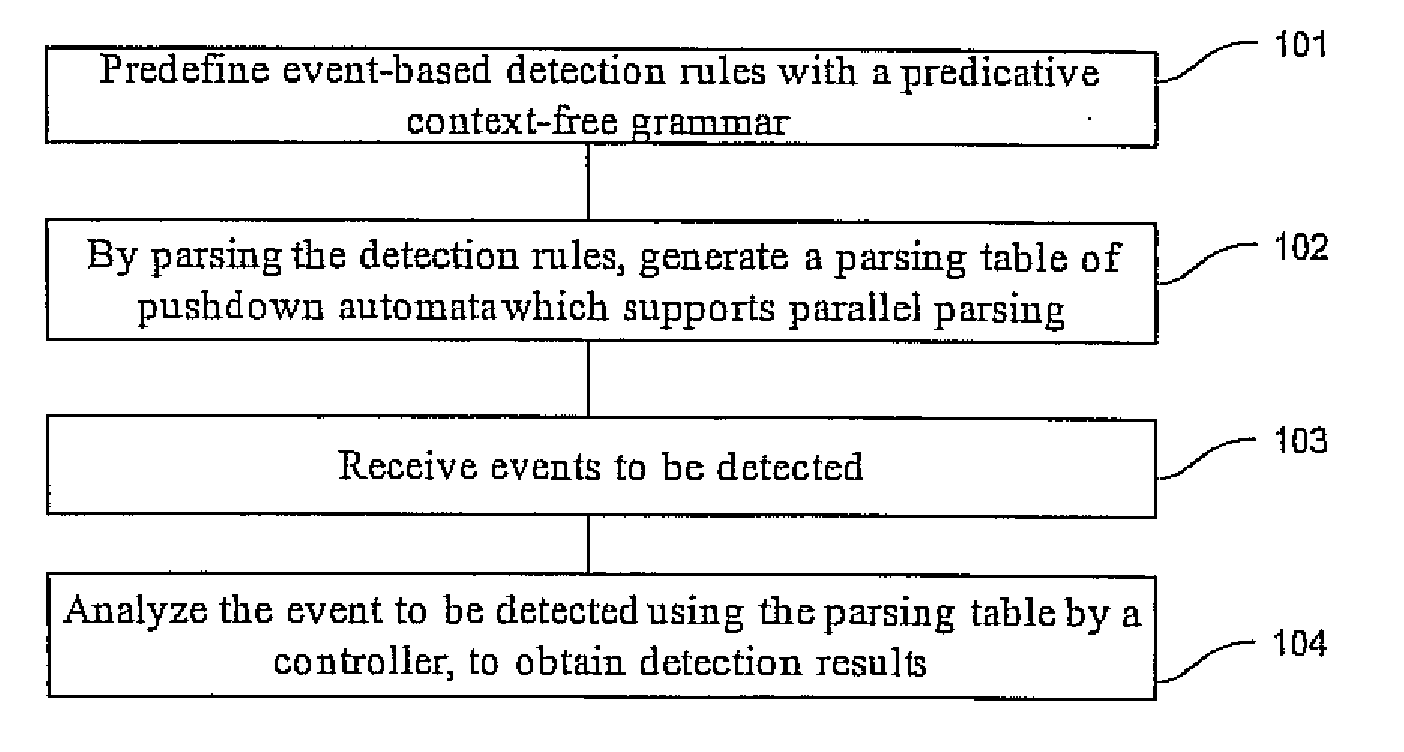

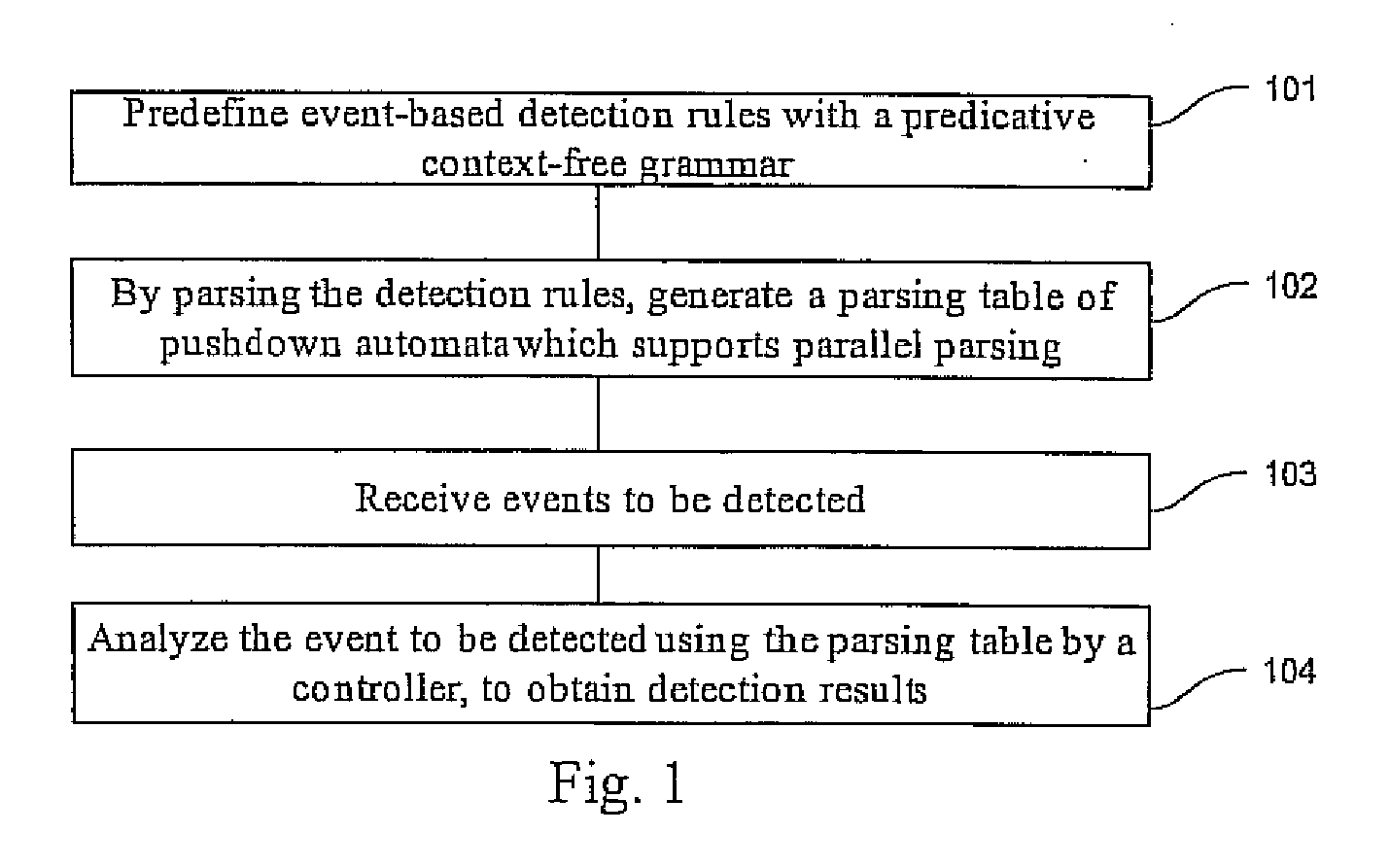

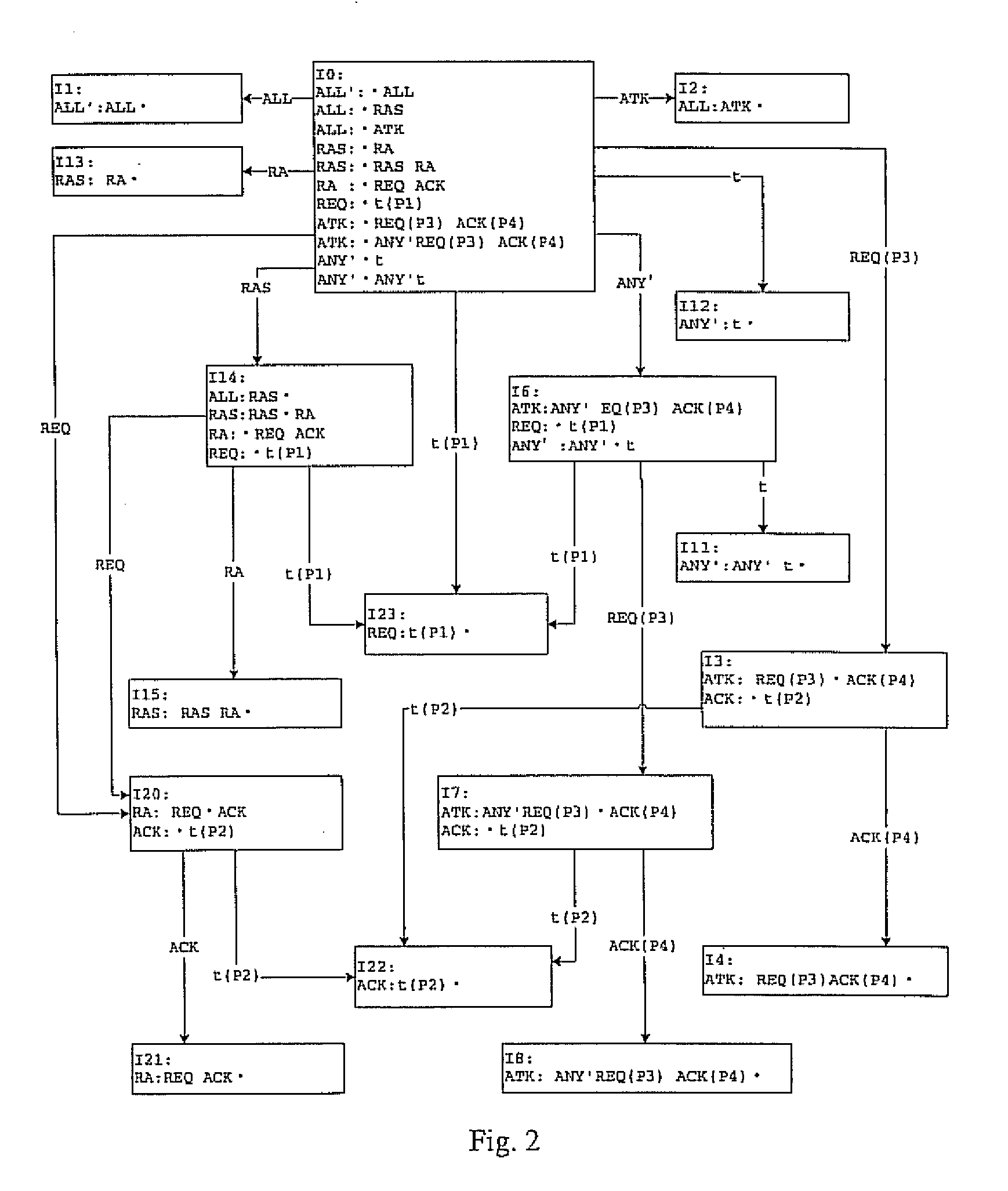

Event detection method

InactiveUS20080010680A1Improve acceleration performanceImprove efficiencyMemory loss protectionError detection/correctionPushdown automatonAlgorithm

The embodiments of the present invention disclose an event detection method and device. The method includes: predefining event-based detection rules with a predicative context-free grammar; generating by parsing the detection rules a parsing table of pushdown automaton which supports parallel parsing; receiving an event to be detected; and analyzing by a controller the event to be detected according to the parsing table, to obtain a detection result. The present invention is especially applicable to detection of network attack events. The embodiments of the present invention detect the attacks with a predicative context-free grammar on the basis of events, and ensure a close combination of a protocol parsing process and an attack detection process, as well as a close combination of multiple attack detection rules, thus decreasing unnecessary calculations. In addition, with an optimized parallel pushdown automaton, the embodiments of the present invention can efficiently analyze the predicative context-free grammar. Consequently, besides hierarchical processing capability and state description capability, the embodiments of the present invention deliver high efficiency.

Owner:NEUSOFT CORP

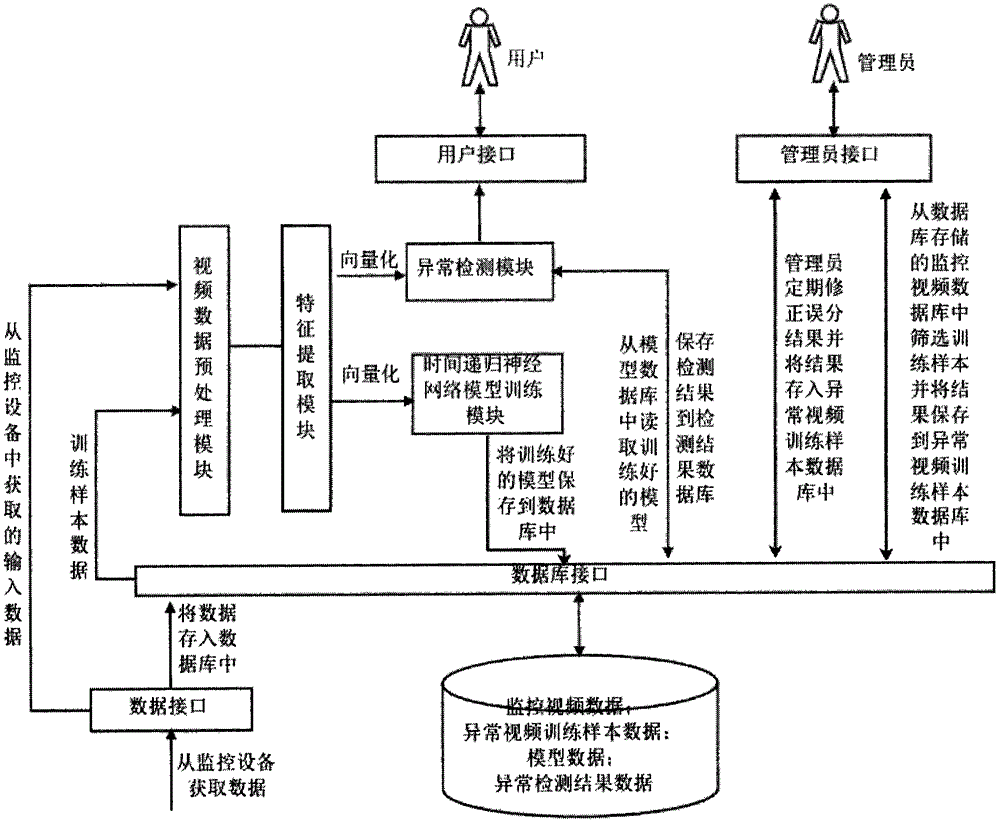

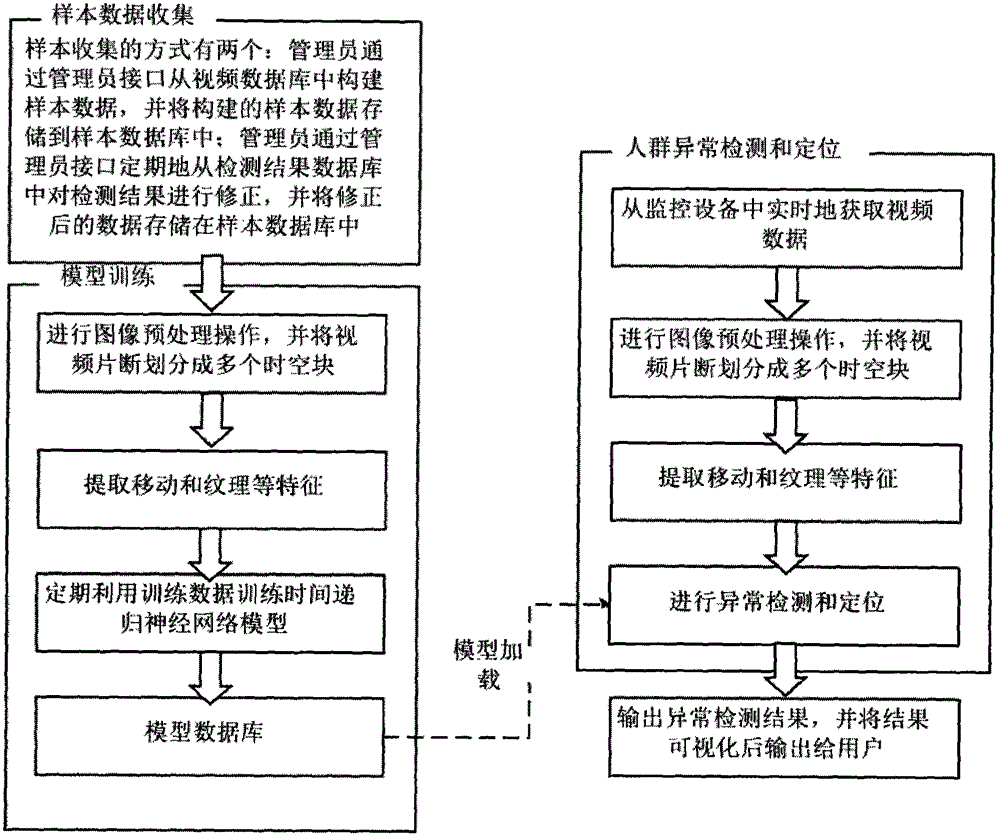

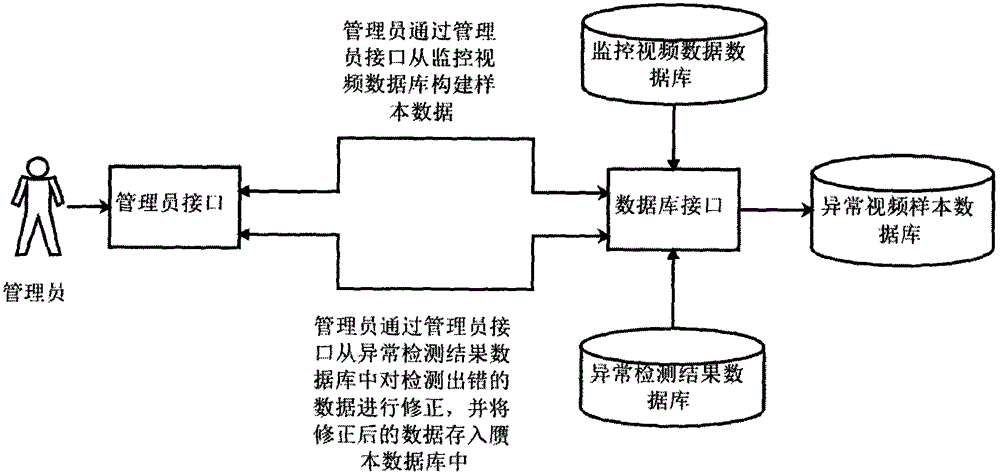

Crowd abnormity detection and positioning system and method based on time recurrent neural network

InactiveCN104636751AHigh detection efficiencyImprove real-time performanceBiological neural network modelsCharacter and pattern recognitionNODALCrowds

The invention discloses a crowd abnormity detection and positioning system and a crowd abnormity detection and positioning method based on a time recurrent neural network. The method comprises the steps of carrying out gridding division on a scene on the basis of preprocessing acquired sample data, and dividing a video fragment consisting of n frames into a plurality of time-space blocks; then constructing a multi-scale optical flow histogram and Gabor wavelet texture features in each time-space block; vectoring and combining the features in the multiple time-space blocks, finding out a relation between a space dimension and a time dimension by taking the video fragment as a time sequence through respectively using hidden nodes and feedback nodes of the time recurrent neural network, and training a time recurrent neural network model capable of detecting a long dependency relation; finally detecting and positioning a crowd abnormity by the model. The method is higher in instantaneity and accuracy, and can detect abnormities activated by a small quantity of individuals or a large quantity of individuals.

Owner:GUANGDONG UNIV OF TECH

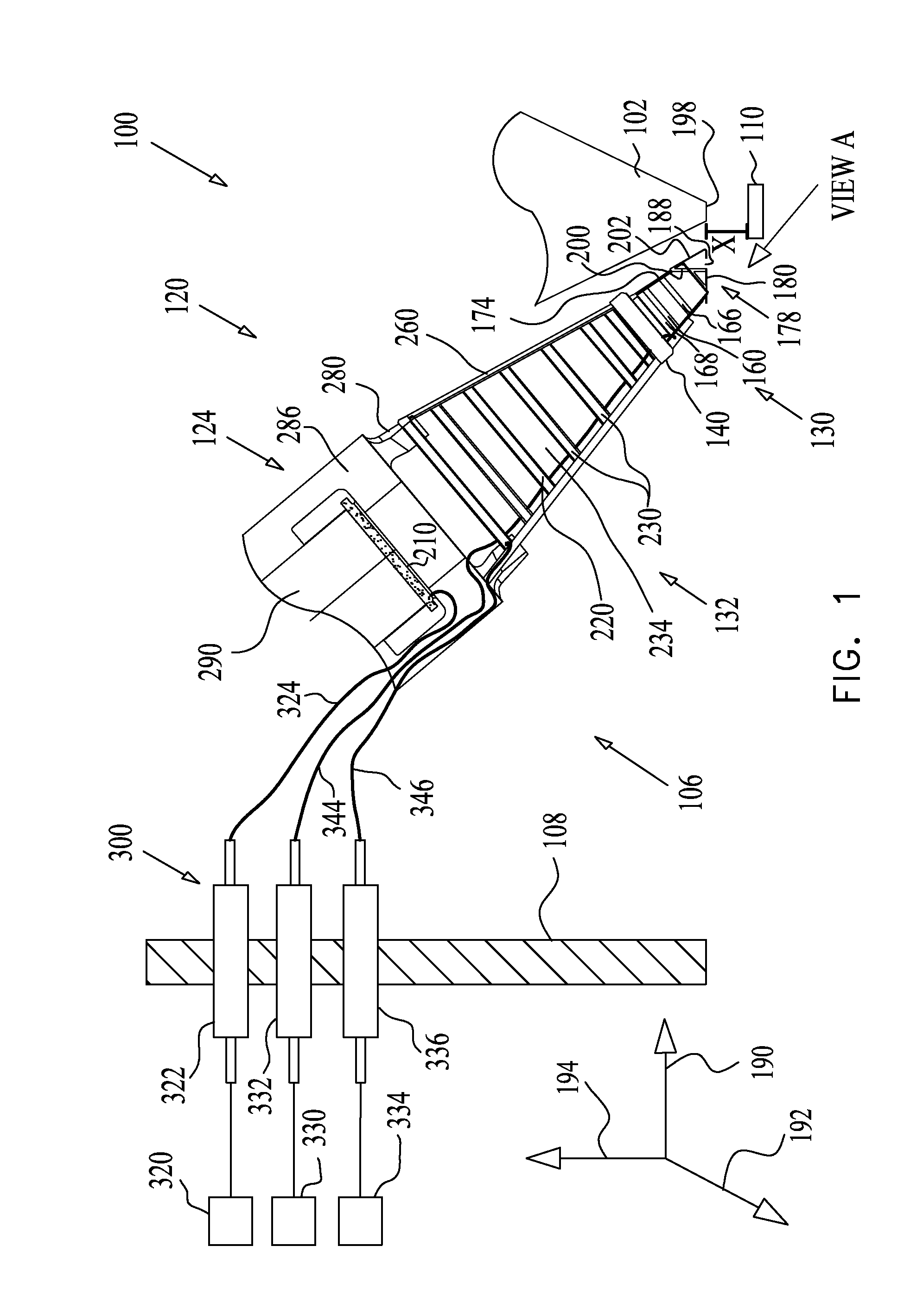

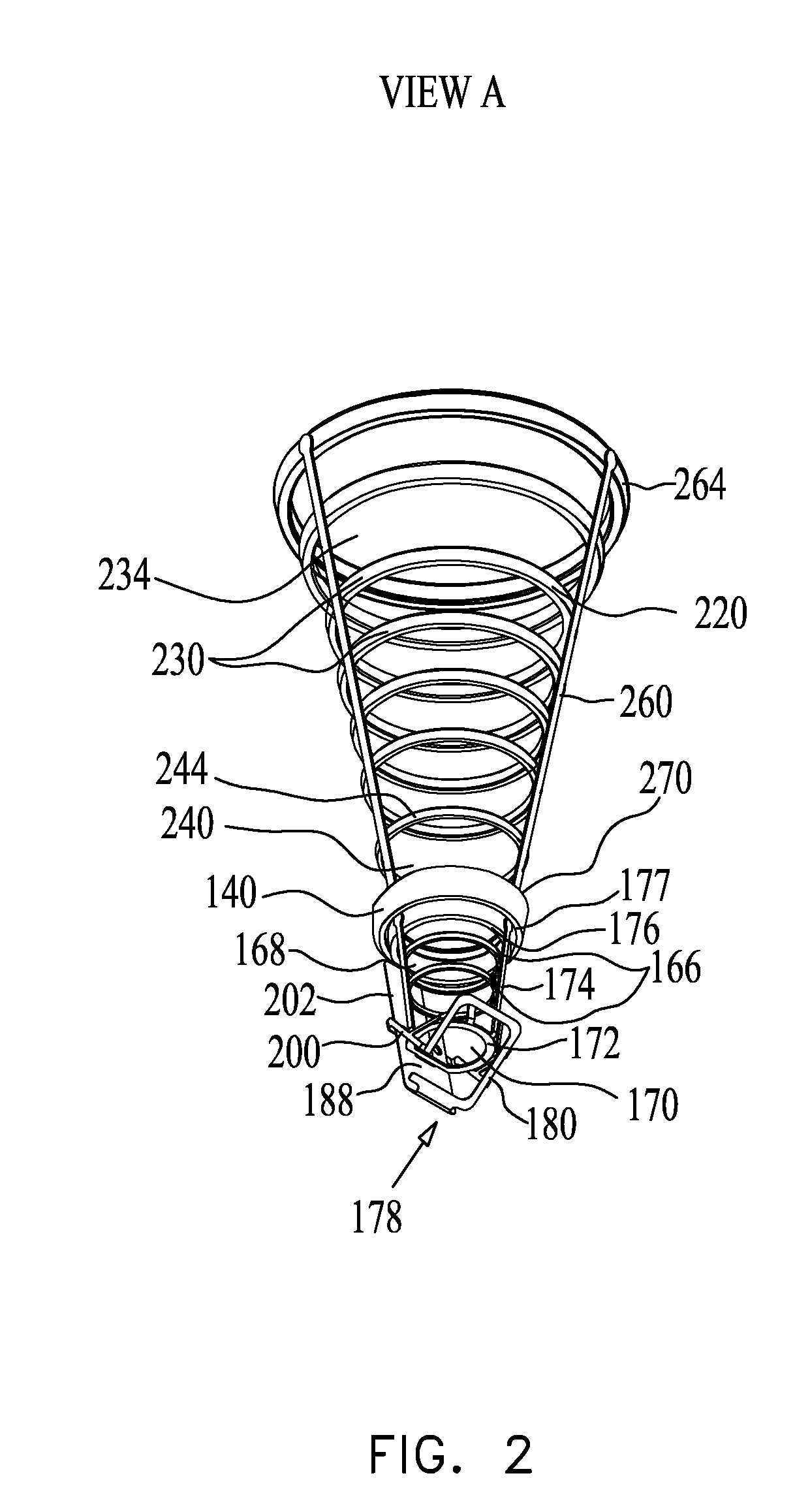

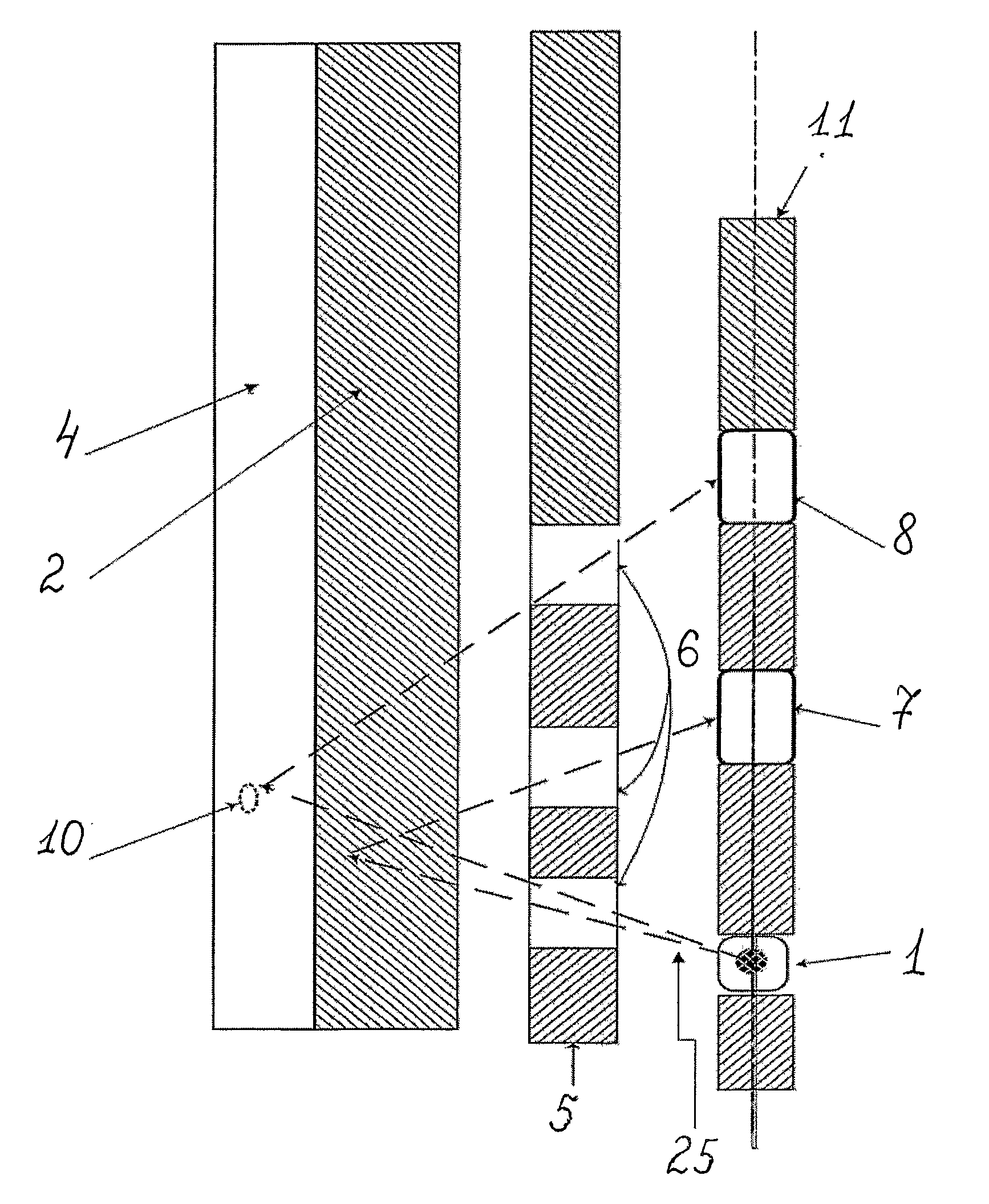

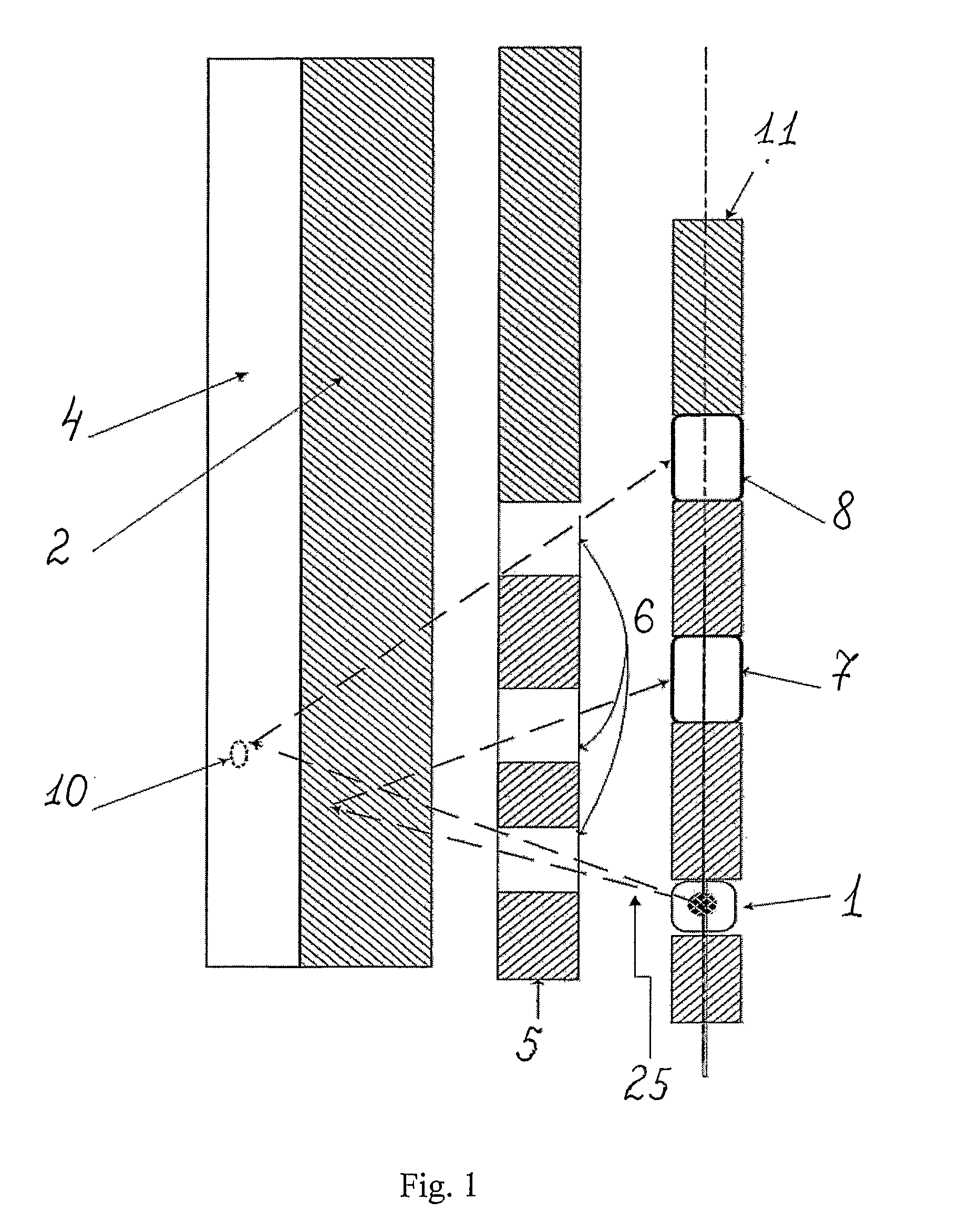

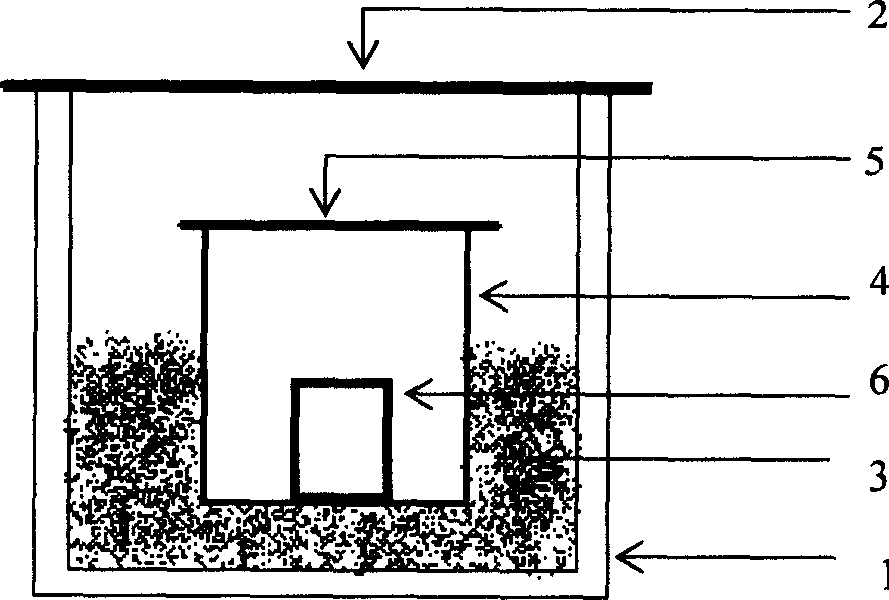

Well Flaw Detection System (Embodiments)

ActiveUS20110284732A1Solve the low detection efficiencyHigh temperaturesSurveyConstructionsQuality controlOil well

This invention relates to nondestructive control, more specifically, to the detection of cracks, flaws and other defects in oil and gas wells and cementing quality control.

Owner:SCHLUMBERGER TECH CORP

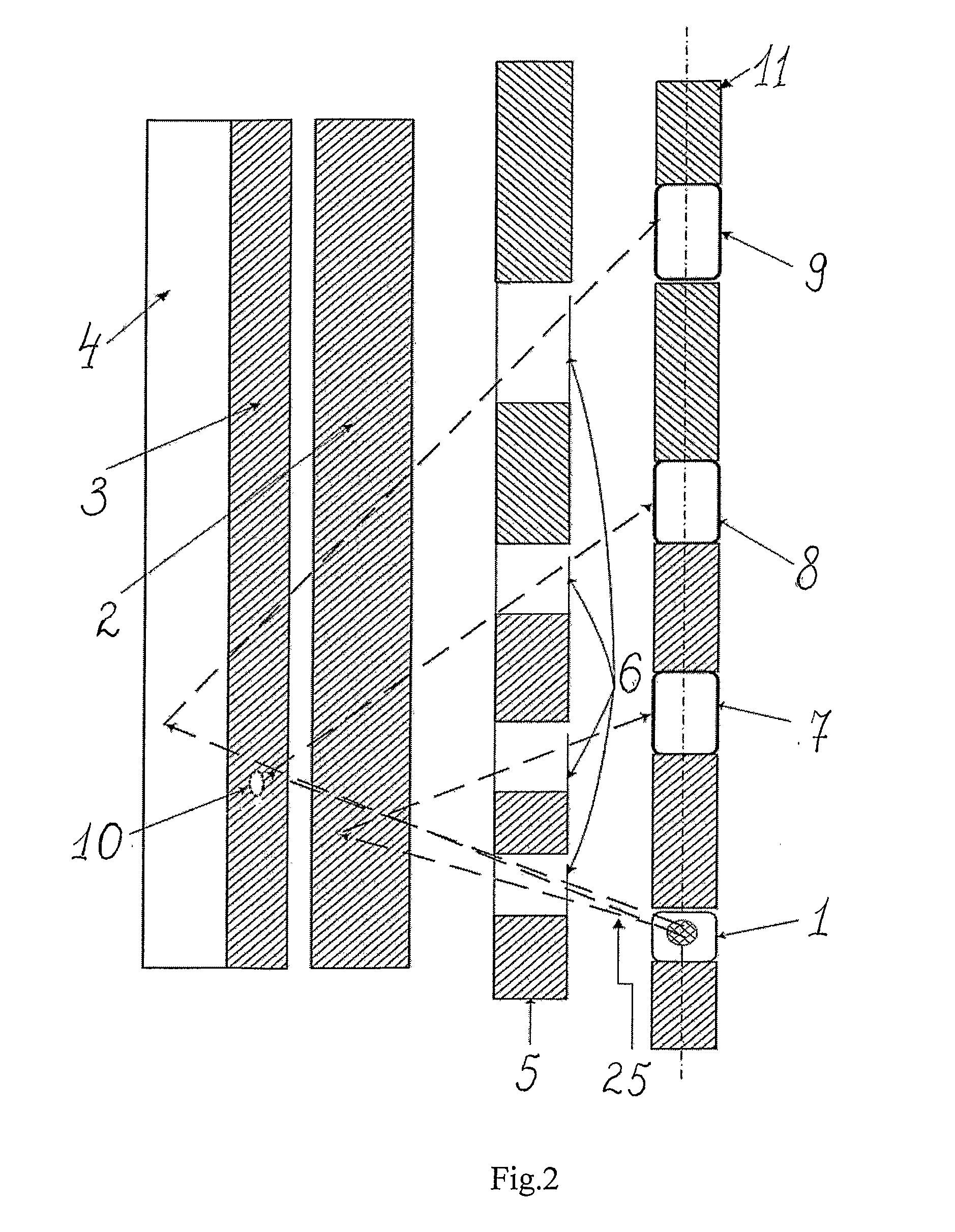

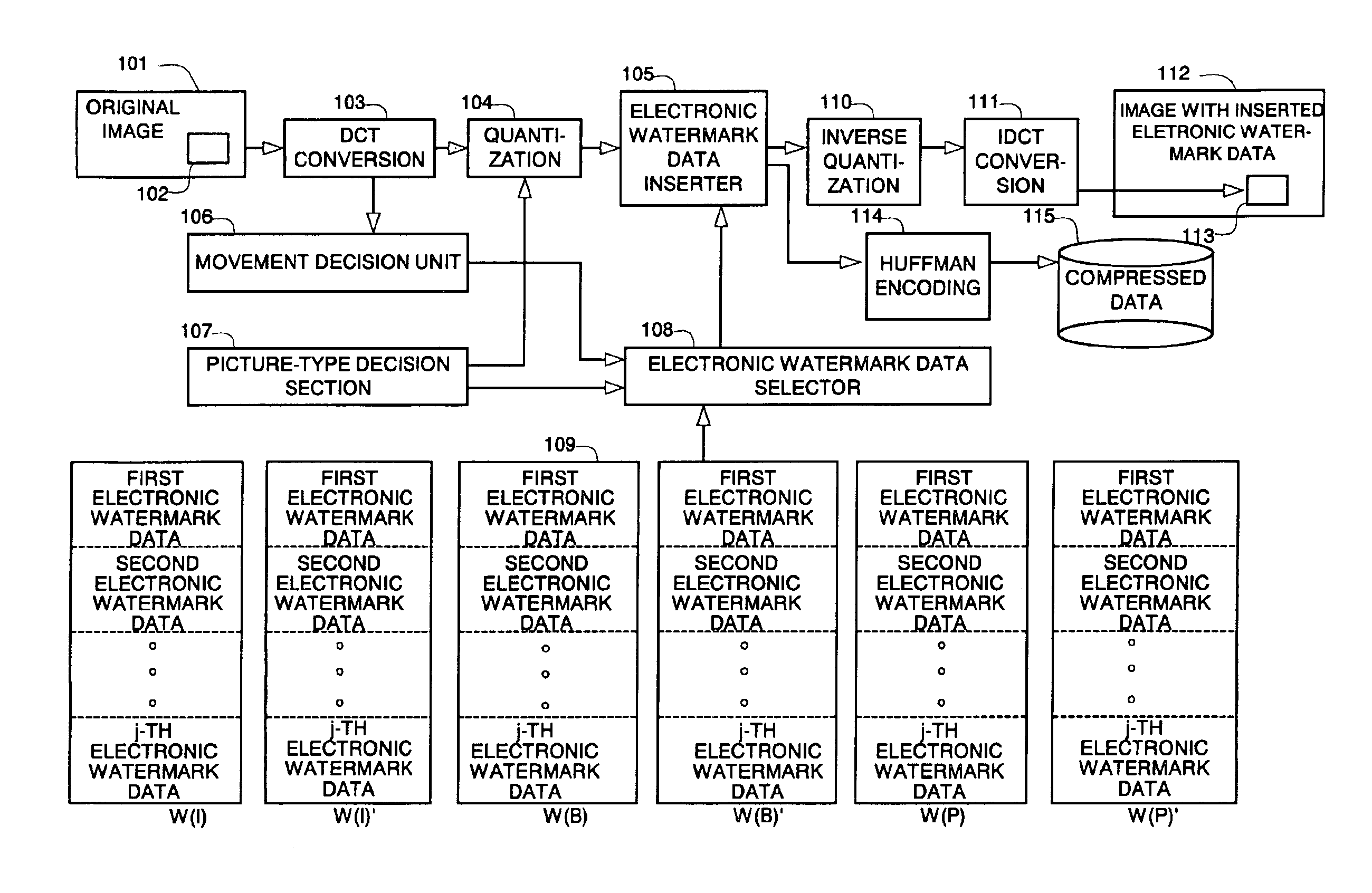

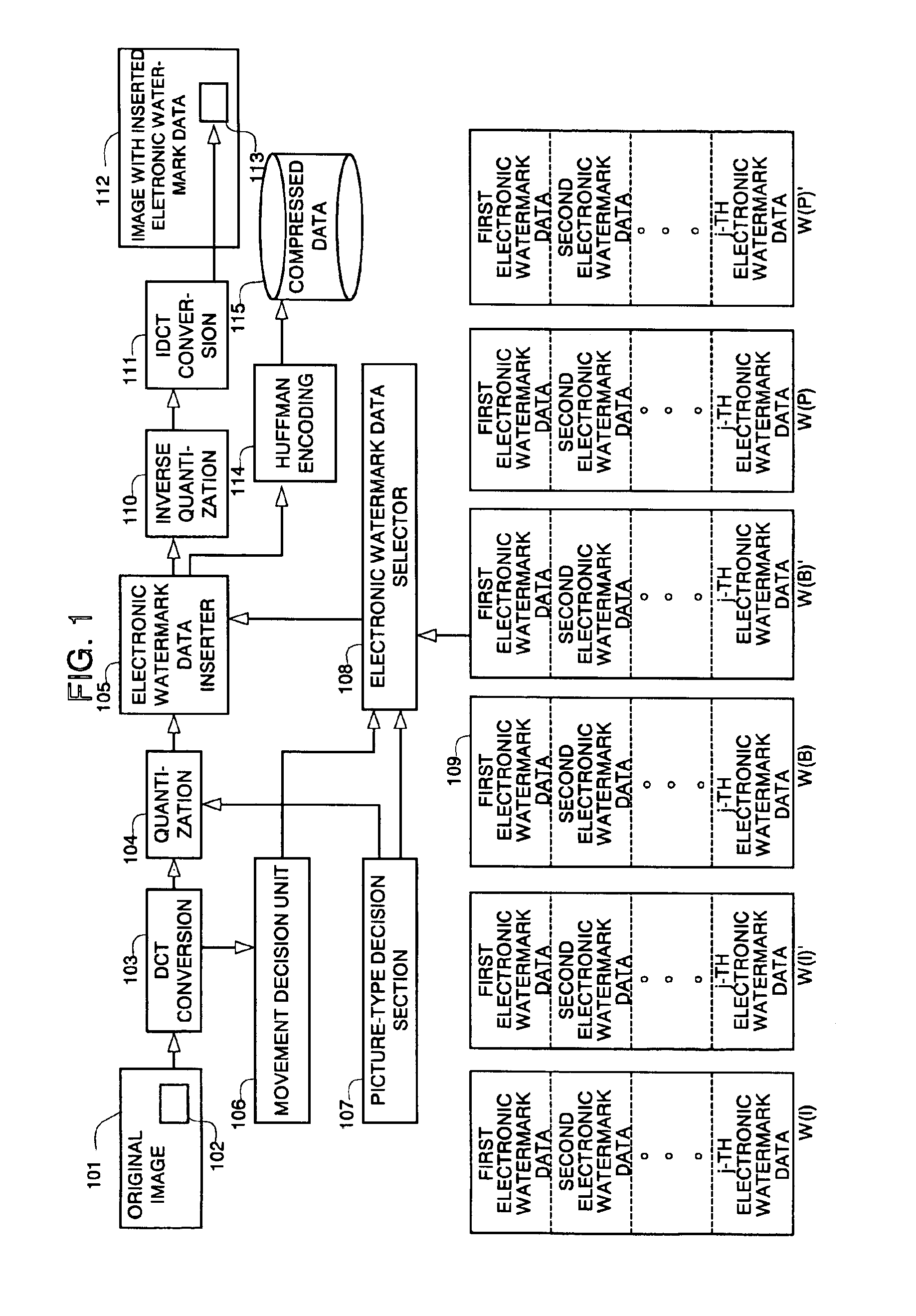

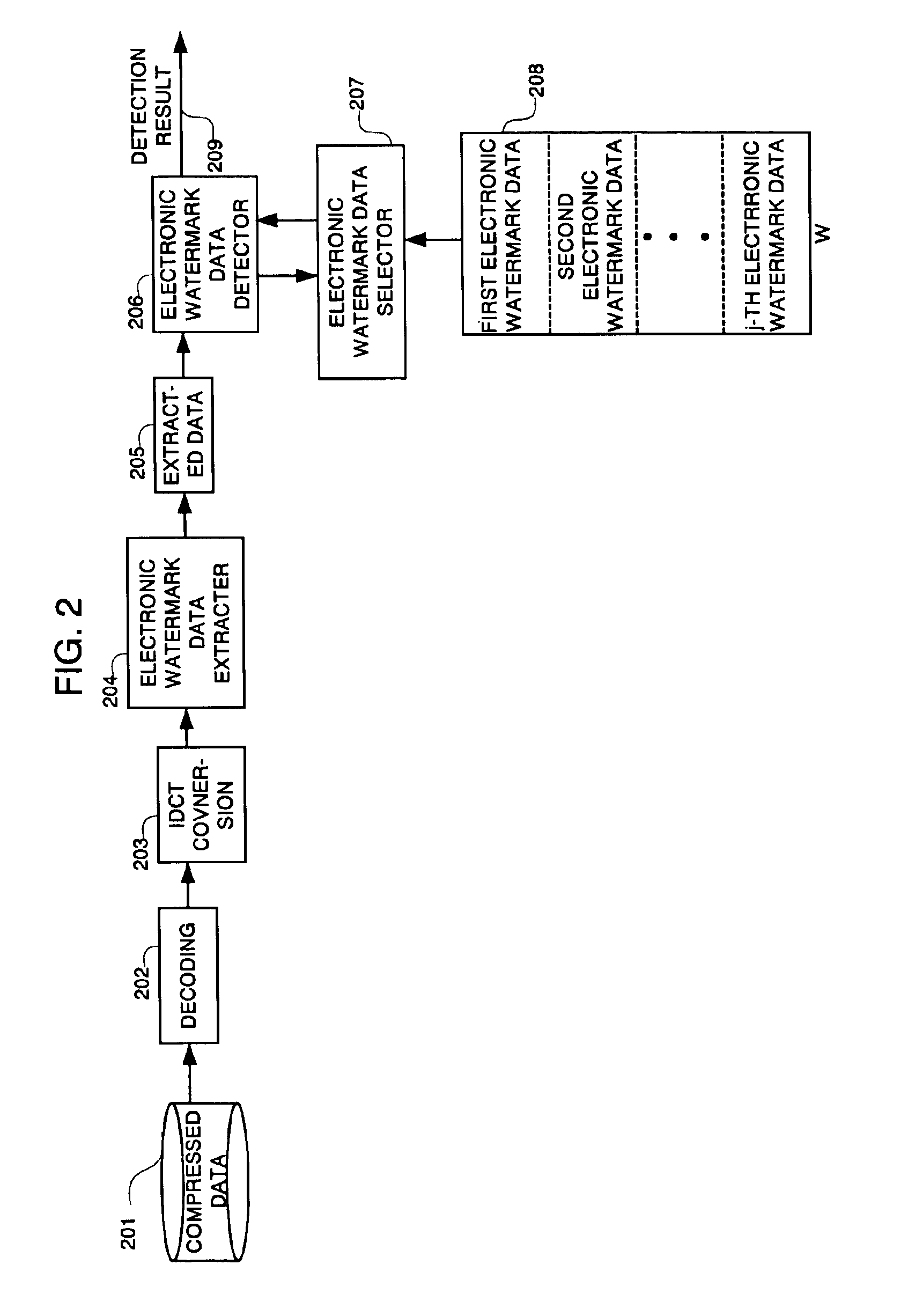

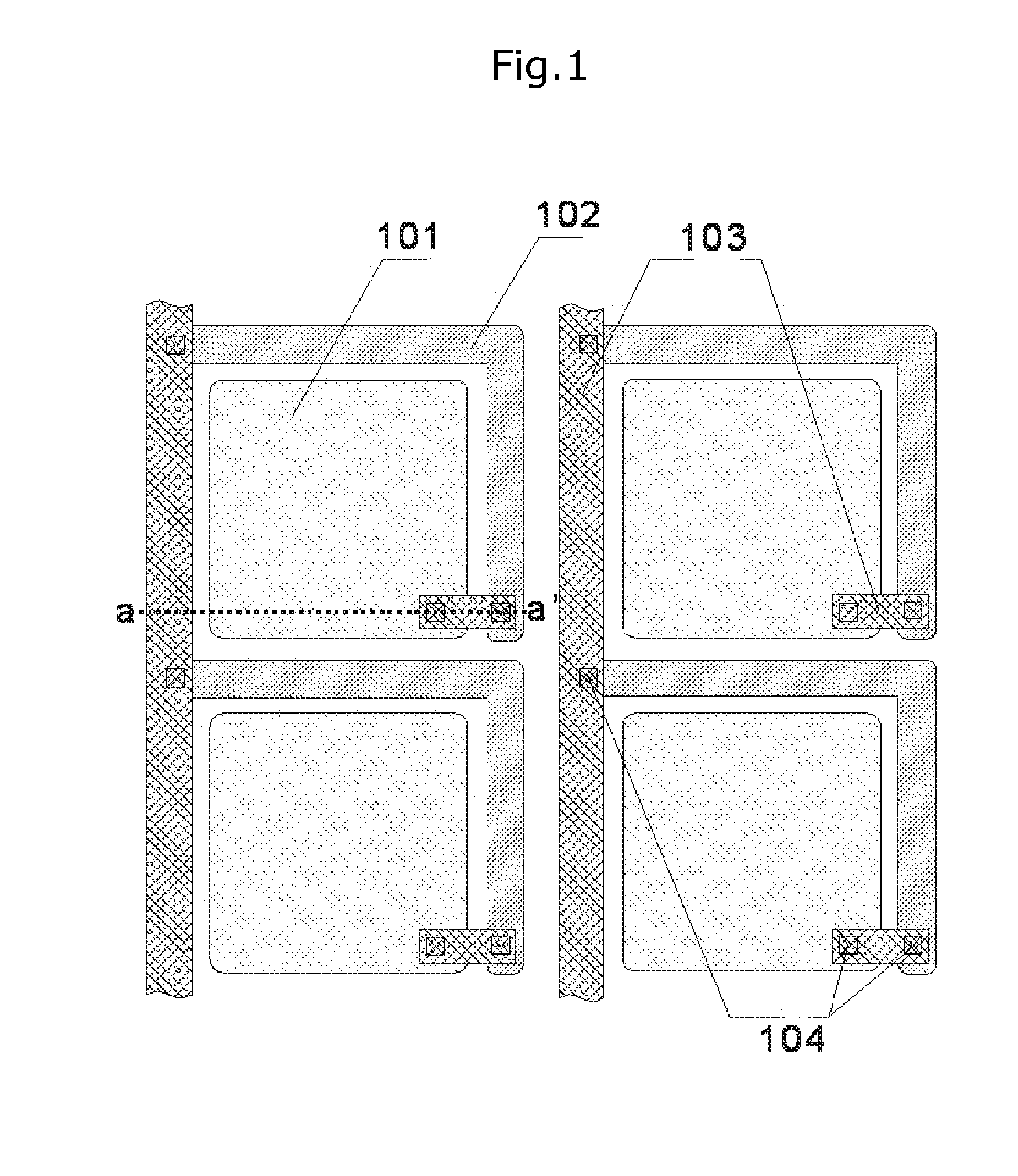

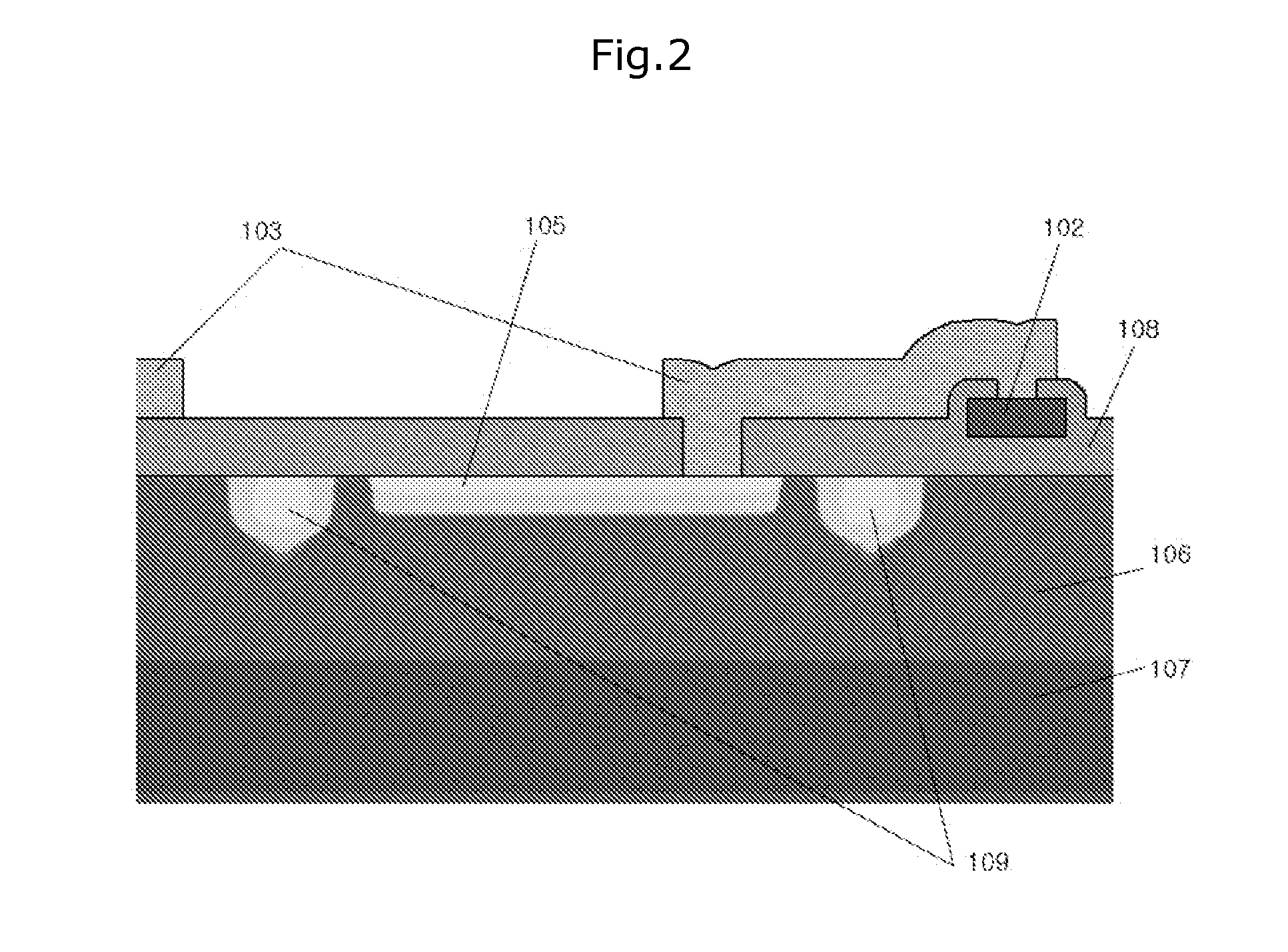

System and apparatus for inserting electronic watermark data

InactiveUS6915000B1Solve the low detection efficiencyAppropriate strengthTelevision system detailsPulse modulation television signal transmissionDct transformComputer science

The DCT converter 103 extracts block data 102 of a 8×8 pixel size from the original image 101 and then subjects it to DCT conversion. The quantizer 104 quantizes the DCT coefficient. The movement decision unit 106 obtains the difference between the number V(t) of DCT coefficients obtained by the DCT converter 103 and the number V(t−1) of DCT coefficients of the previous frame previously held. The movement decision unit 106 decides the movement as a large value if the difference exceeds a certain threshold value and decides the movement as a small value if the difference is less than the threshold value. The electronic watermark data inserter 105 extracts electronic watermark data W(j) which matches the location where 8×8 block data is extracted from the electronic watermark data table 109, the picture type and the movement and then inserts it into the data after quantization output from the quantizer 104.

Owner:NEC PERSONAL COMPUTERS LTD

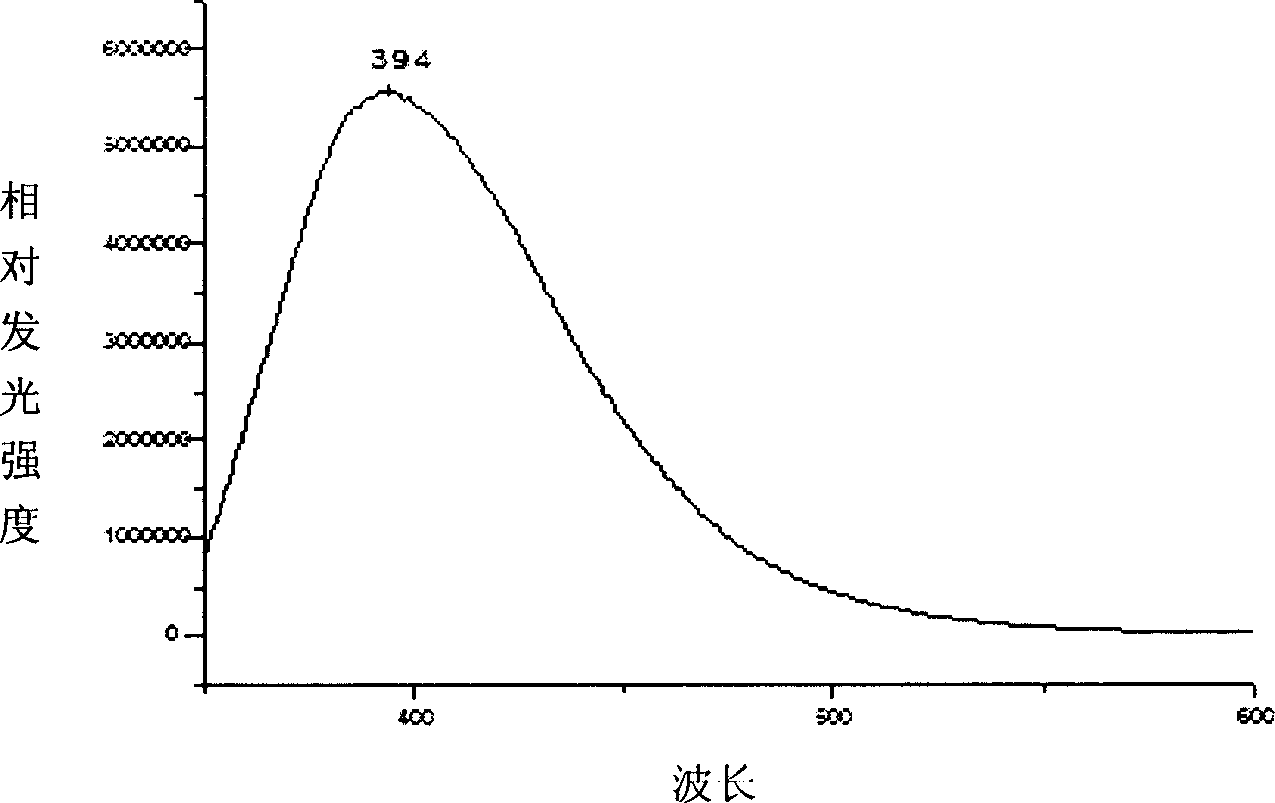

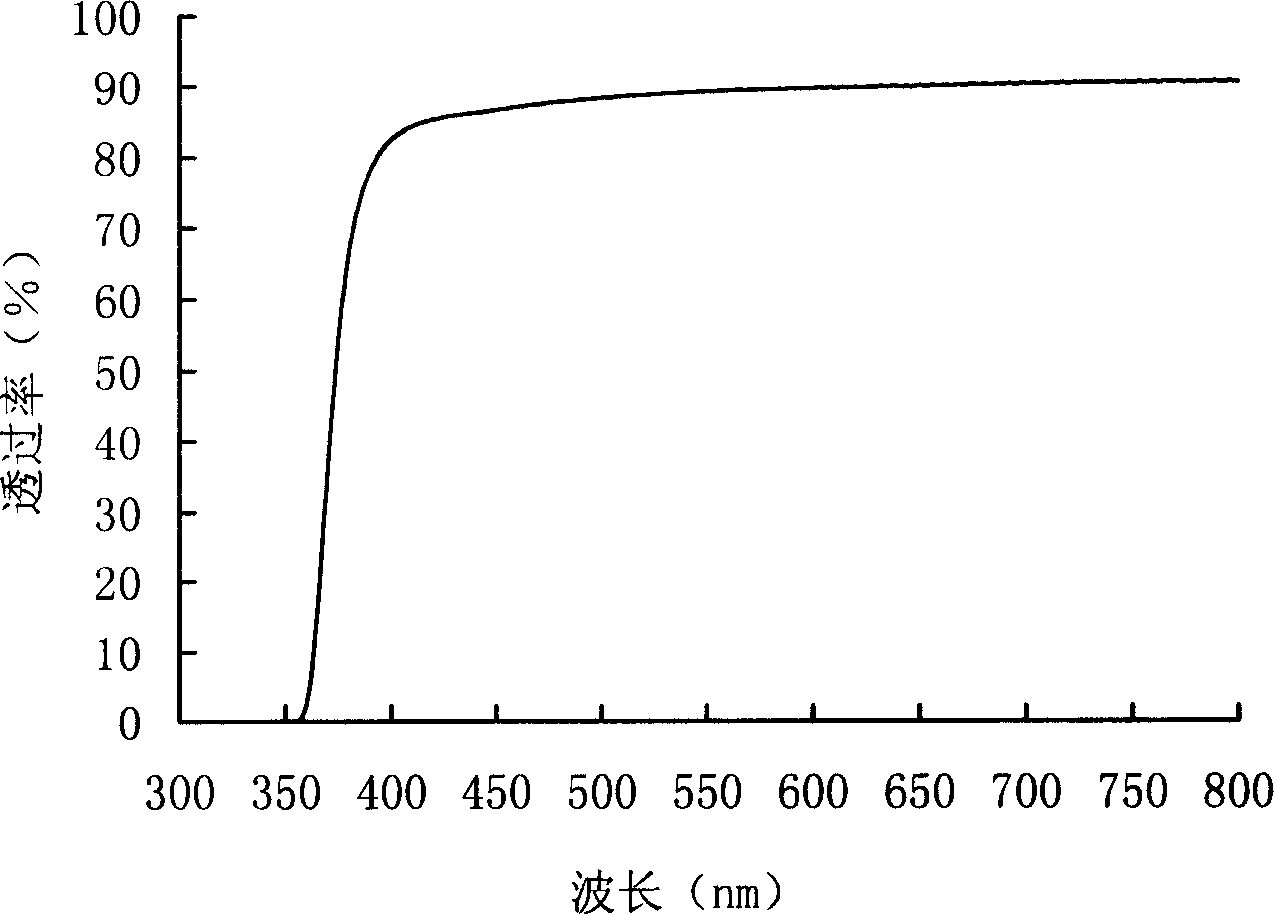

Glass scintillator for thermal neutron detection and its preparation method

The present invention discloses a glass scintillator for detecting thermal neutron and its preparation method. It is characterized by that it uses Ce3+ as lithium-6 glass scintillation material, the lithium element is existed in the glass scintillator in the form of lithium-6 isotope, and has the action of producing nuclear reaction. The luminous efficiency of glass scintillator obtained by making raw materials undergo the three steps of preparing material, melting and annealing is 12% of NaI(T1), strongest emission wavelength is about 400nm, UV cut-off wavelength is 360nm, luminous decay time is about ns and thermal neutron detection efficiency is about 90%. Said glass scintillator mainly is used for detecting thermal neutron, and also can be used for detecting alpha ray, beta ray and gamma ray, etc.

Owner:CHINA BUILDING MATERIALS ACAD

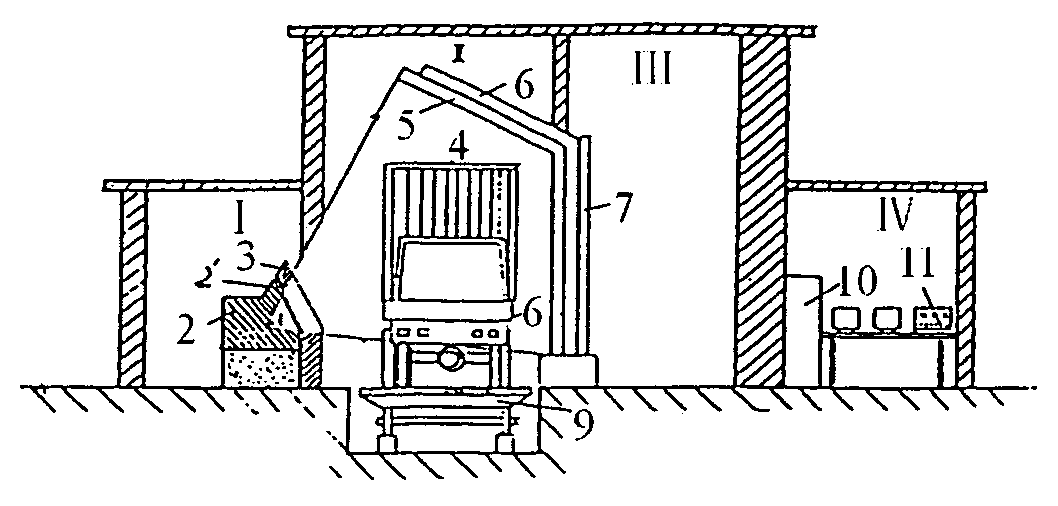

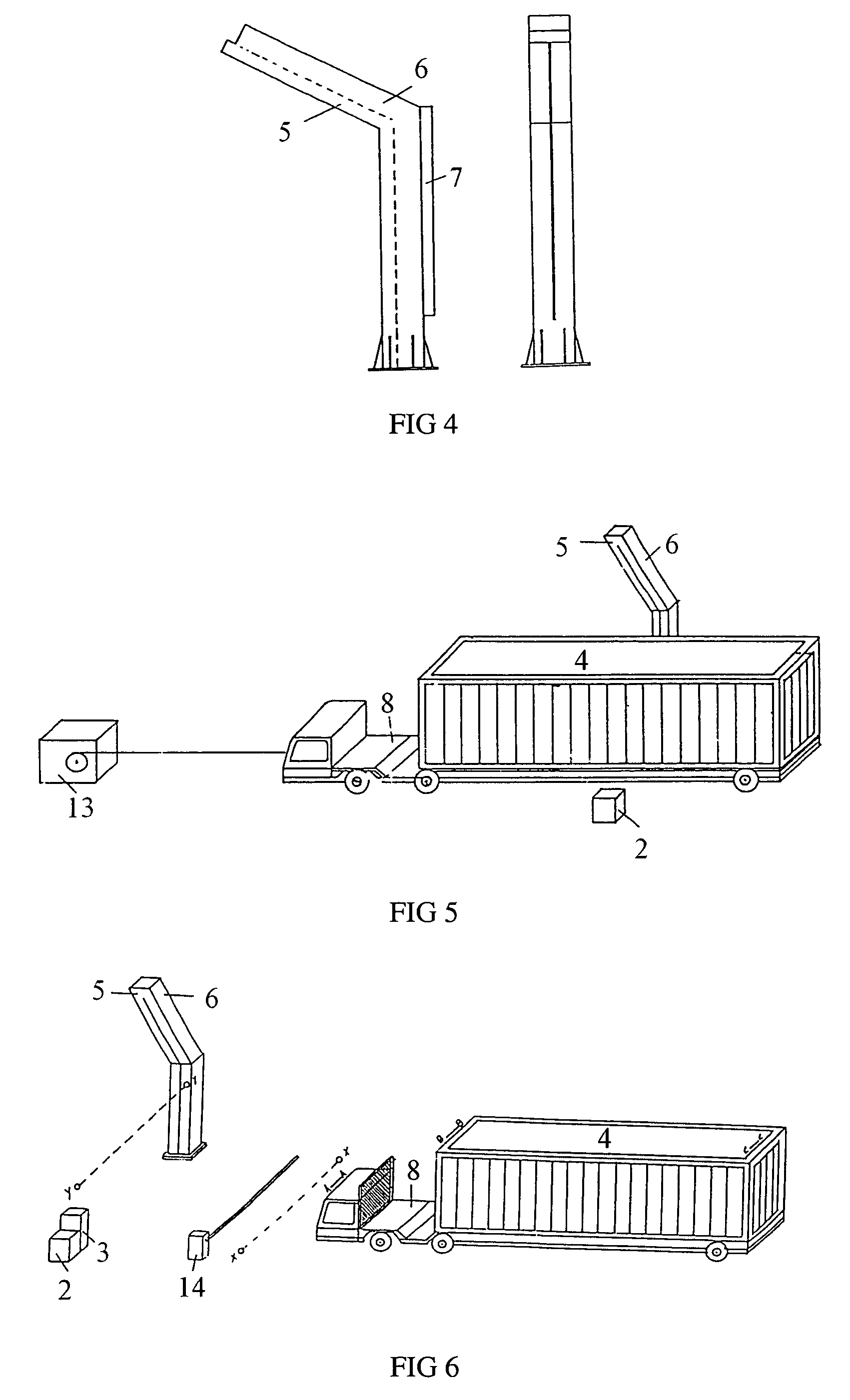

Container inspection system using cobalt-60 γ-ray source and cesium iodide or cadmium tungstate array detector

InactiveUS7082186B2Easy to produceLow costHandling using diaphragms/collimetersX/gamma/cosmic radiation measurmentAutomatic controlNuclear engineering

A container inspection equipment with cobalt-60 γ-ray source and cesium iodide or cadmium tungstate detector includes a cobalt-60 γ-ray source, a cask, a front collimator, a rear collimator, a cesium iodide or cadmium tungstate detector, signal and image processing systems, container trailer system, and automatic control system. The cask of the cobalt-60 γ-ray source, the beam shutter, and the front collimator are fixed on the same chassis to form an integration and placed in the source room. The rear collimator, cesium iodide or cadmium tungstate array detector and the radiation catcher are fixed on the same chassis to form an integration and placed in the detector room. A container inspection tunnel is formed between the source room and the detector room. The equipment is mainly used for inspecting smuggling goods and contrabands etc., in large containers, container trucks, train carriage and air containers. The equipment either can be installed in the sea port and land frontier customs or installed at the air port, vital communication line, and railway station.

Owner:BEIJING ISOTOPE NUCLEAR ELECTRONICS MACHINE

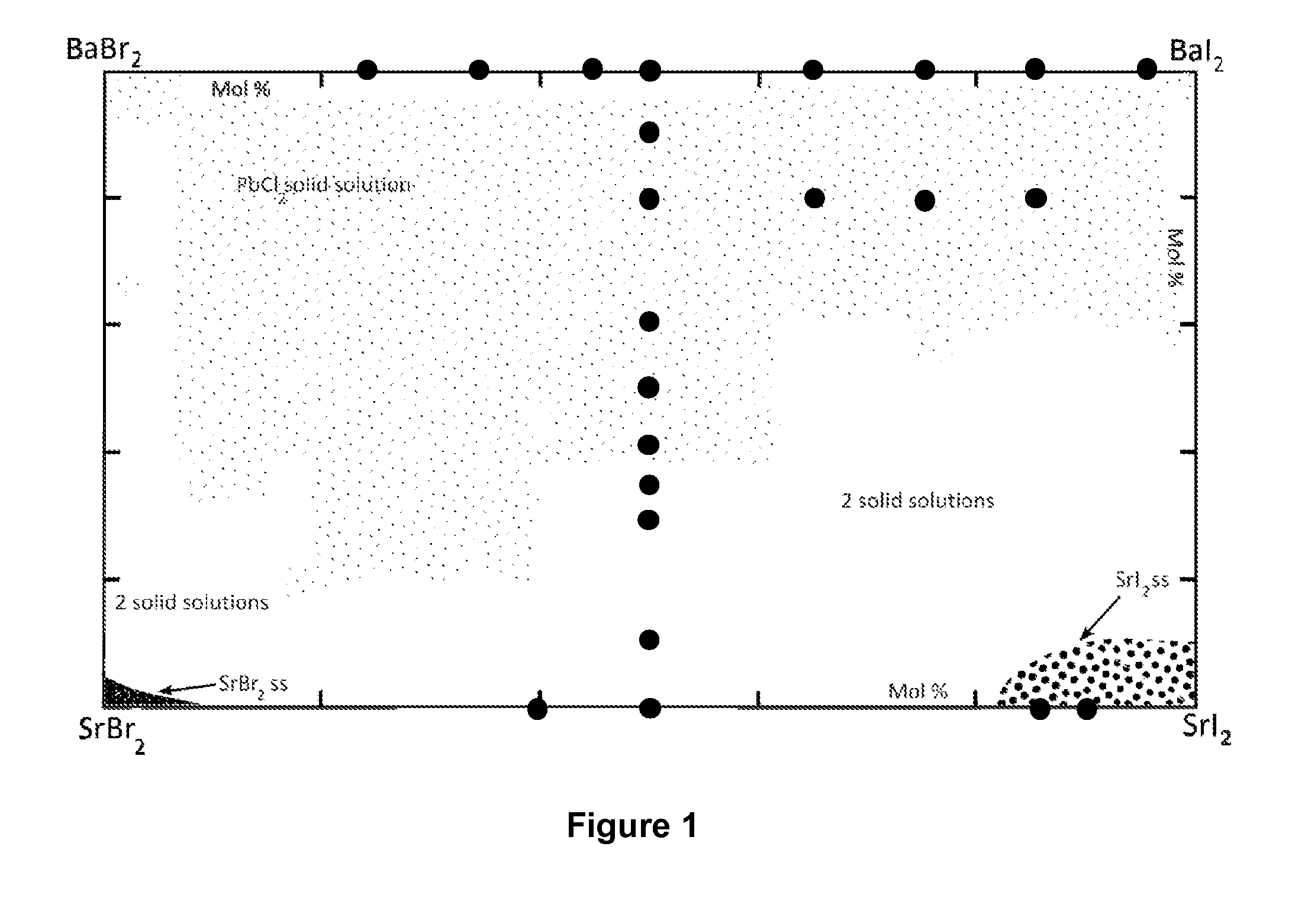

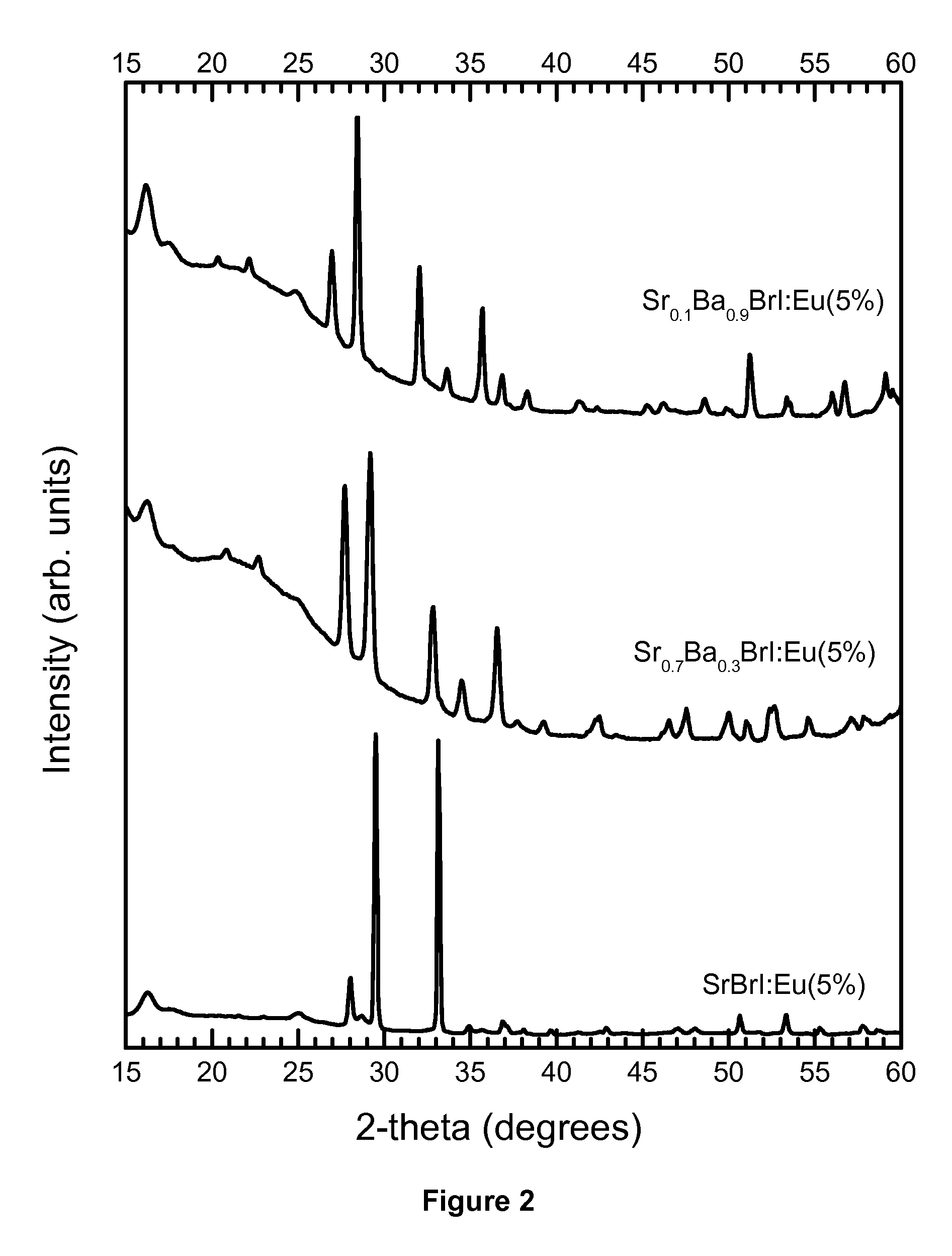

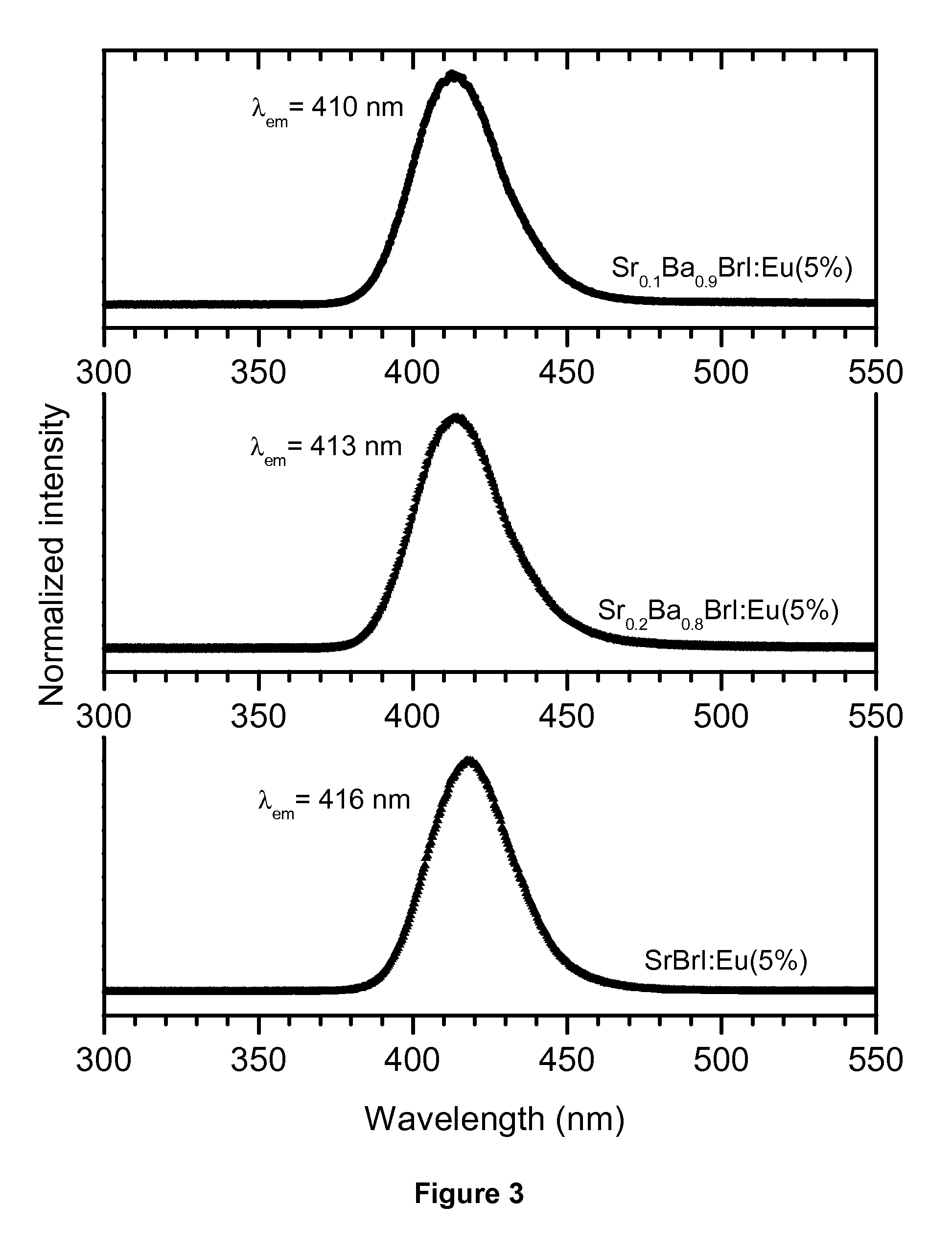

Novel Lanthanide Doped Strontium Barium Mixed Halide Scintillators

ActiveUS20110165422A1High detection efficiencyShort decay timeFrom frozen solutionsGlass/slag layered productsChemistryLanthanide

The present invention provides for a composition comprising an inorganic scintillator comprising a lanthanide-doped strontium barium mixed halide useful for detecting nuclear material.

Owner:RGT UNIV OF CALIFORNIA

Silicon photomultiplier with trench isolation

InactiveUS20120153423A1Photo detection efficiency be maintain highHigh detection efficiencySolid-state devicesDiodeFill factorOptoelectronics

The present invention relates to a silicon photomultiplier with trench isolation for maintaining the photon detection efficiency high while increasing the dynamic range, by reducing the degradation of the effective fill factor that follows the increase of cell number density intended for a dynamic range enhancement.

Owner:ELECTRONICS & TELECOMM RES INST

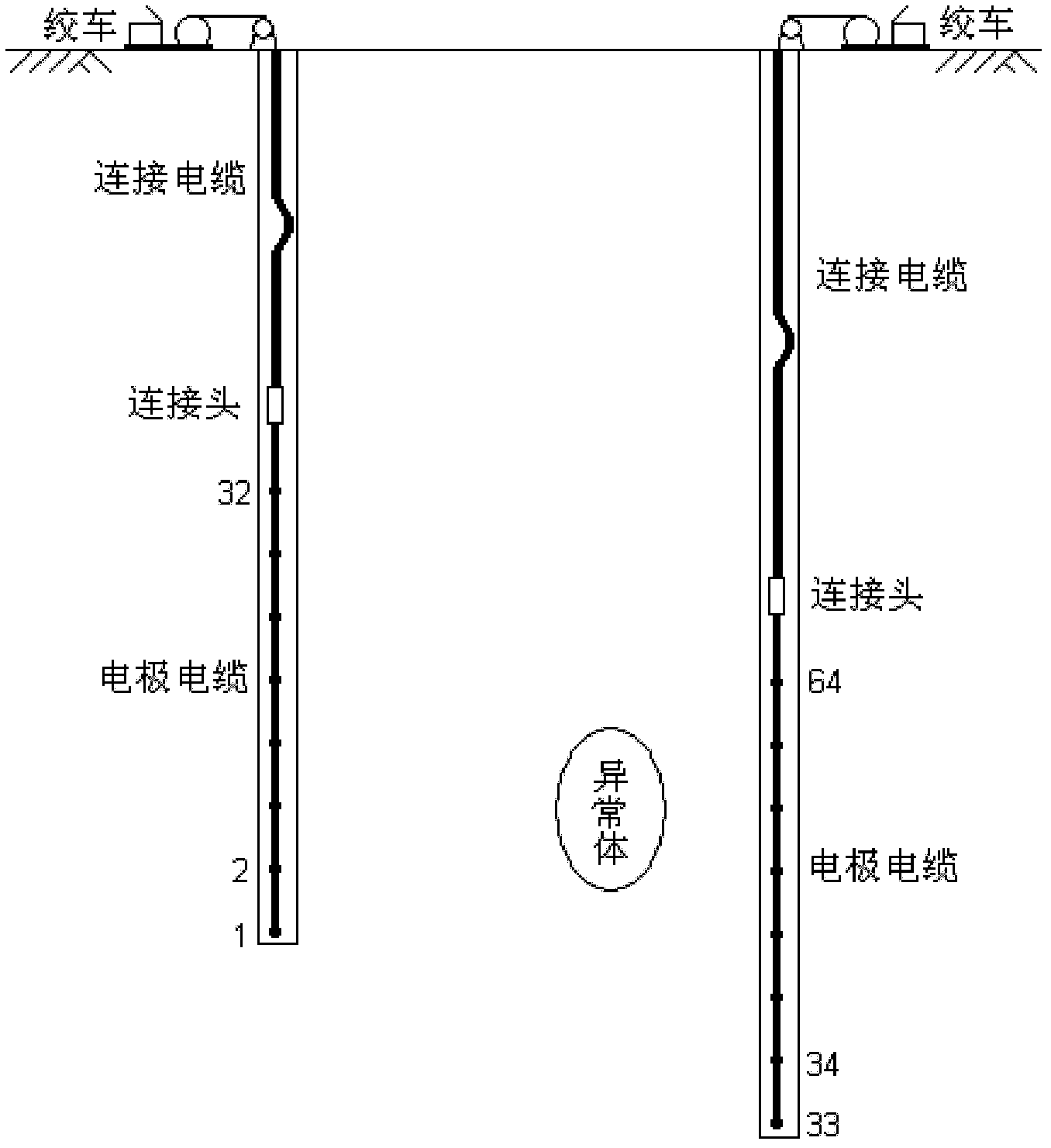

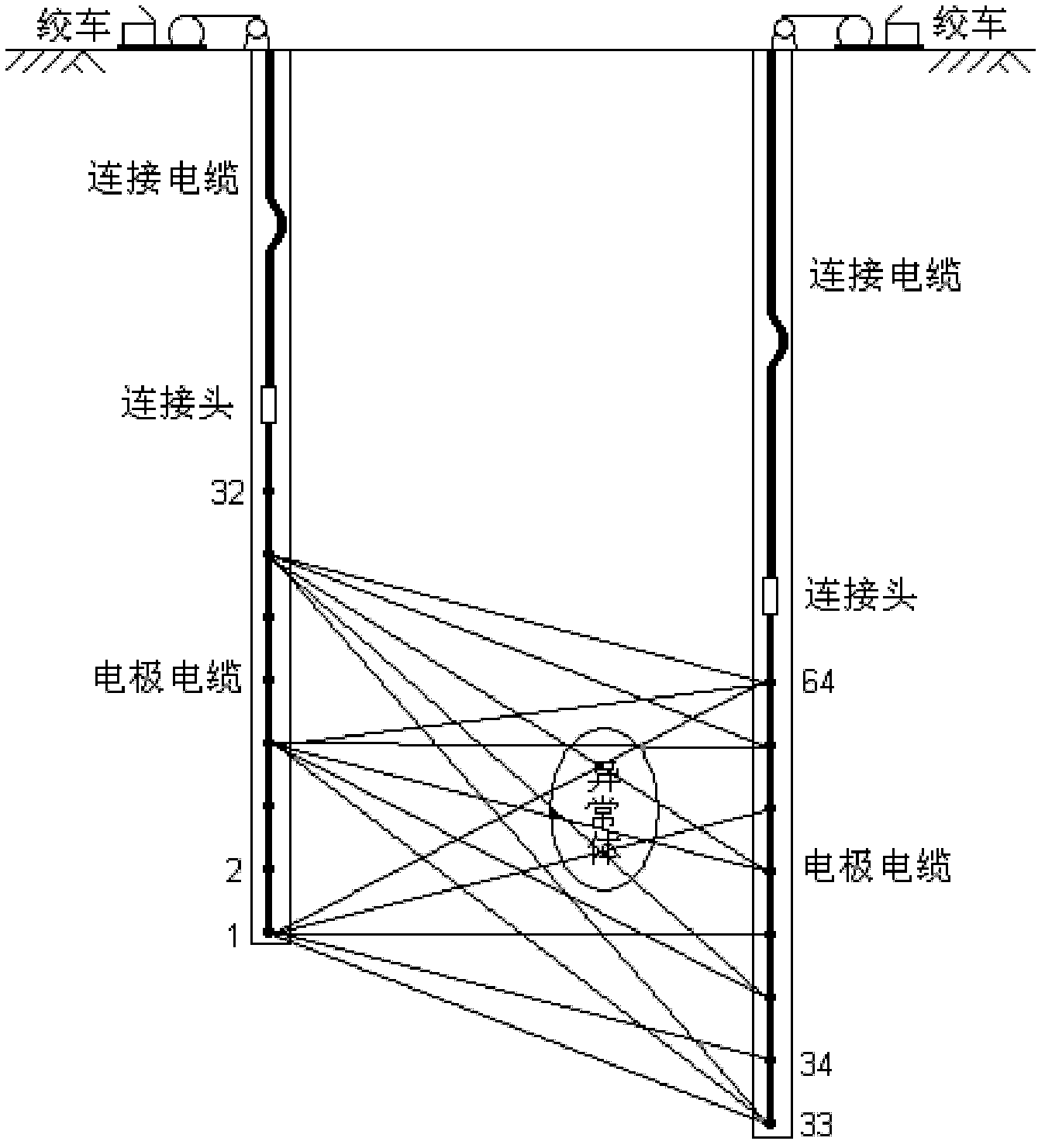

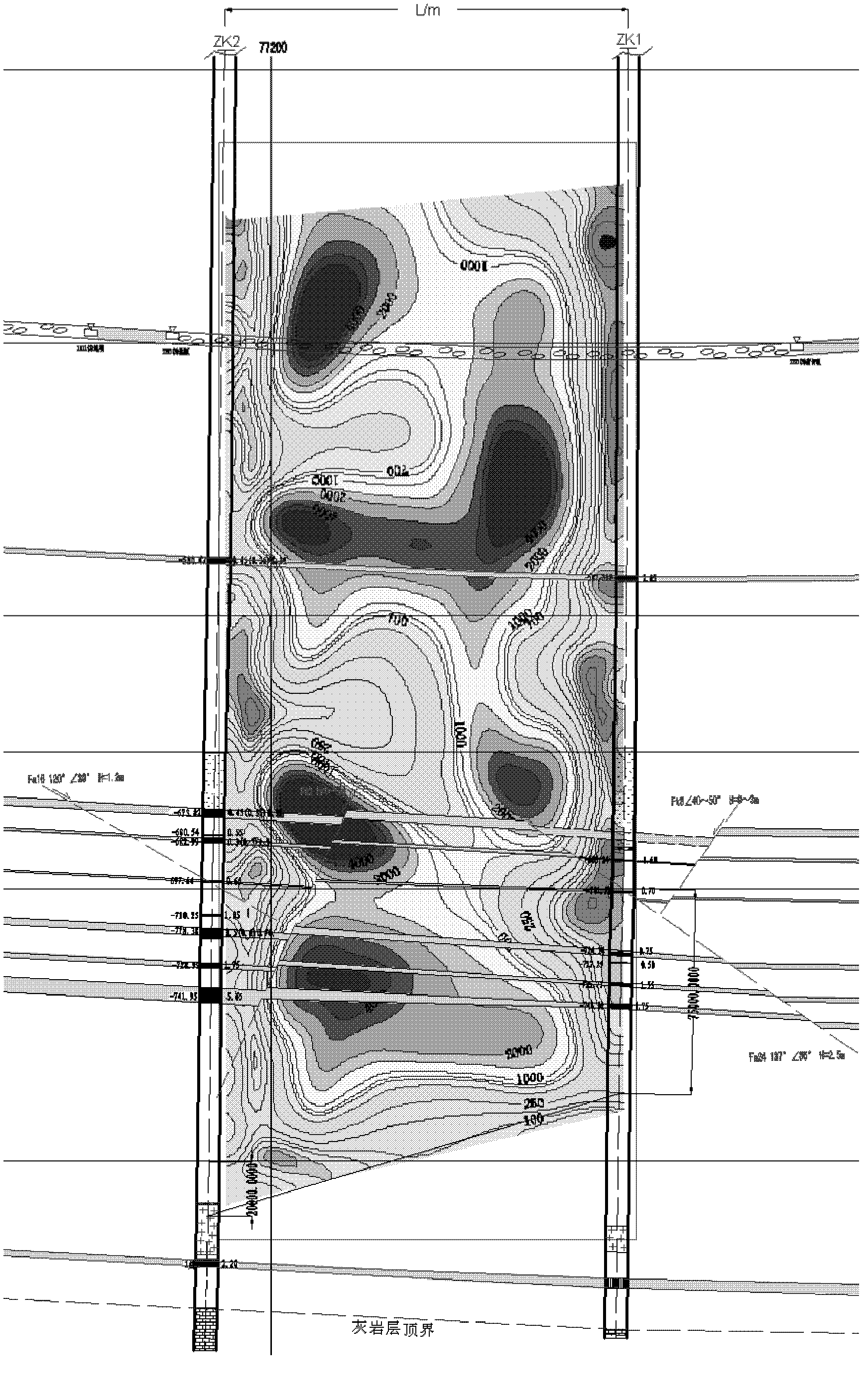

Interwell parallel resistivity CT (computed tomography) testing method

ActiveCN102419455ARealize integrationRealize lifting automationElectric/magnetic detection for well-loggingComputed tomographyData acquisition

The invention discloses an interwell parallel resistivity CT (computed tomography) testing method which is a geophysical prospecting technology for probing geologic conditions and structural features between drill holes. In the method, through arranging a testing system between every two drilling wells, an interwell measuring line with 64 electrodes is formed; a parallel electrical method data collection technology is utilized to carry out monopole or dipole power supply and test, thus interwell electrical property collected data are obtained, and intewell chromatography data bodies between different electrodes are formed; and an interwell resistivity tomography technology is utilized to carry out resistivity and induced polarization parameter tomography on a test area, thus the terrane and structural feature conditions are further evaluated, and geologic interpretation achievement and recognition are obtained. The testing system can be used for achieving data collection of a 1200m deep well.

Owner:ANHUI UNIV OF SCI & TECH

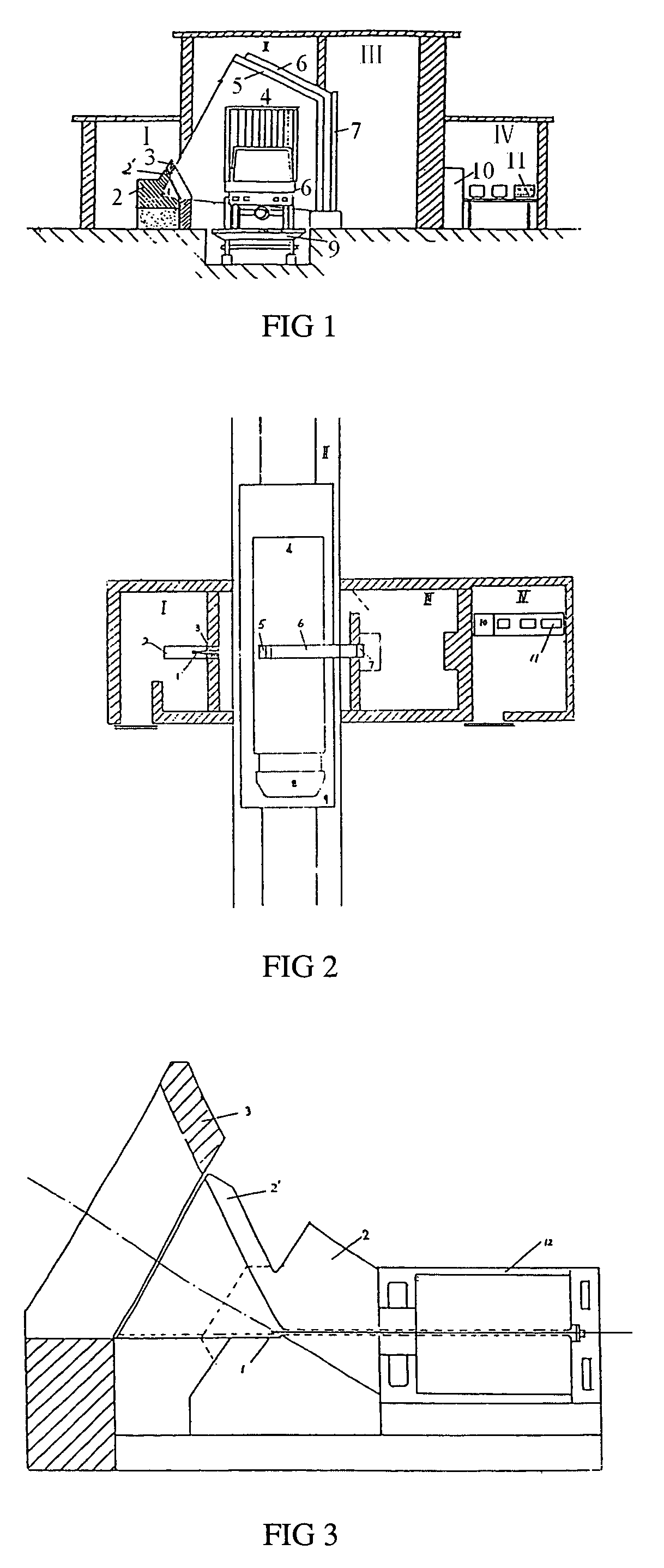

Method and equipment for discriminating materials by employing fast neutron and continuous spectral X-ray

ActiveUS20070096036A1High detection efficiencyImprove qualityMaterial analysis by optical meansNeutron radiation measurementDual energyImage resolution

Disclosed is a method of discriminating materials by employing fast neutron and continuous spectral X-ray and an equipment for the same. The method comprising the steps of: (a) transmitting a fast neutron beam produced by a fast neutron source and a continuous spectral X-ray beam produced by a continuous spectral X-ray source through inspected objects; (b) directly measuring the intensity of the transmitted X-rays and the intensity of the transmitted neutrons by a X-ray detector array and a neutron detector array respectively; and (c) identifying the materials of the inspected object by Z-dependency curves formed by the attenuation differences between the neutron beam and X-ray beam transmitted through different materials of the inspected object. This direct measurement of transmitted dual-ray technique has much more efficient than secondary radiations measurement such as neutron activation analysis, has much more material discrimination sensitivity than dual-energy x-ray technique. The respective measurements of neutrons and x-rays make the usages of high detect efficiency neutron detectors and x-ray detectors possible. The using continuous spectral x-ray produced by Linac adds more advantages such as: high penetration ability, high spatial resolution, and high image quality over monoenergetic dual-ray technique.

Owner:TSINGHUA UNIV +1

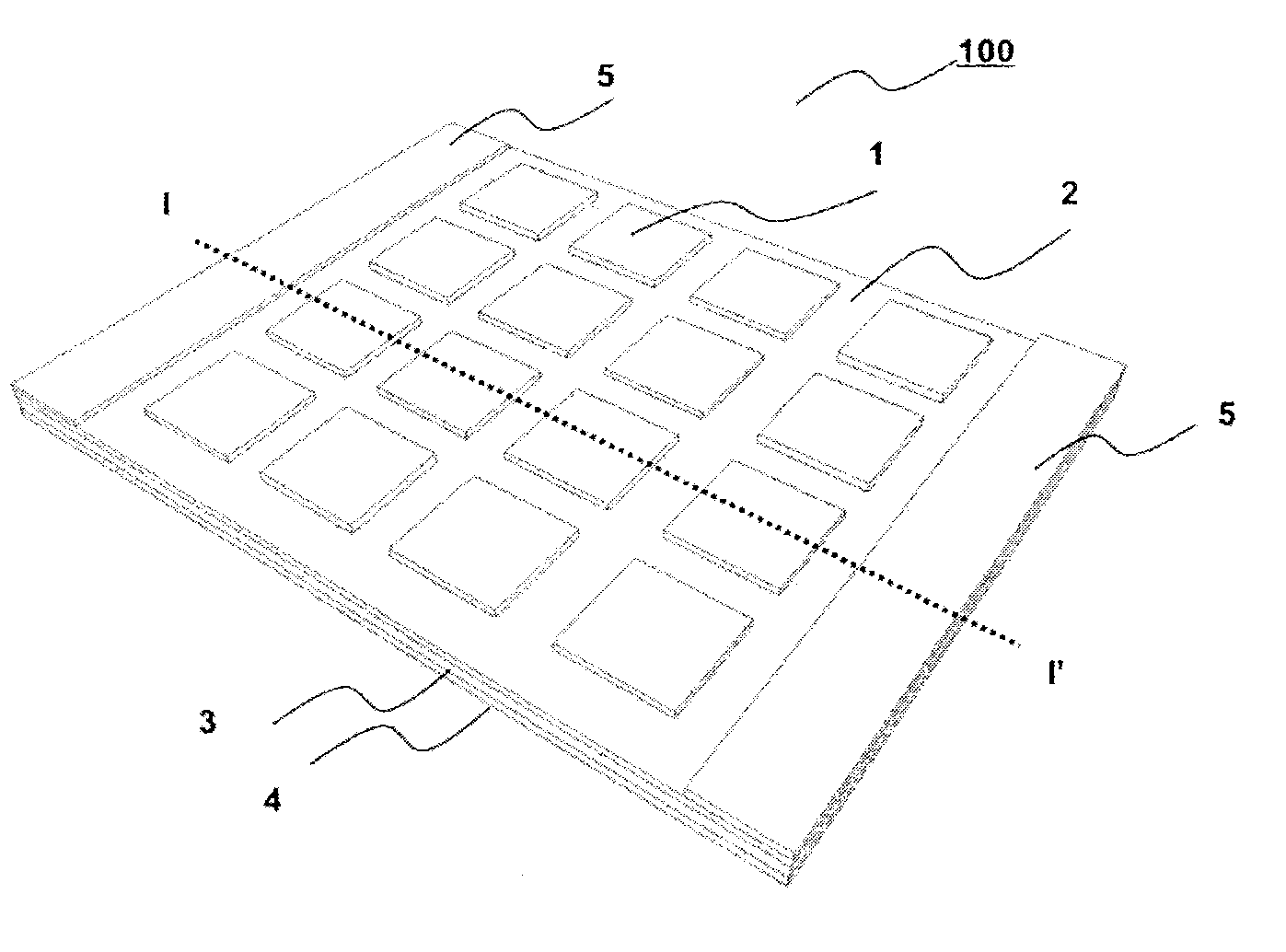

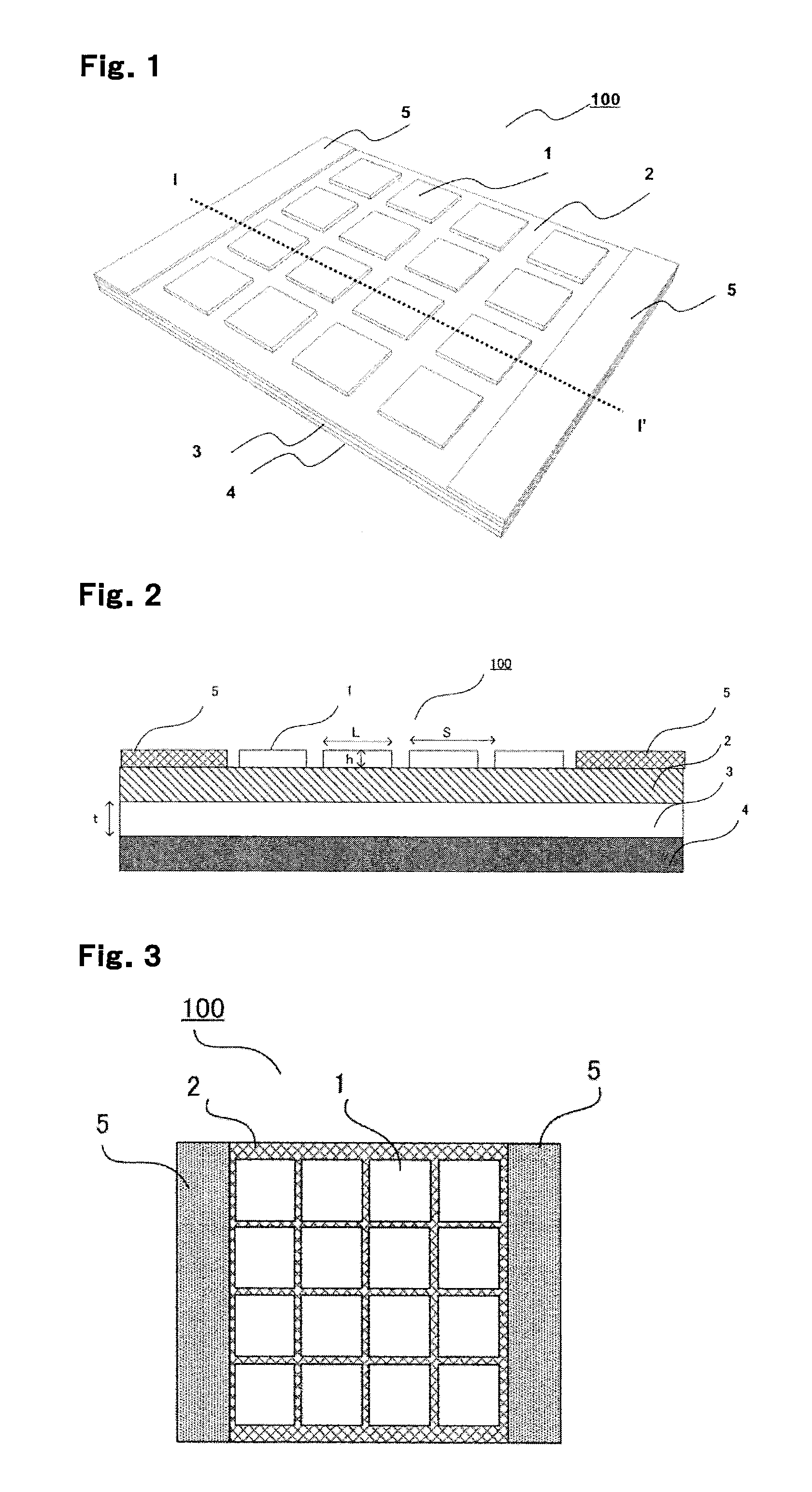

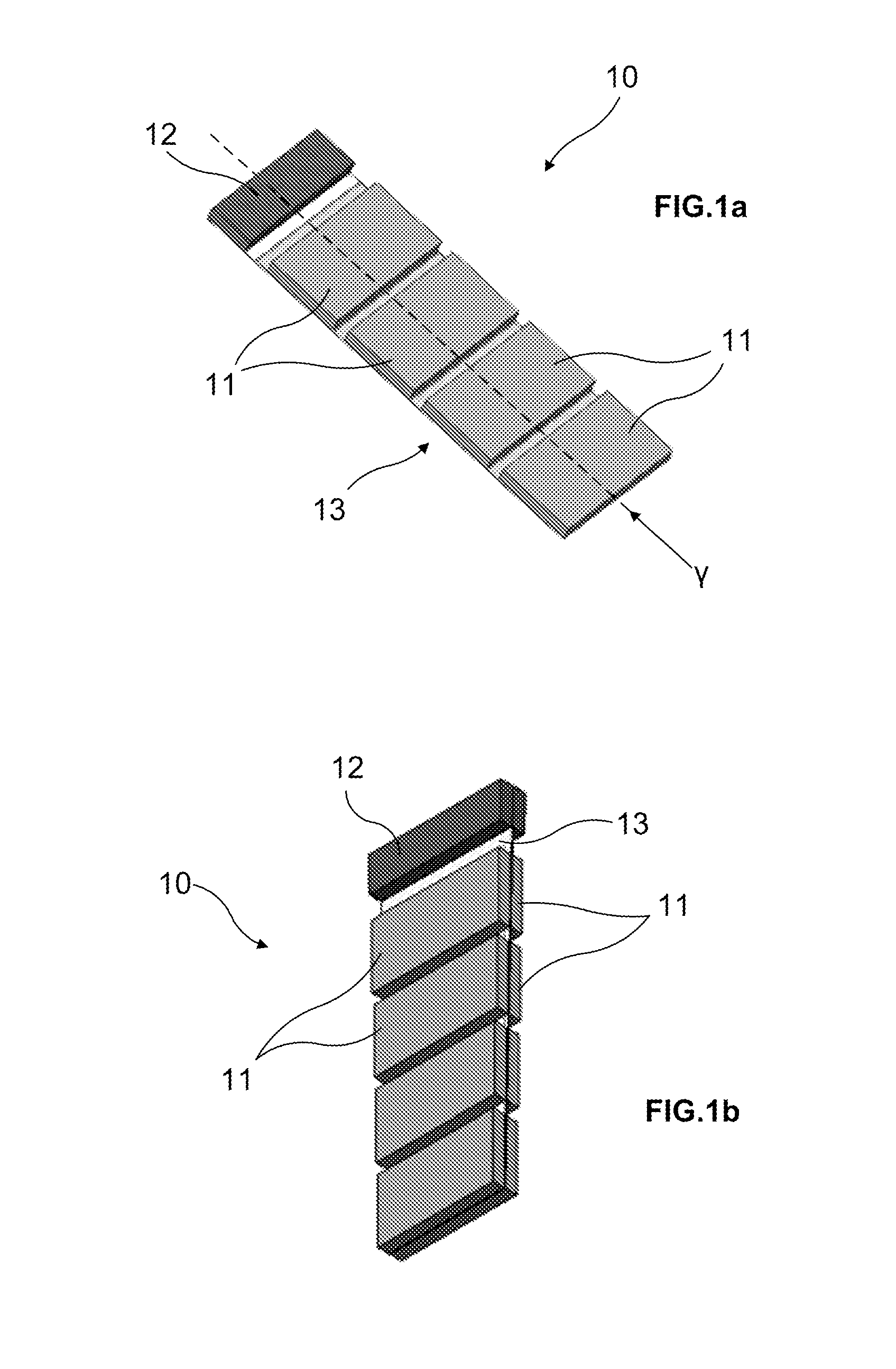

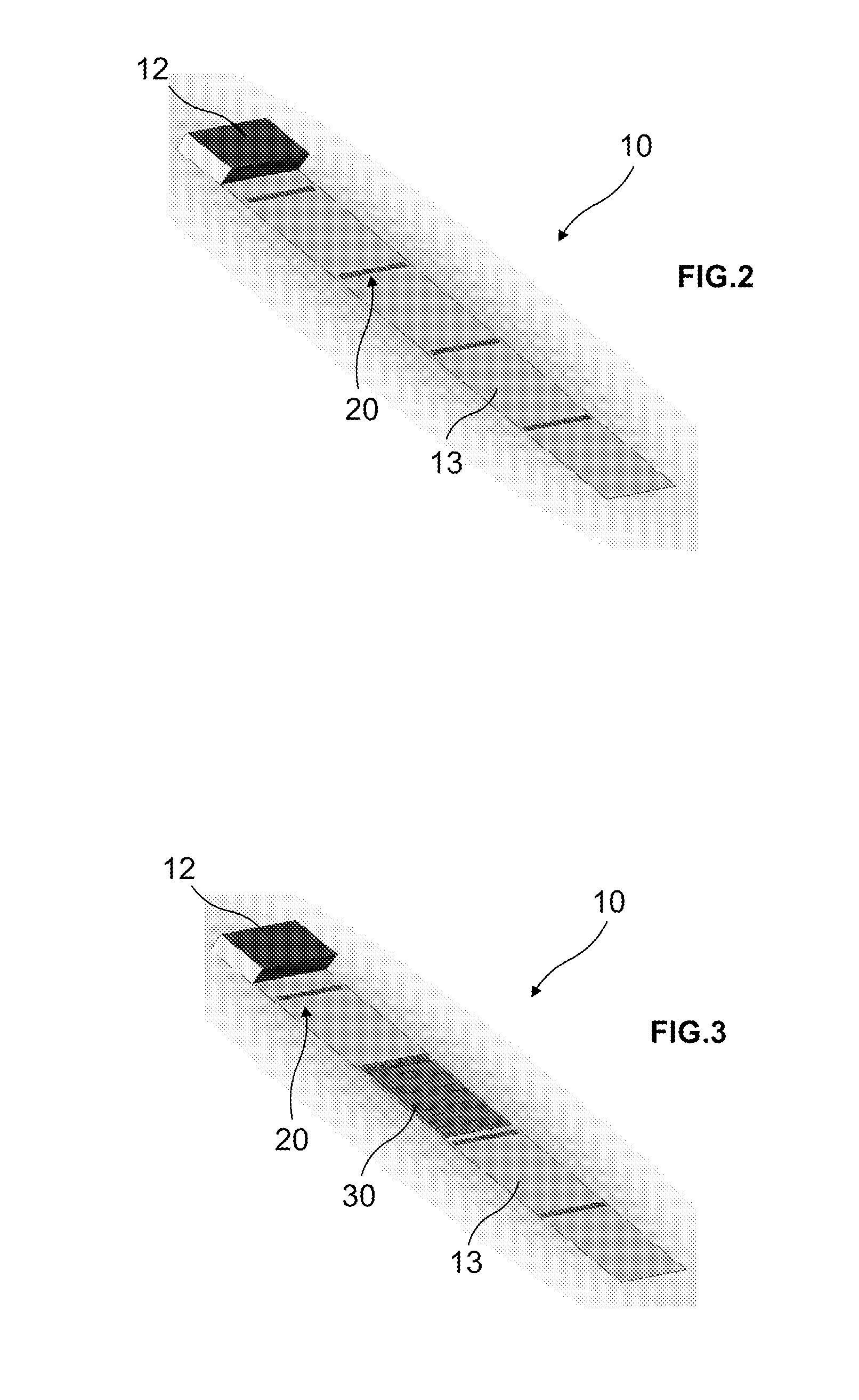

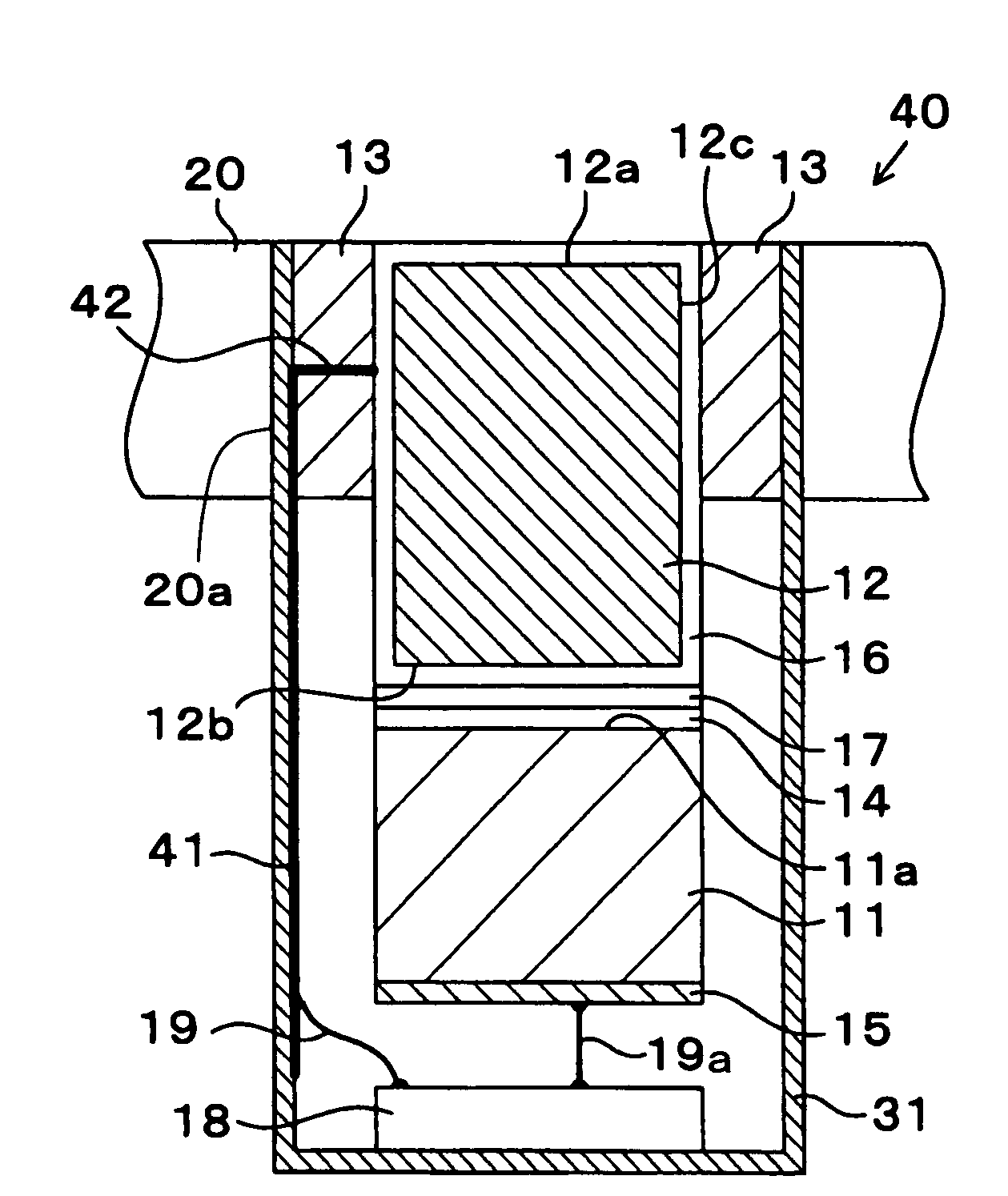

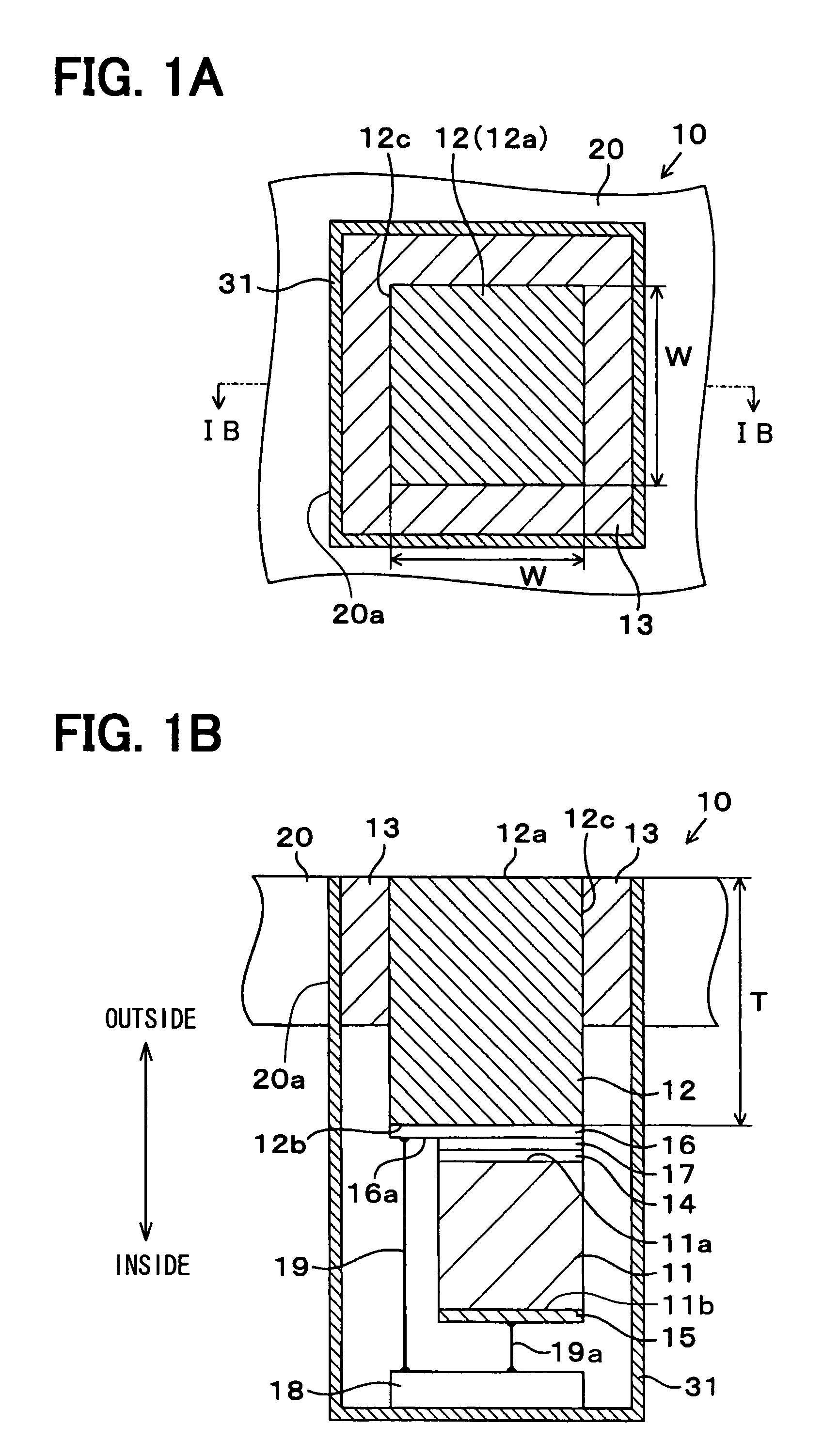

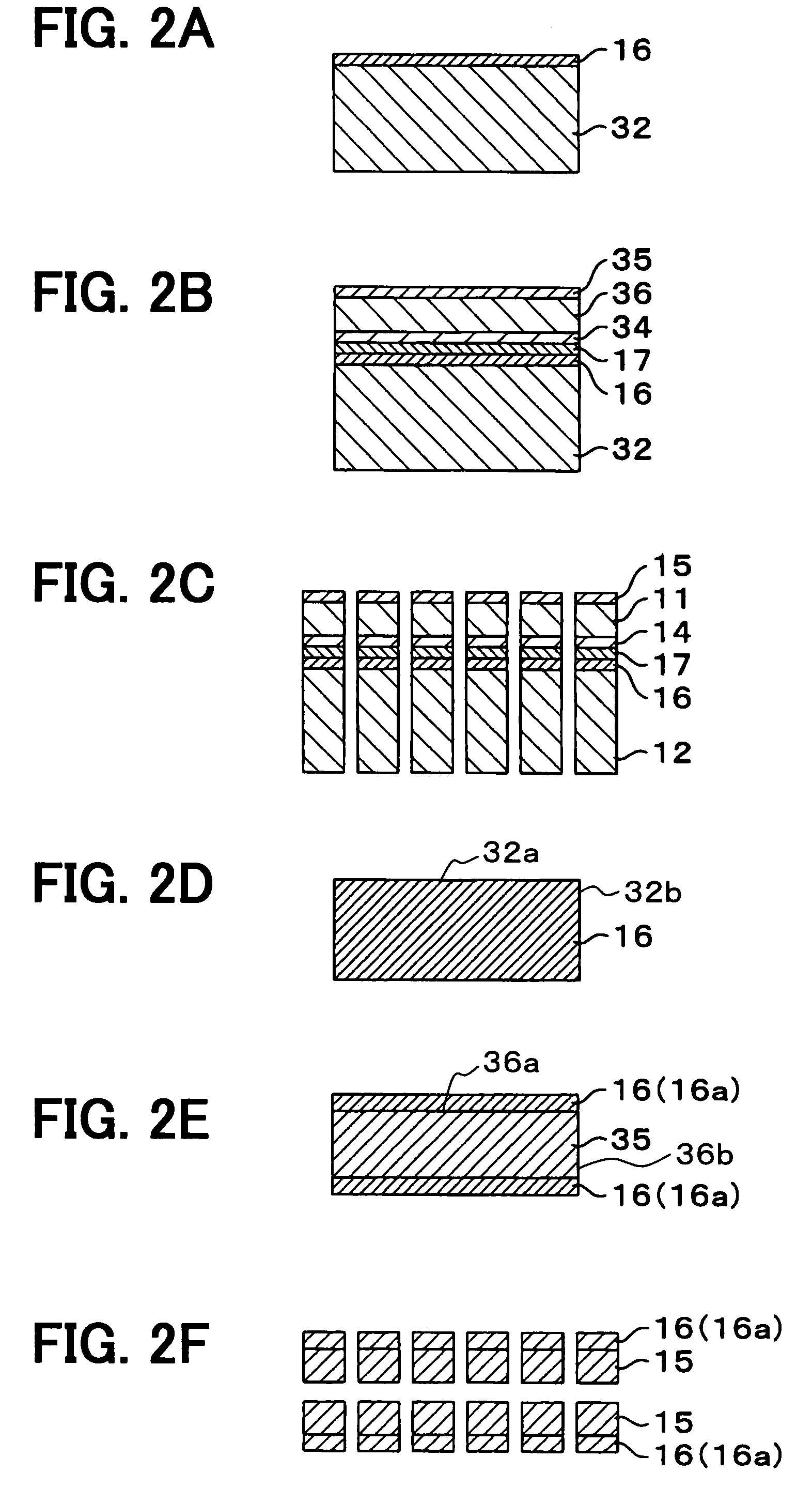

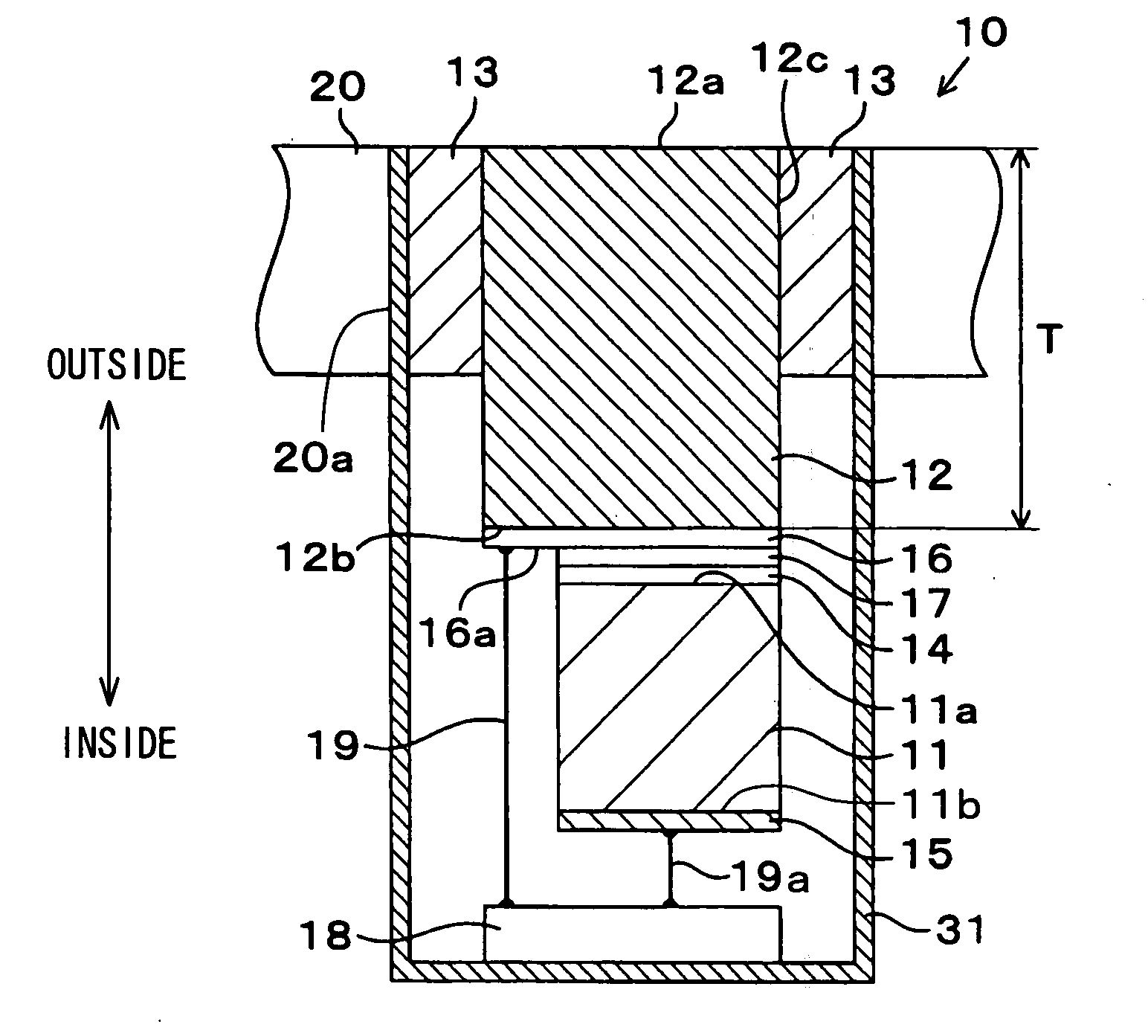

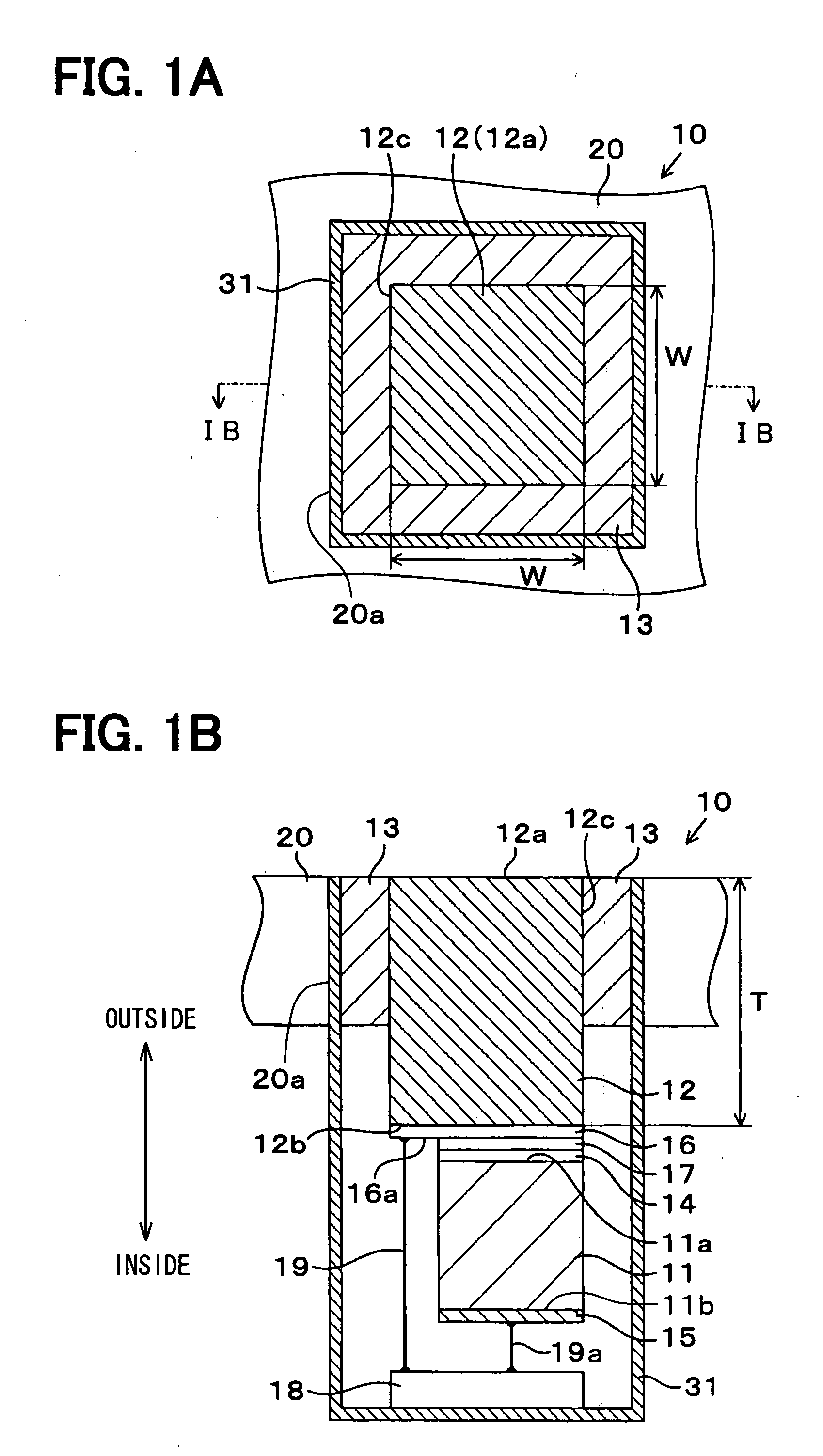

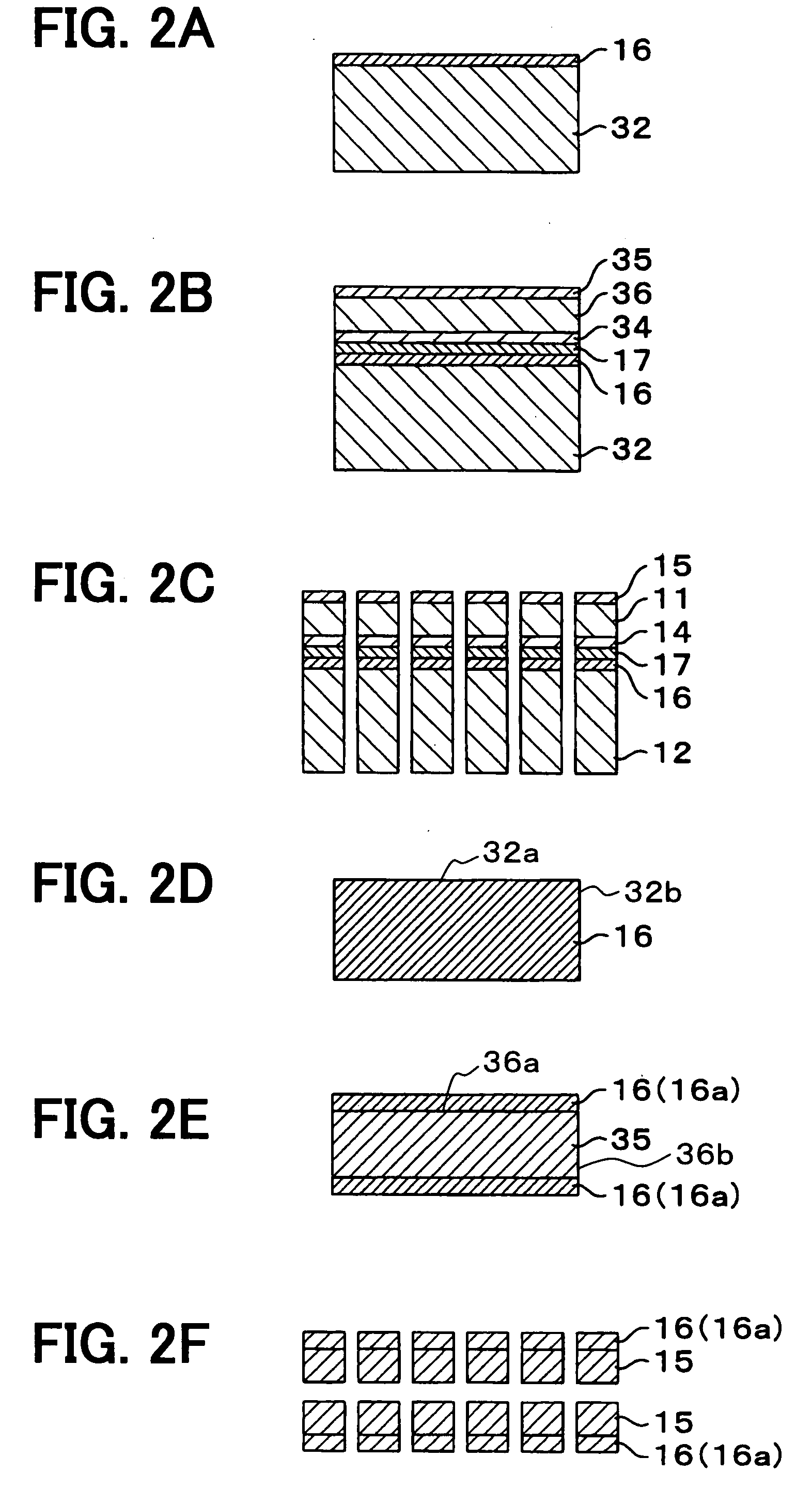

Device for detecting highly energetic photons

ActiveUS20110253901A1Improve spatial resolutionSolve the low detection efficiencySolid-state devicesMaterial analysis by optical meansSolid state detectorEngineering

A device (10) for detecting highly energetic photons, comprising one or more pixelated solid-state detectors (11) for detecting the highly energetic photons; means for providing a high voltage for polarizing said solid-state detectors; one or more pixelated readout elements (30), a readout element being connected to each of said one or more pixelated solid-state detectors (11); an input / output element (12) connected to said readout elements (30) for data input and output; and a base layer (13) for mounting the pixelated solid-state detectors (11), the readout elements (30) and the input / output element (12).

Owner:INST DE FISICA D ALTES ENERTIES (IFAE)

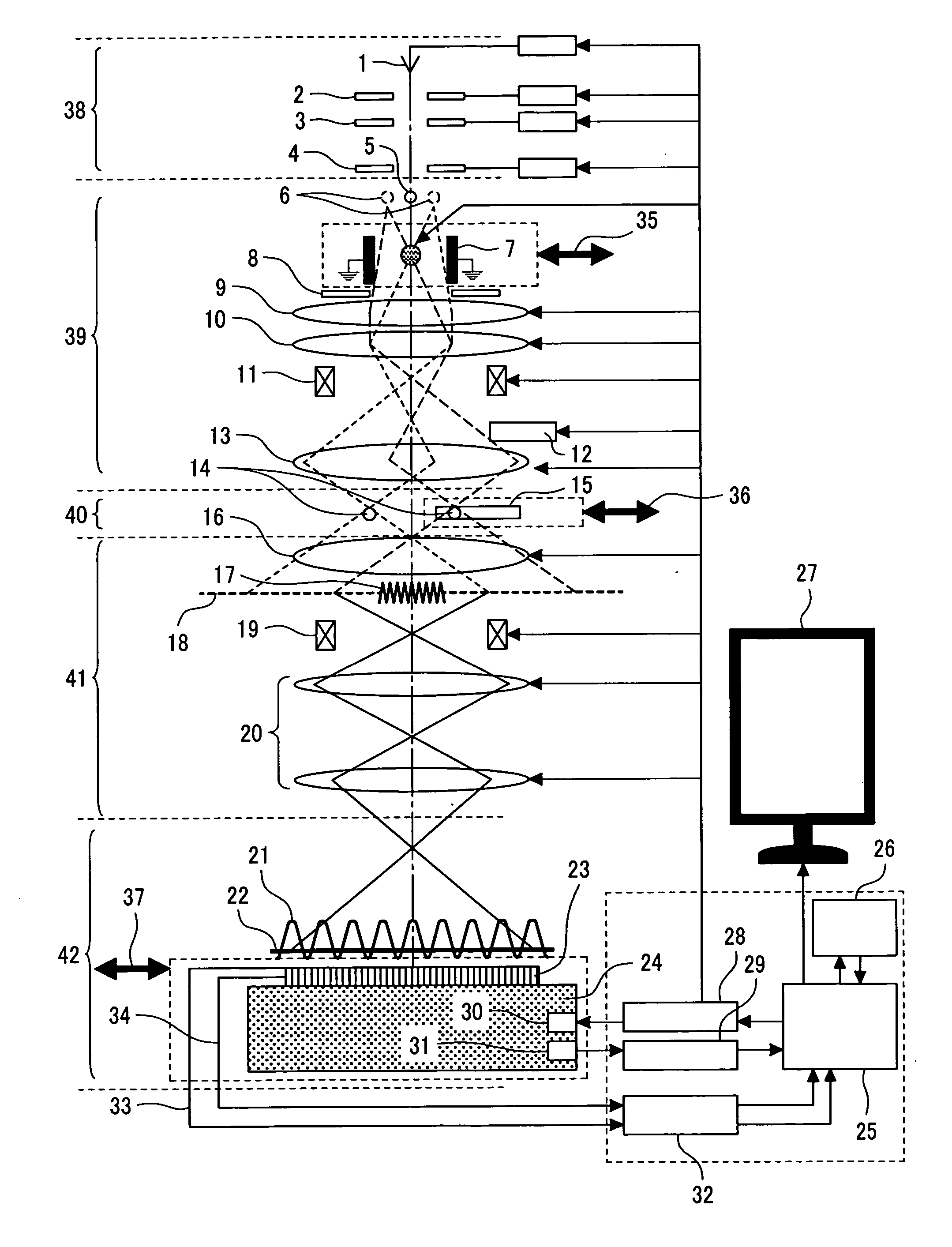

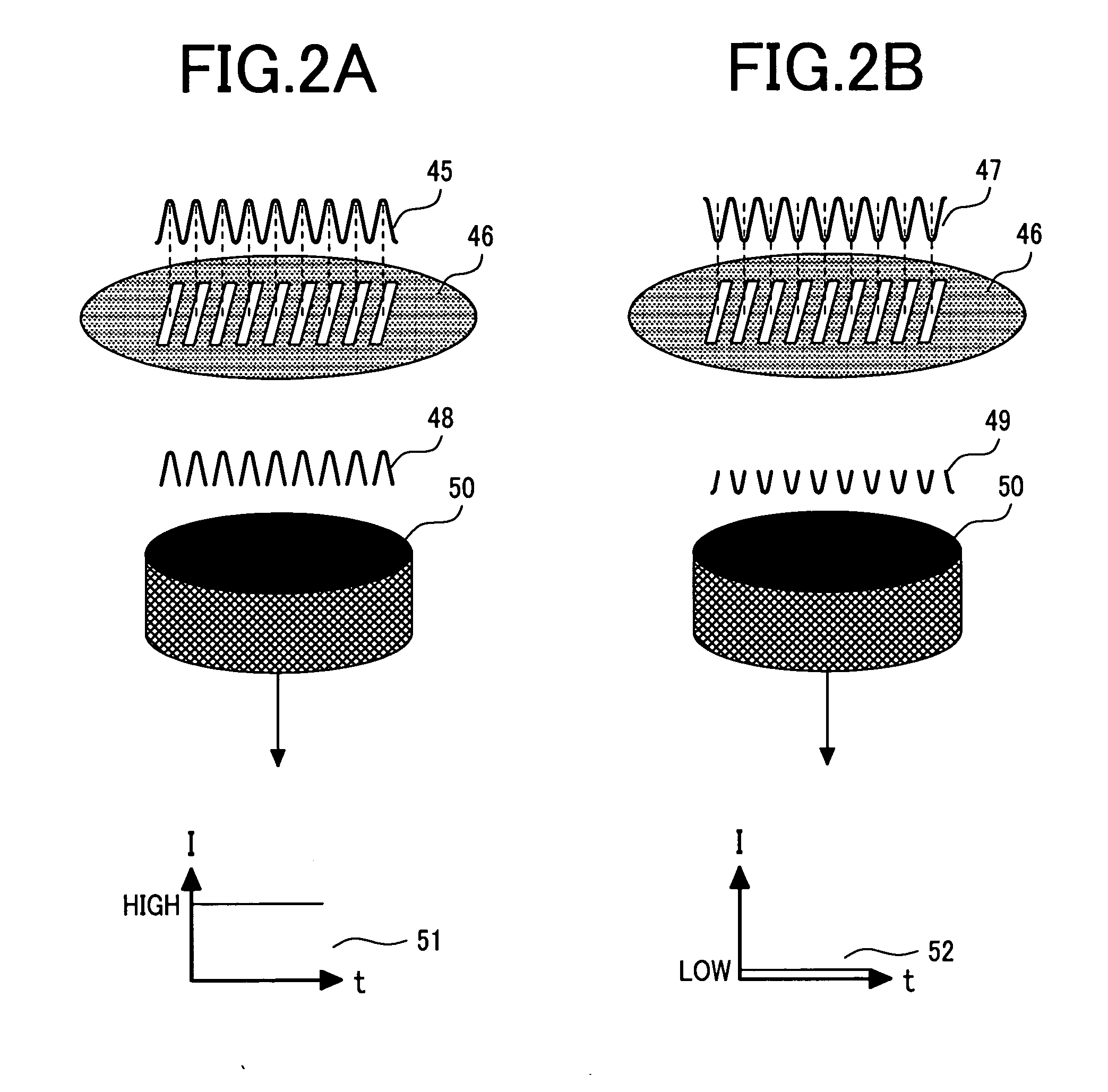

Scanning interference electron microscope

InactiveUS20060124850A1Solve the lack of convenienceHigh detection sensitivityMaterial analysis using wave/particle radiationElectric discharge tubesElectron microscopeElectron

The conventional detection technique has the following problems in detecting interference fringes: (1) Setting and adjustment are complex and difficult to conduct; (2) A phase image and an amplitude image cannot be displayed simultaneously; and (3) Detection efficiency of electron beams is low. The invention provides a scanning interference electron microscope which is improved in detection efficiency of electron beam interference fringes, and enables the user to observe electric and magnetic information easily in a micro domain of a specimen as a scan image of a high S / N ratio under optimum conditions.

Owner:HITACHI HIGH-TECH CORP

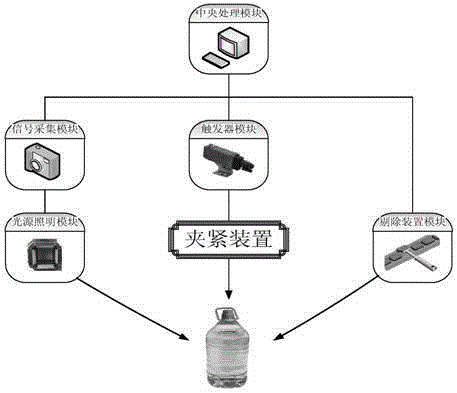

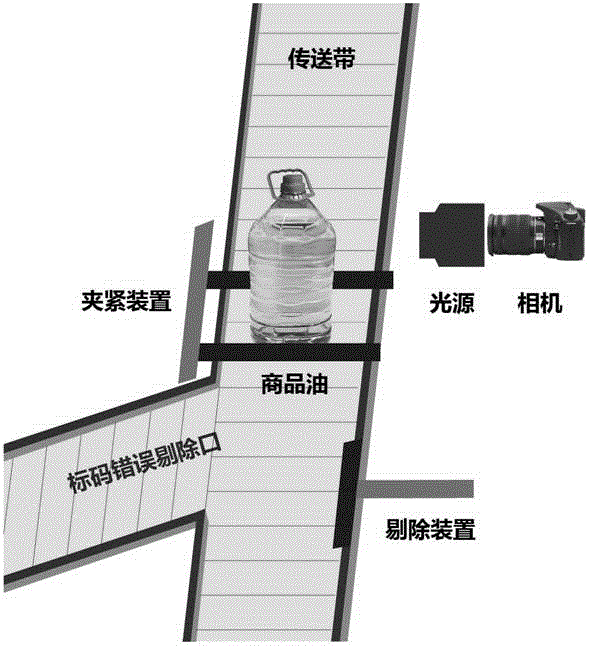

Commercial oil surface laser code recognition method with self modeling function

InactiveCN105260734AStable alignmentImprove detection accuracyNeural learning methodsCharacter recognitionImaging processingCranial nerves

The invention discloses a commercial oil surface laser code recognition method with a self-modeling function. The content of the method comprises the steps that model statistics is carried out on a commercial oil laser code based on a neural network recognition algorithm, and a self modeling technology is realized; a character template image of the designated commercial oil laser code to be detected is acquired, a brain cranial nerve function of the human is simply simulated through the neural network recognition algorithm so as to realize an input-output mapping model, classification, recognition and acquisition for characters are completed, and the characters act as a template; a commercial oil laser code image is acquired, and an image processing phase of character recognition and character reading is carried out; if a matching result is that the character is qualified, the commercial oil is qualified and continuous to be transported, and if the matching result is that the character is not qualified, the unqualified commercial oil is removed by a removing device; and finally, a function of character recognition is realized, character detection for a laser barcode on the commercial oil is completed, and thus accurate detection for the commercial oil laser barcode can be achieved.

Owner:YANSHAN UNIV

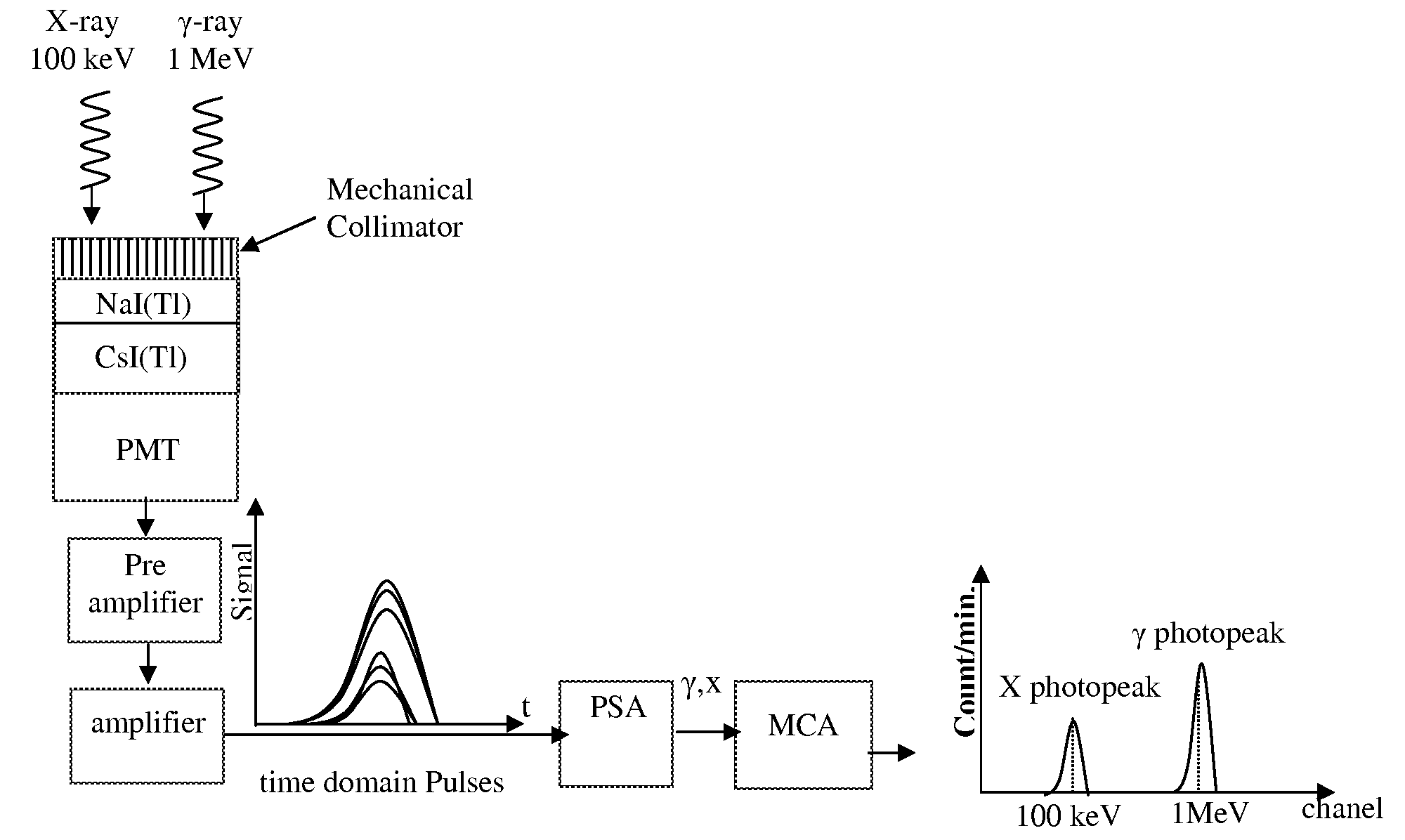

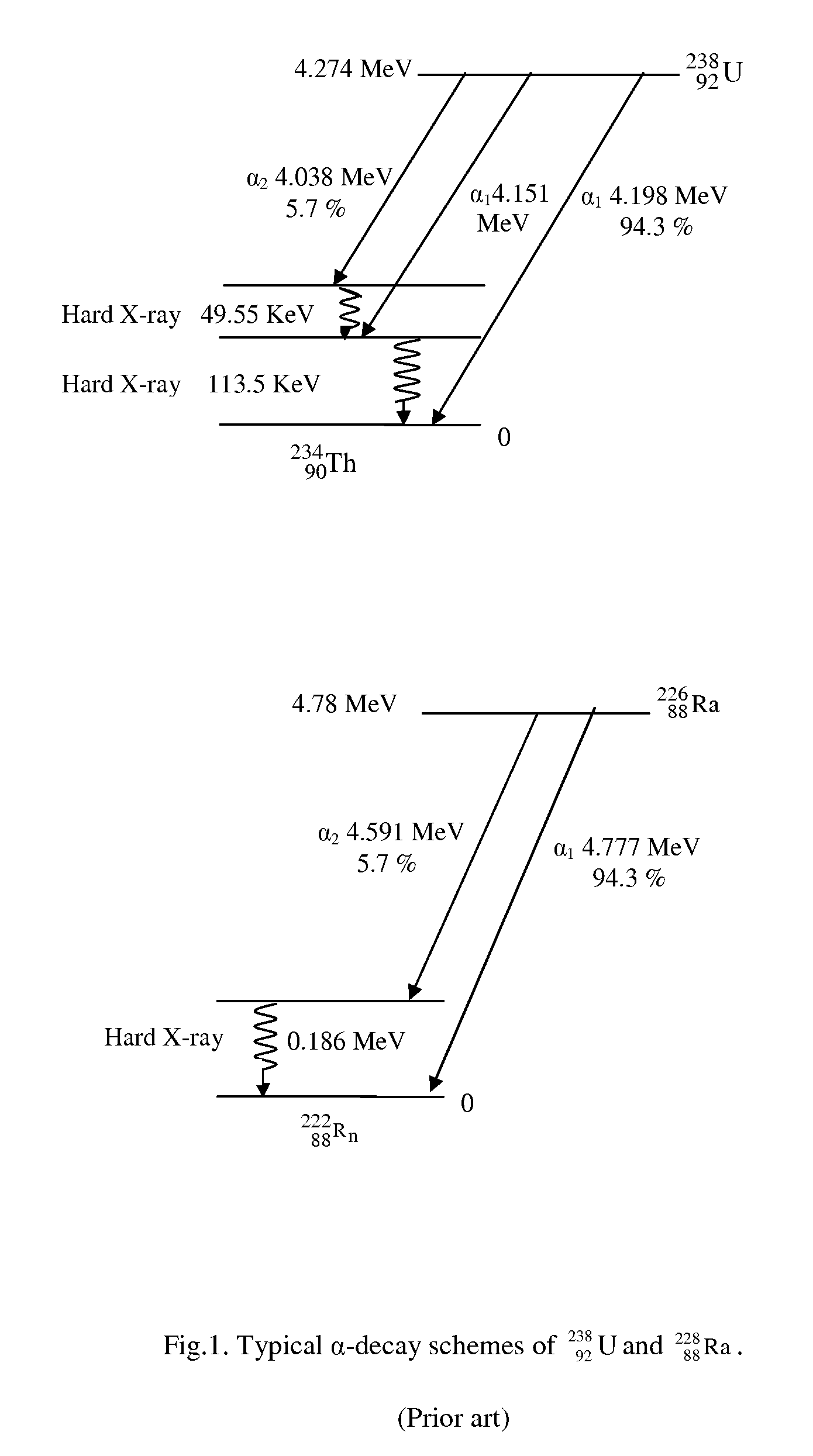

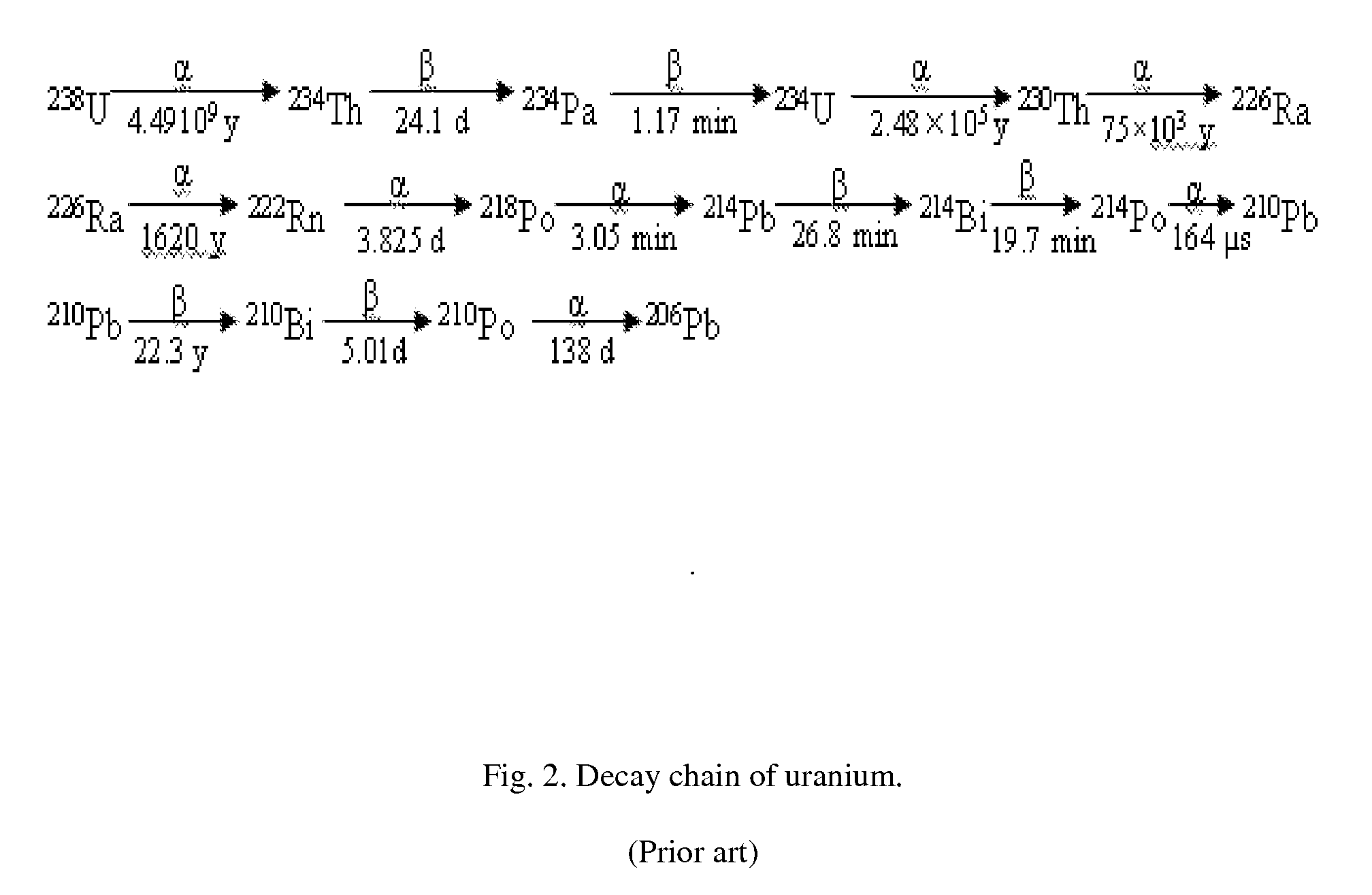

DIAL-Phoswich hybrid system for remote sensing of radioactive plumes in order to evaluate external dose rate

InactiveUS20080149838A1Rapid responseHigh gainMass flow measurement devicesMaterial analysis by optical meansDose rateNuclear power

An interactive combination of Phoswich detector array (PDA) and differential absorption lidar (DIAL) is proposed to trace the unknown radioactive plumes released into the atmosphere from a reactor stack, containment of the nuclear power plants, radioisotope separation laboratories, reprocessing plants or the uranium conversion facilities. The hybrid system represents a powerful technique for the prompt identification and quantification of the effluents with various radionuclide contents to determine the corresponding external dose rate accordingly.

Owner:SHAHI LAILA

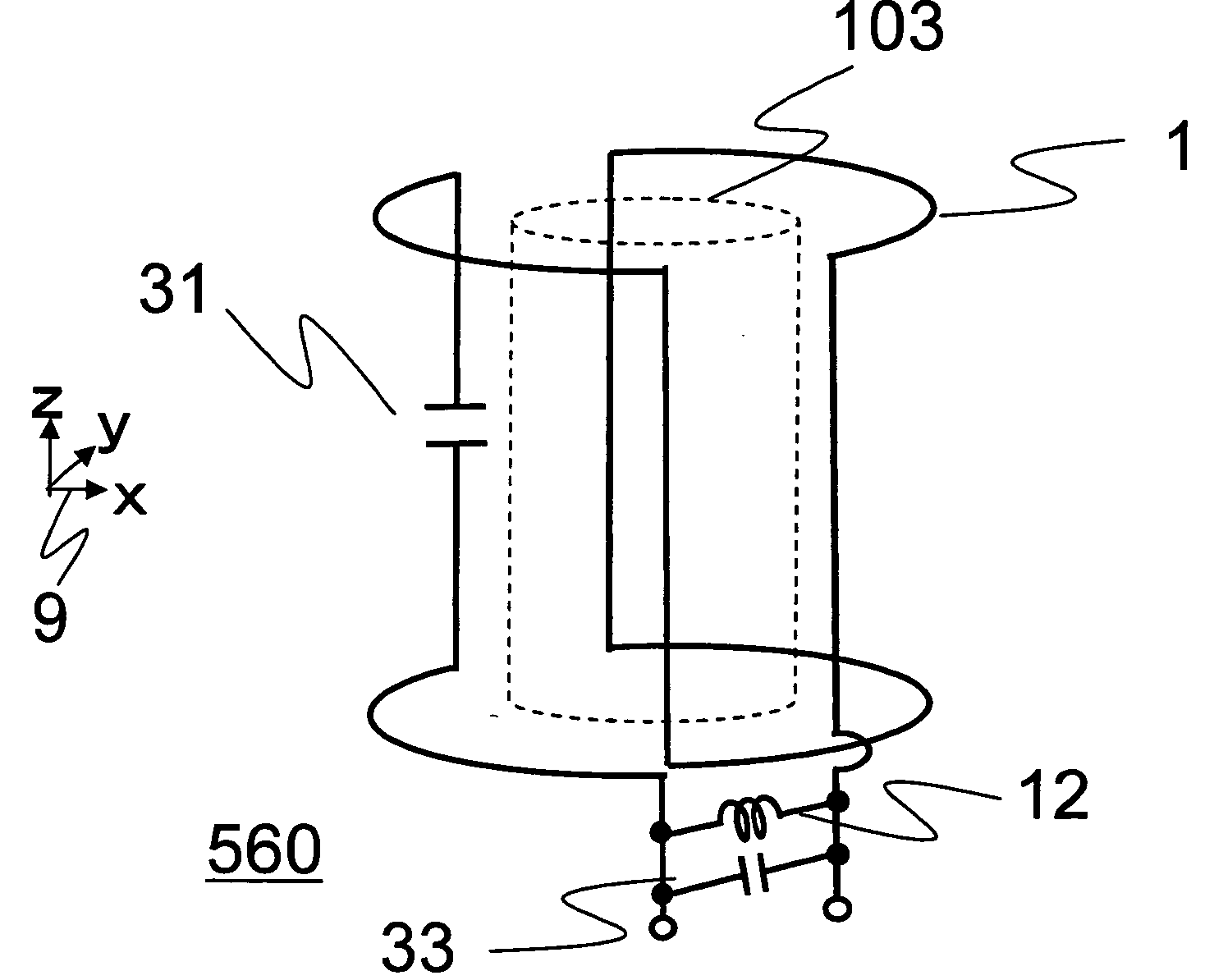

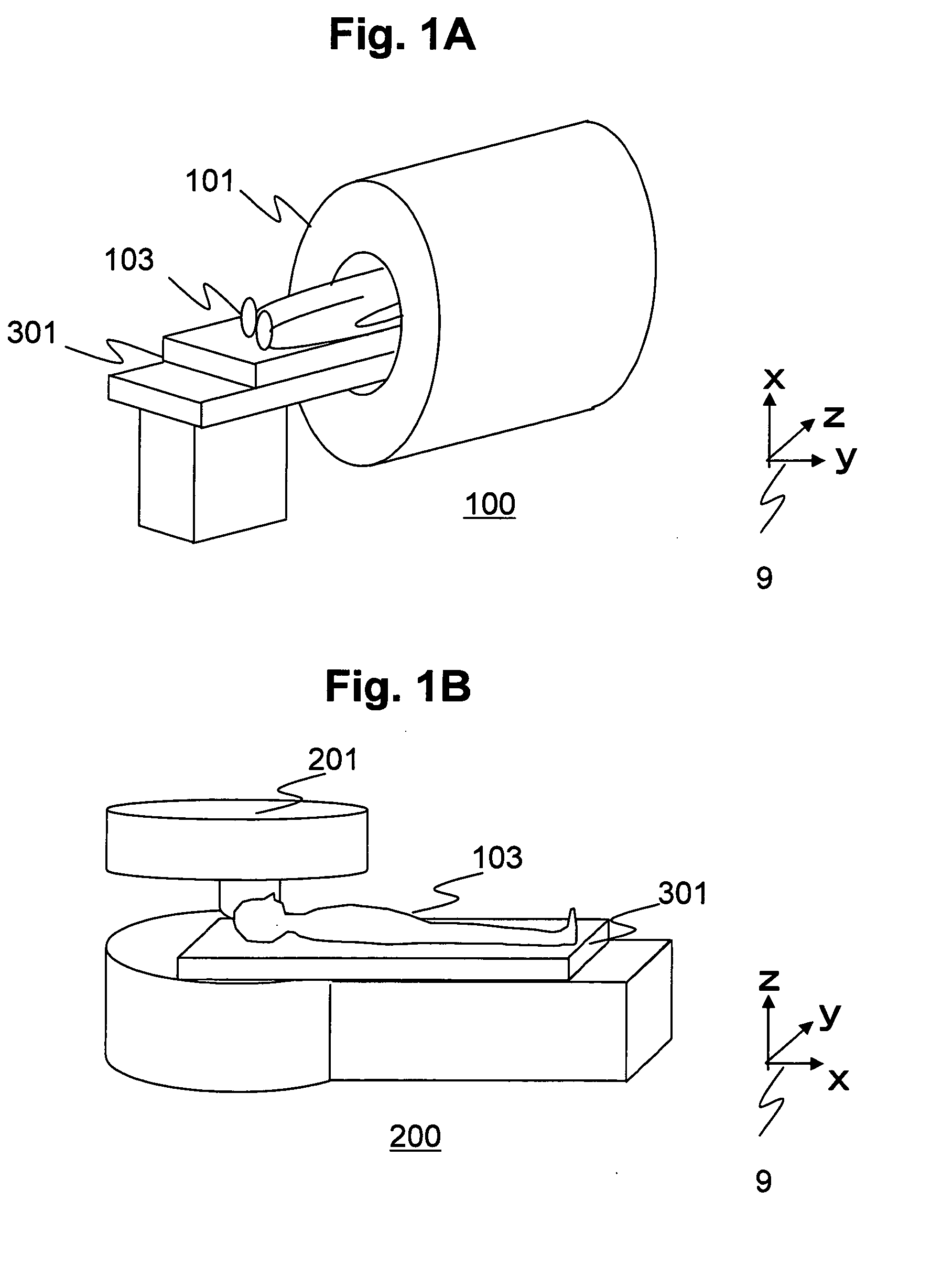

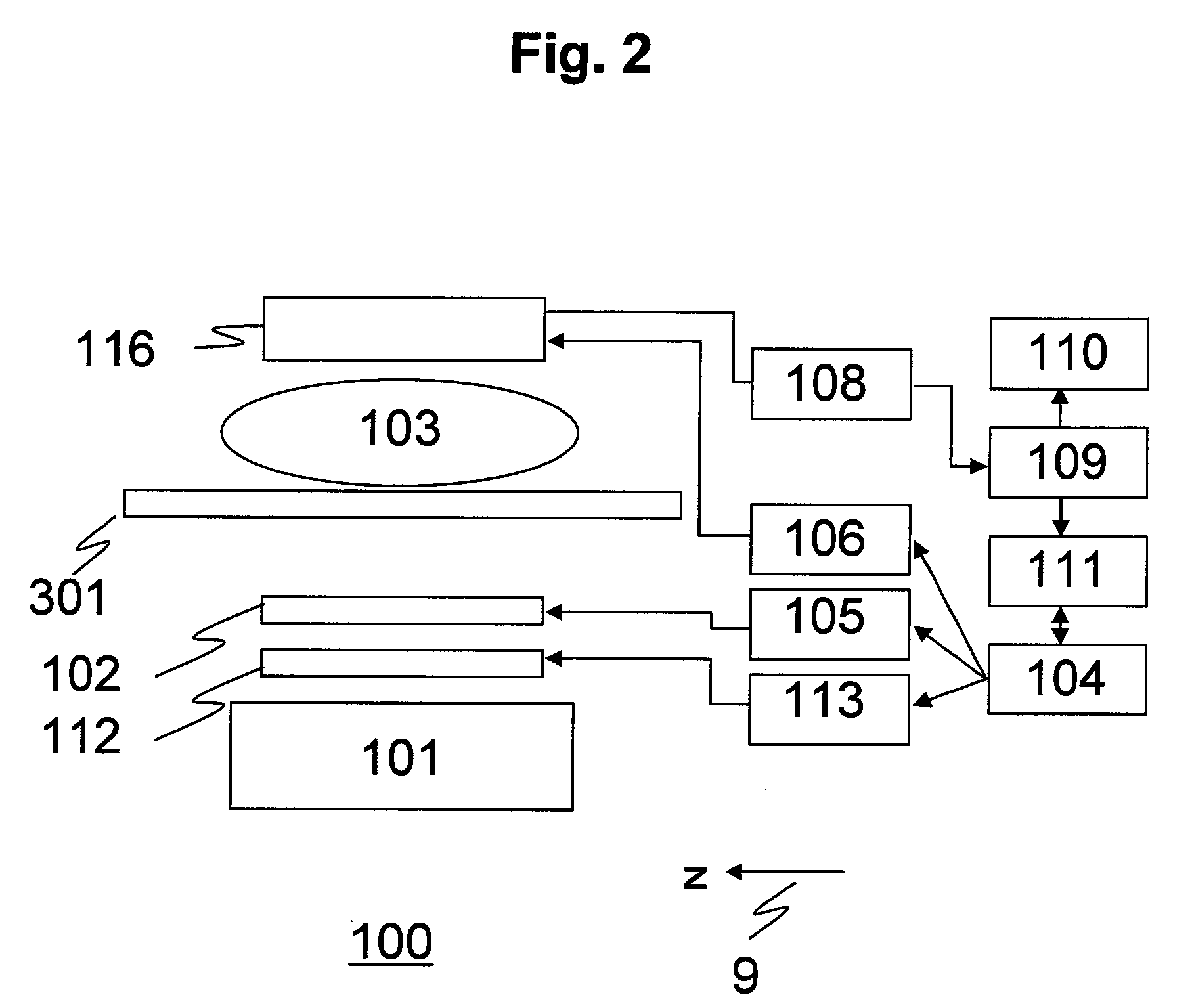

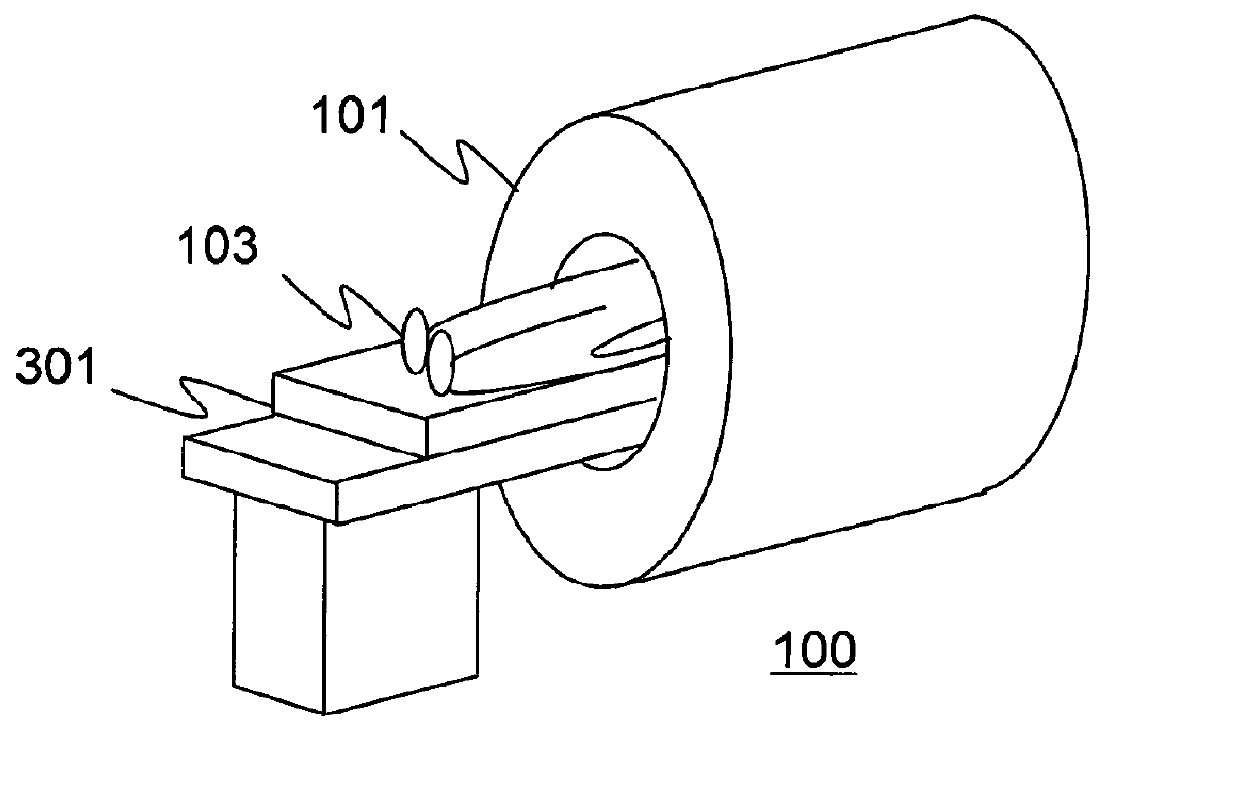

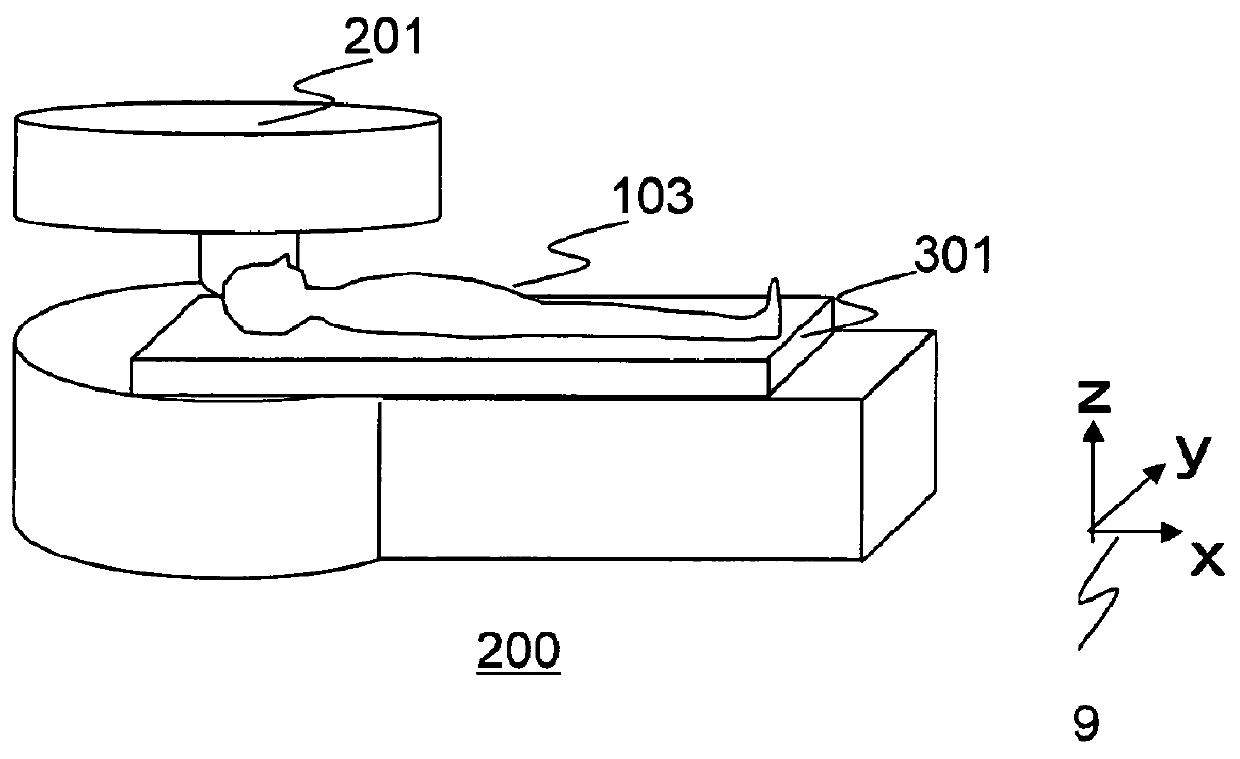

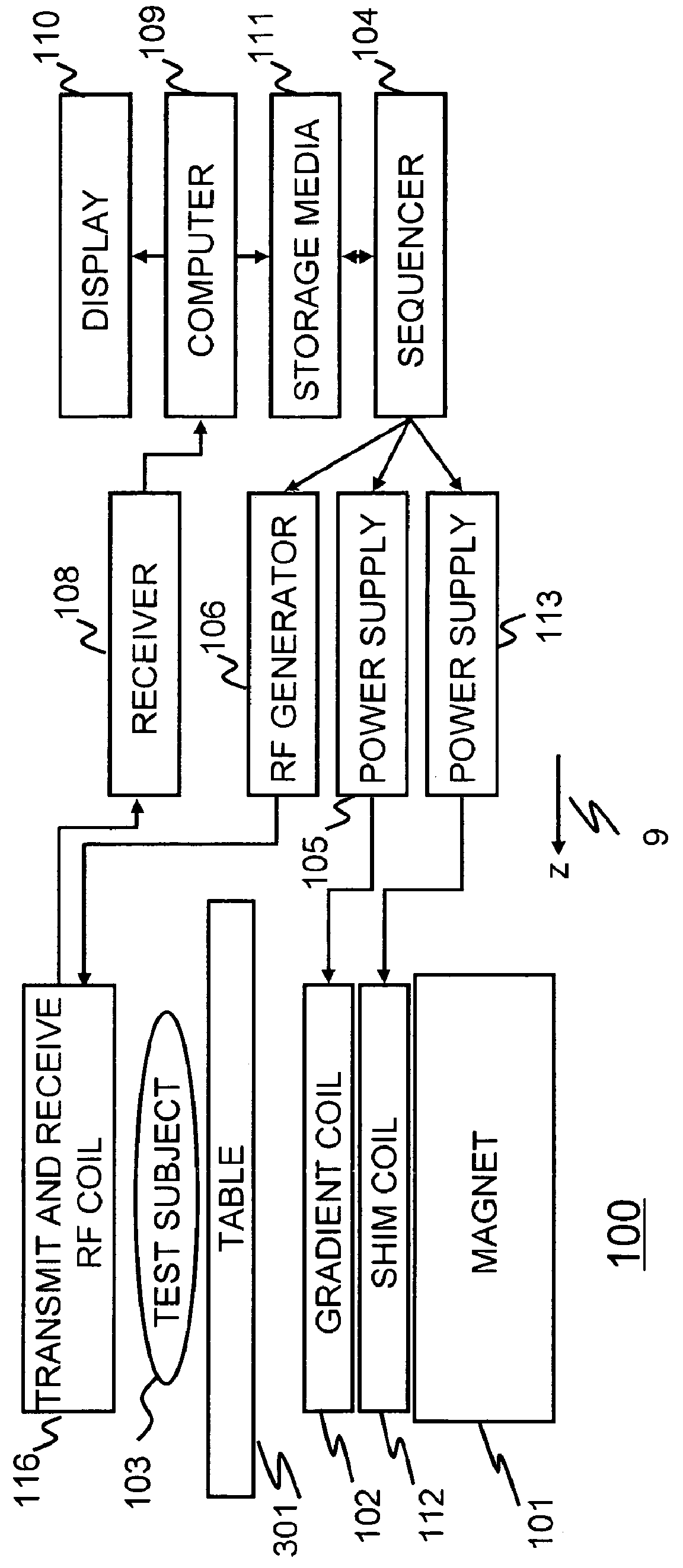

RF coil and MRI apparatus

InactiveUS20090128155A1Solve the low detection efficiencyElectric/magnetic detectionMeasurements using magnetic resonanceRadio frequencyRadiofrequency coil

An RF coil having at least three different resonance frequencies, wherein one of the resonance frequencies is adjusted to be a frequency fA of a magnetic resonance signal generated by a test subject, and the coil is adjusted so that ratio of difference between the frequency fA and a first frequency fB lower than fA and nearest to fA among the resonance frequencies (fA−fB), and difference between the frequency fA and a second resonance frequency fC higher than fA and nearest to the frequency fA among the resonance frequencies(fC−fA), should be from 0.5 to 2.0. There is provided a technique for receiving magnetic resonance signals always with high detection efficiency by an RF coil of an MRI apparatus even if significant loss is caused in the RF coil, or test subject is changed.

Owner:HITACHI LTD

Event detection method and device

ActiveUS20080052780A1Improve acceleration performanceImprove efficiencyMemory loss protectionError detection/correctionPushdown automatonAlgorithm

The embodiments of the present invention disclose an event detection method and device. The method includes: predefining event-based detection rules with a predicative context-free grammar; generating by parsing the detection rules a parsing table of pushdown automaton which supports parallel parsing; receiving an event to be detected; and analyzing by a controller the event to be detected according to the parsing table, to obtain a detection result. The present invention is especially applicable to detection of network attack events. The embodiments of the present invention detect the attacks with a predicative context-free grammar on the basis of events, and ensure a close combination of a protocol parsing process and an attack detection process, as well as a close combination of multiple attack detection rules, thus decreasing unnecessary calculations. In addition, with an optimized parallel pushdown automaton, the embodiments of the present invention can efficiently analyze the predicative context-free grammar. Consequently, besides hierarchical processing capability and state description capability, the embodiments of the present invention deliver high efficiency.

Owner:NEUSOFT CORP

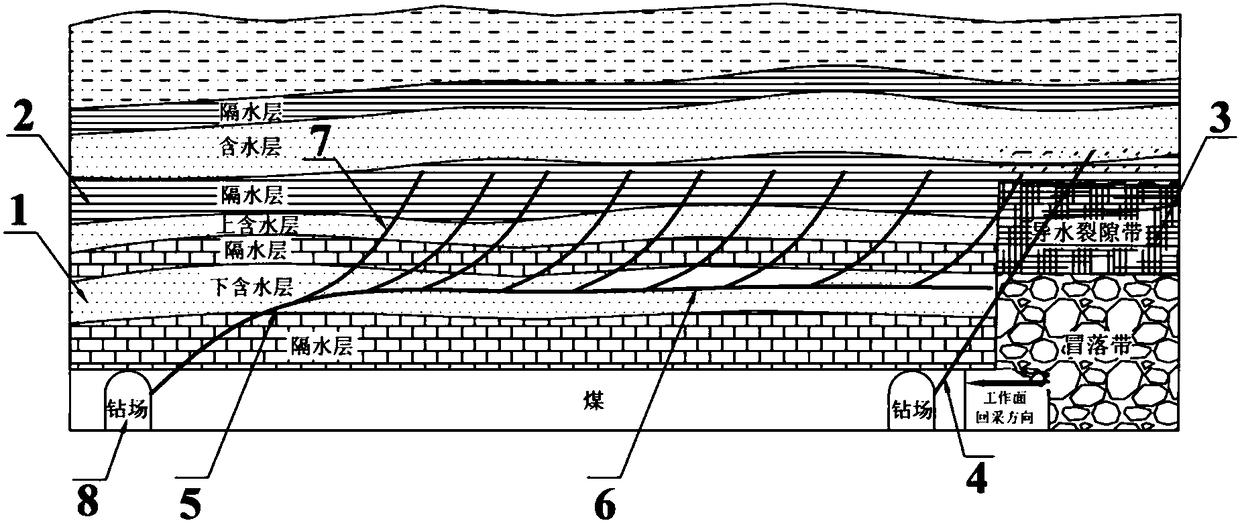

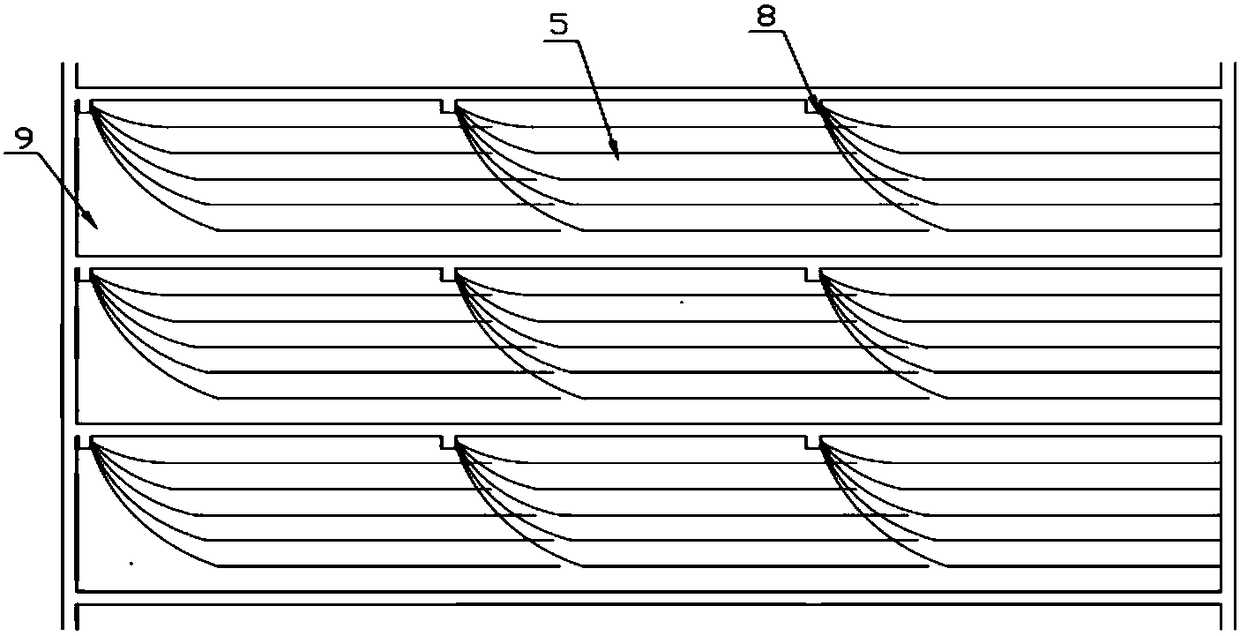

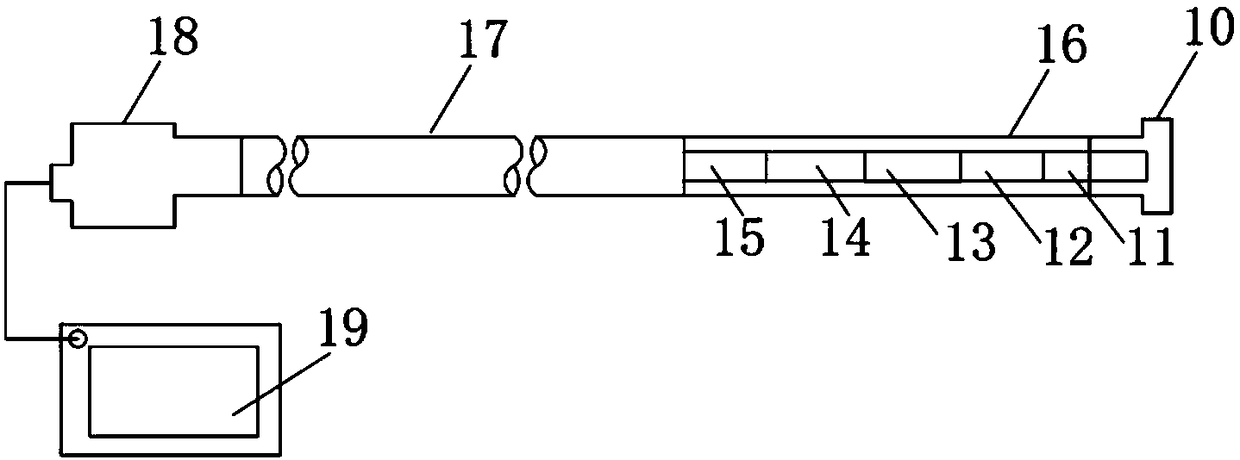

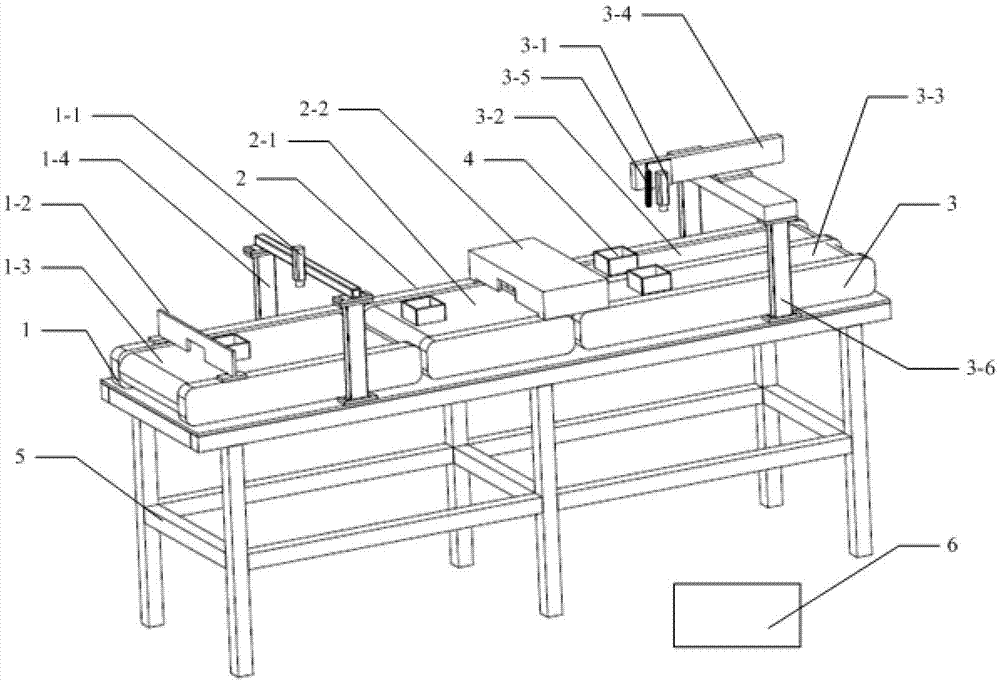

Method and device for detecting water body in advance area of multi-aquifer arborescence directional drilling of top plate

ActiveCN108518182AHigh detection efficiencyEffective hole lengthSurveyDirectional drillingCoal miningEngineering

The invention relates to a method and device for detecting water body in advance area of multi-aquifer arborescence directional drilling of top plate. According to the invention, a drilling geologicalguide directional drilling tool is used for carrying out arborescence directional drilling construction, the drilling trajectory is controlled to extend along the designed aquifer and the designed trajectory, and the water body is thinned after the holes are formed; the arborescence directional drilling is composed of a main hole and a plurality of upward arborescence holes, wherein the main holeextends along the lower aquifer for a long distance and is used for detecting the water body in the lower aquifer; the upward arborescence holes passe through the upper aquifer and is used for detecting the water body in the upper aquifer. According to the invention, the problems of low water body detecting efficiency, large detecting error, high treatment cost and the like when the number of thewater layers of the top plate of the coal layer is large is solved, the method has the advantages of high detection efficiency, small construction quantity, high detection precision, wide coverage area and the like, realizes the advanced detecting of the water body of multi-aquifer for once and ensures the safe and efficient coal mining.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

MRI apparatus with RF surface coil having at least three resonance frequencies

InactiveUS8193810B2Solve the low detection efficiencyMagnetic measurementsElectric/magnetic detectionSurface coilMR - Magnetic resonance

An RF coil having at least three different resonance frequencies, wherein one of the resonance frequencies is adjusted to be a frequency fA of a magnetic resonance signal generated by a test subject, and the coil is adjusted so that ratio of difference between the frequency fA and a first frequency fB lower than fA and nearest to fA among the resonance frequencies (fA−fB), and difference between the frequency fA and a second resonance frequency fC higher than fA and nearest to the frequency fA among the resonance frequencies (fC−fA), should be from 0.5 to 2.0. There is provided a technique for receiving magnetic resonance signals always with high detection efficiency by an RF coil of an MRI apparatus even if significant loss is caused in the RF coil, or test subject is changed.

Owner:HITACHI LTD

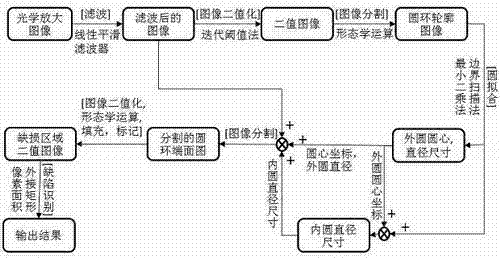

Method and system for detecting and screening end defects in circular parts

ActiveCN103499590ASolve the large amount of calculationSolve the speed problemOptically investigating flaws/contaminationPneumatic pressureOptical amplifier

The invention relates to a method and a system for detecting and screening end defects in circular parts. The system comprises an optical amplifier, a control computer, a controller, a pneumatic nozzle device, a step motor and a conveyor belt. The method includes the steps of 1, photographing a circular part to be detected by the optical amplifier to obtain an optically amplifier image of the end of the circular part to be detected; 2, subjecting the optically amplified image to image processing and defect recognition by the control computer, and judging whether the circular part is qualified or not according to defect conditions; 3, allowing the controller to receive a command of controlling the computer, control the pneumatic nozzle device to operate, remove unqualified parts, and control the conveyor belt to convey next part to a detection position. The method and the system have the advantages that end defects in circular parts can be reflected truly, whether an object is qualified or not can be judged accurately, automation level is high, and detection efficiency is improved.

Owner:FUZHOU UNIVERSITY

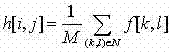

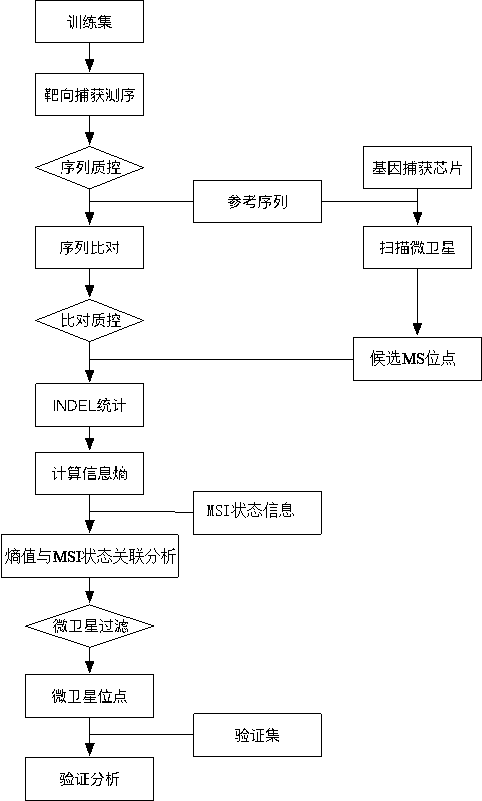

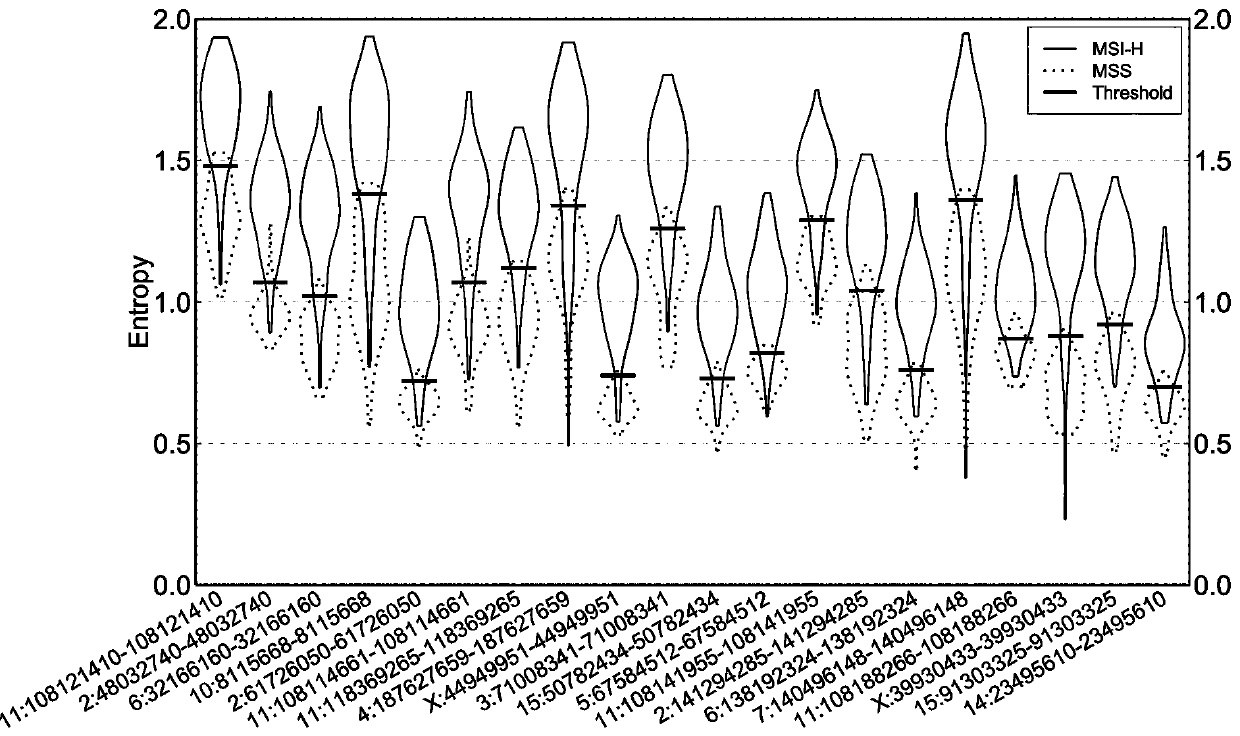

Microsatellite unstable site screening and analysis model construction method and device

InactiveCN110797078AImprove featuresHigh sensitivityBiostatisticsProteomicsMutation detectionMicrosatellite Stable

The invention provides a microsatellite unstable site screening and analysis model construction method and device. The method comprises the following steps of: S1, taking a microsatellite site of a reference genome as a candidate MS site, S2, selecting a plurality of samples with known microsatellite instability detection state information as training set samples, carrying out mutation detection on candidate MS site areas of the training set samples, respectively recording mutation types and numbers, and calculating information entropy of mutation of each candidate MS site, and S3, correlatingthe microsatellite instability detection state information with the entropy of the information entropy of the mutation of each candidate MS site, selecting an entropy threshold of each candidate MS site for distinguishing the microsatellite instability detection result, and screening out the candidate MS site with a high distinguishing degree as an MSI site. According to the scheme, the problemsof low detection efficiency caused by excessive fixed MSI sites and low detection specificity and sensitivity caused by incapability of covering all types of samples in the prior art are solved.

Owner:BEIJING GENEPLUS TECH +1

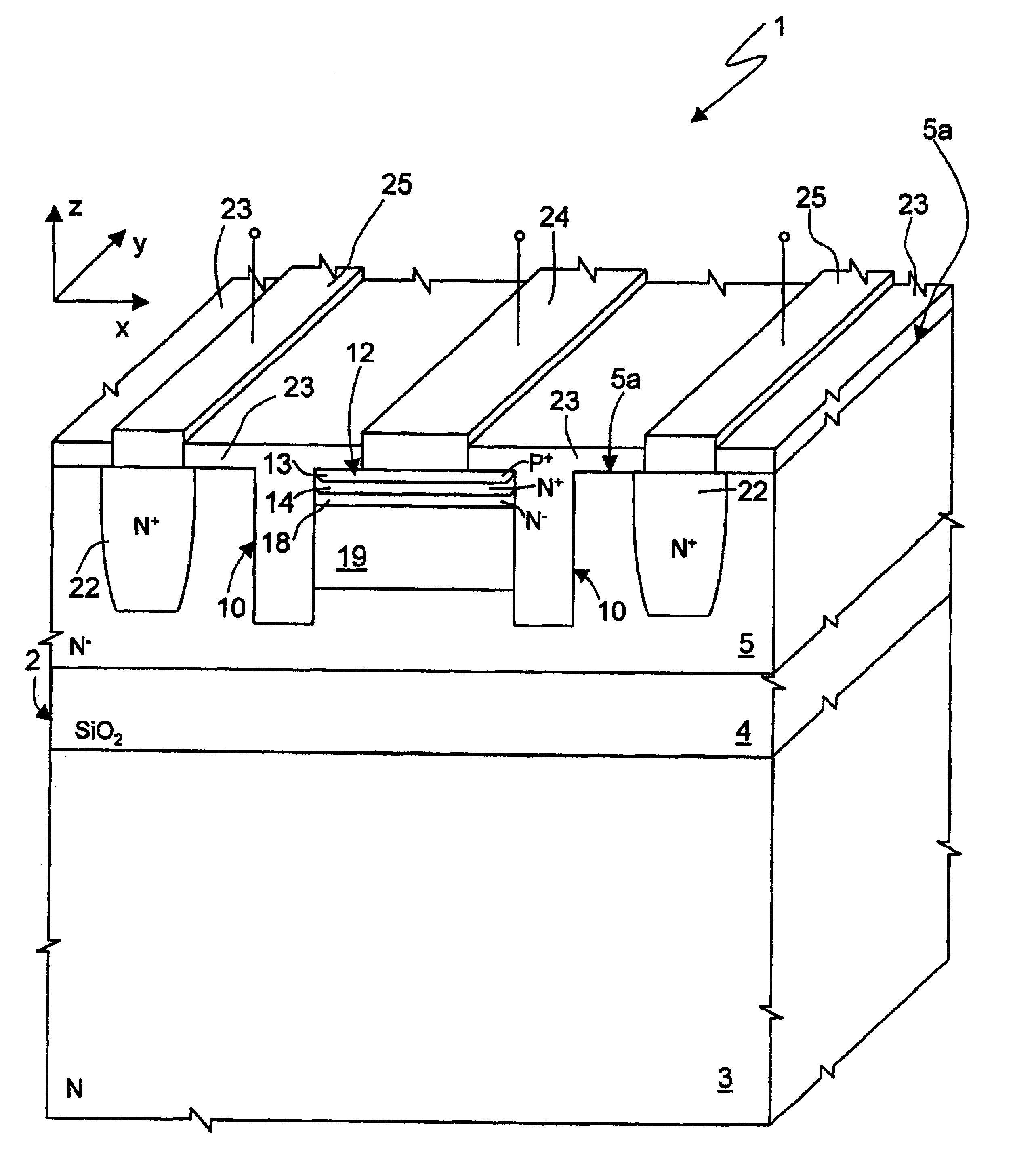

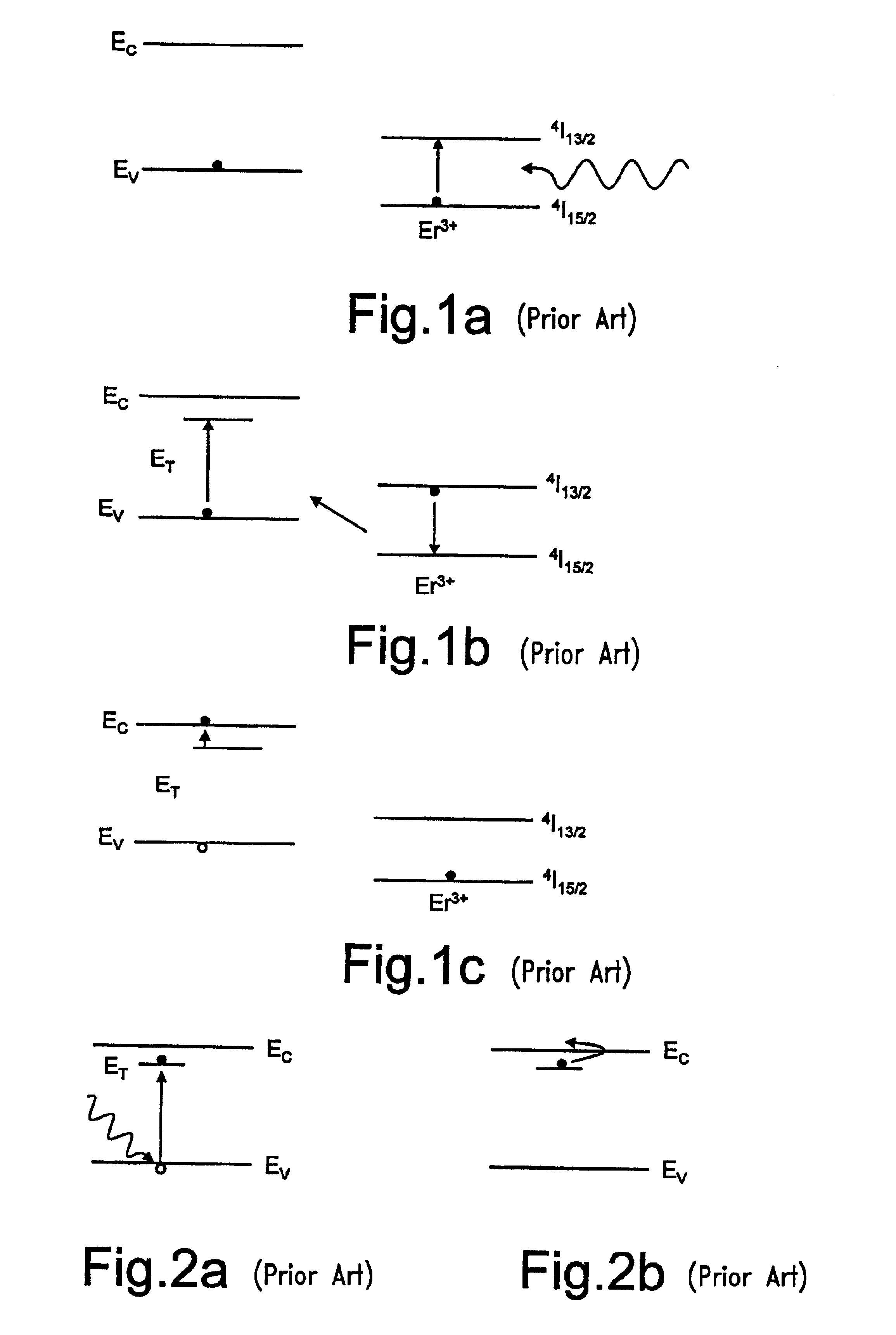

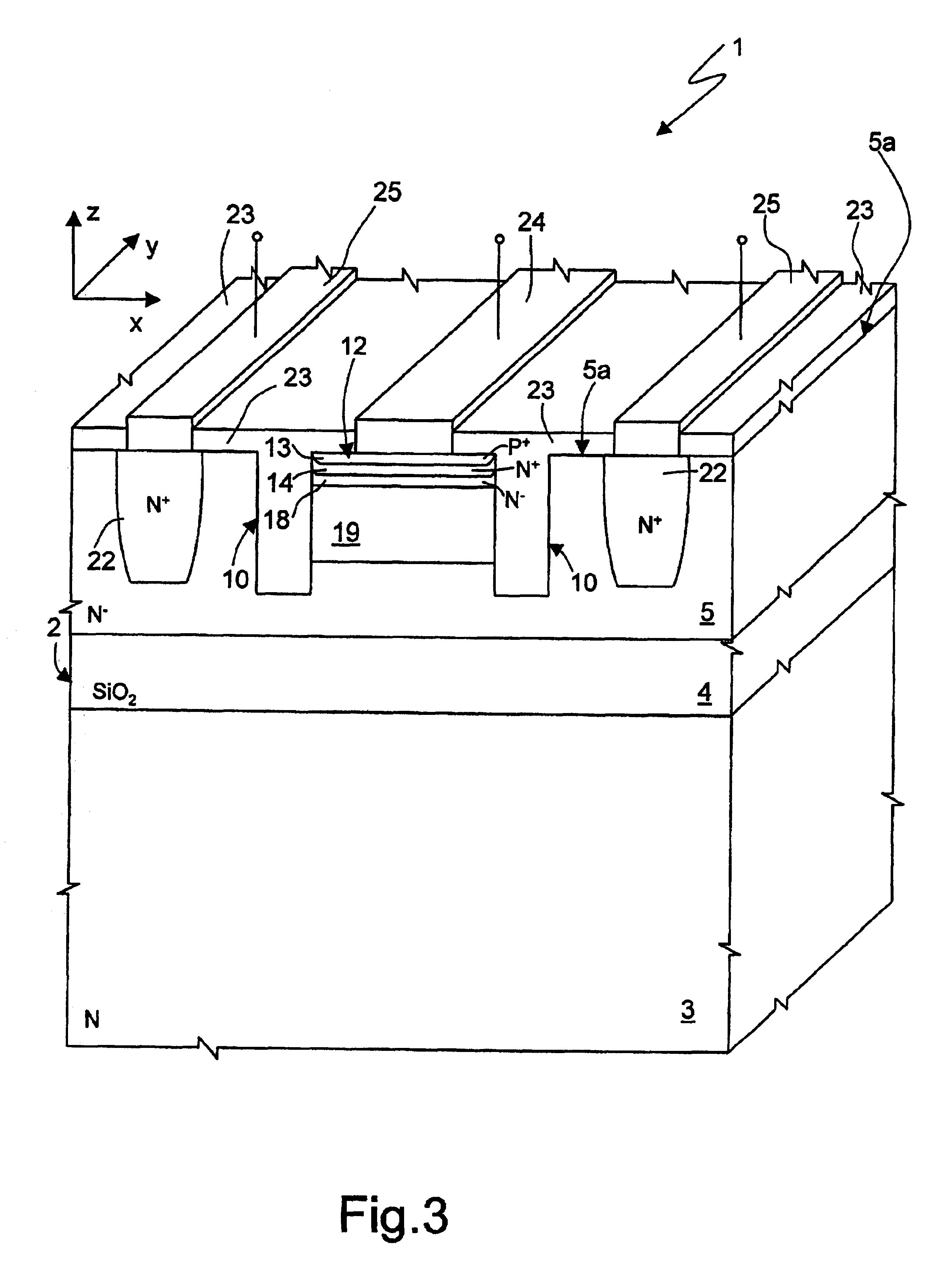

High-gain photodetector with separated PN junction and rare earth doped region and a method of forming the same

InactiveUS6943390B2High detection efficiencySolve the low detection efficiencySolid-state devicesSemiconductor/solid-state device manufacturingSecondary electronsAtomic physics

The high-gain photodetector is formed in a semiconductor-material body which houses a PN junction and a sensitive region that is doped with rare earths, for example erbium. The PN junction forms an acceleration and gain region separate from the sensitive region. The PN junction is reverse-biased and generates an extensive depletion region accommodating the sensitive region. Thereby, the incident photon having a frequency equal to the absorption frequency of the used rare earth crosses the PN junction, which is transparent to light, can be captured by an erbium ion in the sensitive region, so as to generate a primary electron, which is accelerated towards the PN junction by the electric field present, and can, in turn, generate secondary electrons by impact, according to an avalanche process. Thereby, a single photon can give rise to a cascade of electrons, thus considerably increasing detection efficiency.

Owner:STMICROELECTRONICS SRL

Ultrasonic sensor having acoustic matching member with conductive layer formed on and extending only along acoustic matching member connecting surface

InactiveUS7696672B2Solve the low detection efficiencySuppresses vibration transmissionPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive transducersMobile vehicleUltrasonic sensor

Owner:DENSO CORP

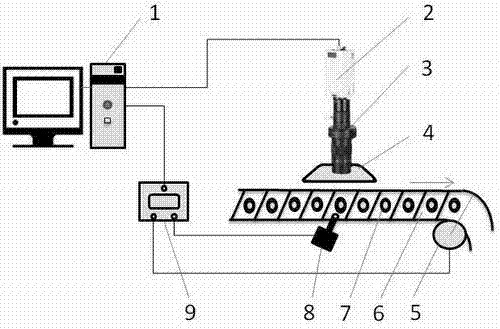

Food-borne pathogenic bacterium detection system and method based on high spectrum

ActiveCN103398994AResolve resolutionSolve efficiency problemsRaman scatteringColor/spectral properties measurementsBiological cellFood borne

The invention discloses a food-borne pathogenic bacterium detection system based on a high spectrum. The food-borne pathogenic bacterium detection system comprises a surface detection line, a sorting line, a qualified product conveying belt and a point detection line, which are connected with a control system respectively. The invention further discloses a detection method of the food-borne pathogenic bacterium detection system based on the high spectrum. The surface detection line based on a near-infrared high-spectrum system is used for rapidly positioning food-borne pathogenic bacteria; the sorting line is used for conveying pork polluted by the food-borne pathogenic bacteria to the point detection line; Raman chemical imaging is used for realizing species identification of the food-borne pathogenic bacteria. According to the food-borne pathogenic bacterium detection system disclosed by the invention, the problems that the resolution ratio of detecting a microorganism cell structure by the near-infrared high-spectrum system is limited and the large-area scanning and imaging efficiency of the Raman chemical imaging is low are solved; the food-borne pathogenic bacterium detection system based on the high spectrum has the advantages of convenience for utilization and obvious detection efficiency.

Owner:SOUTH CHINA UNIV OF TECH

Ultrasonic sensor having piezoelectric element and acoustic matching member

InactiveUS20080224567A1Improve adhesionImprove detection efficiencyPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesMobile vehicleUltrasonic sensor

An ultrasonic sensor according to the present invention is used, for example, for detecting an obstacle positioned in front of an automotive vehicle. The ultrasonic sensor includes an piezoelectric element connected to an acoustic matching member and a processing circuit, all contained in a casing. Ultrasonic waves reflected on an object are received by the acoustic matching member and converted into electrical signals in the piezoelectric element. The electrical signals are processed in the processing circuit to thereby detect a distance to the object and / or positions of the object. A surface of the acoustic matching member connected to the piezoelectric element is made larger than the piezoelectric element to form an overhang area on a conductive layer formed on the acoustic matching member. In this manner, electrical connection in the ultrasonic sensor is easily made, and detection sensitivity of the ultrasonic sensor is enhanced.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com